Anti-leakage lubricating oil supply system of power device

A technology of supply system and power unit, applied in the direction of turbine/propulsion unit lubrication, engine lubrication, lubricating oil container, etc., can solve problems such as oil leakage, and achieve the effect of reducing operating cost, convenient operation and simple technical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

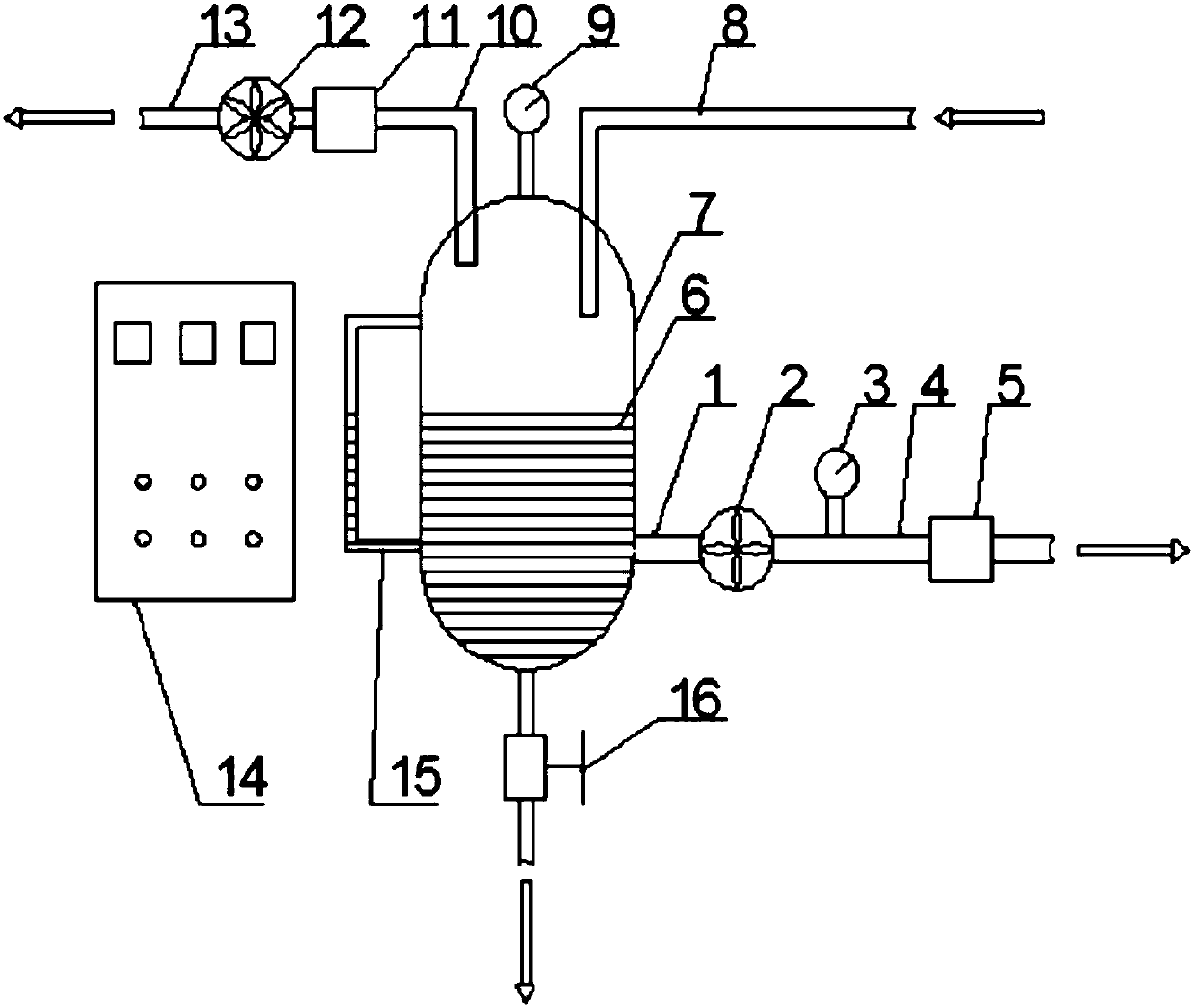

[0038] to combine figure 1 Describe this embodiment, a kind of anti-leakage lubricating oil supply system of a power plant (such as a gas turbine) in this embodiment, the anti-leakage lubricating oil supply system includes an oil supply pump inlet pipe 1, an oil supply pump 2, an oil supply pressure gauge 3, Oil pump outlet pipe 4, oil supply filter 5, lubricating oil 6, oil storage tank 7, equipment oil return pipe 8, oil storage tank pressure gauge 9, vacuum pump intake pipe 10, vacuum pump 12 and vacuum pump exhaust pipe 13; of which: The top of the oil storage tank 7 is provided with a vacuum pump intake pipe 10, the inlet end of the vacuum pump intake pipe 10 is inserted into the inside of the oil storage tank 7 from the top of the oil storage tank 7, and the outlet end of the vacuum pump intake pipe 10 is connected with the vacuum pump 12 intake ports, The outlet end of the vacuum pump 12 is connected with the vacuum pump exhaust pipe 13; the top of the oil storage tank ...

Embodiment approach 2

[0045] This embodiment adds a technical feature liquid level gauge 15 on the basis of Embodiment 1. The anti-leakage lubricating oil supply system of this embodiment also includes a liquid level gauge 15; connected.

[0046] The liquid level gauge 15 adopted in this embodiment can conveniently observe the liquid level height of the lubricating oil 6 in the oil storage tank 7 .

Embodiment approach 3

[0048] This embodiment is to increase the technical feature sewage pipe 16 on the basis of Embodiment 1 or 2. In this embodiment, the lowest part of the oil storage tank 7 is provided with a sewage pipe 16 that communicates with the inside of the oil storage tank 7; There is a drain valve on it.

[0049] In this embodiment, one end of the drain valve 16 communicates with the lowest position of the oil storage tank 7 , and the other end leads to the outside of the oil storage tank 7 .

[0050] In this embodiment, a sewage outlet is provided at the lowest part of the oil storage tank. After stopping for a period of time, part of the lubricating oil with impurities can be exhausted out of the oil storage tank through the sewage outlet. It is not necessary to replace all the lubricating oil, which can effectively reduce the loss of lubricating oil. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com