Lubricating device for supplying a tool with lubricant

A lubricating device and lubricant technology, applied in the direction of engine lubrication, distribution device, lubricating parts, etc., can solve problems such as tool damage, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

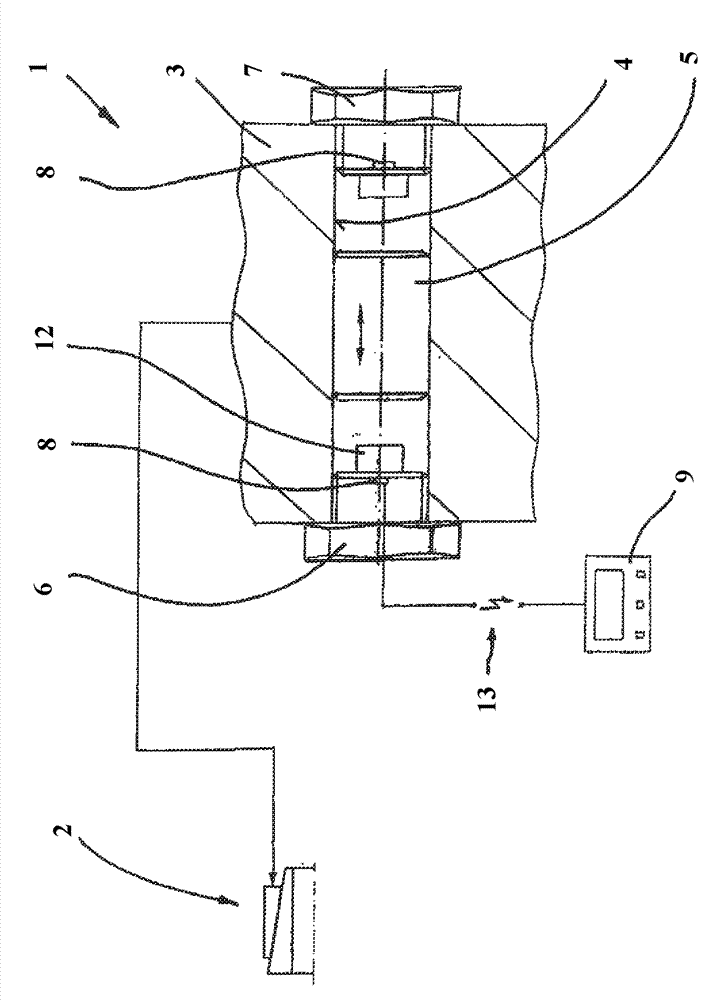

[0035] exist figure 1 A lubricating device 1 for supplying a tool 2 with a lubricating substance is shown. Tool 2 is a tube expansion tool, for example the tool described in document DE 100 08 688 C1.

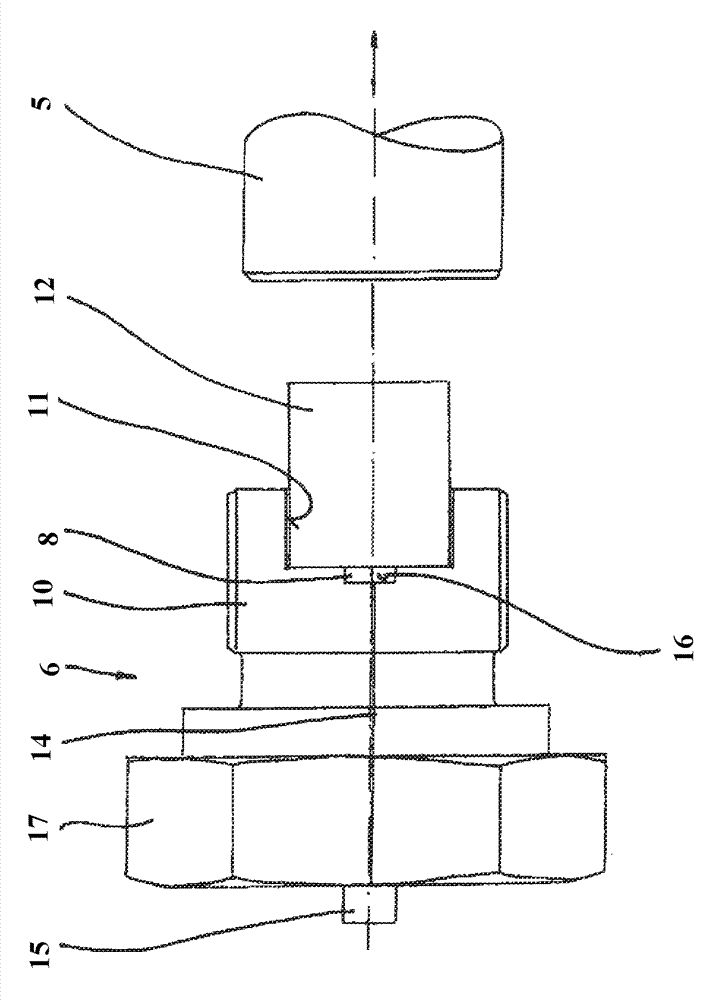

[0036] The core component of the lubricating device 1 is the lubricating distributor 3, the general construction of which is known as such. The lubricating distributor 3 therefore has a piston bore 4 in order for the piston 5 to be able to move back and forth in the bore 4; this is achieved by figure 1 indicated by the double arrows in . The piston bore 4 is blocked at its end, and the blocking bolts 6 and 7 are used for this purpose.

[0037] The blocking screws 6 and 7 are also used for metering the precise lubricant volume, since for this purpose the axial mobility of the piston 5 and thus the volume of lubricant applied per piston stroke is also limited.

[0038] What is important and new is that a sensor 8 is arranged on each of the two locking bolts 6 and 7 . These t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com