Patents

Literature

66 results about "Accelerated curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Accelerated curing is any method by which high early age strength is achieved in concrete. These techniques are especially useful in the prefabrication industry, wherein high early age strength enables the removal of the formwork within 24 hours, thereby reducing the cycle time, resulting in cost-saving benefits. The most commonly adopted curing techniques are steam curing at atmospheric pressure, warm water curing, boiling water curing and autoclaving.

2-K PU systems

ActiveUS7205356B2Synthetic resin layered productsPolyurea/polyurethane coatingsOrganic solventPolyol

Catalysts for the accelerated curing of polyisocyanates with polyols, and to polyurethane systems comprising these. The catalysts are used in a two-component coating system based on polyurethanes including (a) polyisocyanates, (b) compounds having groups which are reactive with isocyanates, in water and optionally in the presence of organic solvents or solvent mixtures, (c) one or more compounds of elements of Group VB or Group VIB of the Periodic Table, in which the element in each case has an oxidation state of at least +4, and (d) optionally further additives and auxiliary agents. The coating systems are used in lacquers, paints and adhesives.

Owner:COVESTRO DEUTSCHLAND AG

Radiation polymerisable compositions having accelerated cure

InactiveUS20040044094A1Fast aggregationImprove adhesionMicrowave heatingAccelerated curingCharge-transfer complex

A radiation polymerisable composition comprising: (A) a donor / acceptor component for forming a charge transfer complex said component being selected from the group consisting of: (i) a bifunctional compound having an electron donor group and an electron withdrawing group and a polymerisable unsaturated group; (ii) a mixture of (a) at least one unsaturated compound having an electron donor group and a polymerisable unsaturated moiety; and (b) at least one unsaturated compound having an electron acceptor group and a polymerisable unsaturated group; and (B) a Lewis acid.

Owner:GARNETT JOHN LYNDON

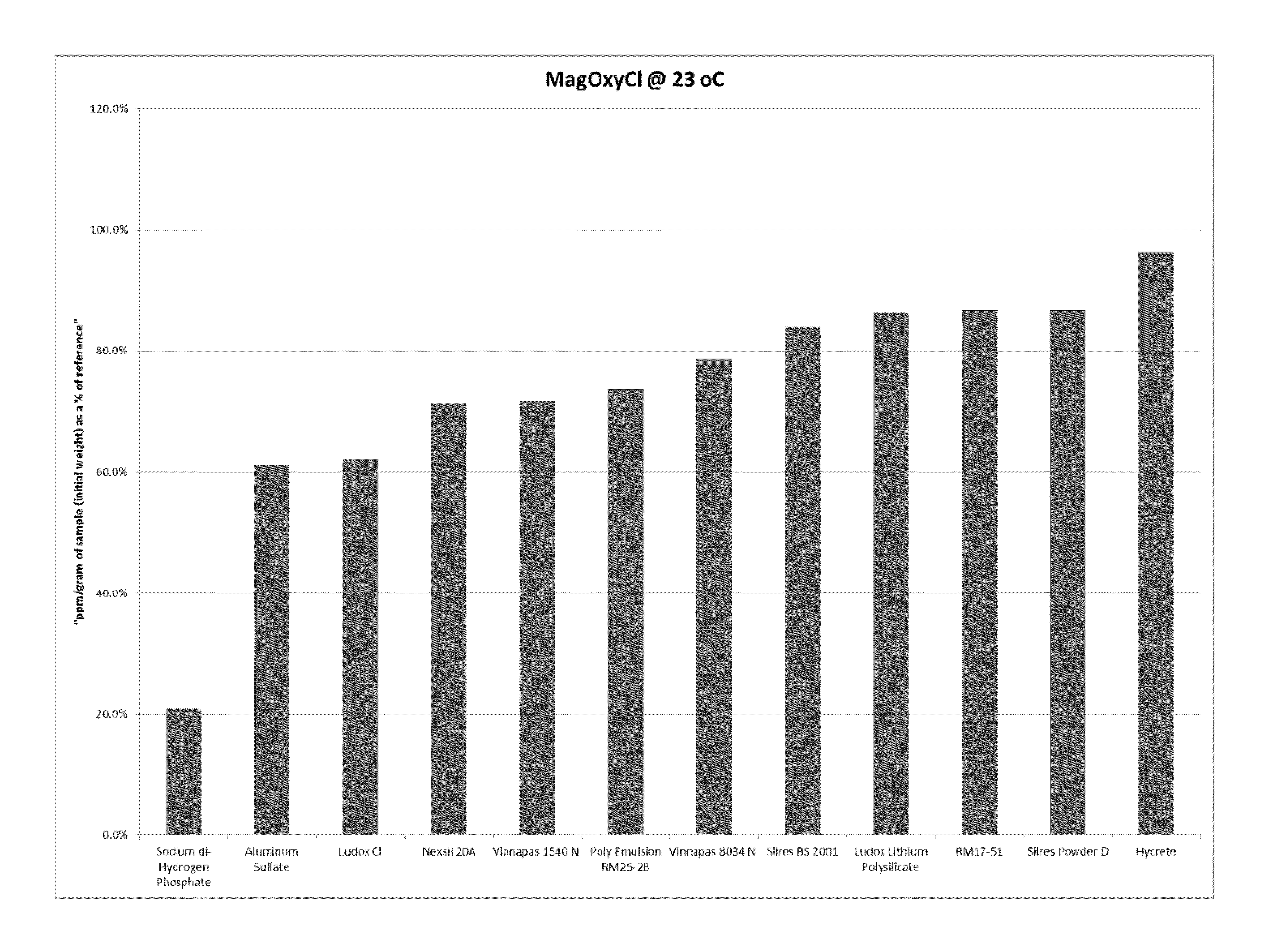

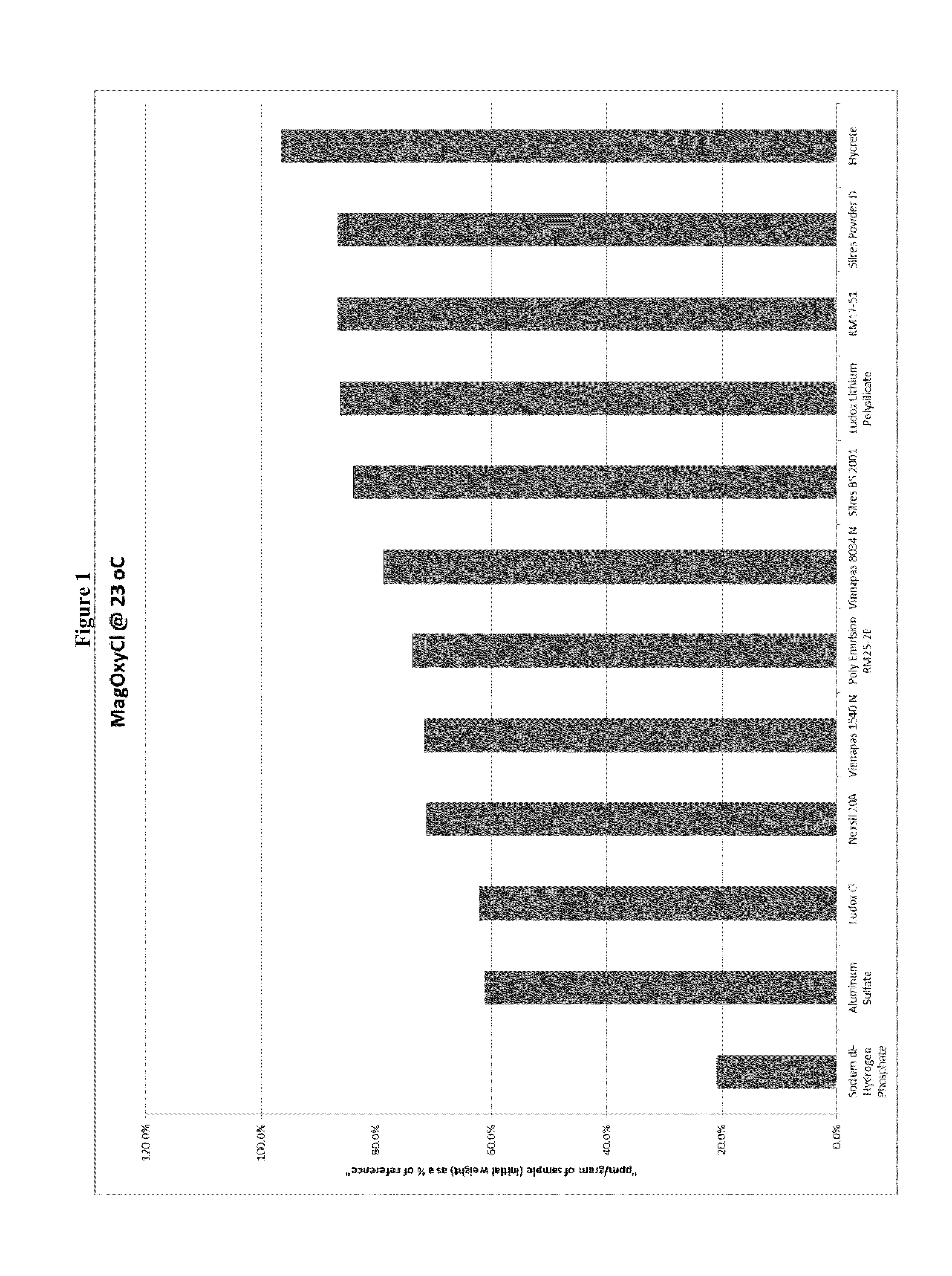

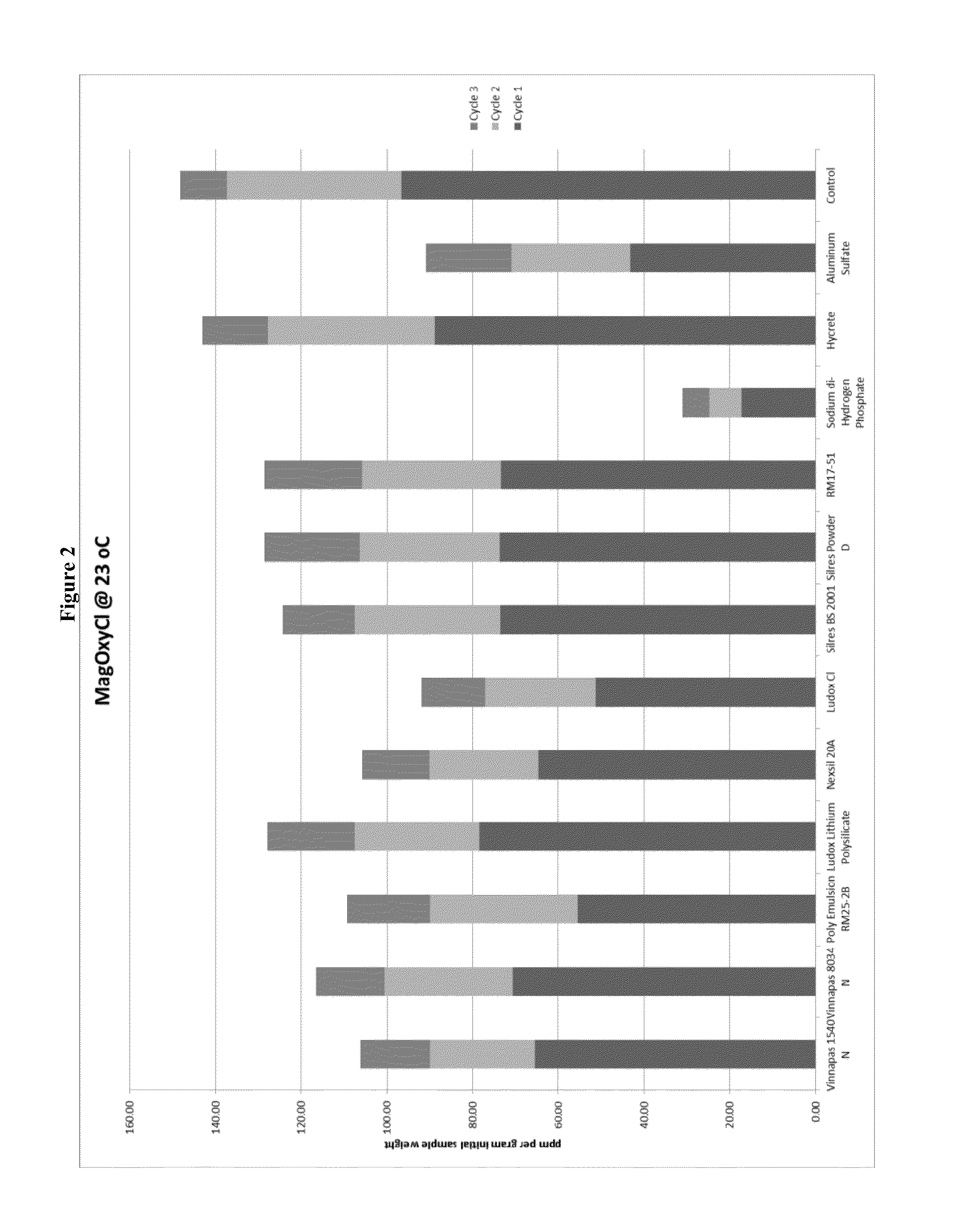

Method and compositions for improving performance properties of magnesium oxychloride cements

ActiveUS20130263759A1Improve water resistanceEarly water resistanceSolid waste managementMonomagnesium phosphatePhosphate

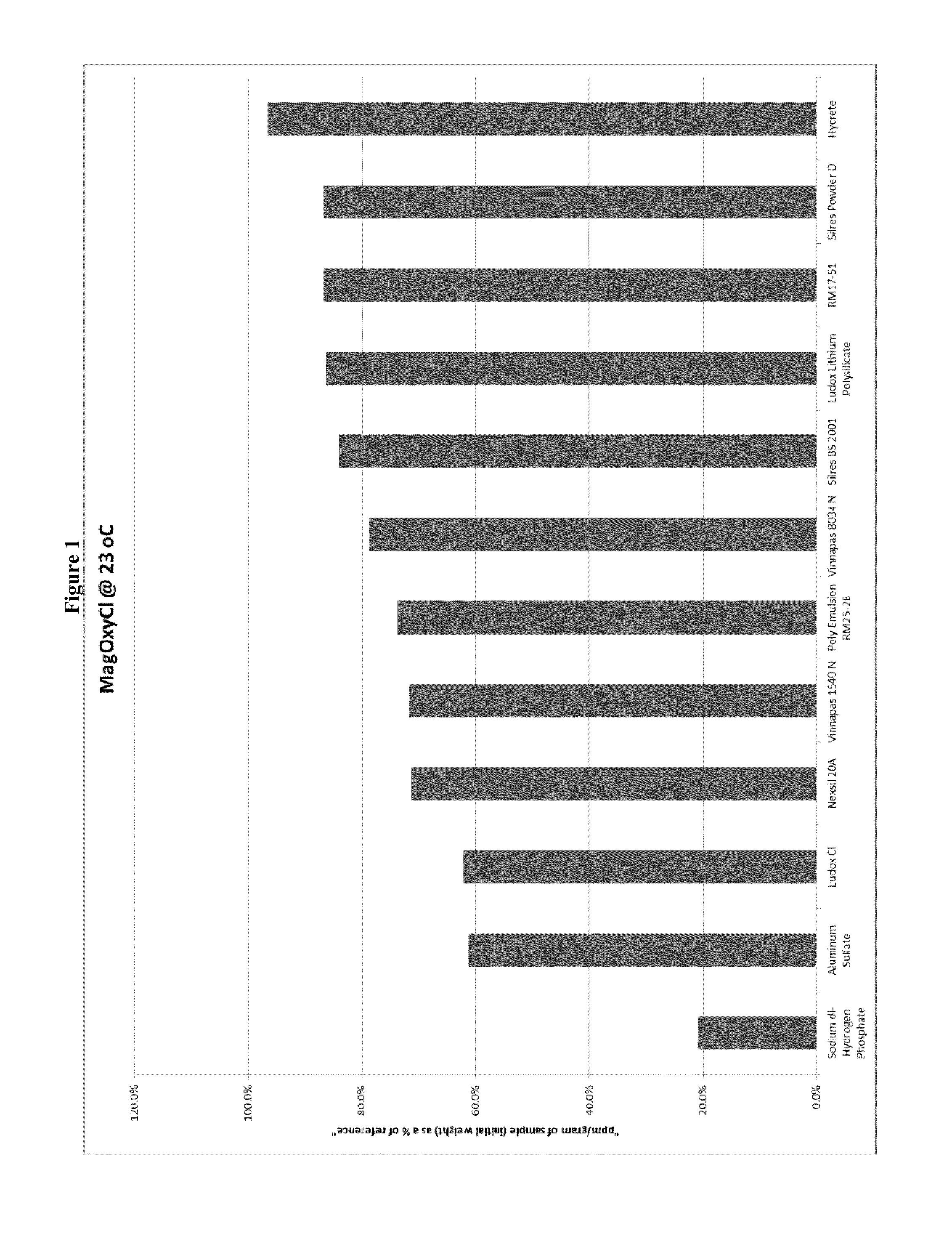

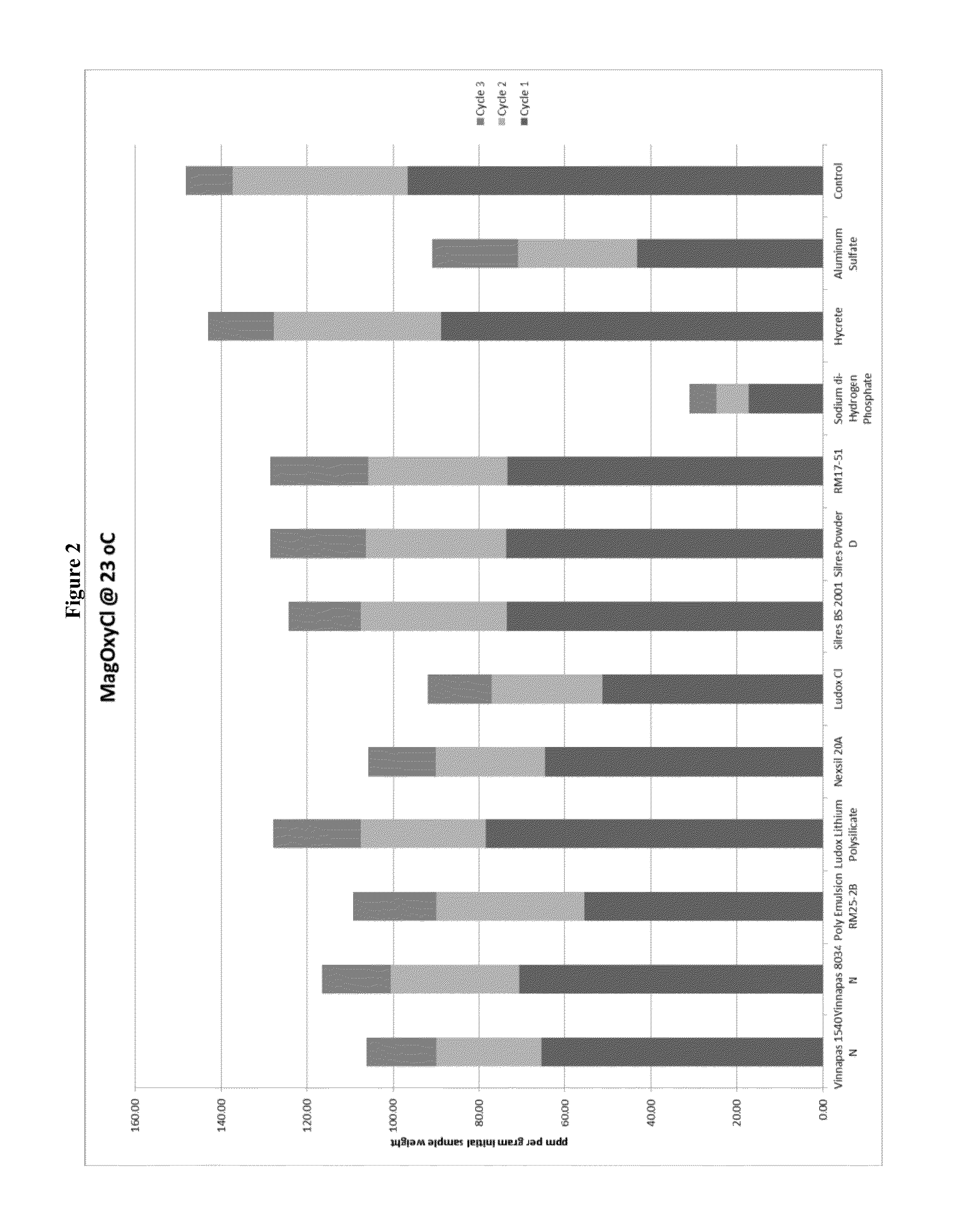

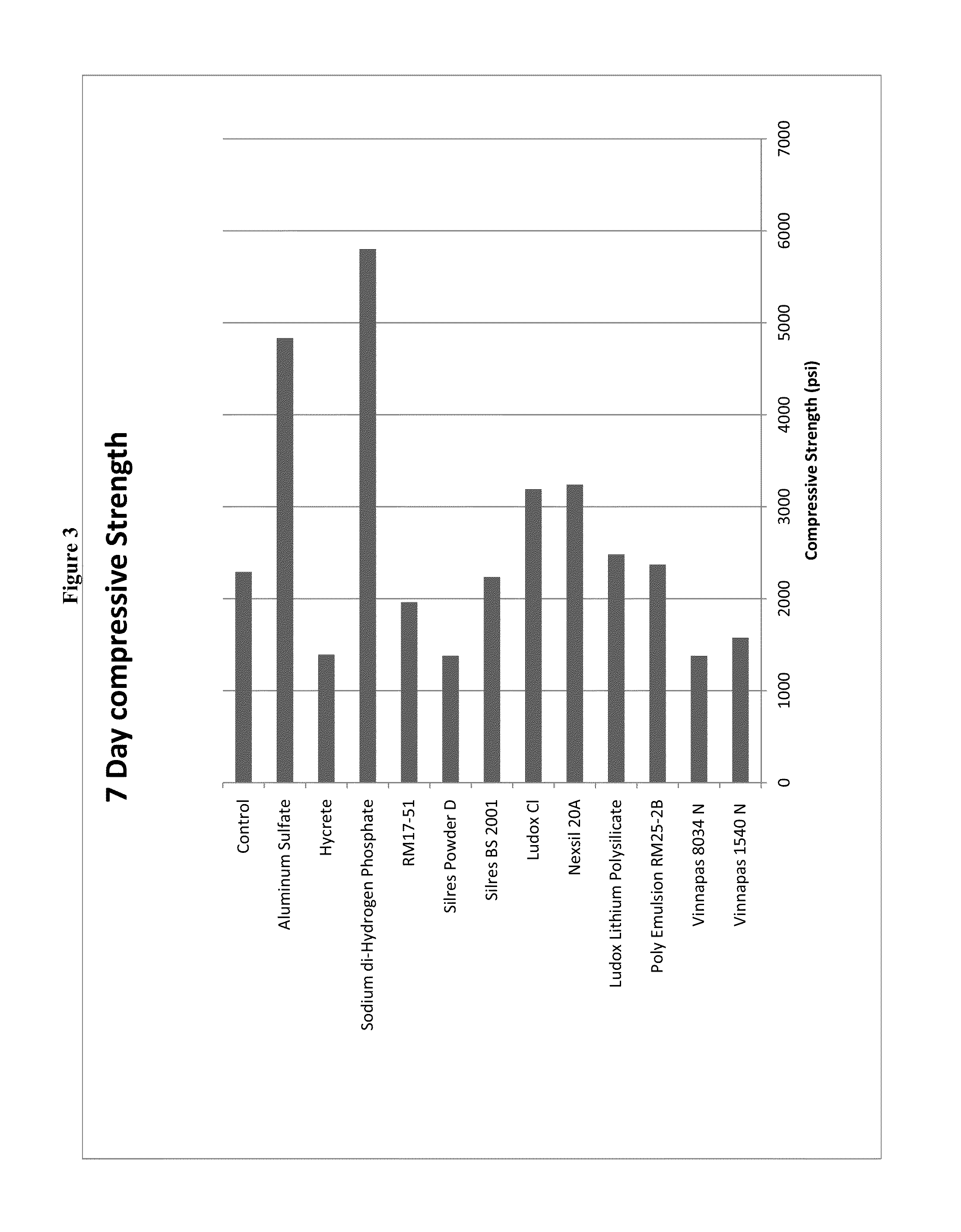

Despite the excellent properties associated with Magnesium OxyChloride (Sorel) based cements and Magnesium OxySulfate based cements, water and corrosion resistance has been limiting factors for achieving greater commercial applications. Such issues can be addressed by incorporating various alkali metal phosphates, such as Magnesium mono- or dihydrogen phosphate (MgHPO4 or MgH2PO4) with alkali metal fatty acids; such as Magnesium Stearate; and metal or alkali metal sulfates such as Aluminum Sulfate or Magnesium Sulfate. Water resistance is further enhanced by either pre-carbonating the mix water or the liquid magnesium chloride phase of the cements, or by adding a carbonate into the powder phase. Accelerated cure of this system has also been obtained by using various inorganic metal oxides. Additionally, improved corrosion resistance is achieved through the use of certain phosphates, zeolites, nitrites and other novel additives.

Owner:PREMIER MAGNESIA

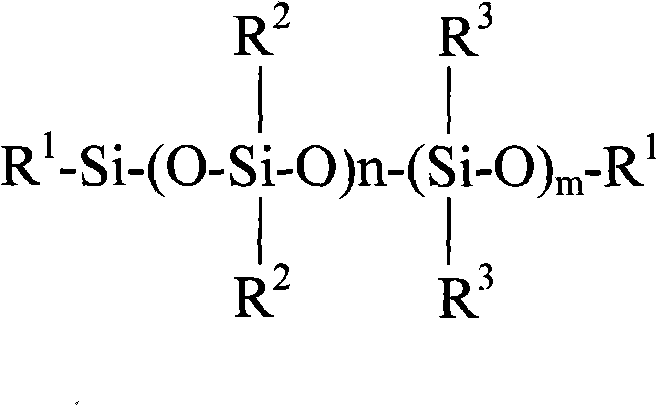

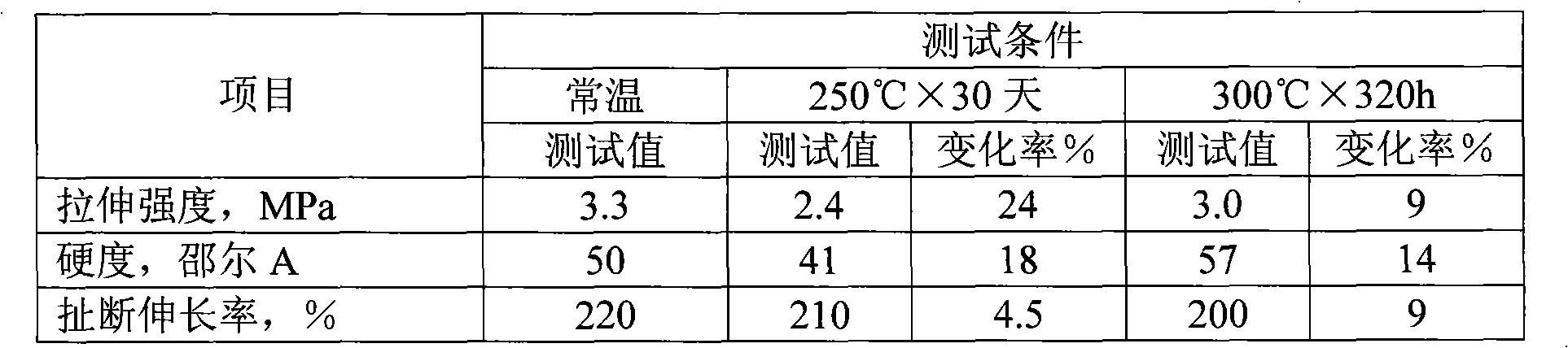

Light-coloured high temperature resistant organic silicone adhesive/sealant

InactiveCN101311238AImprove agingImprove temperature resistanceOther chemical processesAdhesivesHeat conductingCross linker

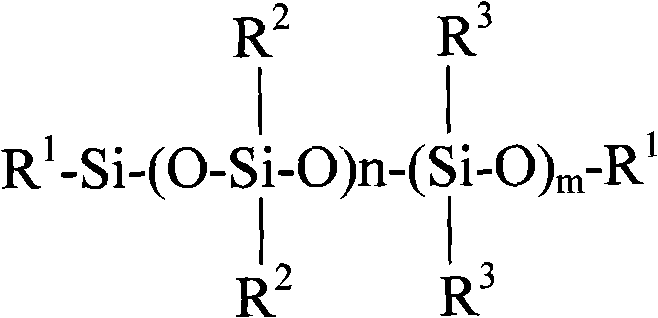

The invention relates to a tint high-temperature resistant organic silicon adhesive / sealant, which takes the polysiloxane with the end capped by active functional groups as the foundation, the white carbon soot with the surface going through hydrophobic treatment as reinforcing stuffing, the vapor phase titanium dioxide as a free oxygen consumption agent and the silane coupling agent containing phenyl as a cross linker and combines with proper heat conducting stuffing and catalyst. The silicon adhesive / agent can be solidified at room temperature or rapidly solidified through heating. The product is French grey paste, which allows diversified color matching. The solidified product of the silicon adhesive / agent can endure the temperature as high as 300 DEG C.

Owner:上海橡胶制品研究所有限公司

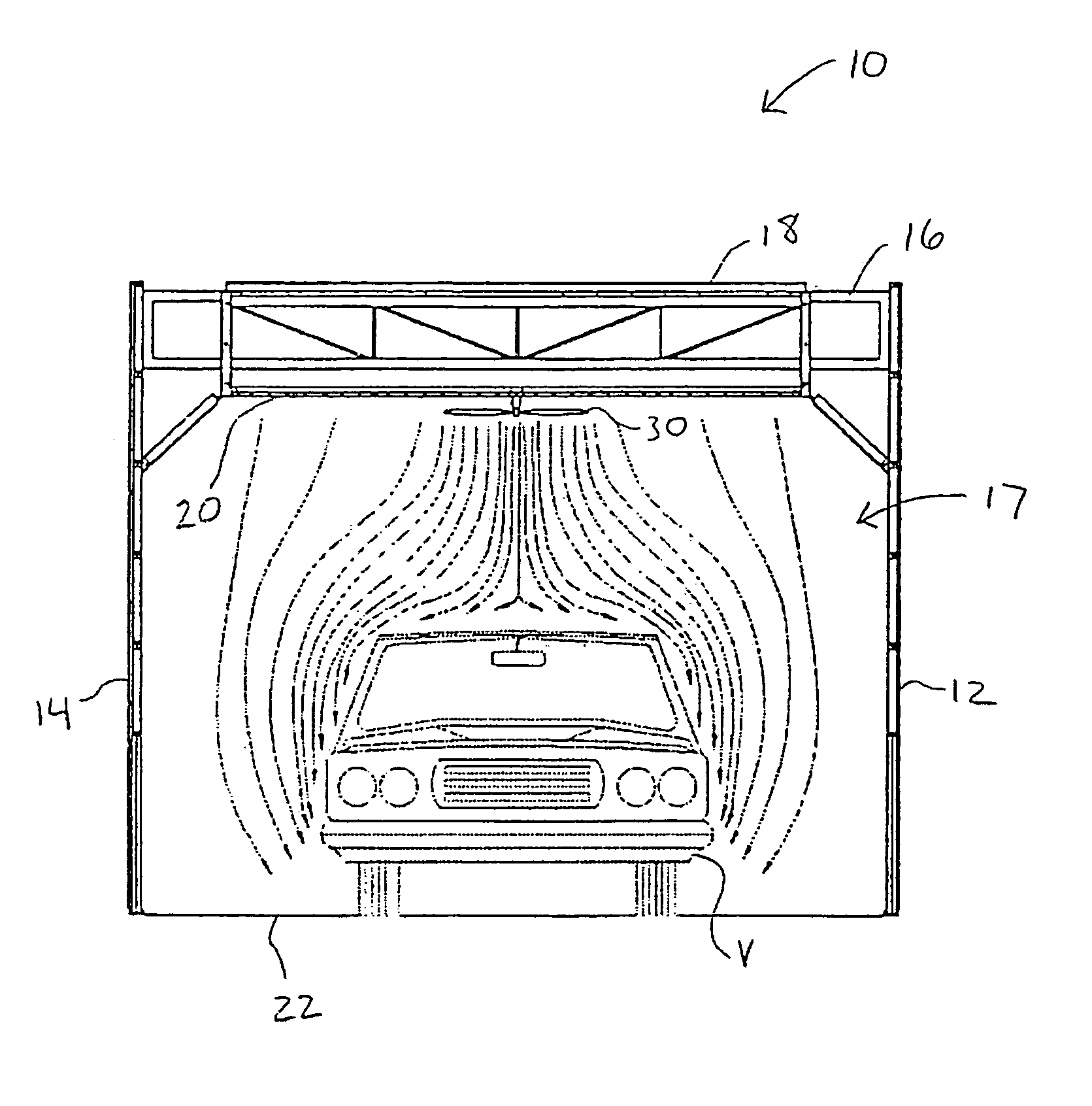

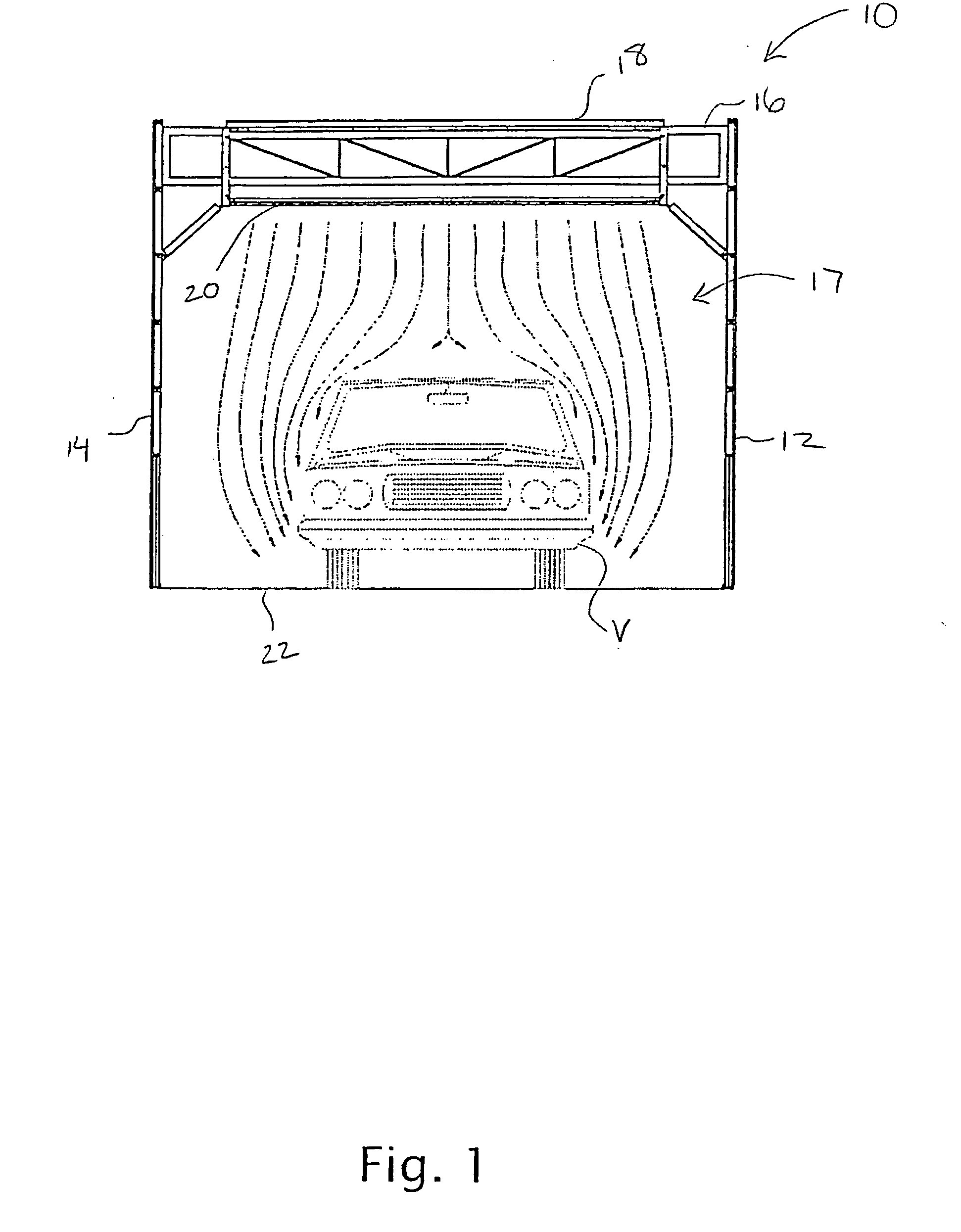

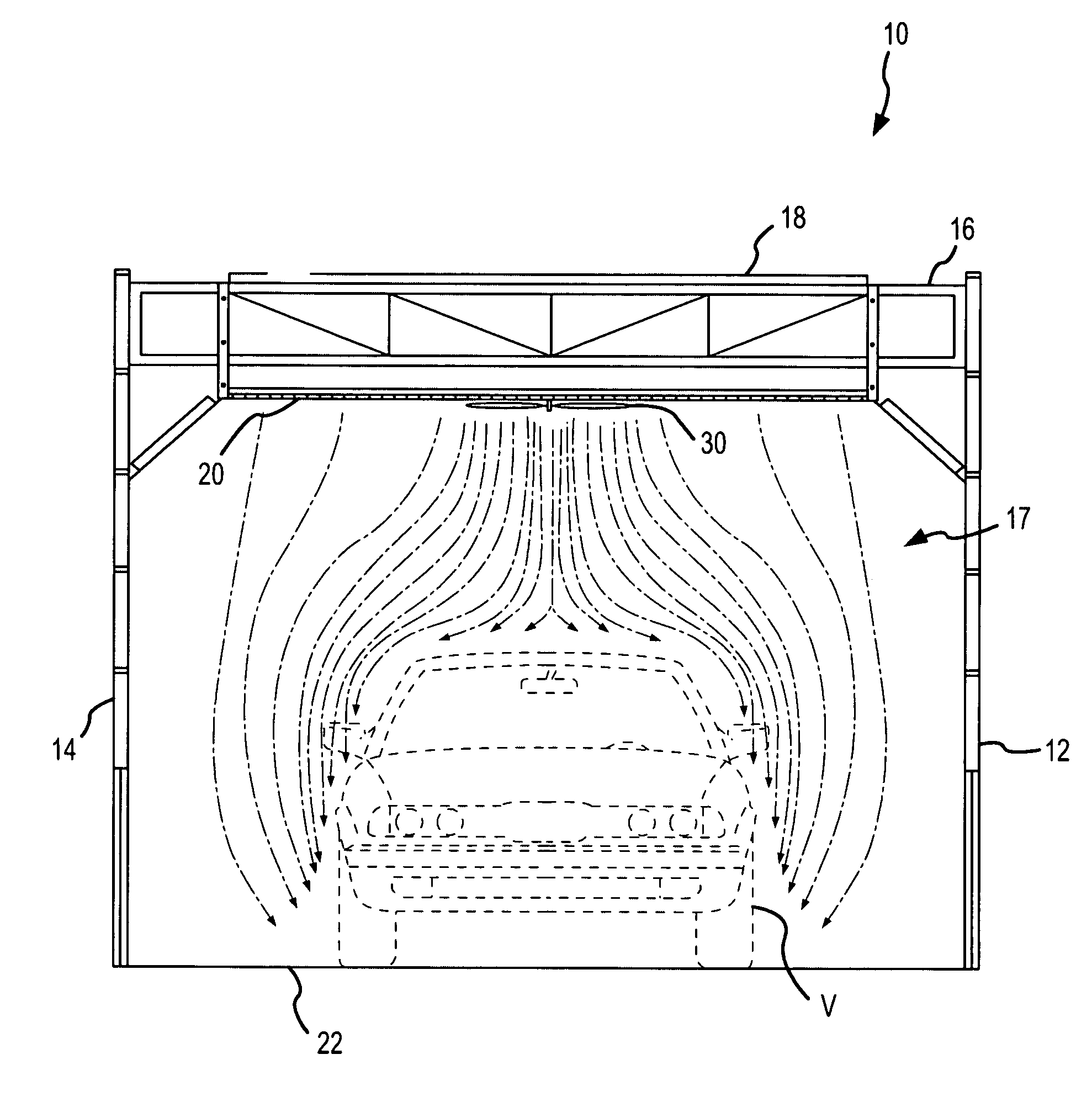

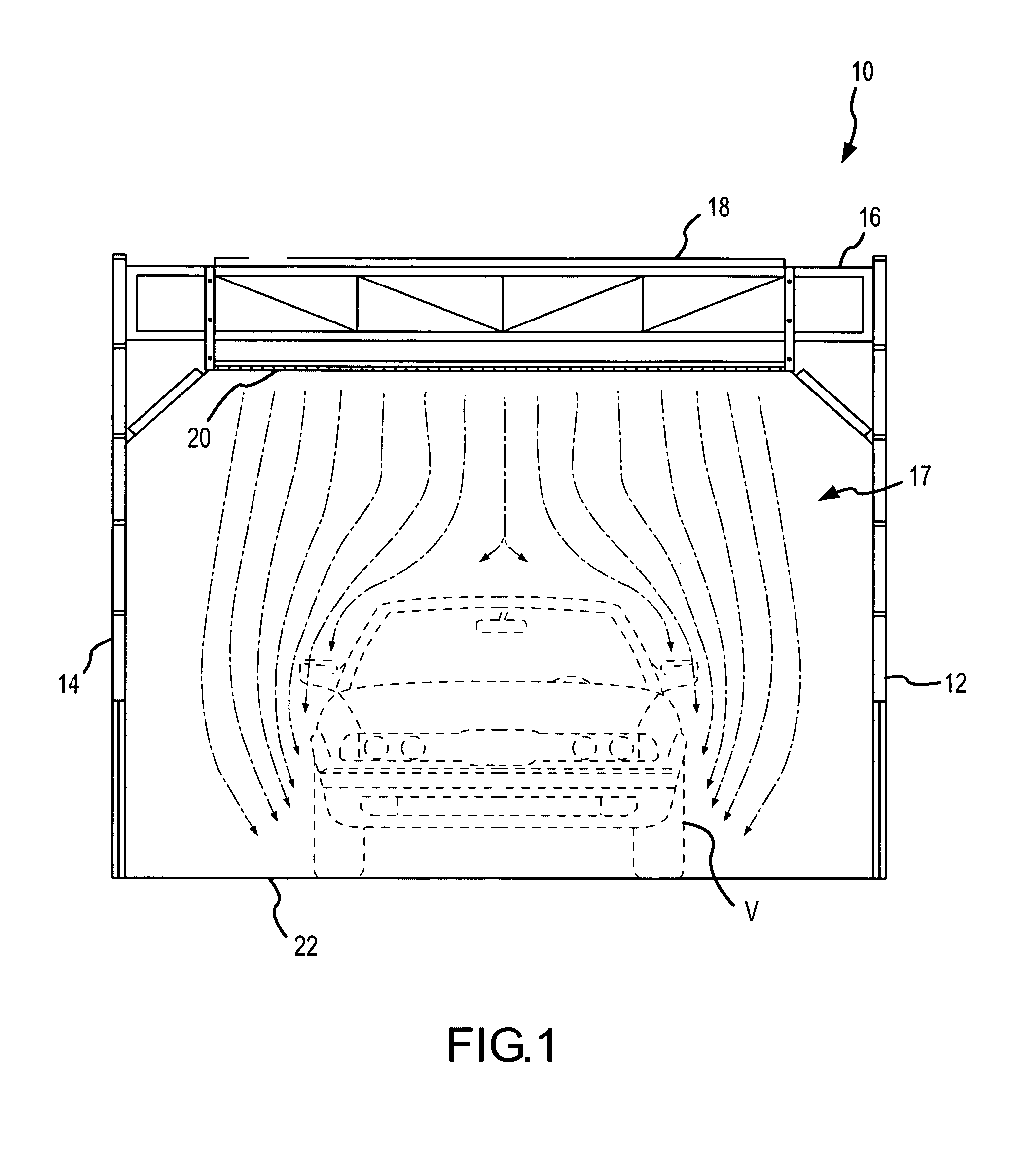

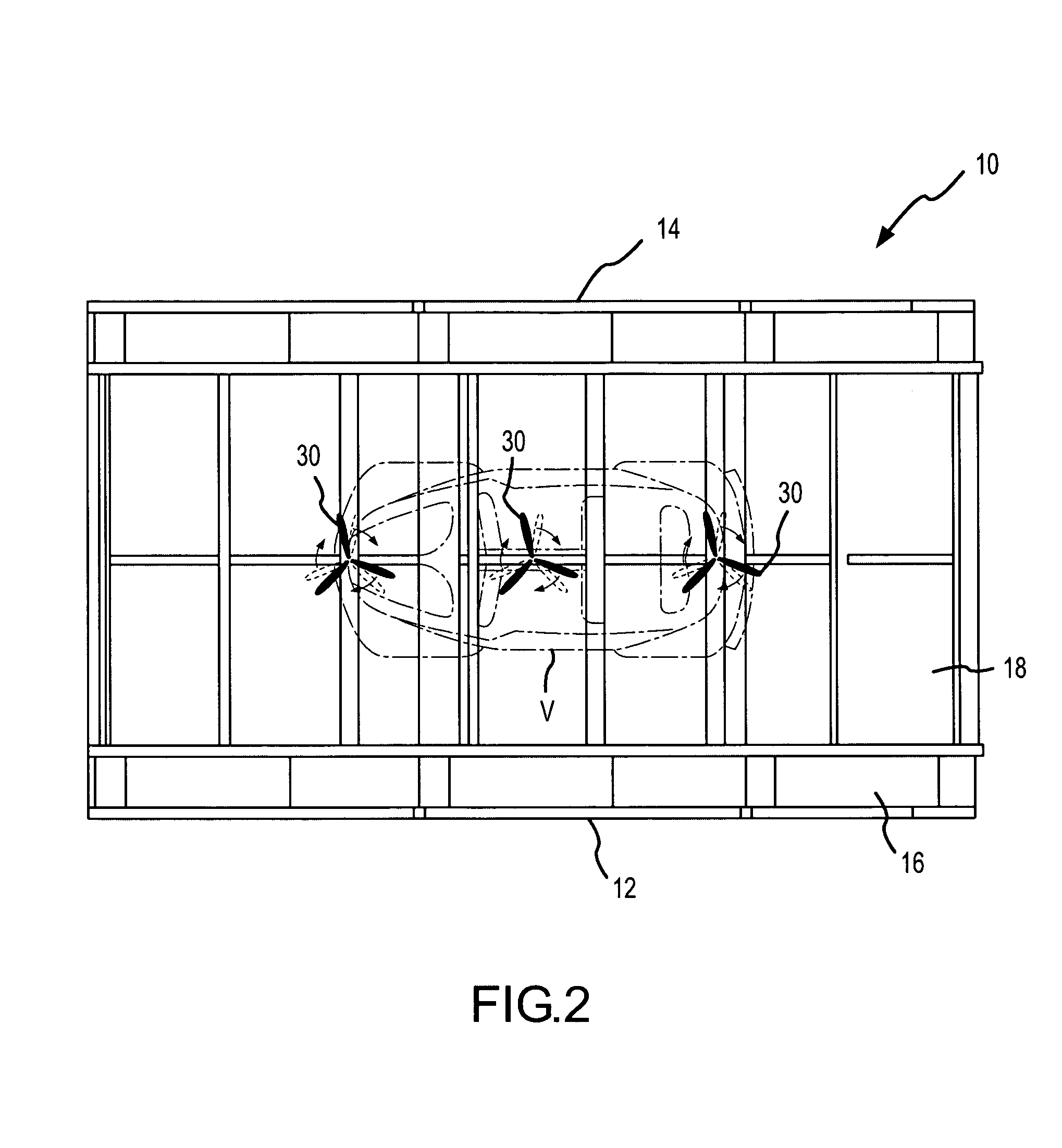

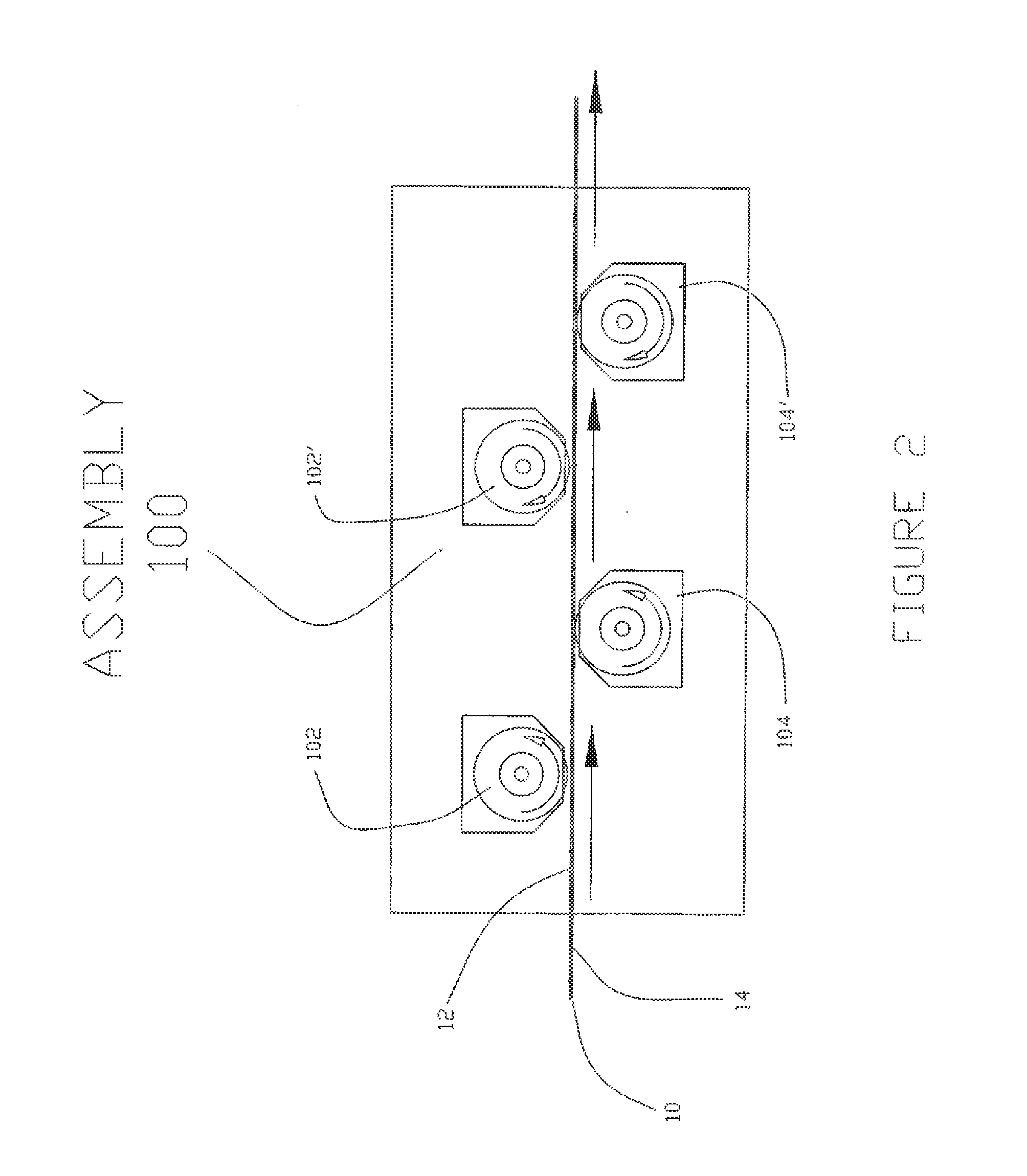

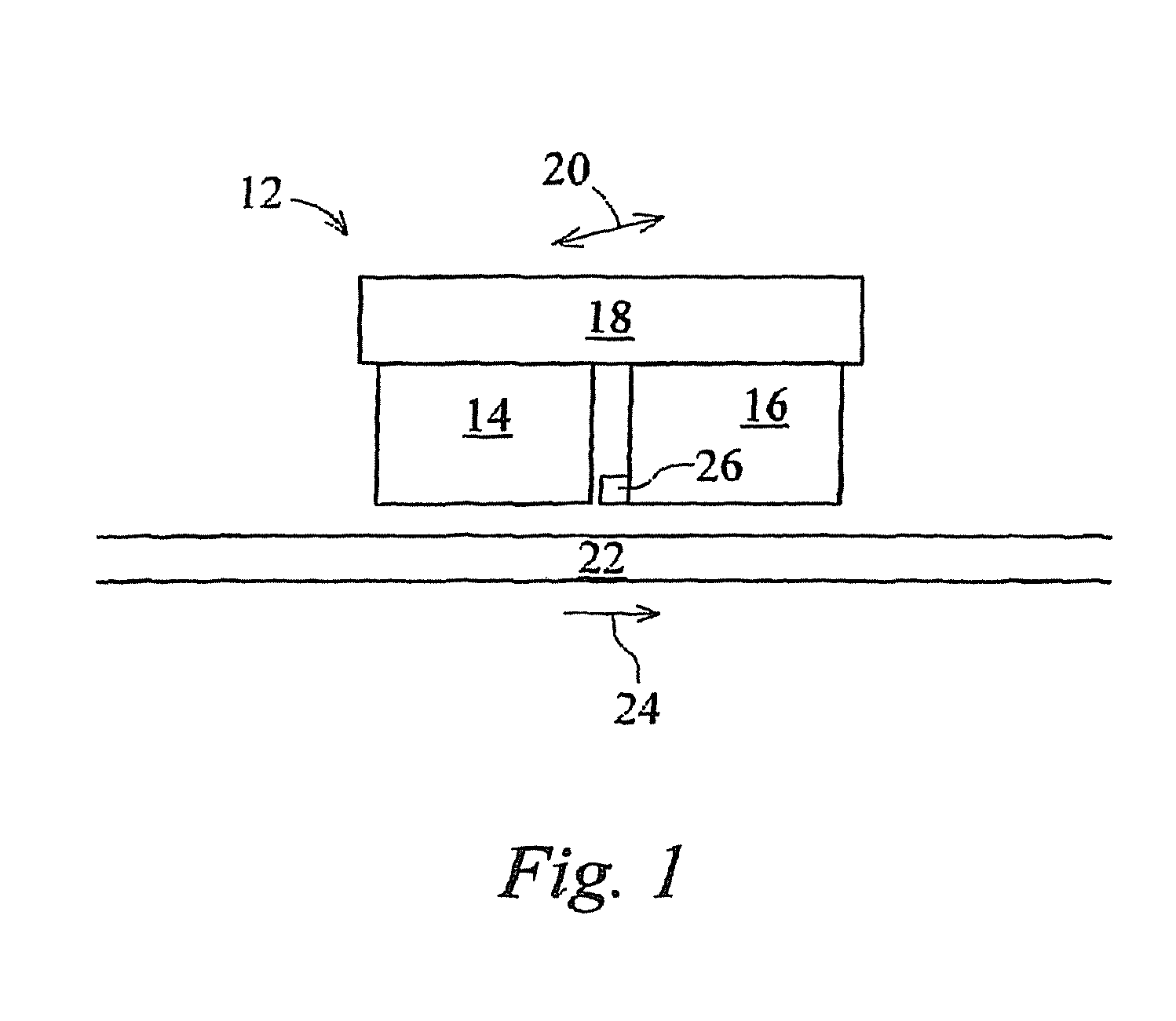

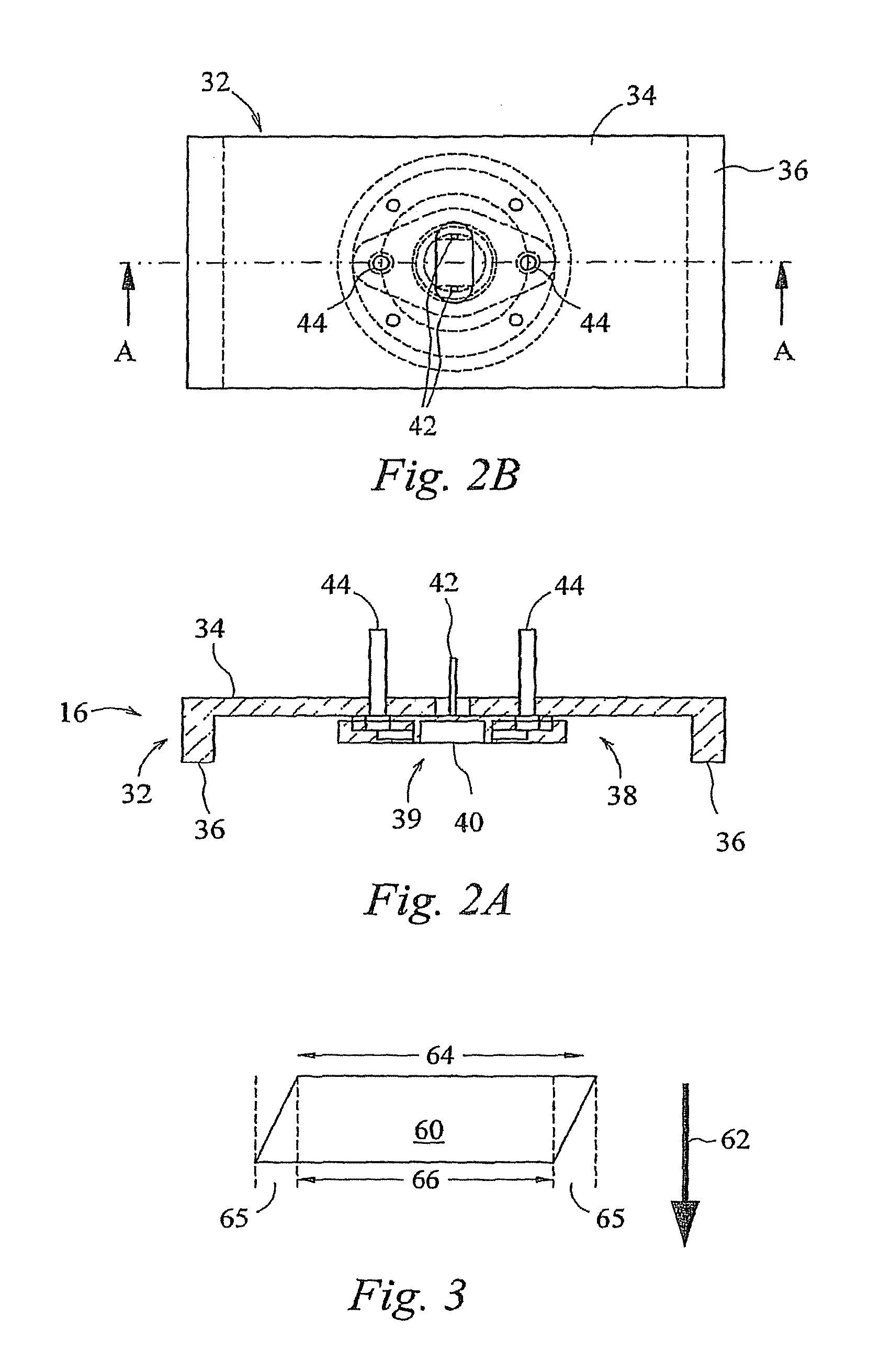

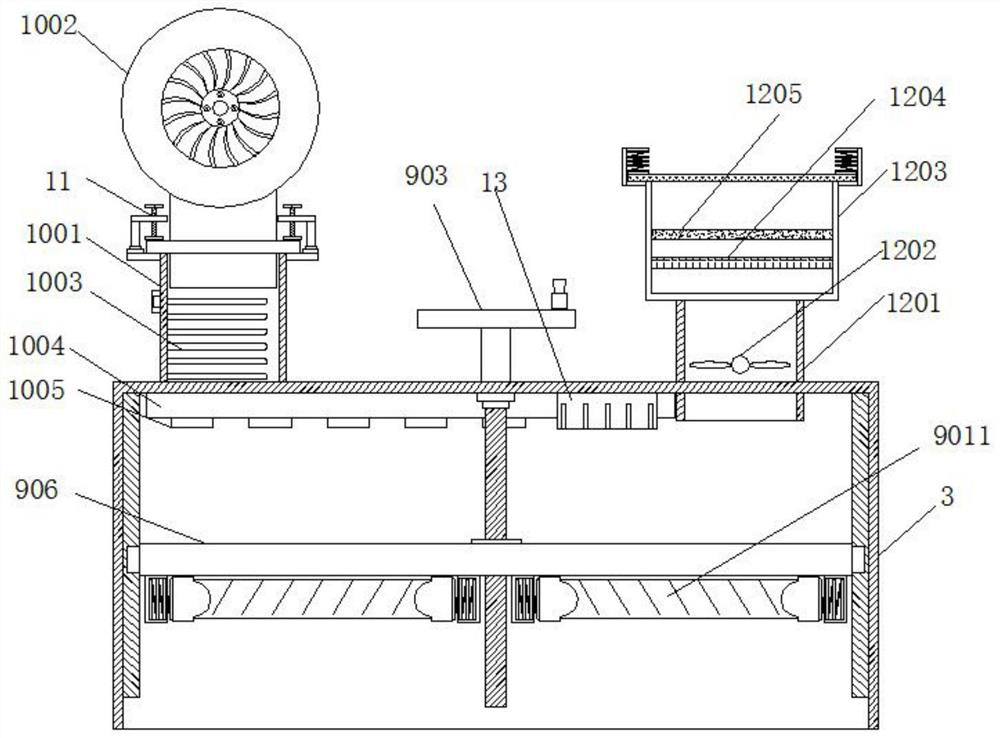

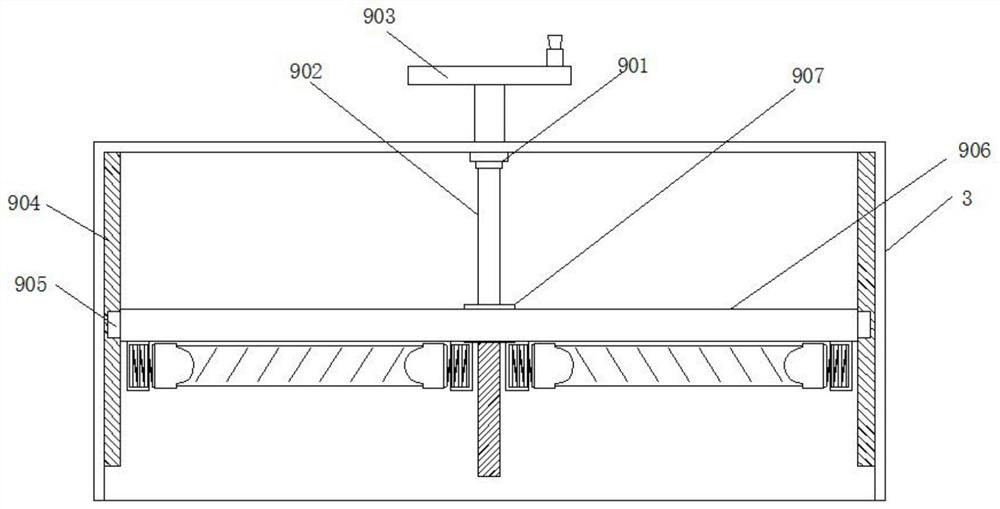

Spray booth systems and methods for accelerating curing times

ActiveUS20050120948A1Increase pressureIncrease airflowLiquid surface applicatorsDrying gas arrangementsAccelerated curingFilter media

One embodiment of the invention provides a spray booth that comprises a spray booth housing having a ceiling and side walls that define an interior for holding an object to be sprayed. A pressurized air plenum is disposed above the ceiling and is adapted to supply air into the interior. A filter media is used to filter air from the plenum before entering into the interior. At least one fan is disposed in the interior below the filter media. The fan is operable to locally increase air flows in the vicinity of the object to increase evaporation rates associated with a spray application on the object, and to enhance air flow over the object during a dry or a cure cycle.

Owner:GARMAT USA LLC

Normal-temperature solidifying wear-resistance coating and preparation method thereof

InactiveCN102250538ANo need to consume energyHigh hardnessPolyurea/polyurethane coatingsVinyl etherAccelerated curing

The invention relates to a normal-temperature solidifying wear-resistance coating and a preparation method thereof. The normal-temperature solidifying wear-resistance coating consists of a component A and a component B, which are in a weight ratio of (7-12):1, wherein the component A consists of graphite fluoride, silicon carbide micropowder, fluorinated ethylene vinyl ether (FEVE) fluorocarbon resin, a first solvent, a dispersant, a coupling agent and a thixotropic agent; and the component B comprises a solidifying agent and a second solvent. The normal-temperature solidifying wear-resistance coating can be applied by the conventional brushing, dipping and spraying coating processes without consuming a large amount of energy and can be applied on surfaces susceptible to high temperature. And with the high hardness and high wear resistance of silicon carbide and the excellent lubricating performance of graphite fluoride, the normal-temperature solidifying wear-resistance coating has the characteristics of high hardness and high wear resistance. In addition, the normal-temperature solidifying wear-resistance coating has high heat resistance and can solidify at normal temperature or solidify quickly with heating.

Owner:WUHAN UNIV OF TECH

Method and compositions for improving performance properties of magnesium oxychloride cements

ActiveUS8603237B2Improve water resistanceEarly water resistanceSolid waste managementPhosphatePhosphoric acid

Despite the excellent properties associated with Magnesium OxyChloride (Sorel) based cements and Magnesium OxySulfate based cements, water and corrosion resistance has been limiting factors for achieving greater commercial applications. Such issues can be addressed by incorporating various alkali metal phosphates, such as Magnesium mono- or dihydrogen phosphate (MgHPO4 or MgH2PO4) with alkali metal fatty acids; such as Magnesium Stearate; and metal or alkali metal sulfates such as Aluminum Sulfate or Magnesium Sulfate. Water resistance is further enhanced by either pre-carbonating the mix water or the liquid magnesium chloride phase of the cements, or by adding a carbonate into the powder phase. Accelerated cure of this system has also been obtained by using various inorganic metal oxides. Additionally, improved corrosion resistance is achieved through the use of certain phosphates, zeolites, nitrites and other novel additives.

Owner:PREMIER MAGNESIA

Spray booth systems and methods for accelerating curing times

ActiveUS7045013B2Increase airflowIncrease evaporation rateLiquid surface applicatorsDrying gas arrangementsAccelerated curingFilter media

One embodiment of the invention provides a spray booth that comprises a spray booth housing having a ceiling and side walls that define an interior for holding an object to be sprayed. A pressurized air plenum is disposed above the ceiling and is adapted to supply air into the interior. A filter media is used to filter air from the plenum before entering into the interior. At least one fan is disposed in the interior below the filter media. The fan is operable to locally increase air flows in the vicinity of the object to increase evaporation rates associated with a spray application on the object, and to enhance air flow over the object during a dry or a cure cycle.

Owner:GARMAT USA LLC

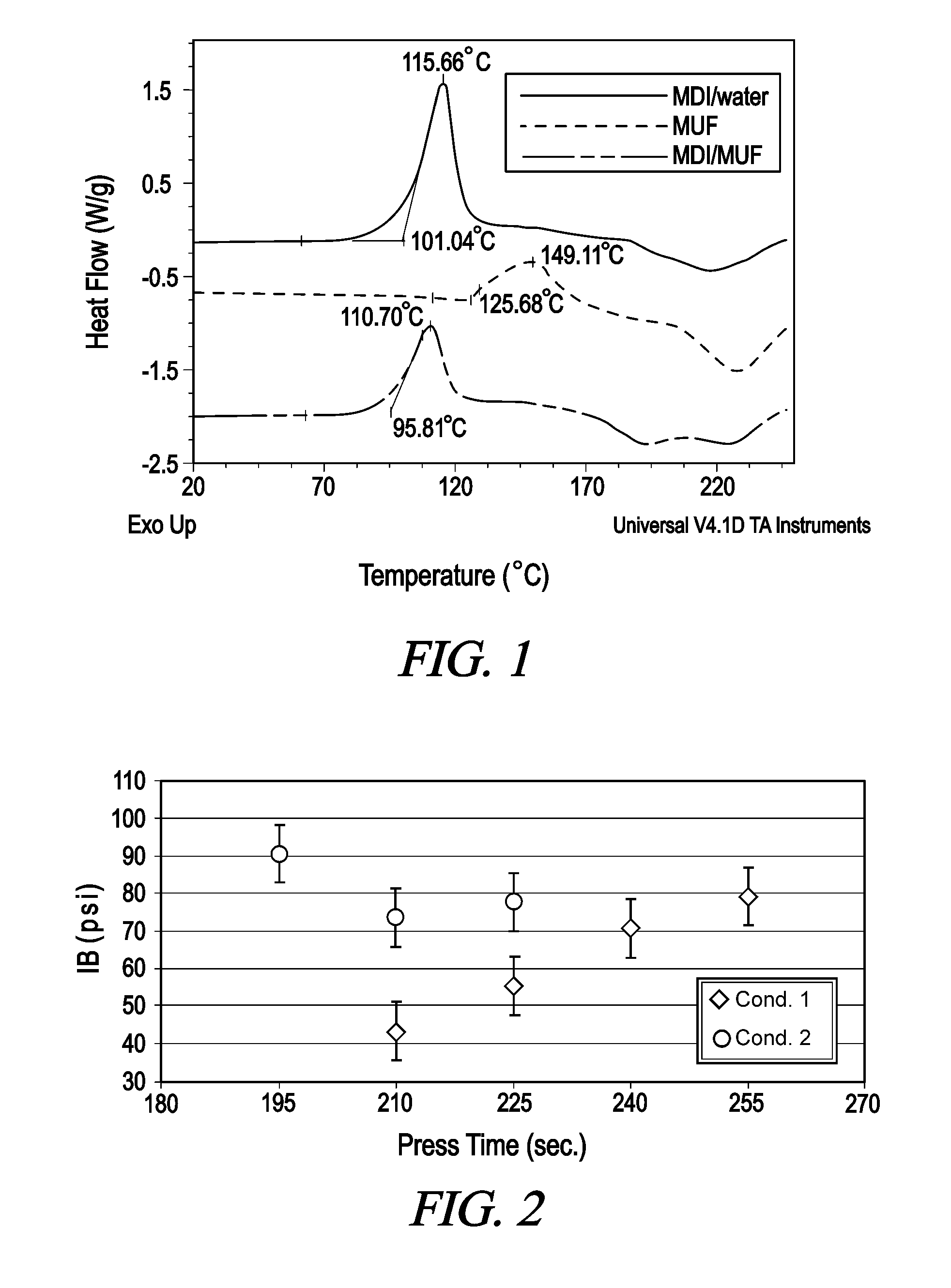

Accelerated Curing Adhesive For Wood Composites

InactiveUS20100071829A1Speed up the processEmission reductionWood working apparatusAbsorbent padsAdhesive cementAccelerated curing

An adhesive system for, inter alia, the manufacturing of wood composites, which includes a MDI adhesive and a formaldehyde-containing resin accelerator.

Owner:GANG NAIL SYST

Accelerated curing of epoxy gelcoats

InactiveUS20030130481A1Reduced room temperature gel timeDecrease room temperature gelling timePretreated surfacesCoatingsVitrificationAccelerated curing

Aqueous solutions of inorganic nitrate salts are used to accelerate the gelling of epoxy gelcoat resins without adversely affecting the glass transition temperature of the finally cured gelcoat. The aqueous accelerants may be used to accelerate gelling of gelcoats that are formed during initial fabrication of composite parts. The aqueous acclerants are also useful for shortening the gel time of gelcoats that are intended for use in repairing damaged structures.

Owner:HEXCEL COMPOSITES LTD (GB)

Cure accelerator system for phenolic resins

InactiveUS7049387B2Improve curing speedCure rate can be further acceleratedCoatingsAccelerated curingAccelerant

The cure rate of phenol-aldehyde resins is accelerated by conjoint use of a cyclic carbonate cure accelerant and an amine cure accelerant. The cure rate is accelerated still further by addition of a resorcinol source to resin comprising a cyclic carbonate and an amine cure accelerator. Also, cured resins made in accordance with the method.

Owner:GEORGIA PACIFIC CHEM LLC

Preparation method of moisture-curing polyurethane hot melt adhesive

InactiveCN110256998AImprove performanceExtended service lifePolyureas/polyurethane adhesivesMacromolecular adhesive additivesPolyesterAntioxidant

The invention discloses a preparation method of a moisture-curable polyurethane hot melt adhesive. The method comprises the following steps: 1) adding adipic acid polyester polyol, phthalic anhydride polyester polyol, polyoxypropylene ether glycol and an antioxidant into a reaction kettle, uniformly stirring the components, heating the mixture to 120-130 DEG C, and dehydrating the mixture for 2 h under the vacuum degree of less than 100 Pa; (2) cooling the mixture to 75-95 DEG C, adding MDI and a catalyst, and stirring the mixture to carry out a reaction for 2 hours at the temperature of 85-90 DEG C and the vacuum degree of less than 100Pa; 3) adding an auxiliary agent, and quickly stirring the mixture for 30 minutes under the vacuum degree of less than 100 Pa; and 4) rapidly discharging and packaging the product under the protection of nitrogen. According to the PUR prepared through the method, curing is accelerated, meanwhile, the mode that -NCO groups react with water vapor in air for curing is changed, the -NCO groups react with active hydrogen in a latent curing agent, a carbon dioxide product is not generated, meanwhile, due to addition of a combined auxiliary, the product performance is further stabilized, and the service life is prolonged.

Owner:南通天洋新材料有限公司 +2

High-density gypsum fiberboard and production technique thereof

The invention discloses a high-density gypsum fiberboard which is prepared from a gelating material, a filling material, recovered waste newspaper, and reinforcing fiber prepared from packaging materials, wherein the gelating material is composed of alpha-semi-hydrated gypsum, beta-semi-hydrated gypsum and cement; and the filling material comprises calcium carbonate particles and inorganic perlite. The invention also discloses a production technique of the high-density gypsum fiberboard, which comprises the following steps: (1) mixing; (2) automatically feeding the mixture into a mold frame; (3) carrying out press molding; (4) stripping; and (5) carrying out multilayer drying tunnel accelerated curing and drying. The technique is mainly characterized in control on mixing raw materials with different particle sizes and modification on the equipment and draining technique; and the gypsum fiberboard prepared by the new formula materials and new technique has higher strength than simply using high-strength alpha-semi-hydrated gypsum, and the cost is obviously lowered.

Owner:JIANGSU XIANGLI ANTI STATIC DECORATION MATERIALS

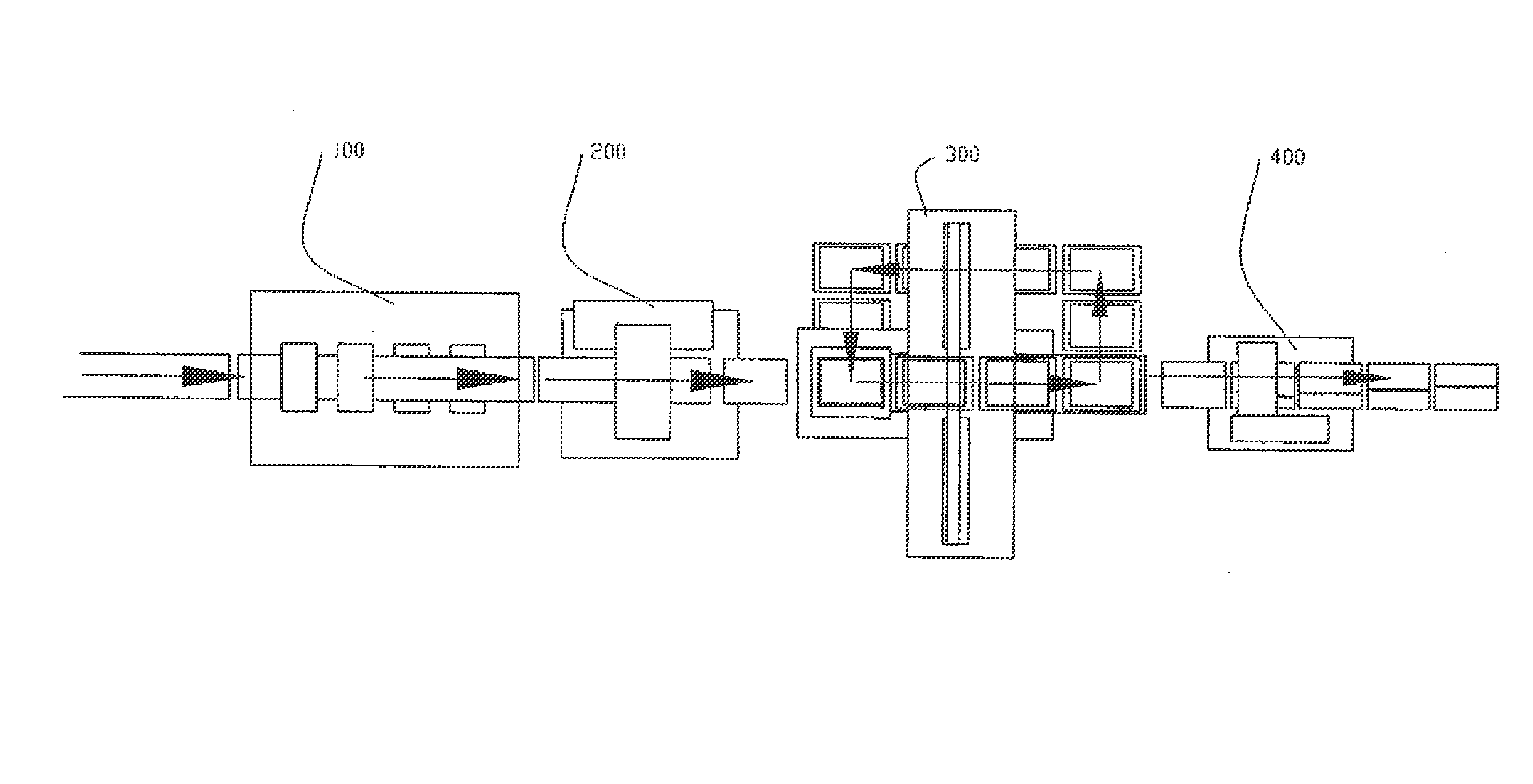

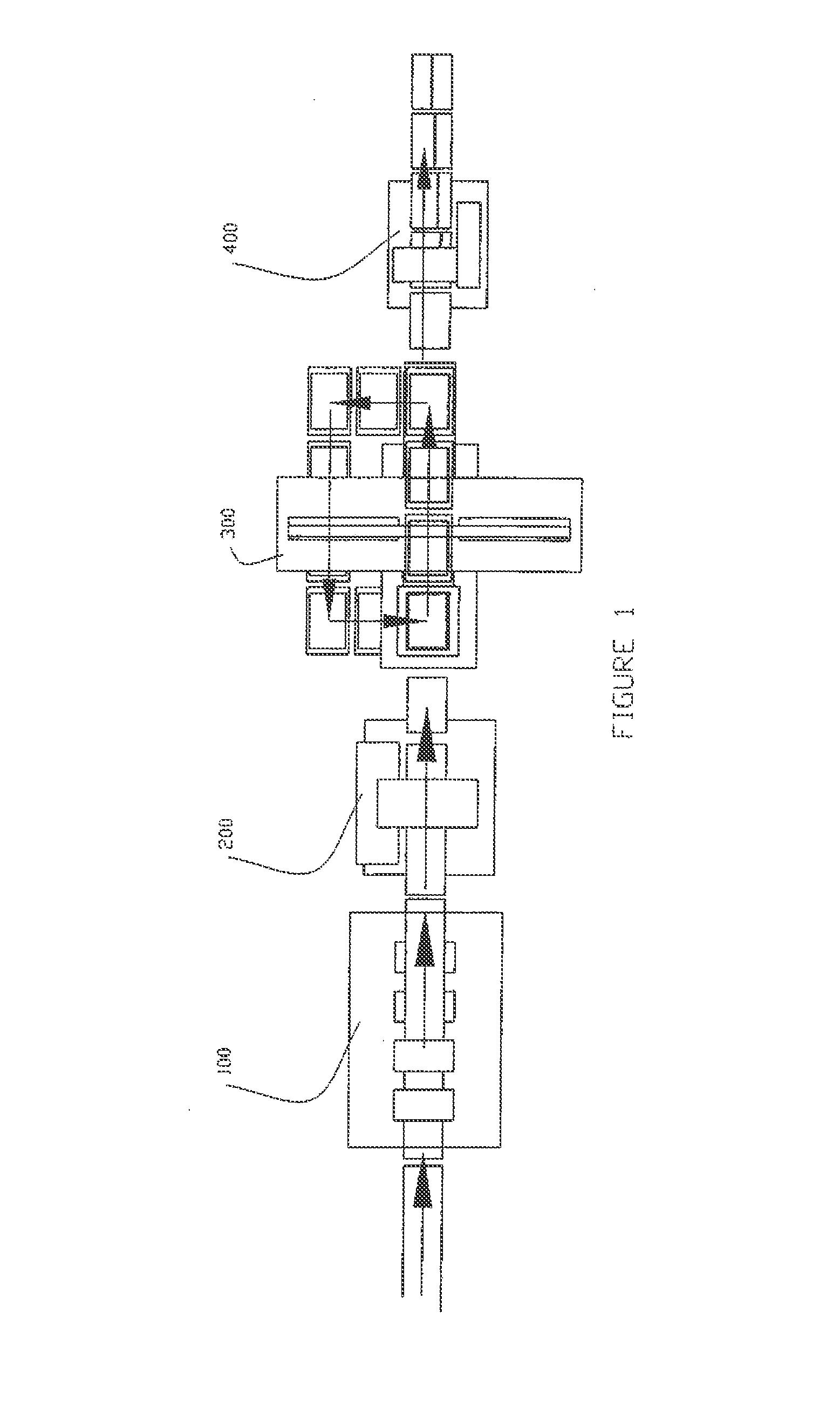

Apparatus and method of manufacturing shingles from cellular polyvinyl chloride

ActiveUS8420172B1Minimize fadeImprove performanceRoof covering using tiles/slatesPretreated surfacesCross cutAccelerated curing

A method for forming shingles from cellular polyvinyl chloride boards comprising brushing, parting, cutting and coating the boards to desired dimensions and finish. The method comprises passing cellular polyvinyl chloride boards through one or more of a specially designed brushing assembly, cross cut saw assembly, parting assembly, and sizing saw assembly, wherein the assemblies are in-line. The method may further include an in-line, high speed application and accelerated curing of a uniquely formulated solar reflective, ceramic-based finish.

Owner:JAIN AMERICA HLDG INC

Biomass curing-acceleration phenolic resin and phenolic resin preparation method

ActiveCN106750060ASimple preparation processLow curing temperatureNon-macromolecular adhesive additivesMacromolecular adhesive additivesAccelerated curingWaste material

The invention discloses biomass curing-acceleration phenolic resin and a phenolic resin preparation method. Compared with the prior art, the curing-acceleration reagent adopted in the invention is a biomass material with low price; and since a degradable biomass material is introduced into the phenolic resin, the degradation effect of the waste material embedded into soil can be enhanced due to the microbial action; the preparation technology of the phenolic resin is relatively simple, and the adopted curing acceleration reagent is simply added before the use of the phenolic resin, so that the operation is simpler; and the prepared phenolic resin has relatively low curing temperature and relatively short curing time and is suitable for artificial board production and furniture making.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Curing

ActiveUS8398229B2Reduce the environmentCure reaction can be acceleratedLamination ancillary operationsLaminationAccelerated curingLight-emitting diode

A method of curing radiation-curable fluid is described. In one example, the method includes emitting radiation from an array of light-emitting diodes towards ink to be cured. LEDs are cheap, light weight, highly efficient in their conversion of electrical power, and give effectively instant switching to full power. Another advantage is that the emission spectrum of an LED is sharply peaked around the nominal frequency. Thus LEDs give several advantages over conventional radiation sources such as mercury lamps. A low oxygen environment is preferably provided at the radiation source to accelerate the curing reaction. Also described are inks which are specially formulated to respond to the radiation emission spectrum of an LED.

Owner:AGFA NV

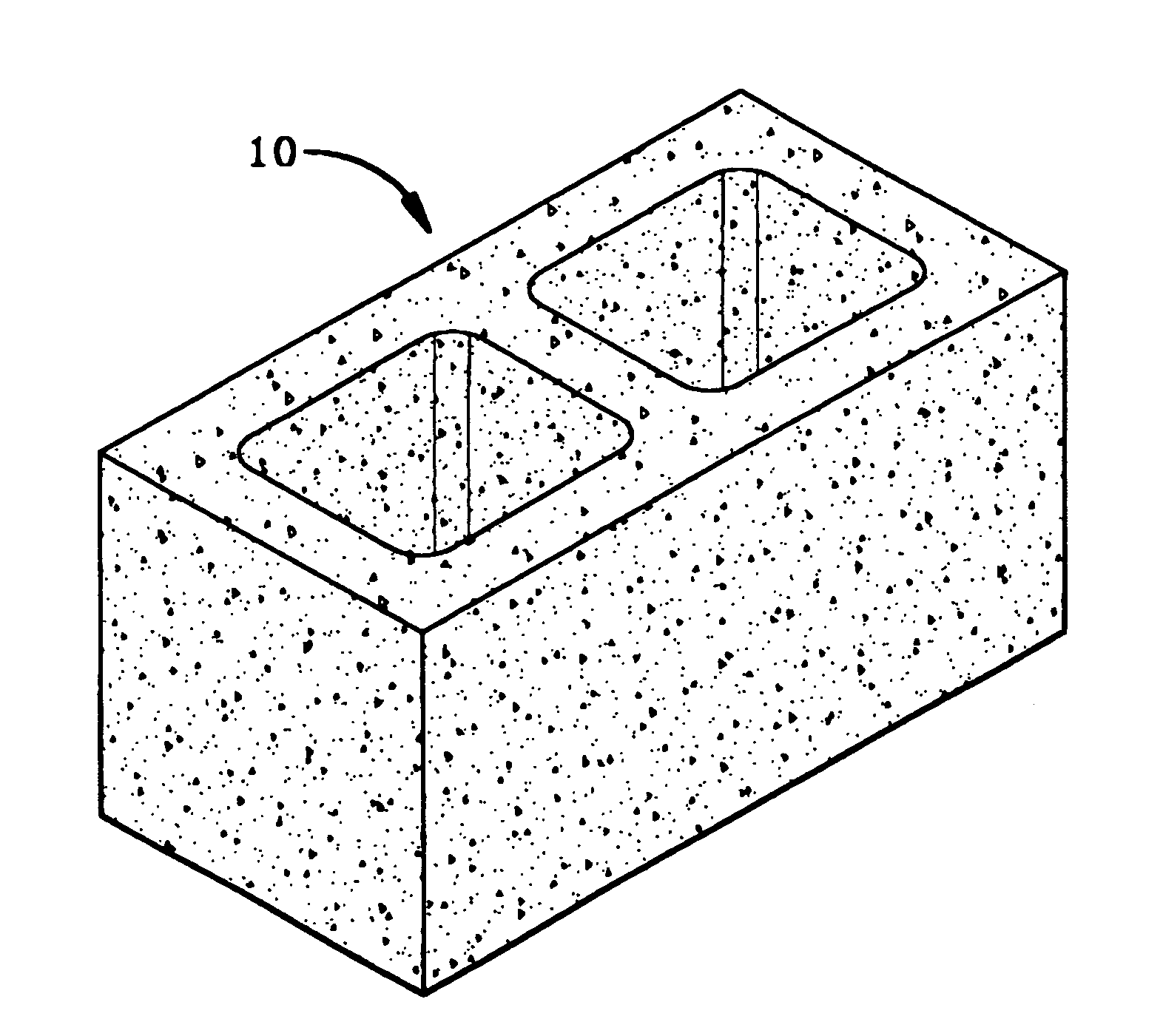

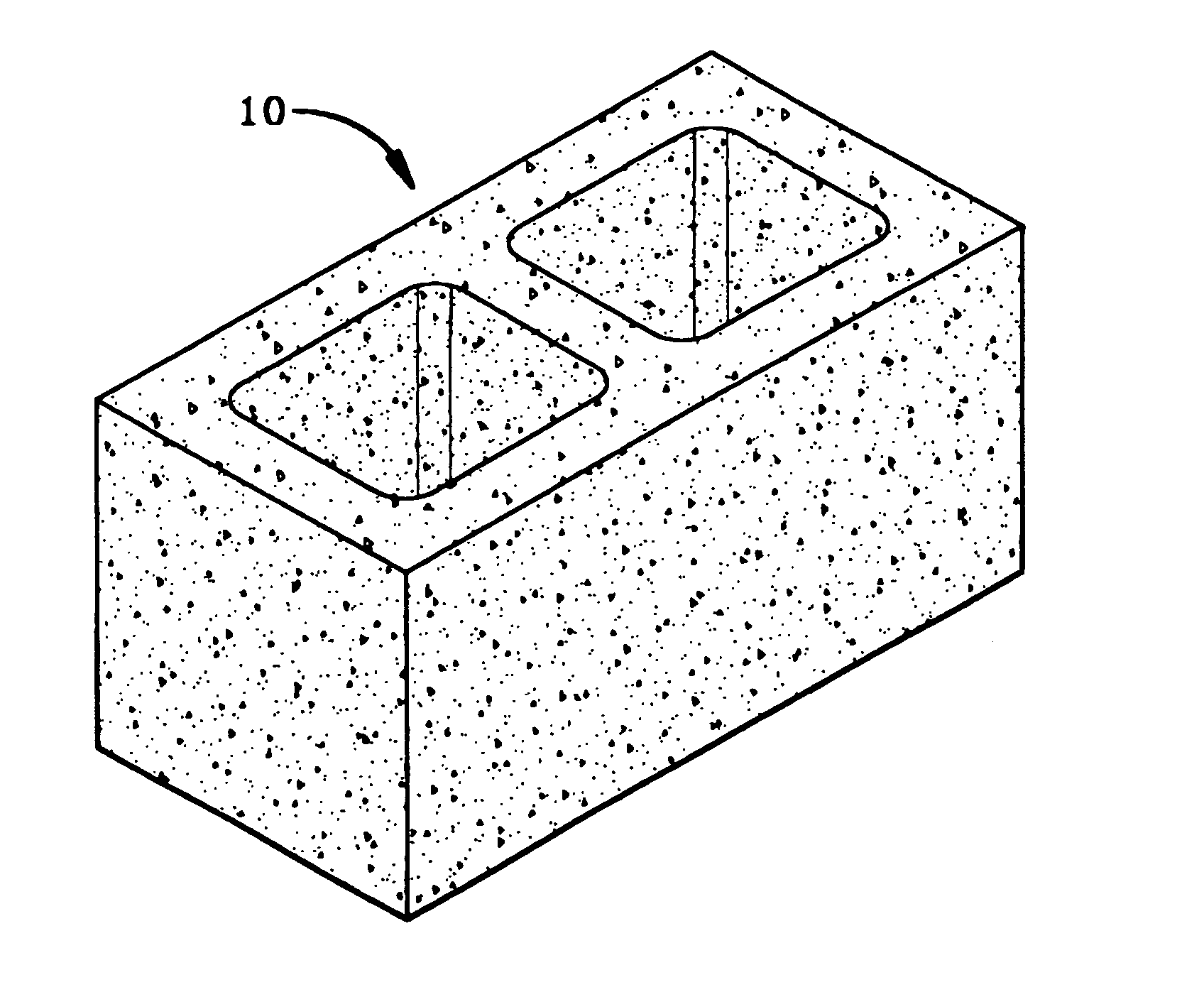

Cementitious block material utilizing spent blasting abrasive particles

An accelerated-curing concrete masonry unit (CMU) mixture includes aggregate material, hydraulic cement and spent blasting abrasive particles, and may also include paint residue particles. The abrasive particles or abrasive and paint particles combined preferably make up at least 5.0% of the mixture by volume. Preferably, the hydraulic cement is Portland cement and the abrasive or combined particles make up about 10.0% to 17.0% of the mixture by volume. The abrasive particles typically have a fineness modulus ranging from 0.6 to 1.5 and more preferably from 0.75 to 1.2. Plastic particles may make up some or all of the abrasive particles. CMUs formed with this mixture are substantially more water repellent than standard CMUs and have a water absorption often no greater than 9.0 pounds per cubic foot. Preferred CMUs have an average net compressive strength of over 2,500 psi while levels of 3,000 psi or 3,500 psi are not uncommon.

Owner:U S TECH MEDIA INC

Processing method of high-performance carbon fiber-reinforced calcium silicate board

The invention discloses a processing method of a high-performance carbon fiber-reinforced calcium silicate board. The method comprises the following steps of 1 proportioning and pulping, wherein raw materials are separately weighed according to proportions and added into a ball mill, water of which the mass is 5 times that of the raw materials is added, all the materials are ball-milled to be uniform, and a pulp is obtained; 2 blank making, wherein a mold is prepared according to a needed size, and the pulp is injected into the mold for molding; 3 steam curing, wherein the mold injected with the pulp is subjected to an accelerating curing reaction in high temperature and high pressure saturated steam; 4 surface treatment, wherein the surface of the well-prepared fiber-reinforced calcium silicate board is sprayed with a layer of self-cleaning coating before use, and the high-performance carbon fiber-reinforced calcium silicate board is obtained. The processing method of the high-performance carbon fiber-reinforced calcium silicate board has the excellent advantages that the prepared calcium silicate board is fireproof, resistant to moisture, resistant to oil fouling, high in strength and good in tensile property.

Owner:上海轩颂建筑科技股份有限公司

Mixed type powder coating and preparation method thereof

The invention relates to a mixed type powder paint and a preparation method thereof. The mixed type powder paint is characterized by comprising 20 to 28 portions of epoxy powder composition and 20 to 80 portions of modified PE powder composition. The preparation method comprises the following steps: epoxy and curing agent are mixed according to the proportion, added with addition agent such as flatting agent, subjected to mixing and extrusion, and granulated; products are crushed by a plastic crusher into micropowder which is screened; components with 180 to 200 meshes are taken to prepare the epoxy powder composition; silane modified PE, curing accelerator, flatting agent and so on are subjected to mixing melt extrusion according to the proportion in a double screw extruder at a temperature of between 150 and 180 DEG C, crushed and screened; and components with 180 to 200 meshes are taken to prepare a crosslinked PE powder composition; the silane modified PE adopts moisture for curing; and the epoxy powder composition and the crosslinked PE powder composition are dispersed and mixed evenly according to a certain proportion to prepare the mixed powder paint, wherein the ratio of the epoxy powder composition to the crosslinked PE powder composition is 20-80 to 80-20. The mixed type powder paint has the advantages that the mixed type powder paint has super strong weather resisting property, has certain compatibility with the epoxy and integration of a surface layer and a bottom layer due to the modification treatment, can be cured by self under natural condition, and can also be steeped into hot water for accelerating the curing.

Owner:SHUNDE POLYTECHNIC

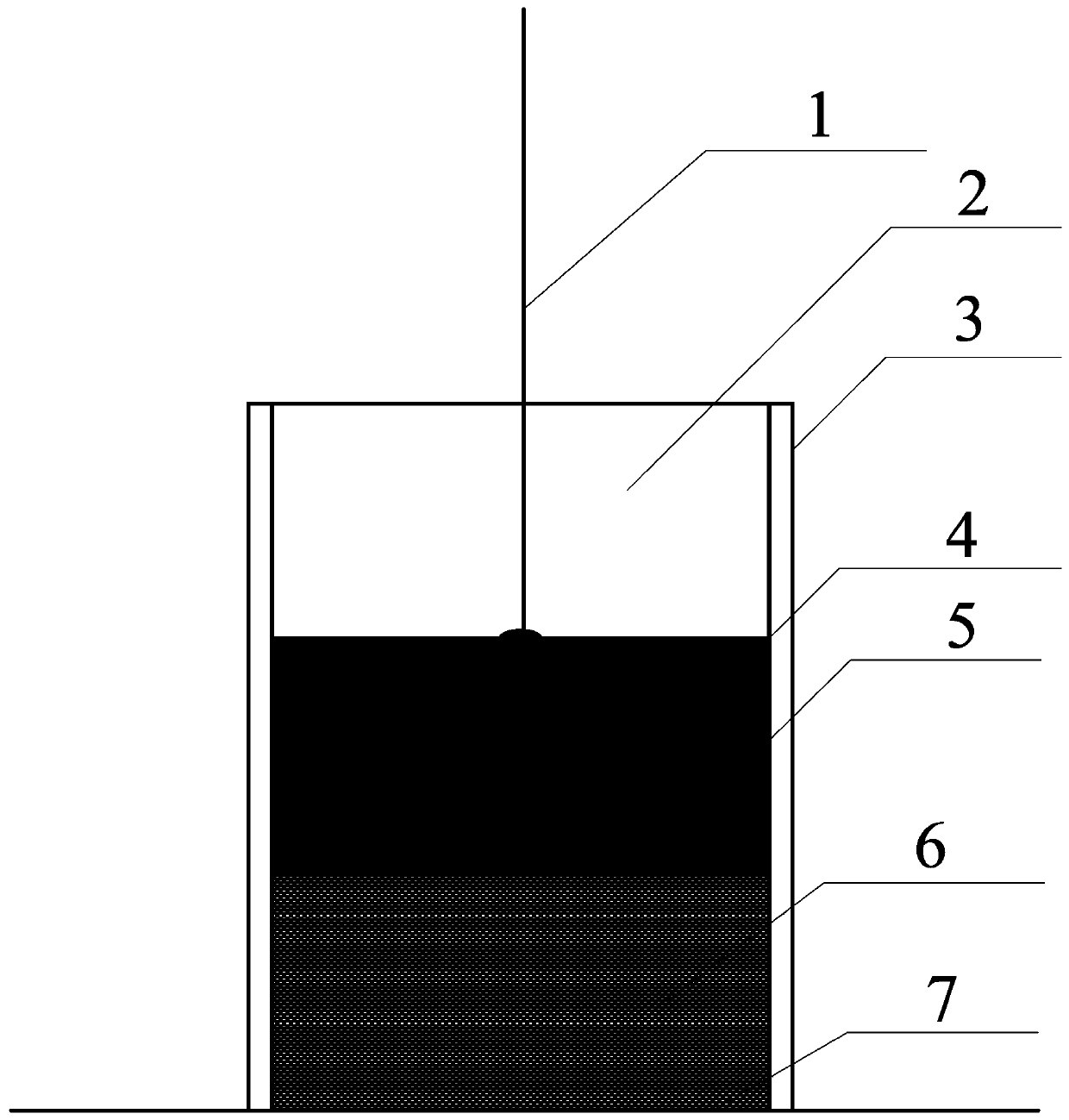

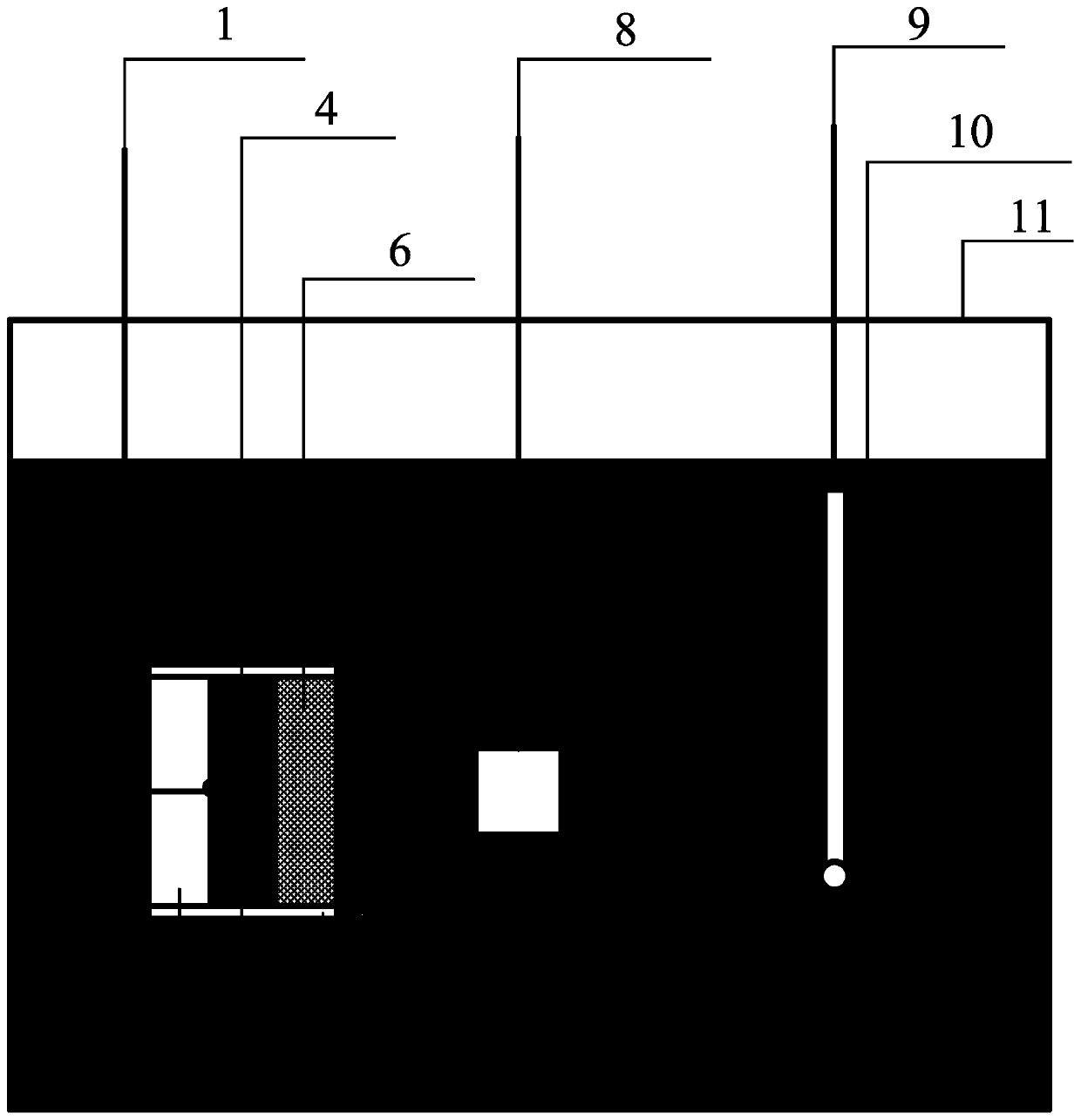

Corrosion detection electrode in conductive concrete environment, preparation method of corrosion detection electrode in conductive concrete environment and corrosion detection method in conductive concrete environment

ActiveCN110333275ACalculation of Corrosion Current DensityEvenly distributedMaterial electrochemical variablesPlane surface grinding machinesEpoxyAccelerated curing

The invention belongs to the field of corrosion electrochemistry testing, and particularly relates to a corrosion detection electrode in a conductive concrete environment, a preparation method of thecorrosion detection electrode in the conductive concrete environment and a corrosion detection method in the conductive concrete environment. A columnar sample, a hot inlaying layer, an epoxy resin layer, a conductive concrete layer and a wire are all included. In the preparation method, by sample sealing mode of firstly performing hot inlaying and then performing cold inlaying for a test metal, atest surface is enabled to be combined with an inlaying material tightly, a problem that a concrete work electrode is liable to generate gas corrosion in a cement accelerated curing process can be solved, a simple and convenient work electrode preparation method is provided for realizing metal material corrosion electrochemistry detection in the concrete environment, the preparation method not only is suitable for performing corrosion resistance detection for a conductive concrete composite material newly researched and developed on the market, but also can be used for research on electrochemical corrosion mechanism of the metal material in the concrete environment and evaluation on corrosion inhibition performance of an corrosion inhibitor in the internal / external environment of the concrete.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST +3

Cementitious block material utilizing spent blasting abrasive particles

Owner:U S TECH MEDIA INC

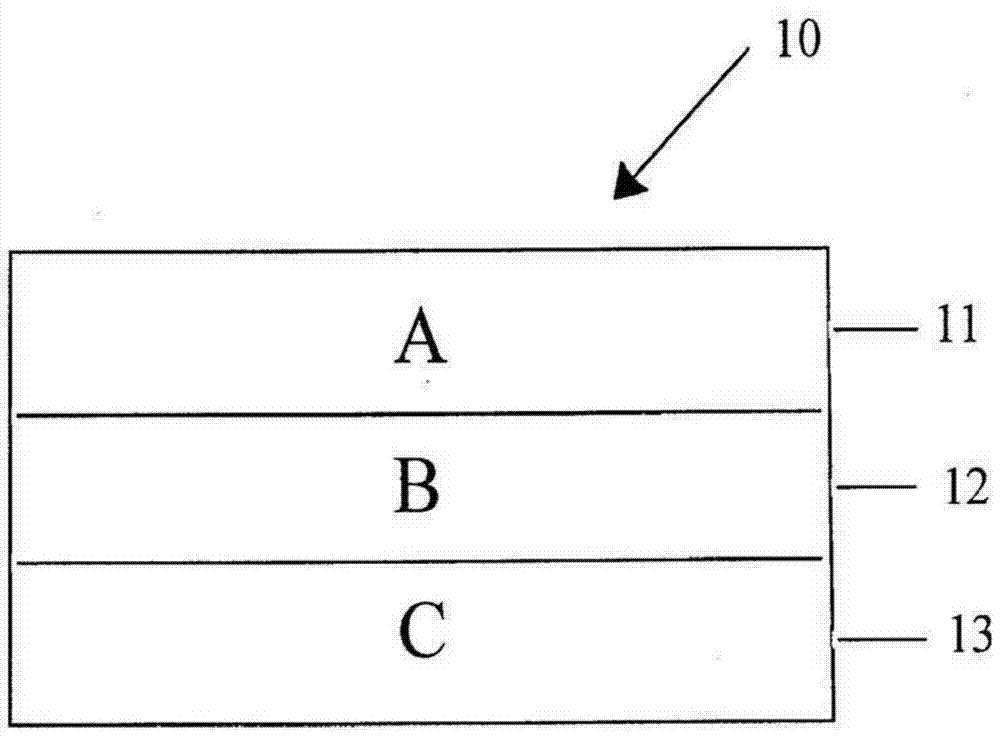

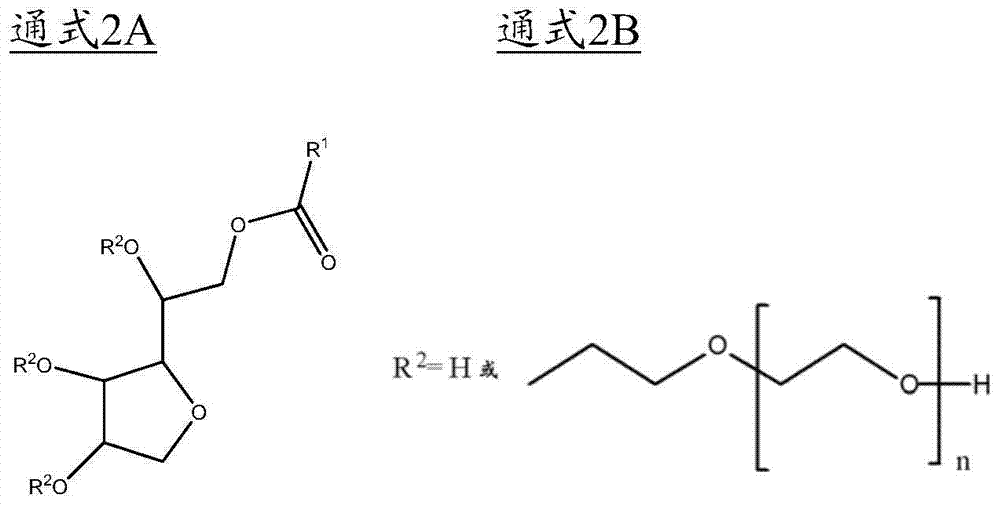

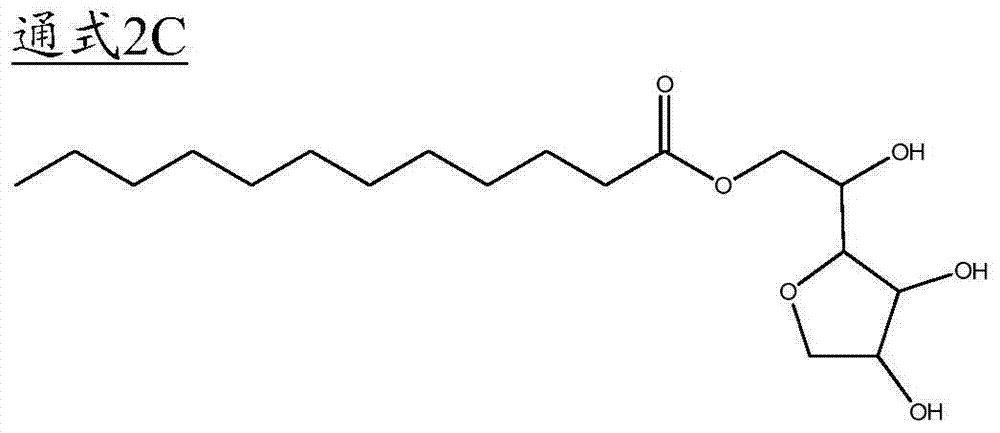

Modified ethylene-based films to promote isocyanate chemical reactions in polyurethane laminating adhesives

InactiveCN104755261ASynthetic resin layered productsDomestic containersChemical reactionZinc ricinoleate

In the construction of a multilayer film in which an ethylene-based polymer layer is joined to one another layer by a polyurethane (PU) adhesive, the rate of cure and the degree of cure of the PU adhesive are accelerated by incorporating into the ethylene-based polymer layer a functional compound with active hydrogens, e.g., a polyol, and / or a cure catalyst, e.g., an amine, zinc or tin-based compound. The catalyst and reactive functionality may be present on the same molecule (e.g. alkoxylated amine or zinc ricinoleate). The catalyst and isocyanate reactive compound will migrate into the PU adhesive over time and accelerate the rate and promote the degree of PU adhesive cure, and the functional compound will promote the migration of the cure catalyst into the PU adhesive. In turn, this accelerated cure inhibits the migration of residual, monomeric amines from the PU adhesive into and through the ethylene-based polymer.

Owner:DOW GLOBAL TECH LLC +1

Cure accelerator system for phenolic resins

The cure rate of phenol-aldehyde resins is accelerated by conjoint use of a cyclic carbonate cure accelerant and an amine cure accelerant. The cure rate is accelerated still further by addition of a resorcinol source to resin comprising a cyclic carbonate and an amine cure accelerator. Also, cured resins made in accordance with the method.

Owner:GEORGIA PACIFIC CHEM LLC

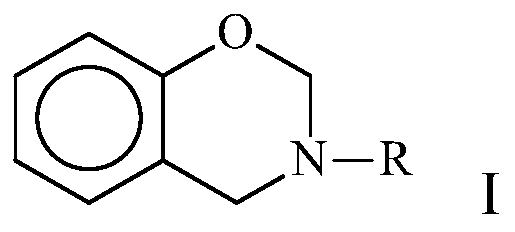

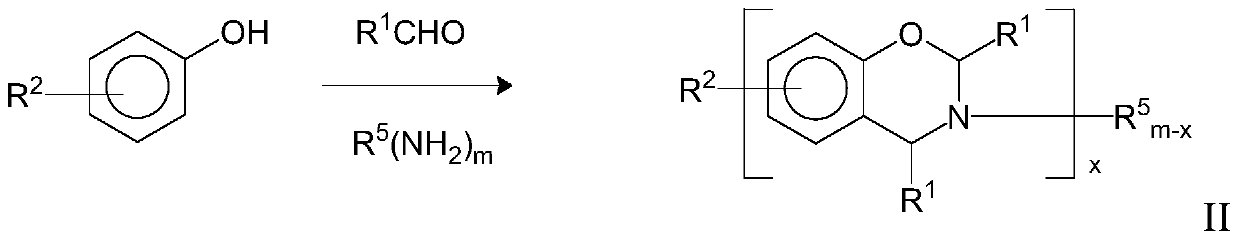

Benzoxazine composition

ActiveCN109715689AOvercome many of the notable drawbacks of aggregationLess heat releaseCoatingsHalogenAccelerated curing

The disclosure provides a catalyst for use with a benzoxazine resins which imparts accelerated curing at reduced temperatures. The catalyst is selected from elemental halogen or onium polyhalide compounds.

Owner:3M INNOVATIVE PROPERTIES CO

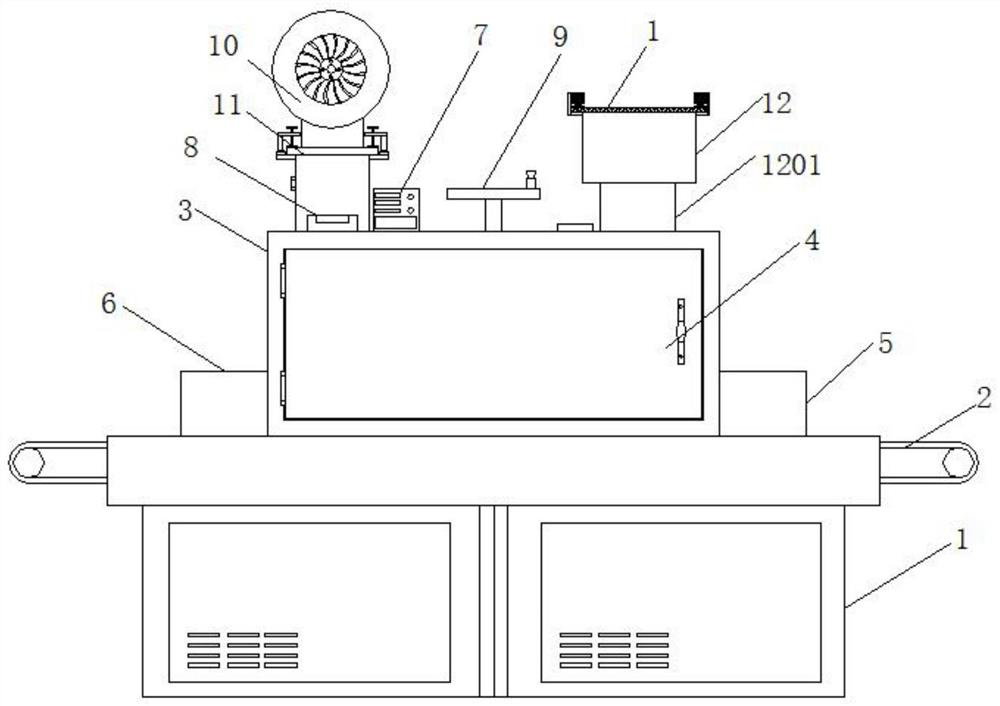

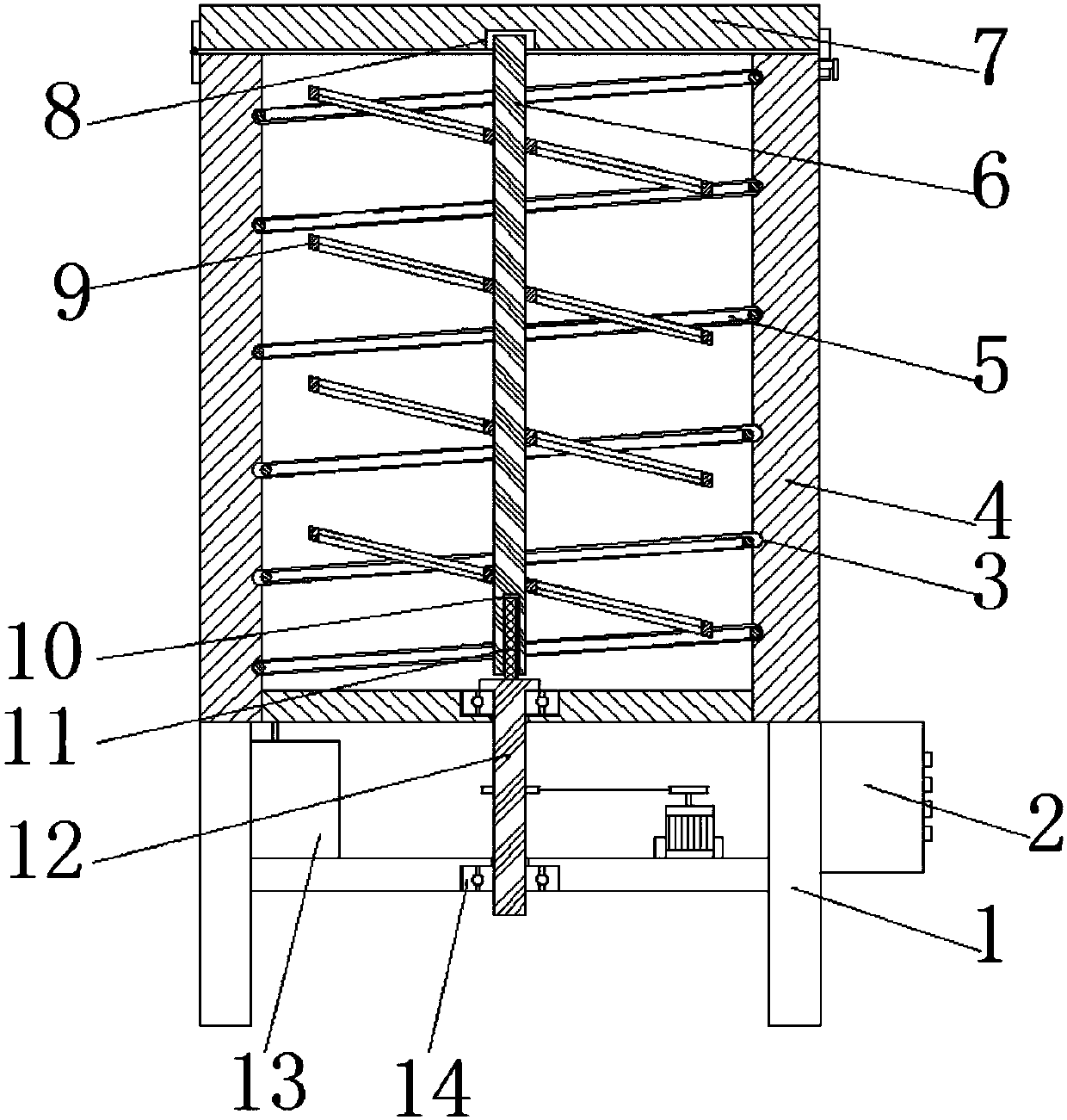

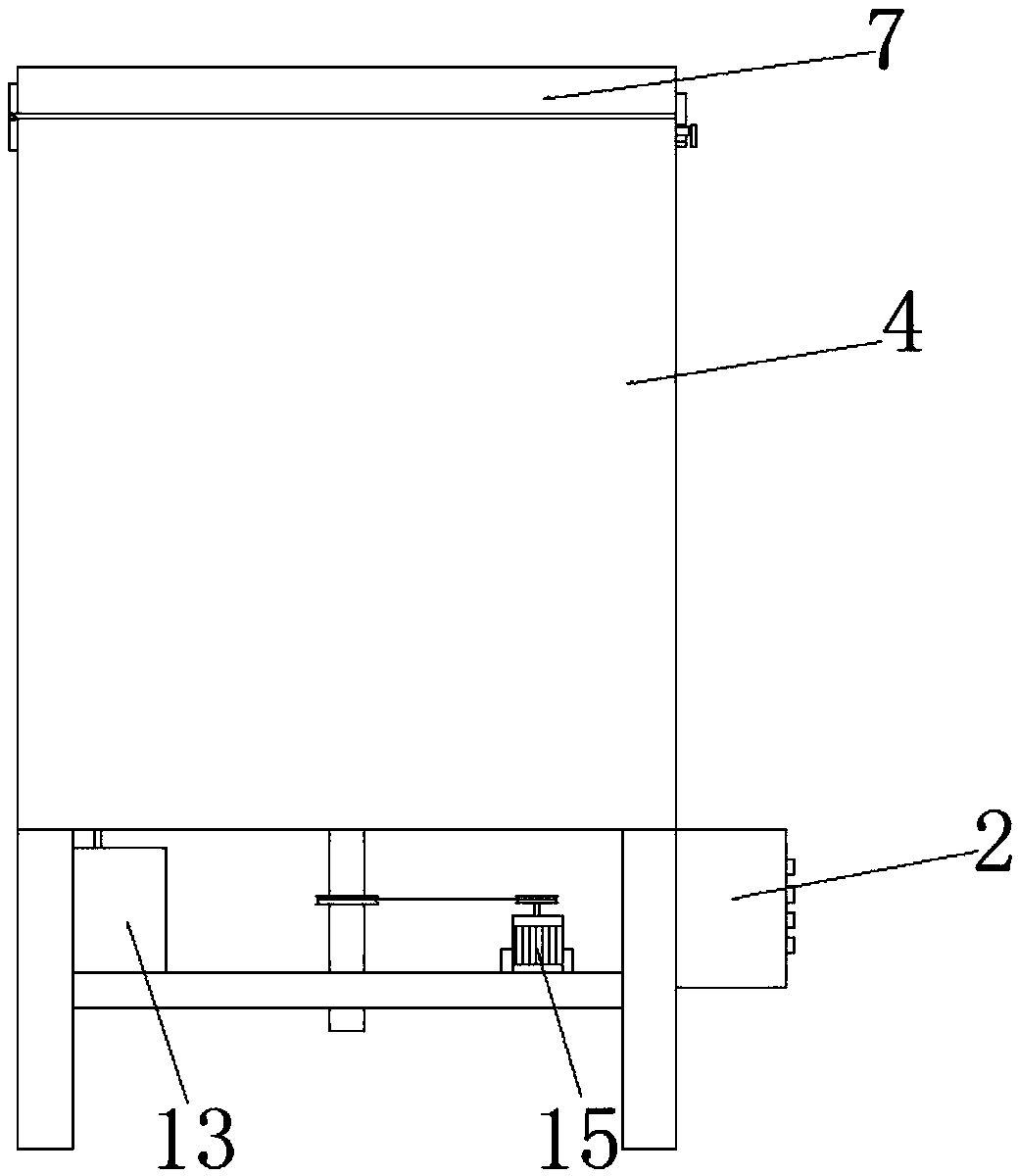

Accelerated curing device for UV light-cured polymer resin material and using method

InactiveCN111941701AFast curingQuick installationDispersed particle filtrationDirt cleaningPolymer resinAccelerated curing

The invention relates to an accelerated curing device for a UV light-cured polymer resin material. The accelerated curing device comprises a curing machine body. A conveying belt is installed at the top end of the curing machine body in an embedded mode; a curing box is fixedly connected with the top end of the curing machine body; a door body is installed on the surface of the curing box; a feeding port is formed in one side of the curing box, and a discharging port is formed in the other side of the curing box; a temperature sensor is fixedly connected with the top end of the inner wall of the curing box; and a PLC panel is fixedly connected with one side of the top end of the curing box, and a buzzer is fixedly connected with the other side of the top end of the curing box. According tothe accelerated curing device for the UV light-cured polymer resin material, under the action of a curing mechanism, through a preset first reset spring, two mounting bases can be driven to relatively move, so that a UV lamp tube can be rapidly mounted or dismounted for replacing; and a threaded rod of a rotary disc can rotate by rotating the rotary disc, so as to drive a mounting plate and the UV lamp tube to ascend and descend, and the distance between the UV lamp tube and a resin raw material can be flexibly adjusted, and the resin raw material is irradiated for rapid curing.

Owner:深圳市深赛尔股份有限公司

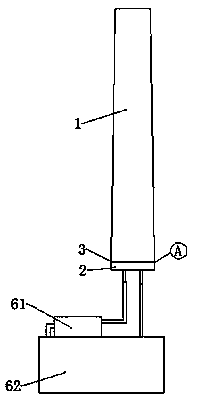

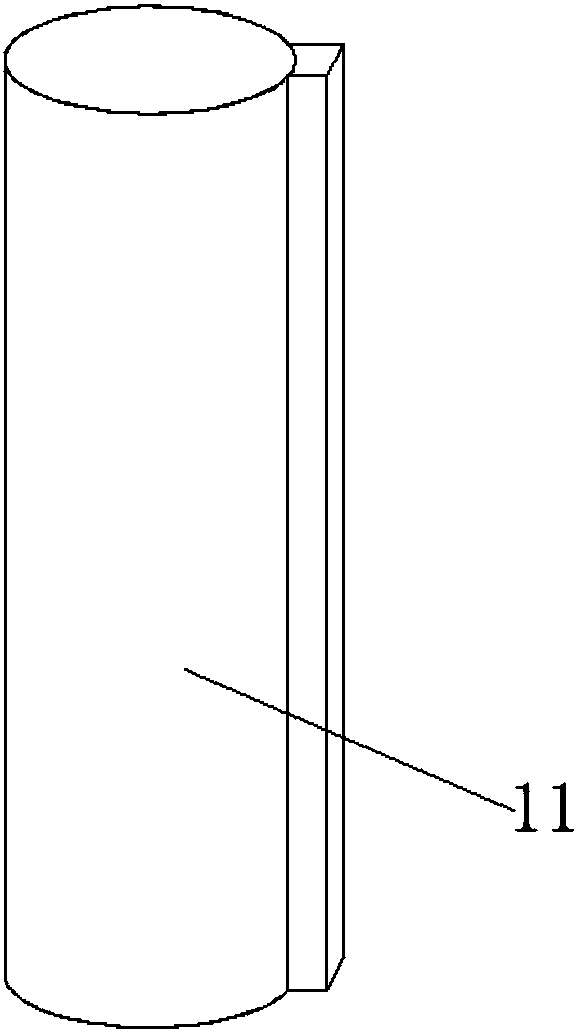

Composite pole and tower winding die with accelerated curing effect

PendingCN109571988AImprove curing efficiencyImprove curing effectDomestic articlesAccelerated curingMaximum diameter

The invention belongs to the technical field of composite pole and tower winding dies, and particularly relates to a composite pole and tower winding die with an accelerated curing effect. The composite pole and tower winding die includes a die body and a heating module, the die body is composed of a bottom part with the large external diameter and a top part with the small external diameter, andthe lower part of the bottom part is connected with a cylinder part consistent with the maximum diameter of the bottom part; and the die body is of a cavity structure with an open bottom, the cylinderpart is internally provided with a blocking ring, a sealing plate is arranged on the blocking ring through a bolt and a sealing gasket, and the heating module is arranged in the cavity structure andfixed through the sealing plate. According to the composite pole and tower winding die with the accelerated curing effect, shortcomings of the prior art are overcome, the heating module is arranged inside the winding die, the curing process is realized by heating the winding die body, that is, winding and curing are conducted at the same time, the curing efficiency is high, and the effect is good.

Owner:HEFEI HAIYIN TOWER

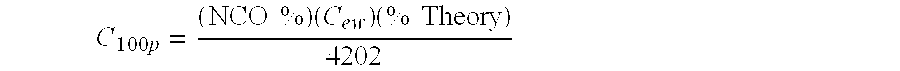

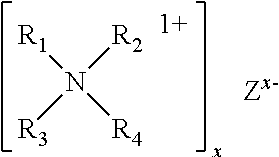

Accelerated cure of isocyanate terminated prepolymers

Owner:LANXESS SOLUTIONS US INC

Cementitious compositions with accelerated curing at low temperatures

PendingUS20210380482A1Easy to operateReduce errorsSolid waste managementCeramicwareAlkaline earth metalAccelerated curing

A cementitious composition with accelerated curing at low temperatures particularly at temperatures <5° C., especially at temperatures <0° C. The cementitious composition consists of 2 components with a first component A including at least one ordinary Portland cement, at least one cement selected from calcium aluminate cement and / or calcium sulfoaluminate cement, a powder P, selected from the group consisting of carbonates or hydrogen carbonates of alkali and / or alkaline earth metals, optionally aggregates, optionally other additives and a second component B comprising at least one accelerator, an anti-freeze agent, water, and optionally other additives. The composition shows increased development of compressive strength, maintain good workability, and have particularly low shrinkage, also when cured at temperatures <5° C., especially <0° C., and as low as −10° C.

Owner:SIKA TECH AG

High-efficiency drying device for tea leaf processing

InactiveCN107677076ASame surface drynessSpread evenlyPre-extraction tea treatmentTea dryingSurface layerAccelerated curing

The invention discloses a high-efficiency drying device for tea processing, which comprises a bracket with a crossbeam fixing plate in the middle, the top of the bracket is fixed with a baking oven body by bolts, and the oven body is a cavity The barrel-shaped structure, the bottom inner wall of the oven body and the middle part of the lower surface of the beam fixing plate are provided with counterbore holes, and tapered roller bearings are welded in the counterbore holes, and the inner walls of the inner rings of the two tapered roller bearings The same transmission rod is welded, the outer wall of the middle part of the transmission rod is keyed to the first pulley, the upper surface of the beam fixing plate is away from the two sides of the transmission rod, and the motor and the electric heater are respectively fixed by fastening bolts, and the bracket is far away from the transmission rod. One side of the motor is mounted with a controller by screws. The invention enables the semi-dried tea leaves on the stainless steel metal net to be dried in a dynamic posture, which accelerates the drying rate and makes the surface of the tea leaves on each layer have the same drying degree, avoiding uneven drying and even burnt phenomenon .

Owner:湖北金莓科技发展有限公司

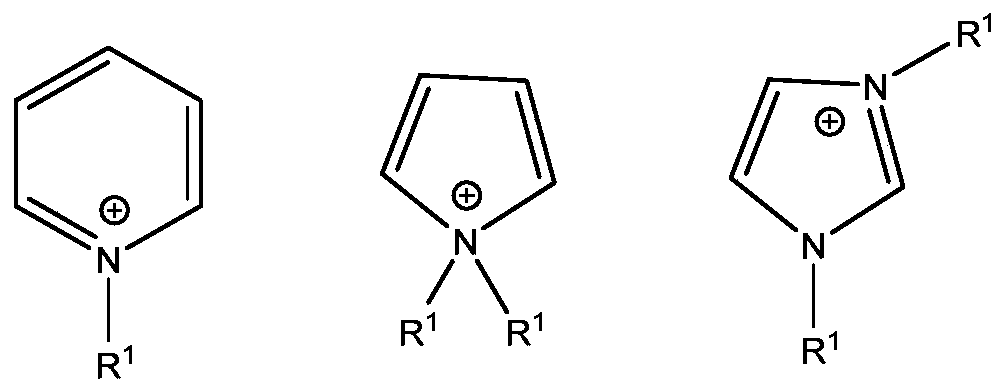

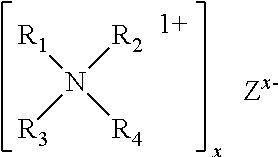

Accelerated Cure of Isocyanate Terminated Prepolymers

A prepolymer mixture for preparing a polyurethane elastomer, the mixture comprising an isocyanate terminated prepolymer and a nitrogen-containing organic salt. The nitrogen-containing organic salt may be selected from the group consisting of an ammonium salt, an imidazolium salt, a pyridinium salt, a pyrrolidinium salt, a piperidinium salt, and a morpholinium salt.

Owner:LANXESS SOLUTIONS US INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com