Patents

Literature

56results about How to "Reduce curing costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

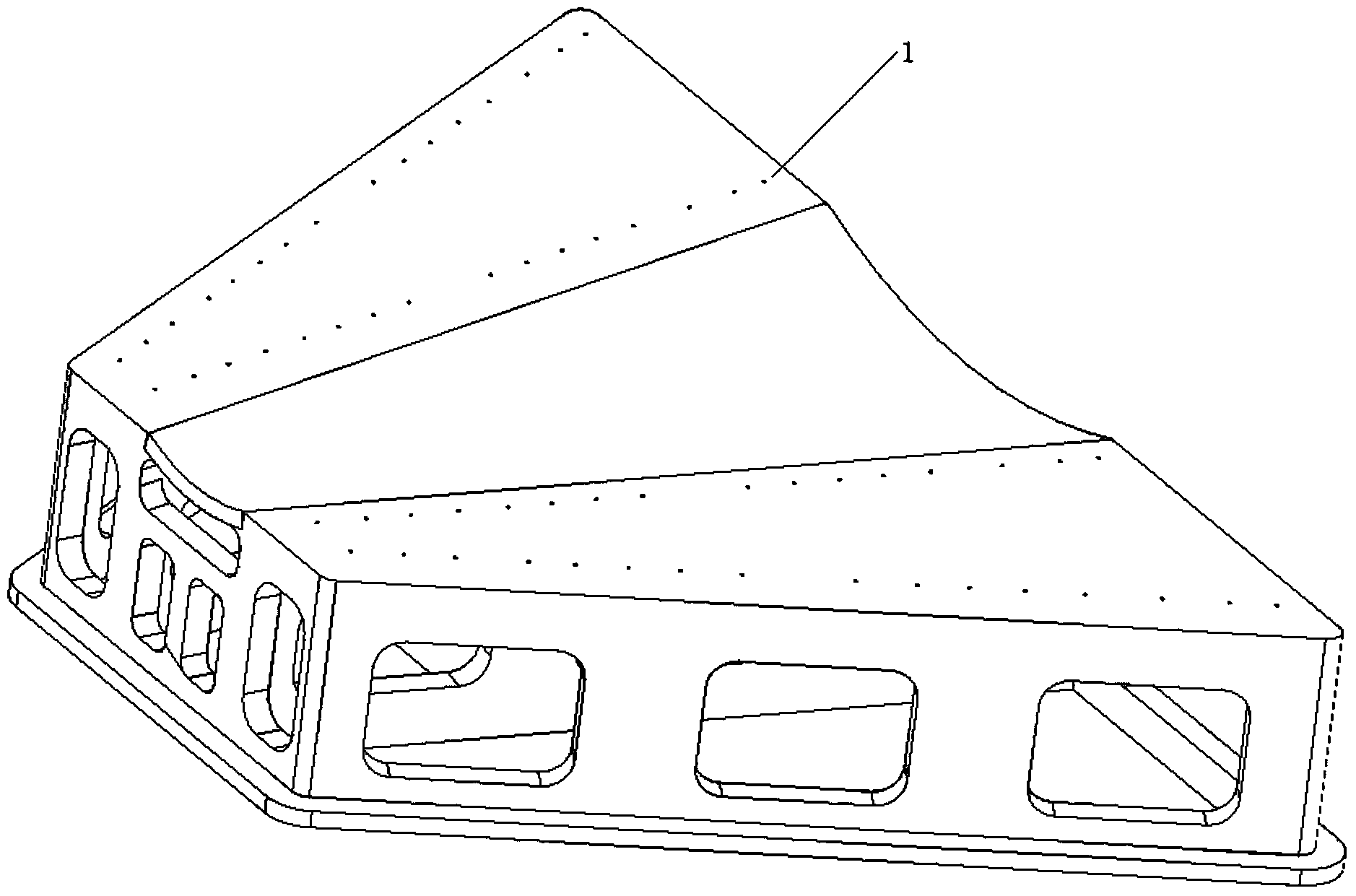

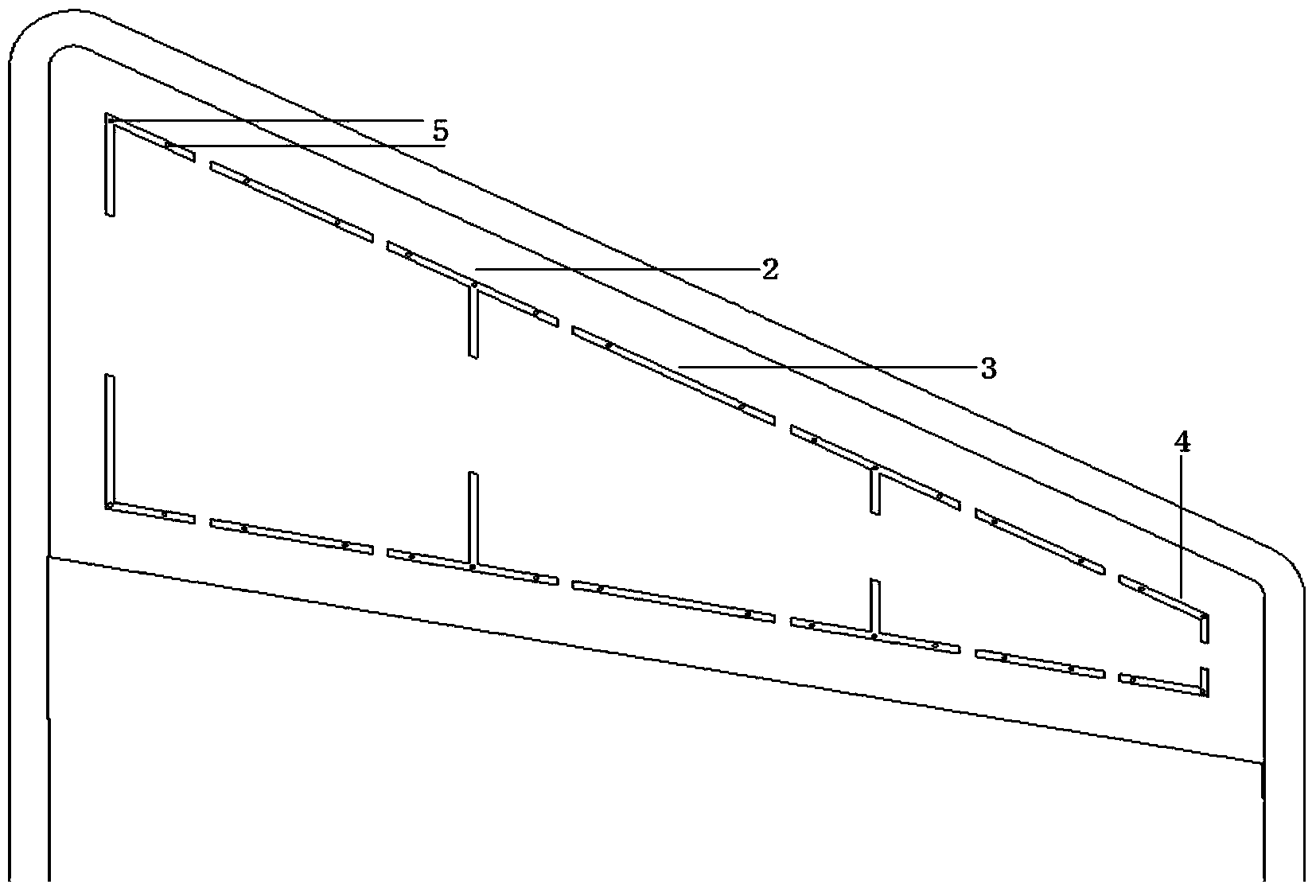

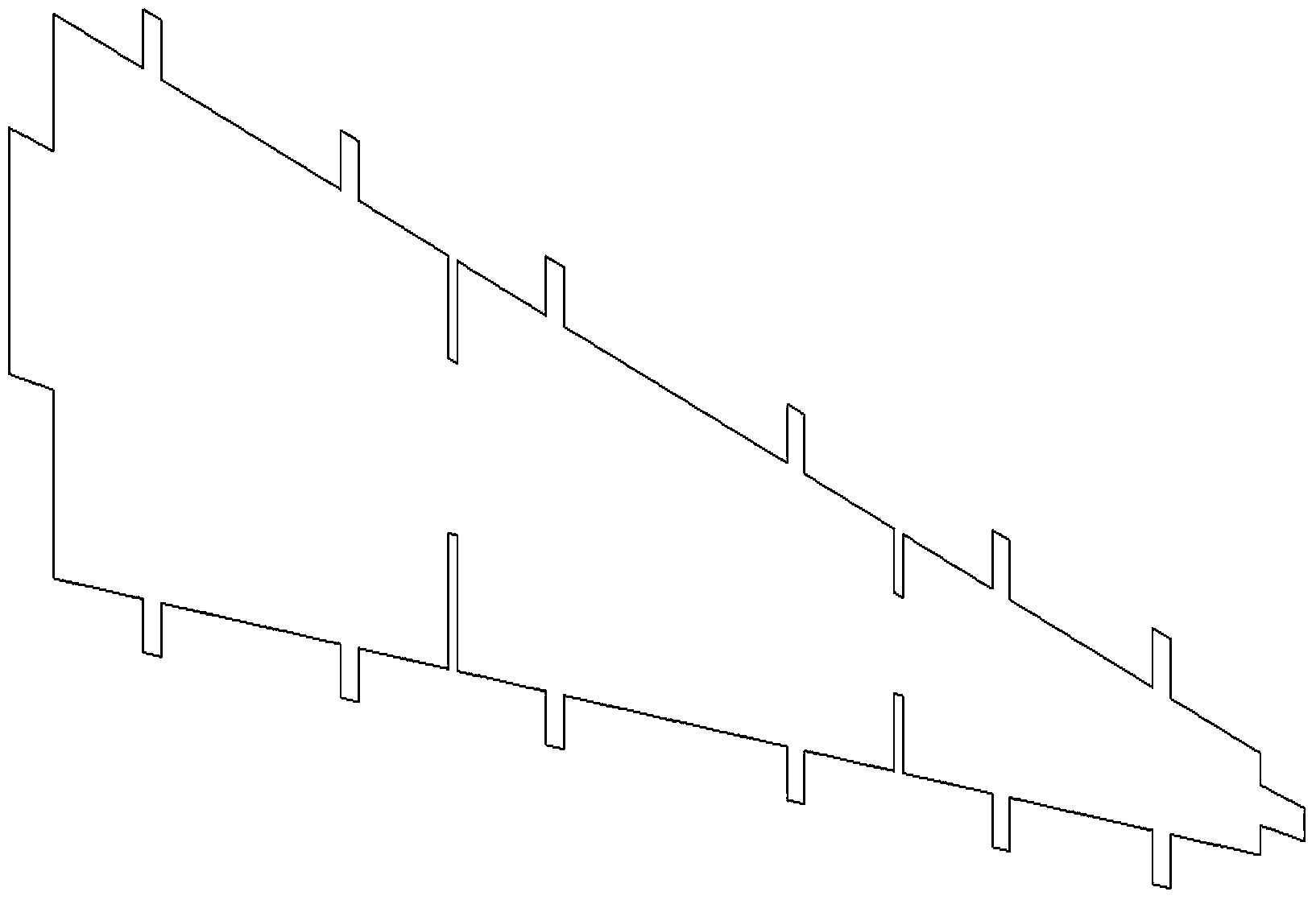

Manufacturing method of wing-body integrated honeycomb sandwiched composite material skin

The invention provides a manufacturing method of a wing-body integrated honeycomb sandwiched composite material skin. The manufacturing method comprises the steps of preparing a hot-pressing die of the wing-body integrated honeycomb sandwich composite material skin, laying and hot-pressing, wherein a plurality of antiskid positioning holes having the diameter of 0.5mm are formed in the profile of the die along honeycomb mounting edges. Flexible honeycomb antiskid positioning ribs are mounted on the profile of the die and a beneficial solidification process in a hot-pressing tank is obtained by virtue of lots of tests, so that shortcomings caused by the deviation of a honeycomb sandwich in a co-solidification process are eliminated thoroughly, the solidification period is shortened and the solidification cost is reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Biological solidification and stabilization method of bottom mud in riverways and lakes

InactiveCN102092916ASolve the way outReduce curing costsSludge treatment by de-watering/drying/thickeningBiological sludge treatmentAmylaseActive agent

The invention relates to improvement of a biological solidification and stabilization method of dredge bottom mud. The biological solidification and stabilization method is characterized by comprising the following steps: primarily dehydrating clay particles which have less possibility of being dehydrated, and mixing and stirring the dehydrated clay particles with dry soil to form mixed soil; and spraying a compound biological enzyme liquid at least consisting of reductase, amylase, cellulase, esterase, lipase, ligninase, prolease, urease, xylanase and a detergent surface active agent to be mixed with the mixed soil, then compacting and solidifying. The biological solidification and stabilization method has the advantages of short process flow and simplicity; by utilizing the method, the volume of the bottom mud to be solidified and stabilized is greatly reduced, the volume of the bottom mud to be solidified after classification and dehydration is 10%-15% of that of the bottom mud to be conventionally solidified, the processing flow is reduced compared with the existing biological enzyme solidification, the solidification cost is reduced, the solidification strength is high, the solidification filling shear strength can reach the Mpa grade, thus the method can be used for road construction, parking lots, slope solidification, reservoir surface solidification, refuse landfill bottom solidification and seepage prevention and public road building. By using the method, the outlet problem of the dredge bottom mud is effectively solved, and a novel decrement and solidification process for the bottom mud in the lakes is created.

Owner:GUANGZHOU ZHUSHUI ENVIRONMENT TECH

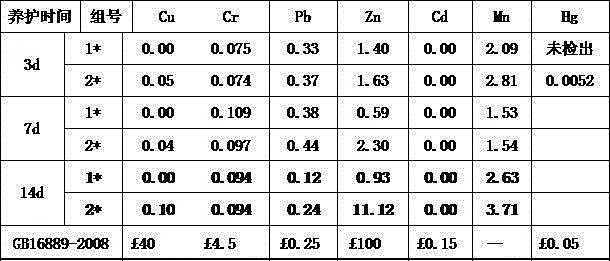

Municipal solid waste incineration fly ash curing method

InactiveCN104607434AReduce dosageRealize comprehensive utilizationSolid waste disposalStrontium carbonateEnvironmental engineering

The invention discloses a municipal solid waste incineration fly ash curing method. The method comprises the steps of mixing waste incineration fly ash, cesium carbonate waste residue, potassium carbonate and cement according to the ratio of (40-50): (25-38): (3-6): (15-25); then, feeding right amount of purified water into the mixture, evenly mixing, enabling a molding model to be filled with the mixture, extruding and compacting; after that, standing the model in the air for 24 hours, and then demoulding to obtain a cured green body; maintaining the cured green body to obtain a cured body which can be directly buried, wherein the maintaining time is not shorter than 14 days. According to the method, the cesium carbonate waste residue is taken as an important raw material for curing the fly ash, so that the consumption of the cement is greatly reduced, waste recycling is realized, and the waste incineration fly ash curing cost is lowered. After the method is used, the compressive strength of the cured body and the heavy metal leaching completely meet the landfill requirements.

Owner:CHONGQING UNIV

Solidification treatment method for sludge of urban sewage plant

InactiveCN102424511AHigh strengthReduce voidsSludge treatment by de-watering/drying/thickeningAluminatePortland cement

The invention discloses a solidification treatment method for sludge of urban sewage plants. The method comprises the following steps of (1) adding curing agent consisting of lime, sulfate aluminum cement, portland cement and fly ash in dehydrated sludge based on the weight of the dehydrated sludge, wherein the weight percentage of lime, sulfate aluminum cement, portland cement and fly ash in the curing agent are as follows: 1.2-1.9% of lime, 3.0-6.1% of sulfate aluminum cement, 3.0-3.7% of portland cement and 4.7-6.0% of fly ash; and (2) mixing the sludge added with the curing agent to form precursors of solidified blocks, piling the precursors up according to a height of 7 cm, and covering with waterproof membrane, maintaining the precursors for three days with a dry maintaining method, and forming sludge solidified blocks. The method provided by the invention has the advantages of efficiency, low cost, simple operation and the like.

Owner:CHONGQING UNIV

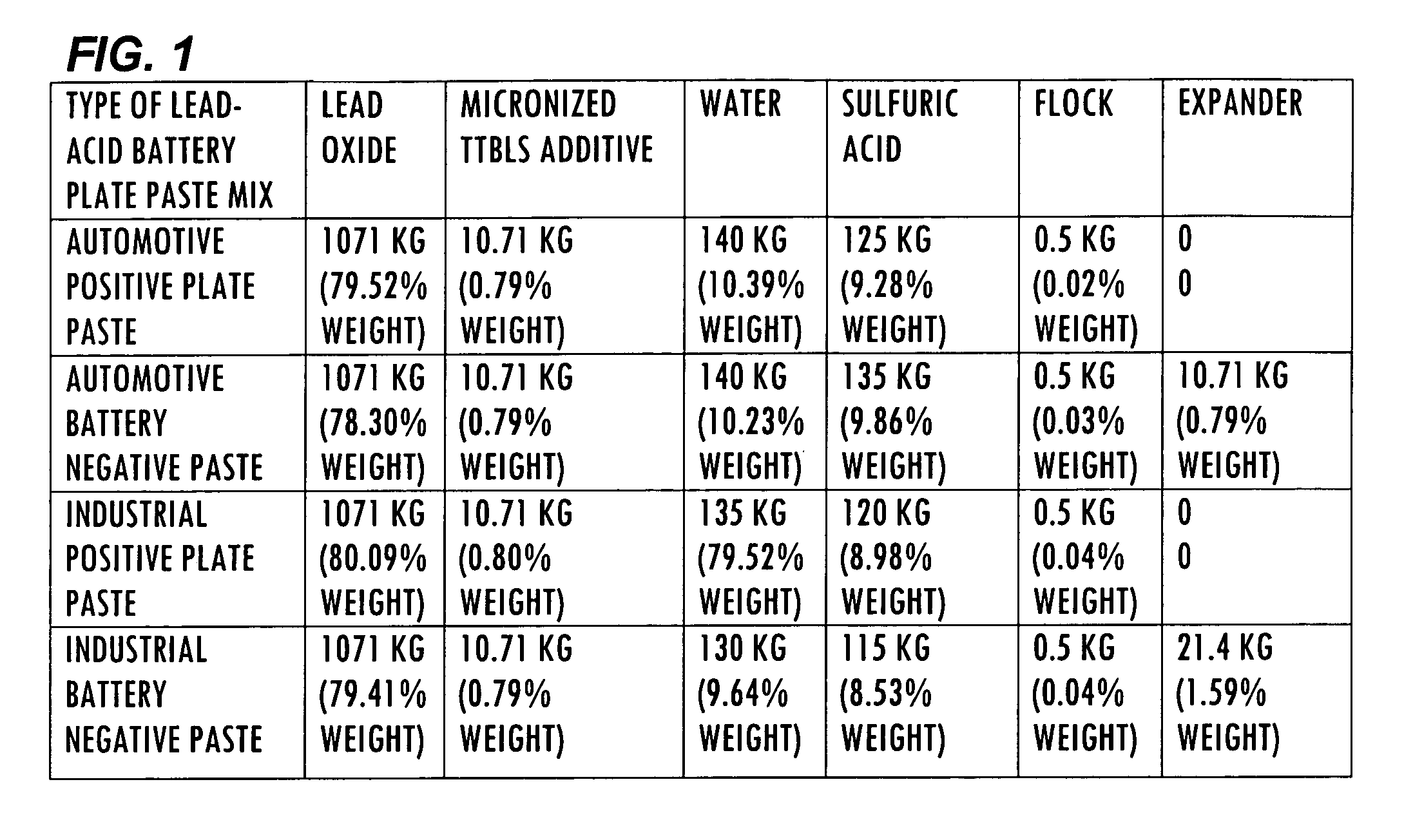

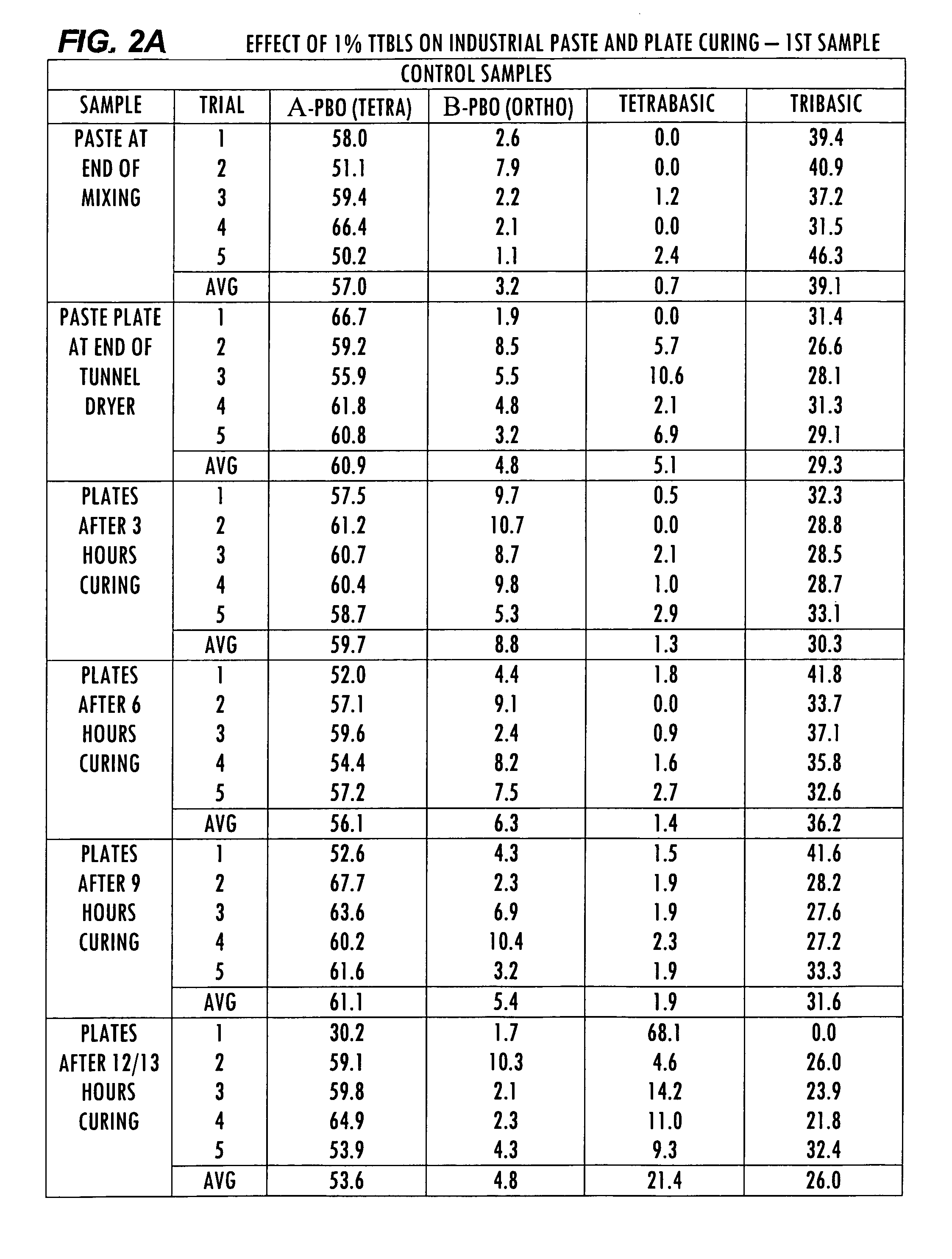

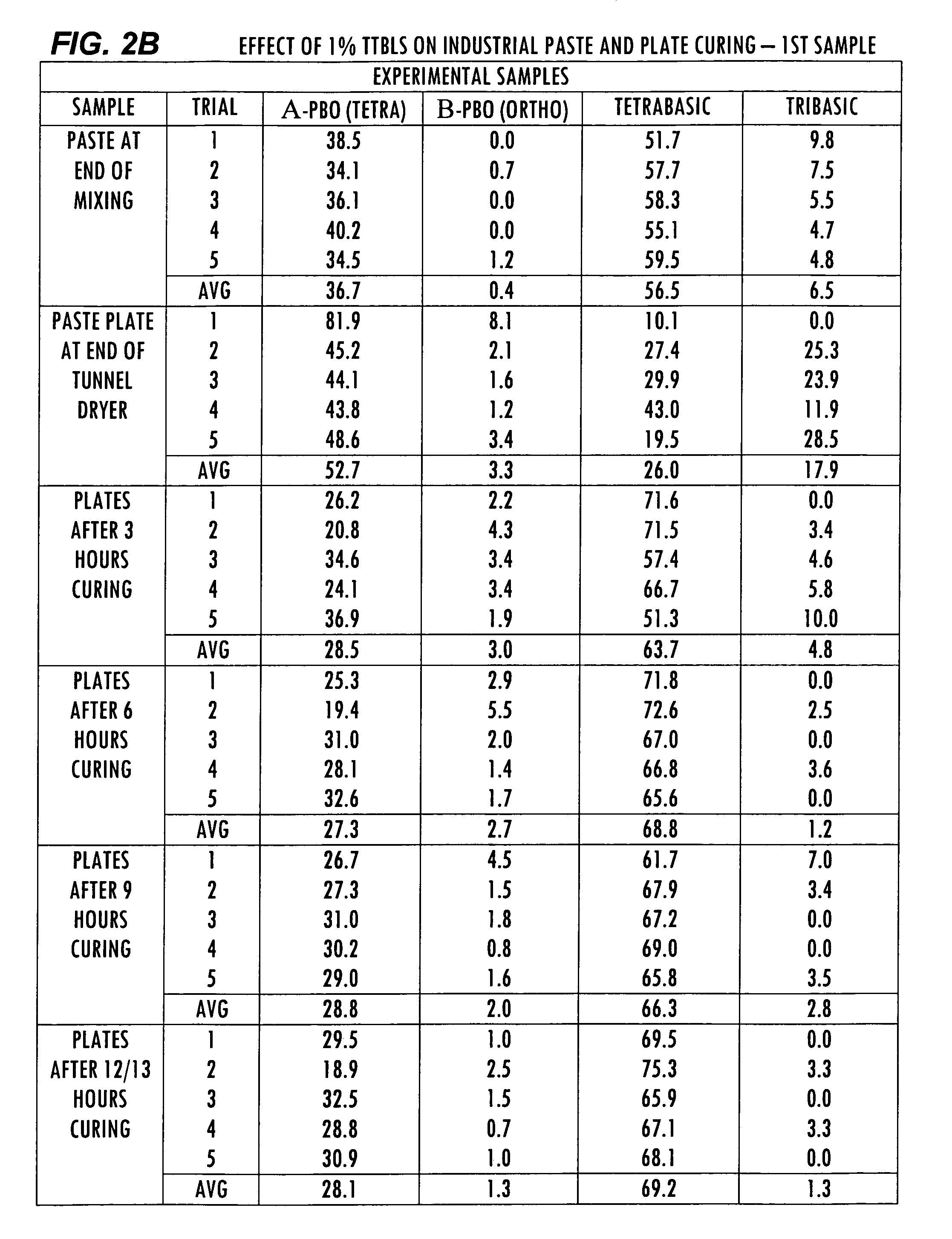

Battery paste additive and method for producing battery plates

ActiveUS7118830B1Increase productionShorten treatment timeLead-acid accumulatorsElectrode carriers/collectorsSeed crystalElectrical battery

A battery paste additive, and process for making the same comprising micronized seed crystals of tetra basic lead sulfate, is added to battery paste and results in accelerated curing time and other improvements in battery performance. The battery paste additive may be used to produce positive or negative battery plates and may be use with conventional mixing, pasting and curing processes and equipment.

Owner:HAMMOND GRP INC

Fine grain tailing low-cost solidification disposal method

The invention discloses a fine grain tailing low-cost solidification disposal method which comprises five processes: tailing concentration and transportation, curing agent mixing grinding, mixing of tailing and curing agent, aging and molding, and conserving. Curing agent is composed of pulverized fuel ash, quick lime and sintering desulfurization ash. The weight ratio of the pulverized fuel ash, the quick lime and the sintering desulfurization ash is 1:0.4-0.5:0.12-0.15. Tailing is mixed with the curing agent, and dry tailings are added so that in the final discharged materials, water is presented in amount of 24%-29%. By dry weight, the ratio between the tailing and the curing agent is 76.2-90.4:9.6-23.8. The conserving process comprises natural conserving, or combination of the natural conserving and atmospheric steam or high-pressure steam. The curing agent is simple in formula, little in use dosage, good in catalytic effect, high in strength of curing products, and low in tailing curing cost. Through adjustment of dosage of the curing agent, curing products of various construction materials like construction bricks for filling or producing can be produced, and combination of tailing processing and tailing comprehensive utilization are achieved.

Owner:武钢资源集团有限公司 +1

Method for curing dredged sludge by doping incinerated bottom ash of domestic garbage

InactiveCN102941209ASolve the way outImproved soil mechanical propertiesSolid waste disposalSocial benefitsBottom ash

The invention discloses a method for curing dredged sludge by doping incinerated bottom ash of domestic garbage. The ratio between the doping amount of the incinerated bottom ash of the domestic garbage and the weight of the dredged sludge is 0.3-0.5:1, the ratio between the doping amount of a curing agent and the weight of the incinerated bottom ash of the domestic garbage is 0.1-0.2:1, the unconfined compressive strength of a cured body with the 28-day age is 50-80kPa, and the cured body is not collapsed when being soaked by water. The method disclosed by the invention has the beneficial effects that the characteristics of aggregate characteristic, absorbability and potential hydraulicity of the incinerated bottom ash of the garbage are utilized to solve the problems of high clay content, high moisture content and low strength and the like of the dredged sludge in a targeted way, and the dredged sludge after curing treatment can be used as a soil filling material for recycling; the physical and chemical characteristics of the incinerated bottom ash of the garbage are fully utilized, so that the treatment of wastes with wastes is achieved; and compared with the existing dredged sludge curing technology, the method has the advantages that the curing cost is obviously reduced, simultaneously the problem of the treatment way of two types of wastes is solved, and the environmental benefit and the social benefit are obvious.

Owner:ZHEJIANG SCI-TECH UNIV

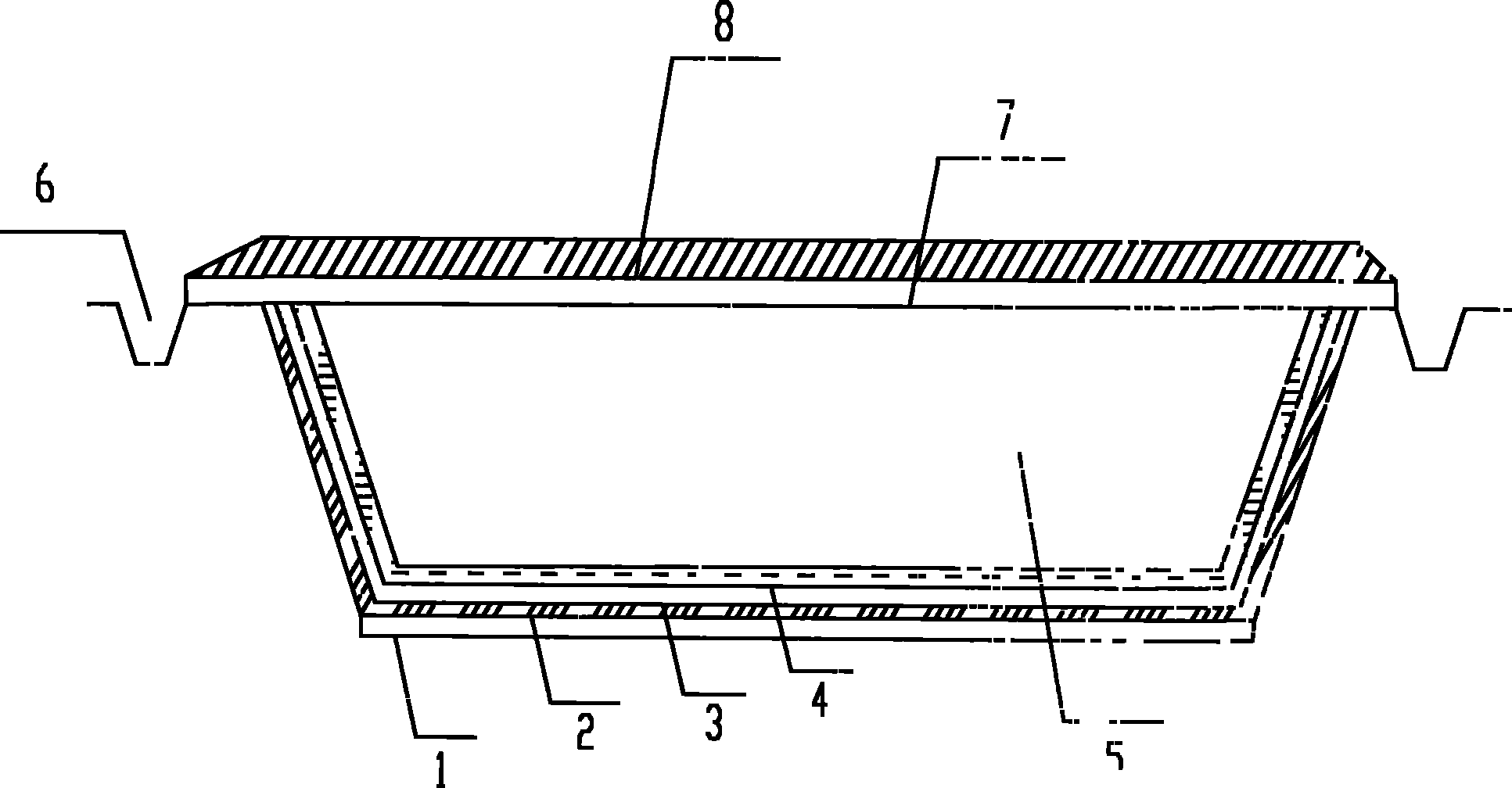

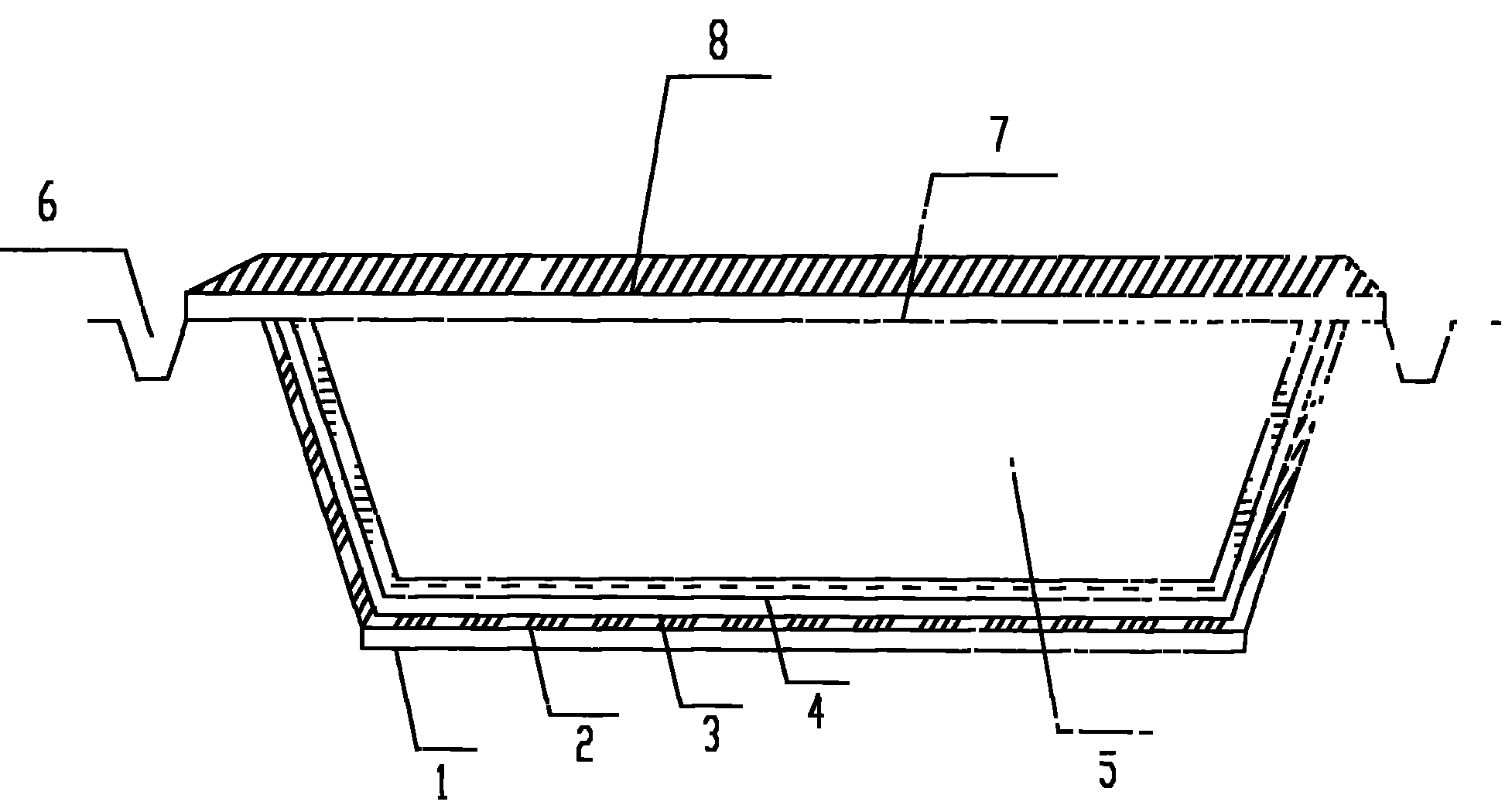

Method for constructing oil drilling waste mud solidification pool

ActiveCN101979781AImprove anti-seepage effectWill not puncture the polyethylene geomembraneArtificial islandsUnderwater structuresGeomembraneWell drilling

The invention provides a method for constructing an oil drilling waste mud solidification pool and relates to the technical field of oil and gas exploration drilling pollution control. A scheme of the method comprises the following steps of: excavating the solidification pool on site, wherein the slope of a pool wall is 45 to 60 DEG, and the pool height is 2.0 to 2.5 m; performing seepage control on a pool bottom by adopting clay-(non-woven geotextile)-(high-density polyethylene geomembrane)-(non-woven geotextile); continuously packaging solid waste to a top part by using the clay-(non-woven geotextile)-(high-density polyethylene geomembrane)-(non-woven geotextile); and capping the top part by using C20 concrete so as to prevent a solidified body from seeping. The process is simple and easy, the cost investment is small, the construction period is short, and the drilling waste mud is propelled to be solidified rapidly and timely so as to effectively prevent the waste mud from overflowing and polluting the environment in the drilling operation process.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD +1

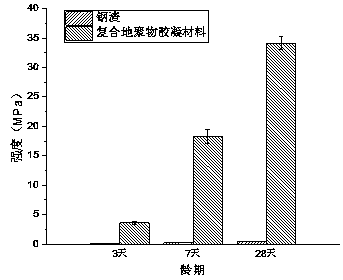

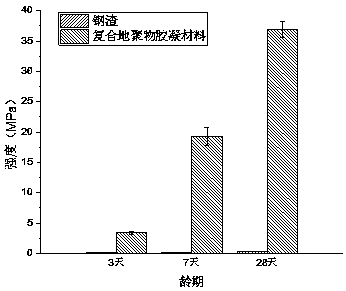

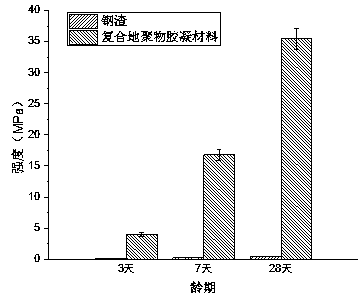

Red mud-steel slag composite geopolymer cementing material for soft base solidification

The invention discloses a red mud-steel slag composite geopolymer cementing material for soft base solidification. The cementing material is adopted for soft base solidification and soil improvement.The main body of the cementing material consists of red mud, steel slag, cement, metakaolin and an early strength water reduction agent. Active aluminate and silicate components of the cementing material are provided from the red mud and the metakaolin, minerals in the steel slag, the metakaolin and the red mud are activated by the alkali properties of the red mud self and a small amount of the cement to carry out a hydration reaction, then cementing substances can be generated, and the red mud-steel slag composite geopolymer cementing material is relatively high in strength and good in property. The mass ratio of the red mud to the steel slag to the cement to the metakaolin is (42-50):(35-41):(4.5-10.5):(4-10):(1-2). When the cementing material is applied to soft soil solidification, theutilization rates of the two wastes, namely the red mud and the steel slag, can be increased, application of the cement in soft base solidification can be also reduced, the soft base solidification cost can be reduced, and good environment benefits can be made.

Owner:SOUTHEAST UNIV +1

Intermittent sectional quick solidification method for cadmium-free internal formation storage battery

ActiveCN102683651AImprove cycle lifeEfficient methodLead-acid accumulator electrodesHigh humidityLead sulfate

The invention belongs to an intermittent sectional quick solidification method for a cadmium-free internal formation storage battery. An intermittent sectional high-temperature and high-humidity solidification method, a short-time high-temperature high-humidity seven-stage solidification method and a process clearance pause method are combined, and formation of a great amount of tetrabasic lead sulfate (4PbO.PbSO4.H2O) is avoided, so a mixture of tribasic lead sulfate and tetrabasic lead sulfate is easily formed in a pole plate, the tribasic lead sulfate is a major part in the pole plate, the cycle life of the storage battery can be prolonged, and the primary discharge capacity can be improved. The sectional high-temperature and high-humidity solidification method is employed, and the intermittent sectional quick solidification method is effective, practical and convenient and has the advantages that solidification time is greatly shortened, energy is saved, consumption is reduced, the quality of products is improved, and the cycle life of the storage battery is long.

Owner:江苏超威电源有限公司

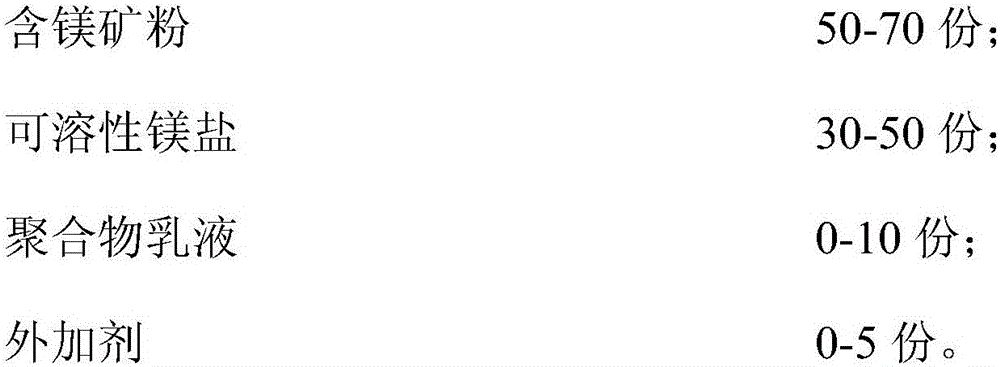

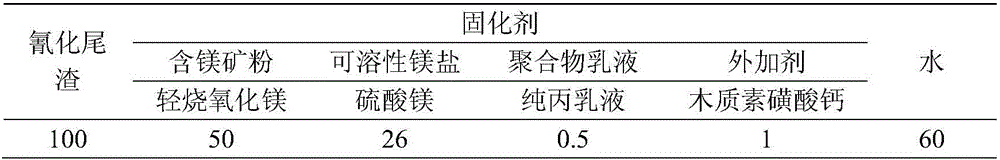

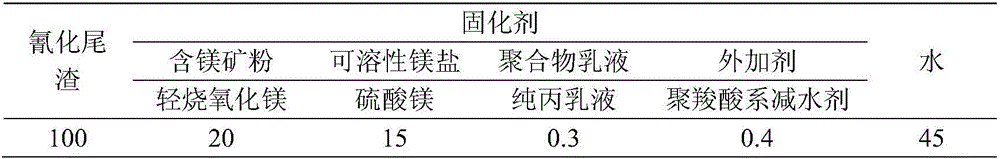

Cyanidation tailing solidification agent and application of solidification agent

The invention relates to a cyanidation tailing solidification agent and an application of the solidification agent. The cyanidation tailing solidification agent comprises the following components in parts by mass: 50-70 parts of magnesium ore powder, 30-50 parts of a soluble magnesium salt, 0-10 parts of a polymer emulsion and 0-5 parts of an admixture. The solidification agent provided by the invention can motivate self cementation solidification of inactive cyanidation tailings, and also provides solidification strength which is high enough. A solidification body formed by combination with the cyanidation tailings has a compact structure, and pollutants of CN<-> and heavy metals are controlled by solidification and stabilization, so that the leaching rate meets the relative requirements of national standards. The solidification agent provided by the invention has less doping amount, employs cheap raw materials, decreases the solidification cost of the cyanidation tailings, is suitable for industrialized production, and has good economic benefits and wide application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

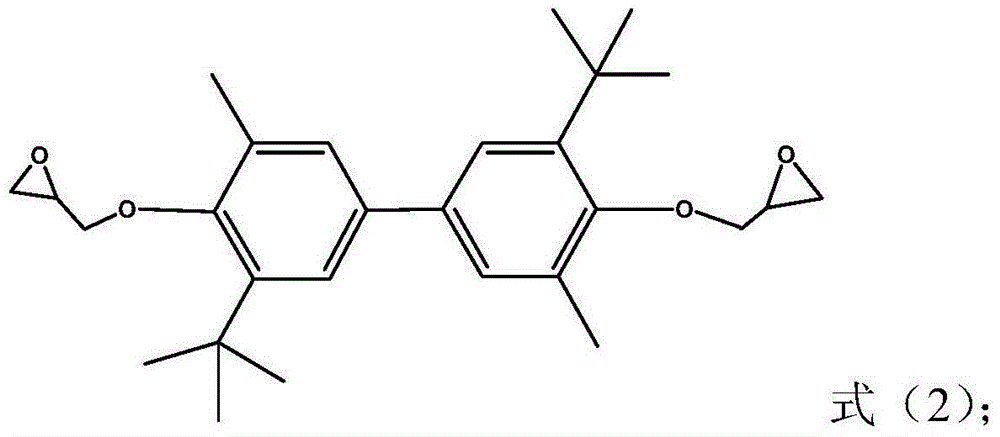

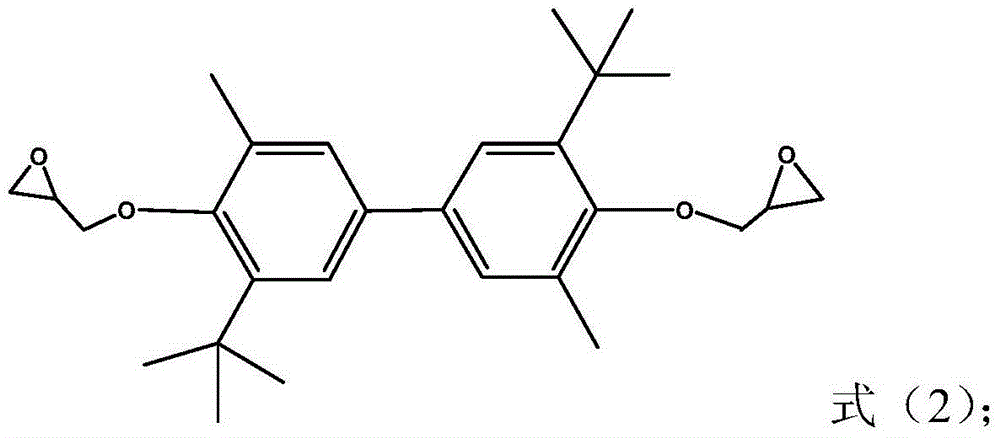

Liquid crystal epoxy resin as well as preparation method and application thereof

The invention discloses liquid crystal epoxy resin as well as a preparation method and an application thereof. The preparation method comprises the following steps: reacting 3,5'-di-tert-butyl-5,3'-dimethyl biphenol with excessive epichlorohydrin in the presence of a phase transfer catalyst, thereby obtaining 3,5'-di-tert-butyl-5,3'-dimethyl diphenyl diglycidyl ether, wherein the softening point of 3,5'-di-tert-butyl-5,3'-dimethyl diphenyl diglycidyl ether is measured to be 10 DEG C through DSC, and the 3,5'-di-tert-butyl-5,3'-dimethyl diphenyl diglycidyl ether is a thick non-solid product at the room temperature; then, selecting a proper curing agent to pre-cure at a low temperature, enabling a biphenyl rid-rod-shaped structure to orientate and arrange with enough time, curing and cross-linking at a high temperature, thereby obtaining a liquid crystal structure. Compared with the conventional preparation method for the rigid-rod-shaped epoxy resin, the preparation method disclosed by the invention is low in curing cost.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Sludge and sand curing agent

ActiveCN101029233AReduce curing costsImprove the environmentOther chemical processesOrganic fertilisersSludgeAluminum silicate

A curing agent for sludge and sand consists of fly-ash 1-50 proportion, aluminum silicate 5-70 proportion, polymerized ferric sulfate 0.1-15 proportion, phosphogypsum 0.1-60 proportion, glauber salt 0.1-20 proportion and calcium carbonate 5-60 proportion. It can be added into various sludge, mud and sands, which makes sludge, mud and sands coagulation and curing rapidly. It can have better early-stage strength and more heat and accelerate chemical reaction between curing material and mud.

Owner:DAQING OILFIELD CO LTD +2

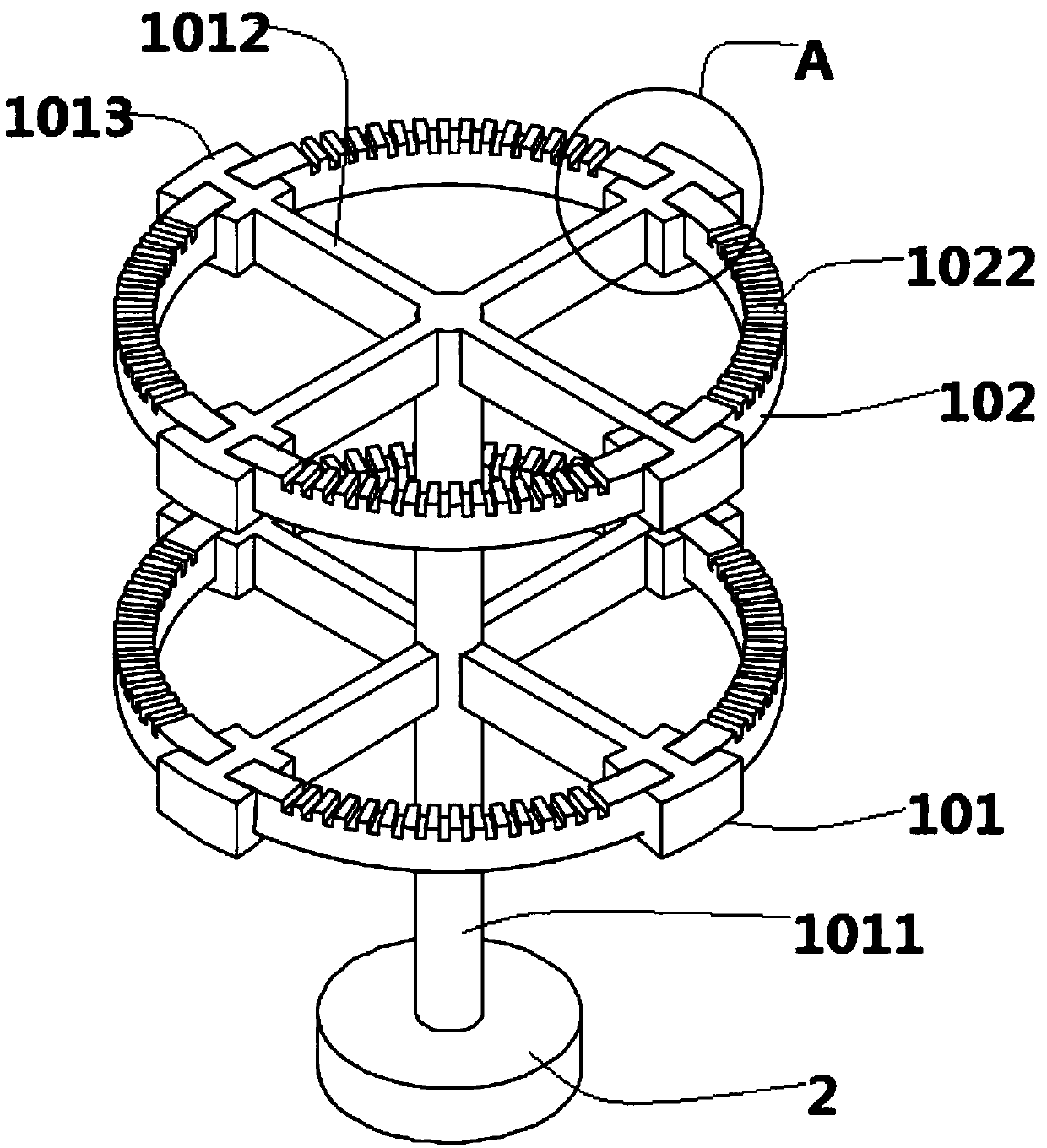

UV LED area source for offset printing press and manufacturing method thereof

InactiveCN101706065AImprove printing efficiencyUniform and stable irradiation and flexible and adjustableLighting applicationsPlanar light sourcesWater insolubleUltraviolet lights

The invention relates to a UV LED area source for an offset printing press, which is a semiconductor luminous device directly generating ultraviolet light, and belongs to the field of offset printing press printing. The UV LED area source is mainly characterized in that: high-power LED chips of which the luminous wavelength is between 200 and 450nm are integrated in a certain ratio to form the area source or linear source with a certain wavelength in a wave band of which the peak wavelength is between 200 and 450nm; the emission spectrum of the light source is matched with an absorption spectrum of a photosensitizer in a sensitive glue material, namely the length of waves emitted by the UV LED area source is concentrated at the periphery of the absorption wavelength of the photosensitizer so as to effectively improve the absorption rate and highly efficiently trigger the photosensitizer in the sensitive glue; and under the action of the photosensitizer and the ultraviolet light, the glue is combined with the photosensitizer so as to generate a water insoluble solid matter. Because the area source or the linear source is the LED semiconductor light source device, and compared with a supervoltage mercury lamp and a Iodine gallium light, the area source or the linear source cannot cause energy loss caused by infrared light, has extreme low loss and not great temperature rise, avoids the temperature influencing printing materials, and is nontoxic and green; and the area source can be designed into any geometrical shapes such as a linear shape, a surface shape and a three-dimensional shape as required in the actual use. The UV LED area source has strong usability and obvious economic benefit, industry innovation benefit and social benefit.

Owner:江苏广发光电科技有限公司

Ultraviolet curing molding machine

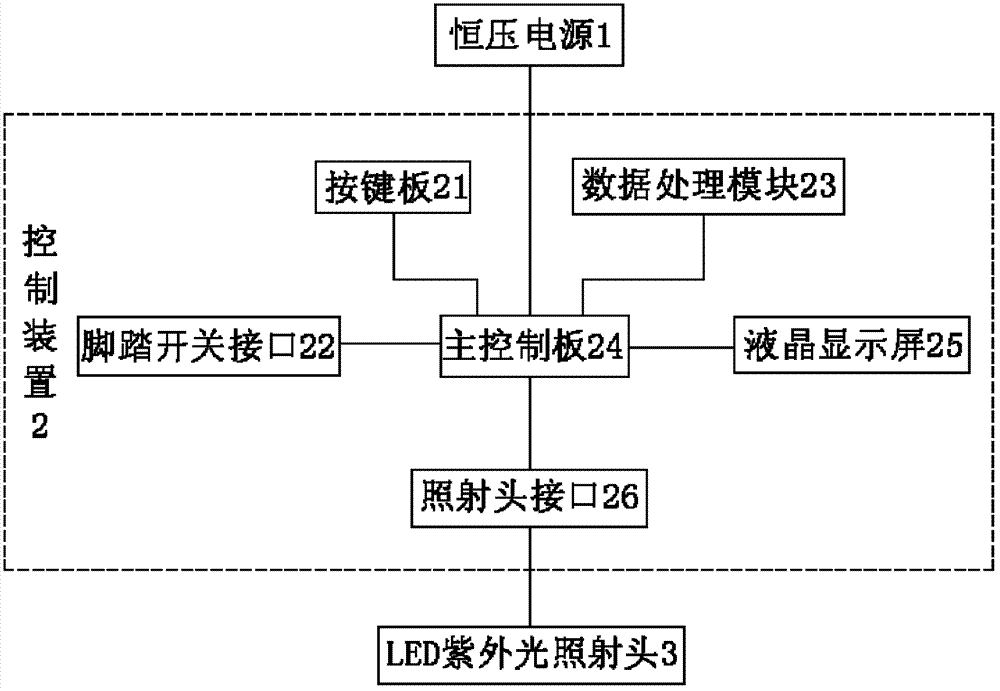

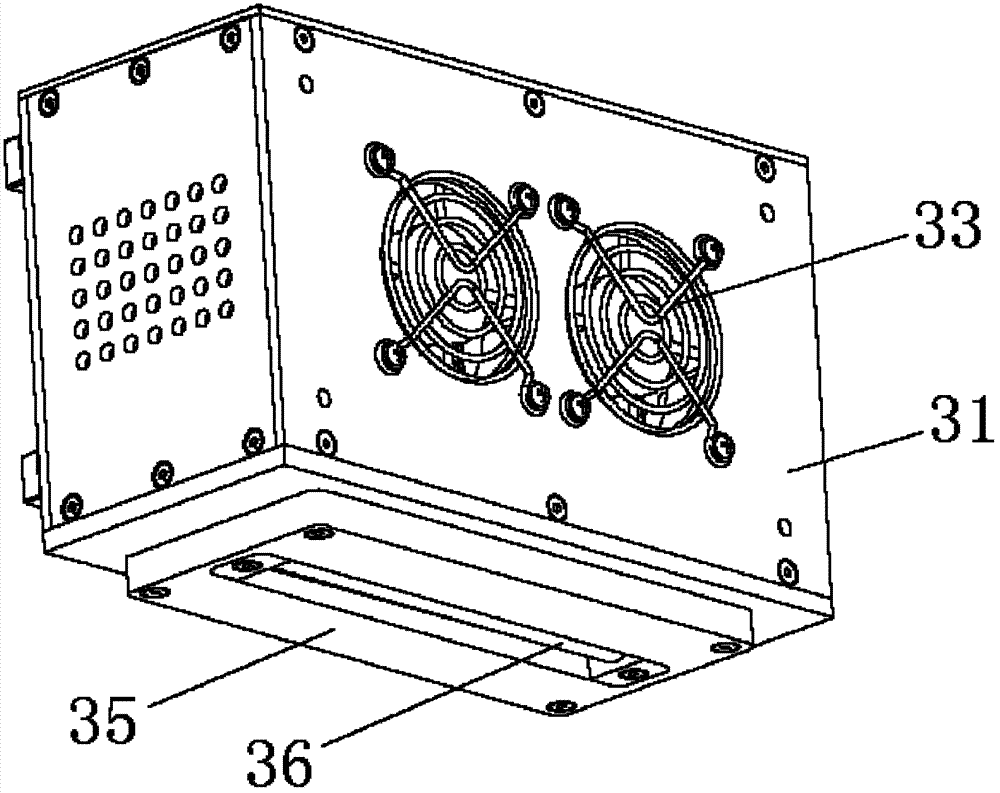

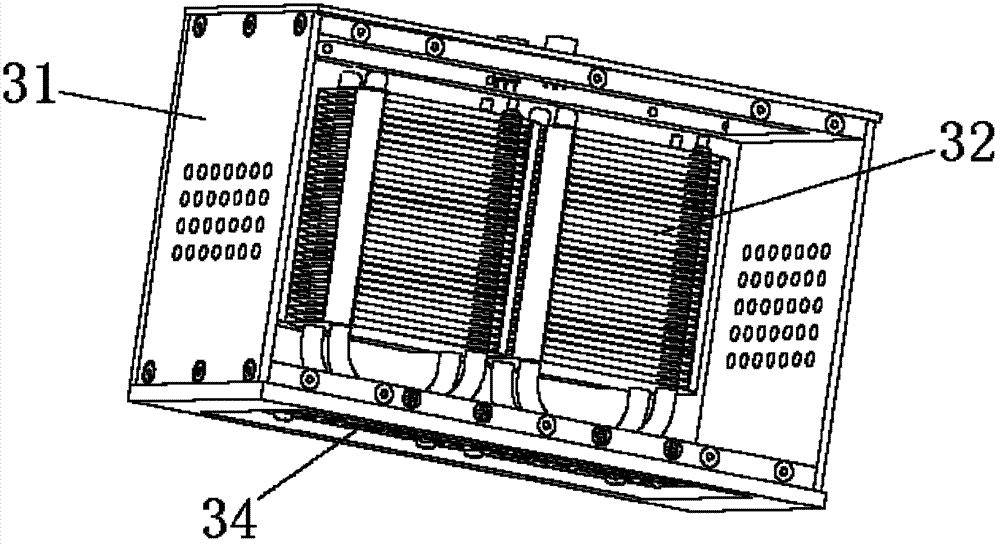

ActiveCN103240216AReduce consumptionReduce curing costsLighting heating/cooling arrangementsPretreated surfacesElectricityLiquid-crystal display

The invention discloses an ultraviolet curing molding machine which comprises a constant-voltage power supply, a control device and an LED ultraviolet irradiating head. The control device comprises a master control board, a keyboard plate, a data processing module, a liquid crystal display and an irradiating head interface, and the keyboard plate, the data processing module, the liquid crystal display and the irradiating head interface are electrically connected with the master control board; the constant-voltage power supply is electrically connected with the master control board of the control device; and the LED ultraviolet irradiating head is electrically connected with the irradiating head interface of the control device. The ultraviolet curing molding machine has the advantages that UV (ultraviolet) resin materials are cured by the aid of an ultraviolet LED cold light source, so that electric energy consumption is reduced, the curing cost is saved, the requirement on environmental protection is met, and the ultraviolet curing molding machine can be used flexibly and conveniently and has an excellent popularization prospect.

Owner:JIANGSU GULIDE PRECISION PHOTOELECTRIC

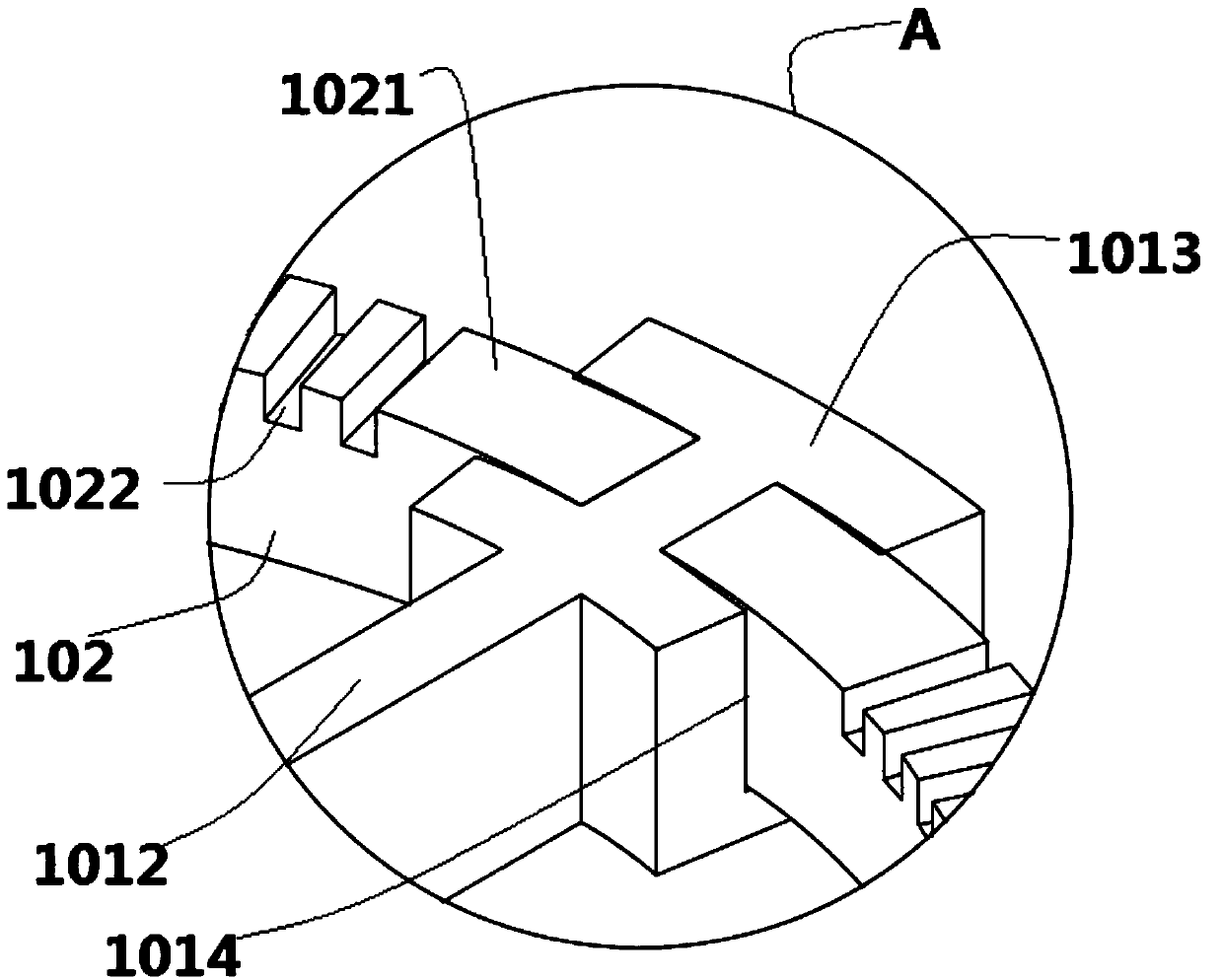

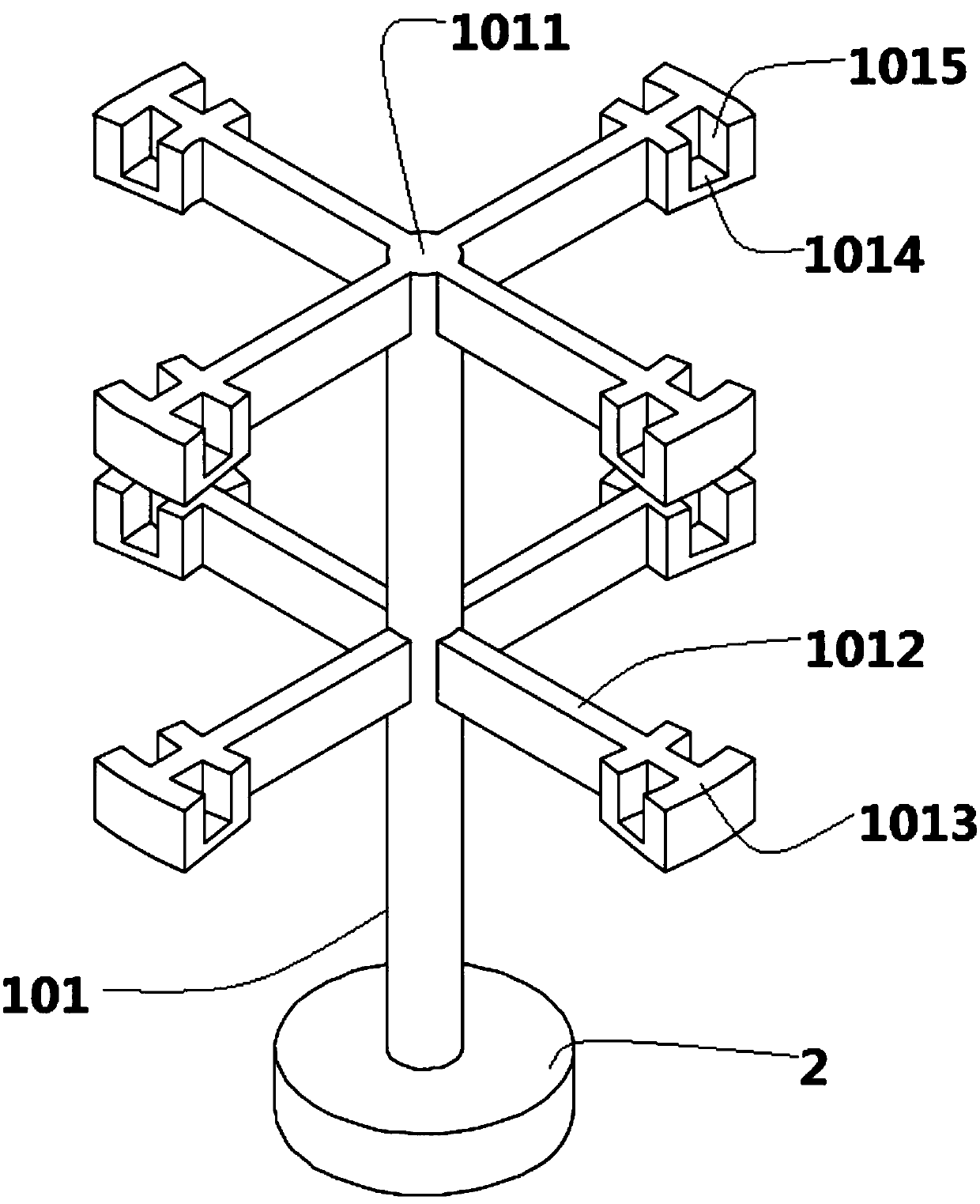

Solidifying device used for storage battery pole plate

Owner:ANHUI HONGDA ELECTRICAL SOURCE

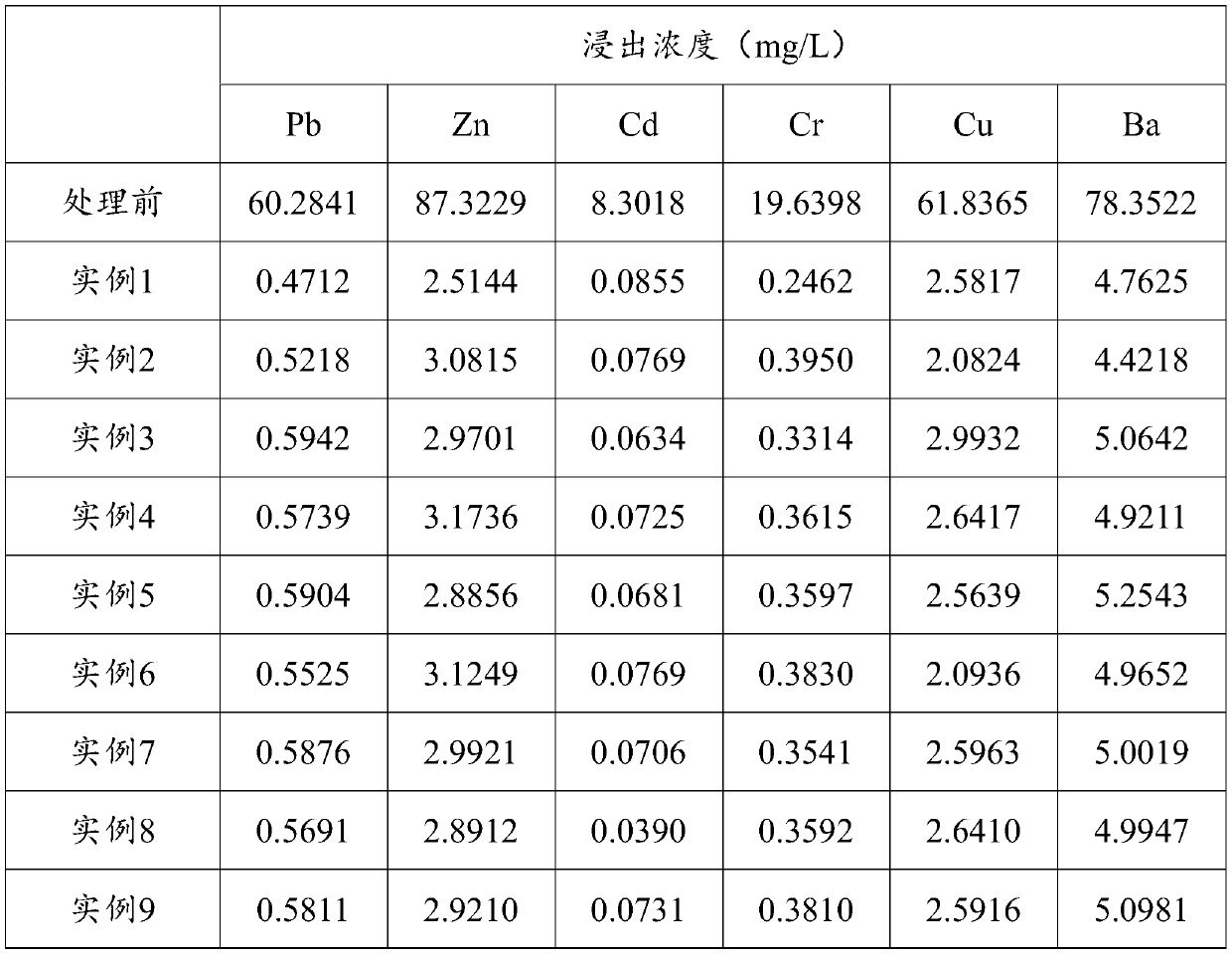

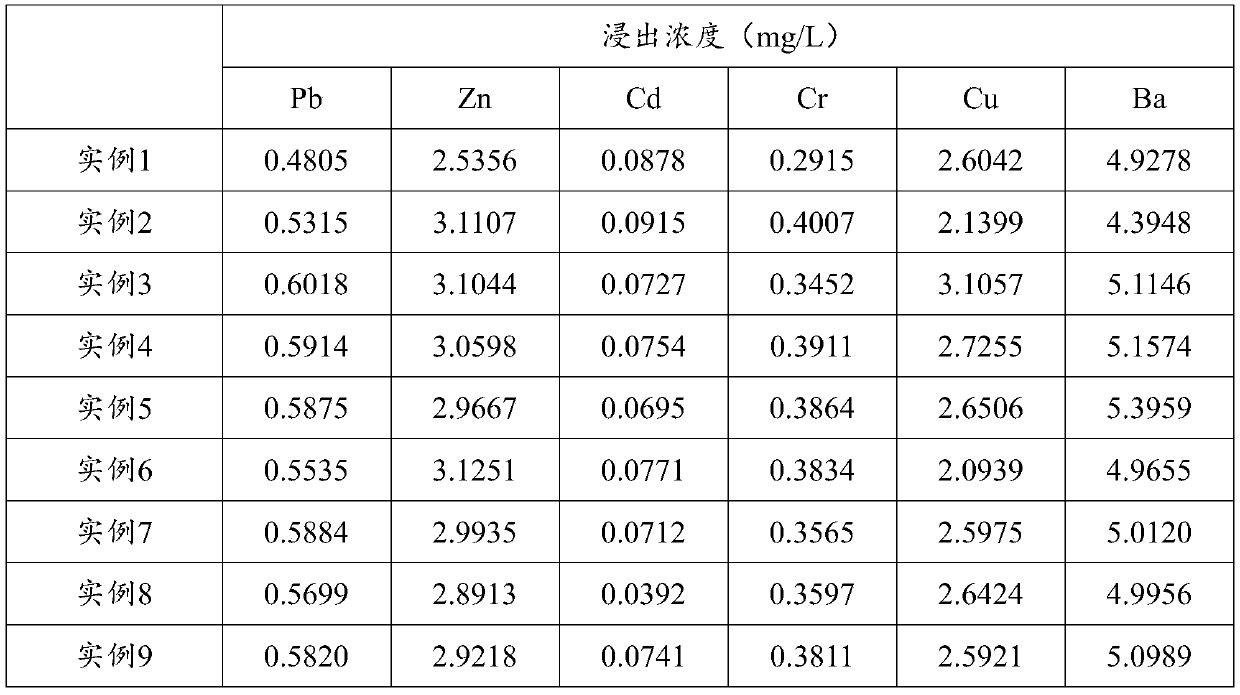

Heavy metal normal temperature solidifier and method for solidifying heavy metal in heavy metal pollutant by using heavy metal normal temperature solidifier

InactiveCN110452703ASimple methodSimple and fast operationOther chemical processesContaminated soil reclamationMaterials scienceWater content

The invention discloses a heavy metal normal temperature solidifier and a method for solidifying heavy metal in a heavy metal pollutant by using the heavy metal normal temperature solidifier. The heavy metal normal temperature solidifier is produced from the following raw materials in parts by weight: 1-10 parts of a nanometer molecular sieve, 3-20 parts of calcium oxide, 1-30 parts of aluminum sulfate and 1-10 parts of ferric oxide. When the heavy metal in the heavy metal pollutant is solidified, firstly, the heavy metal pollutant and the heavy metal normal temperature solidifier are mixed evenly under a normal temperature condition to obtain a mixture; the produced mixture stands under the normal temperature condition for 48-72 hours; and water is added for mixing to make the water content in an obtained mixture reach 25-40%, and the mixture stands under the normal temperature condition. By means of the heavy metal normal temperature solidifier, the problems that in the prior art, the high-temperature solidifying production cost is high, secondary pollution is liable to be generated, a normal temperature solidifying effect is poor, the dosage is high are solved, moreover, the method for solidifying the heavy metal in the heavy metal pollutant by means of the heavy metal normal temperature solidifier is very simple, operation is simple and convenient, the solidifying cost is low, and a solidifying effect is good.

Owner:孙毅

Pneumatic compression and curing method for self-lubricating bushing

The invention discloses a pneumatic compression and curing method for a self-lubricating bushing. The self-lubricating bushing comprises a bushing substrate and a PTFE fabric self-lubricating liner. A high temperature-resisting air bag which is cylindrical after air inflation is sleeved with the PTFE fabric self-lubricating liner, pneumatic compression is carried out on the air bag under room temperature via an inflator with a pressure meter; pressure in the air bag applies a force to the PTFE fabric self-lubricating liner until the pressure value on the pressure meter is the corrected value F1 of cured pressure and then air inflation is stopped and the air bag is sealed; the self-lubricating bushing with the air bag is put in an oven whose temperature is the room temperature T1; the oven is started to enable temperature inside the oven to reach the temperature T2 needed by curing of the PTFE fabric self-lubricating liner, the temperature T2 is kept for a period of time, and pressure suffered by the PTFE fabric self-lubricating liner is the cured pressure F2. The curing method has the advantages of greatly ensuring accuracy of cured pressure and reducing curing cost.

Owner:FUJIAN LONGXI BEARING (GROUP) CO LTD

Method for curing sludge and sludge curing agent using titanium extracting slag

ActiveCN109502937ARealize rational utilizationReduce curing costsFixation/solidifcation sludge treatmentSludgeSlag

The invention provides a method for curing sludge and a sludge curing agent using titanium extracting slag. The curing agent is prepared from the following raw materials in parts by mass: 25 to 50 parts of titanium extracting slag, 12 to 26 parts of lime, 0 to 18 parts of metakaolin, 10 to 30 parts of steel slag micro powder, 1 to 3 parts of excitant and 0.1 to 0.5 part of acrylate. The method forcuring sludge comprises the following step of curing the sludge by adopting the sludge curing agent. The method has the beneficial effects that the titanium extracting slag is taken as the main raw material of the curing agent, so that reasonable utilization of industrial solid waste materials can be realized. The best curing effect can be achieved by adjusting the adding amount of the curing agent according to the organic matter content, porous ratio and water content of the sludge to be cured. The curing agent has the advantages of low curing cost, high sludge strength after curing and highwater stability, can be applied to engineering backfill and the like, and has good economical benefits and high practical value.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Novel aqueous alkyd rust-resisting paint

InactiveCN105623485AReduce curing costsLow VOC contentAnti-corrosive paintsPolyester coatingsPhosphateHuman health

The invention relates to a novel aqueous alkyd rust-resisting paint. The novel aqueous aqueous alkyd rust-resisting paint has the advantages of no toxicity, no odour, no pollution, no harm on human health, and environmental protection. The novel aqueous aqueous alkyd rust-resisting paint comprises the following components by mass fraction: 15-25 parts of deionized water, 30-40 parts of water-soluble alkyd resin, 10-15 parts of iron oxide red, 4-5 parts of sericite powder, 3-4 parts of zinc oxide, 6-8 parts of barium sulfate, 8-10 parts of aluminium triphosphate, 6-10 parts of zinc chromate phosphate, 4-6 parts of ethylene glycol monobutyl ether, 0.1-0.3 parts of an X-405 wetting agent, 0.6-1.2 parts of a GA40 dispersant, 0.1-0.3 parts of a 1488 antifoaming agent, 0.3-0.6 parts of a DWB-95 multifunctional auxiliary agent, and 0.5-1 part of an ASE-60 thickening agent.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

Curing agent for waste incineration fly ash

InactiveCN110279975AImprove curing effectImprove stabilityChemical protectionHigh concentrationPyrite

The invention relates to a curing agent for waste incineration fly ash. Every 100 parts of the curing agent is prepared by mixing 80-95 parts of pyrite and 5-20 parts of calcium carbonate powder. The curing agent for the waste incineration fly ash involved in the invention is prepared by compounding the pyrite and the calcium carbonate powder, and the curing agent prepared according to the proportion has good curing effects ; by using the curing agent for treating the waste incineration fly ash, hazardous substances (including heavy metal, arsenic, fluorine and the like) in the waste fly ash can be effectively cured, the curing age is short, the curing cost is largely reduced, the curing agent has good stability, the problem of leaching of the hazardous substances after curing does not exist, and other high-concentration wastes are not produced either.

Owner:哈德逊(苏州)水技术有限公司

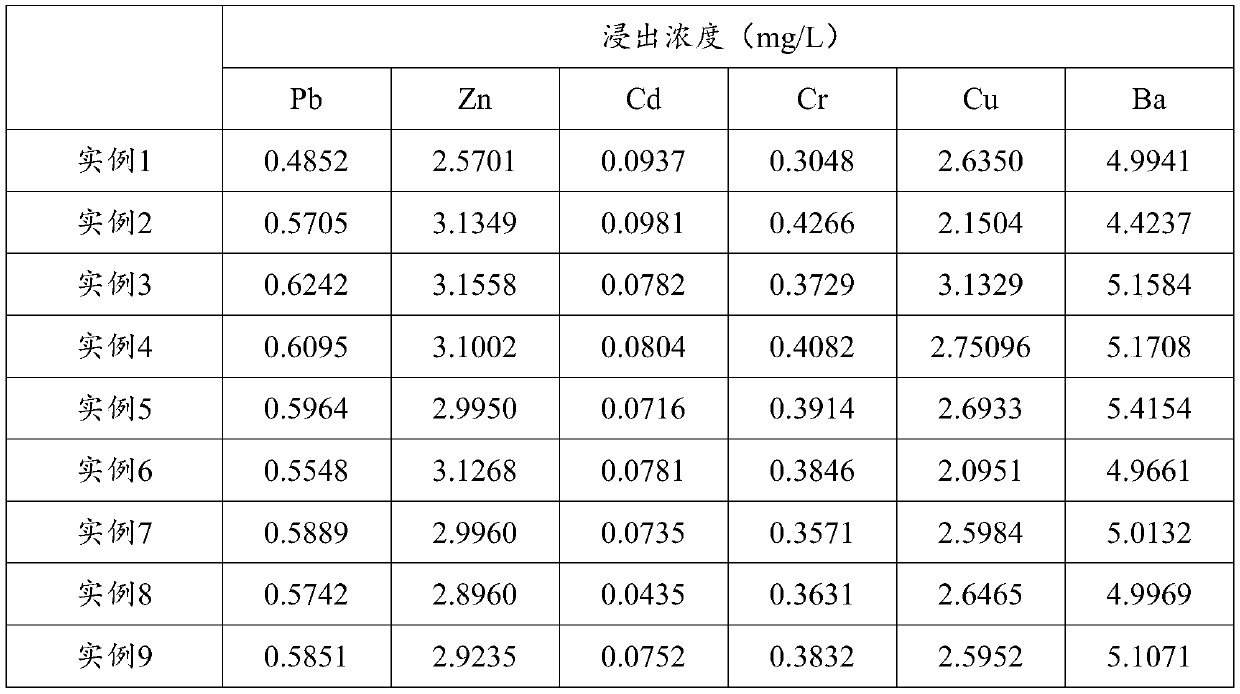

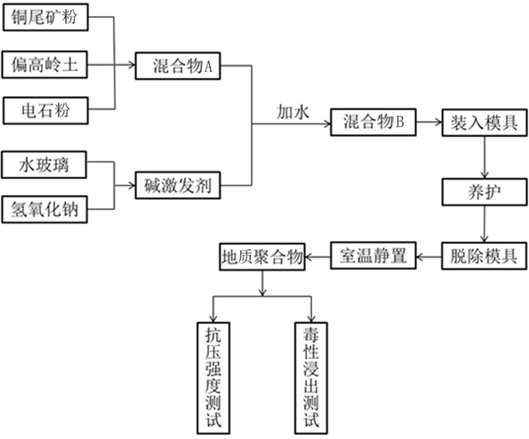

Method for curing heavy metals in copper tailings by using industrial waste carbide slag and kaolin

ActiveCN111995276AReduce curing costsEasy to operateSolid waste managementCement productionSlagKaolin clay

The invention discloses a method for curing heavy metals in copper tailings by using industrial waste carbide slag and kaolin, which comprises the following steps: S1, drying, crushing and sieving theindustrial waste carbide slag to obtain calcium carbide powder, and drying, crushing and sieving the copper tailings to obtain copper tailing powder; S2, uniformly mixing calcium carbide powder and copper tailing powder according to a mass ratio of 0.15-0.25: 1 to obtain a mixture A; S3, adding NaOH into the water glass, uniformly stirring, regulating the modulus of the water glass to 1.2-1.8, and performing standing at normal temperature for 20-24 hours to obtain an alkali activator; S4, uniformly mixing the mixture A, an alkali activator and water according to a water-cement ratio of 0.2-0.4: 1 and a mass ratio of the mixture to the alkali activator of 100: 5-8 to obtain a mixture B; and S5, putting the mixture B into a mold, maintaining at 30-40 DEG C for 28 days, demolding, and performing standing at normal temperature for 24-28 hours to obtain the geopolymer. The method is simple to operate, the raw materials are cheap and easy to obtain, the curing cost of the copper tailings can be reduced, and the environmental pressure on the surrounding ecological environment caused by long-term stockpiling of the carbide slag and the copper tailings is relieved.

Owner:KUNMING UNIV OF SCI & TECH

Garbage incineration fly ash curing agent

InactiveCN107050734AImprove curing effectImprove stabilityTransportation and packagingSolid waste disposalHigh concentrationHazardous substance

The invention discloses a garbage incineration fly ash curing agent. The curing agent is prepared by mixing heavy magnesium powder, bentonite and quicklime. The components include, by mass percent, 60%-75% of the heavy magnesium powder, 5%-15% of the bentonite and 15%-25% of the quicklime, and the sum of the content of the above components is 100%. The garbage incineration fly ash curing agent is formed by mixed powder of the heavy magnesium powder, the bentonite and the quicklime, due to optimization of the ratio of all the components, the prepared curing agent is good in curing effect, heavy metal ions in garbage fly ash are effectively cured, the curing age is short, the curing cost is greatly reduced, in addition, the curing agent is good in stability, the problem of leaching of harmful substances does not exist after curing, and other high-concentration waste cannot be generated.

Owner:哈德逊(苏州)水技术有限公司

Fly ash composite chelating agent, and preparation method and application thereof

The invention discloses a fly ash composite chelating agent and a preparation method and application thereof, belonging to the field of treatment of incineration fly ash. The fly ash composite chelating agent comprises the following components: organic agents, NaH2PO4 and Na2S, wherein the organic agents comprise potassium dimethyl dithiocarbamate, sodium diethyl dithiocarbamate, dithiocarbamate and ethylenediamine tetraacetic acid. The fly ash composite chelating agent can undergo a chelating reaction with almost all the heavy metal ions at normal temperature, is good in stabilizing effect, small in use amount, simple in step, low in curing cost and high in practicability, and has high efficiency and economical efficiency in treatment of heavy metals in hazardous waste, namely the incineration fly ash.

Owner:厦门晖鸿环境资源科技有限公司

Alkyd resin magnetic protective paint with high flash point

InactiveCN111205754AEasy to modifyReduce curing costsMagnetic paintsPolyester coatingsPolymer scienceVegetable oil

The invention relates to the technical field of paint coating processing, and discloses an alkyd resin magnetic protective paint with a high flash point. The paint comprises the following raw materials in parts by weight: 70 to 80 parts of acrylic acid modified alkyd resin, 0.4 part of a wetting dispersant AT203, 0.4 part of bentonite, 20 to 30 parts of titanium dioxide, 0.6 to 0.8 part of a composite drier, 0.1 to 0.2 part of an anti-skimming agent, and 3 to 5 parts of solvent oil. Through a two-step esterification method, a carboxyl group on an acrylic resin chain segment completely reacts with polyol ester so as to embed acrylic resin into an alkyd resin chain segment, and a good modification effect is achieved. The main raw material source of the alkyd resin magnetic protective paint is vegetable oil or fatty acid, the dependence on petroleum products is small, and the alkyd resin magnetic protective paint is cured in an air / oxygen mode, so that the resin curing cost is low. The paint has the advantages of quick drying and good outdoor weather resistance of an acrylic resin paint, overcomes the defects of low hardness and low drying speed of an alkyd resin paint, and has a great market application prospect.

Owner:哈尔滨市雪鹰工程材料有限公司

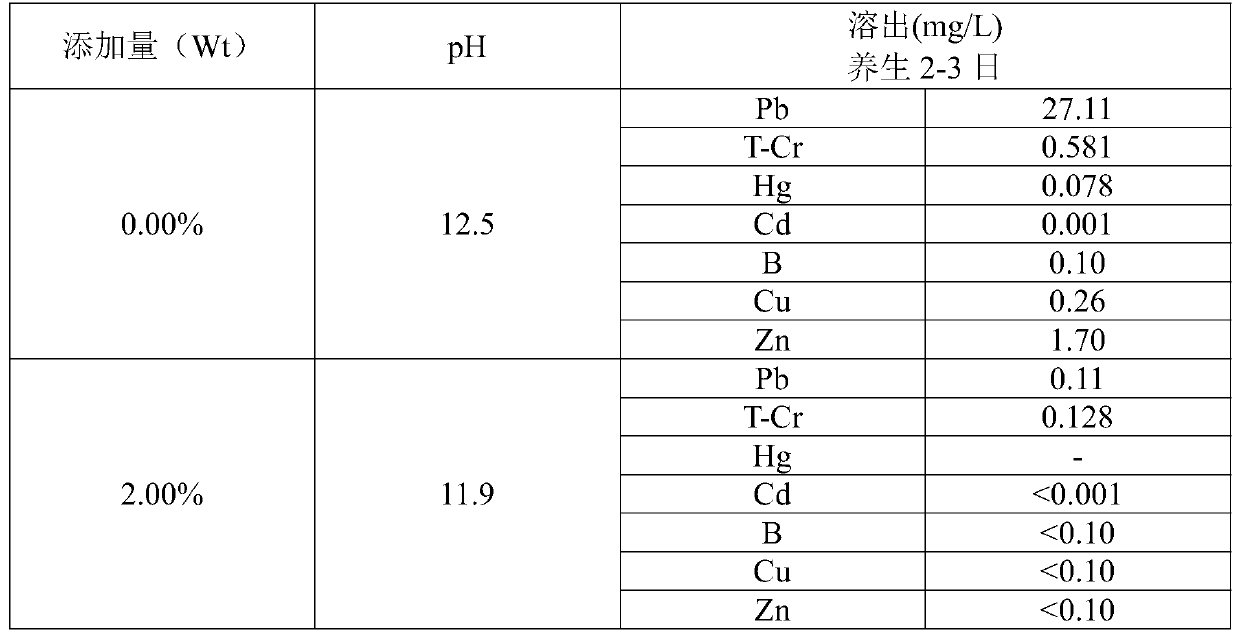

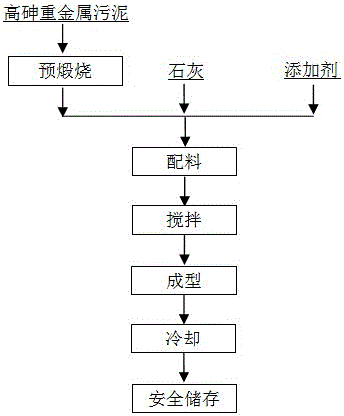

Harmless disposal method for high-arsenic heavy metal sludge

ActiveCN105693050AGood curing effectLow costFixation/solidifcation sludge treatmentSludgeMixed materials

The invention relates to a harmless disposal method for high-arsenic heavy metal sludge and belongs to the technical field of hazardous waste treatment. The harmless disposal method comprises the following steps of firstly, precalcining the high-arsenic heavy metal sludge with water content of less than 40 percent under the condition that the temperature is 100 to 300DEG C for 0.5 to 3 hours to obtain a calcined product; adding lime and additives into the obtained calcined product according to the mass ratio of (30 to 80): (10 to 40):(1 to 30), and uniformly stirring to obtain a mixed material; forming the obtained mixed material to produce a solidified body, cooling and then safely storing. According to the sludge disposed by the harmless disposal method, leaching concentrations of all heavy metal elements meet the requirements of Identification Standard and Leaching Toxicity Identification of Hazardous Waste (GB5085.3-2007) and Landfill Pollution Control Standard for Hazardous Waste (GB18598-2001).

Owner:YUNNAN COPPER CO LTD +2

Modified g-C3N4 activator for UV-EB radiation curing

InactiveCN108752989ALarge specific surface areaStrong activation modificationCoatingsUltraviolet lightsBiological activation

The invention provides a modified g-C3N4 activator for UV-EB radiation curing. A UV-EB radiation curing body is firstly subjected UV (ultraviolet light) radiation curing, and then is subjected to EB (electron beam) radiation curing. The modified g-C3N4 activator is prepared from g-C3N4 according to an acid and alkali double activation modification method, and separately serves as a photoinitiatorand an active stabilizer in a curing system during a UV radiation curing process and an EB radiation curing process. The invention initiatively provides a g-C3N4 acid and alkali double activation modification method, successfully applies the modified g-C3N4 activator to a UV-EB radiation curing system, and obviously reduces energy consumption, improves the production efficiency and reduces the cost, and curing coating has excellent comprehensive operation performances.

Owner:NANJING INST OF TECH

Waste incineration treatment system with high-temperature dust remover

InactiveCN105605586ALow concentration of dioxinsMeet the requirements for non-hazardous wasteIncinerator apparatusActivated carbonFlue gas

The invention provides a waste incineration treatment system with a high-temperature dust remover. Flue gas produced by waste incineration is exhausted after being subjected to multistage dust removal purification, first-stage dust removal is completed by the high-temperature dust remover, and collected fly ash is less in dioxin content and capable of being recycled; low-temperature dust removal is adopted by second-stage dust removal and third stage dust removal, the dust removal efficiency is high due to the combination of the second-stage dust removal and the third-stage dust removal, the dust content and dioxin content of the exhausted flue gas are low, and the flue gas is cleaner; activated carbon is sprayed into the flue gas at an inlet of a third-stage remover, dioxin in the flue gas is adsorbed, activated carbon is collected by the third-stage remover and sent back to f hearth of an incinerator, dioxin adsorbed by the activated carbon is disintegrated at high temperature, and the toxicity is removed. The waste incineration treatment system with the high-temperature dust remover has the advantages that the fly ash collected through high-temperature dust removal can be recycled, dioxin adsorbed by the activated carbon is disintegrated at high temperature after being sent back to the hearth, the total quantity of dioxin exhausted from waste incineration is effectively reduced, and the adverse effect of waste incineration on the environment is reduced.

Owner:JIMEI UNIV +1

Solidification stabilizing material for water-based drilling cutting landfill and solidification method of water-based drilling cutting

The invention discloses a solidification stabilizing material for water-based drilling cutting landfill and a solidification method of water-based drilling cutting. The solidification stabilizing material comprises coal cinder, cement, carbide slag, gypsum, a metal ion solidification unit and an oxidation unit. The metal ion curing unit comprises a metal ion curing agent and dithioamino salt, and the oxidation unit comprises citric acid, H2O2 and ferrous ion metal salt. According to the method, citric acid which can be decomposed by itself and is high in acidity is used for adjusting the pH value of the water-based drilling cuttings, so that traditional Fenton oxidation is changed, Fenton oxidation reaction is activated in the environment with the pH value of 6-7, and the degradation capacity of organic matter in the water-based drilling cuttings is improved; on the other hand, the chelation reaction between the dithioamino salt and heavy metal ions is promoted, so that more heavy metal ions form chelate precipitates, and meanwhile, the chelate precipitates and arsenic are subjected to complexation reaction; and the formed chelate and complex are coated by inorganic silicate formed by the metal ion curing agent and water, thereby avoiding environmental hazards caused by escape of harmful substances.

Owner:鄂尔多斯市固邦环保科技有限公司

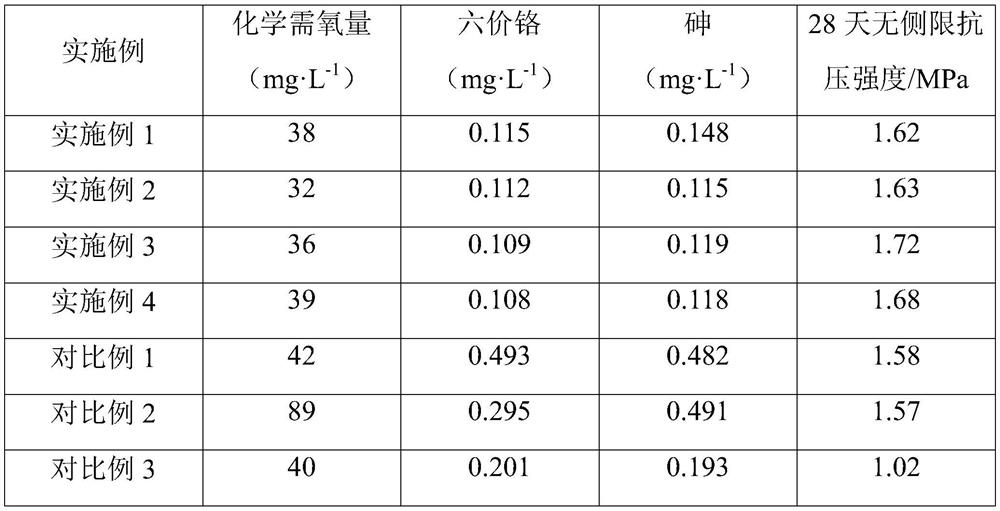

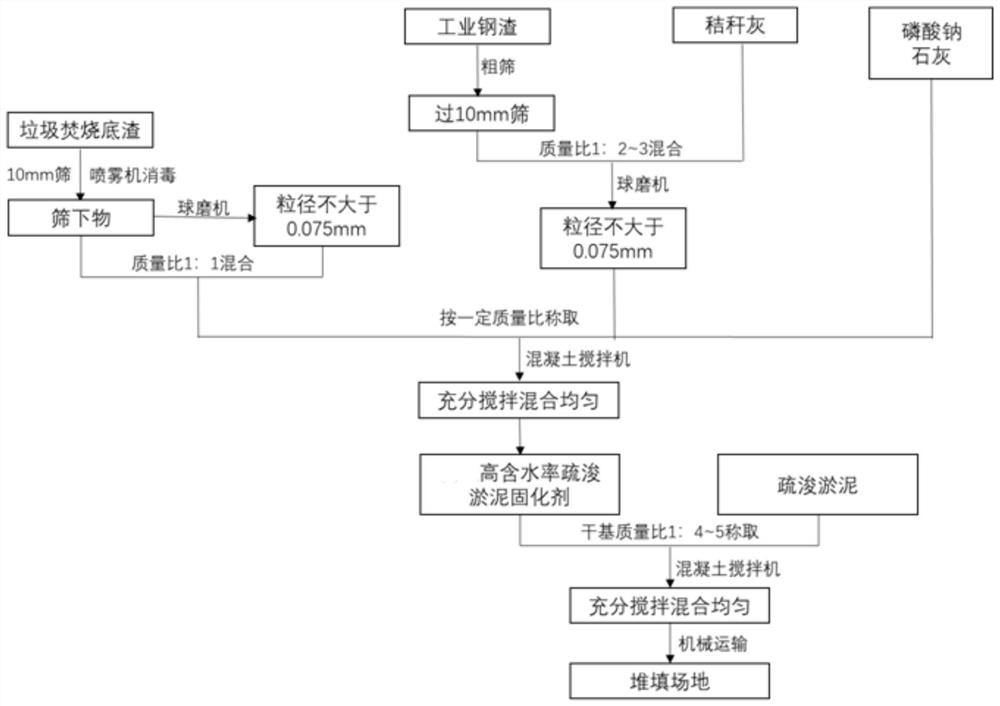

High-water-content dredged sludge curing agent as well as preparation method and application thereof

PendingCN114149202ARealize resource reuseSave landfillFixation/solidifcation sludge treatmentSlagSludge

The invention discloses a high-water-content dredged sludge curing agent as well as a preparation method and application thereof. The curing agent is prepared from the following raw materials: industrial steel slag, a waste incineration bottom slag mixture, sodium phosphate, straw ash and lime. During preparation, the waste incineration bottom slag and the waste incineration bottom slag ground powder are mixed to obtain a waste incineration bottom slag mixture, the straw ash and the industrial steel slag are mixed and subjected to ball milling to obtain a mixture of the straw ash ground powder and the industrial steel slag ground powder, and finally the raw materials are mixed according to the proportion to prepare the curing agent. The waste is adopted as the raw material, resource utilization of the waste is achieved, the prepared curing agent can effectively cure the dredged sludge, the water content of the dredged sludge is reduced, the low-strength characteristic of the dredged sludge is improved, the dredged sludge can be used as a filling material after being cured, and the purposes of treating waste with waste and protecting the environment are achieved.

Owner:HOHAI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com