Patents

Literature

259results about How to "Avoid embrittlement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot-rolled steel sheet and cold-rolled steel sheet and manufacturing method thereof

InactiveUS20080202639A1Excellent mechanical propertiesLower transition temperatureHot-dipping/immersion processesFurnace typesMaterials scienceRaw material

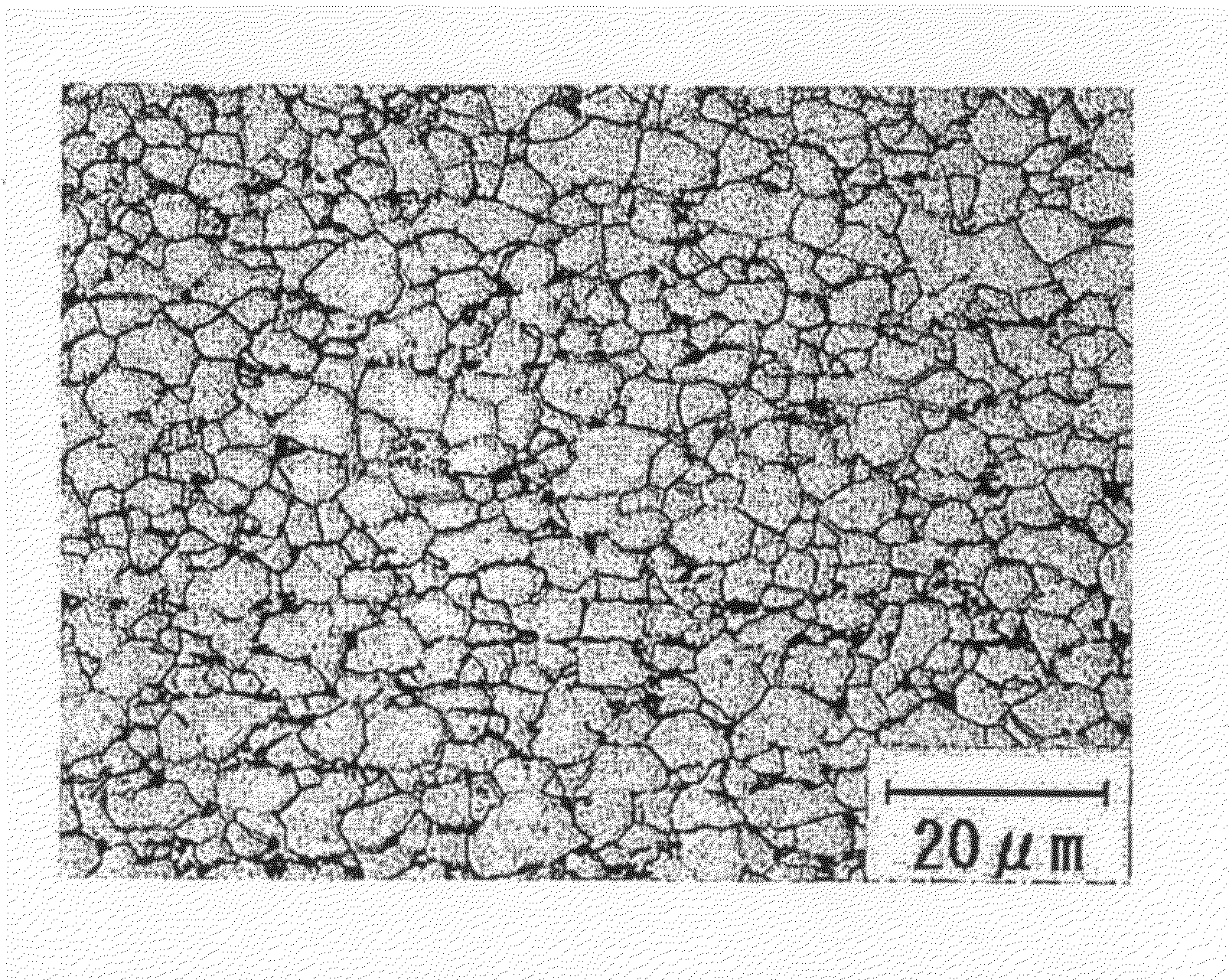

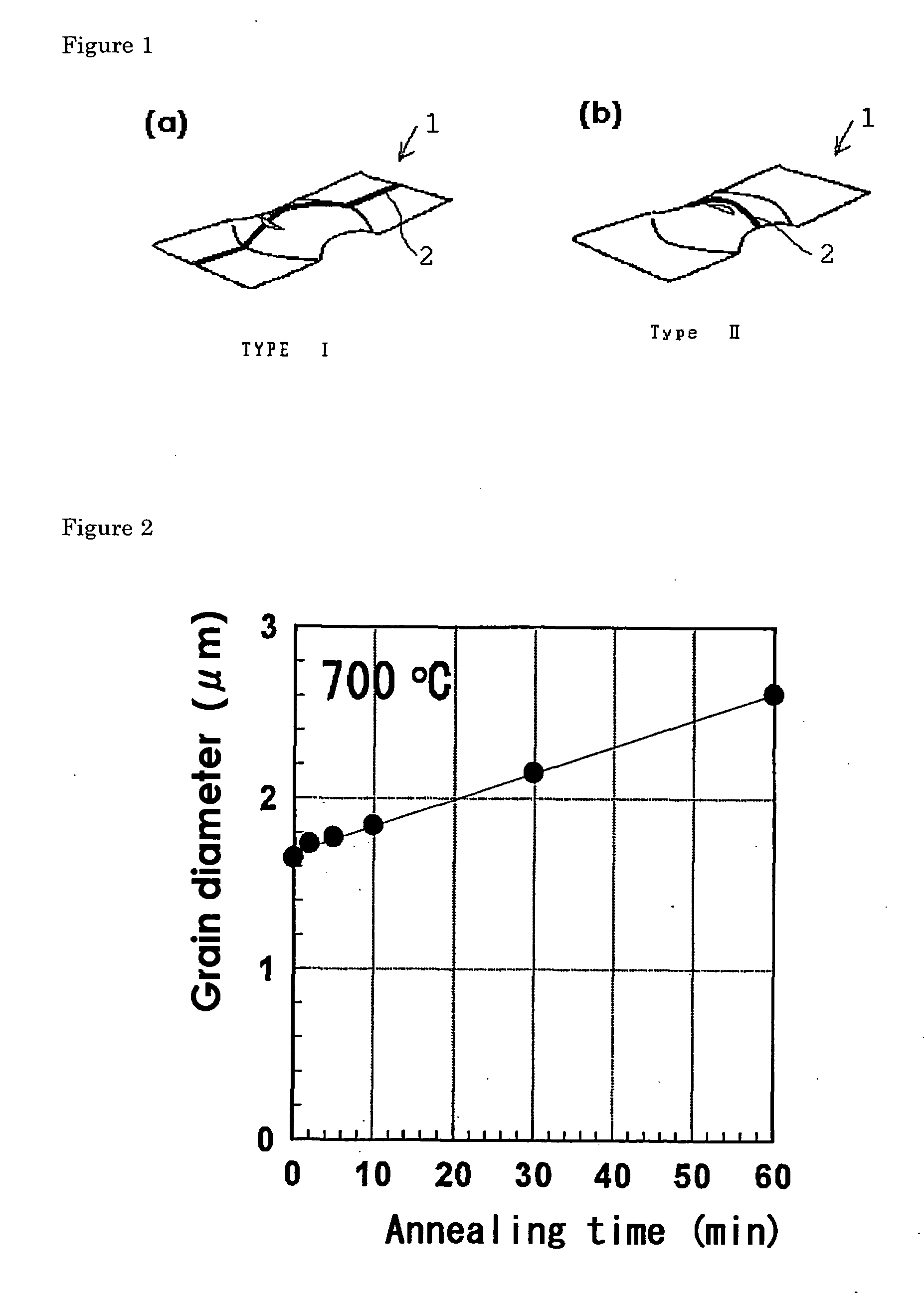

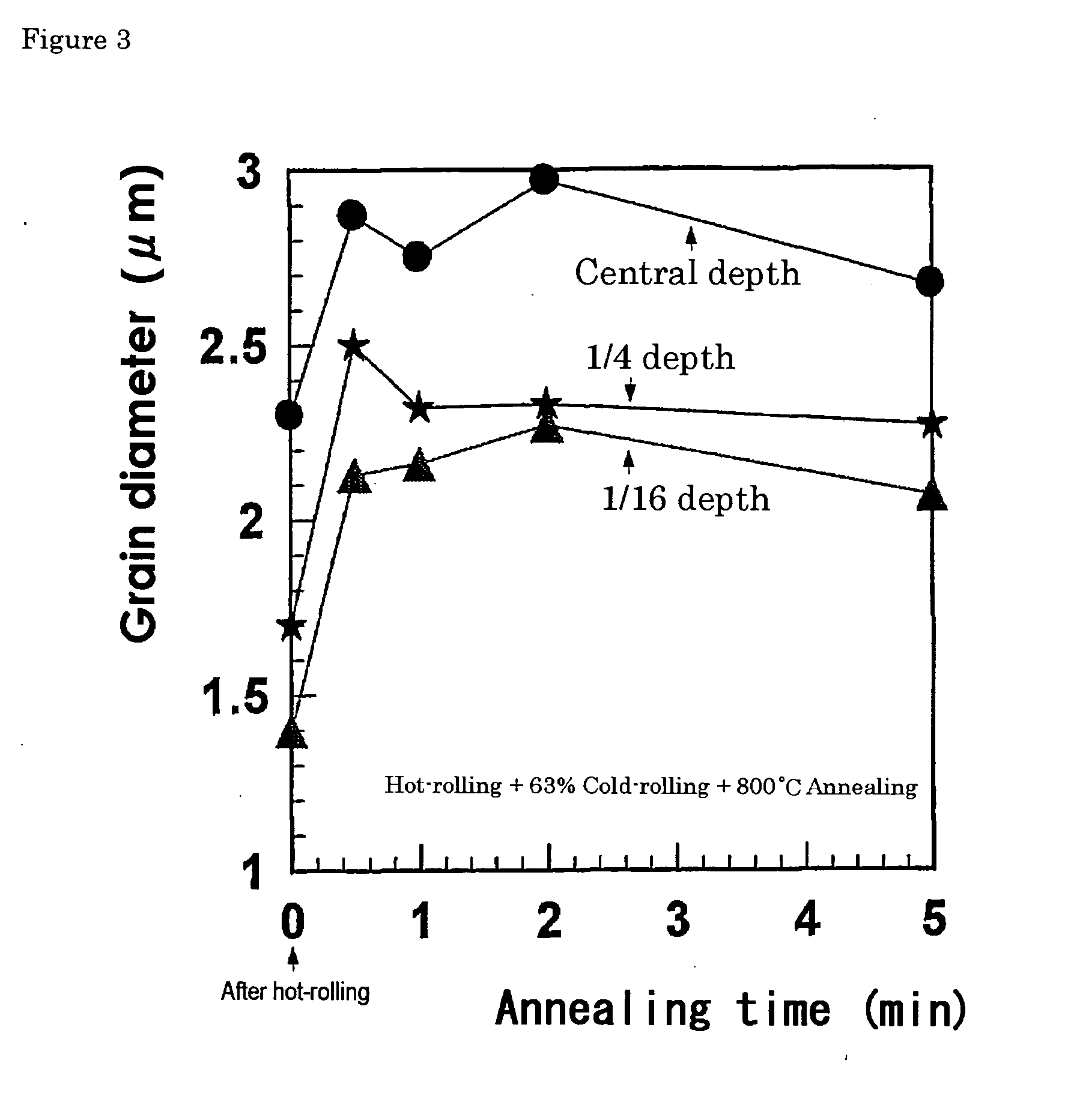

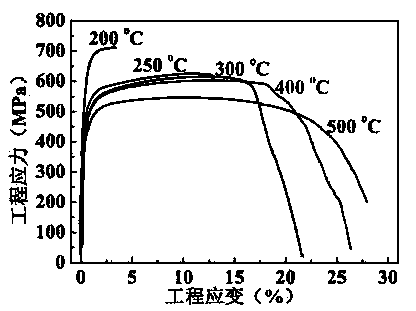

A steel sheet excellent in mechanical strength, workability and thermal stability and suited for use as a raw material in such fields of manufacturing automobiles, household electric appliances and machine structures and of constructing buildings, and a manufacturing method thereof. are provided.The steel sheet is a hot-rolled steel sheet of carbon steel or low-alloy steel, the main phase of which is ferrite, and is characterized in that the average ferrite crystal grain diameter D (μm) at the depth of ¼ of the sheet thickness from the steel sheet surface satisfies the relations respectively defined by the formulas (1) and (2) given below and the increase rate X (μm / min) in average ferrite crystal grain diameter at 700° C. at the depth of ¼ of the sheet thickness from the steel sheet surface and said average crystal grain diameter D (μm) satisfy the relation defined by the formula (3) given below:1.2≦D≦7 formula (1)D≦2.7+5000 / (5+350·C+40·Mn)2 formula (2)D·X≦0.1 formula (3)wherein C and Mn represent the contents (in % by mass) of the respective elements in the steel.

Owner:NIPPON STEEL CORP

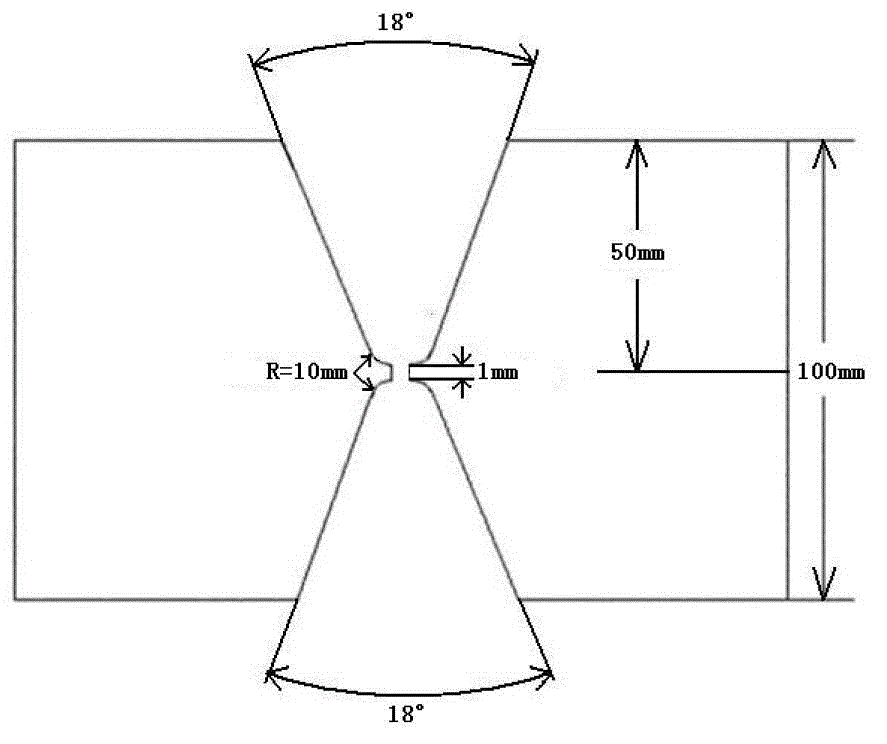

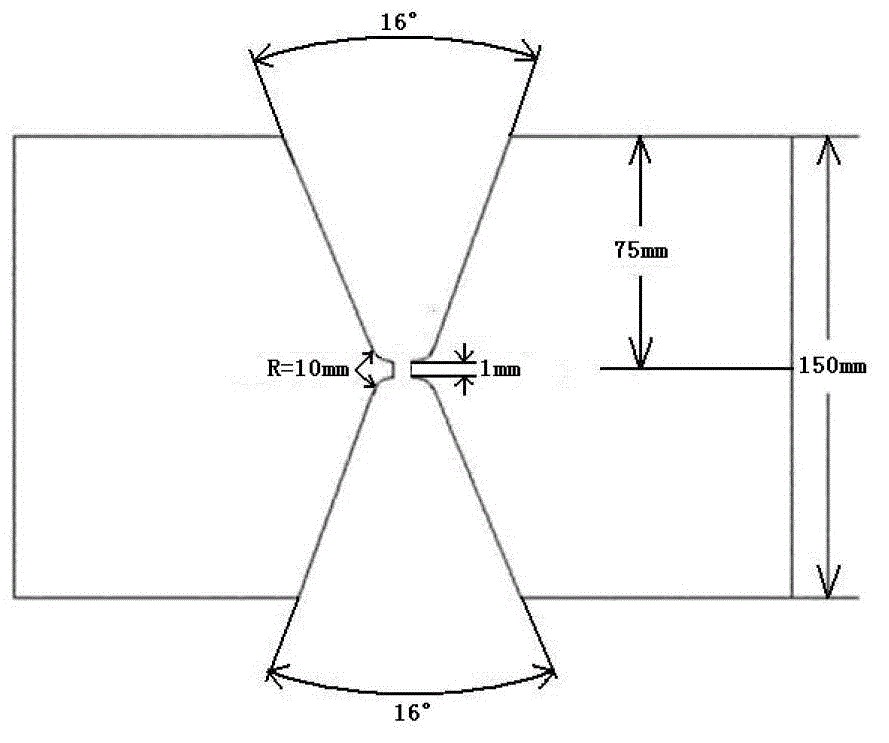

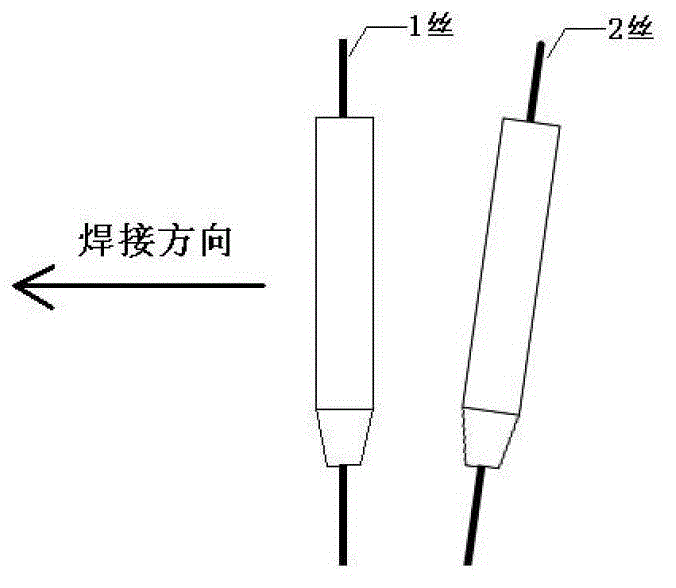

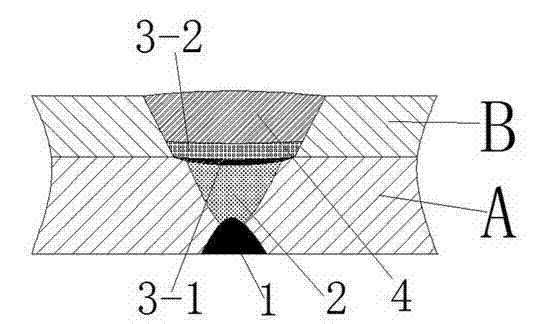

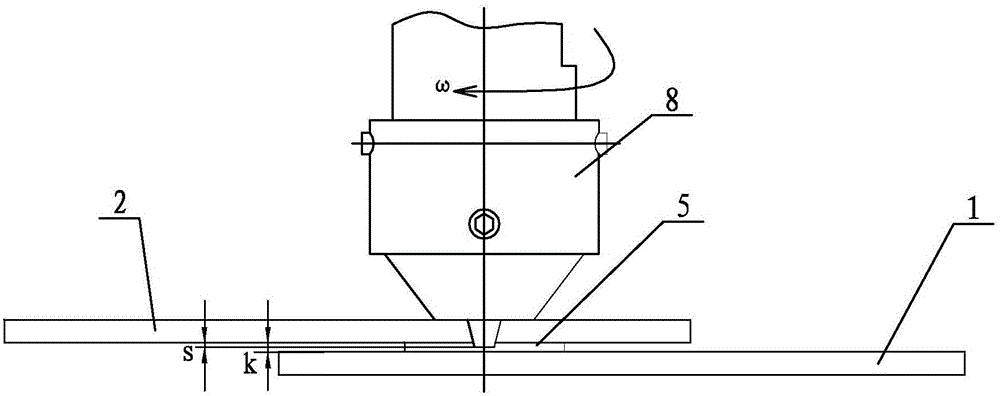

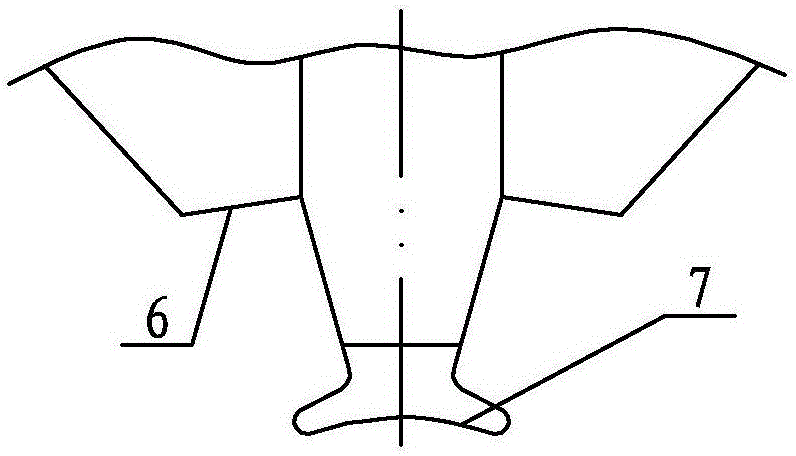

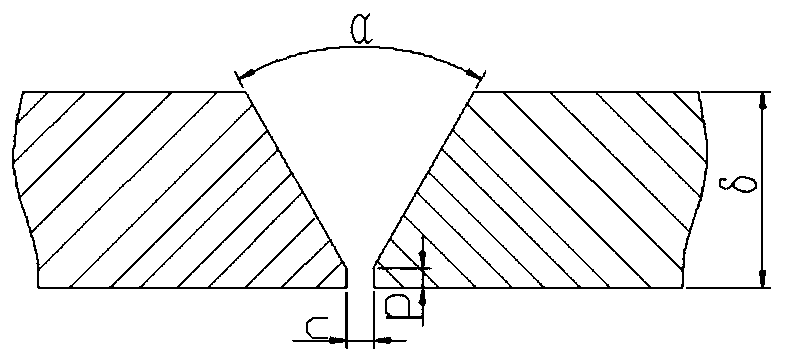

Method for welding specially-thick high-strength bridge steel plate

InactiveCN102744498AImprove welding efficiencyReduce manufacturing costArc welding apparatusWorkpiece edge portionsSteel platesSubmerged arc welding

The invention provides a method for welding a specially-thick high-strength bridge steel plate and belongs to the technical field of specially-thick plate welding. The test plate of the method adopts a symmetric narrow gap U-shaped groove form, is combinedly welded by using two efficient welding methods, namely gas shielded welding for priming and bottom filling, and double-wire submerged arc welding for continuous filling and finishing, so as to achieve the purposes of reducing filling level and giving full play to the efficient double-wire submerged arc welding and high automation degree. The method has strong operability, greatly improves the welding efficiency of the specially-thick bridge steel plate, and significantly reduces manpower cost. Furthermore, by selecting a proper welding sequence, the method solves the problem that the welding deformation of the specially-thick steel plate is hard to control.

Owner:SHOUGANG CORPORATION

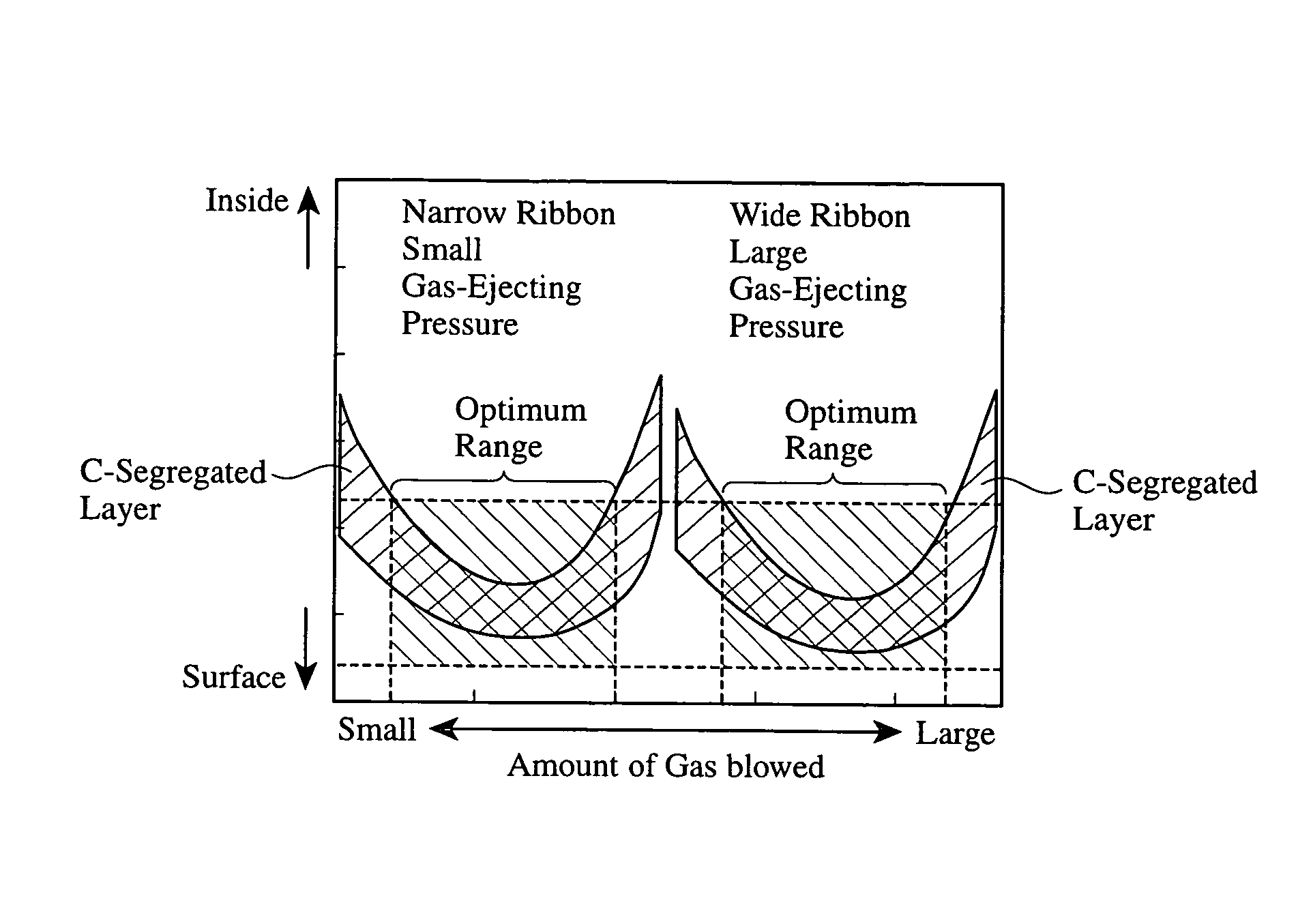

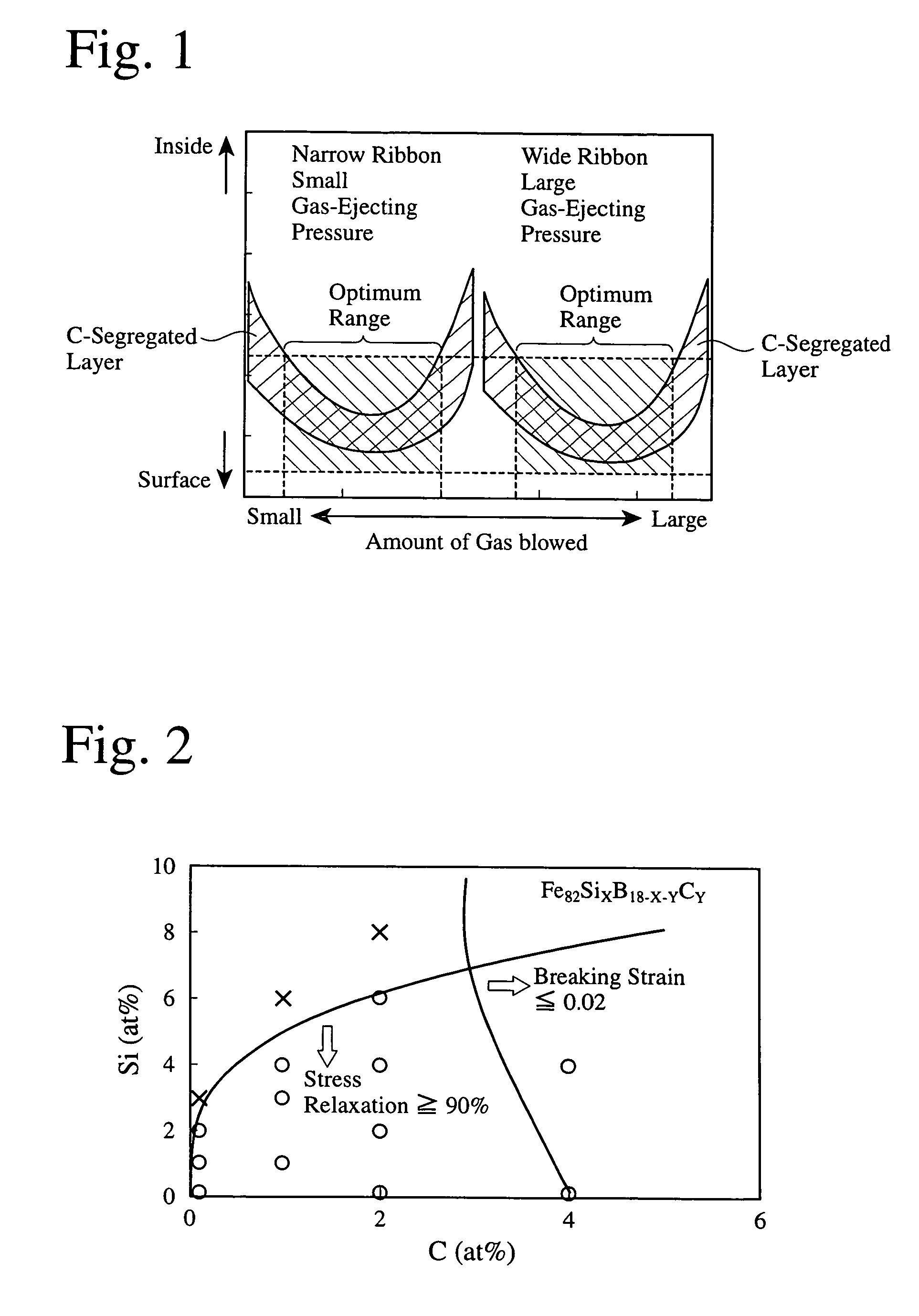

Fe-based amorphous alloy ribbon

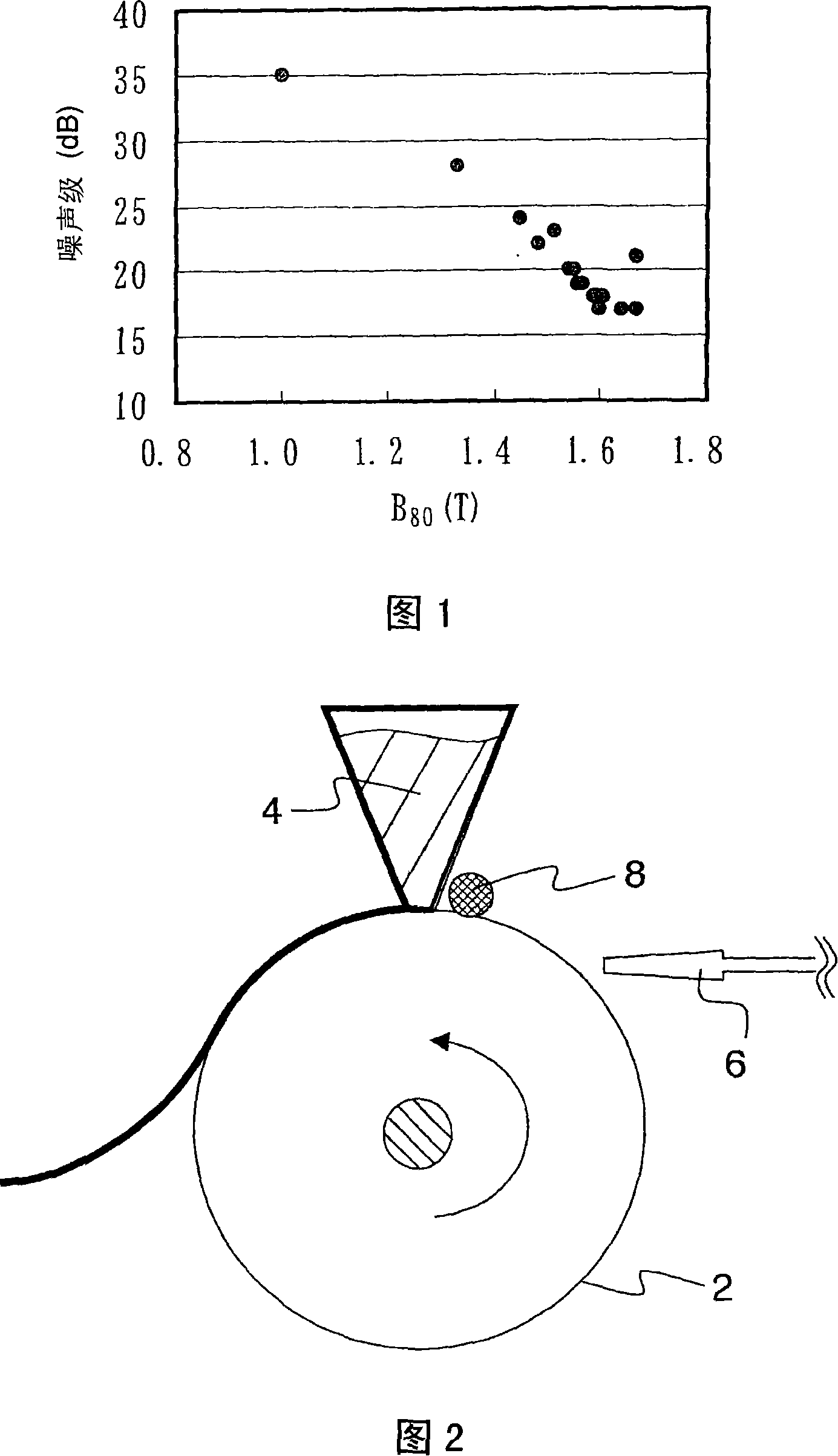

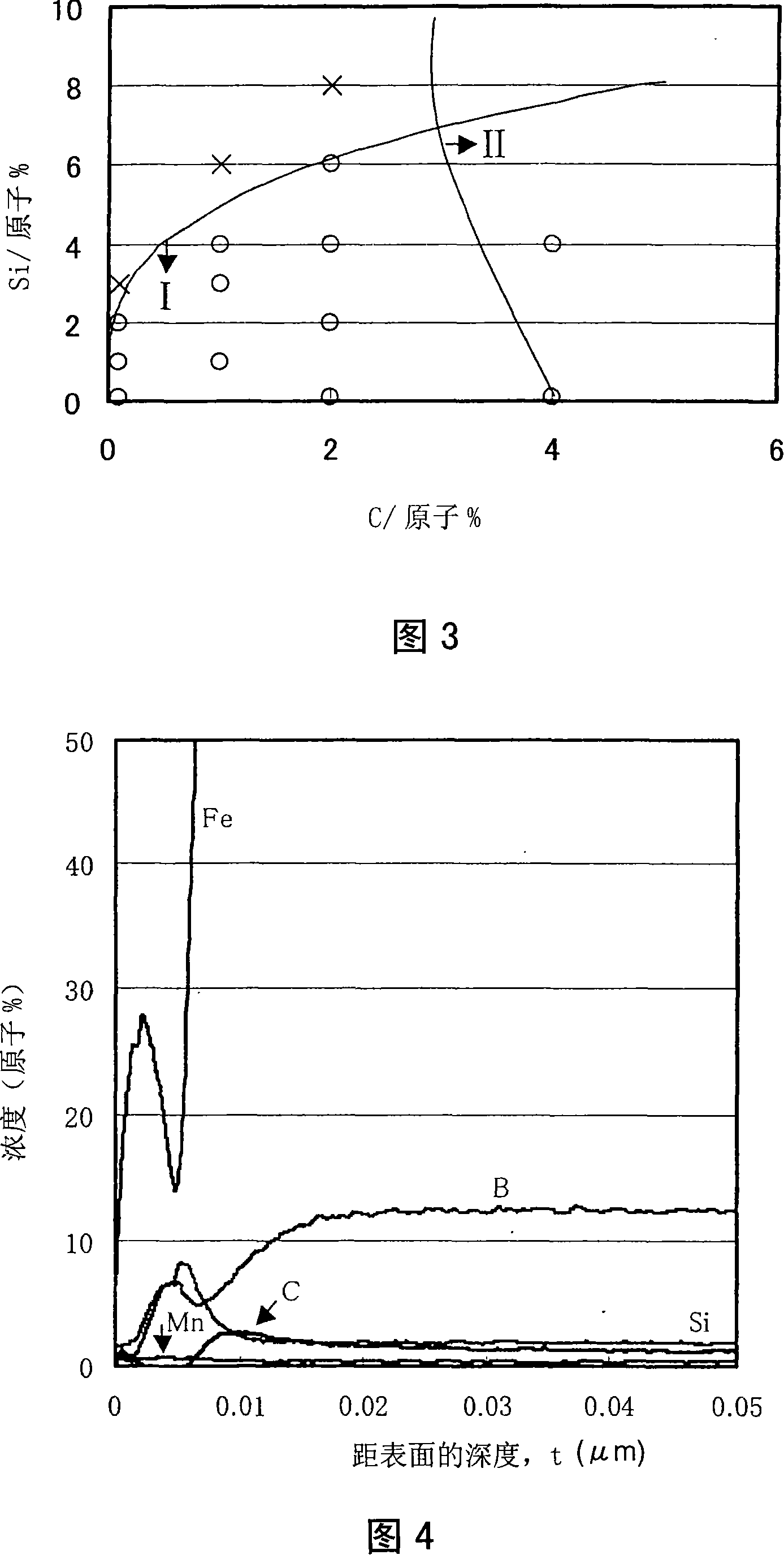

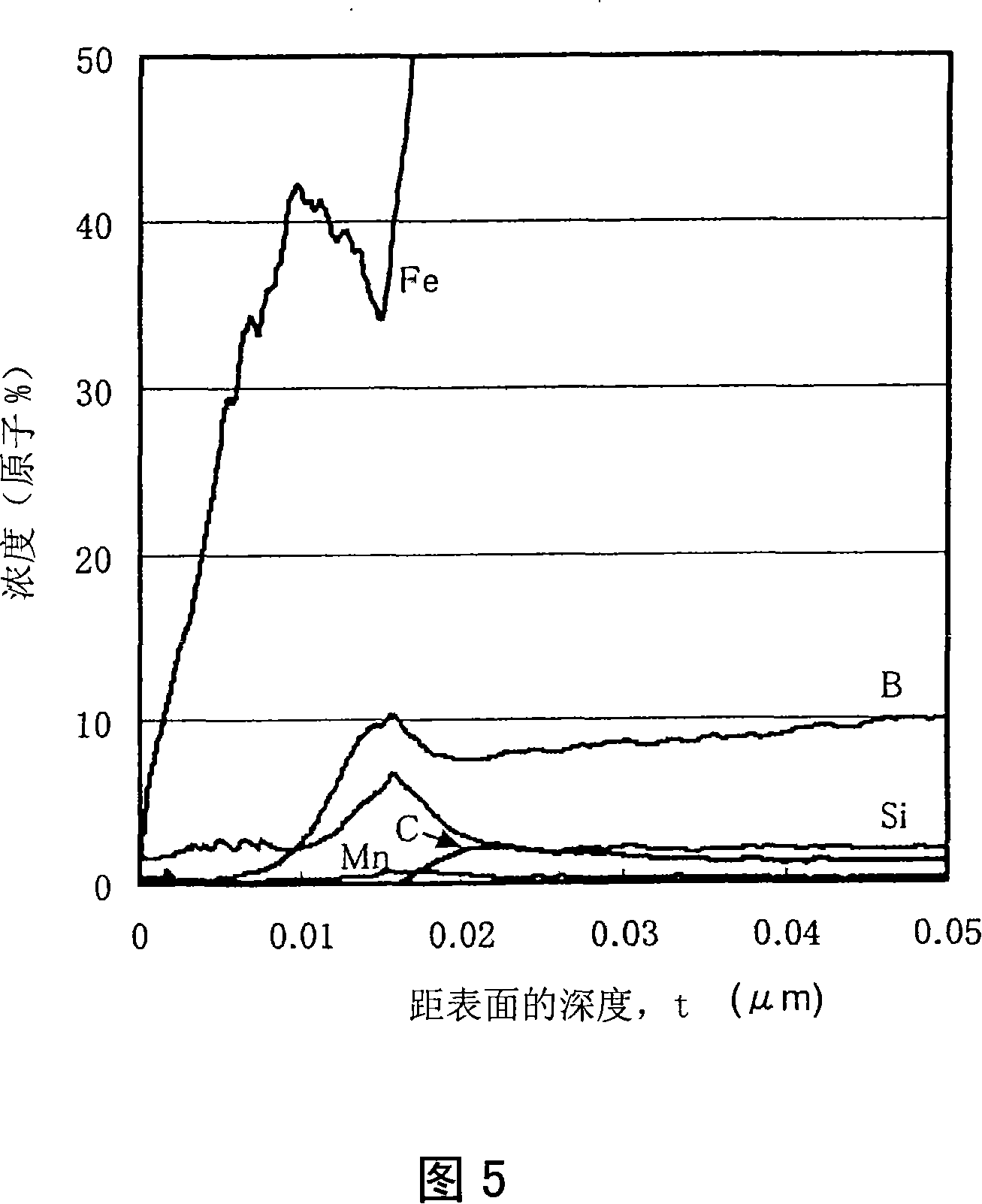

ActiveUS7425239B2High magnetic flux densityLow core lossInductances/transformers/magnets manufactureMagnetic materialsTO-18Impurity

An Fe-based amorphous alloy ribbon having a composition comprising FeaSibBcCd and inevitable impurities, wherein a is 80 to 83 atomic %, b is 0.1 to 5 atomic %, c is 14 to 18 atomic %, and d is 0.01 to 3 atomic %, the concentration distribution of C measured radially from both surfaces to the inside of said Fe-based amorphous alloy ribbon having a peak within a depth of 2 to 20 nm.

Owner:HITACHI METALS LTD

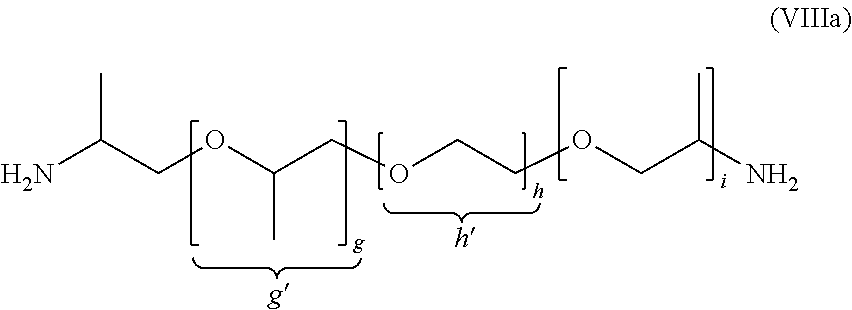

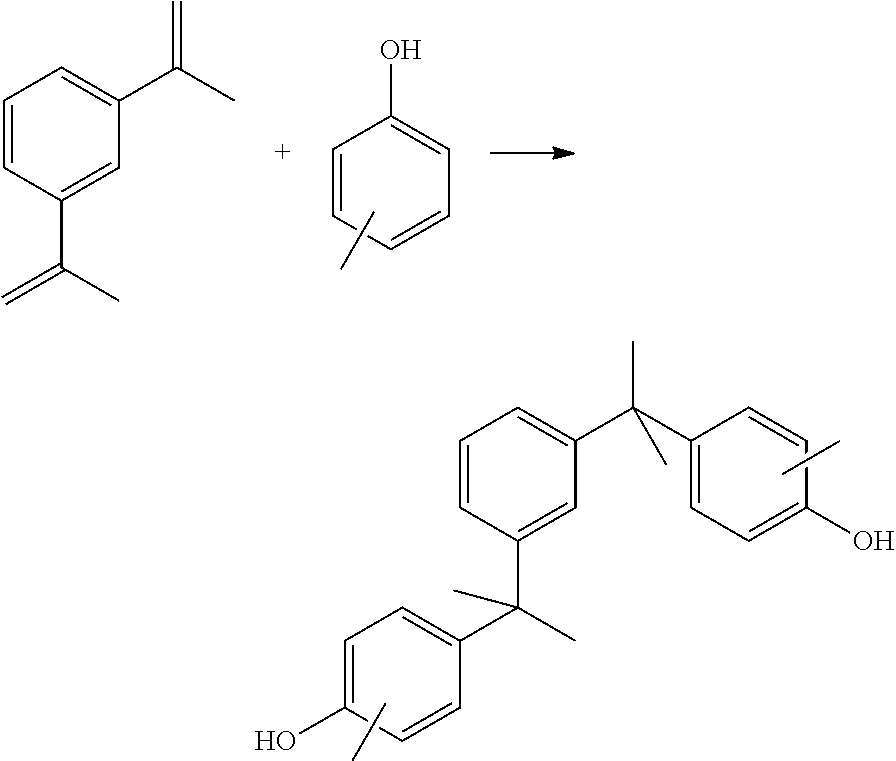

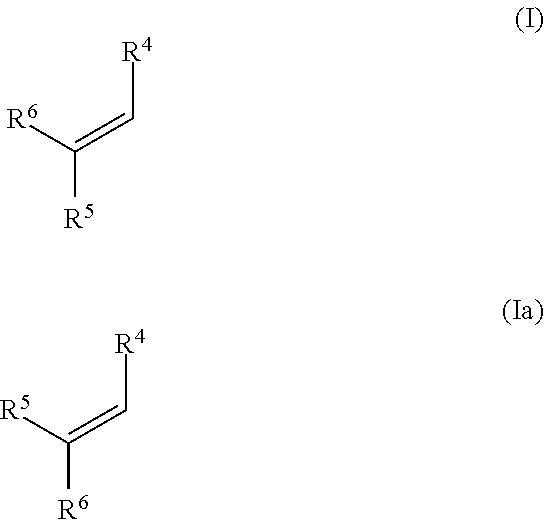

Amino group terminated impact strength modifier and use thereof in epoxy resin compositions

ActiveUS20130037213A1Efficiency and flexibilityHigh tensile shear strengthPolyureas/polyurethane adhesivesLaminationEpoxyUltimate tensile strength

The present disclosure relates to impact strength modifiers, the derivative products thereof, and the use thereof in producing two-component epoxy resin compositions. The disclosure in particular relates to amino group terminated impact strength modifiers prepared by reacting a polyurethane prepolymer having isocyanate groups, a primary diamine, and optionally at least one Michael acceptor. The two-component epoxy resin compositions thus formulated are characterized by a great increase in impact strength while retaining an acceptable tensile shear strength. The impact strength modifiers according to the disclosure and the epoxy resin compositions comprising same are in particular suitable for vehicle manufacturing.

Owner:SIKA TECH AG

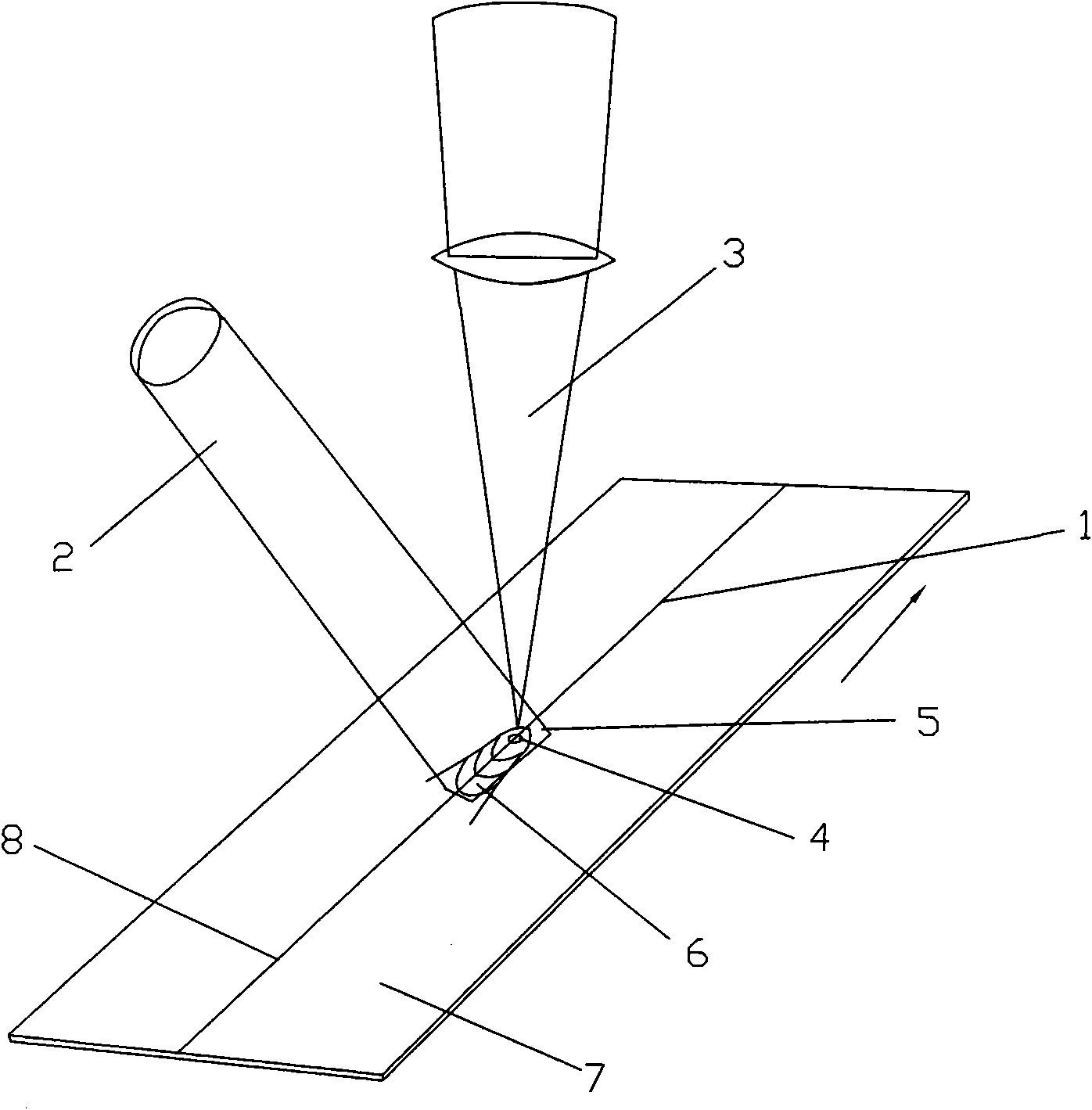

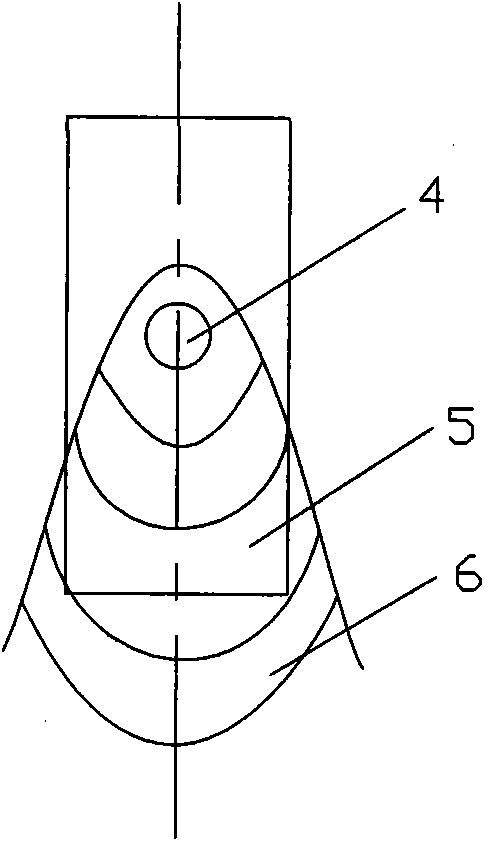

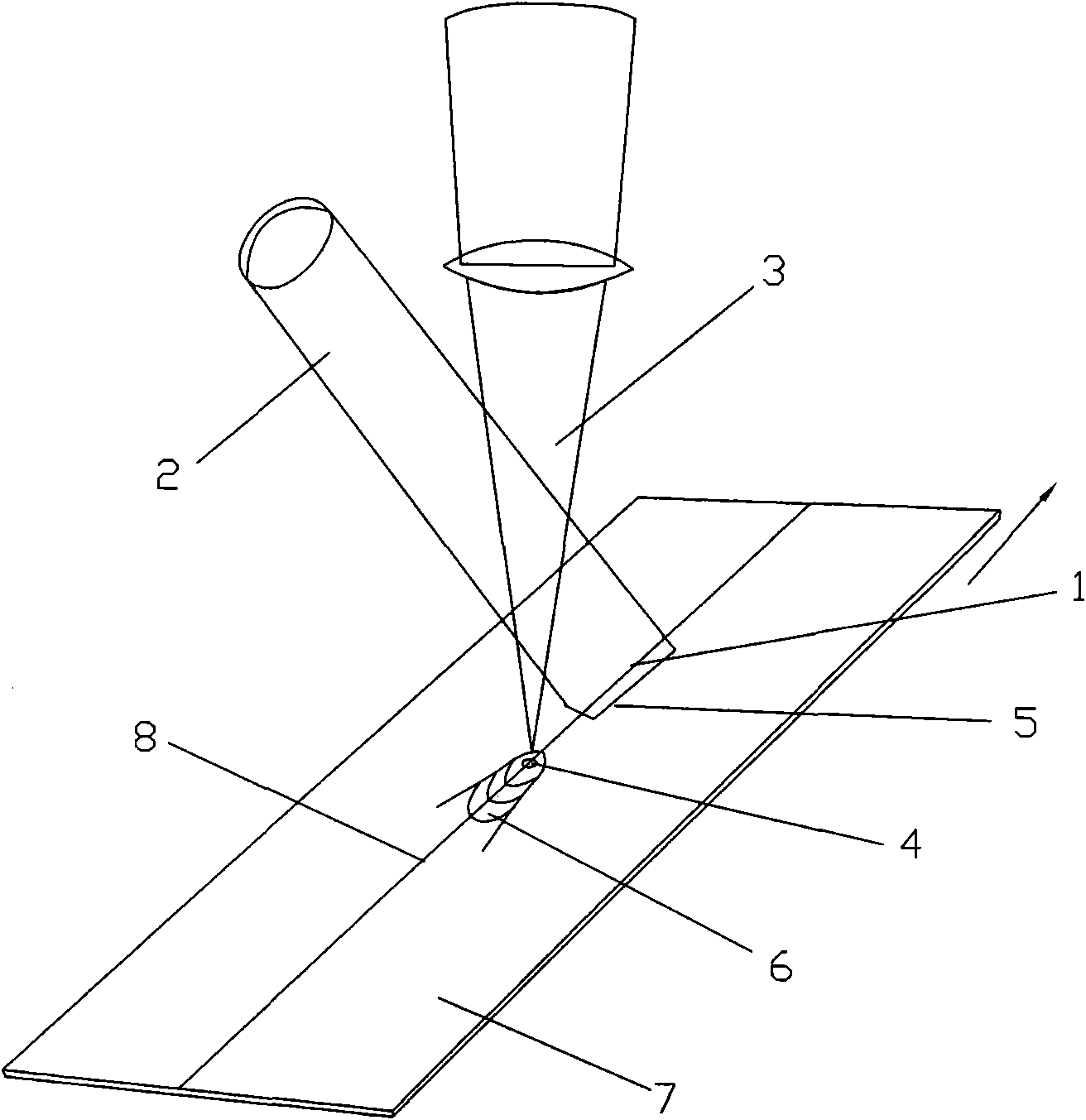

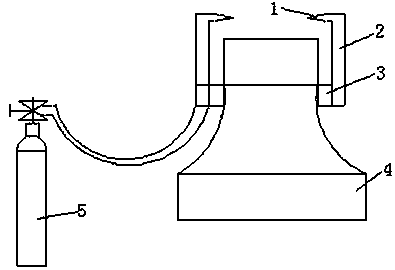

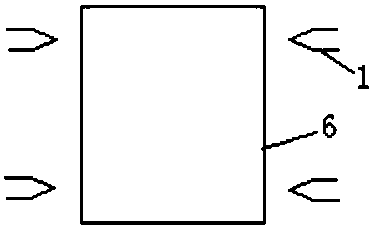

Compound welding method by using semiconductor laser and CO2 laser

InactiveCN101564799AFast preheating and homogenizationReduce temperature gradientLaser beam welding apparatusThermal treatmentCo2 laser

A compound welding method by using semiconductor laser and CO2 laser comprises the steps: using a semiconductor laser and a CO2 laser to be positioned on one side of a welding line of welded metals in a certain angle, adjusting a focusing position of the CO2 laser to cause a light spot of the CO2 laser to be positioned in the light spot of the semiconductor laser so that the welding direction is consistent with the slow axis direction of the semiconductor laser; using the semiconductor laser to pre-heat the welded metals, heating the part to be welded entering into the light spot of the semiconductor laser to 200-400 DEG C, using the CO2 laser to weld, and performing a post-welding thermal treatment to the welded metals by using the semiconductor laser for the welded parts of the welded metals welded by the welding of the CO2 laser. Due to synchronous pre-heating and post-heating treatments to the welding process, the invention can effectively solve the problem of cold cracking in high-strength steel welding and improve the quality of high-strength steel laser welding.

Owner:BAOSHAN IRON & STEEL CO LTD

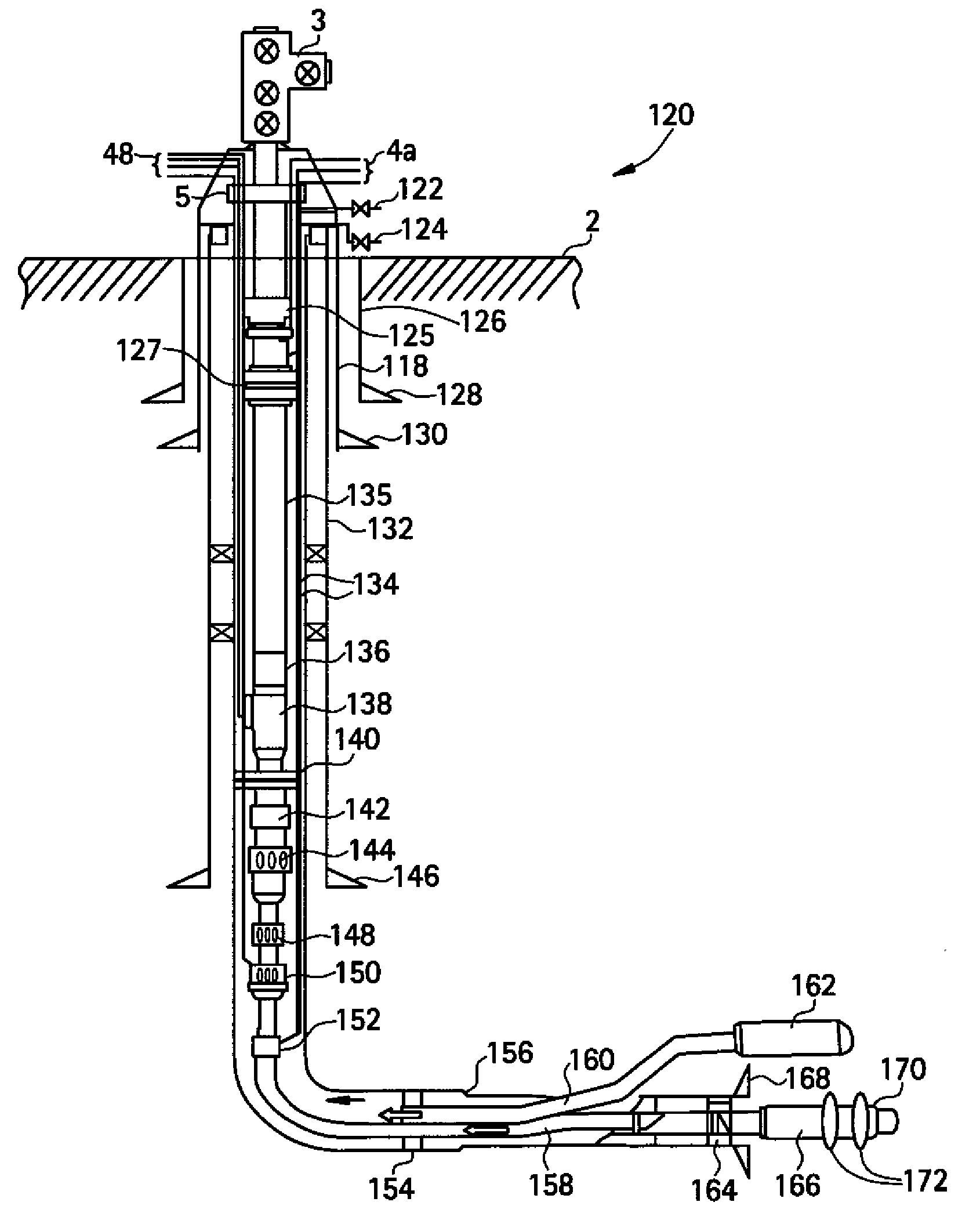

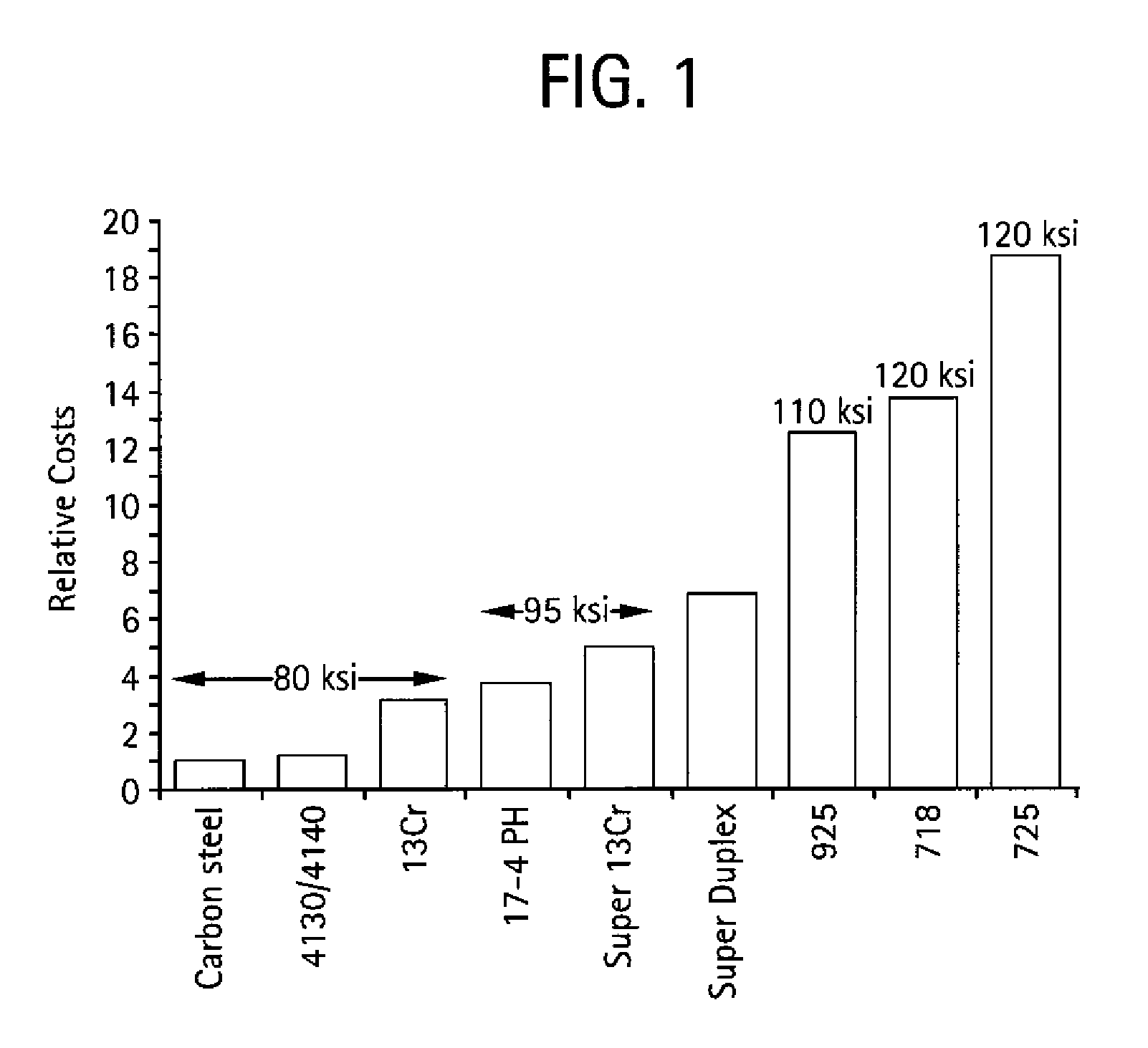

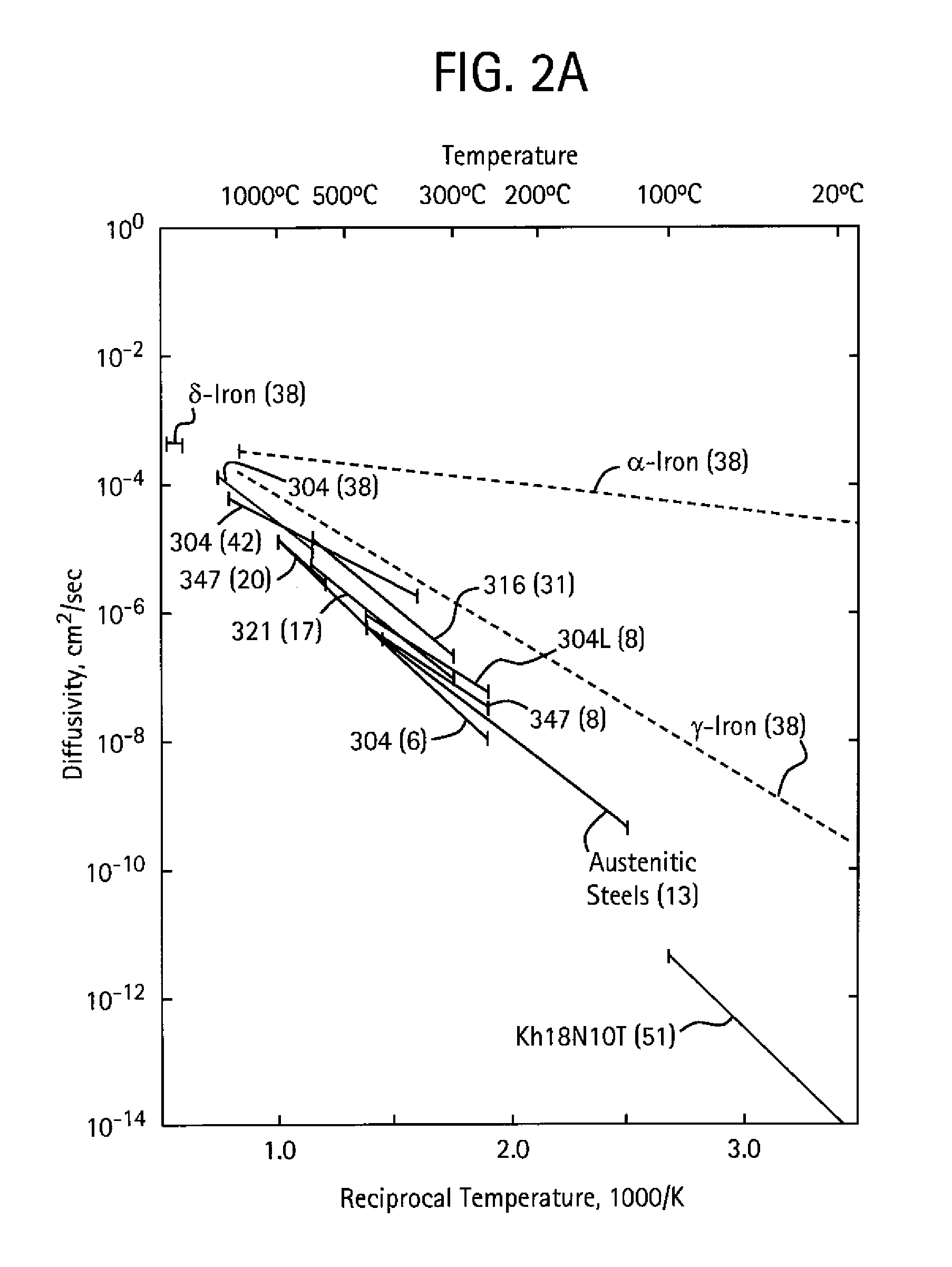

Interstitially strengthened high carbon and high nitrogen austenitic alloys, oilfield apparatus comprising same, and methods of making and using same

InactiveUS20080141826A1Material costHigh strengthQuenching agentsThin material handlingHigh carbonSubject matter

Novel carbon-plus-nitrogen corrosion-resistant ferrous and austenitic alloys, apparatus incorporating an inventive alloy, and methods of making and using the apparatus are described. The corrosion-resistant ferrous and austenitic alloys comprise no greater than about 4 wt. % nickel, are characterized by a strength greater than about 700 MPa (100 ksi), and, when being essentially free of molybdenum (<0.3 wt. %), have minimum Pitting Resistance Equivalence (PRE) numbers of 20 and minimum Measure of Alloying for Corrosion Resistance numbers (MARC) of 30 because of the use of both carbon and nitrogen. The ferrous and austenitic alloys are particularly formulated for use in oilfield operations, especially sour oil and gas wells and reservoirs. This abstract allows a searcher or other reader to quickly ascertain the subject matter of the disclosure. It will not be used to interpret or limit the scope or meaning of the claims.

Owner:SCHLUMBERGER TECH CORP

Neodymium iron boron magnetic materials and preparation method of the same

The invention discloses neodymium iron boron magnetic materials and a preparation method of the neodymium iron boron magnetic materials. The neodymium iron boron magnetic materials comprise, by weight, 27-34.5 % of neodymium (Nd), 4.5-5.75 % of praseodymium (Pr), 0.45-0.575 of gadolinium (Gd), 2-4% of boron (B), 0.08-0.16 % of niobium (Nb), 0.01-0.02 % of hafnium (Hf), 0.01-0.02 % of wolfram (W) and 0.045-0.0575 % of scandium (Sc), and the rest is ferrum (Fe). The neodymium iron boron magnetic materials have uniform textures and strong structures, and can not only improve tenacity performance of the materials but also improve magnetic performance to some extent. The preparation method of the neodymium iron boron magnetic materials fully utilizes praseodymium-neodymium waste materials to directly produce raw materials for alloy, is flexible in composition proportion, qualified in quality control, capable of reducing cost and simple in technology, and fully utilizes waste powder materials with high oxygen content.

Owner:江苏澳芯微电子有限公司

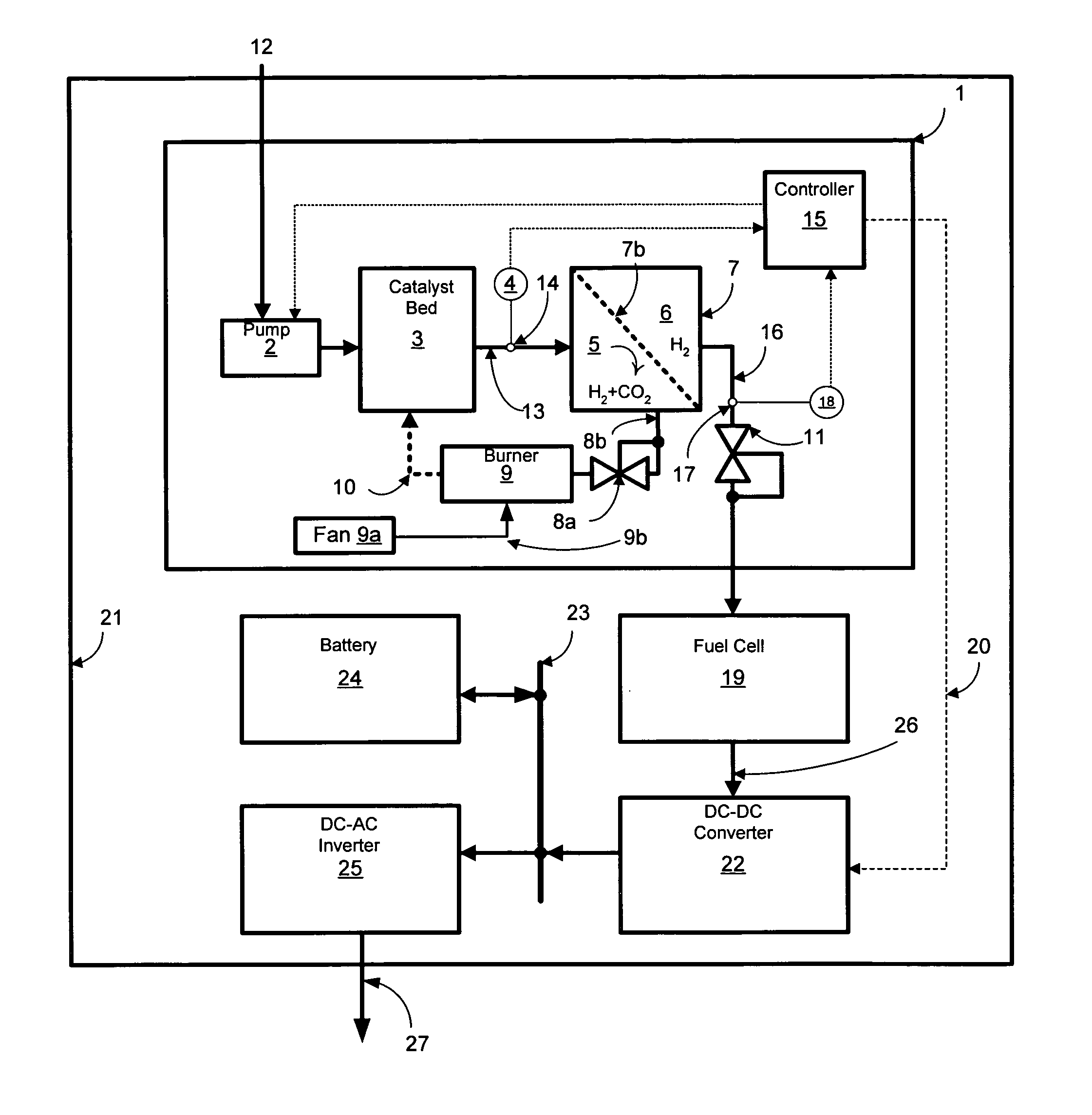

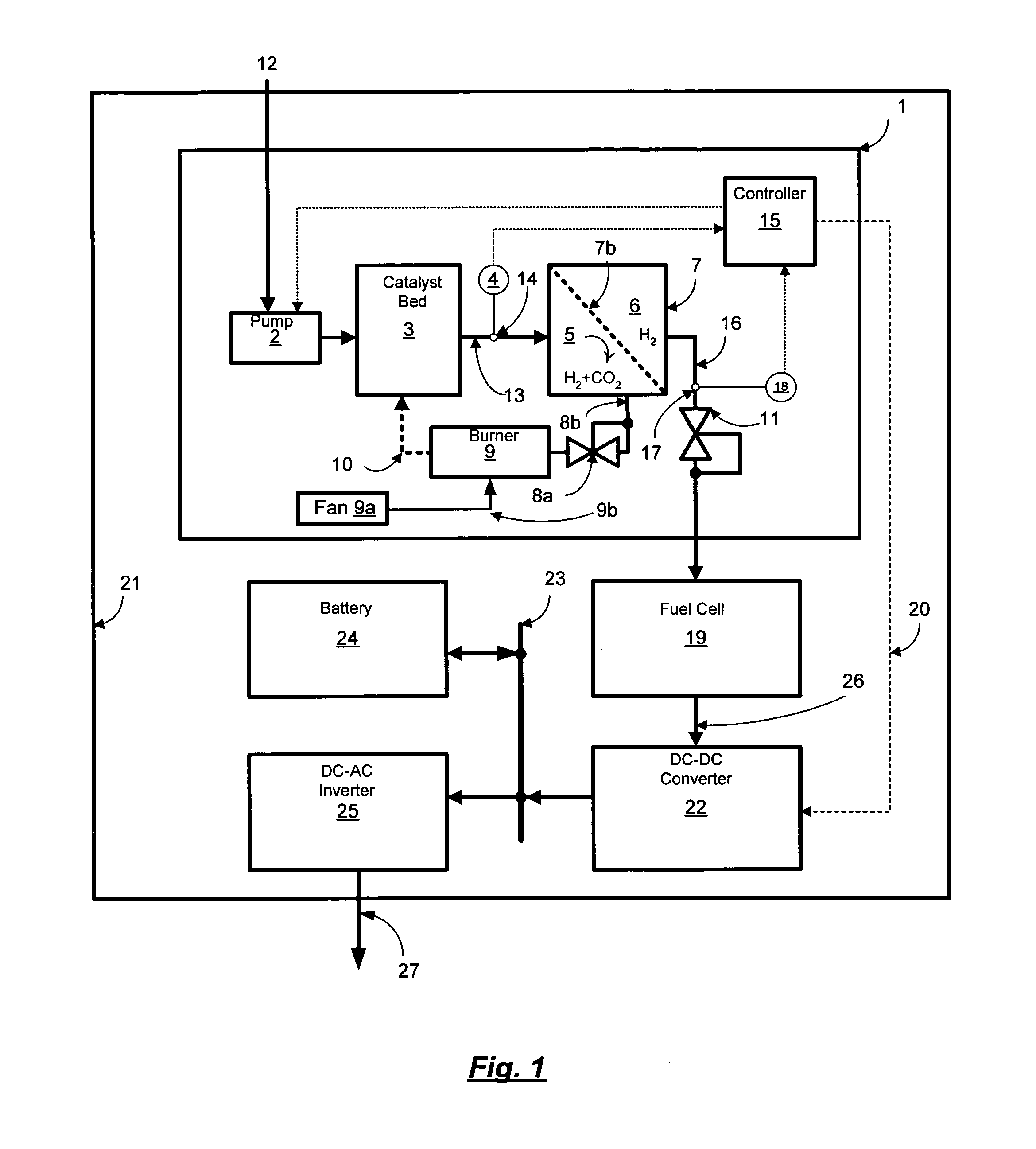

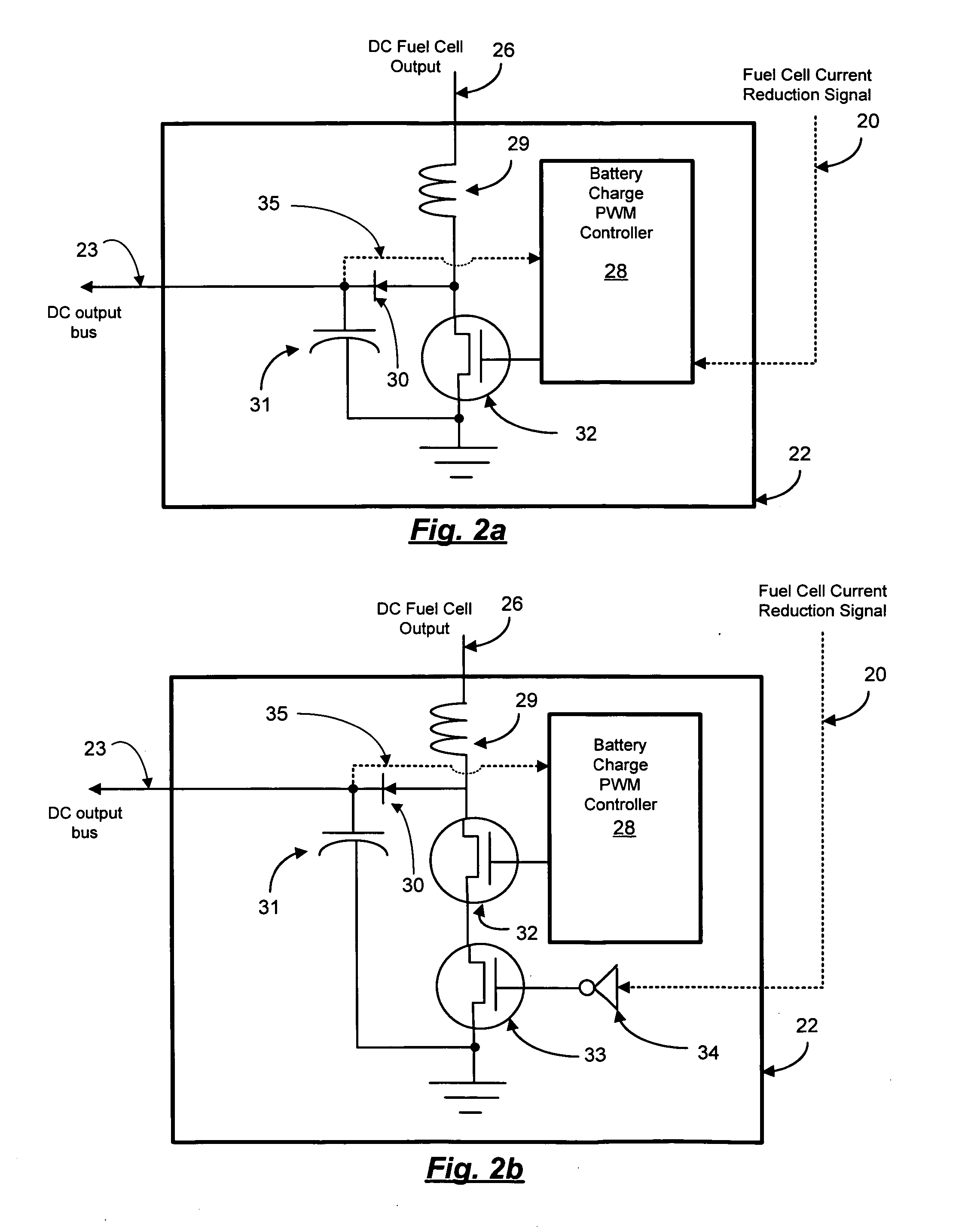

Reformer and fuel cell system control and method of operation

InactiveUS20070190380A1Reduce current outputEasy to integratePhysical/chemical process catalystsReactant parameters controlFuel cellsHydrogen pressure

A fuel cell system includes a reformer producing hydrogen from fuel, a regulator for regulating the output pressure of the produced hydrogen, a fuel cell utilizing the produced hydrogen, a pressure sensor for monitoring the pressure of the hydrogen upstream of the pressure regulator, a temperature sensor for monitoring at least one temperature within the reformer, a pump for introducing the fuel into the reformer, a first controller for controlling the output current of the fuel cell, and a second controller for controlling at least the fuel introduction rate into the reformer. The introduction rate of the fuel is responsive to output hydrogen pressure from the reformer in order to maintain at least one temperature within the reformer above a minimum level, as well as maintaining the pressure of the delivered purified hydrogen above a set pressure. Further, the output current of the fuel cell is reduced responsive to the pressure of the purified hydrogen in order to maintain a minimum hydrogen pressure to the fuel cell.

Owner:GENESIS FUEL TECH INC

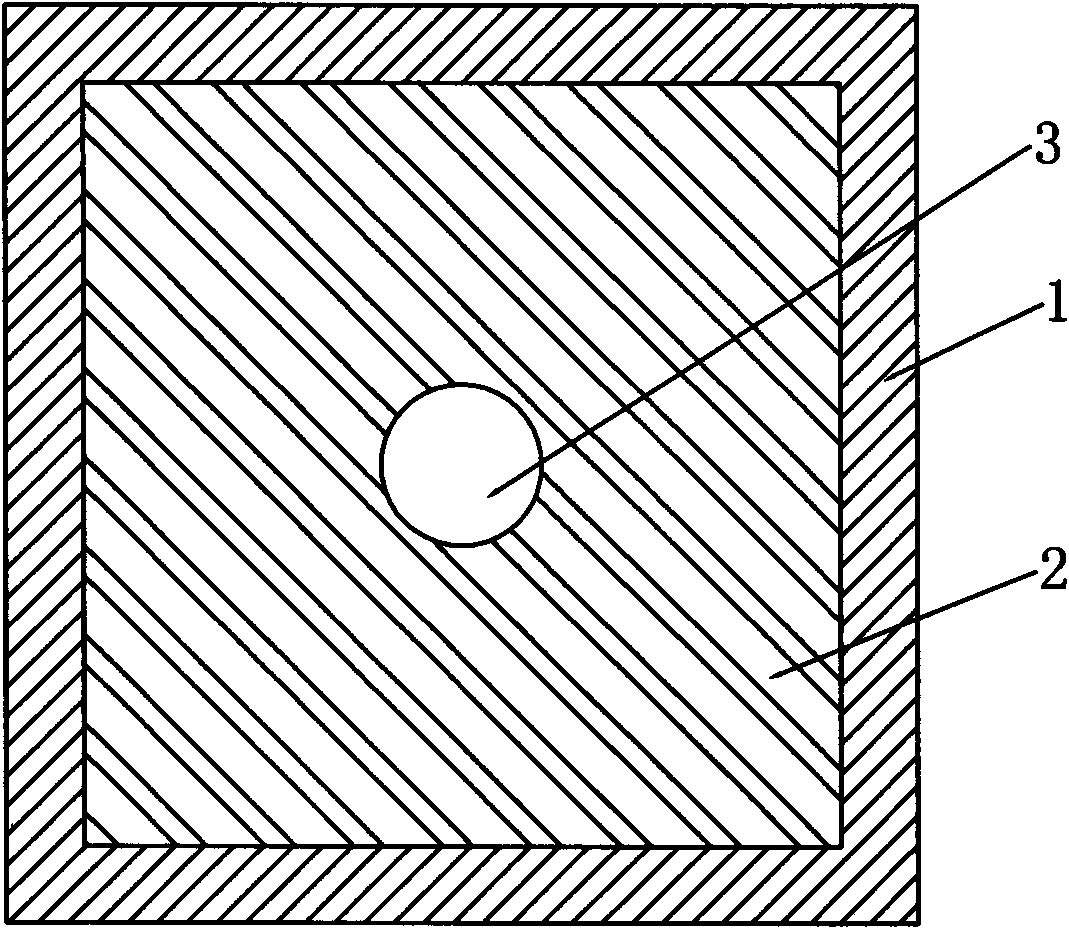

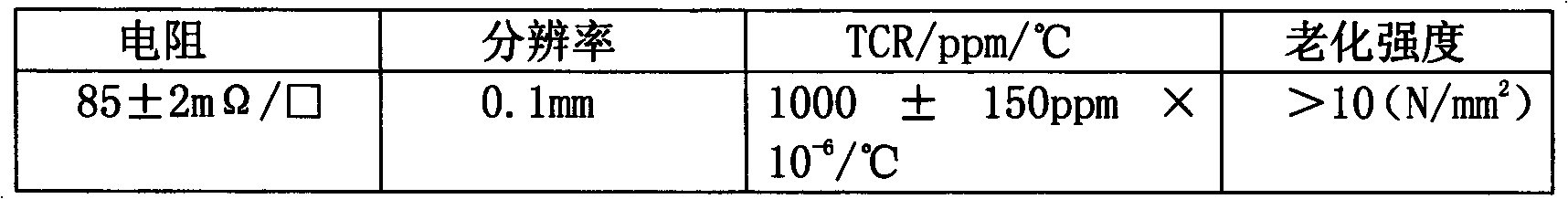

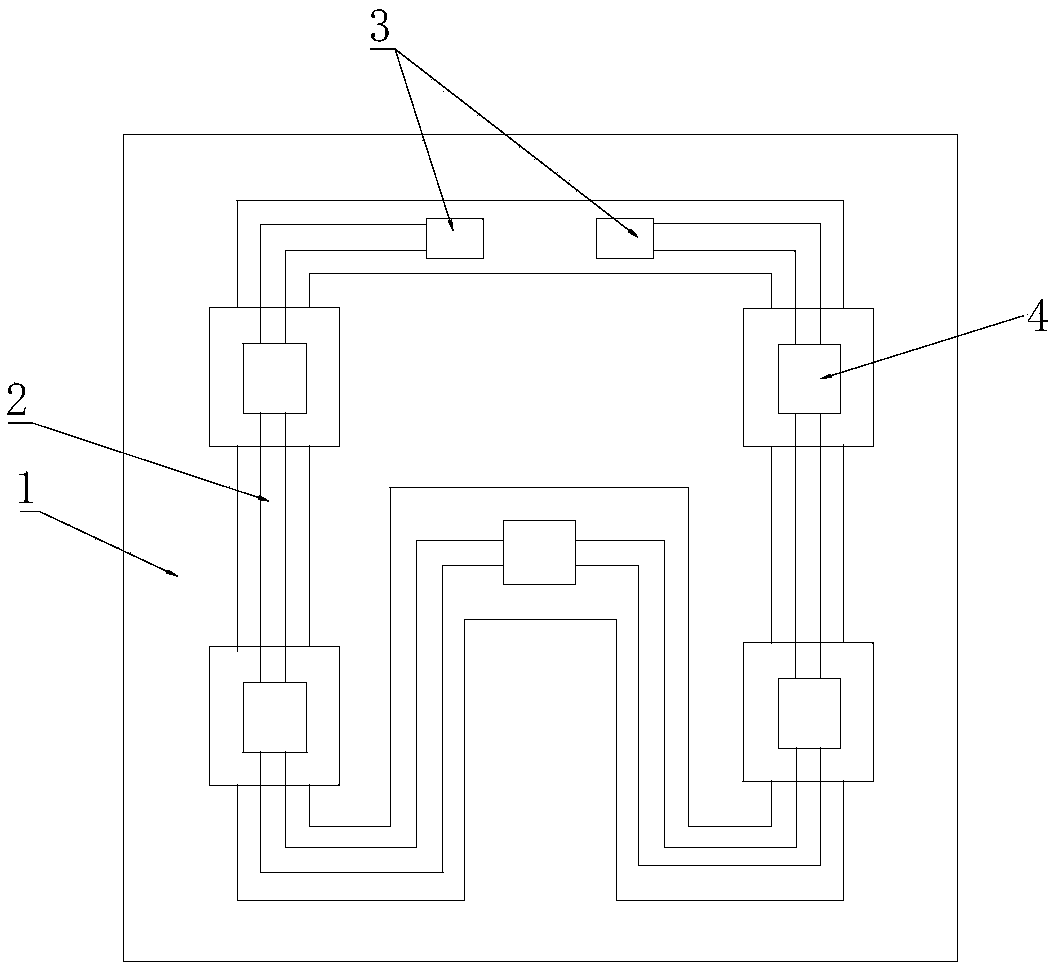

High-temperature aluminum alloy base rare earth thick film circuit electric heating element and preparation technology thereof

ActiveCN102158993ALow costImprove thermal efficiencyNon-conductive material with dispersed conductive materialHeating element materialsRare earthFar infrared

The invention discloses an aluminum alloy base plate-based rare earth thick film circuit controllable electric heating element and a preparation technology thereof. The electric heating element comprises a substrate and a series electronic sizing agent, wherein the series electronic sizing agent is prepared on the substrate, the series electronic sizing agent comprises a packaging sizing agent and a rare earth electrode sizing agent, and a rare earth medium sizing agent and the series electronic sizing agent respectively consist of a function phase, an inorganic bonding phase and an organic dissolvent carrier. The series electronic sizing agent is prepared on an aluminum alloy base plate in the manner of a thick film circuit. The series electronic sizing agent further comprises a series rare earth electric resistance sizing agent. The invention further discloses the prescription of the aluminum alloy base plate, the packaging sizing agent, the series rare earth electric resistance sizing agent, the rare earth electrode sizing agent and the rare earth medium sizing agent. The invention has the advantages of being high-speed in heat transfer and heat dissipation, even and controllable in heating temperature field, good in compatibility, firm in combination, large in power density, high in heat resistance and impact resistance, and the electric heating element has high-temperature far infrared function, are green, environment-friendly, energy-saving, low-carbon, safe and reliable.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

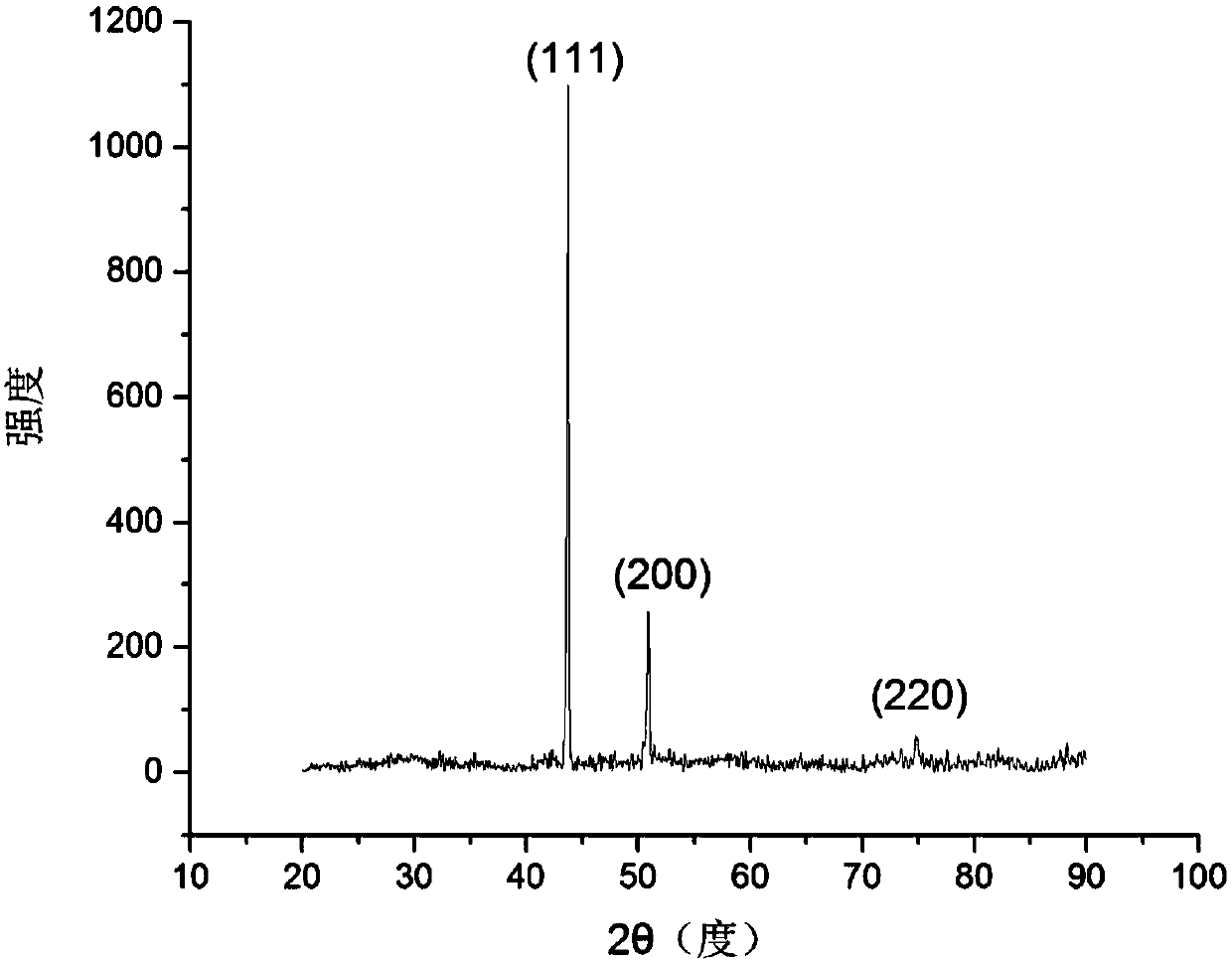

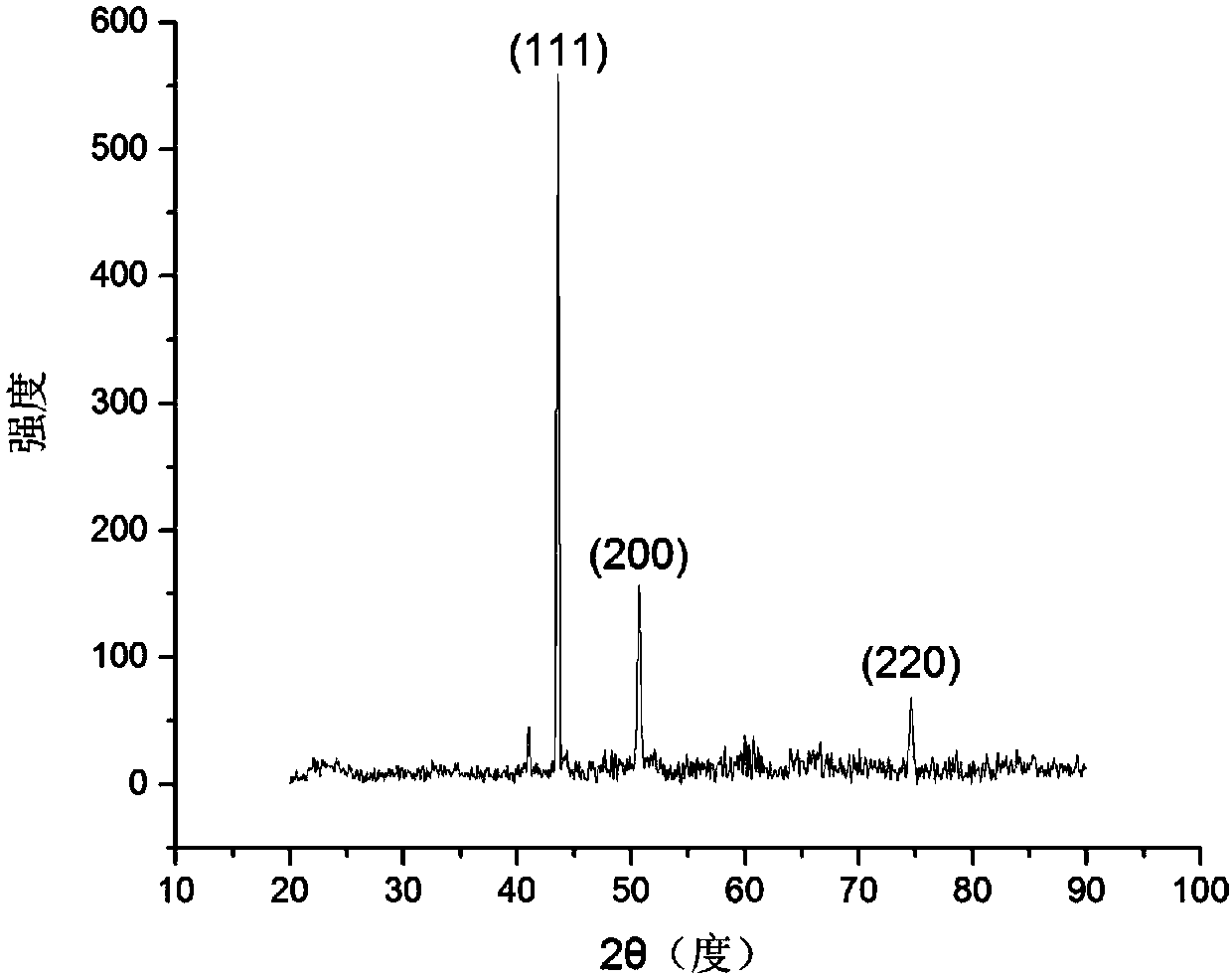

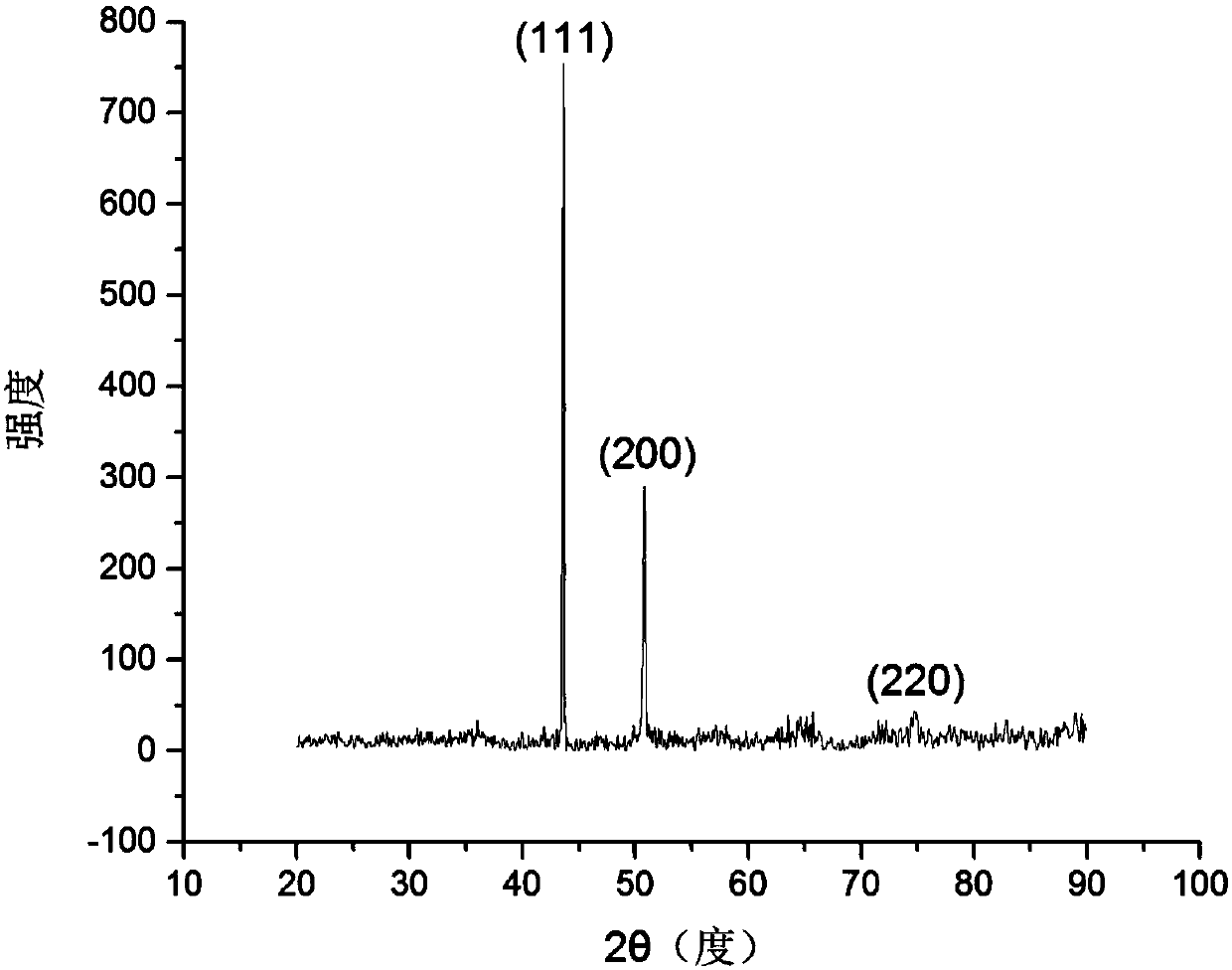

Nb microalloyed Ni-Co-Fe-Cr-Al high-entropy alloy

The invention relates to an Nb microalloyed Ni-Co-Fe-Cr-Al high-entropy alloy, and belongs to the technical field of metal materials. According to the Nb microalloyed Ni-Co-Fe-Cr-Al high-entropy alloy, through adjusting of proportioning of basic components of Al, Ni, Co, Cr and Fe and adding of microelement Nb, forming of an L12 phase is promoted, and occurrence of detrimental phases such as a B2phase, an Laves phase and a sigma phase is avoided; the high-entropy alloy is mainly composed of an FCC phase, the grain size is within 100 [mu]m-400 [mu]m, the yield strength is not lower than 300 MPa, the tensile strength is not lower than 740 MPa, the elongation rate is not lower than 18%, the good toughness and the high yield strength are both achieved, and the Nb microalloyed Ni-Co-Fe-Cr-Al high-entropy alloy meets the requirements of a modern industry for mechanical properties of materials.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

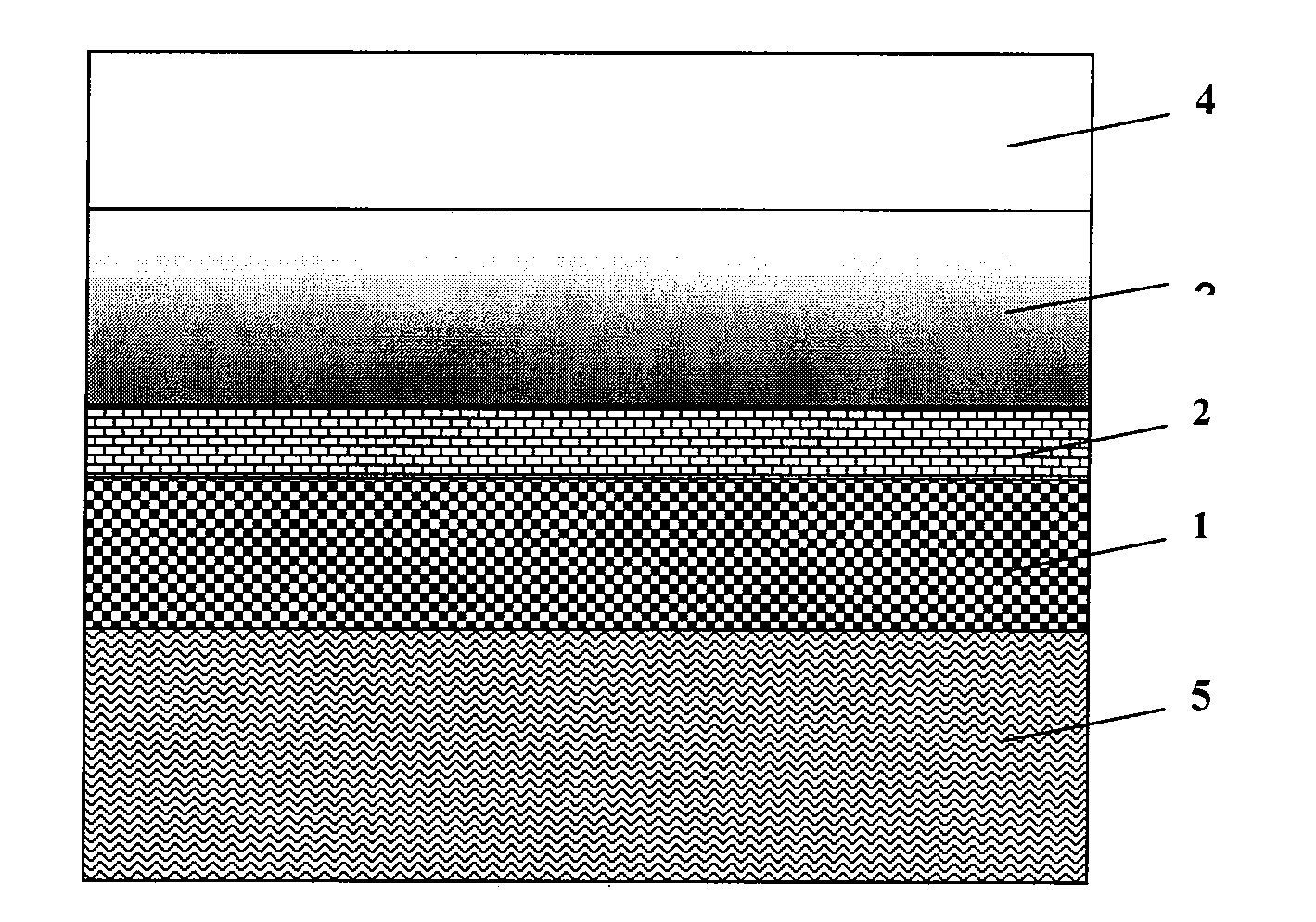

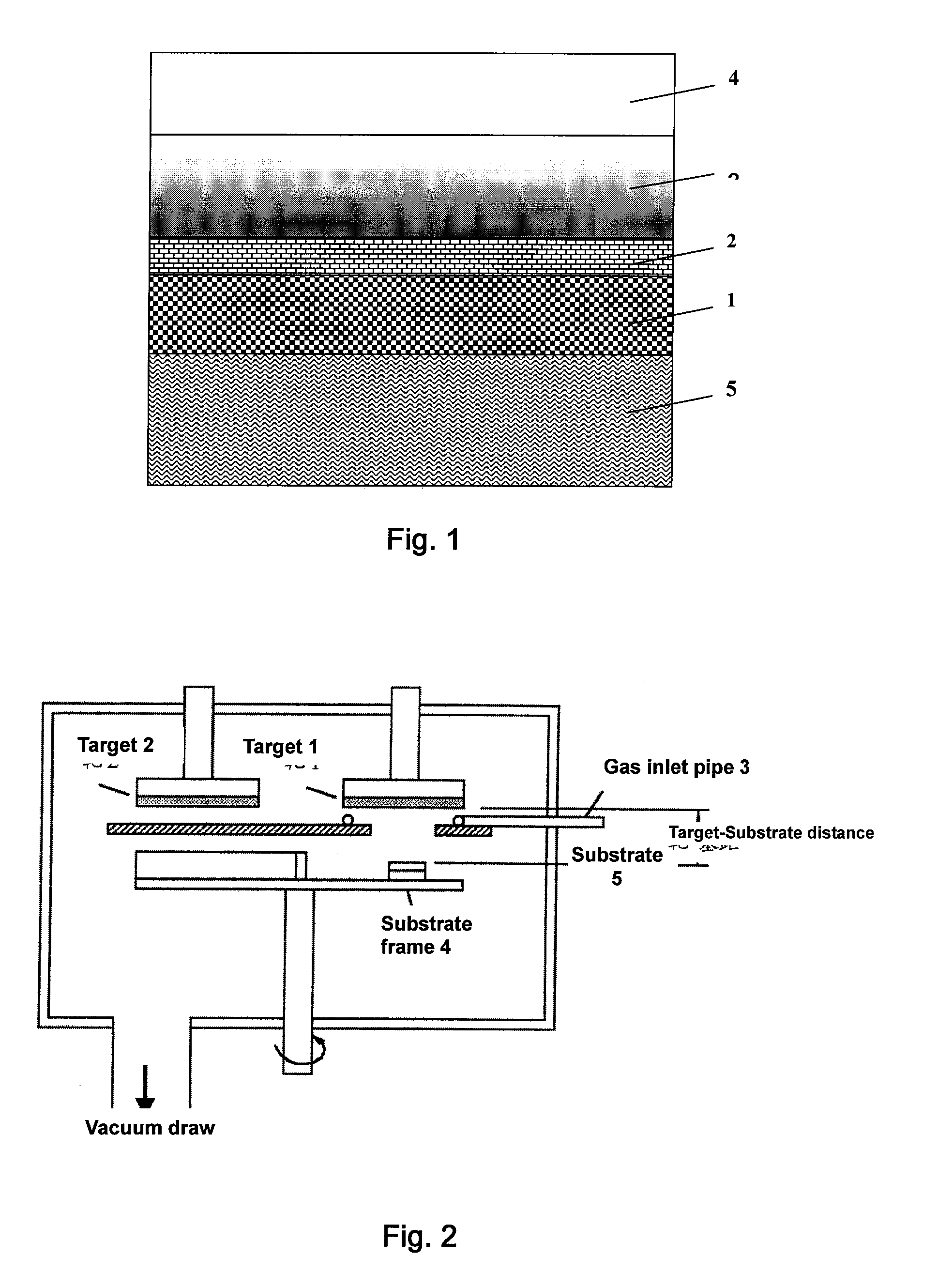

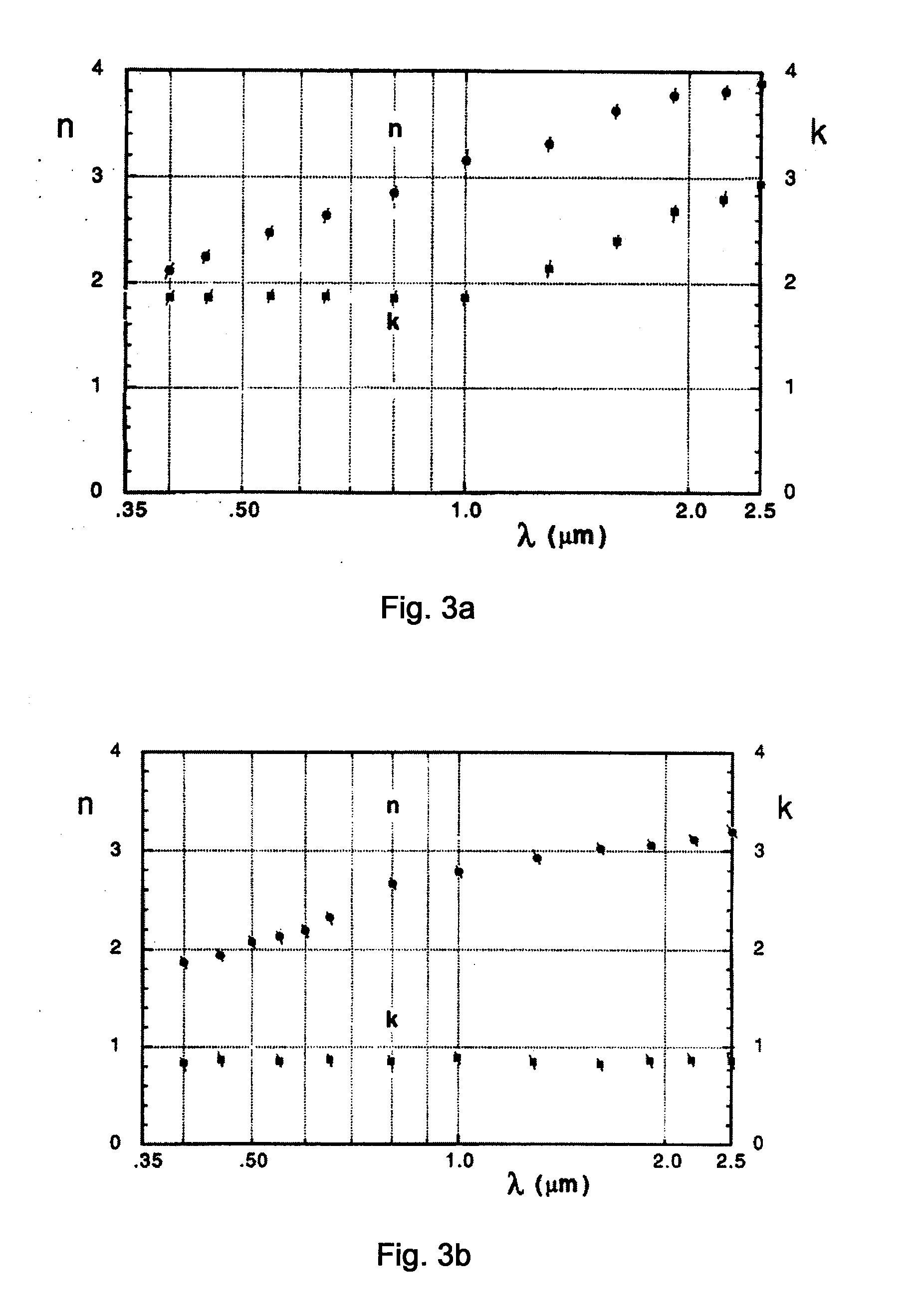

Light selective absorbing coating and its process

InactiveUS20100035034A1Easy to controlExcellent property of corrosion resistance and workability and compatibilitySolar heat devicesSynthetic resin layered productsCoating systemNitrogen

The present invention relates to a light selective absorbing coating and a production process thereof. The light selective absorbing coating consists of a composite material film deposited by reaction of iron chromium alloy and a non-metal gas with vacuum deposition technology. Said non-metal gas comprises gases of nitrogen and oxygen elements. The present invention also relates to a solar energy heat collecting element or solar energy selective absorbing coating system comprising said light selective absorbing coating and a production process thereof. The present invention further relates to use of said composite material film as a light selective absorbing coating of a solar energy heat collecting element or of a solar energy selective absorbing coating system.

Owner:SHENZHEN COMMONPRAISE SOLAR

Fusion casting method of large-size high-performance titanium and titanium alloy ingot

The invention relates to a fusion casting method of a large-size high-performance titanium and titanium alloy ingot, which comprises the following steps: (1) electrode compression: compressing pure titanium or titanium alloy materials into electrode blocks; (2) assembly and welding of an electrode: carrying out argon arc welding on the compressed electrode blocks to obtain a large consumable electrode; (3) primary vacuum consumable fusion: carrying out primary fusion on the assembled and welded electrode in a vacuum consumable-electrode arc furnace to obtain a primary cast ingot; and (4) secondary vacuum consumable fusion: carrying out secondary fusion on the primary cast ingot used as the electrode to obtain a finished cast ingot product. Compared with the prior art, the invention can effectively overcome the segregation of alloy components in the titanium alloy and improve the metallographical microscopic structure, thereby preventing the fusion ingot from being subject to coarse grain boundary, embrittlement of carbide networks and the like, reducing the generation of cracks, enhancing the strength and the mechanical property of the titanium alloy and improving the fusion efficiency.

Owner:BAOJI LIXING TITANIUM IND

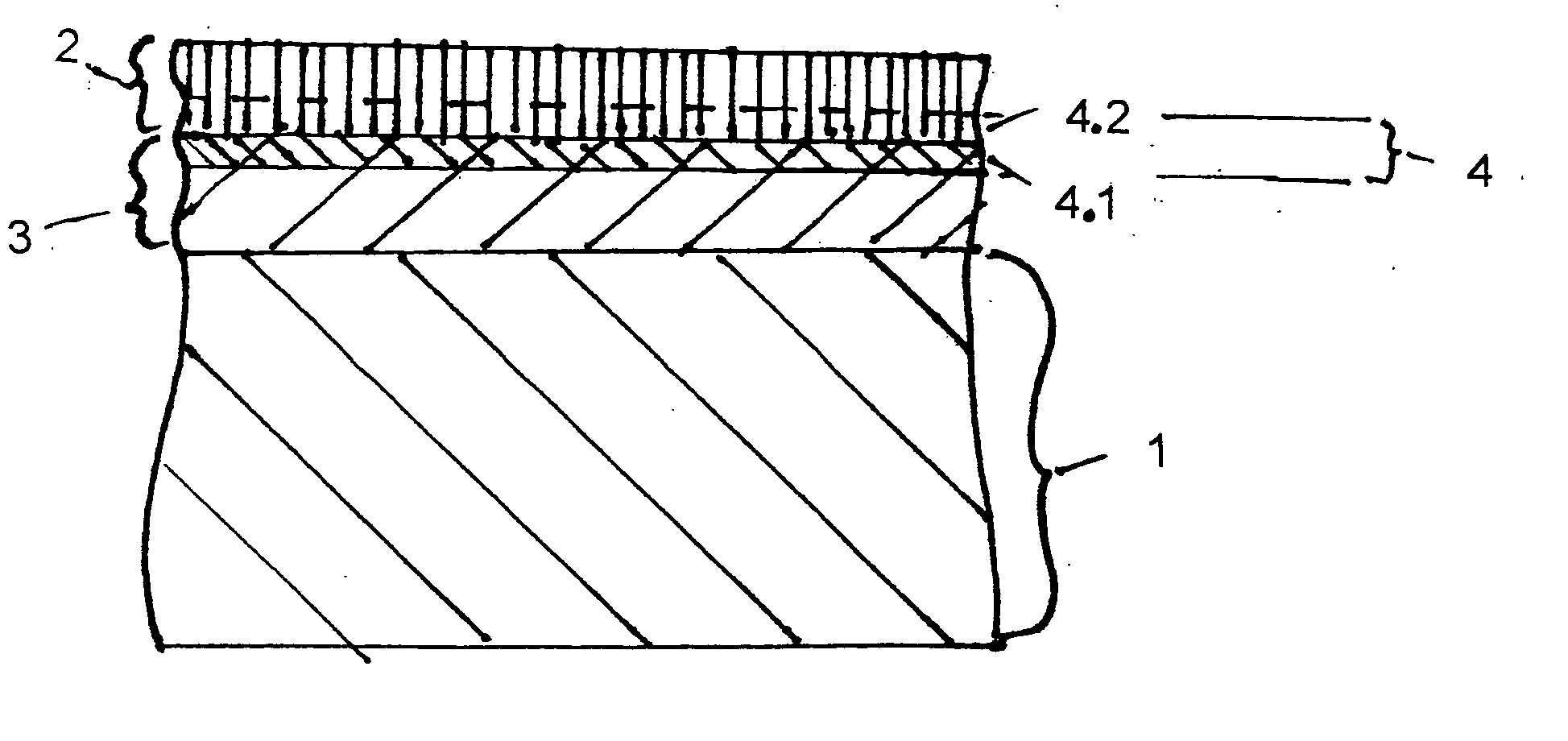

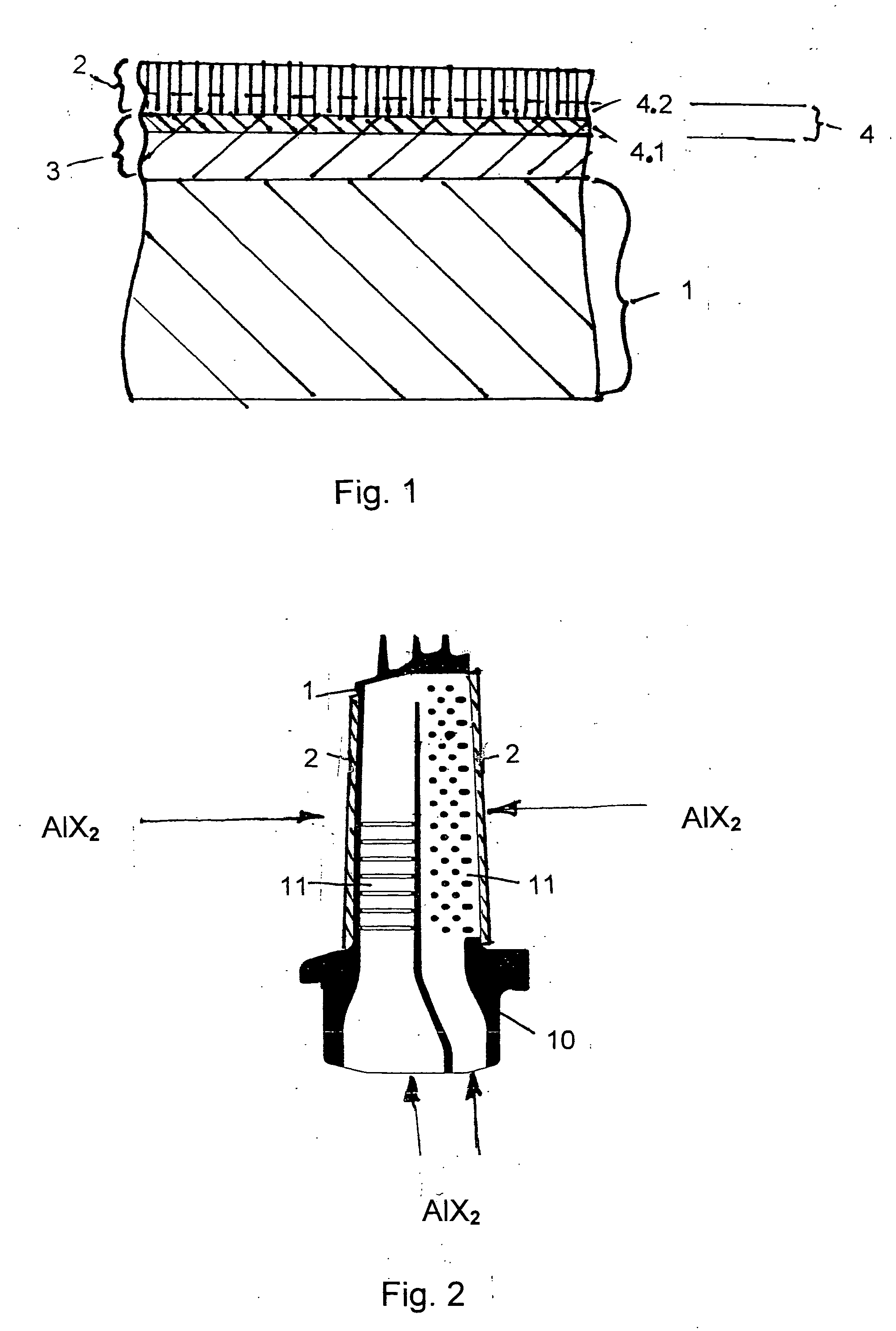

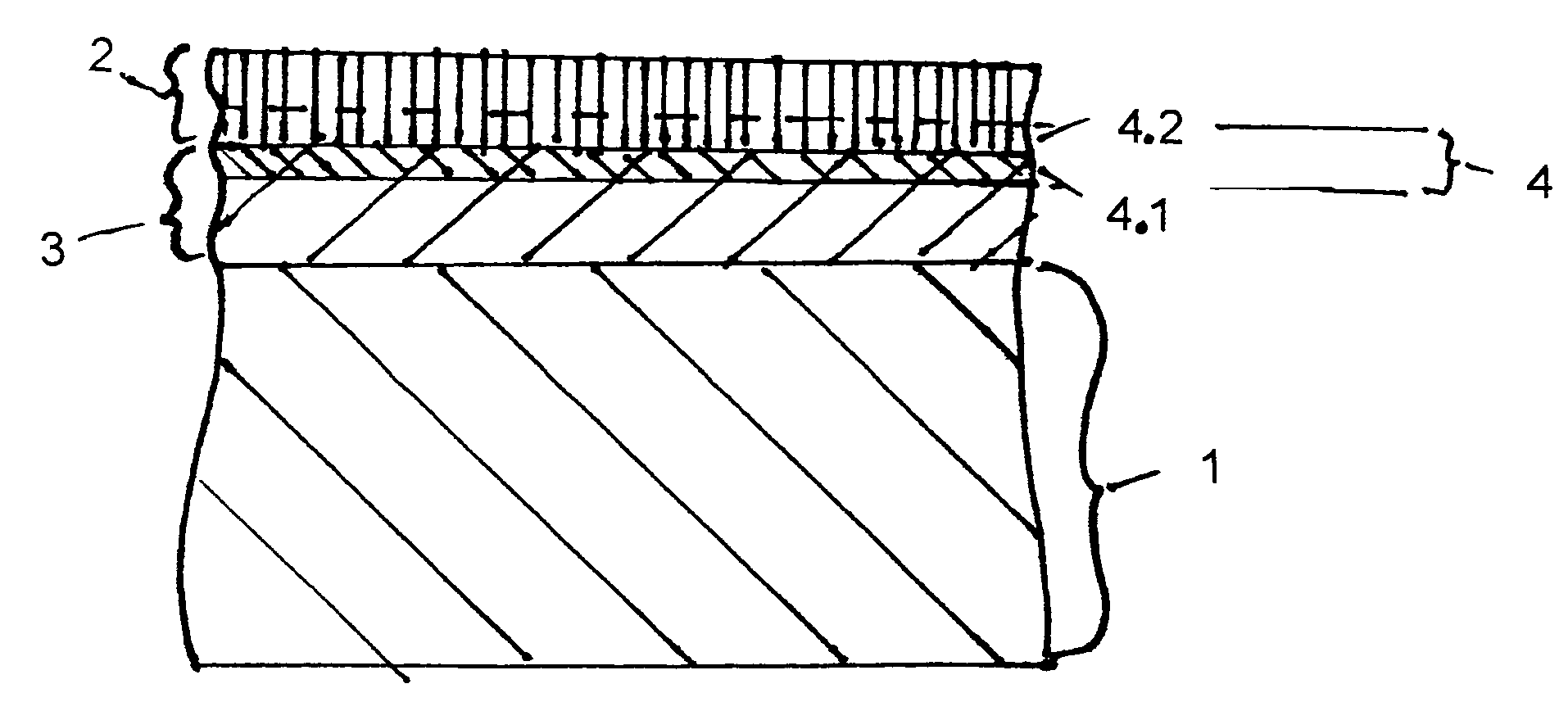

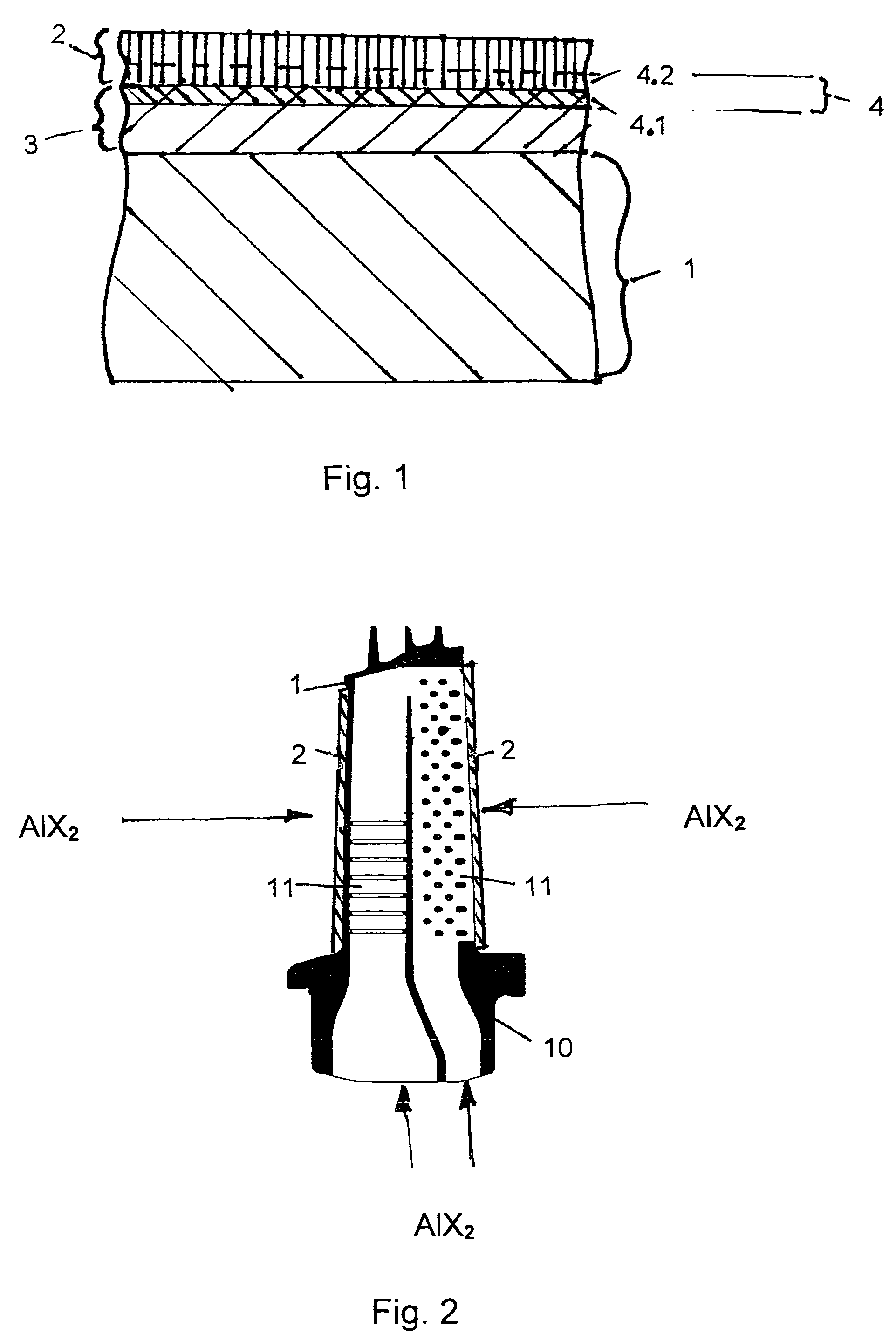

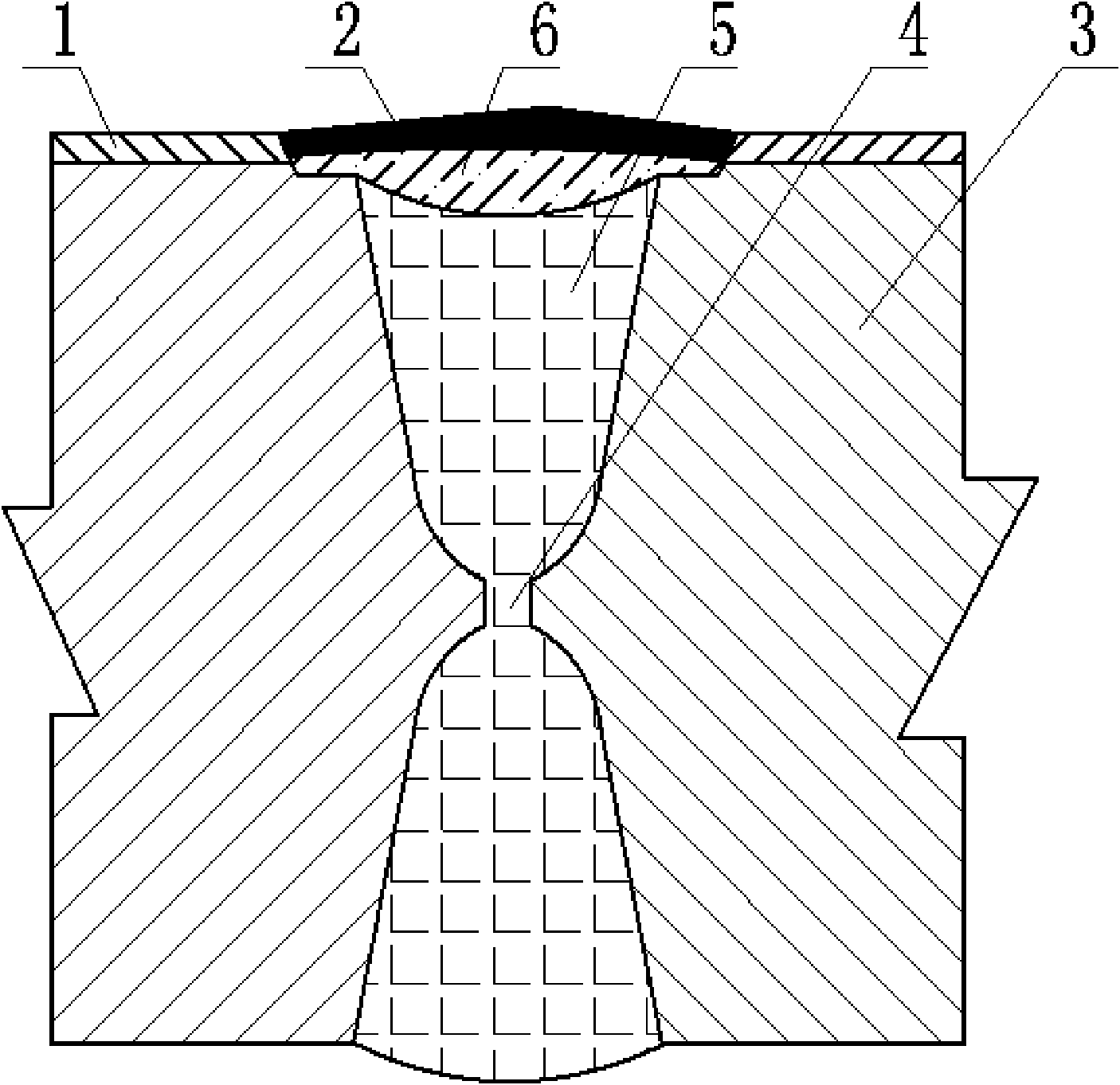

Process for applying a protective layer

InactiveUS20060177582A1Simple layerImprove the immunityPretreated surfacesSolid state diffusion coatingInsulation layerProtection layer

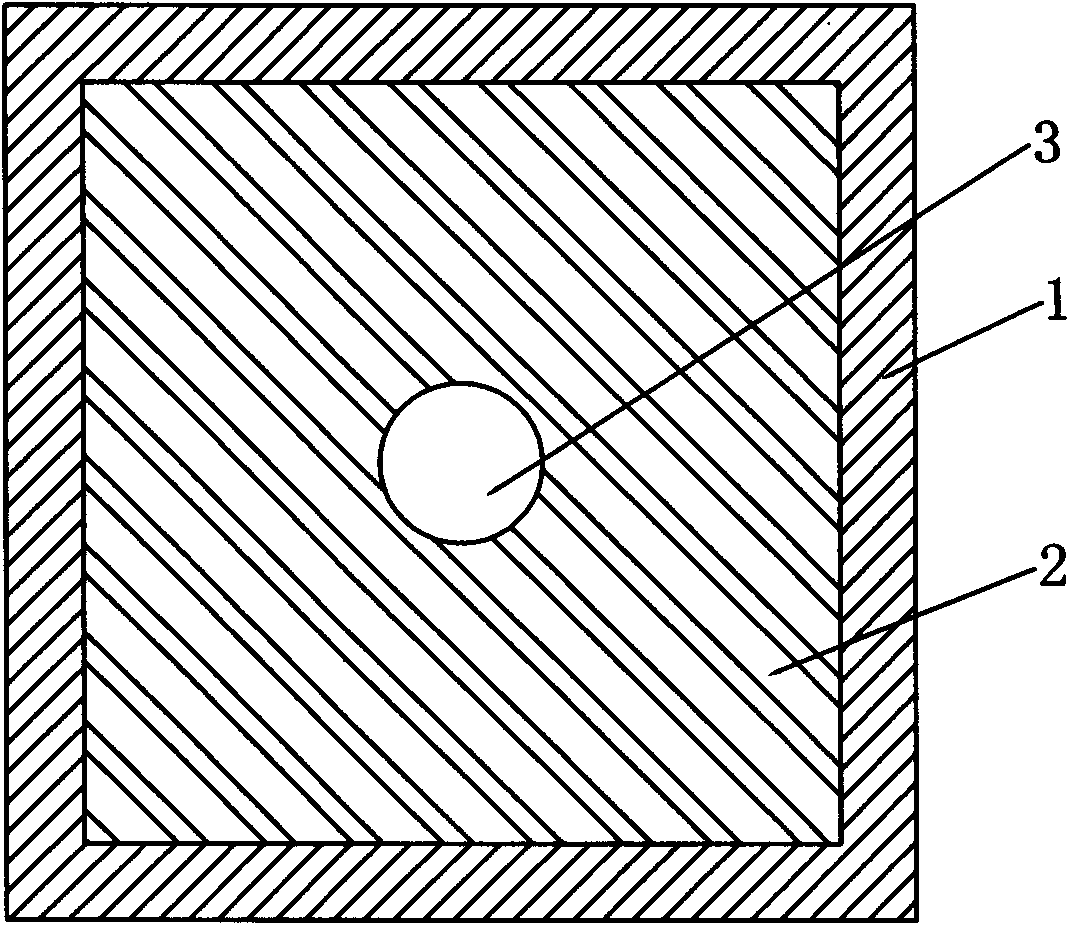

To protect a base metal layer (1) against high-temperature corrosion and high-temperature erosion, an adhesive layer (3) based on MCrAlY is applied to the base metal layer (1). The adhesive layer (3) is coated with an Al diffusion layer (4) by alitizing. The diffusion layer (4) is subjected to an abrasive treatment, so that the outer built-up layer (4.2) on the diffusion layer (4) prepared by alitizing is removed by the abrasive treatment. A ceramic heat insulation layer (2) consisting of zirconium oxide, which is partially stabilized by yttrium oxide, is applied to the diffusion layer (4) thus treated.

Owner:MAN ENERGY SOLUTIONS SA

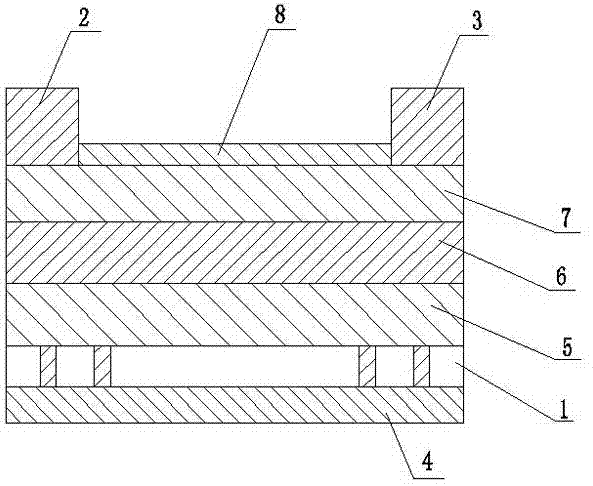

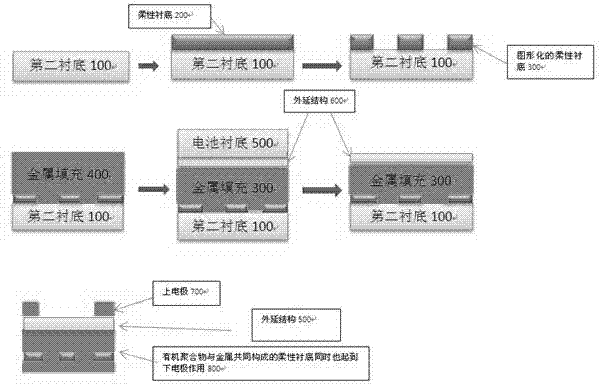

Flexible multi-joint GaAs solar battery and manufacturing method thereof

ActiveCN103594539ASave spaceUnbreakableFinal product manufacturePhotovoltaic energy generationSemiconductor materialsEngineering

The invention discloses a flexible multi-joint GaAs solar battery and a manufacturing method of the flexible multi-joint GaAs solar battery, and belongs to the technical field of semiconductor materials. Firstly, a flexible substrate and a battery epitaxial structure which is bonded with metal in the same way and composed of a base battery, a middle battery and a top battery are respectively prepared, and a first battery substrate is manufactured at the outer side of the top battery; secondly, a Ti layer, a Pt layer and an Au layer are sequentially plated on the back of the base battery of the battery epitaxial structure in an vacuum evaporation mode, and the battery epitaxial structure is bonded with a metal layer fully covering the outer surface of a polyimide coating; thirdly, Si3N4 deposits on the surface of the bonded metal layer, and then the first battery substrate on the battery epitaxial structure is removed through alkaline corrosion liquid; fourthly, two upper electrodes and an antireflection film are manufactured on the top battery of the battery epitaxial structure; finally, after a manufactured chip and a Si wafer are bonded on a second substrate through photoresist, and then the second substrate is removed through alkaline corrosion liquid. The manufactured flexible multi-joint GaAs solar battery is wholly flexible, can be applied to surfaces of different shapes, and is not broken easily.

Owner:YANGZHOU CHANGELIGHT

Nanostructure tungsten-zirconium carbide alloy and preparation method thereof

ActiveCN104388789AGood mechanical properties and high temperature stabilityAvoid stress concentration and embrittlementEmbrittlementZirconium alloy

The invention discloses a nanostructure tungsten-zirconium carbide alloy. The nanostructure tungsten-zirconium carbide alloy comprises the following components by weight percentage: 98-99.8% of tungsten, and 0.2-2.0% of zirconium carbide with the grain diameter of 5-300 nm, wherein the zirconium carbide grains are mostly uniformly distributed in the interiors of the tungsten crystal grains. The invention further discloses a preparation method of the alloy. The prepared alloy has good mechanical property and high-temperature stability; the zirconium carbide nanograins can be uniformly distributed in the interiors of the tungsten crystal grains, so that stress concentration and embrittlement generated by coarse particle in the tungsten crystal grains are avoided; the strength and high-temperature performance can be improved by pinning dislocation, and meanwhile, the toughness is ensured.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Multi-wire submerged-arc multi-layer multi-pass welding process

InactiveCN102581450AAvoid embrittlementPrevents solder joint softening problemsArc welding apparatusHeat-affected zoneEngineering

The invention provides a multi-wire submerged-arc multi-layer multi-pass welding process, which includes the steps: firstly, making preweld preparation including preparing and cleaning a welding joint groove, preheating a welding position before welding and selecting proper welding materials; secondly, setting reasonable welding parameters; and thirdly, performing multi-wire submerged-arc multi-layer multi-pass welding. By means of reasonably selecting welding materials, setting the reasonable welding parameters and controlling heat input, preheating temperature and interlayer temperature, the problems of welding cracks, embrittlement of a heat-affected zone and softening of a welding joint are effectively prevented, welding deformation is effectively controlled, the workload of post-weld correction and deformation adjustment is decreased, and welding efficiency and quality are improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Magnetic core and application article using it

ActiveCN101156222ANo noiseReduce iron lossInorganic material magnetismTransformers/inductances magnetic coresMiniaturizationNoise reduction

A magnetic core making use of an Fe-based amorphous alloy ribbon that simultaneously attains miniaturization and noise reduction through realization of high BS; and an applied product making use of the same. There is provided a magnetic core making use of an Fe-based amorphous alloy ribbon, wherein the saturated magnetic flux density (BS) of the Fe-based amorphous alloy ribbon is = 1.60 T and wherein the ratio between magnetic flux density at a core external magnetic field of 80 A / m (B80) and BS of the Fe-based amorphous alloy ribbon, B80 / BS, is = 0.90.

Owner:HITACHI METALS LTD

Welding method for stainless steel clad plates

ActiveCN103752993AAvoid embrittlementAvoid crackingArc welding apparatusWelding/cutting media/materialsButt weldingThree stage

The invention relates to a welding method for stainless steel clad plates, in particular to a welding method for the stainless steel clad plates with 316L stainless steel as clad layers. Butt welding of two stainless steel clad plates made of the same materials is finished through three stages and five-layer weld joints. The three stages include welding of carbon steel layers, welding of joints between the carbon steel layers and stainless steel layers and welding of the stainless steel layers. The five weld joints are gradually welded by different welding materials specific to different base materials according to a mutual fusion relation among the welding materials, and finally, welded plates are combined into a whole.

Owner:SHANGHAI ZHENHUA HEAVY IND GRP NANTONG TRANSMISSION MACHINERY +1

Re-alsic-rare-earth-aluminum-silicon-carbide-based LED rare earth thick film circuit electric light source device

InactiveCN104244486AImprove wettabilityImprove thermal performanceElectrical apparatusElectroluminescent light sourcesHemt circuitsEngineering

The invention discloses a Re-alsic-rare-earth-aluminum-silicon-carbide-based LED rare earth thick film circuit electric light source device which is characterized in that the device comprises a substrate and serial rare earth electronic slurry, the serial rare earth electronic slurry is prepared on the substrate in the mode of a thick film circuit, the serial rare earth electronic slurry comprises coating slurry, rare earth resistance slurry, rare earth electrode slurry and rare earth medium slurry. Substrate vacuum impregnation ingredients comprise, by weight ratio, 2-7% of magnesium and 1.5-2.5% of rare earth metal neodymium and scandium together except for aluminum. The Re-alsic-rare-earth-aluminum-silicon-carbide-based LED rare earth thick film circuit electric light source device is good in compatibility, firm in combination, large in power density, high in thermal shock resistance, high in heat dissipation efficiency, environmentally friendly, capable of saving energy and safe and reliable, and good match of the device and LED chips is achieved.

Owner:王晨 +1

Process for applying a protective layer

InactiveUS7736704B2Increase contentImprove the immunityPretreated surfacesSolid state diffusion coatingInsulation layerProtection layer

To protect a base metal layer (1) against high-temperature corrosion and high-temperature erosion, an adhesive layer (3) based on MCrAlY is applied to the base metal layer (1). The adhesive layer (3) is coated with an Al diffusion layer (4) by alitizing. The diffusion layer (4) is subjected to an abrasive treatment, so that the outer built-up layer (4.2) on the diffusion layer (4) prepared by alitizing is removed by the abrasive treatment. A ceramic heat insulation layer (2) consisting of zirconium oxide, which is partially stabilized by yttrium oxide, is applied to the diffusion layer (4) thus treated.

Owner:MAN ENERGY SOLUTIONS SA

Application of natural tobacco additive with effects of increasing aroma and preserving moisture

ActiveCN102613694AThe smoke is soft and mellowFull and smooth smokeTobacco treatmentUnsaturated fatty acidChemistry

The invention discloses an application of a natural tobacco additive with effects of increasing aroma and preserving moisture. The application is characterized in that one purpose of fire oil is to serve as a moisture preserving additive for preparing cigarettes, and the effective amount is that the weight ratio of the unsaturated fattyacid macromolecule and alcohol compounds in fire oil in each cigarette is 0.01% to 1.50%. The special additive with effects of increasing aroma and preserving moisture is applied to cut tobacco, during the smoking process of cigarettes, the unsaturated fattyacid macromolecule and alcohol compounds are cracked to generate large amounts of ester, aldehyde and ketone and the like which have strong nut flavor, therefore, the natural tobacco additive is characterized in that cigarette aroma is soft and smooth, the smoke is full and smooth, the taste is sweet and comfortable, and the remaining taste is mild and long; the unsaturated fattyacid macromolecule is attached to the surface of cut tobacco, so that a protective film is generated on the surface of cut tobacco, has moisture preserving property, can prevent tobacco from tendering, can not absorb moisture from outside under an environment with large humidity, and further has the moisture preservation and damp proof effects, so that the special effects of increasing aroma and preserving moisture of cigarettes are high-lightened.

Owner:CHINA TOBACCO GUANGXI IND

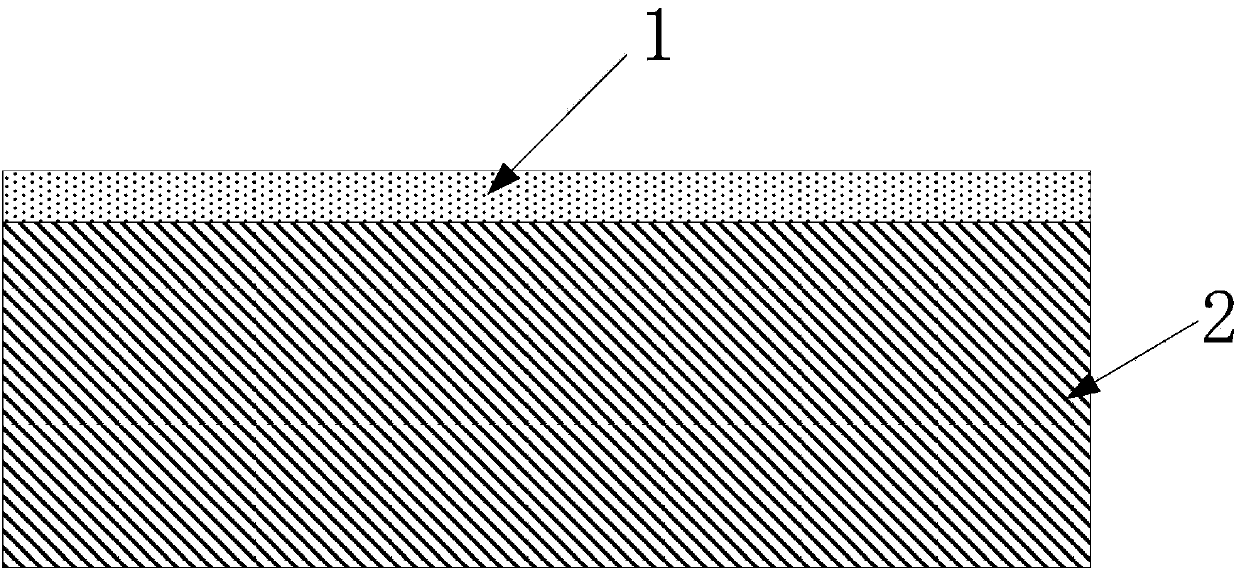

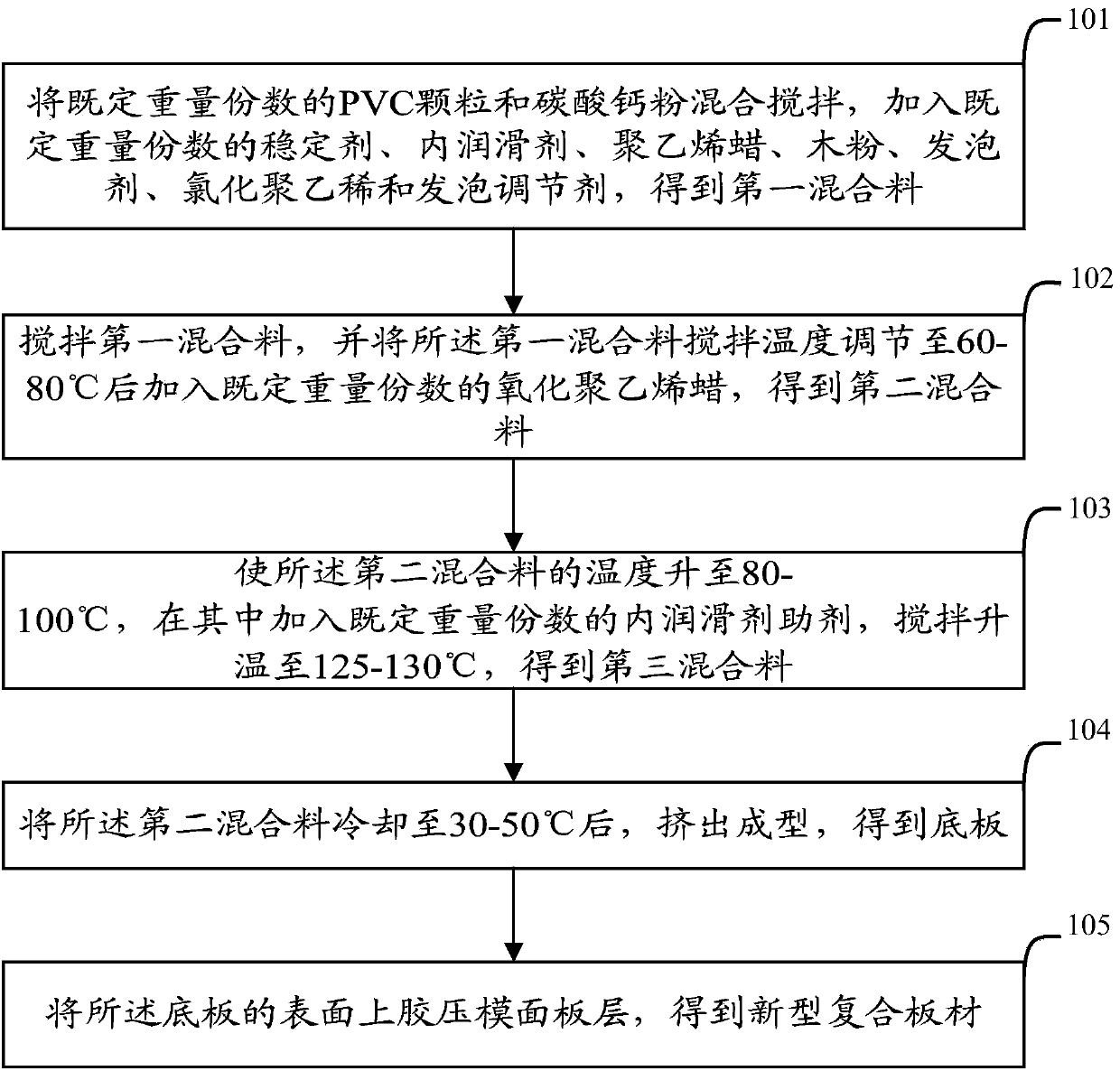

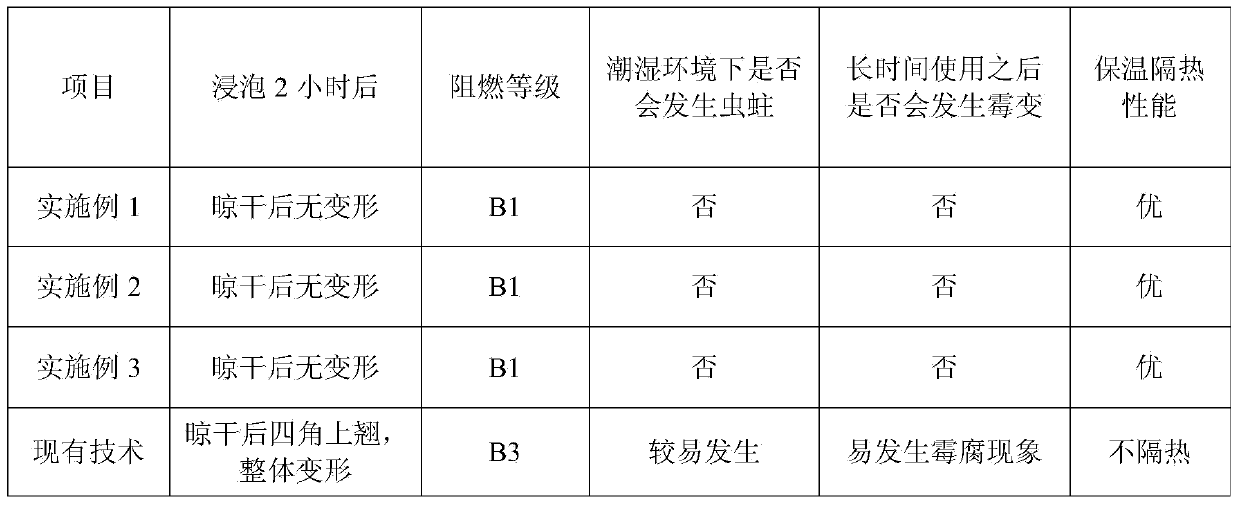

Novel composite board and preparation method thereof

ActiveCN104175660ASave resourcesRaw material environmental protectionSynthetic resin layered productsWood layered productsWaxFoaming agent

The invention relates to the field of building boards and in particular relates to a novel composite board and a preparation method thereof. The novel composite board comprises a bottom board and a panel layer which is stuck on the bottom board, wherein the bottom board comprises the following raw materials in parts by weight: 90-110 parts of PVC particles, 40-60 parts of calcium carbonate powder, 3-6 parts of a stabilizer, 1.0-1.4 parts of a foaming agent, 6-8 parts of a foaming regulator, 0.3-0.5 part of polyethylene wax, 0.3-0.4 part of internal lubricant, 0.2-0.4 part of oxidized polyethylene wax, 4-6 parts of chlorinated polyethylene, 0.5-1.5 parts of an internal lubricant additive and 9-11 parts of wood powder. The novel composite board has the good waterproof and damp-proof effects and solves the problem that common boards in the prior art are soaked by water so as to seriously deform. The novel composite board also has the recycling characteristic and solves the technical problem that a large amount of wood needs to be consumed in wooded boards in the prior art.

Owner:朱青海

Fully anti-ultraviolet, anti-fatigue, and anti-malignant melanoma optical protective material

The invention relates to a fully anti-ultraviolet, anti-fatigue, and anti-malignant melanoma optical protective material. The optical protective material is characterized by comprising the following materials in percentage by weight: 0.010 to 30.000 weight percent of additive and the balance of base stock, wherein the additive is a fluorescent whitening agent and / or an ultraviolet absorber, and also No.beta-1 decomposition antireflective agent, color-changing agent and / or toner can be added into the additive and the base stock. The optical protective material has the effect of full ultraviolet protection, namely 100 percent of ultraviolet UV400 protection, can prevent harmful light from causing human body to generate malignant melanoma, avoid human fatigue, furniture color change and embrittlement caused by the harmful light, particularly has better advanced protective effect on infants, students and young ladies, and can protect tender skin and slow down the aging process.

Owner:ZHEJIANG PURPLE LIGHT TECH CO LTD

Forging technology of Hastelloy C-276

ActiveCN109590421AGrain Boundary Embrittlement Phase ReductionEliminate forging crackingHeating/cooling devicesEmbrittlementStaying time

The invention discloses a forging technology of a Hastelloy C-276. The forging technology comprises a pre-forging heat treatment process, a heating process and a forging process. The pre-forging heattreatment process is characterized in that an alloy material is heated to 980 DEG C-1020 DEG C, and heat is preserved for 1-1.5 hours; the material is heated to 1080 DEG C-1120 DEG C again, and heat is preserved for 15-16 hours; and the material is taken out of a furnace for air cooling. The heating process is characterized in that the alloy material is heated to 980 DEG C-1020 DEG C, and heat ispreserved for 1-1.5 hours; and the material is heated to 1140 DEG C-1160 DEG C again, and heat is preserved for 5-6 hours. The forging process is characterized in that multi-heating-number forging isadopted, wherein a temperature compensation device of a forging machine is adopted for heating during forging, and the final forging temperature of each heating number is controlled to be 1000 DEG C or above. According to the technology, a heat treatment technology is adopted, a precipitated phase of the Hastelloy C-276 is redissolved, so that grain boundary embrittlement is reduced, and forging cracks caused by weakening of grain boundary are eliminated; and the temperature compensation device is used for carrying out temperature compensation on the material in the forging process, so that the staying time of a blank in the forging temperature interval is prolonged, and then the forging time of each heating number is prolonged.

Owner:HEBEI IRON AND STEEL

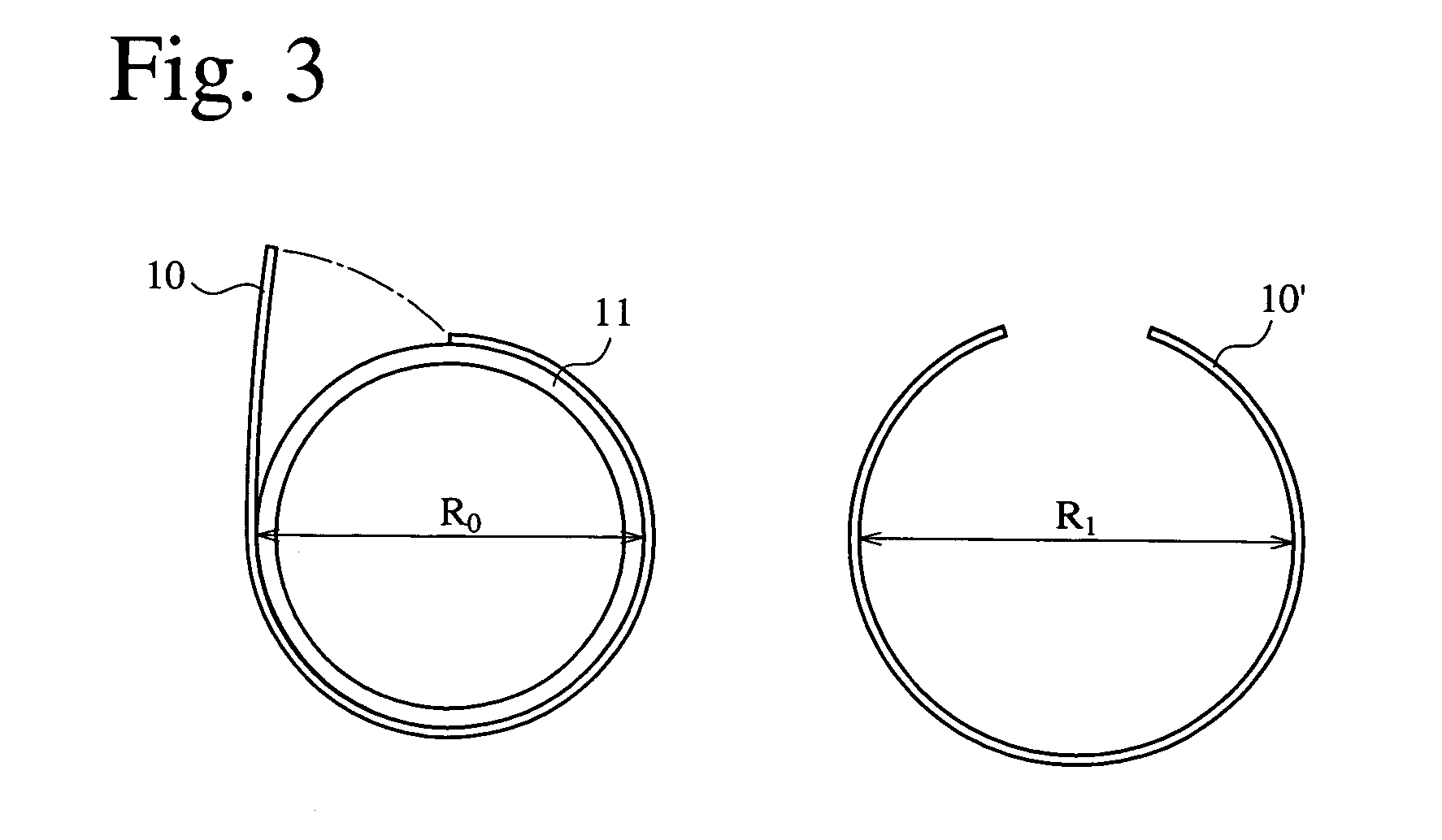

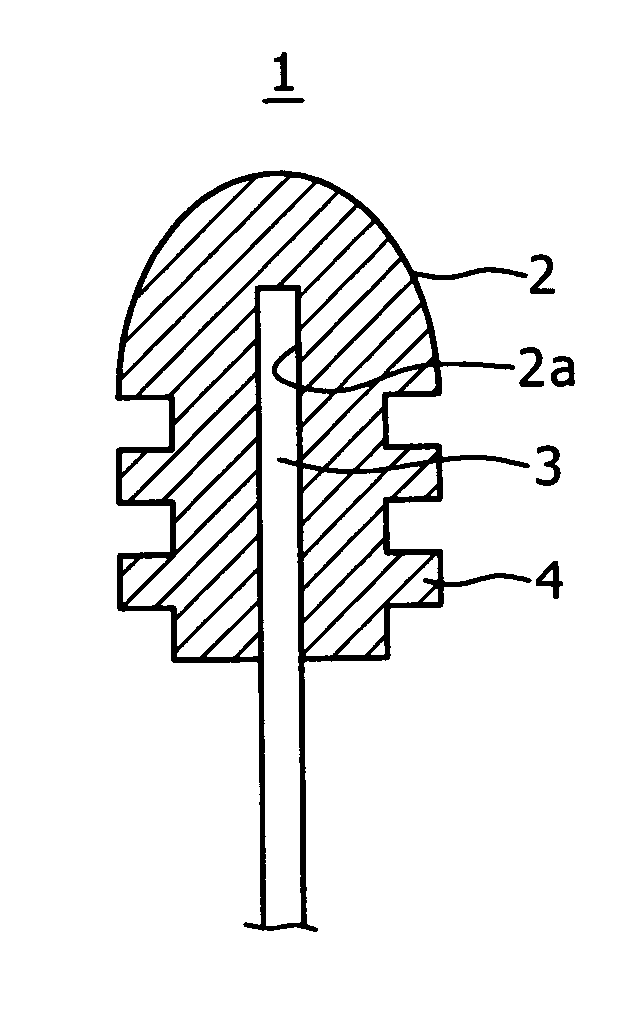

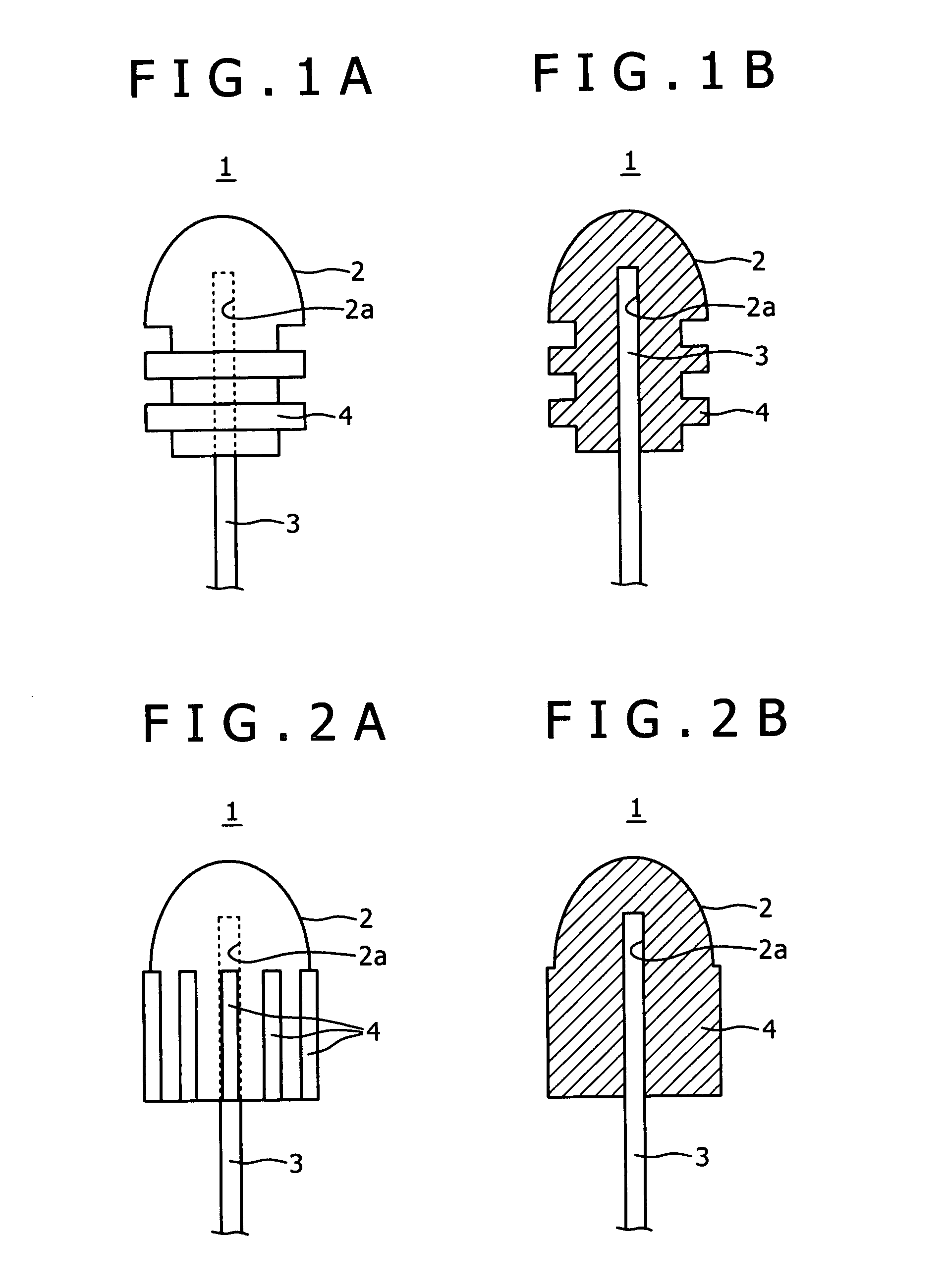

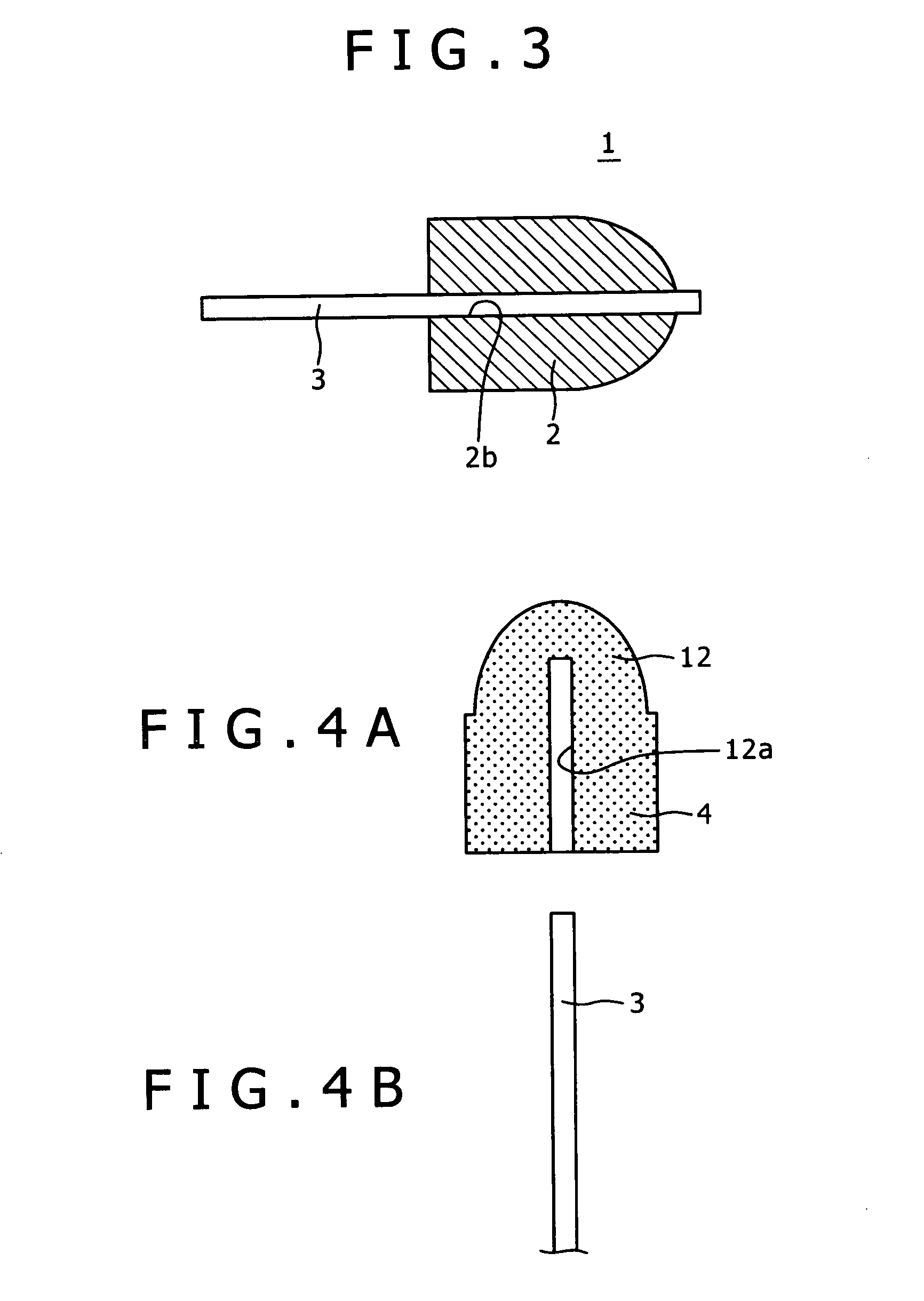

Short arc type high voltage electrical discharge electrode, short arc type high voltage electrical discharge tube, short arc type high voltage electrical discharge light source apparatus, and their manufacturing methods

InactiveUS20070108911A1High yieldImproved uniform propertyHigh-pressure discharge lampsSolid cathode detailsHigh pressureMaterials science

A short arc type high voltage electrical discharge electrode includes an electrode center spindle made from a refractory metal and having a tip; and an electrode main body made from a refractory metal and disposed at the tip of the electrode center spindle. The electrode center spindle is subjected to final sintering, the electrode main body is subjected to temporary sintering, and the final-sintered electrode center spindle is inserted into a center hole of the temporary-sintered electrode main body so as to form combination which is sintered together.

Owner:SONY CORP

Welding process of hydrogenation reaction kettle cylinder body

InactiveCN101579783AImprove fusion qualityAvoid Weld CrackingNon-electric welding apparatusHydrogenation reactionCarbon steel

The invention discloses a welding process of a hydrogenation reaction kettle cylinder body which is used for producing various chemical raw materials with a method of continuous hydrogenation. A plate resulted from compounding common carbon steel and stainless steel with the explosive technology is welded and processed into a cylinder shape, thereby overcoming phenomena such as easily-occurring welding cracks, and the like, which are caused by different material properties of the carbon steel and the stainless steel and by the welding among great-thickness carbon steels; and the production cost of the reaction kettle is greatly reduced. The hydrogenation reaction kettle cylinder body produced according to the welding process is widely applied in chemical engineering, pharmaceutical and other industries for producing sorbierite, xylitol, maltose, furfuryl alcohol, and the like.

Owner:倪加明

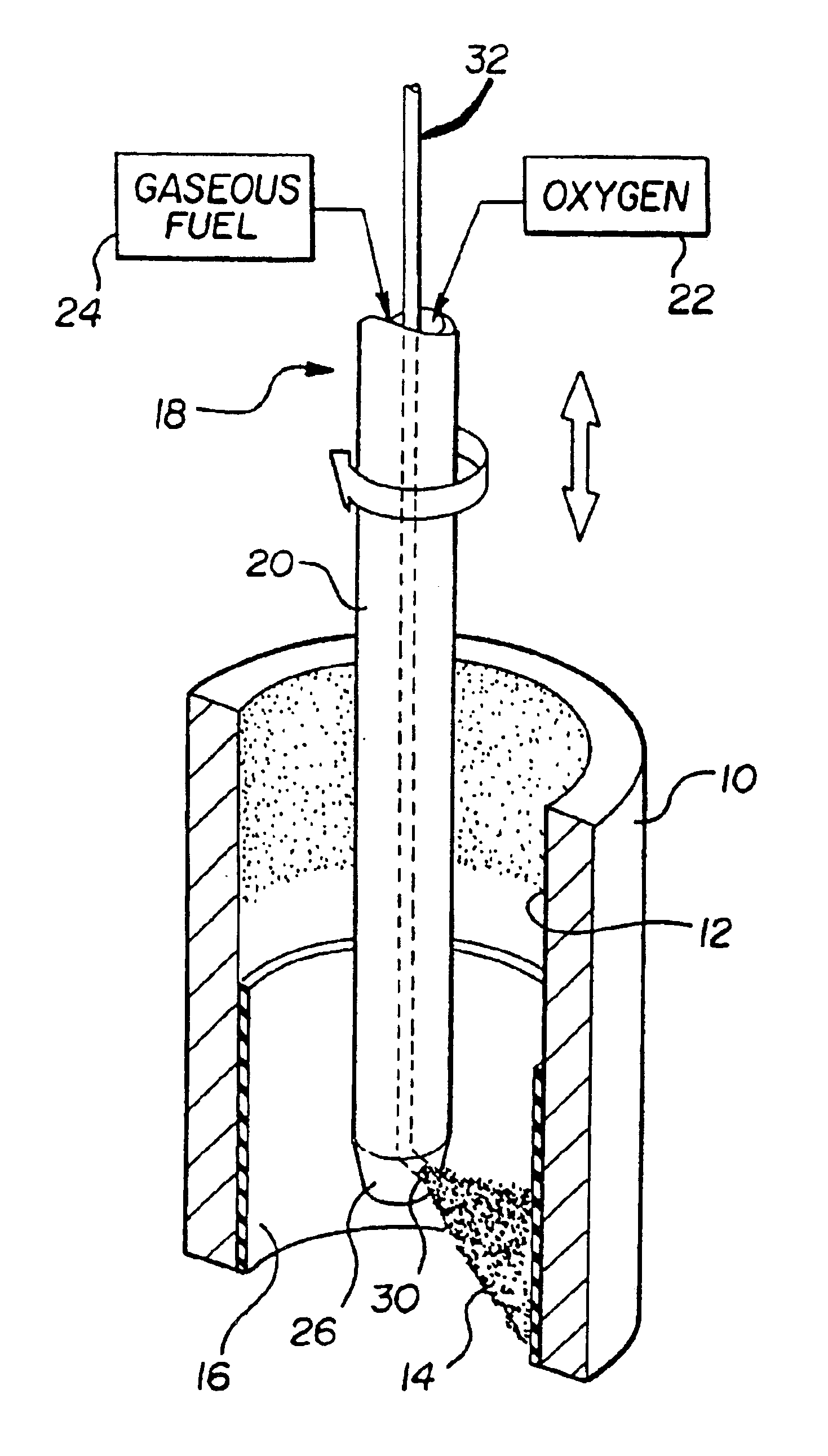

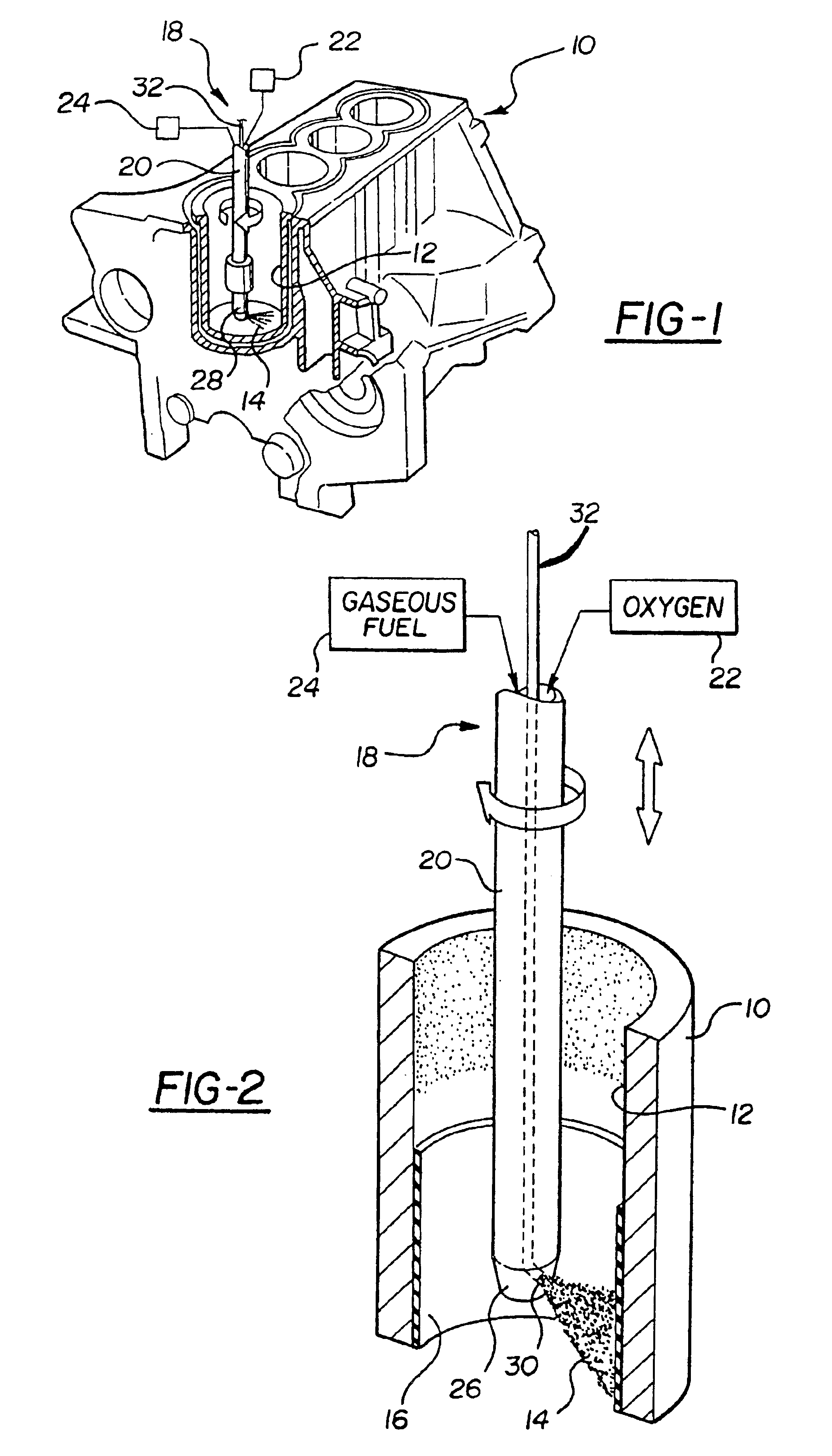

Method of producing thermally sprayed metallic coating with additives

InactiveUS6902768B2Reduce dependenceIncrease heating capacityLiquid surface applicatorsMolten spray coatingWire rodExcess oxygen

The cylinder walls of light metal engine blocks are thermally spray coated with a ferrous-based coating including aluminum using an HVOF device. A ferrous-based wire is fed to the HVOF device to locate a tip end of the wire in a high temperature zone of the device. Jet flows of oxygen and gaseous fuel are fed to the high temperature zone and are combusted to generate heat to melt the tip end. The oxygen is oversupplied in relation to the gaseous fuel. The excess oxygen reacts with and burns a fraction of the ferrous-based feed wire in an exothermic reaction to generate substantial supplemental heat to the HVOF device. The molten / combusted metal is sprayed by the device onto the walls of the cylinder by the jet flow of gases.

Owner:GM GLOBAL TECH OPERATIONS LLC

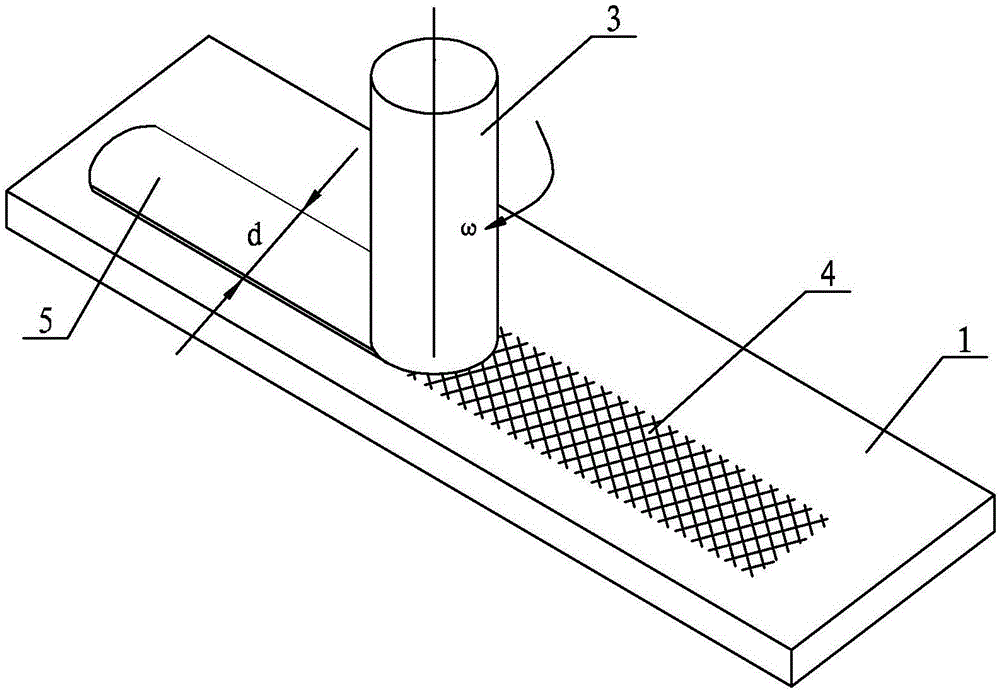

Method for overlap joint of special-shaped titanium aluminum metal through friction stir welding by utilizing pre-stacking aluminum layer

InactiveCN105057881AInhibitionAvoid embrittlementWelding/soldering/cutting articlesNon-electric welding apparatusSolid phasesTitanium

The invention discloses a method for overlap joint of special-shaped titanium aluminum metal through friction stir welding by utilizing a pre-stacking aluminum layer, which is used for solving the problems that when the special-shaped titanium aluminum materials are subjected to overlap joint, a connecting joint is embrittled, the connecting strength is low, and a welding tool is worn seriously due to a titanium aluminum metal compound. The method comprises the steps of firstly, roughening the surface of a titanium alloy plate to be welded; secondly, ultrasonically cleaning the roughened titanium alloy plate, wiping the titanium alloy plate, an aluminum alloy plate and an aluminum rod by adopting an organic solvent or a cleaning agent; thirdly, forming a pre-stacking solid phase aluminum layer subjected to combined action of alloy connection and mechanical connection at the joint of the roughening part; and fourthly, forming an overlap joint head on which the aluminum alloy plate is arranged at the upper part and the titanium alloy plate is arranged at the lower part, carrying out friction stir welding on the aluminum alloy plate and the titanium alloy plate, controlling the end part of a stirring needle to prick into the pre-stacking solid phase aluminum layer and controlling the end part of the stirring needle to not contact with the surface of the titanium alloy plate, thus realizing the effective connection between the pre-stacking solid phase aluminum layer and the aluminum alloy plate to be welded under the effect of the stirring of the stirring needle and the upsetting of a shaft shoulder. The method is used for the overlap welding of the special-shaped titanium aluminum materials.

Owner:HARBIN INST OF TECH

Welding method of nickel-based material pipeline

InactiveCN110560844AAvoid embrittlementImprove welding qualityArc welding apparatusShielded metal arc weldingAlloy

The invention discloses a welding method of a nickel-based material pipeline. The welding method comprises the steps that first, the pipeline is subjected to cold cutting, a groove is machined, and then the two sides of the groove are polished and cleaned through a solvent; second, a welding workpiece is placed on a refitting tool; third, air in the pipeline is replaced with argon, and positionedwelding is conducted; and fourth, during welding, argon tungsten-arc welding backing weld and manual arc welding are adopted for filling and capping. According to the welding method of the nickel-based material pipeline, the welding quality of a nickel-based alloy material is improved by adopting argon tungsten-arc welding backing weld and manual arc welding for capping.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

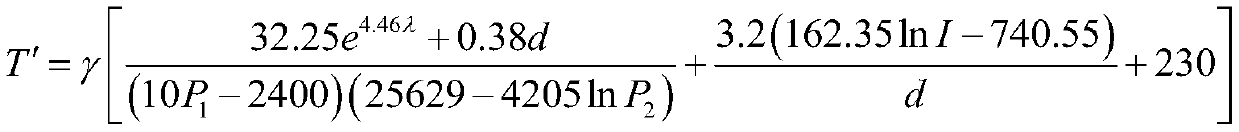

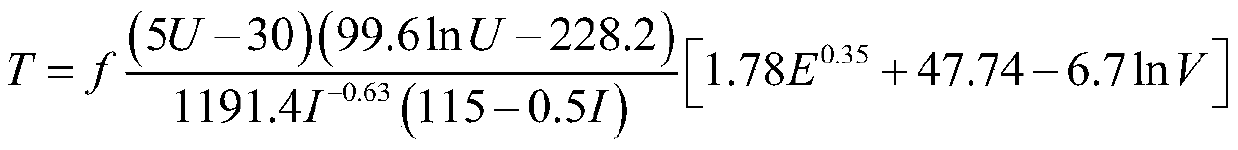

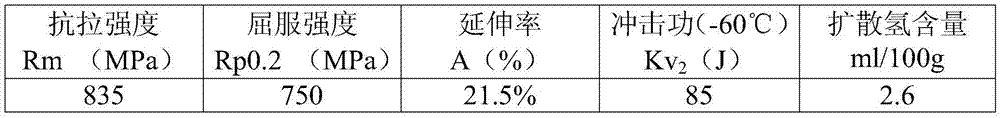

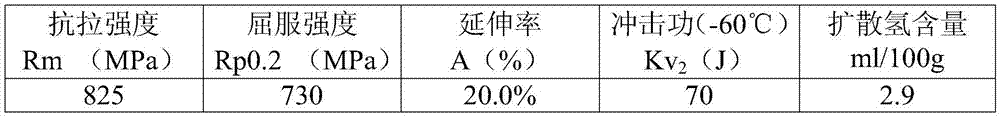

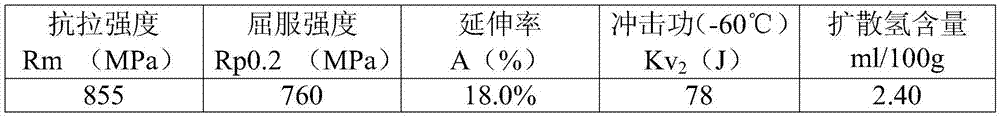

Hydroelectric 800 MPa low-alloy high-strength steel welded rod and preparation method thereof

ActiveCN105436742AImprove solderabilityGood mechanical propertiesWelding/cutting media/materialsSoldering mediaChemical compositionThick plate

The invention discloses a hydroelectric 800 MPa low-alloy high-strength steel welded rod and a preparation method thereof. The hydroelectric 800 MPa low-alloy high-strength steel welded rod comprises a core wire and a microalloyed coating wrapping the surface of the core wire. Welded rod deposited metal is composed of, by weight, 0-0.06% of C, 0.20%-0.45% of Si, 1.40%-1.70% of Mn, 0.20%-0.40% of Cr, 1.80%-2.60% of Ni, 0.25%-0.45% of Mo, 0-0.005% of S, 0-008% of P, 0-0.020% of Ti, 0-0.001% of Re and the balance Fe. The welded rod can be applied to welding of 800 MPa high-strength steel thick plates in construction of water pumping and energy storage power stations. Welding metal still has good comprehensive mechanical properties under the work condition of minus 60 DEG C, and the safety and reliability of welded joints in high and cold regions are improved. The welded rod preparation method is feasible in process, and production and manufacturing can be achieved easily.

Owner:SICHUAN XIYE NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com