Patents

Literature

3024results about How to "Enhanced interface binding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

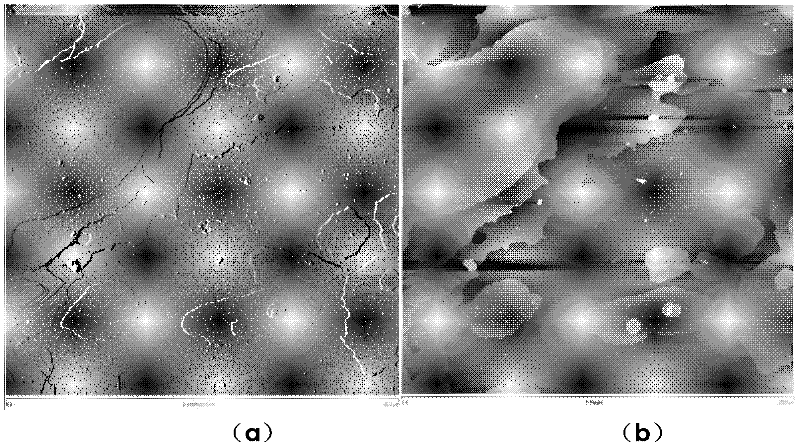

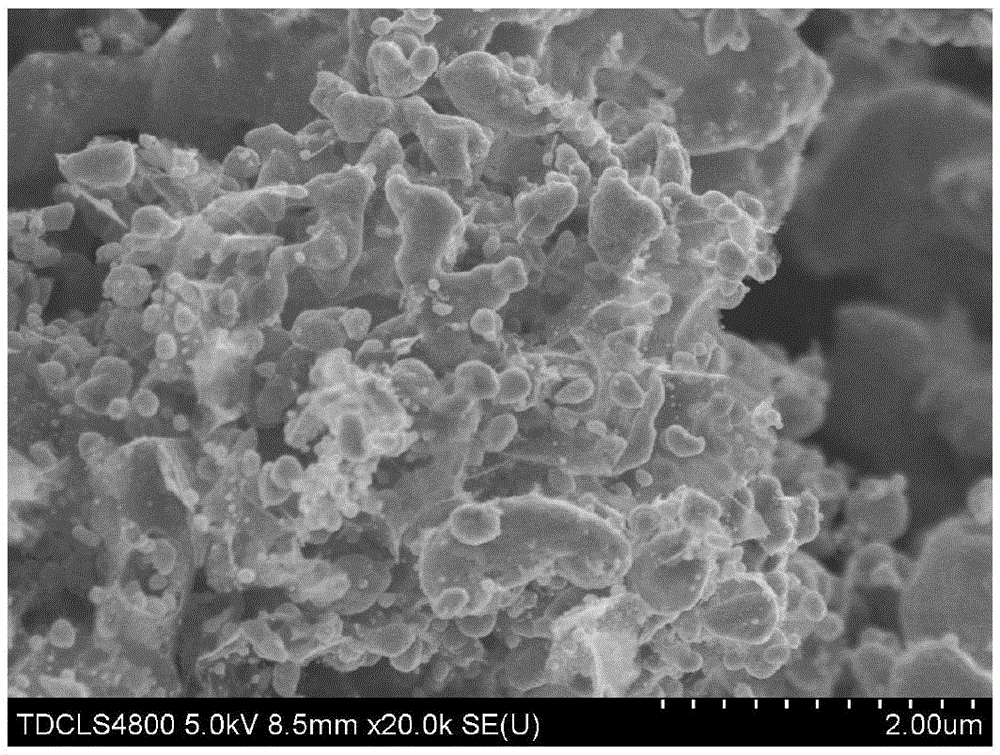

Preparation method of completely peeled oxidation graphene/ rubber nanometer composite material

A preparation method of completely peeled oxidation graphene / rubber nanometer composite material adopts combination of emulsion compounding and flocculation processes or combination of emulsion compounding and spraying drying processes. The preparation method retains the phase state structure of the oxidation grapheme / rubber composite emulation in the liquid state and obtains the phase-state structure which is highly dispersed, highly peeled and dispersed in nanometer scale dispersion. Simultaneously, substances capable of acting with generating ionic bond effect or chemical bond effect with an oxidation graphene surface functional group are added into the oxidation graphene / hydrosol to serve as an interface agent, thereby improving interface combination effect of oxidation graphene and rubber. Vulcanized rubber prepared by the composite material of the preparation method through follow-up mixing and vulcanizing has mechanical property such as high tensile strength, stretching stress and tearing strength and is capable of greatly improving abrasion resistance and gas separation performance of the vulcanized rubber. The preparation method is simple, easy, low in cost, apt to industrialization and wide in suitable aspect, saves energy and has better economical and social benefits.

Owner:JIANGSU LVYUAN RUBBER RESOURCE RECYCLING INNOVATION CENT CO LTD

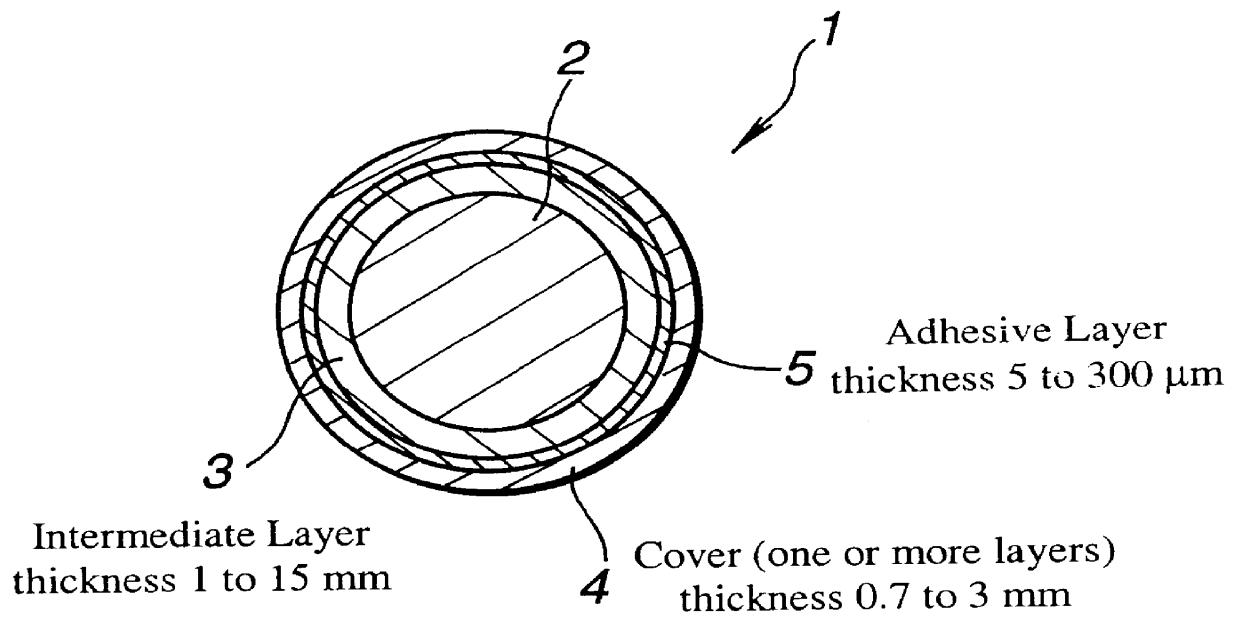

Multi-layer structure solid golf ball

InactiveUS6106415AImproved in rebound and spin propertyInterface be avoidedGolf ballsSolid ballsIonomerEngineering

Owner:BRIDGESTONE SPORTS

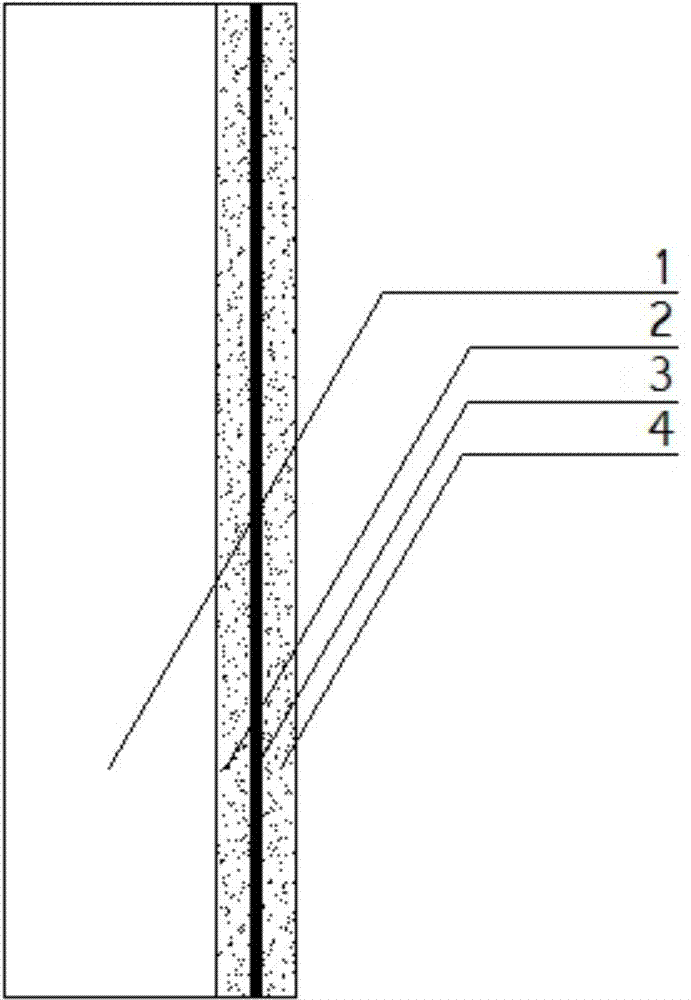

Reinforced aerogel composite material and preparation method thereof

The invention provides a reinforced aerogel composite material and a preparation method thereof. The reinforced aerogel composite material comprises single aerogel or two aerogels or more than two aerogels, the surfaces or block interfaces of the block aerogel are coated or bound into a whole by virtue of fiber mesh fabric-reinforced waterborne adhesive. The preparation method of the reinforced aerogel composite material comprises the following steps: (1) carrying out hydrophobic modification treatment on the surfaces; (2) carrying out hydrophilic / hydrophobic modification treatment on the surfaces; and (3) preparing the reinforced aerogel composite material: uniformly coating the surface of the block aerogel or the interface of two aerogels with waterborne adhesive and fiber mesh fabric and curing to obtain the reinforced aerogel composite material. The reinforced aerogel composite material provided by the invention has the characteristics of excellent thermal-insulation property, heat preservation property, sound insulation property, fireproof property, explosion resistance, shock absorption, energy absorption, light weight, better mechanical properties, the preparation process of the material is simple and practical and the material has wide range of applications.

Owner:NANJING WEICAI NEW ENERGY TECH

Environmental-friendly waterproof polymer mortar

InactiveCN101560084AImprove adhesionStrong bondSolid waste managementSilicate CementConstruction aggregate

The invention relates to environmental-friendly waterproof polymer mortar, which comprises the following components in portion by weight: 50 to 230 portions of low-clinker silicate cement, 200 to 450 portions of quartz sand, 80 to 120 portions of fly ash, 1 to 18 portions of re-dispersible polyethylene vinyl acetate latex powder, 1 to 10 portions of dispersible polyvinyl acetate vinyl versatate latex powder, 0.2 to 0.6 portion of water reducing agent, 0.05 to 0.3 portion of antifoaming agent, and 0.25 to 2.25 portions of polypropylene fibers. A gel material prepared from steel slag, tailings and the fly ash replaces silicate cement and partial aggregate in the prior mortar; the modified waterproof polymer mortar has the advantages of excellent impermeability, good mechanical property and construction property, simple production technology, and easy manufacture, greatly consumes industrial and mining wastes, controls the ecological environment, and lowers the cost; and the product has reliable quality and wide market; and the environmental-friendly waterproof polymer mortar can be popularized and applied in large area.

Owner:黑龙江省学府环艺雕塑有限公司

Composite material of modified micro plant fiber powder and natural rubber and its prepn process and application

The present invention discloses one kind of composite material of modified micro plant fiber powder and natural rubber and its preparation process and application. The composite material includes natural rubber or latex 100 weight portions, modified micro plant fiber powder 1-60 weight portions, sulfur 0.5-3.3 weight portions, promoter 1.2-4.3 weight portions, antiager 1-3 weight portions and other assistant. The preparation process includes mixing, forming, vulcanizing and other steps. The composite material has high tensile strength, high tearing strength, high ageing resistance, high virus permeation resistance, etc. and may be used widely in making urinary catheter, blood transfusion tube, condom, medical gloves and other products.

Owner:JINAN UNIVERSITY

Resistive nanocomposite compositions

InactiveUS20030100653A1Improve mechanical propertiesEasy to wearNanotechPrinted electric component incorporationScreen printingOrganic solvent

A resistive composition for screen printing onto a substrate. The resistive composition, based on total composition has a) 5-30 wt. % of polymer resin, b) greater than 0 up to and including 10 wt. % of thermosetting resin, c) 10-30 wt. % conductive particles selected from the group consisting of carbon black, graphite and mixtures thereof and d) 0.025 -20 wt. % carbon nanoparticles, wherein all of (a), (b), (c) and (d) are dispersed in a 60-80 wt. % organic solvent.

Owner:CTS CORP ELKHART

Thermoplasticity sizing agent for carbon fiber and preparation and usage thereof

The invention provides a thermoplasticity sizing agent for a carbon fiber as well as a preparation method and a usage method thereof and relates to solvent sizing agent for a carbon fiber as well as a preparation method and a usage method thereof. According to the invention, the problems that the existing thermoplastic sizing agent is complicate in preparation process and pollutes the environment are solved. The preparation method is as follows: the thermoplastic resin, an organic solvent A and an adjuvant are mixed and stirred uniformly so as to obtain the thermoplastic sizing agent, when being used, the carbon fiber is dipped in the thermoplasticity sixing agent, then fractioning is carried out on the carbon fiber with agent and the treated carbon fiber is dipped in an organic solvent B, and finally the carbon fiber is dried. According to the invention, the wettability of the carbon fiber and the high performance thermoplasticity resin of polyarylether can be improved, the boundary bonding performance of the carbon fiber or the resin matrix composite of thermoplasticity polyarylether can be improved, and the thermoplasticity sizing agent has the advantages that the cost is low, the performance is stable, the utilization is stable and the environment is not polluted. The thermoplasticity sizing agent for the carbon fiber is used for the surface treatment of a carbon fiber material.

Owner:HARBIN INST OF TECH

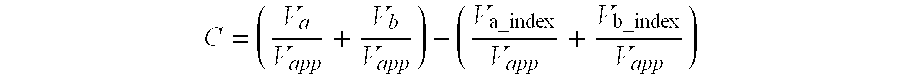

High-performance powder concrete for 3D (three-dimensional) printing

The invention relates to high-performance powder concrete for 3D (three-dimensional) printing. The concrete is prepared from the following raw materials in parts by weight: 500-900 parts of ordinary Portland cement, 250-350 parts of active mineral admixture, 800-1,300 parts of inert filler, 10-20 parts of composite efficient water reducing agent powder, 2-5 parts of thickener, 4-10 parts of self-curing agent, 2-10 parts of fast setting time regulator, 145-230 parts of water, 3 parts of organic fiber and 40-200 parts of copper plated fiber. The concrete material for 3D printing has the characteristics of ultrahigh strength and toughness, good durability, long full life cycle, high curing rate, good flowing property and easiness in pumping and lifting and is suitable for constructing 3D-printed building structural materials in all kinds of engineering.

Owner:黄贺明

Multifunctional concrete structure endurance protective agent, preparation and application method thereof

The invention discloses a multifunctional concrete structure endurance protective agent as well as the preparation and application method thereof. The protective agent provided by the invention contains the following ingredients of: an organic / inorganic composite fluorosilicone-acrylate copolymer, lithium silicate, sodium silicate, lithium molybdate, sodium tetraborate, sal glauberi, 1,2-aminoazophenylene, nanometer titanium dioxide, anhydrous ethanol and water. The protective agent can penetrate inside concrete, wherein a densification ingredient can minimize internal holes and cracks to raise the compactness of concrete, and a rust-resistant ingredient can penetrate into concrete and be adsorbed on the surface of steel bar so as to passivate and protect the steel bar; the low-surface energy silicon fluoride ingredient can be solidified to form a cured film on the surface of concrete so as to endow the protective agent with the hydrophobic performance; a nanometer ingredient can endow the cured film layer with properties of resisting ultraviolet and ageing and improving the organic polymer performance as well as the self-cleaning performance. In addition, hydroxy generated from the hydrolysis of siloxane group can perform a condensation reaction with hydroxy on the surface of concrete to produce chemical bond, so as to raise the anchoring strength between the film and concrete and improve the interface combination. The protective agent provided by the invention can be widely applied in various concrete structure engineering protections to raise the service life of concrete.

Owner:CENT SOUTH UNIV +1

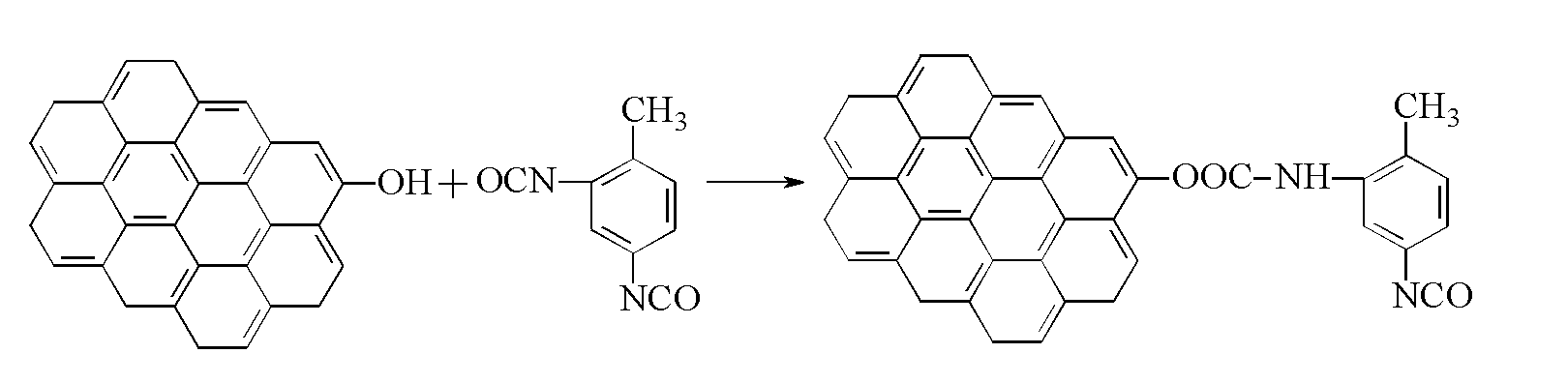

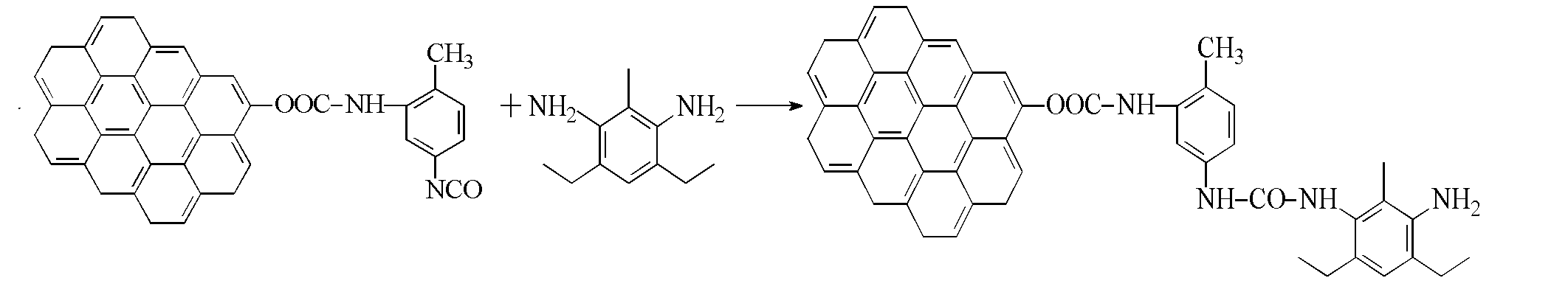

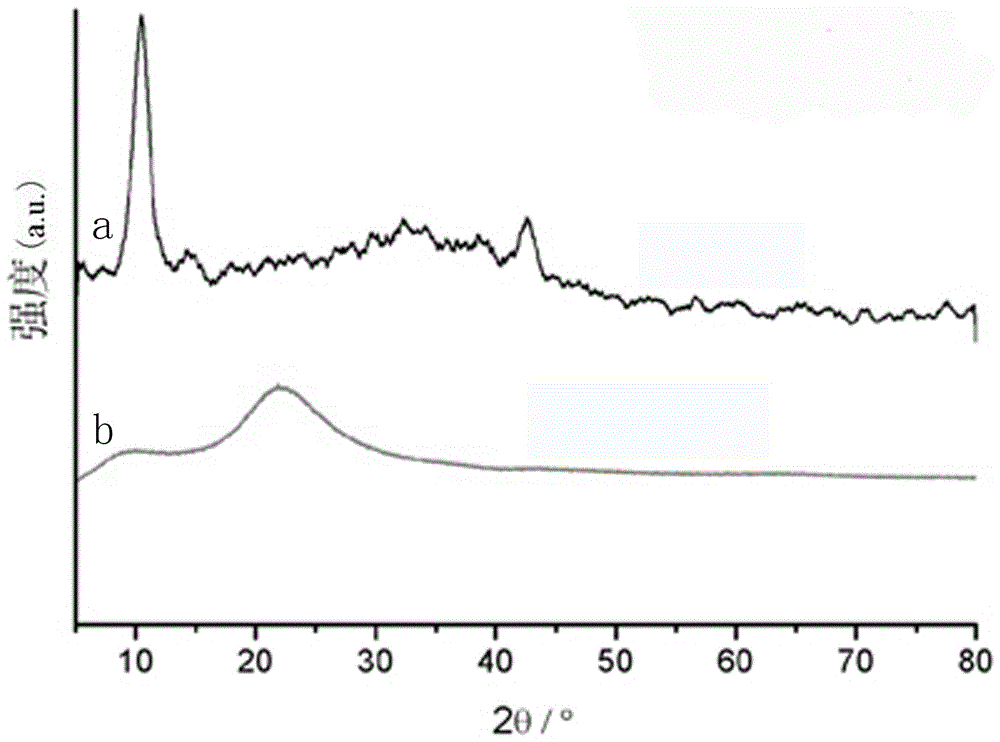

Modified graphene/epoxy resin composite material and preparation method thereof

The invention provides a modified graphene / epoxy resin composite material and a preparation method thereof. The modified graphene / epoxy resin composite material has a two-phase structure, wherein an epoxy resin substrate serves as a main body, and black modified graphene serves as a wild phase. A preparation process comprises the following steps of: preparing graphite oxide; preparing graphene oxide; and preparing a modified graphene / epoxy resin composite material. The modified graphene / epoxy resin composite material has higher toughness compared with epoxy resin and a graphene / epoxy resin composite material, the interface bonding performance between graphene and epoxy resin is greatly enhanced, and the utilization of the performance of graphene is facilitated. By adopting the preparationmethod of the modified graphene / epoxy resin composite material, provided by the invention, the reaction temperature for the preparation of graphite oxide serving as an intermediate product is raised,thus the reaction speed is increased.

Owner:BEIHANG UNIV

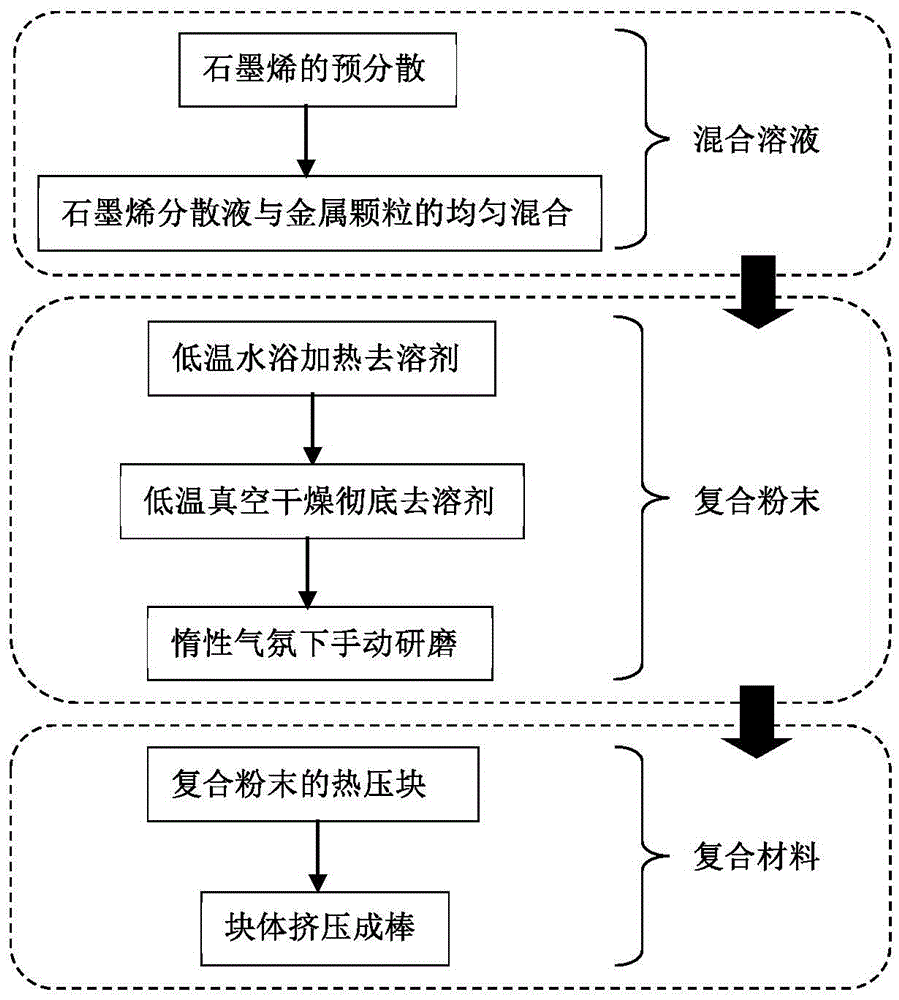

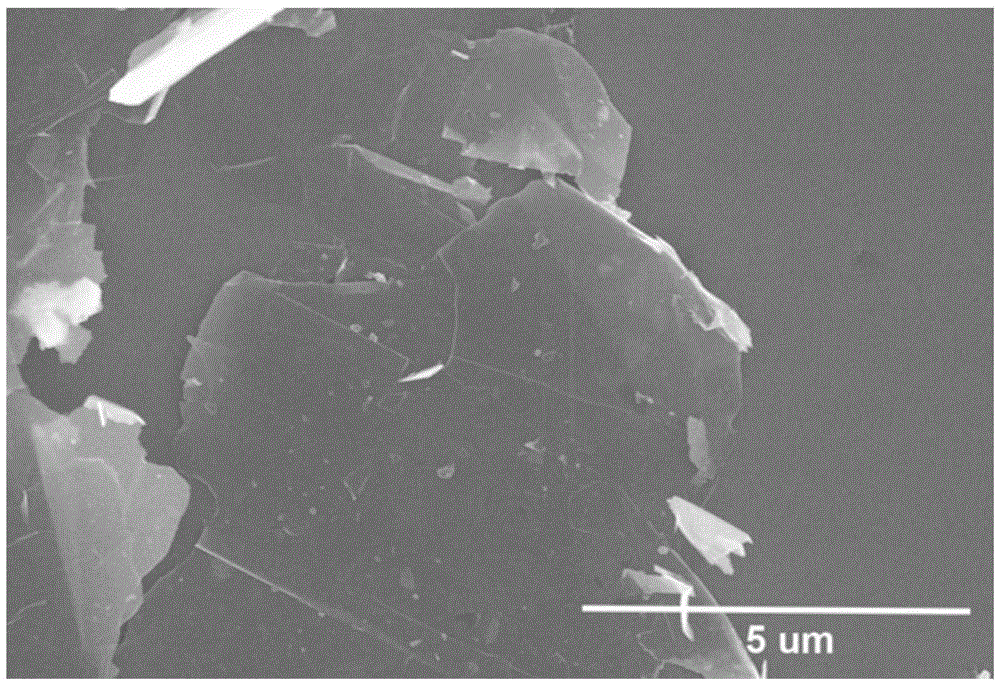

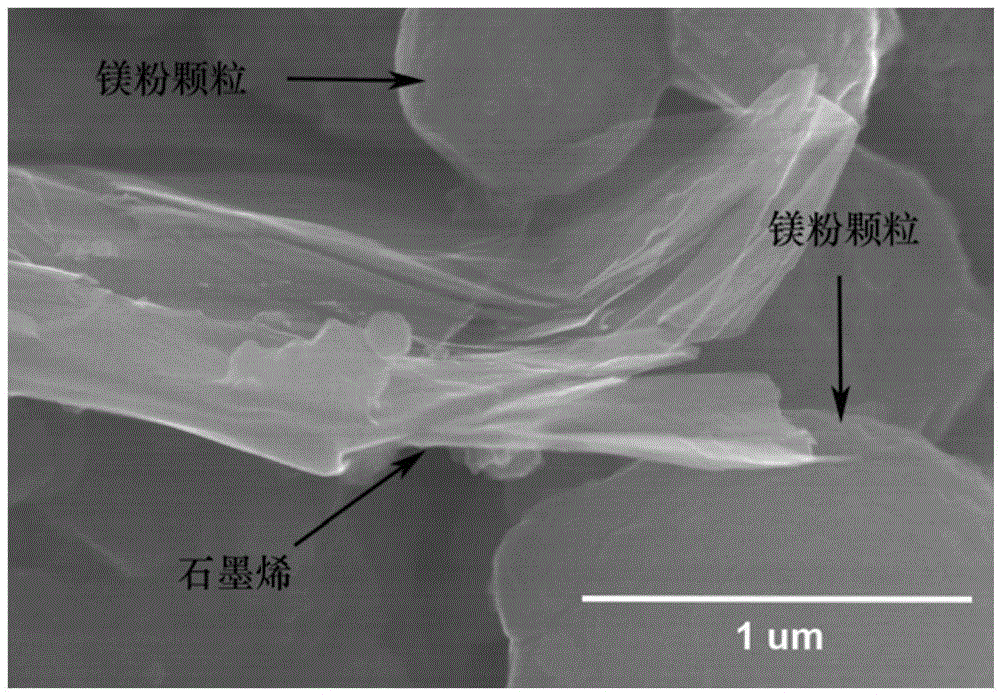

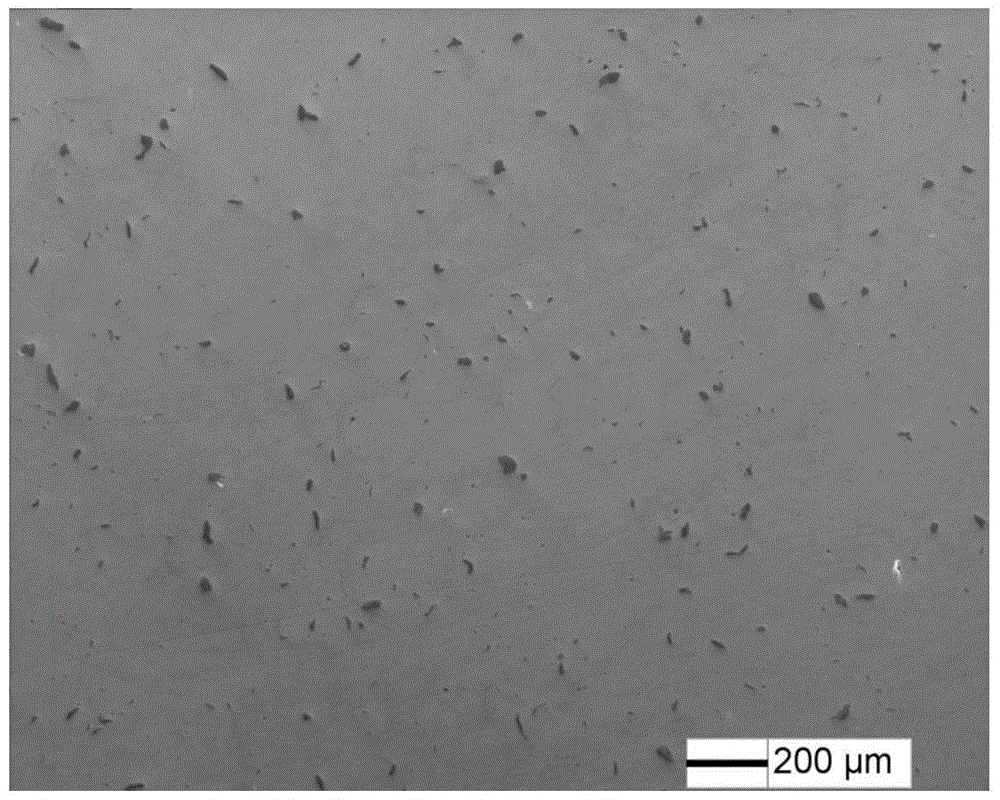

Graphene-reinforced magnesium-aluminium matrix composite material and preparation method thereof

The invention discloses a graphene-reinforced magnesium-aluminium matrix composite material and a preparation method thereof, and belongs to the technical field of composite materials. The preparation method comprises the following steps: dissolving graphene in an appropriate amount of ethanol solution and ultrasonically dispersing, then intermittently adding a metal powder in the solution, and ultrasonically dispersing and mechanically stirring simultaneously to obtain graphene / metal particle mixed solution with high dispersibility; sequentially carrying out the operations of heating in a low-temperature water bath to remove a solvent, drying in vacuum to obtain a powder, and continuously manually grinding the powder under an inert atmosphere, on the mixed solution, so as to obtain a graphene / metal particle composite powder with uniform dispersion; and carrying out hot-pressing on the composite powder into blocks, carrying out hot extrusion, and finally obtaining the graphene / metal matrix composite material. The preparation process disclosed by the invention is simple, environment-friendly, and free from addition of a non-volatile organic dispersant; low-temperature inert protection is adopted during the process of preparing the composite powder, and high own dispersion of graphene and high dispersion thereof in a metal matrix are achieved while the structural integrity of a graphene reinforcement is kept; and the preparation method is suitable for preparing the high-performance graphene-reinforced metal matrix composite material.

Owner:BEIJING UNIV OF TECH

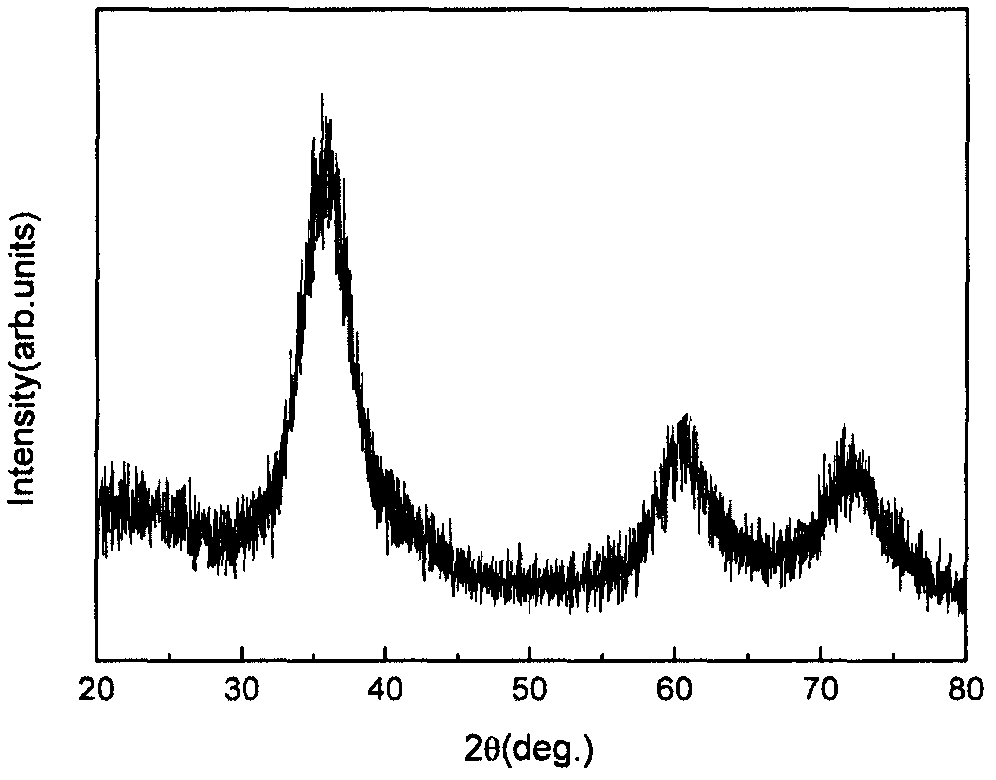

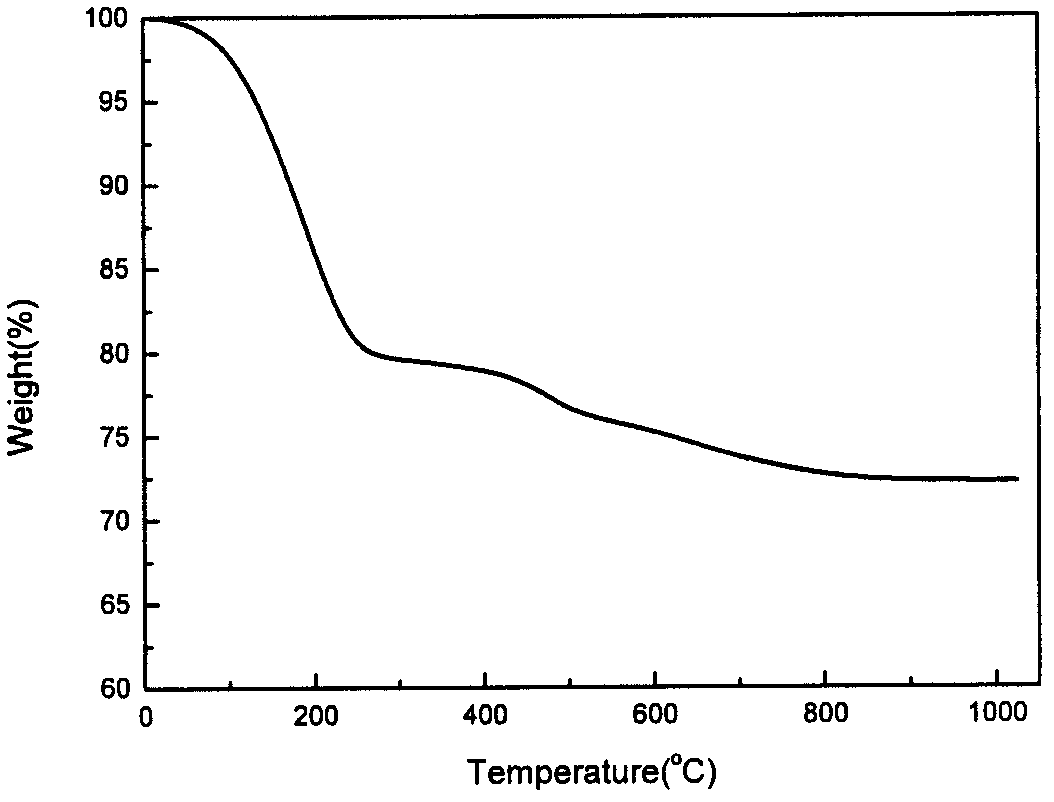

Preparation method of graphene/g-C3N4 compound photocatalyst

InactiveCN103769187AHigh degree of oxidationIncrease the areaPhysical/chemical process catalystsDecompositionHigh energy

The invention relates to a preparation method of a graphene / g-C3N4 compound photocatalyst, and adopts a high temperature decomposition method to prepare the graphene / g-C3N4 compound photocatalyst. The method comprises the following steps of (1) preparing g-C3N4 powder by adopting concentrated hydrochloric acid melamine through high temperature decomposition; (2) synthesizing high specific surface area graphite oxide by adopting an improved Hummers method, stripping the graphite oxide in an ultrasound manner, removing the graphene with the low oxidation degree through centrifugation, finally extracting a supernatant liquid, drying, and preparing polarity graphene oxide powder; and (3) uniformly mixing the prepared graphene oxide powder and the g-C3N4 through a high energy ball grinder to dissolve in hydrazine hydrate, and preparing the graphene / g-C3N4 compound photocatalyst with a high photocatalytic activity. The preparation method provided by the invention has the advantages that a raw material is cheap, the technology is simple and convenient and the like, and the prepared compound photocatalyst has the wide application prospect on the fields such as wastewater treatment and gas purification.

Owner:JIANGSU YUEDA NEW MATERIALS TECH

Wood-plastic composite material and method of preparing the same

The invention discloses a wood-plastic composite material and a preparation method thereof. The composite material includes the following materials by the weight portion: 100 portions of reclaimed plastic particles, 80-100 portions of bamboo powder, 80-100 portions of inorganic filler, 1-2.5 portions of titanic acid ester, 1-5 portions of compatibilizing agent, 8-10 portions of lubricant and 1-2 portions of functional auxiliary agent. Compared with the prior art, the invention integrates the advantages of inorganic filler and bamboo fiber, reduces the dosage of vegetable fiber in the traditional wood-plastic formula, and increases the dosage of inorganic filler; the composite material prepared by the method has higher toughness and rigidity, lower water absorption rate and smaller molding shrinkage; and the pollution of waste plastics and vegetable fibers to the environment is reduced.

Owner:HUANGSHAN HUASU NEW MATERIAL SCI & TECH CO LTD +1

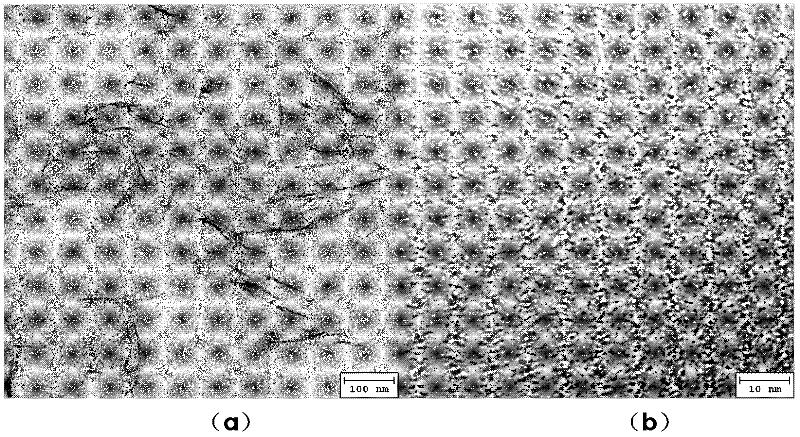

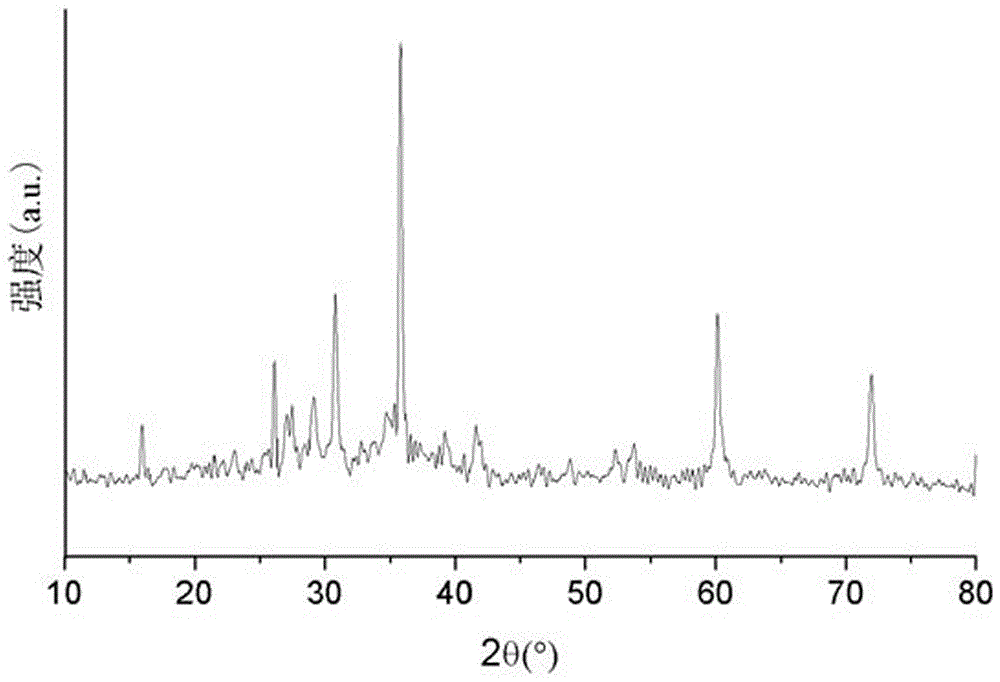

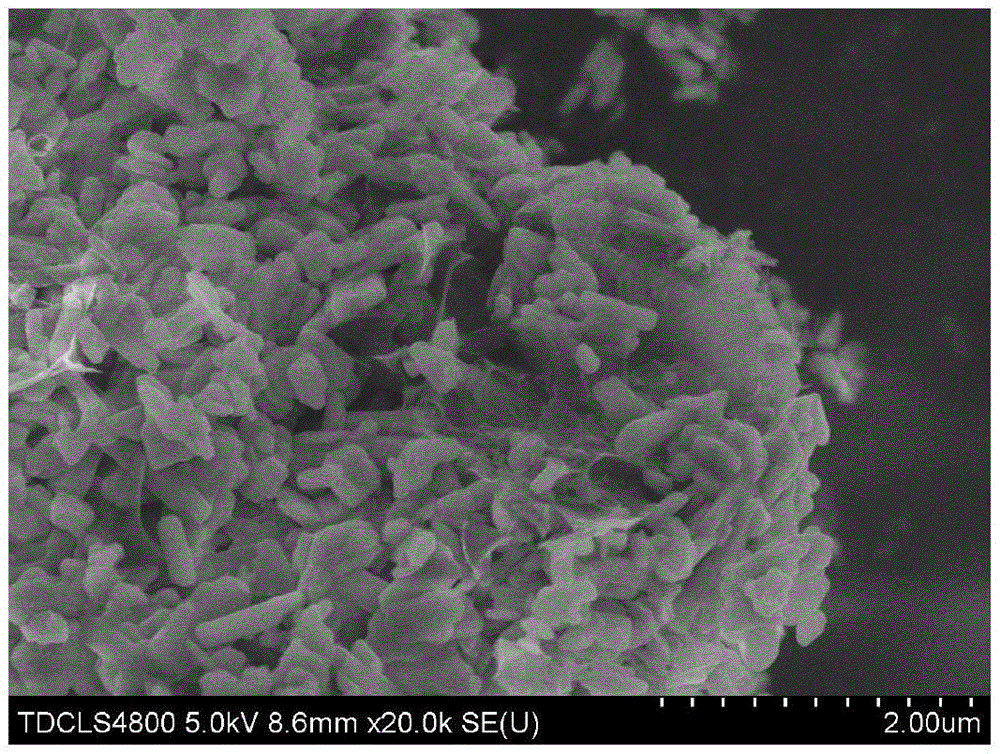

Method for preparing graphene toughened silicon carbide ceramic composite material

ActiveCN105801154AImprove mechanical propertiesEnhanced interface bindingCeramic compositeOxidation resistant

The invention belongs to the field of macromolecule inorganic chemistry, and in particular relates to a method for preparing a graphene toughened silicon carbide ceramic composite material. Specifically, the method comprises the following steps: by taking graphite oxide as a carbon source, wrapping the surface of reduced graphene oxide with a layer of SiO2 granules by using a hydrothermal method so as to form a good interface layer between graphene and SiC, uniformly dispersing, and implementing carbon thermal reduction reaction at the interface of graphene and SiO2 in the high-temperature sintering process so as to growth silicon carbide crystal whisker and granules in situ, thereby improving the interface strength and the oxidation resistance, achieving an interface intensification function, improving crack expansion resistance and further improving the fracture toughness of ceramic. The method aims at the defects that graphene is poor in dispersity and high-temperature oxidation resistance in a conventional graphene / silicon carbide composite material, in-situ growth, crack self-healing and toughness mechanisms are applied to a preparation technique of a graphene / silicon carbide material, and thus graphene toughened silicon carbide ceramic with excellent mechanical properties and interface binding properties can be prepared.

Owner:ZHONGYUAN ENGINEERING COLLEGE

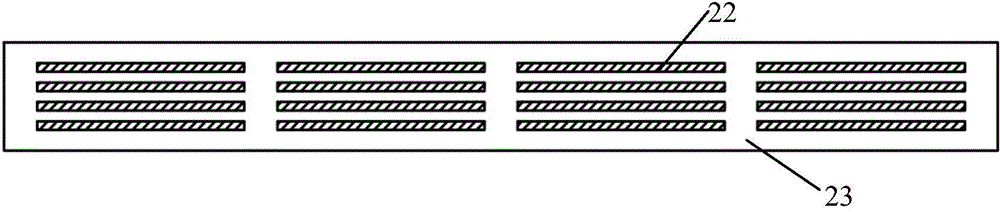

Pultrusion method for thermoplastic composite material and forming die thereof

InactiveCN1730270AImprove impregnation effectImprove mechanical propertiesPolymer scienceFiber bundle

The invention relates to a pultrusion method for thermoplastic composite, which takes fortifying fiber and matrix fiber as raw material, including the following steps: a. placing matrix fiber and fortifying fiber on the creel in the weight ratio of 95-20:5-80; b. loading the fortifying fiber and matrix fiber to demand scale into the preheat chamber by the thread wire and board and preheating them; c. loading the preheated mixed fiber tuft into the preforming die, so the tuft near to the entrance shape of the forming die; d. loading the preformed mixed fiber into the forming die. Certainly the performing die and forming die can be diad, with performing segment and forming segment in one die; e. after loading out from the forming die the section bar cooling and shaping to get products. The invention overcomes the socking problem of high molecular polymer, improving the socking effects of thermoplastic composites, and the mechanical property enhances dramatically.

Owner:SINOMA SCI & TECH

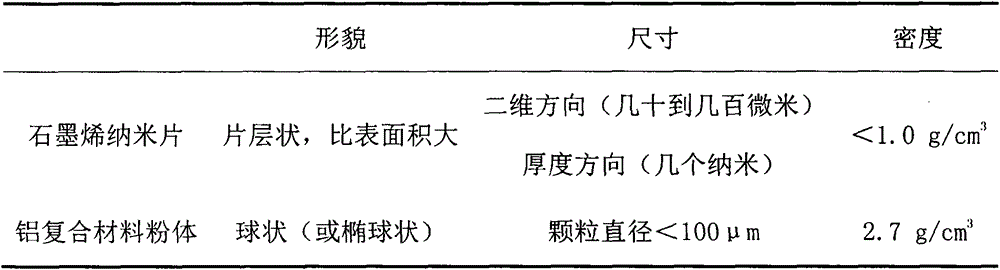

Method for preparing graphene reinforced metal-based composite material through discharge plasma (SPS) sintering

The present invention relates to a method for preparing a graphene reinforced metal-based composite material through discharge plasma (SPS) sintering. The method is characterized in that the graphene reinforced metal-based block material is prepared through SPS sintering and has the following advantages that: the preparation method is simple, the material is compact and does not have pores, the graphene mass fraction can be arbitrarily regulated, the distribution is uniform, no aggregation is generated, the material mechanical property isotropy is provided, and the wettability of the metal and the graphene interface is good. The method comprises: (1) reducing graphene oxide through a chemical method or a hydrothermal method to obtain graphene sheets with a sheet layer thickness of not more than 4 nm and sheet layer diameter of not more than 50 [mu]m; and (2) preparing metal powder with a particle size of not more than 200 [mu]m through a rotating electrode atomization method, mechanical crushing or a high-speed ball milling method; (3) carrying out mechanical or ball milling mixing on the graphene powder and the metal powder according to the required mass ratio; and (4) carrying out SPS sintering forming on the mixed powder, wherein the obtained material has characteristics of improved mechanical property, decreased density, good heat conduction capability, and good electric conduction capability, and the performance customizing can be achieved by adjusting the preparation parameters.

Owner:BEIHANG UNIV

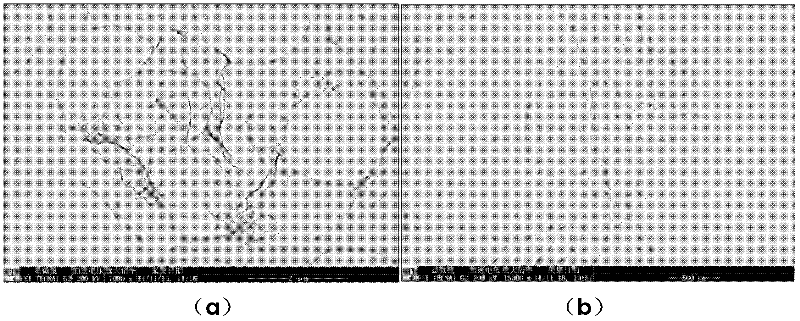

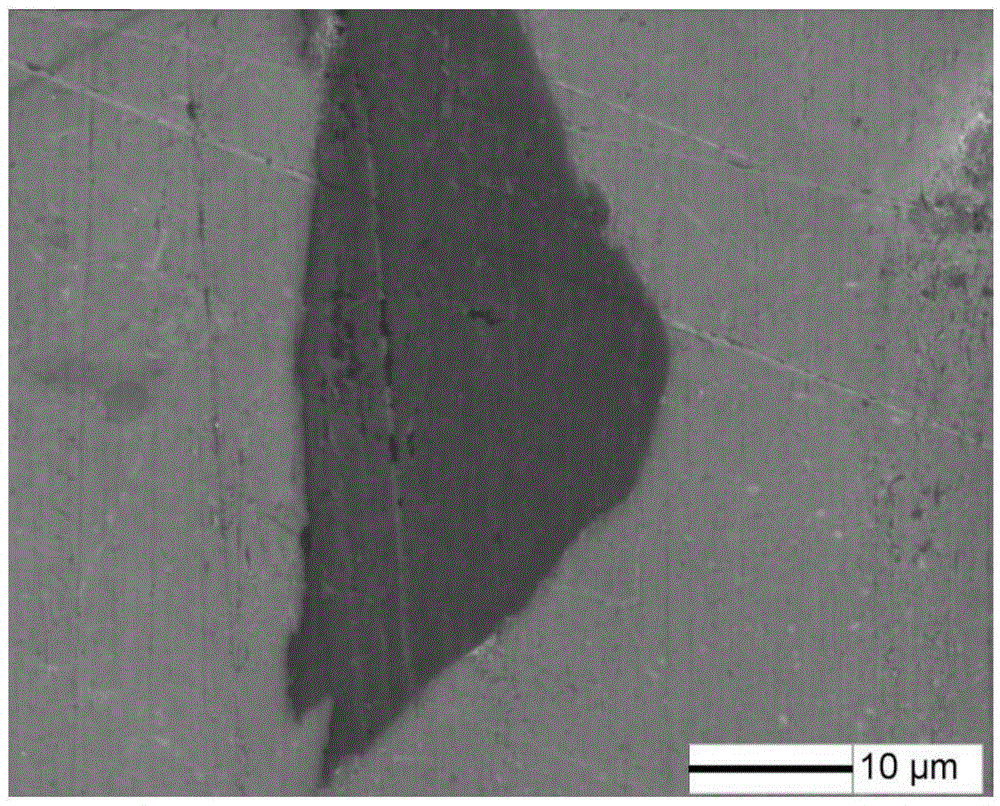

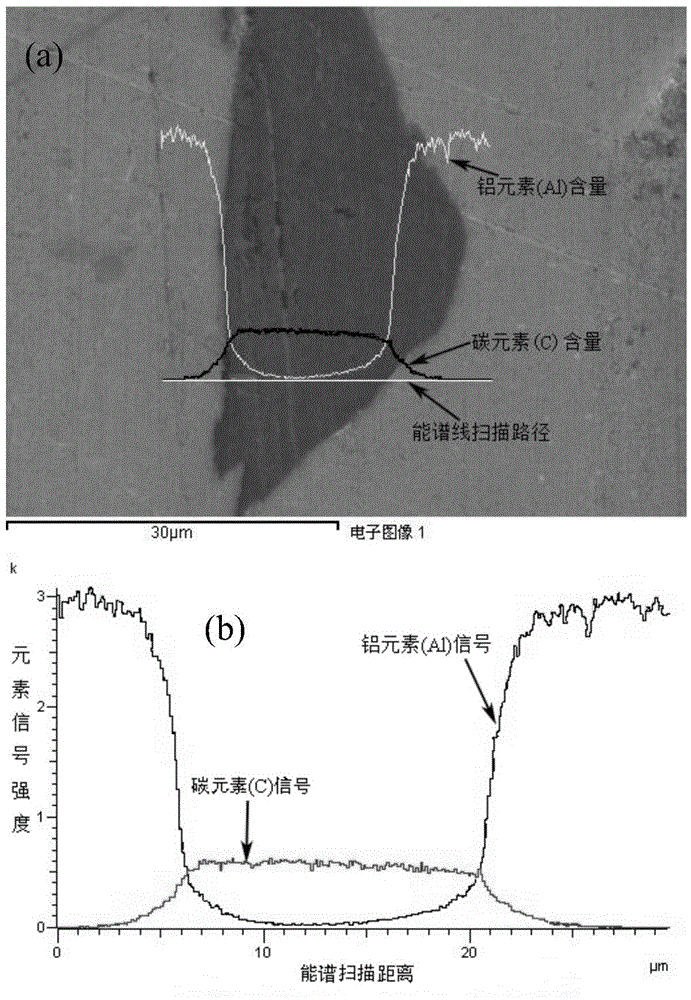

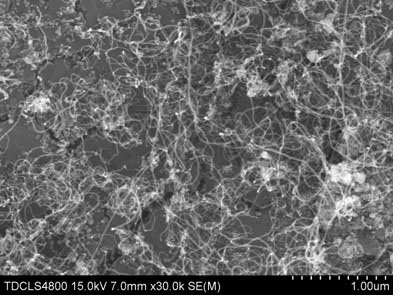

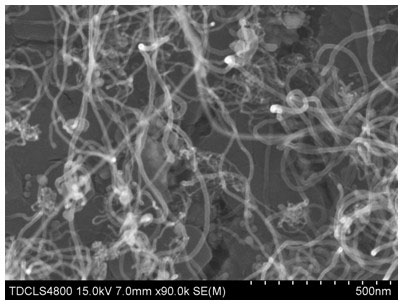

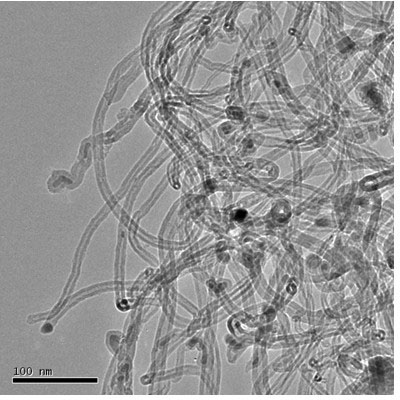

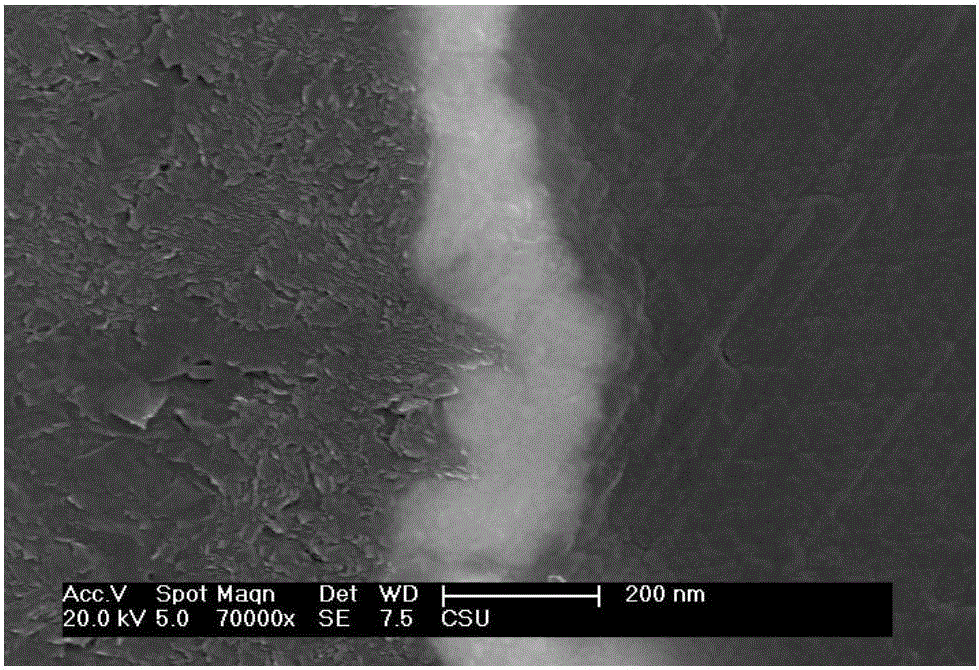

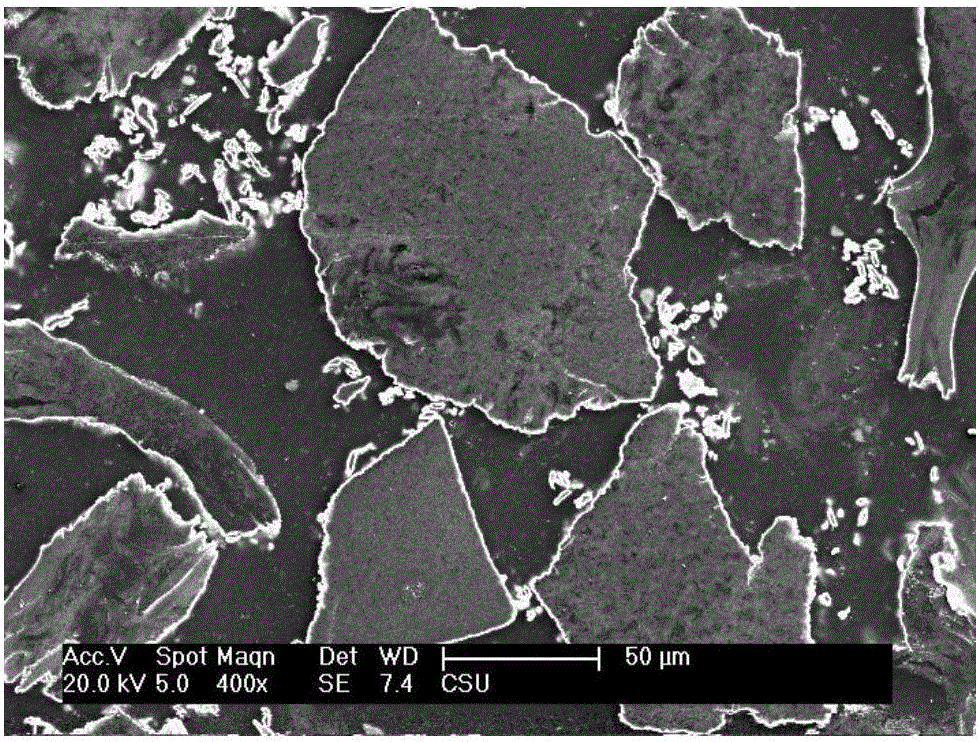

Method for preparing carbon nanotube reinforced aluminum-based composite material

InactiveCN102424919AImprove mechanical propertiesEnhanced interface bindingCarbon nanotubeAluminum substrate

The invention relates to a method for preparing a carbon nanotube reinforced aluminum-based composite material and belongs to a technique for preparing aluminum-based composite materials. The method comprises: preparing composite powder in which carbon nanotubes are uniformly distributed on the surface of aluminum powder by using cobalt as a catalyst and by using a chemical vapor deposition process; allowing the carbon nanotubes to reach deep parts of the aluminum powder substrate by using a ball milling process; densifying the composite powder by a pressing and sintering process or hot pressing process to obtain a blocky material; and obtaining the carbon nanotube reinforced aluminum-based composite material through hot extrusion forming. The method has the advantages that: the aluminum particle bridging function of carbon nanotubes is fully played, and the interface combination between carbon nanotubes and the aluminum substrate is strengthened; and the ball milling time is relatively short, so the damage to the structure of carbon nanotubes in a ball milling process is avoided. The composite material prepared by the method has a much higher mechanical property than that of pure aluminum substrate and thus, has a bright industrial application prospect.

Owner:TIANJIN UNIV

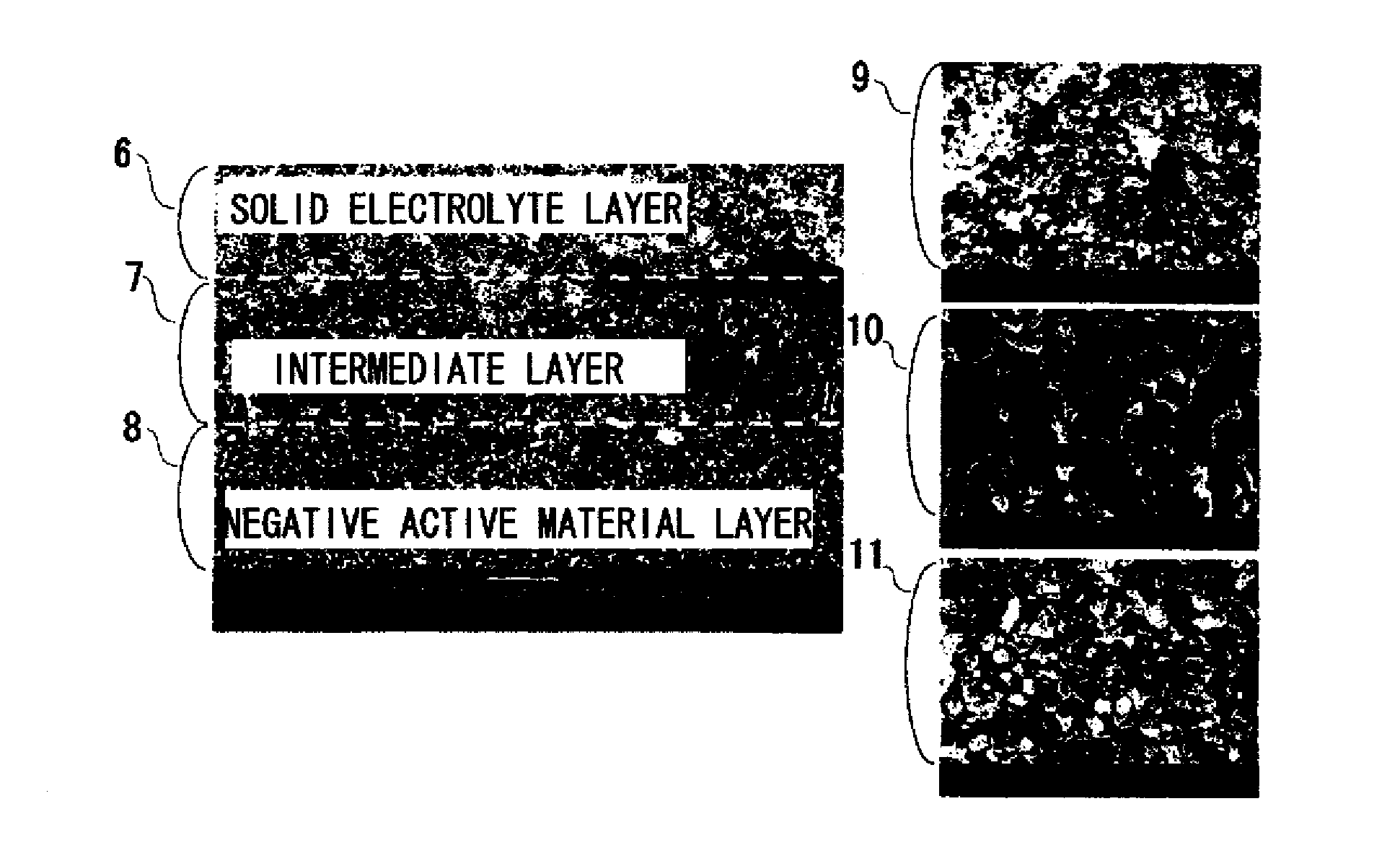

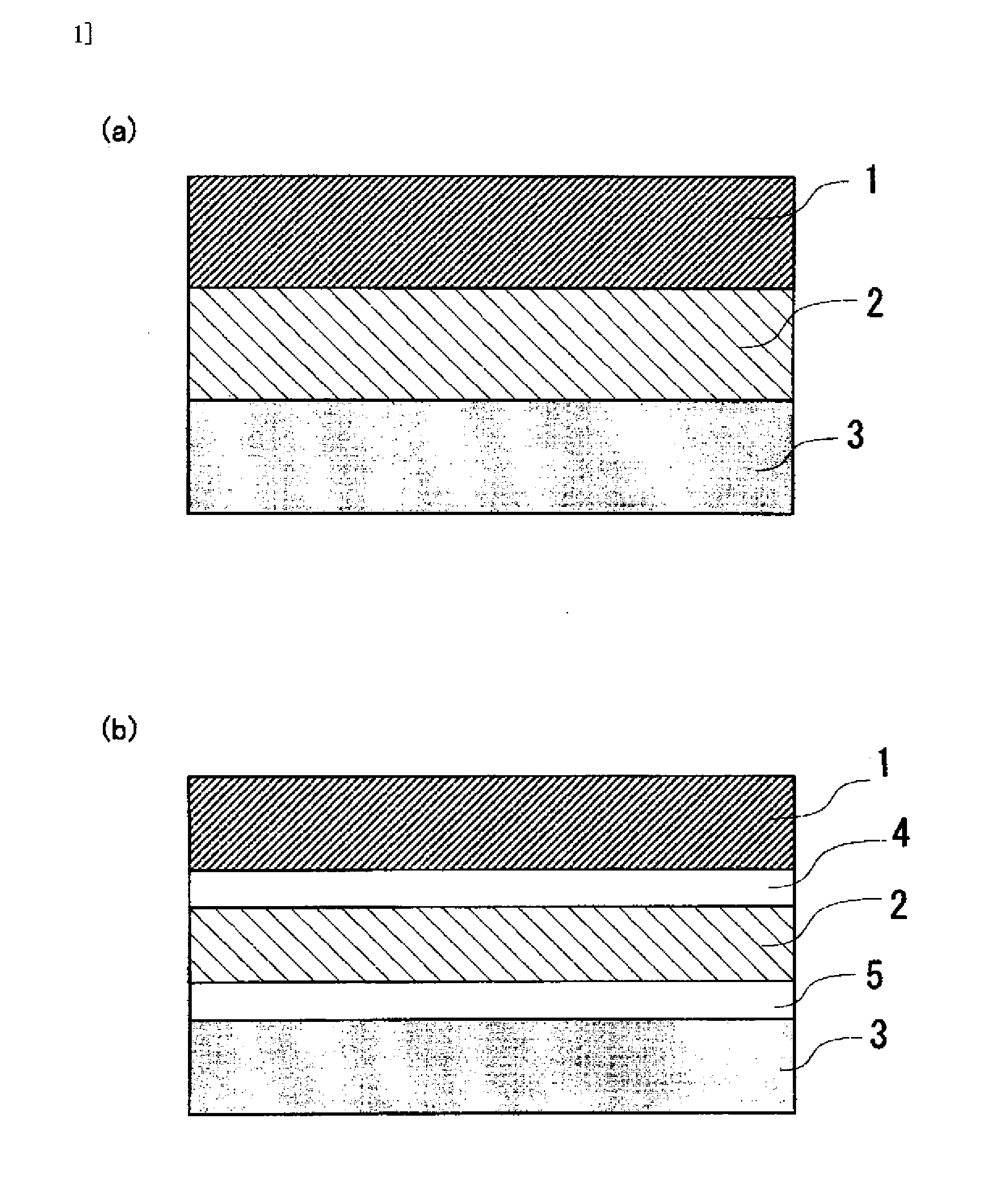

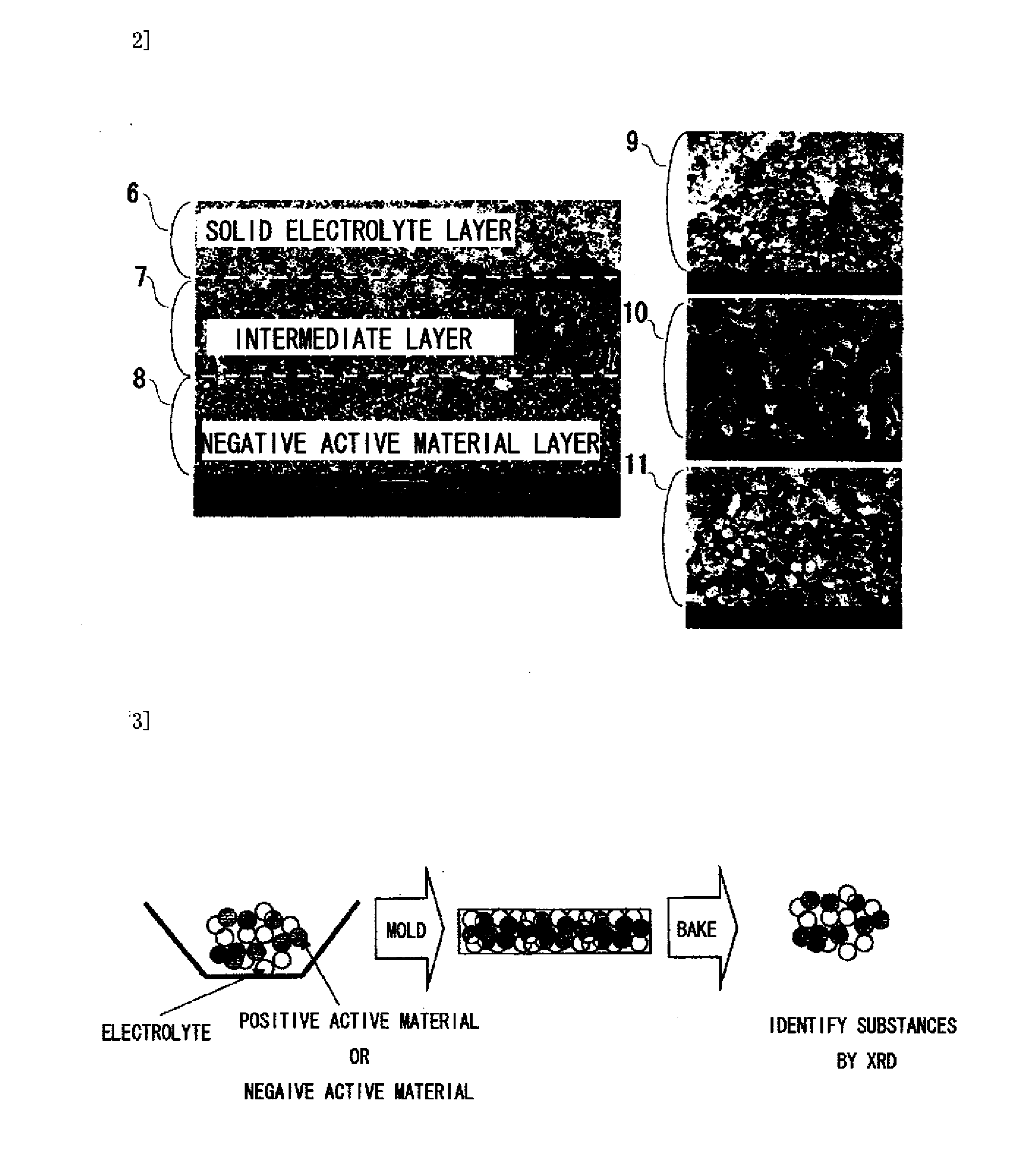

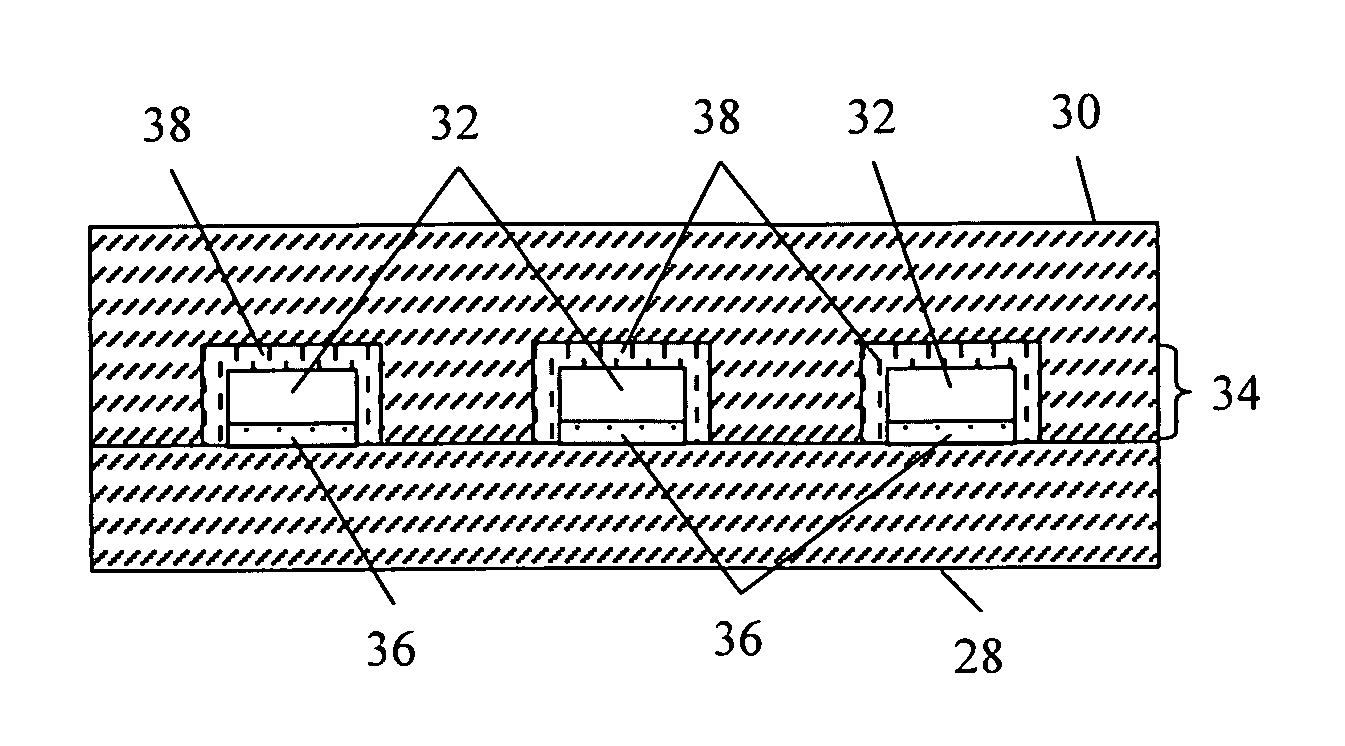

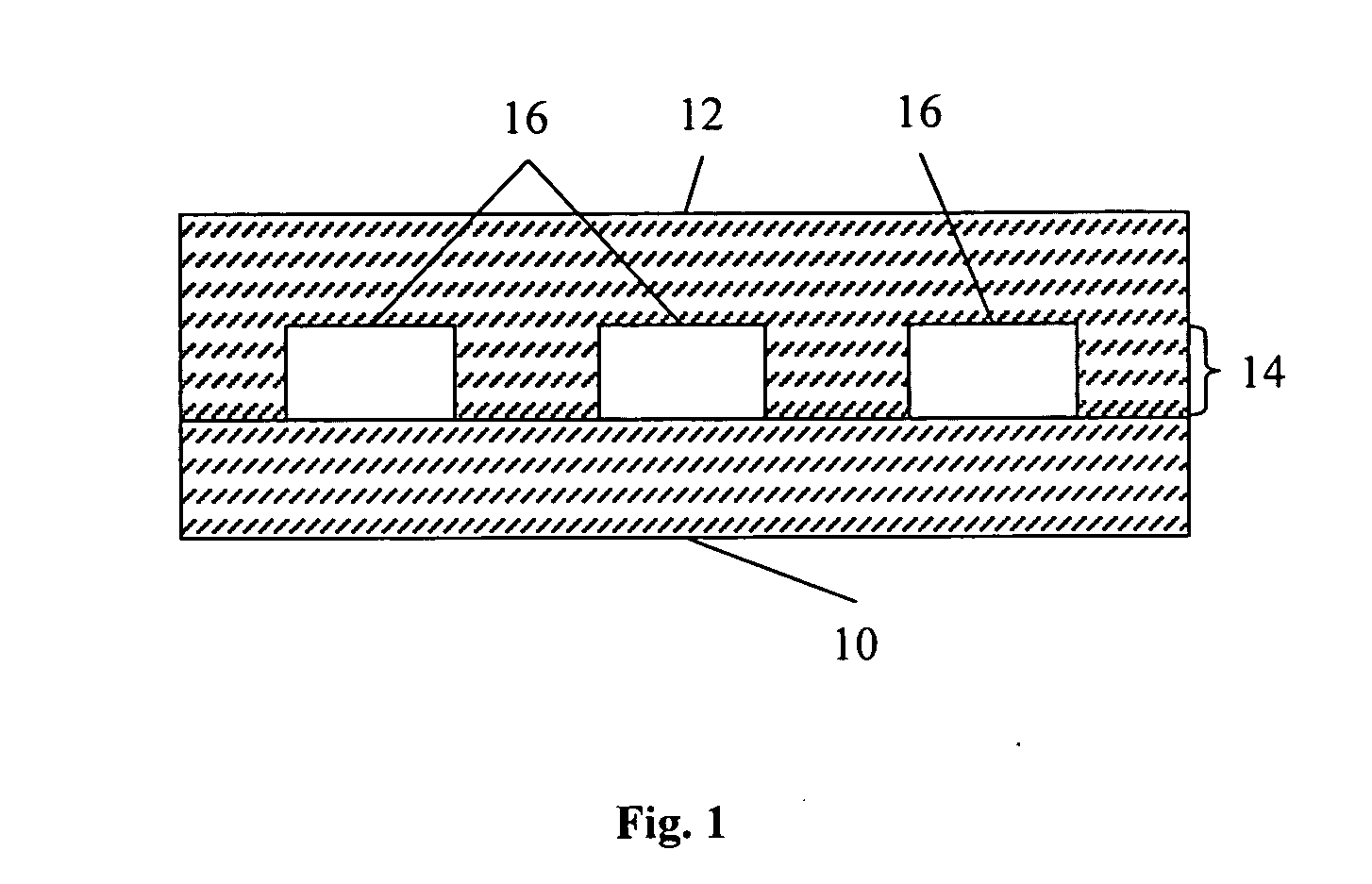

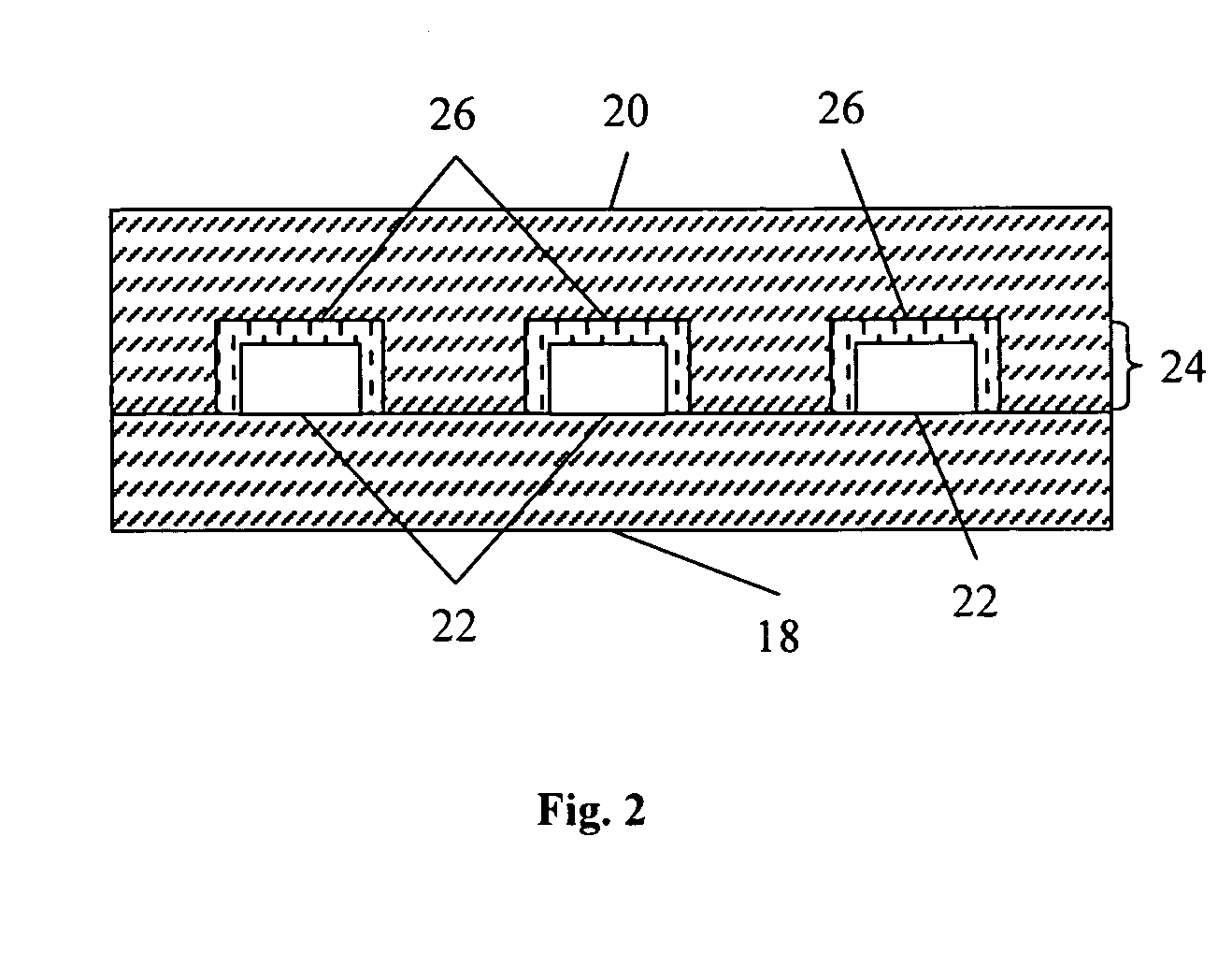

Lithium ion rechargeable battery and process for producing the lithium ion rechargeable battery

InactiveUS20100216032A1Enhanced interface bindingReduce interface resistanceFinal product manufactureElectrode carriers/collectorsCooking & bakingLithium

Conventional ion rechargeable batteries having an electrode layer on an electrolyte layer suffer from an impurity layer formed at the interface, degrading performance. Conventional batteries with no such impurity layer have a problem of weak interface bonding. In the present invention, in a baking process step after an electrode layer is laminated on an electrolyte layer, materials for an electrode layer and an electrolyte layer are selected such that an intermediate layer formed of a reaction product contributing to charging and discharging reactions is formed at the interface of the electrode layer and the electrolyte layer. In addition, a paste that an active material is mixed with a conductive material at a predetermined mixing ratio is used to form a positive electrode layer and a negative electrode layer. Reductions in electrode resistance and interface resistance and improvement of charging and discharging cycle characteristics are made possible.

Owner:NAMICS CORPORATION

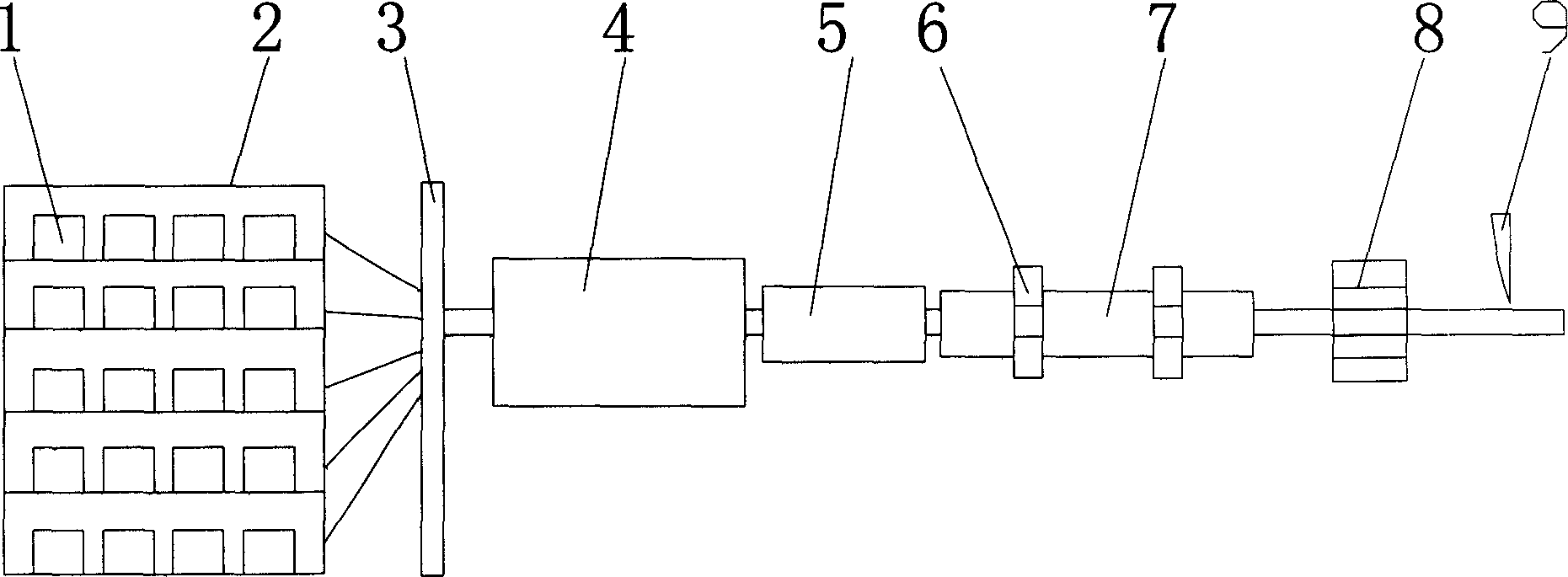

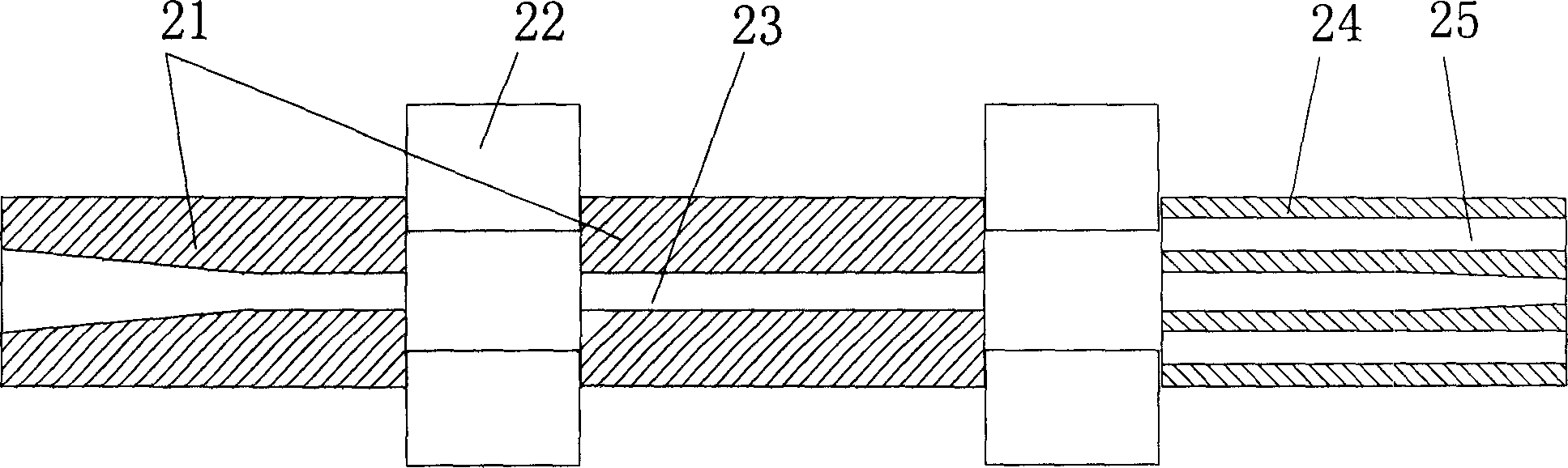

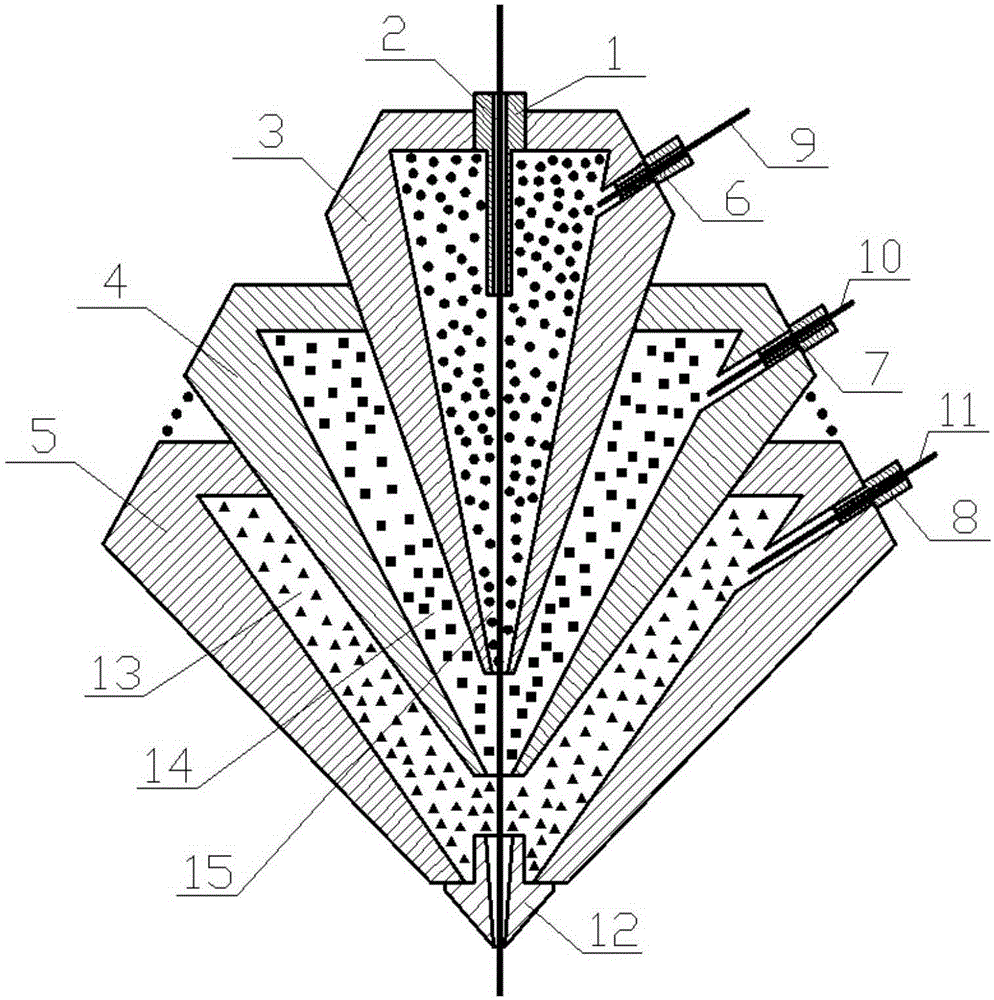

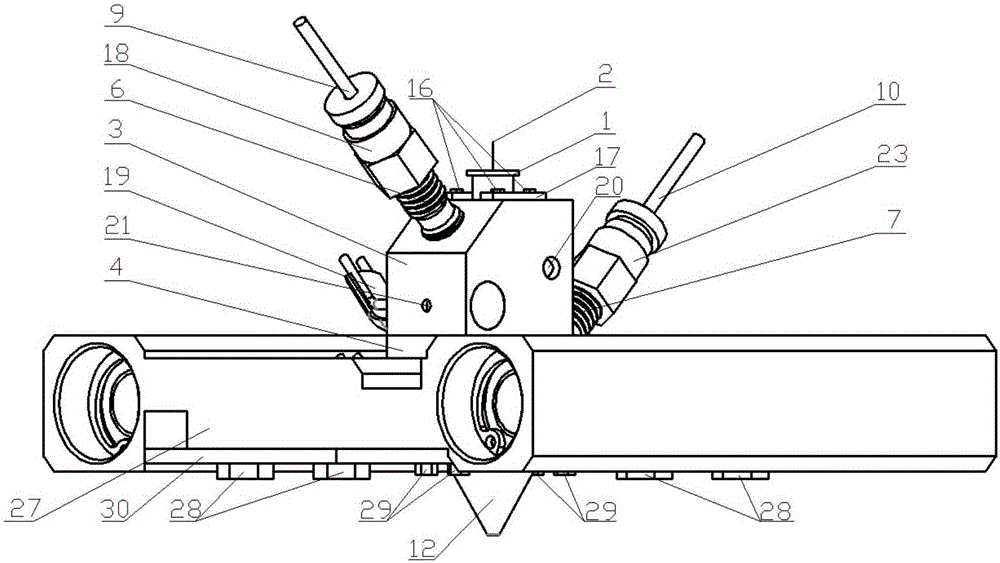

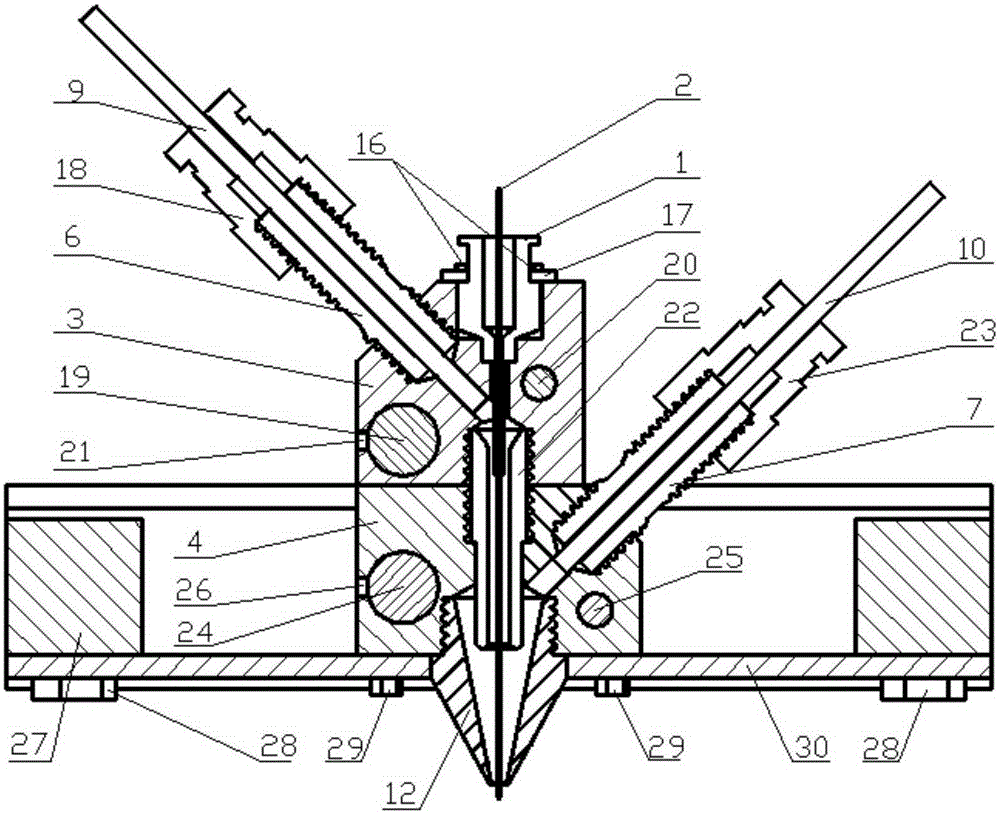

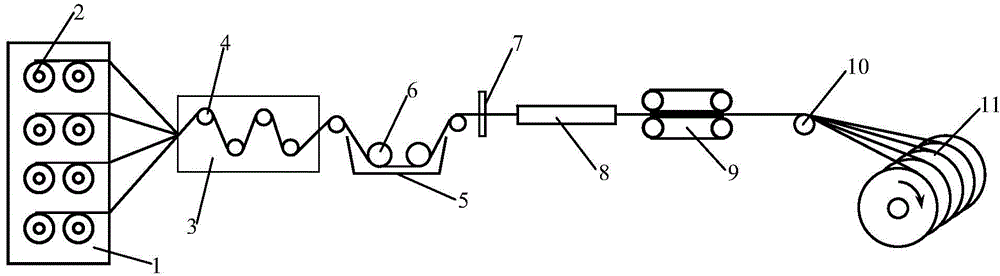

Multi-stage wire feeding printing head for 3D printing of continuous fiber reinforced composite materials

ActiveCN105172144AEnhanced interface bindingImprove performanceAdditive manufacturing apparatusSpray nozzleFiber-reinforced composite

A multi-stage wire feeding printing head for 3D printing of continuous fiber reinforced composite materials comprises a fiber guiding pipe fixed to the upper surface of a first-stage heating block. An inner hole channel of the fiber guiding pipe forms a fiber channel. A first-stage throat pipe is fixed to one side of the first-stage heating block. An inner hole channel of the first-stage throat pipe forms a first-stage inner hole channel. High polymer materials penetrate the first-stage inner hole channel and enter a melting cavity of the first-stage heating block. The first-stage heating block is fixed above a second-stage heating block. A second-stage throat pipe is fixed to one side of the second-stage heating block. A second-stage throat pipe inner hole channel forms a second-stage inner hole channel. High-performance thermoplastic materials penetrate the second-stage inner hole channel and enter a melting cavity of the second-stage heating block. As analogized according to the same structure, finally, all the heating blocks are fixed to the upper face of the last-stage heating block, and a spray nozzle is fixed to the lower surface of the last-stage heating block. The multi-stage wire feeding printing head is adopted, multi-stage wrapping can be well performed on base materials for continuous fibers, and continuous fiber reinforced composite material parts with good comprehensive performance are obtained.

Owner:XI AN JIAOTONG UNIV

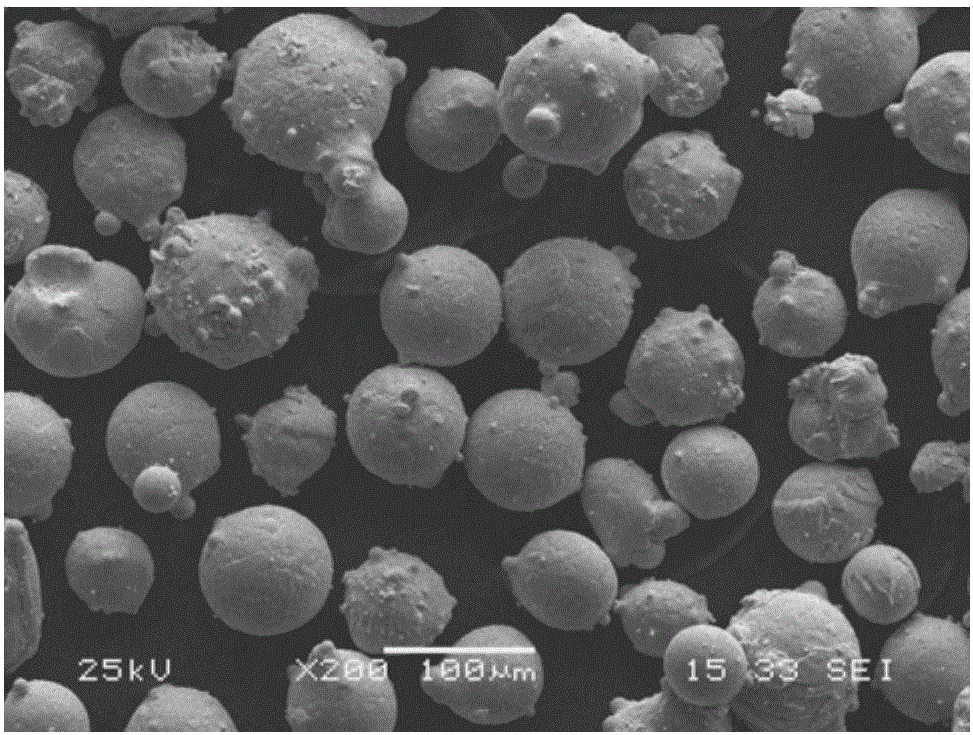

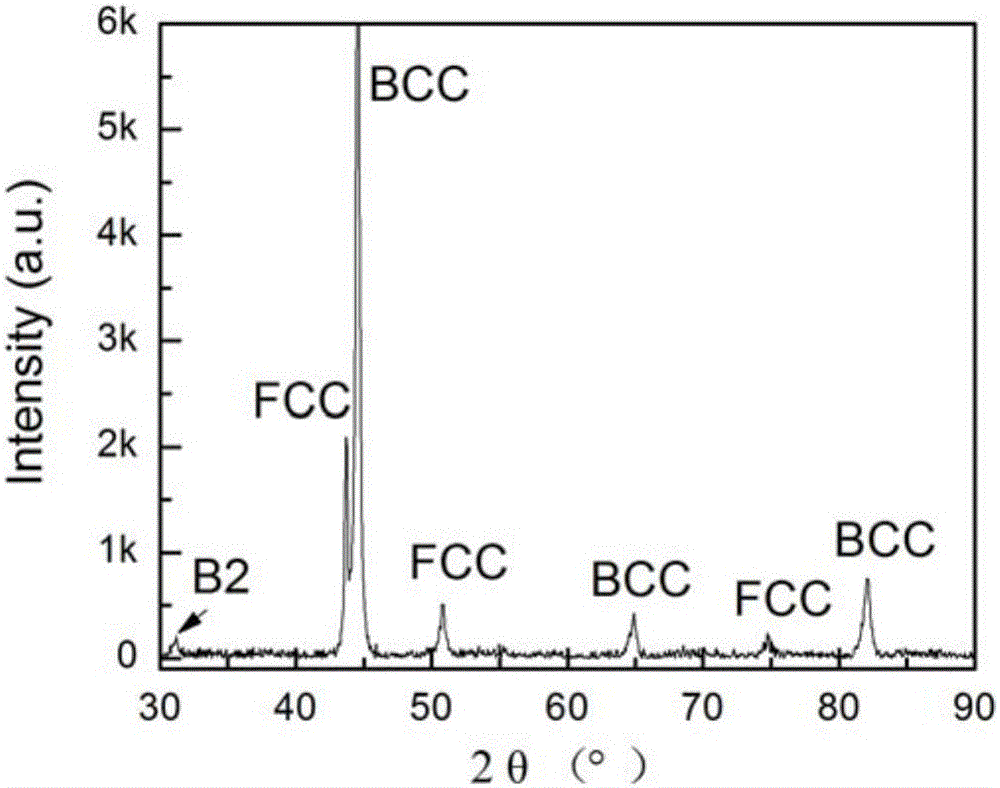

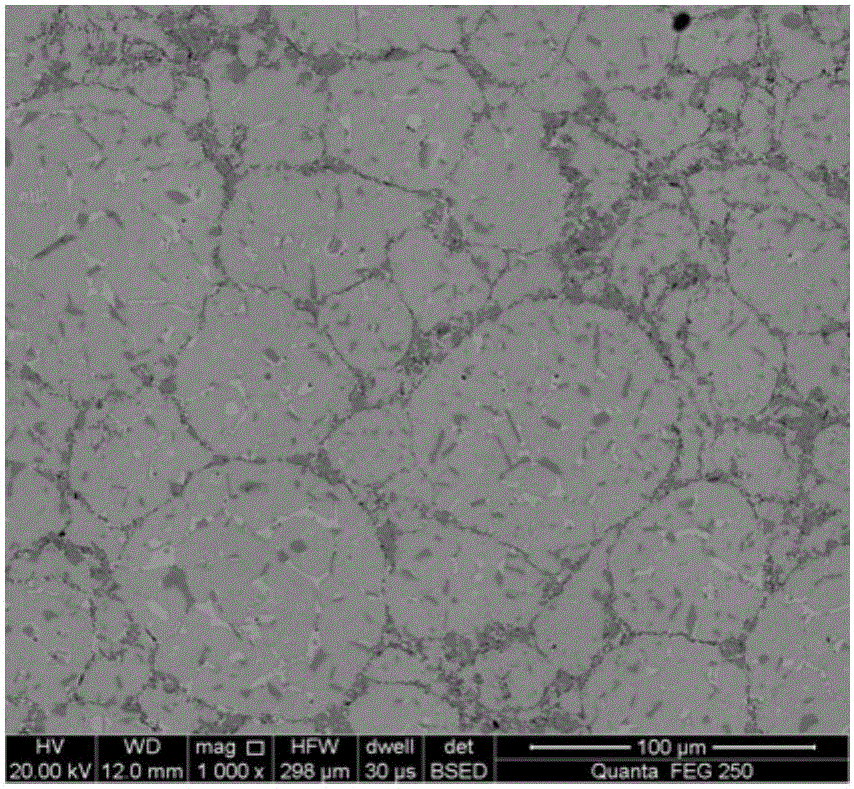

Preparing method for powder metallurgy high-entropy alloy based composite material

InactiveCN105734324AEvenly distributedGood combination of reinforcement and matrix interfaceIncreasing energy efficiencyHigh entropy alloysPowder metallurgy

The invention relates to a preparing method for a powder metallurgy high-entropy alloy based composite material, and belongs to the field of powder metallurgy materials. The preparing method includes the steps that all components are prepared and taken according to component proportions of a designed high-entropy alloy matrix, and high-entropy alloy powder is prepared through a gas atomization method; and then according to the component proportions of the designed high-entropy alloy based composite material, the high-entropy alloy powder and wild phase titanium diboride powder are prepared and taken, and rapid sintering molding is achieved after even mixing is carried out. According to the preparing method, the atomization method is adopted for preparing spherical high-entropy alloy powder with relatively-even ingredients in advance, and therefore a simple solid solution phase structure of a high-entropy alloy is guaranteed; and discharging plasma rapid sintering is adopted for preparing the needed powder metallurgy high-entropy alloy based composite material, and therefore the shortcoming that the material is prepared with metal powder as a raw material through a powder metallurgy method traditionally, and consequently the high-entropy alloy of the simple solid solution structure is difficult to obtain is overcome. The preparing method is simple in process procedure; according to the prepared powder metallurgy high-entropy alloy based composite material, titanium diboride is evenly distributed, reinforcement and base body interface bonding is better, the comprehensive performance is more excellent, the specific strength is high, the specific rigidity is high, and the abrasive resistance and the corrosion resistance are excellent. The preparing method is suitable for industrial production.

Owner:CENT SOUTH UNIV

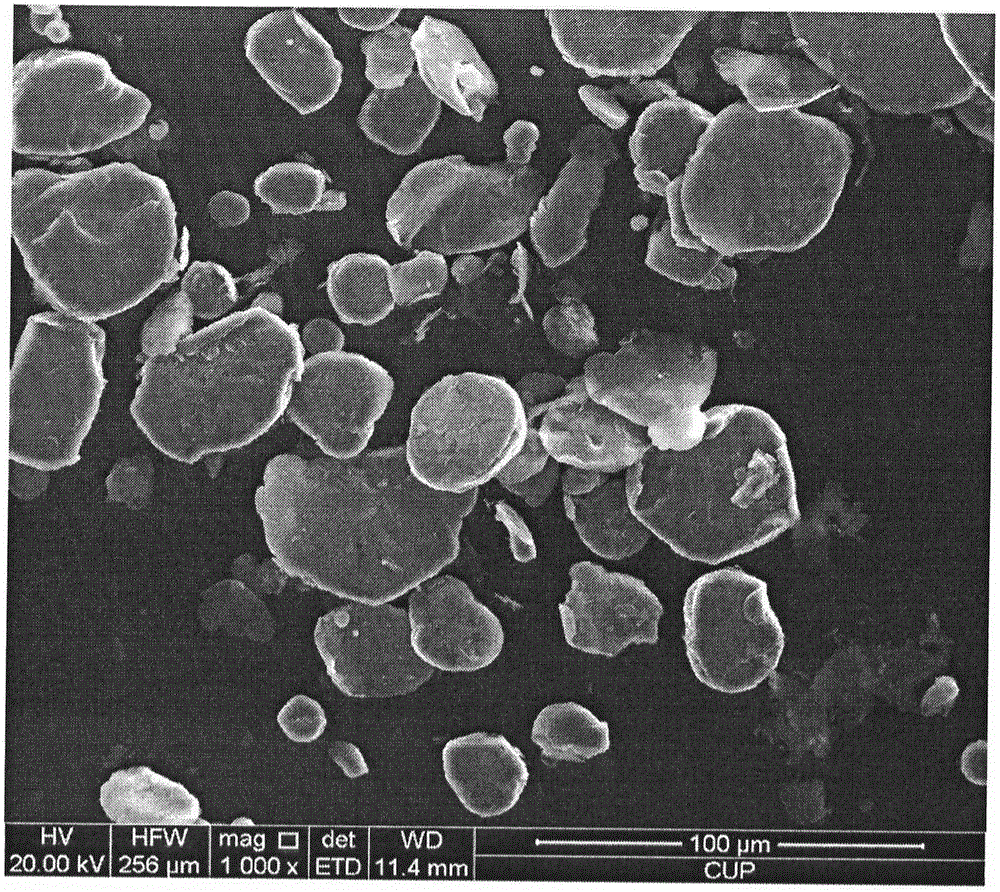

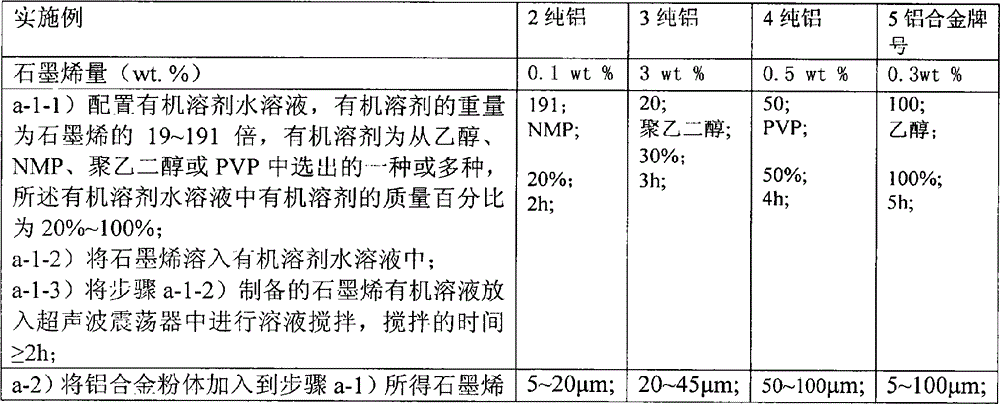

Preparation method of graphene/aluminum alloy composite material

The invention provides a preparation method of a graphene / aluminum alloy composite material. The addition quantity of graphene in the composite material accounts for 0.1wt.%-5.0wt.% of the total quantity of the composite material. Compared with tensile strength and electrical performance of an aluminum alloy without graphene, the mechanical properties and the electrical performance of the graphene / aluminum alloy composite material are improved to varied degrees. With the appearance of an intermediate alloy of the graphene / aluminum alloy composite material, the graphene can be added to molten aluminum in a form of a graphene / aluminum alloy intermediate alloy, and the dispersion uniformity of the graphene in the molten aluminum is improved to the greatest degree, so that industrial batch production of graphene modified aluminum conductor cables can be realized with a melt-casting method. The preparation method of the composite material comprises steps as follows: mechanical mixing, low-temperature ball milling, vacuum degassing, hot isostatic pressing and extrusion and the like, adopts simple and controllable technology, has lower production cost, is applicable to industrial production and has good market prospect.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Optical article

InactiveUS20050145968A1Increase radiation transmittedEliminates orTransparent/reflecting heating arrangementsSemiconductor/solid-state device manufacturingEngineeringElectrically conductive

An optical article and method of making the same are provided. The optical article has optical multi-aperture operation. The optical article has one or more electrically conductive and selectively passivated patterns.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

High-performance fire-resistant abrasion-proof composite material

The present invention discloses a high-performance flame-proof abrasion-resisting composite material which is prepared mainly by the components of particle material alumina or / and corundum or / and mullite 50-70 parts; hard particle 5-25 parts; binding agent 8-25 parts; aluminum oxide micro powder or / and silicon micronized quartz powder 8-15 parts and surfactant 0.1 parts. The composite material is developed according to the scientific knowledge obtained in the long-term researching and producing for the flame-proof abrasion-resisting composite material in our company and absorbing the latest accomplishment of the present material science, the material has the advantages of increasing the high-temperature bonding strength and toughness of the composite material, increasing the binding ability of the interface between the composite material and the equipment, facilitating the two sides forming a compact and high-strength whole body, optimizing the capability of the composite material in the high-temperature state, prolonging the service lifetime of the equipment, reducing the number of the breakdown maintenance, reducing the material consumption and the labor intensity of the worker thereby obtaining the purpose of increasing the economic benefit of the enterprise.

Owner:郑州市鑫磊冶金材料有限公司

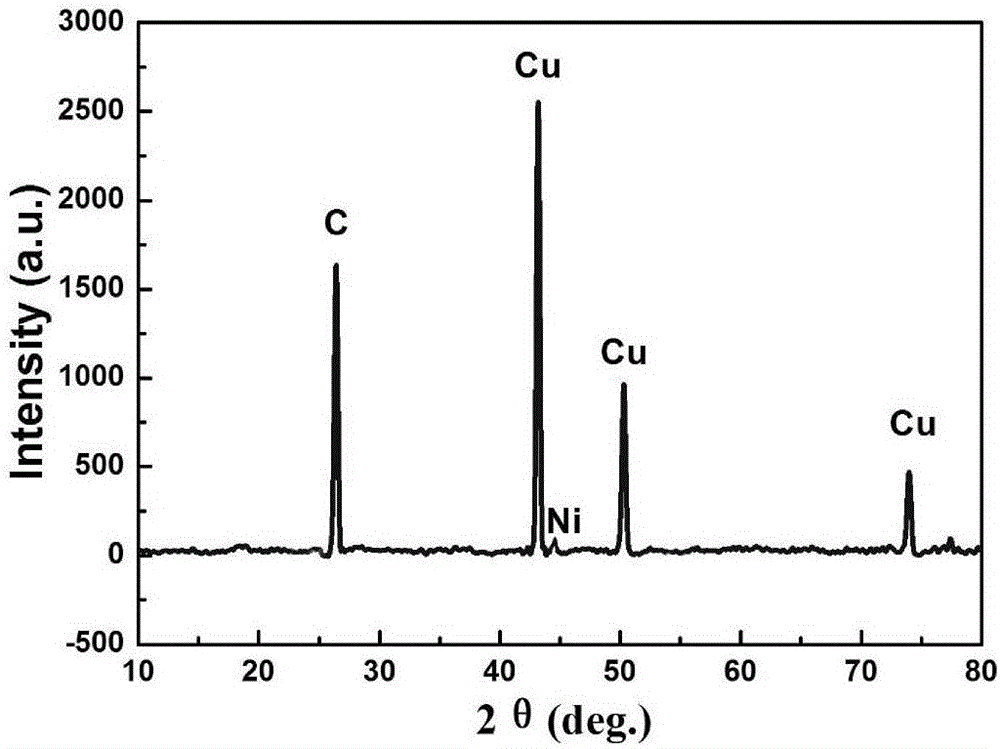

Copper-carbon composite material and preparing method thereof

ActiveCN106424713APromotes even distributionImprove performanceTransportation and packagingMetal-working apparatusFiberCarbon composites

The invention discloses a copper-carbon composite material and a preparing method thereof. Natural flake graphite, colloidal graphite, nano graphite, carbon fiber and the like can be selected as a carbon material in the copper-carbon composite material. The preparing method of the copper-carbon composite material includes the steps that firstly, a chemical nickel plating method is used for preparing a nickel plating carbon material; then a chemical copper plating method is used for plating copper on the nickel plating carbon material; and finally, vacuum semi-solid-state low-pressure sintering is conducted on the copper plating carbon material under the copper melting point temperature, and the copper-carbon composite material is prepared. The copper-carbon composite material and the preparing method thereof have the beneficial effects that a layer of even thin nickel plating layer is formed on the surface of carbon through the nickel plating method so as to reduce the wetting angle of the carbon material, the copper plating layer is formed on the surface of the nickel plating carbon material through the copper plating method so that a three-dimensional copper network can be formed by the material in the sintering process, and the bonding strength of a base body is improved through vacuum semi-solid-state low-pressure sintering. The two phases of the base body and the carbon of the copper-carbon composite material prepared through the method are distributed evenly and are well combined, and the good electricity and mechanical properties and the good frictional wear performance are achieved.

Owner:CENT SOUTH UNIV

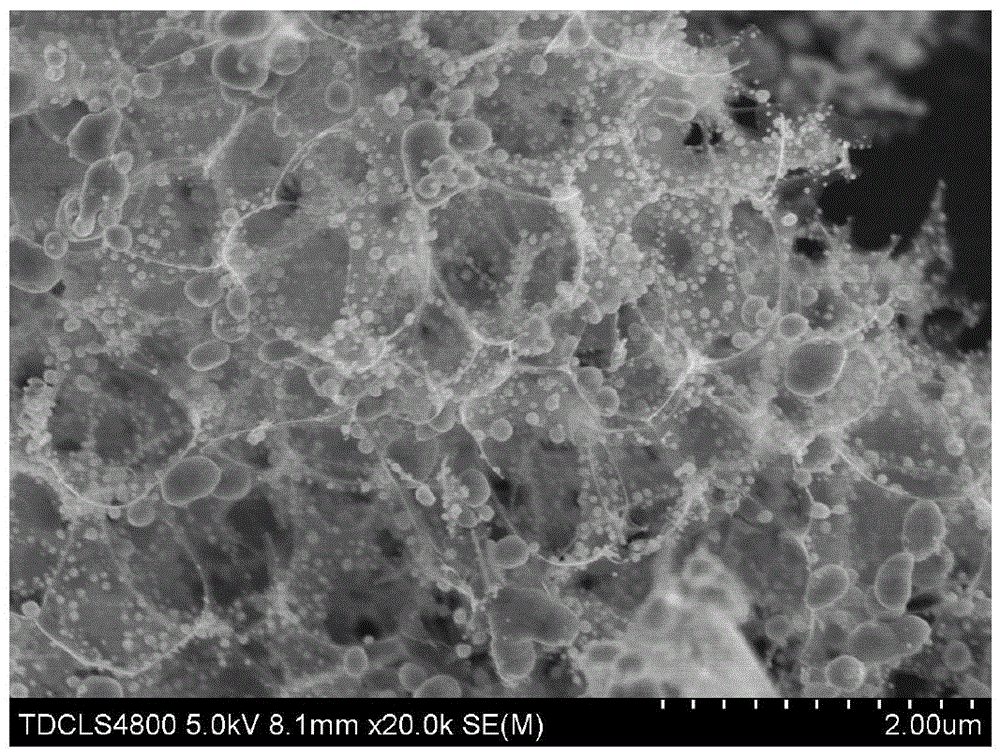

Preparation method for in-situ synthesis of three-dimensional graphene-reinforced copper-based composite material

The invention relates to a preparation method for in-situ synthesis of a three-dimensional graphene-reinforced copper-based composite material. The preparation method comprises the following steps: taking copper nitrate trihydrate as a copper source, mixing the copper source with a solid carbon source (glucose or citric acid) and a water-soluble salt template (sodium chloride), then adding the mixture into water to dissolve the mixture, performing stirring uniformly to obtain a precursor solution; performing freeze-drying dehydration to obtain a mixed powder precursor; performing heating to 600-800 DEG C, performing heat preservation for 1-3 h, and then perform cooling quickly to obtain self-assembly powder; washing off sodium chloride by suction filtration, and performing vacuum drying; pouring the product into an ethanol solution of copper nitrate; performing water-bath evaporation drying and vacuum drying; under atmosphere protection, performing heating to 600-800 DEG C, performing heat preservation for 1-3 h, and obtaining three-dimensional graphene-copper particle composite powder by furnace cooling; and molding according to a vacuum hot-pressing sintering technology. The blocky material prepared according to the method has the characteristic that the graphene has good dispersity and is closely combined with a copper base; and meanwhile, the blocky material has excellent toughness and mechanical properties.

Owner:TIANJIN UNIV

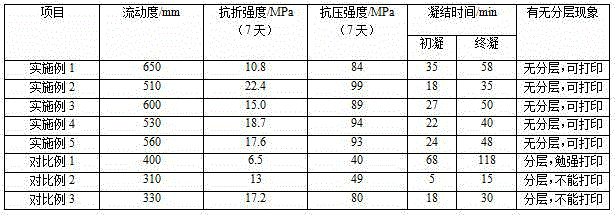

Preparation method of organic-inorganic composite capsule wall energy-storage microcapsule

ActiveCN103769021AImprove thermal stabilityHigh mechanical strengthHeat-exchange elementsMicroballoon preparationFiltrationOil phase

The invention discloses a preparation method of an organic-inorganic composite capsule wall energy-storage microcapsule. The method is as below: mixing an organic phase change material and a surface active agent, heating with stirring to obtain an even oil phase material; adding silica-containing silica sol and ethyl orthosilicate in a mass ratio of 1:1-10:1 into deionized water to prepare a water phase material; then adding an oil phase material into the water phase material, and uniformly dispersing into an emulsion; then adding polyisocyanate and a crosslinking agent, maintaining the original temperature and stirring speed, so as to obtain the microcapsule with the organic-inorganic composite capsule wall; and finally, conducting vacuum filtration, washing and drying on the obtained liquid substance to obtain the product. The phase change energy-storage microcapsule obtained by the method can be used in several fields such as building energy saving and insulation of pipeline storage tank, and the capsule wall of the microcapsule has the advantages of organic material and inorganic material and longer cycle of usage.

Owner:CHINA PETROLEUM & CHEM CORP +1

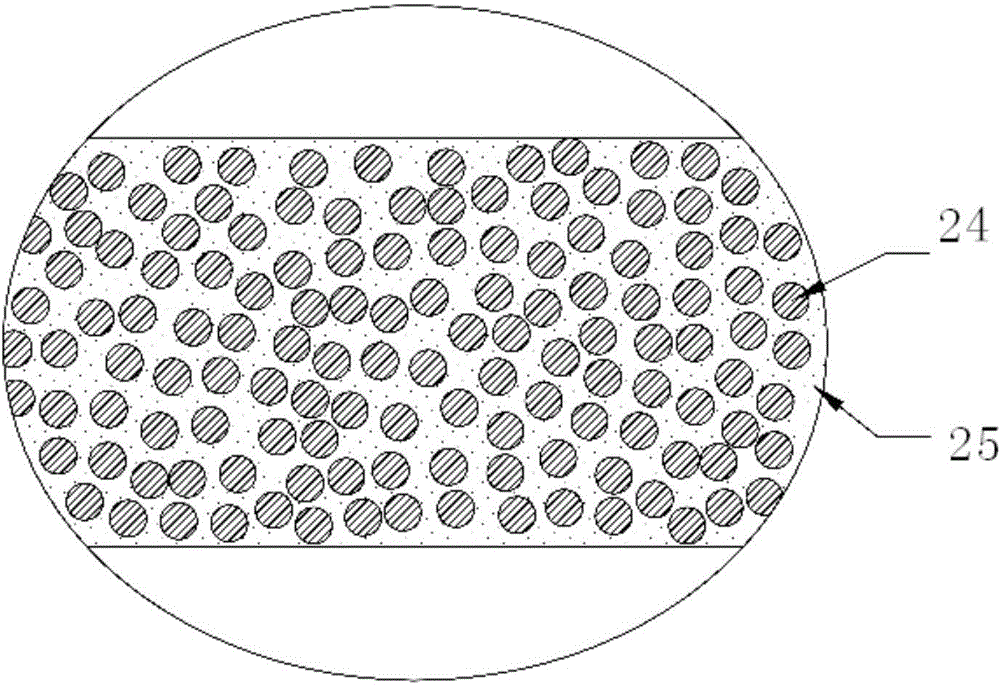

Preparation method and preparation system for ultralight composite traction belt

ActiveCN104552988AReduce internal defectsImprove tensile propertiesRope making machinesBeltsYarnAgricultural engineering

The invention discloses a preparation method and a preparation system for an ultralight composite traction belt, and provides a preparation method and a preparation system for the ultralight composite traction belt with uniform bearing and long service life. The preparation method comprises the following steps: a twist-free continuous monofilament is led out of a fiber yarn group, unfolded uniformly, and introduced into an impregnation tank for impregnation, wherein the impregnation tank is added with a glue solution, then arrangement is performed, and composite enhanced pieces are obtained after pultrusion and curing; the composite enhanced pieces are led out respectively, preheated and introduced into a head die of an extruder, an extruding die core corresponding to the section of the traction belt is arranged in the head die, the composite enhanced pieces are uniformly coated with molten thermoplastic resin in the head die and led out of the head die of the extruder, preliminary forming is realized, and the traction belt is obtained after cooling setting and cooling. The prepared traction belt is light in weight, high in strength, easy to bend, anti-fatigue, long in service life, low in maintenance cost and more applicable to a long-distance elevator.

Owner:TIANJIN GOLDSUN WIRE ROPE

Plant fiber-reinforced polylactic acid foam material and preparation method thereof

The invention discloses a plant fiber-reinforced polylactic acid foam material, which is prepared from the following components: 20 to 95 percent of polylactic acid, 1 to 60 percent of plant fiber powder, 1 to 5 percent of foaming agent, 1 to 5 percent of nucleating agent, 1 to 5 percent of antioxidant and 1 to 5 percent of bulking agent. The invention also discloses a preparation method for the material. The foam material has the advantages of low apparent density, biodegradability, no environmental pollution, capacity of replacing polyolefin foam materials, wide application in the fields of heat insulation, buffer and packaging, simple preparation process and high production efficiency.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

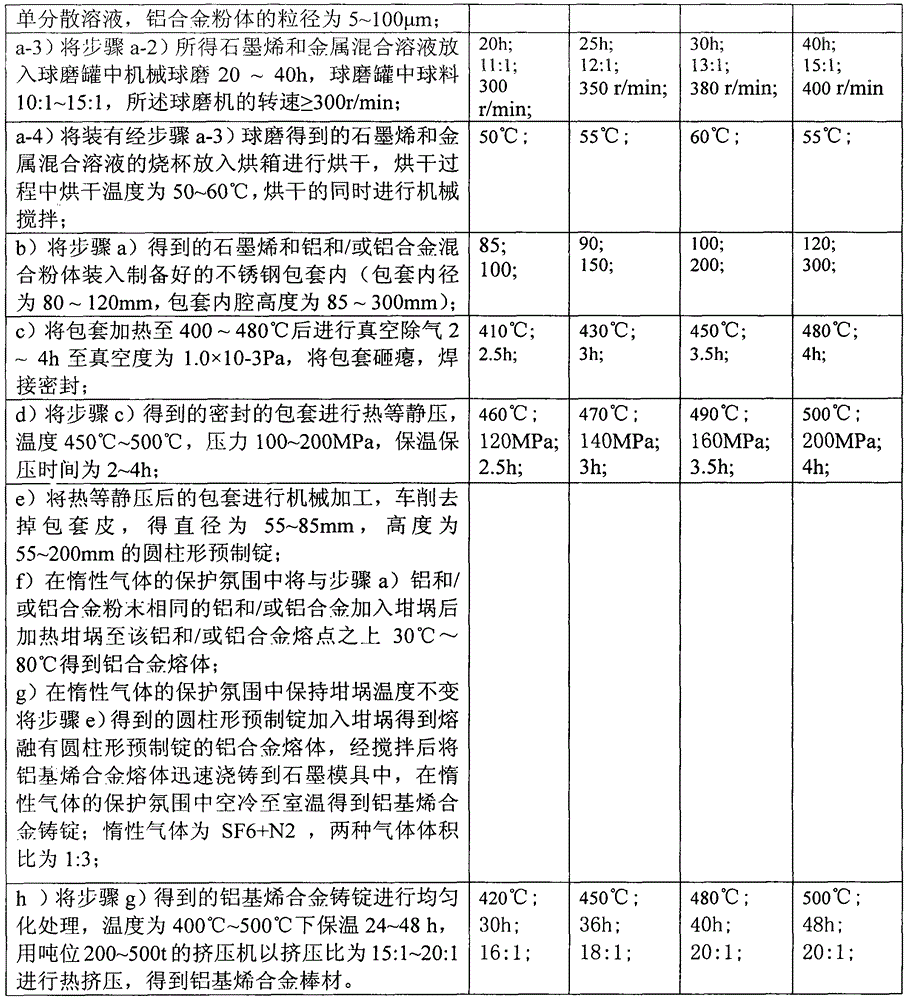

Preparation method of aluminum base graphene alloy

The invention provides a preparation method of aluminum base graphene alloy. The method comprises the following steps: preparing graphene and aluminum and / or aluminum alloy mixed powder, filling a jacket with the mixed powder, carrying out vacuum degassing, carrying out hot isostatic pressing, re-melting, and homogenizing. A certain amount of the aluminum base graphene alloy precast ingots are re-melted in aluminum alloy melt, the content of graphene in a composite material can be well controlled through calculating, and graphene cannot float, so the content of graphene in the aluminum base graphene alloy can be accurately controlled; and the preparation method is provided on the basis of semi-continuous melting casting, and has the advantages of simple operation, high production efficiency, low preparation cost, and easy realization of large scale industrialization.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Novel polycarbosilane and preparation method thereof

The invention relates to novel polycarbosilane and a preparation method thereof. A polycarbosilane ceramic precursor is prepared by adopting a Grignard reagent coupling method; a molecular structure contains unsaturated groups such as a Si-H bond, C=C and the like; the precursor can be crosslinked and cured at a certain temperature, and has low curing weight loss and high manufacturability; the Si / C ratio in the precursor and the process performance of a precursor product can be adjusted effectively by adjusting the functionality and feed ratio of a chlorosilane monomer serving as a reactant and optimizing reaction conditions; and the obtained product has excellent heat resistance, high ceramic yield, low free carbon content in ceramic and high SiC ceramic phase purity, is suitable for serving as a high-performance SiC ceramic precursor, and can be used for preparing an ultrahigh-temperature ceramic-based composite material submerged substrate as well as high-performance materials such as SiC ceramic coatings, fibers and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com