Ultraviolet curing molding machine

A technology of ultraviolet light and forming machine, which is applied to the cooling/heating device of lighting devices, lighting devices, pre-treated surfaces, etc., and can solve problems such as shortened service life, low thermal efficiency of LED light-emitting tubes, and accelerated aging of LED light-emitting tubes. Achieve the effects of saving power consumption, facilitating replacement and maintenance, and saving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

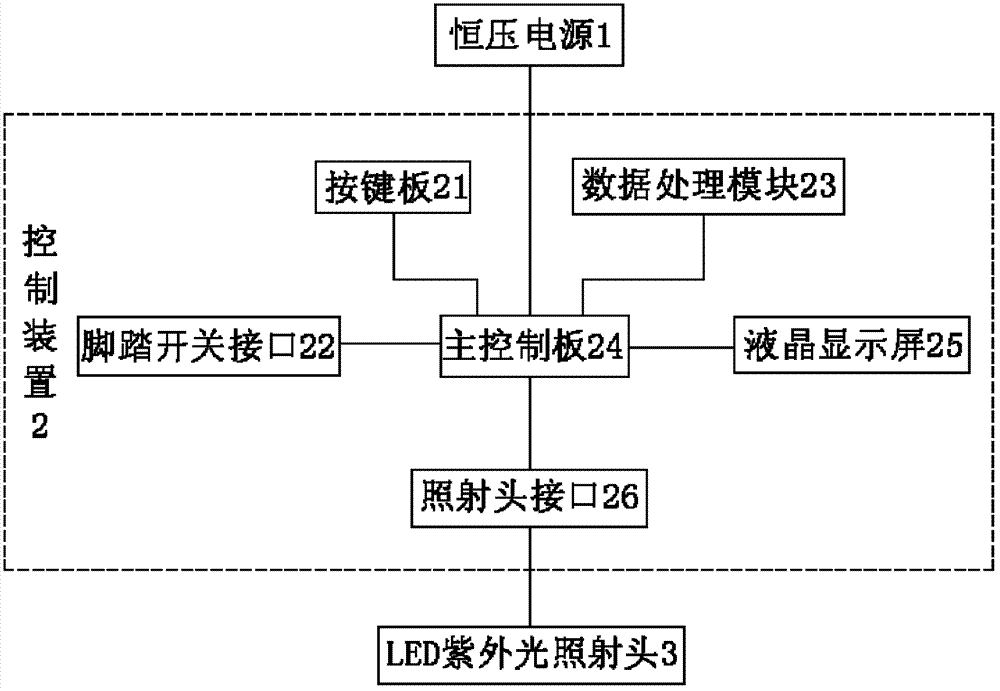

[0036] See figure 1 , The UV curing molding machine of this embodiment includes a constant voltage power supply 1 , a control device 2 and an LED UV irradiation head 3 .

[0037] The control device 2 includes a main control board 24 , a keypad 21 electrically connected to the main control board 24 , a foot switch interface 22 , a data processing module 23 , a liquid crystal display 25 and an irradiation head interface 26 . The constant voltage power supply 1 is electrically connected to the main control board 24 of the control device 2 . The LED ultraviolet light irradiation head 3 is electrically connected with the irradiation head interface 26 of the control device 2 . The data processing module 3 of the control device 2 is a computer or PLC.

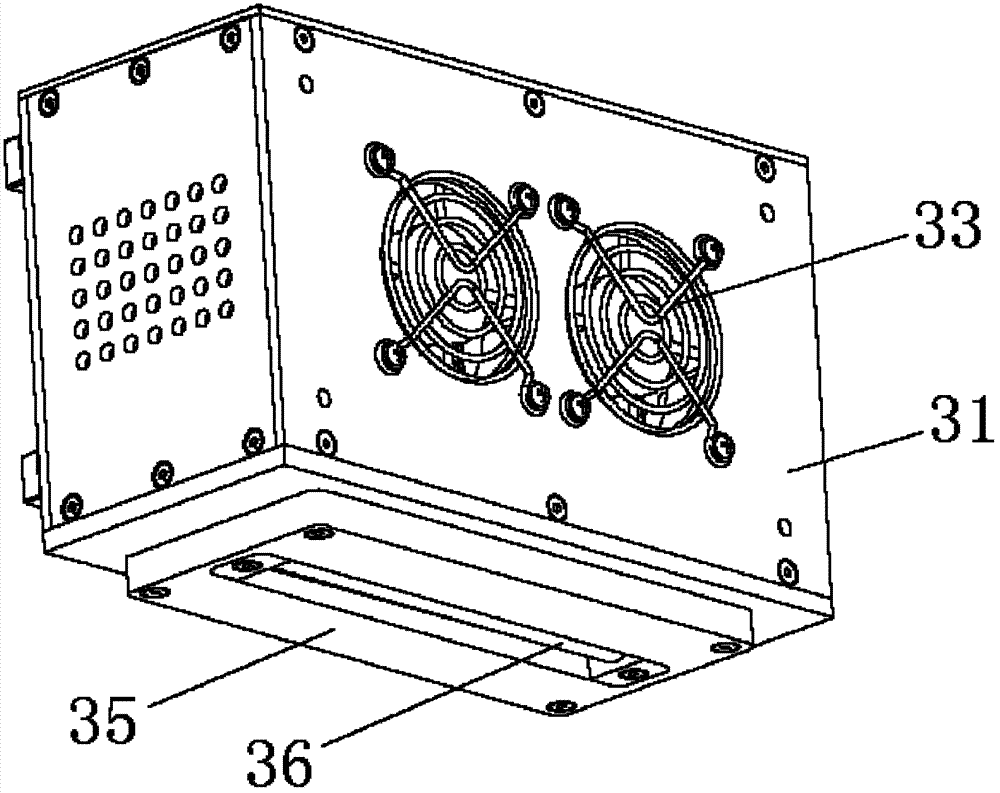

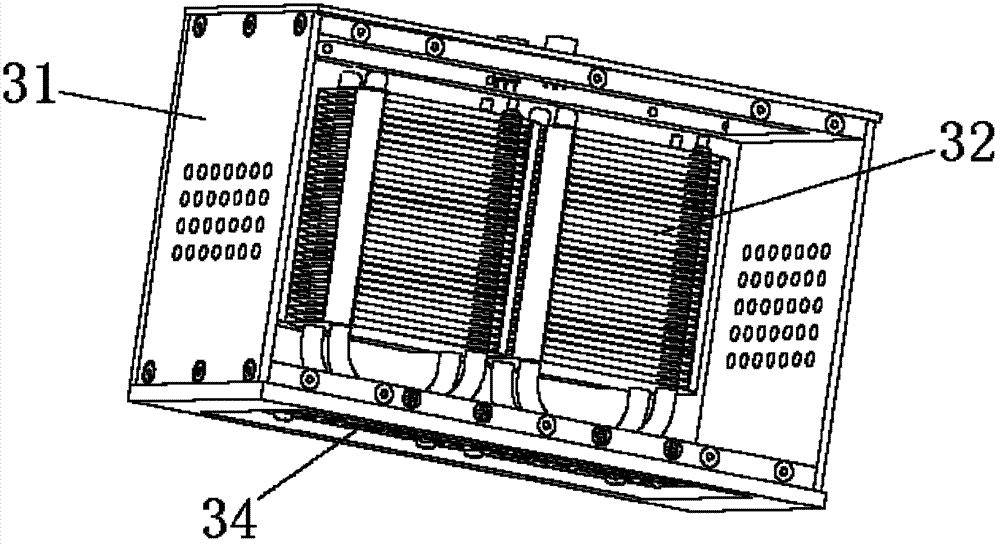

[0038] See figure 2 and image 3 , The LED ultraviolet irradiation head 3 includes a housing 31 , a cooling module 32 , a cooling fan 33 , an ultraviolet LED 34 , a lens 35 and a mirror column 36 . Both the cooling module 32 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com