Patents

Literature

192results about "Engine pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

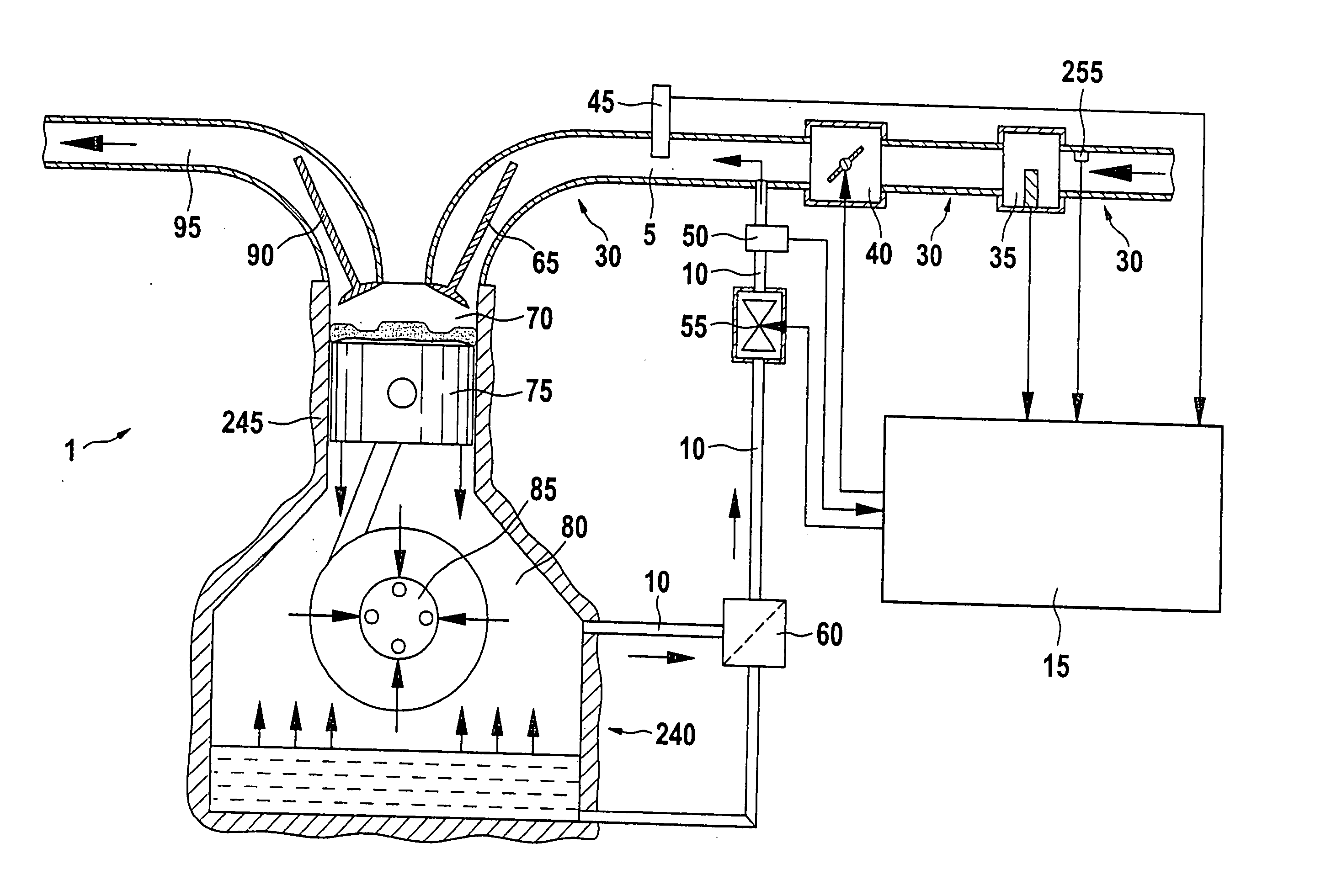

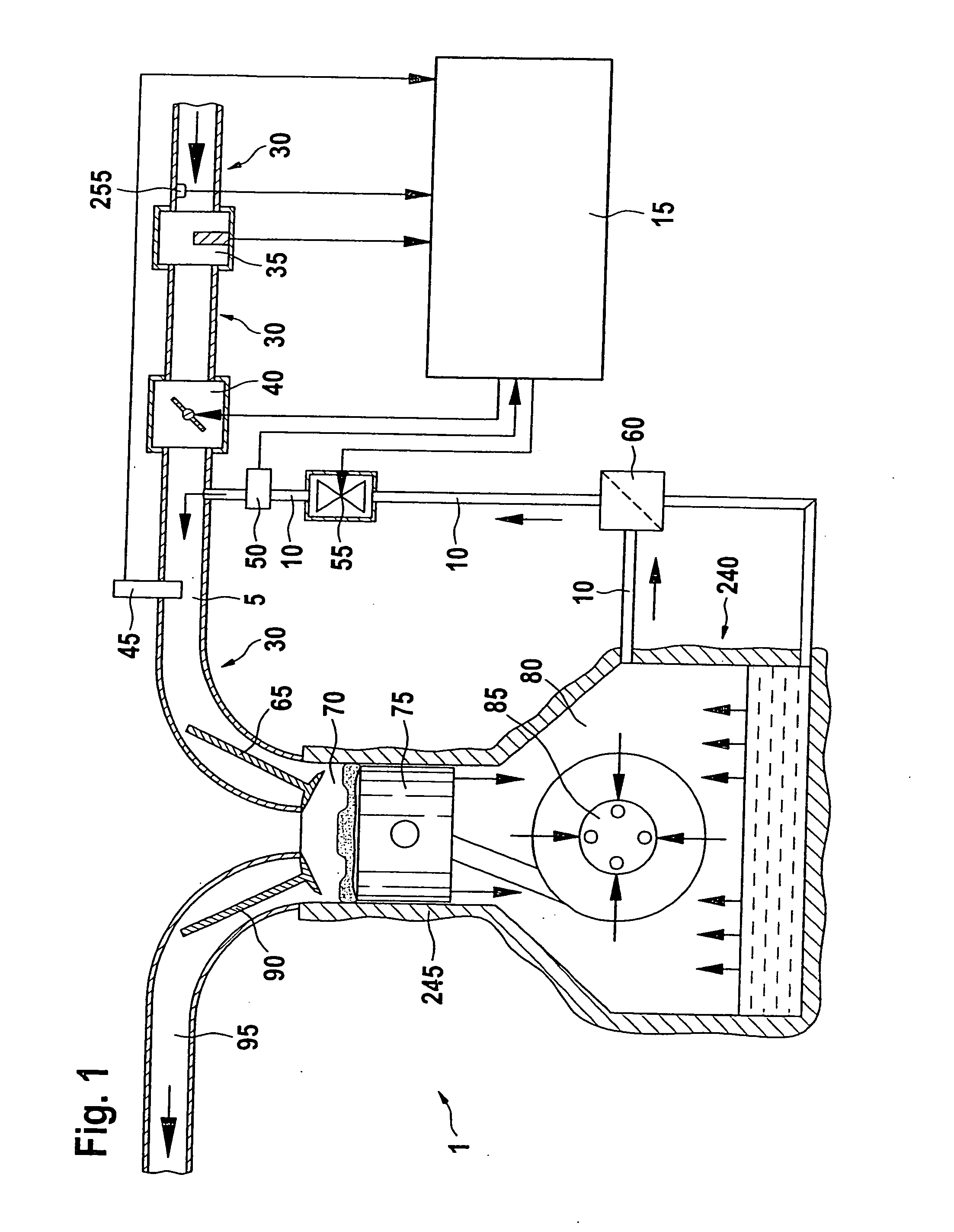

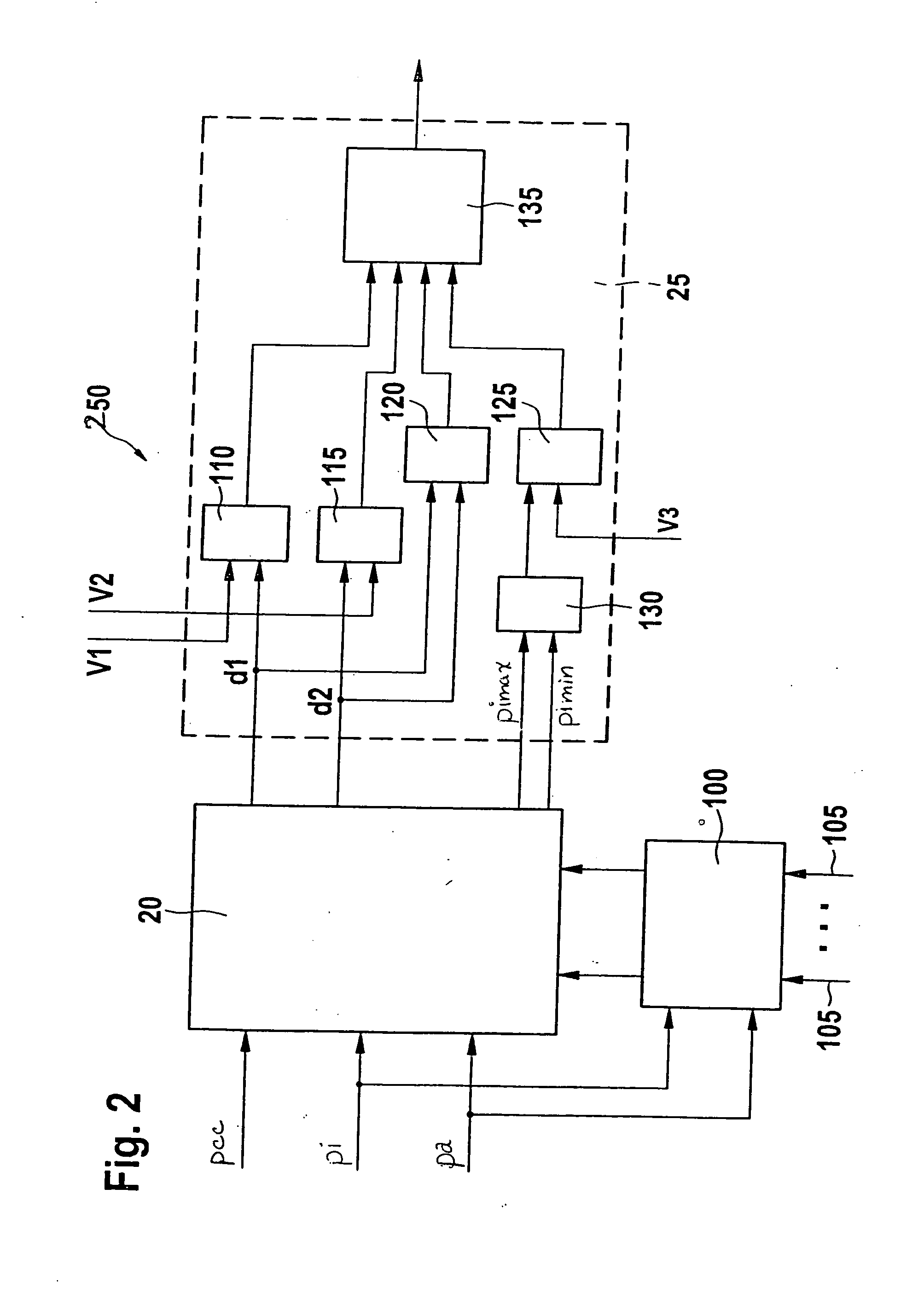

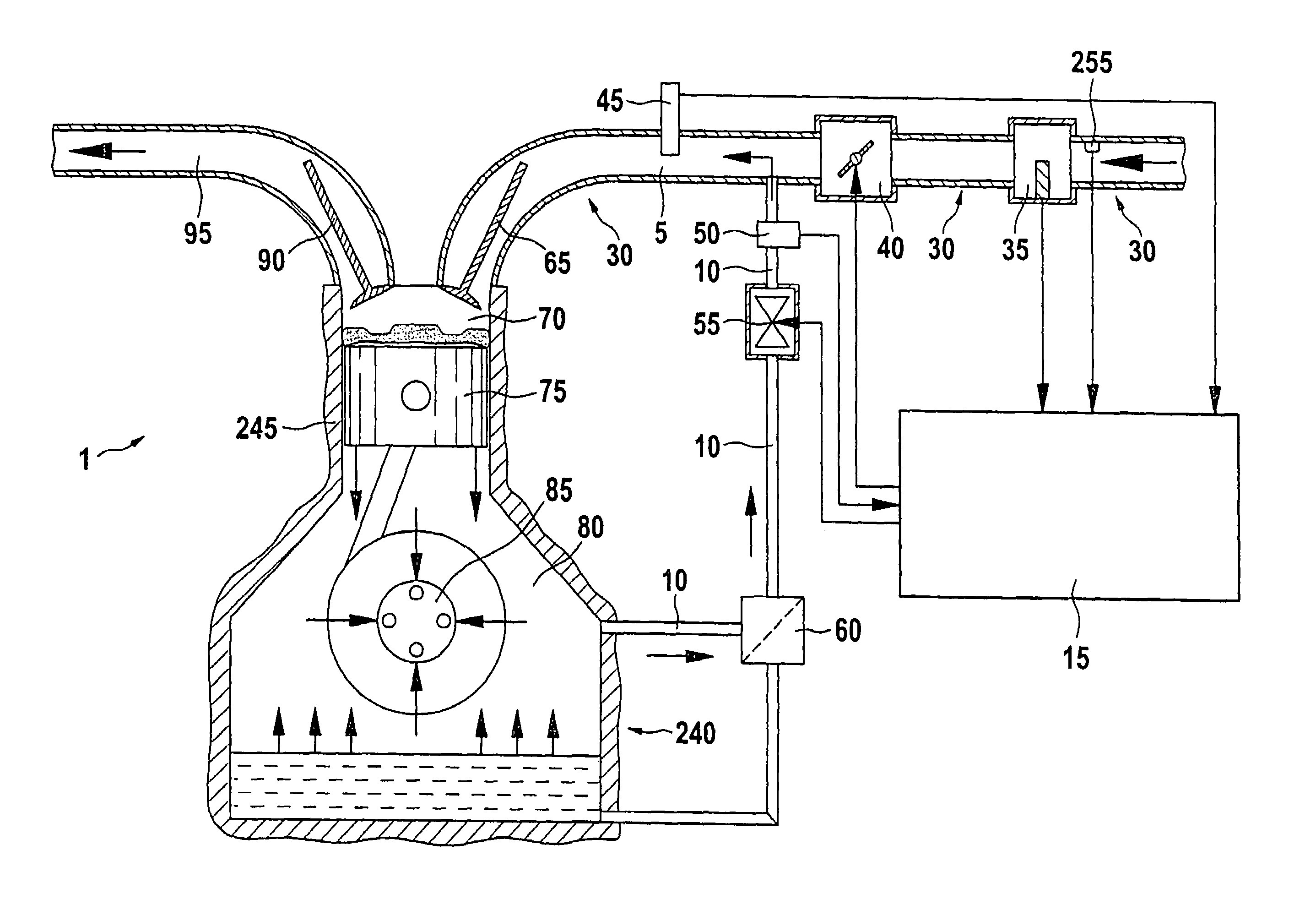

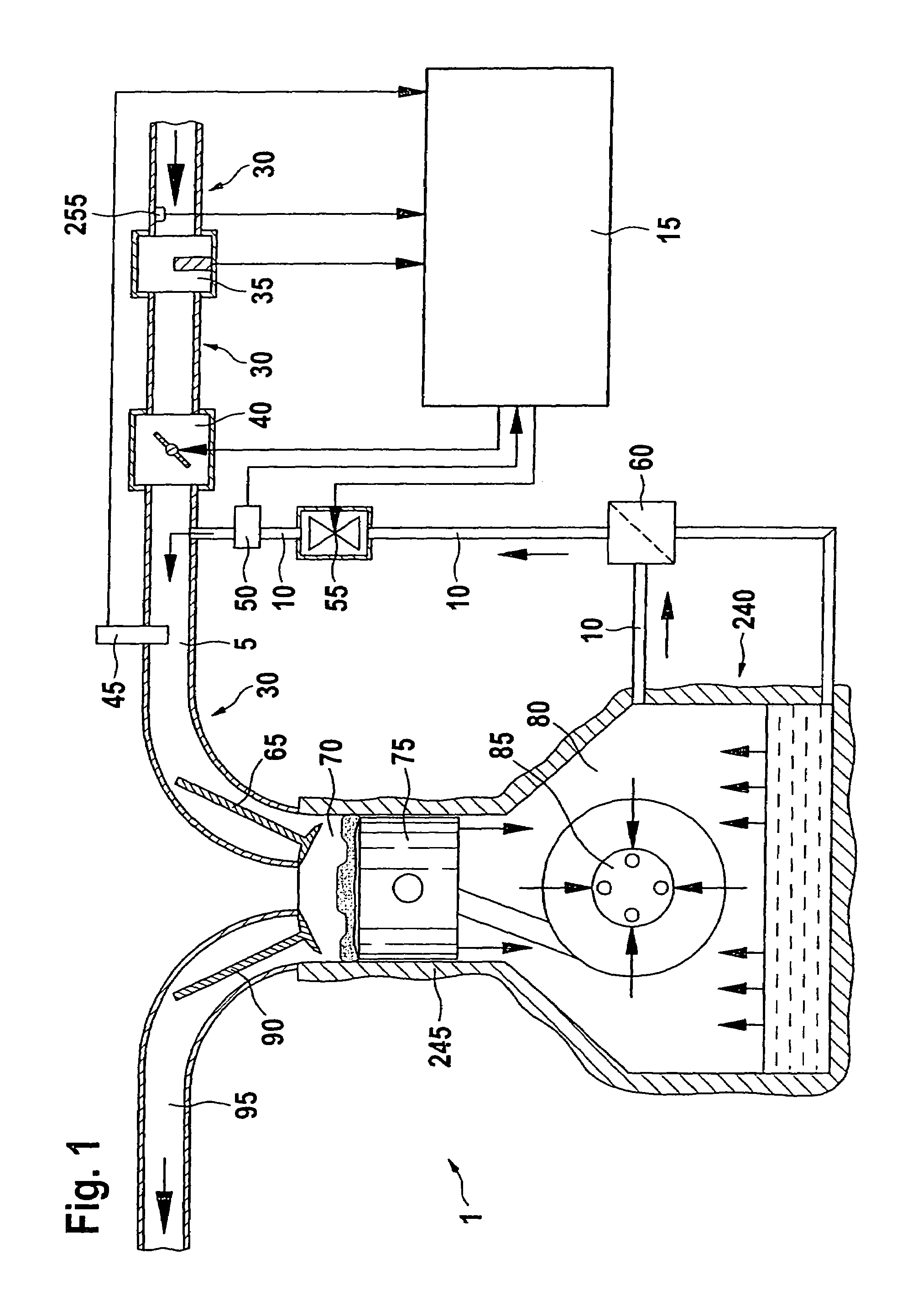

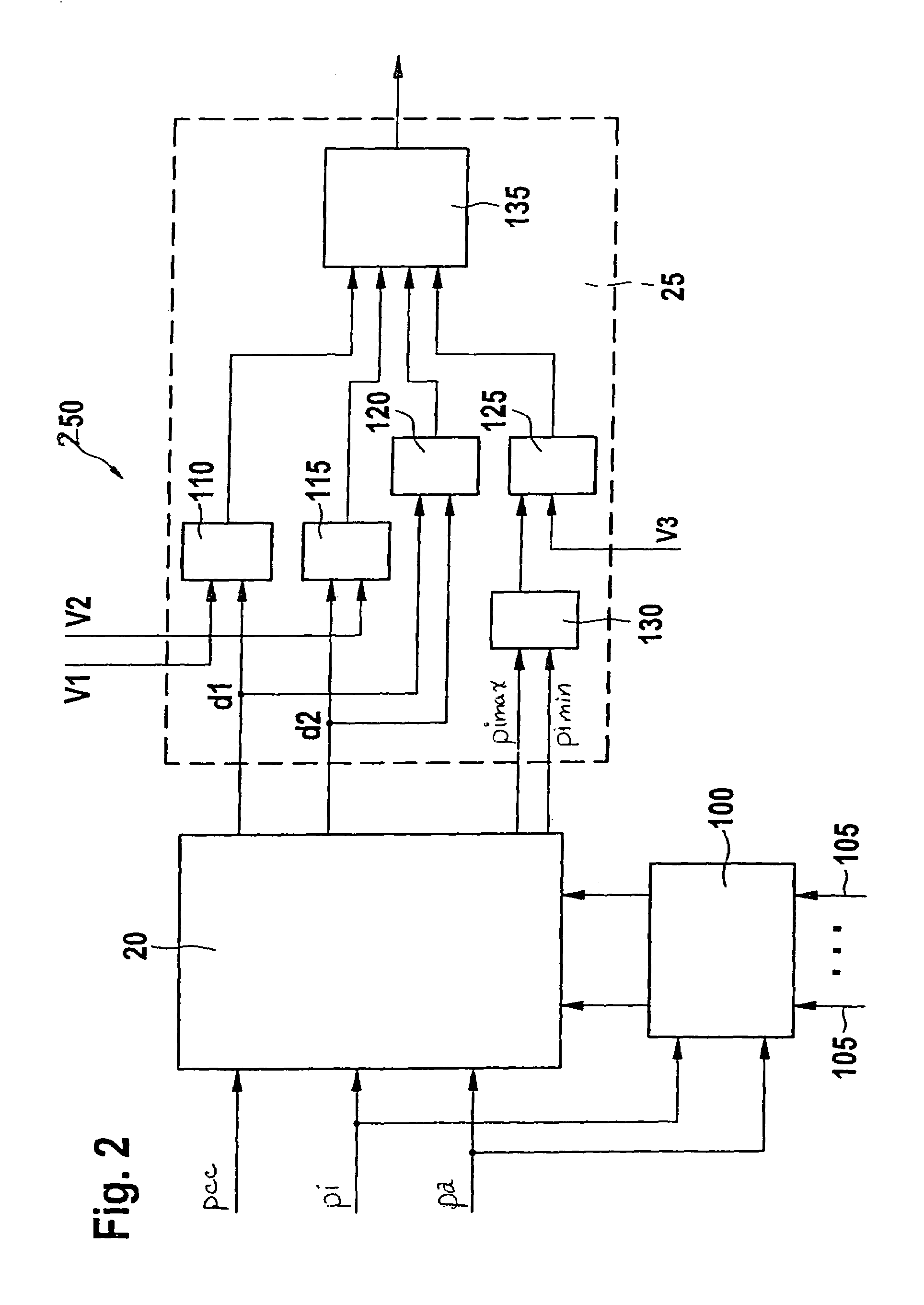

Method and device for operating an internal combustion engine

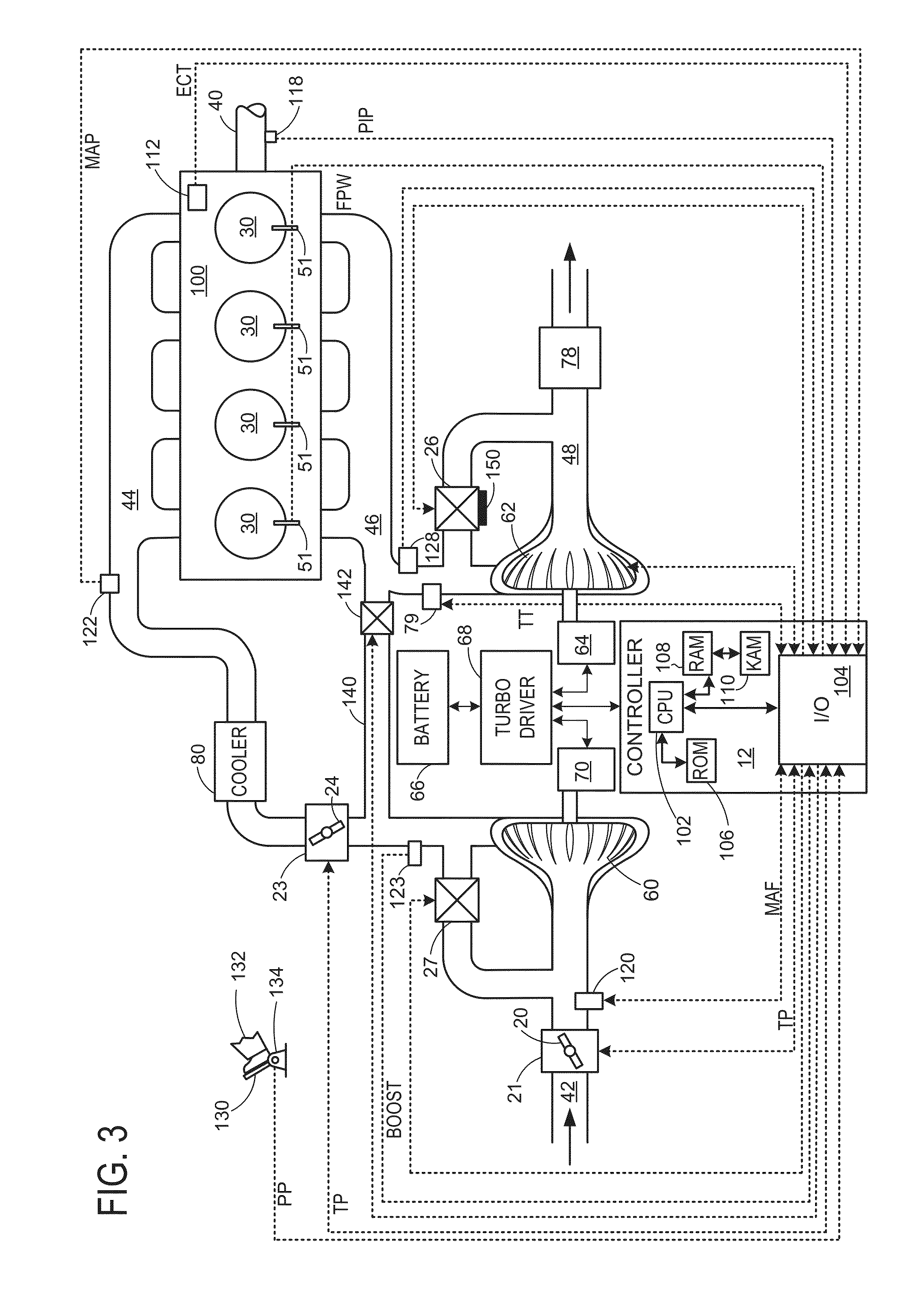

InactiveUS20050022795A1Reliable detectionReduce riskEngine pressureElectrical controlFuel tankAmbient pressure

A method and a device for operating an internal combustion engine having an intake manifold and a ventilation system may allow a reliable and fault-free diagnosis of a fault in the ventilation. The ventilation system may be a tank ventilation or a crankcase ventilation. The ventilation duct is conducted to the intake manifold of the internal combustion engine. At least one pressure differential may be determined between an intake-manifold pressure or an ambient pressure, on the one hand, and a pressure in the ventilation duct, on the other hand. A fault in the ventilation may be diagnosed as a function of the at least one pressure differential.

Owner:ROBERT BOSCH GMBH

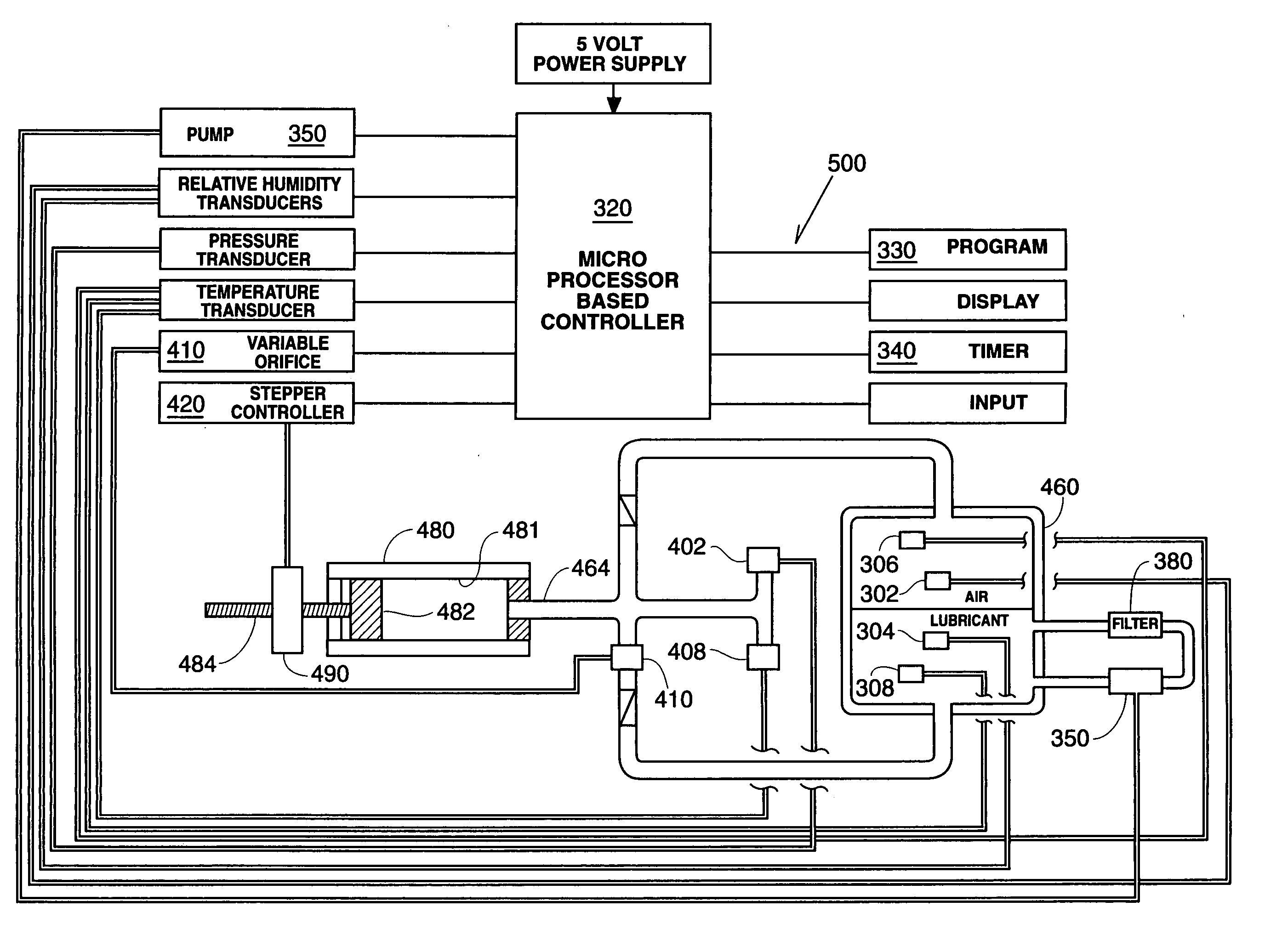

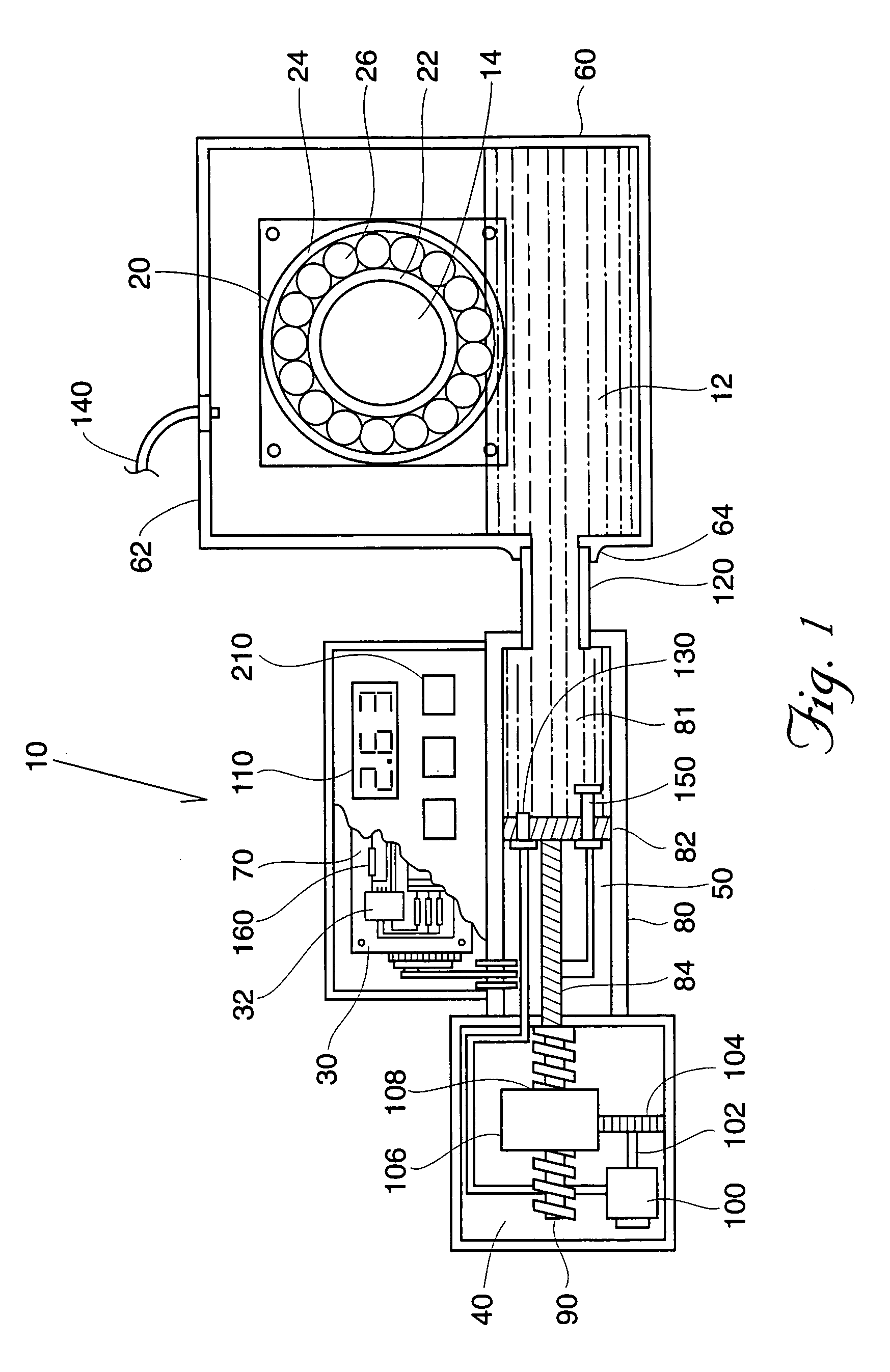

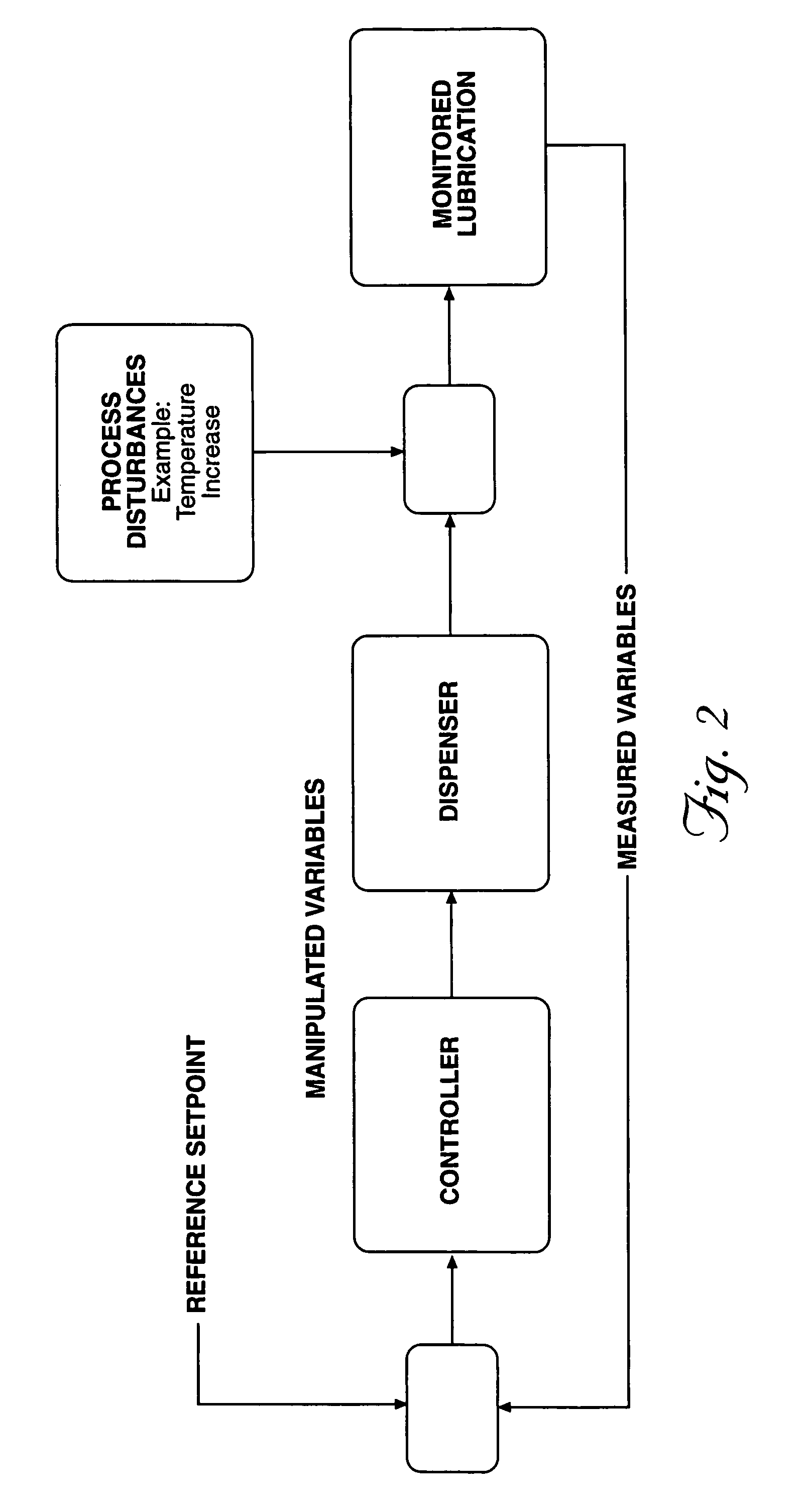

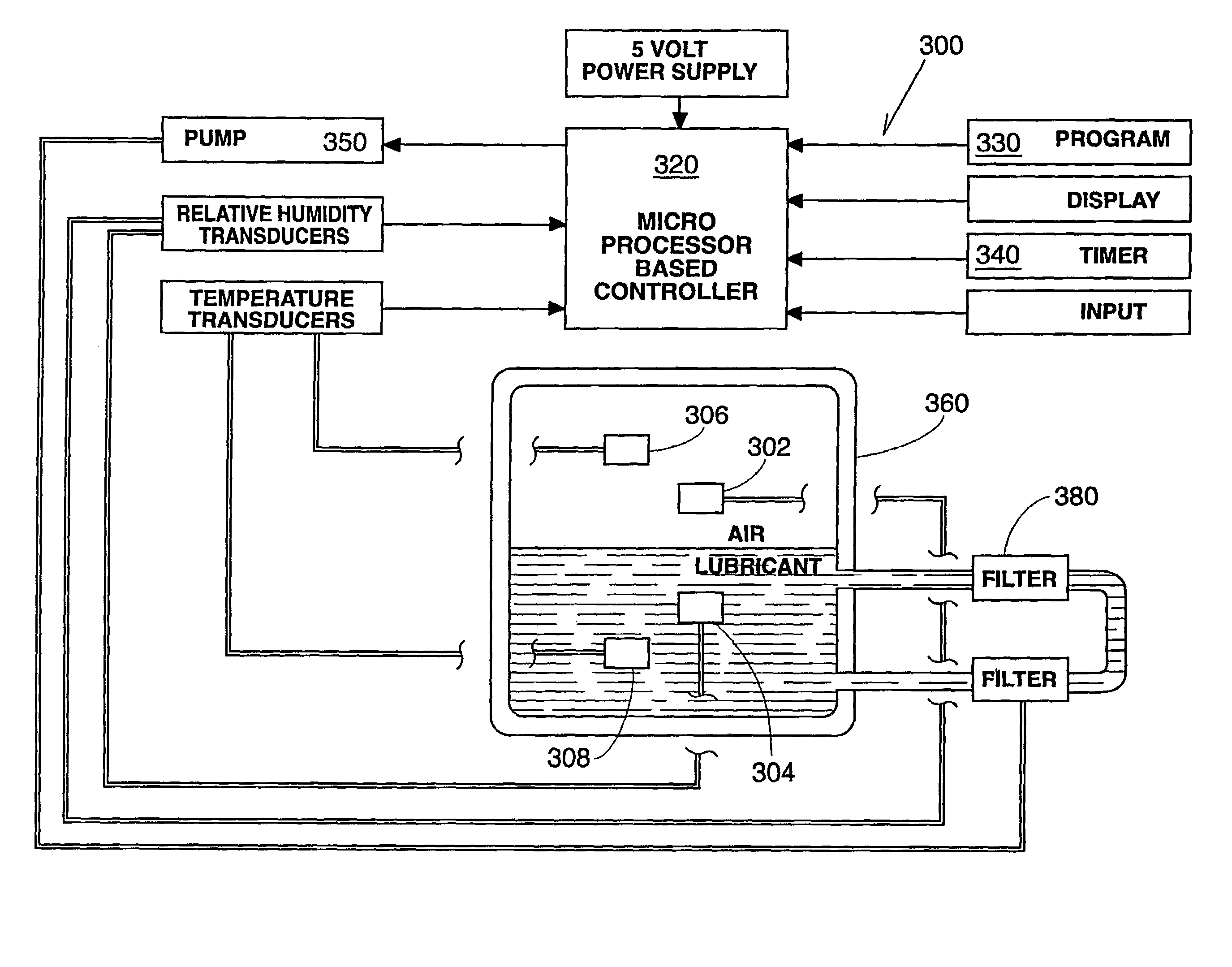

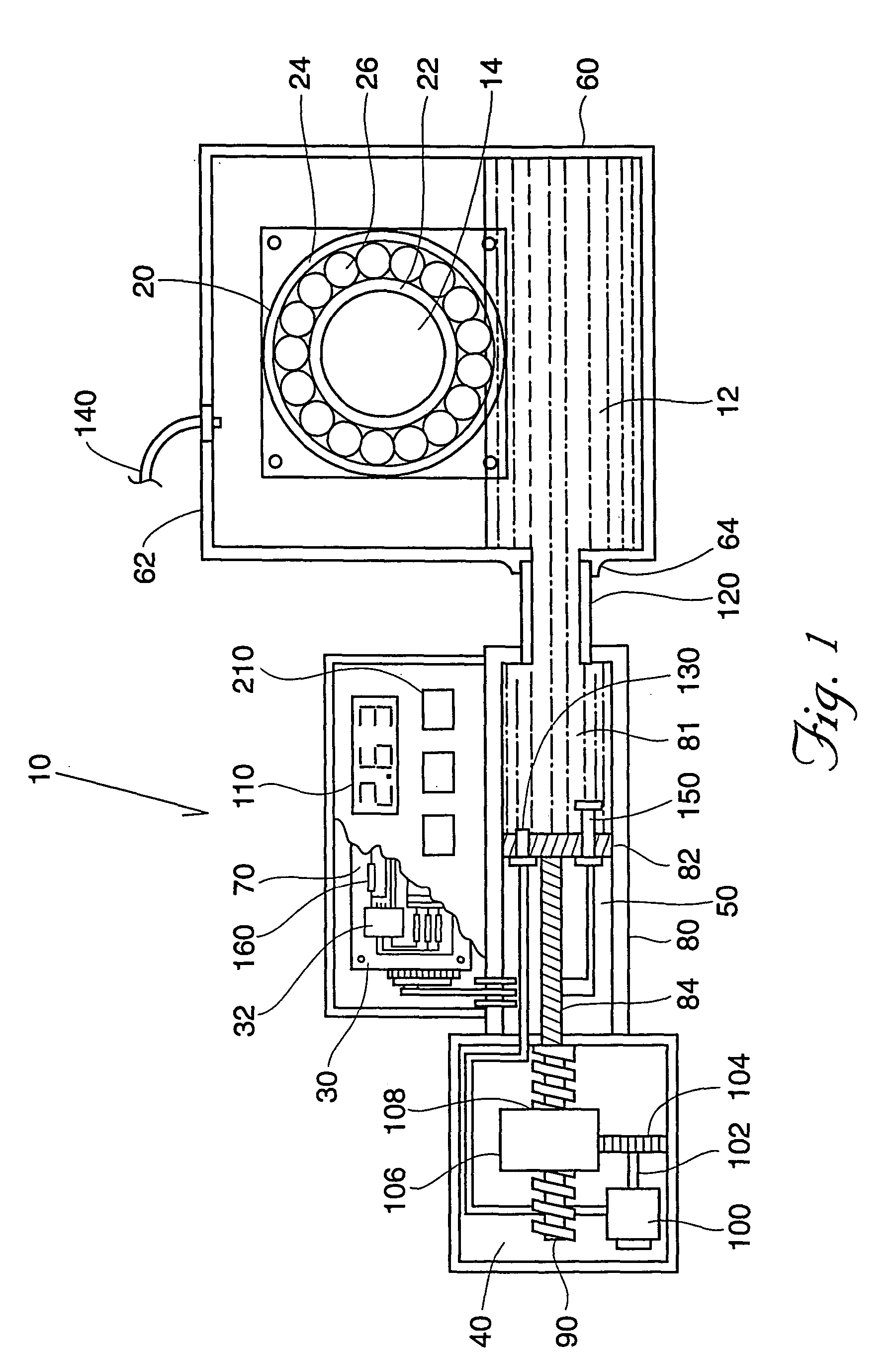

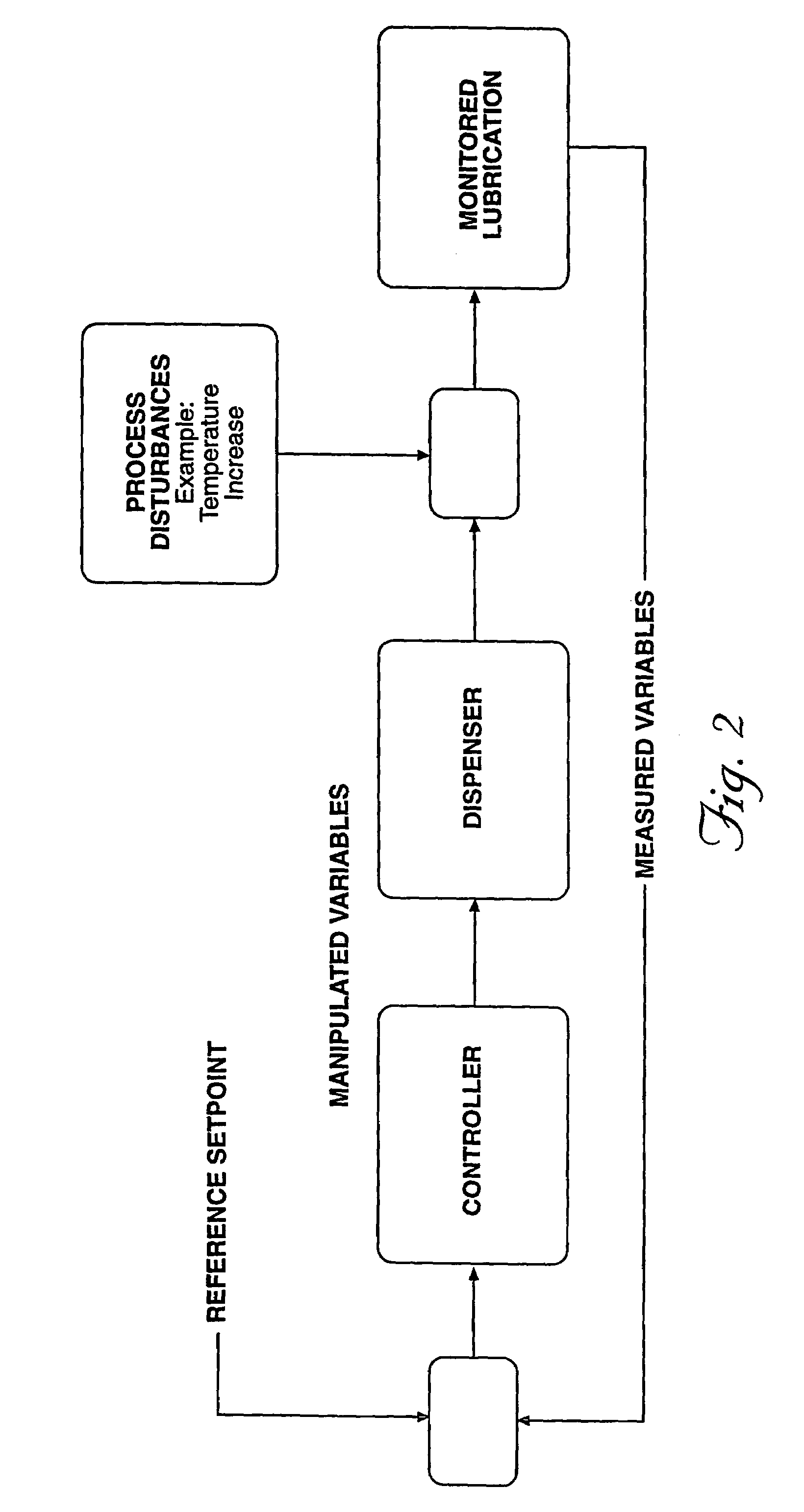

Apparatus and method for lubricant condition control and monitoring

InactiveUS7017712B1More and lessOvercome problemsEngine temperatureEngine pressureProcess engineeringKetone

A volumetric lubricant dispensing apparatus for delivering a precise volume of lubricant, such as oil, to a rotating machine element. The delivery mechanism includes a piston and cylinder assembly. A plurality of sensors are utilized to record operating conditions of the machine, element, environment, and lubricant. The apparatus is controlled either manually or with the aid of a controller unit such as a microprocessor. The output from each sensor is inputted into the microprocessor wherein an algorithm computes an responsive output. The responsive output is sent to the piston and cylinder assembly, which maintains an optimum lubricant condition within the reservoir wherein a rotating machine element located. Alternatively, for the purpose of qualitative control, the present invention may be described as a system intended for controlling lubricants, both mineral (natural) and synthetic based by measuring the condition characteristics of the lubricant. Some condition characteristics may include water or moisture content (the content could be any liquid, e.g., solvents like ketones are known to change condition characteristics like viscosity) and viscosity. Viscosity is related to temperature, therefore, temperature correlation to viscosity is helpful to provide relative indications for condition characteristics like lubricant flow.

Owner:TRICO CORP

Apparatus and method for lubricant condition control and monitoring

A plurality of sensors are utilized to record operating conditions of the machine, element, environment, and lubricant. The apparatus is controlled either manually or with the aid of a controller unit such as a microprocessor. A stand-alone humidity sensor mechanism is disclosed, in which signal process circuitry is electrically coupled to a humidity sensor, designed to be attached to the mechanism to be monitored so that it is juxtaposed in the atmosphere above the lubricant material that is being monitored.

Owner:TRICO CORP

Method and device for operating an internal combustion engine

InactiveUS7080547B2Reduce riskLess diagnosticEngine pressureElectrical controlExternal combustion engineAmbient pressure

Owner:ROBERT BOSCH GMBH

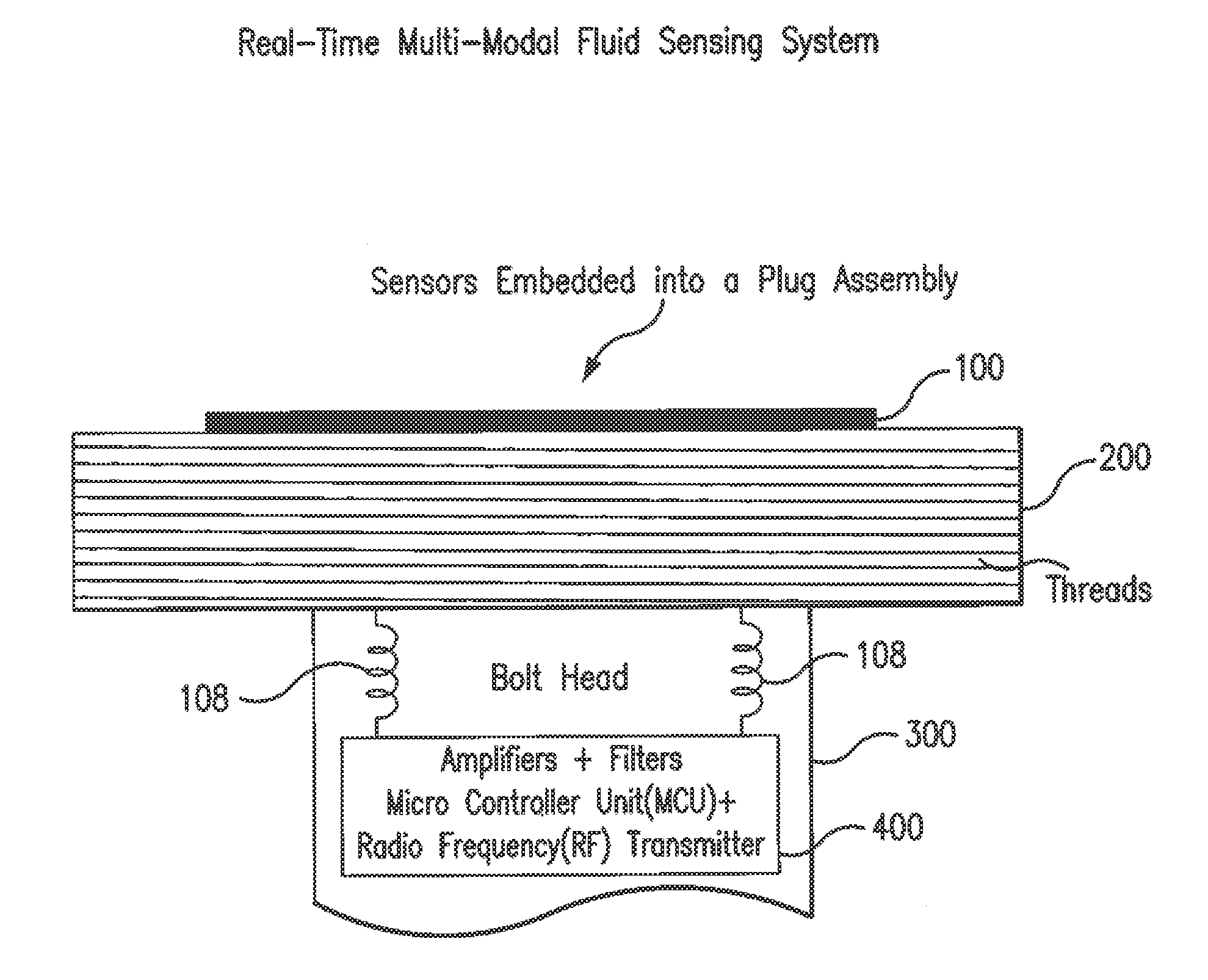

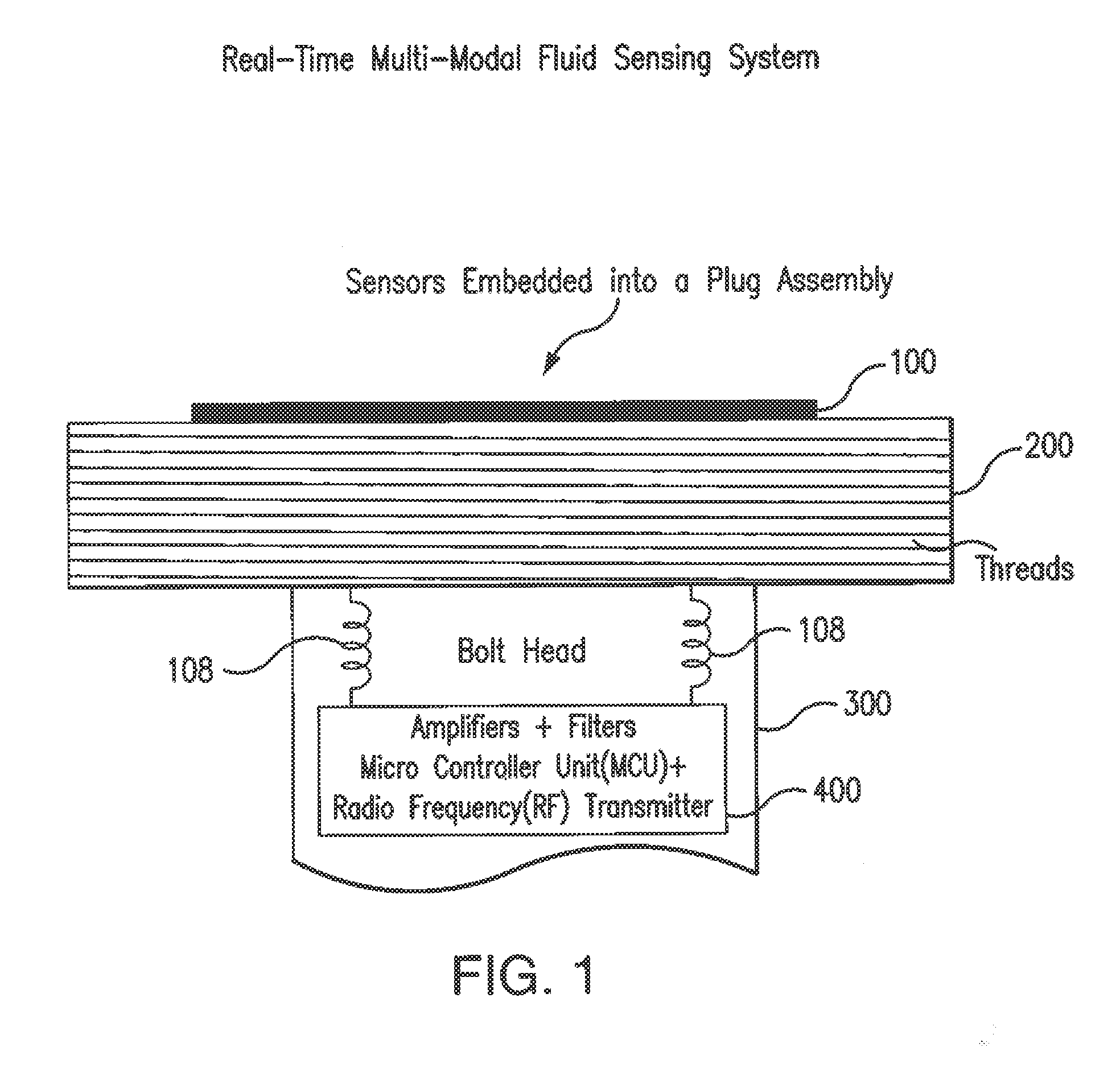

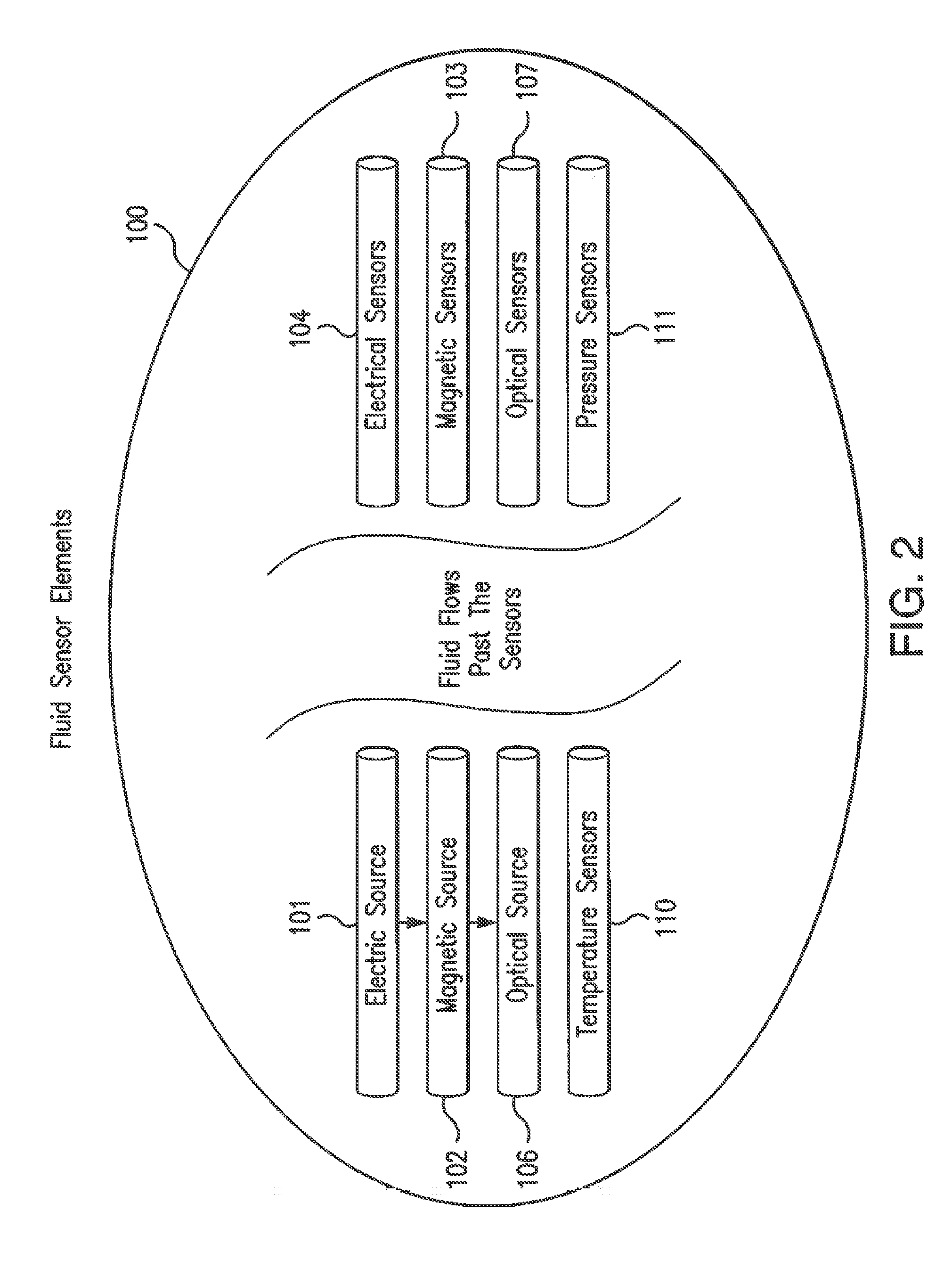

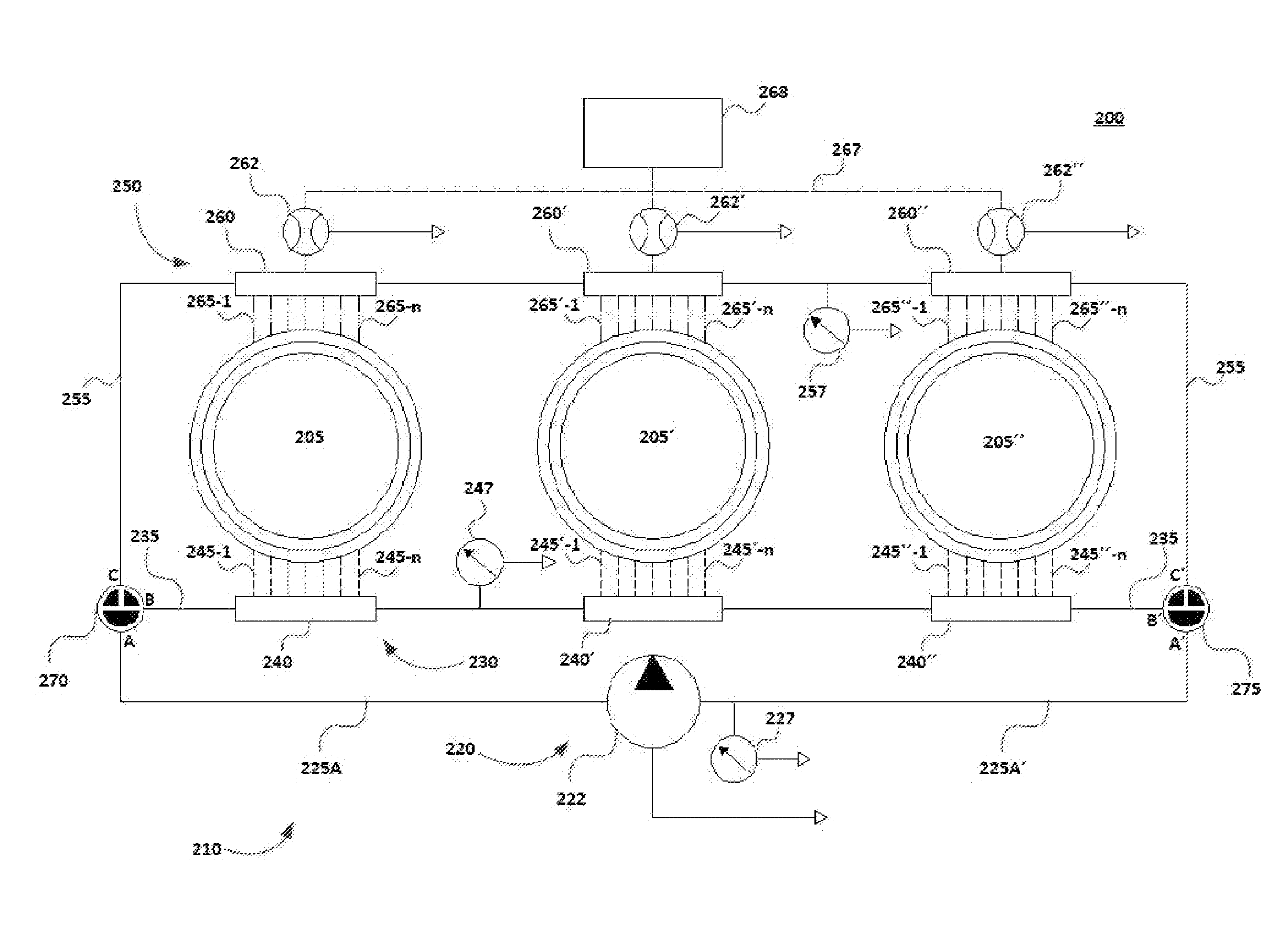

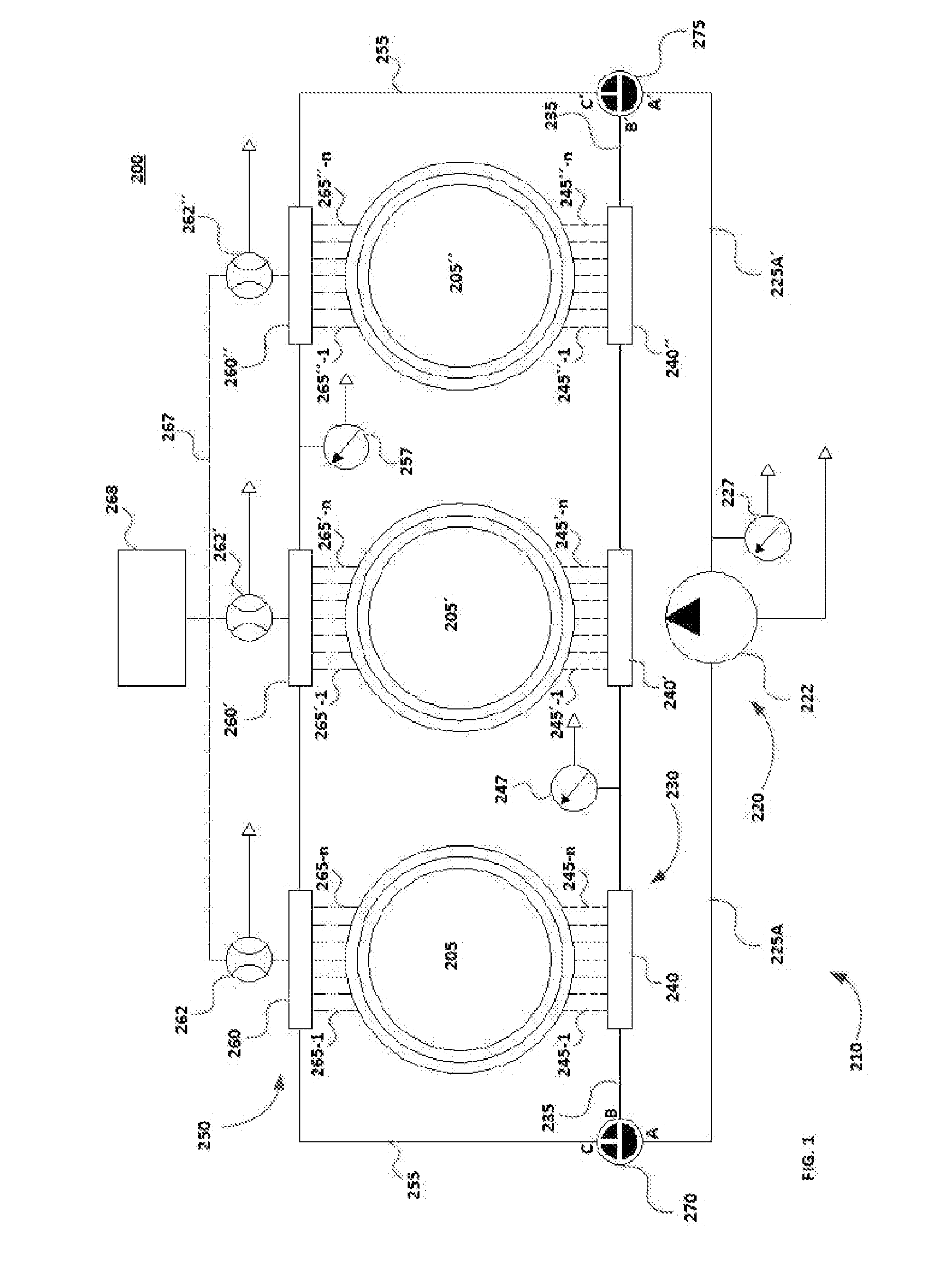

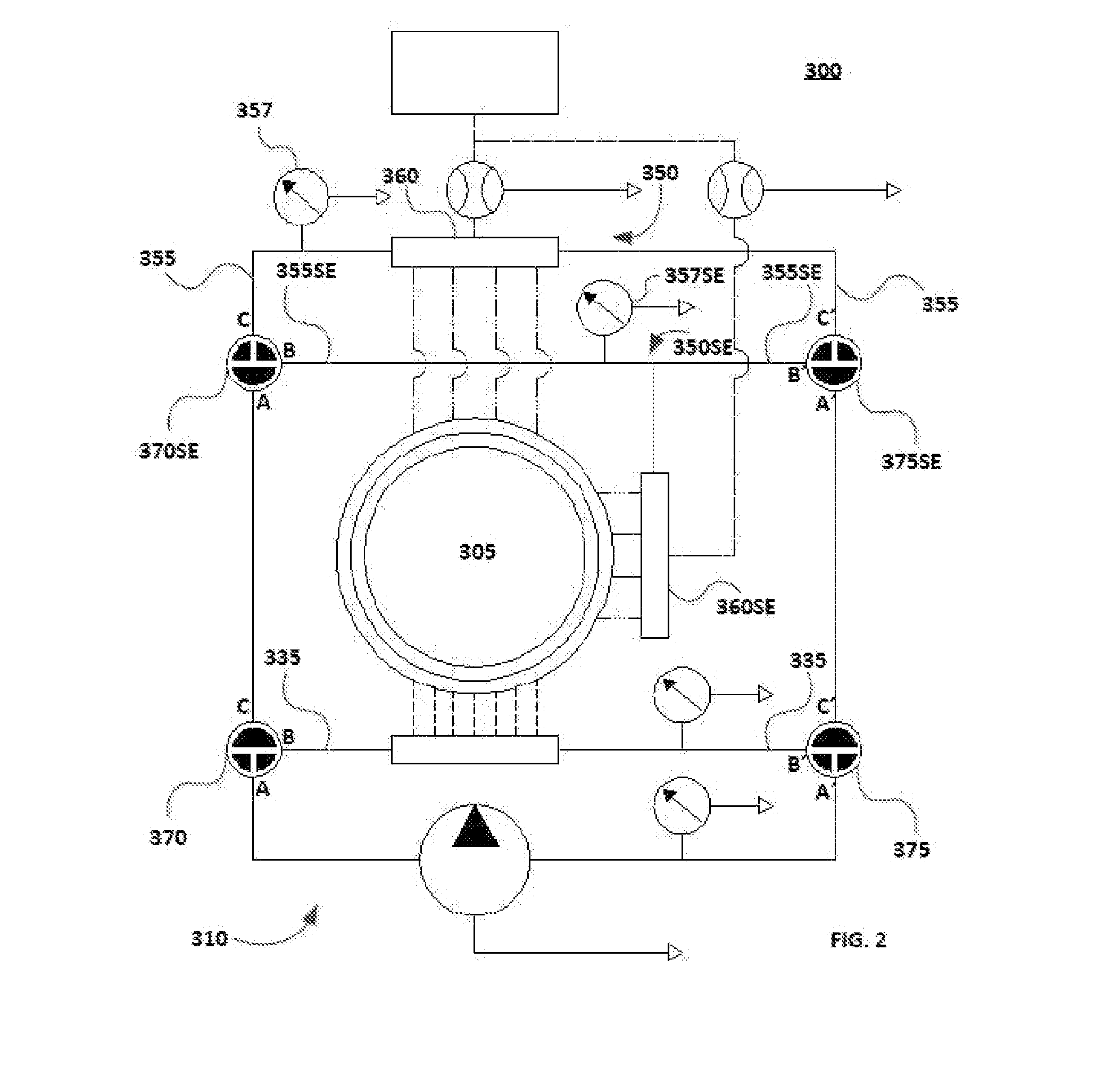

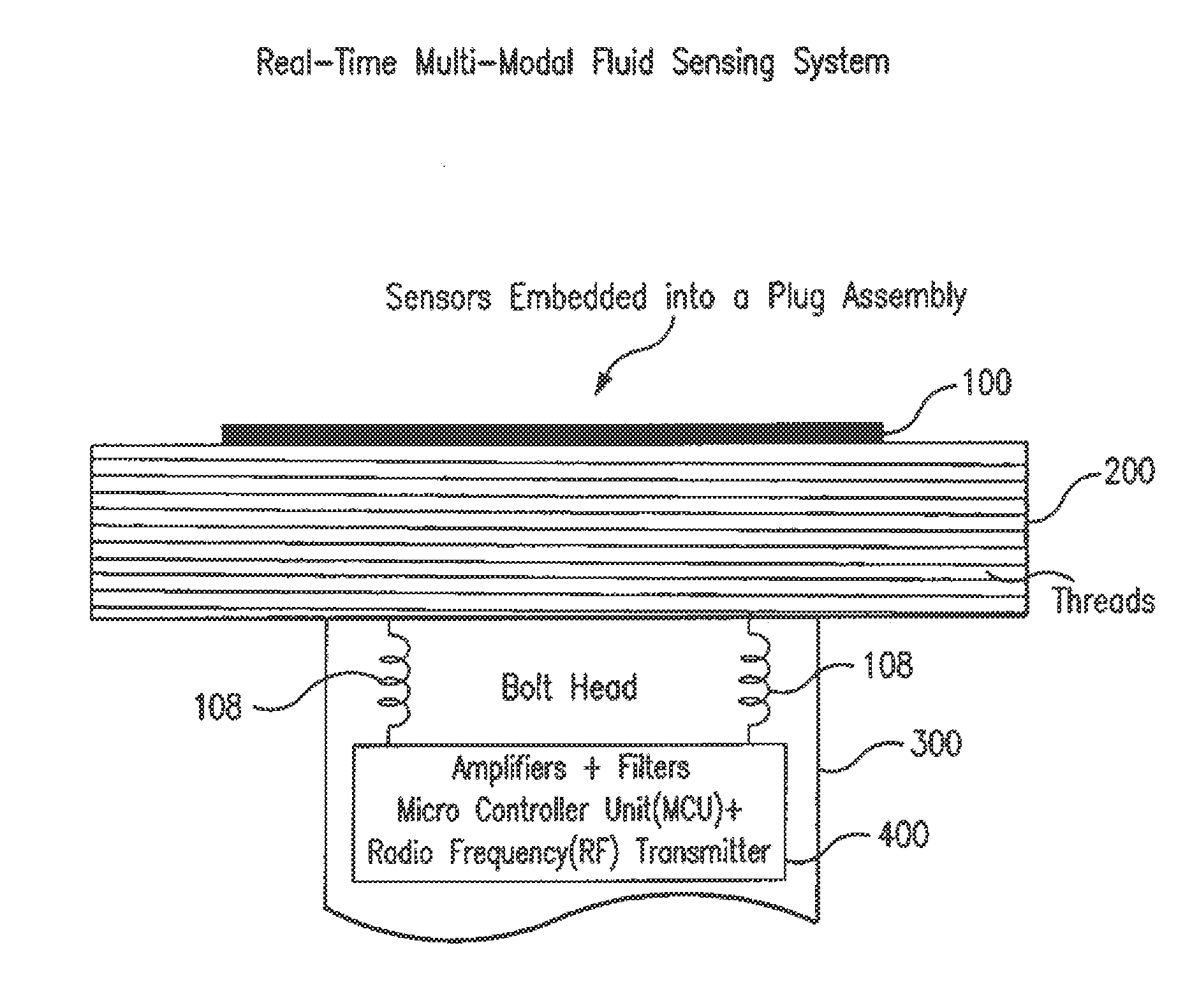

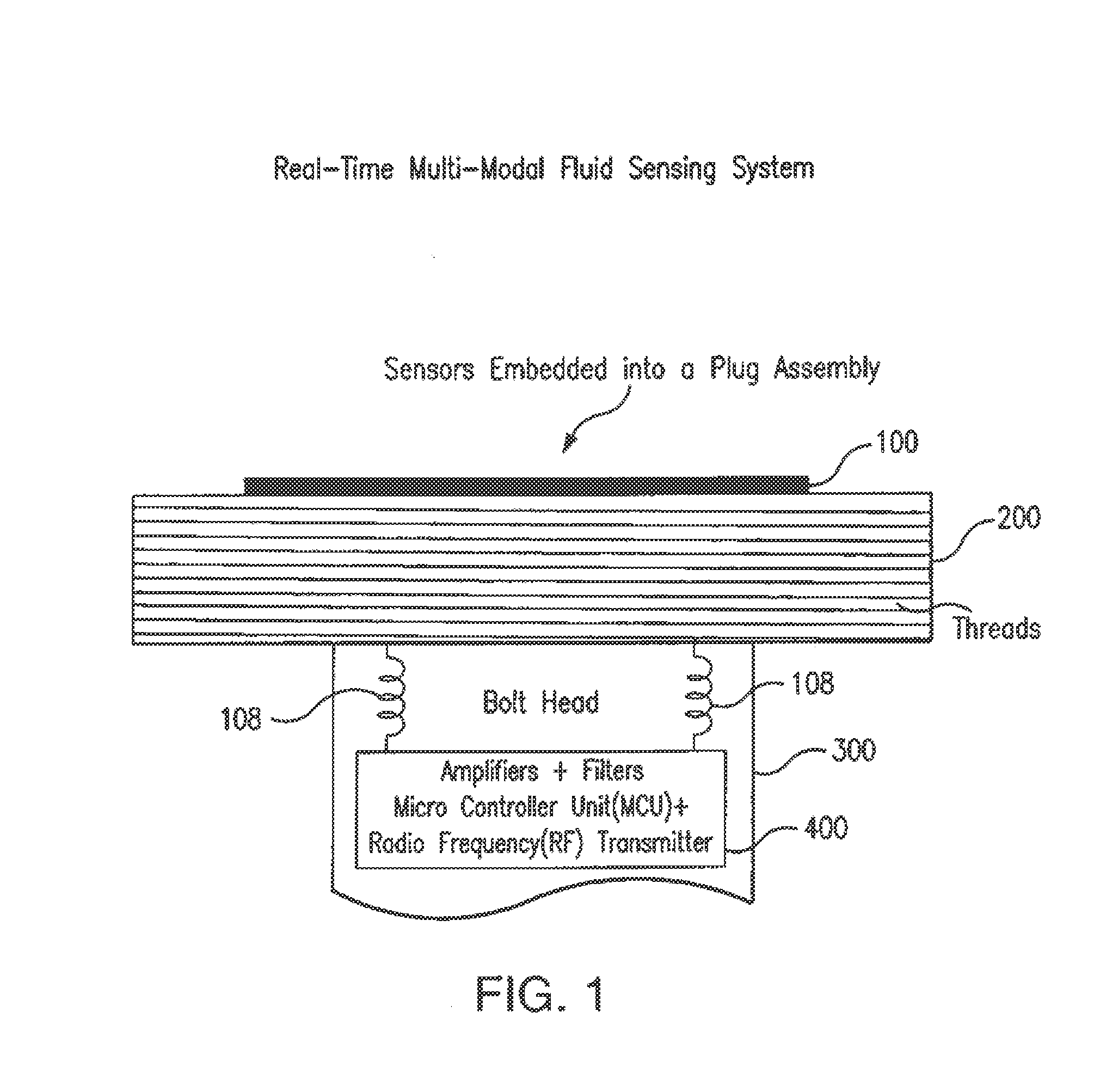

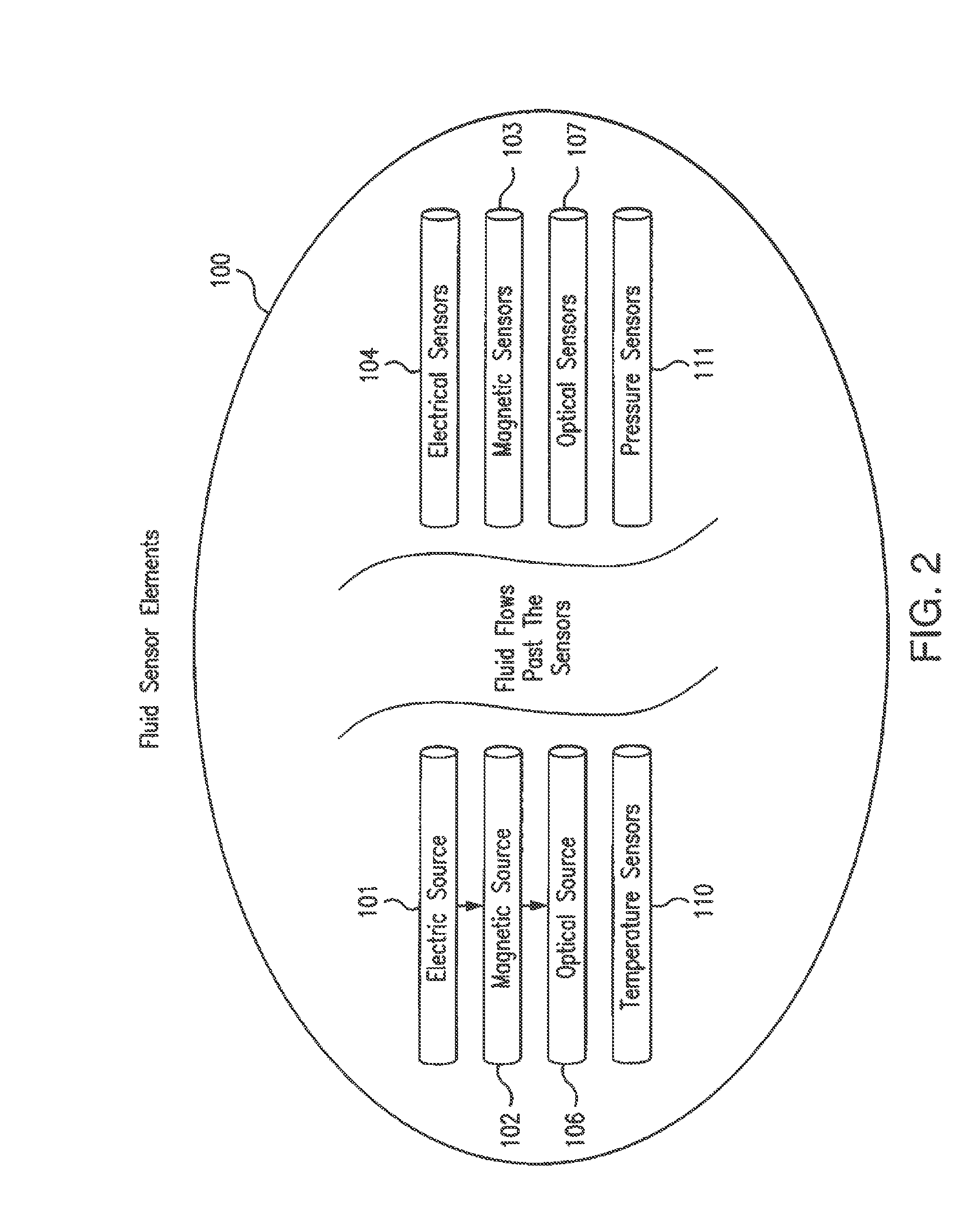

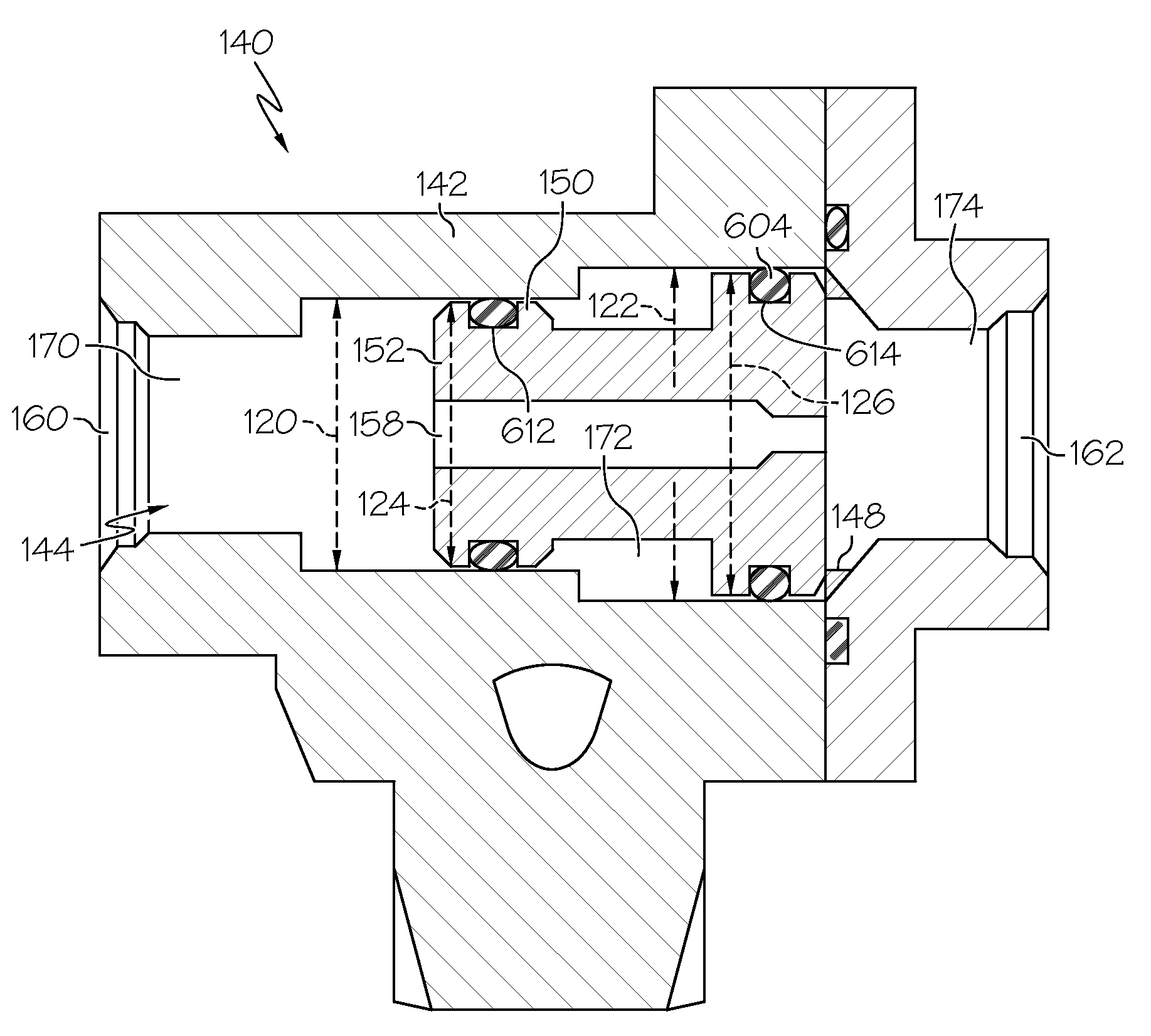

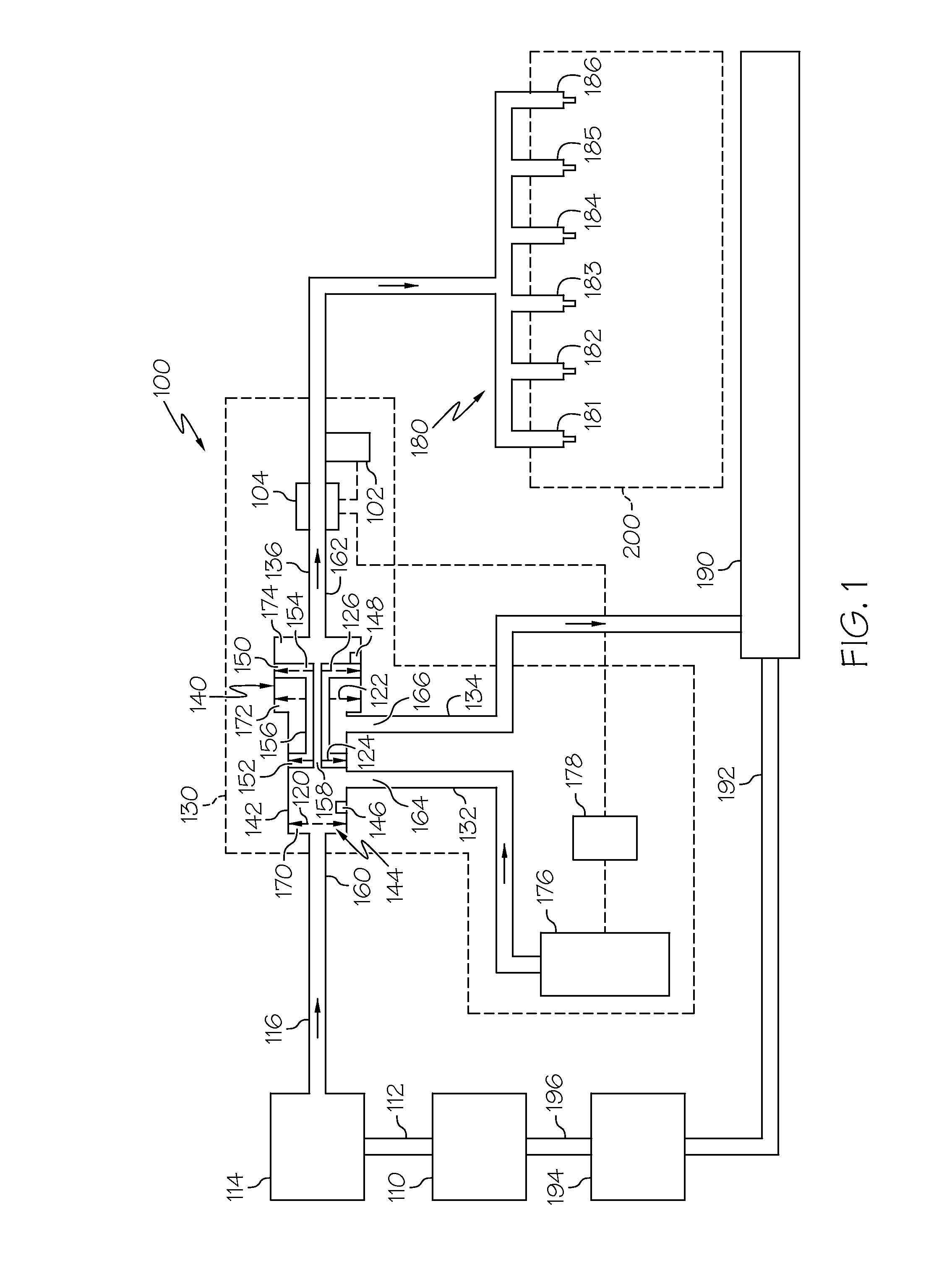

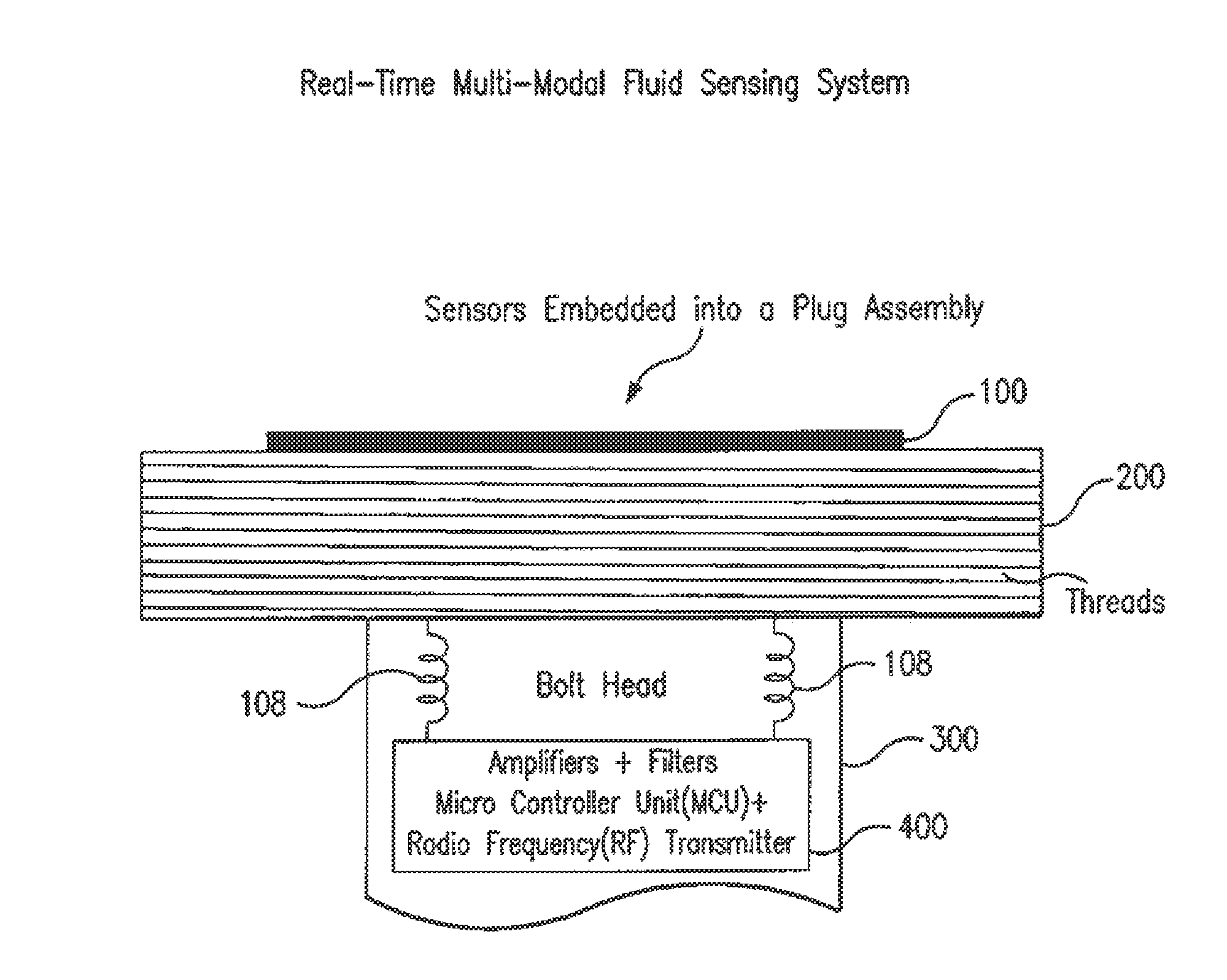

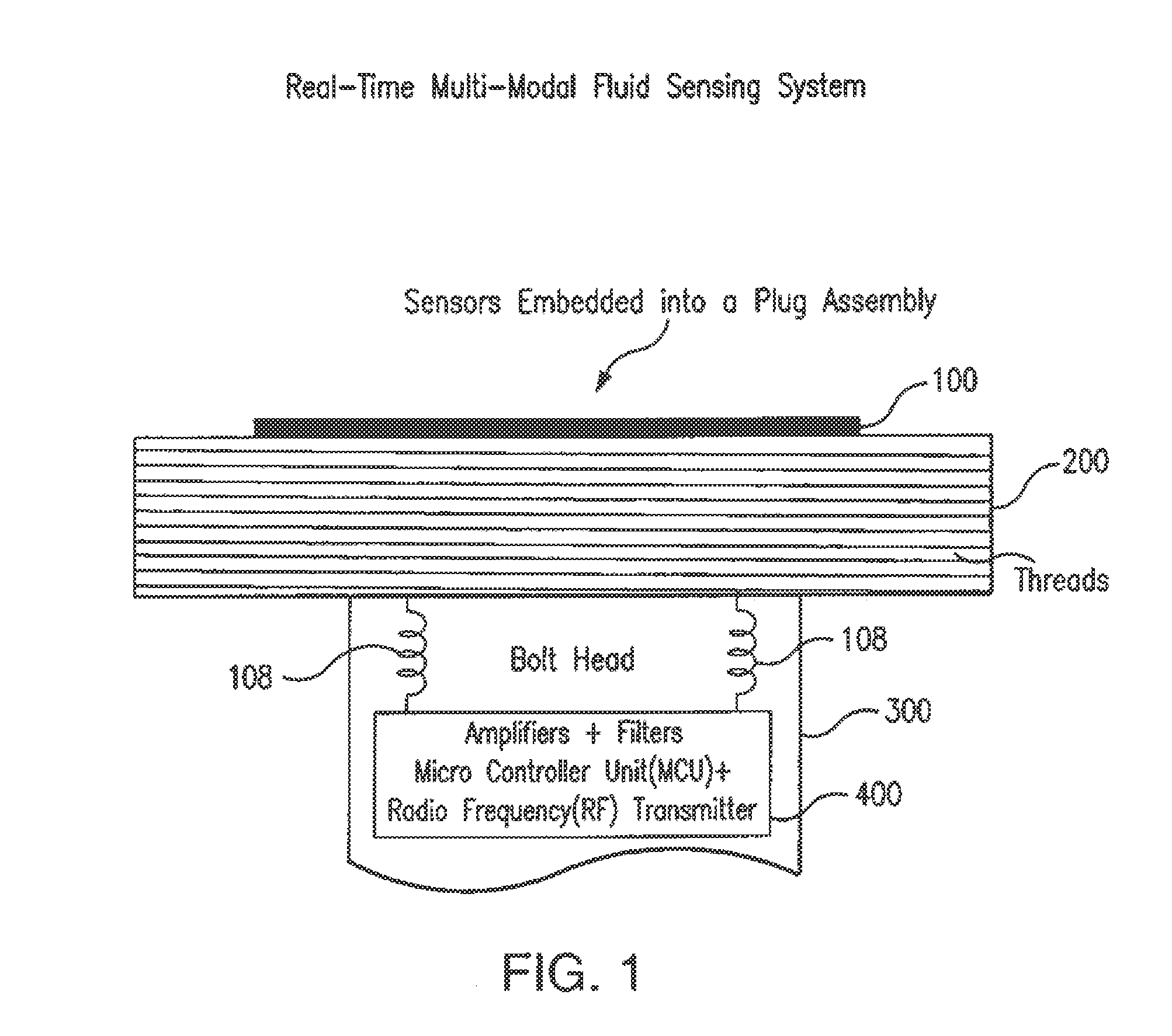

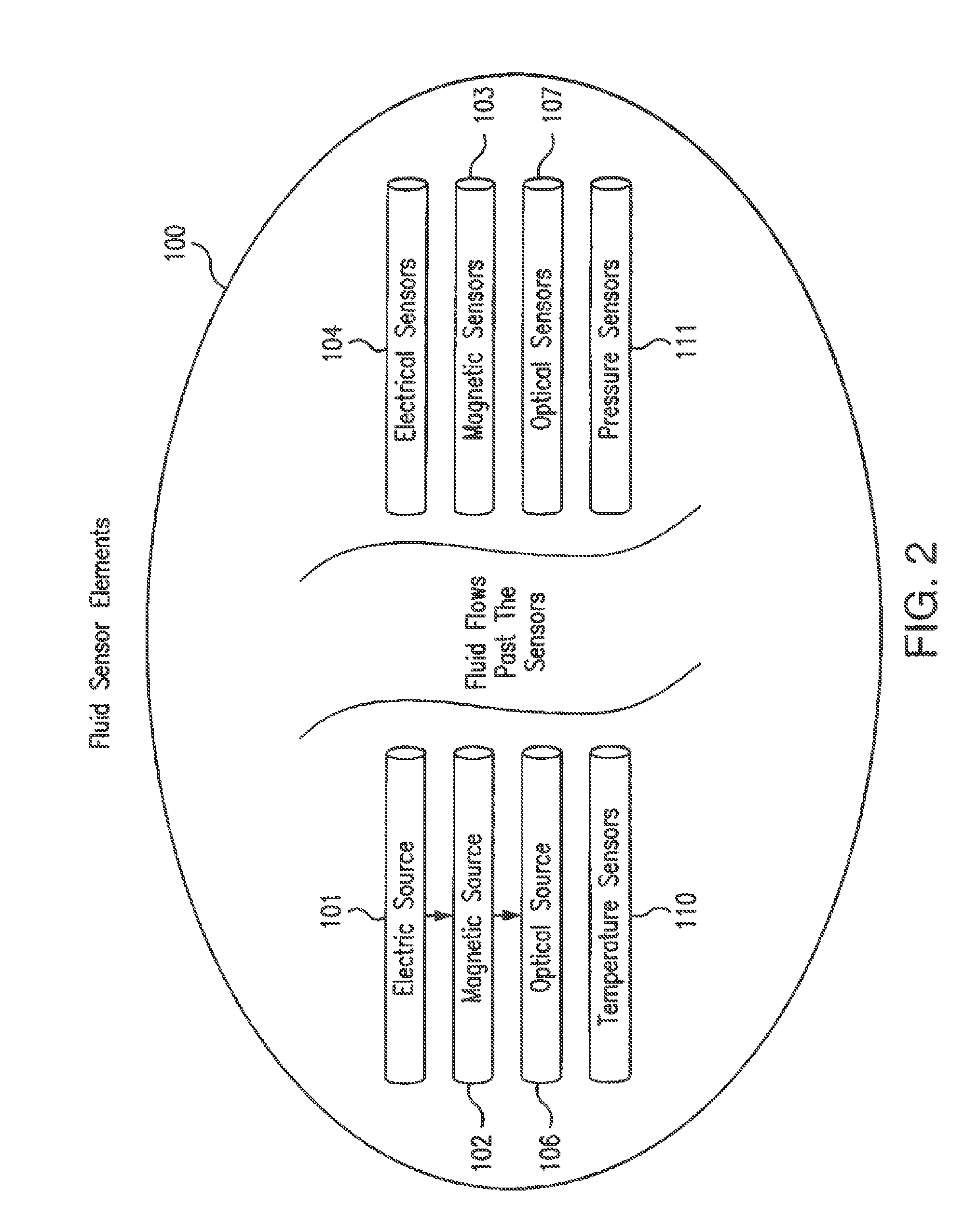

Multi-modal fluid condition sensor platform and system therefor

InactiveUS20140188404A1High pressure environmentEngine temperatureEngine pressureEngineeringLubrication

This invention encompasses embodiments for multi-modal integrated simultaneous measurement of various aspects of fluids contained in circulating systems such as automotive reciprocating engines and vehicle transmissions. These circulating systems perform constant internal lubrication, and heat and contaminant removal to protect the internal moving parts from the inherent friction and damage in normal operation. Most commonly this is achieved with fluids based on hydrocarbon and / or related synthetics, which, over time, can lose their protective properties, and vary in their performance or breakdown / decay due to internal and external events. Several components within the lubricant fluid can be measured and can provide insight into the efficacy of the system to perform its designed mission. Described herein is a real-time, simultaneous, integrated, multi-modal sensor system for early warning notification.

Owner:MAST INC

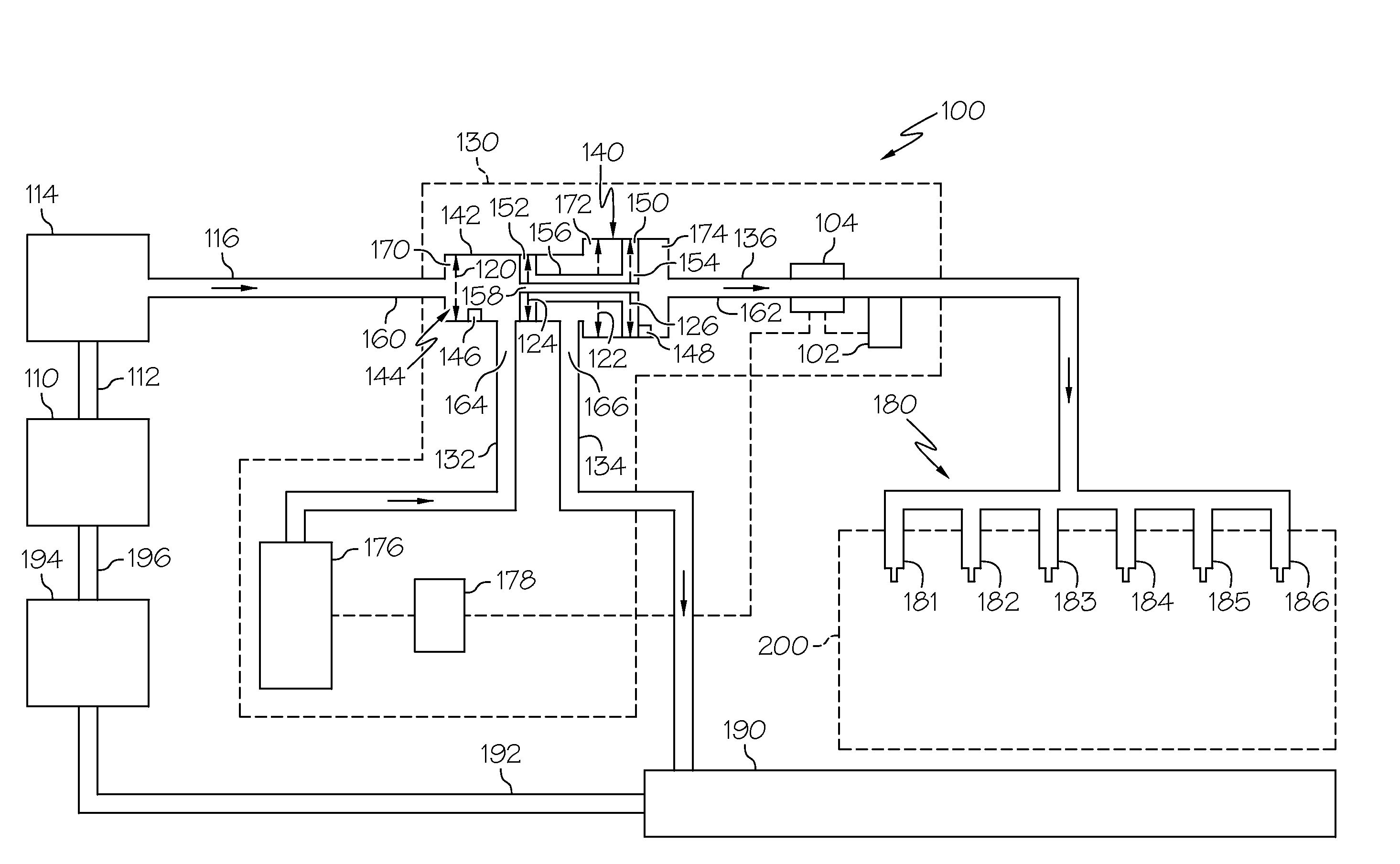

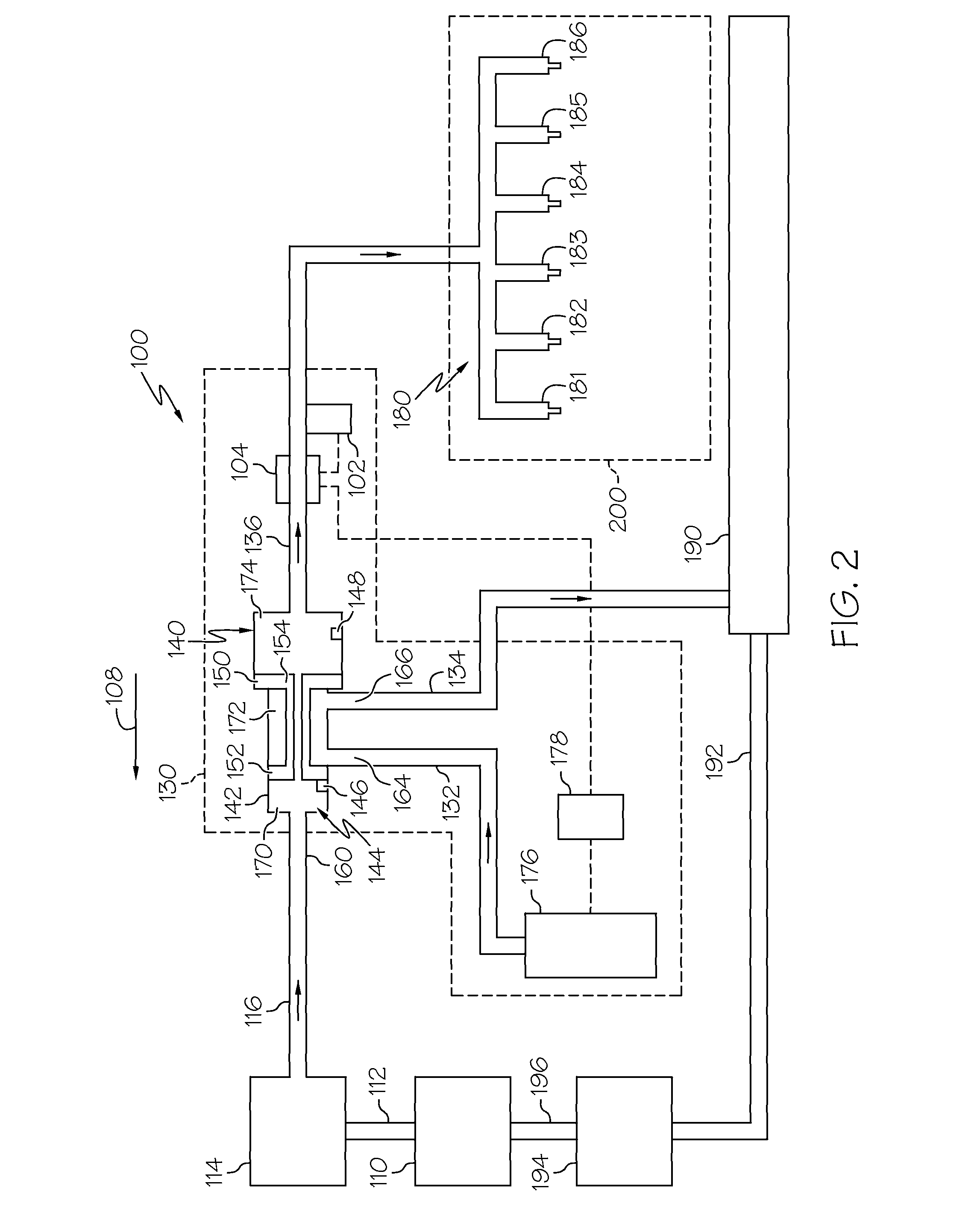

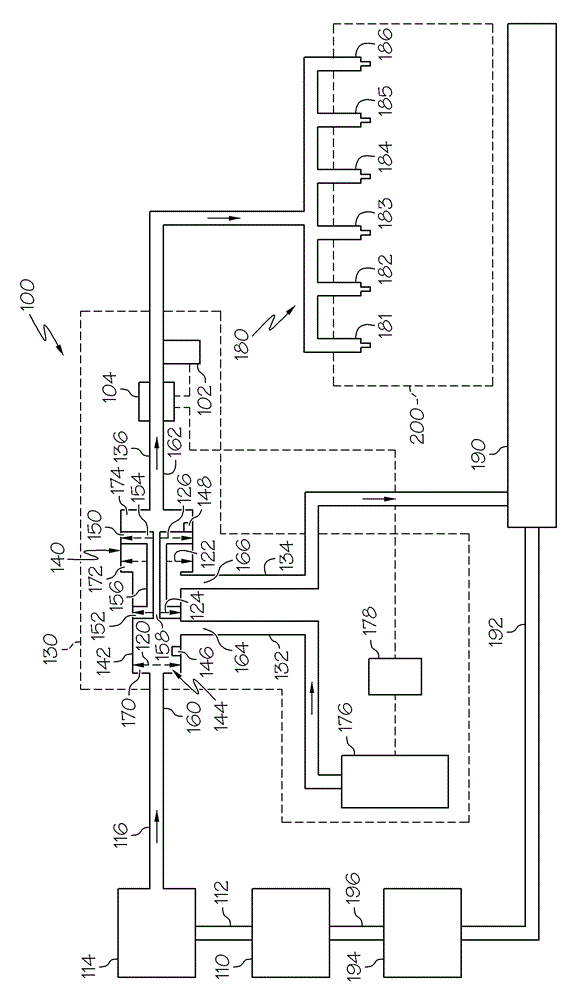

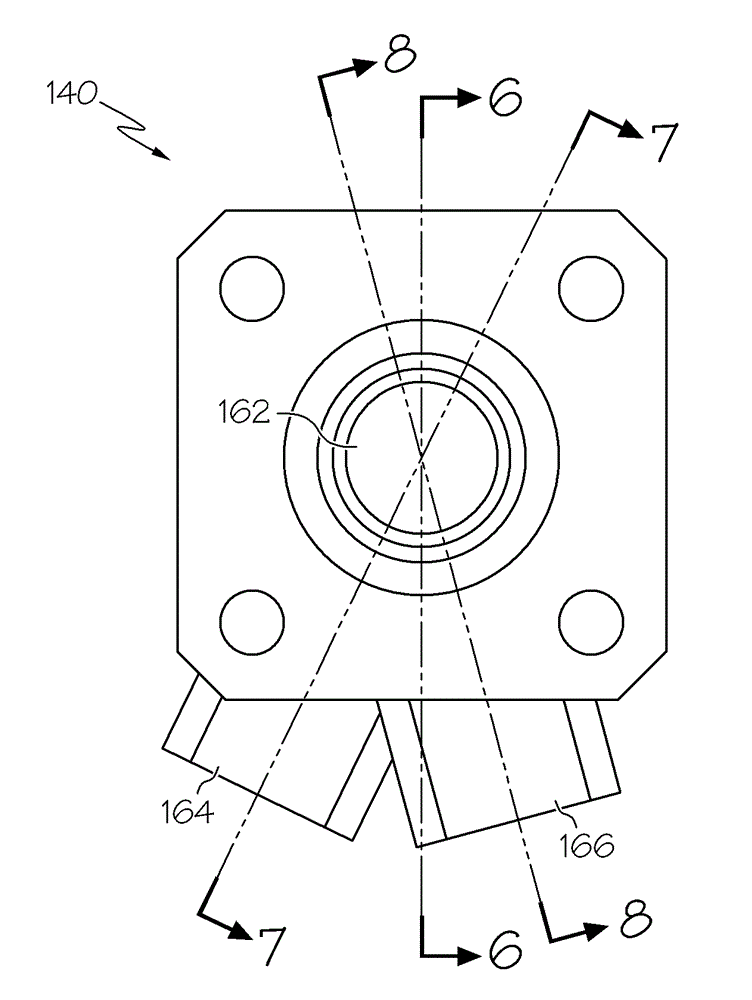

Lubrication systems with nozzle blockage detection systems

A lubrication system is provided for delivering a lubricant to a plurality of nozzles. The lubrication system includes a reservoir for the lubricant; a pump fluidly coupled to the reservoir and configured to remove a flow of the lubricant from the reservoir; a lubrication sensor positioned between the pump and the plurality of nozzles and configured to detect a blockage in the plurality of nozzles and to generate a blockage signal when the blockage is detected; and an indicator coupled to the lubrication sensor and configured to generate a warning based on the blockage signal from the lubrication sensor

Owner:HONEYWELL INT INC

Filter diagnostics and prognostics

ActiveUS20160206981A1Reduce excessively early filter replacementLow costEngine pressureWater/sewage treatmentEngineeringPressure difference

Various systems and methods are provided for a lubricant filter. In one example, a method for a lubricant filter comprises indicating a condition of the filter based on a difference between a measured pressure differential and an expected pressure differential during select conditions in which all lubricant pumped by a pump upstream of the filter flows into the filter.

Owner:FORD GLOBAL TECH LLC

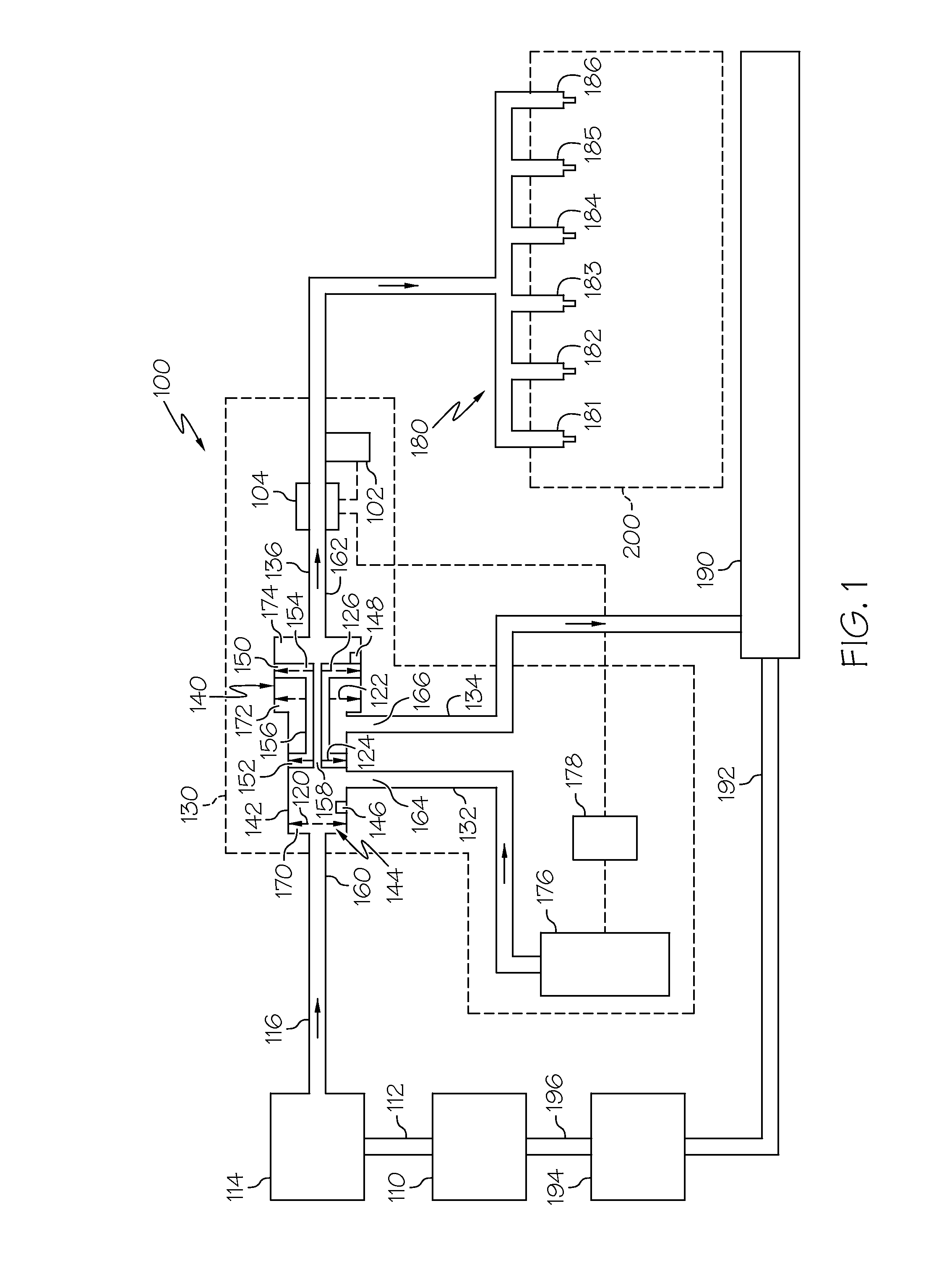

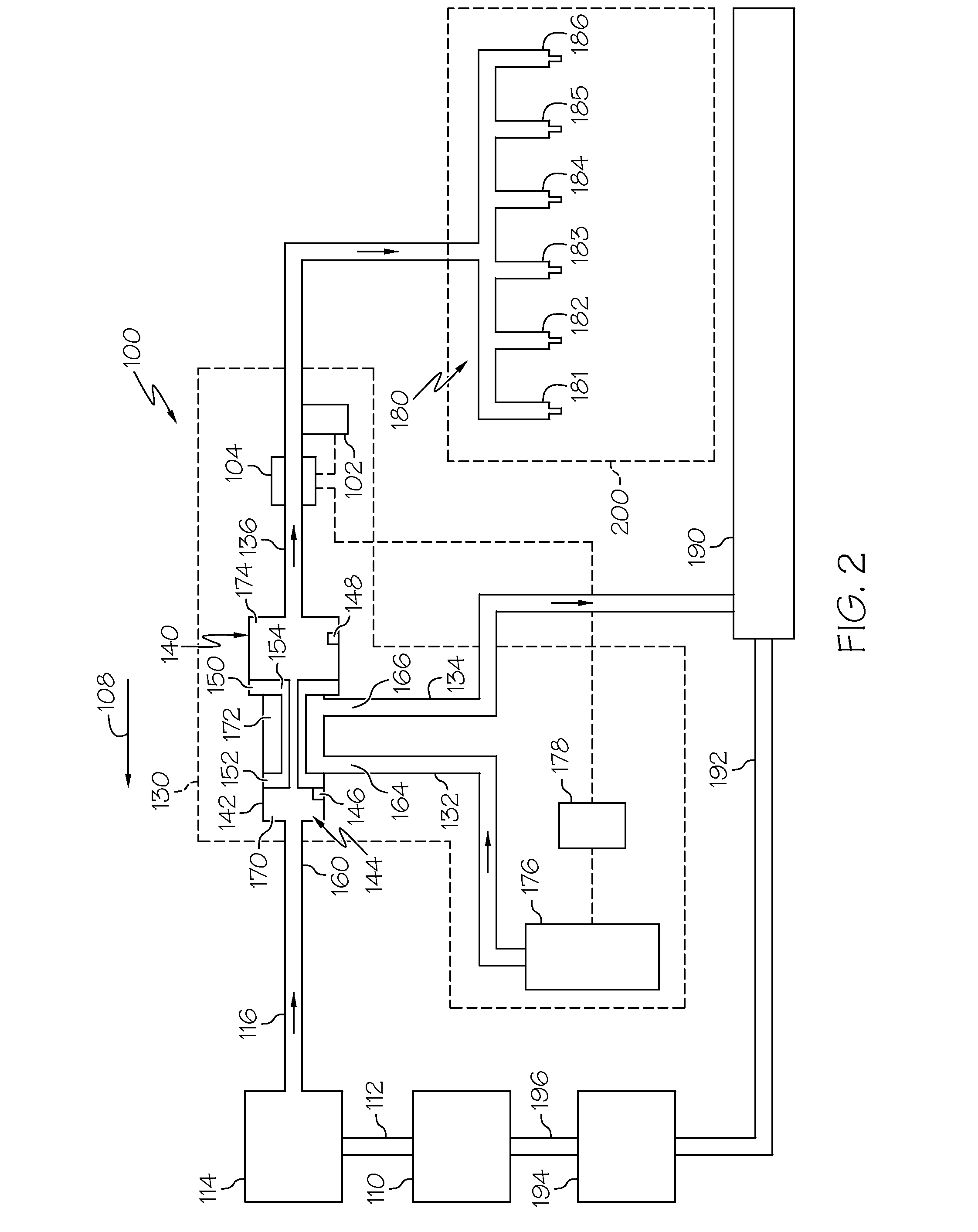

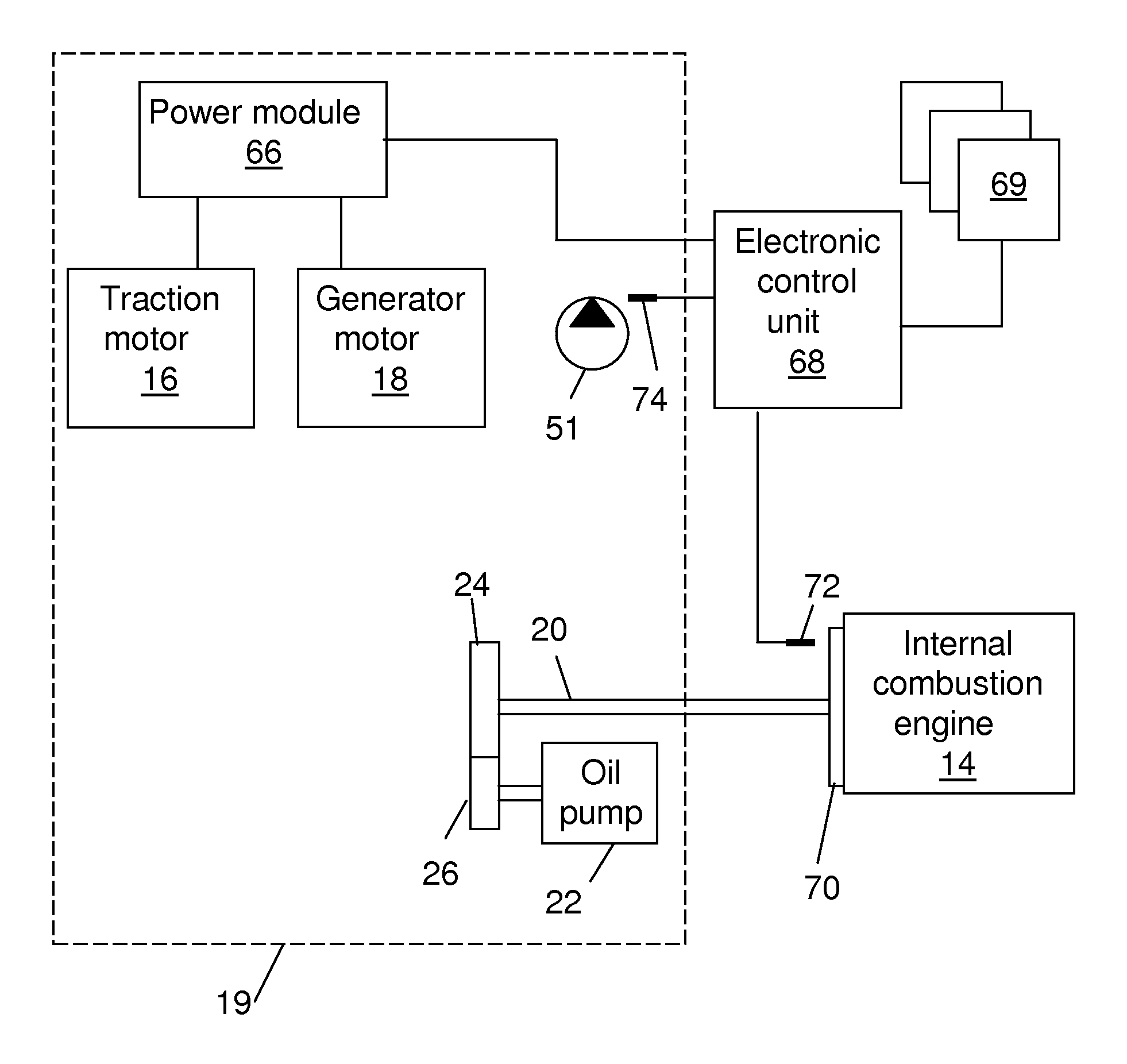

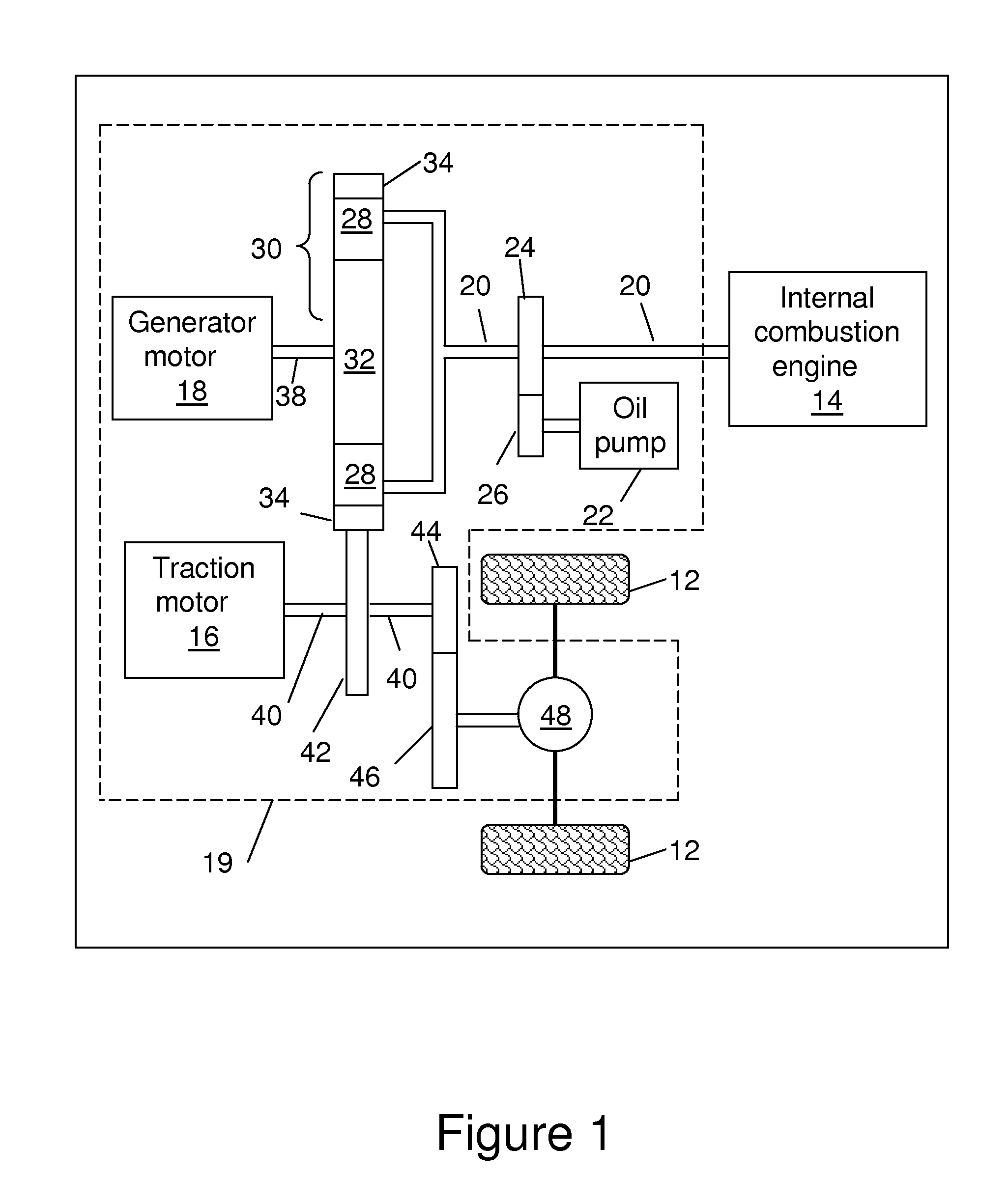

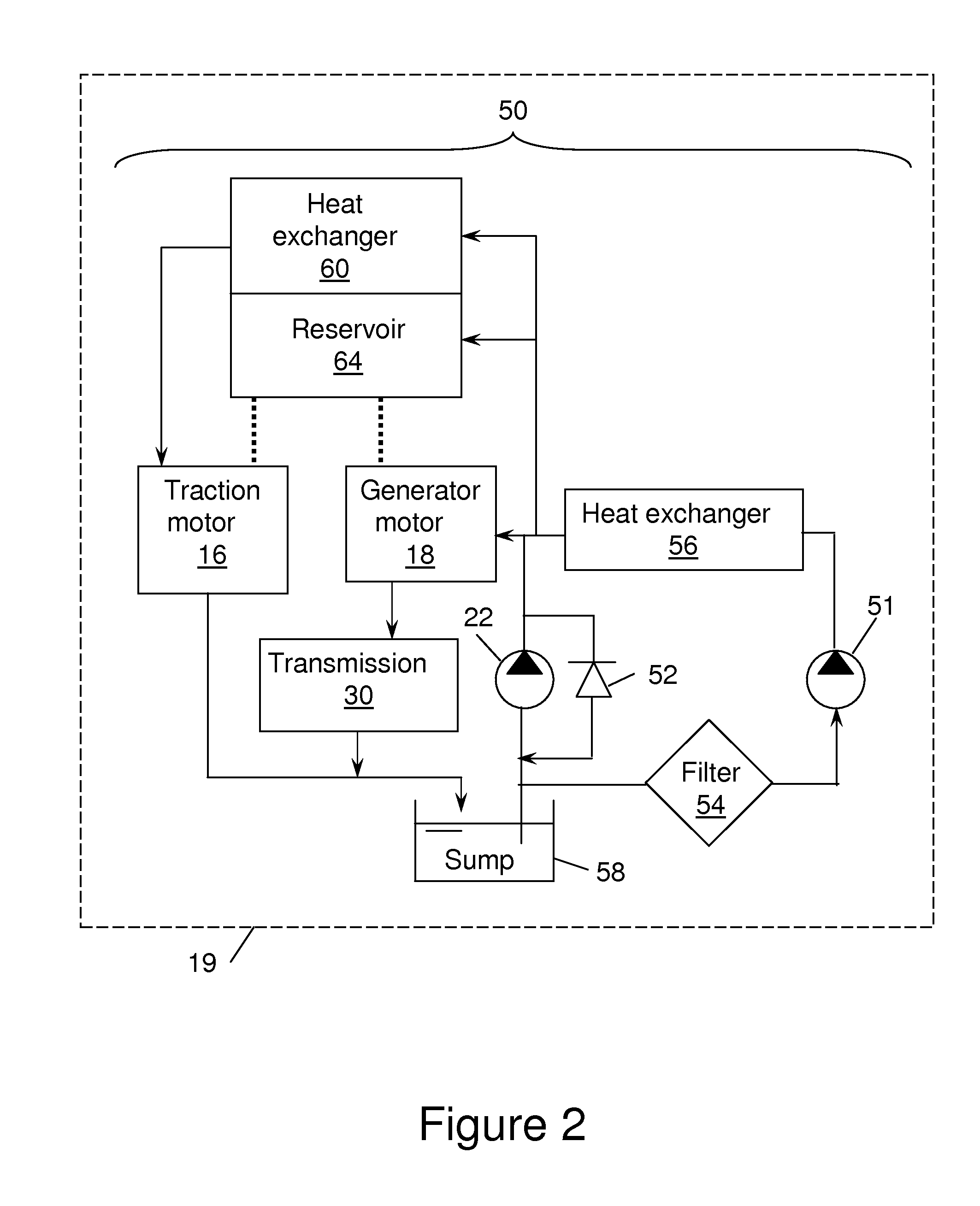

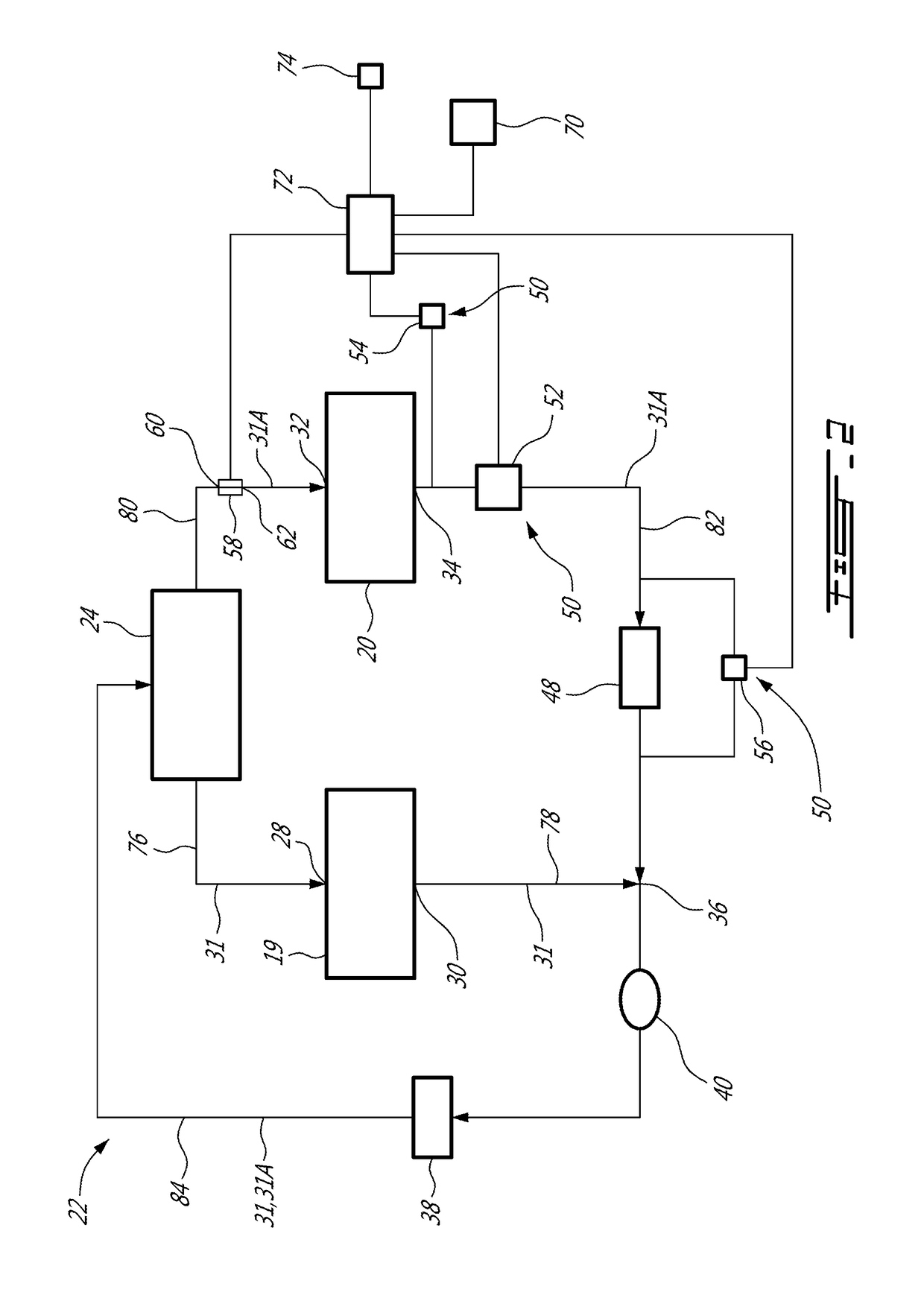

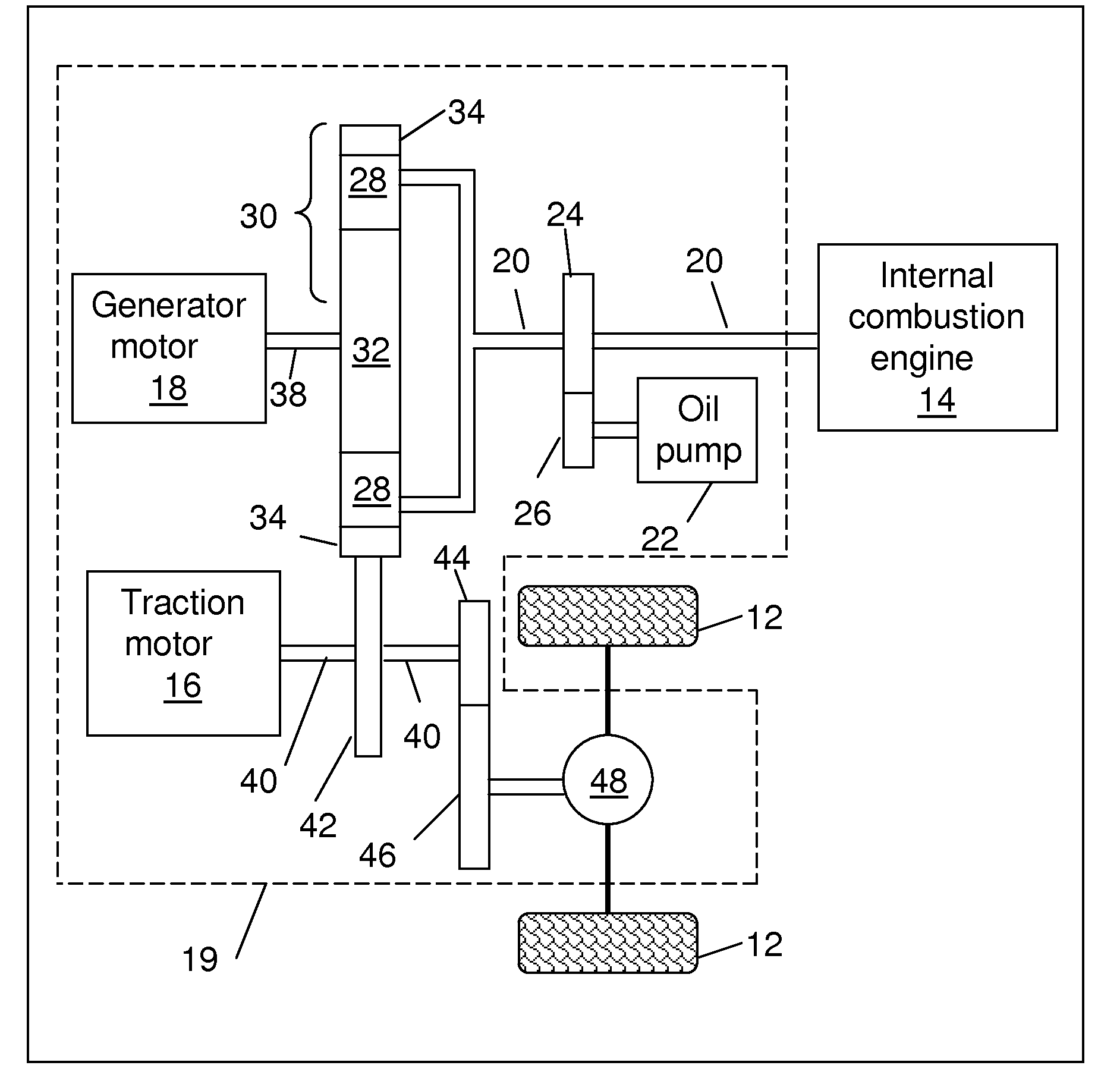

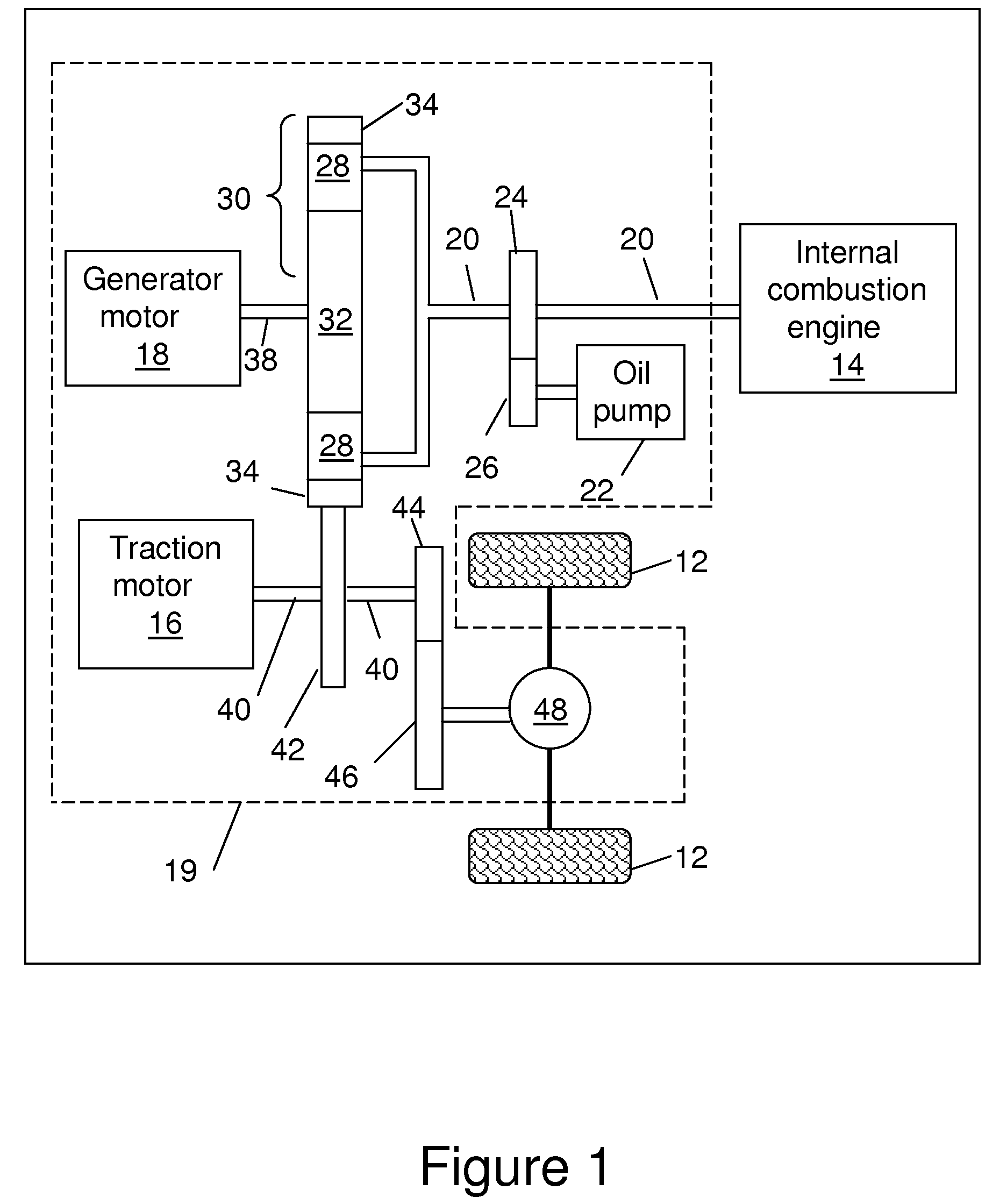

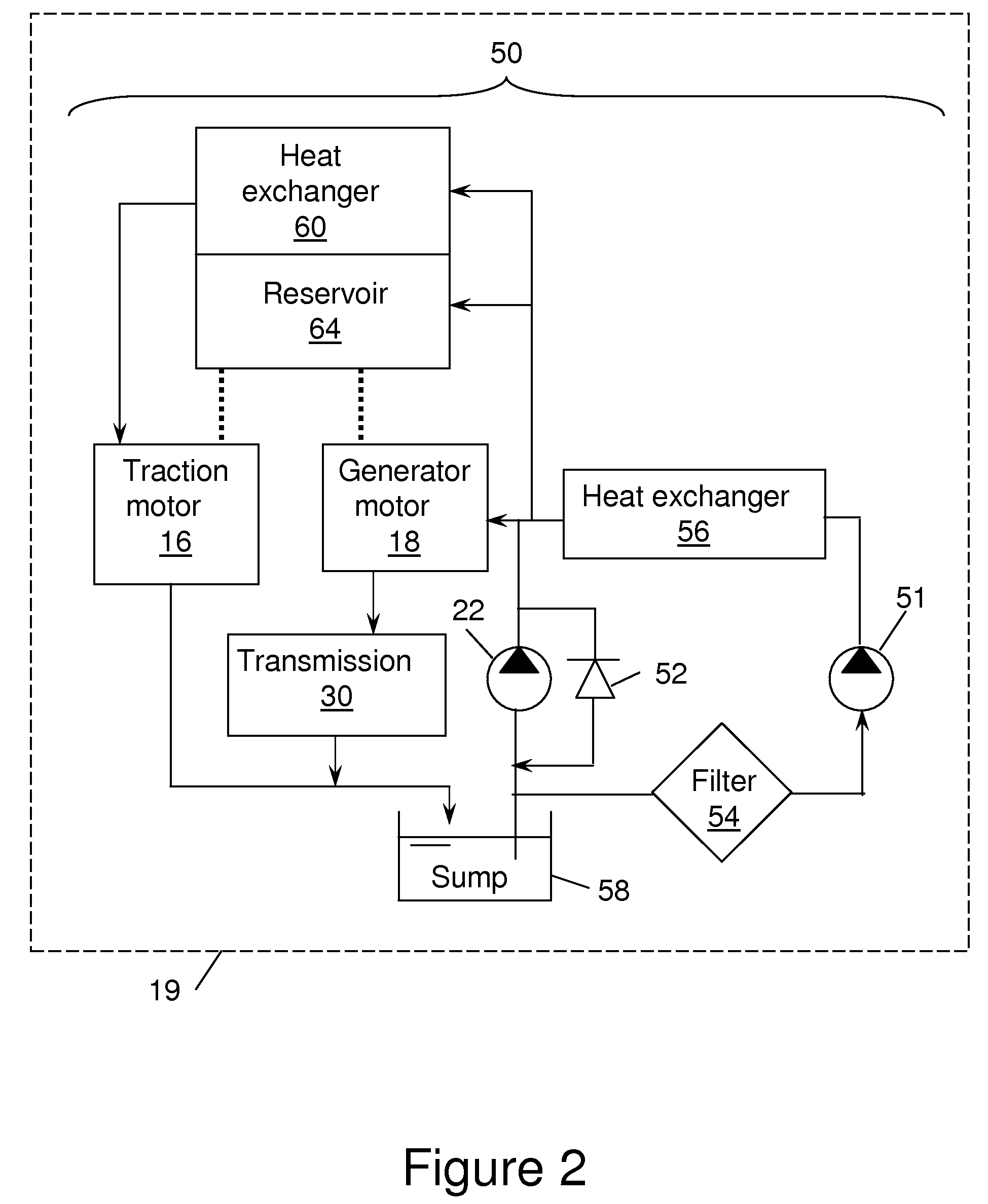

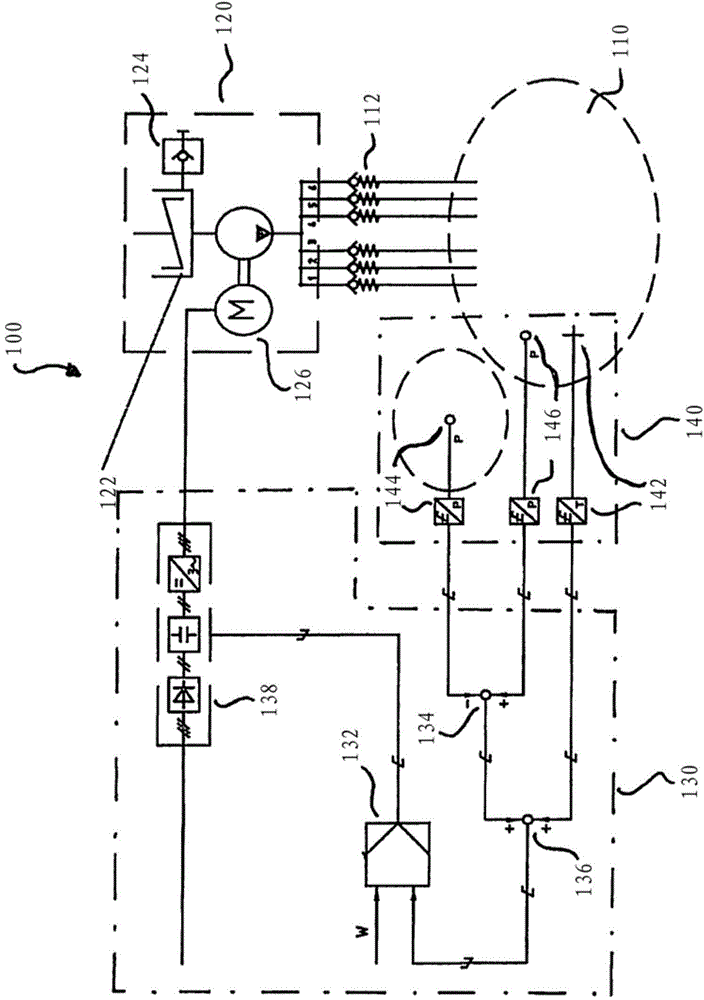

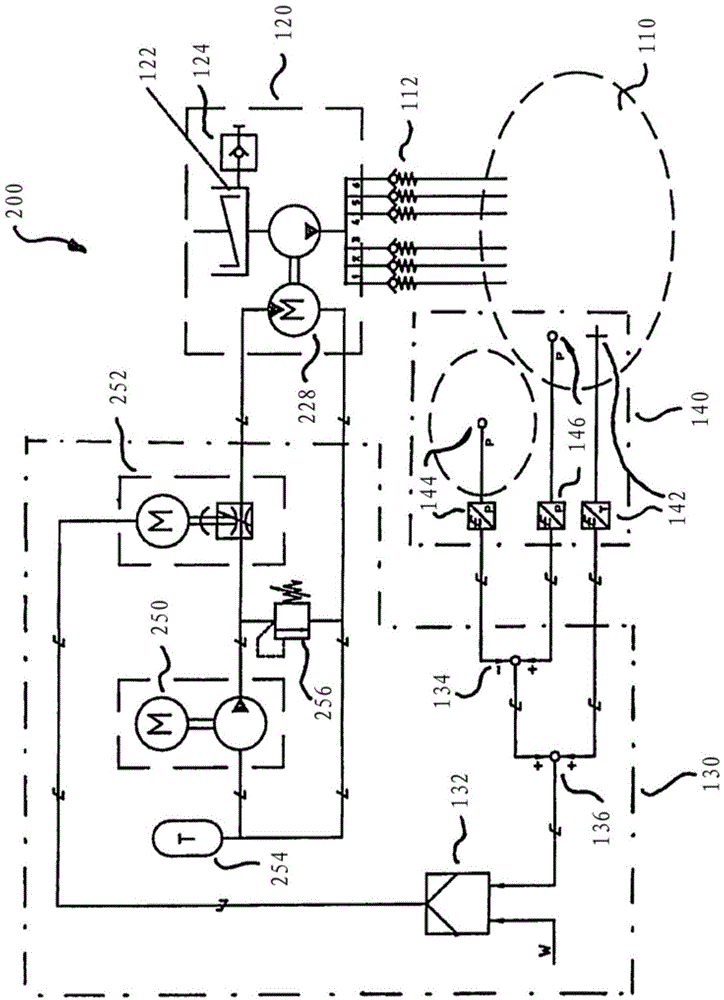

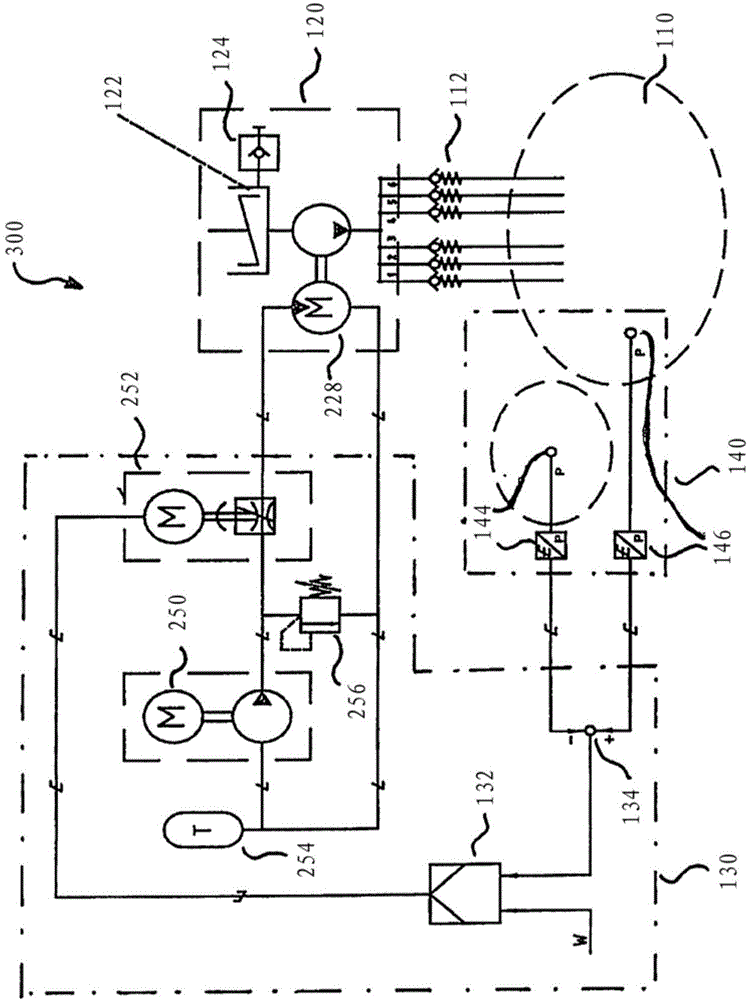

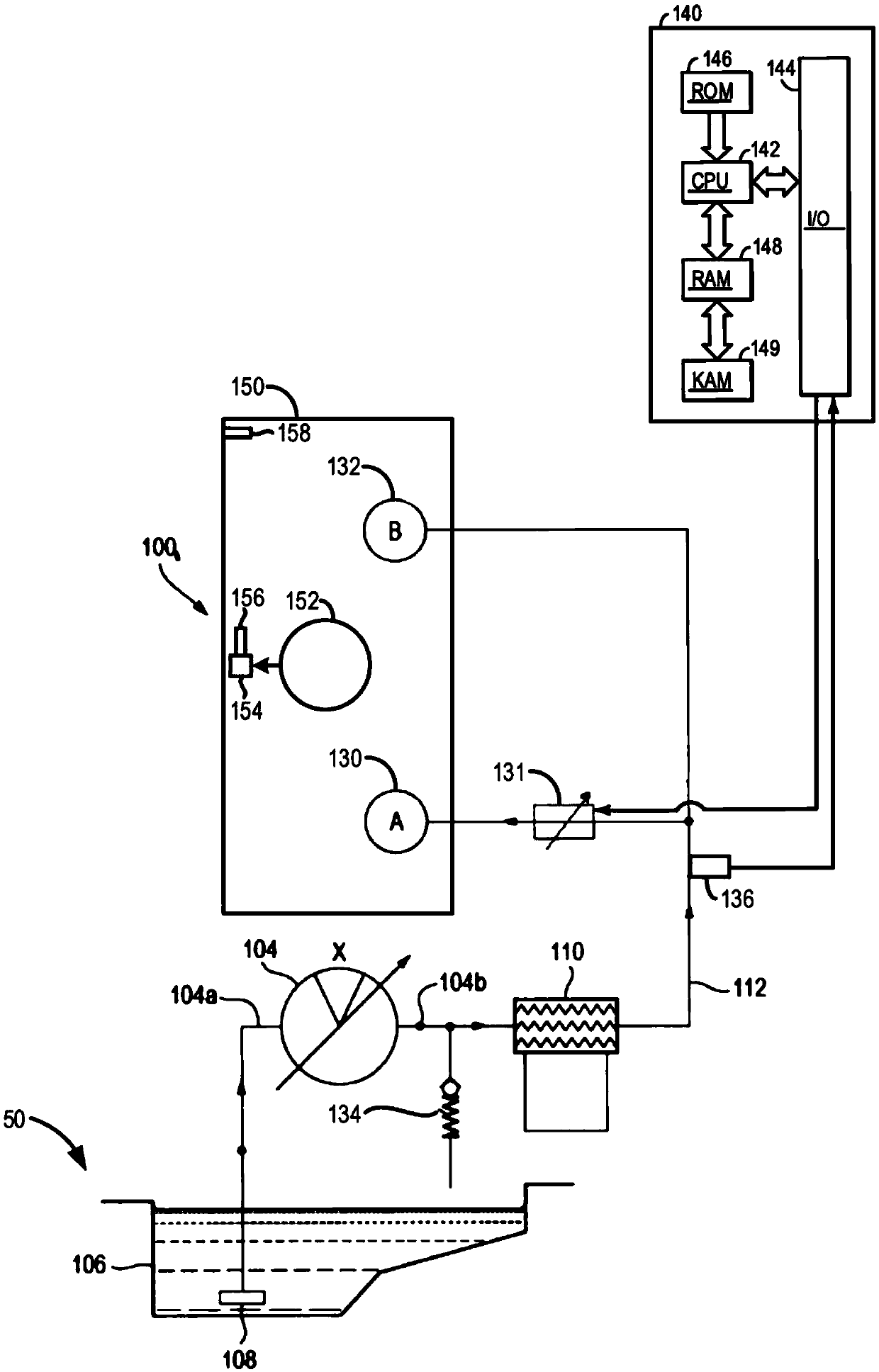

System and method to provide lubrication for a plug-in hybrid

In hybrid electric vehicles having increased battery storage capacity and plug-in capability, electric-only operation of significant duration is available. To supplement lubrication for the electric and mechanical components provided in a fluid circuit by an engine-driven mechanical pump, an electric pump is provided in parallel to the mechanical pump. When the electric pump is operating, a diagnostic can be performed to determine system integrity. According to one embodiment, an actual quantity provide to the circuit is determined; an expected quantity is estimated; and a fault is determined when the actual and expected quantities differ by more than a predetermined amount. The fault may indicate a leak or plug in the fluid circuit or a failure of a component in the fluid circuit.

Owner:FORD GLOBAL TECH LLC

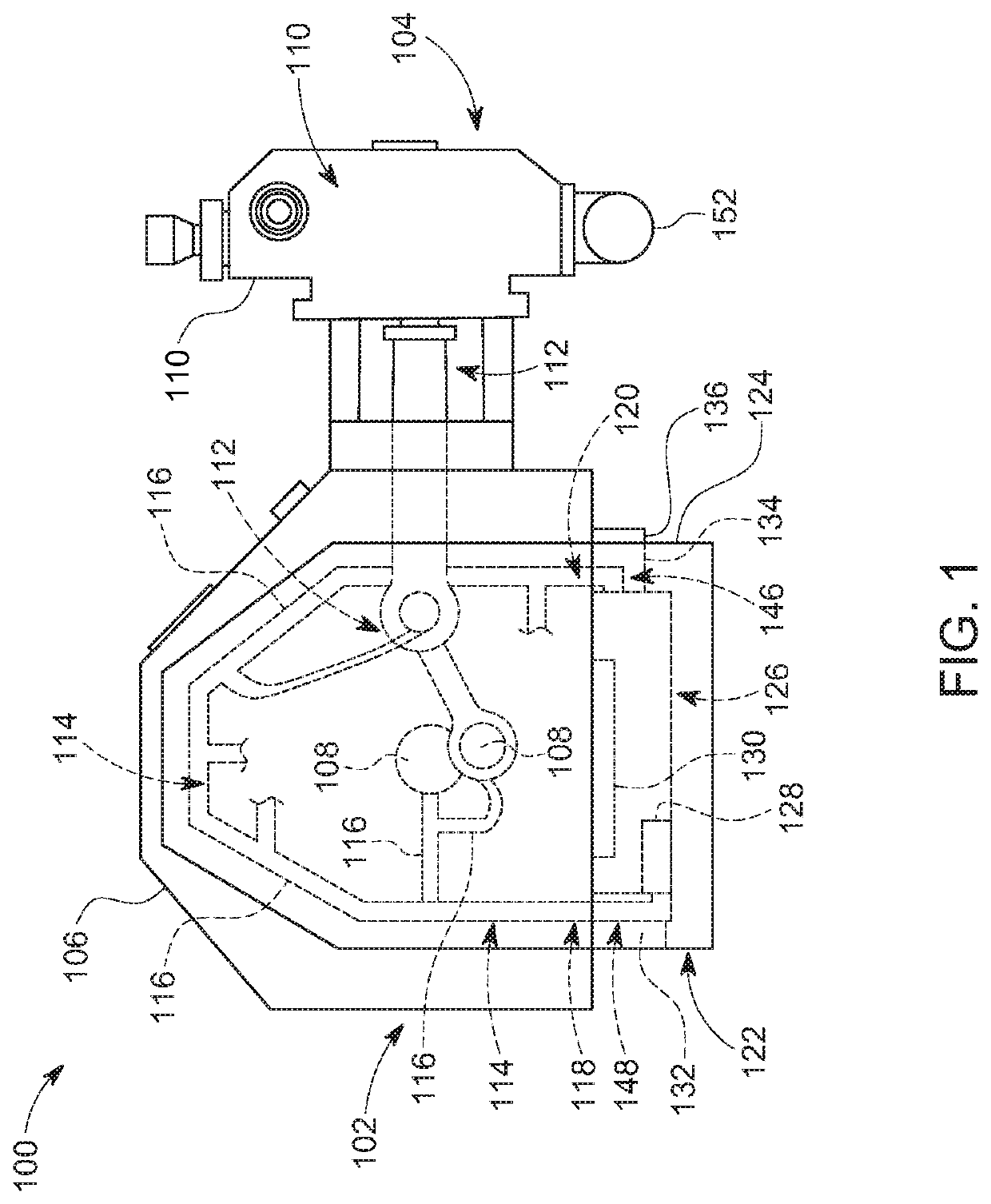

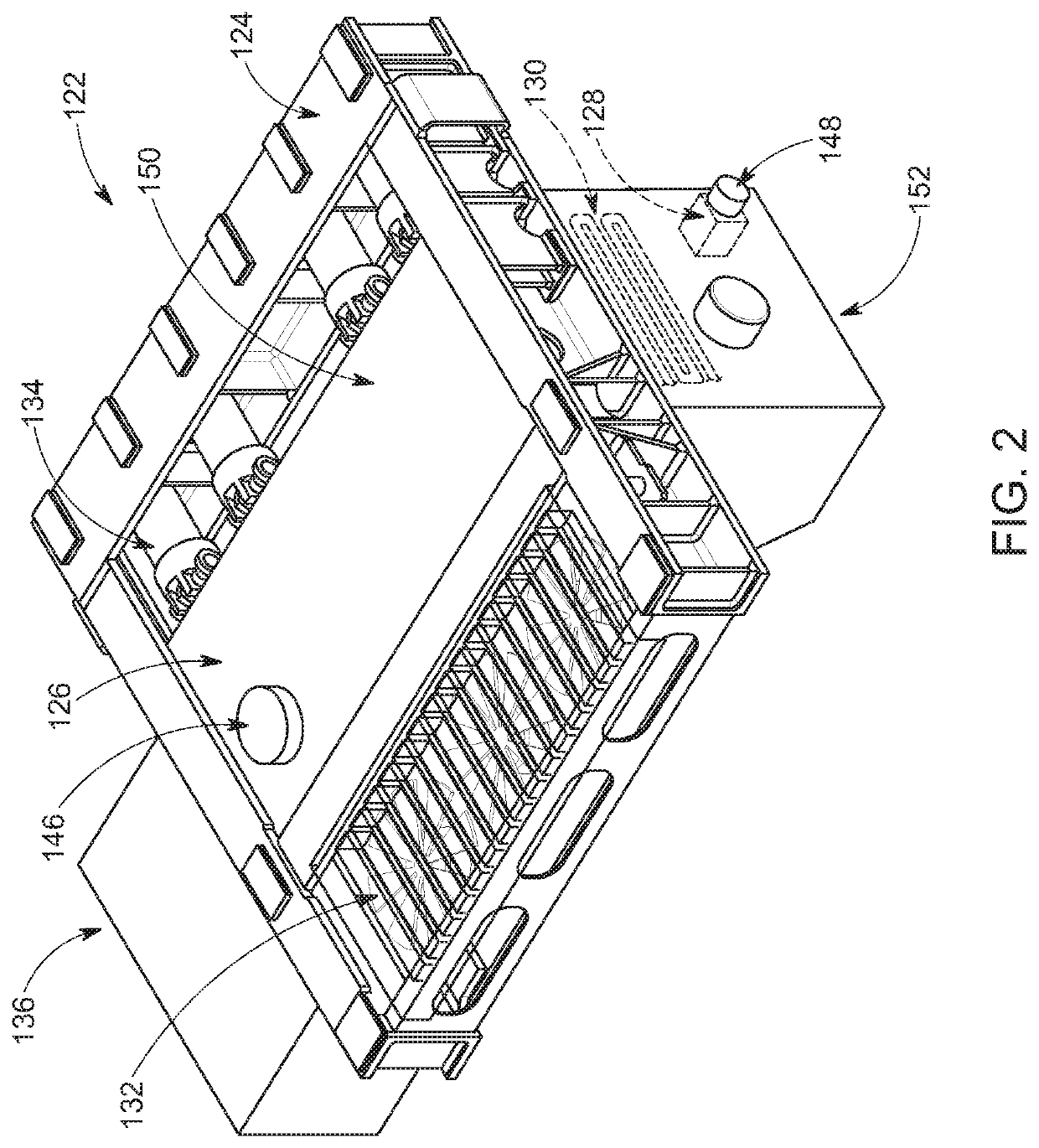

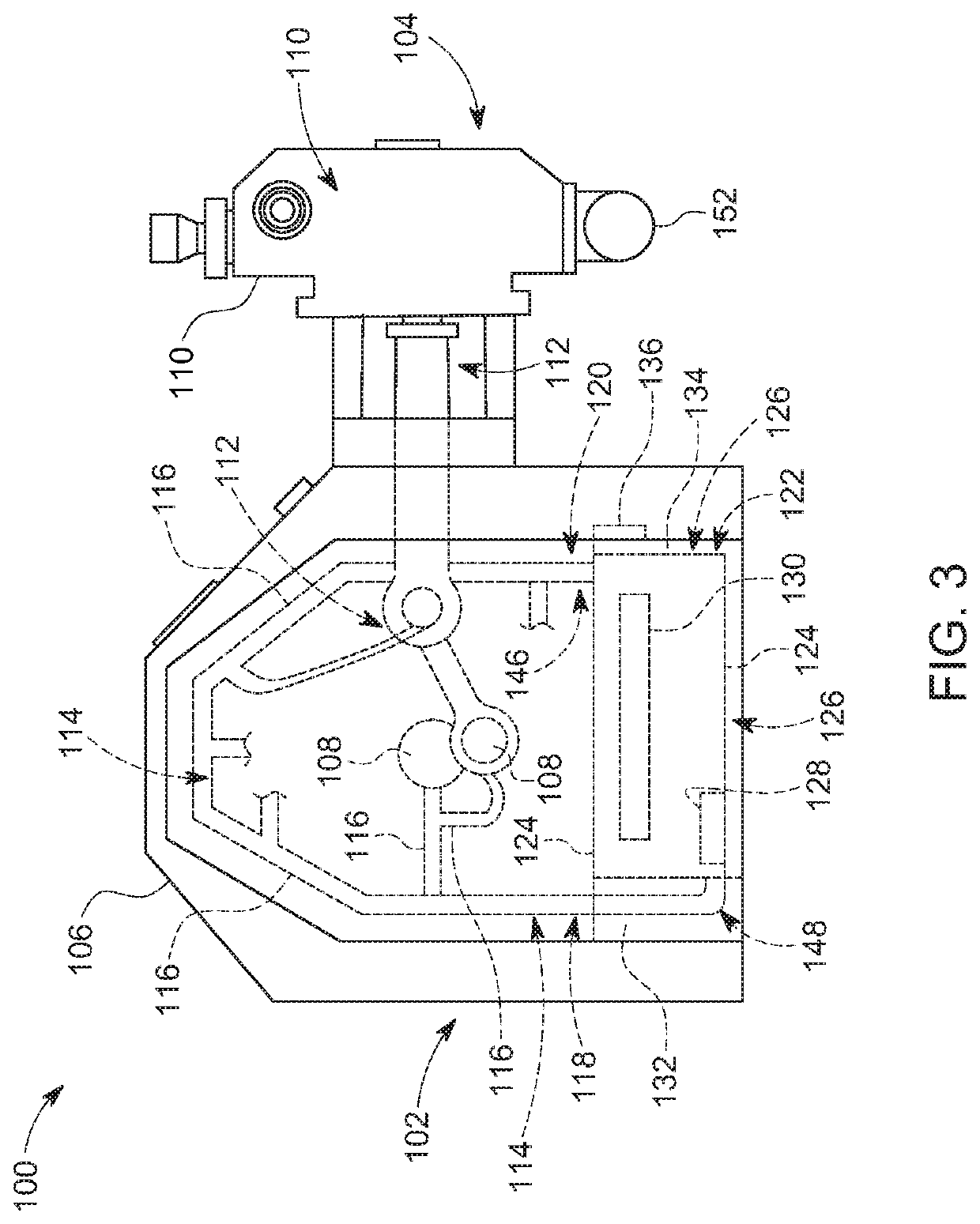

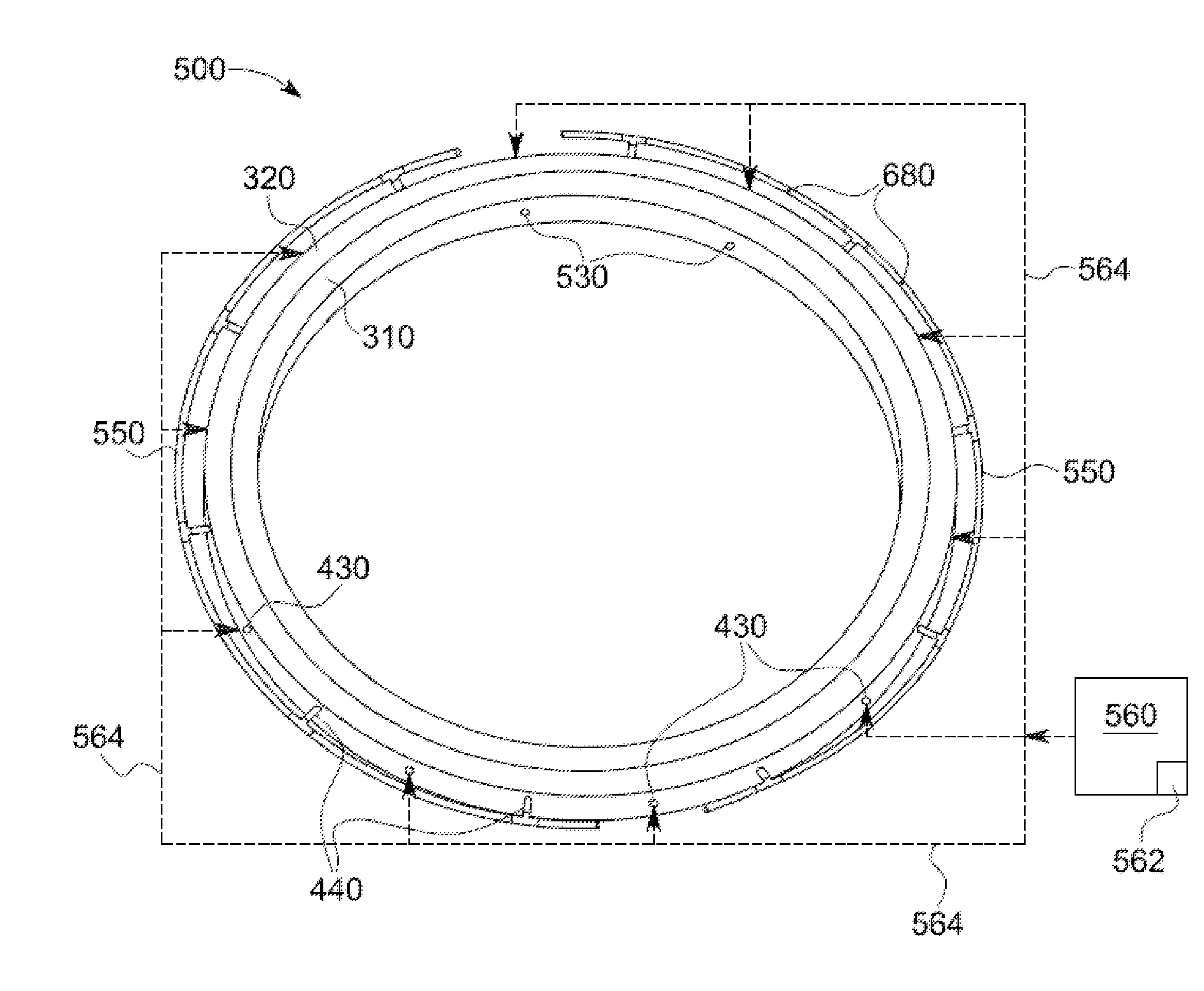

Lubrication systems for bearing assemblies

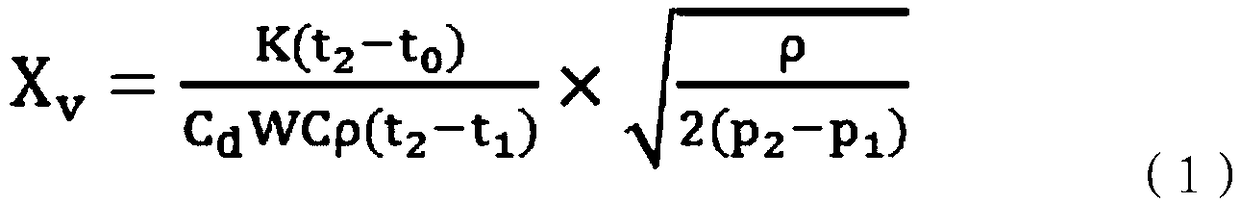

ActiveUS20140193263A1Maintain balanceRestricts distributionPropellersPump componentsLubricationLubricant

A lubrication system is disclosed for a bearing assembly, the bearing assembly having at least one bearing. The lubrication system may comprise a pump circuit, an injection circuit, an extraction circuit and at least one three-way valve. The pump circuit may comprise at least a pump. The injection circuit may provide lubricant to the bearing during an injection mode of operation. The extraction circuit may extract lubricant from the bearing during an extraction mode of operation. A flow combination topology of the first three-way valve may allow operation of the lubrication system in the injection mode or in the extraction mode or in both modes simultaneously.

Owner:GE RENEWABLE TECH WIND BV

Multi-modal fluid condition sensor platform and system therefor

This invention encompasses embodiments for multi-modal integrated simultaneous measurement of various aspects of fluids contained in circulating systems such as automotive reciprocating engines and vehicle transmissions. These circulating systems perform constant internal lubrication, and heat and contaminant removal to protect the internal moving parts from the inherent friction and damage in normal operation. Most commonly this is achieved with fluids based on hydrocarbon and / or related synthetics, which, over time, can lose their protective properties, and vary in their performance or breakdown / decay due to internal and external events. Several components within the lubricant fluid can be measured and can provide insight into the efficacy of the system to perform its designed mission. Described herein is a real-time, simultaneous, integrated, multi-modal sensor system for early warning notification.

Owner:MAST INC

Lubrication systems with nozzle blockage detection systems

Owner:HONEYWELL INT INC

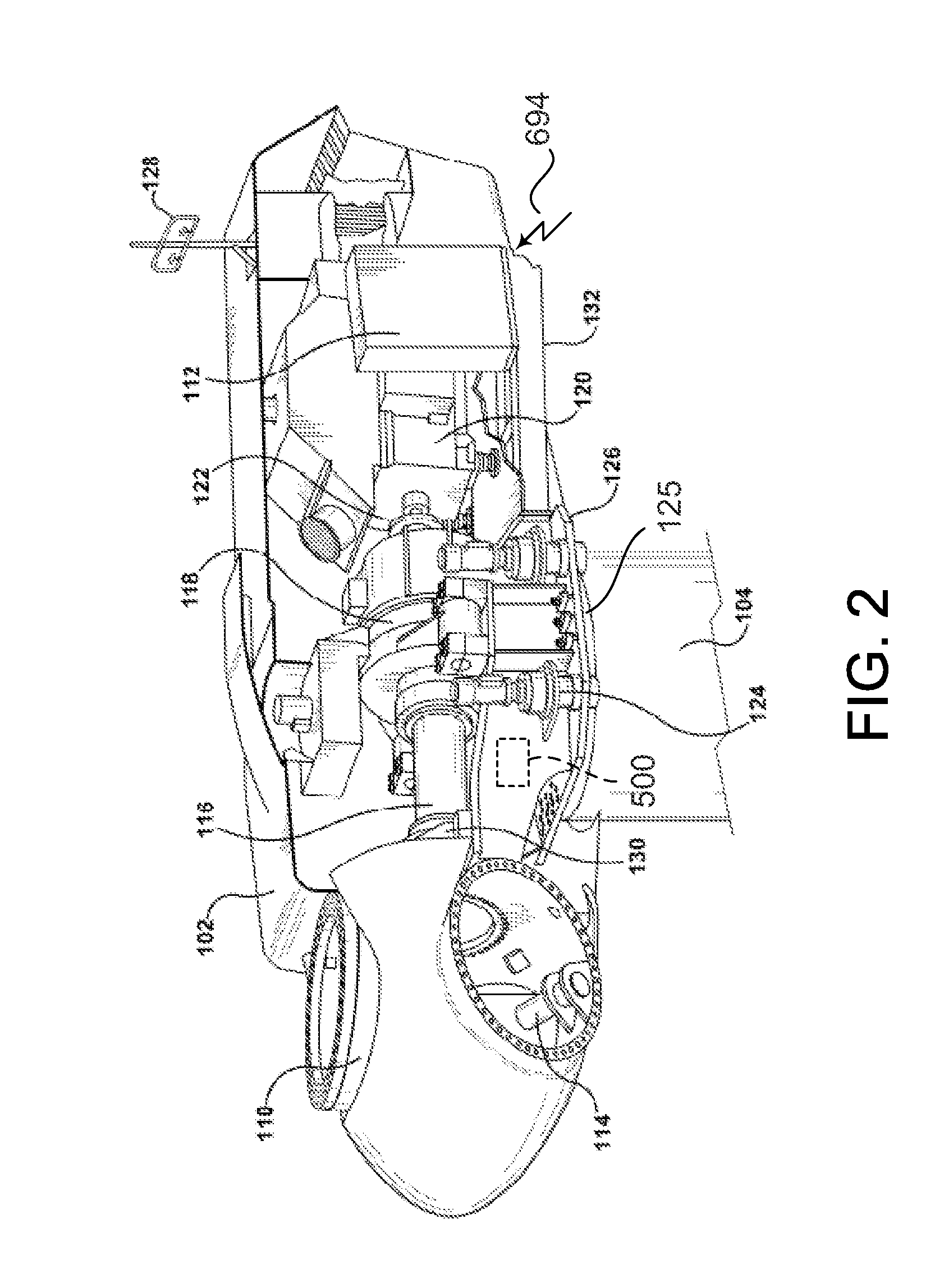

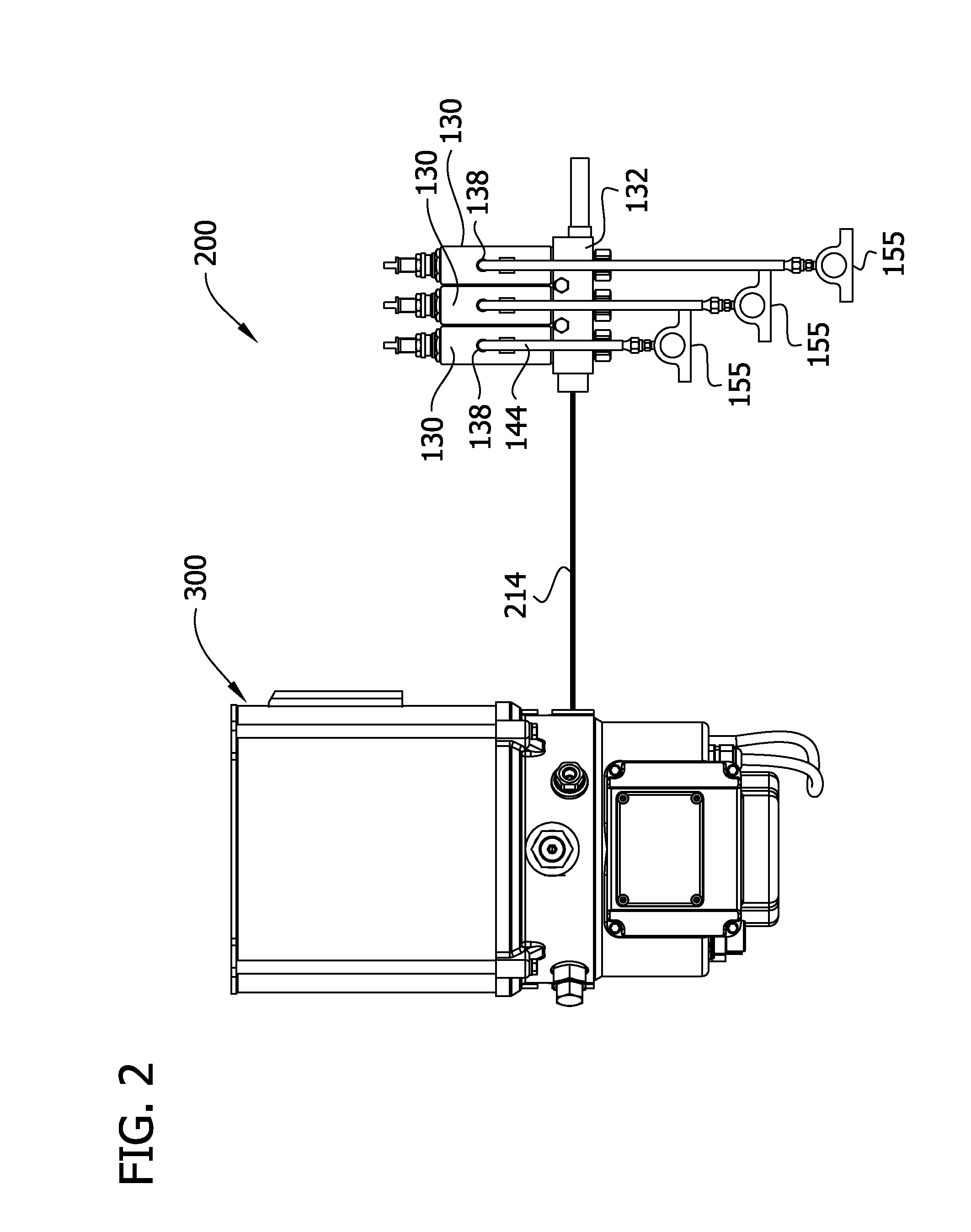

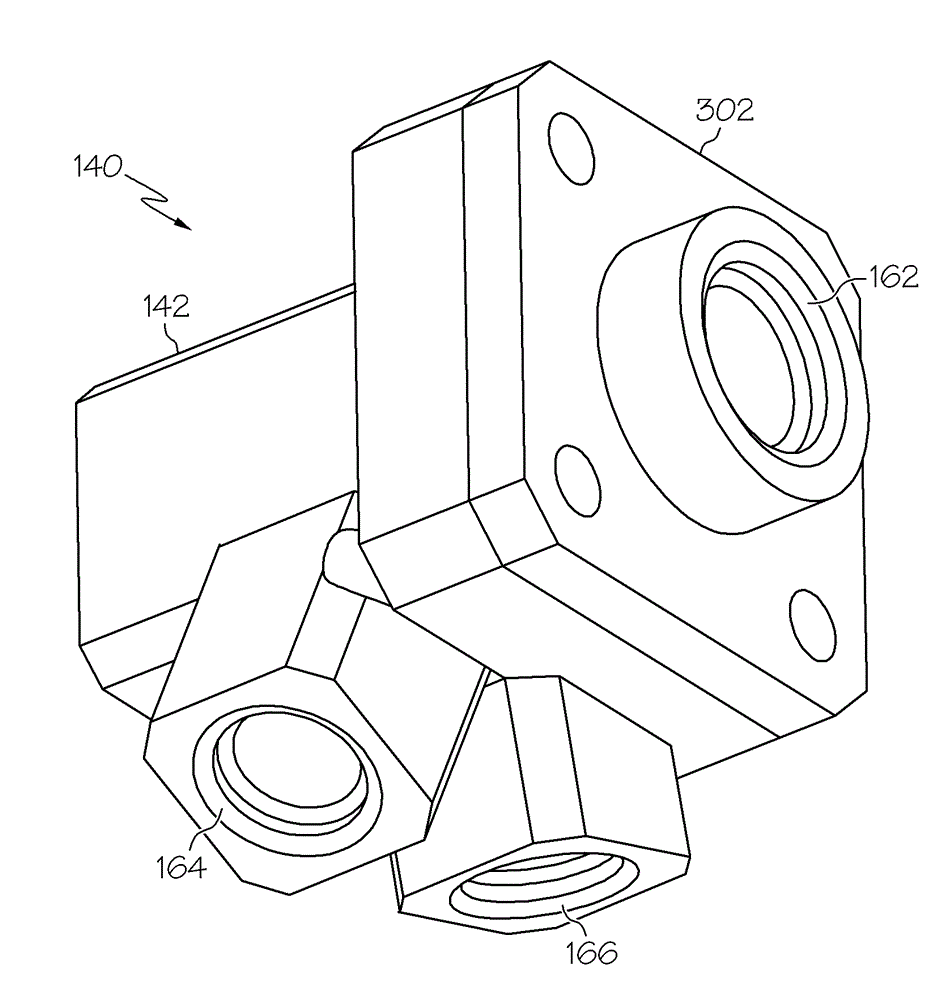

Lubrication system for a frac pump

A lubrication system for a frac pump includes a lubrication system housing, a lubricant tank held by the lubrication system housing, a heating device held by the lubrication system housing, a cooling device held by the lubrication system housing, and a filtration device held by the lubrication system housing. The lubrication system housing is configured to be at least one of mounted to a frac pump housing of the frac pump or held within the frac pump housing.

Owner:SPM OIL & GAS INC

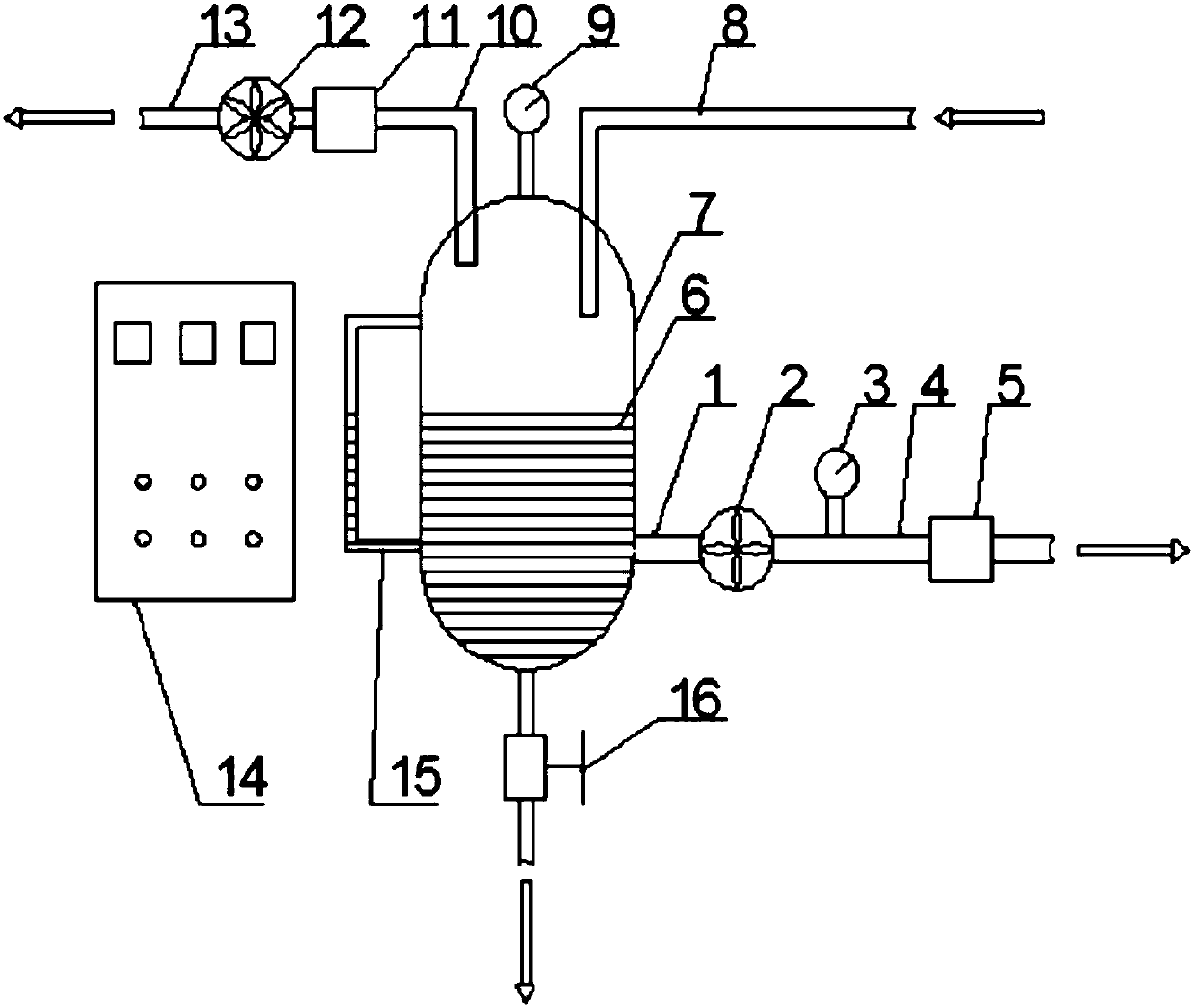

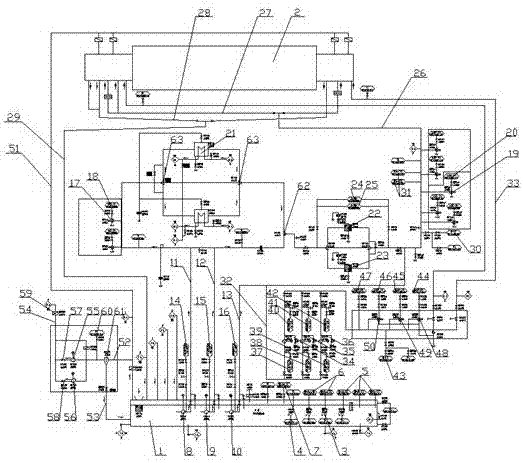

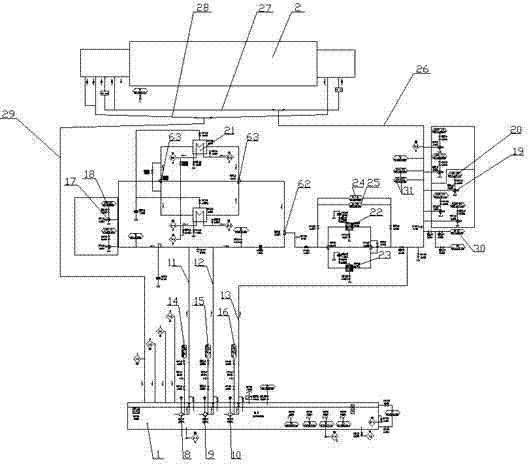

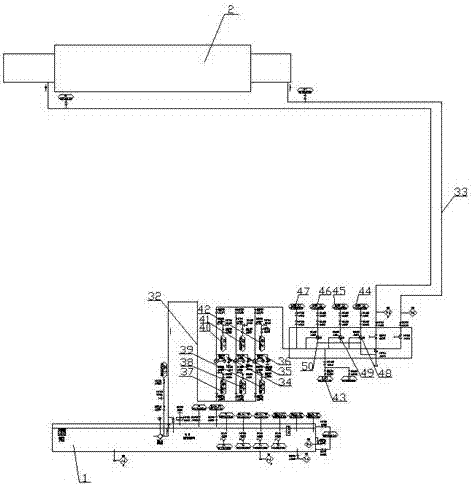

Gearbox lubricating system and lubricating oil flow control method of gearbox lubricating system

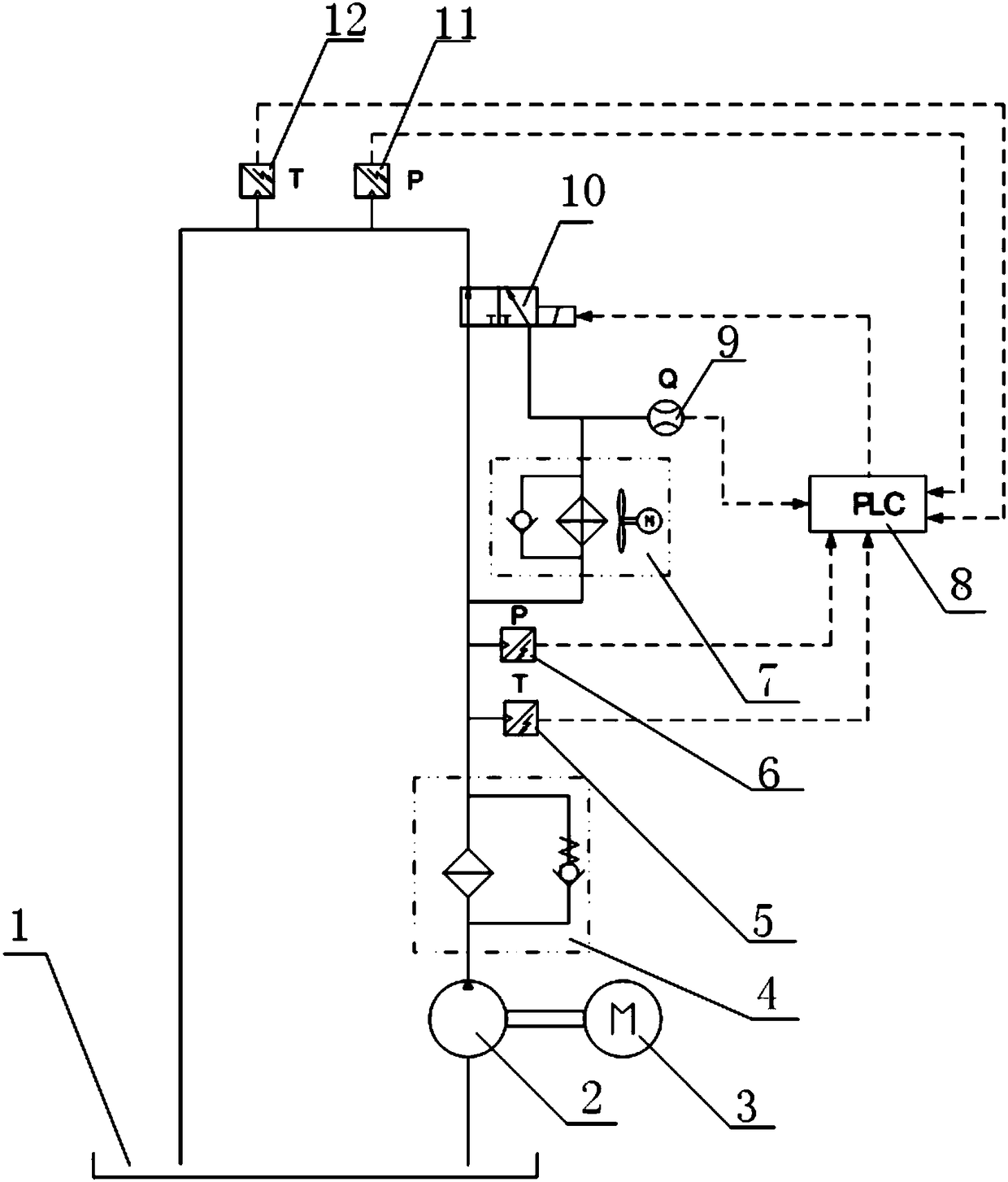

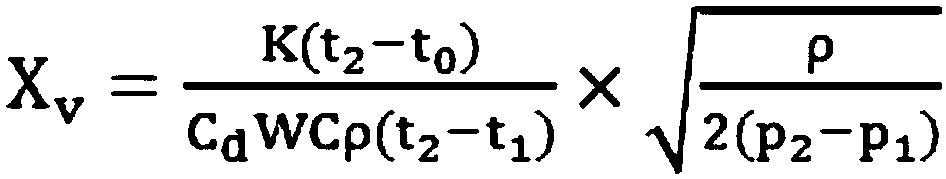

PendingCN108302188AEasy to operateEasy to controlTurbinesEngine temperatureElectric controlControl valves

The invention discloses a gearbox lubricating system. The system comprises an annular loop which is sequentially connected with a lubricating oil tank, an oil pump, a radiator and an electric controlreversing valve, wherein a through passage is further arranged between the oil pump and the control valve, and the through passage is arranged in parallel with the radiator; the system further comprises a PLC main controller, a first temperature sensor, a second temperature sensor, a first temperature sensor and a second temperature sensor, wherein the first temperature sensor, the second temperature sensor, the first temperature sensor and the second temperature sensor are connected with the PLC main controller; the electric control reversing valve is connected with the PLC main controller, the control of an open precision of the electric control reversing valve is realized through the PLC main controller according to the monitoring data of the first temperature sensor, the second temperature sensor, the first temperature sensor and the second temperature sensor. The invention further discloses a lubricating oil flow control method of the gearbox lubricating system. According to the system and method, the PLC main controller is additionally arranged, the electric control reversing valve, the temperature sensors and pressure sensors are connected with the PLC main controller, wherein the service life and the precision control of the electric control reversing valve are relatively high, so that the service life and the intelligent control degree of the gear box lubricating system can be greatly improved.

Owner:GUODIAN UNITED POWER TECH

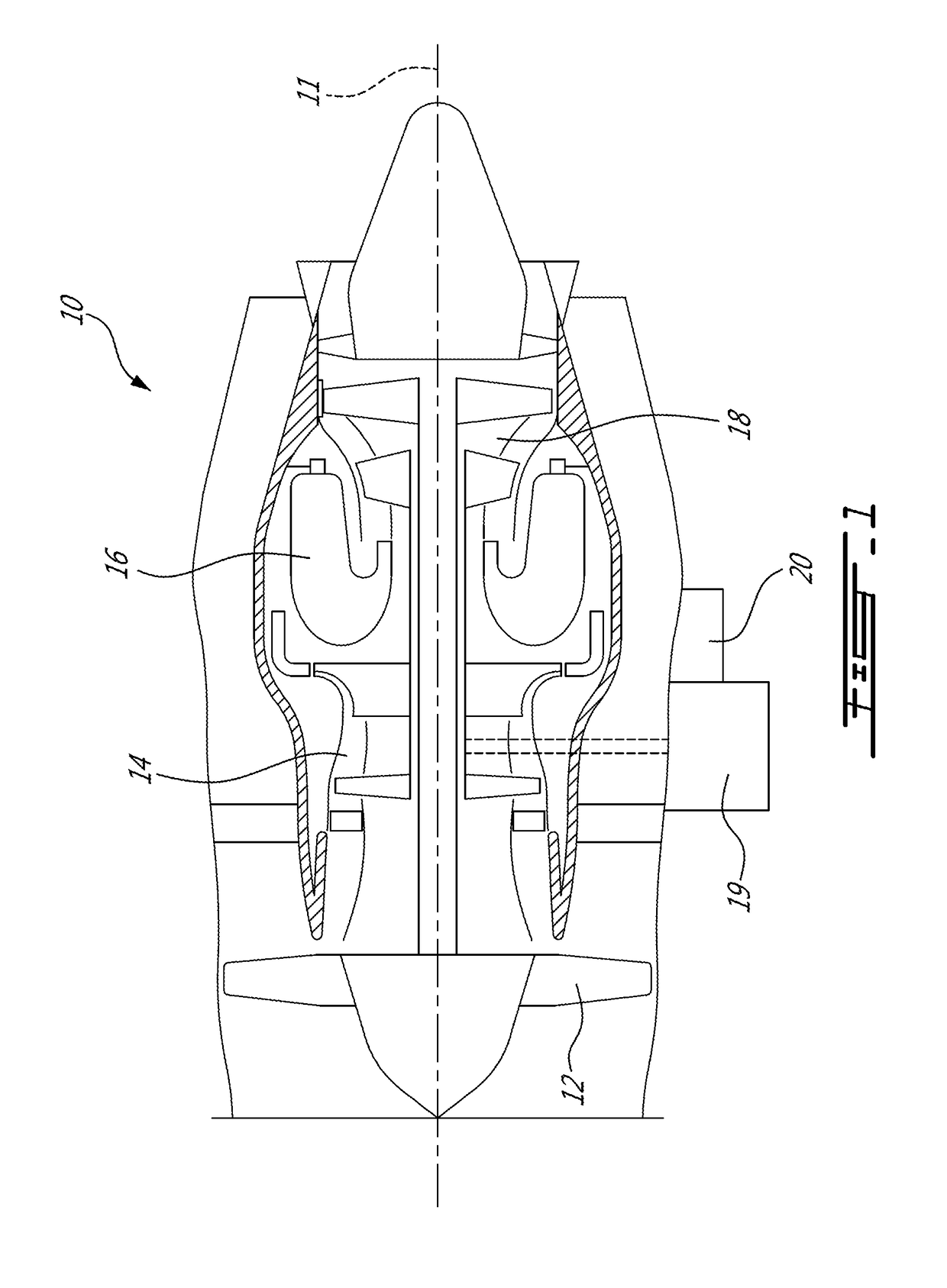

Shared oil system arrangement for an engine component and a generator

A method of distributing oil to a component within a gas turbine engine includes directing a first oil flow from an oil source to an engine component and back to the oil source, directing a second oil flow from the oil source to a generator driven by the engine and back to the oil source, monitoring a parameter of the second oil flow downstream of the generator and upstream of the oil source, detecting a contaminant in the second oil flow based on the parameter, and reducing the second oil flow to the generator when the contaminant is detected without reducing the first oil flow to the engine component. A shared oil system for a component of a gas turbine engine and a generator driven by the gas turbine engine is also discussed.

Owner:PRATT & WHITNEY CANADA CORP

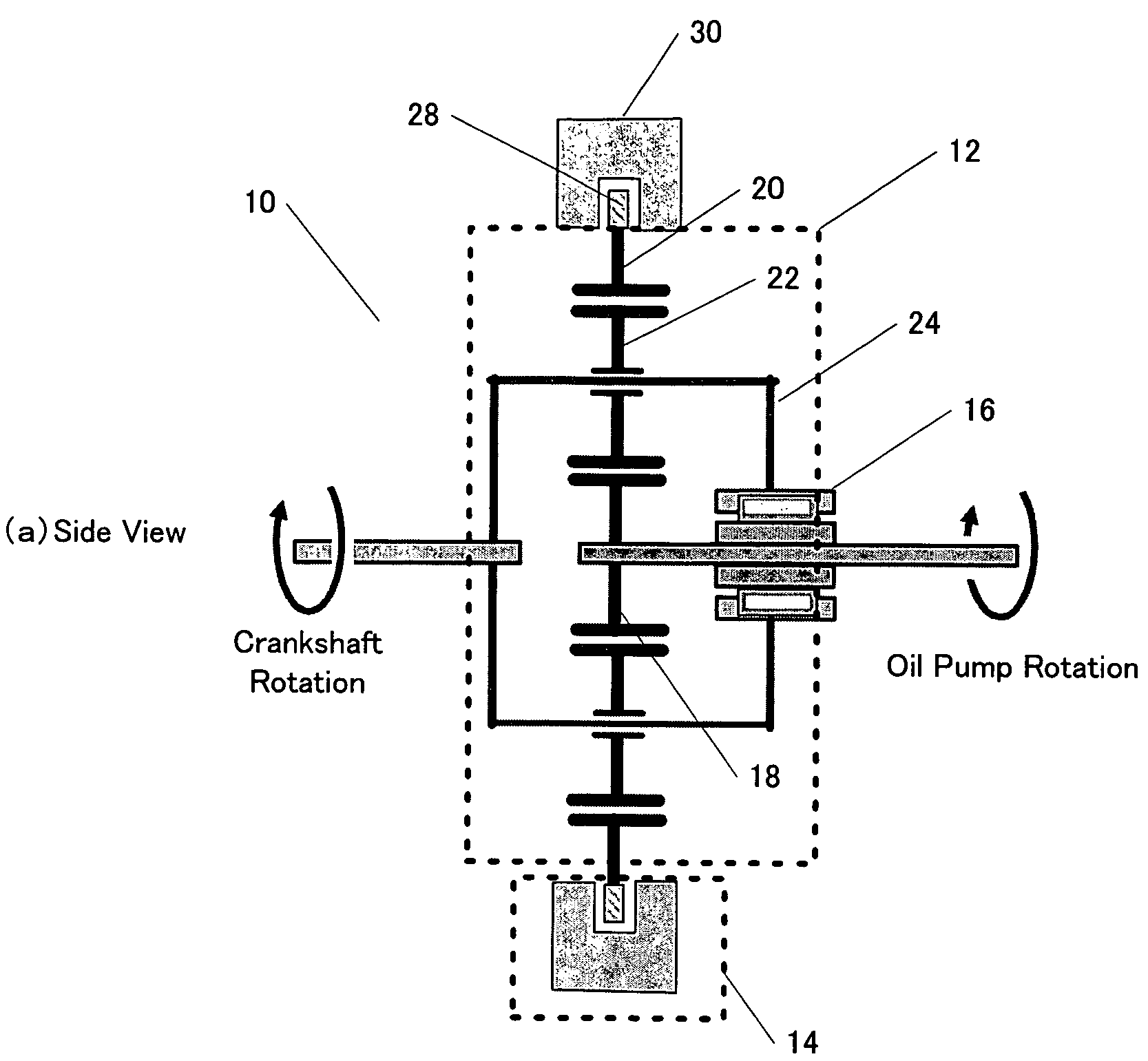

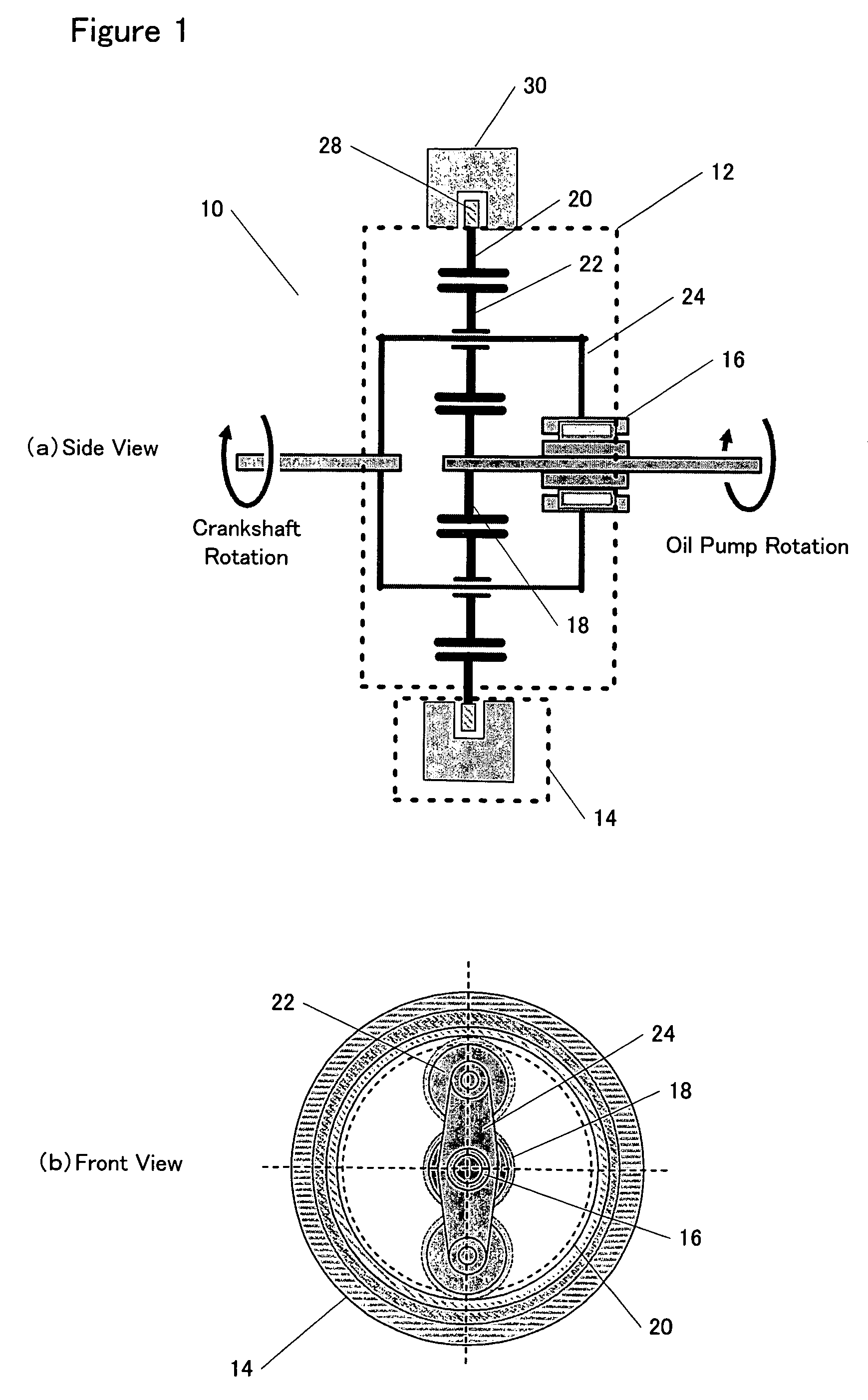

Variable capacity fluid pump for an engine

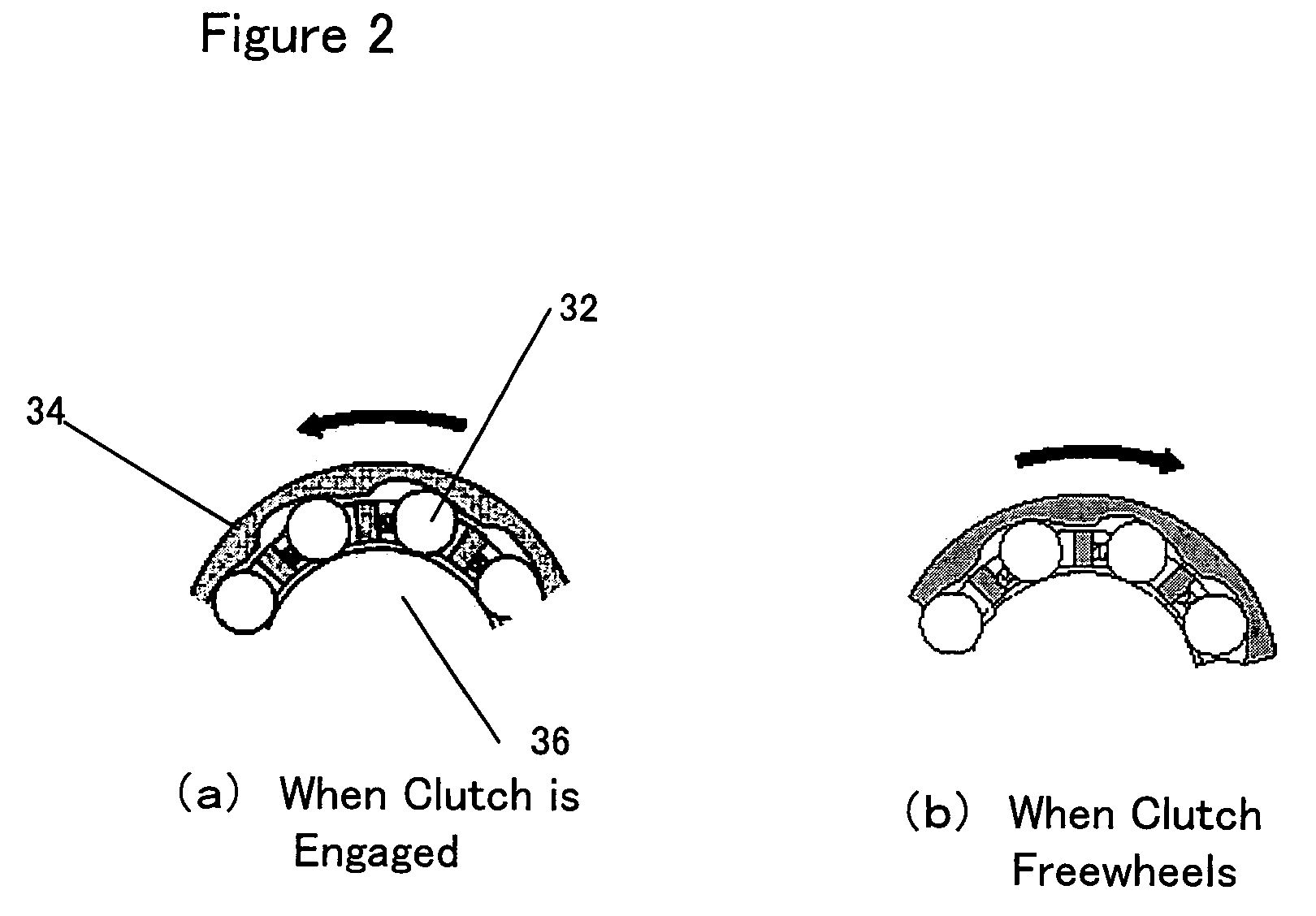

InactiveUS7503753B2Work lessImprove fuel efficiencyEngine pressureCoolant flow controlGear wheelCrankshaft

A variable capacity fluid pump that can be controlled independently of the rotation of the engine is provided. The fluid pump comprises a planetary gear mechanism having a first gear, second gears and a third gear. The second gears are connected to a crankshaft of the engine and transmits a rotational force of the crankshaft. The third gear is connected to the fluid pump. The fluid pump further comprises braking means connected to the first gear. The breaking means generates a braking force upon the first gear. The fluid pump further comprises a one-way clutch provided between the second gears and the third gear. The braking means controls a rotational speed of the first gear so that a rotational speed of the fluid pump is controlled independently of a rotational speed of the crankshaft of the engine.

Owner:HONDA MOTOR CO LTD

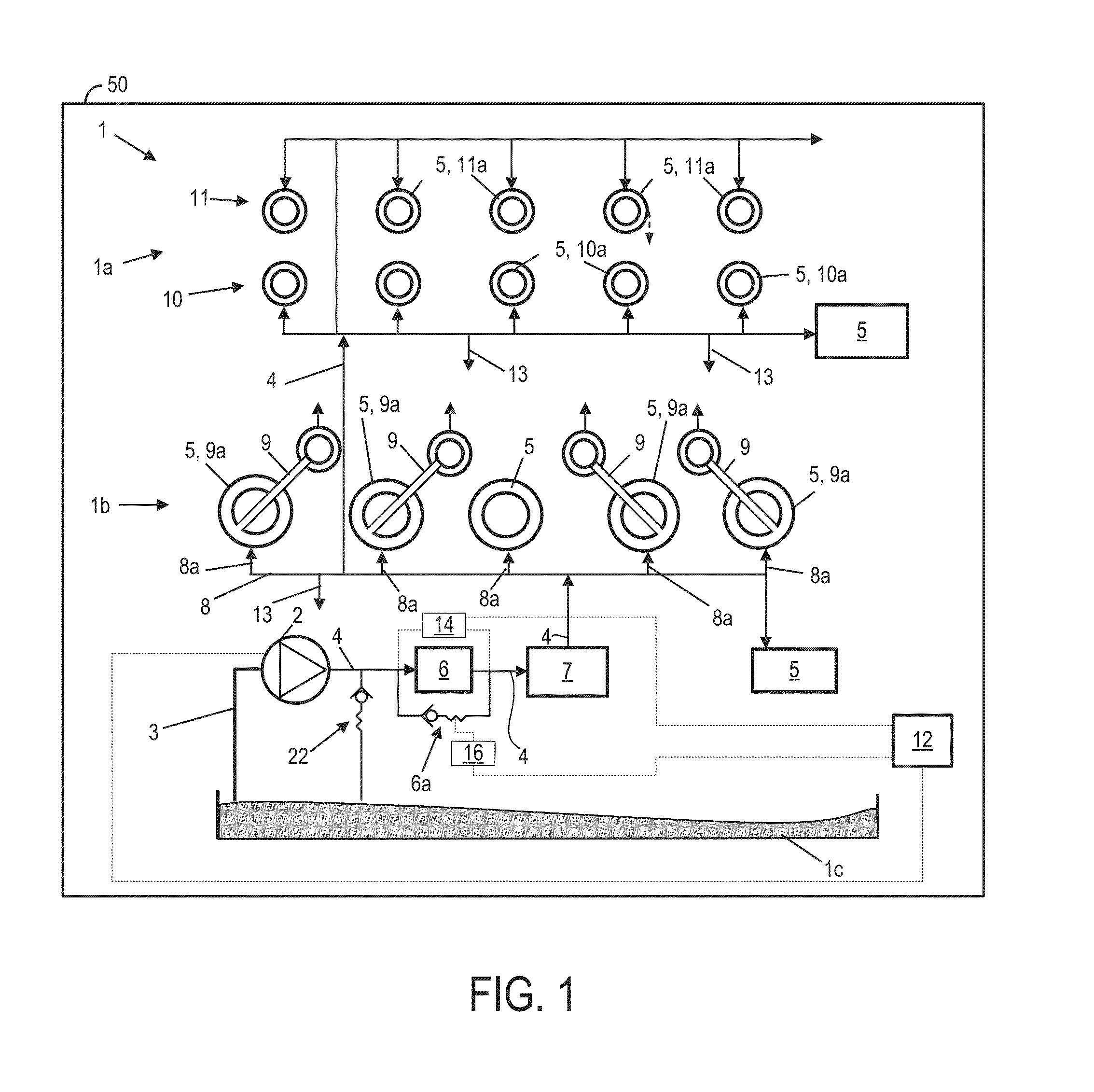

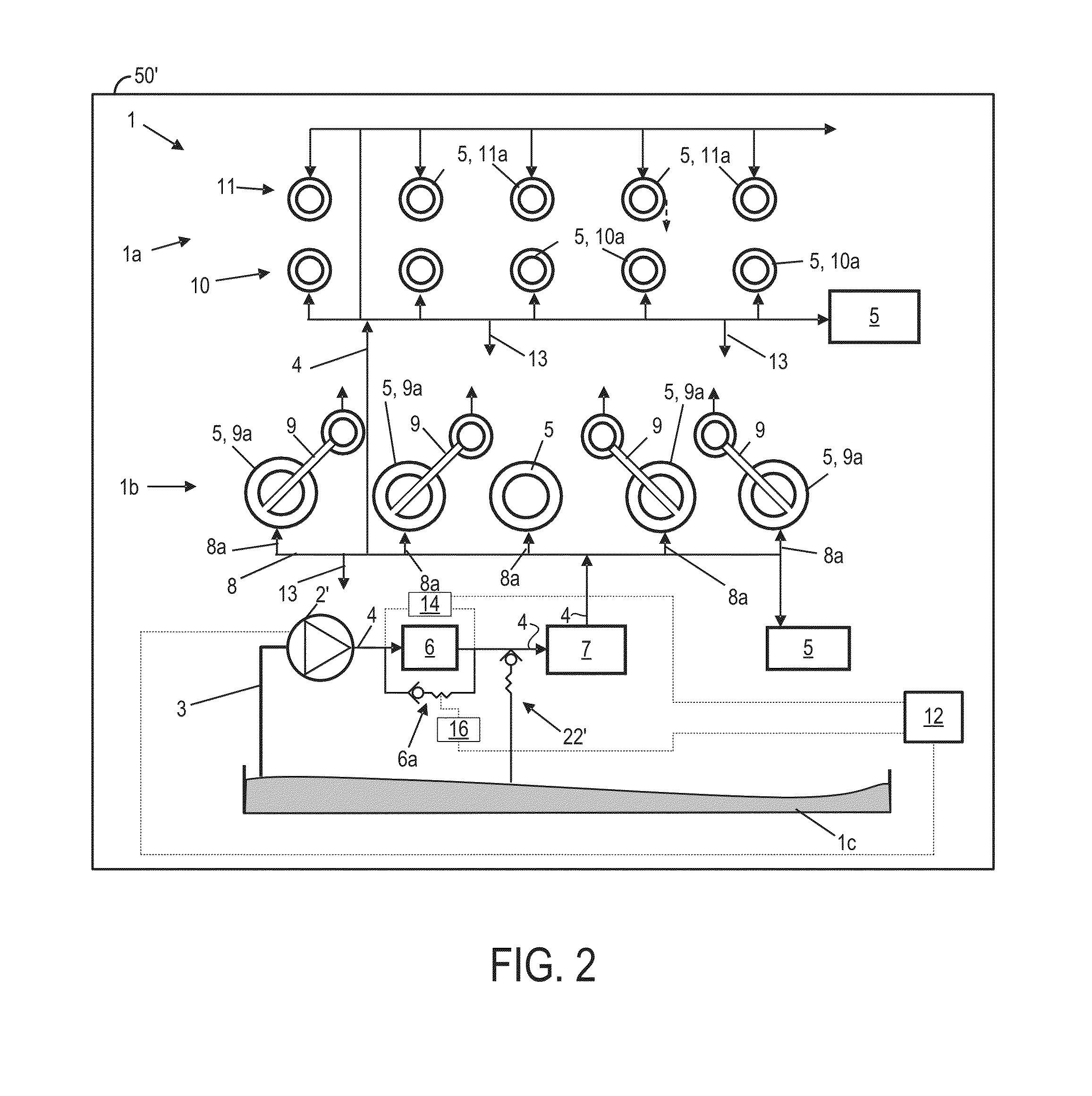

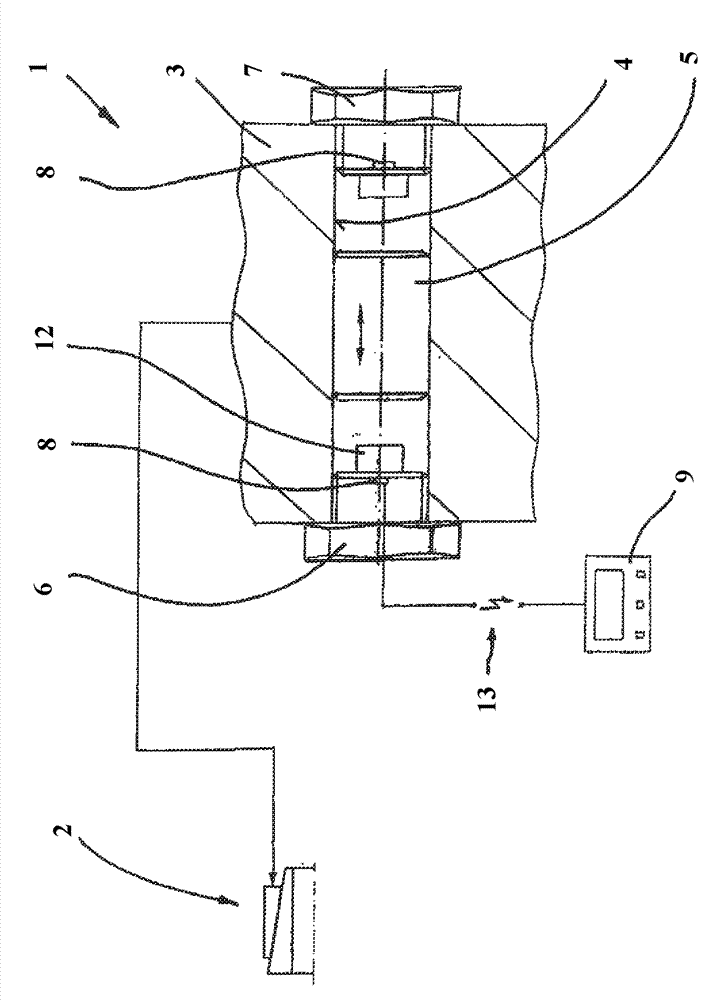

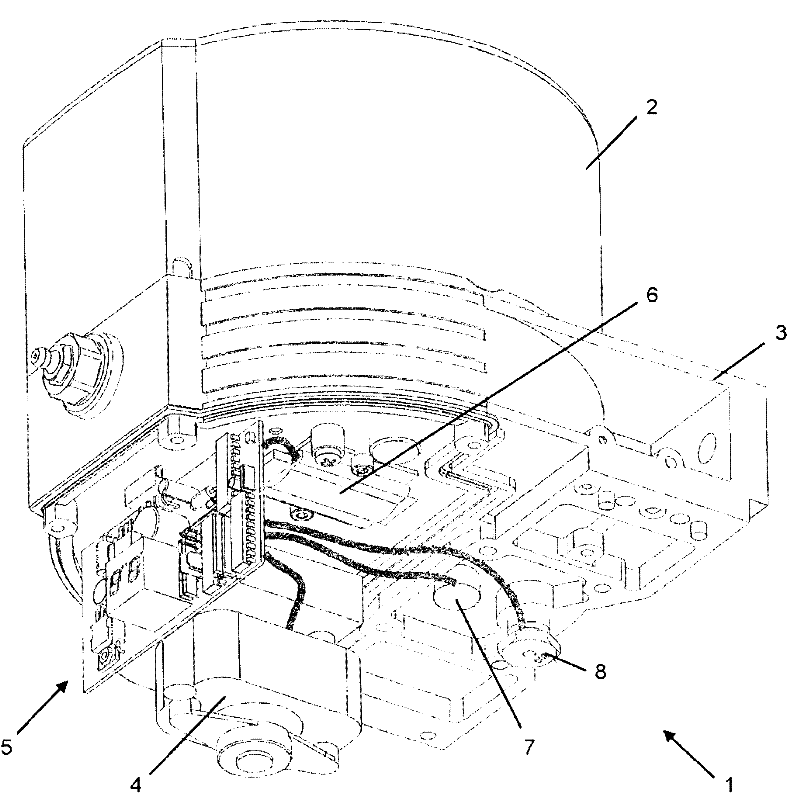

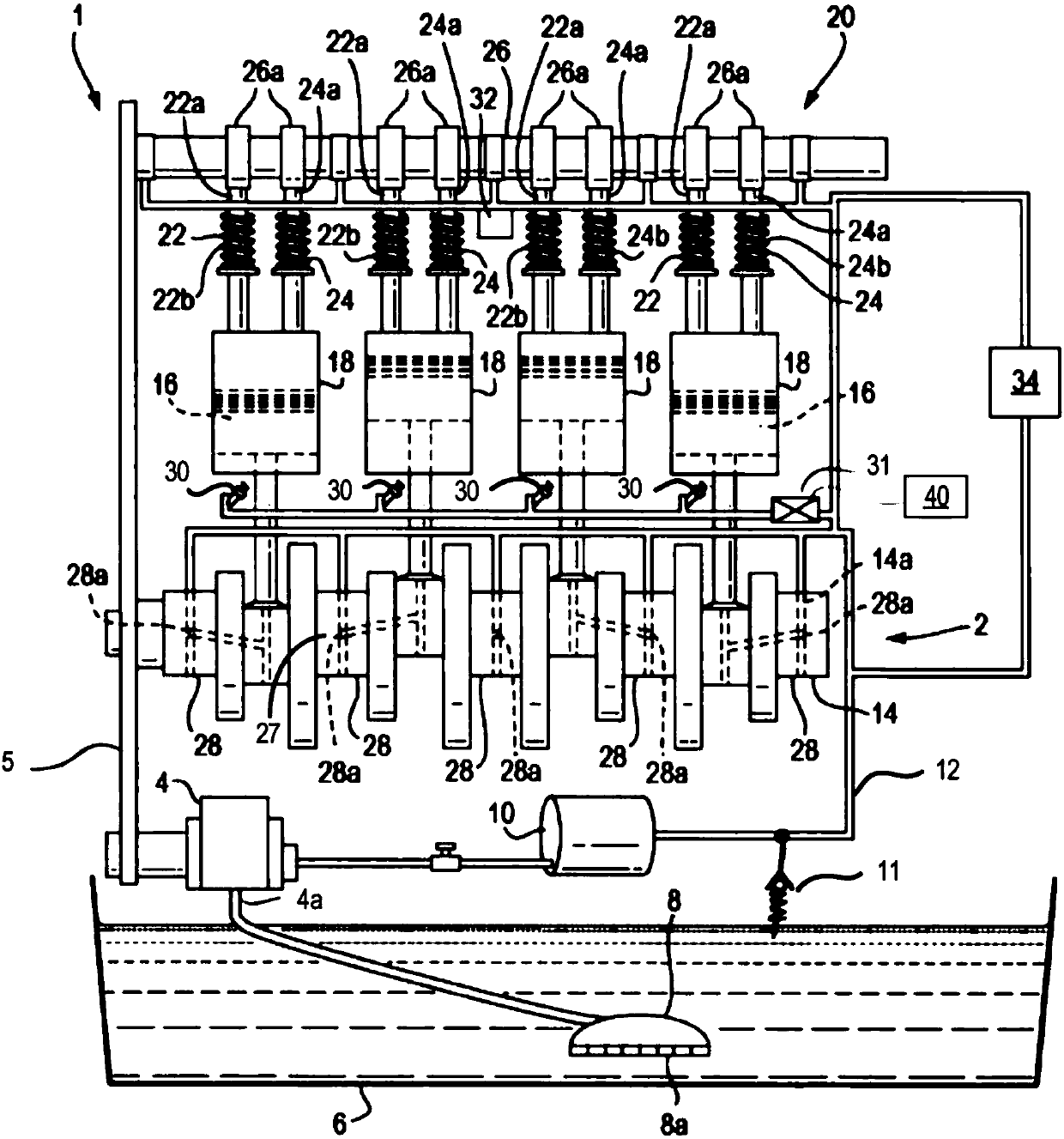

Lubricating device for supplying a tool with lubricant

InactiveCN103542246ATimely detection of wearAvoid damageEngine temperatureEngine pressureEngineeringLubricant

The invention relates to a lubricating device (1) supplying lubricating agents, especially lubricating grease or lubricating oil to a tool (2). The lubricating device (1) comprises a lubricating distributor (3). At least one piston hole (4) is introduced into the lubricating distributor. A piston (5) which can move back and forth is arranged inside the piston hole. The piston hole (4) parts in the axial end part areas can be locked respectively through locking bolts (6, 7). In order to guarantee the monitoring of a lubricating system especially when used in a pipe expanding tool, the invention has at least one sensor (8) arranged in or beside at least one locking bolt (6). The sensor is connected with a monitoring device (9) so as to detect and monitor at least one running parameter of the lubricating distributor (3).

Owner:SMS MEER

System and method to provide lubrication for a plug-in hybrid

In hybrid electric vehicles having increased battery storage capacity and plug-in capability, electric-only operation of significant duration is available. To supplement lubrication for the electric and mechanical components provided in a fluid circuit by an engine-driven mechanical pump, an electric pump is provided in parallel to the mechanical pump. When the electric pump is operating, a diagnostic can be performed to determine system integrity. According to one embodiment, an actual quantity provide to the circuit is determined; an expected quantity is estimated; and a fault is determined when the actual and expected quantities differ by more than a predetermined amount. The fault may indicate a leak or plug in the fluid circuit or a failure of a component in the fluid circuit.

Owner:FORD GLOBAL TECH LLC

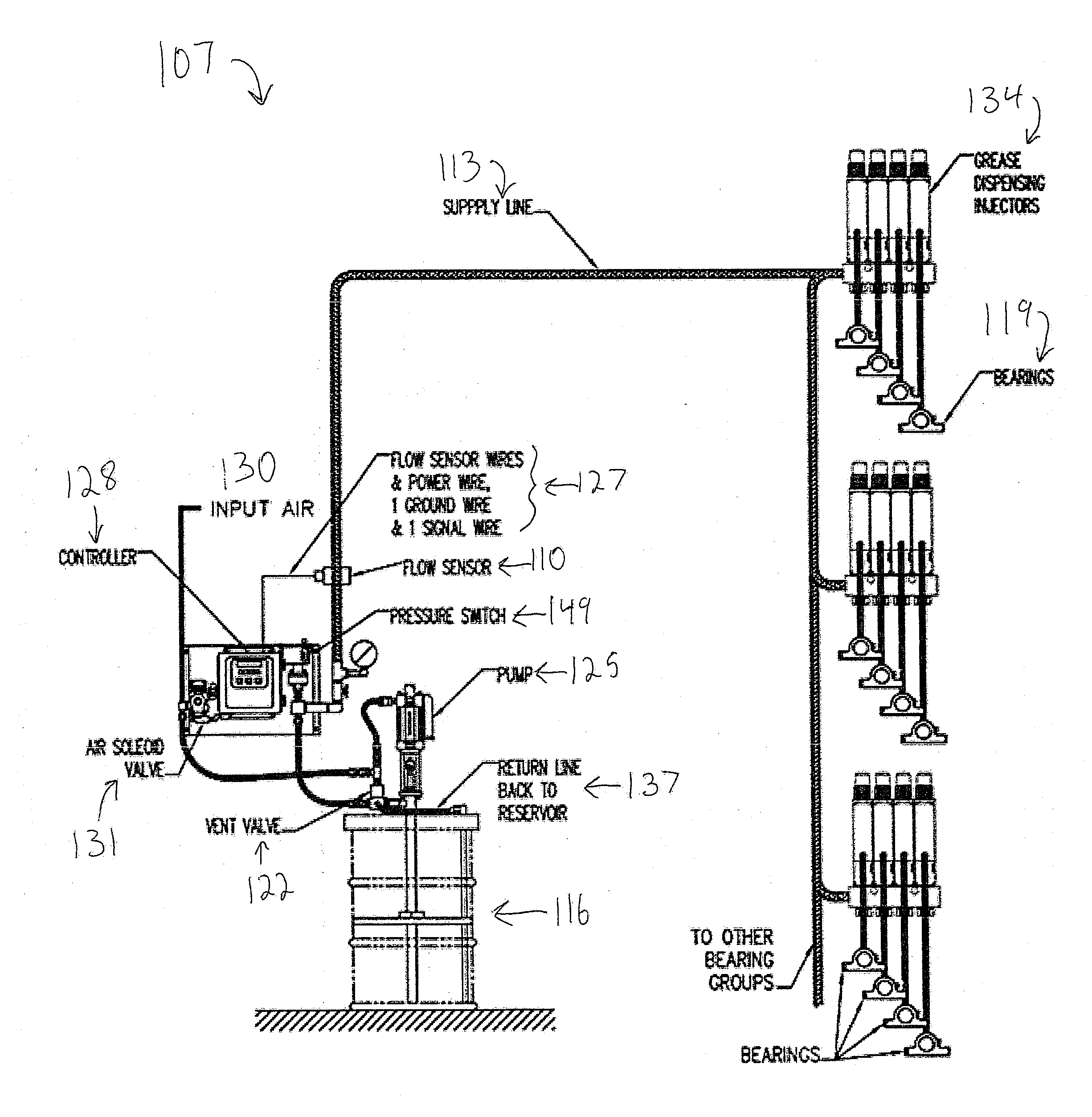

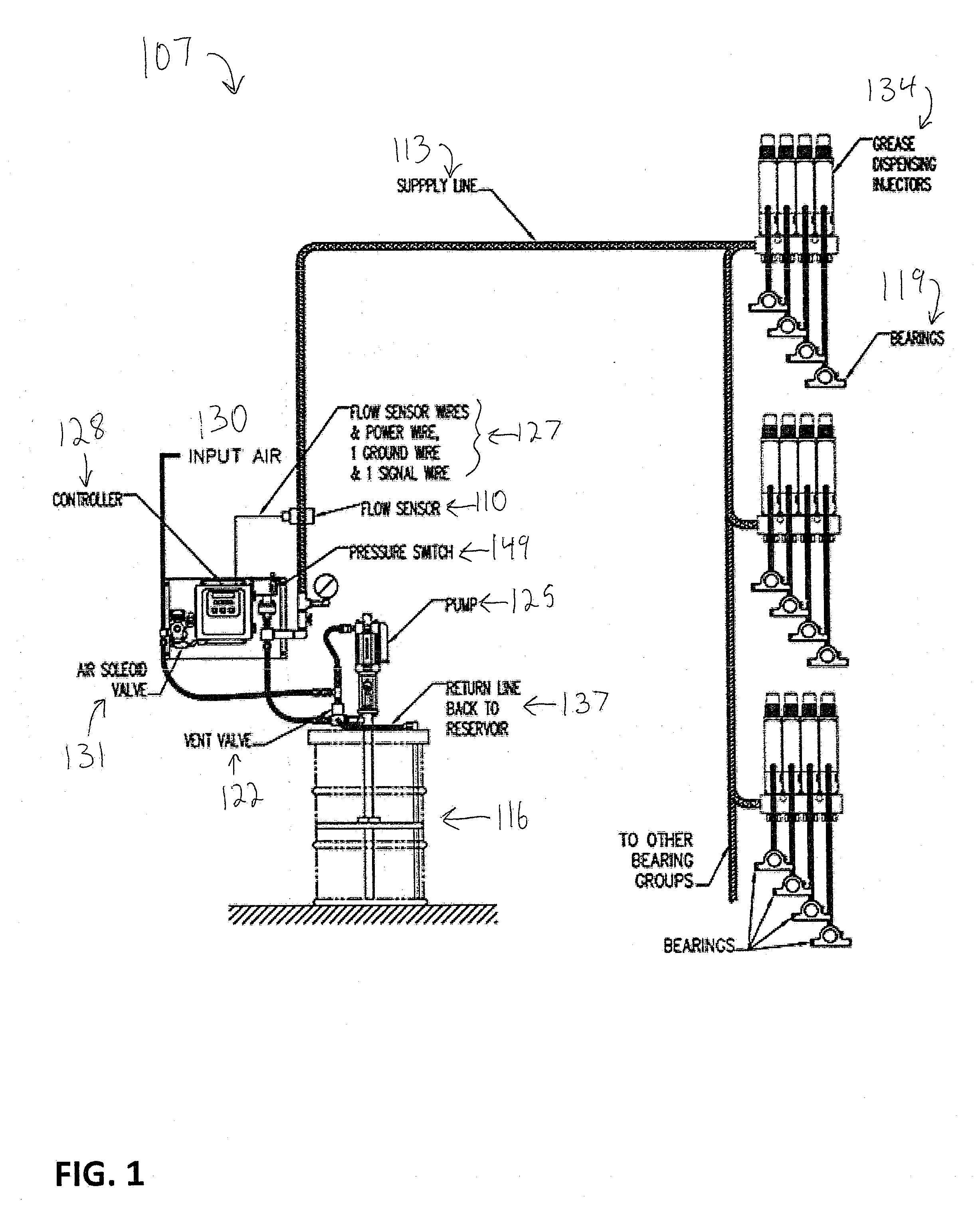

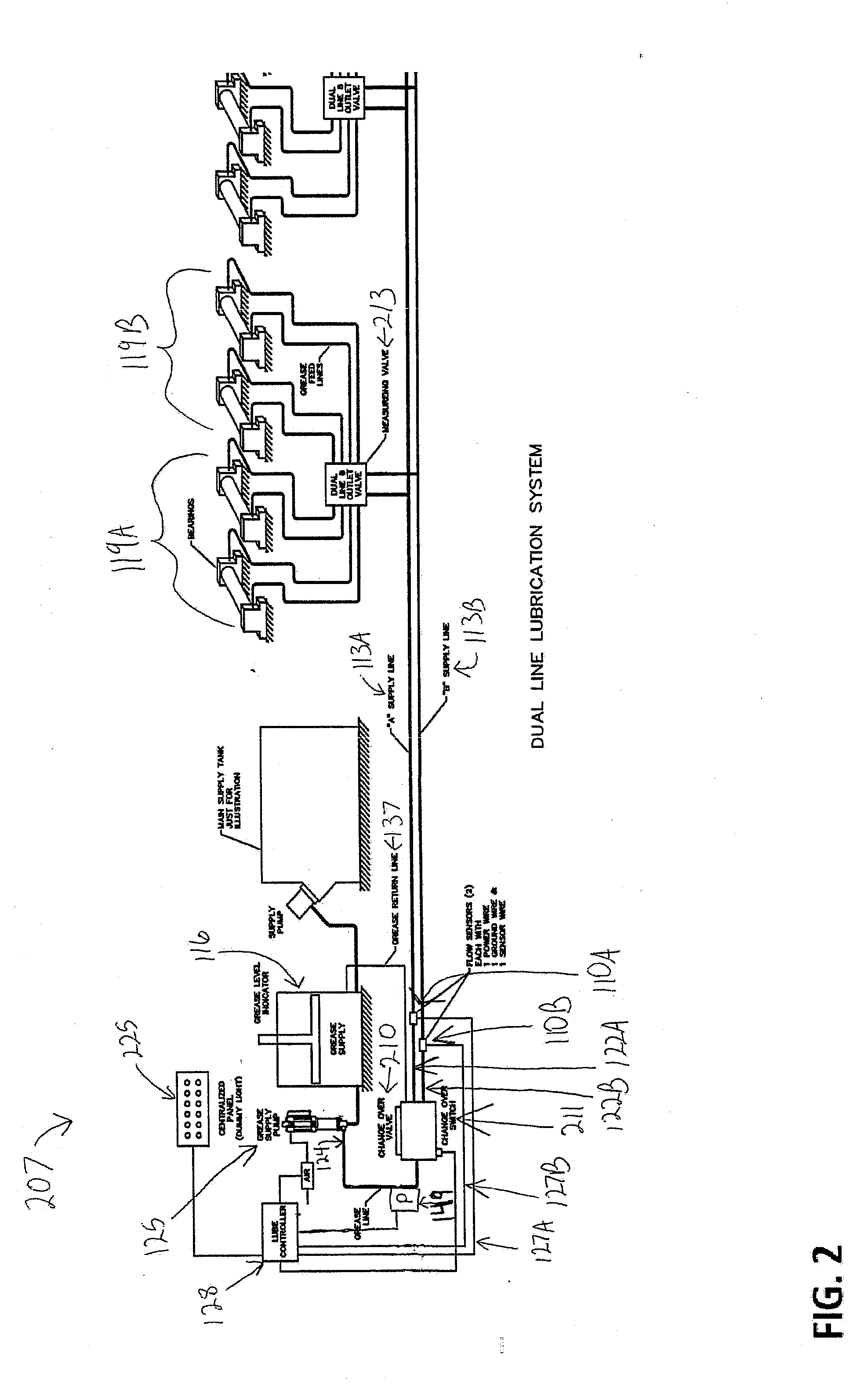

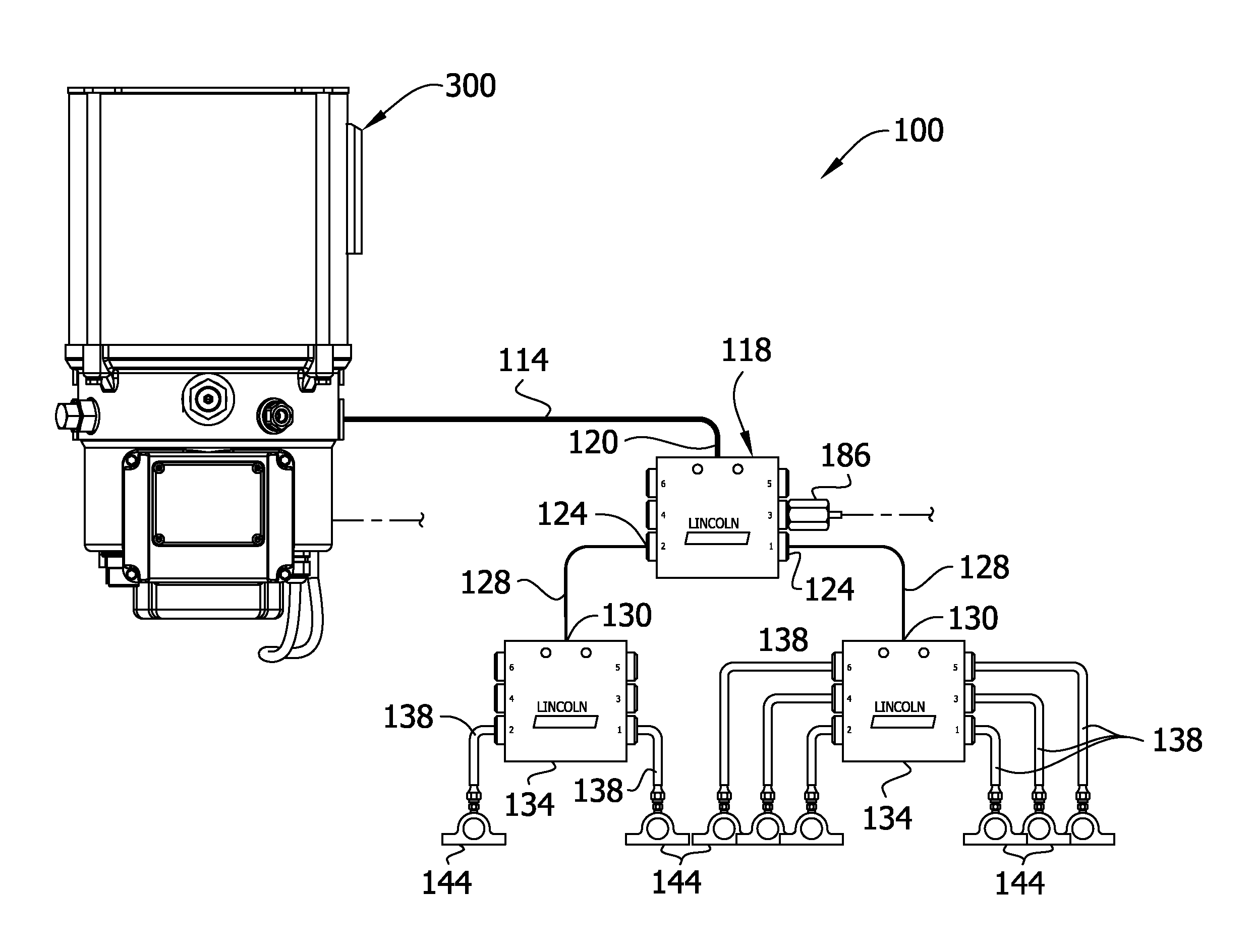

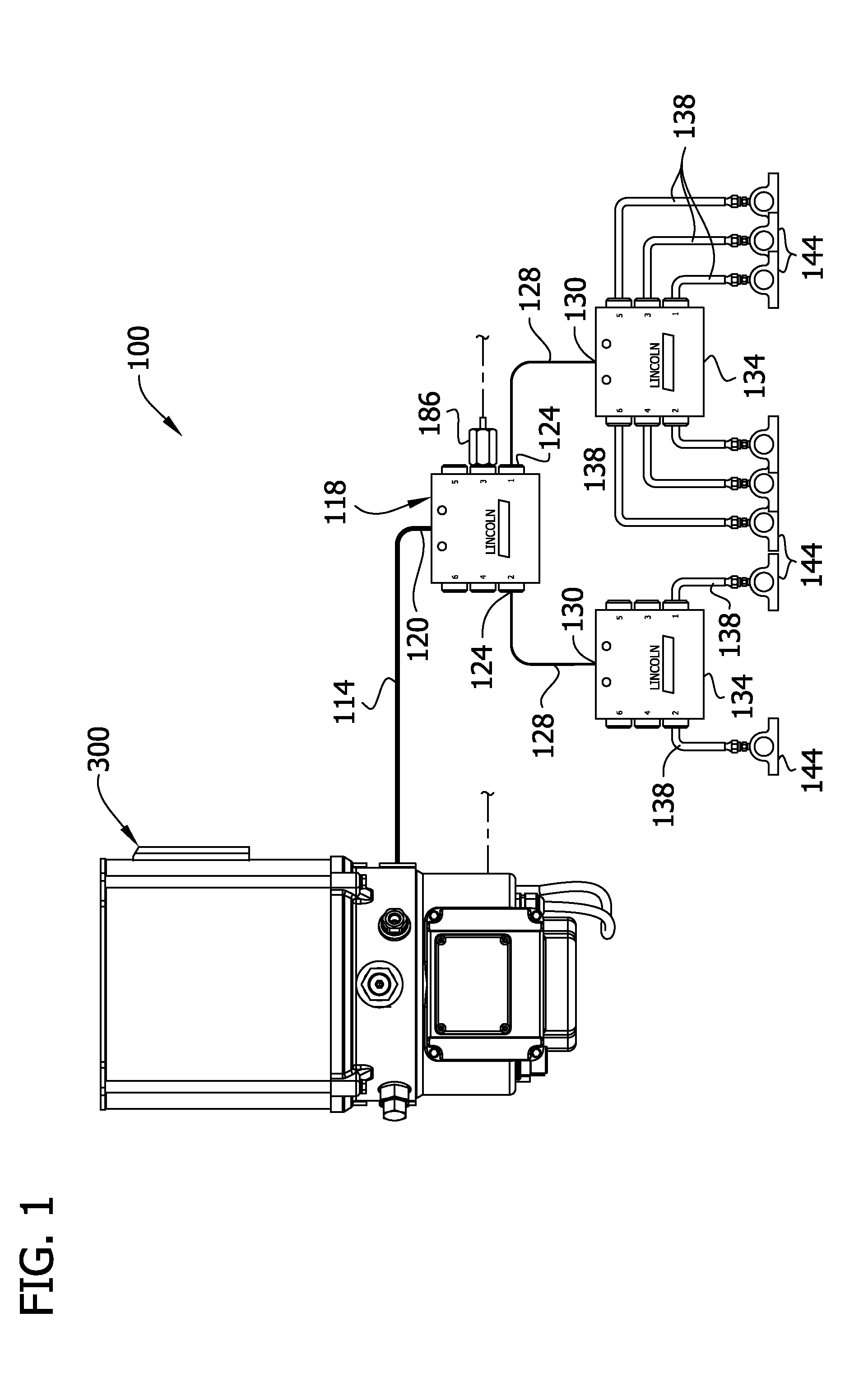

System and method of confirming lubrication to bearing

Methods and systems for determining lubrication flow dispensed to lubrication points. Lubricant delivery is determined based upon the difference between volume measurements detected as the lubricant is delivered to the lubrication points, and volume measurements detected as the lubricant is vented after delivery. A flow sensor in the lubricant supply line measures lubricant delivered and lubricant vented and a controller determines the amount dispensed based upon the difference between the delivered and vented measurements.

Owner:LINCOLN INDUSTRIES CORP

Anti-leakage lubricating oil supply system of power device

The invention discloses an anti-leakage lubricating oil supply system of a power device, and belongs to the technical field of mechanical and power equipment lubrication supply. The lubricating oil supply system comprises an oil supply pump oil inlet pipe, an oil supply pump, an oil supply pressure meter, an oil supply pump oil outlet pipe, an oil supply filter, lubricating oil, an oil storage tank, an equipment oil return pipe, an oil storage tank pressure meter, a vacuum pump air inlet pipe, a vacuum pump air inlet filter, a vacuum pump and a vacuum pump exhaust pipe. According to the system, the lubricating system conducts lubrication in the running manner of the negative pressure lower than the environment pressure, an inlet and an outlet of a lubricating oil pump are in negative pressure; during work, the lubricating oil pump conveys the lubricating oil to the lubricating part; through control the pressure of the vacuum pump and the oil pump, it is guaranteed that the pressure atthe lubricating part is lower than the outer pressure of the lubricating system, a small amount of gas flows into a sealing cavity from the exterior of the lubricating system, the lubricating oil is driven to flow in the equipment oil return pipe direction, and accordingly the purpose that lubricating oil is prevented from leaking outwards from a gap is achieved. The system is applicable to gas turbines or other high-speed rotation power machines.

Owner:HARBIN ENG UNIV

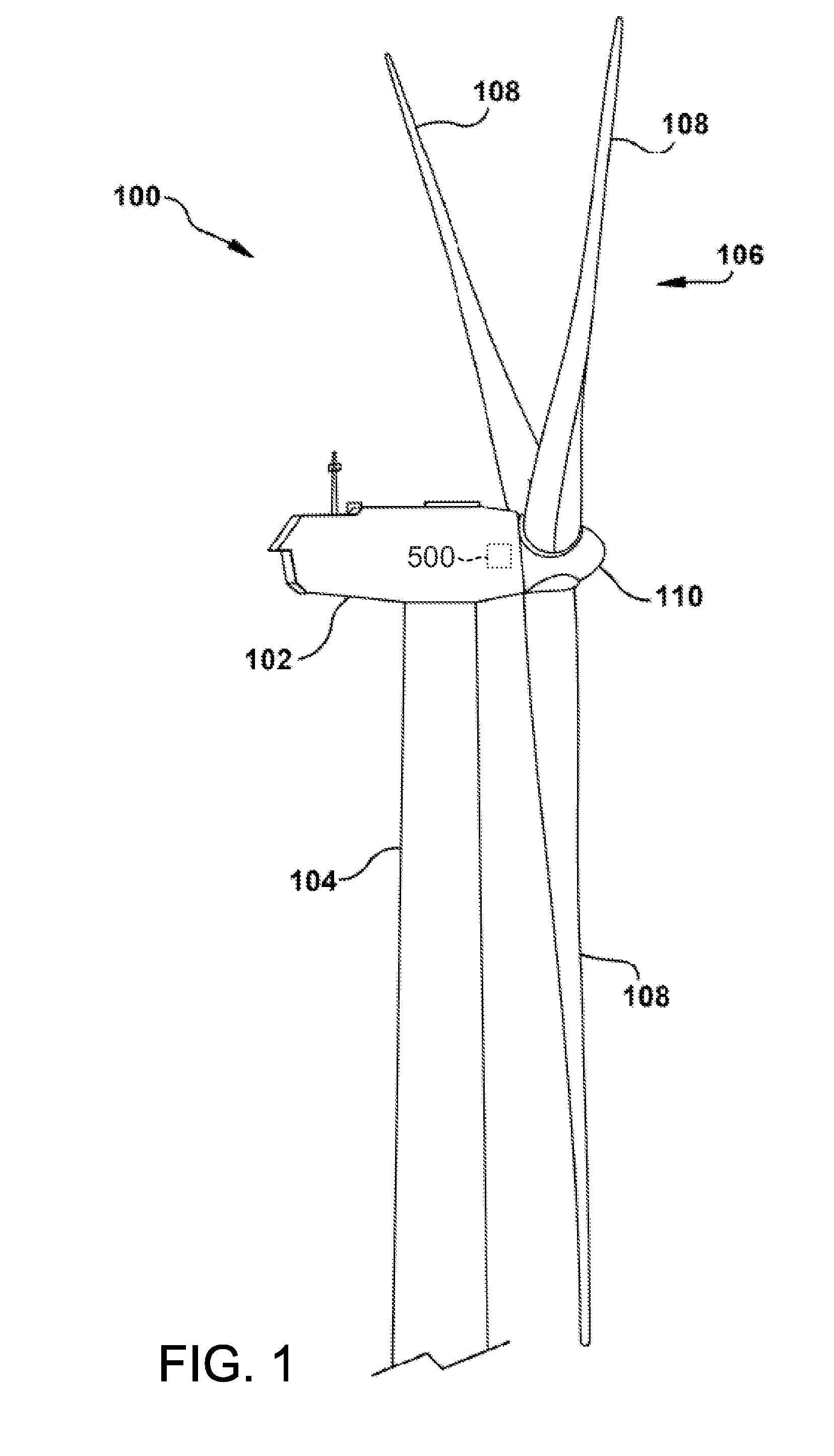

Lubrication system and wind turbine incorporating same

Owner:GENERAL ELECTRIC CO

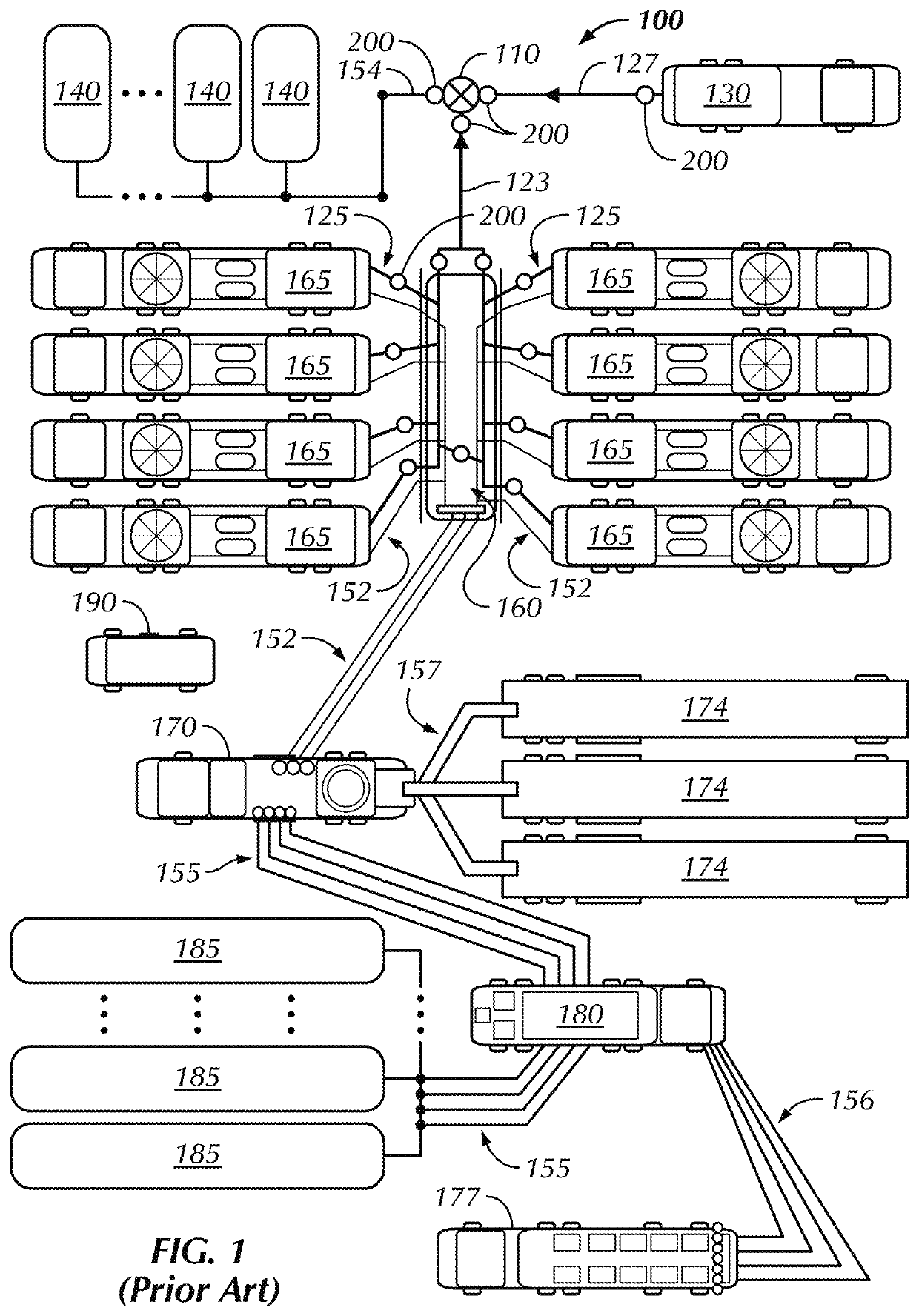

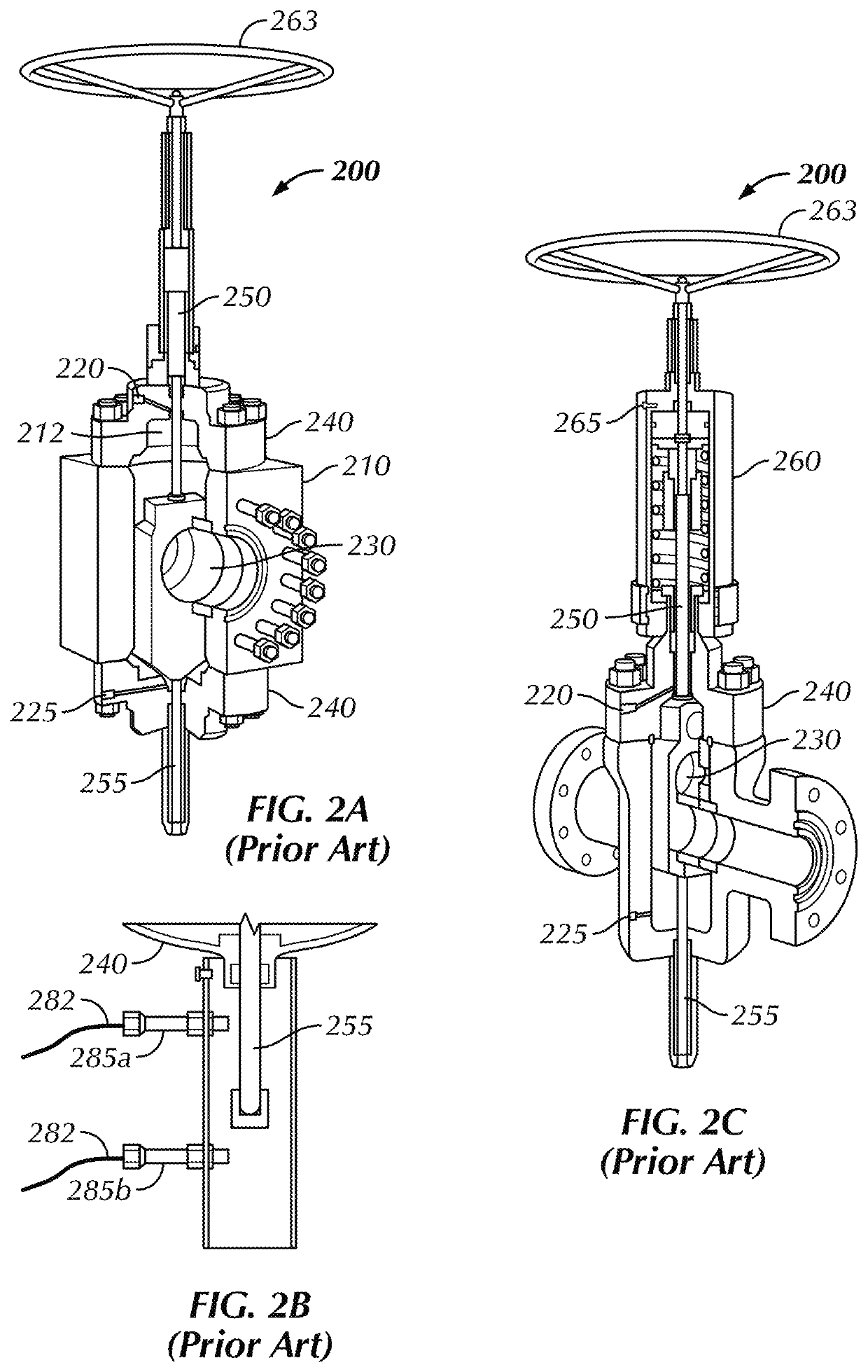

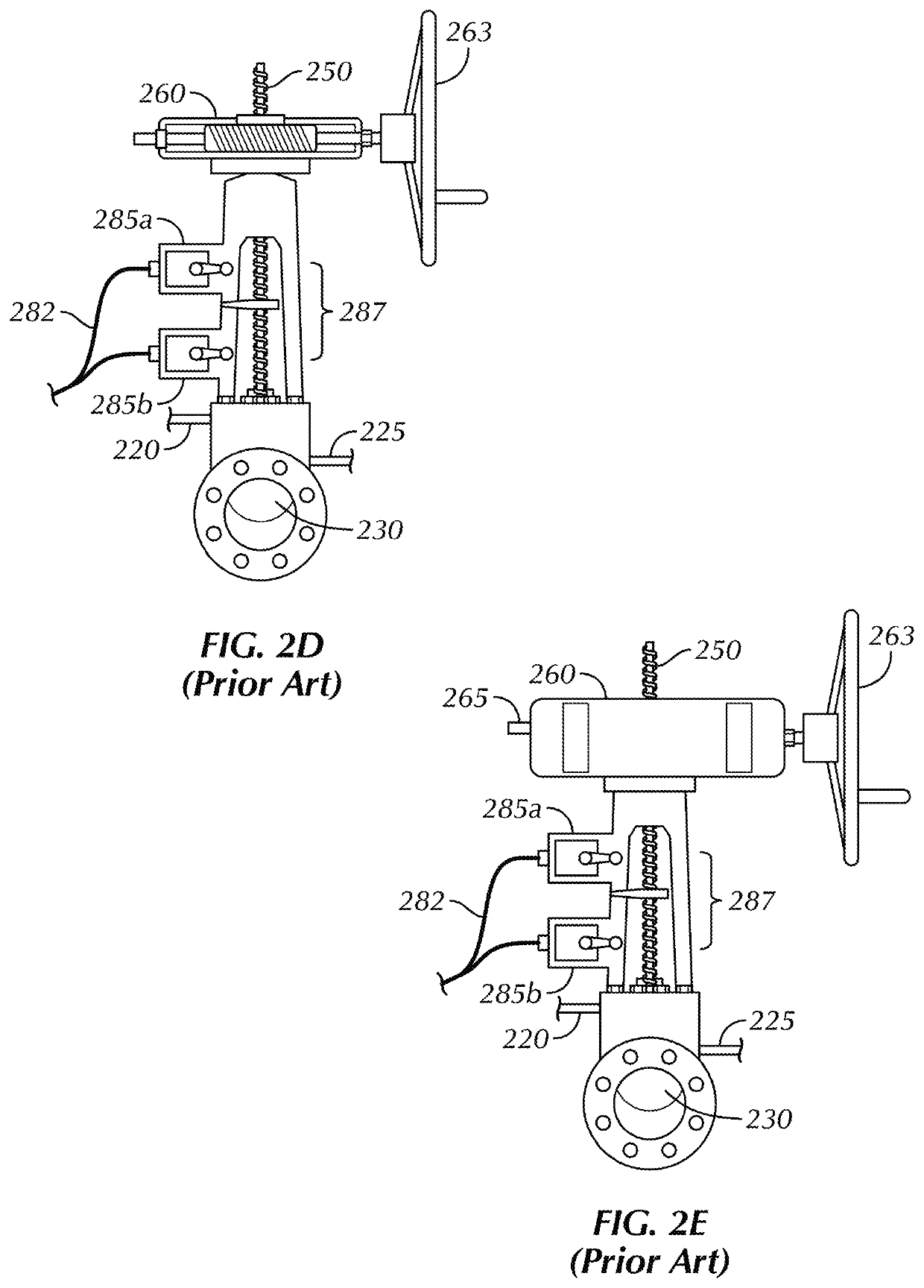

Method and Apparatus for Monitoring and On-demand Lubricating of Industrial Valves

A method of monitoring industrial valve actuation and maintaining an industrial valve by lubricating it on-demand and in coordination with in-service valve operations through an automated system eliminating downtime and / or exposure of personnel to hazardous environments through centralized lubricant supply and spent fluid collections.

Owner:BATFER INVESTMENT SA

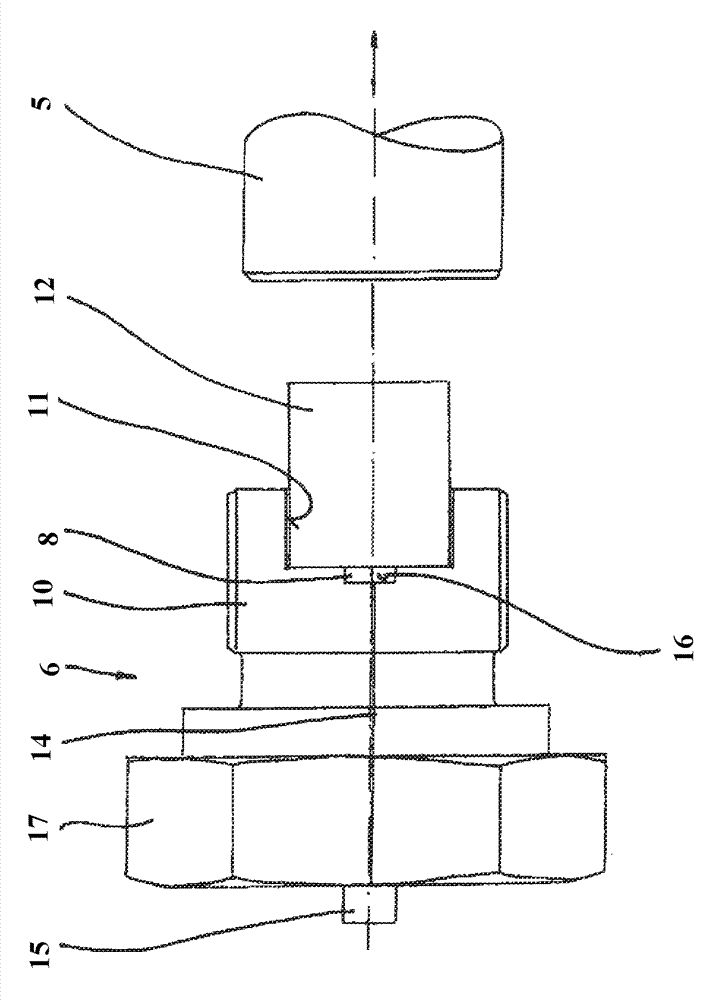

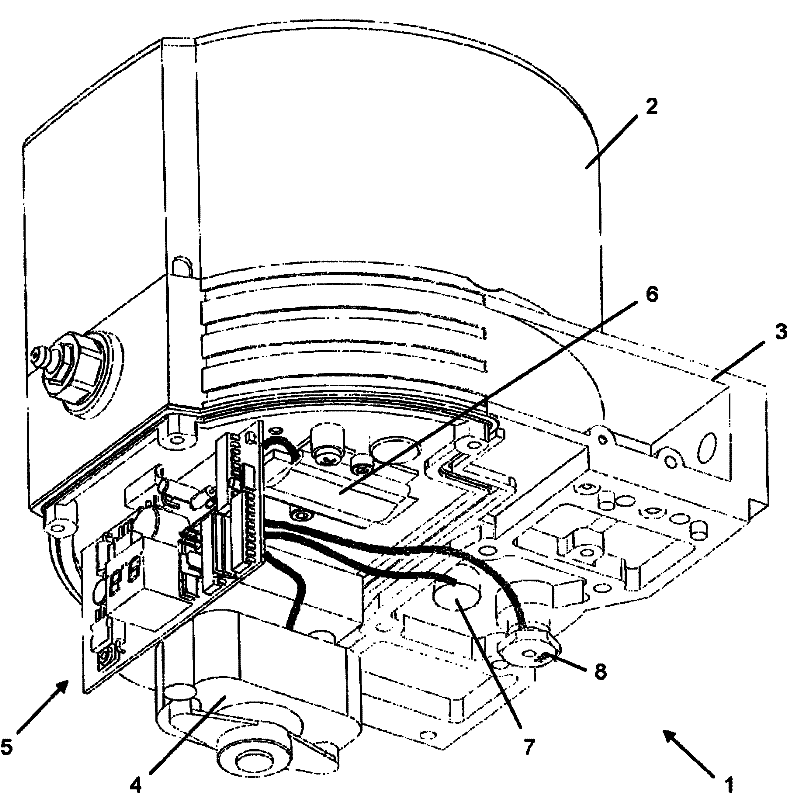

Lubricant pump and lubricating system with pump heater

InactiveCN102537629AEliminate the cause of the failureReduce usageEngine temperatureEngine pressureEngineeringLubricant

A lubricant pump is disclosed for delivering lubricant to at least one lubricating point. The pump features a lubricant container (2), a pump unit, a drive (4) assigned to the pump unit, and at least one lubricant outlet and a control unit (5) assigned to the drive (4). At least one heating element (6) is also provided and can be actuated by the control unit and / or another control unit (5). In addition, the invention further relates to a lubricating system with the lubricant pump.

Owner:LINCOLN GMBH

Device for supplying lubricant to a lubrication point in a machine

InactiveCN104006281AReduce lossesEngine pressureProportioning devicesTunnel boring machineEngineering

A device for supplying lubricant to a lubrication point in a machine, a tunnel boring machine, for example, includes a lubrication pump unit and a control unit. The lubrication pump unit is configured to supply a quantity of the lubricant to the lubrication point, and the control unit is configured to regulate the quantity of lubricant based on a sensor measurement signal. The sensor measurement signal may be based on a temperature measured in a region of the lubrication point, a pressure measured in a region of the lubrication point, a measured viscosity of the lubricant, a measured dielectricity of the lubricant, a measured water content of the lubricant, a vibration intensity measured at a part of the machine, or a measured rotational speed of a part of the machine.

Owner:SKF LUBRICATION SYST GERMANY

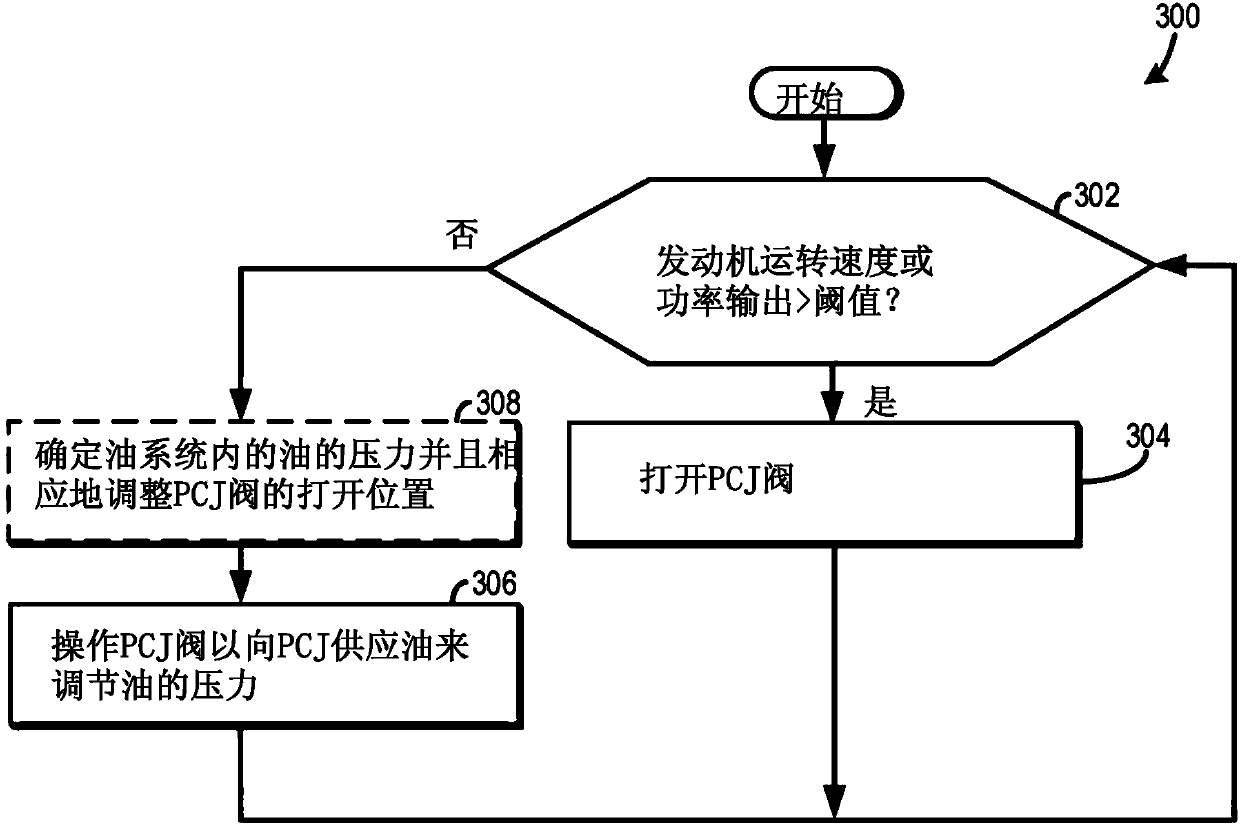

Method and apparatus to regulate oil pressure via controllable piston cooling jets

InactiveCN107781022AImprove efficiencyLow costLiquid coolingEngine pressureSpray nozzleControl valves

The invention relates to a method and apparatus to regulate oil pressure via controllable piston cooling jets. A method of regulating oil pressure within an engine assembly is provided. The engine assembly includes an oil pump configured to provide oil to an oil system of the engine assembly; a piston cooling jet configured to direct a jet of oil from the oil system towards a piston of an engine;and an electronic control valve configured to control the flow of oil to the piston cooling jet. The method includes operating the electronic control valve to provide a flow rate of oil above a threshold flow rate to the piston cooling jet when the engine assembly is operating above a threshold power output or engine running speed; and regulating the pressure of oil within the oil system when theengine assembly is operating below the threshold power output or engine running speed, by operating the electronic control valve.

Owner:FORD GLOBAL TECH LLC

Multi-modal fluid condition sensor platform and system therefor

This invention encompasses embodiments for multi-modal integrated simultaneous measurement of various aspects of fluids contained in circulating systems such as automotive reciprocating engines and vehicle transmissions. These circulating systems perform constant internal lubrication, and heat and contaminant removal to protect the internal moving parts from the inherent friction and damage in normal operation. Most commonly this is achieved with fluids based on hydrocarbon and / or related synthetics, which, over time, can lose their protective properties, and vary in their performance or breakdown / decay due to internal and external events. Several components within the lubricant fluid can be measured and can provide insight into the efficacy of the system to perform its designed mission. Described herein is a real-time, simultaneous, integrated, multi-modal sensor system for early warning notification.

Owner:MAST INC

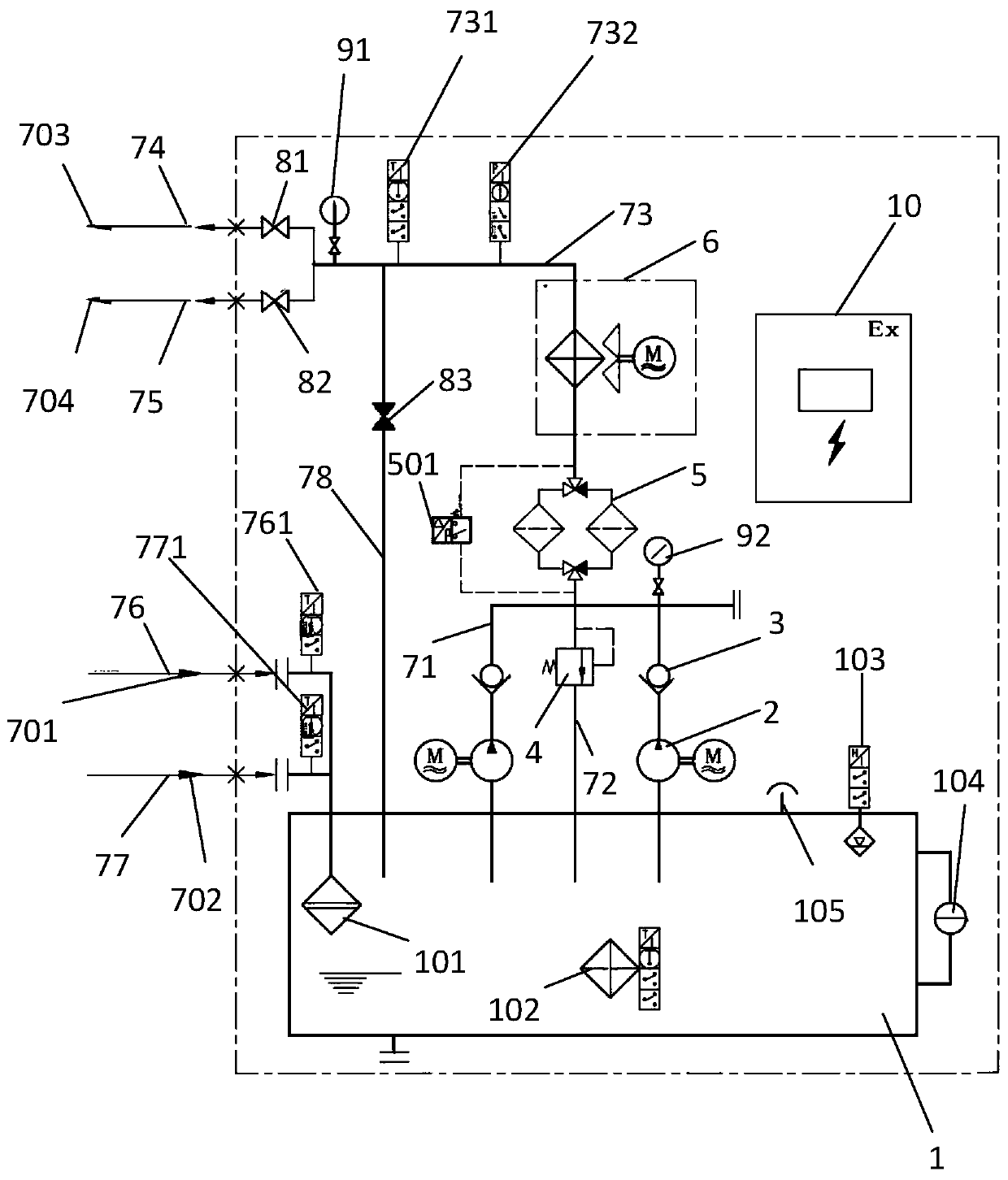

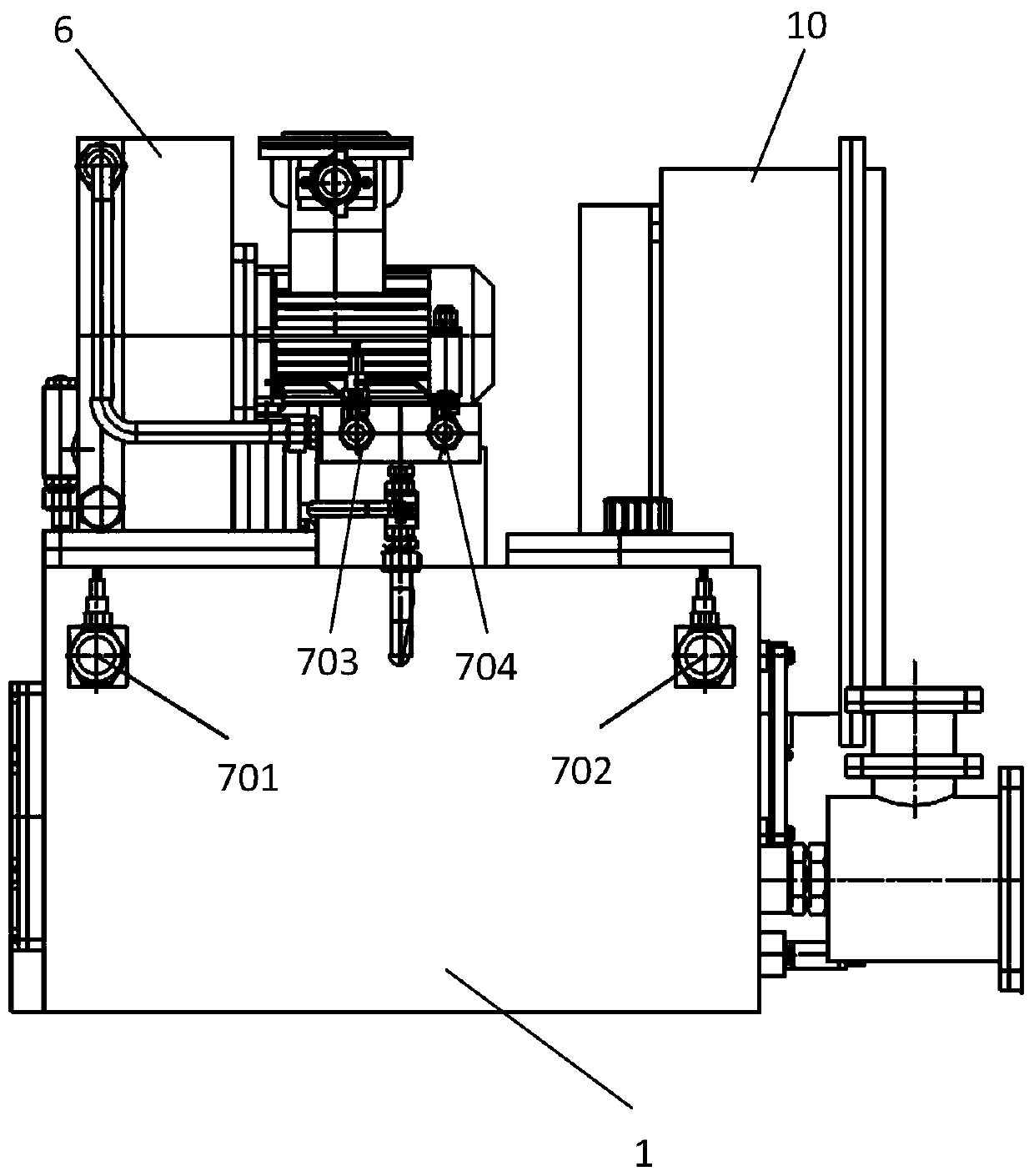

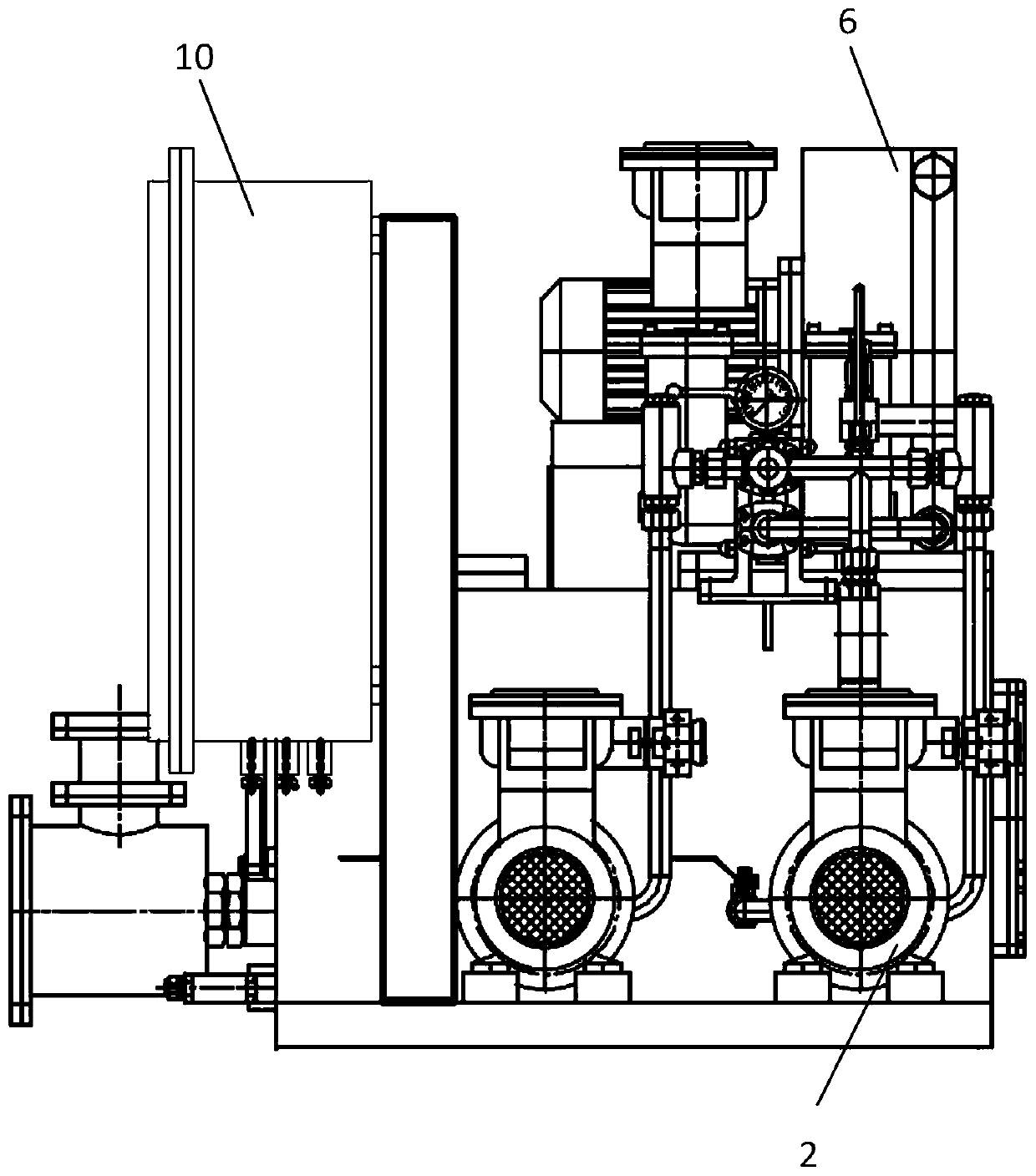

Mining explosion-proof type thin oil lubrication station

PendingCN110778902AEasy to installLow costEngine temperatureEngine pressureElectric controlLubrication

The invention provides a mining explosion-proof type thin oil lubrication station. The station comprises an oil tank, an oil outlet pipeline, an oil return pipeline, an oil pump, a one-way valve, a safety valve, a double-barrel filter, a cooler and an electric control box, wherein the oil return position of the oil tank is provided with a magnetic filtering device, the oil outlet pipeline comprises a first pipeline, a second pipeline and a third pipeline, wherein one end of the first pipeline and one end of the second pipeline communicate with the oil tank, the other end of the first pipelineand the other end of the second pipeline communicate with the input end of the double-barrel filter, one end of the third pipeline communicates with the output end of the double-barrel filter, the other end of the third pipeline is branched into a fourth pipeline with a first oil outlet and a fifth pipeline with a second oil outlet, one end of the oil return pipeline communicates with the magneticfiltering device, the other end of the oil return pipeline is branched into a sixth pipeline with a first oil return port and a seventh pipeline with a second oil return port, the cooler is an air cooler, and a shell of the electric control box is a metal closed explosion-proof type panel.

Owner:南通信仁润滑液压设备有限公司

Pump having wear and wear rate detection

Apparatus and method for supplying lubricant to a plurality of lubrication sites. The apparatus includes a controller that diagnoses piston wear by driving the pump to achieve a predetermined pressure, stopping the pump with the piston in a home position, and measuring pressure at a preselected time interval after the step of stopping the pump. The amount of piston wear is approximated based on a difference between the predetermined pressure and the measured pressure at the predetermined time interval.

Owner:LINCOLN INDUSTRIES CORP

Control method for phase modifier oil system

ActiveCN107355663AGuaranteed uptimeImprove efficiencyEngine temperatureEngine pressureAutomatic controlFuel tank

The invention discloses a control method for a phase modifier oil system. The control method for the phase modifier oil system comprises the following steps that (1) when starting is conducted, a self-checking signal is sent out by a controller of the phase modifier oil system, a lubricating oil supply system and a jacking oil system conduct self-checking; (2) the controller of the phase modifier oil system controls the temperature and the liquid level of lubricating oil in an oil tank automatically; (3) the controller connected with the oil tank sends out a lubricating oil supply instruction, and the lubricating oil passes a cooler and a filter sequentially and enters a phase modifier; (4) the controller sends out a jacking oil system jacking instruction; (5) the redundant lubricating oil in the phase modifier is controlled by the controller which sends out an oil return signal and enters the oil tank through an oil return pipeline; and (6) the controller sends out a discharge signal aiming at oil smoke of the phase modifier oil system. The control method for the phase modifier oil system has the advantages that full automated control of the phase modifier oil system over supply, jacking, return and oil contamination discharging of the lubricating oil is achieved, and normal operation of the system is ensured under the condition that main parts of the system fail.

Owner:JIANGSU JIANGHAI LUBRICANTS HYDRAULIC EQUIP

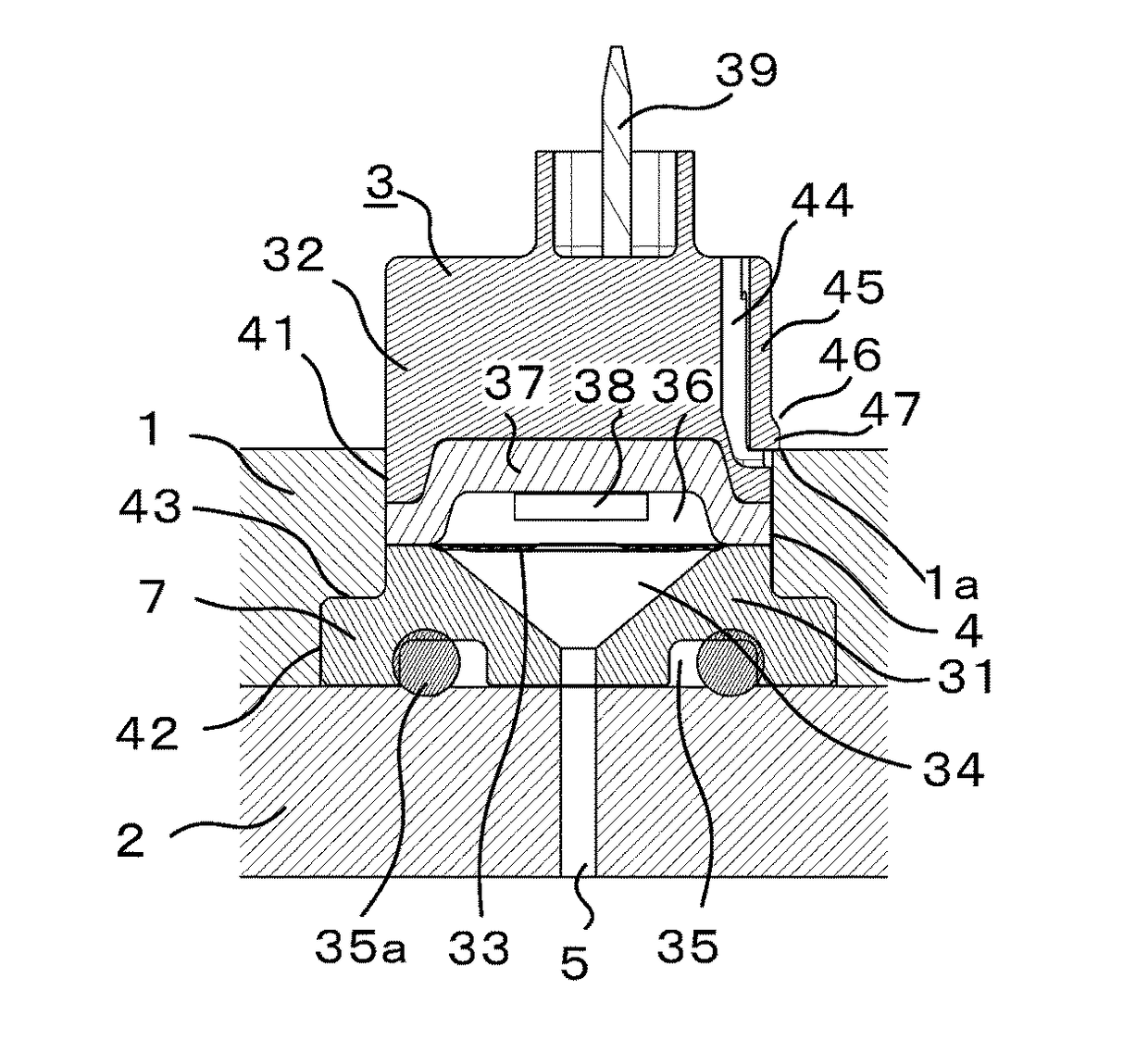

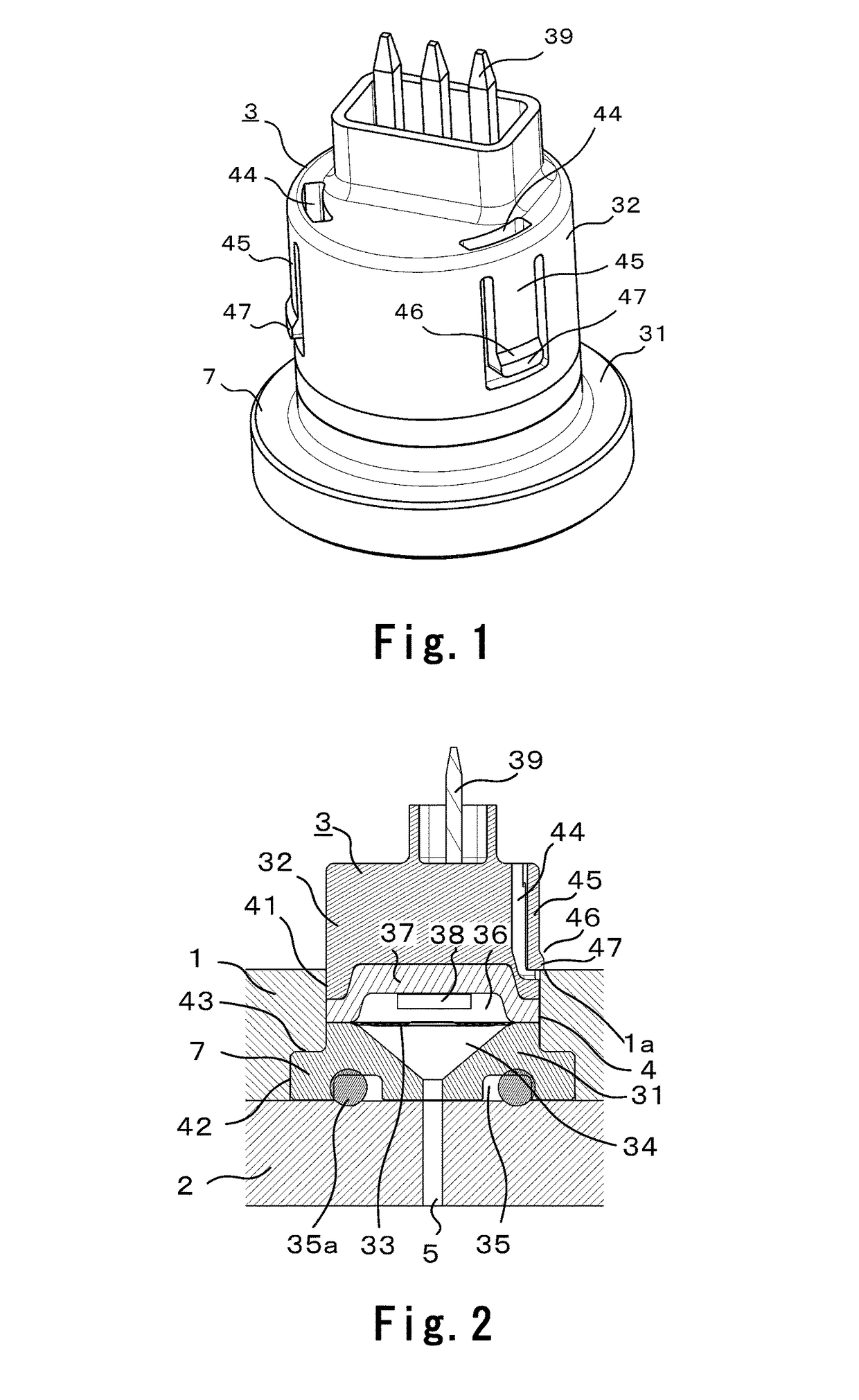

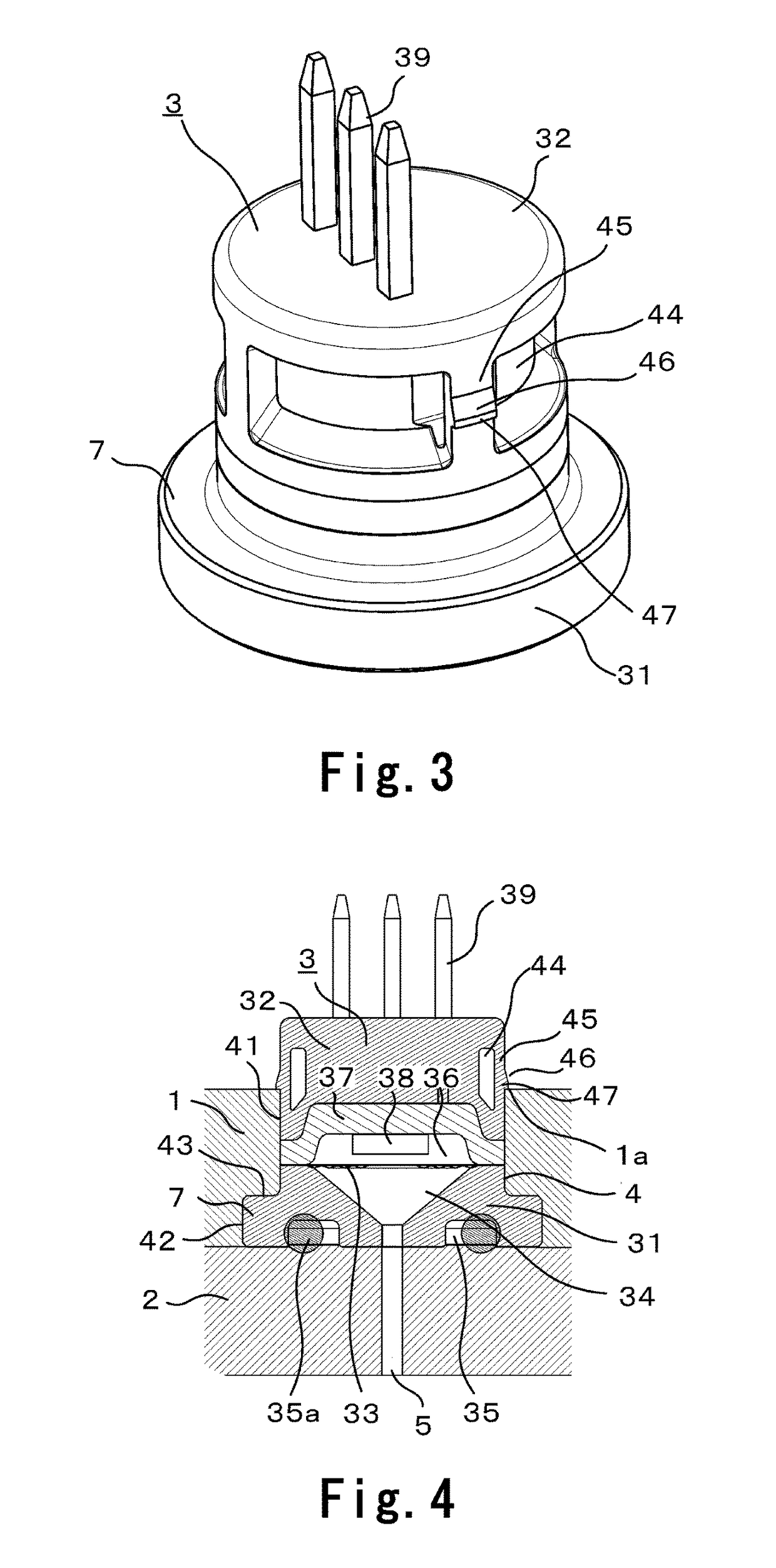

Sensor attachment structure

ActiveUS20180023469A1Prevent downward movementValve arrangementsEngine pressureEngineeringOil pressure

A sensor casing includes a lower case and an upper case that is fixed to an upper part of the lower case. A valve body includes an upper body including an accommodation space in which a sensor casing is disposed and a lower body in which an oil passage is formed. The upper body includes a stopper that prevents downward movement of the oil pressure sensor along a central axis. The sensor casing includes an engagement portion that engages with the stopper to retain the oil pressure sensor in the accommodation space.

Owner:NIDEC TOSOK CORP

Lubrication systems with nozzle blockage detection systems

A lubrication system is provided for delivering a lubricant to a plurality of nozzles. The lubrication system includes a reservoir for the lubricant; a pump fluidly coupled to the reservoir and configured to remove a flow of the lubricant from the reservoir; a lubrication sensor positioned between the pump and the plurality of nozzles and configured to detect a blockage in the plurality of nozzles and to generate a blockage signal when the blockage is detected; and an indicator coupled to the lubrication sensor and configured to generate a warning based on the blockage signal from the lubrication sensor.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com