Hybridization liquid precursor, preparing method and method for preparing ZrC-SiC superhigh temperature ceramics and composite materials of ZrC-SiC superhigh temperature ceramics through hybridization liquid precursor

A technology of ultra-high temperature ceramics and composite materials, applied in the field of ultra-high temperature ceramics, can solve the problems of human body and environmental damage, low ceramic yield, precursor viscosity change, etc., and achieves good impregnation, low impregnation temperature, and good oxidation resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The carbon-rich liquid polycarbosilane (LPCS) and solid zirconium acetylacetonate (PZC) precursors were mixed uniformly at a mass ratio of 1:1, and the hybridization treatment was performed at a temperature of 30°C and a magnetic stirring condition of 200 rpm for 3 hours. , the molecular structure of the obtained hybrid liquid LPCS-PZC ceramic precursor is as follows:

[0047]

[0048] Where: R=CH 3 or H.

[0049] The structural formula of the carbon-rich vinyl substituted liquid polycarbosilane precursor LPCS is as follows:

[0050]

[0051] Where: R=CH 3 or H;

[0052] The structural formula of the solid zirconium acetylacetonate precursor PZC is as follows:

[0053]

[0054] Where: R=CH 3 or H.

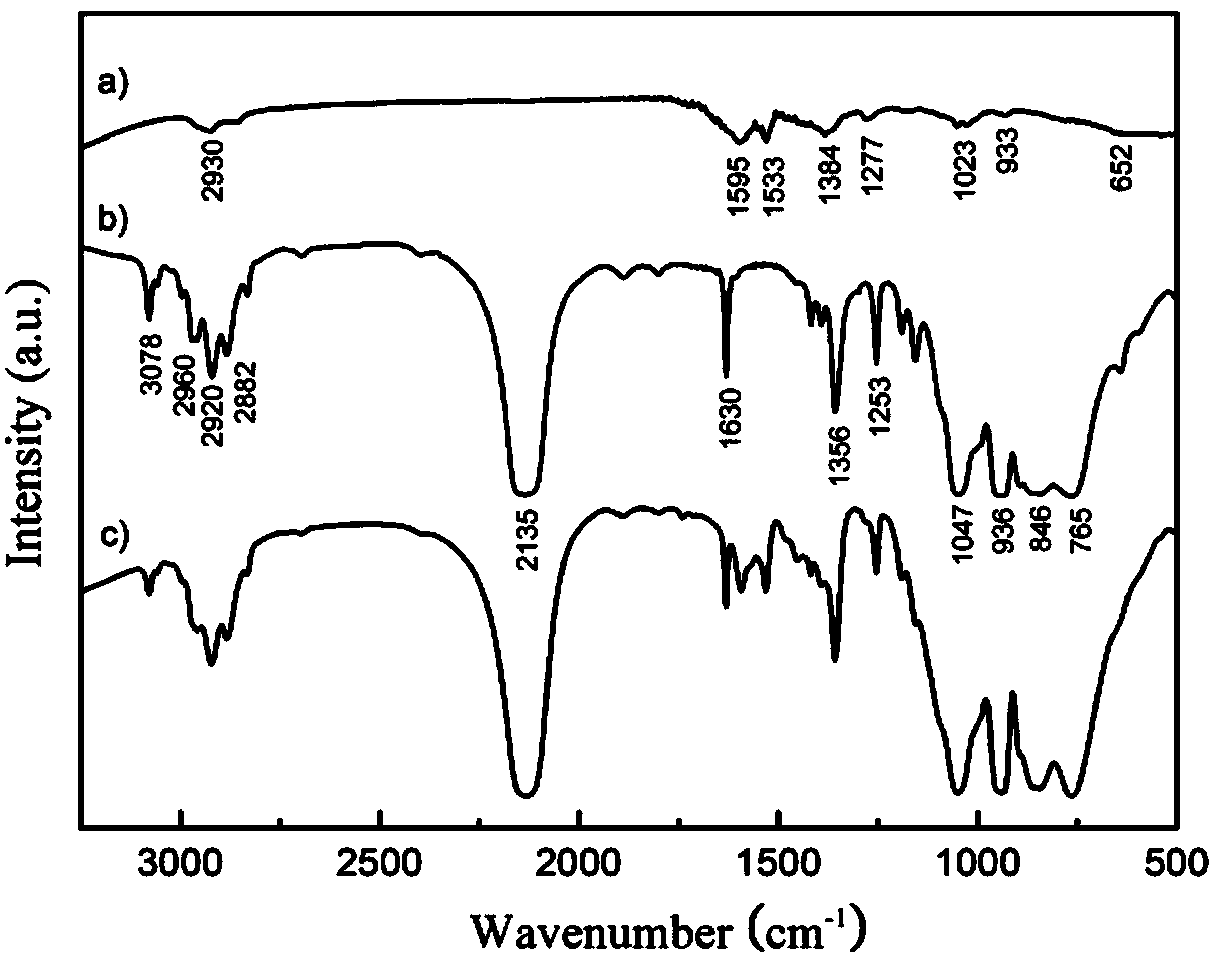

[0055] Such as figure 1 Shown is the infrared spectrogram of the hybrid liquid LPCS-PZC ceramic precursor obtained by the present invention using carbon-rich liquid polycarbosilane (LPCS), solid zirconium acetylacetonate precursor (PZC) and hybrid treatment; ...

Embodiment 2

[0058] The carbon-rich liquid polycarbosilane (LPCS) and solid zirconium acetylacetonate (PZC) precursors were mass-produced at 1:1, 1:1.5, 1:2, 1:2.5, 1:3, 1:3.5, 1:4 Mix evenly, and perform hybridization treatment for 5 hours under the condition of 25° C. and 250 rpm magnetic stirring to obtain a hybrid liquid LPCS-PZC ceramic precursor. The obtained hybrid liquid LPCS-PZC ceramic precursor has good fluidity and is suitable for preparing fiber-reinforced ZrC-SiC ultra-high temperature ceramic matrix composites by impregnation-curing-cracking process.

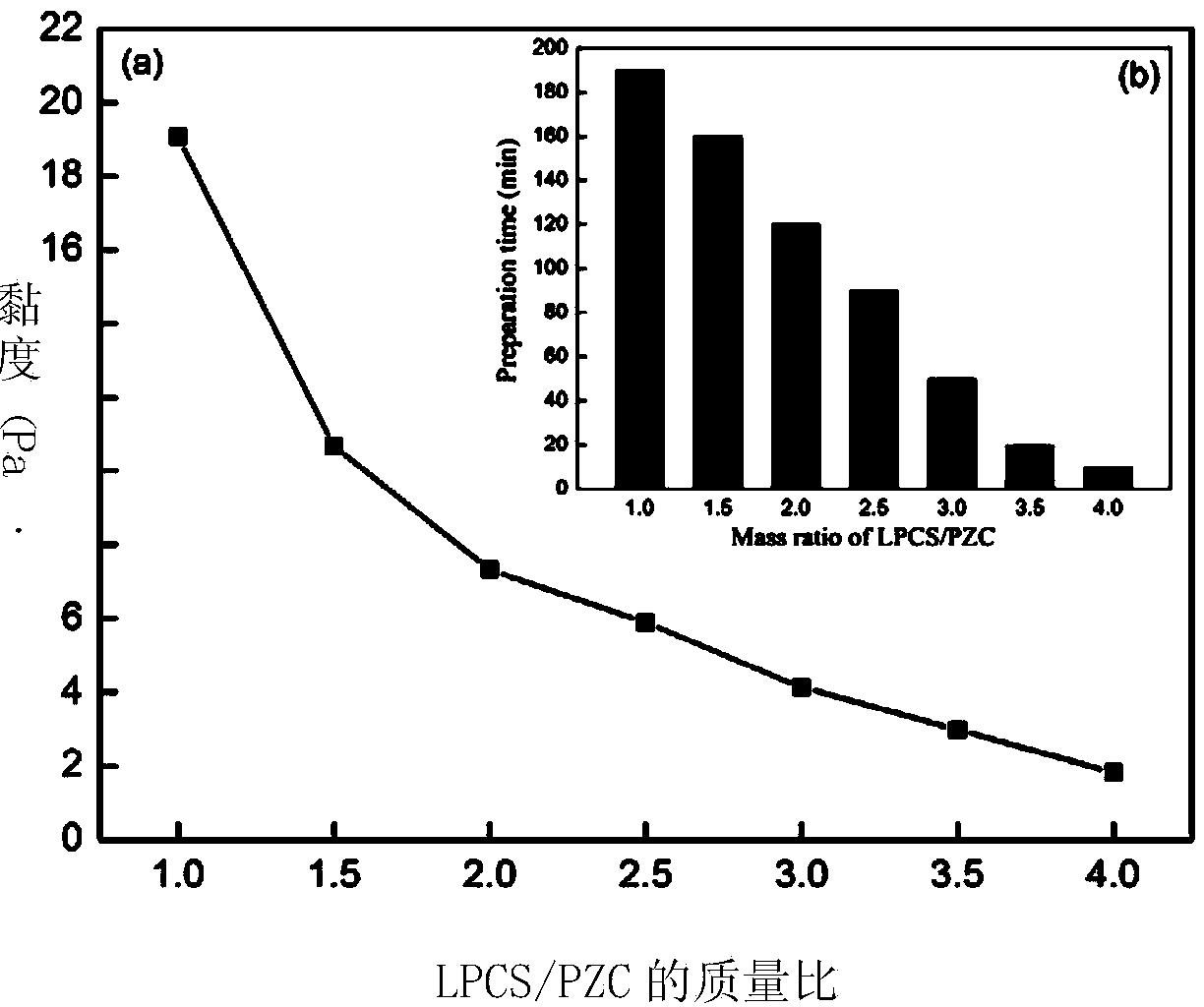

[0059] Such as figure 2 Shown is the relationship between the viscosity of the hybrid liquid LPCS-PZC ceramic precursor of the present invention and the ratio of liquid polycarbosilane (LPCS) and solid zirconium acetylacetonate (PZC); the illustration shows the dissolution of different contents of solid zirconium acetylacetonate (PZC) into Minimum time required in liquid polycarbosilane (LPCS). Depend on figure 2 It can b...

Embodiment 3

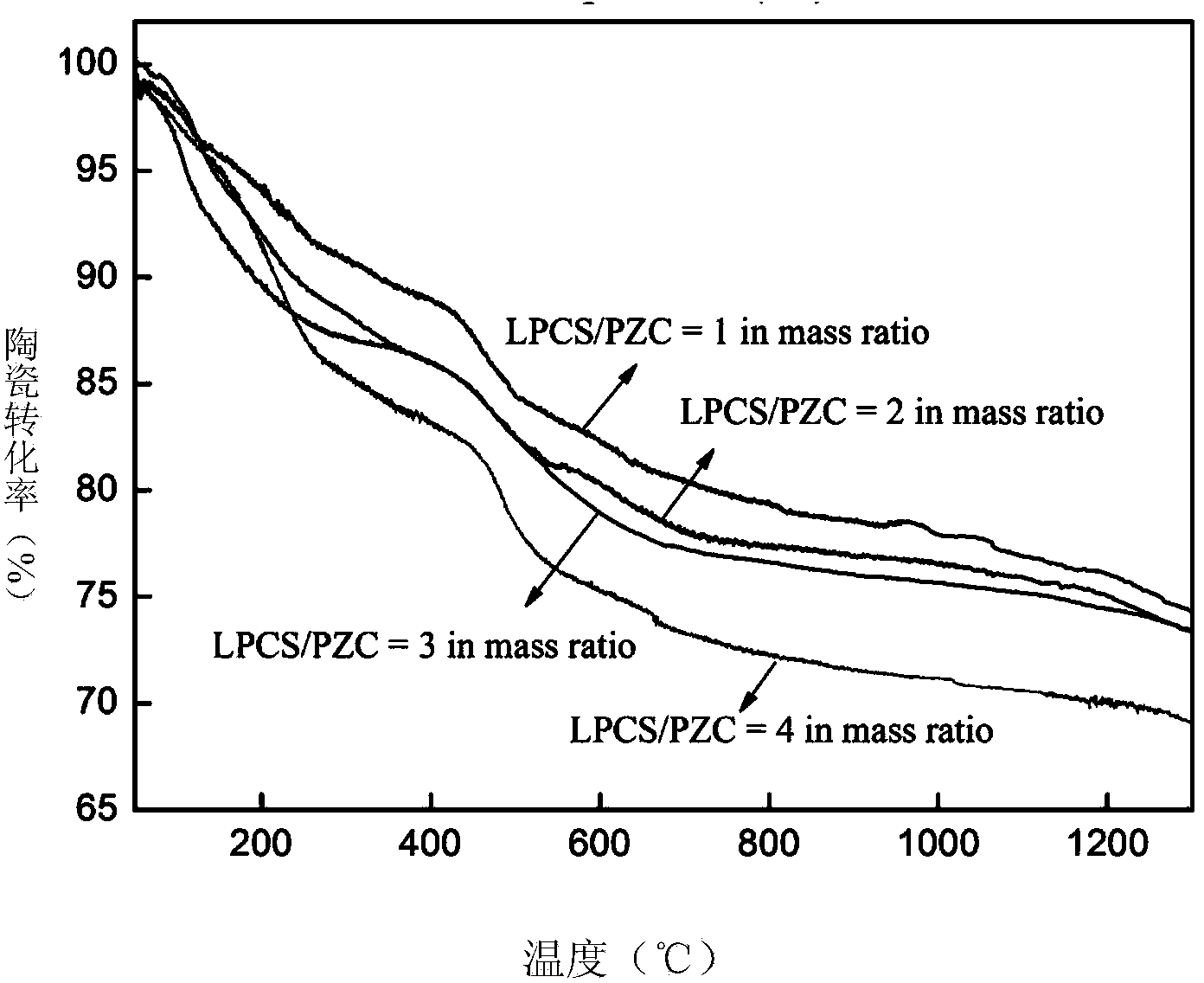

[0061] Mix the carbon-rich liquid polycarbosilane (LPCS) and solid zirconium acetylacetonate (PZC) precursors at a mass ratio of 1:1, 1:2, 1:3, and 1:4, and mix them uniformly at a temperature of 35°C and 180 rpm The hybridization treatment was carried out under magnetic stirring conditions for 8 hours to obtain a hybrid liquid LPCS-PZC ceramic precursor. The fluidity of the hybrid liquid LPCS-PZC ceramic precursor is good. The hybrid liquid LPCS-PZC ceramic precursor was cured at 195°C for 4 hours, and the thermogravimetric analysis showed that the ceramic yield of the hybrid liquid LPCS-PZC ceramic precursor was 77% when the ratio was 1:1, and 1:2 75% at 1:3, 74% at 1:4, and 69% at 1:4. Such as image 3 Shown is the cured ceramic conversion rate of the hybrid liquid LPCS-PZC ceramic precursors prepared in the present invention with different ratios of liquid polycarbosilane (LPCS) and solid zirconium acetylacetonate (PZC).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com