Patents

Literature

67results about How to "Low core loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

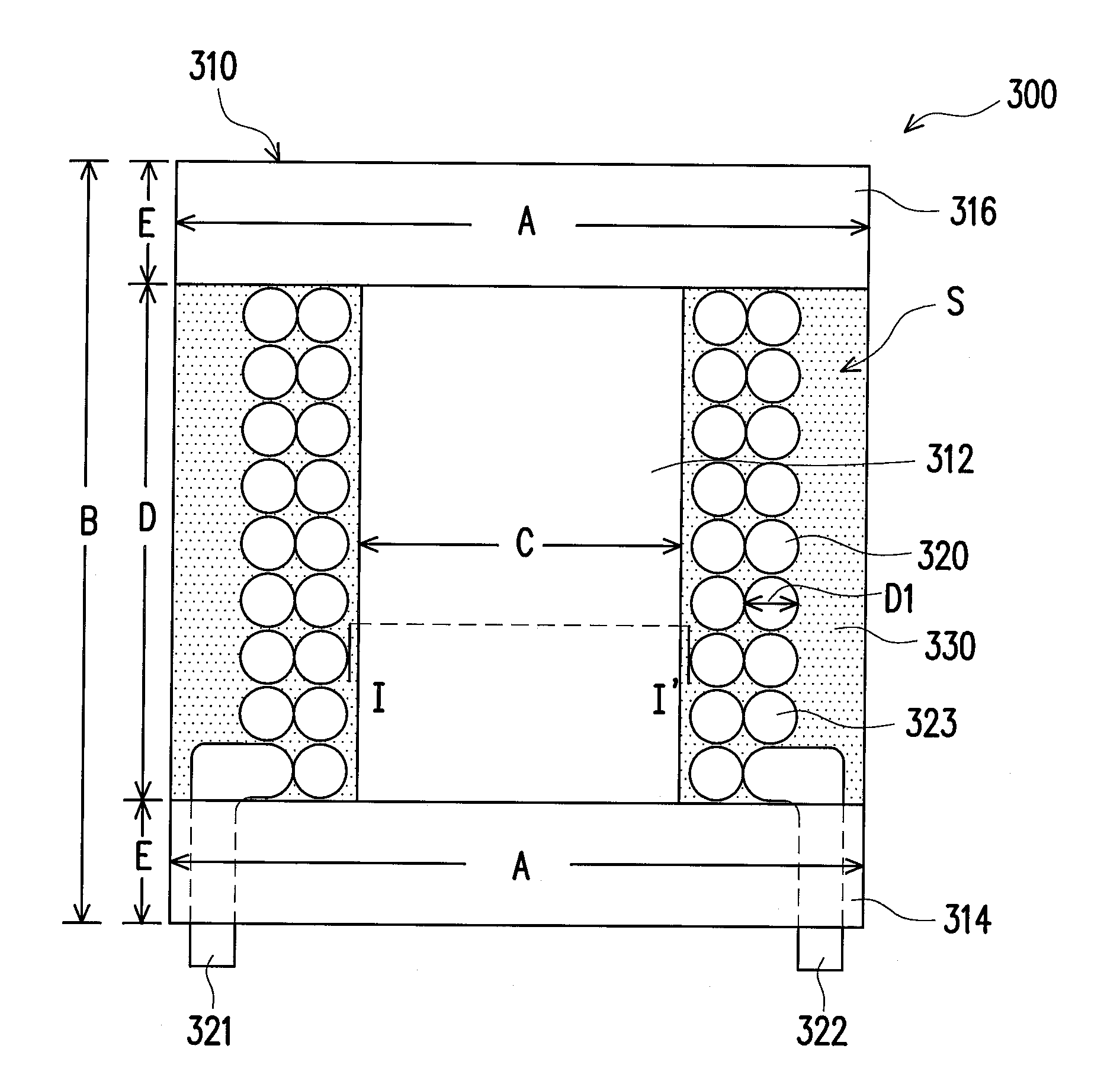

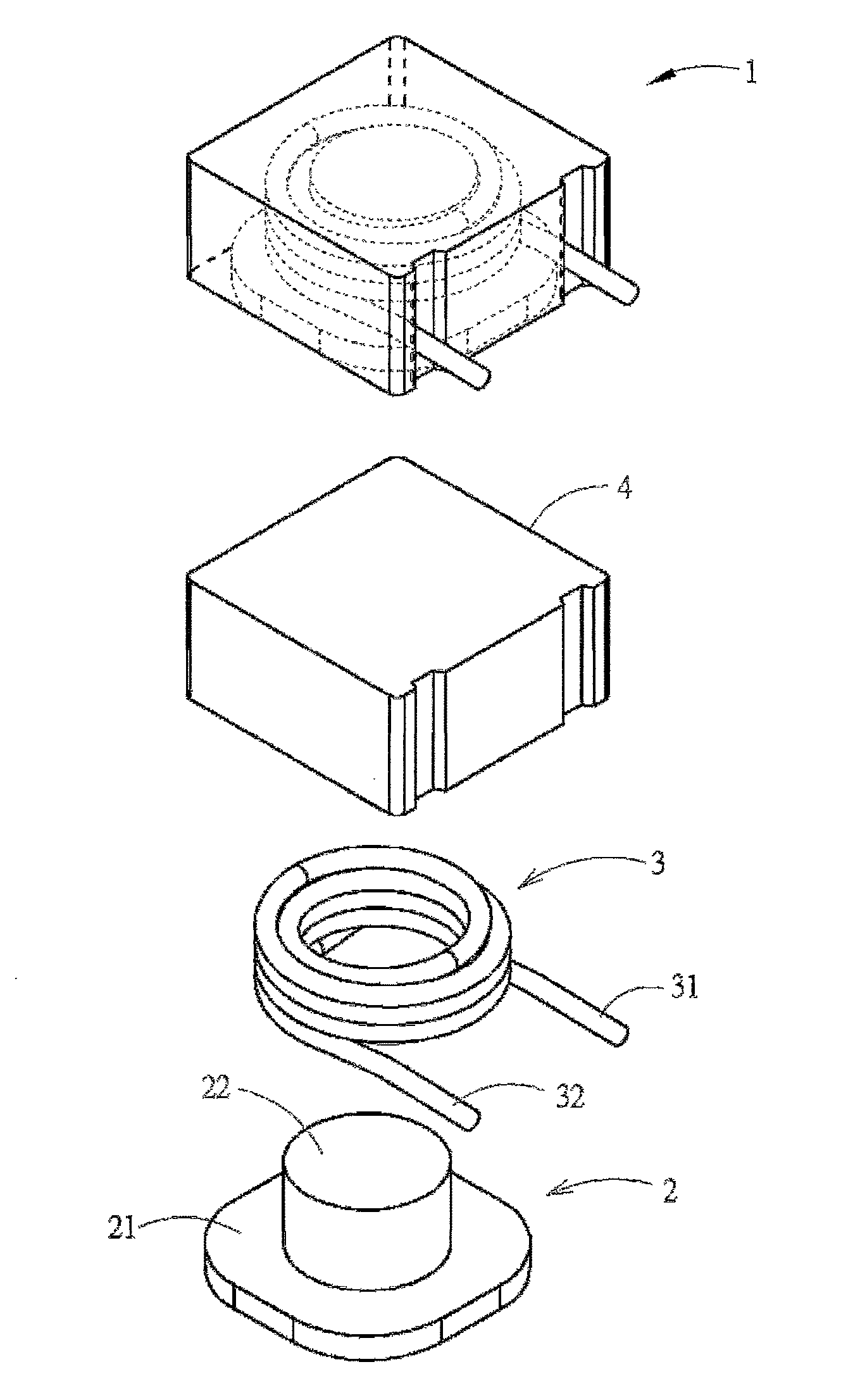

Magnetic device with high saturation current and low core loss

ActiveUS8723629B1Low costHigh saturation currentTransformers/inductances casingsTransformers/inductances coils/windings/connectionsPower flowMagnetic flux

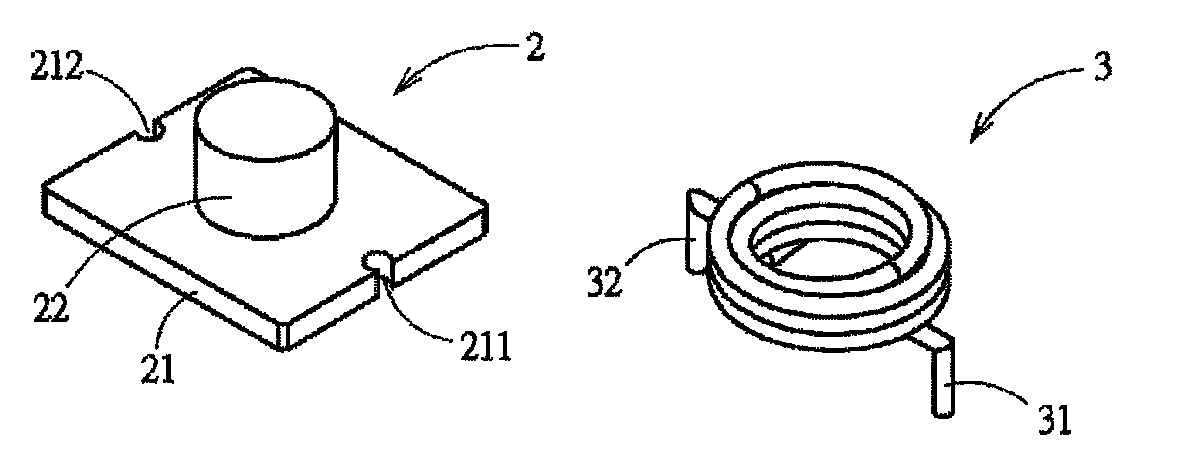

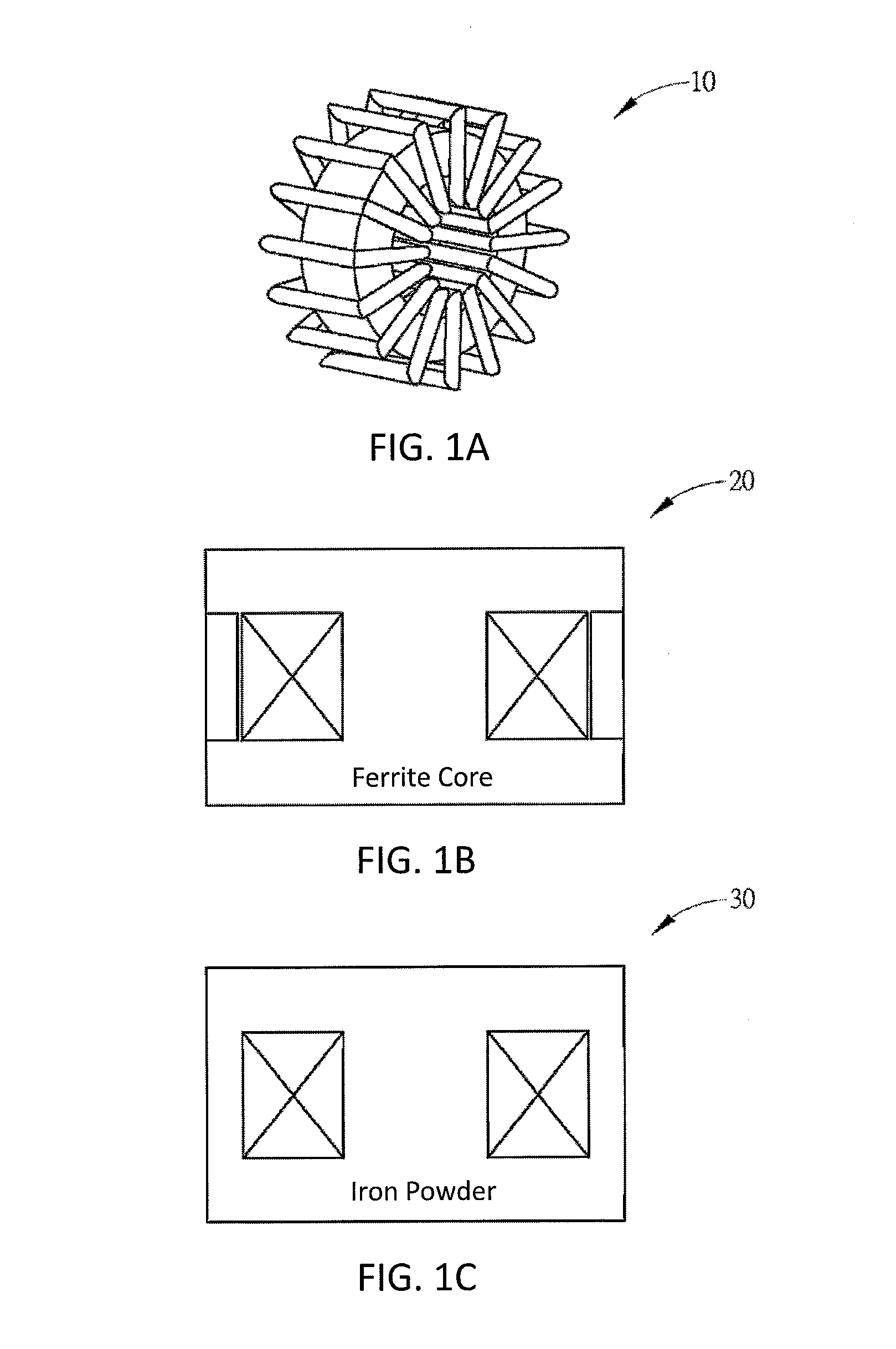

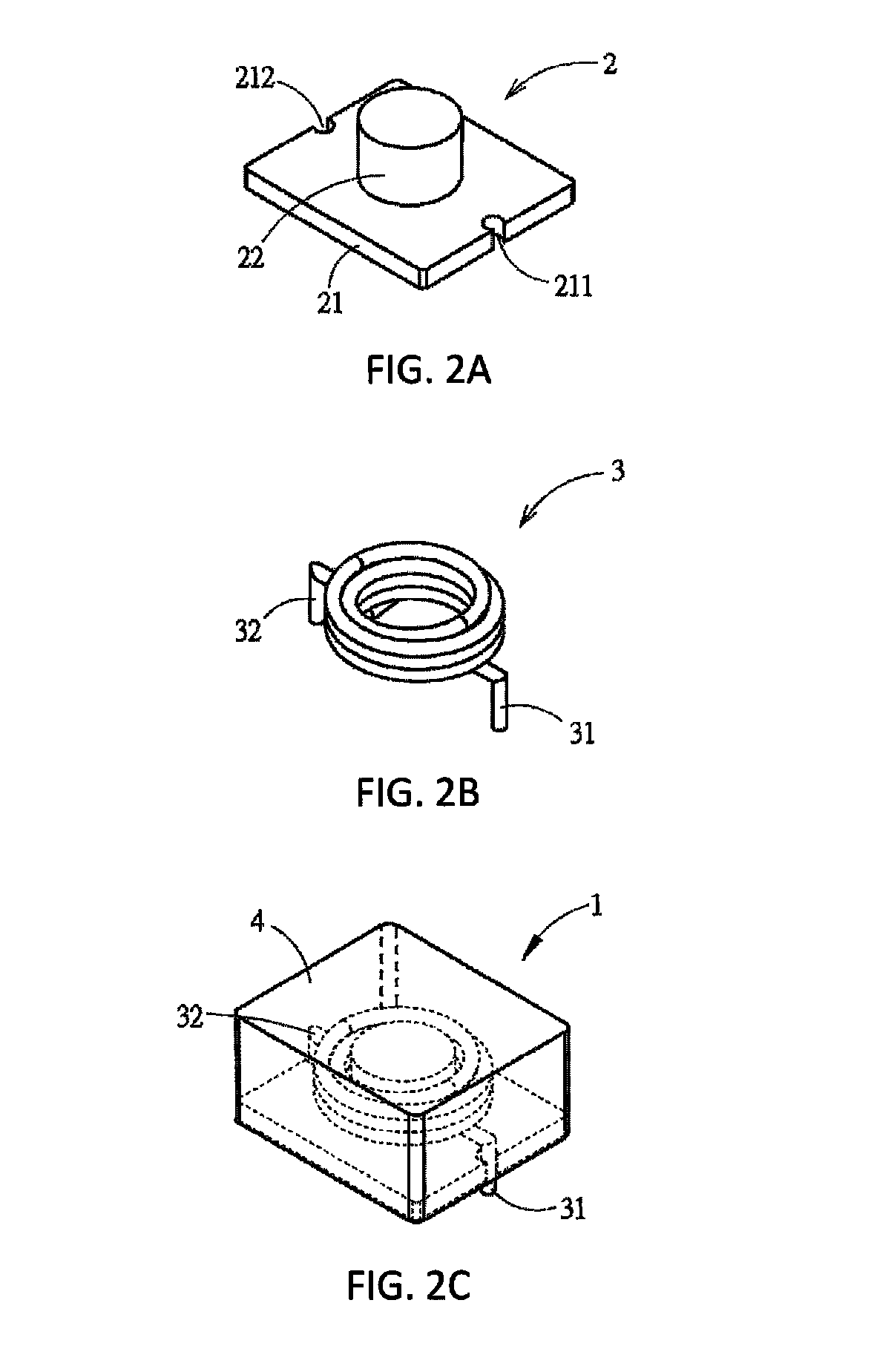

A magnetic device includes a T-shaped magnetic core, a wire coil and a magnetic body. The T-shaped magnetic core includes a base and a pillar, and is made of an annealed soft magnetic metal material, a core loss PCL (mW / cm3) of the T-shaped magnetic core satisfying: 0.64×f0.95×Bm2.20≦PCL≦7.26×f1.41×Bm1.08, where f (kHz) represents a frequency of a magnetic field applied to the T-shaped magnetic core, and Bm (kGauss) represents the operating magnetic flux density of the magnetic field at the frequency. The magnetic body fully covers the pillar, any part of the base that is located above the bottom surface of the base, and any part of the wire coil that is located directly above the top surface of the base.

Owner:CYNTEC

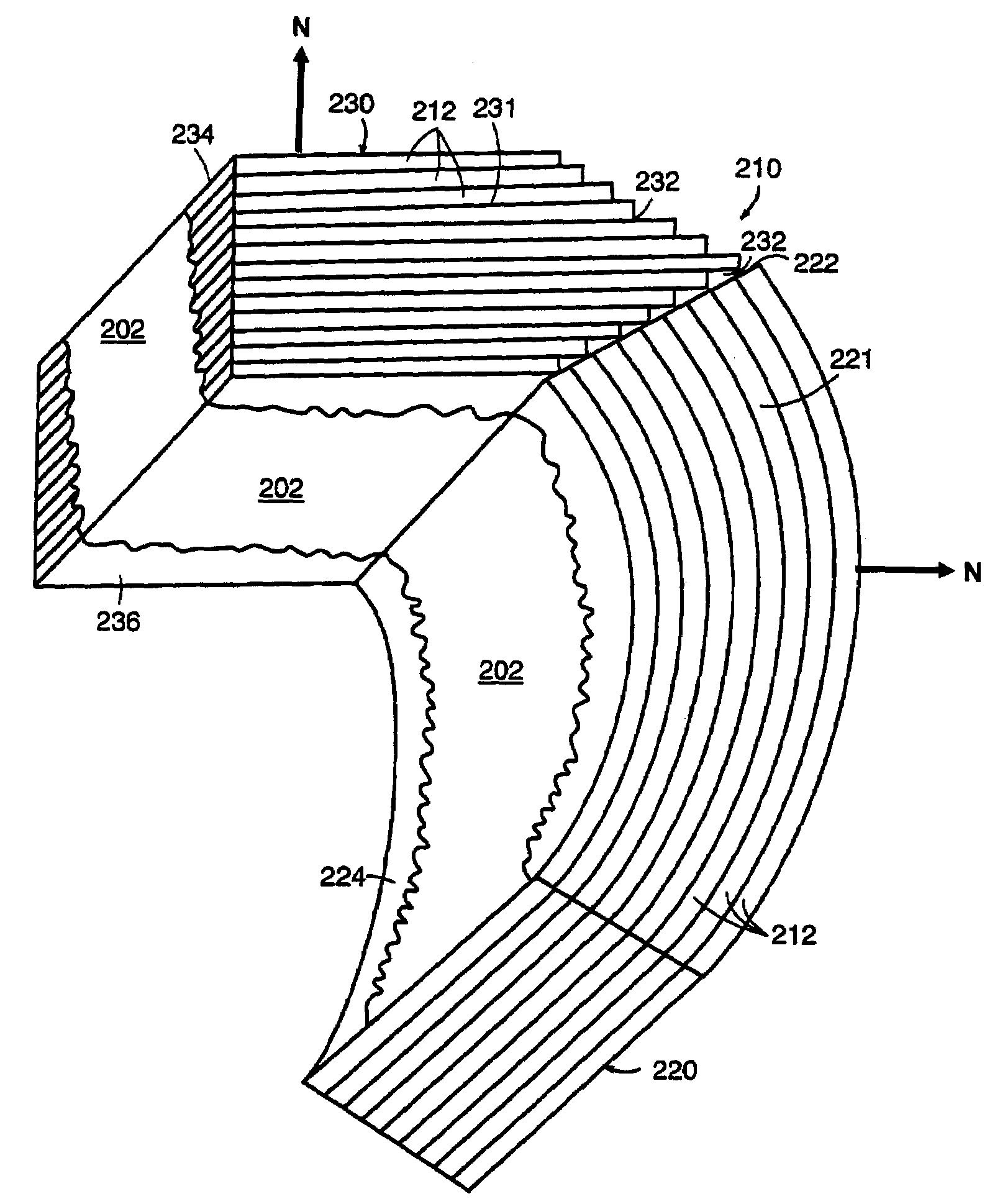

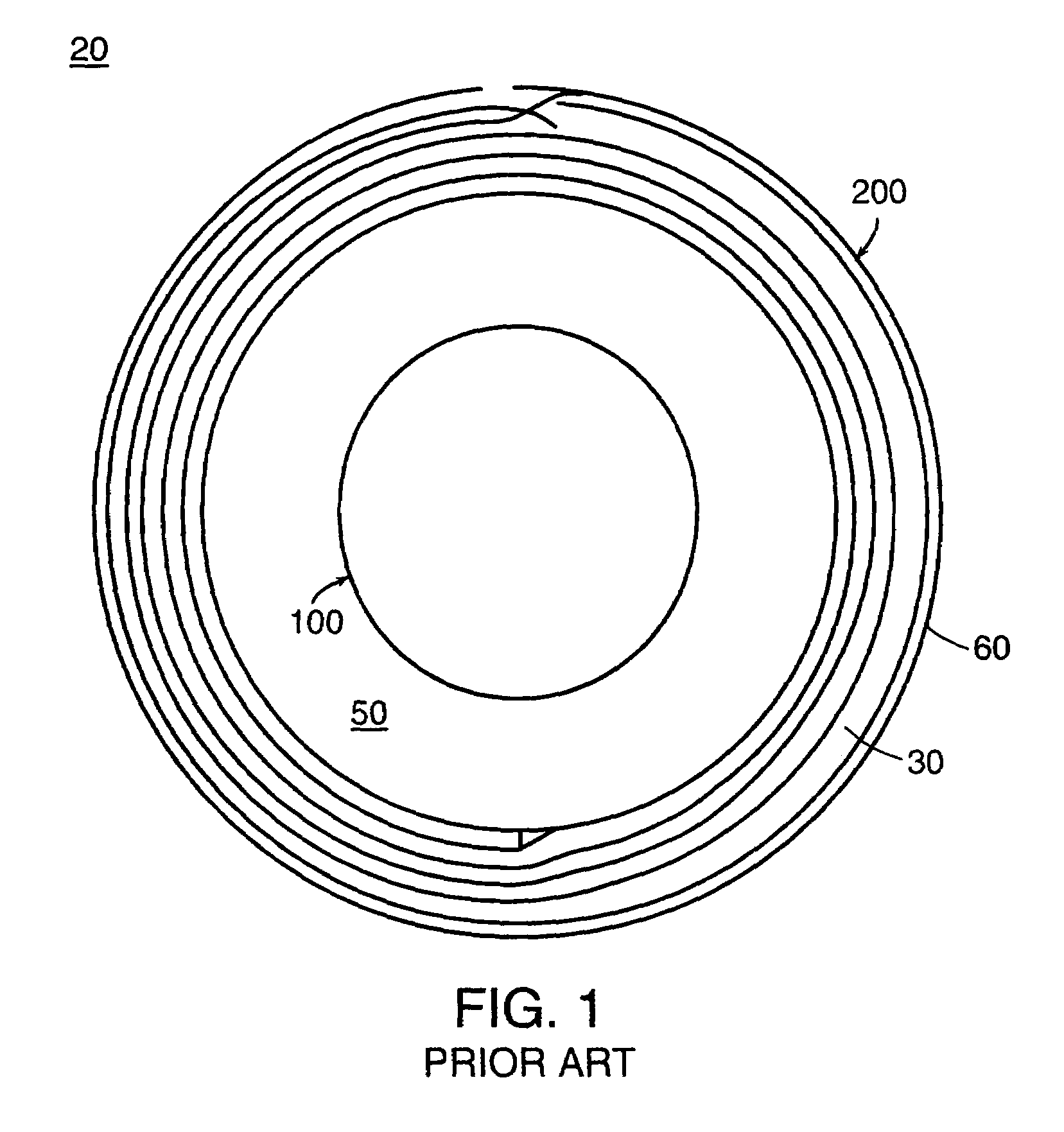

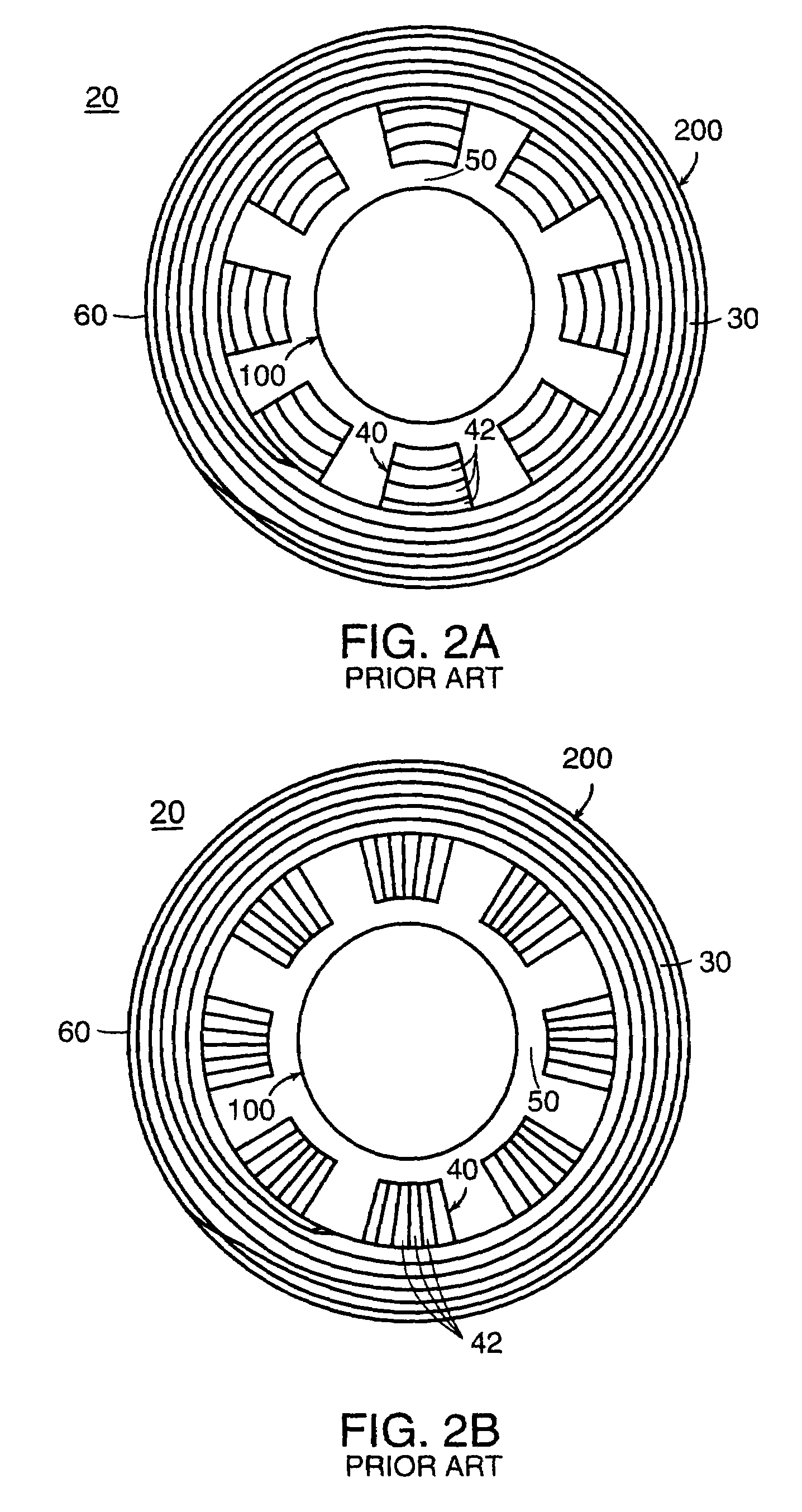

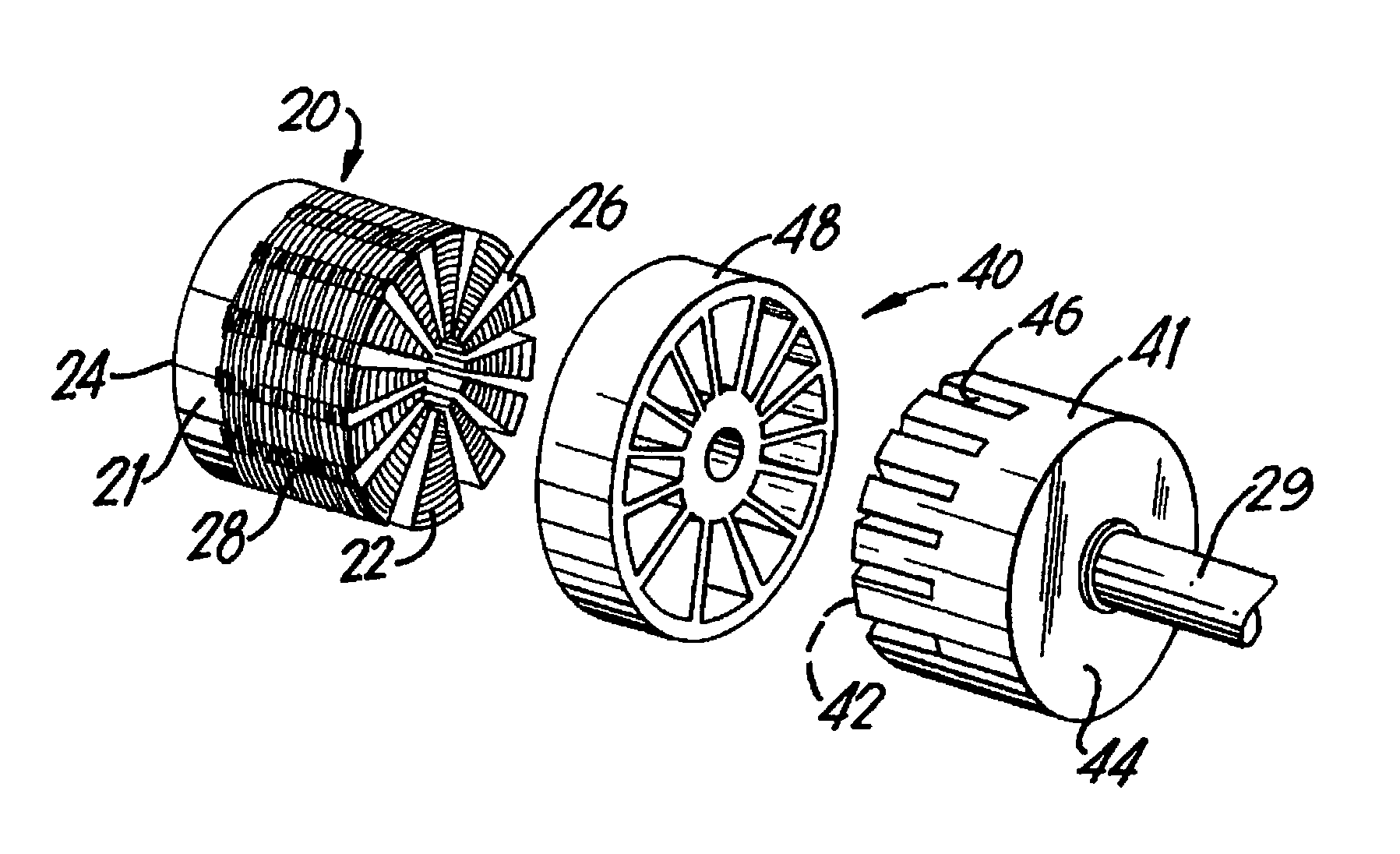

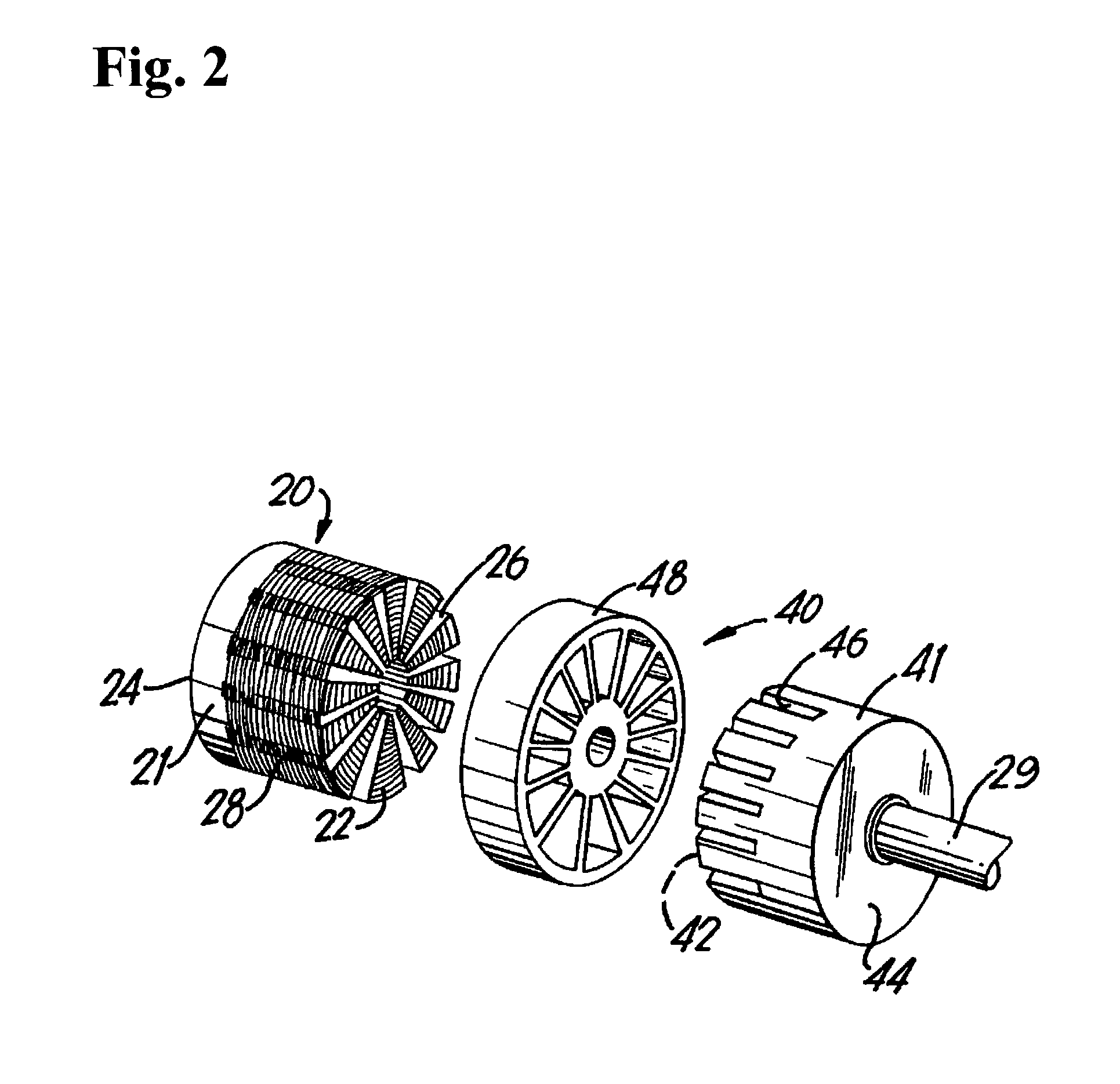

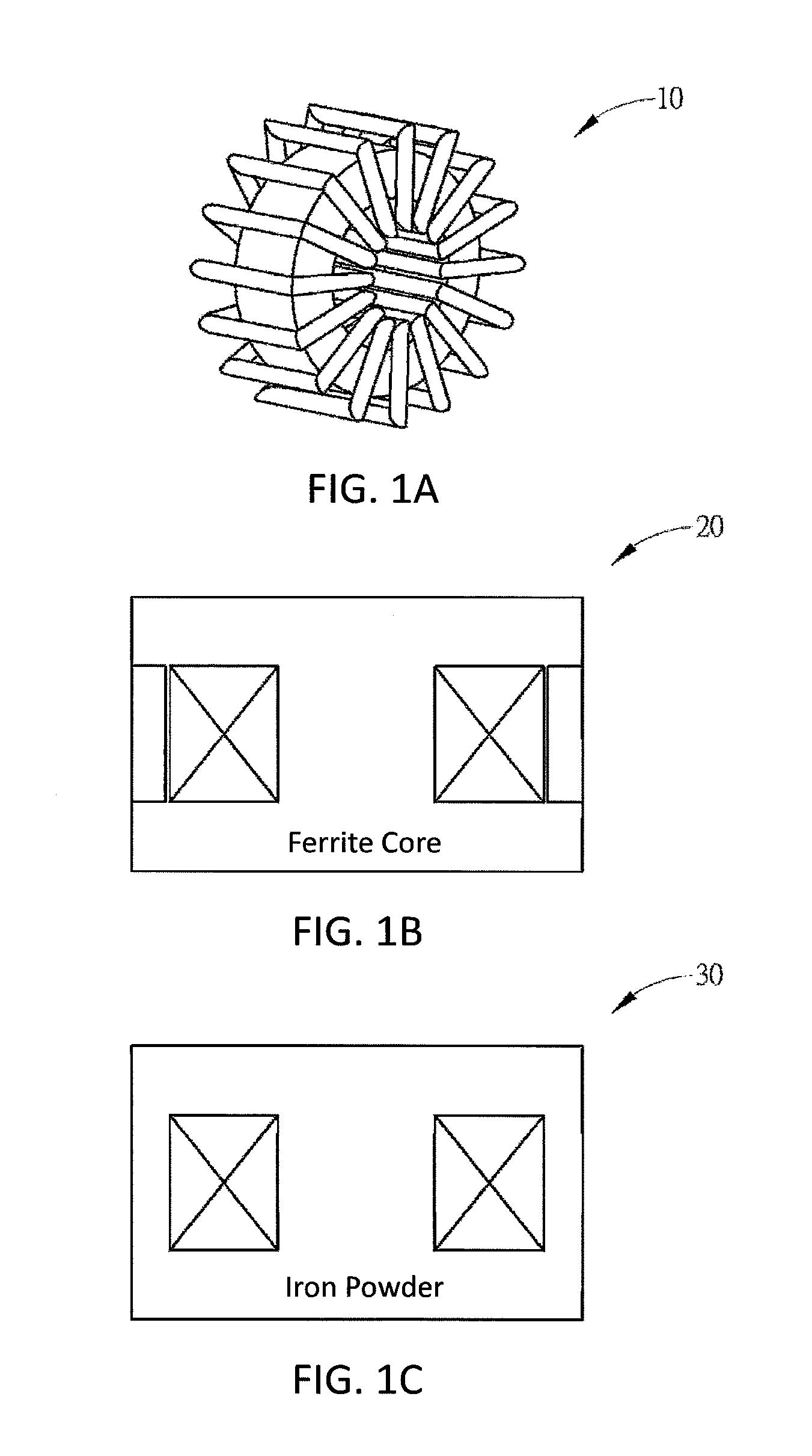

Amorphous metal stator for a radial-flux electric motor

InactiveUS6960860B1Improve motor efficiencyLow core lossMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesEngineering

An amorphous metal stator for a high efficiency radial-flux electric motor has a plurality of segments, each of which includes a plurality of layers of amorphous metal strips. The plural segments are arranged to form a generally cylindrical stator having a plurality of teeth sections or poles protruding radially inward from the inner surface of the stator. In a first embodiment, the stator back-iron and teeth are constructed such that radial flux passing through the stator crosses just one air gap when traversing each segment of the stator. In a second embodiment, the stator back-iron and teeth are constructed such that radial flux passing through the stator traverses each segment without crossing an air gap.

Owner:METGLAS INC

Low-loss magnetic powder core, and switching power supply, active filter, filter, and amplifying device using the same

InactiveUS6897718B2Reduced core lossLess distortionDc-dc conversionInorganic material magnetismMetallurgyAlloy

A magnetic powder core comprises a molded article of a mixture of a glassy alloy powder and an insulating material. The glassy alloy comprises Fe and at least one element selected from Al, P, C, Si, and B, and has a texture primarily composed of an amorphous phase. The glassy alloy exhibits a temperature difference ΔTx, which is represented by the equation ΔTx=Tx−Tg, of at least 20 K in a supercooled liquid, wherein Tx indicates the crystallization temperature and Tg indicates the glass transition temperature. The magnetic core precursor is produced mixing the glassy alloy powder with the insulating material, compacting the mixture to form a magnetic core precursor, and annealing the magnetic core precursor at a temperature in the range between (Tg−170) K and Tg K to relieve the internal stress of the magnetic core precursor. The glassy alloy exhibits low coercive force and low core loss.

Owner:ALPS ALPINE CO LTD

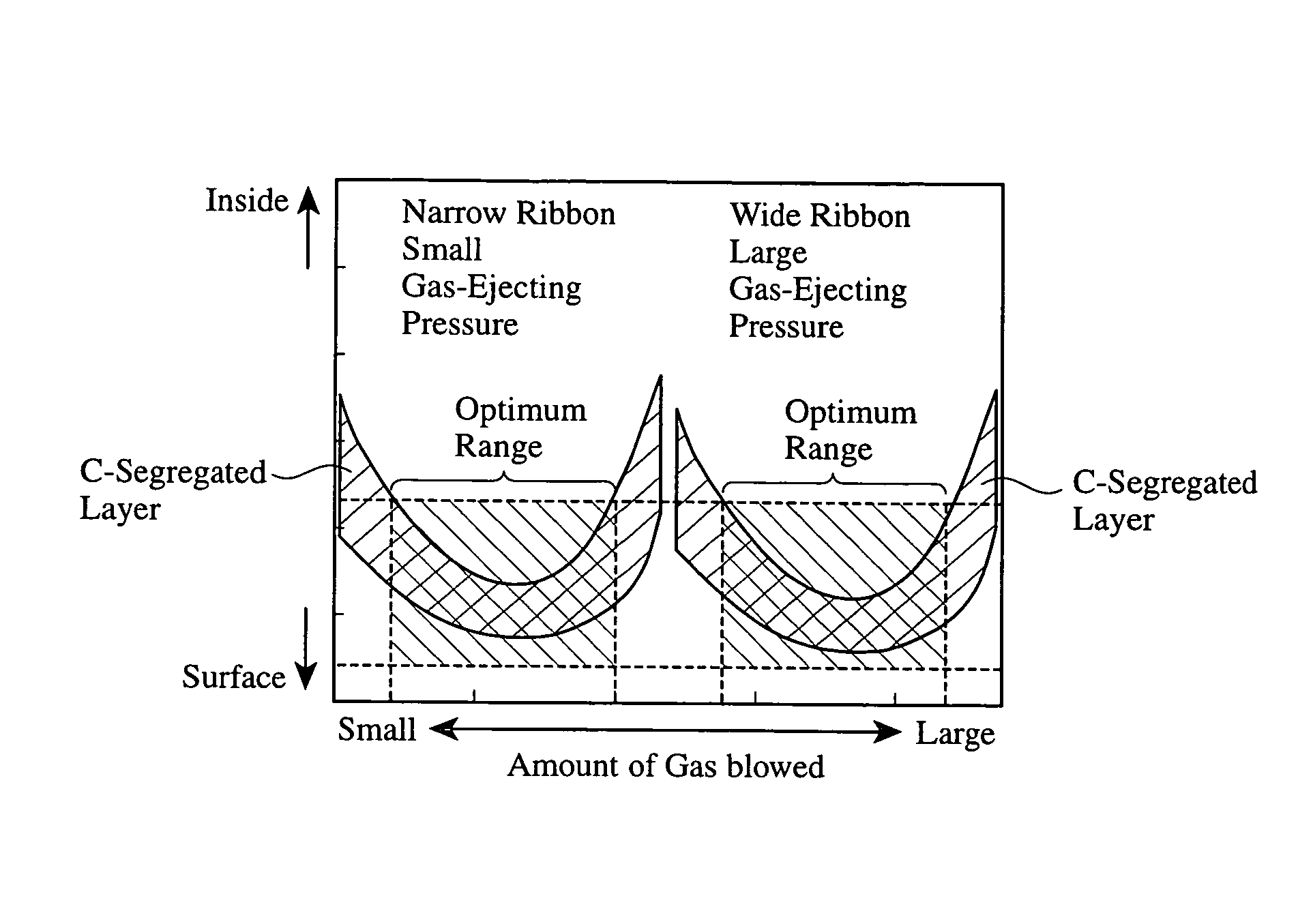

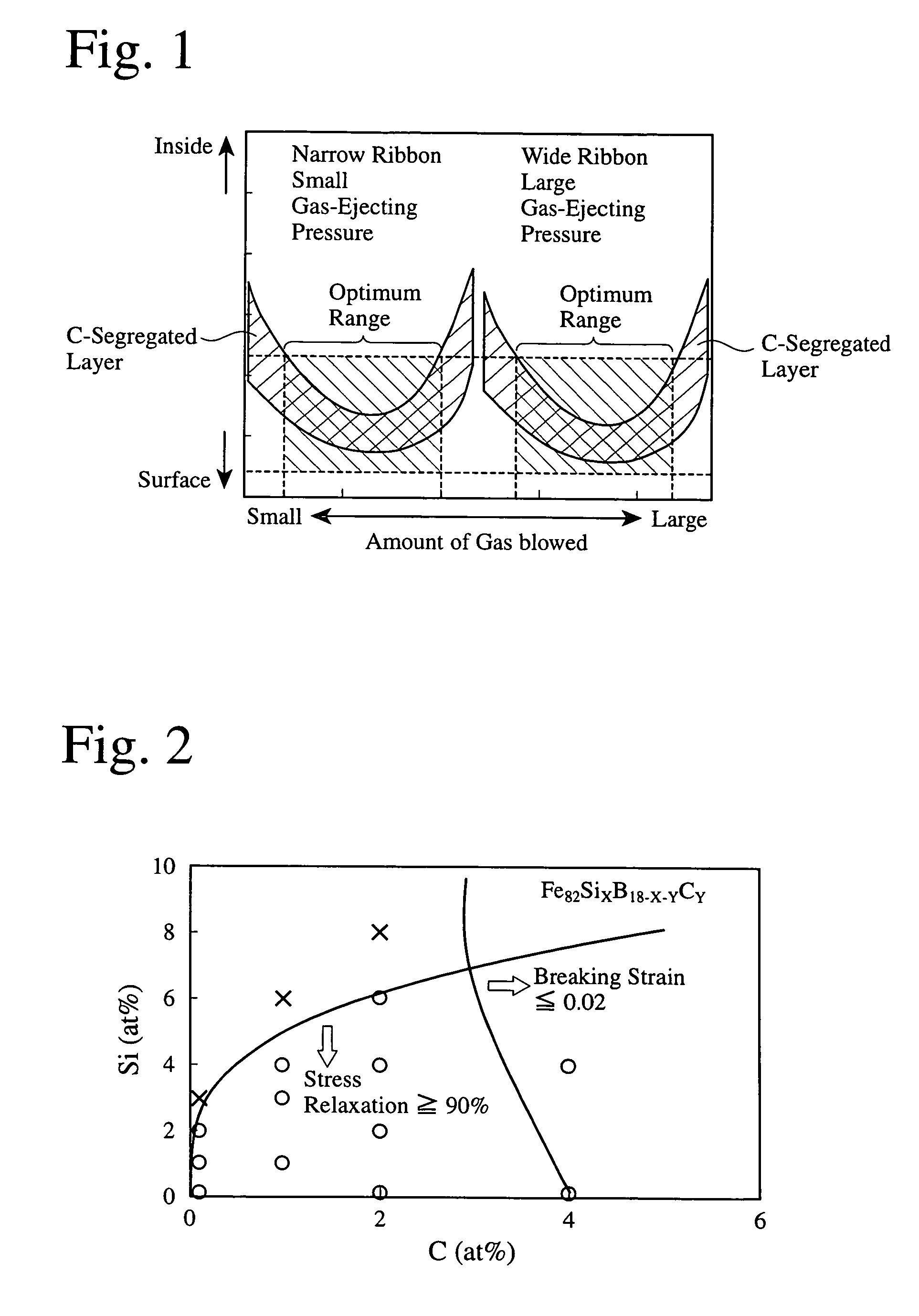

Fe-based amorphous alloy ribbon

ActiveUS7425239B2High magnetic flux densityLow core lossInductances/transformers/magnets manufactureMagnetic materialsTO-18Impurity

An Fe-based amorphous alloy ribbon having a composition comprising FeaSibBcCd and inevitable impurities, wherein a is 80 to 83 atomic %, b is 0.1 to 5 atomic %, c is 14 to 18 atomic %, and d is 0.01 to 3 atomic %, the concentration distribution of C measured radially from both surfaces to the inside of said Fe-based amorphous alloy ribbon having a peak within a depth of 2 to 20 nm.

Owner:HITACHI METALS LTD

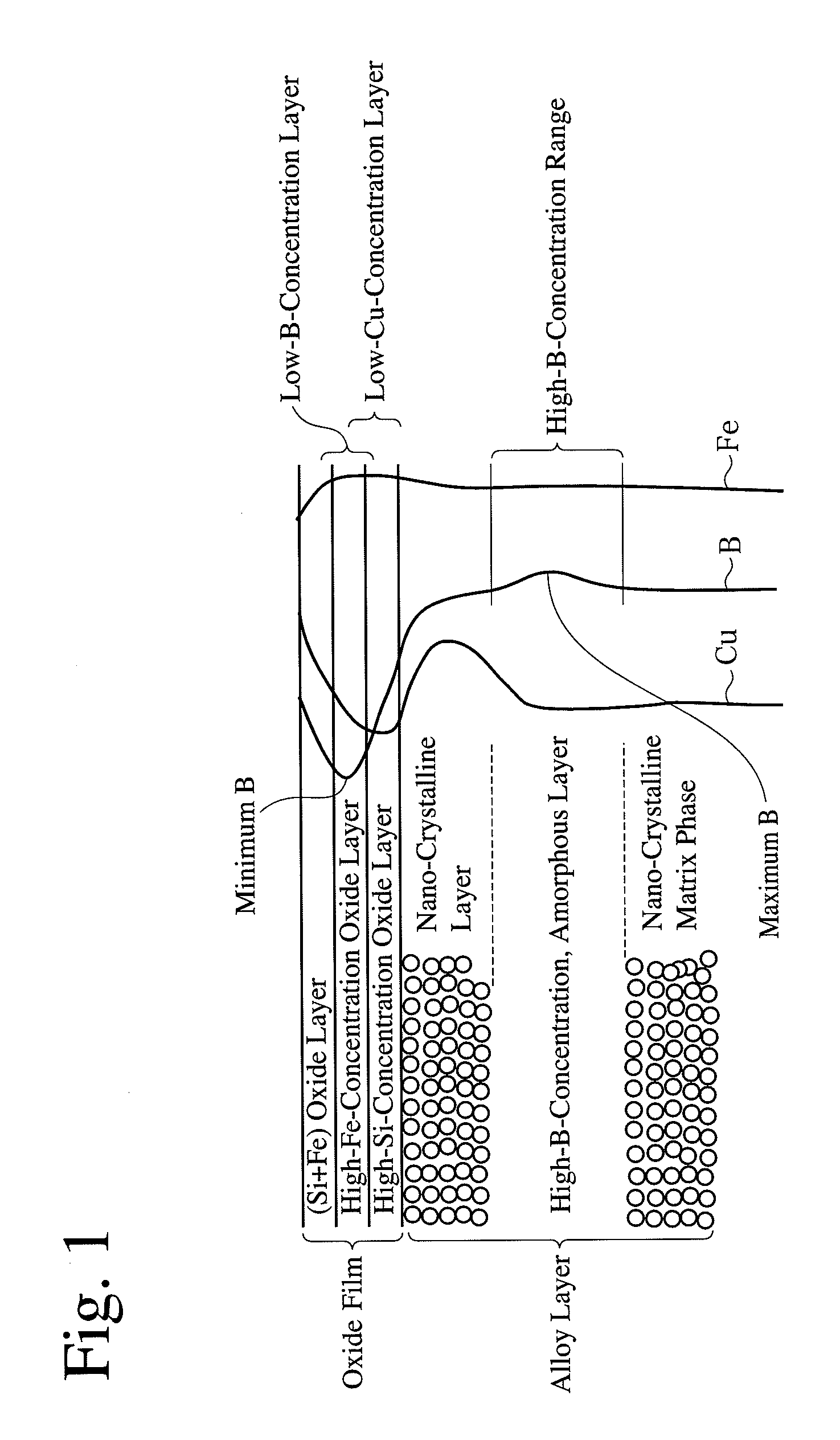

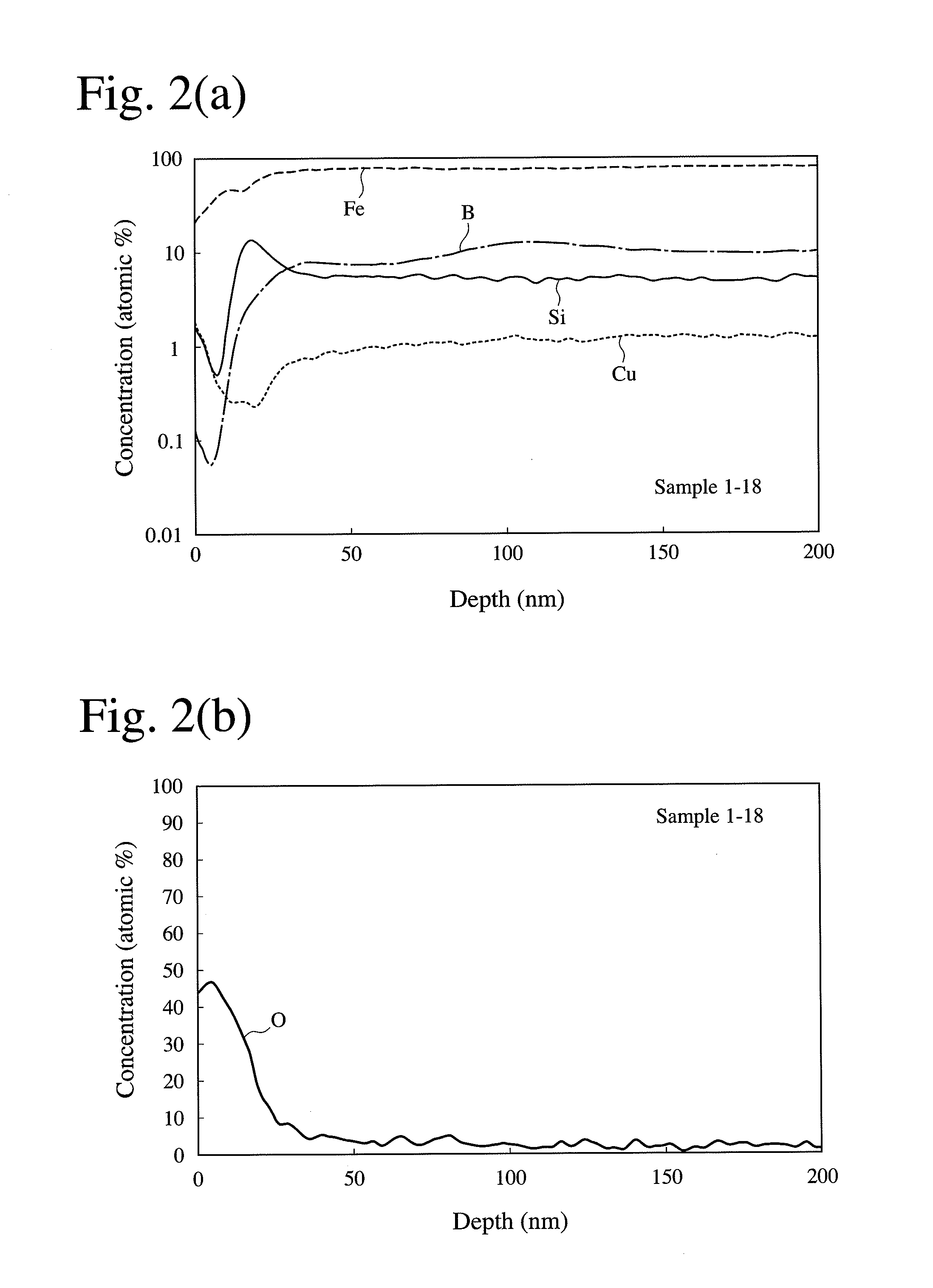

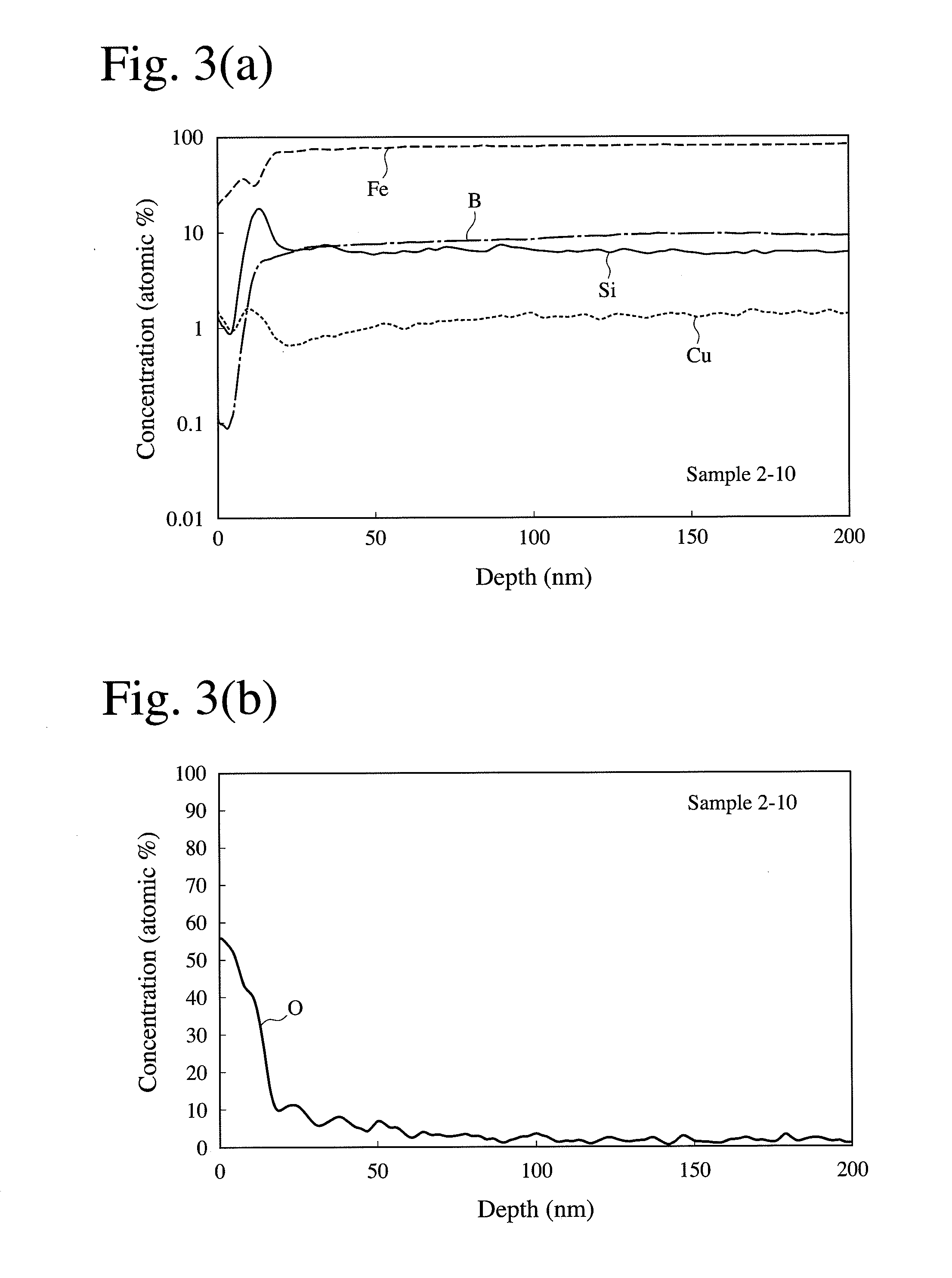

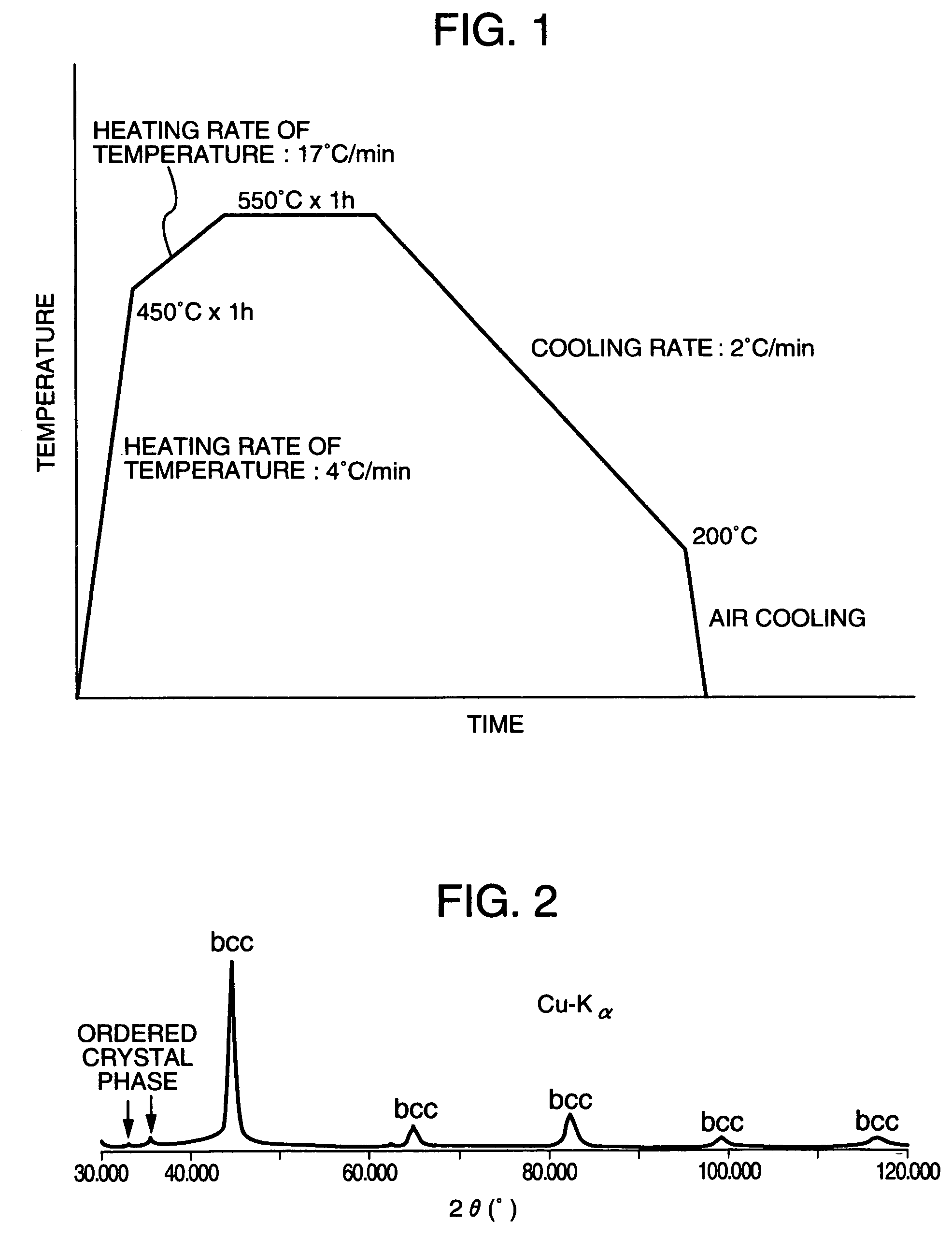

Soft magnetic alloy ribbon and its production method, and magnetic device having soft magnetic alloy ribbon

ActiveUS20110272065A1High saturated magnetic flux densityLow core lossMaterial nanotechnologyNanomagnetismAmorphous phaseQuenching

A method for producing a soft magnetic alloy ribbon having a composition represented by Fe100−x−y−zAxByXz, wherein A is Cu and / or Au, X is at least one element selected from the group consisting of Si, S, C, P, Al, Ge, Ga and Be, and x, y and z are numbers (by atomic %) meeting the conditions of 0<x≦5, 10≦y≦22, 1≦z≦10, and x+y+z≦25, and comprising a matrix phase in which fine crystal grains having an average diameter of 60 nm or less are dispersed at a volume fraction of 50% or more, part of an oxide film formed on the surface being a layer having a lower B concentration than the average B concentration of the matrix phase; comprising the steps of (1) ejecting an alloy melt having the above composition onto a rotating cooling roll for quenching, to form a primary fine-crystalline alloy ribbon having a matrix phase, in which fine crystal nuclei having an average diameter of 30 nm or less are dispersed at a volume fraction of more than 0% and less than 30% in an amorphous phase; and then (2) annealing the primary fine-crystalline alloy ribbon in an atmosphere having an oxygen concentration of 6-18%.

Owner:HITACHI METALS LTD

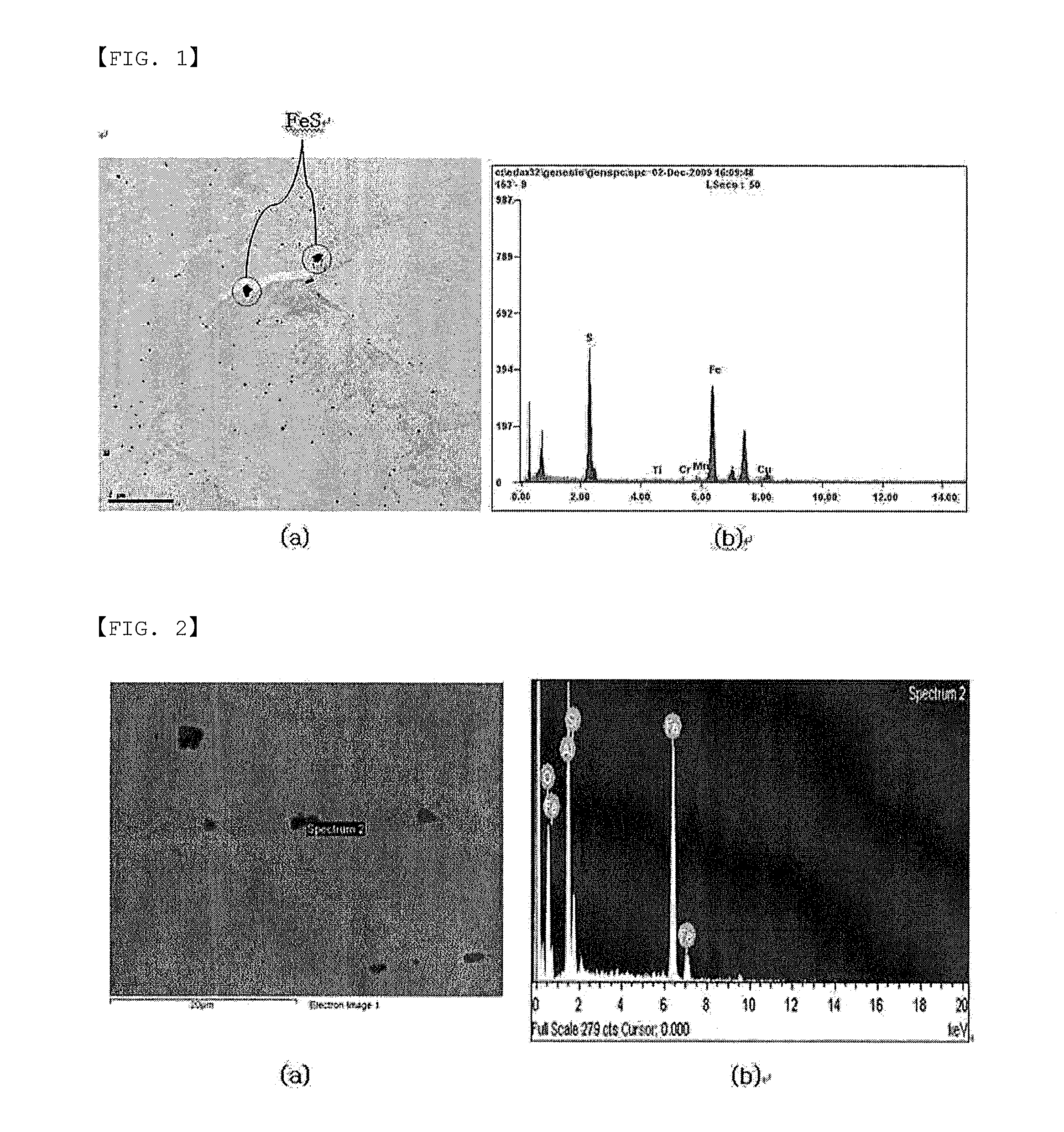

Method for Manufacturing Grain-Oriented Electrical Steel Sheets Having Excellent Magnetic Properties

ActiveUS20130306202A1High magnetic flux densityLow core lossFurnace typesHeat treatment furnacesSheet steelElectrical steel

Provided is a method for manufacturing a grain-oriented electrical steel sheet, the method comprising: heating a grain-oriented electrical steel sheet slab; hot-rolling the heated slab; optionally annealing the hot-rolled steel sheet; subjecting the resulting steel sheet to one cold rolling or two or more cold rollings with intermediate annealing therebetween; subjecting the cold-rolled steel sheet to primary recrystallization annealing; and subjecting the annealed steel sheet to secondary recrystallization annealing, wherein the primary recrystallization annealing sequentially comprises an ultra-rapid heating process of heating the steel sheet at an average heating rate of 300° C. / sec or higher, a rapid heating process of heating the steel sheet at a lower average heating rate than the average heating rate of the ultra-rapid heating process, but not lower than 100° C. / sec, and a general heating process of heating the steel sheet at a lower average heating rate than the average heating rate of the rapid heating process.

Owner:POHANG IRON & STEEL CO LTD

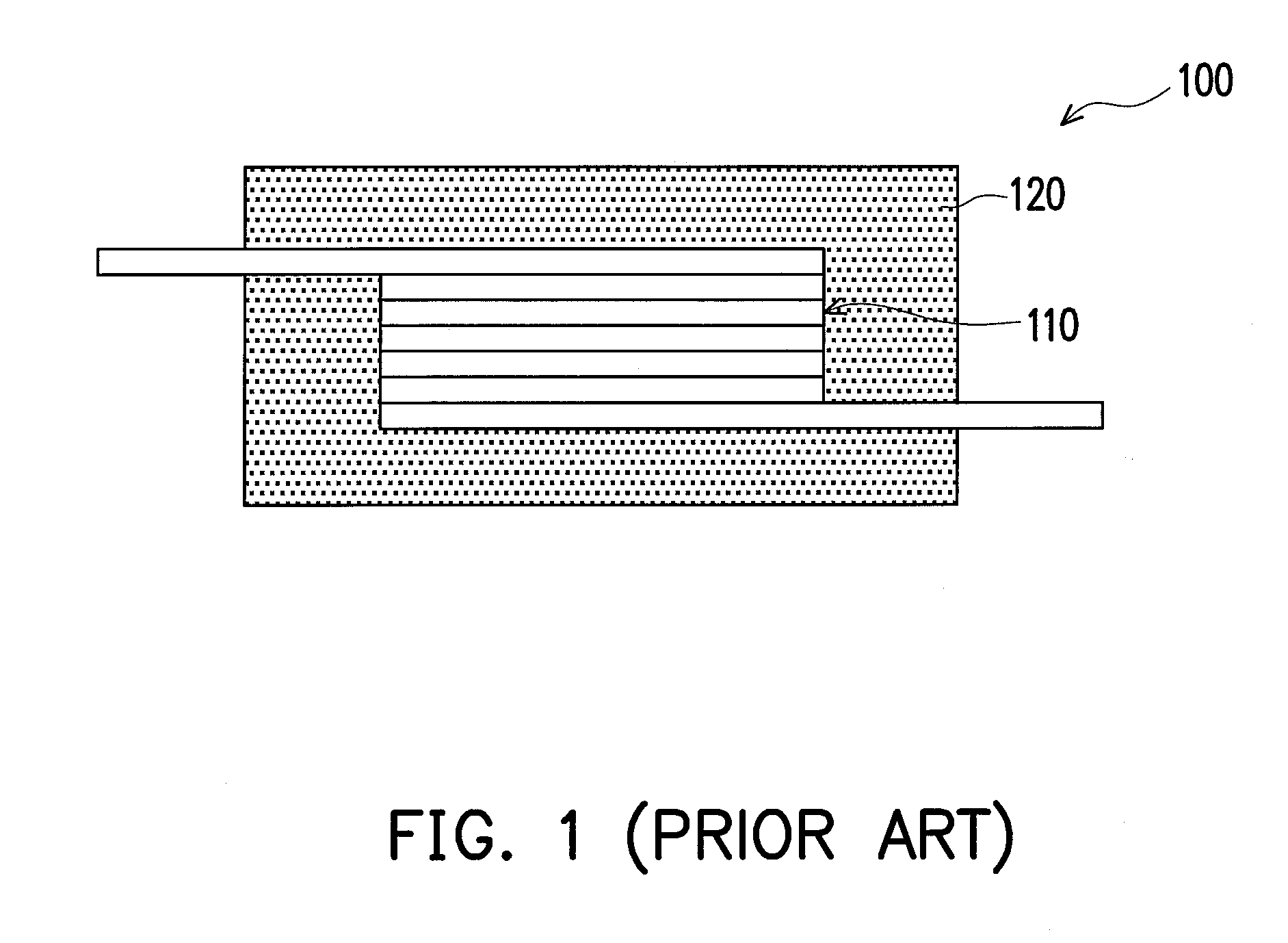

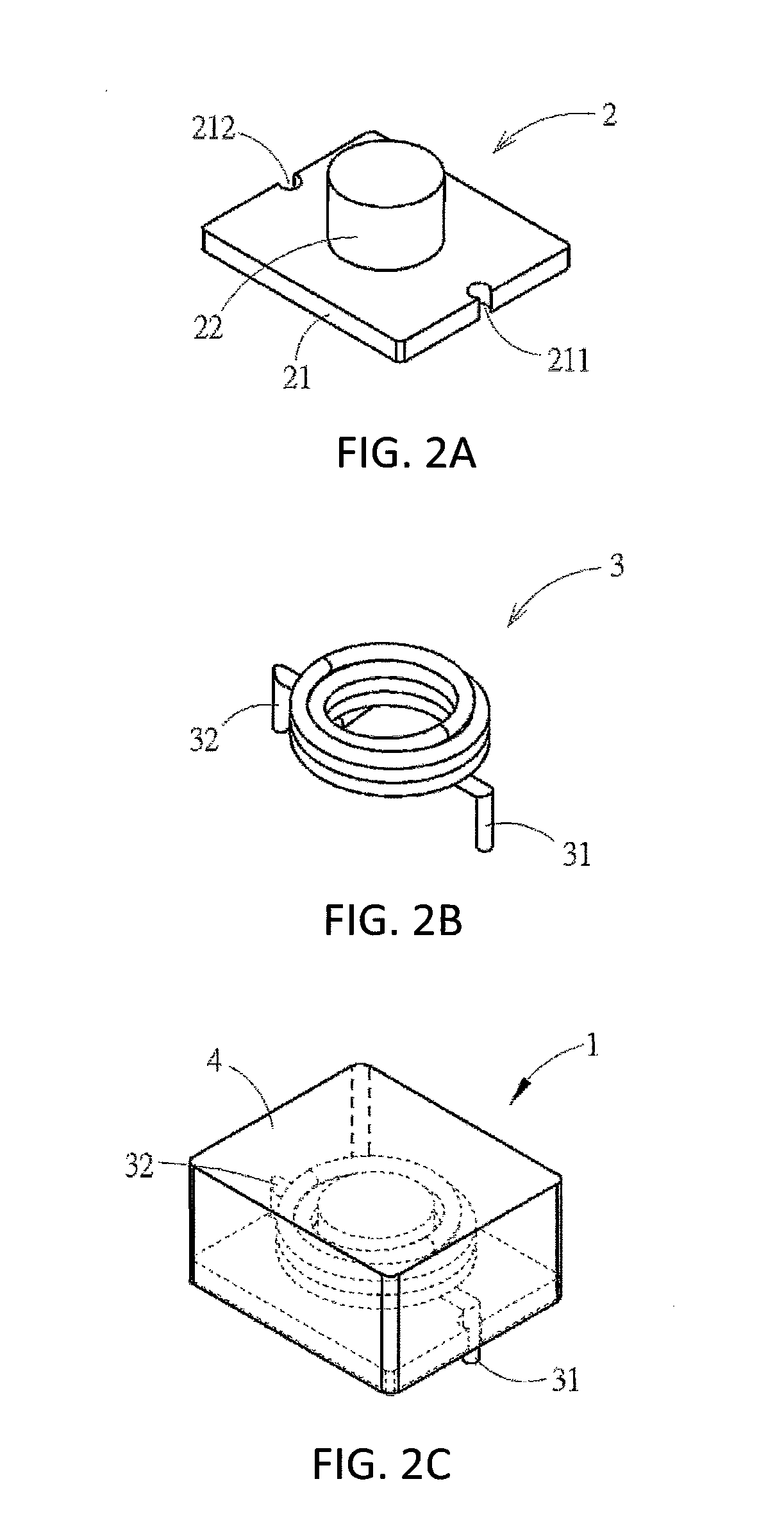

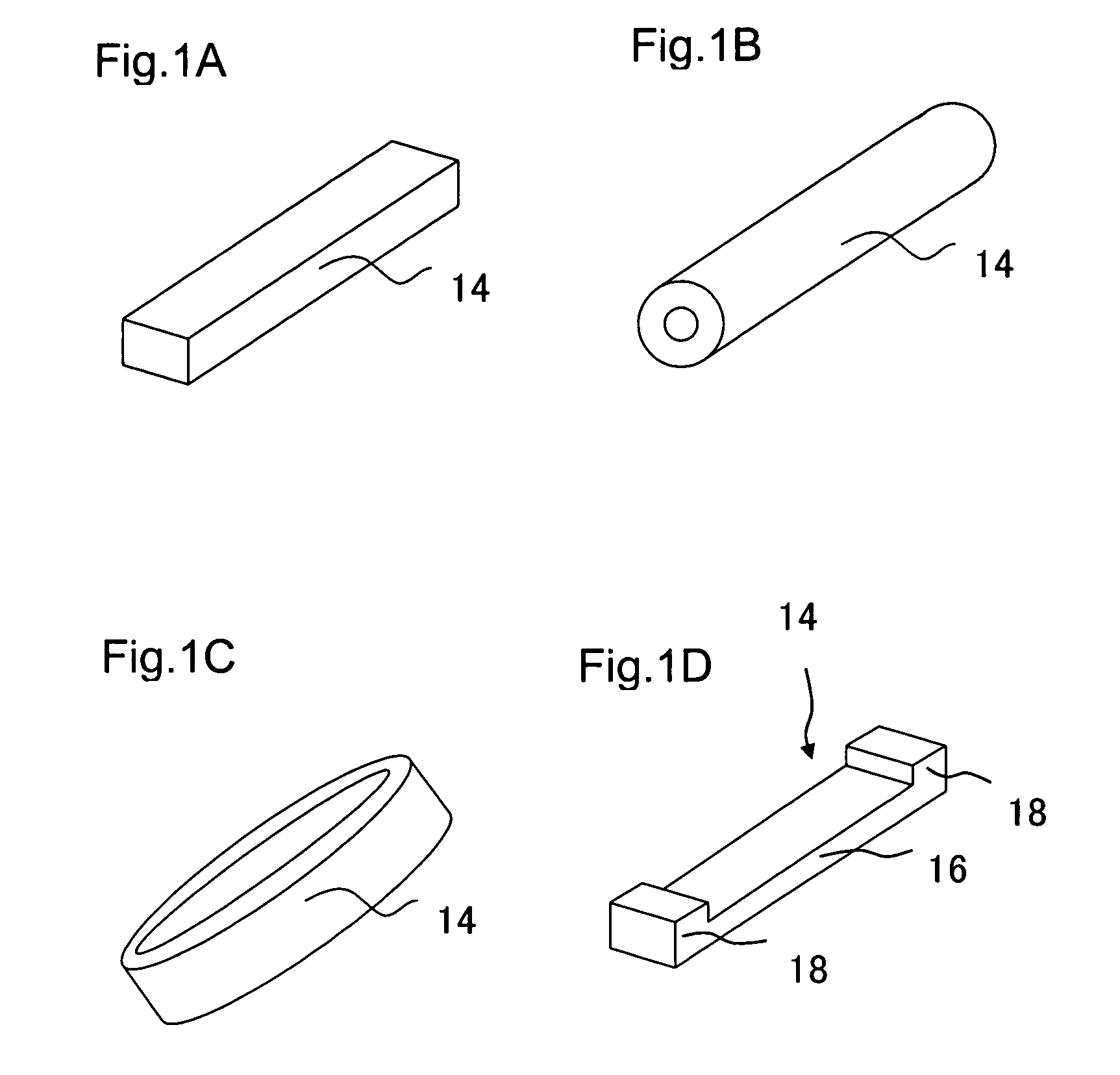

Wire wound type choke coil

InactiveUS20100182115A1Low core lossLow human labour costTransformers/inductances casingsCores/yokesEngineeringAlloy

A choke coil including a drum-core and at least one wire is provided. The drum-core includes a pillar, a first board and a second board. Two ends of the pillar are respectively connected to the first board and the second board. A material of the drum-core includes ferrous alloy. The wire has a winding portion wrapped around the pillar.

Owner:CYNTEC

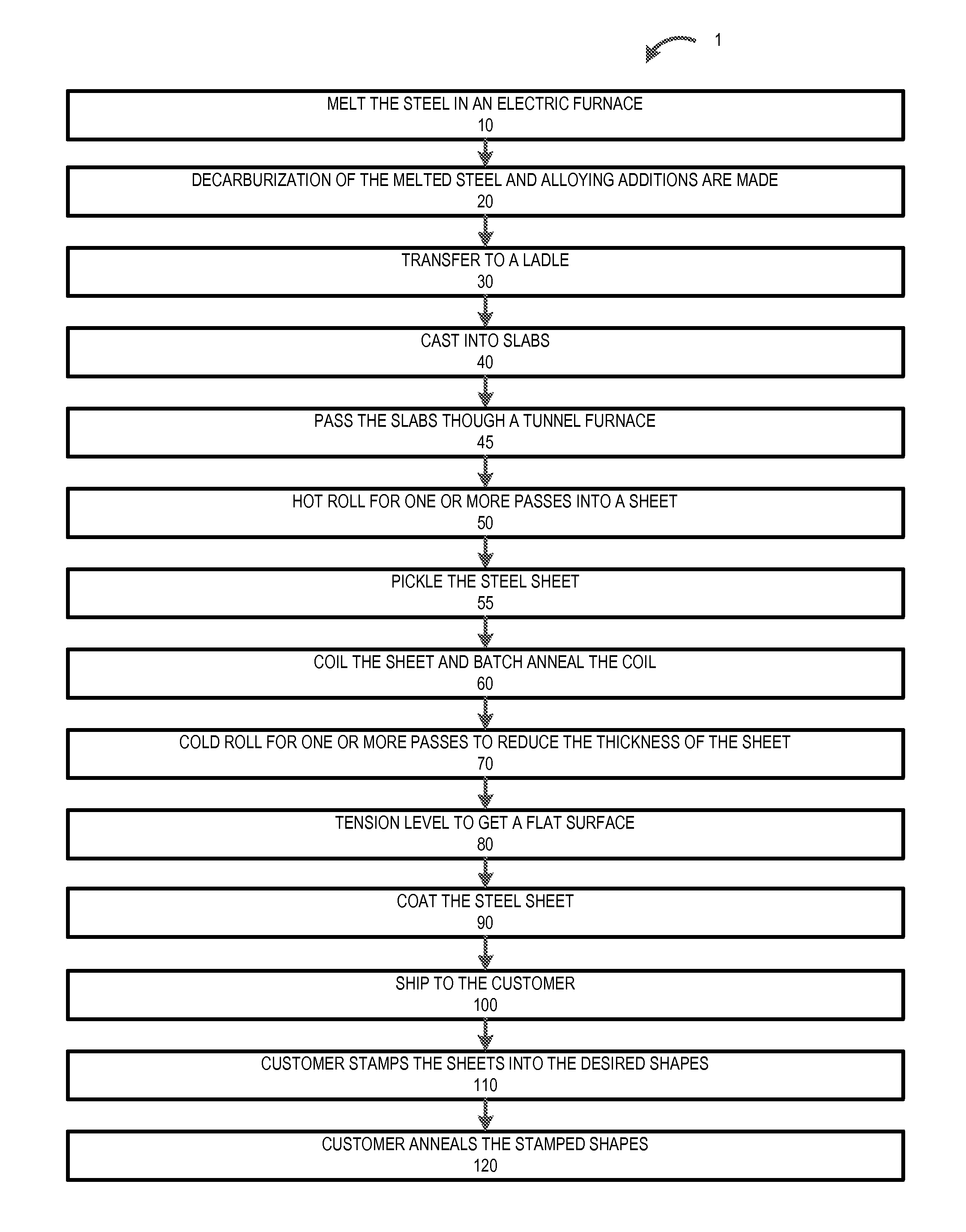

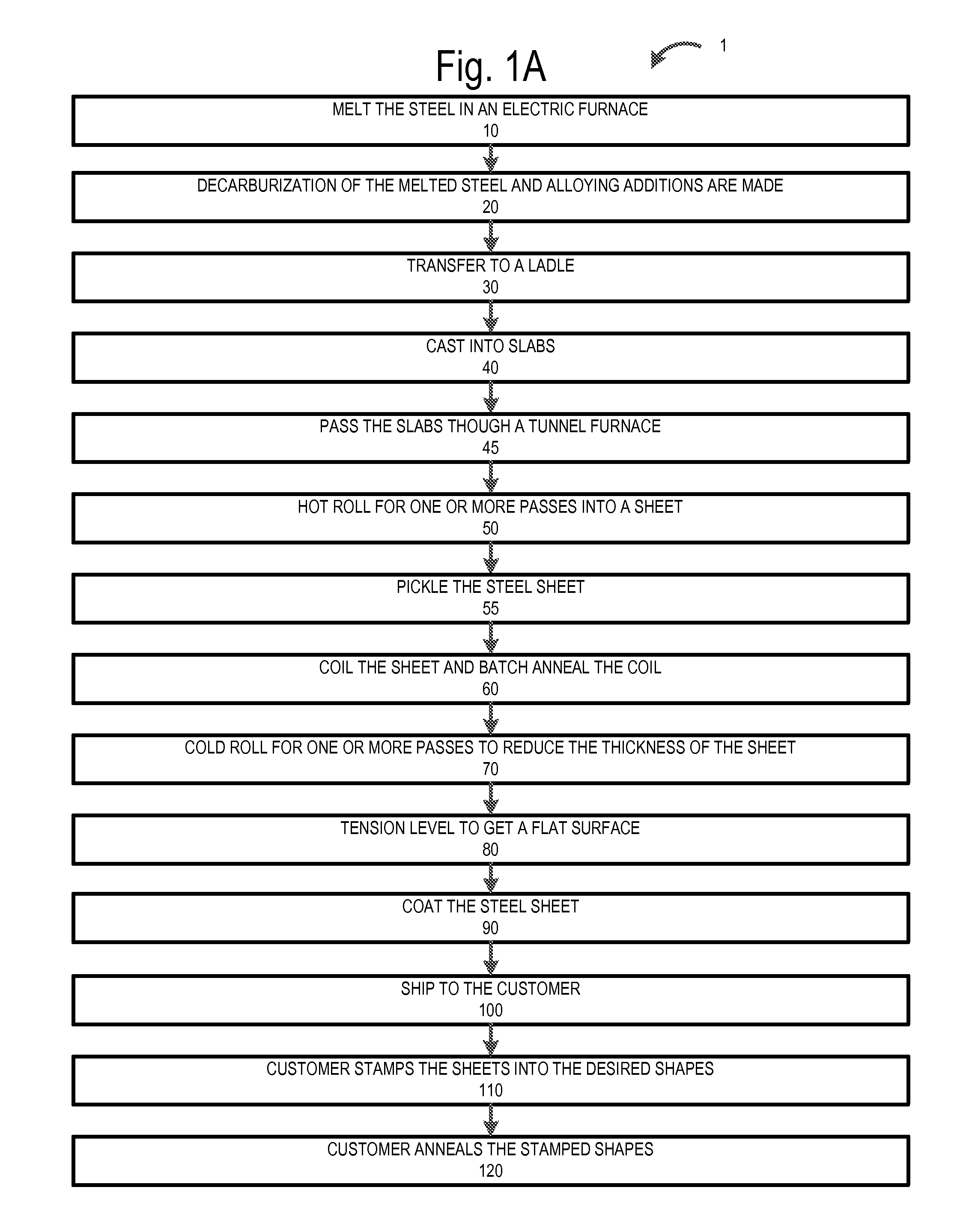

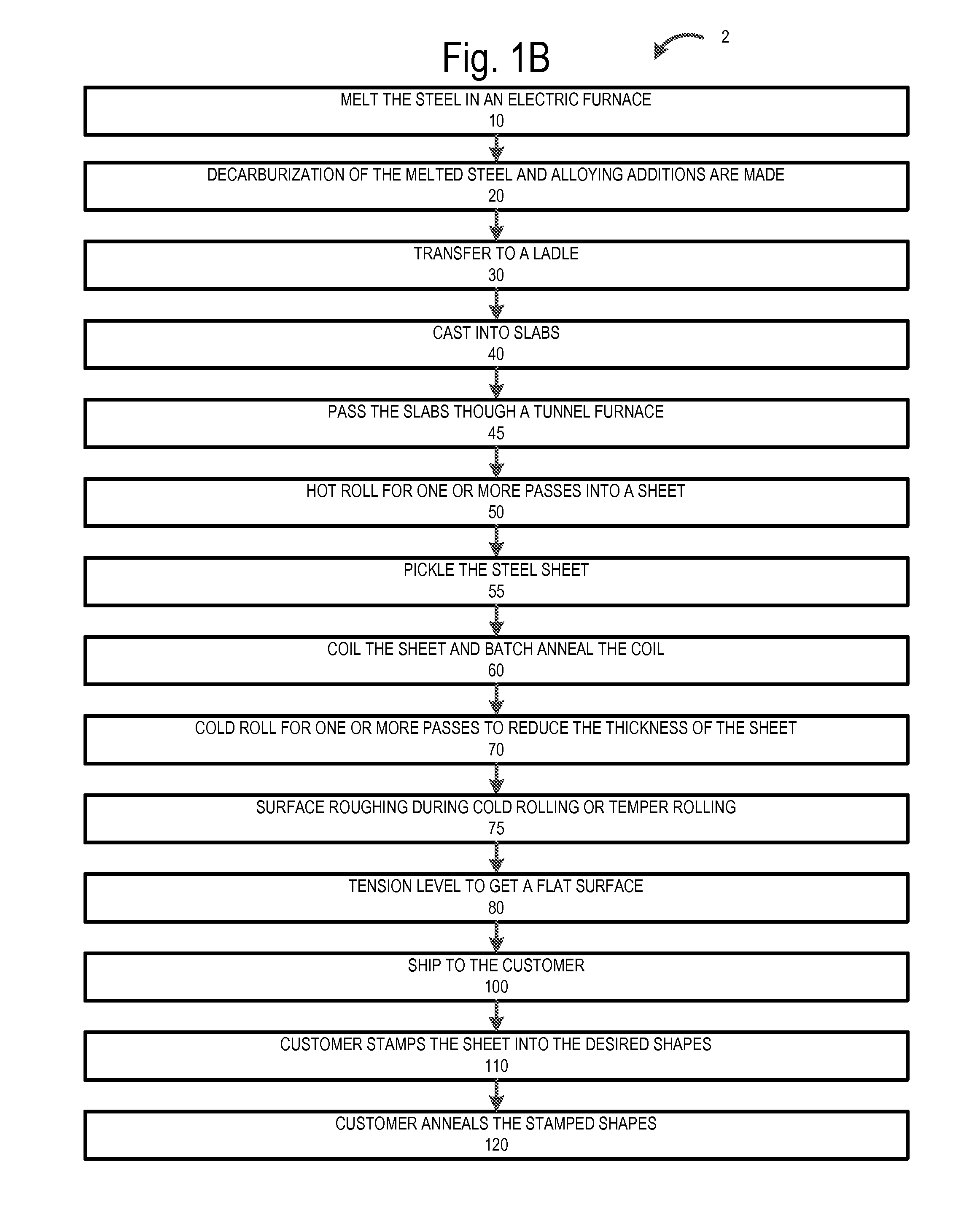

Electrical steel processing without a post cold-rolling intermediate anneal

InactiveUS20150318093A1Promotes an increase in inductionImprove permeabilityInorganic material magnetismFurnace typesElectrical steelStrip steel

Embodiments of the present invention comprise; annealing steel sheets (e.g., hot rolled steel sheets or thin cast strip steel); cold rolling the sheets in one or more cold rolling steps (e.g., with annealing steps between multiple cold rolling steps); and performing one or more of tension leveling, a rough rolling, or a coating process on the sheets after cold rolling, without an intermediate annealing step between the final cold rolling step and the tension leveling, the rough rolling, or the coating process, or the customer stamping or final customer annealing. In order to achieve the desired properties for the steel sheet, stamping and final annealing is performed by the customer. The new process provides an electrical steel with the similar, same, or better magnetic properties than an electrical steel manufactured using the traditional processing that utilizes an intermediate annealing step after cold rolling and before the stamping and final annealing.

Owner:NUCOR CORP

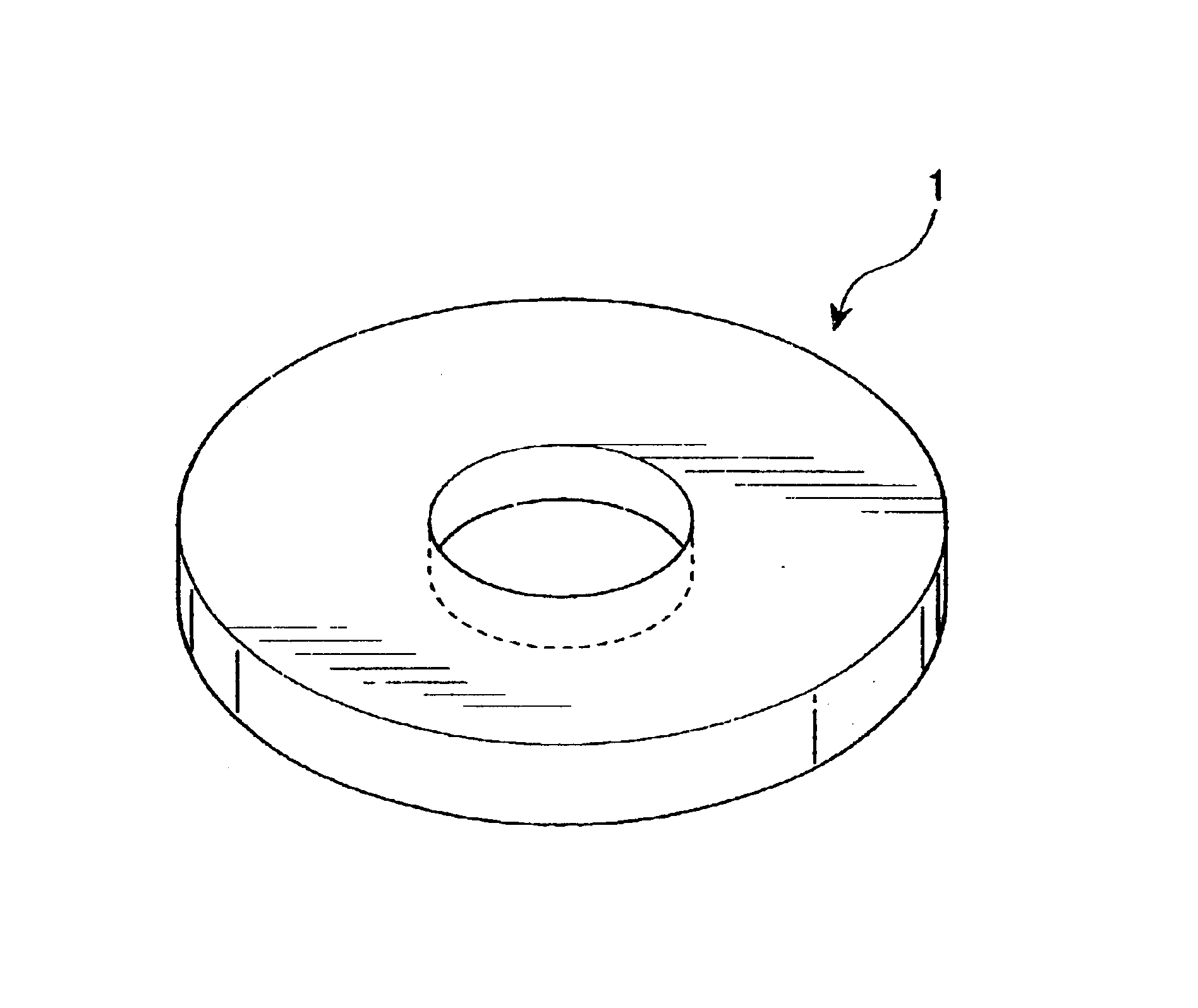

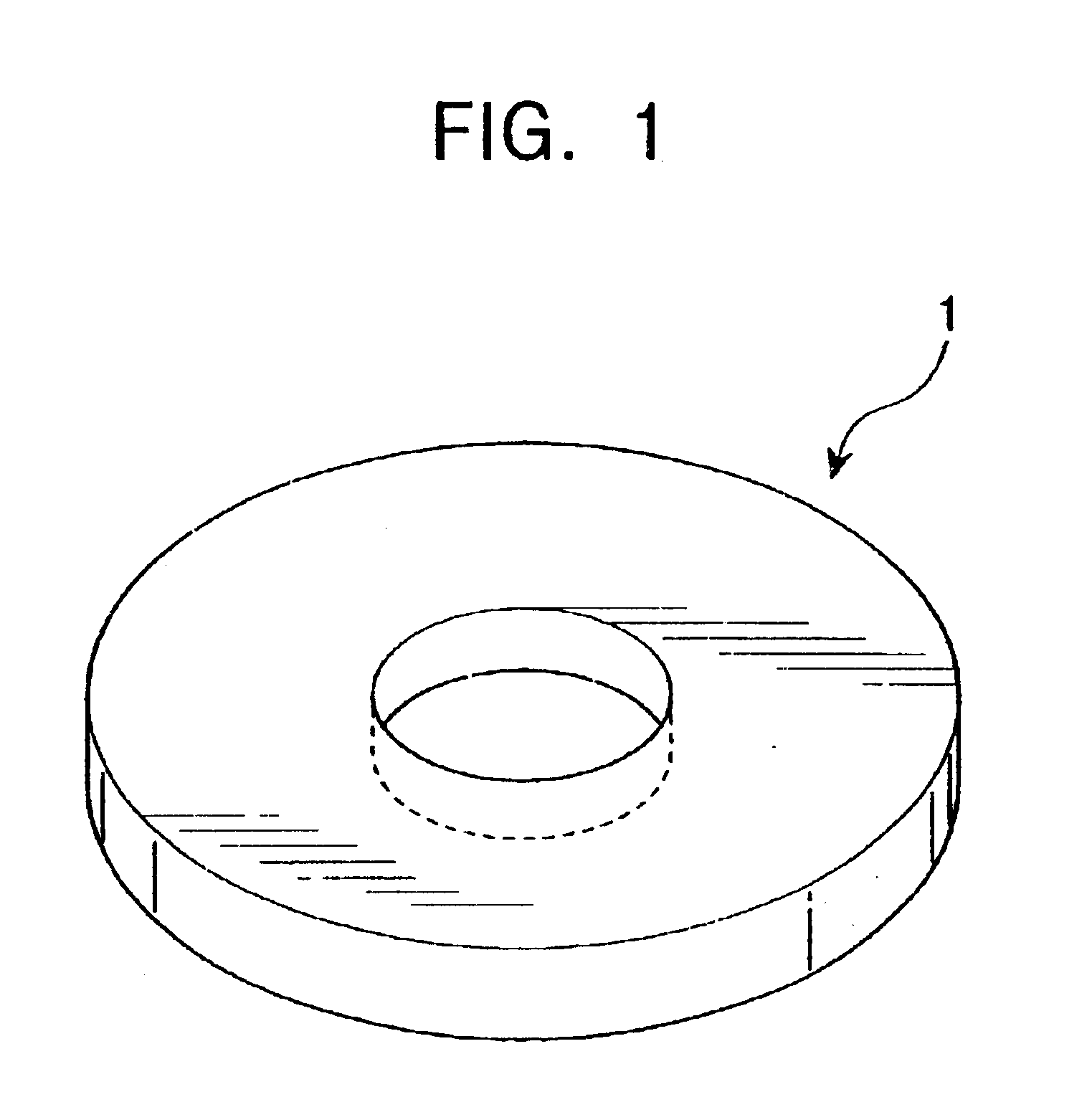

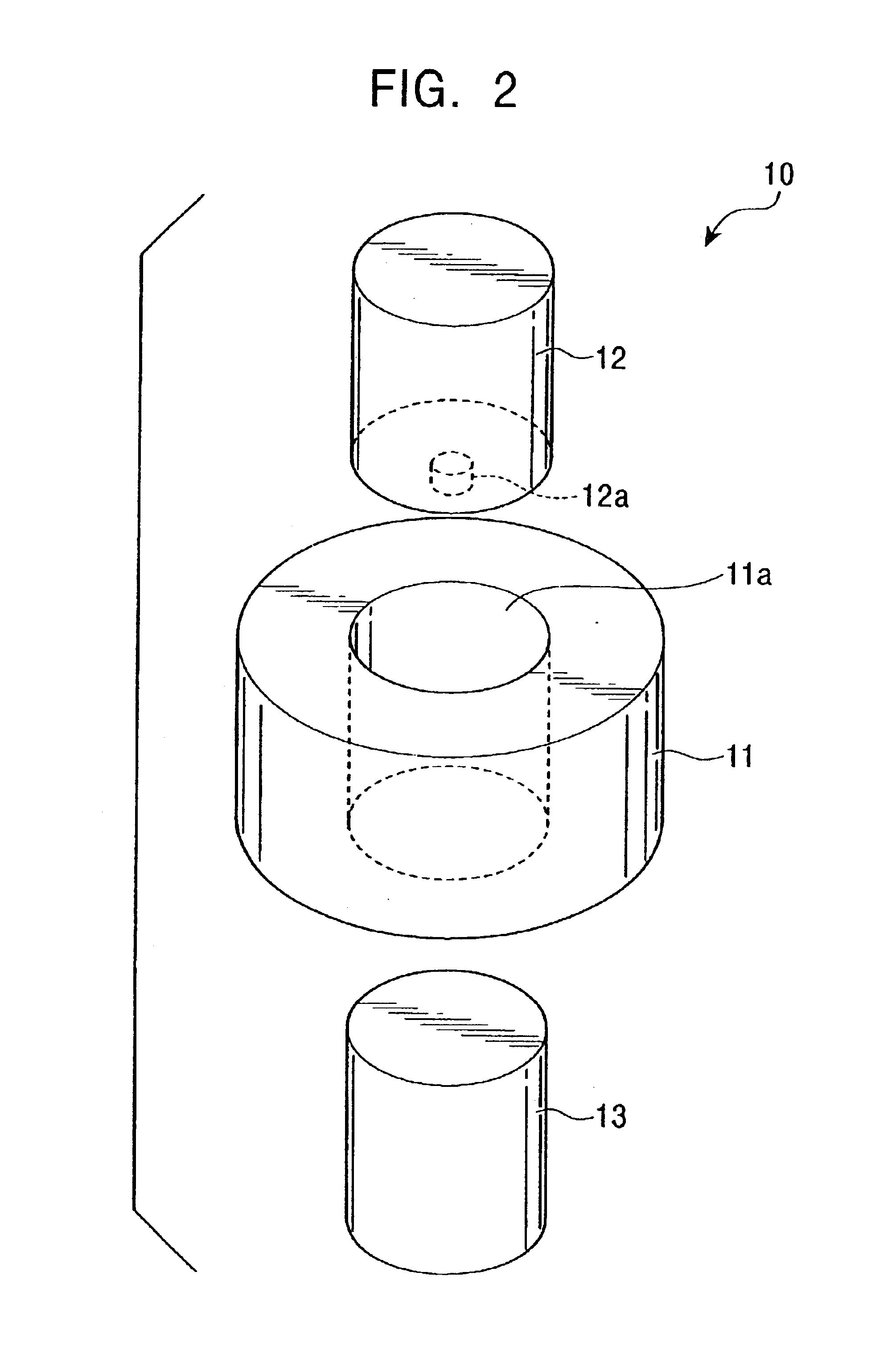

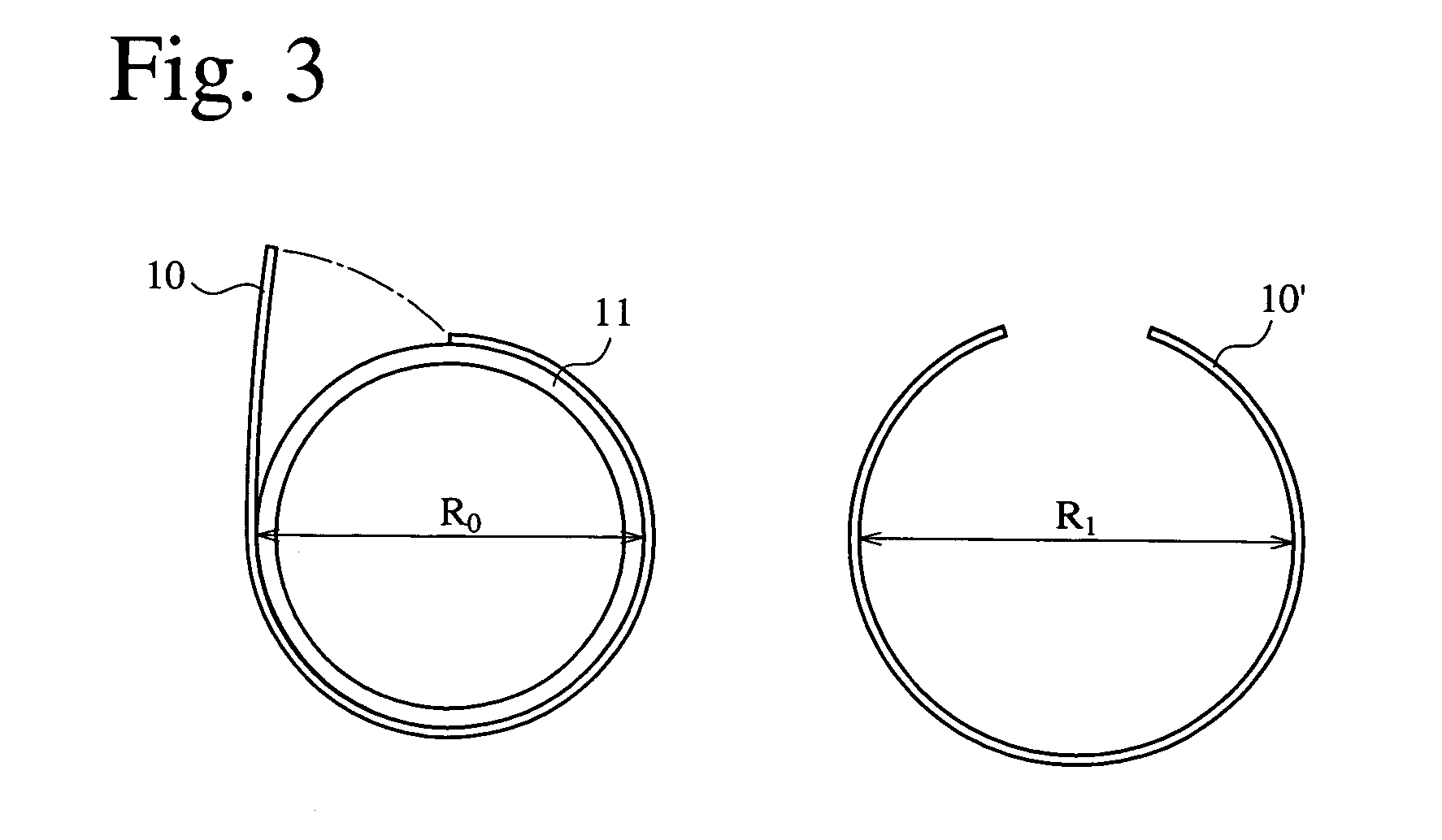

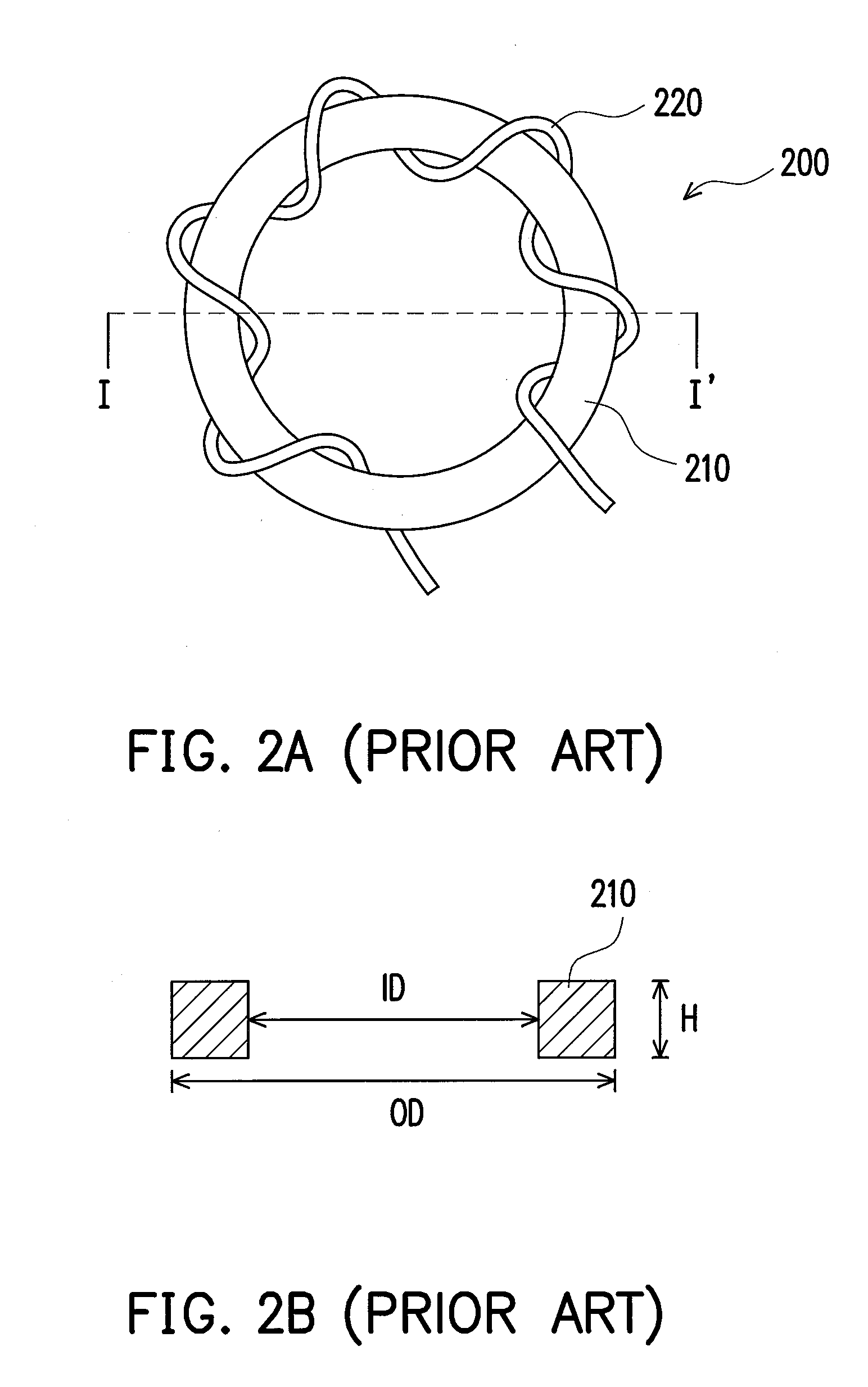

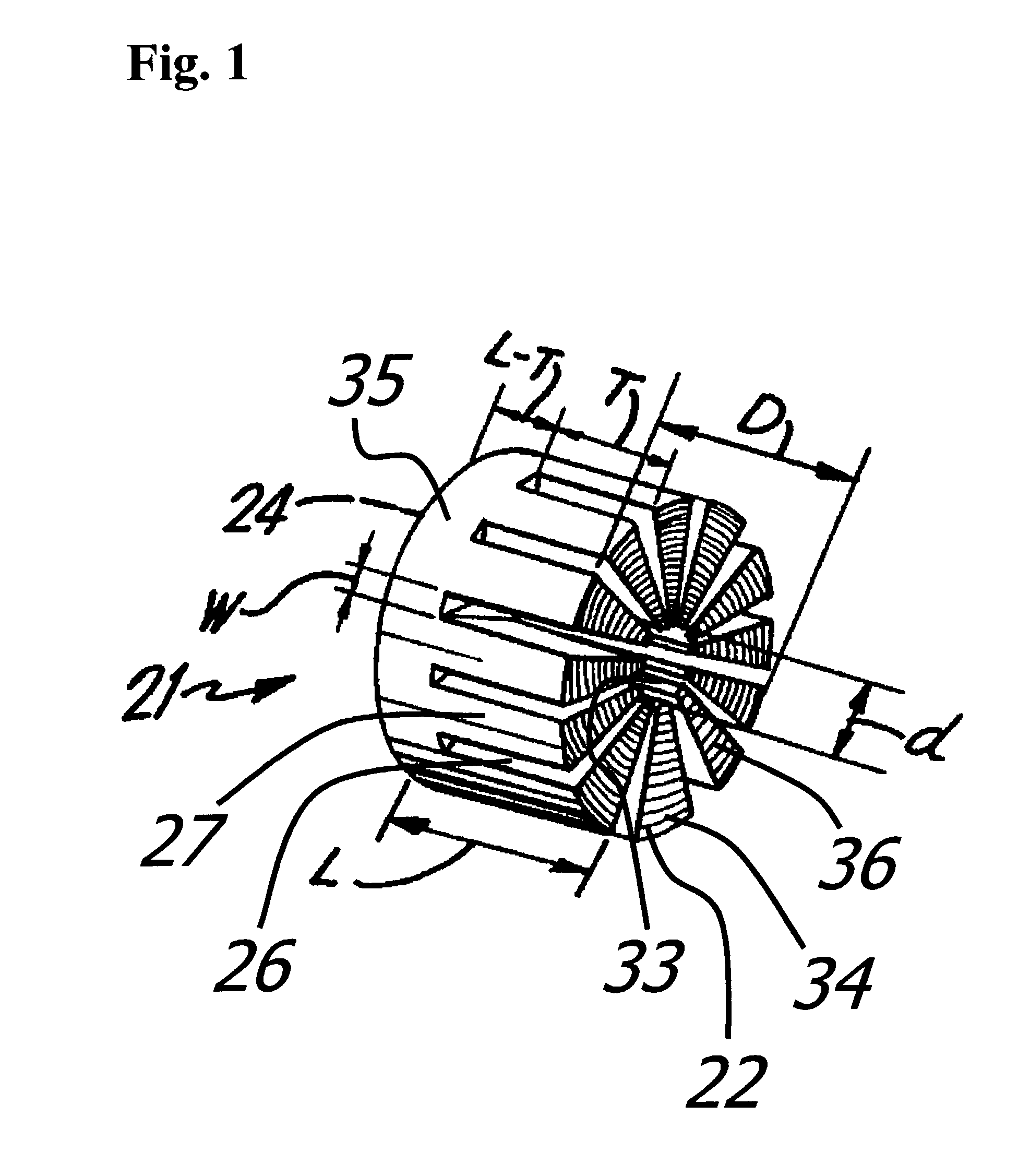

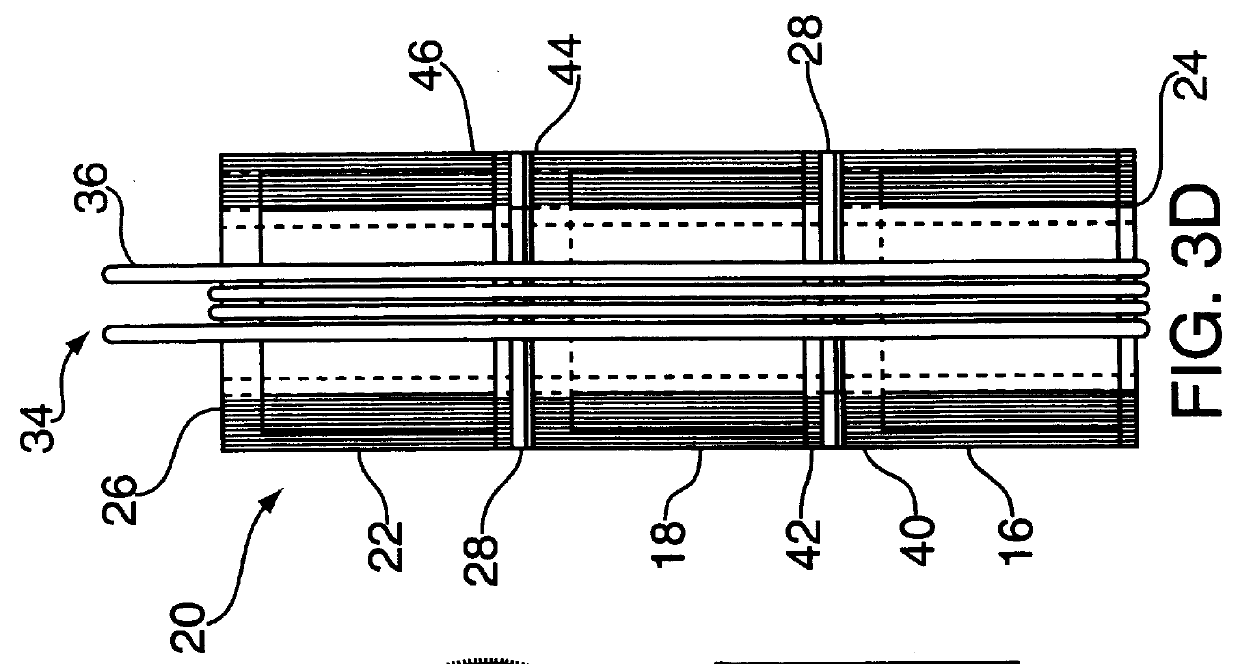

Method of constructing a unitary amorphous metal component for an electric machine

ActiveUS7144468B2Easy to manufactureShorten production timeLamination ancillary operationsLaminationElectric machineEngineering

A unitary amorphous metal magnetic component for an axial flux electric machine such as a motor or generator is formed from a spirally wound annular cylinder of ferromagnetic amorphous metal strips. The cylinder is adhesively bonded and provided with a plurality of slots formed in one of the annular faces of the cylinder and extending from the inner diameter to the outer diameter of the cylinder. The component is preferably employed in constructing a high efficiency, axial flux electric motor. When operated at an excitation frequency “f” to a peak induction level Bmax the unitary amorphous metal magnetic component has a core-loss less than “L” wherein L is given by the formula L=0.0074f(Bmax)1.3+0.000282f1.5(Bmax)2.4, the core loss, excitation frequency and peak induction level being measured in watts per kilogram, hertz, and teslas, respectively.

Owner:METGLAS INC

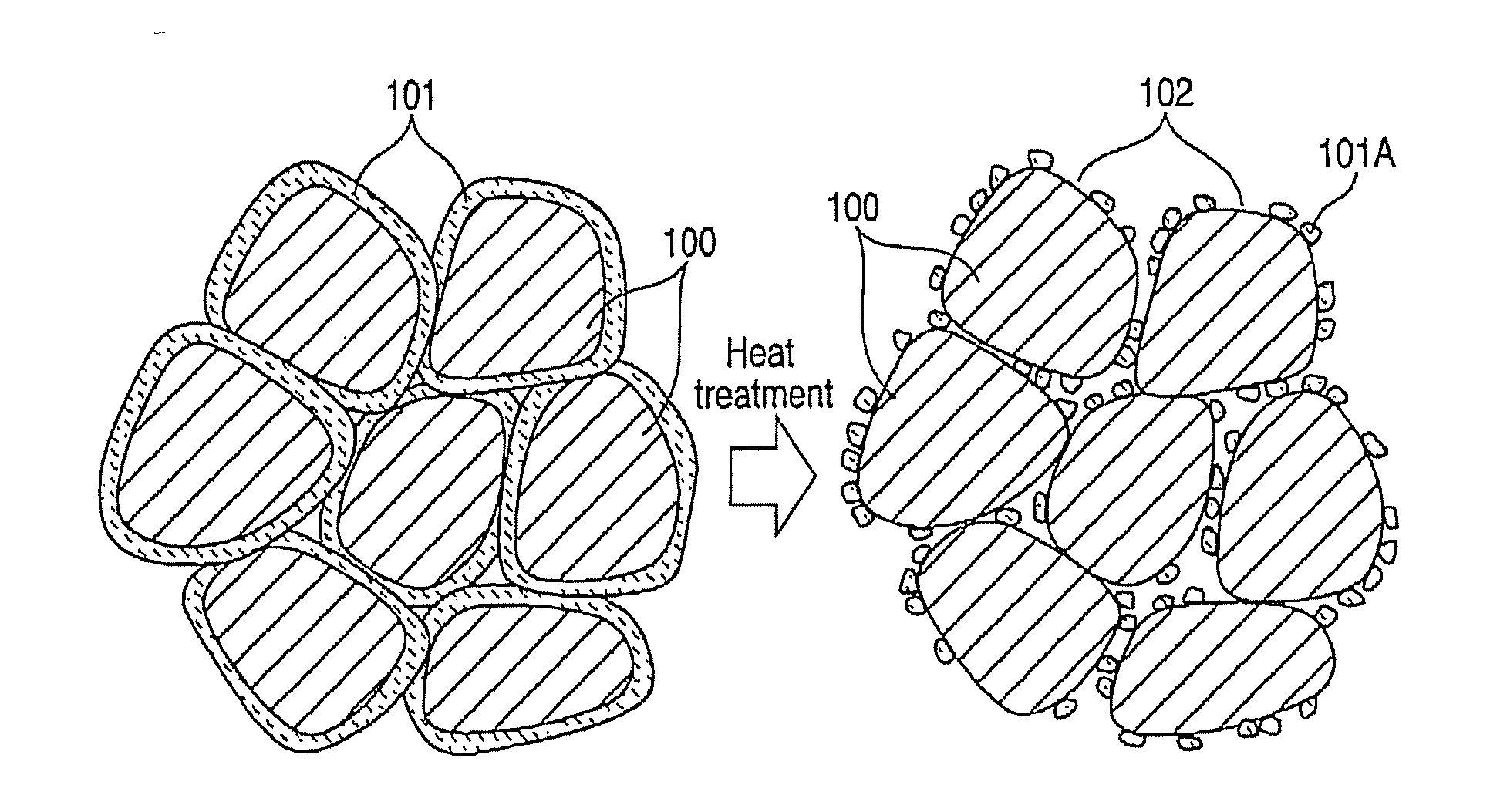

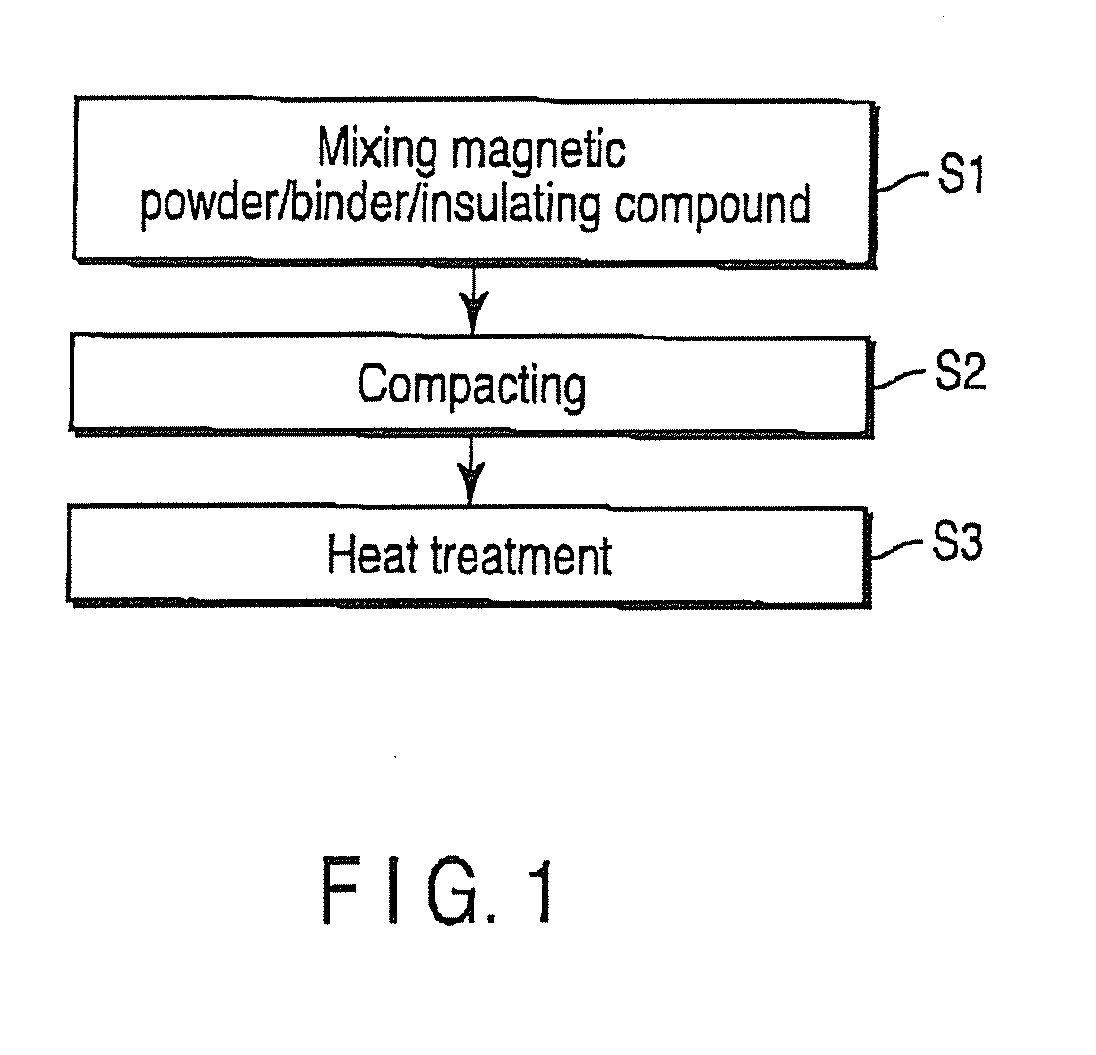

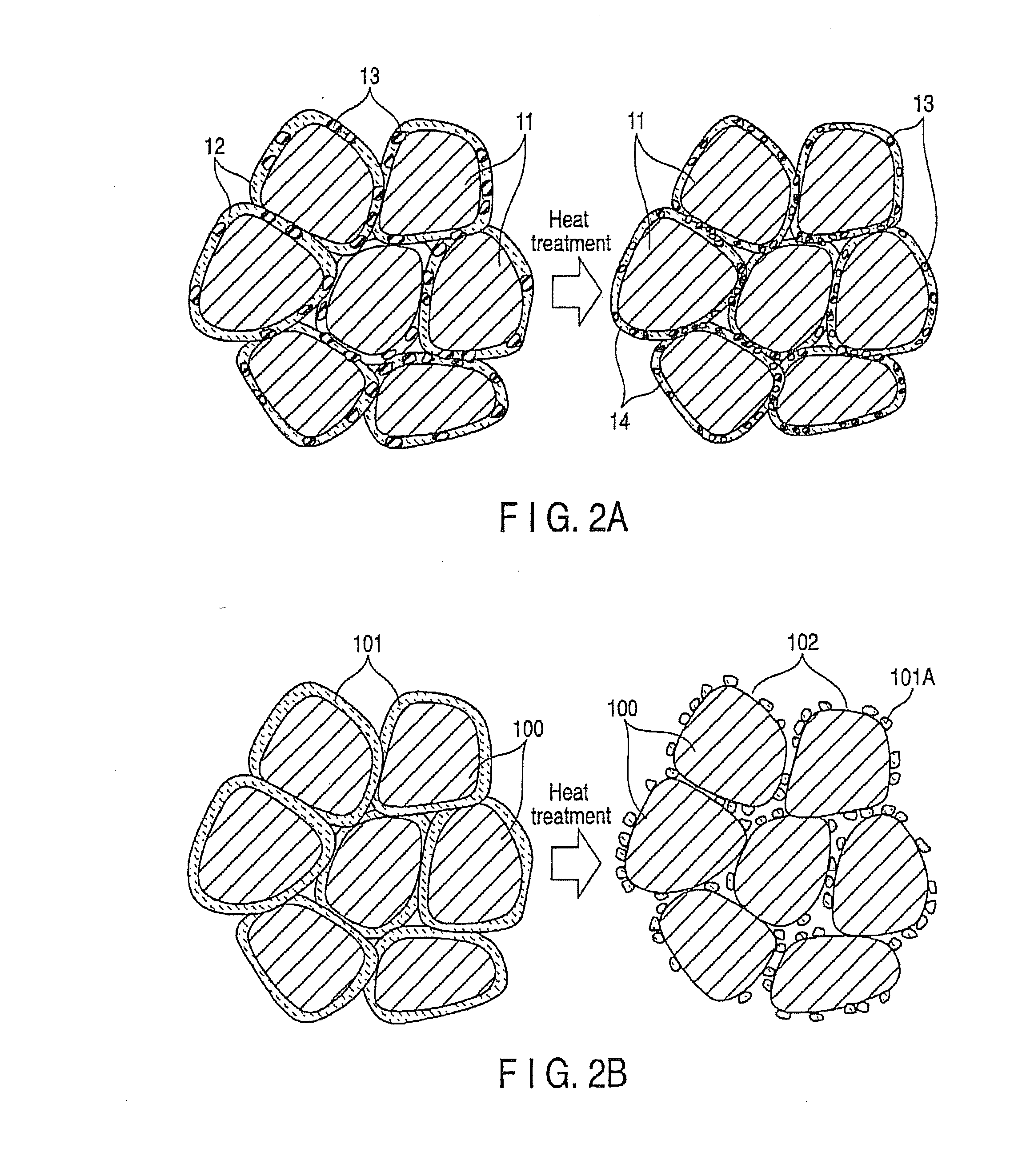

Method of producing composite magnetic material and composite magnetic material

InactiveUS20110024671A1Improve insulation performanceImprove pressure resistanceTransportation and packagingMetal-working apparatusNon magneticMetal powder

In one embodiment, a method is disclosed for producing a composite magnetic material, wherein the non-magnetic binder comprises a layered compound having an insulation property and the non-magnetic binder and soft magnetic metal powder is admixed with each other, the admixture is compacted to a desired shape, and the compact is heat-treated under predetermined condition to form a thin insulating layer made of the insulating layered compound on the surface of the soft magnetic metal powder, thereby producing the composite magnetic material having a withstand voltage of 20 V or more.

Owner:TOHO ZINC

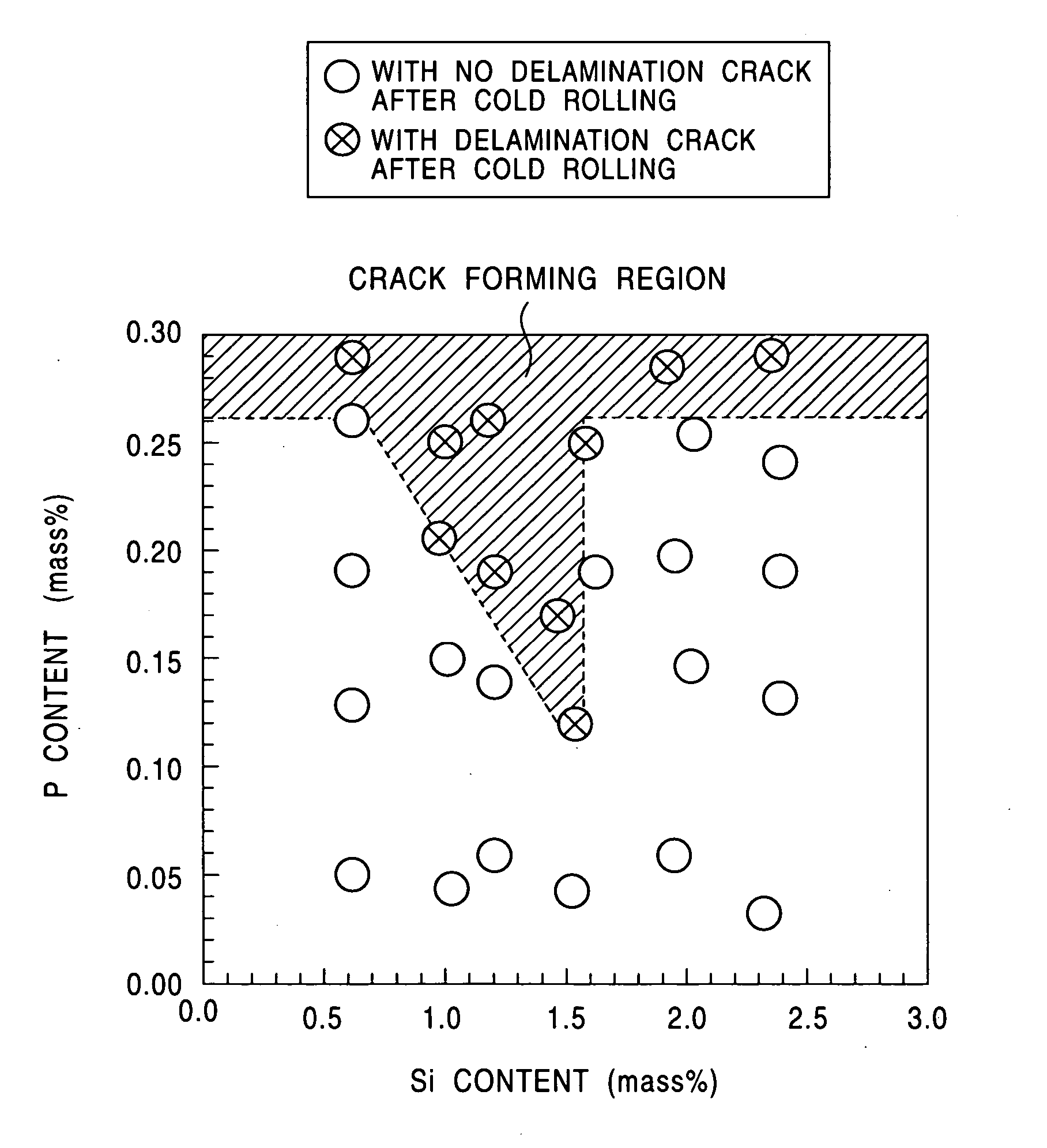

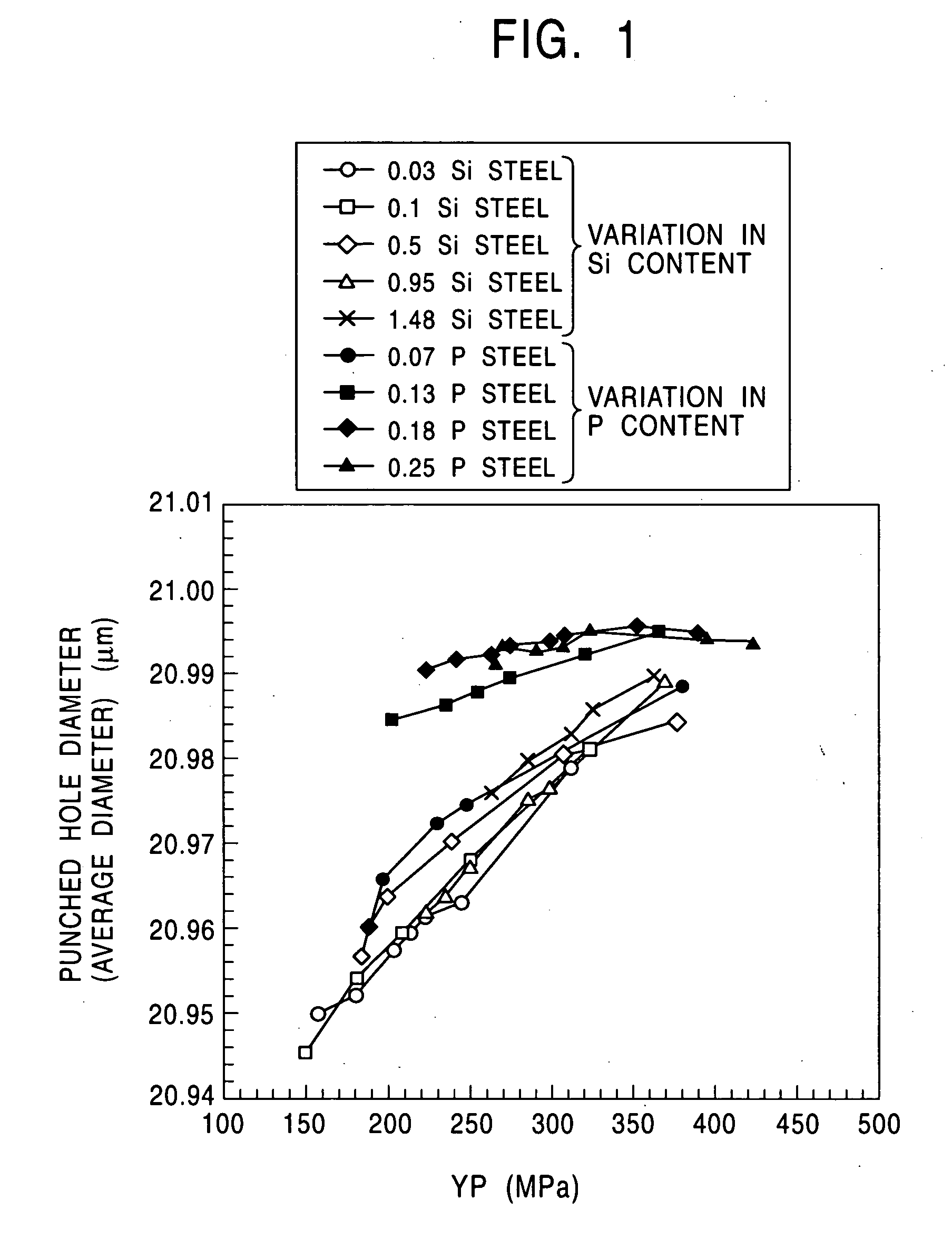

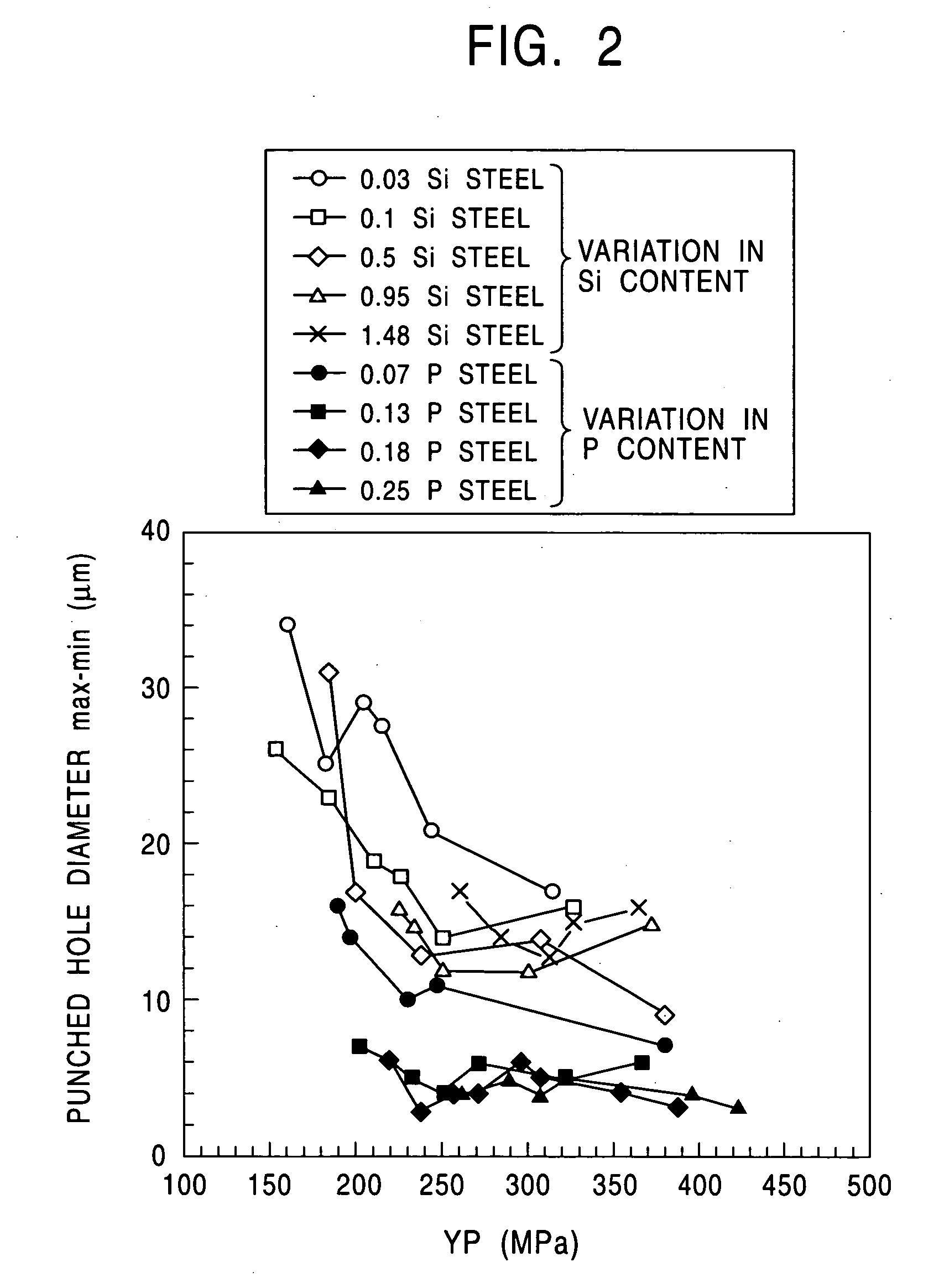

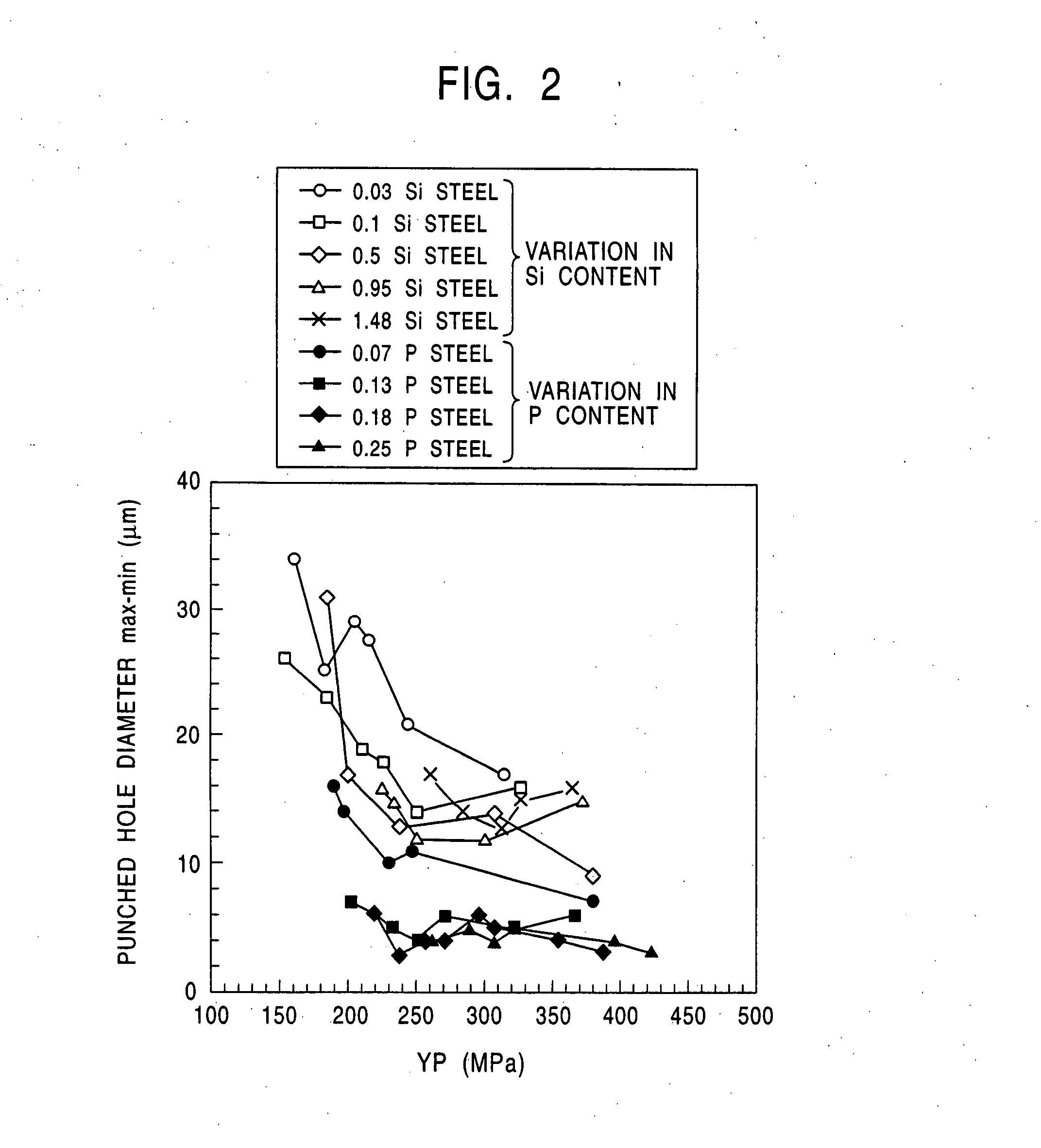

Nonoriented electromagnetic steel sheet

InactiveUS20040149355A1Reduce regionHigh magnetic flux densityInorganic material magnetismFurnace typesSheet steelElectrical steel

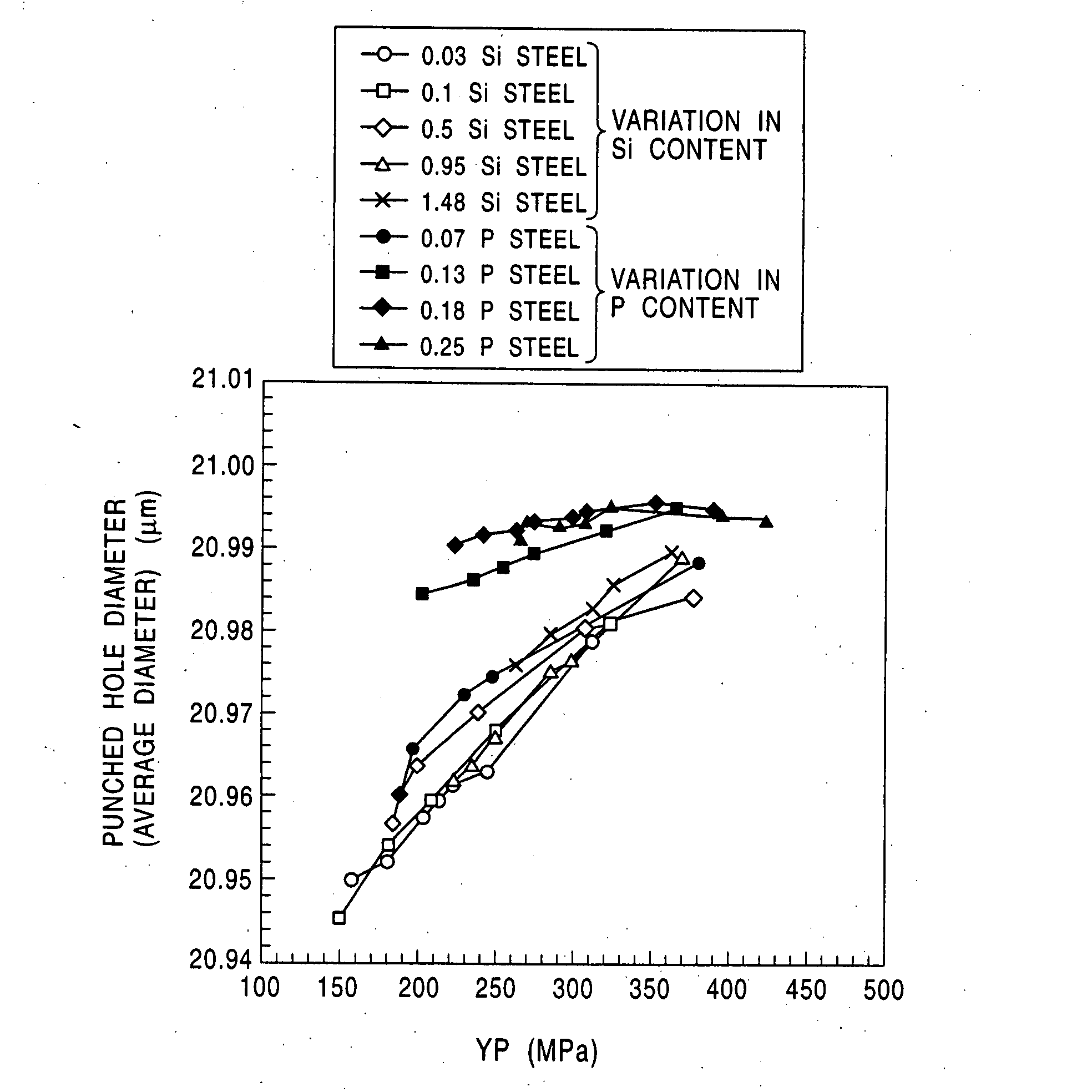

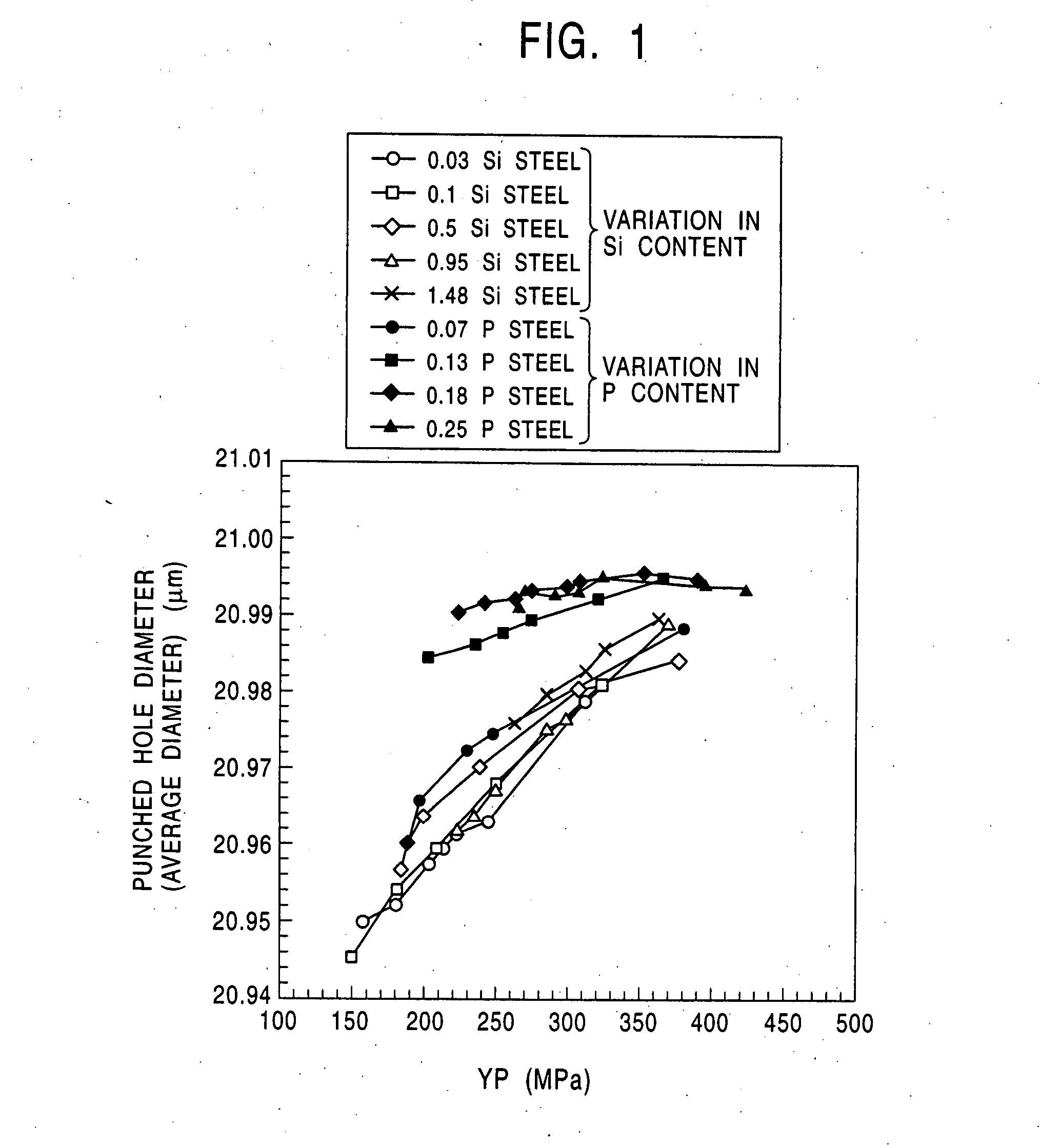

The present invention provides a non-oriented electrical steel sheet containing: 0-0.010% of C; at least one of Si and Al in a total amount of 0.03% to 0.5%, or more than 0.5% to 2.5%; 0.5% or less of Mn; 0.10% or more to 0.26% or less of P; 0.015% or less of S; and 0.010% or less of N, on a mass percentage basis, wherein the non-oriented electrical steel sheet has excellent dimensional accuracy during a punching step. When the Si content is low, the non-oriented electrical steel sheet has the excellent balance between high magnetic flux density and low core loss. When the Si content is medium or high, the non-oriented electrical steel sheet has the excellent balance between high magnetic flux density and high strength.

Owner:JFE STEEL CORP

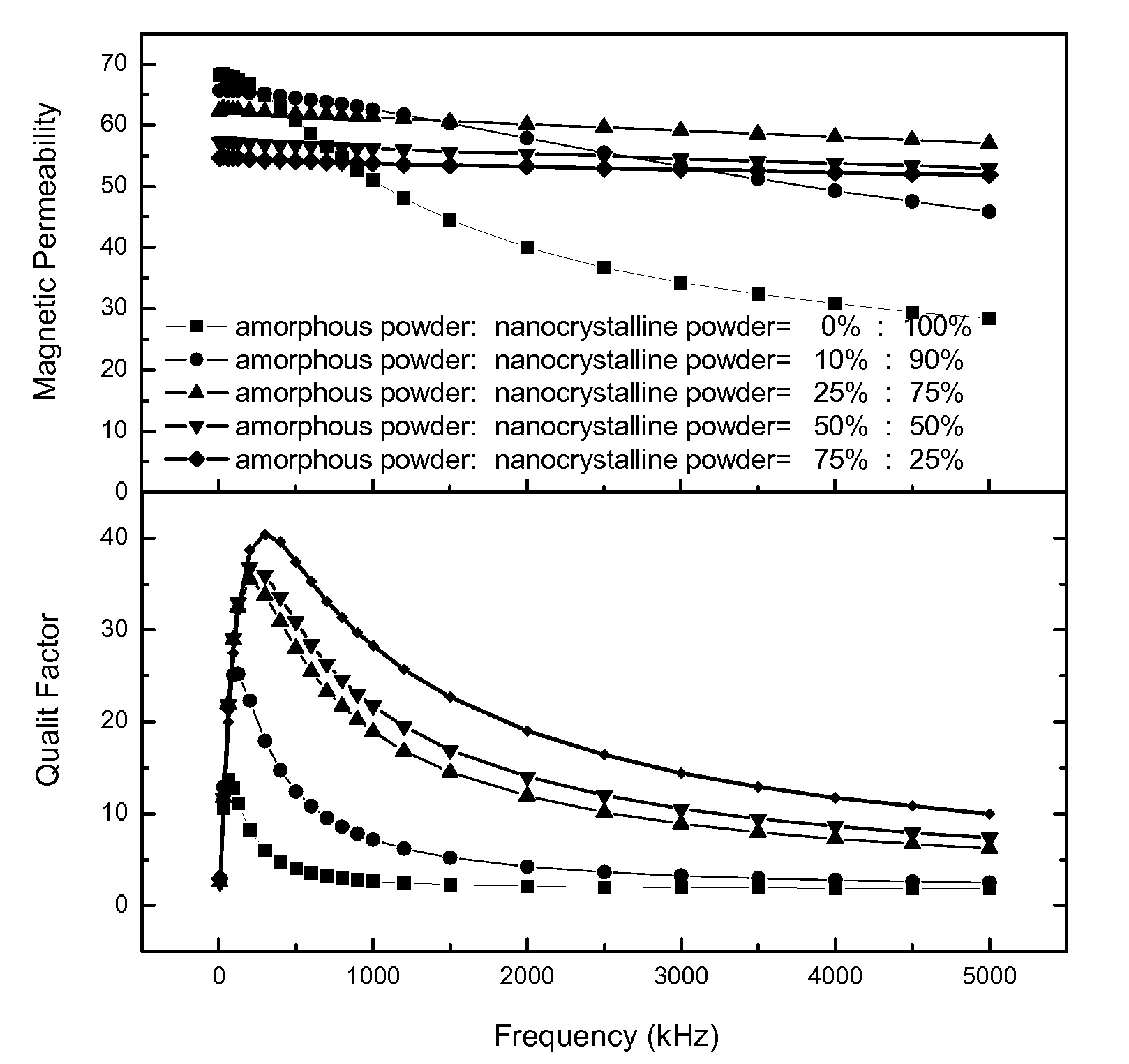

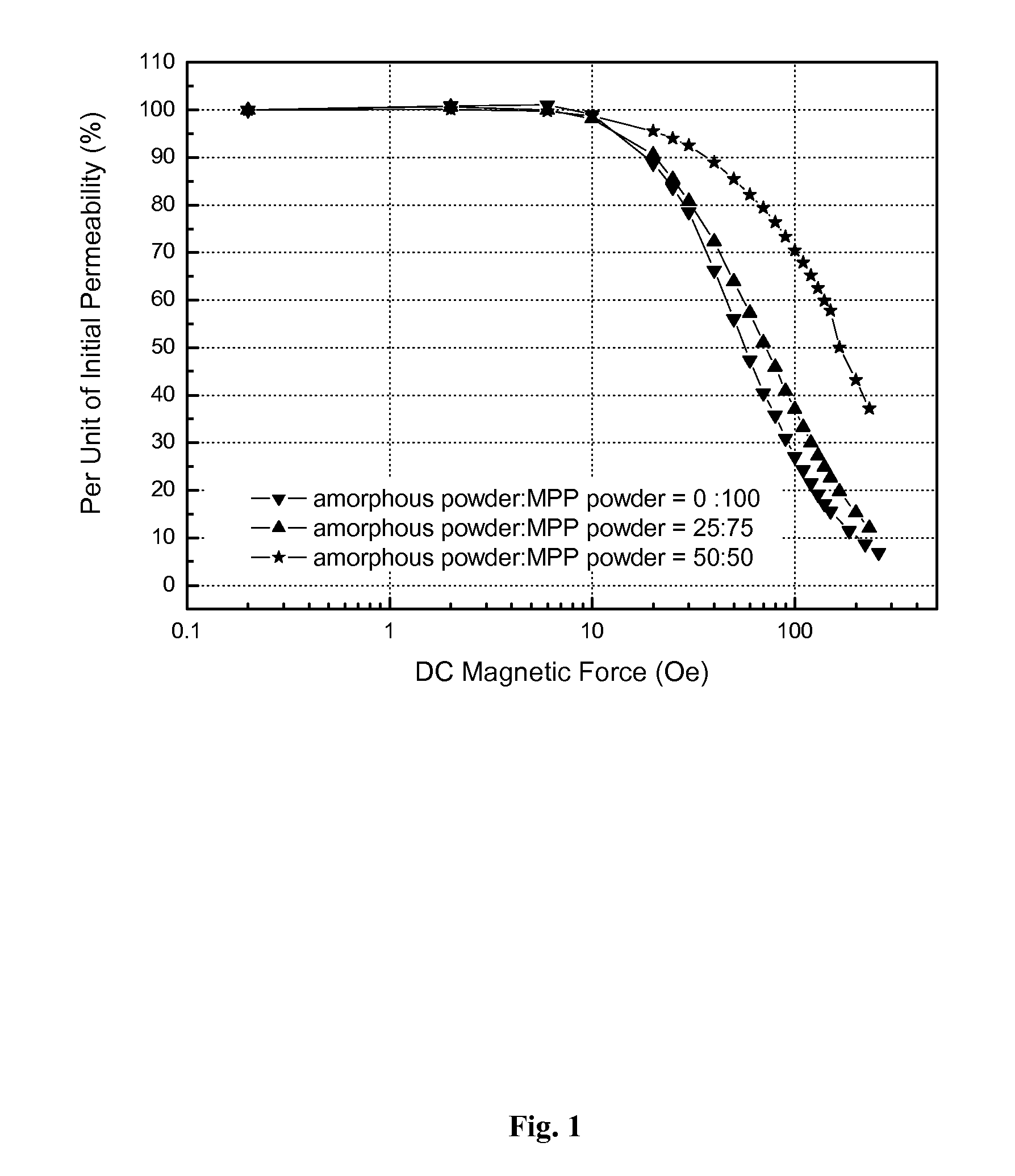

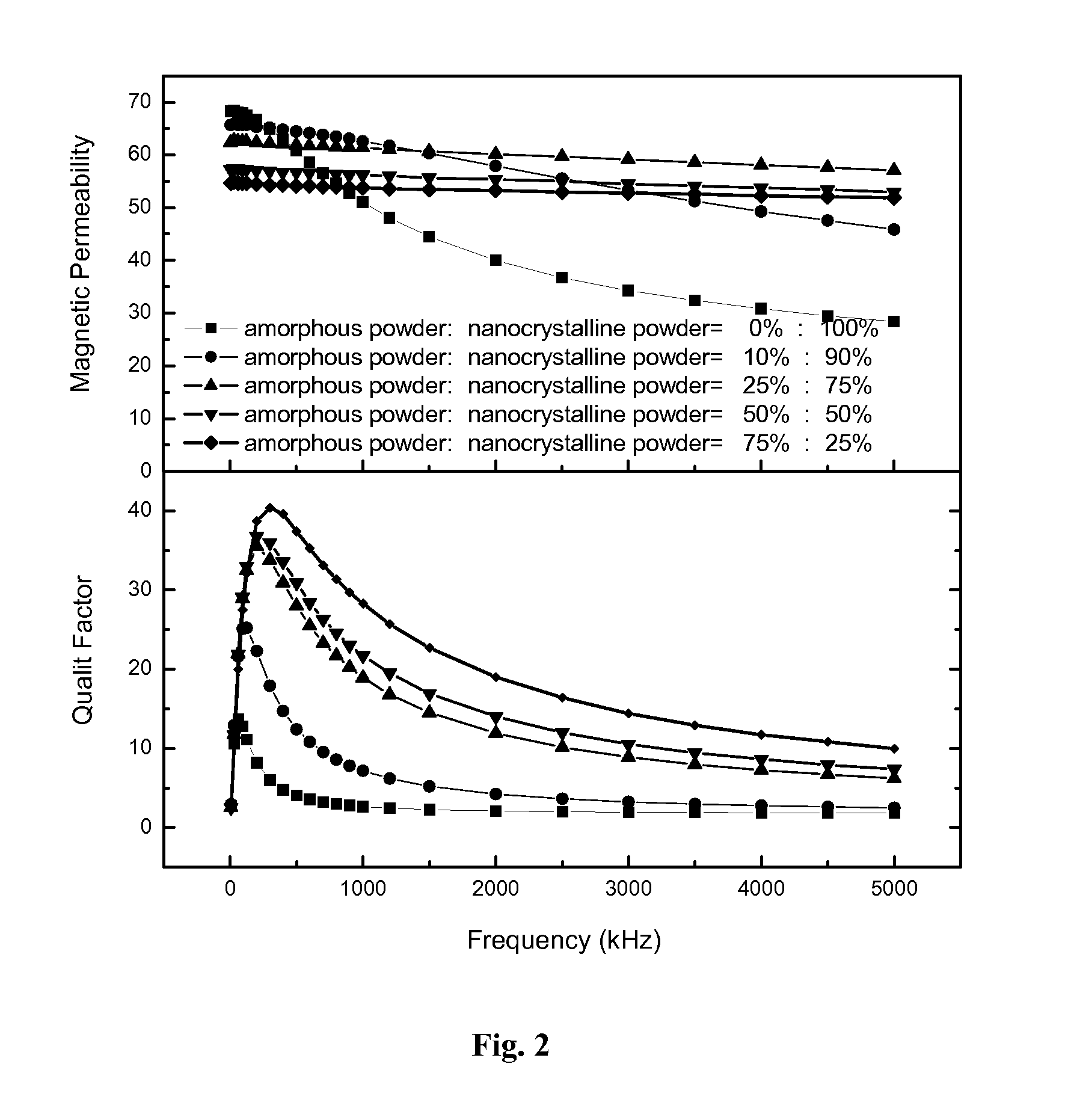

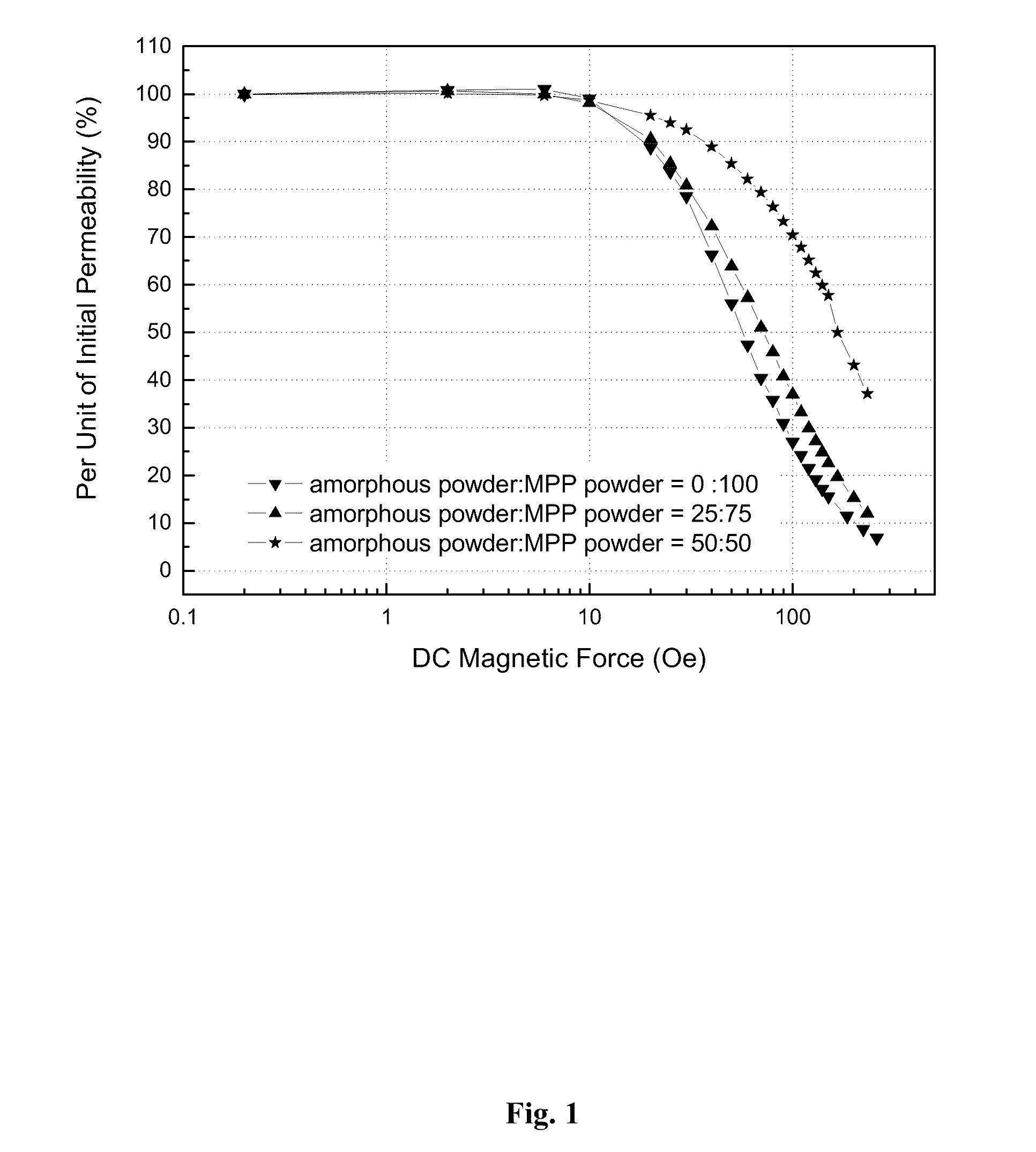

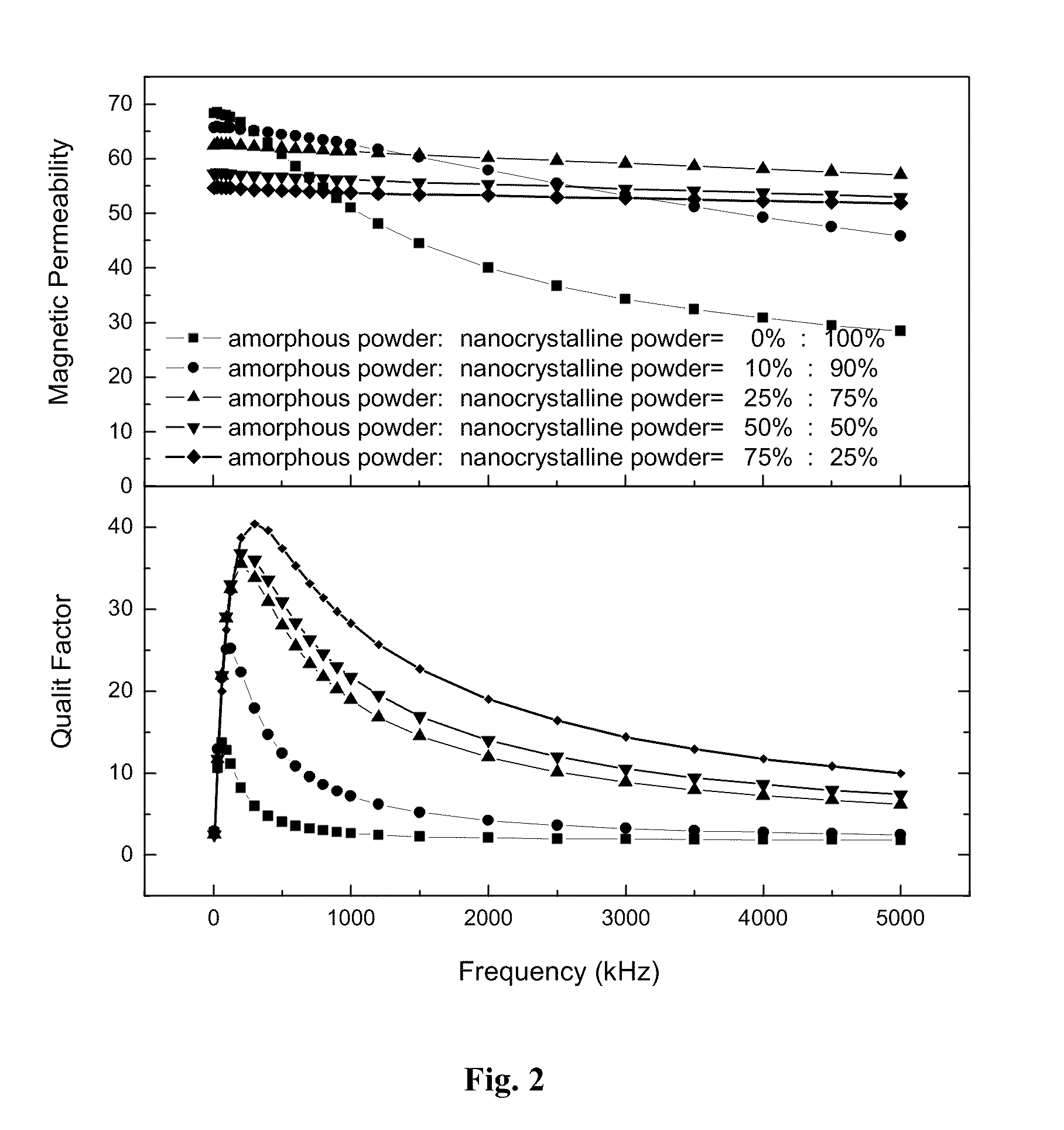

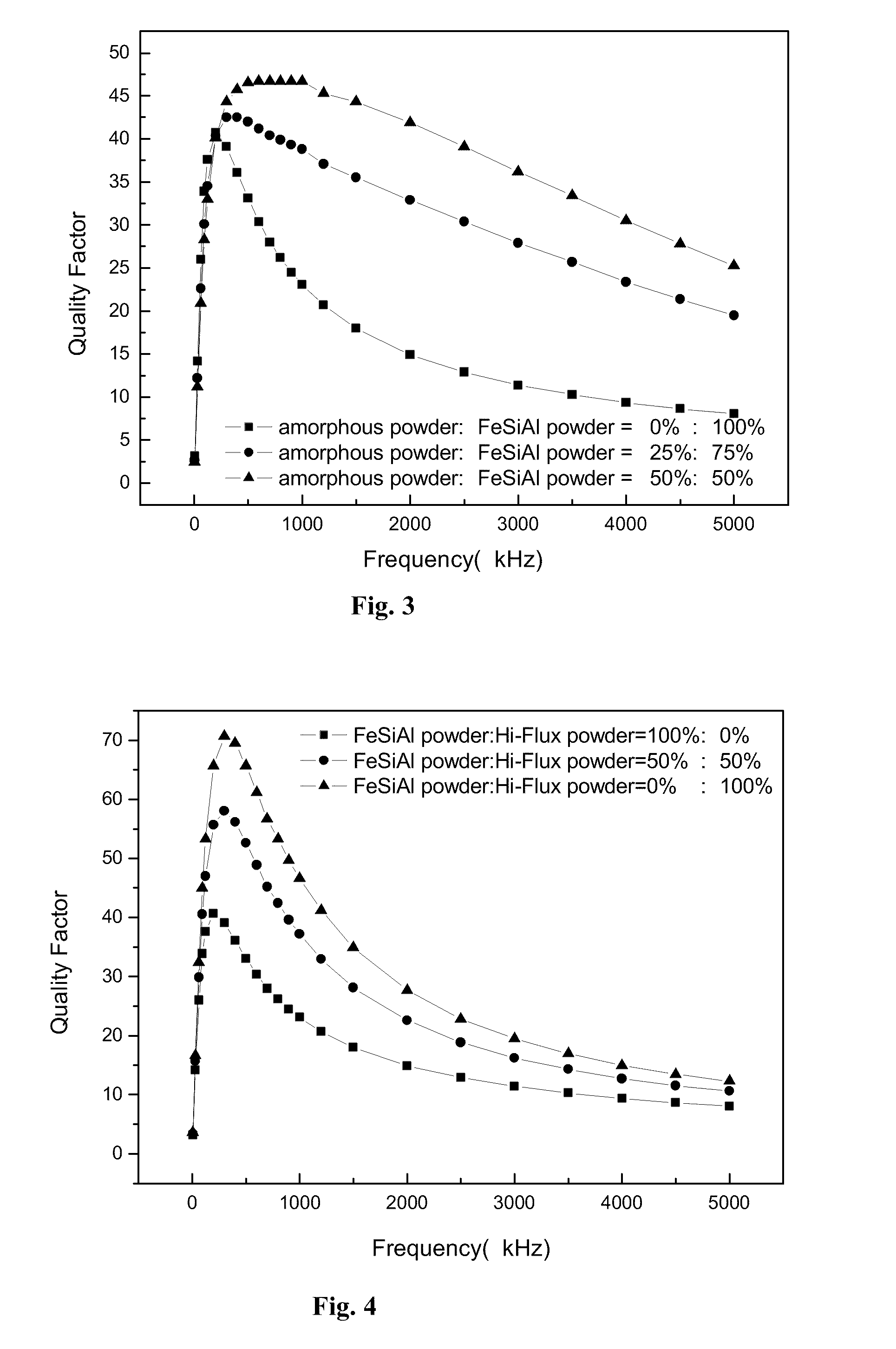

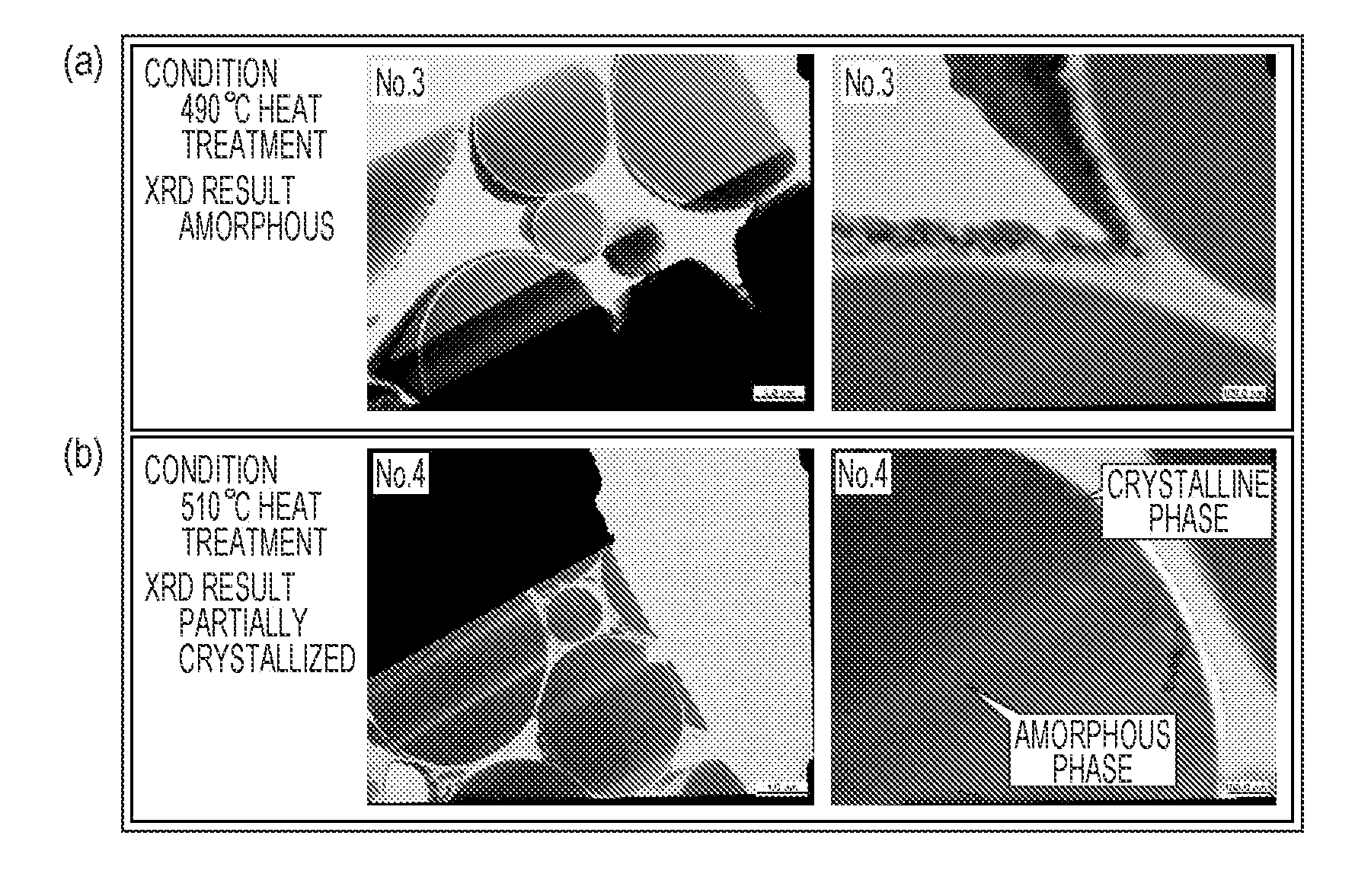

Compound magnetic powder and magnetic powder cores, and methods for making them thereof

ActiveUS20070144614A1Reduce penetrationLow core lossTransportation and packagingMetal-working apparatusAl powderIron powder

The present invention provides a compound powder for making magnetic powder cores, a kind of magnetic powder core, and a process for making them. Said compound powder is a mixture composing of powder A and powder B, the content of powder A is 50-96 wt % and the content of powder B is 4-50 wt %, wherein powder A is at least one selected from iron powder, Fe—Si powder, Fe—Si—Al powder, Fe-based nanocrystalline powder, Fe-based amorphous powder, Fe—Ni powder and Fe—Ni—Mo powder; powder B bears different requirement characteristics from powder A and is at least one selected from iron powder, Fe—Si powder, Fe—Si—Al powder, Fe-based nanocrystalline powder, Fe-based amorphous powder, Fe—Ni powder and Fe—Ni—Mo powder. Said powder B adopts Fe-based amorphous soft magnetic powder with good insulation property as insulating agent and thus core loss of magnetic powder core decreases. The decrease of magnetic permeability of magnetic powder core resulting from a traditional insulating agent is remedied and the initial magnetic permeability of magnetic powder core is improved by taking advantage of soft magnetic properties of Fe-based amorphous powder.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

Magnetic device with high saturation current and low core loss

ActiveUS20140218157A1Low costHigh saturation currentTransformers/inductances coils/windings/connectionsMagnetic materialsPower flowMagnetic flux

Owner:CYNTEC

Ferrite core for RFID application, method of manufacturing the same, and ferrite coil using the same

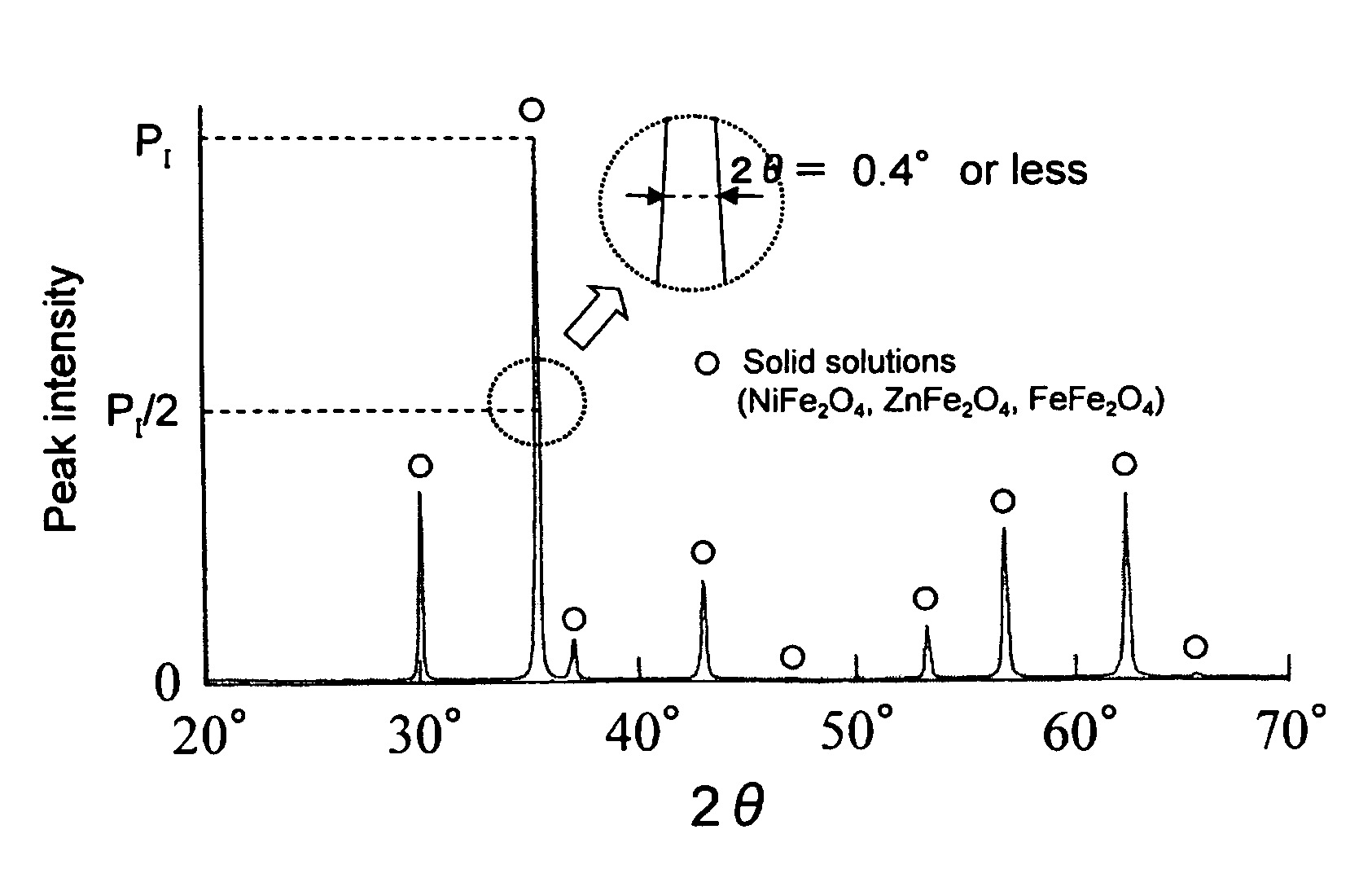

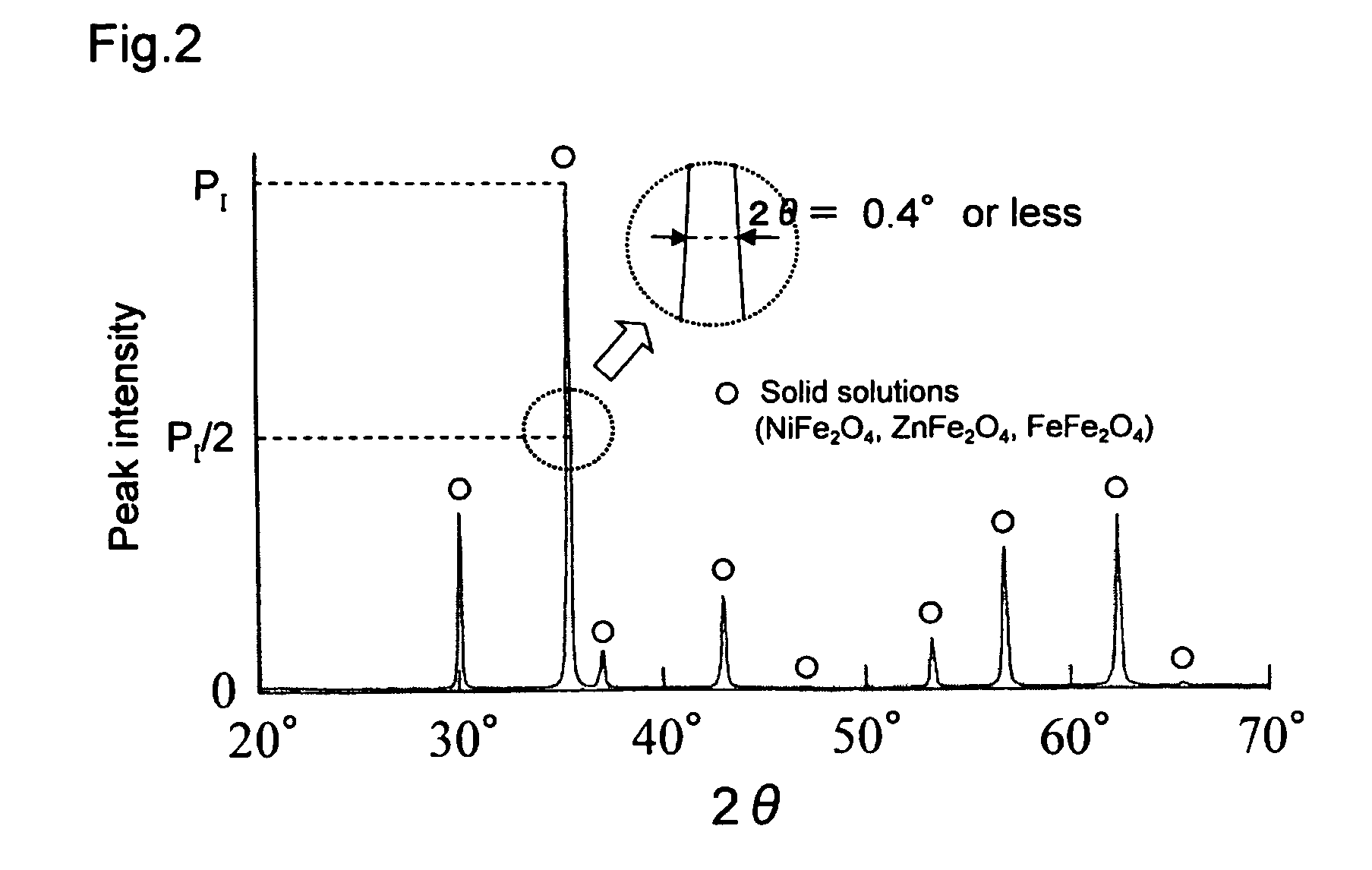

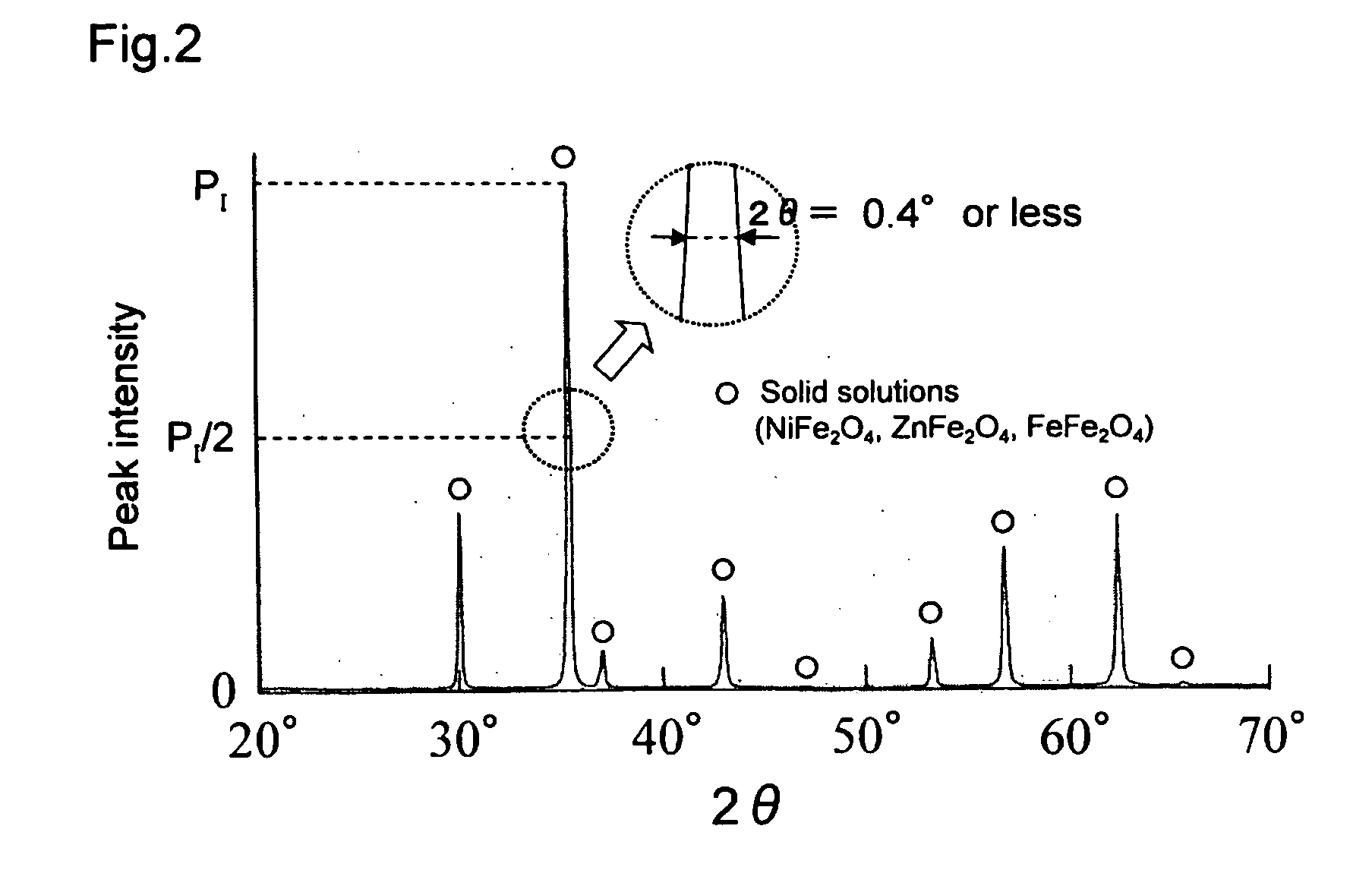

ActiveUS7195717B2Low core lossHigh curie temperatureFoundry mouldsInorganic material magnetismFull width at half maximumX-ray

Owner:KYOCERA CORP

Iron-based soft magnetic powder for dust core, method for producing the same and dust core

ActiveUS20100051851A1Improve heat resistanceReduce the amount requiredMetal-working apparatusInorganic material magnetismElectricityO-Phosphoric Acid

Disclosed herein is an iron powder for dust cores which effectively keeps insulation among iron powder particles and excels in mechanical strength even though the amount of insulating material is reduced to achieve high-density forming and which also exhibits good thermal stability necessary for electrical insulating properties even after heat treatment at high temperatures.The iron-based magnetic powder has layers of phosphoric acid-based film and silicone resin film sequentially formed on the surface thereof, said phosphoric acid-based film containing at least one element selected from the group consisting of Co, Na, S, Si, and W.

Owner:KOBE STEEL LTD

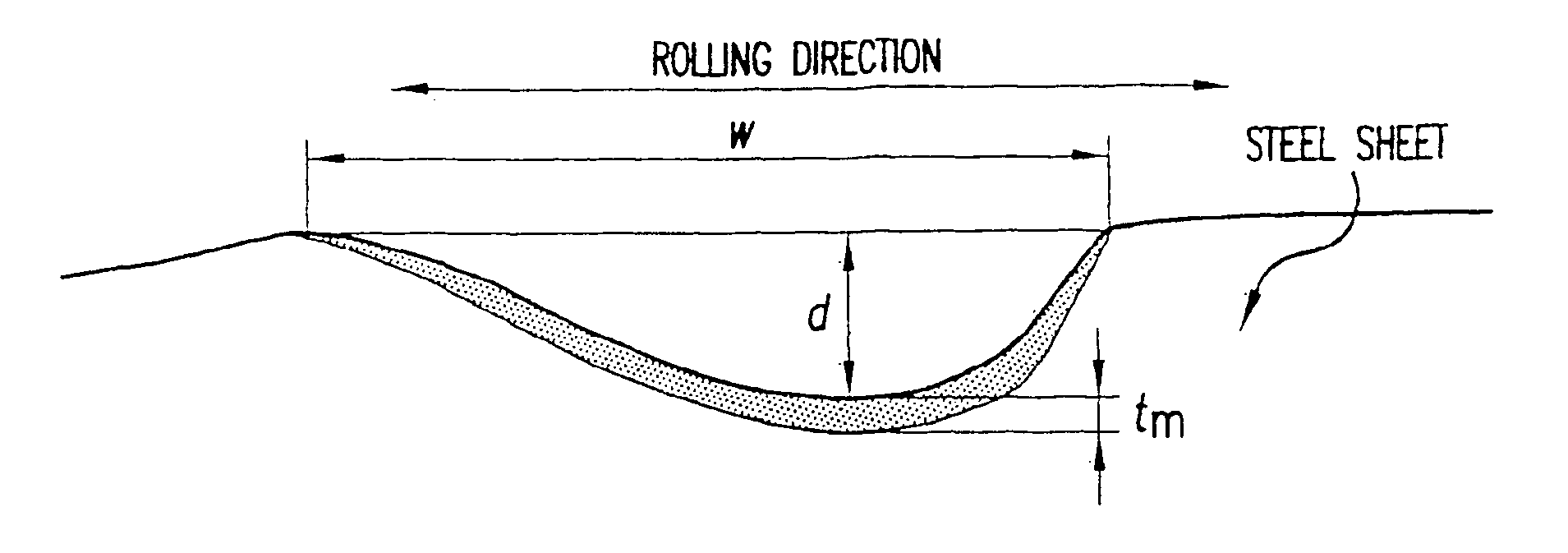

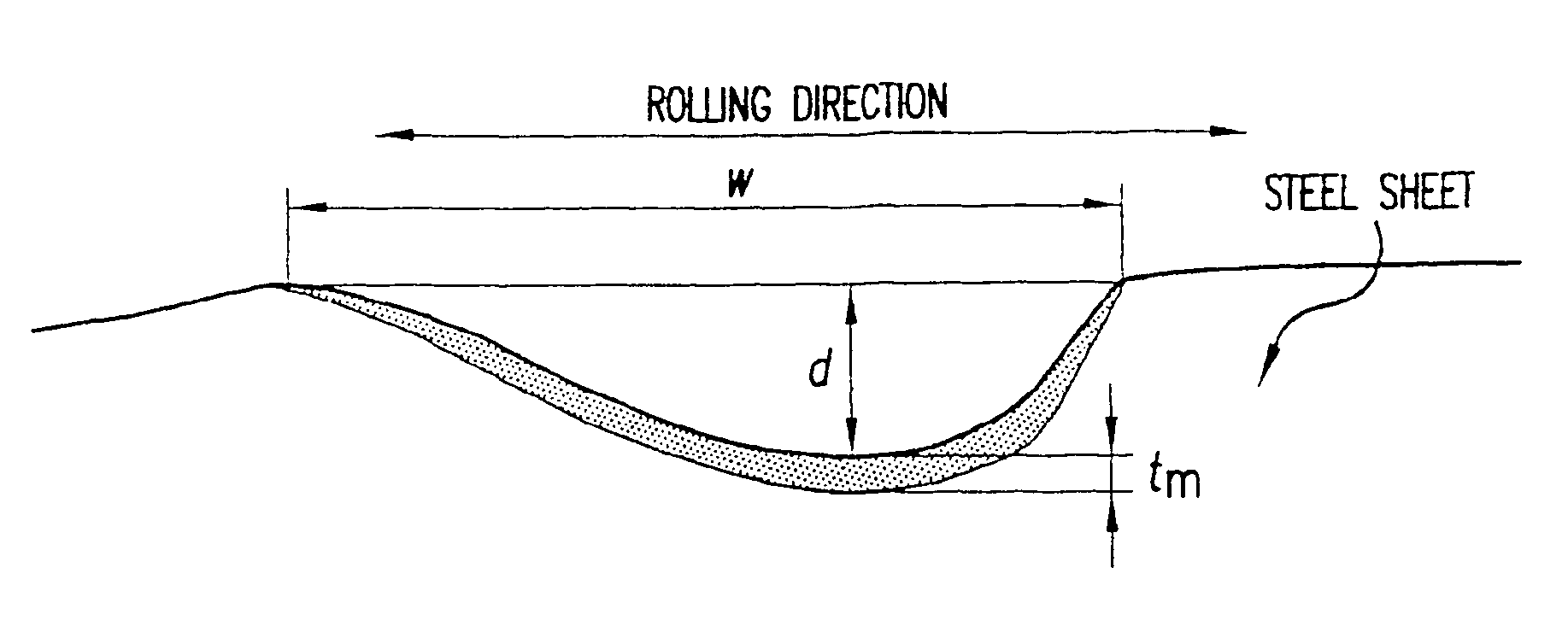

Low core loss grain-oriented electrical steel sheet and method for producing the same

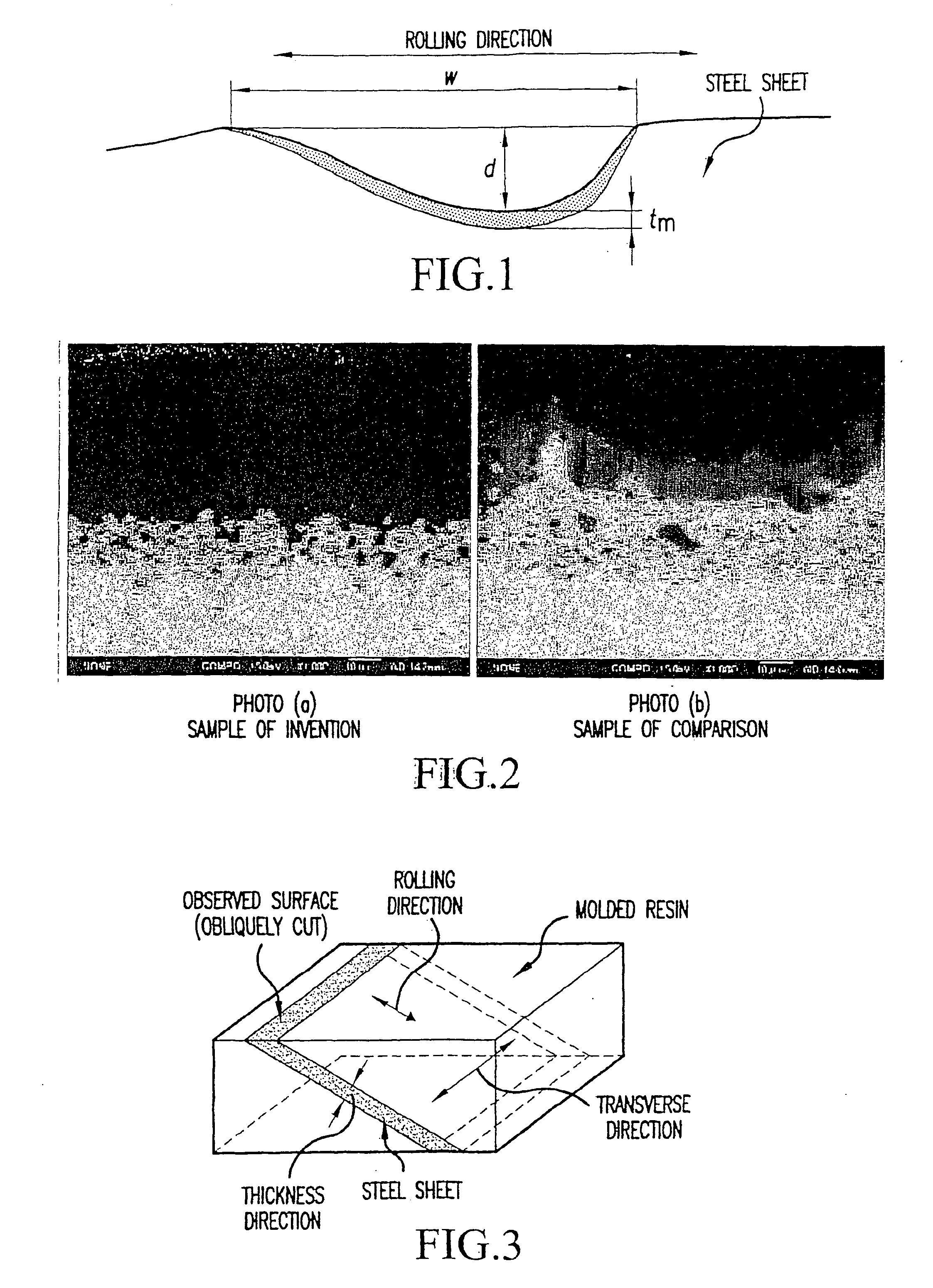

ActiveUS20090145526A1Reduce magnetostrictionLow core lossLaser detailsInorganic material magnetismElectrical steelSheet steel

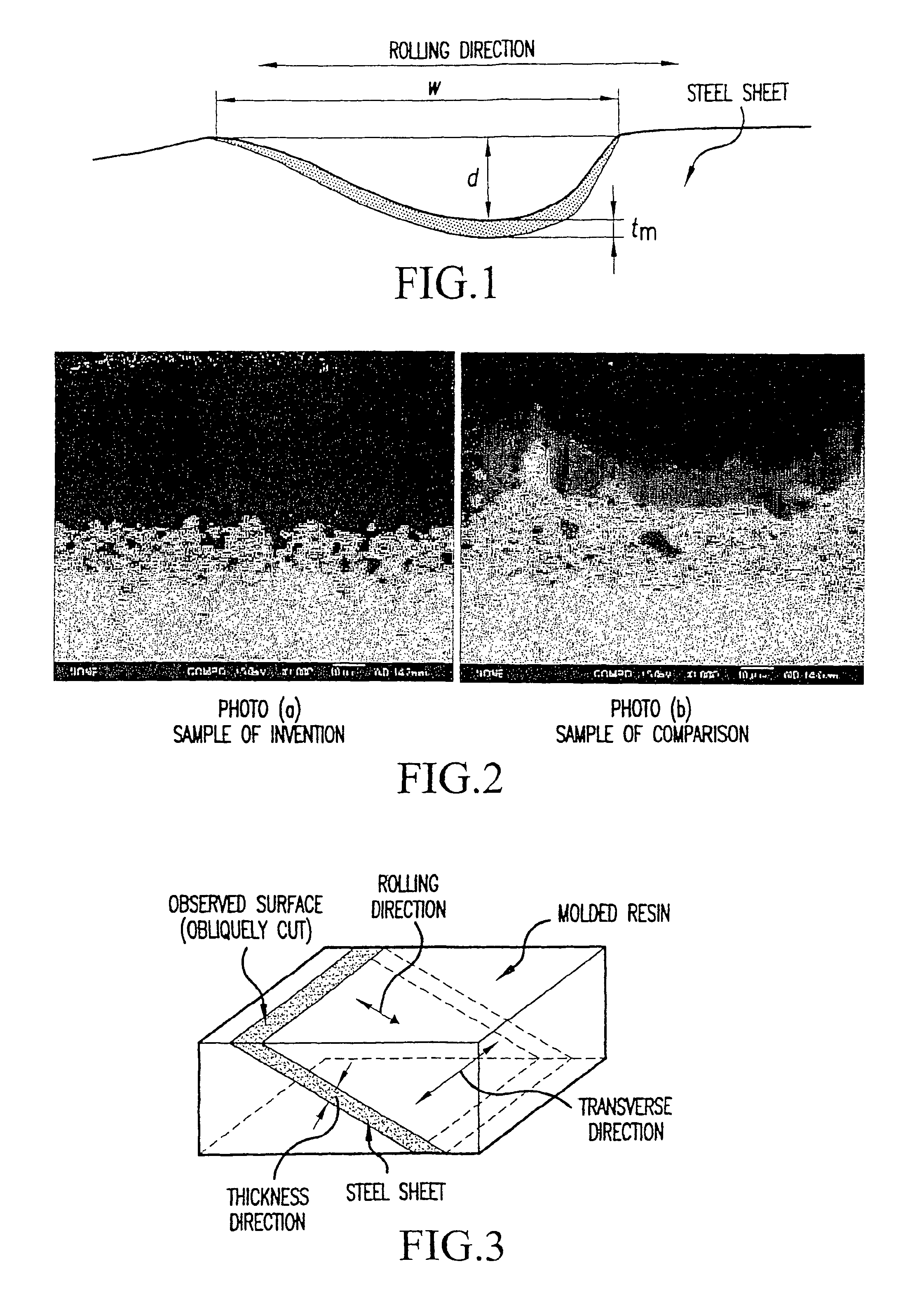

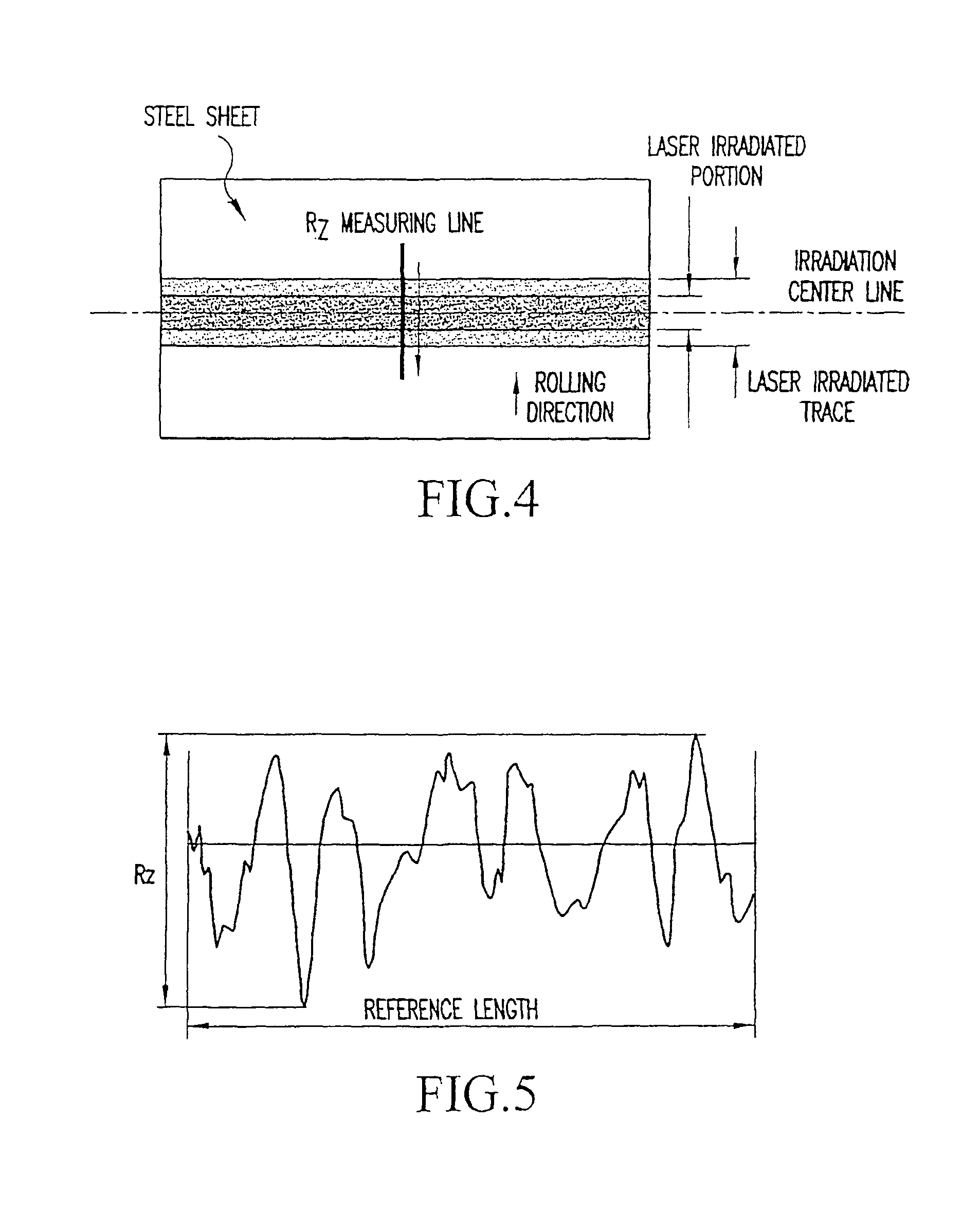

An object of the present invention is to provide a grain-oriented electrical steel sheet with low core loss and low magnetostriction and a method for producing the same. The grain-oriented electrical steel sheet is excellent in reduced core loss and magnetostriction while under a high flux density of 1.9 T, comprises a refined magnetic domain comprising a laser irradiated portion which has melted and resolidified to form a solidified layer, wherein the thickness of the solidified layer is 4 μm or less. The grain-oriented electrical steel sheet may further comprise a laser irradiated portion where a surface roughness Rz is small and a cross section viewed from a transverse direction has a concave portion having a width of 200 μm or less and a depth of 10 μm or less for further improvement.

Owner:NIPPON STEEL CORP

Powder core and iron-base powder for powder core

ActiveUS20090226751A1Hysteresis loss be thereby reduceLarge crystal grain sizeInorganic material magnetismInductances/transformers/magnets manufactureCrystalliteHysteresis

The present invention relates to an iron-base powder for a powder core, wherein when cross-sections of at least 50 iron-base powders are observed and a crystal grain size distribution containing at least a maximum crystal grain size is determined by measuring a crystal grain size of each iron-base powder, 70% or more of the measured crystal grains are a crystal grain having a crystal grain size of 50 μm or more. According to the iron-base powder of the invention, a coercivity of the powder core can be made small and a hysteresis loss can be reduced.

Owner:KOBE STEEL LTD +1

Ferrite core for RFID application, method of manufacturing the same, and ferrite coil using the same

ActiveUS20050023501A1Low core lossHigh curie temperatureInorganic material magnetismCeramic shaping apparatusFull width at half maximumX-ray

A ferrite core comprising a sintered oxide containing at least 48.6 to 53.9 mol% of Fe on Fe2O3 basis, 12.3 to 35.2 mol % of Ni on NiO basis and 16.4 to 37.0 mol % of Zn on ZnO basis as metal elements, and contains a crystal phase comprising two or more kinds of solid solutions selected from NiFe2O4, ZnFe2O4 and FeFe2O4, wherein full width at half maximum of a diffraction peak, of crystal phase of which diffraction angle 2θ is in a range from 34.6 to 36.4° as measured by X-ray diffraction analysis using Cu—Kα beam, is 0.4° or less.

Owner:KYOCERA CORP

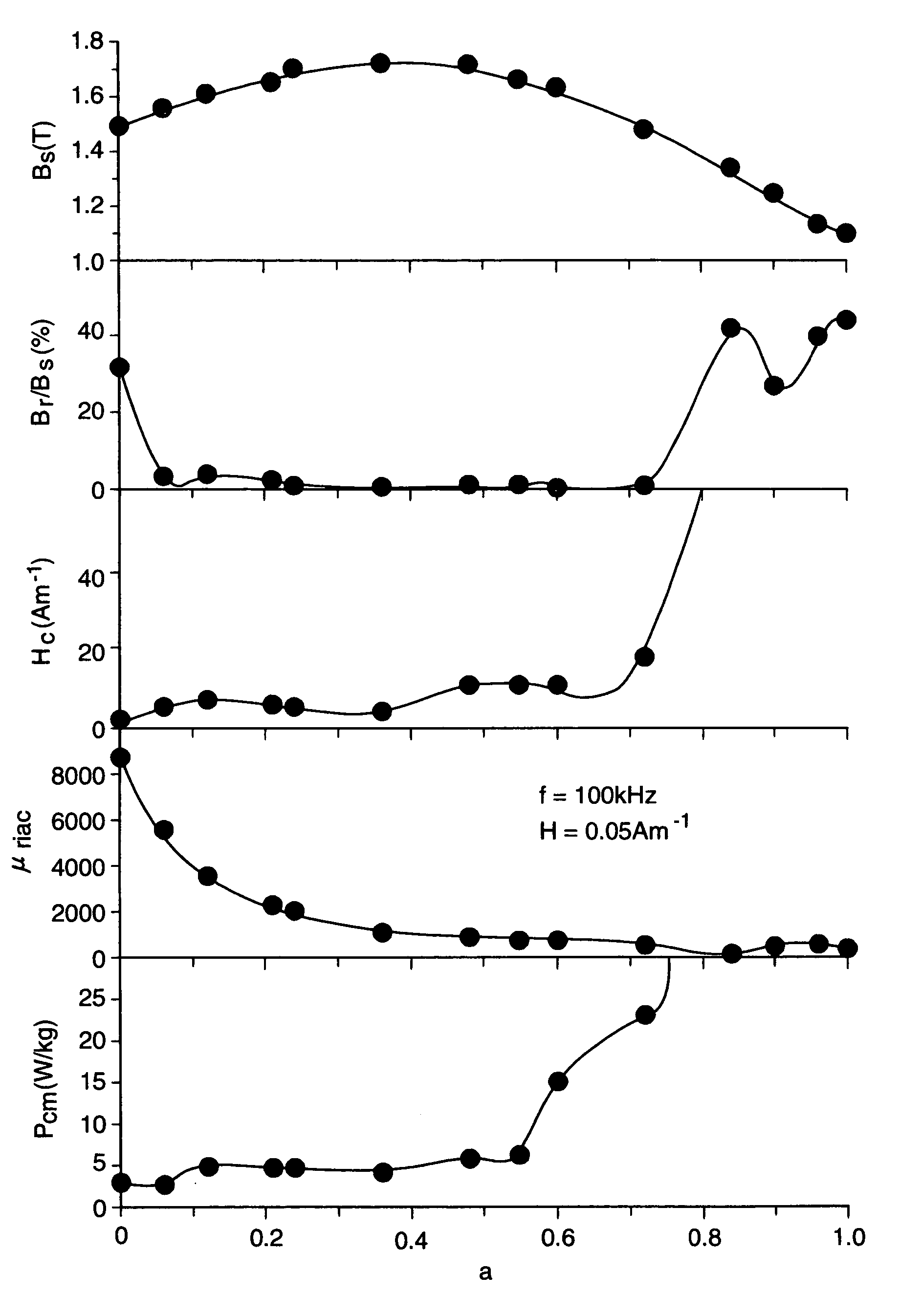

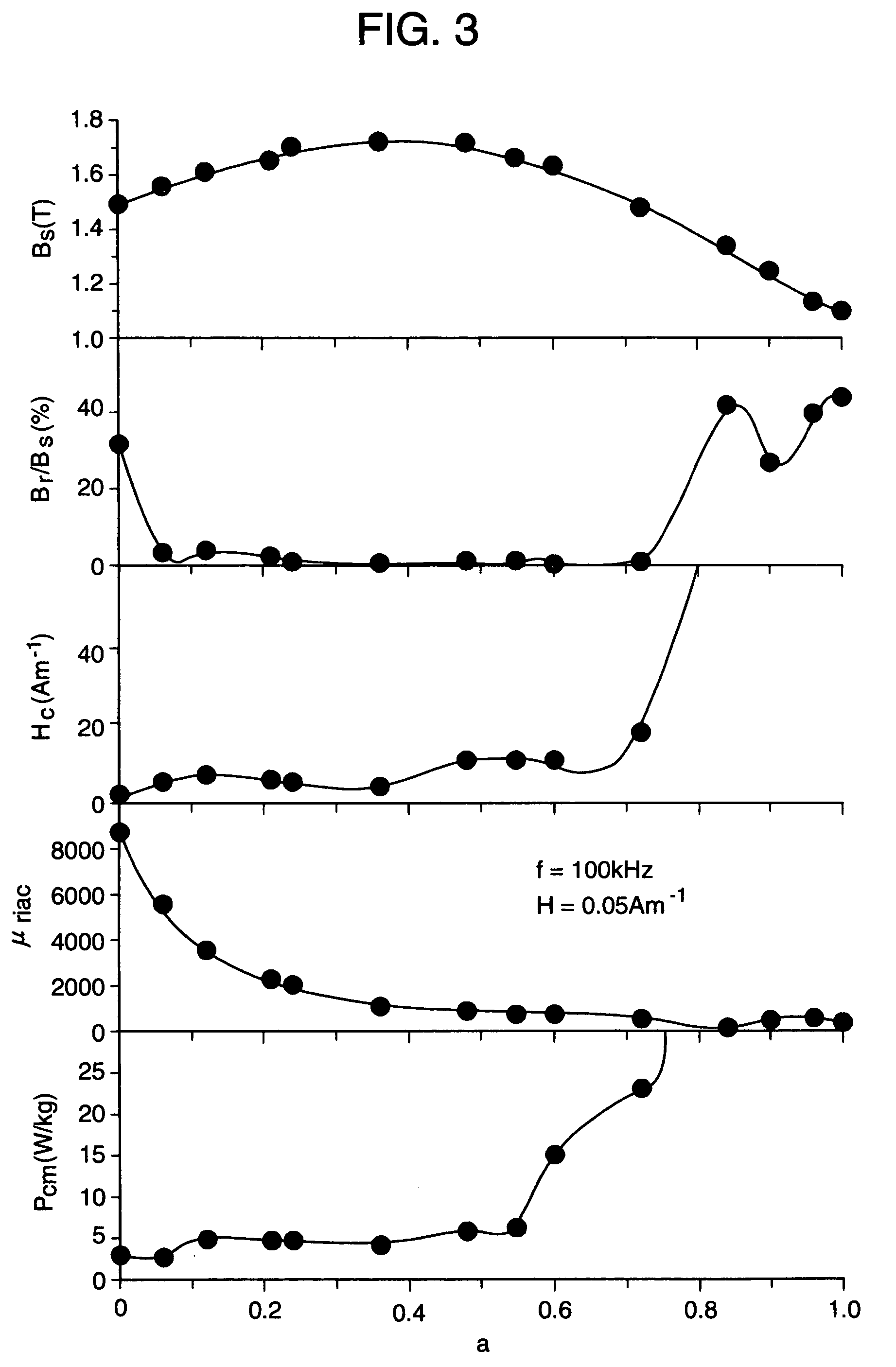

Low core loss magnetic alloy with high saturation magnetic flux density and magnetic parts made of same

ActiveUS7141127B2High saturated magnetic flux densityLow core lossInorganic material magnetismInductances/transformers/magnets manufactureMaterials scienceCrystallite

A low core loss magnetic alloy with a high saturation magnetic flux density, which has a composition represented by the general formula:(Fel-aCoa)100-y-cM′yX′c(atomic %)where M′ represents at least one element selected from V, Ti, Zr, Nb, Mo, Hf, Ta, and W, X′ represents Si and B, an Si content (atomic %) is smaller than a B content (atomic %), the B content is from 4 to 12 atomic %, and the Si content is from 0.01 to 5 atomic %, a, y, and c satisfy respectively 0.2<a<0.6, 6.5≦y≦15, 2≦c≦15, and 7≦(y+c)≦20, at least a part of an alloy structure being occupied by crystal grains having grain size of not larger than 50 nm, a saturation magnetic flux density Bs being not less than 1.65 T, and a core loss Pcm per unit volume in conditions at 80° C., f=20 kHz, and Bm=0.2 T being not more than 15 W / kg.

Owner:HITACHI METALS LTD

Compound magnetic powder and magnetic powder cores, and methods for making them thereof

InactiveUS20100034687A1Reduce penetrationLow core lossTransportation and packagingMetal-working apparatusAl powderIron powder

The present invention provides a compound powder for making magnetic powder cores, a kind of magnetic powder core, and a process for making them. Said compound powder is a mixture composing of powder A and powder B, the content of powder A is 50-96 wt. % and the content of powder B is 4-50 wt. %, wherein powder A is at least one selected from iron powder, Fe—Si powder, Fe—Si—Al powder, Fe-based nanocrystalline powder, Fe-based amorphous powder, Fe—Ni powder and Fe—Ni—Mo powder; powder B bears different requirement characteristics from powder A and is at least one selected from iron powder, Fe—Si powder, Fe—Si—Al powder, Fe-based nanocrystalline powder, Fe-based amorphous powder, Fe—Ni powder and Fe—Ni—Mo powder. Said powder B adopts Fe-based amorphous soft magnetic powder with good insulation property as insulating agent and thus core loss of magnetic powder core decreases. The decrease of magnetic permeability of magnetic powder core resulting from a traditional insulating agent is remedied and the initial magnetic permeability of magnetic powder core is improved by taking advantage of soft magnetic properties of Fe-based amorphous powder.

Owner:LU ZHICHAO +8

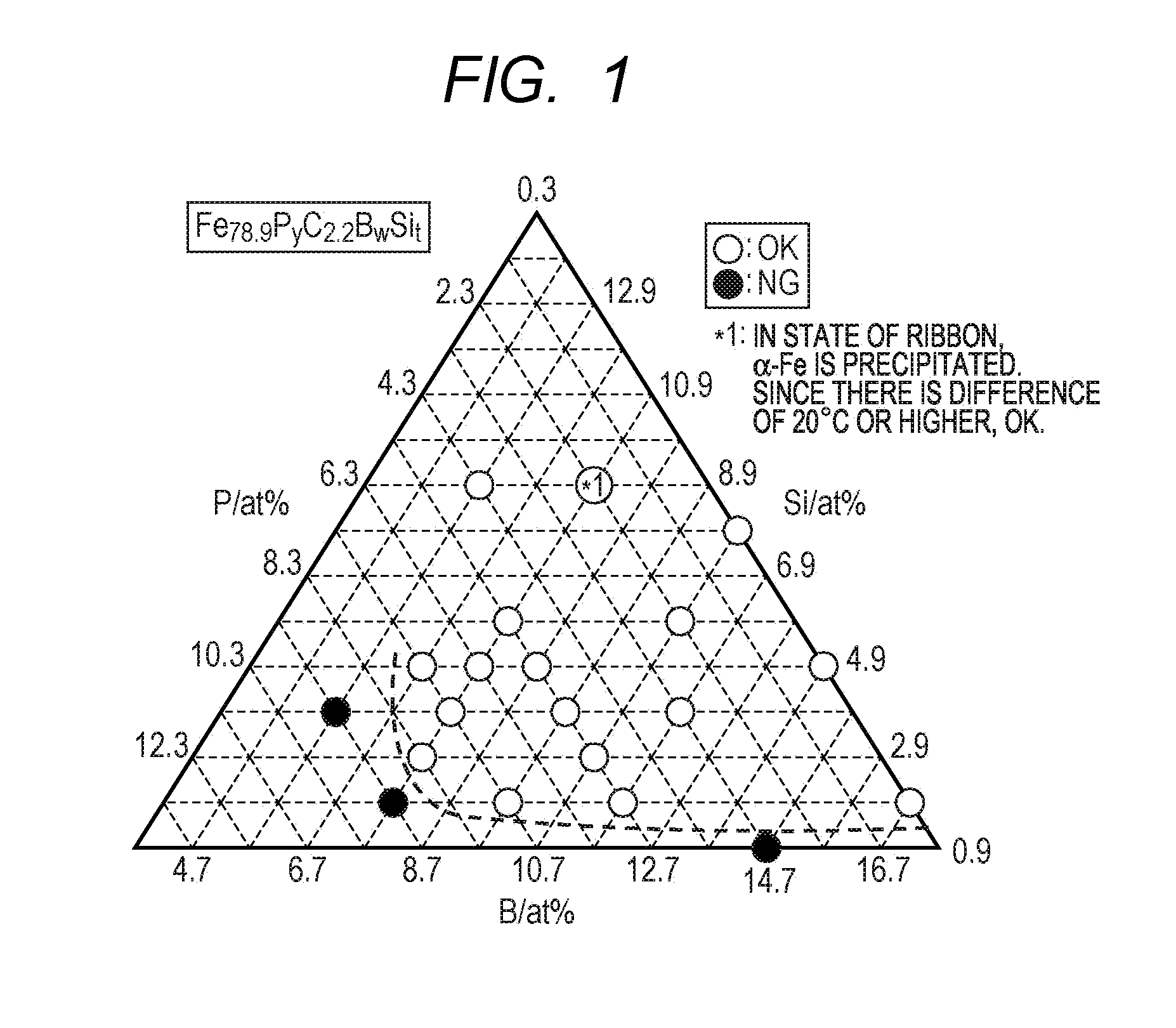

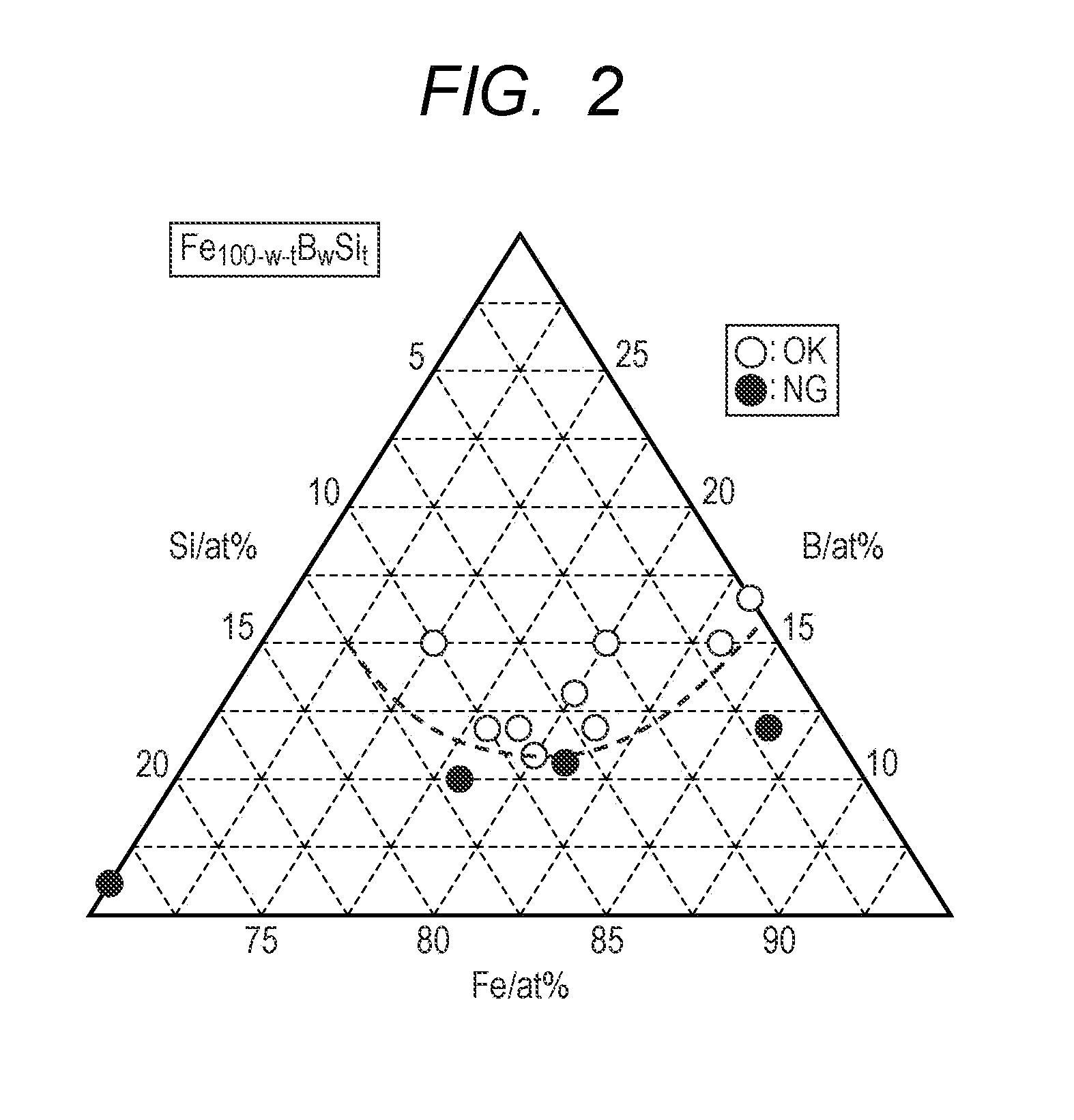

Fe-BASED SOFT MAGNETIC ALLOY AND DUST CORE USING Fe-BASED SOFT MAGNETIC ALLOY

ActiveUS20110265915A1High saturation magnetizationGood magnetic permeabilityMaterial nanotechnologyNanomagnetismCrystalliteFe based

An Fe-based soft magnetic alloy includes: Fe; and a component R, wherein the component R contains at least one of P, C, B, and Si, there is a temperature difference of equal to or greater than 20° C. between a precipitation temperature of an α-Fe crystal phase and a precipitation temperature of an Fe compound, the Fe-based soft magnetic alloy is formed of a mixed-phase structure in which an amorphous phase and the α-Fe crystal phase are mixed, and a diameter of a crystallite of the α-Fe crystal phase is equal to or smaller than 50 nm, and a volume fraction of the α-Fe crystal phase to the total is equal to or lower than 40%. In addition, the composition formula is represented by Fe100-x-uJxRu, a component J contains at least one of Cr, Co, Ni, and Nb, and 0 at %≦x≦6 at %, 17 at %≦u≦25 at %, and 17 at %≦x+u≦27.1 at % are satisfied.

Owner:ALPS ALPINE CO LTD

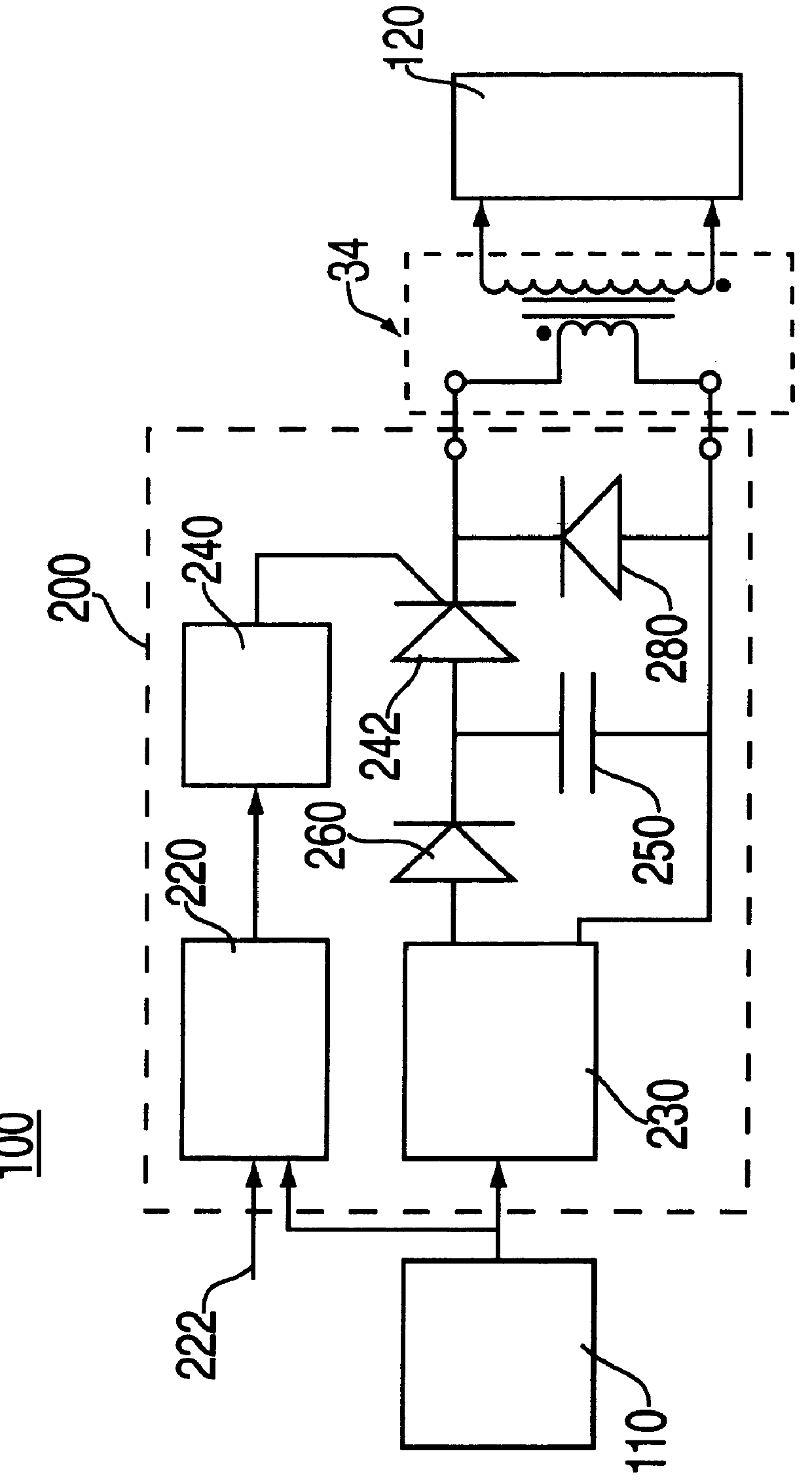

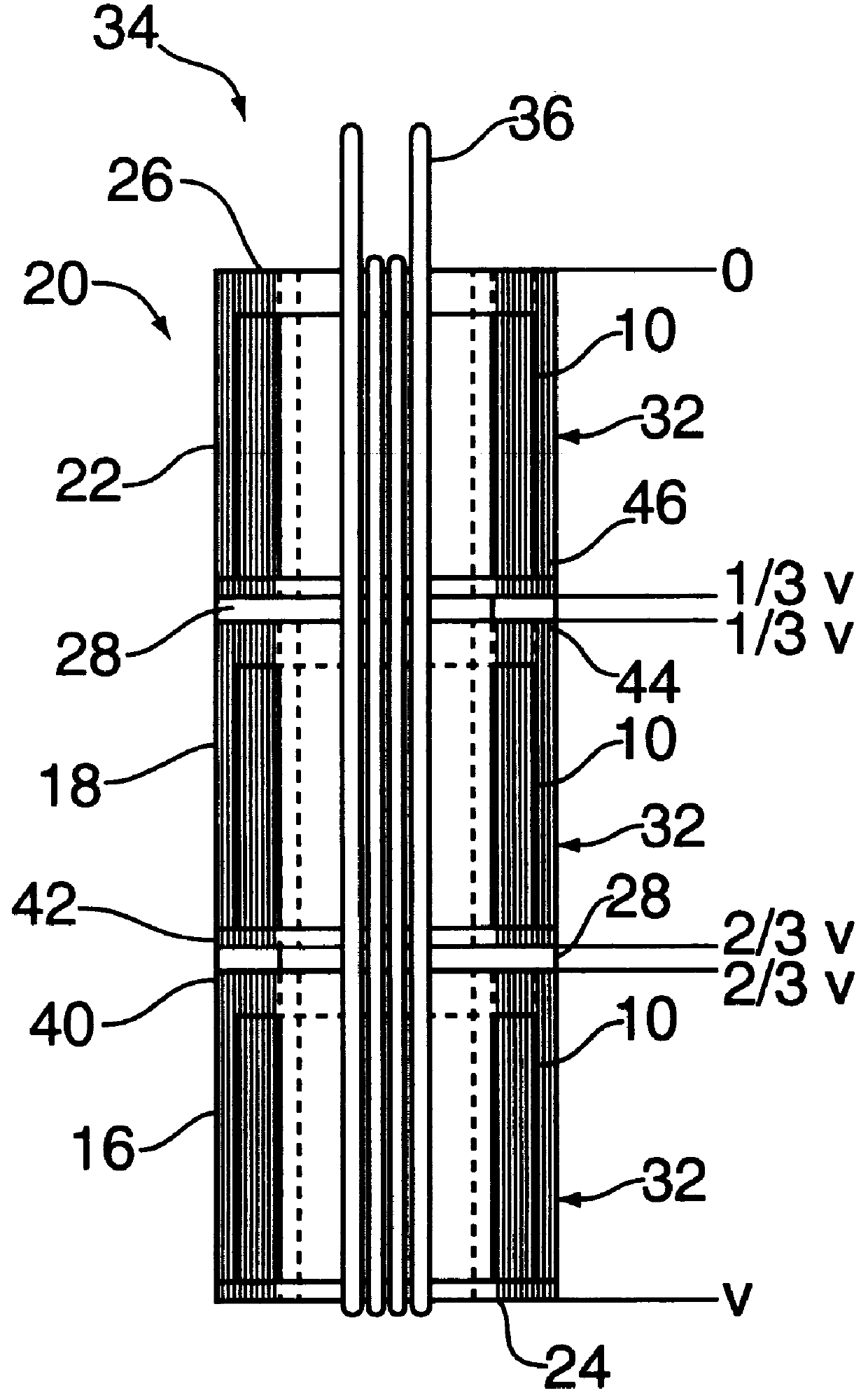

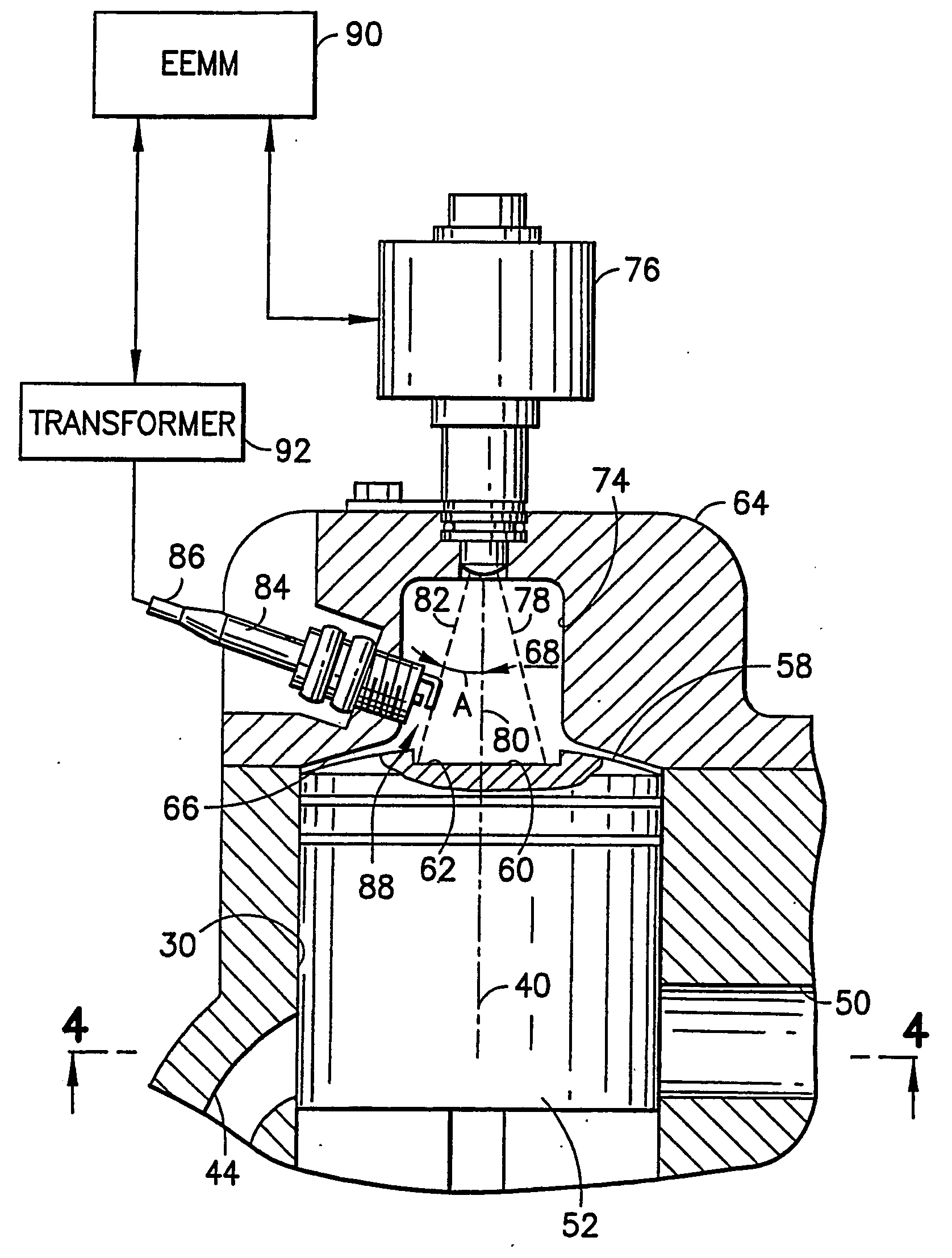

Spark ignition system having a capacitive discharge system and a magnetic core-coil assembly

InactiveUS6123062ALow magnetic lossLow resistance and inductanceTransformersMachines/enginesCapacitanceSilicon-controlled rectifier

A spark ignition system for an internal combustion engine has a capacitive discharge (CD) system connected to a coil-per-plug (CCP) magnetic core-coil assembly. The spark ignition system is connected to a spark plug and is adapted to initiate an ignition wherein a spark is produced across the gap of the spark plug. The spark ignition system includes a magnetic core-coil assembly having an amorphous metal magnetic core, a primary coil and a secondary coil for a high voltage output to be fed to a spark plug. The CD system is charged and rapidly discharged through the primary coil of the magnetic core-coil assembly using a silicon controlled rectifier (SCR) as the switch. Operation of the SCR is controlled by circuitry that controls the firing of the spark ignition system. The magnetic core-coil assembly acts as a pulse transformer, so that voltage across its secondary coil is related to the turns ratio of secondary to primary.

Owner:ALLIEDSIGNAL INC +1

Grain-Oriented Electric Steel Sheet Having Superior Magnetic Property and Method for Manufacturing Same

ActiveUS20130180634A1Reduce amountLow manufacturingPolycrystalline material growthInorganic material magnetismElectrical steelSheet steel

Owner:POSCO

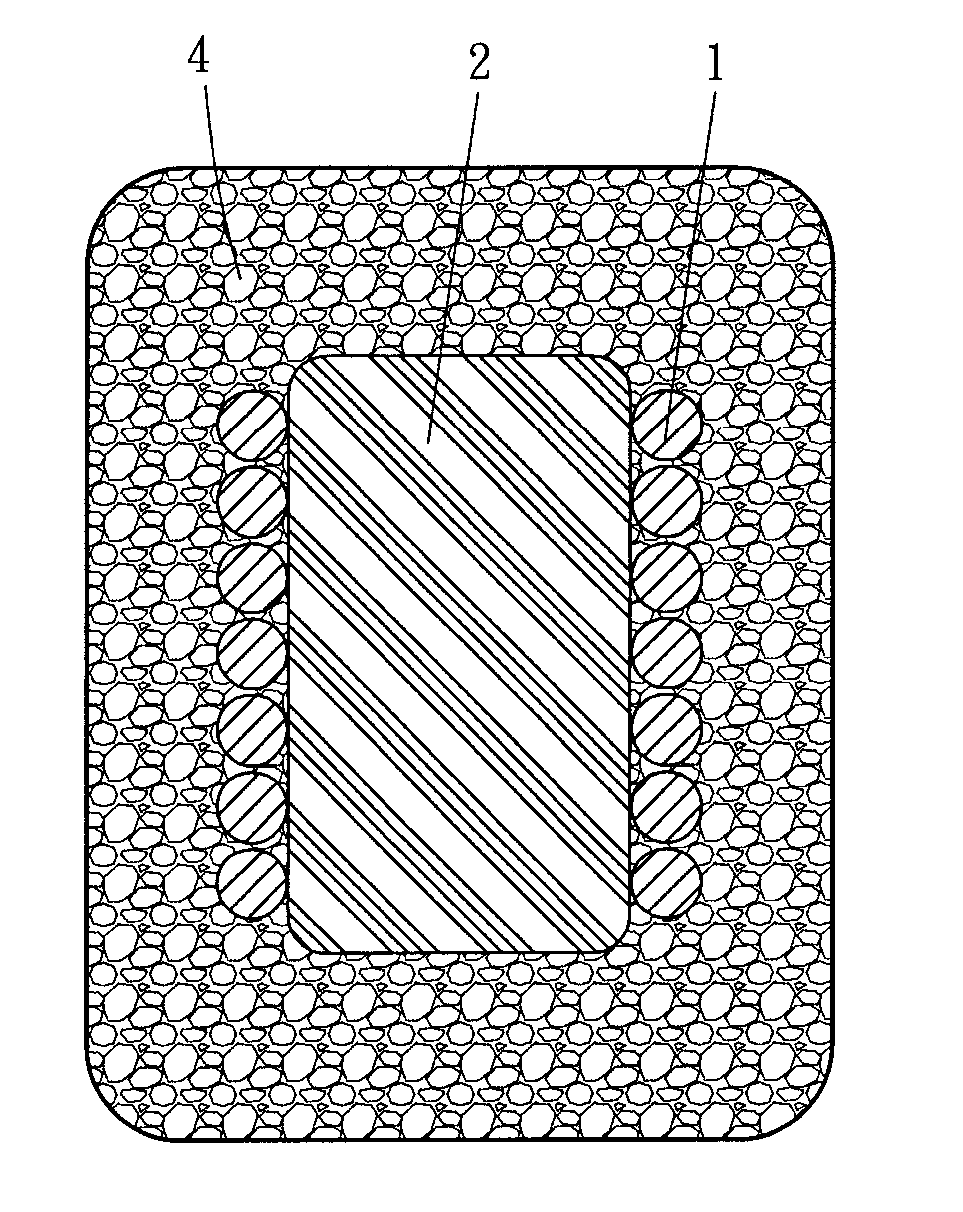

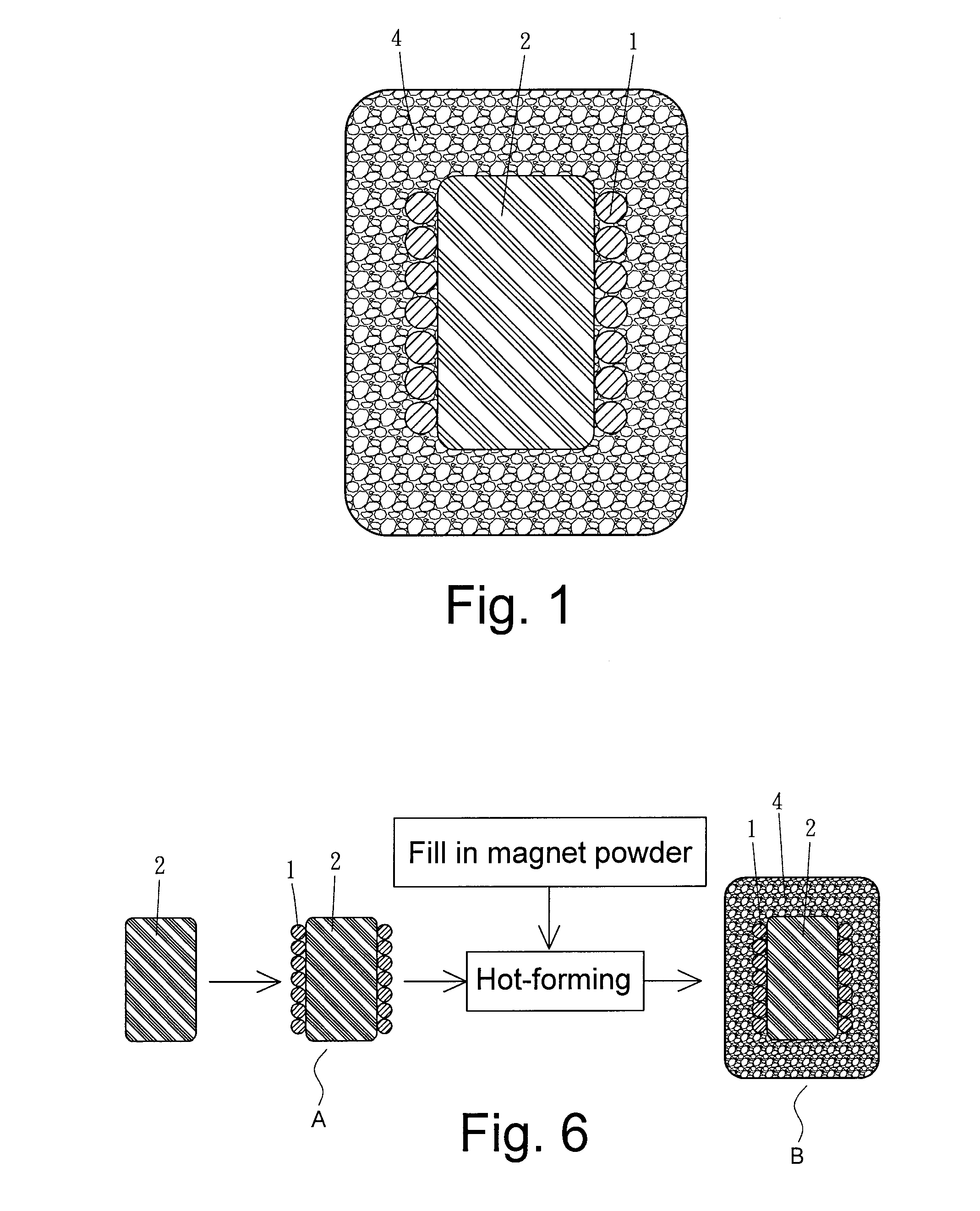

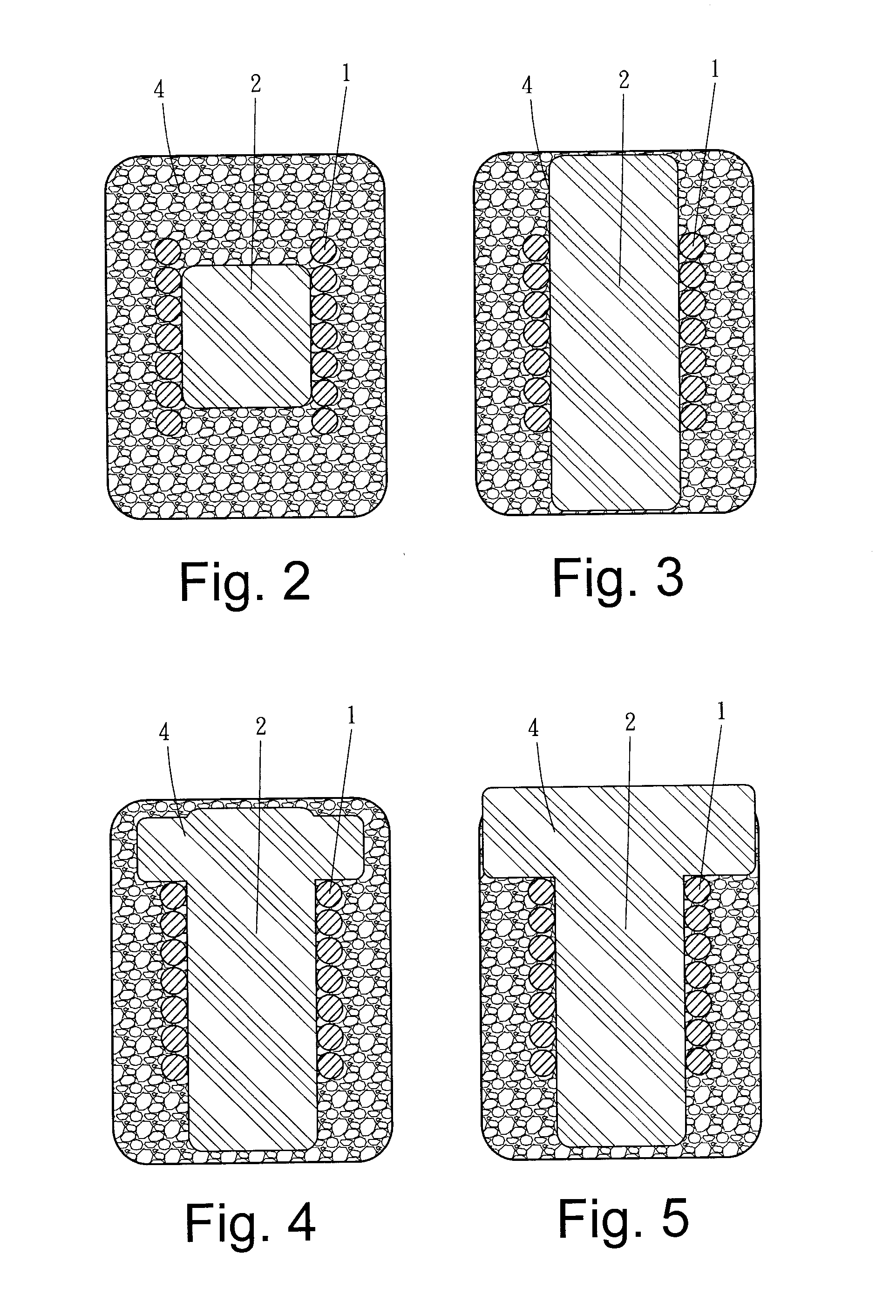

Hot-forming fabrication method and product of magnetic component

InactiveUS20100245015A1Improve performanceHigh materialCeramic shaping apparatusTransformers/inductances magnetic coresThermoformingEngineering

A hot-forming fabrication method of a magnetic component and a hot-formed magnetic component fabricated by the same are provided. More particularly, a magnetic powder hot-forming technique is provided, along with a hot-formed magnetic component fabricated by the hot-forming technique so as to have high inductance, low core loss, and high electromagnetic wave shielding efficiency. A low core low-core loss core for use in a common basic magnetic component is enclosed and thereby shielded by a single-layer or multi-layer EMI shielding material, thus producing an enhanced magnetic component with high inductance, low core loss, and low electromagnetic wave interference.

Owner:CURIE IND

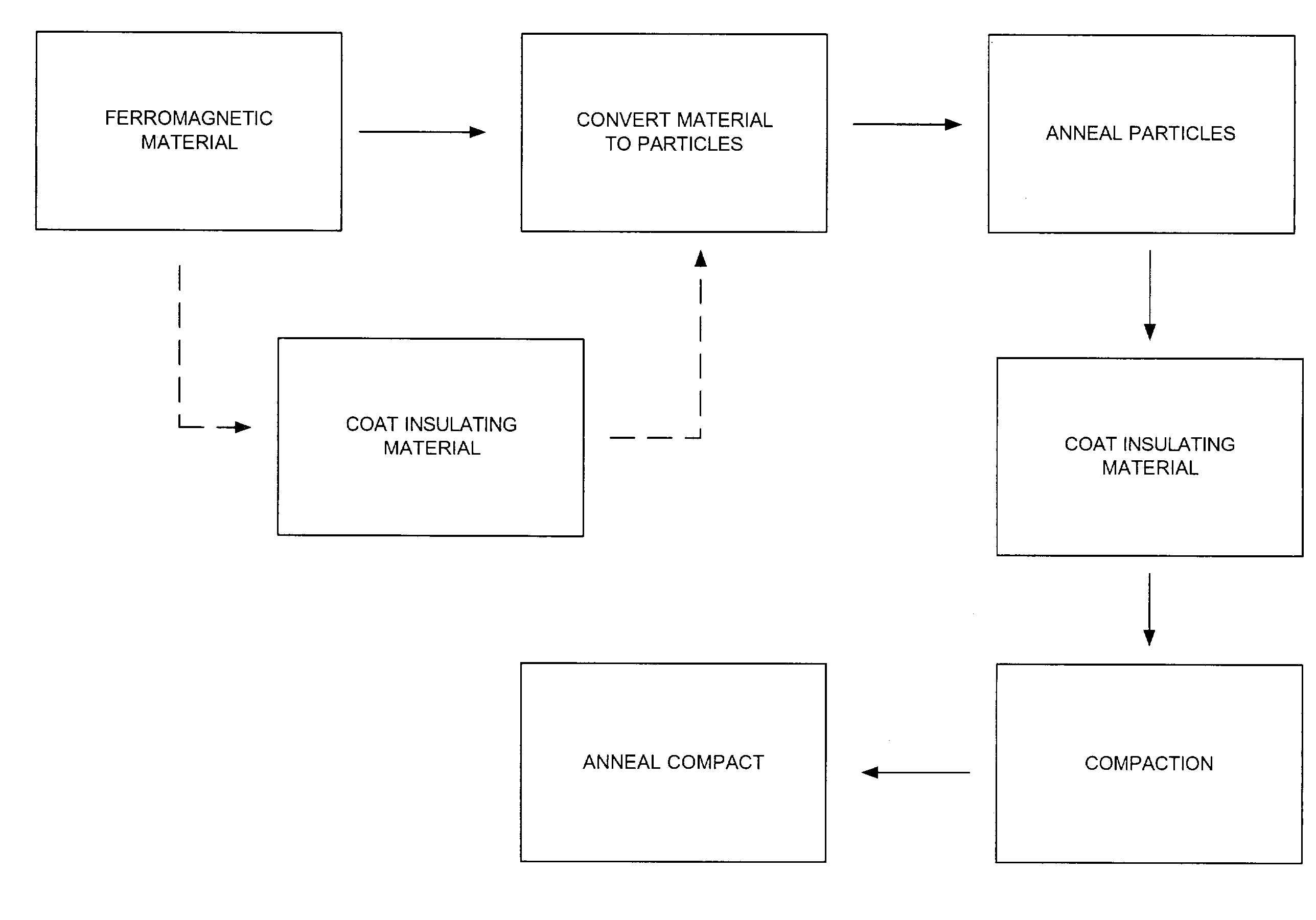

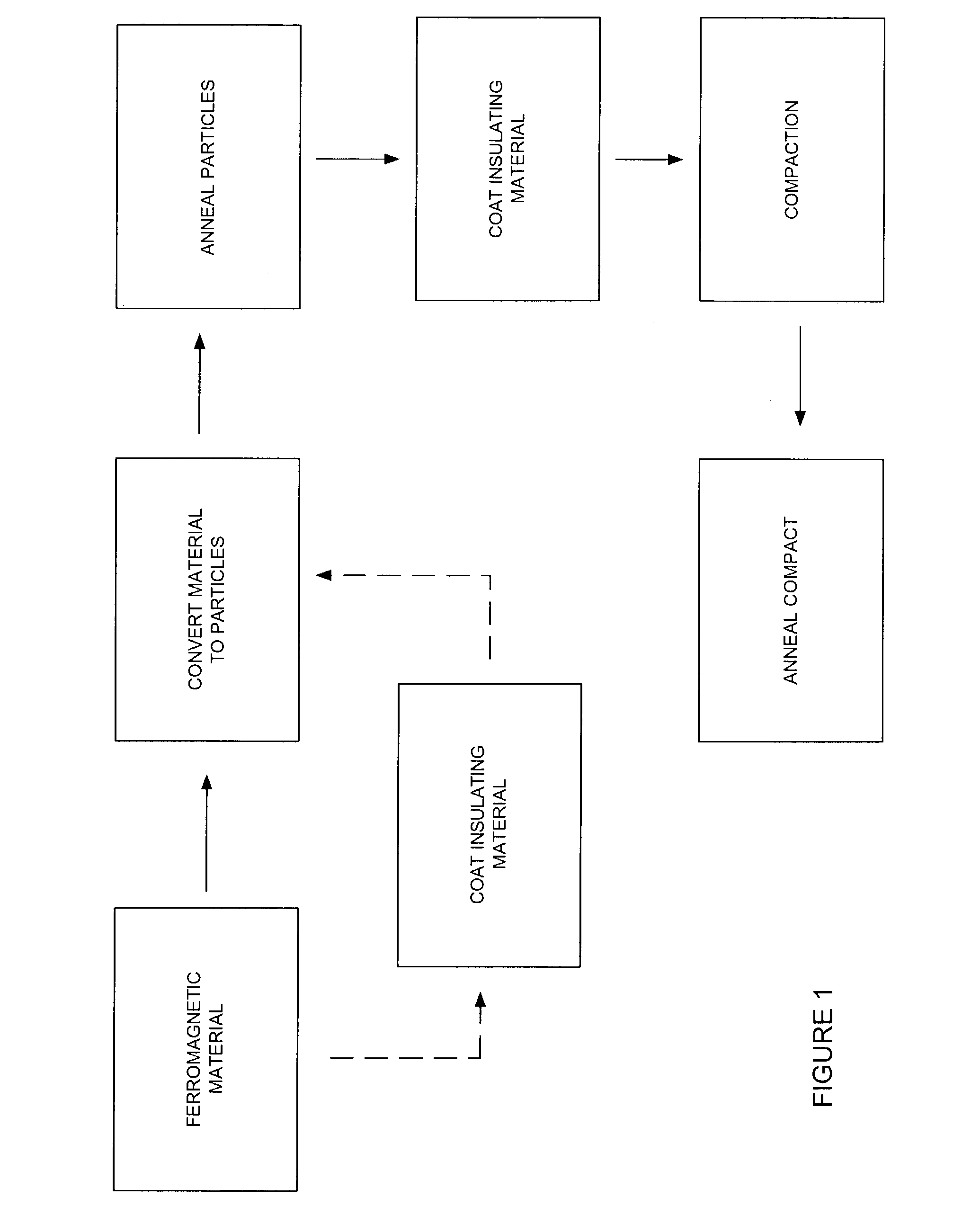

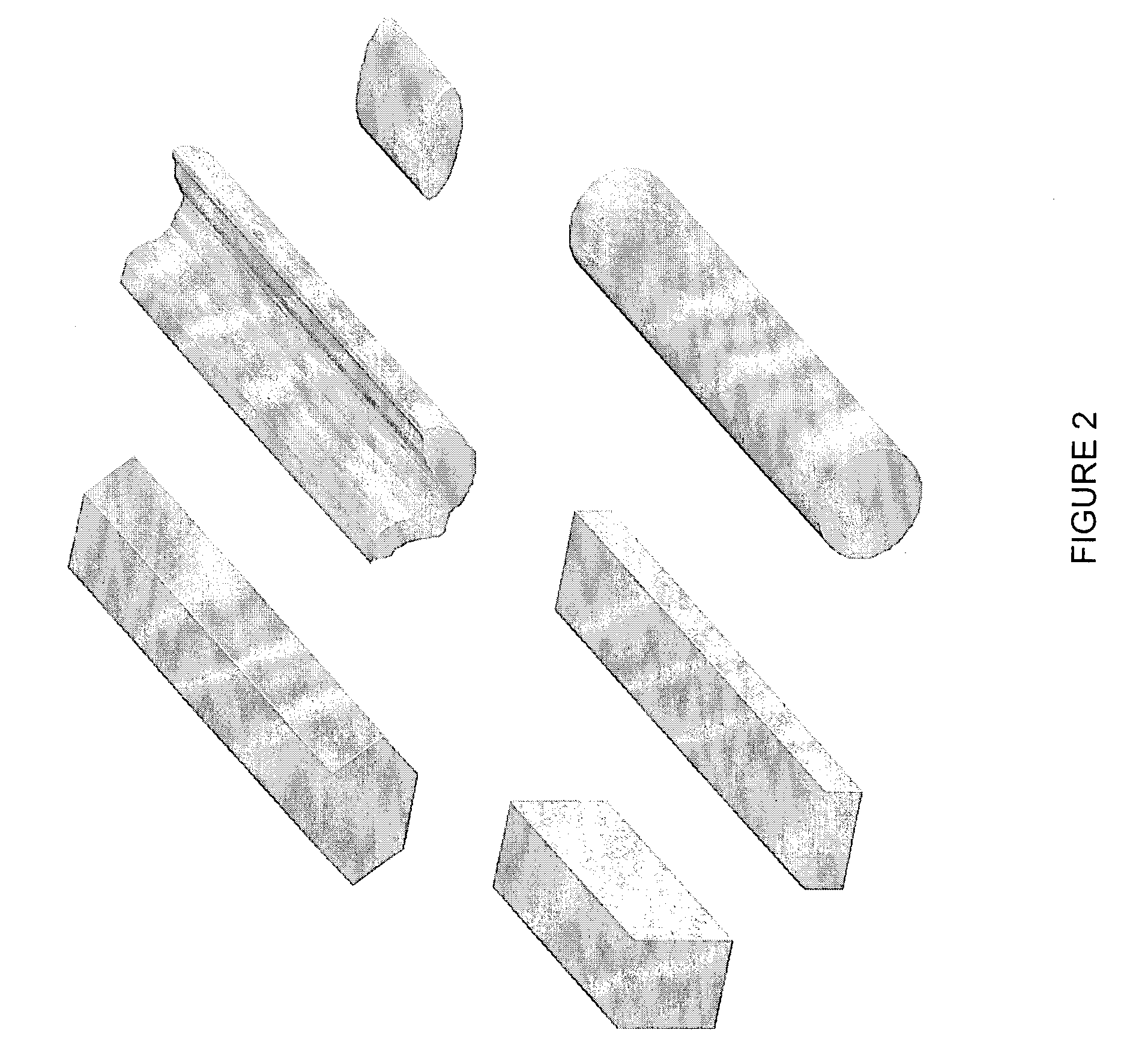

Coated ferromagnetic particles and compositions containing the same

InactiveUS7041148B2Improve permeabilityIncrease flux densitySynthetic resin layered productsCellulosic plastic layered productsFiberMaterials science

High-permeability, low-core-loss soft magnetic composite materials, compositions containing the same, and methods for making the same are described. These magnetic materials are made by forming fiber or flake shaped particles from a ferromagnetic material, annealing the particles, and then coating an insulating material on the particles. These particles can then be compacted to form an article that has high permeability, high saturation, low core loss, and is a suitable replacement for laminations in various applications, such as motors.

Owner:GENERAL ELECTRIC CO

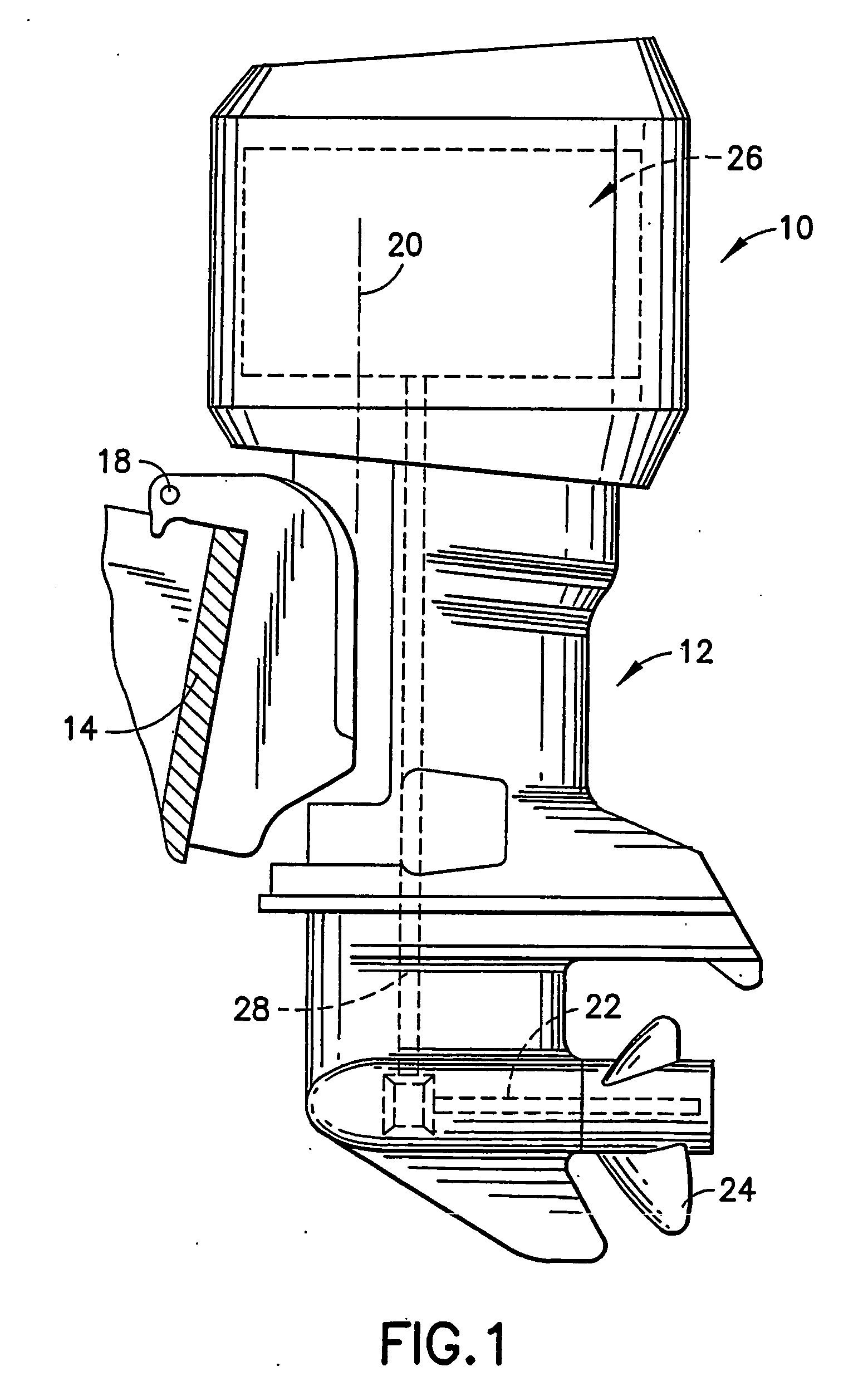

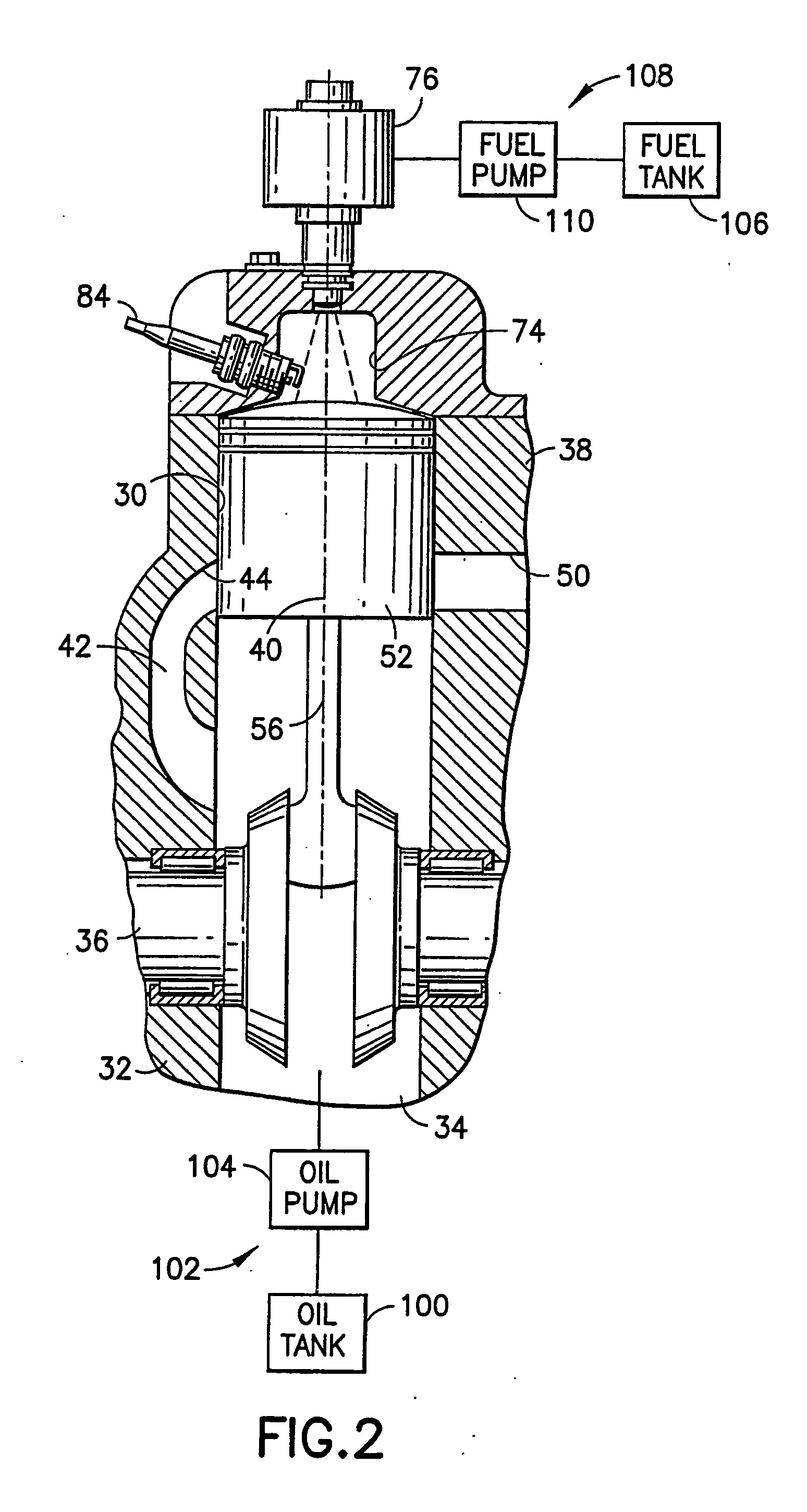

Direct fuel-injected internal combustion engine having improved spark ignition system

InactiveUS20050061294A1Minimize the numberRapid voltage riseElectrical controlInternal combustion piston enginesLow voltageEngineering

A direct fuel injection outboard marine engine having an improved spark ignition system. This spark ignition system includes a magnetic core-coil assembly for generating a high-voltage signal within a short period of time and an electronic engine management module for energizing a primary coil of the magnetic core-coil assembly with a low-voltage signal at the appropriate time. The magnetic core is made of ferromagnetic amorphous metal alloy which exhibits low core loss and a permeability in the range of 100 to 500. The high-voltage signal is output by a secondary coil wound around a major portion of the core, with the primary coil being wound around a minor portion of the core. The secondary coil outputs a high-voltage signal to a spark plug in response to excitation of the primary coil with a low-voltage signal generated by the electronic engine management module.

Owner:BRP US

Low core loss grain-oriented electrical steel sheet and method for producing the same

ActiveUS8016951B2Low core lossReduce noiseLaser detailsInorganic material magnetismElectrical steelHigh flux

An object of the present invention is to provide a grain-oriented electrical steel sheet with low core loss and low magnetostriction and a method for producing the same. The grain-oriented electrical steel sheet is excellent in reduced core loss and magnetostriction while under a high flux density of 1.9 T, comprises a refined magnetic domain comprising a laser irradiated portion which has melted and resolidified to form a solidified layer, wherein the thickness of the solidified layer is 4 μm or less. The grain-oriented electrical steel sheet may further comprise a laser irradiated portion where a surface roughness Rz is small and a cross section viewed from a transverse direction has a concave portion having a width of 200 μm or less and a depth of 10 μm or less for further improvement.

Owner:NIPPON STEEL CORP

Method of manufacturing a nonoriented electromagnetic steel sheet

InactiveUS20080060728A1High magnetic flux densityLow core lossInorganic material magnetismFurnace typesElectrical steelAustenite

A method for manufacturing a non-oriented electrical steel sheet including hot-rolling a steel slab containing 0-0.010% of C; at least one of Si and Al in a total amount of 0.03% to 0.5%; 0.5% or less of Mn; 0.10% or more to 0.26% or less of P; 0.015% or less of S; and 0.010% or less of N, on a mass percentage basis, the remainder being Fe and unavailable impurities, under conditions of a heating temperature in a single-phase austenite region and a coiling temperature of 650° C. or less; descaling the hot-rolled sheet to cold-roll the descaled sheet once or twice or more with an intermediate annealing sub-step therebetween; and then finish-annealing the cold-rolled sheet at a temperature of 700° C. or more in the single-phase ferrite region.

Owner:JFE STEEL CORP

Soft magnetic powder

ActiveUS20100038580A1Large specific resistanceLow core lossMetal-working apparatusInorganic material magnetismVolumetric Mass DensityMaterials science

A powder magnetic core is provided for operating at high frequencies that is obtained by pressure forming an iron-based magnetic powder covered with an insulation film, which has a specific resistance less than 1000, preferably less than 2000, and most preferably less than 3000 μm, and a saturation magnetic flux density B above 1.5, preferably above 1.7, and most preferably above 1.9 (T). A method for the preparation of such cores as well as a powder which is suitable for the preparation also are provided.

Owner:HOGANAS AB

Ferrite material

ActiveCN101038807AHigh saturation flux densityLow core lossInorganic material magnetismMaterials scienceFerric

Owner:TDK CORPARATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com