Three-motor driven single-screw compressor

A single-screw compressor, three-motor technology, used in machines/engines, pump combinations for elastic fluid rotary piston/oscillating pistons, mechanical equipment, etc., can solve the problem of poor results, no large-scale promotion, star Wheel wear and other problems, to achieve the effect of solving the serious wear of the screw and the star wheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

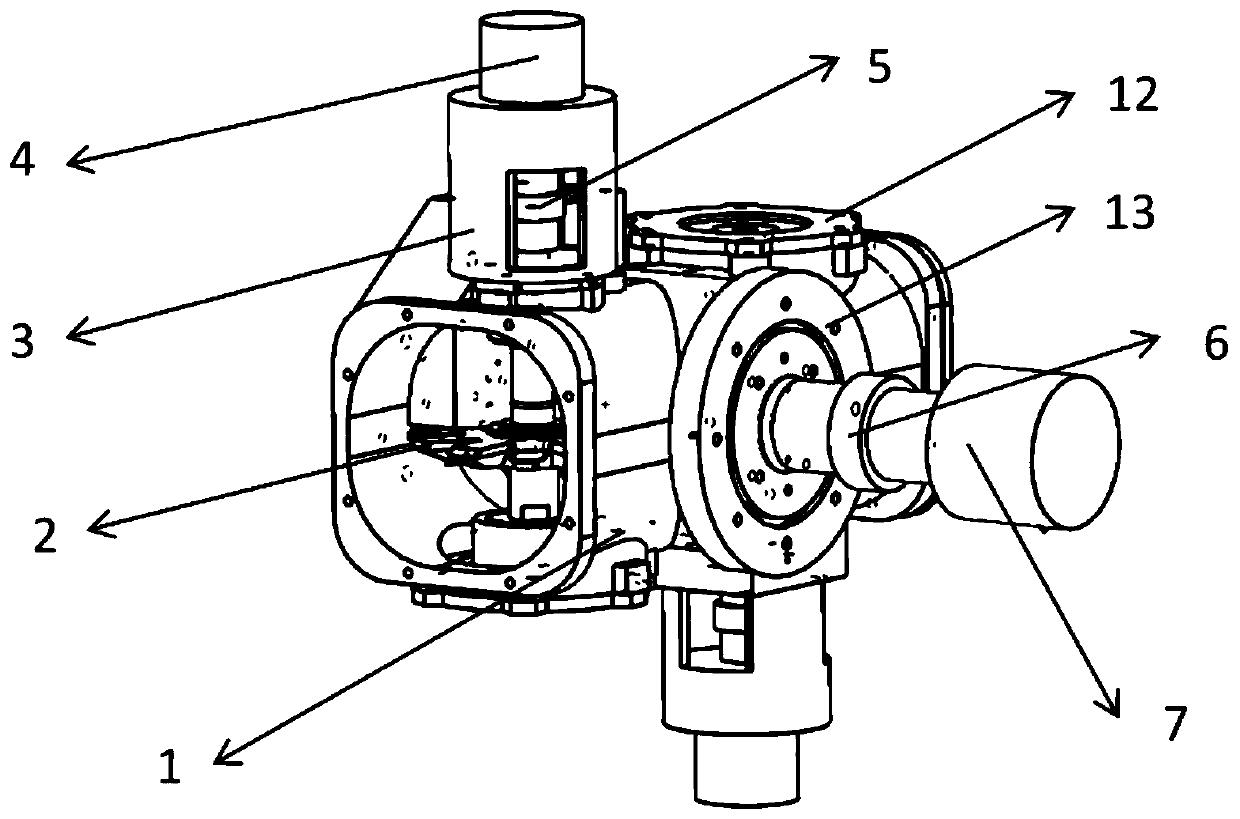

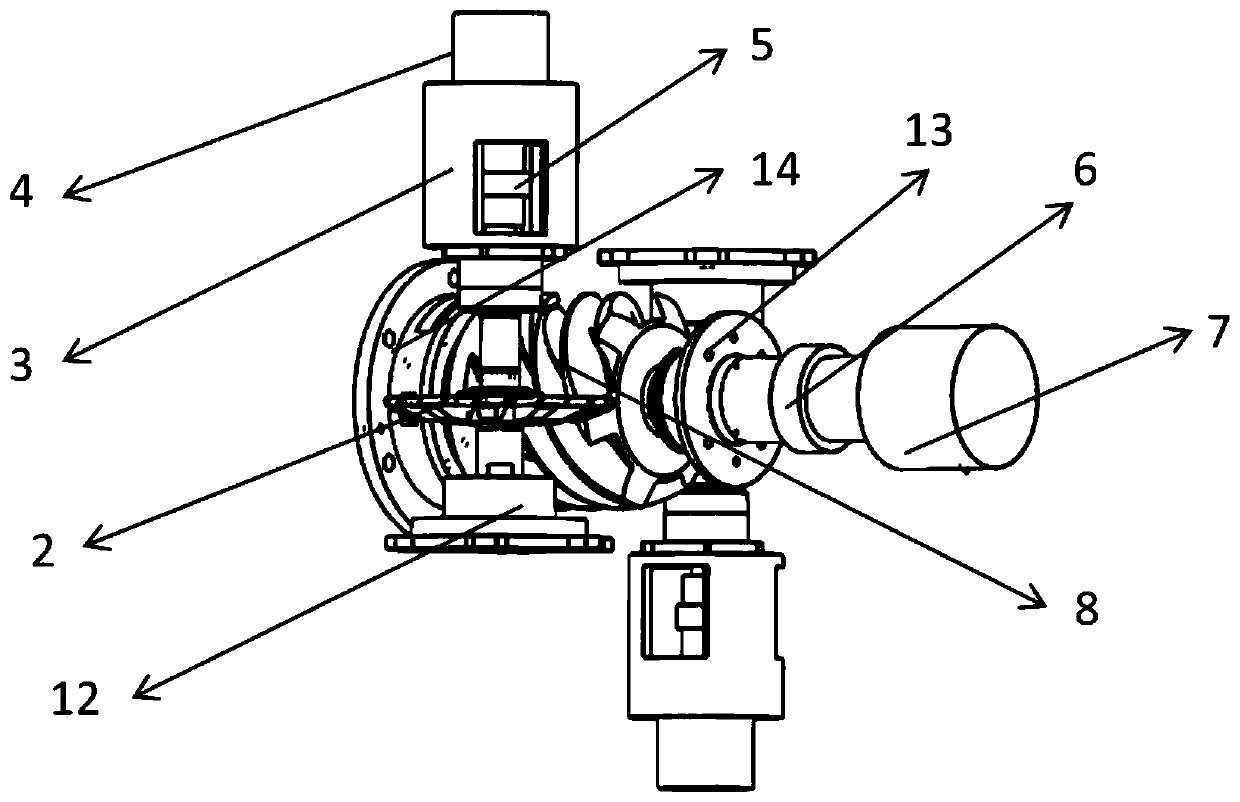

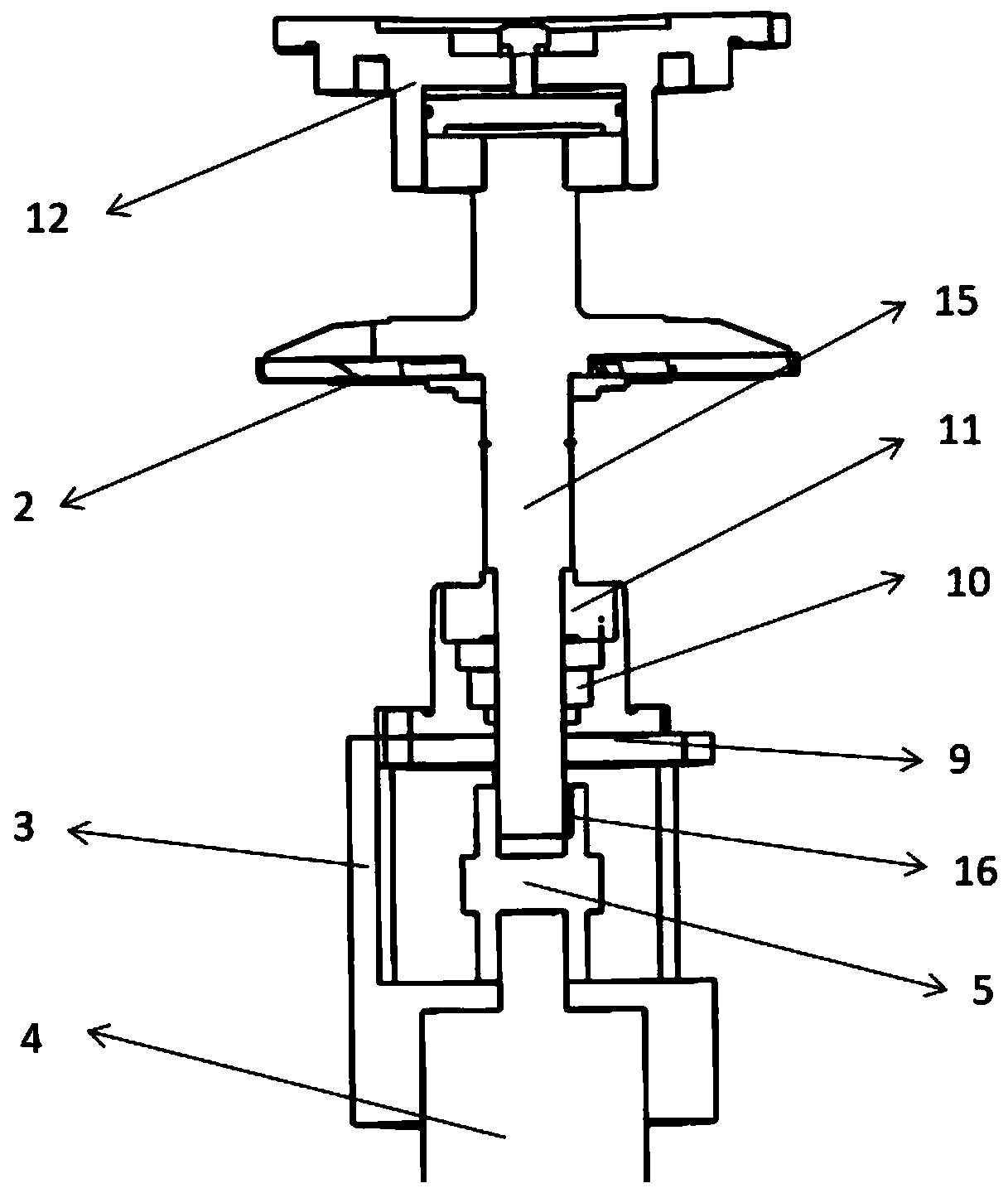

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0019] see Figure 1-3 , the single-screw compressor driven by the three motors of the present invention can be obtained directly on the basis of traditional single-screw compressors. In the original structure, a motor drives the screw 8 and then drives two star wheels 2 to rotate, and is transformed into three motors respectively Drive the screw 8 and the two star wheels 2 so that the screw 8 and the two star wheels 2 rotate synchronously without contacting each other.

[0020] The structure of the single-screw compressor of the present invention is different from the traditional single-screw compressor in that the screw 8 and the two star wheels 2 are respectively driven by three motors so that the three rotate synchronously. During the working process, the screw 8 and the two star wheels The star wheels 2 are not in contact with each other, which can solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com