Patents

Literature

82results about "Engine levels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

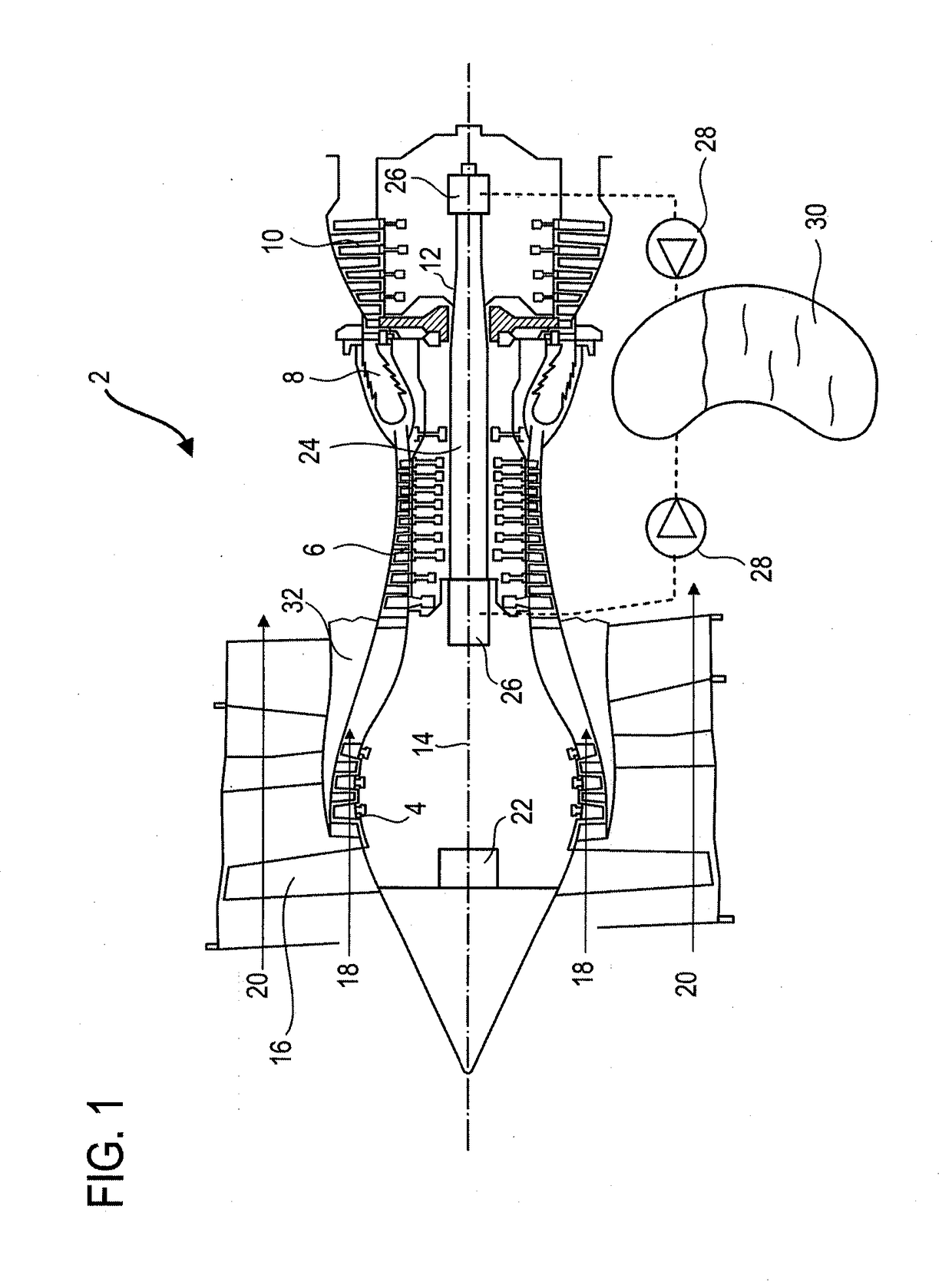

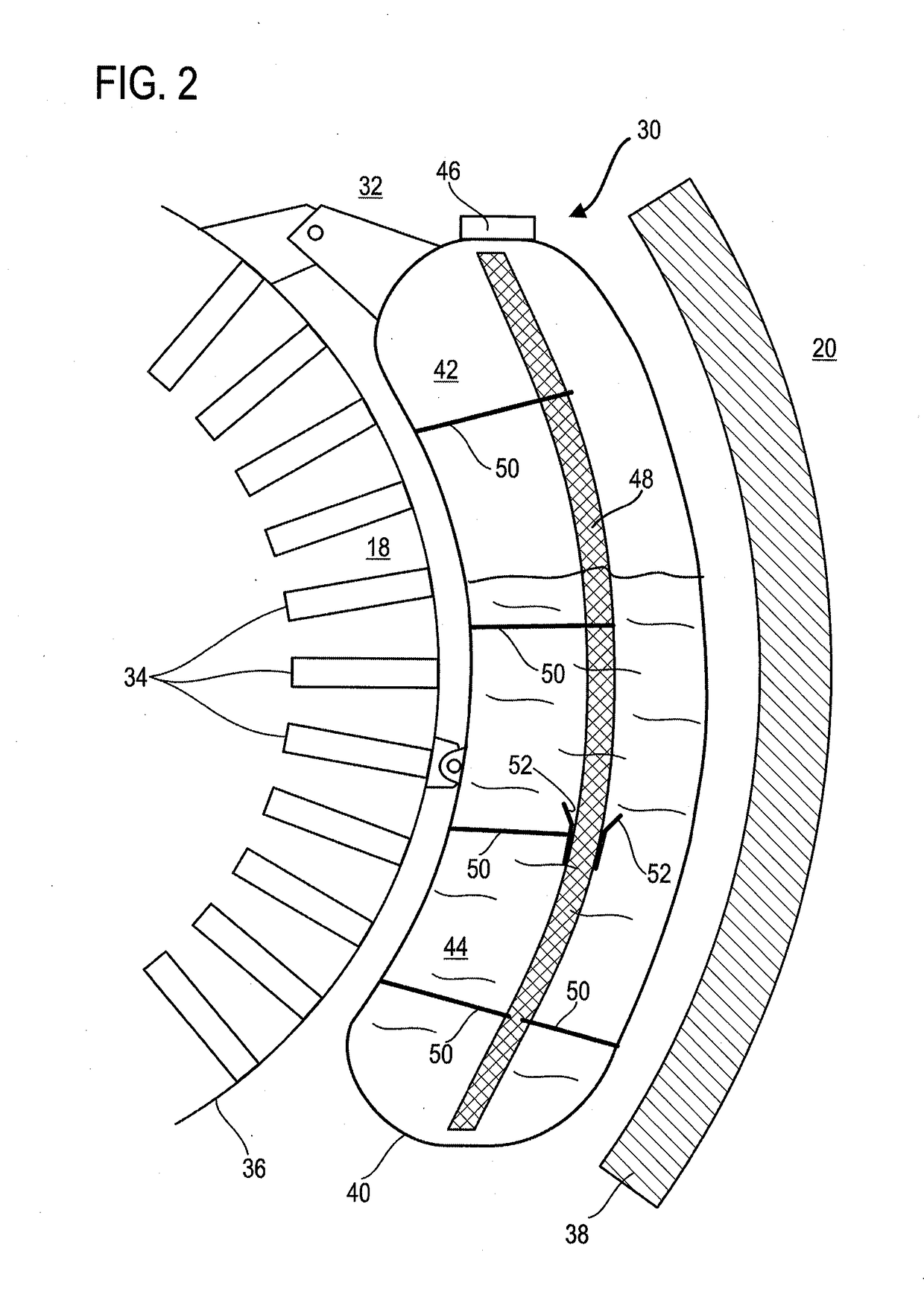

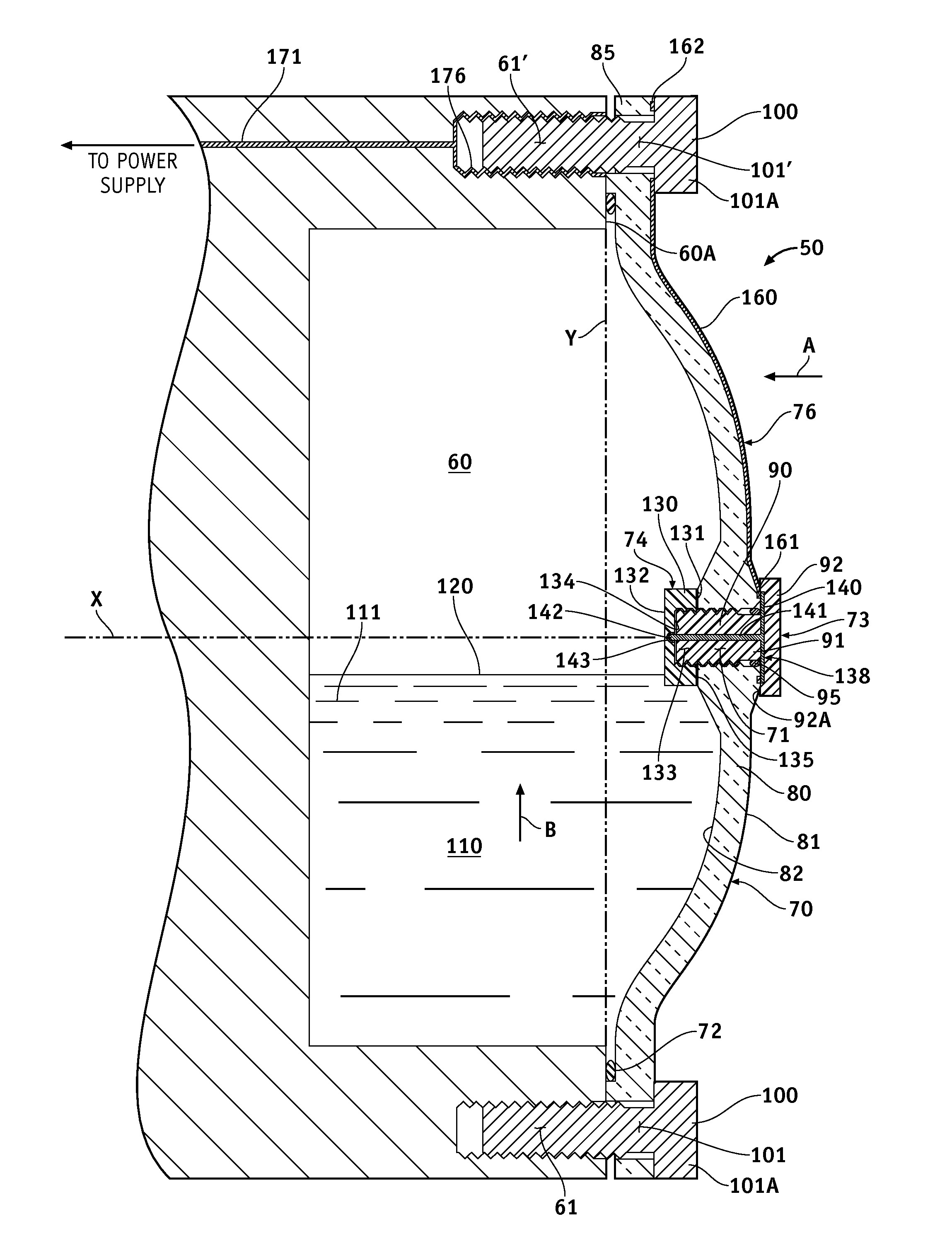

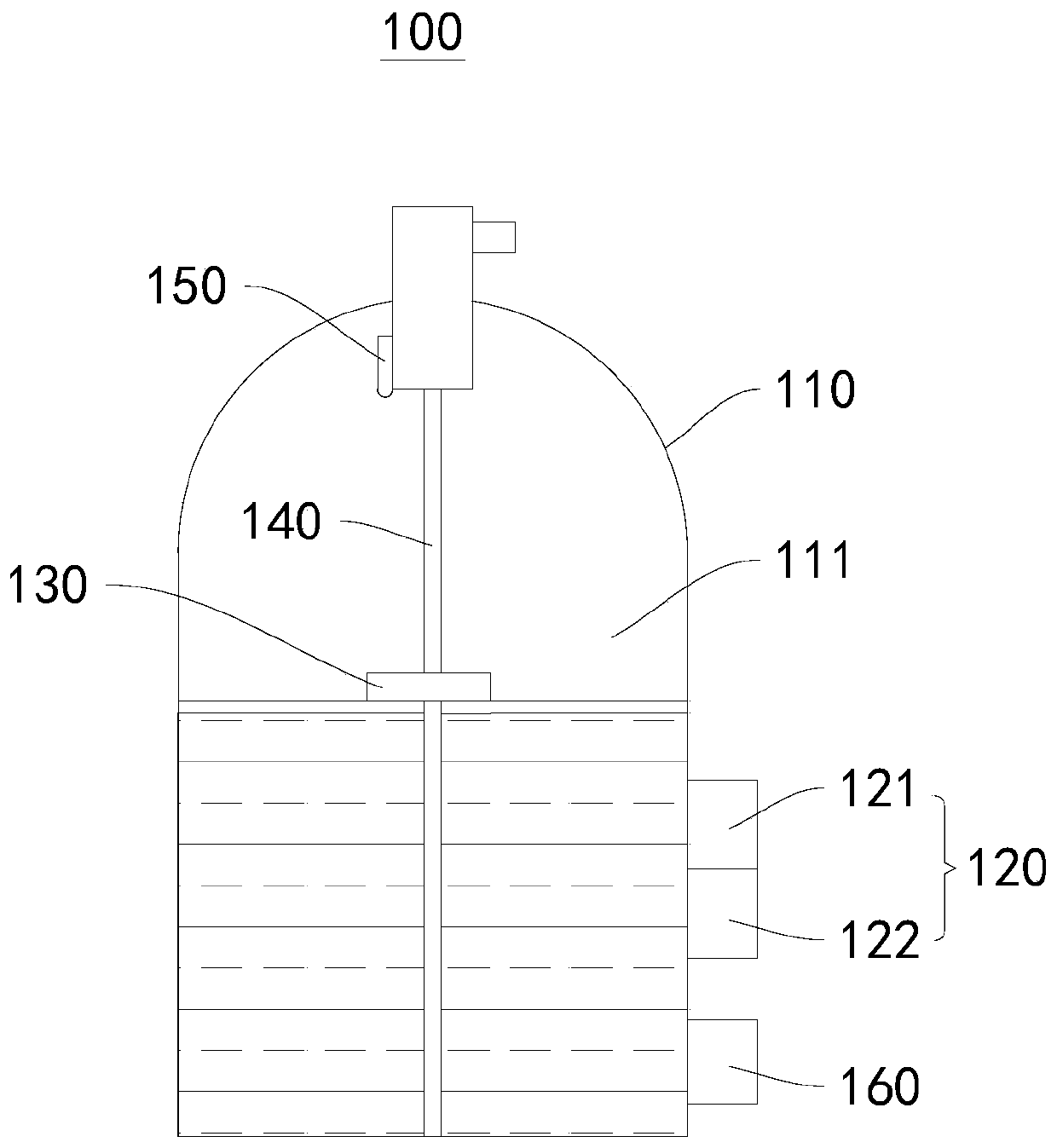

Oil Level Sensor Tank for Turbine Engine

An oil tank of a turbine engine, particularly of an aircraft turbojet includes an external wall forming a generally curved main cavity. This cavity includes an arched sensor for electrically measuring the oil level, for example in a capacitive manner. Said arched sensor matches the curvature of the main cavity in order to be integrated therein. Sensor supporting arms distributed along the curvature of the arched sensor and / or an arched sleeve with an arched cavity receive the arched sensor. A turbine engine is provided with an oil tank, as well as a method for mounting a sensor in an oil tank.

Owner:SAFRAN AERO BOOSTERS SA

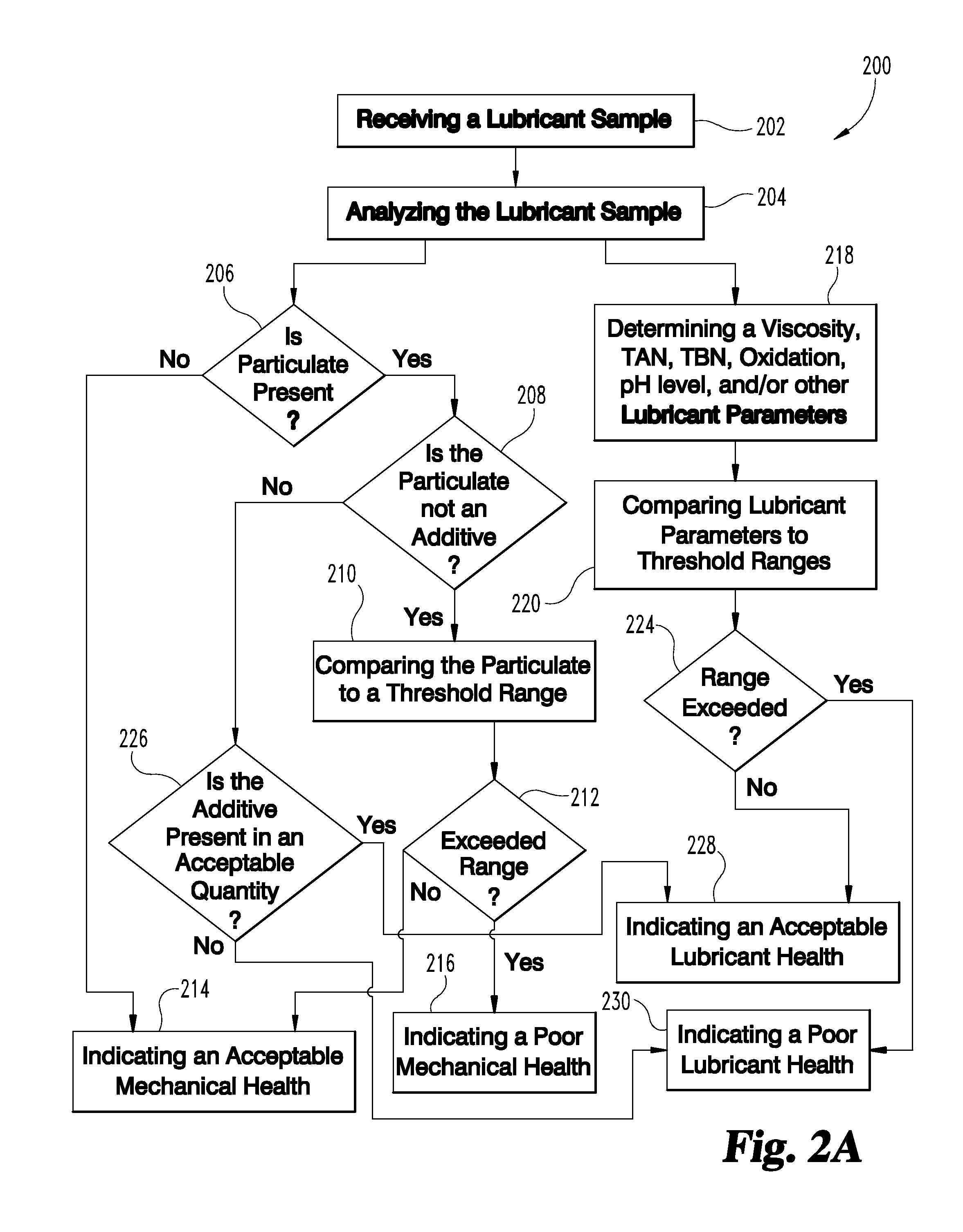

Lubricant health and service determination

A method is disclosed that includes determining a current level of a plurality of lubricant parameters present in a portion of lubricant, comparing the current level of each of the plurality of lubricant parameters to a threshold value corresponding to each of the plurality of lubricant parameters, analyzing a priority of each of the lubricant parameters, and determining a health status of the lubricant in response to the comparing and the analyzing.

Owner:INGERSOLL RAND IND U S INC

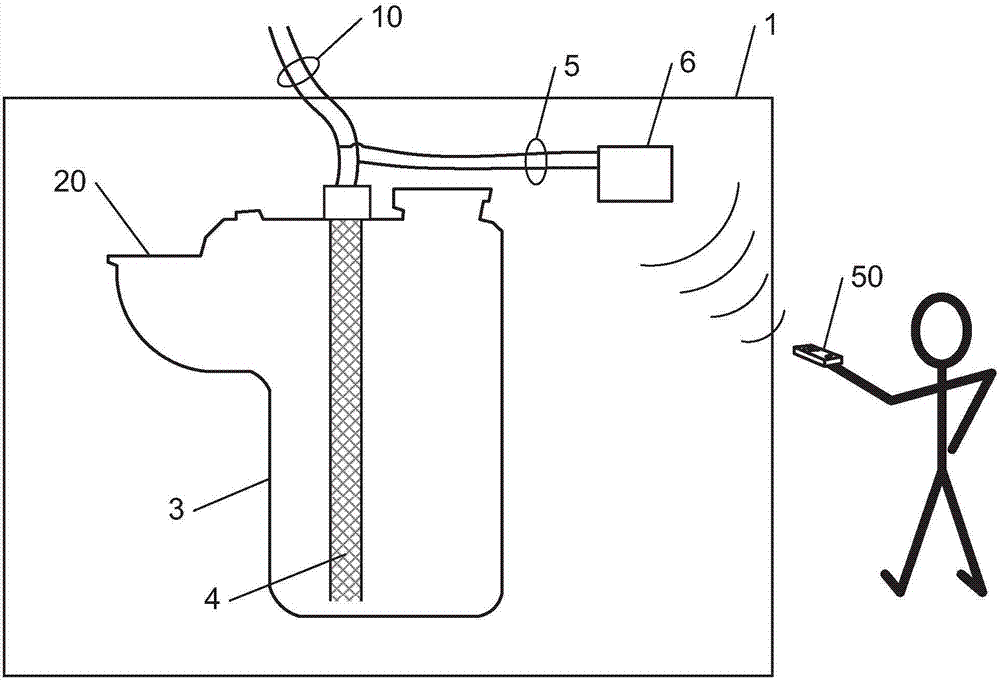

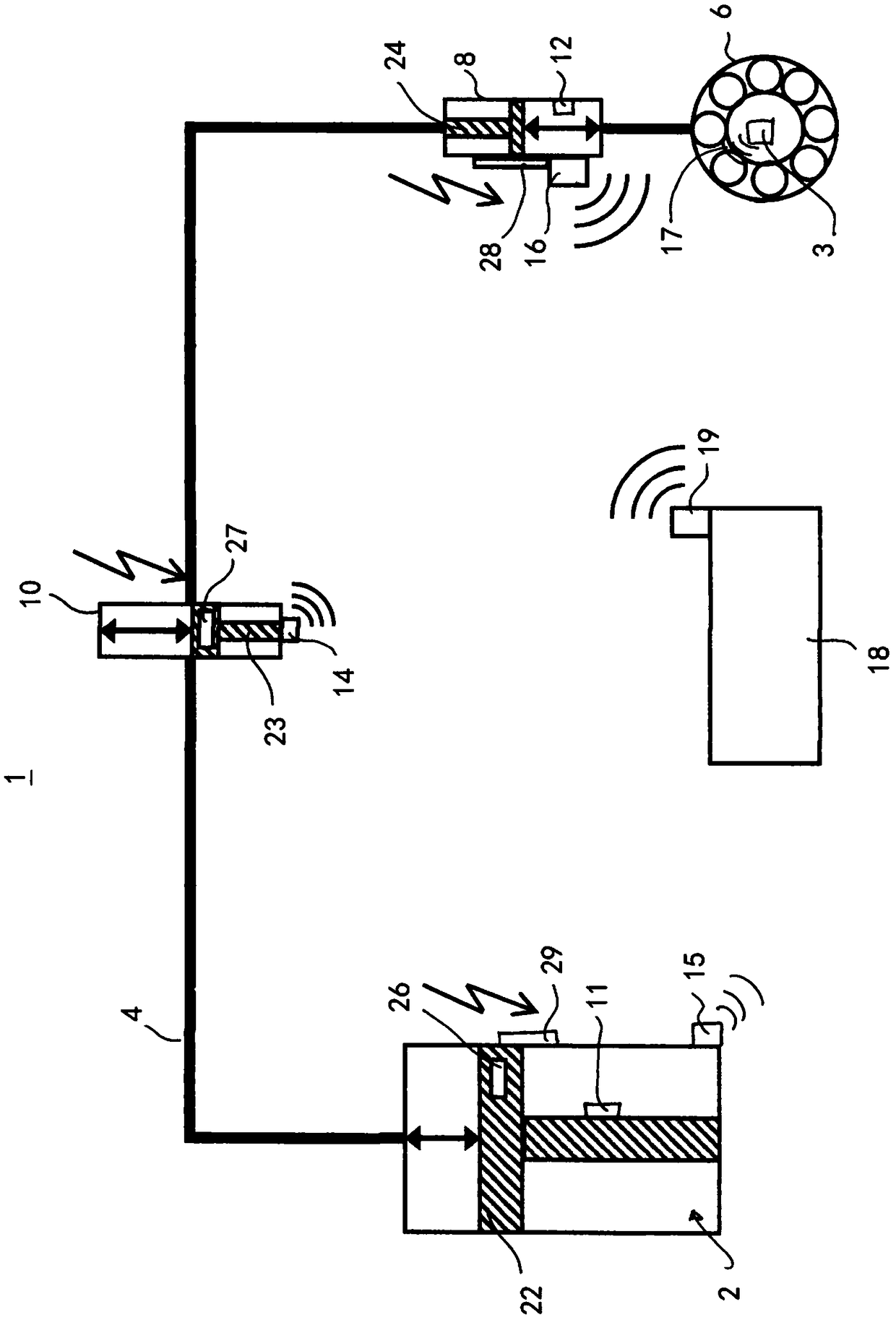

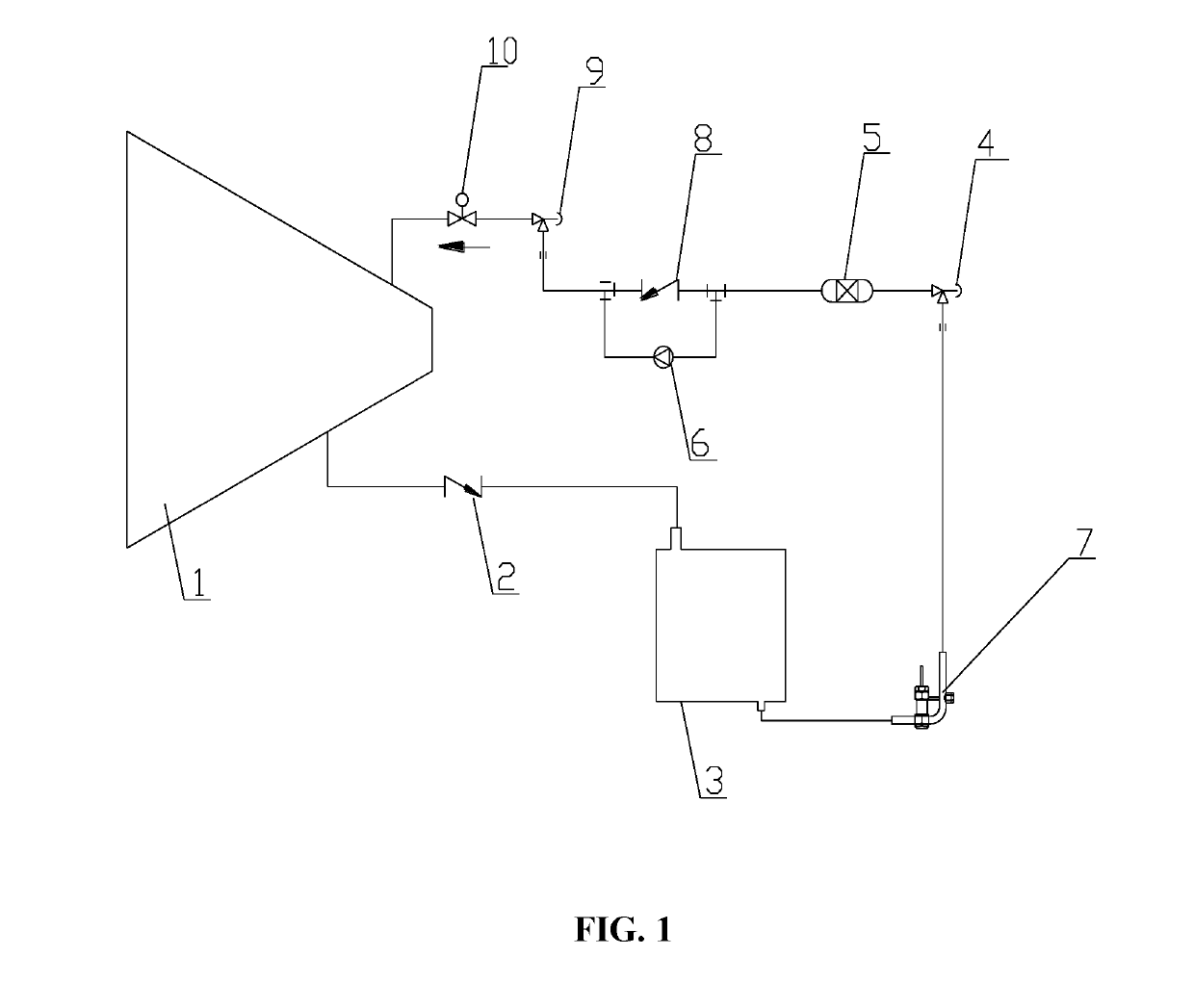

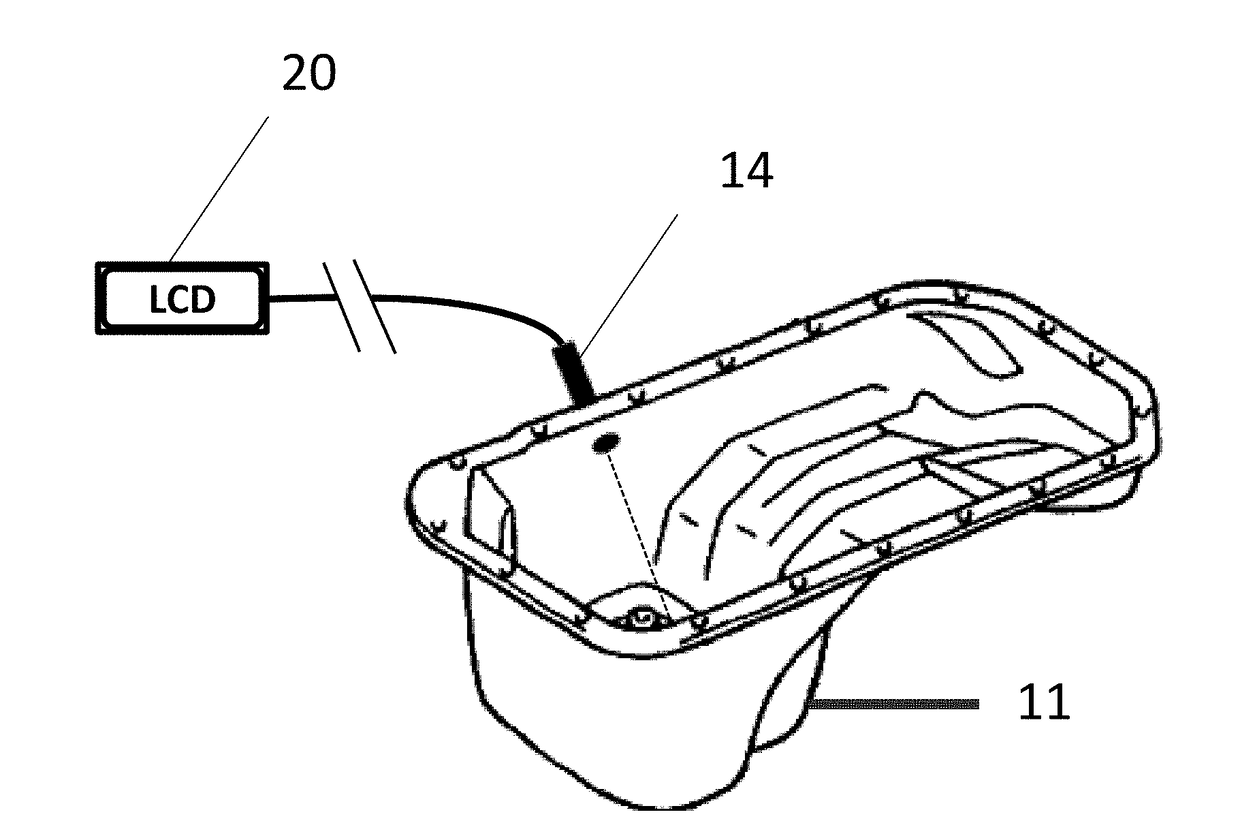

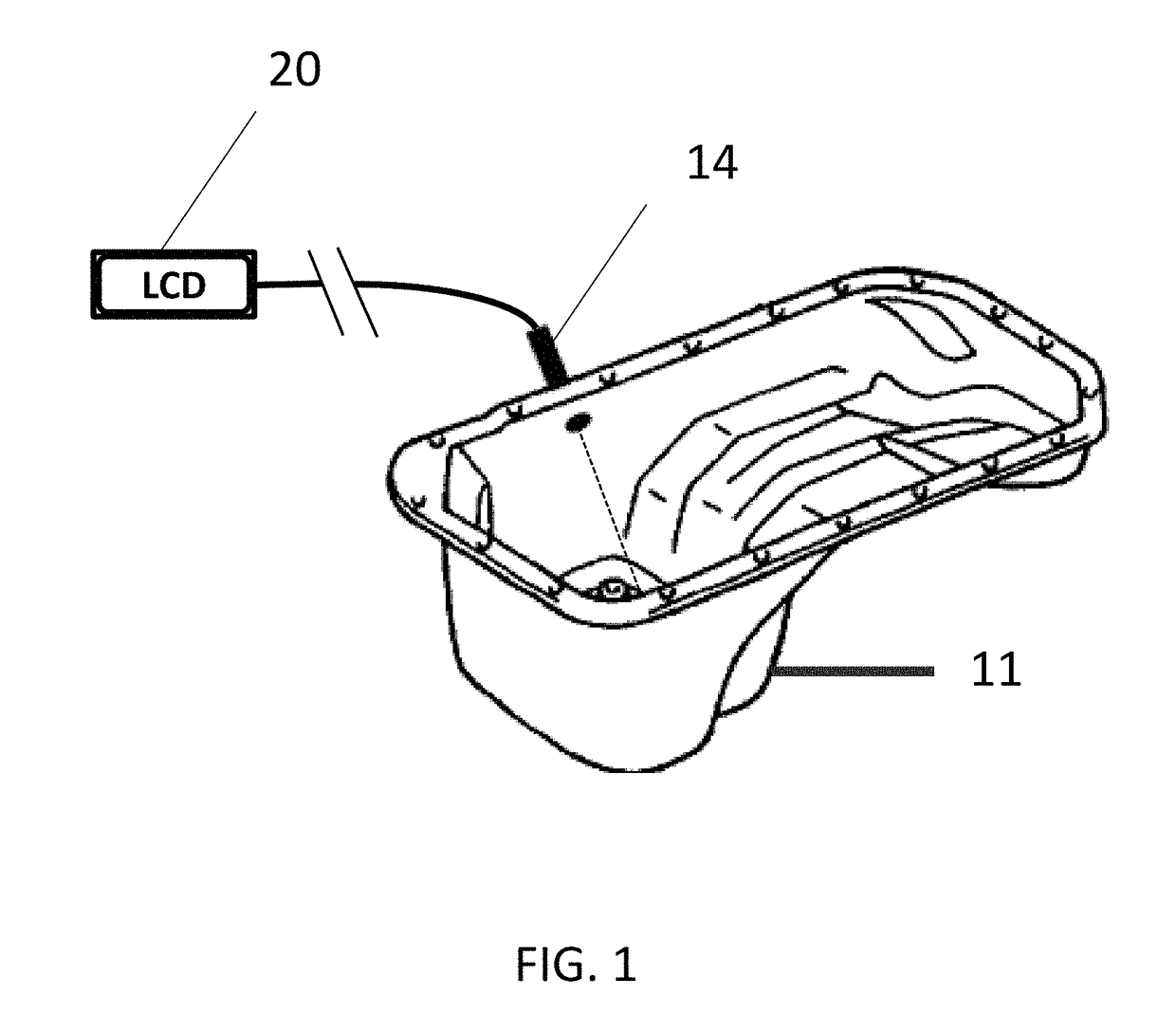

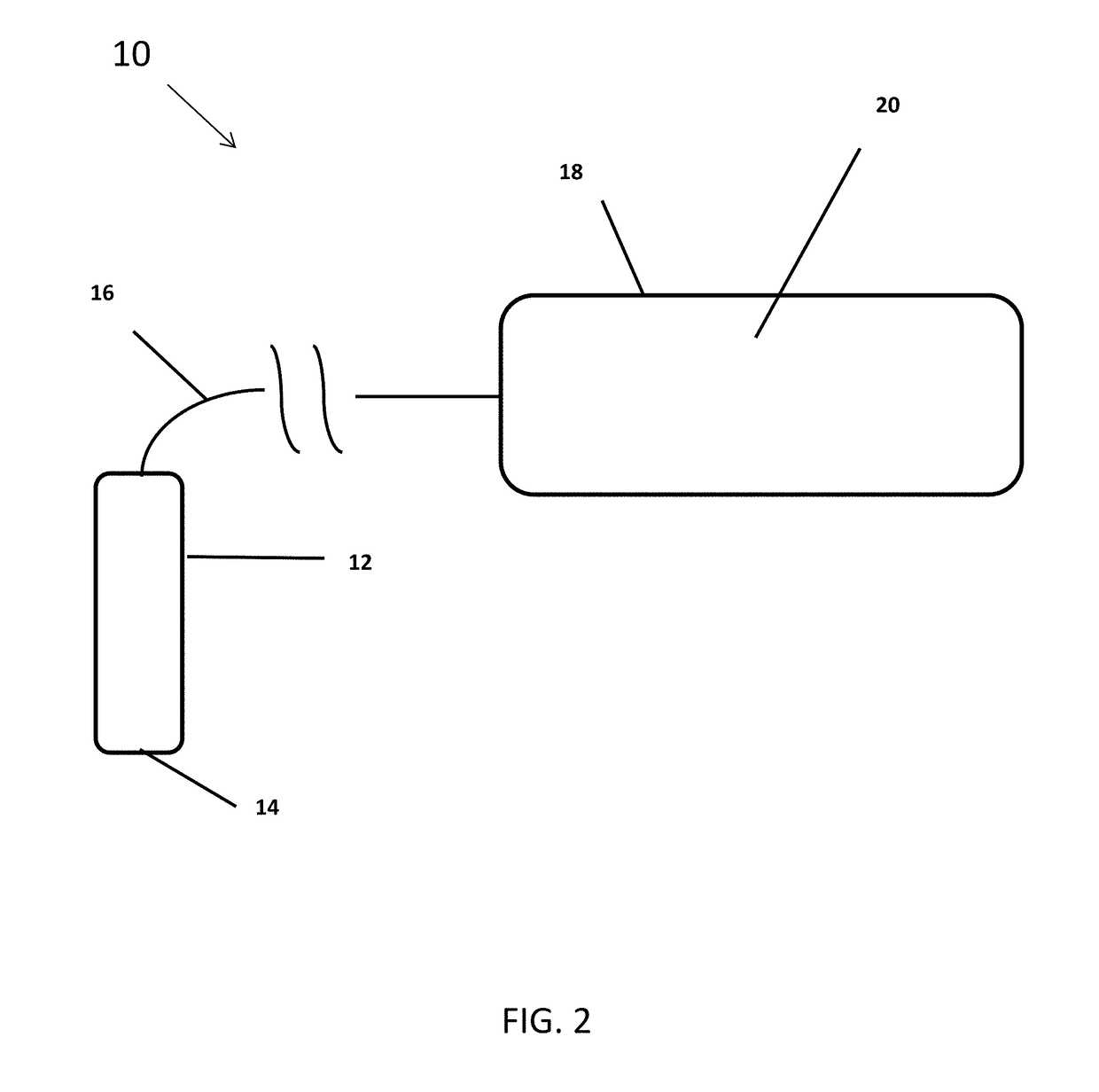

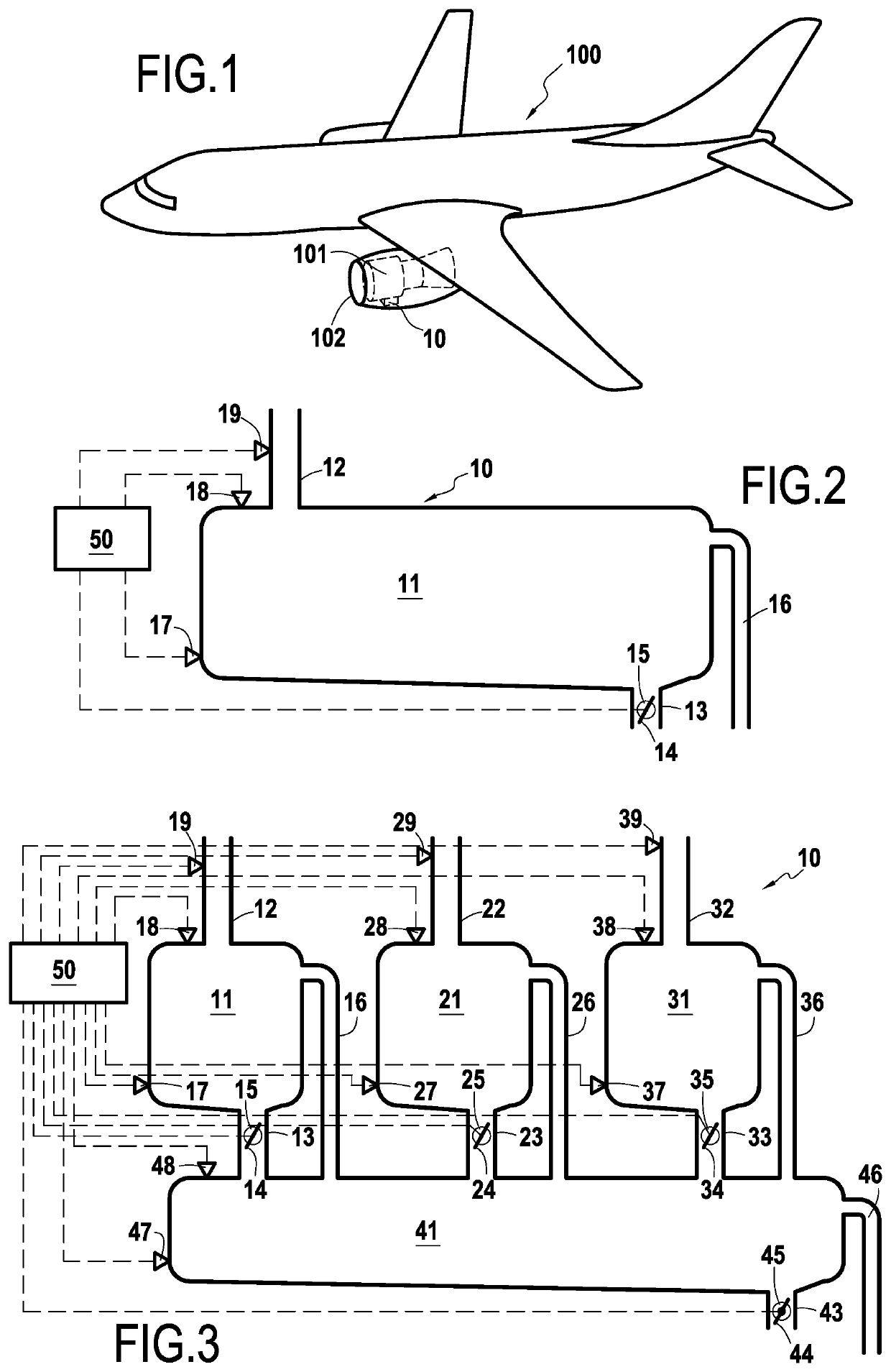

System for maintaining an aircraft turbine engine

InactiveCN107054691ASimplify maintenance proceduresReduce downtimeEngine levelsEngine fuctionsDisplay deviceTurbine

System for maintaining a turbine engine (1) comprising said turbine engine (1) of an aircraft (2) comprising: an oil reservoir (3), a sensor (4) able to measure an oil level in the oil reservoir (3), a transmission device (5) for transmitting a signal coupled to said sensor (4) in order to transmit information relating to an oil level measured by said sensor (4), communication means (6) coupled to said transmission devices (5) for communicating to the outside of the aircraft (2) information representing an oil level measured by said sensor (4). The maintenance system further comprises a mobile apparatus (50) able to communicate with said communication means (6) and comprising a display for displaying said information representing an oil level to an operator situated on the ground outside the aircraft (2).

Owner:SAFRAN AERO BOOSTERS SA

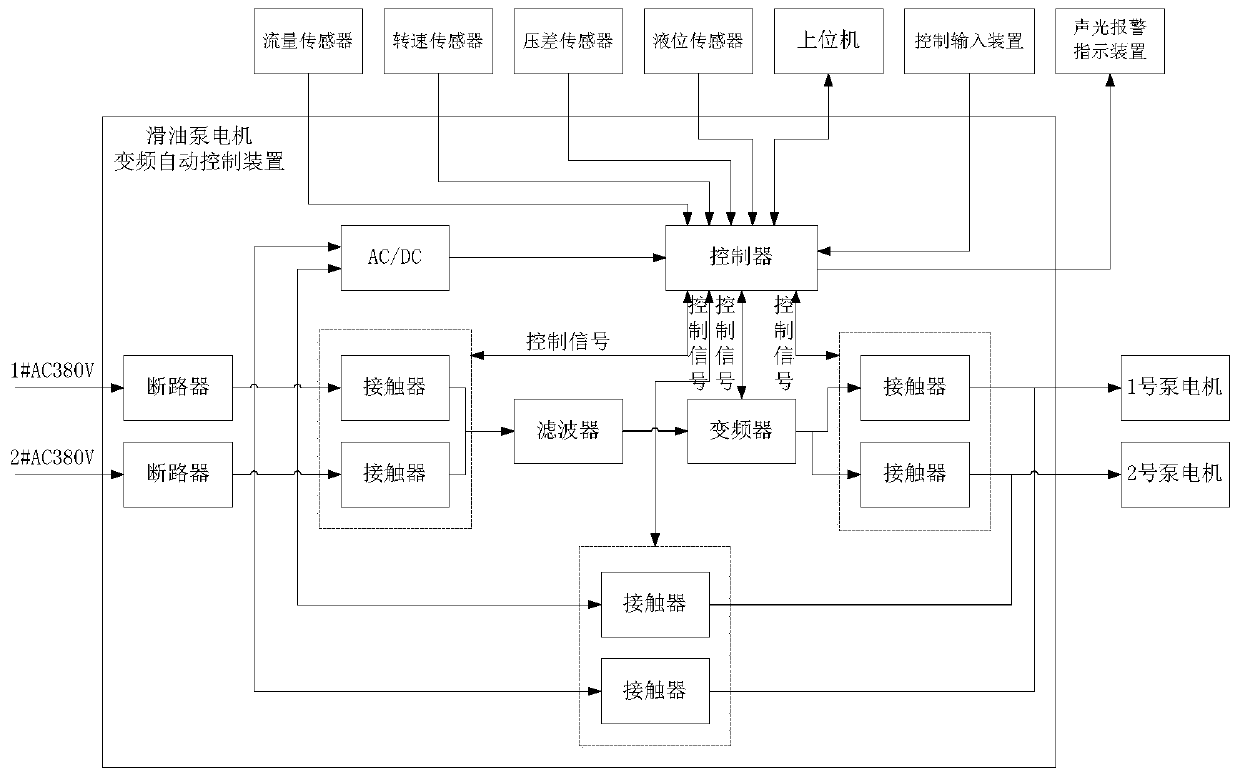

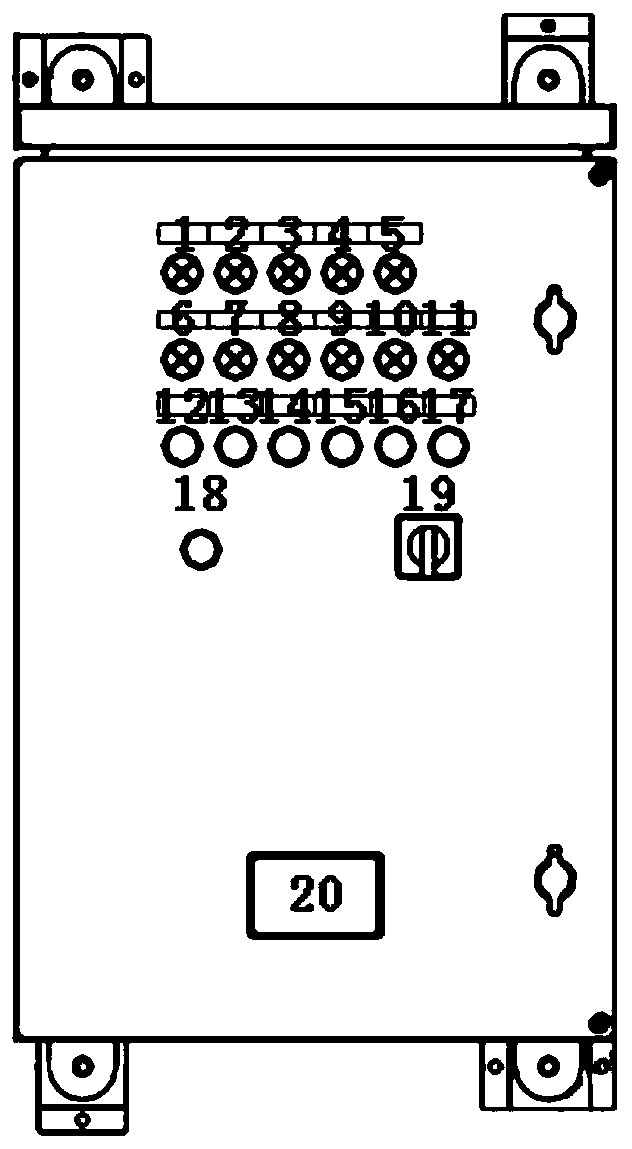

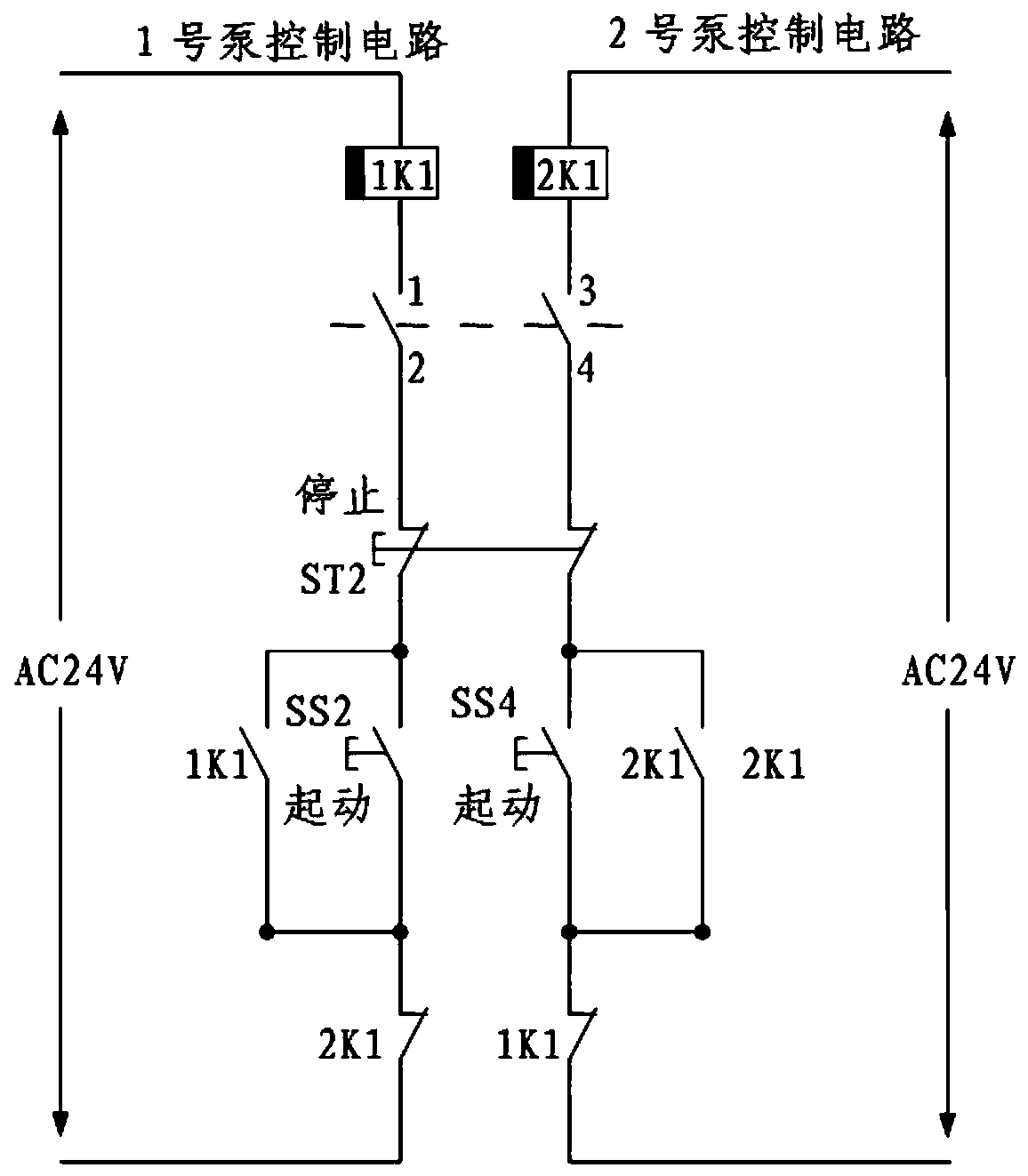

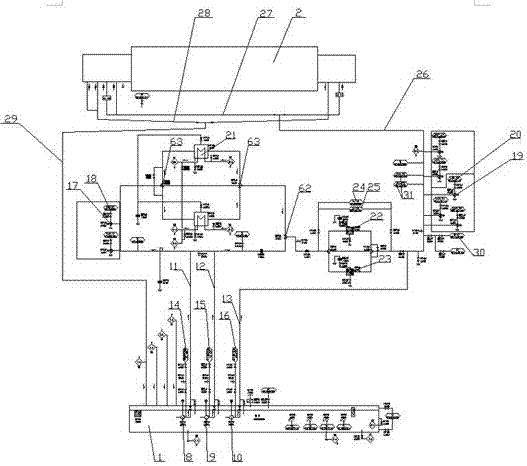

Frequency conversion automatic control device and method of motor of shafting lubricating oil pump

InactiveCN110486609AAvoid getting out of controlLow powerEngine pressureAC motor controlFrequency changerAutomatic control

The invention provides a frequency conversion automatic control device and method of a motor of a shafting lubricating oil pump. The device comprises a sensor, a controller, a frequency converter anda contactor; the function of adjusting the flow and controlling frequency conversion output by using the shafting rotating speed is realized on the basis of automatically controlling the operation oftwo motors of the lubricating oil pump, and the device is used for providing the fine control requirements of lubricating oil according to the user requirements of a lubricating oil system under different operating working condition; the device has lubricating oil flow monitoring, fault alarming and manual emergency operation functions; and when the frequency converter breaks down, an input powersupply of a power grid is directly used as the power supply of the lubricating oil pump motors, so that the flow of a lubricating oil pipe is prevented from being out of control due to the failure ofthe lubricating oil system, maintenance personnel can be timely reminded to repair the frequency converter, and the equipment use reliability is further improved.

Owner:CHINA SHIP DEV & DESIGN CENT

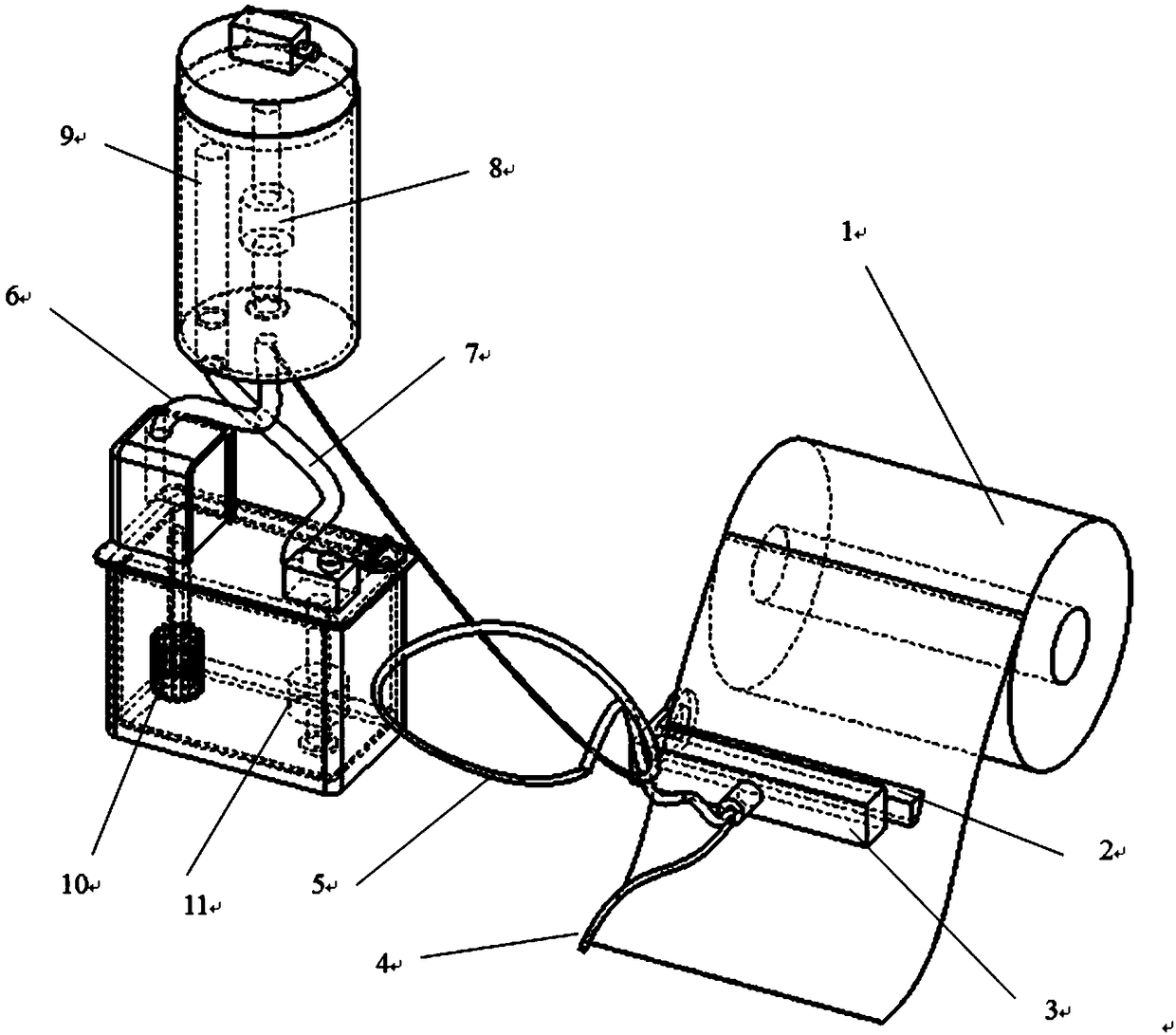

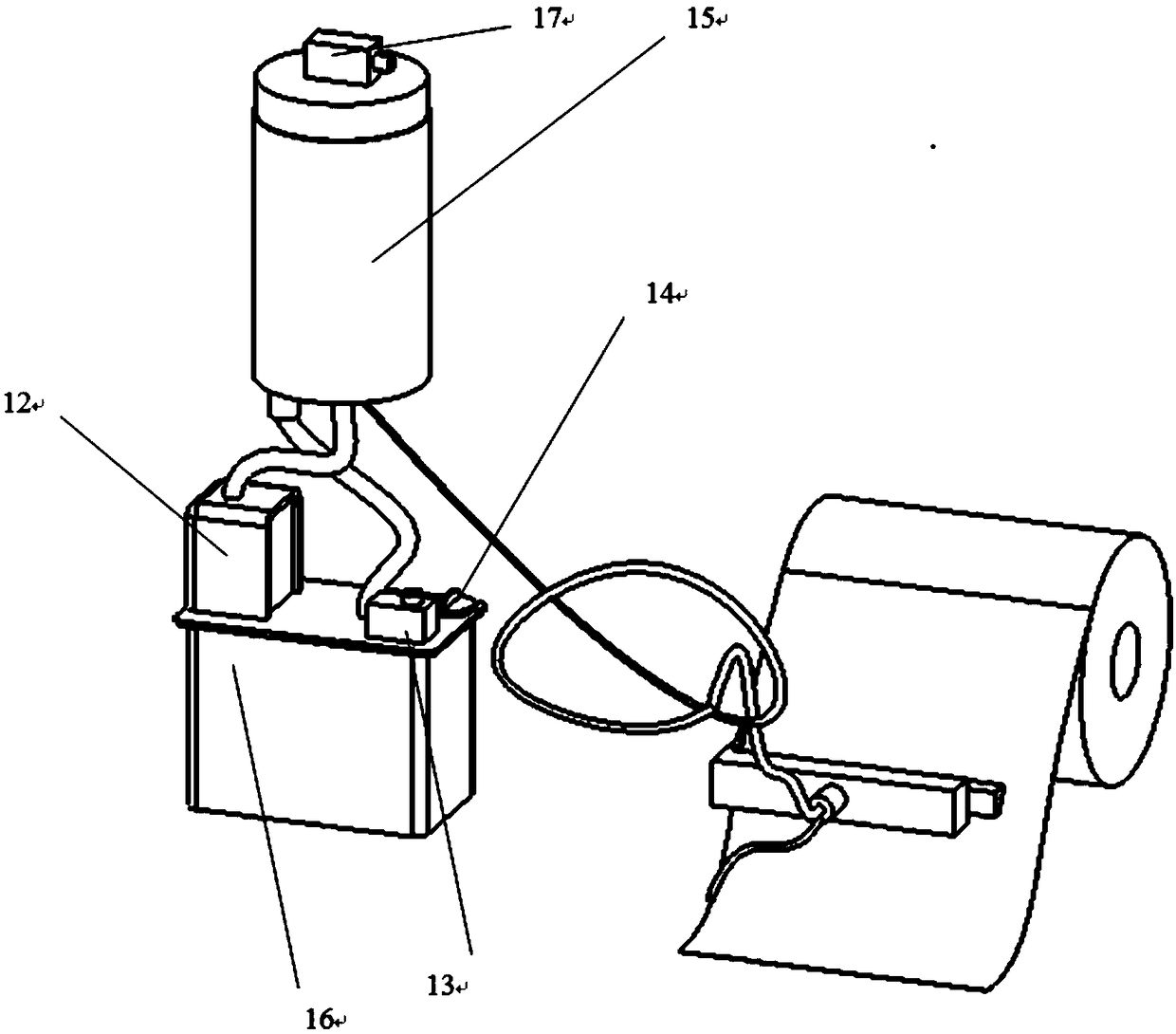

Automatic oiling device and method for cigarette packaging machine

The invention discloses an automatic oiling device and method for a cigarette packaging machine. The device comprises an oil felt used for oiling aluminum paper, and further comprises a big oil tank,a small oil tank, an oil pump and a controller, wherein a first liquid level sensor is arranged in the big oil tank, the small oil tank is located above the big oil tank, a second liquid level sensoris arranged in the small oil tank, an oil outlet is formed in the bottom of the small oil tank, the small oil tank is connected with the oil felt through an oil conveying pipeline, the oil pump is used for pumping lubricating oil from the big oil tank into the small oil tank, both the first liquid level sensor and the second liquid level sensor are connected into the controller, and the oil pump is connected into and controlled by the controller. The device and the method are mainly used for lubricating the aluminum foil paper, and the problem that the surface friction coefficient of the aluminum foil paper is large, as a result, equipment is blocked by the aluminum paper is solved.

Owner:CHINA TOBACCO ZHEJIANG IND

Lubrication system with a signal transmission element

PendingCN109386717ARealize automatic monitoringSignal transmission is simple and fastEngine pressureBatteries circuit arrangementsEngineeringDistributor

The invention discloses a lubrication system configured to supply a lubricant to at least one lubrication point. The lubrication system includes at least one lubricant pump configured to pump the lubricant to the at least one lubrication point, a lubricant distributor configured to distribute the lubricant at the at least one lubrication point, a control unit configured to control at least the lubricant pump and / or the lubricant distributor, at least one lubrication system monitor configured to monitor a monitoring variable of the lubrication system, and at least one signal transmission deviceconfigured to wirelessly transmit a signal indicative of the monitoring variable provided by the lubrication system monitor to the control device or to receive signals therefrom.

Owner:德国斯凯孚润滑油系统有限责任公司

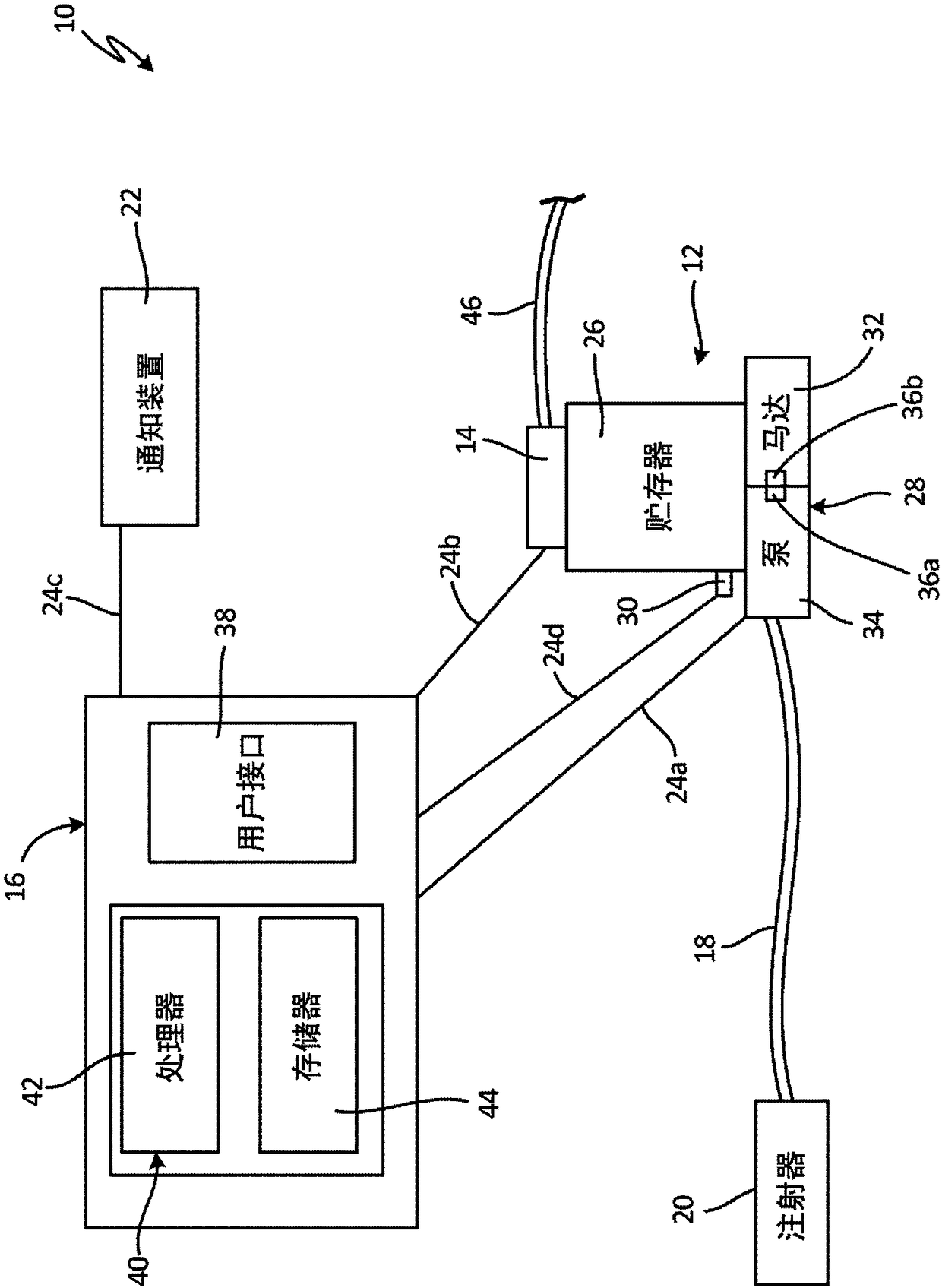

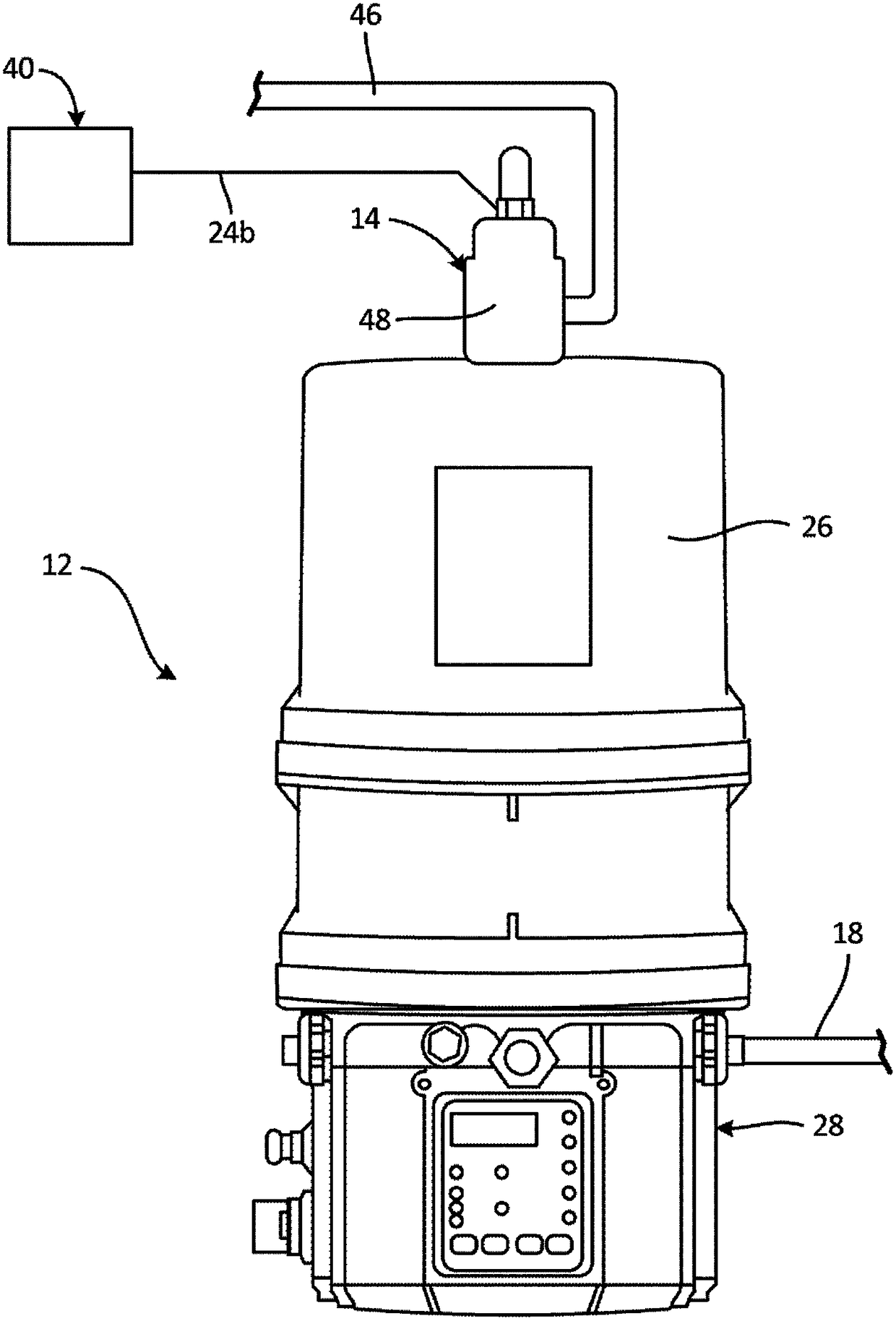

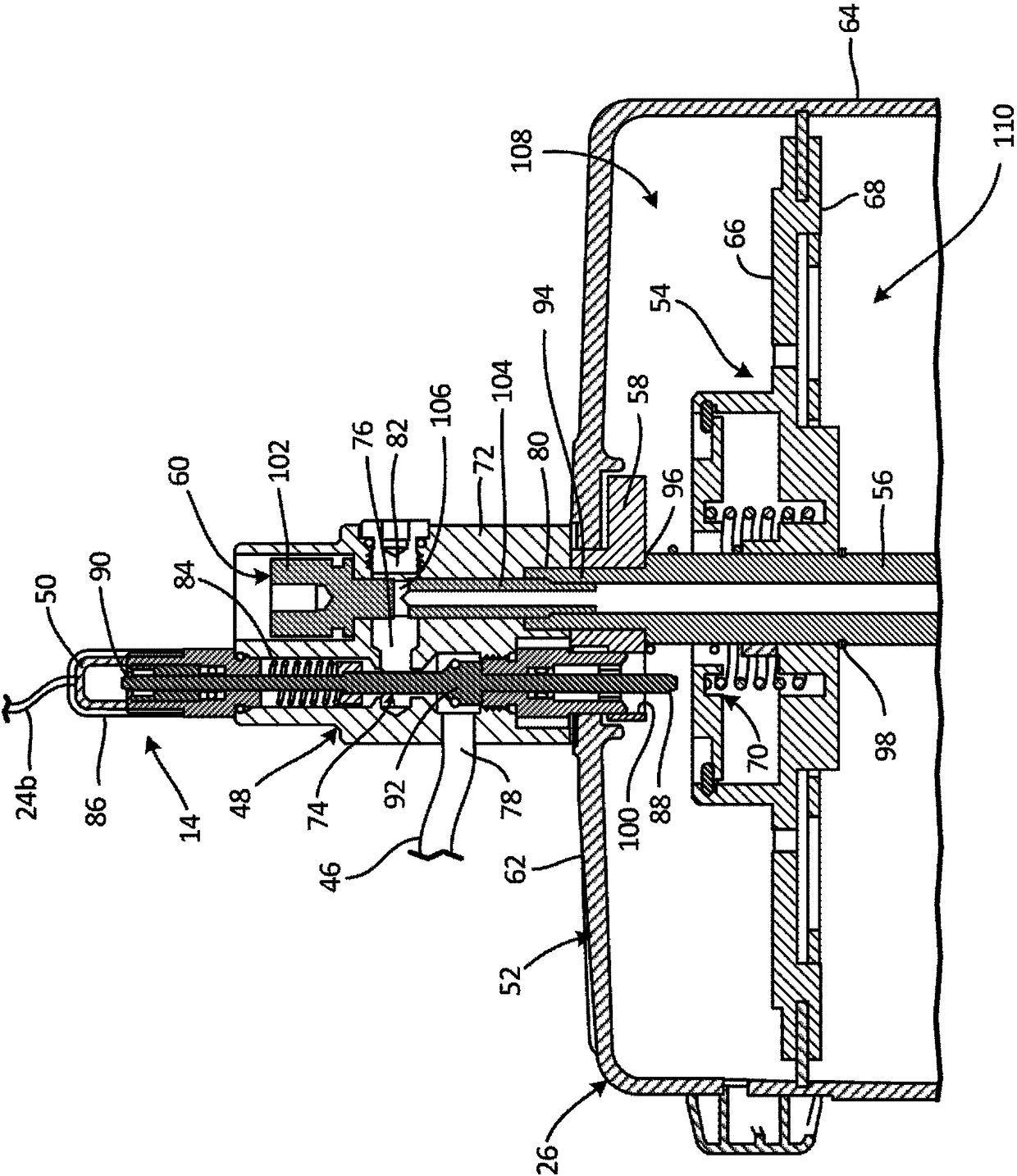

Continuous reservoir level monitoring

The lubricant level within a reservoir is difficult to monitor, leading to the reservoir being refilled more often than necessary to ensure that the reservoir always contains lubricant. A lubricant level sensing system is connected to and monitors various aspects of the pump assembly that draws lubricant from the reservoir. The pump assembly displaces a known volume of lubricant with each pump stroke. A lubricant-level estimator calculates an estimated lubricant level remaining in the reservoir based on a stroke-count value as sensed from the pump assembly and on a reference value stored in amemory. The estimated lubricant level provides the lubricant remaining and the rate of usage such that maintenance can be scheduled ahead of time to prevent the reservoir from running dry.

Owner:GRACO INC

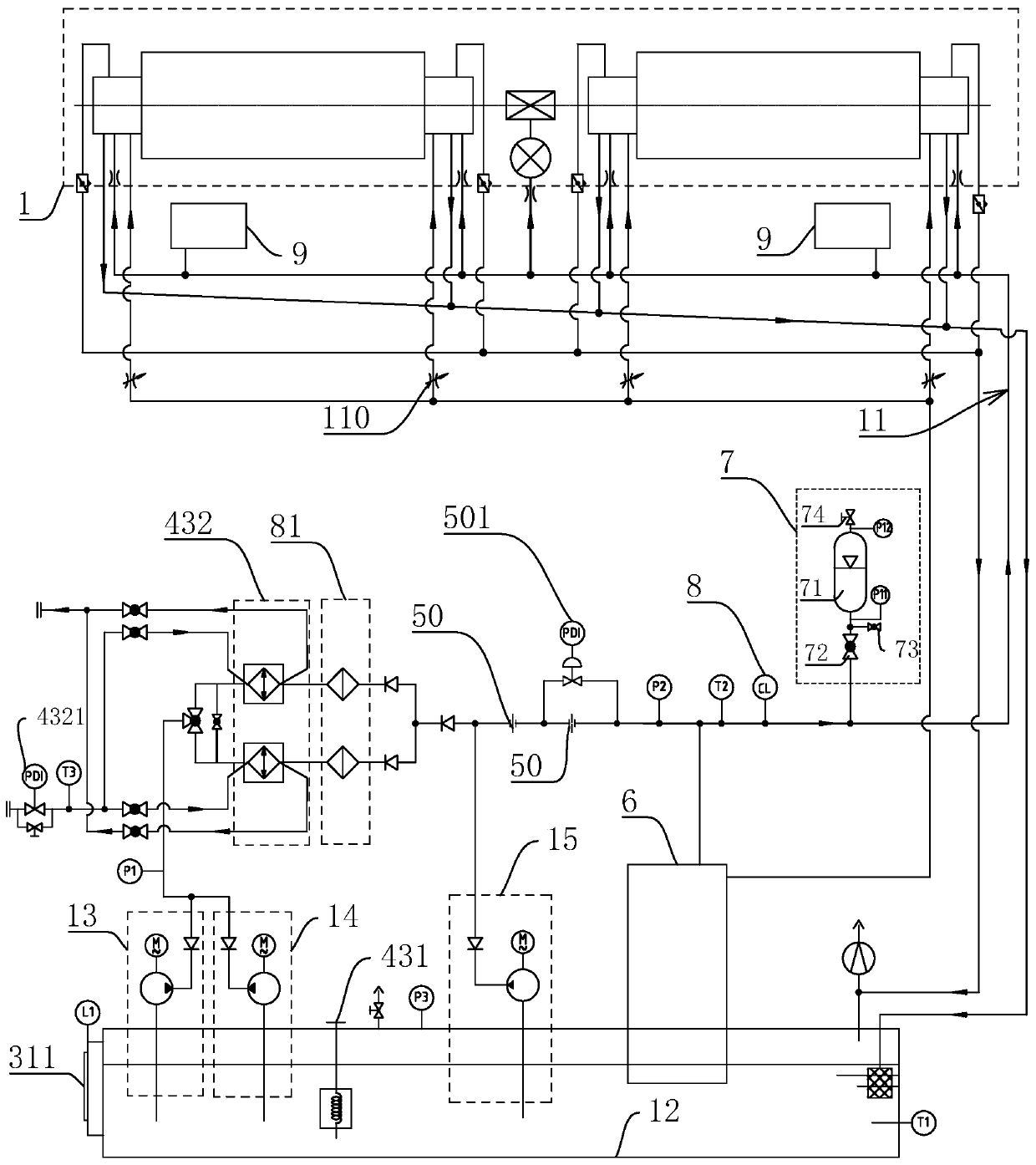

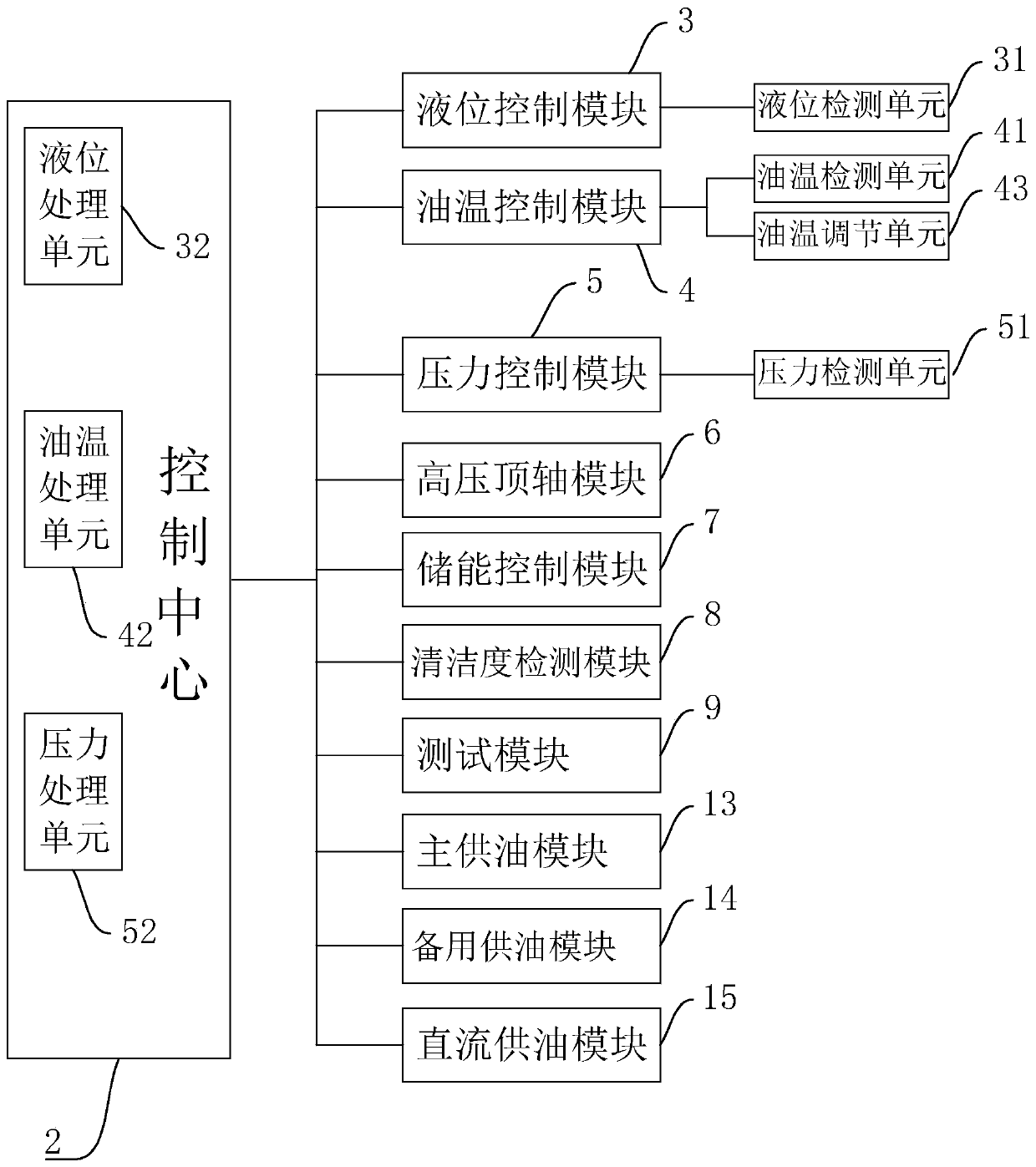

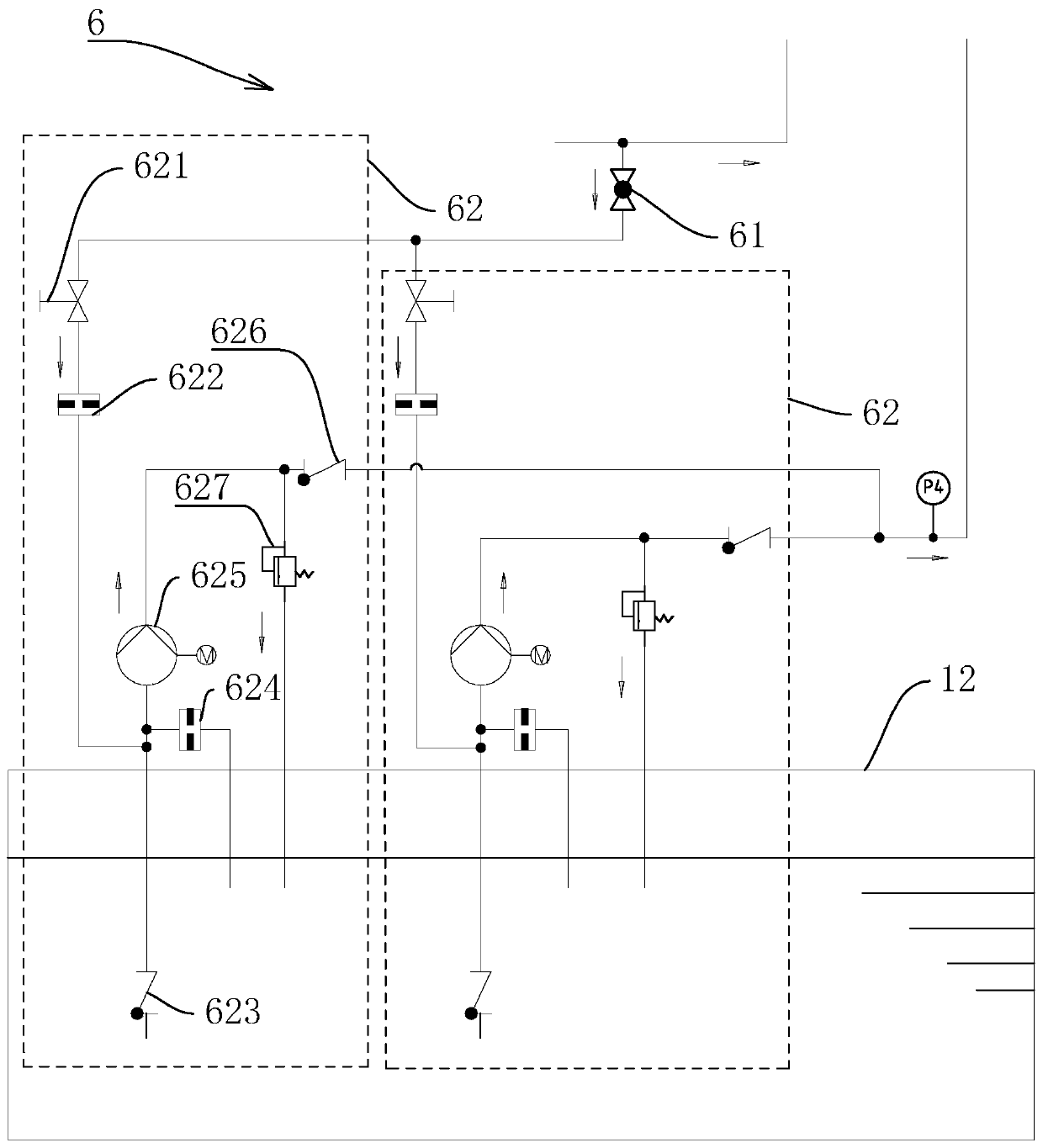

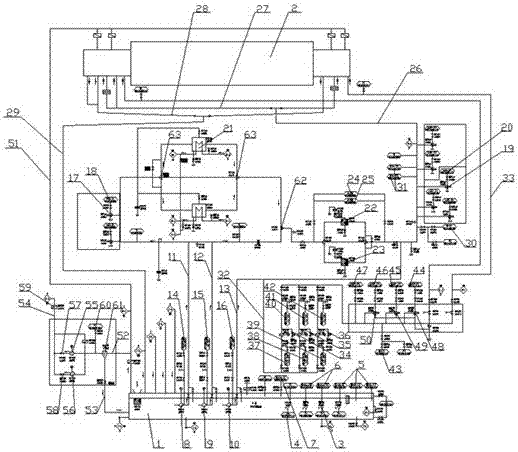

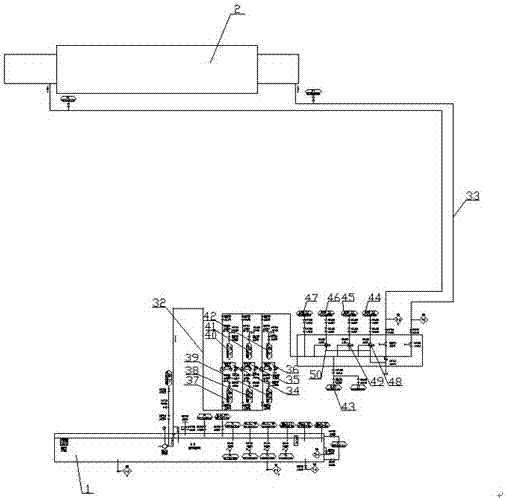

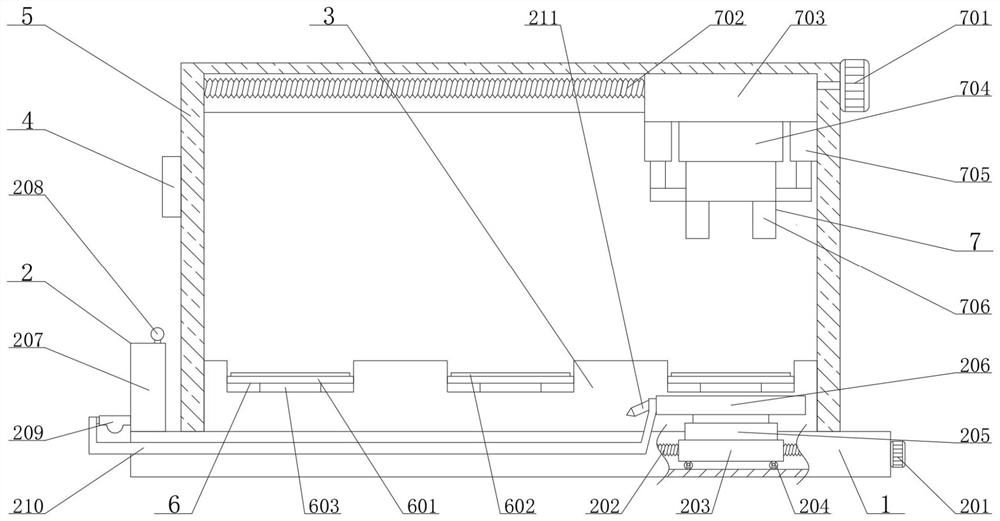

Rotating-shaft-type main engine intelligent lubricating system and control method thereof

PendingCN111336397AProduces the effect of a secure bootEnsure safetyEngine temperatureEngine pressureControl engineeringProcess engineering

The invention discloses a rotating-shaft-type main engine intelligent lubricating system and a control method thereof, and relates to the technical field of lubricating systems. The rotating-shaft-type main engine intelligent lubricating system and the control method thereof aim to solve the technical problem that a standby pump needs to be started manually in an existing lubricating oil system, and consequentially, intelligent operation of the whole lubricating system is inconvenient to realize. According to the key points of the technical scheme, the rotating-shaft-type main engine intelligent lubricating system comprises a unit, an oil supply pipeline, an oil tank, a main oil supply module, a standby oil supply module and a direct-current oil supply module, the main oil supply module, the standby oil supply module and the direct-current oil supply module are all arranged on the oil tank and connected to the oil supply pipeline, and the oil supply pipeline is connected to a to-be-lubricated position of the unit; and a control center, a liquid level control module, an oil temperature control module, a pressure control module, a high-pressure shaft jacking module, an energy-storagecontrol module, a cleanliness detecting module and a testing module which are matched and the corresponding control method are further included. The automation and intelligence effects of the lubricating system are improved.

Owner:JIANGSU JIANGHAI LUBRICANTS HYDRAULIC EQUIP

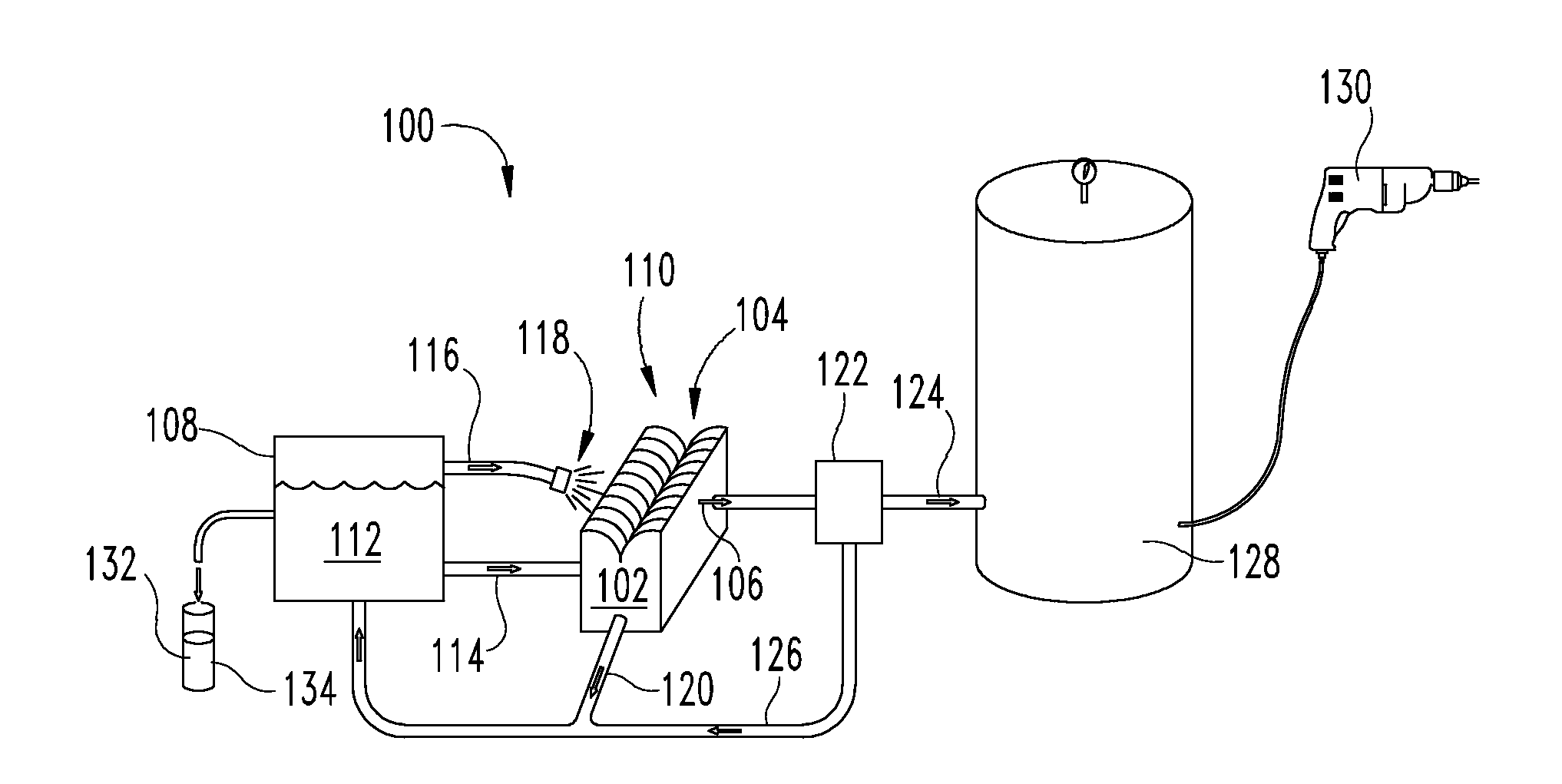

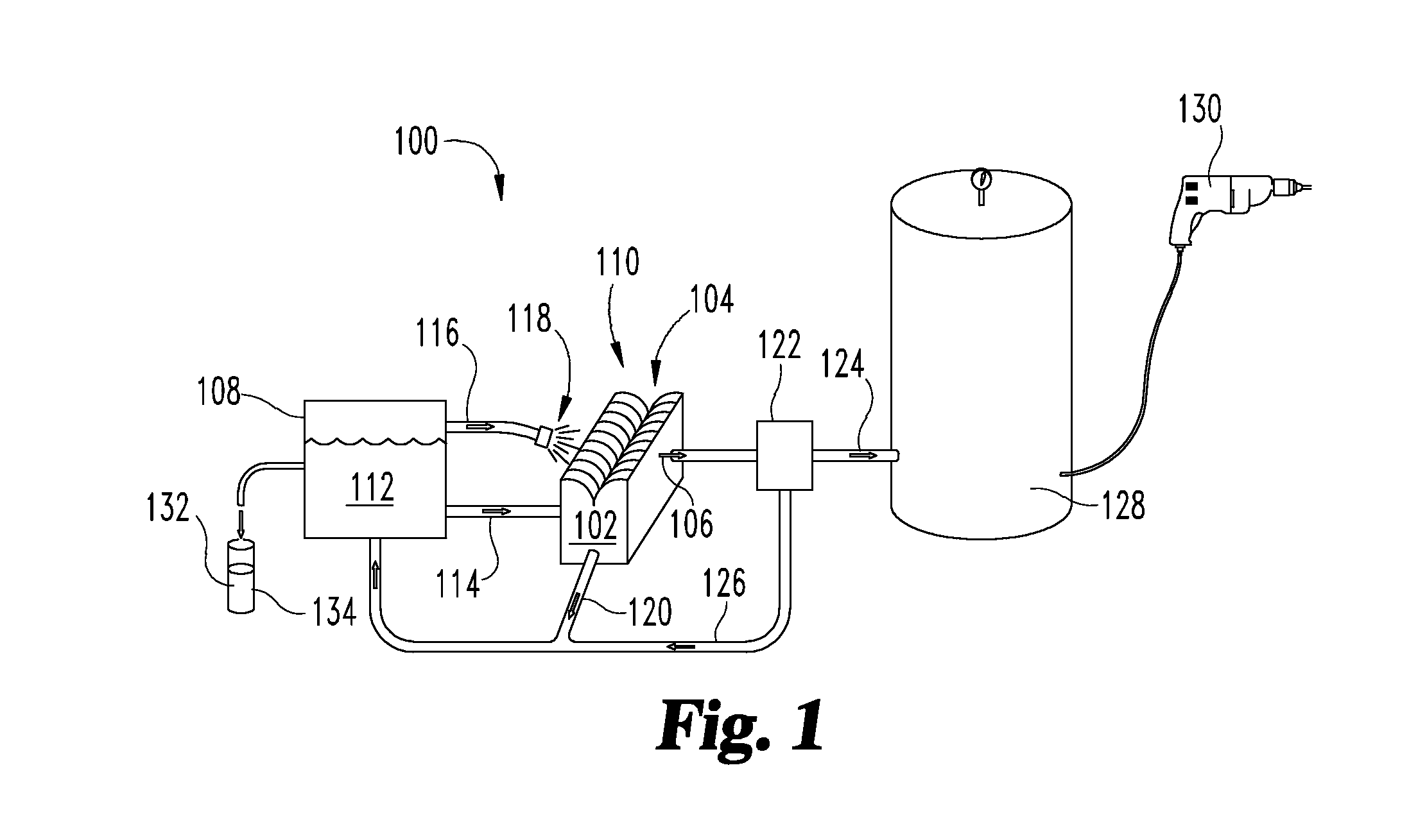

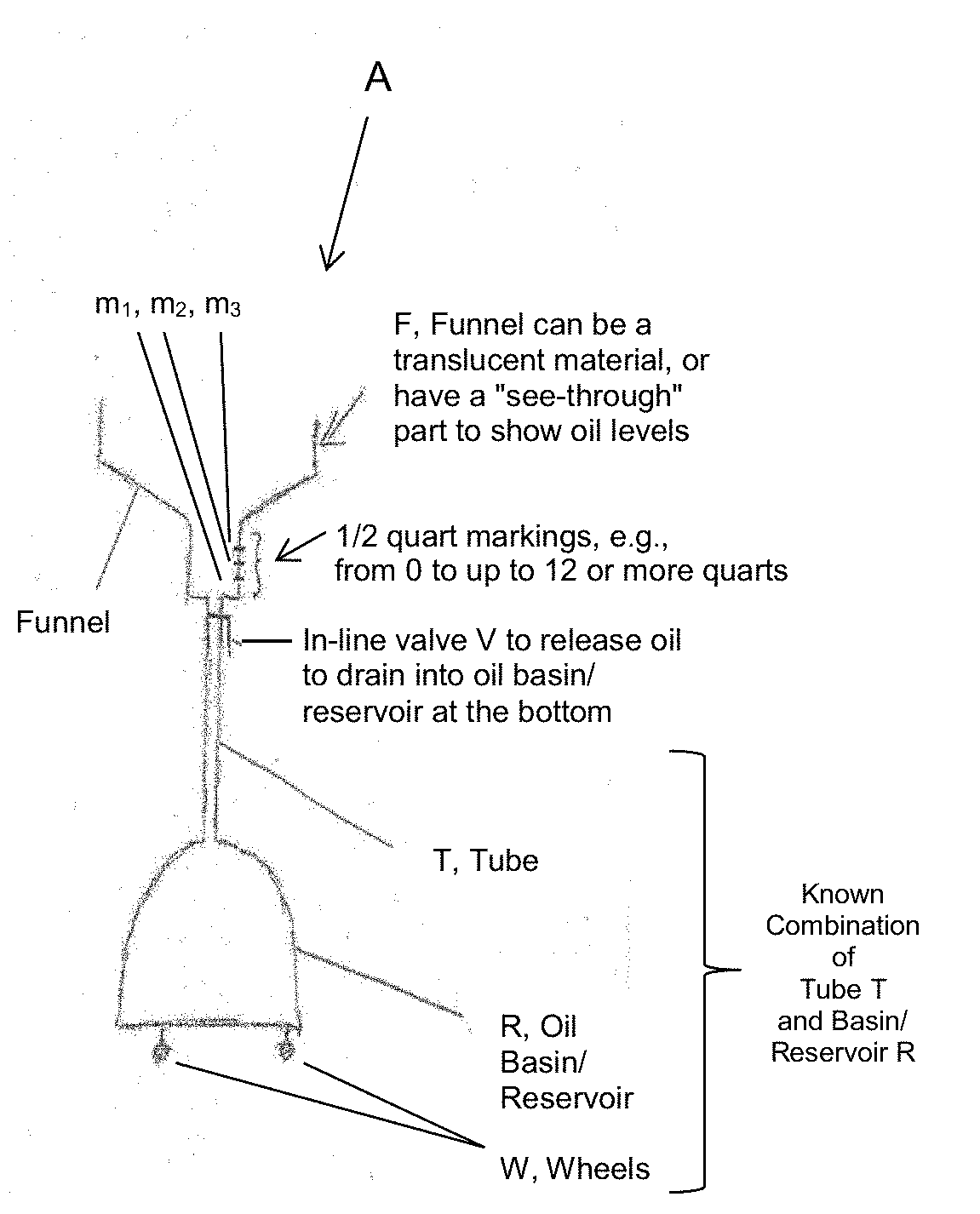

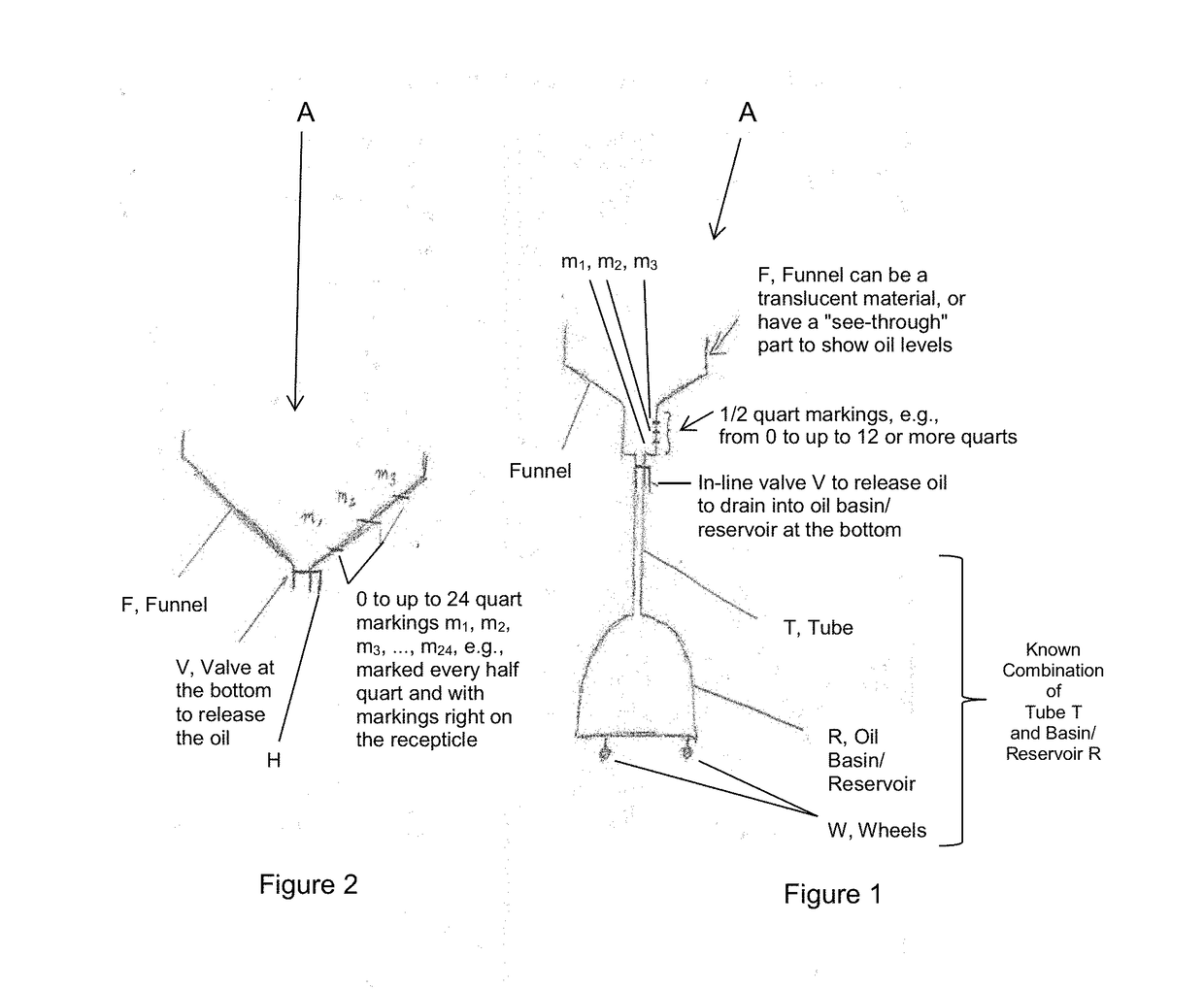

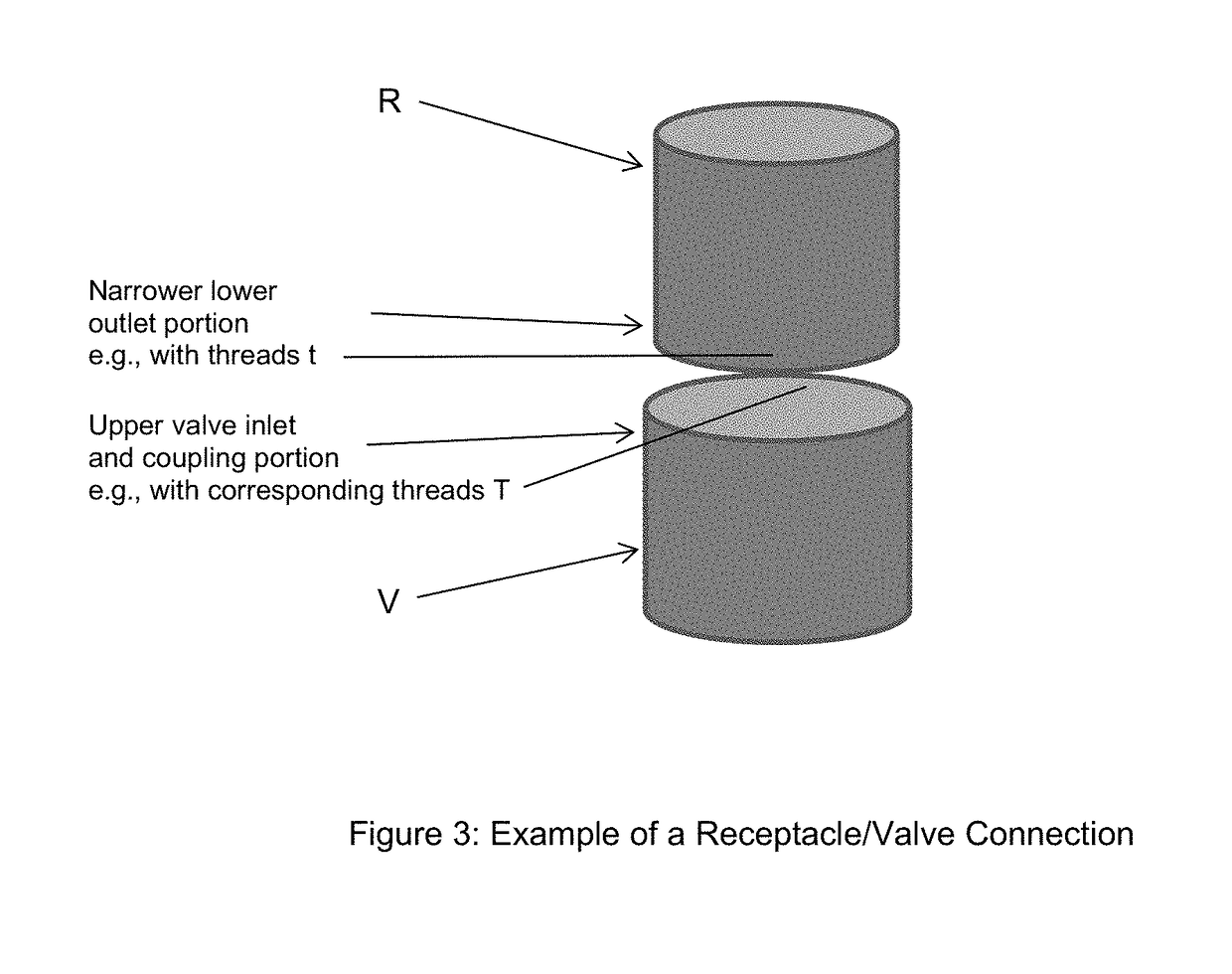

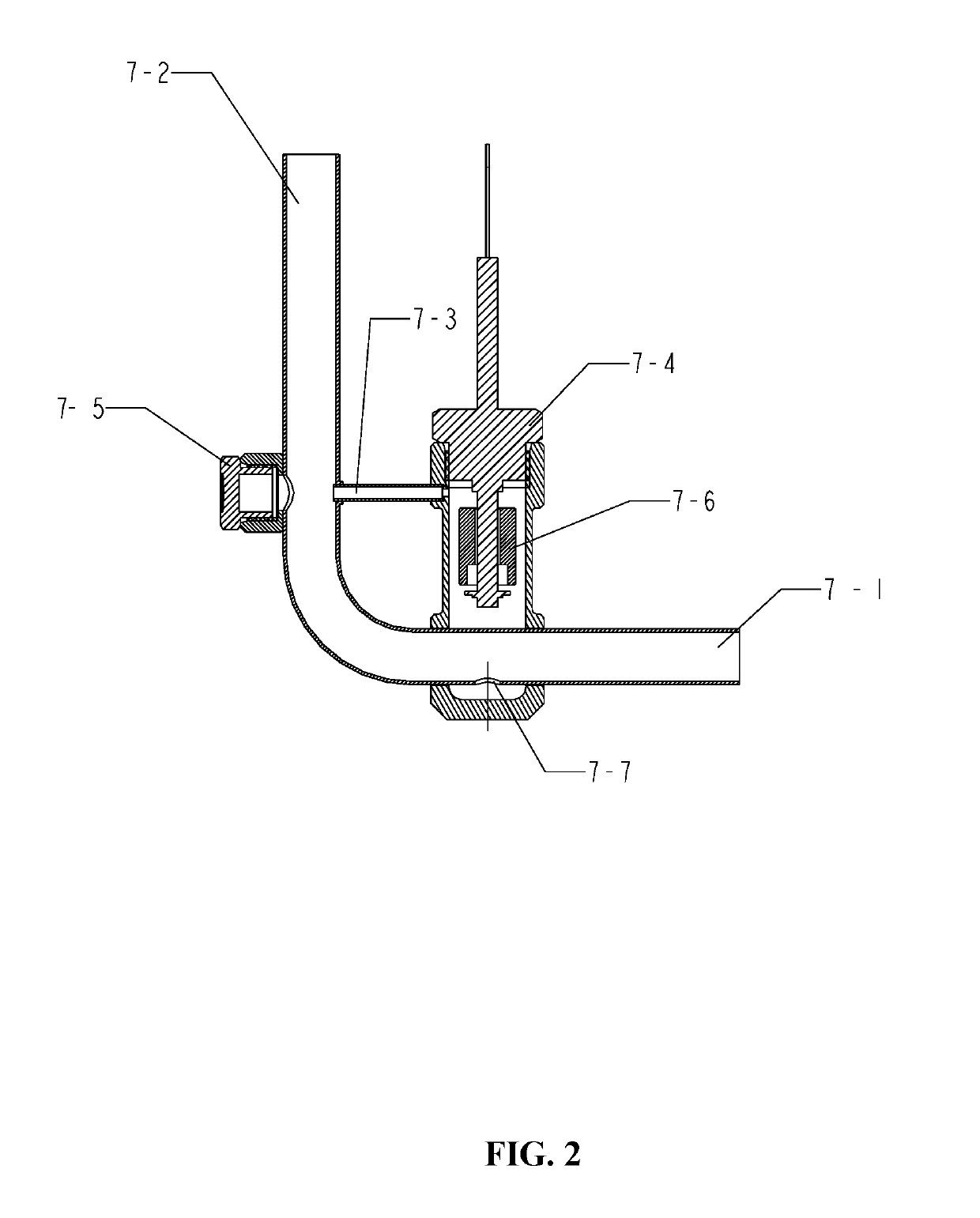

Technique for collecting and measuring oil drained from a vehicle

ActiveUS20180334936A1Facilitate oil consumption testingValve arrangementsSignal processingCouplingValve opening

Apparatus for collecting and measuring oil drained from a vehicle includes a receptacle and a valve. The receptacle includes a wide upper oil collection portion with an upper receptacle wall configured to collect and contain oil drained from a vehicle, and includes a narrower lower outlet portion having a lower receptacle wall configured to allow the oil to drain from the receptacle via a gravity feed. The receptacle has markings arranged on at least one of the upper receptacle wall or the lower receptacle wall and configured to measure the oil drained and collected from the vehicle. The valve includes an upper valve inlet and coupling portion configured to connect to the narrower lower outlet portion of the receptacle and allow the oil to drain into the valve, includes a valve opening / closing portion configured either to open and allow the oil to drain through the valve or to close and allow oil to collect in the receptacle, and includes a lower valve outlet and coupling portion configured to connect to a tube or oil basin / reservoir to allow the oil to drain from the valve into the tube or oil basin / reservoir.

Owner:SCHALLER ARTHUR D

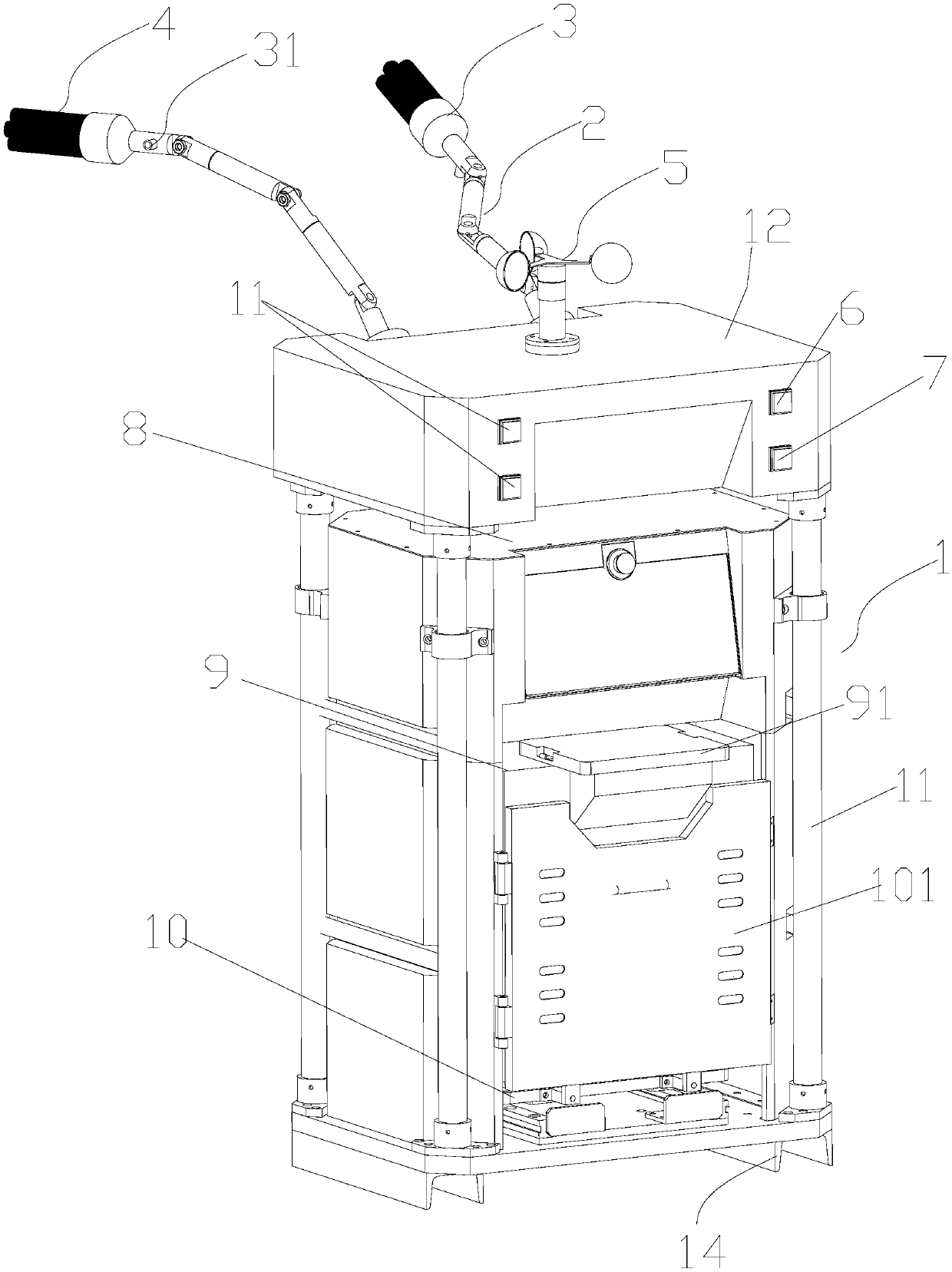

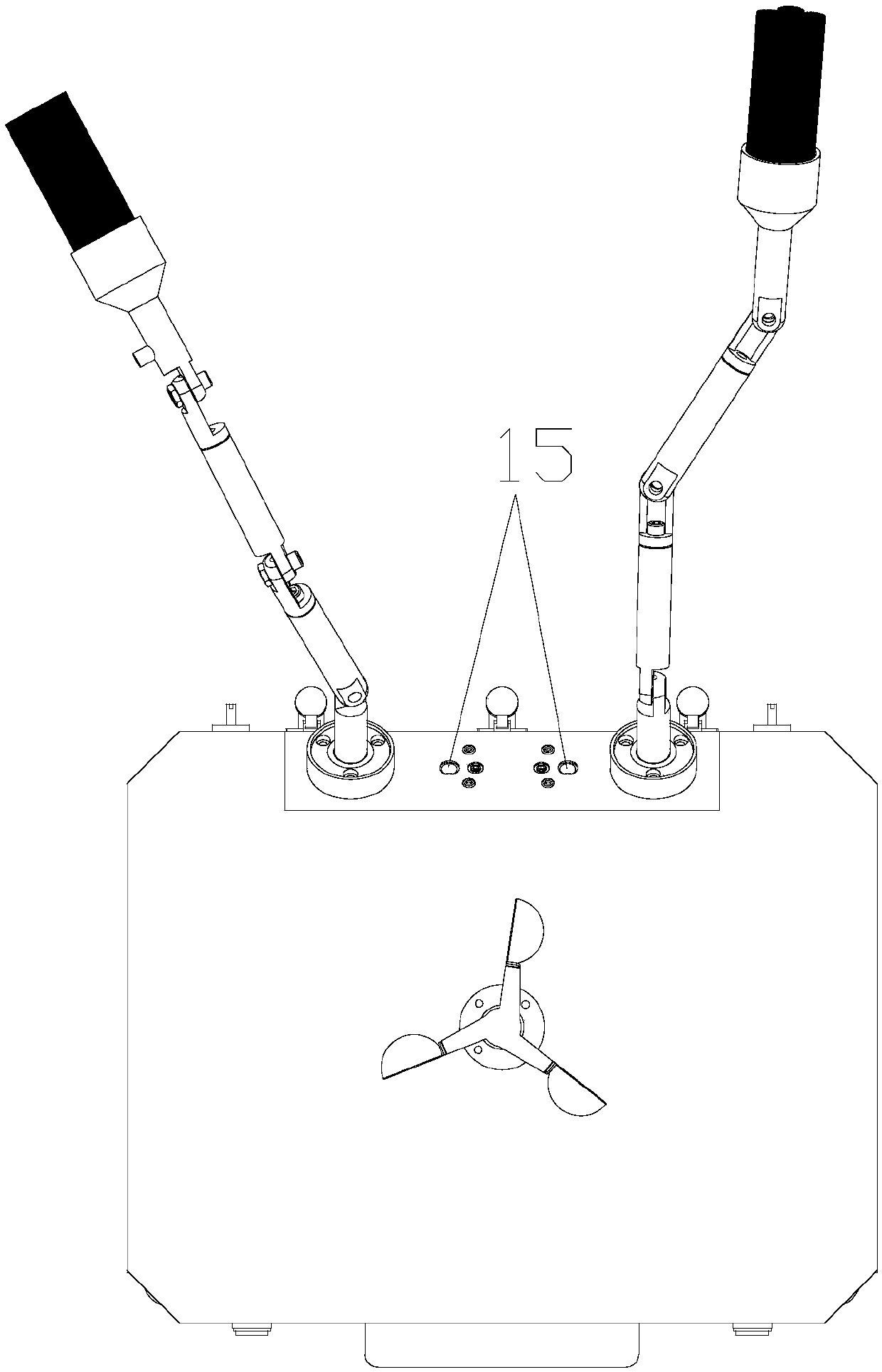

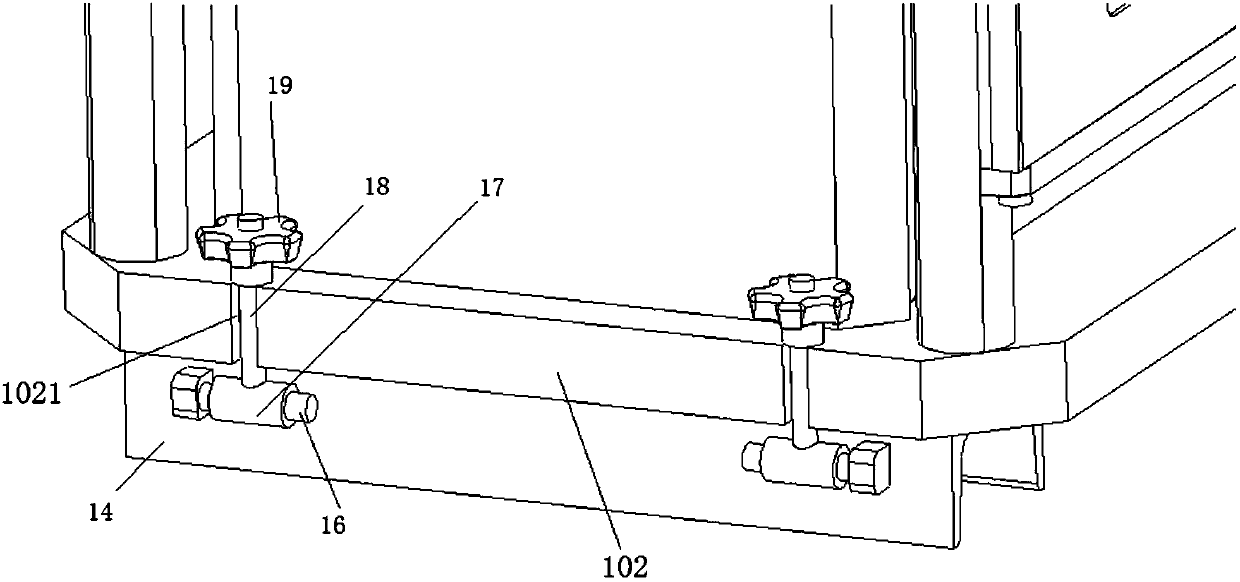

Automatic intelligent steel wire rope oiling device

PendingCN107906352AControl speedRealize smart oilingWaterborne vesselsEngine levelsSmart controlStress sensors

The invention discloses an automatic intelligent steel wire rope oiling device, which comprises a rack. An intelligent conveying control module, an oil tank installation module for bearing a lubricating oil tank, and a power module are arranged on the rack; the intelligent conveying control module is located on the upper part of the rack; a joint type mechanical arm is fixed to the top part of a bin body of the intelligent conveying control module; an oil outlet nozzle is arranged on the joint type mechanical arm; an oiling brush is arranged on the oil outlet nozzle; the oil tank installationmodule comprises a pressure sensor for detecting oil quality in the lubricating oil tank; a wind speed sensor for detecting the wind strength of an external environment is arranged on the top part ofthe bin body of the intelligent conveying control module; an oil quantity indicator light and an electric quantity indicator light are arranged on the bin body of the intelligent conveying control module; the pressure sensor, the wind speed sensor, the oil quantity indicator light and the electric quantity indicator light are connected with an intelligent control module of the intelligent conveying control module; and the intelligent control module is connected with an oil delivery pump. The automatic intelligent steel wire rope oiling device provided by the invention can be used for intelligently oiling.

Owner:天津博宜特科技有限公司

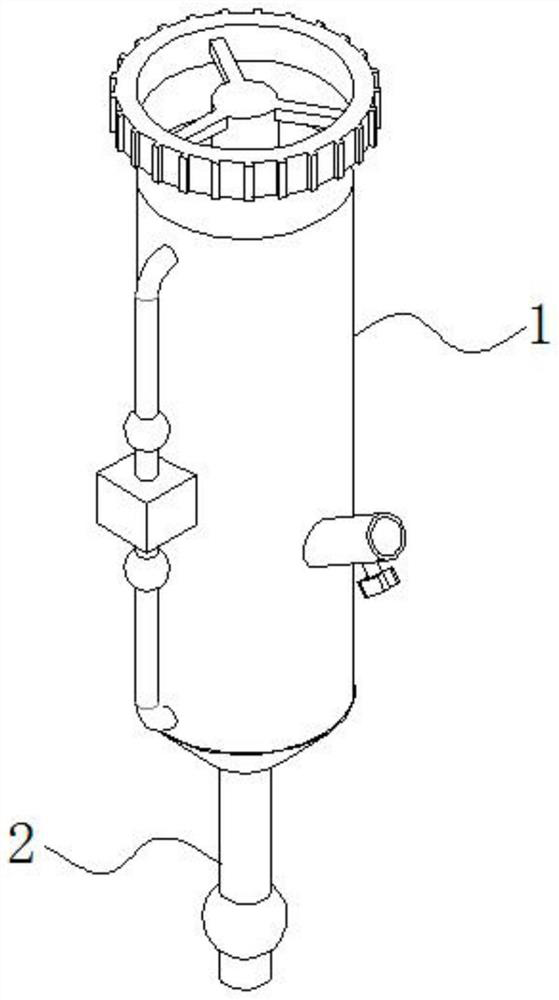

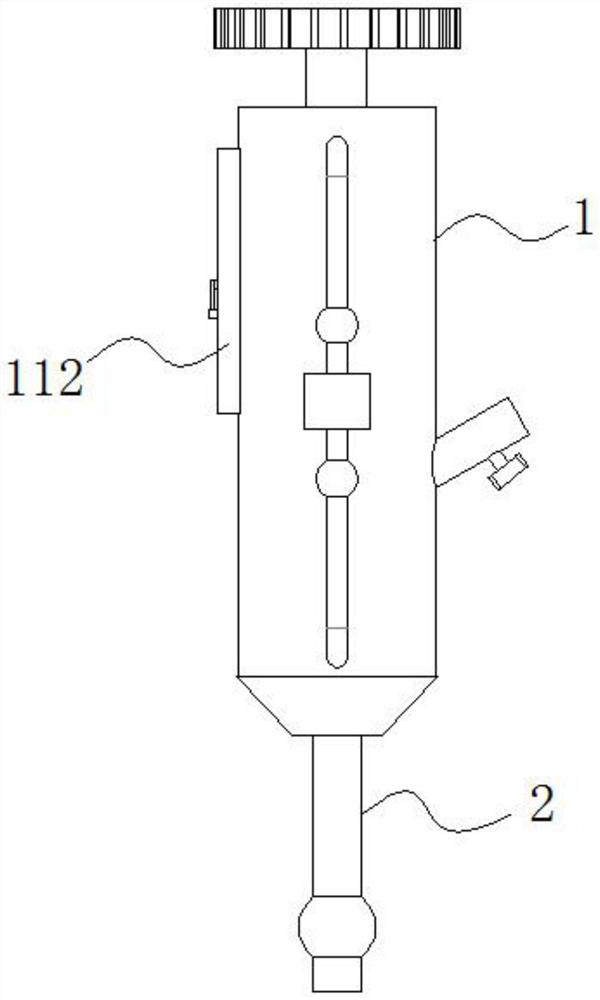

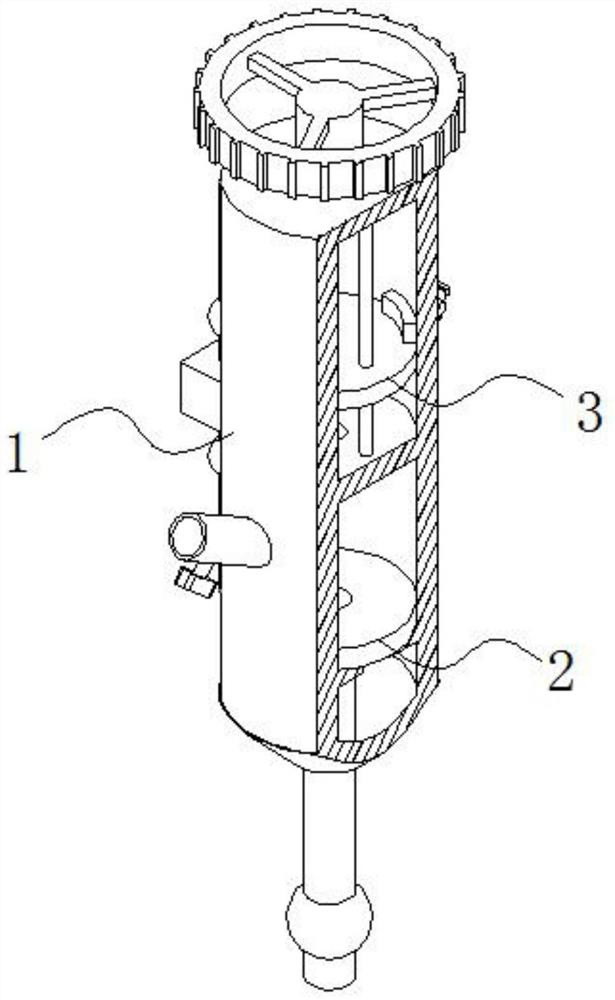

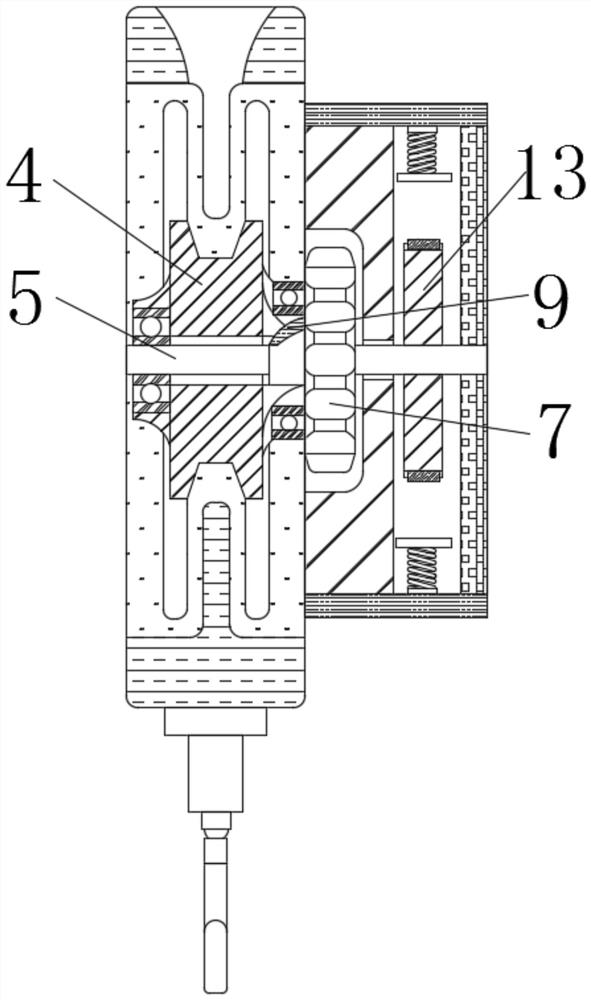

Adjusting assembly based oil injector for mechanical equipment maintenance

InactiveCN113280246AImprove oil injection efficiencyMove up and down flexible controlValve arrangementsProportioning devicesMechanical equipmentBase oil

The invention discloses an adjusting assembly based oil injector for mechanical equipment maintenance, and relates to the technical field of machinery. The oil injector comprises an oil storage mechanism; a supporting disc is fixedly connected in the oil storage mechanism; a through hole is formed in the upper surface of the supporting disc; an oil outlet assembly and a floating assembly are arranged in the oil storage mechanism in a sliding fit manner; an oil storage chamber is arranged between the floating assembly and the oil outlet assembly; a driving gas chamber is arranged above the floating assembly; and an oil quantity control gas chamber is arranged below the oil outlet assembly. Through the design of a first gas guide tube, a second gas guide tube, a first electromagnetic valve, a second electromagnetic valve, the oil storage chamber, the driving gas chamber and the oil quantity control gas chamber, the second gas guide tube is utilized to realize pressurization of the oil quantity control gas chamber, and therefore up-down movement of the oil storage chamber is realized, and then movement of a floating disc is flexibly controlled up and down; and the first gas guide tube can be utilized to realize pressurization of the interior of the driving gas chamber, and therefore lubricating oil in the oil storage chamber is pressed out from a lower port of an oil outlet pipe, and the lubricating oil injection efficiency is greatly improved.

Owner:郑杰

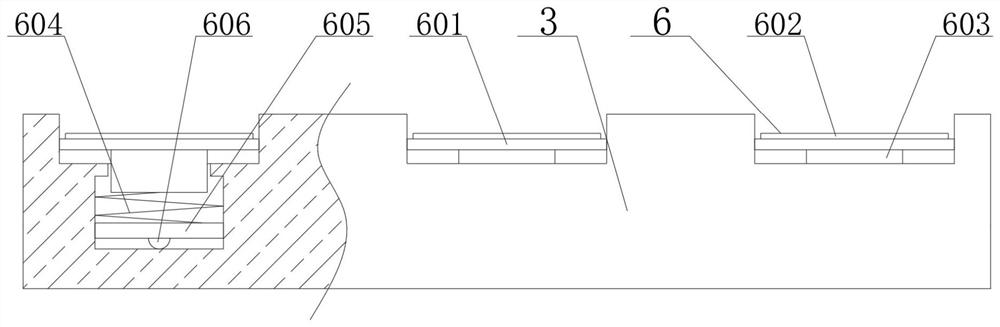

Oil system of phase modifier

ActiveCN107202241AAvoid pollutionImprove recycling ratesEngine temperatureEngine pressureFuel tankFilter effect

The invention discloses an oil system of a phase modifier. The oil system comprises an oil tank, the phase modifier, a lubricating oil supply system, a lifting oil system and an oil smoke recycling system, wherein the lubricating oil supply system and the lifting oil system are arranged between the oil tank and the phase modifier, the inlet end of the oil smoke recycling system is connected with the outlet end of the phase modifier, the outlet end of the oil smoke recycling system is divided into two ways, one way is connected to the oil tank, and the other way is discharged into the air. According to the oil system, oil smoke containing lubricating oil passes through an oil smoke removing device, and filtered oil is transmitted to the oil tank, so that the recycling rate of the lubricating oil is increased; filtered clean gas is discharged into the air, so that the filtering effect is increased, air pollution is prevented, the recycling rate of the lubricating oil is high, and normal operation of the system can be guaranteed in the condition that main components of the system fail.

Owner:JIANGSU JIANGHAI LUBRICANTS HYDRAULIC EQUIP

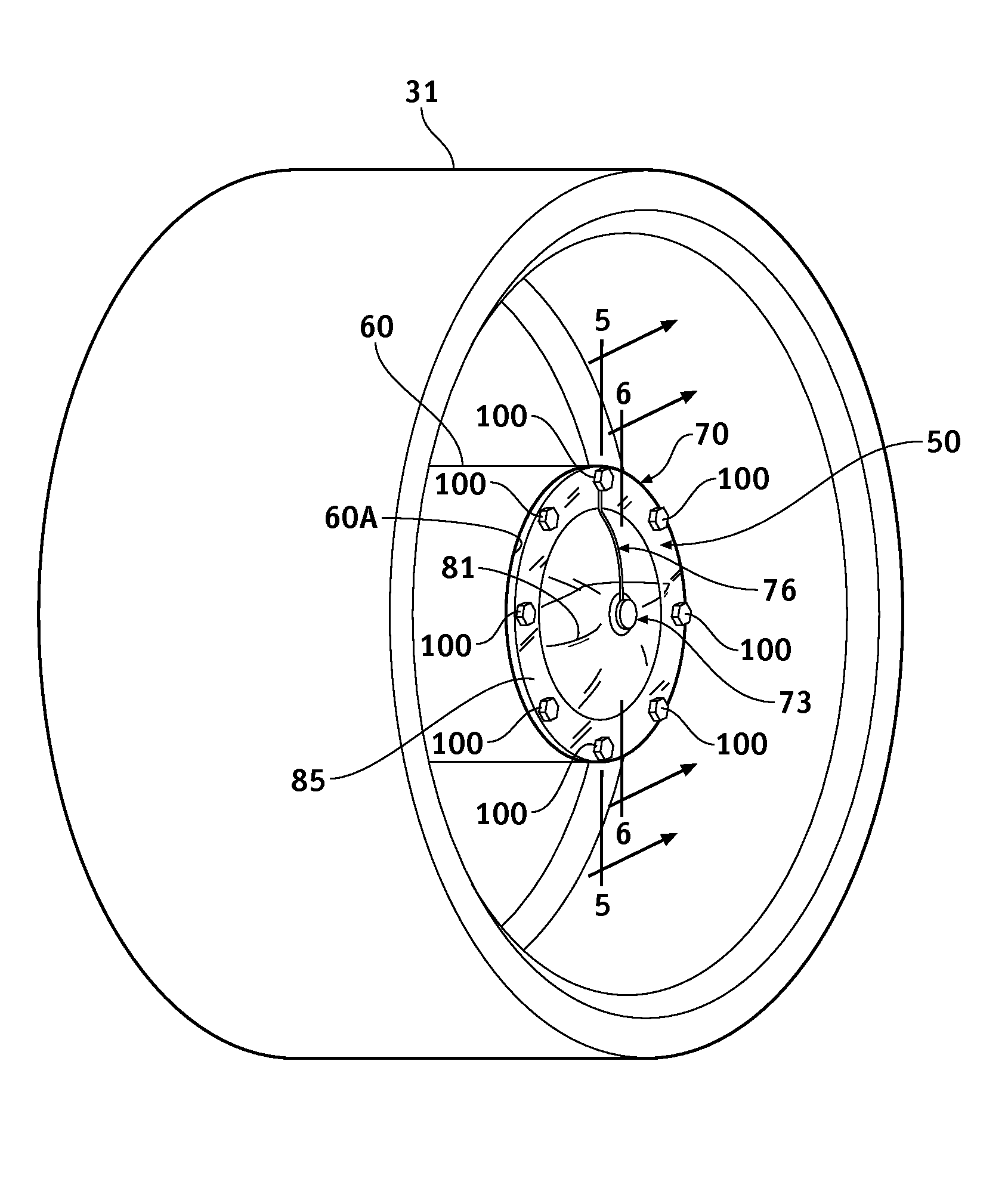

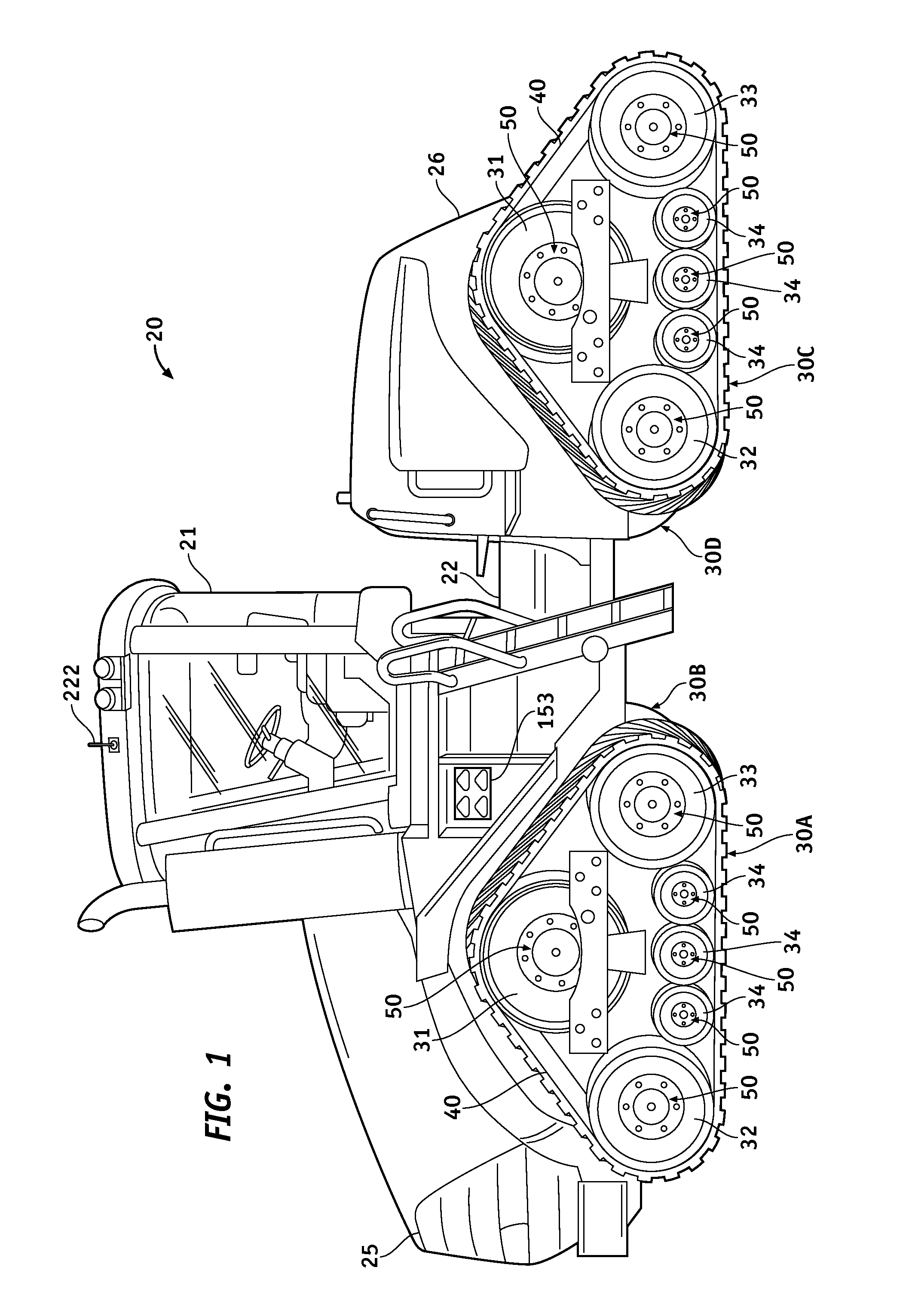

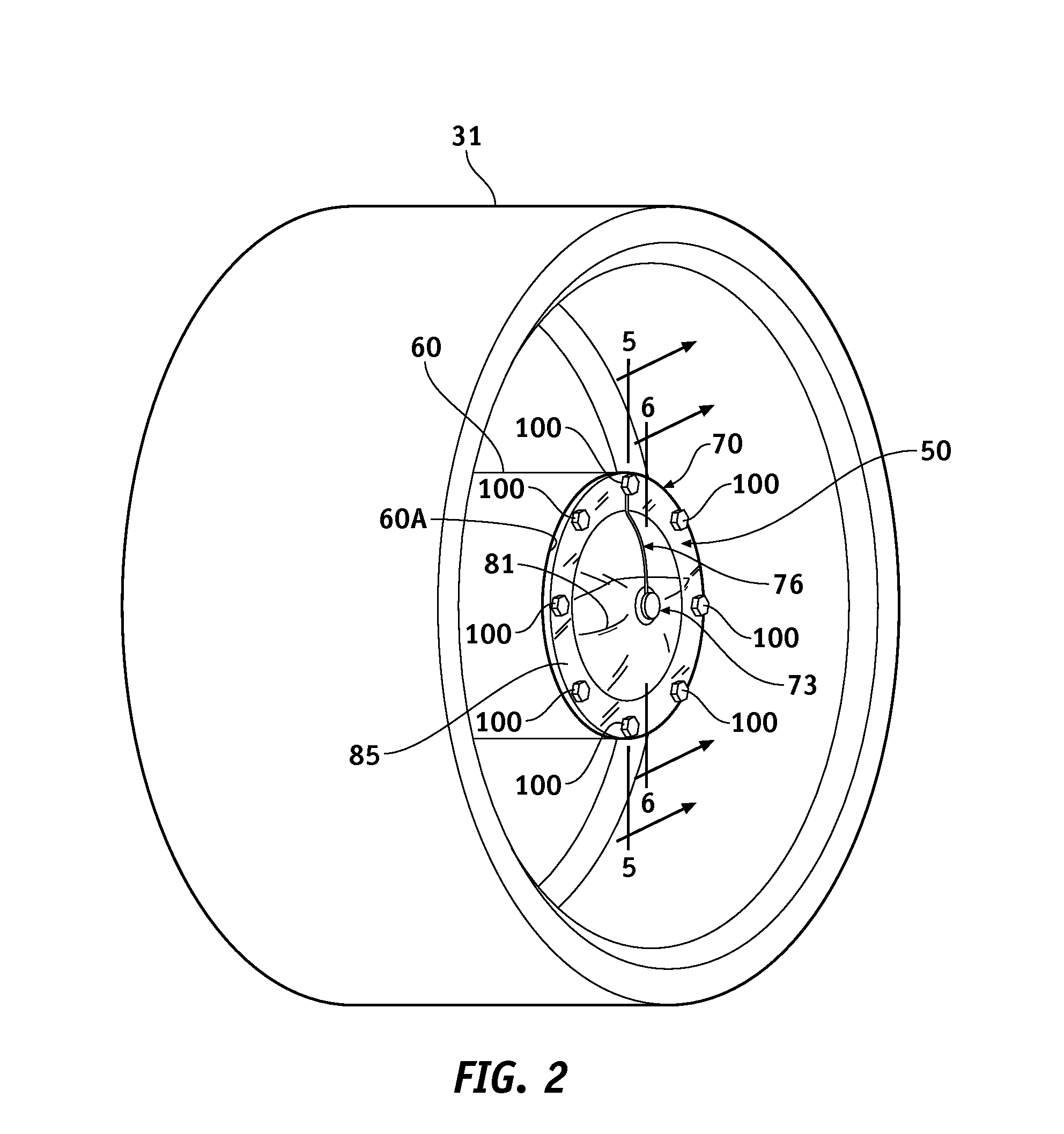

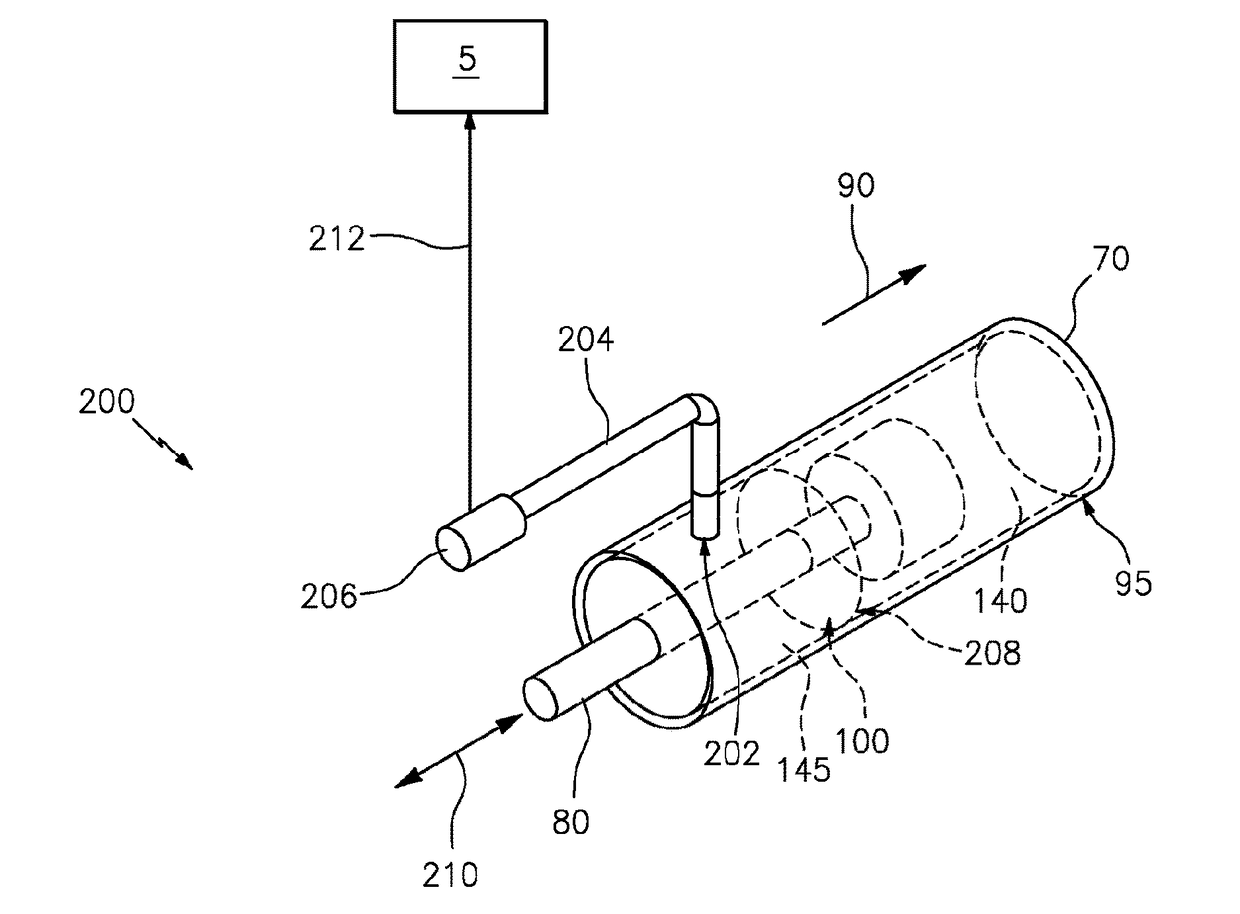

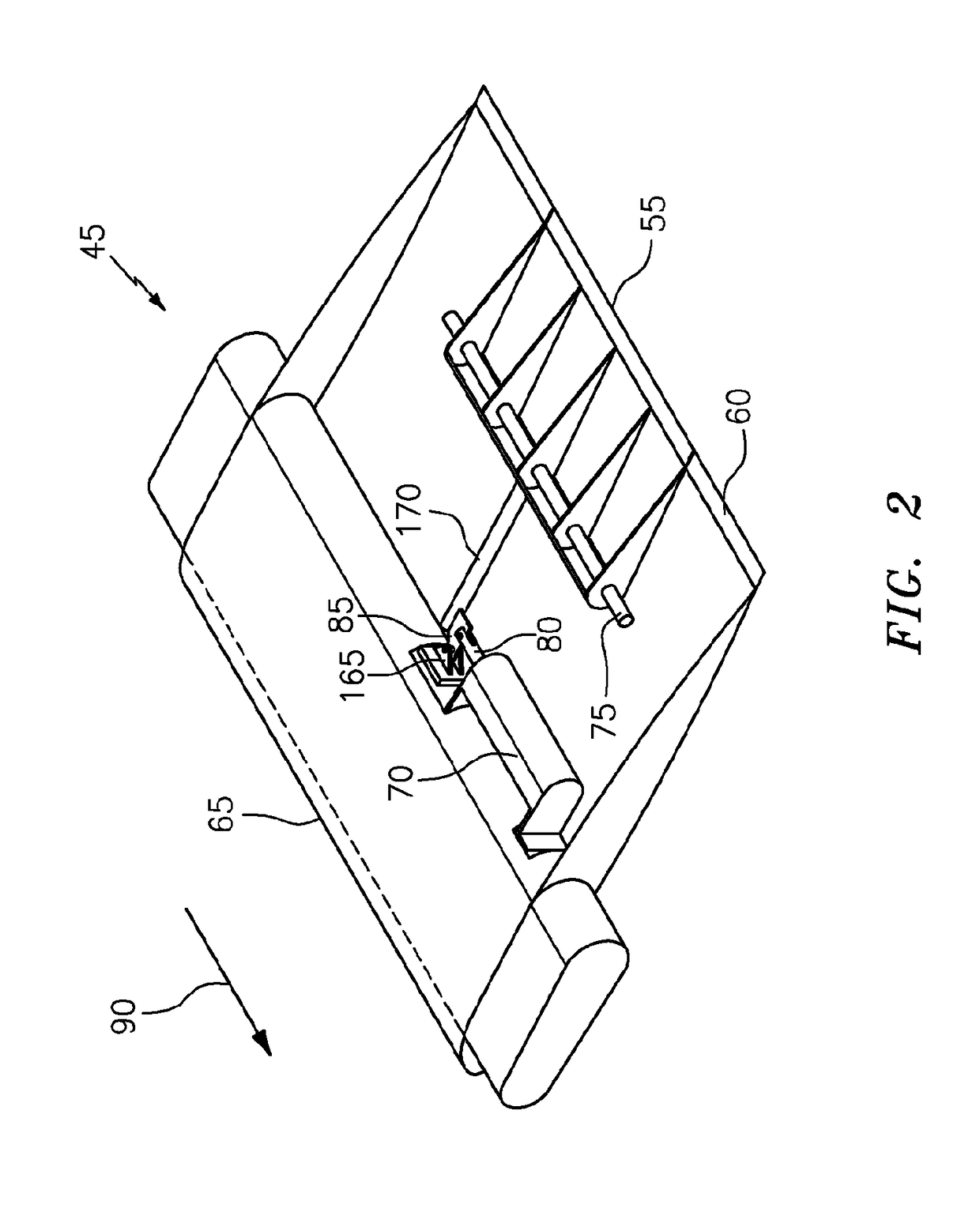

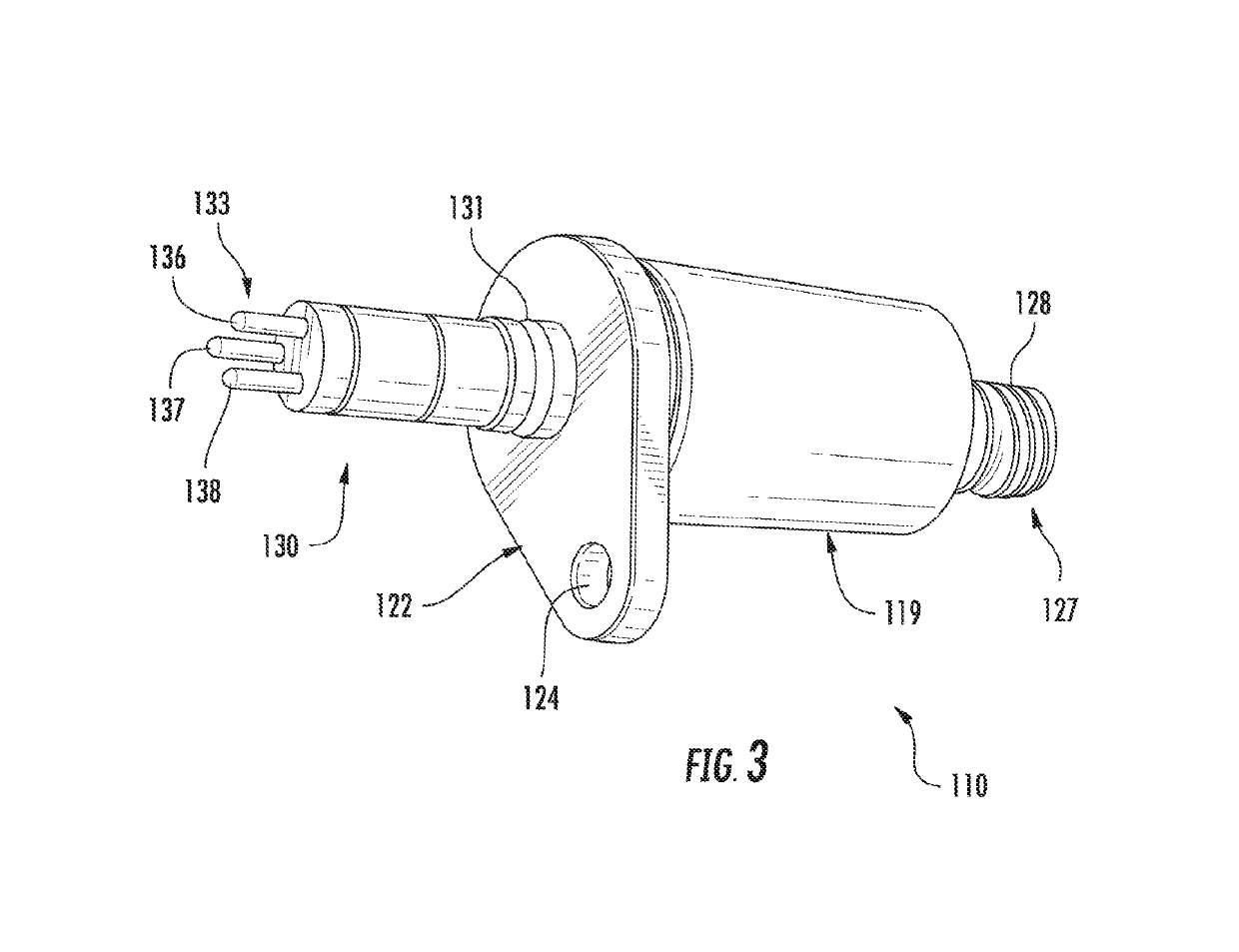

Lubricant level sensing for an actuator

According to one aspect, a lubricant level sensing system for an actuator is provided. The lubricant level sensing system includes a pressure port in an outer housing of the actuator, a pressure sensor, and a pathway from the pressure port to the pressure sensor. The pathway establishes fluid communication between the pressure sensor and a free volume of an internal cavity of the outer housing relative to a lubricant level in the internal cavity such that the pressure sensor detects a pressure of the free volume used to derive the lubricant level.

Owner:SIKORSKY AIRCRAFT CORP

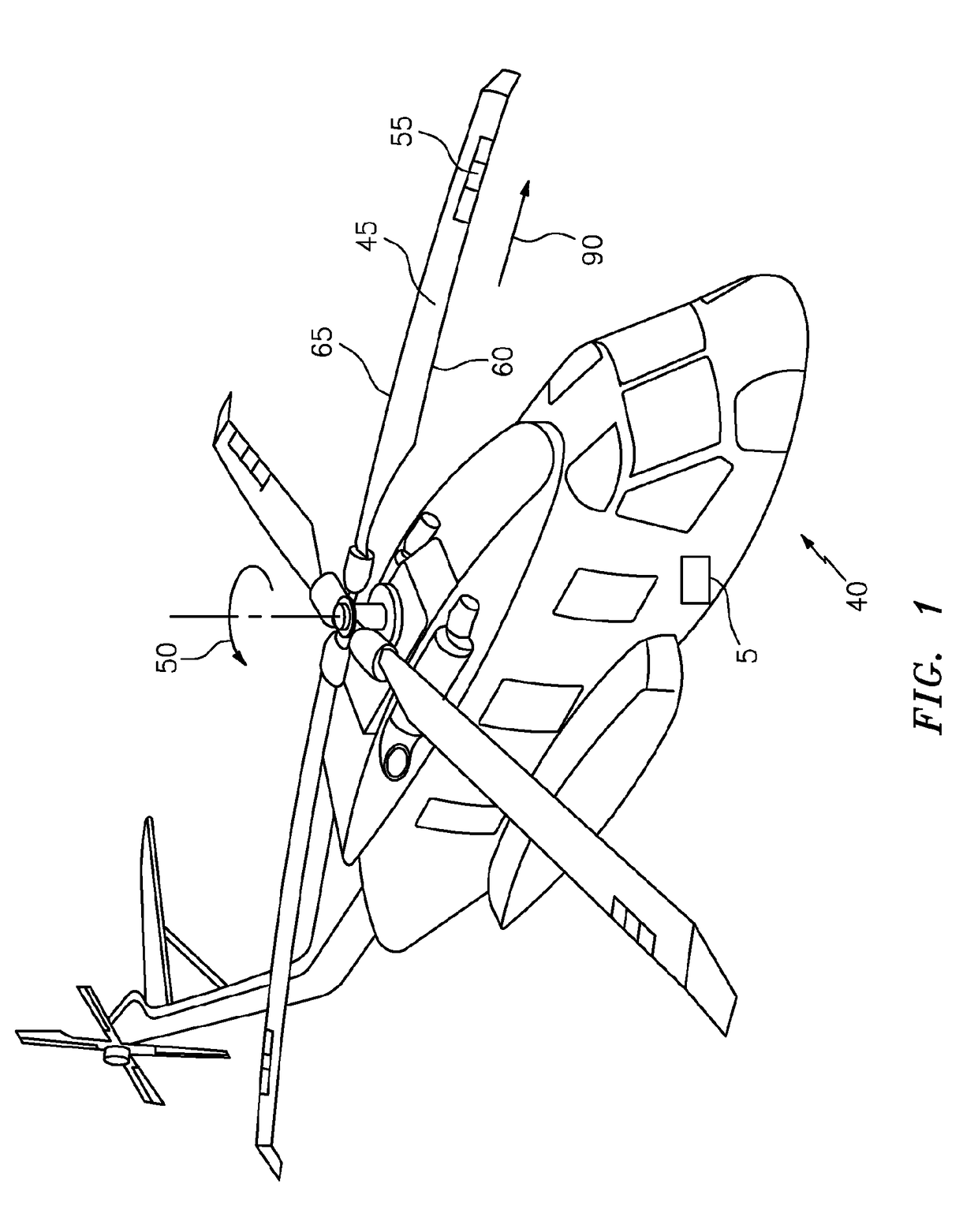

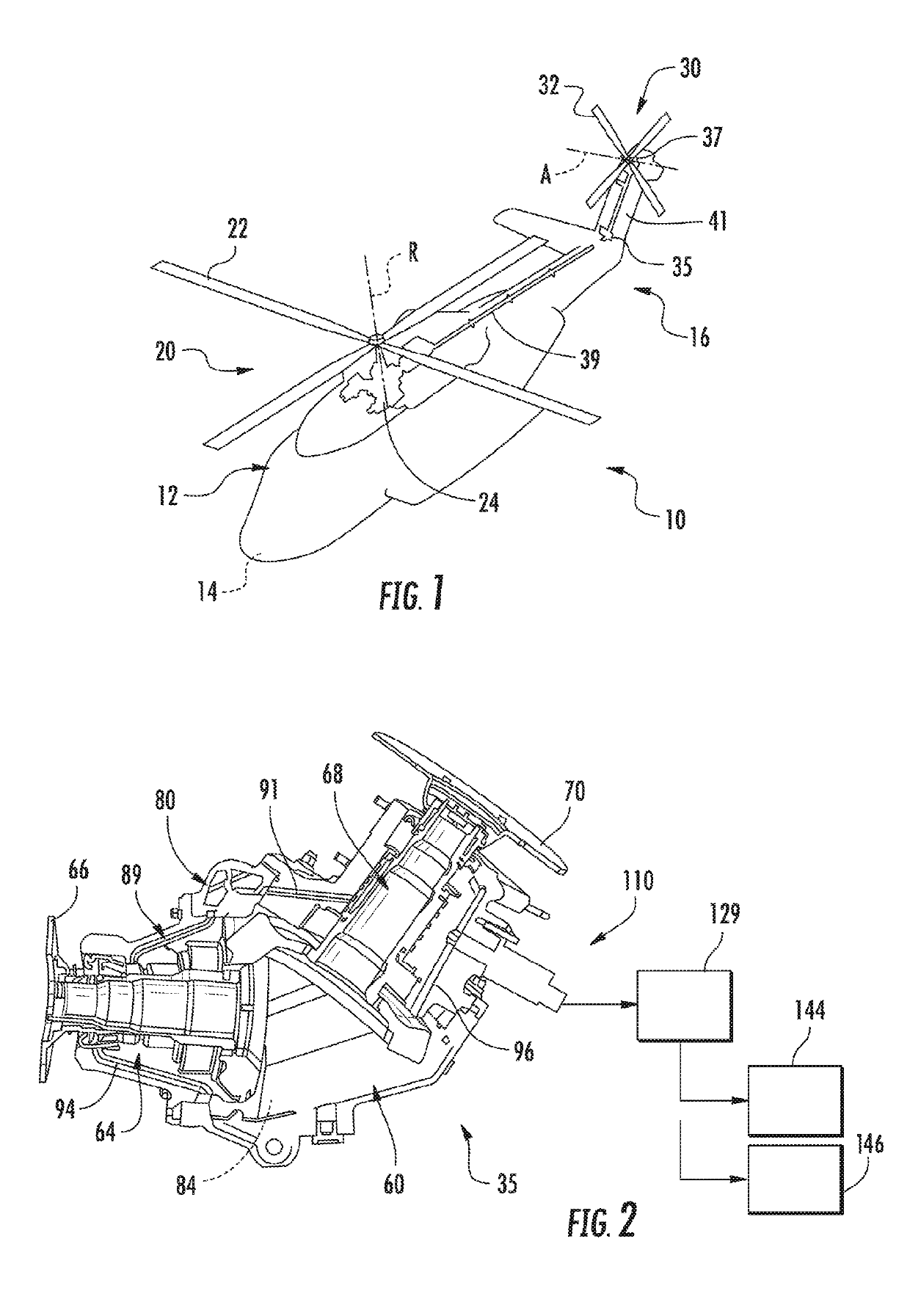

System and method for detecting a lubricant-out condition in an aircraft gearbox

A gearbox includes a housing including a lubricant reservoir, at least one gear system arranged in the housing, at least one lubricant delivery passage operable to direct a flow of lubricant from a lubricant reservoir onto the at least one gear system, at least one lubricant return passage operable to guide the flow of lubricant to the lubricant reservoir, and a lubricant-out sensor fluidically connected to the at least one lubricant return passage. The lubricant-out sensor is operable to detect a non-pressure based parameter of the lubricant.

Owner:SIKORSKY AIRCRAFT CORP

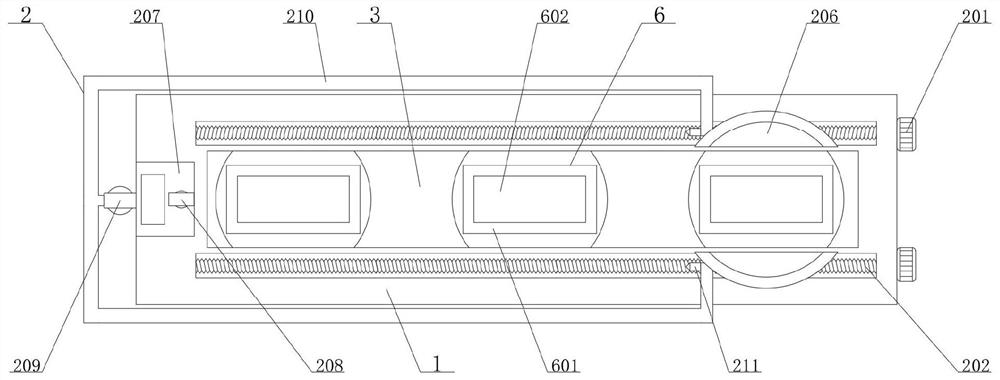

Automatic container transfer equipment for nuclear industry

The invention relates to the technical field of nuclear industry, in particular to automatic container transfer equipment for nuclear industry. The automatic container transfer equipment for the nuclear industry comprises a base, a transfer device, a buffer detection device and a supporting device, a positioning seat is fixedly connected to the top end of the base, the transfer device is arrangedon the inner side of the base, the buffer detection device is arranged on the inner side of the positioning seat, the buffer detection device comprises a positioning plate, the top end of the positioning seat is slidably connected with the positioning plate, the bottom end of the positioning plate is fixedly connected with a fixing block, and the fixing block is slidably connected with the positioning seat. According to the automatic container transfer equipment for the nuclear industry, a gasket, a pressure sensor and the positioning plate are arranged, the arrangement is matched with the fixed connection of the positioning plate, the gasket and the fixing block, the elastic force of a spring to the fixing block and a pressing plate and the fixed connection of the pressing plate and the pressure sensor, when the automatic container transfer equipment is used for transferring a container, noise generation is avoided, the container cannot be damaged, meanwhile, automatic detecting can be carried out on the material amount in the container, and the application range of the automatic container transfer equipment is enlarged.

Owner:常州嘉业智能装备科技有限公司

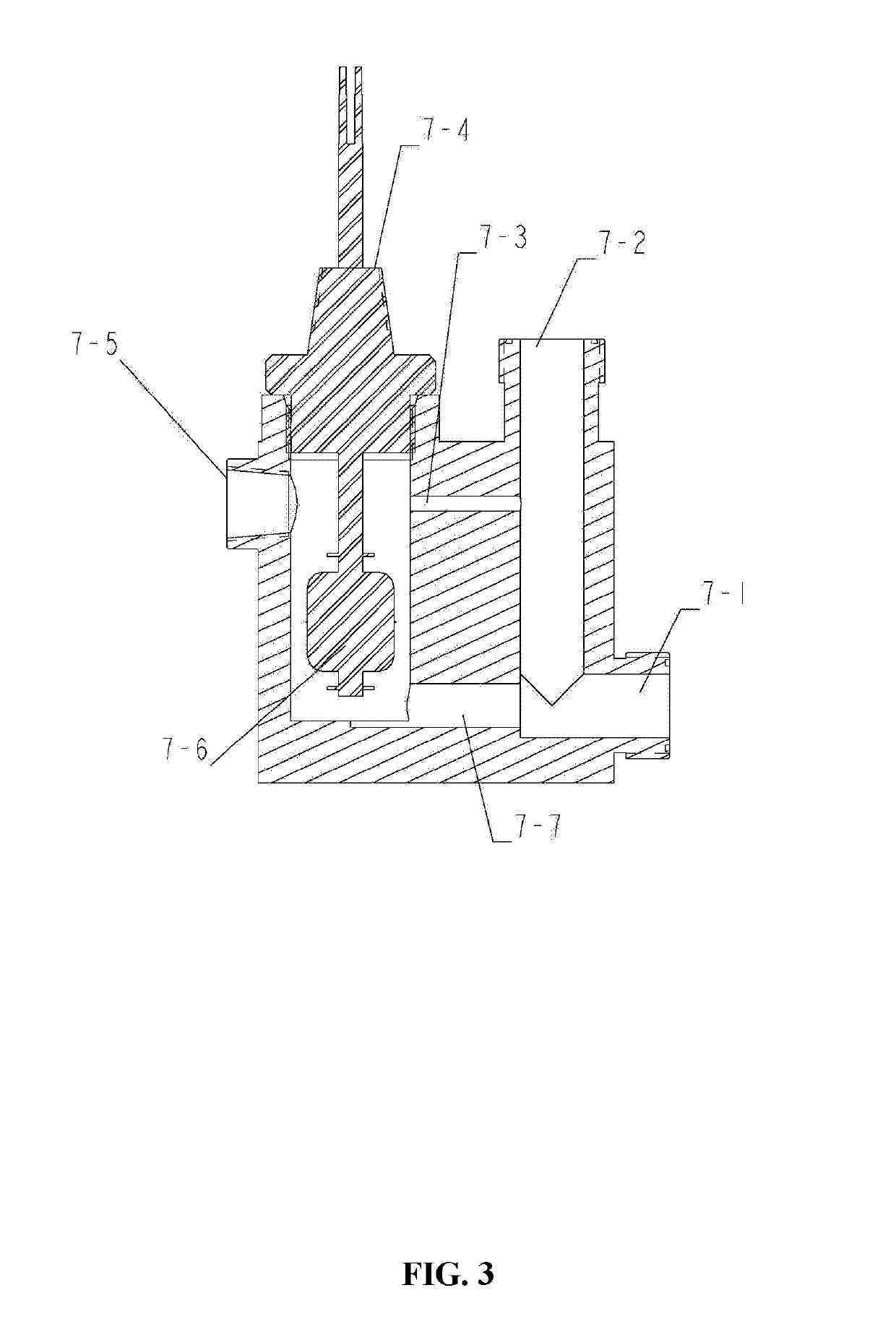

Oil flow switch and lubrication system with the same for a refrigeration system

ActiveUS20190203882A1False alarms caused by various reasons may be effectively preventedCompressorValve arrangementsRefrigerationLubrication

The present disclosure relates to an oil flow switch, comprising a float device connected to a circulating oil passage and a floating liquid level switch element provided in the float device, wherein the float device comprises an oil inlet, an oil outlet, and a float chamber provided between the oil inlet and the oil outlet, the floating liquid level switch element is provided in the float chamber, and the float device is provided with a channel in communication with the float chamber. The oil flow switch according to the present disclosure may avoid a false alarm of the oil level switch and meanwhile mitigate disturbance to the float caused by liquid level fluctuation to reduce friction between the float and the sleeve rod. Further, a lubrication system with the above oil

Owner:JOHNSON CONTROLS AIR CONDITIONING & REFRIGERATION WUXI +2

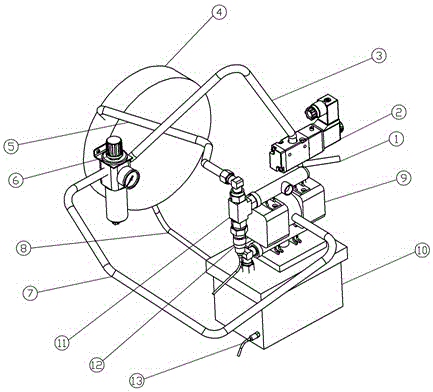

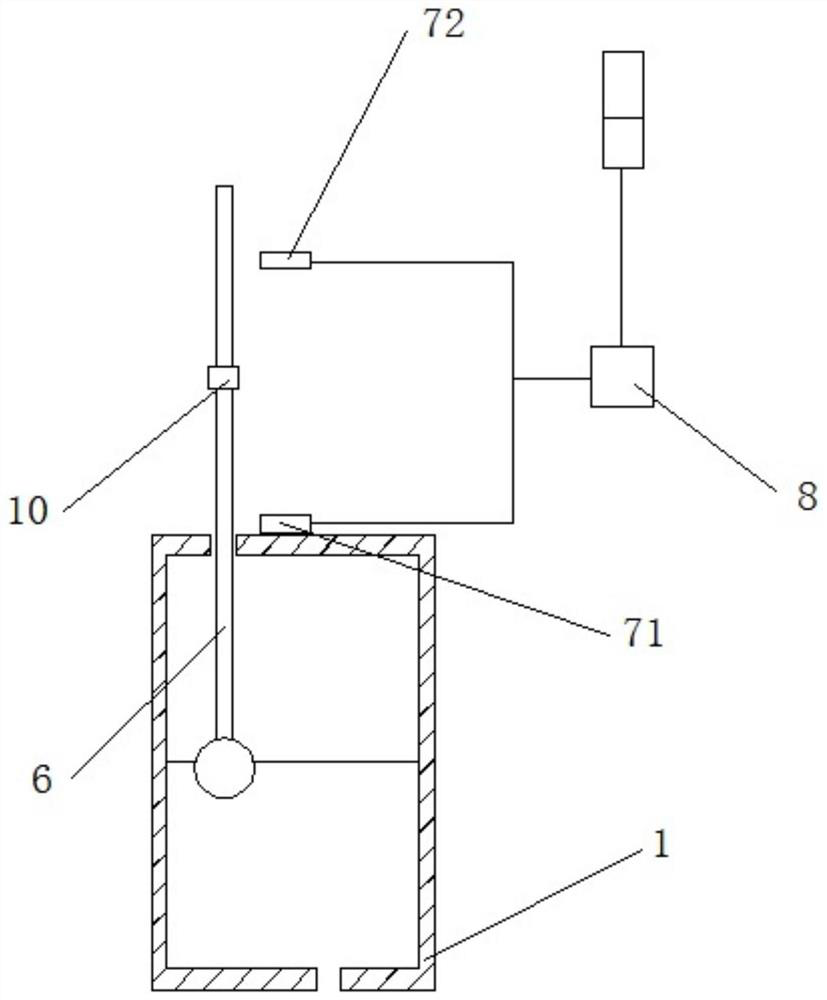

Knitter table automatic lubricating device and control method

InactiveCN106051438ASolve lubricitySolving Online Monitoring ProblemsEngine pressureEngine levelsFuel tankExhaust pipe

The invention discloses a knitter table automatic lubricating device. The knitter table automatic lubricating device comprises a control electromagnetic valve, an air pressure adjusting valve, a double-cylinder diaphragm pump, a lubricating oil storage tank and a three-way valve; an inlet of the control electromagnetic valve is connected with a compressed air intake pipe, and an outlet is connected with an inlet of the air pressure adjusting valve through an electromagnetic valve exhaust pipe; an outlet of the air pressure adjusting valve is connected with an air supply port of the double-cylinder diaphragm pump through a double-cylinder diaphragm pump intake pipe; the three-way valve is mounted in an oil outlet of the double-cylinder diaphragm pump; an oil pressure sensor is mounted on a bypass port in the lower part of the three-way valve; an oil outlet of the three-way valve is connected with one end of a lubricating oil drain pipe; the other end of the lubricating oil drain pipe is positioned above a knitter table; an oil level sensor is mounted at the bottom of the lubricating oil storage tank; and the oil level sensor, the oil pressure sensor and the control electromagnetic valve are respectively connected with a knitter controller. The knitter table automatic lubricating device solves the knitter table automatic lubricating and online monitoring problems, realizes automatic production, and improves the production efficiency.

Owner:NANJING ORIENTLEADER TECH CO LTD

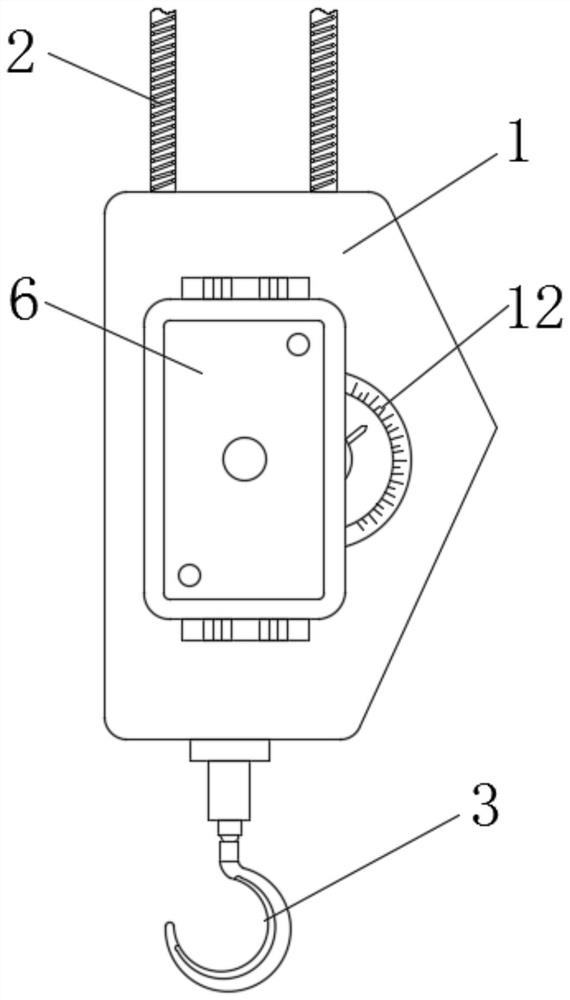

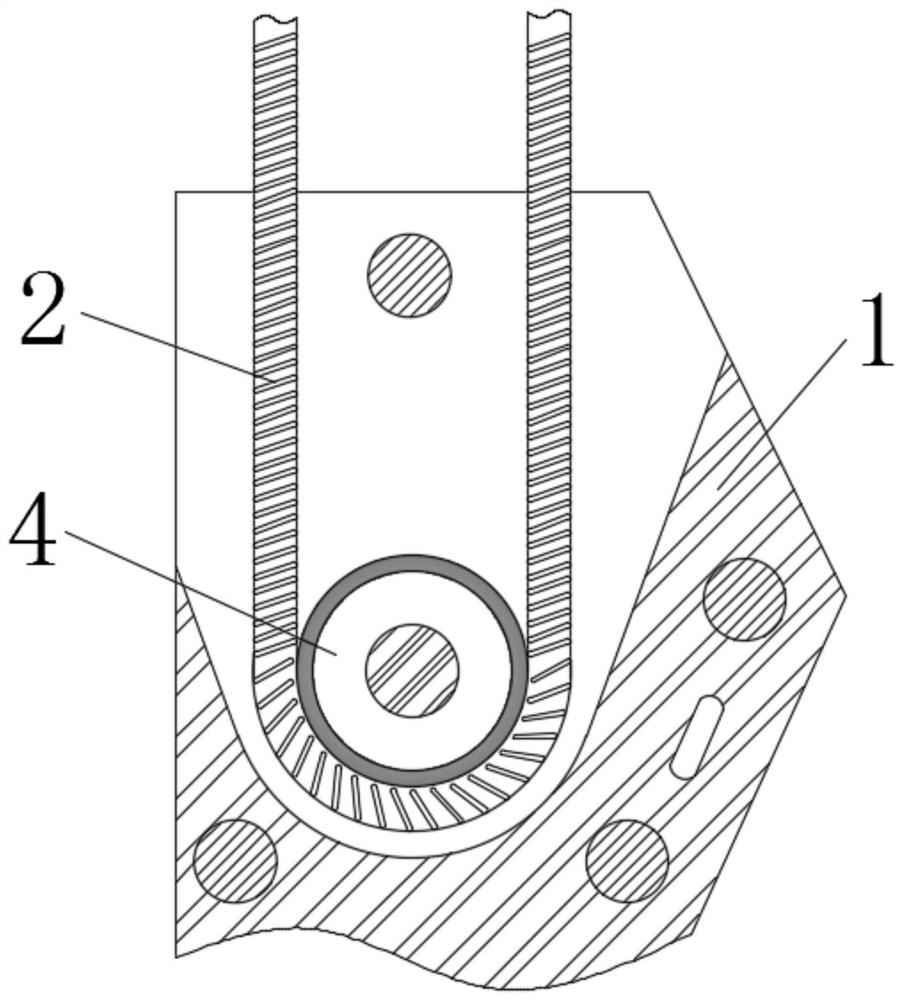

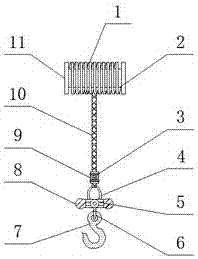

Crane pulley device capable of automatically supplementing oil

InactiveCN112830378ASolve the problem of severe wear and tearSave installation spaceEngine levelsMachines/enginesExternal energyGear wheel

The invention relates to the technical field of cranes, and discloses a crane pulley device capable of automatically supplementing oil. The crane pulley device comprises a shell, wherein a sling is arranged above the shell, a lifting hook movably connected to the lower end of the shell, a guide wheel is arranged inside the shell, a main shaft is coupled to the center of the guide wheel, a lubricating bin is arranged on the front side of the shell, an oil injection wheel is coupled to the front part of the main shaft, a crank piston is arranged in the oil injection wheel, an oil outlet nozzle is arranged on the oil injection wheel close to the axis, a right gear of the oil injection wheel is in meshed connection with a pointer wheel, a pointer is arranged on the front side of the pointer wheel, and a dial plate is arranged on the front side of the shell corresponding to the pointer. According to the crane pulley device capable of automatically supplementing oil, when a pulley works, a vibration block vibrates due to insufficient lubrication, the vibration block is driven to drive a lubricating bin shell to vibrate, a ratchet wheel is shifted by a pawl, then the oil injection wheel is driven to rotate for oil injection, harmful vibration mechanical energy in work is recycled without the help of external energy, and the oil injection device is driven to inject oil, and the service life of the pulley is prolonged.

Owner:梁瑶

Real time fluid level monitoring system

InactiveUS20180298798A1Accurate readingSignal processingTesting/calibration apparatusReal-time dataTime of flight sensor

The present invention is a real time fluid level monitoring system comprising a time of flight sensor coupled to a data processing unit with a means to output the measured fluid level data. The system may be configured to monitor fluid levels such as engine oil, hydraulic oil, coolant, fuel, and wiper fluids in automobiles and commercials. The time of flight sensor may be installed at the top of the fluid vessel and calibrated for the vessel size. The data processing unit communicates with the time of flight sensor to relay real time data concerning fluid level measurements to the operator of the automobile or commercial vehicle.

Owner:DIKEMAN ALLAN

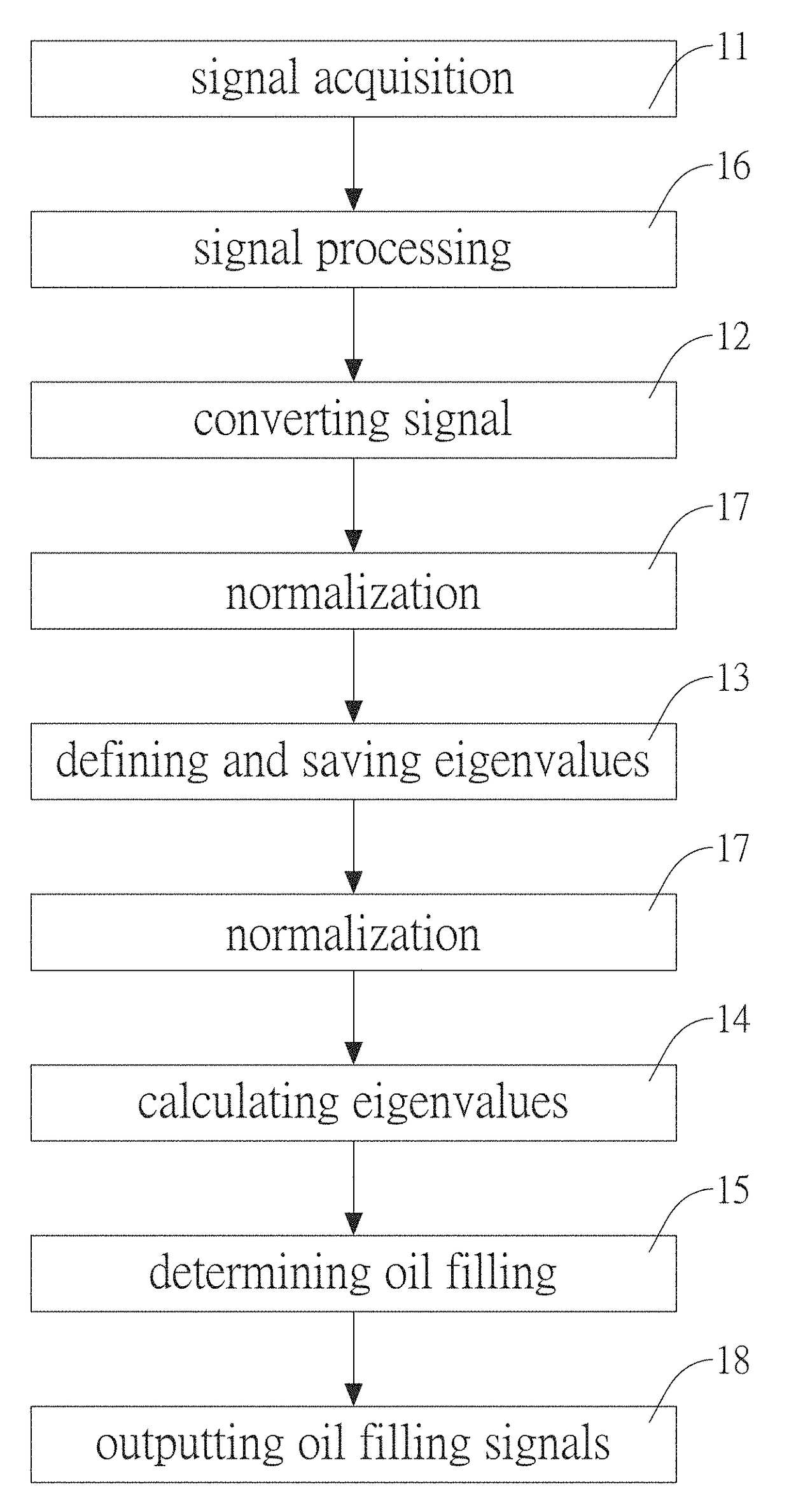

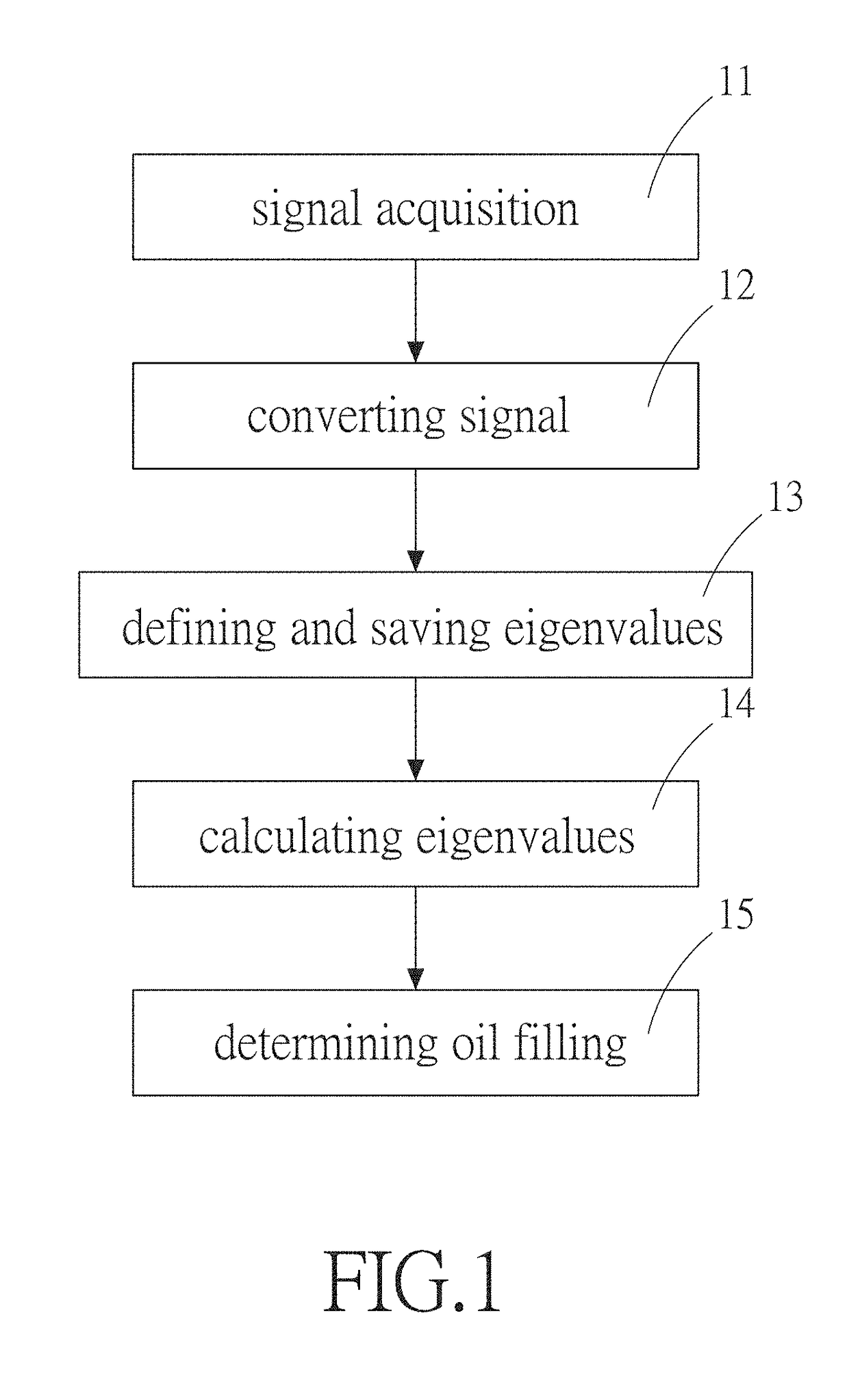

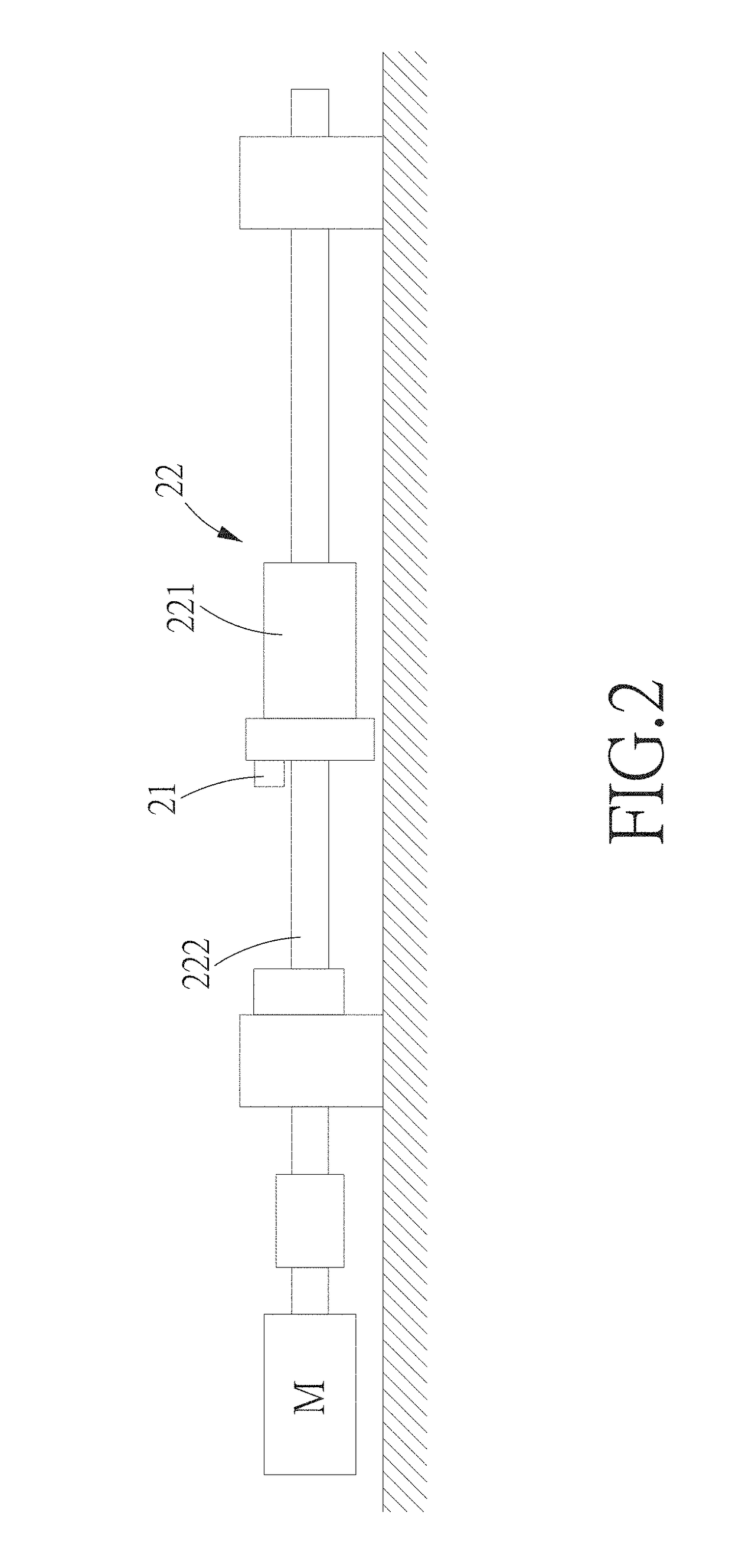

Method for determining timing of oil filling for a ball screw

A method for determining timing of oil filling for a ball screw can determine whether the oil film in a specific time period is sufficient, falling or insufficient, and then know the optimum timing of oil filling, by comparing the sum of the slope values within respective time periods with a predetermined value. The method is further capable of determining the timing of oil filling even when the rotation speed of the ball screw changes. The method includes a step of signal acquisition, a step of converting signal, a step of defining and saving eigenvalues, a step of calculating eigenvalues, and a step of determining oil filling.

Owner:HIWIN TECH

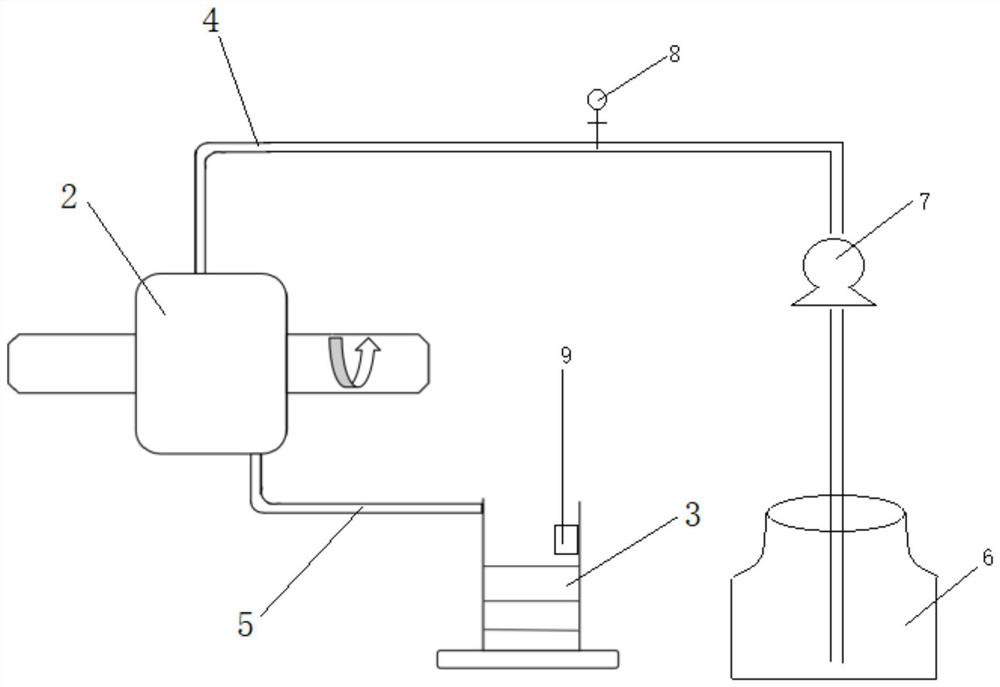

Atomized lubricator controlling and adjusting device and method

ActiveCN110726063AReduce reminderImprove work efficiencyEngine levelsLubrication elementsEngineeringOil mist

The invention provides an atomized lubricator controlling and adjusting device and method, and relates to the field of atomized lubricators. The atomized lubricator controlling and adjusting device comprises an alarming assembly, an atomized lubricator body, a floating element, a distance measurement element and a control element, wherein a containing cavity used for containing oil is formed in the atomized lubricator body; the floating element is arranged in the containing cavity, and the density of the floating element is lower than that of the oil; the distance measurement element which isopposite to the floating element is arranged on the atomized lubricator body, and the distance measurement element is used for measuring whether the difference between the heights of the floating element and the distance measurement element exceeds a preset range or not; and the control element is separately connected with the distance measurement element and the alarming assembly, and the controlelement is used for receiving a signal of the distance measurement element and controlling the alarming assembly to work according to the signal of the distance measurement element. The atomized lubricator controlling device can be flexibly adjusted according to different kinds of oil and different using environments, and the applicability is high.

Owner:芜湖精艺铜业有限公司

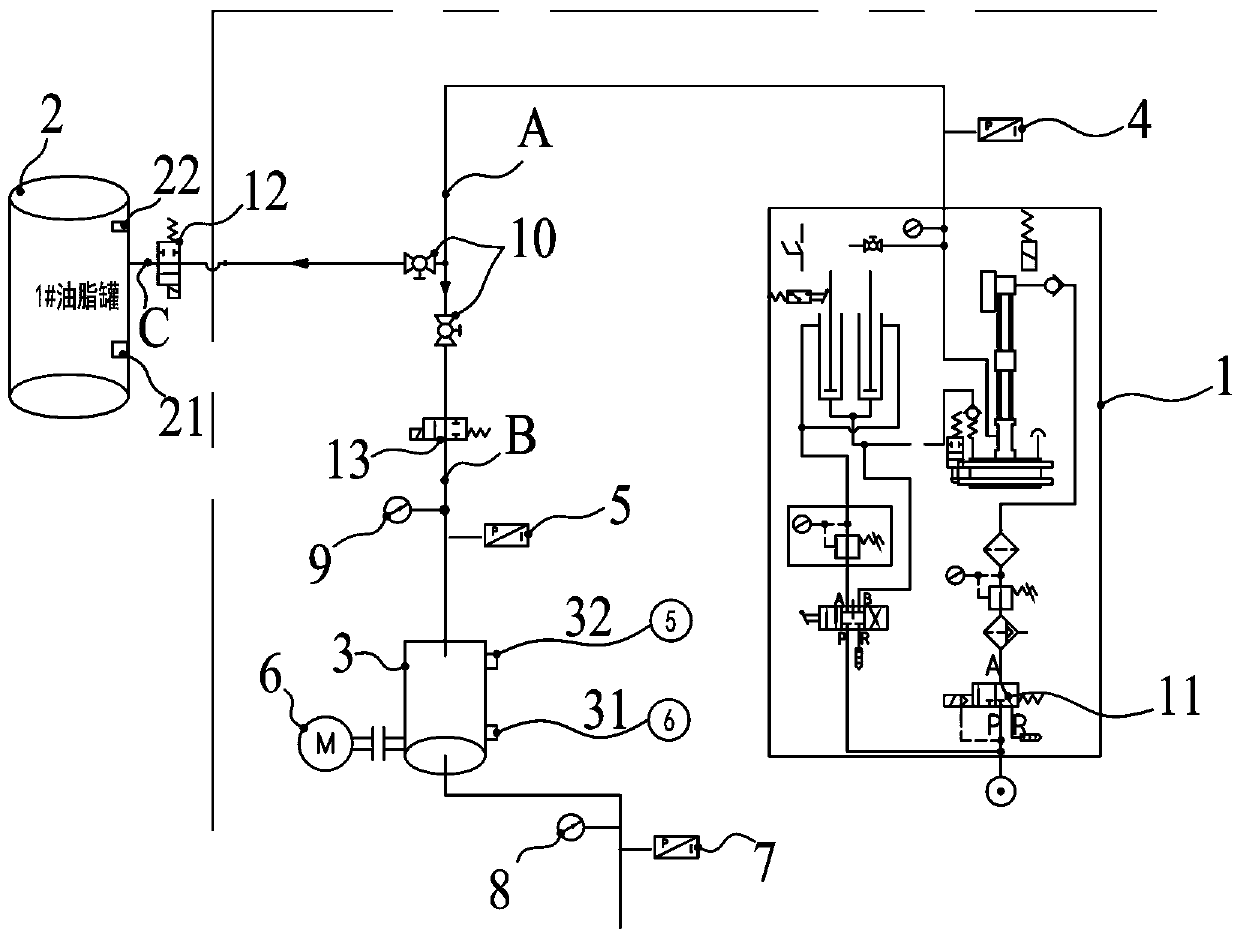

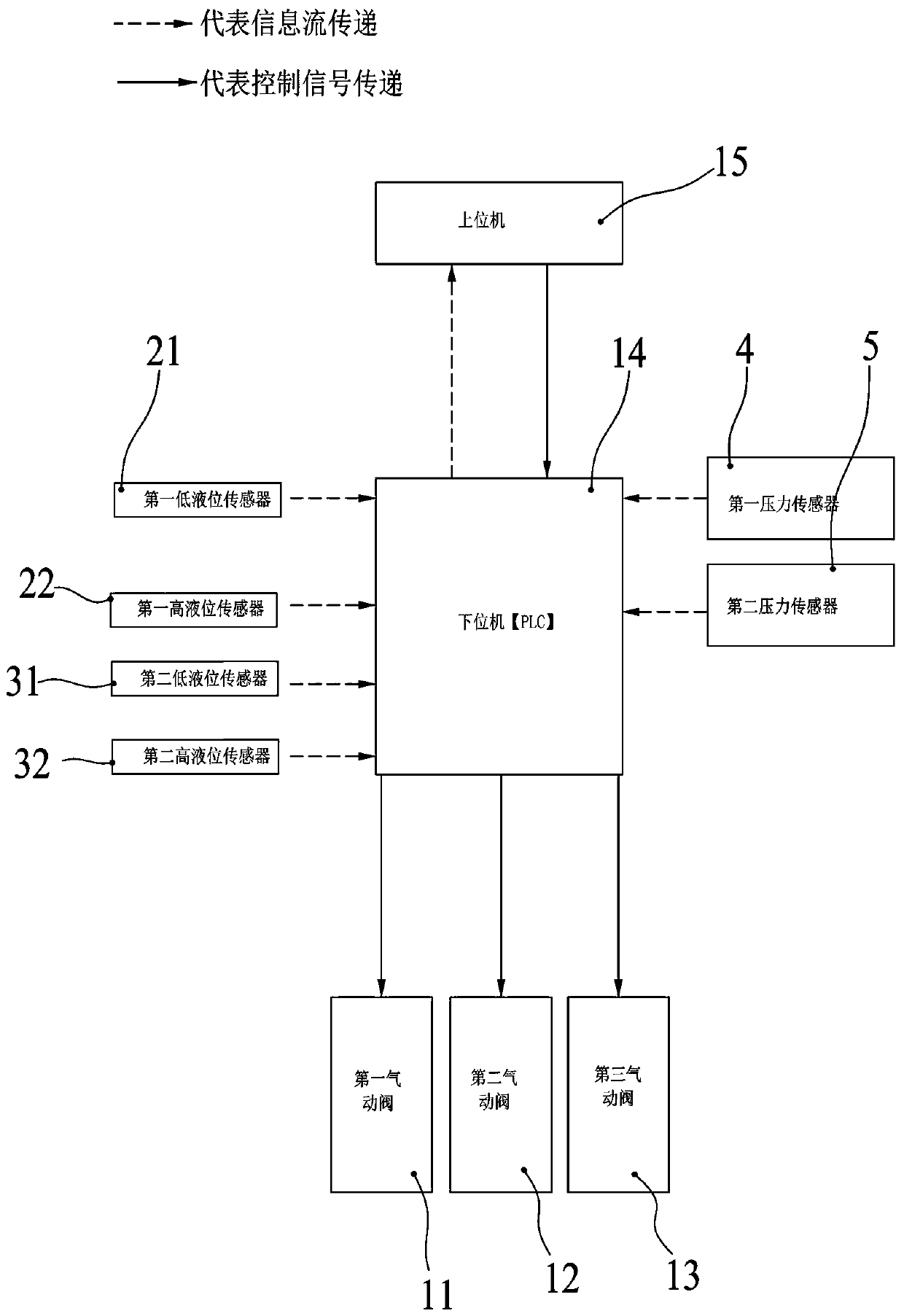

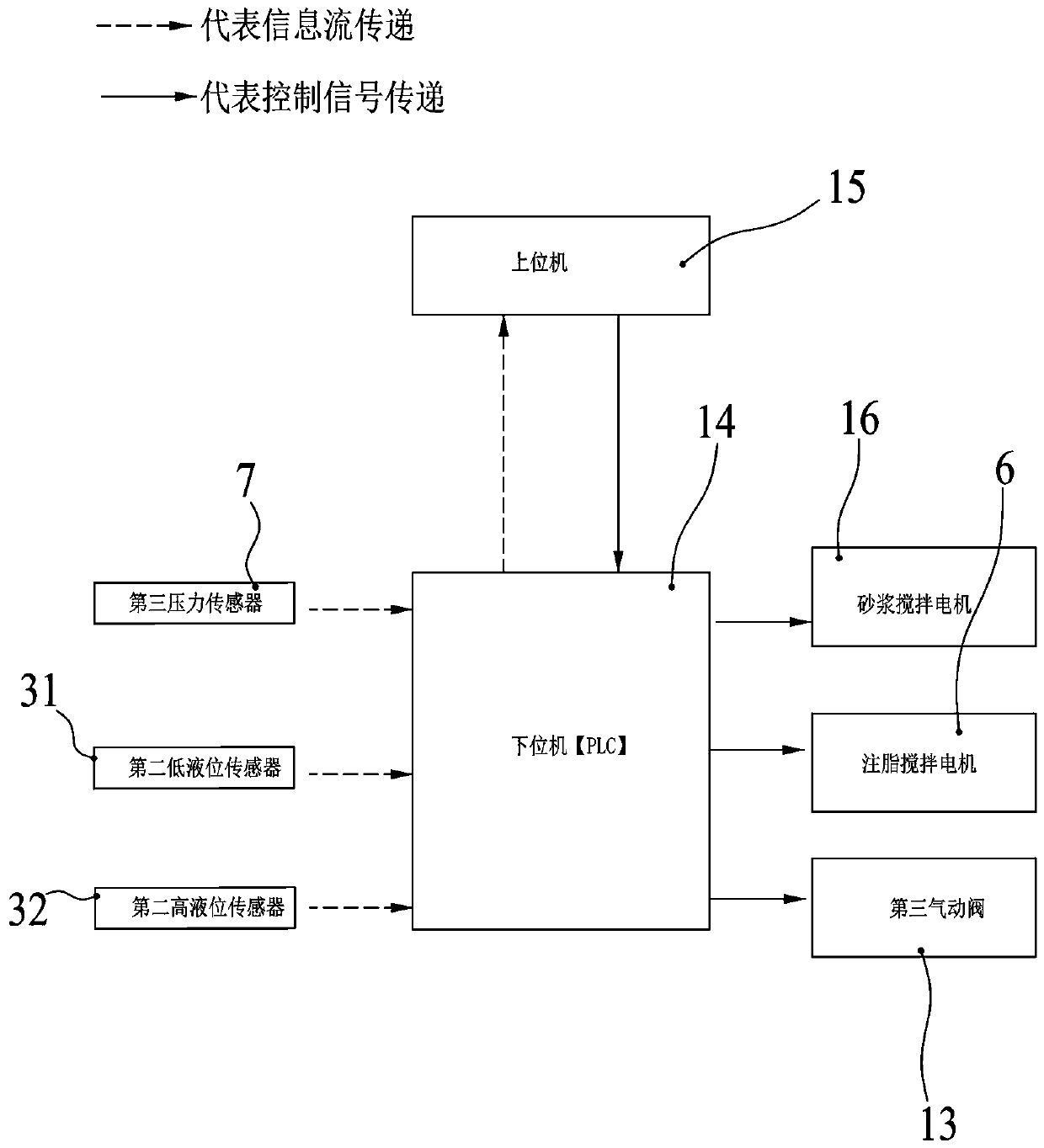

Grease lubrication grease injection system for shield machine and grease lubrication grease injection method for shield machine

The invention provides a grease lubrication grease injection system for a shield machine and a grease lubrication grease injection method for the shield machine. The grease lubrication grease injection system for the shield machine comprises a grease pump assembly, a pipeline A, a pipeline B, a pipeline C, a first grease tank and a second grease tank. The grease pump assembly is provided with a first control valve, wherein the grease pump assembly, the pipeline A, the pipeline C and the first grease tank are sequentially communicated. The pipeline C is provided with a second control valve. Thepipeline B, the second grease tank and the pipeline A are sequentially communicated. The pipeline B is provided with a third control valve. The first grease tank is internally provided with a first low liquid level sensor and a first high liquid level sensor. The second grease tank is internally provided with a second low liquid level sensor and a second high liquid level sensor. A lower computeris correspondingly connected with the first control valve, the second control valve, the third control valve, the first low liquid level sensor, the first high liquid level sensor, the second low liquid level sensor, the second high liquid level sensor and an upper computer. The grease lubrication grease injection system can realize automatic start or stop of grease injection into the first grease tank and the second grease tank.

Owner:XIAMEN XIAGONG CHINA RAILWAY HEAVY MACHINERY CO LTD

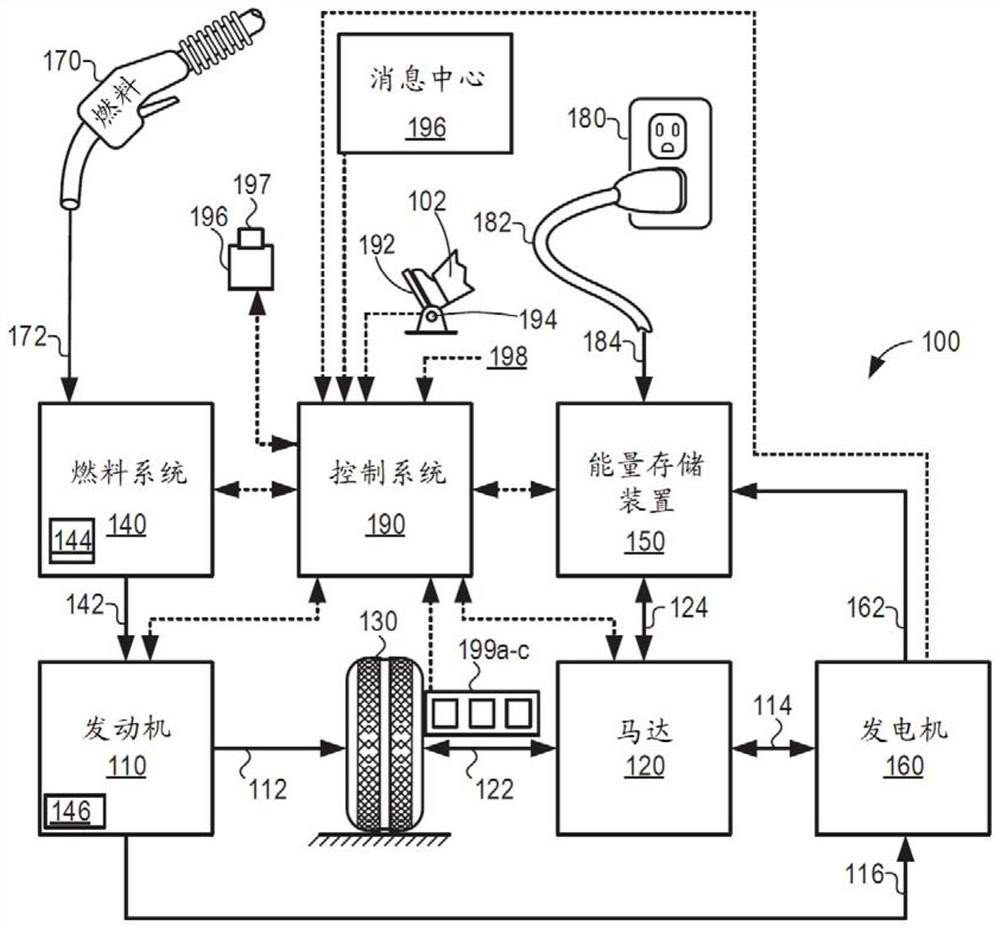

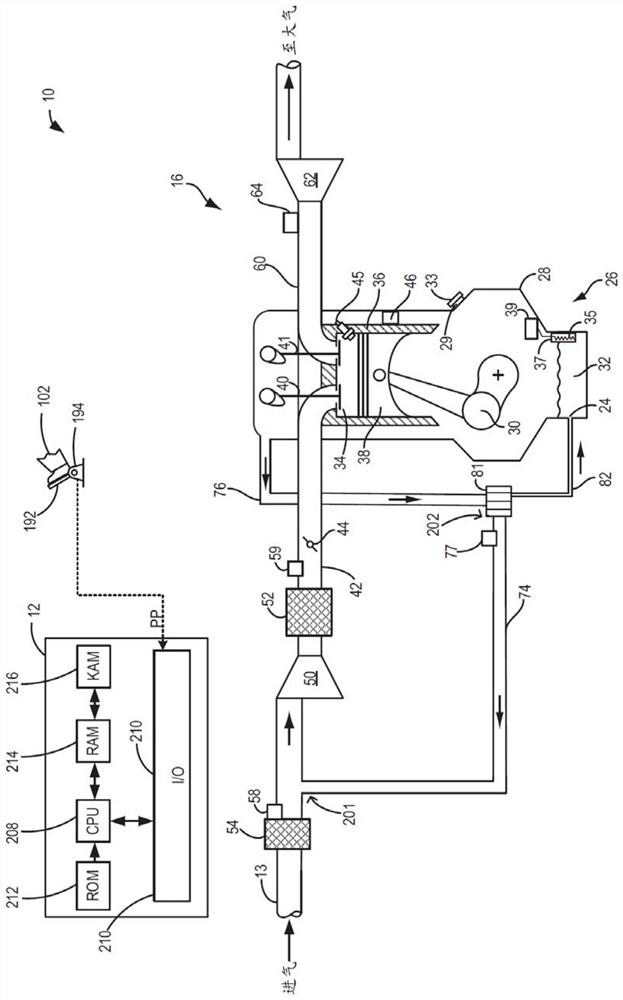

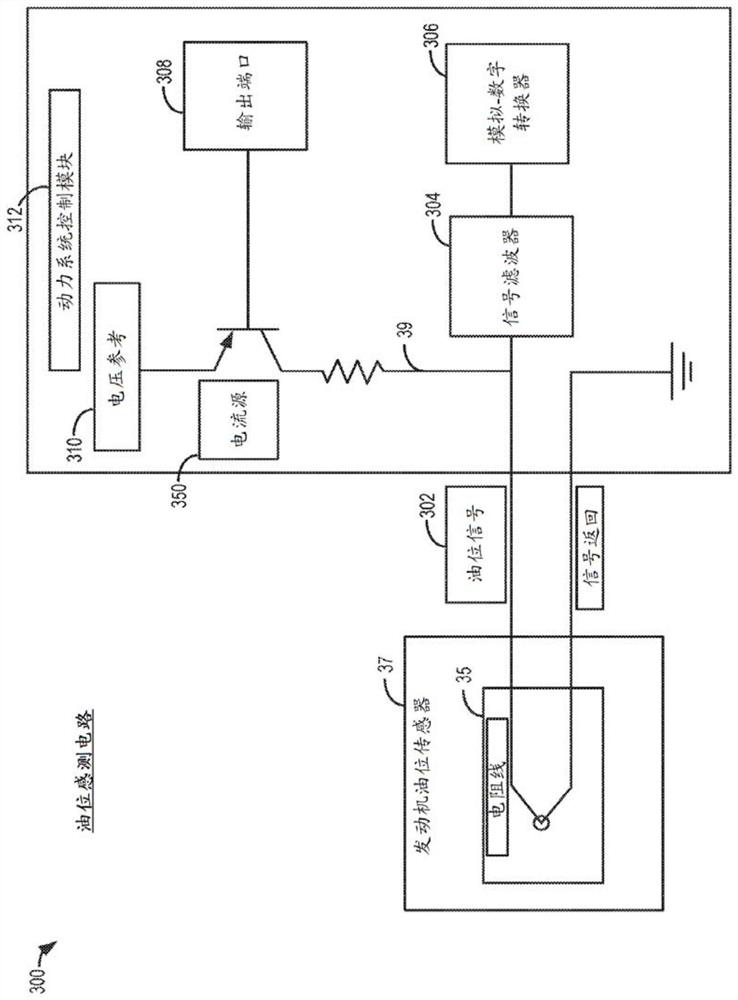

Method and system for engine oil level sensing

PendingCN112081640AEarly detectionReliable detectionSignal processingEngine levelsControl theoryMechanical engineering

Methods and systems are provided for improving engine oil level sensing while a vehicle is moving. The output of a hot wire sensor partially immersed in an engine oil well is sampled during selected vehicle moving conditions when lateral and longitudinal acceleration is limited and the vehicle is driving in a straight line. A transfer function is used to correlate a rate of change in sensor output, sampled during the selected vehicle operating conditions, with engine oil level.

Owner:FORD GLOBAL TECH LLC

On-board tank for the drainage of an aircraft engine

The invention relates to the field of aeronautical propulsion, and more particularly an on-board drainage reservoir of an aircraft engine, the on-board reservoir including a first compartment with a first intake passage for receiving fluid drained from the engine, a first closeable emptying passage, and a first quality sensor assembly for detecting at least one quality parameter of the fluid drained from the engine.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

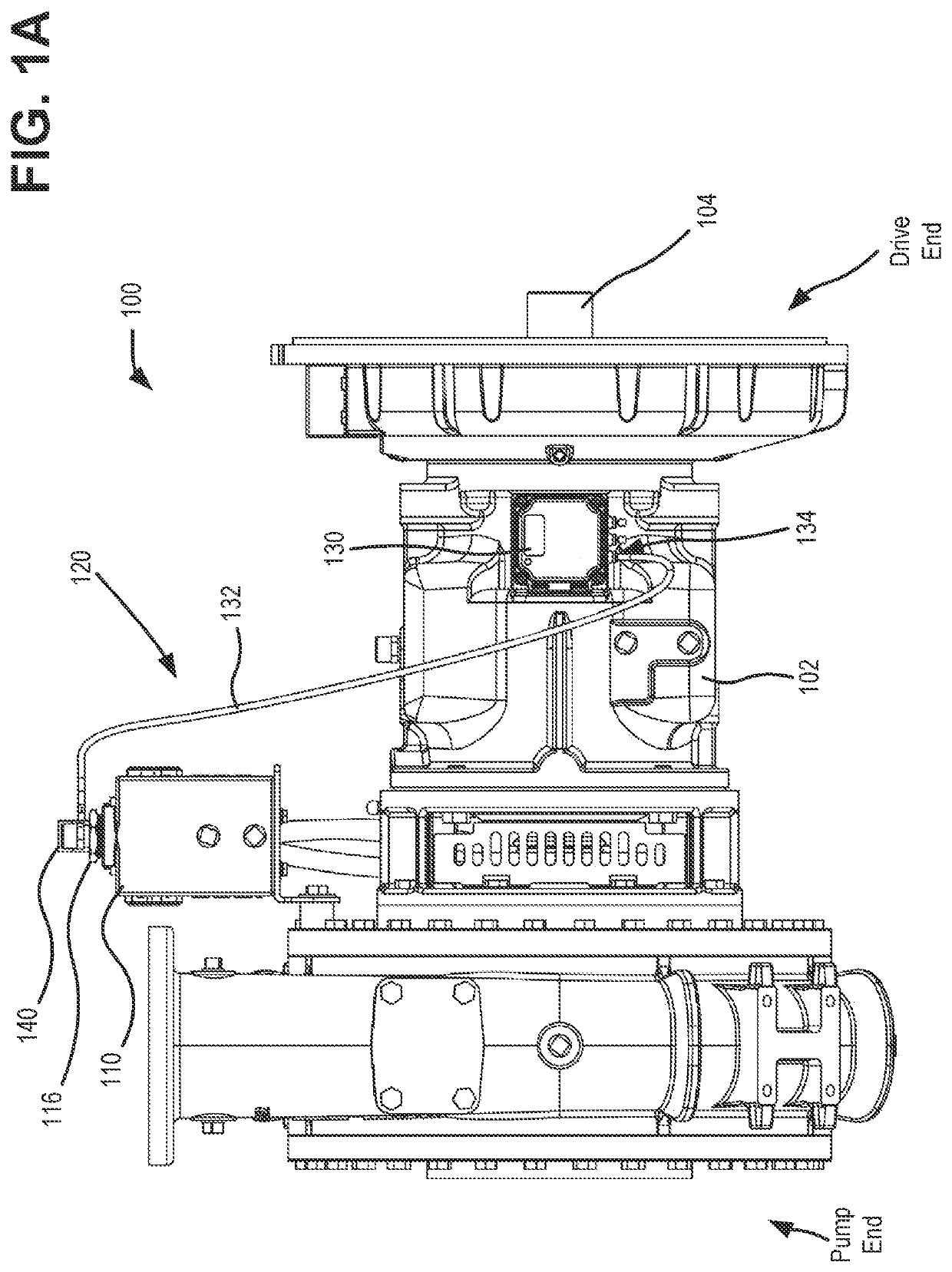

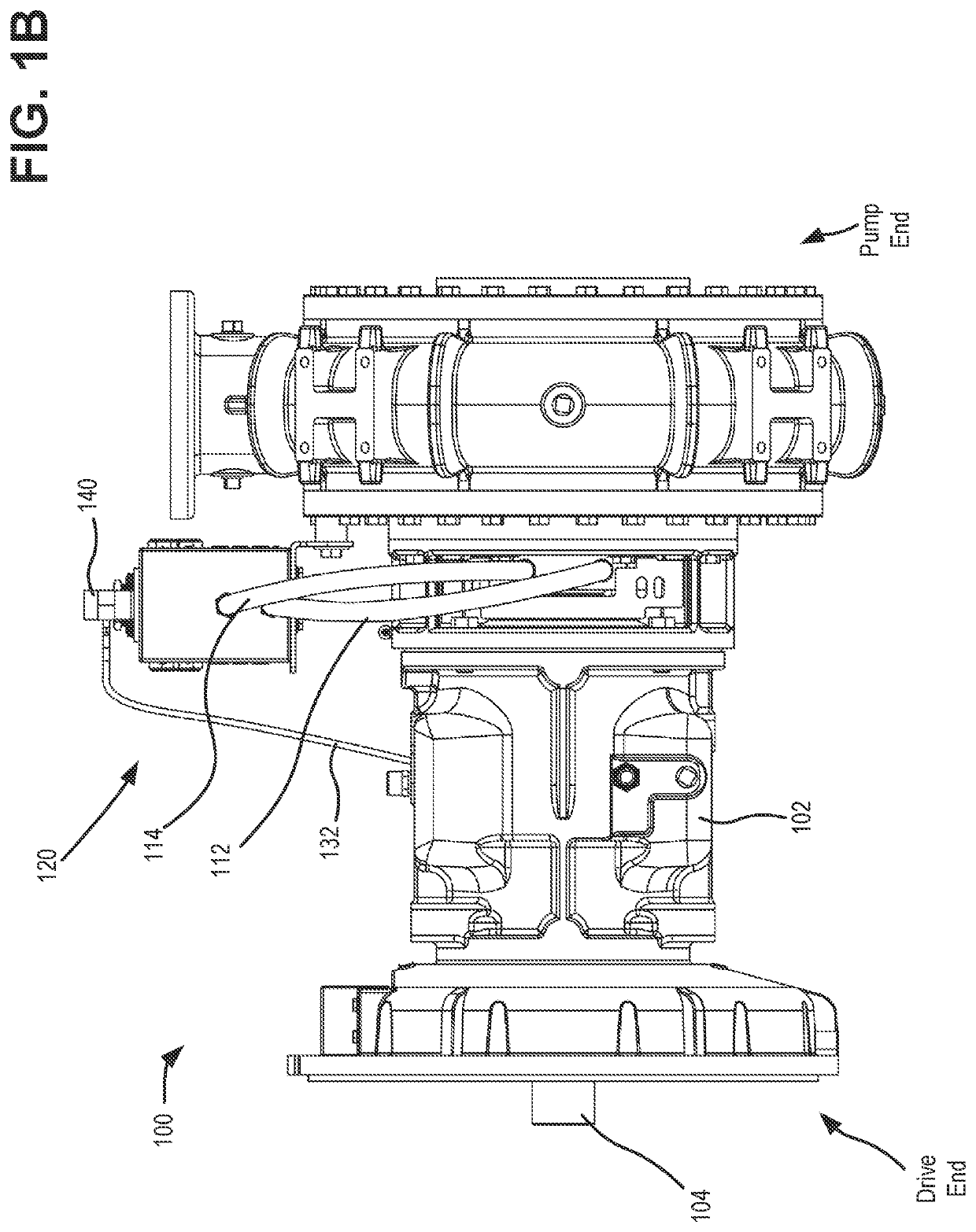

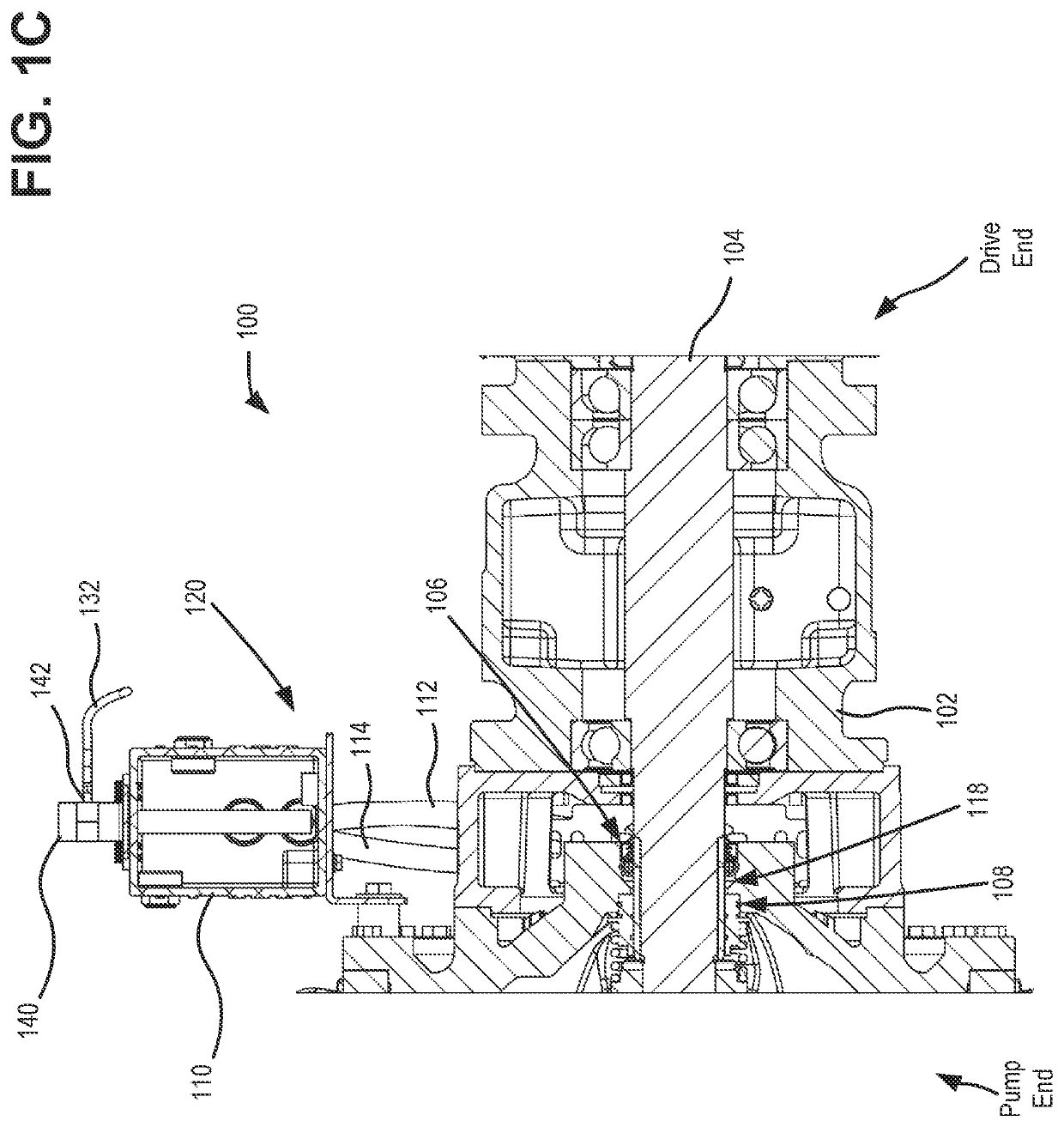

Monitoring system for pump with mechanical seal lubrication arrangement

Systems and methods are provided for remotely monitoring liquid lubricant levels for pump equipment. A system includes a reservoir to store lubricant and a lubrication gland to expose a shaft seal of the pump equipment to the lubricant. A feed line and a return line circulate the lubricant between the reservoir and the lubrication gland. A level sensor is configured to measure a fluid level in the reservoir. The level sensor uses a communication interface to transmit fluid level data a monitoring device mounted to the pump equipment. The monitoring device is configured to compare the fluid level data against stored alert thresholds and send, to a provider network, an alert signal when the fluid level data is below an alert threshold. If the fluid level data is not below an alert threshold, the monitoring device stores the fluid level data for periodic reporting.

Owner:CORNELL PUMP CO LLC

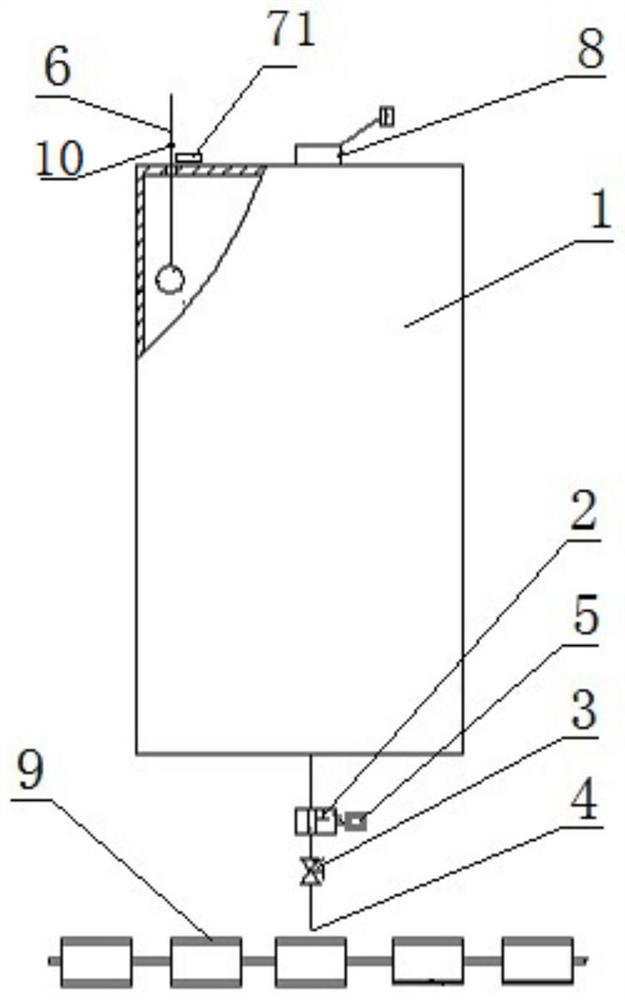

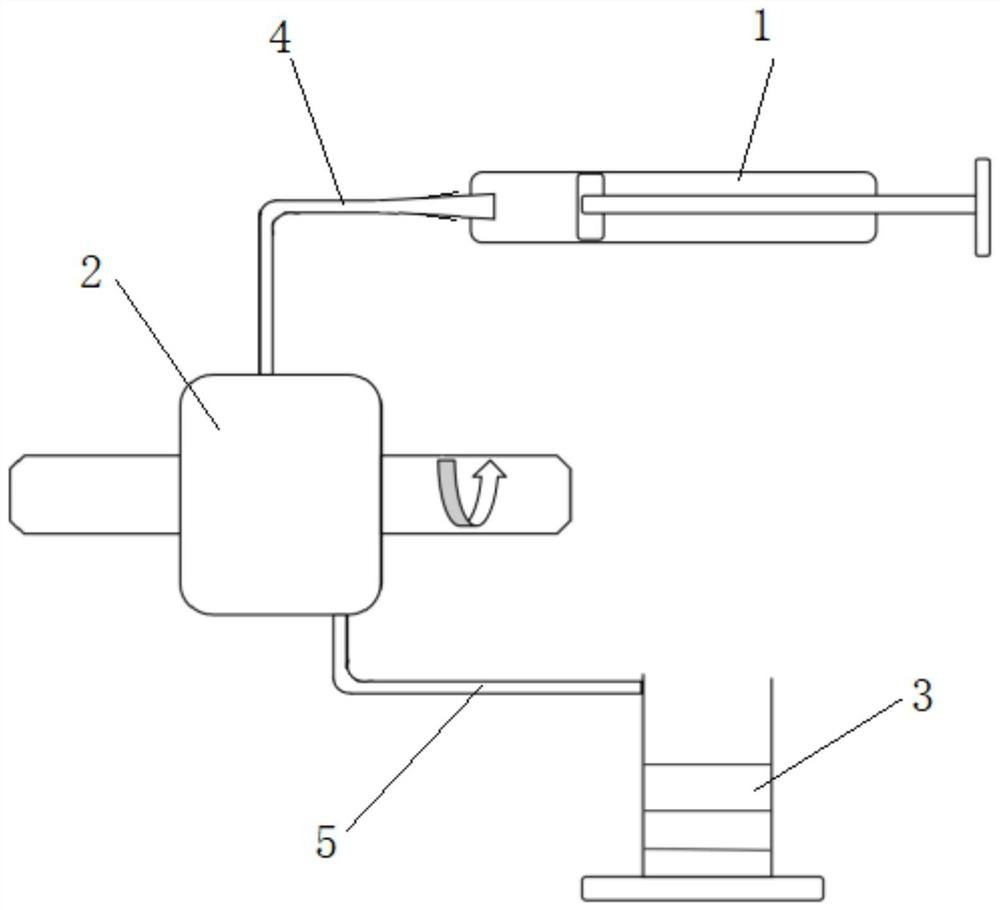

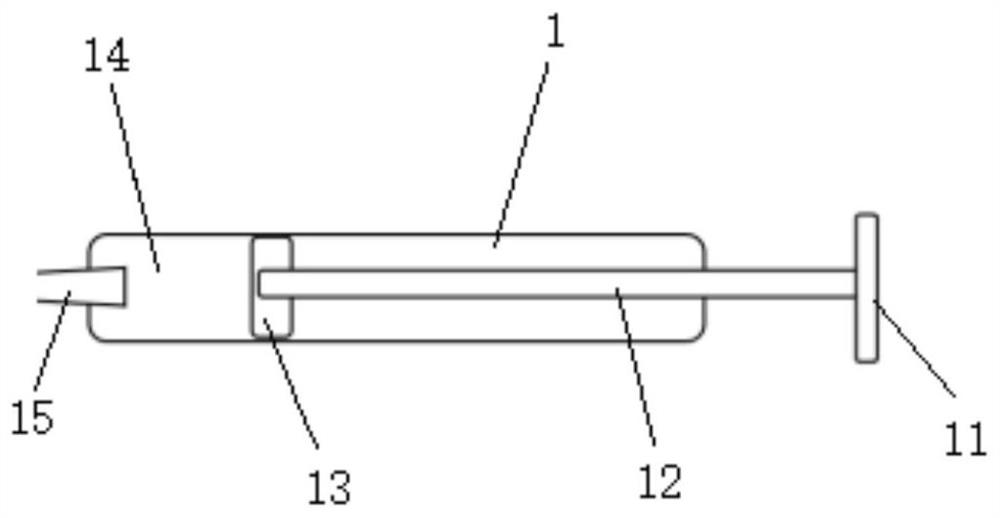

Automatic lubricating device

PendingCN112128597ASolve the problem of waste and low work efficiencyRefueling work is safe and reliableValve arrangementsSignal processingEngineeringChain type

The invention discloses an automatic lubricating device, and relates to the technical field of engine assembly. The device is used for adding lubricating oil to a ground drag chain type engine assembly line, and is characterized by comprising an oil storage tank (1), a two-position two-way electromagnetic reversing valve (2), a throttle valve (3) and an oil nozzle (4) which are sequentially connected from top to bottom through oil pipes, and further comprising a time relay (5), and the time relay (5) is used for driving opening and closing of the two-position two-way electromagnetic reversingvalve (2). The device realizes automatic lubrication of a ground drag chain to replace current manual operation, solves the problems of easy waste and low working efficiency in an oil adding process,and ensures safe and reliable oil adding work as well.

Owner:GUANGXI YUCHAI MASCH CO LTD

Device and method for replacing lubricating grease of bearing of rotating equipment

PendingCN114738652AShorten transition timeWell formedEngine levelsLubricant transferOil and greaseWaste oil

The invention discloses a rotating equipment bearing lubricating grease replacement device and method, and the device comprises a new lubricating grease filling device which is arranged above a rotating equipment bearing, is connected to the rotating equipment bearing through an oil injection pipeline, and is used for filling the rotating equipment bearing with lubricating grease; and the measuring tool is arranged below the rotating equipment bearing, is connected to a waste oil outlet of the rotating equipment bearing through a grease collecting pipeline, and is used for measuring the volume of grease discharged by the rotating equipment bearing. The lubricating grease is added in the speed reduction and idle running process of equipment, old lubricating grease is still in a moving state, the temperature is not prone to being reduced, and flowing and discharging of the lubricating grease are easily guaranteed; and the filled new lubricating grease can easily absorb heat, so that the conversion time of the lubricating grease from a semi-solidified state to a flowable state is shortened, and a protective oil film is easily formed.

Owner:HUANENG CLEAN ENERGY RES INST

Safe steel wire rope capable of monitoring oil quantity

InactiveCN107021414AMonitor the situation at any timeScientific and reasonable structureEngine levelsLubrication elementsEngineeringDynamometer

The invention discloses a safe steel wire rope capable of monitoring the oil quantity. The safe steel wire rope comprises a weight dynamometer, a vertical steel wire rope and a steel wire rope reel, wherein a rotating shaft is arranged on the steel wire rope reel, a winding steel wire rope is arranged on the rotating shaft, the vertical steel wire rope is installed below the steel wire rope reel, a steel wire rope fixer is arranged below the vertical steel wire rope, and a lubricating oil detector is arranged on the front surface of the steel wire rope fixer. Compared with the prior art, the safe steel wire rope has the beneficial effects that the lubricating oil detector is arranged on the existing steel wire rope so that the lubricating oil condition on the steel wire rope can be monitored at any time, when the oil spilling occurs, timely early warning can be carried out, workers can be reminded to stop to check and maintain the steel wire rope, when the oil amount is small, the workers can be reminded to add the lubricating oil, the weight dynamometer is arranged on the steel wire rope so that the weight of lifted objects can be visually measured, and therefore the purpose of safe and convenient use can be realized.

Owner:丁灏

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com