Patents

Literature

728results about "Safety devices for pressure lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

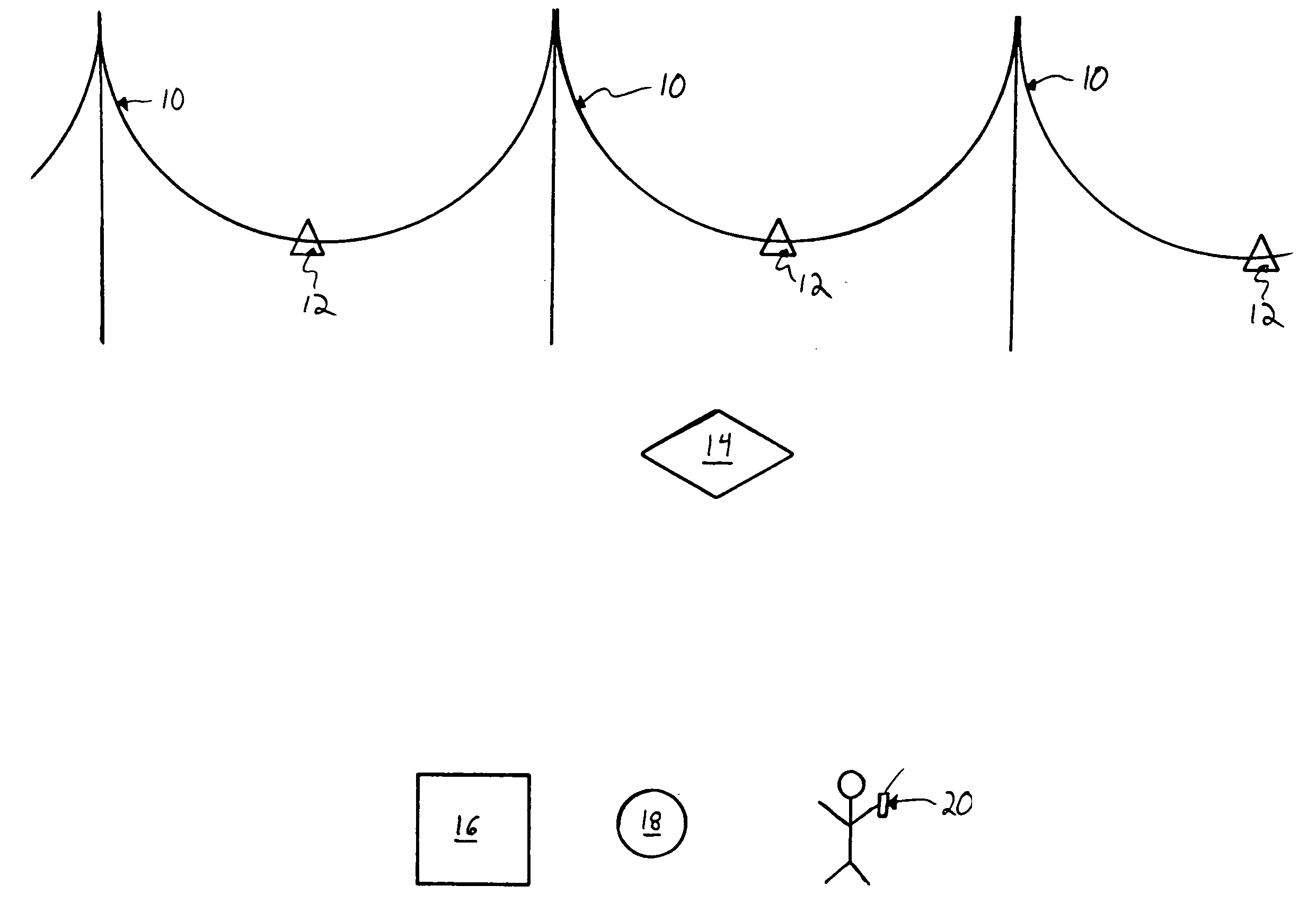

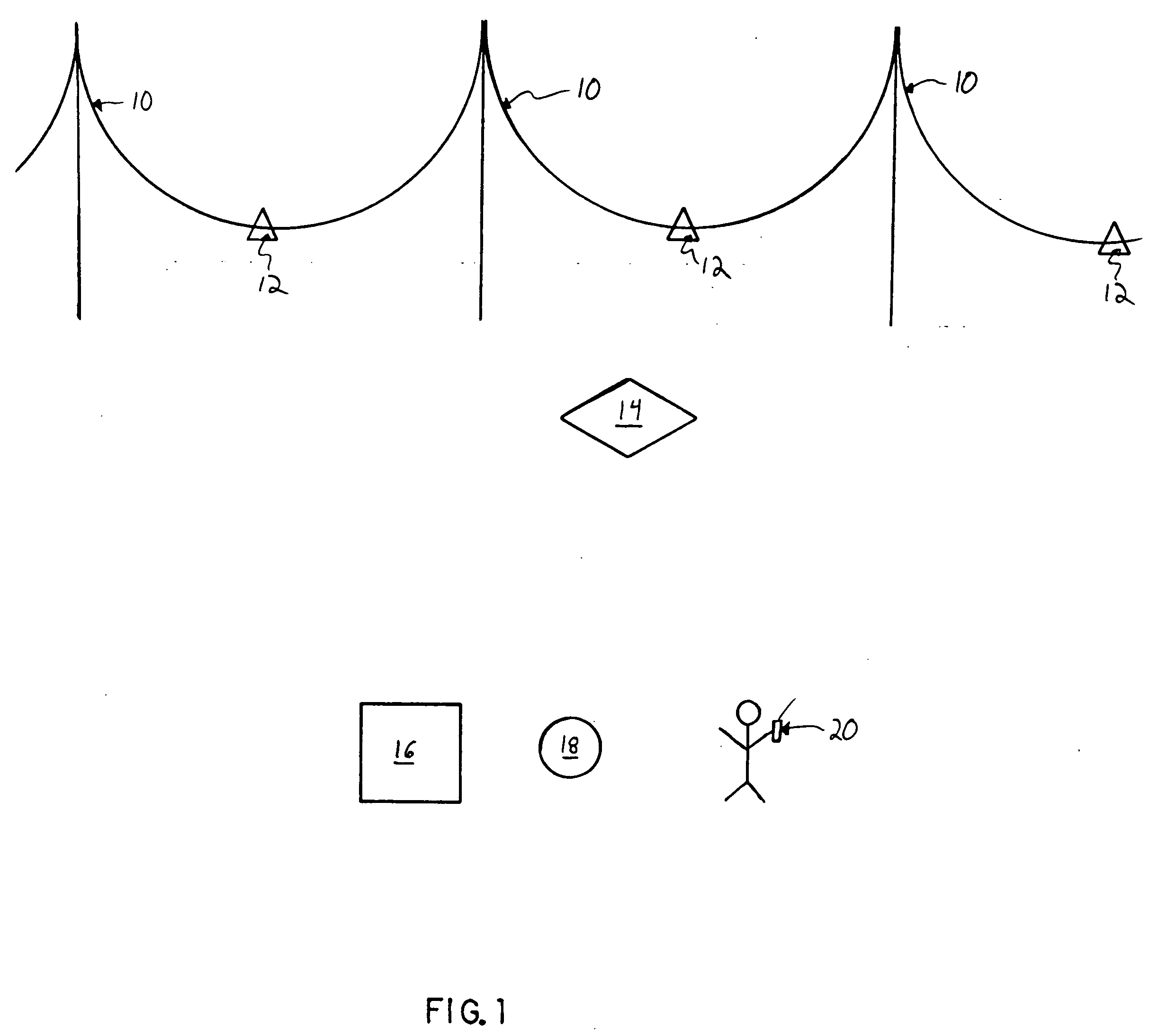

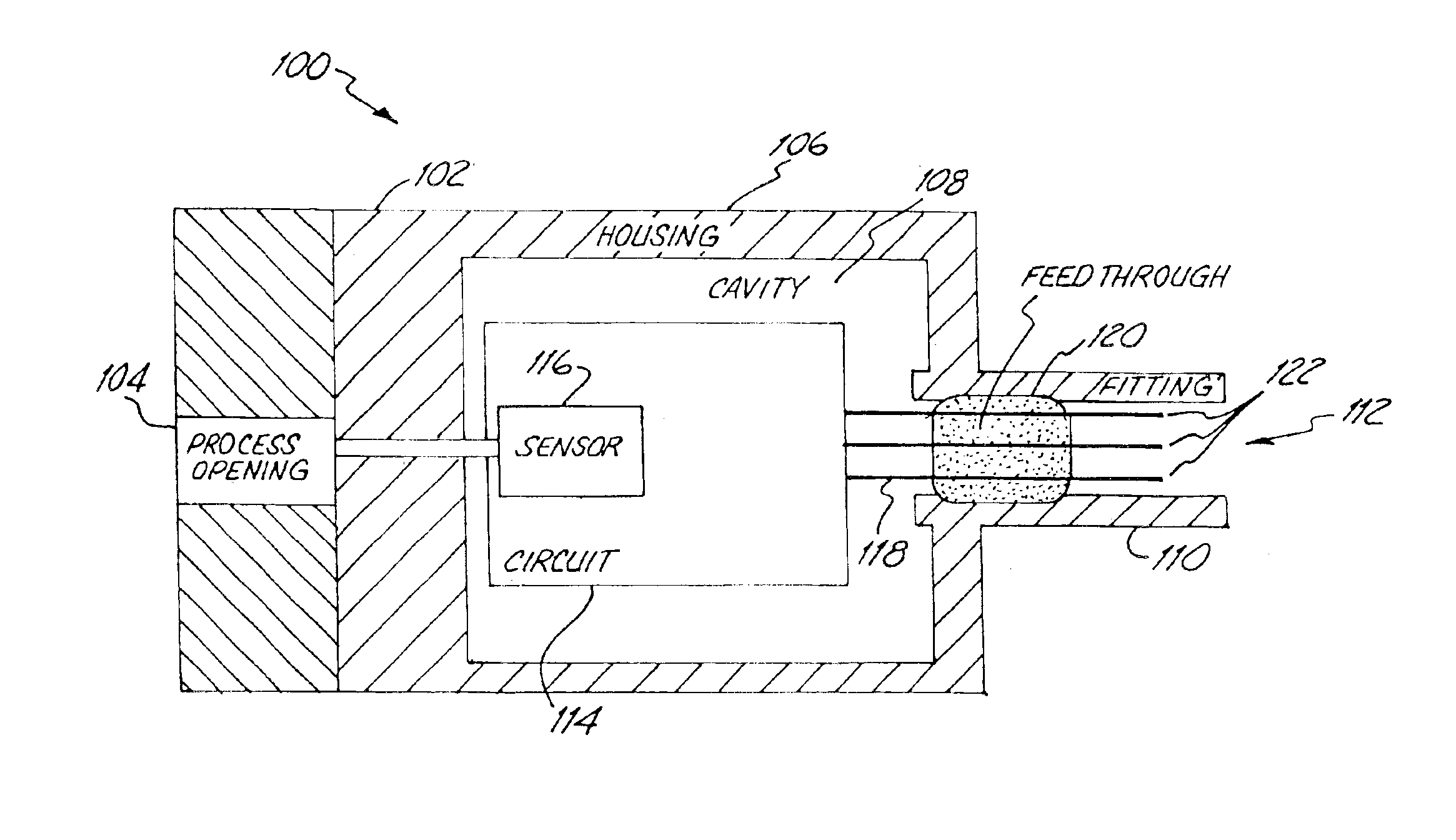

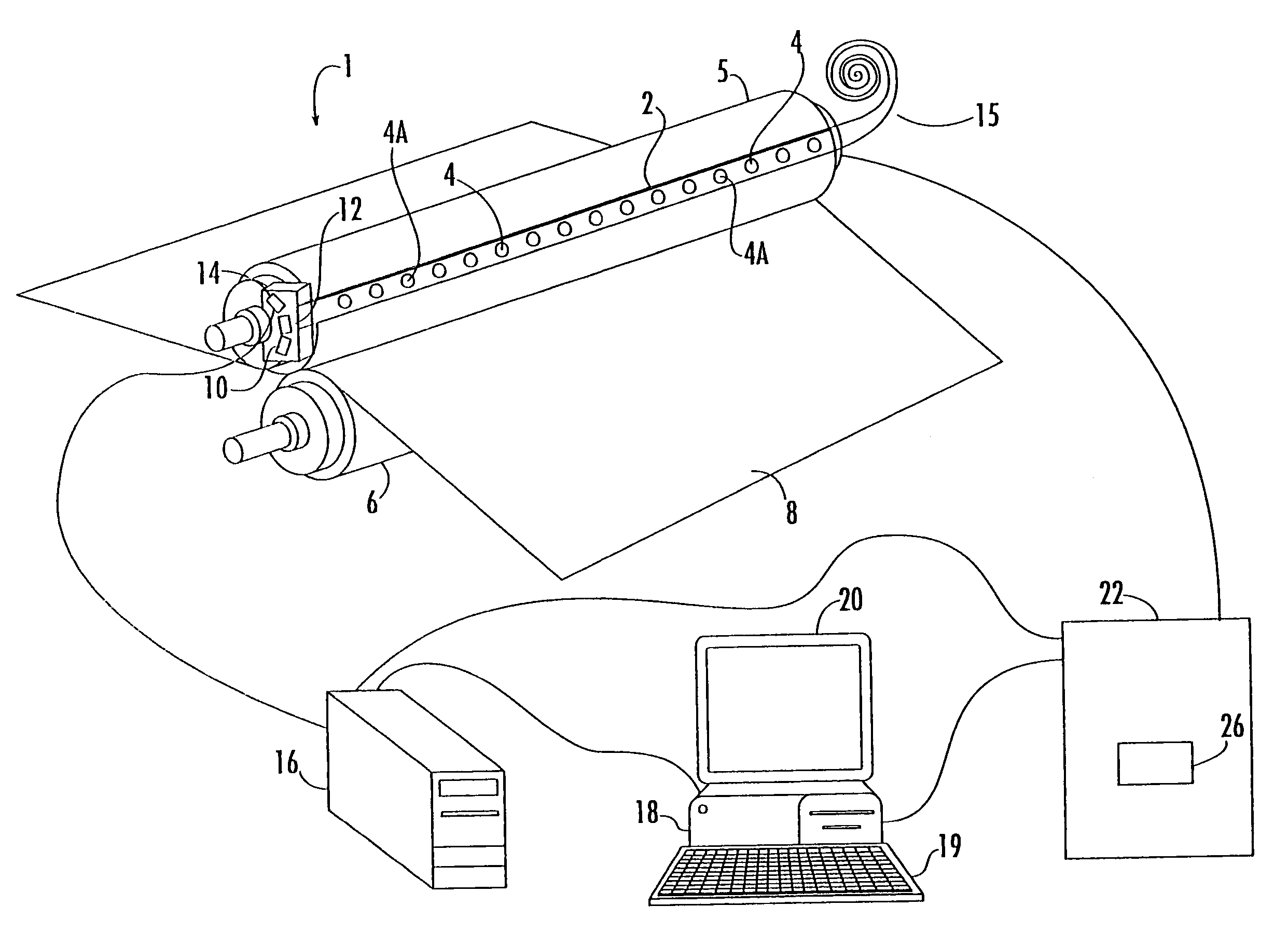

Transmission/distribution line fault indicator with remote polling and current sensing and reporting capability

InactiveUS20050151659A1Overhead installationTransmission systemsCurrent loadElectric power transmission

The present invention includes a fault indicator for an electrical transmission line comprising: a fault indicator circuit; and a remote communicator operatively coupled to the fault indicator circuit to transmit condition data to a remote location, where such condition data includes current load data. The invention also includes a method of monitoring and responding to current faults and load variations across an electrical transmission network, the method comprising: installing two fault indicators in electrical communication with an electrical transmission network and including two-way communication capability; generating, by the two fault indicators, condition data specific to a respective location of each of the two fault indicators, where such condition data includes current load data; transmitting the condition data from the two fault indicators to a remote location; receiving, at the remote location, the condition data transmitted from the two fault indicators; and, monitoring and processing the condition data received.

Owner:DONOVAN DAVID L +2

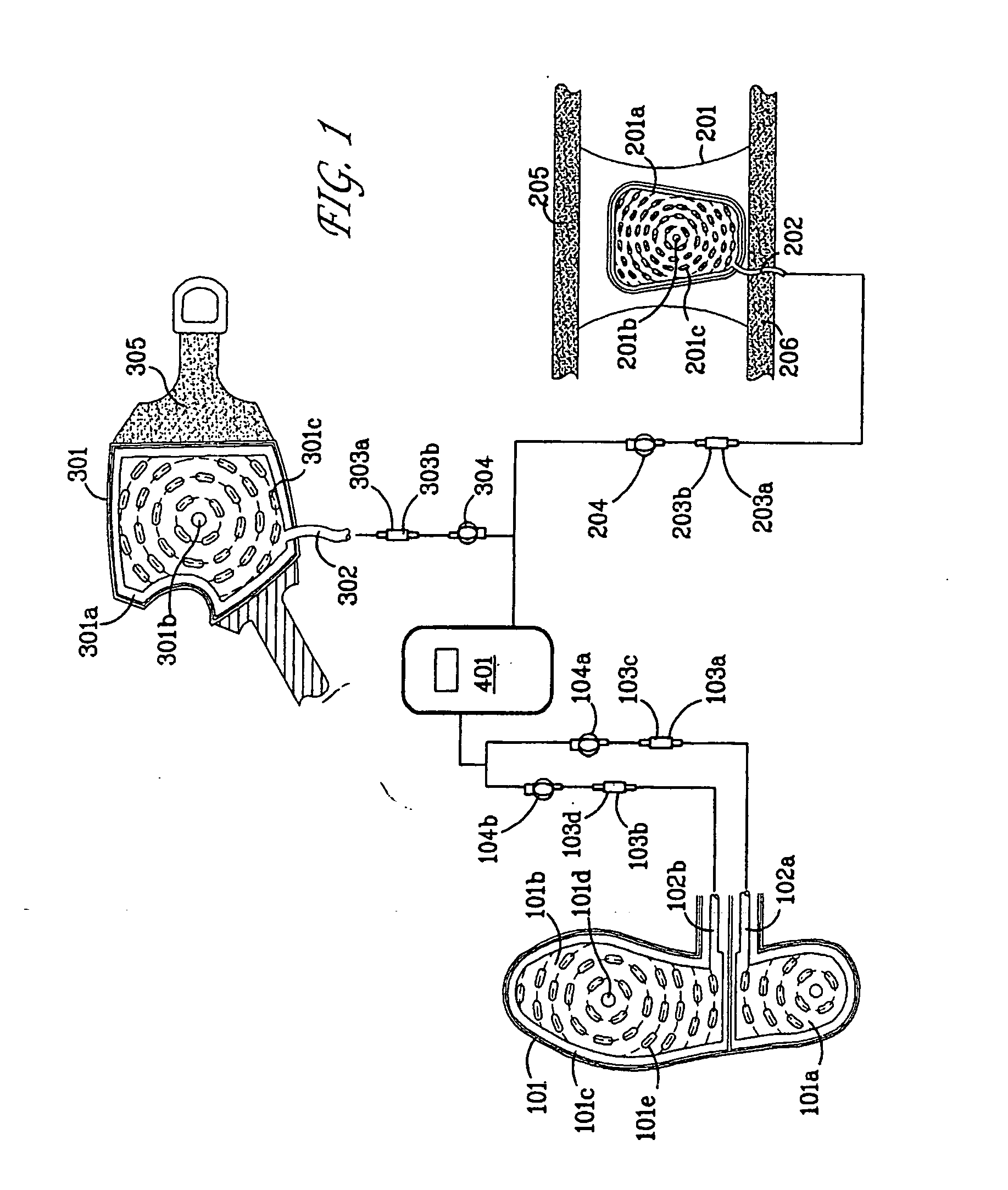

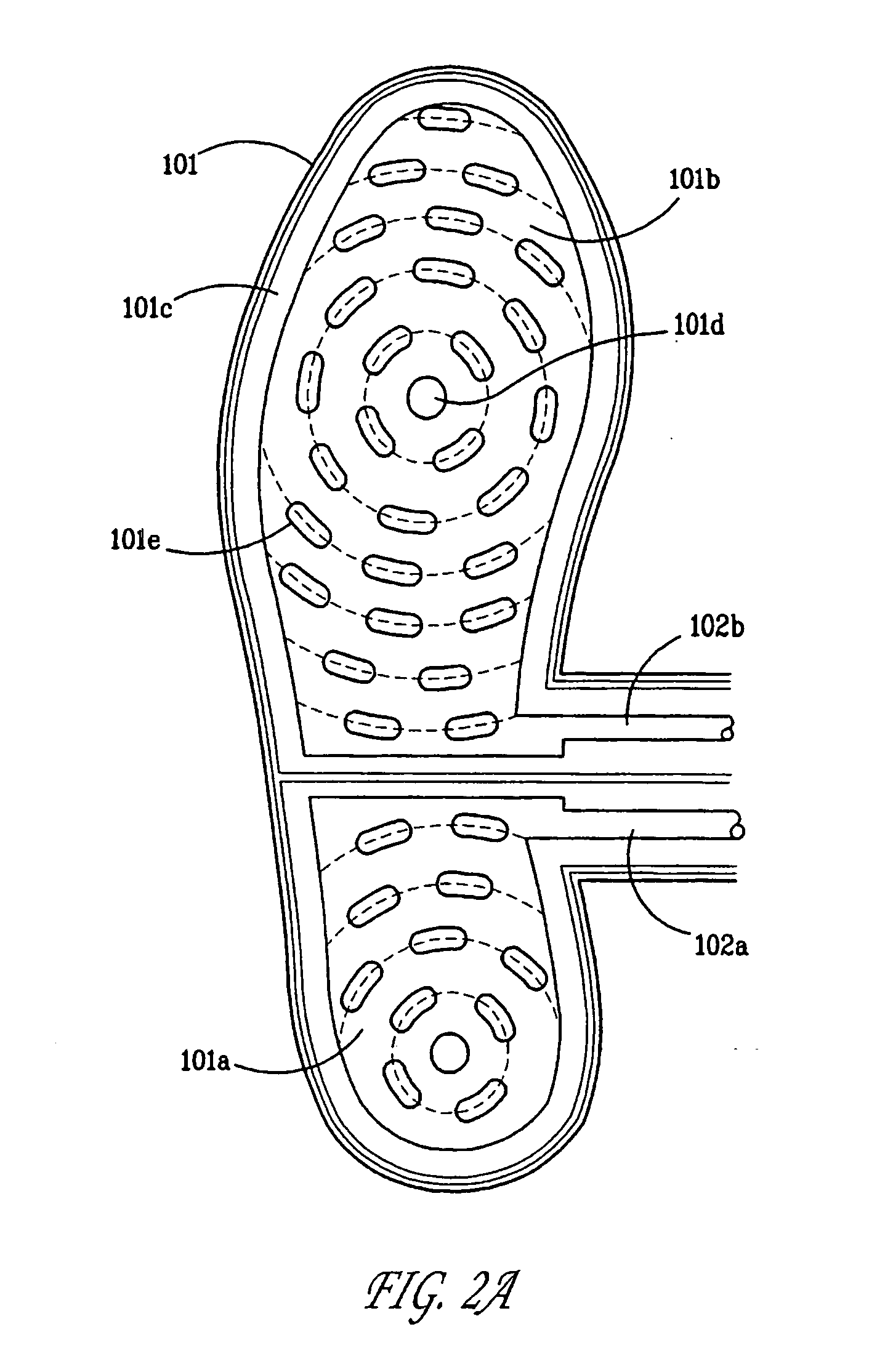

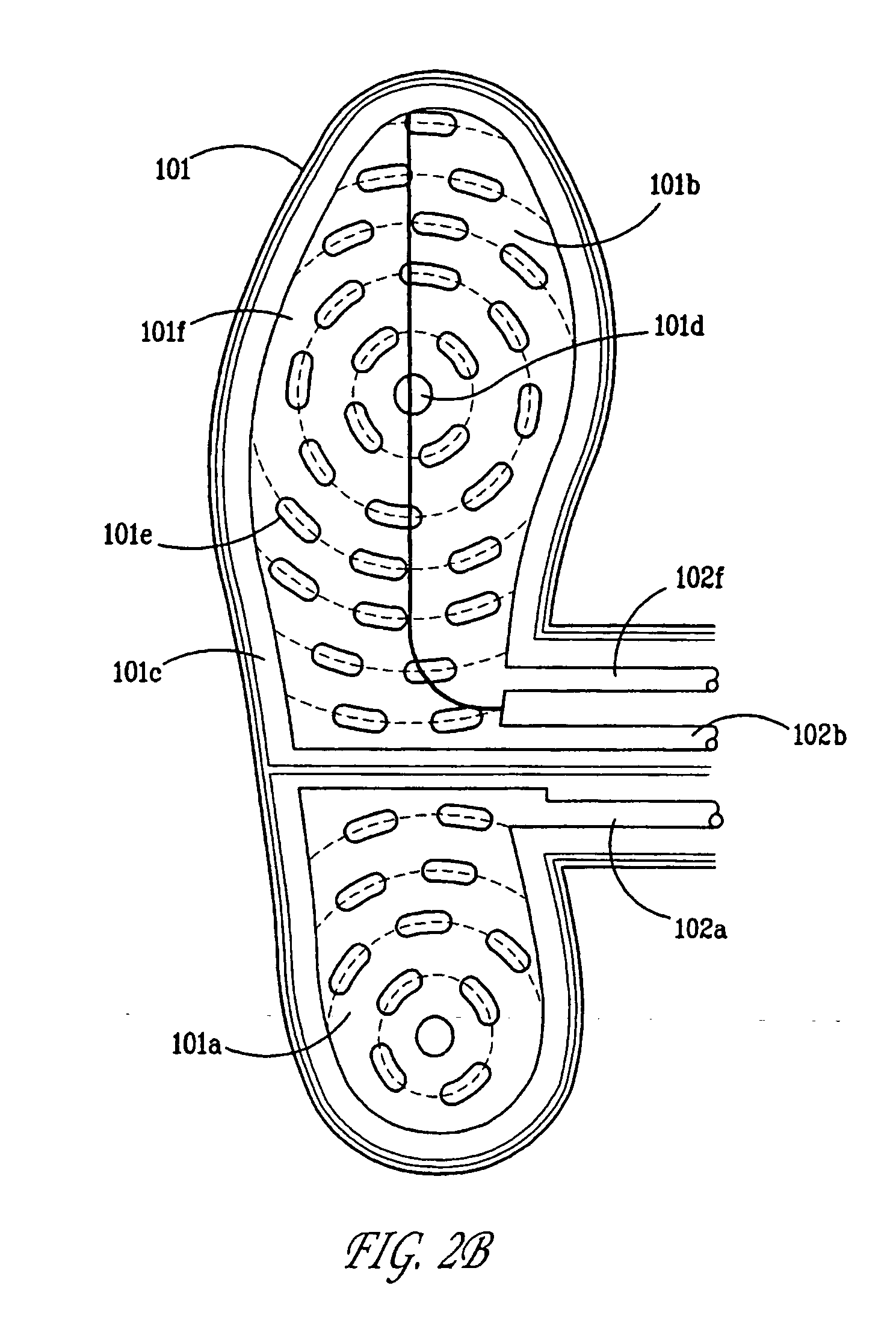

Force sensor system for use in monitoring weight bearing

InactiveUS20060282017A1Quality improvementNormalize gait patternElectrotherapySolesEngineeringBiological activation

A force sensor system for use in monitoring weight bearing on a location. The force sensor system comprises at least one a foot force sensor, a palm force sensor, and a knee force sensor. The foot force sensor comprises a flexible insole containing a plurality of inflatable pockets that are inflated with air or liquid. The palm force sensor and knee force sensor each comprise a wrap to be worn around the palm and knee, respectively. Each wrap comprises a pocket. Each pocket is connected to a tube that, in turn, connects with a pressure sensor and a connector coupling that is remote from the pocket. Each coupling contains a valve. The valve opens to allow inflation and deflation of each inflatable pocket. The pressure sensors measure the air or liquid pressure within each of the inflatable pockets, and convert the corresponding pressure signal into a suitable output signal medium, usually electrical signals. The output signal from the sensors provides accurate real time input data to a weight bearing biofeedback system or to control a stimulator for activation of an electronic orthosis to normalize dynamic gait patterns.

Owner:ANDANTE MEDICAL DEVICES

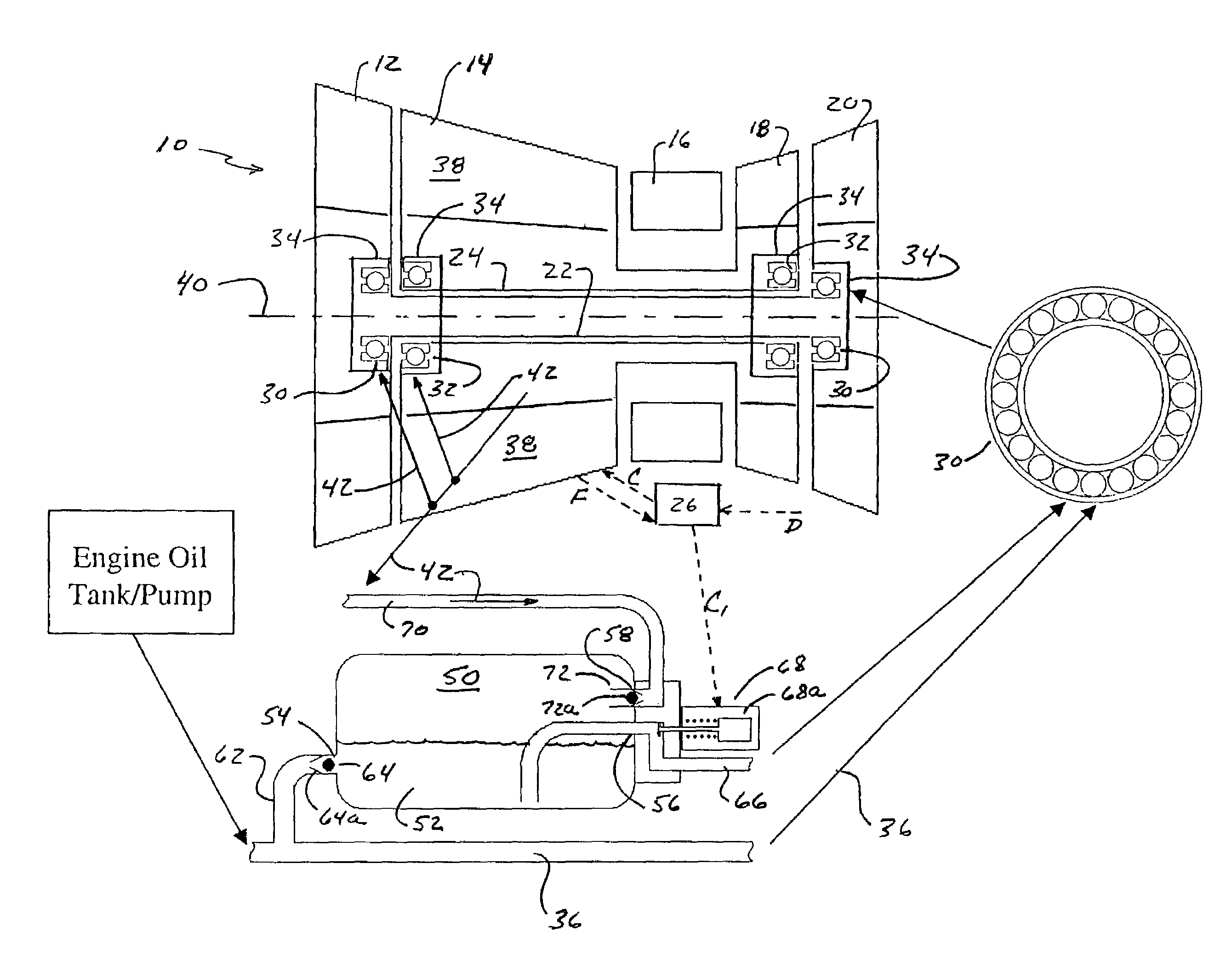

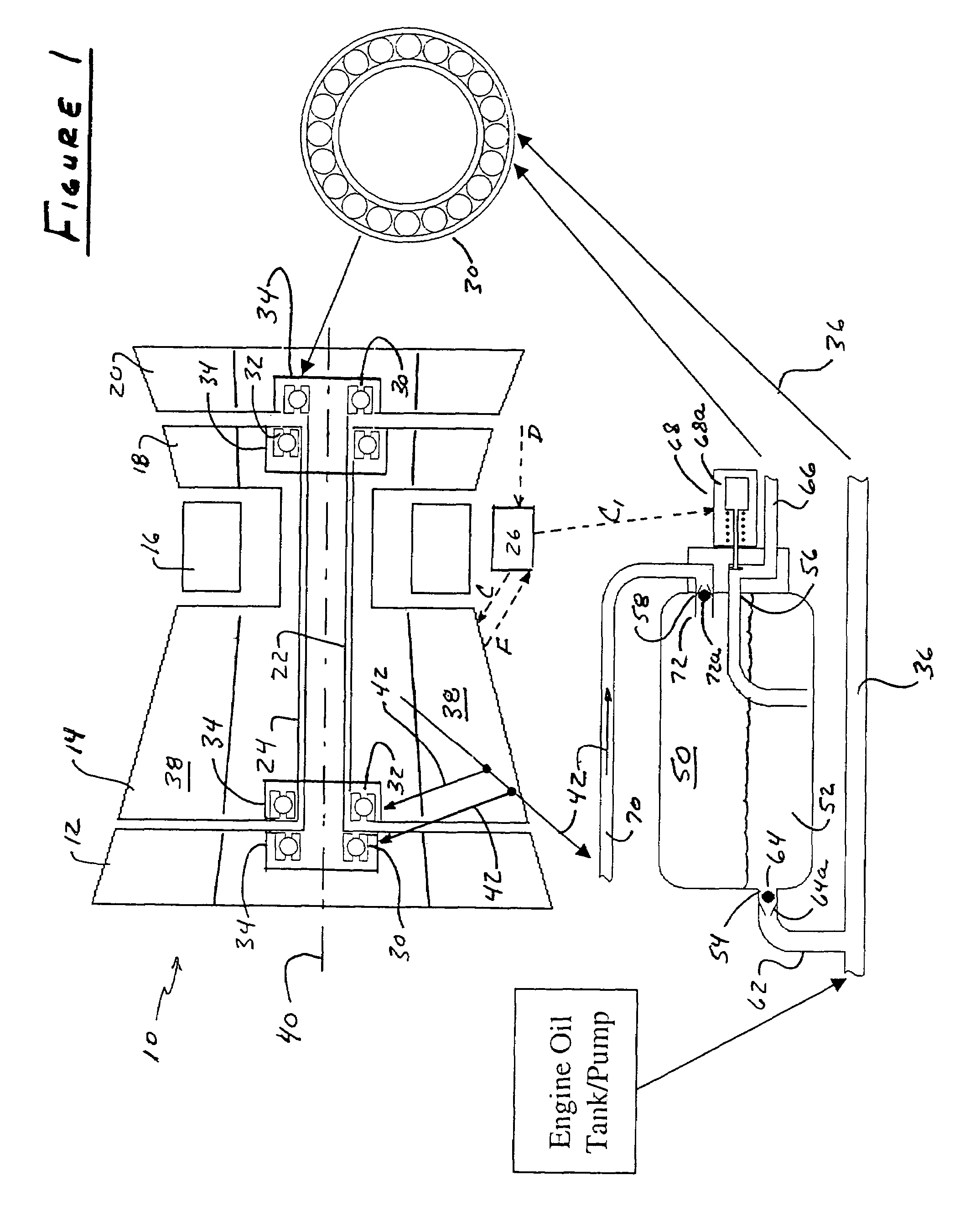

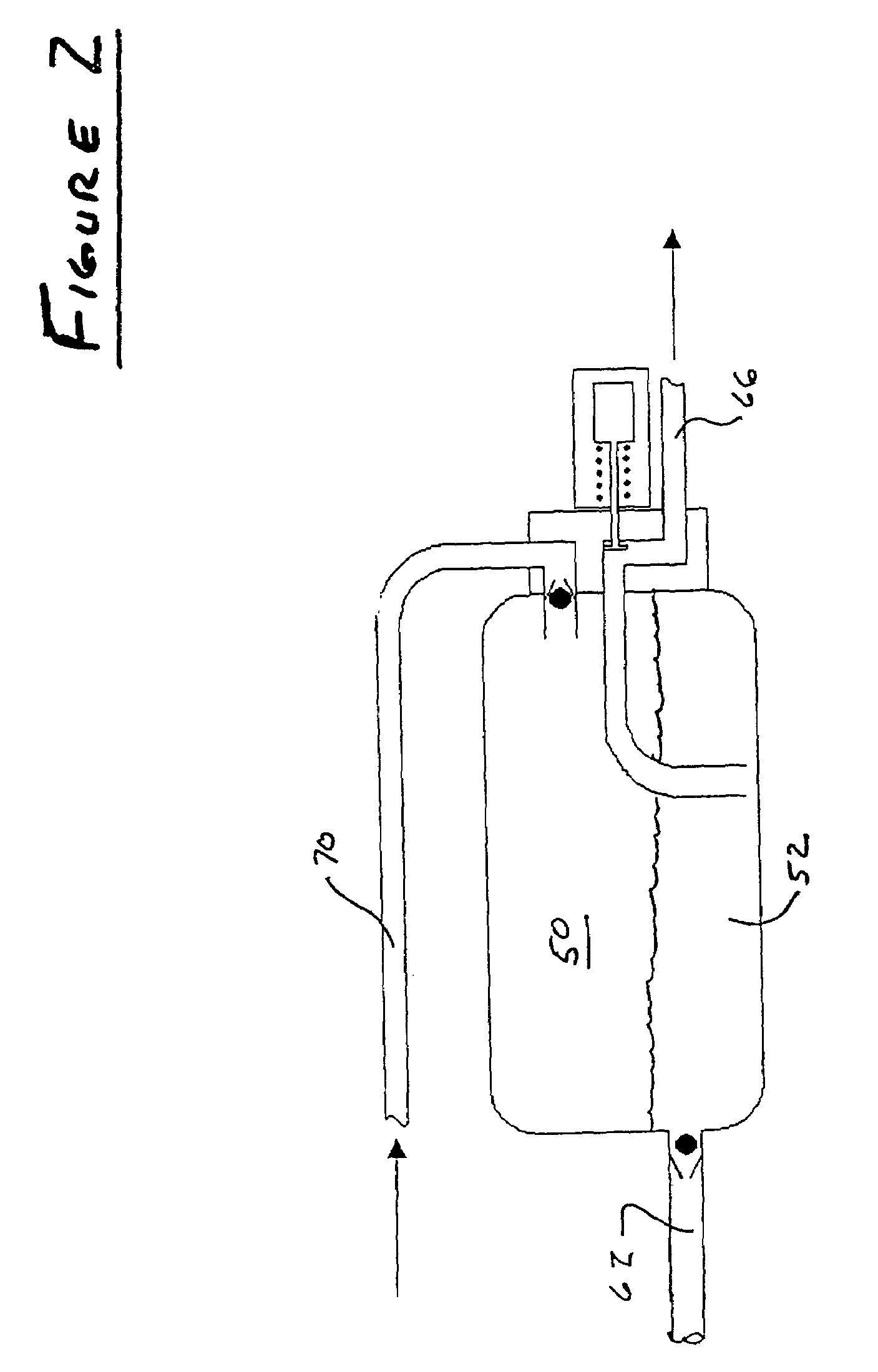

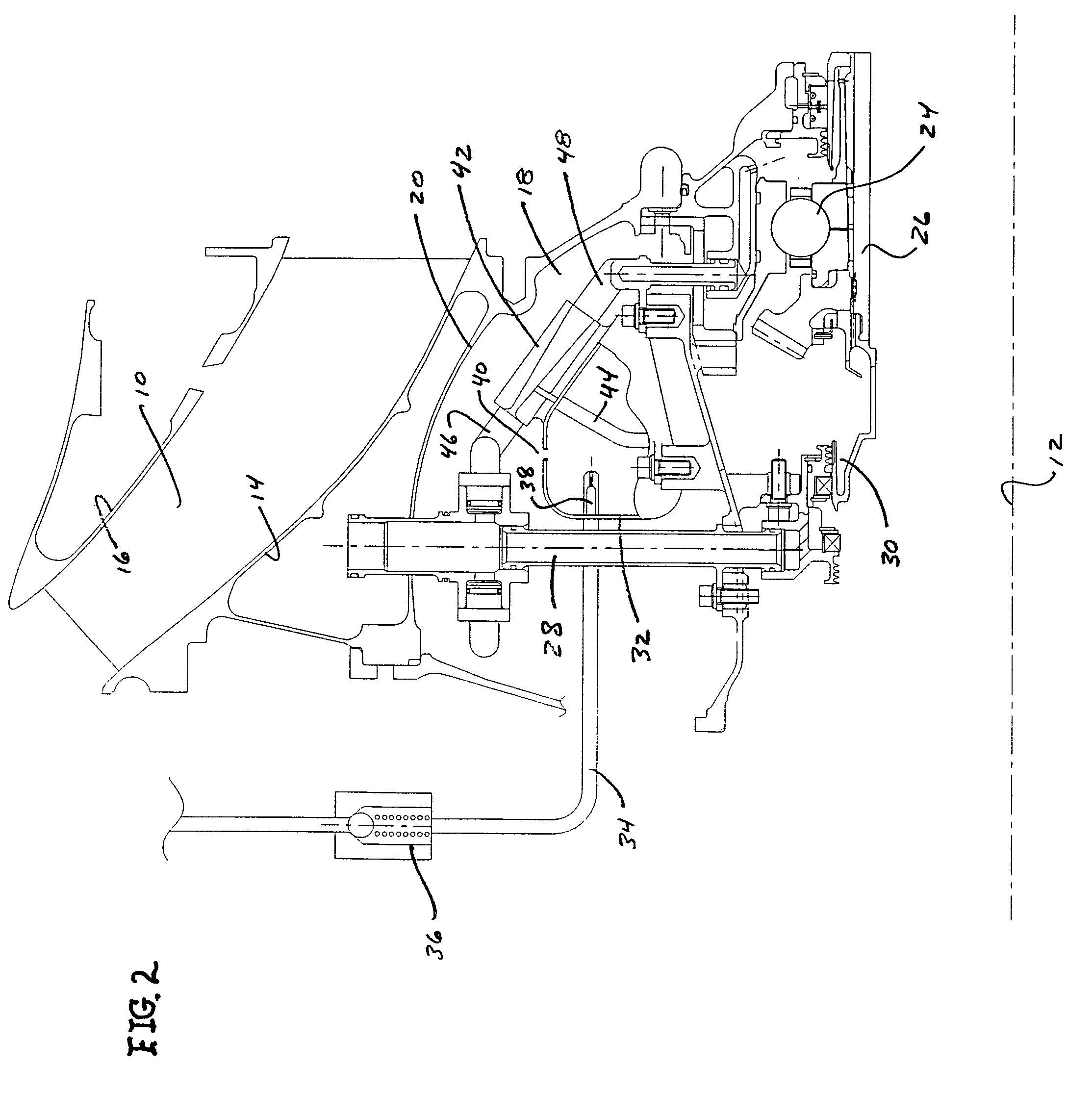

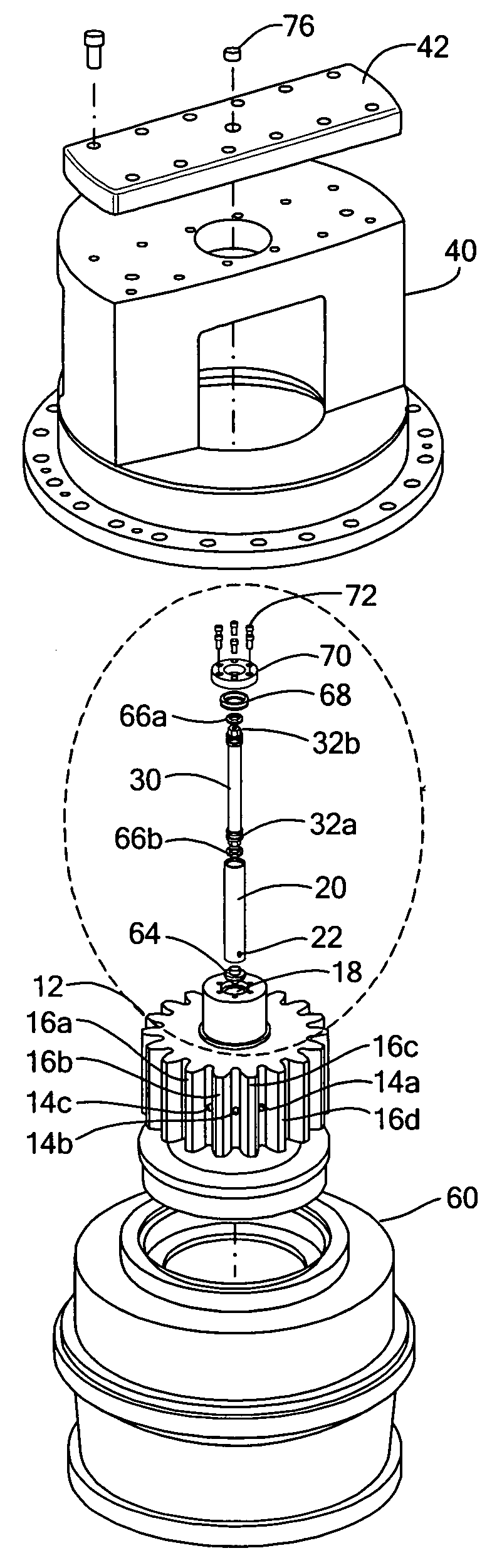

Emergency lubrication system

ActiveUS7387189B2Extended time intervalLight weightEfficient propulsion technologiesMachines/enginesNormal rateInlet valve

An emergency lubrication system for a turbine engine includes a reservoir 50 containing a reserve quantity of lubricant 52 and having a lubricant inlet 54 and a lubricant outlet 56. A lubricant supply line 62 and a lubricant outlet line 66 each have a respective valves 64, 68 for regulating lubricant flow into and out of the reservoir. A fluid supply line 70 includes a valve 72 for selectively establishing communication between the reserve quantity of lubricant and a source of pressurized fluid. During normal operation the lubricant outlet valve continuously releases lubricant at a normal rate to the component requiring lubrication while the lubricant inlet valve concurrently admits fresh lubricant into the reservoir. During abnormal operation, the lubricant inlet valve closes in response to abnormally low lubricant pressure outside the reservoir thereby preventing backflow of reserve lubricant out of the reservoir. The fluid inlet valve opens to admit pressurized fluid into the reservoir thus pressurizing the reserve lubricant. The lubricant outlet valve opens or cycles open and closed in response to a command from a controller 26 so that the pressurized fluid forces lubricant through the outlet 56 as a subnormal rate, which persists until the lubricant reserve is substantially depleted. The subnormal rate is ideally achieved by intermittently releasing lubricant from the reservoir, but may also be achieved by releasing a continuous stream of lubricant at a rate less than the normal rate of release.

Owner:RTX CORP

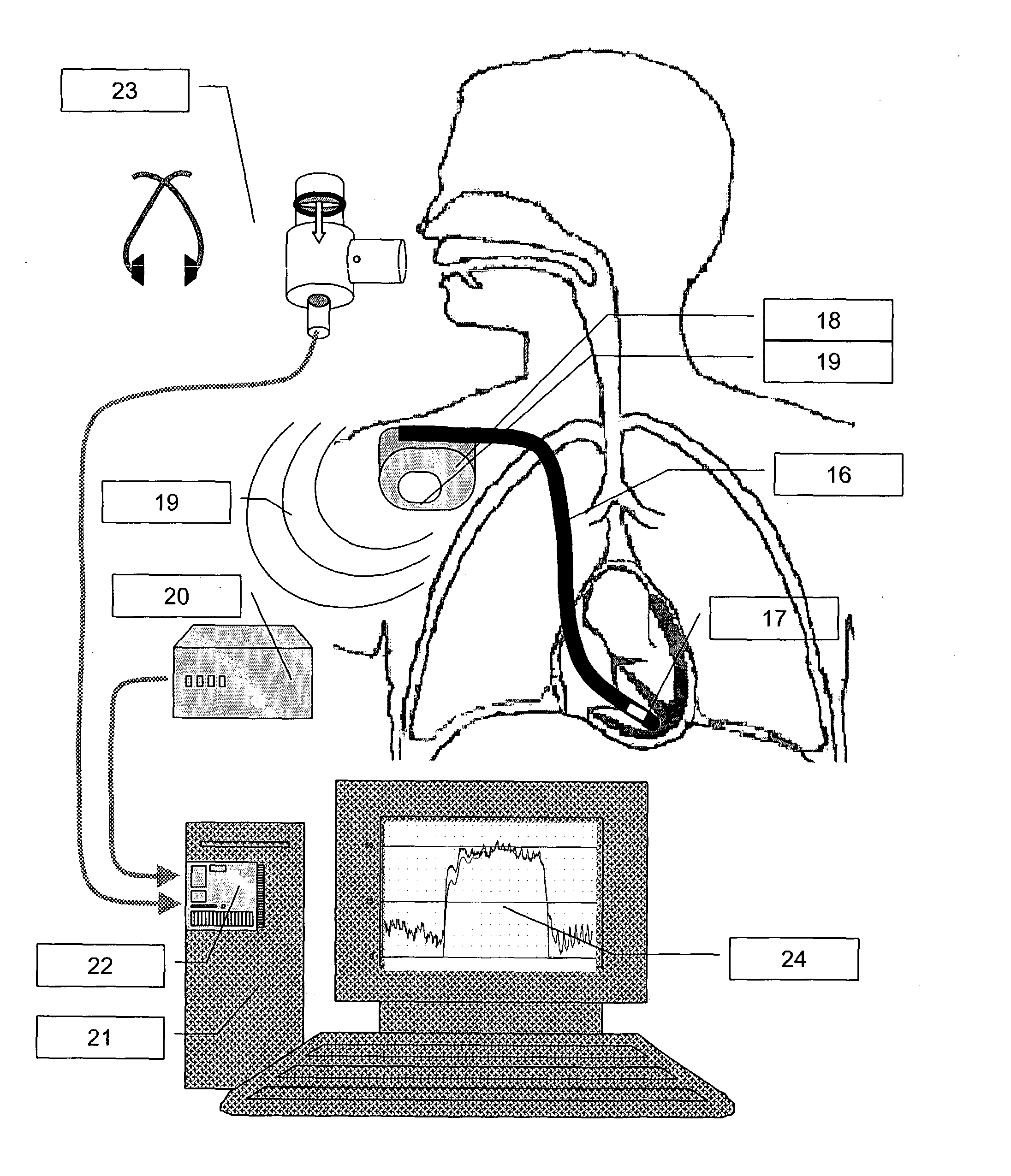

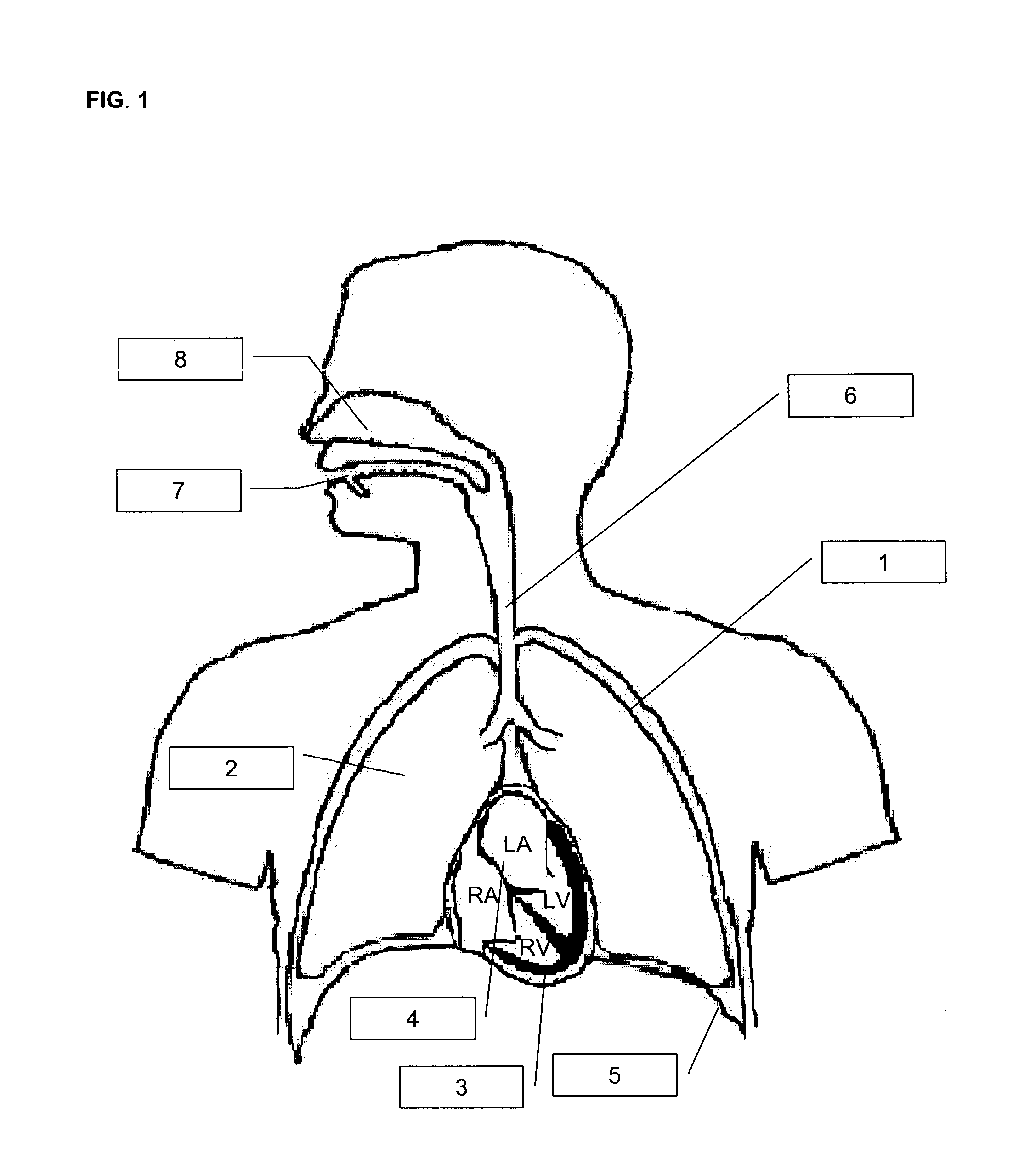

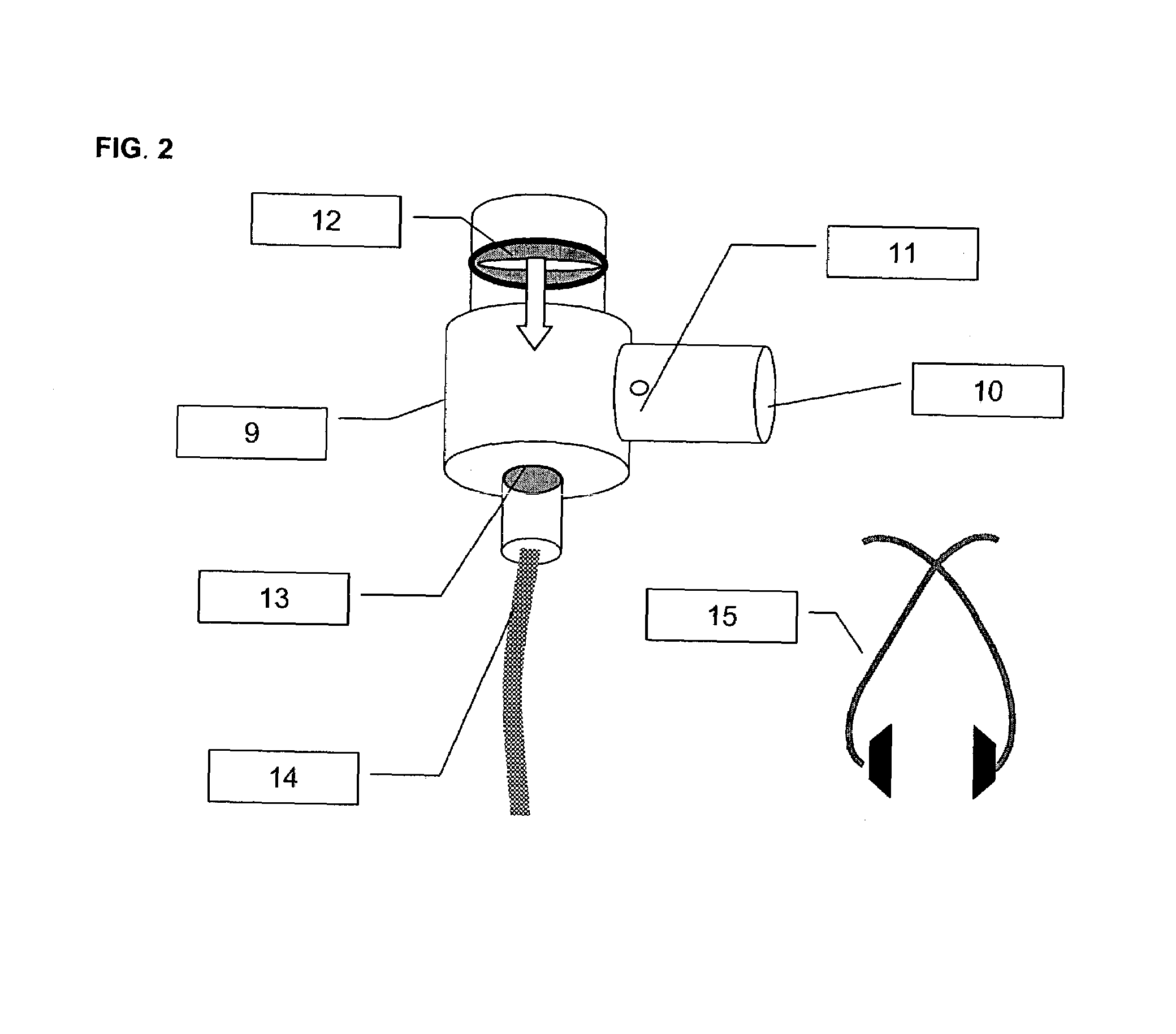

Method for minimally invasive calibration of implanted pressure transducers

This invention relates generally to apparatus and methods for the calibration of implanted pressure transducers. It is an object of several embodiments of the present invention to provide apparatus and methods for the calibration of one or more implanted pressure transducers implanted in the body of medical patients. Various embodiments of the present invention are particularly advantageous because they offer a calibration system that is less invasive than the systems currently available.

Owner:PACESETTER INC

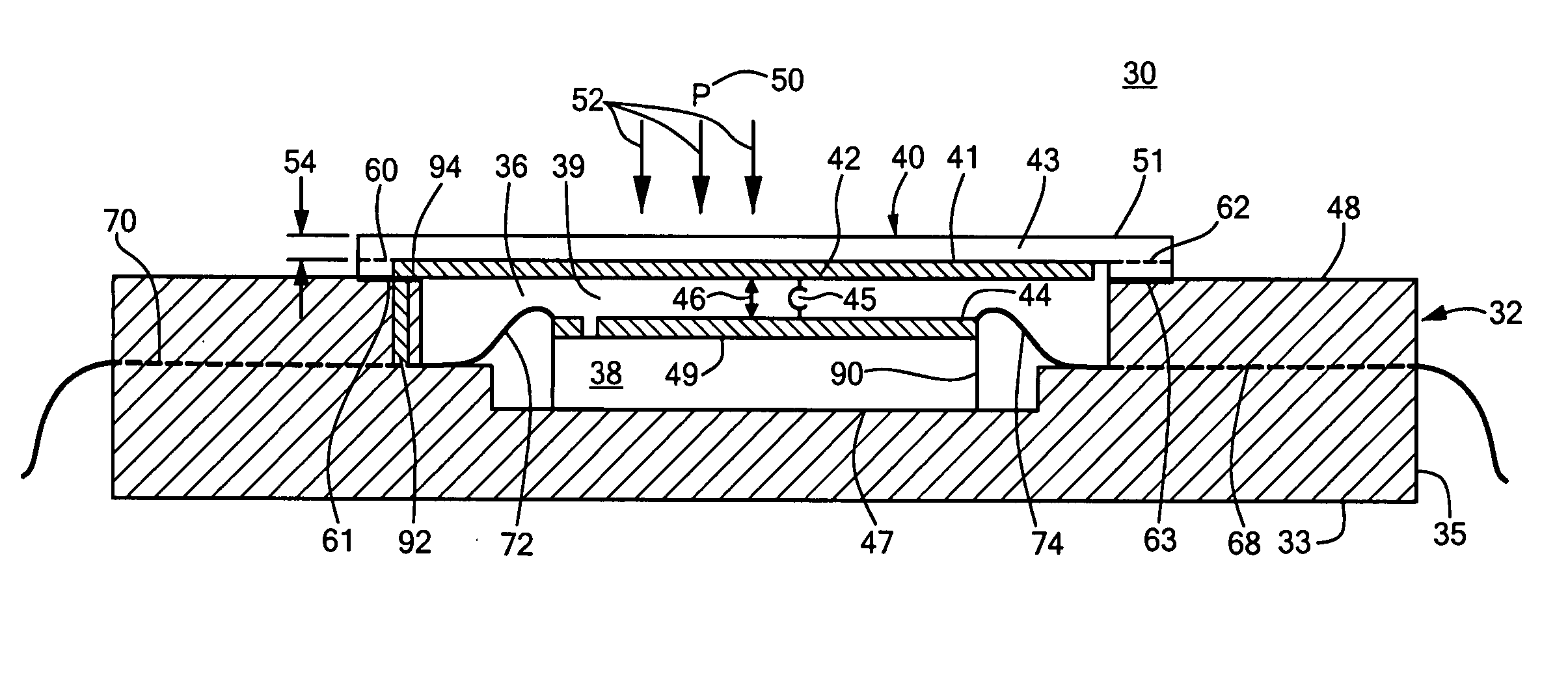

Capacitive sensor

ActiveUS20050229710A1Effective protectionEliminate needSolid-state devicesMachines/enginesEngineeringCapacitor

A capacitive sensor including a housing having a hermetically sealed cavity, a plate in the cavity, a diaphragm forming a part of the cavity and spaced from the plate, a conductive layer on the first diaphragm, and a second conductive layer on the plate, the first and second conductive layers being the electrodes of a capacitor whose capacitance varies with the position of the diaphragm relative to the plate.

Owner:ANALOG DEVICES INC

Capacitive sensor

ActiveUS7353711B2Simple designReduce manufacturing costSolid-state devicesMachines/enginesHermetic sealCapacitive sensing

A capacitive sensor including a housing having a hermetically sealed cavity, a plate in the cavity, a diaphragm forming a part of the cavity and spaced from the plate, a conductive layer on the first diaphragm, and a second conductive layer on the plate, the first and second conductive layers being the electrodes of a capacitor whose capacitance varies with the position of the diaphragm relative to the plate.

Owner:ANALOG DEVICES INC

Crankcase breech detection for boosted engines

InactiveUS20100147270A1Prolonged duty cycleIncreased blow-byCombustion enginesLubrication pressure controlMobile vehicleAtmospheric air

Methods for indicating whether a crankcase of an engine is breeched are provided. One example method comprises restricting a communication of the crankcase with atmosphere, acting to increase or decrease a crankcase pressure, and indicating whether the crankcase is breeched based on the crankcase pressure. Another example method comprises sensing a crankcase pressure component, and indicating whether the crankcase is breeched based on the crankcase pressure component, the crankcase communicating with atmosphere via a conduit, a restrictedness of the conduit responsive to one or more of a crankcase pressure and a signal from an electronic control unit of the motor vehicle. Still other examples provide more particular methods for indicating whether the crankcase is breeched, and example configurations that enable the various methods.

Owner:FORD GLOBAL TECH LLC

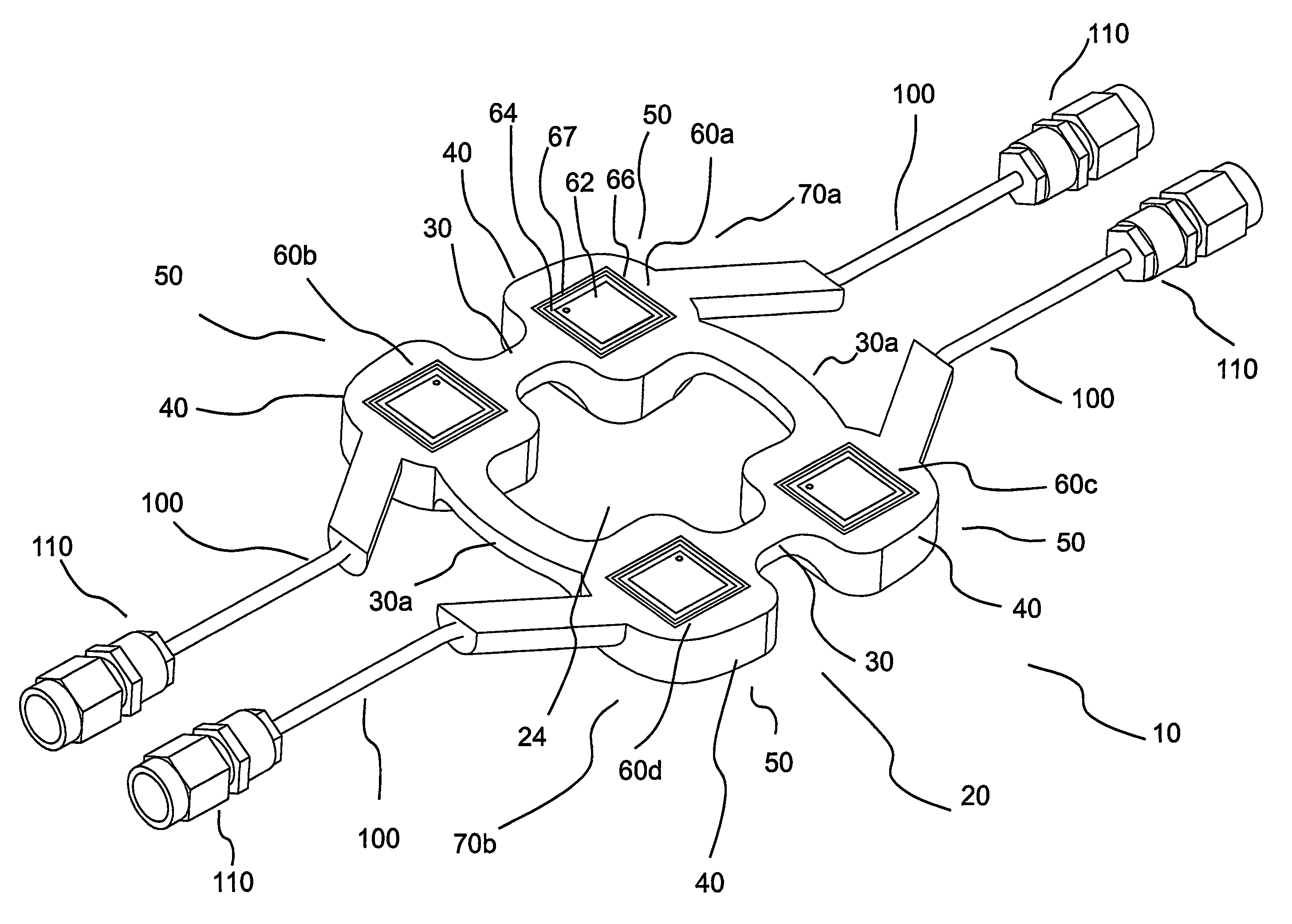

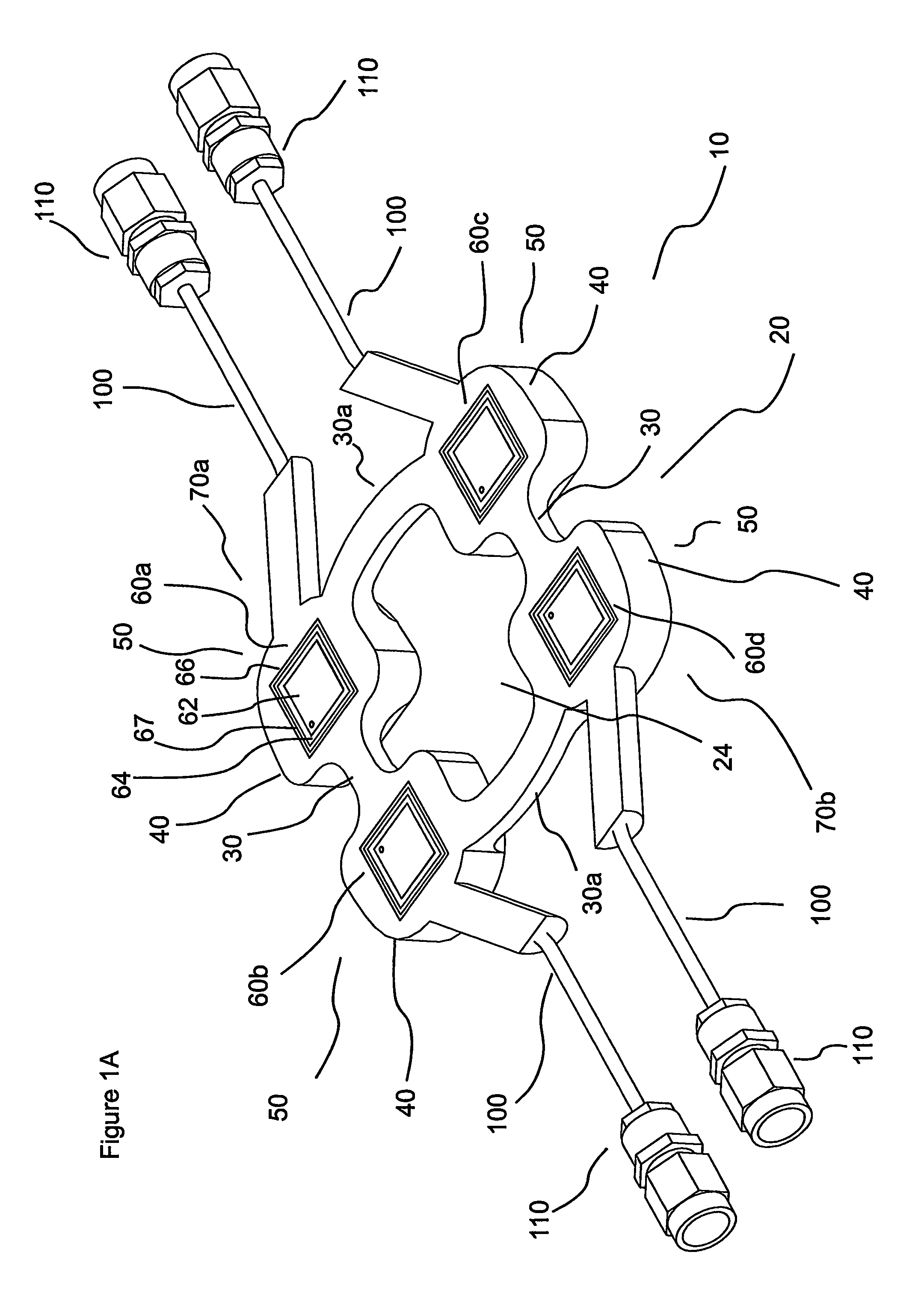

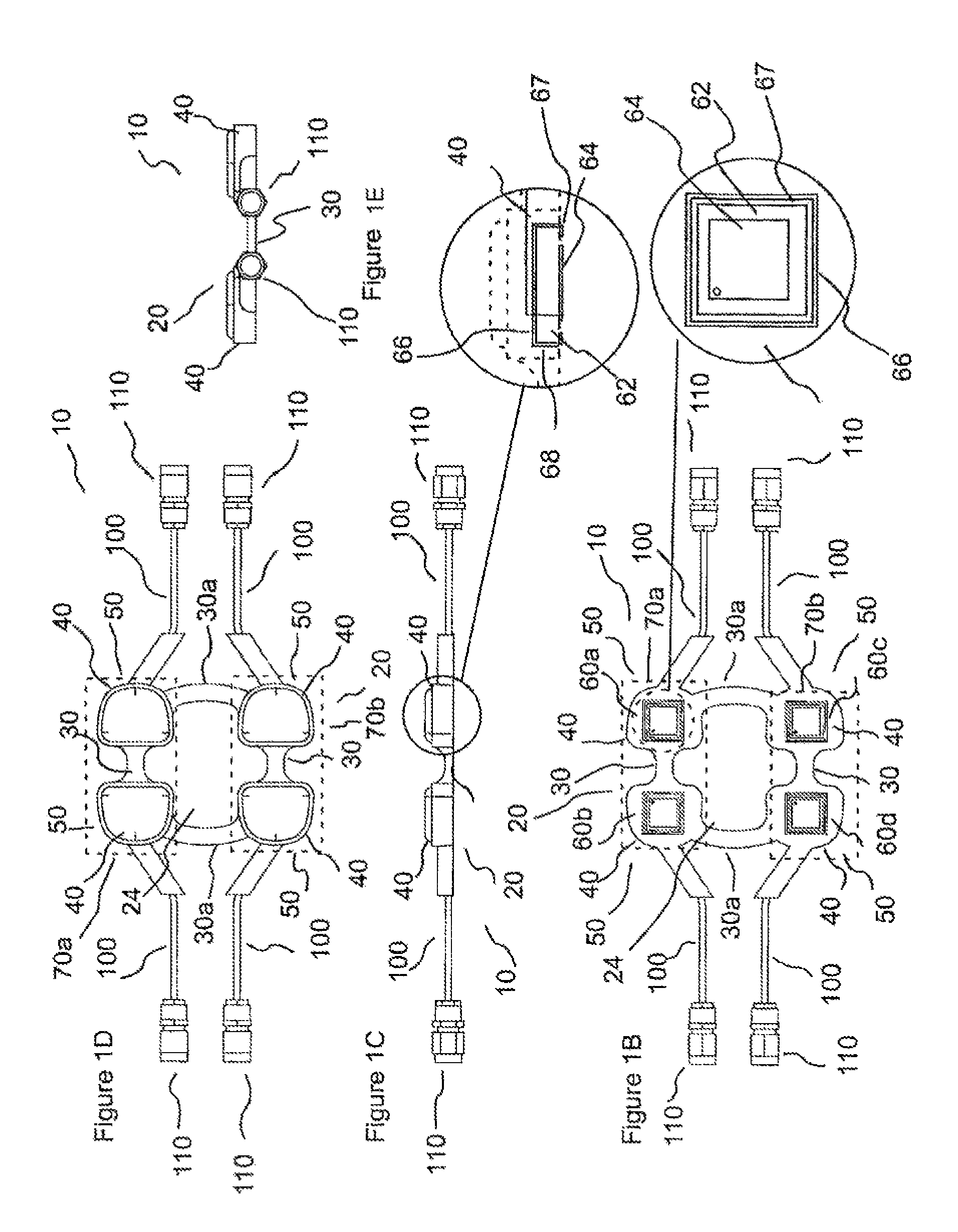

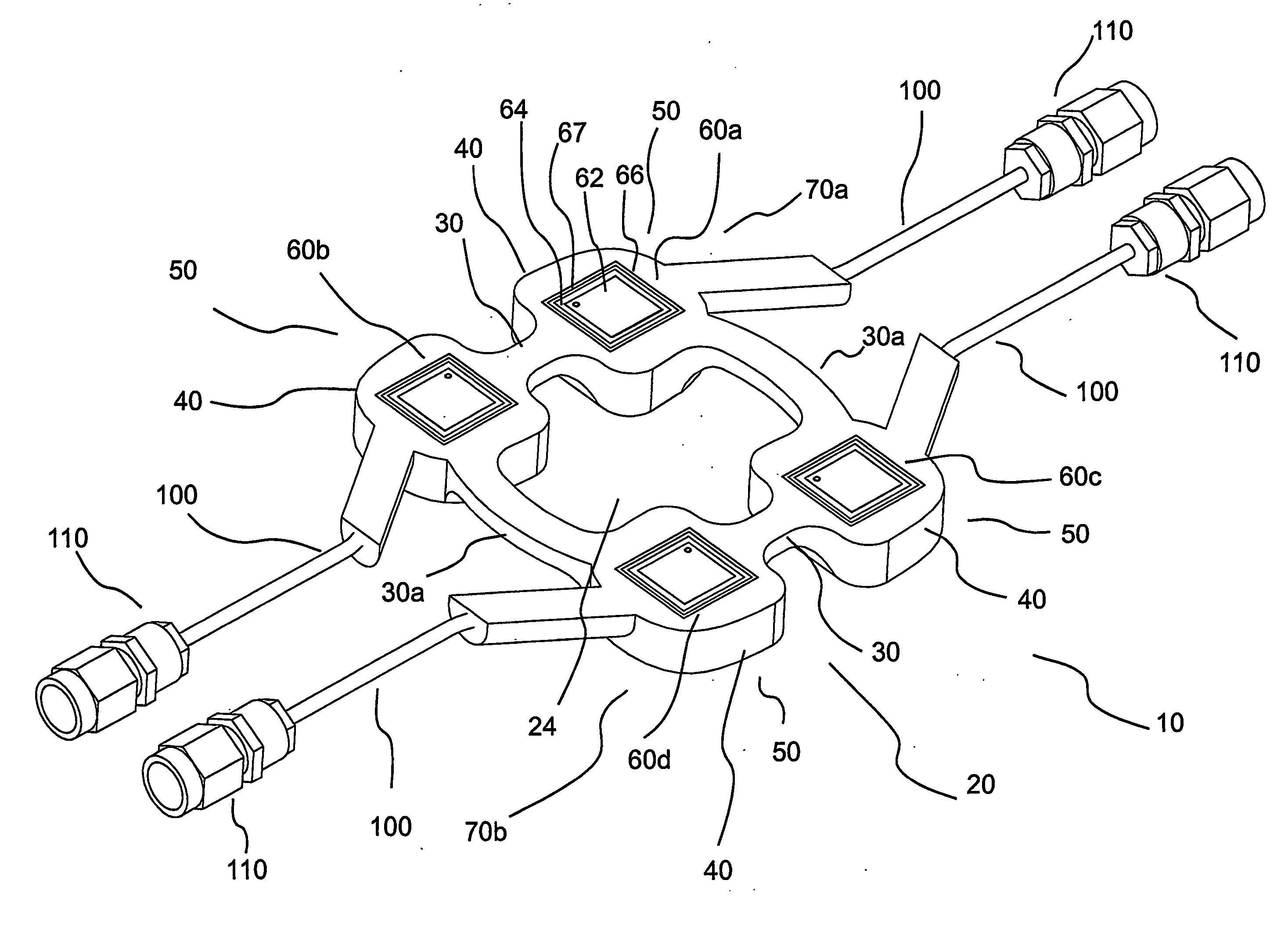

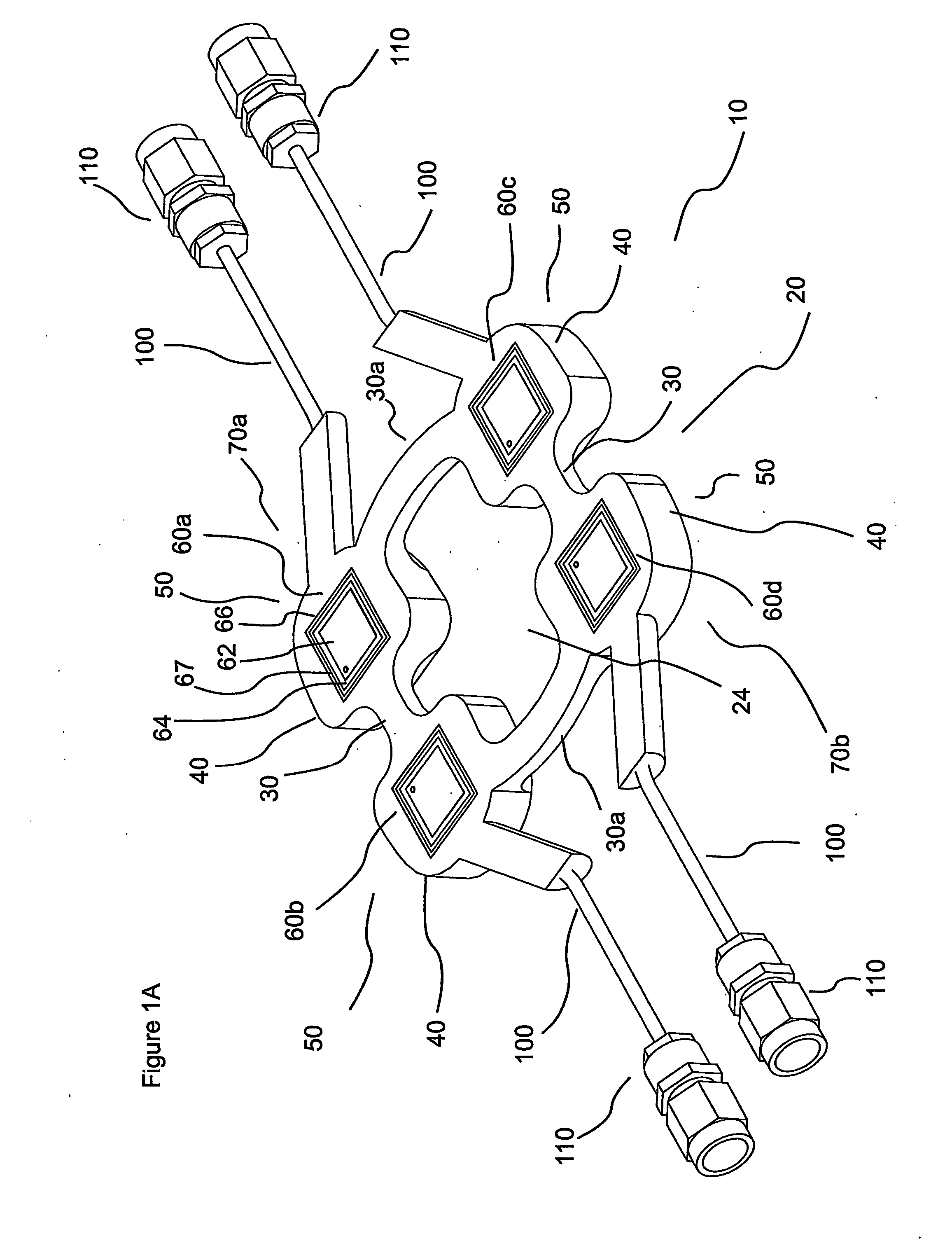

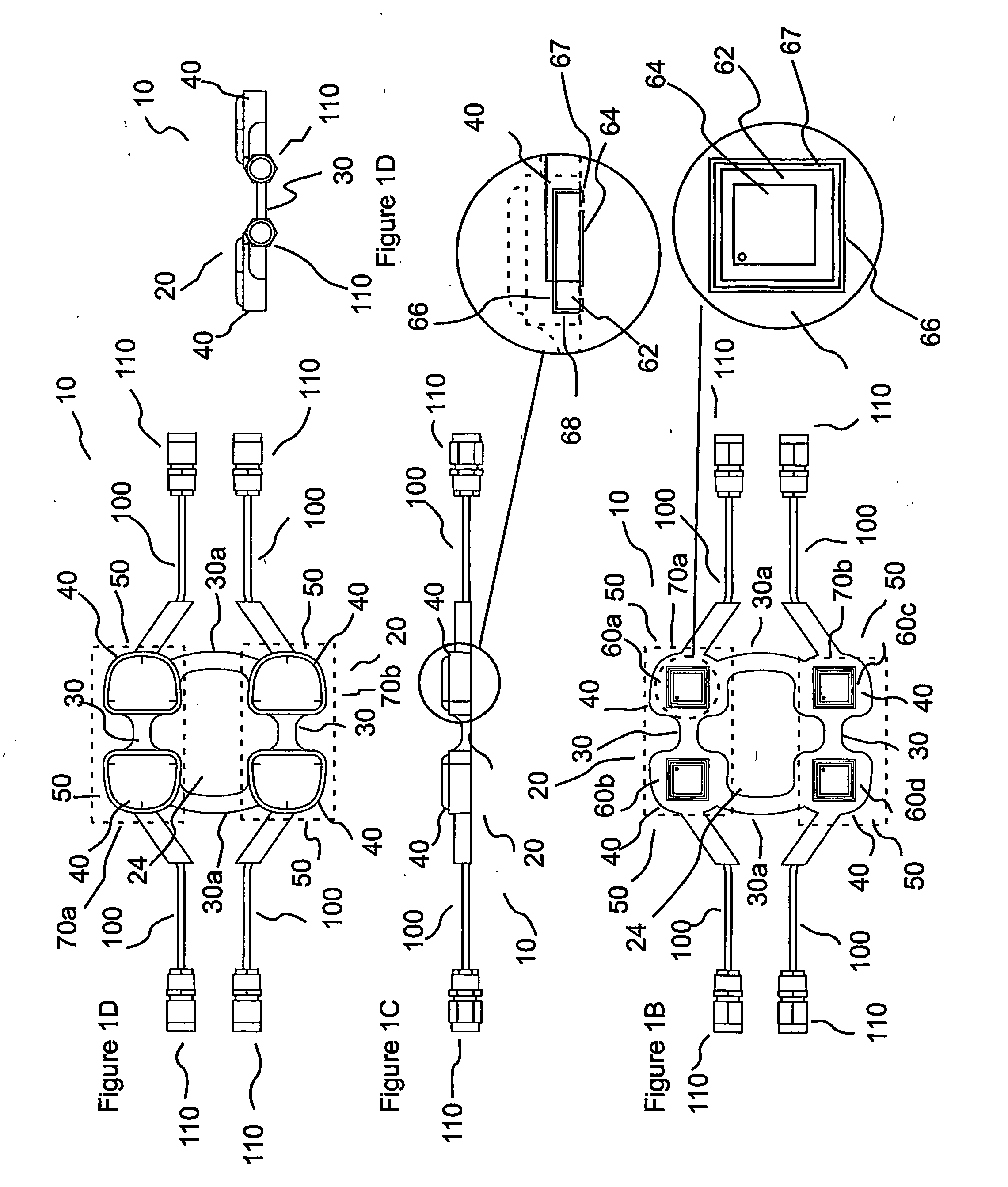

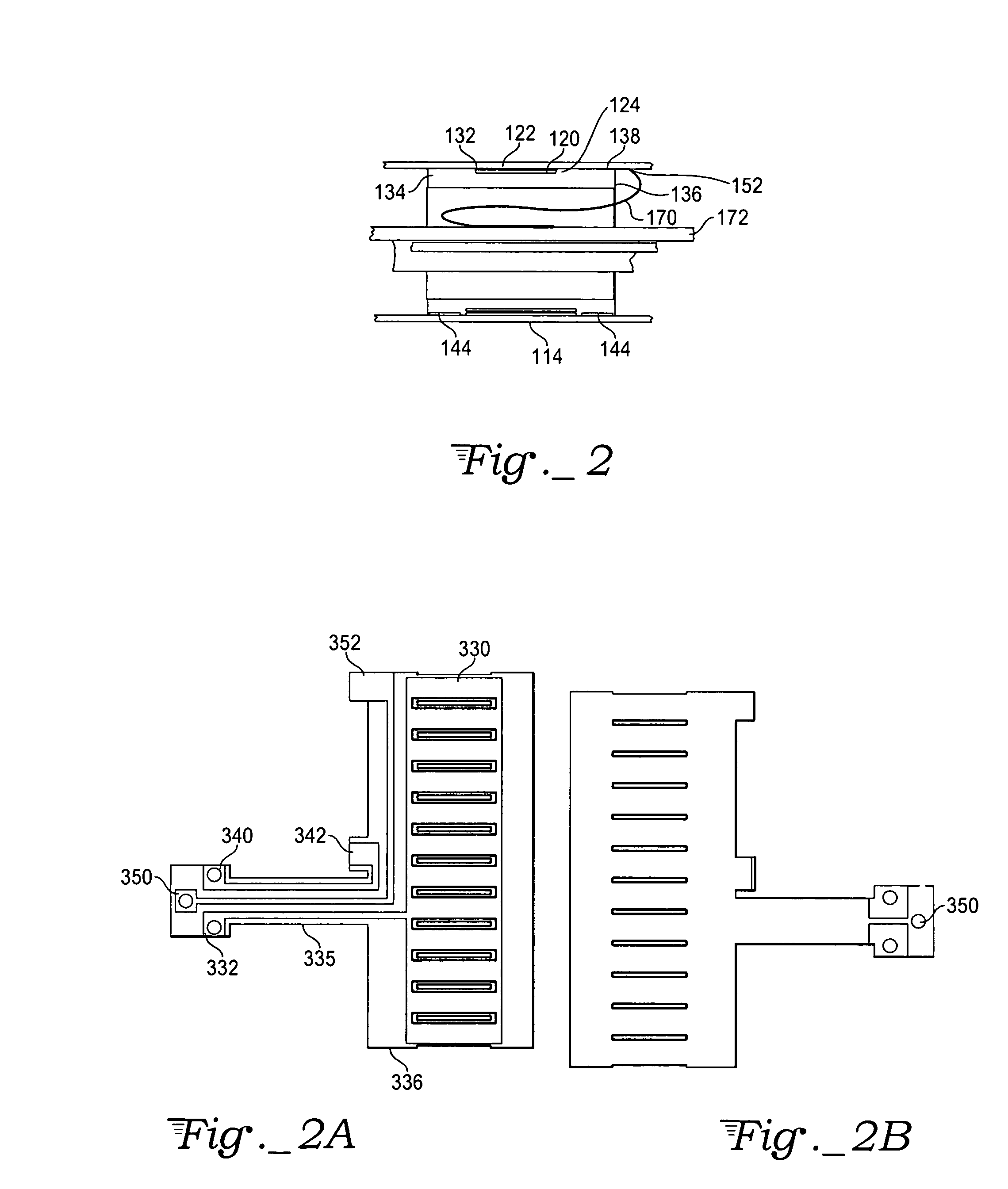

System for detecting fluid changes and sensoring devices therefor

ActiveUS8295920B2Reduce sensitivityEasy to disassembleMaterial analysis using microwave meansMedical devicesEngineeringFluid level

A sensor device for detecting a change fluid level within body tissue comprising a housing with bridge segments connecting at intersections arranged to circumscribe an opening. Further, antenna elements are partially seated within the housing at intersections of bridge segments, comprise a generally planar antenna mounted to a substrate material at a base of the planar antenna, and an electrical shield surrounding the substrate. Also, an outer surface of the planar antenna faces away from the substrate. The antenna elements comprise at least first and second antenna element pairs having transmitting and receiving antenna elements and a bridging segment. A high sensitivity zone is formed between the transmitting antenna and receiving antenna. The antenna element pairs are spaced to create an area of reduced sensitivity between the high sensitivity zones, and the space is set so that the sensor is insensitive to fluid changes of a predetermined volume.

Owner:BAYER HEALTHCARE LLC

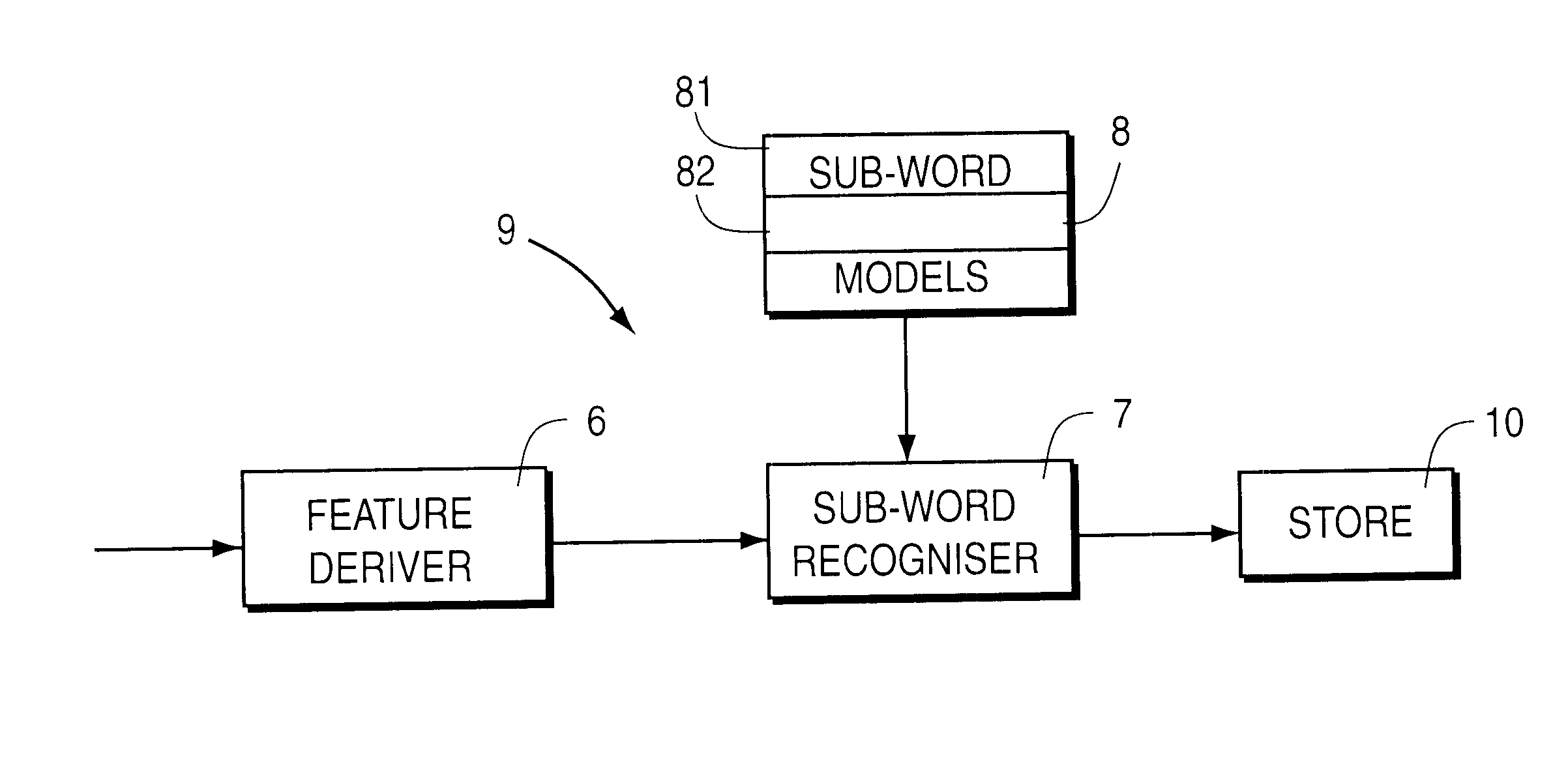

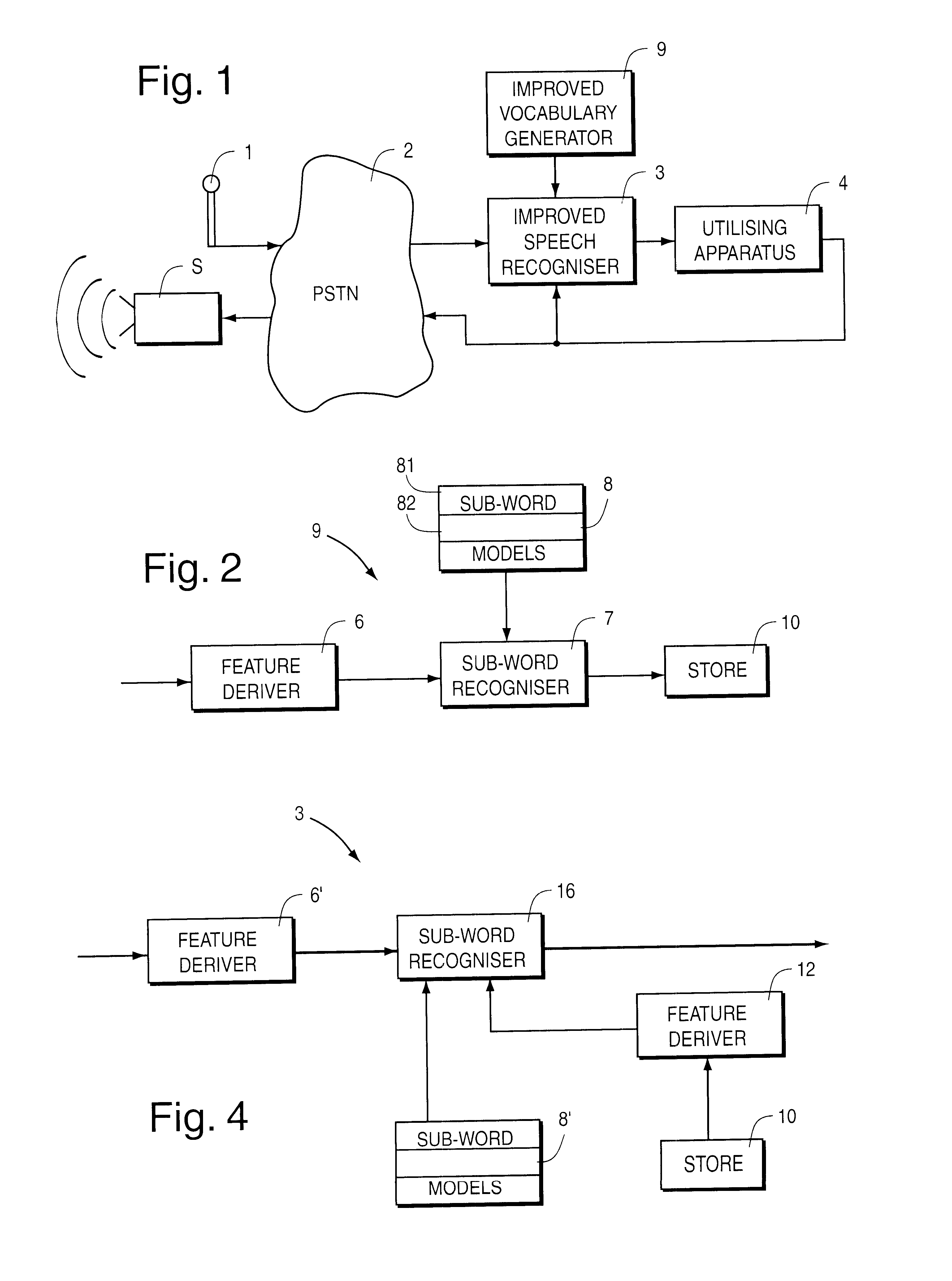

System and method for generating a phonetic baseform for a word and using the generated baseform for speech recognition

Out-of-vocabulary word models for a speech recognizer vocabulary are generated by forming phonemic transcriptions (phonetic baseforms) of user's utterances in terms of existing reference phonemes by using a speech recognition algorithm to match input sub-word feature sample sequences to suitably-constrained allowable sequences of existing reference phoneme features. The resultant new-vocabulary-word phonetic baseform models are stored for subsequent speech recognition using the same recognition algorithm.

Owner:CISCO TECH INC

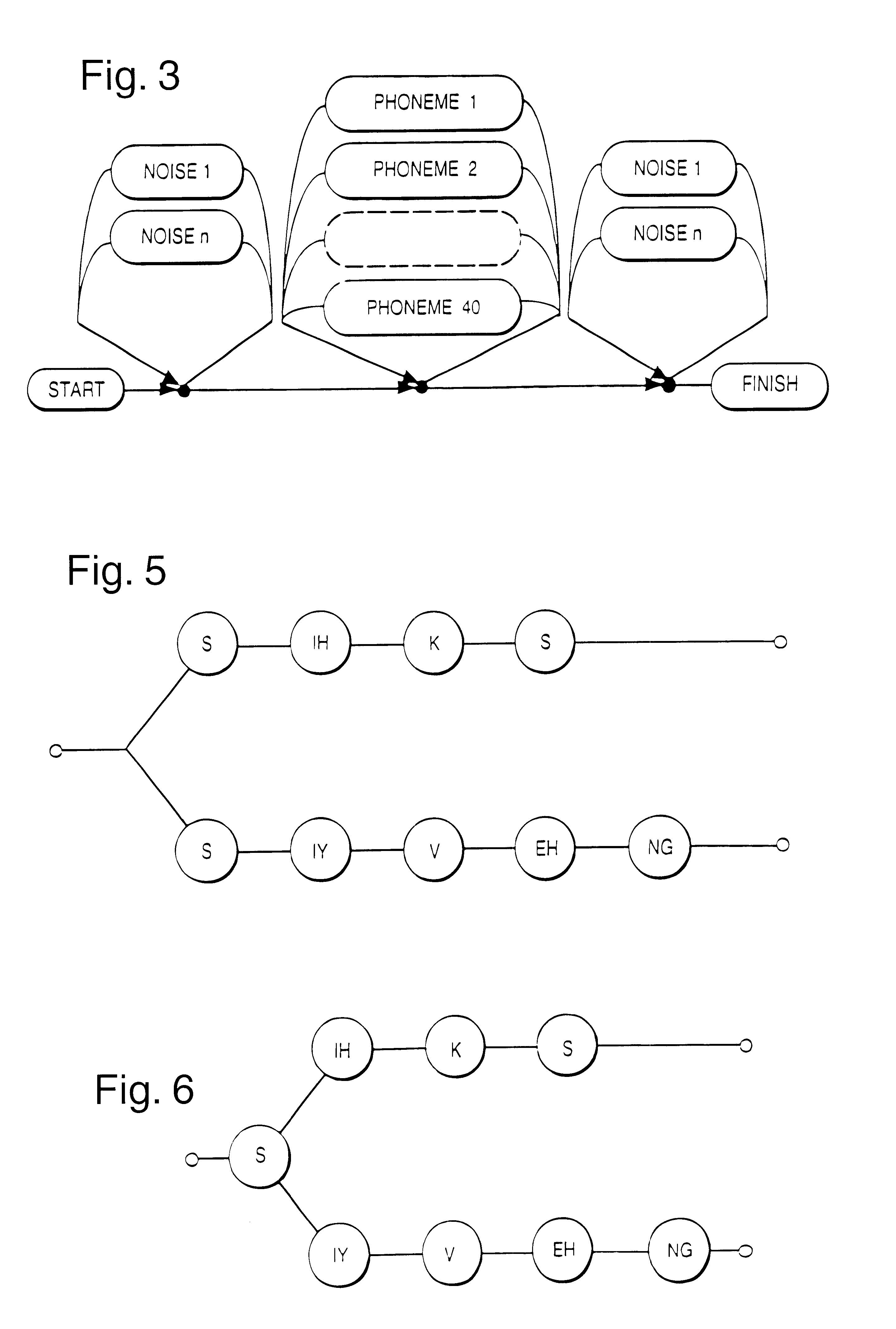

Scalable process transmitter

InactiveUS6898980B2Improve functionalityImprove scalabilityWave amplification devicesCoupling device detailsComputer moduleComputer science

A scalable process transmitter architecture includes a unitized sensor module and an optional scalable transmitter. The sensor module has a sensor output that is configurable which can connect locally to a scalable transmitter module to form a transmitter, or can be wired directly to a remote receiver. The scalable transmitter can mount on the unitized sensor module and generates a scalable output for a remote receiver. The transmitter module can provide more advanced features for specific applications.

Owner:ROSEMOUNT INC

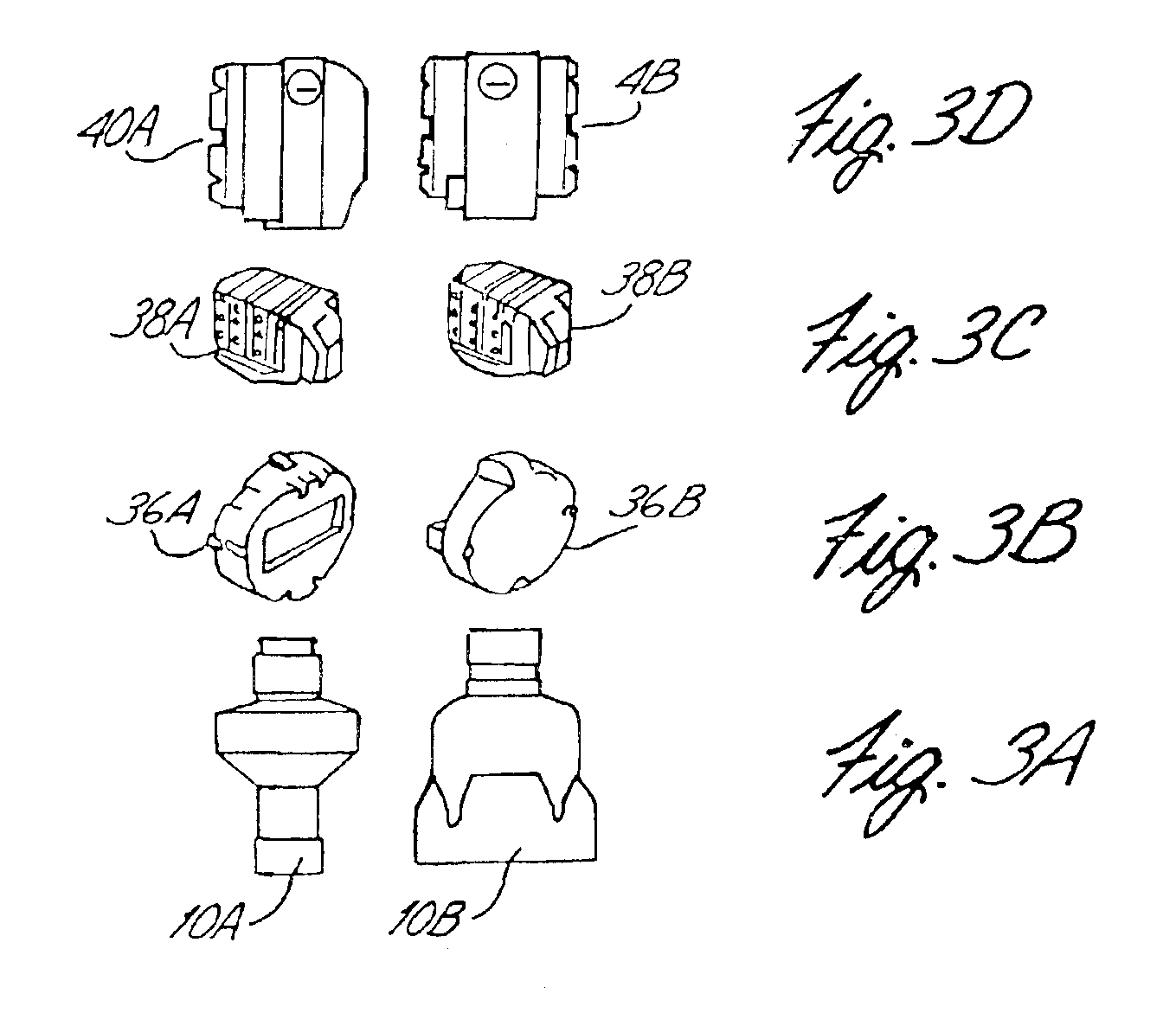

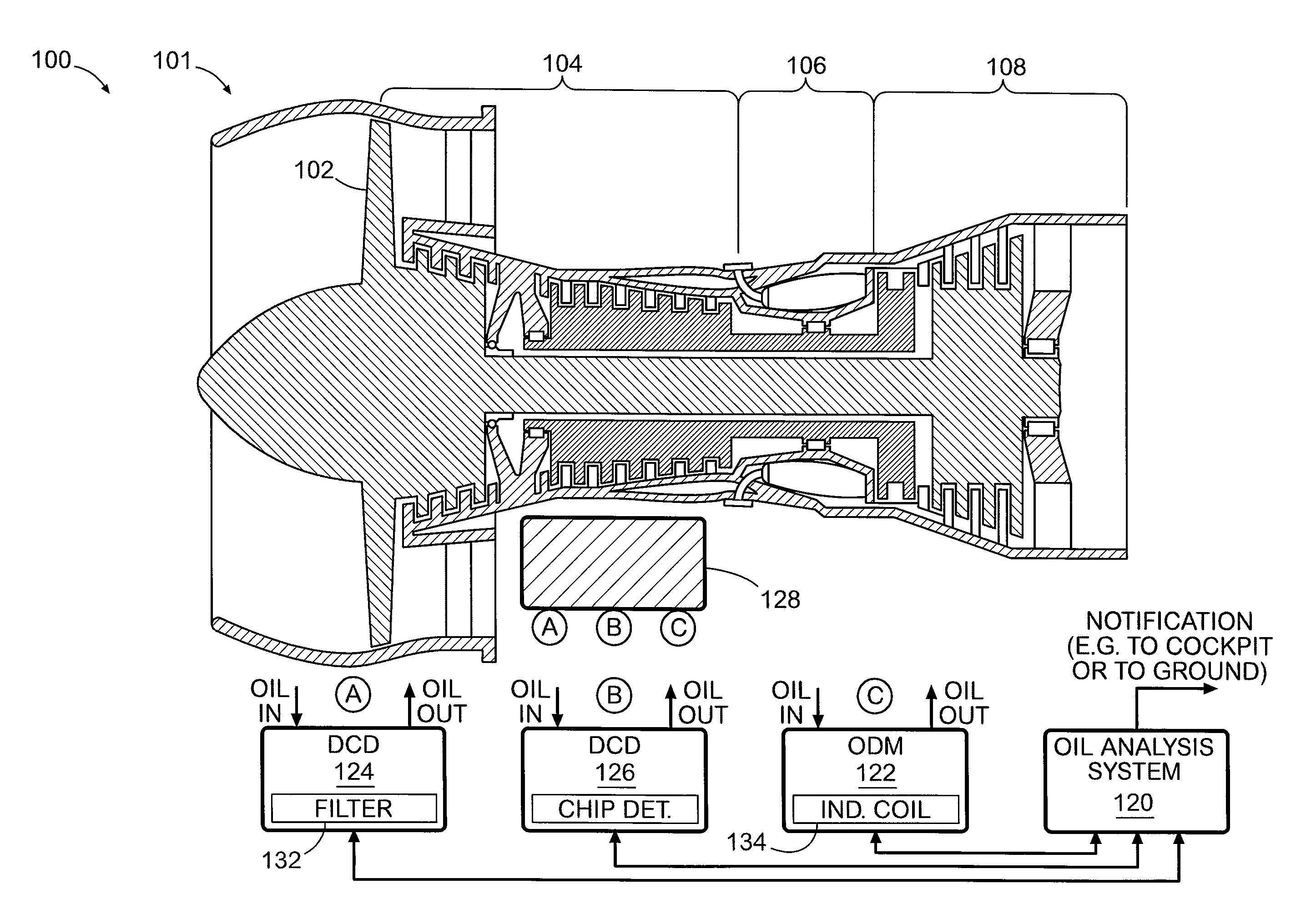

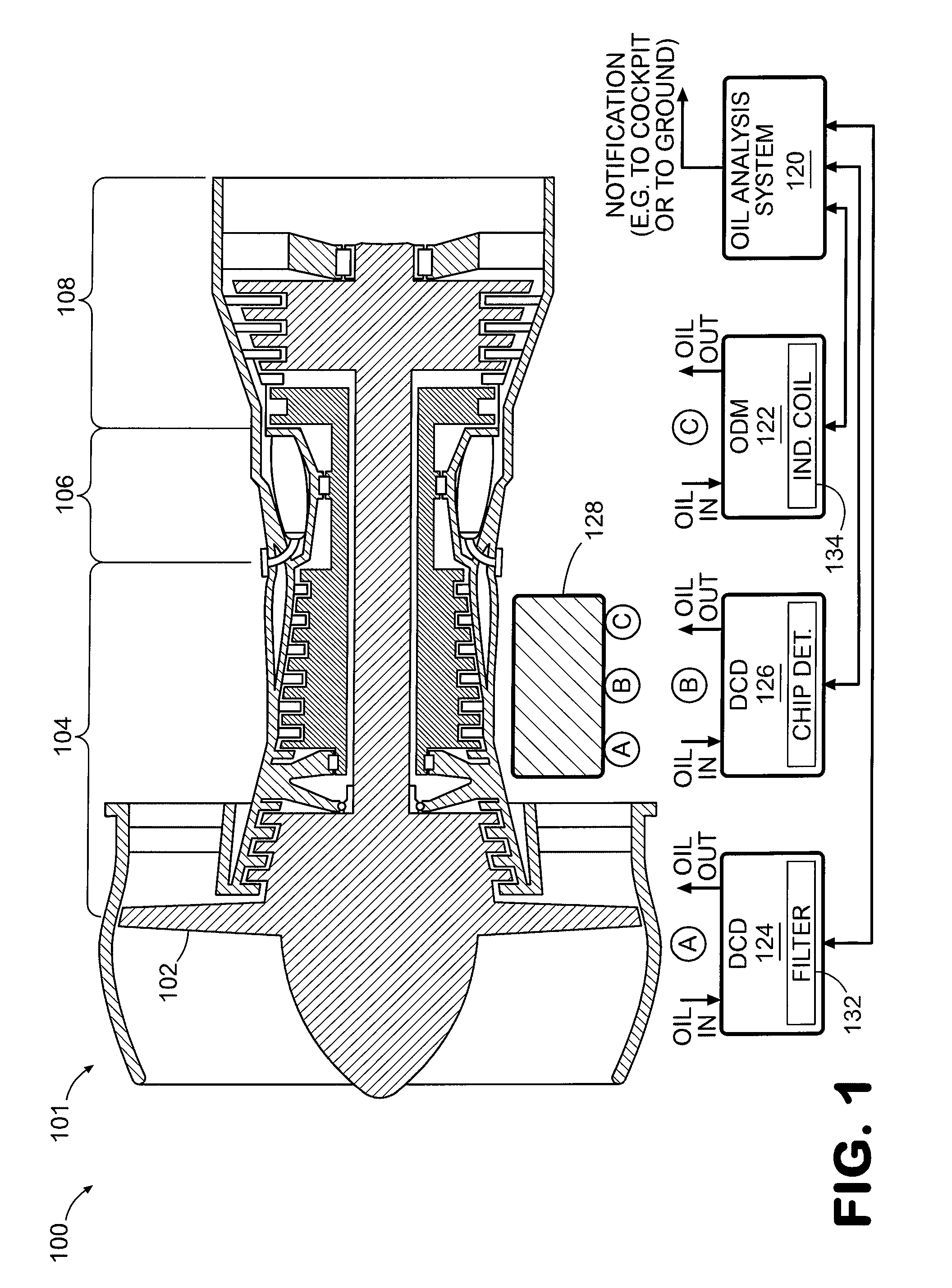

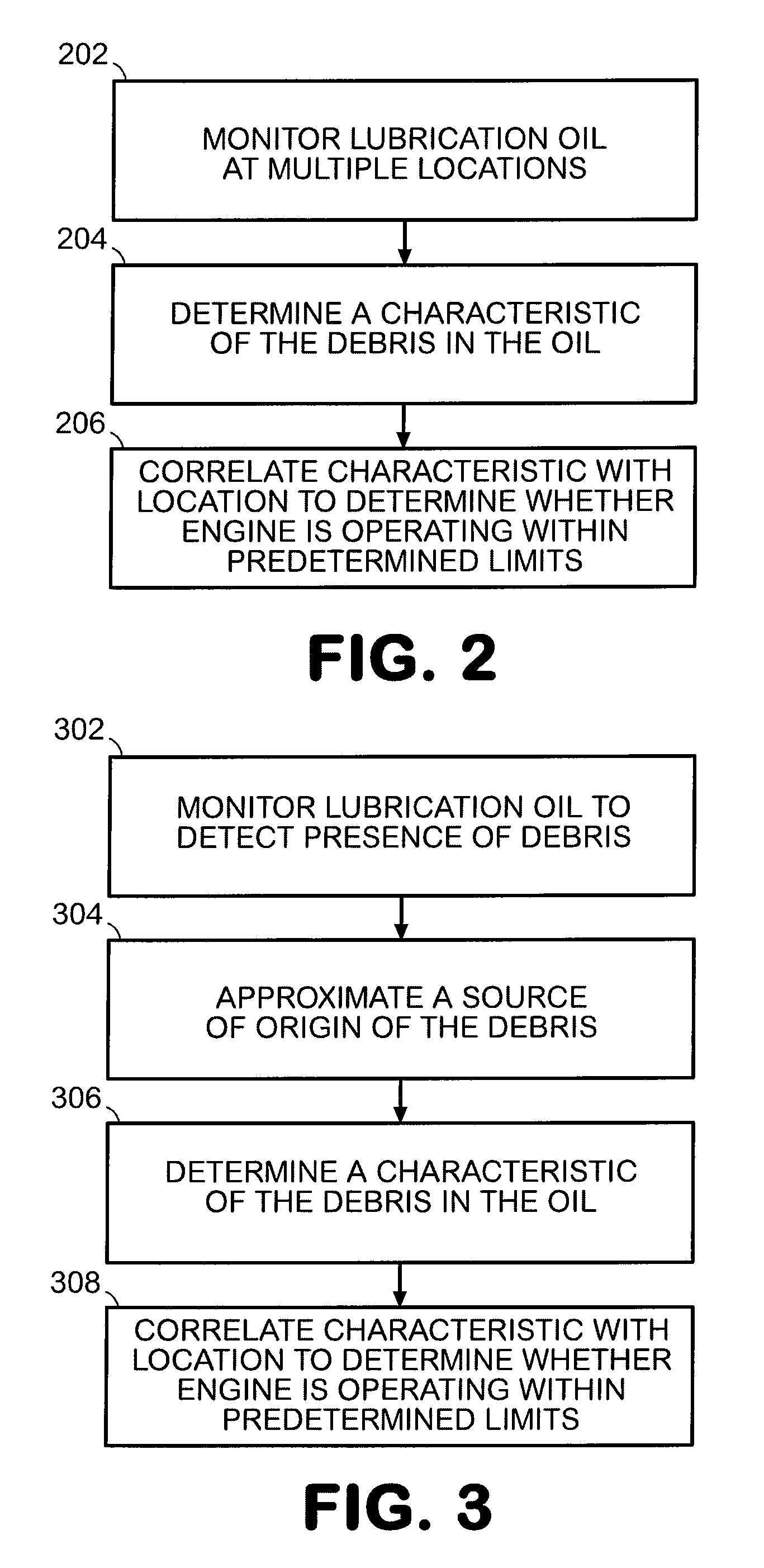

Systems and methods for monitoring gas turbine engines

ActiveUS7886875B2Engine fuctionsFluid pressure measurement by mechanical elementsLubricationGas turbines

Systems and methods for monitoring gas turbine engines are provided. In this regard, a representative method includes: monitoring lubrication oil at multiple locations of the gas turbine engine to detect a presence of debris in the oil; determining a characteristic of the debris in the oil; and correlating the characteristic of the debris with the location of detection to determine, while the gas turbine engine is operating, whether the engine is operating within predetermined limits.

Owner:RTX CORP

System for detecting fluid changes and sensoring devices therefor

ActiveUS20070123770A1Reduce sensitivityEasy to disassembleMaterial analysis using microwave meansMedical devicesEngineeringAntenna element

Owner:BAYER HEALTHCARE LLC

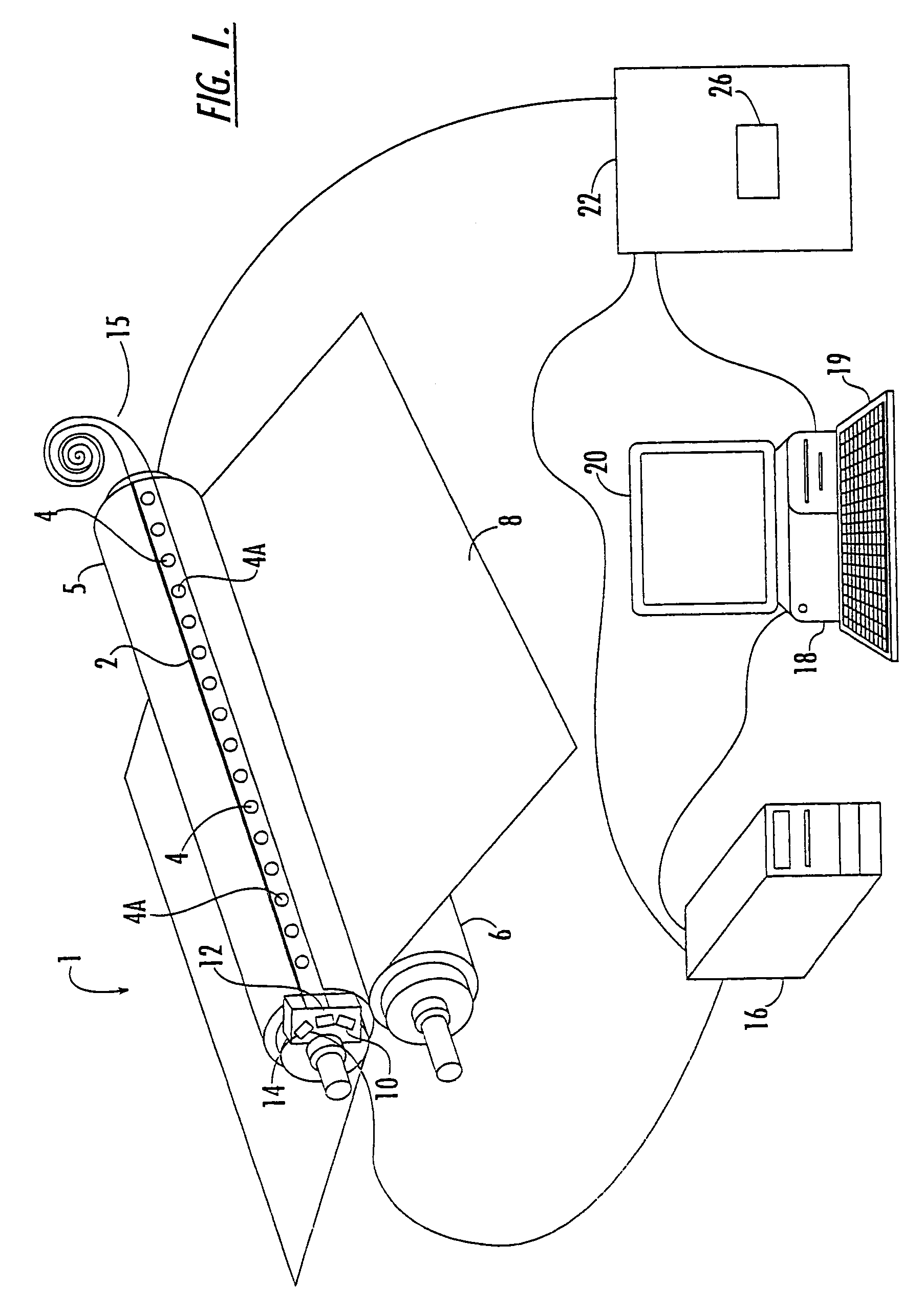

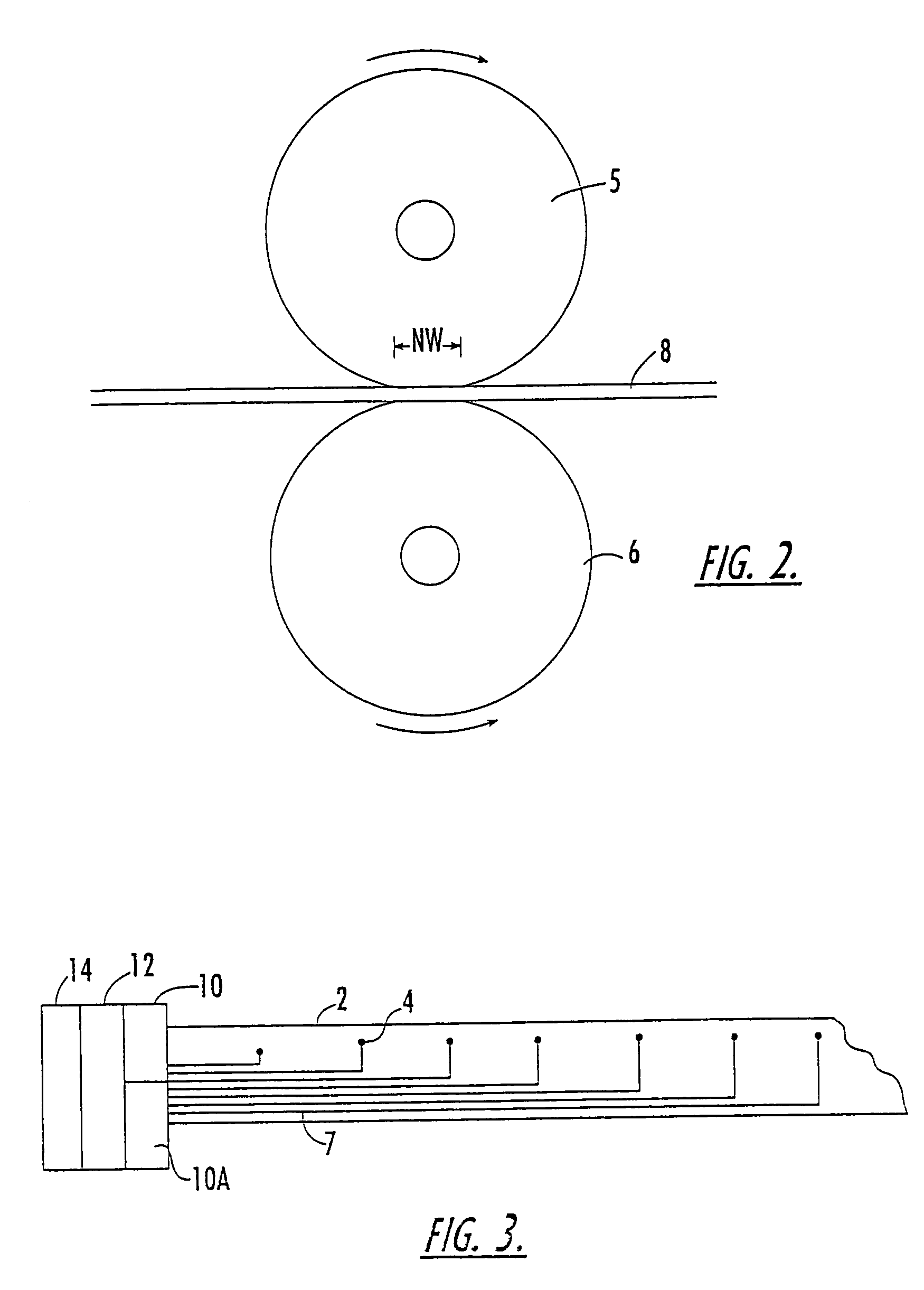

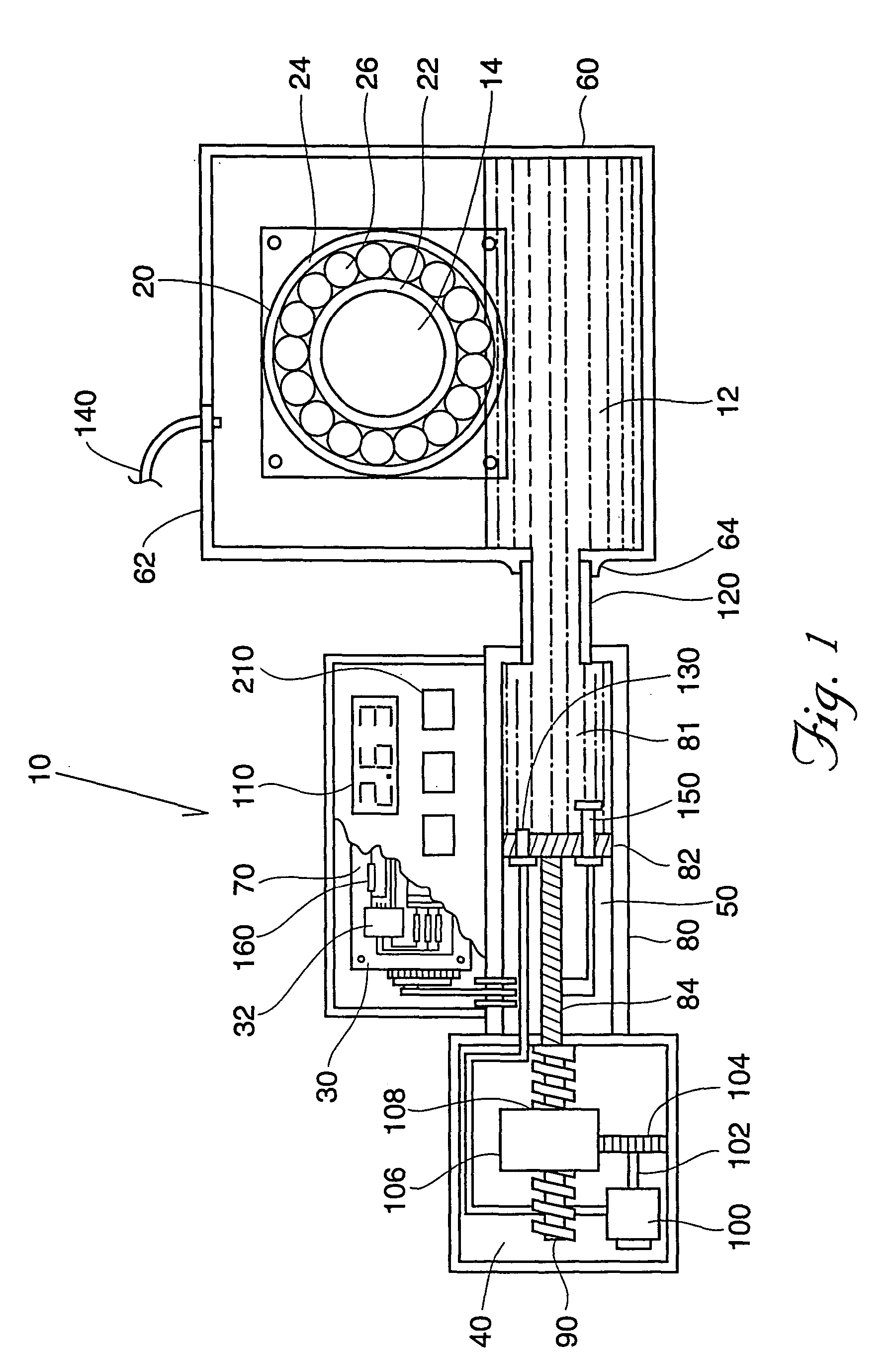

Nip width sensing system and method

InactiveUS7225688B2Force measurementUsing electrical meansElectrical resistance and conductanceResistor

Devices for measuring a nip width between rolls of a press nip include one or more sensors adapted to be placed in the nip while the nip is stationary. The electrical resistance of each sensor corresponds to the size of the nip width, whereby a nip width or a nip width distribution may be determined by measuring the sensor resistance(s). Methods of measuring a nip width distribution include providing a plurality of force sensitive resistor sensors each of which respond to pressure applied thereto to provide a variable sensor resistance as a function of the amount of pressure and the area of the pressure exerted on the sensor.

Owner:U S BANK NAT ASSOC

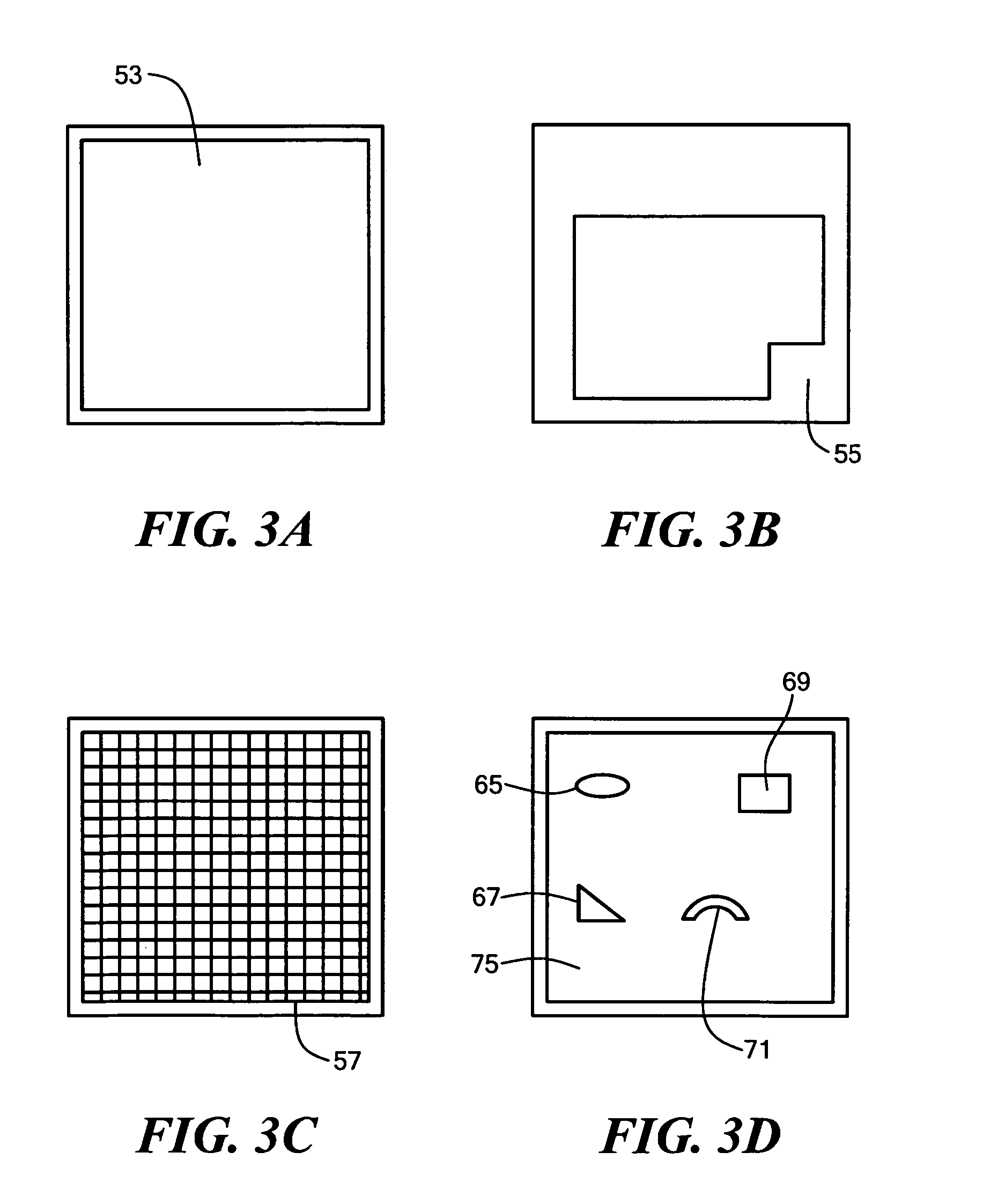

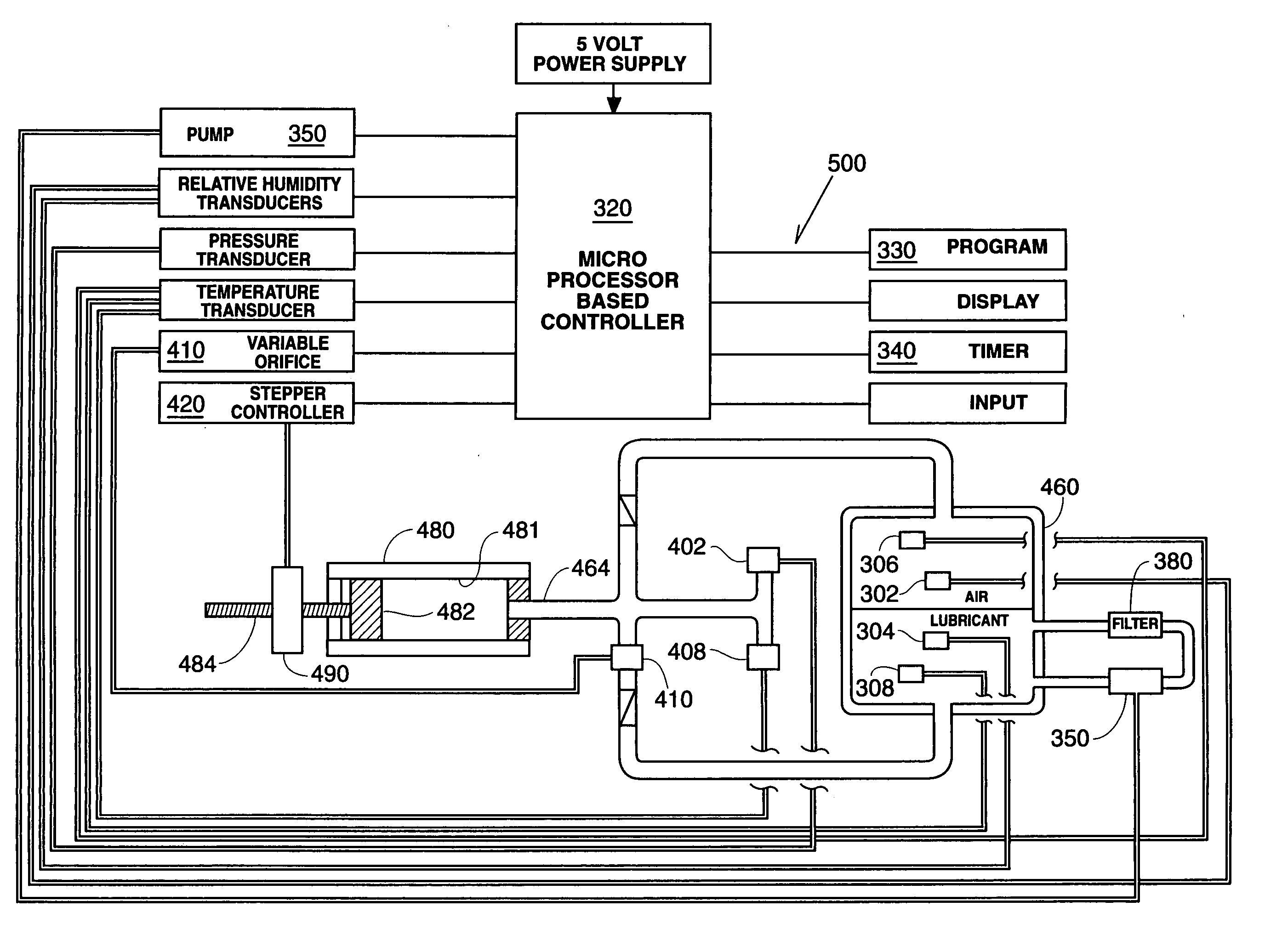

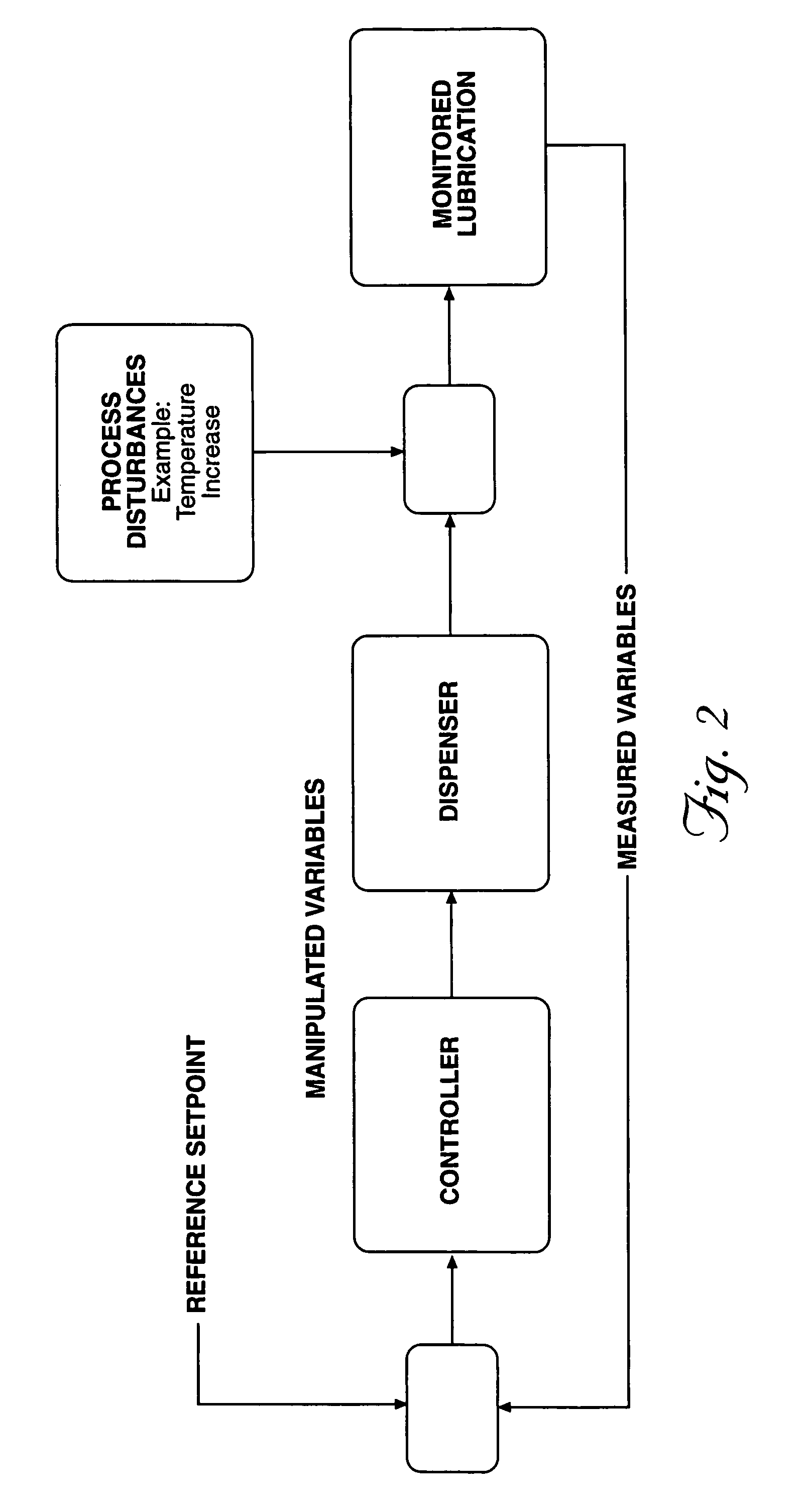

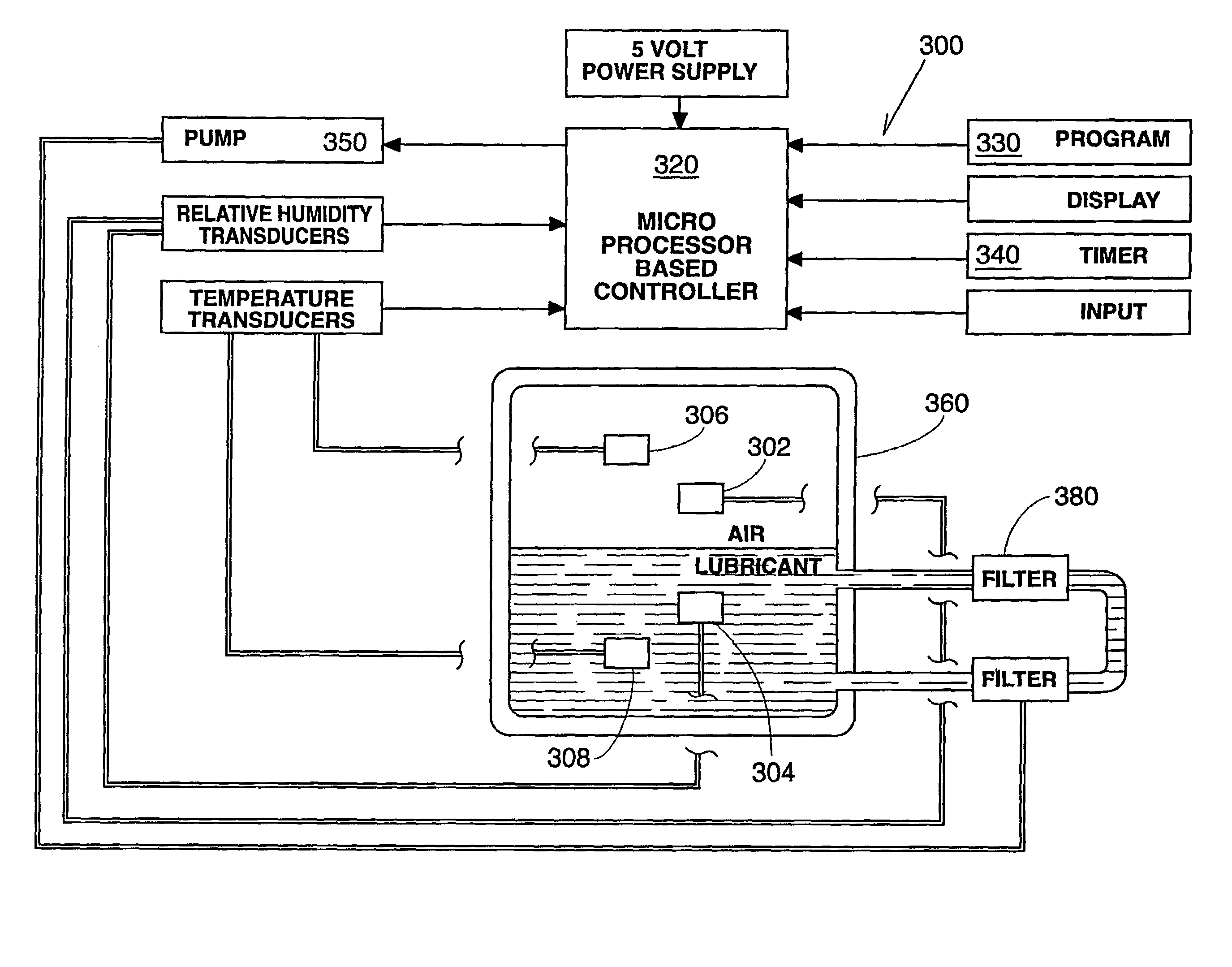

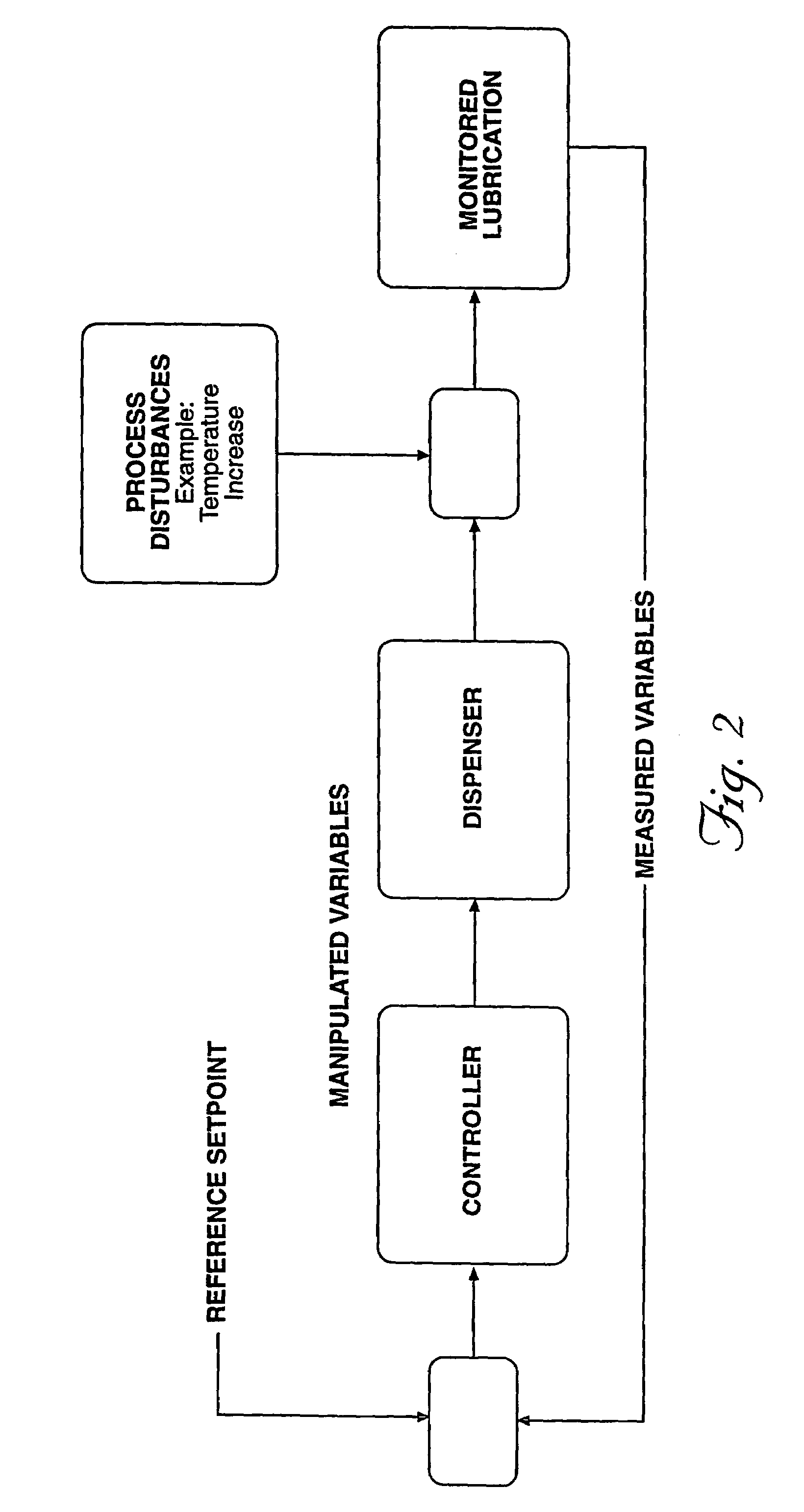

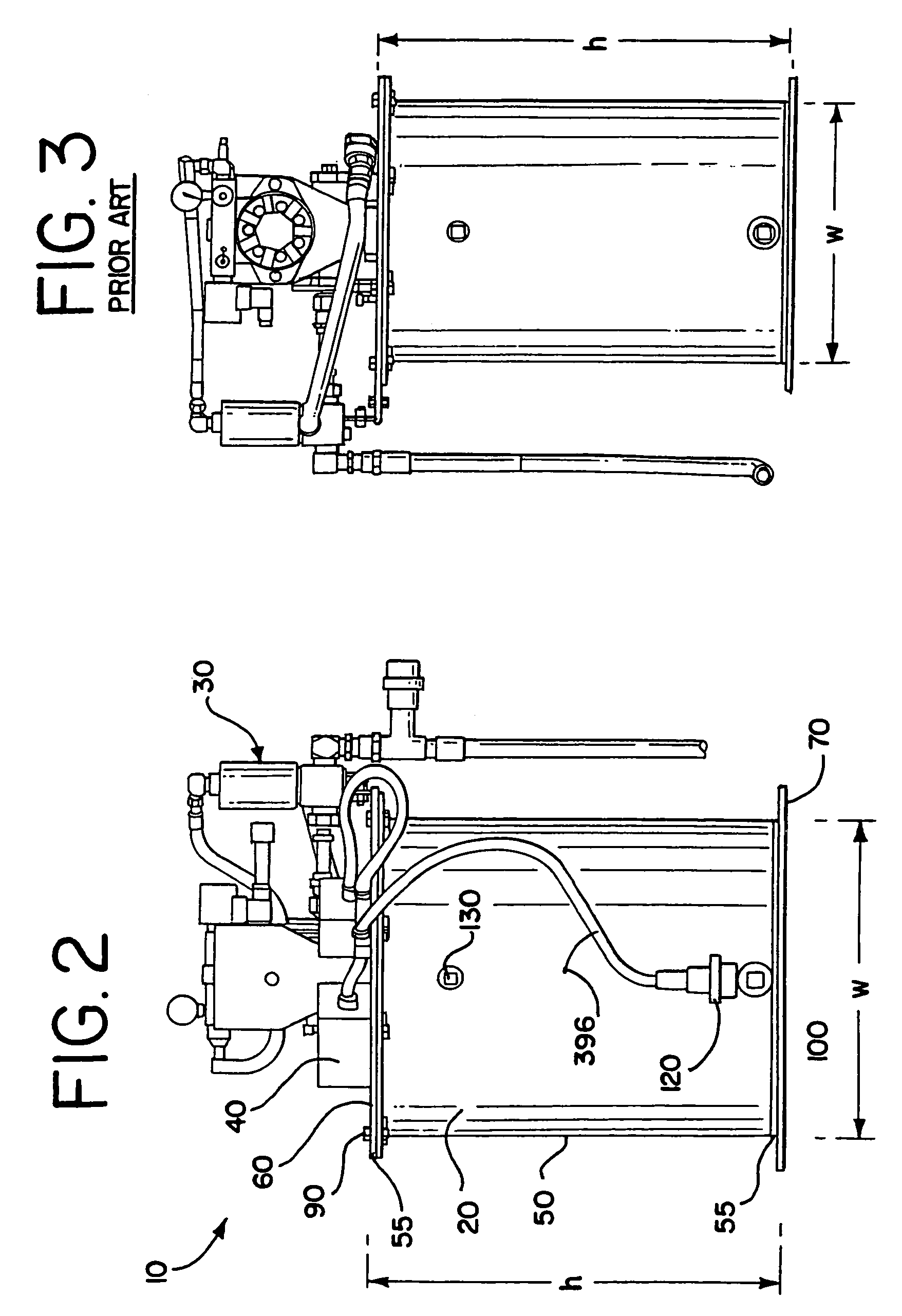

Apparatus and method for lubricant condition control and monitoring

InactiveUS7017712B1More and lessOvercome problemsEngine temperatureEngine pressureProcess engineeringKetone

A volumetric lubricant dispensing apparatus for delivering a precise volume of lubricant, such as oil, to a rotating machine element. The delivery mechanism includes a piston and cylinder assembly. A plurality of sensors are utilized to record operating conditions of the machine, element, environment, and lubricant. The apparatus is controlled either manually or with the aid of a controller unit such as a microprocessor. The output from each sensor is inputted into the microprocessor wherein an algorithm computes an responsive output. The responsive output is sent to the piston and cylinder assembly, which maintains an optimum lubricant condition within the reservoir wherein a rotating machine element located. Alternatively, for the purpose of qualitative control, the present invention may be described as a system intended for controlling lubricants, both mineral (natural) and synthetic based by measuring the condition characteristics of the lubricant. Some condition characteristics may include water or moisture content (the content could be any liquid, e.g., solvents like ketones are known to change condition characteristics like viscosity) and viscosity. Viscosity is related to temperature, therefore, temperature correlation to viscosity is helpful to provide relative indications for condition characteristics like lubricant flow.

Owner:TRICO CORP

Low pressure measurement devices in high pressure environments

Owner:ACIST MEDICAL SYST

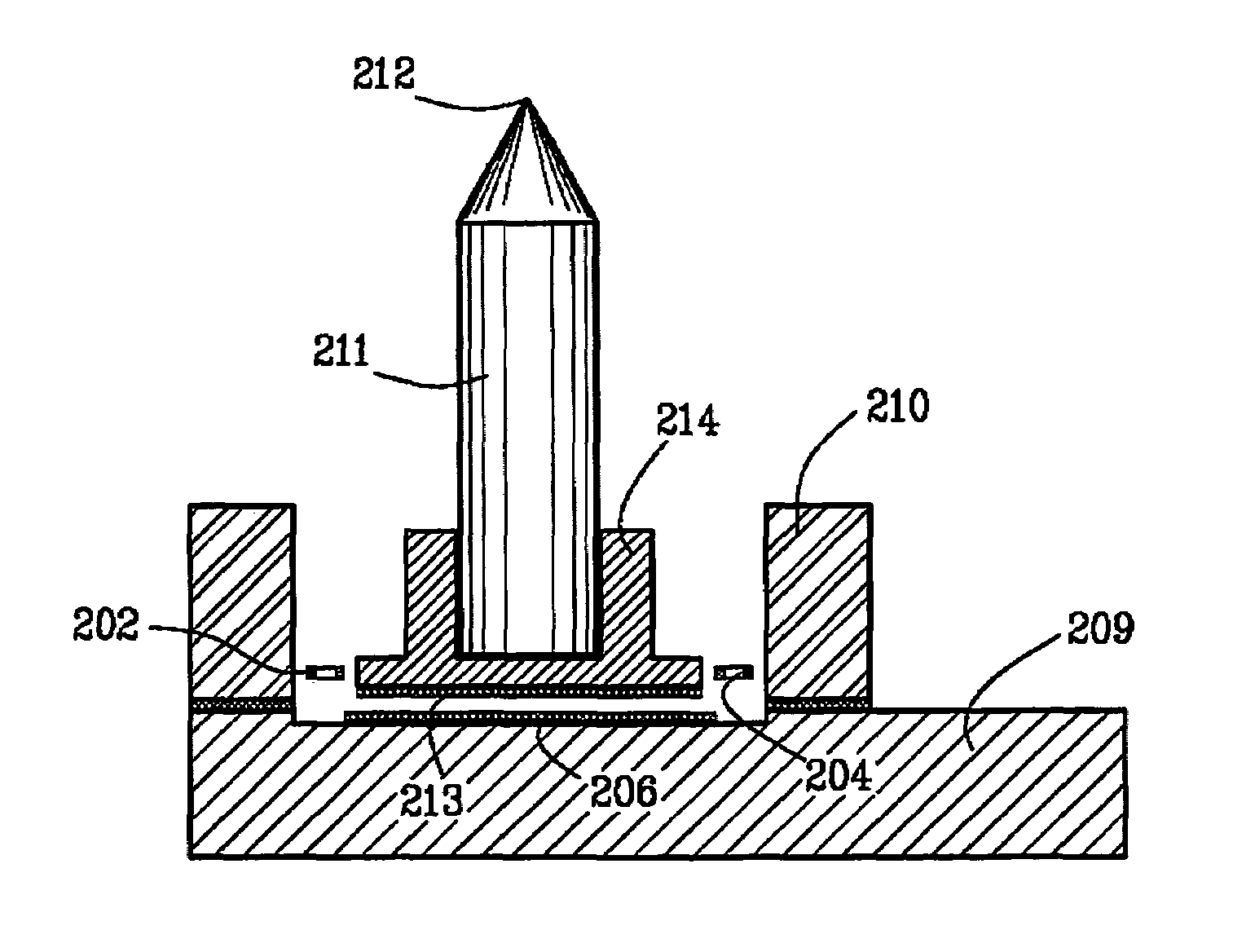

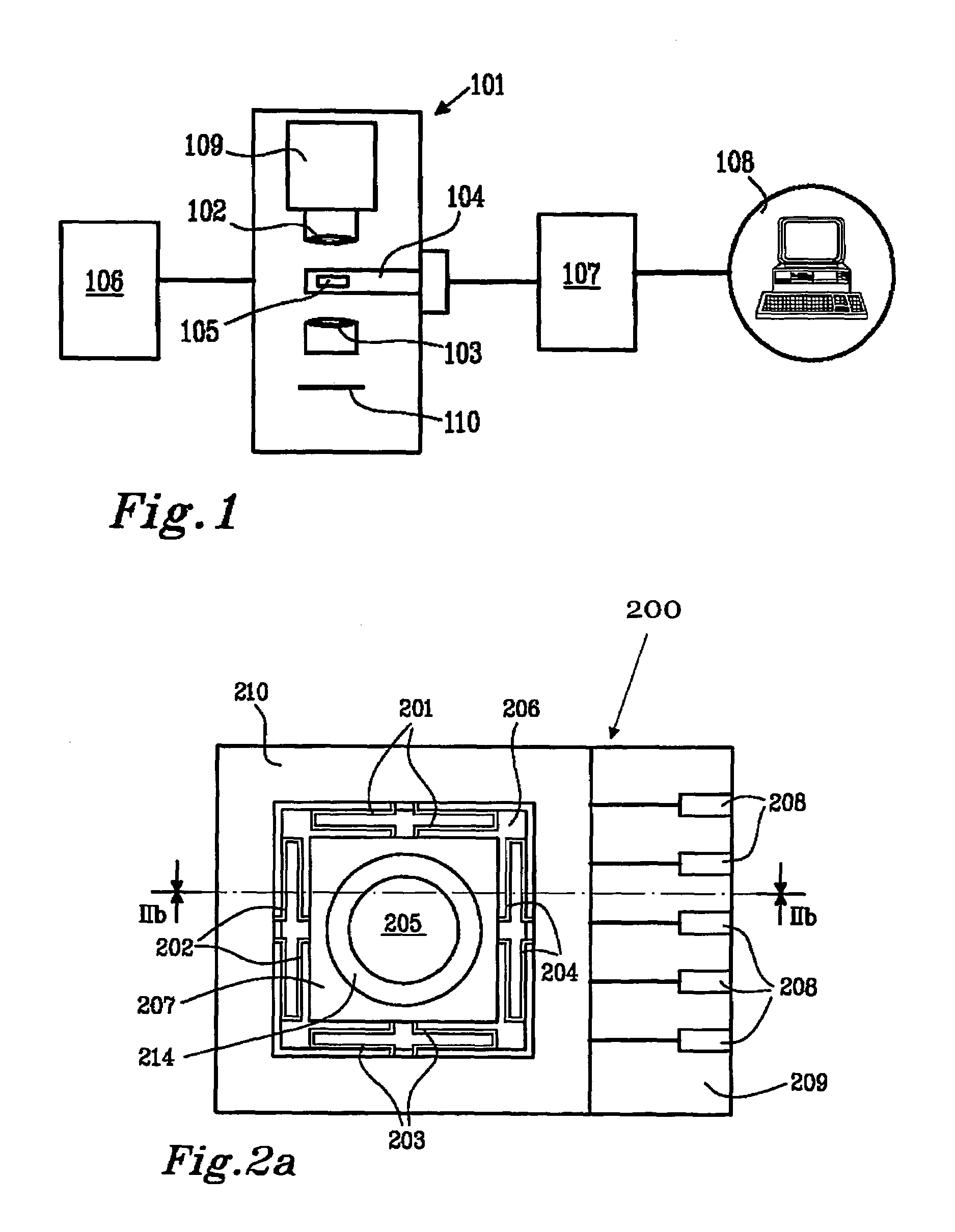

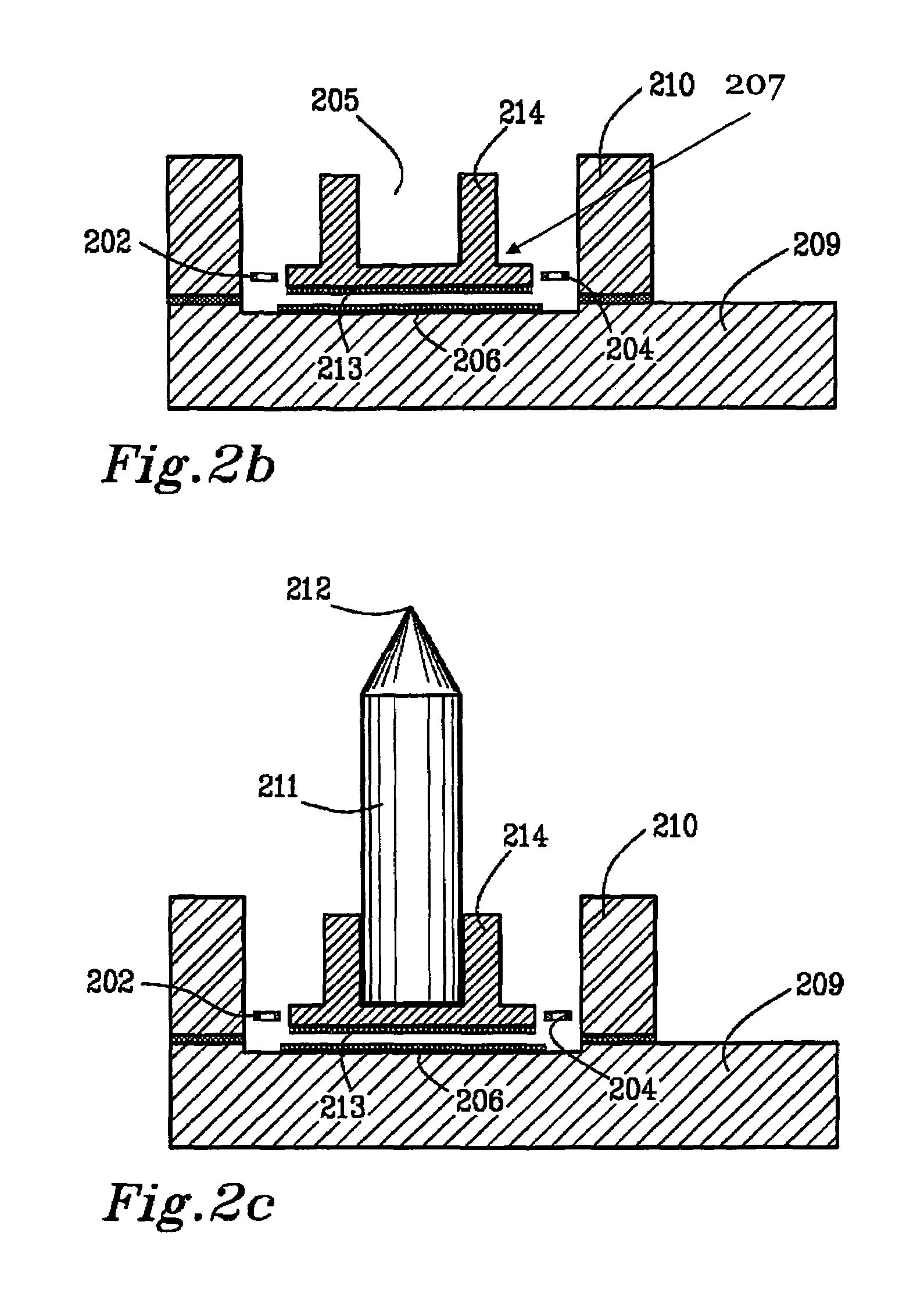

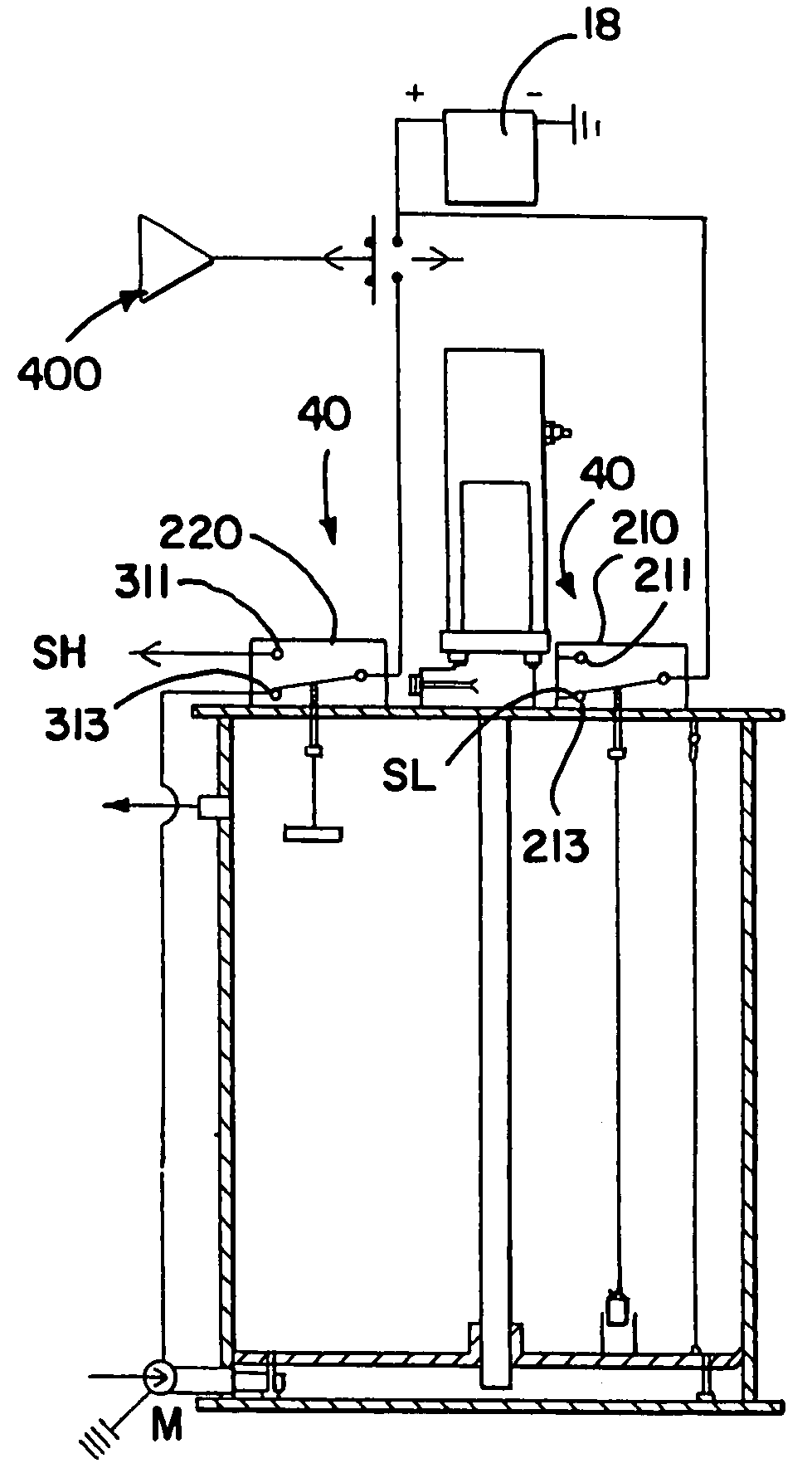

MEMS nanoindenter

ActiveUS7654159B2Material nanotechnologyFluid pressure measurement using elastically-deformable gaugesEngineeringNanometre

A force sensor (200) and nanoidenation system (300) using such force sensor (200), wherein the force sensor (200) comprise a movable membrane (207) attached to a fixed bulk structure (210) with springs (201, 202, 203, 204) formed between the membrane (207) and bulk structure (210); the springs (201, 202, 203, 204) may be provided two on each side of a rectangular membrane(207) and each in the form of a U-shape with displacing elements (801) formed perpendicular to each open end of each U-shaped spring (800). The force sensor further comprises electrodes (206) for detecting capacitive changes between the movable membrane (207) and the electrodes (206) in order to measure a movement in relation to an applied force. The membrane (207) further comprises a probe holding structure (214) for providing a solution for interchangeable probes (211).

Owner:FEI CO

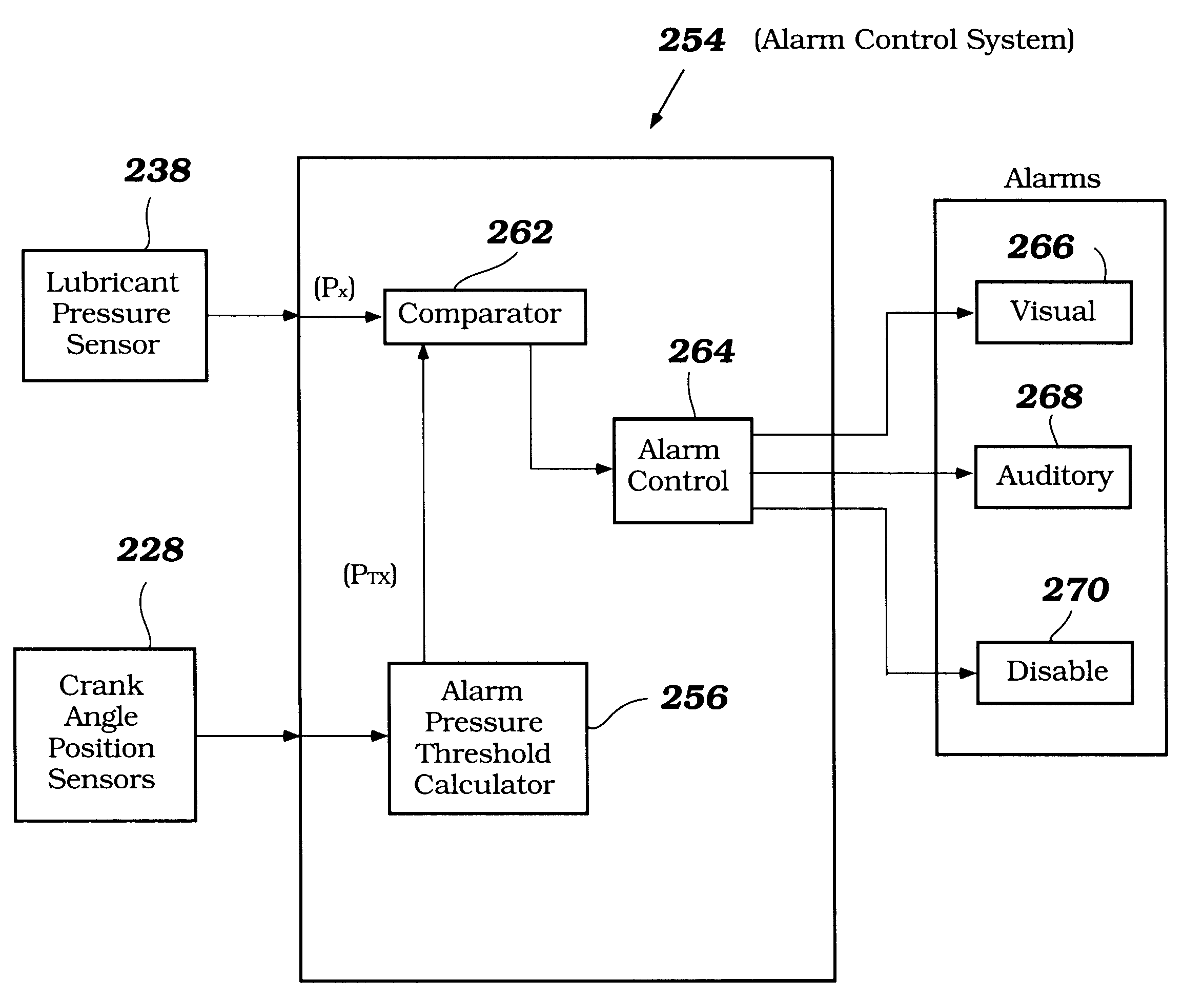

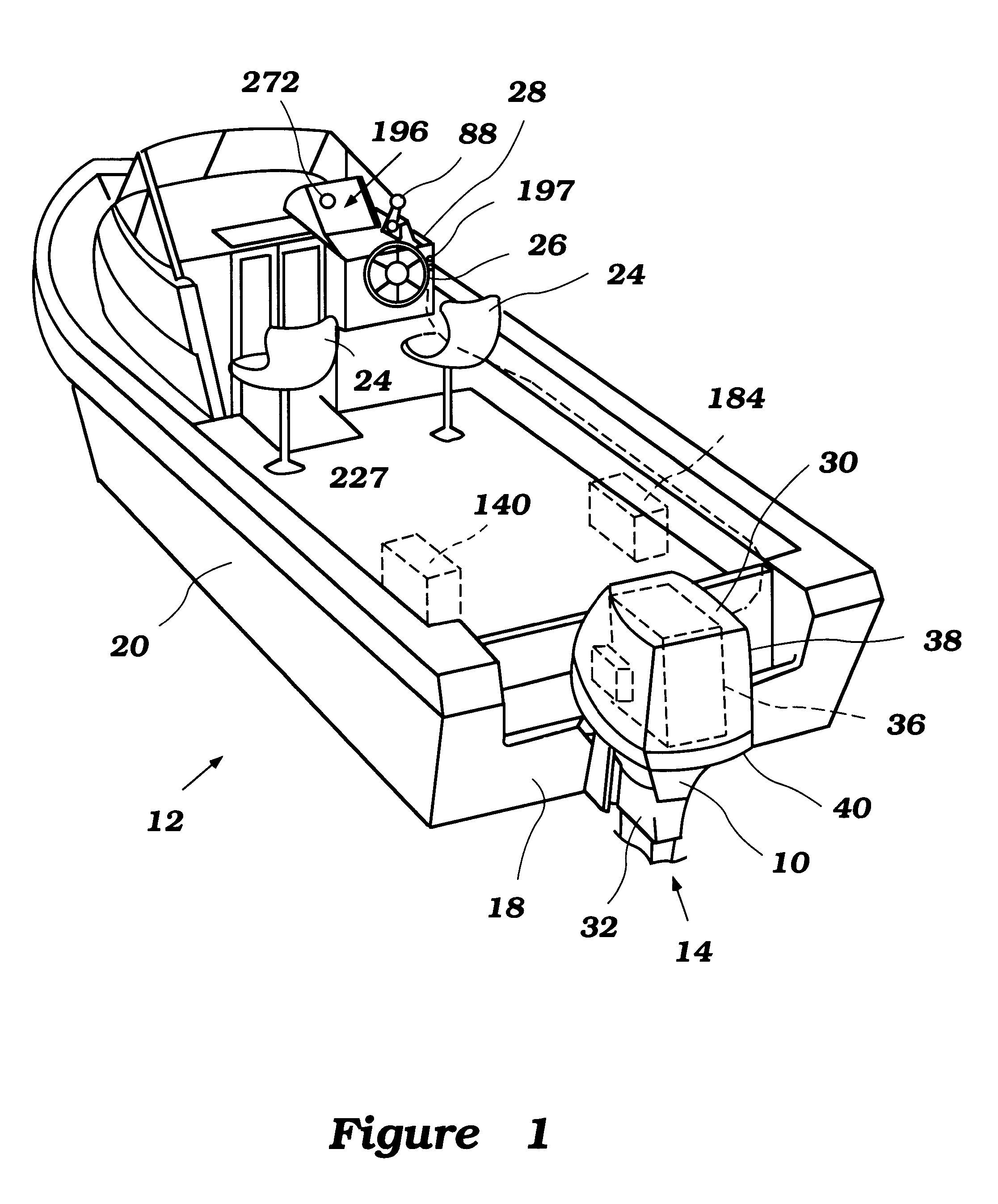

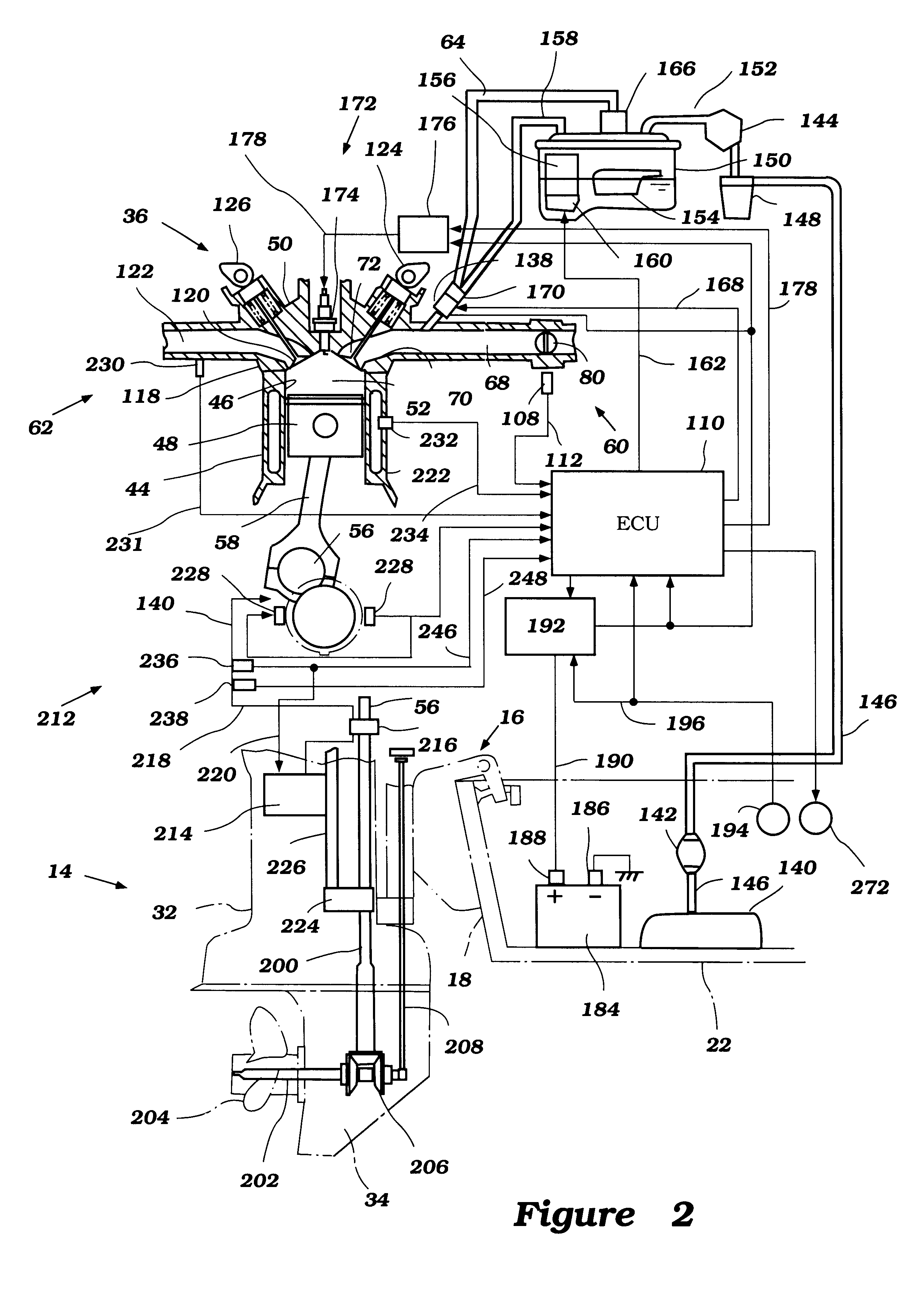

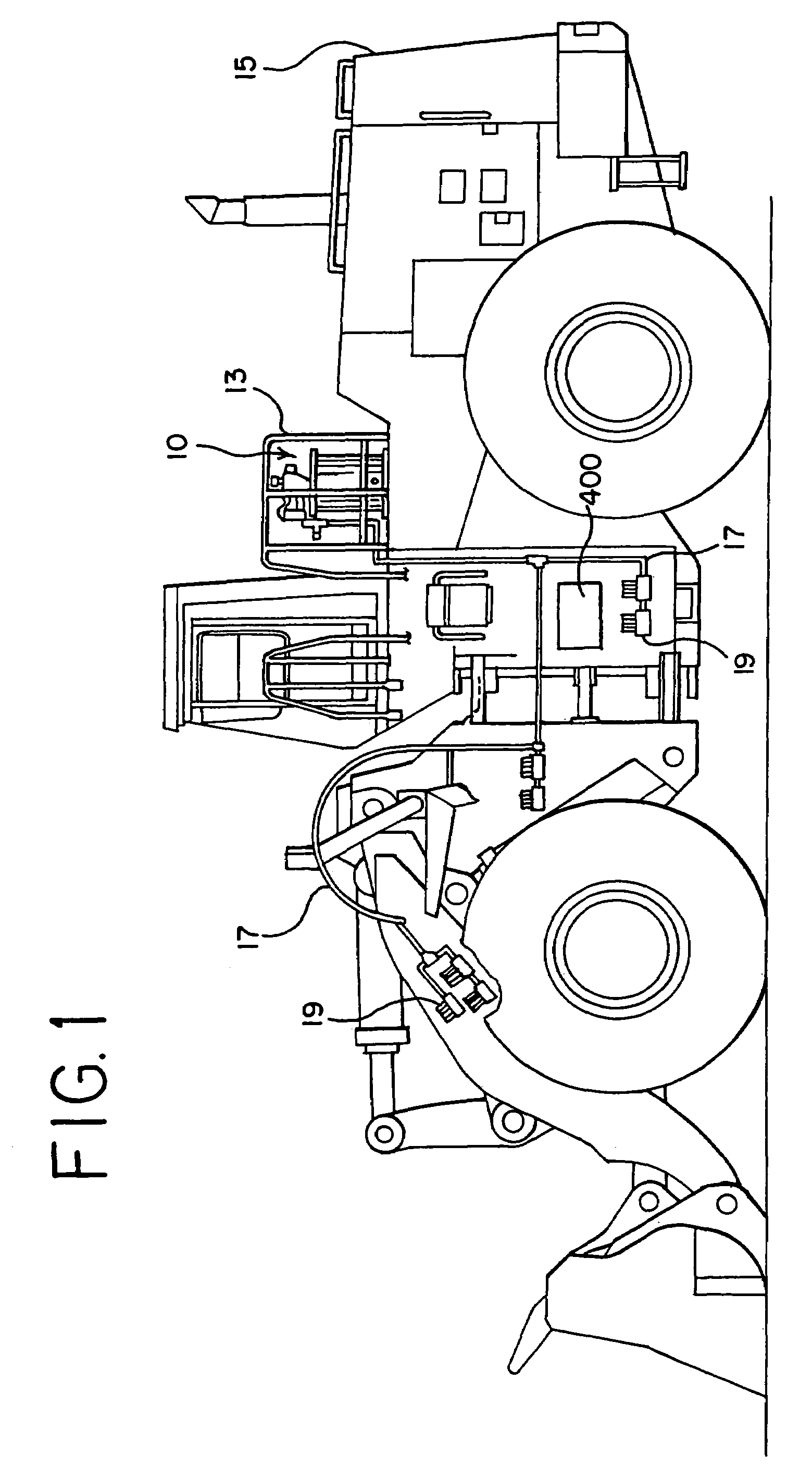

Control for watercraft engine

A watercraft engine includes a lubrication system alarm control system which initiates an alarm when lubricant pressure within the lubrication system falls below an acceptable pressure. The alarm system compares lubricant pressure during engine operation with a lower pressure threshold which is determined as a function of engine speed. Thus, partial reductions in lubricant pressure are identified. Additionally, the alarm control system may be configured to emit an alarm if lubricant pressure fluctuates at a rate that is greater than a predetermined pressure fluctuation rate threshold.

Owner:SANSHIN KOGYO CO LTD

Apparatus and method for lubricant condition control and monitoring

A plurality of sensors are utilized to record operating conditions of the machine, element, environment, and lubricant. The apparatus is controlled either manually or with the aid of a controller unit such as a microprocessor. A stand-alone humidity sensor mechanism is disclosed, in which signal process circuitry is electrically coupled to a humidity sensor, designed to be attached to the mechanism to be monitored so that it is juxtaposed in the atmosphere above the lubricant material that is being monitored.

Owner:TRICO CORP

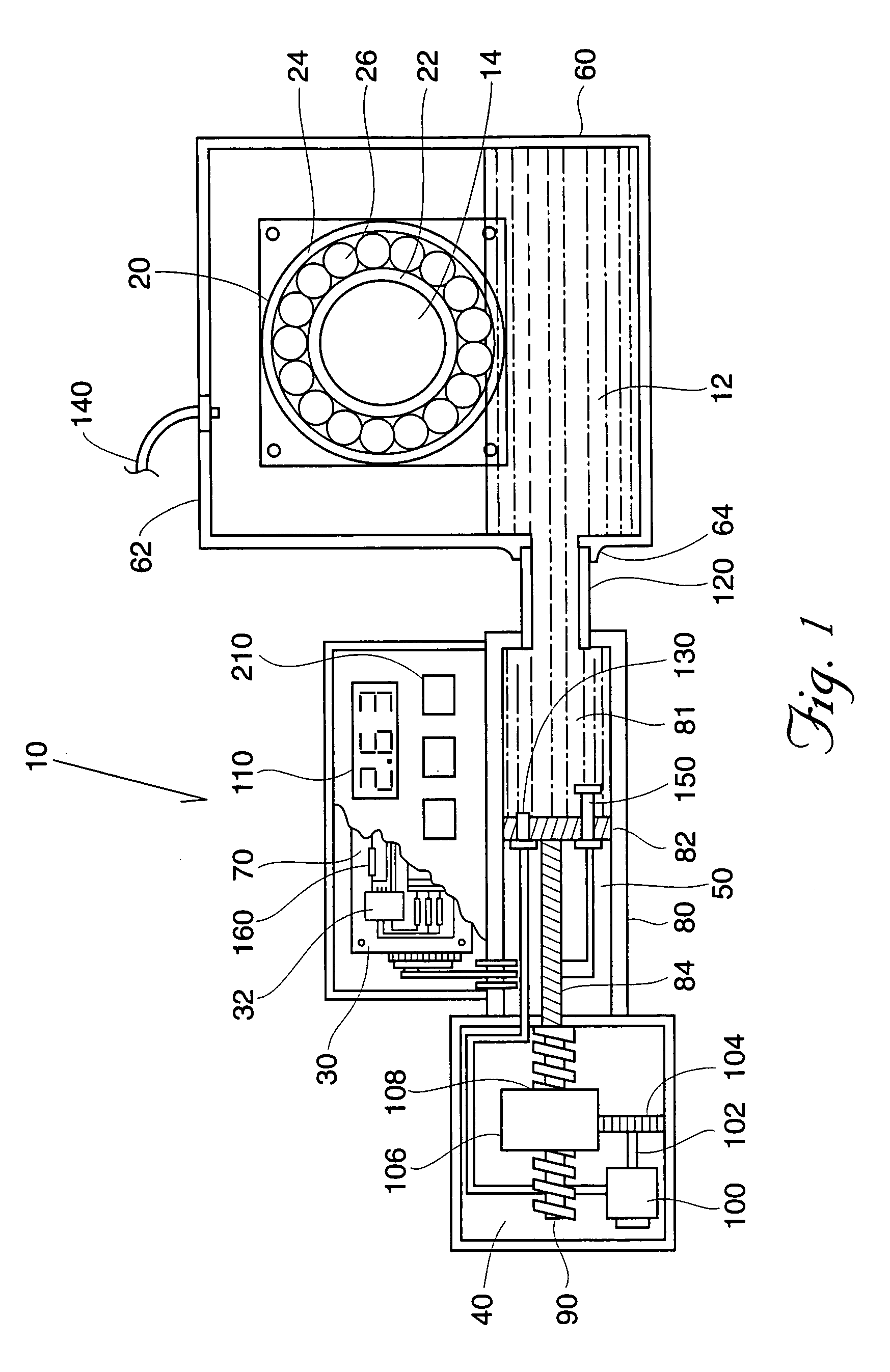

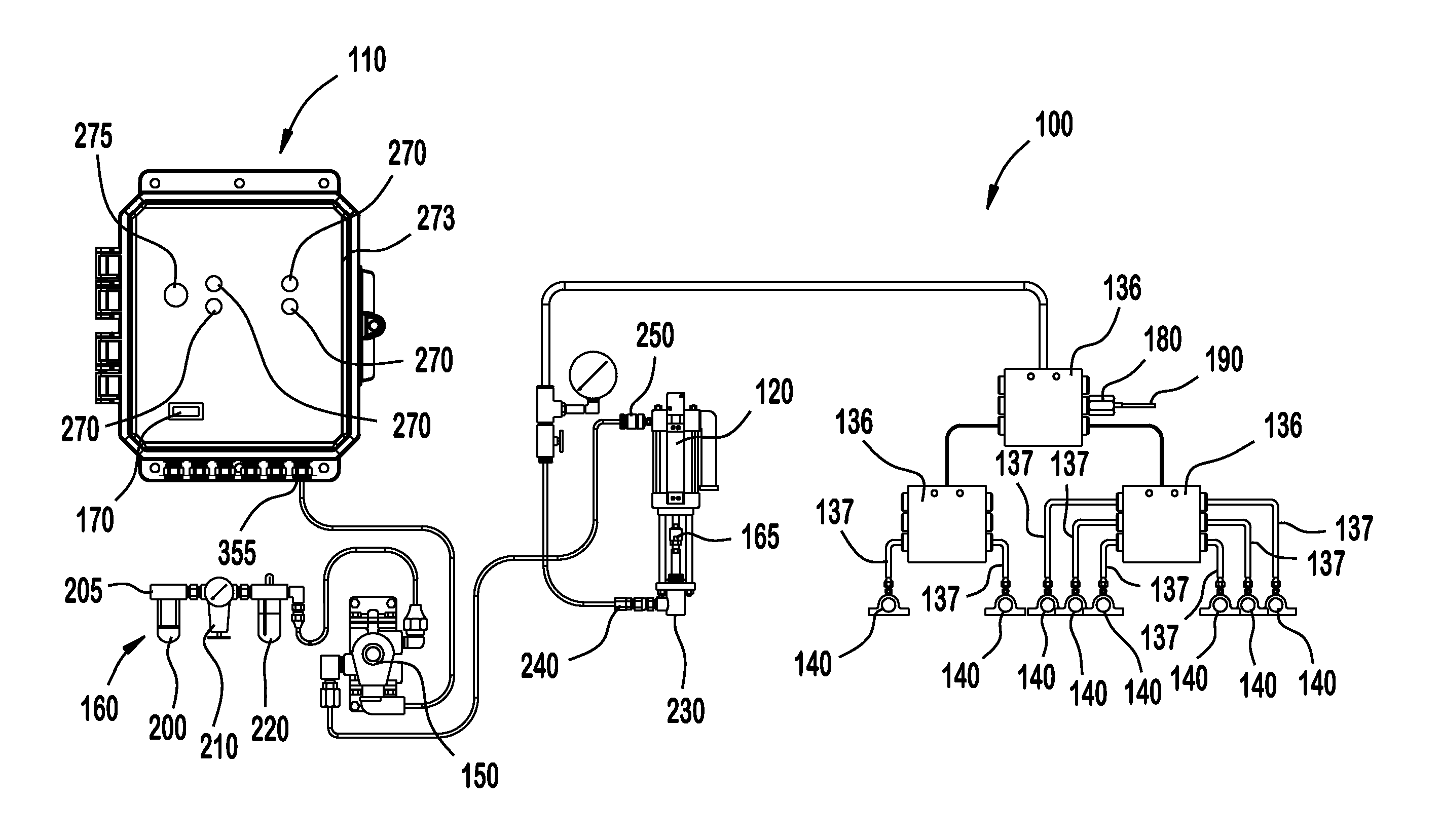

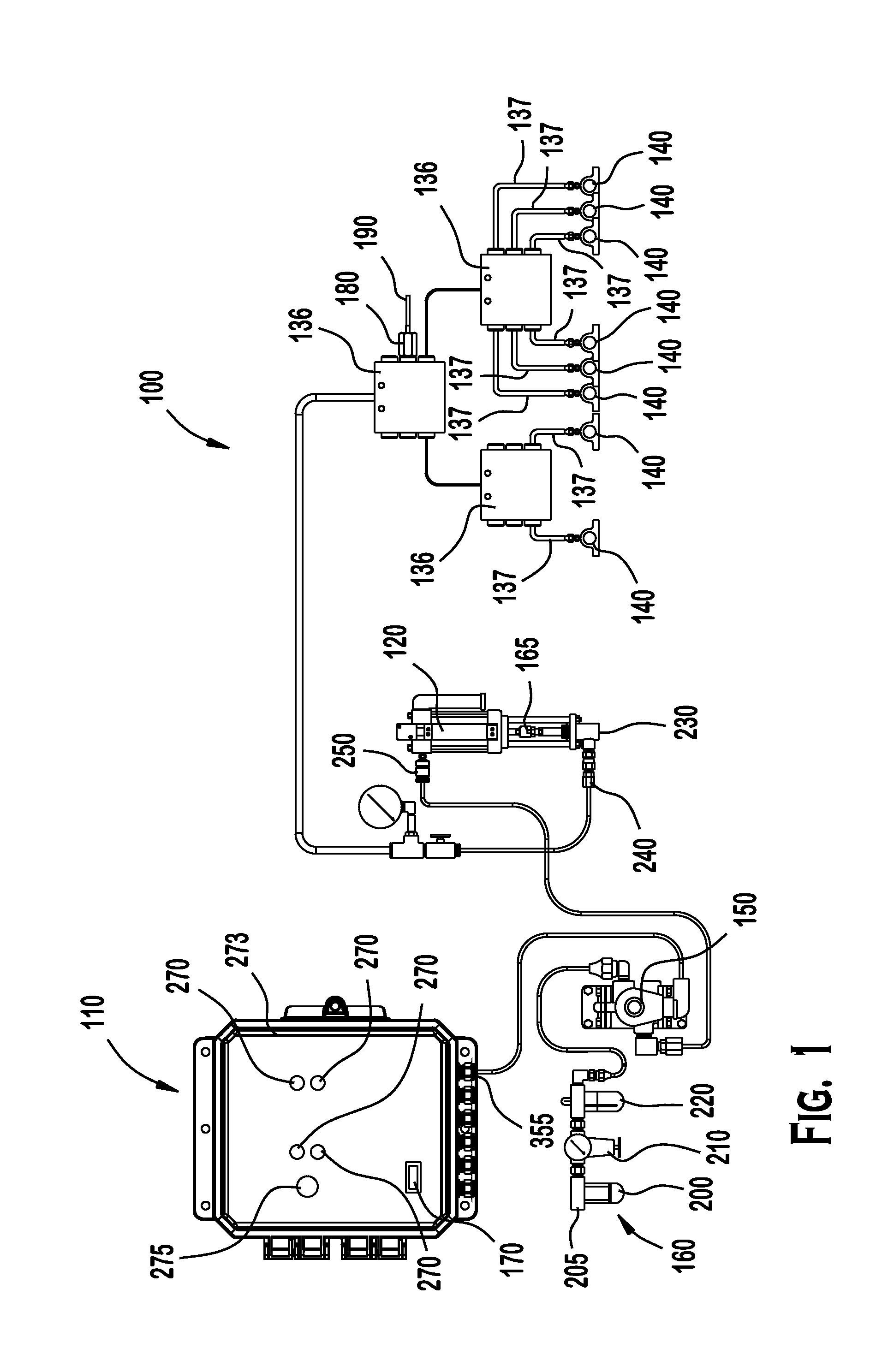

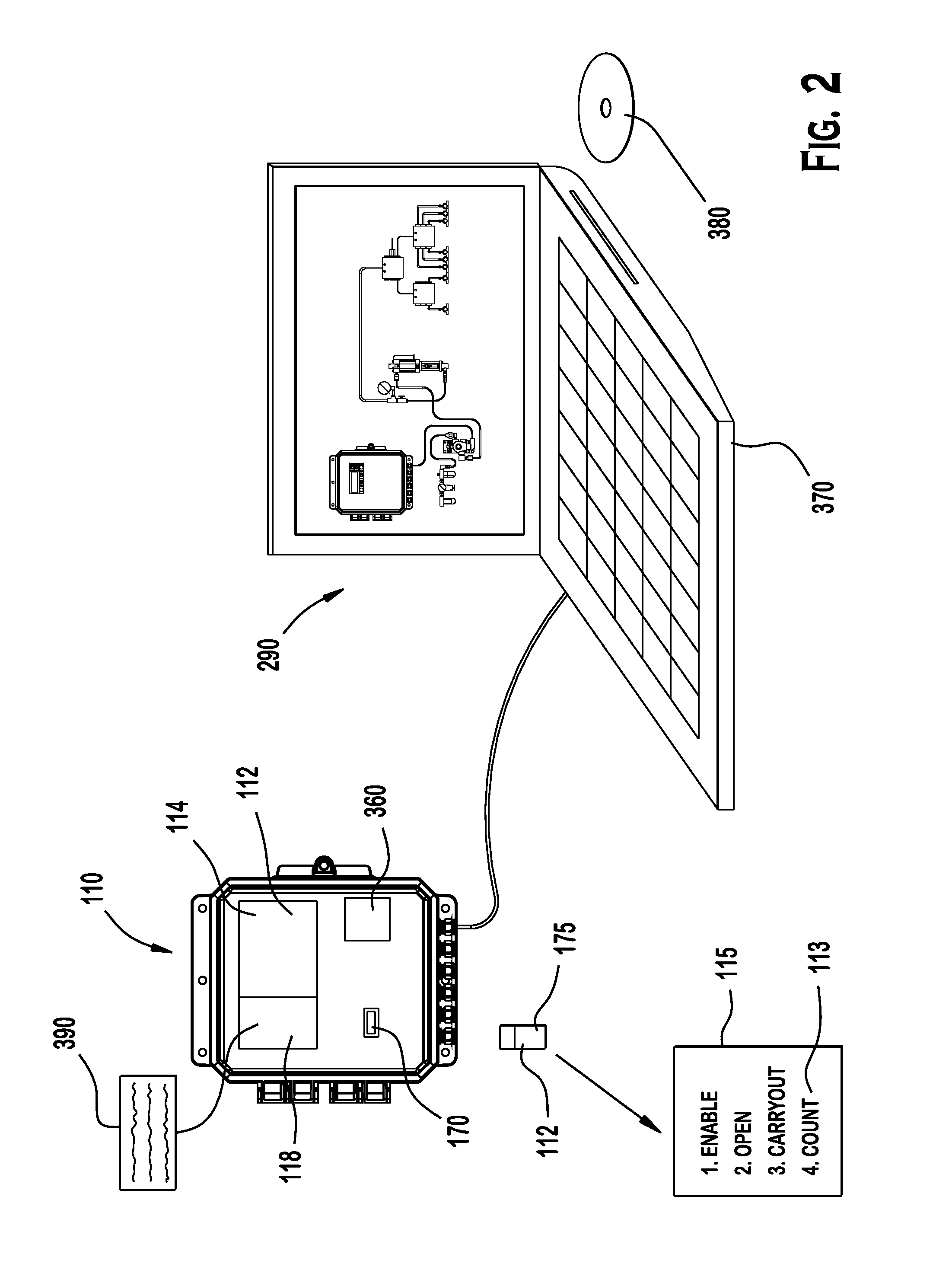

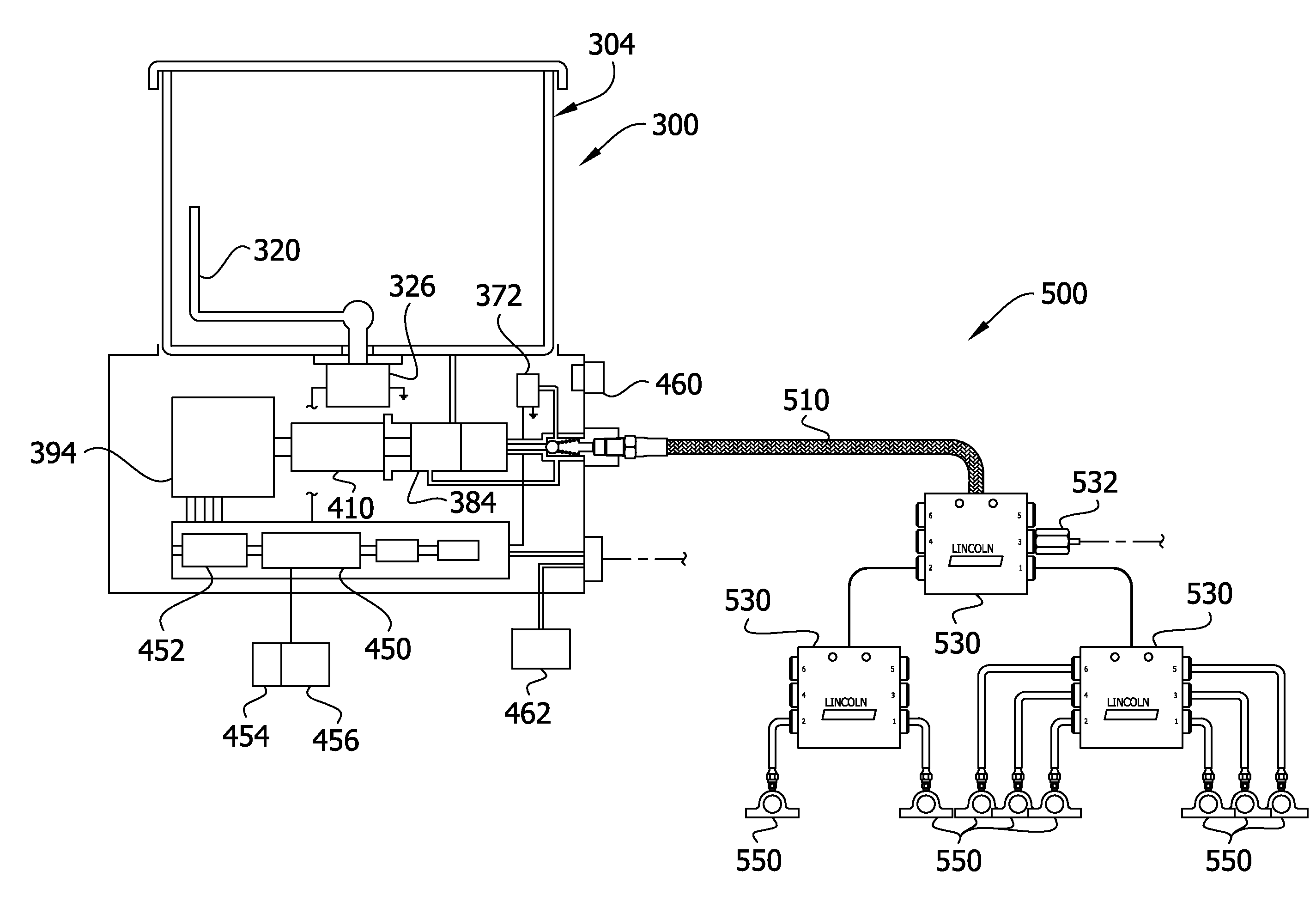

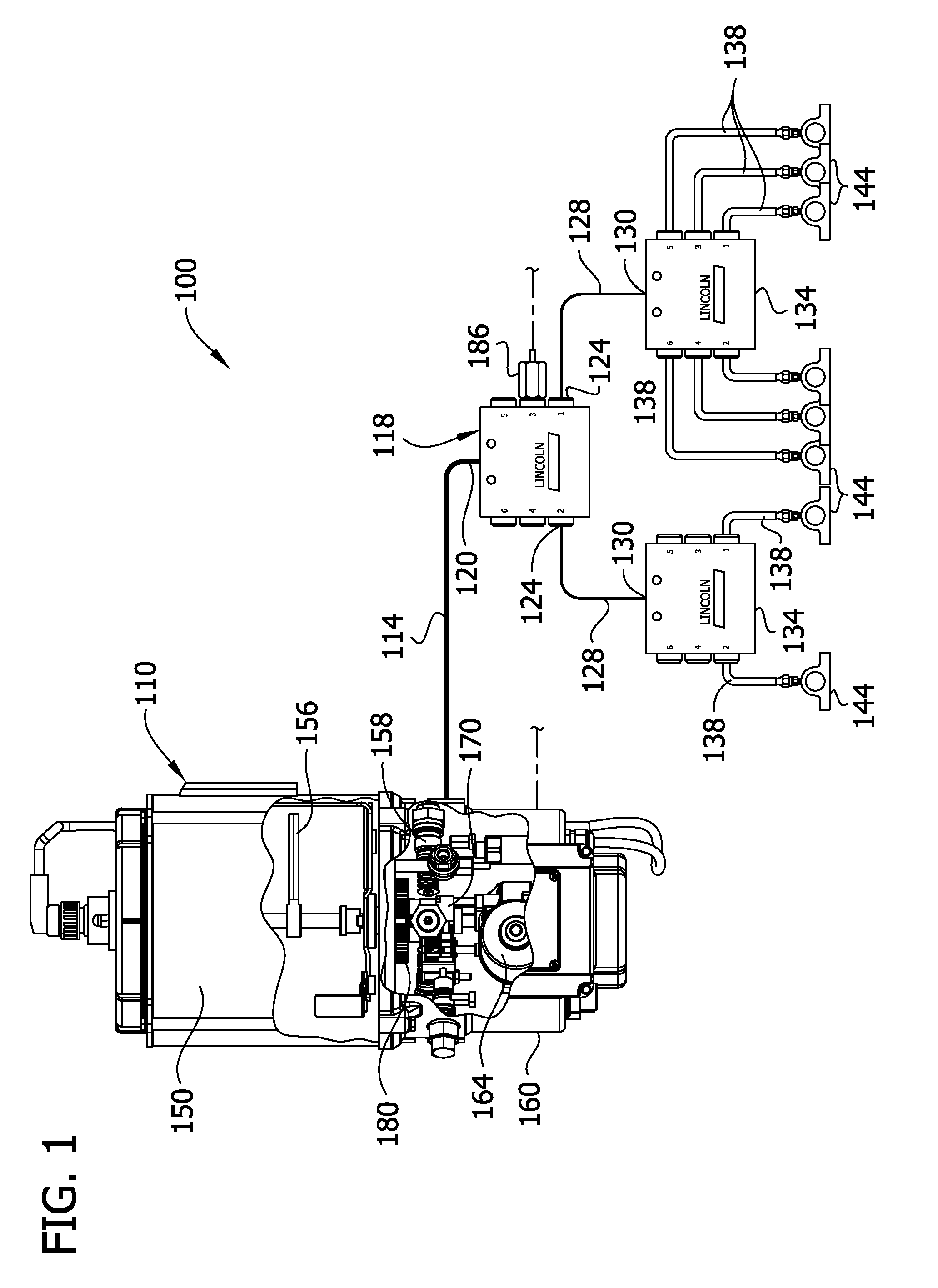

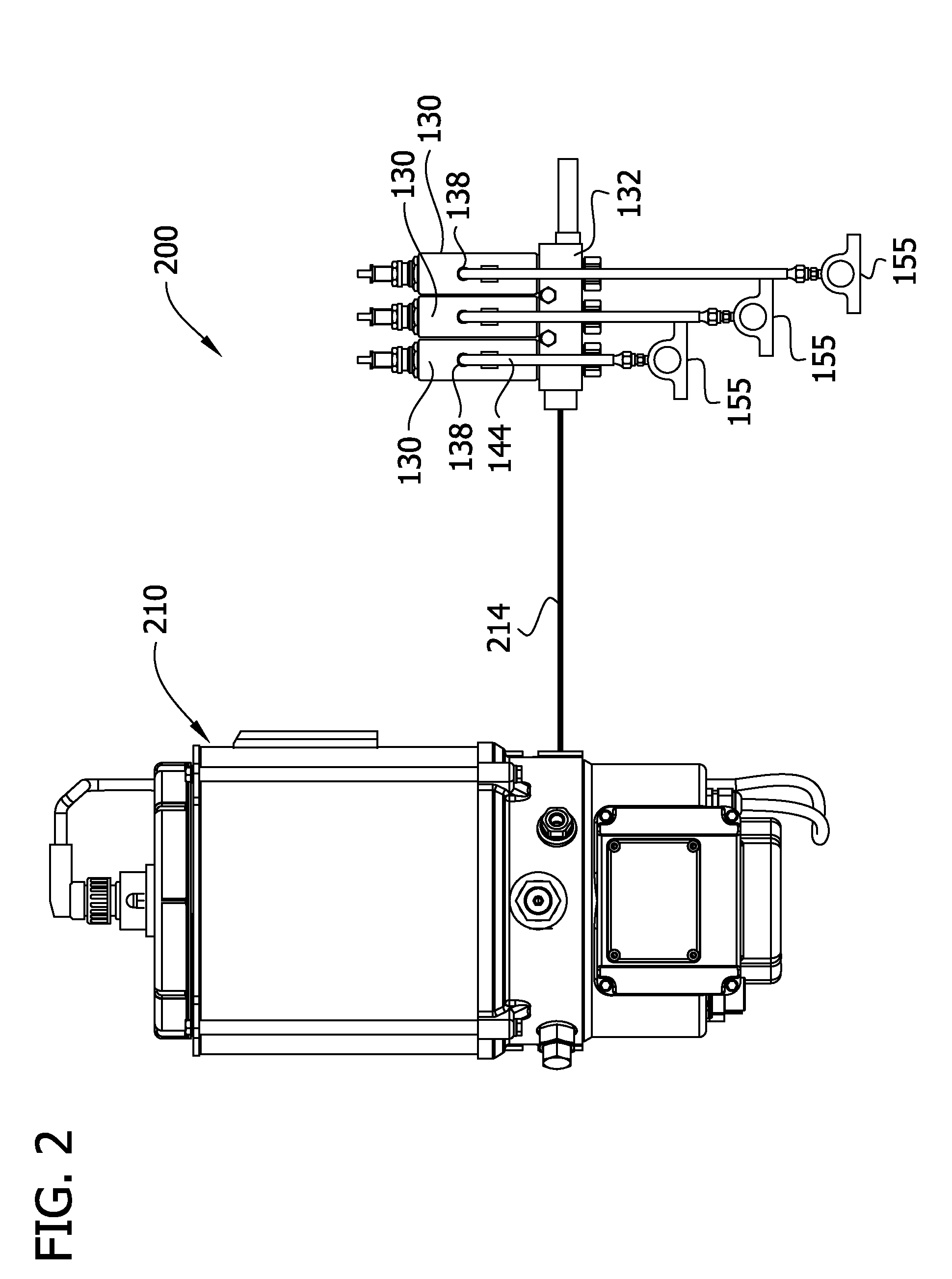

Lubrication system and controller

A lubrication system for lubricating bearings that includes at least one lubrication pump for pumping lubricant to the bearings and at least one metering valve for distributing the pumped lubricant throughout the lubrication system to the bearings. The system further includes a lubrication controller in communication with the at least one lubrication pump and at least one metering valve for controlling the lubrication system. The controller has firmware configured to provide a sequence of instructions to perform specified tasks and hardware that carries out the sequence of instructions to perform the specified tasks. In an unconfigured and unconnected state, the lubrication controller can be configured by reprogramming the firmware, to selectively control at least one of a series progressive lubrication system, a dual line lubrication system and a single line parallel lubrication system.

Owner:LINCOLN INDUSTRIES CORP

Wheel and other bearing hubs safety restraint devices, locks and visual warning indicators

InactiveUS7547077B2Prevent sudden and possible catastrophic lossLoss and damageThermometer detailsRolling contact bearingsDrive wheelEngineering

Owner:MELBERG NELS +1

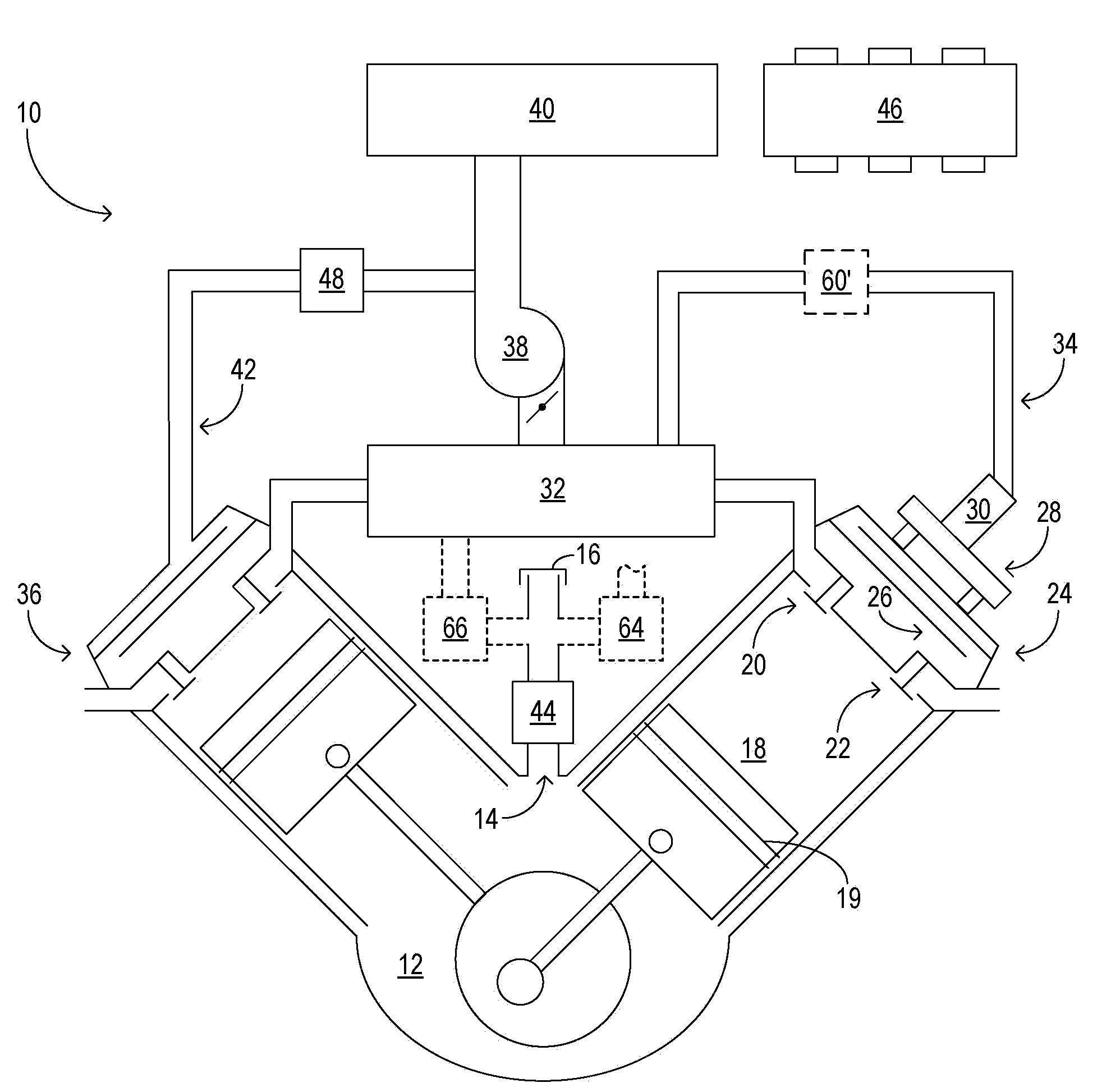

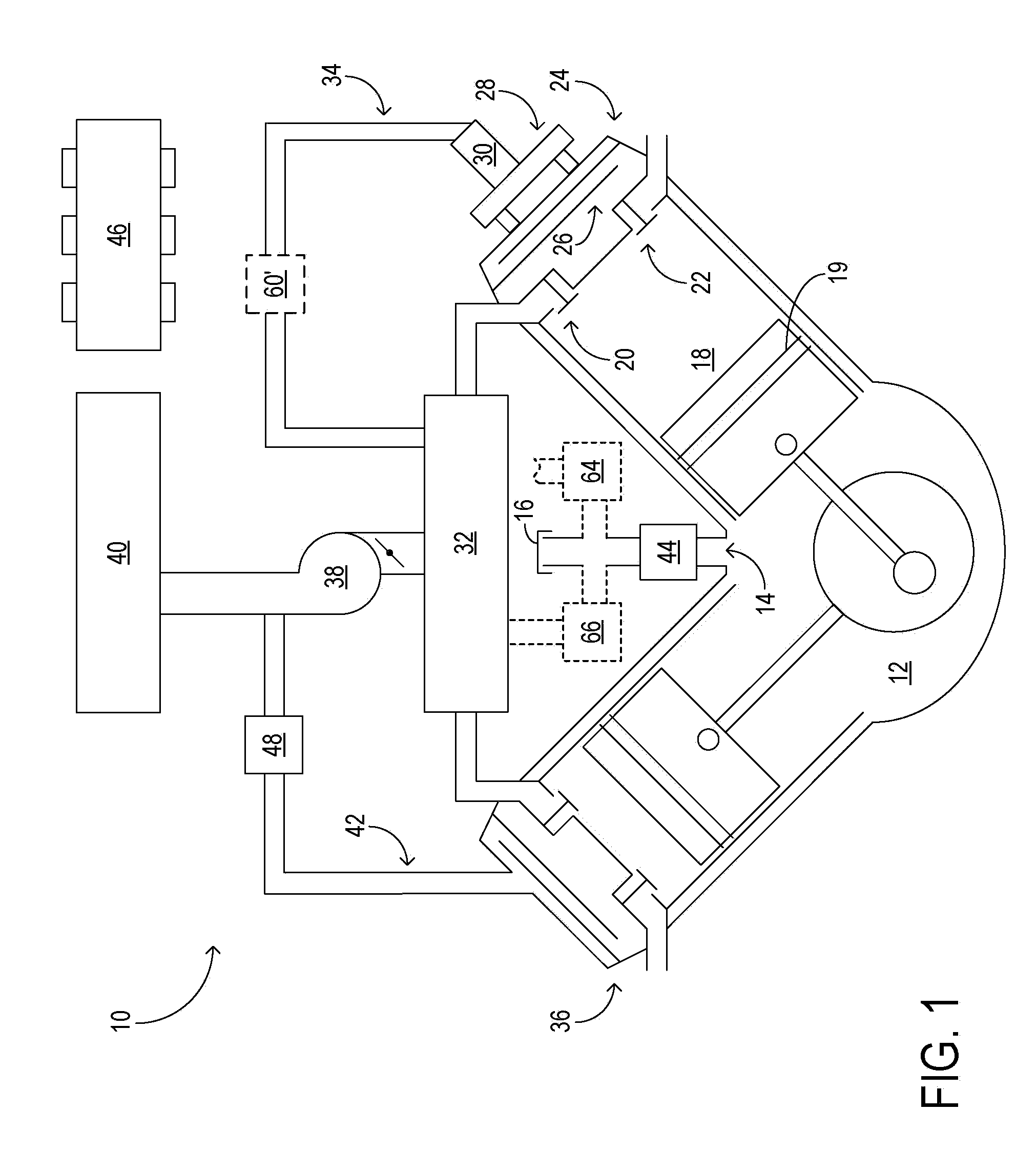

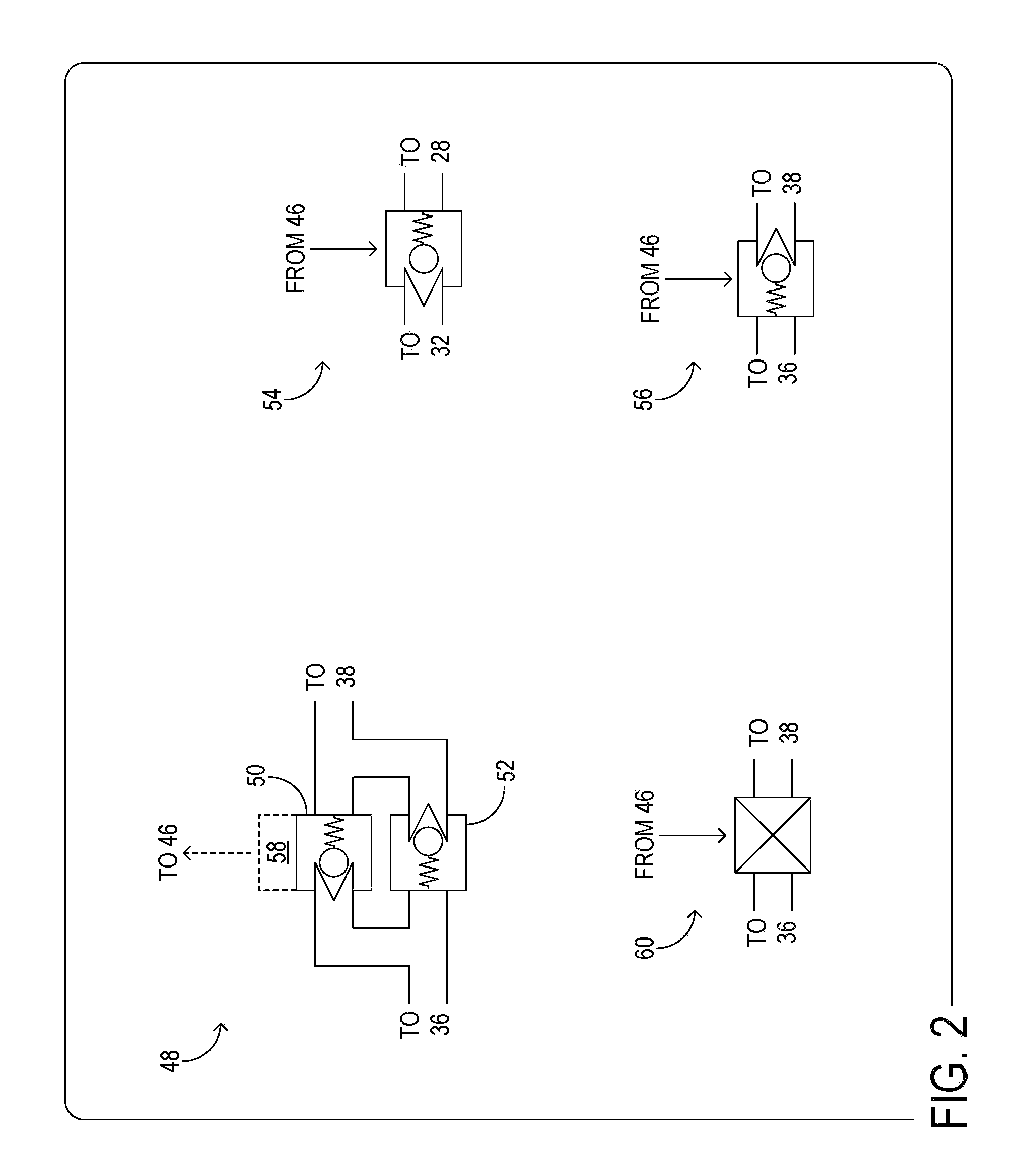

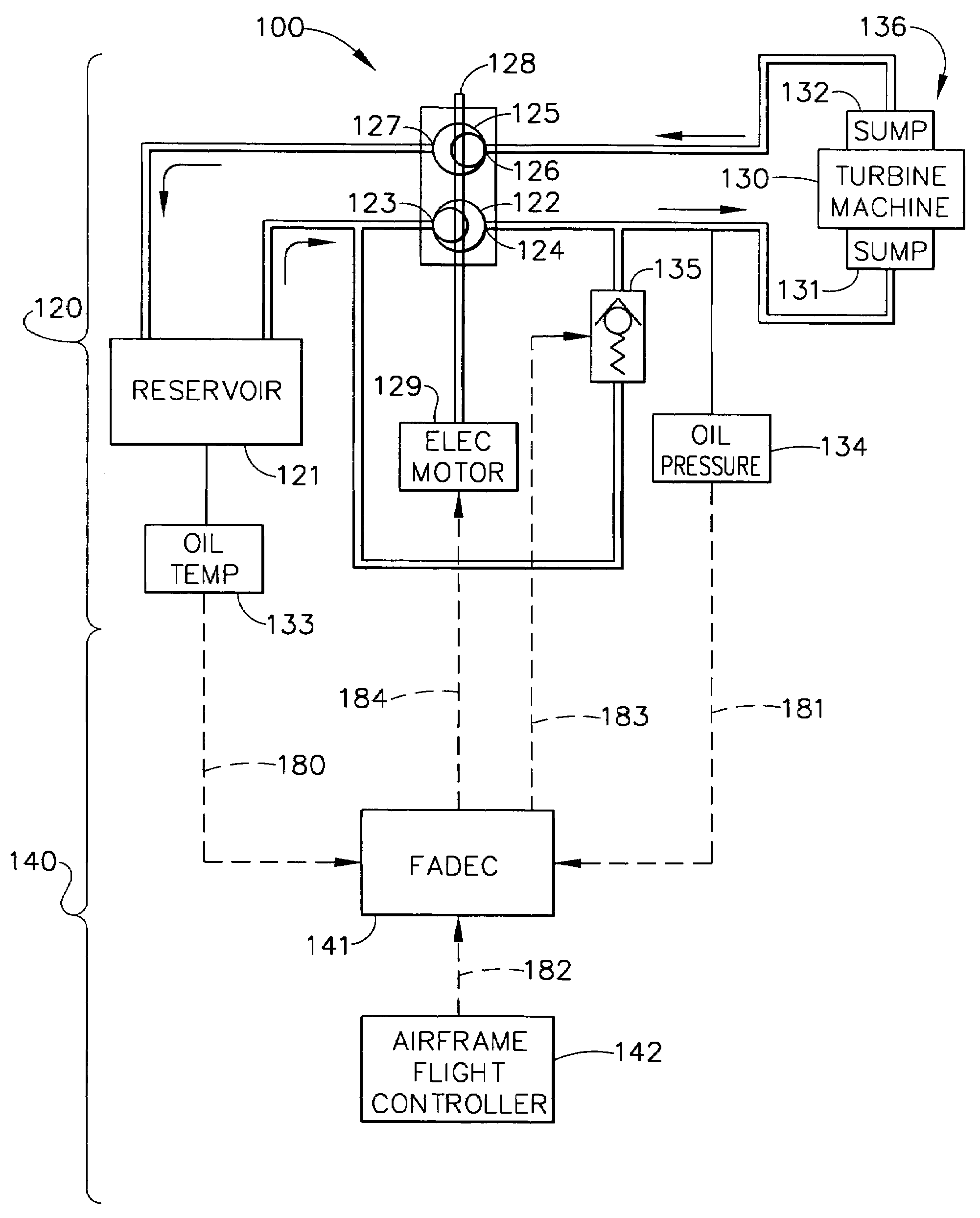

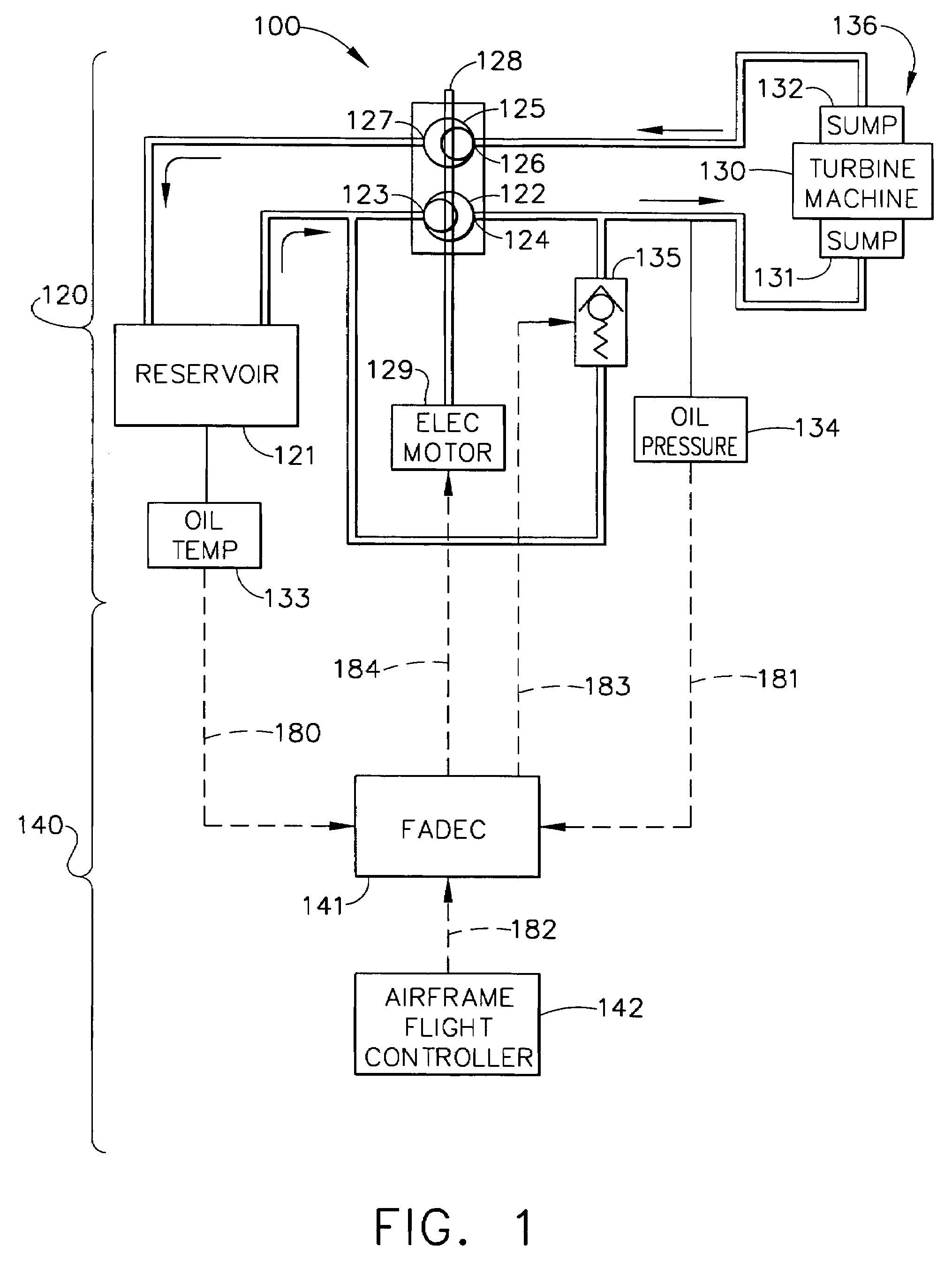

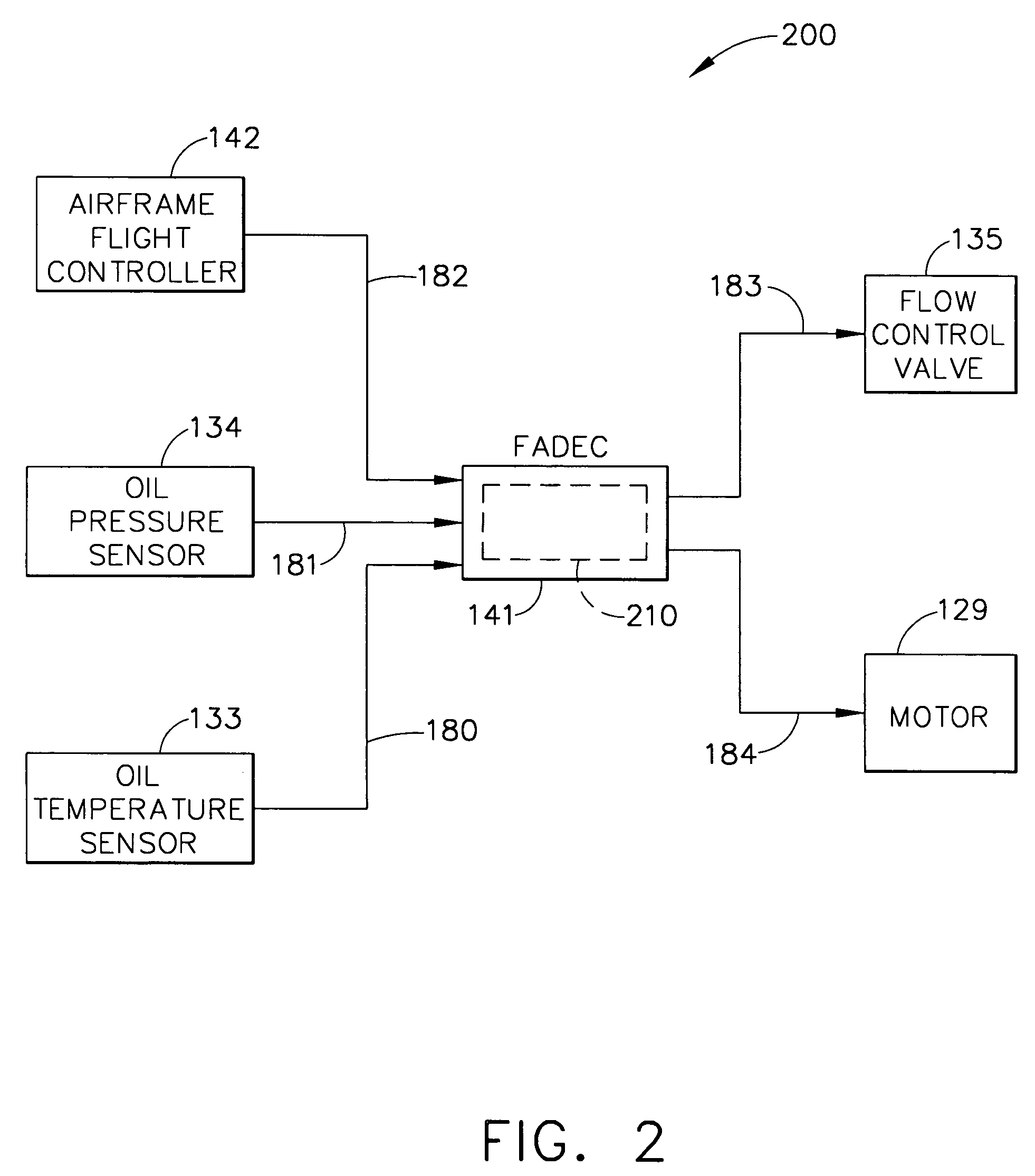

Active gas turbine lubrication system flow control

A lubrication system is provided for an aircraft turbine machine, the lubrication system being controlled by a closed-loop logic arrangement, wherein the oil pressure of a lubricant circulated therein is monitored and altered according to attitude data, acceleration data, operating mode data, or some combination thereof contained in a signal received from an airframe flight controller and according to a oil pressure signal and an oil temperature signal. The logic responsively provides a supply pump speed control signal, according to a predetermined target oil pressure value selected to correspond to the data contained in the signals. The target value may be continuously compared to the present oil pressure value and the present oil pressure adjusted by sending a motor control signal to the supply pump and a valve flow control signal to a flow control valve that conditionally allows oil from the outlet side of the supply pump to be fed back to its inlet side.

Owner:HONEYWELL INT INC

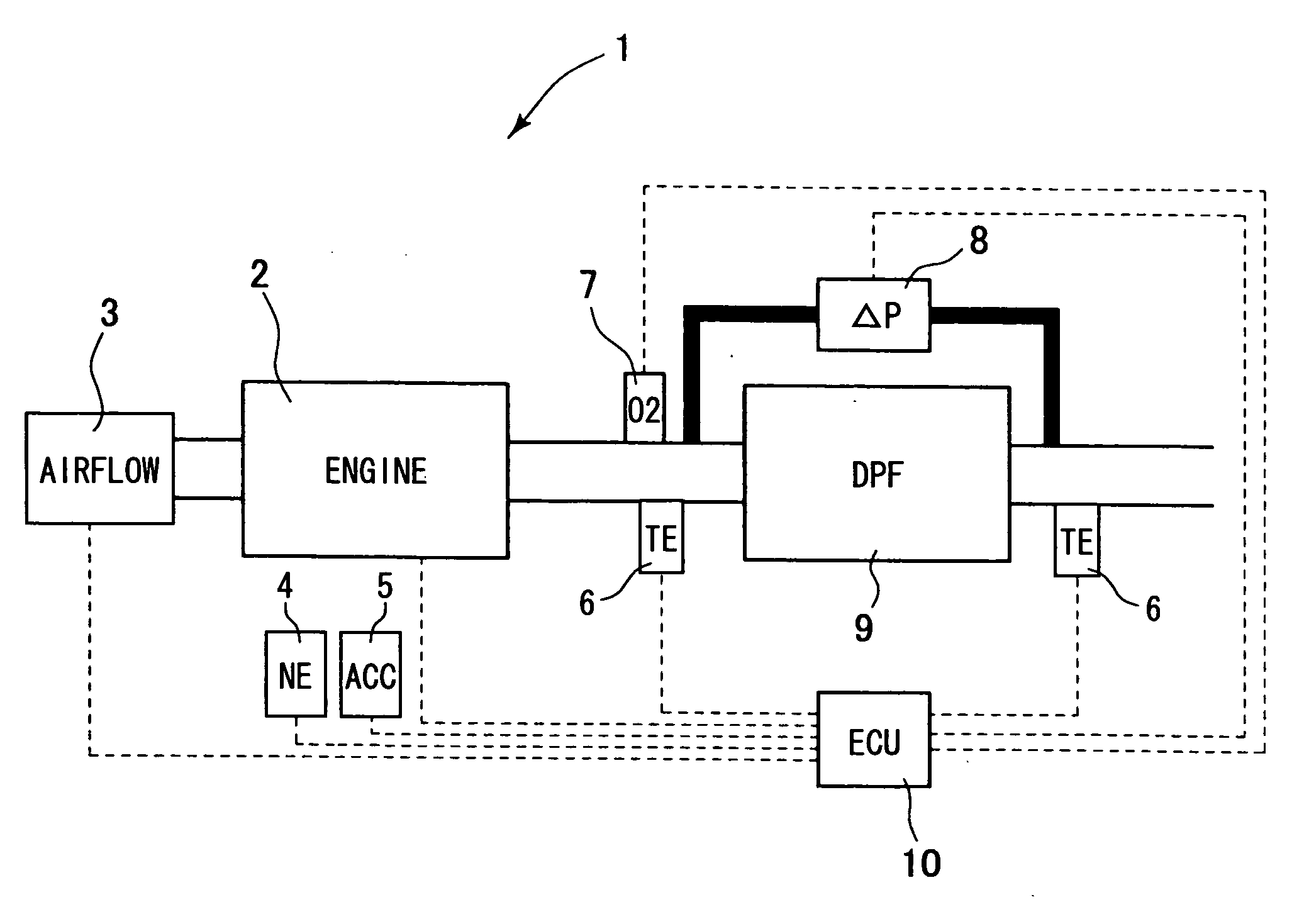

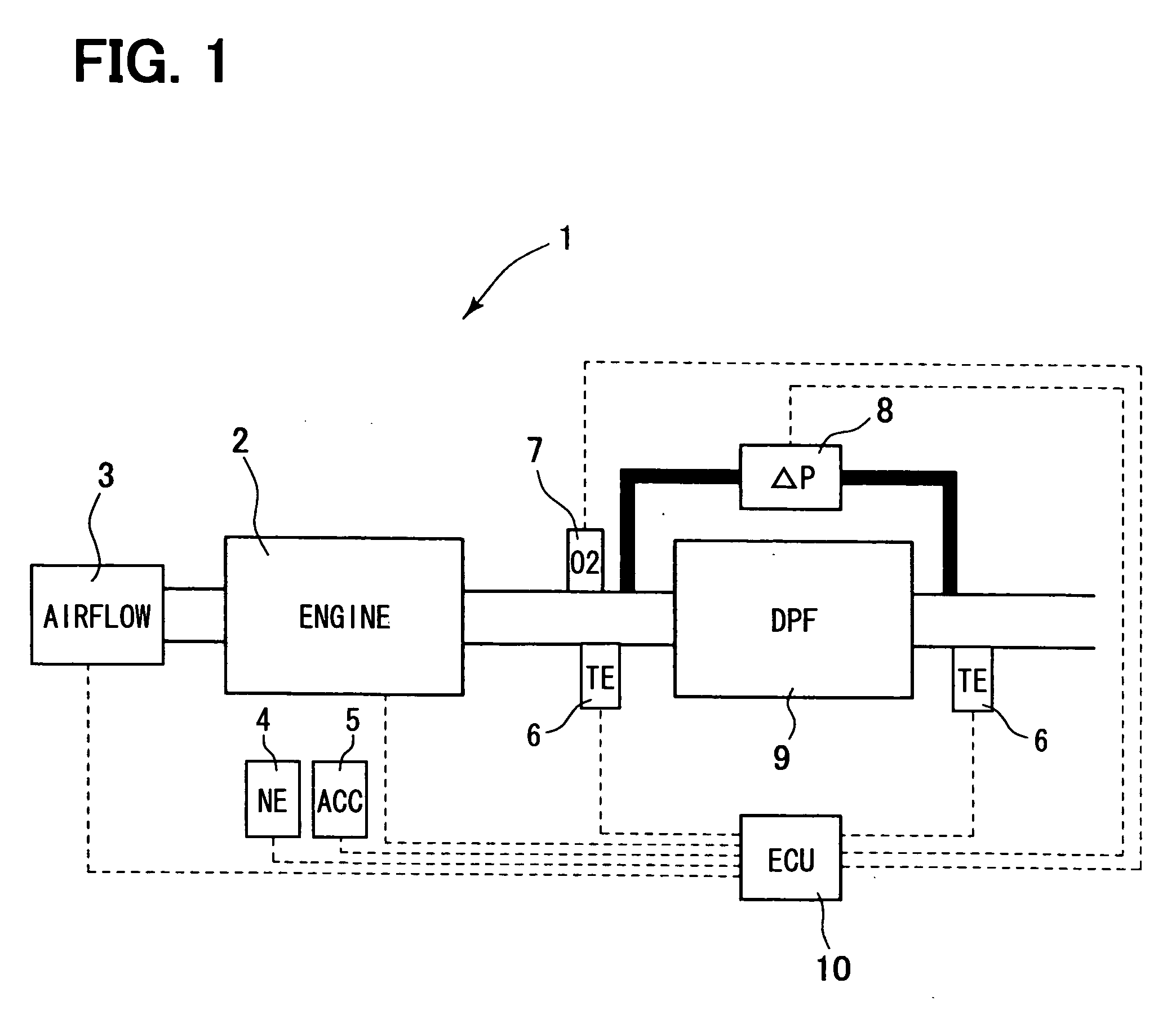

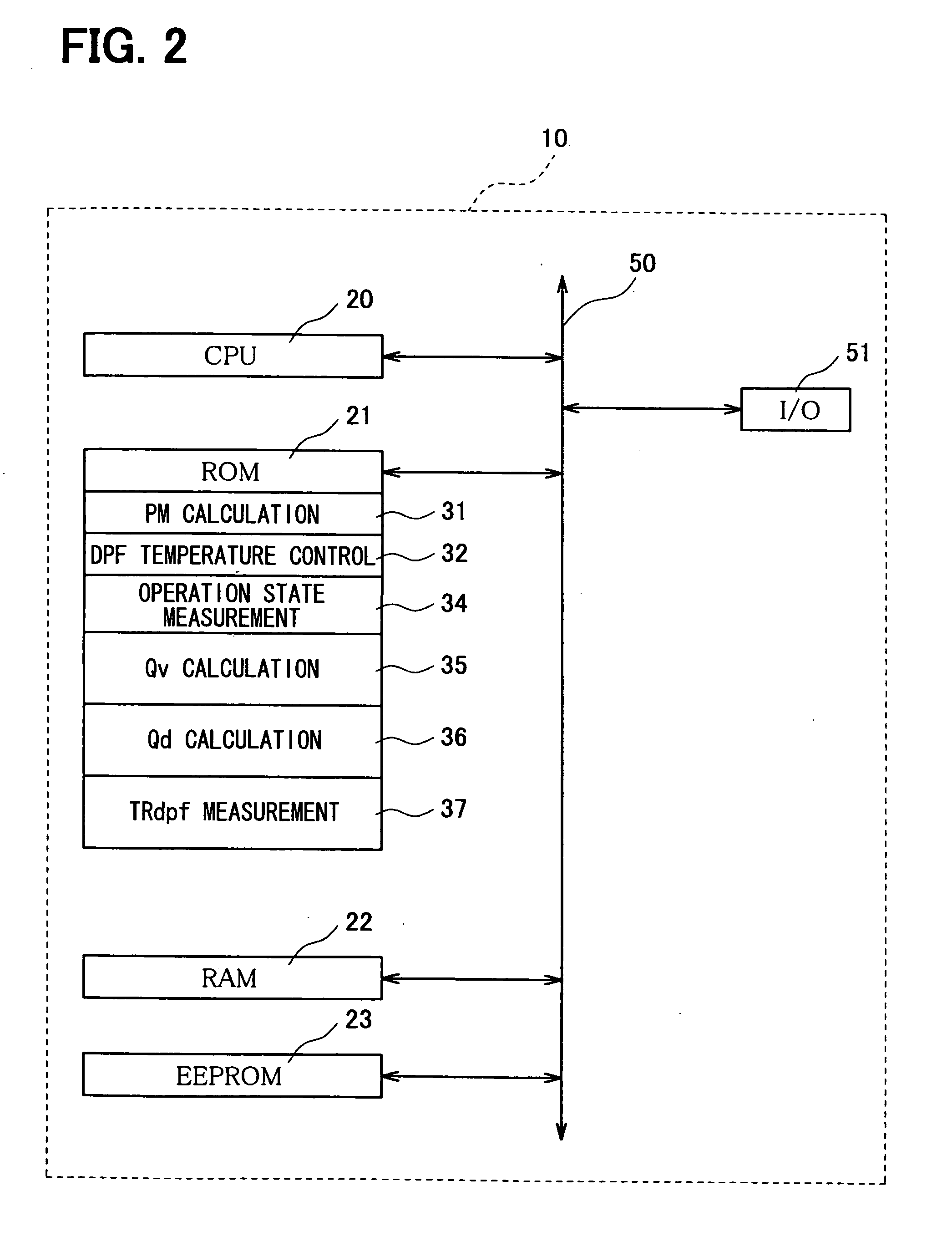

Exhaust gas purification device for internal combustion engine

InactiveUS20080295491A1Accurately derivedAchieve inhibitionElectrical controlInternal combustion piston enginesExternal combustion engineExhaust fumes

An exhaust gas purification device of a diesel engine having a DPF (diesel particulate filter) for collecting particulate matters such as soot and unburned components from exhaust gas of the diesel engine calculates an oil dilution quantity as a quantity of fuel diluting engine oil from a regeneration time of the DPF and an operation state. The exhaust gas purification device alleviates an increase in the oil dilution quantity by using a regeneration device that causes the oil dilution quantity less than the oil dilution quantity caused by another regeneration device when the oil dilution quantity exceeds a predetermined value. Thus, both of suppression of the oil dilution quantity and inhibition of deterioration of fuel consumption due to post-injection can be achieved.

Owner:DENSO CORP

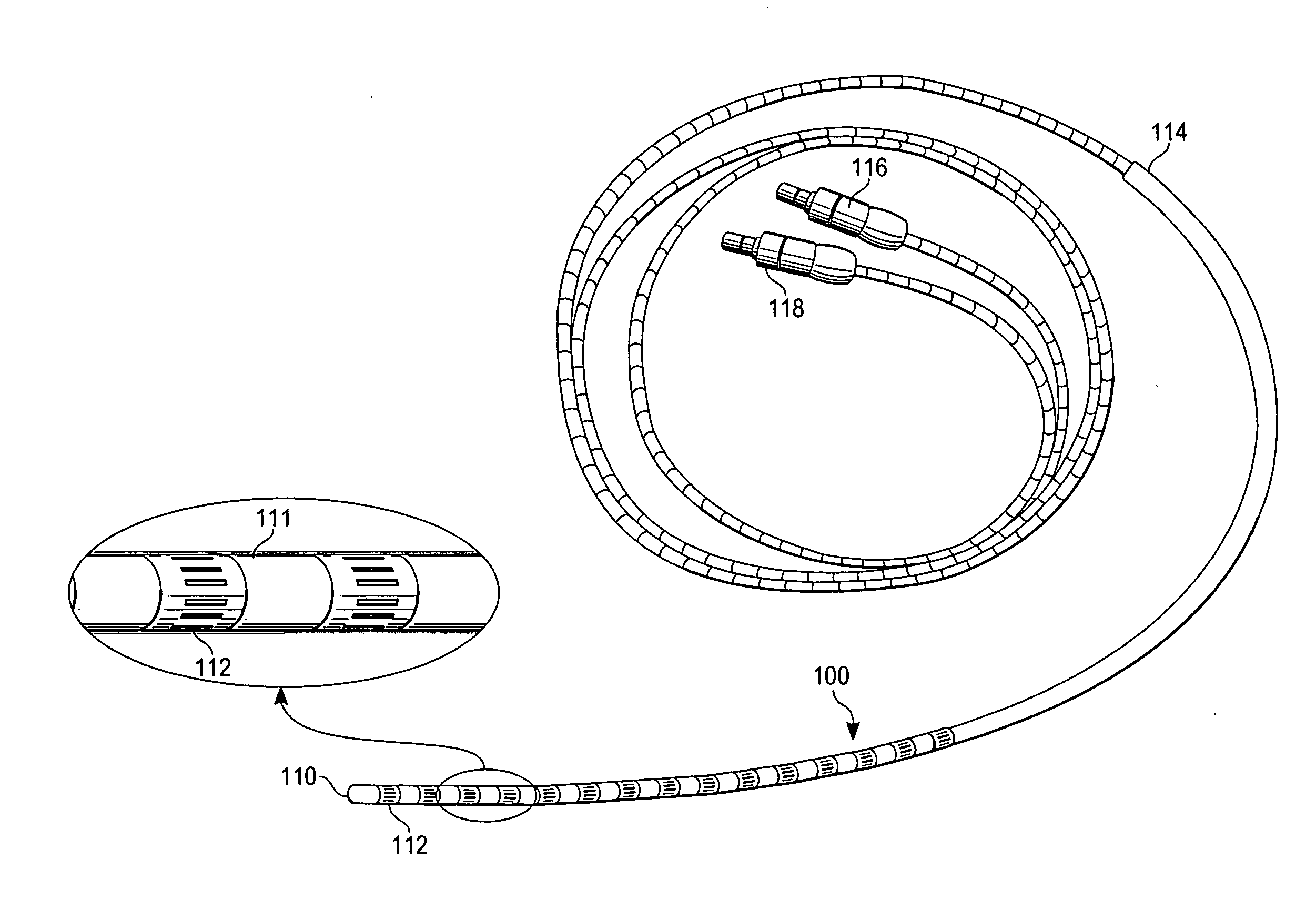

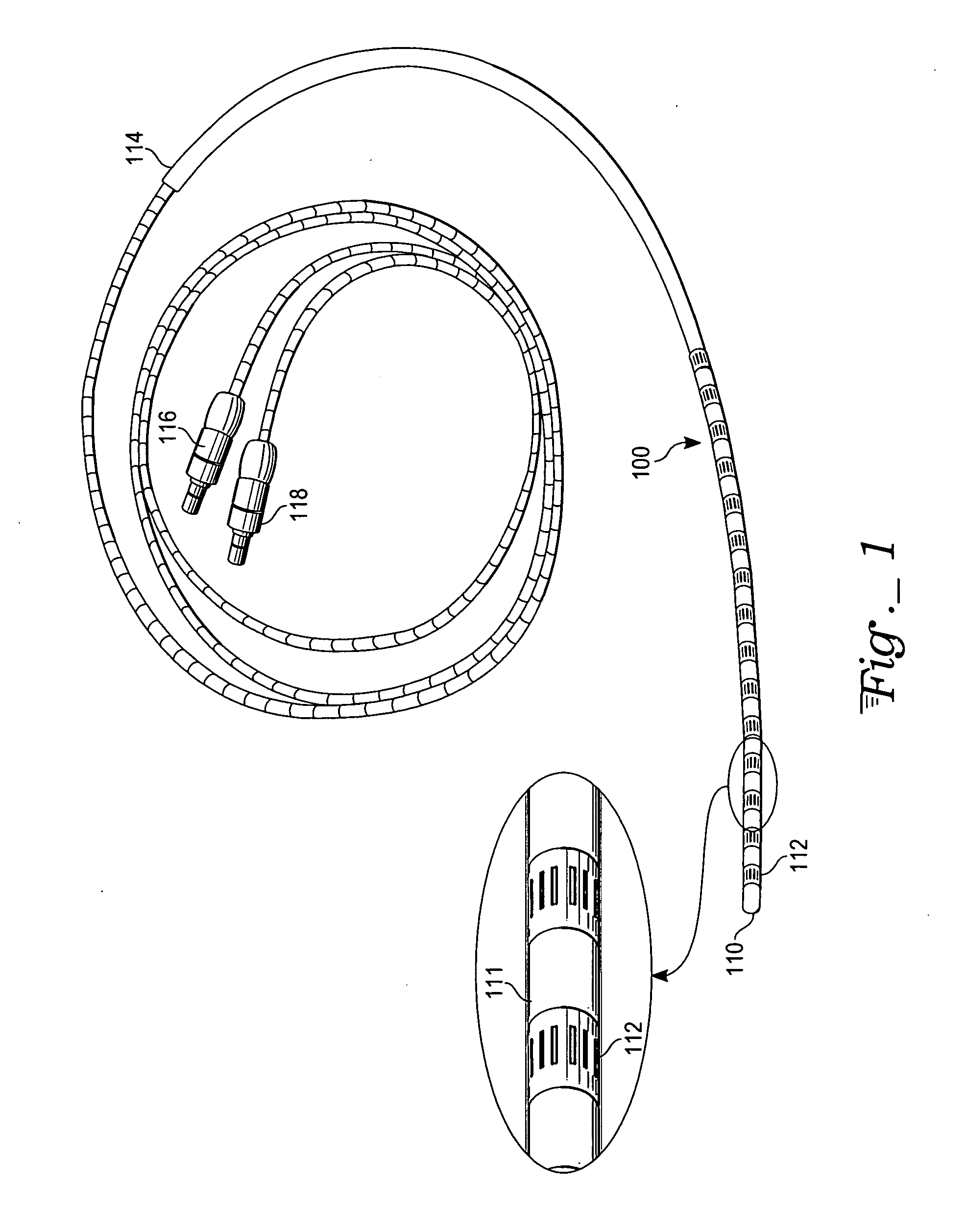

High resolution solid state pressure sensor

A pressure sensor and pressure-sensing catheter in which a deformable pressure sensing membrane is separated from an inner metalized surface on a rigid support by an air gap. An input allows a voltage to be applied to an electrode on the sensing membrane and an output allows reading of the signal modulation from the support surface. An outer sleeve overlays the membrane and a wire bus transmits the signals to a terminal connector. The catheter may include a vented air gap, a multiplexing wire bus, and an internal cable to maintain tension.

Owner:TYCO HEALTHCARE GRP LP

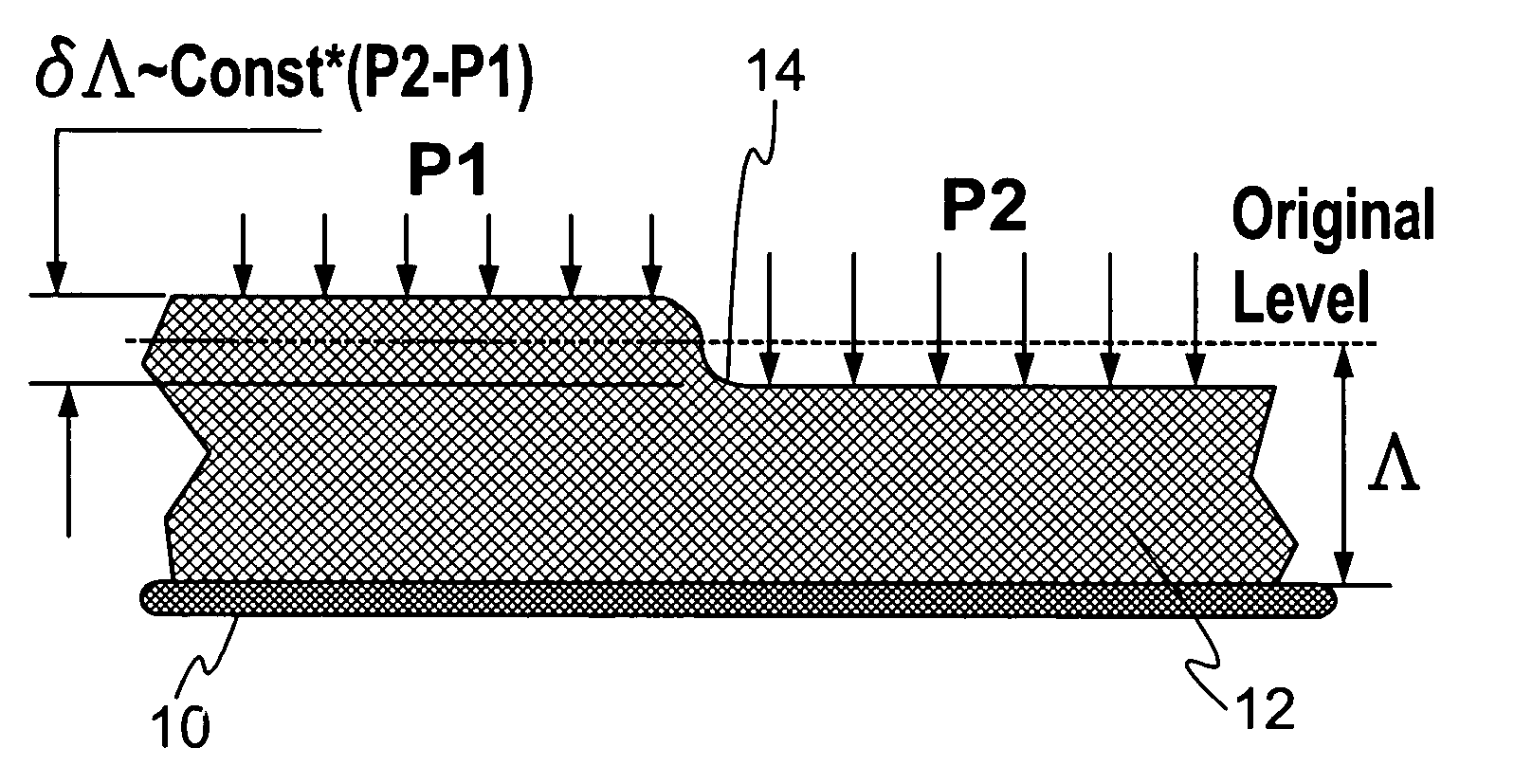

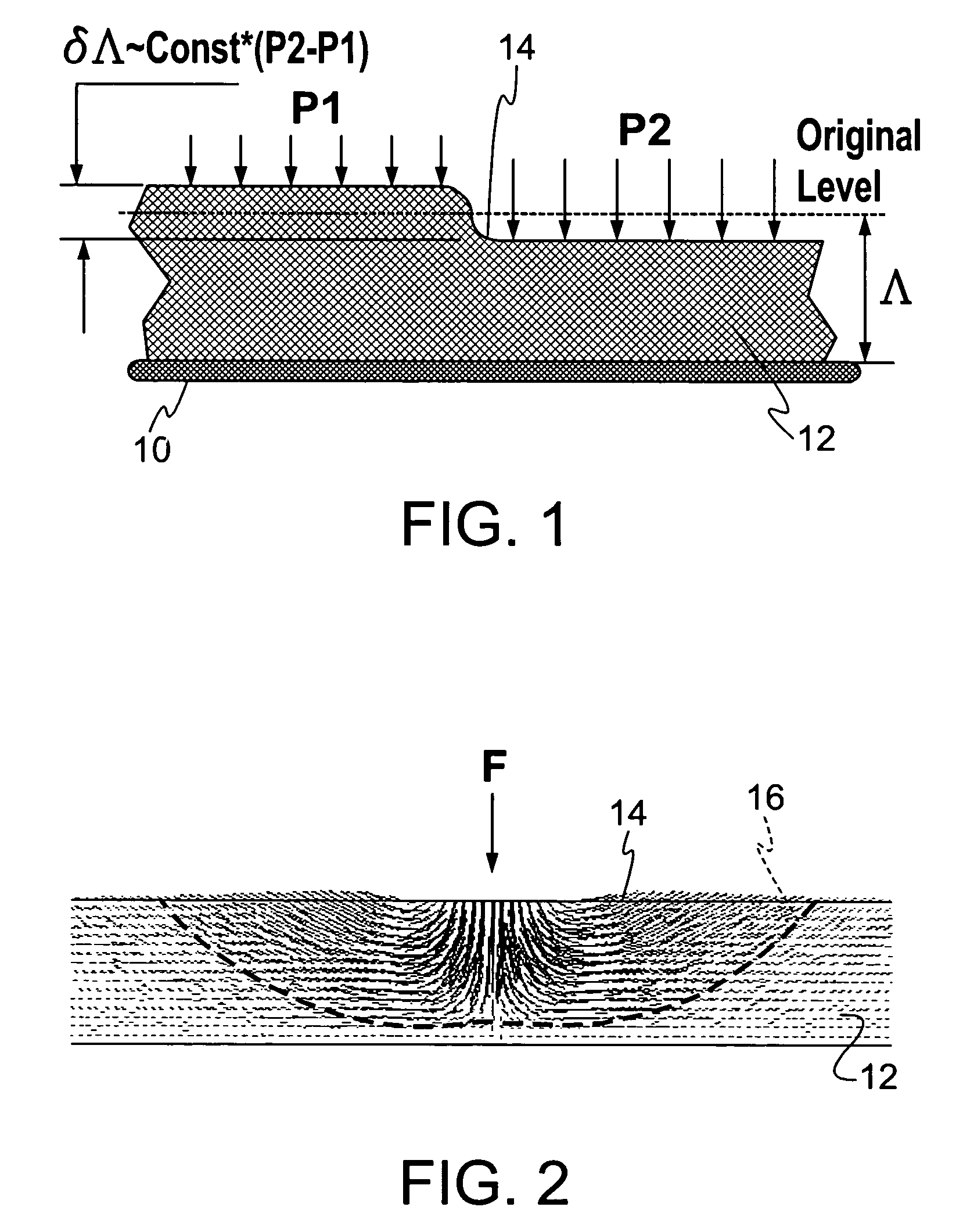

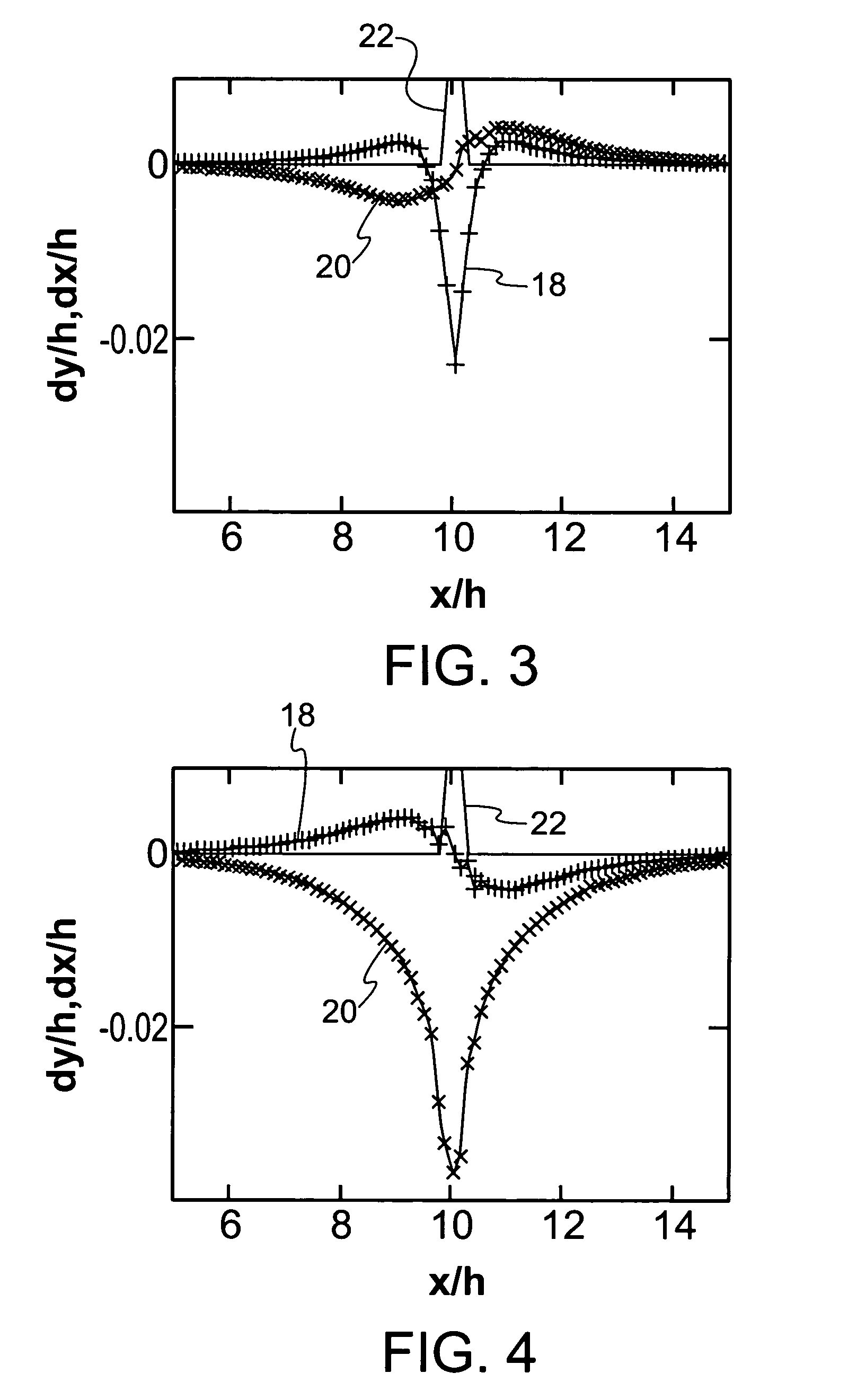

Method for determining a surface contact force

ActiveUS7127950B2Aerodynamic testingForce measurement by measuring optical property variationLuminophoreTangential displacement

A method of measuring a load on a surface produced by a contact force. An elastic film or coating is located on a supporting surface to provide an indication of normal and tangential or shear forces applied to the surface. A thickness measurement, corresponding to a normal displacement, and a tangential displacement of the film, corresponding to a shear displacement, is obtained and input to a response function to reconstruct the normal and shear load components of the contact force on the surface. A differential thickness measurement of the film is detected by an optical method in which a luminescent output from a luminophore in the film is measured. A luminescent output from a reference luminophore located below the film is also measured to provide a measurement system independent of the illumination source used to produce the luminescent output.

Owner:INNOVATIVE SCI SOLUTIONS

Pump having stepper motor and overdrive control

ActiveUS20120132483A1Speed up the flowReduce pressureMachines/enginesLubricating pumpsEngineeringLubrication

Apparatus and method for supplying lubricant to a plurality of lubrication sites. Embodiments include a pump with venting and non-venting piston return, a pump with stirrer and direct feed mechanism, a pump with CAN system and self-diagnostics, a pump with heated housing and reservoir and a pump with stepper motor and overdrive control.

Owner:LINCOLN INDUSTRIES CORP

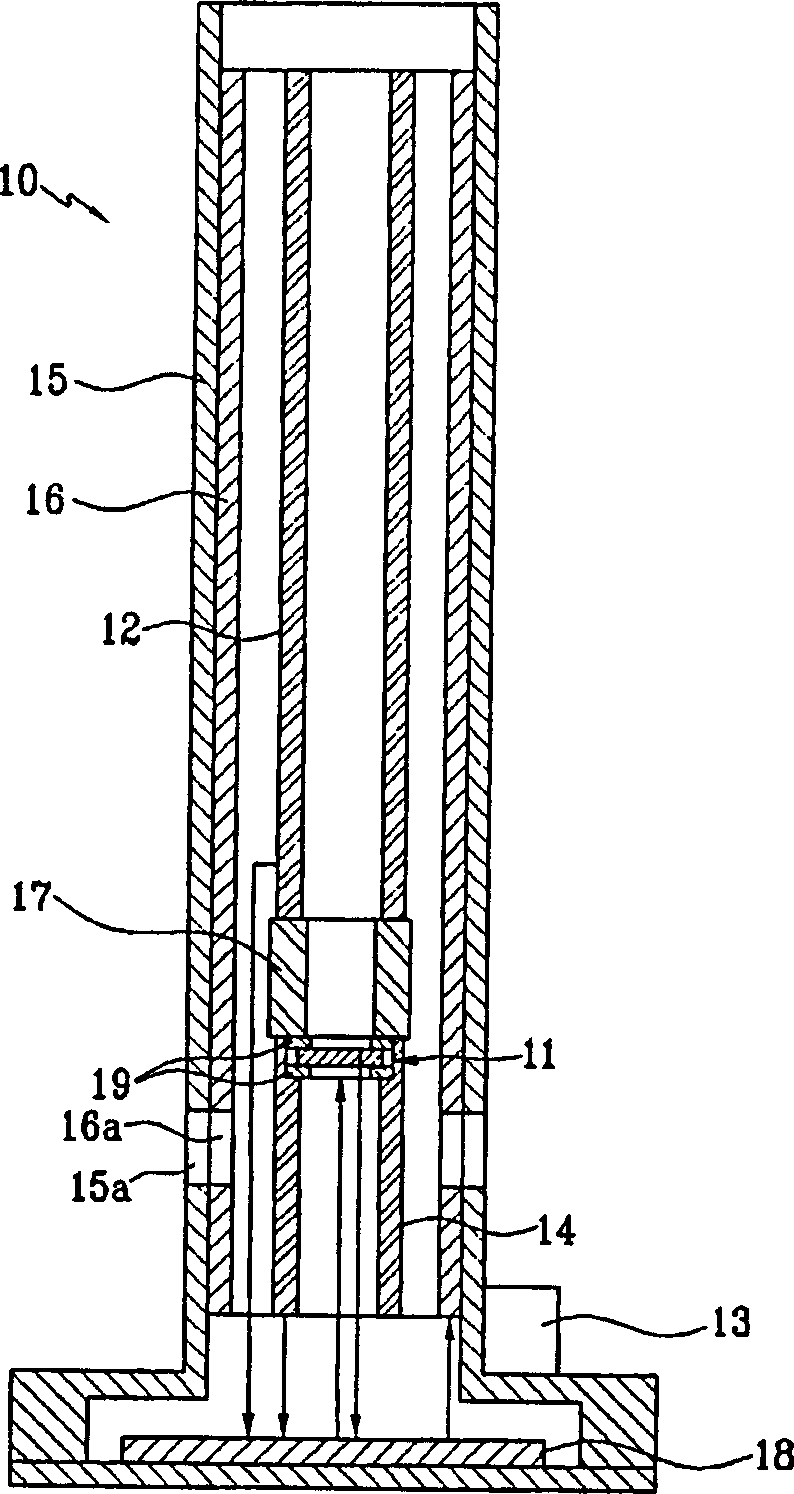

Lubrication system

The present invention is directed to lubrication system having a reservoir having a body. A follower is moveably disposed in the body. The system further comprises an alarm system having an electrical switch operably associated with the follower. The alarm generates a signal when the follower is at a predetermined location in the body. The alarm system may generate a signal when the follower is at a lower location in the body such as when the reservoir has an amount of lubricant representing a predetermined amount of usage time remaining. The alarm system may also generate a signal when the follower is at an upper location in the body such as when the reservoir is filled with lubricant wherein the signal acts to automatically interrupt the fill of lubricant.

Owner:METCO ENG

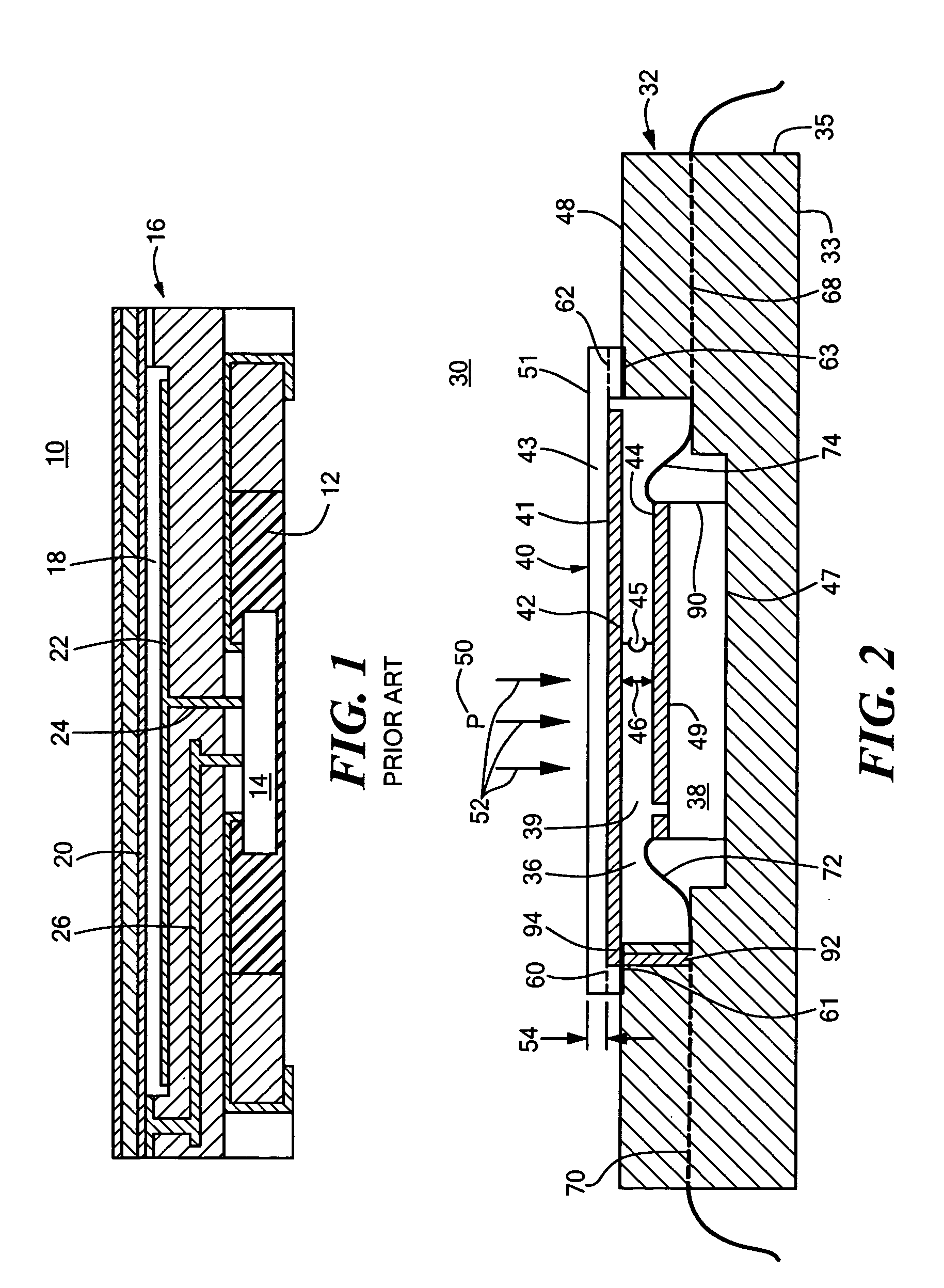

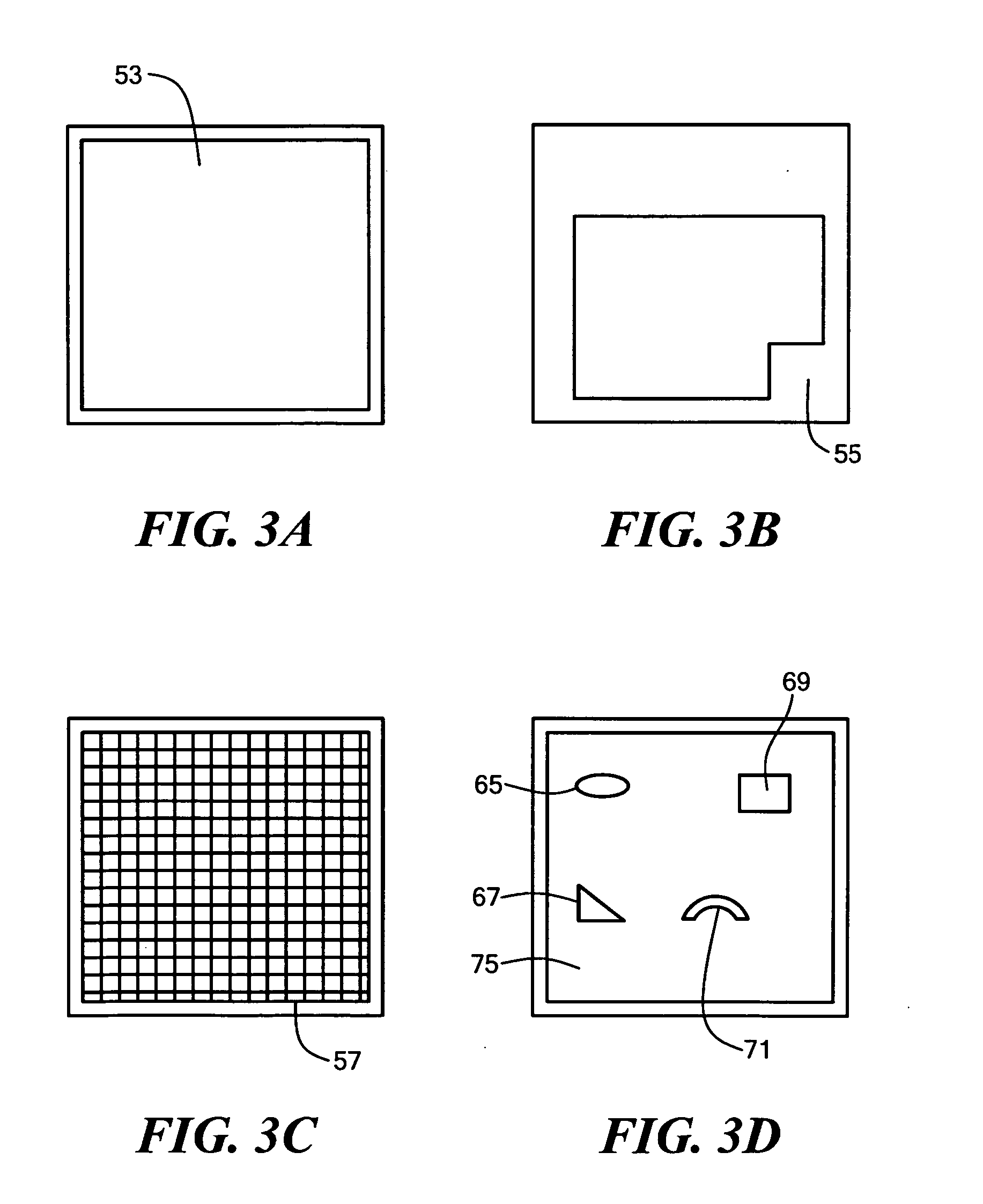

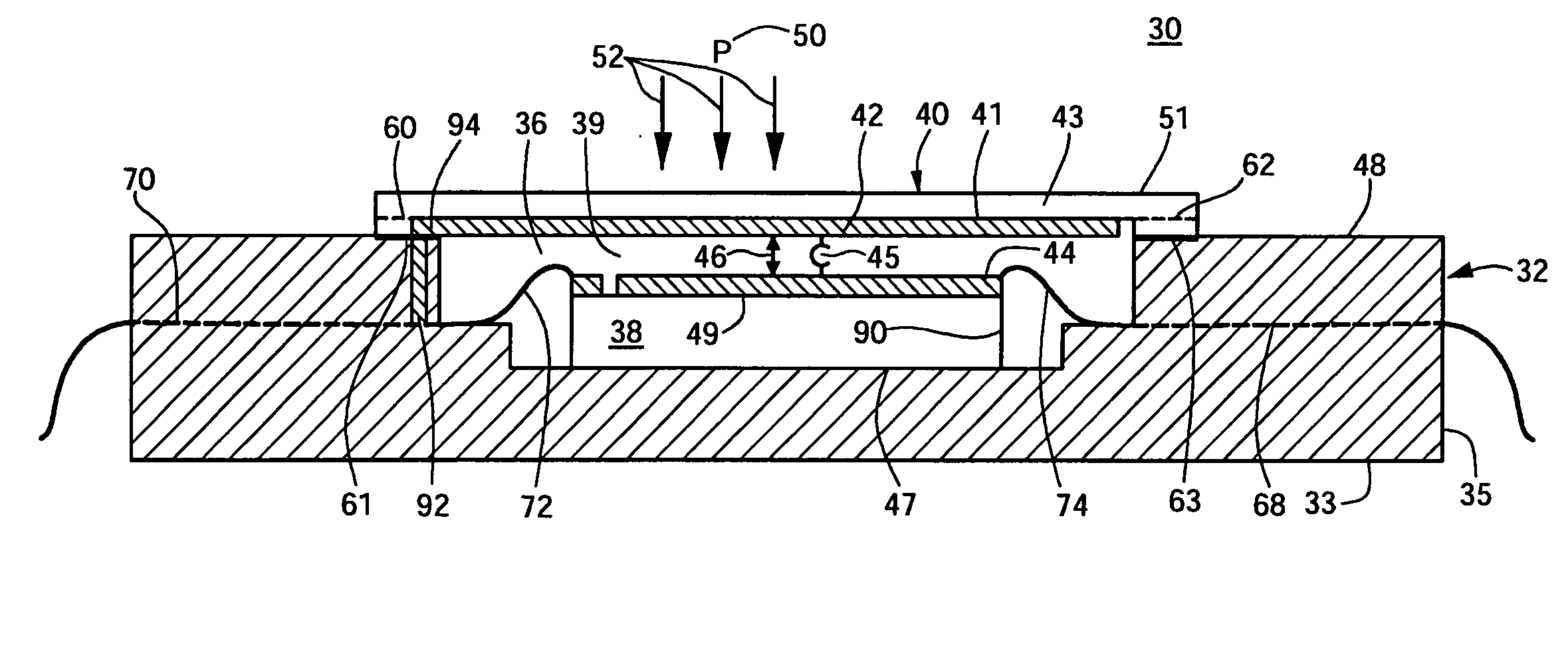

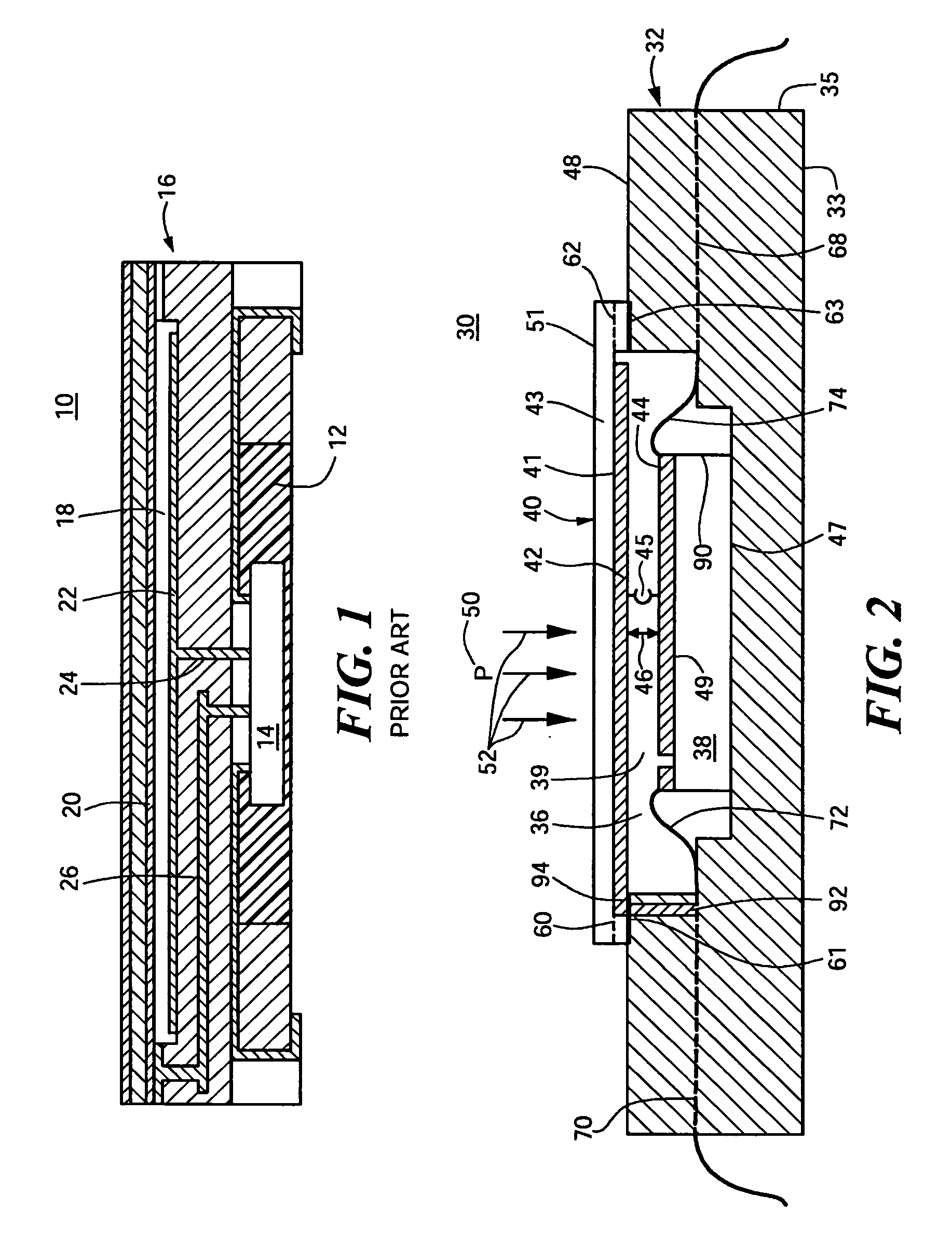

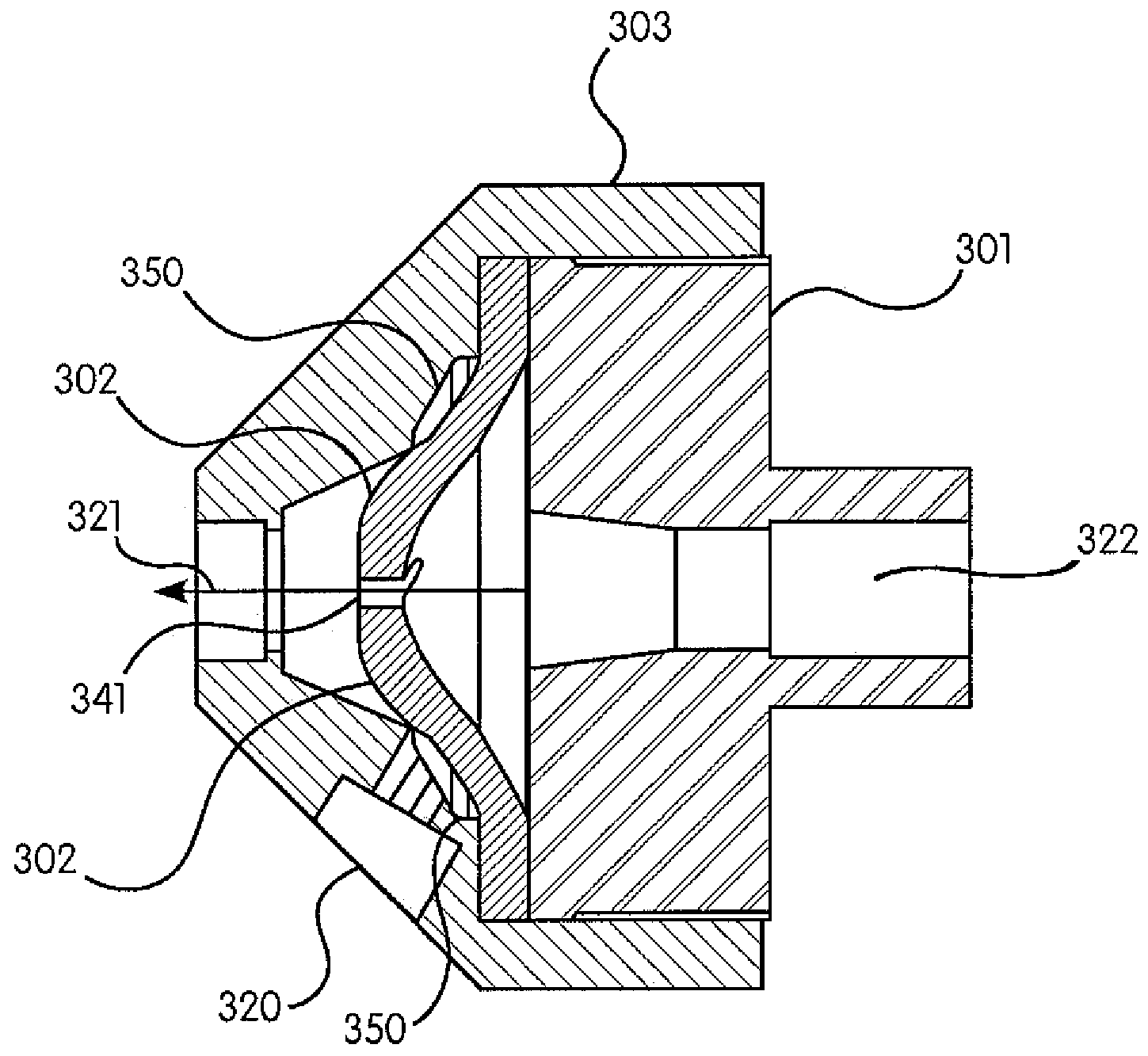

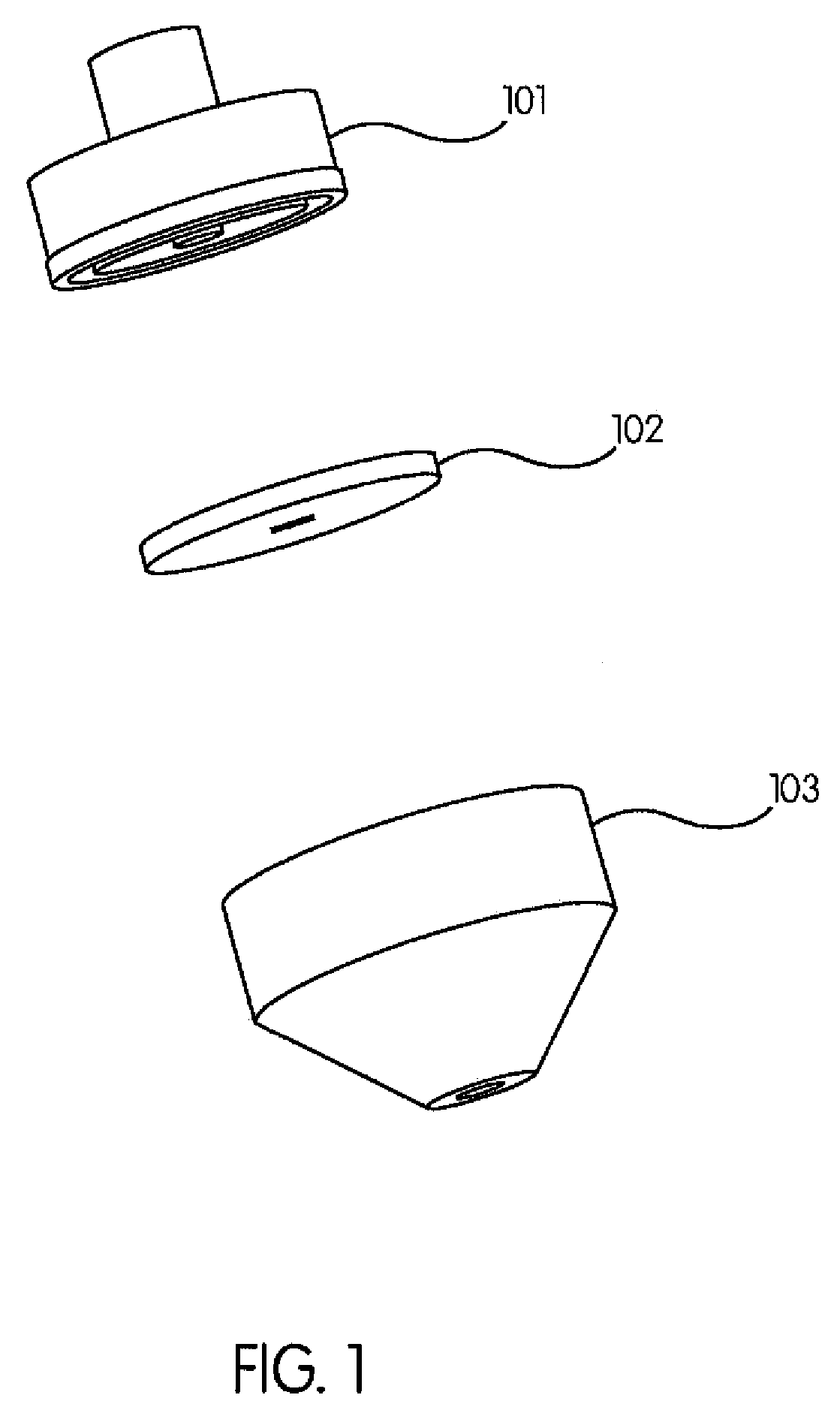

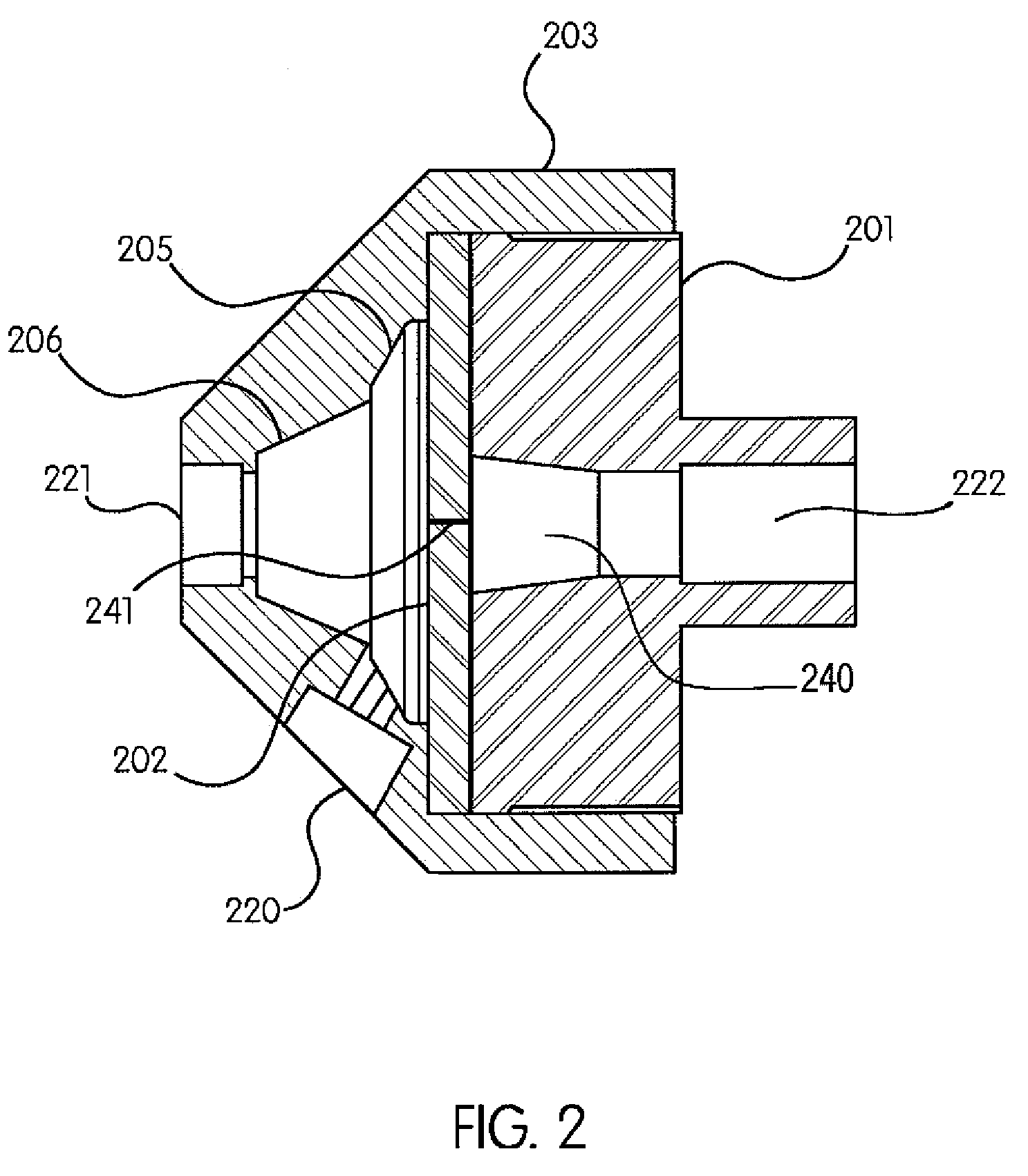

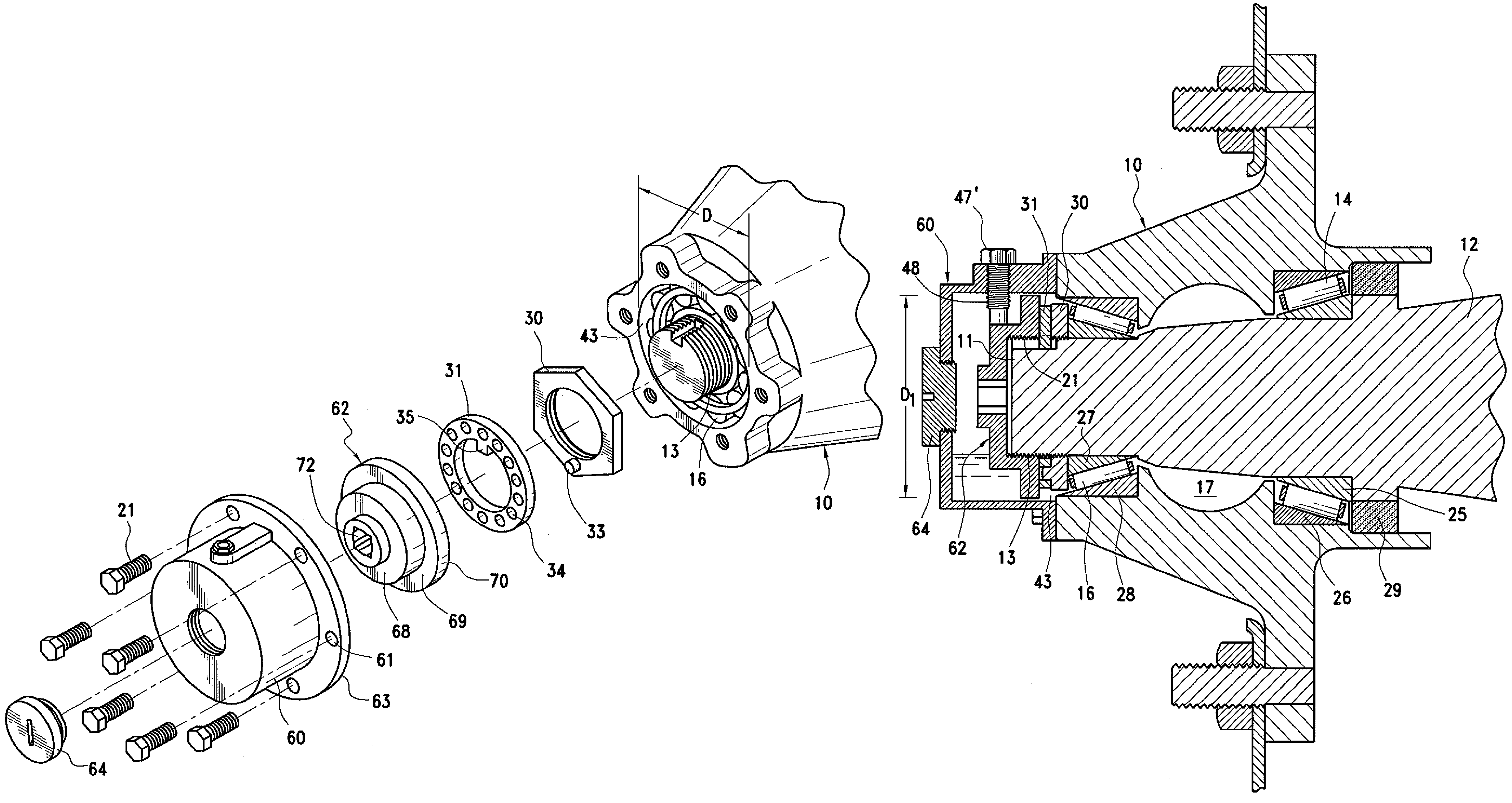

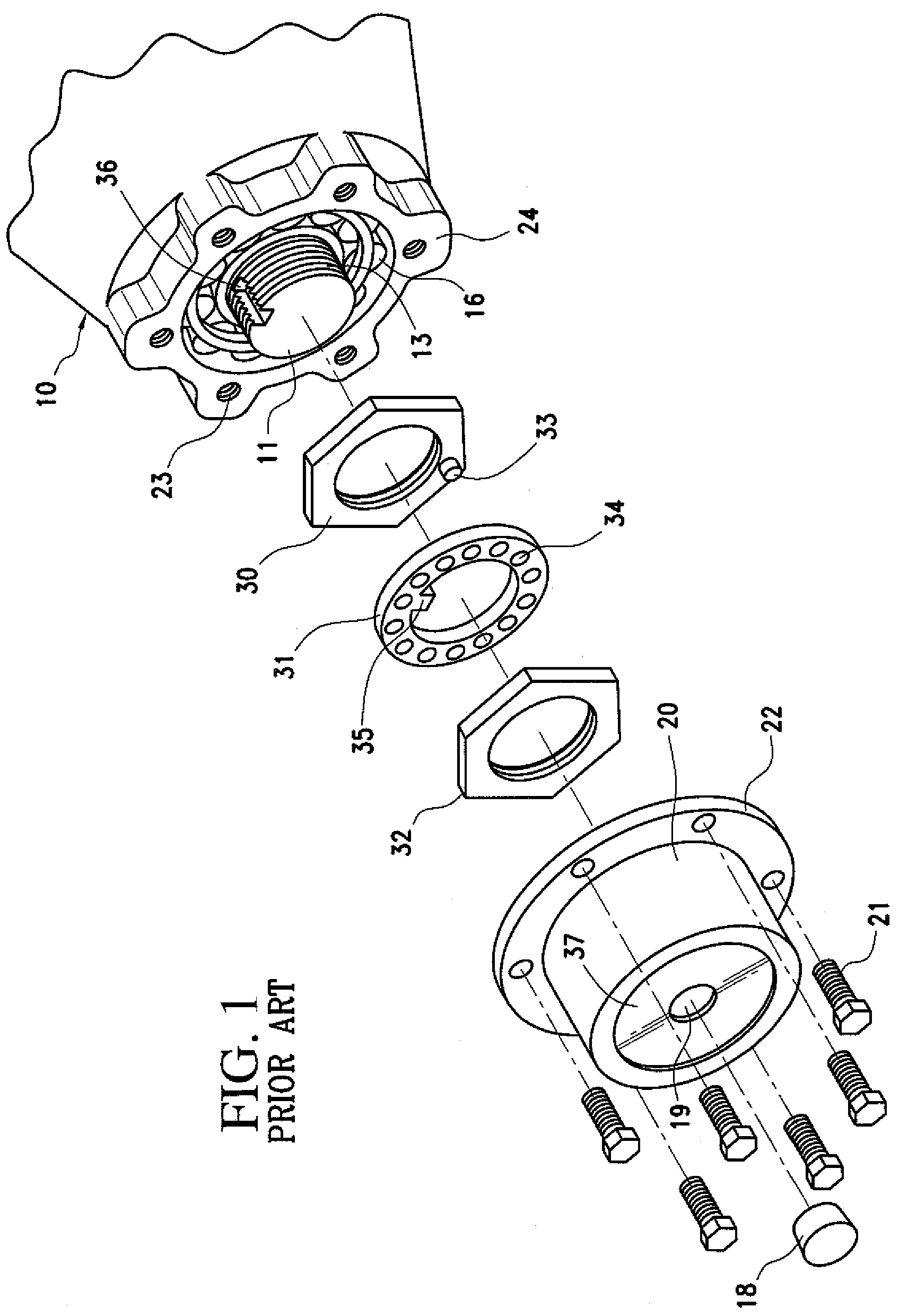

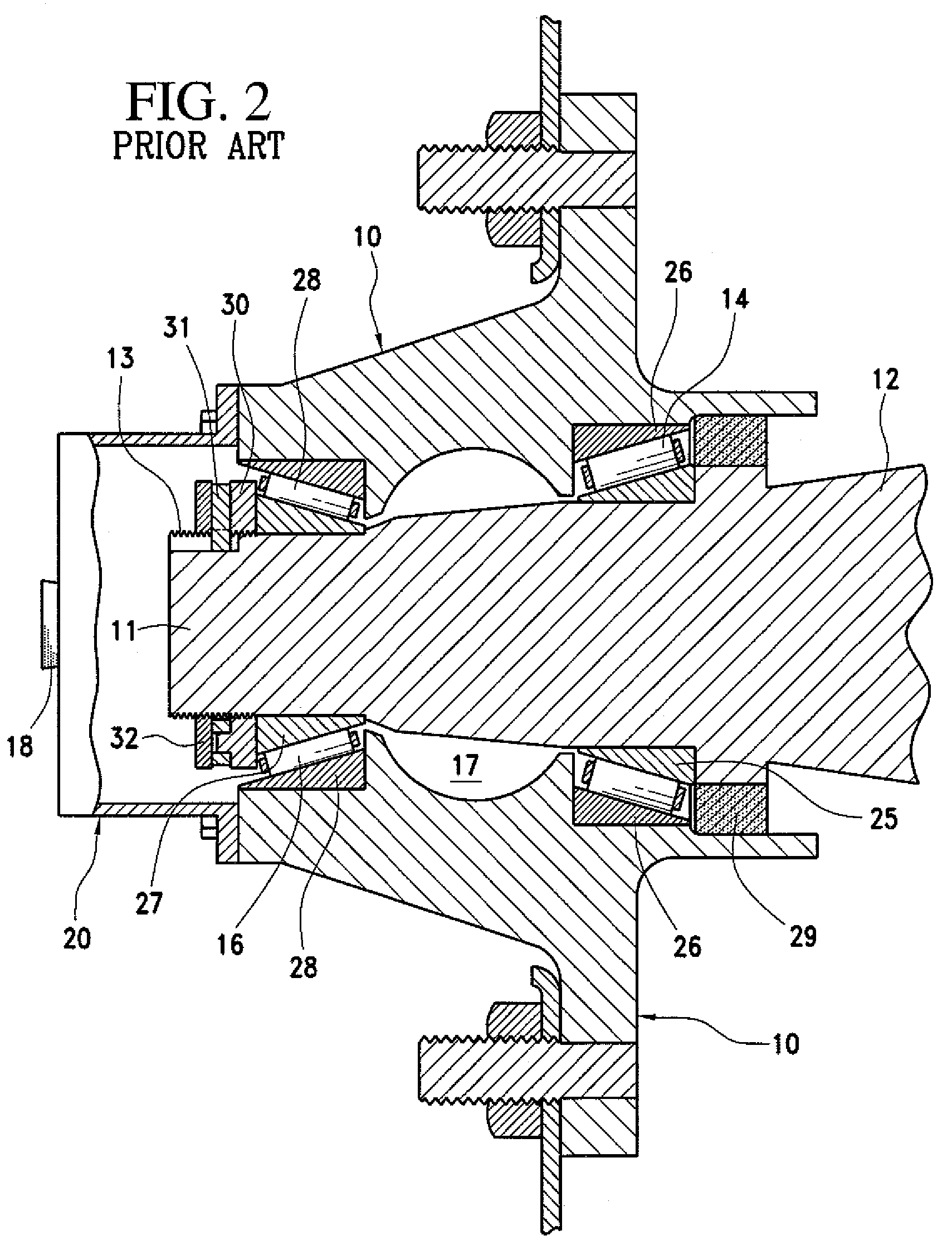

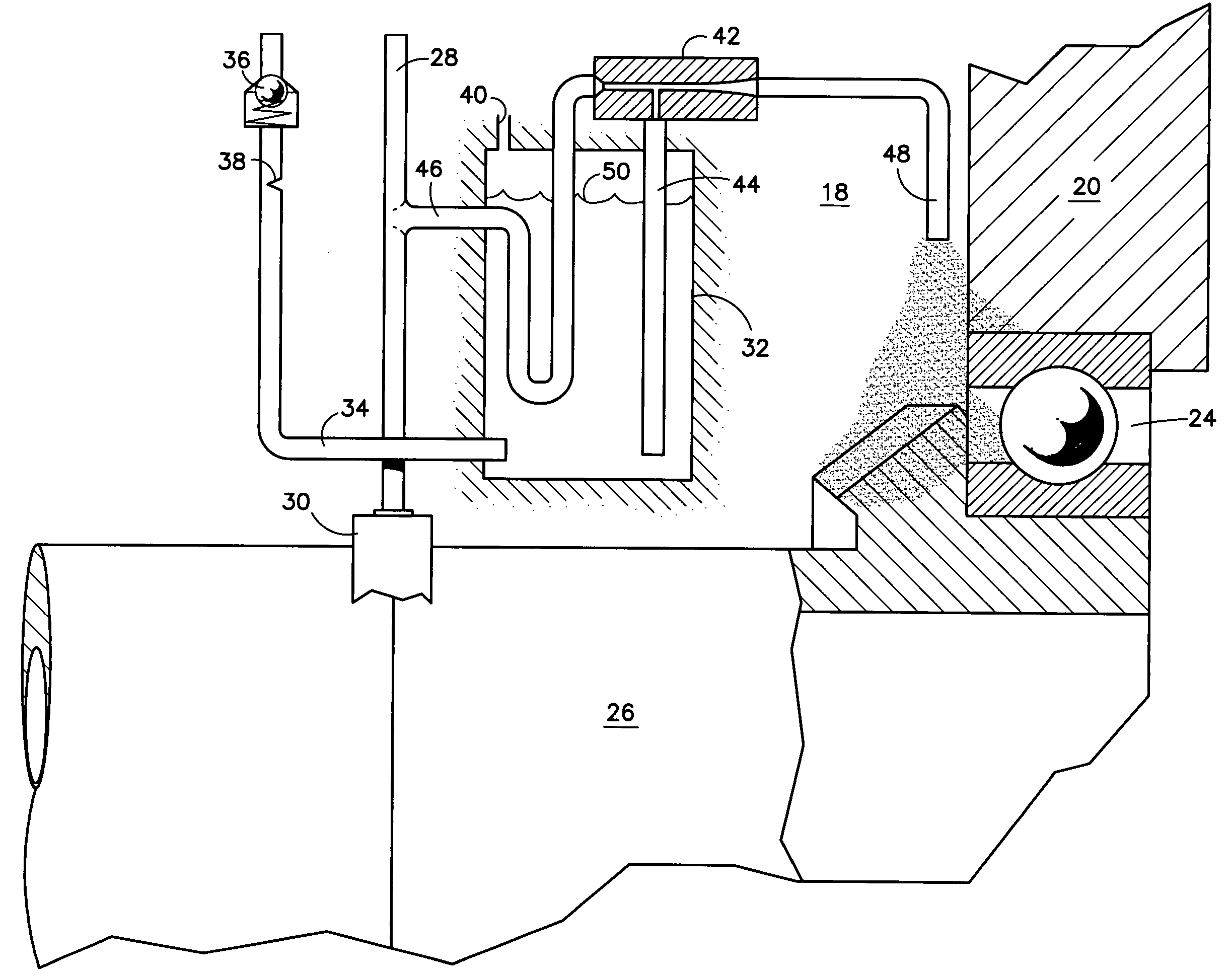

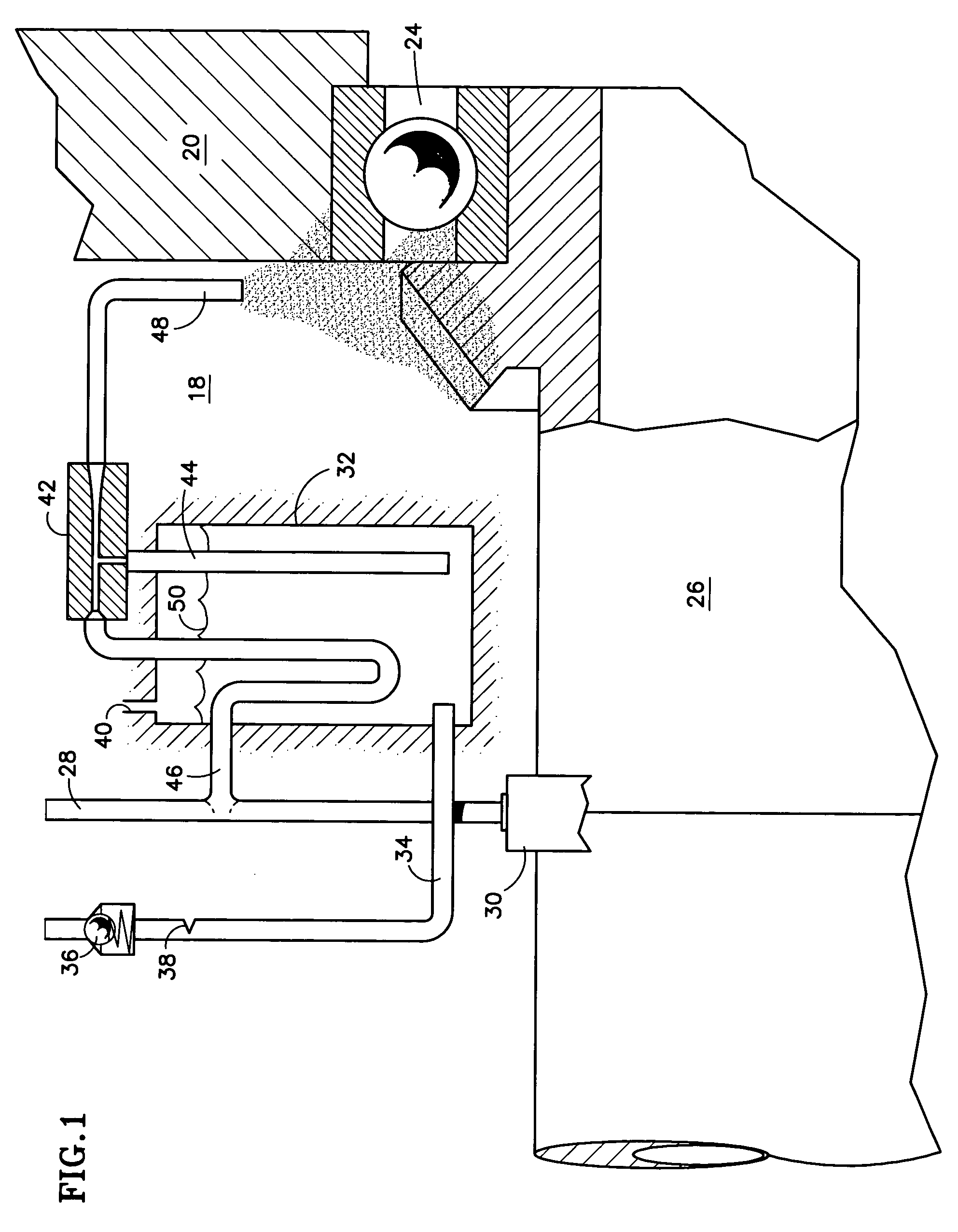

Failure tolerant passive lubrication system

ActiveUS7174997B2Light weightInexpensive and reliableTurbinesRolling contact bearingsHigh pressureNormal conditions

An auxiliary lubrication system for an aircraft turbine engine includes a reservoir 32 of lubricant 50 and a venturi 42 to suction lubricant out of the reservoir and direct an lubricant mist at a bearing 24 or other component requiring lubrication. The venturi is directly connected to a source of motive fluid, such as pressurized air extracted from an engine flowpath 10, and is continuously driven by the motive fluid. The auxiliary system accommodates a failure or malfunction of the primary, high pressure lubrication system. The auxiliary system operates during normal conditions, when the primary system is fully functional. If the primary system fails, the auxiliary system continues to operate for a limited time, until the lubricant in the reservoir is depleted, to provide an lubricant mist to the component being lubricated. The limited-duration lubricant supply allows the aircraft crew time to carry out actions required to safeguard the aircraft and its occupants.

Owner:RTX CORP

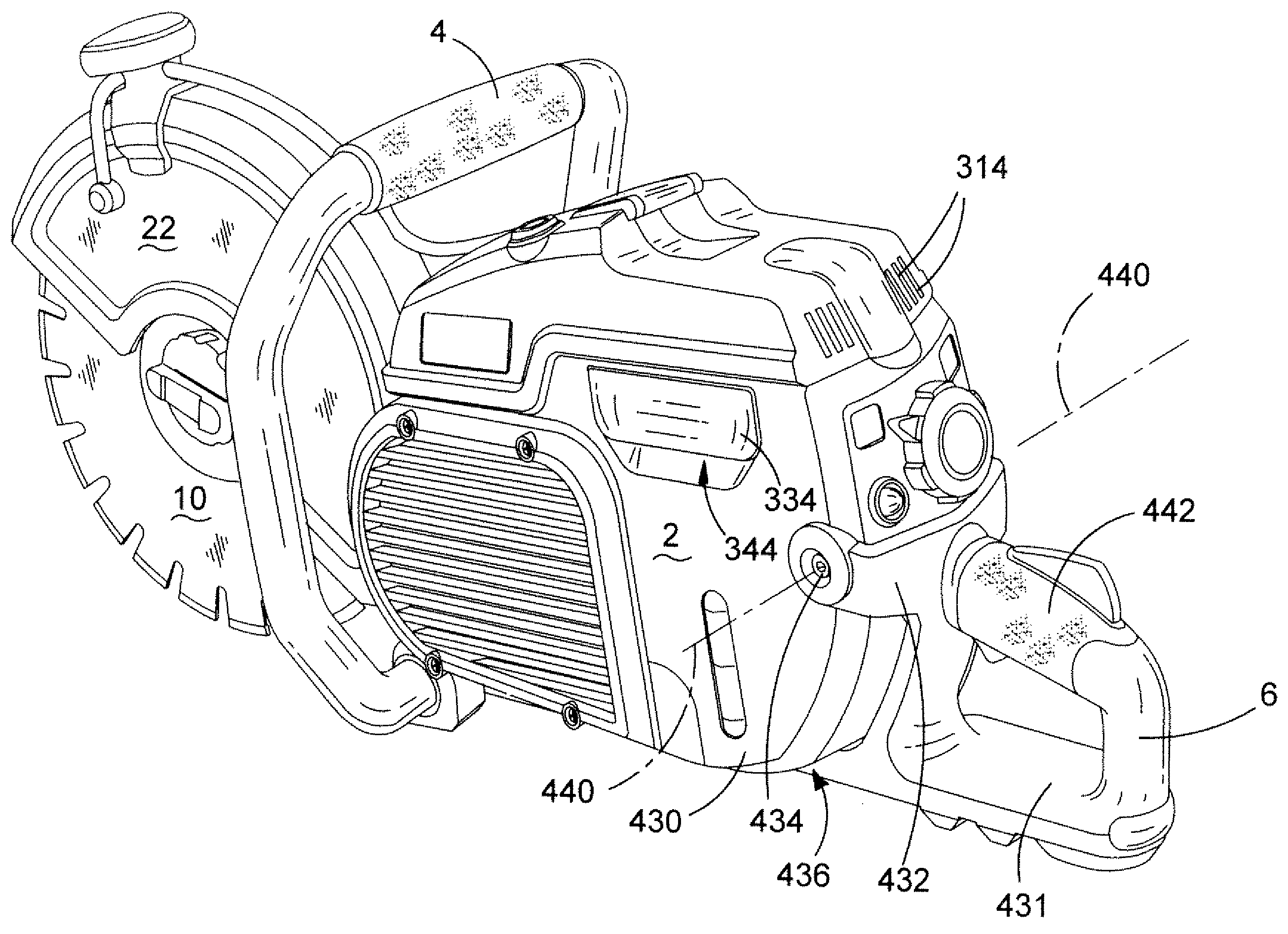

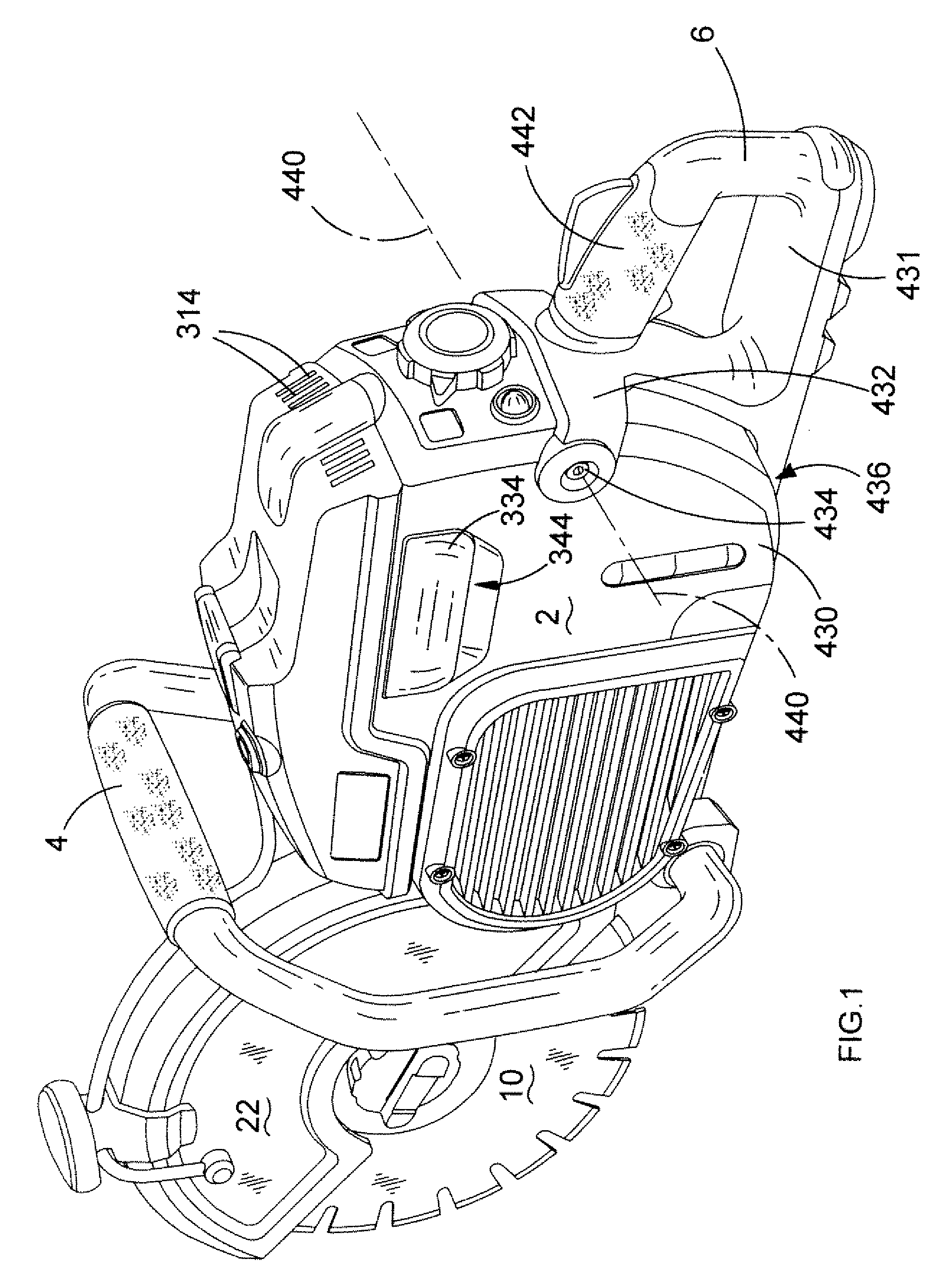

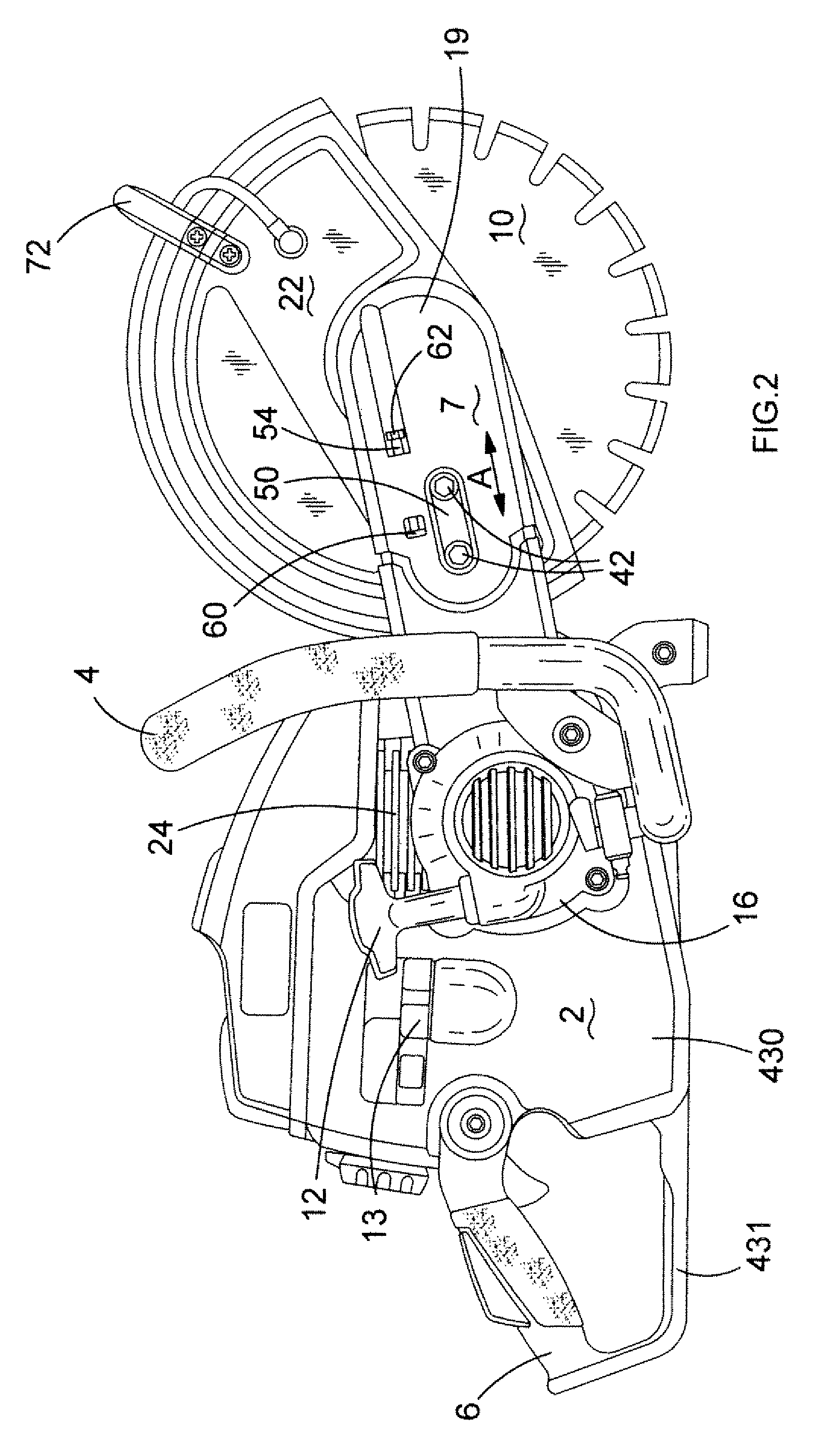

Power cutter

InactiveUS20090019710A1Easy to cleanEasy constructionMetal sawing devicesDispersed particle filtrationAir filtrationAir filter

A power cutter comprising: a housing 2; an engine 24 mounted within the housing 2; a support arm 7 mounted on the housing and which projects forward of the housing; a blade mounting mechanism 70,90, 86, 92 rotatably mounted on the end of the support arm and which is capable of being rotationally driven by the engine 24 when the engine is running; a liquid fuel aeration mechanism 126 to generate aerated fuel for the engine; an air intake 314 for the provision of air for the liquid fuel aeration device 126; an air filtration mechanism 316 to filter the air drawn in from the air intake for the liquid fuel aeration mechanism; a fuel tank 124 for providing fuel to the liquid fuel aeration mechanism; and an exhaust 146 through which the exhaust gases generated by the operation of the engine are expelled; wherein the air filtration mechanism comprises an air filter 320 comprising a plurality of pleats and wherein the air filtration mechanism further comprises an air filter cleaning mechanism comprising a moveable pleat stroker 328; 342; 420 located adjacent the air filter 320 and which is capable of being moved over the pleats of the air filter 320, and which, when moved over the pleats, engages with the pleats and causes the pleats to flex in order to knock any dust trapped on the pleats, off the pleats.

Owner:BLACK & DECKER INC

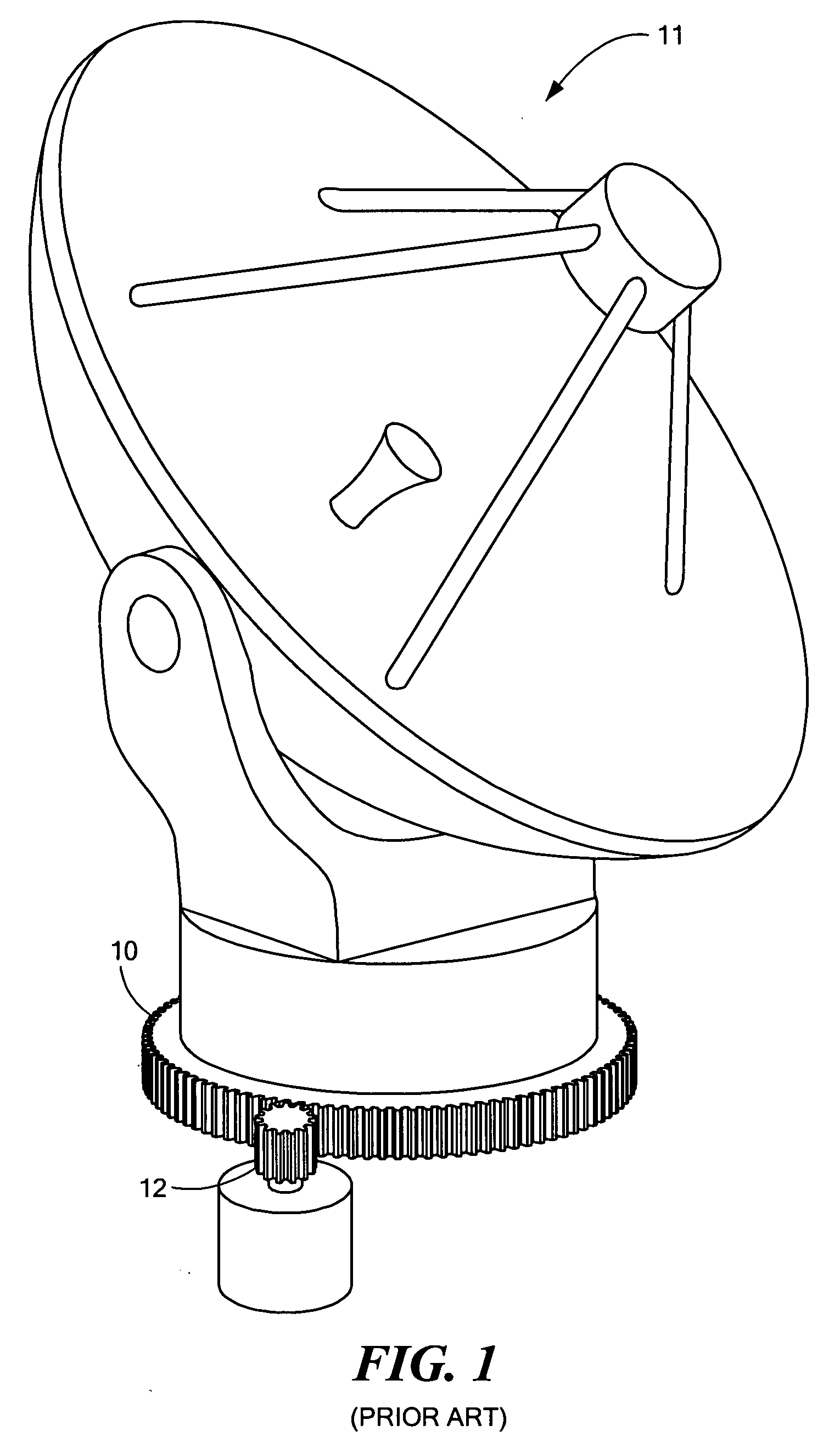

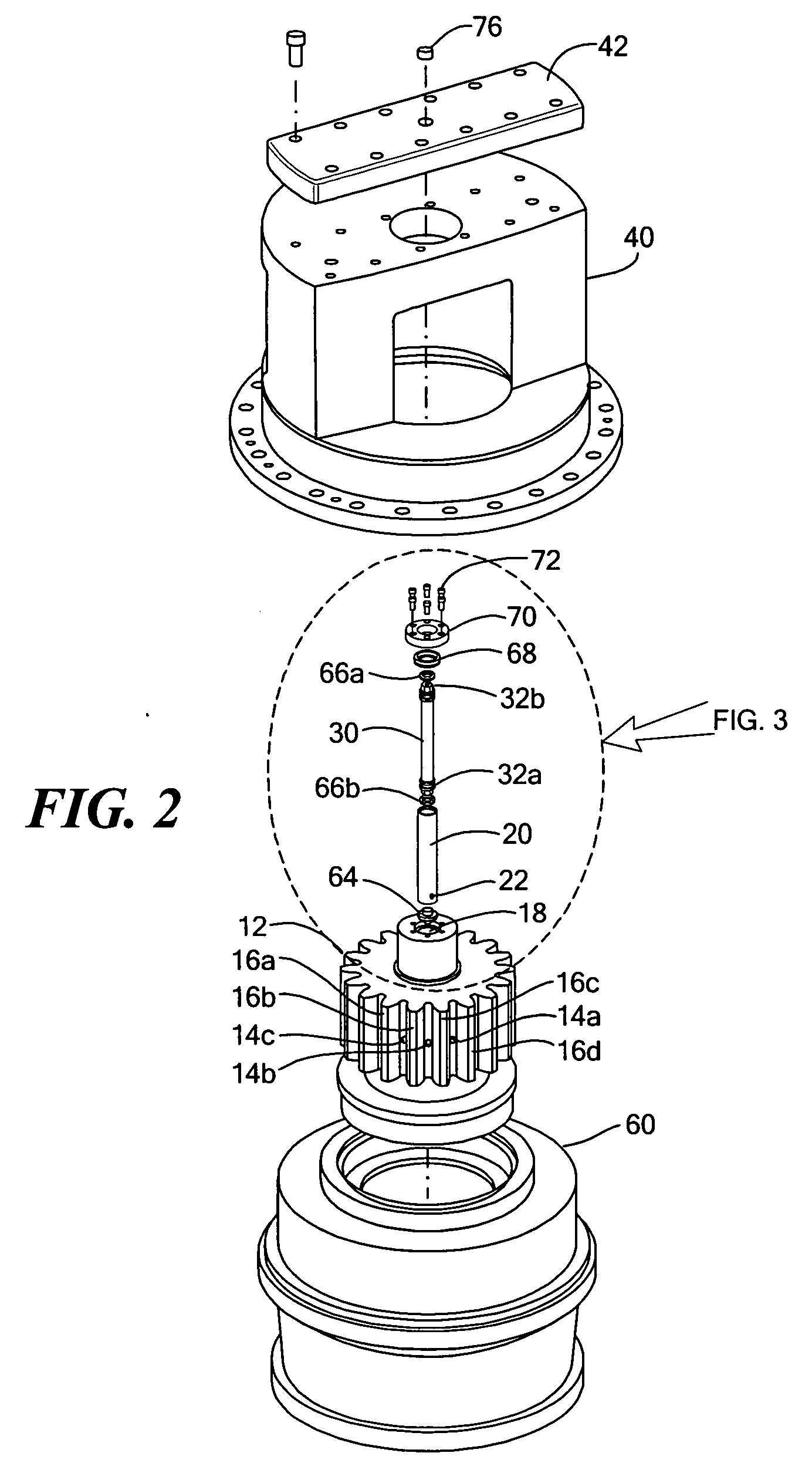

Direct grease injection for large open gearing

ActiveUS20080276743A1Minimize messReduce wearRoller bearingsDrip or splash lubricationGear driveGear wheel

A drive gear includes a plurality of internal radial channels extending between the axial bore and the periphery of the gear, and an axial bore includes a lubricant distribution structure therein to provide lubrication where the teeth of the drive gear mesh with the teeth of a gear driven by the drive gear.

Owner:RAYTHEON CO

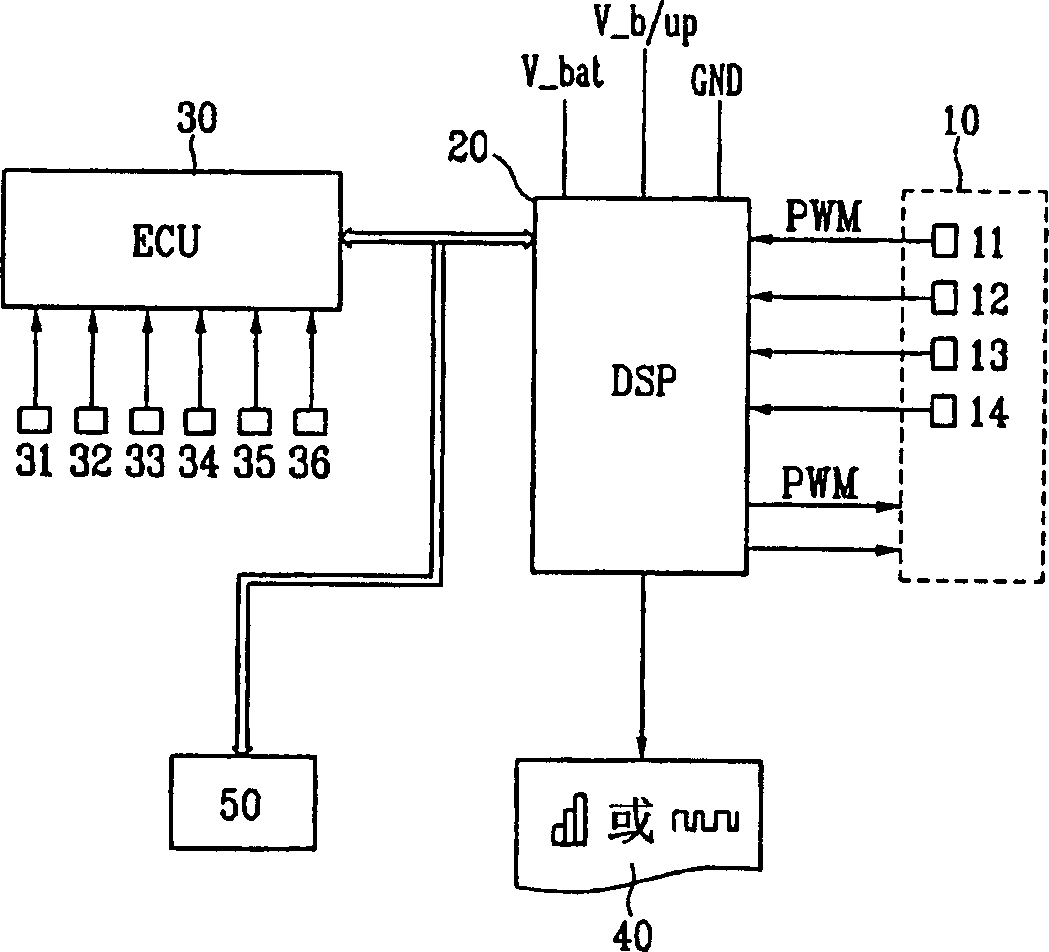

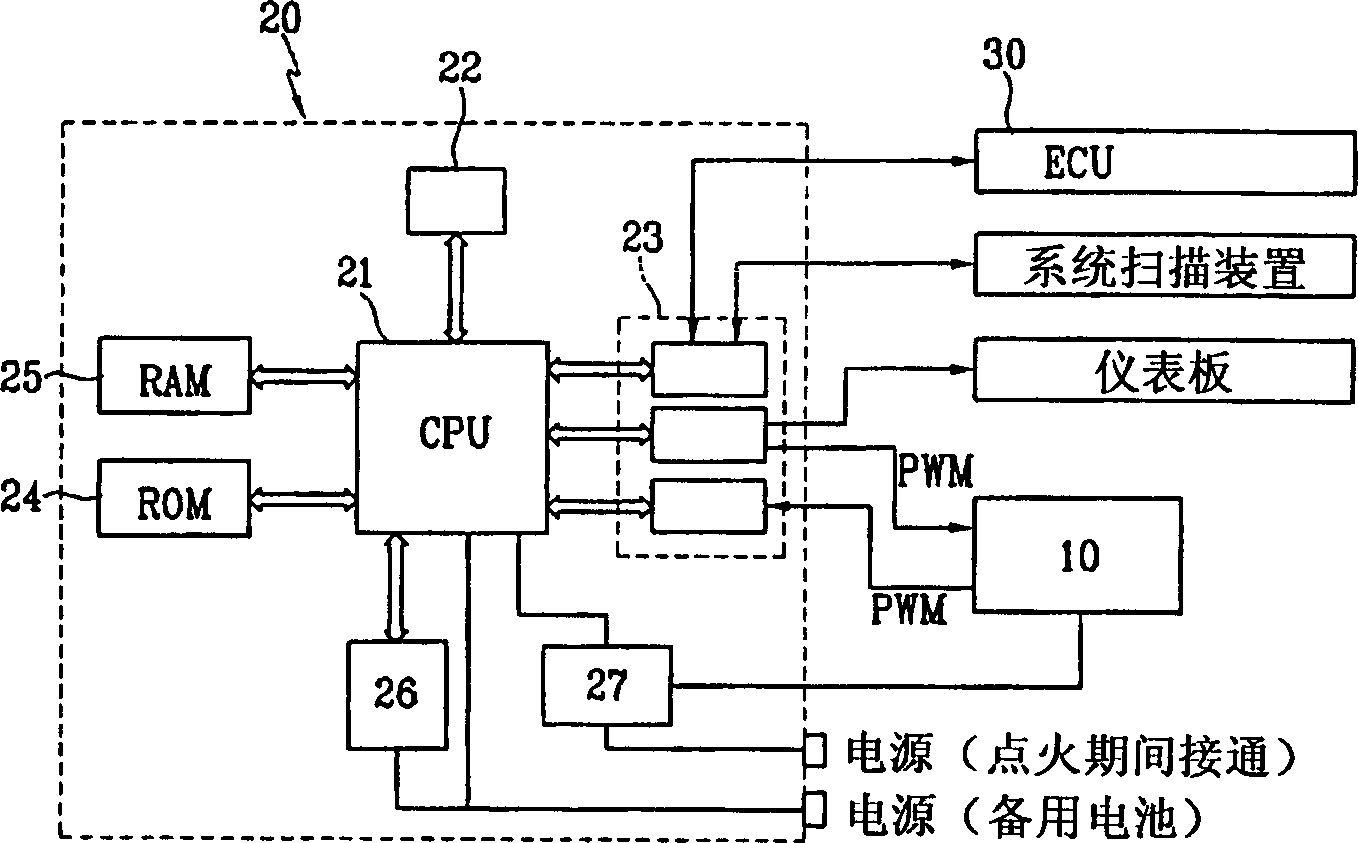

Apparatus, a method, and measuring sensors for scanning states of engine oil

InactiveCN1807850AFlow propertiesThermometers using electric/magnetic elementsEngineeringChemical property

Owner:HYUNDAI MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com