Patents

Literature

652results about "Distribution equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

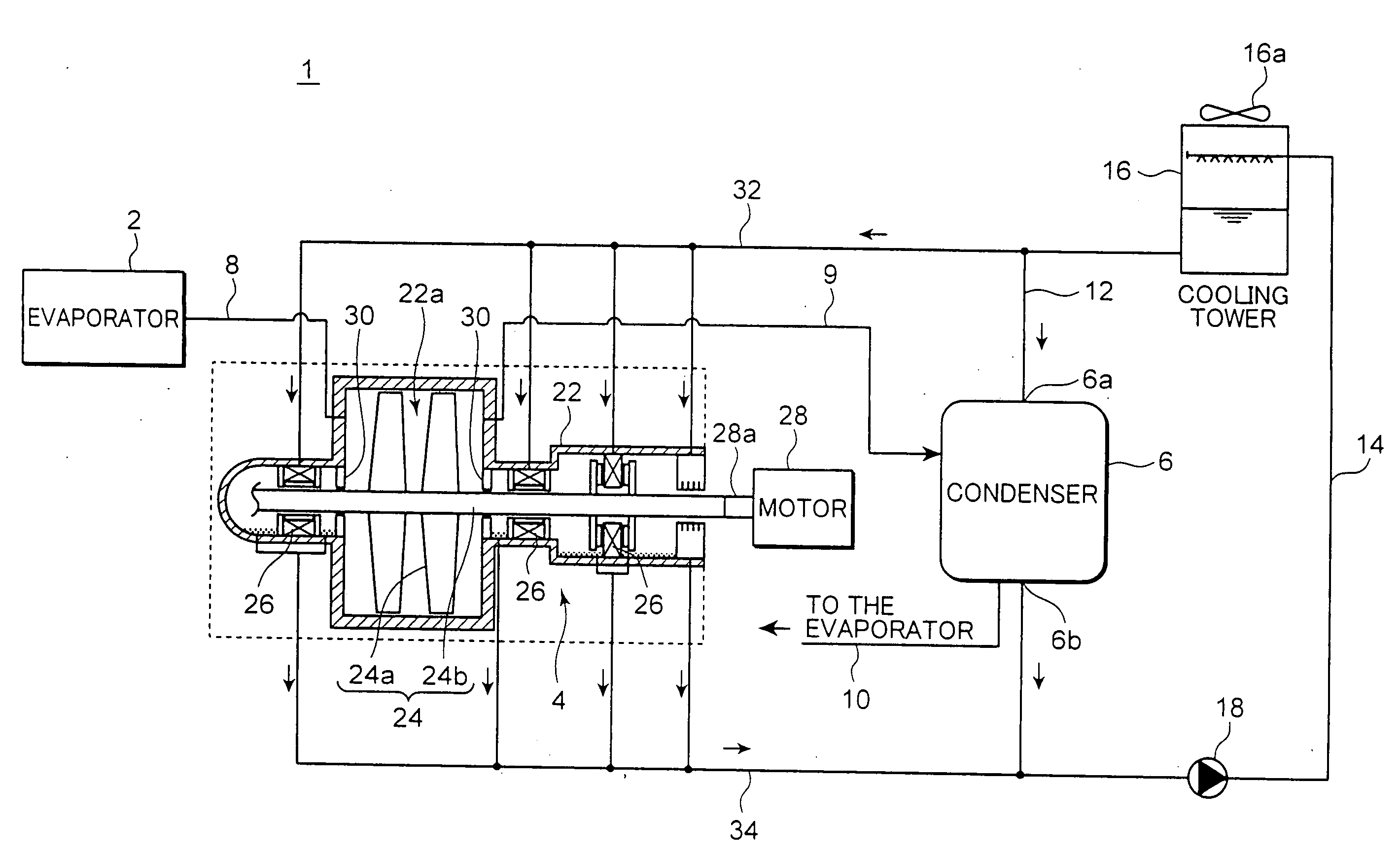

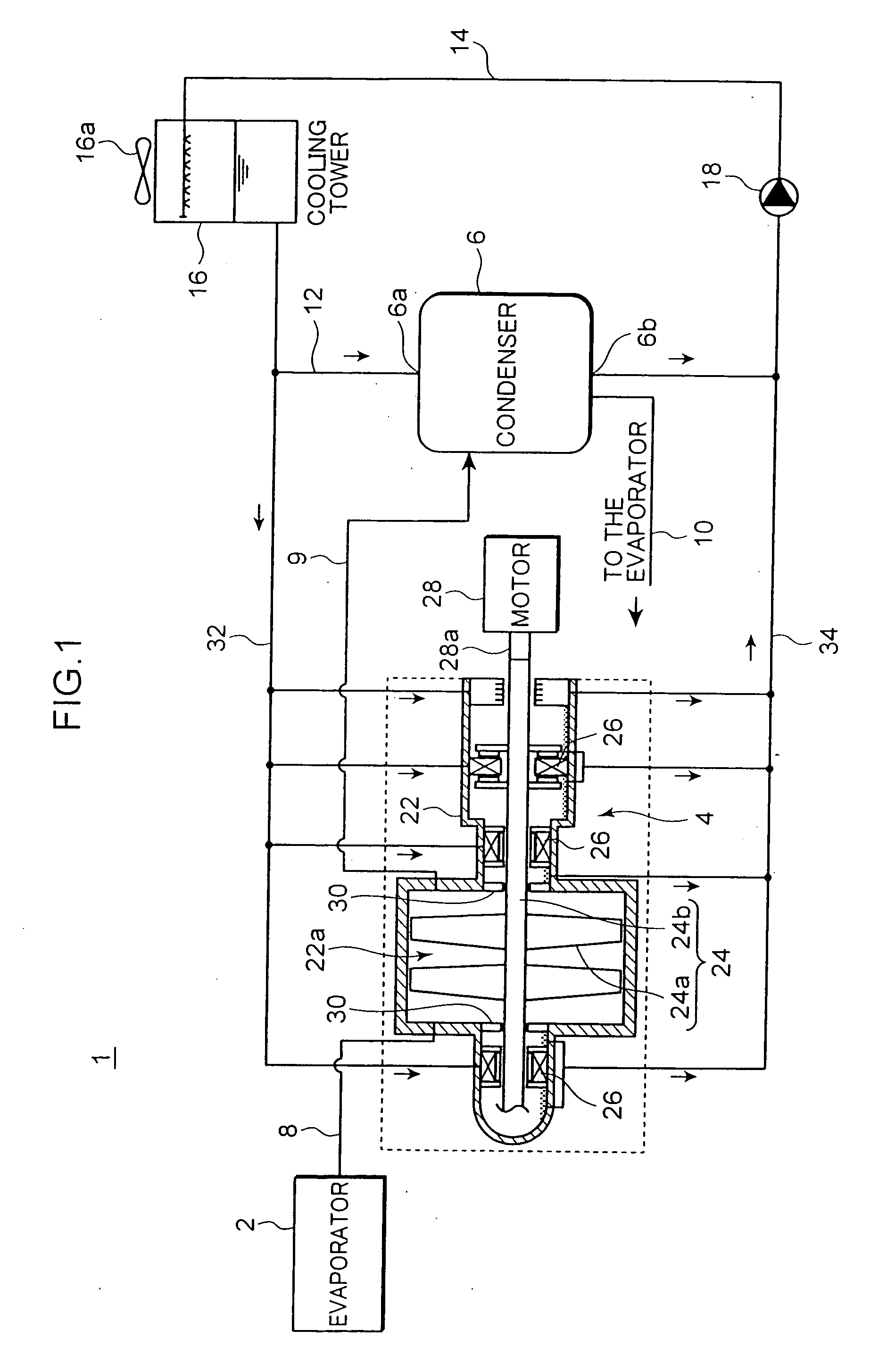

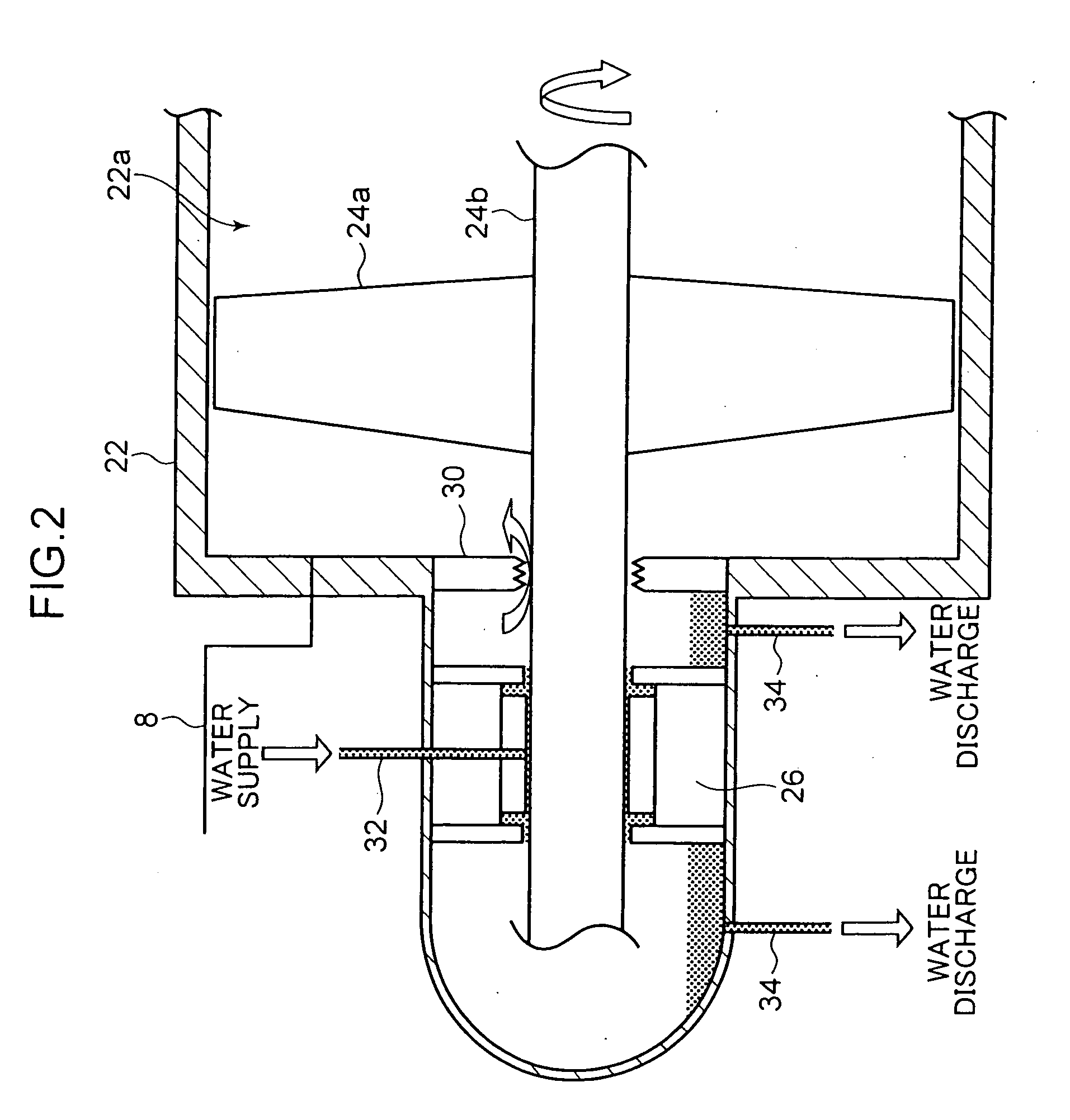

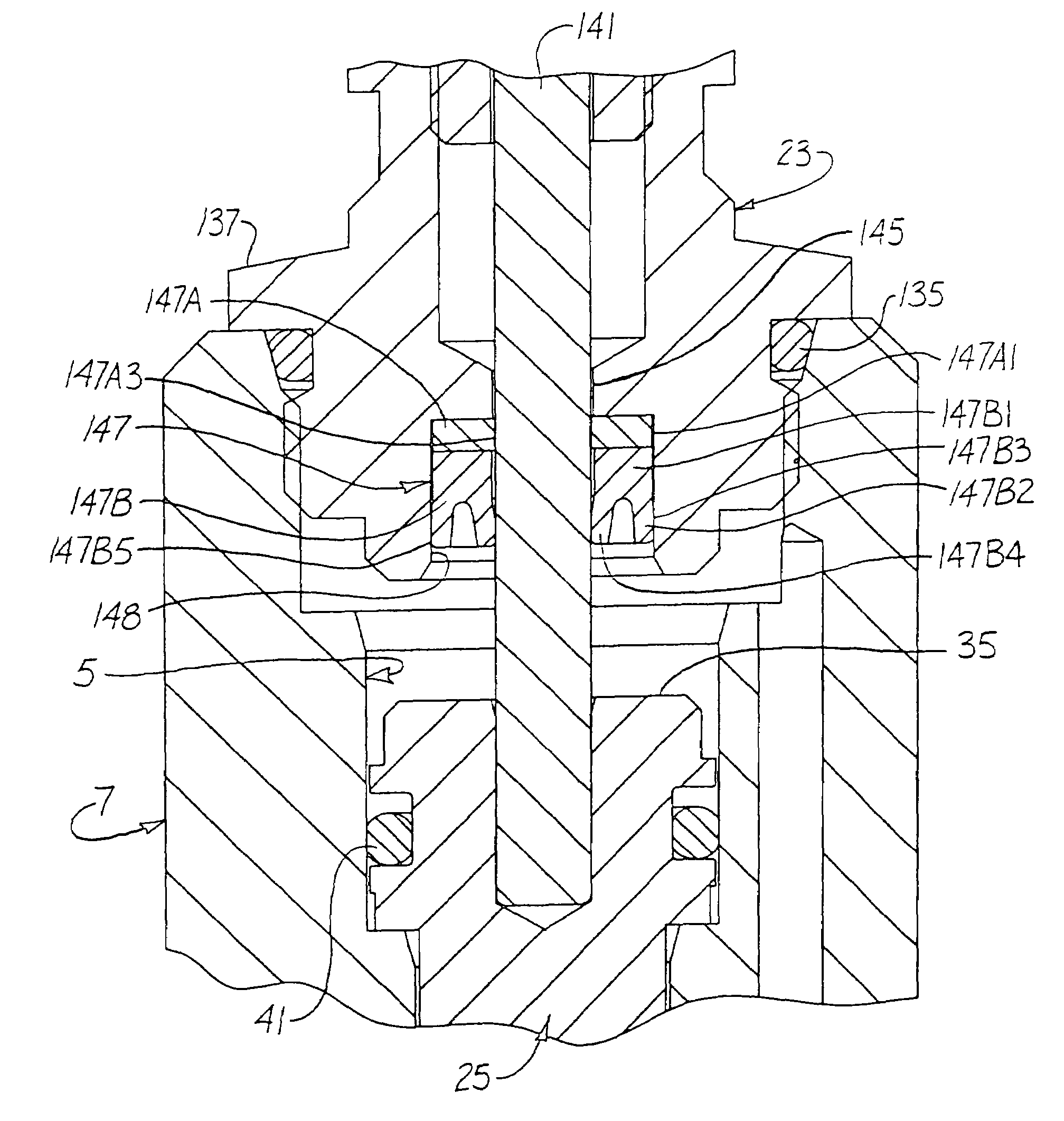

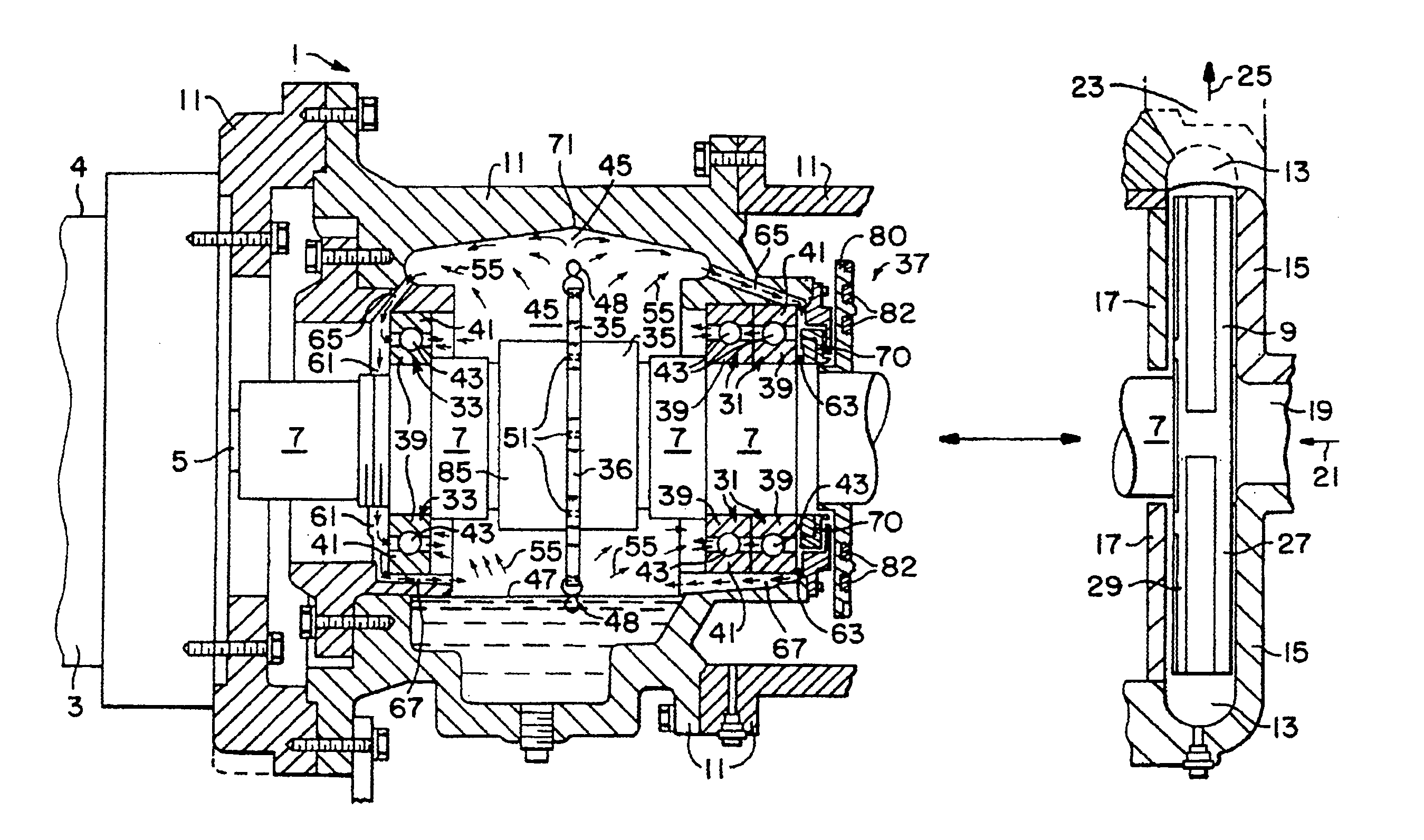

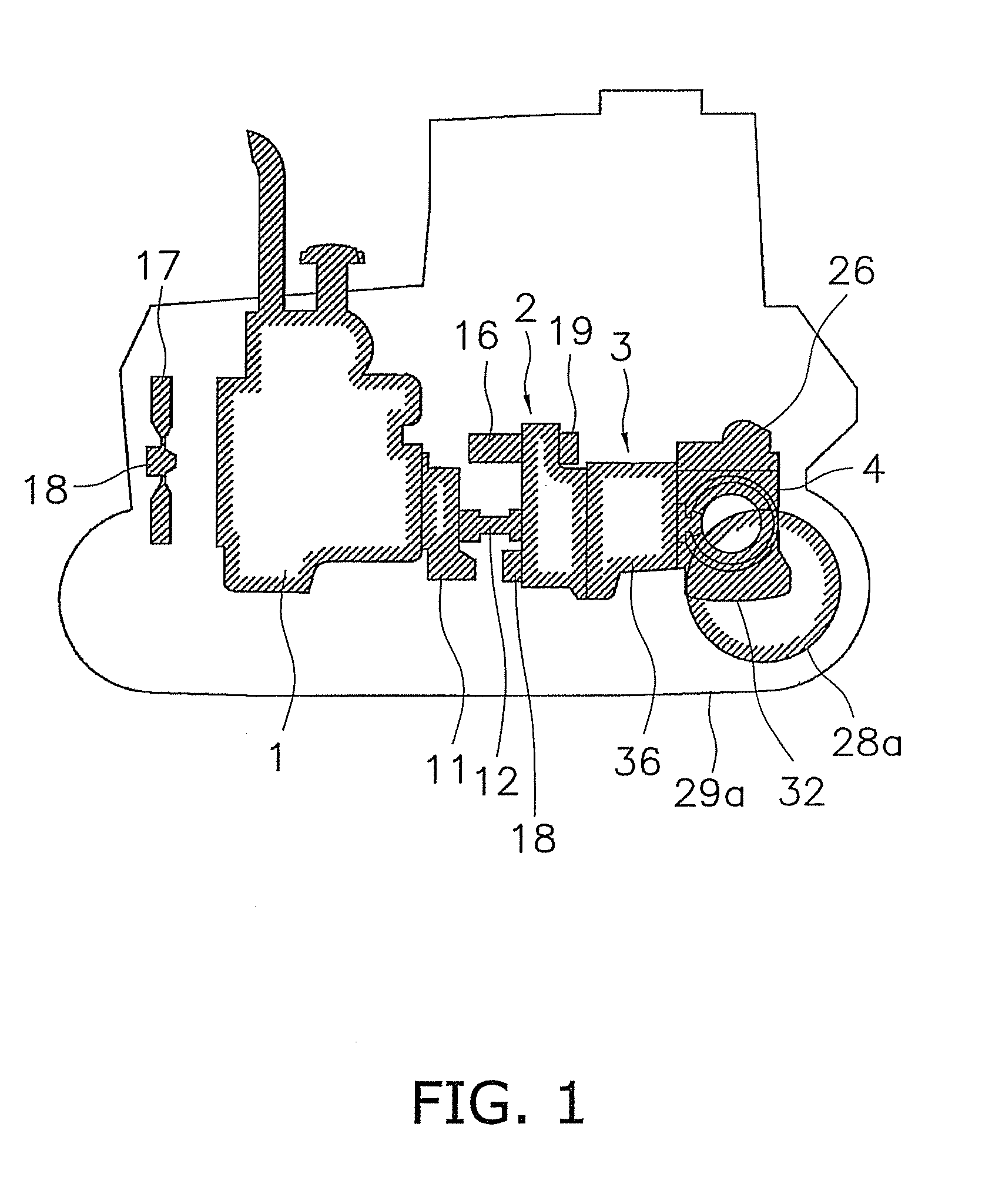

Compressor and refrigerating machine

ActiveUS20110174009A1Easy disposalSimple configurationCompressorPump componentsRotational axisWater vapor

A compressor and a refrigerating machine which enable an easy disposal of a lubricant, are friendly to the natural environment, and have simple configurations, are provided.The compressor which is used in a refrigerating machine including an evaporator and a condenser and adapted for compressing refrigerant gas evaporated in the evaporator to convey the compressed refrigerant gas to the condenser, includes: a motor; a housing having a compression chamber inside; a rotary member which has a rotating shaft and is rotated by a driving force of the motor so as to compress water vapor serving as the refrigerant gas in the compression chamber; a bearing for supporting the rotating shaft of the rotary member in the housing; and a lubricant supplier for supplying water serving as a lubricant to the bearing.

Owner:THE TOKYO ELECTRIC POWER CO INC +3

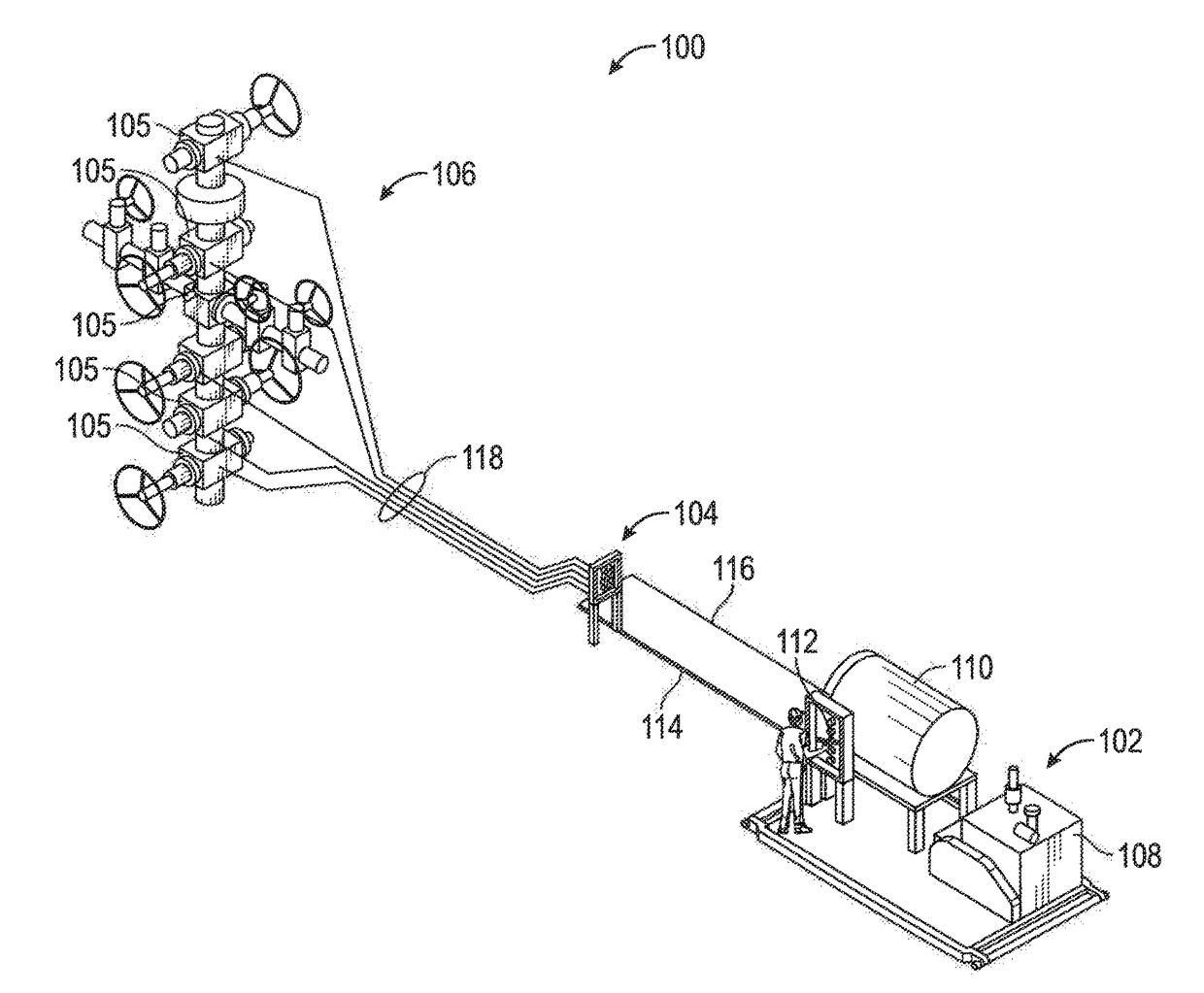

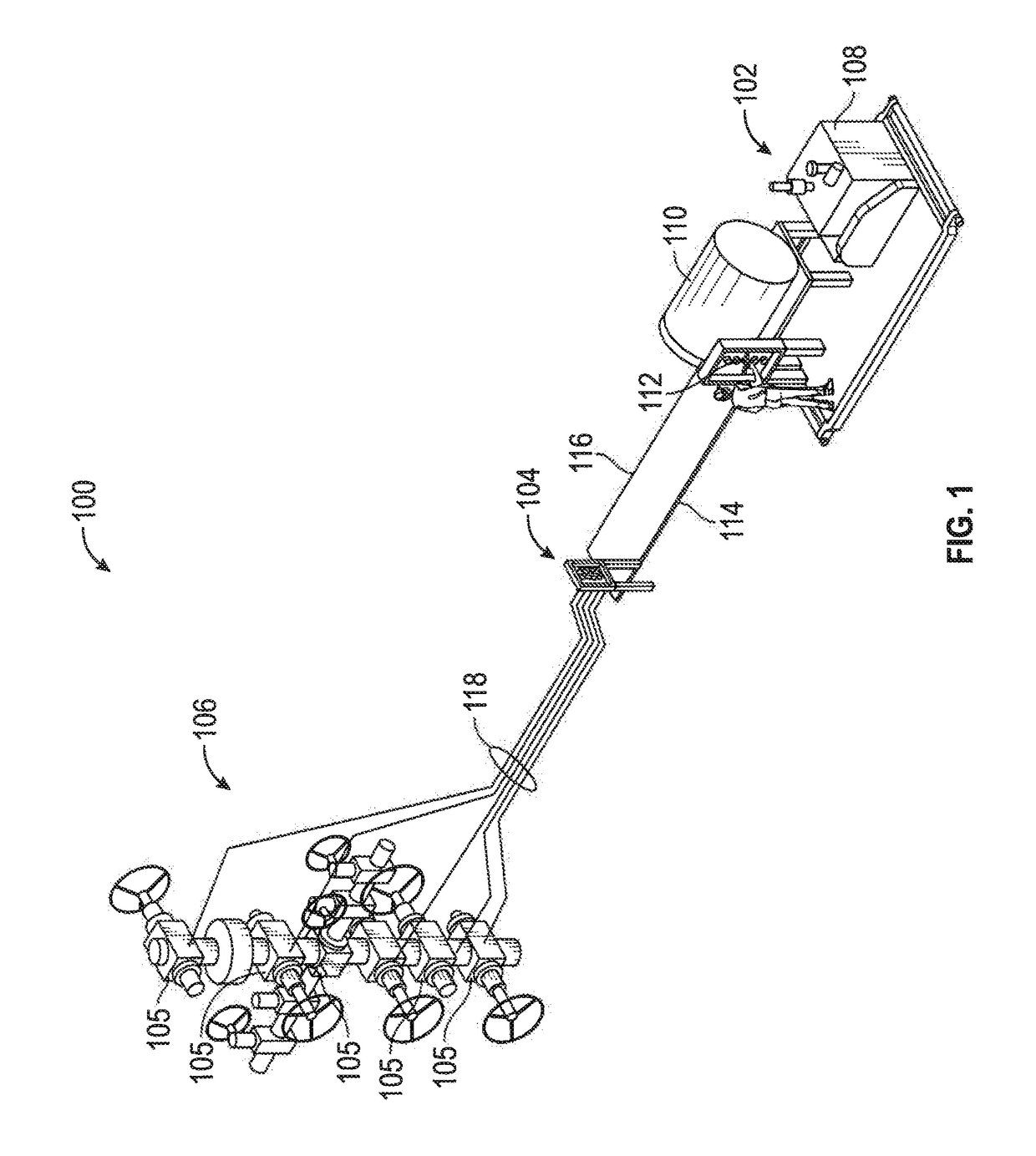

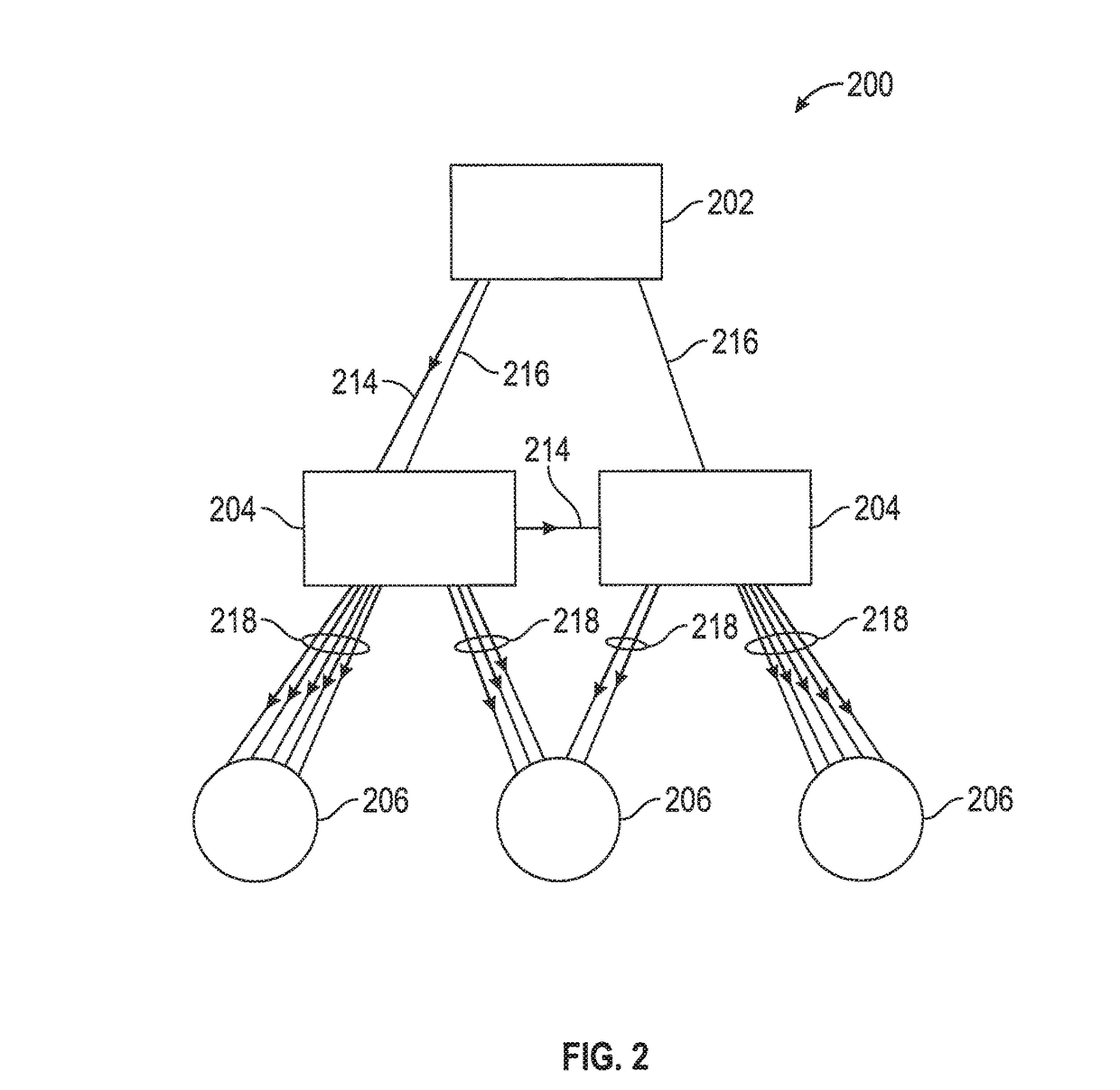

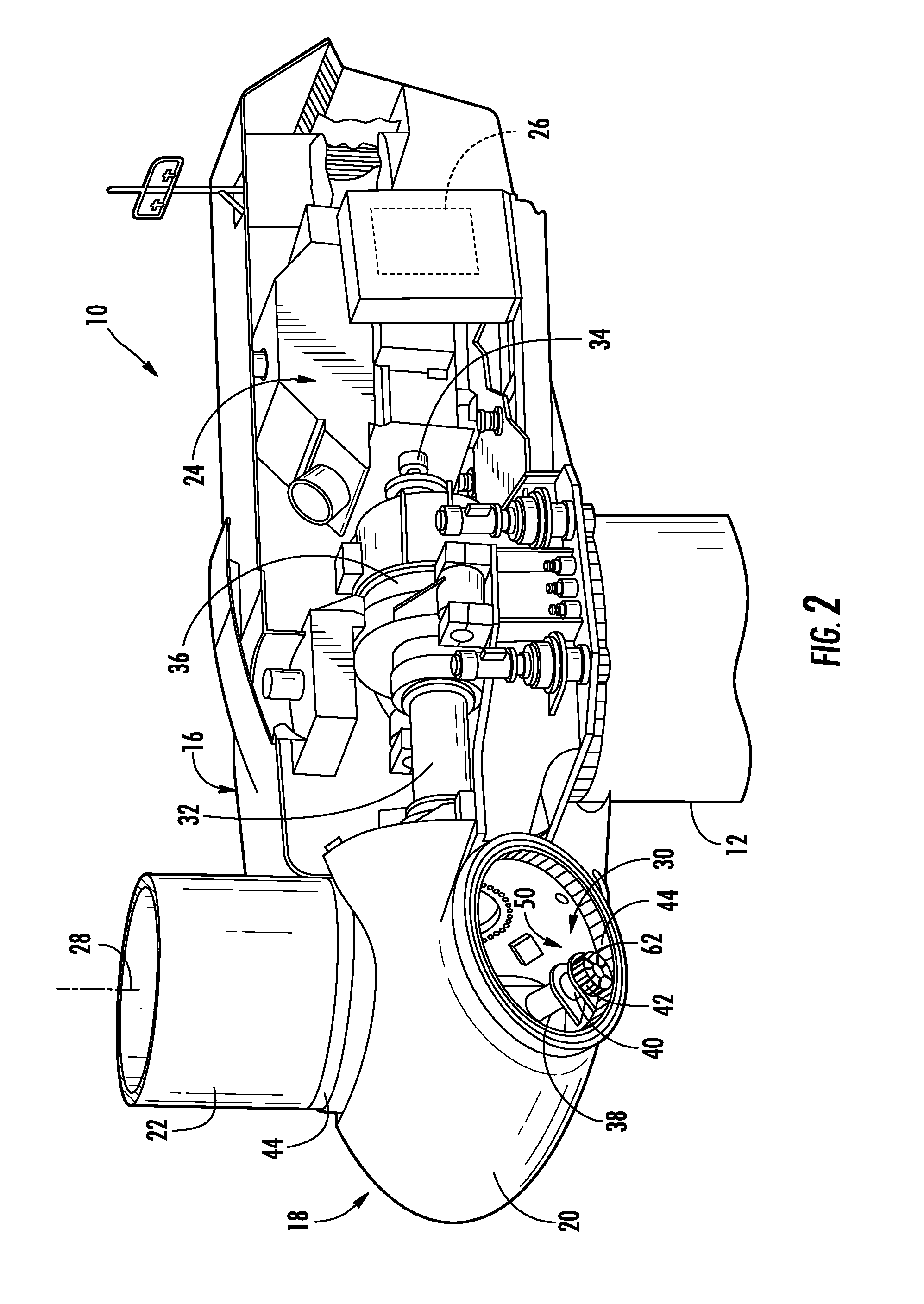

Remote well servicing systems and methods

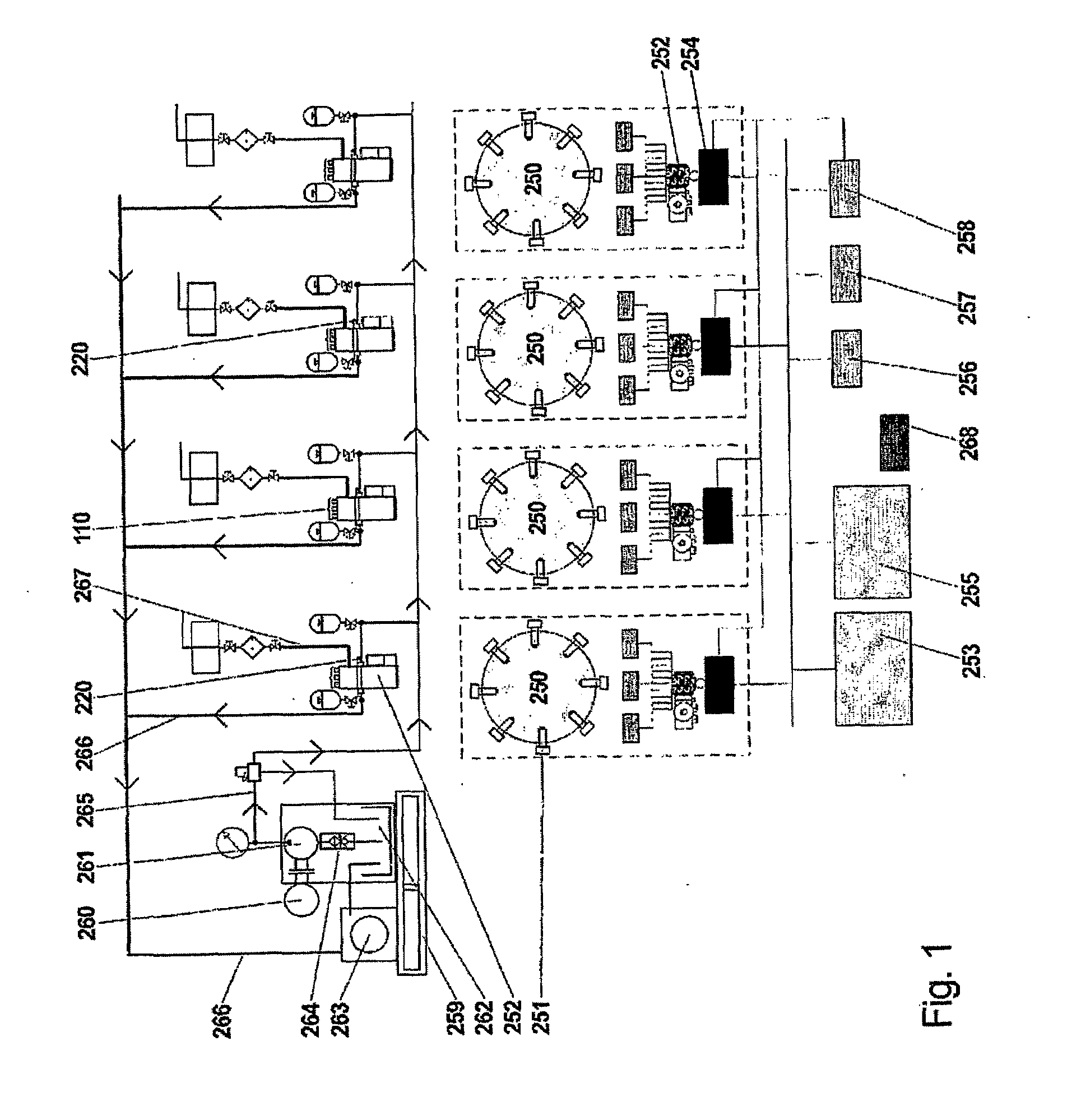

Embodiments of the present disclosure include a remote well servicing system including a control unit and a remote servicing manifold. The control unit further includes a service fluid source and a control system. The remote servicing manifold further includes a fluid input line coupled to the service fluid source, a fluid output line couplable to a well component, and a valve coupled to the fluid input line and the fluid output line, wherein the valve, when actuated, places the fluid input line in fluid communication with the fluid output line and permits delivery of a service fluid from the service fluid source to the well component. The remote servicing manifold also includes a control line coupling the valve and the control system wherein the control system controls actuation of the valve via the control line.

Owner:VAULT PRESSURE CONTROL LLC

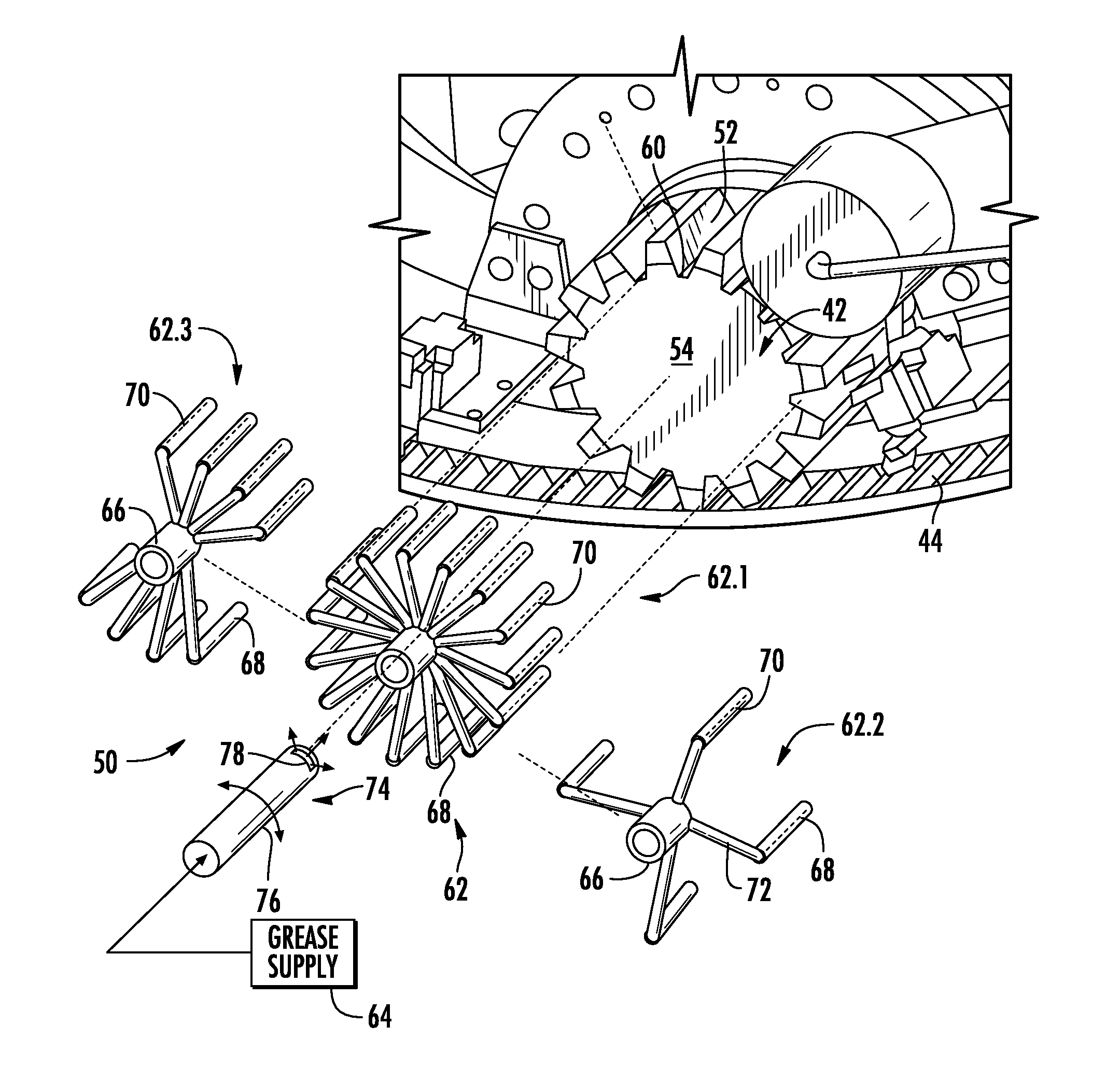

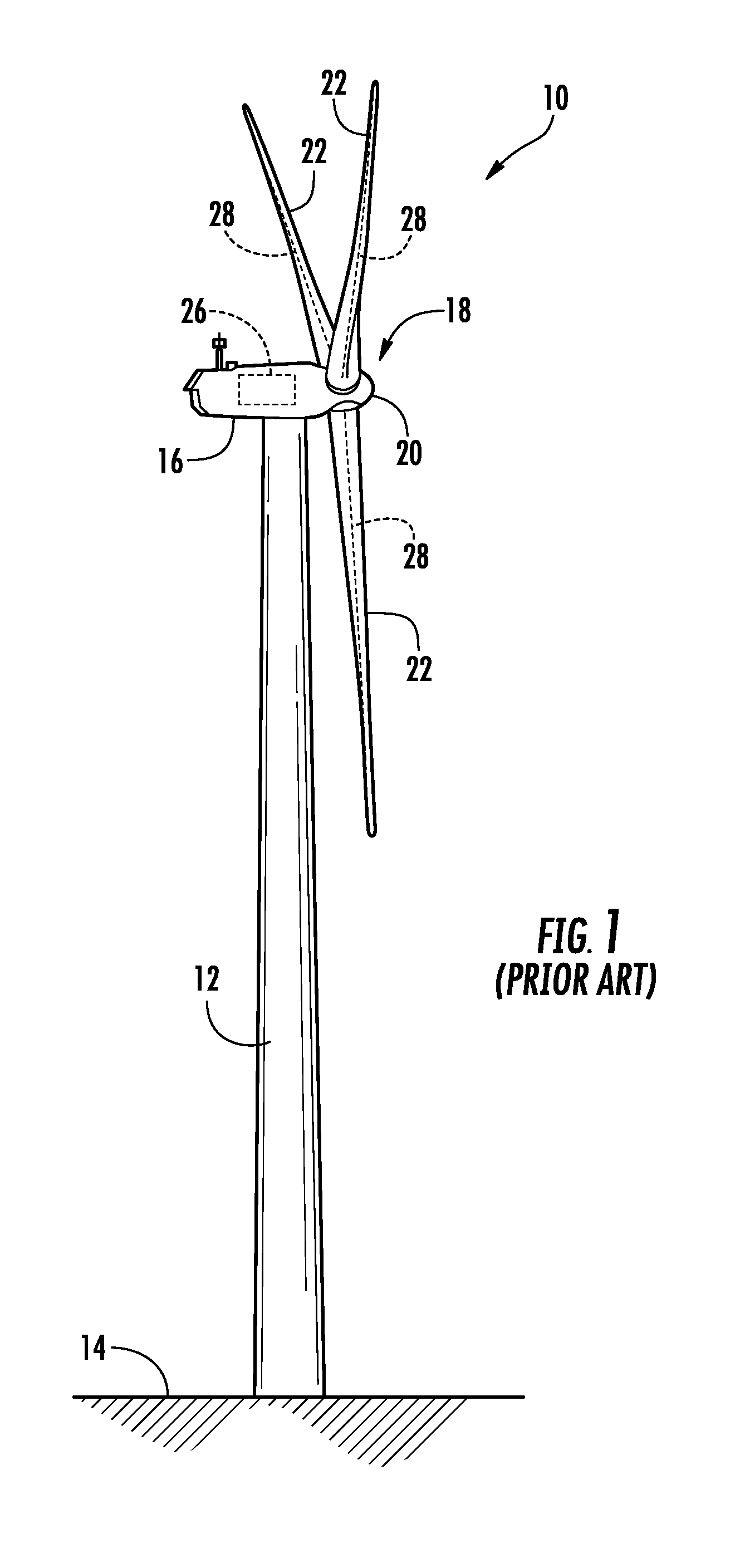

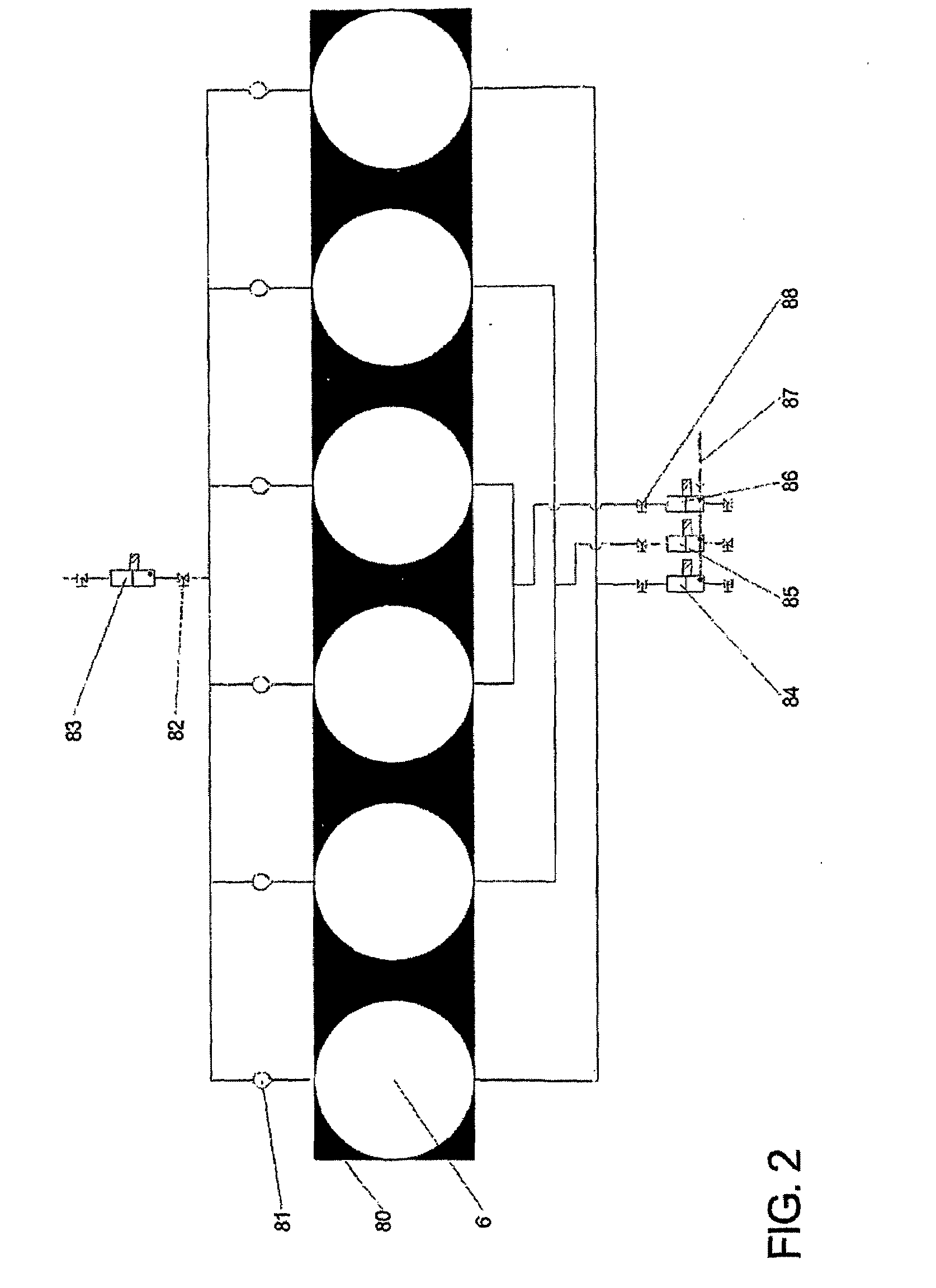

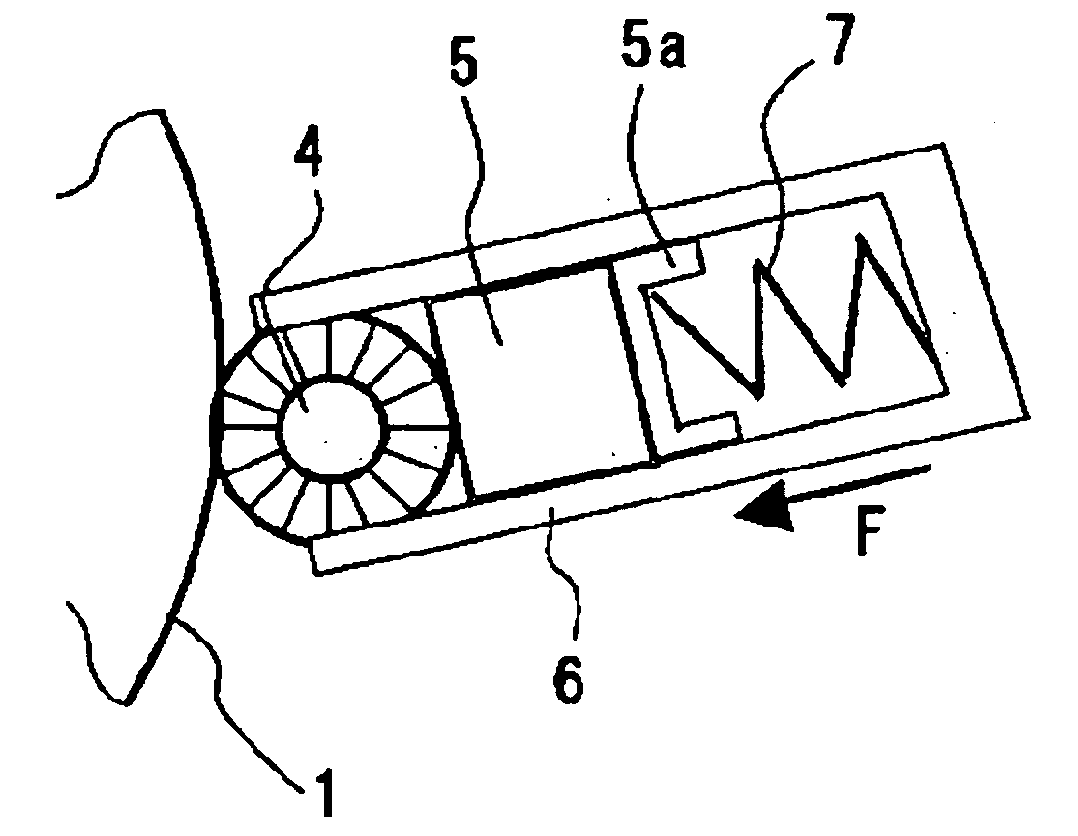

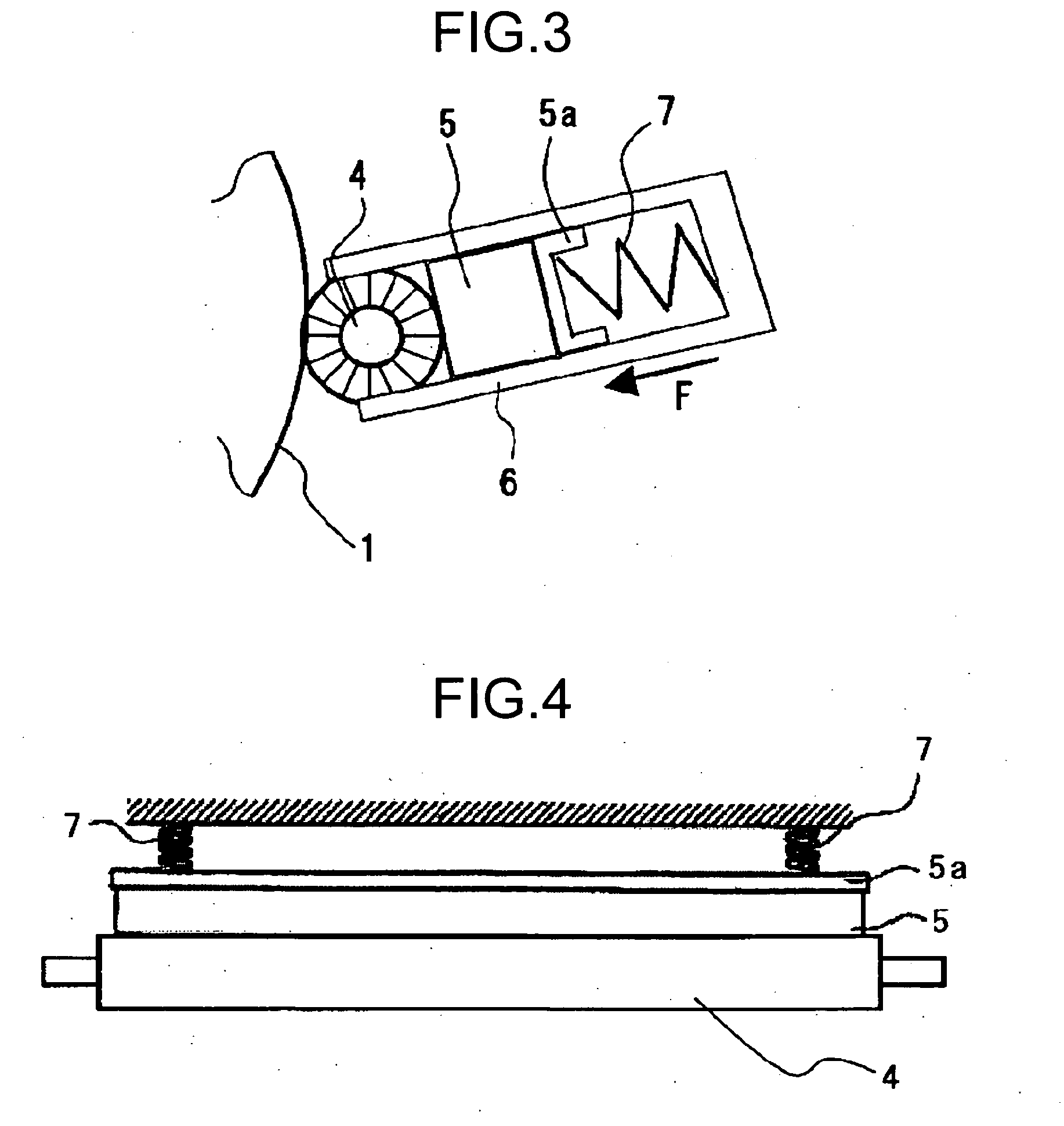

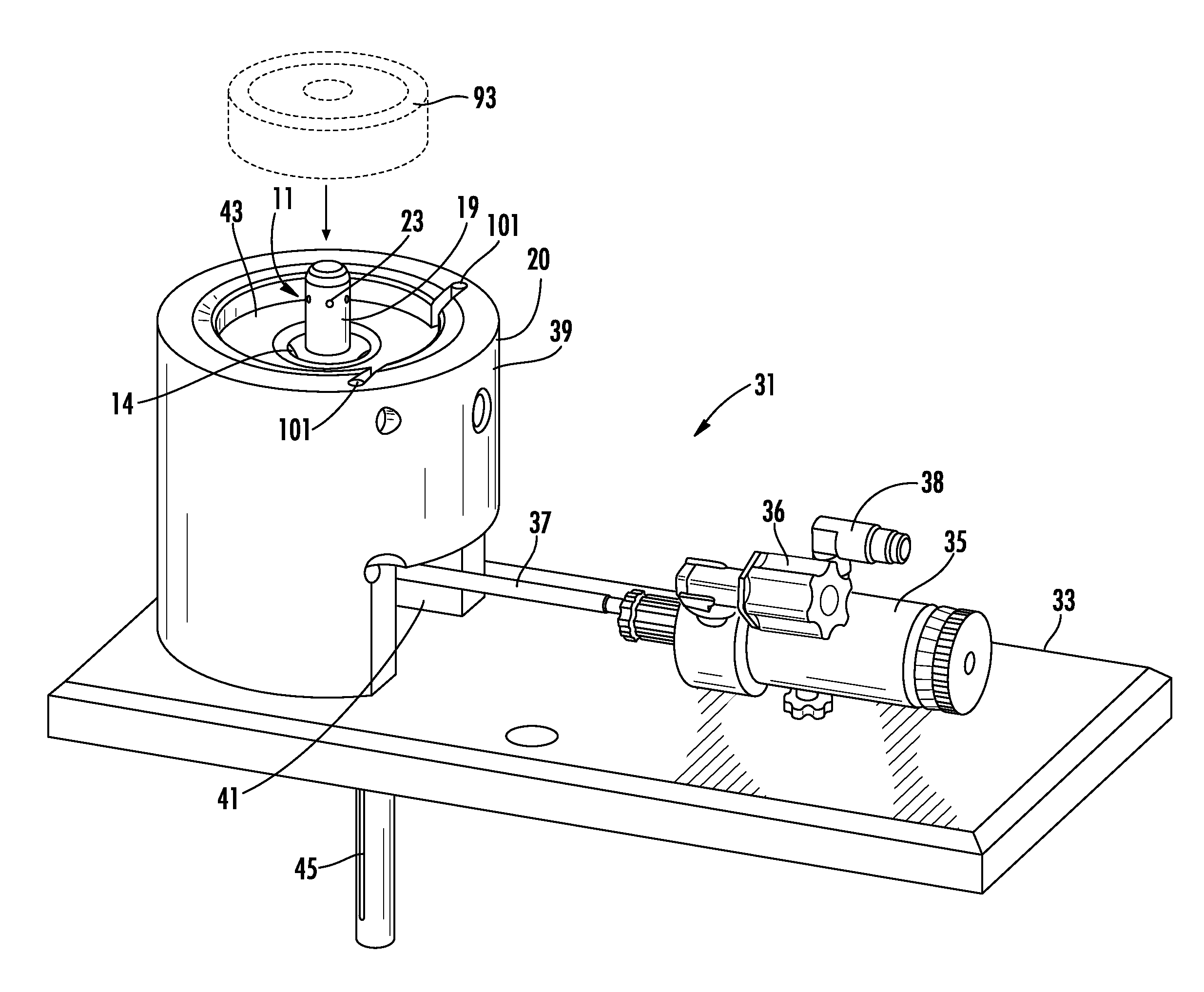

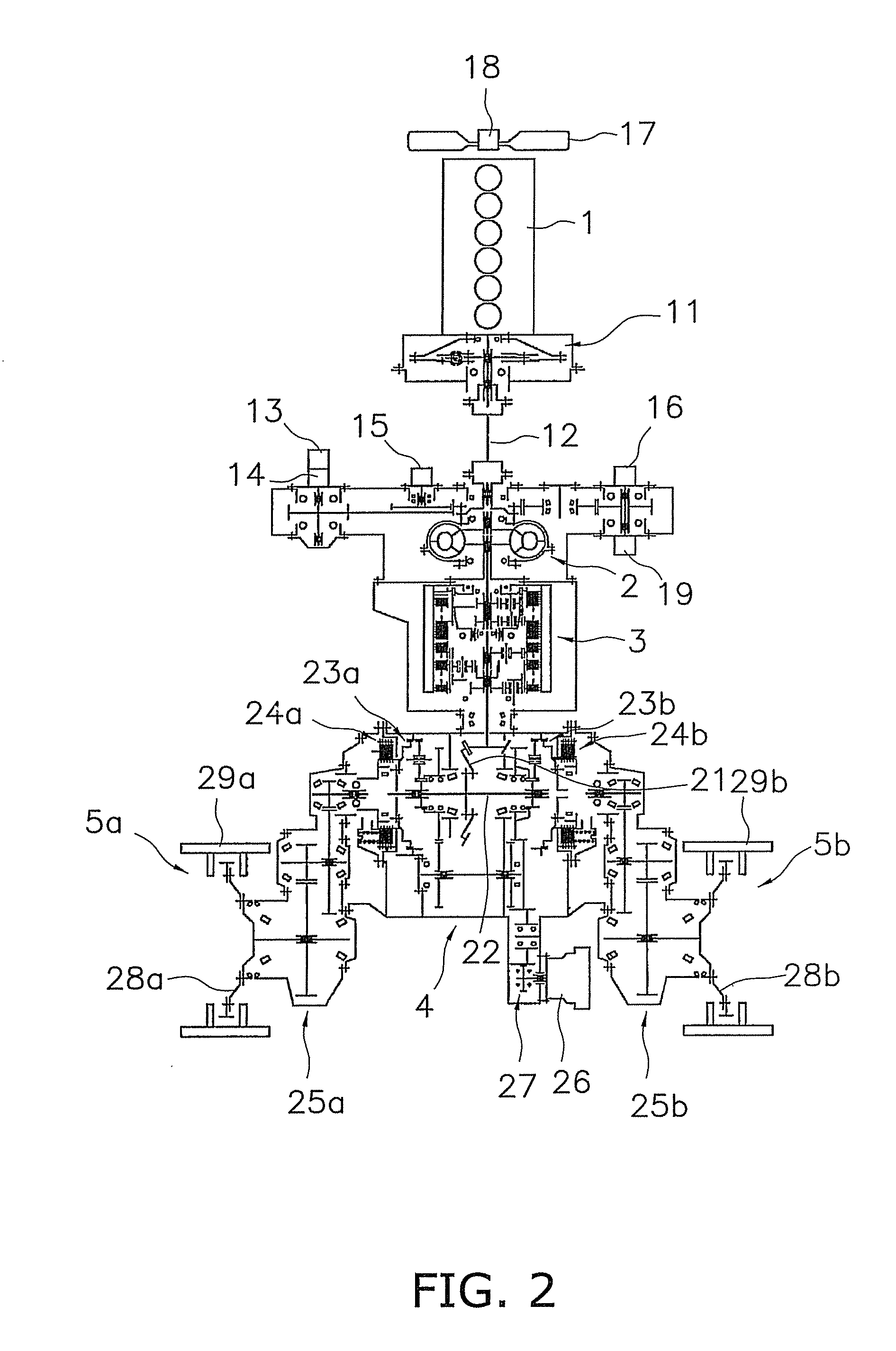

System and method for lubricating gears in a wind turbine

A system and method for lubricating gears in a wind turbine blade pitch drive are provided, wherein the pitch drive comprises a drive pinion gear with gear teeth that engage a pitch bearing gear coupled to a respective wind turbine blade. A grease distributor is configured to mount onto and rotate with the pinion gear, and is configured to deliver grease from an external grease supply to at least one valley defined between adjacent teeth of the pinion gear in a contact area of the pinion gear with the bearing gear without the distributor contacting inter-engaging teeth of the bearing gear.

Owner:GENERAL ELECTRIC CO

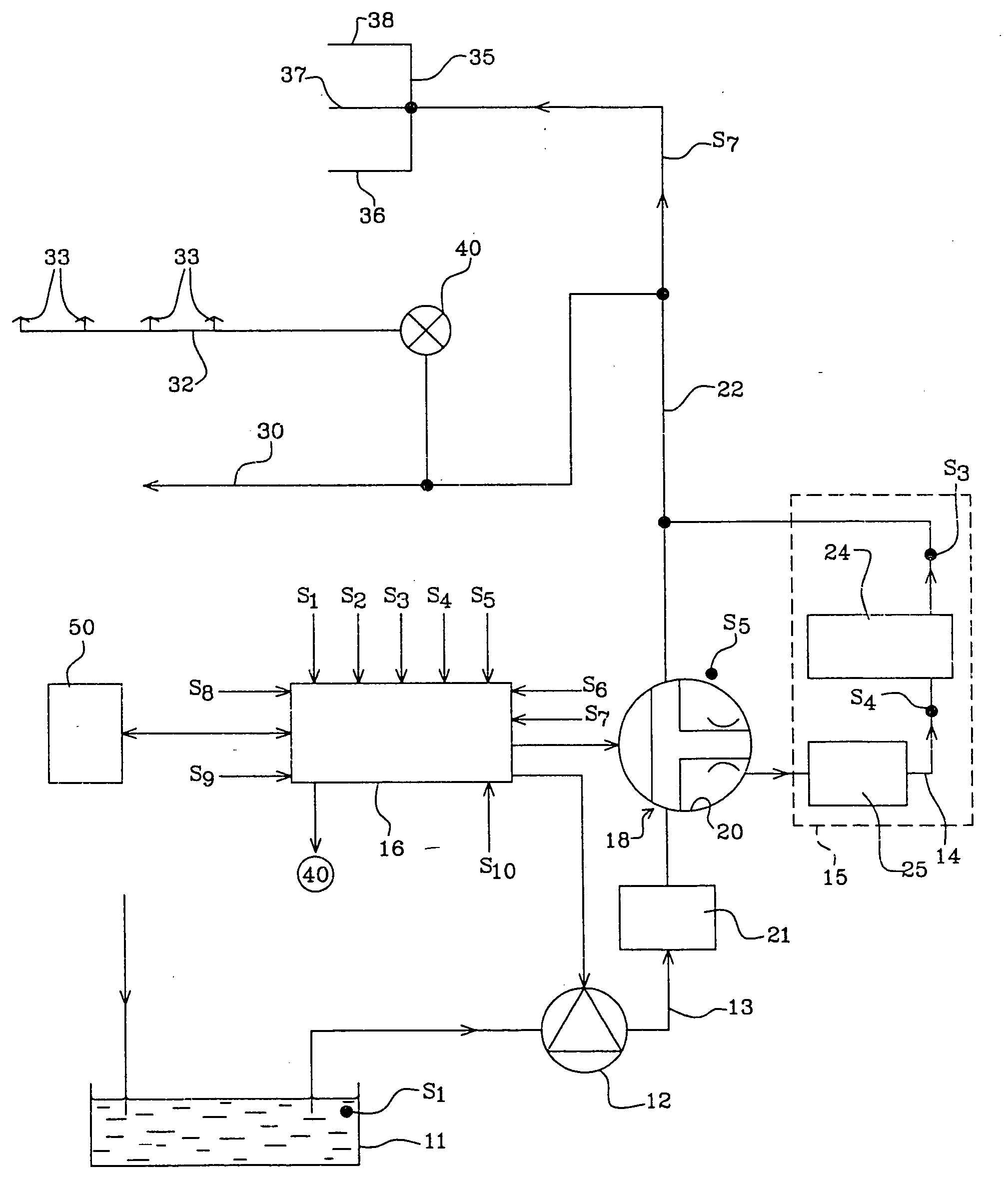

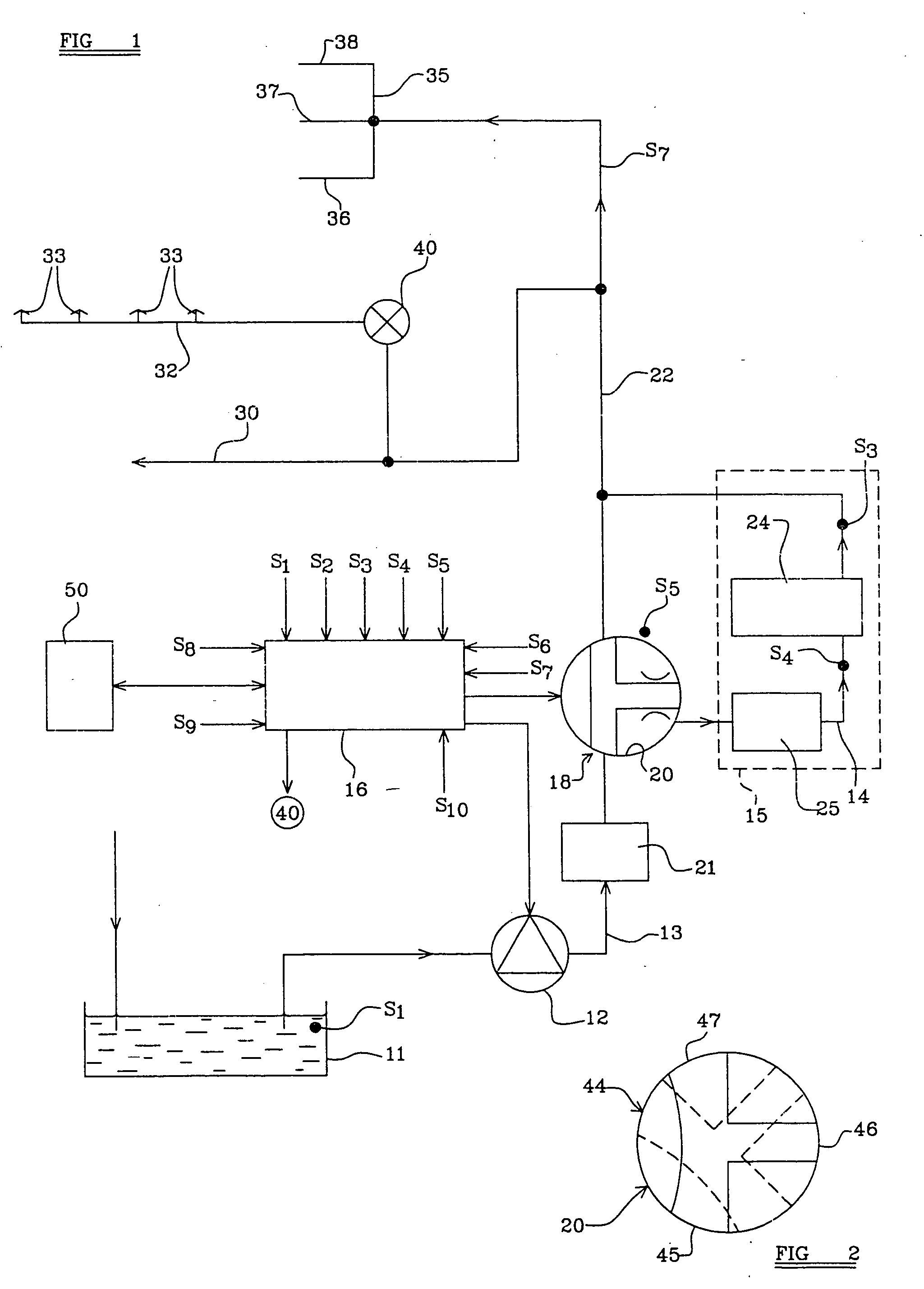

Engine lubrication system

InactiveUS20040031463A1Increase temperatureEasy to disassembleLubricant conduit arrangementsMachines/enginesSystem controllerLubrication

A lubrication system for an engine includes a sump for lubricant, a pump to pump lubricant along a lubricant feed line to lubrication positions within the engine, and a lubricant conditioner, and wherein the pump is an electrically driven pump which is controlled by a system controller, there being a diverter valve which is under the control of the controller selectively to divert at least a proportion of the lubricant from the lubricant feed line to the lubricant conditioner.

Owner:PIERBURG PUMP TECH UK

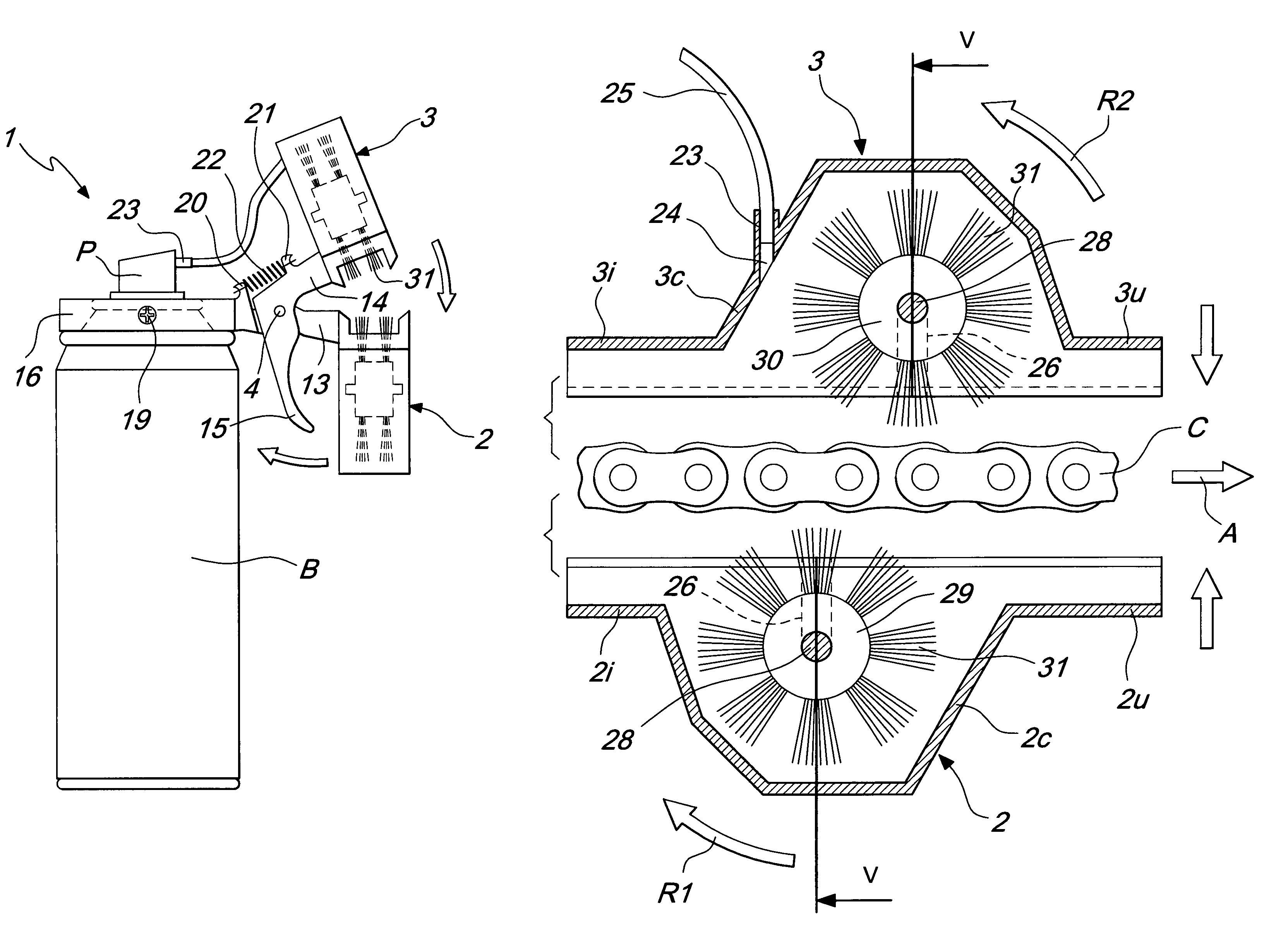

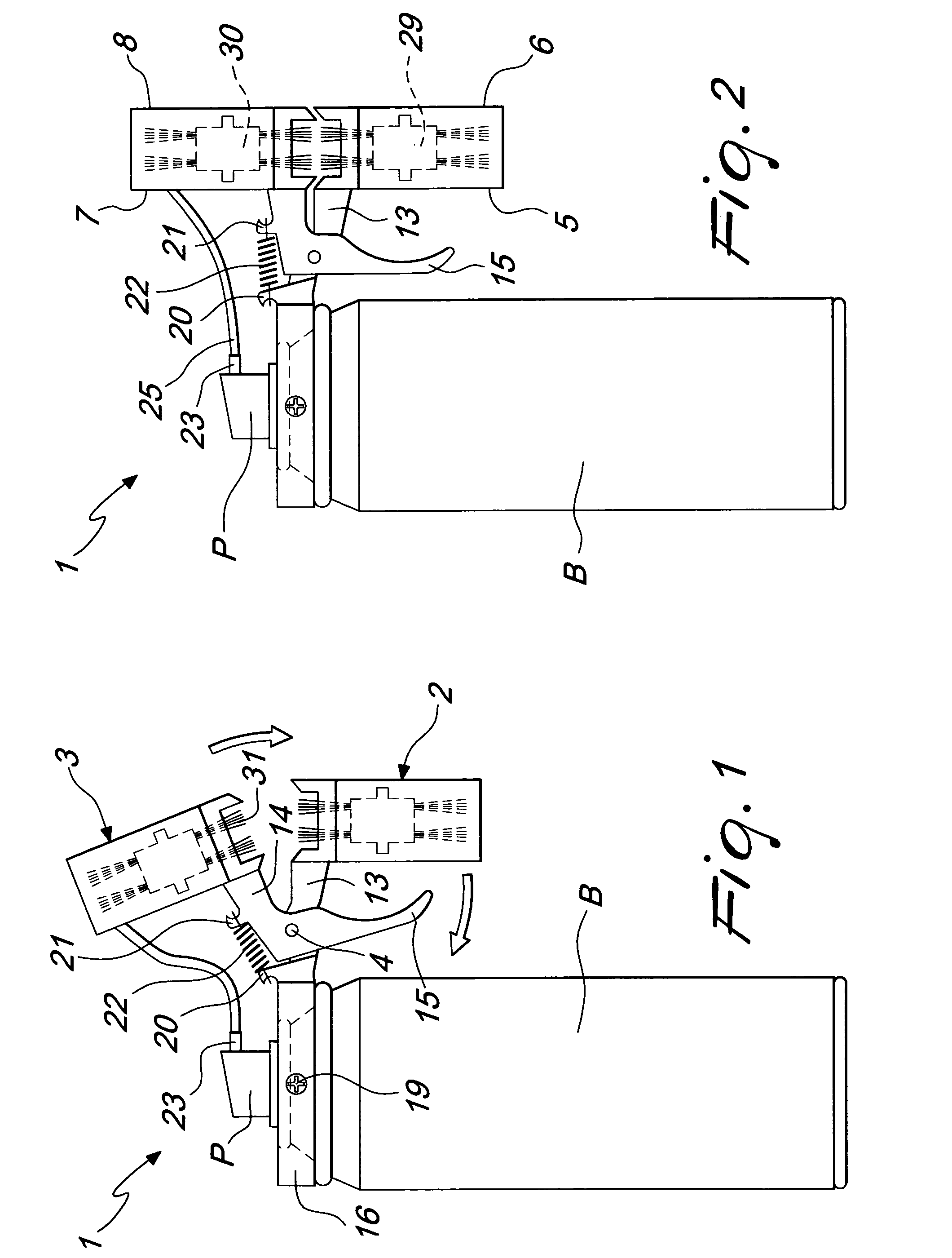

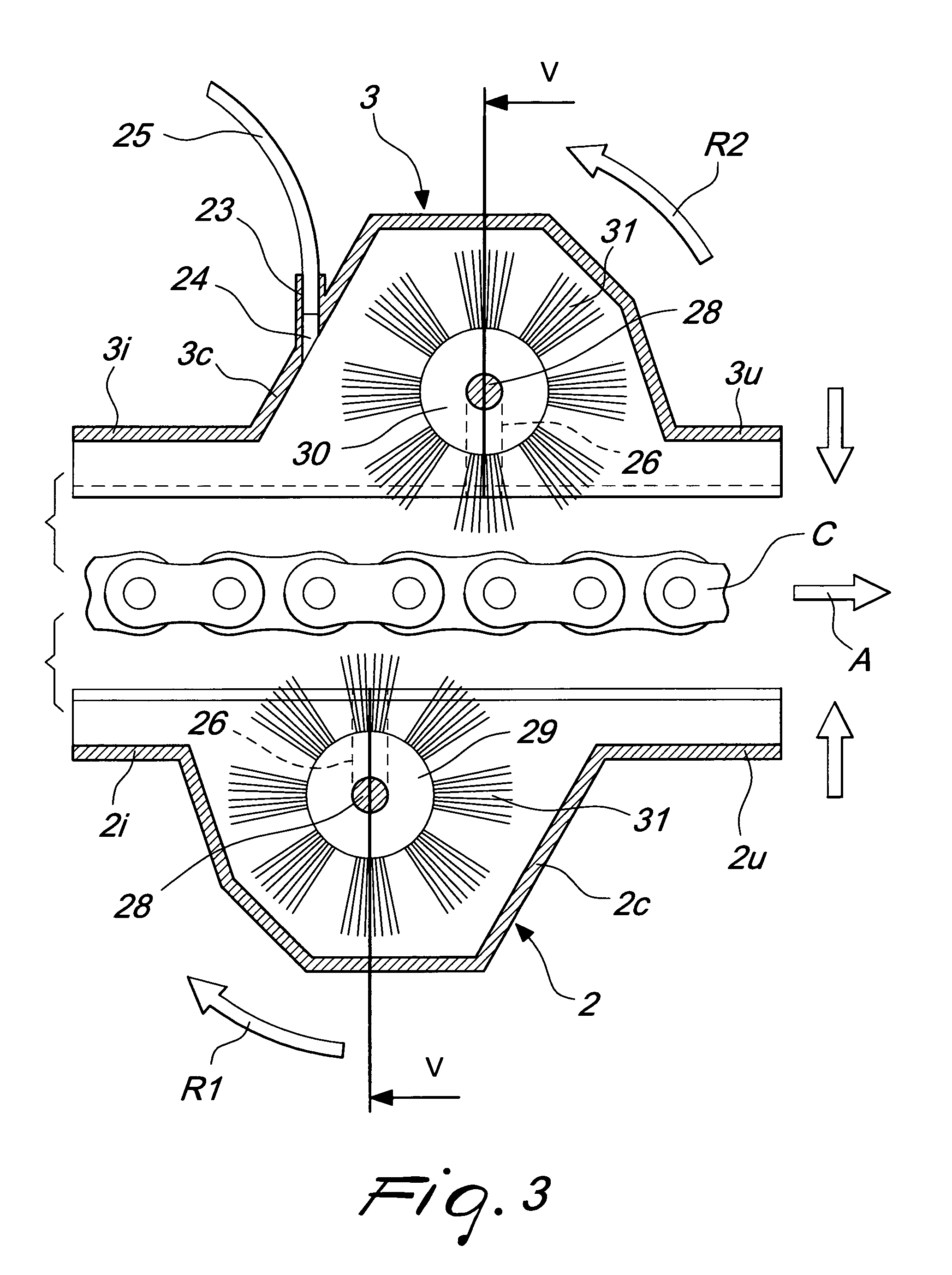

Bicycle chain cleaner fitted on a spray can of cleaning and lubricating solution

InactiveUS6942409B2Allocation is accurateEasy to practiceLiquid surface applicatorsBrush bodiesBristleEngineering

A bicycle chain cleaner fitted on a spray can of cleaning and lubricating solution, comprising: a lower half-shell and an upper half-shell, which are provided centrally with a flat and elongated tray, respectively for collection and for covering the region where a sprayed solution is dispensed, the half-shells being provided with an inlet and an outlet for the chain, which are aligned and co-planar; articulation elements, which are interposed between the half-shells; elements for coupling to the top of the spray can one of the half-shells; and a sort of trigger, which is associated with the other one of the half-shells in order to make the edges of the half-shells mate, respective brushes with tufts of radial bristles being fitted in the half-shells so that they can rotate, the tufts being adapted to penetrate, when the chain advances in the half-shells, between links of the chain.

Owner:BARBIERI DI BARBIERI NADIA E KALMAN

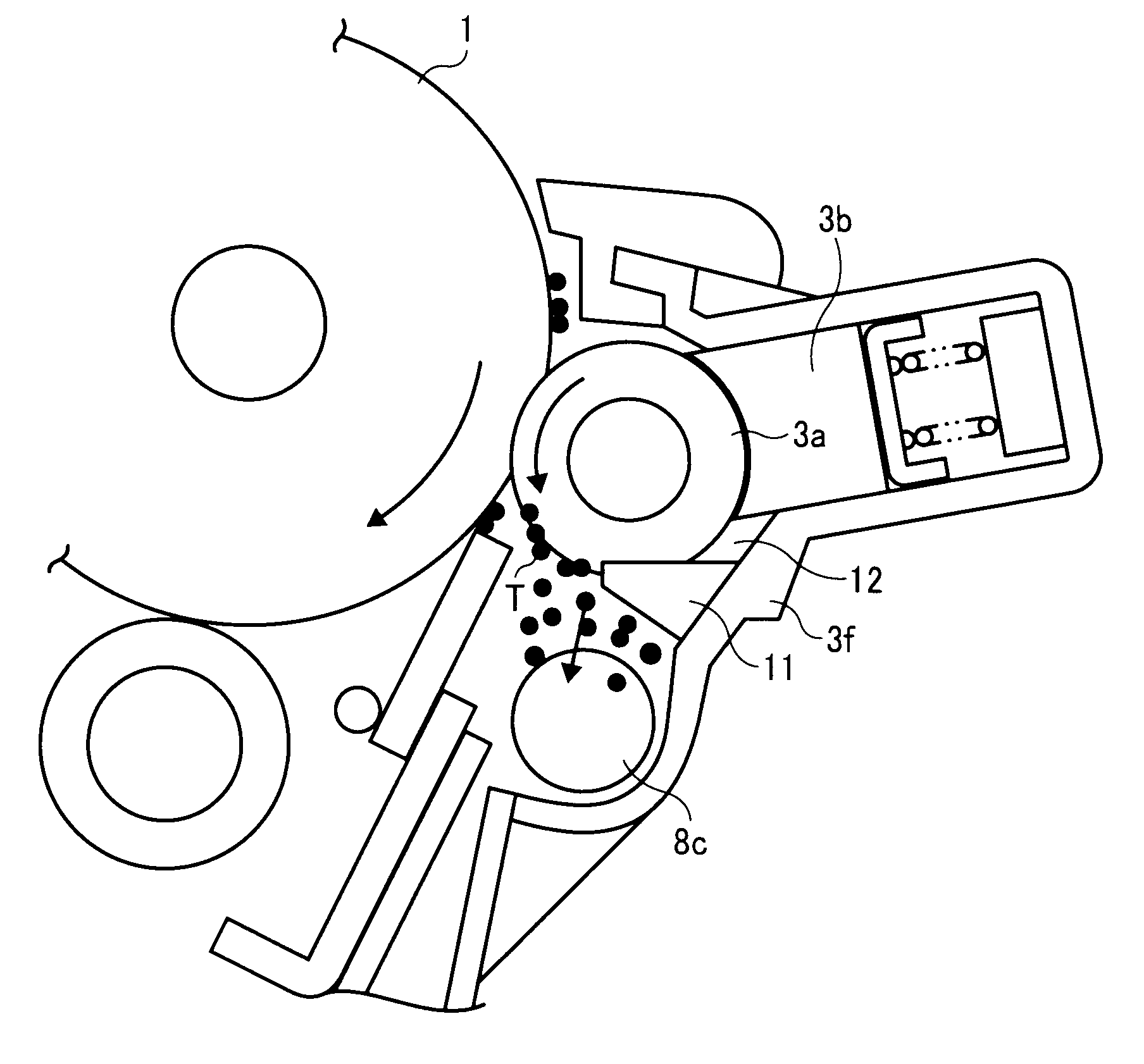

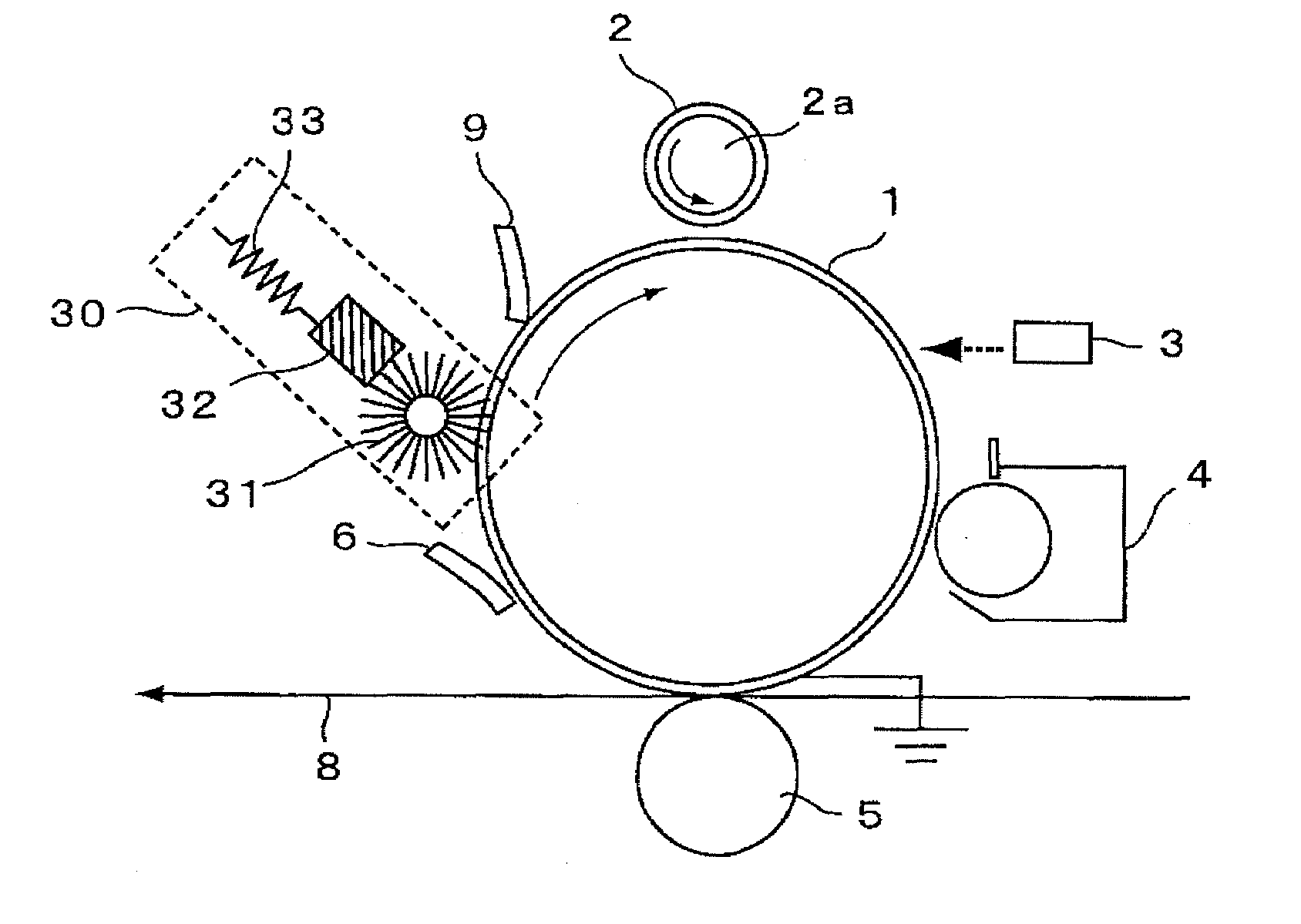

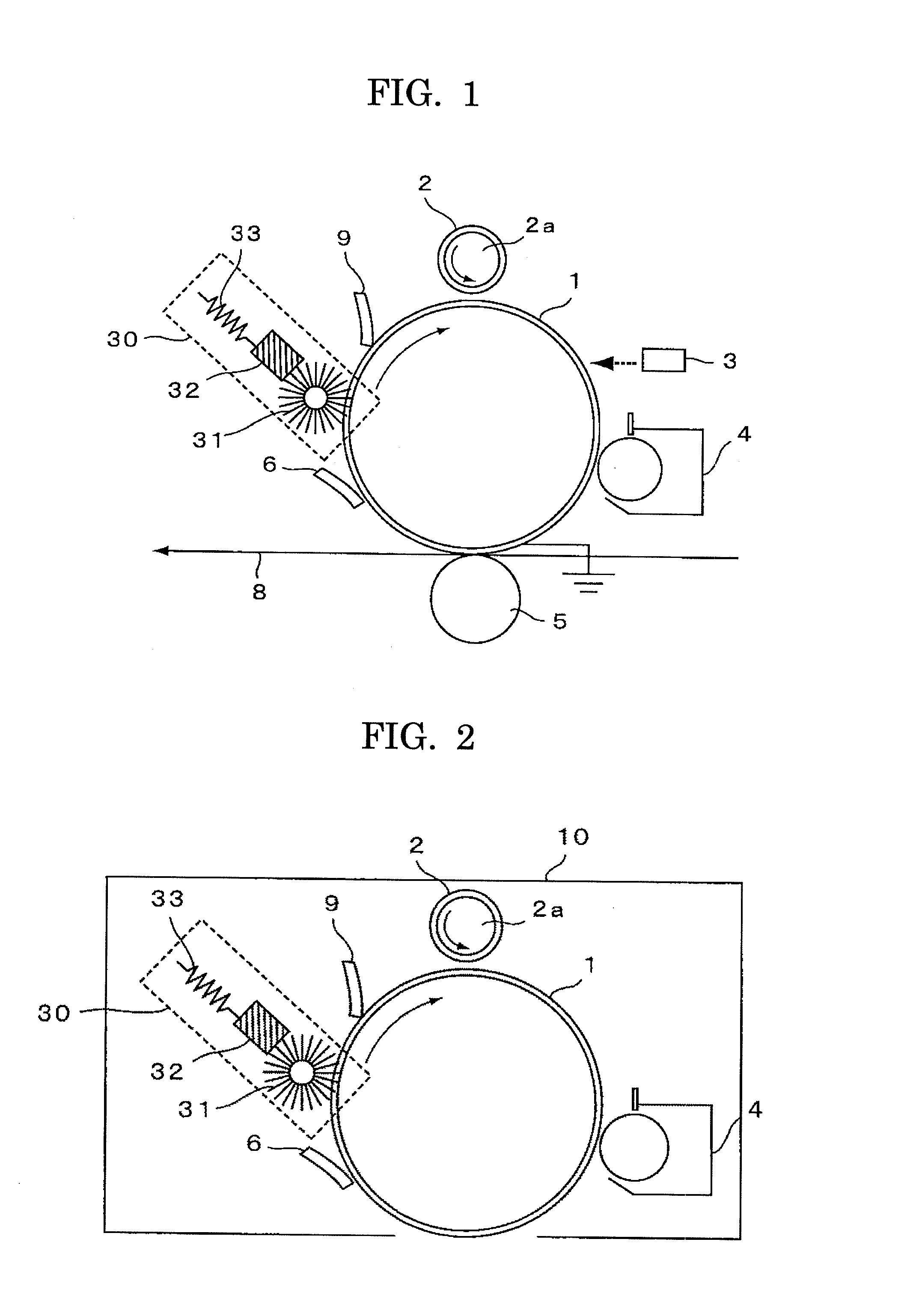

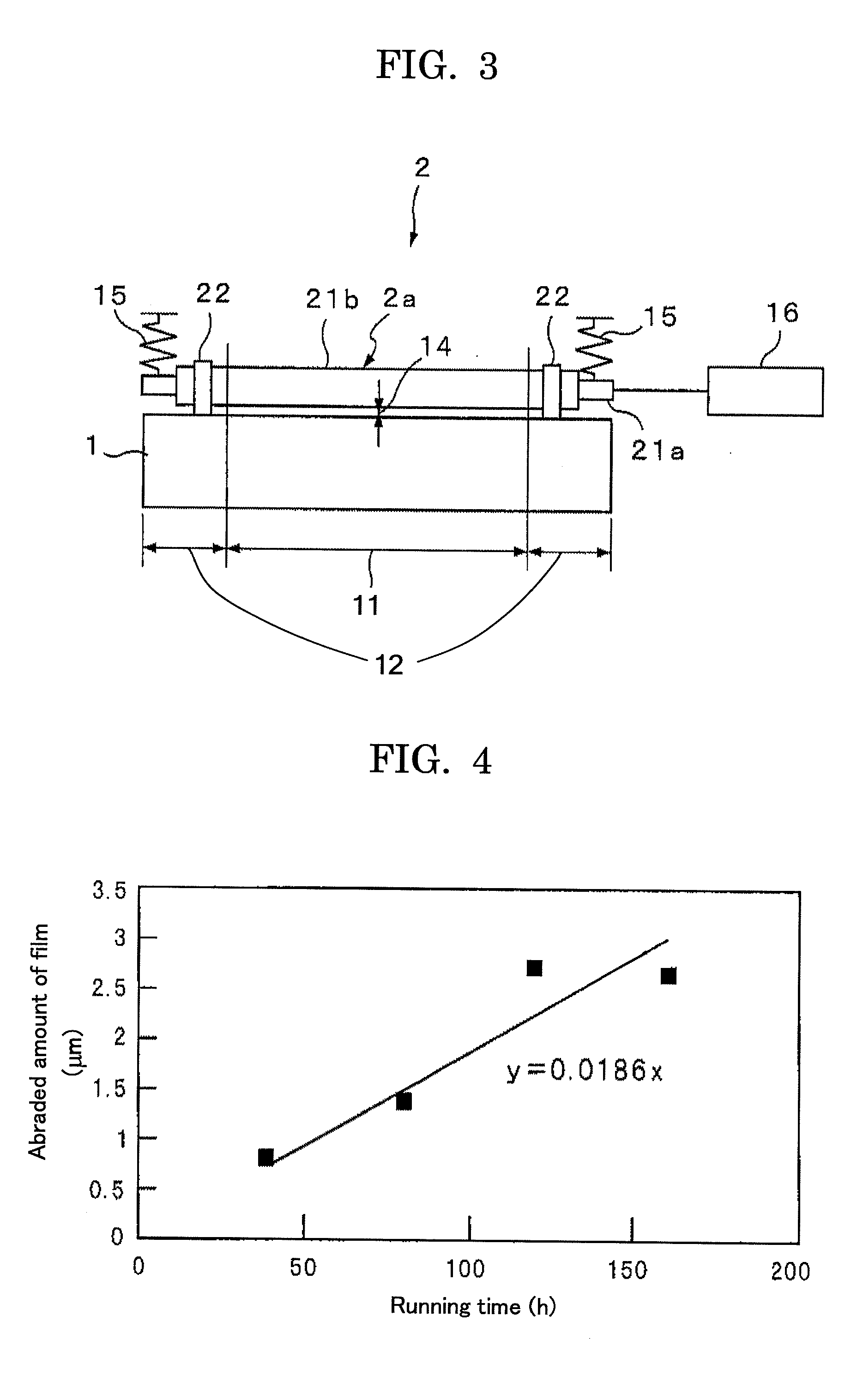

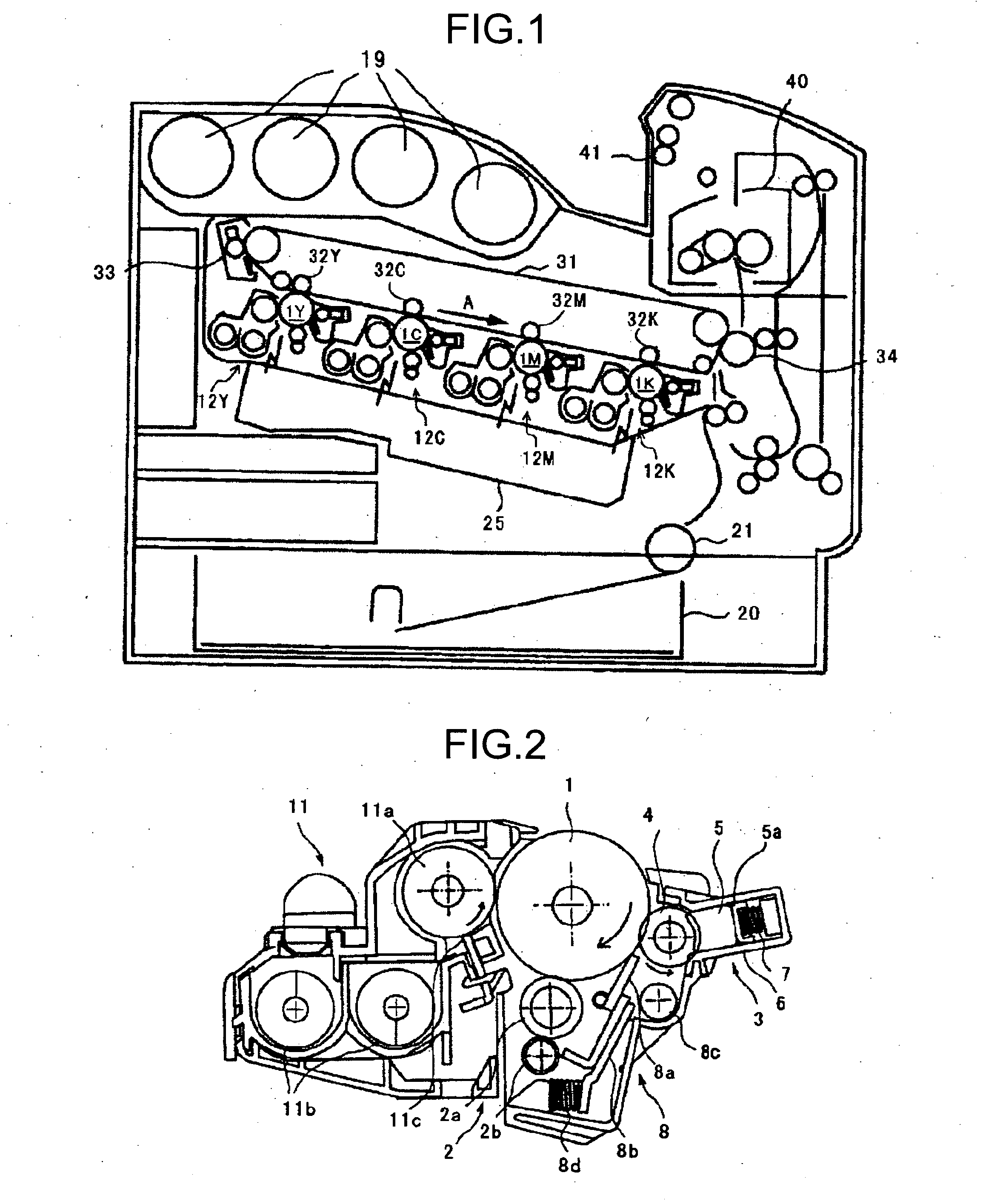

Lubricant applicator and image forming apparatus including same

A lubricant applicator includes a solid mold lubricant, a lubricant application roller, and a flicker member. The lubricant application roller scrapes and applies the lubricant to an image bearing member. The flicker member removes a powder substance adhered to the surface of the lubricant application roller and is disposed upstream of the solid mold lubricant in a direction of rotation of the lubricant application roller. The lubricant application roller, the flicker member, and the solid mold lubricant define a sealed space therebetween. A lubricant applicator includes the solid mold lubricant, the lubricant application roller, the flicker member, and an adherence prevention member that prevents the substance removed by the flicker member from adhering again to the lubricant application roller. A lubricant applicator includes the solid mold lubricant, the lubricant application roller, and a lubricant receiver that receives the scraped lubricant from the lubricant application roller.

Owner:RICOH KK

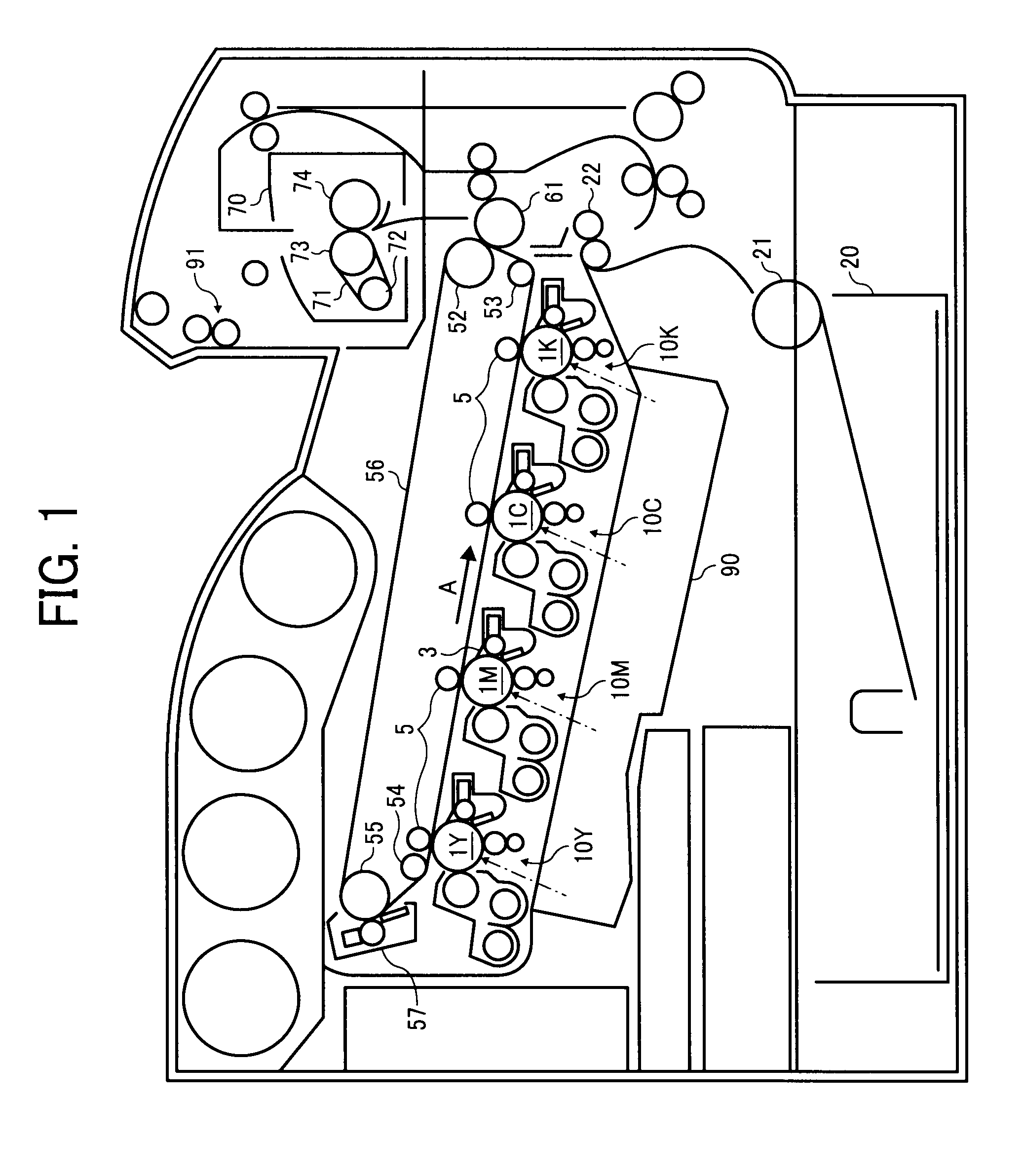

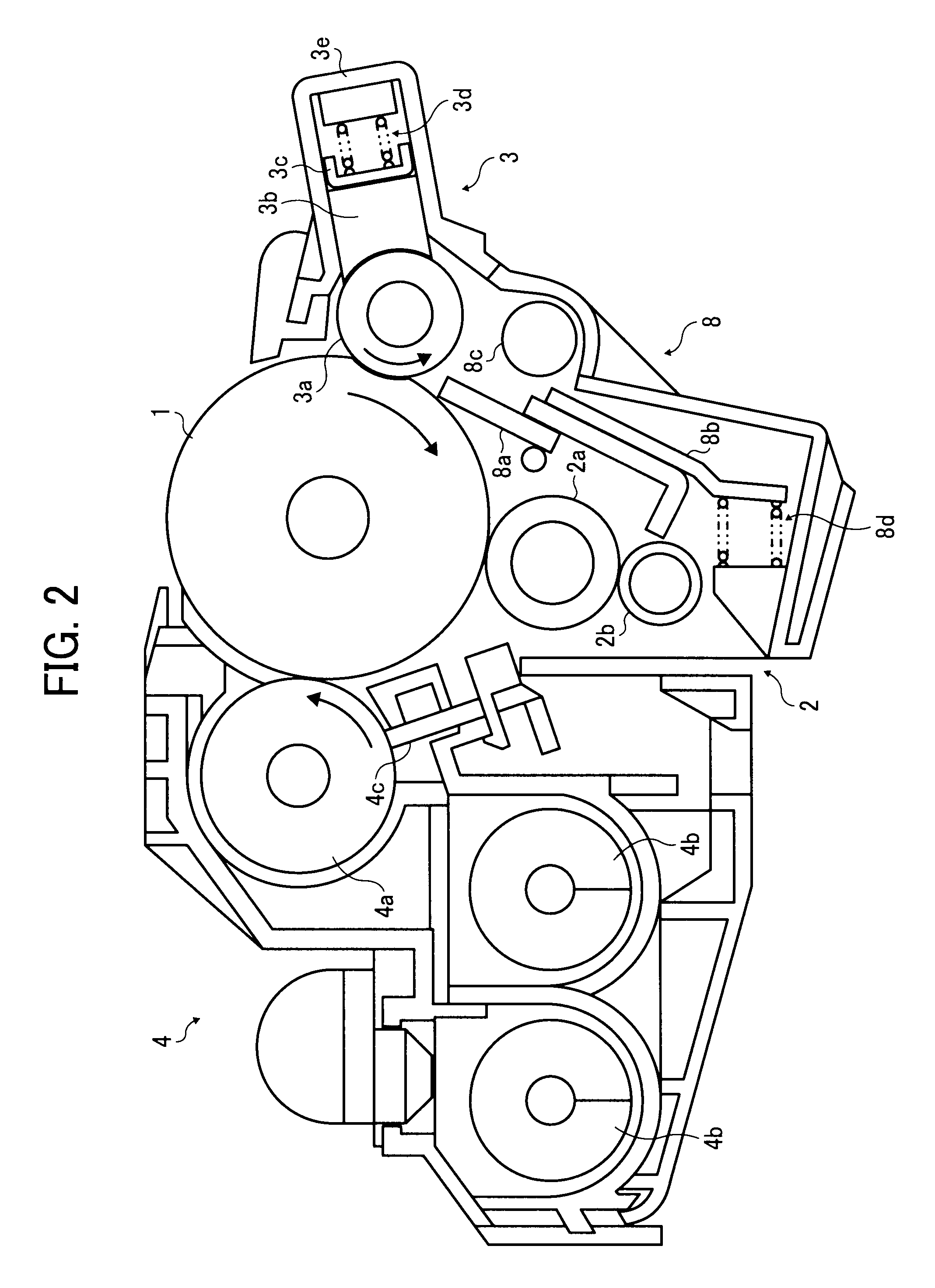

Image forming apparatus and process cartridge

InactiveUS20090304423A1Avoid smearingImprove accuracyElectrography/magnetographyDistribution equipmentAC - Alternating currentImage formation

An image forming apparatus including a charging unit configured to charge a surface of an image bearing member utilizing discharge generated by applying a voltage containing an alternating current component to a charging member disposed in contact with or close to the image bearing member, so that a latent electrostatic image is formed on the image bearing member; a developing unit configured to develop the latent electrostatic image formed on the image bearing member using a toner; a cleaning unit configured to clean the surface of the image bearing member using a blade; a protecting agent applying unit configured to rub and scrape a protecting agent by a brush roller and apply the protecting agent to the surface of the image bearing member; and a protecting agent charging member configured to charge the protecting agent, the member being disposed between the protecting agent applying unit and the charging unit.

Owner:RICOH KK

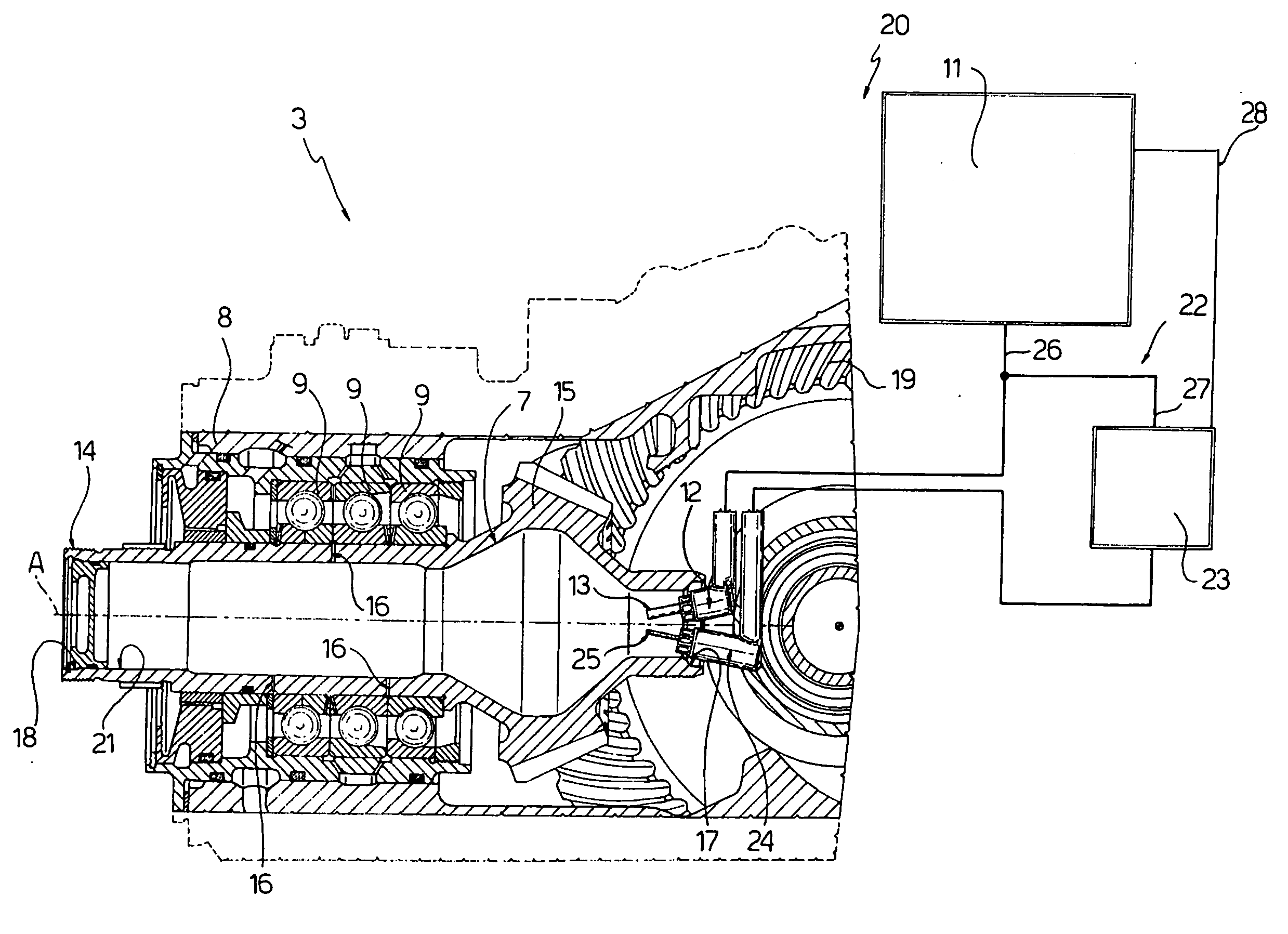

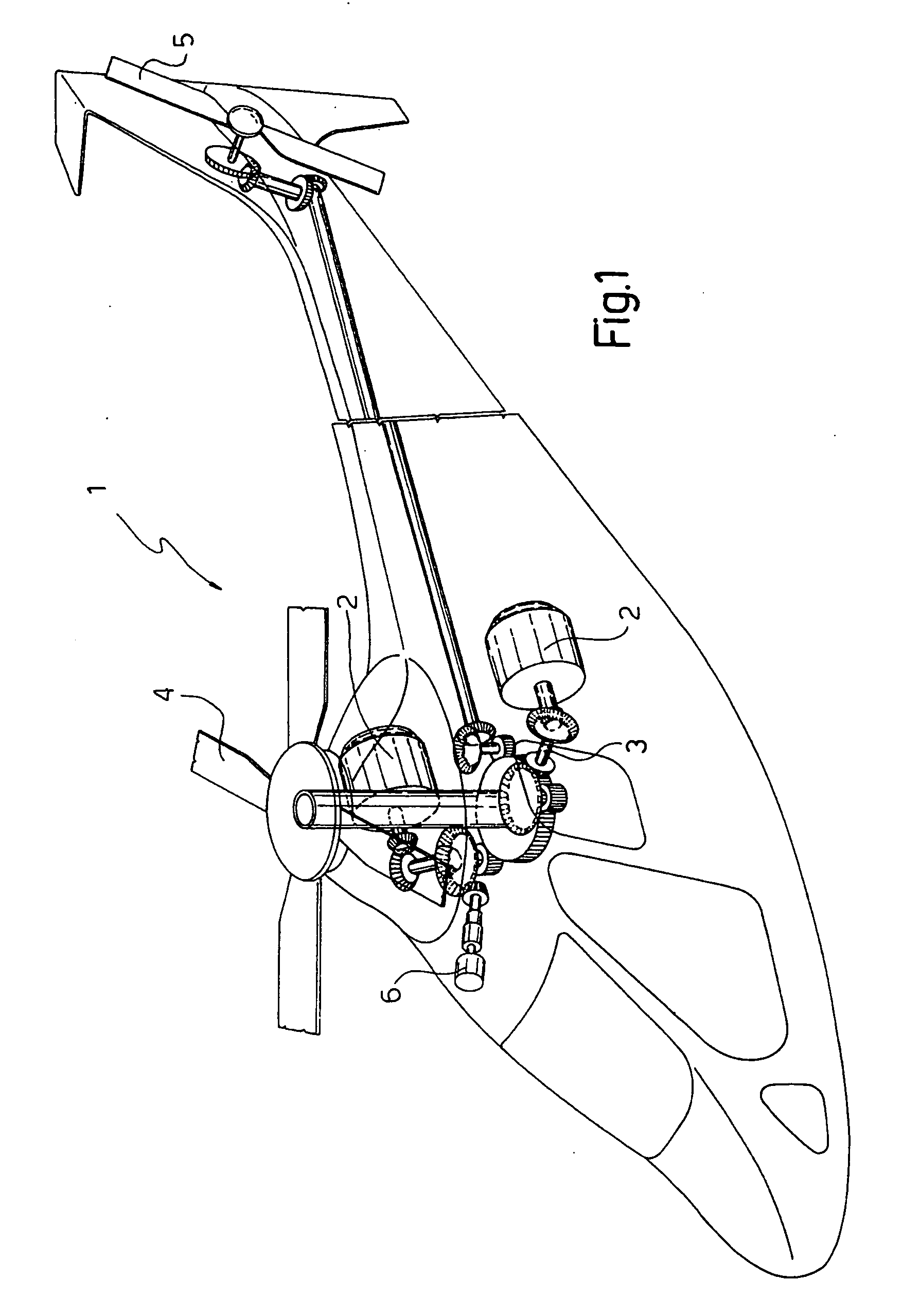

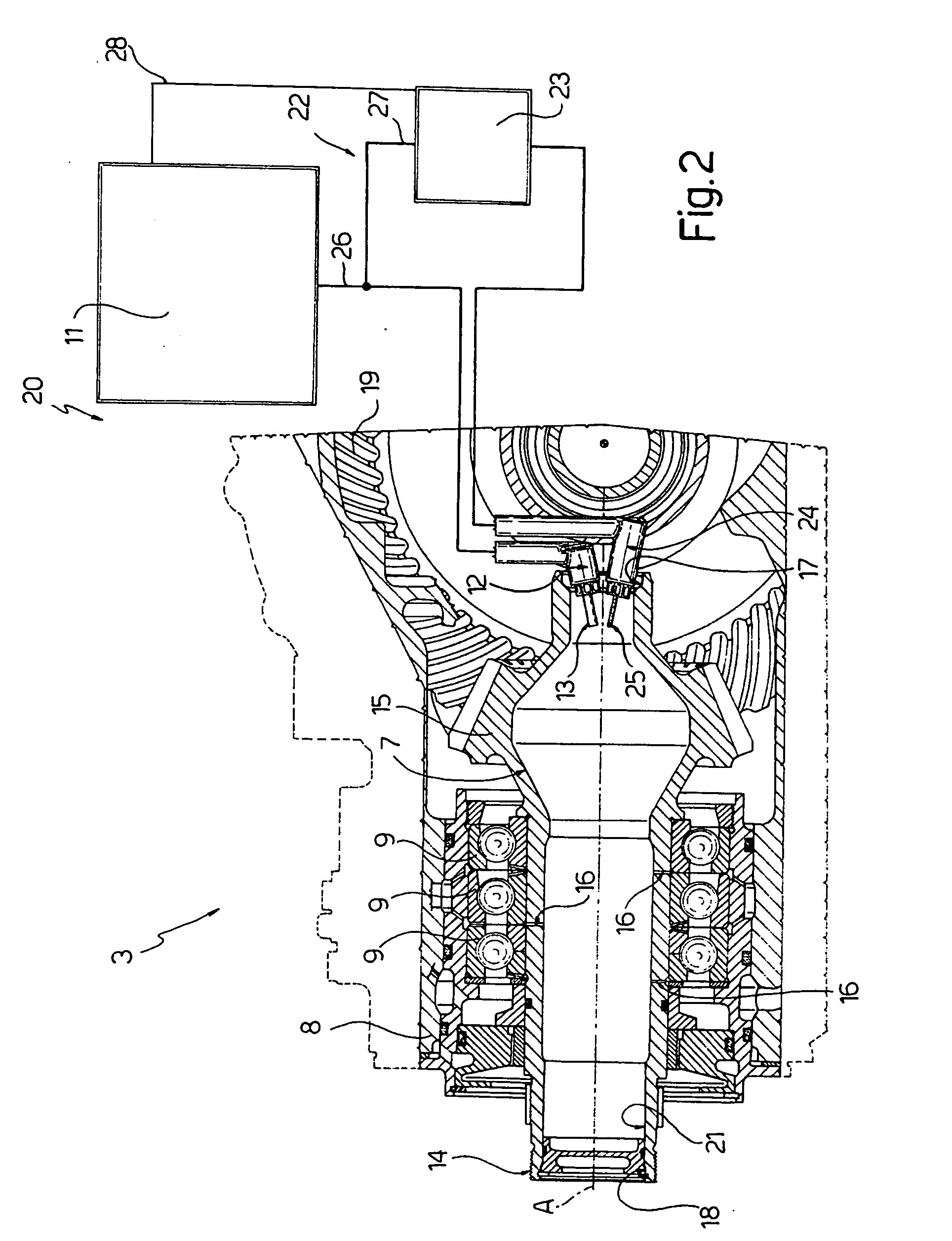

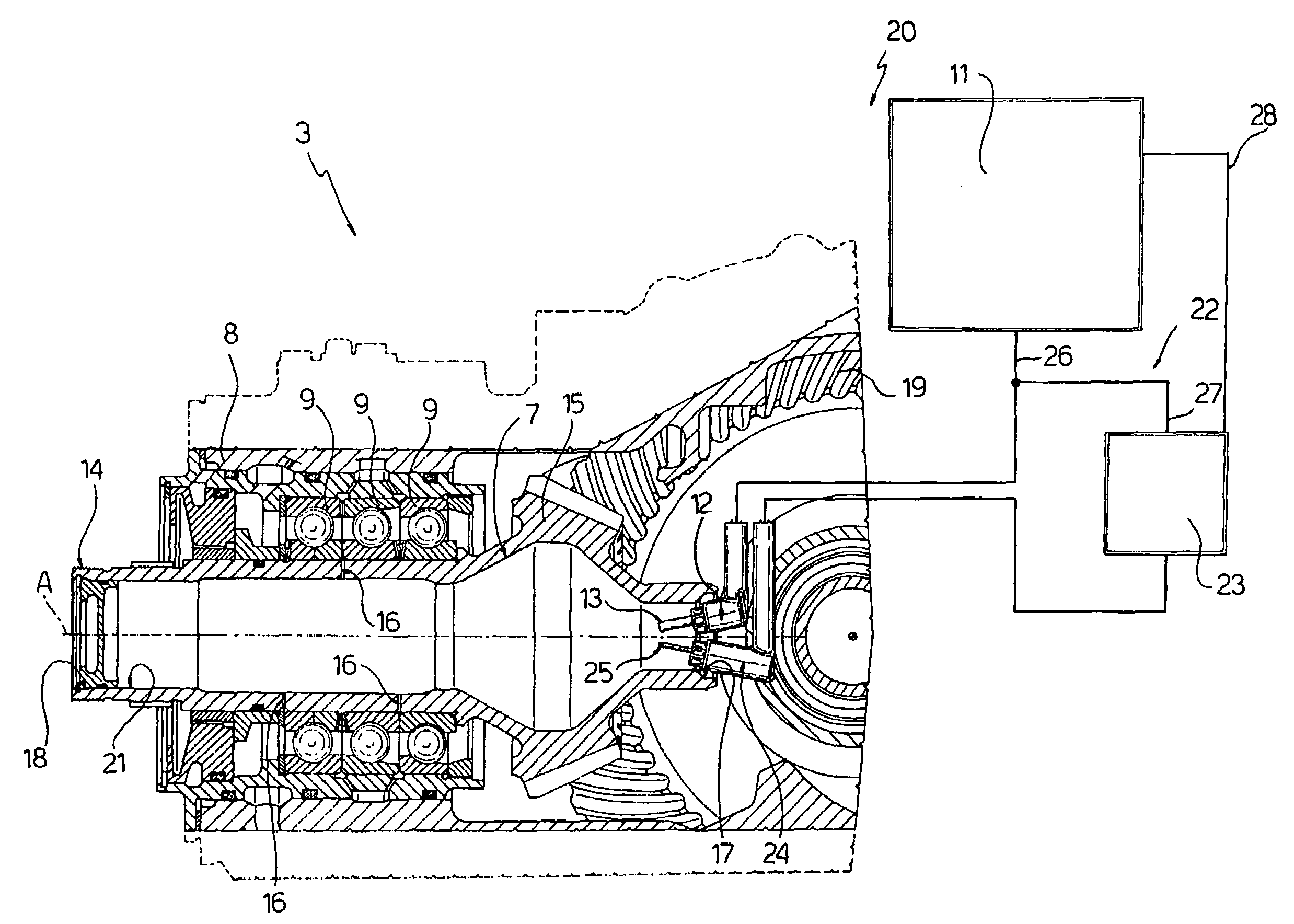

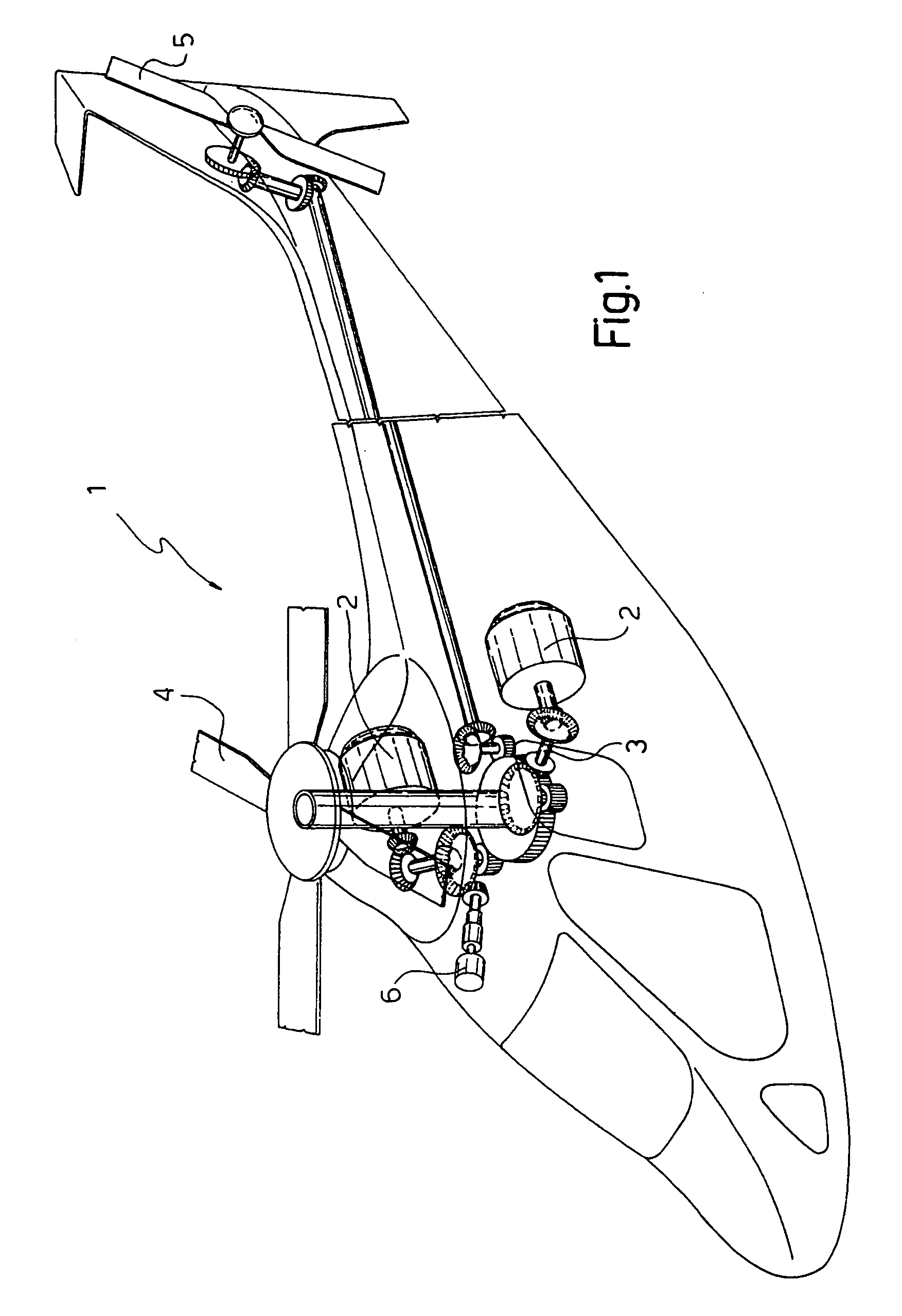

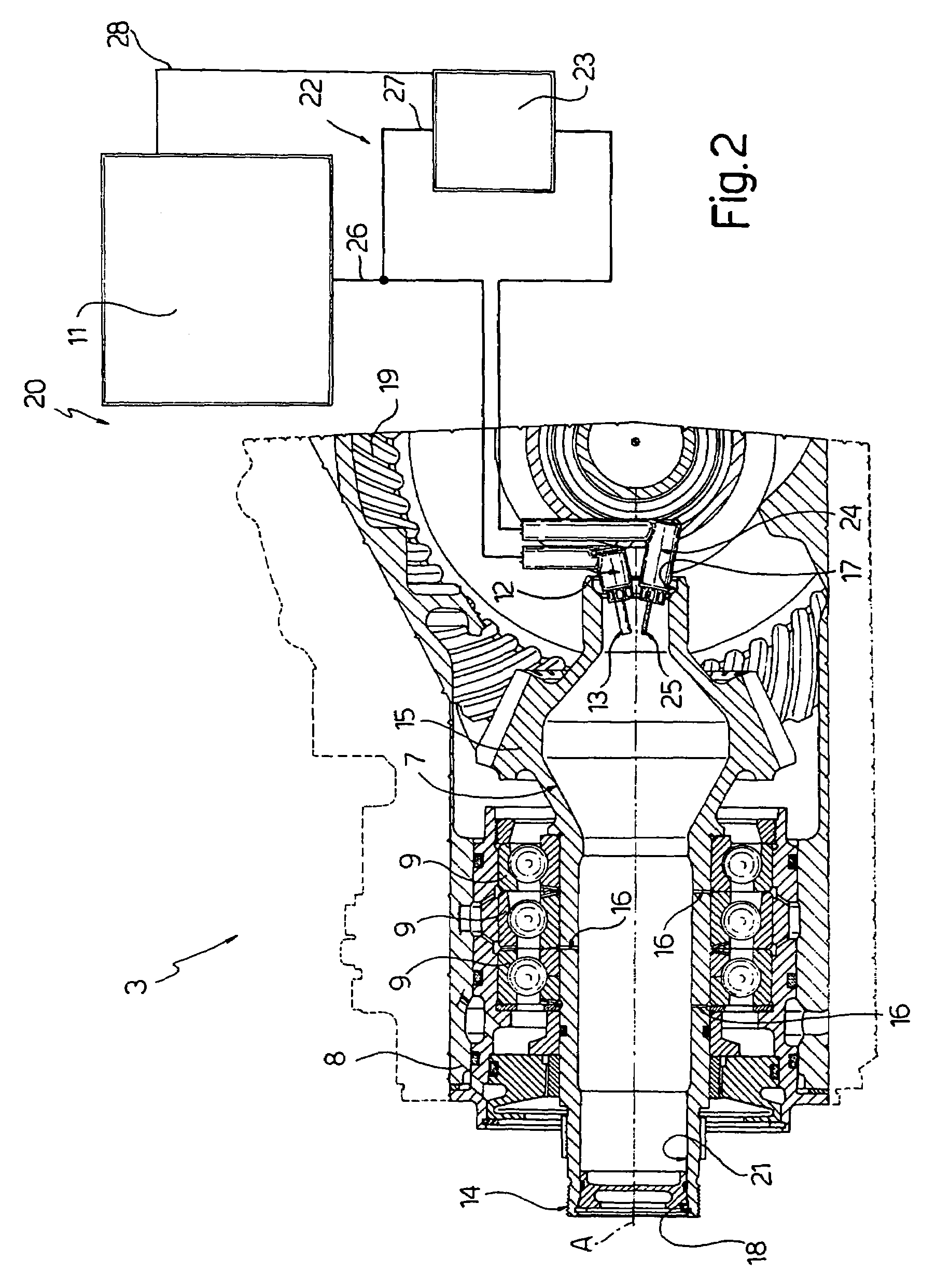

Helicopter with an auxiliary lubricating circuit

ActiveUS20090071753A1Meet the requirementsDrip lubricationDrip or splash lubricationAuxiliary memoryEngineering

Owner:LEONARDO FINMECCANICA SPA

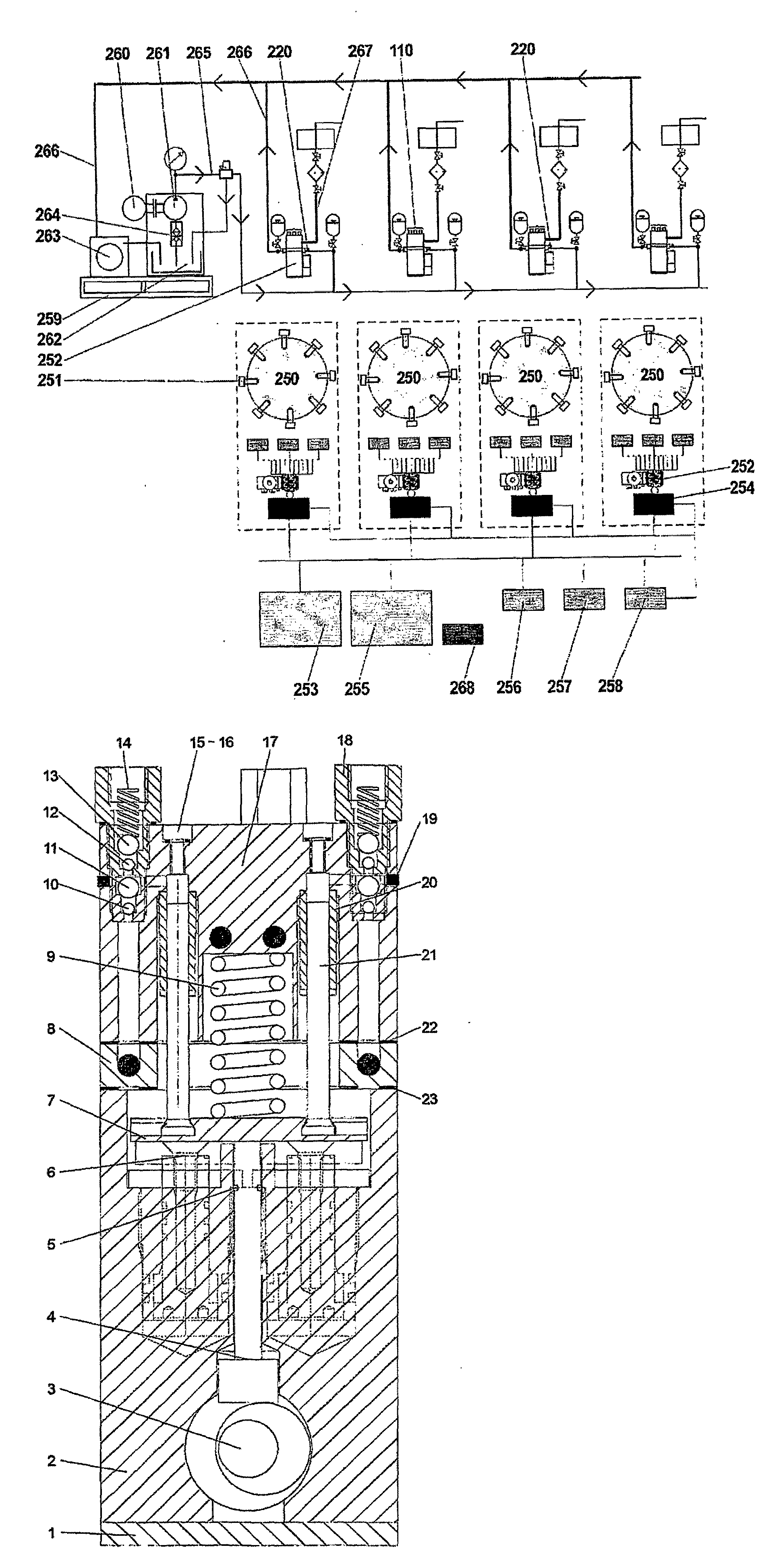

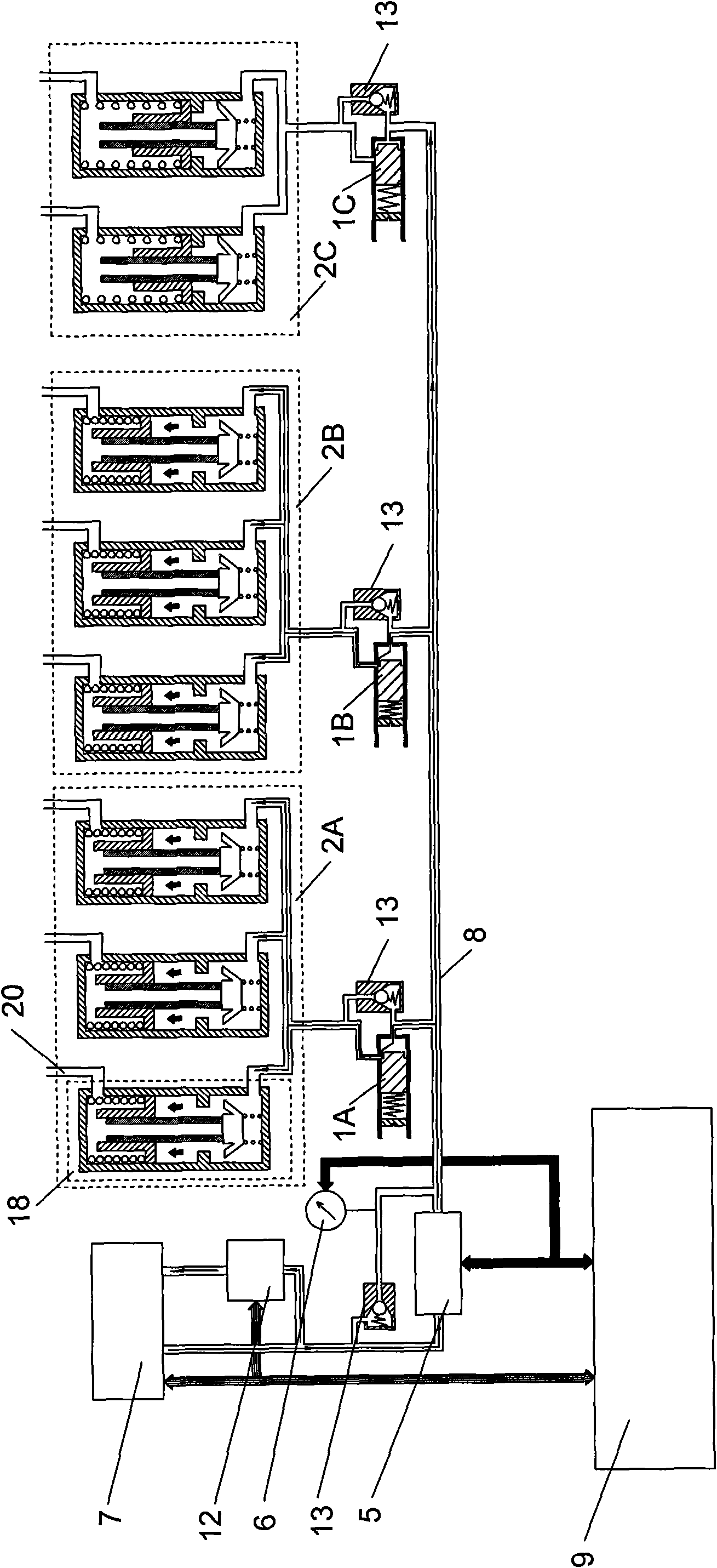

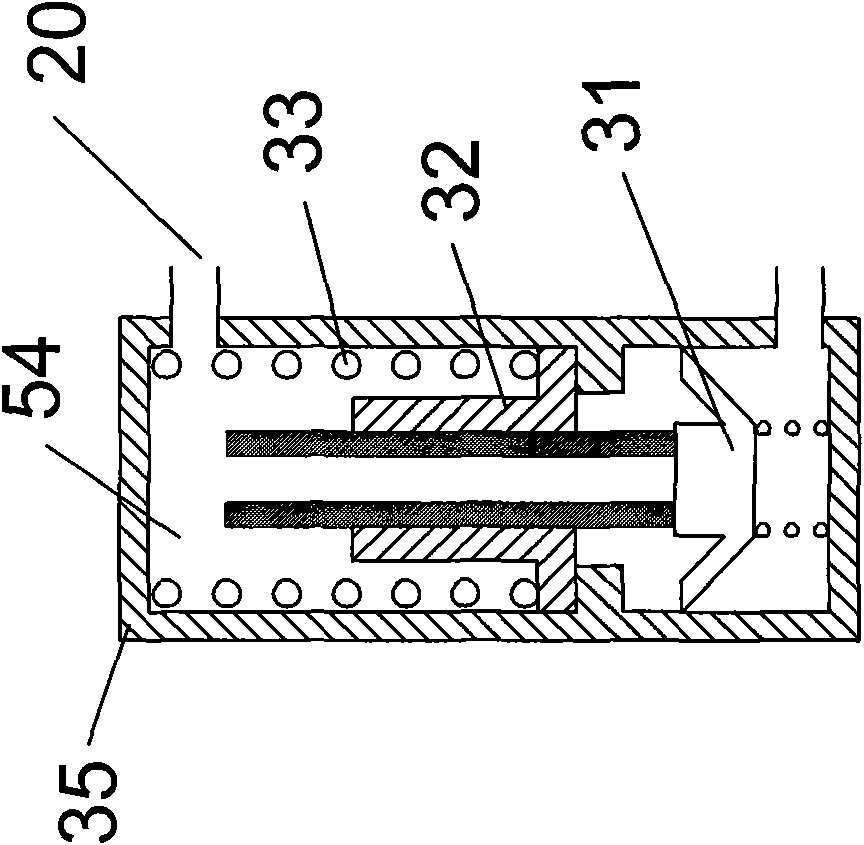

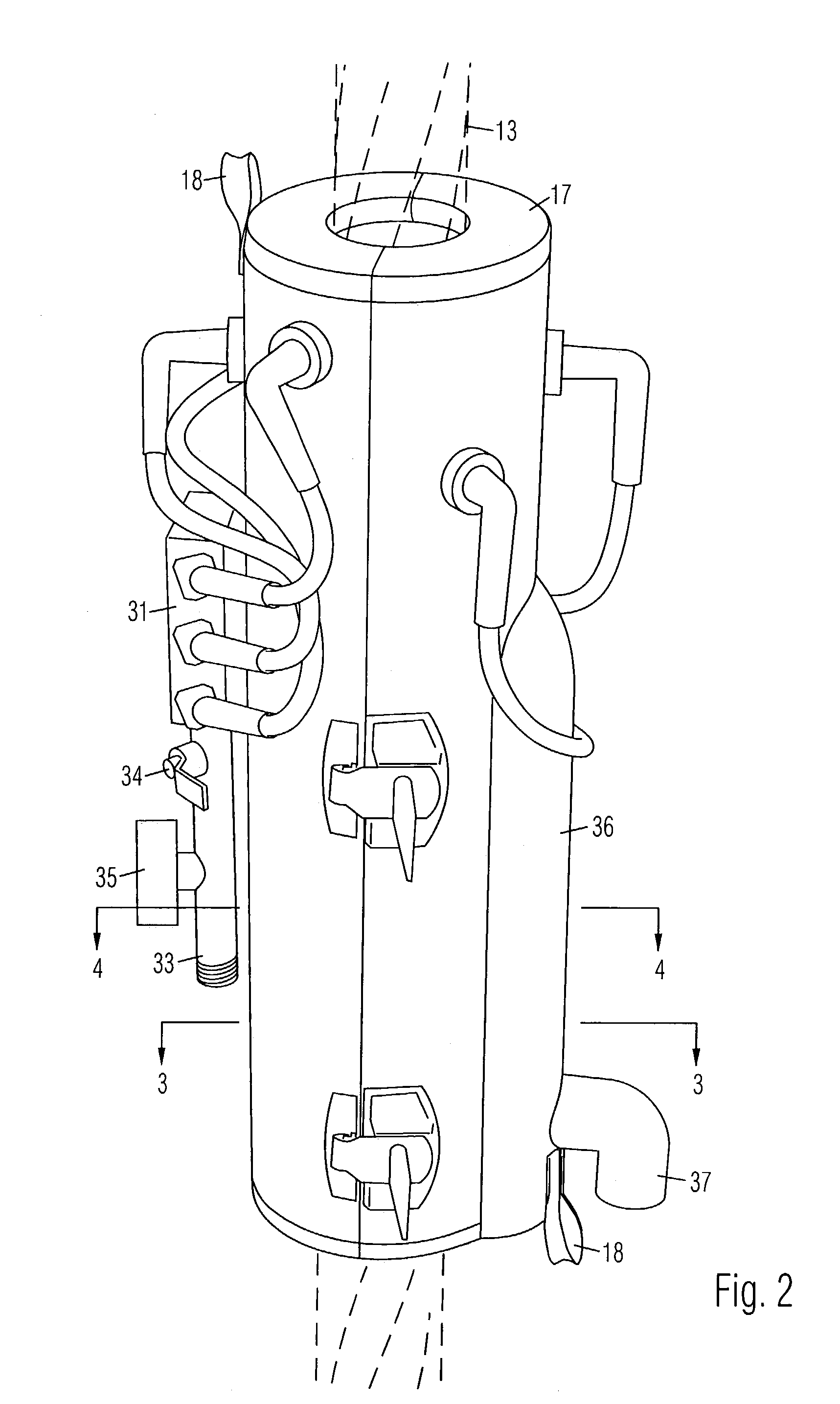

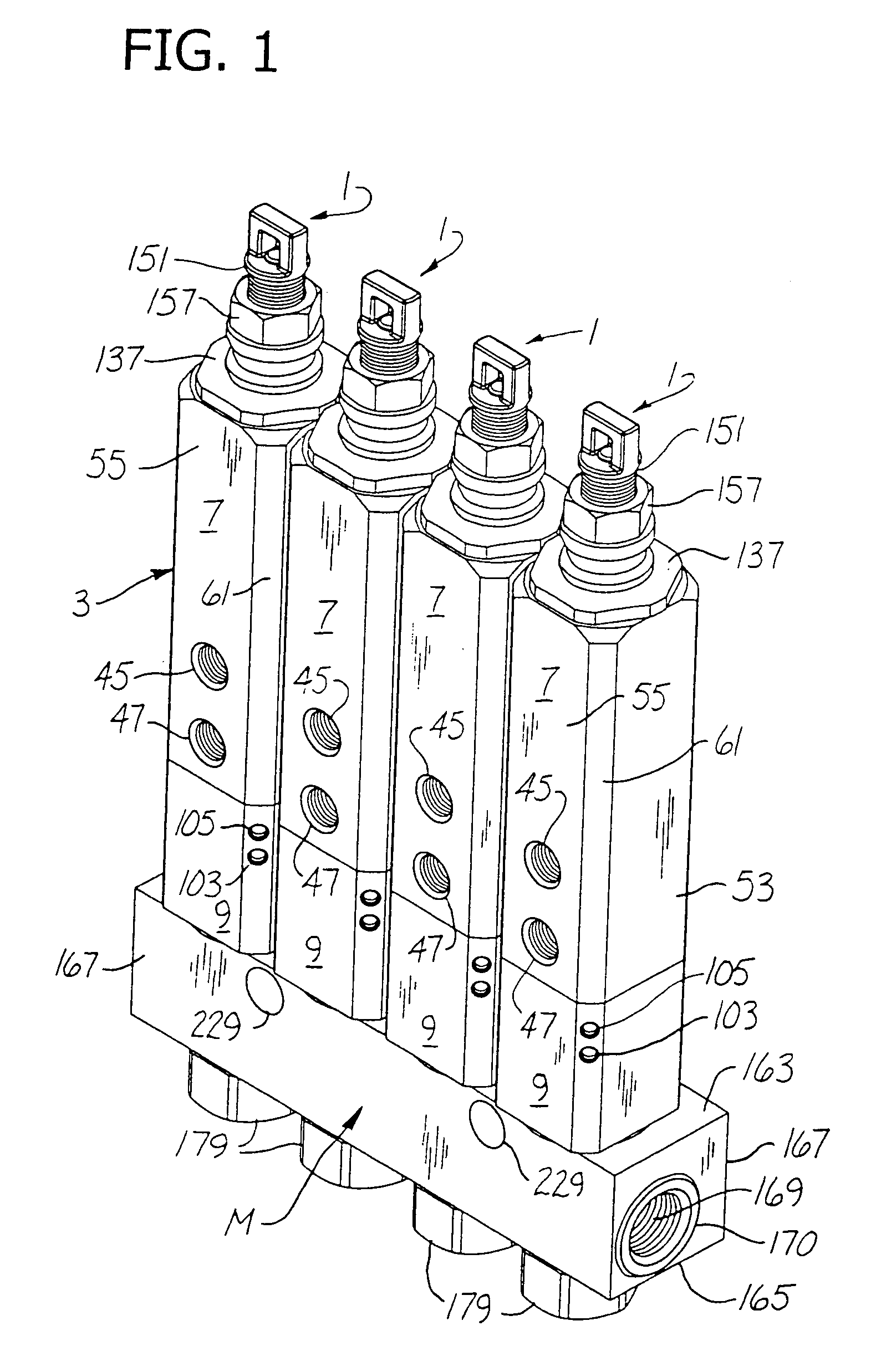

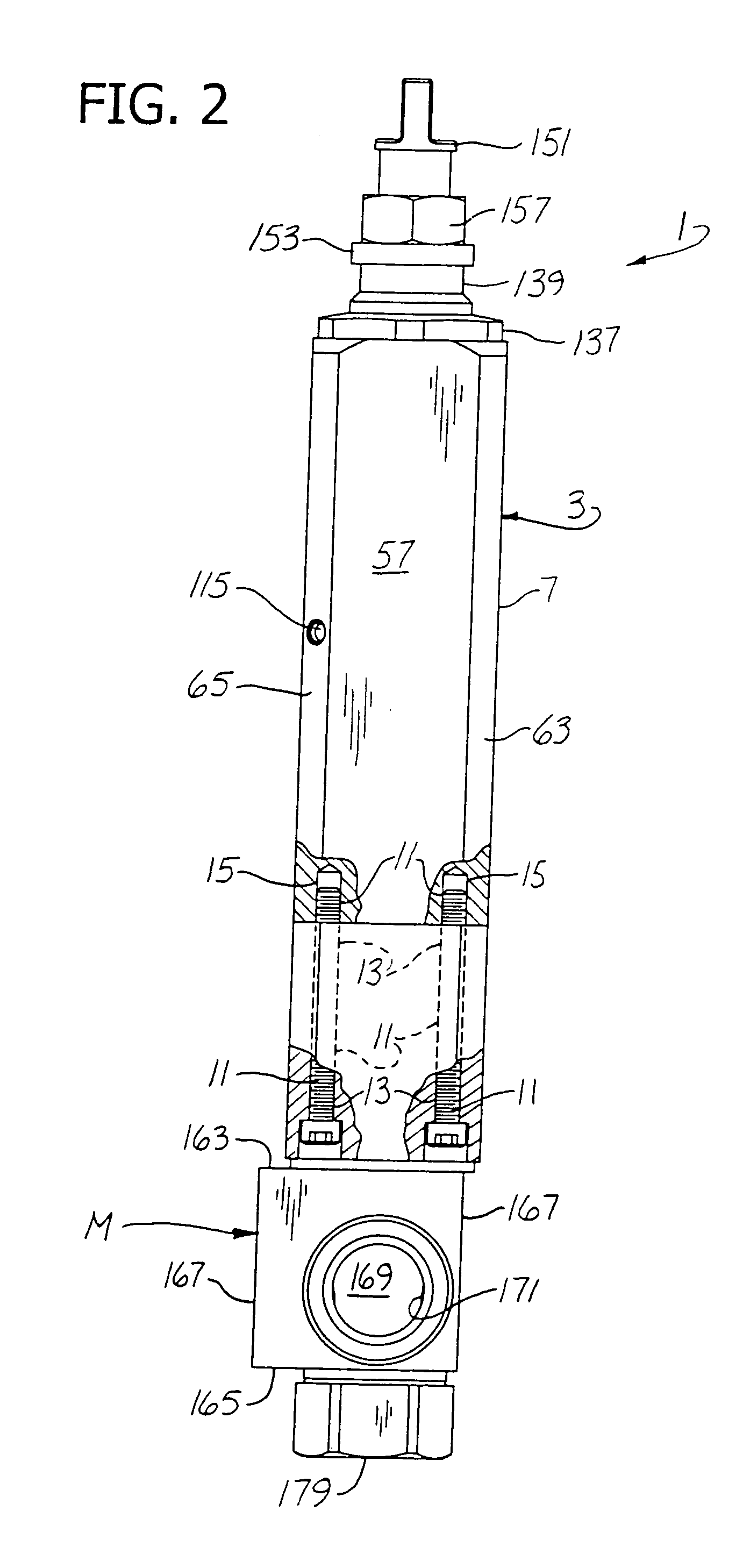

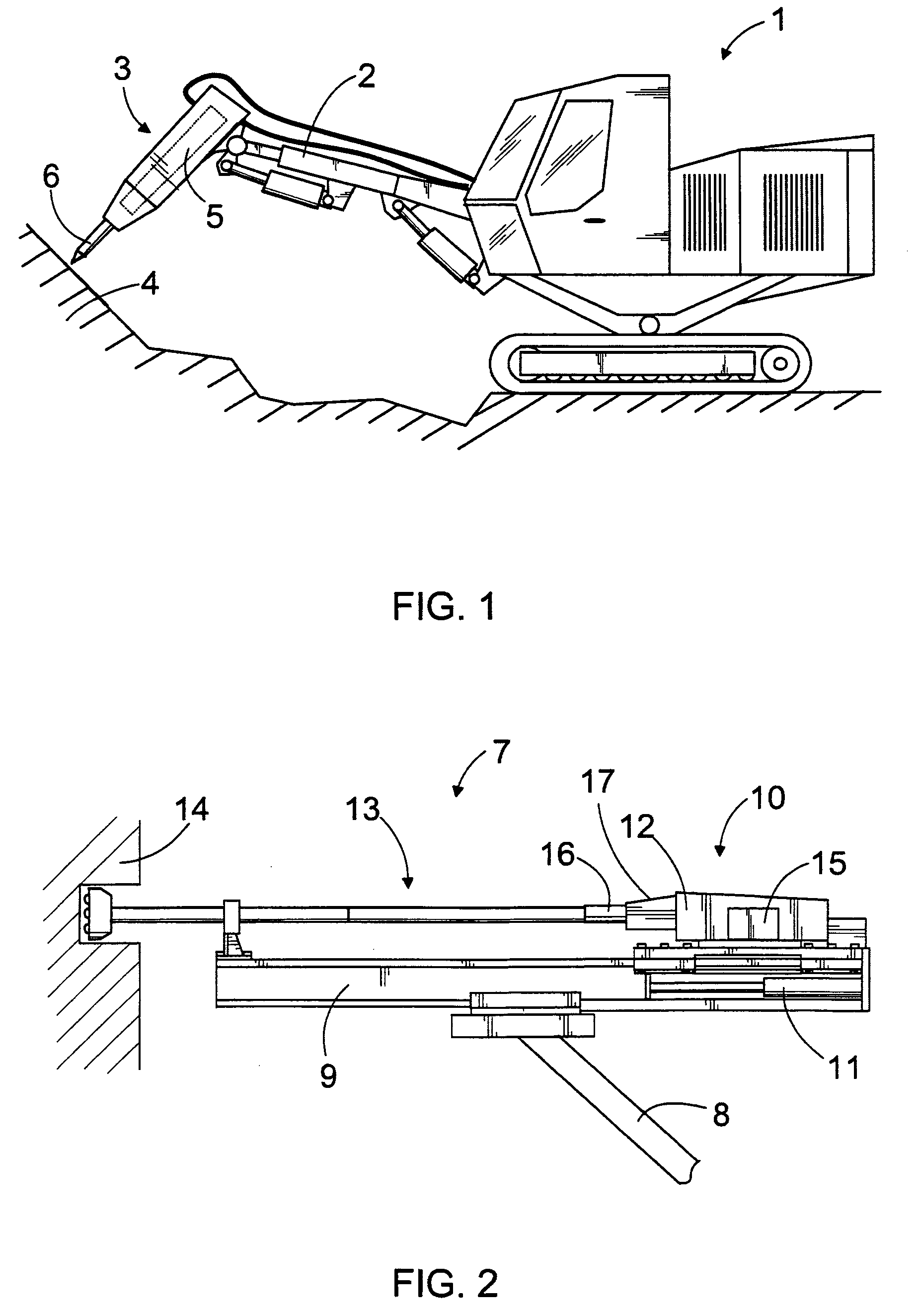

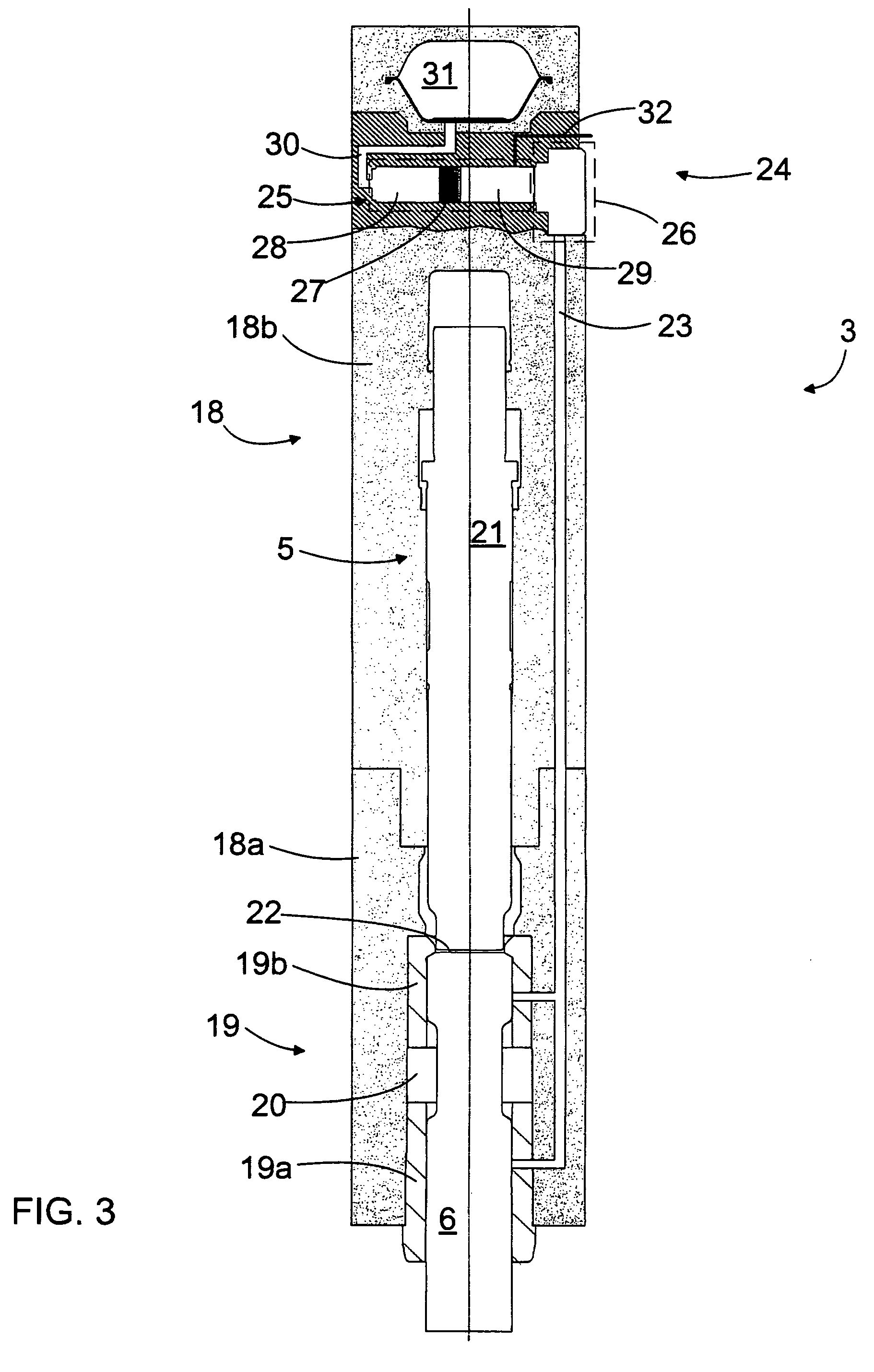

Lubricating apparatus for a dosing system for cylinder lubrication oil and method for dosing cylinder lubricating oil

ActiveUS20100006056A1Easy to adjustEasy to replaceLubrication of auxillariesPropulsion power plantsHydraulic cylinderEngineering

There is disclosed a method and a hydraulic lubricating apparatus for dosing cylinder lubricating oil. The dosing system includes a supply line and a return line connected with the lubricating apparatus via each one or more valves for supplying hydraulic oil, a central hydraulic oil feed pump connected with hydraulic cylinders, each having a hydraulic piston and which may be subjected to pressure by hydraulic oil via the supply line, a number of injection units corresponding to a multiple of the cylinder number in the engine and which are connected with each their dosing cylinder with a dosing piston and a supply line for cylinder lubricating oil. In order to provide a system which is reliable and cheap and where there is no risk of disruptions, even if a hydraulic cylinder fails, the lubricating apparatus is designed with a distributor plate which at one side is in contact with the dosing pistons and which at its other side is in contact with two or more hydraulic pistons for displacing the distributor plate for activating the dosing pistons.

Owner:HANS JENSEN LUBRICATORS

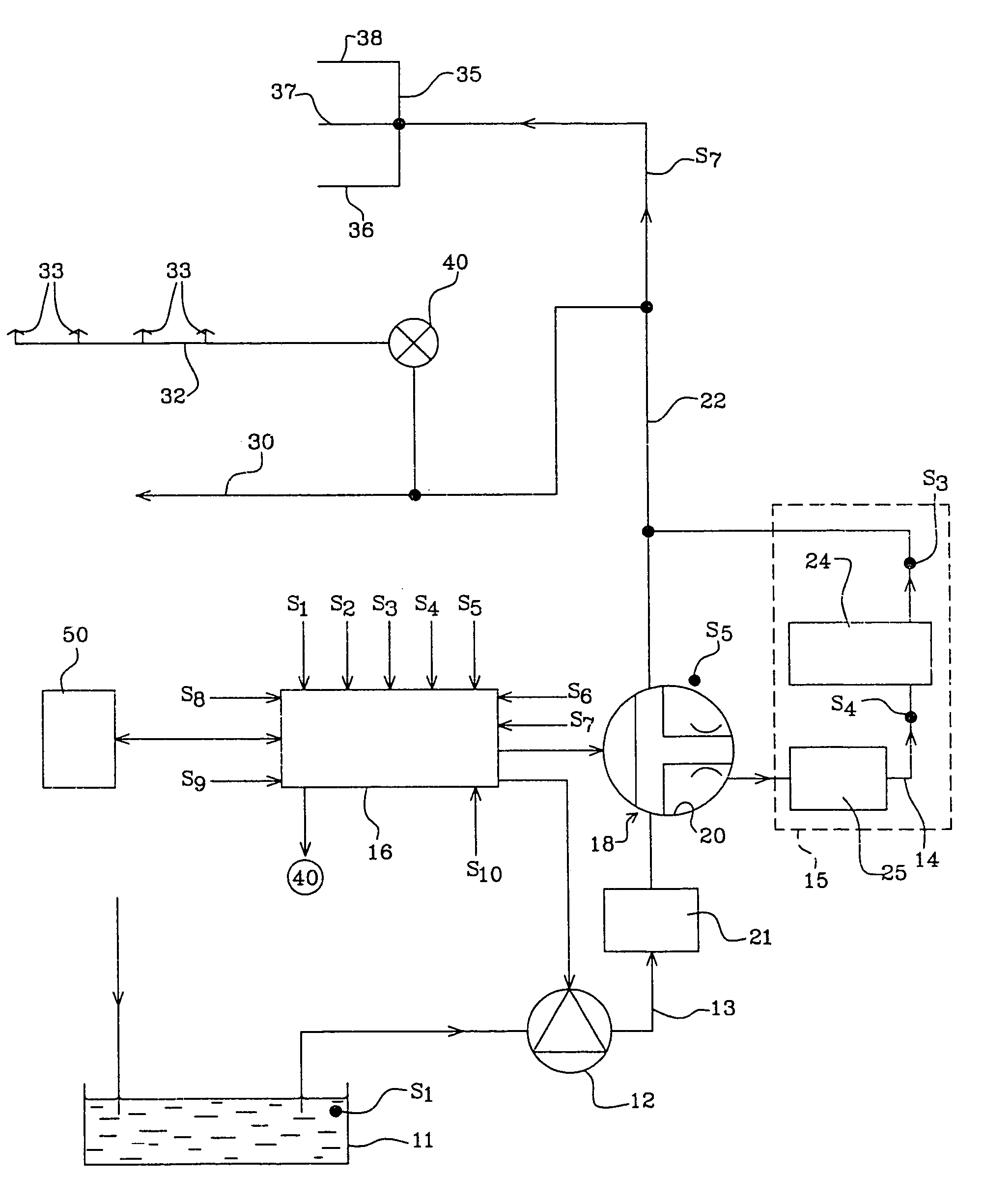

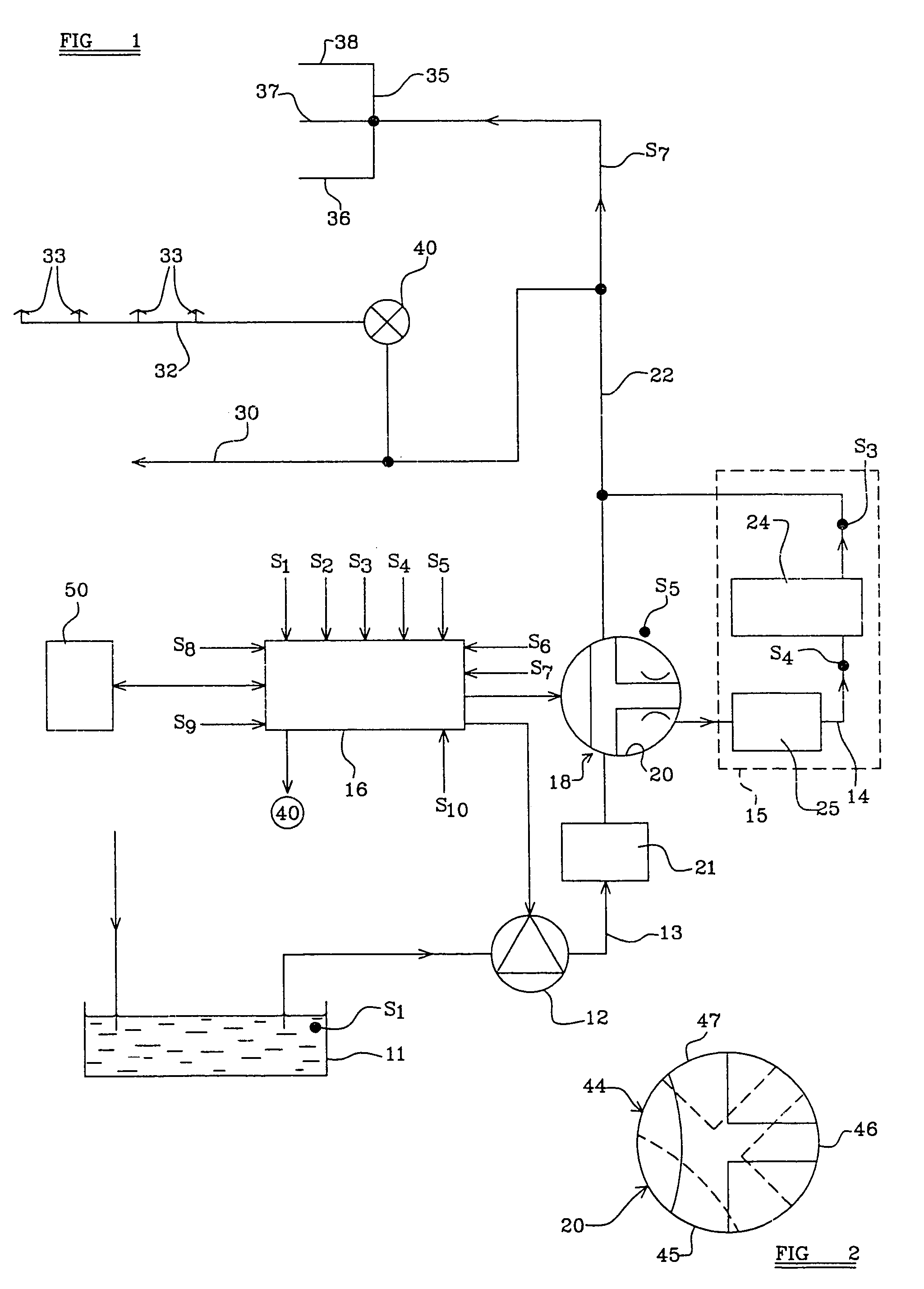

Method for monitoring lubricant distribution system and lubricant distribution system using same

InactiveCN101561076ARealize intelligent detectionProgramme controlComputer controlDistribution systemEngineering

The invention discloses a method for monitoring a lubricating system and a lubricating system using the same. The method comprises the following steps that: when the pressure or pressure change of the control fluid of a pressure control valve is matched with the pressure property of a pressure control valve arranged at the lower reach of a lubricant supply source arranged in the lubricating system, the pressure control valve acts; according to the flow direction of lubricant, a flow sensor is arranged at the upper reach of the pressure valve for acquiring the flow value of passing lubricant; a pressure sensor I is arranged on the path of the control fluid of the pressure control valve for acquiring the pressure value of the control fluid; the acquired flow value of the lubricant and the acquired pressure value of the control fluid are transmitted to an intelligent controller; and the intelligent controller stores a comparative judgment program, and judges whether a lubricated point is blocked and determines the position of a blocked lubricated point. The method saves the arrangement of a detection element on a distributor, uses few oil path connectors, can point out exact position of the blocked lubricated point, and realizes the intelligent detection of the position of a lubricated point failure.

Owner:职子竖

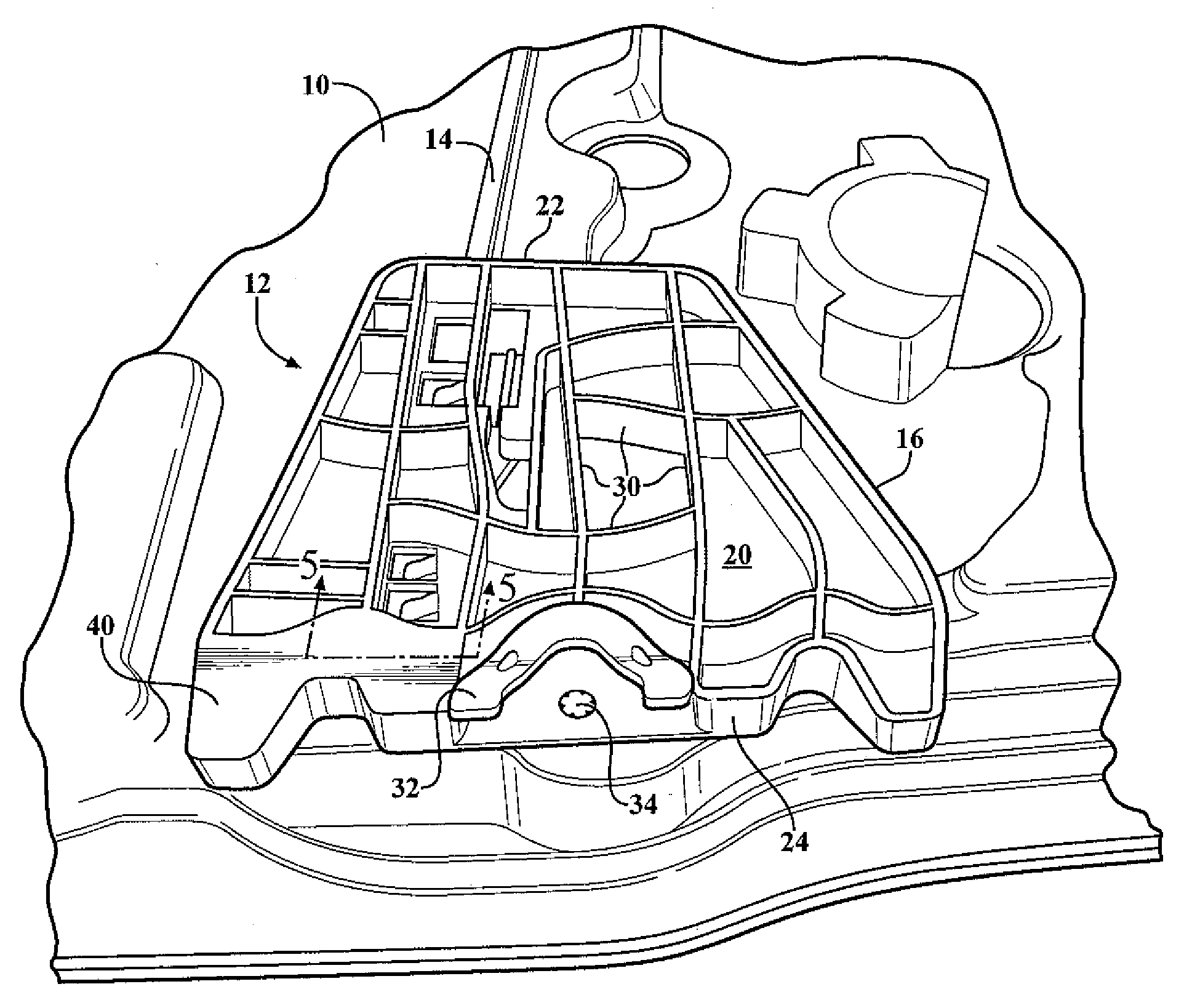

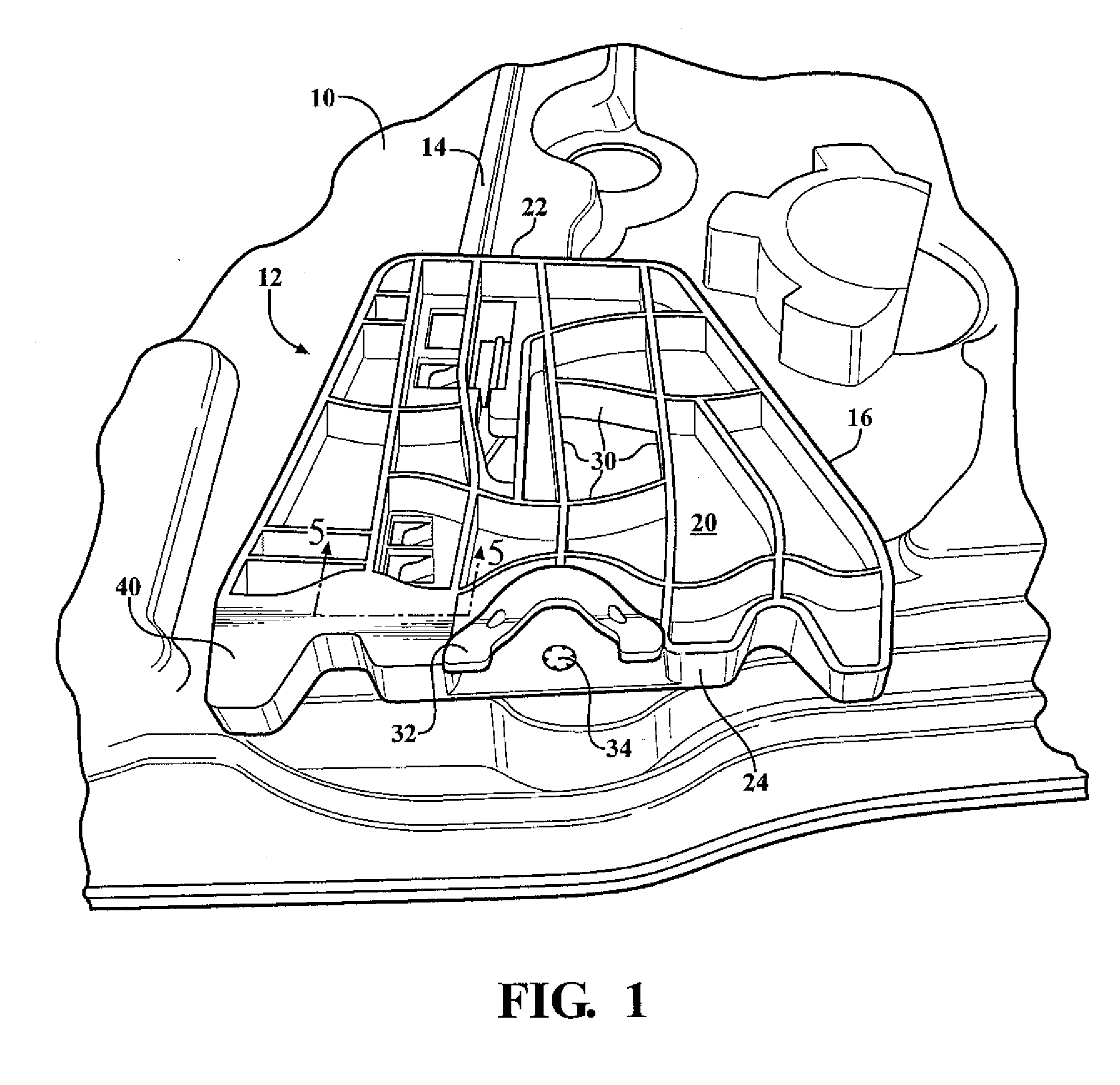

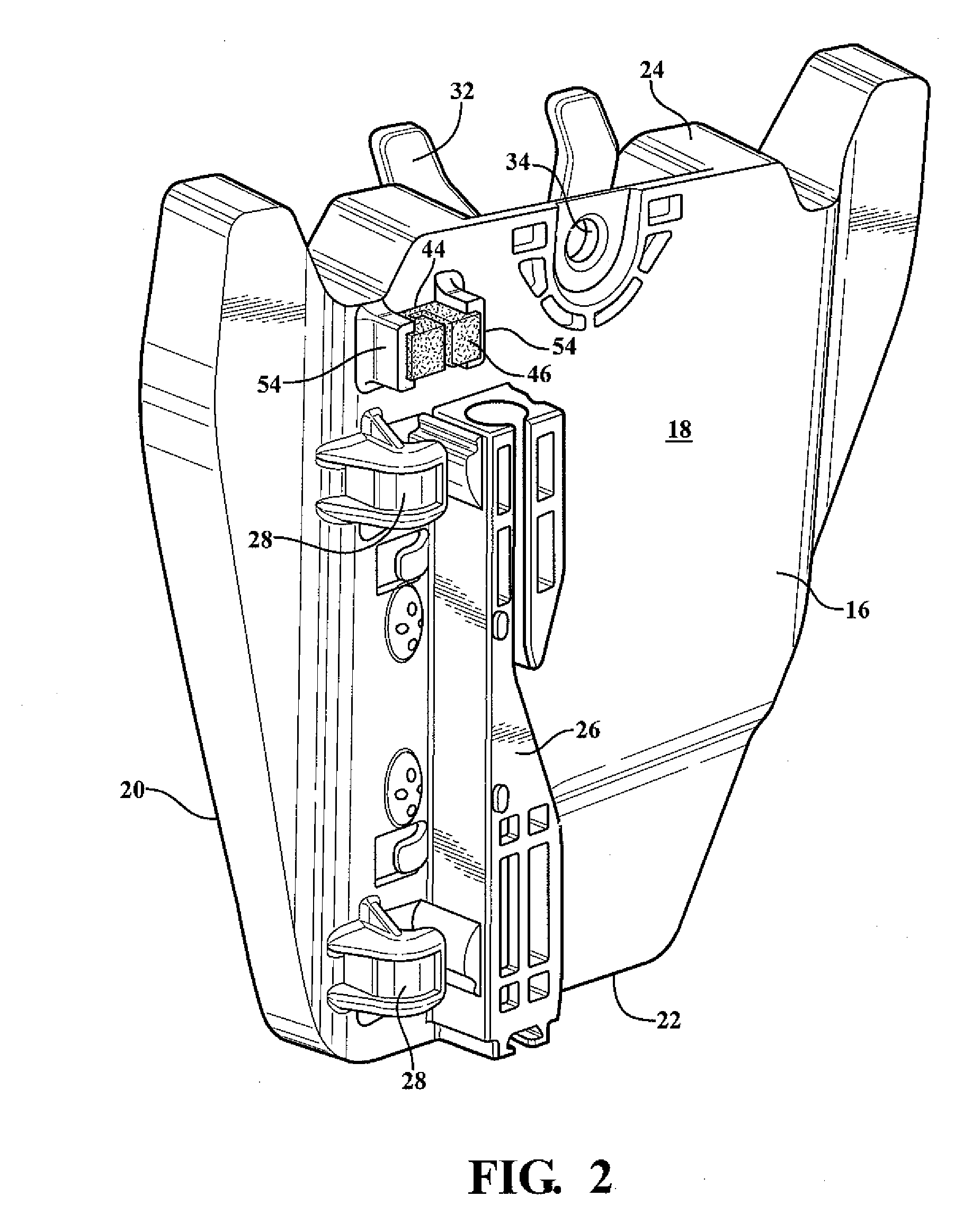

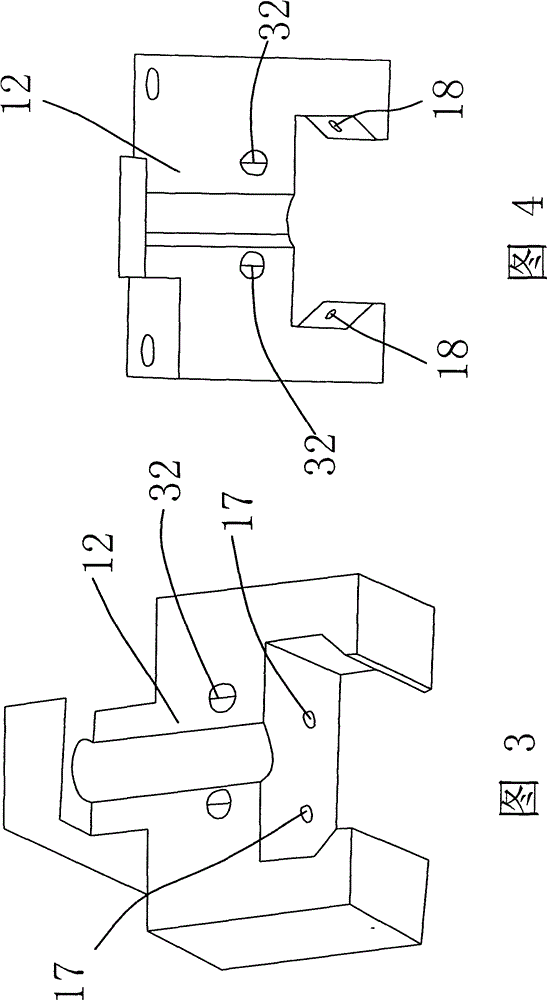

Window Regulator Lifter Plate With Integrated Lubrication System

A window regulator assembly for moving a window pane between an open position and a closed position includes a rail and a lifter plate slidably coupled with the rail. The lifter plate is coupled with the window pane and is guided by the rail to move the window pane between the open and closed positions. A lubrication system lubricates the rail as the lifter plate moves the window pane between the open and closed positions. The lubrication system includes a reservoir contained within the lifter plate, a lubricant storing and releasing material disposed in the reservoir, and an applicator extending from within the reservoir to lubricate the rail.

Owner:PERMAWICK

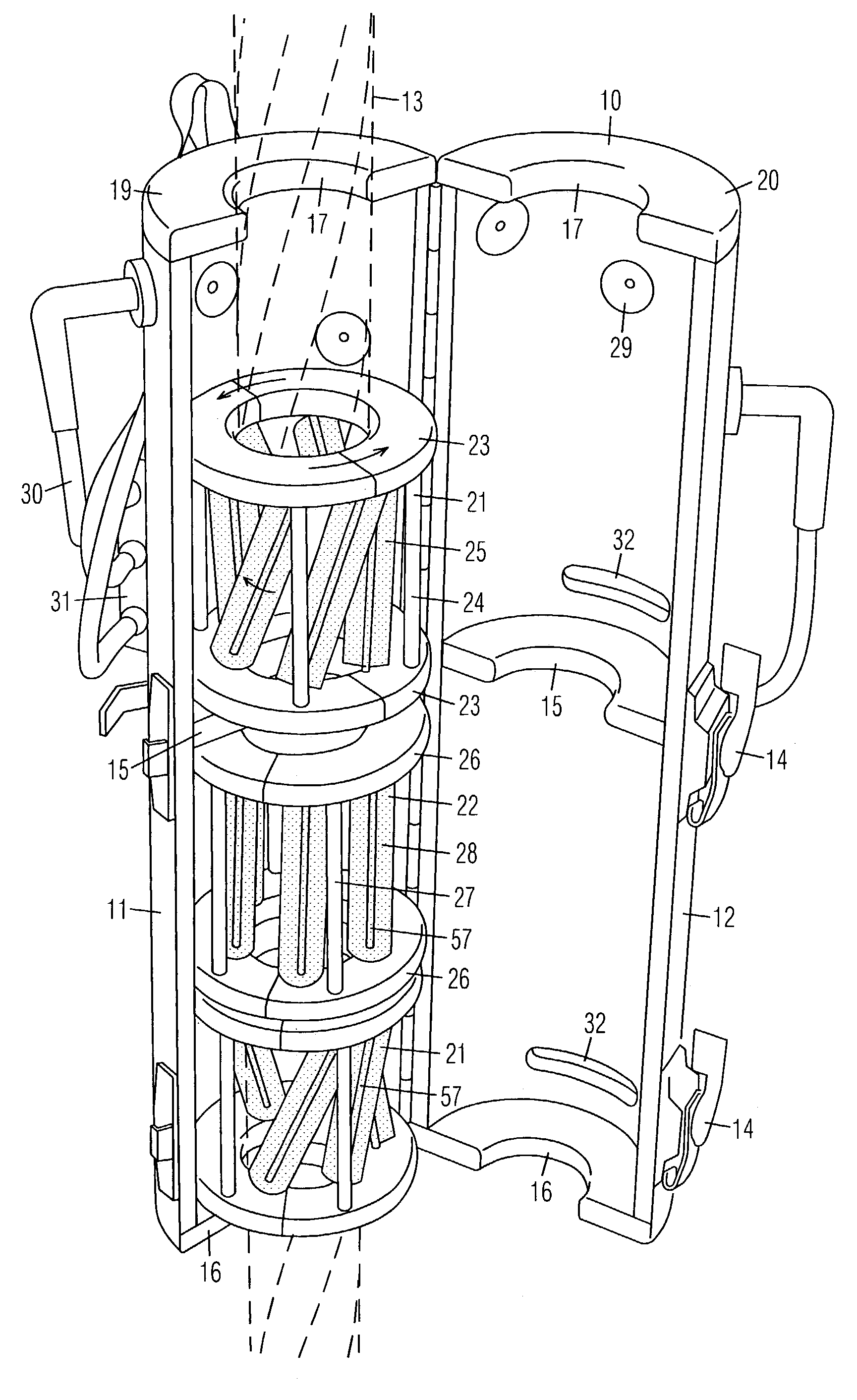

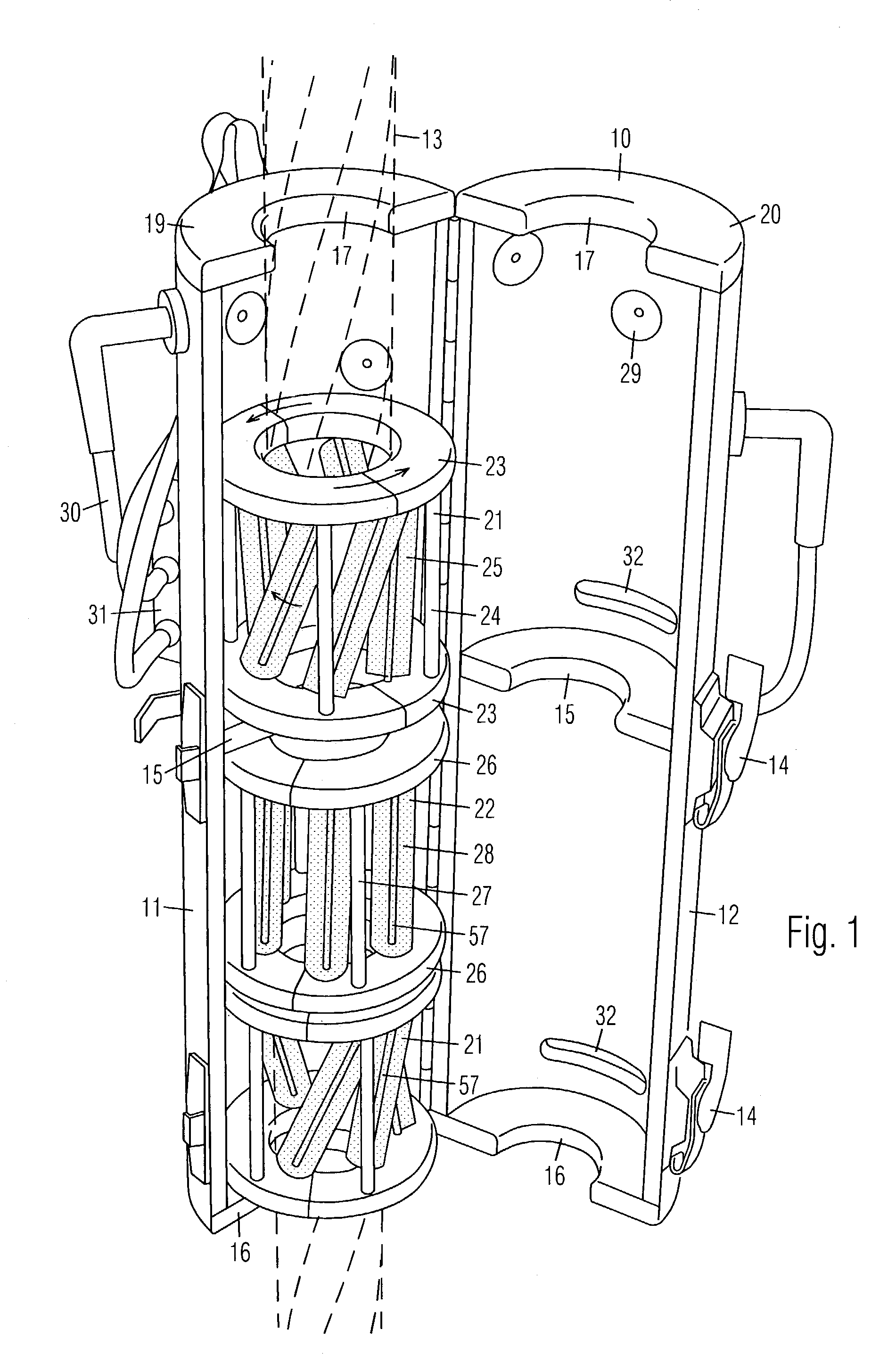

Cylindrical member maintenance device

A cylindrical member maintenance device is comprised of a housing comprised of two hinged halves for being closed around a cylindrical member, such as a stranded steel cable. A rotary helical brush assembly and a rotary longitudinal brush assembly are positioned in the housing and rotatable about an axis of the housing. Each rotary brush assembly is comprised of coaxial split rings with rotary cylindrical wire brushes connected in between and which are independently rotatable about their own axes. Nozzles are positioned on the inside of the housing for applying a cleaning fluid or paint to the cylindrical member. Apertures in the housing are for connecting to a suction device for removing debris, cleaning fluid, and paint to avoid contaminating the environment. Loops on the housing are for attaching to cables for moving the housing along the cylindrical member.

Owner:HEUMANN STEVEN A +1

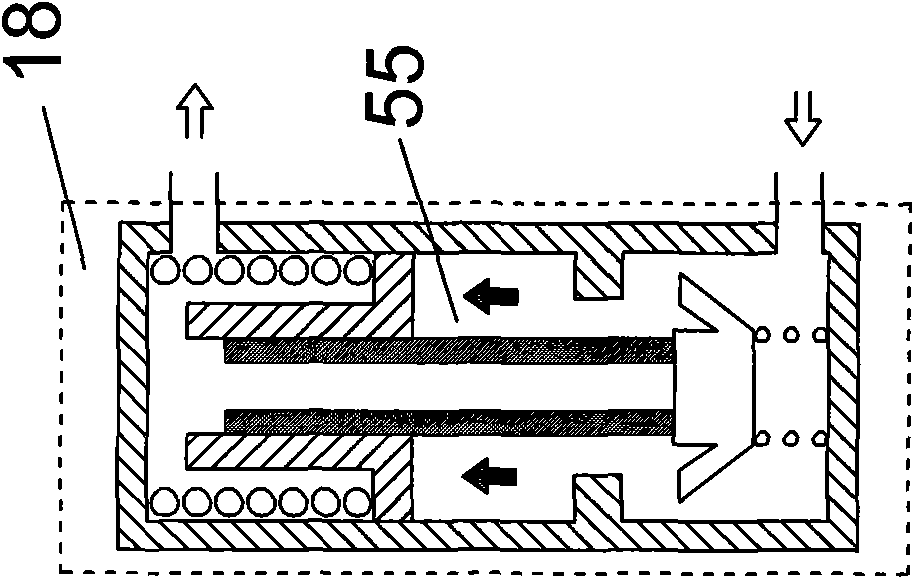

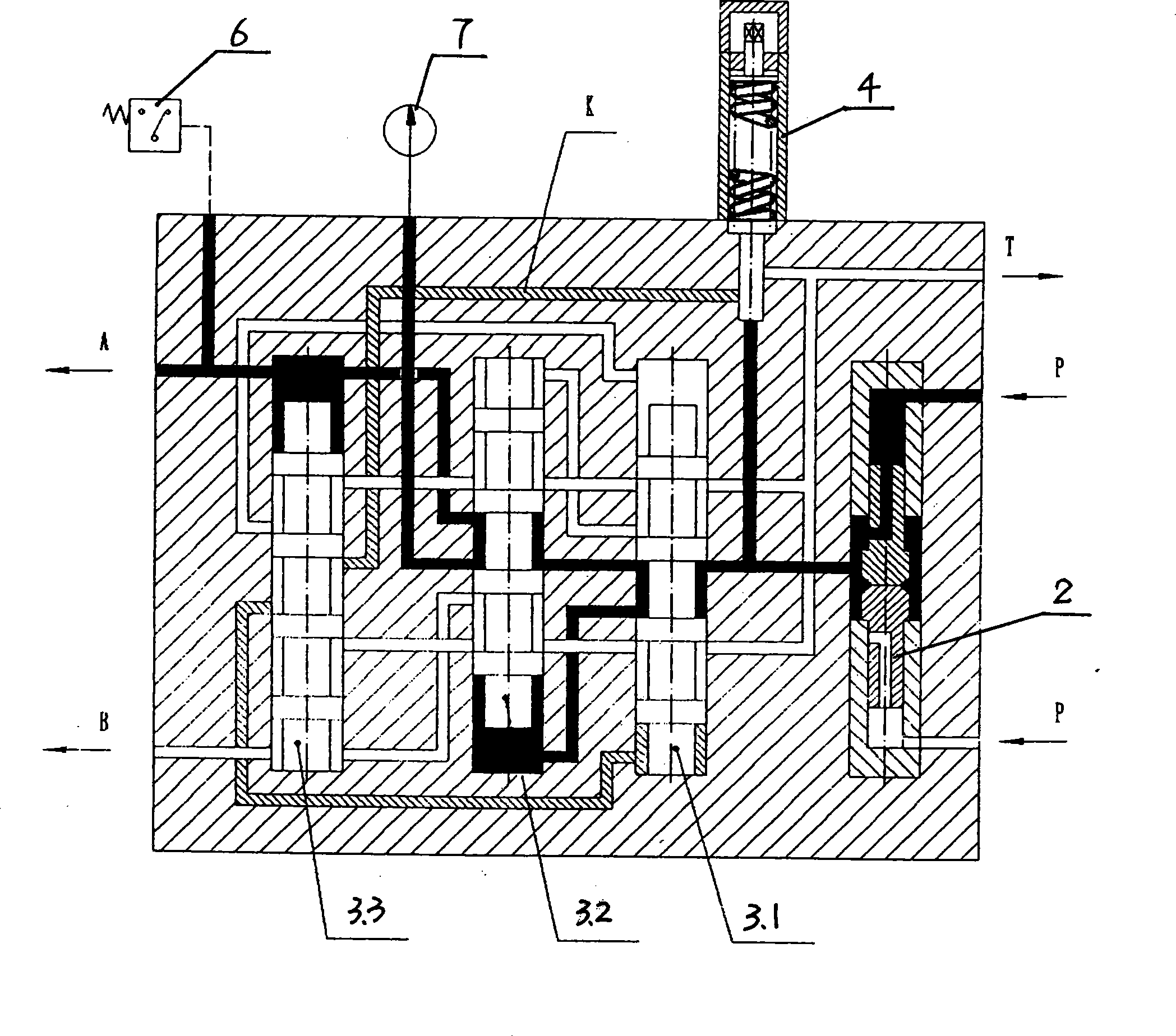

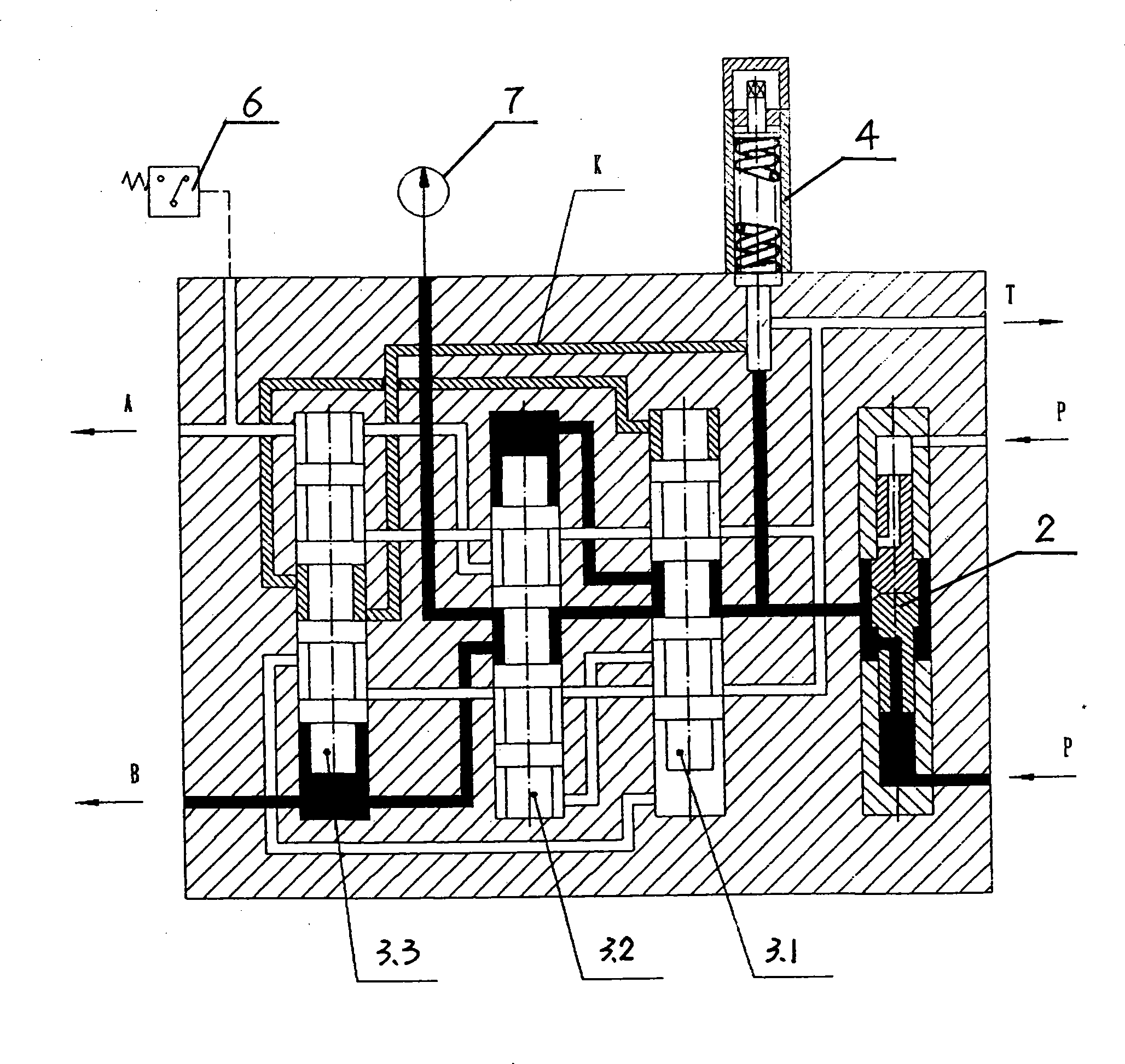

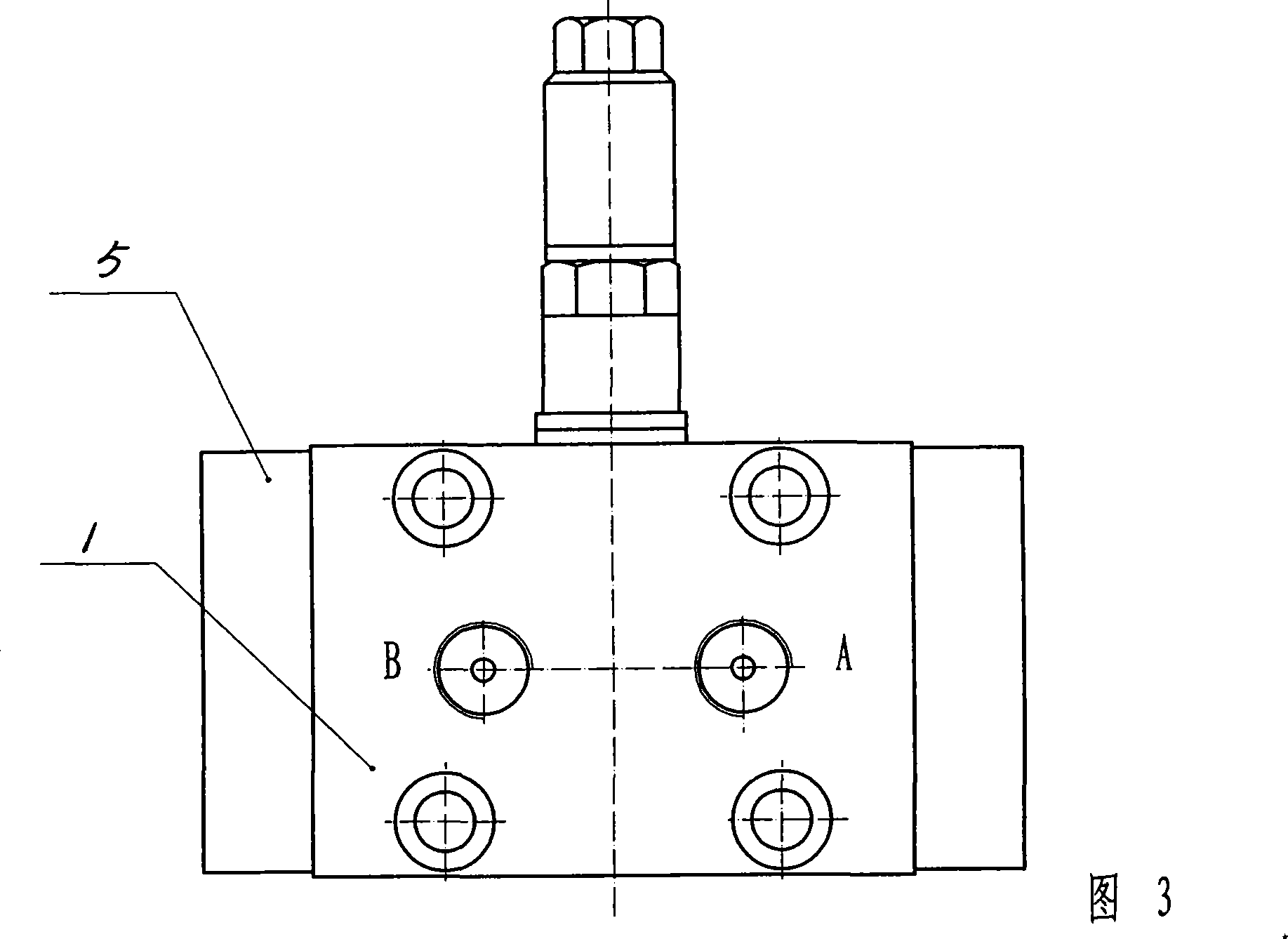

Hydraulic pressure pressure-regulating automatic reverse combined valve for double line grease lubricating system

InactiveCN101251225ALarge reversing pressure rangeFlexible commutationDistribution equipmentLubrication check valvesSpool valveCheck valve

The invention belongs to the hydraulic reversing valve technical field, particularly relates to an automatic hydraulic pressure-regulation reversing combination valve used for a double line grease lubricating system, and provides a reversing valve which is applicable to the grease supply of high-pressure electric grease pumps as well as middle and low pressure electric grease pumps. The automatic hydraulic pressure-regulation reversing combination valve used for a double line grease lubricating system comprises a valve body, the valve body is provided with two grease inlets and two grease outlets, and three reversing slide valves are arranged inside the valve body. The invention is characterized in that: two symmetrical plunger type grease distribution check valves are arranged between the grease inlets and the slide valves, the grease distribution check valves and a reversing slide valve grease path are connected with a pressure-regulation safety valve, and one grease outlet is provided with a pressure sensor interface. Compared with the prior art, the valve has the following advantages that: the valve adopts the hydraulic control to automatically change directions, is applicable to the lubrication systems less than 40MPa pressure, and has big reversing pressure-regulation range (from 3.5MPa to 35MPa), flexible direction change, no noise, strong anti-pollution capacity and reliable work.

Owner:义小毛

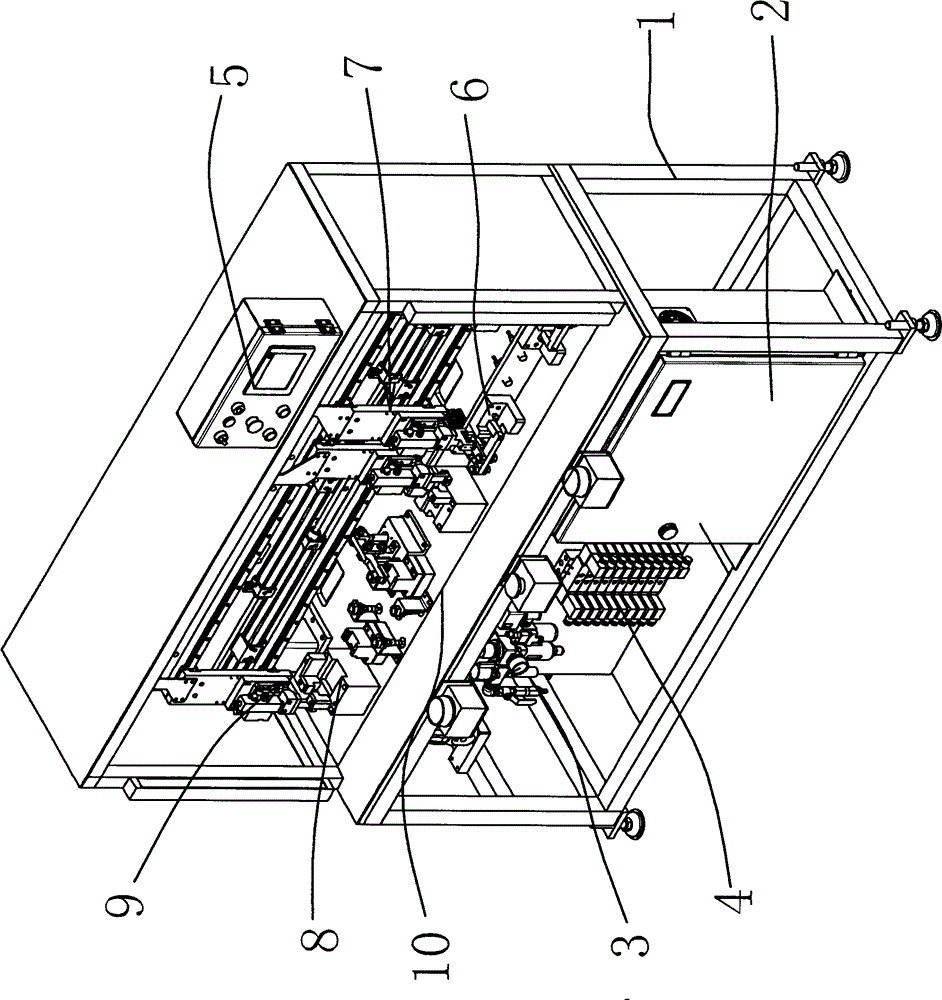

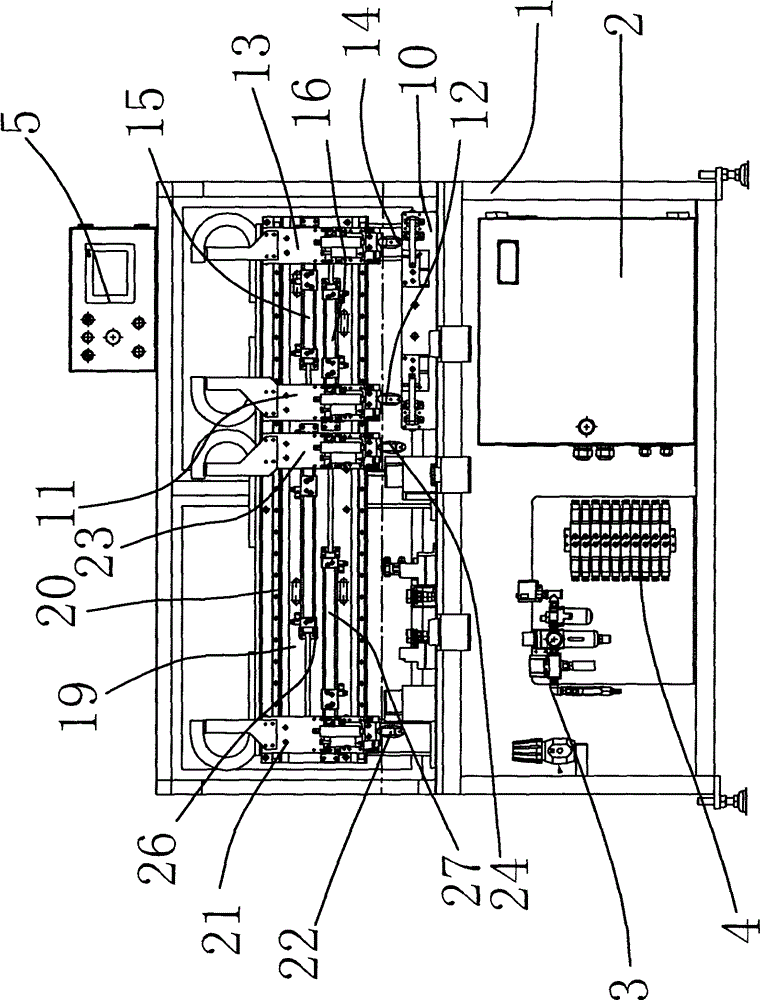

Special oiling machine used for producing sliding rails of automobile seats

ActiveCN103335200AReduce pollutionStable amount of coatingConduits/junctionsDistribution equipmentOil canCar seat

The invention belongs to the technical field of the processing of automobile spare parts, and provides a special oiling machine used for producing sliding rails of automobile seats. The special oiling machine comprises a machine frame, an electronic control system, an air source component, an oil circuit system, a central control system, an upper sliding rail fixing jig, an upper sliding rail oiling mechanism, a lower sliding rail fixing jig, a lower sliding rail oiling mechanism and a working table board, wherein an upper sliding rail and a lower sliding rail which are to be oiled are respectively placed on the upper sliding rail fixing jig and the lower sliding rail fixing jig, and then the electronic control system, the air source component, the oil circuit system, the upper sliding rail oiling mechanism and the lower sliding rail oiling mechanism are controlled by the central control system to oil the sliding rails. The special oiling machine has the advantages that the oiling amount of the special oiling machine can be adjusted, parts needing to be oiled of the sliding rails are oiled by using a copy out-spraying oil nozzle, the oiling amount is steady and accurate, the oiling face range is wide (areas which cannot be manually oiled can also be oiled by using the special oiling machine), oil pollution is reduced due to the closeness of an oil source in the production process, besides, the operation is simple, and the like.

Owner:JIAXING MINSHI MASCH CO LTD

Lubricant applicator, image forming apparatus, and method of mounting lubricant applicator

A lubricant applicator includes: a lubricant application unit that is arranged so as to be in contact with a surface of an image carrier, scrapes a solid lubricant, and applies the solid lubricant onto the surface of the image carrier while moving a surface of the lubricant application unit; a lubricant holding member that holds the solid lubricant; and a lubricant biasing unit that biases the solid lubricant against the lubricant application unit. The lubricant biasing unit is housed in a housing under a state that one end of the lubricant biasing unit is held by the lubricant holding member so that a position of the one end of the lubricant biasing unit is restricted, and another end of the lubricant biasing unit is held by a biasing-unit holding member that is provided to restrict a position of the another end of the lubricant biasing unit.

Owner:RICOH KK

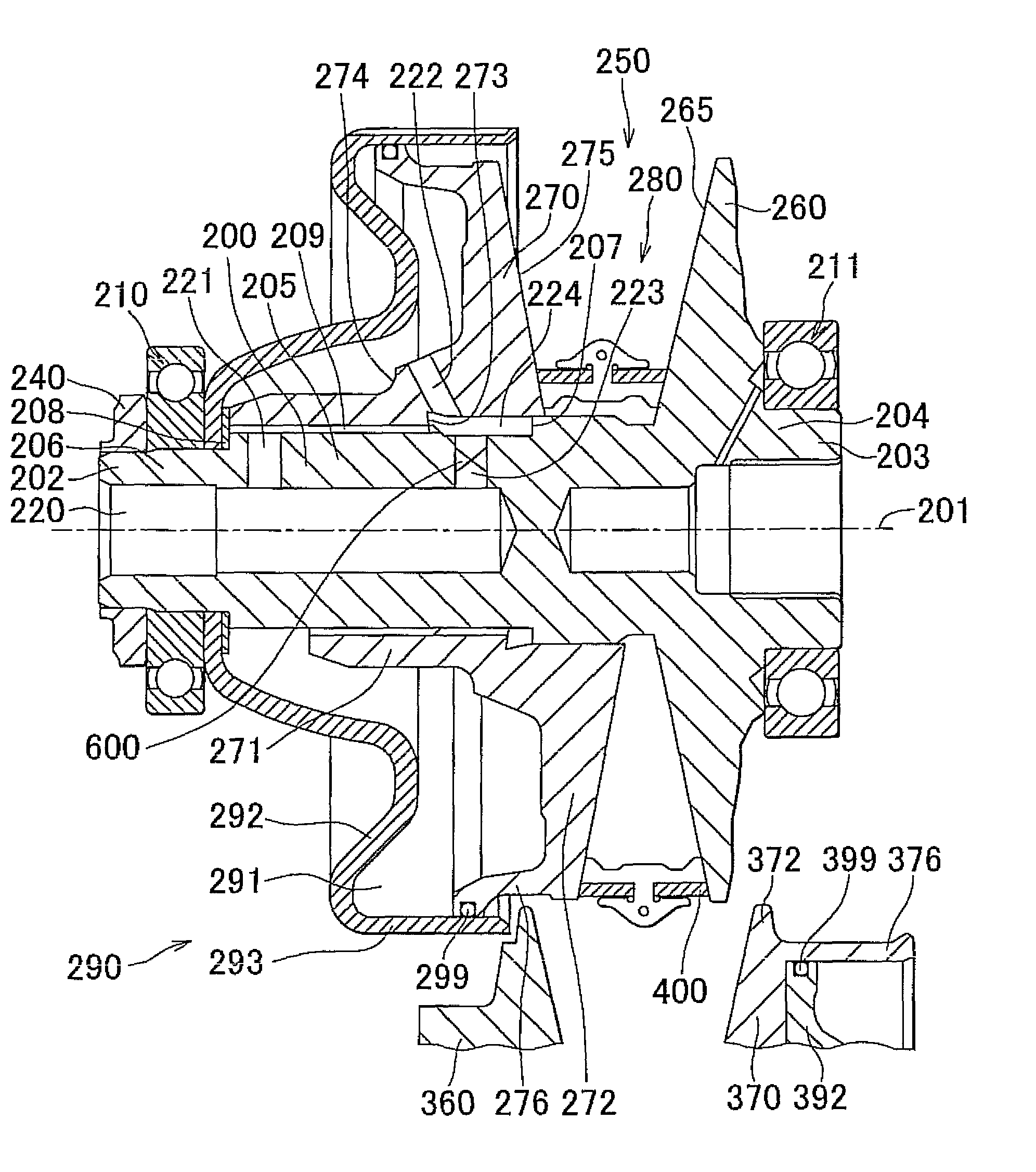

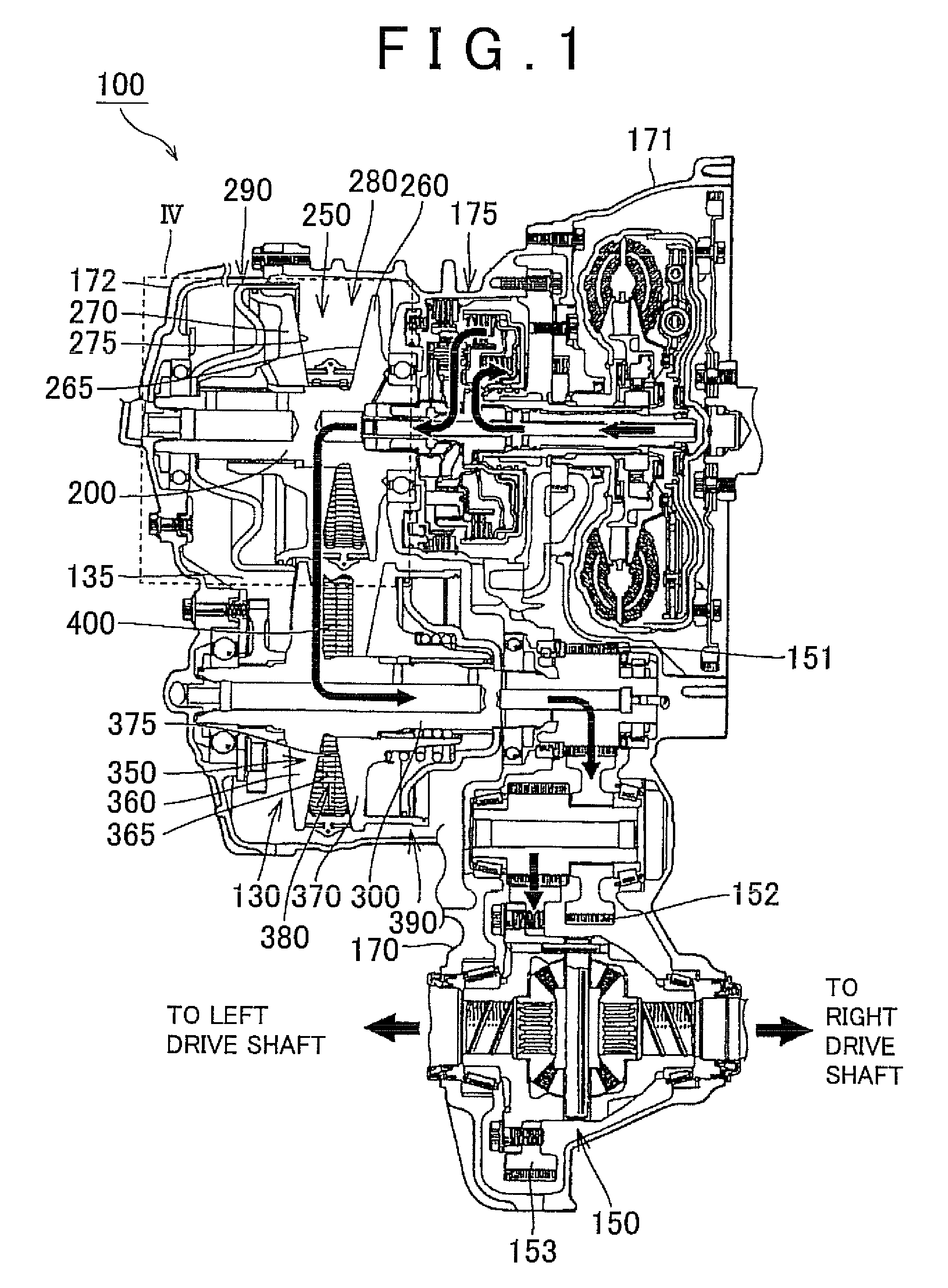

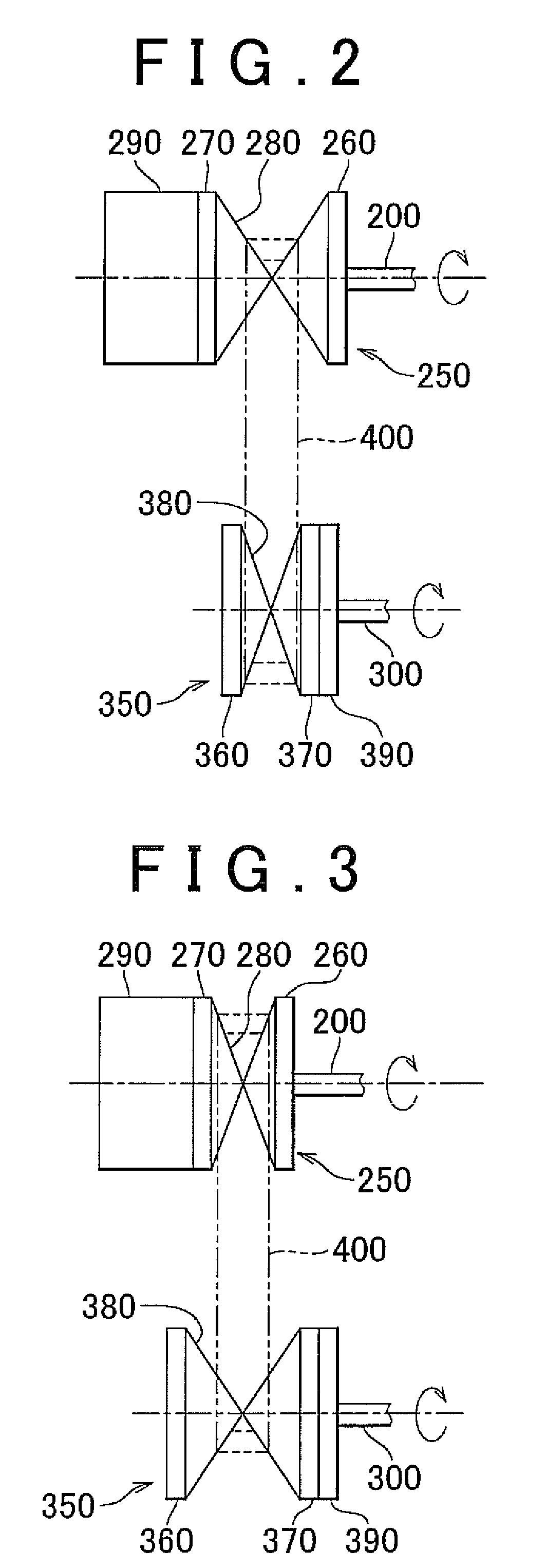

Continuously variable transmission

ActiveUS8100791B2Precise positioningReduce internal pressureProportioning devicesPortable liftingPulleyPetroleum engineering

Owner:TOYOTA JIDOSHA KK

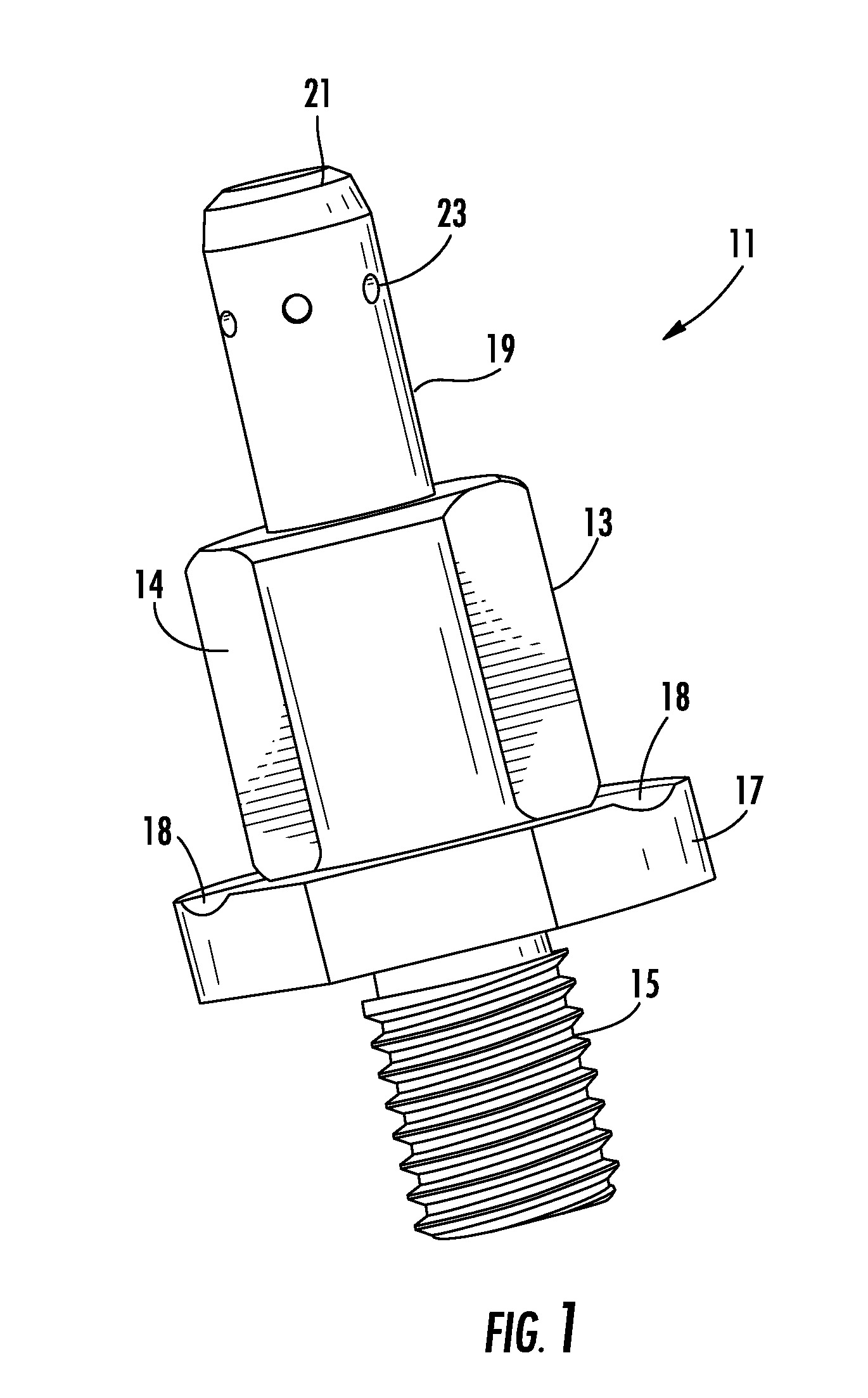

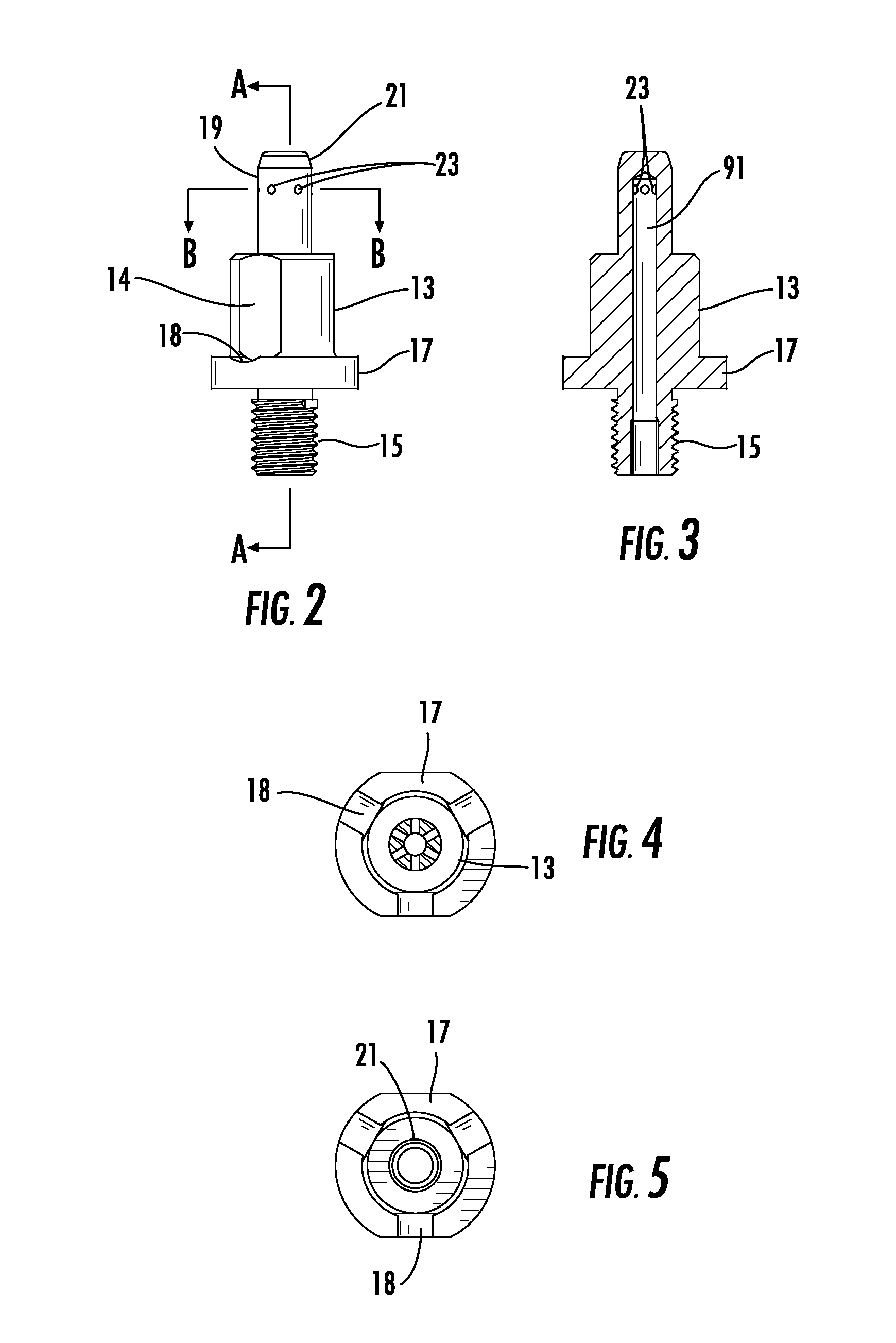

Sealing assembly for lubricant injector

InactiveUS6986407B2Exhaust fastImprove performanceProportioning devicesPiston ringsEngineeringHigh pressure

Owner:LINCOLN INDUSTRIES CORP

Bushing lubricator and system

A bushing lubricator includes an elongate body having a lubricant passage extending from an inlet opening to an outlet port. The elongate body includes a connection portion at the inlet opening for engaging with a lubricant tray of a lubricating system, a main body portion in a central region, and a bushing lubricator portion of a width to accommodate a bushing with an interior surface of the bushing surrounding the bushing lubricator portion. The outlet port on a periphery of the bushing lubricator portion discharges lubricant onto the interior surface of a bushing.

Owner:BSH HOME APPLIANCES CORP

Sealing assembly for an ink chamber which includes self-lubricating anilox roll seal with improved blade/seal area

InactiveUS7597761B2Avoid uneven wearImprove sealingLiquid surface applicatorsRotary intaglio printing pressSupport surfaceLubricant

A sealing assembly for an ink chamber associated with an anilox roll, includes a doctor blade having a doctoring edge, with each end having a notch at the doctoring edge, and first and second seals adapted to seal ends of the ink chamber. Each seal includes a peripheral supporting wall, an upper wall thereon including an upper concave surface for engaging an outer surface of the anilox roll, a flat upper supporting surface at opposite ends of the upper wall on which ends of the doctor blade seat, and an extension above the flat upper supporting surface for engaging within the notch at the end of the doctor blade to permit the doctor blade to bend thereat. A lubricant chamber is defined therein and the upper wall includes an opening through which the lubricant is forced out of the lubricant chamber due to external pressure.

Owner:VALLEY HLDG

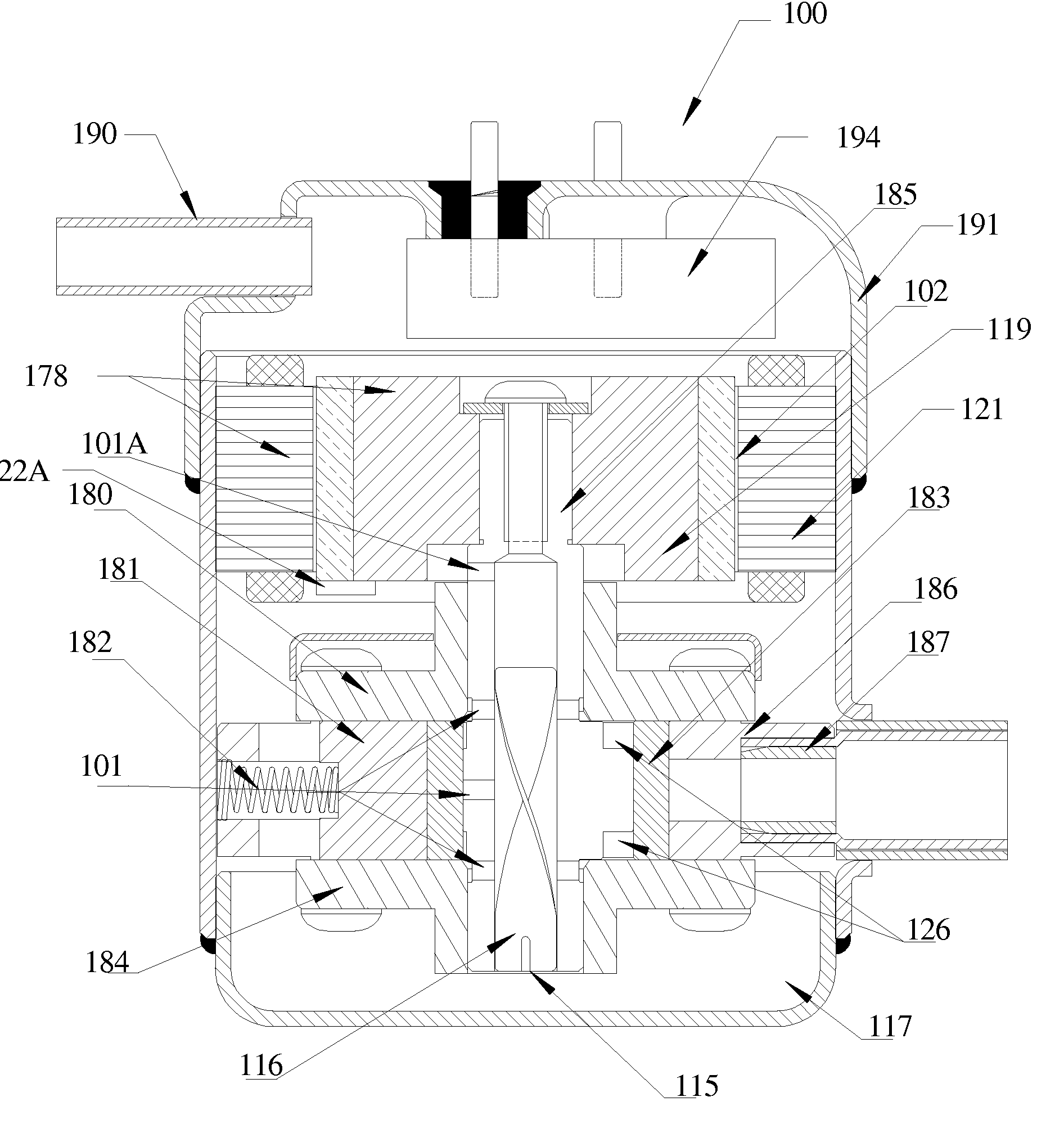

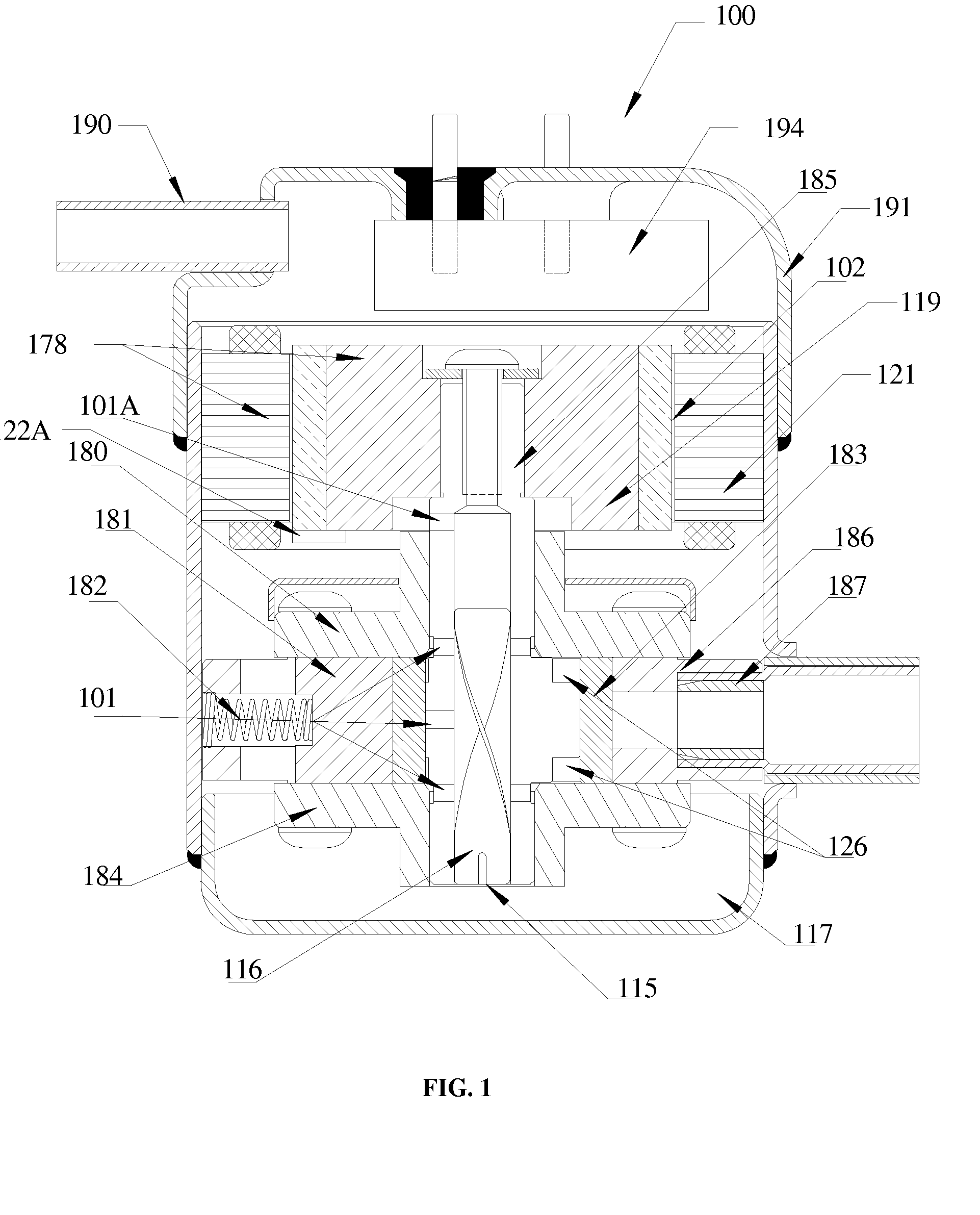

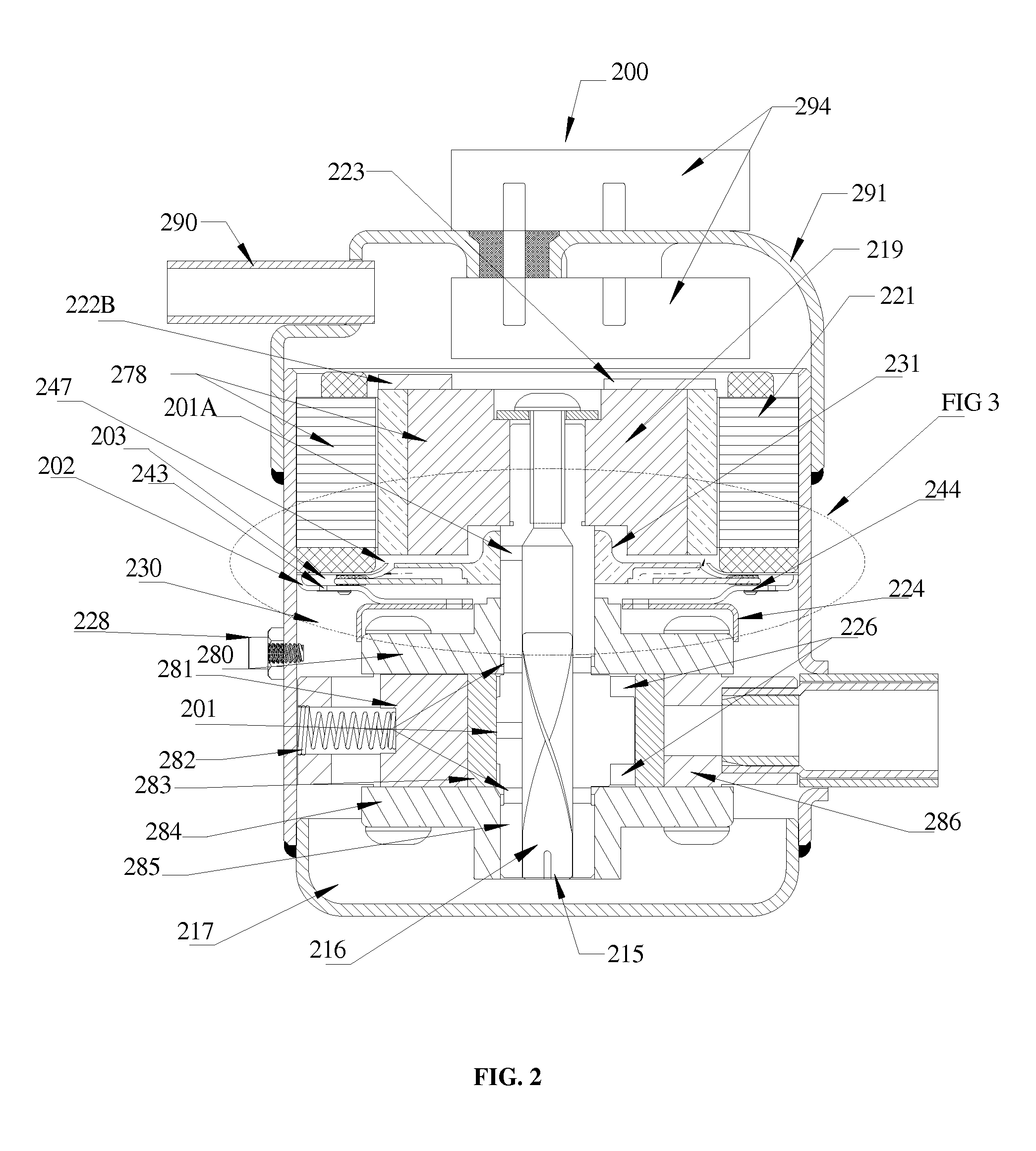

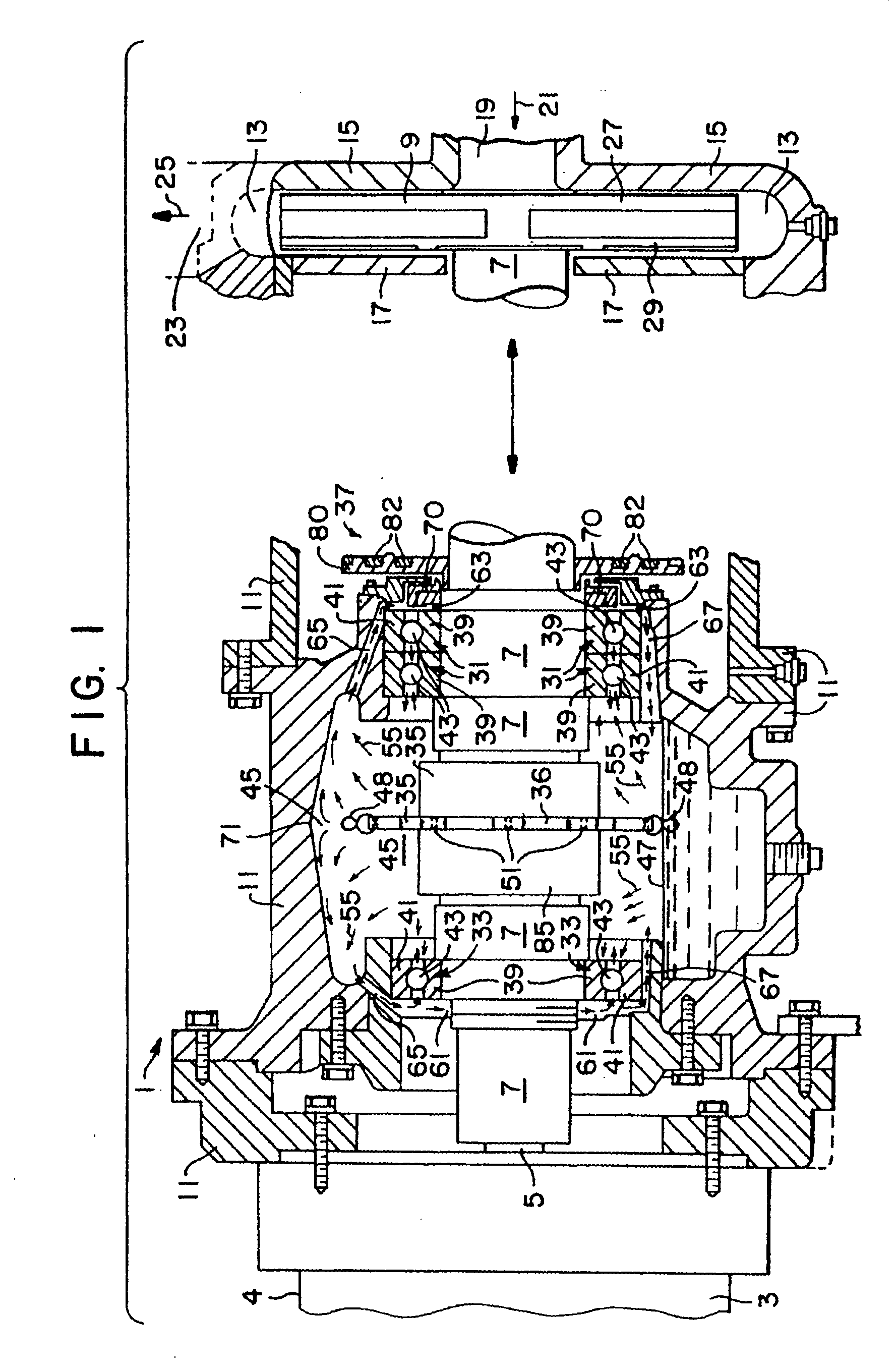

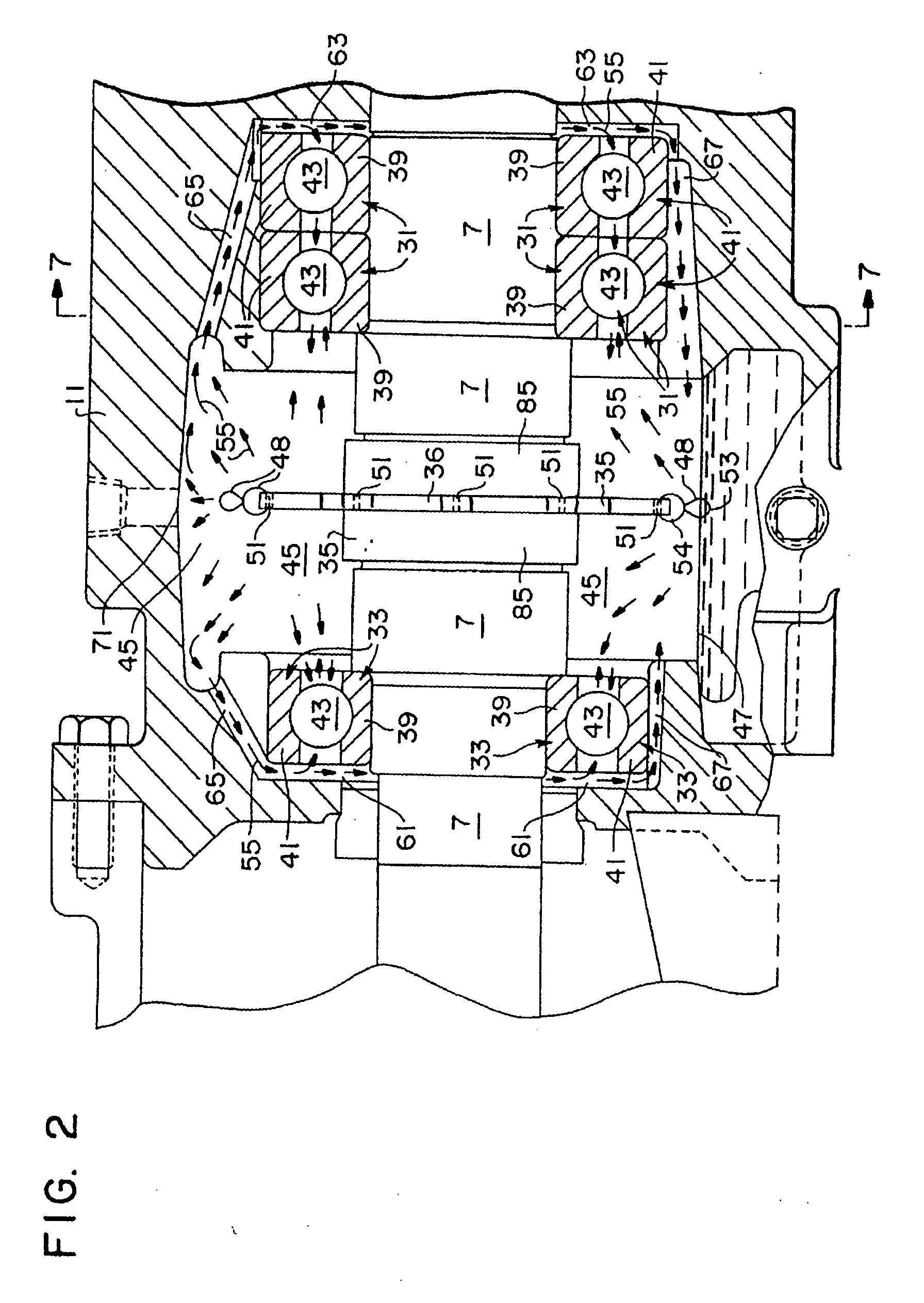

Orientation and gravity insensitive in-casing oil management system for fluid displacement devices, and methods related thereto

InactiveUS20080078618A1Rotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeAviationElectronics cooling

Disclosed is a pressurized internal oil management system, comprising an oil dam, at least one oil separator, at least one oil collection manifold, at least one oil pump, and one or more paths for returning the separated oil; said system integrated within the casing of a fluid displacement device to supply adequate lubrication regardless of orientations under zero to full gravity, and methods and applications related thereto. Fluid displacement devices useful herein include oil lubricated rotary or reciprocating machinery, such as compressors, expanders, pumps and engines, in the casing of which exists one or more drive mechanisms that can be utilized to operate the oil management system, in most cases without even increasing the size of the casing. The present invention is especially useful for applications where small size and low weight of the fluid displacement device or the system containing it are important, such as personal or electronic cooling systems in terrestrial mobile applications or various cooling systems in aerospace applications.

Owner:ASPEN COMPRESSOR

Pump oil mister with improved service life

A centrifugal environmentally safe pump including a motor driven pump shaft having a fluid pumping impeller affixed thereto. A plurality of annular shaft supporting bearing assemblies are disposed along the shaft adjacent a lubrication chamber, the lubrication chamber housing lubrication fluid (e.g. oil) maintained at a level below rotating portions of the bearing assemblies so as to maintain a low operating temperature within the chamber and adjacent the bearings. A lubricating fluid dispenser having a thin-profile, disc-shaped portion is affixed to the pump shaft within the lubrication chamber for rotation along with the shaft. A plurality of wire-like fluid contacting members are loosely connected along the outer periphery of the disc-shaped portion through respective bearing sleeves, the wire members for dipping into the lubricating fluid when the pump shaft is rotating thereby dispersing or misting the fluid throughout the chamber.

Owner:ENVIRONAMICS

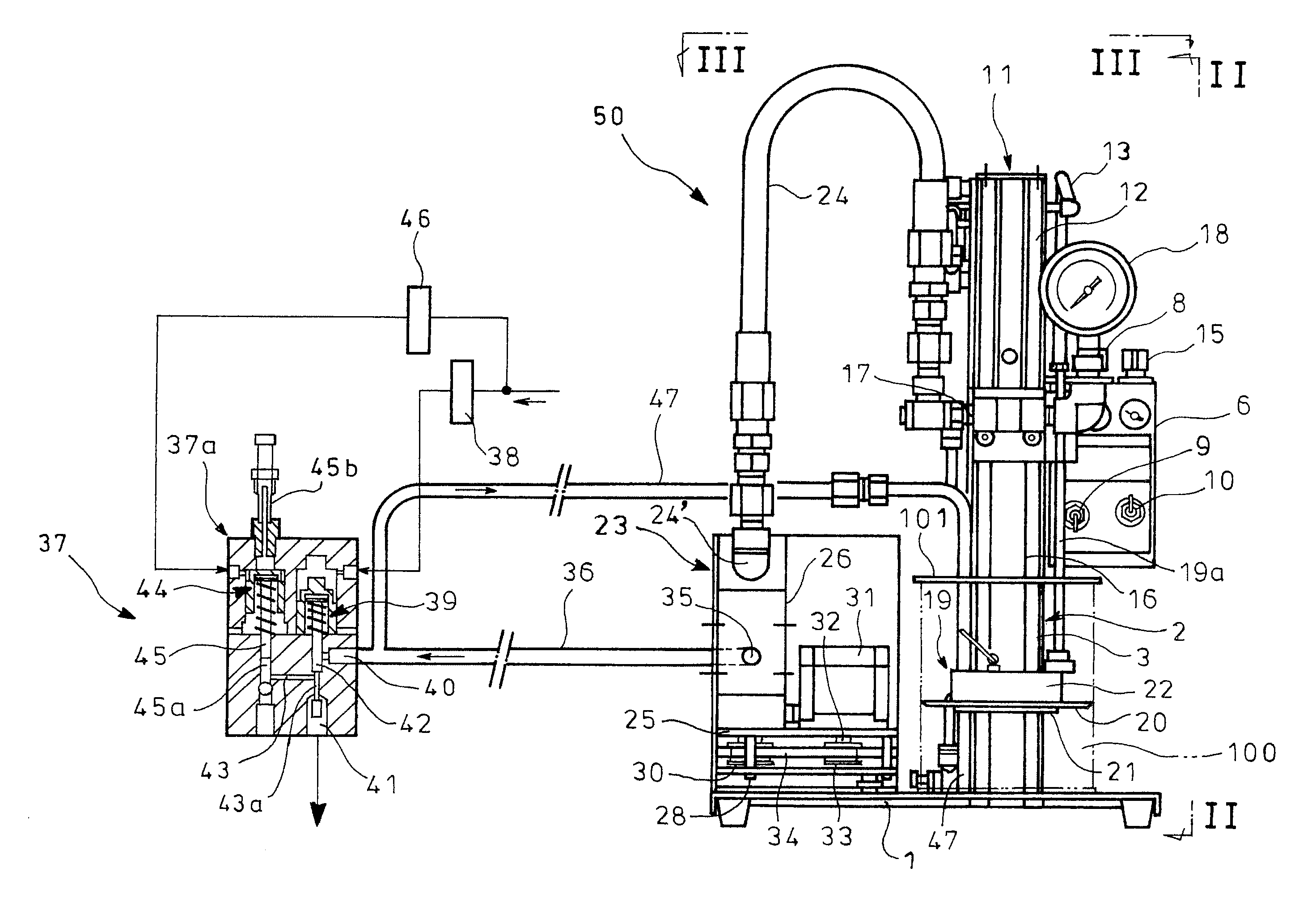

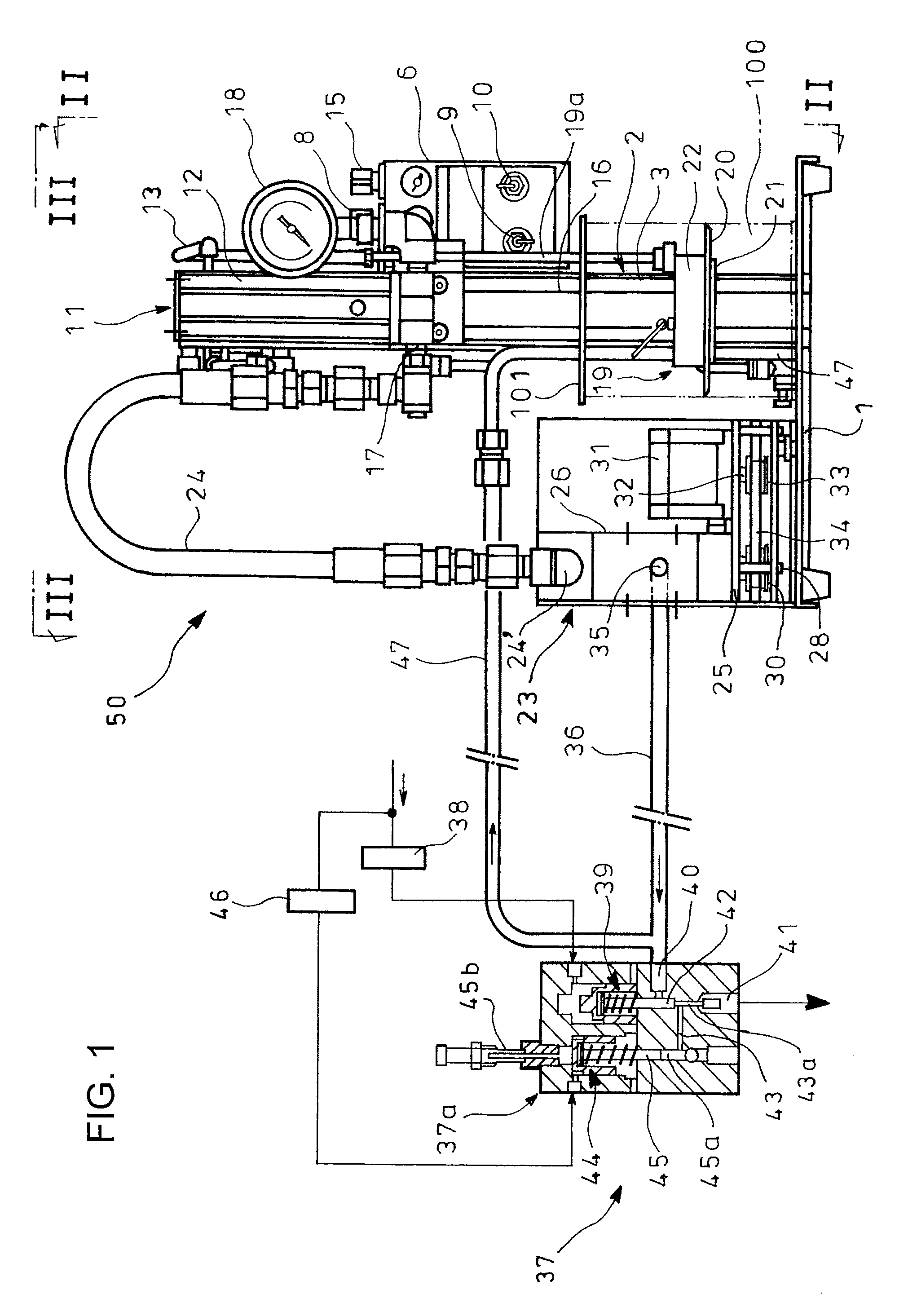

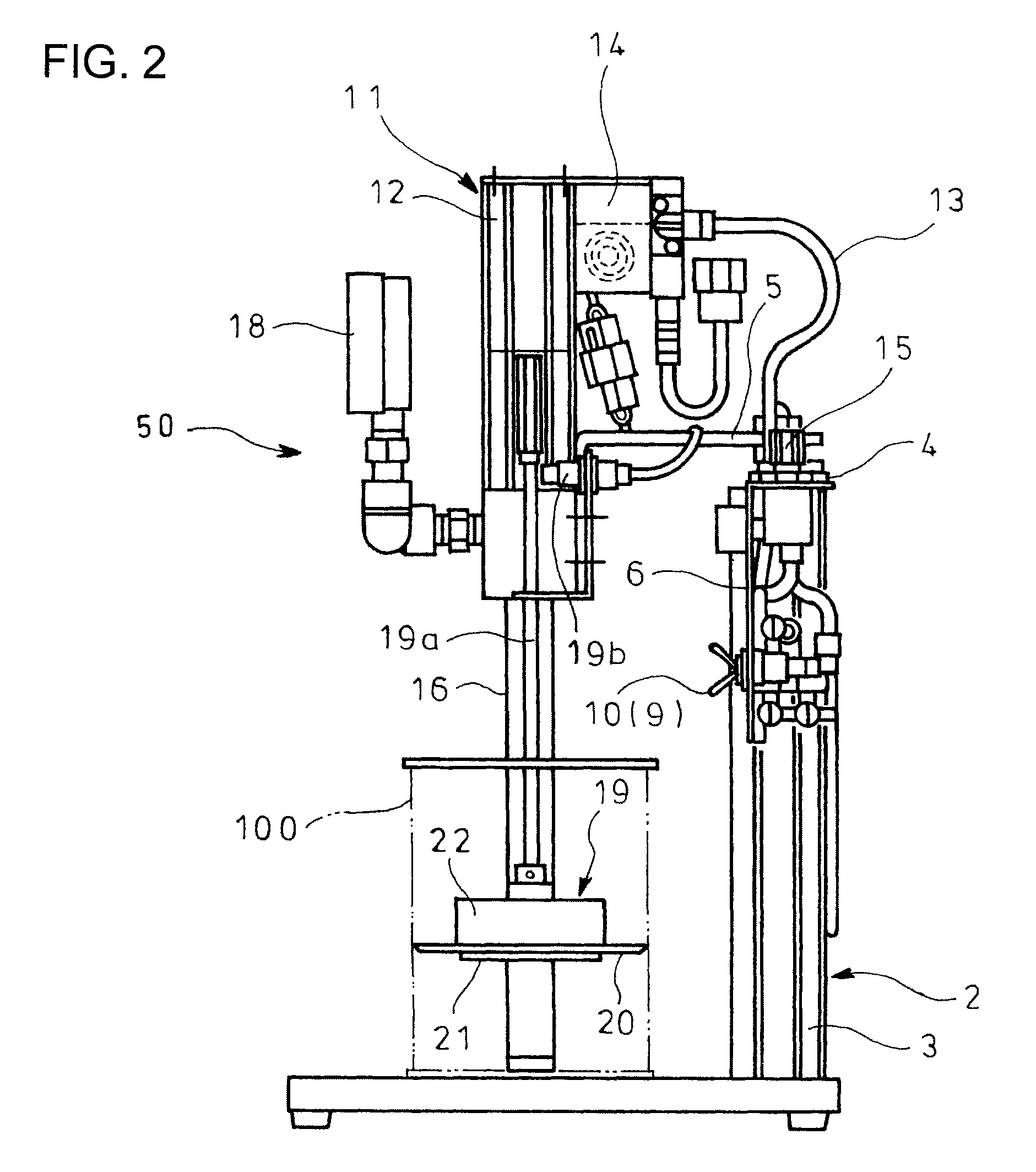

Grease pump unit

ActiveUS9315372B2Good effectSimple structureLiquid transferring devicesThin material handlingEngineeringBiological activation

A grease pump unit has a metering valve 37 and a grease supplying device 50 in which a suction tube 16 on a pump device 11 extends through a follower plate 19 in a grease can 100, grease in the grease can 100 being sucked through the suction tube 16 and discharged through a discharge port 17 by activation of the pump device 11. Provided are a bubble dividing device 32 which supplies the grease discharged through the discharge port 17 through an supply pipe 24 to micronize bubbles in the grease and which supplies the grease through a supply pipe 36 to the metering valve 37, and a return pipe 47 which returns a portion of the grease not discharged through the metering valve 37 into the grease can 100 via the follower plate 19.

Owner:IHI ROTATING MACHINERY ENG CO LTD +1

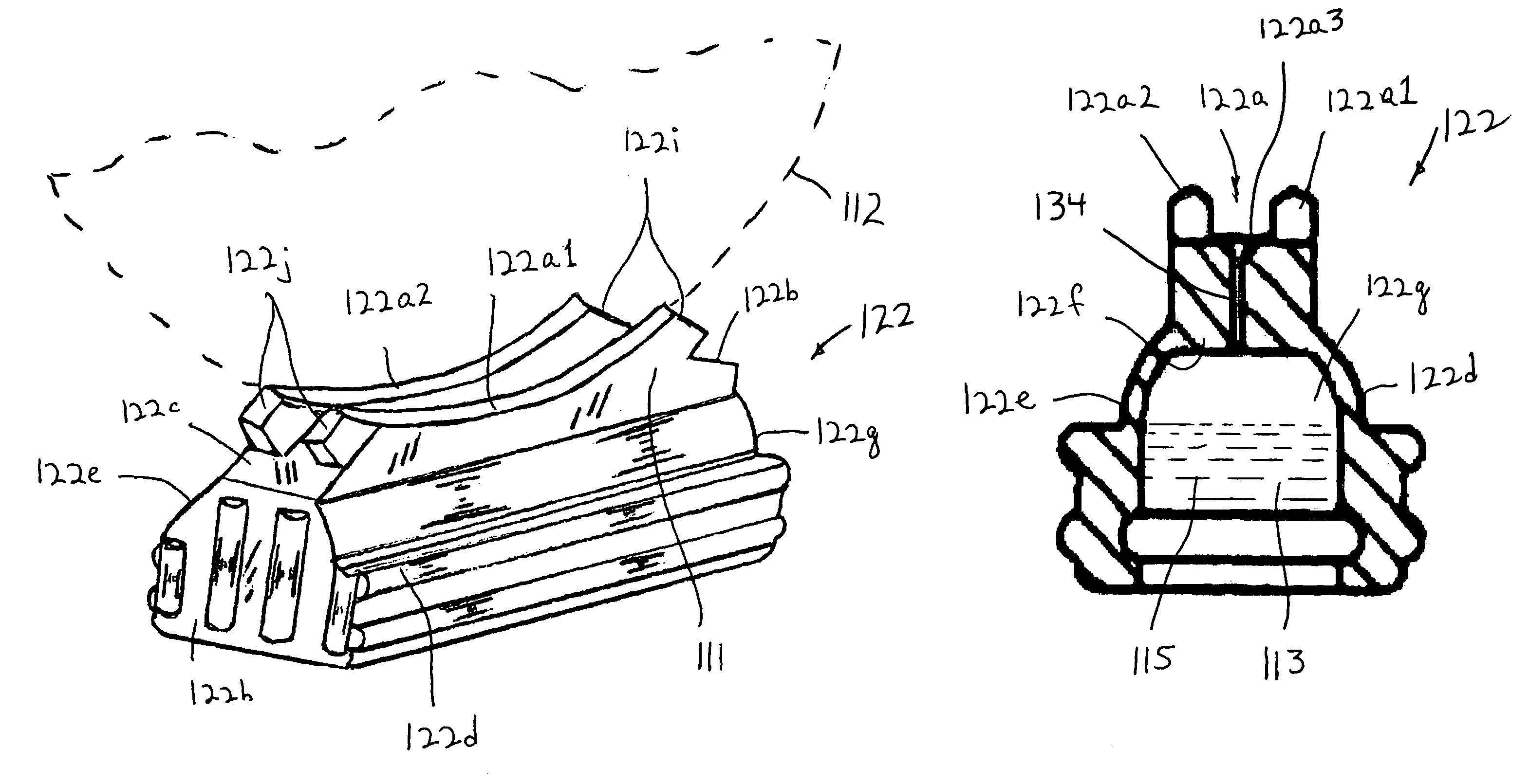

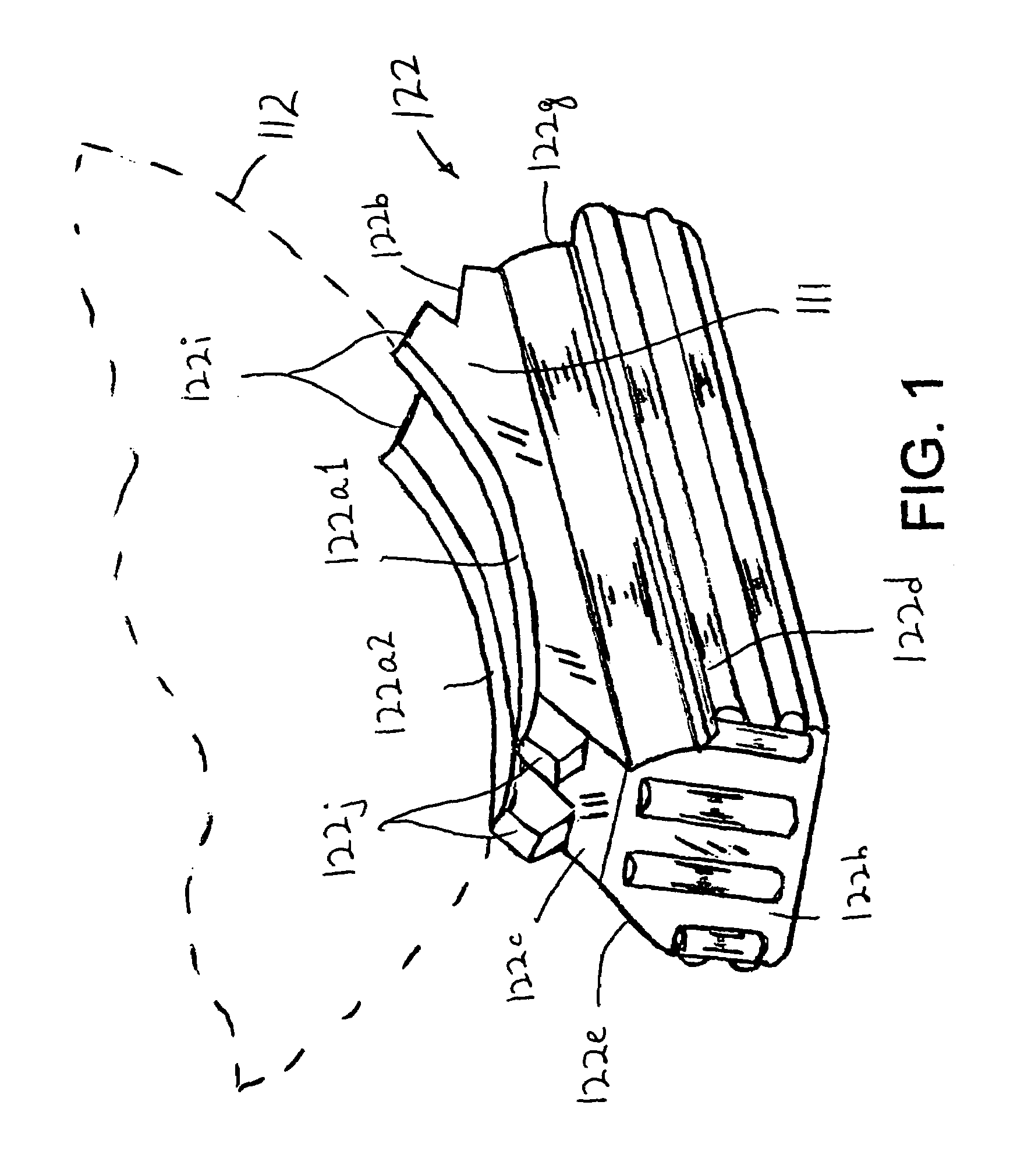

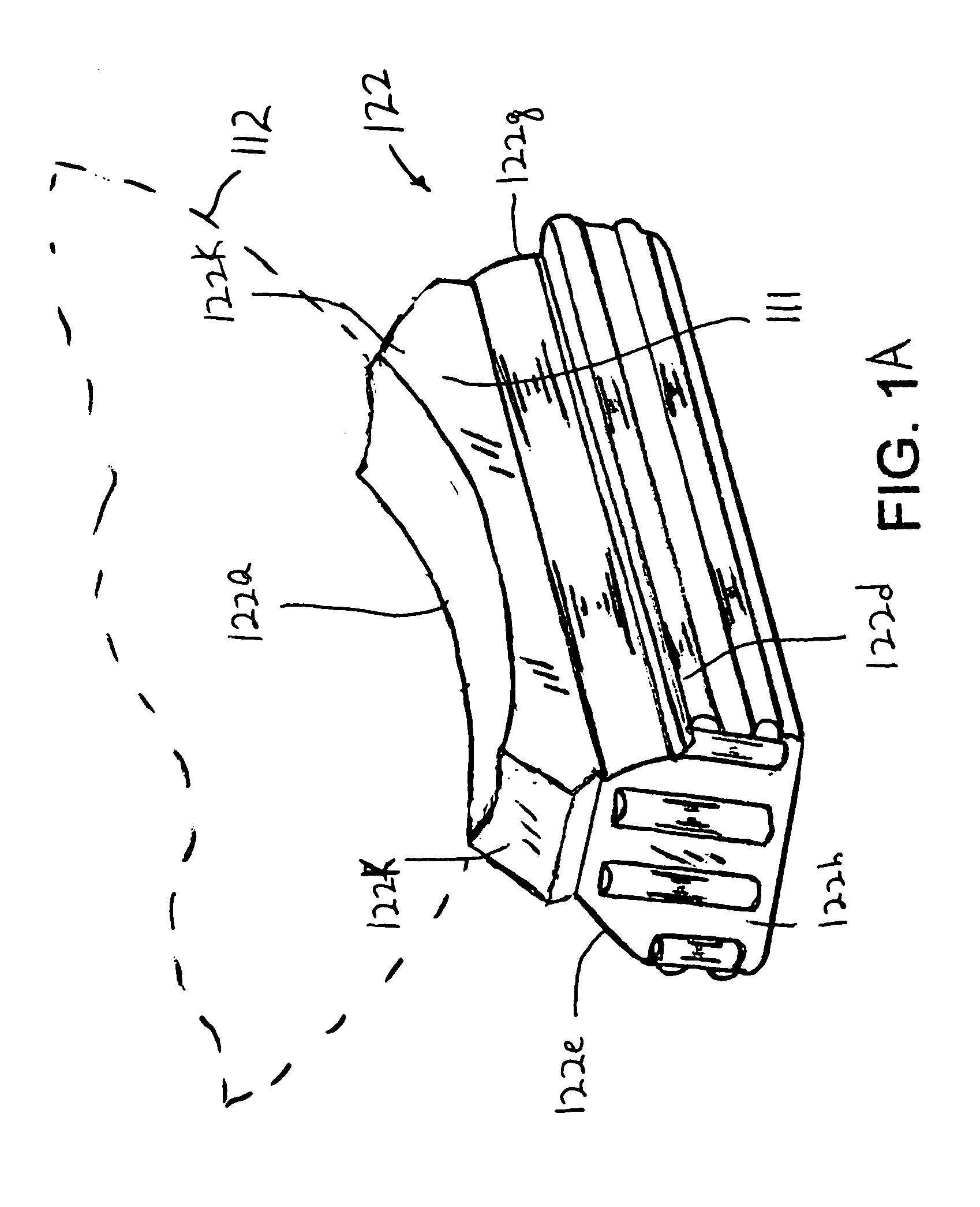

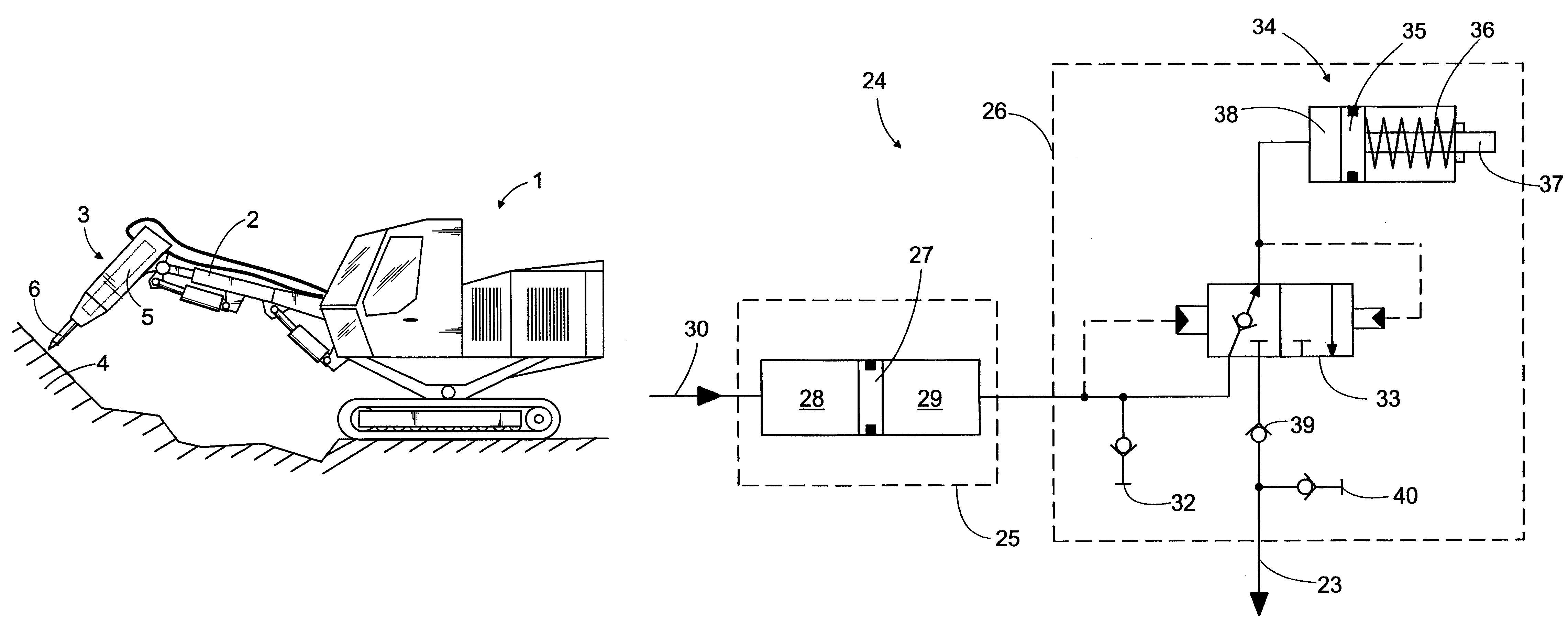

Rock breaking machine and lubricating method

InactiveUS7694748B2Effective lubricationProlong lifeSoil-shifting machines/dredgersPortable power-driven toolsEngineeringLubricant

Owner:SANDVIK MINING & CONSTR OY

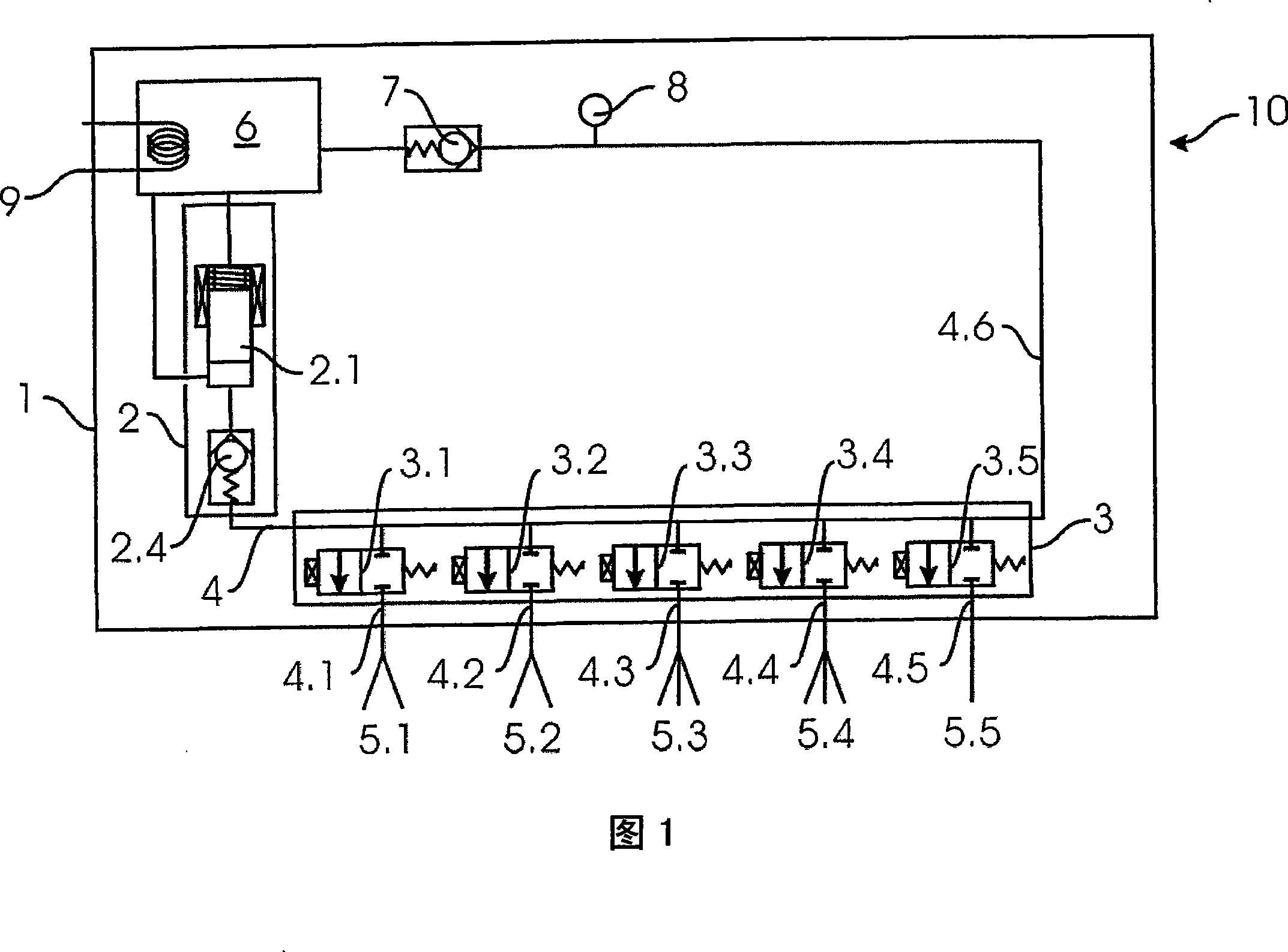

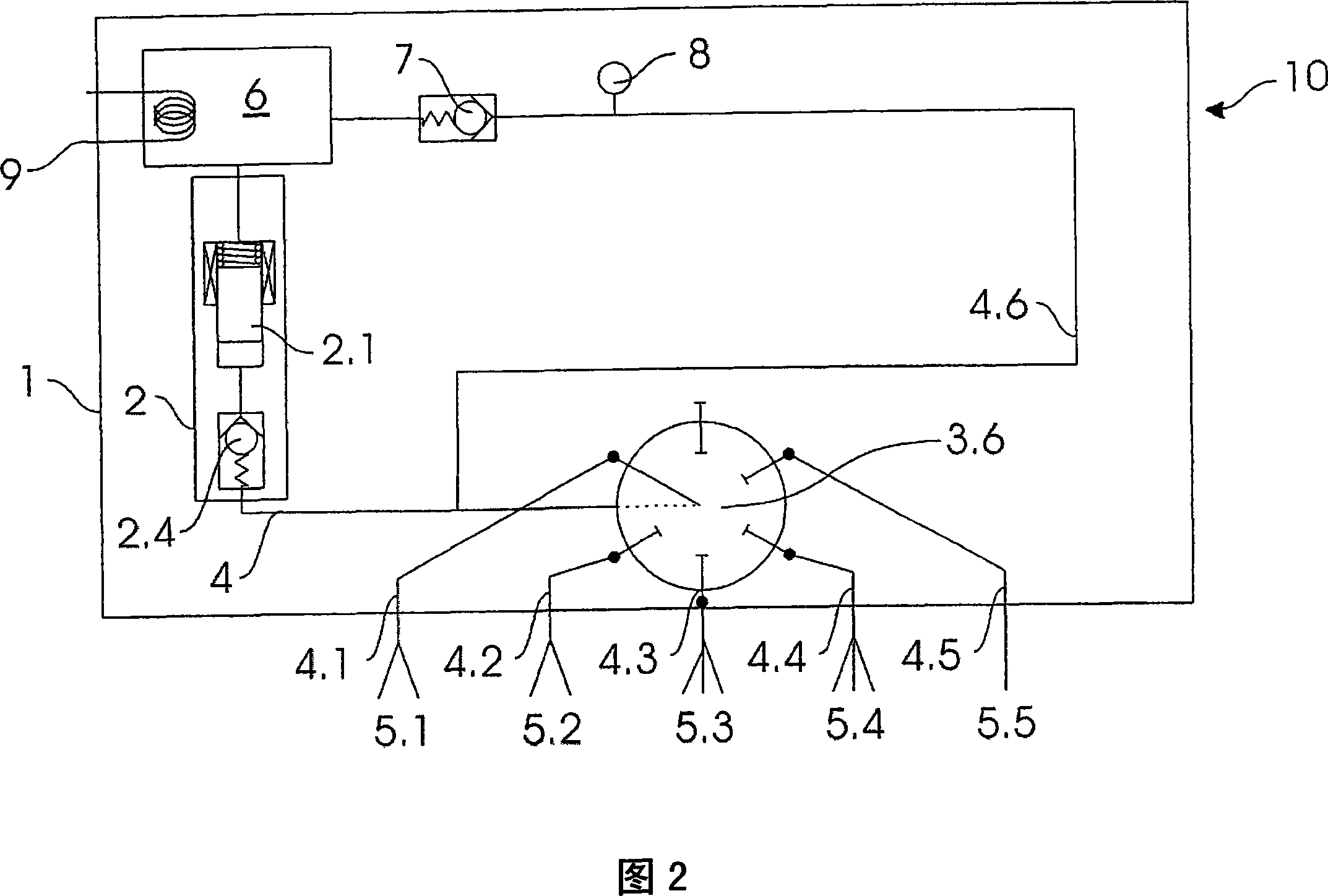

System and method for lubricating a transport device

A lubrication system for a transportation system and, in particular for an escalator or a moving walk, has a piston pump for delivering a prescribed quantity of lubricant per work cycle, an arrangement of lubrication points with at least one lubrication point and a branched lubricant pipeline. Each branch of the lubricant pipeline connects the pump in parallel to a lubricating point of the arrangement of lubrication points. Through a valve arrangement each branch of the lubricant pipeline can be selectively and individually blocked or connected to the piston pump.

Owner:INVENTIO AG

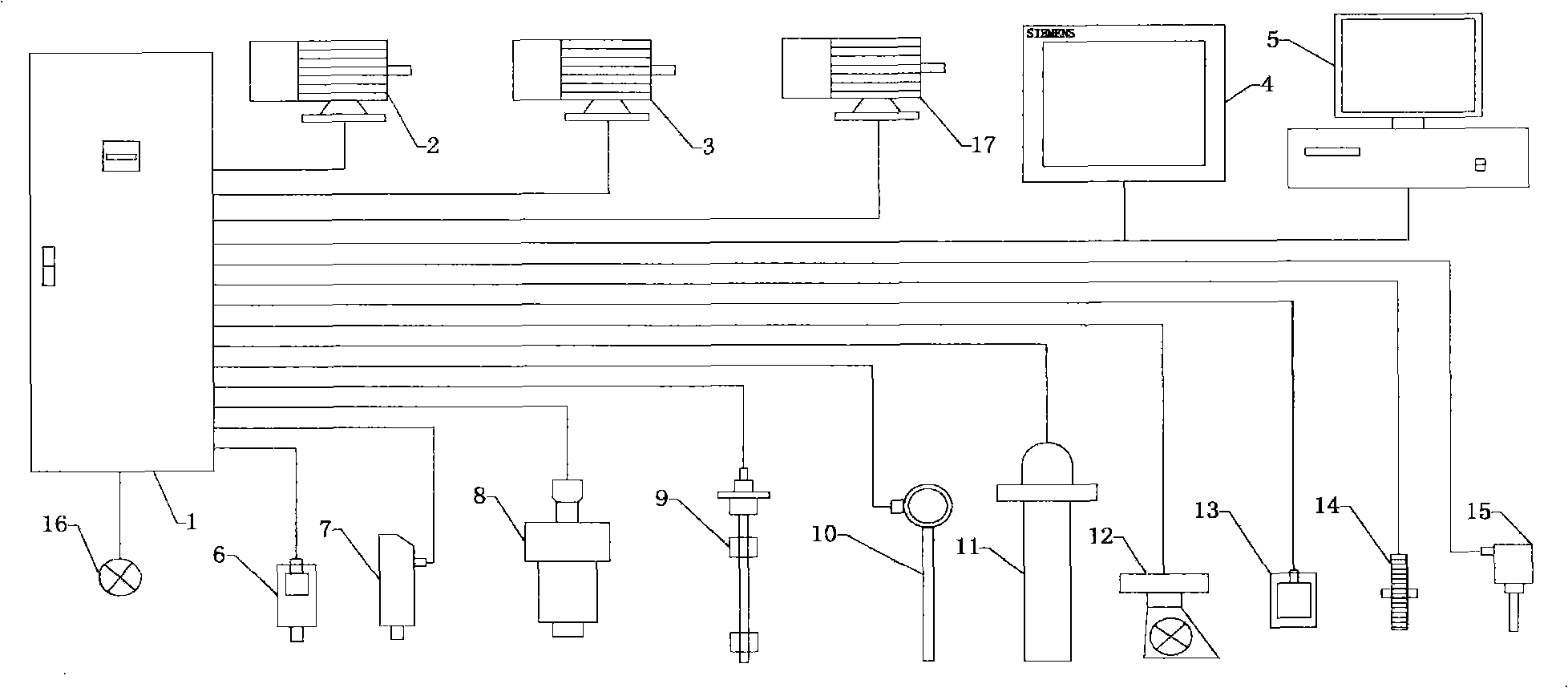

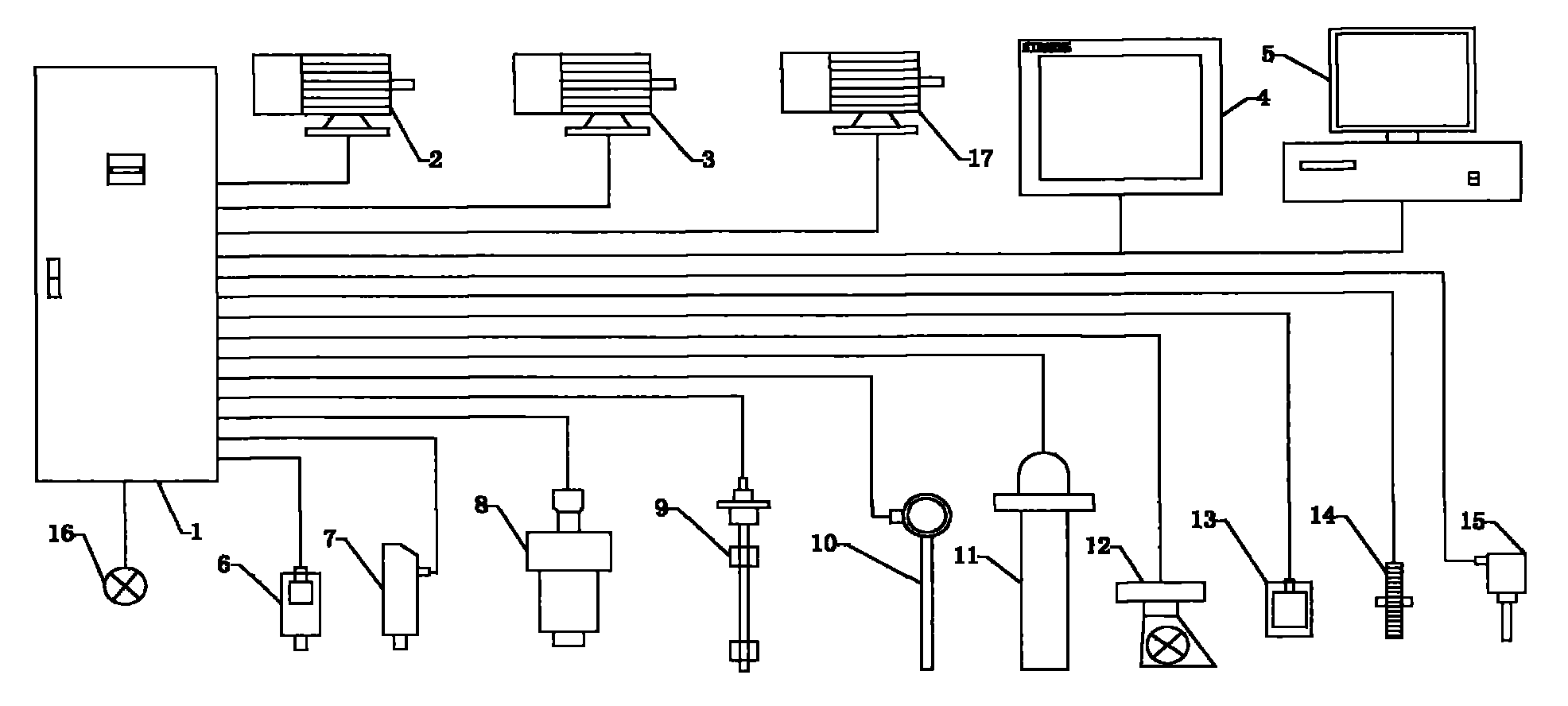

Electric control system for oil-gas lubrication

InactiveCN102494236AImprove the lubrication effectImprove automation controlDistribution equipmentGas lubricationControl system

The invention discloses an electric control system for oil-gas lubrication, comprising a PLC (programmable logic controller) main control cabinet of a lubricating main station, a lubricating oil monitoring sensor, a lubricating pump oiling device and an electromagnetic valve, wherein the PLC main control cabinet is provided with a PLC; the lubricating oil monitoring sensor is connected with the PLC main control cabinet and transmits acquired signal data to the PLC controller; and the PLC controls the lubricating pump oiling device and the opening and closing of the electromagnetic valve according to the acquired signal data. After the technical scheme is adopted, the electric control system has the advantages of high automation degree, simplicity and easiness in operation, convenience in maintenance and installation, low energy consumption and perfect alarming.

Owner:YANTAI HUASHUN MACHINERY ENG EQUIP

Engine lubrication system

InactiveUS7036480B2Pump outputIncrease temperatureLubricant conduit arrangementsMachines/enginesEngineeringSystem controller

A lubrication system for an engine includes a sump for lubricant, a pump to pump lubricant along a lubricant feed line to lubrication positions within the engine, and a lubricant conditioner, and wherein the pump is an electrically driven pump which is controlled by a system controller, there being a diverter valve which is under the control of the controller selectively to divert at least a proportion of the lubricant from the lubricant feed line to the lubricant conditioner.

Owner:PIERBURG PUMP TECH UK

Hydraulic system for working vehicle

ActiveUS8561760B2Great individual variance in efficiencyLow efficiencyProportioning devicesGearboxesAir pumpEngineering

A low-pressure pump supplies oil stored in a steering case to a steering device as lubricating oil via a steering lubricating circuit. A high-pressure pump supplies the oil stored in the steering case to a clutch via a high-pressure circuit. A transmission lubricating circuit branches off from the high-pressure circuit via a relief valve and supplies lubricating oil to a transmission device. A transmission-lubricating assist circuit is provided so as to branch off from the steering lubricating circuit and is connected to the transmission lubricating circuit. A transmission case stores the oil used to lubricate the transmission device. A scavenging pump returns the oil stored in the transmission case to the steering device.

Owner:KOMATSU LTD

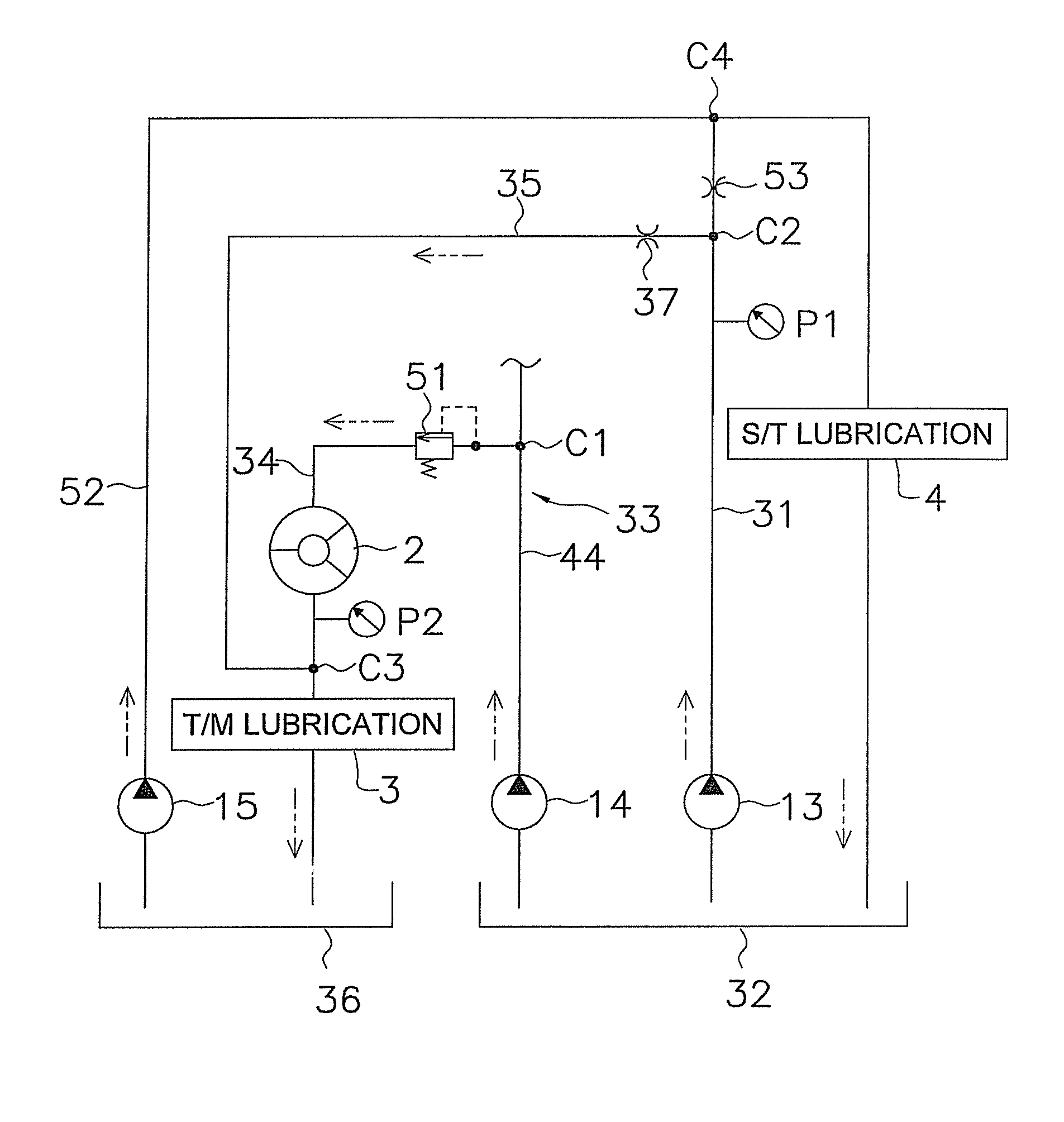

Helicopter with an auxiliary lubricating circuit

ActiveUS7651049B2Meet the requirementsDrip lubricationDrip or splash lubricationAuxiliary memoryMechanical engineering

Owner:LEONARDO FINMECCANICA SPA

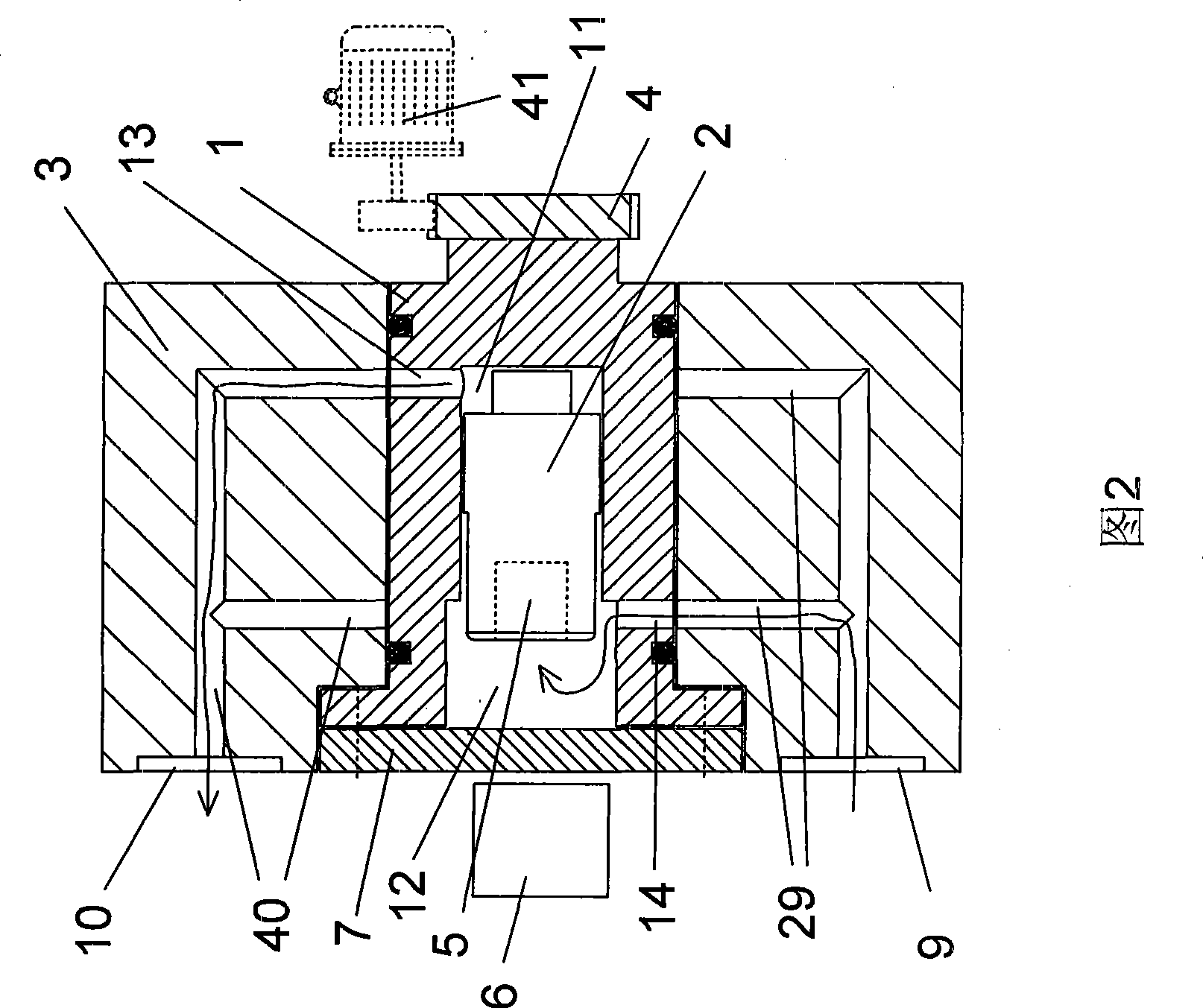

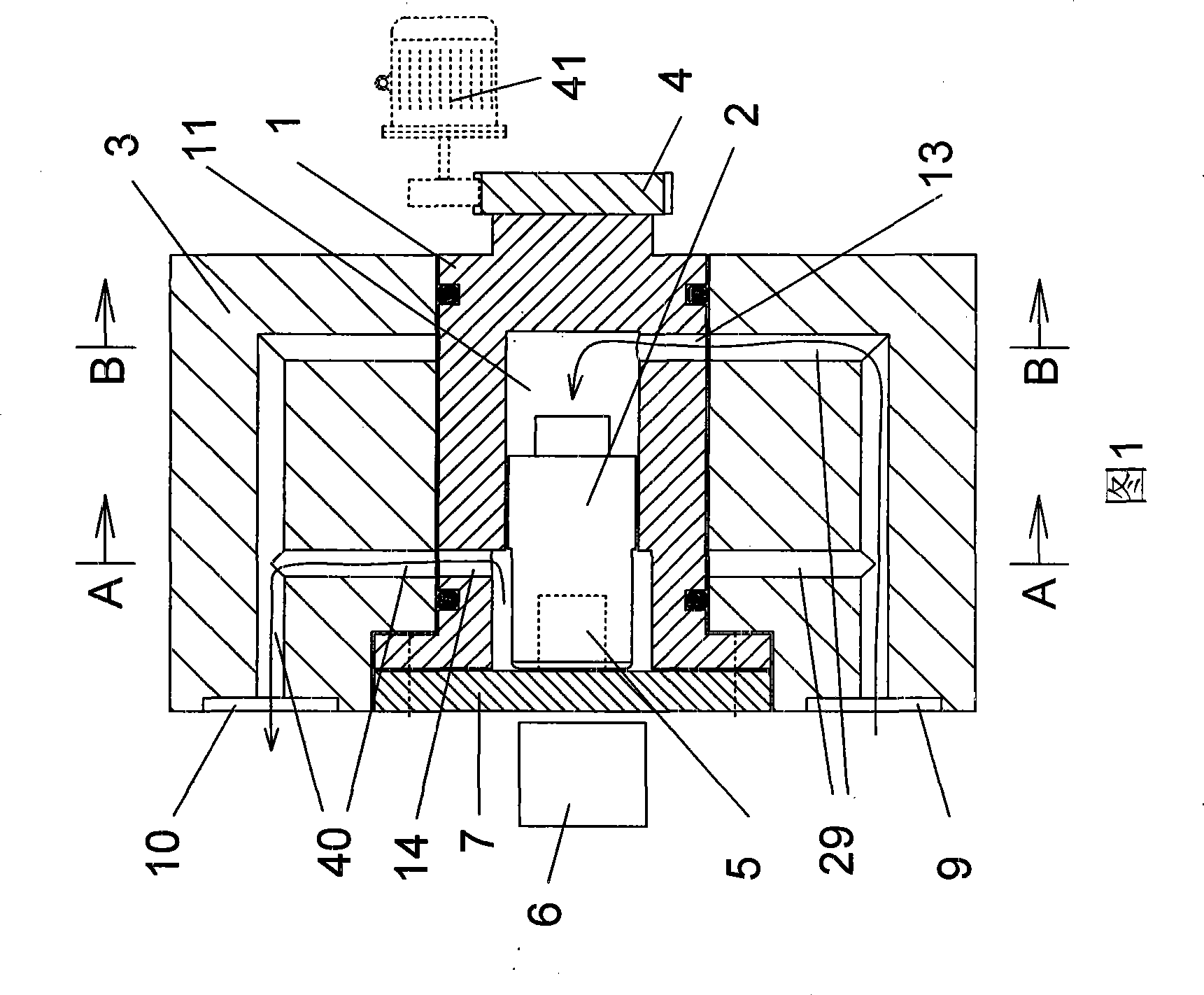

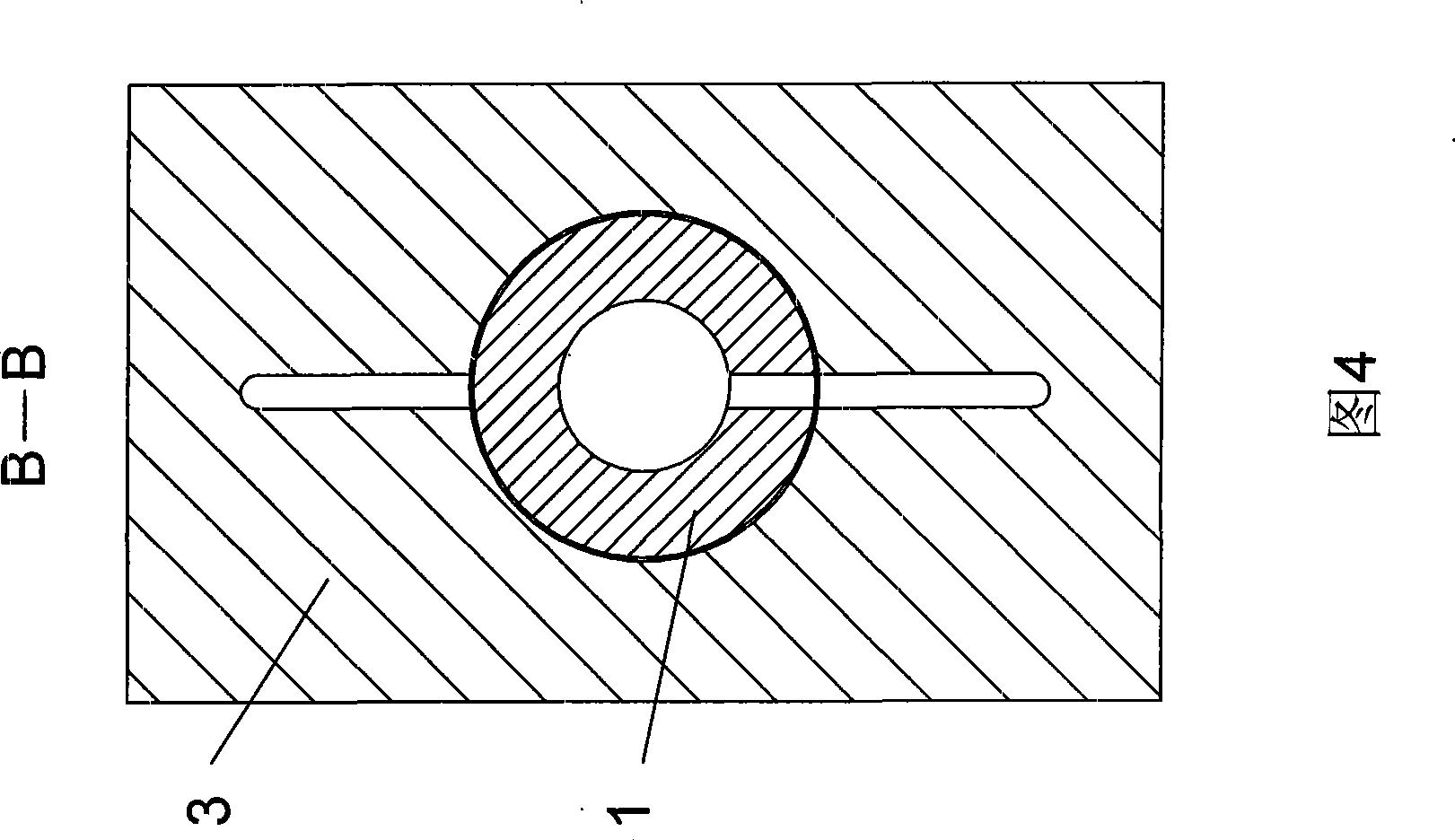

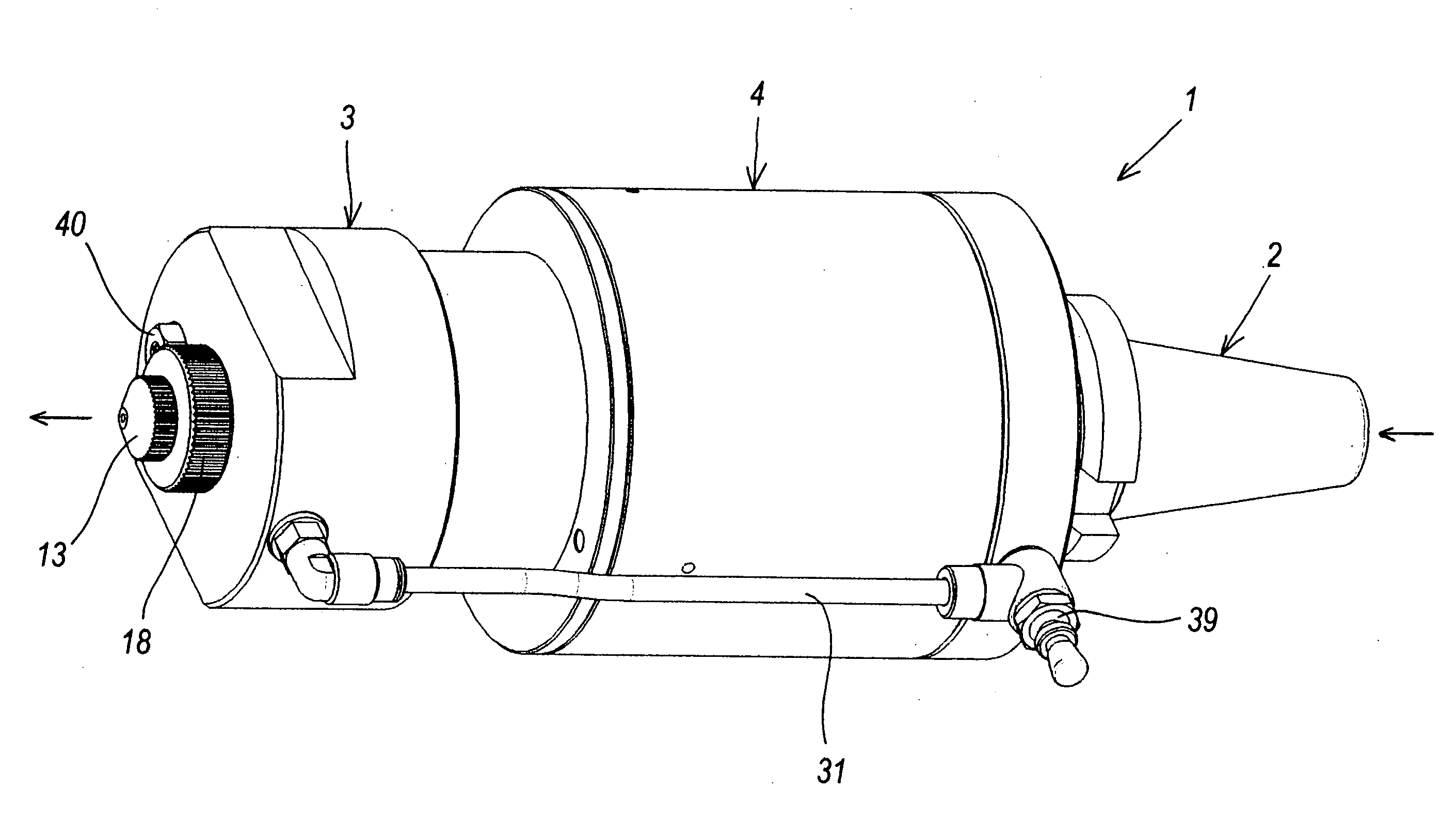

Fluid distributing valve, distributing valve combination unit and distributing system using the distributing valve

The invention discloses a fluid distributing valve, which comprises a valve body, wherein the inside of the valve body is provided with a rotatable valve core in driving connection with an external drive device, the inside of the valve core is provided with a cavity, the inside of the valve body is further provided with an oil inlet valve body passage and an oil outlet valve body passage the openings of which are positioned on the surface of the valve body, the valve core is provided with a valve core passage corresponding to the oil inlet valve body passage and the oil outlet valve body passage inside the valve body, and the inside of the cavity of the valve core is hermetically and slidably connected with a plunger which divides the cavity into a first cavity and a second cavity; and the second cavity selects to be communicate with the oil outlet valve body passage or the oil outlet valve body passage through the second valve core passage. The fluid distributing valve adopts the structure that the inside of the cavity of the rotatable valve core is provided with the plunger which divides the cavity into two parts, has the advantages of strong adaptability to impurities, long service life and difficult blockage brought by the rotatable valve core of the rotary circulating-distributing valve in the document number of 200420029881.1, and can accurately control the amount of the lubricant (the grease lubricant).

Owner:张淑敏

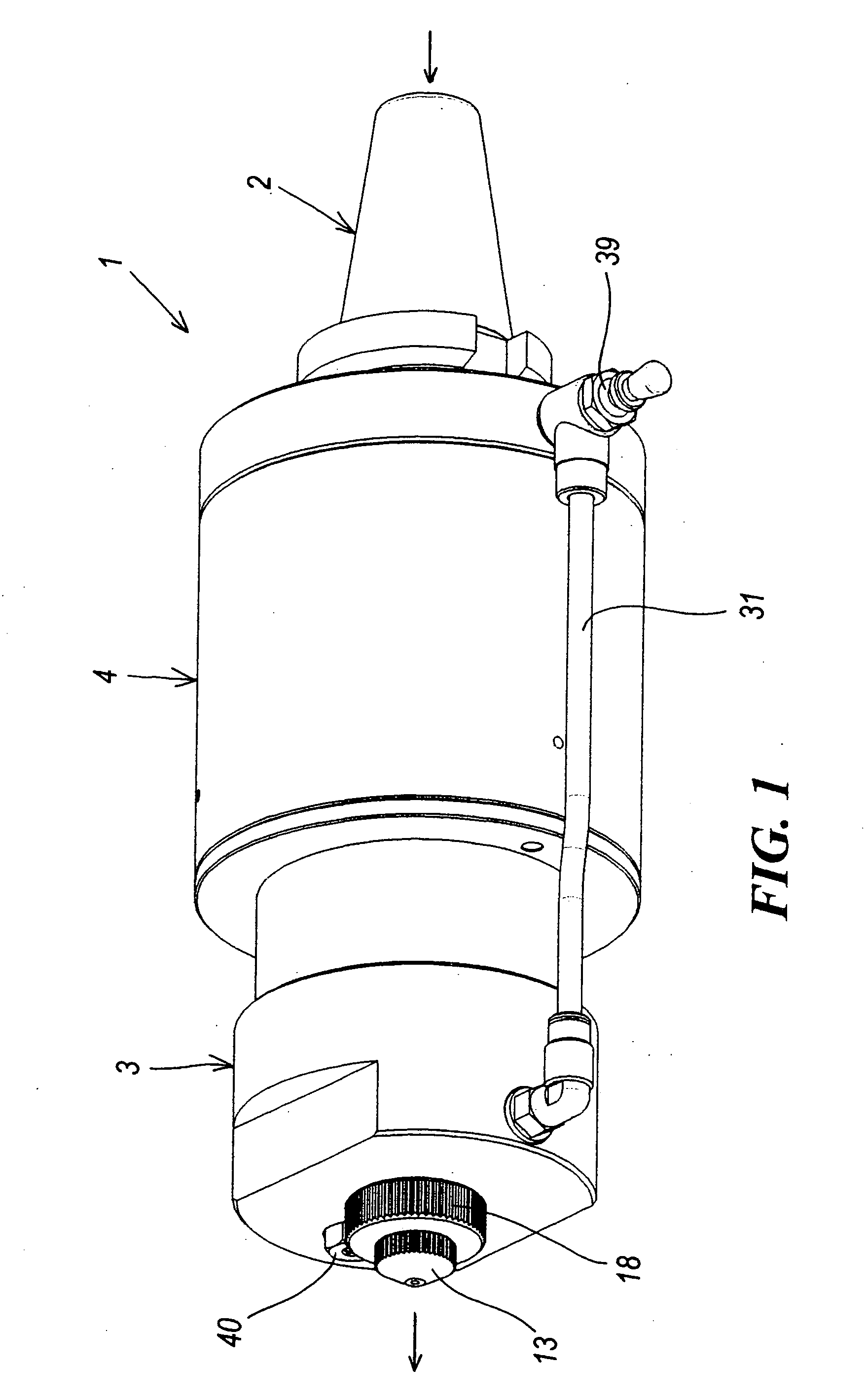

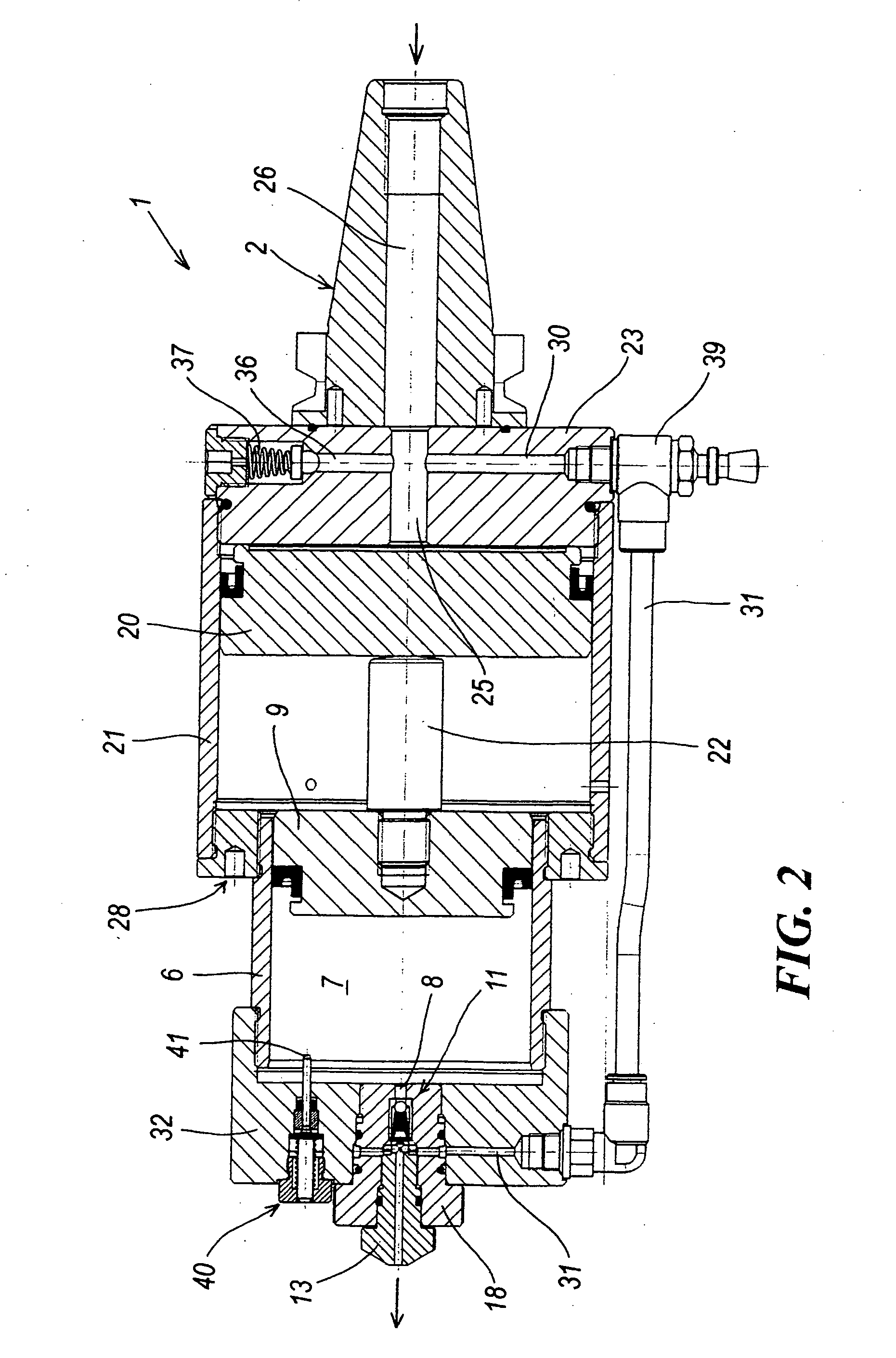

Lubrication device for machine tools

InactiveUS20070145075A1Shorten the timeProduction costs using machine tools to be limitedThread cutting toolsMulti-purpose machinesDistribution controlEngineering

The machine tool lubrication device comprises connection means grippable automatically by a manipulator of the machine tool, lubricant dispensing means, and dispensing control means operable by the machine tool.

Owner:DROPSA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com