Pultrusion method for thermoplastic composite material and forming die thereof

A composite material and pultrusion molding technology, applied in the field of thermoplastic composite pultrusion molding method and its molding die, can solve the problems of difficult operability, high viscosity of thermoplastic resin, etc., to improve impregnation effect, improve mechanical properties, time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

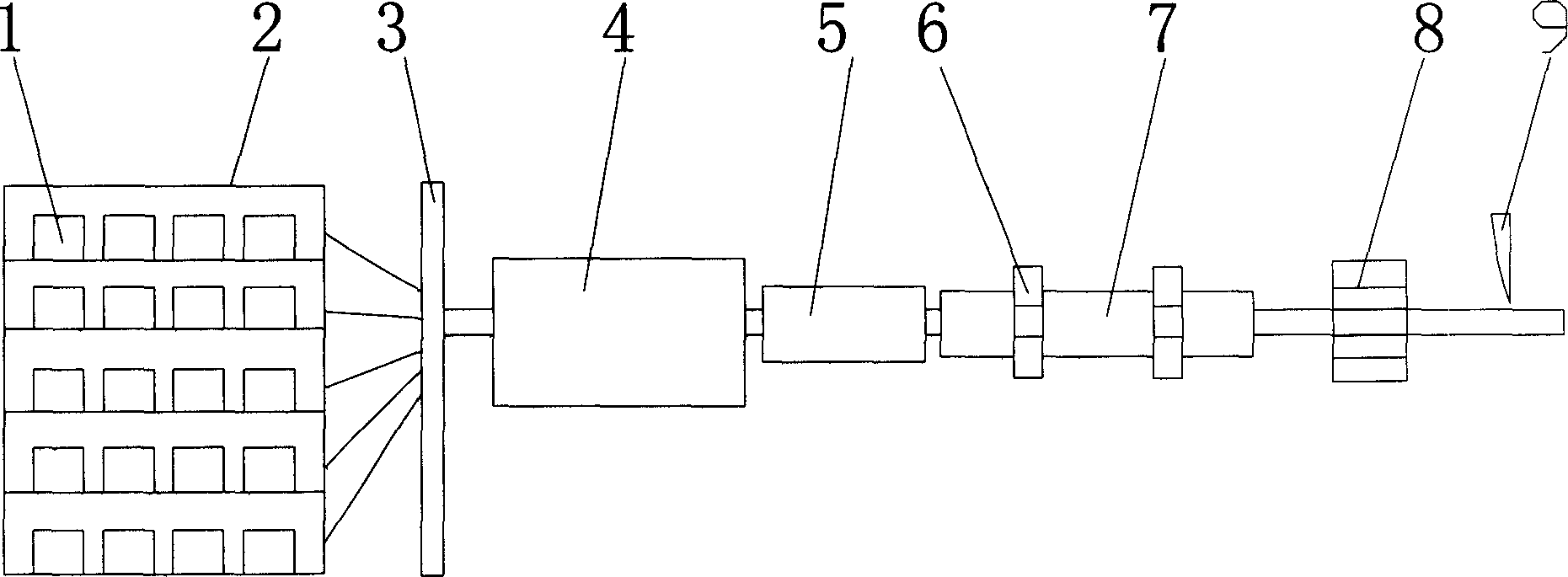

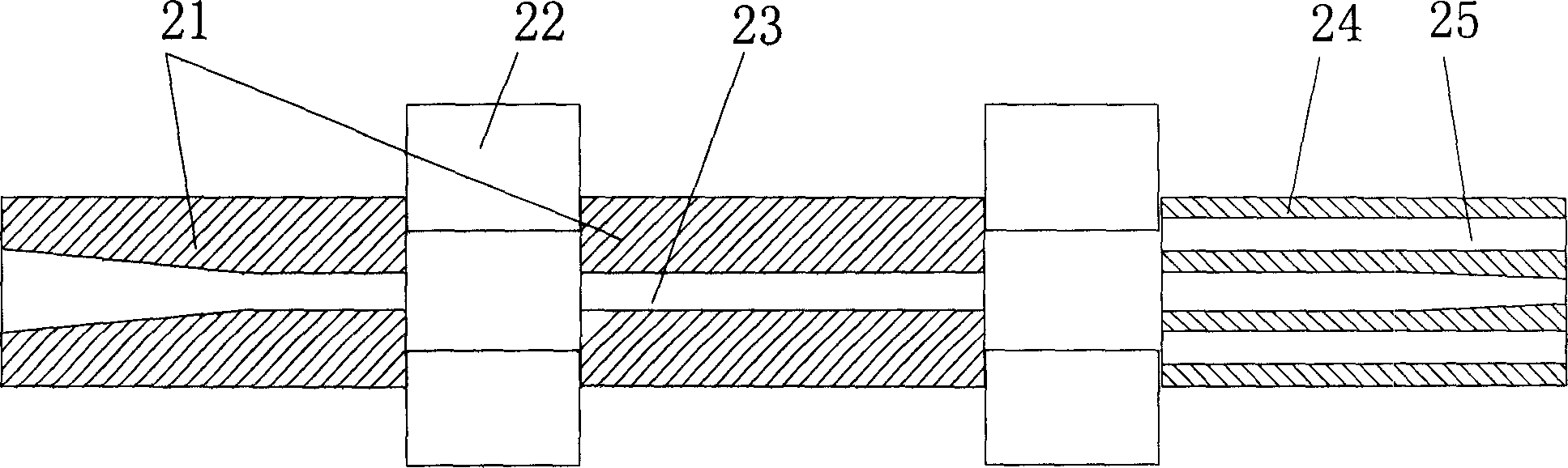

[0040] The thermoplastic fiber selects the applicant's self-made 2000dtex polypropylene fiber, which contains 5% carbon black, and the reinforcing fiber selects 200tex glass fiber, which are arranged alternately on the creel (2), and are directly passed through the guide at a weight ratio of 1:1. The yarn device (3) is plied and bundled into the preheating chamber (4). The temperature of the preheating chamber (4) is 200° C., and the heating method adopts electric heating. The fiber enters the preforming die (5) after coming out of the preheating chamber (4), and the preheated mixed fiber yarn enters the forming die (7) after coming out of the preforming die (5). The forming die selects a circular die with a diameter of φ5. It is divided into three sections, of which the heating section has two sections, the length of each section is 0.03 meters, and the length of the cooling section is 0.3 meters. The mold entrance angle of each heating section in the mold heating zone is 5°,...

Embodiment 2

[0047] The thermoplastic fiber selects the applicant's self-made 1000dtex nylon fiber, which contains 8% carbon black, and the reinforcing fiber selects 48tex high-strength glass fiber, and forms a mixed fiber yarn (1) after being unmerged and plyed at a weight ratio of 2:3 and placed on the creel Above, the mixed fiber yarn (1) is drawn from one creel, bundled through the yarn guide (3) and enters the preheating chamber (4). The temperature of the preheating chamber (4) is 270°C, and the heating method is heated by heat transfer oil. The fiber enters the preforming die (5) after coming out of the preheating chamber (4), and the preheated mixed fiber yarn enters the forming die (7) after coming out of the preforming die (5). The forming die selects a diameter φ10 round rod die, It is divided into three sections, of which the heating section has 5 sections, each section is 0.03 meters long, and the cooling section is 0.3 meters long. The mold entrance angle of each heating sect...

Embodiment 3

[0054] The thermoplastic fiber selects the applicant's self-made 1000dtex PET fiber, which contains 10% carbon black, and the reinforcing fiber selects the 48tex high-strength glass fiber produced by Nanjing Glass Fiber Research and Design Institute, and forms a mixed fiber after being expanded by a bulking machine at a weight ratio of 2:3. The yarn (1) is finally placed on the creel, and the mixed fiber yarn (1) is led out from one side of the creel, bundled through the yarn guide (3) and enters the preheating chamber (4). The temperature of the preheating chamber (4) is 280°C, the heating method can be electric heating. The fiber enters the preforming mold (5) after coming out of the preheating chamber (4), and the preheated mixed fiber yarn comes out of the preforming mold (5) and then enters the forming mold (7). The forming mold chooses a square mold with a diameter of 25×25 , The mandrel is 23×23, divided into two sections, each section is 0.04 meters in length, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com