Patents

Literature

3205 results about "Ceramic composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

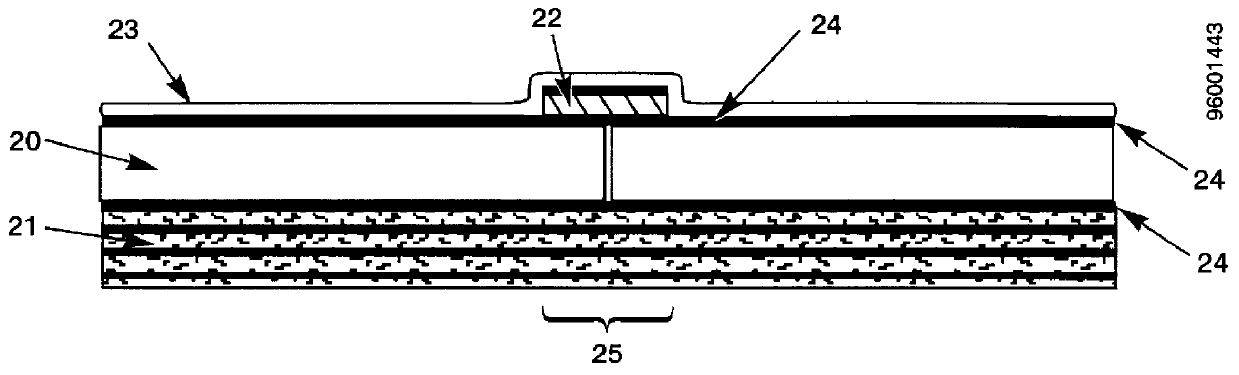

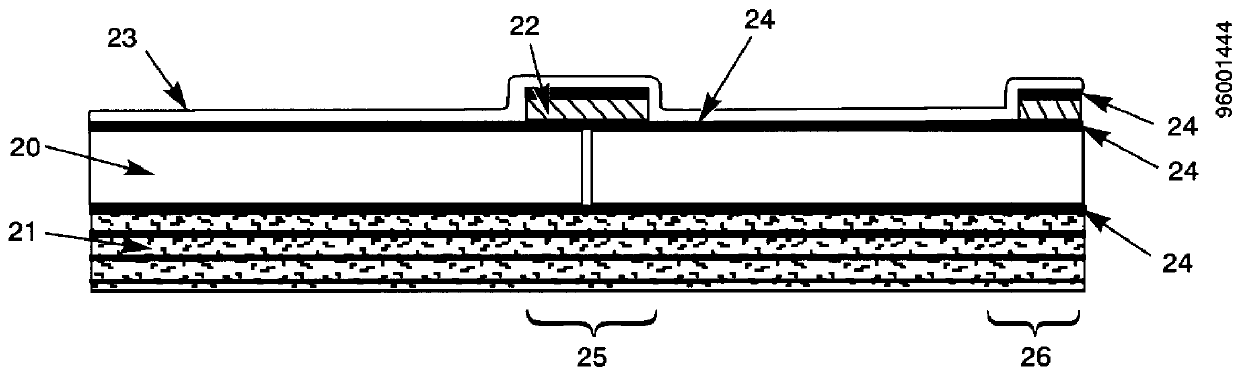

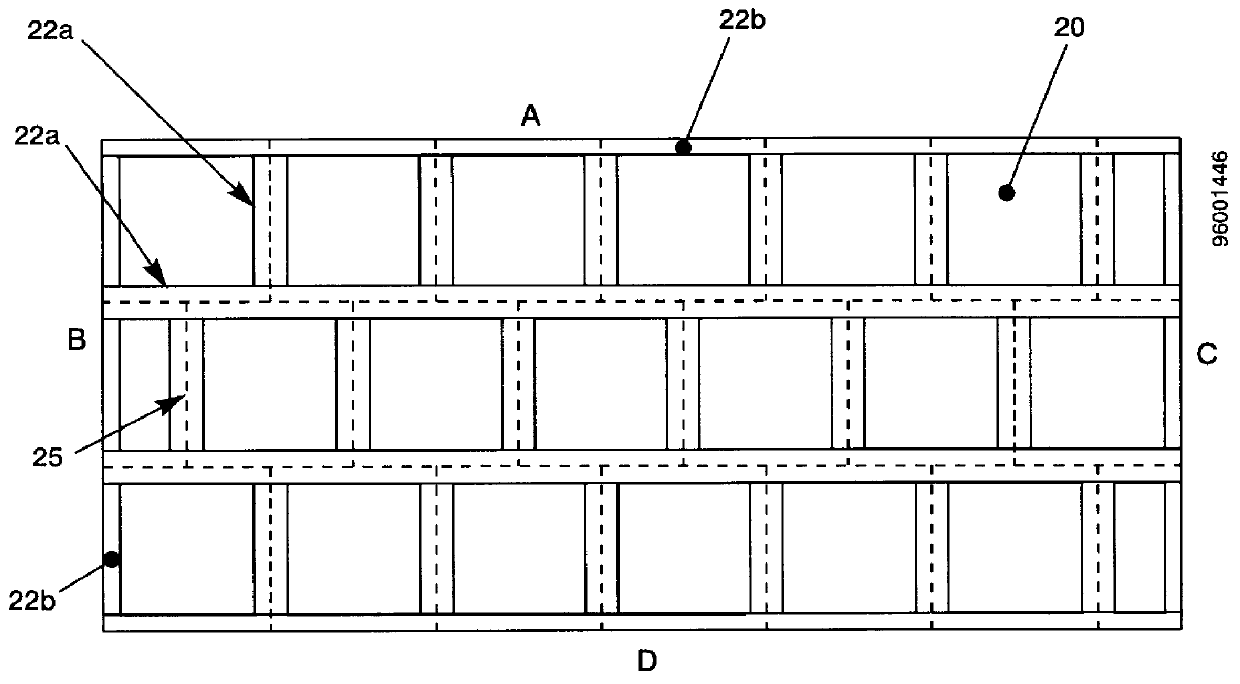

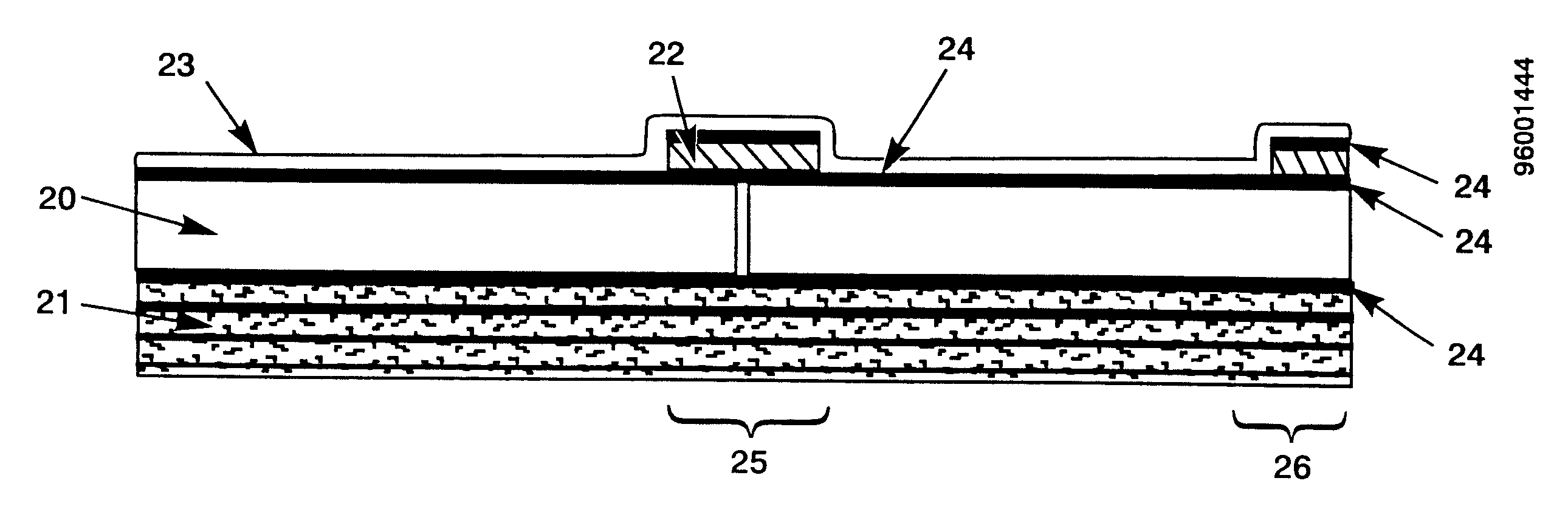

Separator for a high energy rechargeable lithium battery

InactiveUS6432586B1Cell seperators/membranes/diaphragms/spacersNon-aqueous electrolyte accumulator electrodesCeramic compositeMetallurgy

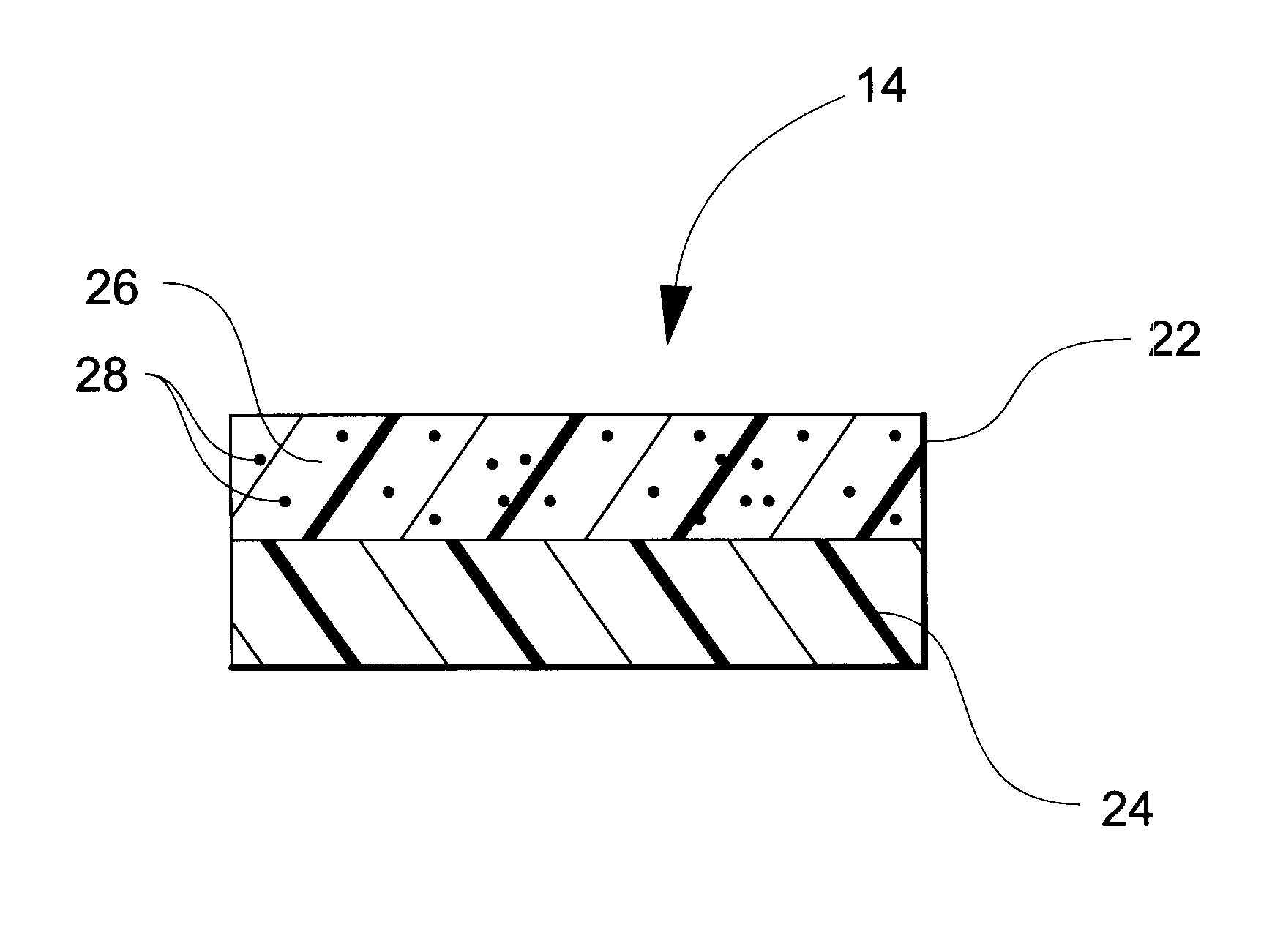

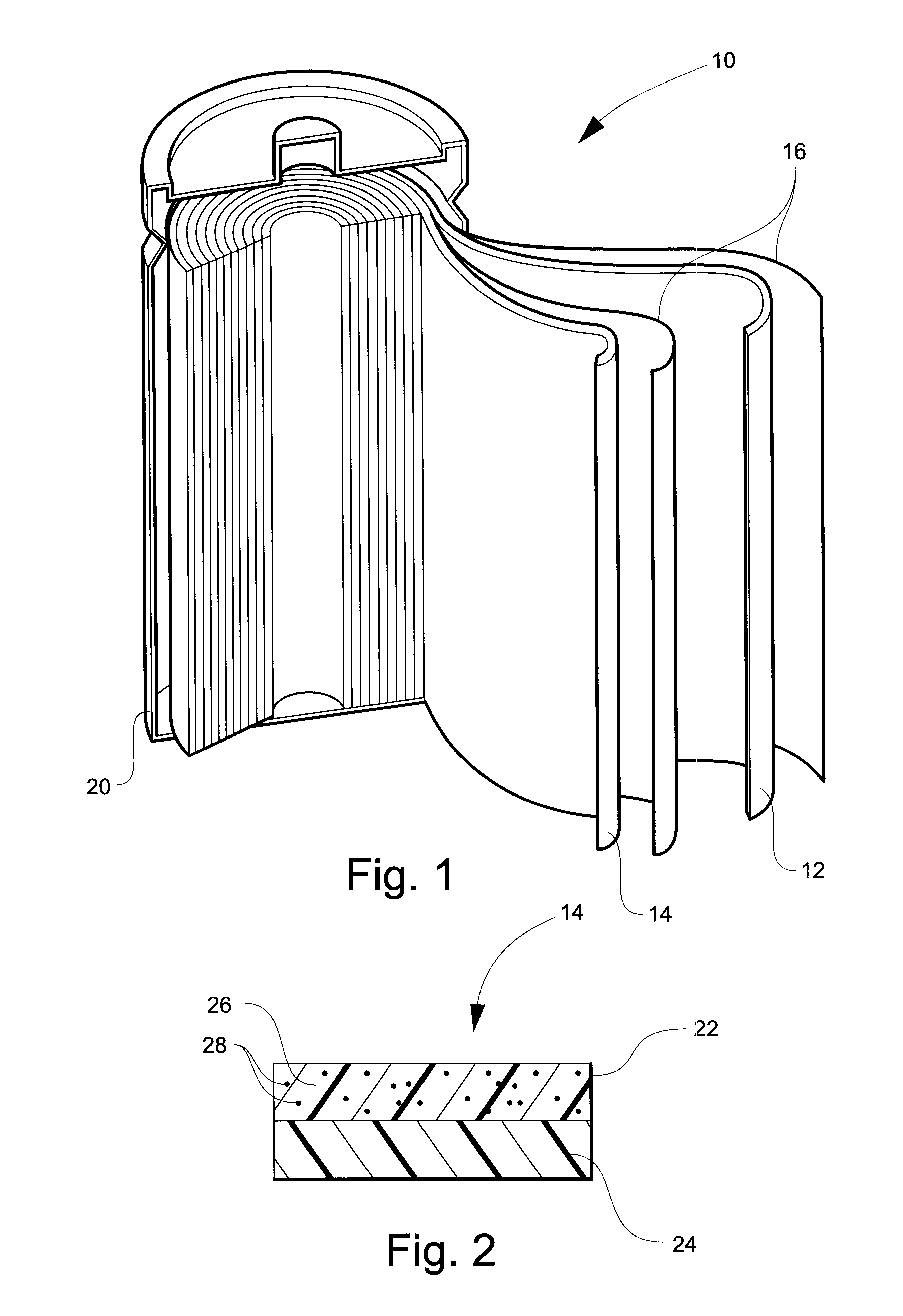

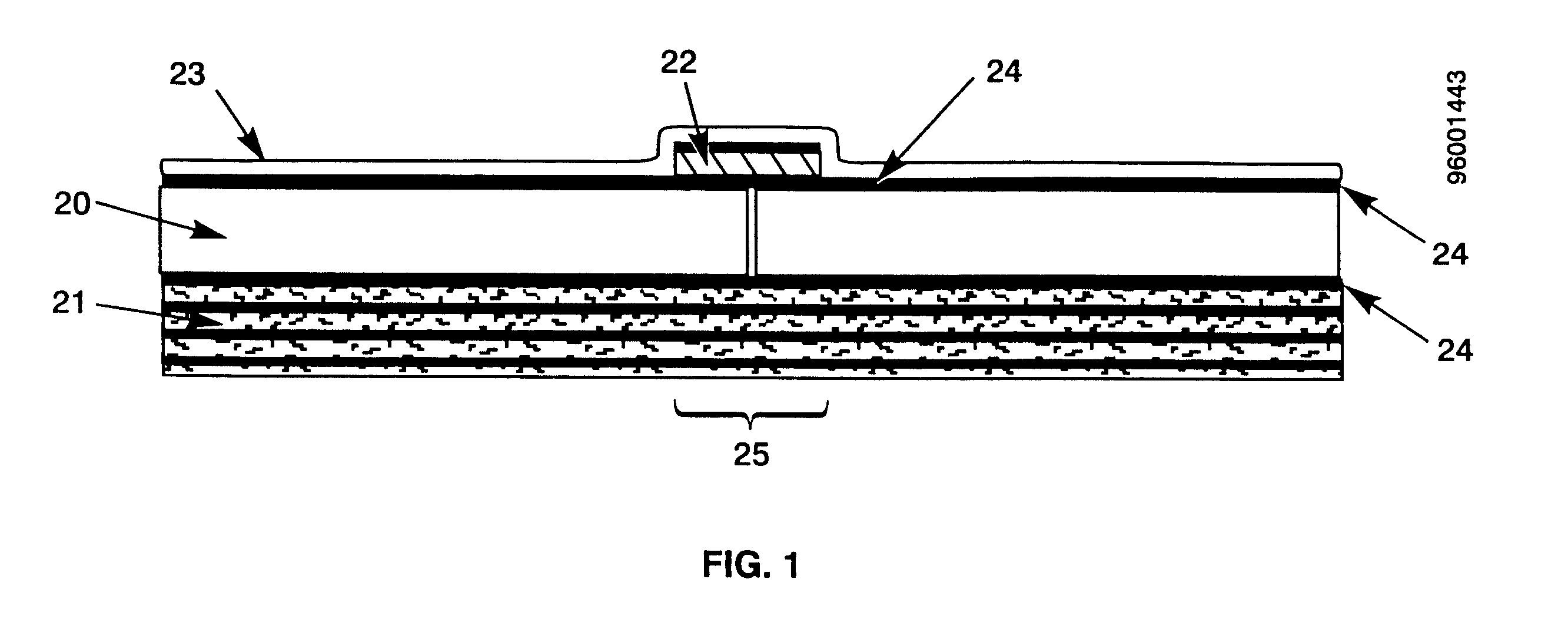

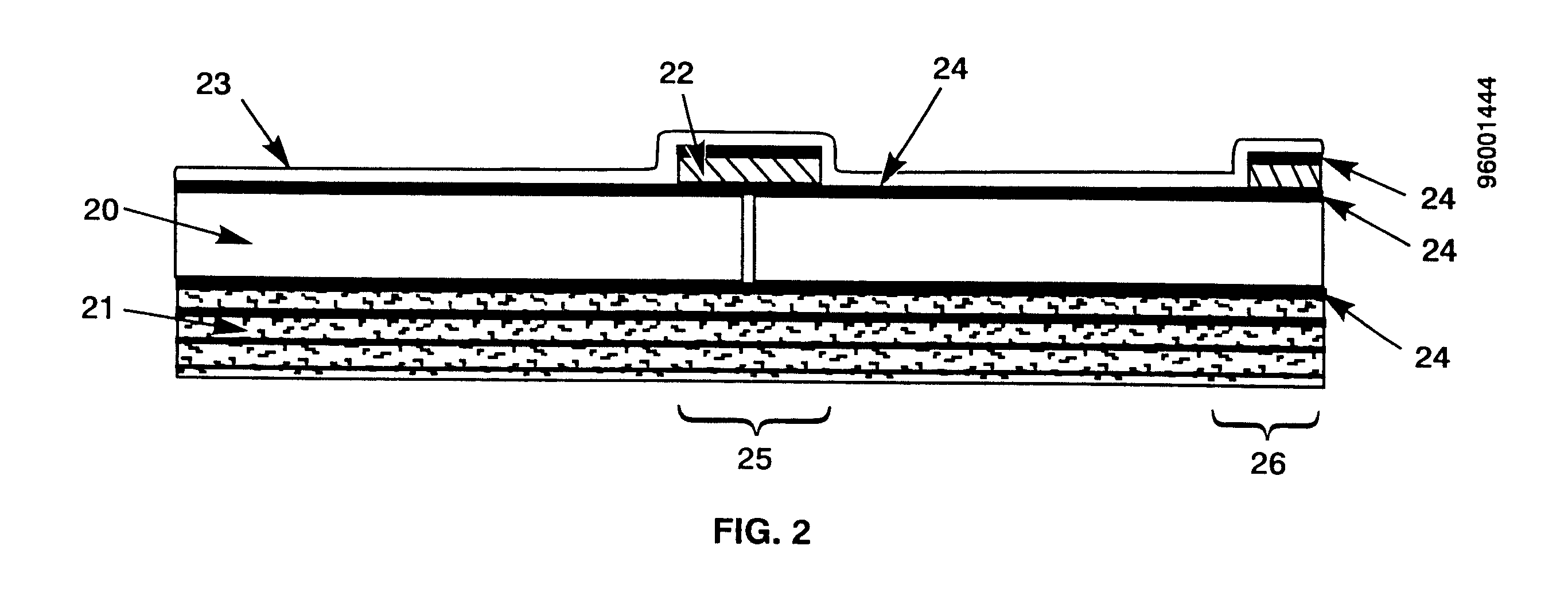

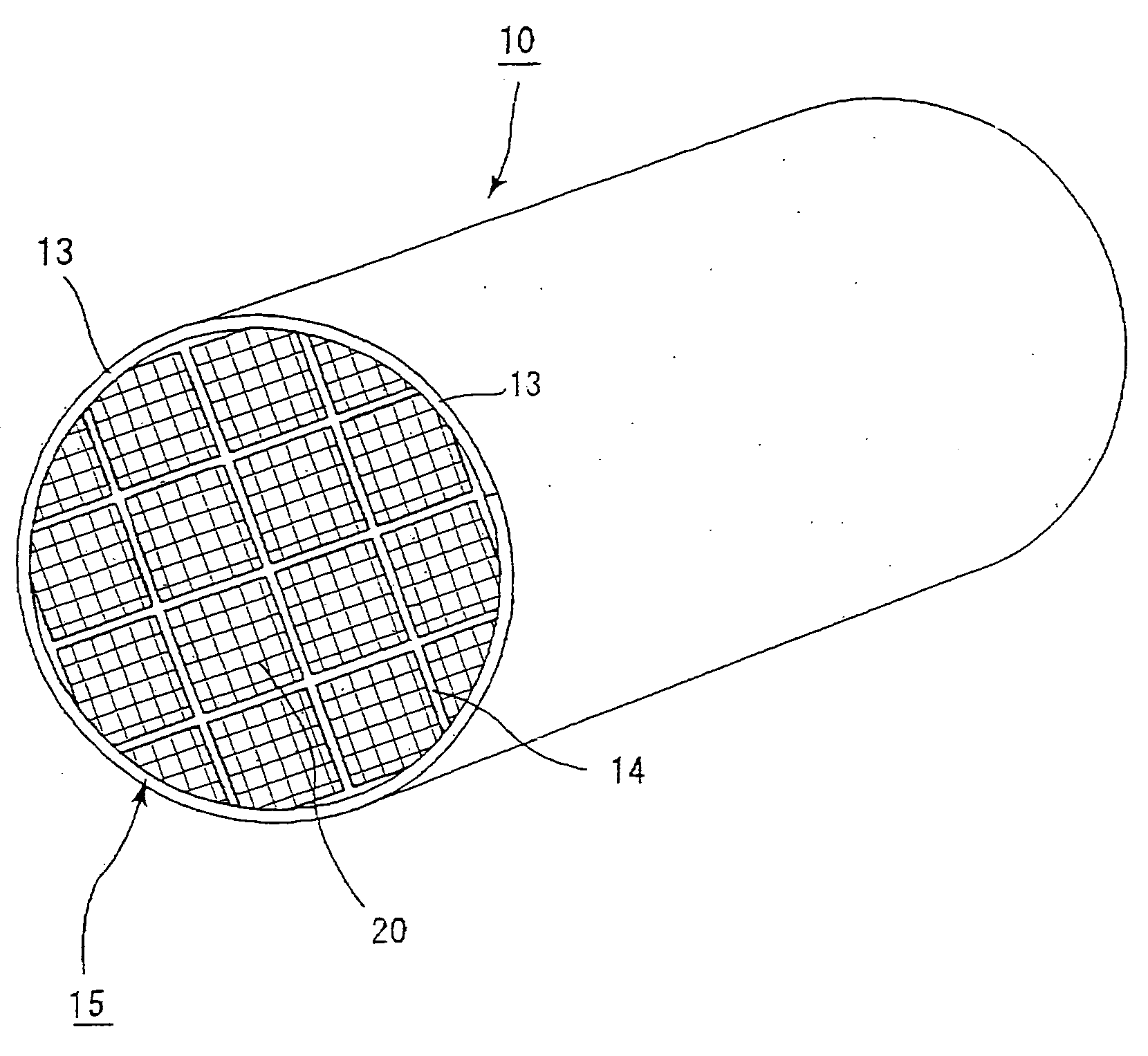

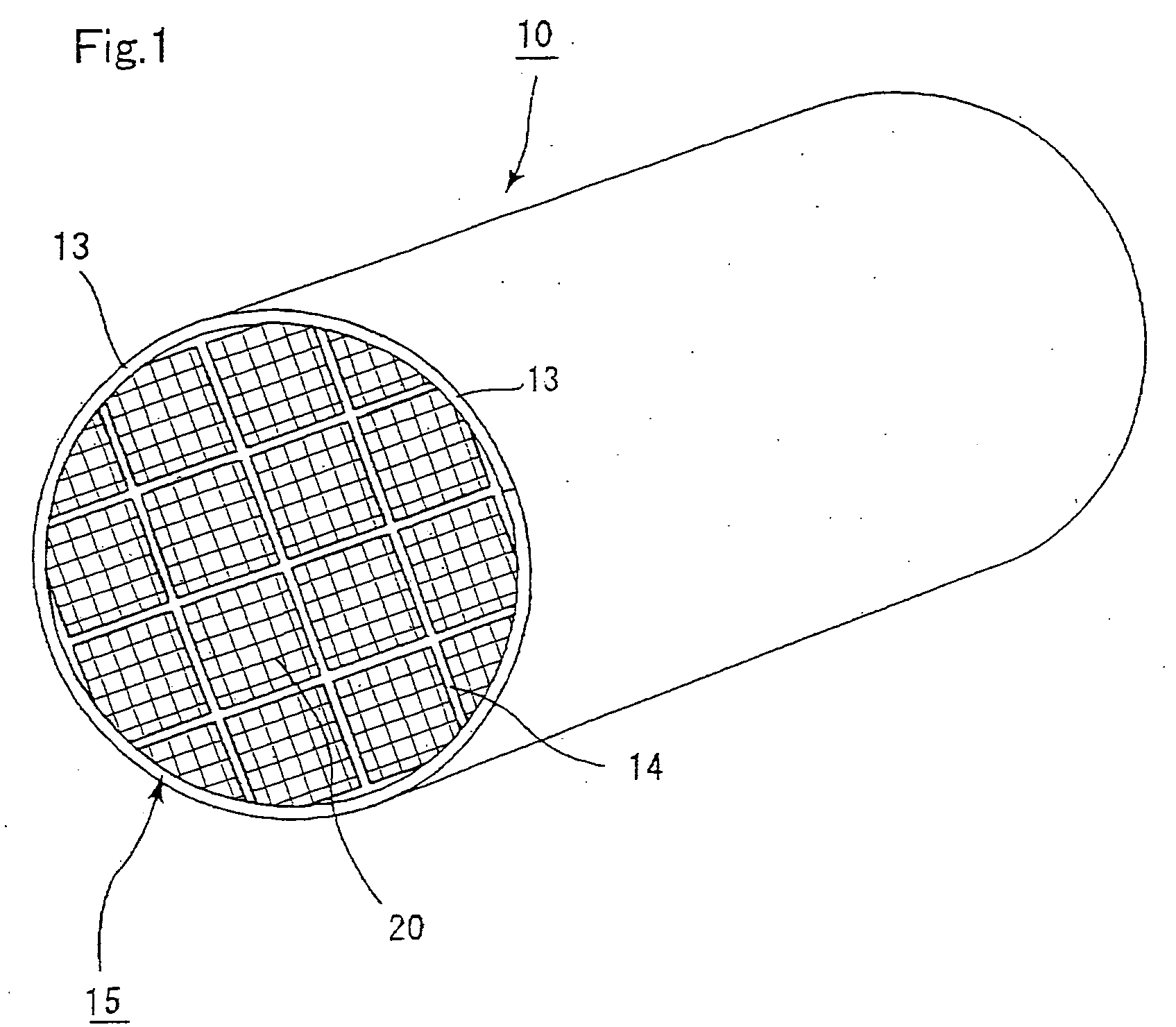

The instant invention is directed to a separator for a high energy rechargeable lithium battery and the corresponding battery. The separator includes a ceramic composite layer and a polymeric microporous layer. The ceramic layers includes a mixture of inorganic particles and a matrix material. The ceramic layer is adapted, at least, to block dendrite growth and to prevent electronic shorting. The polymeric layer is adapted, at least, to block ionic flow between the anode and the cathode in the event of thermal runaway.

Owner:CELGARD LLC

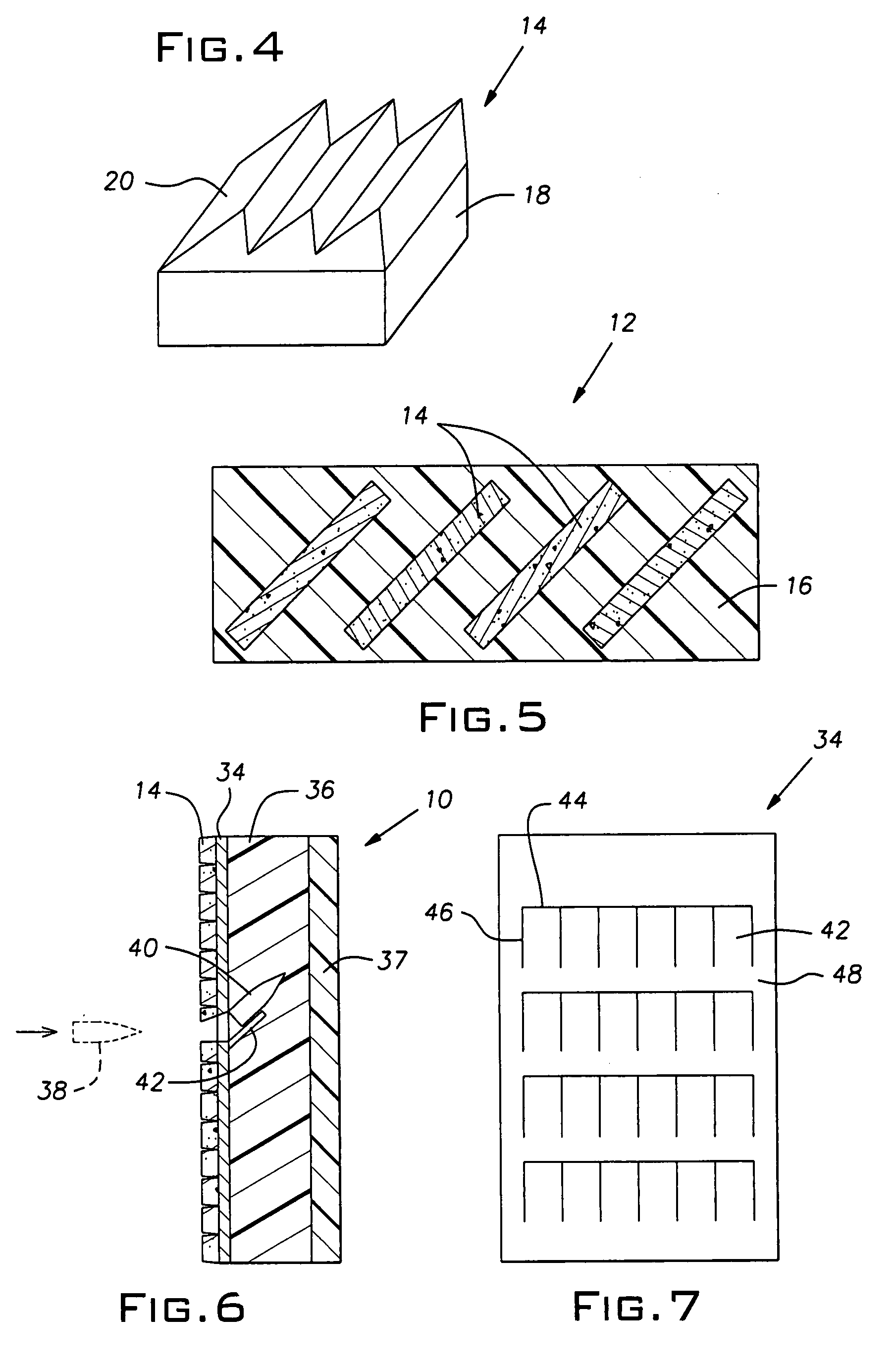

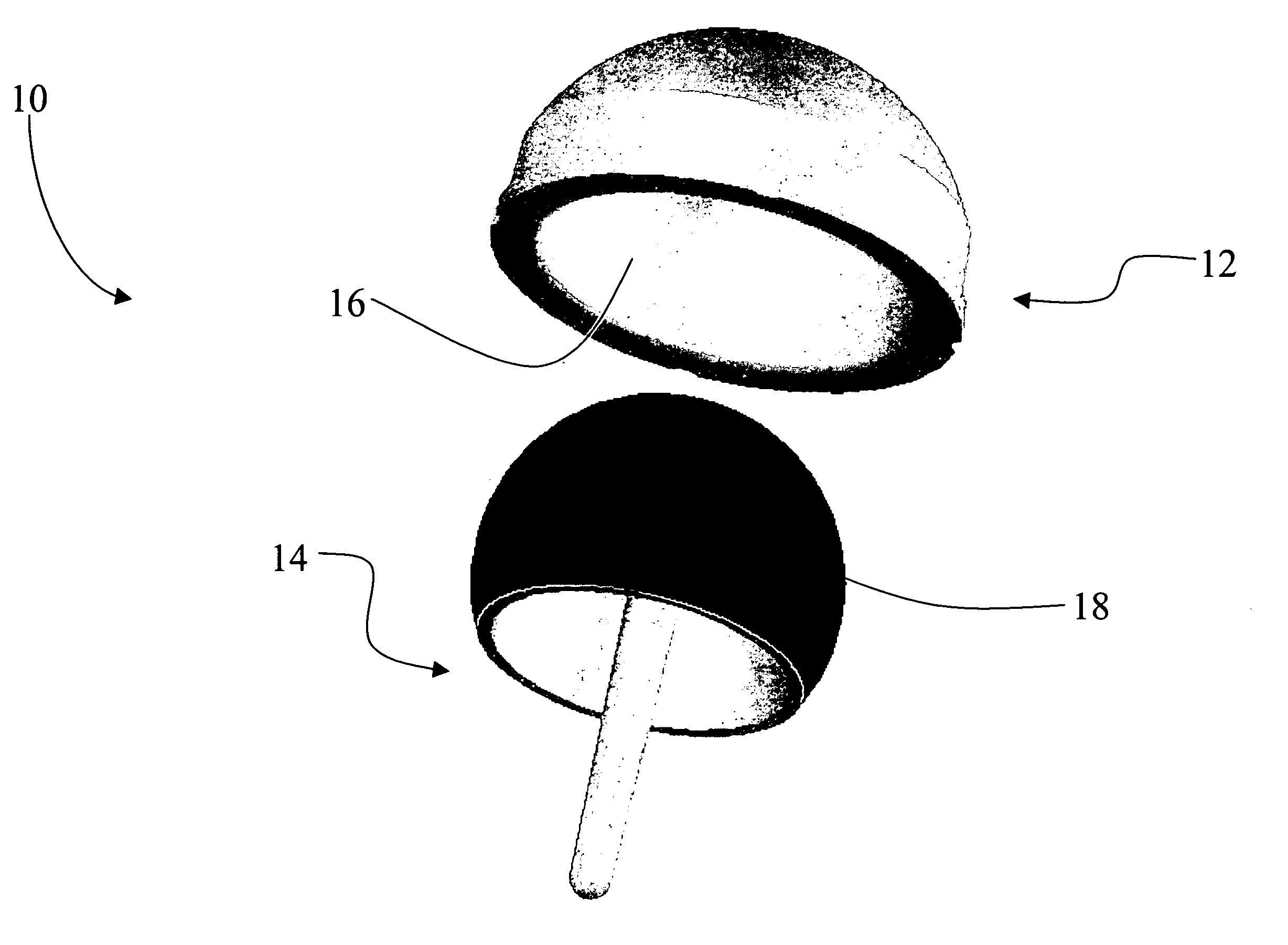

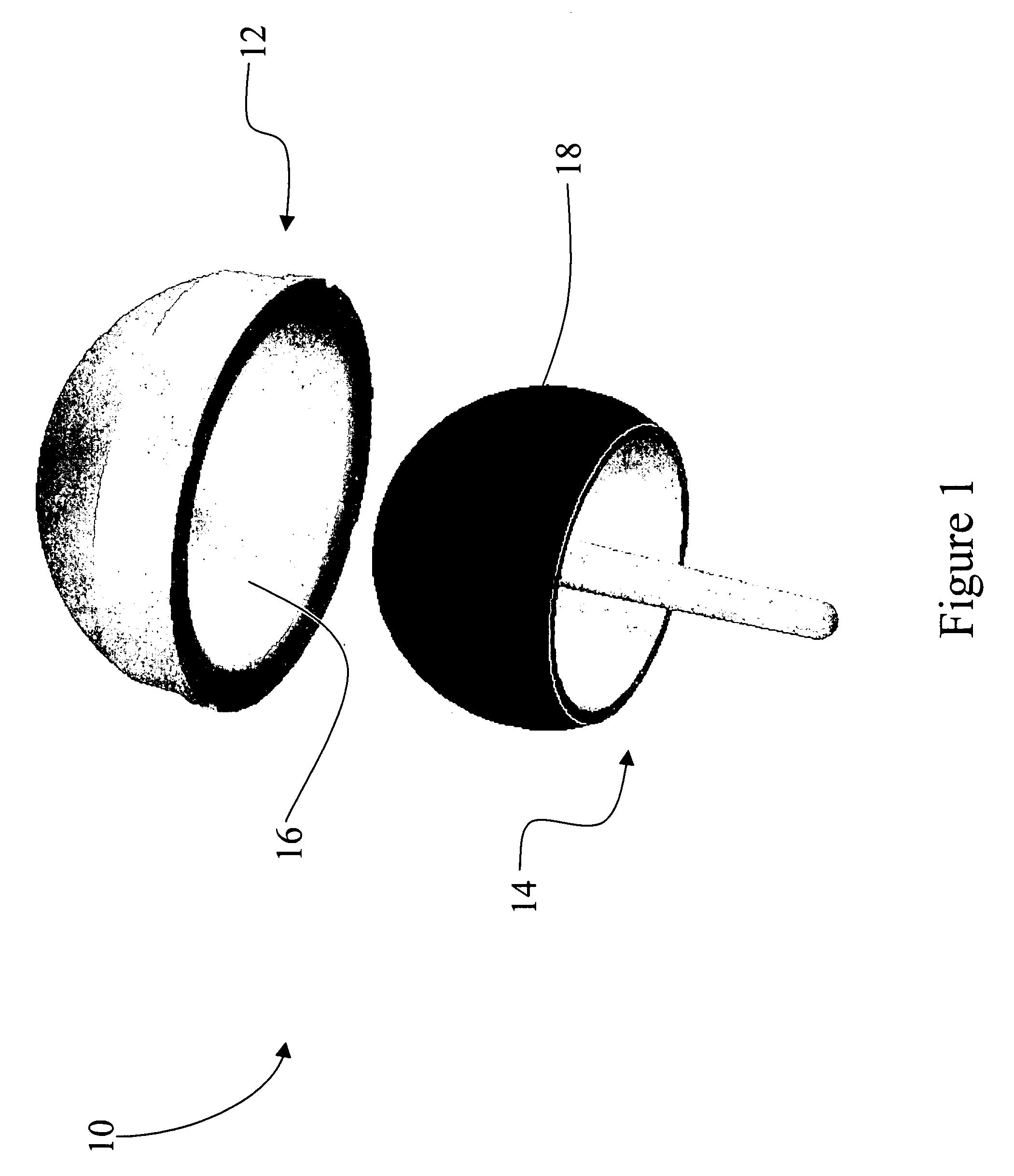

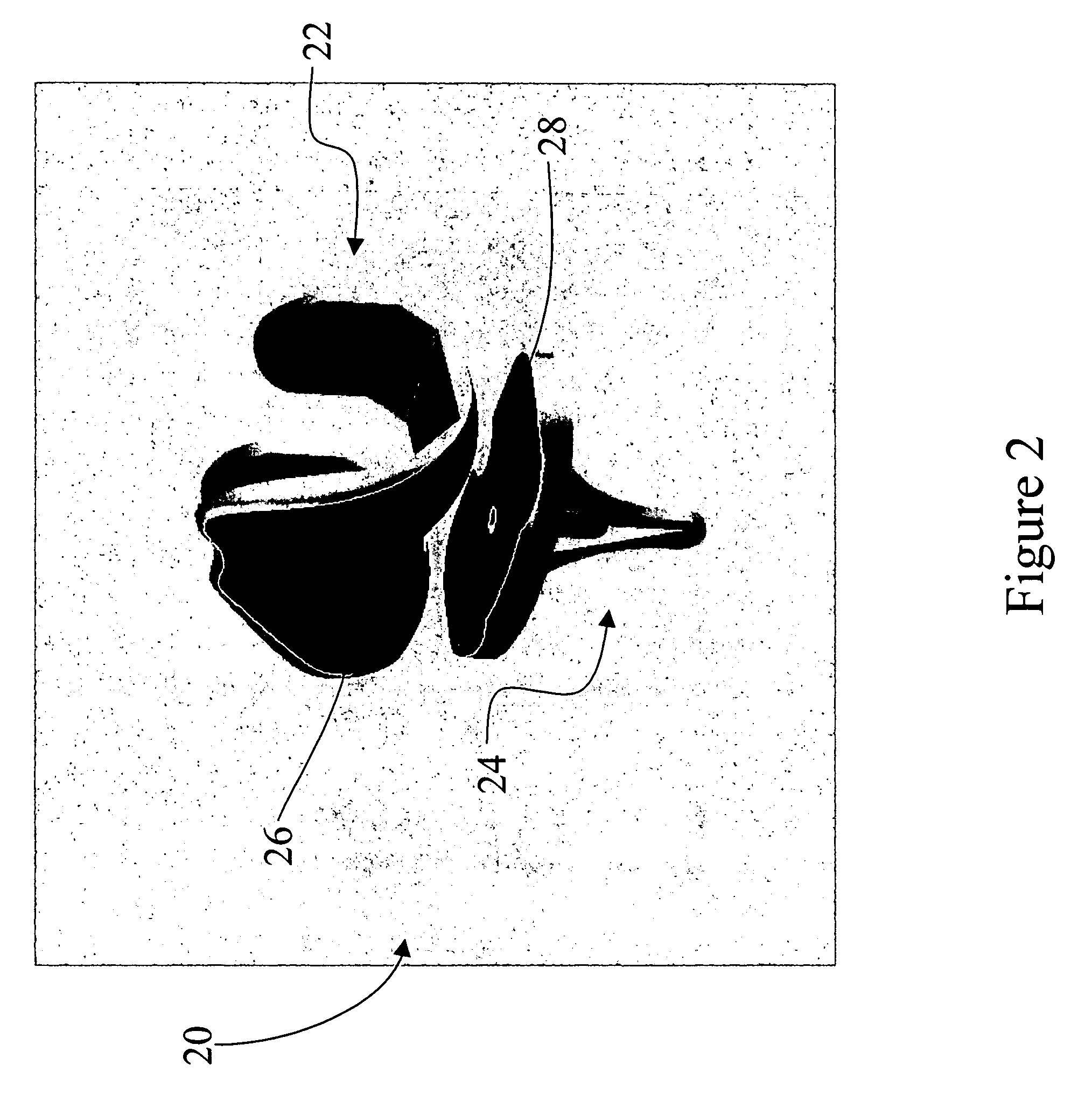

Controlled architecture ceramic composites by stereolithography

InactiveUS6283997B1Quality improvementFast preparationProgramme controlAdditive manufacturing apparatusCeramic compositeMetallurgy

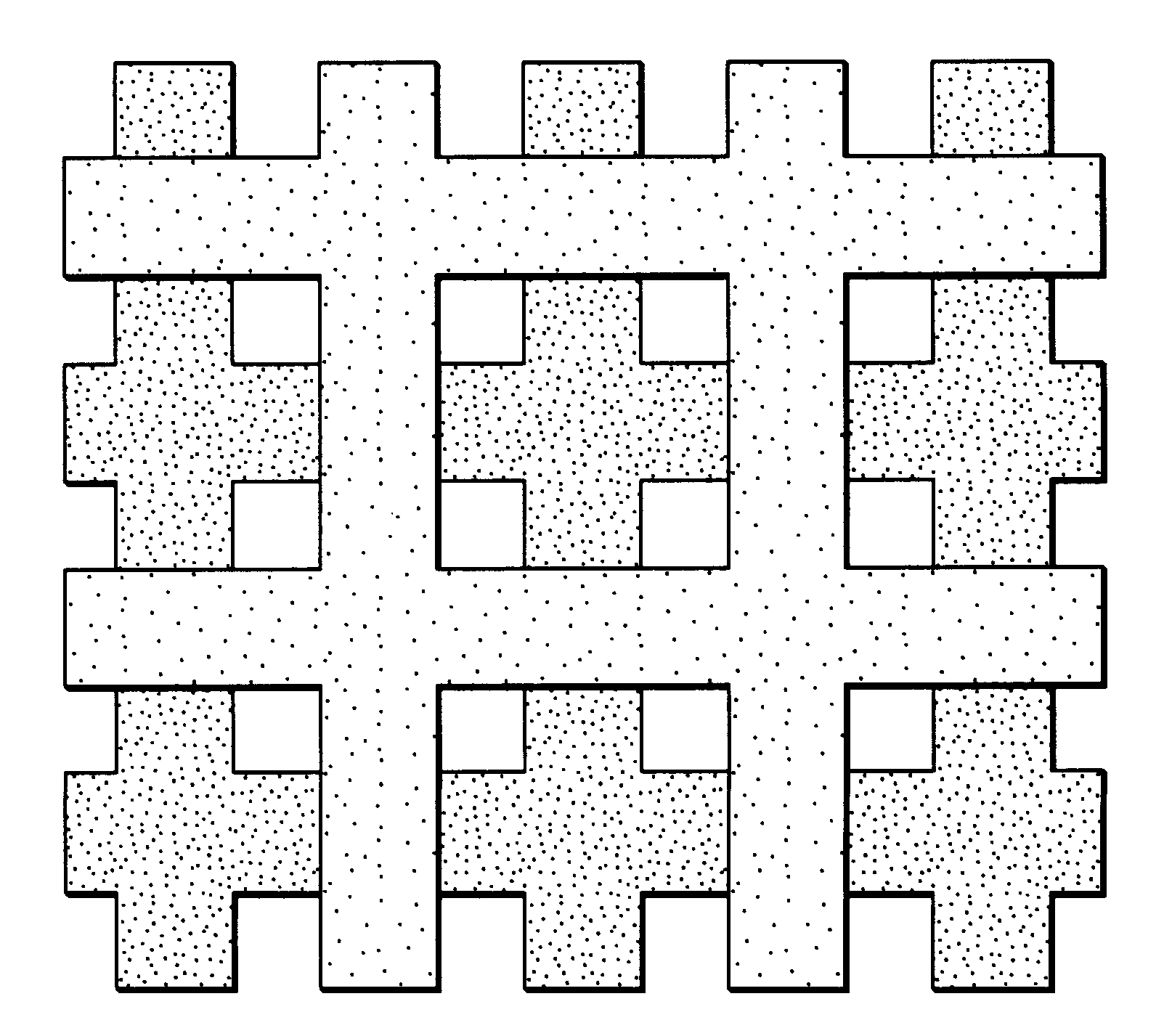

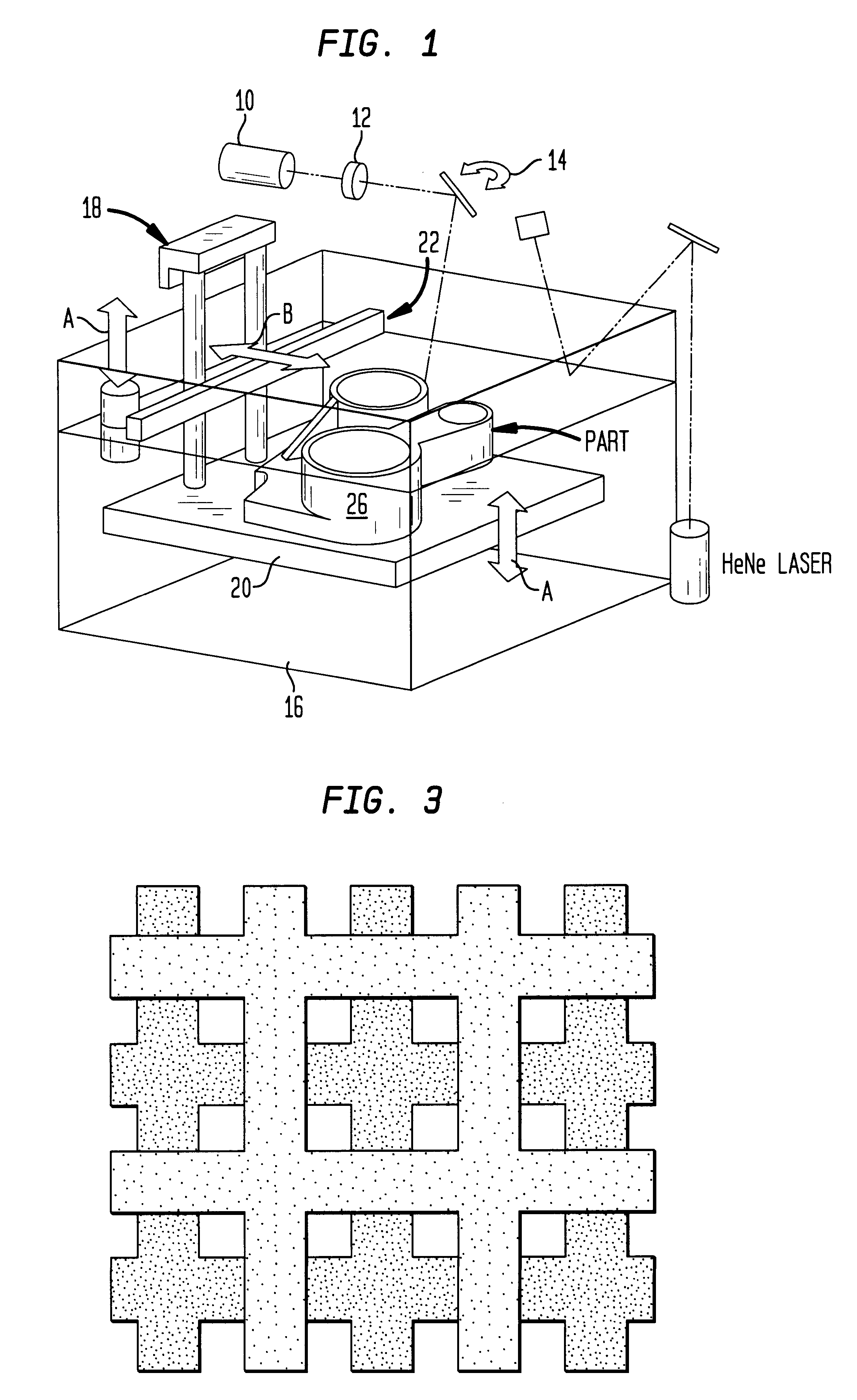

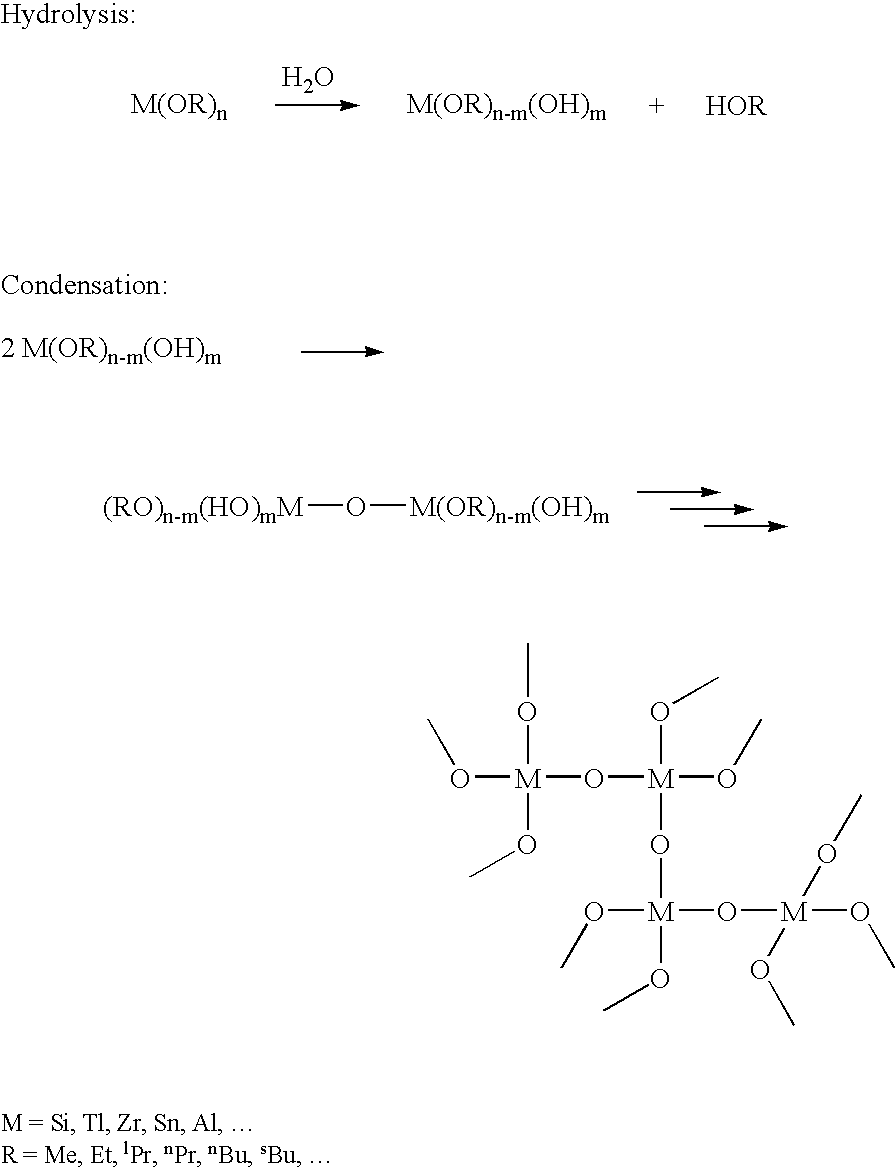

A process for producing a ceramic composite having a porous network. The process includes providing a photocurable ceramic dispersion. The dispersion consists of a photocurable polymer and a ceramic composition. The surface of the dispersion is scanned with a laser to cure the photocurable polymer to produce a photocured polymer / ceramic composition. The photocured composition useful as a polymer / ceramic composite, or the polymer phase can be removed by heating to a first temperature that is sufficient to burn out the photocured polymer. It is then heated to a second temperature that is higher than the first temperature and is sufficient to sinter the ceramic composition to produce a purely ceramic composition having a porous network.Preferably and more specifically, the process uses a stereolithographic technique for laser scanning. The process can form a high quality orthopedic implant that dimensionally matches the bone structure of a patient. The technique relies upon laser photocuring a dense colloidal dispersion into a desired complex three-dimensional shape. The shape is obtained from a CAT scan file of a bone and is rendered into a CAD file that is readable by the stereolithography instrument. Or the shape is obtained directly from a CAD file that is readable by the stereolithography instrument.

Owner:UNITED STATES SURGICAL CORP +2

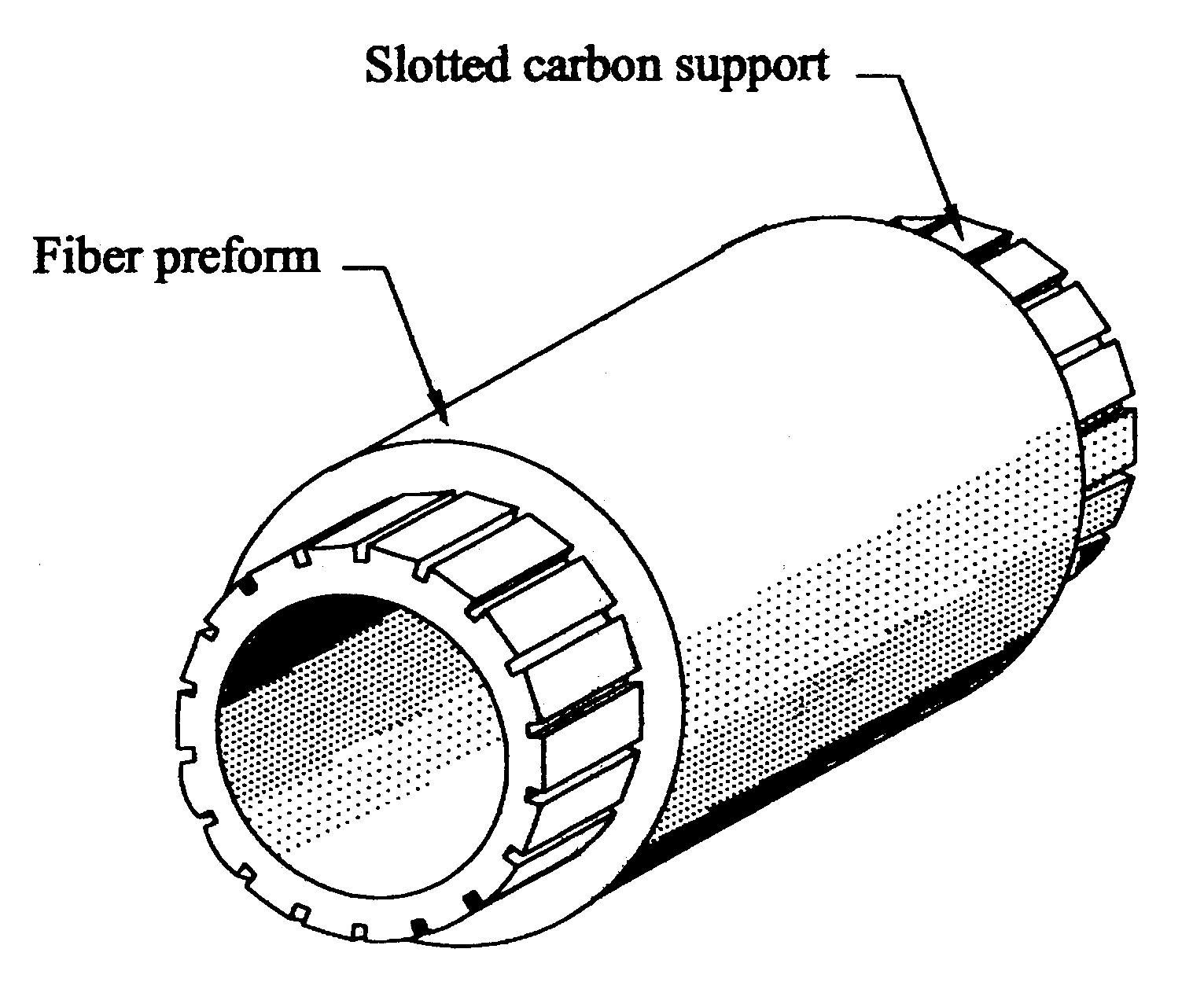

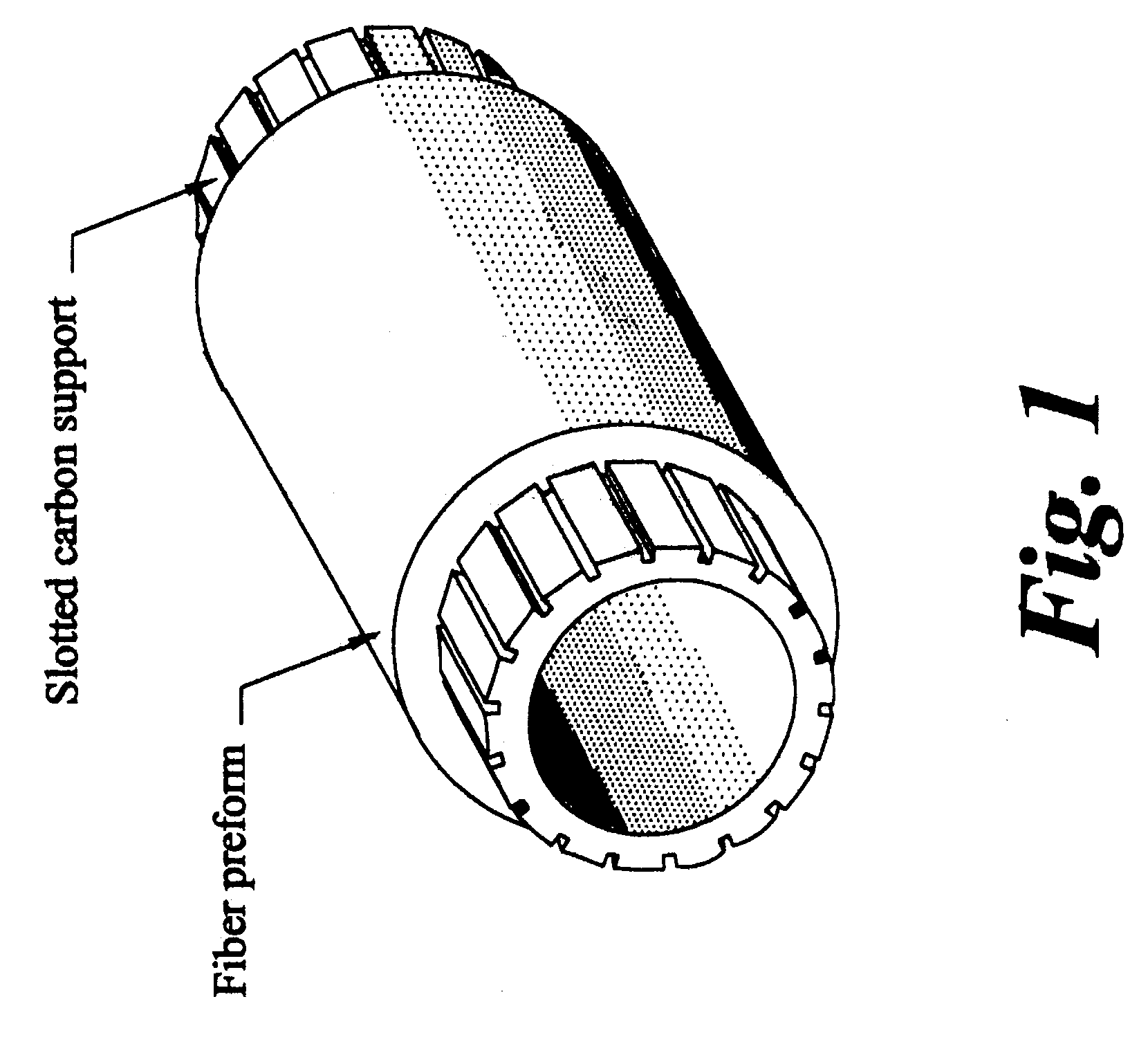

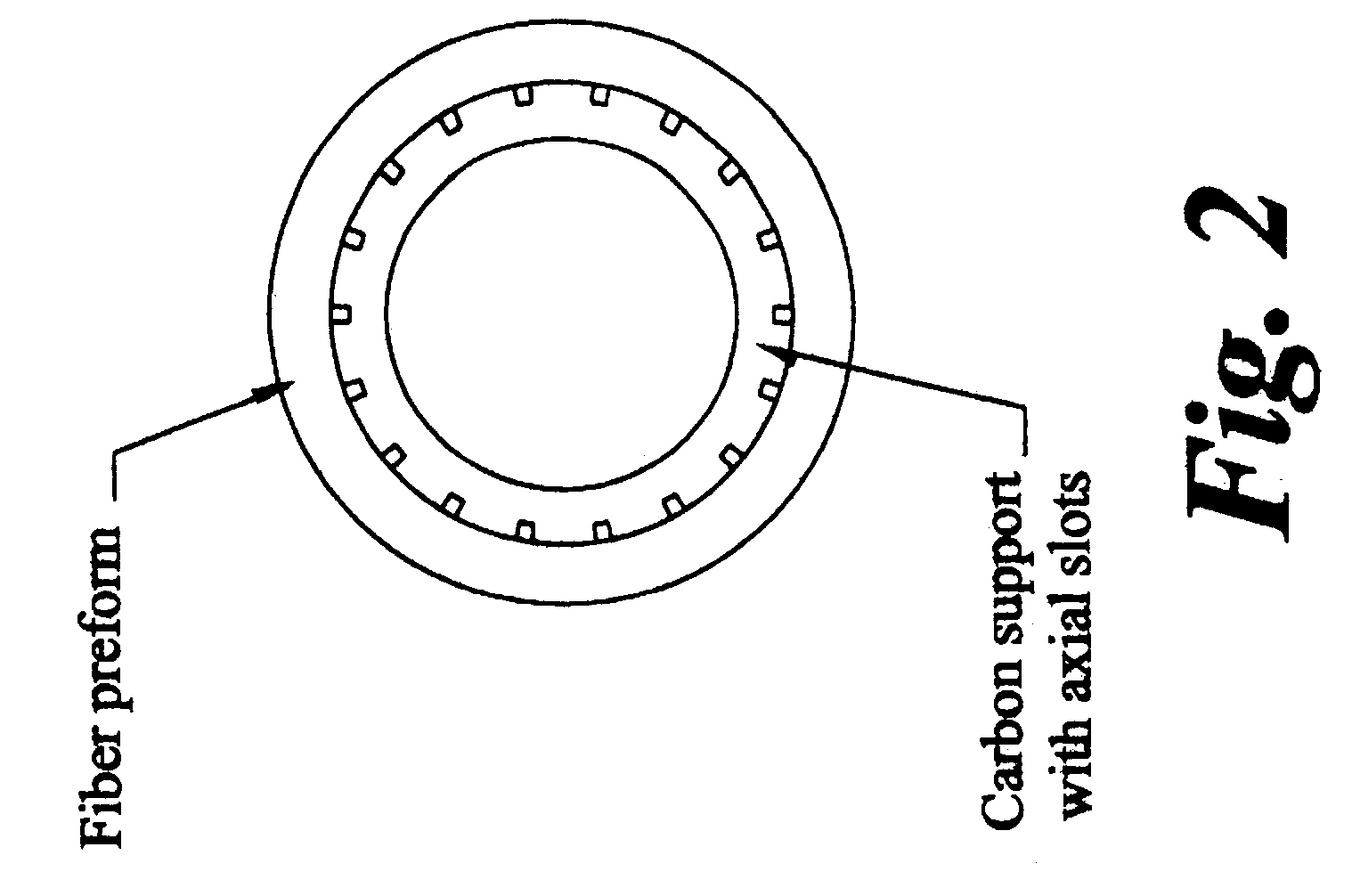

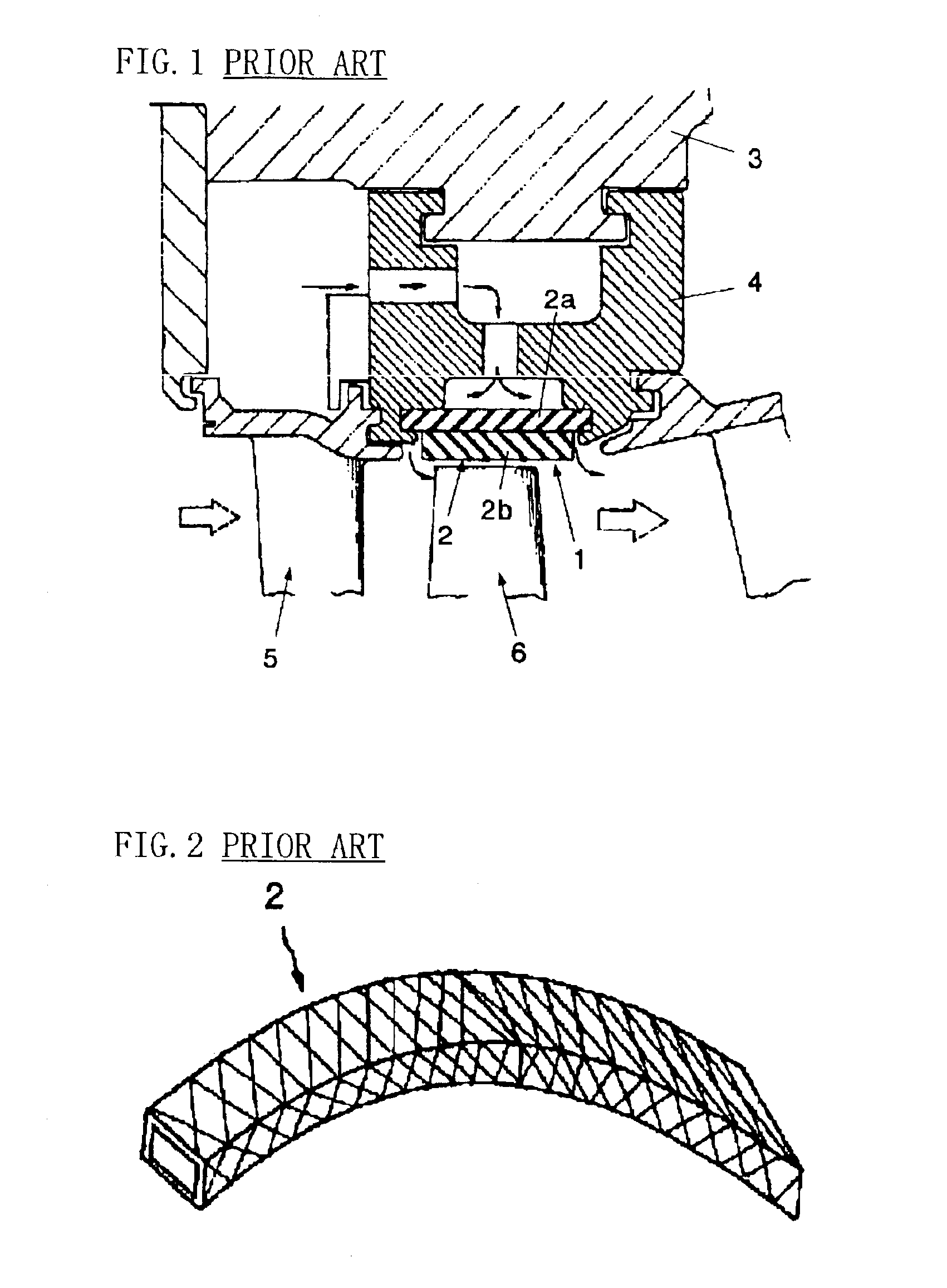

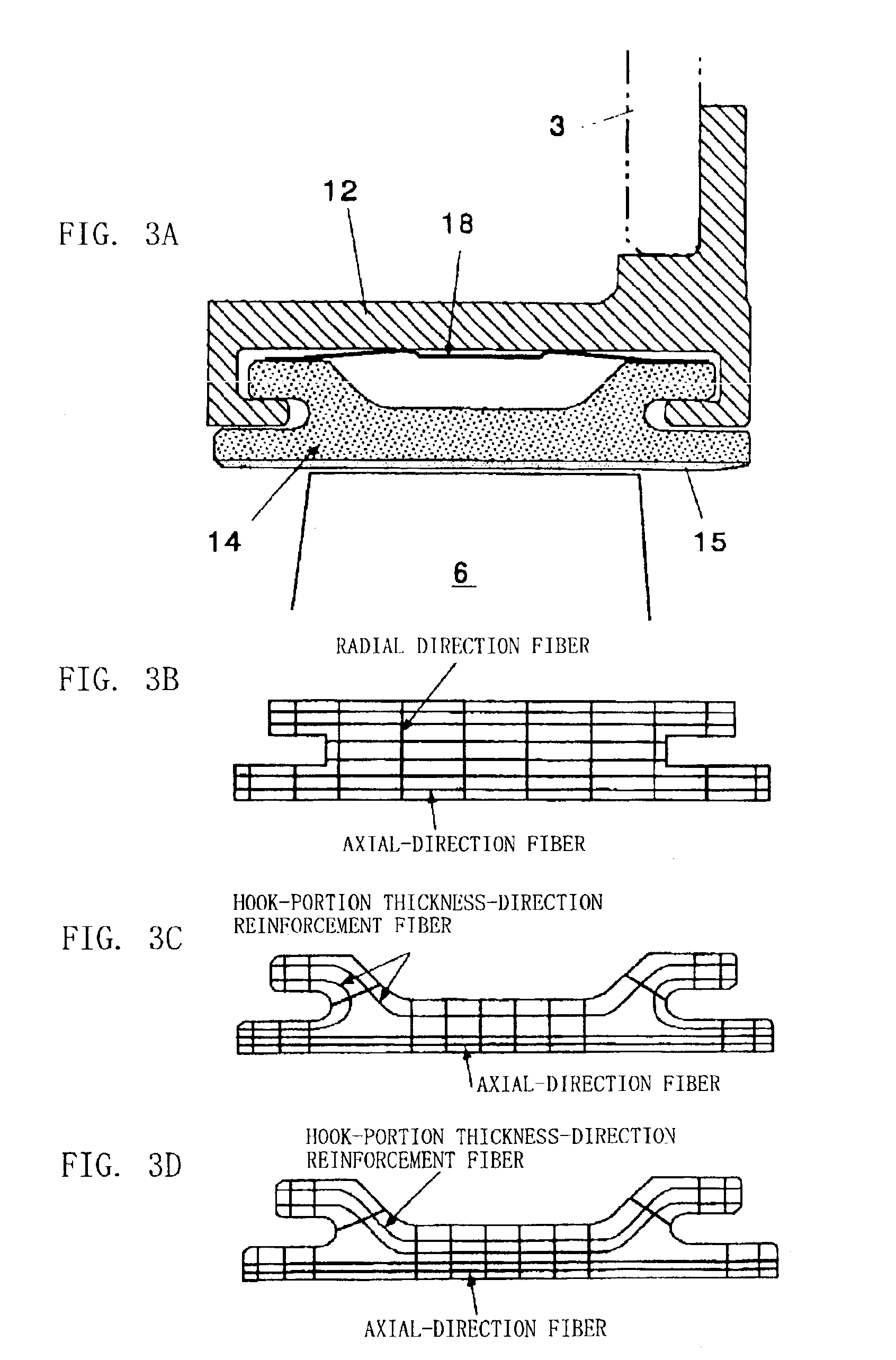

Method for producing melt-infiltrated ceramic composites using formed supports

InactiveUS6503441B2Avoid distortionEvenly distributedPretreated surfacesCeramic shaping apparatusCeramic compositeMetallurgy

A method for producing shaped articles of ceramic composites provides a high degree of dimensional tolerance to these articles. A fiber preform is disposed on a surface of a stable formed support, a surface of which is formed with a plurality of indentations, such as grooves, slots, or channels. Precursors of ceramic matrix materials are provided to the fiber preform to infiltrate from both sides of the fiber preform. The infiltration is conducted under vacuum at a temperature not much greater than a melting point of the precursors. The melt-infiltrated composite article substantially retains its dimension and shape throughout the fabrication process.

Owner:GENERAL ELECTRIC CO

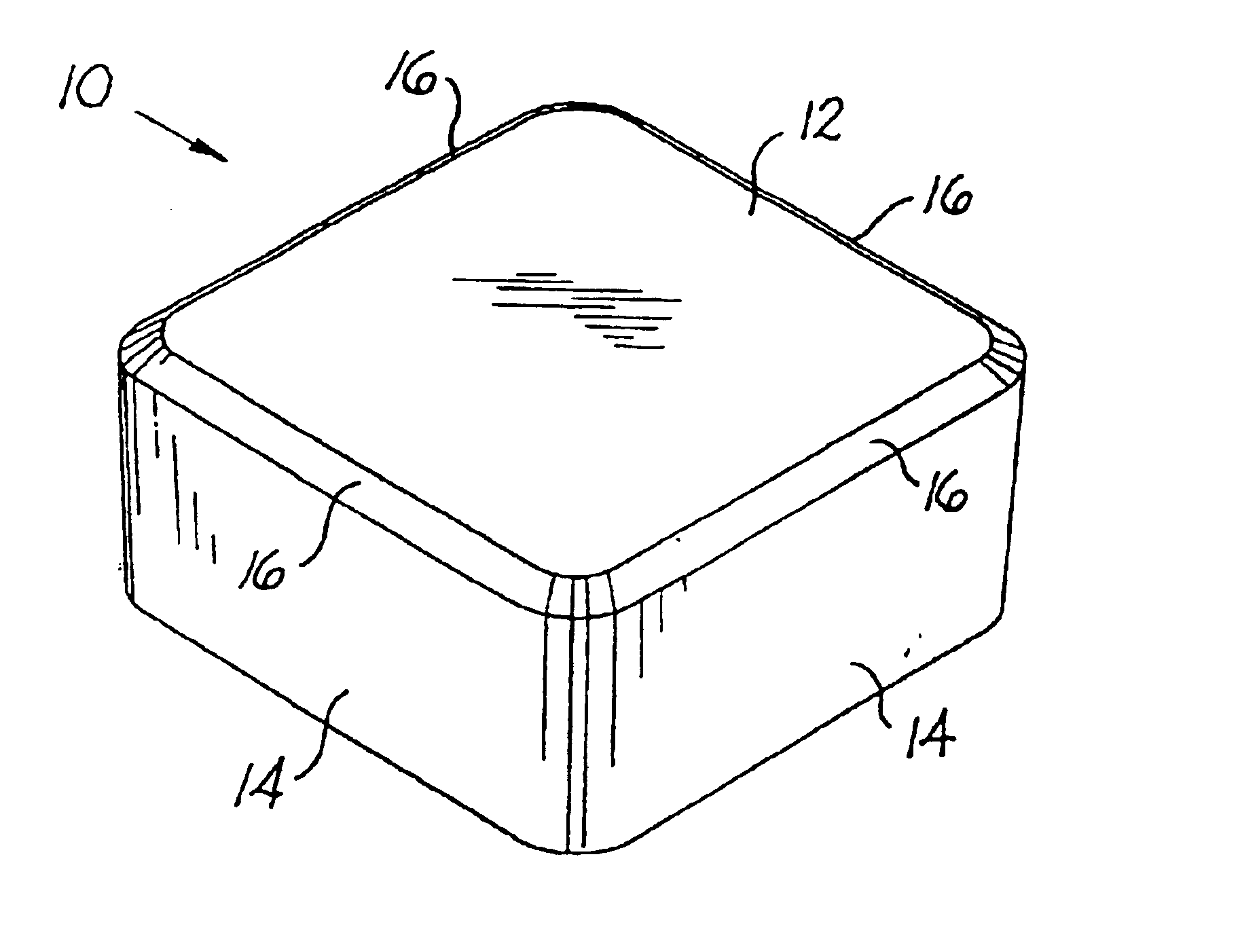

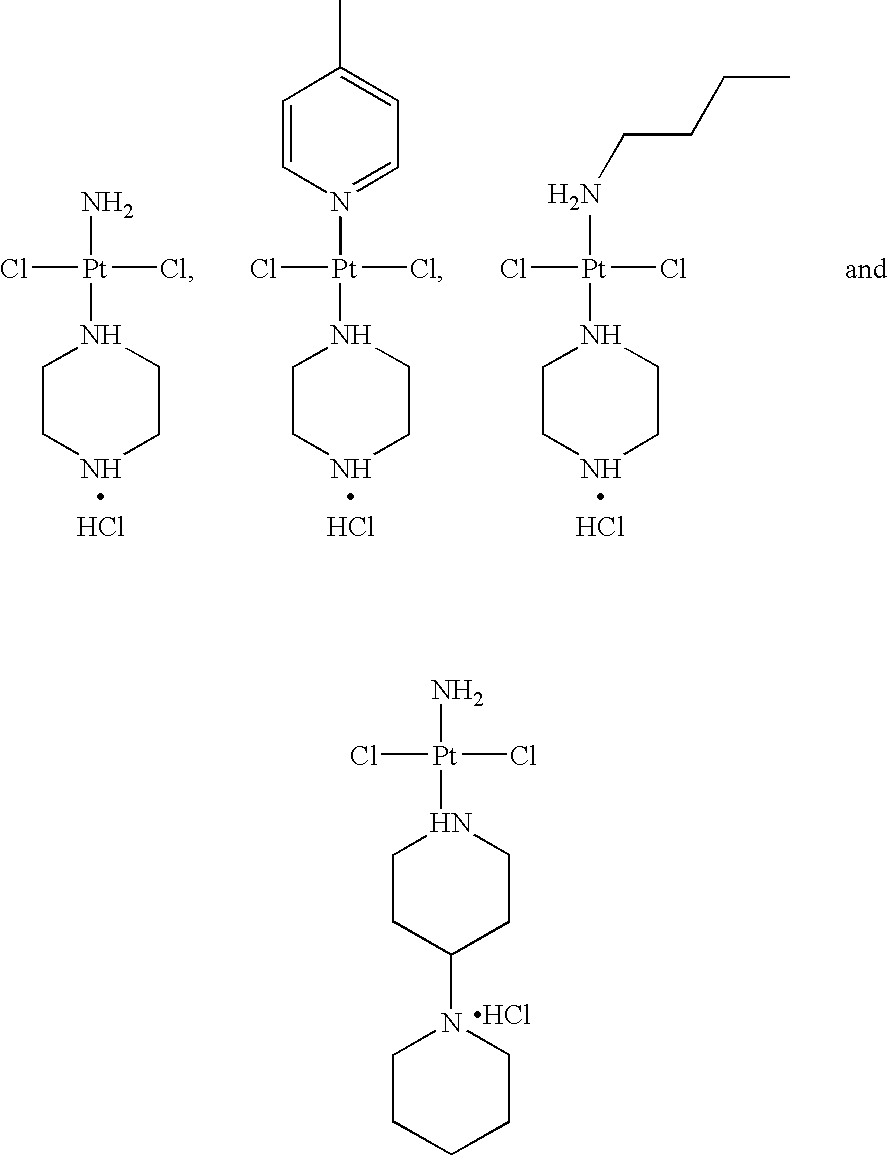

Polymeric/ceramic composite materials for use in medical devices

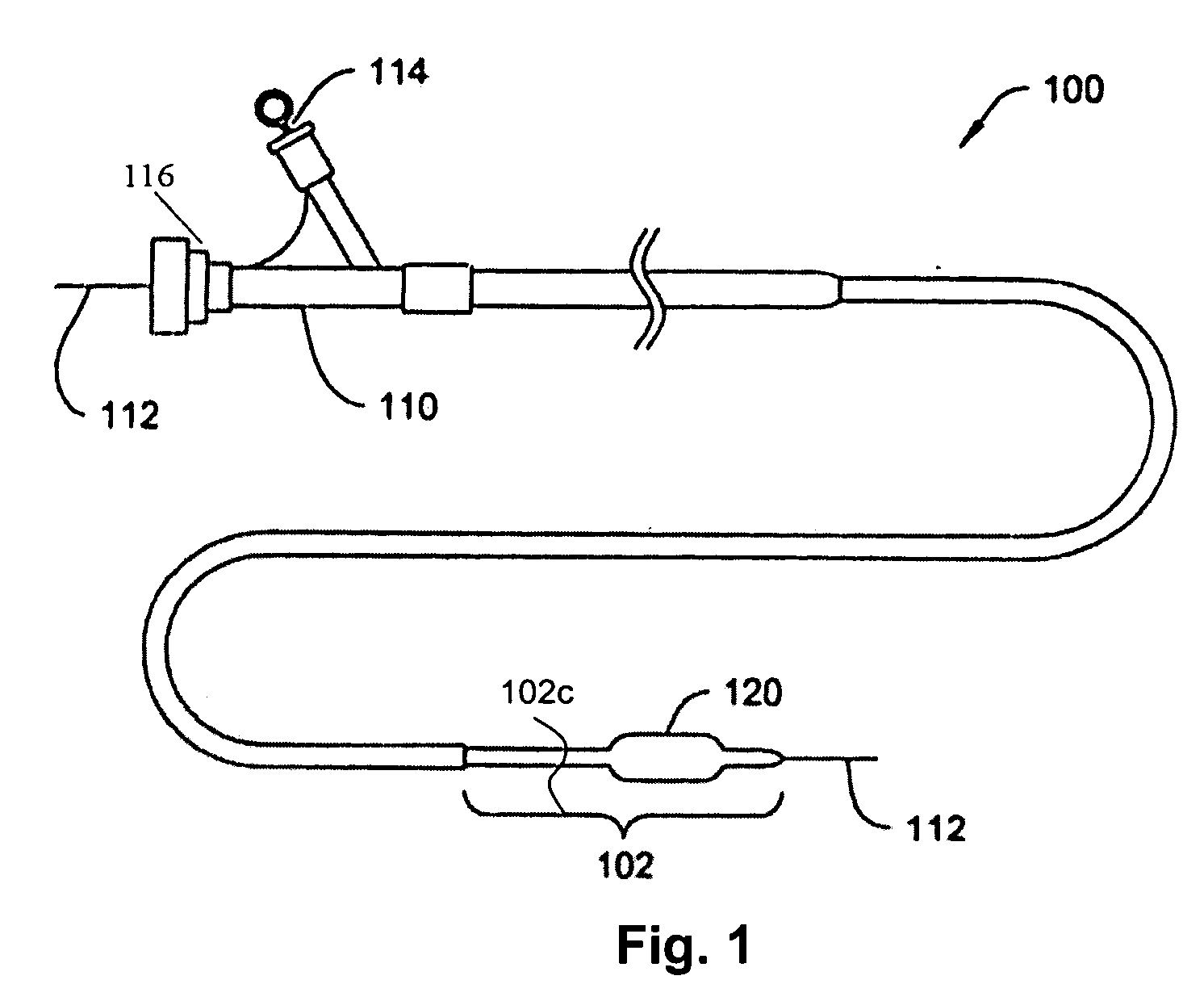

ActiveUS20060230476A1Improve featuresEnhanced abrasionStentsBalloon catheterCeramic compositeMedical device

Owner:BOSTON SCI SCIMED INC

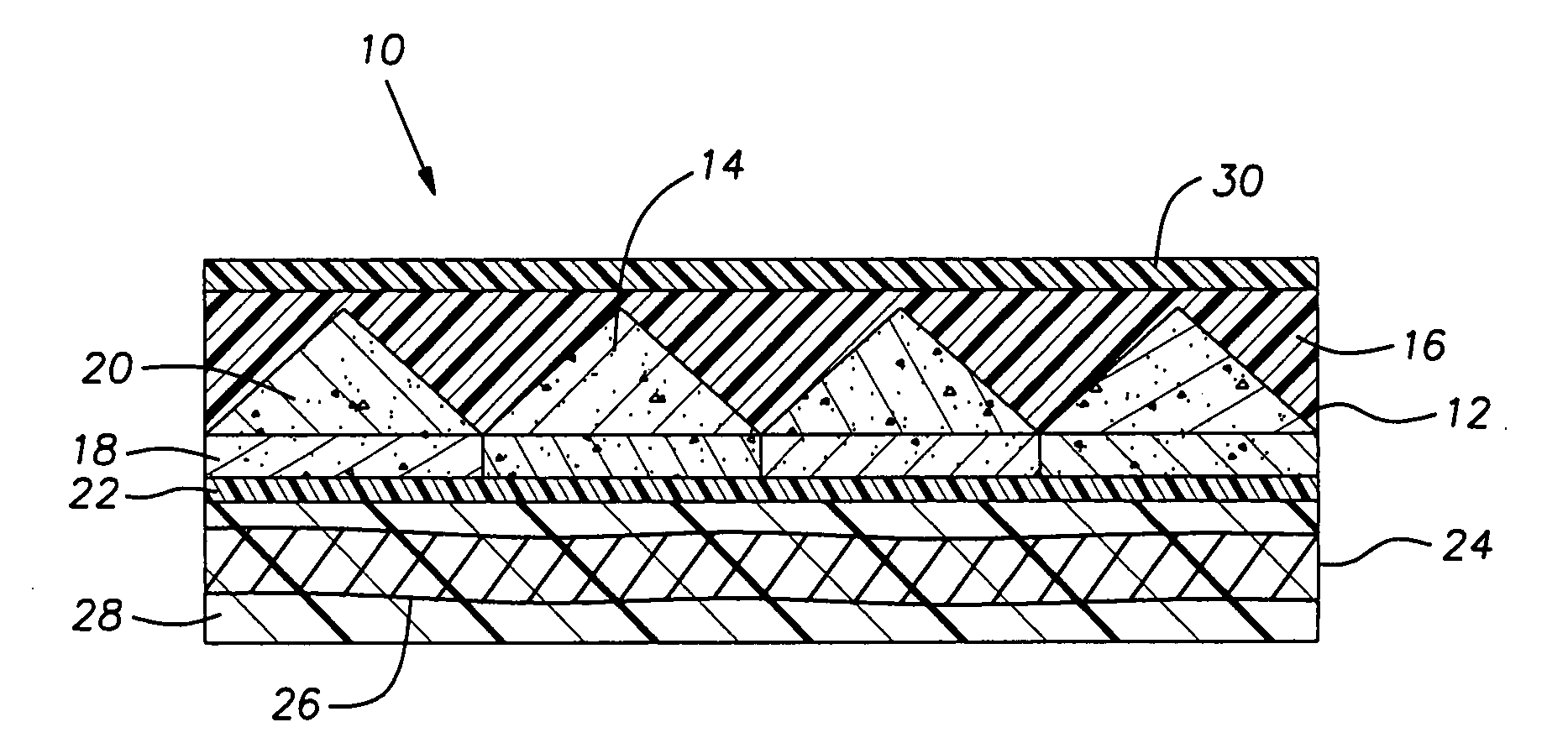

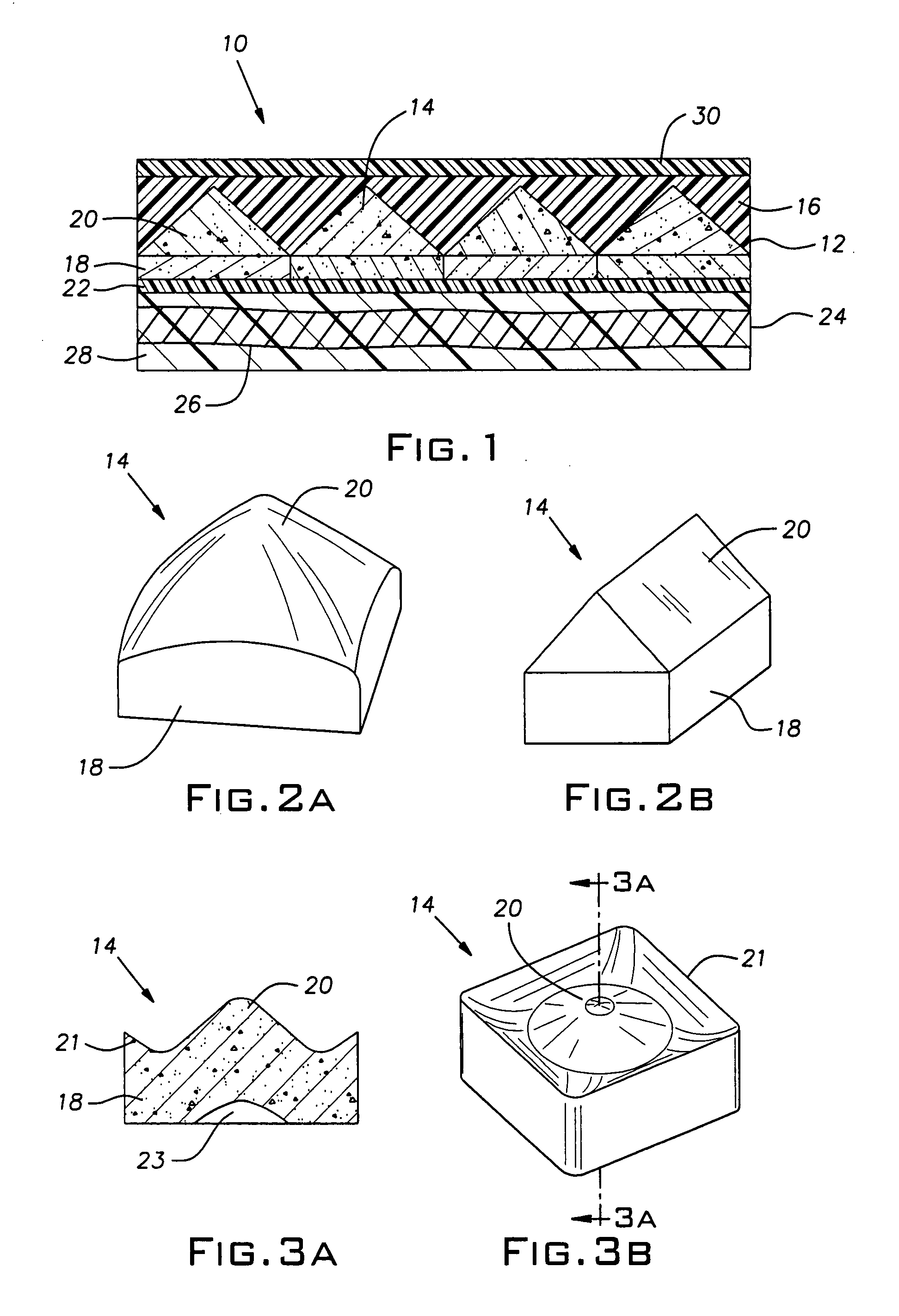

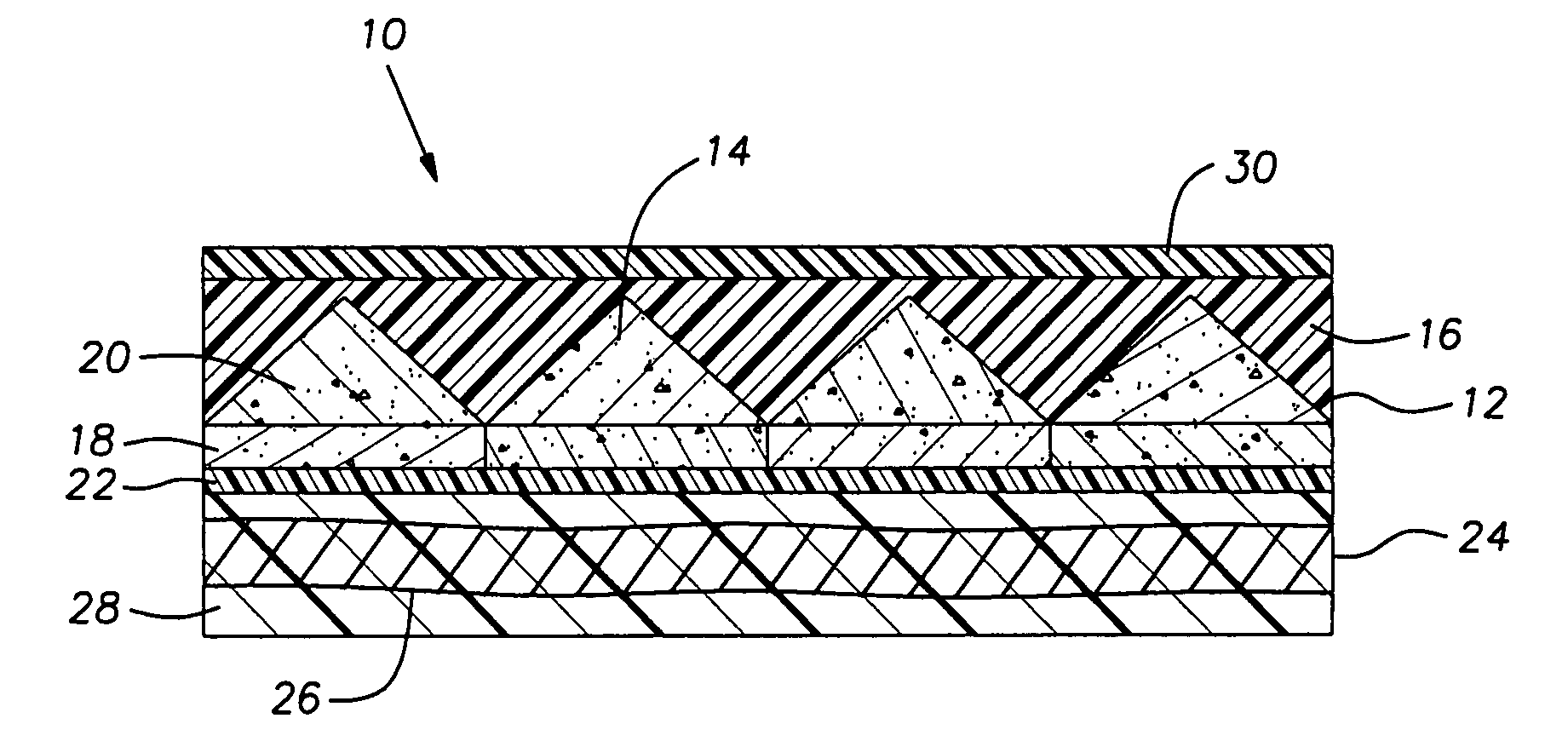

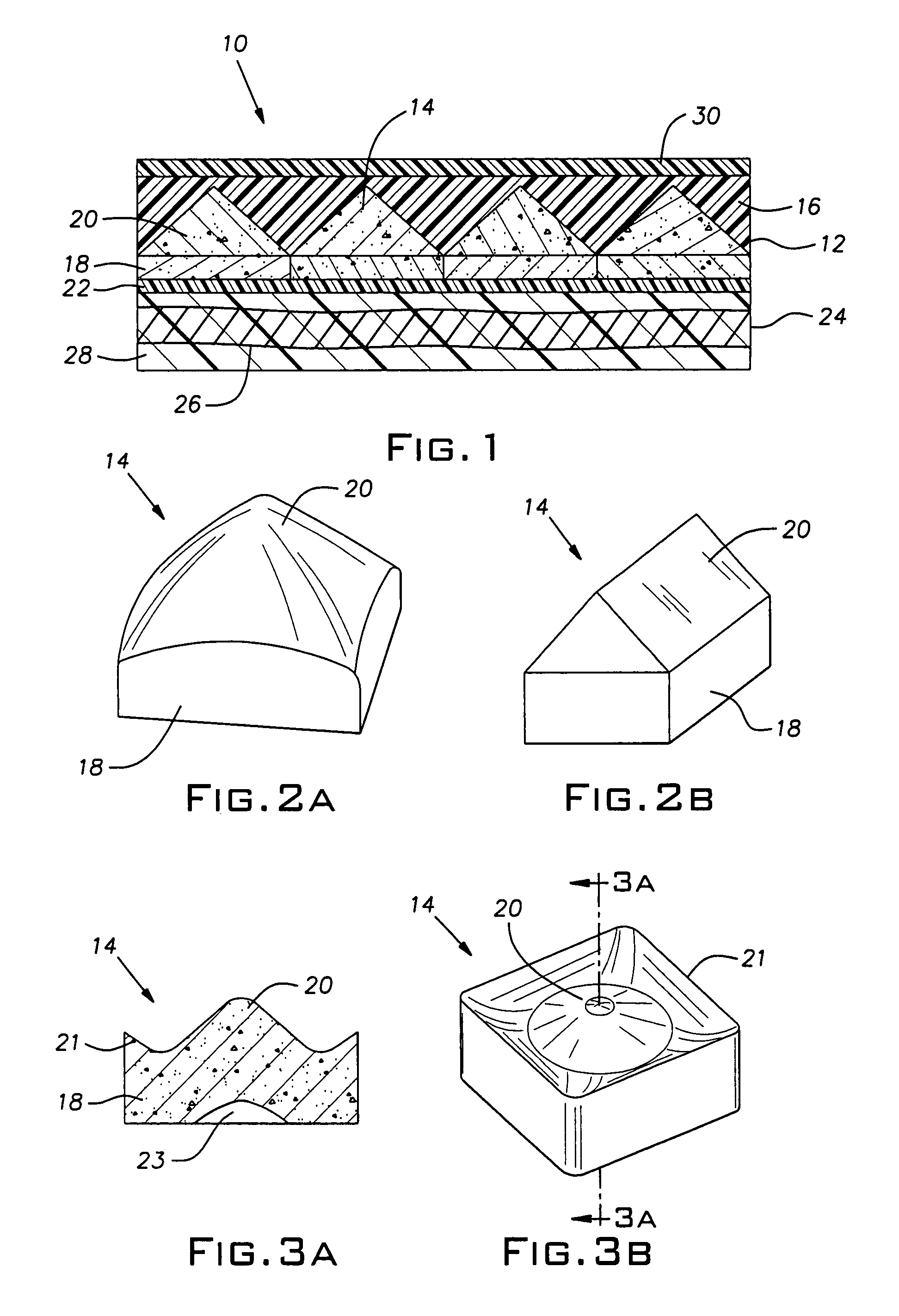

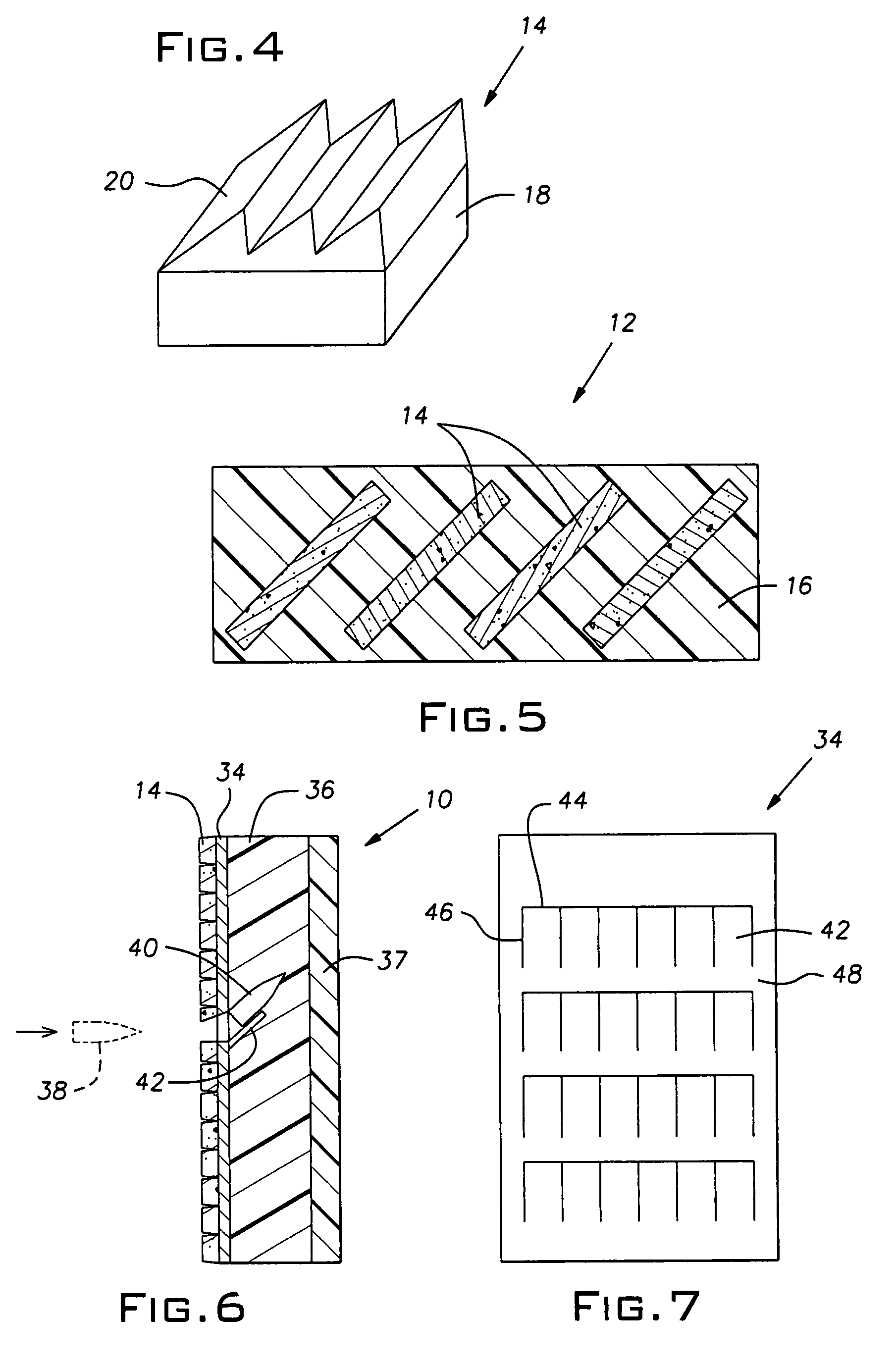

Encapsulated ceramic composite armor

A composite armor including a disrupting layer and a backing layer provides protection against blast and ballistic threats. The disrupting layer includes ceramic particles or tiles that disrupt the incoming projectile, while the backing layer prevents penetration past the armor by the disrupted projectile. The disrupting layer may include a layer of polygonal ceramic tiles with a deflecting front surface, encased by a retaining polymer, and may also include fire-retarding particles.

Owner:INTPROP HLDG

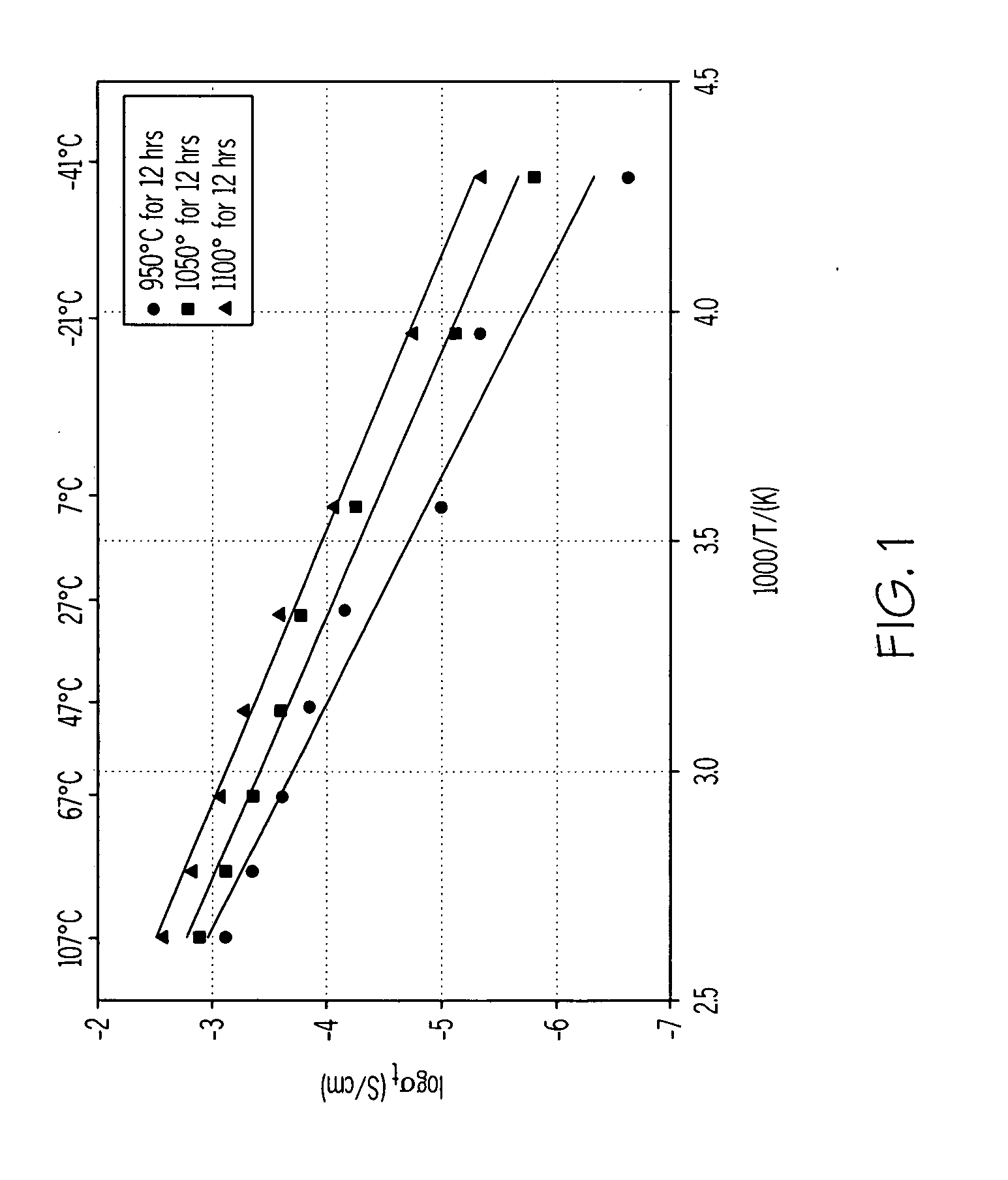

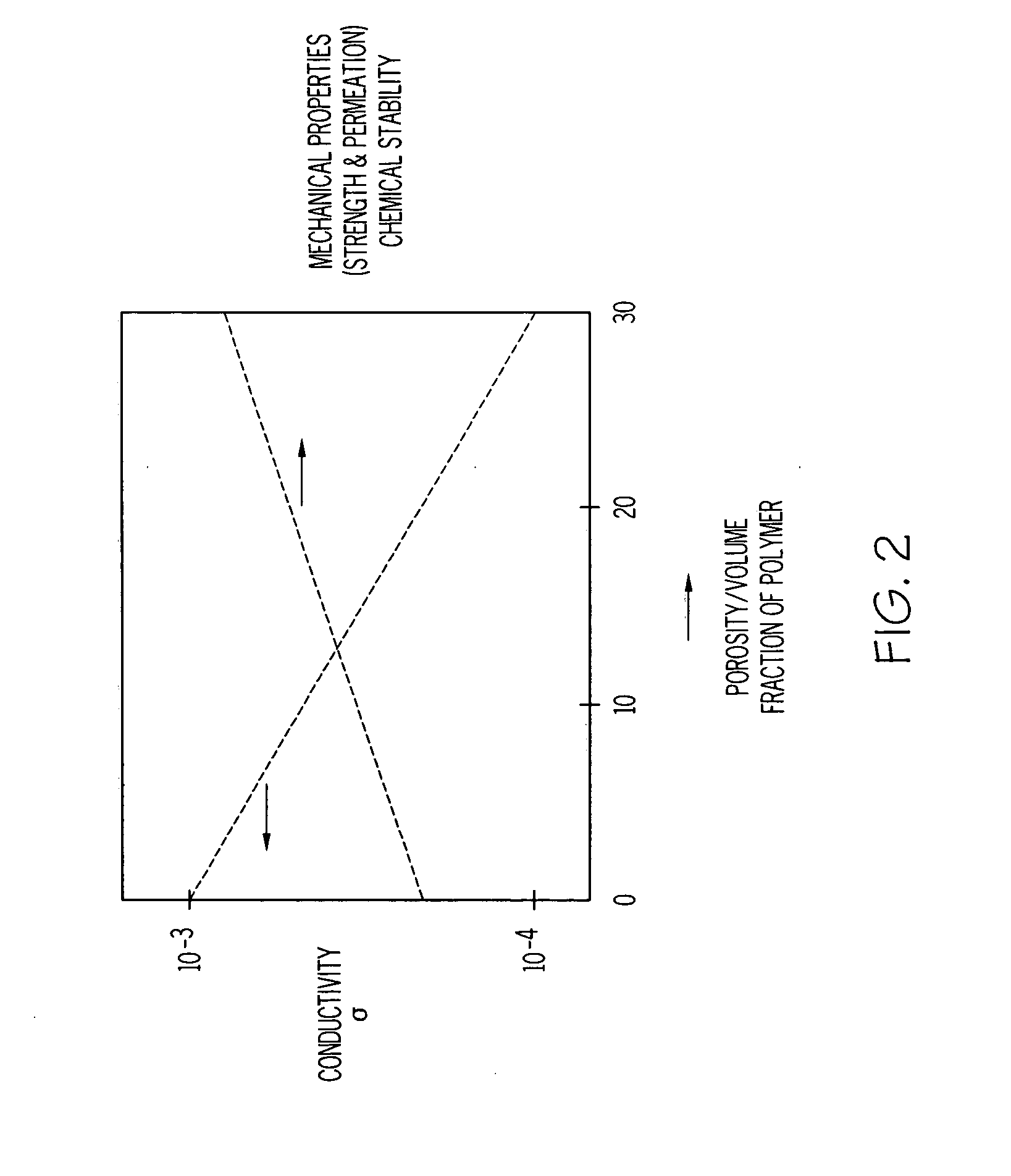

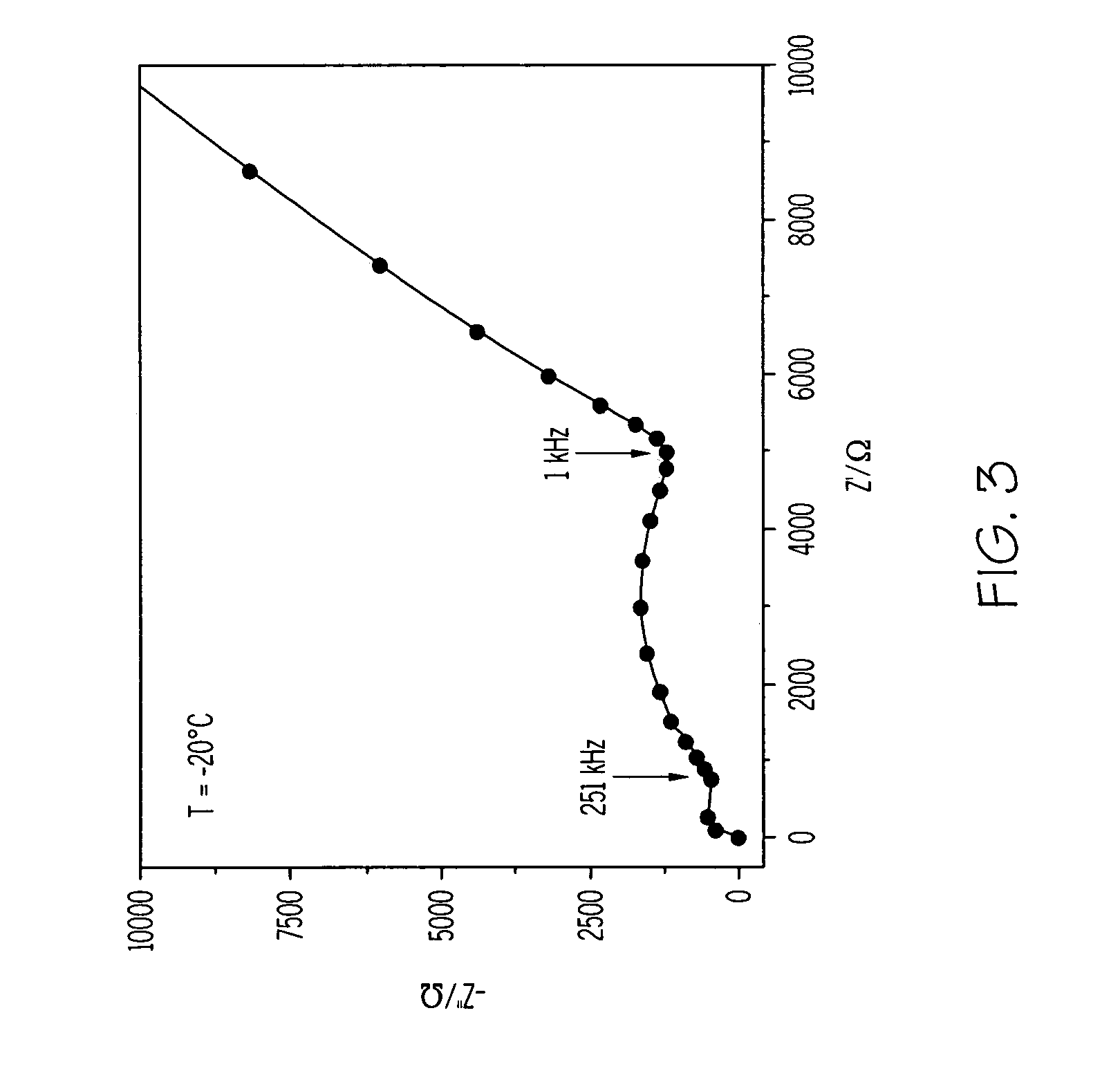

Solid composite electrolyte membrane and method of making

ActiveUS20070117026A1Improve conductivitySolid electrolytesSolid electrolyte cellsPorosityComposite electrolyte

A solid composite electrolyte membrane for use in a lithium battery is provided which exhibits a conductivity ranging from about 10−4 S cm−1 to about 10−3 S cm−1 at ambient temperature. The membrane is formed by providing a glass or glass-ceramic powder formed from a mixture of lithium carbonate, alumina, titanium dioxide, and ammonium dihydrogen phosphate. The powder is mixed with a conditioning agent and at least one solvent, followed by the addition of a binder and one or more plasticizers. The resulting slurry is cast into a tape which is then subjected to a binder burn-off and sintering process to form the membrane. The resulting membrane may be a glass-ceramic composite having a porosity ranging from 0 to 50%, or the membrane may be further infiltrated with a polymer to form a water-impermeable polymeric-ceramic composite membrane.

Owner:UNIV OF DAYTON THE

Encapsulated ceramic composite armor

A composite armor including a disrupting layer and a backing layer provides protection against blast and ballistic threats. The disrupting layer includes ceramic particles or tiles that disrupt the incoming projectile, while the backing layer prevents penetration past the armor by the disrupted projectile. The disrupting layer may include a layer of polygonal ceramic tiles with a deflecting front surface, encased by a retaining polymer, and may also include fire-retarding particles.

Owner:INTPROP HLDG

Ceramic tile armor with enhanced joint and edge protection

InactiveUS6009789AMinimal increase in weightImprove reliabilityArmoured vehiclesPersonal protection gearCeramic compositeGround vehicles

A ceramic composite tile armor which is reinforced at the more vulnerable joint and free edge areas, using glass or ceramic strips or overlays bonded with an adhesive to the outer surface of the tile joints and free edges. This reinforcement provides improved ballistic threat protection for ground vehicle, aircraft, watercraft, spacecraft, and body (personnel) ceramic tile armor applications. Glass or ceramic overlay strips assist in fracturing impacting projectiles that strike the tile joints or free edges. The substrate laminate backing can then capture fragments of the projectile and broken ceramic and prevent penetration. The invention provides improved protection over conventional joint and edge enhancements with higher reliability of accurate positioning over joint and free-edge areas, with less added weight, and at lower associated production costs.

Owner:SIMULA

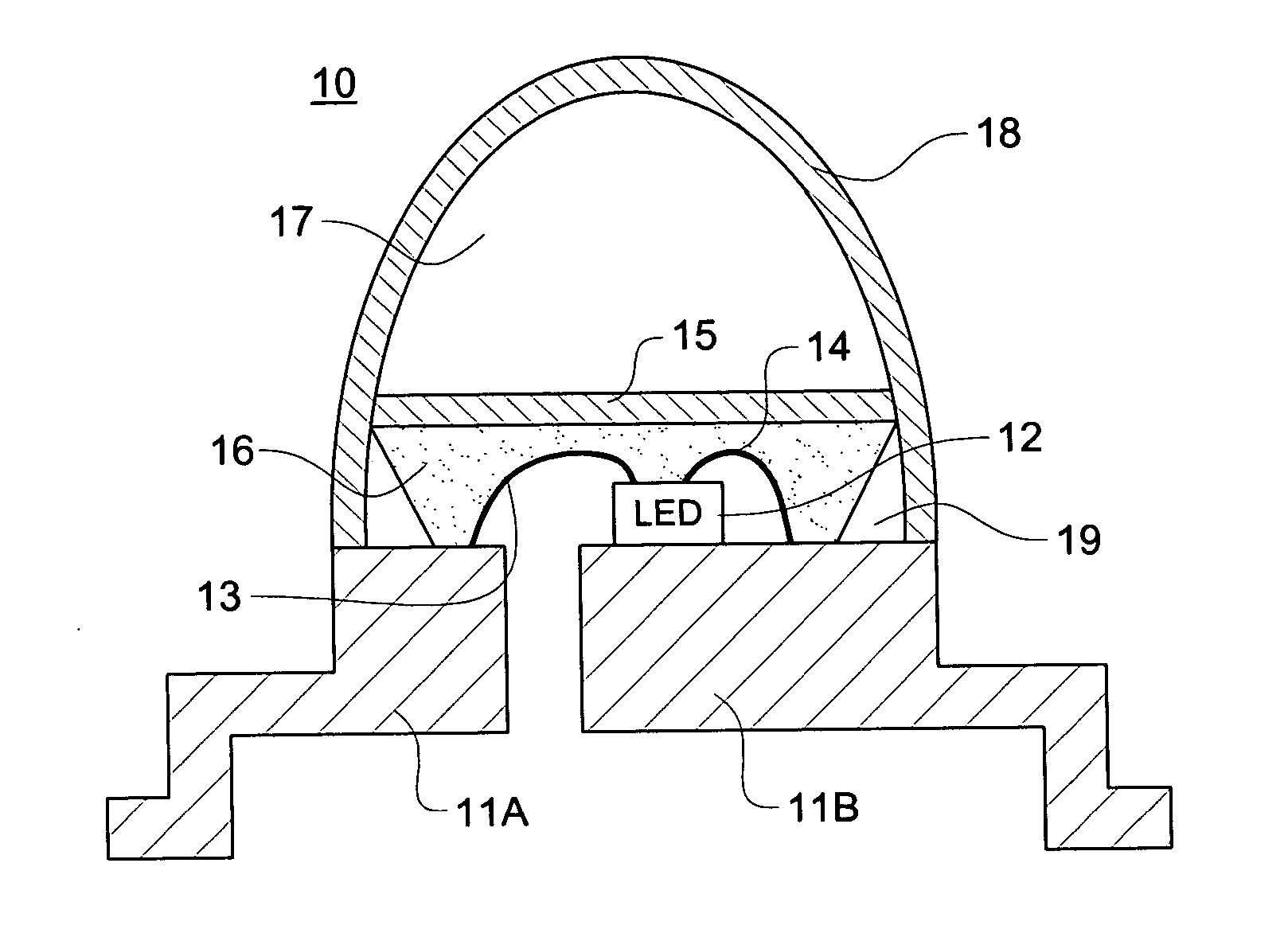

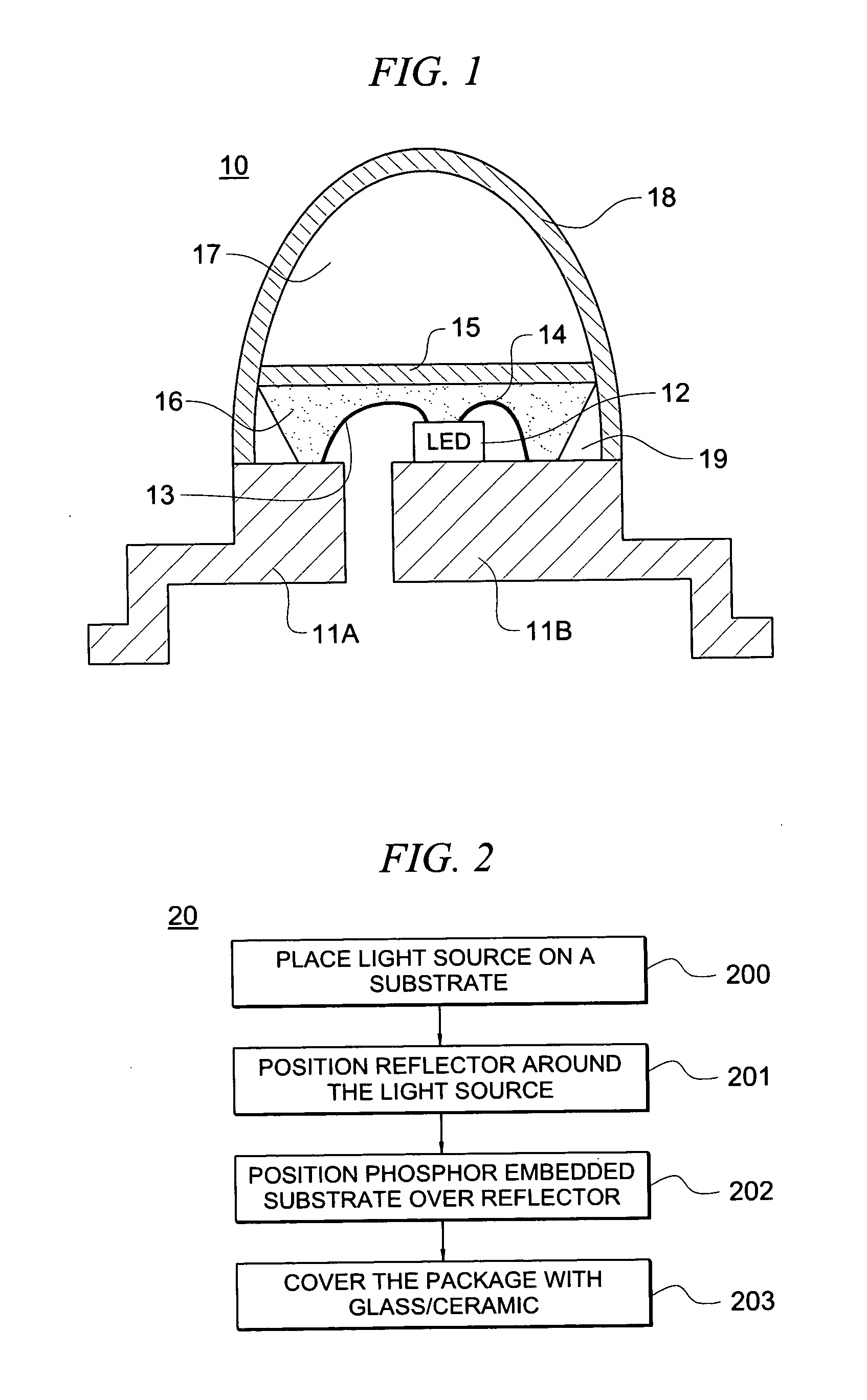

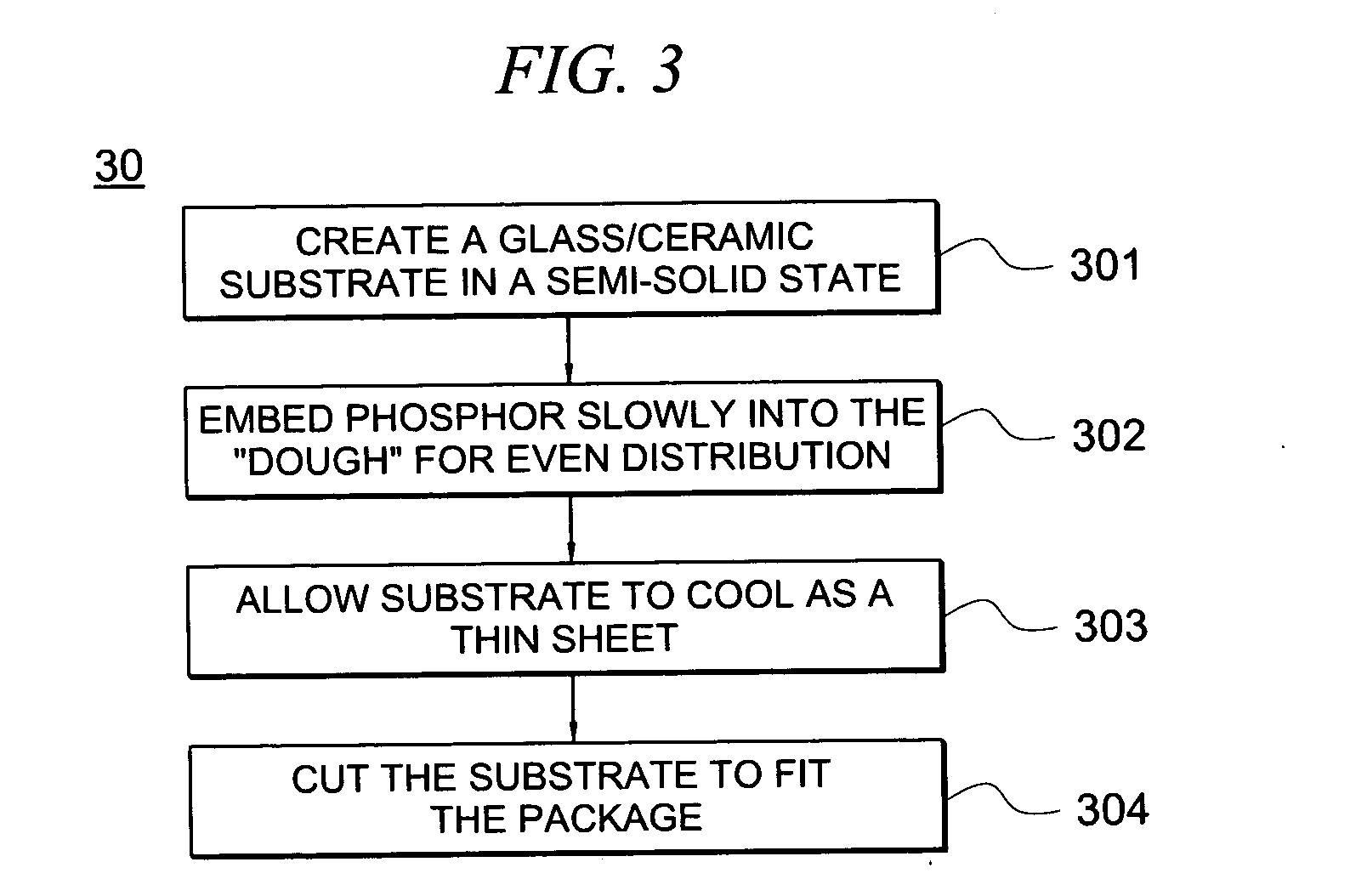

High light output lamps having a phosphor embedded glass/ceramic layer

A lamp having a glass / ceramic composite having phosphor embedded therein is disclosed for use with high power light sources. In one embodiment, the phosphor is embedded in a thin film as quantum dots. In one embodiment, a glass shell surrounds the light source and the composite phosphor matrix to protect the lamp from outside environmental conditions.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

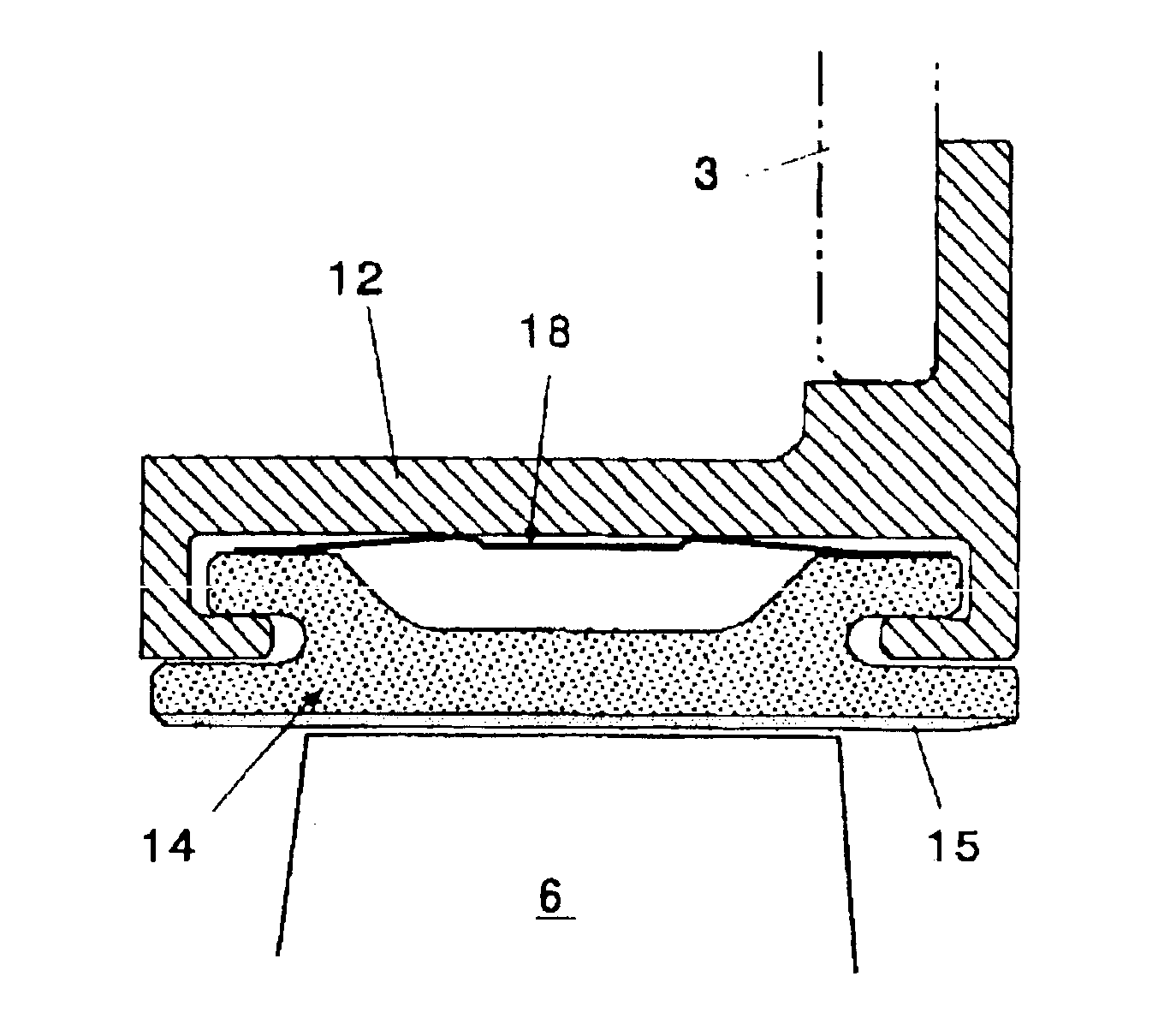

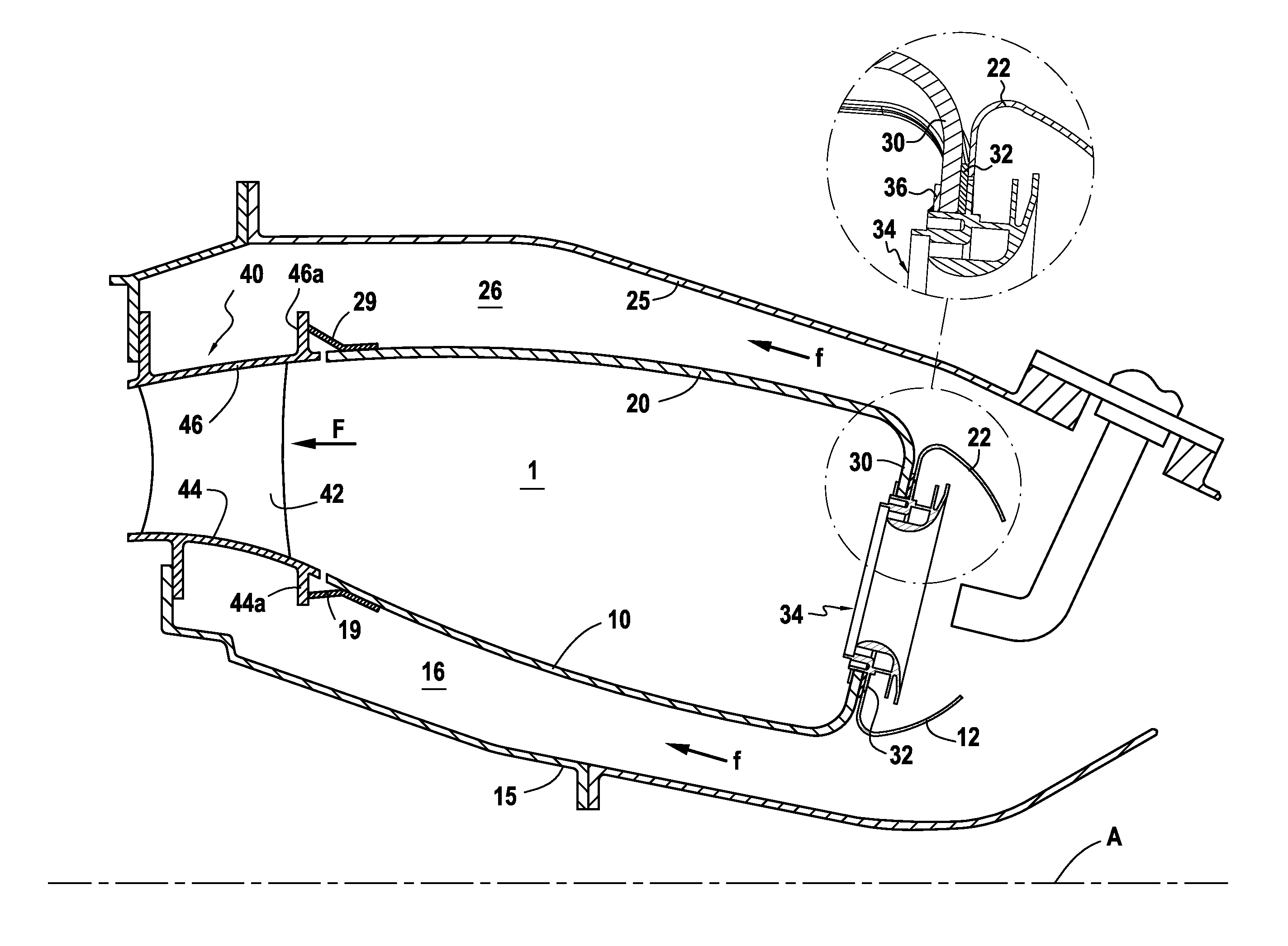

Gas turbine shroud structure

InactiveUS6932566B2Prevent generation of high thermal stressEnhance gas turbine capabilityPump componentsBlade accessoriesCeramic compositeEngineering

Owner:IHI CORP

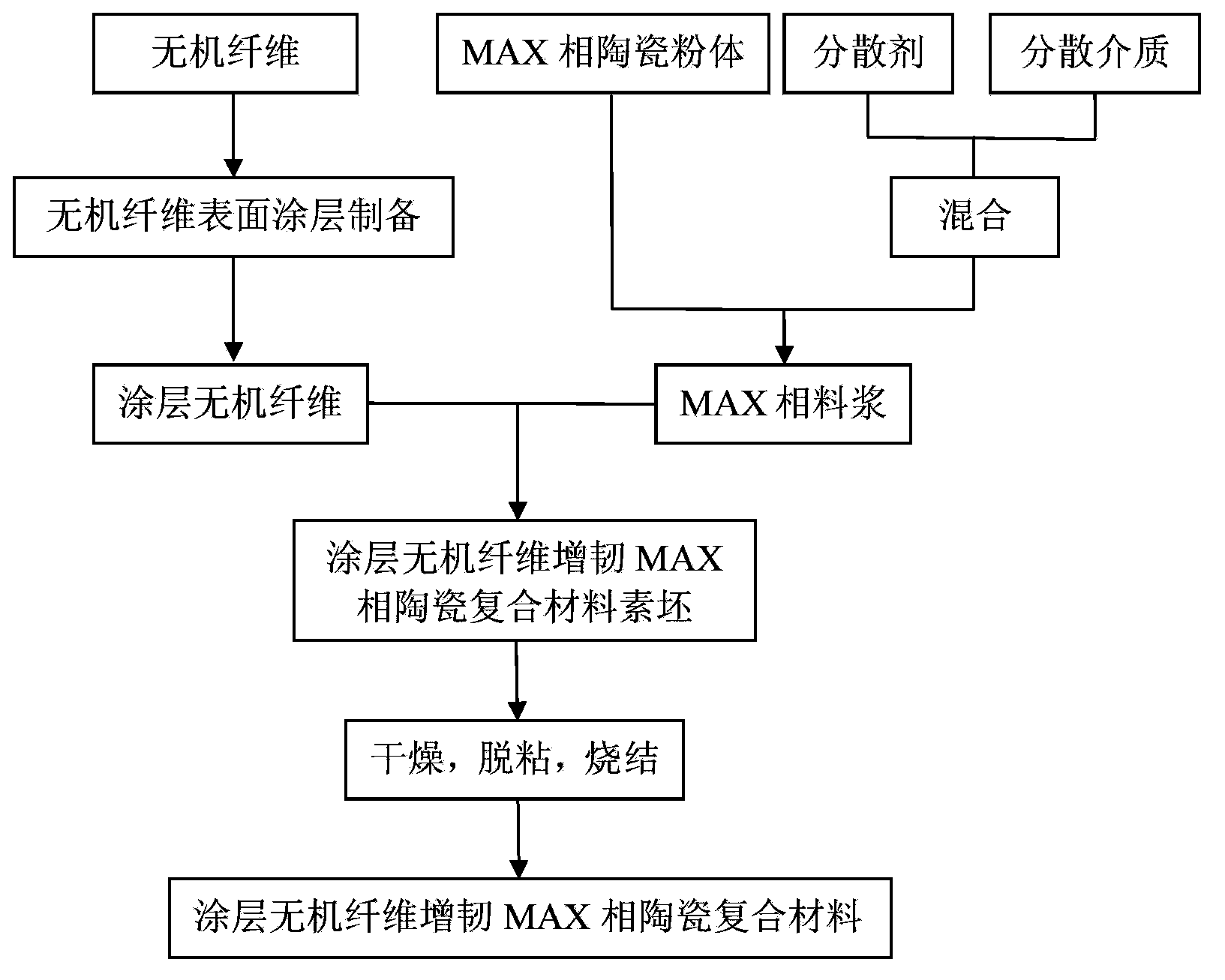

Coating inorganic fiber toughened MAX phase ceramic composite material, preparation method and uses thereof

ActiveCN103910532AAppropriate bonding interface strengthFree control of interface strengthNuclear energy generationContainmentAviationFiber

The present invention provides a coating inorganic fiber toughened MAX phase ceramic composite material and a preparation method thereof. The composite material adopts a MAX phase ceramic material as a matrix and adopts coating inorganic fibers as a toughening phase, wherein the coating inorganic fiber content is 0.5-90% (by volume), and the coating inorganic fibers are completely dispersed in the matrix and are inorganic fibers with the surface coated with the coating. Compared with the composite material in the prior art, the composite material of the present invention has the following characteristics that: the interface reaction between the inorganic fibers and the MAX phase ceramic can be effectively inhibited, the thermal expansion coefficient and elasticity modulus matching degree between the inorganic fibers and the MAX phase ceramic can be effective regulated, the effective improvement of the fracture toughness and the high temperature resistance of the MAX phase ceramic composite material can be achieved, the problems of high brittleness and insufficient use reliability of the MAX phase ceramic can be fundamentally solved, and the coating inorganic fiber toughened MAX phase ceramic composite material has potential application prospects in the high technology fields of civil use, aviation, aerospace, nuclear industry and the like, and is especially for the fission and fusion reactor nuclear power plant inner wall structure material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Ceramic tile armor with enhanced joint and edge protection

InactiveUS6332390B1Minimal increase in weightImprove reliabilityArmoured vehiclesPersonal protection gearCeramic compositeGround vehicles

A ceramic composite tile armor which is reinforced at the more vulnerable joint and free edge areas, using glass or ceramic strips or overlays bonded with an adhesive to the outer surface of the tile joints and free edges. This reinforcement provides improved ballistic threat protection for ground vehicle, aircraft, watercraft, spacecraft, and body (personnel) ceramic tile armor applications. Glass or ceramic overlay strips assist in fracturing impacting projectiles that strike the tile joints or free edges. The substrate laminate backing can then capture fragments of the projectile and broken ceramic and prevent penetration. The invention provides improved protection over conventional joint and edge enhancements with higher reliability of accurate positioning over joint and free-edge areas, with less added weight, and at lower associated production costs.

Owner:SIMULA

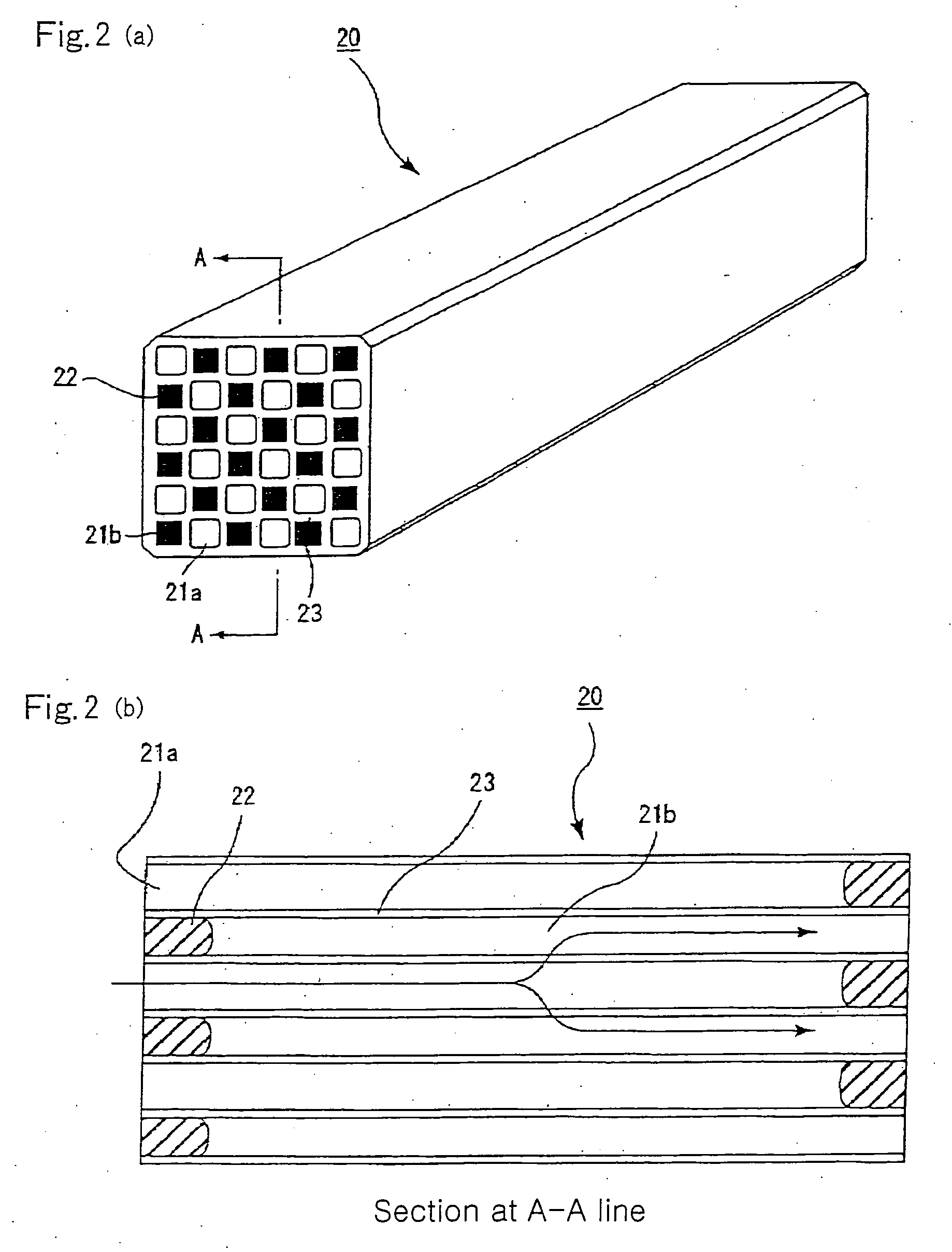

Honeycomb structure

ActiveUS20060068159A1Increased durabilityLarge in catching amount of particulateCombination devicesPhysical/chemical process catalystsParticulatesCeramic composite

It is to provide a honeycomb structural body having an excellent durability, which is large in the catching amount of particulates per unit volume and does not cause uneven accumulation of ash and occurrence of cracks or the like even in use for a long period of time, and there is proposed a honeycomb structural body obtained by assembling one or plural porous ceramic members in which two kinds of through-holes consisting of a group of large volume through-holes and a group of small volume through-holes are arranged side by side in the longitudinal direction through partitions and either one ends of these through-holes are plugged, wherein the ceramic member is made of silicon-ceramic composite material consisting of ceramic and silicon.

Owner:IBIDEN CO LTD

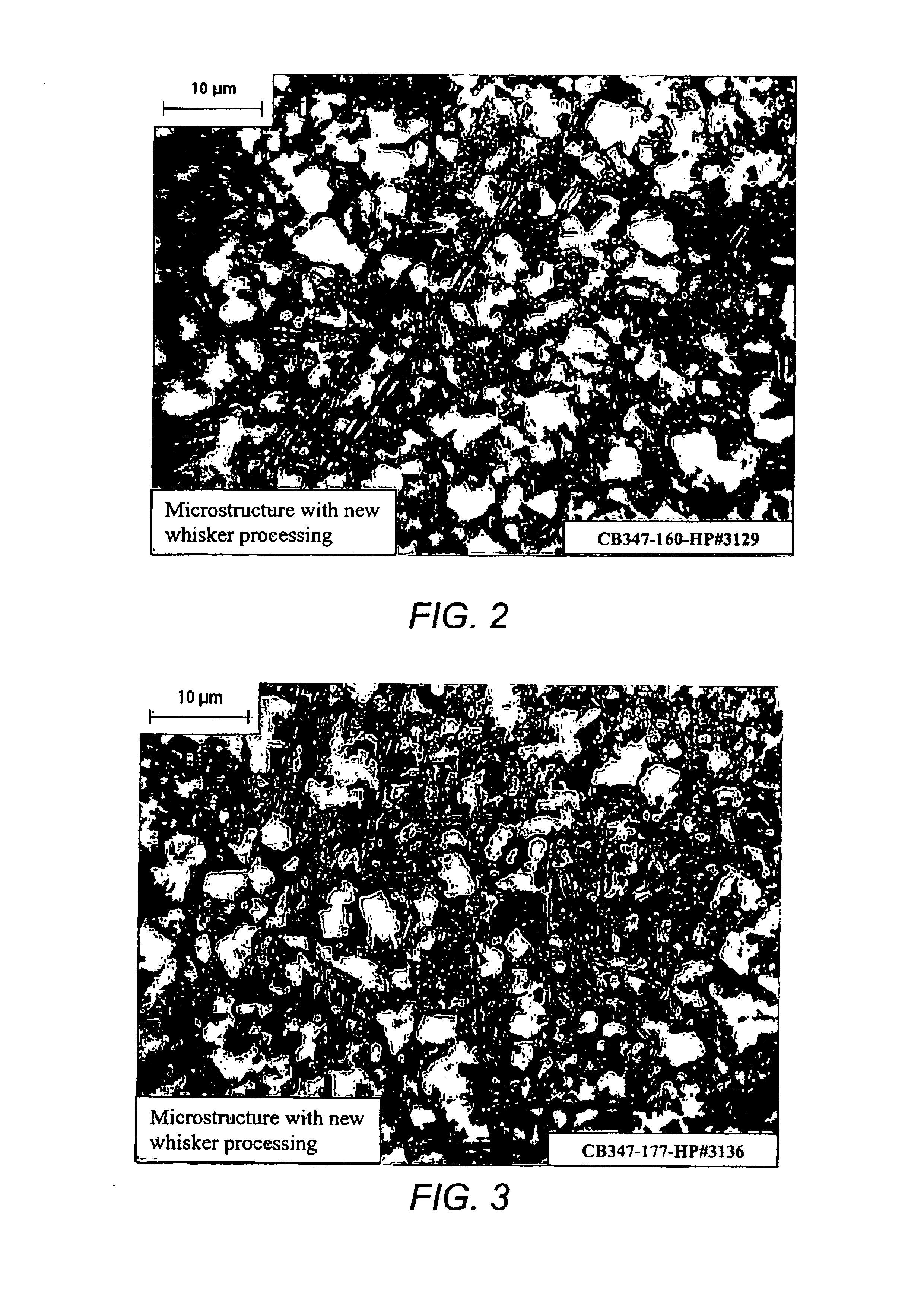

Ceramic body reinforced with coarse silicon carbide whiskers and method for making the same

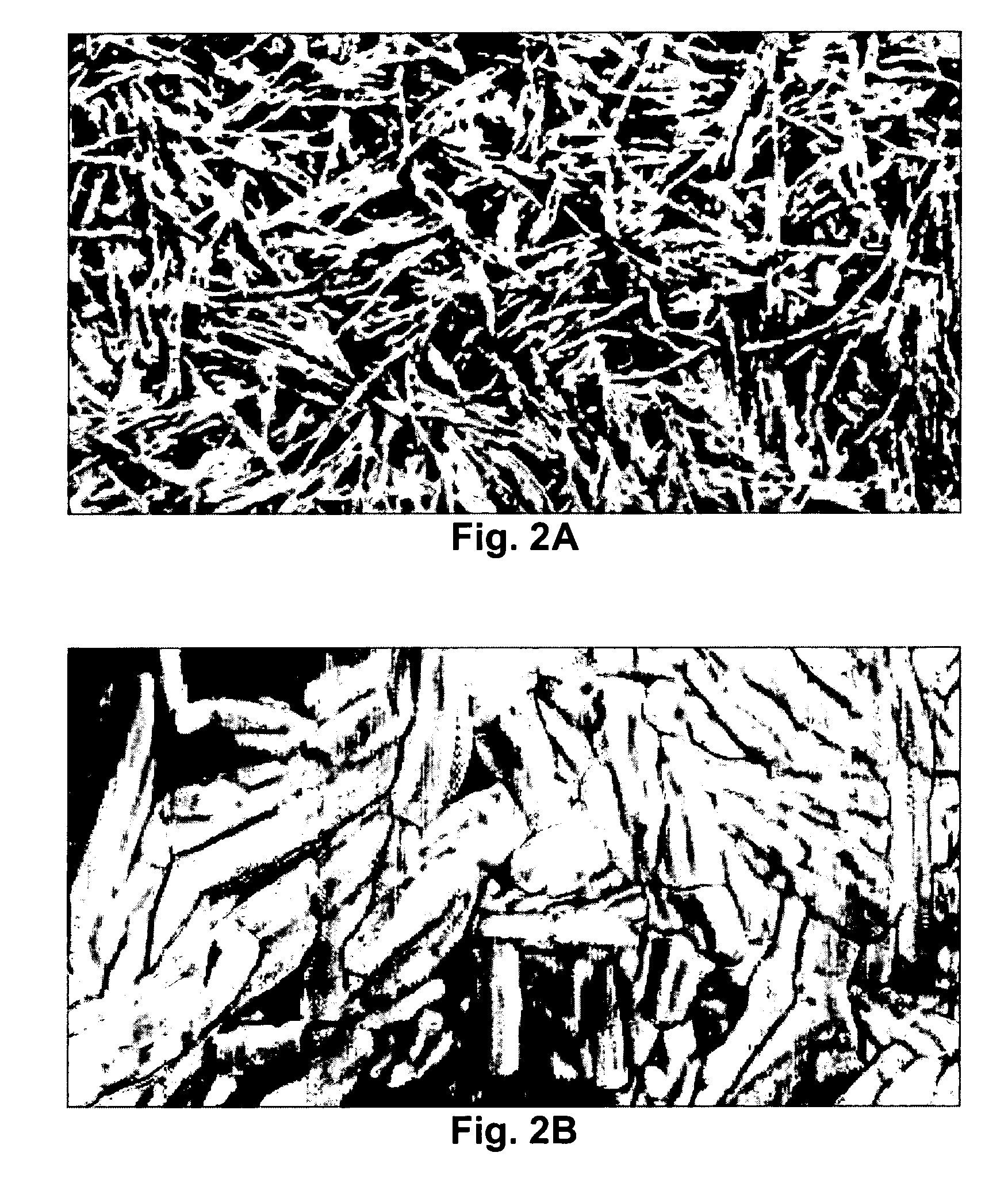

InactiveUS6905992B2Solve the lack of densityThin material handlingMetal layered productsPowder mixtureSquare Millimeter

A ceramic composite made by compacting a starting powder blend. The composite includes between about 50 volume percent and about 99 volume percent of a ceramic matrix; and between about 1 volume percent and about 50 volume percent as-processed silicon carbide whiskers. The ceramic composite having a fracture toughness (KIC) of greater than about 4.0 MPam1 / 2. The ceramic has a silicon carbide whisker density as measured in whiskers per square millimeter equal to or less than about 1500 times the volume percent of silicon carbide whiskers, but in a density sufficient for the ceramic composite to have the fracture toughness.

Owner:KENNAMETAL INC

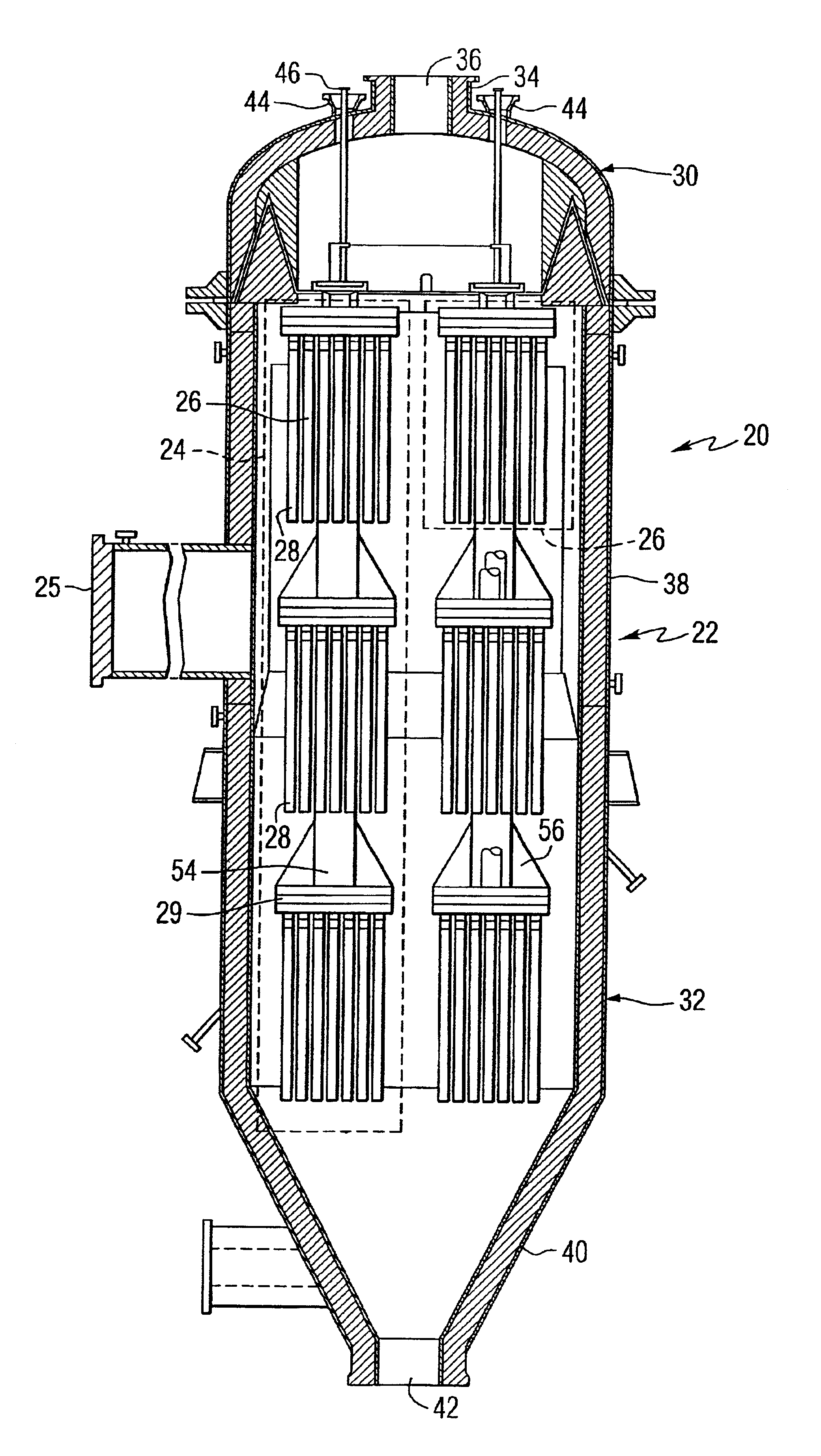

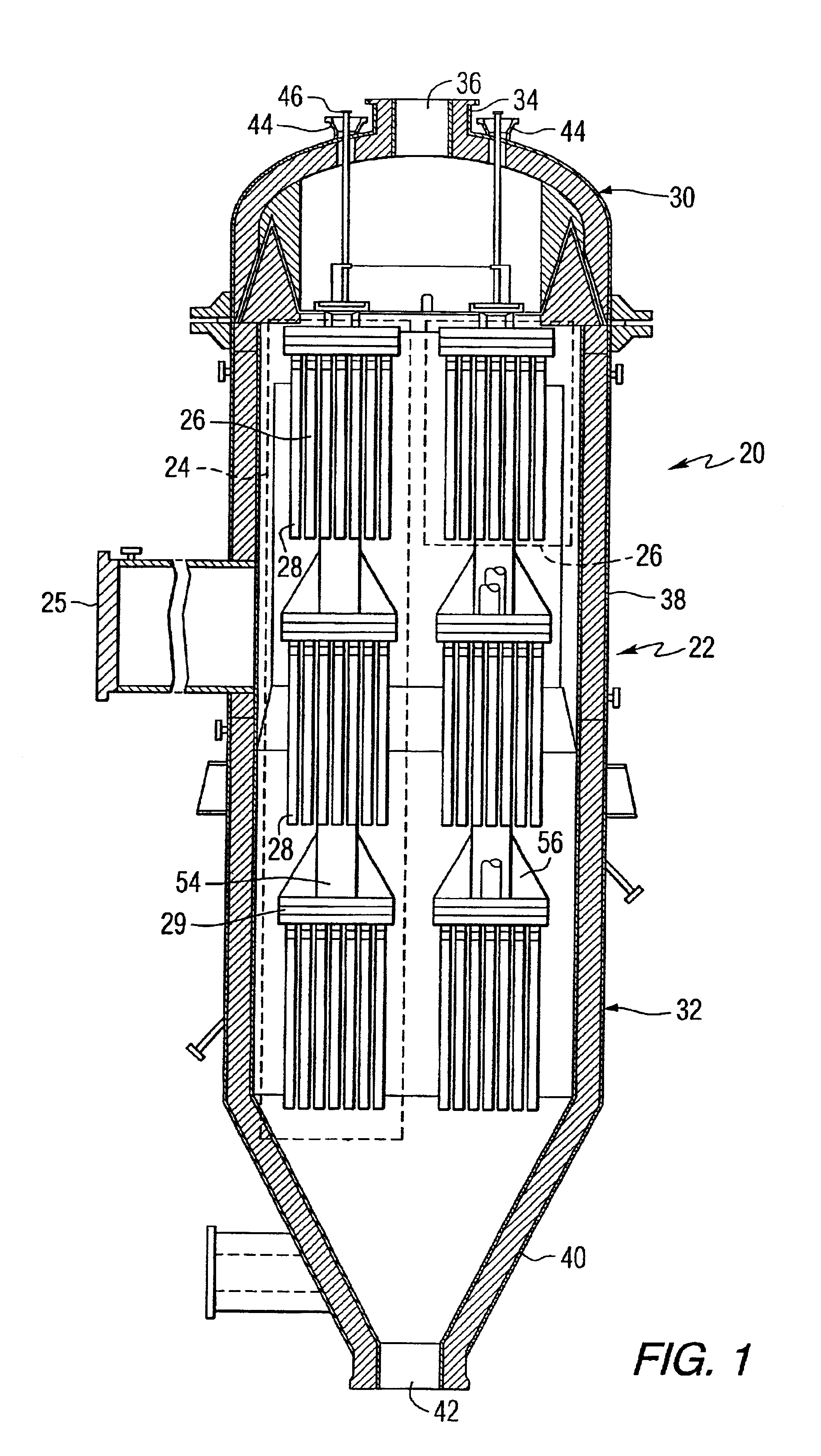

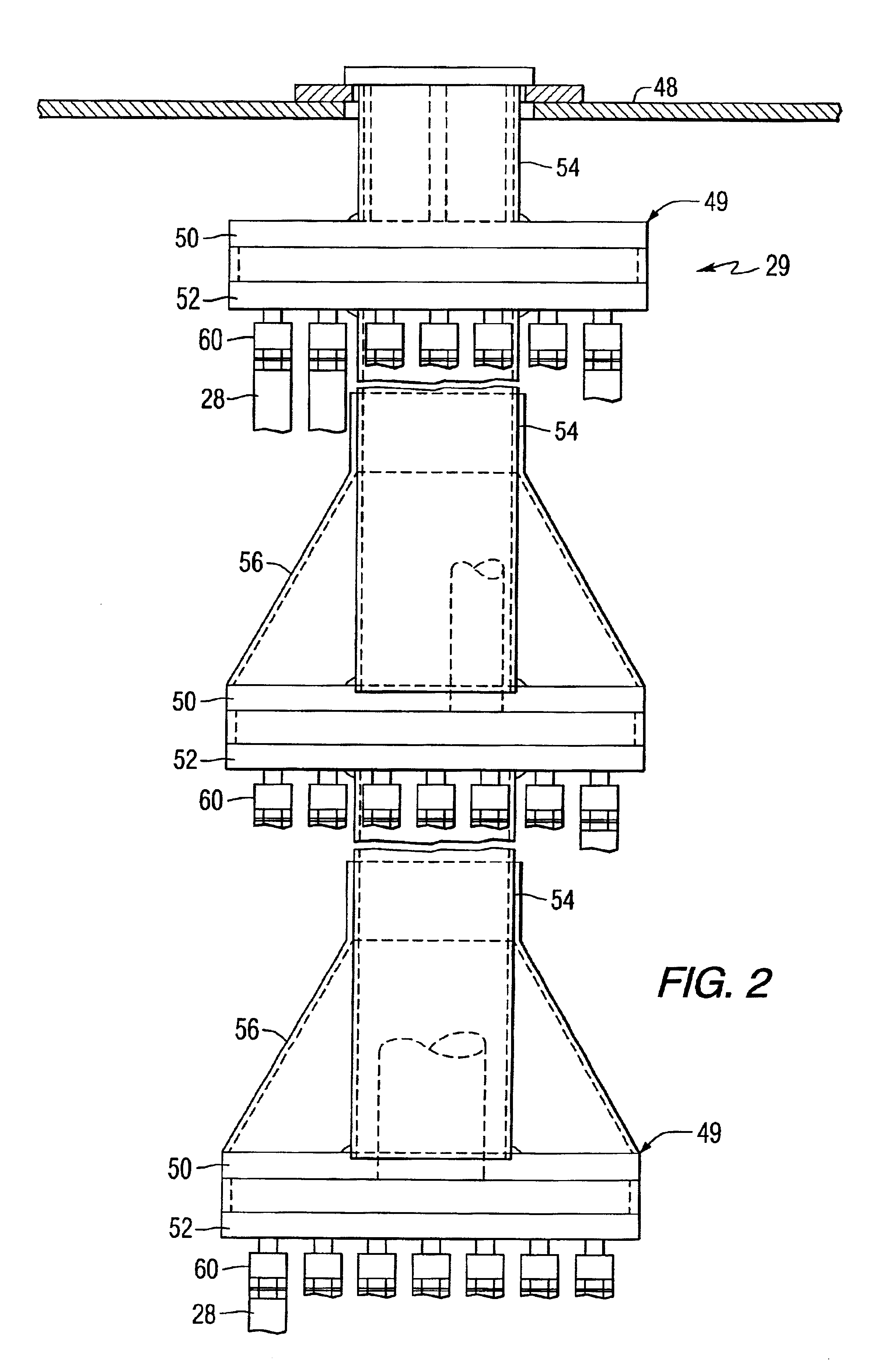

Catalytically enhanced filtration apparatus

A hot gas filtration apparatus includes a vessel, a plurality of filter elements mounted within the vessel and positioned such that hot gas flows through said filter elements, with each of said filter elements having a porous body, and a catalytic layer on surfaces of the porous body. The porous body of the filter element may include one of: a porous ceramic monolithic matrix, a continuous fiber reinforced ceramic composite (CFCC) matrix, a metallic matrix, an intermetallic matrix, a superalloy, and a metal-ceramic composite matrix. When the porous body is a nonoxide ceramic, a metallic matrix, an intermetallic matrix, a superalloy, or a metal-ceramic composite matrix, the invention further includes an oxidative resistant layer coating surfaces within the porous body, and the catalytic layer is on the oxidative resistant layer. A porous particulate removal membrane can be positioned on one or more surfaces of the filter element. The porous membrane can also provide a surface for one or more catalysts. The catalysts on the porous surface of the membrane(s) can be the same as or different from the catalysts on surfaces within the porous body.

Owner:SIEMENS ENERGY INC

Anti-abrasion metal-ceramic composite product and preparation method thereof

The invention provides an anti-abrasion metal-ceramic composite product and a preparation method thereof. The structural performance of the product is improved through at least one type of metallic oxides, metal nitrides or metal borides and intermetallic compounds. Metal-ceramic particle prefabricated parts made of ceramic particles and metal powder, or metal-ceramic particle prefabricated parts made of metal powder and mixtures which are obtained through uniform mixing of ceramic particles and metal powder with auxiliaries are subjected to high-temperature sintering thermal treatment to obtain the product. According to the anti-abrasion metal-ceramic composite product and the preparation method thereof, abrasion resistance of ceramic particles and mechanical performances of metal materials are perfectly combined, so that the hardness and the abrasion resistance of traditional metal materials are greatly improved. Compared with traditional anti-abrasion parts, the service life of metal grinding balls is increased by 1 time to 1.9 times, and the service life of liner plates and hammers is increased by more than 2.5 times, accordingly, a large number of metal materials are saved, and the production efficiency is improved.

Owner:湖北秦鸿新材料有限公司

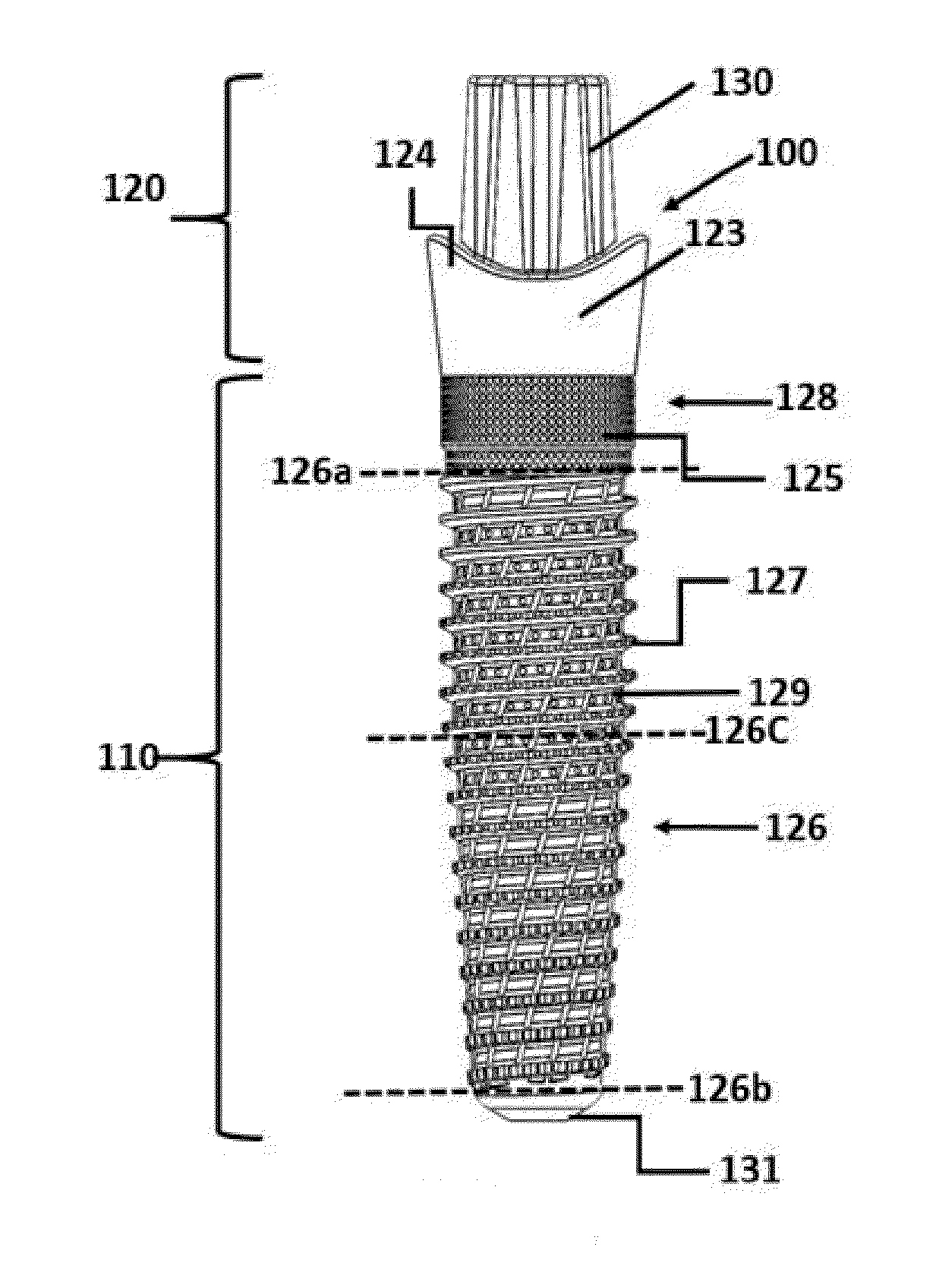

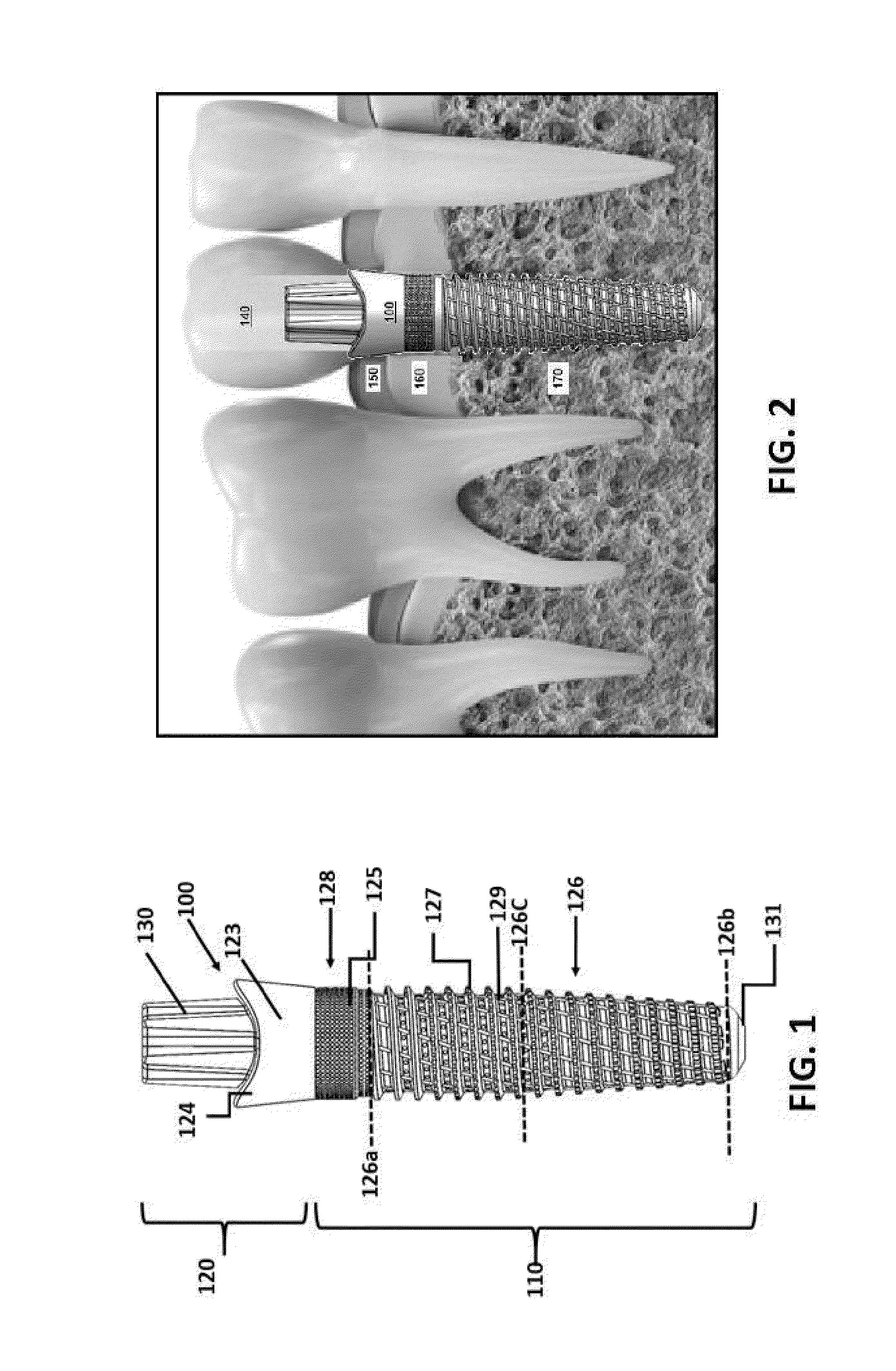

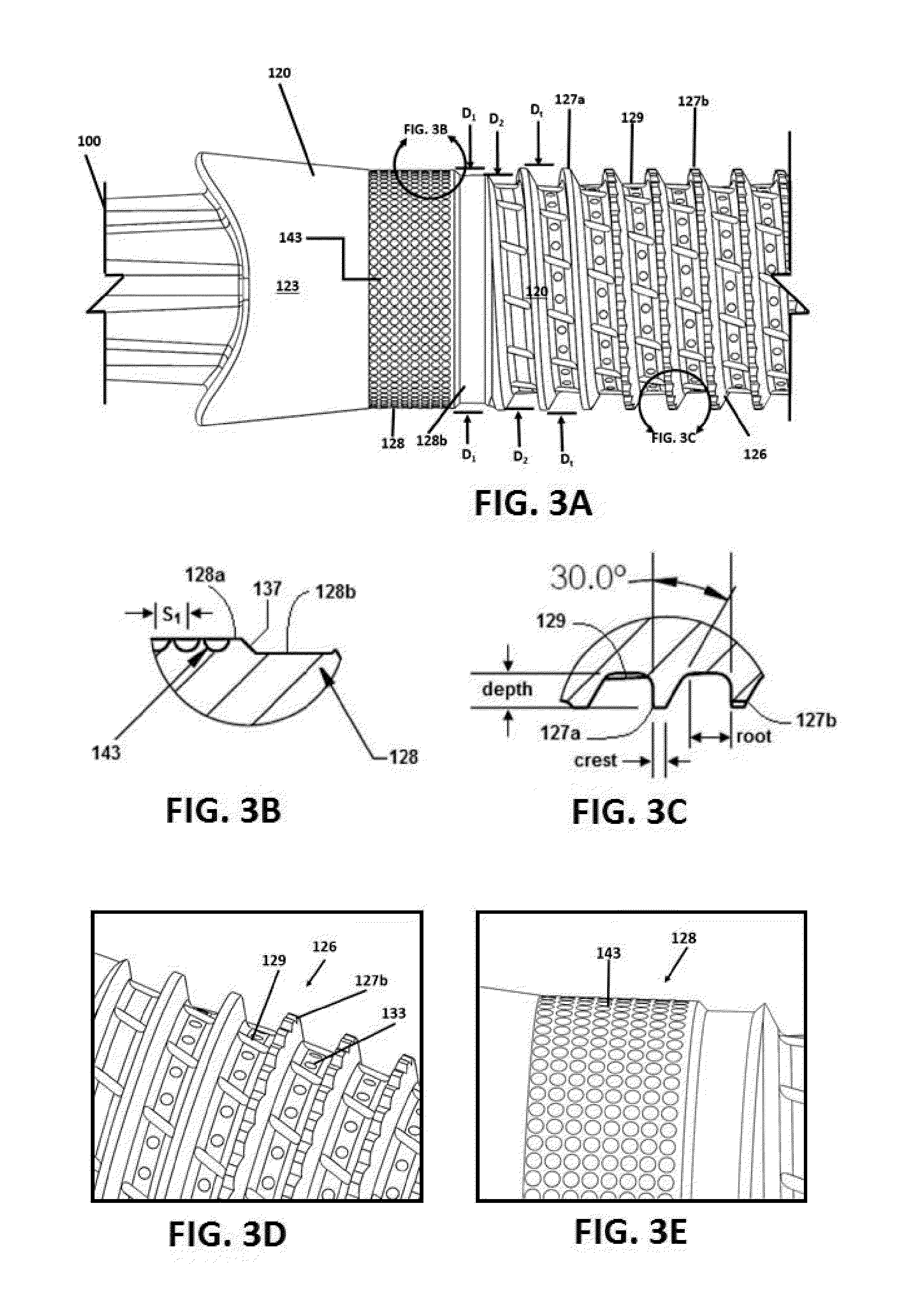

Osseointegrative surgical implant

InactiveUS20160015483A1Improve primary stabilityPromote healingSuture equipmentsDental implantsCeramic compositeSurgical implant

Embodiments of the present invention provide an osseointegrative implant and related tools, components and fabrication techniques for surgical bone fixation and dental restoration purposes. In one embodiment an all-ceramic single-stage threaded or press-fit implant is provided having finely detailed surface features formed by ceramic injection molding and / or spark plasma sintering of a powder compact or green body comprising finely powdered zirconia. In another embodiment a two-stage threaded implant is provided having an exterior shell or body formed substantially entirely of ceramic and / or CNT-reinforced ceramic composite material. The implant may include one or more frictionally anisotropic bone-engaging surfaces. In another embodiment a densely sintered ceramic implant is provided wherein, prior to sintering, the porous debound green body is exposed to ions and / or particles of silver, gold, titanium, zirconia, YSZ, α-tricalcium phosphate, hydroxyapatite, carbon, carbon nanotubes, and / or other particles which remain lodged in the implant surface after sintering. Optionally, at least the supragingival portions of an all-ceramic implant are configured to have high translucence in the visible light range. Optionally, at least the bone-engaging portions of an all-ceramic implant are coated with a fused layer of titanium oxide.

Owner:OSSEODYNE SURGICAL SOLUTIONS LLC

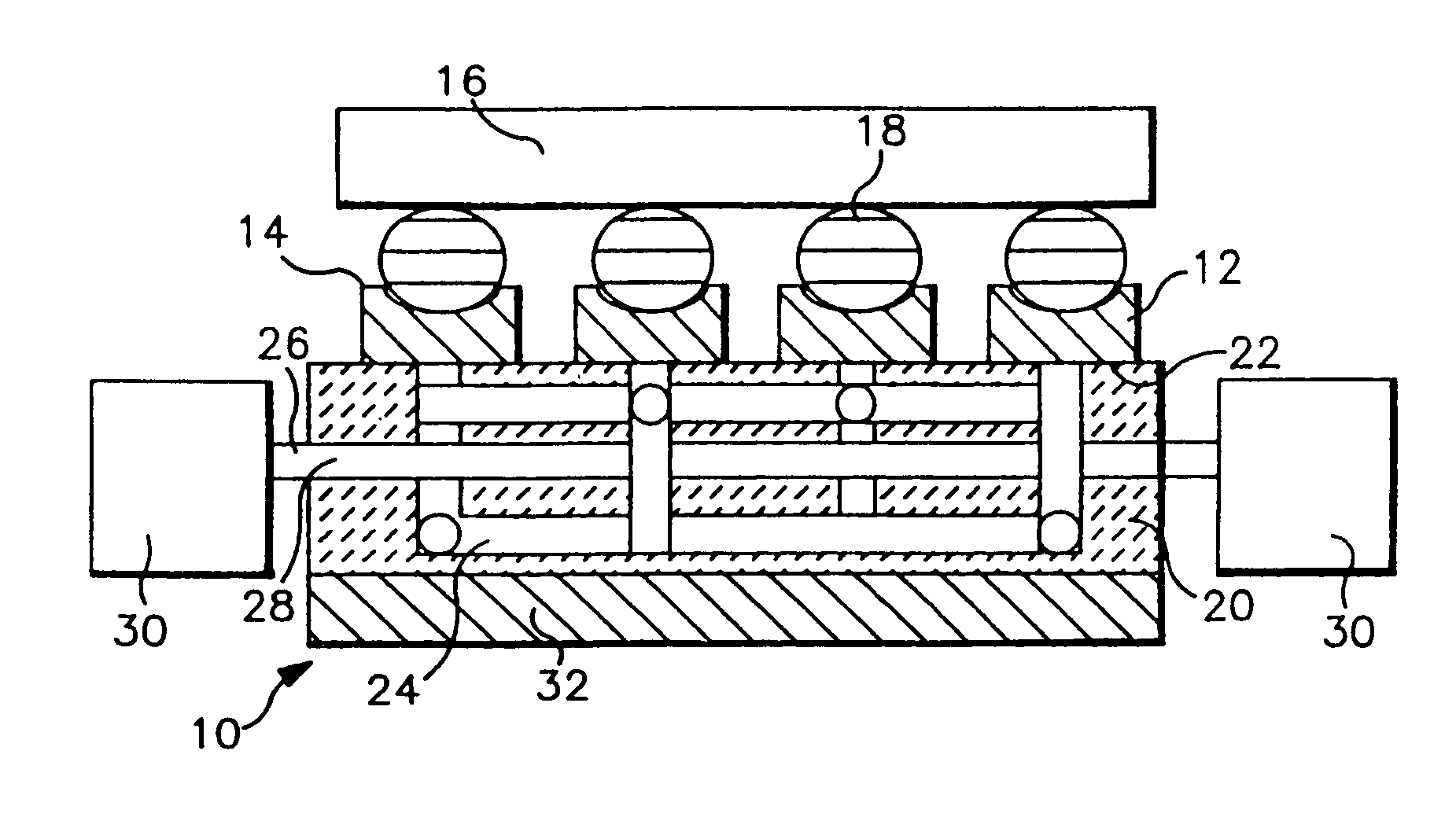

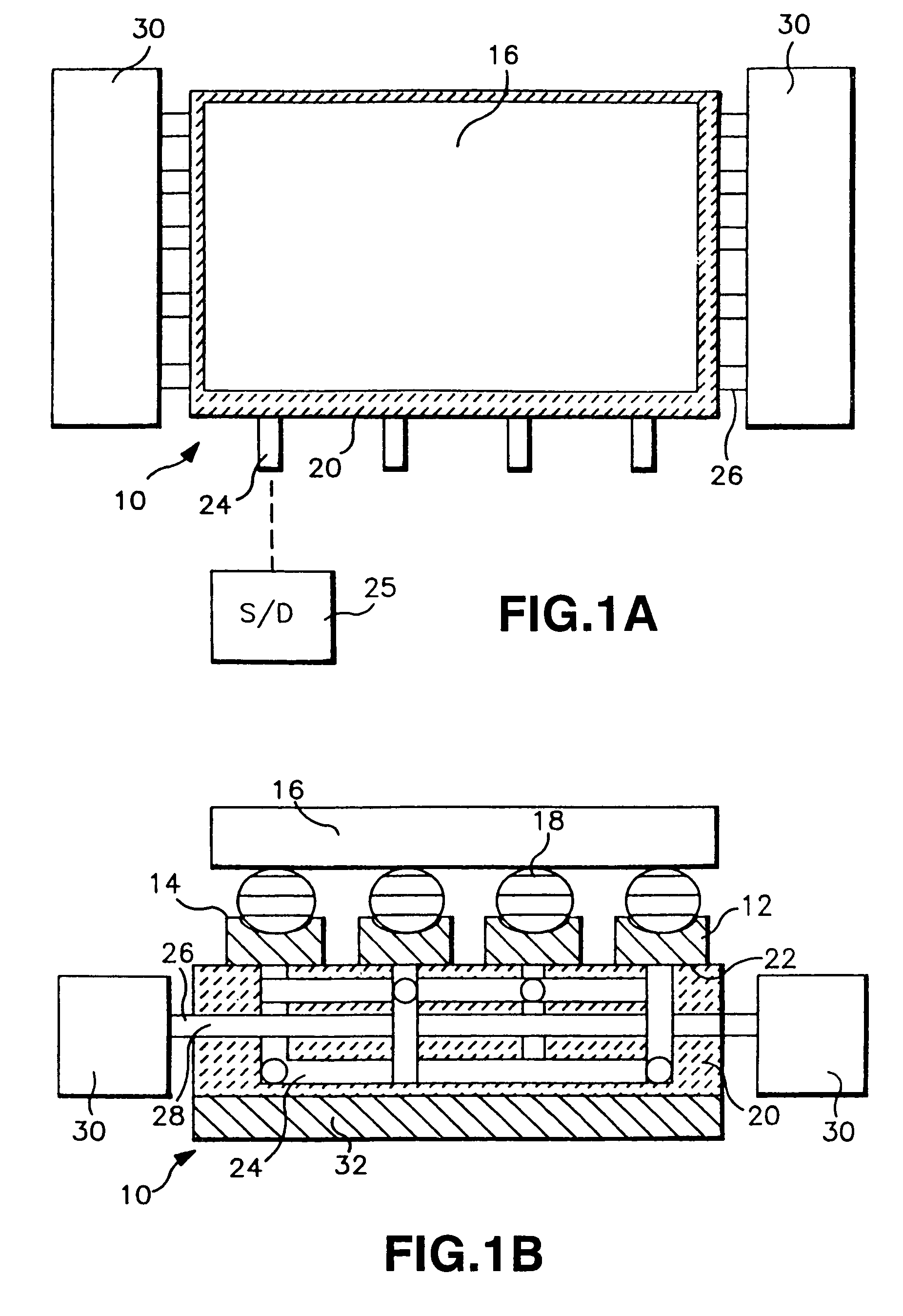

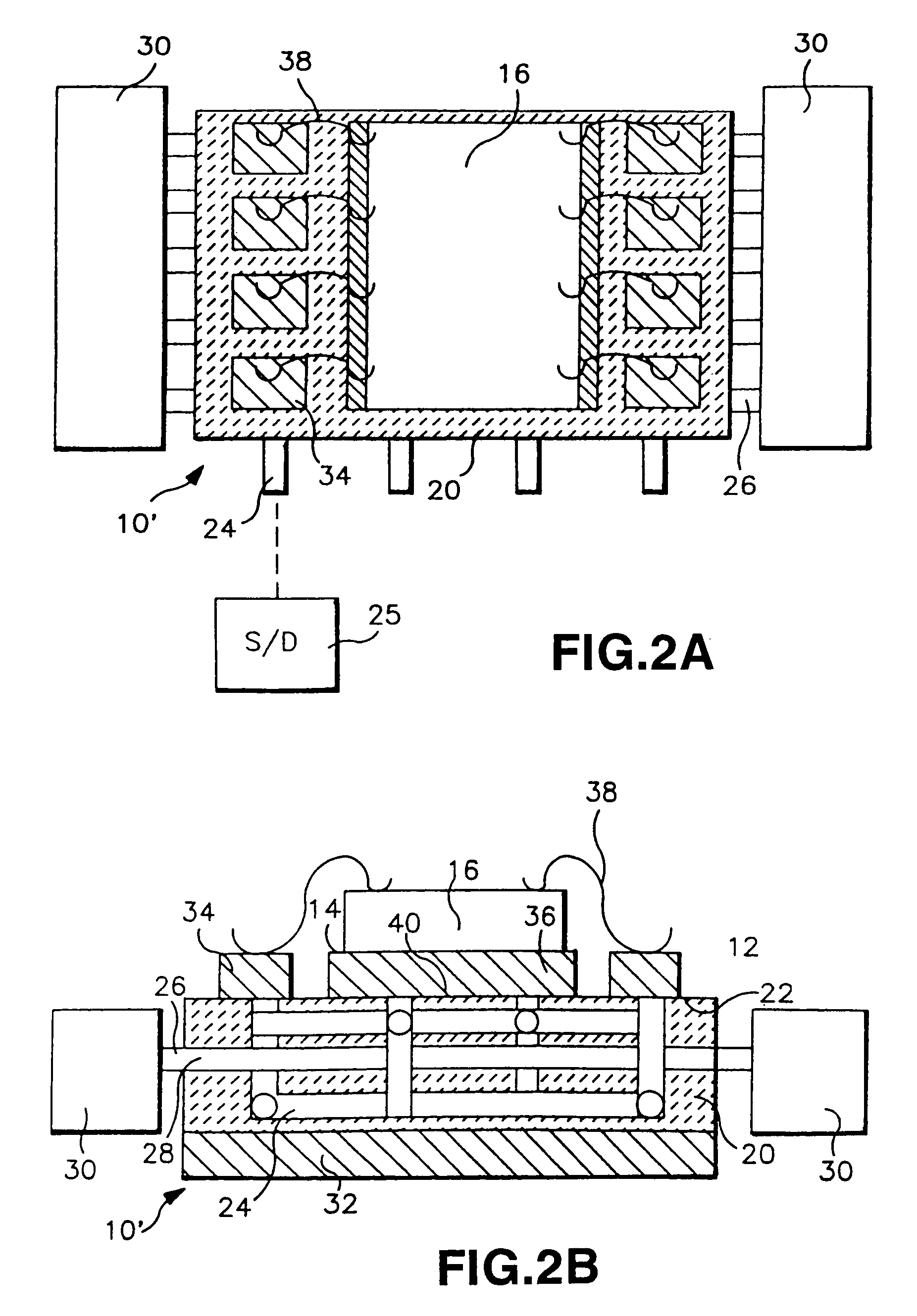

Method of manufacture of ceramic composite wiring structures for semiconductor devices

InactiveUS7047637B2Increase volume fractionEasy to removeSemiconductor/solid-state device detailsSolid-state devicesDielectricCeramic composite

Method of manufacture of a composite wiring structure for use with at least one semiconductor device, the structure having a first conductive member upon which the semiconductor device can be mounted for electrical connection thereto. A dielectric member, made of ceramic or organo-ceramic composite material, is bonded to the first conductive member and contains embedded therein a conductive network and a thermal distribution network. A second conductive member may be incorporated with the composite wiring structure, with a capacitor electrically connected between the conductive network and the second conductive member. Bonding between the dielectric member and the conductive members may be in the form of a direct covalent bond formed at a temperature insufficient to adversely effect the structural integrity of the conductive network and the thermal distribution network.

Owner:L PIERRE DEROCHEMONT C2 TECH

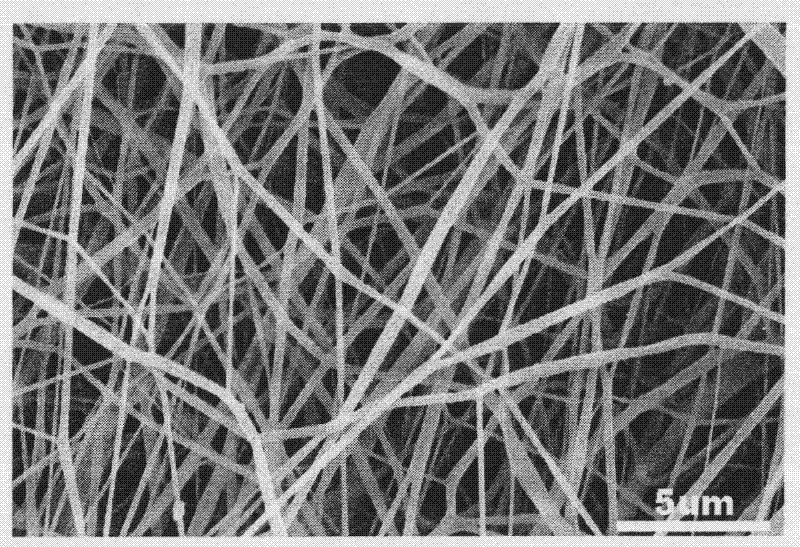

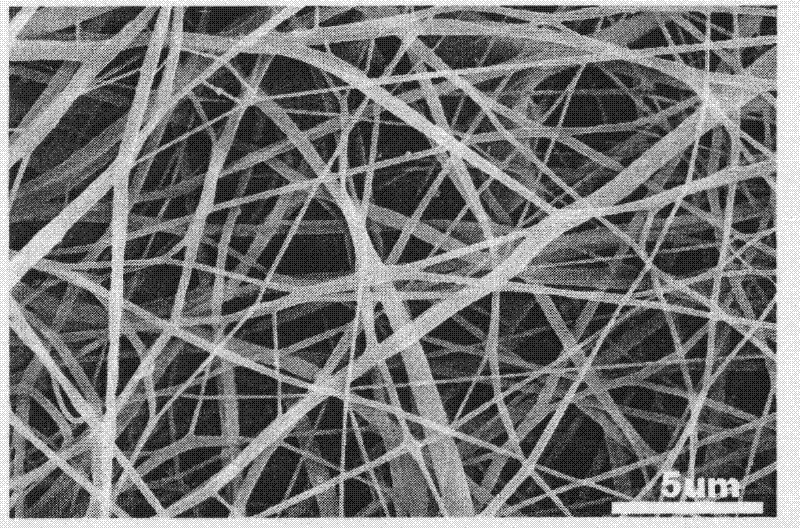

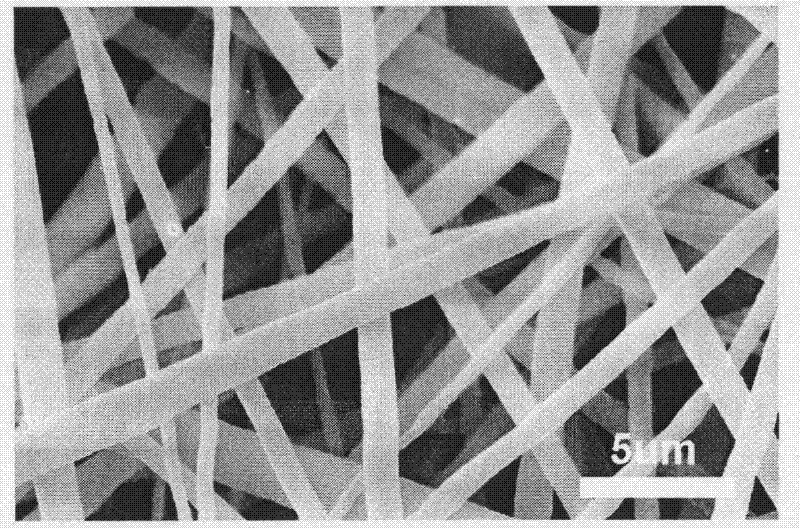

Polymer-ceramic compound nanometer fibrous membrane as well as preparation method and application thereof

ActiveCN102242464AUniform thicknessHigh porositySemi-permeable membranesFixed capacitor dielectricFiberPorosity

The invention relates to a polymer-ceramic compound nanometer fibrous membrane prepared by using an electrostatic spinning method and an application thereof. A polymer material and a ceramic material are compounded, thereby forming the polymer-ceramic compound nanometer fibrous membrane, wherein the weight of the polymer material is 60-90% of the weight of the polymer-ceramic compound nanometer fibrous membrane; the weight of the ceramic material is 10-40% of the weight of the polymer-ceramic compound nanometer fibrous membrane; a porosity factor between polymer-ceramic compound nanometer fibers in the polymer-ceramic compound nanometer fibrous membrane is 40-75%; and an aperture of a hole formed between the polymer-ceramic compound nanometer fibers is 0.2-10 microns. The polymer-ceramic compound nanometer fibrous membrane can be used as a membrane of a lithium ion battery, a supporter of a micro-filtration material, a supporter of a super-filtration material, a supporter of a nano-filtration material, and the like.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

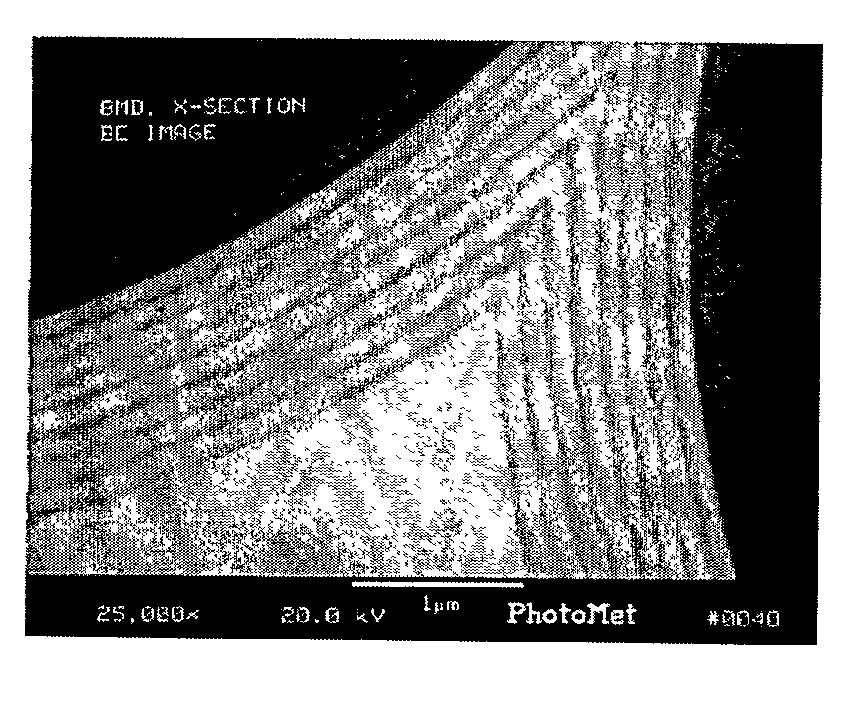

Fiber-reinforced ceramic composite material comprising a matrix with a nanolayered microstructure

InactiveUS20050181192A1Improve the immunityHigh strengthSynthetic resin layered productsCeramic layered productsCeramic compositeToughening

A fiber-reinforced ceramic matrix composite material exhibiting increased matrix cracking strength and fracture toughness is produced by sequentially depositing a plurality of 5-500 nanometer-thick layers of a primary ceramic matrix material phase periodically separated by 1-100 nanometer-thick intermediate layers of a secondary matrix material phase onto the reinforcing fibers upon their consolidation. The resultant nanolayered matrix enhances the resistance to the onset of matrix cracking, thus increasing the useful design strength of the ceramic matrix composite material. The nanolayered microstructure of the matrix constituent also provides a unique resistance to matrix crack propagation. Through extensive inter-layer matrix fracture, debonding and slip, internal matrix microcracks are effectively diverted and / or blunted prior to their approach towards the reinforcing fiber, thus increasing the apparent toughness of the matrix constituent. This unique toughening mechanism serves to dampen energetic co-planar macrocrack propagation typically observed in conventionally manufactured ceramic matrix composites wherein matrix cracks are usually deflected at the fiber / matrix interphase region.

Owner:ROLLS ROYCE HIGH TEMPERATURE COMPOSITES INC

Densification method for carbon fiber reinforced silicon carbonitride ceramic composite material

ActiveCN103724035ASmall coefficient of thermal expansionImprove thermal shock resistanceCeramic compositeCarbon fibers

The invention provides a densification method for a carbon fiber reinforced silicon carbonitride ceramic composite material. The method comprises the following steps: firstly, preparing a C / SiC ceramic composite material by using CVI or PIP; performing CVI on the C / SiC ceramic composite material to carbonize silicon, and as the cross gap between fiber bundles is large, prolonging the CVI time to 20-30 hours ; when the silicon being subjected to carbonization is densified to 80-90% by CVI, brushing silicon powder on the C / SiC surface, and filling large holes particularly; performing nitridation processing after drying; after completion of the nitridation, preparing an SiC coating on the CMC surface through CVD for 20-30 hours to complete the densification of the carbon fiber reinforced silicon carbonitride ceramic composite material. Through the adoption of the densification method, the CMC preparation efficiency is improved, the coefficients of thermal expansion of matrixes are reduced, and the thermal shock resistance of CMC is improved.

Owner:TAICANG PAIOU TECH CONSULTING SERVICE

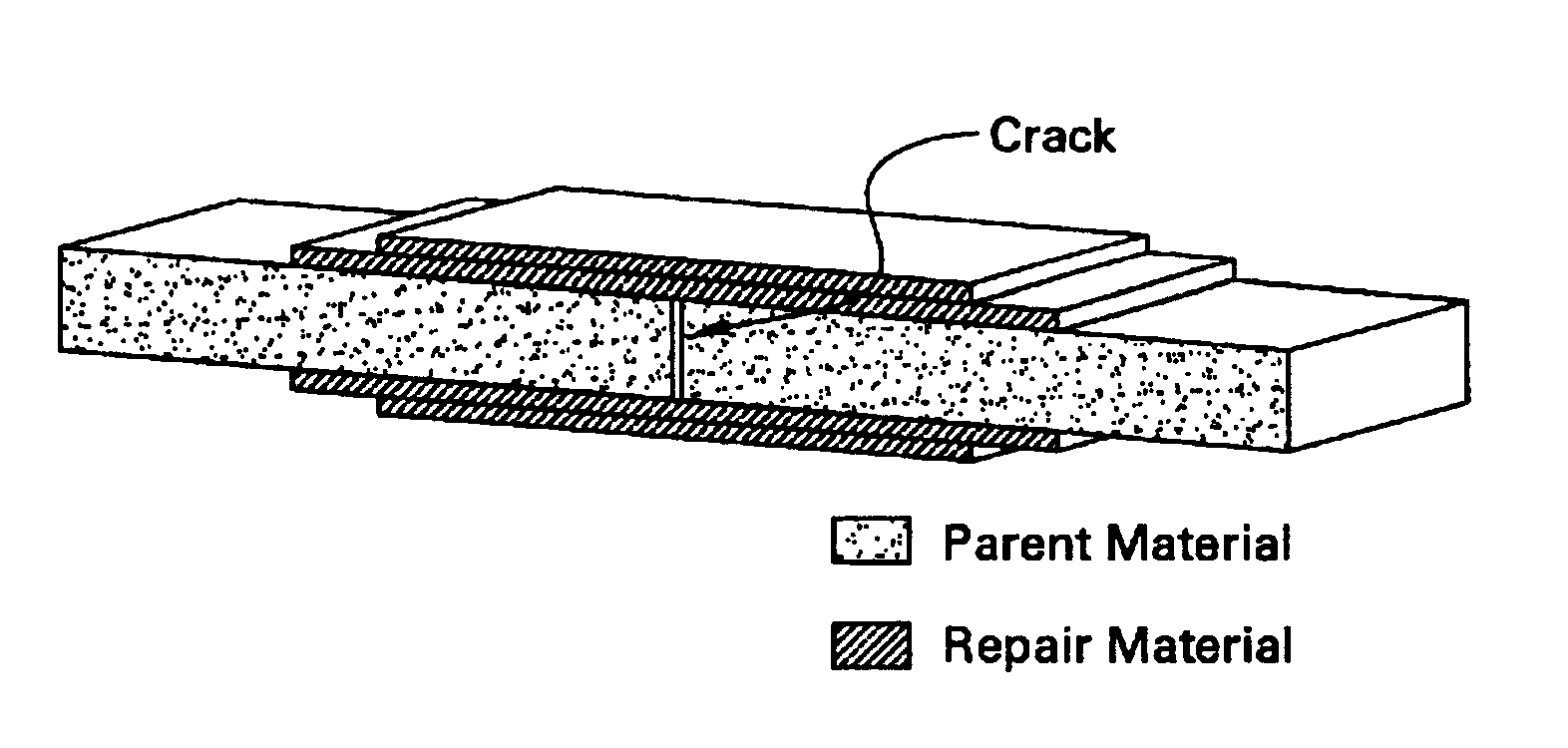

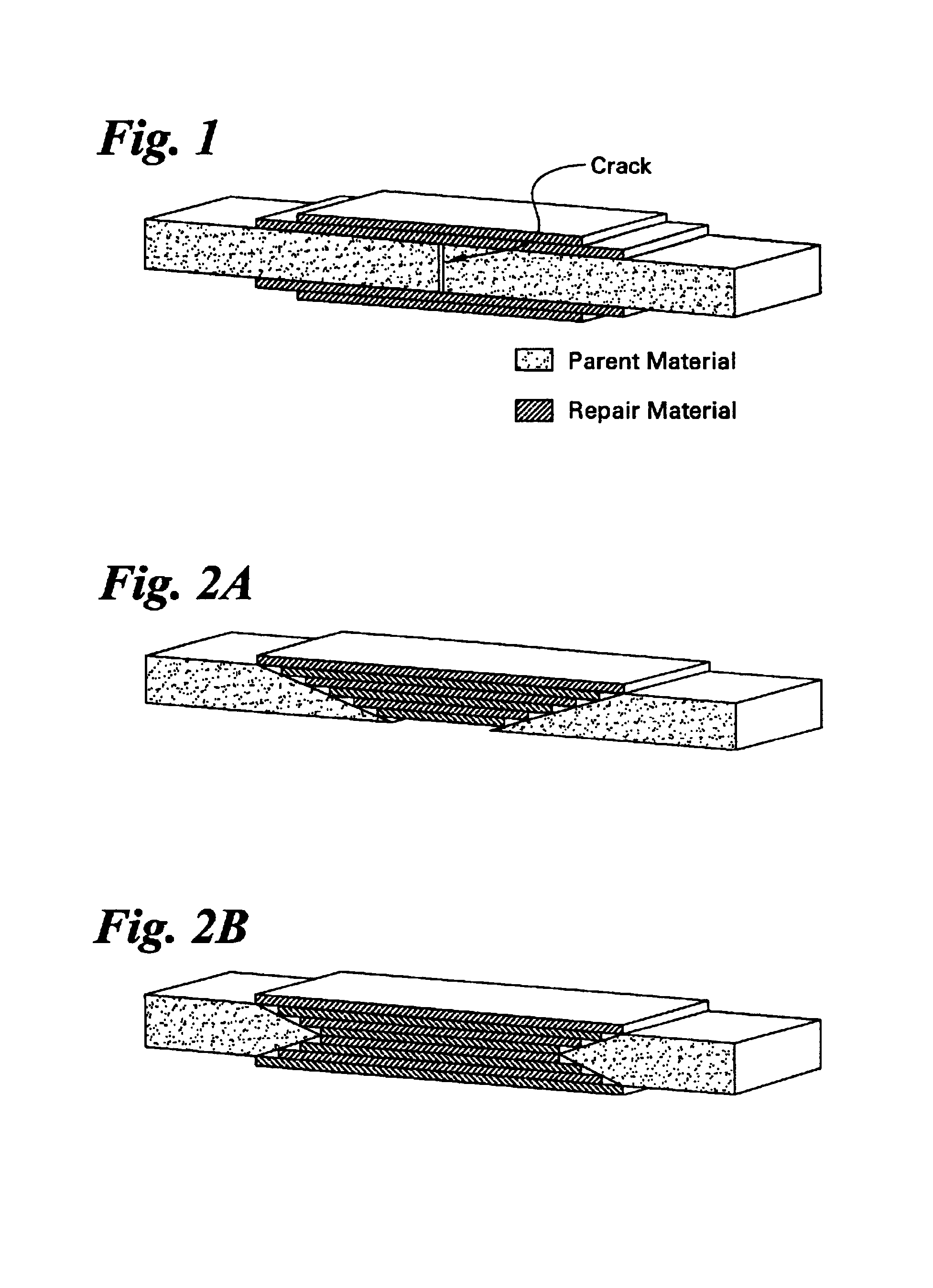

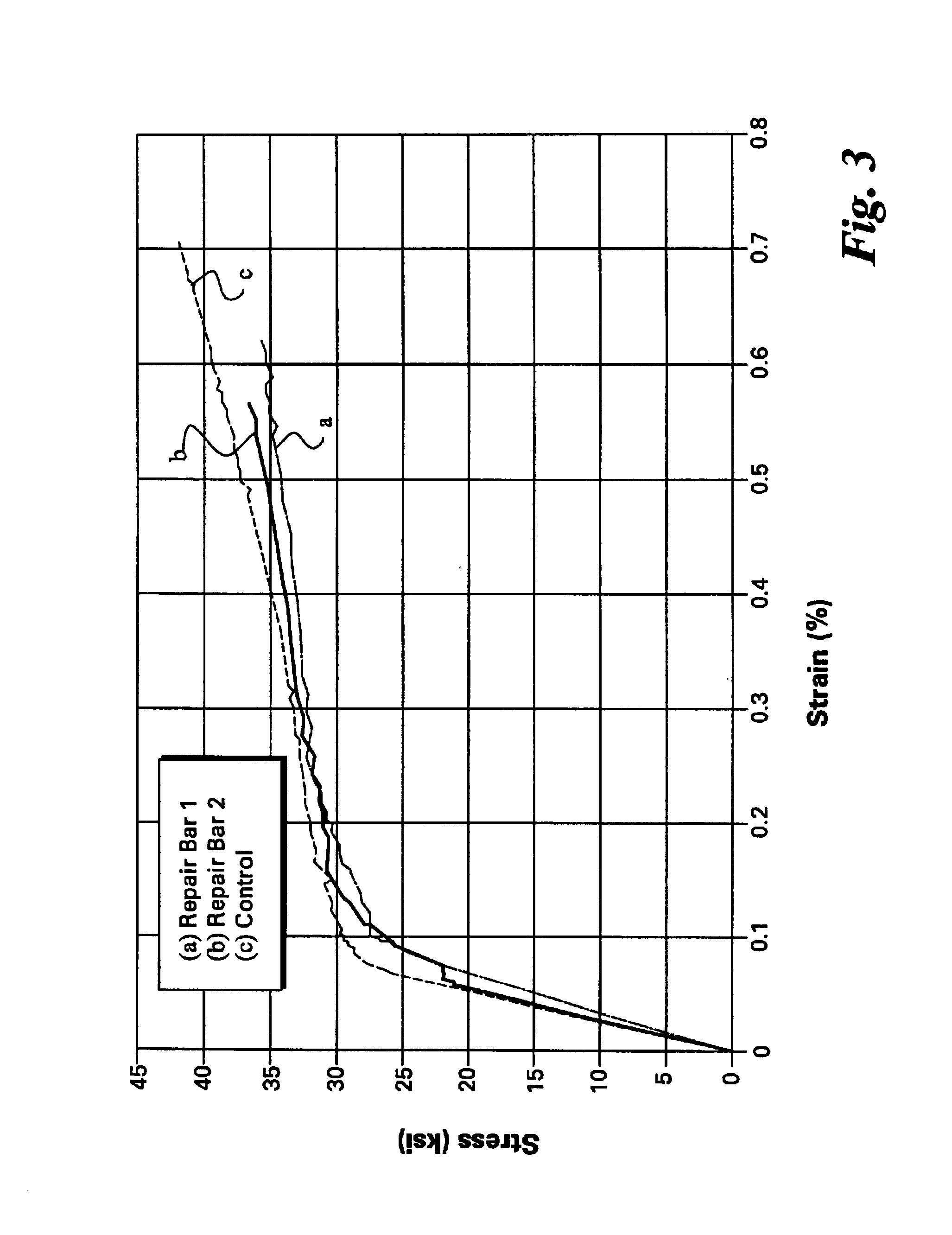

Method for repairing articles of ceramic composites

InactiveUS6820334B2Prolong lifeReduce in quantityBlade accessoriesEfficient propulsion technologiesCeramic compositeMetallurgy

Owner:GENERAL ELECTRIC CO

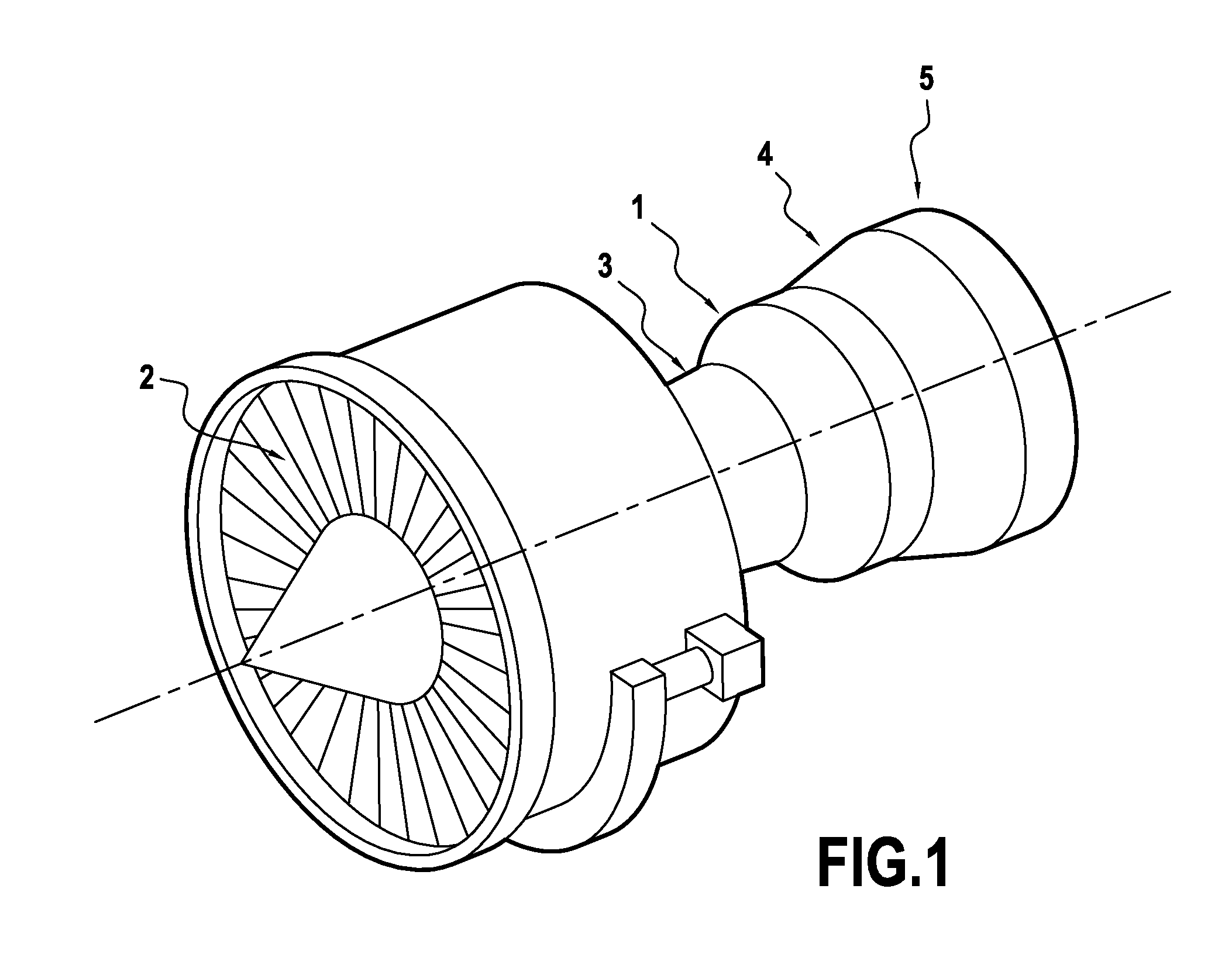

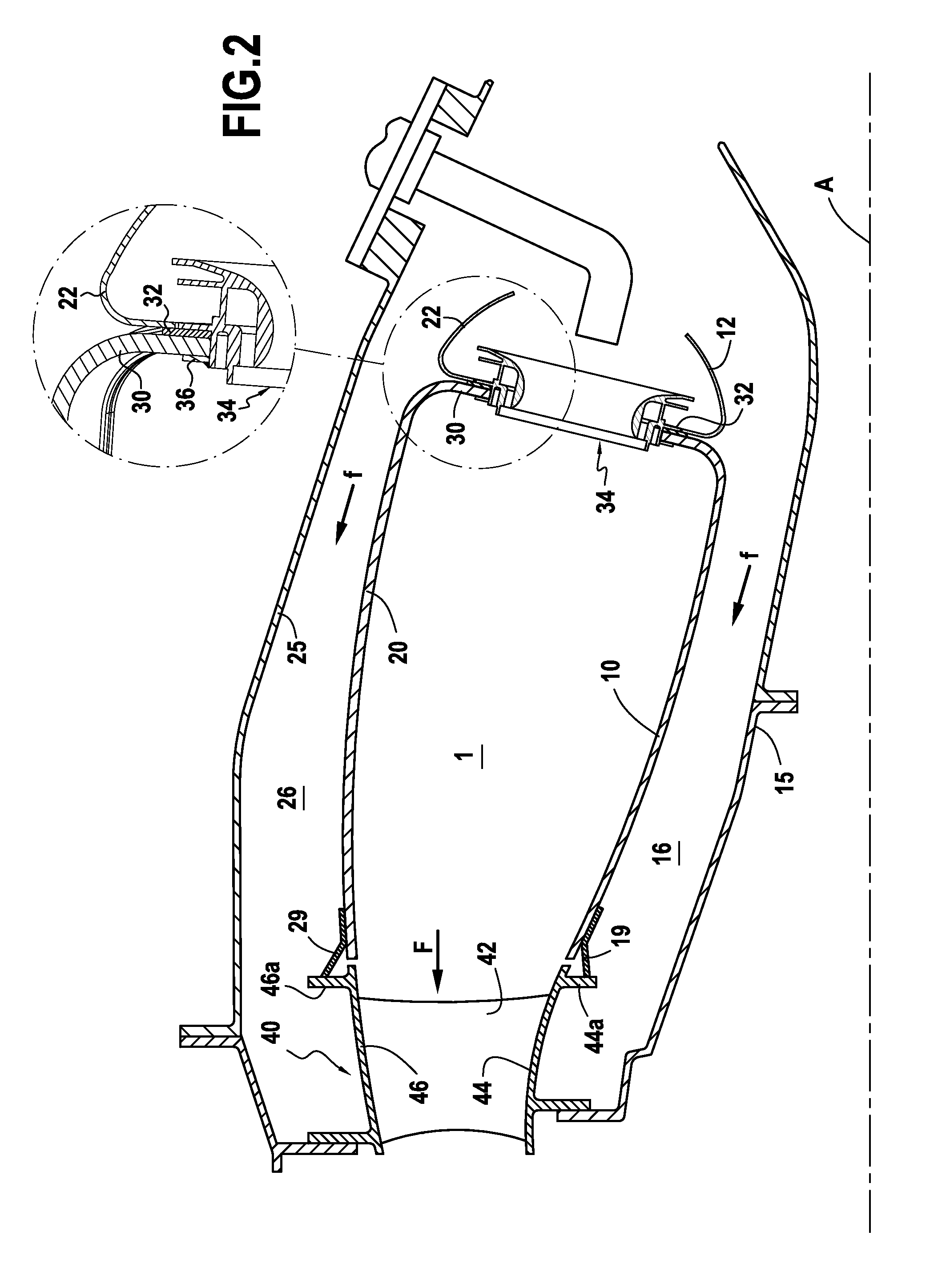

Gas turbine combustion chamber made of CMC material and subdivided into sectors

ActiveUS8141371B1Reduce manufacturing costEasy and effective absorptionContinuous combustion chamberGas turbine plantsCombustion chamberCeramic composite

An assembled annular combustion chamber comprises an annular inner wall and an annular outer wall made of ceramic matrix composite material together with a chamber end wall connected to the inner and outer walls and provided with orifices for receiving injectors. Elastically-deformable link parts connect the inner wall and the outer wall of the chamber to inner and outer casings that are made of metal. The assembly formed by the inner wall, the outer wall, and the combustion chamber end wall is subdivided circumferentially into adjacent chamber sectors, each sector being made as a single piece of ceramic composite material and comprising an inner wall sector, an outer wall sector, and a chamber end wall sector. The link parts connect the inner metal casing and the outer metal casing respectively to each inner wall sector of the combustion chamber and to each outer wall sector of the chamber. The chamber end wall sectors are in contact with a one-piece ring to which they are connected.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

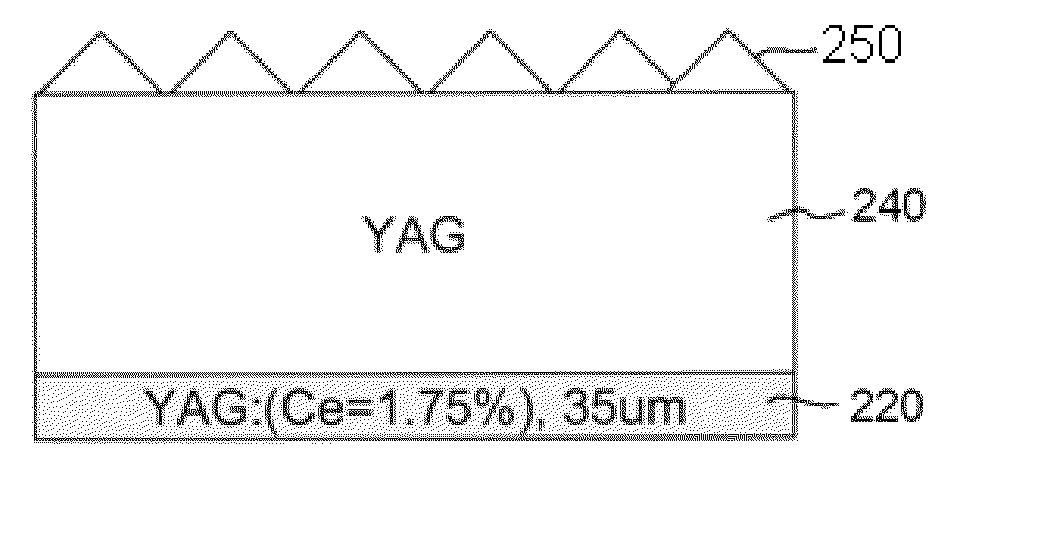

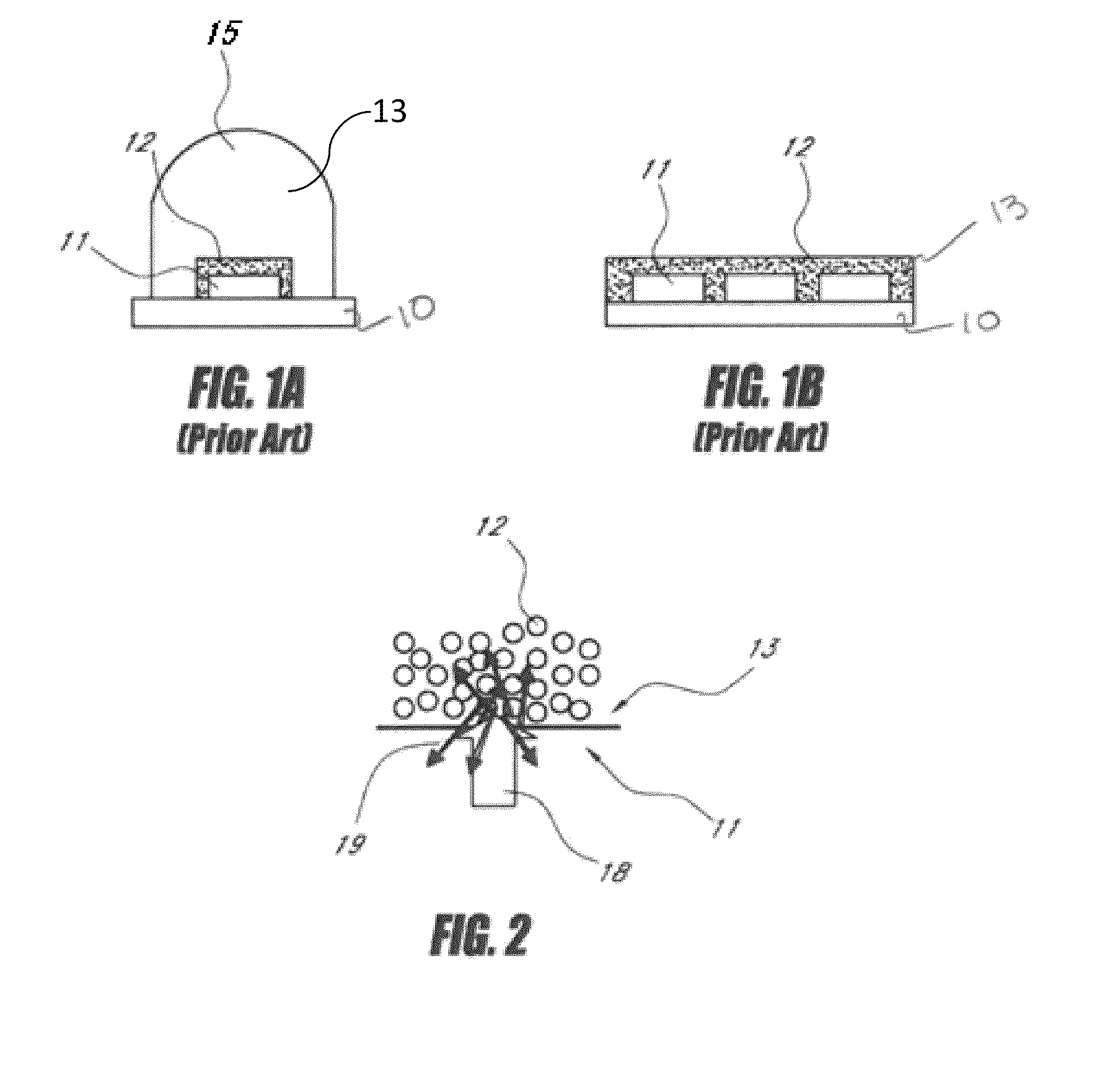

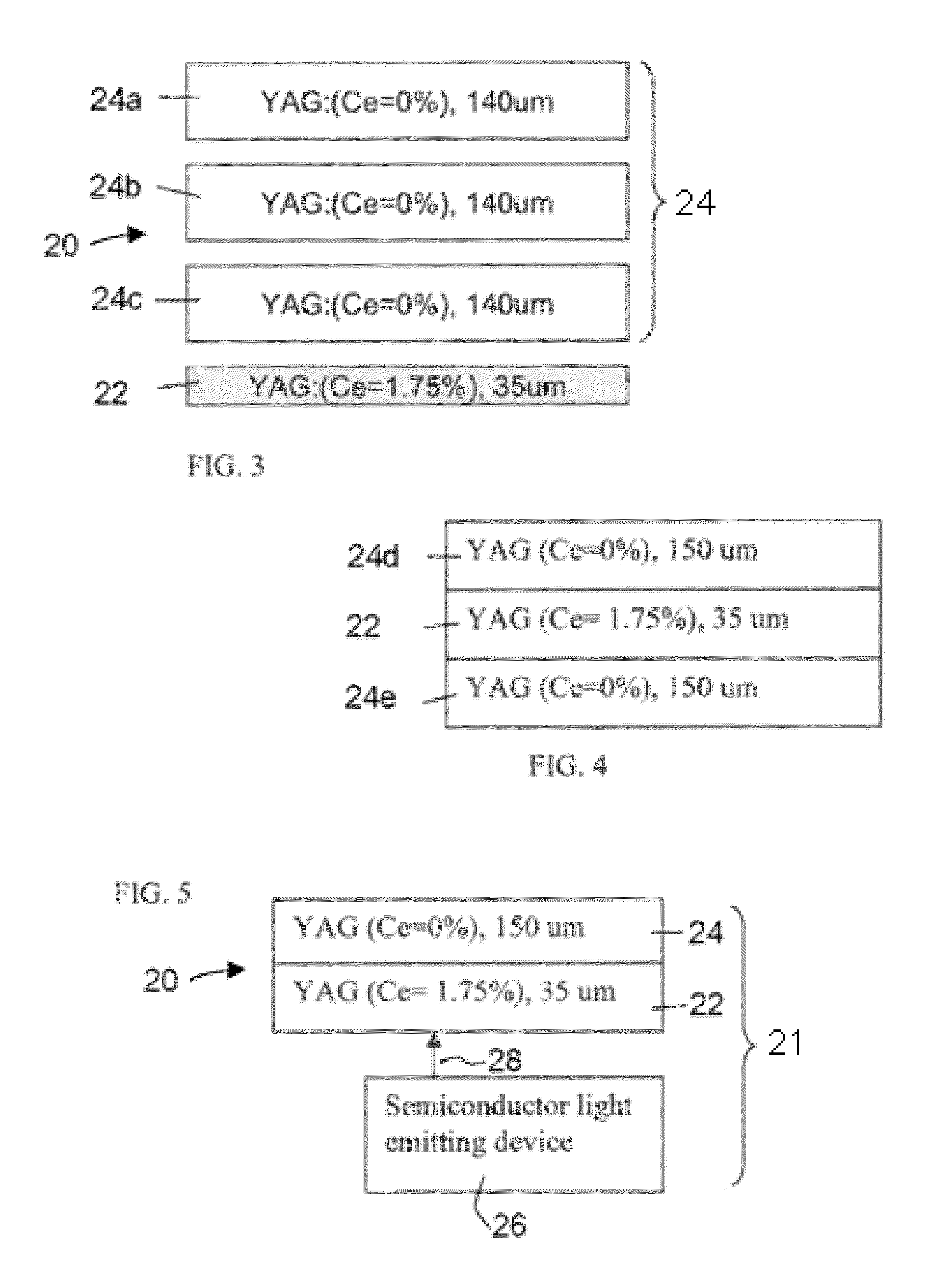

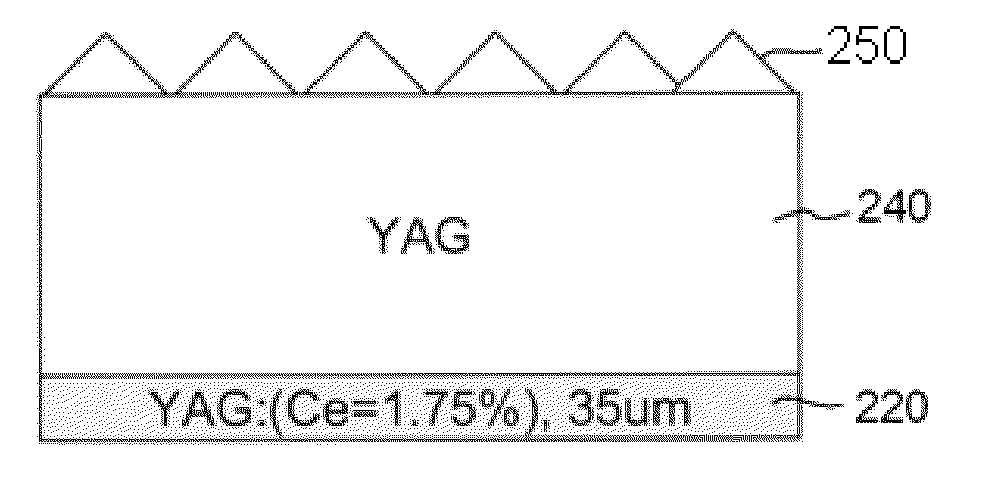

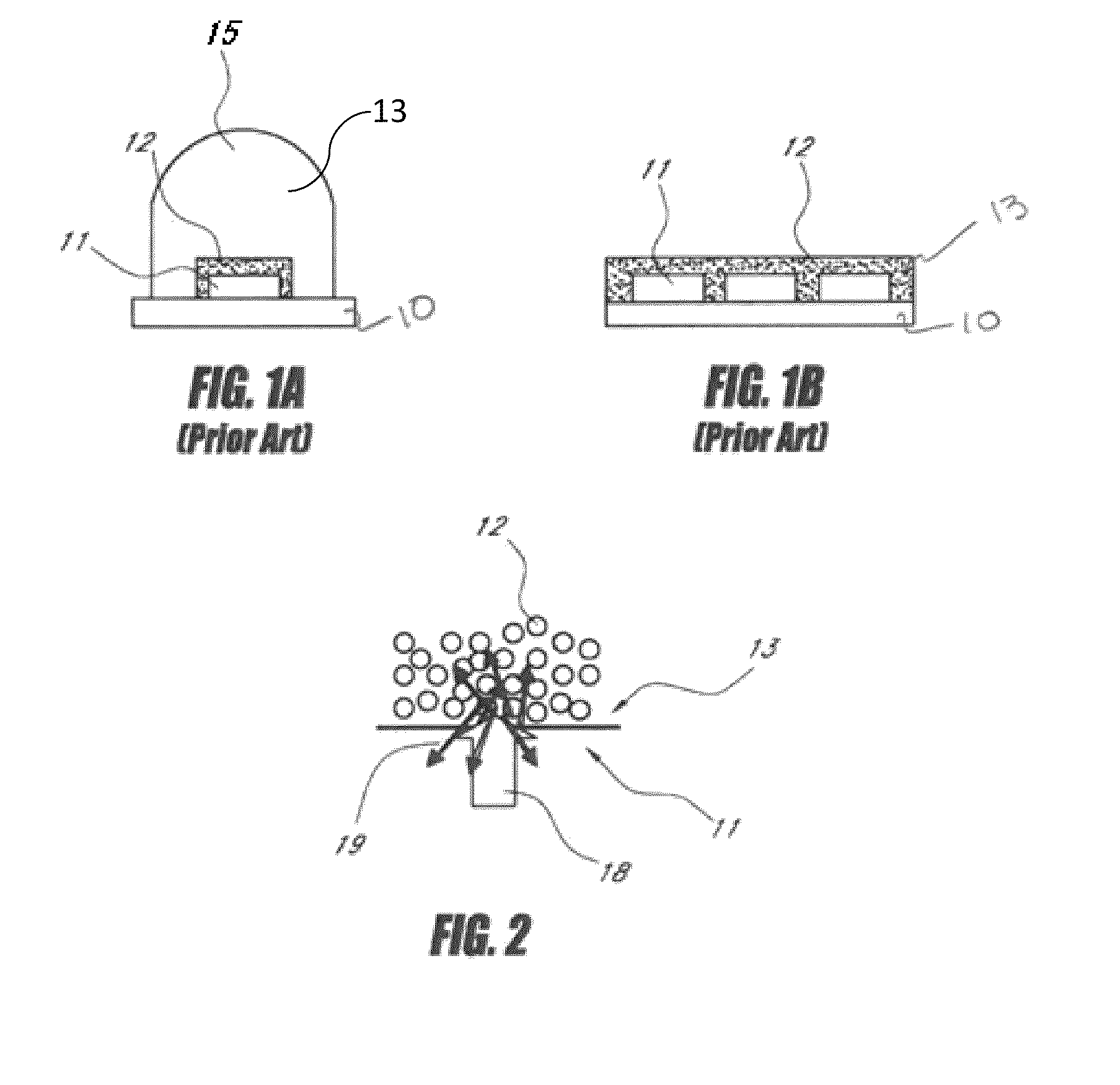

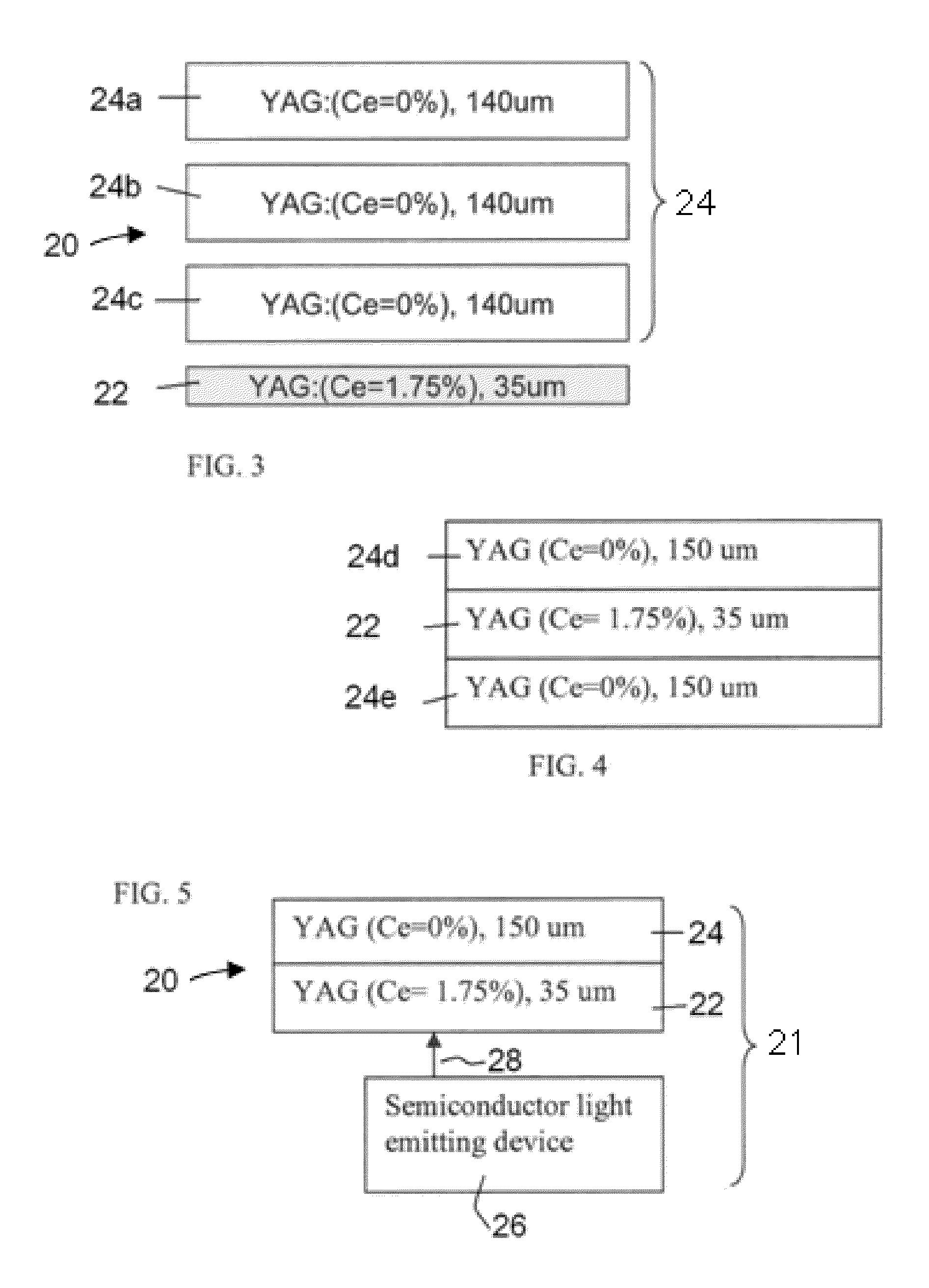

Light emissive ceramic laminate and method of making same

ActiveUS20110210658A1Incadescent screens/filtersElectric discharge tubesCeramic compositeComposite laminates

A ceramic composite laminate includes a wavelength-converting layer and a non-emissive layer, wherein the ceramic composite laminate has a wavelength conversion efficiency (WCE) of at least 0.650. The ceramic composite laminate can also include a wavelength-converting ceramic layer comprising an emissive material and a scattering material, wherein the laminated composite has a total transmittance of between about 40% to about 85%. The wavelength-converting layer may be formed from plasma YAG:Ce powder.

Owner:SCHOTT AG

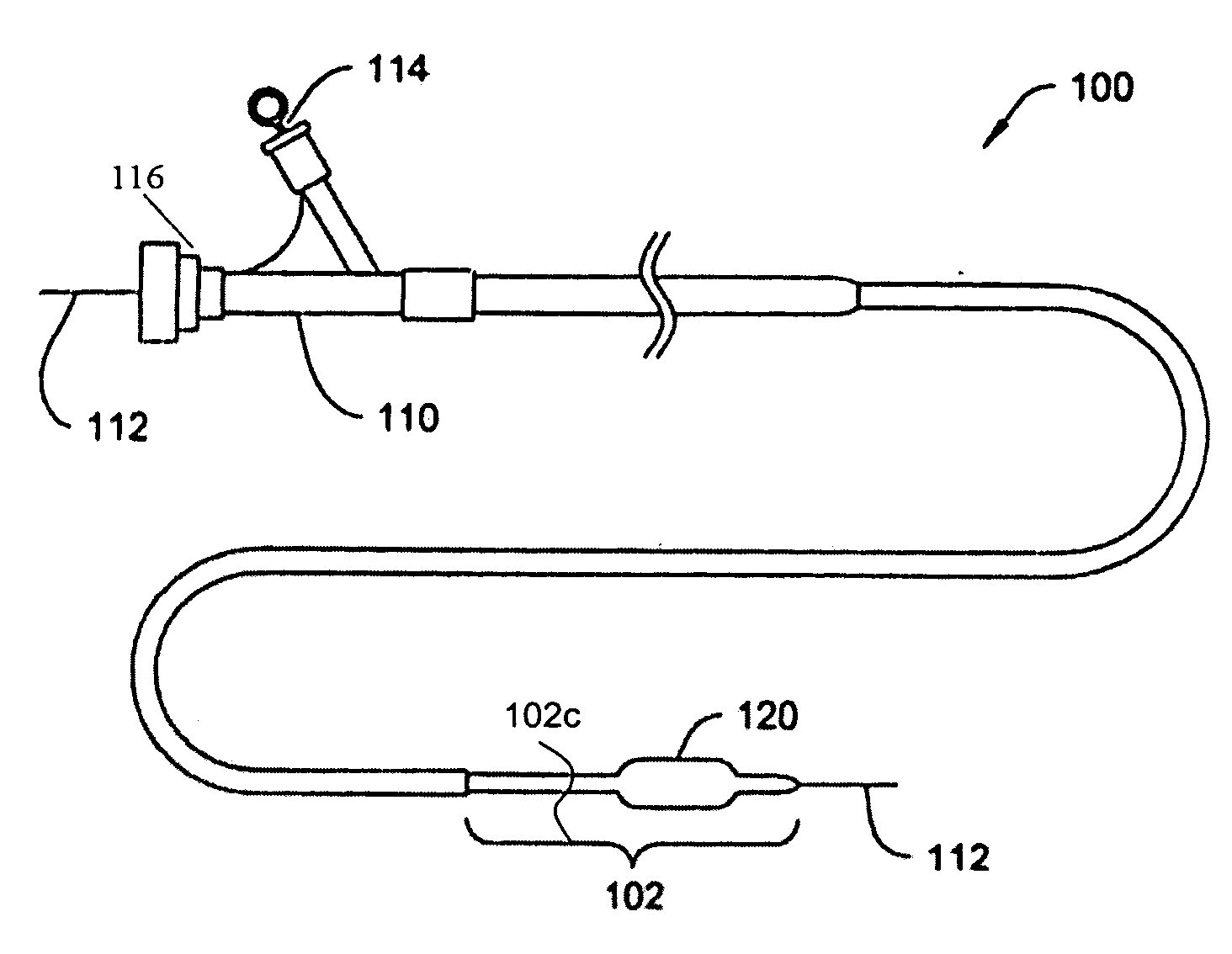

Coated medical devices and methods of making and using

A medical device generally includes a structural member having a surface wherein at least a portion of the surface is coated with a nanostructured material to a thickness of at least about 25 micrometers, and wherein the nanostructured material comprises a ceramic, ceramic composite, ceramic metal composite, or a combination comprising at least one of the foregoing. The implants have increased service lifetimes owing in part to improved wear and abrasion resistance, and may be useful for partial or full replacement of articulating and flexible hinge joints.

Owner:INFRAMAT CORPORATION

Polymeric/ceramic composite materials for use in medical devices

InactiveUS20080050415A1Improve featuresEnhanced abrasionOrganic active ingredientsCosmetic preparationsCeramic compositeMedical device

According to an aspect of the invention, implantable or insertable medical devices are provided, which contain one or more composite regions. These composite regions, in turn, contain (a) a polymeric component comprising a vinyl aromatic polymer and (b) a ceramic component comprising a metal or semi-metal oxide.

Owner:BOSTON SCI SCIMED INC

Light emissive ceramic laminate and method of making same

A ceramic composite laminate includes a wavelength-converting layer and a non-emissive layer, wherein the ceramic composite laminate has a wavelength conversion efficiency (WCE) of at least 0.650. The ceramic composite laminate can also include a wavelength-converting ceramic layer comprising an emissive material and a scattering material, wherein the laminated composite has a total transmittance of between about 40% to about 85%. The wavelength-converting layer may be formed from plasma YAG:Ce powder.

Owner:SCHOTT AG

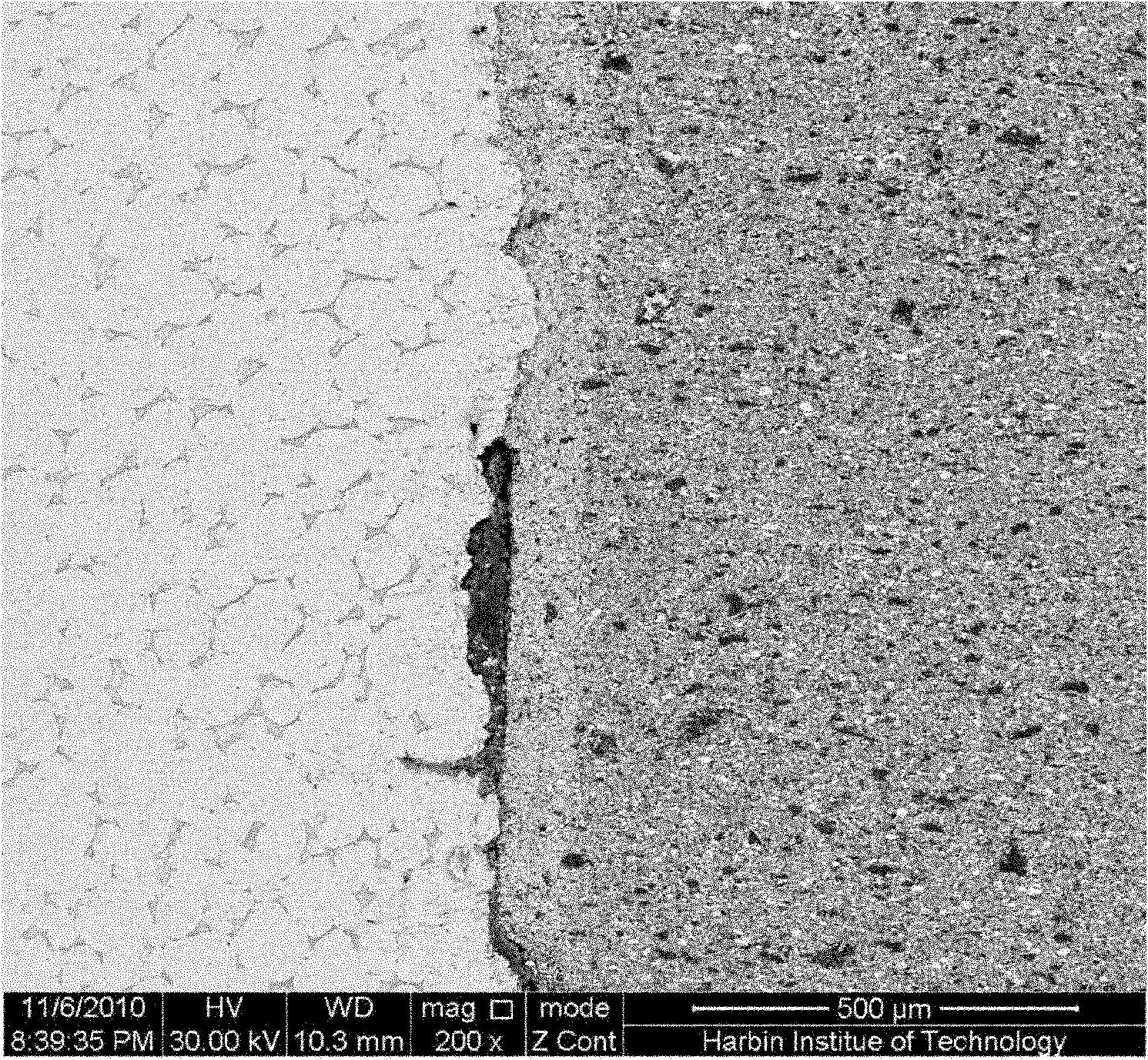

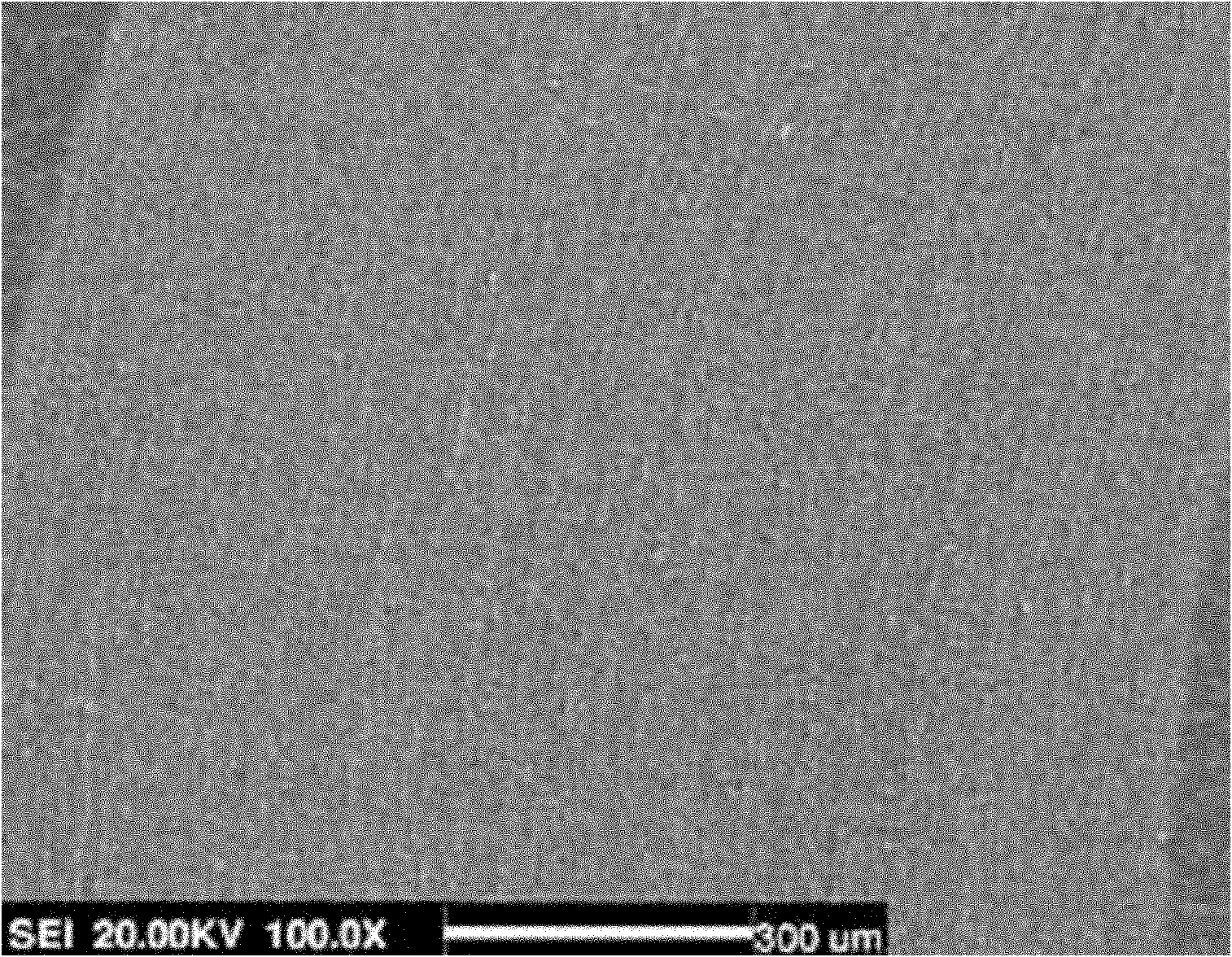

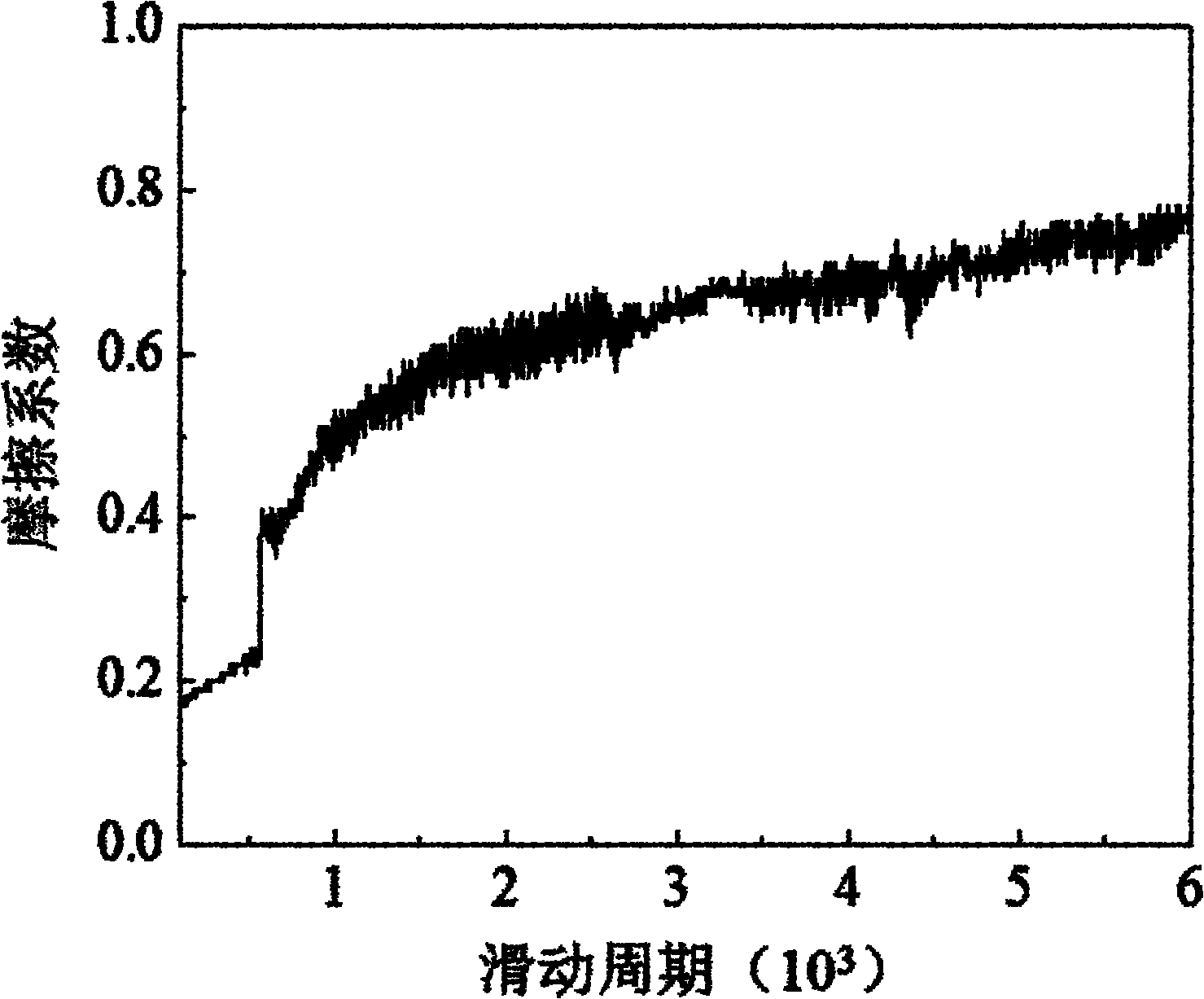

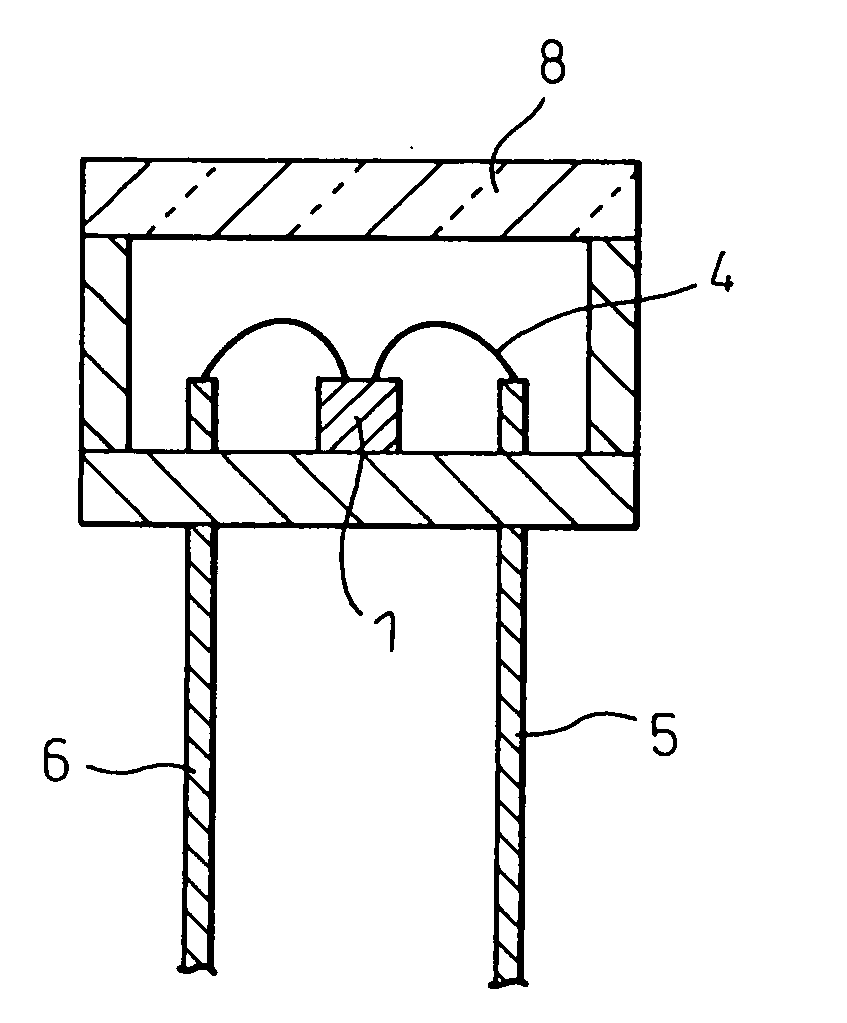

Ceramic composite material for thin-strip casting side sealing plate and preparation method thereof

The invention provides a ceramic composite material for a thin-strip casting side sealing plate and a preparation method thereof, relating to a ceramic composite material and a preparation method thereof and solving the problems that the traditional side sealing plate has high heat conductivity, serious abrasion, poor seal, high preparation cost and large energy consumption, can not be secondarily processed or reused. The ceramic composite material consists of zirconia, boron nitride and additives. The preparation method comprises the following steps: 1, weighing raw materials; 2, ball milling and mixing the raw materials; 3, drying to obtain uniform mixed powder; and 4, carrying out hot pressed sintering, pressureless sintering, air pressure sintering or hot isostatic pressed sintering on the mixed powder, so as to obtain the ceramic composite material for a thin-strip casting side sealing plate. The compactness of the ceramic composite material is 94%-99%, the bending strength of the ceramic composite material, tested by a three-point bending test at room temperature, is 260-420MPa, and the fracture toughness of the ceramic composite material, tested by a unilateral coped beam method, is 3-8 MPa.m<1 / 2>. The ceramic composite material can be widely applied to the field of side sealing plate materials.

Owner:HARBIN INST OF TECH

Ceramic composite material for optical conversion and use thereof

ActiveUS20060124951A1Improve thermal stabilitySolid-state devicesLuminescent compositionsCeramic compositeHeat resistance

A ceramic composite material for light conversion, which is a solidified body comprising two or more matrix phases with respective components being two or more oxides selected from the group consisting of metal oxides and complex oxides each produced from two or more metal oxides, wherein at least one of the matrix phases is a phosphor phase containing an activated oxide. The solidified body is preferably obtained by the unidirectional solidification method. The ceramic composite material for light conversion is excellent in brightness, light-mixing property, heat resistance and ultraviolet light resistance.

Owner:UBE IND LTD

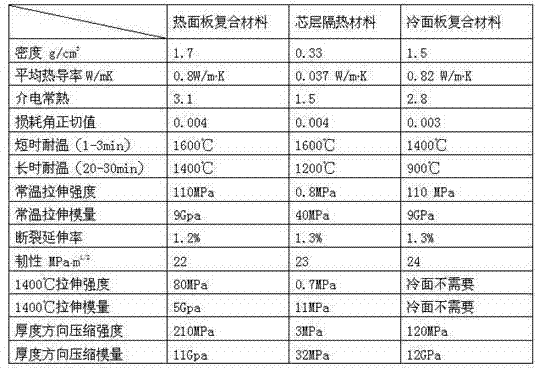

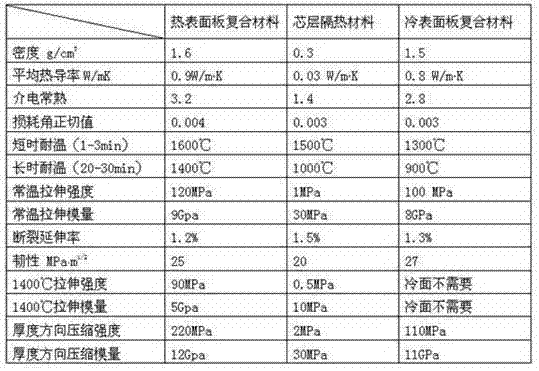

Ceramic composite material of high temperature insulation sandwich structure and method for preparing ceramic composite material

ActiveCN102642350AImprove toughnessImprove thermal conductivityLaminationLamination apparatusOxide ceramicCeramic composite

Disclosed are a ceramic composite material of a high temperature insulation sandwich structure and a method for preparing the ceramic composite material. A core layer of the composite material is an aerogel composite material layer reinforced by high temperature resistant inorganic fibers, oxide ceramic composite material surface plates reinforced by high temperature resistant inorganic fibers are compounded on the upper surface and the lower surface of the core layer, the thickness of the core layer is larger than or equal to 2mm, and the thicknesses of the upper surface plate and the lower surface plate respectively range from 0.1mm to 3.0mm. The method for preparing the ceramic composite material of the high temperature insulation sandwich structure includes the steps: (1) selecting aerogel composite materials reinforced by the high temperature resistant inorganic fibers as materials of the core layer with the thickness larger than or equal to 2mm; (2) tiling high temperature resistant inorganic fiber cloth or thin-layer fabrics on the upper surface and the lower surface of the core layer to perform needling, puncture or sewing; (3) sucking sol in a vacuum manner and gelating the sol at the temperature of 30-200 DEG C; and (4) performing heat treatment. The ceramic composite material of the high temperature insulation sandwich structure integrates the functions of heat insulation, bearing, wave penetration and the like.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com