Graphene-reinforced magnesium-aluminium matrix composite material and preparation method thereof

An aluminum-based composite material and graphene technology, which is applied in the field of graphene-reinforced magnesium, aluminum-based composite materials and their preparation, can solve the problems of increasing difficulty in removing impurities, unfavorable graphene self-dispersion, poor agglomeration, and the like, and achieves good results. The effect of interface combination, environmental friendliness, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

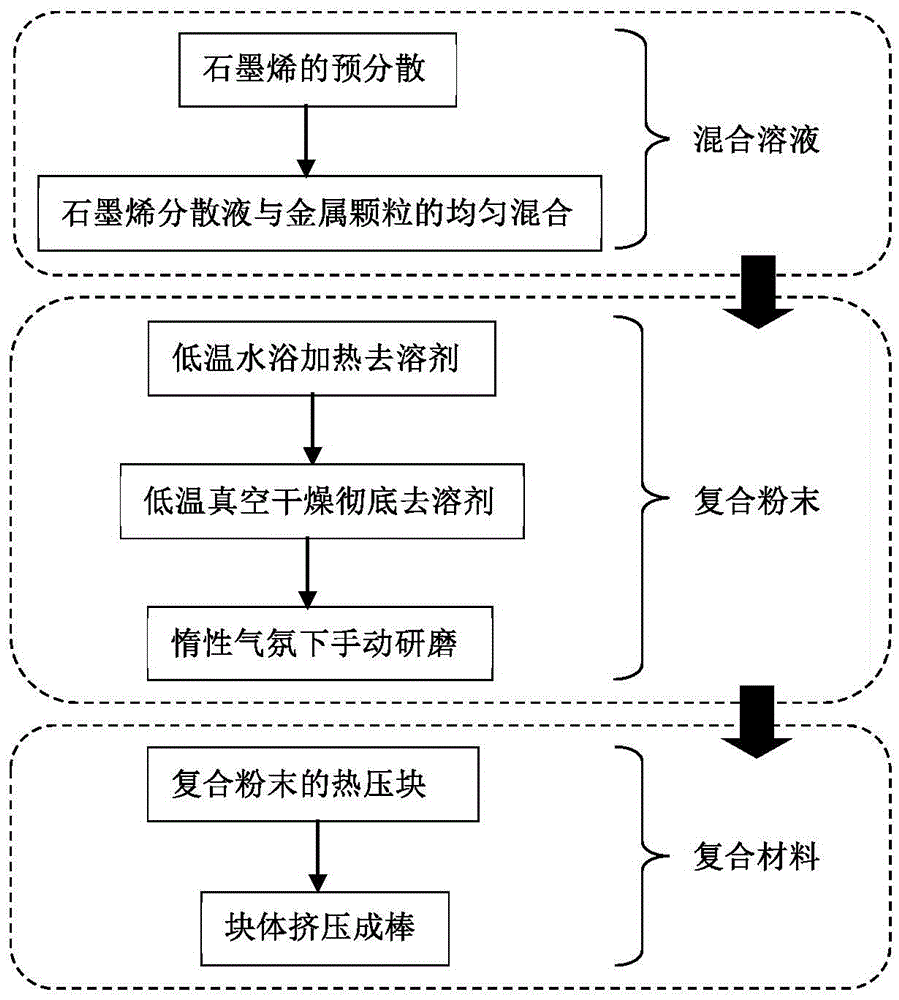

Method used

Image

Examples

Embodiment 1

[0023] The preparation technology of the graphene / pure magnesium-based composite material of the present embodiment is carried out in the following steps:

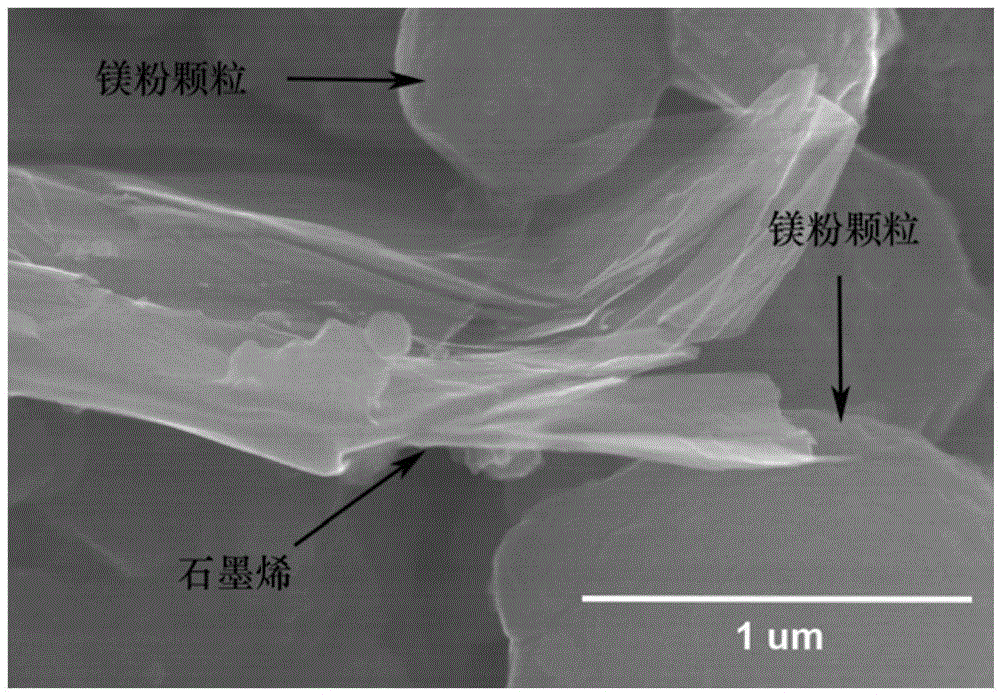

[0024] (1) 200mg of graphene (few layers, purity of 99.0wt.%) is placed in 500ml of absolute ethanol, ultrasonic power is 1000W, and the duration is 30min ultrasonic dispersion treatment to obtain uniformly dispersed graphite with a concentration of 0.4mg / ml Graphene ethanol solution; then, 100g pure magnesium particles (magnesium content is 99.7wt.%, particle size is 400 orders) are intermittently added to the above-mentioned graphene ethanol solution for 20 times, each time adding 5g pure magnesium particles, and adding Finally, the mixed solution needs to be ultrasonically stirred for 5 minutes, and the mechanical stirring speed is 300 rpm to obtain a graphene / pure magnesium particle mixed solution;

[0025] (2) Put the mixed solution obtained in step (1) in a water bath, stir and heat evenly at 30°C, remove the solvent...

Embodiment 2

[0028] The preparation technology of the graphene / magnesium alloy-based composite material of the present embodiment is carried out according to the following steps:

[0029] (1) 200mg of graphene (few layers and multi-layers are mixed by mass 1:1, the purity is 99.0wt.%) is placed in 1000ml of absolute ethanol, and ultrasonic power is 600W, and the duration is 15min for ultrasonic dispersion treatment to obtain Concentration 0.2mg / ml homogeneously dispersed graphene ethanol solution; Immediately, 200g magnesium alloy particles (its composition is 5.9wt.%Zn, 0.5wt.%Zr, surplus is Mg, particle size is 200 orders) is divided into 4 intervals Add to the above-mentioned graphene ethanol solution, add 50g of magnesium alloy particles each time, and after each addition, the mixed solution needs to be ultrasonically stirred for 10min, and the mechanical stirring speed is 1000rpm to obtain a graphene / magnesium alloy particle mixed solution;

[0030] (2) Put the mixed solution obtained...

Embodiment 3

[0033] The preparation process of the graphene / aluminum alloy matrix composite material of the present embodiment is carried out according to the following steps:

[0034] (1) 300mg graphene (multi-layer, purity is 99.0wt.%) is placed in 1000ml dehydrated alcohol, carry out the ultrasonic dispersion treatment that ultrasonic power is 300W, duration is 40min, obtains the graphite of concentration 0.3mg / ml uniform dispersion ethylene alcohol solution; immediately, 600g aluminum alloy particle (its composition is 1.1wt.%Mg, 0.62wt.%Si, 0.65wt.%Fe, 0.29wt.%Cu, 0.13wt.%Mn, 0.22wt.%Zn , 0.10wt.% Cr, 0.15wt.% Ti, the balance is Al, and particle size is 300 orders) divides 6 times and intermittently joins in the above-mentioned graphene ethanol solution, adds 100g aluminum alloy particle each time, and after each addition needs The mixed solution was ultrasonically stirred for 20 minutes, and the mechanical stirring speed was 1500 rpm to obtain a graphene / aluminum alloy particle mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com