Patents

Literature

77results about How to "Solve the problem of severe wear and tear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

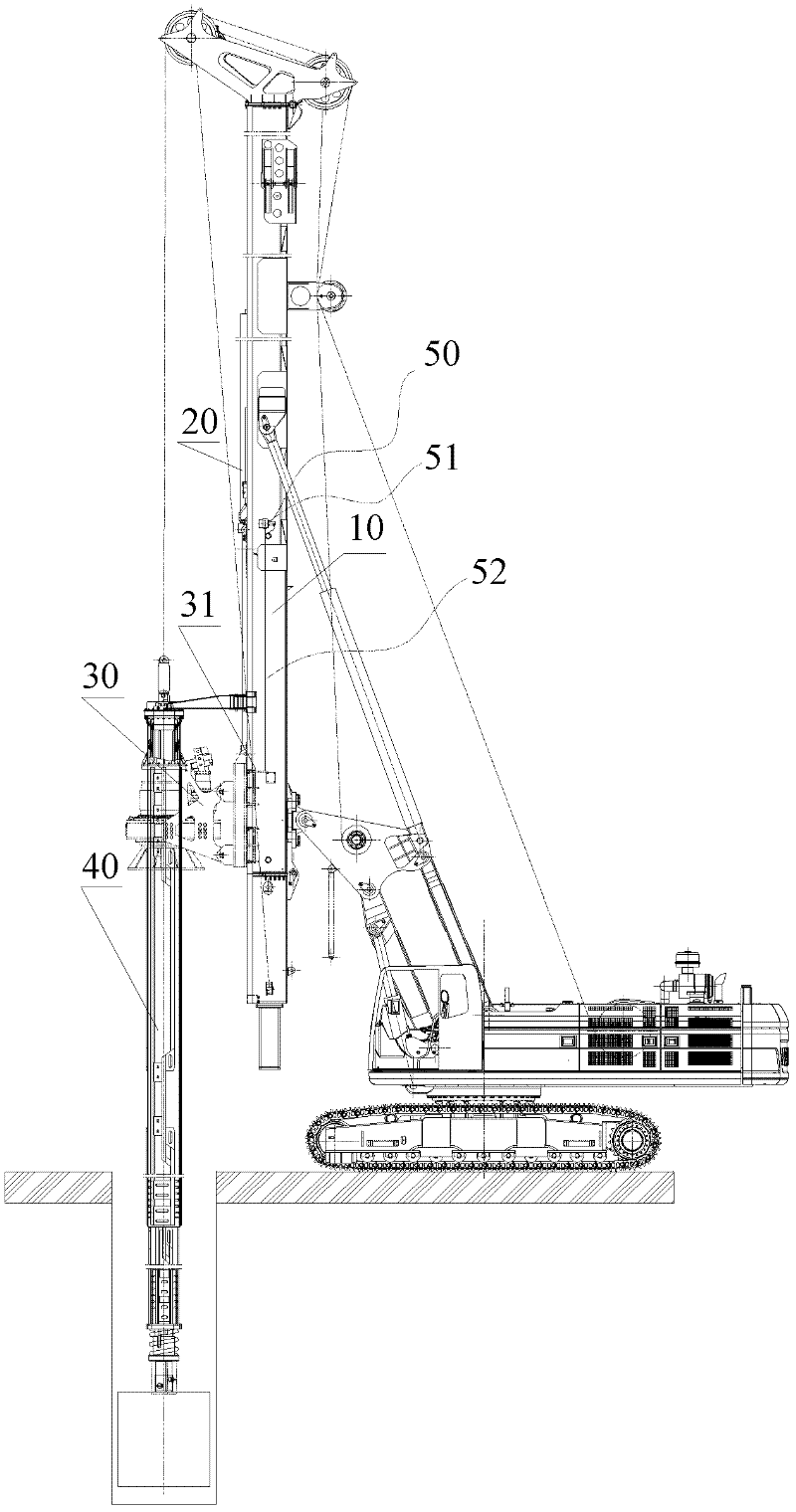

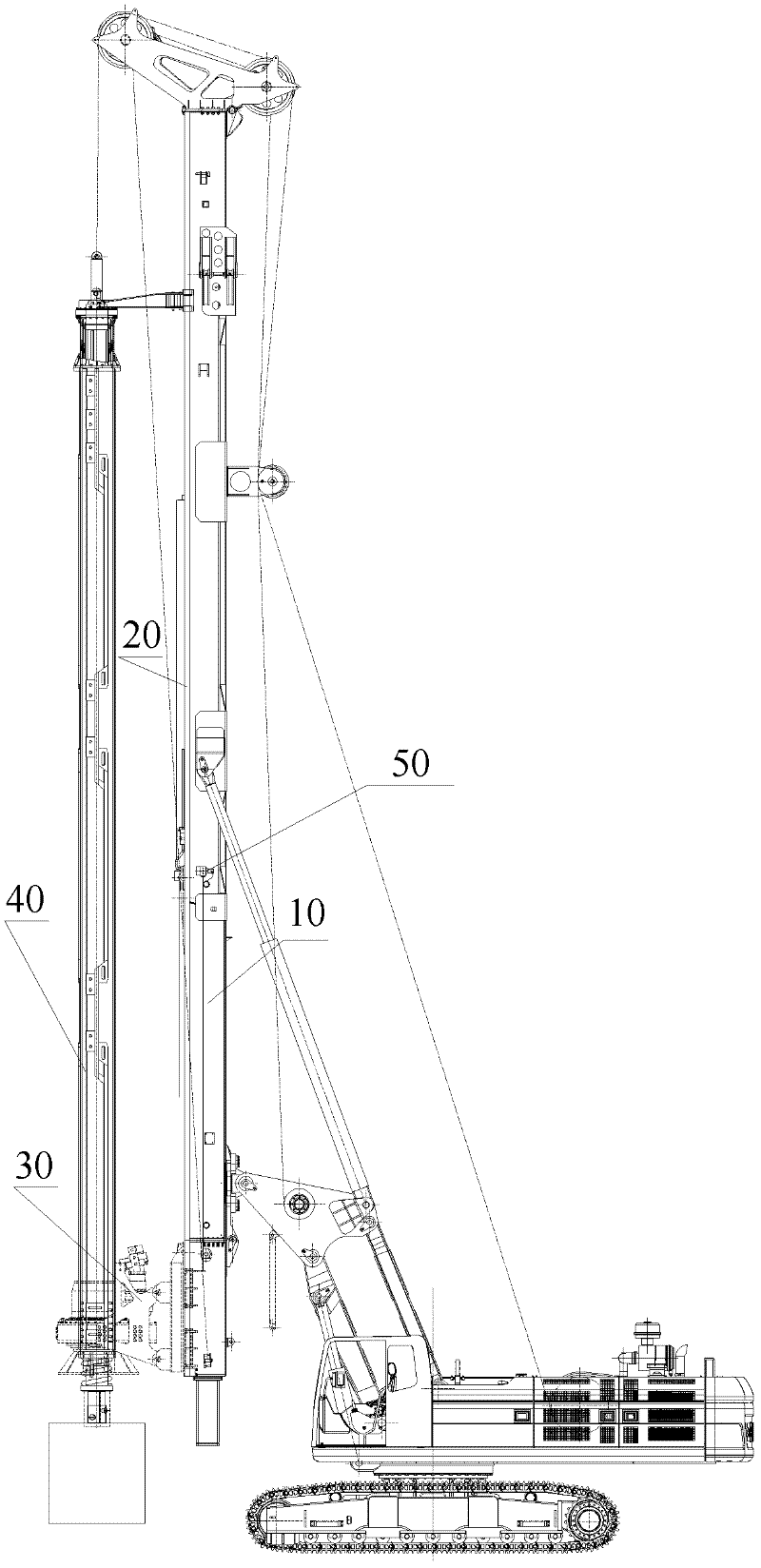

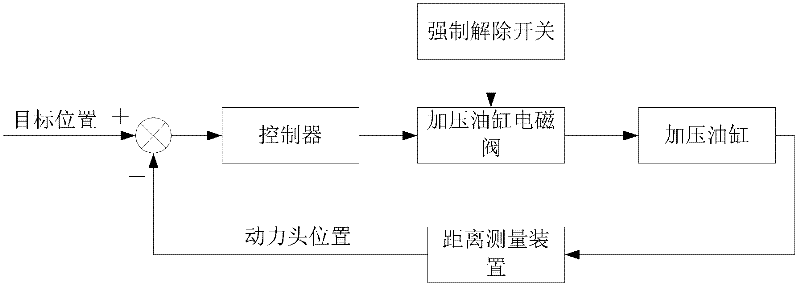

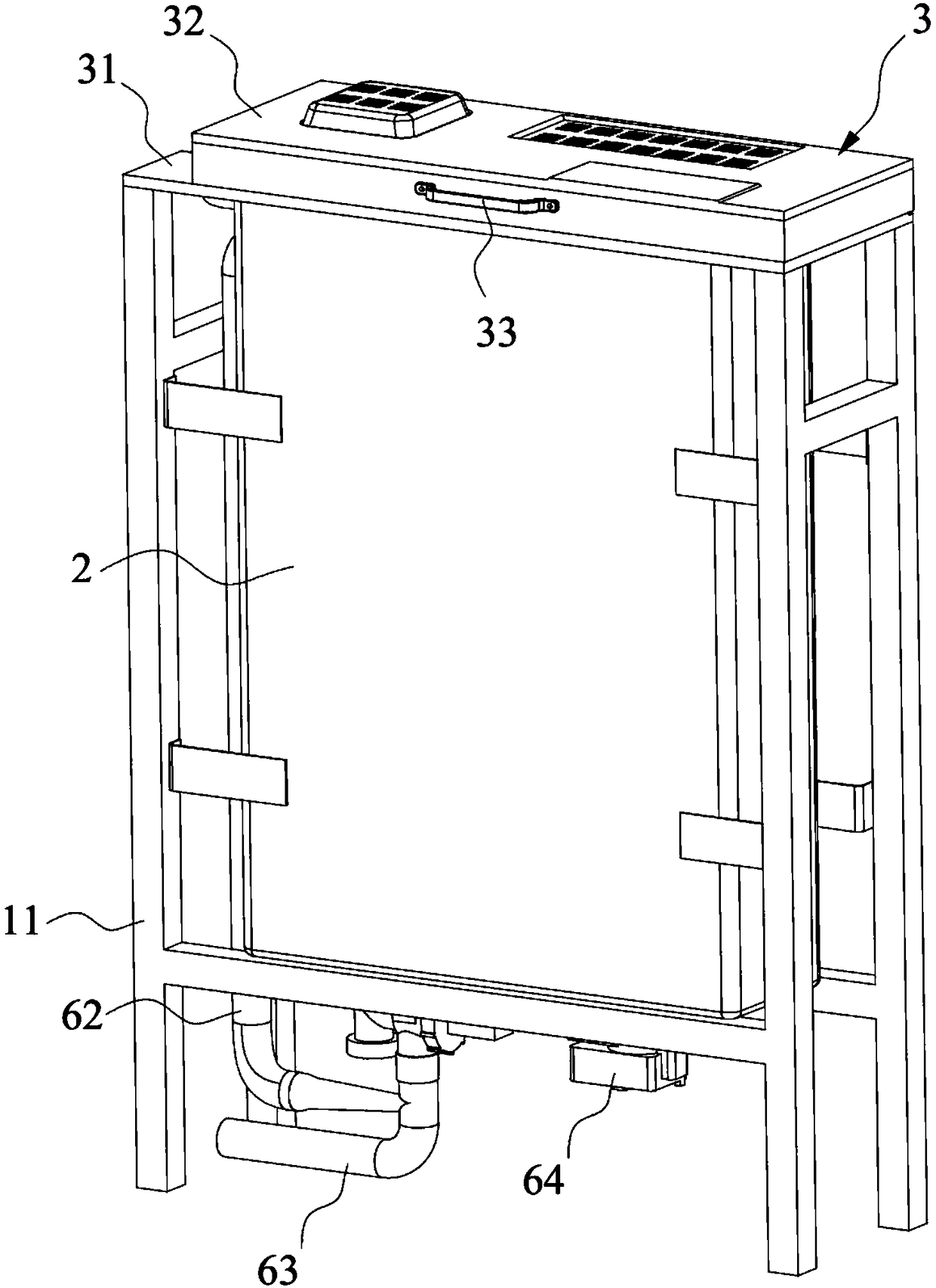

Rotary drilling rig and control mode thereof

InactiveCN102392630AAchieve unlockSolve the problem of severe wear and tearConstructionsRotary drillingControl signalPiston rod

The invention provides a rotary drilling rig comprising a mast (10), a pressurizing oil cylinder (20), a power head (30), a drill rod assembly (40), a distance-measuring device (50) and a controller, wherein the mast (10) is arranged along the vertical direction; the pressurizing oil cylinder (20) is arranged on the mast (10), the piston rod of the pressurizing oil cylinder (20) is arranged downward; the power head (30) is connected with the piston rod of the pressurizing oil cylinder (20); the drill rod assembly (40) is in drive fit with the power head (30) and is provided with a machine-locked type drill rod; the distance-measuring device (50) is used for measuring the moving distance of the power head (30); and the controller is connected with the distance-measuring device (50), determines the current position of the power head (30), compares the current position with an unblocking position where the power head (30) is when the drill rod assembly (40) is unblocked, and sends a control signal to the pressurizing oil cylinder (20) according to the comparative result. The invention effectively solves the problems in the prior art that the drill rod locking efficiency is low, and the equipment wear is serious.

Owner:SHANGHAI ZOOMLION HEAVY IND PILING MACHINERYCO +1

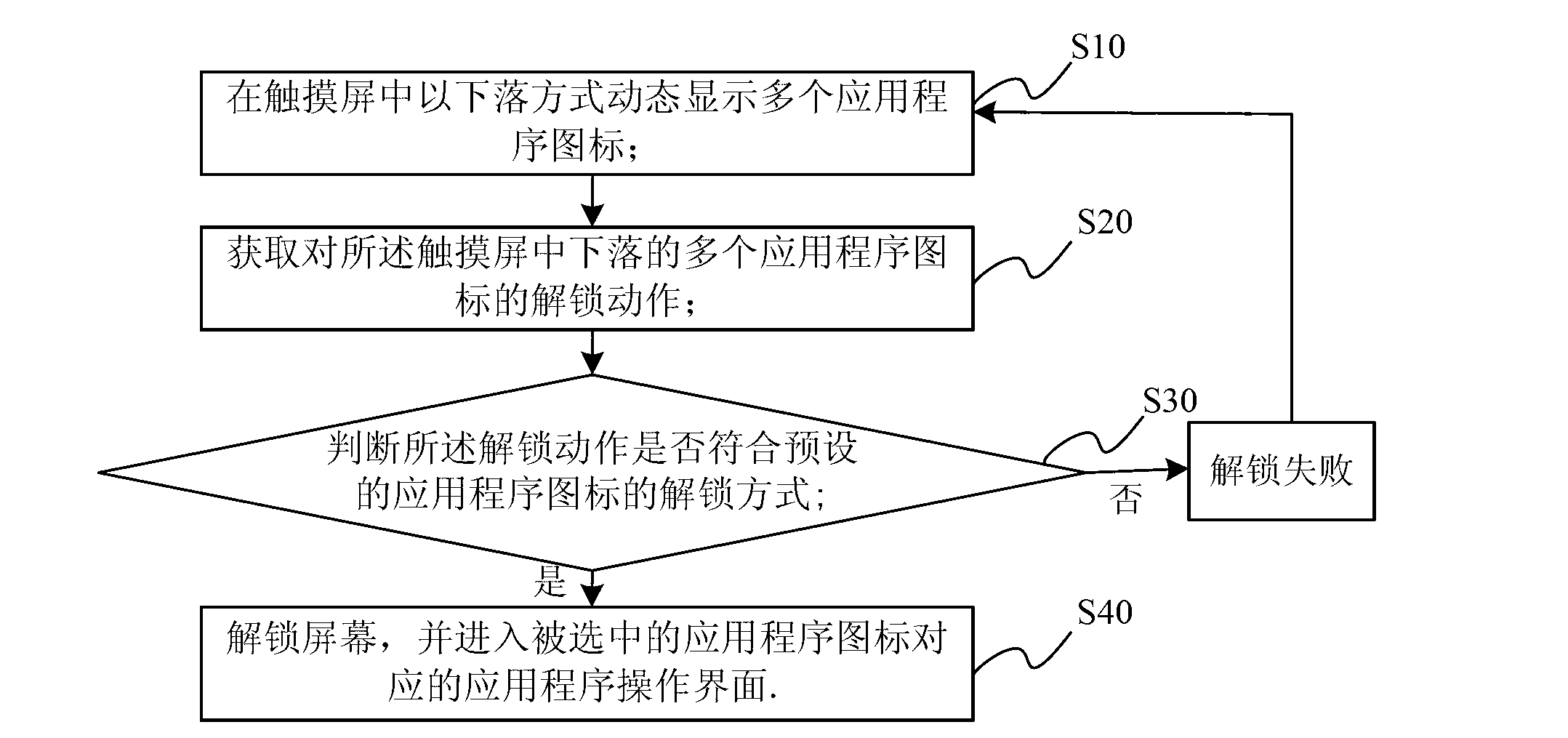

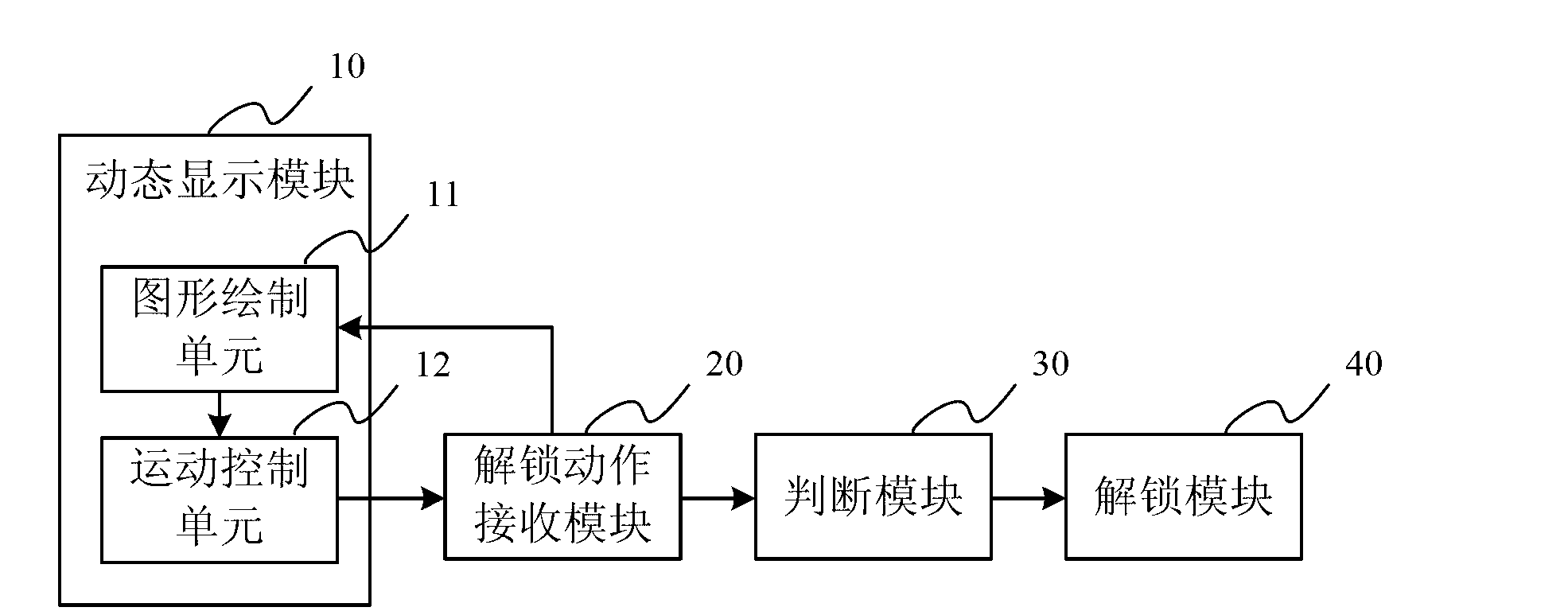

Unlocking method and device of touch screen and touch screen equipment

ActiveCN103076974ASolve the problem of severe wear and tearAdd funInput/output processes for data processingTouchscreenFixed position

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

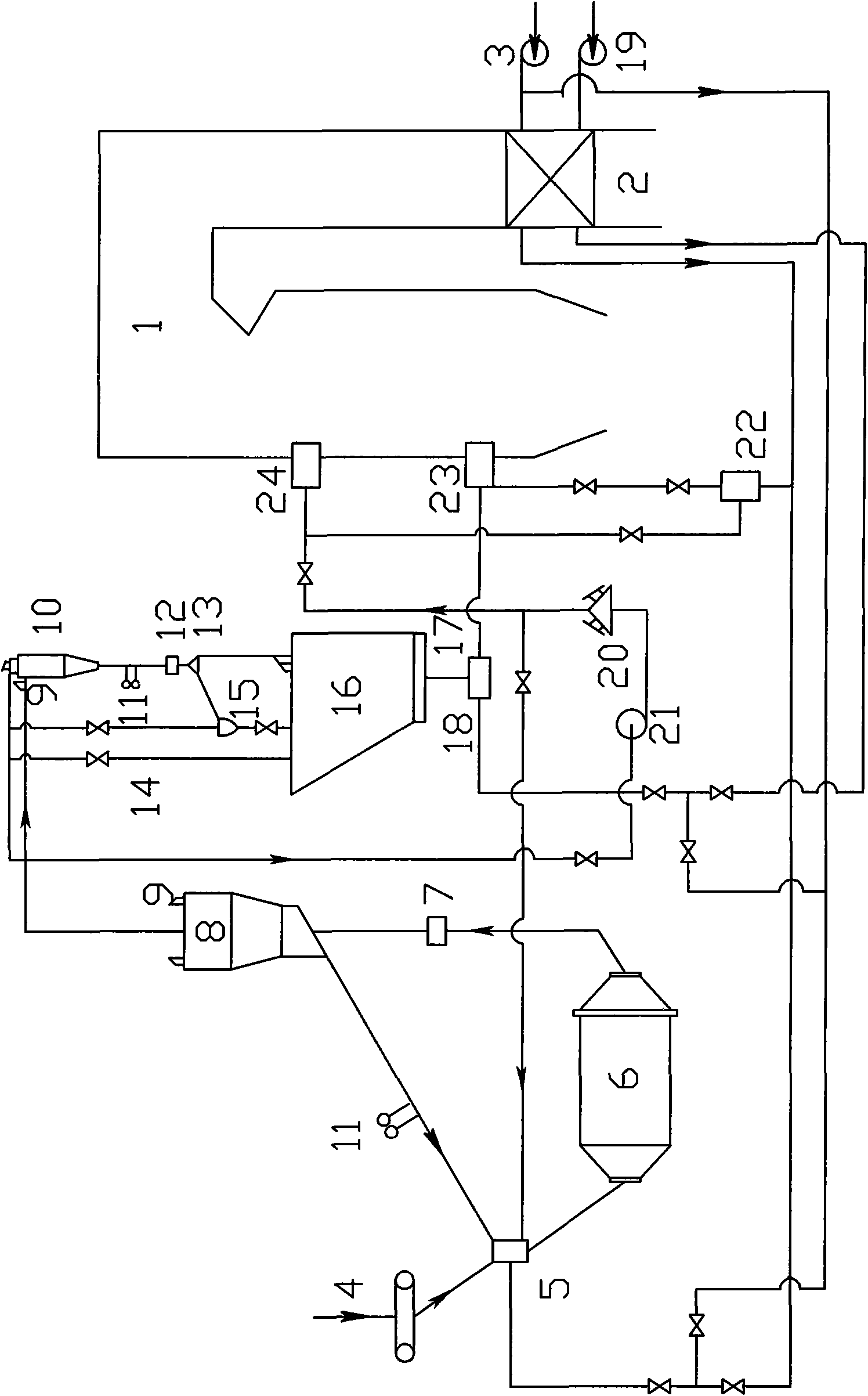

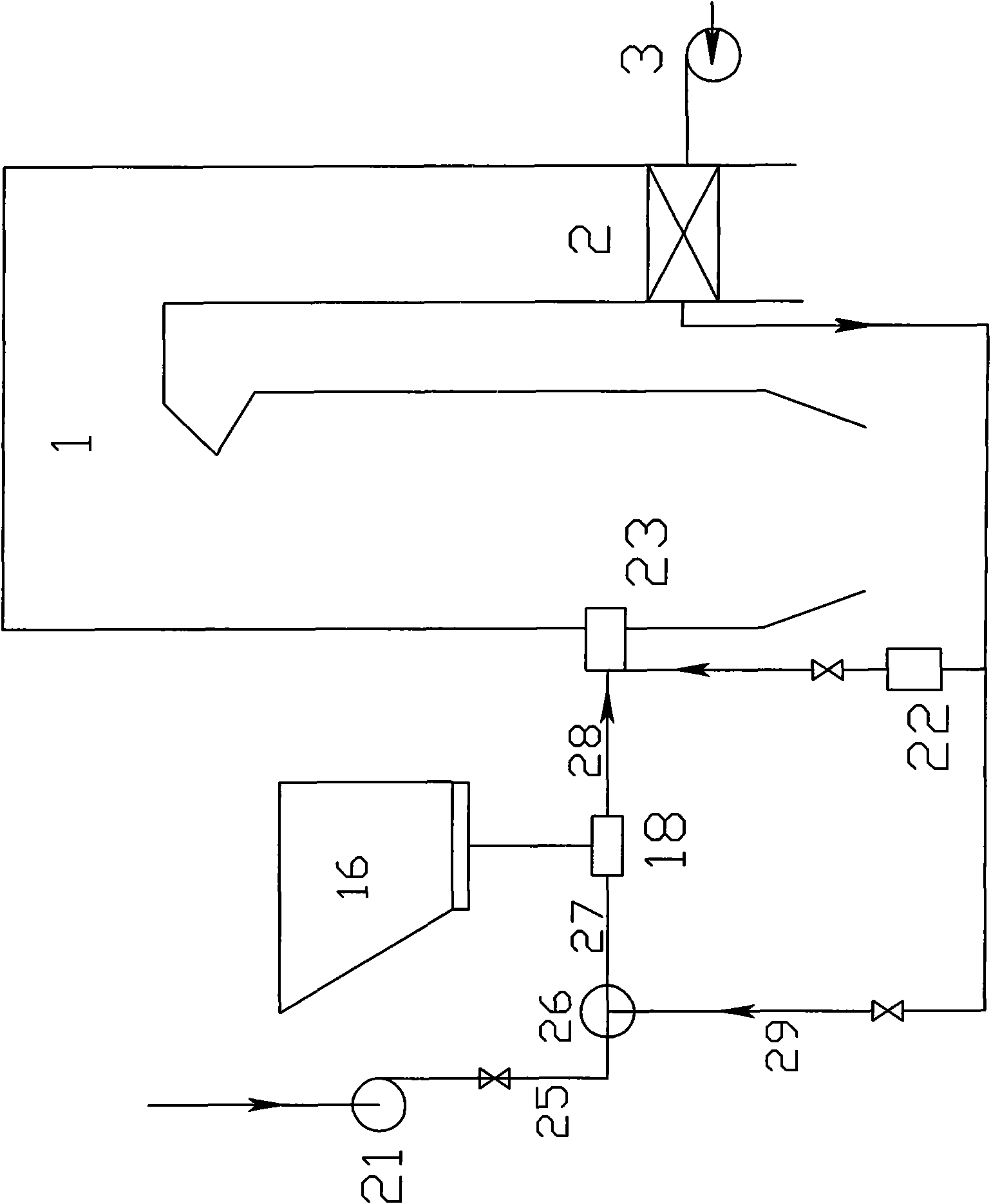

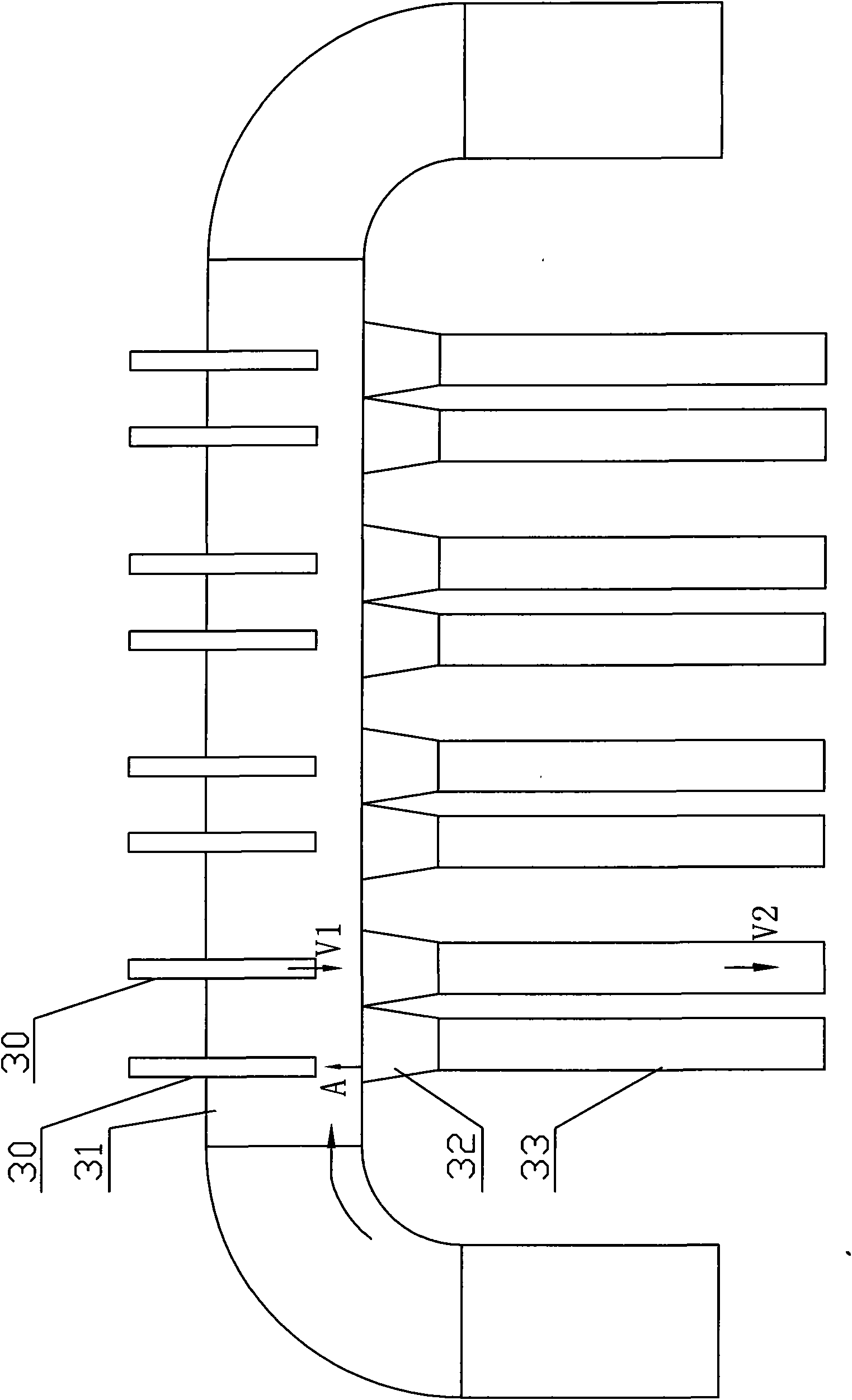

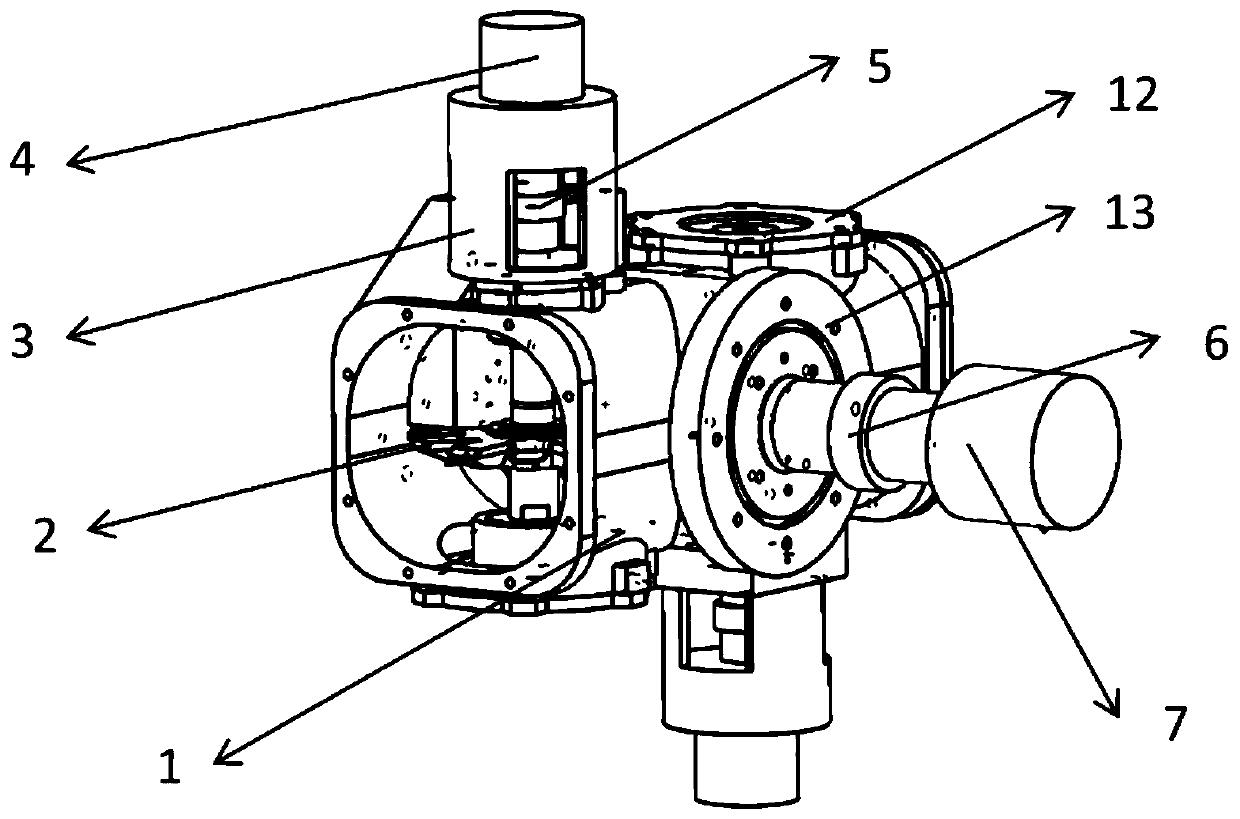

Hot air and exhaust gas double-medium powder delivery method and exhaust gas and hot air mixer

ActiveCN101596980AEmission reductionMeet the stability requirements of combustionBulk conveyorsLump/pulverulent fuel feeder/distributionEngineeringDelivery system

The invention provides a hot air and exhaust gas double-medium powder delivery method and an exhaust gas and hot air mixer and relates to a powder delivery method and a special exhaust gas and hot air mixer in the method, aiming at solving the problems that tertiary air in a hot air powder delivery system is not beneficial to the discharge reduction of NOx and the steady combustion of an exhaust gas powder delivery system boiler, and a primary air pipeline inlet and a valve thereof are severely abraded. Exhaust gas from an exhaust gas pipeline and hot air from a hot air pipeline are mixed and used as primary air together for delivering powder. A plurality of exhaust gas nozzles are dispersedly inserted on the side wall of an air distribution main pipe and communicated with the inner cavity of the air distribution main pipe, a plurality of round platform shape shrinkage pipes are positioned at the outside of the air distribution main pipe, the big ends of the round platform shape shrinkage pipes are respectively communicated with the inner cavity of the air distribution main pipe, and the small ends of the round platform shape shrinkage pipes are respectively communicated with one end of a plurality of mixed pipes. The invention obviously reduces the temperature of the primary air and the temperature of a main combustion area in a furnace, is beneficial to the discharge reduction of the NOx, meets the stability requirement of the combustion of the boiler and relieves the abrasion of the primary air pipeline inlet and the valve thereof.

Owner:HARBIN INST OF TECH

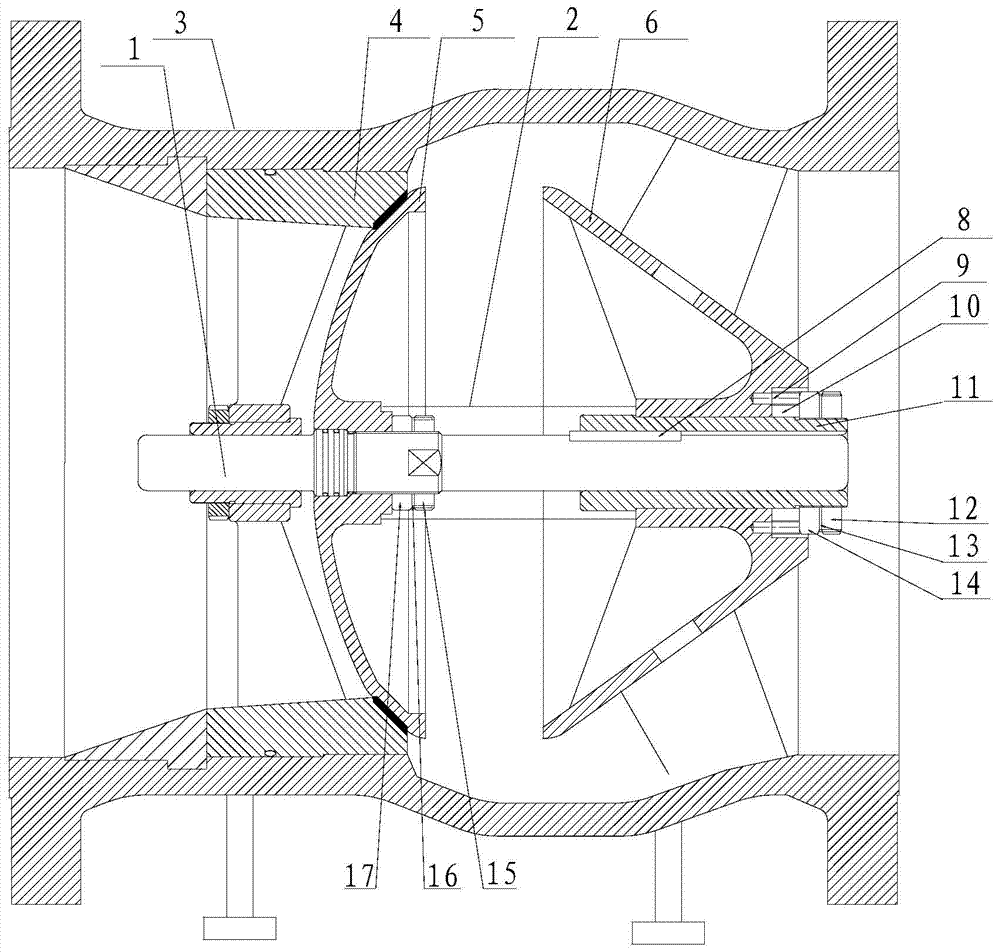

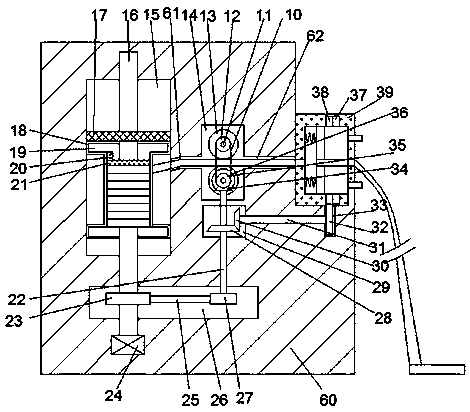

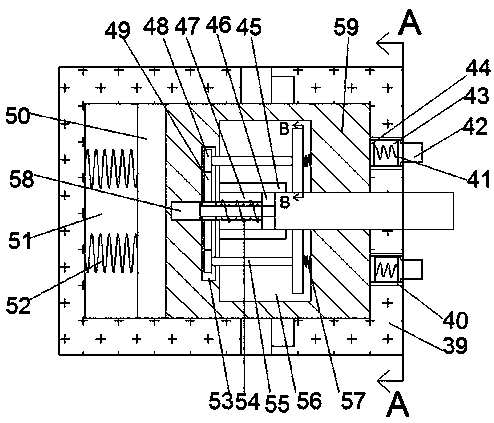

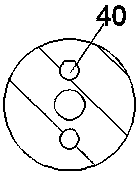

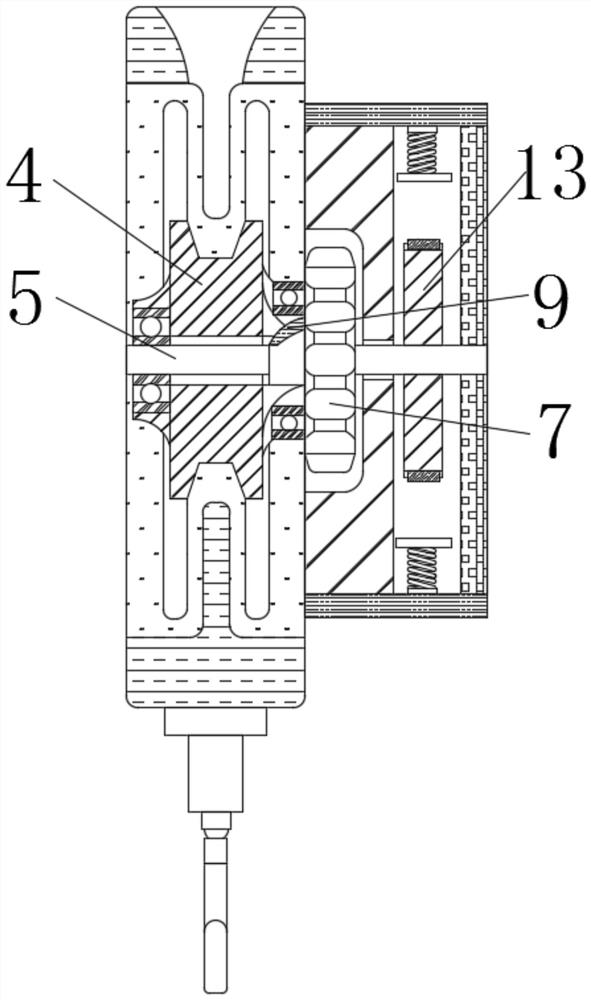

Axial-flow type check valve

ActiveCN104847932AInhibit sheddingAchieve absolute lockingCheck valvesLift valveEngineeringCheck valve

The invention discloses a valve structure, and particularly relates to an axial-flow type check valve. The axial-flow type check valve comprises a valve body, a valve rod, a valve seat, a valve clack, a valve sleeve, a bush, anti-falling locking nuts, thrust washers, closed locking nuts and a spring device. The anti-falling locking nuts comprise the first anti-falling locking nut and the second anti-falling locking nut. The thrust washers comprise the first thrust washer and the second thrust washer. The closed locking nuts comprise the first closed locking nut and the second closed locking nut. The axial-flow type check valve can achieve the effects that all the components of a valve element are prevented from falling and rotating and are resistant to vibrating and detachable, and the problems that the valve element of the axial-flow type check valve is prone to falling off and rotating, hard to maintain and the like are solved. Meanwhile, the use performance of valves of this kind is improved, and the service life of the valve is prolonged.

Owner:自贡新地佩尔阀门有限公司 +1

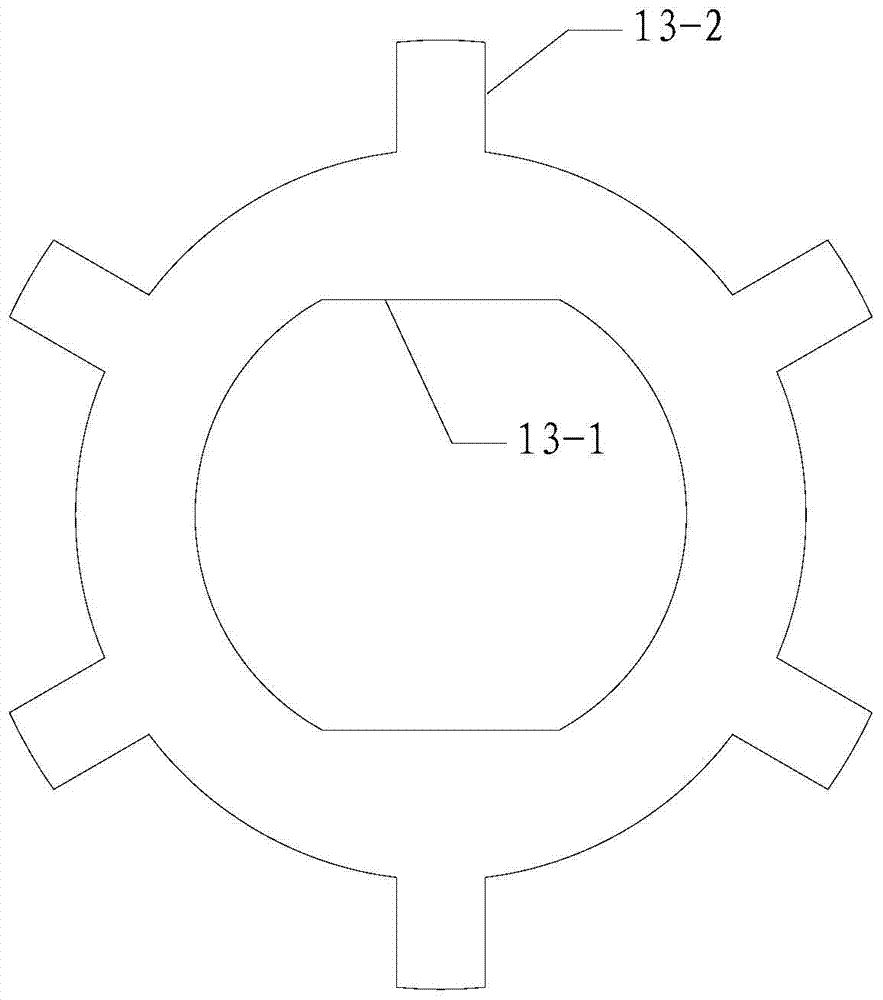

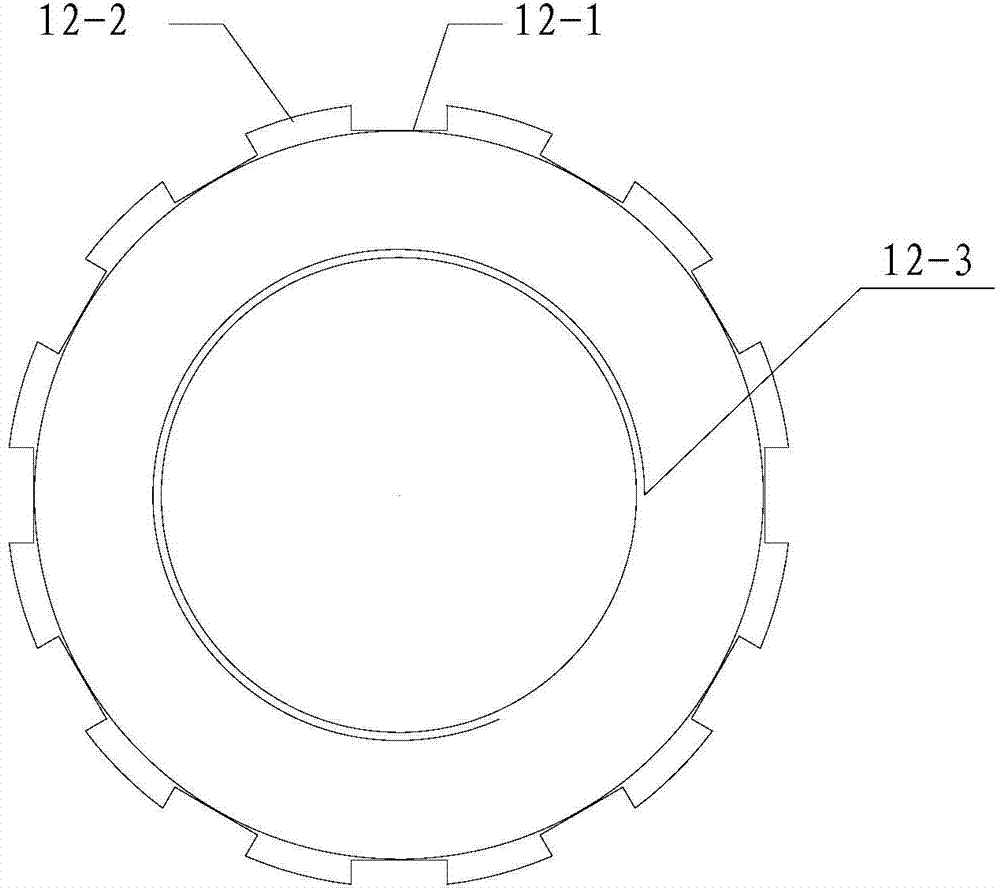

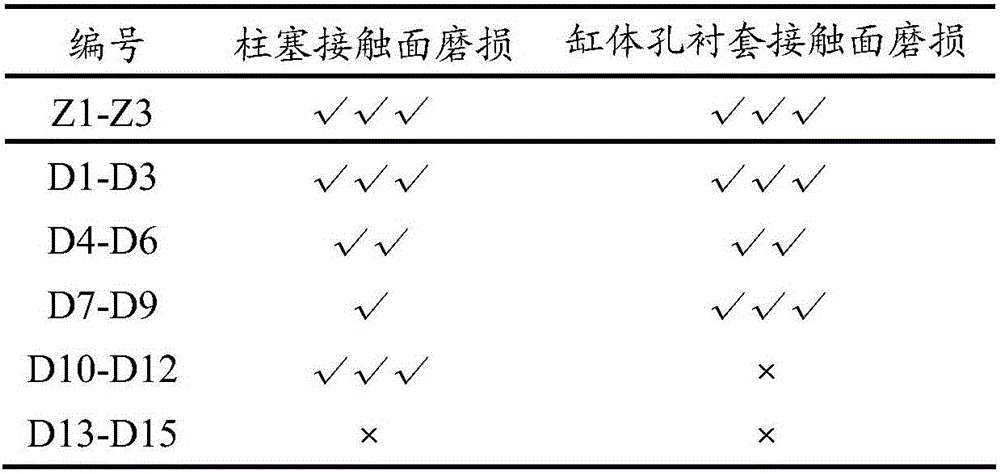

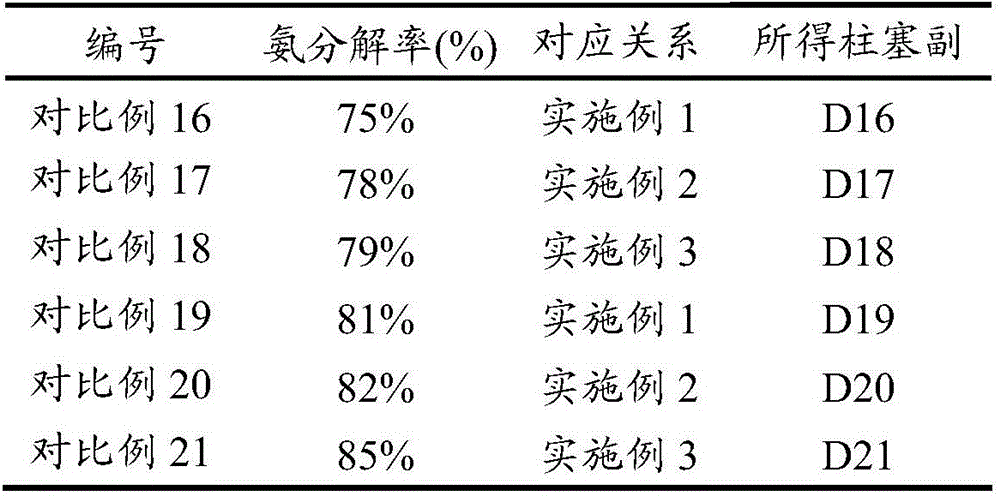

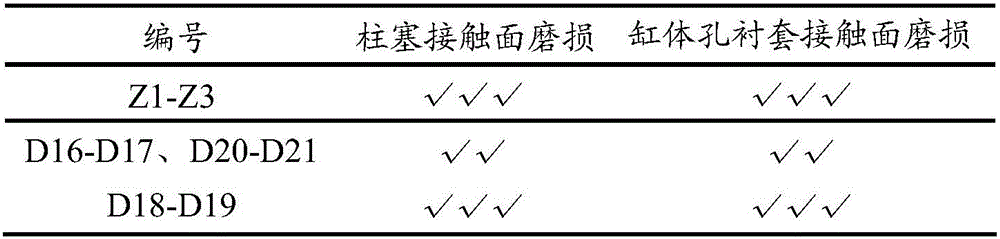

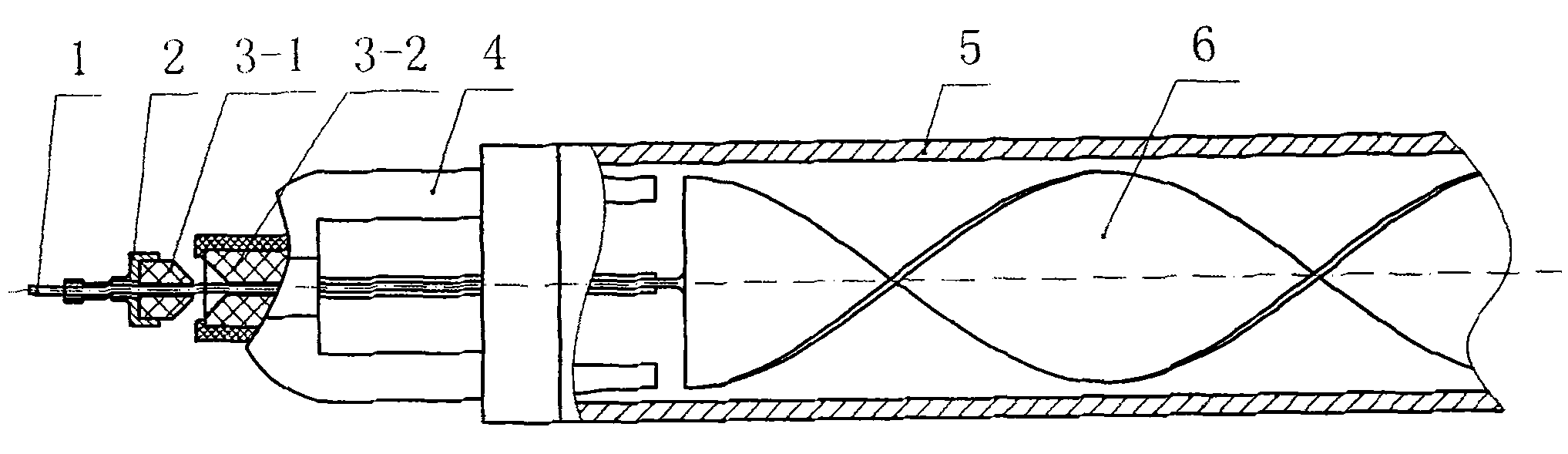

Method for manufacturing plunger pair for plunger pump

InactiveCN105714196AImprove fatigue strengthImprove fracture toughnessMolten spray coatingPositive displacement pump componentsEngineeringMechanical engineering

The invention relates to a method for manufacturing a plunger pair for a plunger pump. The method for manufacturing the plunger pair comprises the following steps that S1,a plunger is manufactured; S2, a cylinder body hole lining is manufactured; and S3, the plunger obtained in the S1 and the cylinder body hole lining obtained in the S2 are mounted in a matched manner, and therefore the plunger pair is obtained. The method for manufacturing the plunger pair can be used for manufacturing the plunger pair with the excellent wear-resisting performance through the unique manufacturing steps and unique compositional selecting of the plungers and the cylinder body hole lining, and the good application potentiality and industrialized production value are achieved.

Owner:FUXIN HAIPU HYDRAULIC MFG

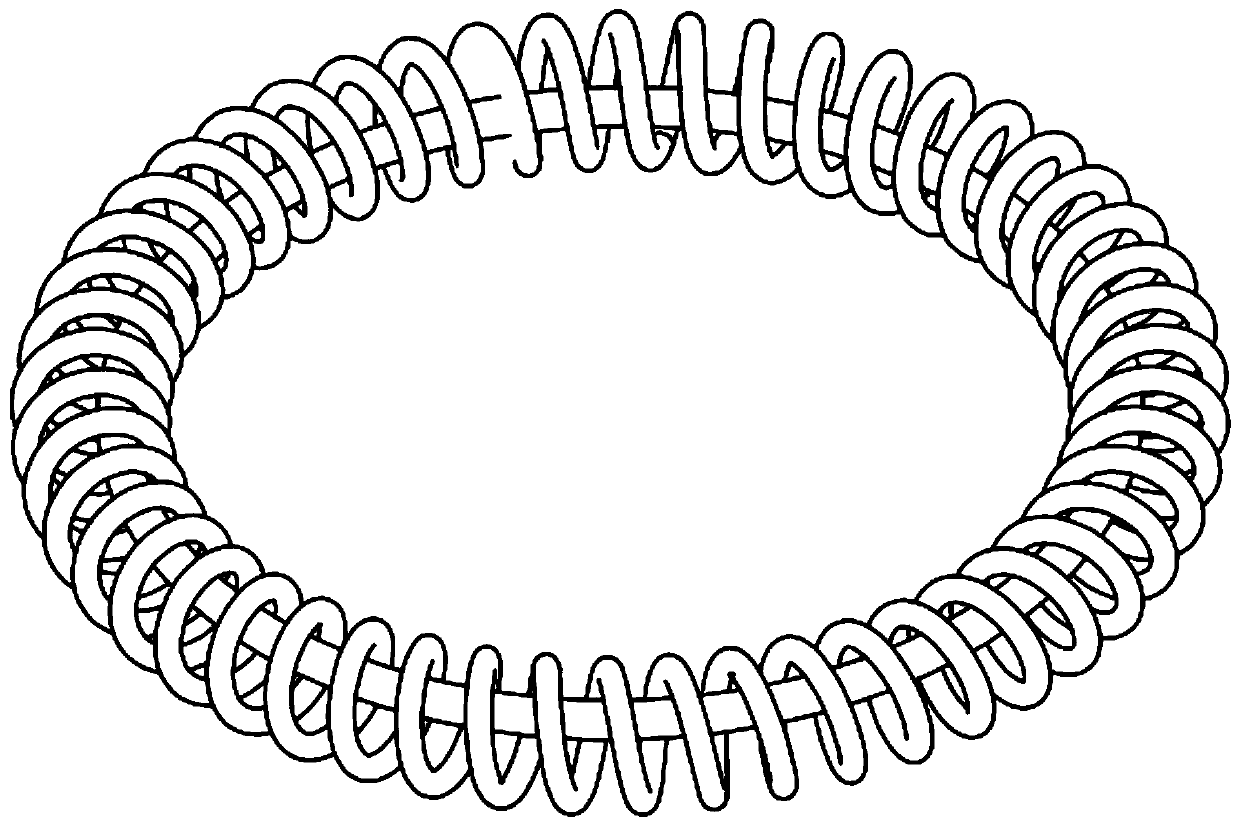

Self-cleaning enhanced heat-transfer magnetic suspension spiral twisted tape in heat-transfer tube

InactiveCN102032837ALow rotational resistanceSolve the problem of severe wear and tearRotary device cleaningScraping - actionEnhanced heat transfer

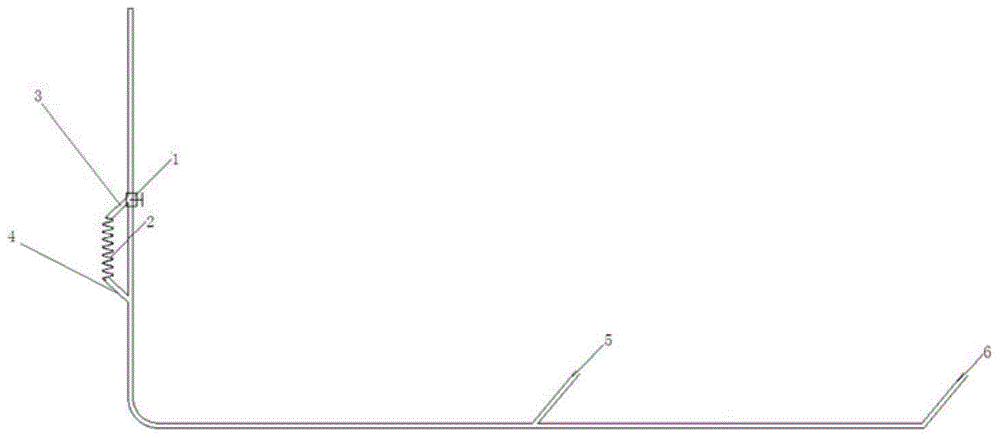

The invention relates to a magnetic suspension spiral twisted tape which comprises a spiral twisted tape and an axial locating device, wherein, the axial locating device is composed of a support frame and a magnet locating device; the magnet locating device is composed of a central conical magnet and an external conical sleeve magnet; the support frame is fixedly arranged on the liquid-inlet end of a heat-transfer tube; the external conical sleeve magnet is fixed with the support frame; the polarity of the central conical magnet is the same as that of the external conical sleeve magnet; one end of the spiral twisted tape is equipped with a pivot, and the pivot passes through the support frame and the external conical sleeve magnet; and the central conical magnet is fixed on the pivot. The magnetic suspension spiral twisted tape has the advantages that by adopting a magnetic suspension locating mode, the problem of severe wear caused by great contact force at a locating position of a liquid inlet is solved, and the service life of an axial locating element of the spiral twisted tape is prolonged; by utilizing a reinforced framework axis core, the strength of the spiral twisted tape can be enhanced; by means of a guide structure, the scraping action of the spiral twisted tape on a tube wall is reduced; and by means of a flow guide structure, fluid flow is further disturbed, the radial flow intensity and turbulent flow intensity of fluid are enhanced, and convective heat transfer is strengthened.

Owner:SINO ECO TECH

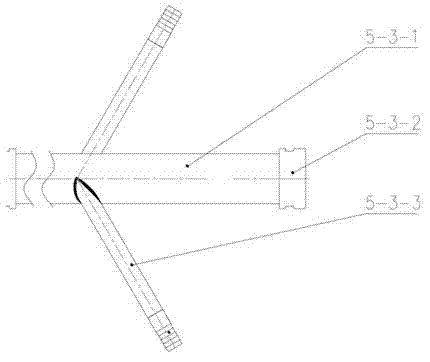

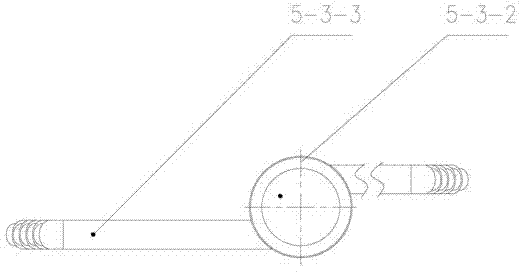

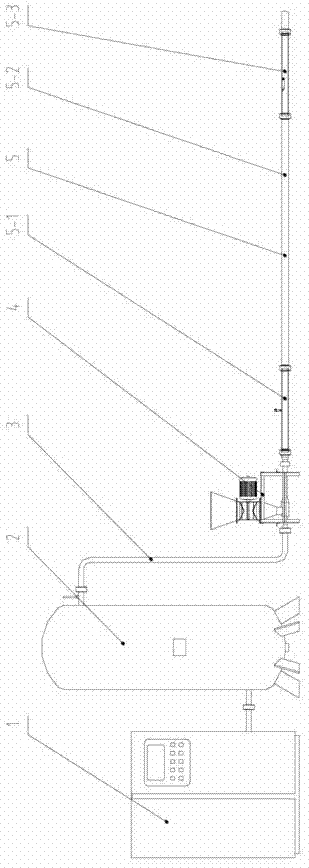

Method and equipment for pneumatically conveying and filling gangue in coal mine well

InactiveCN103321675AFlexible layoutSolve the large power consumptionMaterial fill-upUnderground transportMining engineeringAir compressor

The invention discloses a method and equipment for pneumatically conveying and filling gangue in a coal mine well. An air compressor, a gasholder, a high pressure air pipe, a feeding device and a pneumatic conveying pipe are combined and matched, and in the coal mine well, gangue material is conveyed to filling areas such as a goaf and coal areas under buildings, railways and water. Particles are uniformly distributed via a swirl generating tube, the axial velocity of the particles is increased by over 60 percent compared with that of a horizontal straight pipe, and the ability of a system to convey the particles of the gangue is greatly improved via the swirl generating tube; the particles are conveyed via a pipeline, the system is sealed, less dust floats and escapes, and the environment is protected; the pipeline for conveying can be flexibly arranged, equipment process and configuration are simplified, and problems of large power consumption and serious pipeline abrasion of the pneumatic conveying of the gangue in the coal mine well are solved. The equipment is simple in structure, convenient to operate and good in use effect.

Owner:CHINA UNIV OF MINING & TECH

Device for increasing resistance and regulating pressure in filling slurry pipeline transportation

InactiveCN104948224AFluid stabilityThere will be no problems such as subsidenceJoints with fluid cut-off meansMaterial fill-upSlurry pipelineLocal pressure

The invention relates to a device for increasing the transportation resistance of slurry in a filling pipeline in a small time line high pressure head mine filling system, and discloses a device for increasing the resistance and regulating the pressure in filling slurry pipeline transportation. The problem that the local pressure in filling slurry pipeline transportation is too large is solved in a mode of increasing the resistance loss of the slurry in the pipeline. The input end and the output end of the device for increasing the resistance and regulating the pressure are both connected to the pipeline for transporting the filling slurry, and the horizontal height of the input end of the device for increasing the resistance and regulating the pressure is larger than that of the output end of the device for increasing the resistance and regulating the pressure. The device is simple in technological process and convenient to install, and the flow state of mortar in the pipeline is stable.

Owner:UNIV OF SCI & TECH BEIJING

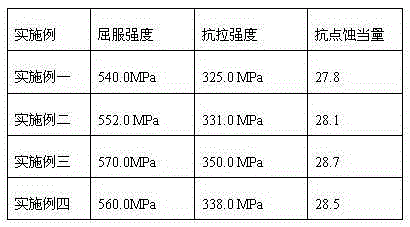

Multi-element low-alloy wear-resistant steel

The invention provides multi-element low-alloy wear-resistant steel, which relates to special multi-element low-alloy wear-resistant steel for manufacturing crusher hammer heads, in particular to multi-element low-alloy air-quench wear-resistant steel, namely 50SiMnCr2MoRe. In order to solve the problem of the severe wear of crusher hammer heads in the prior art, the multi-element low-alloy wear-resistant steel comprises the following element in percentage by weight: 0.46 to 0.52 percent of C, 0.8 to 1.0 percent of Si, 1.0 to 1.4 percent of Mn, less than or equal to 0.035 percent of P, less than or equal to 0.030 percent of S, 2.0 to 2.8 percent of Cr, 0.2 to 0.5 percent of Mo and 0.1 to 0.15 percent of Re, and the steel is manufactured through the following heat treatment of performing air quenching at 900 to 950 DEG C, tempering the obtained product to be between 250 and 300 DEG C, preserving heat for 3 hours and then naturally cooling the obtained product. As the multi-element low-alloy wear-resistant steel disclosed by the invention has high hardness and toughness, the lifespan of the crusher hammer heads manufactured from the steel is 5 times longer than common high-manganese wear-resistant steel, and the multi-element low-alloy wear-resistant steel contains no rare / noble elements and is low in price which is about two thirds of that of common high-manganese steel.

Owner:盂县社会福利高锰耐磨件厂

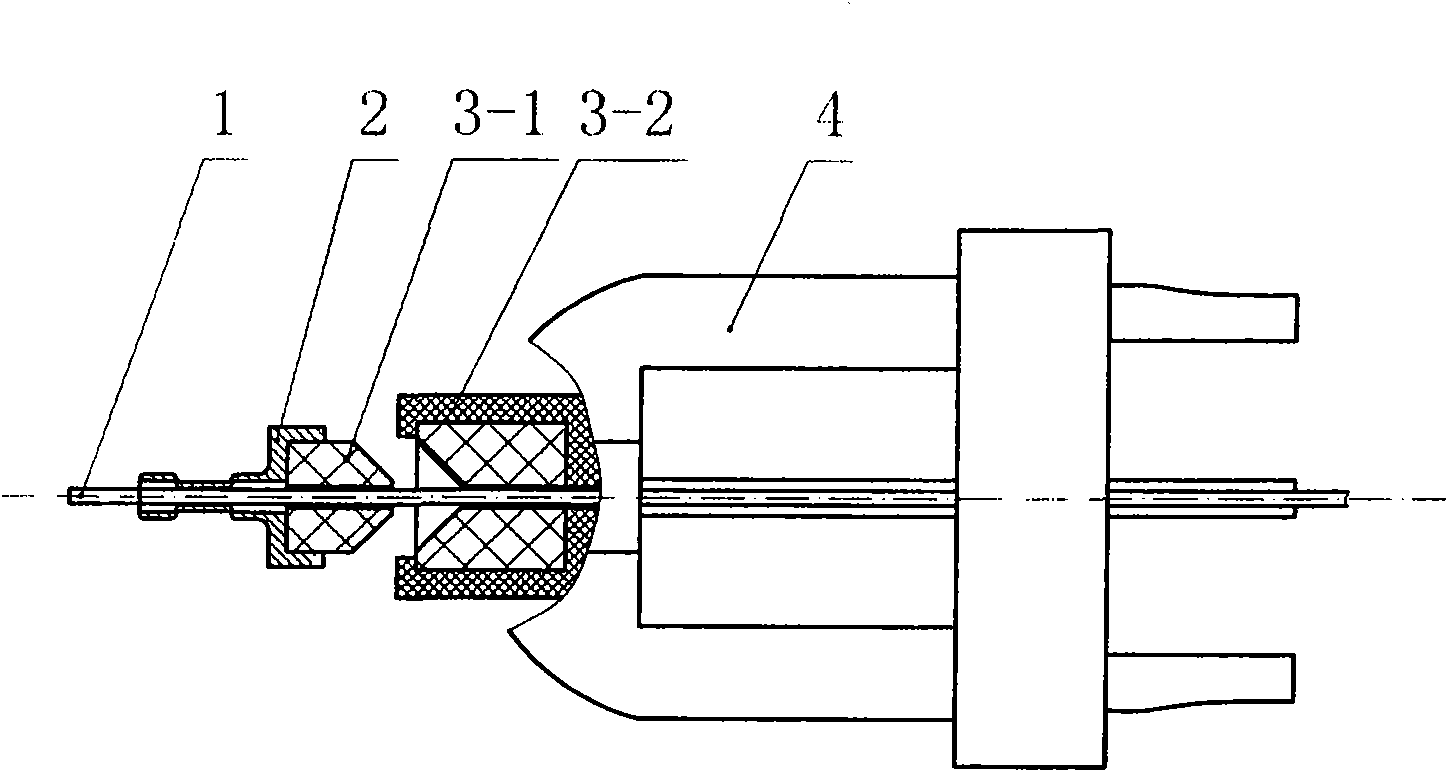

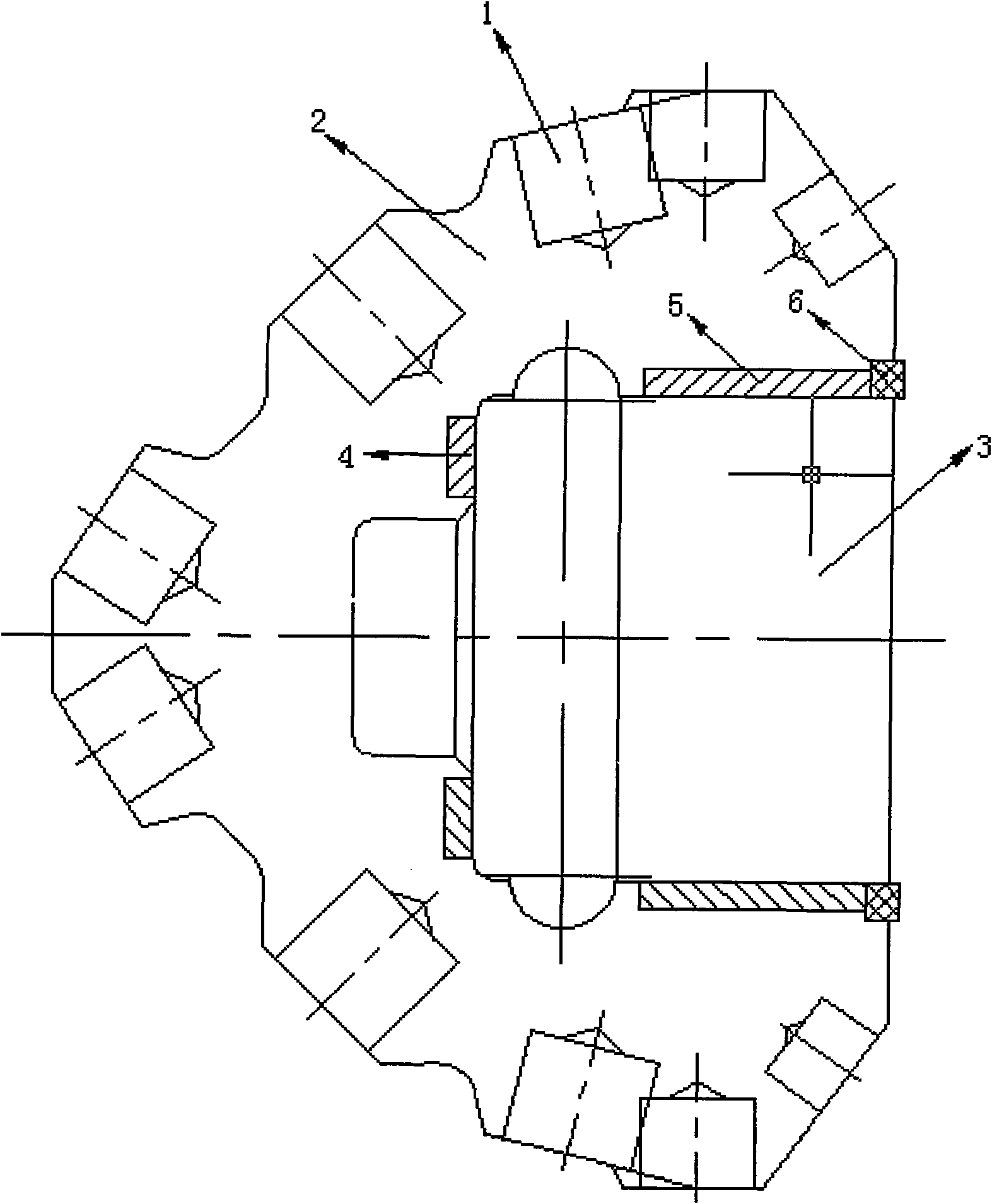

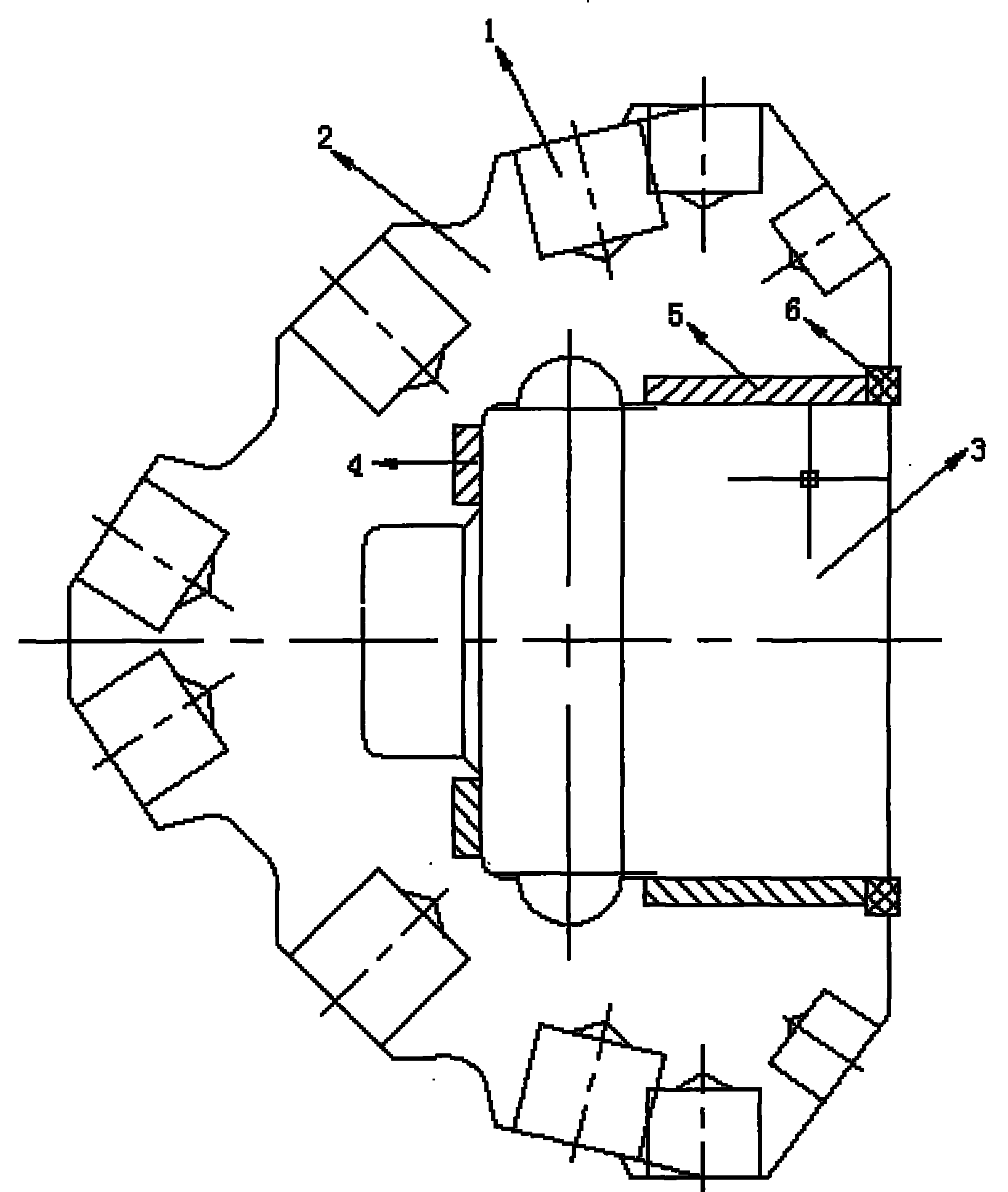

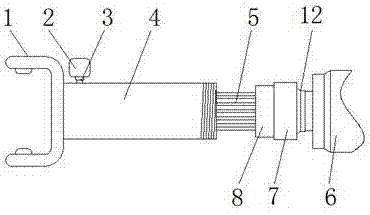

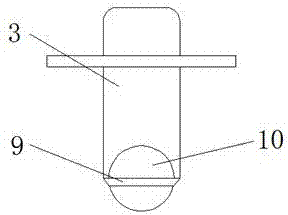

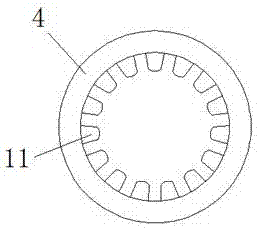

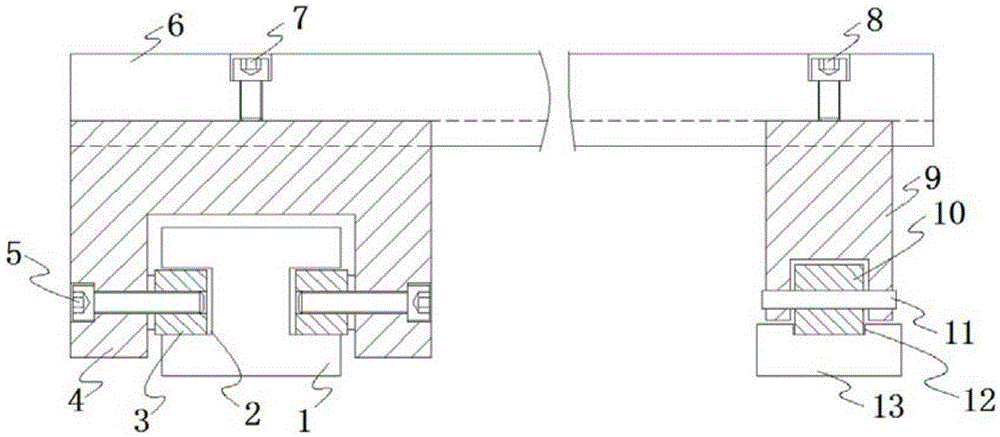

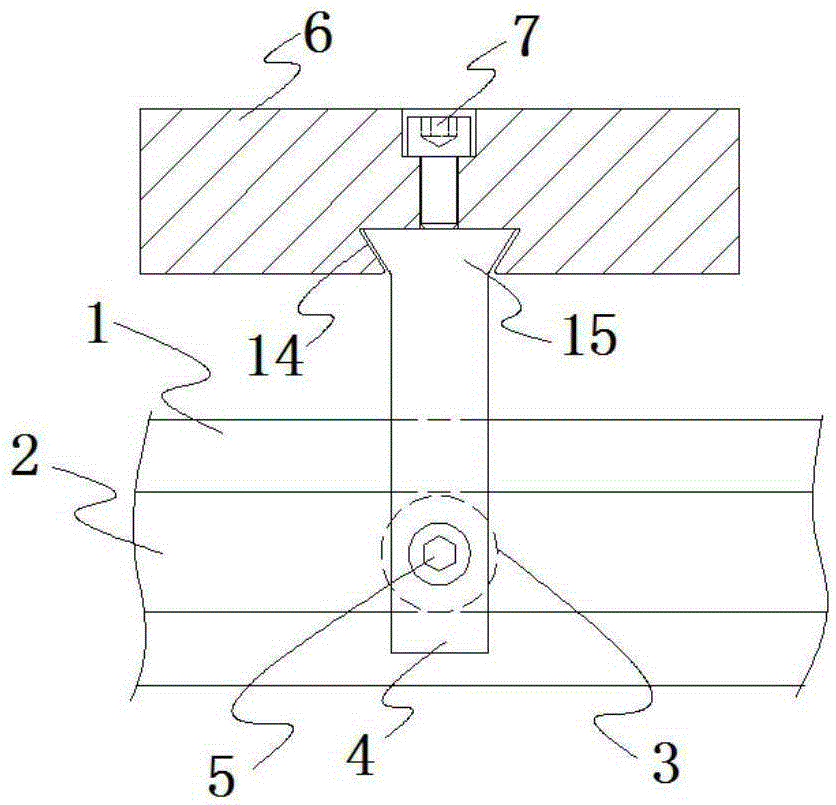

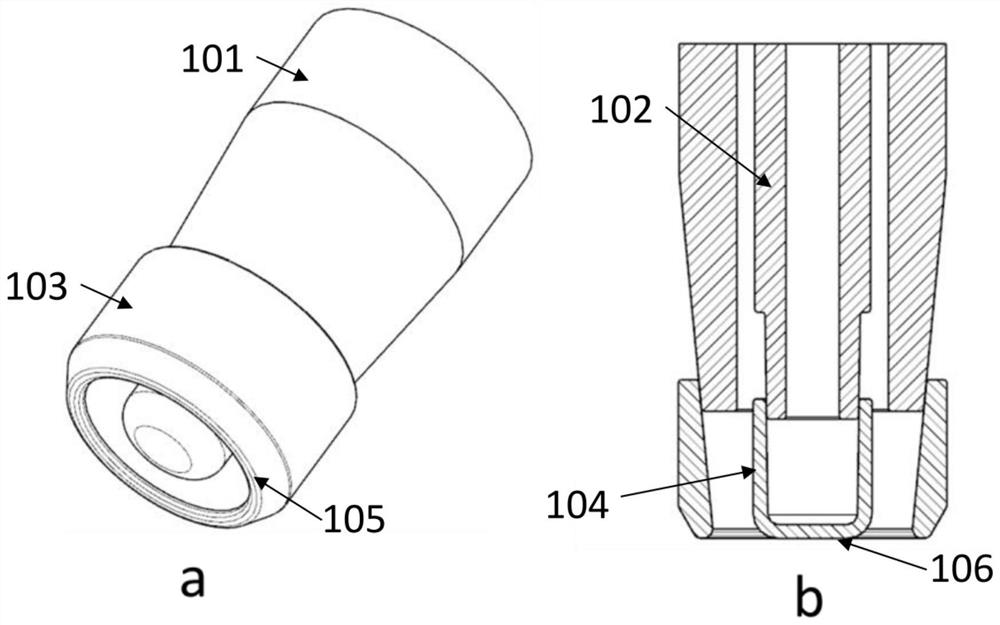

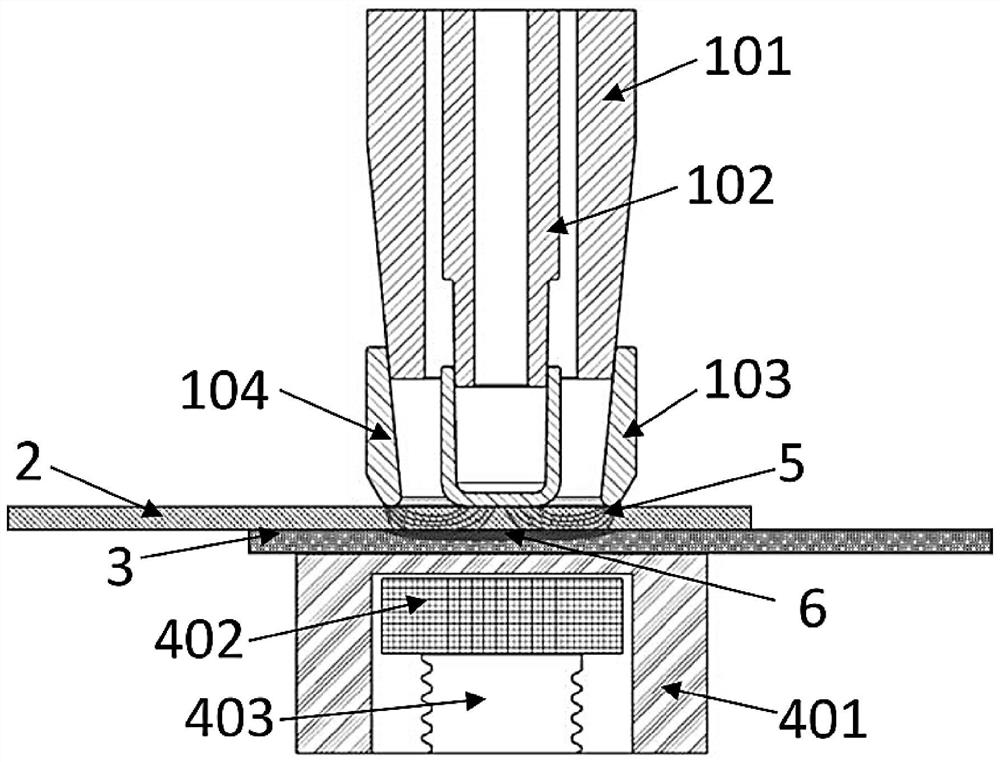

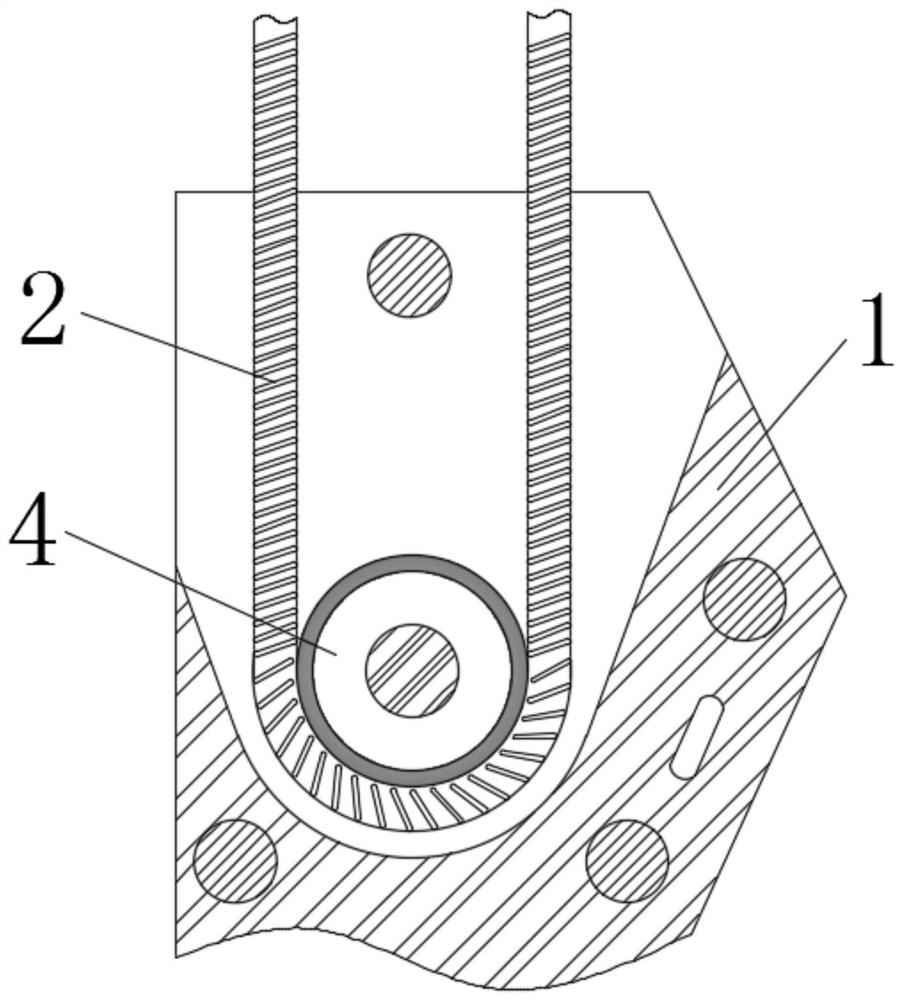

High-strength and wear-resistant roller bit

The invention discloses a high-strength and wear-resistant roller bit for petroleum and gas drilling. The roller bit comprises teeth (1), a roller cone (2) and a roller palm (3) and is characterized in that an embedded ring (4) is arranged at the internal bottom end of the roller cone (2), the embedded ring (4) and the roller cone (2) are connected in the compound manner of hot embedding, a bush (5) is arranged on the internal wall of the roller cone (2), the bush (5) and the roller cone (2) are connected in the compound manner of hot embedding, a compound seal ring (6) is hot embedded between the roller cone (2) and the outermost edge of the roller palm (3), the embedded ring (4) and the bush (5) are made from ceramic materials of carbide, nitride or oxide, and the seal ring (6) is made from cermets or the ceramic materials. Ceramics, cermets and the bit are skillfully combined into a whole, the ceramics and the cermets are not only utilized as connecting pieces, but also play the role of protecting the bit; high strength, wear resistance and corrosion resistance of the ceramics are displayed, and service life and reliability of bit parts are also ensured.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

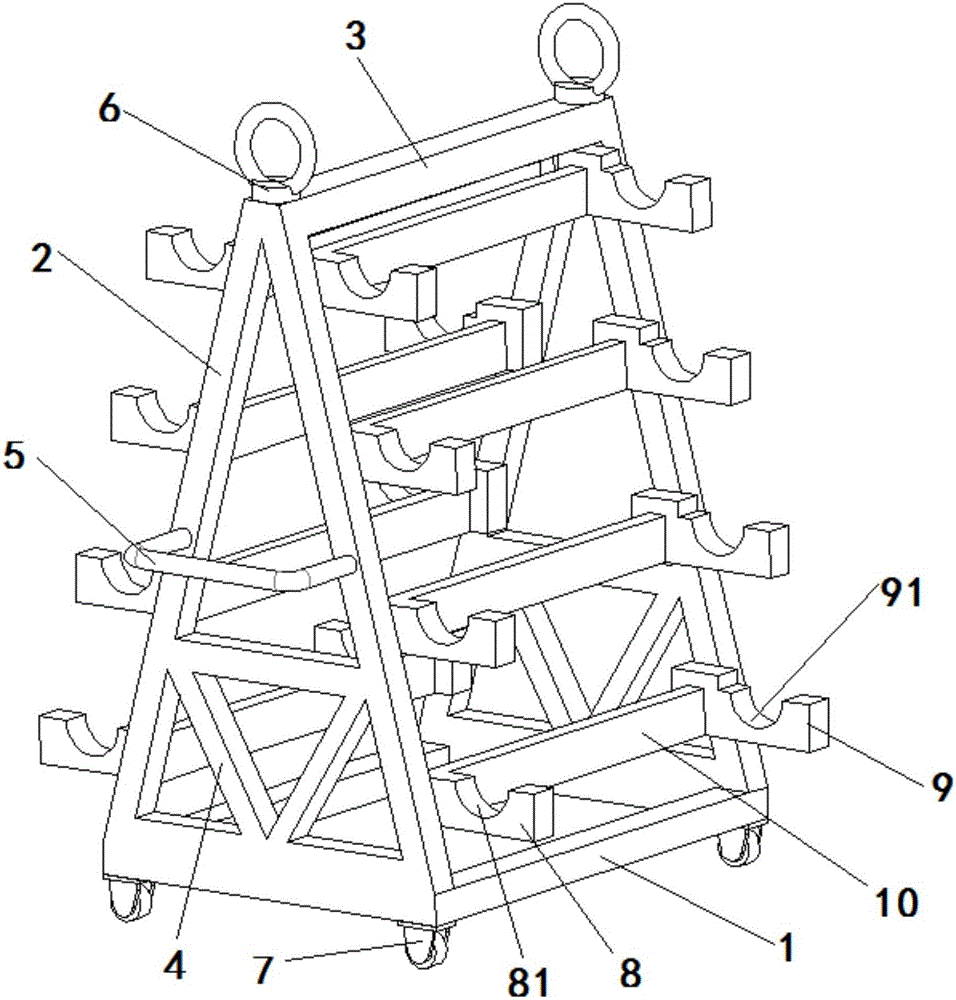

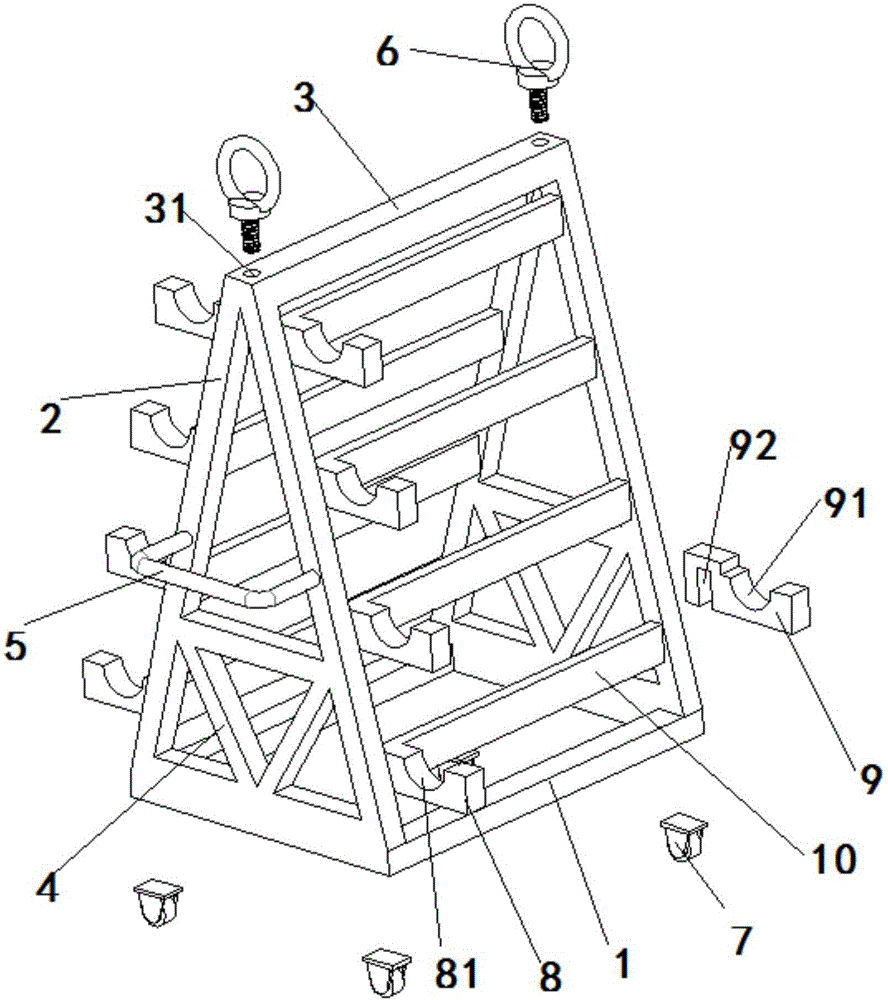

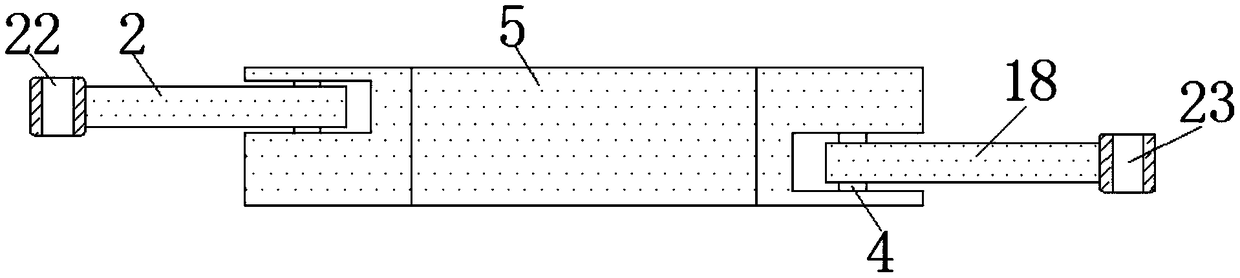

Engine crankshaft storage device

InactiveCN106378761AIncrease the number of placementsImprove protectionWork tools storageEngineeringSlide plate

The invention relates to an engine crankshaft storage device, comprising a base, support seats, a connecting plate, reinforcing ribs, a handle, a lifting ring, trundles, base plates and sliding plates; the herringbone support seats are vertically arranged at left and right sides of the square base, the positions of the support seats close to the bottom ends are provided with the triangular reinforcing ribs connected to the base, the top ends are provided with the connecting plate connected to both sides, threaded holes are arranged in left and right sides above the connecting plate, the lifting rings are disposed in the threaded holes, a plurality of fixing plates are vertically arranged between the left and right support seats, the base plates are horizontally fixed at one sides of the fixing plates, square grooves are arranged in the bottom ends of the left sides of the sliding plates, and the sliding plates are slidably mounted at the other sides of the fixing plates through the square grooves. The engine crankshaft storage device is simple in structure, low in manufacturing cost, more reliable in safety performance and higher in practicability and provides better protection for a crankshaft, an integral structural space of the device is effectively used, and a placing number of the device for the crankshaft is greatly increased.

Owner:周峰

Automatic cable winding and unwinding device for charging pile

InactiveCN111439146ASolve the crushingSolve the problem of severe wear and tearCharging stationsElectric vehicle charging technologyScrew threadBevel gear

The invention discloses an automatic cable winding and unwinding device for a charging pile. The automatic cable winding and unwinding device comprises a charging pile body, a winding cavity is formedin the left side of the charging pile body, a belt groove is formed in the lower side of the winding cavity, a moving groove is formed in the right side of the winding cavity, a bevel gear meshing groove is formed between the moving groove and the belt groove, a winding device is arranged in the winding cavity, the winding device comprises a winding screw rod which is in running fit with the wallbetween the belt groove and the winding cavity, the winding screw rod extends downwards into the winding cavity, and is in threaded connection with a threaded block. A rotating abutting block capableof abutting against a rotating block to rotate is fixedly connected to the inner wall of the left side of a winding space, the winding screw rod rotates to drive the threaded block, and the rotatingblock rotates to enable a winding wheel to ascend and rotate at the same time, so that the uniform winding function is achieved.

Owner:WENZHOU WEITING ELECTRONICS TECH CO LTD

Friction material, carbon ceramic brake pad formed through preparing of friction material and preparing method of carbon ceramic brake pad

InactiveCN107725648AIncrease temperatureReduce wearOther chemical processesBraking membersFailure causesSilicon dioxide

The invention belongs to the technical field of brake materials, and particularly relates to a friction material, a carbon ceramic brake pad formed through preparing of the friction material, and a preparing method of the carbon ceramic brake pad. The friction material comprises, by weight, 8-16 parts of carbon ceramic fiber, 1-6 parts of steel fiber, 3-12 parts of mineral fiber, 8-16 parts of chemigum modified phenolic resin, 5-11 parts of powder chemigum, 4-11 parts of petroleum coke, 9-22 parts of barium sulfate, 1-5 parts of polyacrylonitrile fiber, 6-16 parts of heavy magnesium oxide, 4-12 parts of kaolin and 2-8 parts of silicon dioxide. The above raw materials are mixed to form the mixture and placed into a die to be pressed and cured into a blank, the blank is heated and cured, andthe carbon ceramic brake pad is obtained. The brake pad has the beneficial effects of being small in abrasion thickness and long in service life; the tolerable temperature of the friction material ishigh, the problem of brake failures caused by the high brake pad temperature during frequent braking is solved, and the driving safety is ensured.

Owner:BEIJING TIANYISHANGJIA NEW MATERIAL

Main shaft for machine tool, machine tool, and method for preventing machine tool from being worn

The invention discloses a main shaft for a machine tool, the machine tool, and a method for preventing the machine tool from being worn. A radial air bearing of the main shaft for the machine tool is supported in a main shaft box body, one end of the radial air bearing is connected with the end face of an air floating shaft on the front end face, and the other end of the radial air bearing is connected with the end face of an air floating shaft on the rear end face; a piston is connected with an air floating main shaft; an air floating main shaft piston is connected with a guiding chuck; a side floating disc is connected with the air floating main shaft; the air floating main shaft piston, a taper sleeve and the guiding chuck are connected onto the air floating main shaft; gas is contained in the main shaft. The main shaft for the machine tool is utilized, so that the problem that the main shaft of machine tool equipment in the prior art is mainly mechanically supported by the bearing, and the mechanical wear is severe can be solved; the occurrence of the phenomenon that the rotation stability of the main shaft gets worse along with the increase of processing time can be effectively prevented; the precision machining accuracy and the yield of the product are improved; the production efficiency is further improved remarkably and the production cost is reduced.

Owner:BEIJING HIGH PRECISION TECH DEV

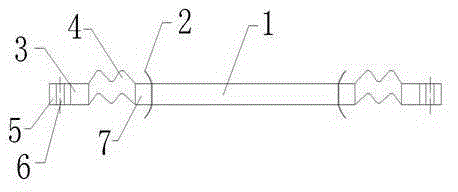

Self-lubricating car transmission shaft

InactiveCN107387584AAchieve lubricationSolve the problem of severe wear and tearYielding couplingRelative displacementUniversal joint

The invention discloses a self-lubricating car transmission shaft. The self-lubricating car transmission shaft comprises a stretchable sleeve, a universal joint fork is arranged at one end of the stretchable sleeve, a sliding spline groove is embedded inside the other end of the stretchable sleeve, an oil sealing ring is arranged at the end, far away from the stretchable sleeve, of the sliding spline groove, an oil sealing cover is arranged on the side, far away from the sliding spline groove, of the oil sealing ring, and a transmission shaft pipe is arranged at the axis position of the side, far away from the oil sealing ring, of the oil sealing cover; a steel ball holder is arranged at the end, located inside the stretchable sleeve, of a lubricating nipple, steel balls are fixed to the steel ball holder and are in contact with the sliding spline groove, a lubricating oil storage tank is arranged above the lubricating nipple, the steel balls are driven to rotate when the sliding spline groove and the stretchable sleeve have relative displacement, and lubricating oil inside the lubricating oil storage tank is brought into the stretchable sleeve; and the lubricating effect on the sliding spline groove and spline teeth is achieved automatically, and the problem that abrasion of the sliding spline groove and the spline teeth is serious due to the fact that the stretchable sleeve is lack of lubricating oil is solved.

Owner:陈九凤

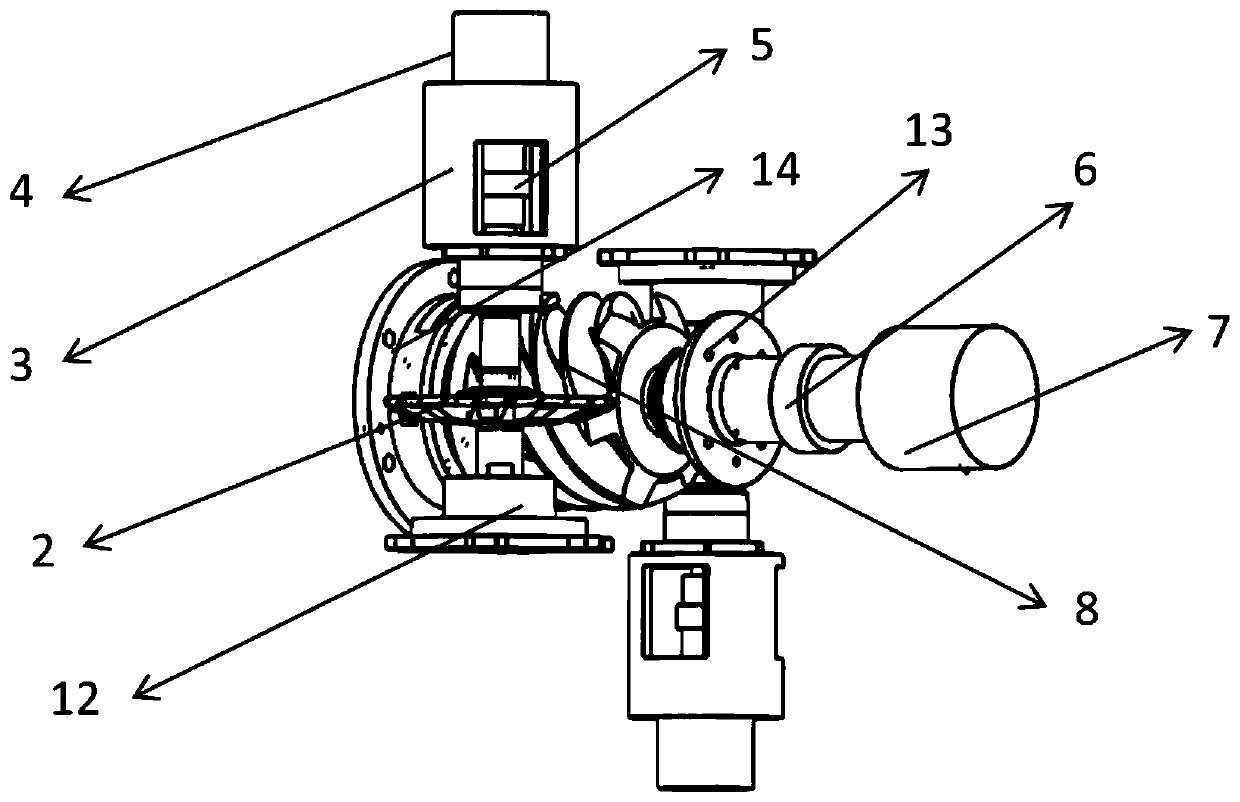

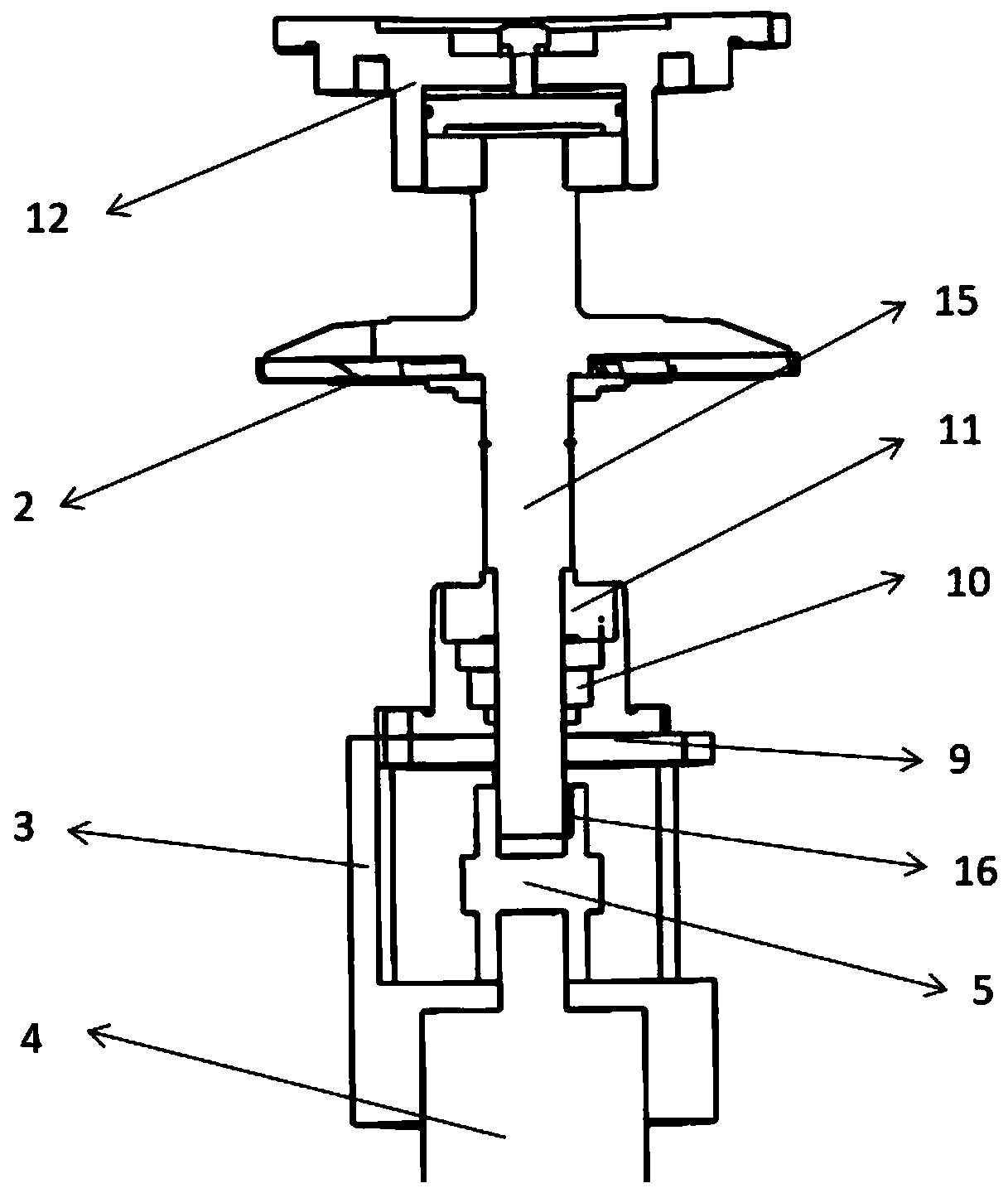

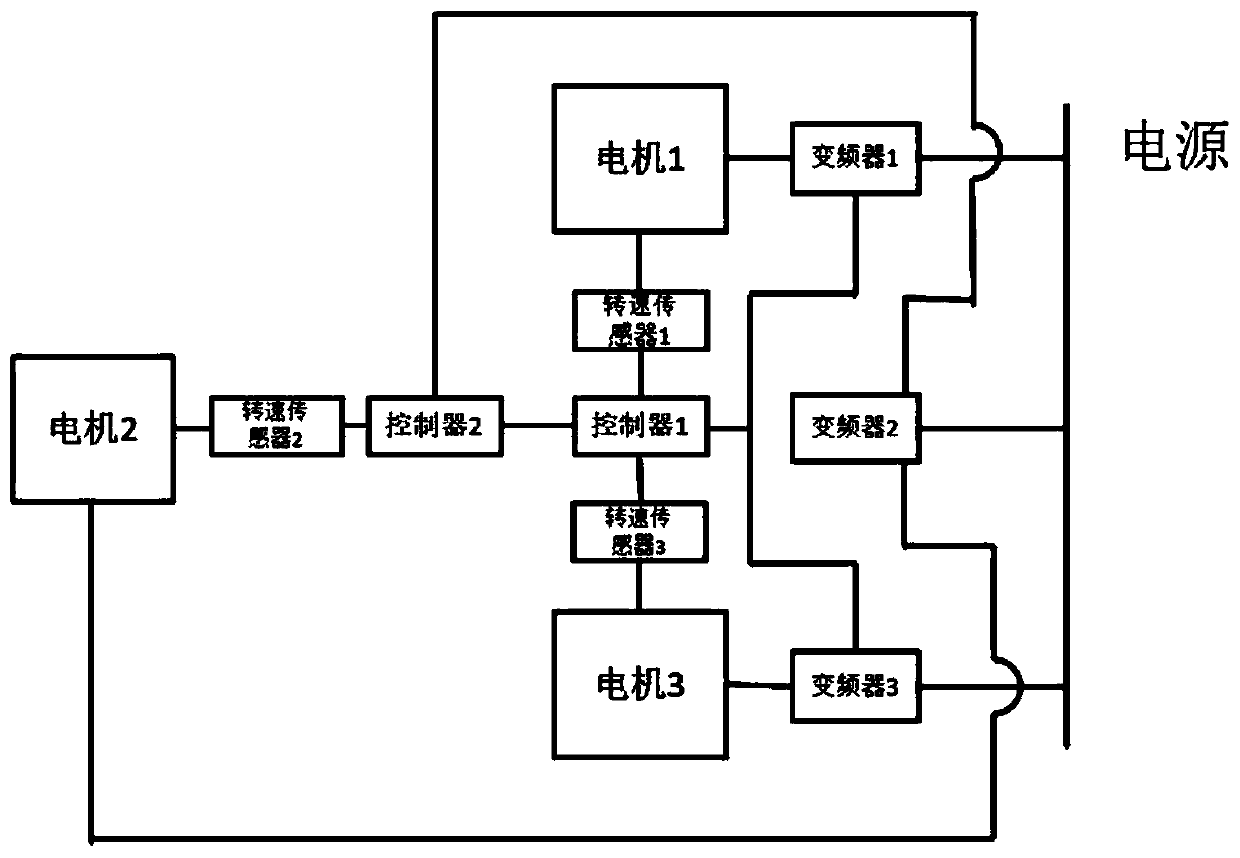

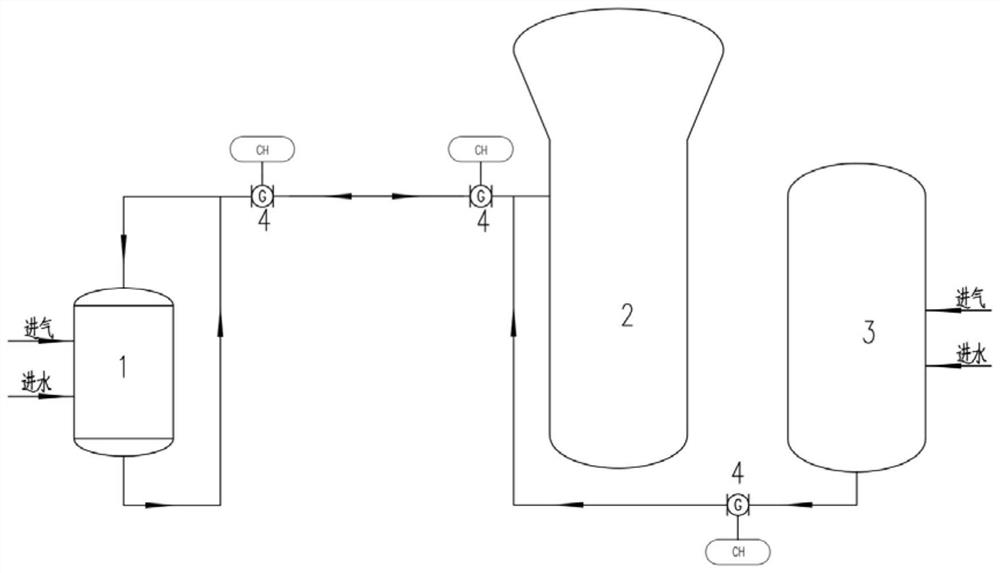

Three-motor driven single-screw compressor

InactiveCN110219802AChange pressure ratioSolve the problem of severe wear and tearRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsFrequency changerMotor drive

The invention discloses a three-motor driven single-screw compressor. The three-motor driven single-screw compressor comprises a screw arranged in a machine shell and two star wheels symmetrically arranged on the two sides of the screw. The screw and the two star wheels are independently connected with three motors through couplers, the three motors are connected with a power source, and the rotating speeds of the motors can be controlled through a frequency converter. The frequency converter is provided with a controller, the rotating speed ratio is set in the controller, and the set frequency is set in the frequency converter. The screw and the star wheels rotate synchronously and do not make contact with one another, and a sealed air cavity is formed by a screw groove of the screw, theinner wall of the machine shell and teeth of the star wheels. The machine shell is provided with a gas inlet and a gas outlet, gas enters the screw groove from the gas inlet through a gas suction cavity, when the teeth of the star wheels move relatively in the screw groove, the volume of the sealed gas cavity is gradually reduced, gas is compressed, and the compressed gas is discharged from the gas outlet through a gas outlet cavity. By means of the three-motor driven single-screw compressor, the star wheel abrasion problem of a single-screw compressor can be solved, the rotating speed of thescrew rod and the star wheels is adjusted, stepless variable-flow adjustment can be achieved, and the pressure ratio of the compressor is changed.

Owner:XI AN JIAOTONG UNIV

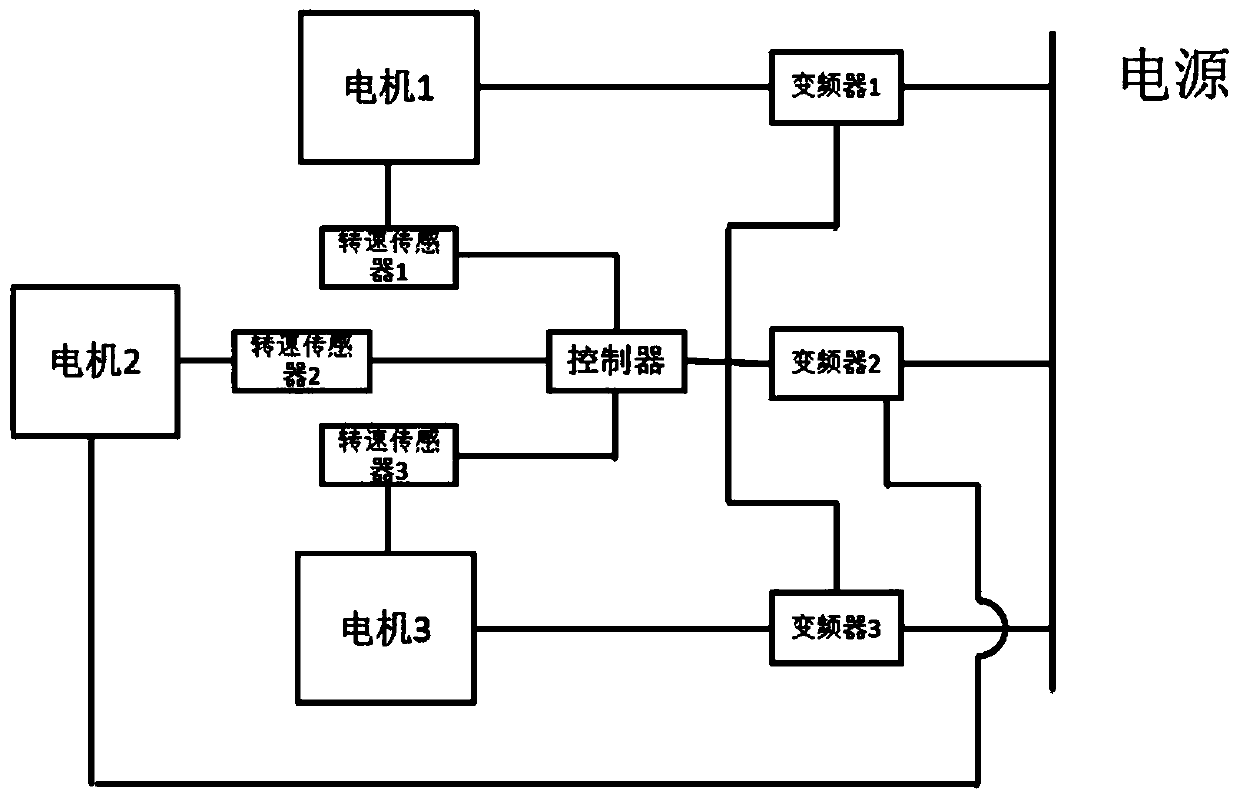

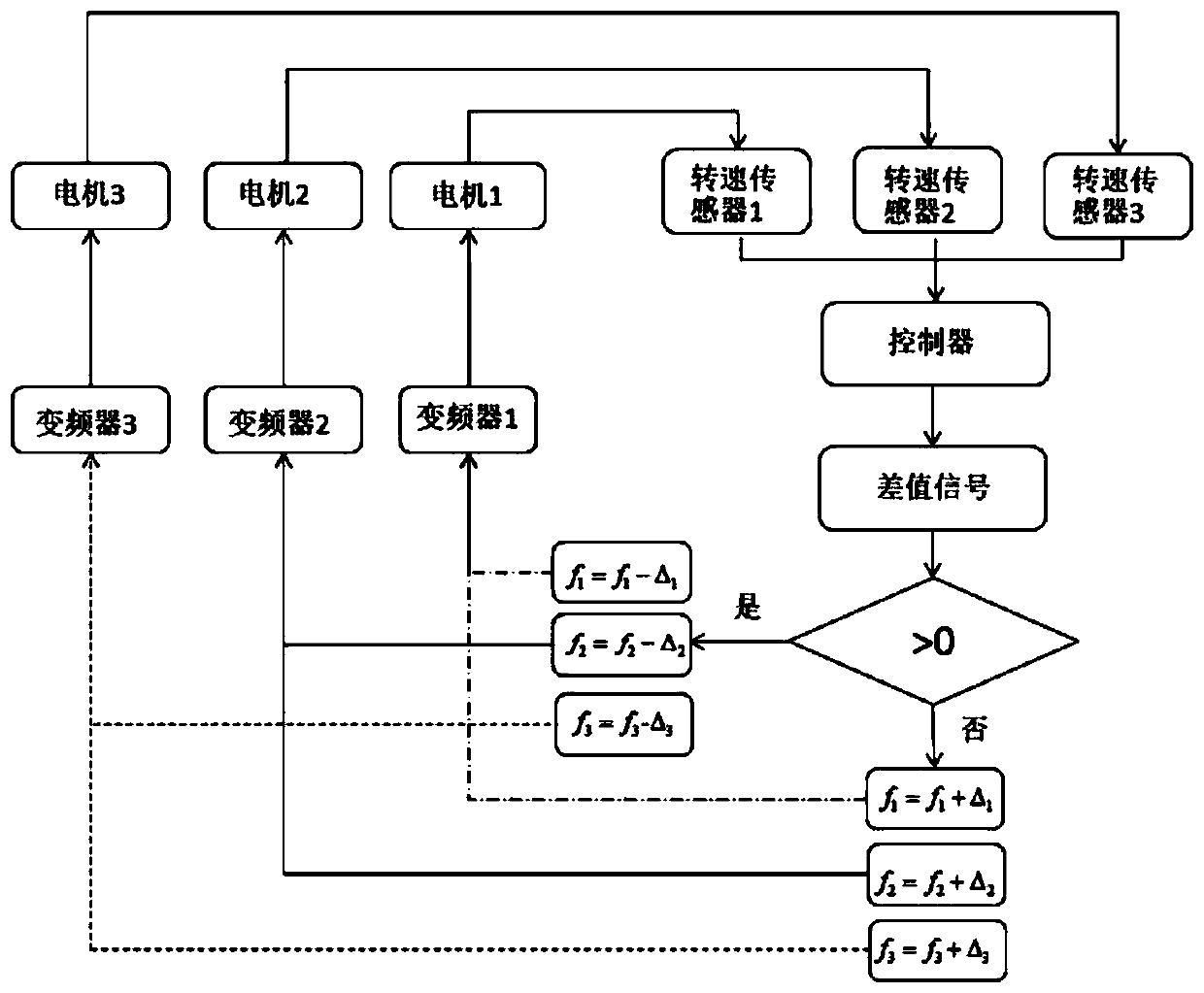

Three motor driven single-screw compressor control method

InactiveCN110195703ASolve the problem of severe wear and tearEasy to controlMachines/enginesPump controlFrequency changerMotor drive

The invention discloses a three motor driven single-screw compressor control method. The method includes the following steps that firstly, a screw rod is arranged in a machine shell, two star wheels are symmetrically arranged on the two sides of the screw rod, the screw rod and the two star wheels are independently connected with three motors through couplers correspondingly, the rotating speeds of the three motors are controlled through frequency converters, and the frequency converters are connected with a controller; and secondly, rotating speed sensors are used for measuring the real-timerotating speed of the three motors, rotating speed signals of the three rotating speed sensors are analyzed through the controller, the rotating speed is set in the controller, the difference value ofthe rotating speed signals of the three motors is analyzed according to the controller, increasing or decreasing of the frequency of the frequency converters is controlled according to difference value signals, then the rotating speeds of the three motors are controlled, and synchronous rotation of the three motors is achieved. By means of the three motor driven single-screw compressor control method, flow of a single-screw compressor can be adjusted, stepless variable-flow adjustment is achieved, the compression ratio of the single-screw compressor can also be changed, the control process issimple and convenient, and the control effect is reliable.

Owner:XI AN JIAOTONG UNIV

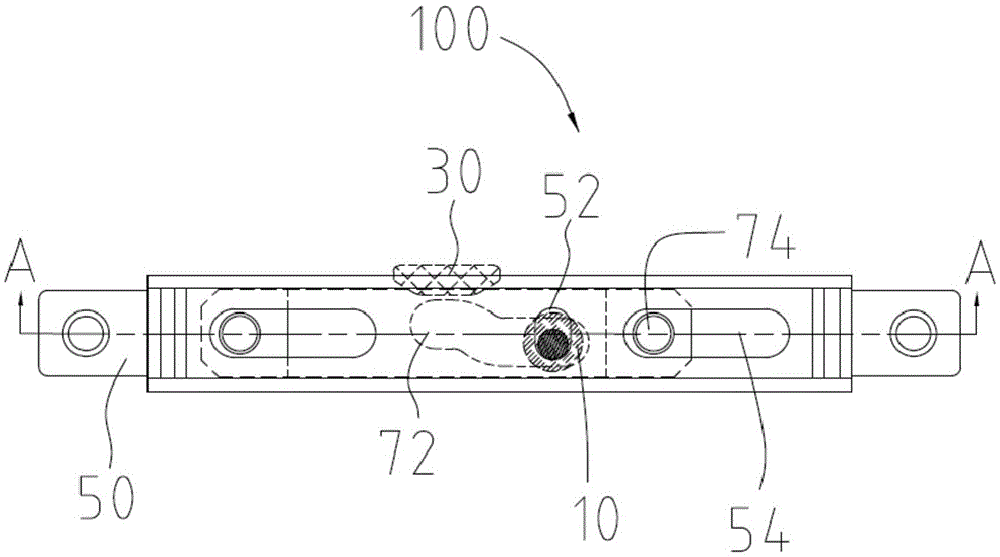

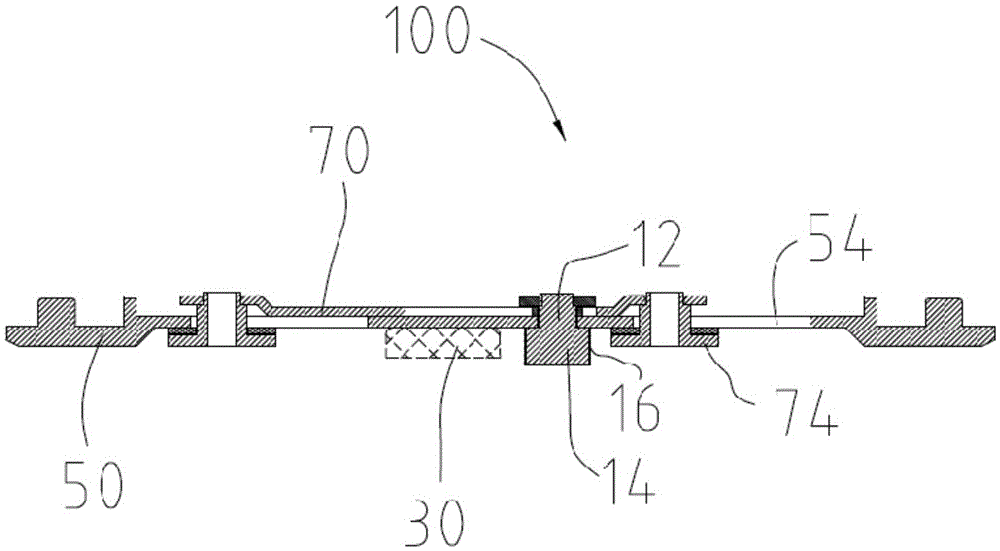

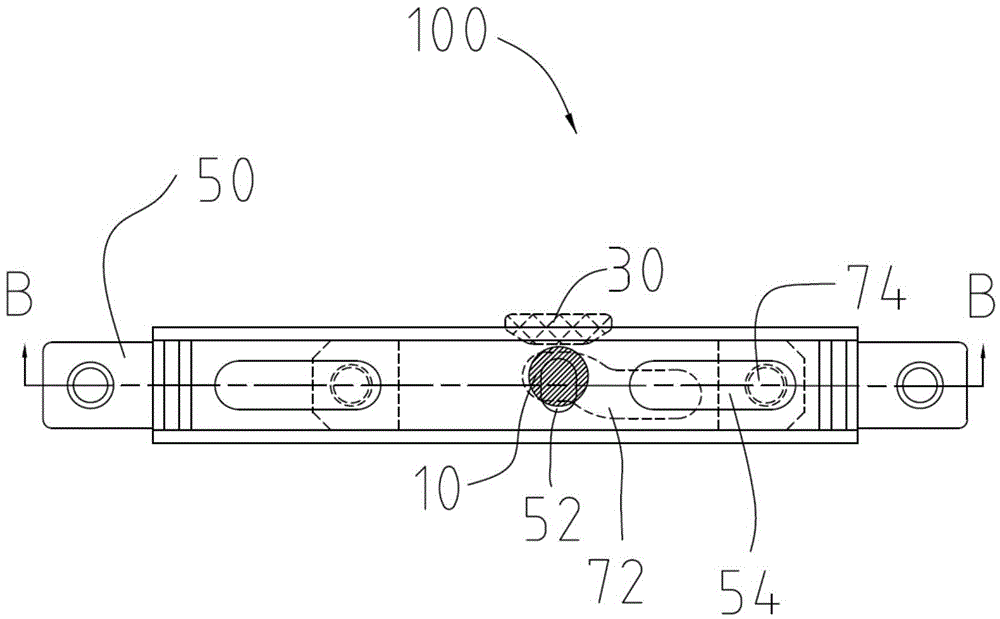

Locking device

Owner:LIP HING YEUNGS IND SHENZHEN

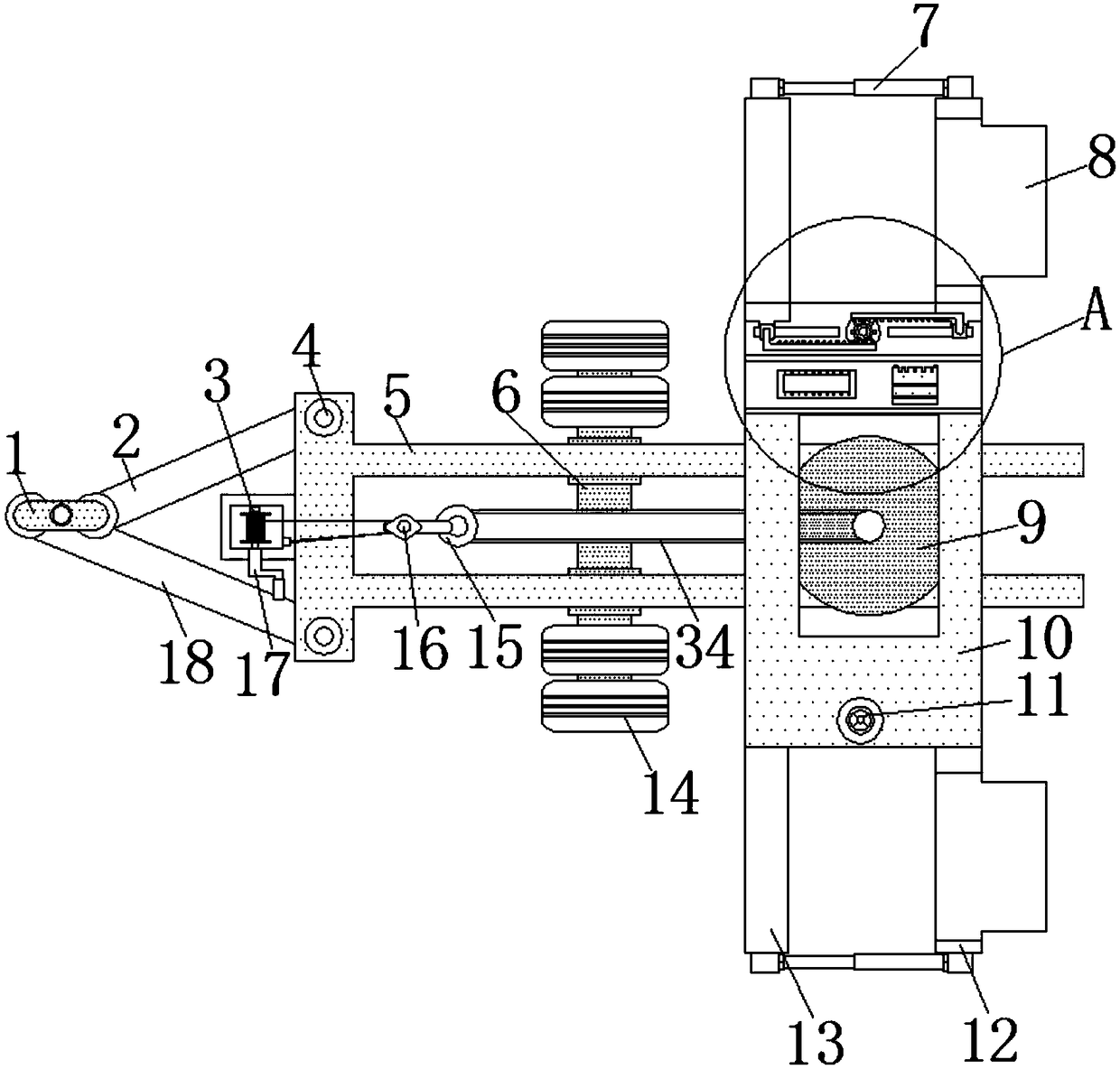

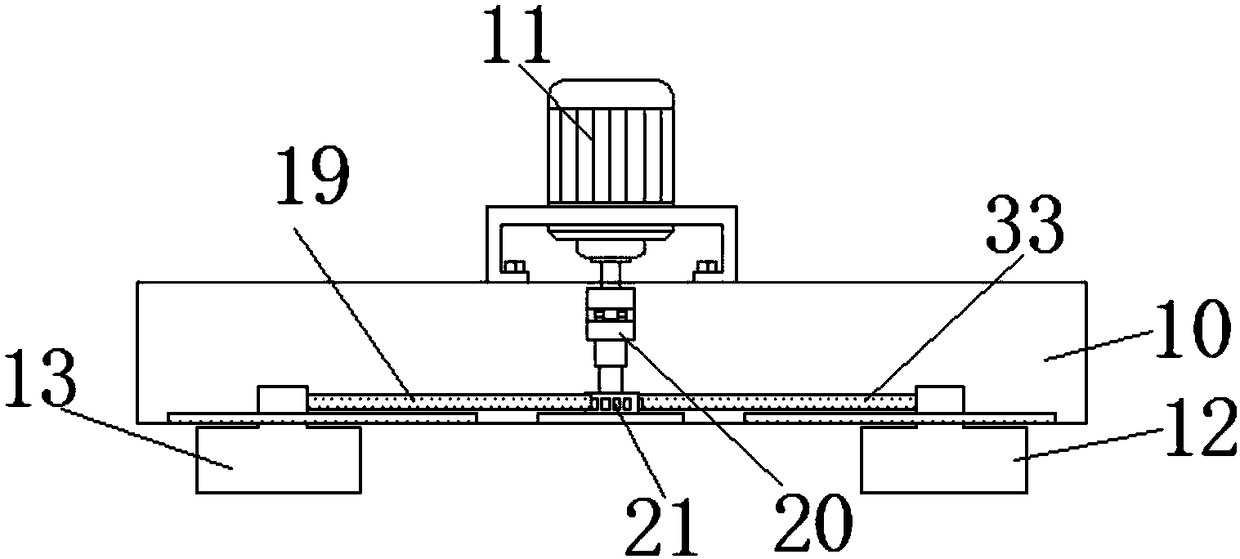

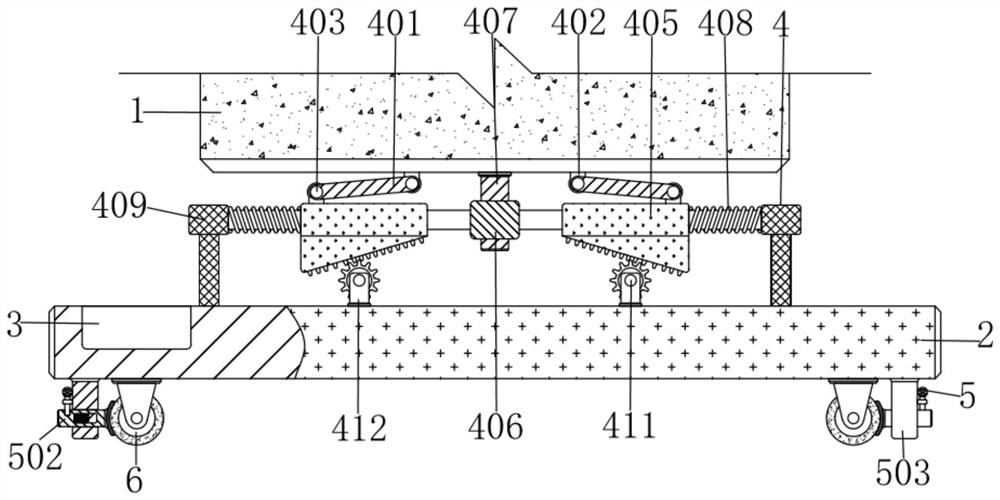

Guide rail auxiliary device for textile printing machine

InactiveCN105328990ASolve the problem of severe wear and tearFulfil requirementsRotary pressesTextile printerEngineering

The invention relates to the technical field of textile, in particular to a guide rail auxiliary device for a textile printing machine. The guide rail auxiliary device solves the problems that guide rails and roller wheels are easy to wear, and vibration noises of a trolley base are great. The guide rail auxiliary device structurally comprises a rectangular trolley base, wherein a primary guide rail device is arranged below one end of the trolley base; a secondary guide rail is arranged below the other end of the trolley base; the primary guide rail device comprises a primary guide rail, a primary roller wheel, a first fastening bolt and a primary bracket; the secondary guide rail device comprises a secondary guide rail, a secondary roller wheel, a rotary shaft and a secondary bracket; the top end of the primary bracket is provided with a positioning boss which is fitted with a positioning groove in the bottom of the trolley base; and the top end of the secondary bracket is provided with a positioning boss which is fitted with the positioning groove in the bottom of the trolley base. The guide rail auxiliary device for the textile printing machine is simple to operate and convenient in use, and the working efficiency is improved.

Owner:SUZHOU BUWU JIAXIANG TEXTILE TECH CO LTD

Fixed rod distance adjustable trailer

ActiveCN109109724AEasy to fixSolve the problem of instability and affecting the operation of the carItem transportation vehiclesEngineering

Owner:赵银宝

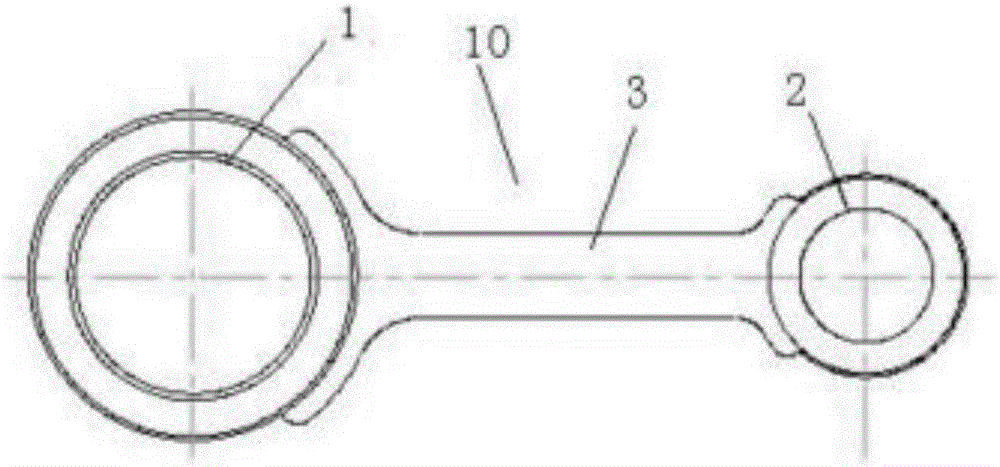

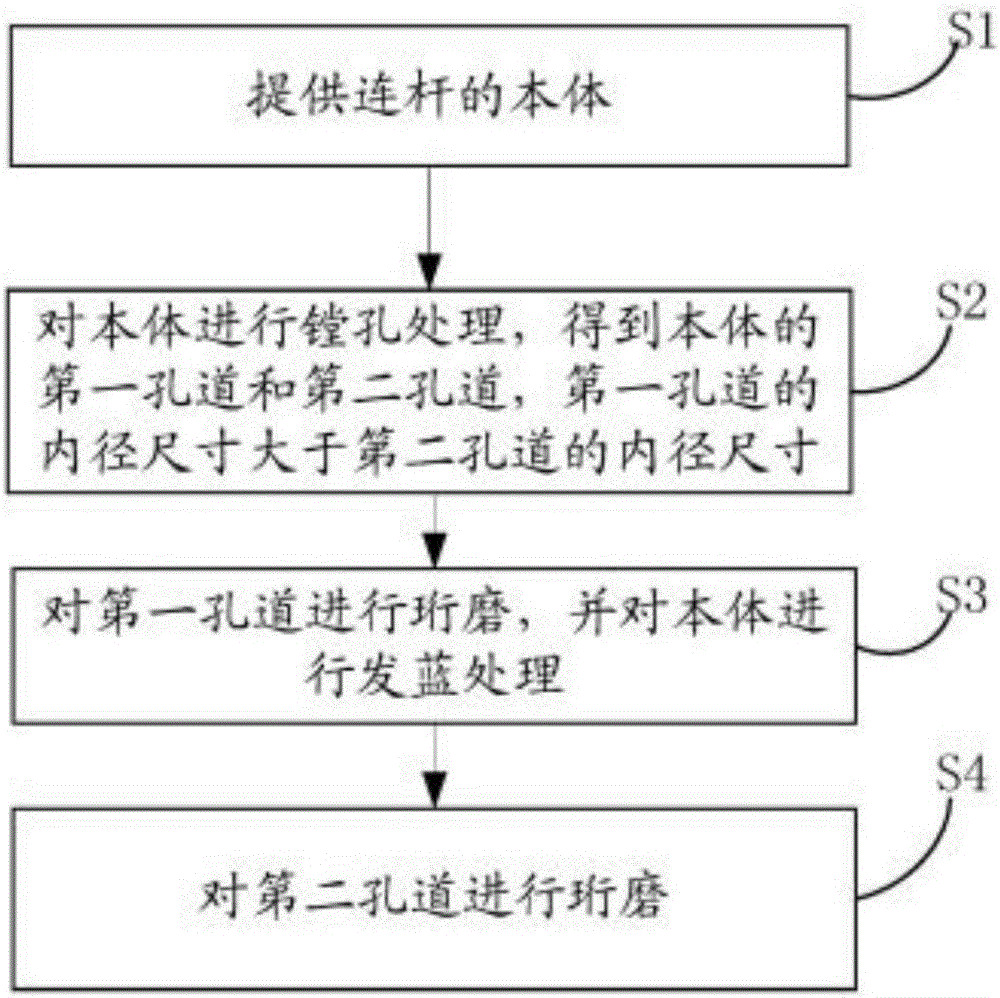

Compressor connecting rod and manufacture method thereof

InactiveCN106014919AImprove wear resistanceExtended service lifeConnecting rodsPositive displacement pump componentsWear resistantEngineering

The invention discloses a compressor connecting rod and a manufacturing method thereof. The compressor connecting rod includes a body, one end of the body is provided with a first hole, and the other end of the body is provided with a second hole. The radial size of the first hole is larger than the radial size of the second hole, and the inner wall of the first hole is provided with a wear-resistant layer. According to the compressor connecting rod of the embodiment of the present invention, the bluing layer can improve the surface hardness and wear resistance, strengthen the first channel, greatly improve the wear resistance of the inner wall surface, and reduce the scratch and wear of the first channel , at the same time, the second hole will not be strengthened synchronously, which avoids the increased wear of the piston pin matched with the second hole, improves the overall wear resistance of the compressor connecting rod, prolongs the service life, and effectively solves the two problems of the connecting rod The channel cannot realize the problem of different hardness.

Owner:淮安市新盛压缩机配件有限公司

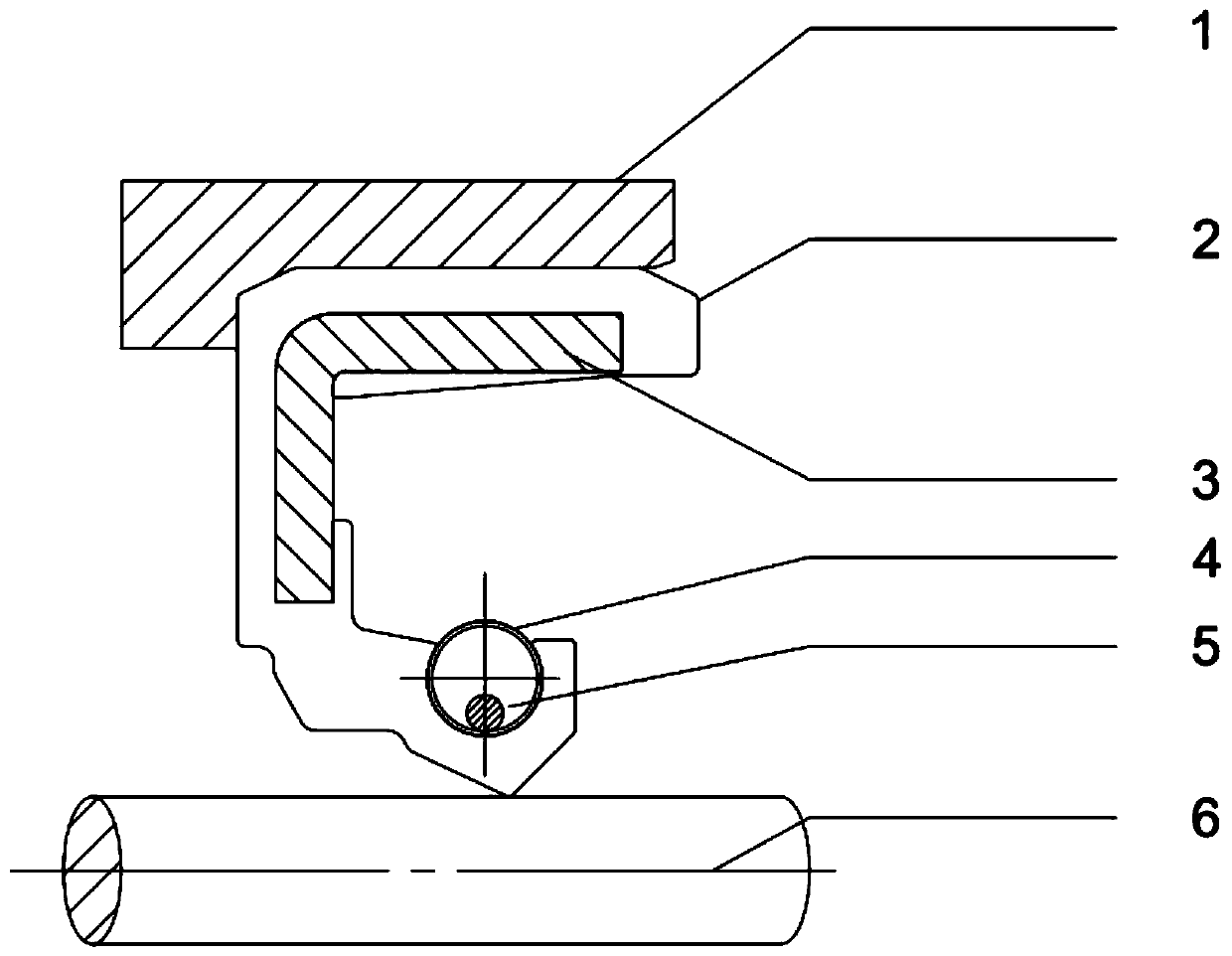

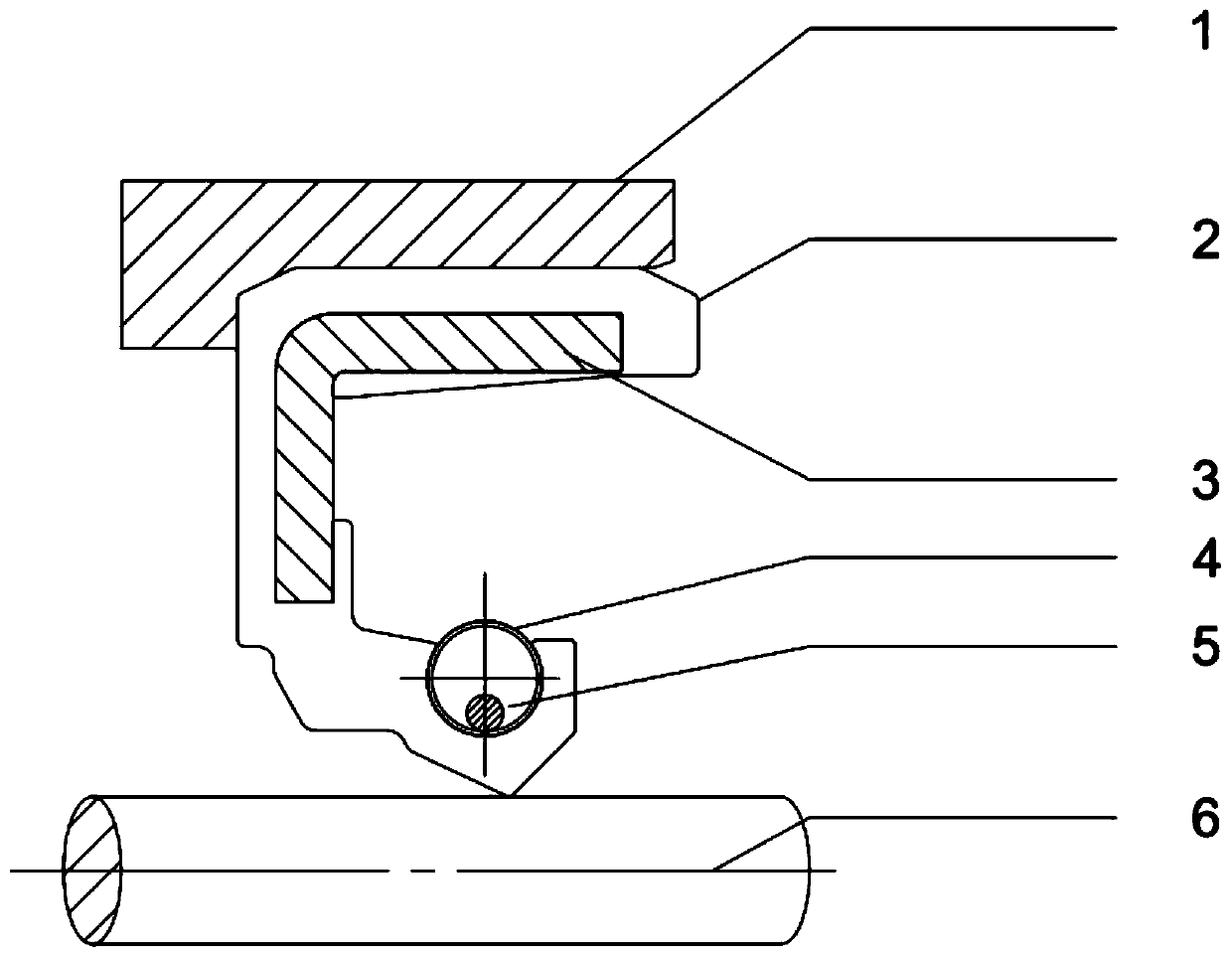

Self-compensation intelligent lip-shaped seal

The invention discloses a self-compensation intelligent lip-shaped seal. The self-compensation intelligent lip-shaped seal comprises a working cavity outer shell, a sealing ring body in interference fit with the outer shell, a metal framework inlaid in the sealing ring body, a common metal spring inlaid in a groove in the lower part of the sealing ring body, an SMA memory alloy ring nested in thecommon metal spring and a rotating shaft in contact with the sealing ring body; and the SMA memory alloy ring and the common metal spring jointly ensure the contact pressure between a sealing lip anda shaft, the radial force is mainly provided by the common metal spring in a low-temperature section and a normal-temperature section, and the radial force is mainly provided by the SMA memory alloy ring in a high-temperature section. According to the self-compensation intelligent lip-shaped seal, the SMA memory alloy ring is nested in the common metal spring, so that compensation of the radial force in a high-temperature environment is met, excessive abrasion caused by overlarge radial force in a low-temperature environment is avoided, and stable and long-term intelligent sealing in a wide temperature region can be realized.

Owner:TSINGHUA UNIV

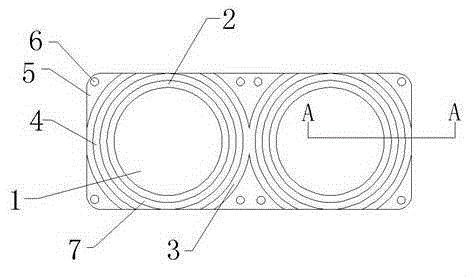

Compound gasket for engine

InactiveCN105402413AImprove sealingSolve the problem of severe wear and tearEngine sealsCylinder (engine)Flange

The invention discloses a compound gasket for an engine, comprising a metal gasket body, wherein a plurality of cylinder holes and mounting holes are formed in the metal gasket body, sealing rings are inlaid in the cylinder holes; the sealing ring comprises a rubber sleeve, a first elastic layer, a second elastic layer and a flexible layer; the sealing rings are connected with the inner walls of the metal gasket body by the first elastic layers, the rubber sleeve is exposed from the upper end and the lower end of the metal gasket body and is folded outwards to form sideways, a plurality of flanges are formed on the flexible layer; and the flanges are arranged on the metal gasket body in parallel at equal intervals, a clearance between the flanges forms a groove, and the flanges and the grooves are combined to form a waveform or a teeth shape. The compound gasket for an engine main solves the problem of poor airtightness in connection of two planes, and also solves the problems of serious abrasion of a sealing gasket, a fastener and a contact surface; and due to the specially-made metal gasket, capabilities of elasticity, toughness, strength and corrosion resistance of the metal gasket are enhanced, and the service life of the metal gasket is prolonged.

Owner:CHENGDU 90 DEGREE IND PROD DESIGN CO LTD

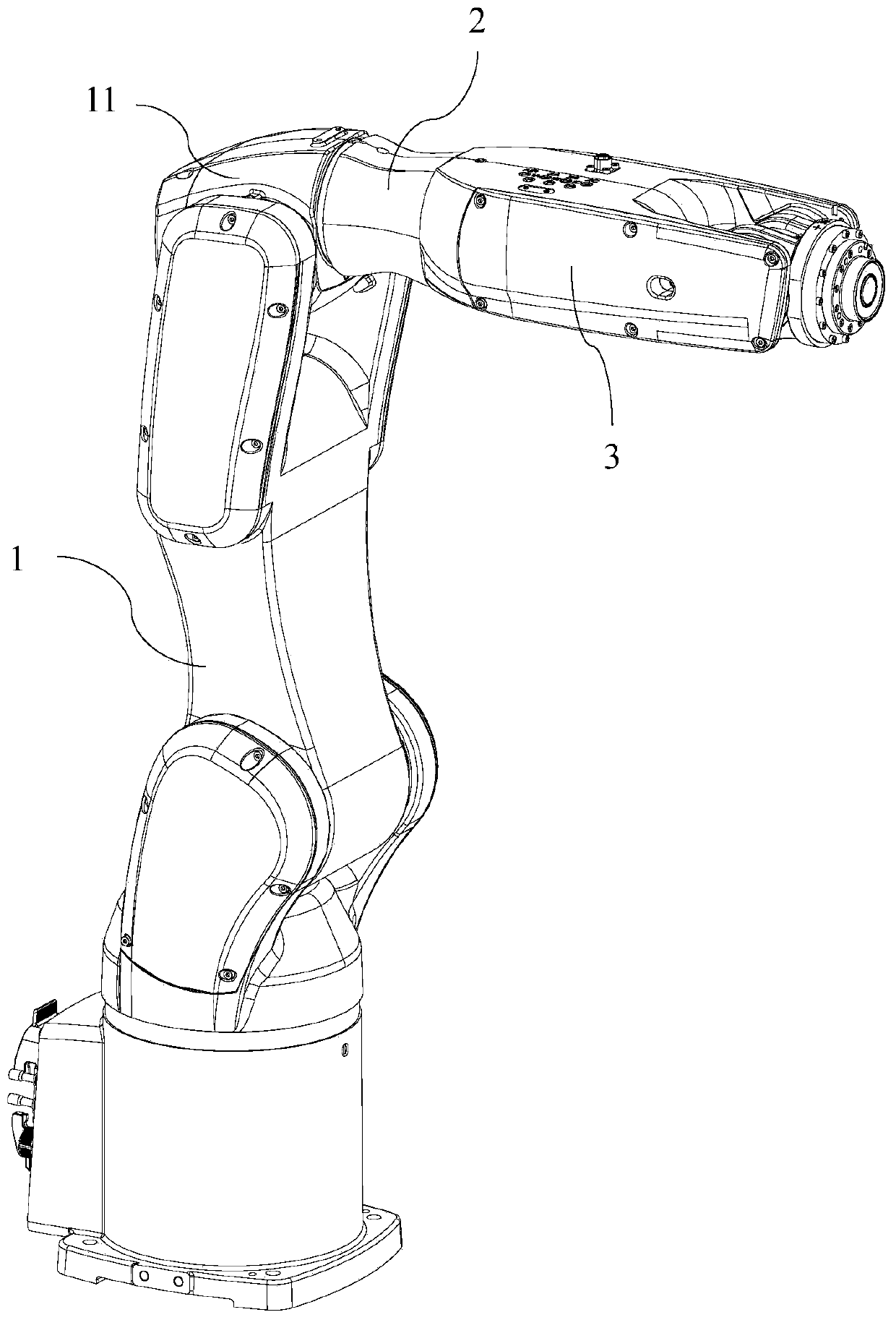

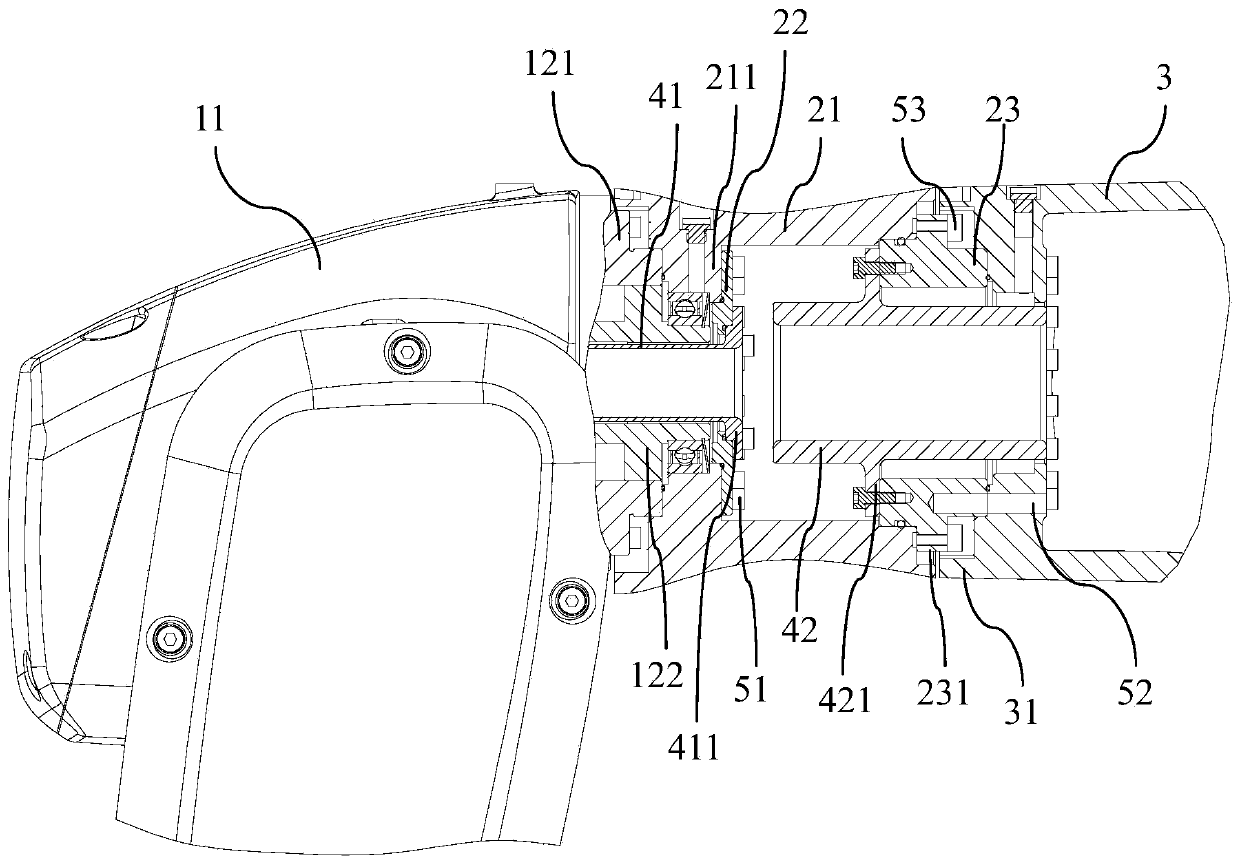

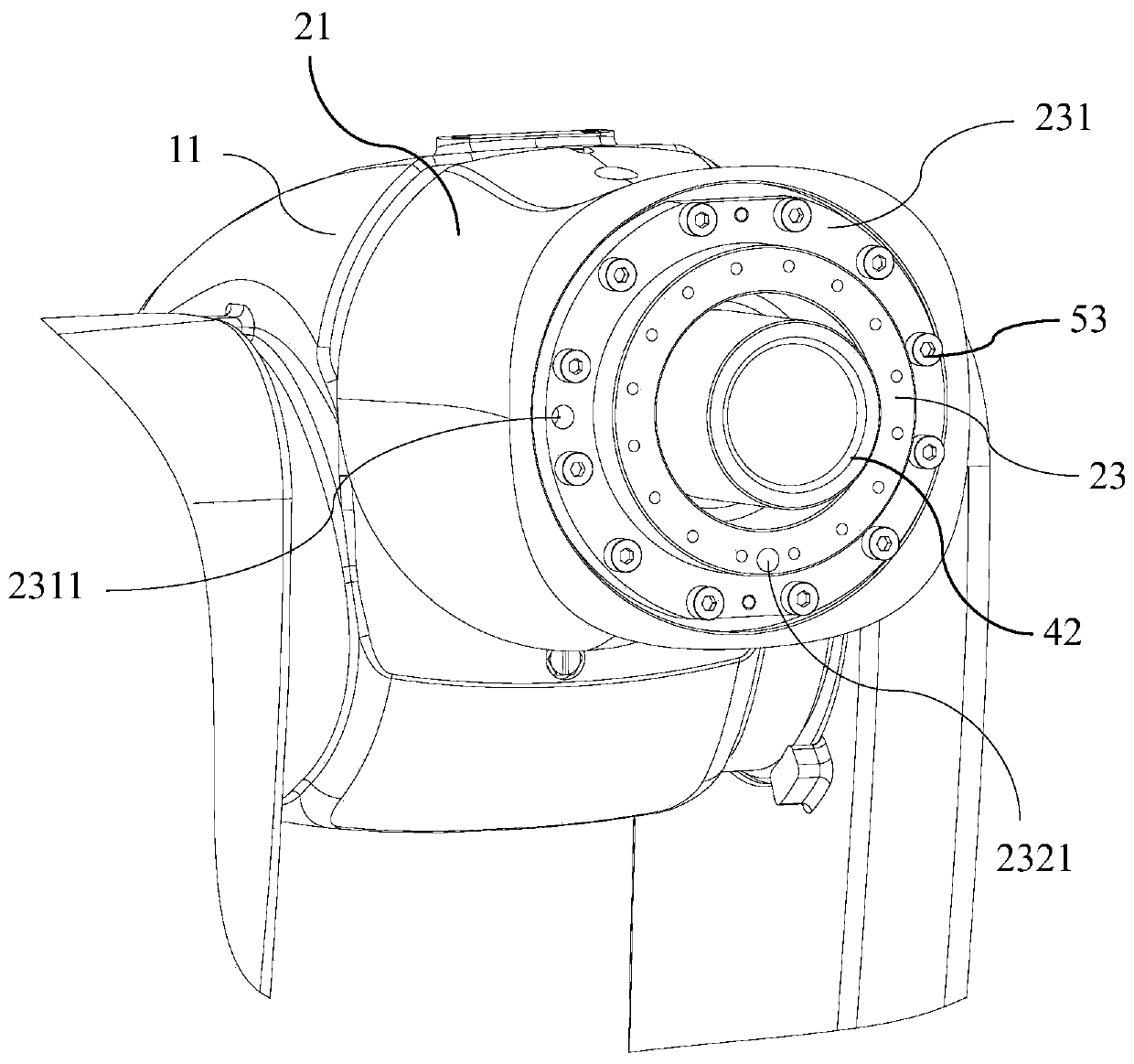

Industrial robot

PendingCN111546314ALarge working radiusIncrease flexibilityProgramme-controlled manipulatorIndustrial roboticsMechanical engineering

The invention provides an industrial robot which comprises a base body assembly, an extension arm assembly and a front arm assembly. The base body assembly comprises an elbow shell and a hollow type speed reducer fixedly arranged on a seam allowance at the front end of the elbow shell; the first end of the axial direction of the extension arm assembly is fixedly arranged at the output end of the speed reducer through a first screw; the front arm assembly is fixedly arranged at the second end of the axial direction of the extension arm assembly through a second screw; the installation surface of the first end of the axial direction of the extension arm assembly and the installation surface of the front arm assembly are the same; and the installation surface of the second end of the axial direction of the extension arm assembly and the installation surface of the output end of the speed reducer are the same. According to the industrial robot provided by the embodiment of the invention, the end faces of two ends of the axial direction of the extension arm assembly are the same as the installation surface of the front arm assembly and the installation surface of the output end of the speed reducer, so that the arm length of the industrial robot can be increased, the working radius of the industrial robot can be effectively increased, and meanwhile, the flexibility in assembling theindustrial robot is improved.

Owner:SUZHOU INOVANCE TECH CO LTD

Aluminum alloy and steel optimized welding method based on magnetic control resistance spot welding

ActiveCN113843488ALow heat inputReduce severe thinningResistance welding apparatusSteel platesHigh resistivity

An aluminum alloy and steel optimized welding method based on magnetic control resistance spot welding comprises the steps that a steel plate and an aluminum alloy plate are arranged between an electrode and a controllable magnetic field, Joule heat is generated in the steel plate by applying welding current, and the temperature of the side, close to the steel plate, of the aluminum alloy plate is evenly increased through the blocking effect of a high-resistivity oxidation film between the steel plate and the aluminum alloy plate; and the side, close to the steel plate, of the aluminum alloy plate is molten to form molten aluminum alloy, the molten aluminum alloy flows and is stirred at a high speed under the action of Lorentz force generated by a magnetic field and current, aggregation of oxide film defects near an interface is inhibited, and thin and uniform intermetallic compounds are formed by heterogeneous materials on the two sides of the interface. By heating a steel side resistor, the heat input of the aluminum side is reduced, the thinning of the aluminum plate is reduced, the surface indentation of the aluminum plate is eliminated, and the thickness of an interface intermetallic compound layer is controlled; and lorentz force is generated through interaction of an external magnetic field and current, molten aluminum alloy is driven to flow at a high speed, the aluminum side nugget structure and defect distribution are improved, and the mechanical performance of a welded joint is improved. By avoiding direct contact between a copper electrode and an aluminum plate, electrode abrasion is reduced, and the performance, appearance quality and welding spot quality stability of an aluminum steel spot welding joint are improved.

Owner:SHANGHAI JIAO TONG UNIV

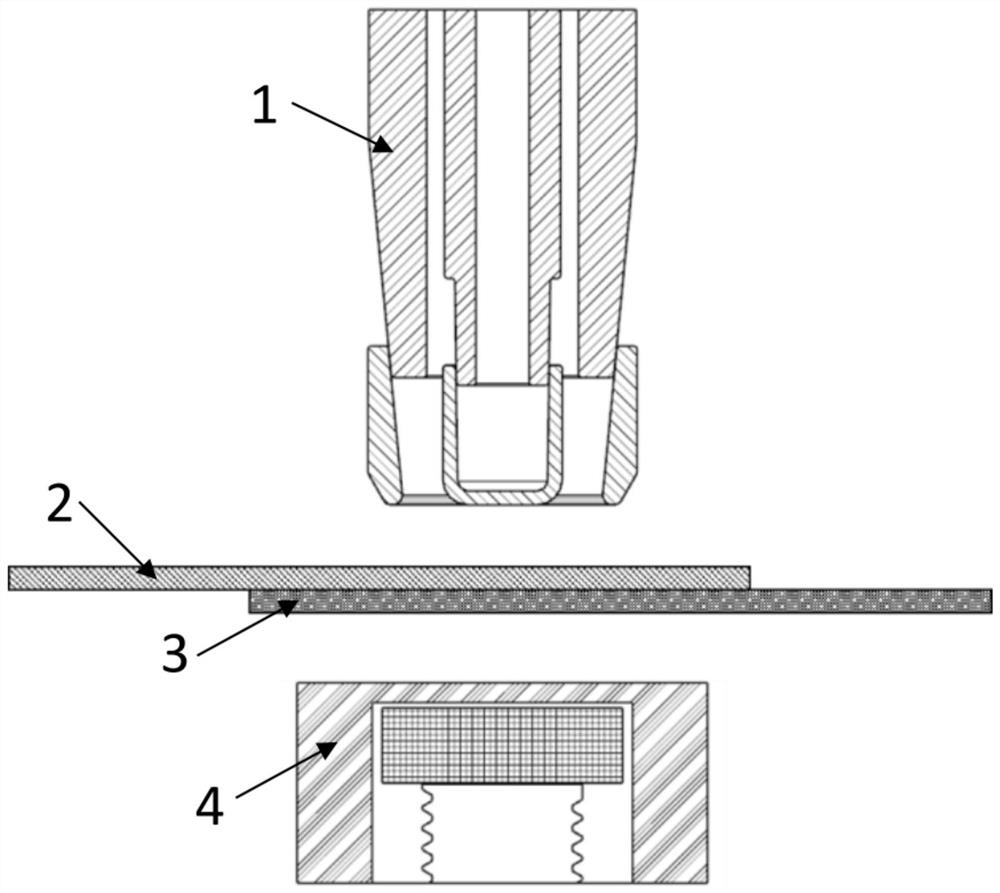

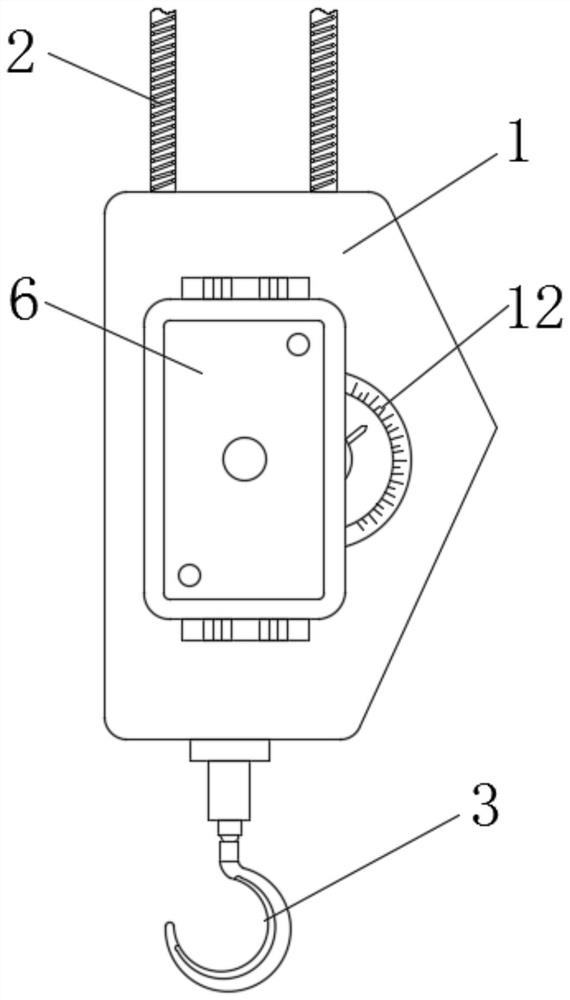

Crane pulley device capable of automatically supplementing oil

InactiveCN112830378ASolve the problem of severe wear and tearSave installation spaceEngine levelsMachines/enginesExternal energyGear wheel

The invention relates to the technical field of cranes, and discloses a crane pulley device capable of automatically supplementing oil. The crane pulley device comprises a shell, wherein a sling is arranged above the shell, a lifting hook movably connected to the lower end of the shell, a guide wheel is arranged inside the shell, a main shaft is coupled to the center of the guide wheel, a lubricating bin is arranged on the front side of the shell, an oil injection wheel is coupled to the front part of the main shaft, a crank piston is arranged in the oil injection wheel, an oil outlet nozzle is arranged on the oil injection wheel close to the axis, a right gear of the oil injection wheel is in meshed connection with a pointer wheel, a pointer is arranged on the front side of the pointer wheel, and a dial plate is arranged on the front side of the shell corresponding to the pointer. According to the crane pulley device capable of automatically supplementing oil, when a pulley works, a vibration block vibrates due to insufficient lubrication, the vibration block is driven to drive a lubricating bin shell to vibrate, a ratchet wheel is shifted by a pawl, then the oil injection wheel is driven to rotate for oil injection, harmful vibration mechanical energy in work is recycled without the help of external energy, and the oil injection device is driven to inject oil, and the service life of the pulley is prolonged.

Owner:梁瑶

Method and system for long-distance conveying of condensate polishing resin

PendingCN113413930ARealize long-distance transmissionImprove delivery rateIon-exchange column/bed processesHollow article cleaningPolymer sciencePolymer chemistry

The invention discloses a method and system for long-distance conveying of condensate polishing resin, and the method comprises the following steps: conveying to-be-conveyed resin in a hydraulic conveying manner, then conveying the to-be-conveyed resin in a pneumatic conveying manner, and then conveying the to-be-conveyed resin in a hydraulic and pneumatic mixed manner. The method and the system can effectively solve the problems of pipeline blockage and serious resin abrasion in long-distance resin transmission.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

Machine tool machine frame for precision instrument machining

InactiveCN111941098APlay a buffering effectAvoid shock wearLarge fixed membersMaintainance and safety accessoriesEngineeringMachine

The invention discloses a machine tool machine frame for precision instrument machining. The machine tool machine frame comprises a machine tool, wherein a machine frame body is installed below the machine tool, a buffer mechanism is installed between the machine tool and the machine frame body, and a first supporting base is arranged at the rear end of the right side of an inclined rod on the left side. According to the machine tool machine frame for precision instrument machining, external force borne by the machine tool can be offset through elasticity of compression springs on the two sides, the buffering effect on the machine tool is achieved, vibration abrasion of equipment on the machine tool is avoided, and the problem that for an existing machine tool machine frame for precision instrument machining, due to the poor damping effect between the machine tool and a machine frame, when moving, machine tool equipment is seriously abraded; and the machine tool on the machine frame can be moved through rolling wheels at the four corners of the machine frame, so that the machine tool is convenient to transport, the working difficulty of workers is reduced, and the problems that theexisting machine tool machine frame for precise instrument machining is inconvenient to carry, and the working difficulty is provided for the workers are solved.

Owner:李经缙

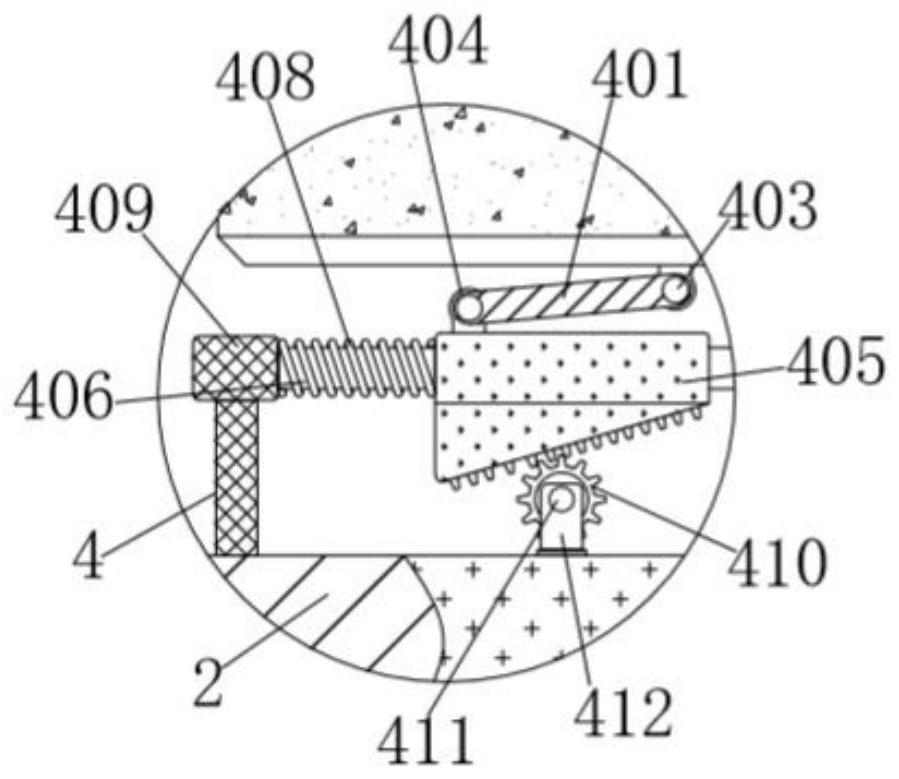

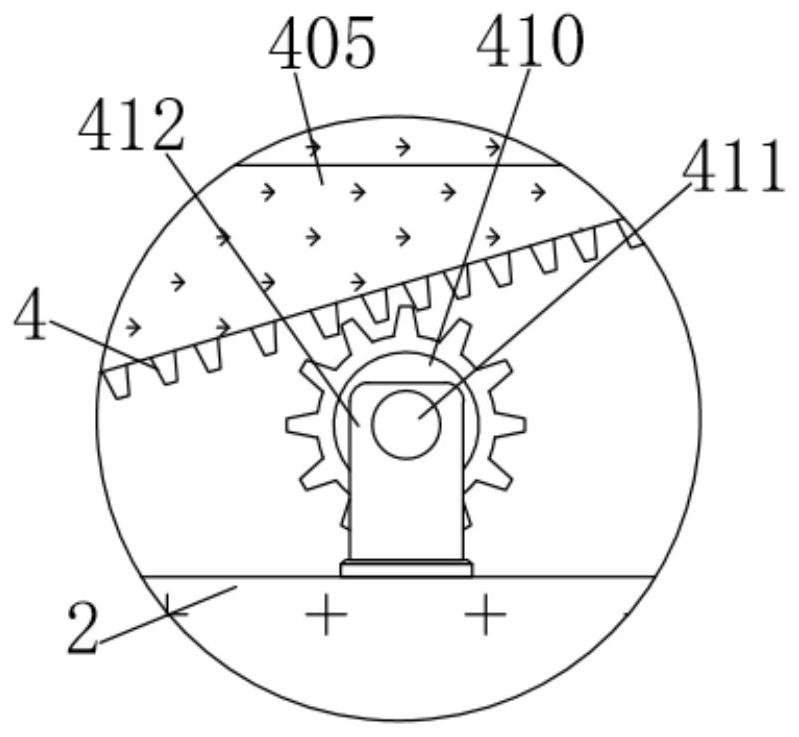

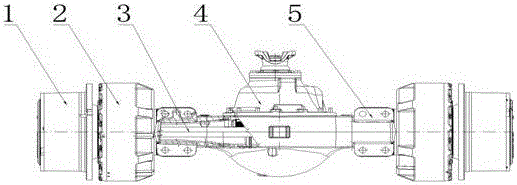

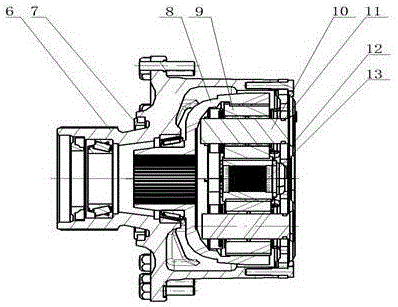

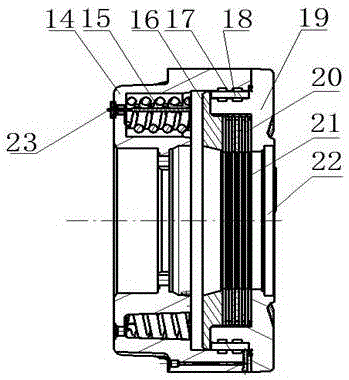

Wet brake drive axle of scraper

ActiveCN106740745ARealize the braking effectImprove rigidityBraking element arrangementsBrake typesGear drivePiston ring

The invention discloses a wet brake drive axle of a scraper. The drive axle comprises a hub reduction mechanism, a wet brake, a half axle, a main drive assembly and an axle housing. The wet brake is provided with a brake shell, a brake spring is arranged in the brake shell and makes a piston cover pressed on a brake piston ring, the brake cover is connected with a fixed static friction plate, a movable friction plate is arranged on the position corresponding to the static friction plate, a connection groove is formed in the outer side of the brake cover, and a floating seal is arranged in the connection groove; a planetary wheel is disposed on the hub reduction mechanism and fixed to a planetary wheel frame through a planetary wheel shaft; a sun gear is fixed to the half axle, the sun gear drives the planetary wheel and the planetary wheel frame to rotate around the sun gear, the planetary wheel frame is fixed to a hub shell through bolts, and the planetary wheel frame drives the hub shell to rotate. The friction force between the movable friction plate and the static friction plate is reduced, the service life is improved, the structure is simple, and the use and maintenance cost is low.

Owner:LAIZHOU YATONG HEAVY EQUIP

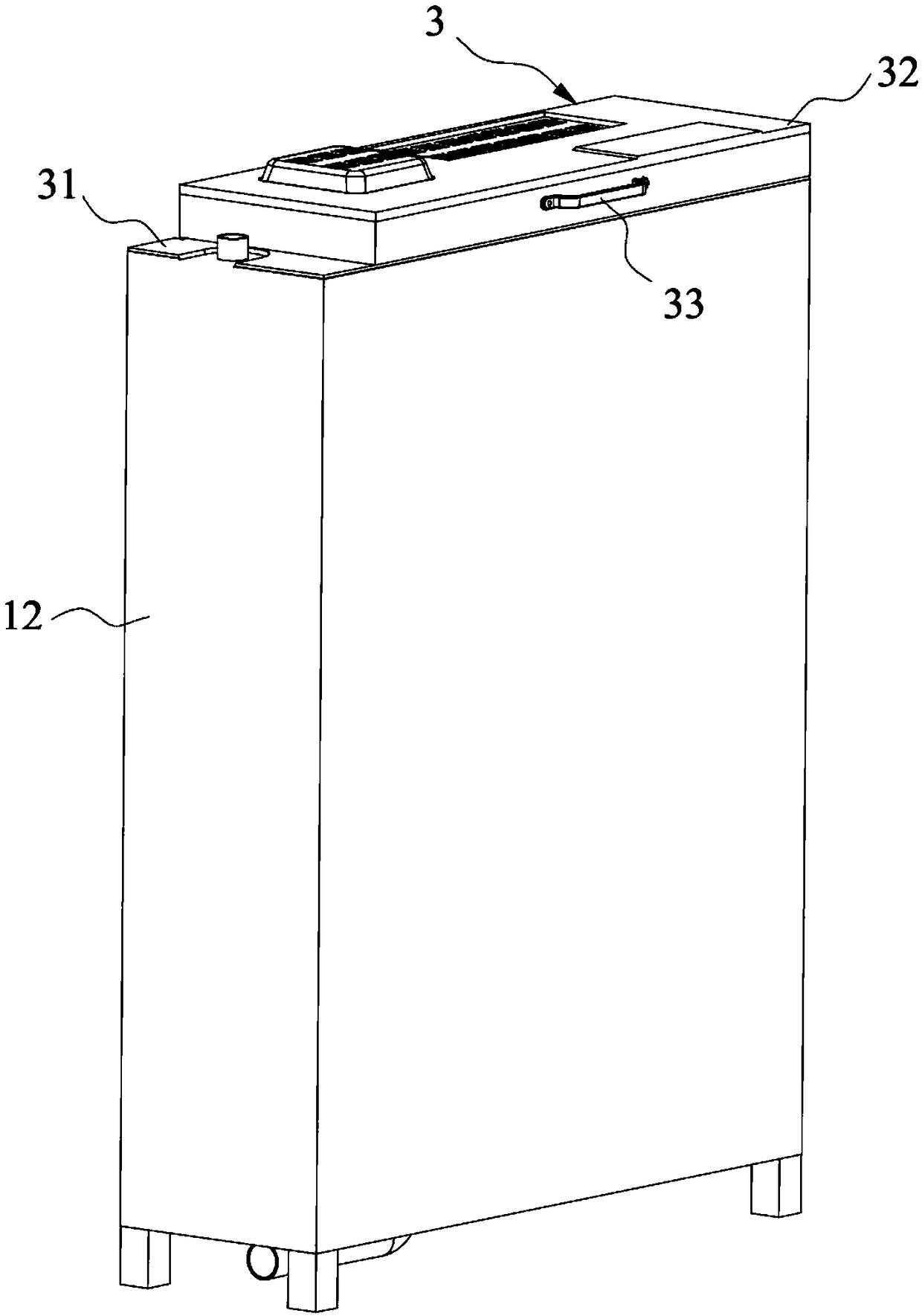

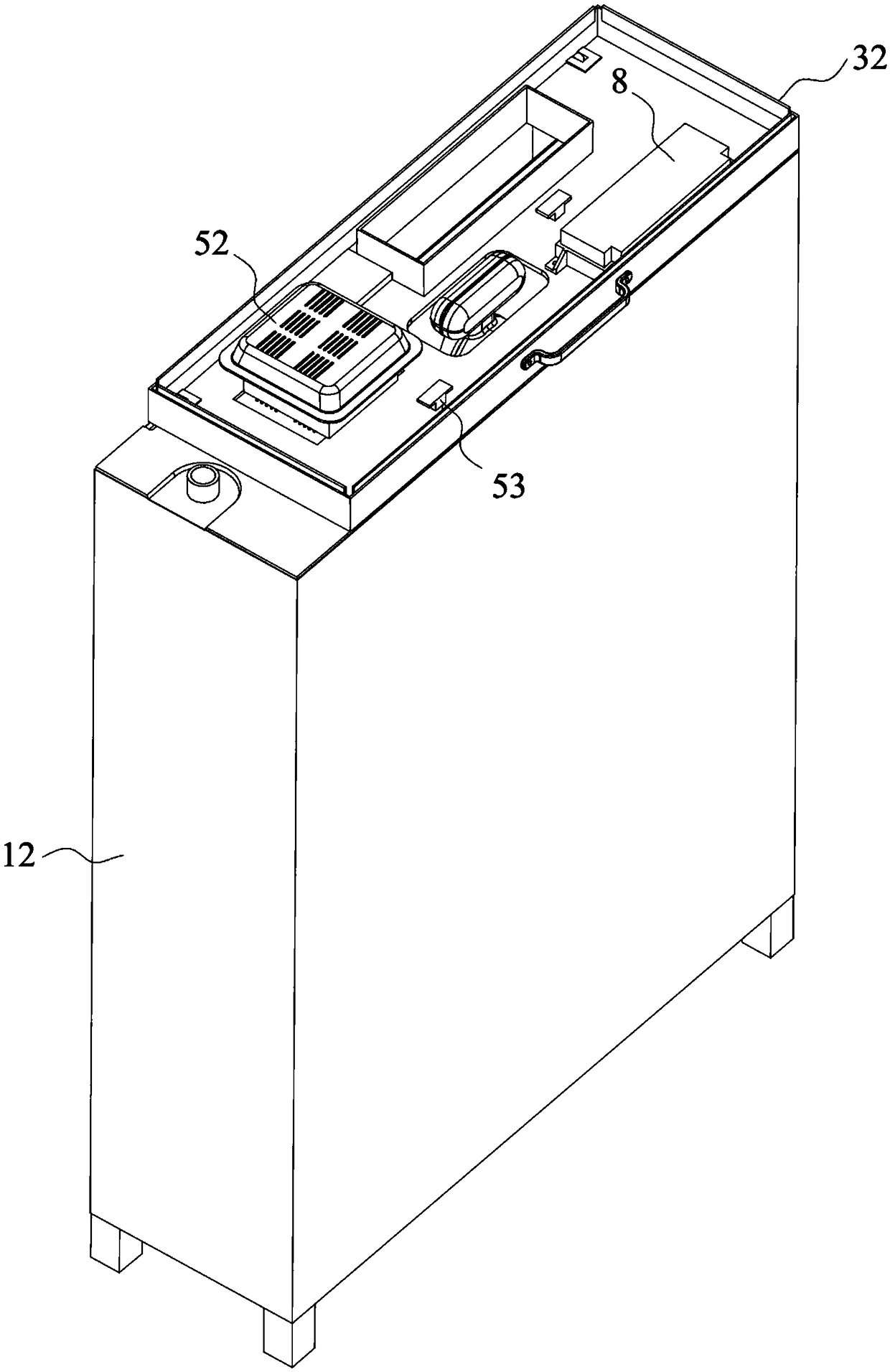

Static washing machine

PendingCN109385795AShorten cleaning timeReduce volumeOther washing machinesWashing machine with receptaclesProcess engineering

The invention particularly discloses a static washing machine which comprises a rack, a main washing box mounted on the rack, an auxiliary washing box internally provided with an auxiliary washing cavity and provided with an opening, a water inlet-outlet for injecting or draining water for the auxiliary washing cavity, a covering assembly for opening or closing ports and the opening and at least one ultrasonic integrated assembly arranged corresponding to the main washing box and the auxiliary washing box, wherein the bottom and the top of the main washing tub are respectively provided with awater draining port and a water injecting port. The static washing machine washes clothes through the ultrasonic integrated assemblies, ultrasonic waves can improve the penetration capacity of a scrubbing solution, the washing efficiency is high, the cleaning time is shortened, the clothes can also be washed thoroughly under the situation that the clothes are not stirred, and clothes damages are decreased; in addition, the static washing machine is low in cost and small in size, is conveniently arranged in a guesthouse or hotel, the main washing box and the auxiliary washing box form multipleindependent washing zones, clothes which are not suitable for simultaneous washing can be simultaneously washed in a zoned way, the washing times can be effectively decreased, and the washing time canbe effectively shortened.

Owner:摩舒(上海)电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com