Patents

Literature

249results about How to "Dispersion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

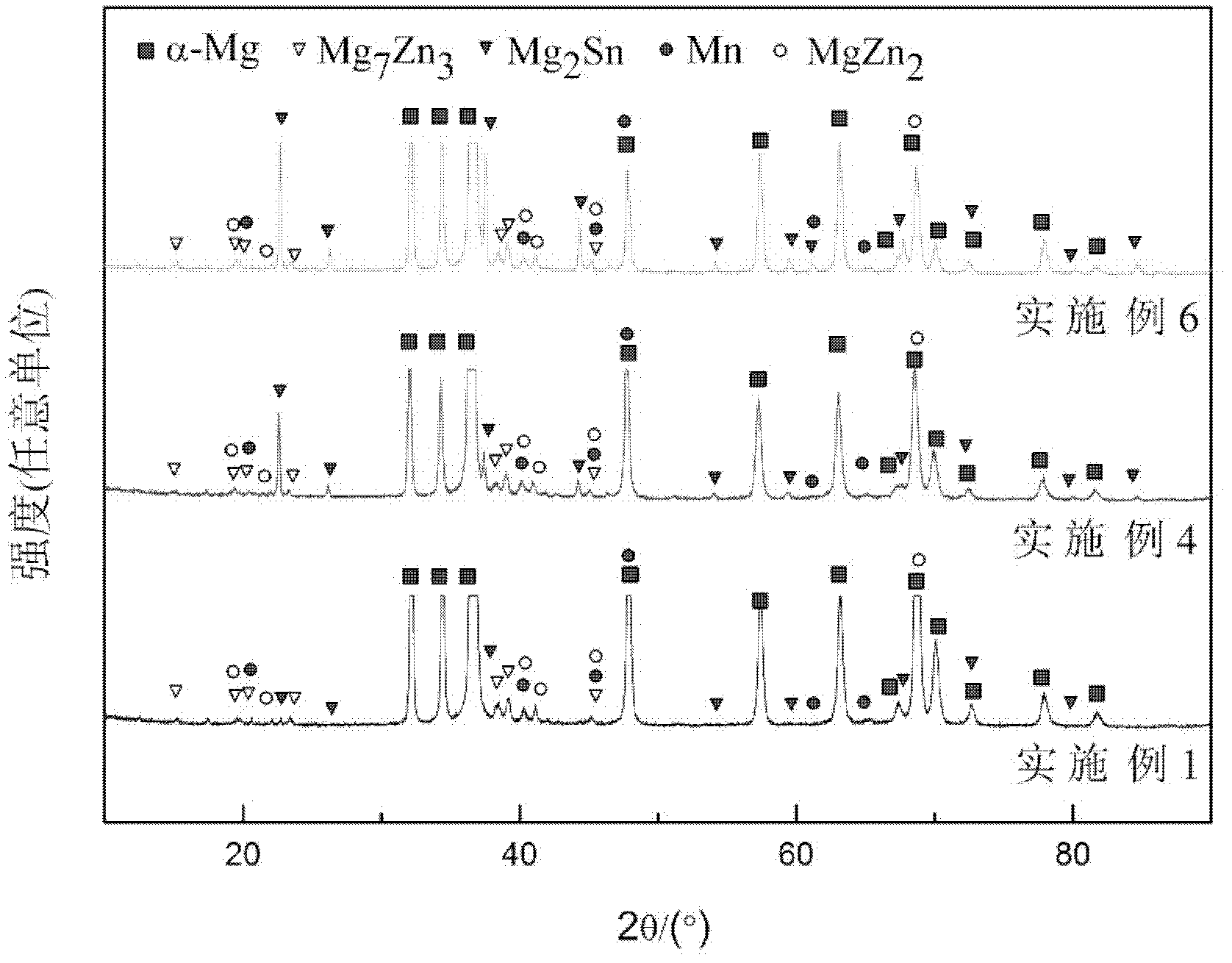

Magnesium alloy of high intensity and high yield ratio and preparation method thereof

The invention provides a magnesium alloy material of high intensity and high yield ratio. The alloy comprises the following components by mass: 5.0-9.0% of Zn; 0.5-1.5% of Mn; 1-10% of Sn; less than 0.15% of inevitable impurities; and the balance magnesium. By means of plastic forming and a choice of reasonable technological conditions for heat treatment after forming, the magnesium alloy material of the invention can be of high intensity and high yield ratio, and is higher than the high-strength wrought magnesium alloy ZK60 in terms of yield strength and tensile strength. With low cost, good extrudability and formability at a low temperature, the magnesium alloy material provided in the invention boasts substantial application potential, thus being able to partly replace the magnesium alloy material ZK60.

Owner:QINGHAI SUNGLOW MAGNESIUM

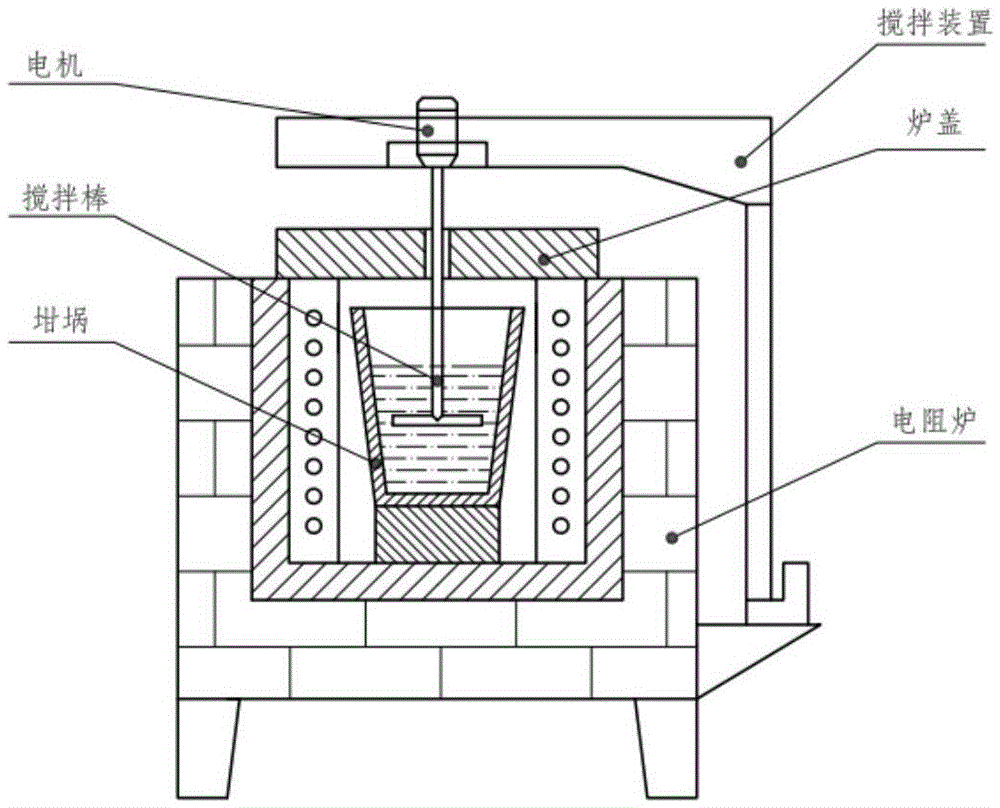

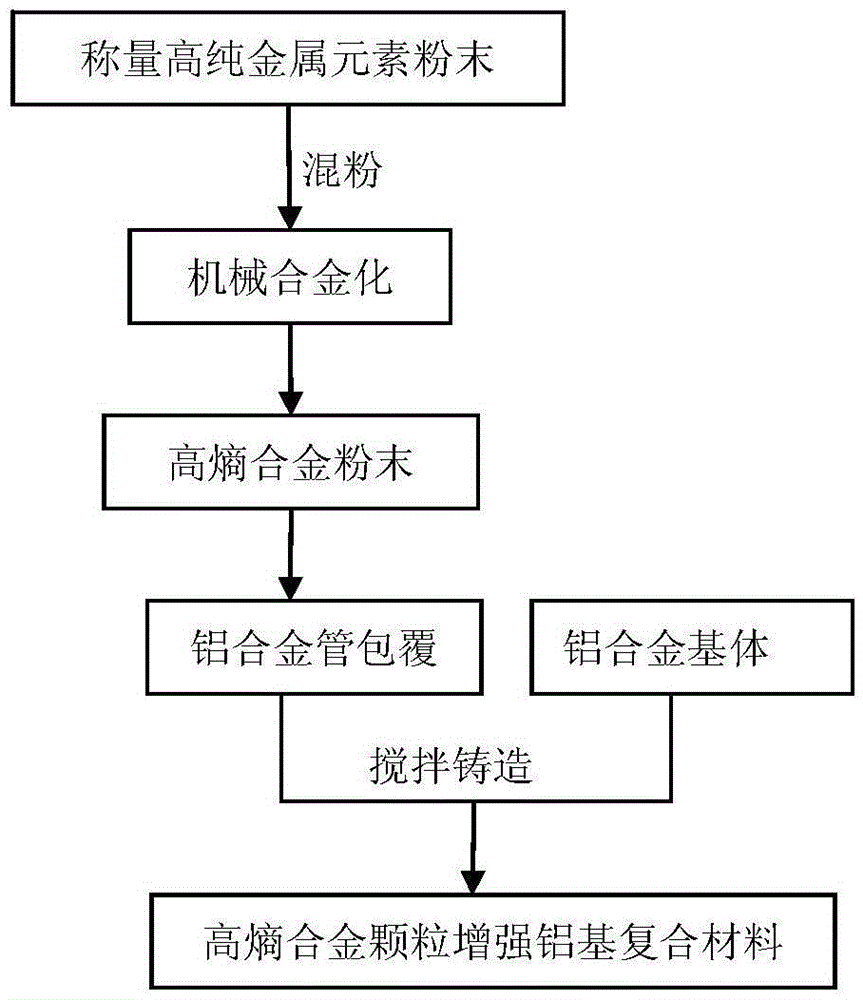

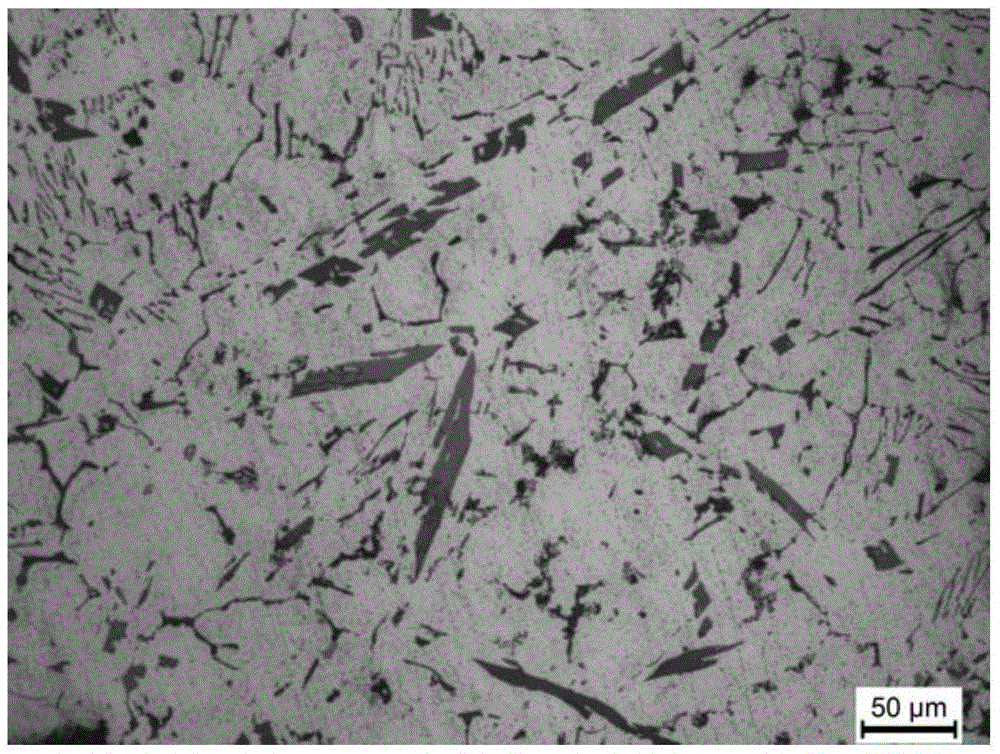

High-entropy alloy particle reinforced aluminum base composite material and stirring casting preparation process thereof

The invention discloses a high-entropy alloy particle reinforced aluminum base composite material and a stirring casting preparation process thereof. The preparation process adopts mechanical alloying to prepare high-entropy alloy powder and screen to obtain high-entropy alloy particles; the high-entropy alloy particles are sealed by adopting an aluminum alloy pipe having the same material with a basal body; the aluminum alloy pipe weighed in a segmented manner is added in the molten basal body; the high-entropy alloy particles are dispersed by a stirring mode; and the high-entropy alloy particle reinforced aluminum base composite material is prepared by a casting process. The high-entropy alloy particles are 0.1-35%; aluminum alloys are 65-99.9%; and the sum of the two is 1. The high-entropy alloy particles in the structure of the prepared composite material are uniformly dispersed; the high-entropy alloy and aluminum alloy interface bonding compatibility is excellent; the strength and the toughness are excellent; the preparation process is simple; the powder has no need to be treated; the cost is low; the stability is good; and the composite material is suitable for large-batch production and standard production, and is excellent in promotion and application prospect.

Owner:GUANGDONG XINGFA ALUMINUM +1

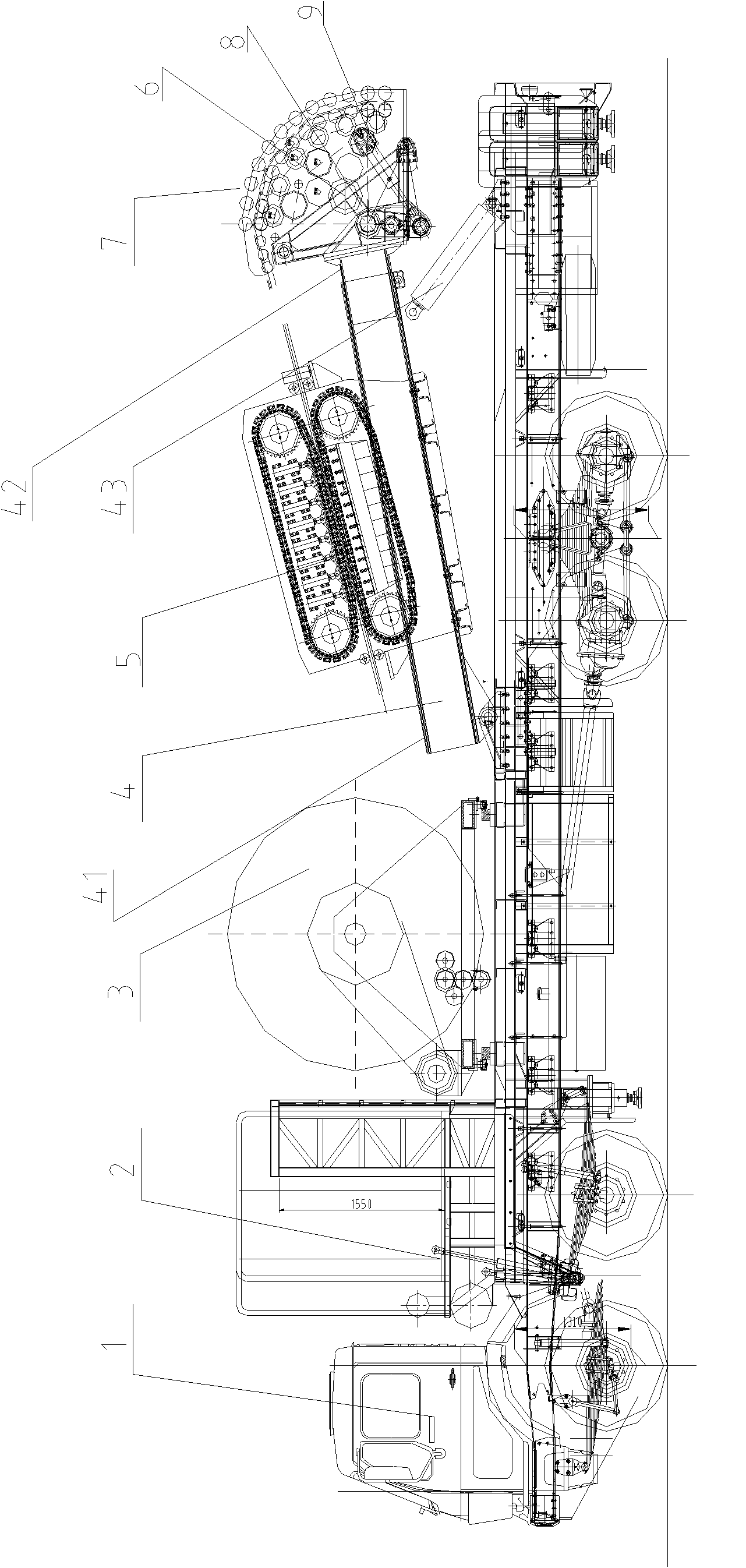

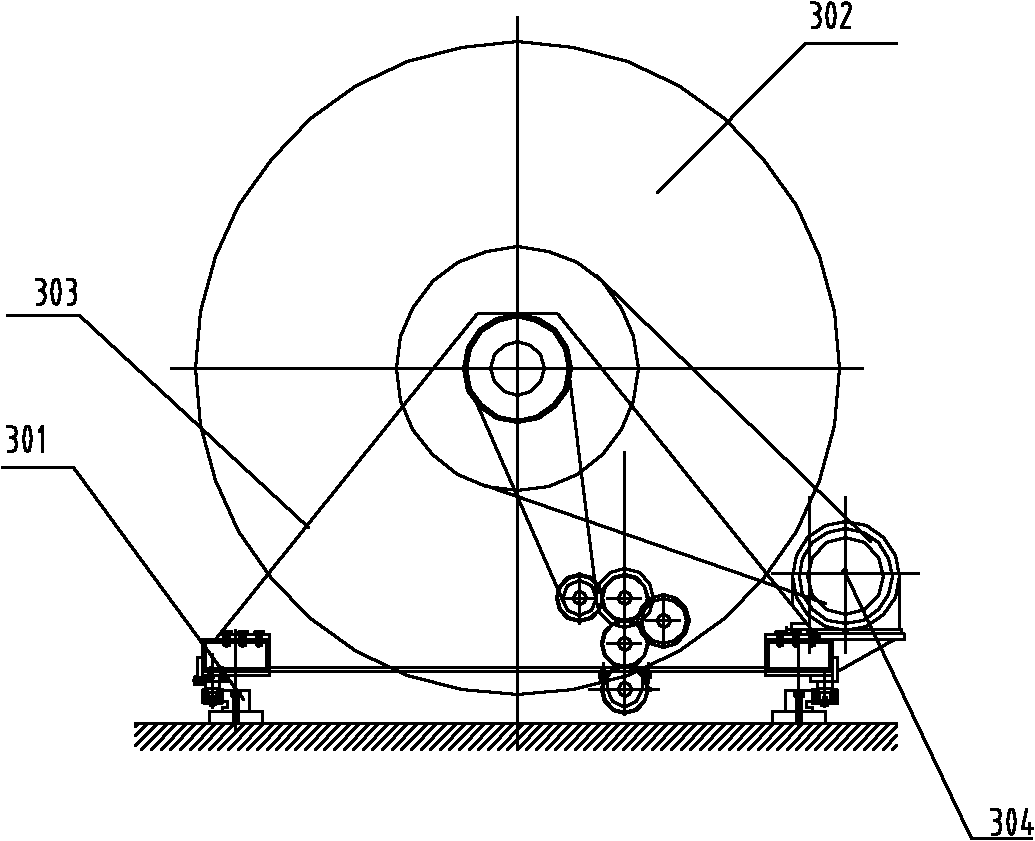

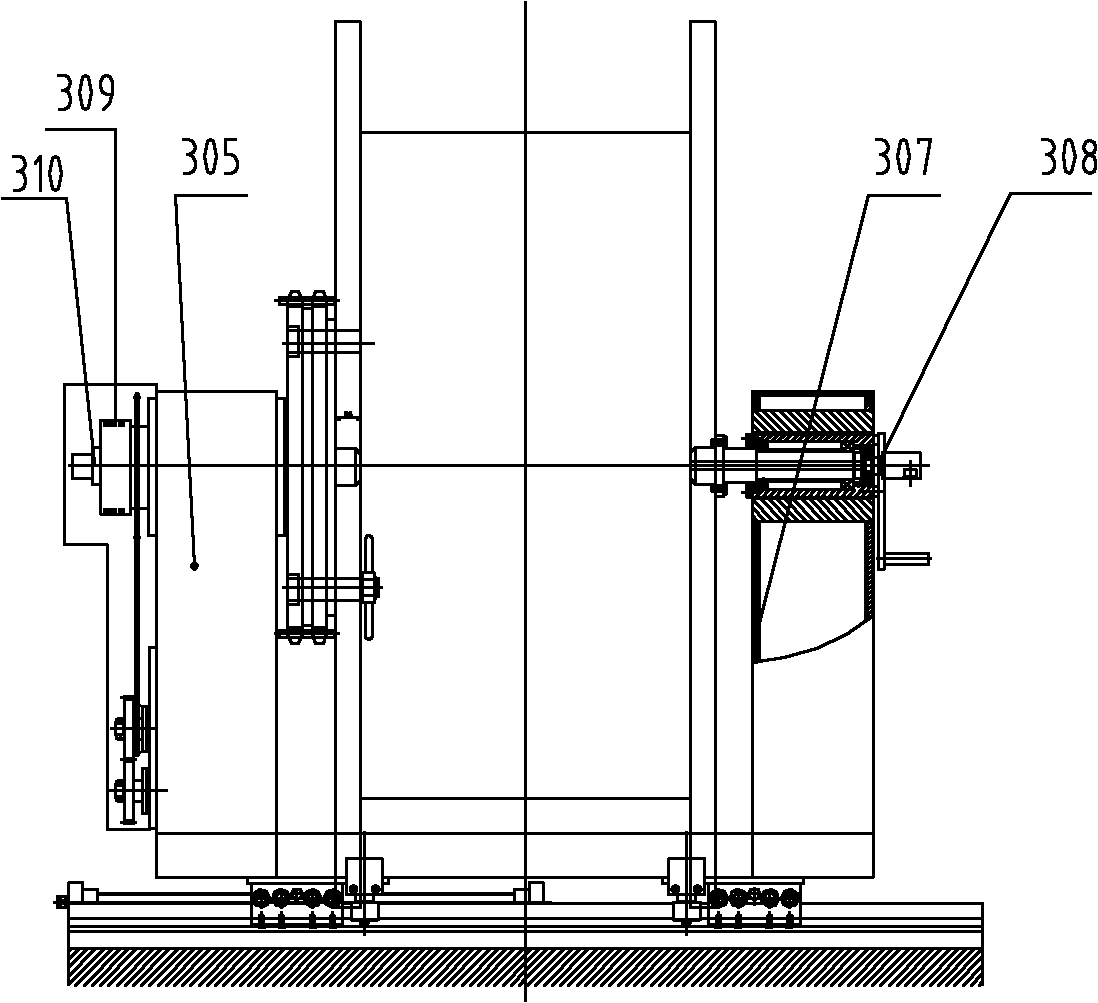

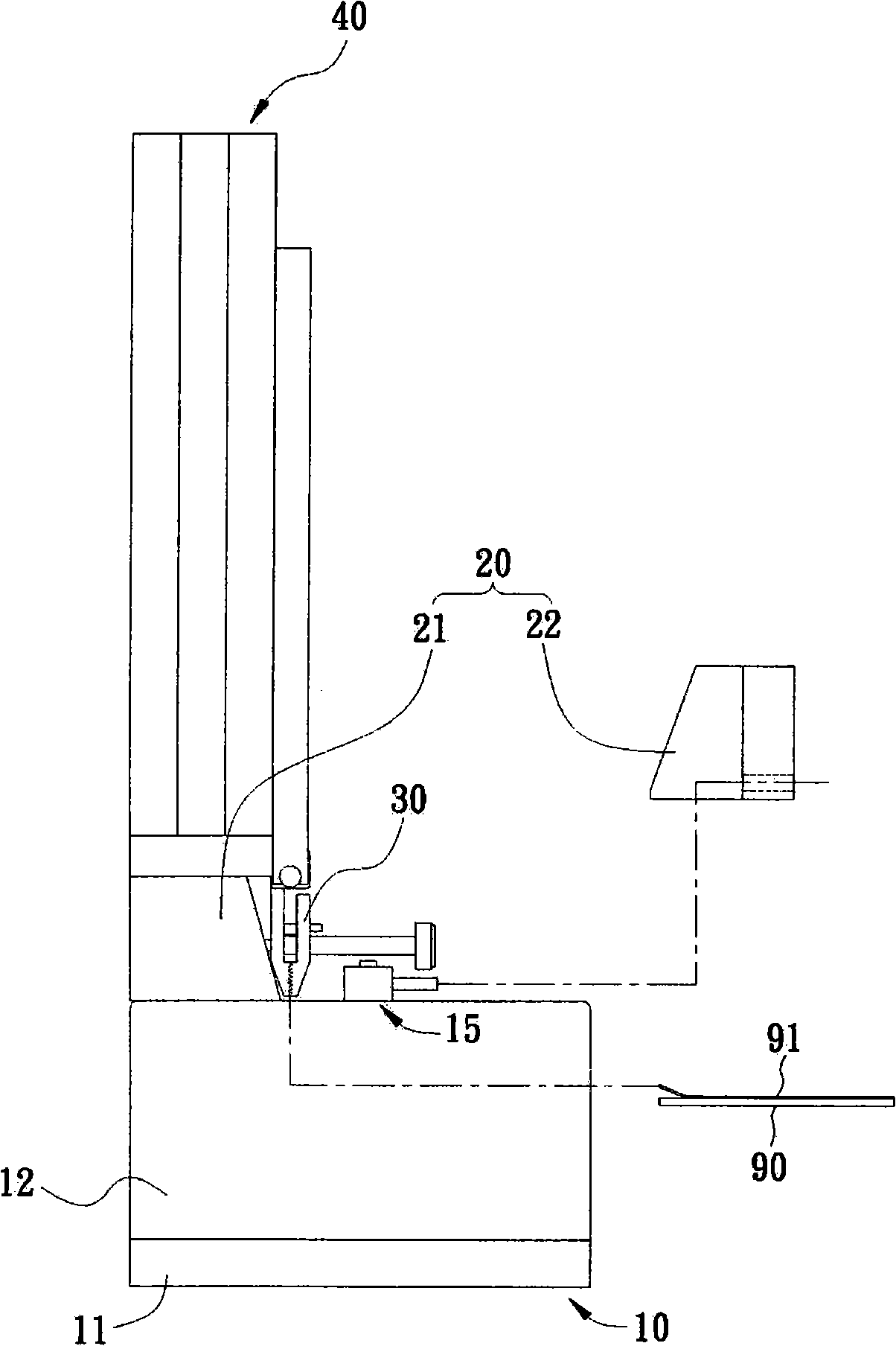

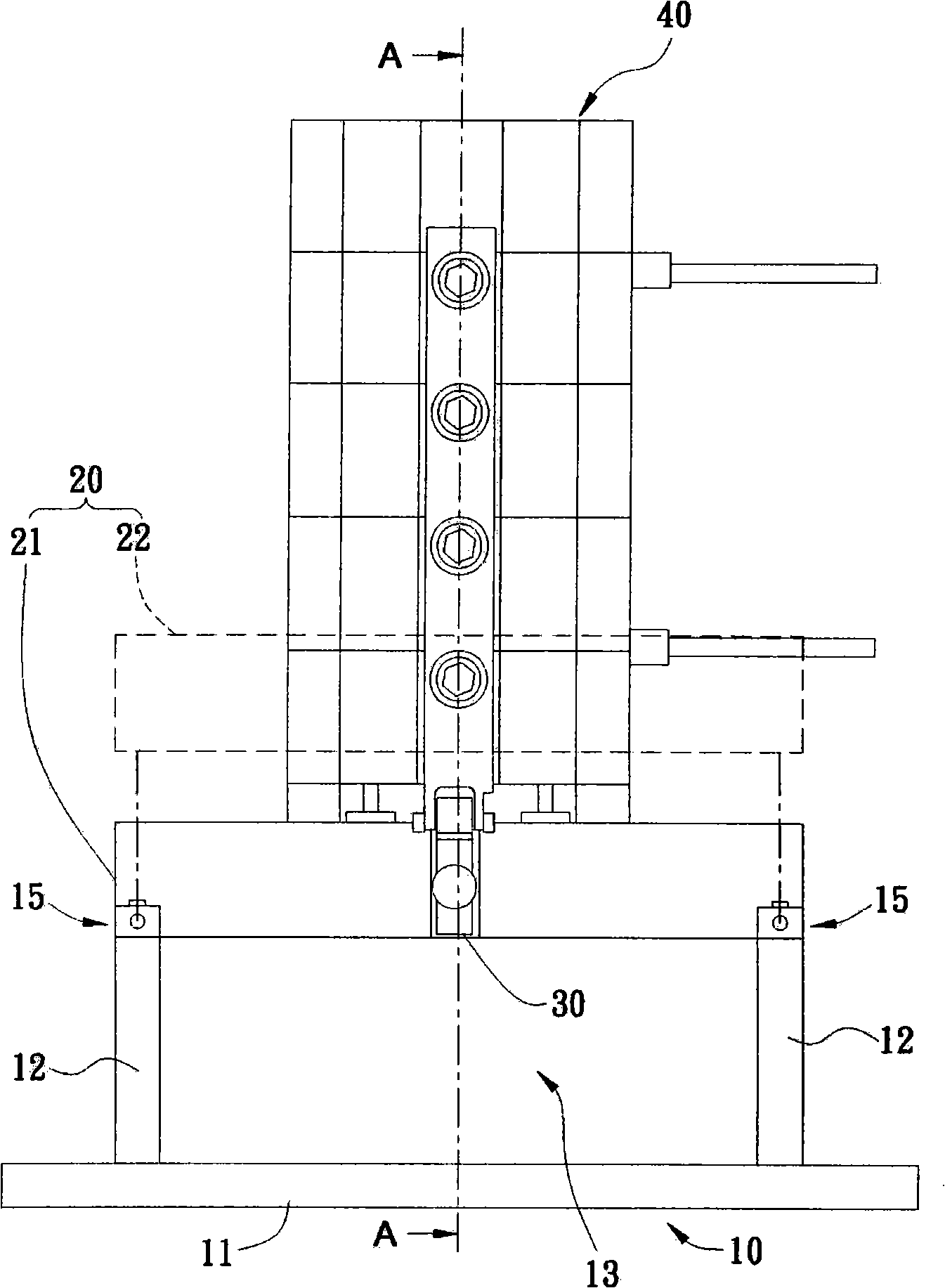

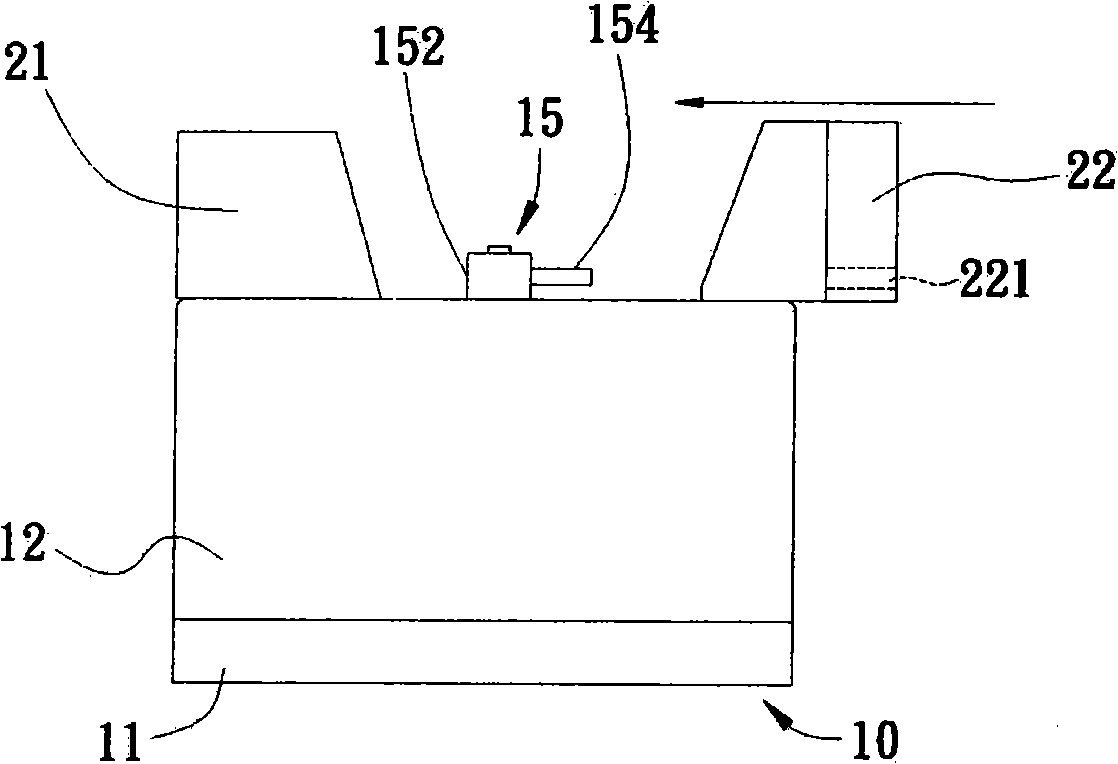

Continuous pipeline tripping device

ActiveCN102733768AQuick connectionEasy to operateDrilling rodsDrilling casingsTraction systemRotating drum

The invention discloses a continuous pipeline tripping device, comprising a rotating drum retracting, laying and releasing system, a guided injection system, a traction system, and a hydraulic power system used for supplying power for the above systems. The rotating drum retracting, laying and releasing system comprises a rotating drum, a cable laying device and a guide rail, wherein the guide rail is fixed on an underpan of a vehicle system, the rotating drum is in a sliding connection with the guide rail through a rotating drum supporting seat, the cable laying device is fixed on one side of the rotating drum, the rotating drum is driven to move along the guide rail by the cable laying device, thereby realizing the arrangement of an oil pipeline on the rotating drum. The traction system comprises a double-arm crane and a flat track frictional transmission device. When the rotating drum rotates, the oil pipeline on the rotating drum passes through the flat track frictional transmission device and a guided injection head in sequence to enter into an oil well. According to the invention, a fast connection with the mouth of the well is guaranteed, the operational process of site construction is simplified, the damage of pipelines is prevented, and the success rate of construction is increased.

Owner:PETROCHINA CO LTD

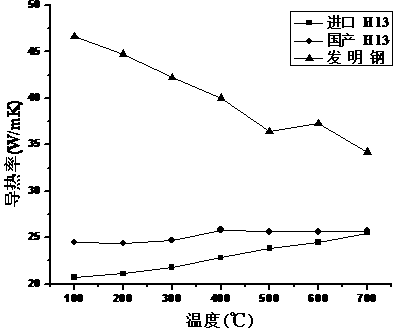

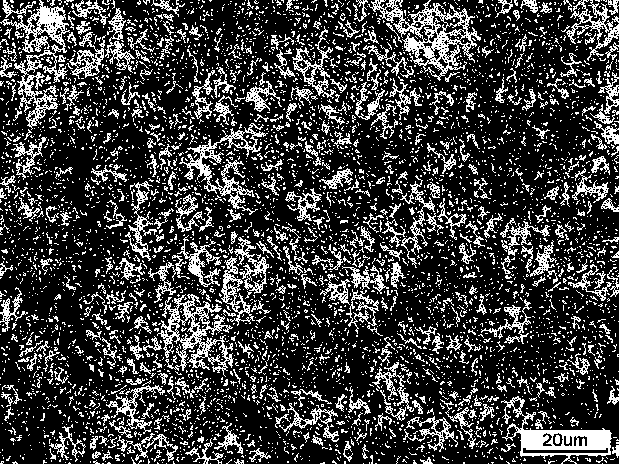

Ultrahigh thermal conductivity wear-resistant hot stamping die steel and manufacturing method thereof

Belonging to the technical field of alloy steel preparation processes, the invention relates to an ultrahigh thermal conductivity wear-resistant hot stamping die steel and a manufacturing method thereof. Current hot stamping die steel on the market is mainly various improved H13, H11 and other high alloy hot work die steel. The steel provided by the invention comprises the following components by mass percent: 0.33-0.40% of C; less than 0.30% of Si; less than 0.30% of Mn; 1.0-2.0% of W; 4.0-5.0% of Mo; less than 0.30% of Cr; 0.10-0.20% of V; and the balance Fe and inevitable impurities. And in the impurity elements, S is smaller than or equal to 0.01%; P is smaller than or equal to 0.01%; and O is smaller than or equal to 30ppm. The steel is characterized in that: simple C, Mo and W are adopted as the main elements to coordinate the ratio of carbides; low Mn, low Cr and low Si content are maintained; after electric furnace smelting, electroslag remelting, annealing, high temperature homogenization, forging and annealing, the material has good machining properties; and after heat treatment, the material has excellent impact toughness, tempering stability and thermal fatigue performance. With ultrahigh thermal conductivity, the steel can be more suitable for hot stamping.

Owner:SHANGHAI UNIV +1

Surface-treated powder and cosmetics containing same

ActiveUS20090263660A1Easily dispersed uniformlyGood dispersionCosmetic preparationsToilet preparationsPolyesterDispersion stability

By coating the surface of a powder comprising a silicone resin and / or an organic powder with a specific hydrophilizing agent, such powder is hydrophilized. The hydrophilizing agent includes water-soluble polyoxyalkylene glycol derivatives. The organic powder is at least one selected from PMMA, nylon, polyester, polystyrene, cellulose, silicone elastomer powder, silicone rubber powder, benzoguanamine, styrenedivinylbenzene pinhole polymer, ethylene tetrafluoride, polyethylene powder, polypropylene powder, polyurethane powder, silk powder, metal soap powder, starch powder, N-acylated lysine, an organic pigment, and a composite of at least one of these organic powders described above with a metal oxide and / or a metal hydroxide. Such coated (treated) powder has extremely great dispersibility (ease of dispersion) and very good dispersion stability (long-term dispersion stability with lapse of time) in aqueous dispersion media, particularly under acidic and alkaline conditions, specifically at pH 3 through 13. Using the surface-treated powder, additionally, a dispersion with good dispersibility (ease of dispersion) and great dispersion stability, preferably for cosmetics can be provided. The use of the surface-treated powder, or the use of the dispersion can provide further a cosmetic excellent in dispersibility and dispersion stability and further in re-dispersibility and dispersion stability with lapse of time and smooth feeling as compared to the related art when selecting aqueous cosmetic as an agent form.

Owner:MIYOSHI KASEI

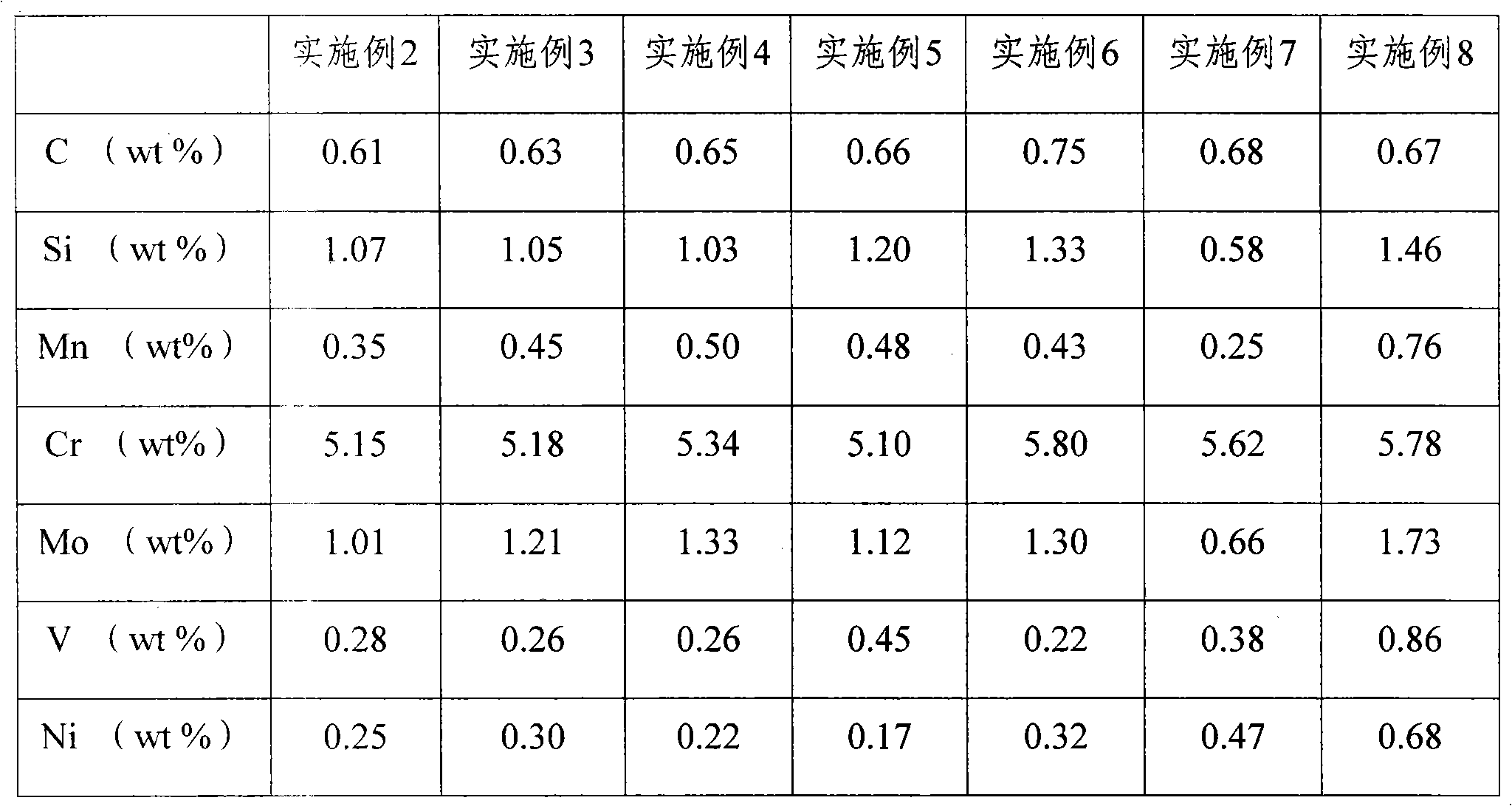

Semi high speed steel cold-rolling intermediate roll and manufacturing method thereof

ActiveCN101956145AImprove performanceGuaranteed performanceRollsMetal rolling arrangementsHardnessWear resistance

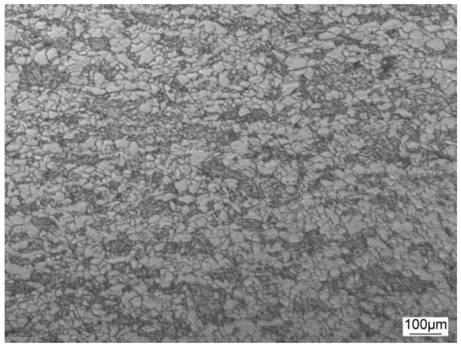

The invention discloses a semi high speed steel cold-rolling intermediate roll and a manufacturing method thereof. The semi high speed steel cold-rolling intermediate roll comprises the following chemical components in percentage by weight: 0.50 to 0.90 percent of C, 0.5 to 2.00 percent of Si, 0.20 to 1.00 percent of Mn, 4.50 to 6.00 percent of Cr, 0.50 to 2.00 percent of Mo, 0.20 to 1.00 percent of V, less than or equal to 0.80 percent of Ni, less than or equal to 0.025 percent of S and less than or equal to 0.025 percent of P. The manufacturing method comprises: manufacturing a steel blank of the cold-rolling roll; roughly turning and tempering; quenching at 940 to 1,000 DEG C; and tempering at 450 to 550 DEG C for 30 to 120 hours. The surface hardness of the cold-rolling intermediate roll made of the material is 75 to 85HSD; the mechanical stress resistance, thermal stress resistance, tissue stress resistance, contact fatigue resistance, wear resistance, hot impact resistance and roll shape retaining performance of the semi high speed steel cold-rolling intermediate roll are high, and the comprehensive service performance of the semi high speed steel cold-rolling intermediate roll is high.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Fine crystal rare earth oxide molybdenum alloy-doped and its preparation method

InactiveCN1757775AGood mechanical propertiesImprove room temperature fracture toughnessRare earthMuffle furnace

A RE oxide doped fine-crystal Mo-alloy is prepared from MoO2 through doping RE oxide by atomizing method, ball grinding, sieving, reducing in H2 atmosphere in muffle furnace at 800-1100 deg.C, cold isostatic pressing under 150-200 MPa for shaping, segmental sintering in MF induction furnace and mechanical deforming to obtain rod or plate. It has high strength, ductility and toughness.

Owner:山东铭特金属材料科技有限公司

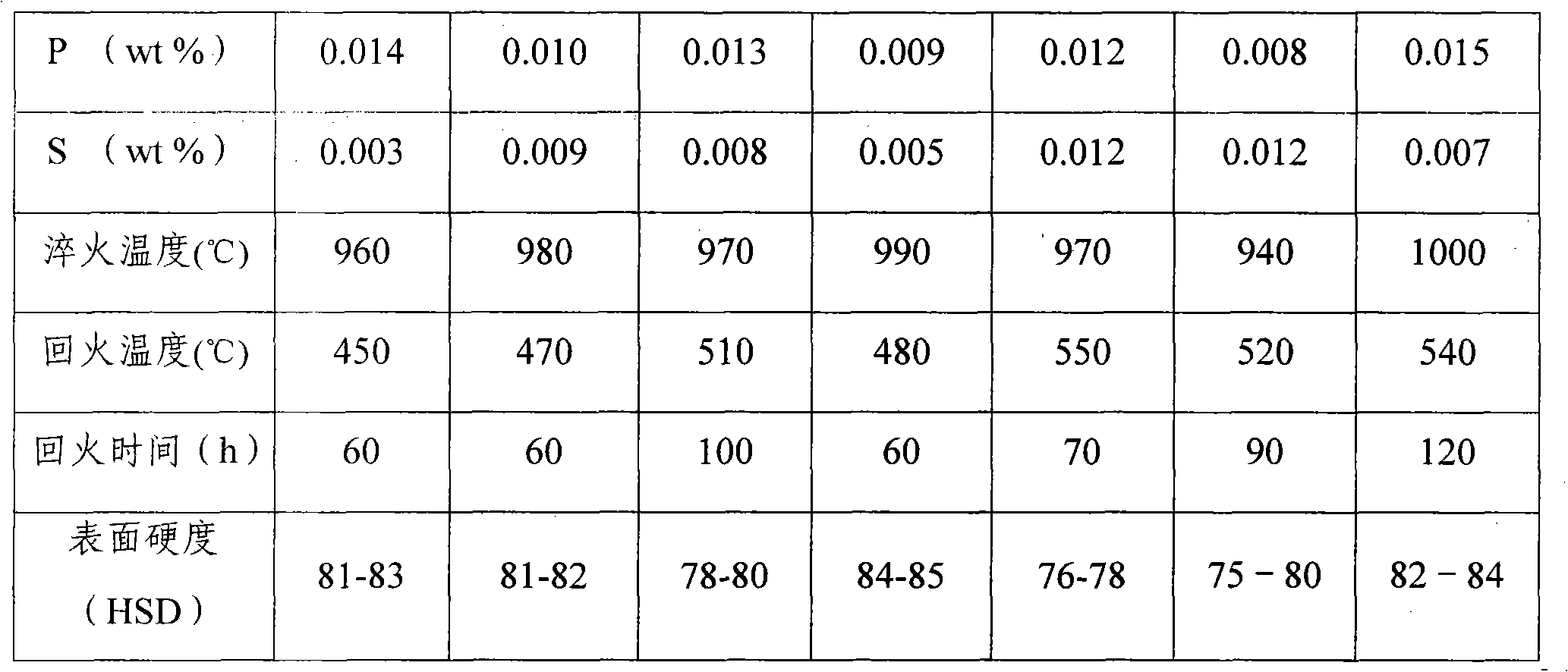

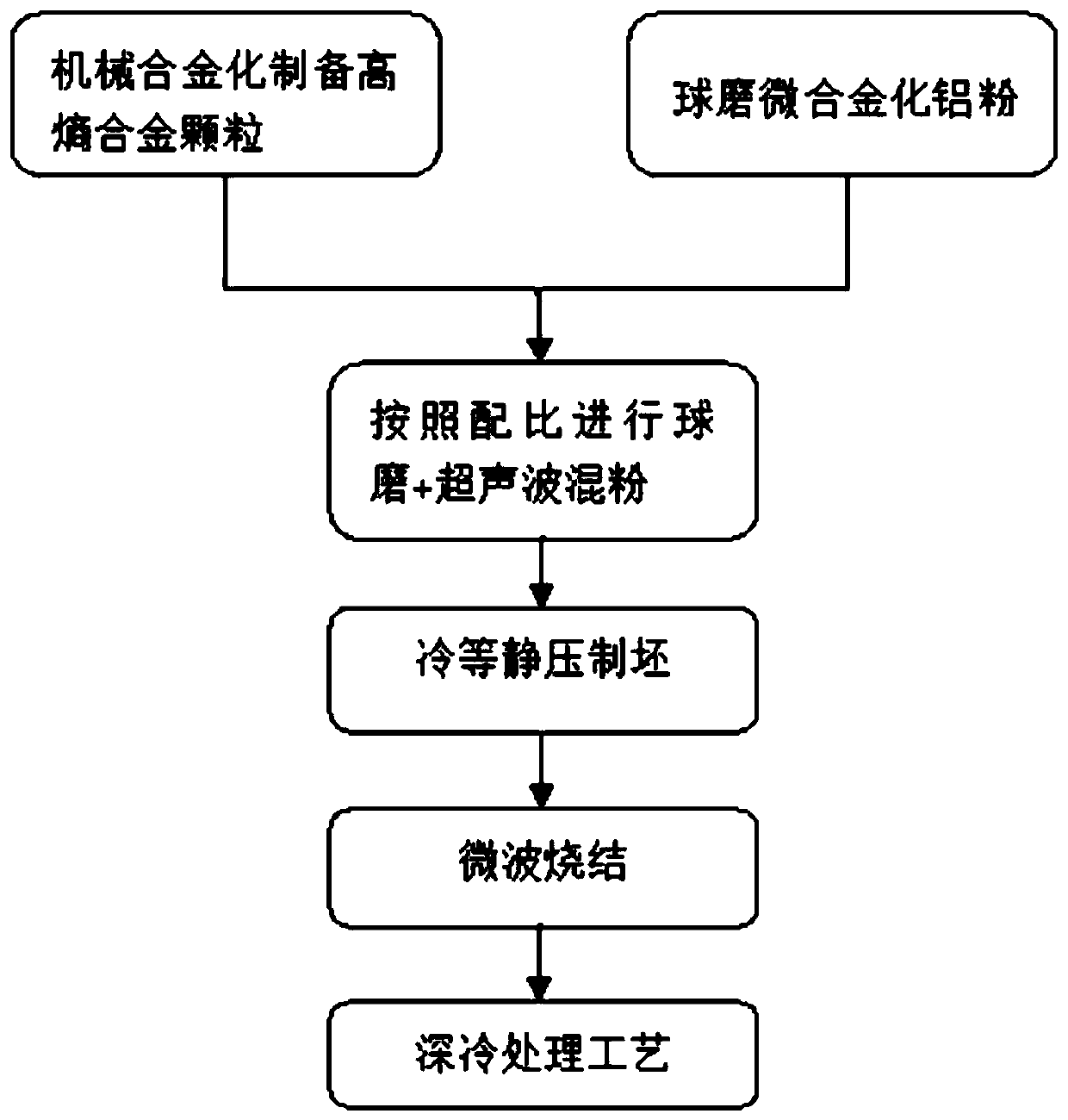

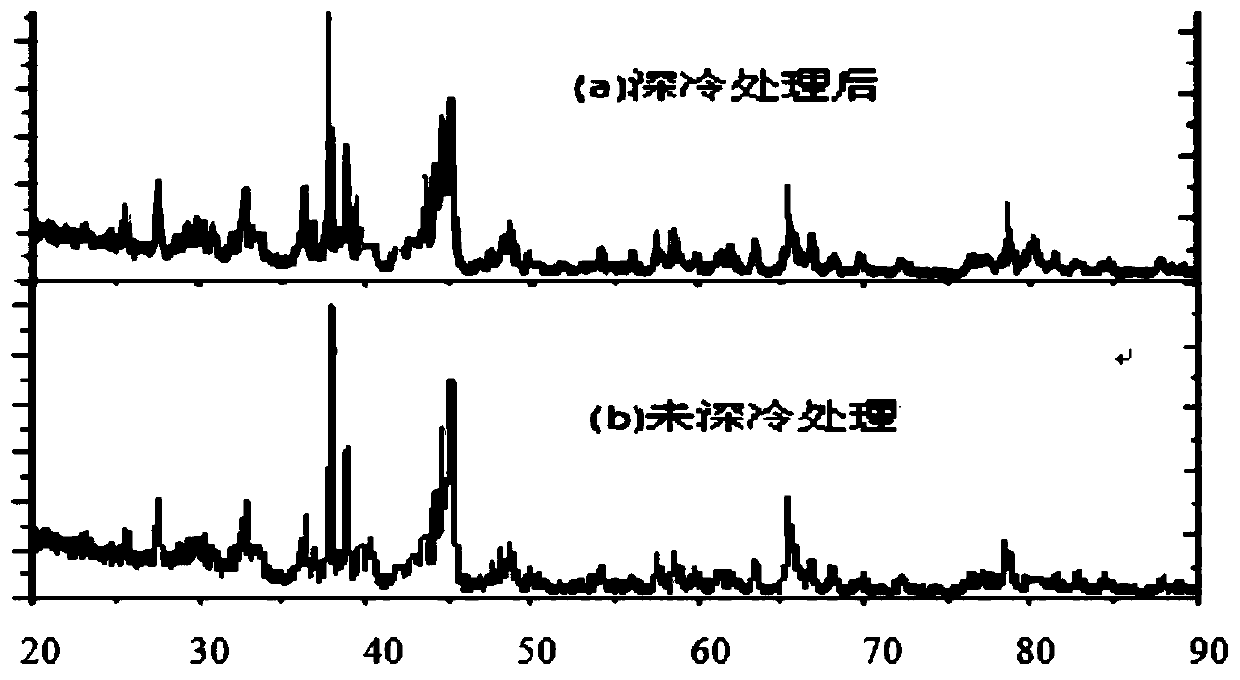

High-entropy alloy particle reinforced cryogenic treatment aluminum-based composite material and preparation method thereof

ActiveCN110523997AHigh strengthEvenly distributedTransportation and packagingMetal-working apparatusCompression moldingMaterials preparation

The invention belongs to the technical field of composite material preparation, and particularly relates to a high-entropy alloy particle reinforced cryogenic treatment aluminum-based composite material and a preparation method thereof. High-entropy alloy components are optimally designed, then vacuum ball milling is conducted to prepare high-entropy alloy, and high-entropy alloy powder and microalloyed aluminum matrix powder are evenly mixed in proportion and dried to obtain mixed powder; compression molding is performed by utilizing isostatic cool pressing to obtain a composite billet; a microwave sintering process is adopted to obtain a high-entropy alloy particle reinforced aluminum-based composite material; and finally, cryogenic treatment is performed on the aluminum-based compositematerial. According to the high-entropy alloy particle reinforced aluminum-based composite material, the strength and plasticity of the aluminum-based composite material are improved, and meanwhile the aluminum-based composite material can have good magnetic performance.

Owner:JIANGSU UNIV

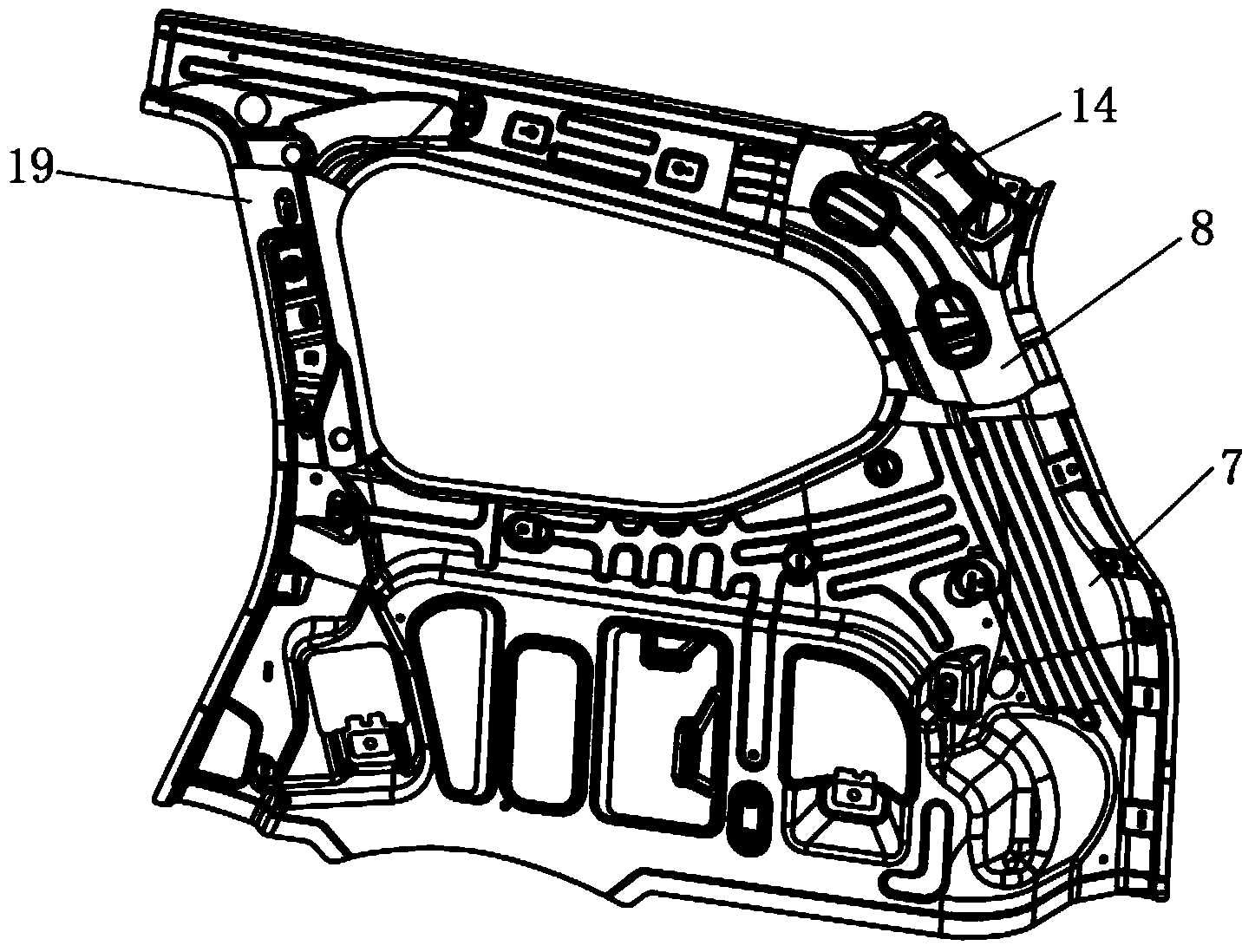

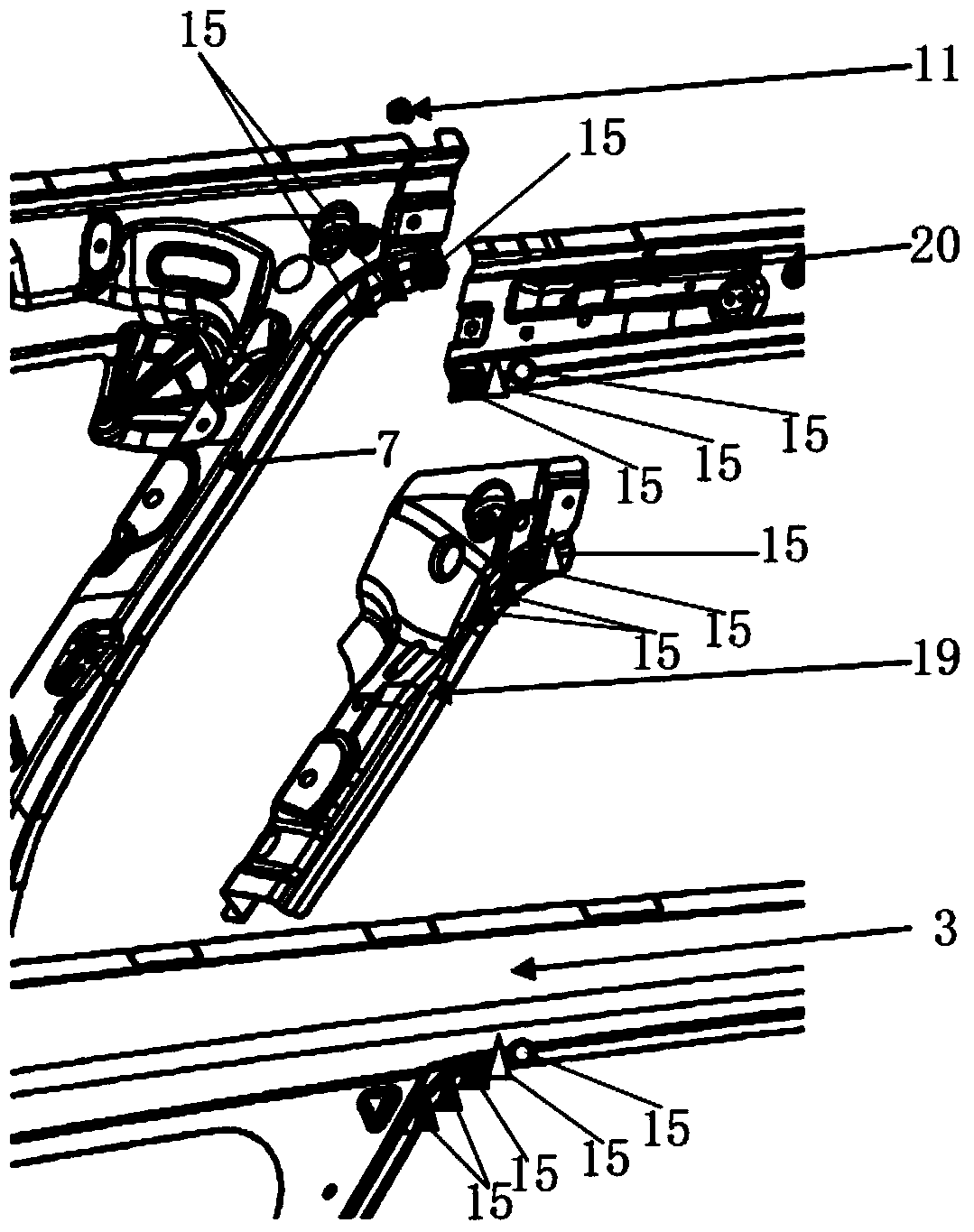

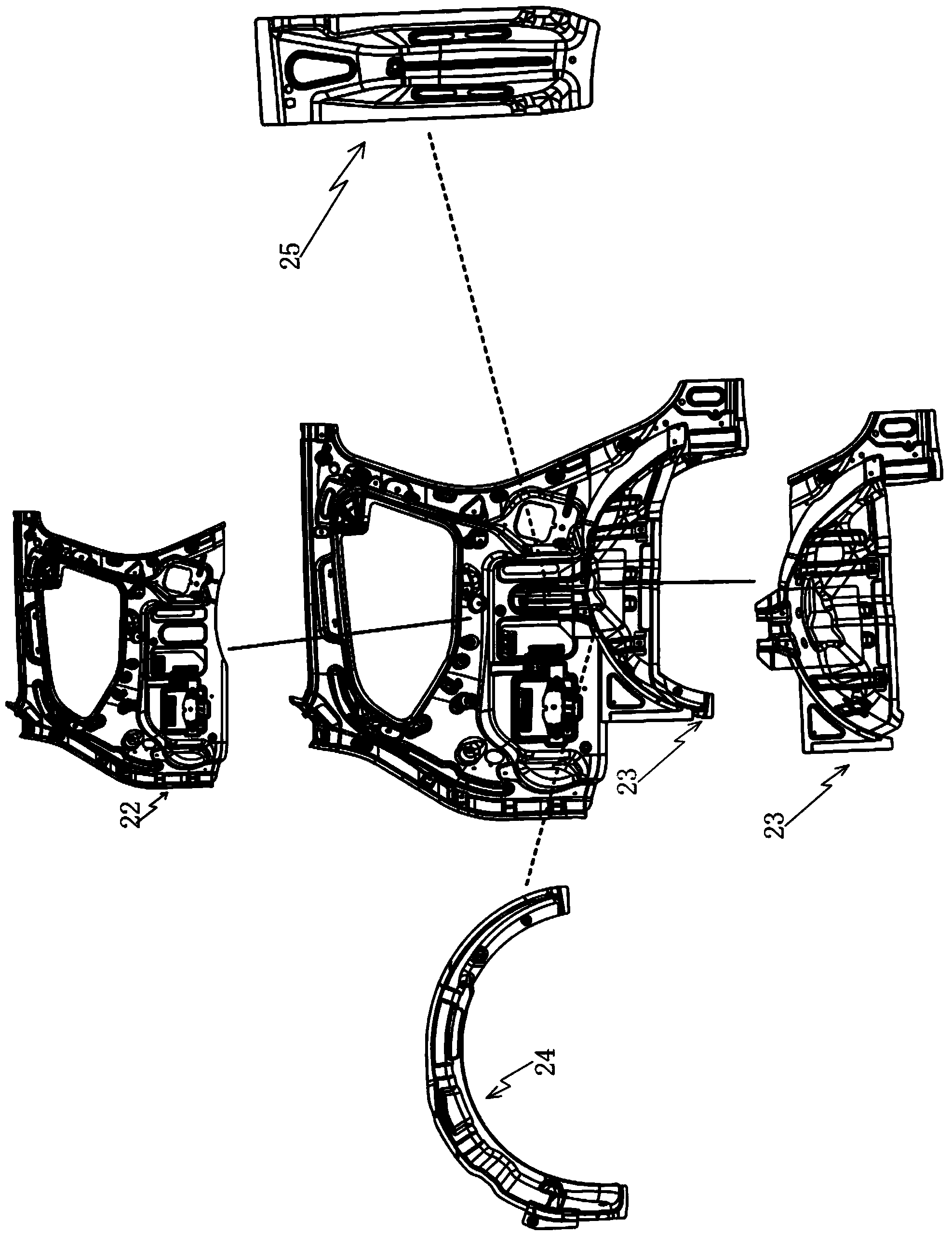

Rear side outer plate welding assembly

ActiveCN103538639AEnsure safetySimple welding processSuperstructure connectionsAgricultural engineeringWelding process

The invention discloses a rear side outer plate welding assembly which comprises a rear side inner plate assembly, a rear wheel cover inner plate welding piece, a rear wheel cover outer plate welding piece and a rear wheel cover outer plate support plate. The rear wheel cover inner plate welding piece comprises a rear wheel cover inner plate and a front protection plate. The rear wheel cover outer plate welding piece comprises a rear wheel cover outer plate. The rear side inner plate assembly comprises a rear side outer plate, an upper side beam inner plate, a rear side inner plate, a C column reinforcing plate and a D column upper end connector. The upper side beam inner plate is welded with the rear side outer plate, the upper side beam inner plate, the C column reinforcing plate and the rear side outer plate are welded, the rear side inner plate, the C column reinforcing plate and the rear side outer plate are welded, the upper side beam inner plate, the rear side inner plate, the C column reinforcing plate and the rear side outer plate are welded, and the upper side beam inner plate, the rear side inner plate and the C column reinforcing plate are fixedly connected. Components of the rear side outer plate welding assembly are welded independently or connected to be assembled, assembly is convenient, a welding process is better, and the middle door frame rigidity can be effectively improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Tensile strength 800-MPa-class hot rolling complex phase steel and production method thereof

InactiveCN110343961AHigh expansion rateQuality improvementProcess efficiency improvementMetallurgyMartensite

The invention discloses tensile strength 800-MPa-class hot rolling complex phase steel and a production method thereof and belongs to the field of metal material and preparation thereof. The tensile strength 800-MPa-class hot rolling complex phase steel comprises the main components of 0.05%-0.09% of C, 0.10%-0.30% of Si, 1.40%-2.00% of Mn, 0.010%-0.050% of Al, 0-0.020% of P, 0-0.008% of S, 0.010%-0.070% of Nb, 0.08%-0.14% of Ti, 0.10%-0.25% of Mo, and the balance Fe and inevitable impurities. Through treatment of casting blank hot charging, hot continuous rolling and related process steps, yield strength is 700 MPa or above, tensile strength is 800 MPa or above, the hole expansion rate is larger than 60%, the microstructural type is a mixed structure composed of ferrite, granular bainiteand a small amount of island-shaped martensite, after the product is subjected to continuous pickling, product surface quality and performance are excellent, and the product is widely used for manufacturing automobile chassis structural parts, safety belt supports, bumpers and other parts.

Owner:MAANSHAN IRON & STEEL CO LTD

Die-casting heat resisting magnesium alloy and preparation thereof

ActiveCN101353747AImprove high temperature strengthImprove plasticityMetallic materialsMagnesium alloy

The invention relates to a die-casting heat resistant magnesium alloy and a preparation method thereof, pertaining to the metal material technology field. The components and weight percentage thereof of the alloy are as follows: 1.5 to 6.0 percent of Sm, 0 to 3.0 percent of Nd, 0 to 2.5 percent of Ca, 0.1 to 2.0 percent of Zn, 0.2 to 0.8 percent of Zr, lower than 0.02 percent of impurity elements, and the rest is Mg. The preparation method of the alloy comprises the following steps: the materials are weighed, and industrial pure Mg is heated under the protection of the mixed gas of N2 and SF6; after Mg is wholly melted, industrial pure Zn, industrial pure Ca and Mg-Sm interalloy and Mg-Nd interalloy are added at the temperature of 650 to 680 DEG C, Mg-Zr interalloy is added at the temperature of 760 DEG C, the temperature is maintained and the mixture is stirred, then the temperature is increased to 780 to 800 DEG C and maintained, after that the temperature is adjusted to 750 to 760 DEG C for refining and maintained for 30min, and when the Mg liquid is cooled to 680 to 700 DEG C, the mixture carries out die casting. The alloy of the invention has excellent tensile strength, yield strength and elongation and creep resistance simultaneously, and has good die-casting performance.

Owner:SHANGHAI JIAO TONG UNIV

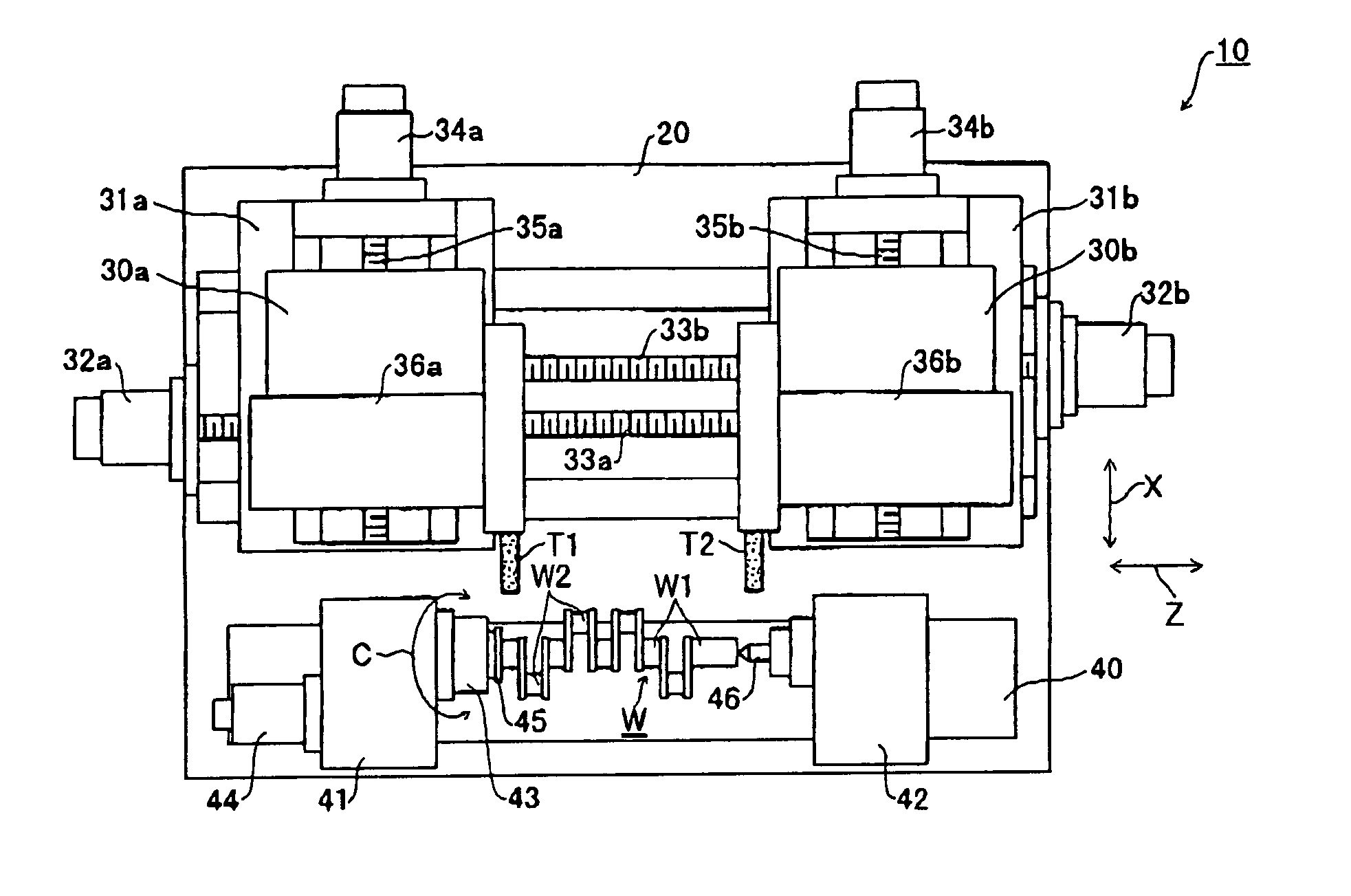

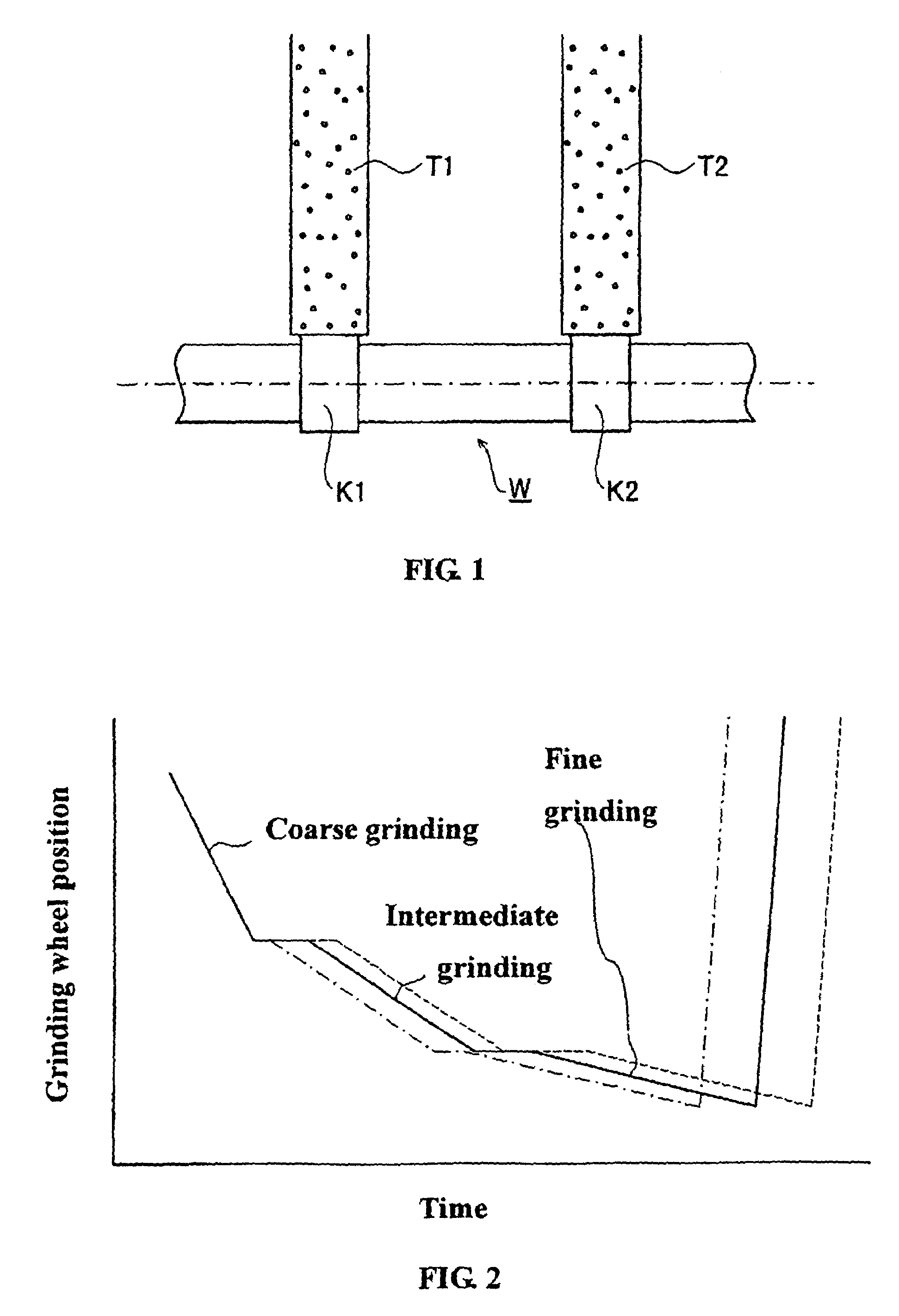

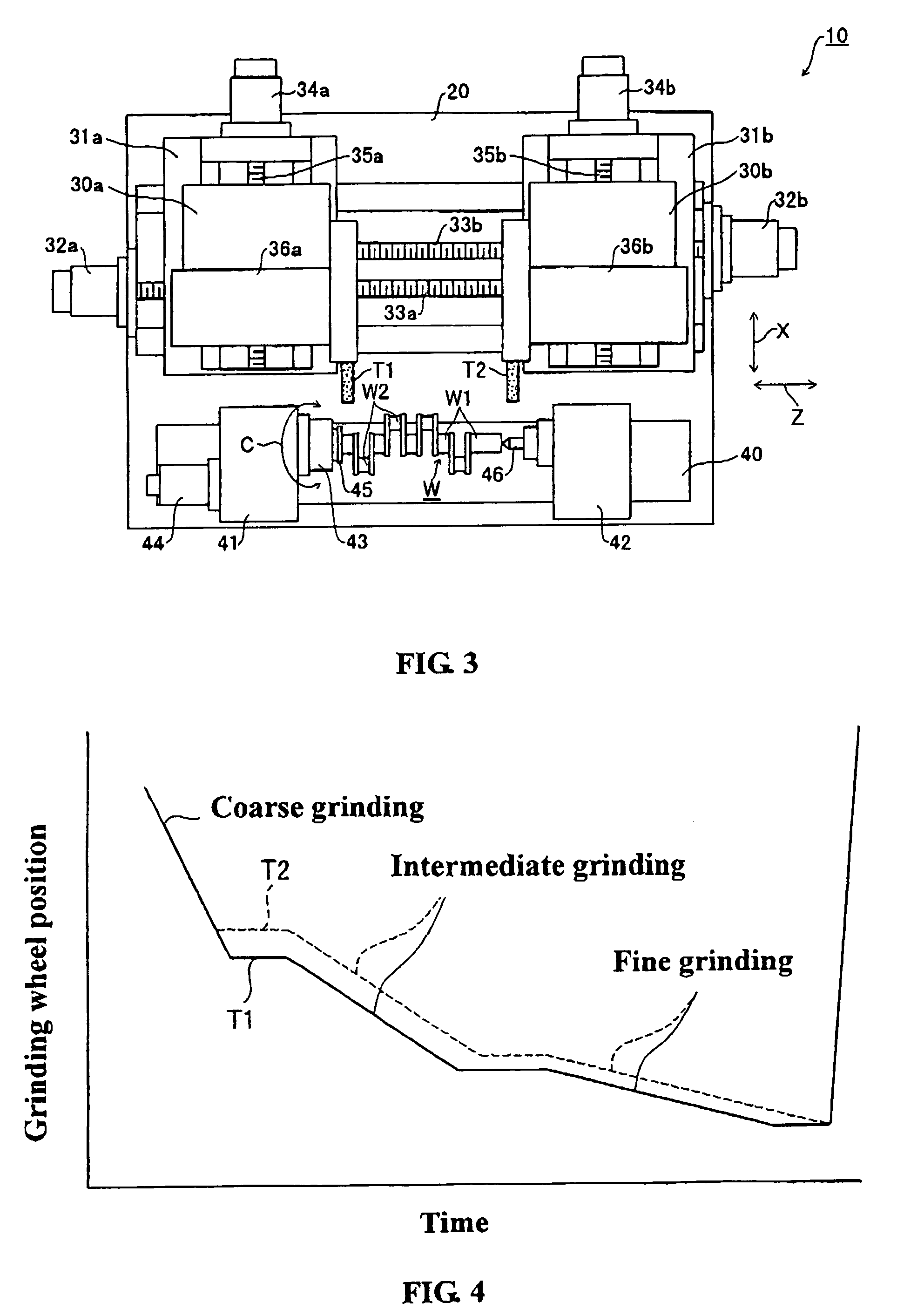

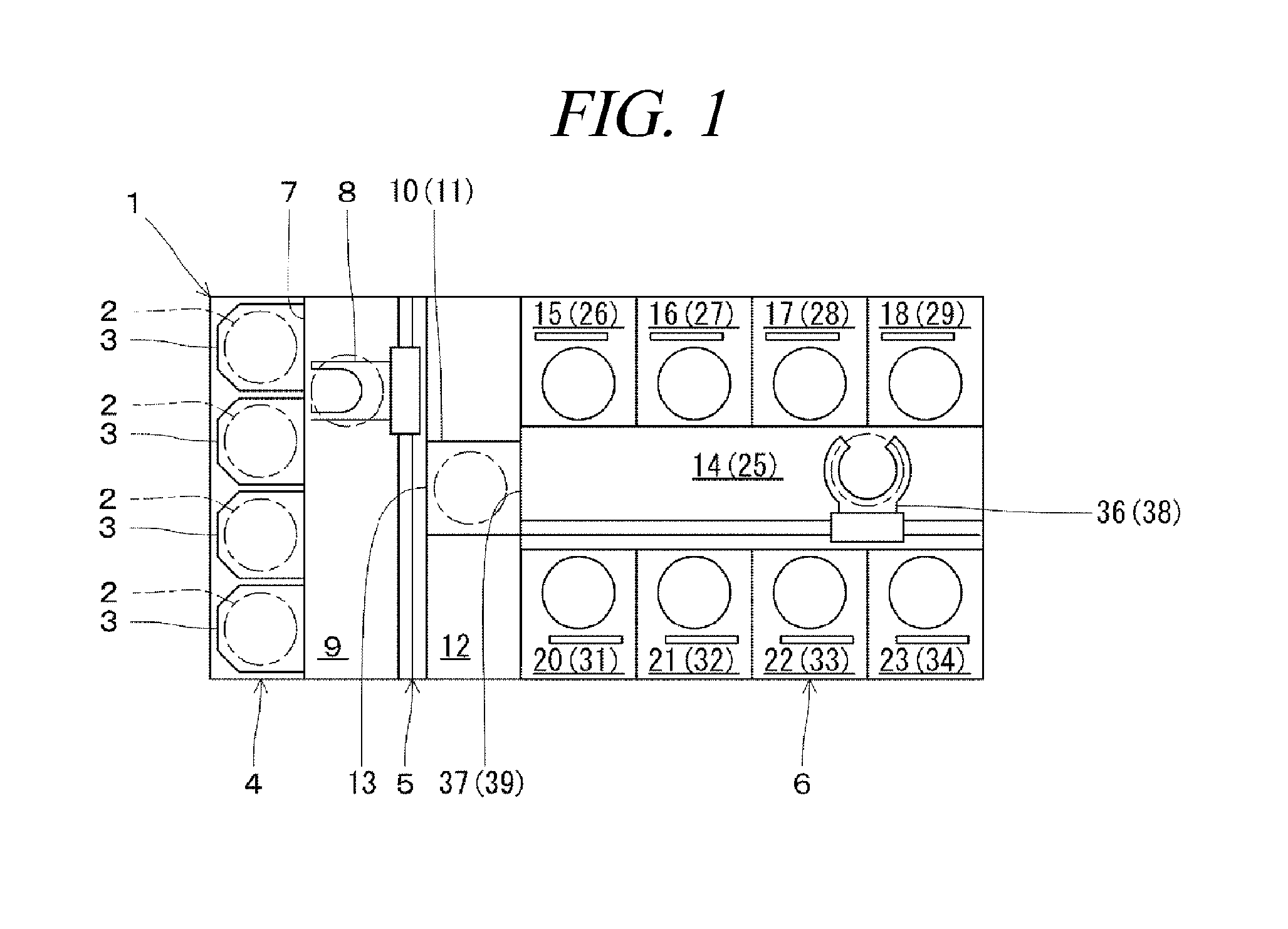

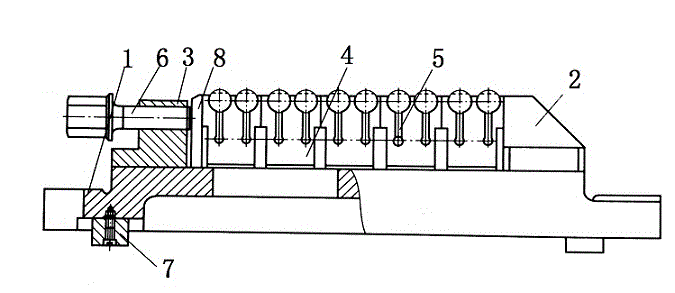

Method of grinding

InactiveUS7037173B2InhibitionGood dispersionProgramme controlAutomatic control devicesEngineeringGrinding wheel

A grinding method comprises steps of simultaneously grinding plural grinding portions of a workpiece by plural grinding wheels T1, T2 moved individually each other, and terminating said grinding by a predetermined grinding wheel T1 prior to a termination of said grinding by the other grinding wheel T2. Whereby, a content of the grinding by each grinding wheel T1, T2 can be same. A grinding condition in each grinding by each grinding wheel T1, T2 can be changed in accordance with a measuring result of the grinding portion in the grinding.

Owner:TOYODA MASCH WORKS LTD

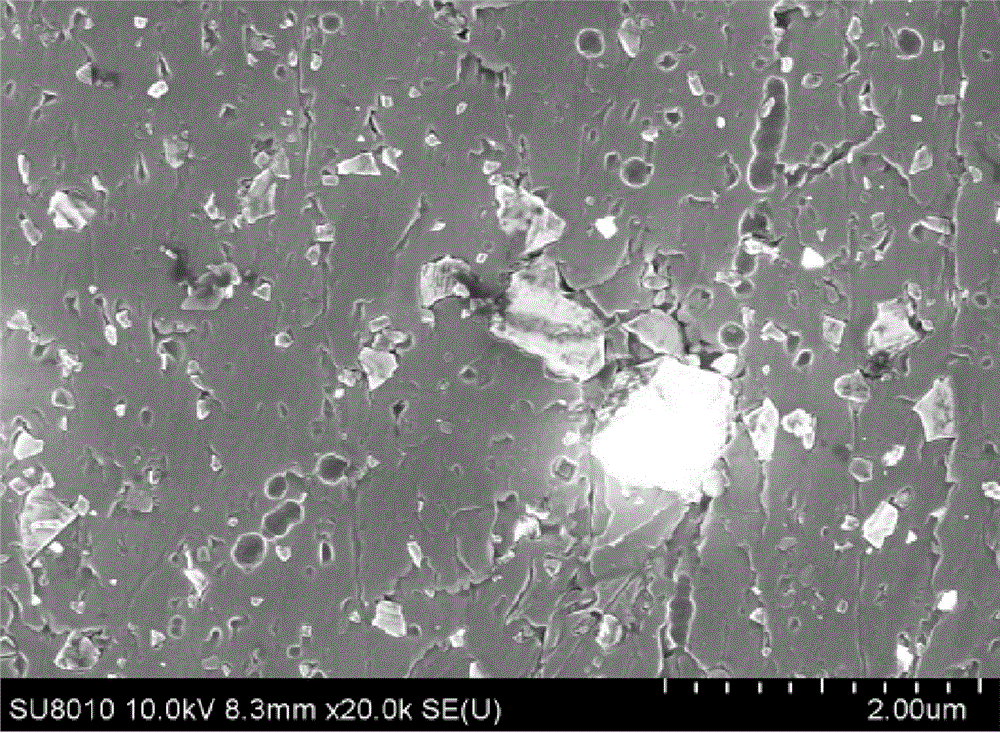

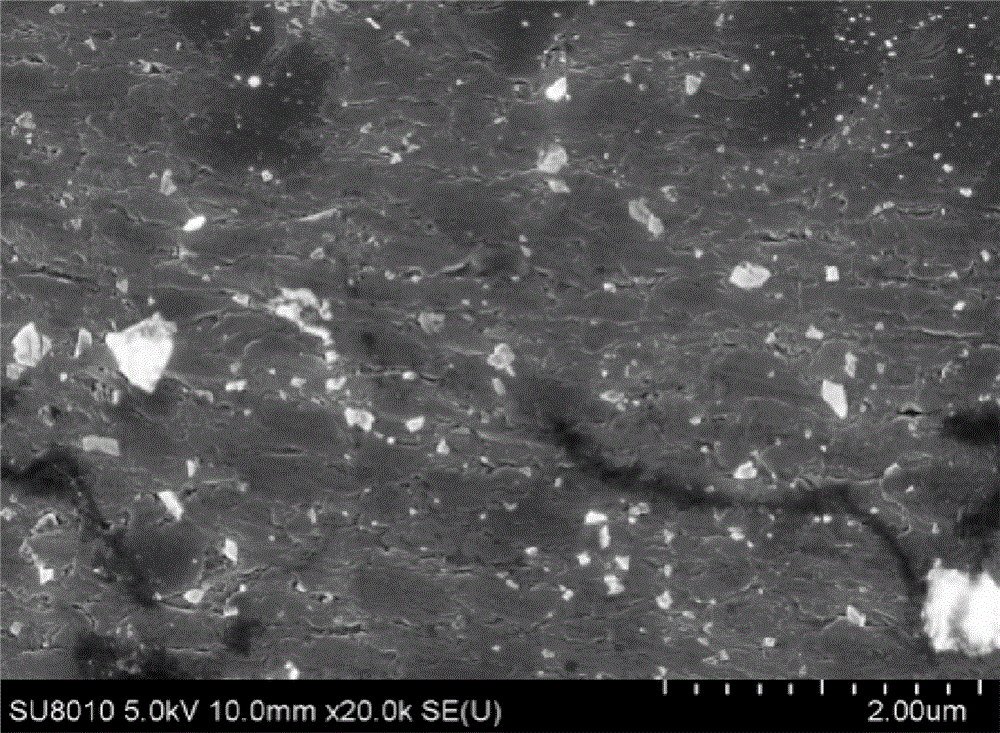

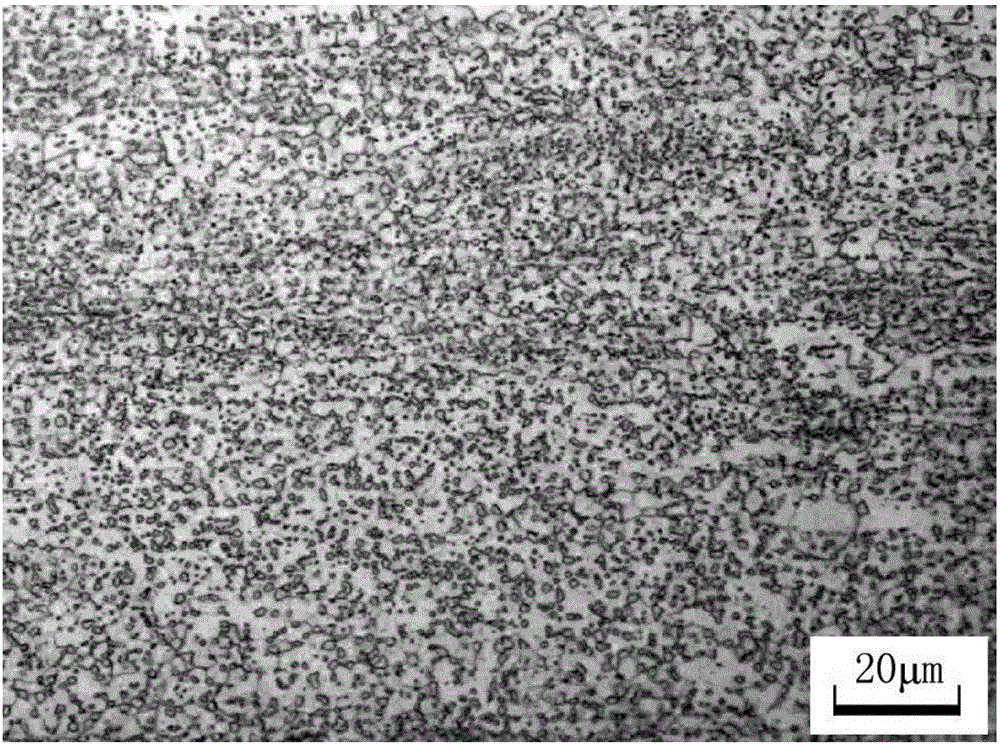

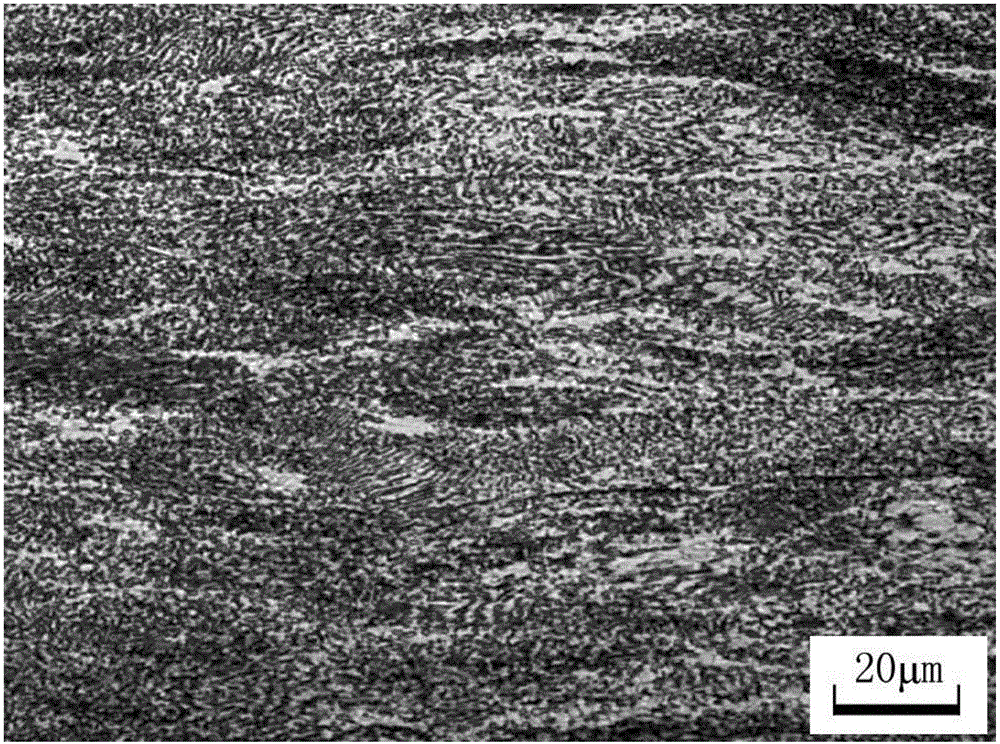

Multi-nanophase composite enhanced magnesium alloy and preparation method thereof

The invention discloses multi-nanophase composite enhanced magnesium alloy and a preparation method thereof, and belongs to the technical field of magnesium alloy. The multi-nanophase composite reinforced and enhanced deforming magnesium alloy is Mg-Gd-Zn alloy, wherein the Gd content is 10-25 wt%, the Zn content is 1-5 wt%, the balance is Mg, and the difference between the mass percent of GD and the mass percent of Zn is not smaller than 8. The deforming magnesium alloy material excellent in mechanical performance is obtained through the multi-stage extrusion and multi-stage thermal treatment process, the yield strength can reach 250-400 MPa, and the elongation can reach 10-25%. The alloy is mainly reinforced by a nanometer needle-shaped phase and a nanometer sheet phase together, the two phases are staggered, and the comprehensive mechanical performance of the alloy can be remarkably improved.

Owner:北京二七铁丰龙科技有限公司

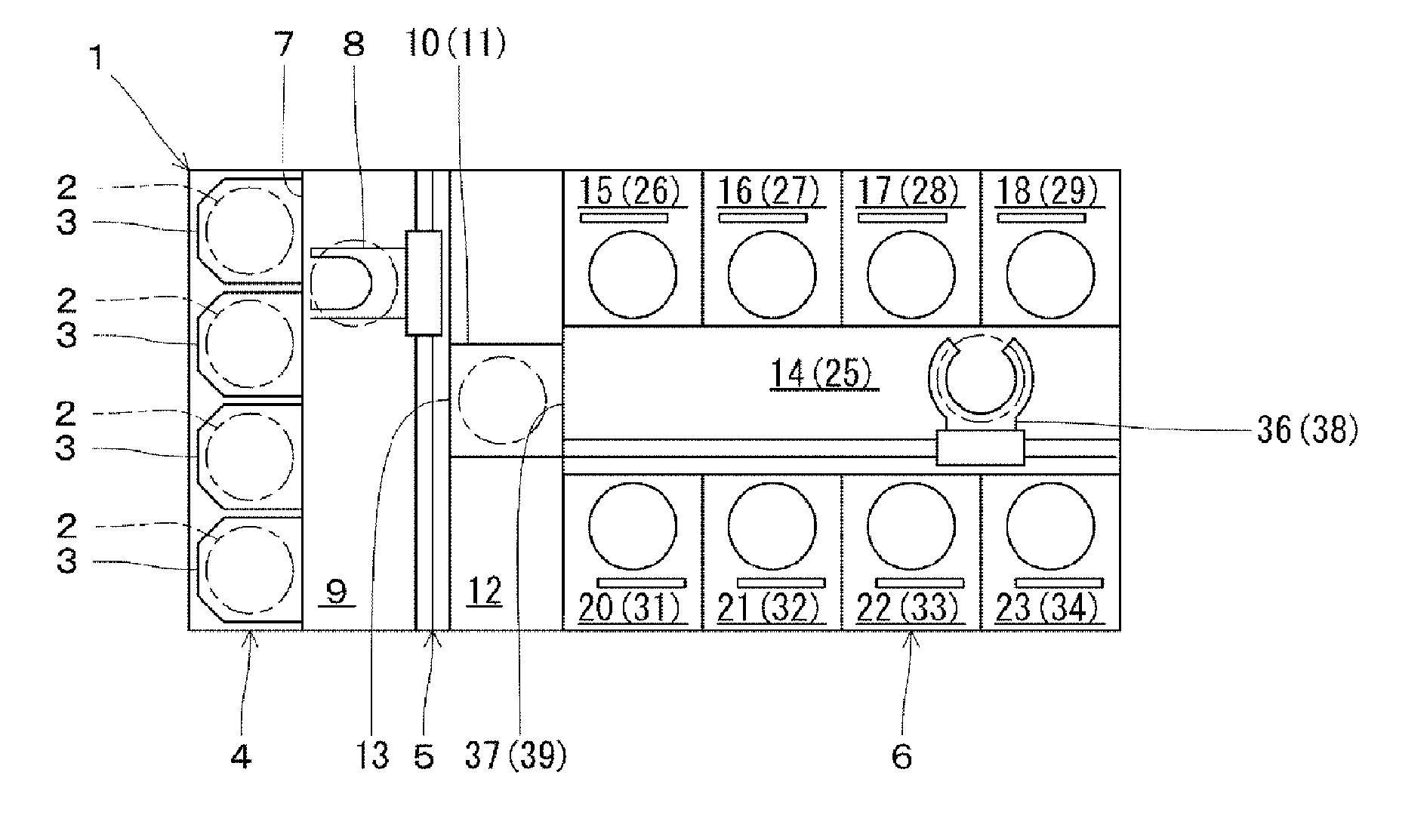

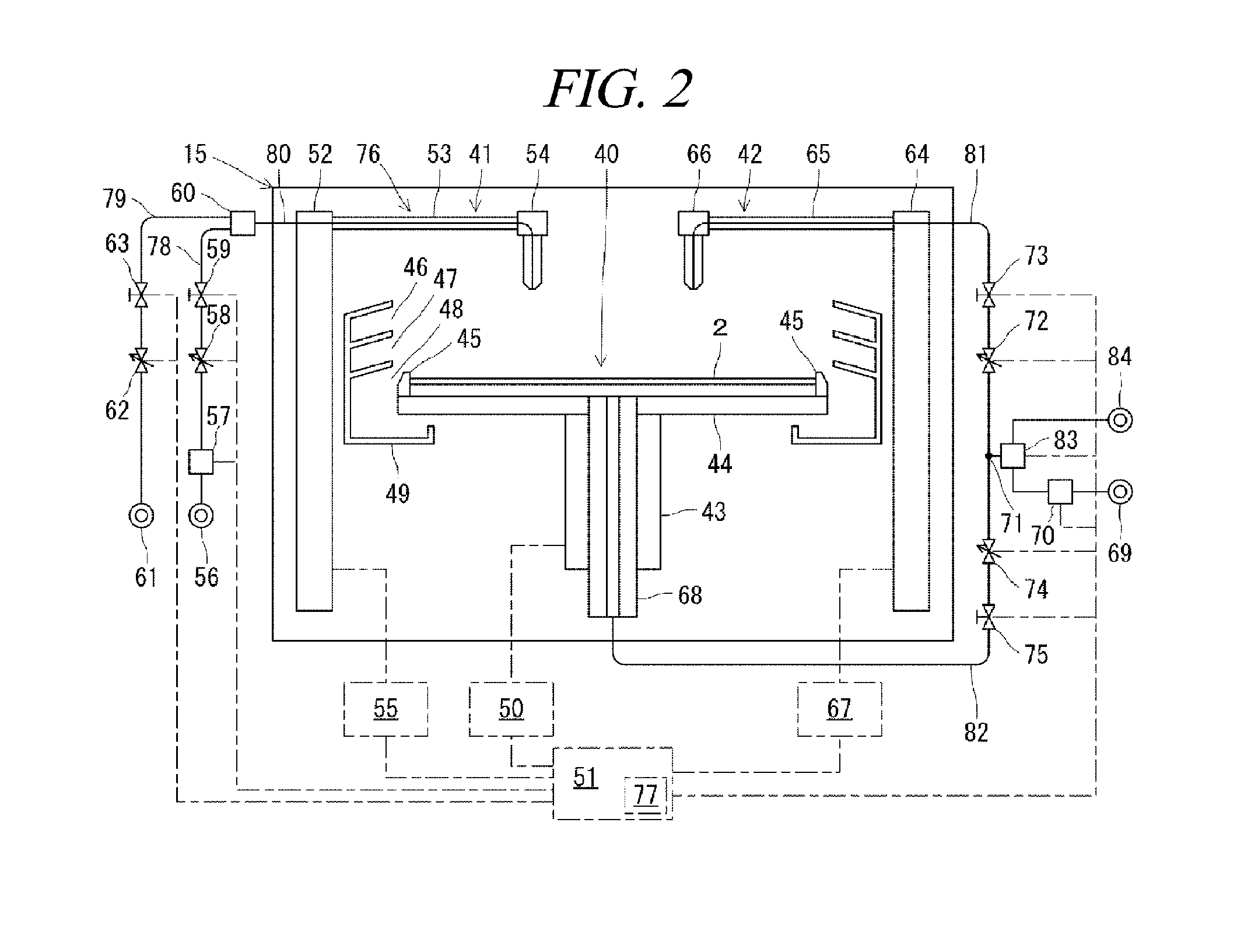

Liquid processing apparatus, liquid processing method and computer-readable storage medium storing liquid processing program

ActiveUS20110277793A1Reduce temperature variationPrevent thermal deformationSemiconductor/solid-state device manufacturingCleaning using liquidsSi substrateAnalytical chemistry

There is provided a liquid processing method for performing a liquid process on a front surface of a substrate by using a processing solution and then performing a rinse process on the front surface of the substrate by using a rinse solution having a temperature lower than a temperature of the processing solution. The liquid processing method includes performing an intermediate process between the liquid process and the rinse process, for adjusting a temperature of the front surface of the substrate to a temperature higher than the temperature of the rinse solution and lower than the temperature of the processing solution.

Owner:TOKYO ELECTRON LTD

Hydrophilized surface-treated powder and cosmetics containing same

ActiveUS8105691B2Easily dispersed uniformlyGood dispersionCosmetic preparationsToilet preparationsHydrophilizationDispersion stability

By coating the surface of a powder comprising a silicone resin and / or an organic powder with a specific hydrophilizing agent, such powder is hydrophilized. Such coated (treated) powder has extremely great dispersibility (ease of dispersion) and very good dispersion stability (long-term dispersion stability with lapse of time) in aqueous dispersion media, particularly under acidic and alkaline conditions, specifically at pH 3 through 13. Using the surface-treated powder, additionally, a dispersion with good dispersibility (ease of dispersion) and great dispersion stability, preferably for cosmetics can be provided. The use of the surface-treated powder, or the use of the dispersion can provide further a cosmetic excellent in dispersibility and dispersion stability and further in re-dispersibility and dispersion stability with lapse of time and smooth feeling as compared to the related art when selecting aqueous cosmetic as an agent form.

Owner:MIYOSHI KASEI

High quality aluminum titanium boron refiner and preparation method thereof

The invention discloses a preparation method of a high quality aluminum titanium boron refiner. The prepared high quality aluminum titanium boron refiner comprises, by mass, 4.8-5.5% of Ti, 0.8-1.2% of B and the balance Al. The preparation method of the intermediate alloy comprises the steps that the quantities of potassium fluoborate and potassium fluotitanate required for two-time feeding are calculated according to a chemical reaction equation; the feeding method is two-time feeding; according to the matching ratio of villiaumite two times of feeding, the mass ratio of the potassium fluotitanate in the first feeding to the potassium fluotitanate in the second feeding is 1.09-1.52 and the mass ratio of the potassium fluoborate in the first feeding to the potassium fluoborate in the second feeding is 0-0.2; but it should be always guaranteed that the mass ratio of the potassium fluoborate to the potassium fluotitanate in the second feeding is 1.05:1; the potassium fluotitanate and the potassium fluoborate which are well proportioned are evenly mixed and dried, and added into a pure aluminum melt at a constant speed in two times; the mixture obtained in the previous step is stored for a period of time and then mixed for 3-5 minutes; and calcium fluoride is added into the mixture, water slag is removed 2-5 minutes later, and sticks are formed by pouring.

Owner:SHENYANG POLYTECHNIC UNIV

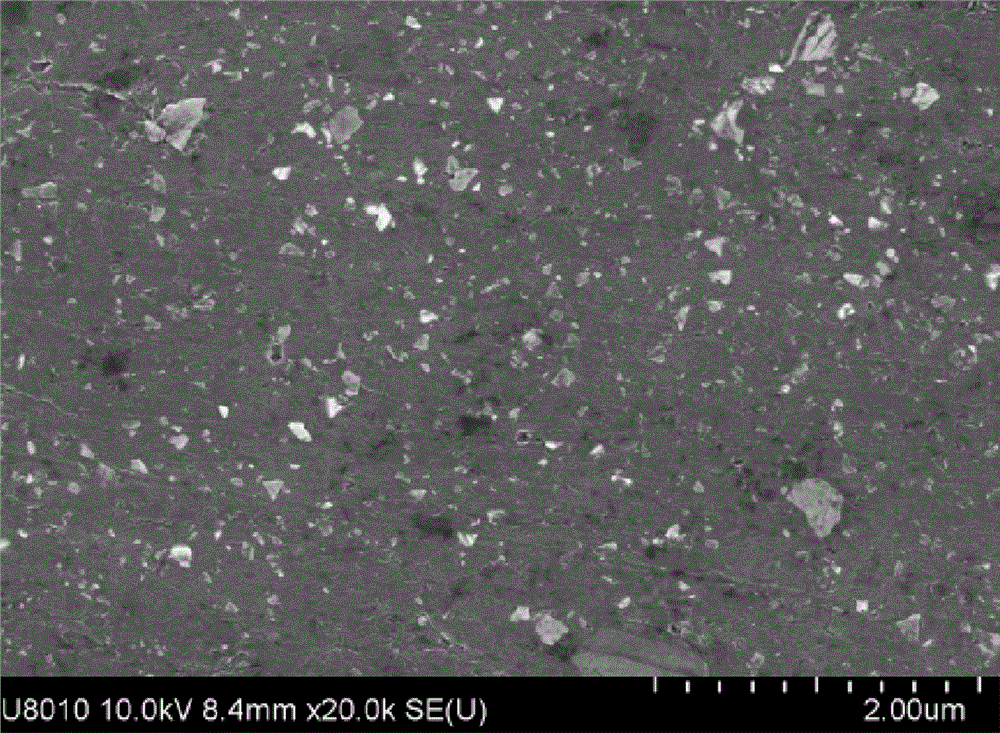

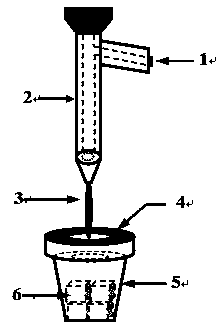

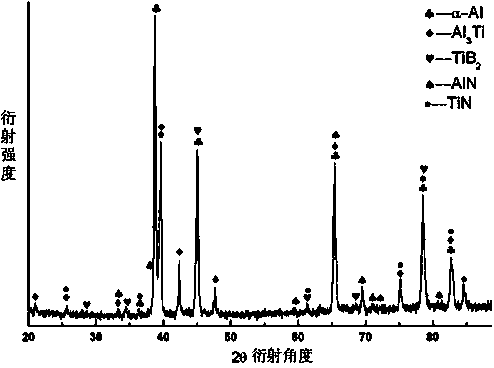

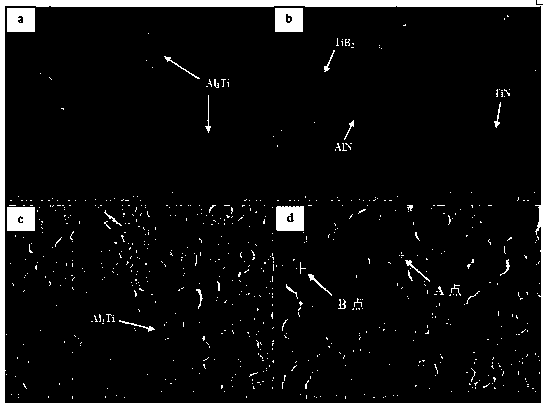

Preparation method for in-situ aluminium base composite material inoculant

ActiveCN102864343BHighlight substantive featuresSignificant progressElectric arc furnaceAlloy composite

The invention discloses a preparation method for an in-situ aluminium base composite material inoculant, and relates to an aluminium base alloy, in particular to a method for preparing a thin-strip AlN-TiN / Al nanometer in-situ aluminium base composite material inoculant by the plasma metallurgy nitridation and rapid solidification technology. The preparation method comprises the following steps of: weighing domestic Al-5Ti-1B alloy and metal pure Ti of the required amount at the following set ingredient ratio: 10.0-10.5% of Ti, 0.9-1.2% of B and the balance of Al; putting all raw materials into a nonconsumable vacuum arc furnace to be smelted to obtain a smelted blocky Al-10Ti-1B alloy; then, obtaining blocky Al-10Ti-1B alloy composite material by plasma nitriding treatment; and finally, carrying out rapid solidification treatment to obtain the thin-strip AlN-TiN / Al nanometer in-situ aluminium base composite material inoculant. The inoculant is provided with nucleation particles with smaller size and more dispersed distribution, and the particle enhancement effect is improved. The method has the advantages of high production efficiency and low cost.

Owner:HEBEI UNIV OF TECH

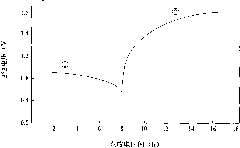

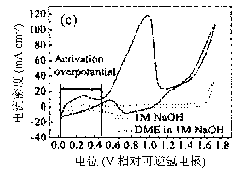

Reversible air battery using piperidine as hydrogen storage media

InactiveCN101826645AHigh specific capacityFix security issuesFuel and secondary cellsFuel cellsProton

The invention relates to a reversible air battery, which aims at providing a reversible air battery using piperidine as hydrogen storage media. The reversible air battery adopts piperidine as a hydrogen storage media and also as negative electrode active substance, a proton exchange membrane as an electrolyte, and an air electrode as a positive electrode. When the negative electrode discharges, the piperidine is electrochemically oxidized to generate pyridine. During charging, the pyridine is electrochemically reduced to generate the piperidine. Compared with a traditional regenerated hydrogen-oxygen fuel battery, by using the piperidine as the hydrogen storage media, the invention can greatly improve the specific capacity of the battery, and can realize large-scale commercial application. The piperidine reversible air battery can be used as a portable and mobile power supply for electric automobiles, electronic products, military equipment and the like. The piperidine reversible air battery can be made into a semienclosed type battery, i.e. the fuel side is sealed, and the air side is opened. The invention can solve the safety problem caused by the defect of full open type of the traditional fuel battery, and can greatly improve the practicability of the fuel battery.

Owner:ZHEJIANG UNIV

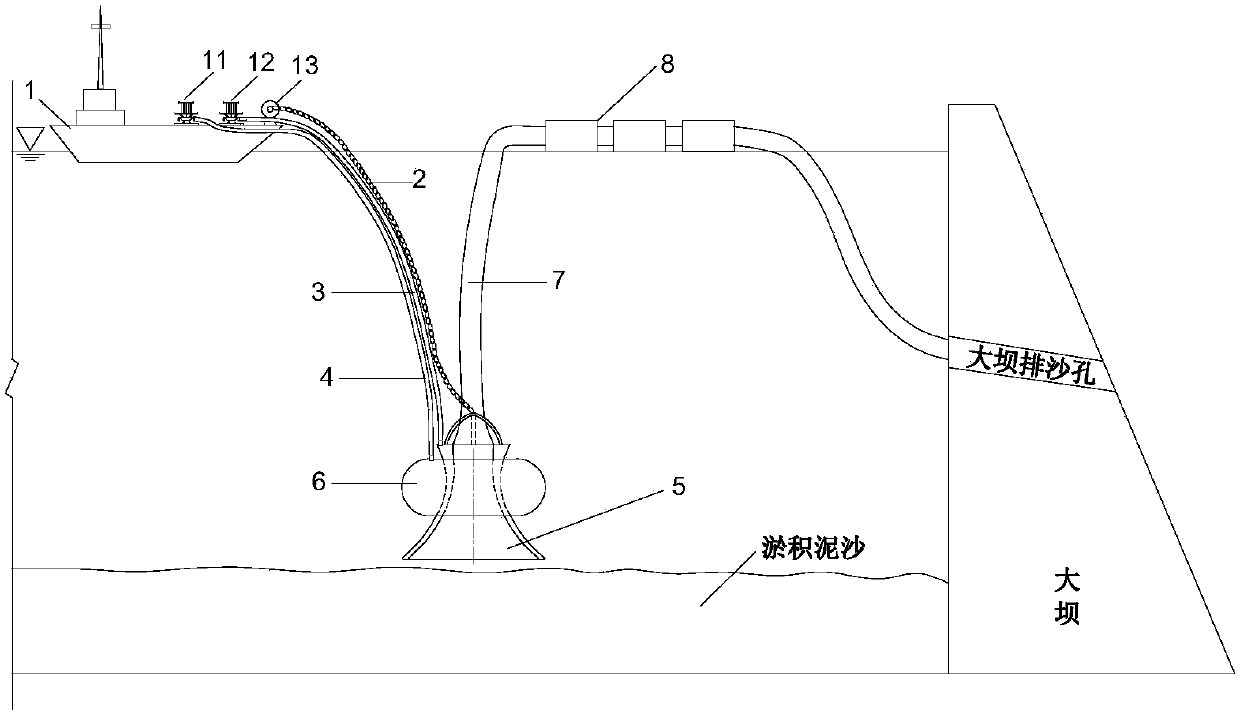

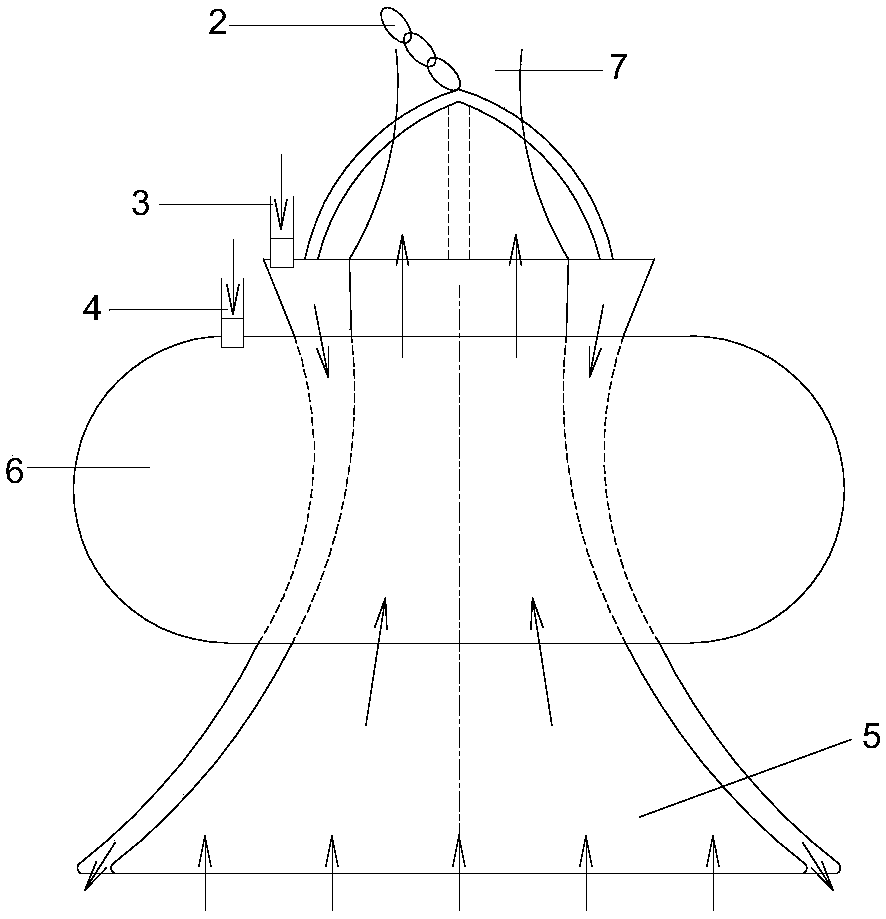

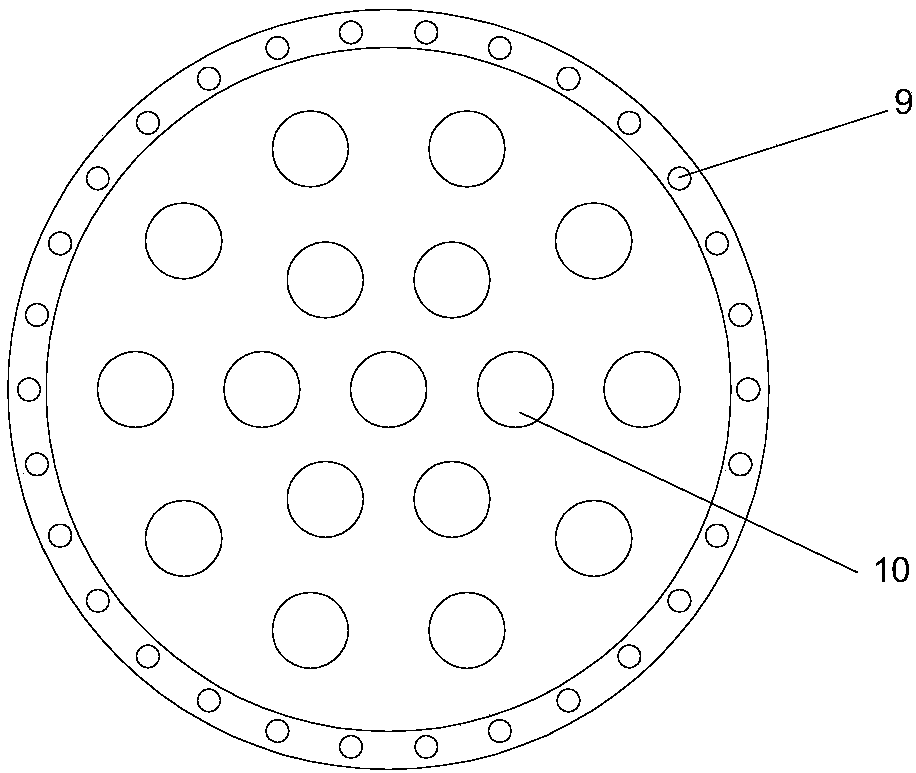

Reservoir underwater walking sand suction and discharge device

ActiveCN105951664ADispersionAchieve perturbationMechanical machines/dredgersStream regulationHigh concentrationEngineering

The invention provides a reservoir underwater walking sand suction and discharge device. The device comprises a working ship, a water pump, an air pump, a windlass and a positioning system arranged on the working ship, and a porous sand suction disc arranged on a silting bed surface of the bottom of a reservoir. An annular air cavity is formed in the porous sand suction disc; a sand punching hole and a sand suction hole are formed in the porous sand suction disc; the water pump is communicated with the sand punching hole through a water charging pipe; the sand suction hole is connected into a dam sand discharge hole through a sand conveying pipe; the air pump is communicated with the annular air cavity through an inflation pipe; and the windlass is connected with the porous sand suction disc through a traction steel rope. The device is arranged in a reservoir area; high-pressure water is injected in the sand punching hole of the porous sand suction disc through the water pump for dispersing and disturbing silted sediments of the reservoir; a high-concentration water and sand mixture is sucked through the sand suction hole of the porous sand suction disc and the sand conveying pipe for realizing efficient dam passing of the silted sediments of the reservoir; the dispersion, the disturbance and the suction of the silted sediments at the bottom of the reservoir can be synchronously realized; high-concentration muddy water is easy to form; the water consumption is low; and the sand sucking and desilting efficiency is high.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Preparation of nano rare-earth oxide doping molybdenum alloys

The invention discloses a method for preparing a nano rare earth oxide doped molybdenum alloy. In the method, by taking rare earth ammonium dimolybdate crystals as raw materials and adopting the roasting and hydrogen reduction method, molybdenum alloy powder is obtained, the powder after reduction is in press-forming by the isostatic cool pressing with a pressure of between 180 and 200 Mpa, the formed blank materials are presintered in a muffle furnace with a temperature of between 1, 100 and 1, 300 DEG C, and sintered in a vacuum intermediate frequency induction sintering furnace at a temperature of between 1, 600 and 1, 900 DEG C for 10 to 24 hours; the materials sintered can be made by the prior mechanical processing methods into materials and products with different shape such as molybdenum alloy bar materials or plate materials, etc. as required. The molybdenum alloy containing nano rare earth oxide, prepared by the method of the invention, has the advantages of high intensity, ductility and toughness and wide application.

Owner:临沂明华管业有限公司

Fireproof door core plate and making method thereof

InactiveCN107162633AImprove fire resistanceImprove thermal insulationFireproof doorsCeramicwareFiberThermal insulation

The invention discloses a fireproof door core plate and a making method thereof, and relates to the technical field of door cores. The fireproof door core plate comprises 55-65 parts of a polymer matrix, 45-55 parts of desulfurized gypsum, 40-43 parts of borax, 37-38 parts of anhydrous magnesium chloride, 32-34 parts of cenosphere, 30-32 parts of a filler material, 26-28 parts of refractory particles, 20-23 parts of reinforcing fibers, 17-19 parts of wood powder, 16-18 parts of phosphonate, 10-15 parts of an assistant, 4-10 parts of stearic acid and 60-63 parts of water. The fireproof door core plate has the advantages of good fire resistance, good thermal insulation resistance, light weight, high strength and easiness in fragmentation.

Owner:合肥市旺友门窗有限公司

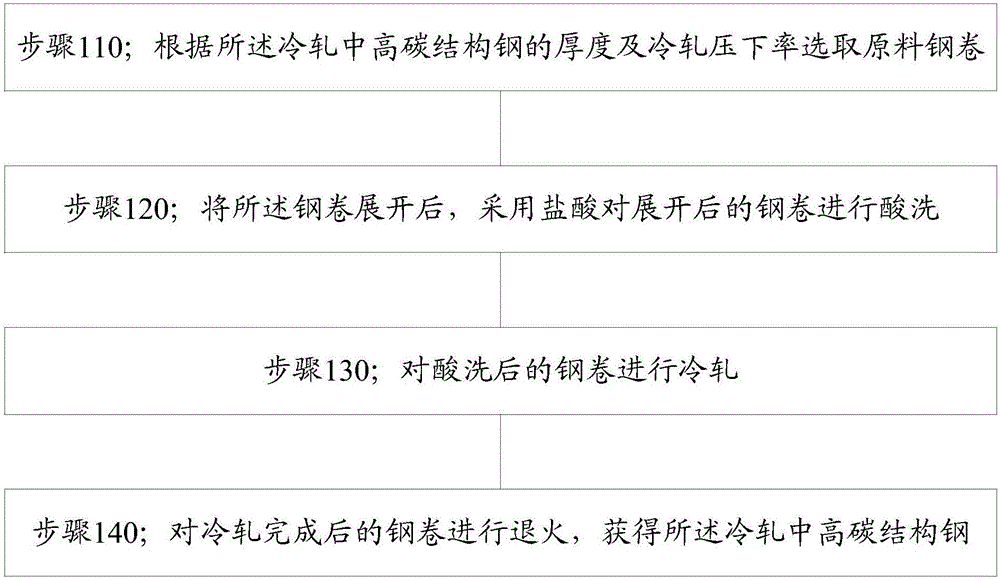

Manufacturing method of cold-rolled medium-high carbon structural steel

The invention discloses a manufacturing method of cold-rolled medium-high carbon structural steel. The steel is prepared from components in percentage by weight as follows: 0.30%-0.70% of C, 0.15%-0.35% of Si, 0.10%-1.20% of Mn, 0.10%-1.10% of Cr, less than or equal to 0.030% of Alt, less than or equal to 0.020% of P, less than or equal to 0.010% of S, no more than 0.3% of other added alloy elements and the balance of Fe and inevitable impurity elements. According to the manufacturing method, one-time annealing and one-time cold-rolling are adopted, a raw material steel coil can be cold-rolled directly by controlling hot rolling process parameters, the cold-rolling reduction ratio is larger than or equal to 50%, deformation can infiltrate the structural core part, lamellar carbide in a hot-rolled raw material pearlite structure is broken through cold-rolling deformation, a lot of dislocation is produced in grains, the broken carbide and defects provide a core for separation of carbide in the annealing process, the uniform structure and the tiny carbide are obtained, and technical effects of improving the production efficiency and reducing the cost are realized.

Owner:武汉钢铁有限公司

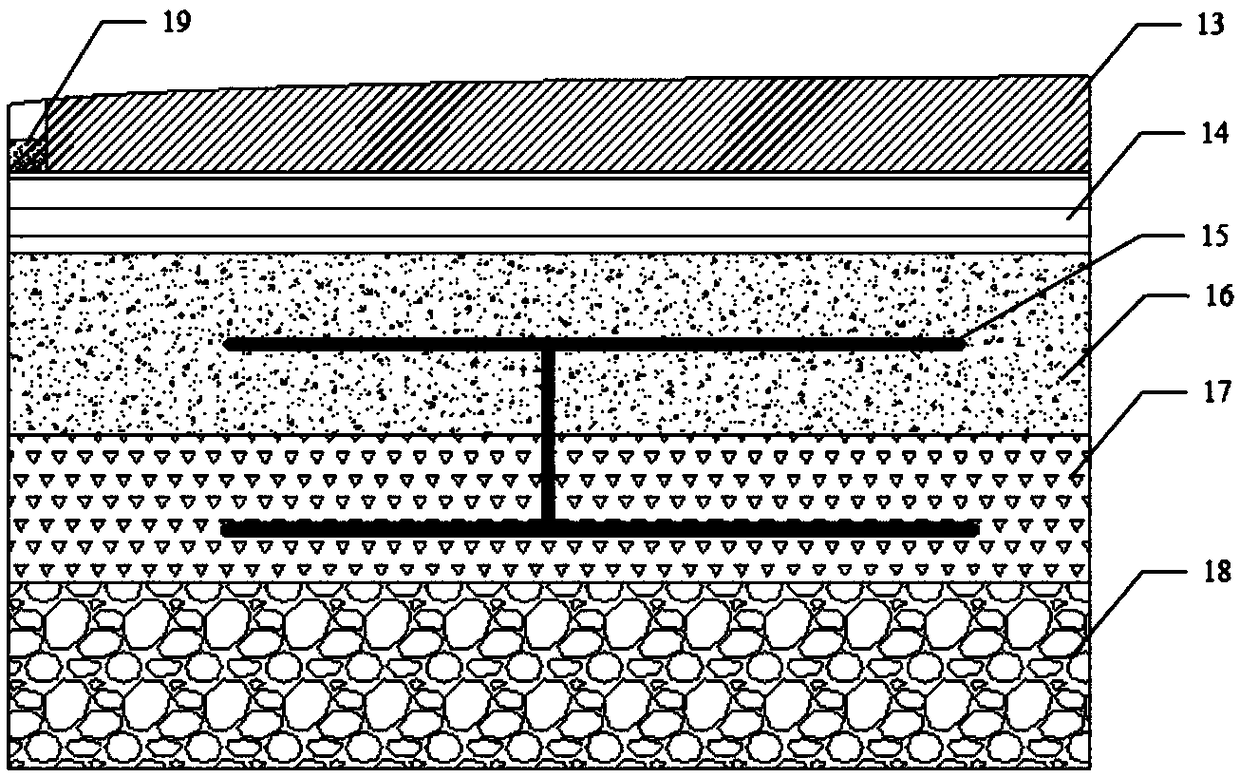

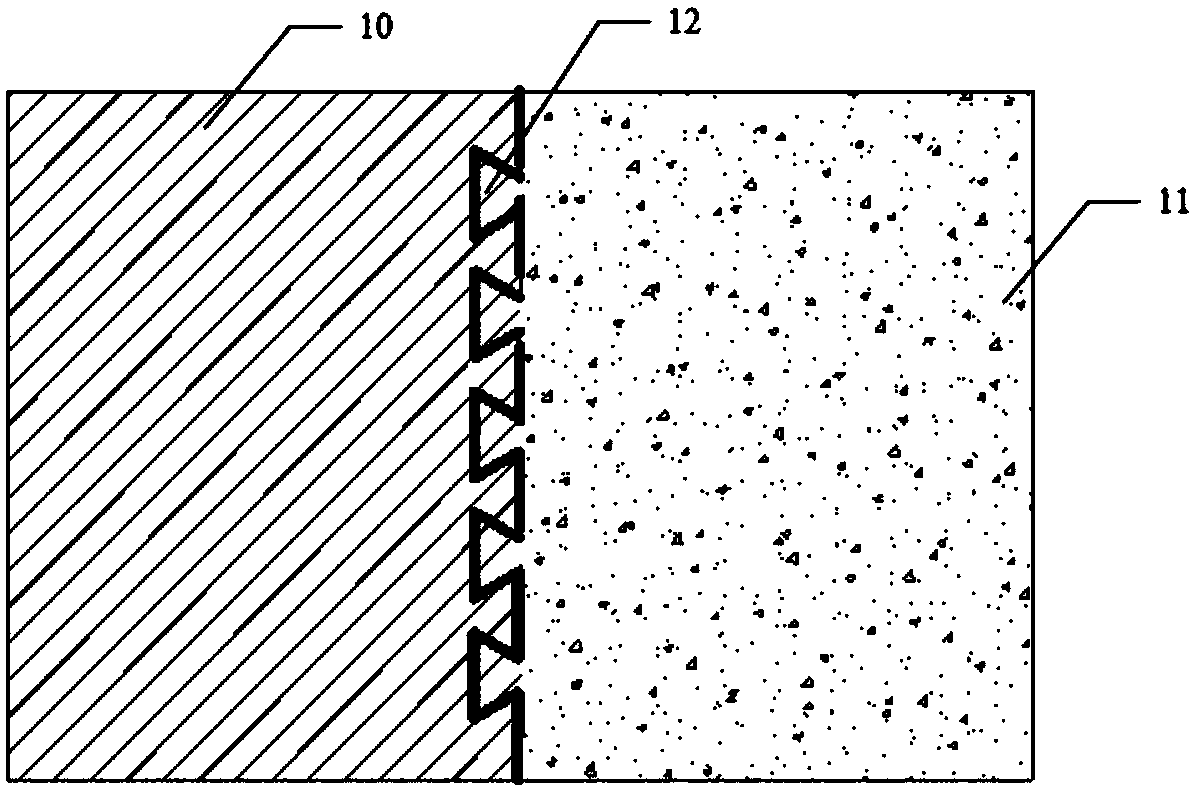

Roadbed paving structure for highway extension and construction method

The invention discloses a roadbed paving structure for highway extension and a construction method of the roadbed paving structure for the highway extension. The roadbed paving structure for the highway extension comprises a cushion layer, a lower base layer, an upper base layer and a surface layer, wherein a fixing frame is arranged between an intermediate layer and a gravel layer to increase thebonding strength of the upper base layer and the lower base layer so as to prevent hierarchical separation, furthermore, the cushion layer is located at the bottom layer, thereby being capable of enhancing the structure stability and dispersing the roadbed stress to prevent sinking, a traction part is arranged between the surface layer and the upper base layer to increase the bonding strength between the layers so as to prevent the surface layer from being separated, wherein one or more of steel wires, manila hemp fibers, carbon fibers and polytetrafluoroethylene fibers are arranged inside the traction part, therefore the materials are combined to make the traction part tough and corrosion-resistant, and then the traction part is not easily corroded by cement, and in addition, the problemof weak adhesive force of the polytetrafluoroethylene fibers and the cement or asphalt is solved. A connecting part is further arranged and comprises a plurality of dovetail grooves and clamping blocks adapted to the dovetail grooves, the dovetail grooves and the clamping blocks are respectively arranged on a joint surface of an old road and the roadbed structure to prevent a newly widened roadbed from sinking or cracking or separating relative to the old road.

Owner:中奋建设有限公司

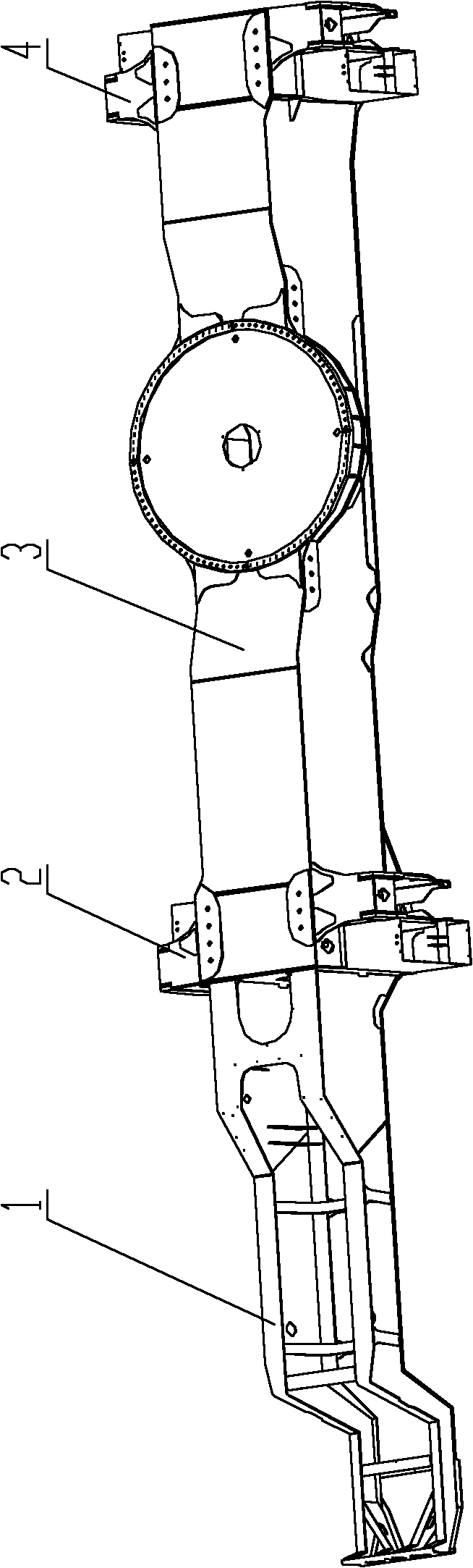

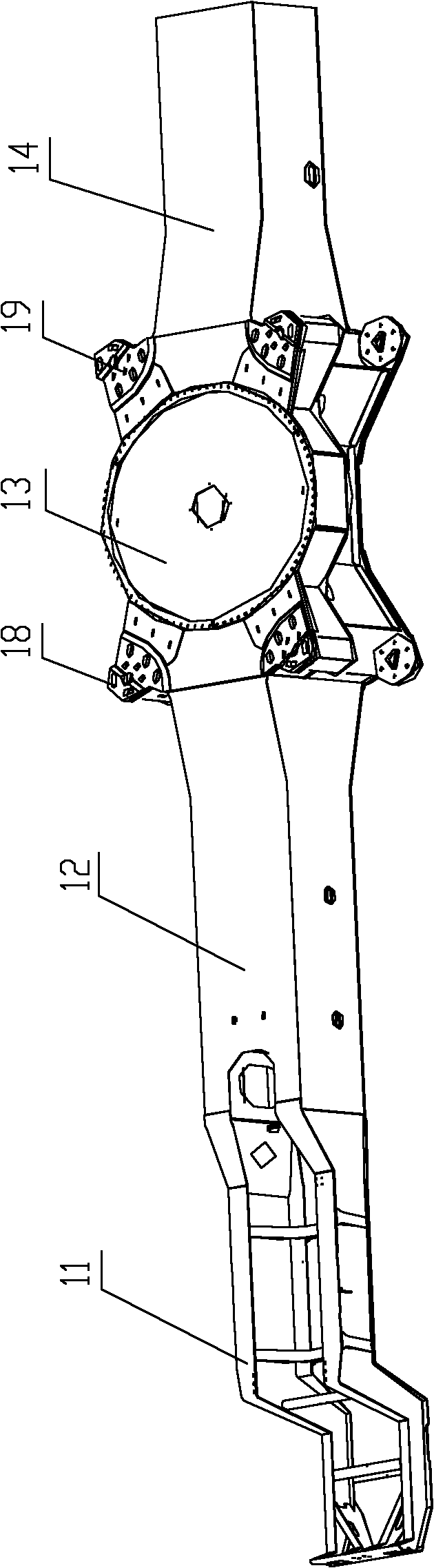

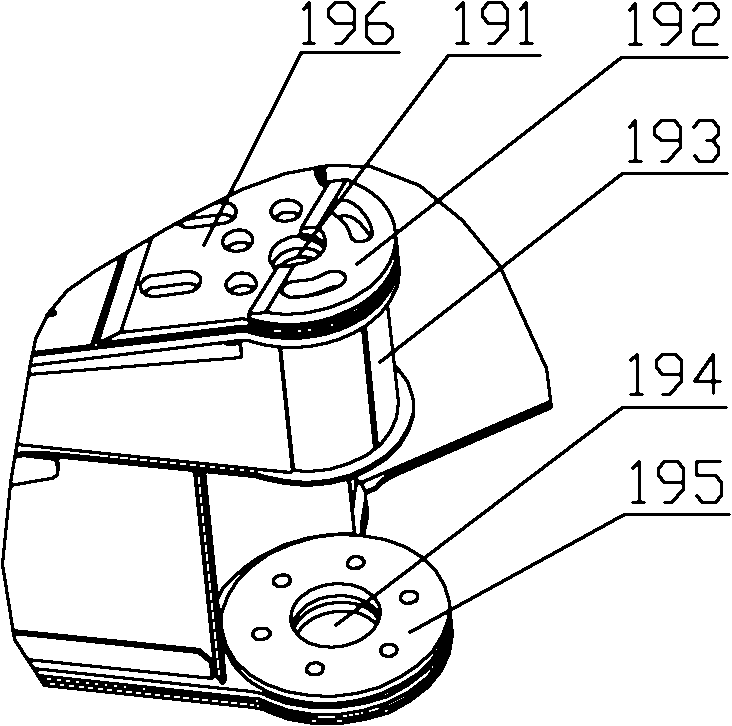

Crane and frame thereof

InactiveCN102001585AReduce horizontal sizeReduce vertical sizeBase supporting structuresBraking devices for hoisting equipmentsVehicle frameEngineering

The invention provides a frame which comprises a frame front section (11) and a frame rear section, wherein the frame rear section comprises a first rear section (12), a washer (13) for mounting a rotating platform and a second rear section (14) which are connected in sequence; the first rear section (12) is connected with the frame front section (11); the outer sides of both end parts of the connecting position of the washer (13) and the first rear section (12) are oppositely provided with two front hinging points (18) for connecting a front support leg device; and the outer sides of both end parts of the connecting position of the washer (13) and the second rear section (14) are oppositely provided with two rear hinging points (19) for connecting a rear support leg device. The frame provided by the invention has the advantages of small rear section box-shaped structure of the frame and light integral weight. In addition, the invention also provides a crane with the frame.

Owner:XUZHOU HEAVY MASCH CO LTD

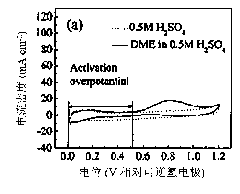

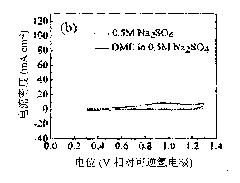

Alkaline direct dimethyl ether fuel cell

InactiveCN101800325AHigh reactivityWide variety of sourcesOrganic-compounds/hydrides/coordination-complexes catalystsCell electrodesFuel cellsIon-exchange membranes

The invention relates to an alkaline fuel cell, which aims to provide an alkaline direct dimethyl ether fuel cell. A cation exchange membrane or an anion exchange membrane is used as a membrane of the fuel cell for partitioning an anode and a cathode, an alkaline dimethyl ether solution contained in an anode catalyst carrier is used as an electrolyte, and the alkaline dimethyl ether solution is an aqueous solution in which dimethyl ether is saturated and the concentration of NaOH or KOH is 1-6 mol / L. In the invention, the dimethyl ether dissolved in lye is used as fuel, which can greatly improve the power generation performance of the direct dimethyl ether fuel cell. The alkaline direct dimethyl ether fuel cell can be applied to portable and mobile power supplies in large-scale commercial applications. An anode catalyst is beneficial to exerting the performance of a cocatalyst on improving the Co poisoning resisting performance of Pt, thereby improving the activity of the catalyst and improving the power generation performance of the dimethyl ether fuel cell. Likewise, the activity of a cathode catalyst can be improved, and the oxygen reduction reaction kinetics can be improved, thereby improving the power generation performance of the dimethyl ether fuel cell.

Owner:ZHEJIANG UNIV

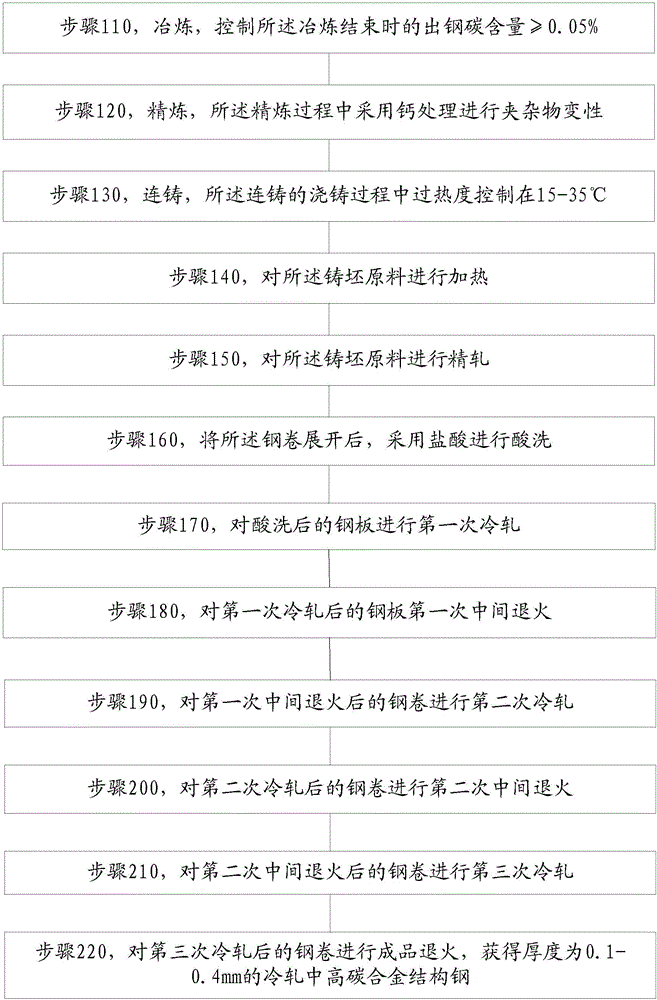

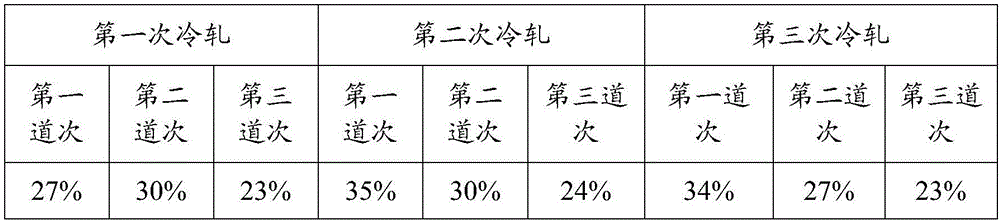

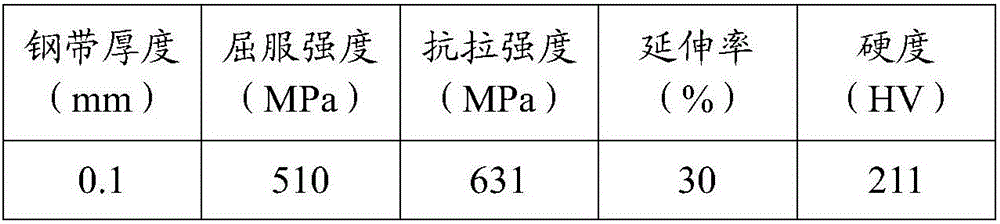

Manufacturing method of cold-rolled medium-high carbon alloy structural steel with thickness ranging from 0.1 mm to 0.4 mm

The invention discloses a manufacturing method of cold-rolled medium-high carbon alloy structural steel with the thickness ranging from 0.1 mm to 0.4 mm. The cold-rolled medium-high carbon alloy structural steel is prepared from components in percentage by weight as follows: 0.25%-0.55% of C, 0.15%-0.35% of Si, 0.10%-2.0% of Mn, 0.10%-2.0% of Cr, 0.010%-0.030% of Alt, less than or equal to 0.015% of P, less than or equal to 0.005% of S, no more than 0.3% of other added alloy elements and the balance of Fe and inevitable impurity elements. The manufacturing method comprises steps as follows: smelting, refining, continuous casting, heating, finish rolling, pickling, cold rolling, intermediate annealing, cold rolling, intermediate annealing, cold rolling and finished product annealing. Through control on inclusions in the steel, three times of cold rolling and three times of annealing, a cold-rolled medium-high carbon alloy structural steel strip with the thickness ranging from 0.1 mm to 0.4 mm is obtained. The total reduction rate of first-time cold rolling and second-time cold rolling is controlled to be larger than or equal to 50%, and the single-pass reduction rate is larger than or equal to 10%, so that lamellar carbide in different areas are crushed, the carbide is evenly separated out in the shape of fine particles through long-time low-temperature intermediate annealing, the strength is further reduced, and the plasticity is further improved.

Owner:武汉钢铁有限公司

Pad pasting tearing-off device and method

Owner:AU OPTRONICS CORP

Decompression shaft head face milling clamping mechanism

InactiveCN104526397AImprove processing efficiencyUniform deformationPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention discloses a decompression shaft head face milling clamping mechanism. A workpiece to be processed is placed in a circular arc slot through the circular arc slot, because an elastic clamp slot communicated with the circular arc slot is opened in the bottom of the circular arc slot, and moreover, the radian of the circular arc slot is larger than 180 degrees, after the workpiece is placed in the circular arc slot, the workpiece would be clamped by a round slot. Through regulating a compression screw rod on a support block and extruding an elastic slide block through the compression screw rod, the deformation of the an elastic slot in the elastic slide block is reduced, and the round slot is driven to clamp the workpiece. Because each elastic slide block is provided with two elastic slots, at least two workpieces can be processed at one time, and moreover, the workpiece clamping precision and processing precision of each workpiece are basically the same, the processing error is the same, and the processing precision is not influenced. The processing efficiency is improved, and the labor intensity is lowered.

Owner:重庆红旗缸盖制造有限公司

Time-efficient reinforced aluminium alloy extrusion

The invention discloses a time-efficient reinforced aluminium alloy extrusion, which belongs to the field of a metal material. The aluminium alloy extrusion comprises components, by weight percentage: 0.75-0.90 of Mg, 0.5-0.6 of Si, 0.10-0.14 of Cu, 0.20-0.25 of Mn, 0-0.1 of Ti, 0-0.1 of Cr, 0.1-0.3 of Fe, and 0.20-0.28 of Zn, and is balanced with Al. According to the invention, alloy components are optimized; steps of melting and casting, homogenization, extrusion, thermal treatment, and surface treatment in production technology are optimized; and mechanical properties and the surface film quality are effectively improved.

Owner:ANHUI XIN FA ALUMINUM PROD

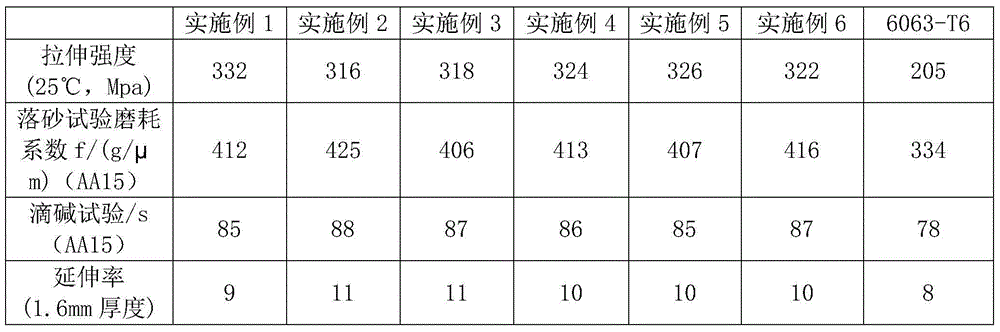

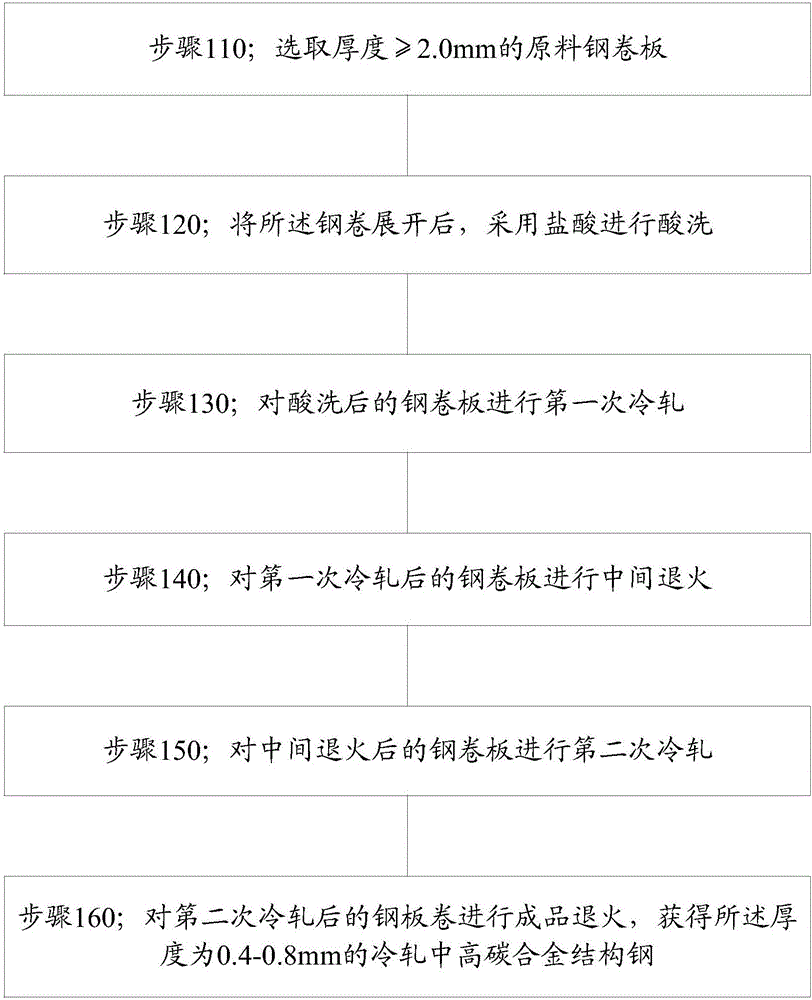

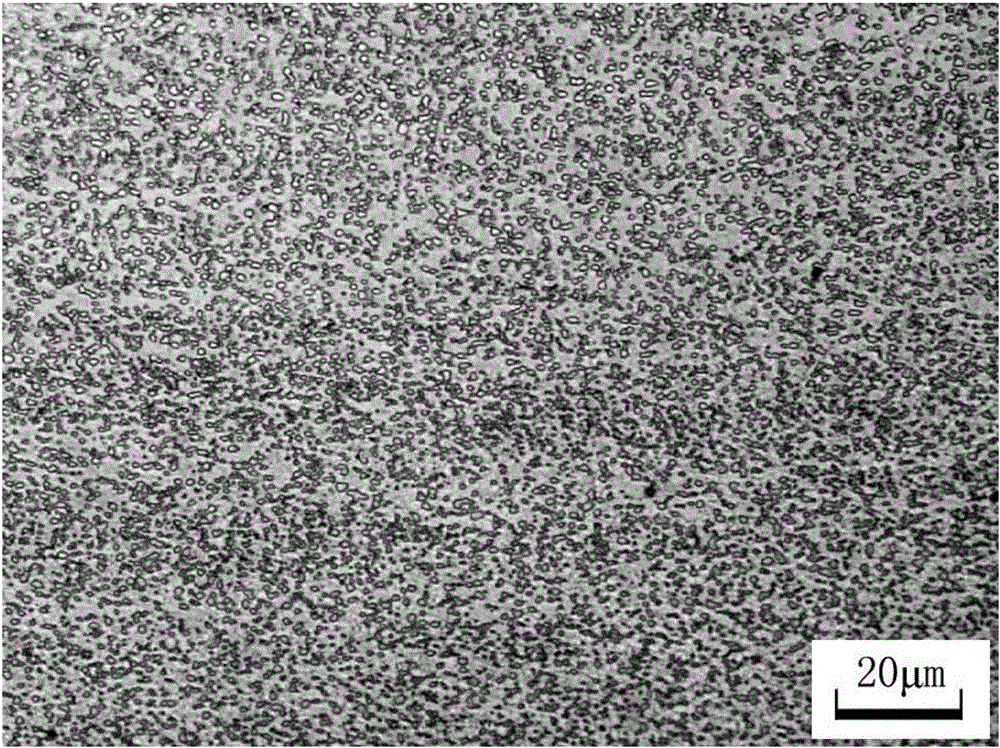

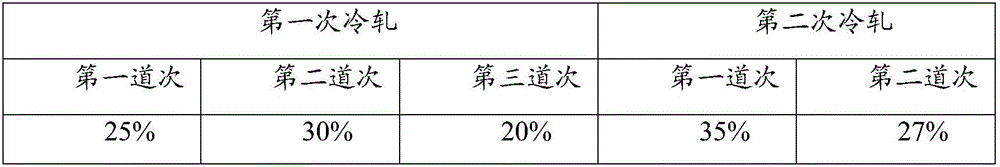

Manufacturing method of 0.4-0.8 mm thick high-carbon alloy structural steel

The invention discloses a manufacturing method of a 0.4-0.8 mm thick high-carbon alloy structural steel. The structural steel comprises the following components in percentage by weight: 0.25-0.55% of C, 0.15-0.35% of Si, 0.10-2.0% of Mn, 0.10-2.0% of Cr, less than or equal to 0.030% of Alt, less than or equal to 0.020% of P, less than or equal to 0.010% of S, no more than 0.3% of other added alloy elements, and the balance of iron and inevitable impurity elements. The manufacturing method comprises finish rolling, acid pickling, first cold rolling, intermediate annealing, second cold rolling, and finished product annealing. The product of the target thickness specification, which is obtained through twice cold rolling and twice annealing for a hot-rolled product that is previously pickled with acid, has good formability and surface quality; precise parts complex in shape and high in precision can be manufactured; in addition, the technical problems of a failure in interpenetration caused by deformation due to a high thickness and a low single-pass cold-rolling reduction ratio of a cold-rooked product and poor formability of the steel strip due to no annealing after the completion of the second cold tooling in the prior art are solved.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com