Patents

Literature

244results about How to "Suppress coarsening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catalyst

InactiveUS7576029B2Inhibit migrationLarge constraining forceGas treatmentInternal combustion piston enginesCatalytic metalRare earth

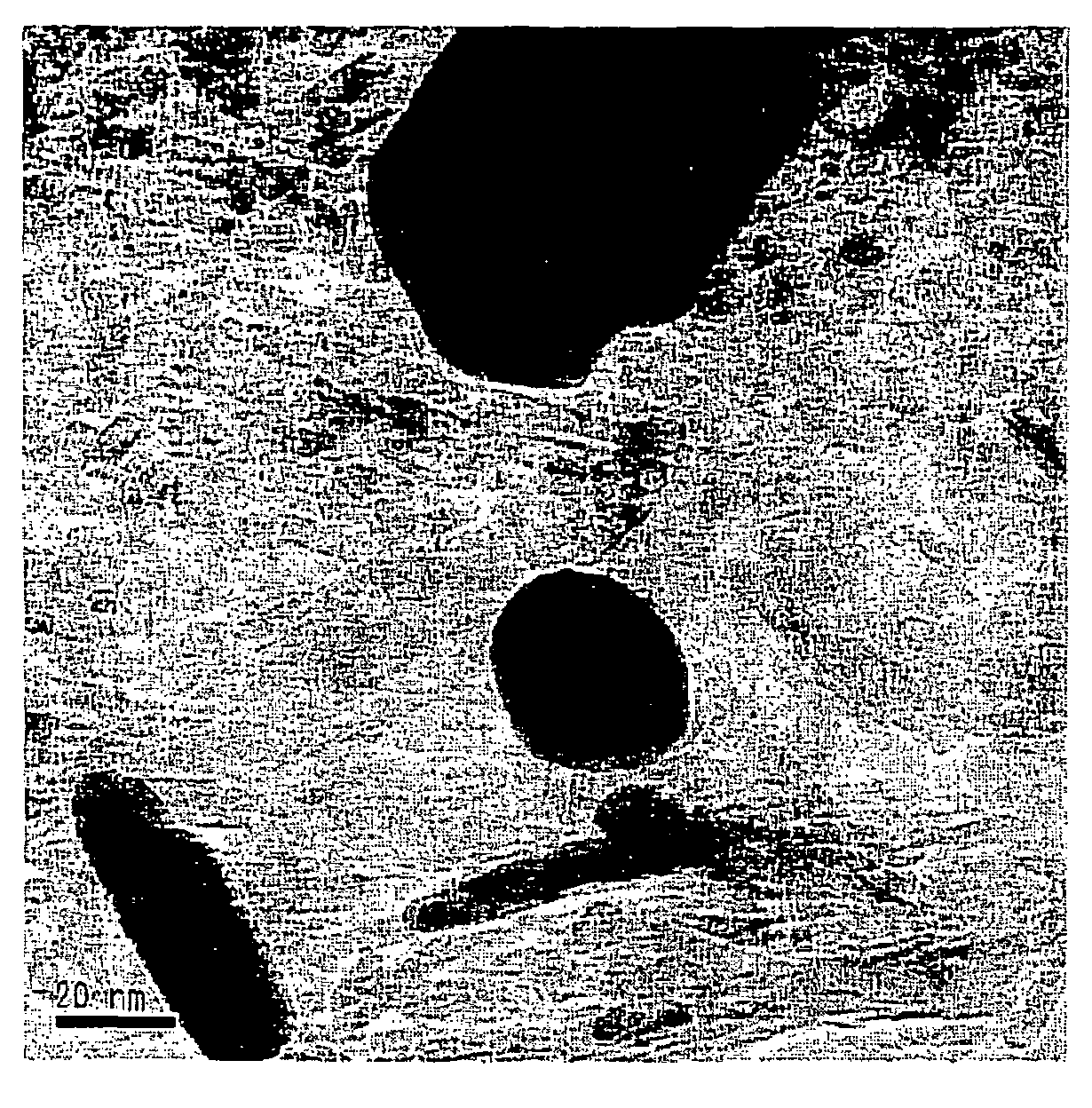

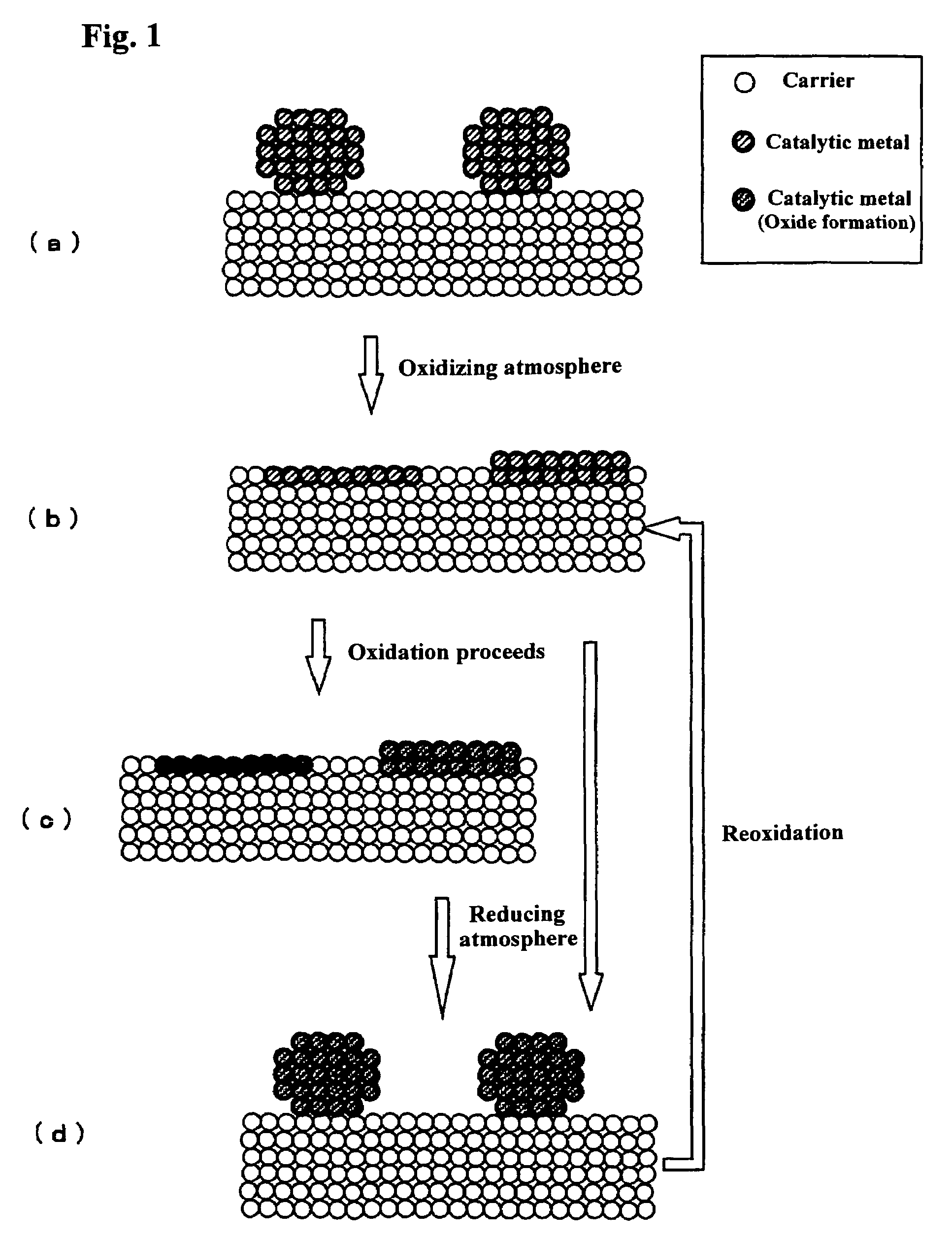

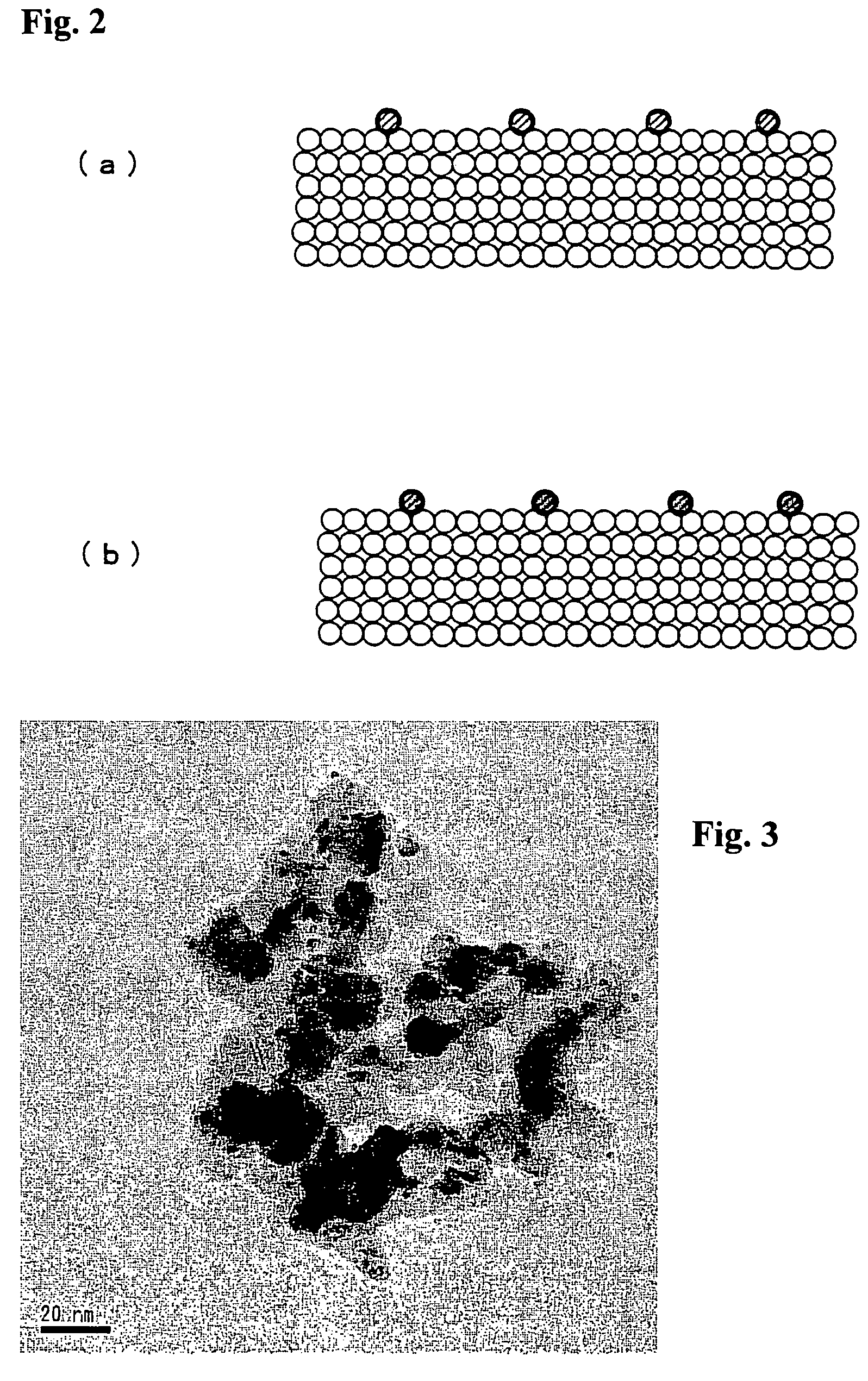

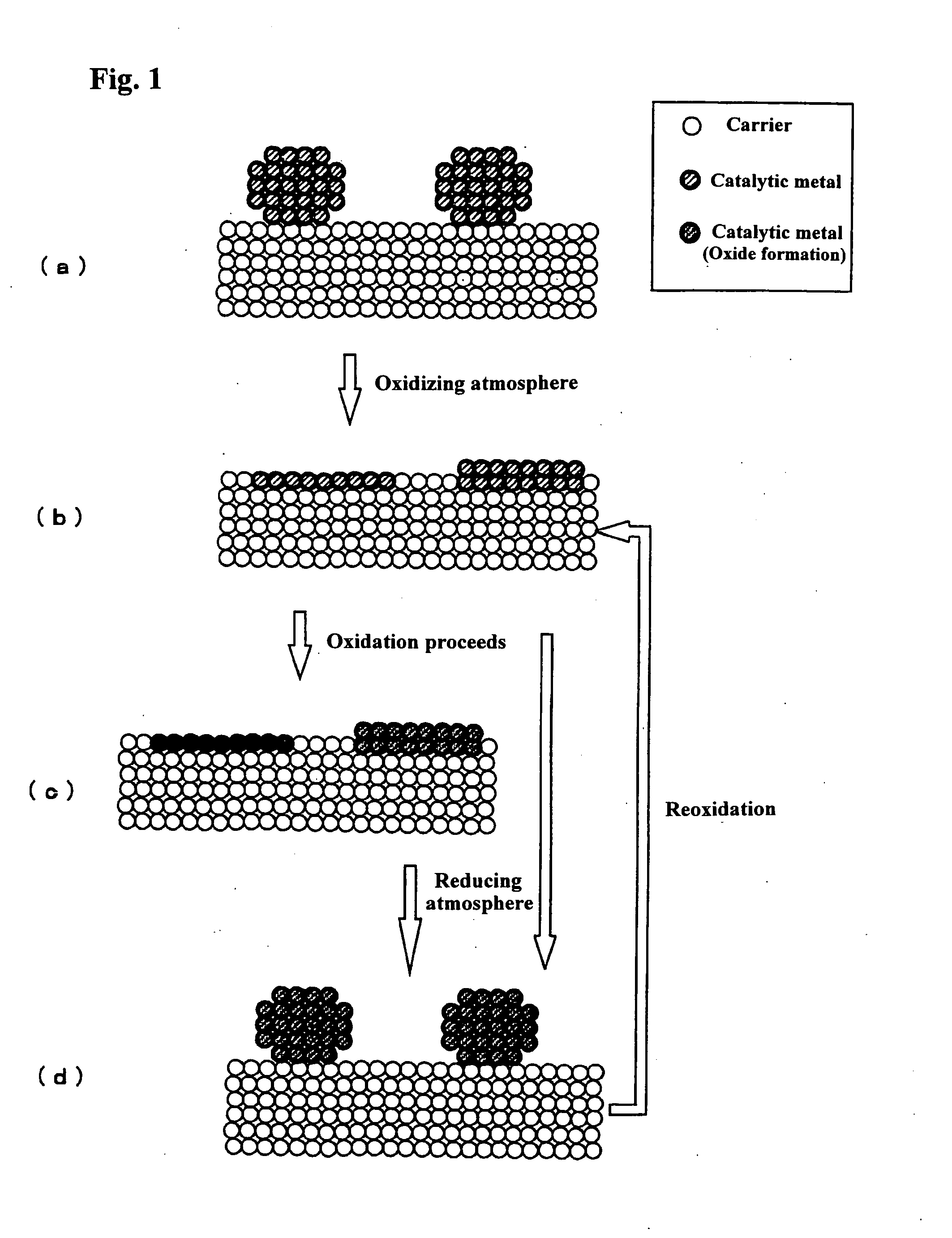

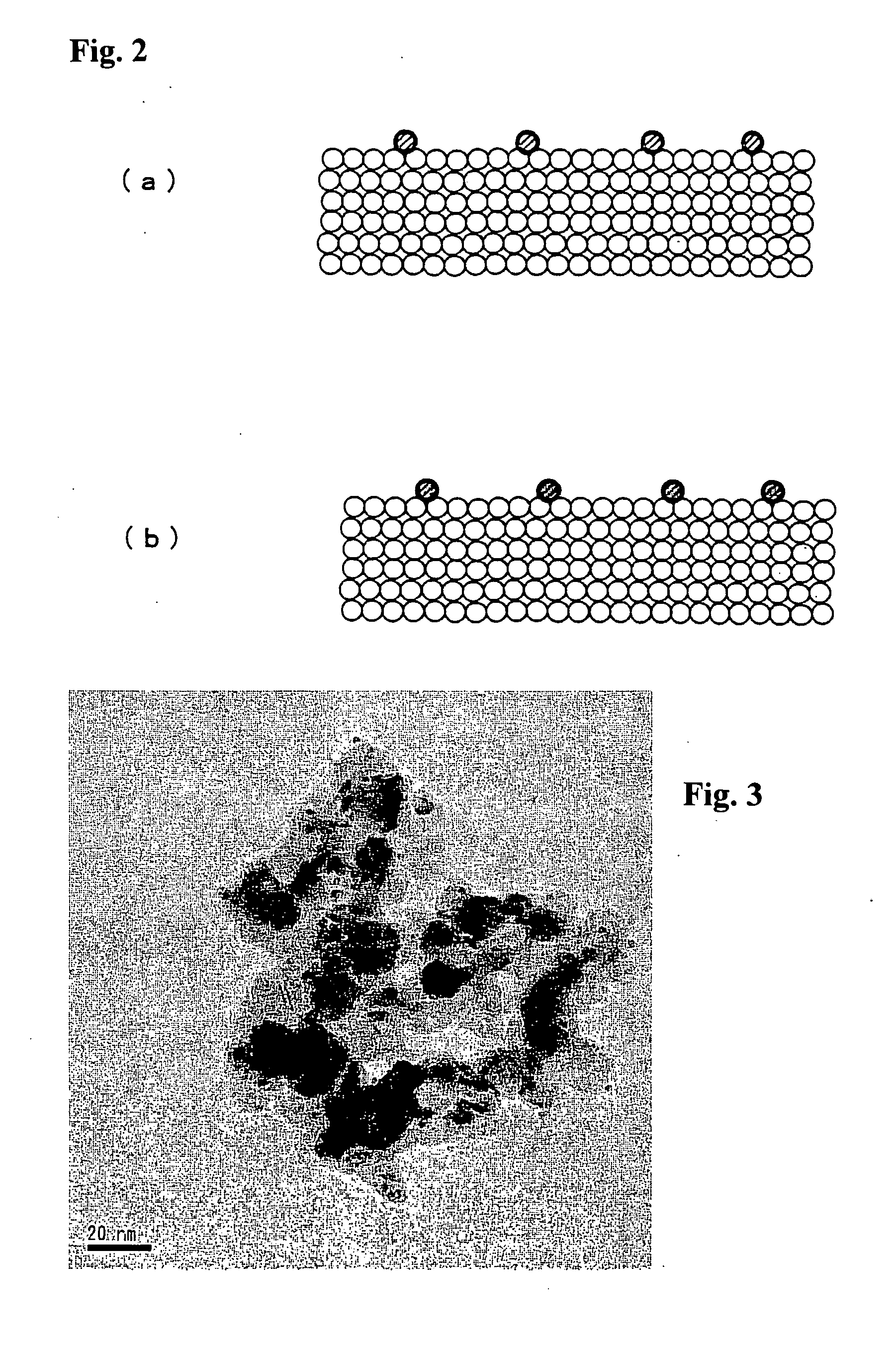

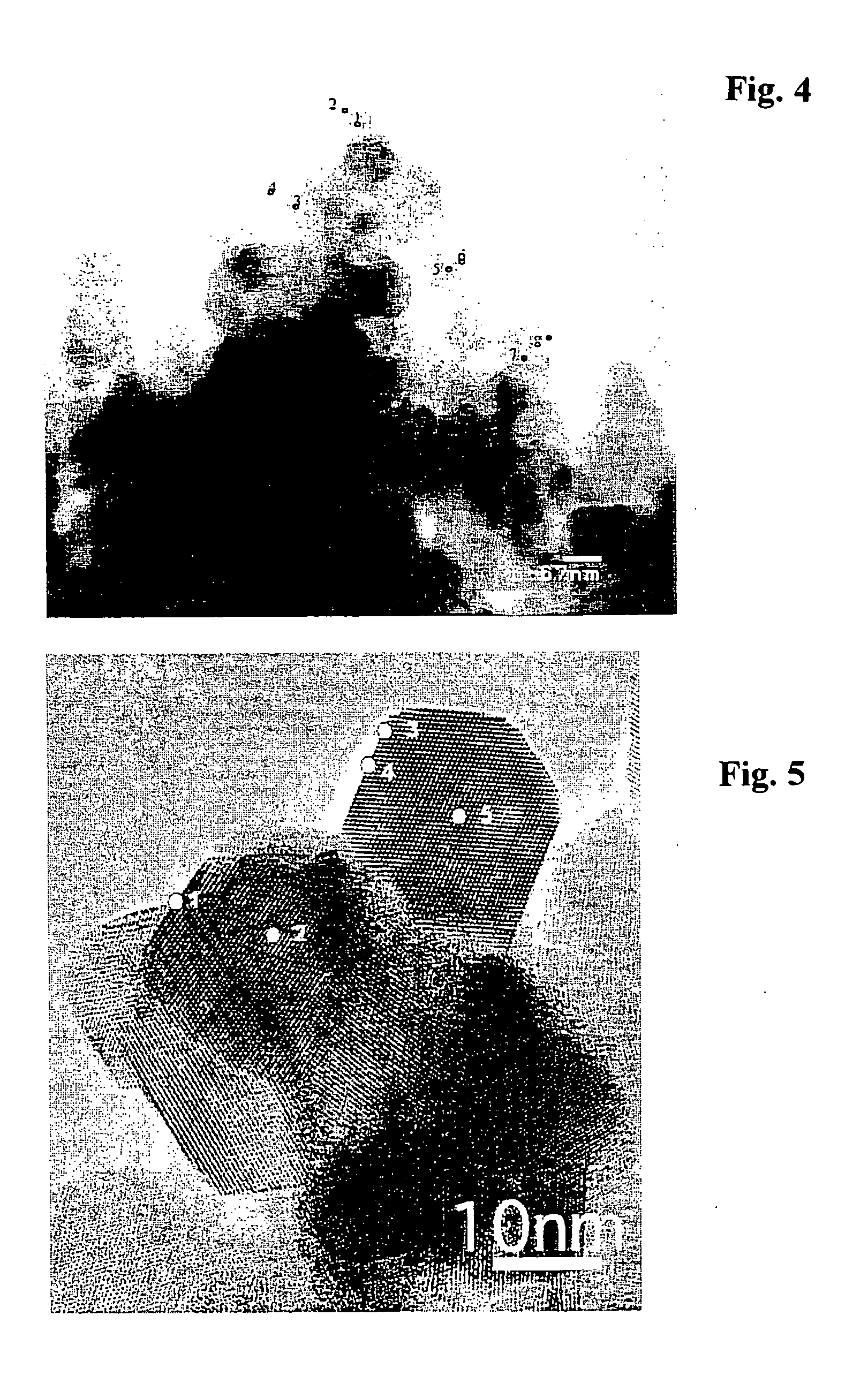

The present invention provides a catalyst comprising particles of one or more catalytic metals supported on a porous carrier made of one or more metal oxides, wherein the porous carrier is made of an oxide containing a rare earth oxide, and that the catalytic metal particles are made of one or more transition metals or transition metal oxides having 10 to 50000 atoms. In the present invention, cluster-like catalyst particles are supported on a specific carrier. The catalyst of the present invention maintains desirable activity while changing the morphology of catalyst particles by the atmosphere of the catalyst.

Owner:TANAKA PRECIOUS METAL IND

Catalyst

InactiveUS20070161506A1High reaction activityHigh durabilityGas treatmentInternal combustion piston enginesChemistryOxide

The present invention provides a catalyst comprising particles of one or more catalytic metals supported on a porous carrier made of one or more metal oxides, wherein the porous carrier is made of an oxide containing a rare earth oxide, and that the catalytic metal particles are made of one or more transition metals or transition metal oxides having 10 to 50000 atoms. In the present invention, cluster-like catalyst particles are supported on a specific carrier. The catalyst of the present invention maintains desirable activity while changing the morphology of catalyst particles by the atmosphere of the catalyst.

Owner:TANAKA PRECIOUS METAL IND

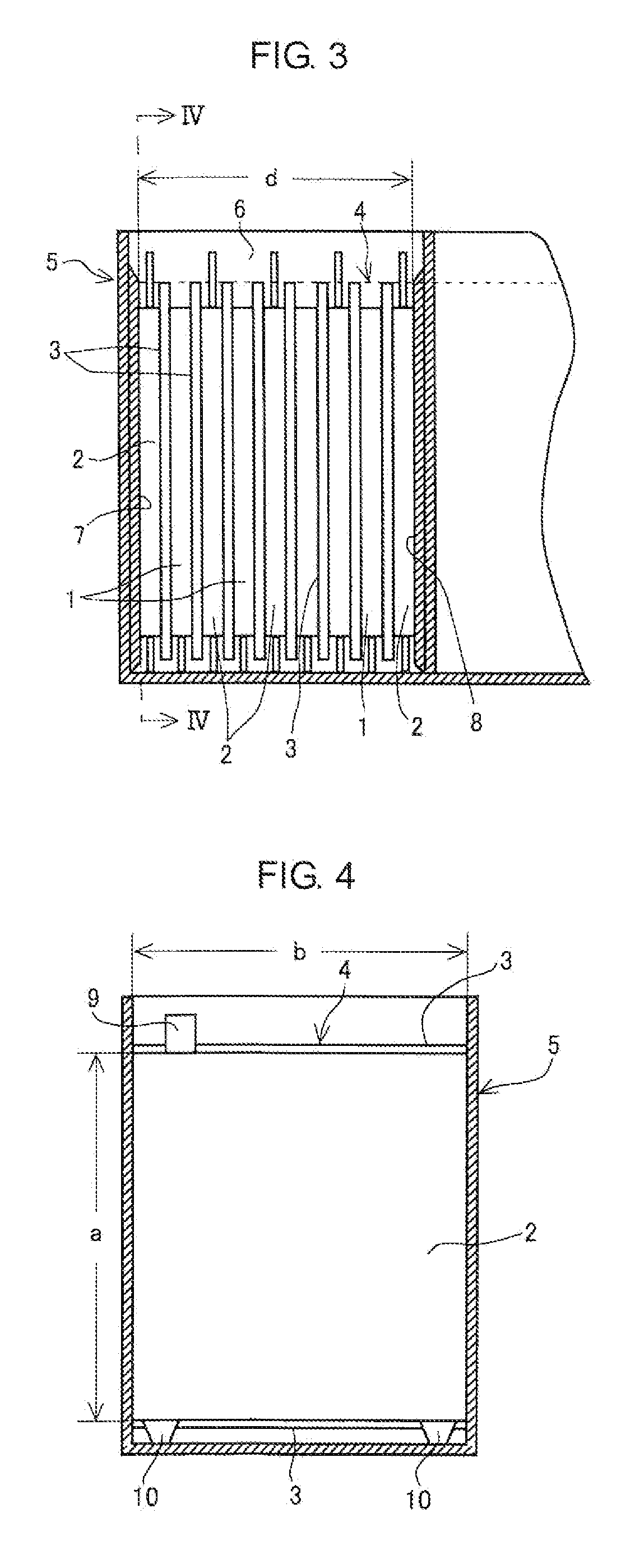

Aluminum Alloy Forging Member and Process for Producing the Same

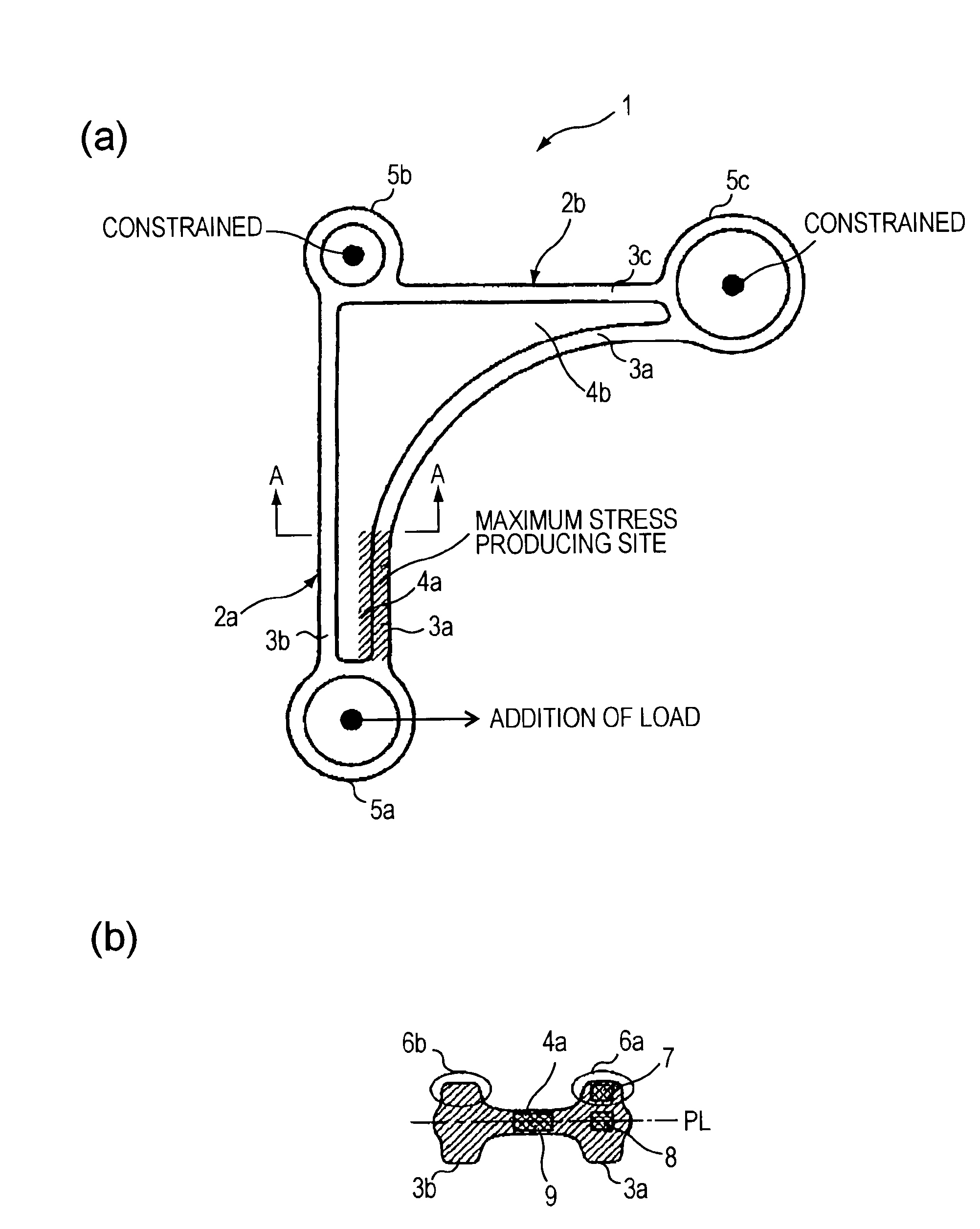

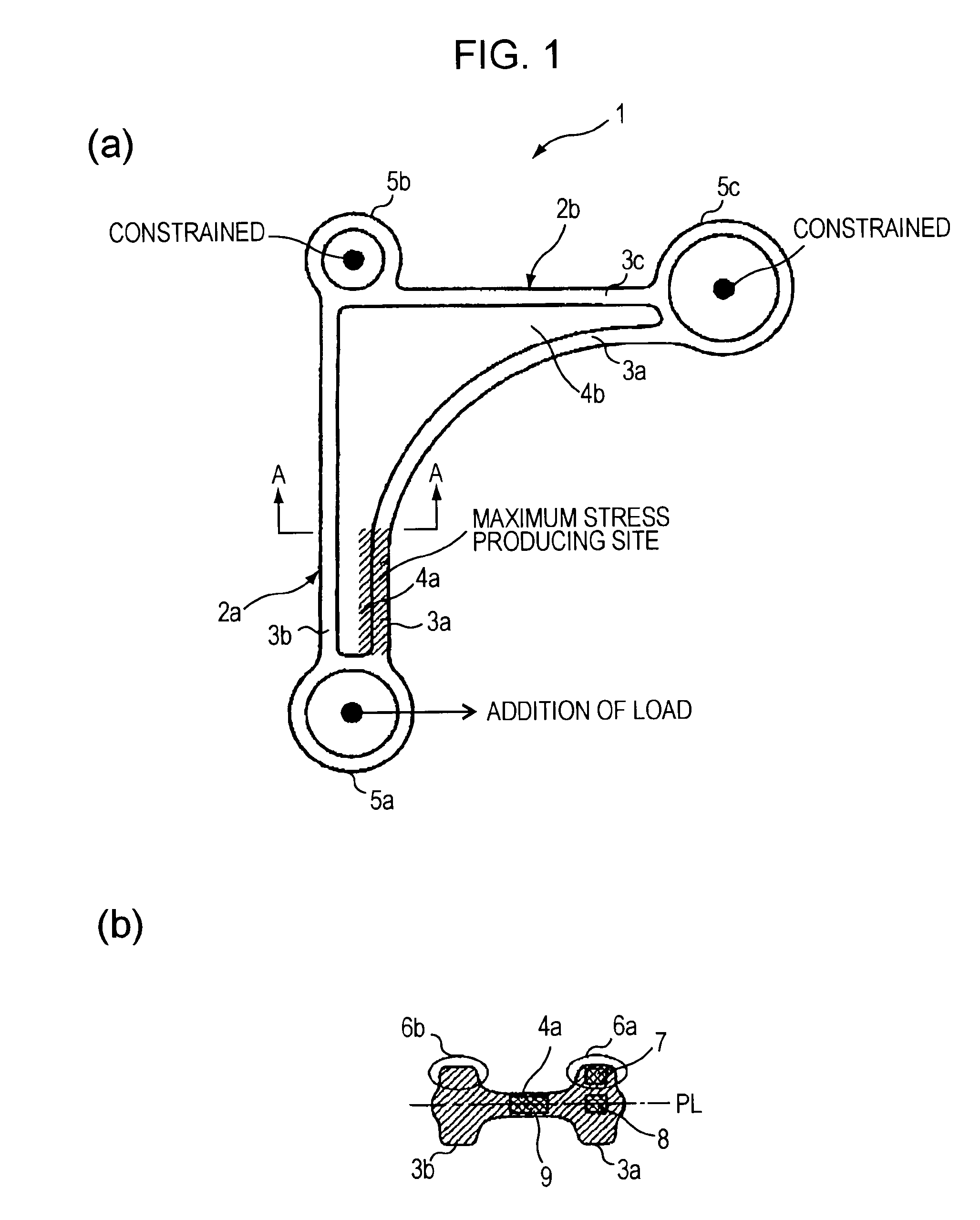

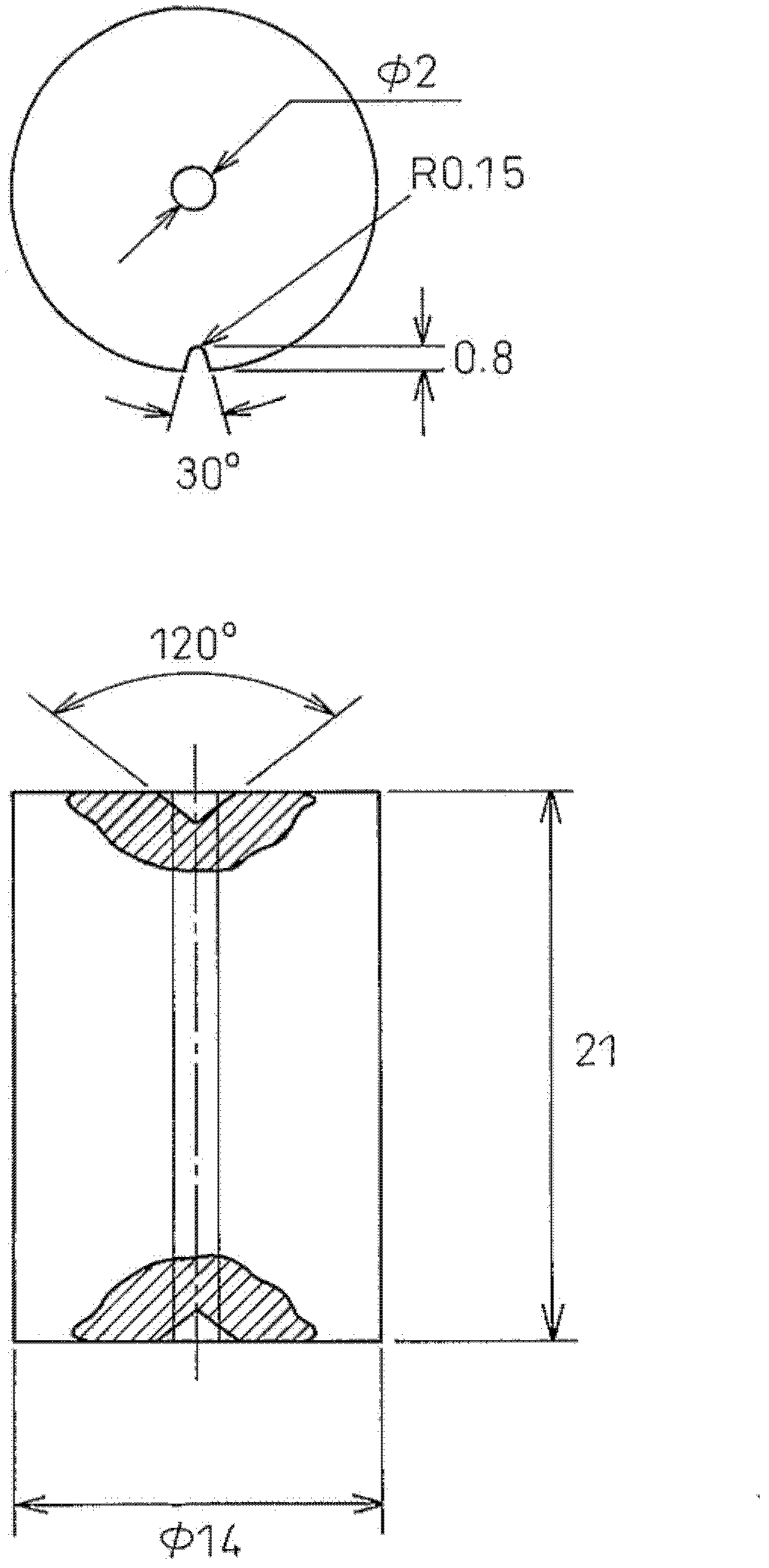

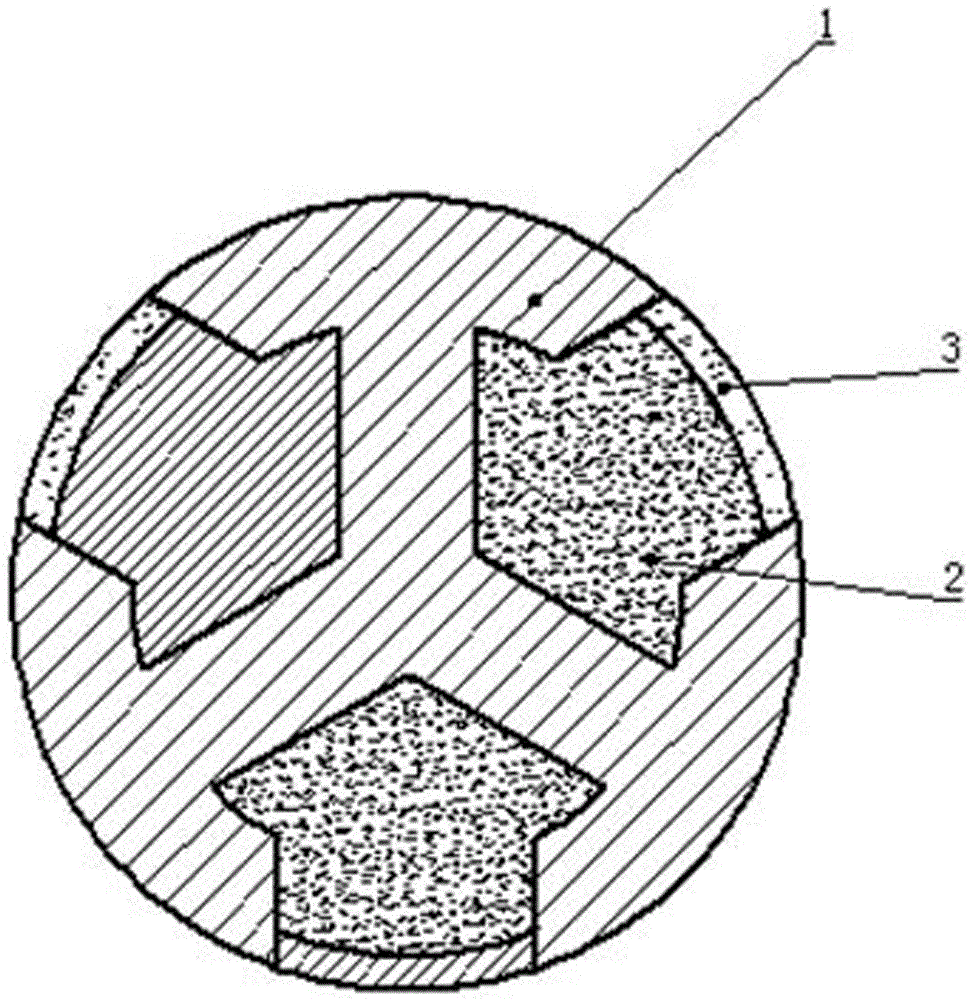

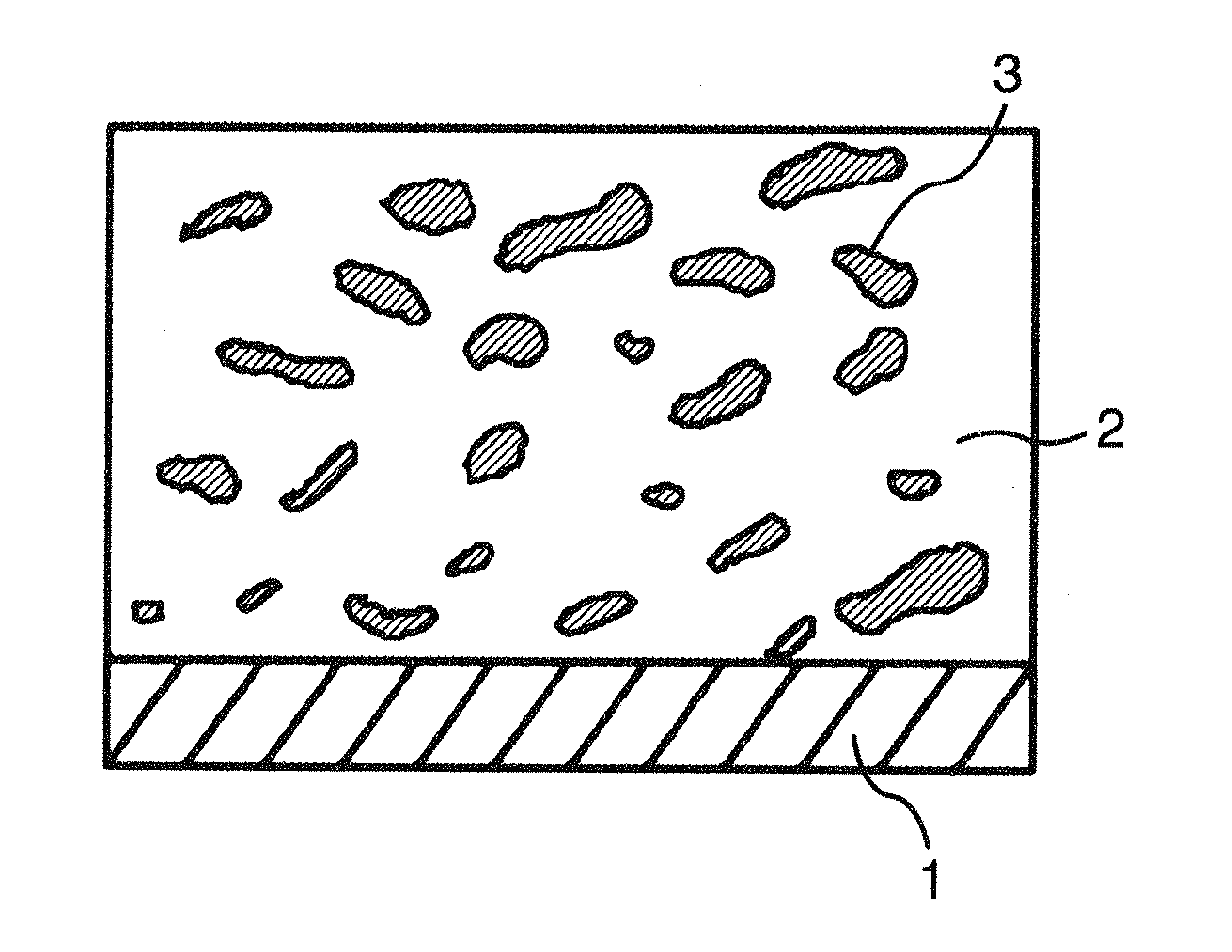

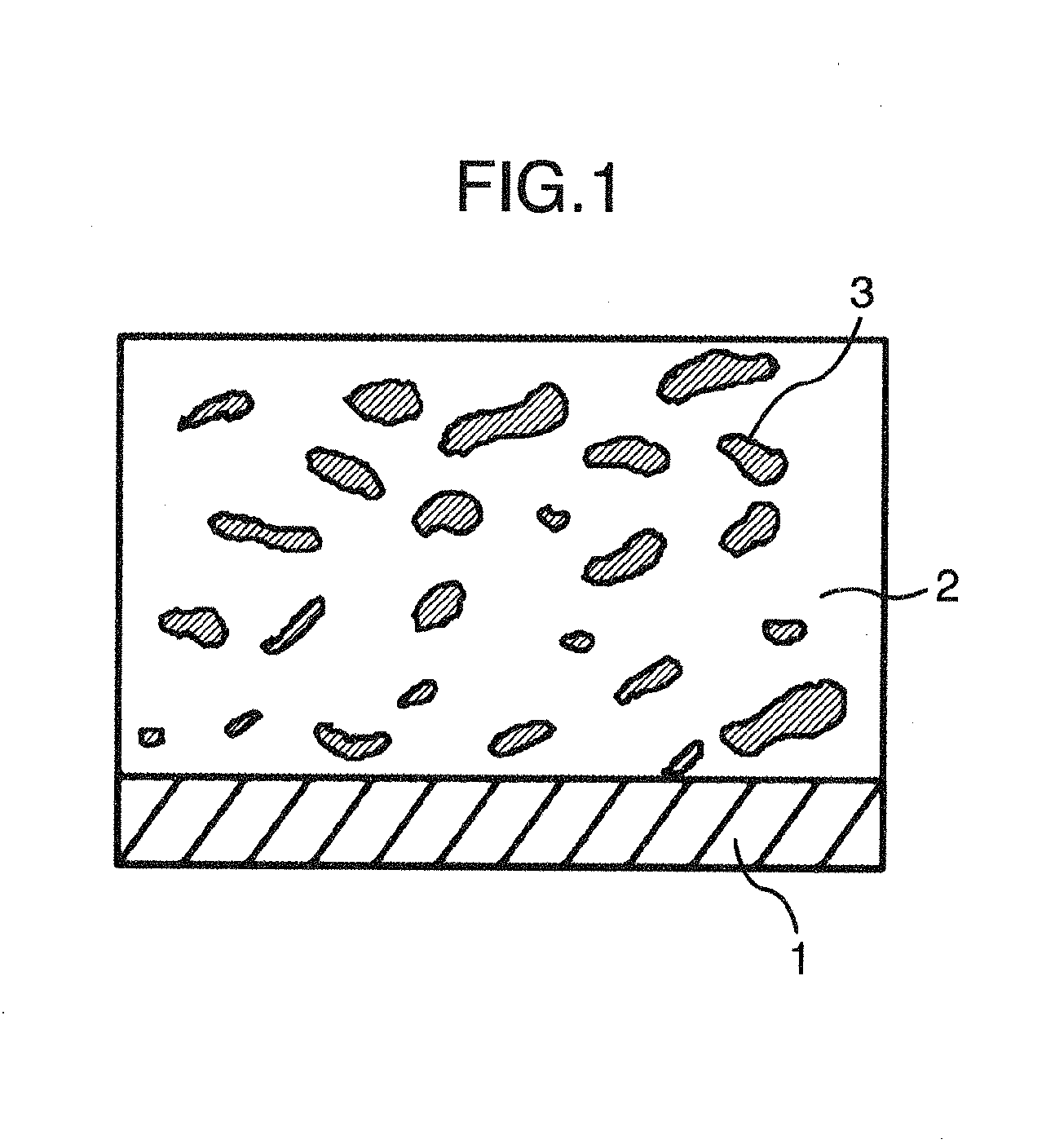

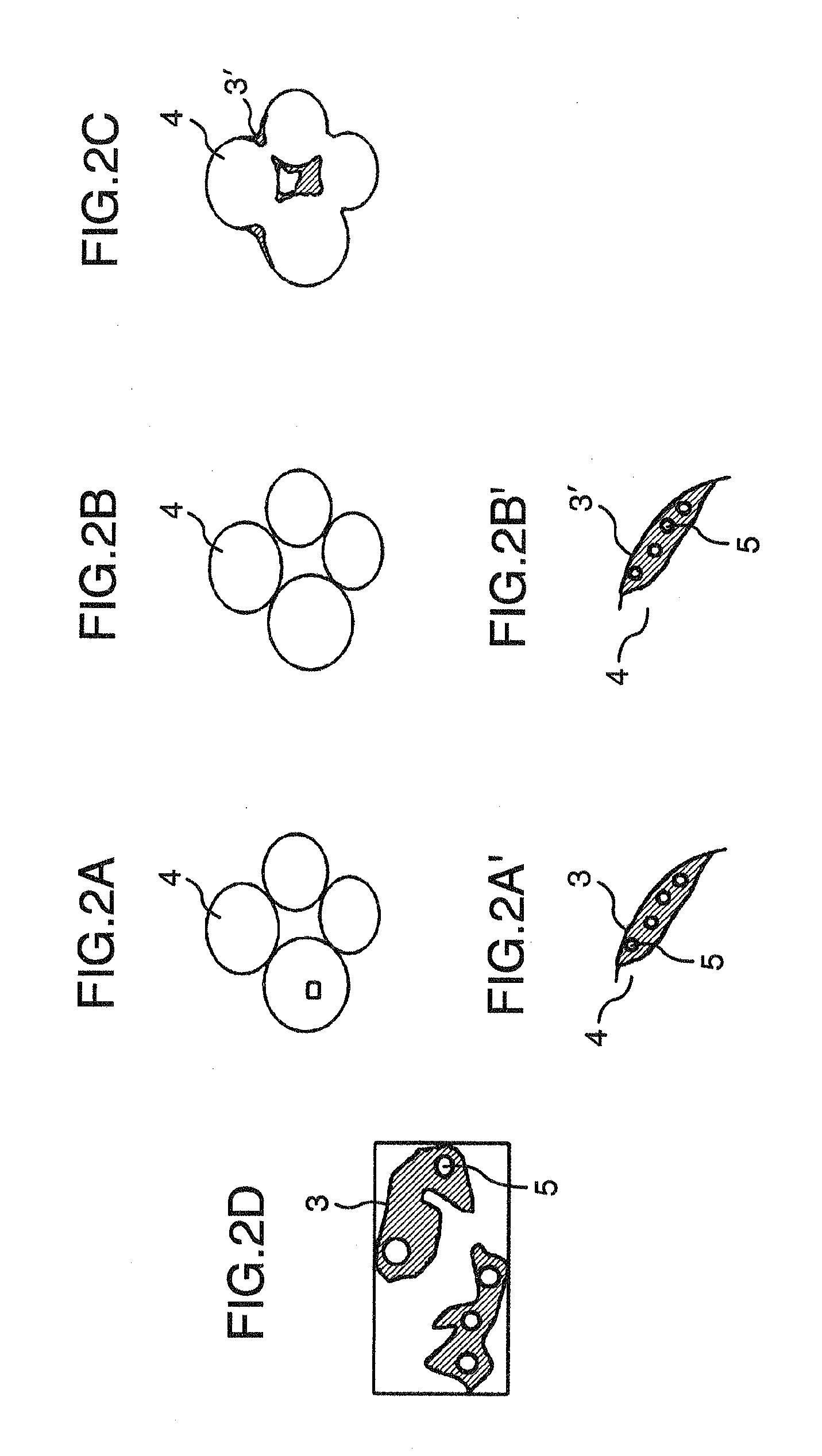

ActiveUS20090000705A1Lighter-weight shapeSuppress coarseningEngine componentsUltimate tensile strengthToughness

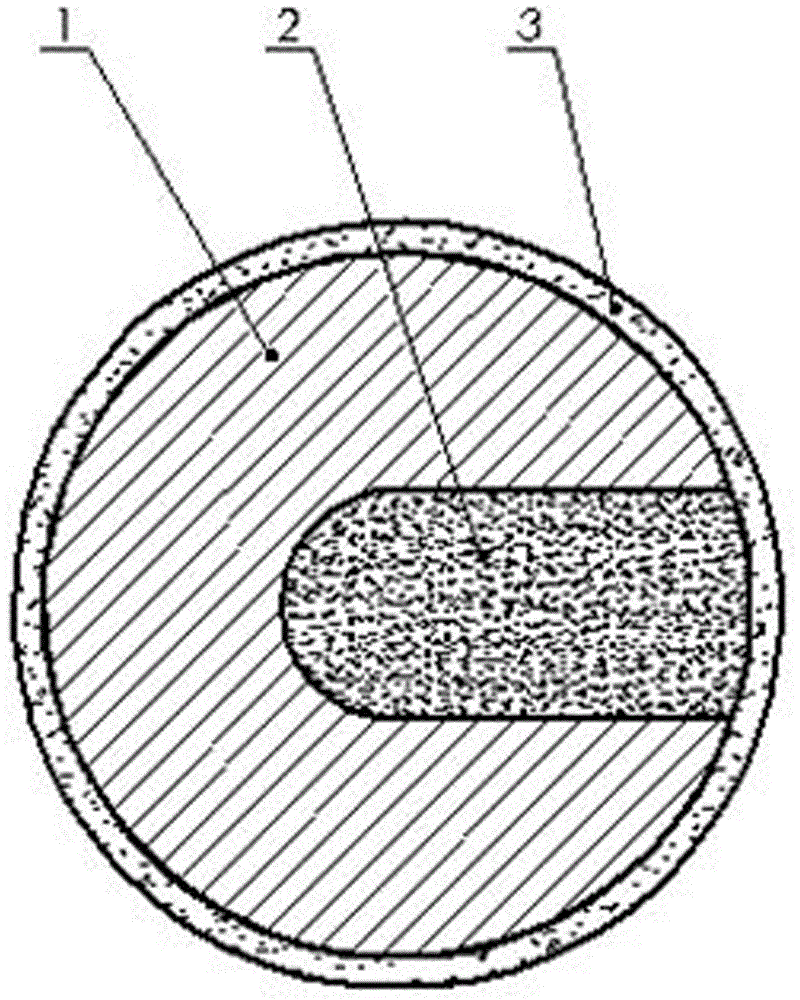

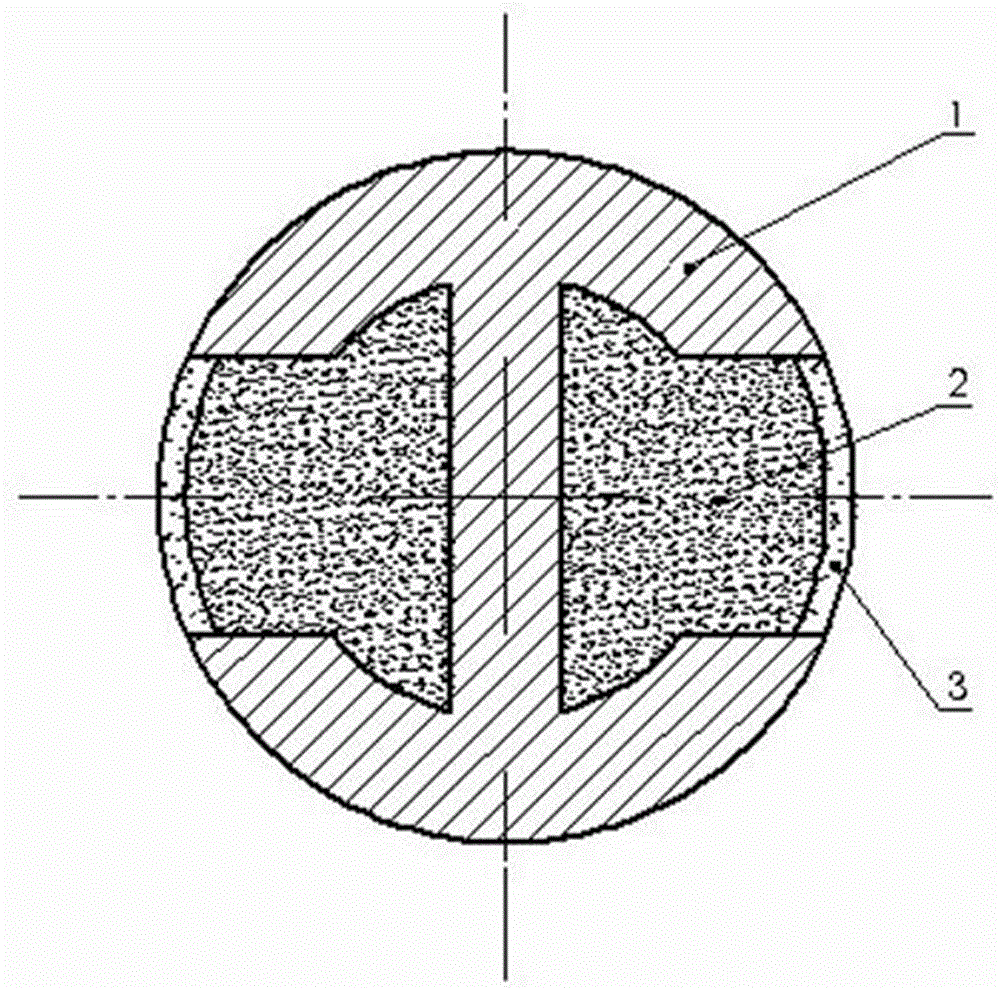

The present invention provides an aluminum alloy forging material having enhanced strength, toughness, and corrosion resistance, and a method of producing the material. An aluminum alloy forging material 1 produced with specified components under specified conditions has an arm portion 2 including a relatively narrow and thick peripheral rib 3 and a thin and relatively wide central web 4 having a thickness of 10 mm or less and having a substantially H-shaped sectional form. In a width-direction section of a maximum stress producing site of the rib 3a, the density of crystals observed in the structure of a sectional portion 7 where the maximum stress is produced, the spacing of grain boundary precipitates and the size and density of dispersed particles observed in the structure of a sectional portion 8 including a parting line, the recrystallization ratio observed in each of the sectional portions 7 and 8 of the rib, and the recrystallization ratio observed in a sectional portion 9 of the web 4a adjacent to the sectional structure of the rib 3a in the width direction are defined for enhancing the strength, toughness, and corrosion resistance of the aluminum alloy forging material.

Owner:KOBE STEEL LTD

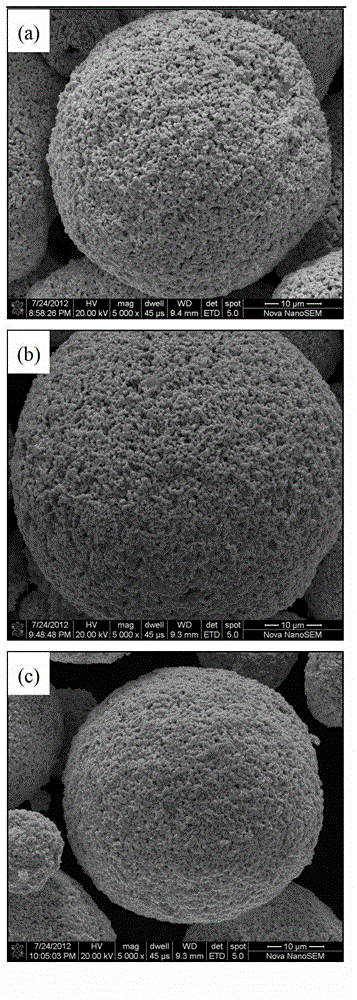

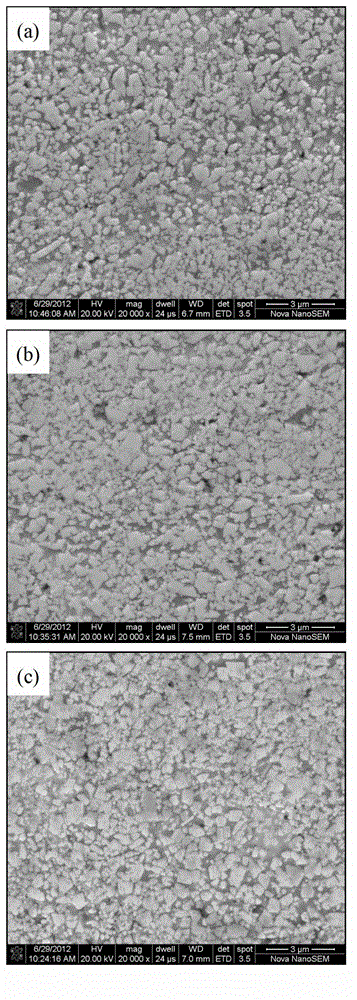

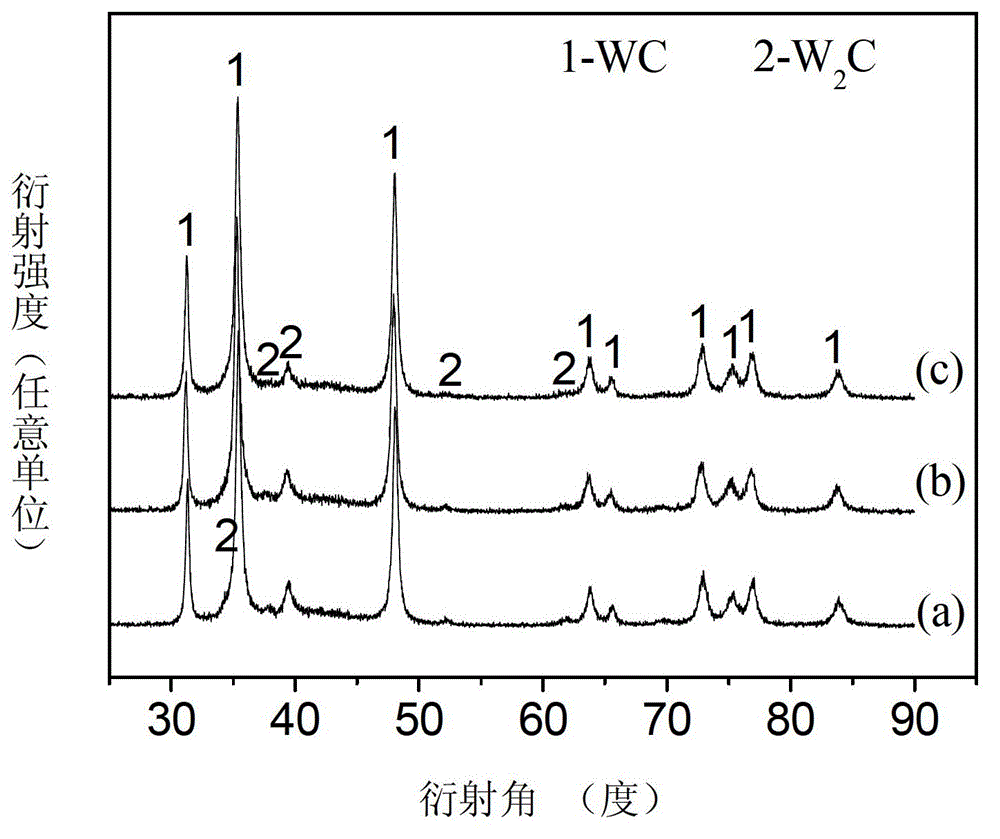

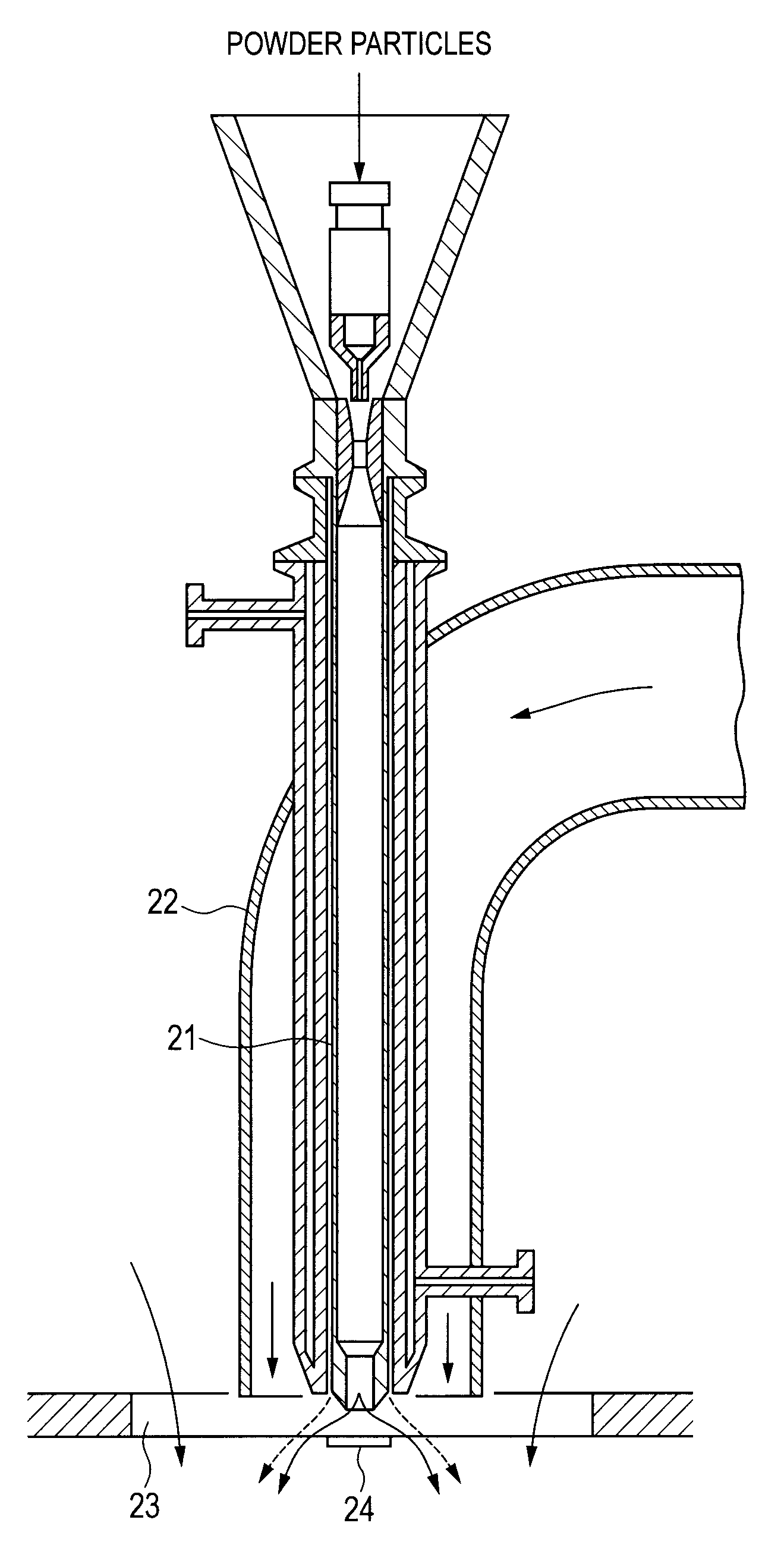

Preparation method for quasi-nanostructure WC-Co (tungsten-cobalt) coating with high compactness and low decarburization

The invention discloses a preparation method for a quasi-nanostructure WC-Co (tungsten-cobalt) coating with high compactness and low decarburization, and belongs to the technical field of preparation of WC-Co coatings. The preparation method comprises the steps as follows: firstly, preparing superfine and nanometer WC-Co compound powder with average particle size of 80-400 nm; secondly, mixing the WC-Co compound powder with Cr3C2 and VC powder according to a certain ratio, carrying out ball milling and drying to obtain mixed powder, granulating, and carrying out heat treatment; and thirdly, sieving for grading, combining into spraying powder with special particle size distribution, and spraying by adopting supersonic flame spraying equipment. The quasi-nanostructure WC-Co coating prepared by the method has the characteristics of high compactness and low decarburization.

Owner:BEIJING UNIV OF TECH

Heat treatment apparatus and method for manufacturing toner

InactiveUS9075328B2Suppress coarseningLess fine powderDrying solid materials with heatDrying gas arrangementsCoarse particleHeat treated

Owner:CANON KK

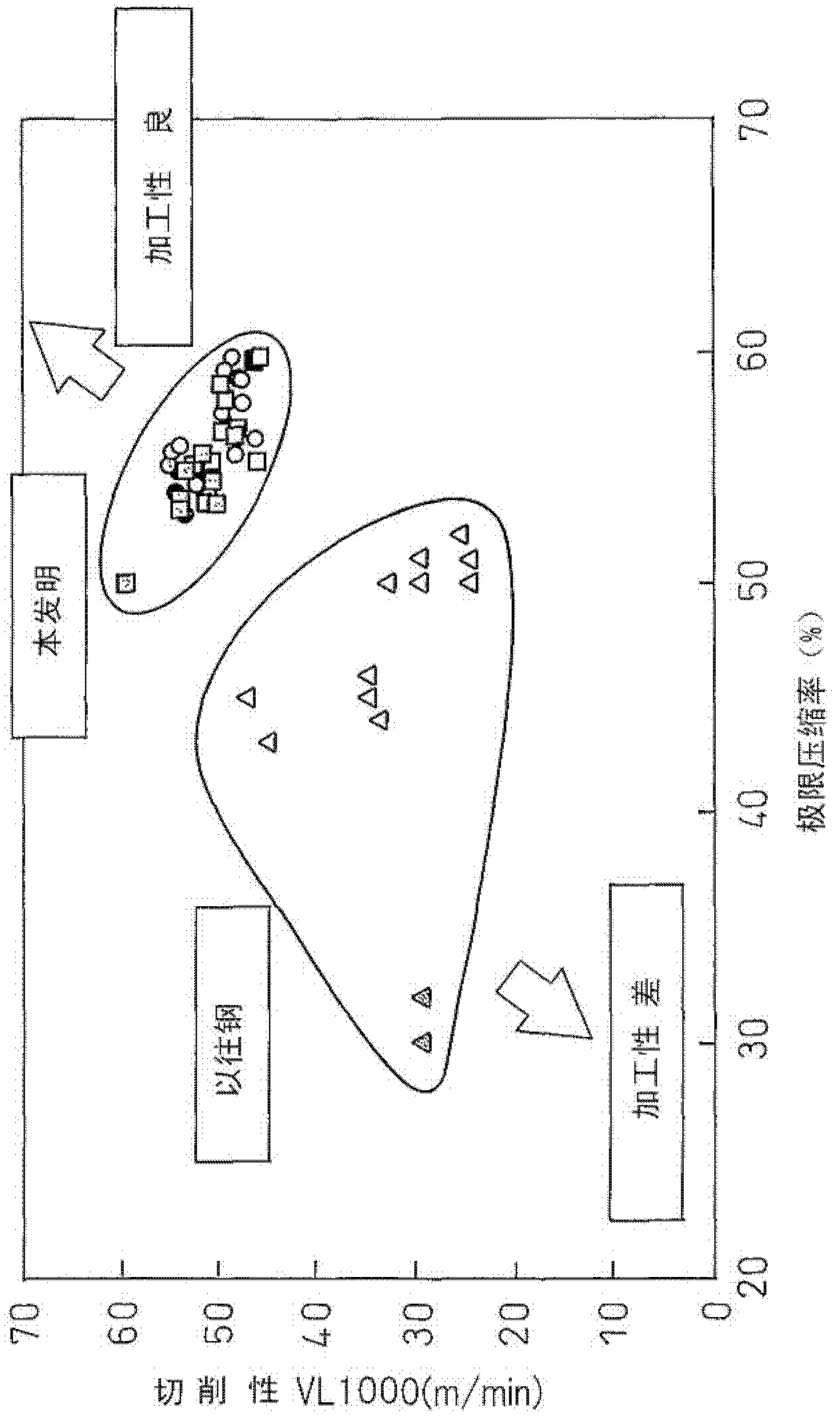

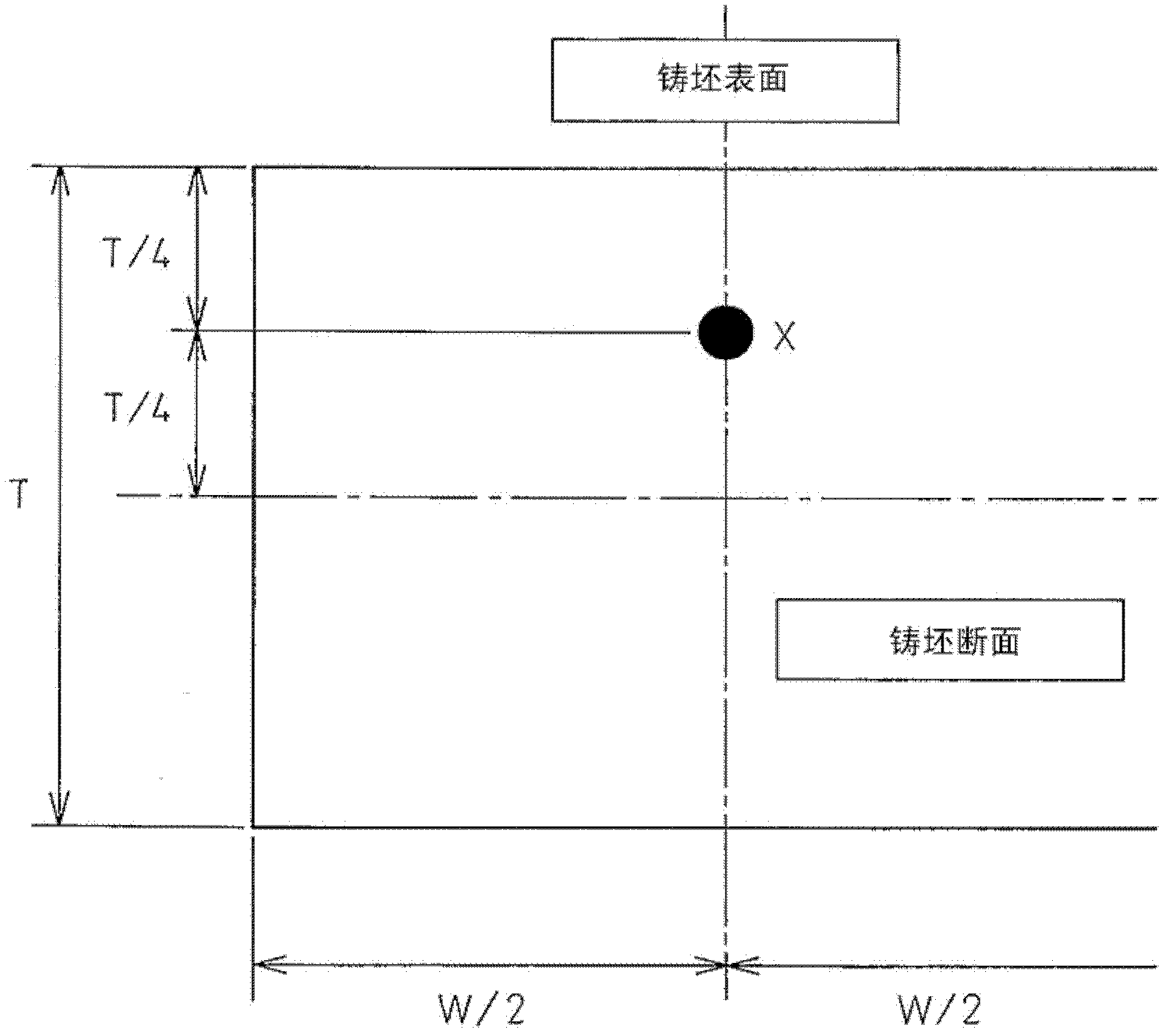

Steel for case hardening which has excellent cold workability and machinability and which exhibits excellent fatigue characteristics after carburizing and quenching, and process for production of same

ActiveCN102378822AOptimizing Forging PerformanceExcellent machinabilitySolid state diffusion coatingSulfideCase hardening

Provided is a steel for case hardening, which is to be subjected to cold working, machining, and carburizing and quenching, and in which the occurrence of coarse particles is prevented. The steel for case hardening has excellent cold workability and machinability and further exhibits excellent fatigue characteristics after carburizing and quenching. The steel for case hardening is characterized by: containing, by mass, 0.001 to 0.15% of S, 0.05 to 0.2% of Ti, at most 0.04% of Al, at most 0.0050% of N, and specific amounts of other specific components, and further containing at most 0.003% of Mg, and / or at most 0.01% of Zr, and / or at most 0.005% of Ca; having a content of precipitated AlN of 0.01% or less; and satisfying the relationship: d = 1700[S]+20 [wherein d is the density (particles / mm2) of sulfides which have equivalent circle diameters exceeding 20[mu]m and aspect ratios exceeding 3; and [S] is the content (mass%) of S].

Owner:NIPPON STEEL CORP

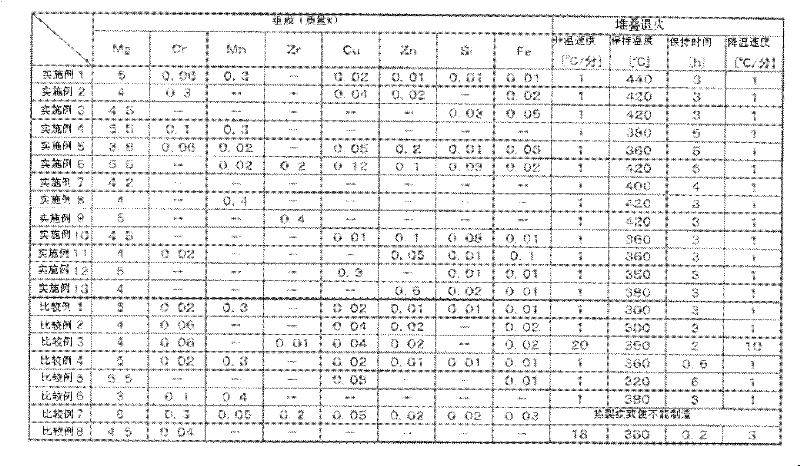

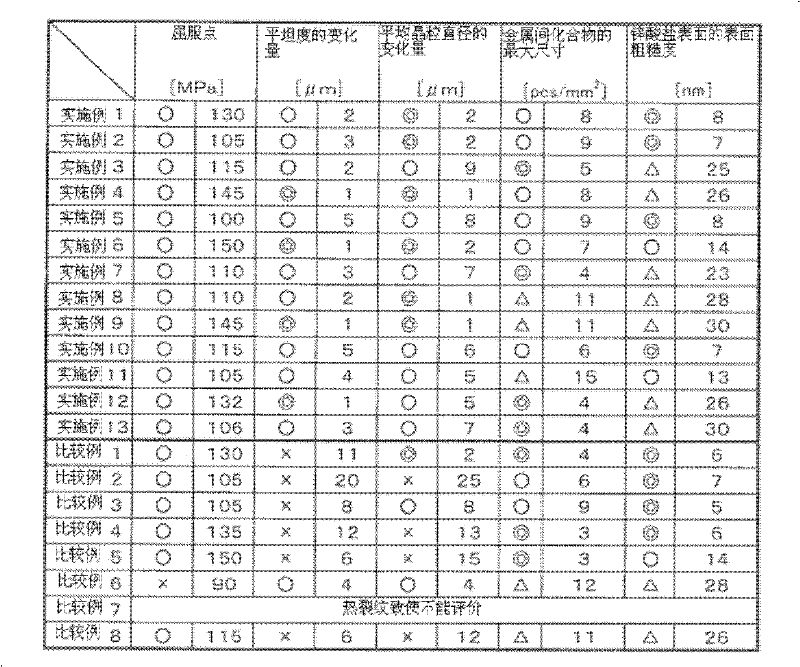

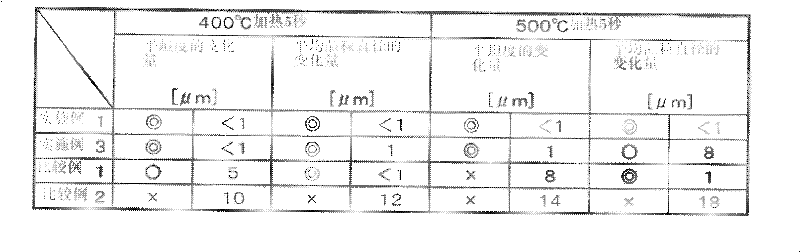

Aluminum alloy substrate used for magnetic disc, and method of manufacturing the same

ActiveCN102465222ASuppress coarseningInhibit deteriorationBase layers for recording layersAlloy substrateImpurity

The invention provides an aluminum alloy substrate used for magnetic discs, and a method of manufacturing the same. Even if an aluminum alloy substrate is heated to be as high as 500 DEG C, worsening of smoothness and thickening of crystalline grains are prevented. The aluminum alloy substrate comprises 3.5% to 6% by mass of Mg, balance being Al and unavoidable impurities. The variable quantity of the smoothness of the aluminum alloy substrate before and after heating within 10 seconds at a tempetature of 500 DEG C is below 5um, and the variable quantity of the average grain diameter of the aluminum alloy substrate before and after heating within 10 seconds at a tempetature of 500 DEG C is below 10um. According to the method of manufacturing the aluminum alloy substrate used for magnetic discs, pack annealing of the aluminum alloy substrate used for magnetic discs includes the steps of holding the substrate for more than two hours at a temperature of more than 350 DEG C under a condition that the temperature rises into over 350 DEG C at a speed of 2 DEG C per minute, and cooling at a cooling speed of below 2 DEG C per minute.

Owner:KOBE STEEL LTD

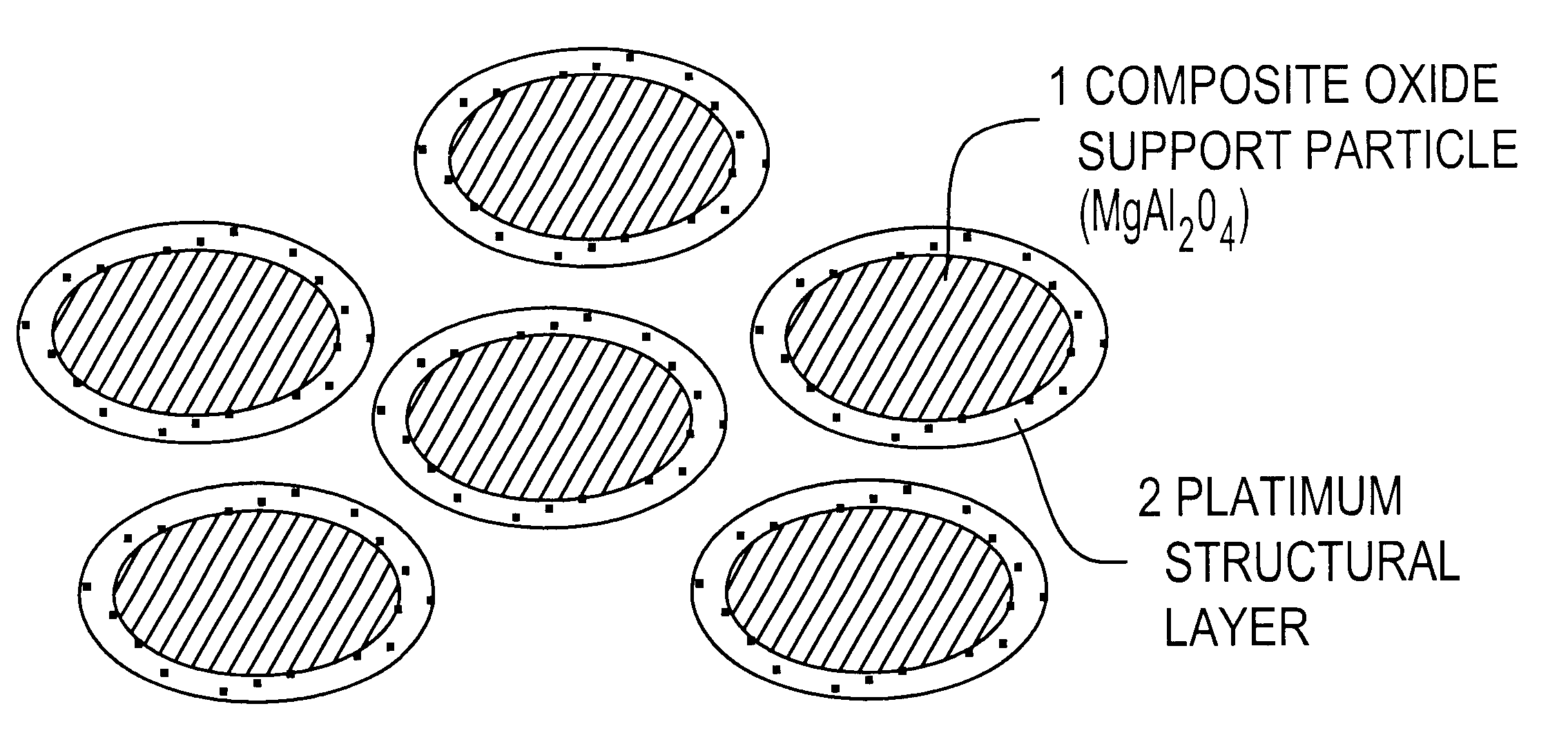

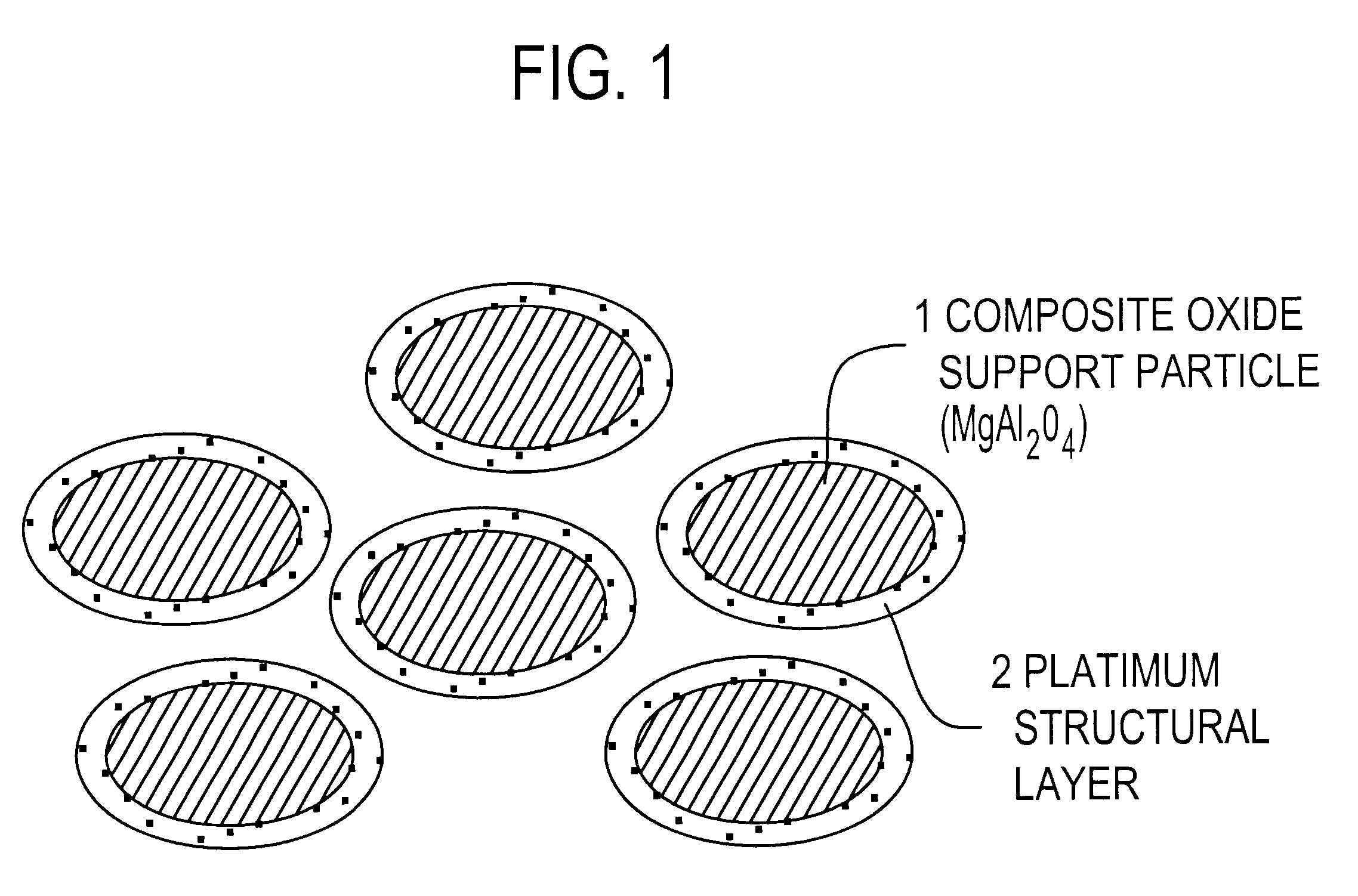

Catalyst for purifying an exhaust gas and process for producing the same

InactiveUS6372688B1Improve performanceCoarsening of the Pt clusters can be furthermore suppressedInorganic chemistryInternal combustion piston enginesPlatinumAlkaline earth oxides

A catalyst for purifying an exhaust gas includes a composite oxide support and a platinum structural layer. The composite oxide support has a spinel structure expressed by M.Al2O4 in which M is an alkaline-earth metal. The platinum structural layer is formed on a surface of the composite oxide support and includes a matrix composed mainly of an alkaline-earth metal oxide in which platinum clusters are dispersed uniformly. A composite oxide layer can be interposed between the composite oxide support and the platinum structural layer. Also disclosed is an optimum process for producing the catalyst.

Owner:TOYOTA JIDOSHA KK

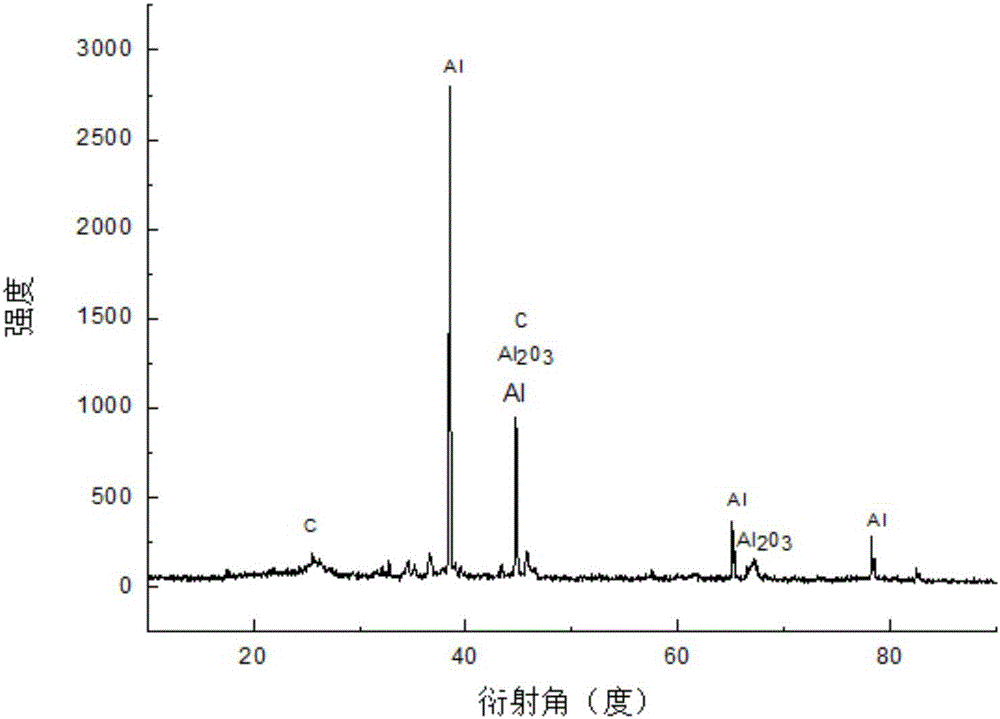

Continuous brazing composite aluminum-based brazing wire applying nanometer aluminum trioxide and preparation method of continuous brazing composite aluminum-based brazing wire applying nanometer aluminum trioxide

InactiveCN105834609AImprove toughnessImprove plasticityWelding/cutting media/materialsWelding/soldering/cutting articlesTrioxideFiller metal

The invention discloses a continuous brazing composite aluminum-based brazing wire applying nanometer aluminum trioxide and a preparation method of the continuous brazing composite aluminum-based brazing wire applying the nanometer aluminum trioxide. The continuous brazing composite aluminum-based brazing wire applying the nanometer aluminum trioxide is composed of an aluminum-based brazing filler metal core material with a groove formed in the outer surface, a no-corrosive flux used for aluminum and applied in the peripheral groove of the core material in a wrapping manner, and a coating layer sprayed on the surface of the composite brazing flux. The obtained product is excellent in material performance, easy to machine and form, good in brazing process performance, capable of fully adapting to efficient and continuous brazing and excellent in brazing connector performance.

Owner:GUILIN QINGTONG NON FERROUS METAL ARTS & CRAFTS MATERIAL DEV CO LTD

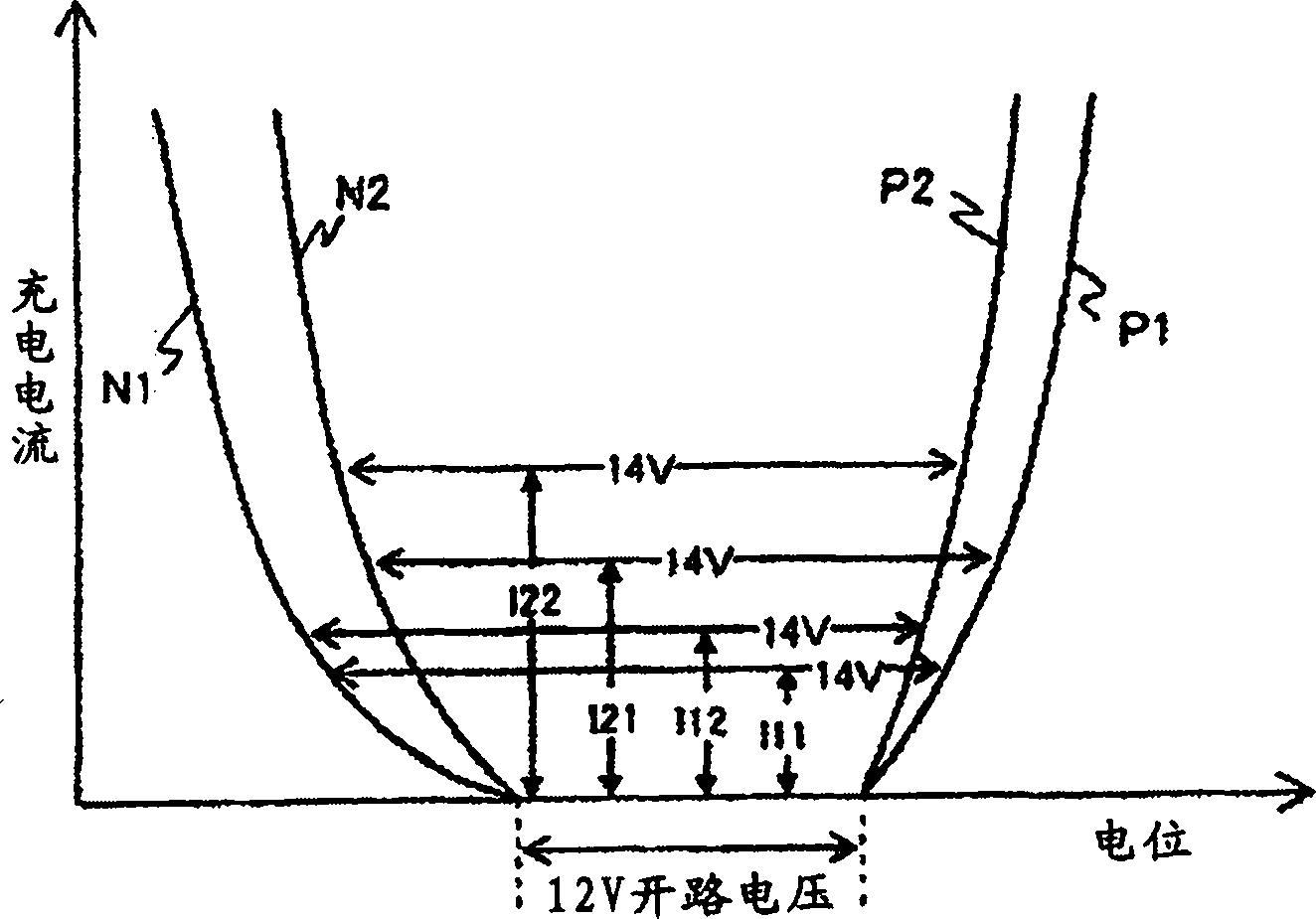

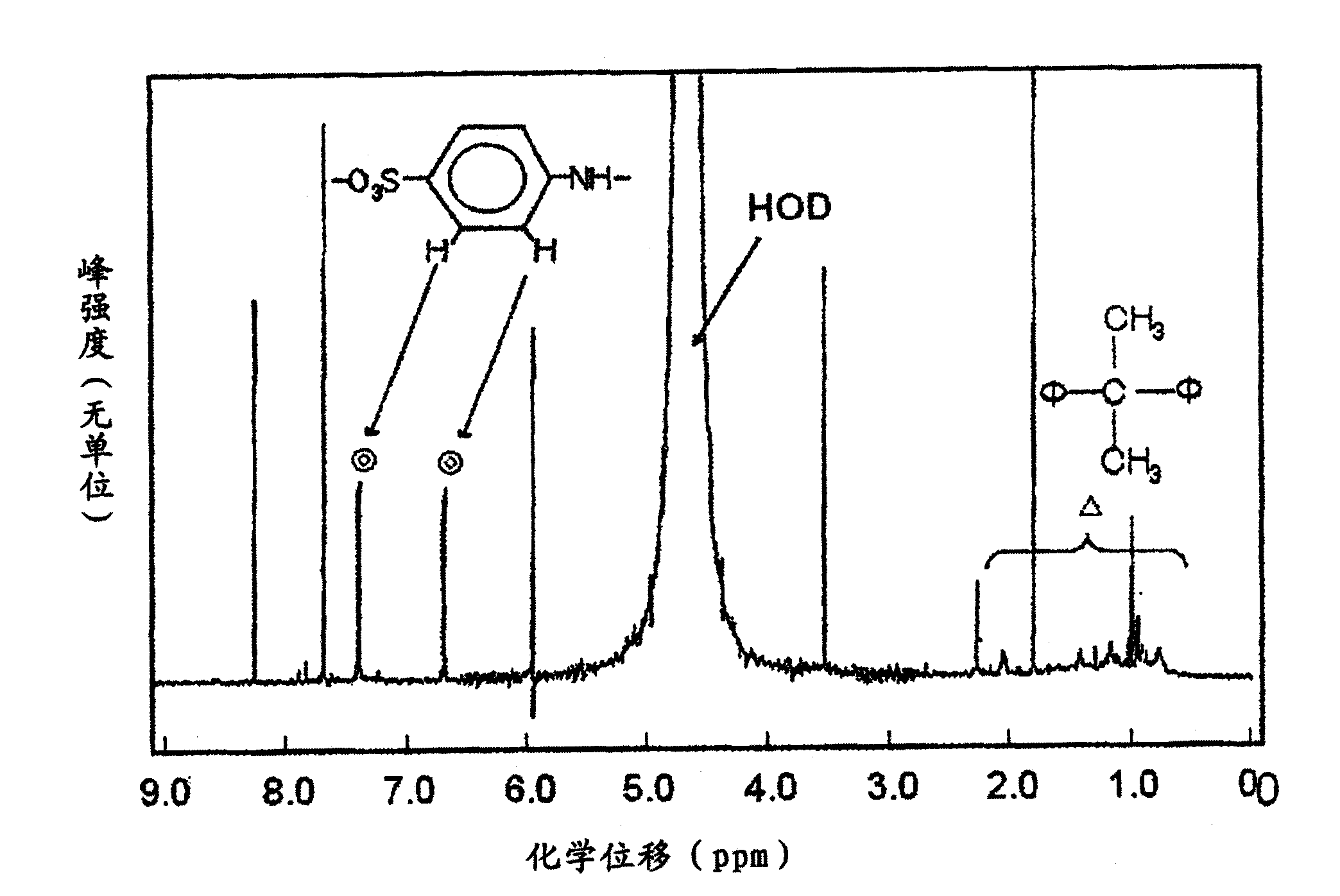

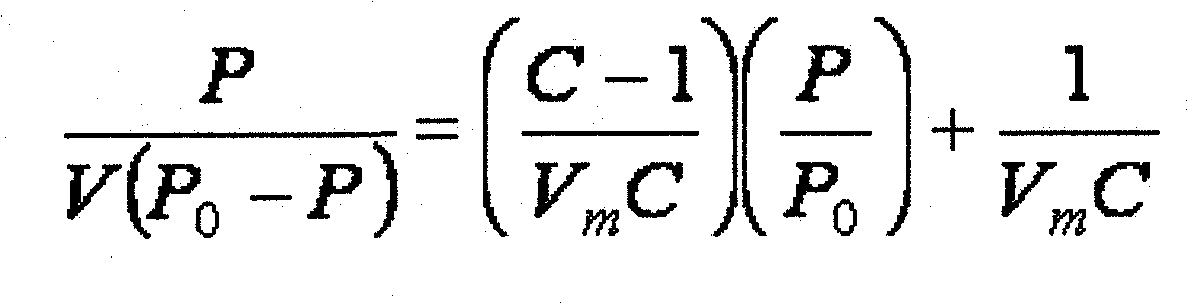

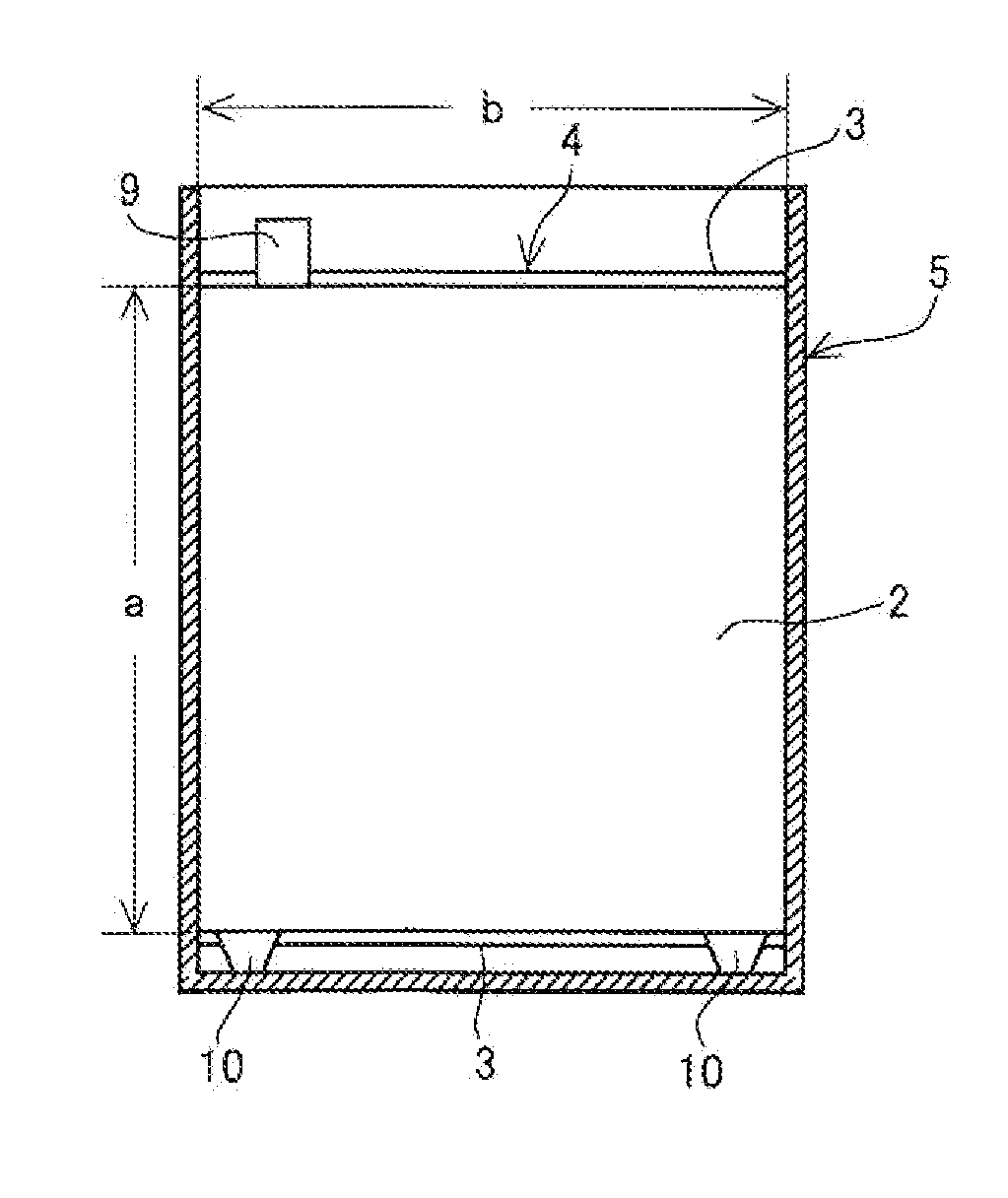

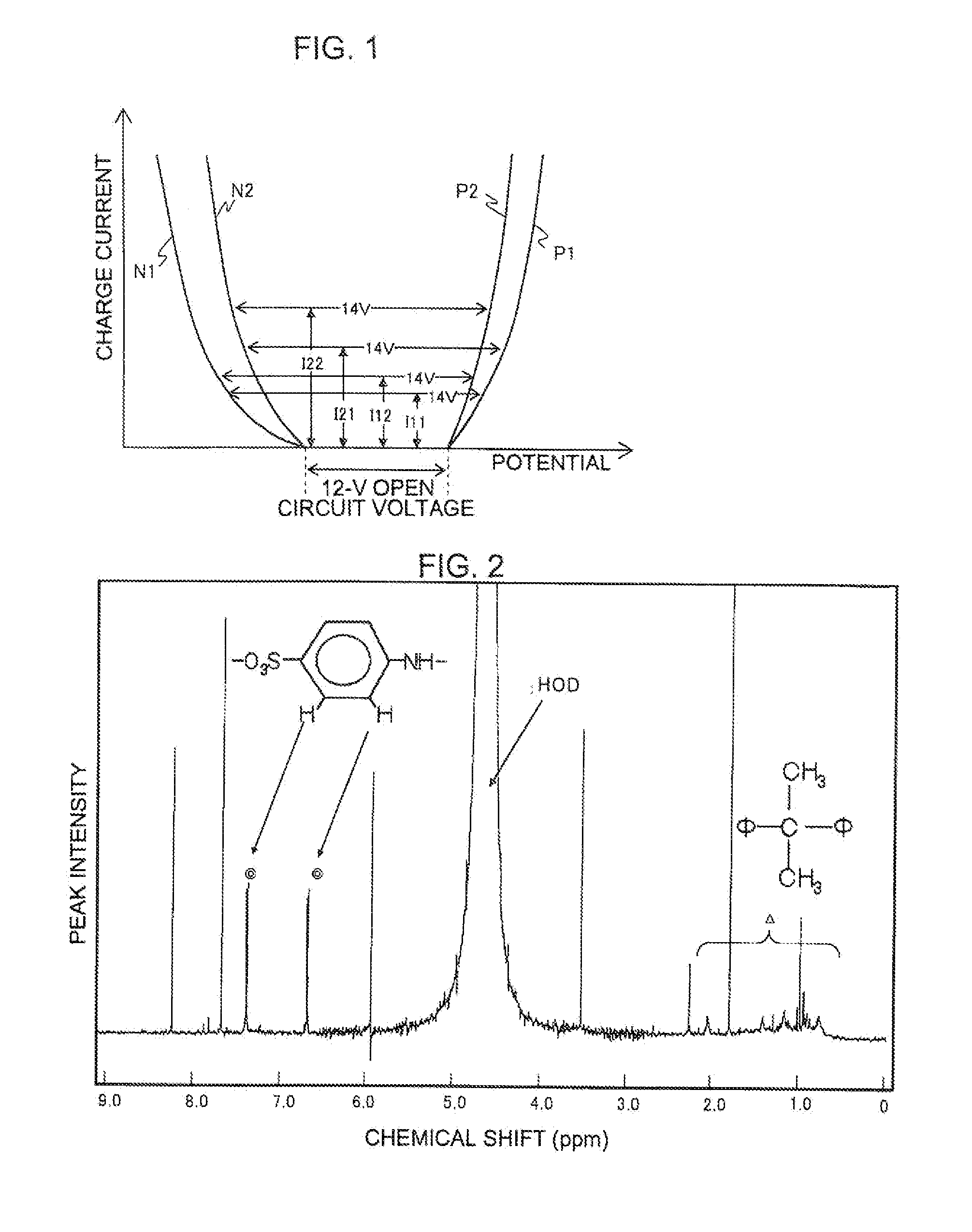

Lead storage battery

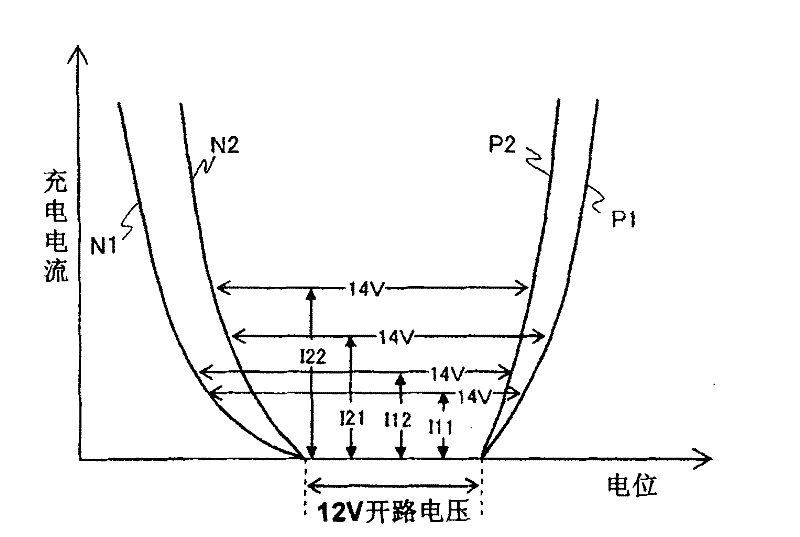

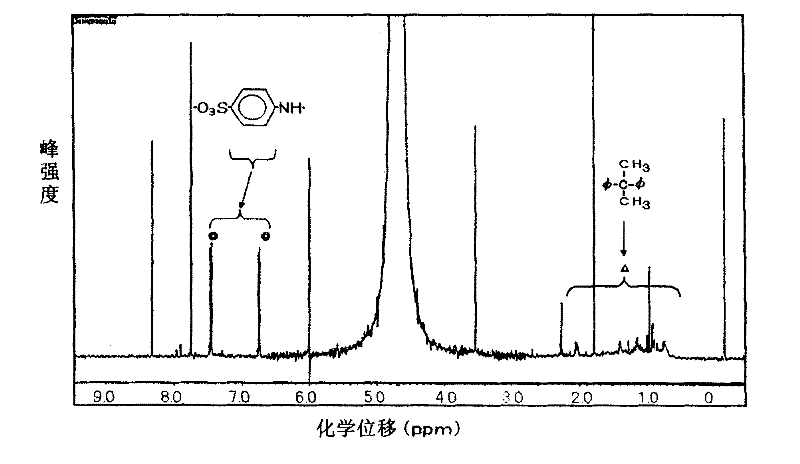

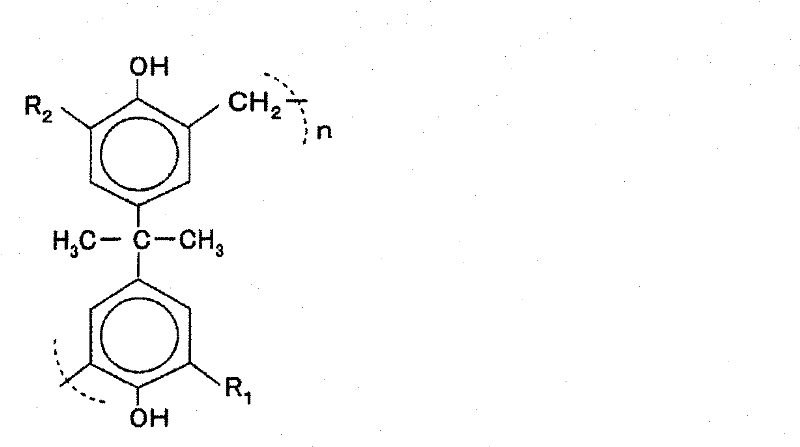

InactiveCN102246343AImprove charge acceptanceSuppress coarseningLead-acid accumulatorsCell seperators/membranes/diaphragms/spacersPolyolefinHigh rate

The disclosed liquid lead storage battery, which is charged intermittently for short periods at a time and which performs high-rate discharge to a load while in a partially charged state, has increased operating-life characteristics and charge acceptance by means of using: a cathode plate wherein the specific surface area of active material is at least 6 m2 / g; an anode plate wherein a carbonaceous conductive material and a bisphenol / aminobenzenesulfonic acid / formaldehyde condensate are added to an anode active material, increasing charge acceptance and operating-life performance; and a separator of which the surface that faces the anode plate is formed from a nonwoven fabric of a material selected from glass, pulp, and a polyolefin.

Owner:SHIN KOBE ELECTRIC MASCH CO LTD

Multi-nanophase composite enhanced magnesium alloy and preparation method thereof

The invention discloses multi-nanophase composite enhanced magnesium alloy and a preparation method thereof, and belongs to the technical field of magnesium alloy. The multi-nanophase composite reinforced and enhanced deforming magnesium alloy is Mg-Gd-Zn alloy, wherein the Gd content is 10-25 wt%, the Zn content is 1-5 wt%, the balance is Mg, and the difference between the mass percent of GD and the mass percent of Zn is not smaller than 8. The deforming magnesium alloy material excellent in mechanical performance is obtained through the multi-stage extrusion and multi-stage thermal treatment process, the yield strength can reach 250-400 MPa, and the elongation can reach 10-25%. The alloy is mainly reinforced by a nanometer needle-shaped phase and a nanometer sheet phase together, the two phases are staggered, and the comprehensive mechanical performance of the alloy can be remarkably improved.

Owner:北京二七铁丰龙科技有限公司

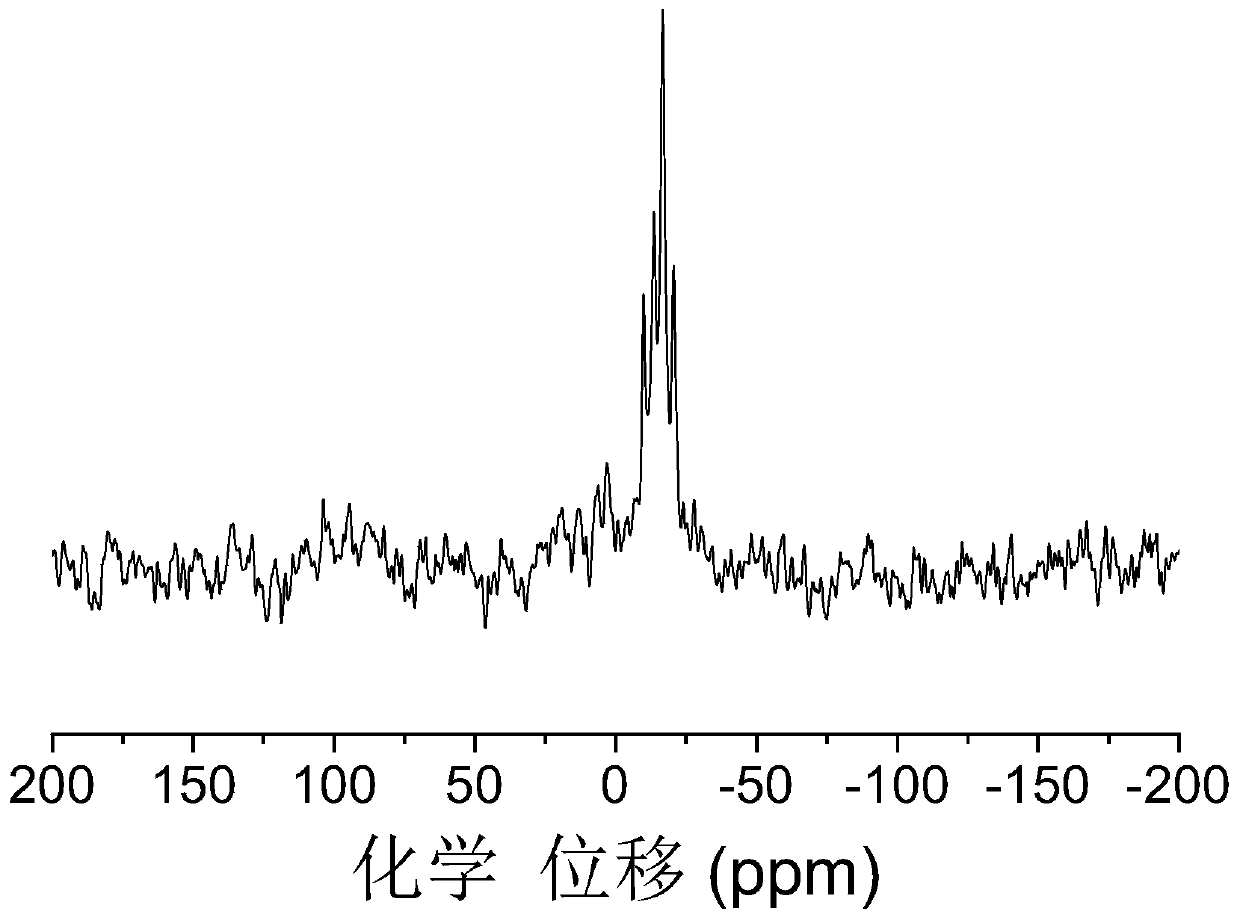

Liquid curable boron-containing polycarbosilane and preparation method thereof

ActiveCN110698678AImprove uneven distributionAvoid equal partsCoatingsAdhesivesPolymer sciencePtru catalyst

The invention discloses liquid curable boron-containing polycarbosilane and a preparation method thereof. The preparation method comprises the following steps: in a closed reaction container, subjecting polycarbosilane and a boron-containing monomer to a first reaction to generate liquid boron-containing polycarbosilane, wherein the polycarbosilane is a low-molecular-weight product obtained afterhigh-temperature cracking of polydimethylsilane, is in a liquid state at room temperature, and has a molecular weight of less than 1000 g / mol; and carrying out a second reaction on a uniformly-mixed reaction system containing the liquid boron-containing polycarbosilane, an organosilicon compound containing a C=C bond and a catalyst to obtain the liquid curable boron-containing polycarbosilane. Theliquid curable boron-containing polycarbosilane precursor disclosed by the invention is in a liquid state at room temperature, is simple in preparation process and long in storage time, can be thermocured, and is applicable to the fields of preparation of silicon carbide ceramic-based composite materials, high-temperature-resistant coatings, adhesives and the like through a precursor infiltrationand pyrolysis (PIP) method; and due to the existence of boron, the temperature resistance of a final product is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Lead storage battery

ActiveCN102576911AImprove charge acceptanceExtend your lifeFinal product manufactureNegative electrodesHigh rateState of charge

Provided is a valve-regulated lead storage battery which is intermittently charged, each charge being conducted for a short period, and which in a partial state of charge (PSOC) is discharged at a high rate to apply a voltage to a load. The battery shows higher charge acceptance and has better life characteristics under PSOC than conventional valve-regulated lead storage batteries. Use is made of a positive electrode plate in which the active material has a specific surface area of 5.5 m2 / g or more. Use is made of a negative electrode plate in which the charge acceptance and life performance have been improved by adding a carbonaceous conductive material and a product of condensation of a bisphenol compound, aminobenzenesulfonic acid, and formaldehyde to a negative active material. The specific gravity of an electrolytic solution is set at 1.30-1.35. Thus, the valve-regulated lead storage battery is produced.

Owner:RESONAC CORPORATION

Lead-acid battery

InactiveUS20130099749A1Improve charge acceptanceImproved life performanceBatteries circuit arrangementsFinal product manufactureState of chargeHigh rate

A flooded-type lead-acid battery in which charging is intermittently carried out in a short period of time and high-rate discharge to a load is carried out in a partial state of charge, wherein the charge acceptance and service life characteristics under PSOC are improved by using a positive plate in which the total surface area of the positive active material per unit of the plate pack volume is set in a range of 3.5 to 15.6 m2 / cm3; a negative plate with improved charge acceptance and service life performance obtained by adding a carbonaceous electrically conductive material, and a formaldehyde condensate of bisphenol and aminobenzene sulfonic acid to the negative active material; and a separator formed from a nonwoven in which a surface facing the negative plate is composed of material selected from glass, pulp, and polyolefin.

Owner:SHIN KOBE ELECTRIC MASCH

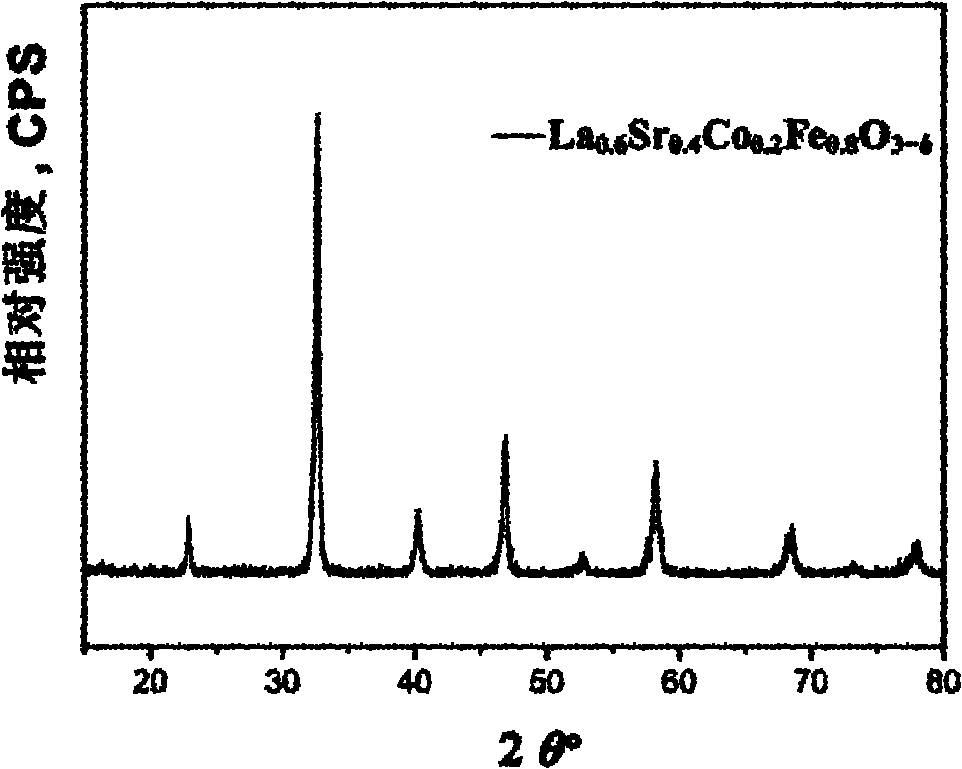

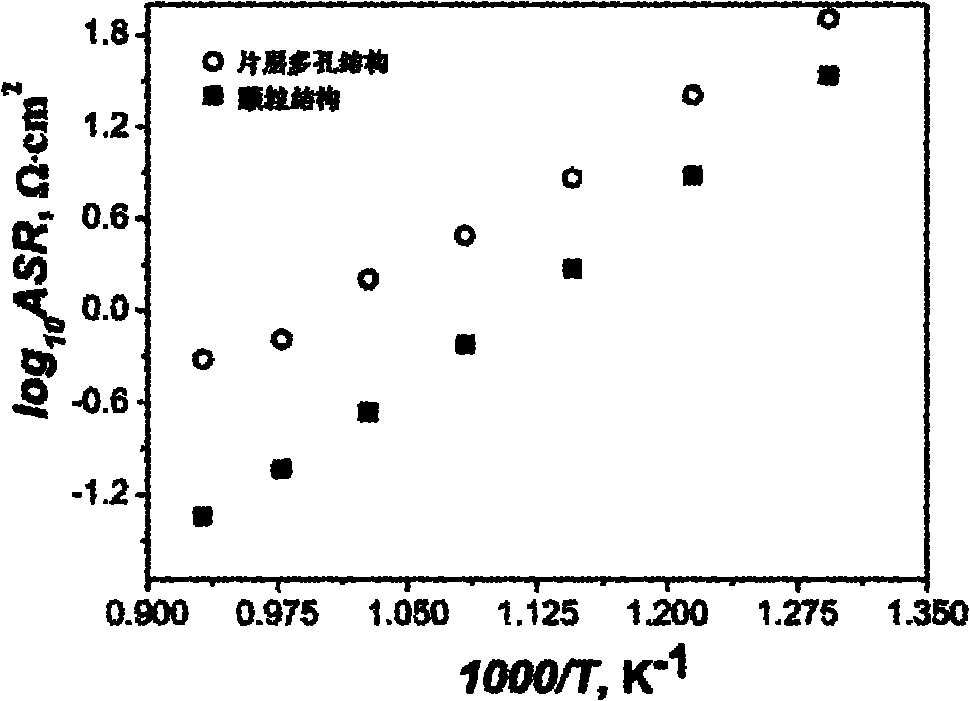

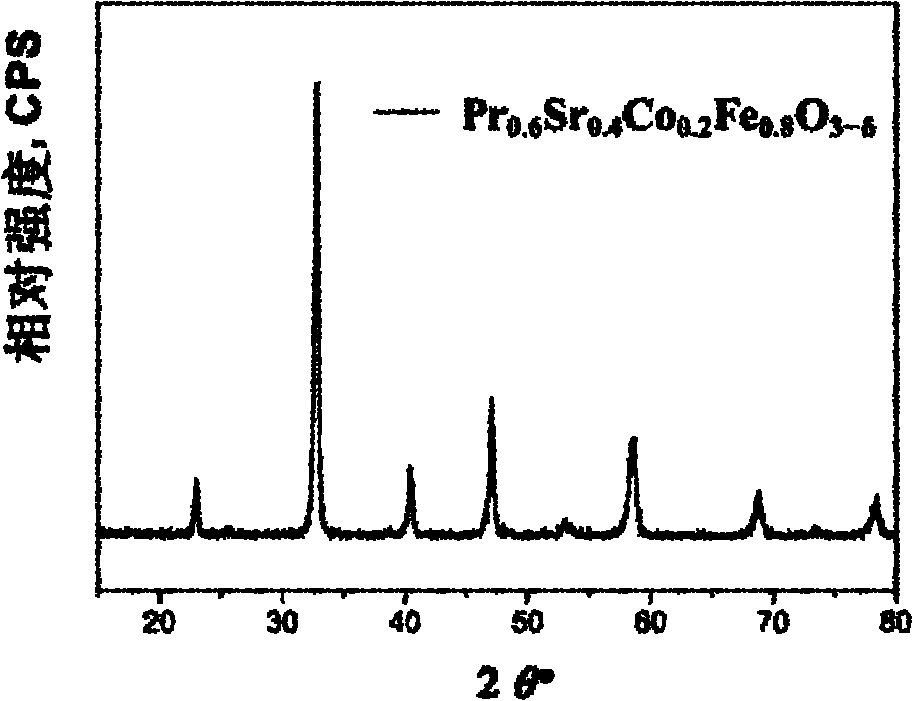

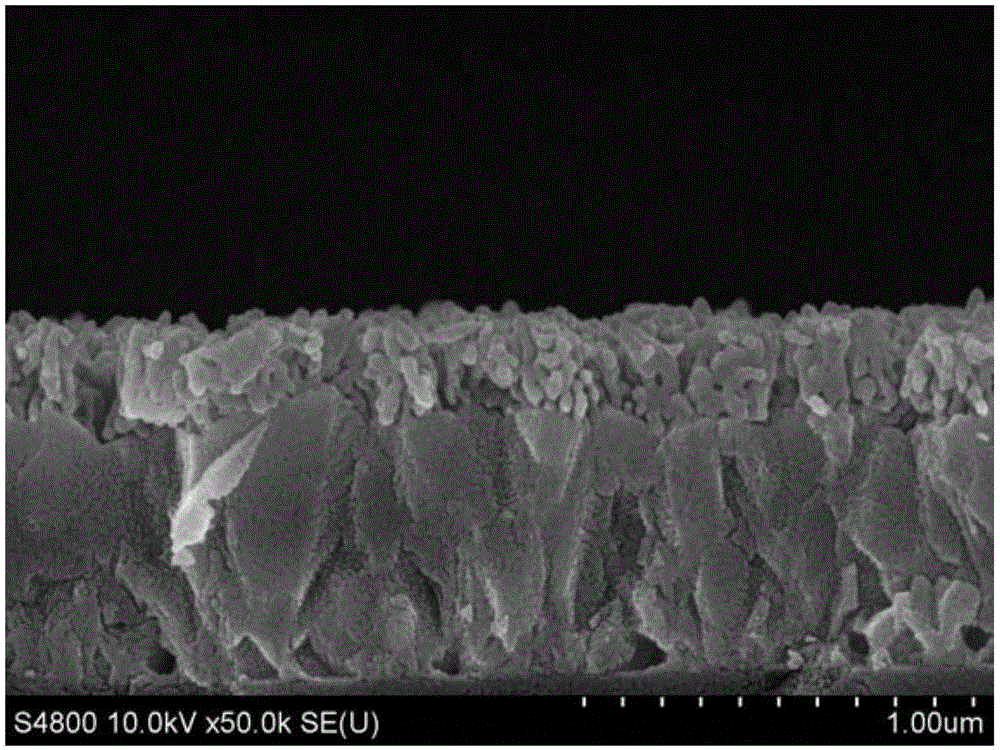

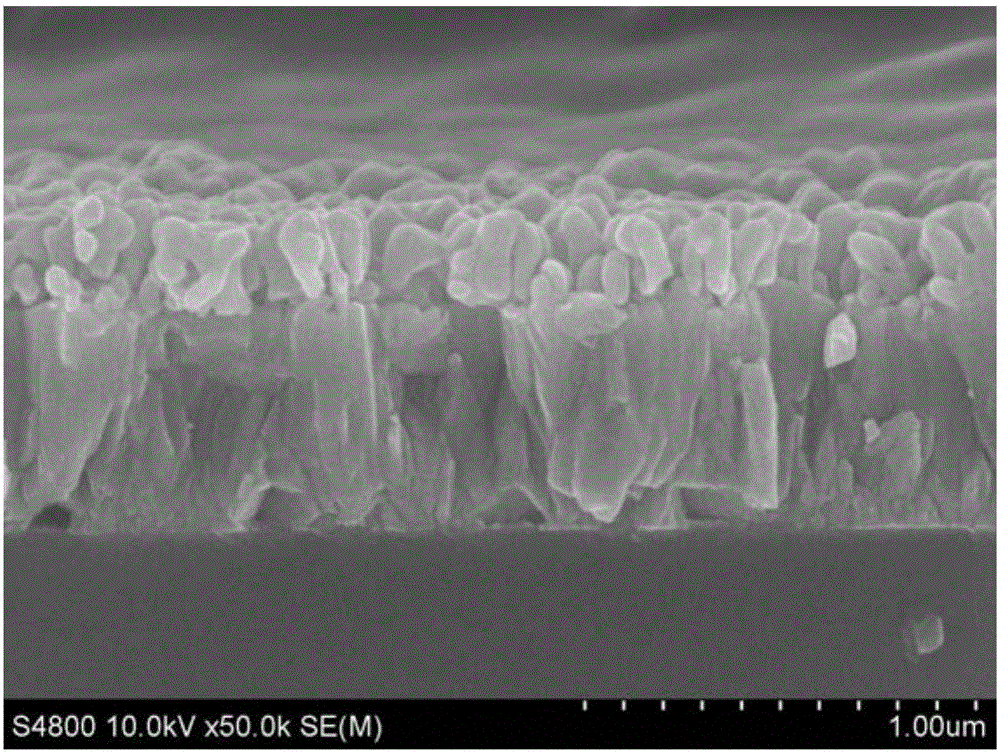

Preparation method of cathode of low-medium temperature solid oxide fuel cell

InactiveCN102104153ASuppress coarseningOptimal Control StructureCell electrodesConcentration polarizationFuel cells

The invention relates to a preparation method of a cathode of a low-medium temperature solid oxide fuel cell, belonging to the technical field of fuel cells. The preparation method comprises the following steps of: preparing a cathode layer chief source by spraying cathode slurry on an electrolytic substrate and drying at the temperature of 100-400 DEG C; and then sintering at 800-1300 DEG C in an air environment for 2-10 hours so as to obtain the cathode of the fuel cell, wherein temperature rise rate is 5-20 DEG C / minute. The invention solves the problems of overhigh oxygenic concentration polarization and higher cathodic polarization impedance which are caused by difficult structure control, poor preparation repeatability and slower oxygenic cathodic transmission of a cathode layer of the prior common low-medium temperature solid oxide fuel cell and prepares the cathode layer which has specific lamellar structure, needs no template and can be prepared easily and repeatedly by selecting a powder synthesis process, calcining temperature and temperature rise rate, thereby obviously enhancing the cathode performance.

Owner:SHANGHAI JIAO TONG UNIV

Narrow-hardenability pinion steel and preparation method thereof

ActiveCN102400052AImprove hardenabilityHardenability improved and stabilizedManufacturing convertersProcess efficiency improvementTemperature resistanceWear resistance

The invention provides a narrow-hardenability pinion steel which comprises the following components in percentage by weight: 0.18%-0.22% of C, 0.20%-0.30% of Si, 0.90%-1.15% of Mn, less than or equal to 0.030% of P, less than or equal to 0.030% of S, 1.00%-1.35% of Cr, 0.04%-0.08% of Ti, 0.004%-0.005% of B, 0.025%-0.038% of W, less than or equal to 11.5*10<-6> of [O], less than or equal to 1.5*10<-6> of [H], 35*10<-6>-45*10<-6> of [N] and the balance of Fe and inevitable impurities. The invention provides a preparation method of the narrow-hardenability pinion steel. The preparation method comprises the following steps: 1) primary smelting based on a top-bottom blowing converter; 2) ladle deoxidizing and alloying; 3) LF (ladle furnace) refining; 4) RH refining; and 5) continuous casting. Compared with the prior art, the narrow-hardenability pinion steel provided by the invention has the characteristics of better wear resistance and high temperature resistance, higher hardenability andnarrower jominy hardenability.

Owner:WANGUAN SMELTING MOLD CASTING

Titanium-doped alpha-iron oxide photo-anode, and preparation method and application thereof

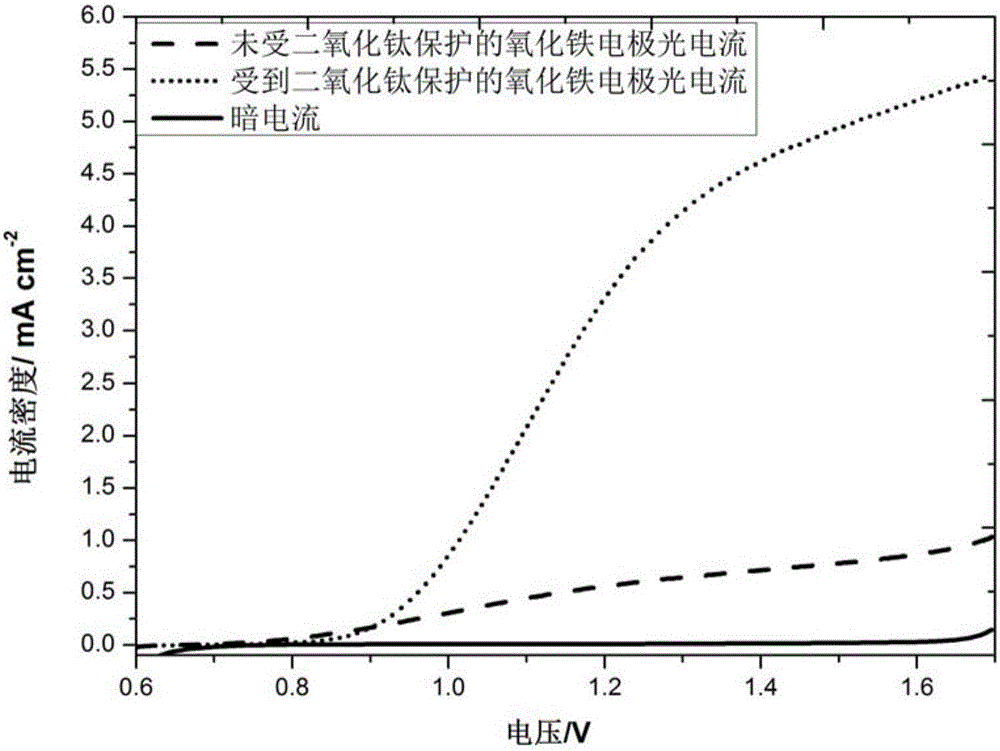

The invention discloses a titanium-doped alpha-iron oxide photo-anode, and a preparation method and an application thereof. The method comprises the steps: coating the surface of a beta-FeOOH membrane with a titanium source solution, forming a TiO2 layer during high temperature annealing, and inhibiting grain coarsening of alpha-iron oxide; at the same time, in the process, diffusing titanium ions to the interior of alpha-iron oxide crystal lattices to realize titanium doping; and after annealing, using a hydrogen peroxide aqueous solution to remove the TiO2 layer, and thus obtaining the titanium-doped alpha-iron oxide photo-anode. The photo-anode has small particle size which is 30 nm-40 nm; the maximum photocurrent density can reach 3.62 mA / cm<2> under a 300 W xenon lamp light source and at the bias of 1.23 V[RHE]; compared with a un-doped alpha-iron oxide photo-anode without introduction of the TiO2 layer, the photocurrent is increased by 5 times, and a positive shift phenomenon of initial potential is not generated.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

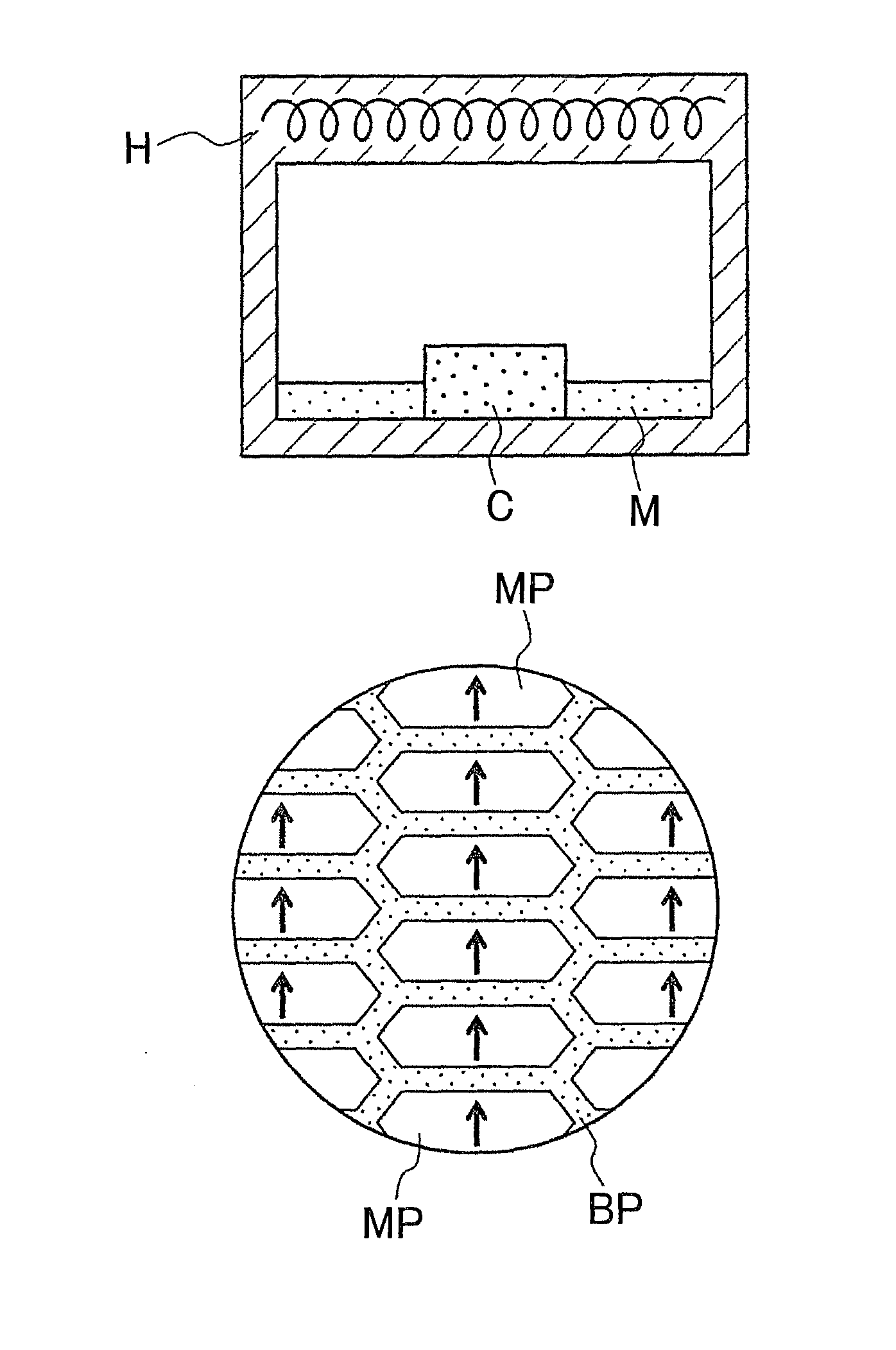

Rare-earth magnet and method for producing the same

ActiveUS20140242267A1Suppress coarseningExcellent coercivity performanceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementMischmetal

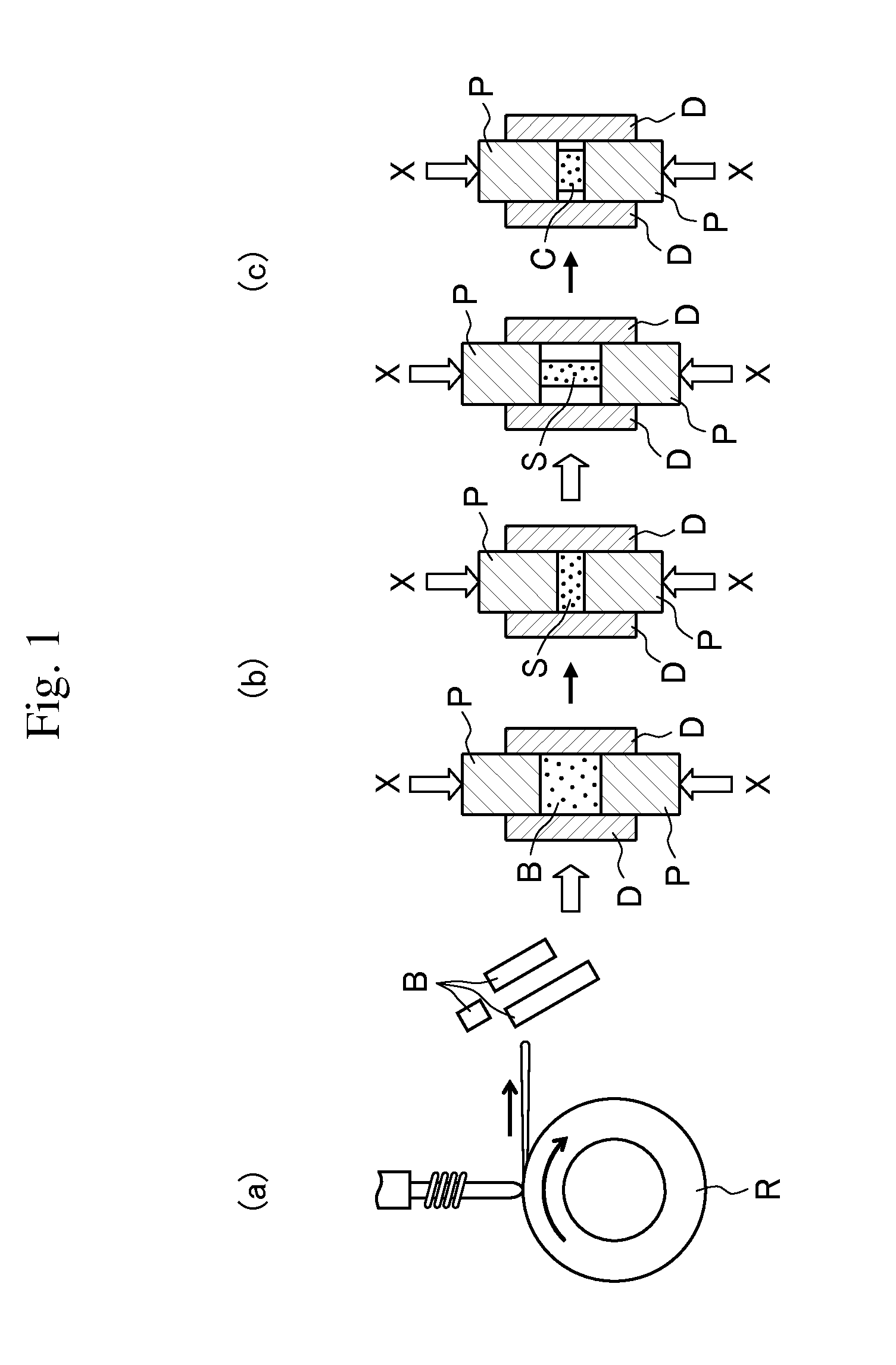

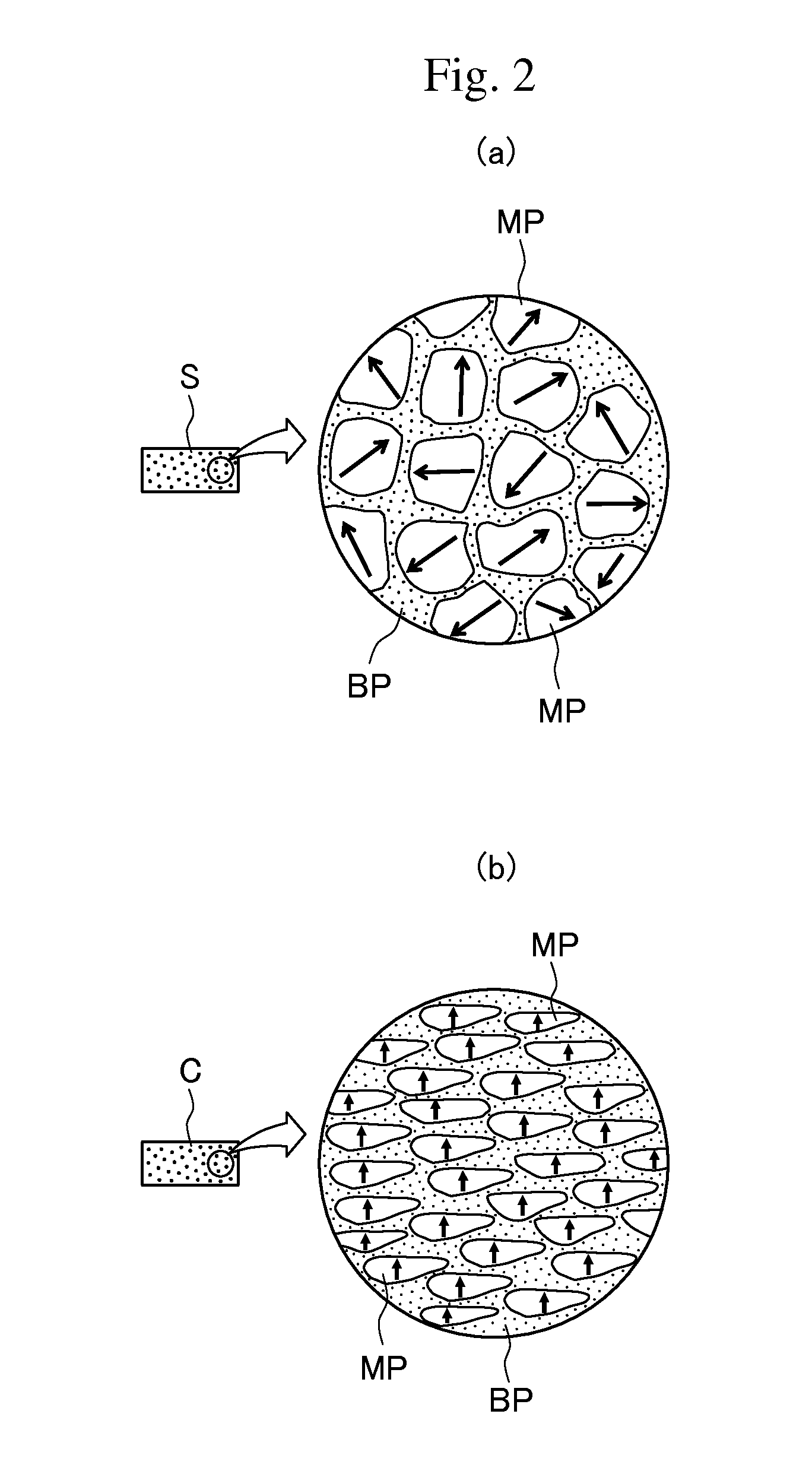

Provided is a rare-earth magnet containing no heavy rare-earth metals such as Dy or Tb in a grain boundary phase, has a modifying alloy for increasing coercivity (in particular, coercivity under a high-temperature atmosphere) infiltrated thereinto at lower temperature than in the conventional rare-earth magnets, has high coercivity, and has relatively high magnetizability, and a production method therefor. The rare-earth magnet RM includes a RE-Fe—B-based main phase MP with a nanocrystalline structure (where RE is at least one of Nd or Pr) and a grain boundary phase BP around the main phase, the grain boundary phase containing a RE-X alloy (where X is a metallic element other than heavy rare-earth elements). Crystal grains of the main phase MP are oriented along the anisotropy axis, and each crystal grain of the main phase, when viewed from a direction perpendicular to the anisotropy axis, has a plane that is quadrilateral in shape or has a close shape thereto.

Owner:TOYOTA JIDOSHA KK

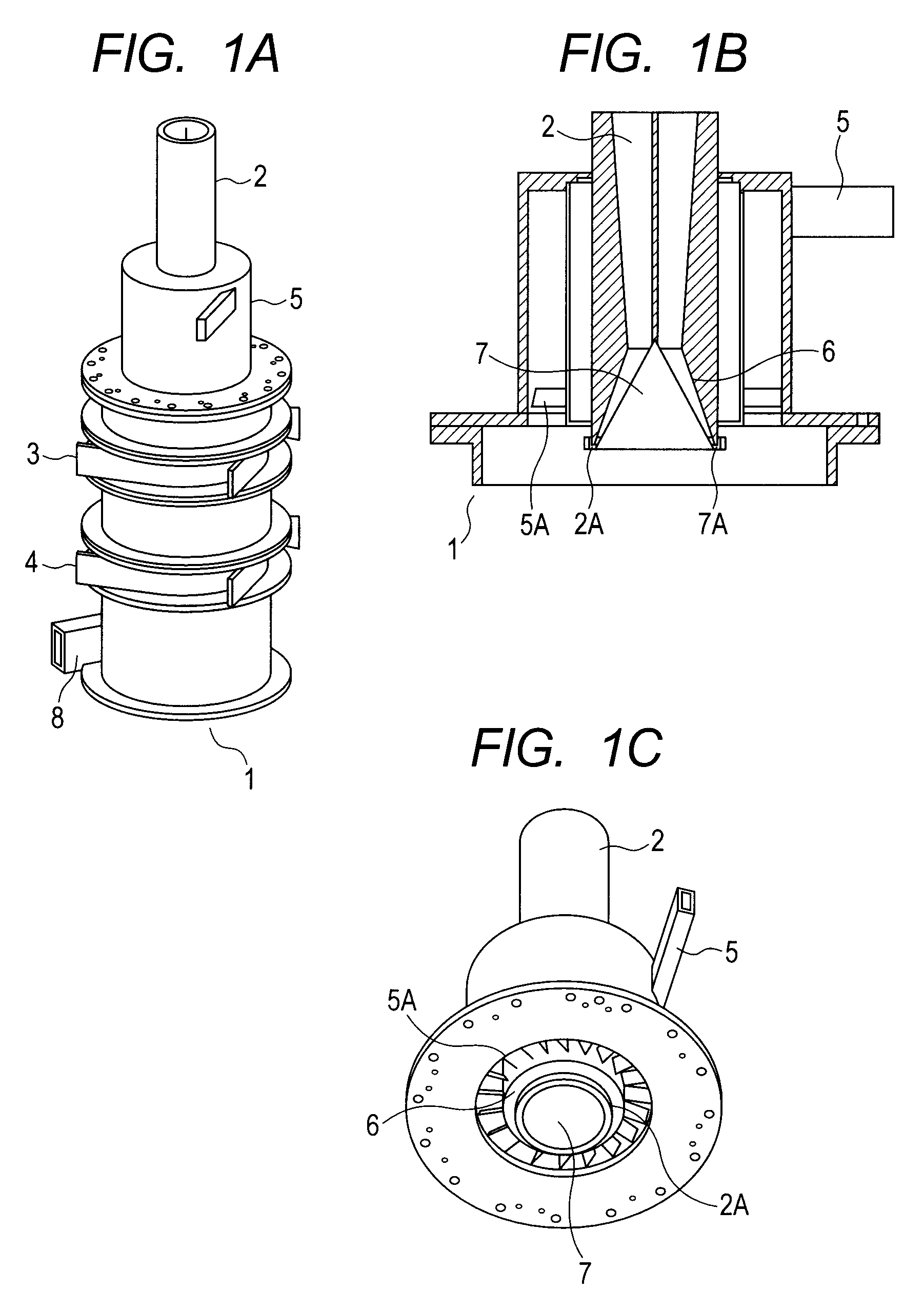

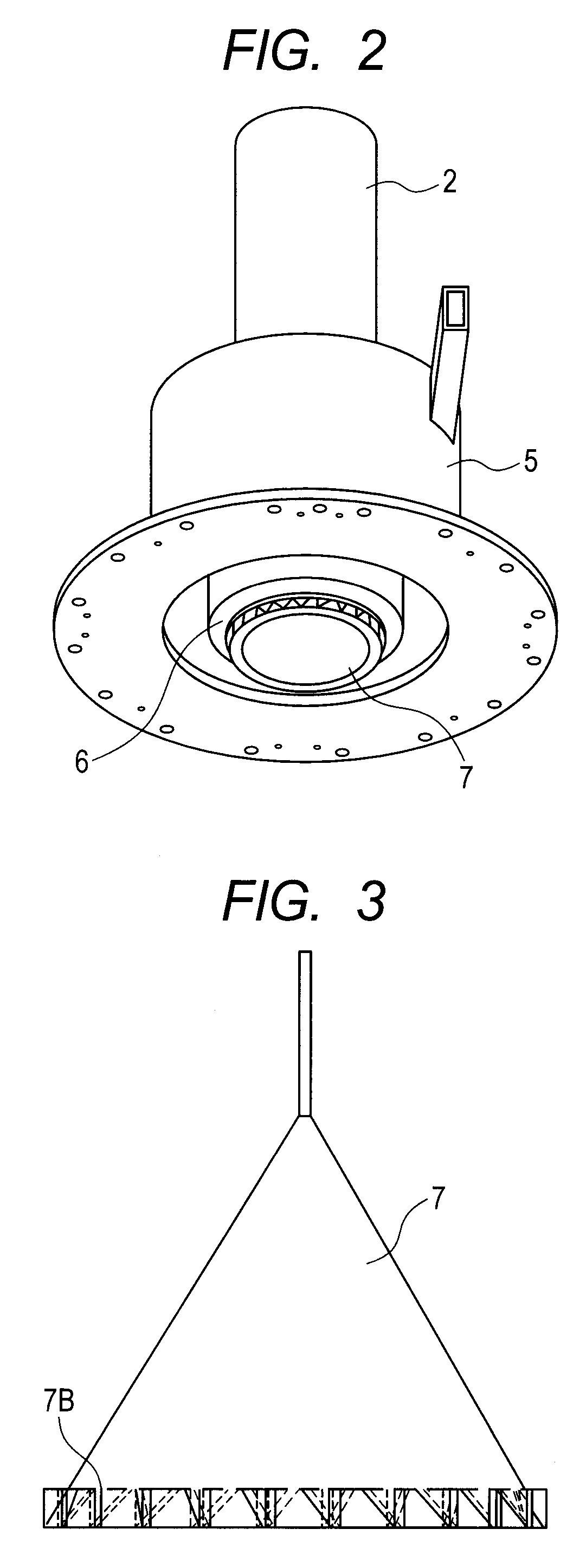

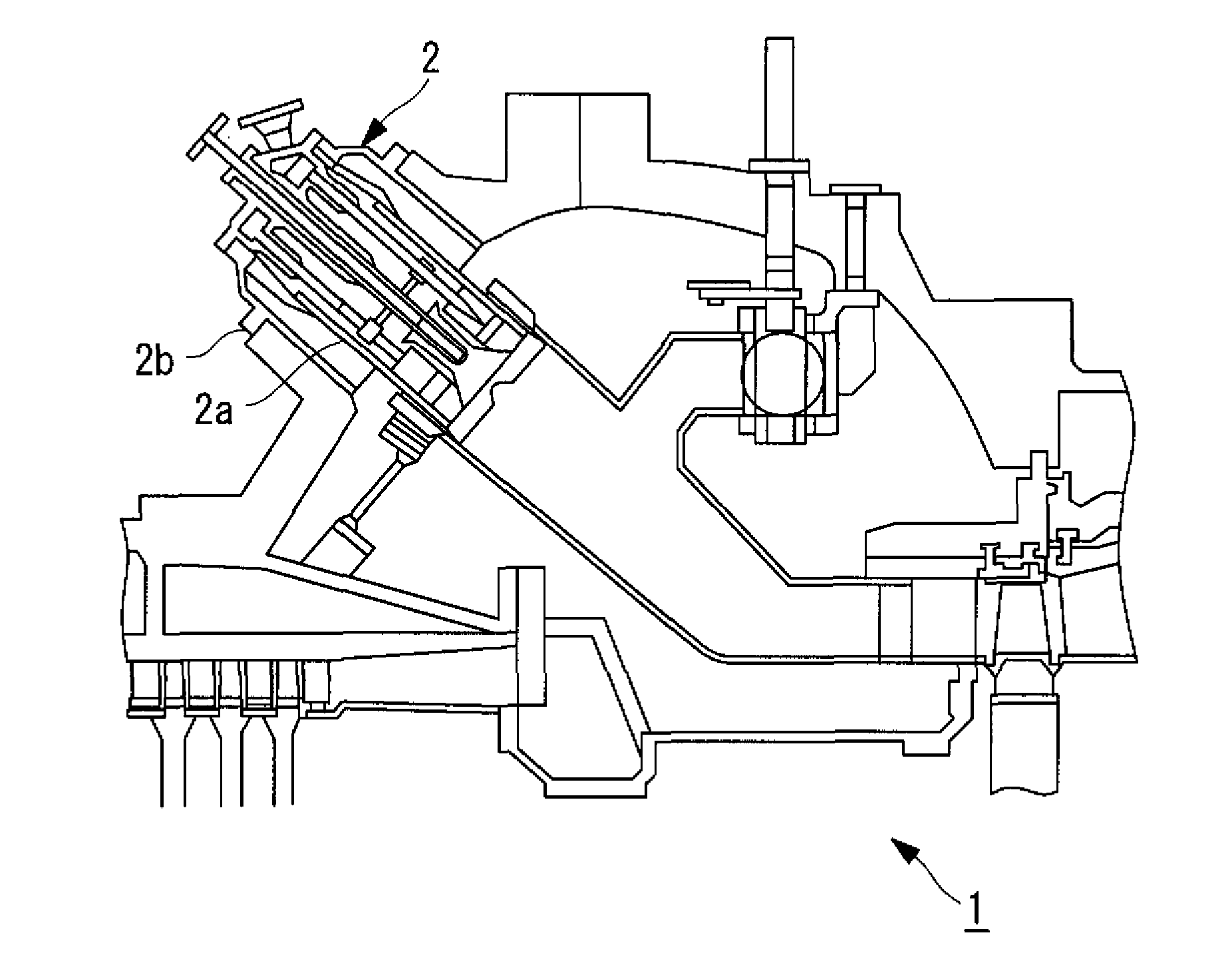

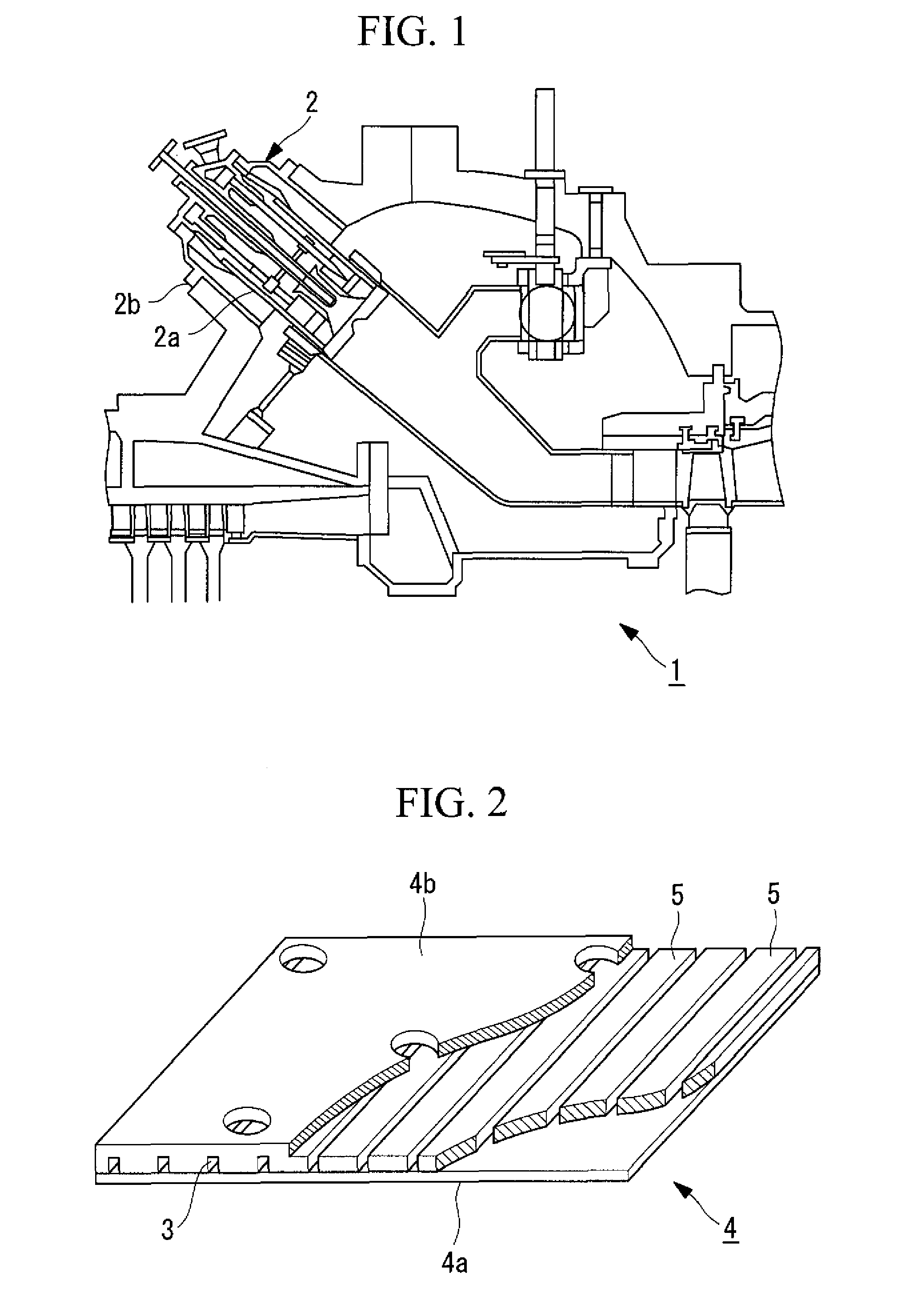

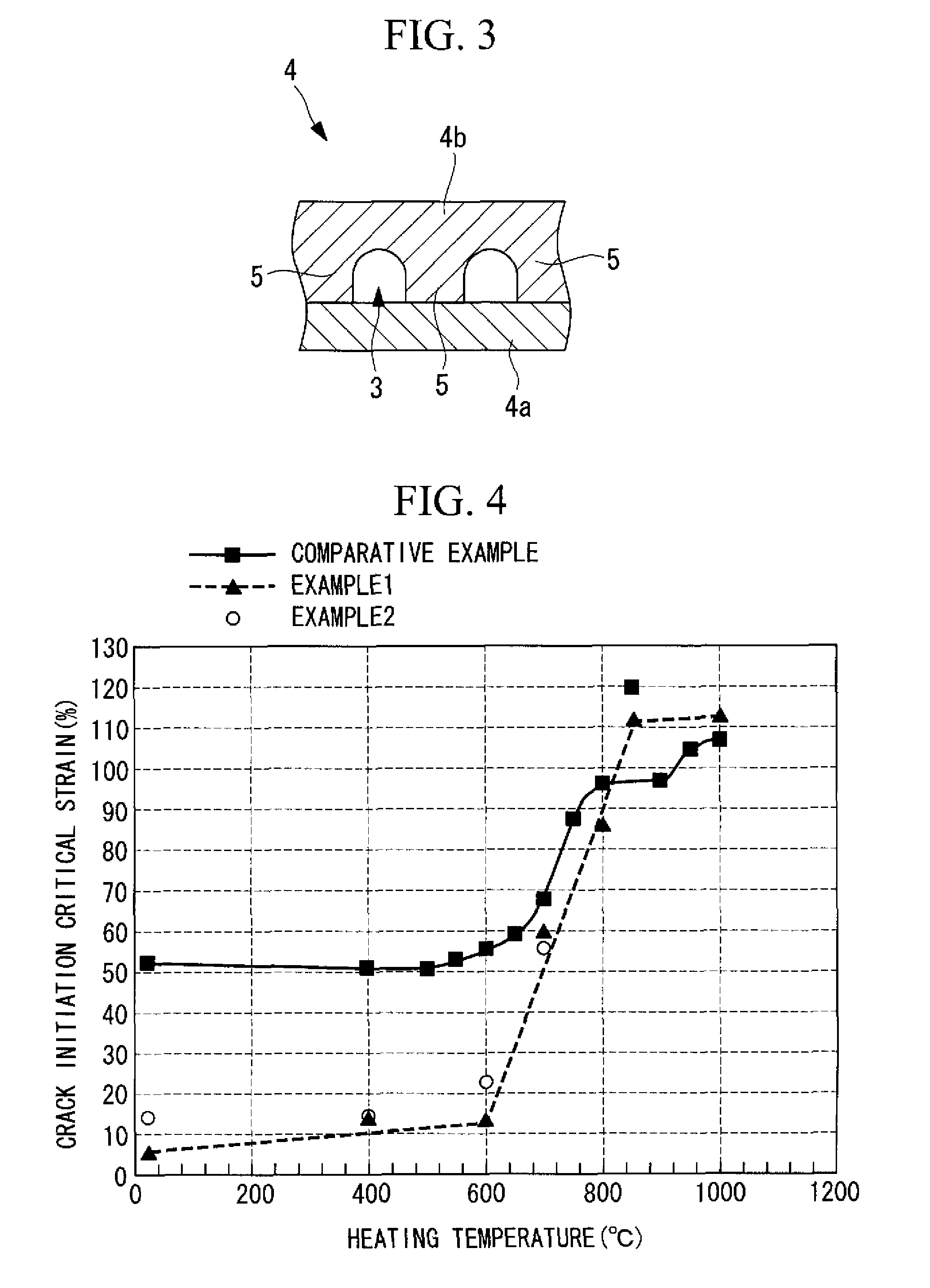

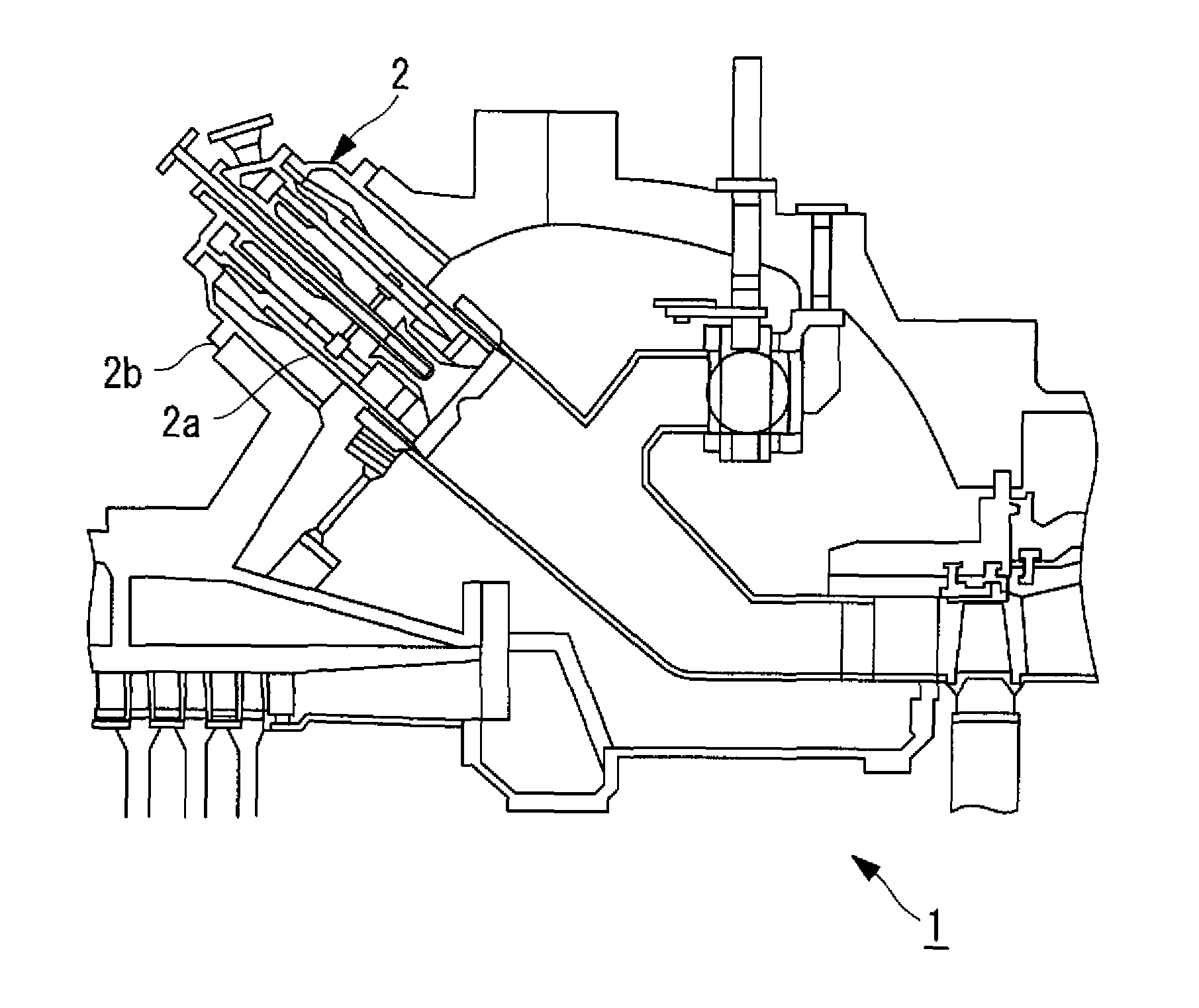

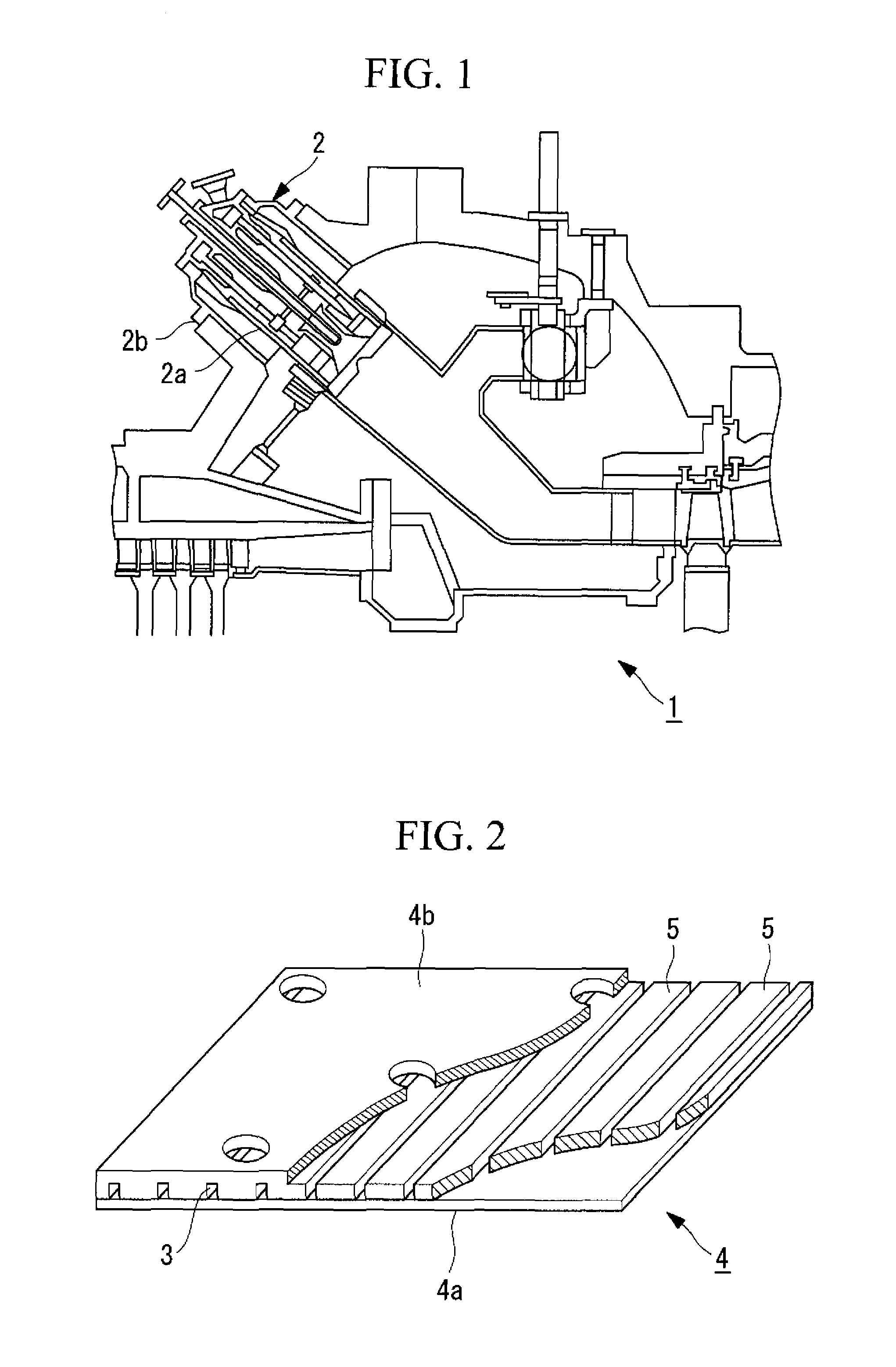

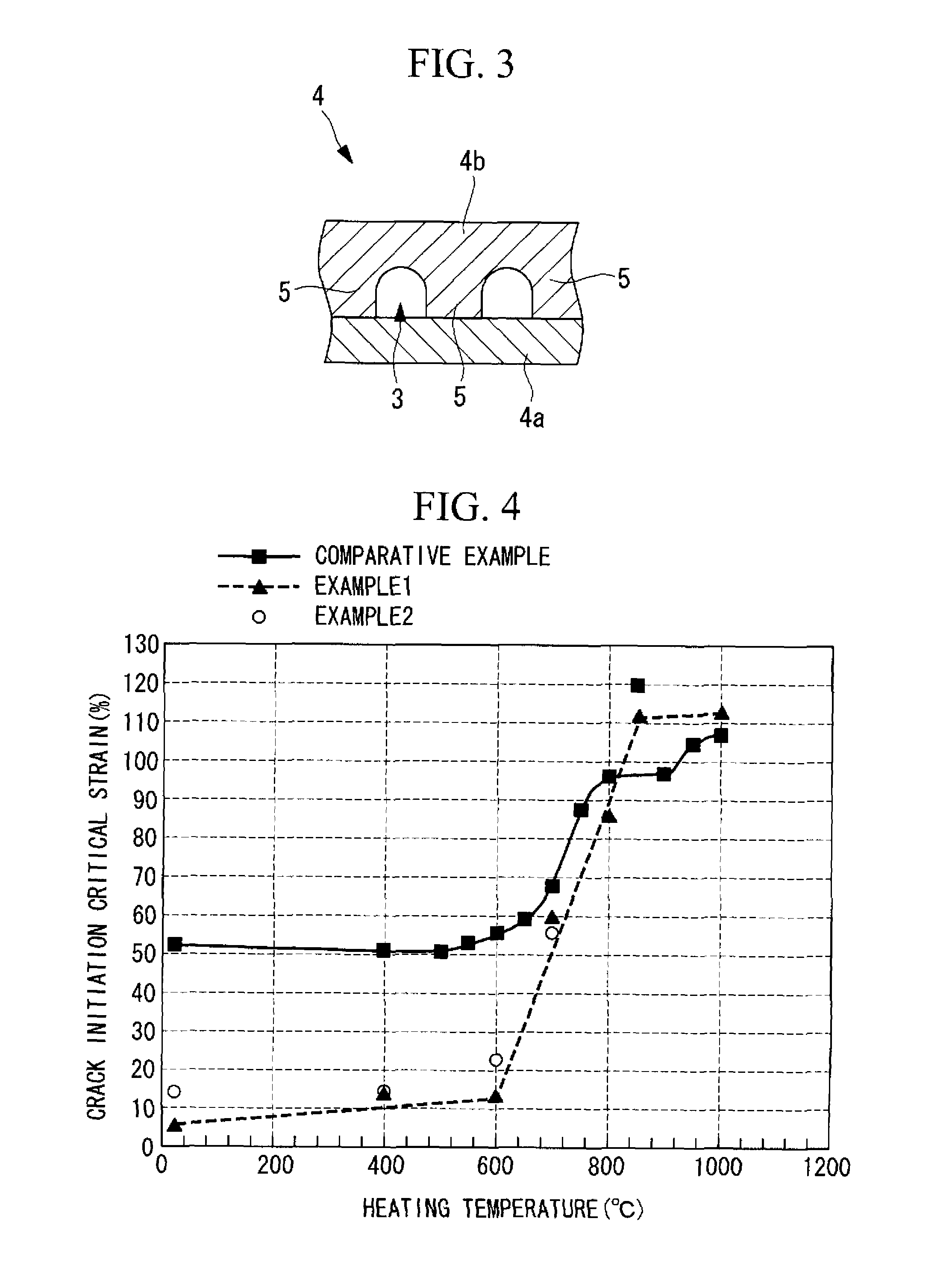

Process for producing combustor structural member, and combustor structural member, combustor for gas turbine and gas turbine

ActiveUS20100300115A1Maintain positioning accuracyNo crackContinuous combustion chamberMetal-working apparatusGas turbinesEngineering

A process for producing a combustor structural member, the process comprising a plate-like assembly formation step of brazing a first plate-like member formed from a heat-resistant alloy, and a second plate-like member formed from a heat-resistant alloy and having a plurality of fins on the surface, with the second plate-like member positioned with the fins facing the first plate-like member, by interposing a brazing filler metal comprising a melting point lowering element between the two plate-like members, thereby forming a plate-like assembly, a press molding step of press molding the plate-like assembly to form a combustor structural member of the desired shape, a strain location identification step of identifying, in accordance with the shape of the combustor structural member, strain locations where the strain generated during the press molding step exceeds a predetermined value, a localized heating step of performing localized heating of the locations within the plate-like assembly corresponding with the strain locations identified in the strain location identification step, and a cold press molding step, which is performed as the above press molding step and comprises subjecting the plate-like assembly to cold press molding with the temperature of the heated locations corresponding with the strain locations maintained at a desired temperature.

Owner:MITSUBISHI POWER LTD

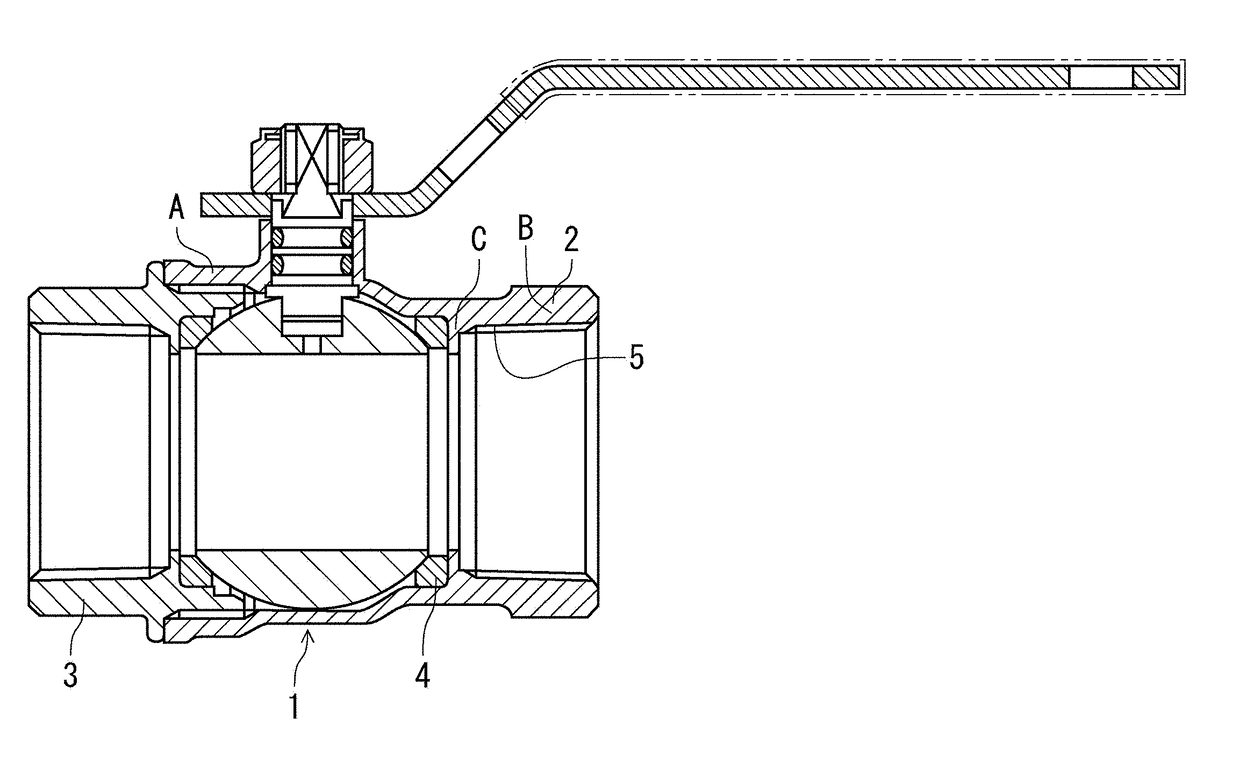

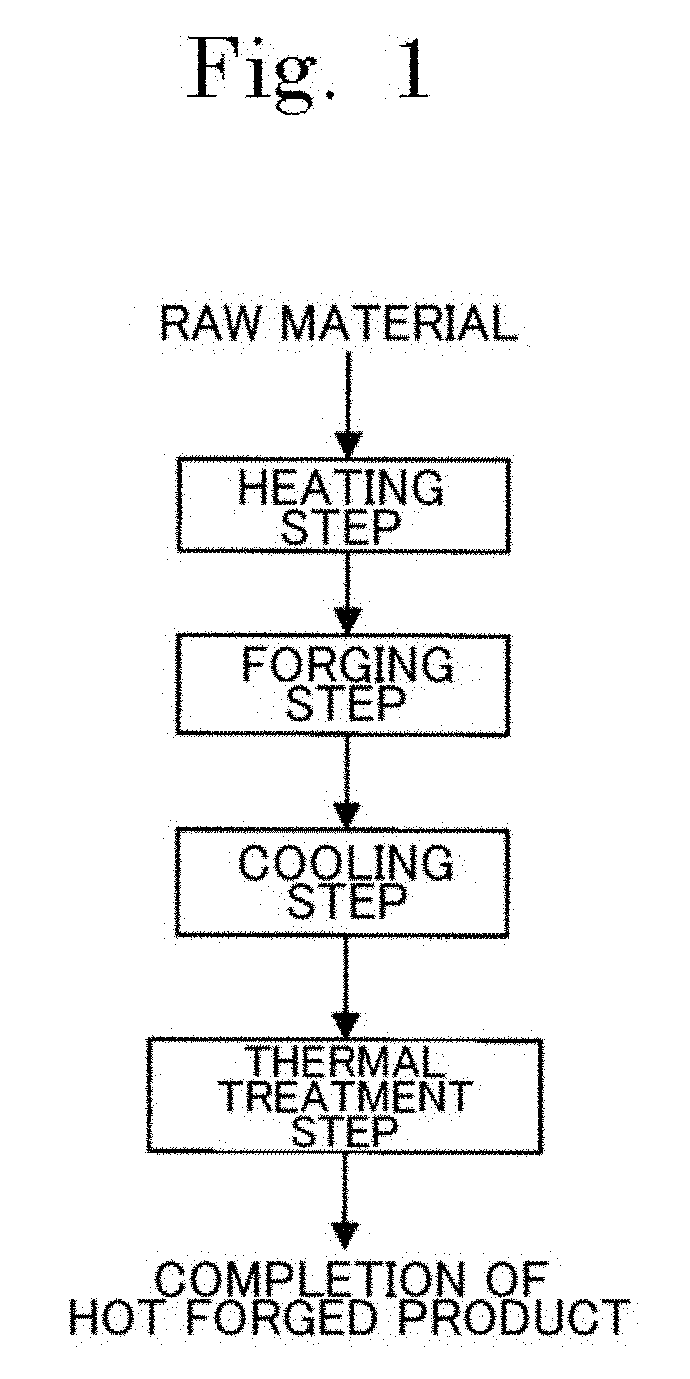

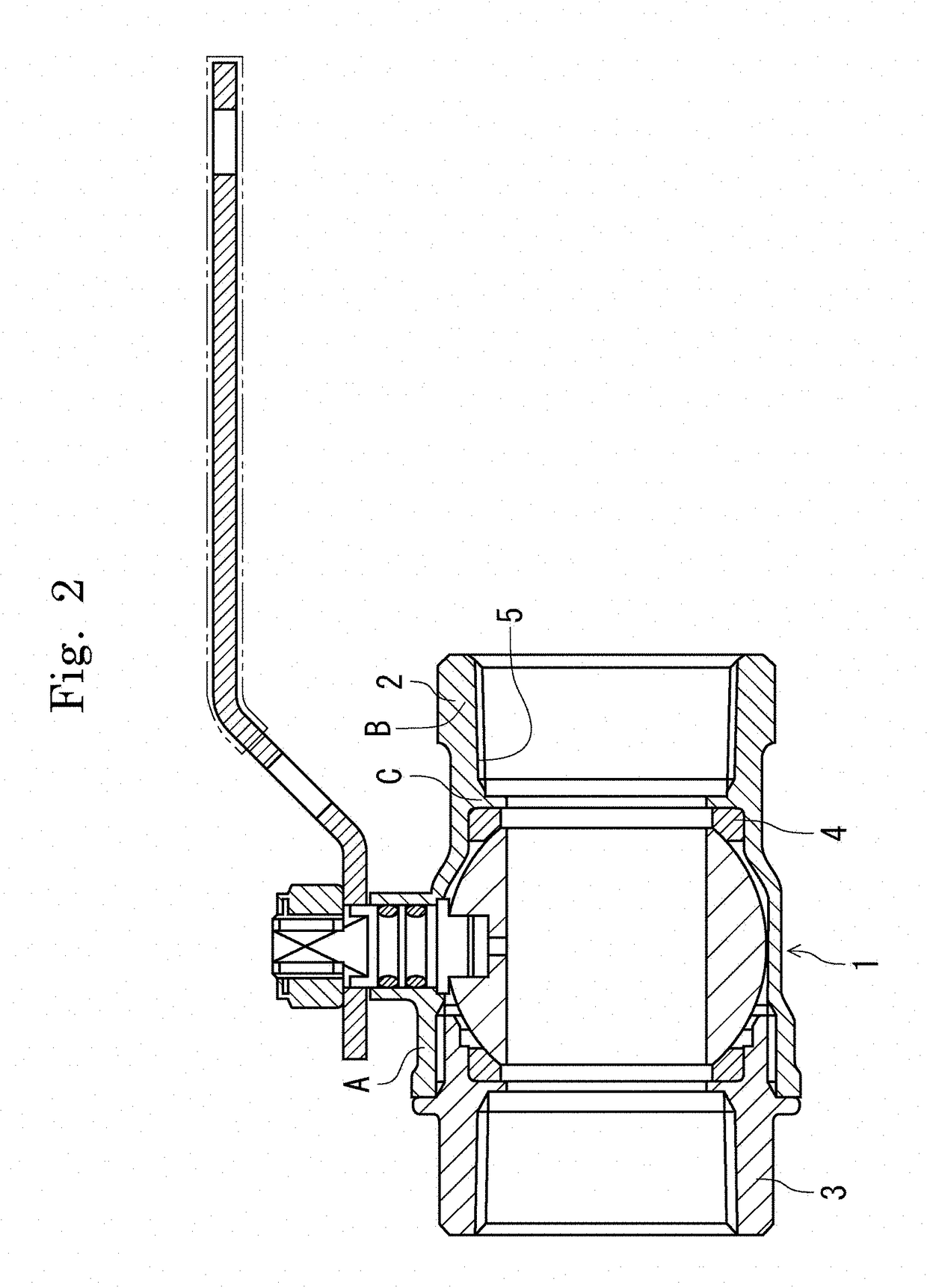

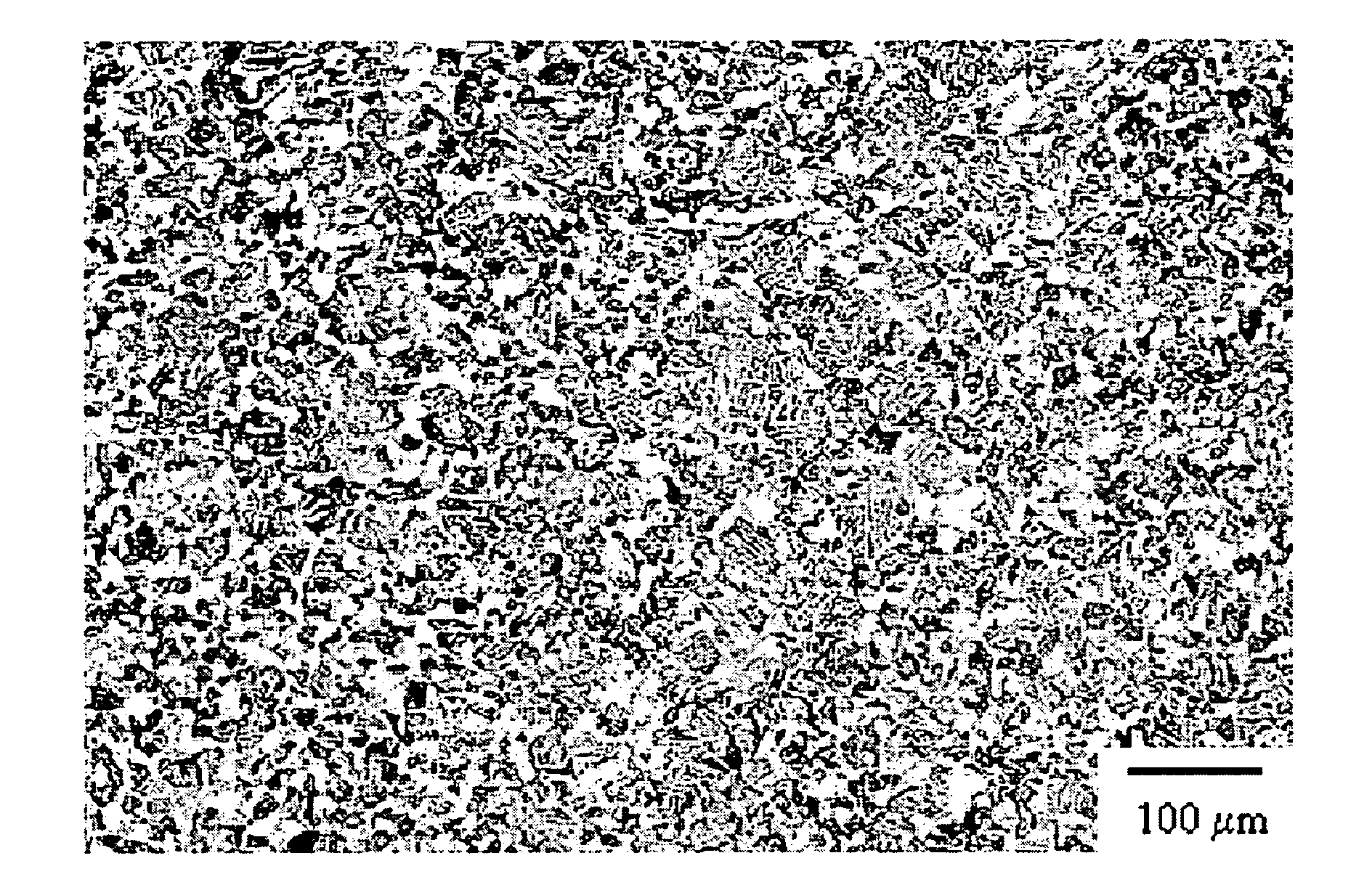

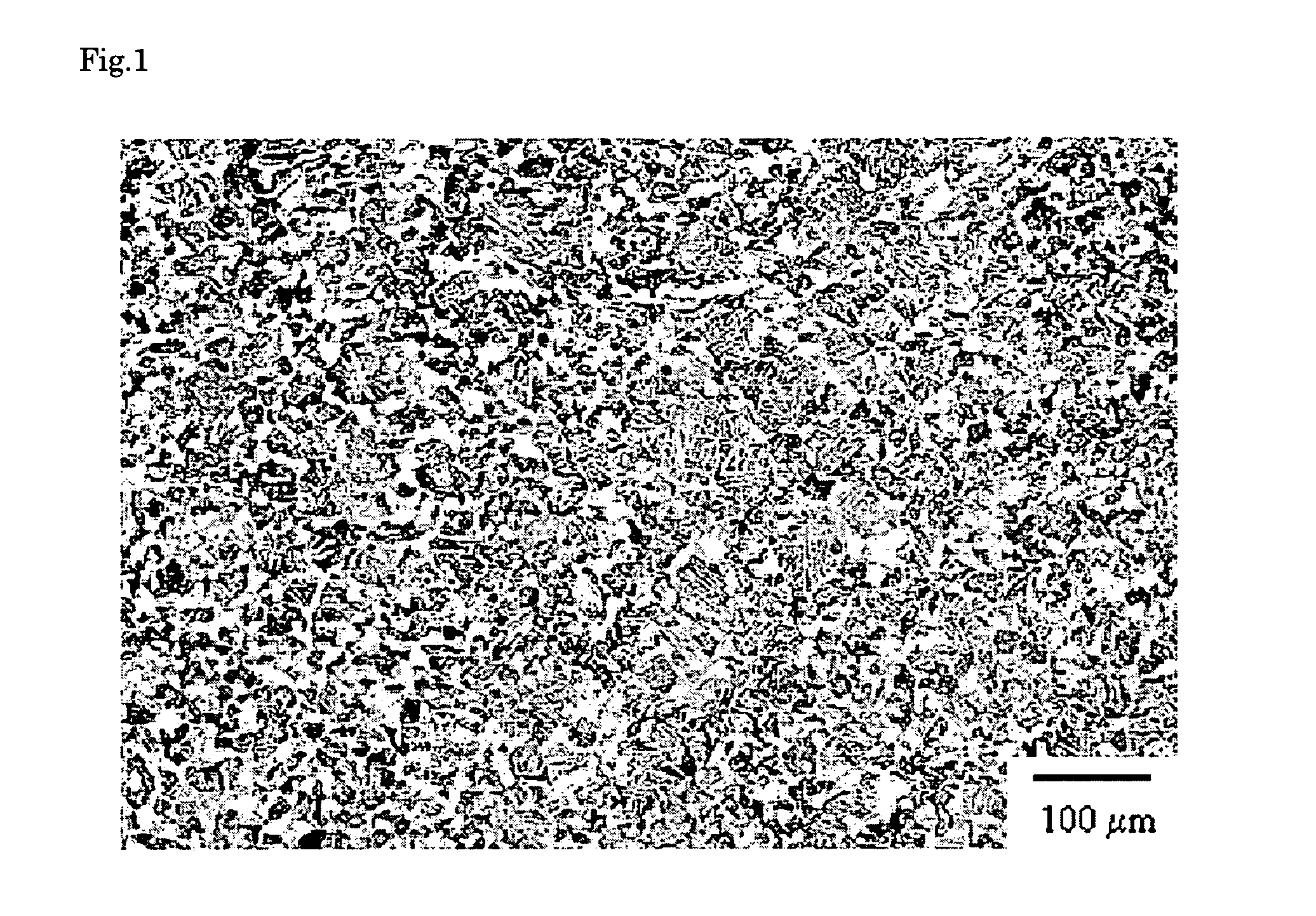

Method of producing hot forged product using brass and hot forged product and wetted product such as valve and water faucet molded using the same

ActiveUS20170211169A1Dezincification resistance can be increasedImproves stress corrosion crackingValve housingsHeat treatedCopper alloy

To contribute to an improvement in a dezincification resistance of a copper alloy, focusing attention on a relation between a dezincification resistance of a copper alloy and the crystal grain size of an α phase, and the specific object is to provide a method of producing a hot forged product using a lead-free brass capable of ensuring corrosion resistances such as a prescribed dezincification resistance and the like even at sites of different thickness and shape, a hot forged product, and a wetted product such as a valve and a water faucet, molded using the same. A method of producing a hot forged product using a brass, comprising heat-treating a raw material to be subjected to forging work using a brass having a composition containing at least 59.2 to 63.0% by mass of Cu, 1.00 to 2.00% by mass of Sn and 0.05 to 0.25% by mass of Pb and containing the residue composed of Zn and inevitable impurities at a heating rate of 5.2° C. / s or more from 350° C. until reaching the forging temperature.

Owner:KITZ CORP

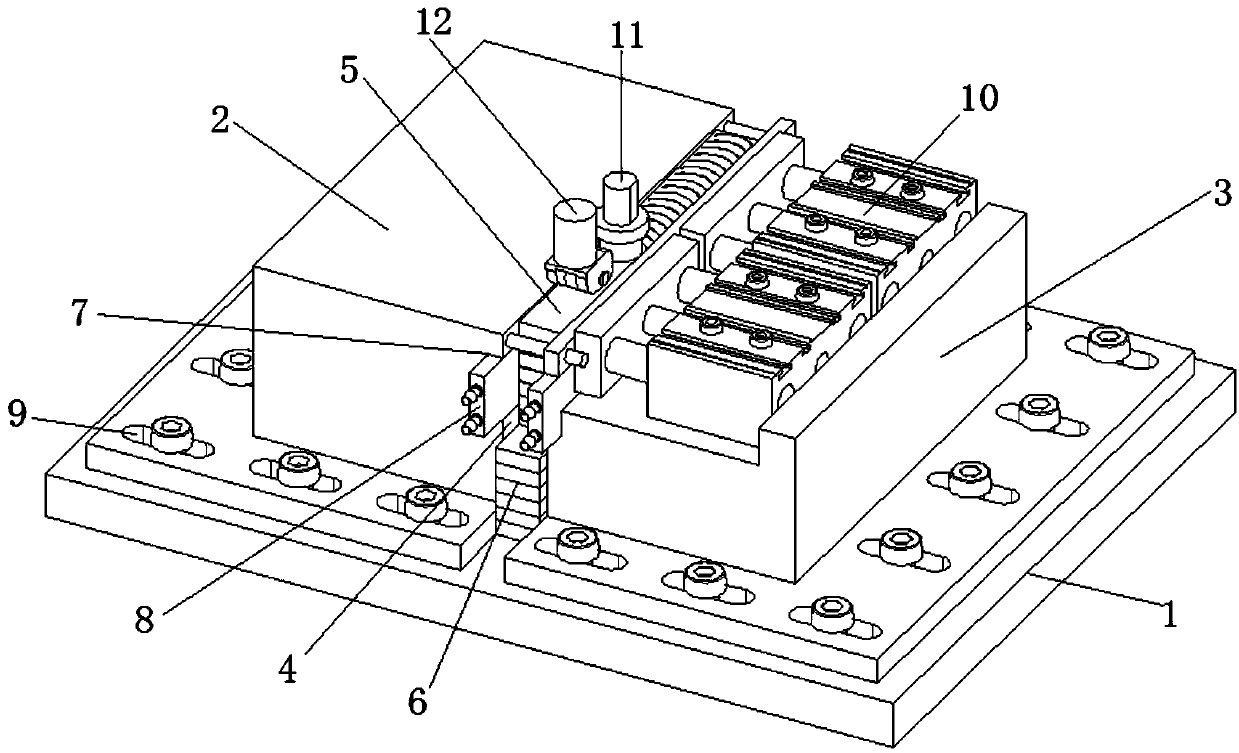

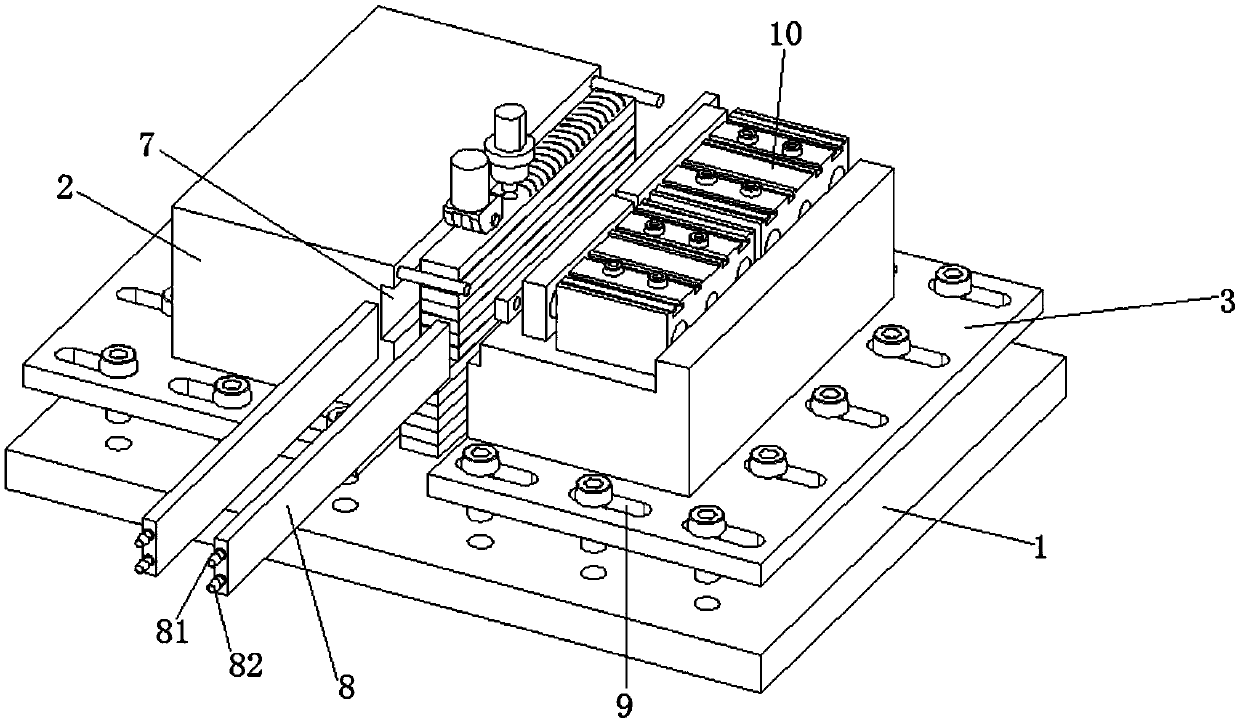

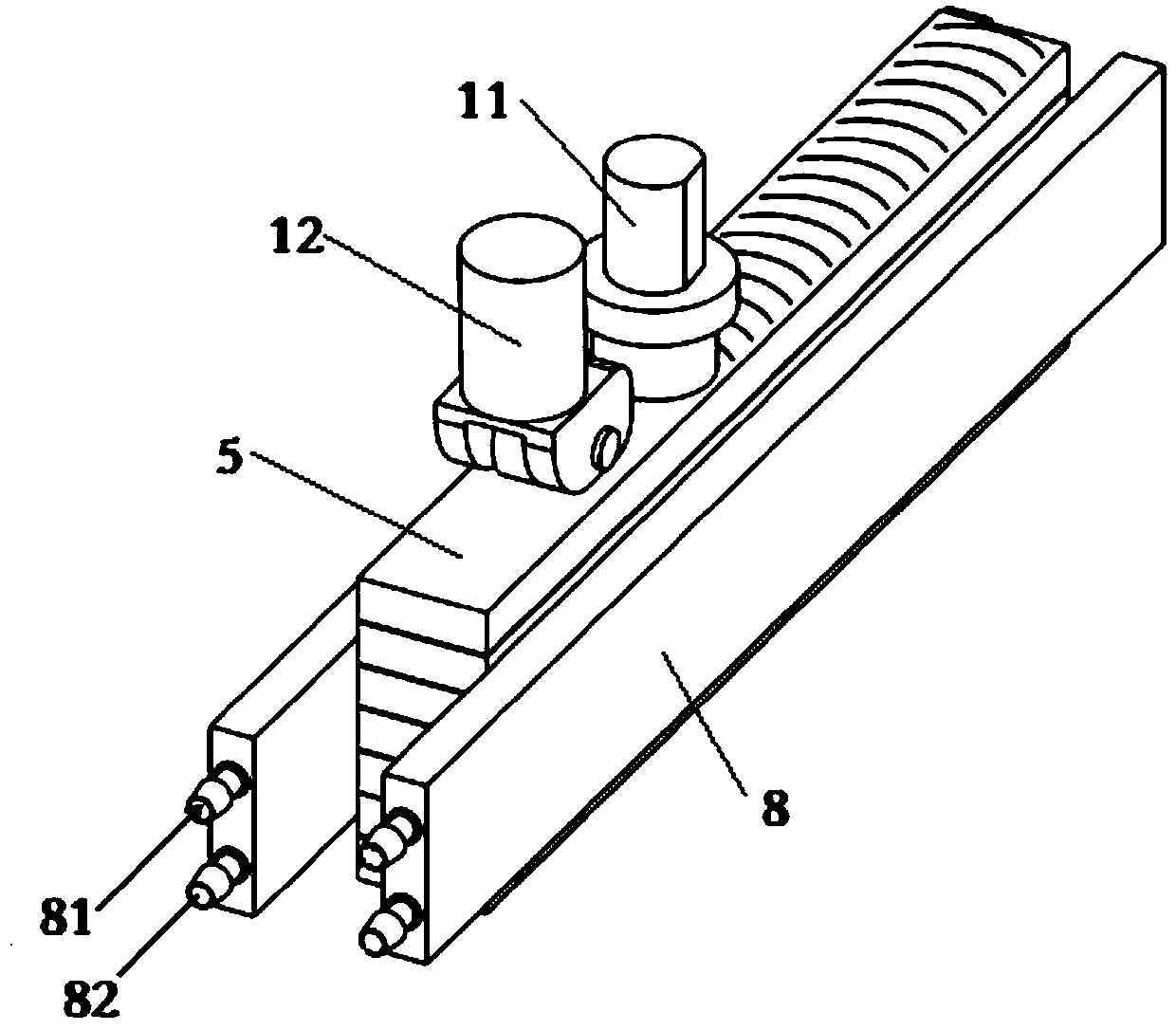

Stirring friction additive manufacturing device and method with cooling applying

ActiveCN109604808ALittle thermal impactUniform tissueNon-electric welding apparatusCushionEngineering

The invention belongs to the technical field of metal material additive manufacturing, and discloses a stirring friction additive manufacturing device with cooling applying. The stirring friction additive manufacturing device comprises a bottom plate, wherein a first base and a second base are correspondingly and fixedly assembled at the top of the bottom plate, a gap is reserved between the firstbase and the second base, and a test plate for additive is placed in the gap; a cushion plate is arranged at the bottom of the test plate for the additive, and grooves are formed in the surfaces, incontact with the test plate for the additive, of the first base and the second base; water cooling blocks are connected into the grooves in an inserted mode, the second base is provided with air cylinders for clamping the test plate for the additive, and air cylinder push rods are disposed perpendicular to the side surface of the test plate for the additive; and a pressure roller and a stirring head are further arranged at the top of the test plate for the additive. The stirring friction additive manufacturing device applies cooling on an existing stirring friction additive manufacturing technology, the thermal influence of the stirring and friction processing thermal cycle on the completed additive part is effectively reduced, and coarsening of a fine uniformity equiaxial crystal structure of an additive area and second phase particles are suppressed to obtain an additive member with a uniform structure and excellent performance.

Owner:NORTHEASTERN UNIV

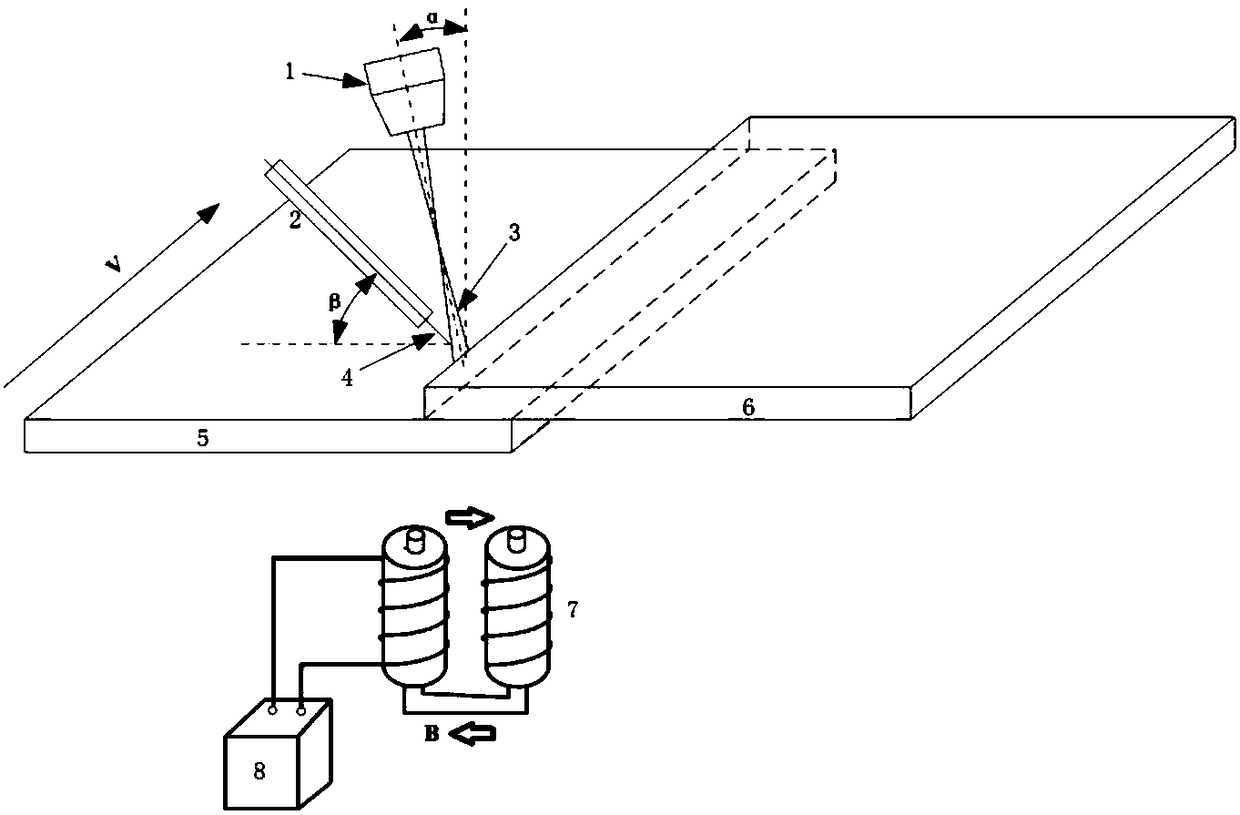

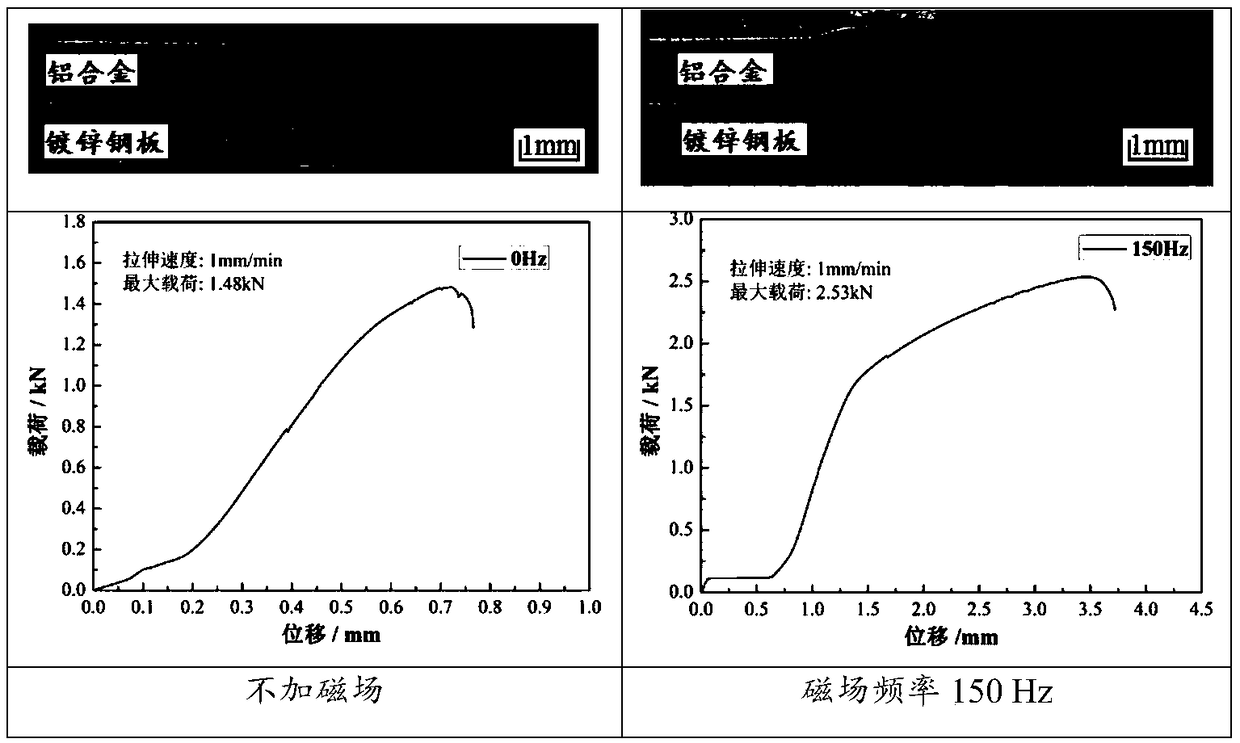

Laser-magnetic field compound melt brazed welding method for aluminum alloy/steel

InactiveCN108856939AImprove connection strengthControl thicknessSoldering apparatusWelding/soldering/cutting articlesInterface layerZinc

The invention discloses a laser-magnetic field compound melt brazed welding method for an aluminum alloy / steel. The method comprises the following steps: cleaning and fixing the aluminum alloy and a steel plate to be overlapped; selecting laser energy according to needed welding thickness and selecting a zinc-aluminum alloy welding stick as filling metal; and controlling the wire feeding velocityand parameters of an alternating magnetic field to form a welding structure in zigzagged connection on an overlapped face of the aluminum alloy and the steel plate. By regulating the shape of a melt brazed joint by means of a synergistic effect of laser and magnetic field, the thickness of a brittle intermetallic compound at the interface is regulated by precisely controlling the laser ray energy,and meanwhile, solute segregation in a welding joint area and an interface layer is inhibited by means of action of the alternating magnetic field and tissues in the welding joint area and on the interface are refined, so that thickness, tissues and shape of the brittle intermetallic compound at the interface are controlled effectively, and a dissimilar alloy welding joint good in formation and performance is obtained.

Owner:WUHAN UNIV OF TECH

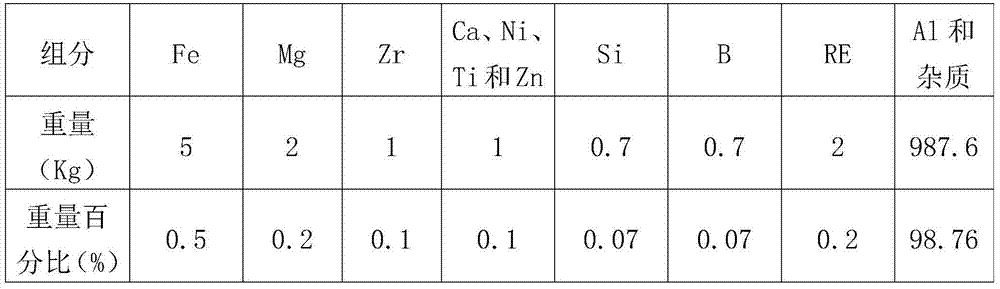

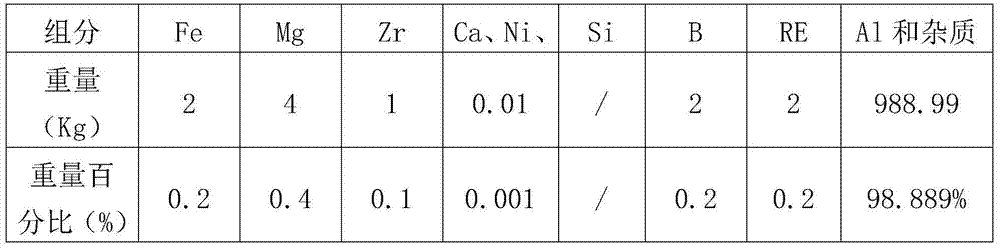

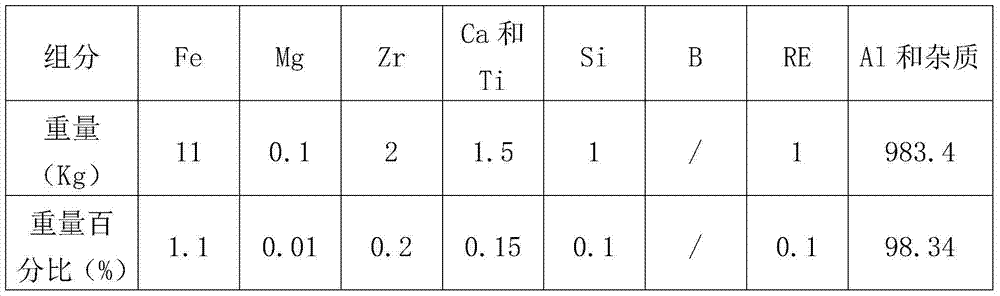

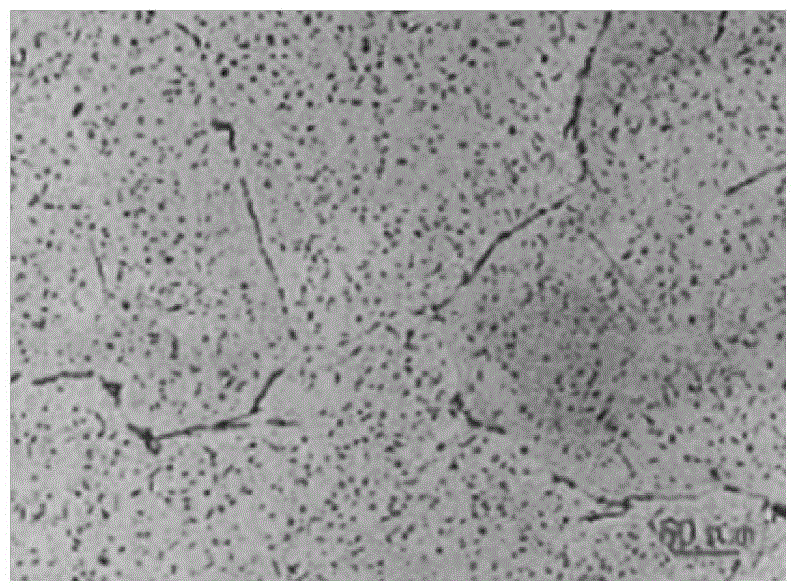

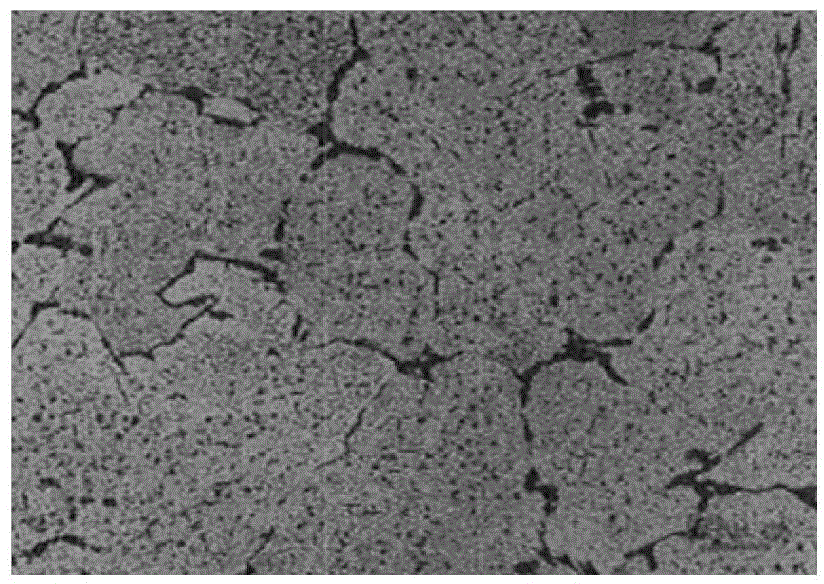

Al-Fe-Mg-Zr aluminum alloy used for coal mine cables, aluminum alloy cable and manufacturing method

PendingCN104299673AImprove performanceHigh mechanical strengthNon-insulated conductorsMetal/alloy conductorsCoalAluminium alloy

The invention discloses Al-Fe-Mg-Zr aluminum alloy used for coal mine cables. The Al-Fe-Mg-Zr aluminum alloy comprises 0.2 percent-1.1 percent of Fe, 0.01 percent-0.4 percent of Mg, 0.001 percent-0.2 percent of Zr, 0 percent-0.1 percent of Si, 0 percent-0.2 percent of B and the balance being Al and impurities, wherein the resistivity of the aluminum alloy is not larger than 0.028164 omega*mm<2> / m, the elongation at break is not lower than 10 percent, and ninety-degree fatigue bending frequency is larger than or equal to thirty. The aluminum alloy material is smelted, cast and rolled, so that an aluminum alloy rod is obtained; afterwards, the aluminum alloy rod is subjected to pulling, bunch stranding and softening, so that an aluminum alloy cable core is formed; next, the cable core is subjected to extruded insulation, cabling, sheath extrusion or armoring, so that an aluminum alloy cable is manufactured. The manufactured aluminum alloy cable has the advantages of being high in strength, high in electric conductivity, good in bending performance and the like, and therefore the requirements for cable performance in the field of coal mines can be satisfied.

Owner:ANHUI JOY SENSE CABLE

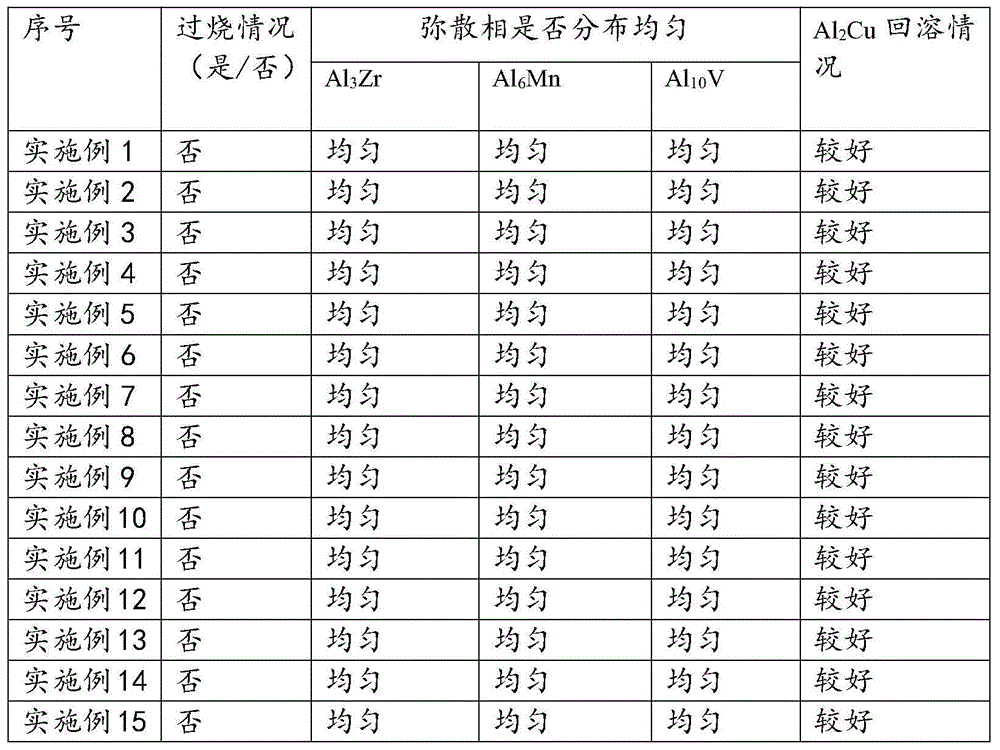

Homogenization thermal-treatment method for ultra-large semi-continuous cast round ingot

The invention discloses a homogenization thermal-treatment method for an ultra-large semi-continuous cast round ingot and relates to the technical field of aluminum alloy processing. The method comprises the following concrete steps: (1) heating the round ingot to the temperature of 180 DEG C at a temperature rising speed below 15 DEG C / h; (2) heating the round ingot to the temperature of 520 to 535 DEG C from the temperature of 180 DEG C at a temperature rising speed of 60-90 DEG C / h, and keeping the temperature for 30h to 80h at the temperature of 520 to 535 DEG C; (3) cooling the round ingot to the temperature of 360 DEG C from the temperature of 520 t0 535 DEG C at a temperature descending speed below 60DEG C / h; (4) cooling the round ingot to the temperature of 130 DEG C from the temperature of 360 DEG C at a temperature descending speed of 80 to 200 DEG C / h; (5) cooling the round ingot to room temperature from the temperature of 130 DEG C. According to the characteristics of the ultra-large semi-continuous cast round ingot, the method disclosed by the invention can be used for fully eliminating dendritic structures and low-melting-point eutectic structures, also enabling the elements such as zirconium, manganese and vanadium to be dispersed and distributed uniformly and guaranteeing the deformation processing structures in the later period and the final comprehensive performances of products.

Owner:广西南南铝加工有限公司

Copper-based sliding material

ActiveUS20110206939A1Suppress coarseningImprove fatigue resistanceShaftsBearing componentsSpecific gravityCopper

Owner:DAIDO METAL CO LTD

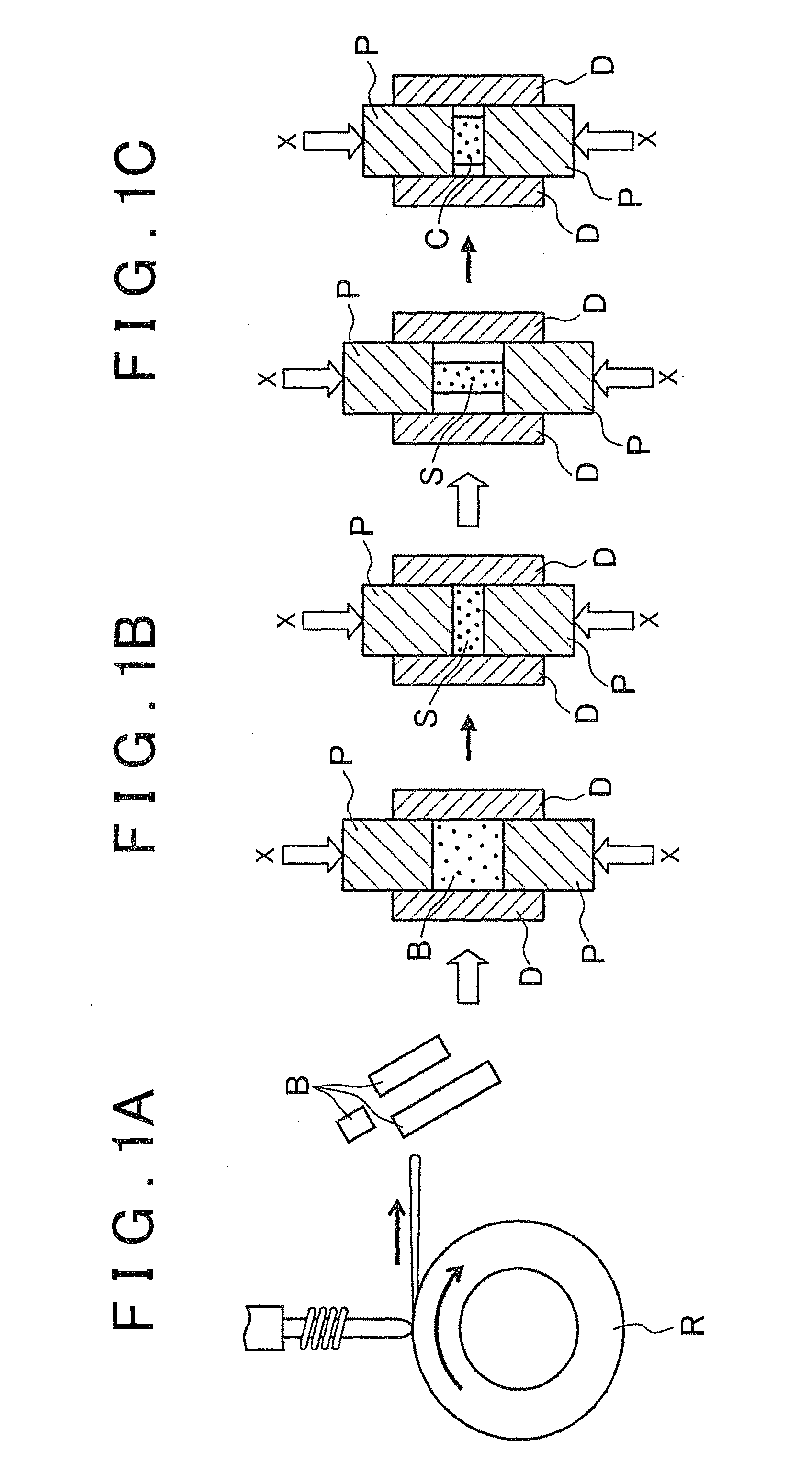

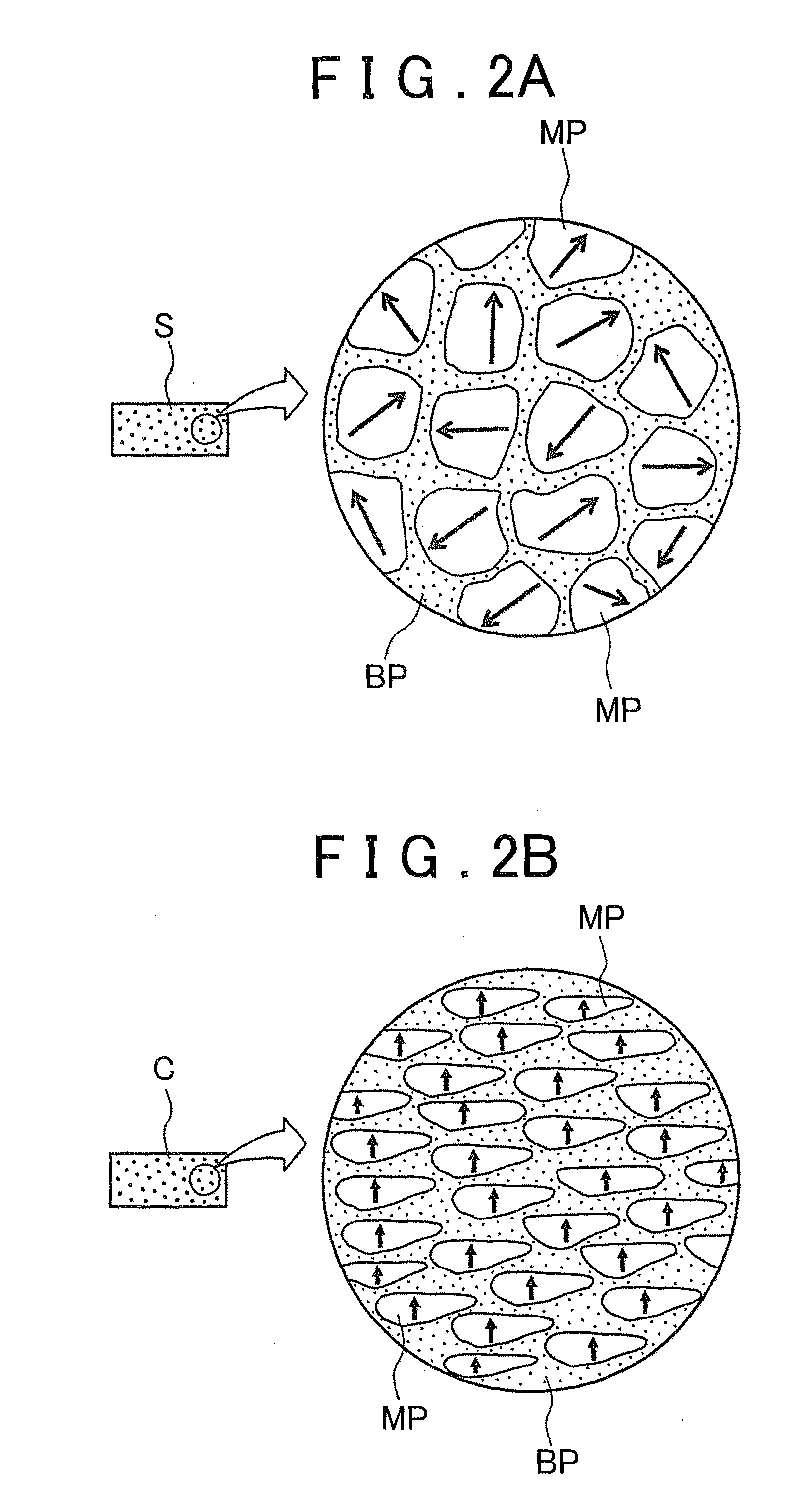

Method of manufacturing rare-earth magnets

InactiveUS20140308441A1Improve coercive forceSuppress coarseningTransportation and packagingMetal-working apparatusRare-earth elementRare-earth magnet

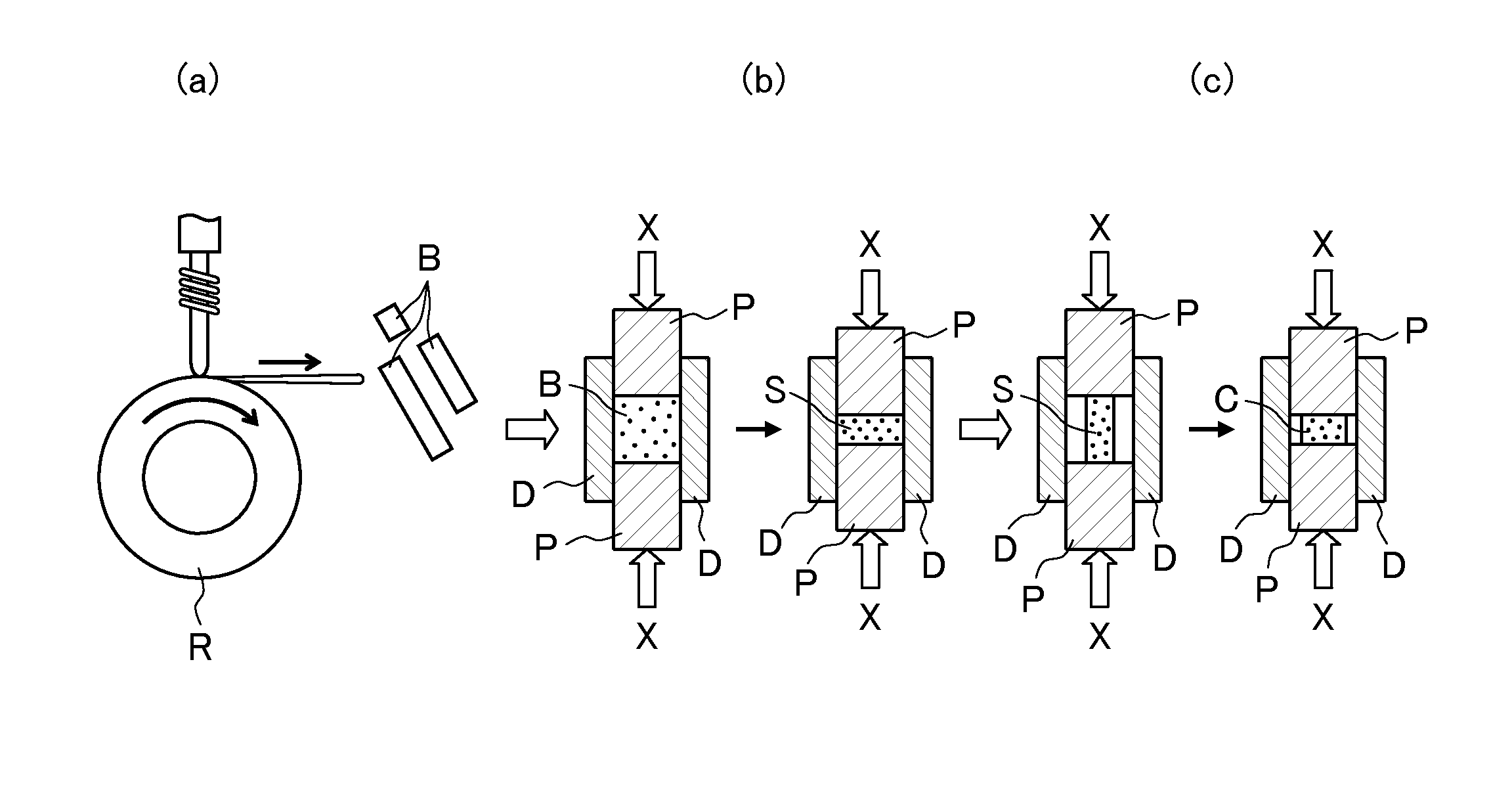

A method of manufacturing rare-earth magnets includes, a first step of producing a compact C by subjecting a sintered body S, which is formed of a RE—Fe—B main phase MP having a nanocrystalline structure (where RE is at least one of neodymium and praseodymium) and a grain boundary phase BP of an RE—X alloy (where X is a metal element) located around the main phase, to hot plastic processing that imparts anisotropy; and a second step of producing a rare-earth magnet RM by melting a RE—Y—Z alloy which increases the coercive force of the compact C (where Y is a transition metal element, and Z is a heavy rare-earth element), together with the grain boundary phase BP, and liquid-phase infiltrating the RE—Y—Z alloy melt from a surface of the compact C.

Owner:TOYOTA JIDOSHA KK

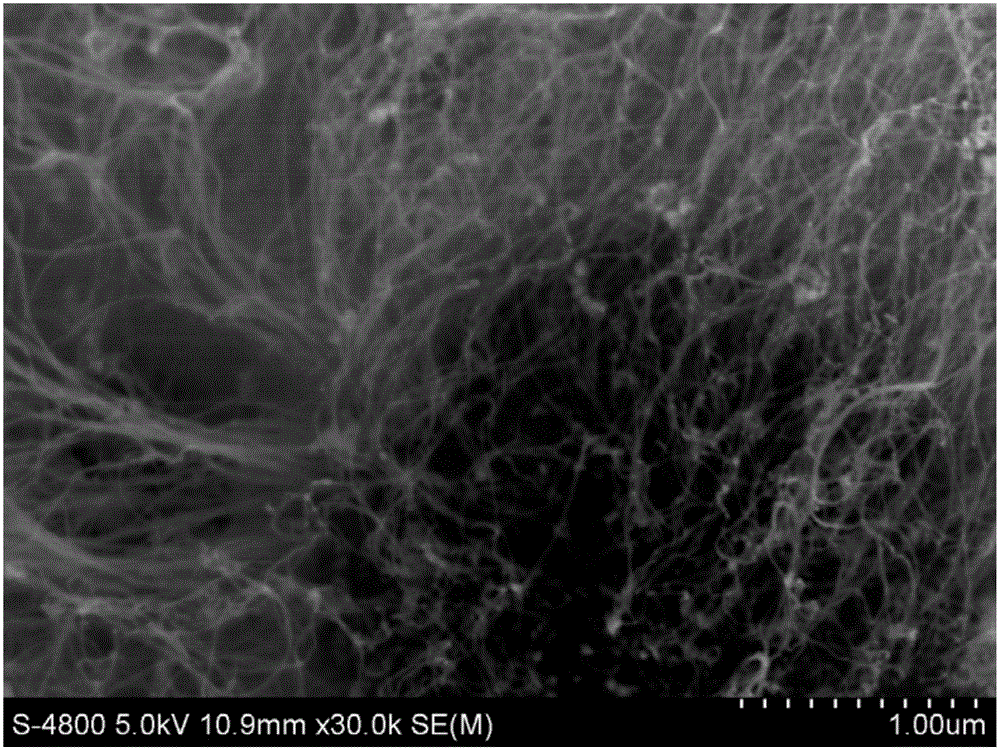

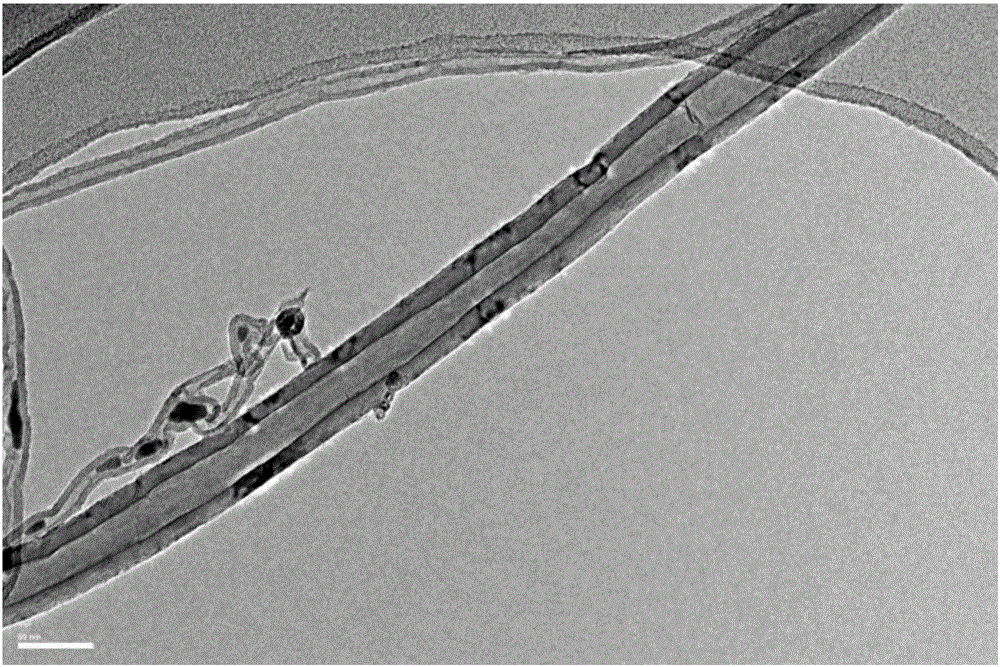

Preparation method for carbon nanotube-alumina mixed reinforced magnesium aluminum alloy composite

InactiveCN106498225AHighlight substantive featuresImprove mechanical propertiesMaterial nanotechnologyChemical vapor deposition coatingCarbon nanotubeGlobular shaped

Owner:HEBEI UNIV OF TECH

Non-heat treated steel for soft-nitriding

Non-heat treated steel for soft-nitriding to form parts having high fatigue strength and excellent bend leveling property even in a case of applying soft-nitriding without thermal refining, comprising, by mass %, C: 0.30 to 0.45%, Si: 0.1 to 0.5%, Mn: 0.6 to 1.0%, Ti: 0.005-0.1% and N: 0.015 to 0.030%, and the balance Fe and impurities, having a mixed microstructure of bainite and ferrite whose bainite fraction is 5 to 90% or having a mixed microstructure of bainite, ferrite and pearlite whose bainite fraction is 5 to 90%, the steel could contain one or more of elements of Nb: 0.003 to 0.1% Mo: 0.01 to 1.0%, Cu: 0.01-1.0%, Ni: 0.01 to 1.0%, B: 0.001 to 0.005%, S: 0.01 to 0.1%, and Ca: 0.0001 to 0.005.

Owner:NIPPON STEEL CORP

Production method of heavy-wall-thickness X80 pipeline steel

The invention provides a production method of heavy-wall-thickness X80 pipeline steel. The production method comprises the following production processes: clean steel smelting, die casting, single reheat rolling, single reheat blank finishing, two-times reheat rolling, and steel plate finishing. The steel comprises the following chemical components in percentage by mass: less than or equal to 0.07% of C, less than or equal to 0.30% of Si, less than or equal to 1.80% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.015%-0.045% of Als, 0.040%-0.080% of Nb, 0.008%-0.025% of Ti, less than or equal to 0.030% of V, less than or equal to 0.30% of Cr, less than or equal to 0.30% of Mo, less than or equal to 0.30% of Ni, less than or equal to 0.30% of Cu, less than orequal to 0.005% of B, and the balance of Fe and inevitable impurities. The steel plate sufficiently exerts the advantages of a die cast ingot as a rolling blank, a uniform and fine microstructure withhigh crack extension resistance and appropriate hardness is obtained through twice-heating production, the steel plate thickness is larger than or equal to 30 mm, and the shear area of a full-thickness DWTT drop hammer section at the temperature of 40 DEG C below zero is larger than or equal to 85%.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Process for producing combustor structural member, and combustor structural member, combustor for gas turbine and gas turbine

ActiveUS9370846B2Maintain positioning accuracyNo crackContinuous combustion chamberMetal-working apparatusCombustorAlloy

A process including brazing a first plate-like member formed from a heat-resistant alloy, and a second plate-like member formed from a heat-resistant alloy and having fins on the surface, with the fins facing the first plate-like member, by interposing a brazing filler metal comprising a melting point lowering element between the two plate-like members, molding the plate-like assembly to form a combustor structural member, identifying, in accordance with the shape of the combustor structural member, strain locations where the strain generated during the press molding step exceeds a predetermined value, performing localized heating of the locations within the plate-like assembly corresponding with the strain locations identified, and as the above press molding step subjecting the plate-like assembly to cold press molding with the temperature of the heated locations corresponding with the strain locations maintained at a desired temperature.

Owner:MITSUBISHI POWER LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com