Preparation method for in-situ aluminium base composite material inoculant

An aluminum-based composite material and an inoculant technology, applied in the field of aluminum-based alloys, can solve the problems of low production efficiency, high production cost, dispersion and distribution, etc., and achieve the effects of high production efficiency, low production cost, and enhancement effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The first step, ingredients

[0050] According to the set composition ratio of 10.0%Ti, 0.9%B and the rest is Al, weigh the required amount of domestic Al-5Ti-1B alloy and metal pure Ti, and carry out the ingredients. The above percentages are weight percentages.

[0051] In the second step, the alloy is smelted to obtain a smelted bulk Al-10Ti-1B alloy

[0052] Put all the ingredients in the first step into a non-consumable vacuum arc furnace, and vacuumize to a degree of vacuum of 1.26×10 -2 Pa, heating all the ingredients to the melting temperature, and pouring into a steel mold after holding for 5 minutes to obtain a smelted Al-10Ti-1B alloy.

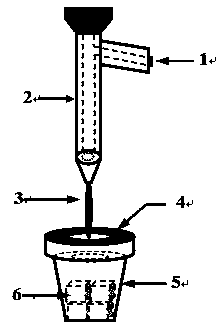

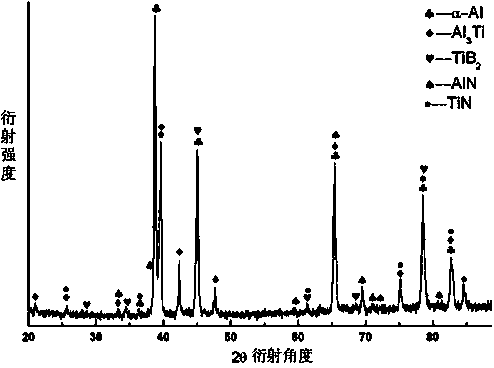

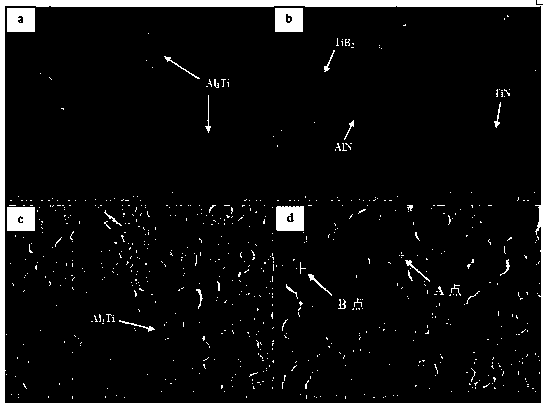

[0053]The third step, plasma nitriding treatment to obtain bulk AlN-TiN / Al composites

[0054] Put the smelted Al-10Ti-1B alloy obtained in the second step into a graphite crucible, and then cover the crucible with a graphite lid with a hole in the middle. Each time the plasma nitriding treatment is performed, the flow rate...

Embodiment 2

[0058] The first step, ingredients

[0059] According to the set composition ratio of 10.2%Ti, 1.1%B and the rest are Al, weigh the required amount of domestic Al-5Ti-1B alloy and metal pure Ti, and carry out ingredients, and the above percentages are weight percentages;

[0060] In the second step, the alloy is smelted to obtain a smelted bulk Al-10Ti-1B alloy

[0061] Put all the ingredients in the first step into a non-consumable vacuum arc furnace, and vacuumize to a degree of vacuum of 1.26×10 -2 Pa, heating all the ingredients to the melting temperature, and pouring into a steel mold after holding the temperature for 6 minutes to obtain a smelted Al-10Ti-1B alloy.

[0062] The third step, plasma nitriding treatment to obtain bulk AlN-TiN / Al composites

[0063] Put the smelted Al-10Ti-1B alloy obtained in the second step into a graphite crucible, and then cover the crucible with a graphite lid with a hole in the middle. Each time the plasma nitriding treatment is perfor...

Embodiment 3

[0067] The first step, ingredients

[0068] According to the set composition ratio of 10.5%Ti, 1.2%B and the rest are Al, weigh the required amount of domestic Al-5Ti-1B alloy and metal pure Ti, and carry out ingredients, and the above percentages are weight percentages;

[0069] In the second step, the alloy is smelted to obtain a smelted bulk Al-10Ti-1B alloy

[0070] Put all the ingredients in the first step into a non-consumable vacuum arc furnace, and vacuumize to a degree of vacuum of 1.26×10 -2 Pa, heating all the ingredients to the melting temperature, and pouring into a steel mold after holding for 8 minutes to obtain a smelted block Al-10Ti-1B alloy.

[0071] The third step, plasma nitriding treatment to obtain bulk AlN-TiN / Al composites

[0072] Put the smelted Al-10Ti-1B alloy obtained in the second step into a graphite crucible, and then cover the crucible with a graphite lid with a hole in the middle. Each time the plasma nitriding treatment is performed, the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com