Patents

Literature

499results about How to "Increase volume fraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

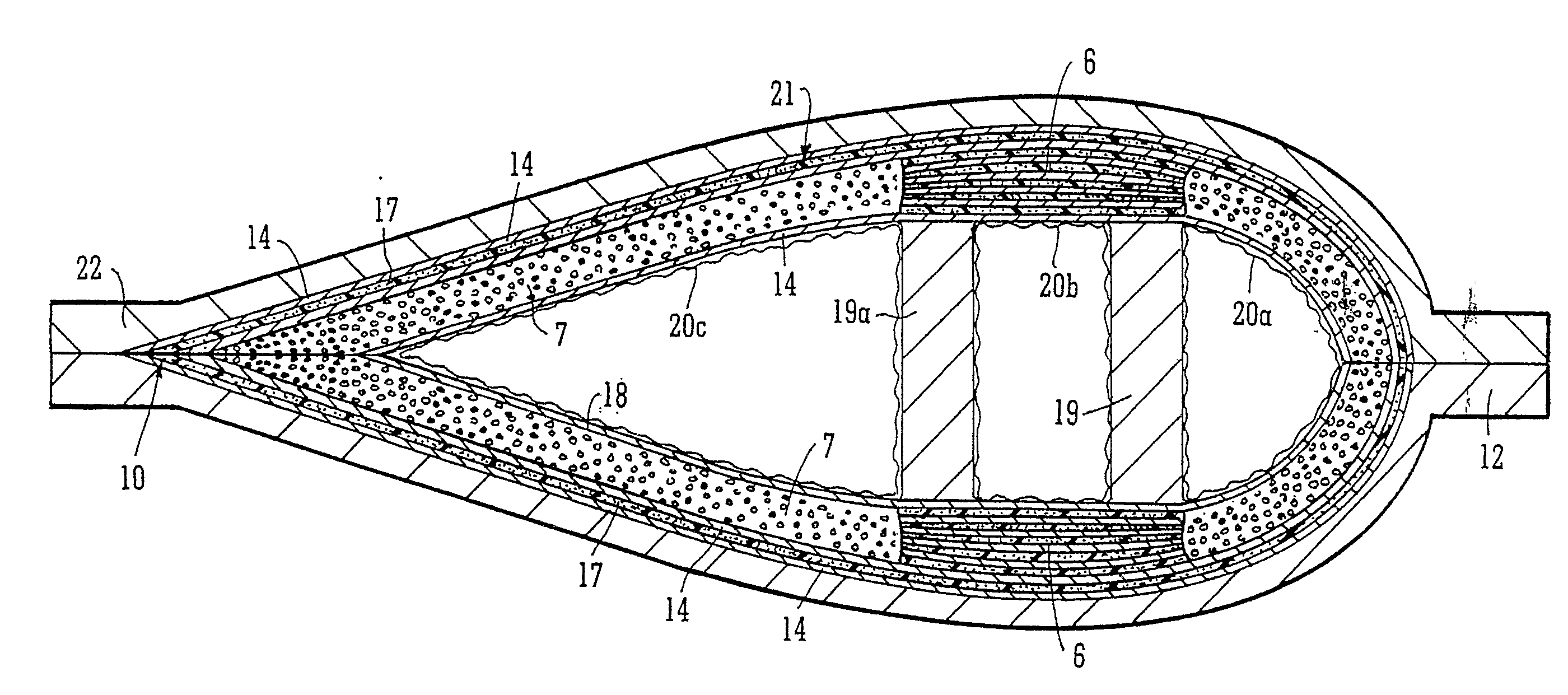

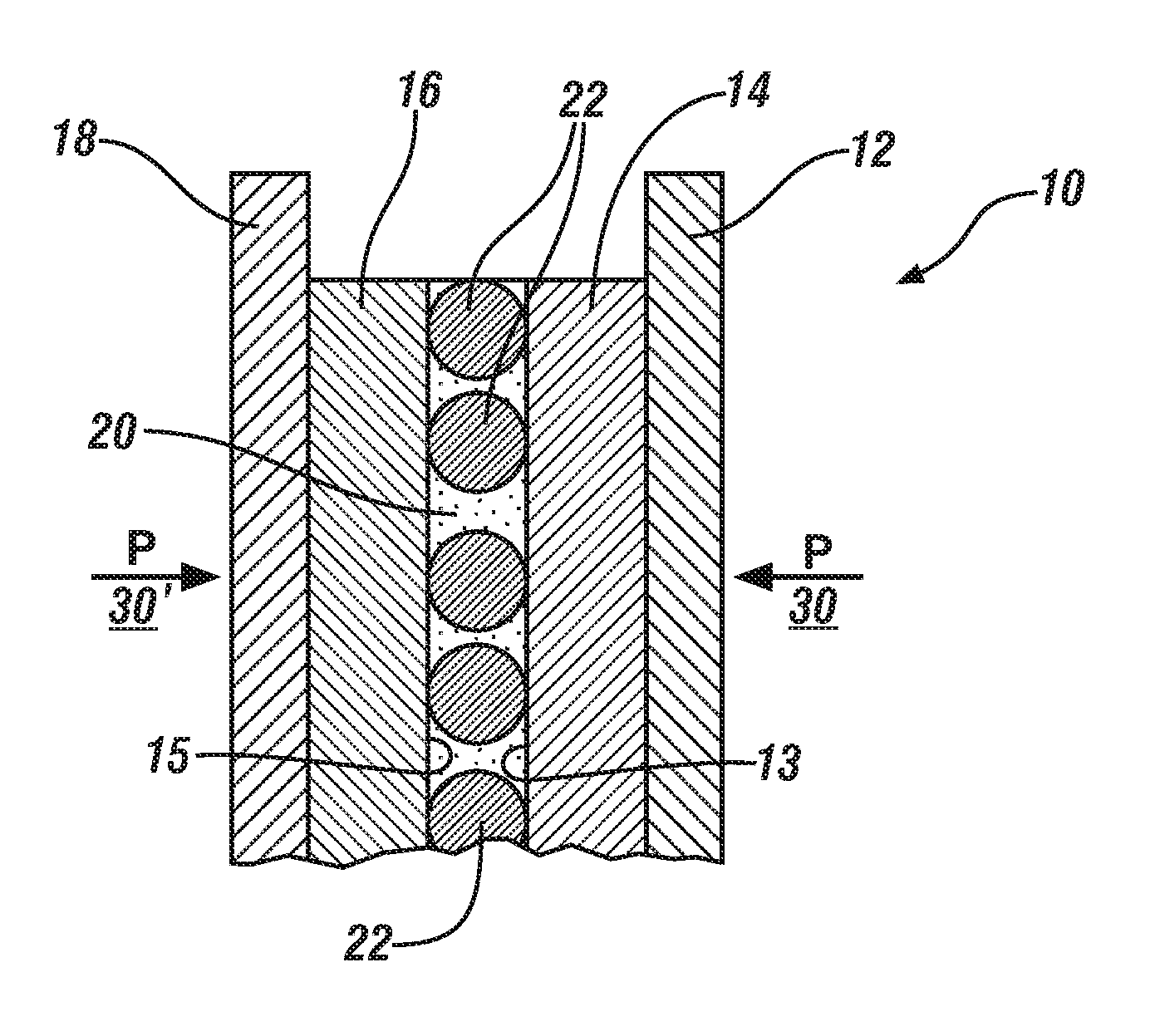

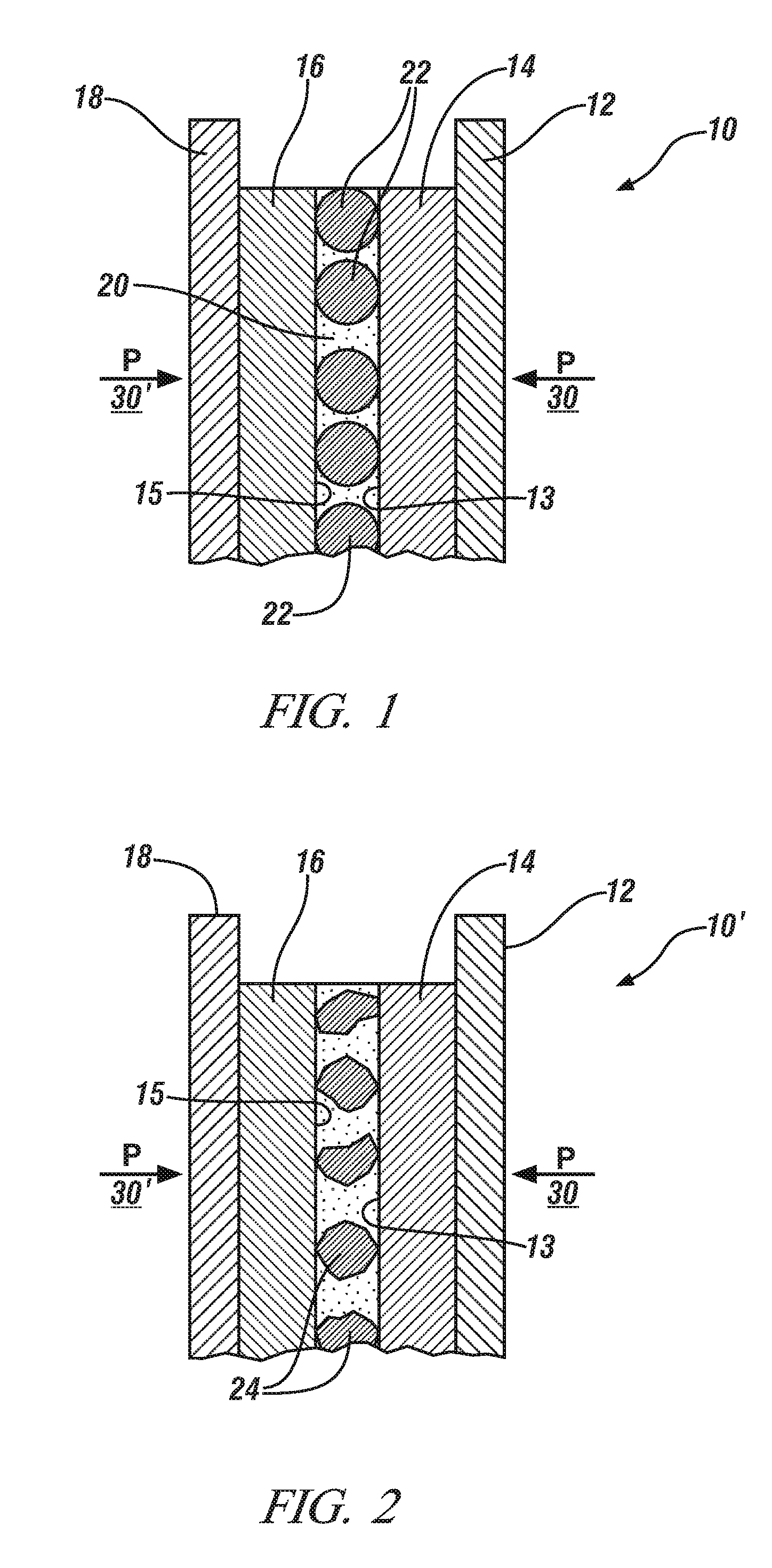

Composite Articles Comprising In-Situ-Polymerisable Thermoplastic Material and Processes for their Construction

InactiveUS20100062238A1Reliable constructionLow costFinal product manufacturePretreated surfacesTurbine bladeIn situ polymerization

A process for the manufacture of a composite article is described wherein the process comprises the steps of (i) providing on a tool (22) a fibrous material (14) having associated therewith in at least one region thereof an in-situ polymerisable non-fibrous form of a thermoplastic material; (ii) applying heat and a vacuum to said material; and additionally (iii) drawing into the fibrous material, from a source external to the tool, additional thermoplastic pre-polymer material. The process described is particularly useful for the manufacture of a large composite structure such as thermoplastic composite wind turbine blade, for example.

Owner:UNIVERSITY OF LIMERICK +2

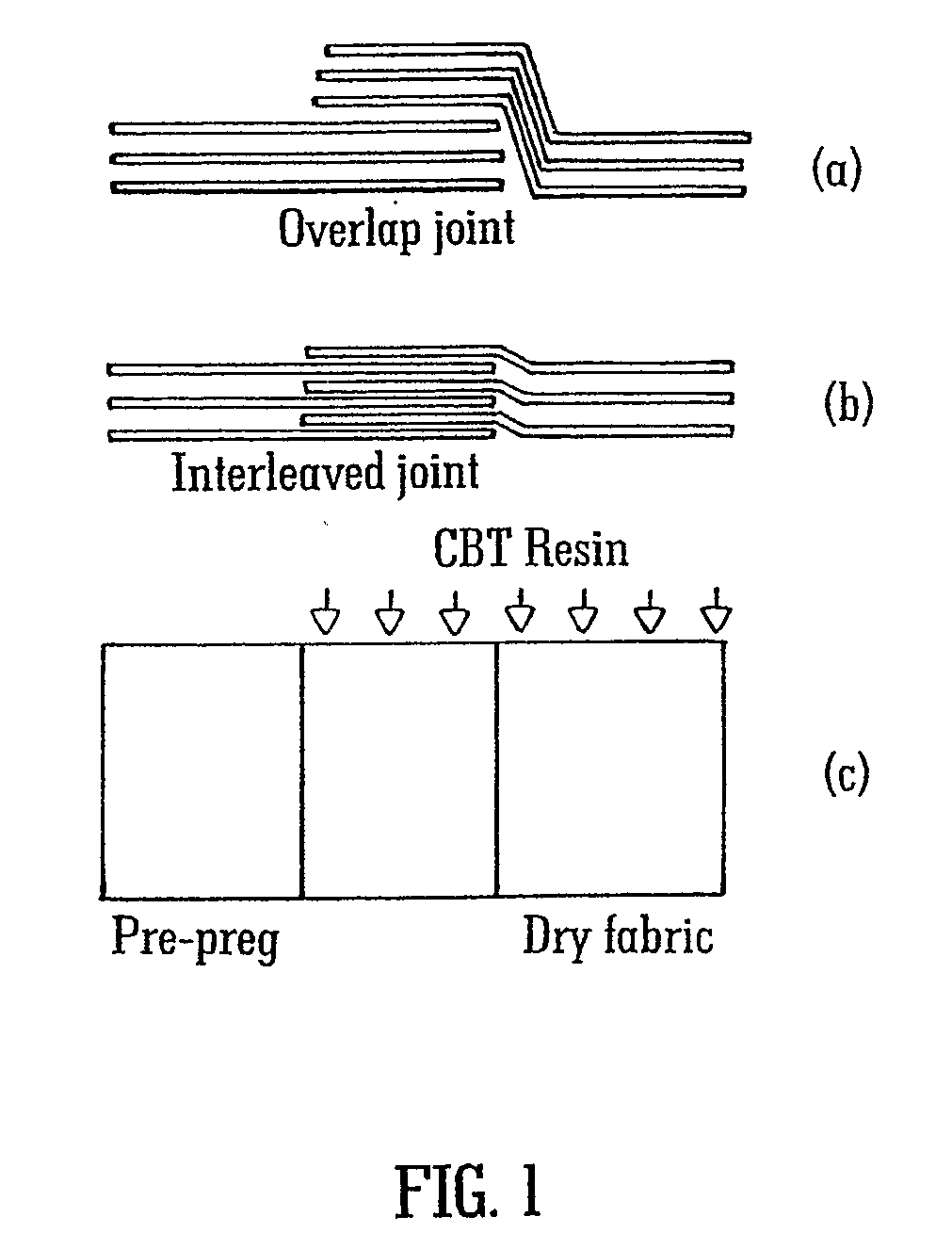

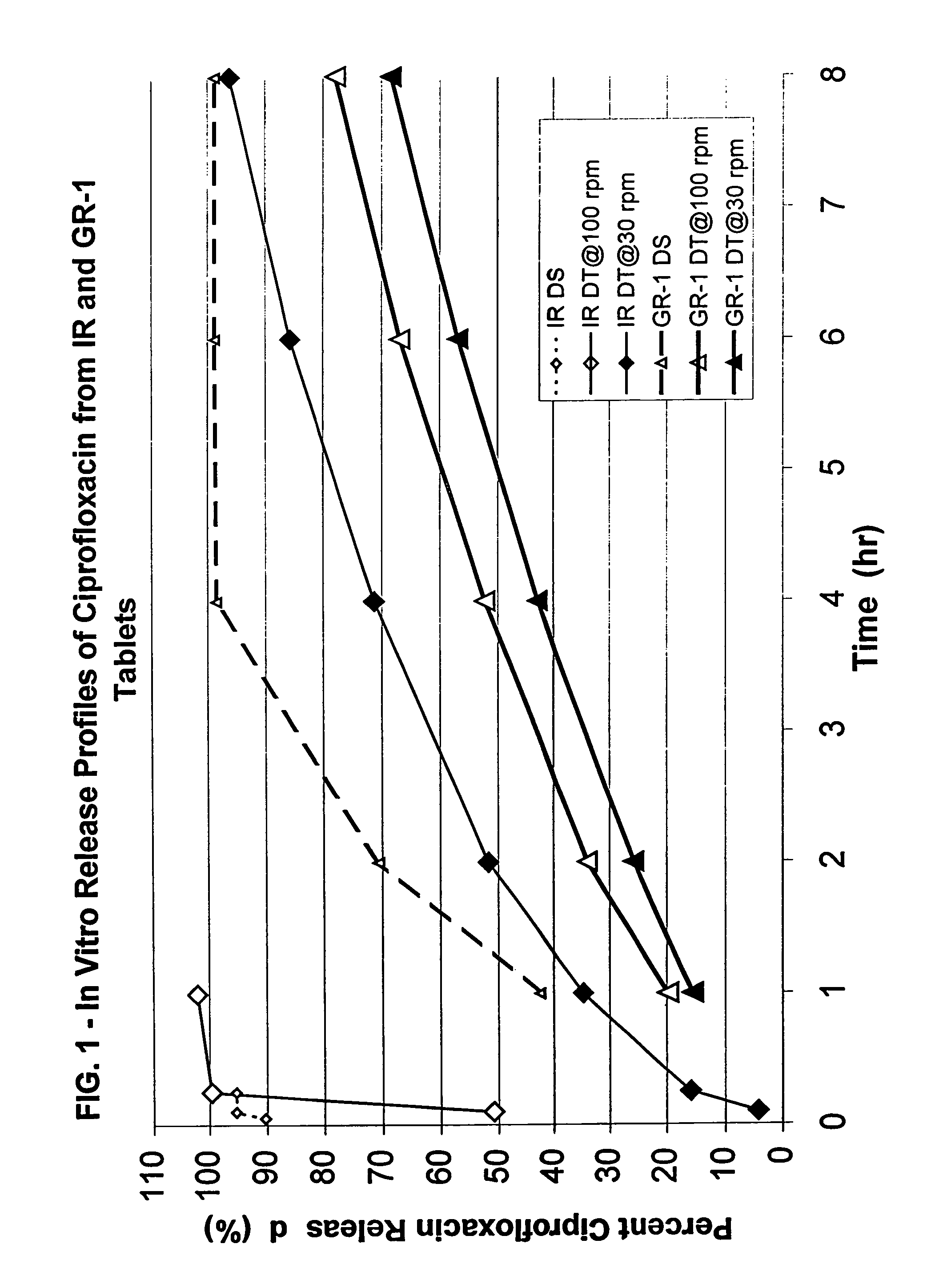

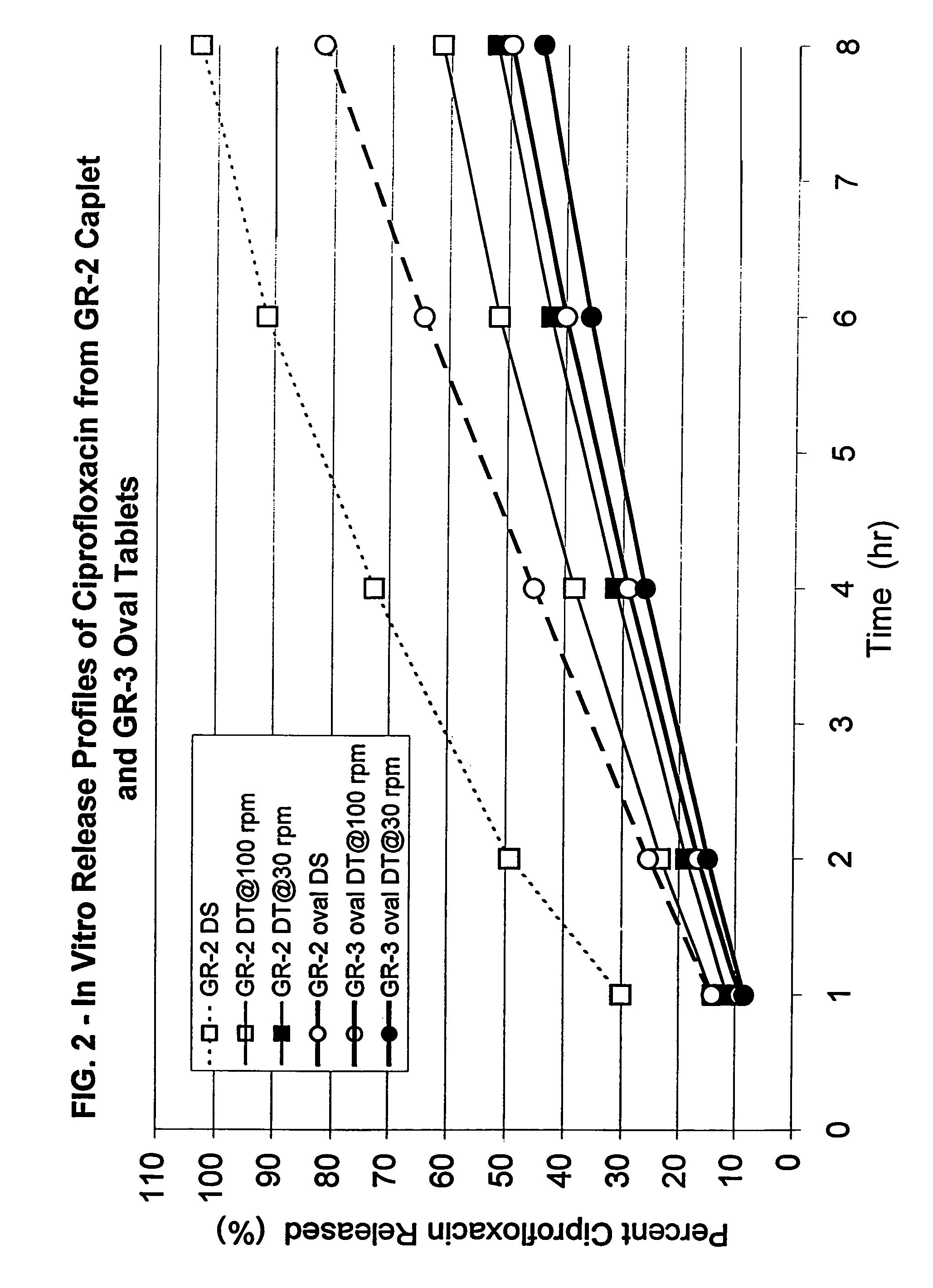

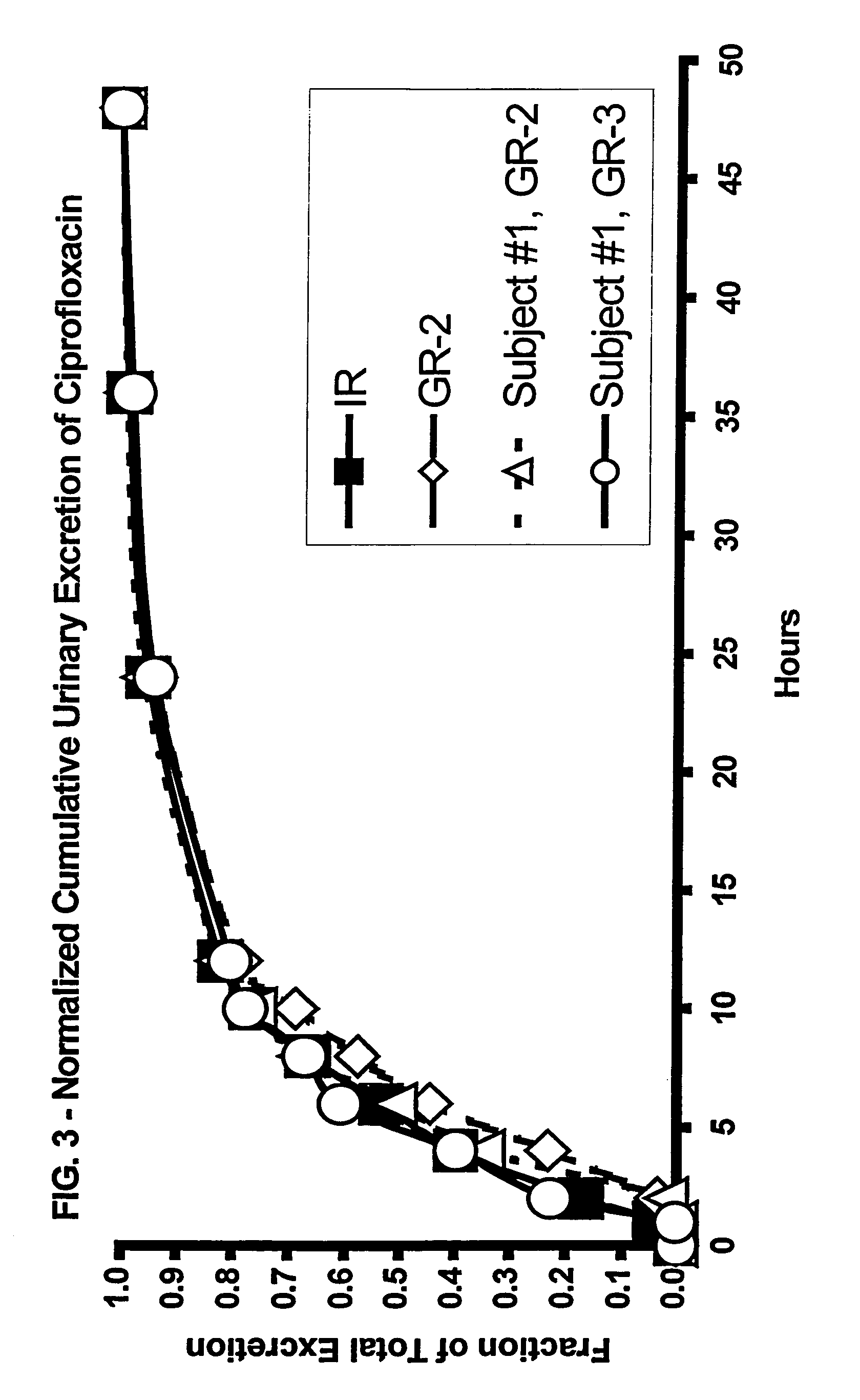

Gastric retentive oral dosage form with restricted drug release in the lower gastrointestinal tract

ActiveUS7976870B2Minimizes variabilityMinimizes deliveryAntibacterial agentsPowder deliveryUpper gastrointestinalActive agent

Controlled release oral dosage forms are provided for the continuous, sustained administration of a pharmacologically active agent to the upper gastrointestinal tract of a patient in whom the fed mode as been induced. The majority of the agent is delivered, on an extended release basis, to the stomach, duodenum and upper regions of the small intestine, with drug delivery in the lower gastrointestinal tract and colon substantially restricted. The dosage form comprises a matrix of a biocompatible, hydrophilic, erodible polymer with an active agent incorporated therein, wherein the polymer is one that both swells in the presence of water and gradually erodes over a time period of hours, with swelling and erosion commencing upon contact with gastric fluid, and drug release rate primarily controlled by erosion rate.

Owner:DEPOMED SYST INC

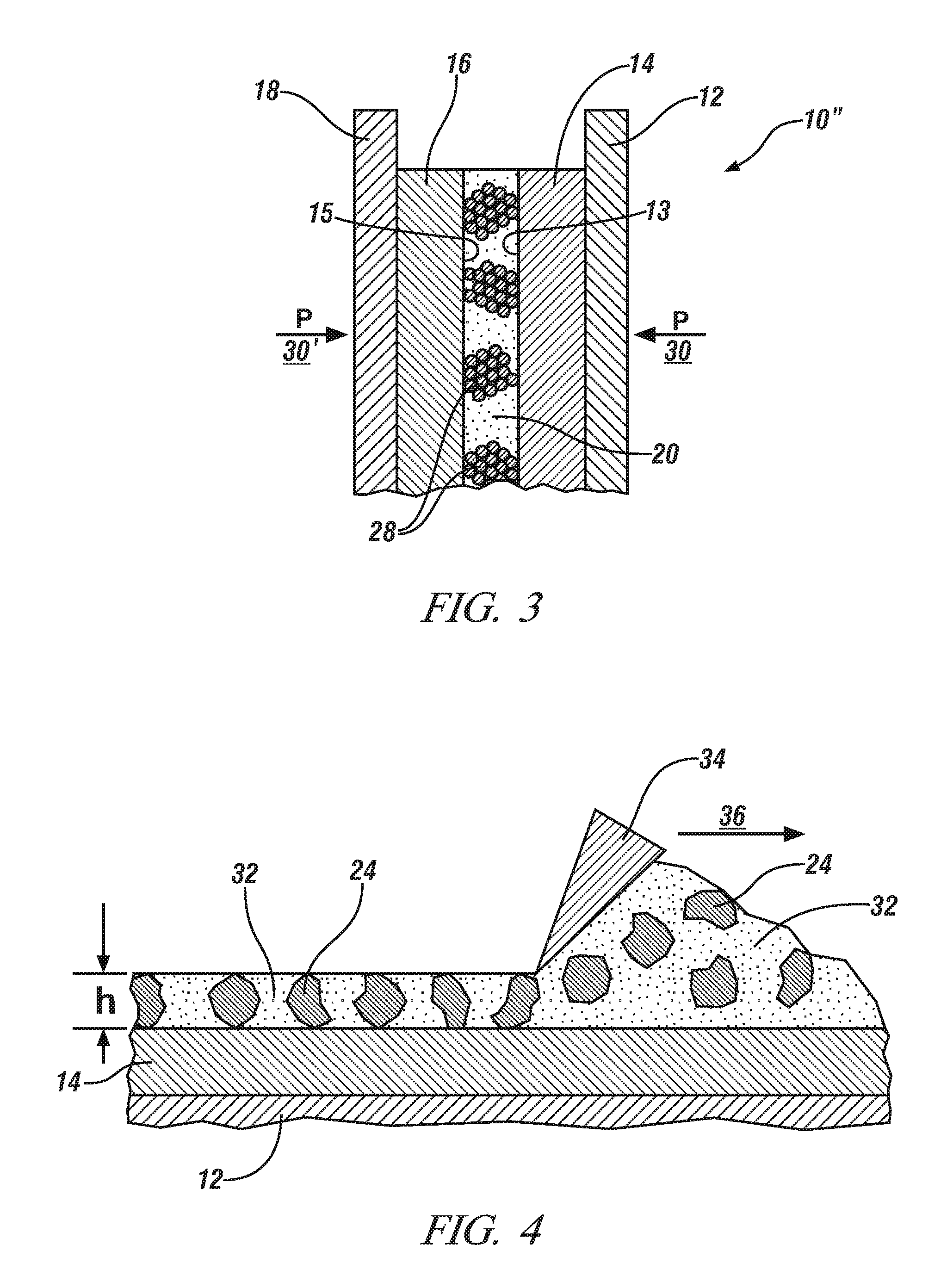

Lithium ion battery with electrolyte-embedded separator particles

InactiveUS20130052509A1Efficient use ofSuitable ionic conductivityFinal product manufacturePrimary cellsLithium-ion batteryViscosity

A lithium ion battery in which electrically-non conducting ceramic particles are interposed between the anode and cathode to enforce separation between them and prevent short circuits is described. The particles, preferably equiaxed or monodisperse, may be generally uniformly dispersed in a non-aqueous gelled or high viscosity electrolyte. The electrolyte may be applied to one or both of the anode and cathode in suitable thickness to deposit the particles with the electrolyte and form a layered composite with substantially uniformly spaced particles suitable for holding the opposing anode and cathode faces in spaced-apart relation. The thickness of the applied electrolyte layer will be selected to enable deposition of the particles substantially as a fractional monolayer, a monolayer, or a multilayer as required for the application.

Owner:GM GLOBAL TECH OPERATIONS LLC

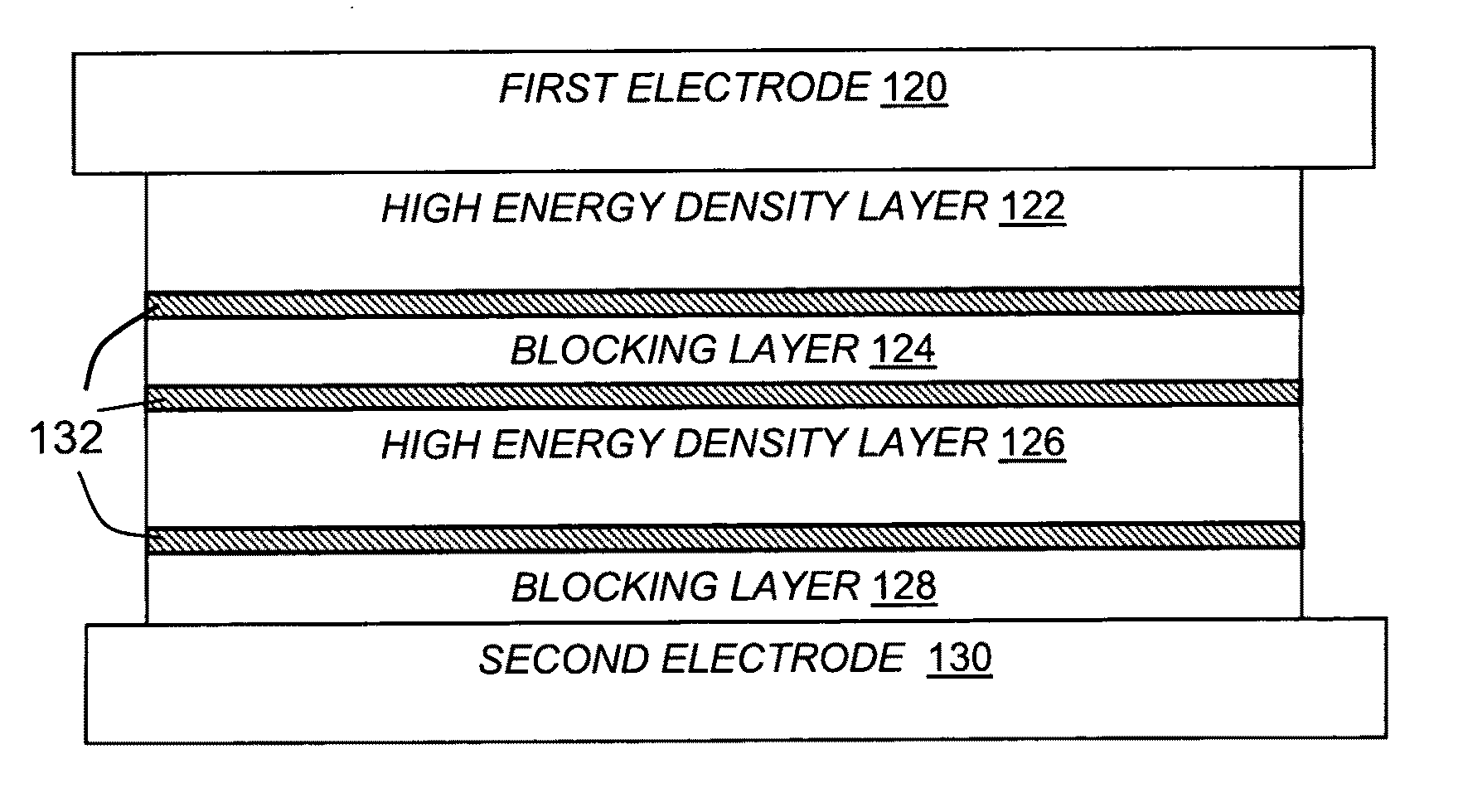

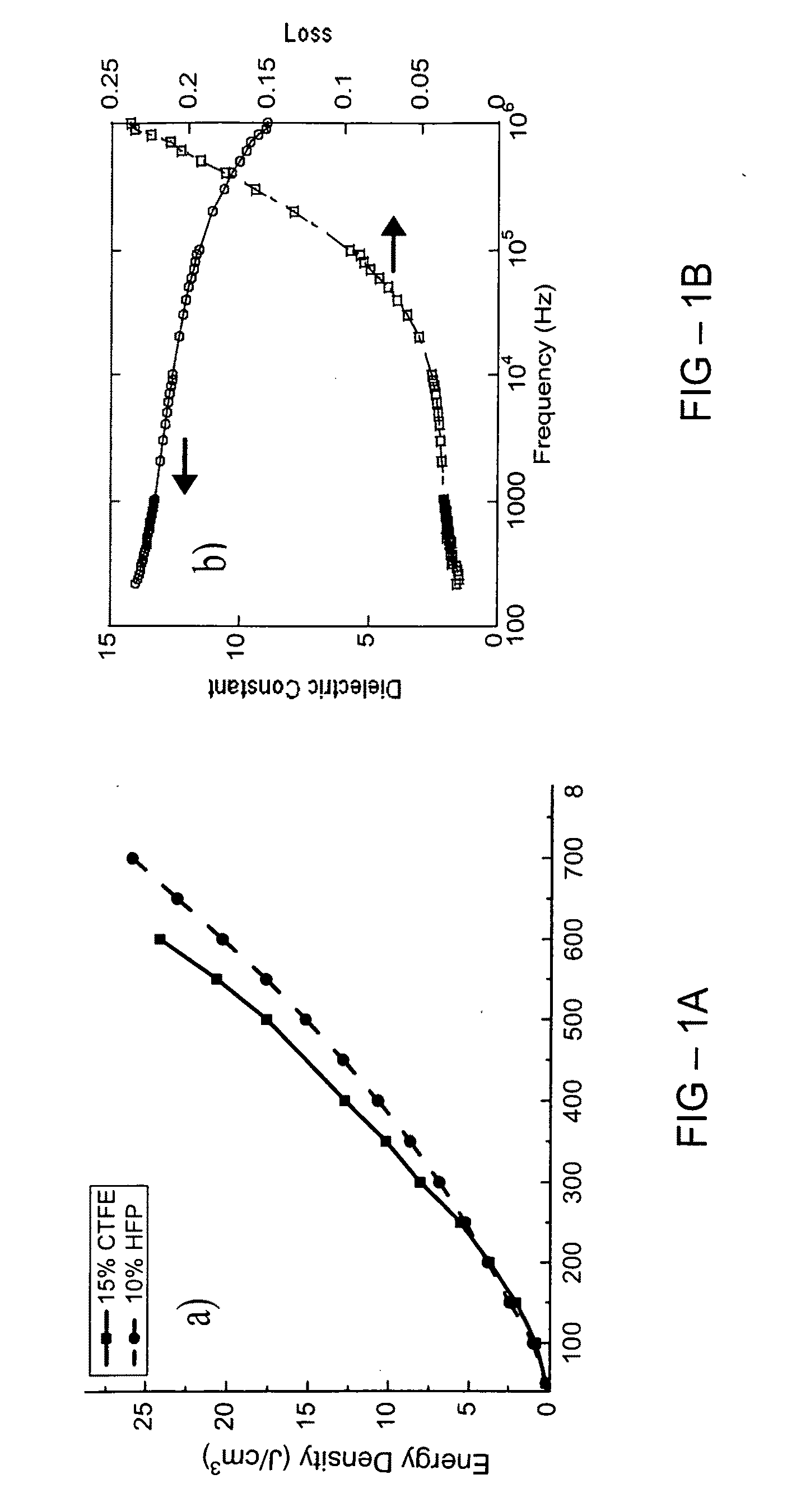

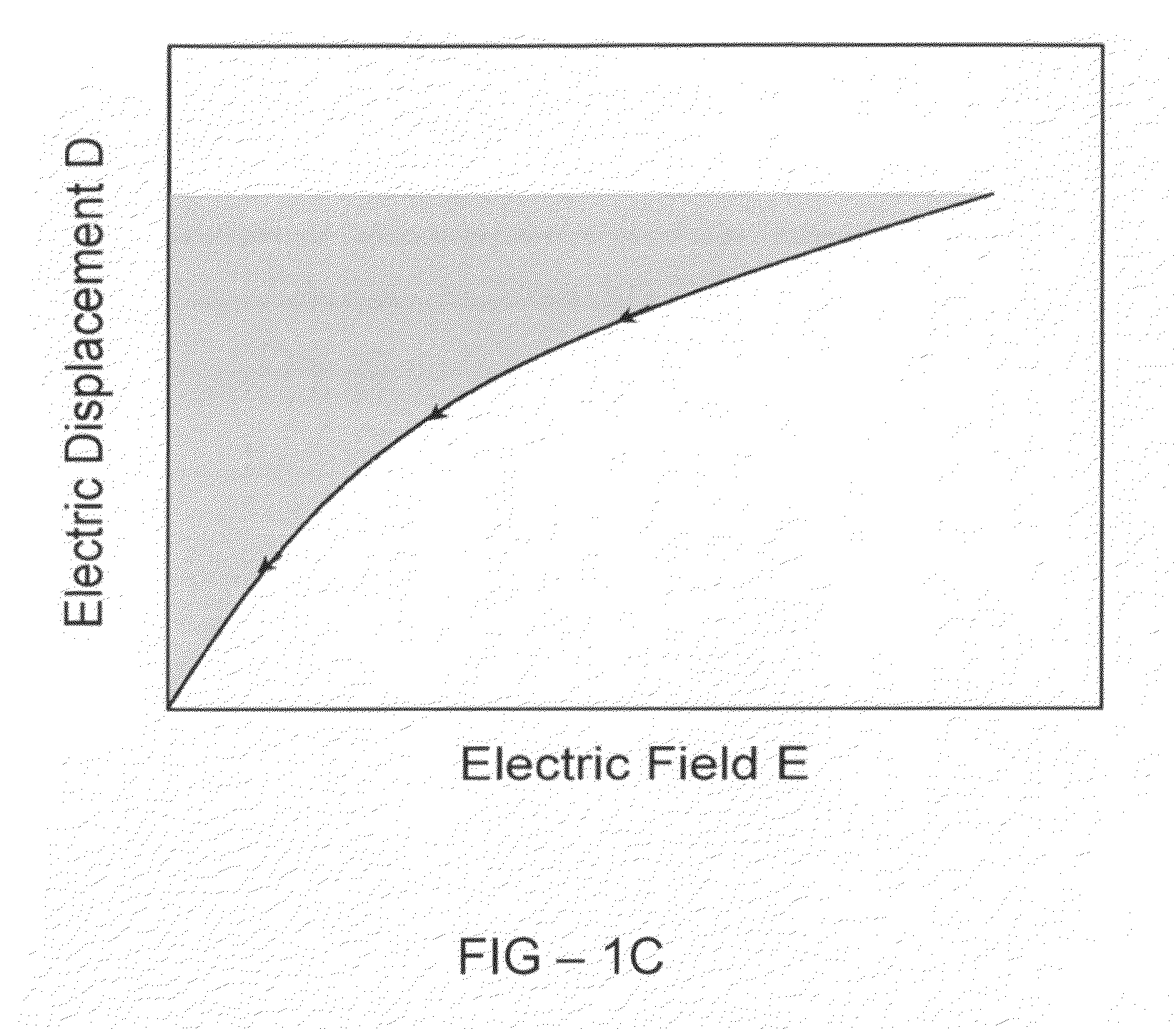

Methods to improve the efficiency and reduce the energy losses in high energy density capacitor films and articles comprising the same

InactiveUS20110110015A1Reduce conduction lossHigh breakdown strengthThin/thick film capacitorFixed capacitor dielectricCapacitanceDielectric loss

A multilayer film useful for capacitive applications comprises a high energy density layer and a dielectric blocking layer. In some embodiments, a conducting film is located between the high energy density layer and the blocking layer. The high energy density layer may be a fluoropolymer, such as a polymer or copolymer of poly-1,1-difluoroethene or a derivative thereof. The multilayer film may have high energy density (for example,. >8 J / cm3) and low dielectric loss, for example less than 2%, and preferably less than 1%.

Owner:PENN STATE RES FOUND

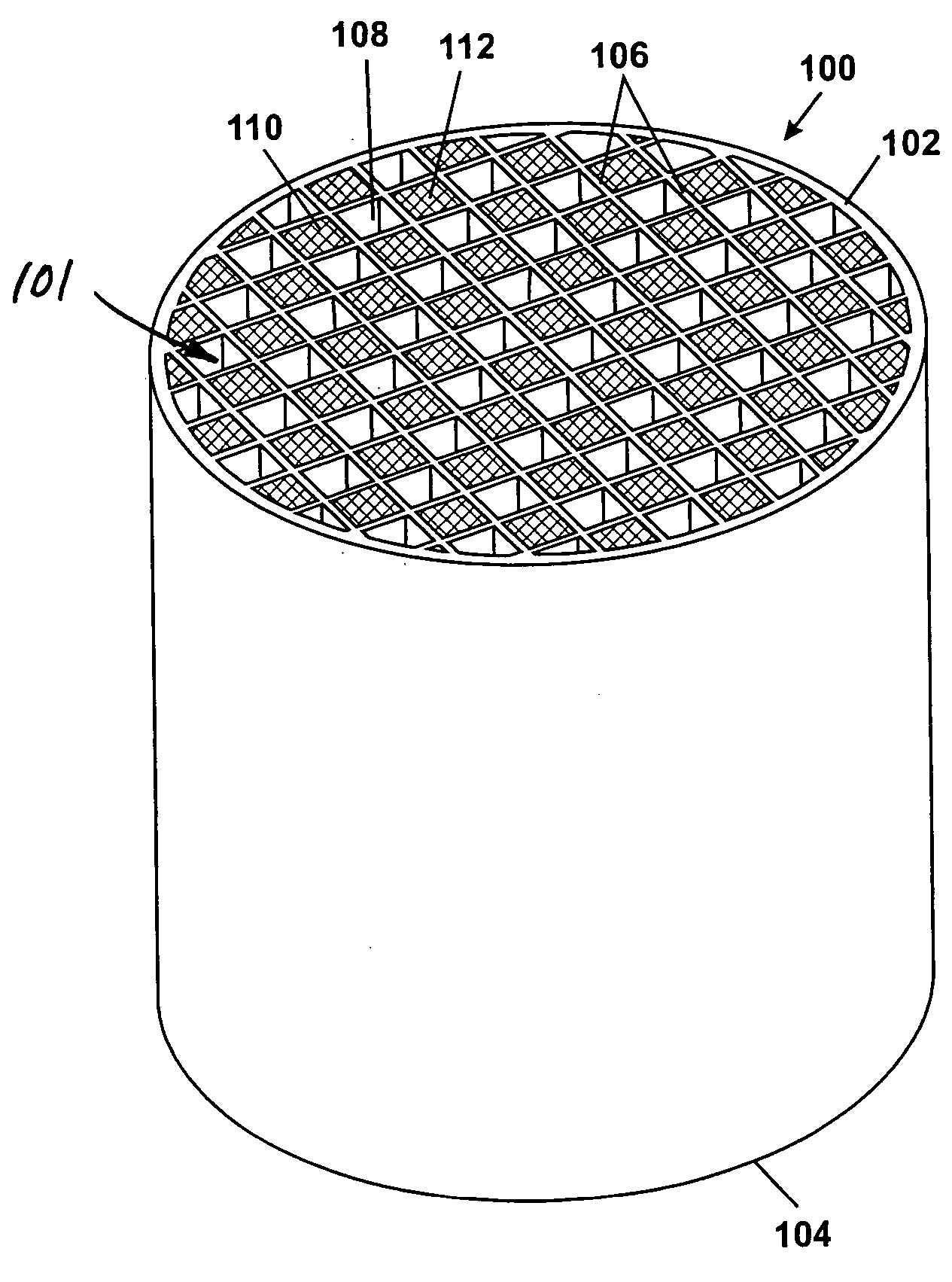

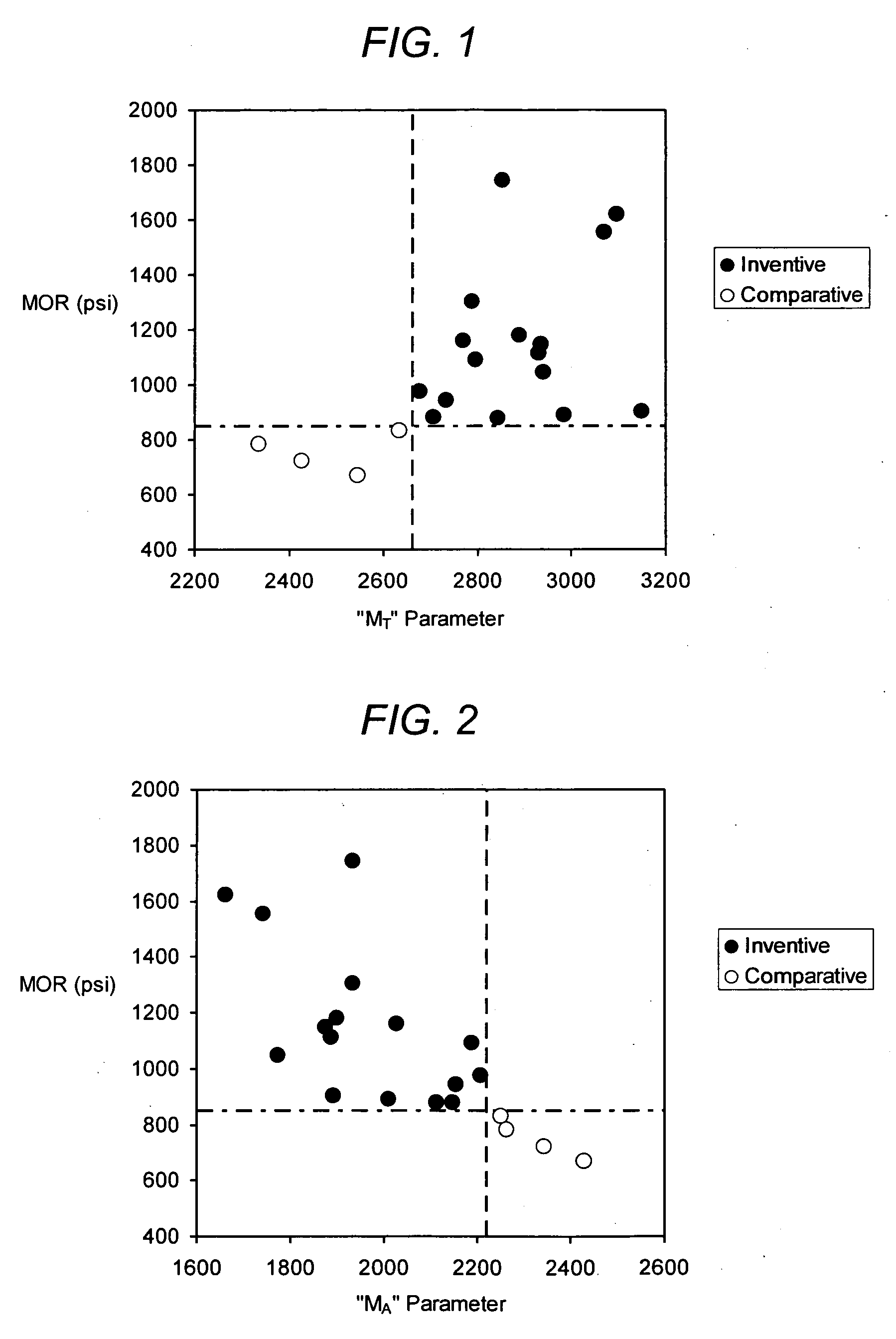

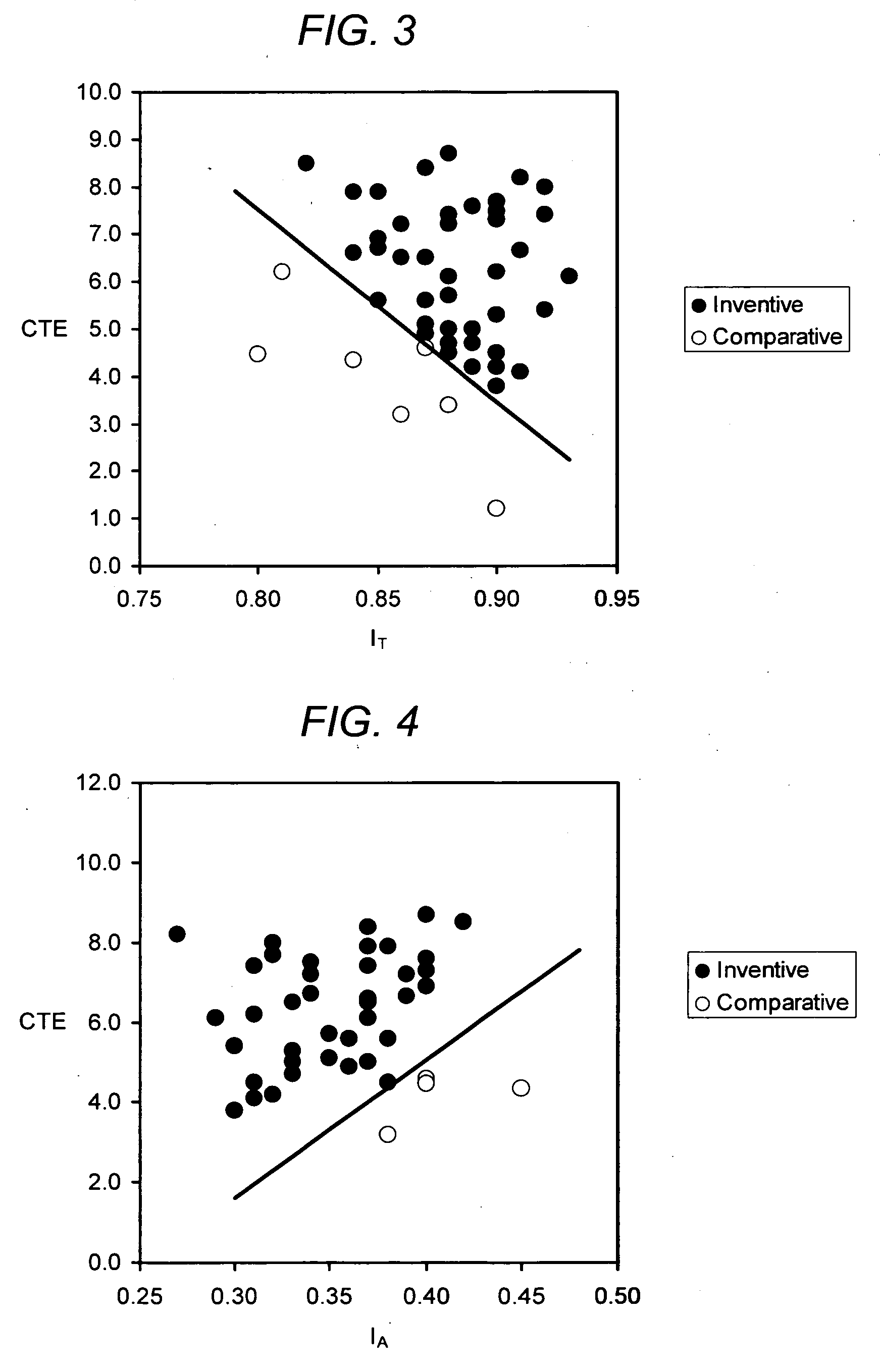

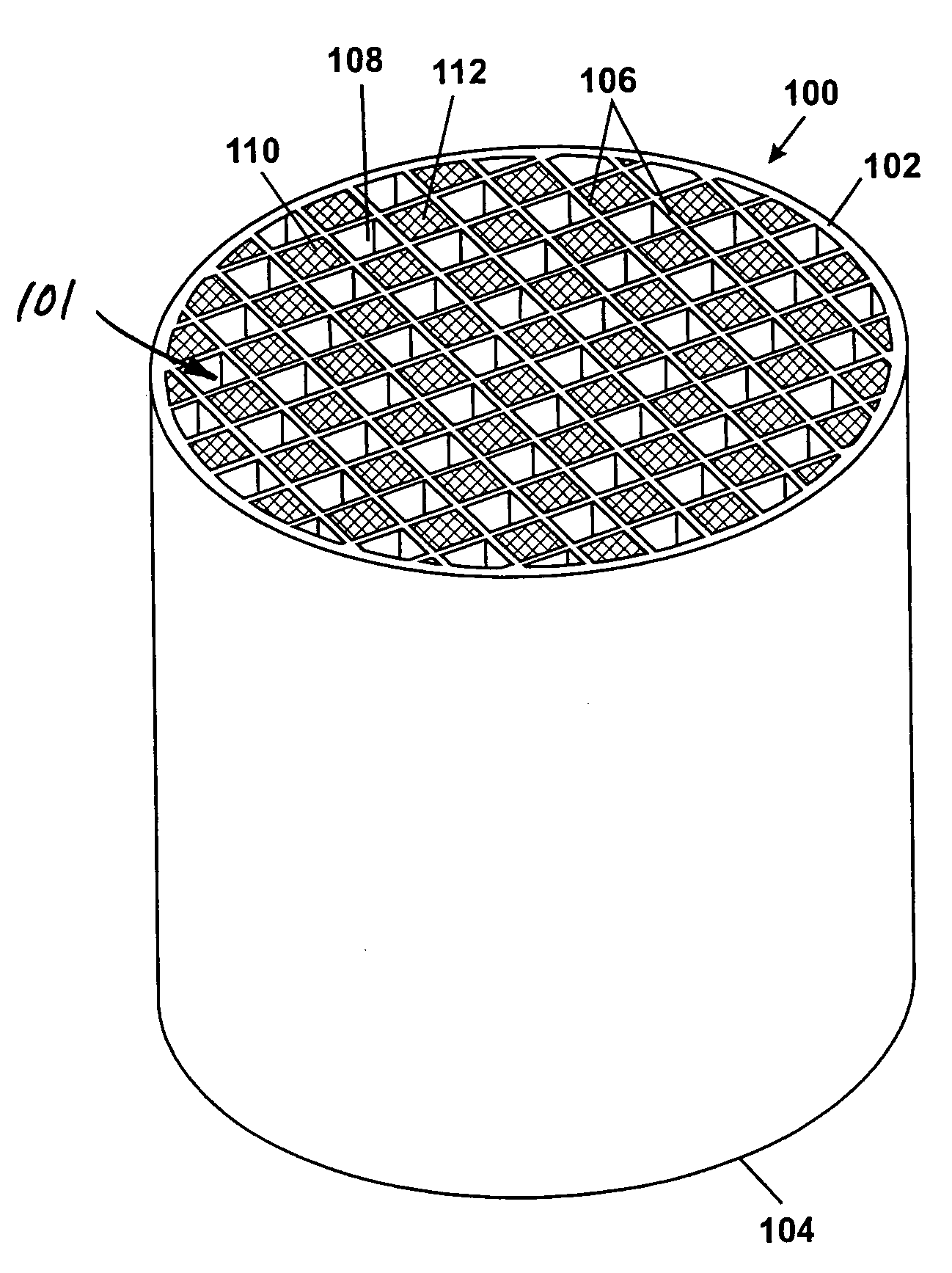

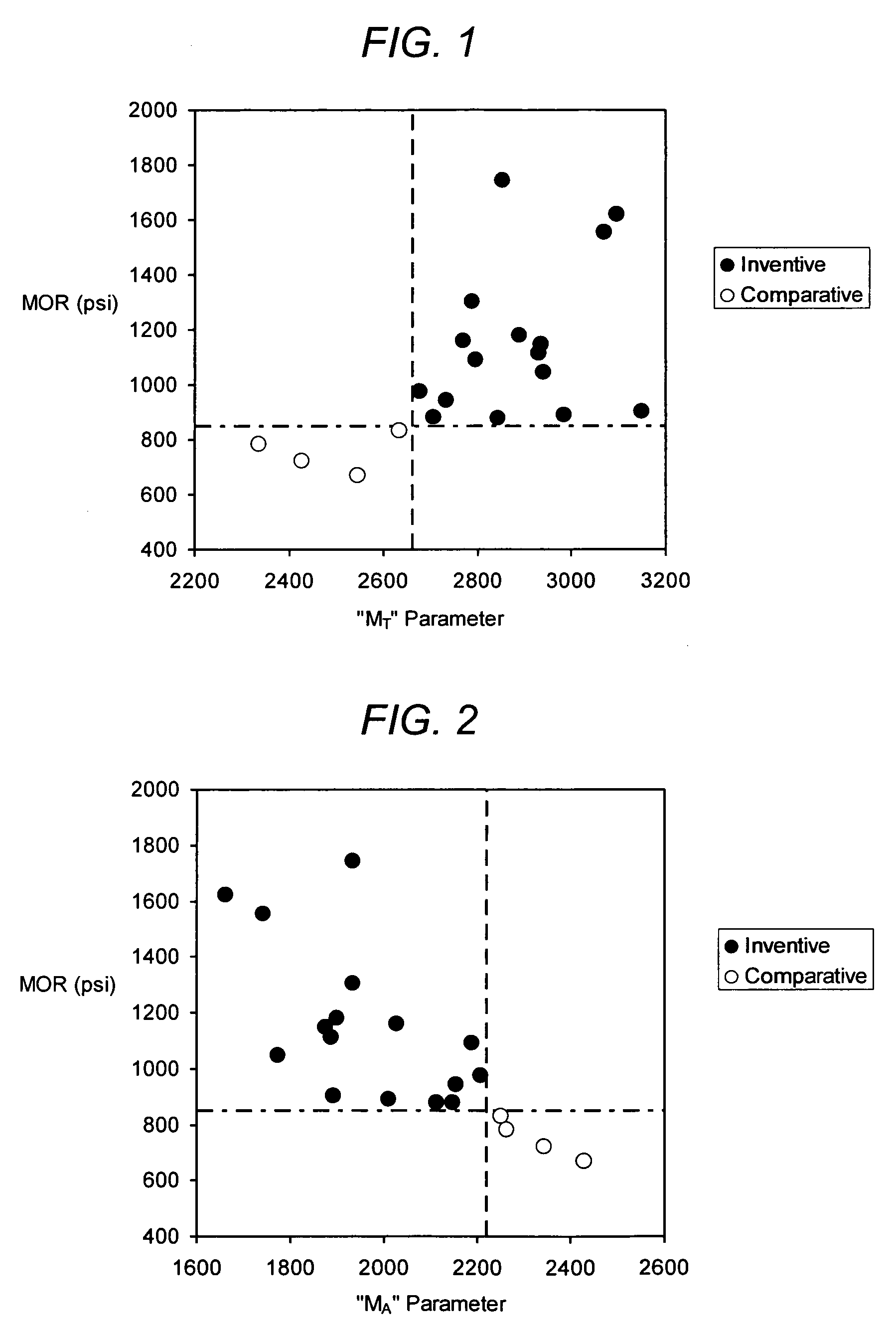

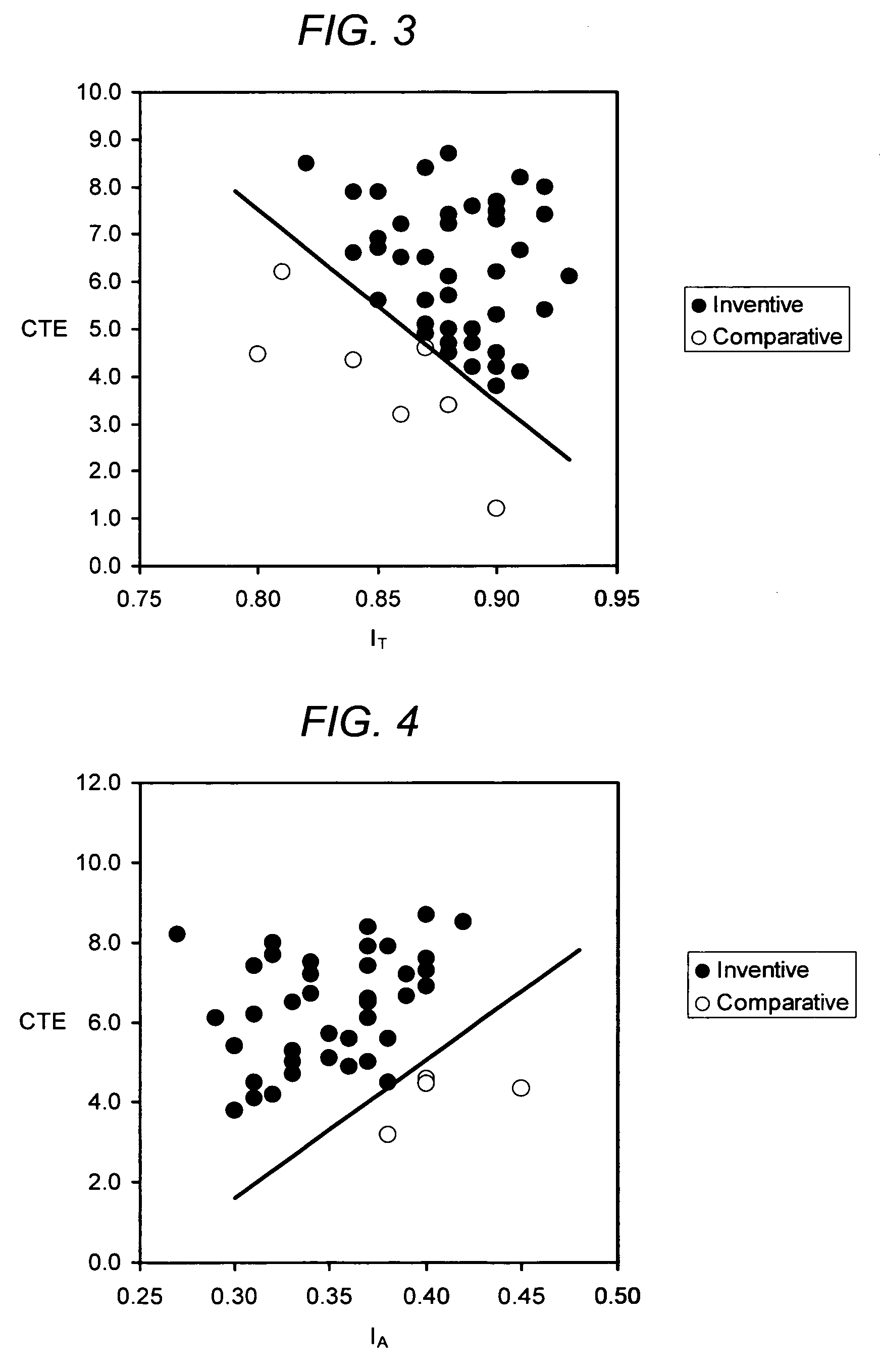

Porous cordierite ceramic honeycomb article with improved strength and method of manufacturing same

ActiveUS20070119133A1Reduce the amount requiredIncrease volume fractionCombination devicesAuxillary pretreatmentCordieritesSilicon dioxide

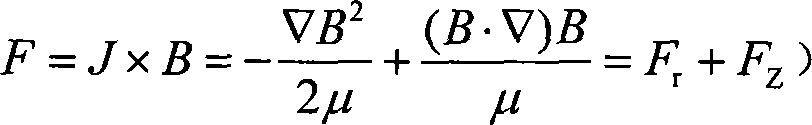

A porous cordierite ceramic honeycomb article with increased mechanical strength and thermal shock resistance. The porous cordierite ceramic honeycomb article has MA<2220, or MT>2660 wherein MA=3645 (IA)−106 (CTE)+19 (d90)+17 (% porosity), MT=4711 (IT)+116 (CTE)−26 (d90)−28 (% porosity), and a CTE≦9×10−7 / ° C. in at least one direction. A method of manufacturing is also disclosed wherein the inorganic raw material mixture contains talc, an alumina-forming source, a silica-forming source, and 0-18 wt. % of a kaolin or calcined kaolin containing not more than 8 wt. % of a fine kaolin source having a median particle diameter of less than 7 μm, wherein the fired porous ceramic cordierite honeycomb article has a porosity<54% . Alternatively, if greater than 8 wt. % of the fine kaolin source is used, then a slow ramp rate is utilized from 1200° C. to 1300° C. of not more than 20° C. / hr.

Owner:CORNING INC

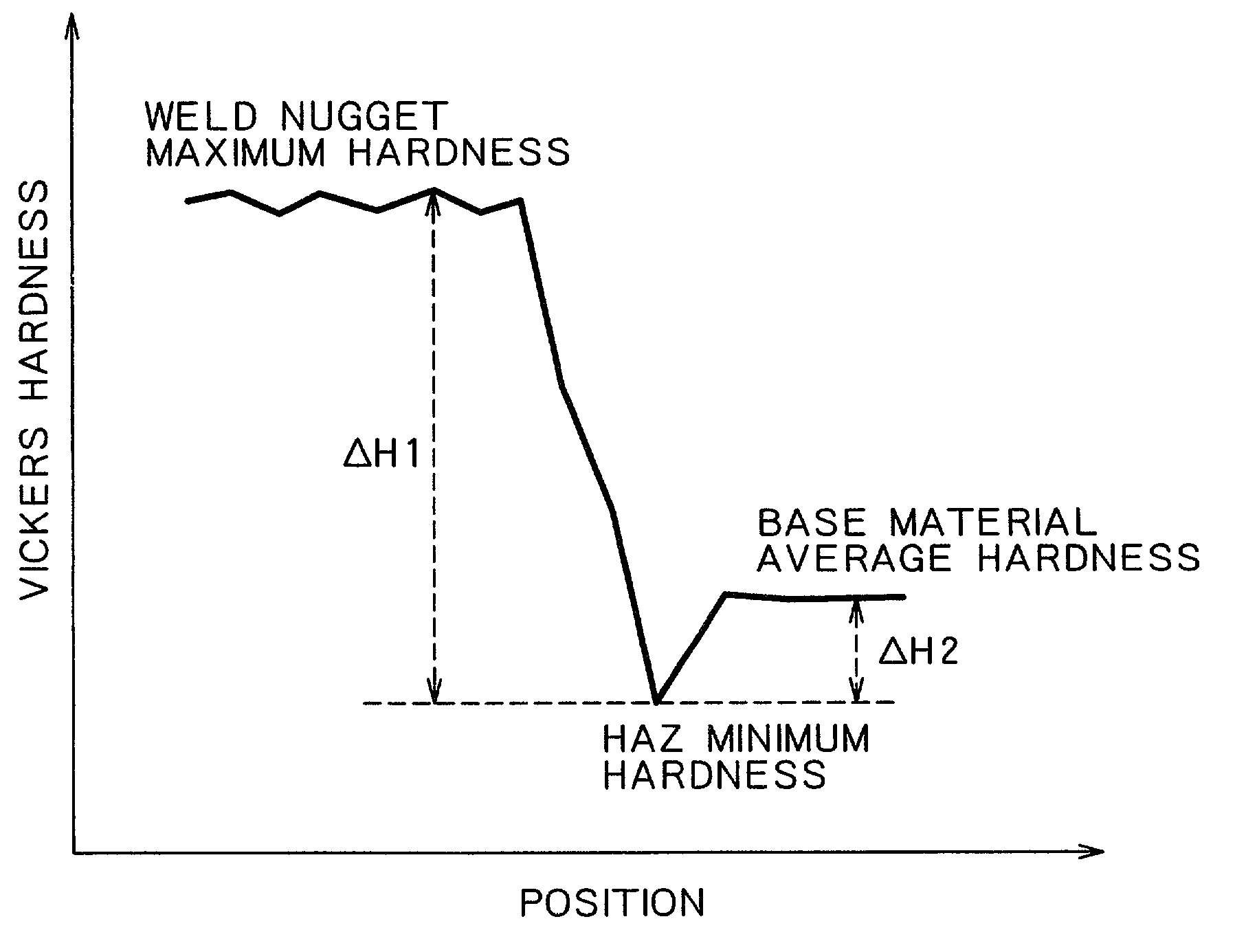

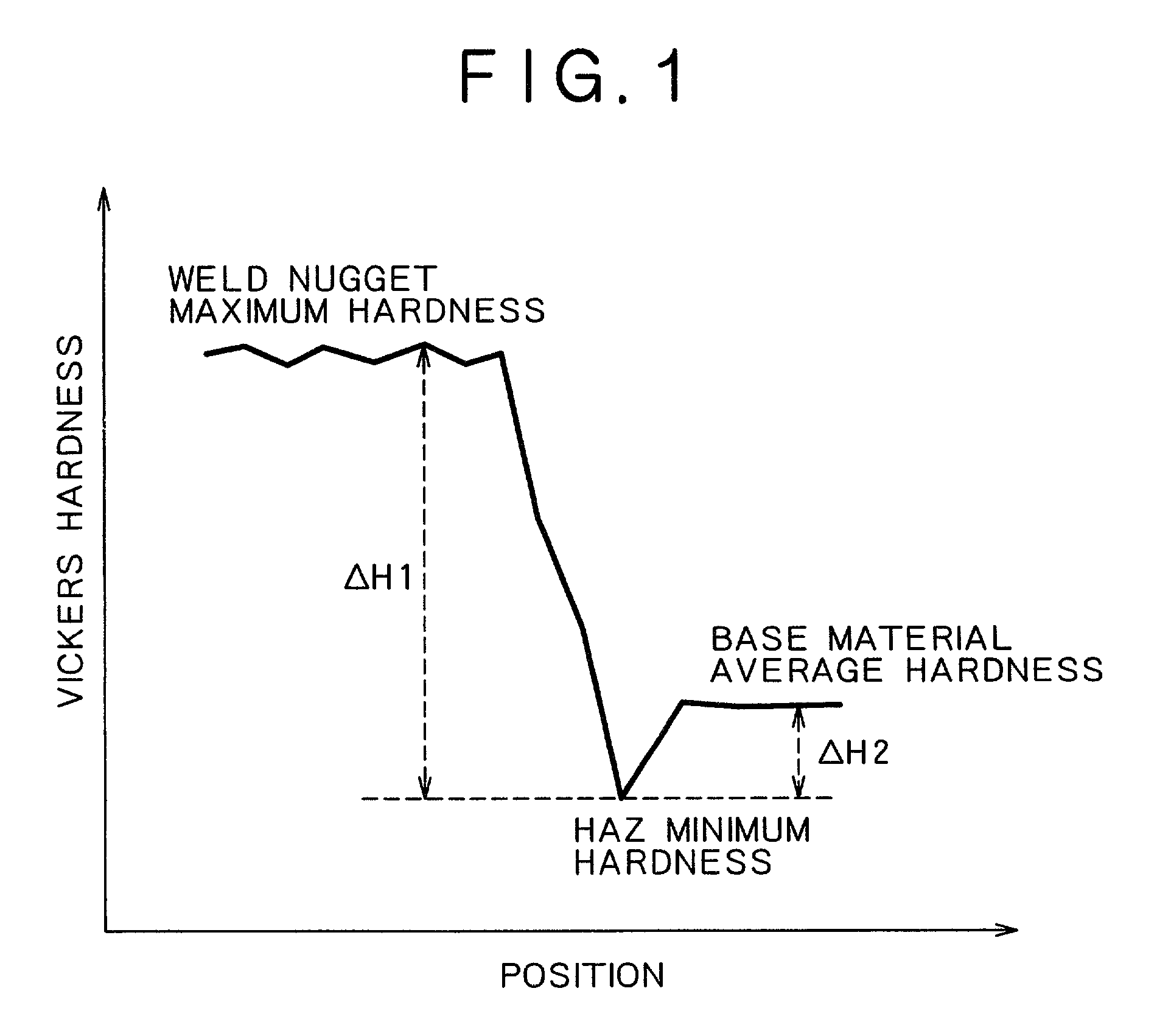

Superhigh-strength dual-phase steel sheet of excellent fatigue characteristic in a spot welded joint

InactiveUS20030221752A1Good effectIncrease volume fractionHot-dipping/immersion processesThin material handlingHardnessUltimate tensile strength

A superhigh-strength dual-phase steel sheet containing ferritic microstructure and a martensitic microstructure-containing composite-phase steel sheet containing: C: 0.08-0.20% (mass % here and hereinafter), Si: 0.5% or less (inclusive of 0%) Mn: 3.0% or less (exclusive of 0%) P: 0.02% or less (inclusive of 0%) S: 0.02% or less (inclusive of 0%), and Al: 0.001-0.15%, and further containing Mo: 0.05-1.5%, and Cr: 0.05-1.5%, and which satisfying that: the average Vickers hardness of the ferritic microstructure is 150 Hv or more and the average Vickers hardness of the martensitic microstructure is 500 Hv or more, the superhigh-strength dual-phase steel sheets being of excellent fatigue characteristic in a spot welded joint.

Owner:KOBE STEEL LTD

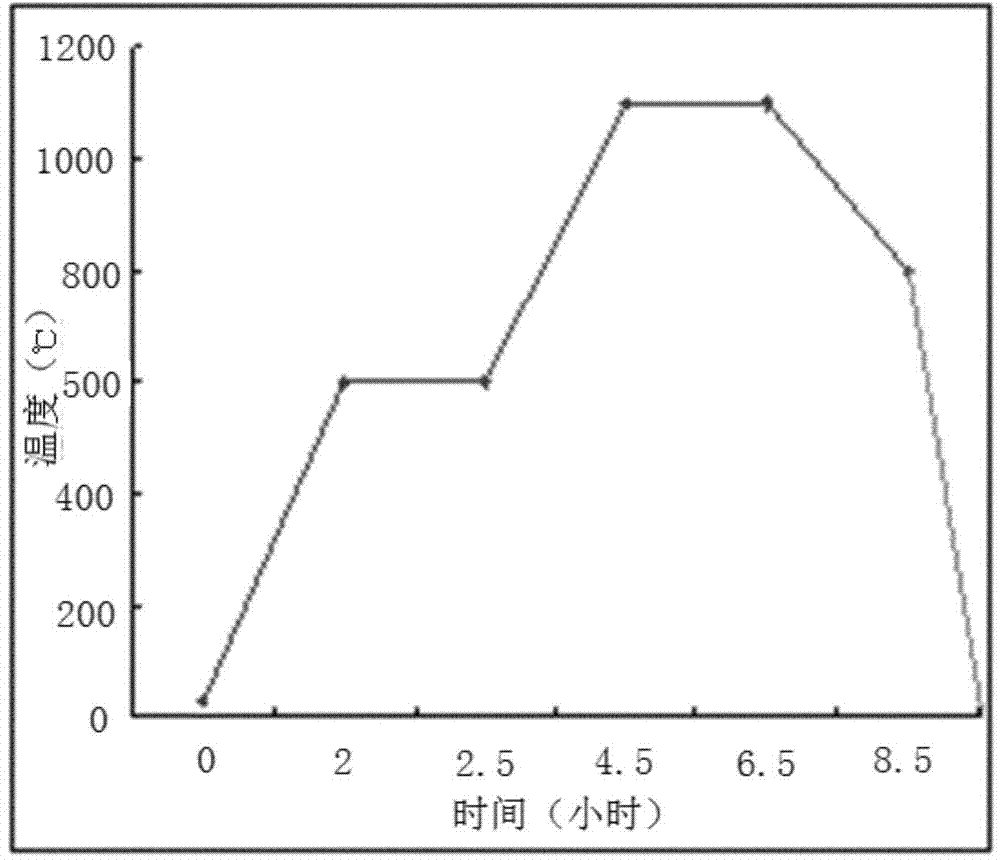

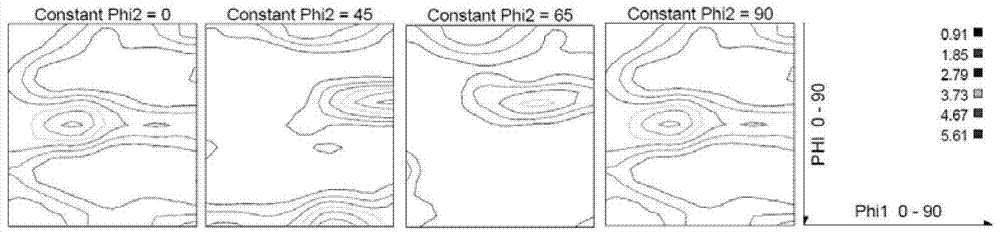

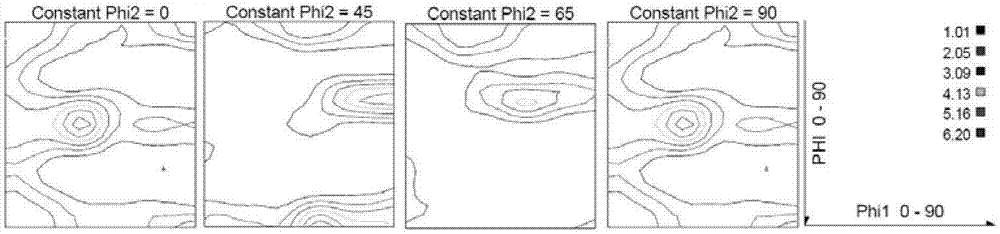

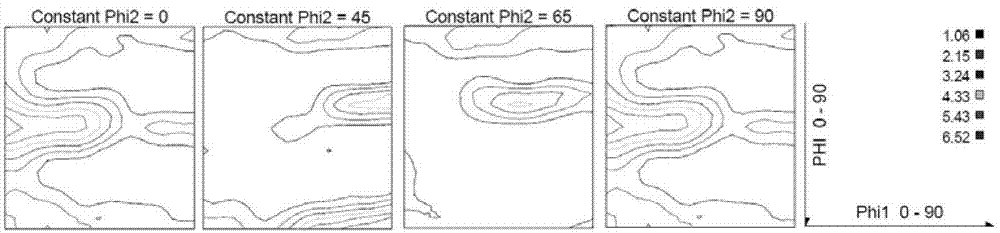

Method for Manufacturing Grain-Oriented Electrical Steel Sheets Having Excellent Magnetic Properties

ActiveUS20130306202A1High magnetic flux densityLow core lossFurnace typesHeat treatment furnacesSheet steelElectrical steel

Provided is a method for manufacturing a grain-oriented electrical steel sheet, the method comprising: heating a grain-oriented electrical steel sheet slab; hot-rolling the heated slab; optionally annealing the hot-rolled steel sheet; subjecting the resulting steel sheet to one cold rolling or two or more cold rollings with intermediate annealing therebetween; subjecting the cold-rolled steel sheet to primary recrystallization annealing; and subjecting the annealed steel sheet to secondary recrystallization annealing, wherein the primary recrystallization annealing sequentially comprises an ultra-rapid heating process of heating the steel sheet at an average heating rate of 300° C. / sec or higher, a rapid heating process of heating the steel sheet at a lower average heating rate than the average heating rate of the ultra-rapid heating process, but not lower than 100° C. / sec, and a general heating process of heating the steel sheet at a lower average heating rate than the average heating rate of the rapid heating process.

Owner:POHANG IRON & STEEL CO LTD

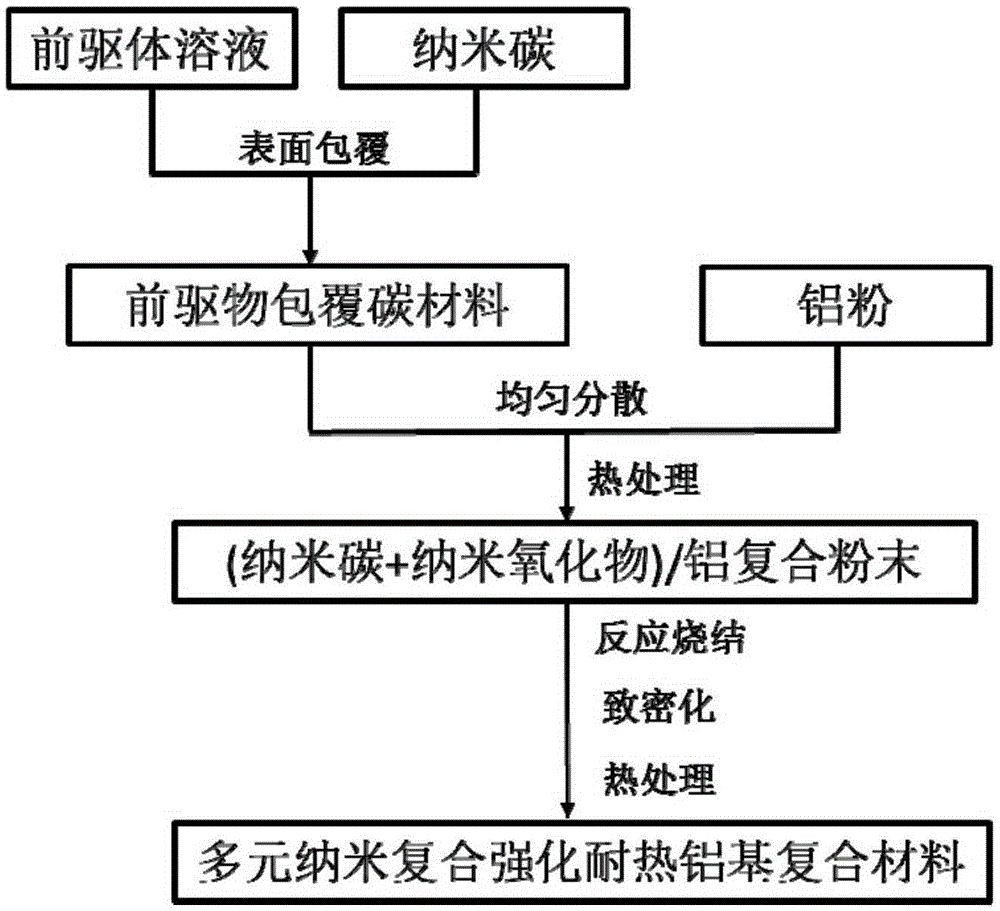

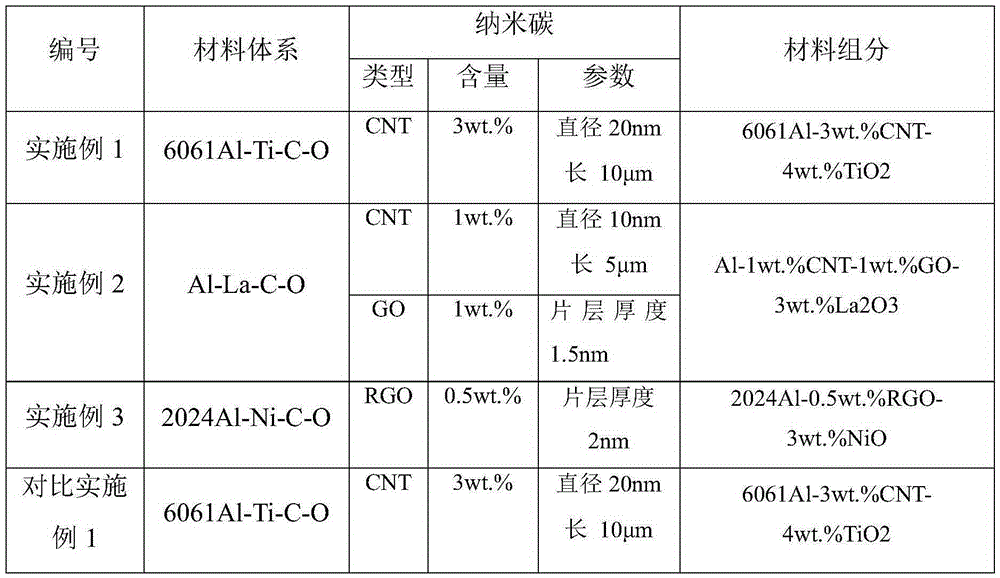

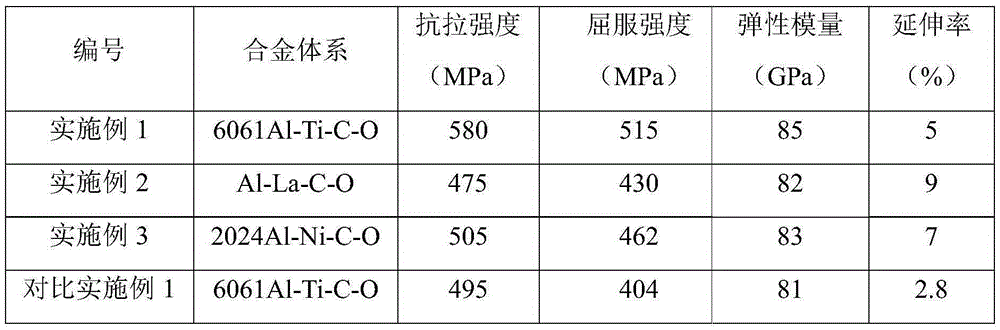

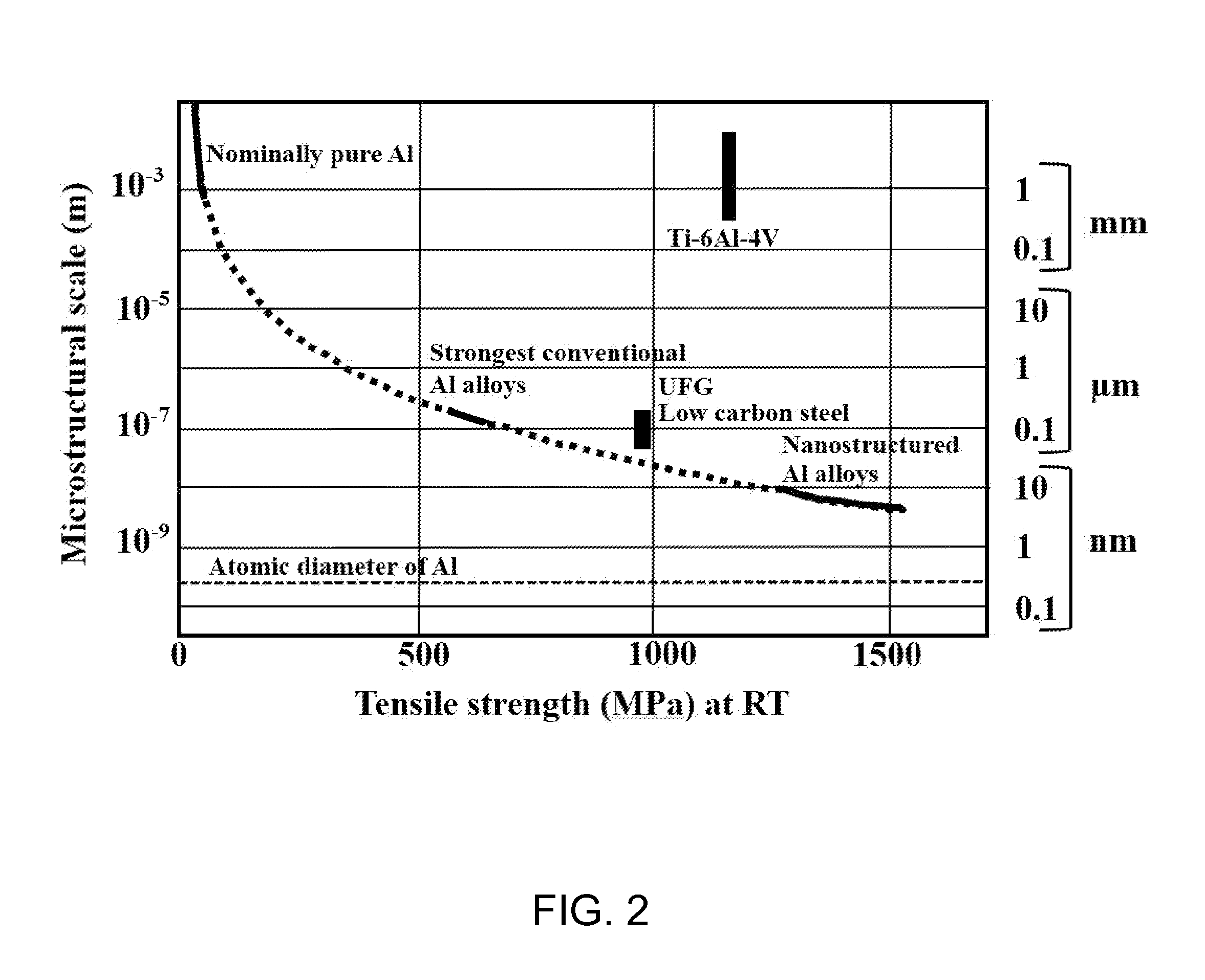

Preparing method of multielement nanometer composite strengthening thermal-resisting aluminum matrix composite

The invention provides a preparing method of a multielement nanometer composite strengthening thermal-resisting aluminum matrix composite. The surface of nanocarbon is coated with a metal ion precursor in advance, the nanocarbon is evenly scattered in aluminum powder, the precursor is converted into oxide through thermal treatment, reactive sintering and densifying treatment are carried out on the obtained composite powder, and the multielement nanometer strengthening aluminum matrix composite is obtained. The nanocarbon has the high specific surface area, the feature size of the nanocarbon is far larger than that of the nanometer oxide, and therefore a proper amount of nanometer oxide can be loaded and evenly led into the aluminum powder, metallic oxide, carbide, an intermetallic compound and other multielement nanometer strengthening phases are generated through the in-situ reaction, and the tissue stability and the thermal resistance of the aluminum matrix composite are improved coordinately. The method achieves the purposes of even leading of high-volume-content multielement nanometer strengthening phases and the space occupation control, and the conventional powder metallurgy technology can be adopted for preparing the multielement nanometer composite strengthening thermal-resisting aluminum matrix composite.

Owner:SHANGHAI JIAO TONG UNIV

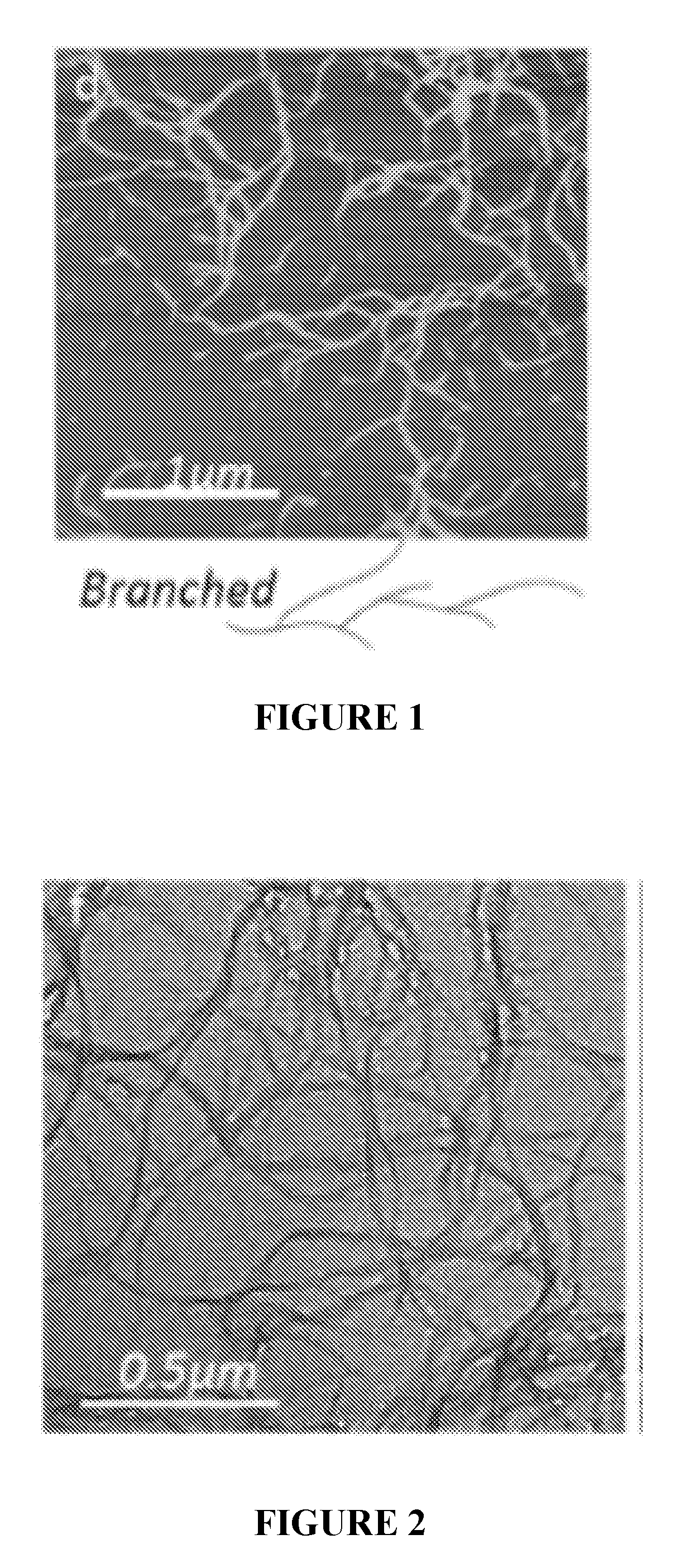

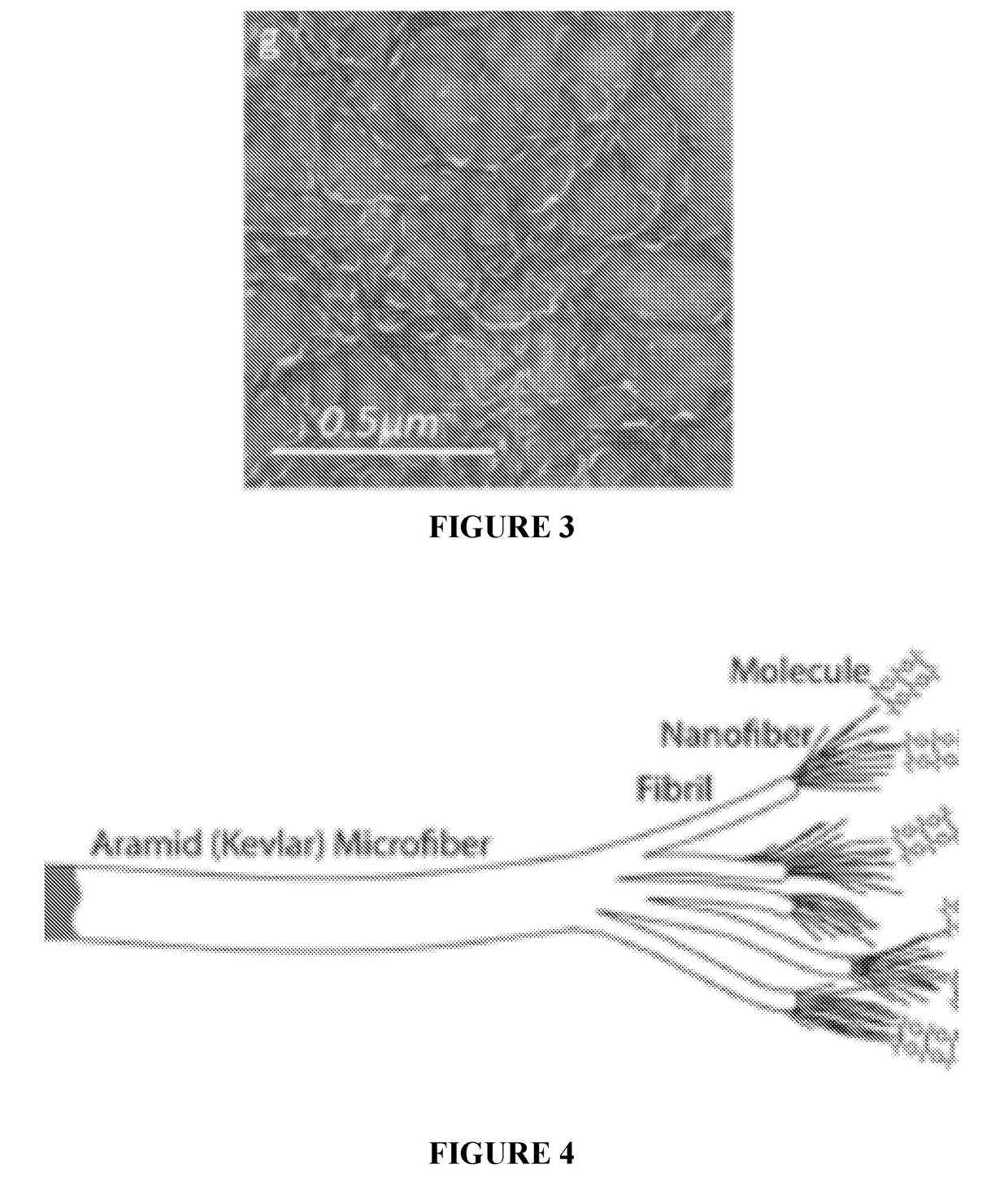

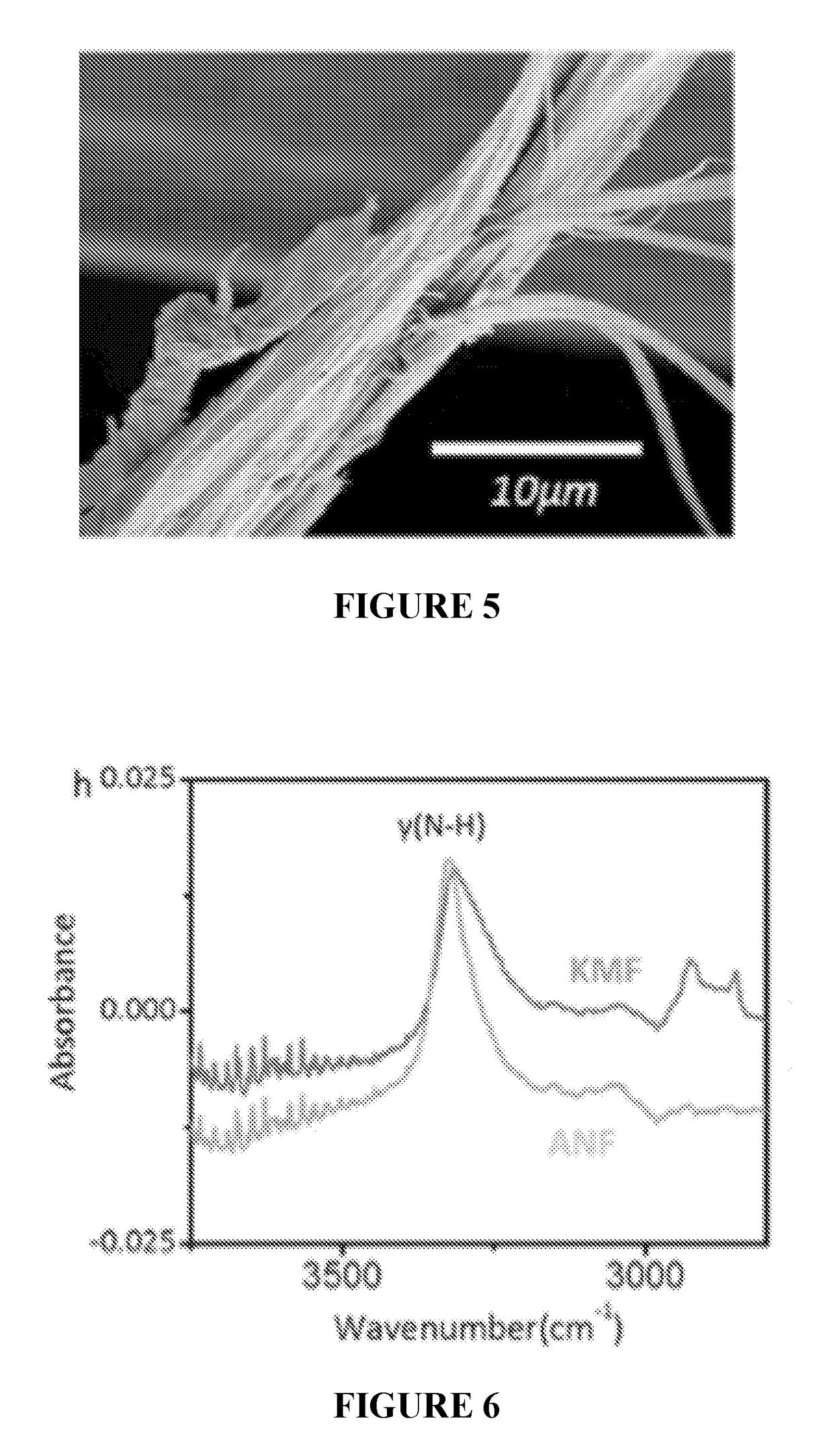

Gels and nanocomposites containing anfs

ActiveUS20190085139A1Easy to assembleIncrease rangeSpecific nanostructure formationMaterial nanotechnologyAramidMechanical property

Branched aramid nanofibers (ANFs) can be made by controlled chemical splitting of micro and macroscale aramid fiber by adjusting the reaction media containing aprotic component, protic component and a base. Branched ANFs have uniform size distribution of diameters in the nanoscale regime (below 200 nm) and high yield exceeding 95% of the nanofibers with this diameter. The method affords preparation of branched ANFs with 3-20 branches per one nanofiber and high aspect ratio. Branched ANFs form hydrogel or aerogels with highly porous 3D percolating networks (3DPNs) frameworks that are made into different shapes. Polymers and nanomaterials are impregnated into the 3DPNs through several methods. Gelation of branched ANFs facilitates layer-by-layer deposition in a process described as gelation assisted layer-by-layer deposition (gaLBL). A method of manufacturing battery components including ion conducting membranes, separators, anodes, and cathodes is described. The method of manufacturing of materials with high mechanical performance based on branched ANFs and 3DPNs from them is disclosed.

Owner:RGT UNIV OF MICHIGAN

Preparation method of high-volume-fraction diamond/aluminum composite material with heat conduction function

The invention belongs to the technical field of preparation of composite materials, and relates to a preparation method of a high-volume-fraction diamond / aluminum composite material with heat conduction function. The diamond / aluminum alloy interface binding performance is improved by metallizing the diamond grain salt bath coated surface, using gel injection molding prefabricated body technique by adding high-temperature aluminum phosphate adhesive, improving the constituent of aluminum alloy and other means. The composite material is prepared by a non-pressure impregnation technique which has the advantages of low cost and is simple to operate and implement. The diamond / aluminum composite material has uniform and compact microstructure, and has favorable diamond / aluminum alloy interface binding performance; and the density is 3.17g / cm<3>, the heat conductivity is up to 518W / m.K, the thermal expansion coefficient is only 4.61*10<-6> / K, the bending strength is 306Mpa, and the Young's modulus is 280GPa. The invention completely satisfies the requirements of superhigh heat conductivity, low density and low thermal expansion coefficient for the high-density electronic packaging material.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

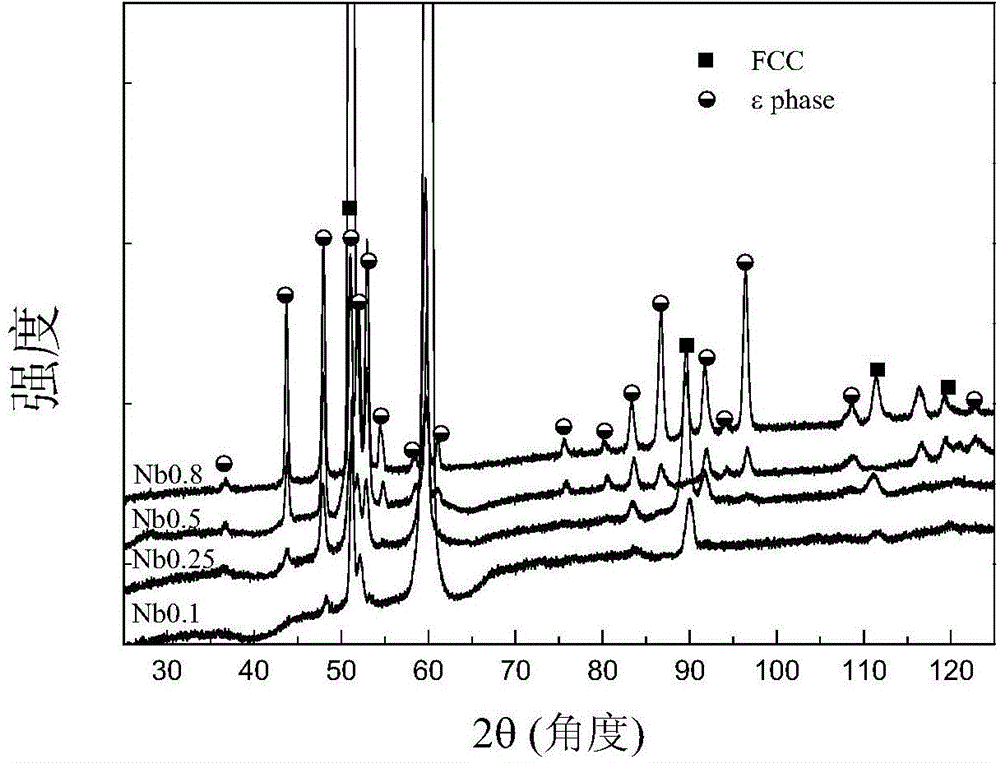

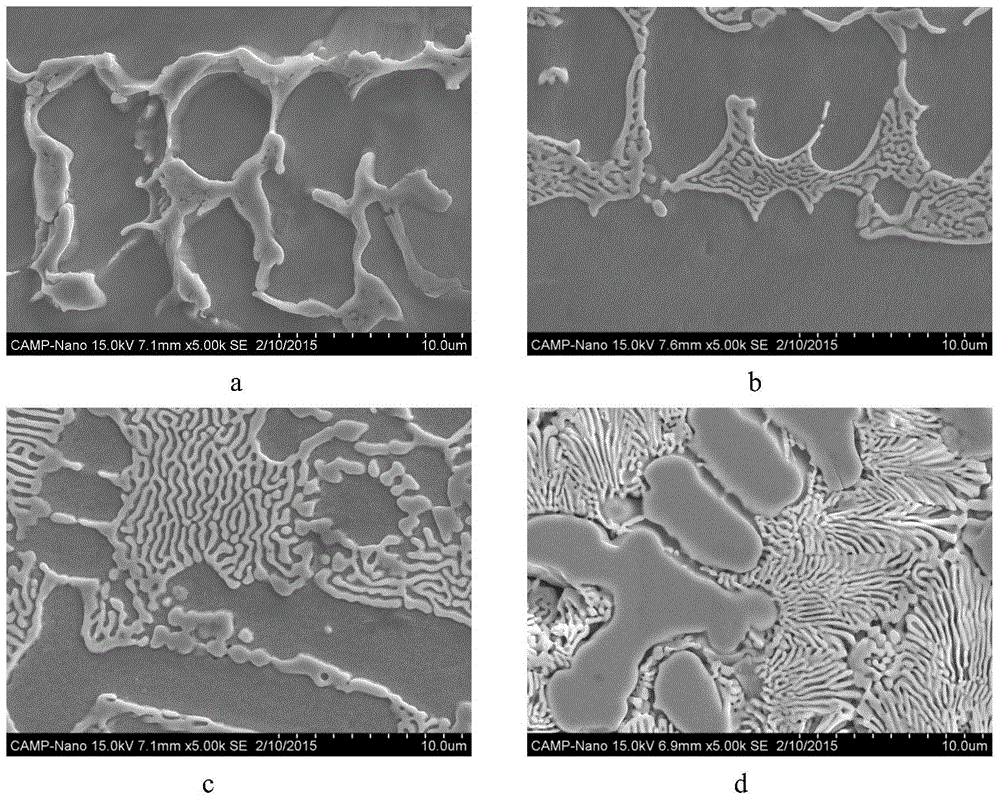

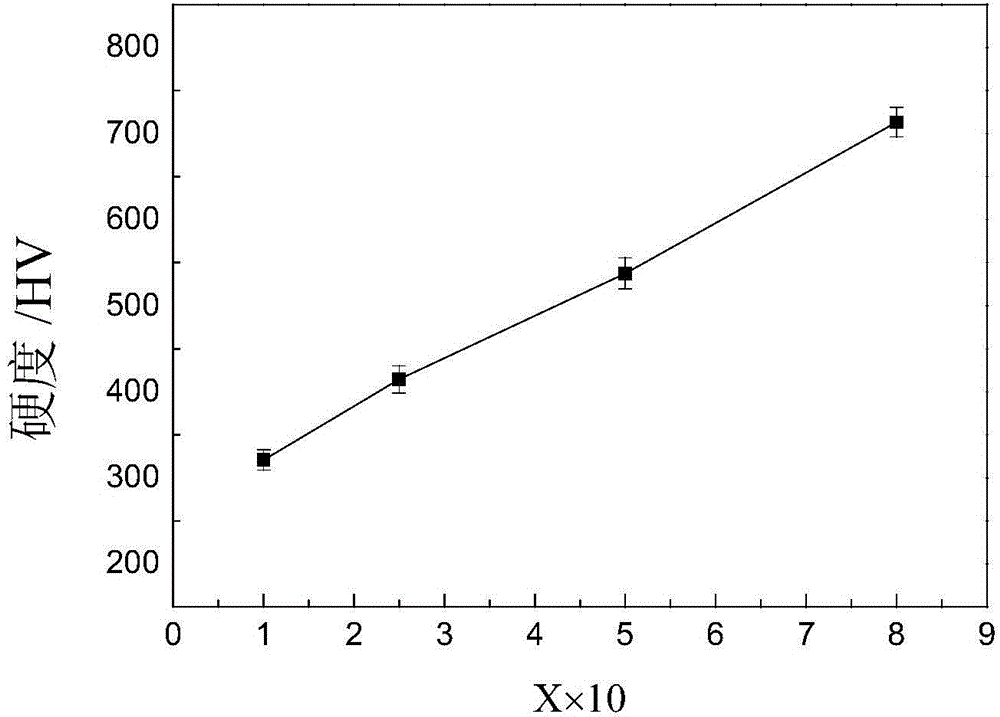

CrFeCoNiNbx high-entropy alloy and preparation method thereof

The invention discloses a CrFeCoNiNbx high-entropy alloy and a preparation method thereof. The CrFeCoNiNbx high-entropy alloy comprises Cr, Fe, Co, Ni and Nb, wherein x ranges from 0.1 to 0.8; the content of Nb is 2.4%-16.7%; Cr, Fe, Co, and Ni are equal in content; and the proportion is mole percentage. An Nb element is added to a Cr-Fe-Co-Ni quaternary alloy, a precipitated phase is formed in single FCC (face-centered cubic) solid solution phase, precipitation strengthening is performed, and the high-entropy alloy has a face-centered cubic structure, high hardness, high strength, good compression plasticity and better mechanical properties.

Owner:东莞市三航军民融合创新研究院

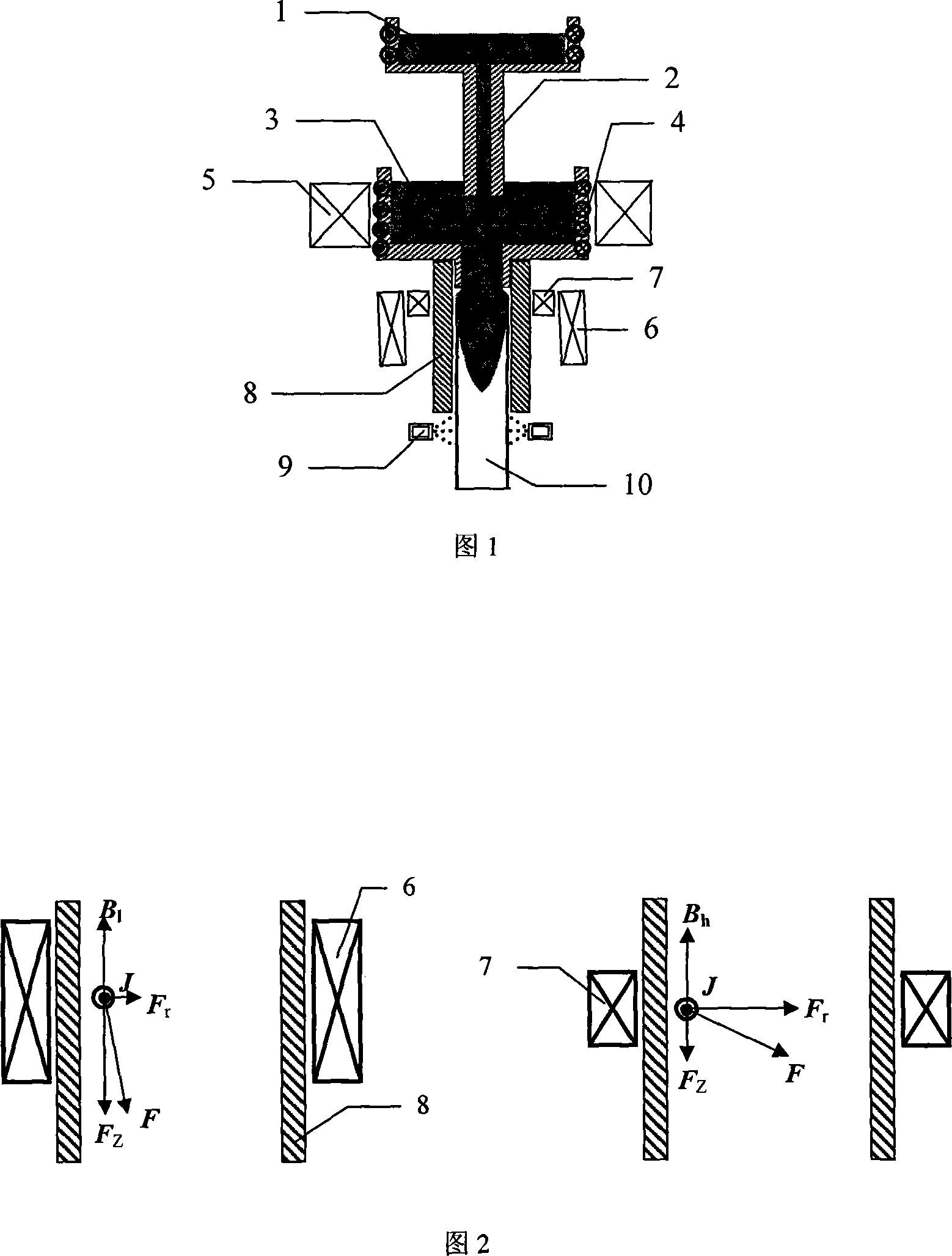

Method of continuous casting particulate reinforced metal matrix composites on different frequency multi-electromagnetic field

Disclosed is a method of particle reinforced metal matrix composite continuous casting in compound magnetic field at different frequency, relating to material processing technology field; in the process of the preparation of the composites melt, low-frequency alternating magnetic field is applied: the frequency is from 5 to 50 Hz, the power range is from 5 to 60 kW; electromagnetic stirring is carried out, making the particles to be fined and evenly distributed; in the process of continuous casting, low-frequency alternating magnetic field is applied to the crystallizer zone: the frequency is from 5 to 50 Hz, the power range is from 5 to 20 kW; electromagnetic stirring is carried out to improve the internal quality; meanwhile, the high-frequency alternating magnetic field is applied in initial solidification zone in crystallizer: the frequency is from10 to 50 kHz, the power range is from 20 to 100Kw, soft contact is applied to improve the surface quality of casting billet. The composites article reinforcement prepared by the method are evenly distributed and fined, the internal organization is compact without any structural defects such as rarefaction or shrinkage hole, the casting billet has high surface finish without any defects.

Owner:JIANGSU UNIV

Ferromagnetic particles and process for producing the same, and anisotropic magnet, bonded magnet and compacted magnet

ActiveUS20140001398A1High purityReadily produce stable FeNitrogen-metal/silicon/boron binary compoundsInorganic material magnetismViewpointsIron oxyhydroxide

The present invention relates to ferromagnetic particles capable of exhibiting a high purity and excellent magnetic properties from the industrial viewpoints and a process for producing the ferromagnetic particles, and also provides an anisotropic magnet, a bonded magnet and a compacted magnet which are obtained by using the ferromagnetic particles. The ferromagnetic particles comprising an Fe16N2 compound phase in an amount of not less than 80% as measured by Mössbauer spectrum and each having an outer shell in which FeO is present in the form of a film having a thickness of not more than 5 nm according to the present invention can be produced by subjecting iron oxide or iron oxyhydroxide having an average major axis diameter of 40 to 5000 nm and an aspect ratio (major axis diameter / minor axis diameter) of 1 to 200 as a starting material to dispersing treatment to prepare aggregated particles; subjecting the iron compound particles passed through a mesh to hydrogen reducing treatment at a temperature of 160 to 420° C.; and then subjecting the resulting particles to nitridation treatment at a temperature of 130 to 170° C.

Owner:TOHOKU UNIV

Porous cordierite ceramic honeycomb article with improved strength and method of manufacturing same

ActiveUS7520911B2Reduce the amount requiredIncrease volume fractionCombination devicesAuxillary pretreatmentCordieritesSilicon dioxide

A porous cordierite ceramic honeycomb article with increased mechanical strength and thermal shock resistance. The porous cordierite ceramic honeycomb article has MA<2220, or MT>2660 whereinMA=3645(IA)−106(CTE)+19(d90)+17(% porosity),MT=4711(IT)+116(CTE)−26(d90)−28(% porosity),and a CTE≦9×10−7 / ° C. in at least one direction. A method of manufacturing is also disclosed wherein the inorganic raw material mixture contains talc, an alumina-forming source, a silica-forming source, and 0-18 wt. % of a kaolin or calcined kaolin containing not more than 8 wt. % of a fine kaolin source having a median particle diameter of less than 7 μm, wherein the fired porous ceramic cordierite honeycomb article has a porosity<54% . Alternatively, if greater than 8 wt. % of the fine kaolin source is used, then a slow ramp rate is utilized from 1200° C. to 1300° C. of not more than 20° C. / hr.

Owner:CORNING INC

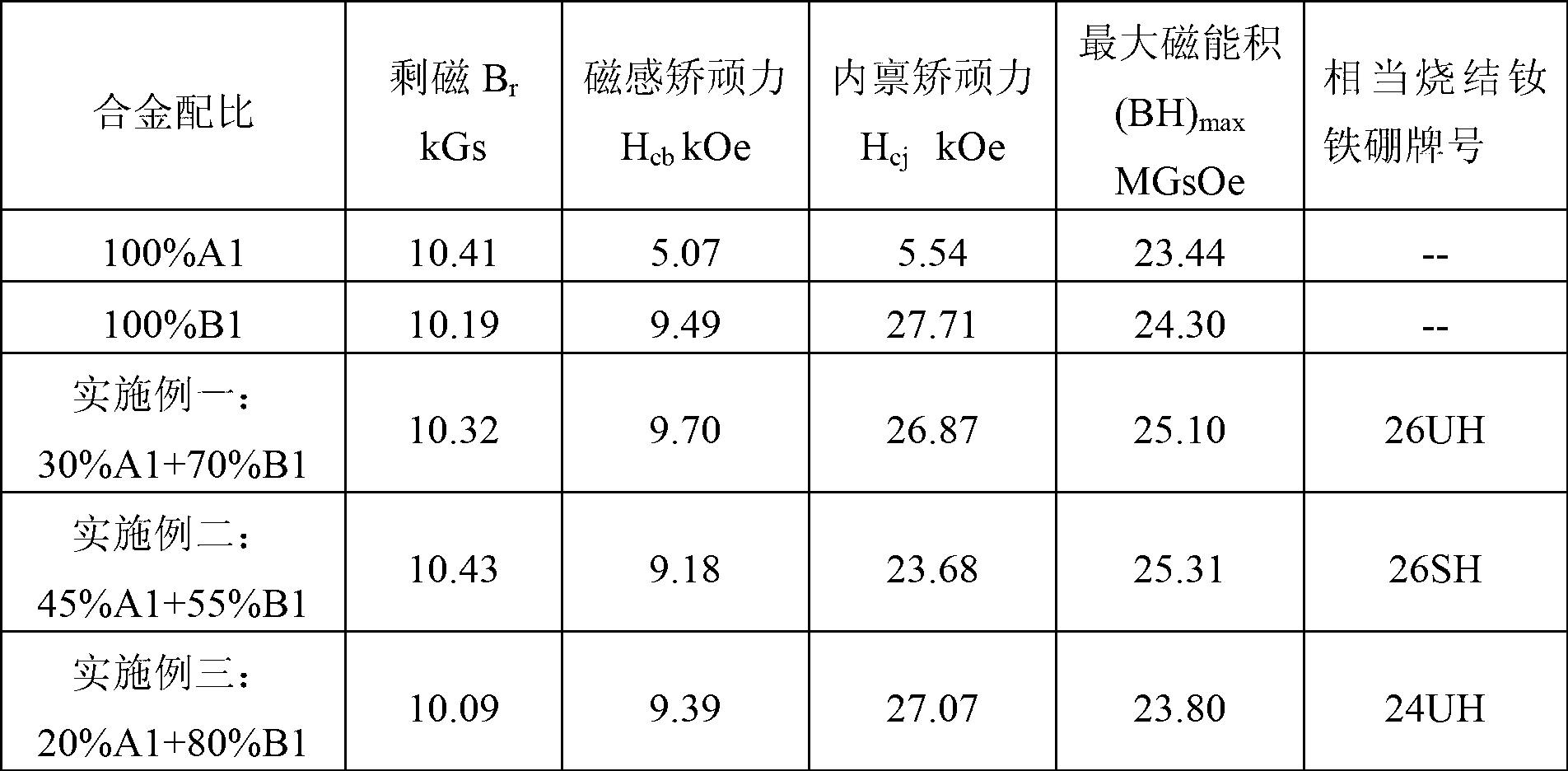

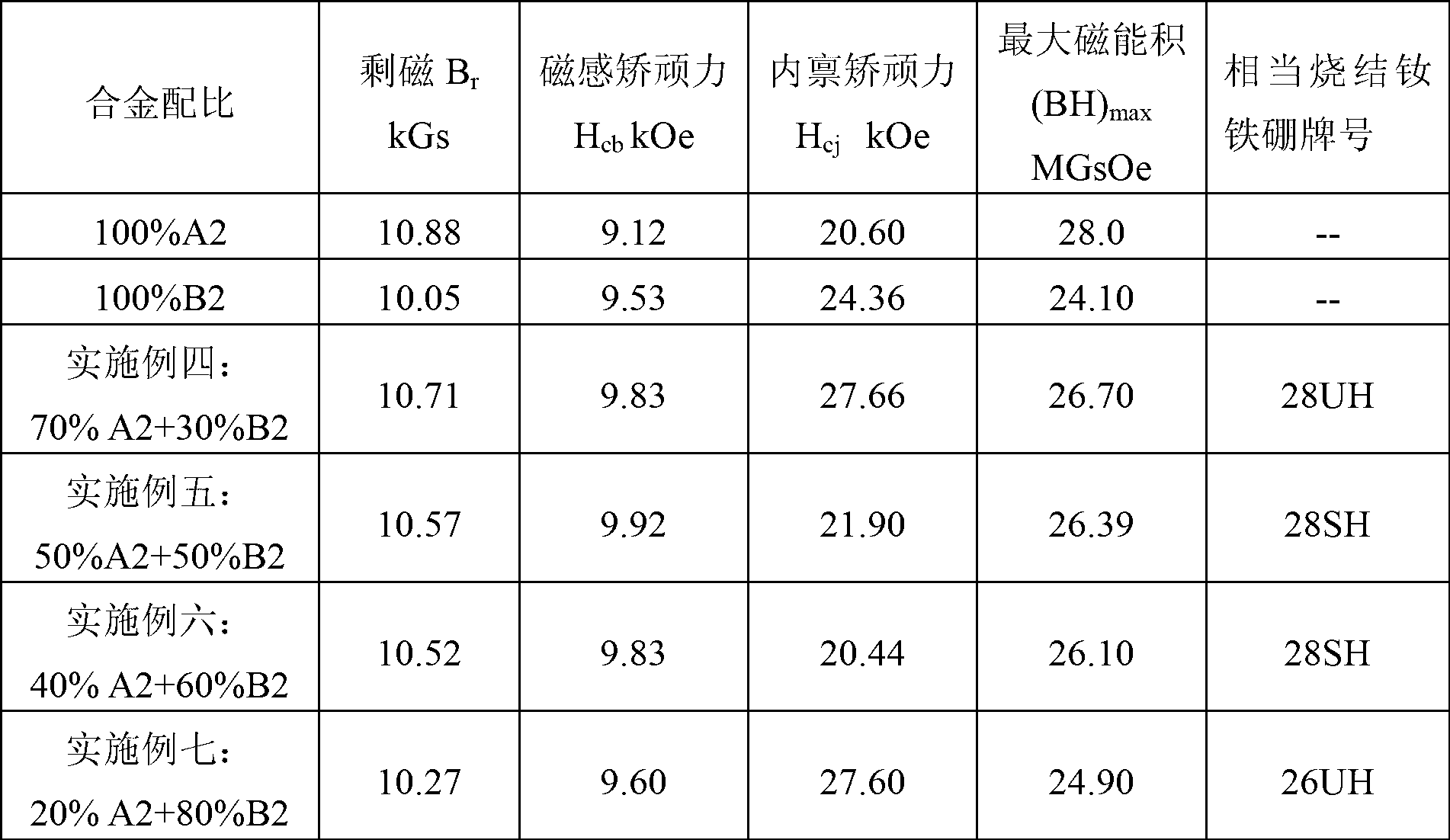

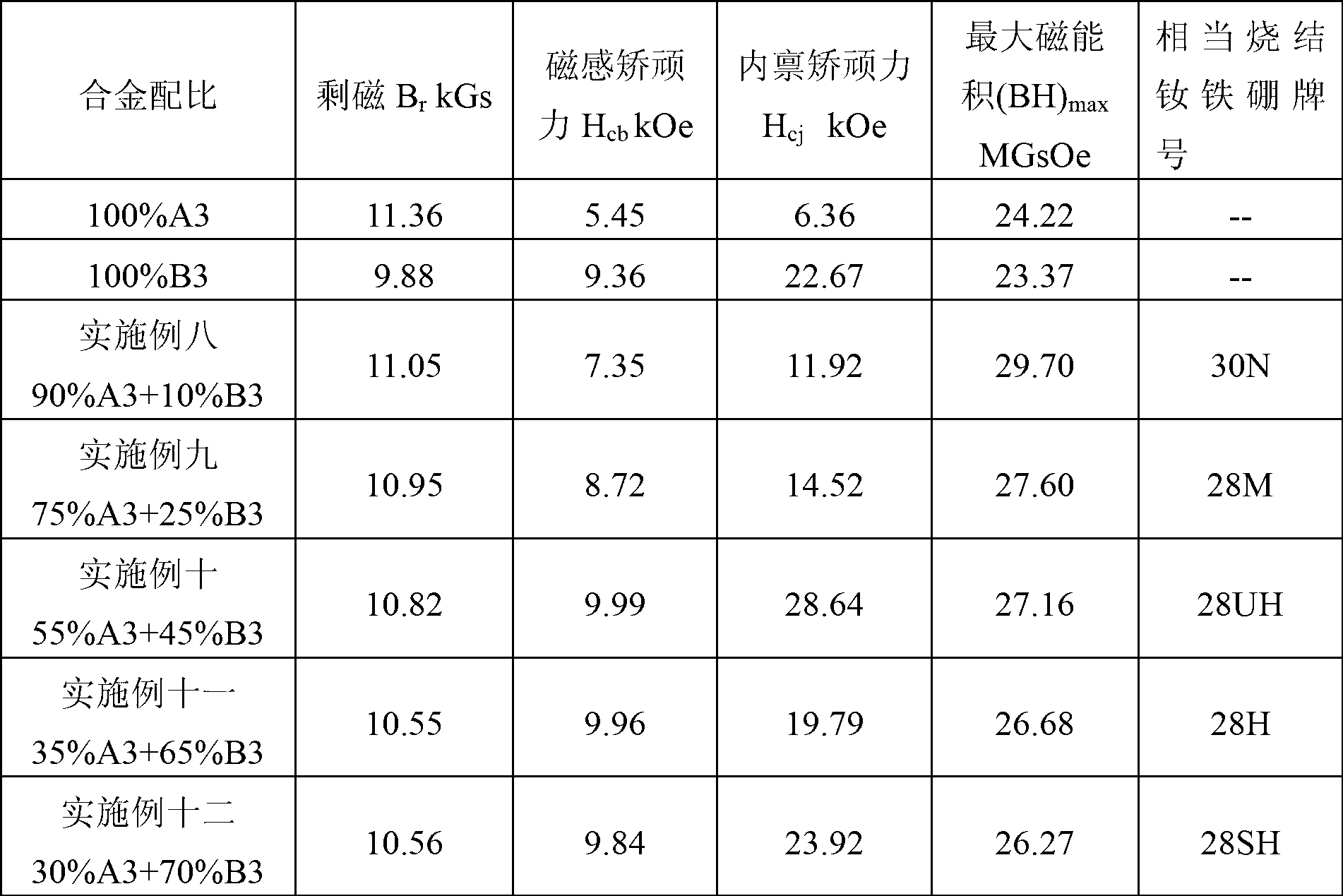

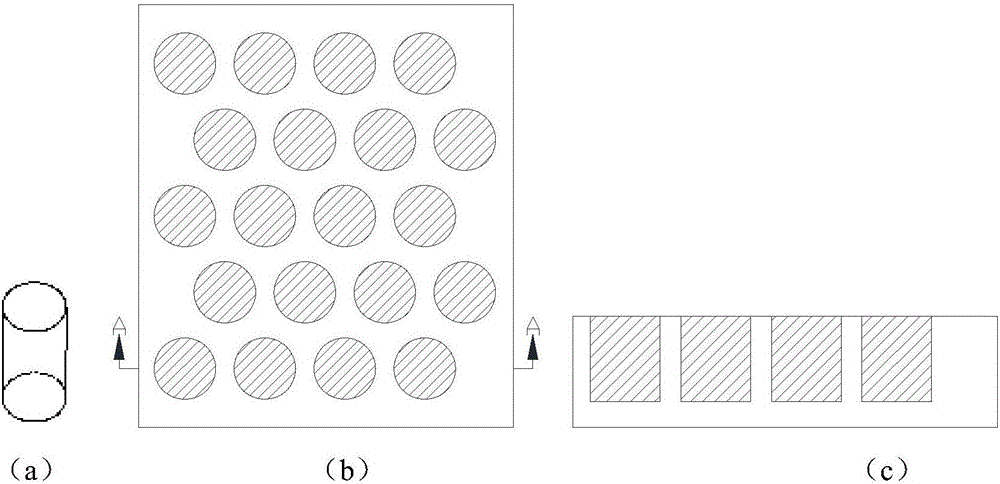

Method for preparing sintered samarium-cobalt magnet

ActiveCN103065788AGet over the actual ingredientsTo overcome the large deviation of design componentsInorganic material magnetismInductances/transformers/magnets manufactureRemanenceSamarium–cobalt magnet

The invention discloses a method for preparing a sintered samarium-cobalt magnet. The method comprises the following steps of: preparing a first samarium-cobalt alloy and a second samarium-cobalt alloy; performing primary crushing on the first samarium-cobalt alloy and the second samarium-cobalt alloy; mixing first samarium-cobalt alloy primarily crushed magnetic powder and second samarium-cobalt alloy primarily crushed magnetic powder, and performing fine crushing, so that primarily crushed mixed magnetic powder is refined, and components are homogenized; and performing magnetic field orientation forming, cold isostatic pressing, sintering, solid solution treatment and ageing treatment on samarium-cobalt magnetic powder obtained by fine crushing in sequence. The method has the advantages that the first samarium-cobalt alloy has high remanence component characteristic, the second samarium-cobalt alloy has high coercivity component characteristic, the sintered samarium-cobalt magnets with various magnetic properties can be obtained by adjusting the mixing ratio of the first samarium-cobalt alloy primarily crushed magnetic powder to the second samarium-cobalt alloy primarily crushed magnetic powder, and the process is stable and low in cost.

Owner:NINGBO YUNSHENG +3

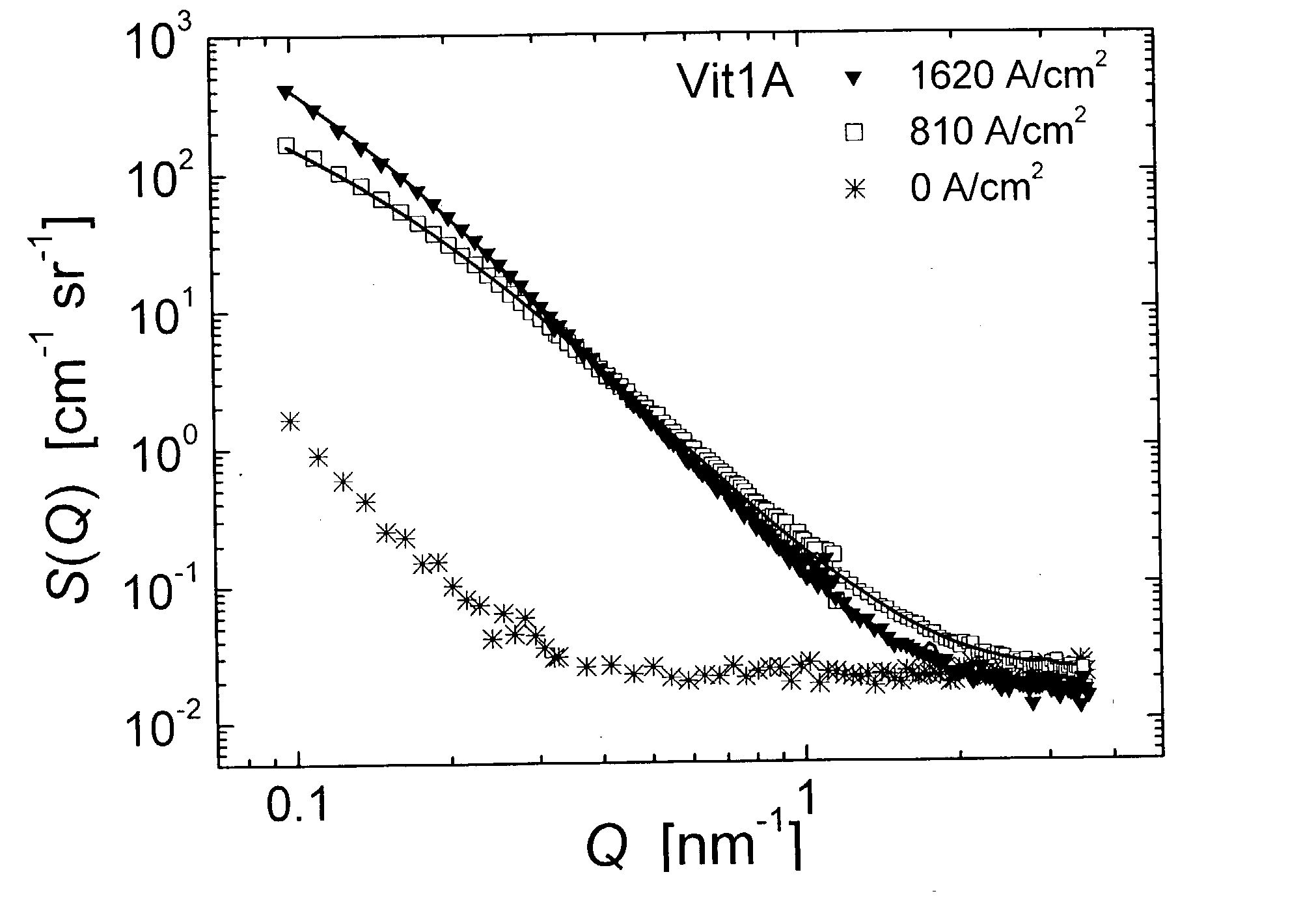

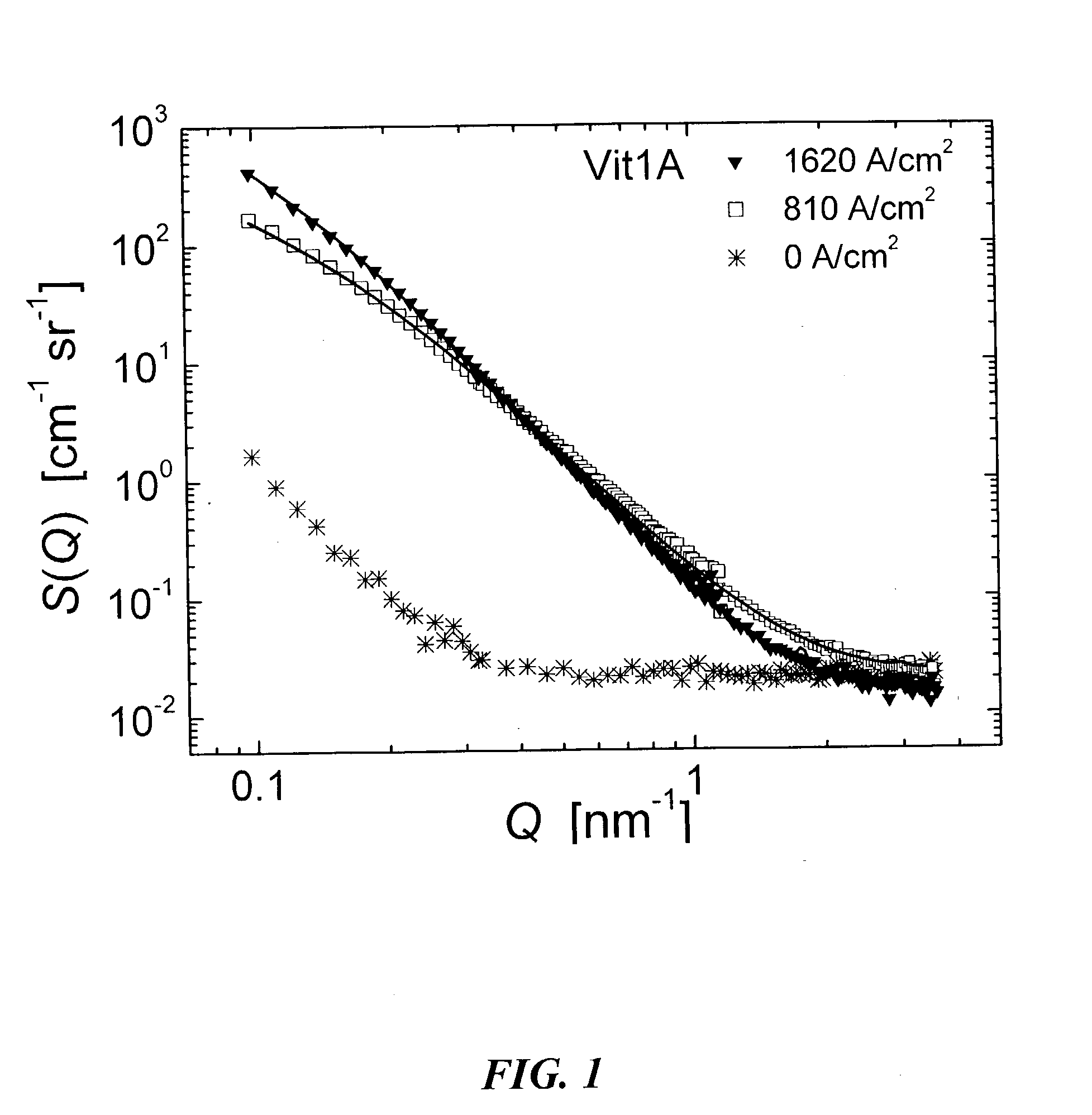

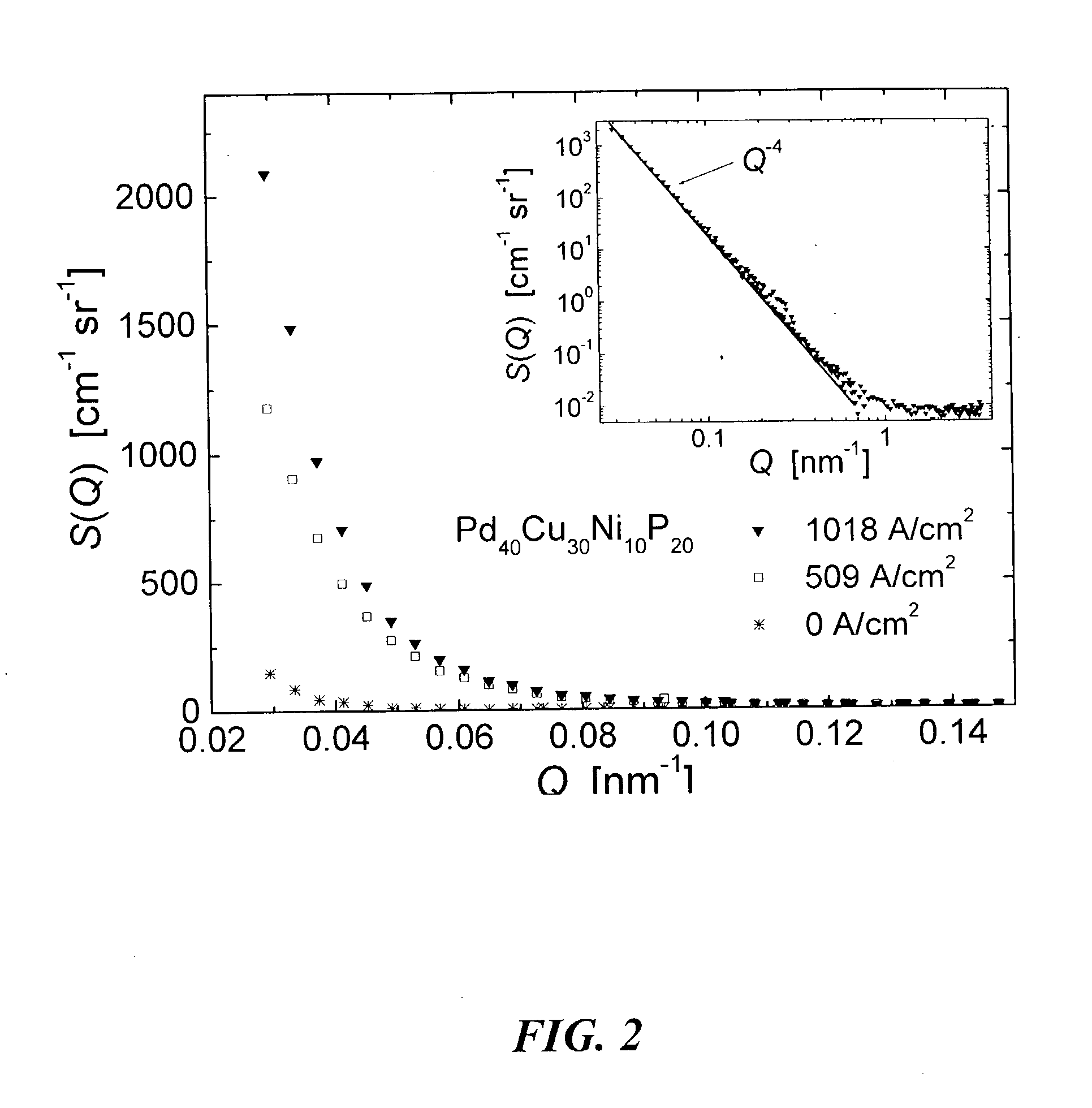

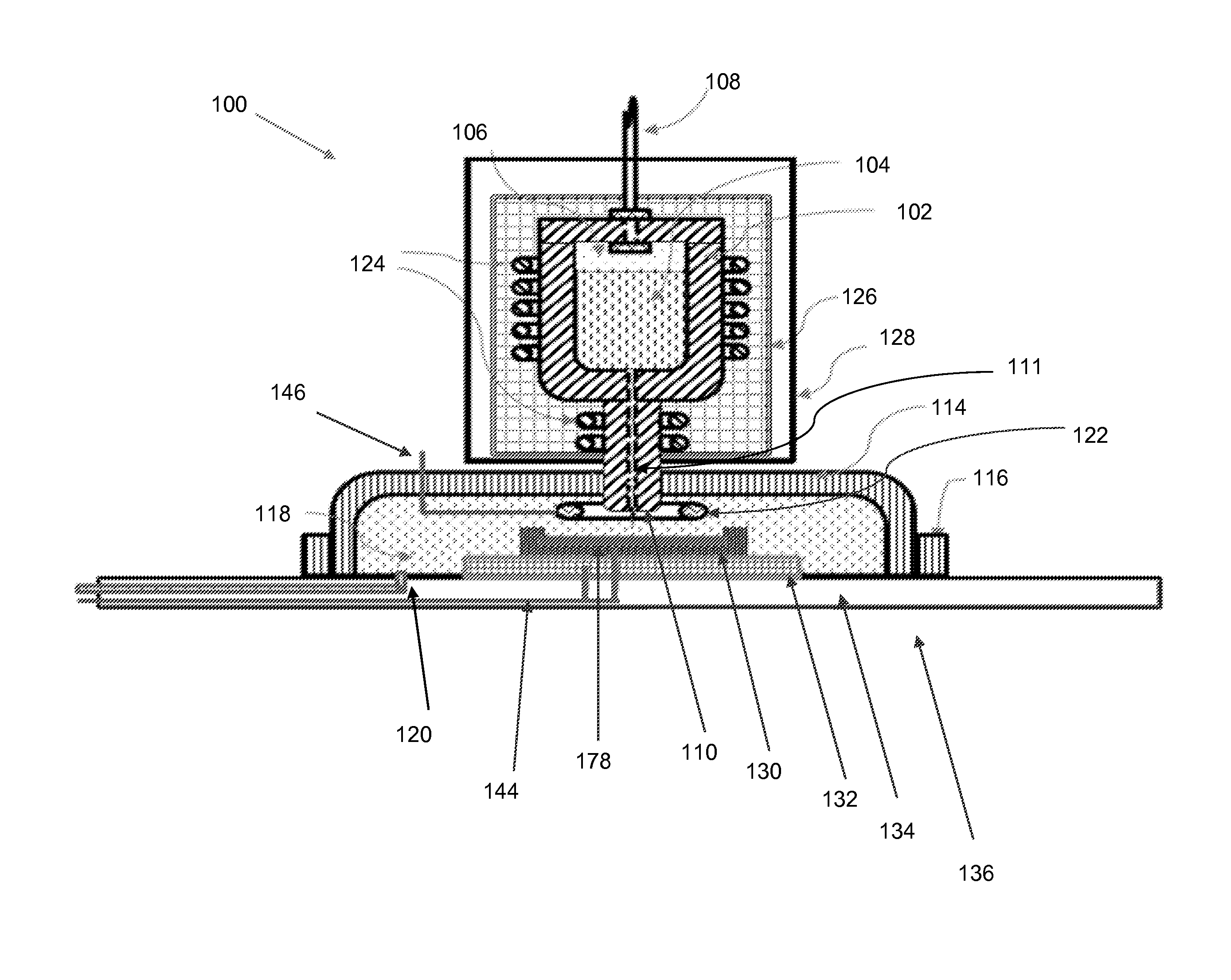

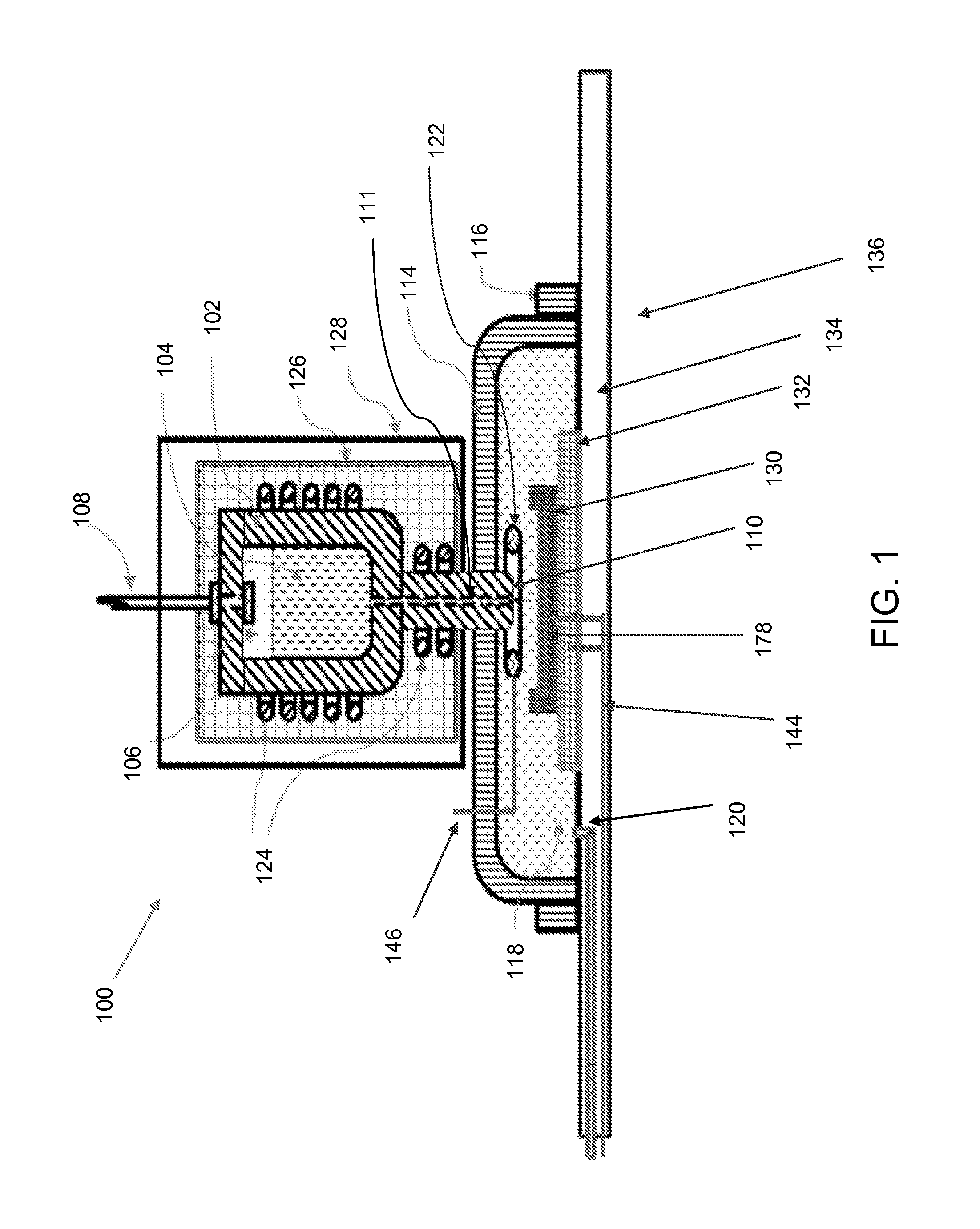

Metallic glasses with crystalline dispersions formed by electric currents

Metallic glasses of superior mechanical and magnetic properties are manufactured by annealing the glasses under the influence of an electric current to convert the glass to a composite that includes crystallites, preferably nanocrystallites, dispersed through an amorphous matrix.

Owner:RGT UNIV OF CALIFORNIA

Electrospray pinning of nanograined depositions

ActiveUS20150251213A1Inhibition of recrystallizationEnhanced nucleationLiquid surface applicatorsAdditive manufacturing apparatusGrain growthElectric field

A method and apparatus for fabrication of objects retaining nano-scale characteristics. A composition is provided comprising grain growth inhibitor particles in solution with a binding agent in a molten phase. An electric field and a magnetic field are generated with a combined extraction electrode. The composition is electrosprayed from a nozzle with the electric field to form a stream of droplets. The electric field drives the droplets toward a moving stage holding an object comprising successive deposition layers. The magnetic field limits dispersion of the stream of droplets. The stage is moved laterally as the stream of droplets impacts the object to form a current deposition layer of the object. The stage is moved vertically as necessary to maintain a target stand-off distance between the nozzle and a previous deposition layer of the object, based on profile data of the previous deposition layer.

Owner:Q21 CORPORATION +1

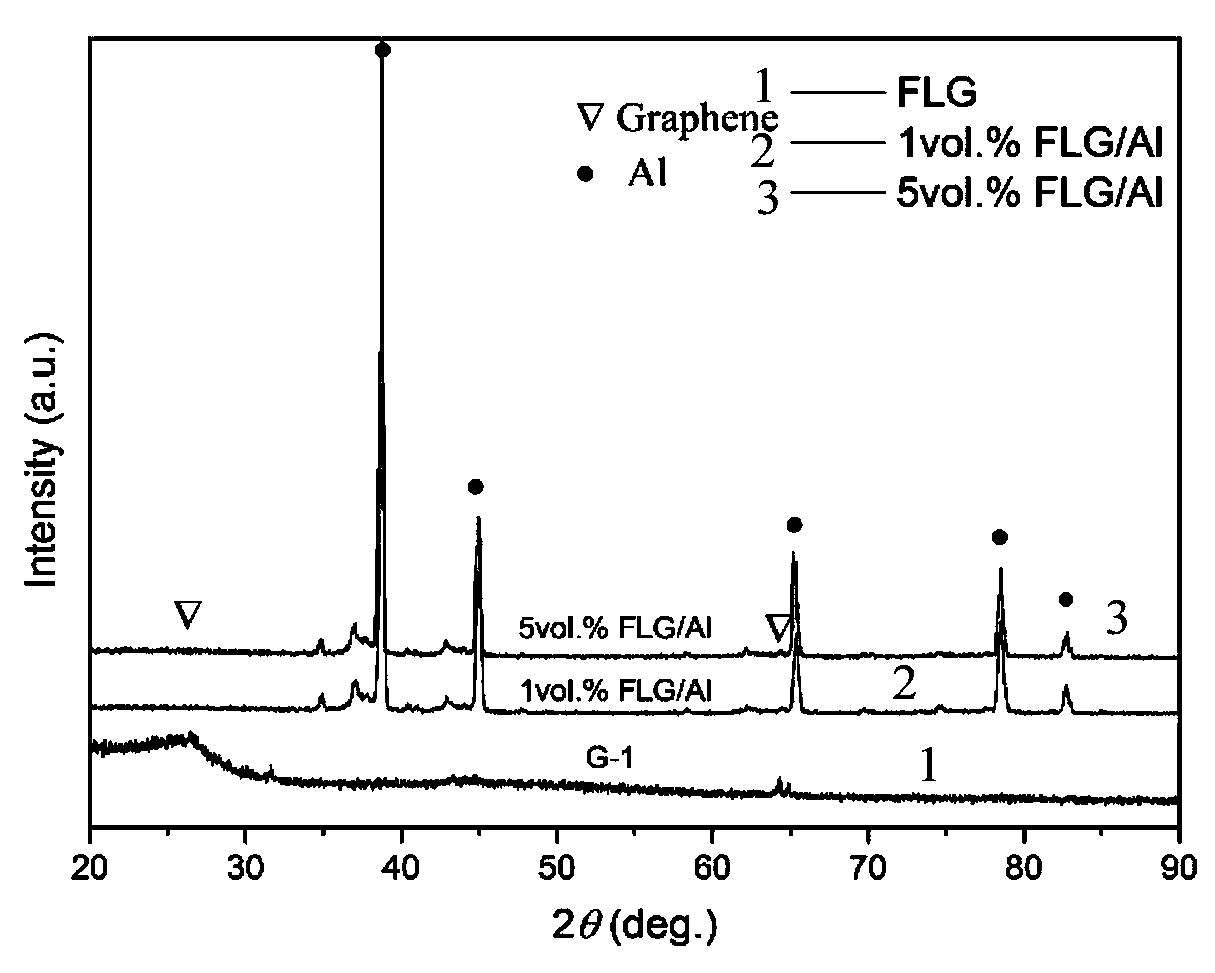

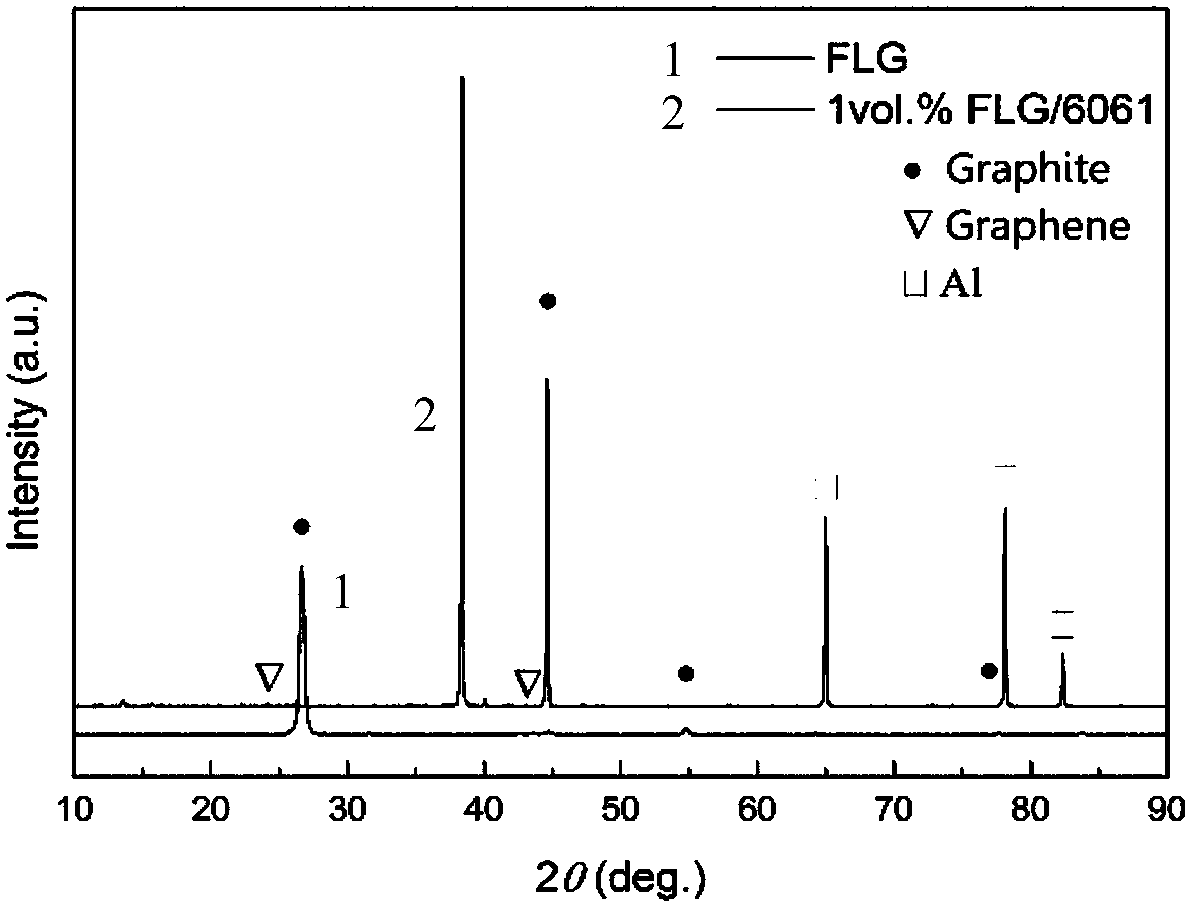

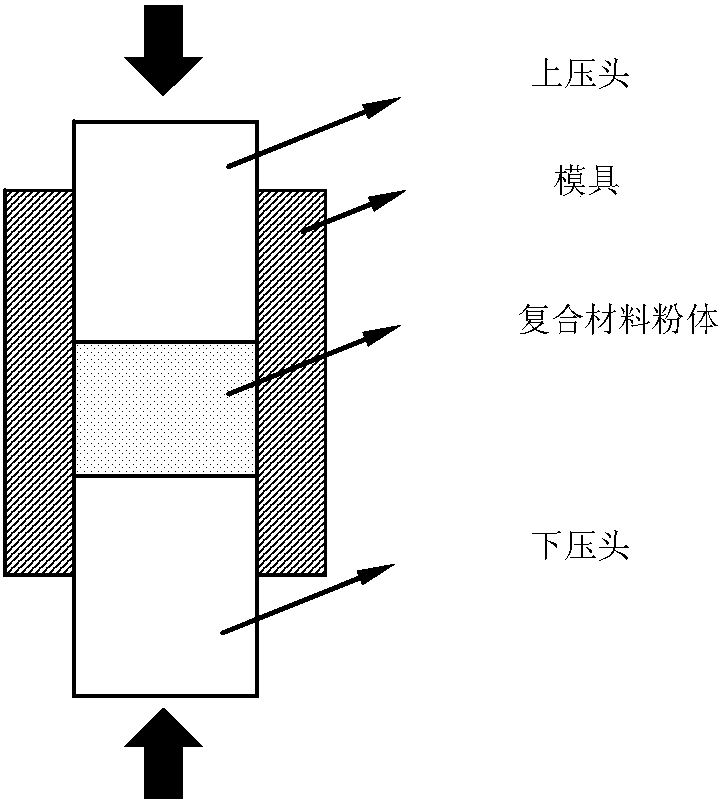

Preparation method of graphene-reinforced aluminum-based composite material

The invention provides a preparation method of a graphene-reinforced aluminum-based composite material. The graphene / aluminum composite material is prepared through the steps of preparing of graphene / aluminum mixed powder through a two-step ball milling method, cold pressing forming of a graphene / aluminum composite material blank, hot squeezing forming and the like. Through a special technologicalmode, graphene is evenly dispersed in aluminum bases, generation of a brittle phase Al4C3 is reduced, and the graphene / aluminum composite material with the high compactness and high volume fraction is obtained finally.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

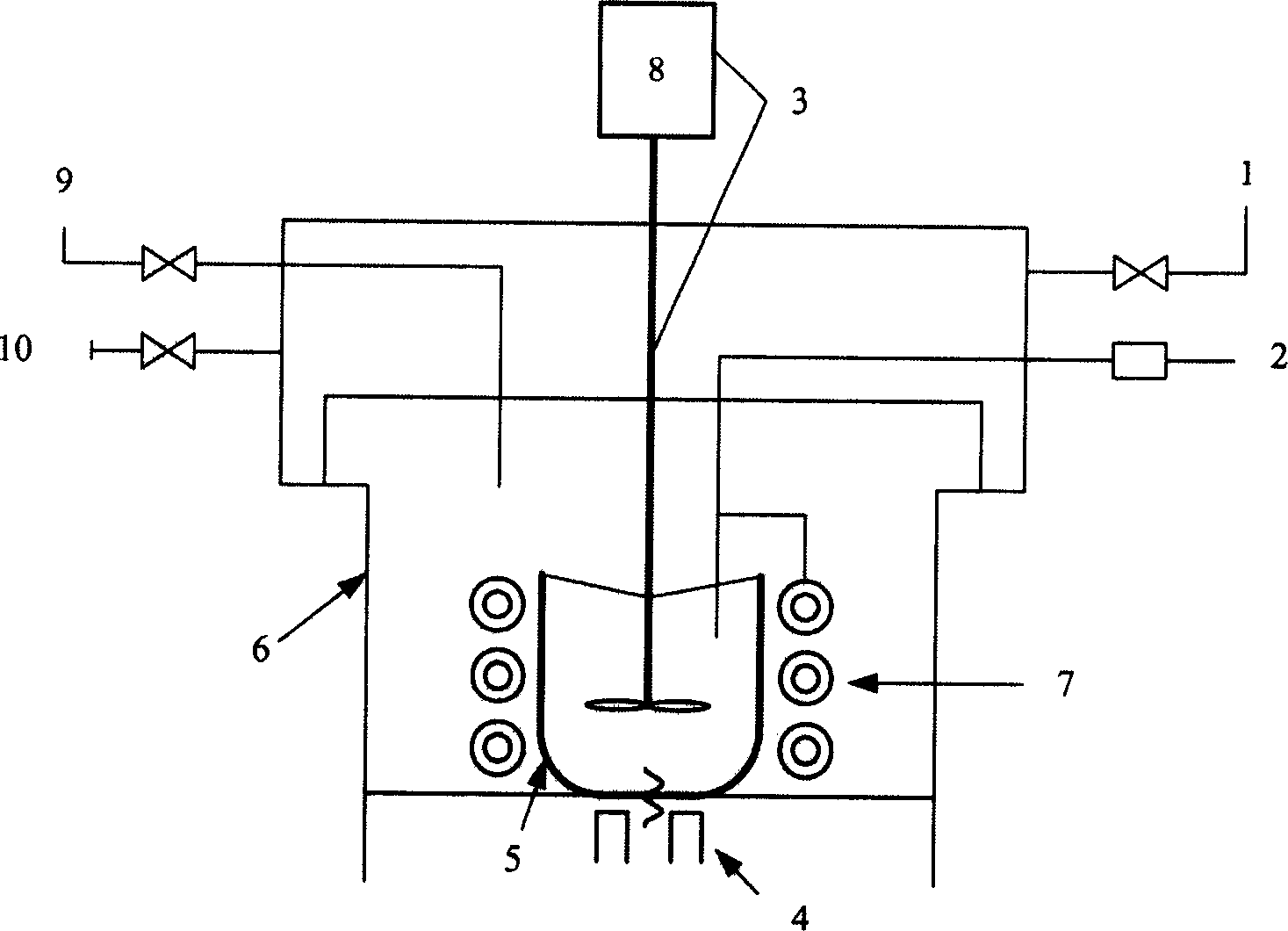

Method and apparatus for preparing composite solder for welding particle enhanced aluminium-based composite material

InactiveCN1827809AEasy to use for weldingAvoid pollutionWelding/cutting media/materialsSoldering mediaSlagShielding gas

The invention provides the preparing method and device for combined welding rod used for particle enhancement composite material aluminium. The method comprises the following steps: putting the clean alloy into crucible, starting vacuum pump to 5 X10-5, then charging protective gas into vacuum system, heating the alloy, controlling the temperature, the lowest which is higher than liquid line of alloy, and the highest of which is lower than liquid line plus 100-125Deg.C, melting alloy, canceling vacuum, carrying out slag-out treatment, adding clean reinforcement particle according to volume fraction, charging protective gas, starting agitating device and ultrasonic vibrator, after stirring and ultrasonic vibration, carrying out slag-out treatment, cooling, and getting casting ingot. The invention improves the preparing efficiency, overcomes the defect that it is not sufficient to wet the enhancement phase / base, and optimizes the alloy solidification structure.

Owner:HARBIN INST OF TECH

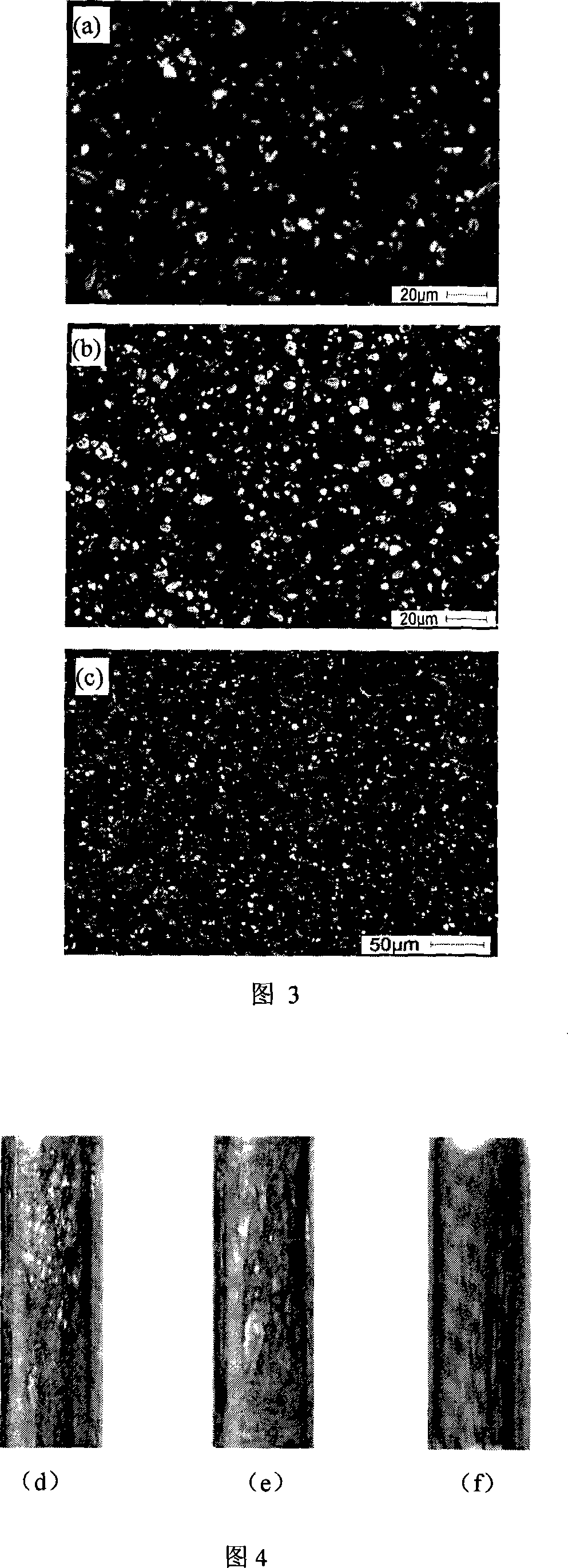

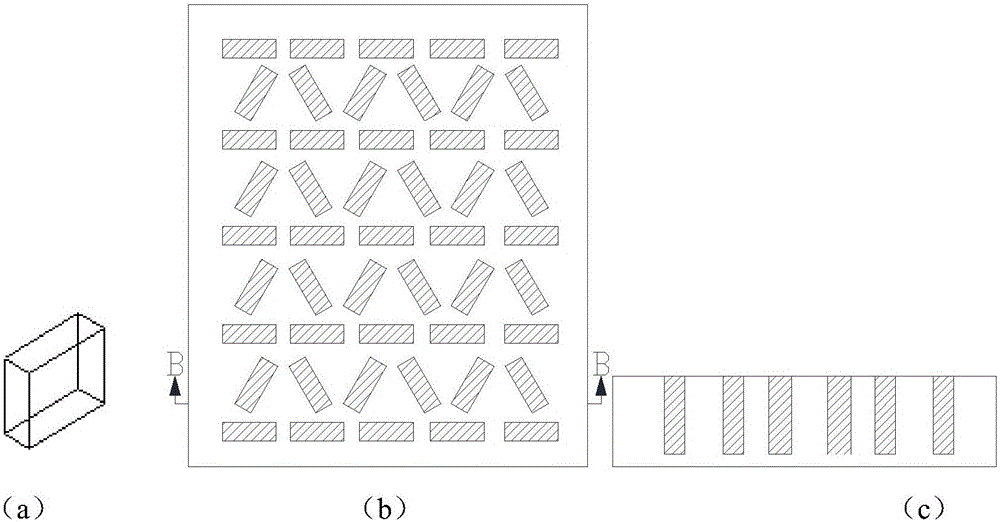

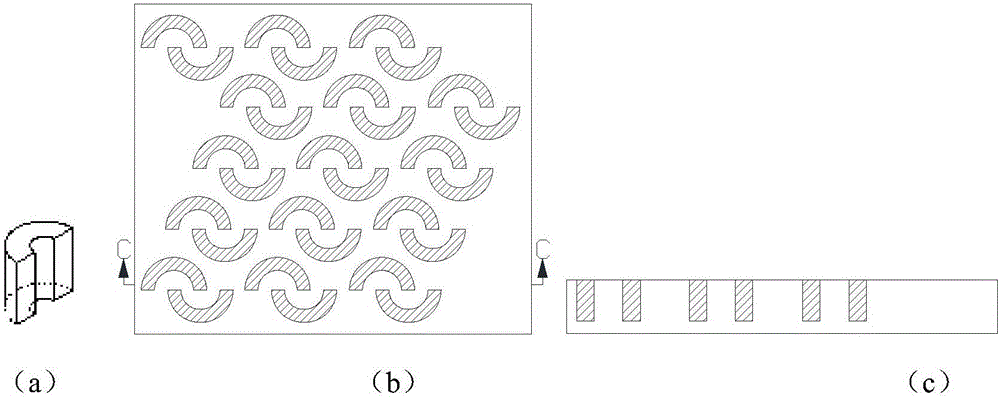

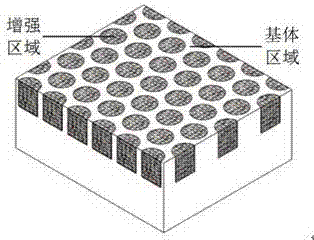

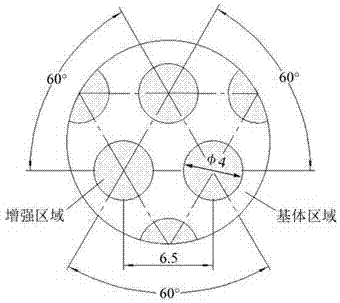

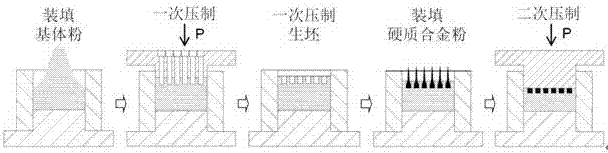

Powder metallurgy preparation method of localization reinforced composite

The invention belongs to the technical field of composite preparation, and particularly relates to a powder metallurgy preparation method of a localization reinforced composite for manufacturing wear-resisting quick-wear parts of mining and building machines. The method comprises the following steps that (1) tungsten carbide powder and titanium carbide powder are used as reinforced particles, reduced iron powder and high-speed steel powder are used as a metal binder, and hard alloy powder is prepared according to a certain proportion; (2) the prepared hard alloy powder is put into a ball mill, and a process control agent is added for ball milling and mixing; and (3) a forming agent is added into the hard alloy powder subjected to uniform ball milling and mixing, and then the steps of mixing, prepressing, smashing, sieving particle making and the like are carried out. In a composite layer of the composite prepared through the method, discontinuous reinforcement areas are uniformly distributed in a continuous matrix area, cracks are not prone to being produced and expanding in the service process of the composite, and strength-toughness matching performance of the composite is achieved well; and the wear resistance of the composite can be obviously improved, and the service life of the composite can be obviously prolonged.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Preparation method of abrasion-proof and corrosion-resistant nickel-based alloy wire

The invention discloses an abrasion-proof and corrosion-resistant nickel-based alloy wire and a preparation method thereof. The alloy wire comprises the following components: 17-21% of C, 20-25% of Co, 1.8-2.2% of W, 6.4-9.5% of Mo, 1.4-1.8% of Al, 3.2-4.5% of Ti, 0.1-0.5% of Nb, 0.1-0.5% of Hf, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr, 0.005-0.008% of Mg, and the balance Ni. The preparation technology of the alloy comprises the steps of vacuum smelting, remelting, forging, hot rolling, drawing, solid solution treatment and aging treatment, namely, raw materials are prepared and smelted based on mass percent and then smelted; the smelted materials are forged and rolled into obtain alloyed wire rods; the alloyed wire rods are drawn at a plurality of times to obtain phi 0.05-0.4mm alloy wires; finally the alloy wires are subjected to solid solution treatment and aging treatment. The abrasion-proof and corrosion-resistant nickel-based alloy wire can be used as a brush wire material for brush sealing of an aircraft engine, a gas turbine, etc., thus the brush sealing effect can be effectively improved, and the service life can be prolonged.

Owner:江苏鑫信润科技股份有限公司

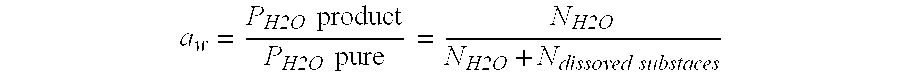

Invert emulsions comprising at least one active agent sensitive to water and cosmetic/dermatological applications thereof

InactiveUS20060029623A1Improve physical stabilityHigh dispersed volume fractionBiocideCosmetic preparationsEmulsionActive agent

Cosmetic / dermatological compositions useful for the treatment of a variety of dermatological conditions, including keratinization disorders, acne, eczema, psoriasis, etc., comprise an invert emulsion containing at least one active agent sensitive to the presence of water, notably a derivative of vitamin D, and solubilized in a glycolic or hydroglycolic dispersed hydrophilic phase, a lipophilic continuous phase and an emulsifier having an HLB ranging from 2 to 7; these invert emulsions exhibit good stability and avoid crystallization of the active agent and / or chemical degradation thereof.

Owner:GALDERMA RES & DEV SNC

Preparation method of boron-containing structural steel

InactiveCN102080179AImprove performanceSimple rolling process and cooling processTemperature control devicePearliteChemical composition

The invention discloses a preparation method of boron-containing structural steel. The boron-containing structural steel comprises the following chemical components by weight percent: 0.08-0.20% of C, 0.10-0.30% of Si, 0.80-1.50% of Mn, no more than 0.010% of P, no more than 0.010% of S, 0.0008-0.0030% of B and the balance of Fe and inevitable impurities. The preparation method comprises the following specific steps: heating to 1175-1225 DEG C for austenitization, and then performing multipass rolling, wherein the deformation temperature is between the austenitic recrystallization region and austenitic unrecrystallization region and the austenite-ferrite two-phase region; and then cooling to 600-660 DEG C at a cooling rate of 1-10 DEG C / s, and then performing air cooling. The boron-containing structural steel prepared by the method provided by the invention mainly contains ferrite, bainite and a small amount of pearlite. The structural steel has the advantages of uniform structure, fine grain and good strength and toughness.

Owner:NANJING IRON & STEEL CO LTD

Method for adding carbon nano tube into metal bath

The invention relates to a method for adding carbon nano tube into metal bath, which is characterized in mixing carbon nano tube, metal powder and stearic acid according to a weight ratio between the carbon nano tube and metal powder of 1:10-2, and a weight ratio between stearic acid, carbon nano tube and metal powder of 1:15-20, putting into a ball mill for ball milling, sieving with a 50-80 mesh stainless steel sieve to obtain a uniform mixture, adding the mixture into the mold, pressing for molding to obtain carbon nano tube / metal composite press block; adding the carbon nano tube / metal composite press block into a metallic or alloy solution, regulating temperature of fused mass to a casting temperature, casting the article.

Owner:NANCHANG UNIV

Nanometer silicon carbide particle reinforced aluminum matrix composite and preparation method thereof

The invention relates to the technical field of particle reinforced aluminum matrix composites and discloses a nanometer silicon carbide particle reinforced aluminum matrix composite and a preparation method thereof. The composite is prepared by uniformly distributing nanometer silicon carbide particles with the volume percentage of 6-16% into aluminum alloy with the volume percentage of 84-94%. The preparation method comprises the steps of firstly, proportioning, ball milling, premolding and carrying out hot pressing molding to prepare 1-5% of nanometer silicon carbide particle reinforced aluminum matrix composite; next, carrying out vacuum concentration on the 1-5% of nanometer silicon carbide particle reinforced aluminum matrix composite to evaporate parts of aluminum alloy matrixes; and finally, carrying out solid solution and aging treatment to prepare the nanometer silicon carbide particle reinforced aluminum matrix composite disclosed by the invention. Experiment data proves that the reinforced aluminum matrix composite with high nanometer silicon carbide particle content, prepared by using the preparation method not only has the functional properties of high heat conductivity, electrical conductivity, specific modulus, wear resistance and the like due to the high nanometer silicon carbide particle content, but also has strength as well as plasticity and toughness.

Owner:HENAN UNIV OF SCI & TECH

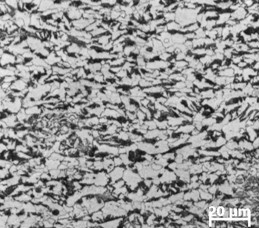

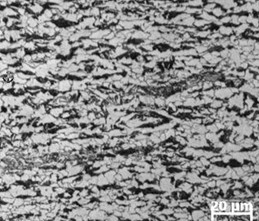

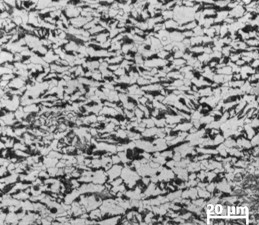

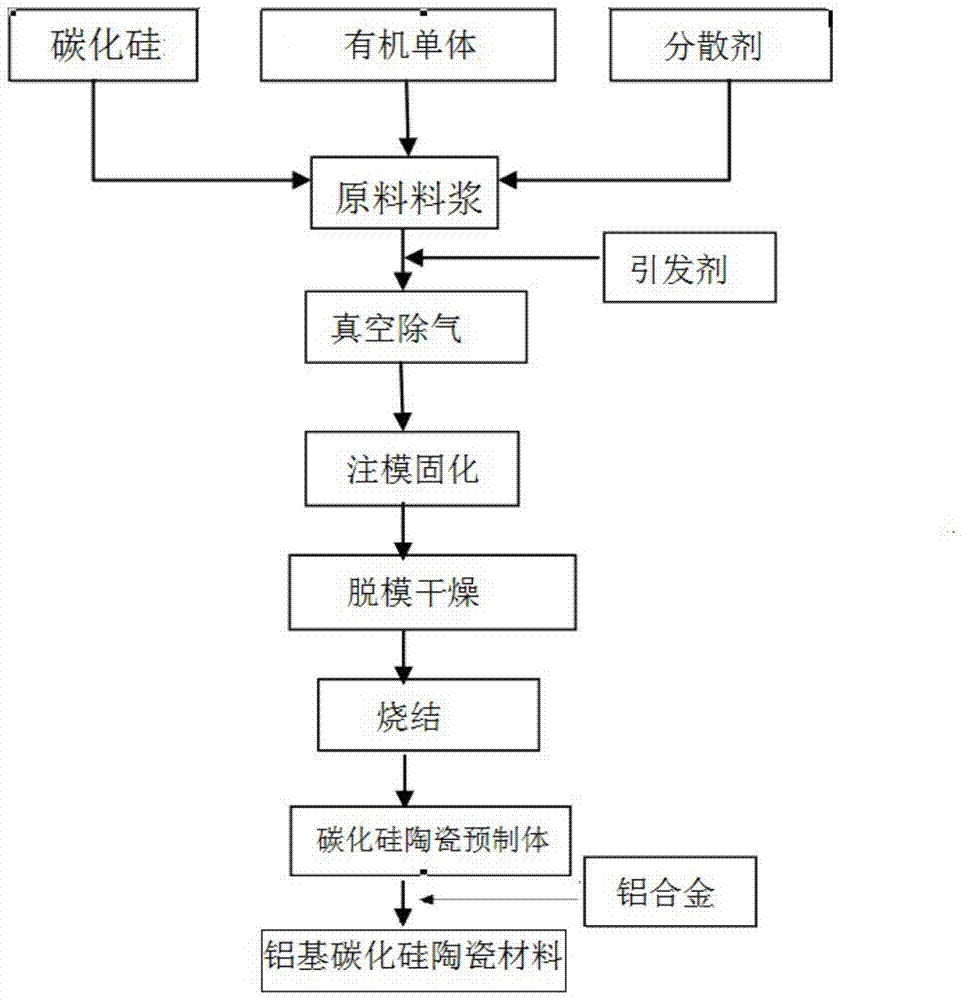

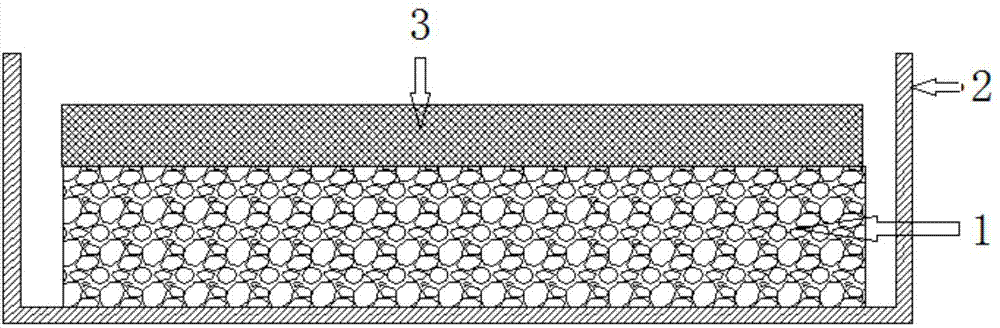

Silicon carbide ceramic preform, aluminum-based silicon carbide ceramic material, and preparation method of silicon carbide ceramic preform

The invention discloses a silicon carbide ceramic preform, an aluminum-based silicon carbide ceramic material, and a preparation method of the silicon carbide ceramic preform, and relates to the technical fields of materials and preparation thereof, and aims at solving the technical problems that the silicon carbide ceramic preform prepared by an existing preparation process is low in strength, uneven in structure, and low in volume fraction of silicon carbide. According to the main technical scheme, the preparation method comprises the following steps: mixing raw materials for preparing the silicon carbide ceramic preform evenly, so as to prepare a raw material slurry, wherein the raw materials for preparing the silicon carbide ceramic preform comprise silicon carbide, a dispersing agent, an organic monomer and water; introducing an initiator into the raw material slurry, and mixing evenly, so as to obtain ceramic slurry; carrying vacuum degassing treatment, injection molding and demolding drying on the ceramic slurry, so as to obtain a ceramic biscuit; and sintering the ceramic biscuit at 800-1200 DEG C, so as to obtain the silicon carbide ceramic preform. The preparation method is mainly used for preparing the silicon carbide ceramic preform with high strength and uniform structure, so as to prepare the aluminum-based silicon carbide ceramic material with high performance.

Owner:CHINA BUILDING MATERIALS ACAD

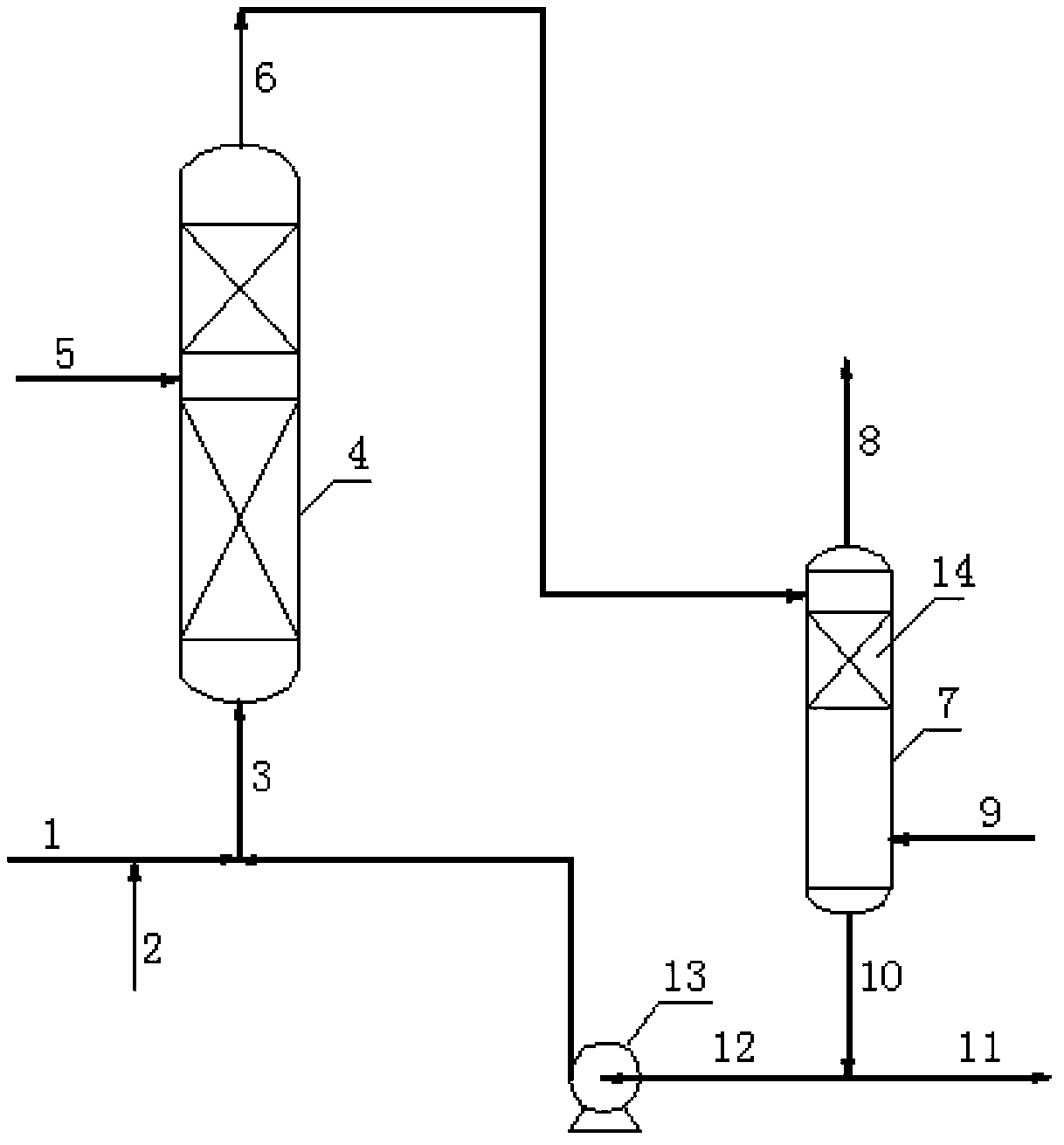

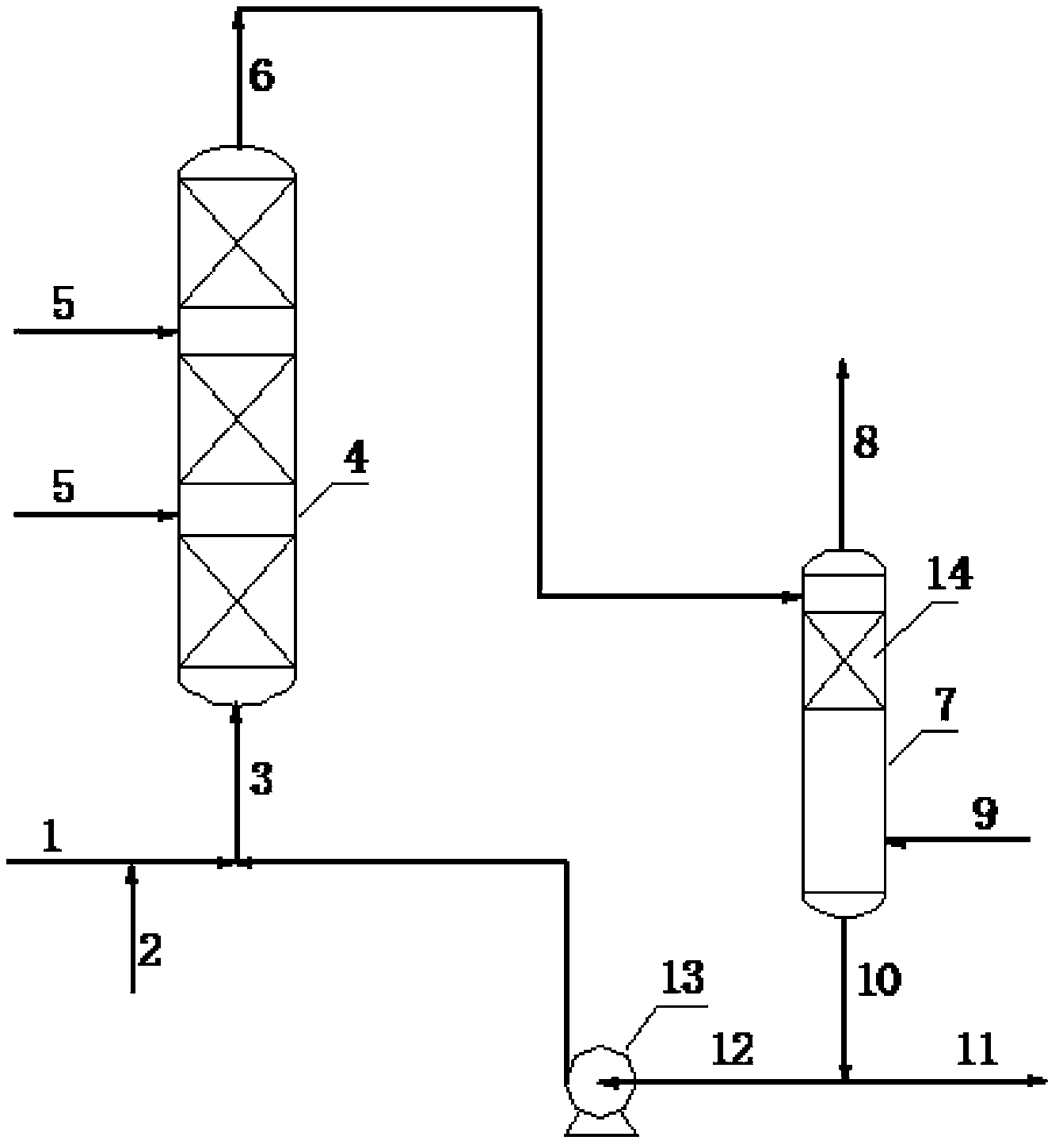

Hydrogenation system for producing ultralow-sulfur diesel oil, and method thereof

ActiveCN103509598ALarge heat capacityReduce temperature riseTreatment with hydrotreatment processesHydrodesulfurizationGas phase

The invention relates to a hydrogenation system for producing ultralow-sulfur diesel oil, and a method thereof. The system comprises a first-segment hydrogenation reaction zone a second-segment hydrogenation reaction zone; the first-segment hydrogenation reaction zone is an upflow fixed bed reactor; the second-segment hydrogenation reaction zone is an active hydrogenation catalyst layer filled in an upper portion of a thermal high stripping reactor; a reaction raw material enters from the bottom of the upflow fixed bed reactor, and a reaction product flows out through the top of the upflow fixed bed reactor and directly enters the thermal high stripping reactor from a position over the second-segment hydrogenation reaction zone; a liquid phase in the upflow fixed bed reactor is a continuous phase, and a gas phase in the upflow fixed bed reactor is a disperse phase; and stripped hydrogen is introduced to the thermal high stripping reactor from a position below the second-segment hydrogenation reaction zone, and the above first-segment hydrogenation reaction product has a countercurrent contact with the stripped hydrogen for a super-deep hydrodesulfurization reaction and product stripping. The above finally-obtained reaction product is partially returned to an inlet of the first-segment hydrogenation reactor as circulation oil. The hydrogenation system for producing ultralow-sulfur diesel oil, and the method are economic and efficient.

Owner:CHINA PETROCHEMICAL CORP +1

Heat treatment method capable of improving anti-fatigue performance of aluminum alloy

ActiveCN103045976AEliminate entangled dislocation configurationsStress reliefRoom temperatureCorrosion fatigue

The invention relates to a heat treatment method capable of improving the anti-fatigue performance of Al-Cu-Mg alloy. The method comprises the following steps: performing intermediate annealing on a cold-rolled plate at the temperature of between 300 and 440 DEG C for 20 to 120 minutes; performing solution hardening treatment at the temperature of between 475 and 505 DEG C for 10 to 120 minutes; and naturally ageing at room temperature for at least 100 hours. The Al-Cu-Mg alloy comprises the following components: Cu, Mg, Mn, Ti and Al. The process method is simple and reasonable. By the intermediate annealing heat treatment process, the Gauss texture score of the alloy is increased, and orientation of most of crystal faces {111} of crystal grains of the cold-rolled Al-Cu-Mg alloy is positioned or close to the direction of the maximum external shearing stress, so that reciprocating sliding dislocated under the action of alternating stress is promoted, the closed effect of fatigue crack is improved, the spreading rate of the fatigue crack is reduced, and the alloy has excellent stress corrosion resistance and anti-stripping corrosion fatigue performance and is suitable for industrialized application.

Owner:CENT SOUTH UNIV

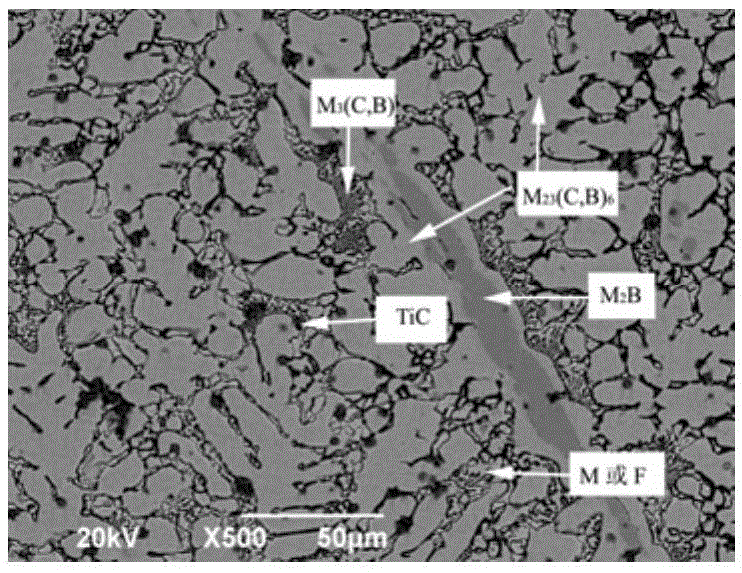

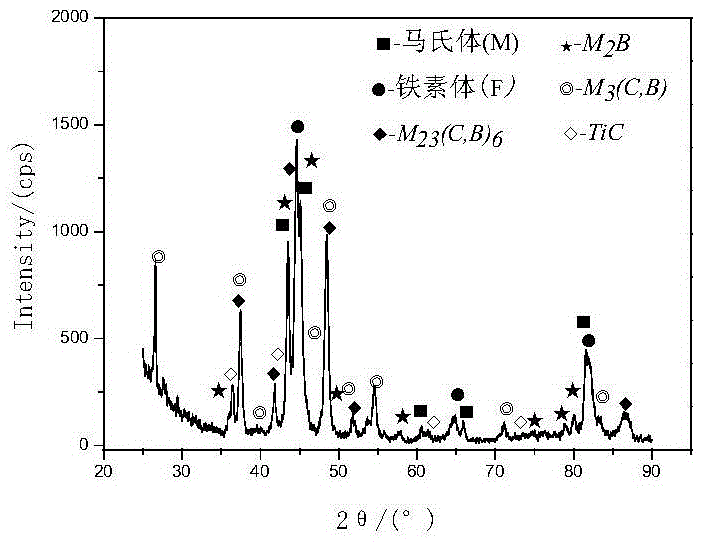

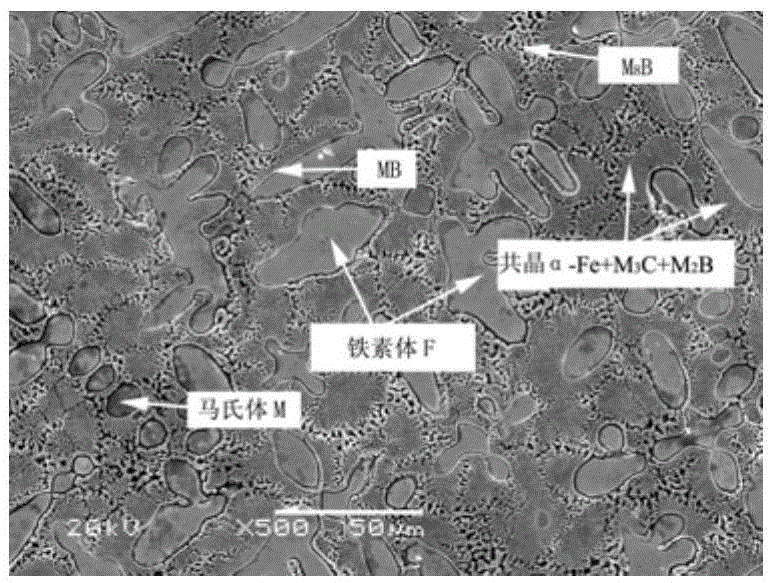

Carbon-controlling and toughening type self-shielded open-arc high-boron surfacing flux-cored wire

InactiveCN105537797ARealize carbon control and tougheningReduce carbon contentWelding/cutting media/materialsSoldering mediaHigh carbonFerrosilicon

The invention discloses a carbon-controlling and toughening type self-shielded open-arc high-boron surfacing flux-cored wire. According to the technical scheme, a low-carbon-steel H08A cold-rolled thin steel strip is adopted as an outer sheath, and an alloy, graphite and other metal powder are mixed in the sheath to form a powder core, wherein the surfacing alloy is alloy powder obtained by adding high-content ferro-boron, high-carbon ferrochrome and ferrotitanium with different melting properties into the flux-cored wire; by virtue of open-arc surfacing current control, a high-boron surfacing melt with the alloy component in an incompletely-molten and unevenly-mixed state is formed, so that an alloy element phase structure is selectively optimized and configured; the powder core mainly consists of the following components: ferro-boron, high-carbon ferrochrome, ferrotitanium, graphite, medium-carbon ferromanganese, ferrosilicon and reduced iron powder. The carbon-controlling and toughening type self-shielded open-arc high-boron surfacing flux-cored wire overcomes the defect that a current high-boron surfacing alloy is great in brittleness due to microstructure characteristics of the high-boron surfacing alloy, can be widely applied to surfacing manufacturing or repairing of parts with abrasive wear resistance, for example, a concrete cement conveying tube, and is especially suitable for surfacing manufacturing or paring of the parts with low-stress abrasive wear resistance.

Owner:XIANGTAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com