Patents

Literature

63results about How to "Good outdoor weather resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

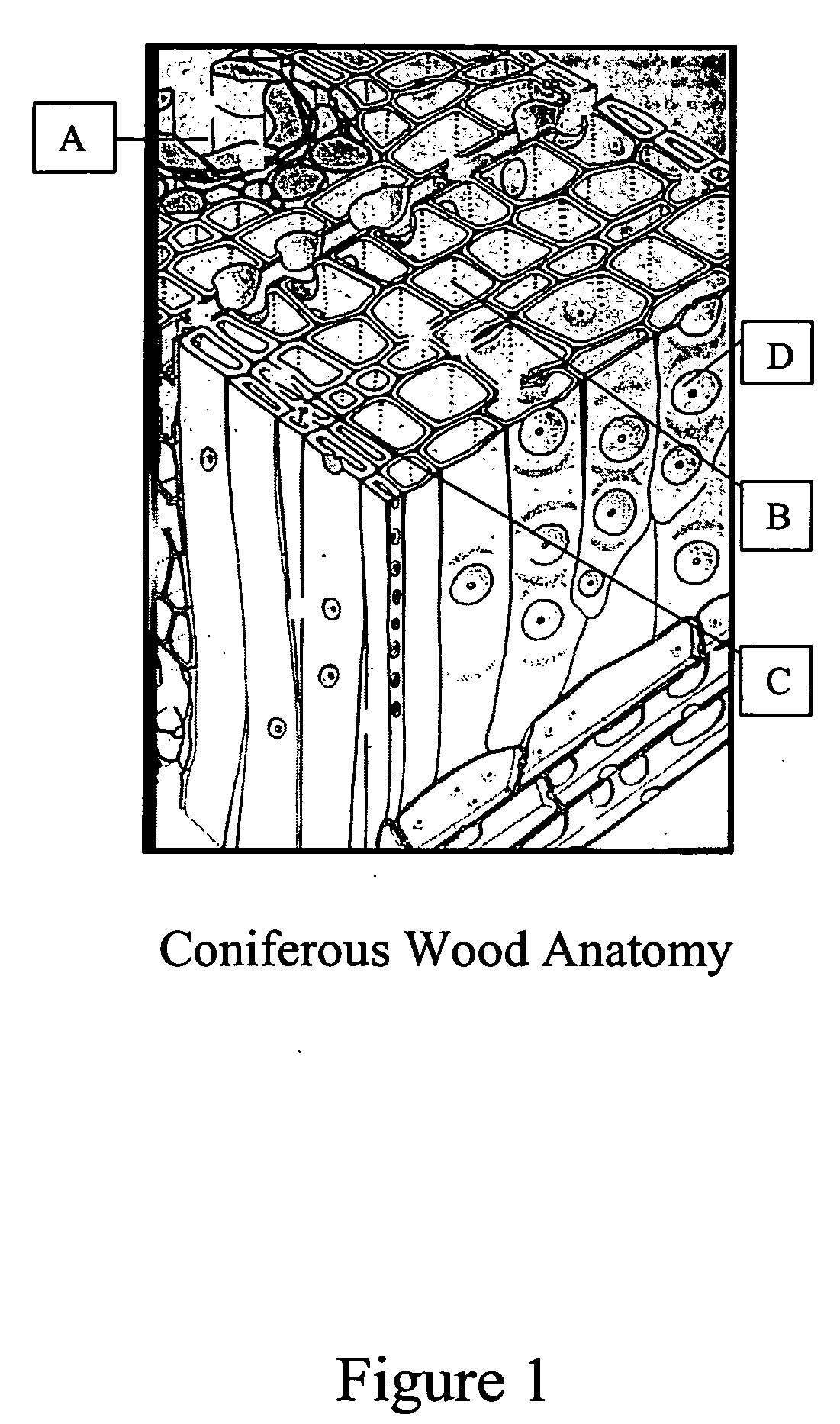

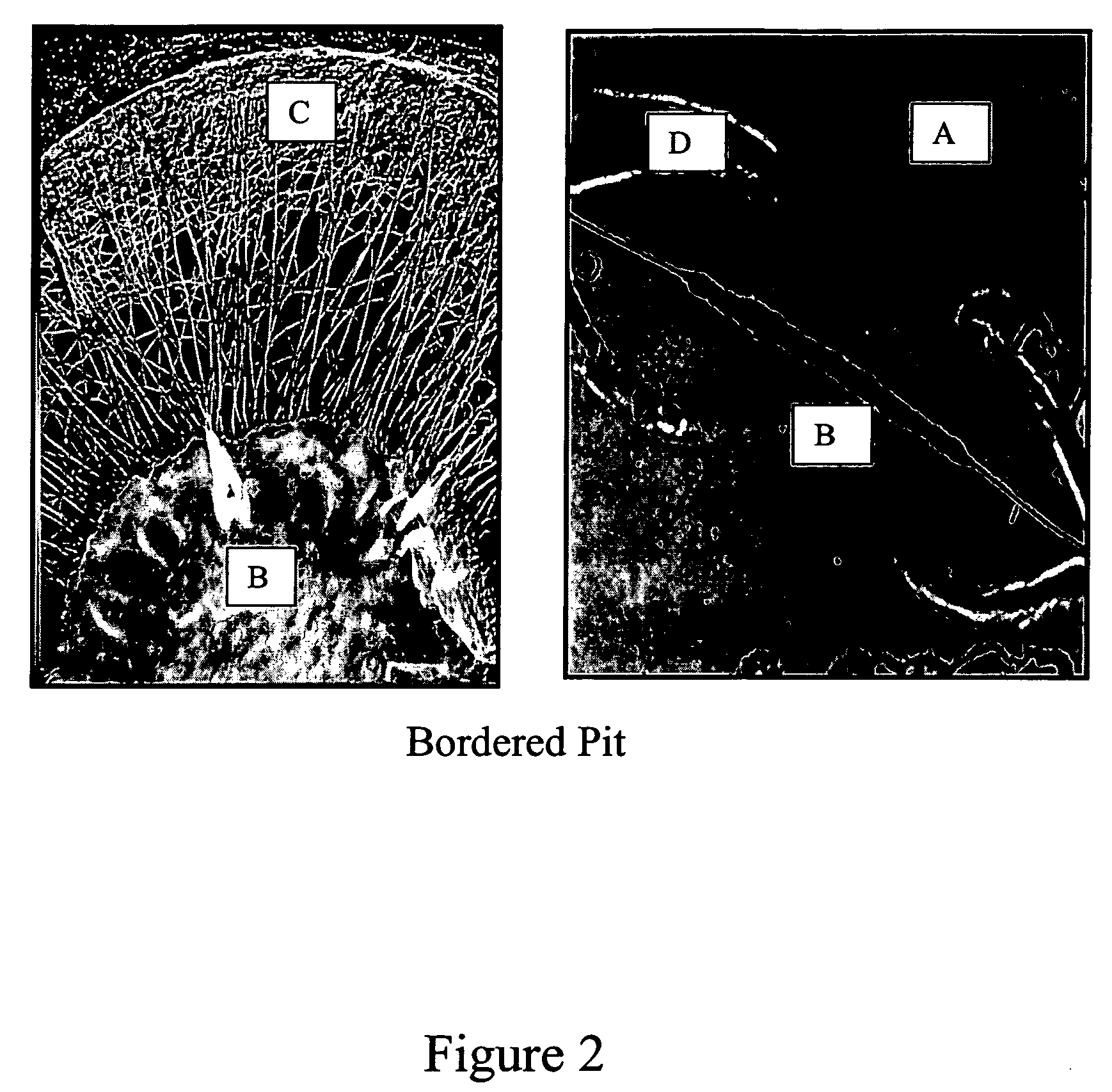

Composition and process for coloring and preserving wood

InactiveUS20060147632A1Preserving it from biological degradationGood outdoor weather resistanceFireproof paintsAntifouling/underwater paintsPolymer sciencePolymer chemistry

Provided is a composition which can color and preserve wood. The composition comprises both micronized pigments and inorganic and / or organic biocides, which may be present as a dispersion, emulsion or in solution also provided is a one step method for the coloring and preservation of wood.

Owner:OSMOSE

Acrylic resin sun-heat reflecting coating

InactiveCN1405248AGood outdoor weather resistanceLow solar heat absorptionReflecting/signal paintsPolymer scienceAcrylic resin

The invention refers to a kind of crylic acid resin sun heat reflecting paint. It uses crylic acid resin as filmed material, it also includes following assistant dispersant, sum heat reflecting compound dye, solvent and plastic-strengthening agent. Thus, its life outdoor can reach to 8-10 years, and it has high sum heat reflecting rate.

Owner:北京京安固特化工有限责任公司

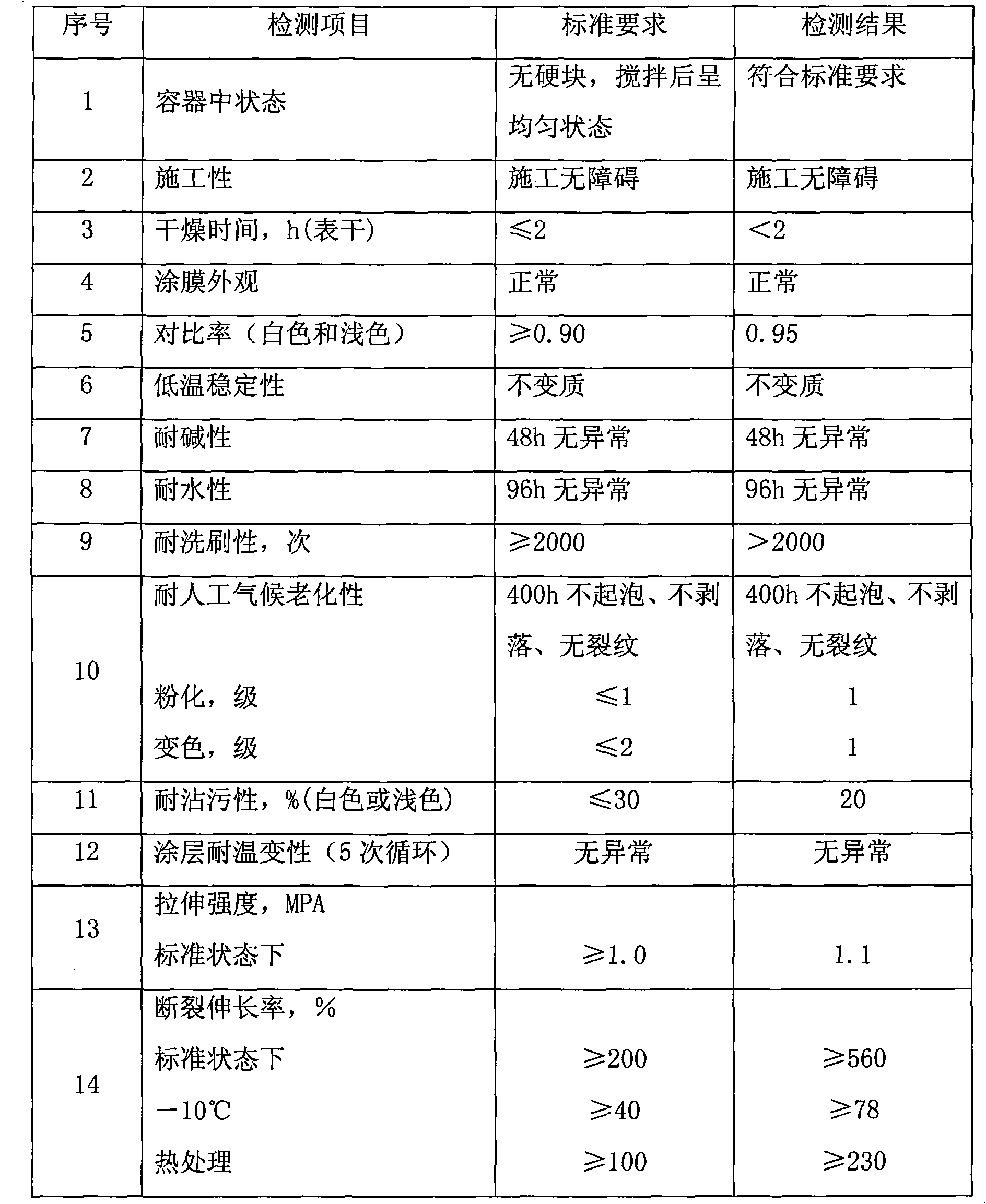

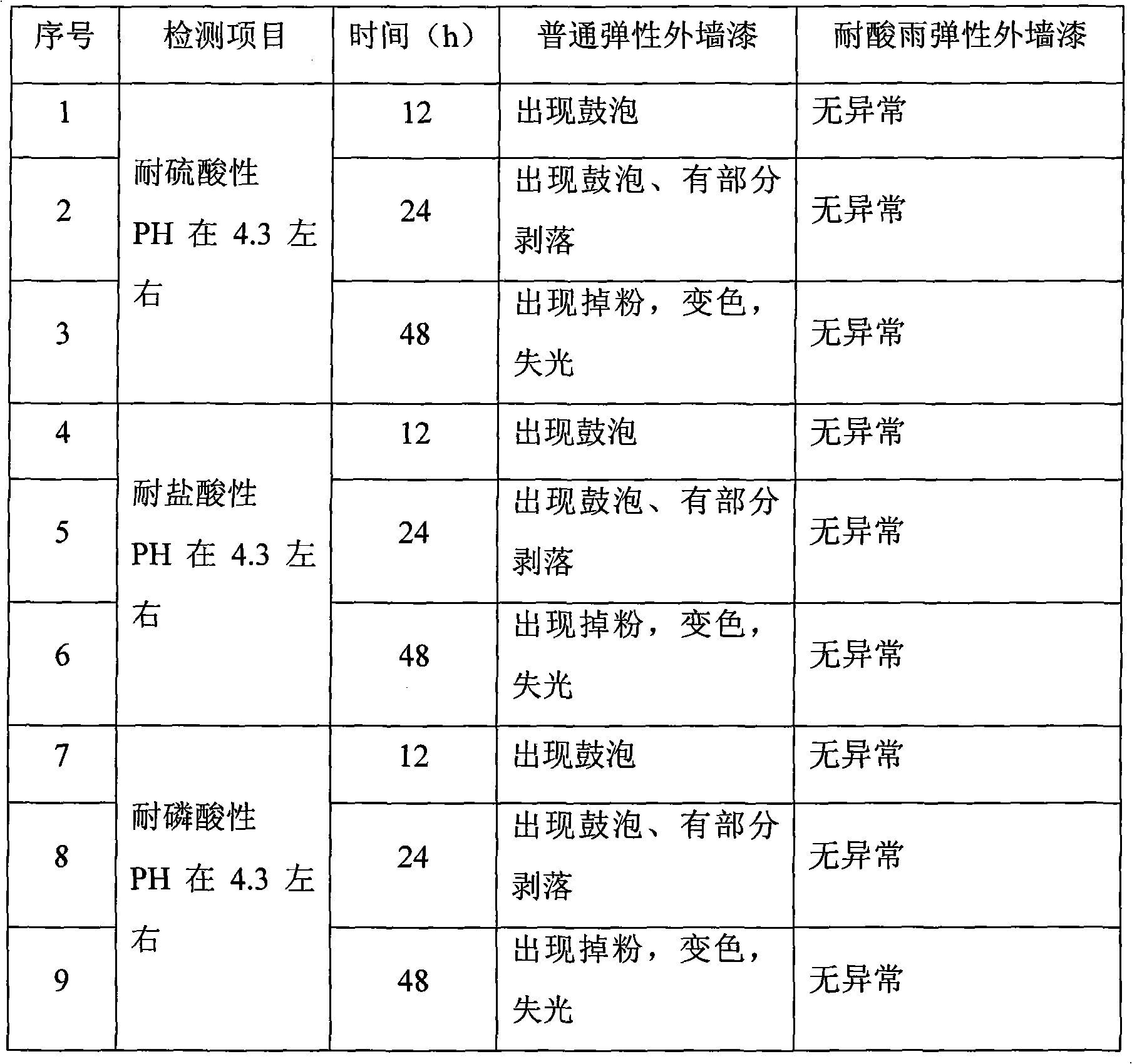

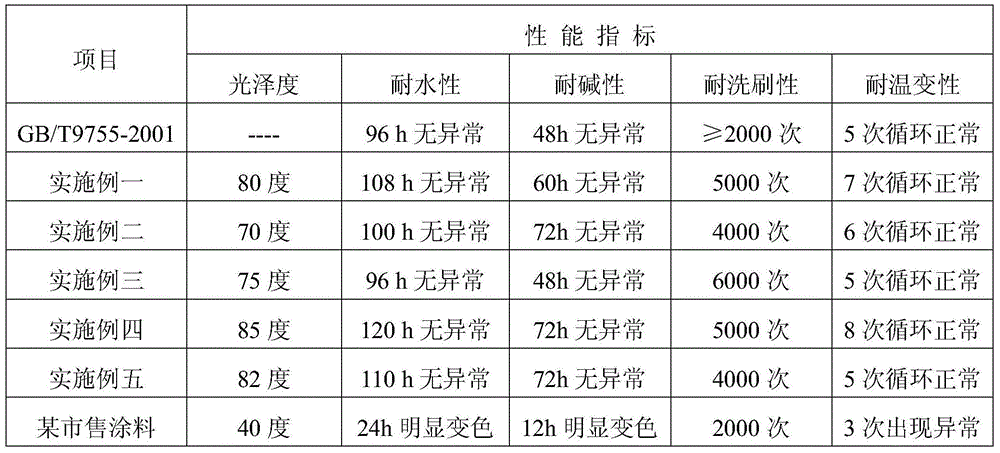

Acid rain resistant flexible outer wall emulsion paint

ActiveCN101955700AGood versatilityGood outdoor weather resistanceEmulsion paintsEmulsionIsopropylene glycol

The invention discloses acid rain resistant flexible outer wall emulsion paint, which comprises the following components in percentage by weight: 10.0 to 35.0 percent of water, 0.3 to 1.5 percent of dispersing agent, 0.1 to 0.4 percent of wetting agent, 0.1 to 0.8 percent of defoaming agent, 1.0 to 4.0 percent of propylene glycol, 0.0 to 25.0 percent of rutile type titanium dioxide, 10.0 to 25.0 percent of filler, 0.1 to 0.3 percent of preservative, 0.1 to 1.0 percent of mildew preventive, 0.05 to 0.20 percent of PH regulator, 0.0 to 2.0 percent of film forming aid, 35.0 to 55.0 percent of elastic latex and 0.1 to 2.0 percent of thickening agent. The acid rain resistant flexible outer wall emulsion paint can reduce the damage to outer walls of buildings due to factors of acid rain, concrete outer wall cracking and the like.

Owner:GUANGDONG MAYDOS BUILDING MATERIALS LTD CO

Nanoparticle modified silicon-acrylic compound exterior wall heat isolating coating and preparation method thereof

InactiveCN107841221AReduce accumulationLow thermal conductivityAntifouling/underwater paintsPaints with biocidesMicrosphereFar infrared

The invention provides a nanoparticle-modified silicon-acrylic composite exterior wall heat-insulating coating, and its raw materials include the following components in parts by weight: 50-60 parts of silicon-acrylic emulsion, 2-5 parts of hollow glass microspheres, and 8-parts of diatomaceous earth 15 parts, 5-10 parts of nano-silica, 6-10 parts of hollow ceramic microspheres, 3-6 parts of nanometer far-infrared ceramic powder, 5-10 parts of heat-reflecting and heat-insulating powder, 5-10 parts of mica powder, aluminum oxide 2-5 parts of powder, 5-10 parts of titanium dioxide, 0.1-0.3 parts of pH regulator, 0.5-1.0 parts of dispersant, 0.2-0.5 parts of defoamer, 1.0-2.5 parts of coalescent, 0.5-0.5 parts of thickener 0.8 parts, 1-3 parts of antifreeze, 0.1-0.3 parts of leveling agent, 0.1-0.3 parts of preservative, 20-50 parts of deionized water. The invention also provides its preparation method, the coating has good properties of nanoparticles, antibacterial properties, alkali resistance, scrub resistance, stain resistance and aging resistance, reflective heat insulation, environmental protection, aesthetics, outdoor weather resistance , Low thermal conductivity and other advantages.

Owner:清远市思彤新材料科技有限公司

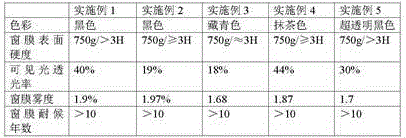

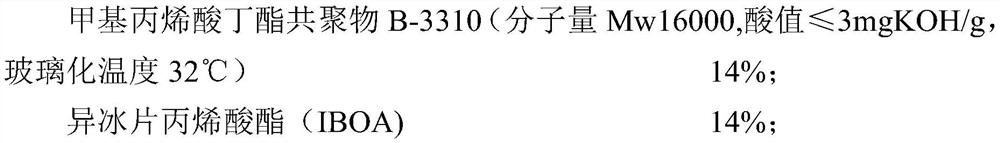

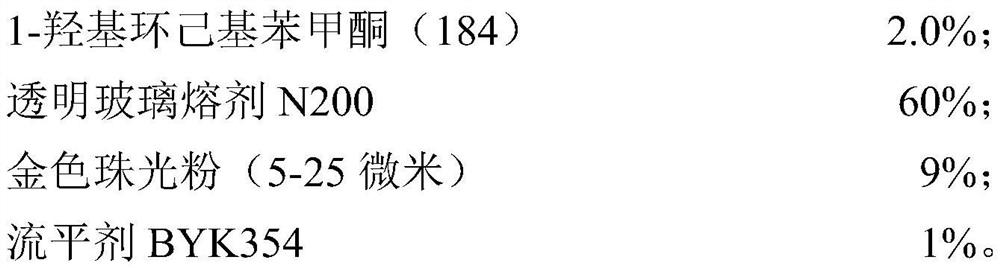

Pigment-type UV curable coating for window film and preparation method of pigment-type UV curable coating

ActiveCN104789110AAnti-fading and anti-ultravioletGood outdoor weather resistancePolyurea/polyurethane coatingsWeather resistancePhotopigment

The invention relates to a special UV curable coating for a PET window film and a preparation method of the pigment-type UV curable coating. The special UV curable coating for the window film comprises the following components in parts by mass: 3-40 parts of UV monomers, 10-50 parts of modified acrylic ester, 1-10 parts of a photoinitiator, 0.4-2 parts of a flatting agent, 3-20 parts of pigment, 0.5-1.5 parts of a coupling agent and 0.4-0.8 part of a dispersing agent. The pigment type window film disclosed by the invention is not easily faded, is UV-resistant and also has very excellent outdoor weather resistance. The color or hue of the pigment can be kept unchanged for several years and even more than ten years, so that the original color of a PET window film produced by using the pigment with good weather resistance can be kept unchanged for several years and more than ten years, and the performances of the window film cannot be influenced by outdoor environmental factors.

Owner:ZHEJIANG NAMEI MATERIAL TECH

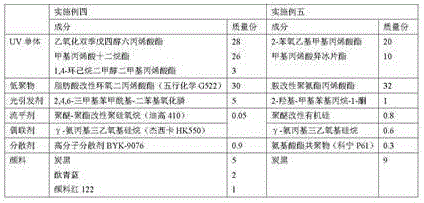

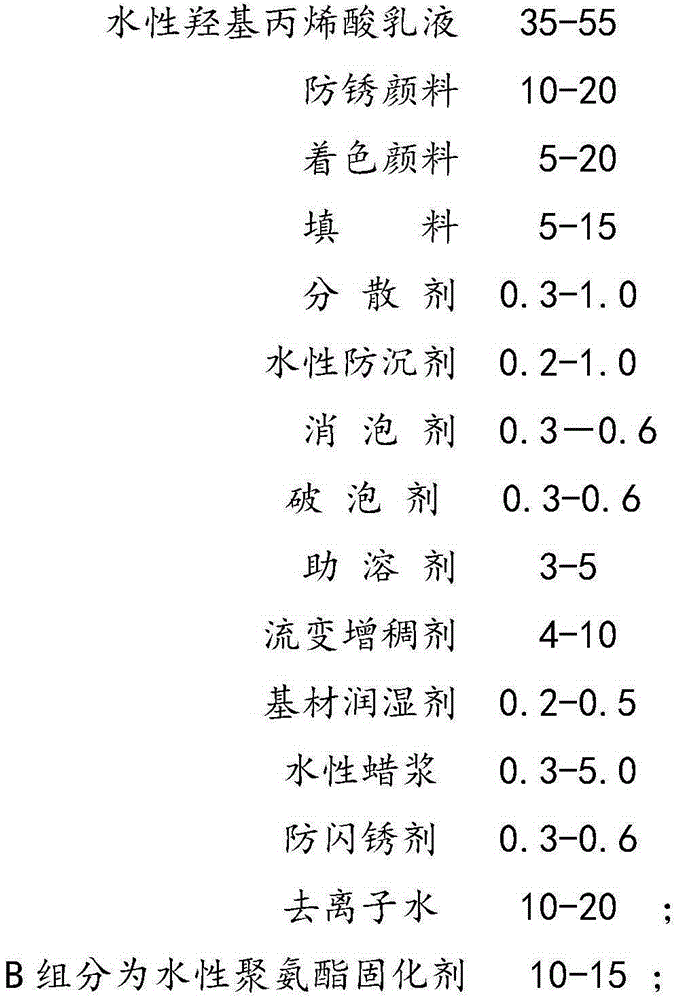

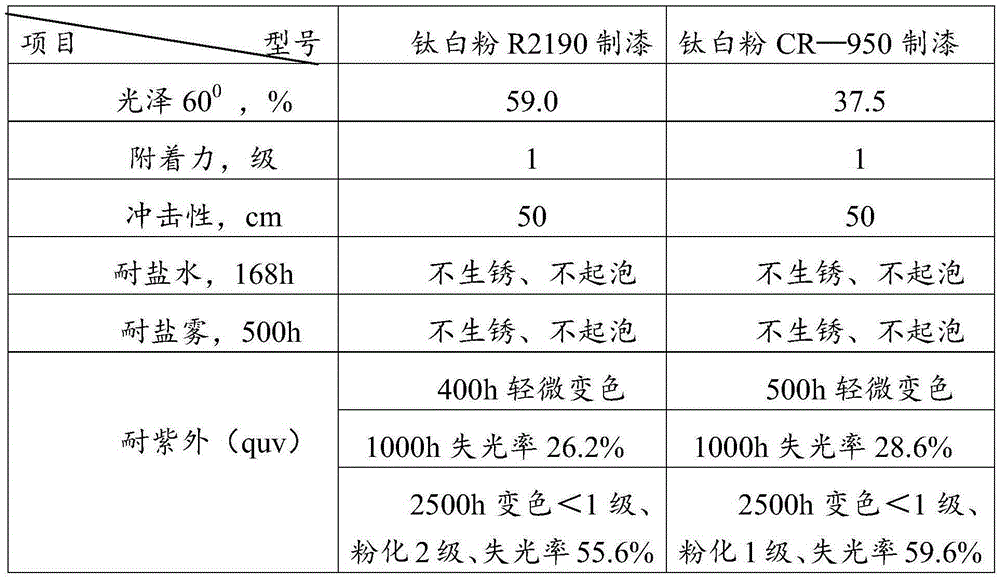

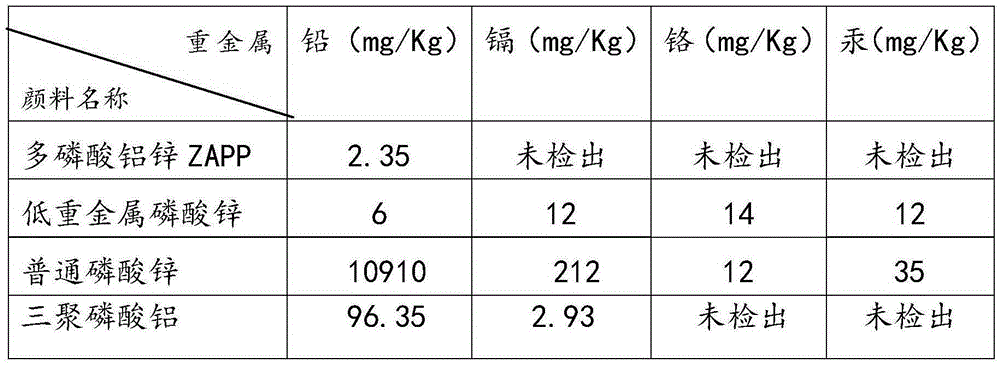

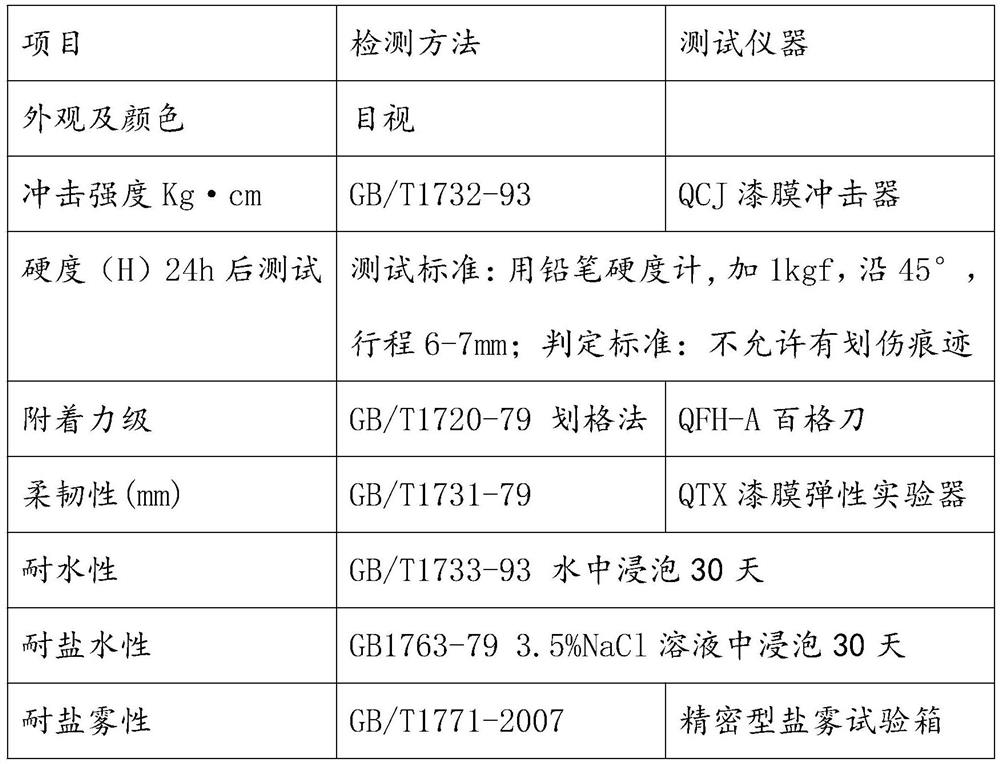

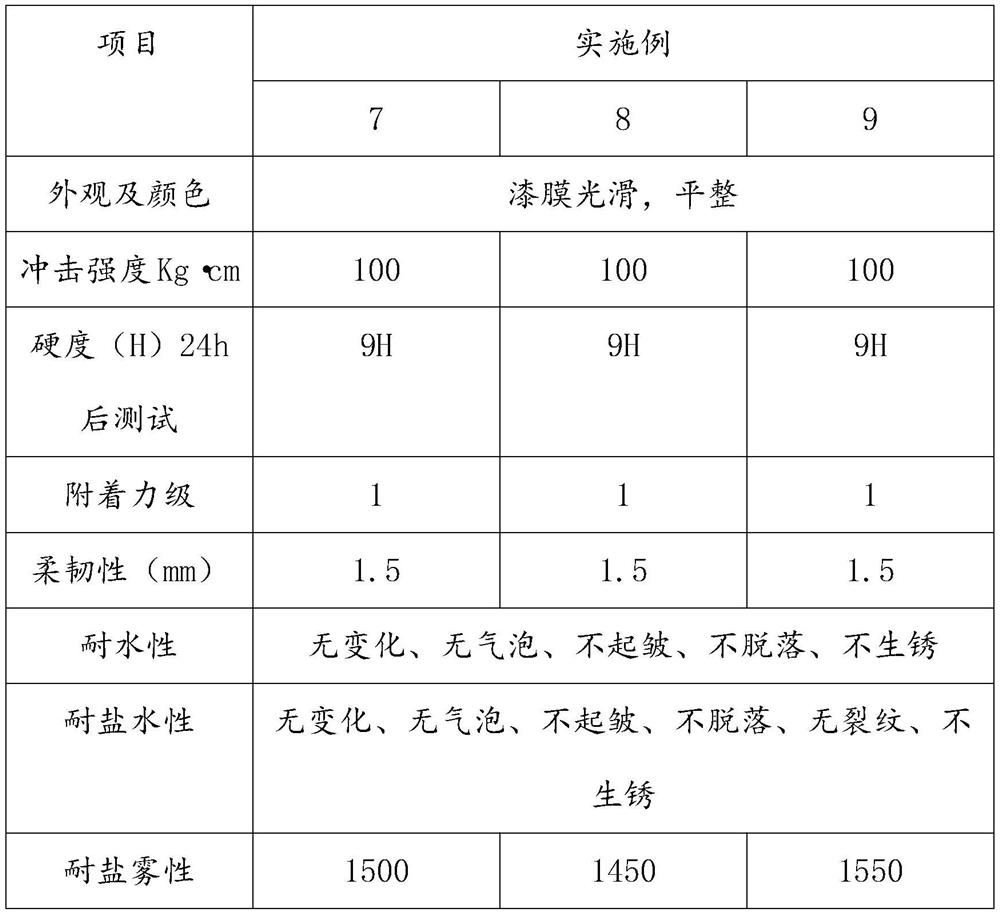

Water-borne acrylic polyurethane primer-topcoat corrosion-resistant decorative coating containing double components and preparation method of coating

InactiveCN105349019AGood outdoor weather resistanceGood weather resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsLacquerSolvent

The invention relates to a water-borne acrylic polyurethane primer-topcoat corrosion-resistant decorative coating containing double components. The water-borne acrylic polyurethane primer-topcoat corrosion-resistant decorative coating comprises a component A and a component B, wherein the component A comprises ingredients in parts by weight as follows: 35-55 parts of a water-borne hydroxyl acrylic acid emulsion, 10-20 parts of anti-rust pigments, 5-20 parts of coloring pigments, 5-15 parts of filler, 0.3-1.0 part of a dispersing agent, 0.2-1.0 part of a water-borne anti-settling agent, 0.3-0.6 parts of a defoaming agent, 0.3-0.6 parts of a foam breaker, 3-5 parts of a cosolvent, 4-10 parts of a rheological thickener, 0.2-0.5 parts of a substrate wetting agent, 0.3-5.0 parts of water-borne wax liquor, 0.3-0.6 parts of a flash rust preventing agent and 10-20 parts of deionized water; the component B comprises 10-15 parts by weight of a water-borne polyurethane curing agent. A preparation method comprises steps as follows: the raw materials are sequentially added to a container, are uniformly stirred at medium and high speeds and then are dispersed for 10 min respectively, a mixture is ground, the deionized water is added for uniform stirring, and the component A is prepared. The water-borne acrylic polyurethane primer-topcoat corrosion-resistant decorative coating containing the double components has the benefits of excellent outdoor weather fastness, adhesive force, water resistance, salt water resistance and salt fog resistance.

Owner:天津灯塔涂料工业发展有限公司

Simulated copper coating and production process thereof

ActiveCN103396725AGood gloss and color retentionImprove impact resistancePolyester coatingsCellulosePolymer science

The invention relates to the technical field of architectural decoration materials and application. The invention provides a simulated copper coating, and the simulated copper coating is prepared from the following raw materials: by weight, 670-700 parts of a mixed solvent, 60-70 parts of cellulose acetate butyrate, 60-70 parts of polyester resin, 40-50 parts of nitrocotton, 30-40 parts of amino resin, 2-5 parts of a leveling agent, 25-35 parts of an anti-settling agent, 55-75 parts of pearlescent pigments and 10-30 parts of a color pigment. The invention also provides a production process of the simulated copper coating, and the production process comprises the following steps: successively adding the mixed solvent, the cellulose acetate butyrate, the polyester resin, the nitrocotton, the amino resin, the leveling agent, the anti-settling agent, the pearlescent pigments and the color pigment into a vat, stirring and mixing evenly. During the production process of the simulated copper coating, a directional assistant with high glass transition temperature is introduced, various pearlescent pigments are selected and used, and through mixing in a certain proportion, a coating film can perfectly reproduce copper material effects and metal texture.

Owner:XINHE NEW MATERIALS CO LTD

Water-soluble acrylic resin and preparation method thereof

InactiveCN102153696AWon't turn yellowGood outdoor weather resistanceCoatingsDispersityFunctional monomer

The invention discloses a water-soluble acrylic resin which comprises functional monomers, (methyl)acrylic acid, (methyl)hydroxyalkyl acrylate, acrylamide, an initiator, a reducer and water. The waterborne resin can not become yellow, has the advantages of high outdoor weather resistance, favorable dispersity for pigment, low cost, favorable water solution resistance, favorable punching oil resistance, favorable solvent resistance, high formability, favorable heat resistance, favorable bending resistance, no odor and simple production technique, and is in the leading position in China. The water-soluble acrylic resin can be widely used for surface coating of aluminum and aluminum alloy products, and especially for coating surfaces of heat exchanger fins of air conditioners.

Owner:SNTO TECH GRP

Composite acrylic transparent film, and preparation method and application thereof

ActiveCN103203917AWith bright silver effectHigh glossSynthetic resin layered productsLaminationTransmittanceViscosity

The invention discloses a composite acrylic transparent film comprising, from top to bottom, a transparent protective film, a low-viscosity movable sensitive adhesive, a composite acrylic transparent film, a metal deposited layer, a high-temperature-resistant pressure-sensitive adhesive, and a PET release film. Also, the invention discloses a preparation method of the composite acrylic transparent film, and an application thereof in three-dimensional vacuum forming. The composite acrylic transparent film provided by the invention has good outdoor weatherability, high-temperature forming performance, and high light transmittance under backlight.

Owner:上海润颐复合材料有限公司

High-solid content and high-gloss anode electrophoretic coating and coating method thereof

ActiveCN104231799AEasy to makeImprove the level ofElectrophoretic coatingsPaints for electrolytic applicationsAcrylic resinAccelerated aging

The invention relates to a high-solid content and high-gloss anode electrophoretic coating which comprises the following components: an acrylic resin modified by glycidyl tertiary carboxylic ester, an amino resin of methyl-butyl compound ether and a catalyst, wherein the mass ratio of the acrylic resin modified by glycidyl tertiary carboxylic ester to the amino resin of methyl-butyl compound ether is 1 to (0.2-1). Compared with a common anode electrophoretic coating, the solid content of the high-solid content and high-gloss anode electrophoretic coating is increased by 60% to 70%, and the solvent content of the high-solid content and high-gloss anode electrophoretic coating is reduced by 5% to 25%. Thus, the high-solid content and high-gloss anode electrophoretic coating can be easily prepared into a high environment-friendly coating and is low in viscosity, thereby bringing convenience for construction operations. According to the high-solid content and high-gloss anode electrophoretic coating and a coating method thereof, the gloss of a coating layer is improved by 90% to 120%; the coating layer is good in levelling property and plumpness, attractive in appearance and excellent in decorative effect; in addition, the coating layer is good in acid resistance, i.e., the coating layer can resist sulfuric acid or 5% hydrochloric acid for 48 hours; and the coating layer is excellent in outdoor weatherability, i.e., the artificial accelerated aging time of the coating layer reaches above 1000 hours.

Owner:郎溪县鑫泽涂料有限公司

Cored solder wire solid soldering flux capable of reducing flyoff

ActiveCN103264241AHigh activityLess corrosiveWelding/cutting media/materialsSoldering mediaCompound organicTin

The invention relates to a cored solder wire solid soldering flux capable of reducing flyoff. The cored solder wire solid soldering flux consists of a compound surfactant, compound organic acid, a compound plasticizer and compound rosin, and is prepared by the following steps of: grinding the balance of the compound rosin into blocks, adding into a reactor, heating, stirring and placing at constant temperature; and adding 1.0 to 3.0 percent of compound surfactant, 1.0 to 4.0 percent of compound organic acid and 1.0 to 3.0 percent of compound plasticizer sequentially, continuing stirring, uniformly pouring into a mold, and molding to obtain a solid soldering flux product. The soldering flux has the advantages that the content of halogen can be controlled to be less than 1,000ppm, and completely accords with a halogen-free standard; the quantity of soldering flux residue and flyoff solder balls in a welding process of a solder wire and the flyoff distance are greatly decreased; softening points are improved; the soldering flux is high in high temperature resistance and high in insulating resistance; an acid value is increased; and the activity is improved.

Owner:广东中实金属有限公司

Polyetheramine-modified waterborne alkyd resin and preparation method thereof

ActiveCN110746590AGood water resistanceGood flexibilityAnti-corrosive paintsPolyester coatingsComposite materialDibutyl tin dilaurate

The invention relates to a polyetheramine-modified waterborne alkyd resin and a preparation method thereof. The polyetheramine-modified waterborne alkyd resin comprises, by weight, 20.0-40.0 parts ofvegetable oil, 4.0-12.0 parts of polyetheramine, 20.0-50.0 parts of organic anhydrides, 25.0-70.0 parts of polyol, 10.0-25.0 parts of xylene, 2.5-6.0 parts of n-caprylic acid, 3.5-7.0 parts of dimethylolpropionic acid, 0.5-1.0 part of sodium bicarbonate, 4.0-12.0 parts of a neutralizer, 0.1-0.5 part of dibutyltin dilaurate and 100.0-200.0 parts of deionized water. The trifunctional polyetheramineis connected with a waterborne alkyd resin structure through chemical bonds, so the performances are stable; and the polyetheramine-modified waterborne alkyd resin has the characteristics of good water resistance, corrosion resistance, impact resistance, outdoor weather resistance, high hardness, good fullness and the like, and can be used for interior / exterior wall coatings, waterborne industrialcoatings and waterborne wood coatings.

Owner:UNION FOSHAN CHEM +1

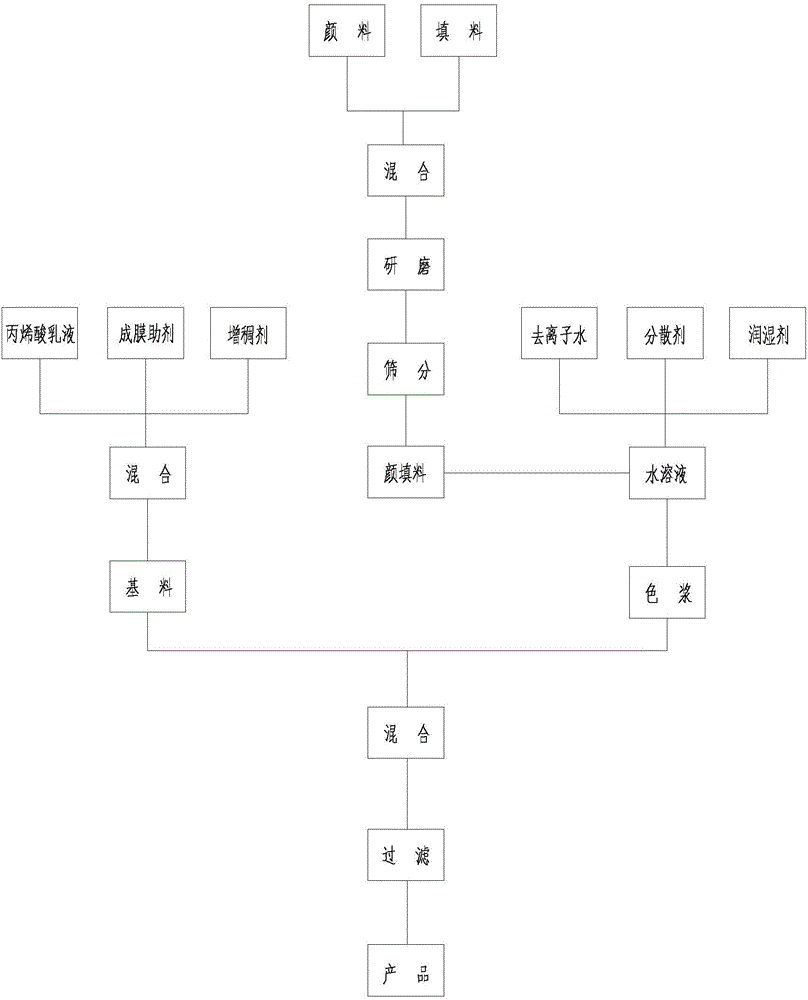

Coating for cement fence and preparation method thereof

InactiveCN105331229AGood outdoor weather resistanceImproved aging and UV resistanceCoatingsEmulsionAcrylic acid

The invention provides a coating for a cement fence and a preparation method thereof to overcome the problems of poor ultraviolet resistance and proneness to ageing of conventional cement fence coatings, belonging to the technical field of constructional materials. The coating comprises the following raw materials by weight: 35 to 50 parts of acrylic acid emulsion, 1 to 5 parts of a film forming auxiliary agent, 1 to 2 parts of a dispersing and wetting agent, 20 to 40 parts of a pigment filling material, 10 to 20 parts of deionized water, 3 to 5 parts of an aging-resistant auxiliary agent, 1 to 2 parts of a leveling agent and 1 to 2 parts of a thickening agent. The preparation method comprises the following steps: mixing the acrylic acid emulsion, the film forming auxiliary agent and the thickening agent so as to obtain a base material; preparing color paste from deionized water, the dispersing and wetting agent and the pigment filling material; mixing the base material with the color paste; adding the aging-resistant auxiliary agent and the leveling agent; and carrying out filtering so as to obtain the coating. Under synergism of the acrylic acid emulsion, the pigment filling material and the aging-resistant auxiliary agent, ultraviolet resistance and aging resistance of the coating are substantially improved, brightness of the surface of the cement fence is improved, and the integral aesthetic properties of a building are improved.

Owner:邢军

Finish paint and preparation method thereof

InactiveCN111138961AGood weather resistanceHigh solidsAnti-corrosive paintsPolyurea/polyurethane coatingsWeather resistanceAcrylic resin

The invention relates to finish paint and belongs to the technical field of paint preparation. The finish paint comprises a component A and a component B. The component A comprises 40-50 parts of hydroxy acrylic resin, 10-12 parts of pigment yellow, 12-15 parts of titanium dioxide, 2-5 parts of a dispersing agent, 0.5-2 parts of a leveling agent, 0.1-0.5 part of an antifoaming agent, 0.2-0.5 partof a drier, 2-5 parts of an anti-settling agent and 5-8 parts of a first mixed solvent. And the component B comprises 80-85 parts of HDI tripolymer aliphatic isocyanate, 14-17 parts of a second mixedsolvent and 1-3 parts of a dehydrator. Hydroxyl acrylic resin has the advantages of high weather resistance, high solid content, low viscosity, good wettability to pigments and fillers, capability offurther improving glossiness and good application property. HDI tripolymer aliphatic isocyanate is used as a curing agent, guarantees high weather resistance and rapid drying, and can increase the film forming speed of the coating. The finish paint is a double-component finish paint, contains a curing agent, can be dried quickly, and has the advantages of favorable fullness, favorable hardness, good gloss retention, corrosion resistance, good outdoor weather resistance and low discoloration tendency.

Owner:广汉华气防腐工程有限公司

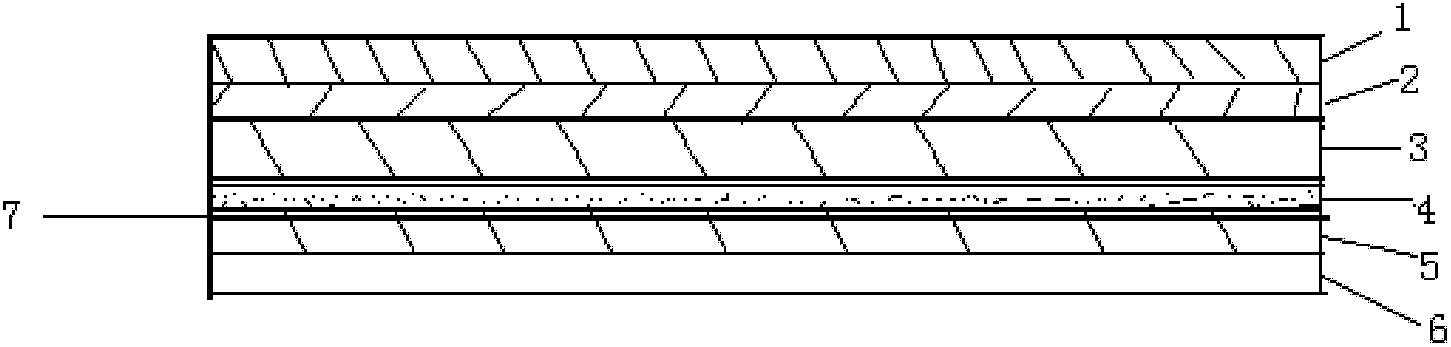

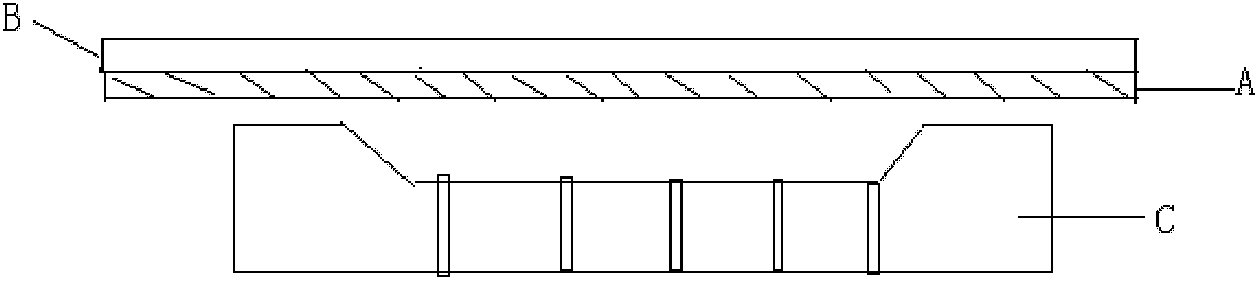

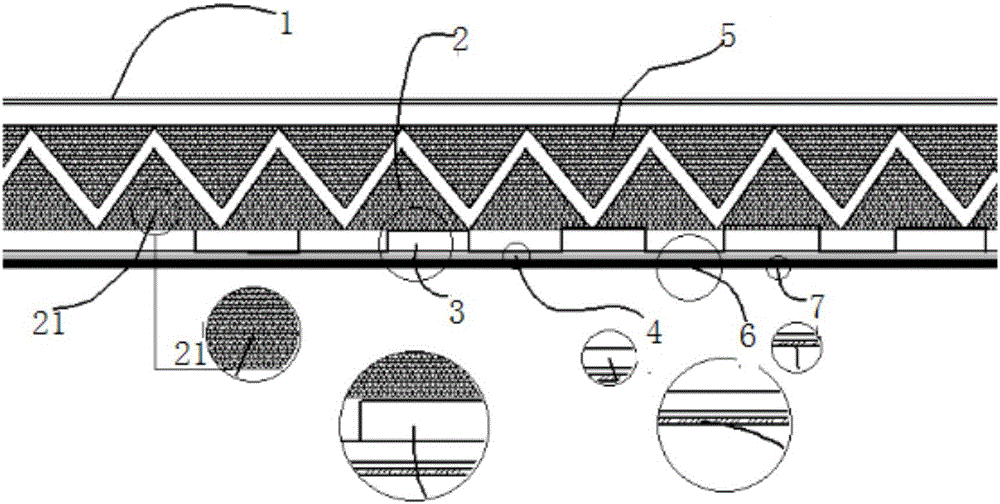

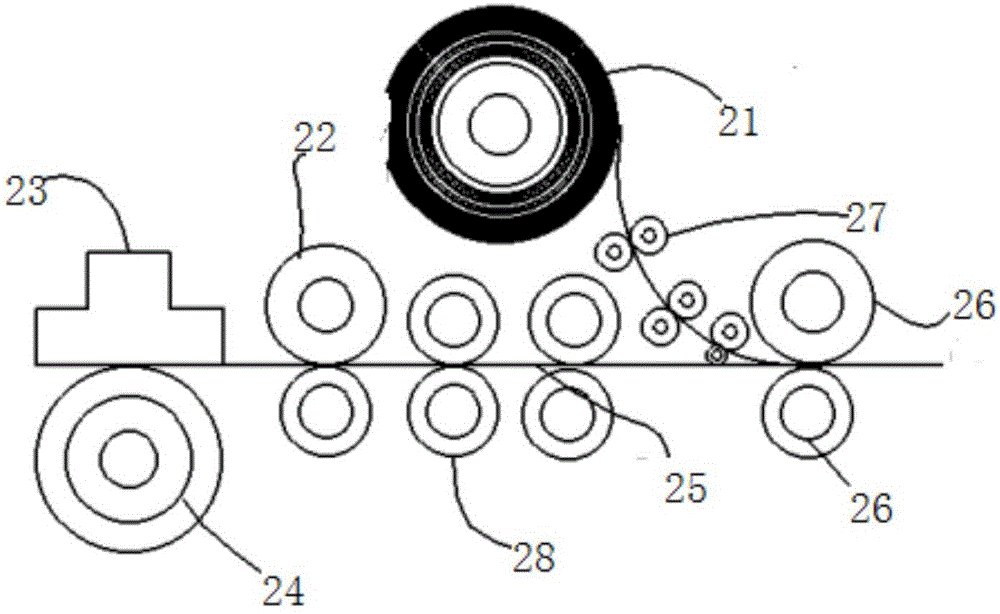

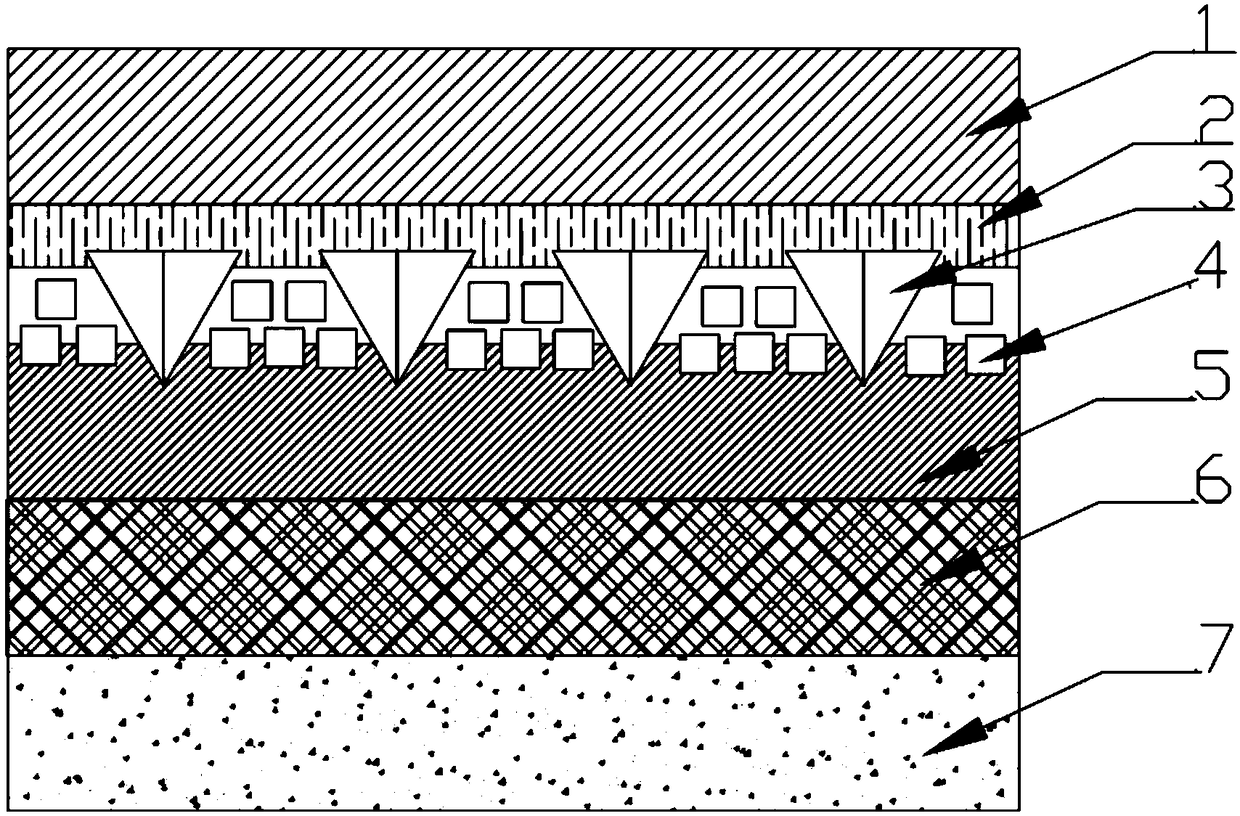

Novel reflective sign and manufacturing technology

ActiveCN106847131ASolve the cumbersome production processReduce utilizationIlluminated signsManufacturing technologyWeather resistance

The invention discloses a novel reflective sign and a manufacturing technology. The novel reflective sign and the manufacturing technology comprise seven layers which are a PMMA material ultraviolet-resistant protective layer, a sign layer, the sign of which can be printed digitally, a micro-prism substrate layer, a micro-prism air capsule layer, a supporting back film, pressure sensitive adhesive and a base paper layer; the novel reflective sign and the manufacturing process further comprise a novel reflective sign structure, a reflective sign manufacturing method, a production and processing technology; the problems are solved that production procedures of reflective signs are complicated, production efficiency and material utilization rate are low, material cost is high, weather resistance is not strong, and continuous production can not be conducted; the novel reflective sign and the manufacturing technology can be widely used in a variety of different signs such as road traffic signs, industrial and mining enterprises signs, urban guide signs, commercial signs, tourist attraction attractions, and has the advantages of outdoor practicality, stronger weather resistance, low production cost.

Owner:湖南鼎一致远科技发展股份有限公司

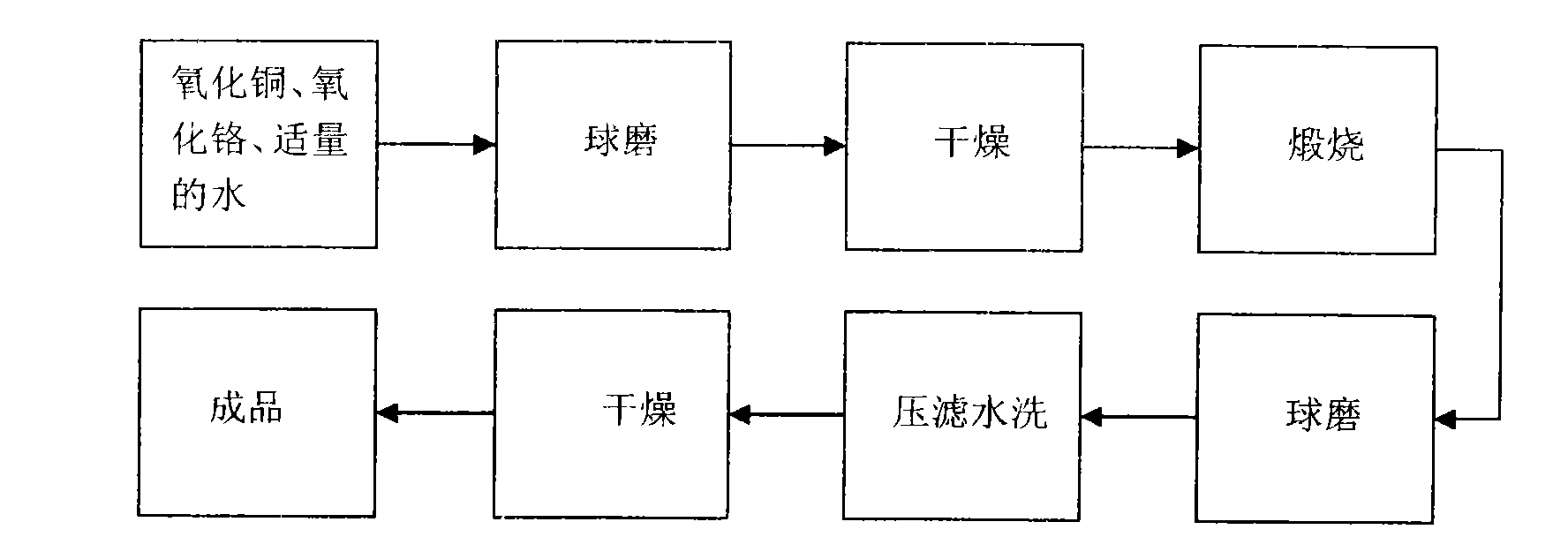

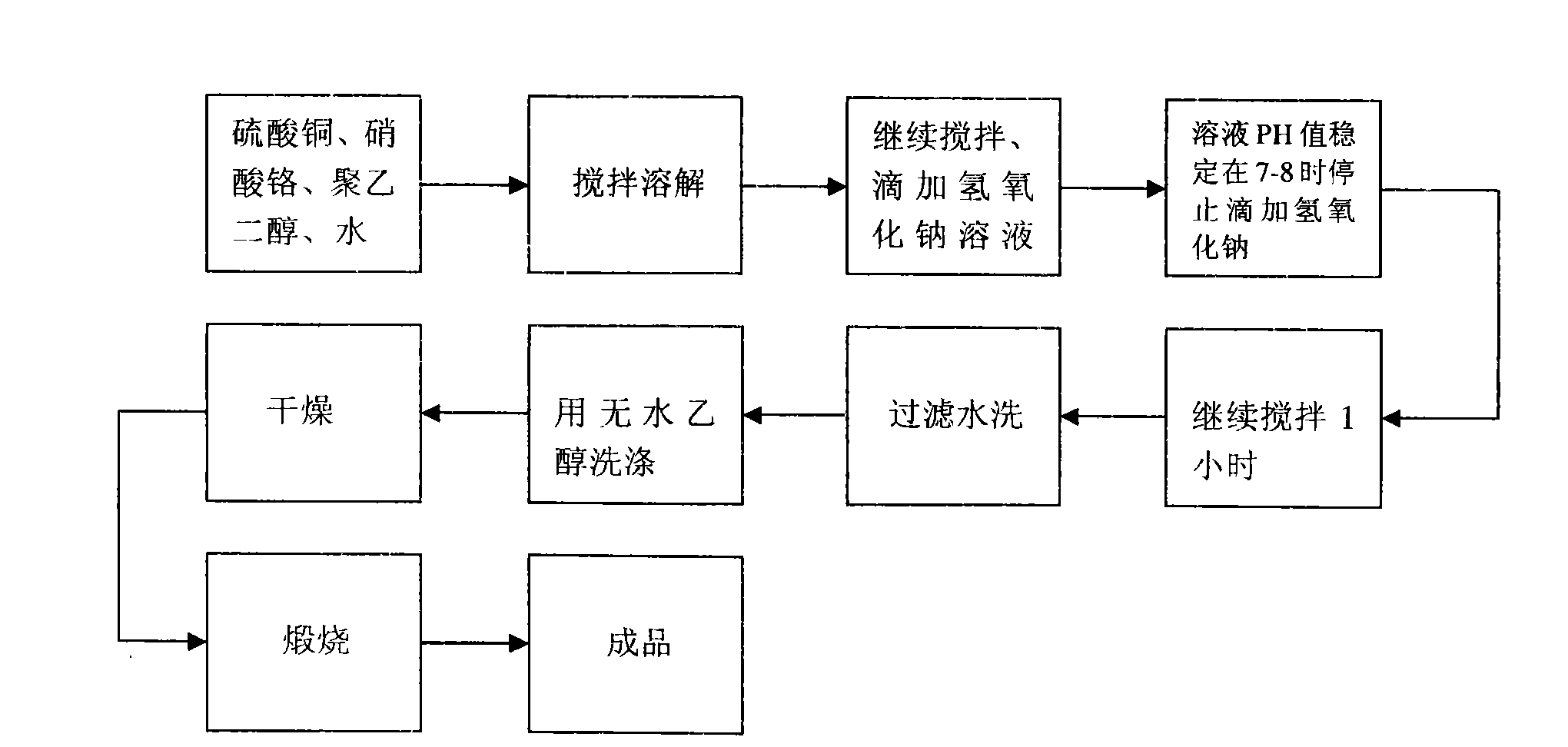

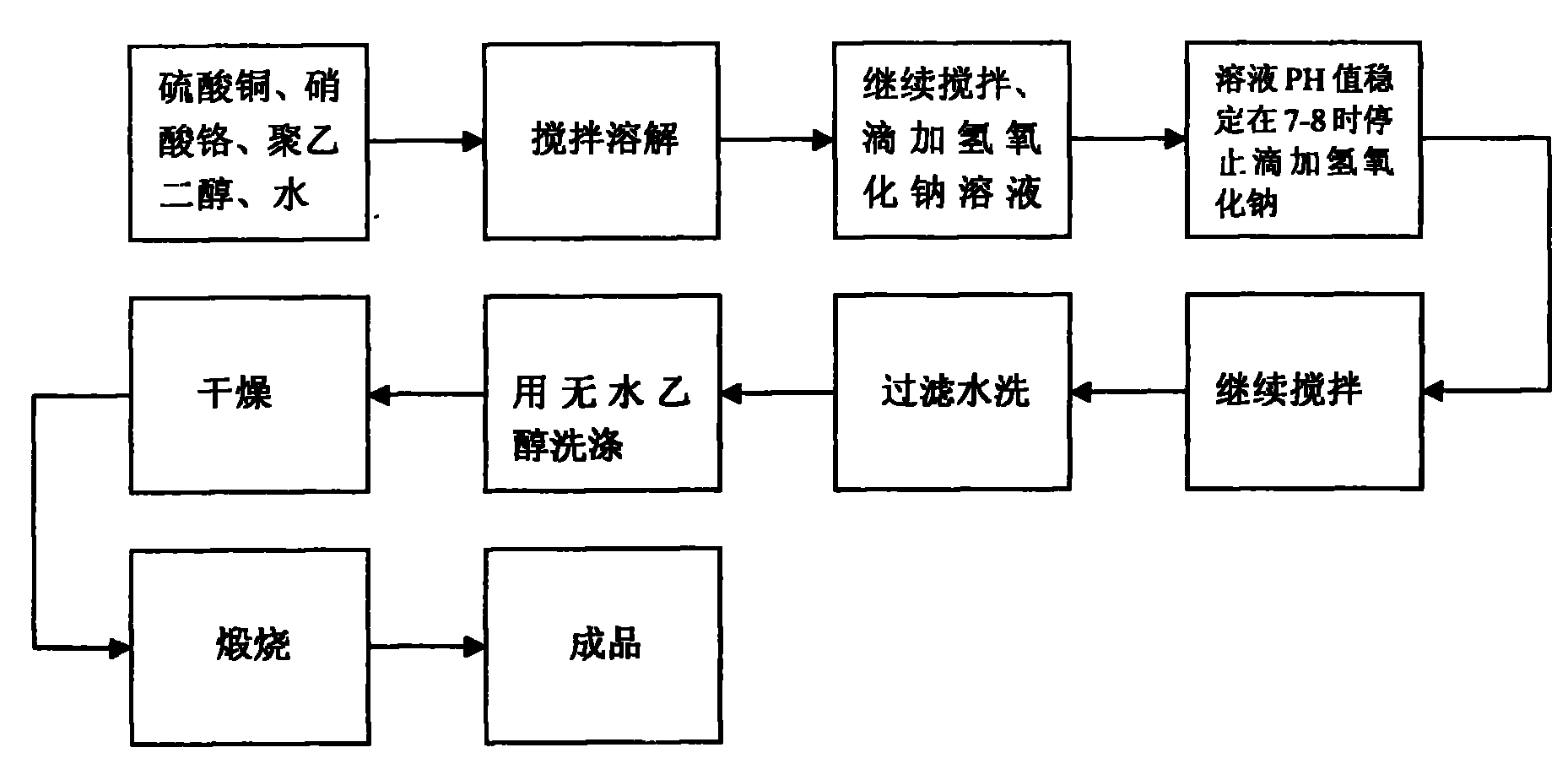

Method for preparing copper and chromium black pigment

InactiveCN102153891AImprove high temperature resistanceNo light fastnessCoatingsPigment treatment with macromolecular organic compoundsAlcoholGram

The invention relates to an inorganic synthesis method for preparing a copper and chromium black pigment. The copper and chromium black pigment has the following raw material formula: 250 grams of bluevitriod, 340 to 460 grams of chromium nitrate nonahydrate, 27 to 37 grams of polyethylene glycol and 170 to 230 ml of absolute alcohol. Due to the adoption of the method, the problems of large particles and uncentralized particle diameter distribution of the copper and chromium black pigment produced by a conventional method are solved; the production steps are simplified; the calcining temperature is reduced; and compared with an organic pigment, the copper and chromium black pigment has good high temperature stability and wide application range.

Owner:邵阳县彩鑫制釉有限公司

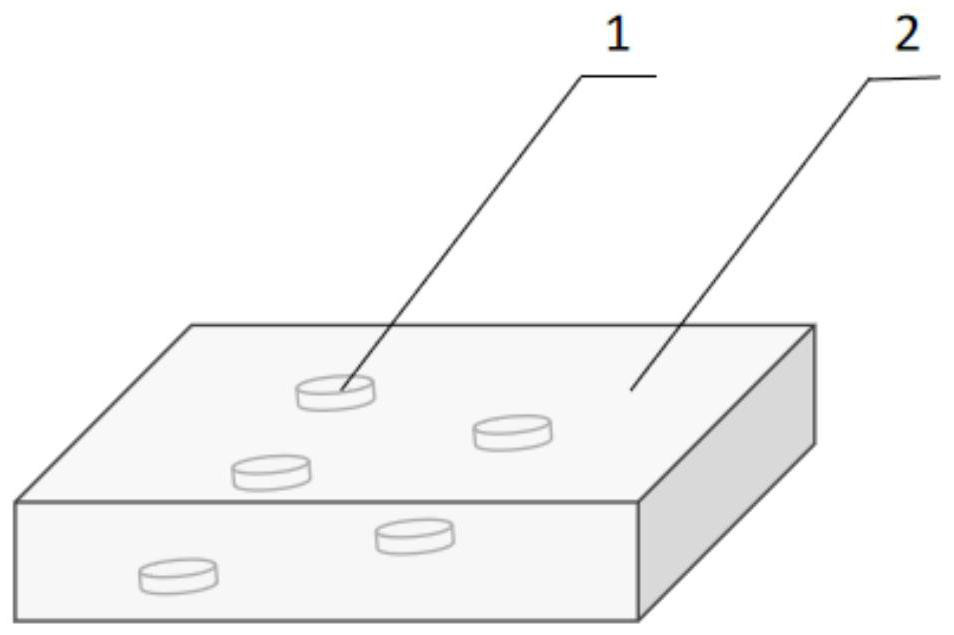

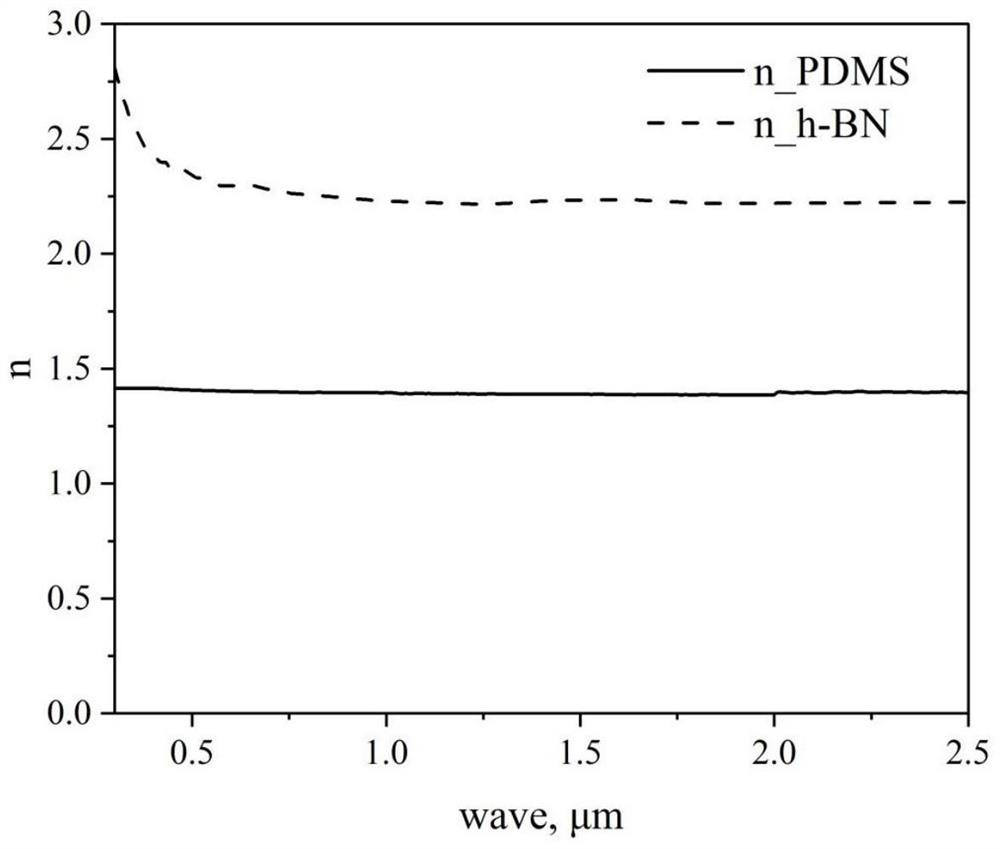

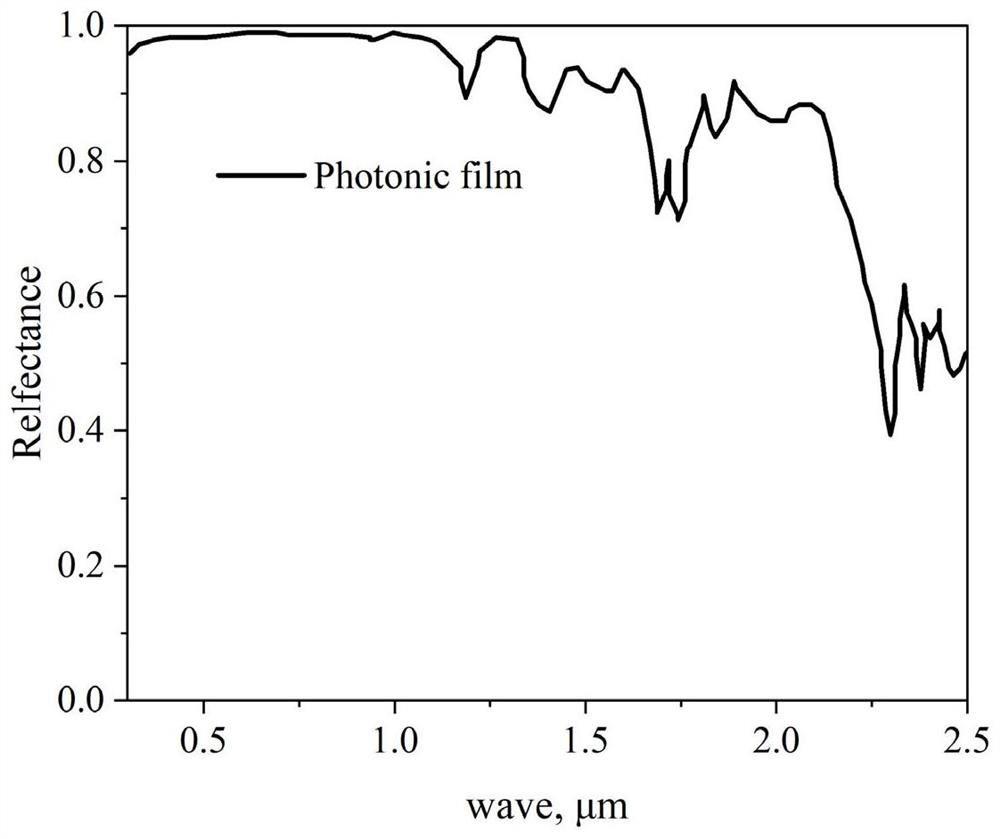

High-thermal-conductivity film as well as preparation method and application thereof

PendingCN114350155AImprove thermal conductivityImprove scattering efficiencyModifications by conduction heat transferPolymer scienceEmissivity

The invention discloses a high-thermal-conductivity film as well as a preparation method and application thereof. The high-thermal-conductivity film comprises a polymer matrix and photon structure nanosheets dispersed in the polymer matrix, the polymer matrix is an organic high-molecular polymer with high light reflectivity and high infrared emissivity; the addition amount is 30-85%, preferably 50-80%. The high-thermal-conductivity film has a good radiation cooling effect, can greatly reduce the surface temperature of an outdoor object, does not consume energy, and is suitable for radiation cooling of objects in a sub-environment and a high-temperature environment.

Owner:SHANDONG UNIV

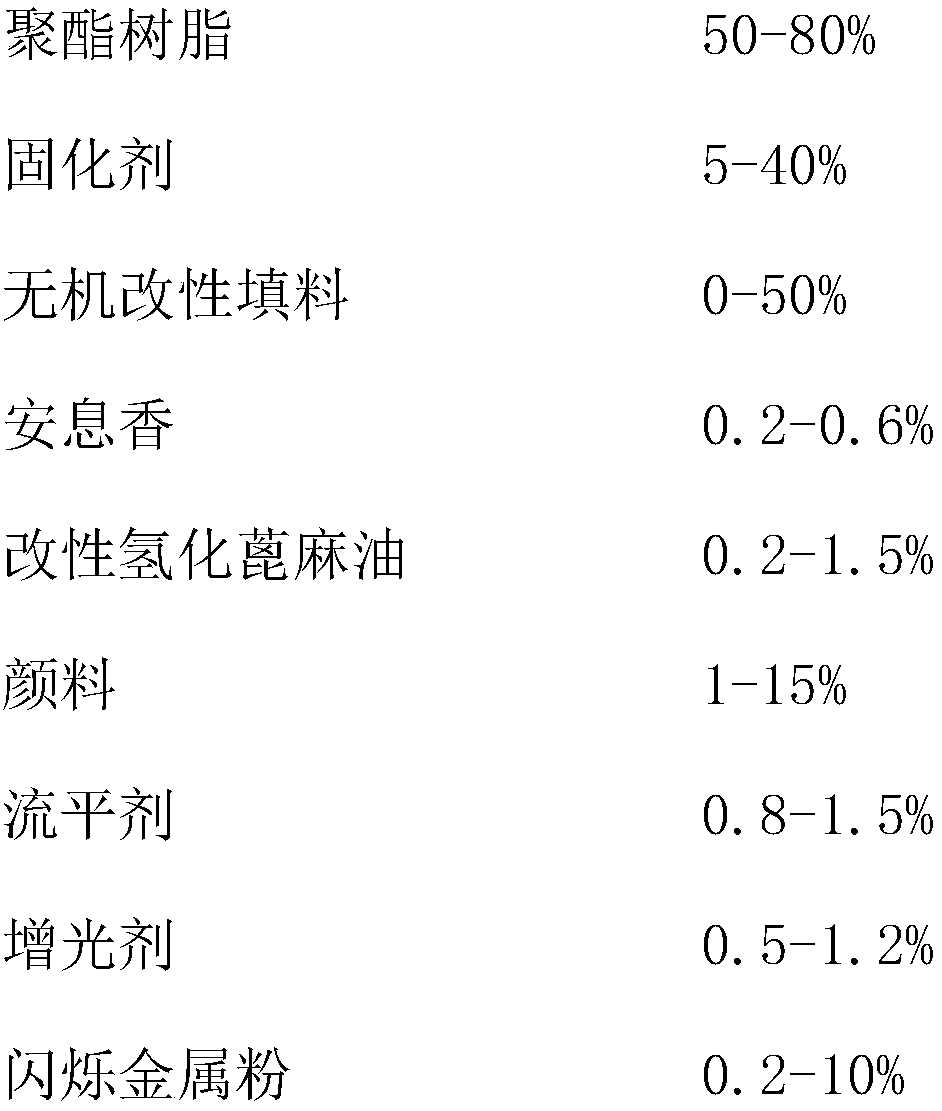

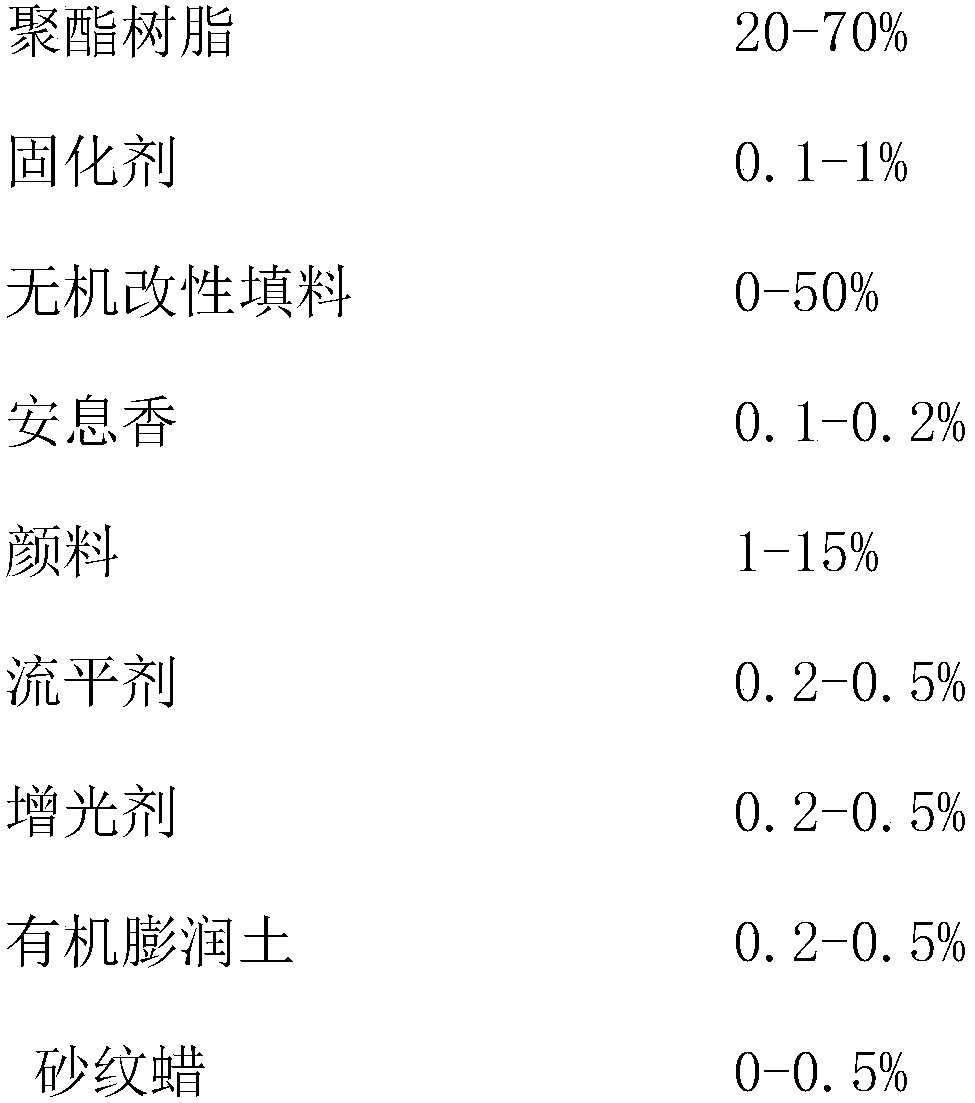

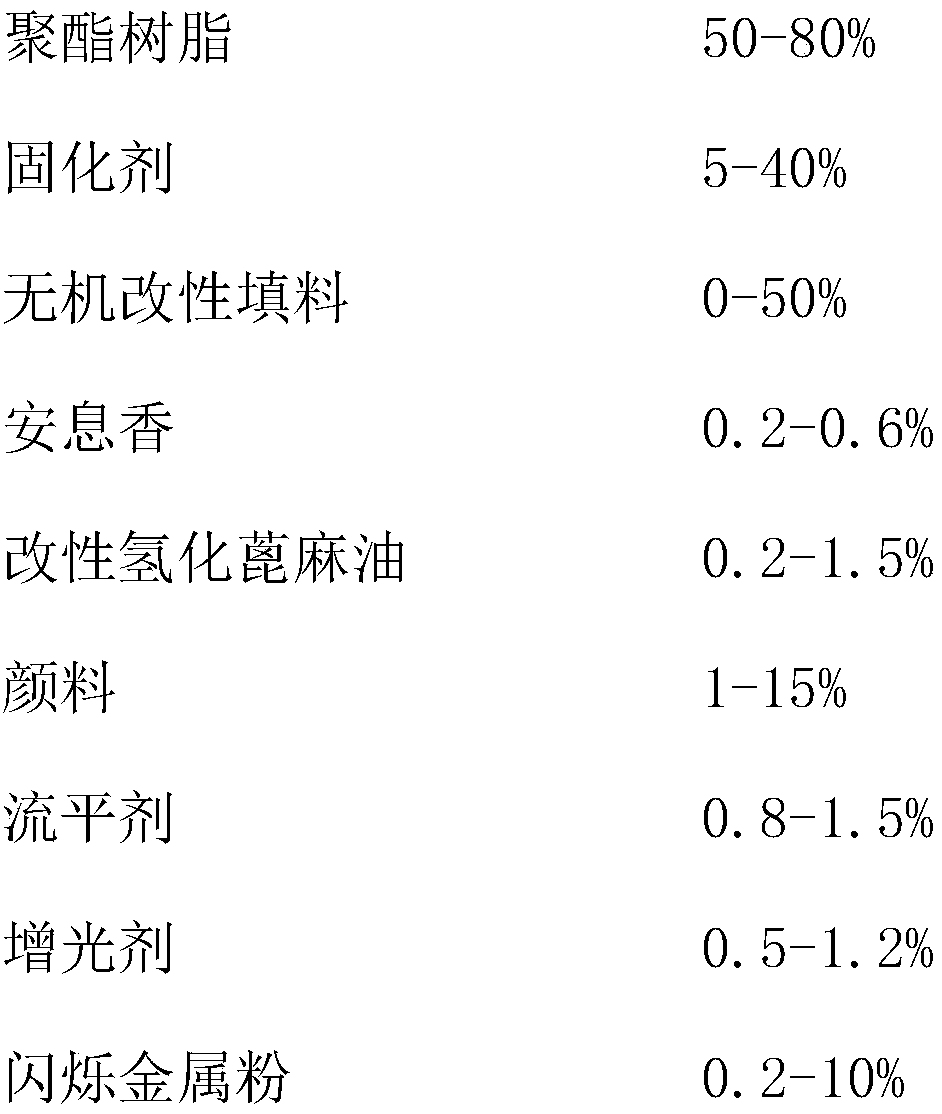

Method for preparing polyester resin for super-weatherability outdoor powder coating

ActiveCN102504219AHigh glossGood outdoor weather resistancePowdery paintsPolyester coatingsPolyolAging resistance

The invention relates to a method for preparing a polyester resin for super-weatherability outdoor powder coating, belonging to the technical field of the production of outdoor powder coating, in particular to the technical field of the processing process of the polyester resin used for producing coating. A polyalcohol and a polyacid condense, and water produced from reaction is removed to guarantee the continuous esterification, thus the polymer polyester resin with a certain degree of polymerization is obtained. The polyester resin produced by adopting the method is used for producing the outdoor powder coating and can ensure that the surface of the product has high gloss and superior outdoor weatherability. The artificial weathering aging resistance test proves that the polyester resin is qualified and can resist the weathering aging for 1,600h.

Owner:YANGZHOU XINBAO RESIN

Fluorocarbon powder coating for outdoor iron towers, and preparation method thereof

InactiveCN110776794AGood weather resistanceImprove hydrophobicityAntifouling/underwater paintsPaints with biocidesPolymer scienceMeth-

The invention discloses a fluorocarbon powder coating for outdoor iron towers, and a preparation method thereof. The fluorocarbon powder coating is prepared from, by weight, 35-45 parts of polyvinylidene fluoride resin, 8-12 parts of polytetrafluoroethylene resin, 12-16 parts of super weather-proof polyester resin, 20-30 parts of cycloaliphatic epoxy resin, 12-18 parts of acrylic resin, 12-18 parts of epoxy modified alkyd resin, 2-5 parts of polyhexamethylene guanidine, 3-6 parts of modified graphene, 6-10 parts of nano-silica, 0.5-3 parts of nano-alumina, 4-10 parts of barium sulfate, 1.8-2.4parts of silane coupling agent KH-792, 0.2-0.4 part of calcium stearate, 0.3-0.5 part of benzoin, 0.5-1 part of a leveling agent and 4-8 parts of a TGIC curing agent. The fluorocarbon powder coatinghas the advantages of excellent mechanical properties and super strong weather resistance, super strong chemical resistance and super strong leveling property, and has the characteristics of crackingresistance, aging resistance and long service life when applied to outdoor iron towers, and the preparation method is simple, and can achieve industrial production.

Owner:广西凯威铁塔有限公司

Outdoor weather-proof terrazzo resin floor and construction process

InactiveCN111847984AAvoid yellowingGood outdoor weather resistanceCovering/liningsPolyurea/polyurethane coatingsBenzoyl peroxideWeather resistance

The invention relates to the technical field of terrazzo, in particular to an outdoor weather-resistant terrazzo resin floor. The outdoor weather-resistant terrazzo resin floor comprises the followingcomponents: 1 part of weather-resistant resin and 6 parts of aggregate, wherein the weather-resistant resin comprises 100 parts of a main agent and 0.5-8 parts of a curing agent; the main agent is composed of, in parts by weight, 5 to 50 parts of polymethyl methacrylate, 5 to 50 parts of ethyl methacrylate, 5 to 50 parts of 1,4-butanediol dimethacrylate, 0.2 to 1 part of a modified organic silicon leveling agent, 10 to 20 parts of toner and 20 to 30 parts of silica powder; the aggregate is composed of, in parts by weight, 4-6 parts of quartz sand, 6-8 parts of transparent glass, 10 to 20 parts of natural shells, 20 to 40 parts of natural marble and 70 to 140 parts of quartz sand; and the curing agent is benzoyl peroxide. The outdoor weather-resistant terrazzo resin floor of the inventionsolves the problem of yellowing of outdoor colored terrazzo resin, and the produced terrazzo resin floor has the advantages of favorable outdoor weather resistance, excellent aging resistance, high bonding strength, uniform color sensation and no seams on the whole.

Owner:宿州典跃新型建筑材料有限公司

Method for preparing polyester resin for super-weatherability outdoor powder coating

ActiveCN102504219BHigh glossGood outdoor weather resistancePowdery paintsPolyester coatingsPolyolAging resistance

The invention relates to a method for preparing a polyester resin for super-weatherability outdoor powder coating, belonging to the technical field of the production of outdoor powder coating, in particular to the technical field of the processing process of the polyester resin used for producing coating. A polyalcohol and a polyacid condense, and water produced from reaction is removed to guarantee the continuous esterification, thus the polymer polyester resin with a certain degree of polymerization is obtained. The polyester resin produced by adopting the method is used for producing the outdoor powder coating and can ensure that the surface of the product has high gloss and superior outdoor weatherability. The artificial weathering aging resistance test proves that the polyester resin is qualified and can resist the weathering aging for 1,600h.

Owner:YANGZHOU XINBAO RESIN

Heat-insulating anticorrosion bi-component coating for outer wall of oil tank and preparation method thereof

InactiveCN109401475AHighlight substantive featuresSignificant progressAnti-corrosive paintsReflecting/signal paintsFoaming agentAcrylic resin

The invention relates to the field of coatings and specifically relates to a heat-insulating anticorrosion bi-component coating for an outer wall of an oil tank and a preparation method thereof. The heat-insulating anticorrosion bi-component coating comprises a component A and a component B; the component A comprises the following raw materials in parts by weight: 50-60 parts of acrylic resin, 15.0-20.0 parts of titanium dioxide, 3.0-5.0 parts of thermal reflection powder, 5.0-8.0 parts of quartz sand, 0.3-0.5 part of surface active agent, 1.5-3.0 parts of dispersing agent, 0.1-0.5 part of anti-settling agent, 0.5-1.0 part of de-foaming agent and the balance of water; the component B comprises the following raw materials in parts by weight: 70-75 parts of biuret and 0.1-2.0 parts of auxiliaries. The coating can achieve ultrahigh reflectivity, is capable of excellently reflecting solar radiation and achieving heat-insulating and cooling effects and has excellent coating hardness, abrasion resistance, alkali resistance and water resistance.

Owner:广西南宁维一防腐科技有限公司

Alkyd resin magnetic protective paint with high flash point

InactiveCN111205754AEasy to modifyReduce curing costsMagnetic paintsPolyester coatingsPolymer scienceVegetable oil

The invention relates to the technical field of paint coating processing, and discloses an alkyd resin magnetic protective paint with a high flash point. The paint comprises the following raw materials in parts by weight: 70 to 80 parts of acrylic acid modified alkyd resin, 0.4 part of a wetting dispersant AT203, 0.4 part of bentonite, 20 to 30 parts of titanium dioxide, 0.6 to 0.8 part of a composite drier, 0.1 to 0.2 part of an anti-skimming agent, and 3 to 5 parts of solvent oil. Through a two-step esterification method, a carboxyl group on an acrylic resin chain segment completely reacts with polyol ester so as to embed acrylic resin into an alkyd resin chain segment, and a good modification effect is achieved. The main raw material source of the alkyd resin magnetic protective paint is vegetable oil or fatty acid, the dependence on petroleum products is small, and the alkyd resin magnetic protective paint is cured in an air / oxygen mode, so that the resin curing cost is low. The paint has the advantages of quick drying and good outdoor weather resistance of an acrylic resin paint, overcomes the defects of low hardness and low drying speed of an alkyd resin paint, and has a great market application prospect.

Owner:哈尔滨市雪鹰工程材料有限公司

Preparation method of decorative golden ceramic tile

The invention relates to the field of ceramic processing manufacture, in particular to a preparation method of a decorative golden ceramic tile. The invention uses an ordinary ceramic tile as a base material, the ceramic tile is firstly cleaned, granular low-temperature melting blocks are printed on the surface of the ceramic tile, blanks printed with the granular low-temperature melting blocks are baked at a high temperature, cooling the blanks to the room temperature, gold trisulfide paste is coated on the blanks, and then, the tiles coated with the gold trisulfide paste is baked and formed again. The decorative golden ceramic tile prepared by the method has magnificent and egyptian yellow effect, and brings strong visual impact to people. When being used, the decorative golden ceramic tile prepared by the invention has the advantages of sun irradiation resistance, wear resistance and good outdoor weather resisting property. In addition, the work procedures are simple, and the operation is easy.

Owner:成都新西南陶瓷艺术股份公司

Ultra-durable three-dimensional metal wiredrawing effect coating and production method thereof

InactiveCN109337529AColorful three-dimensional metal flashing effectImprove corrosion resistancePretreated surfacesAnti-corrosive paintsWeather resistanceMetallurgy

The invention provides an ultra-durable three-dimensional metal wiredrawing effect coating and a production method thereof. The coating is prepared from the following components in percent by mass: 50-70% of a first coat powder coating A, 10-30% of a wiredrawing ultrafine powder coating B and 10-20% of a transparent fluorocarbon aqueous coating. The coating has a colorful three-dimensional metal flickering effect, excellent corrosion resistant performance, excellent mechanical property, good adhesive force and extremely excellent outdoor weather resistance, and can meet the using demands of 15to 20 years outdoors. In addition, the coating is reasonable in design and is designed by an environment-friendly method, and VOCs zero emission from production to construction and application is achieved. By adjusting the color and the metal effect of the first coat powder coating A, ultra-durable three-dimensional wiredrawing coatings of various colors and different metal flickering effects canbe produced, so that the application range of the ultra-durable three-dimensional metal wiredrawing effect coating is enhanced greatly, and the ultra-durable three-dimensional metal wiredrawing effect coating has wide popularizing and application value.

Owner:廊坊艾格玛新立材料科技有限公司

Coil coating and production method thereof

ActiveCN109233568AGood outdoor weather resistanceGood gloss and color retentionEpoxy resin coatingsEpoxyChemical reaction

The invention relates to the field of coating, in particular to coil coating and a production method thereof. The coil coating comprises the following raw materials in parts by weight: 80-120 parts ofepoxy resin, 50-70 parts of acrylic resin, 15-20 parts of polyvinylidene fluoride, 3-5 parts of garnet, 10-15 parts of glass fiber, 5-10 parts of titanium dioxide, 5-10 parts of zinc oxide, and 0.5-2parts of auxiliary agent. The prepared coil coating has a reflection effect on ultraviolet light, prevents the aging, powdering, cracking and other damage of a formed film caused by the photochemicalreaction of the ultraviolet light on a coating, and enhances the weather resistance of the coating; and the coil coating has excellent comprehensive mechanical properties, high storage stability, good decorativeness, protectiveness, durability, stamping resistance, abrasion resistance, light resistance, weather resistance, scratch resistance, physical hardness and the like, fine texture, smooth appearance, no dust accumulation, gloss and color retention and excellent adhesiveness, and is not easy to yellow.

Owner:广西南宁维一防腐科技有限公司

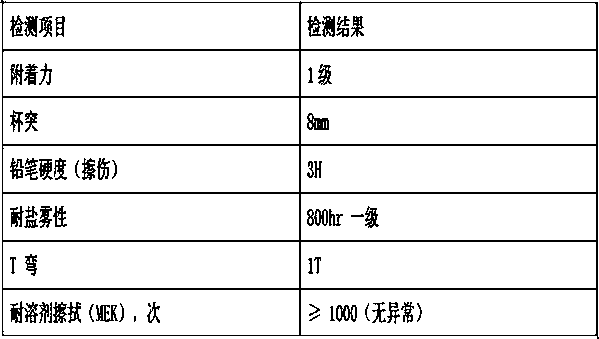

Solar glass panel with honeycomb-shaped colored tempered coating, production method of solar glass panel and colored solar photovoltaic module

ActiveCN113088116AImprove photoelectric conversion efficiencySolve aestheticsCoatingsPhotovoltaic energy generationUltraviolet lightsPhotopigment

The invention discloses a solar glass panel with a honeycomb-shaped colored tempered coating, a production method of the solar glass panel and a colored solar photovoltaic module. The production method comprises the following steps: coating a photovoltaic glass panel with a UV colored tempered coating, and preheating the photovoltaic glass panel; after preheating, adopting ultraviolet light for irradiating the UV colored tempered coating; obliquely punching or scribing the preliminarily-cured UV colored tempered coating by adopting a laser beam so as to enable the UV colored tempered coating to form a honeycomb structure; performing high-temperature tempering on the perforated UV colored tempered coating to form the solar glass panel with the honeycomb-shaped colored tempered coating. The UV colored tempered coating comprises the following raw materials in percentage by mass: 8-25% of a thermoplastic polymer, 10-25% of a low-viscosity photoactive diluent, 1-3% of a photosensitizer, 50-65% of a transparent glass flux, 0.1-15% of an inorganic pigment and 0.01-3% of a leveling agent. The coating of the solar glass panel provided by the invention is excellent in shock resistance and has relatively high light transmittance.

Owner:杭州玻美文化艺术有限公司

Normal-temperature curing high-hardness steel bar anticorrosive coating and preparation method thereof

PendingCN113999551AHigh hiding powerImprove liquidityAntifouling/underwater paintsAlkali metal silicate coatingsKaolin clayAntibacterial activity

The invention discloses a normal-temperature curing high-hardness steel bar anticorrosive coating and a preparation method thereof. The normal-temperature curing high-hardness steel bar anticorrosive coating comprises kaolin, slag, cement, sodium silicate, sodium hydroxide, latex powder, a defoaming agent, an adherence promoter and styrene-acrylic emulsion. According to the invention, kaolin is taken as the raw material, and other inorganic powder and styrene-acrylic emulsion are doped for modification and enhancement, so that the metal anticorrosive coating which is good in film-forming property, high in strength, non-toxic and environment-friendly is obtained; the surface drying time of the coating material is 30 minutes, the hard drying time is 3 hours, the coating hardness is 9H in 24 hours, and the coating material has antibacterial activity, waterproofness and incombustibility and has excellent adhesion to the matrix on a metal or non-metal surface; the inorganic material powder used in the invention is widely distributed around the world, is cheap and easily available, and has the advantages of simple preparation process, low cost, no toxicity and no pollution.

Owner:XIAN UNIV OF TECH

Inkjet reflective film and preparation process thereof

InactiveCN109164523AGood weather resistanceStrong ink absorptionOptical elementsDuplicating/marking methodsWeather resistancePrism

The invention discloses an inkjet reflective film. The inkjet reflective film comprises a modified ink-absorption inkjet layer, a bonding layer, a micro-prism crystal powder layer, a glow powder layer, a white substrate layer, a removable adhesive layer, and a release paper layer; the bonding layer is arranged below the modified ion-absorption inkjet layer, and the micro-prism crystal powder layerand the glow powder layer are arranged at intervals; flat surfaces of the micro-prism crystal powder are upward and the tips are downwards, partial micro-prism crystal powder is embedded into a lowersurface of the bonding layer and partial micro-prism crystal powder is embedded into an upper surface of the white substrate layer; the removable adhesive layer is arranged below the white substratelayer, and the release paper layer is arranged below the removable adhesive layer. The invention further discloses a preparation process thereof. The inkjet reflective film disclosed by the inventionhas the night self-luminous double effect by utilizing a high-reflecting principle of the micro-prism crystal powder and combining the glow powder; the surface layer of the product disclosed by the invention is a good modified ink-absorption inkjet layer and is high in weather-resistant. The inkjet, the luminous and the reflecting three characteristic are perfectly fused in the product disclosed by the invention, and can be easily observed whether under a state of possessing a light source or the state without the light source.

Owner:武义好亮工贸有限公司

Ultraviolet light curing fluorocarbon paint and preparation method thereof

The invention discloses an ultraviolet light curing fluorocarbon paint and a preparation method thereof, and belongs to the technical field of paints. The ultraviolet light curing fluorocarbon paint is used for heat transfer printing, and is prepared from the following ingredients in percentage by mass: 45 to 55 percent of organic fluorine light-cured resin, 25 to 35 percent of active monomers, 10 to 15 percent of solvents, 0.2 to 0.5 percent of flatting agents, 0.2 to 0.5 percent of antifoaming agents and 2 to 4 percent of photoinitiators. All of the ingredients are uniformly mixed in sequence to obtain the ultraviolet light curing fluorocarbon paint provided by the invention. The ultraviolet light curing fluorocarbon paint has the advantages that fluorocarbon resin with excellent weatherability and anti-corrosion performance is selected to be matched with acrylic resin with excellent weatherability and polyfunctional active monomers, so that a coating film has good hardness and adhesive force; meanwhile, the excellent weatherability is realized; the paint is particularly applicable to outdoor decoration plate materials, and has great market popularization value.

Owner:SHANGHAI HENGFENG FLUOROCARBON MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com