Method for overlap joint of special-shaped titanium aluminum metal through friction stir welding by utilizing pre-stacking aluminum layer

A technology of friction stir welding and dissimilar metals, applied in welding equipment, metal processing equipment, welding/welding/cutting items, etc., can solve the problems of low connection strength, wear of welding tools, embrittlement of connection joints, etc., and achieve increased metallurgy Combined area, reduced welding tool wear, and improved joint strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

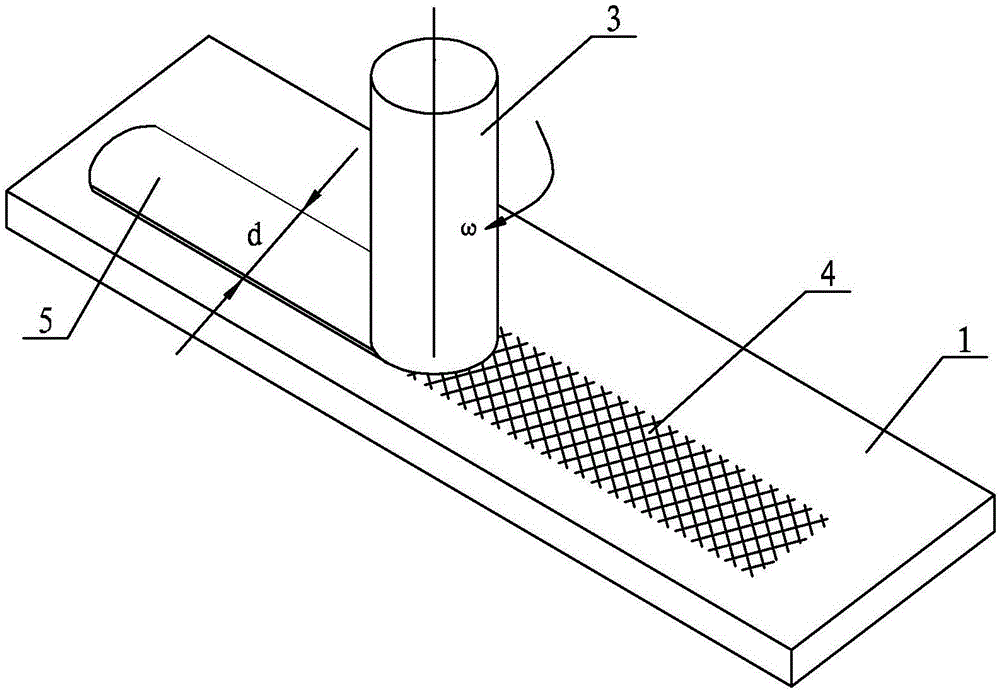

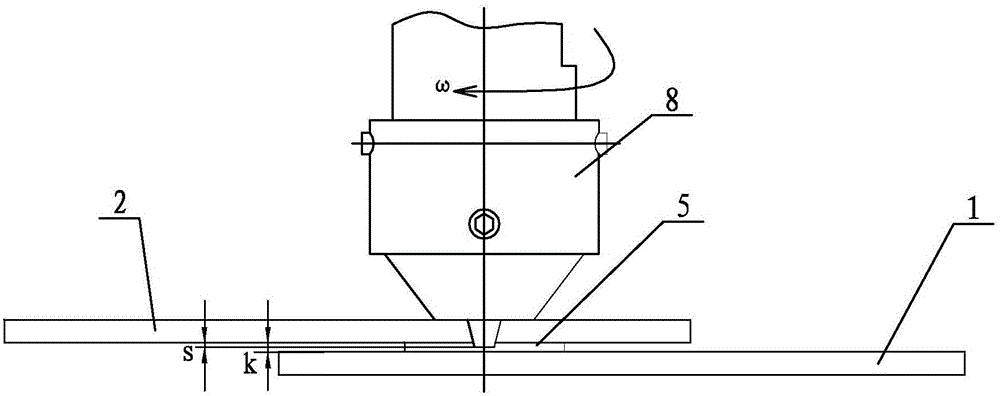

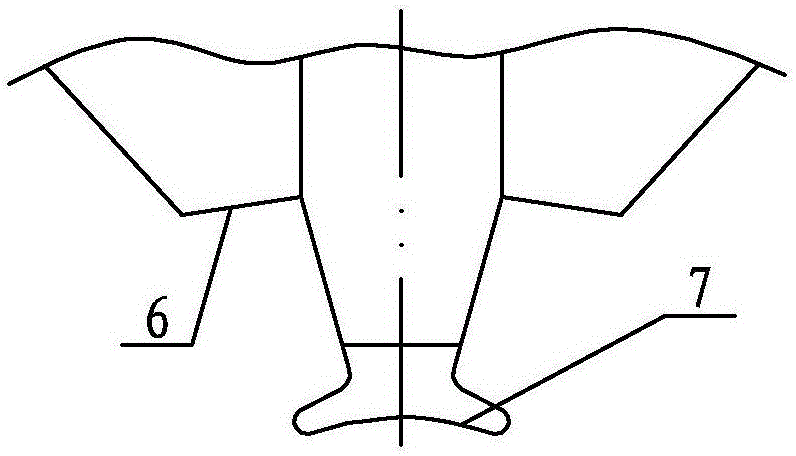

[0018] Specific implementation mode one: combine figure 1 and figure 2 Describe this implementation mode, this implementation mode is realized through the following steps:

[0019] Step 1: Texture treatment: Texturize the surface of the titanium alloy plate 1 to be welded, so that the average surface roughness of the area to be welded on the titanium alloy plate 1 is greater than or equal to 5 μm, and the distance between the texturized part 4 and the edge of the titanium alloy plate 1 is 10 mm ~40mm, the width d of the texturized part 4 is 15mm~25mm, and the texturing method is machining texturing, sandblasting texturing or laser texturing;

[0020] Step 2: Clean the titanium alloy plate 1: first use ultrasonic cleaning to clean the roughened titanium alloy plate 1 to remove residual particles, and then use an organic solvent or cleaning agent to wipe the surfaces of the titanium alloy plate 1, aluminum alloy plate 2 and aluminum rod 3, Remove oil and metal dust; titanium ...

specific Embodiment approach 2

[0023] Specific implementation mode two: combination figure 1 Describe this embodiment. In this embodiment, when the texturing method in step 1 adopts machining to roughen the surface of the titanium alloy plate 1, it is required to carry out texturing in a direction parallel and perpendicular to the welding direction or having an acute angle with the welding direction. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination figure 1 Describe this embodiment, this embodiment is that when the texturing method in step 1 adopts sandblasting treatment, the sandblasting pressure is 8MPa~15MPa, the nozzle distance of the spray gun is 60mm~140mm from the texturing part 4, and the angle of the spray gun is 45°~75° °. Other steps are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com