Patents

Literature

46results about "Drip lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Valve operating mechanism of internal combustion engine

Owner:HITACHI LTD

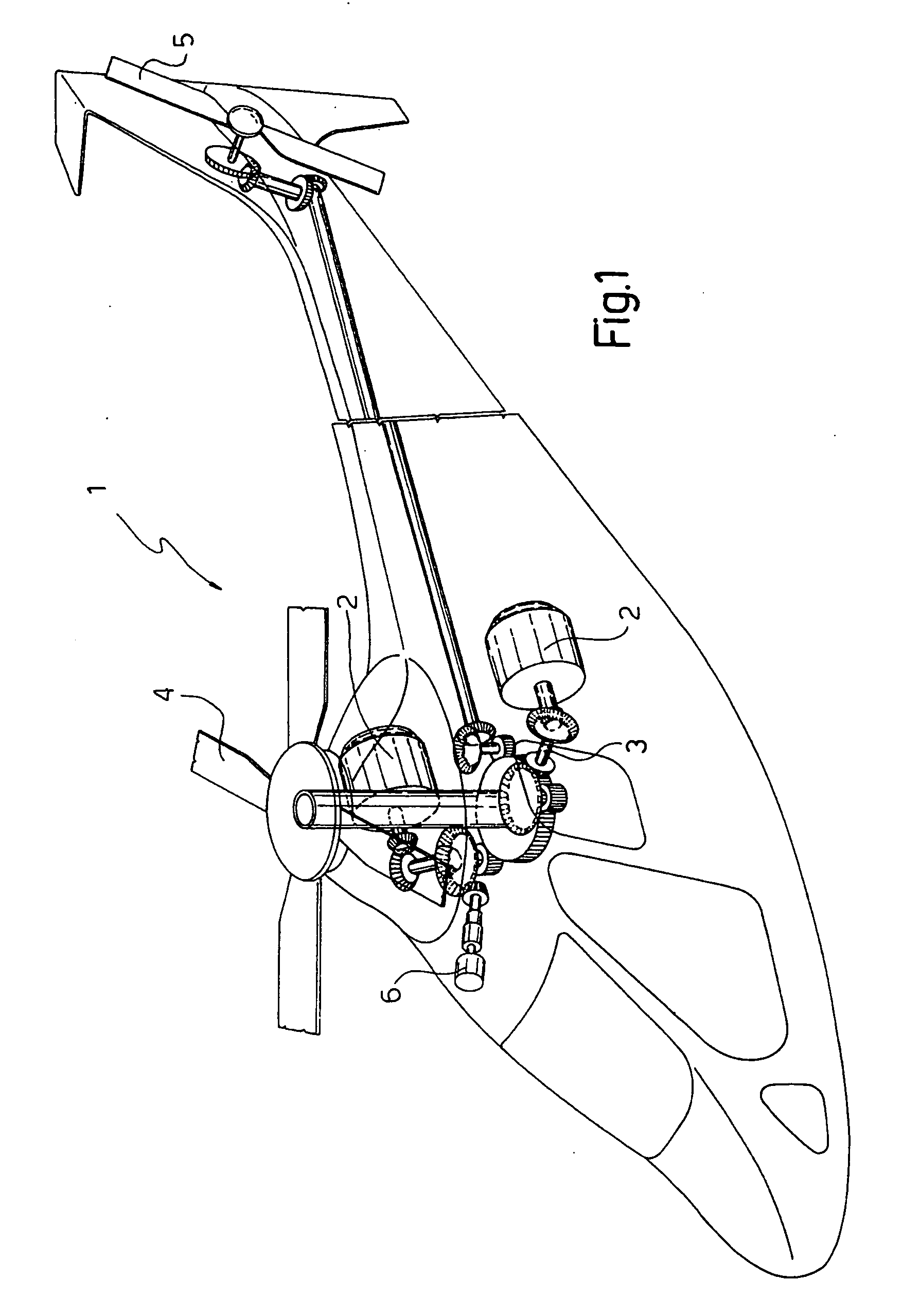

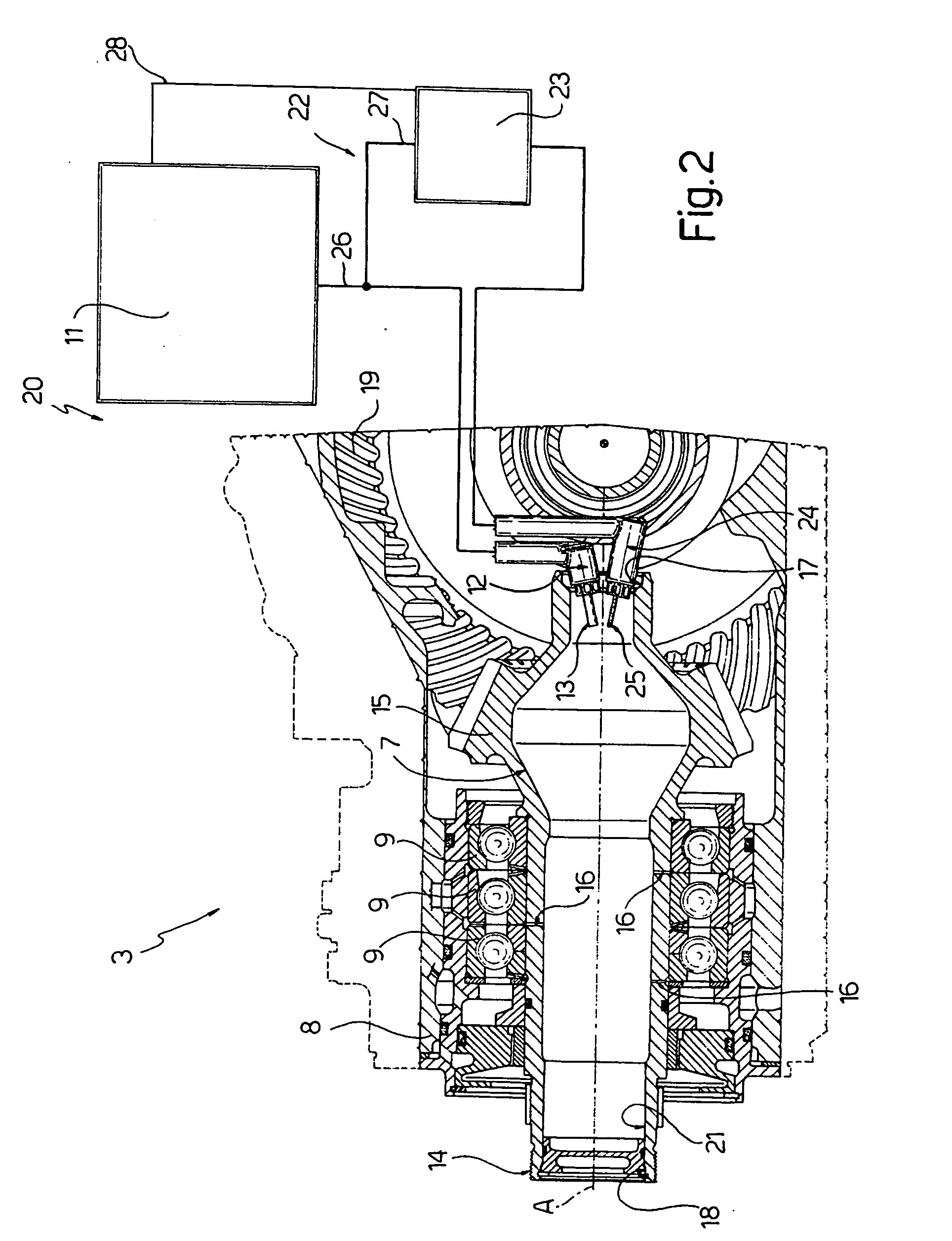

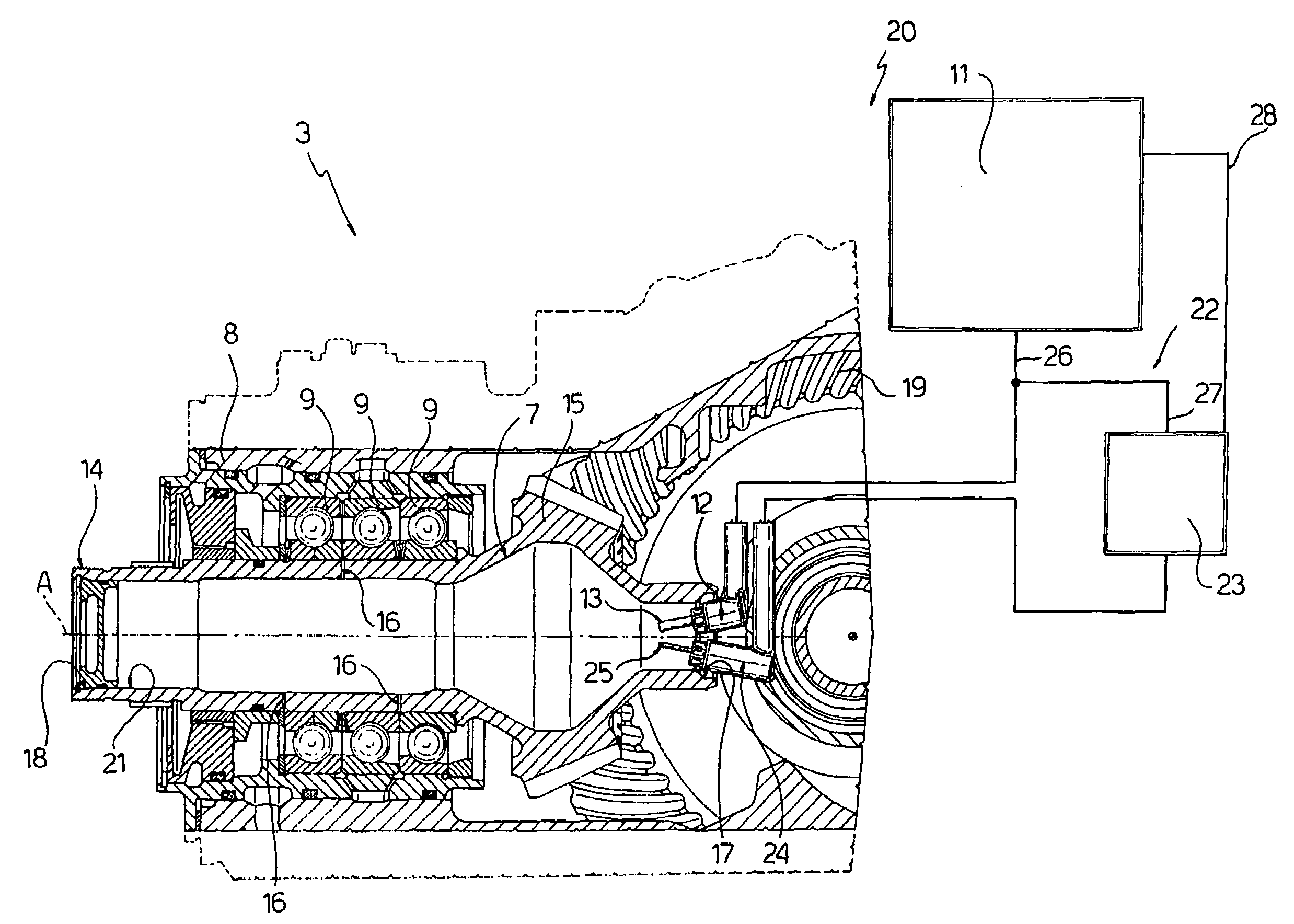

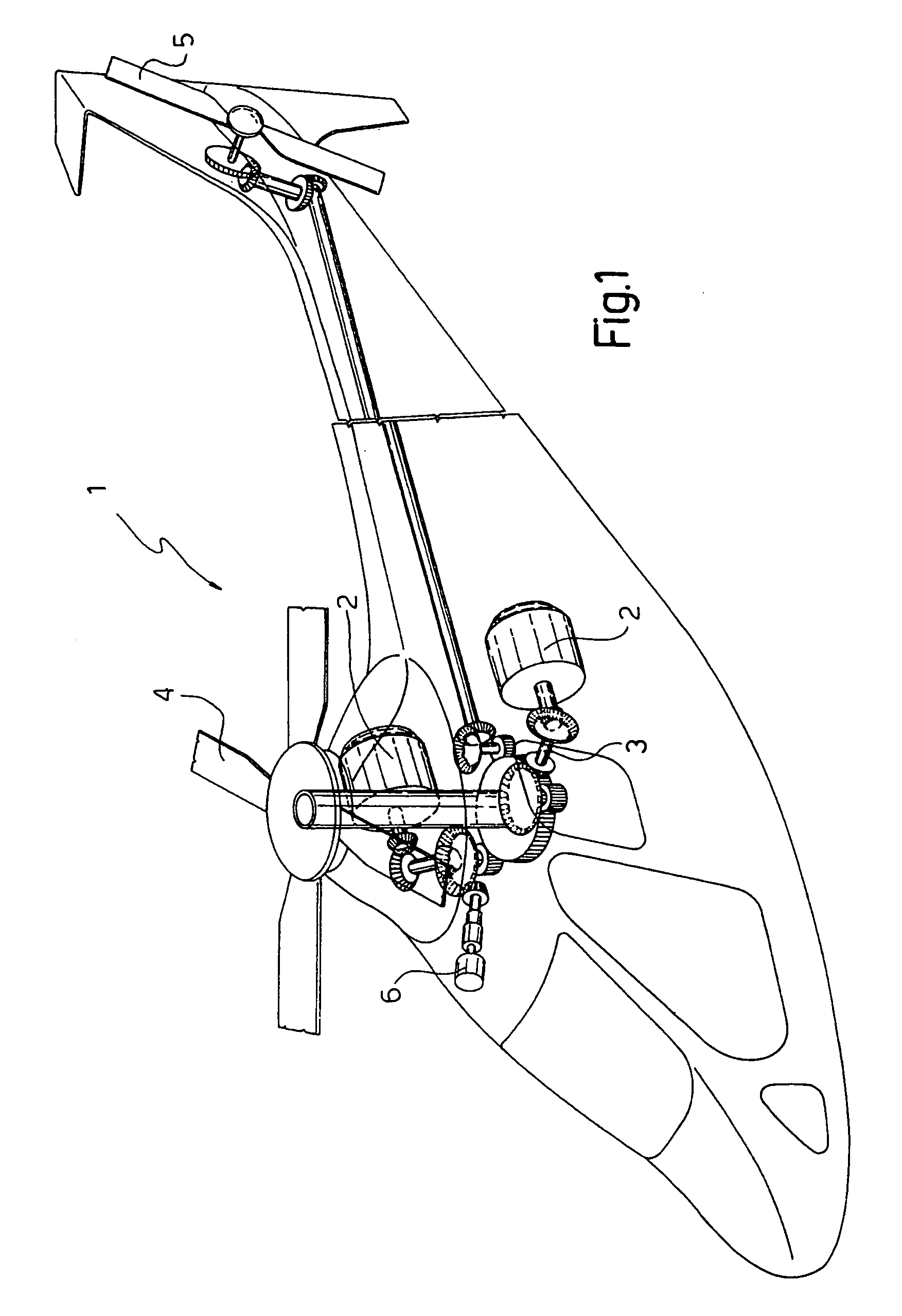

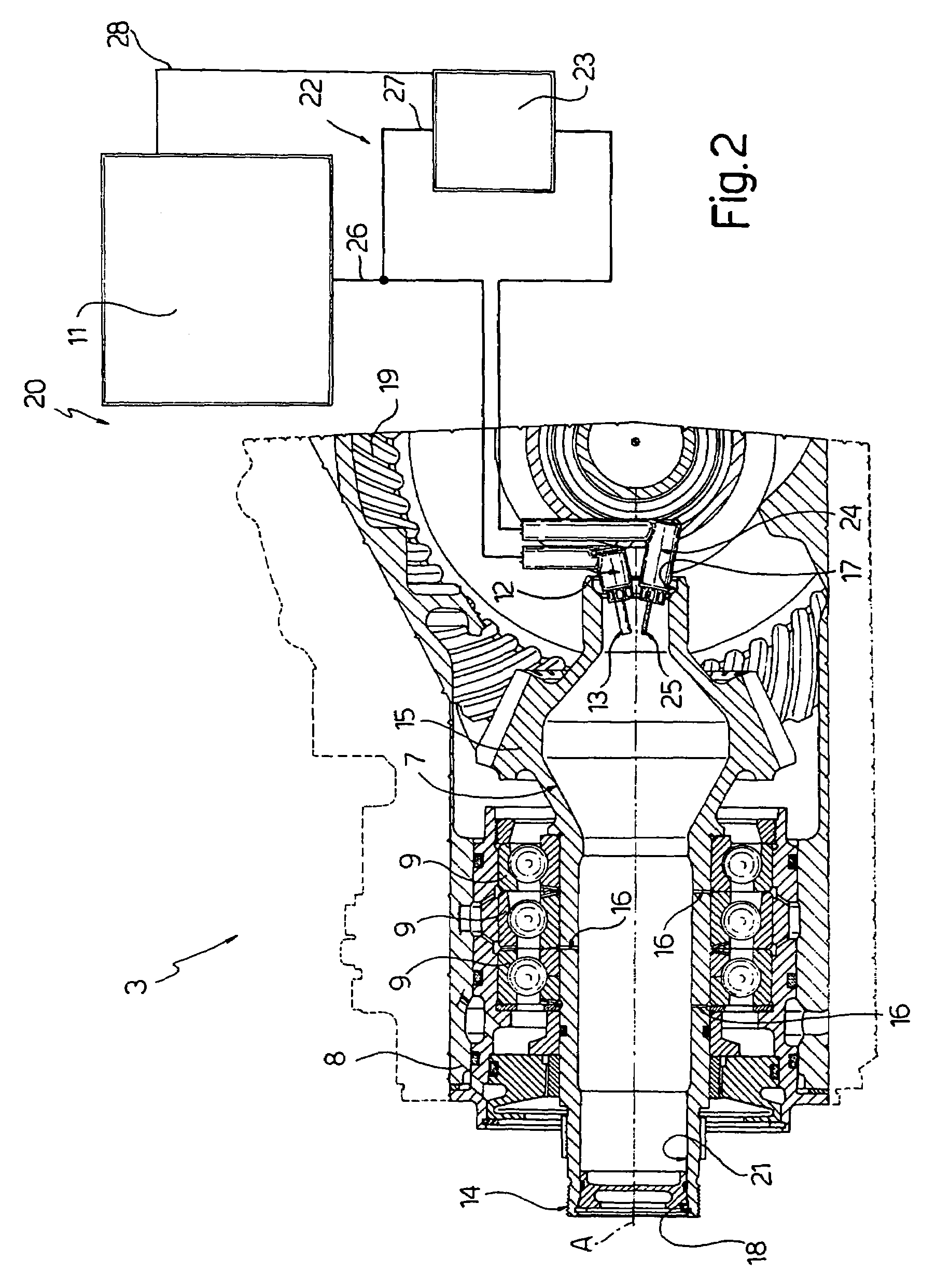

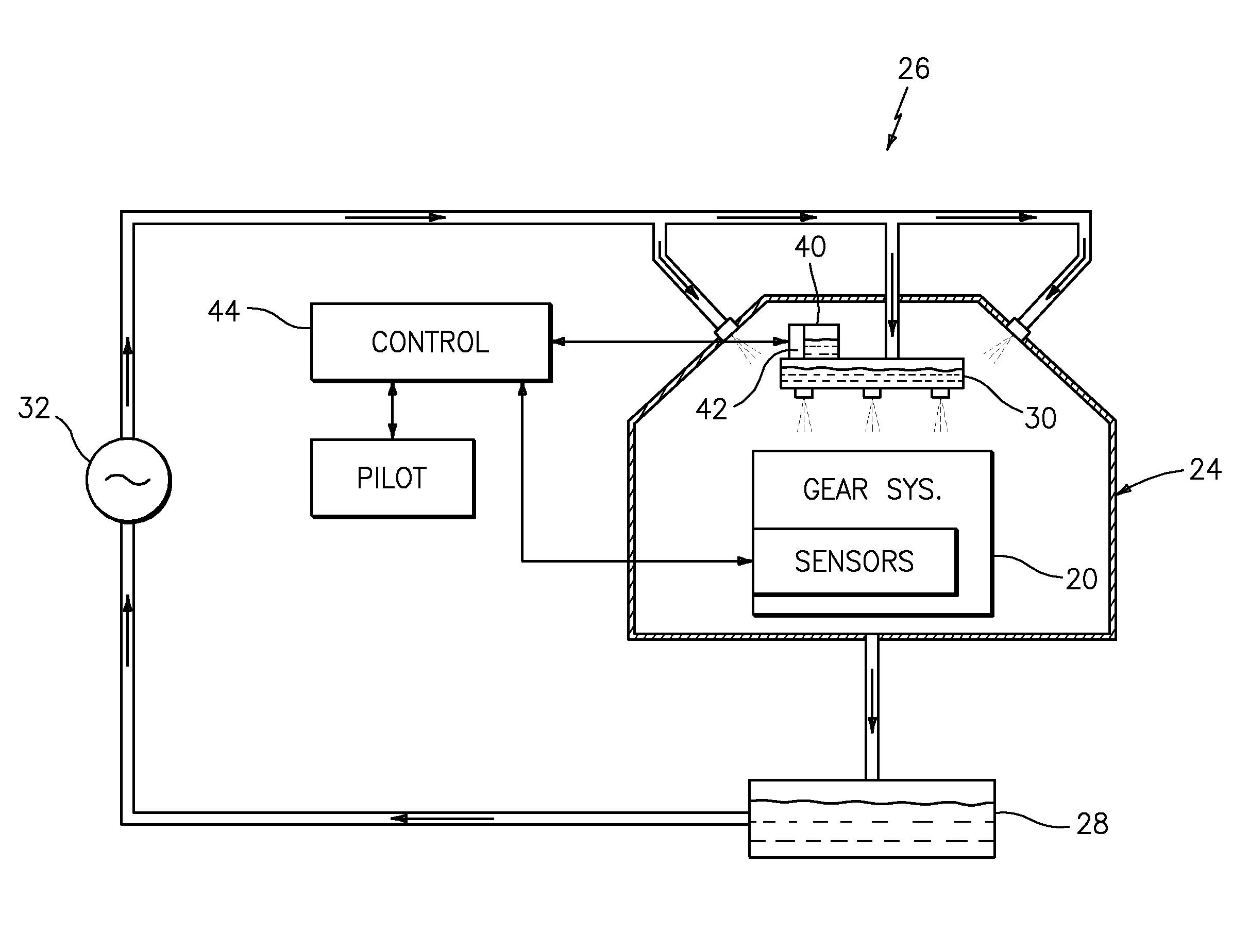

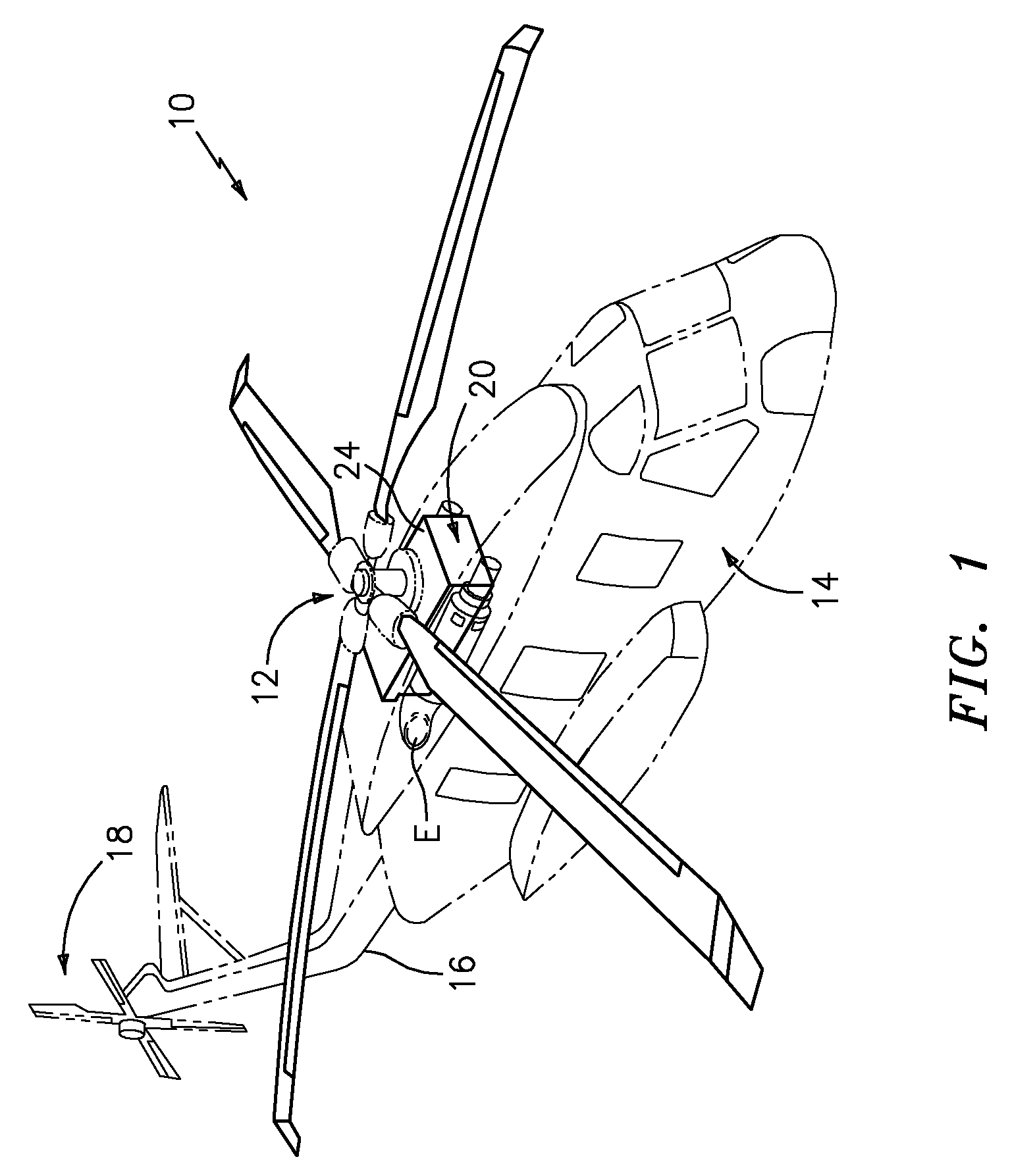

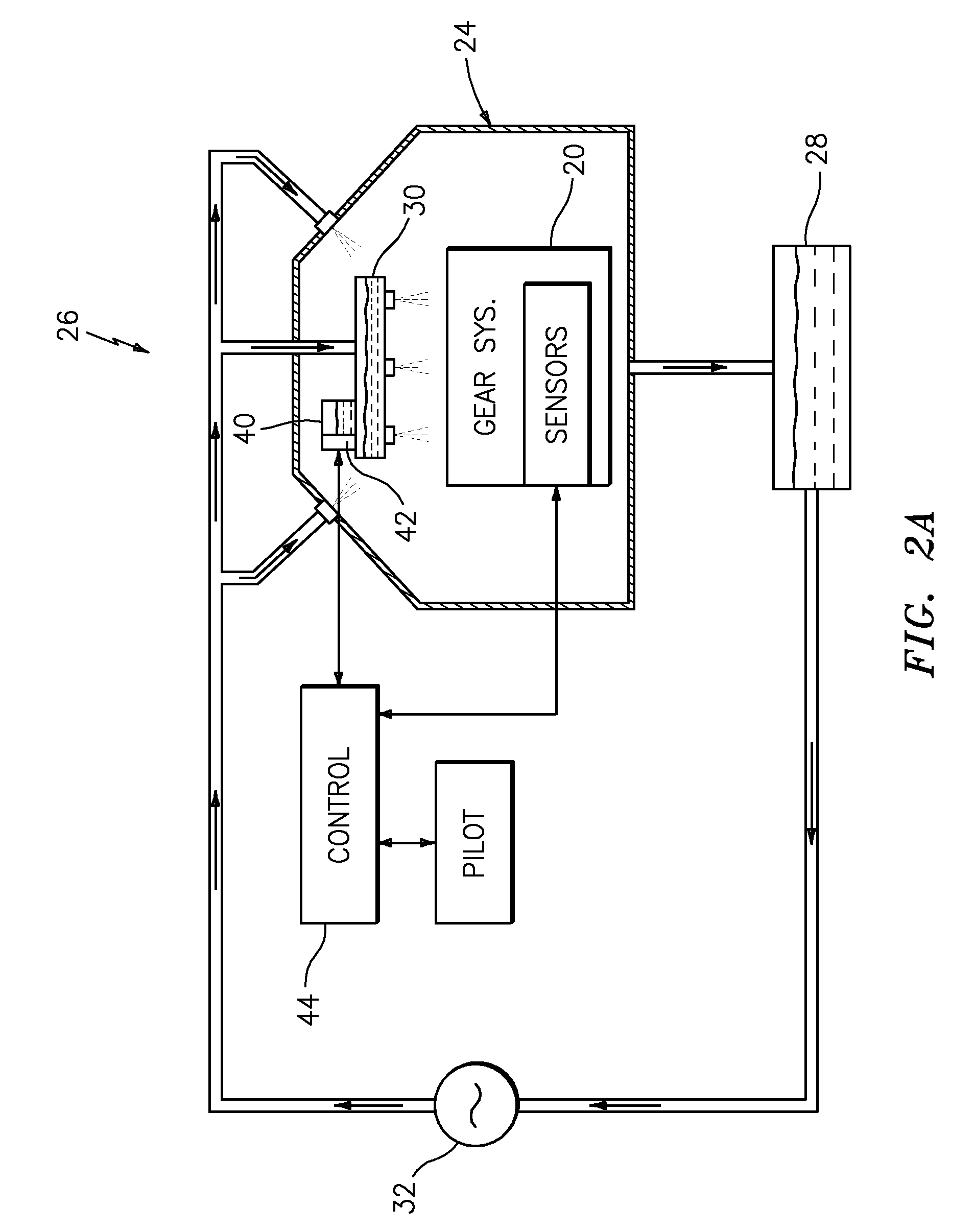

Helicopter with an auxiliary lubricating circuit

ActiveUS20090071753A1Meet the requirementsDrip lubricationDrip or splash lubricationAuxiliary memoryEngineering

Owner:LEONARDO FINMECCANICA SPA

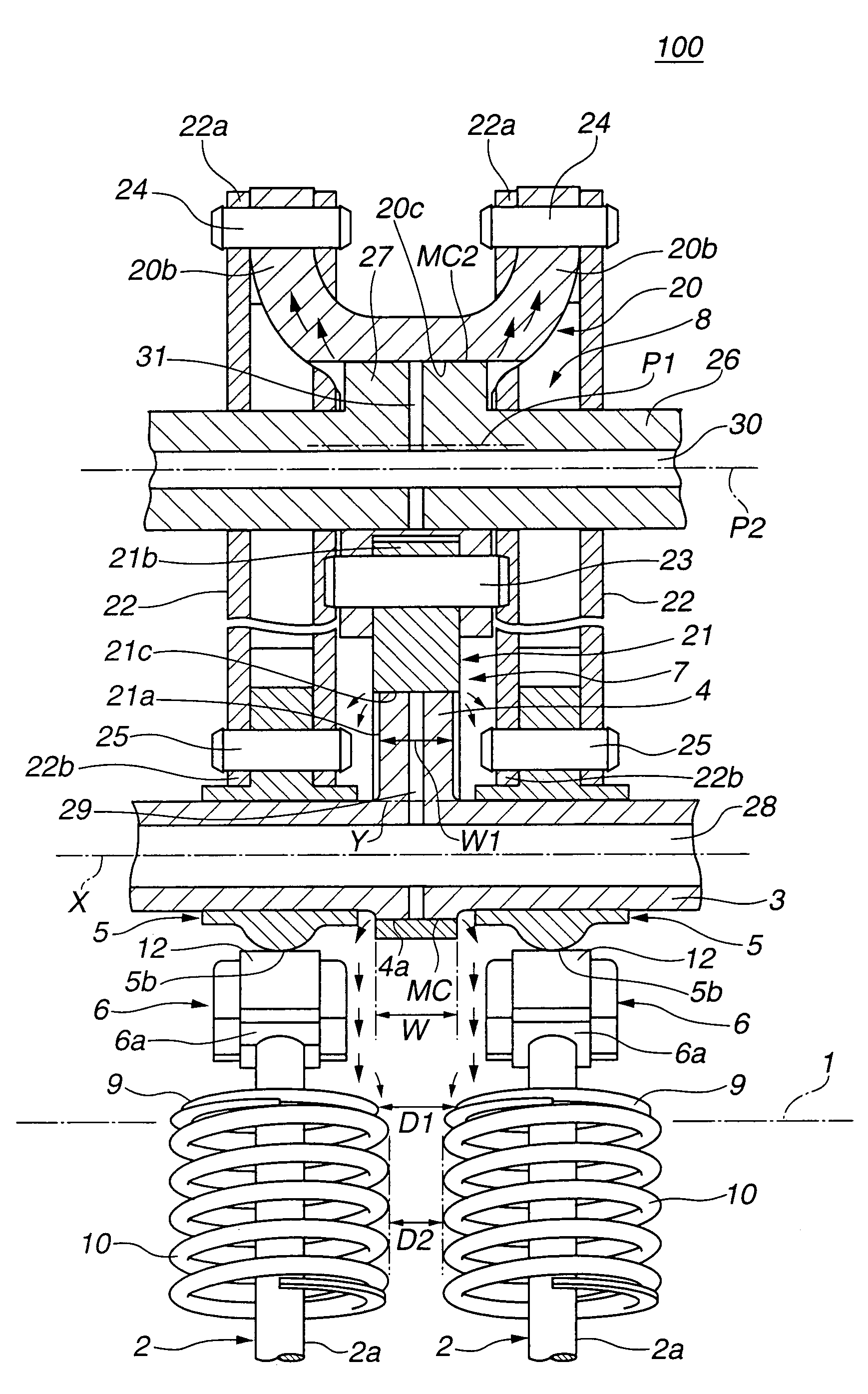

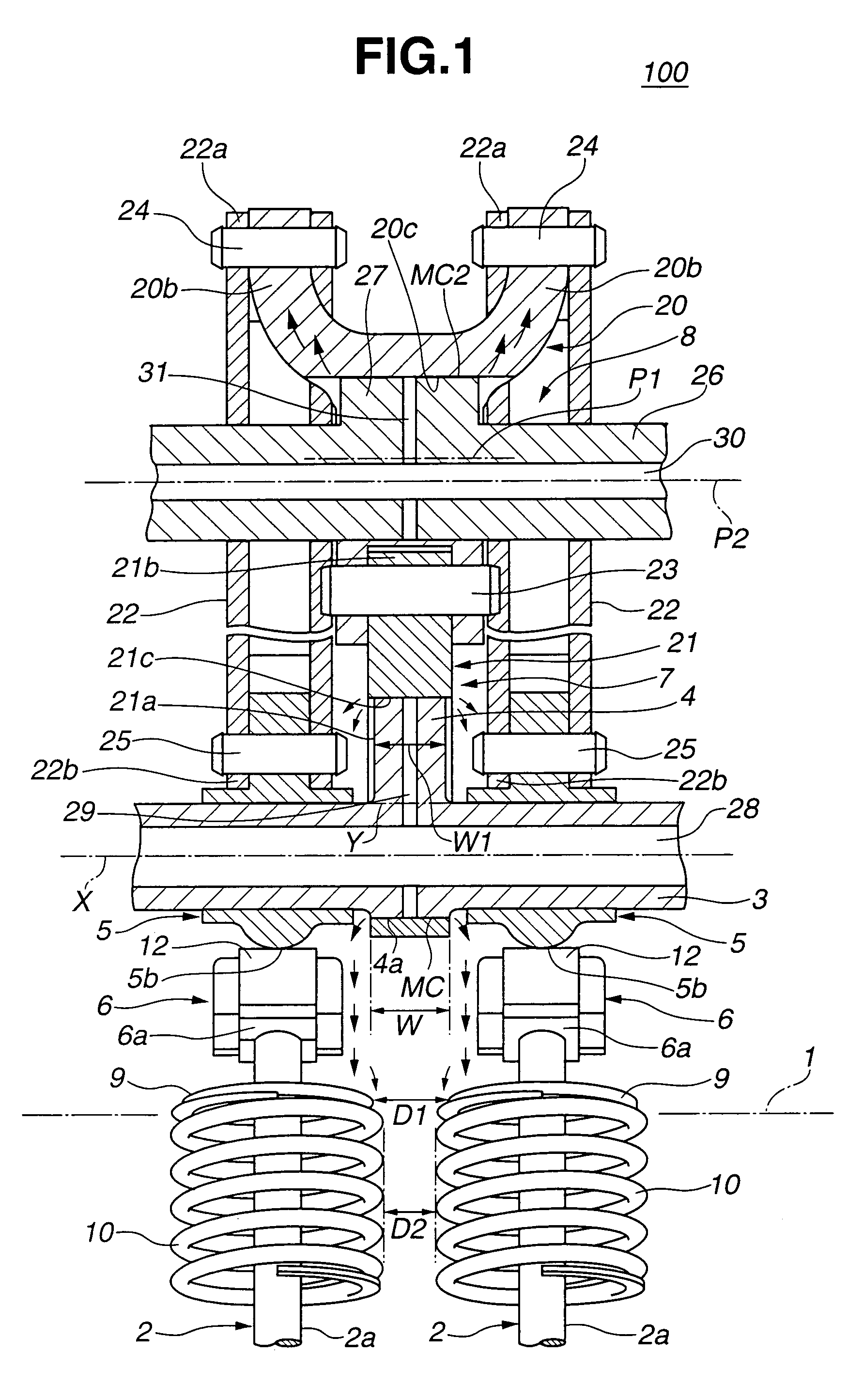

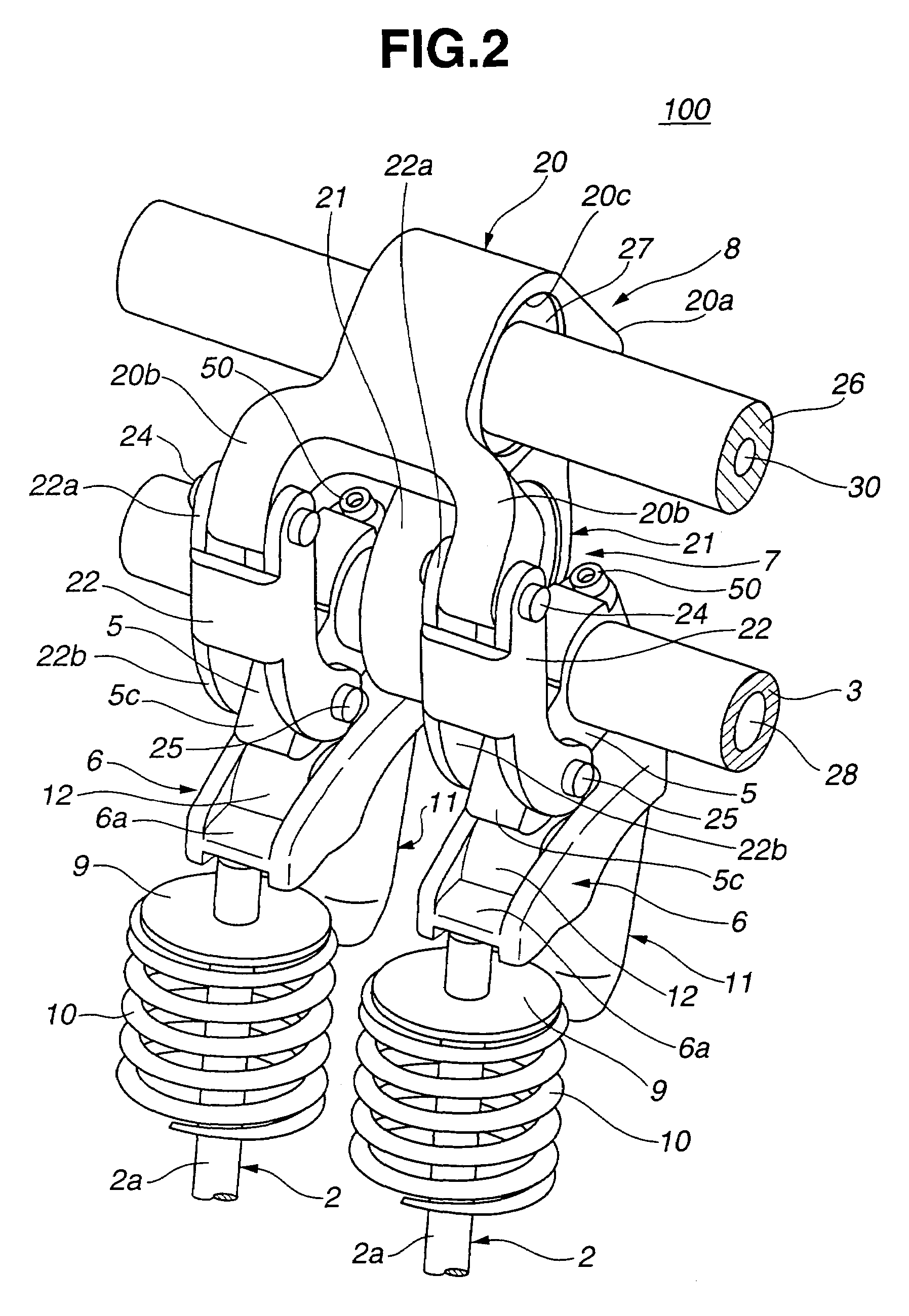

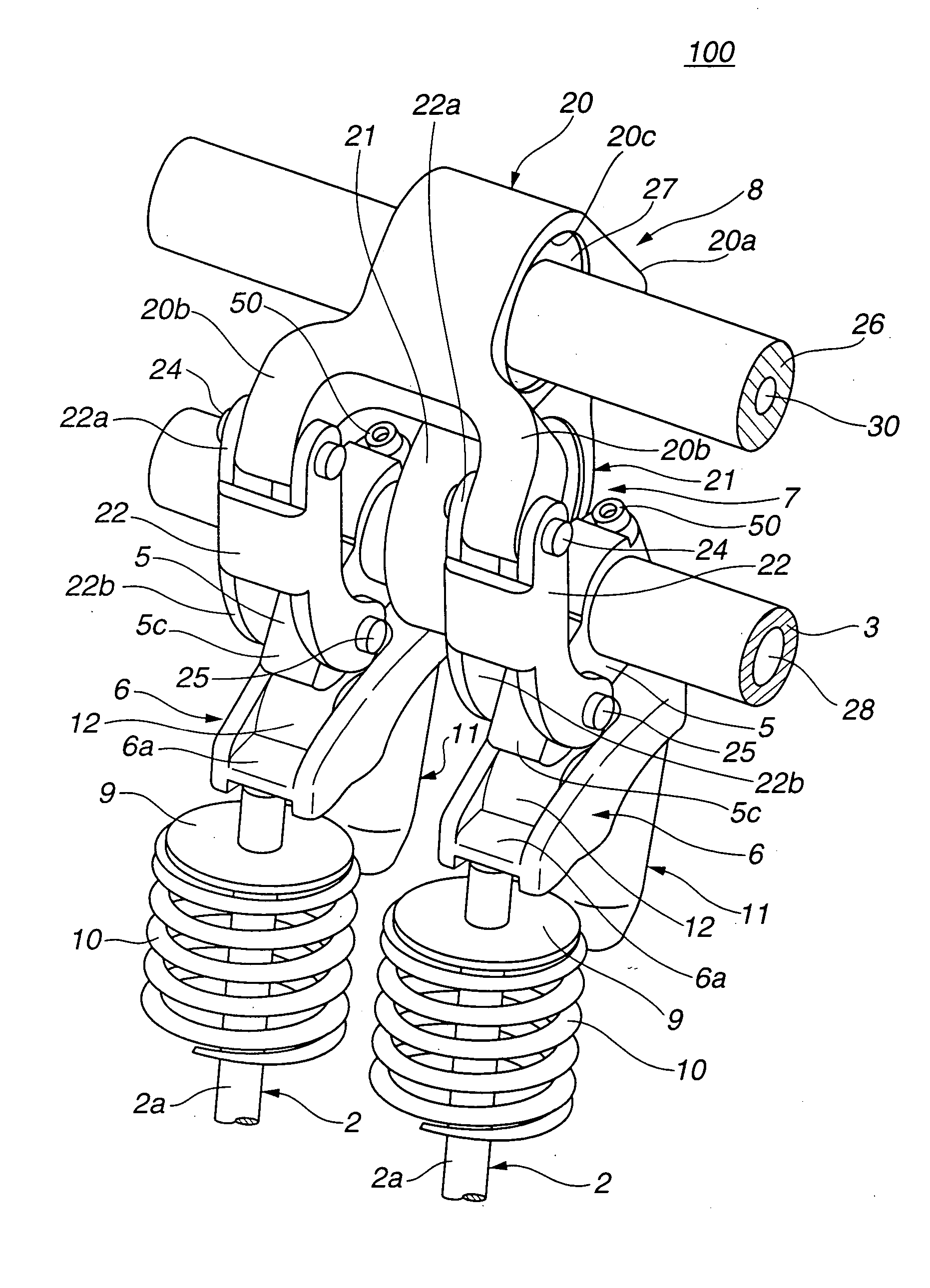

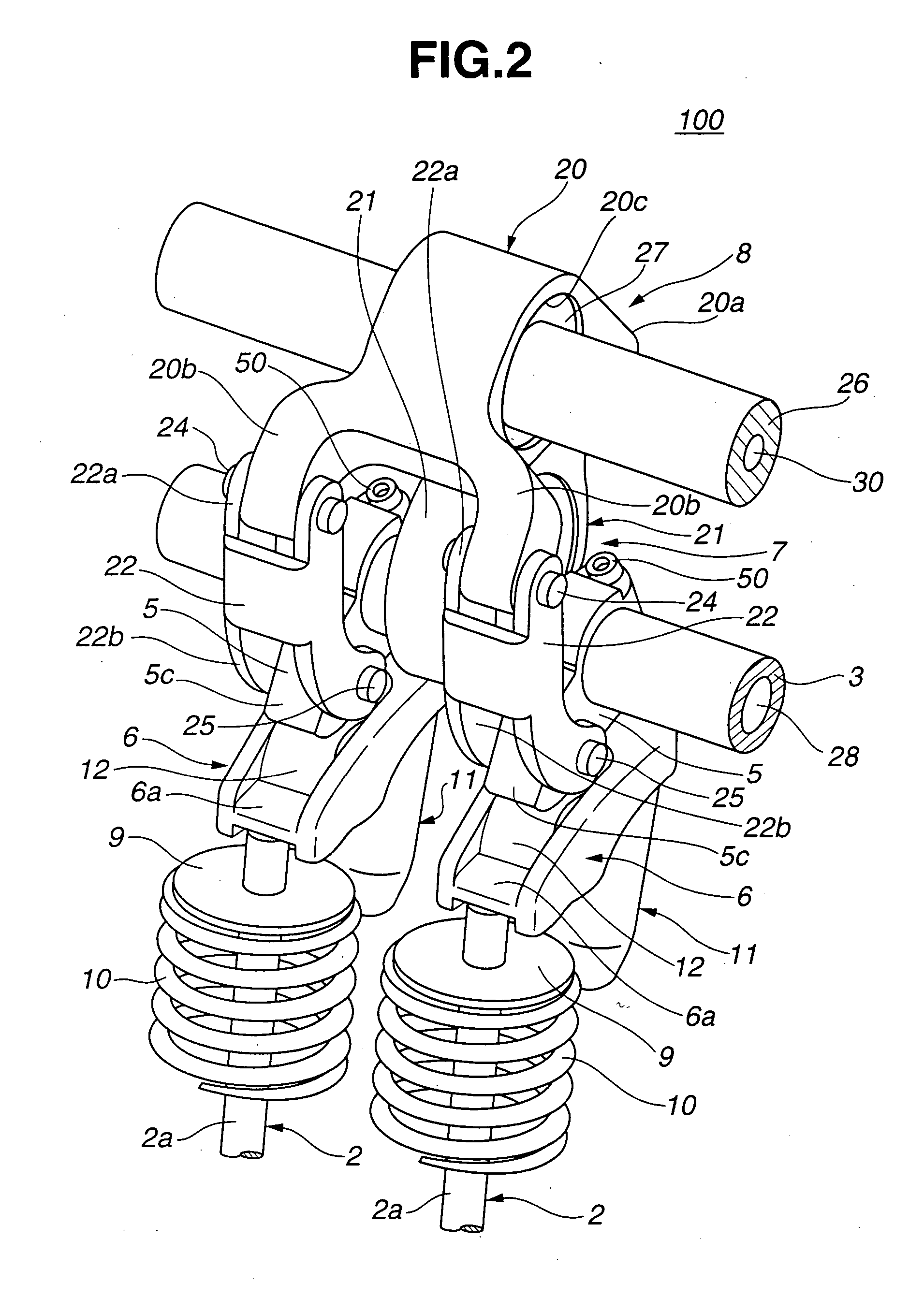

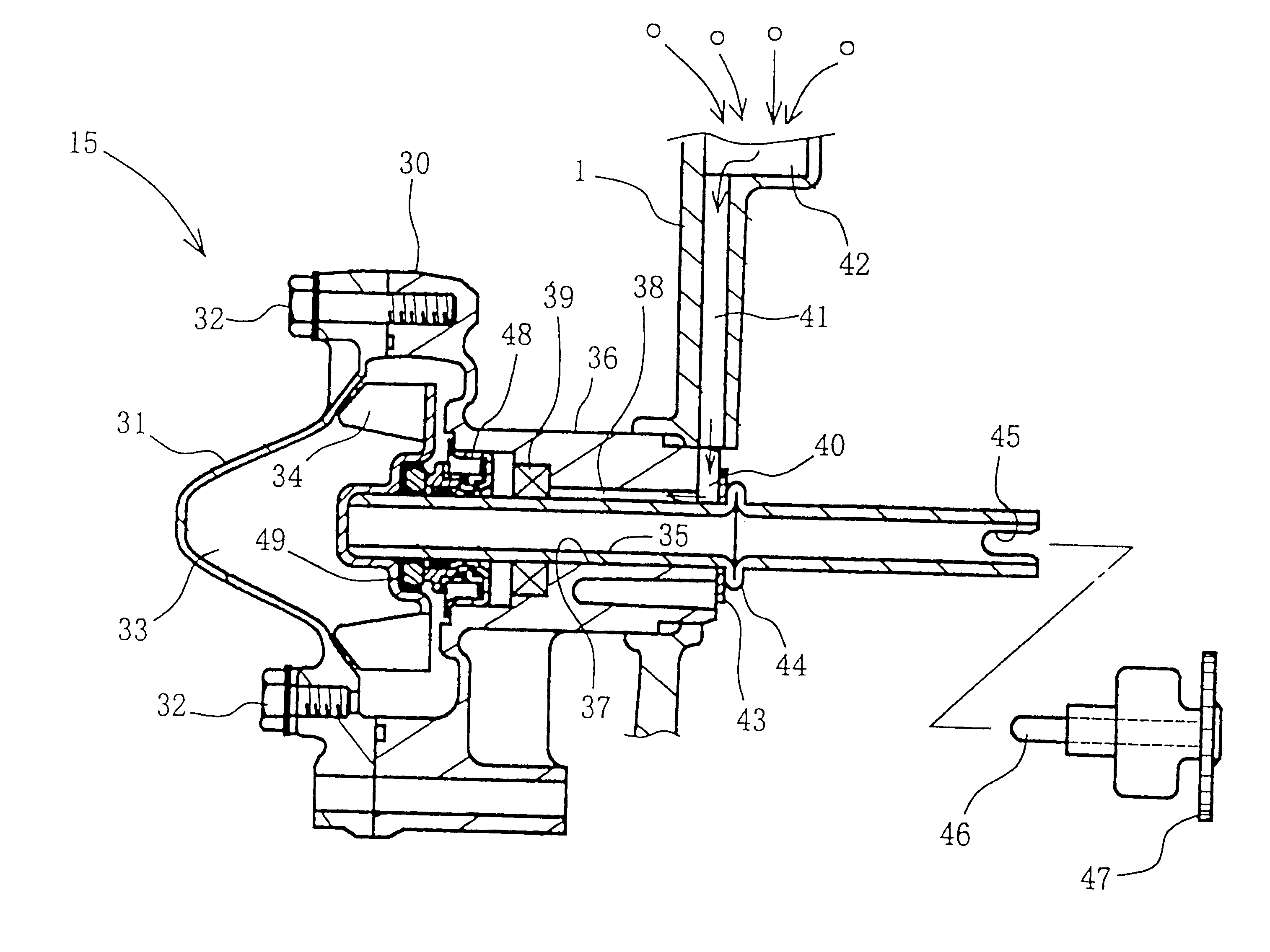

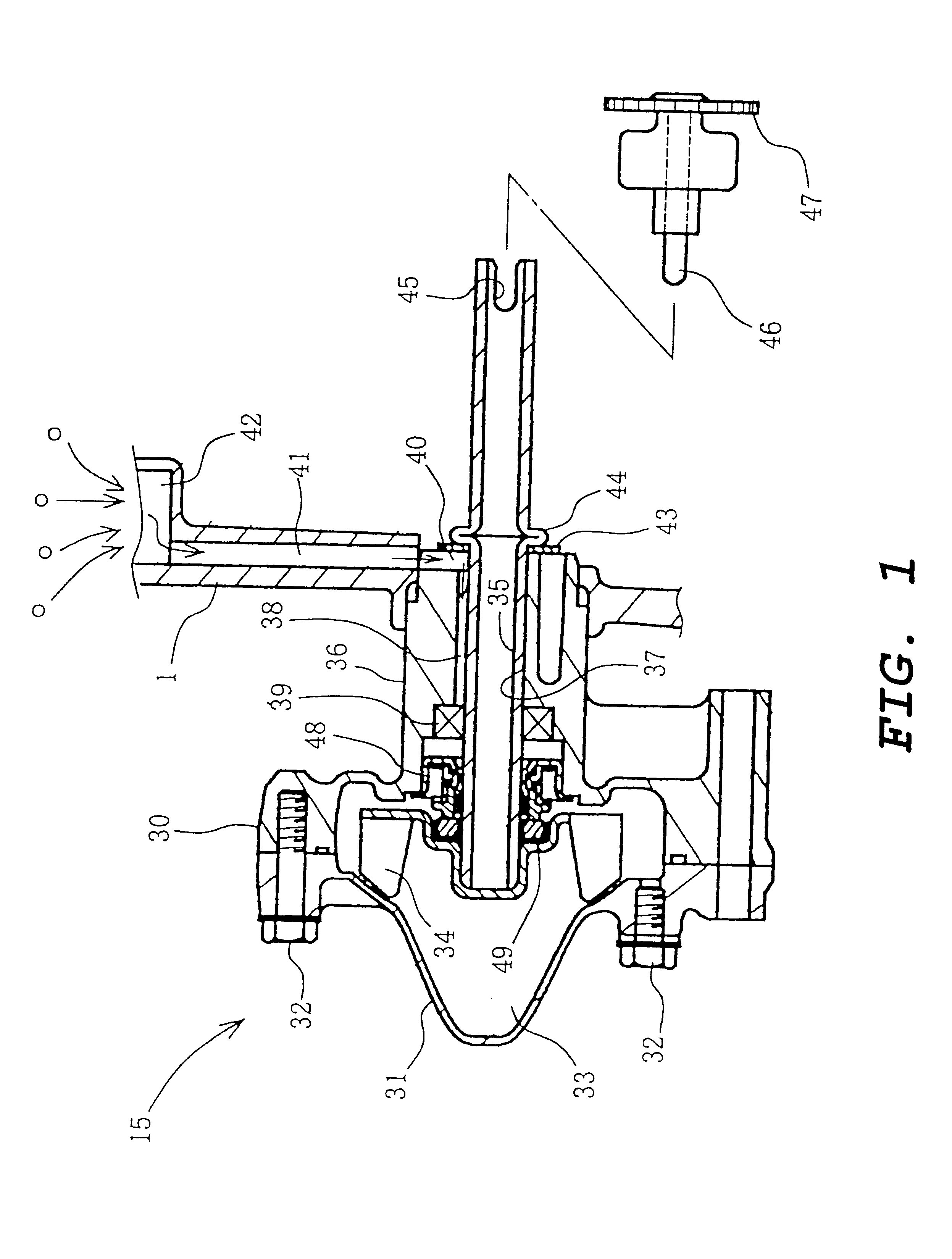

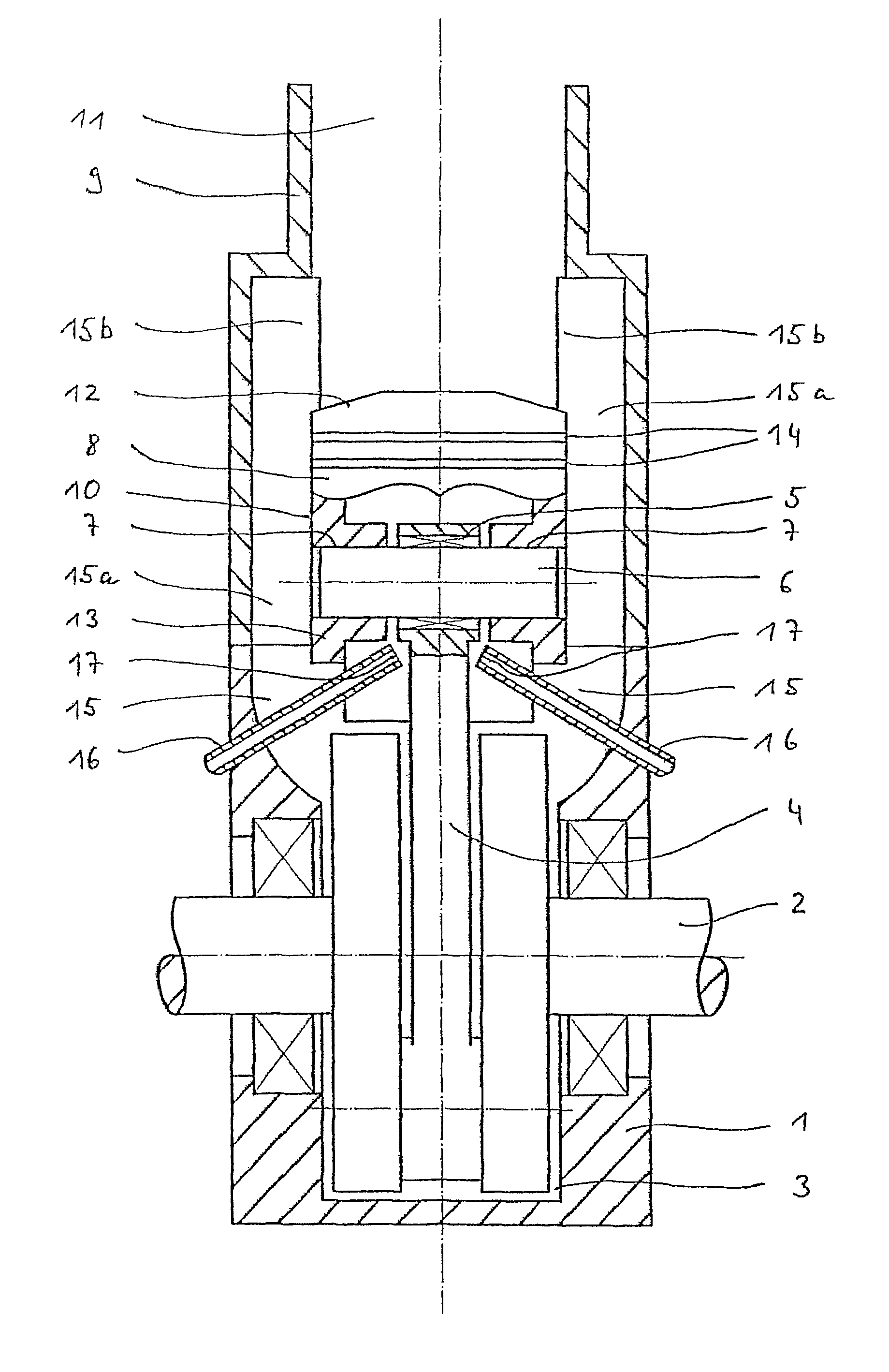

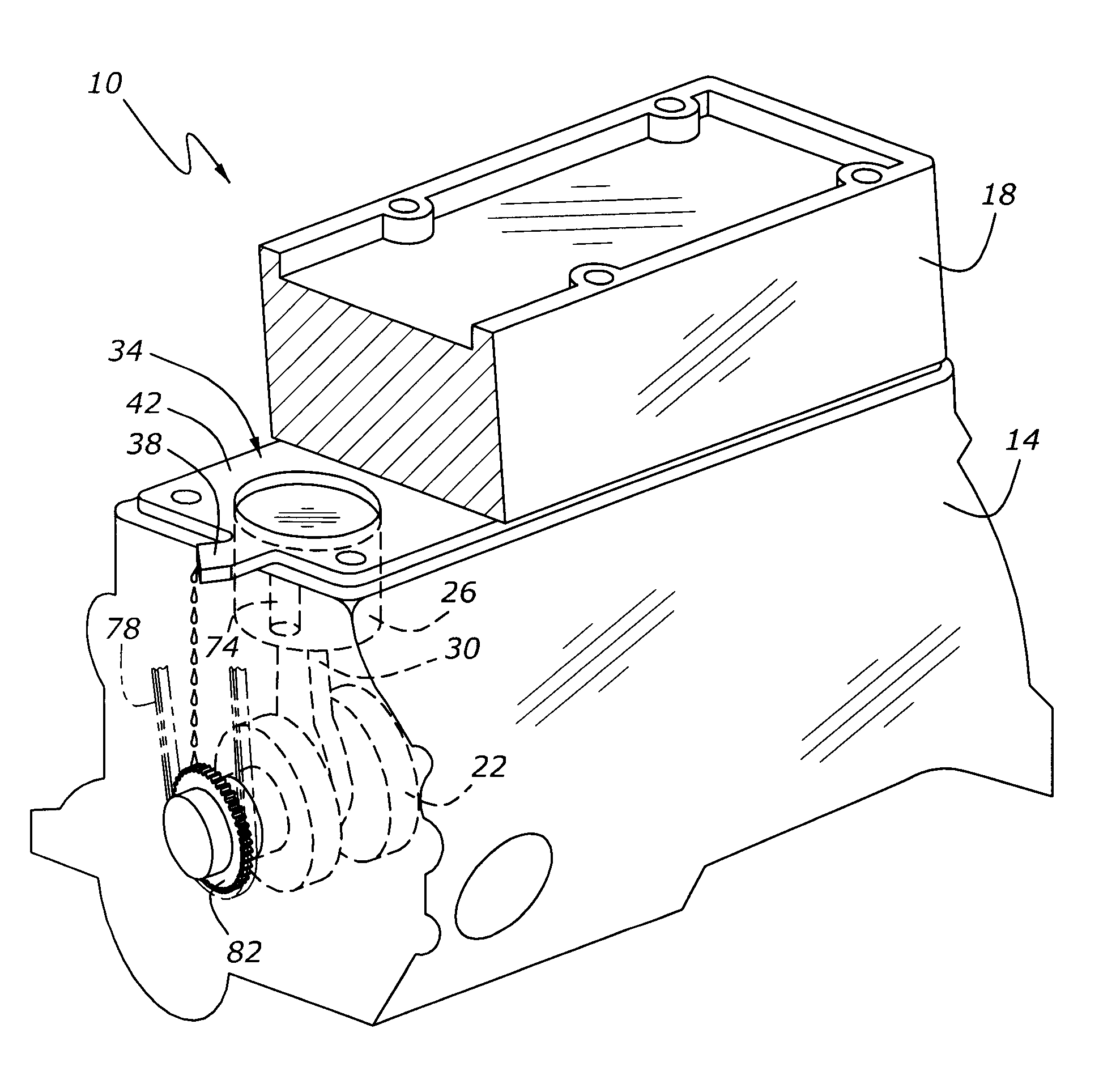

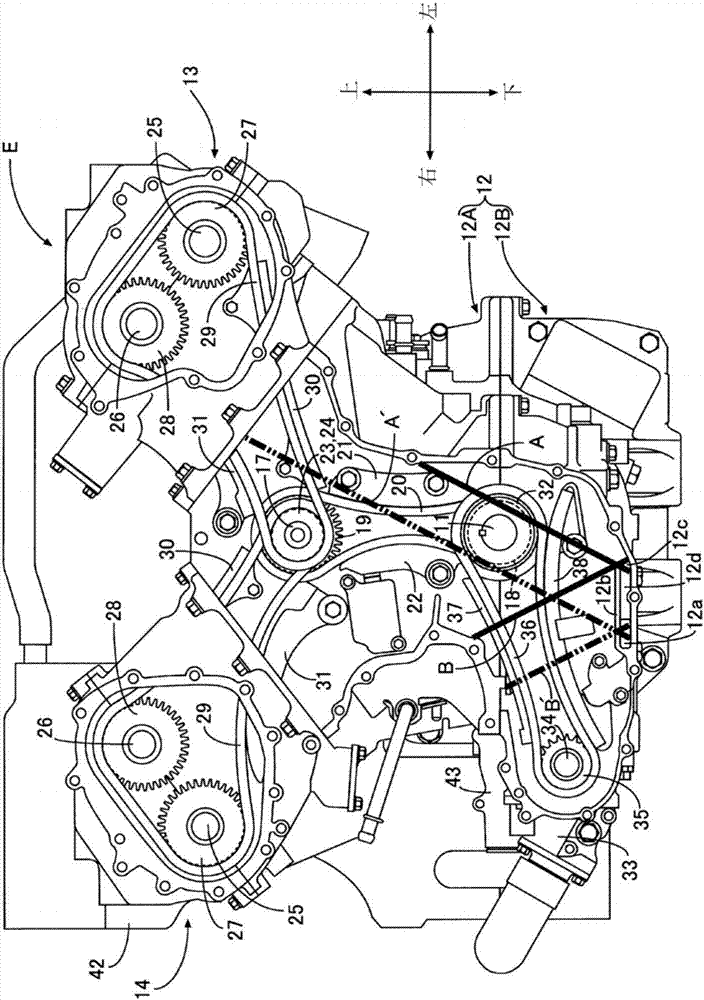

Valve operating mechanism of internal combustion engine

InactiveUS20050178350A1Solution to short lifeGuaranteed uptimeDrip lubricationLubrication of auxillariesDrive shaftEngineering

A valve operating mechanism of an internal combustion engine, comprises a drive cam rotatable with and eccentric to a drive shaft; a link arm having a circular opening in which the drive cam is rotatably received, so that rotation of drive cam about an axis of the drive shaft produces a swing movement of the link arm; a pair of swing cams swingably disposed on the drive shaft at both sides of the drive cam, the swing cams being connected through a movement transmission mechanism to the link arm to be swung when the link arm is subjected to the swing movement; a pair of swing arms respectively actuated by the swing cams for carrying out an open / close operation of a pair of engine valves; a pair of spring retainers respectively provided by the pair of engine valves; and a pair of valve springs respectively held by the spring retainers and biasing the engine valves in a close direction. A lubricating oil passage is formed in the drive cam. The oil passage has one end exposed to an oil feeding passage formed in the drive shaft and the other end exposed to a minute clearance defined between a cylindrical outer surface of the drive cam and a cylindrical inner surface of the circular opening of the link arm.

Owner:HITACHI LTD

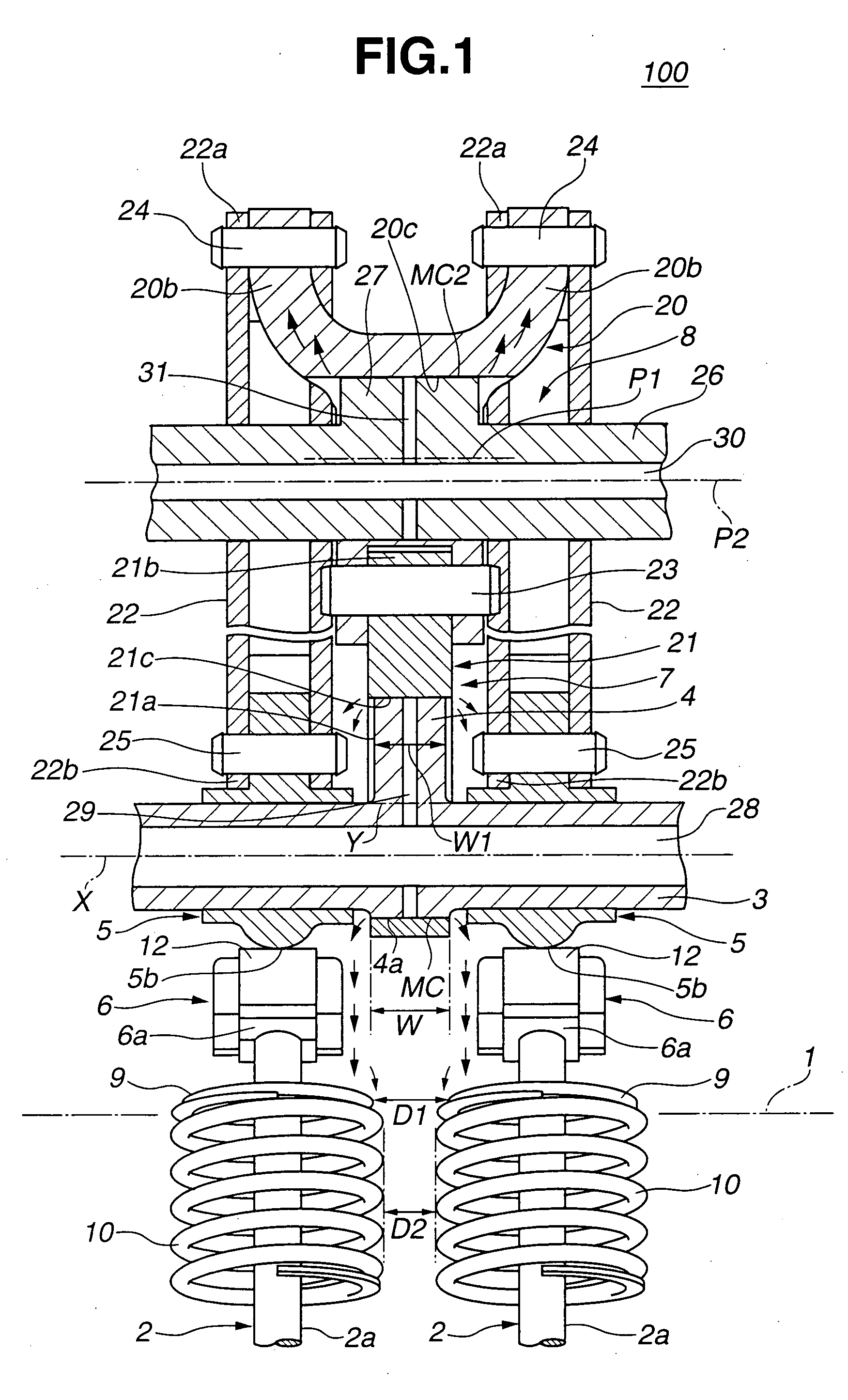

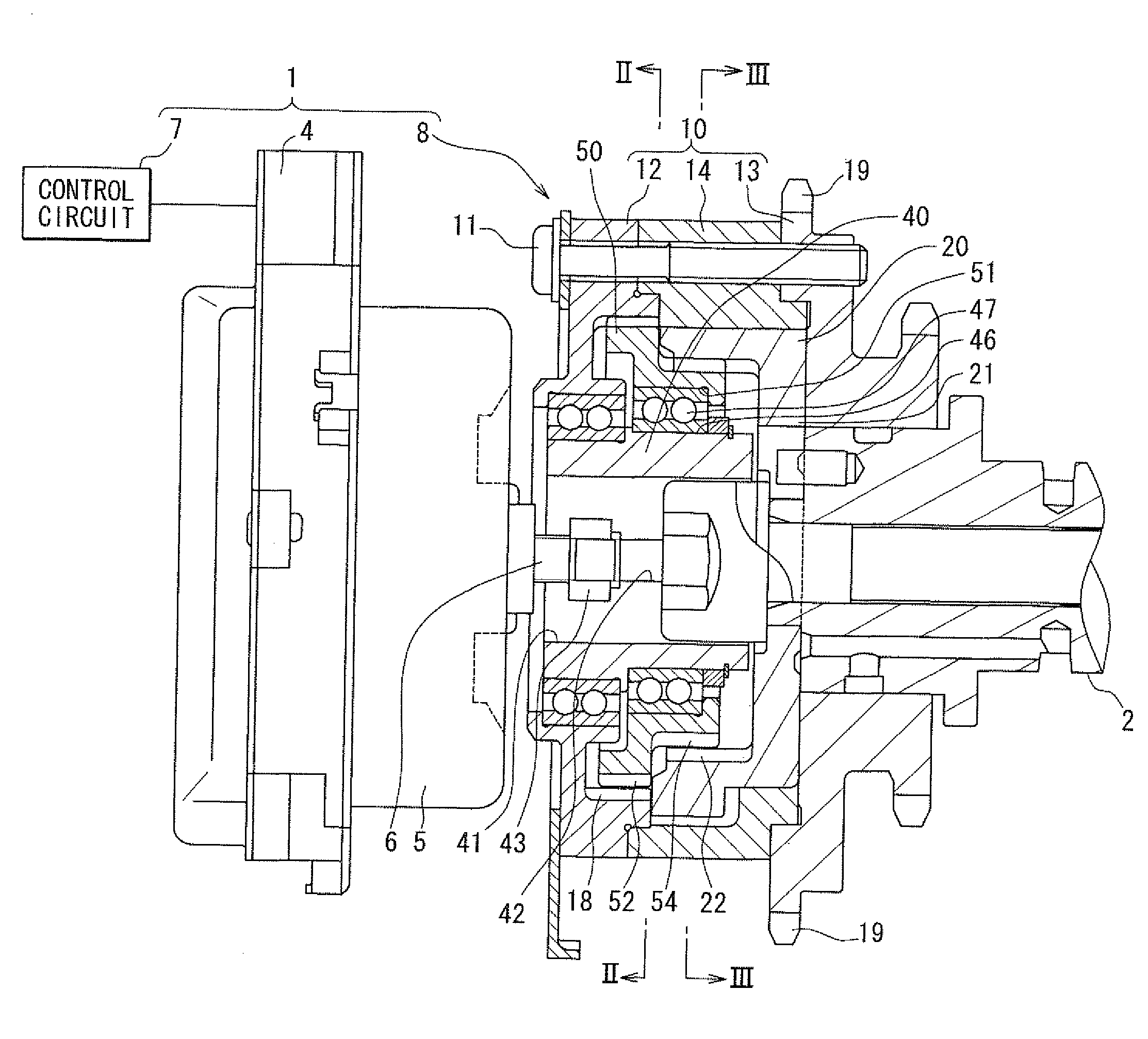

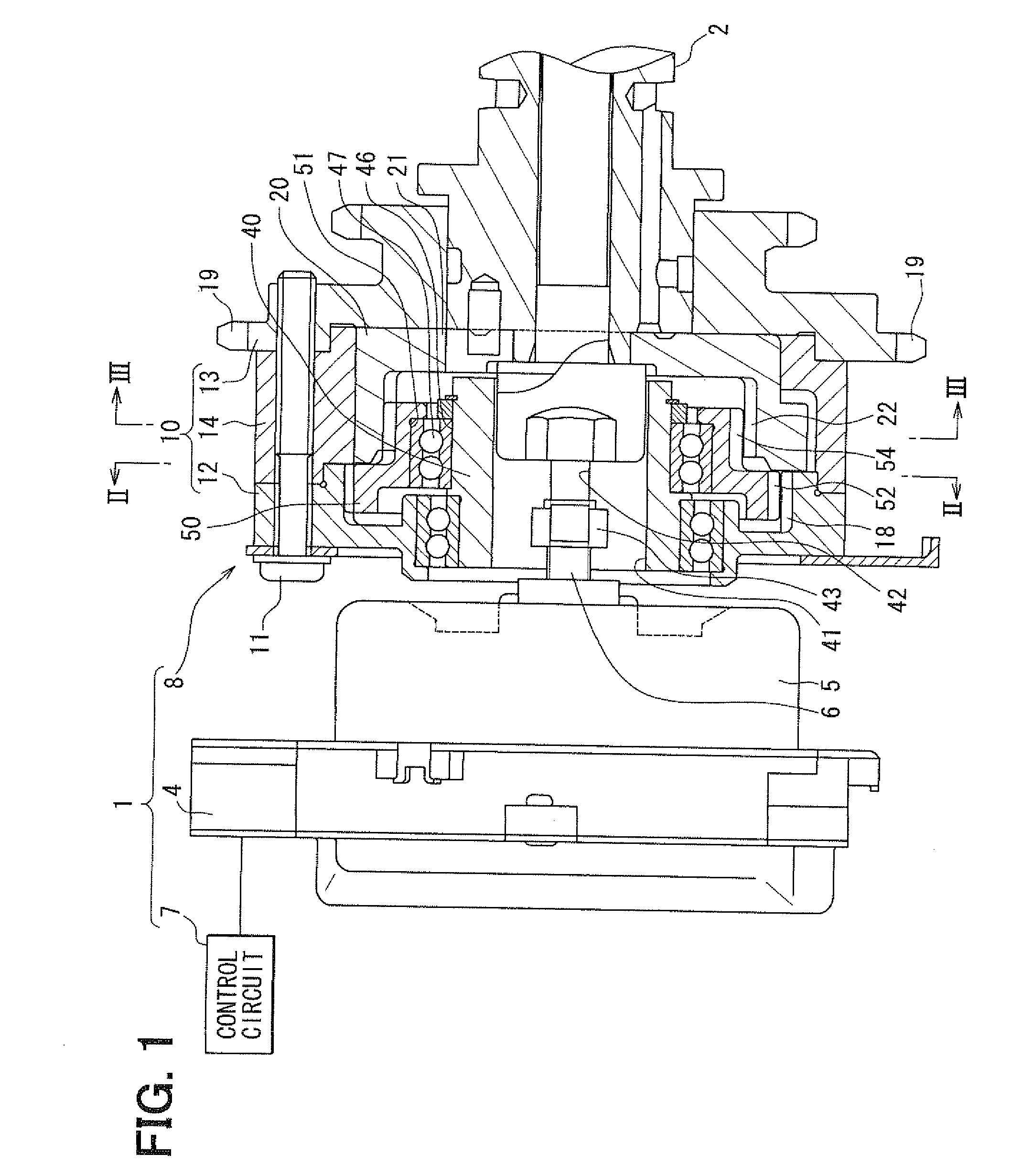

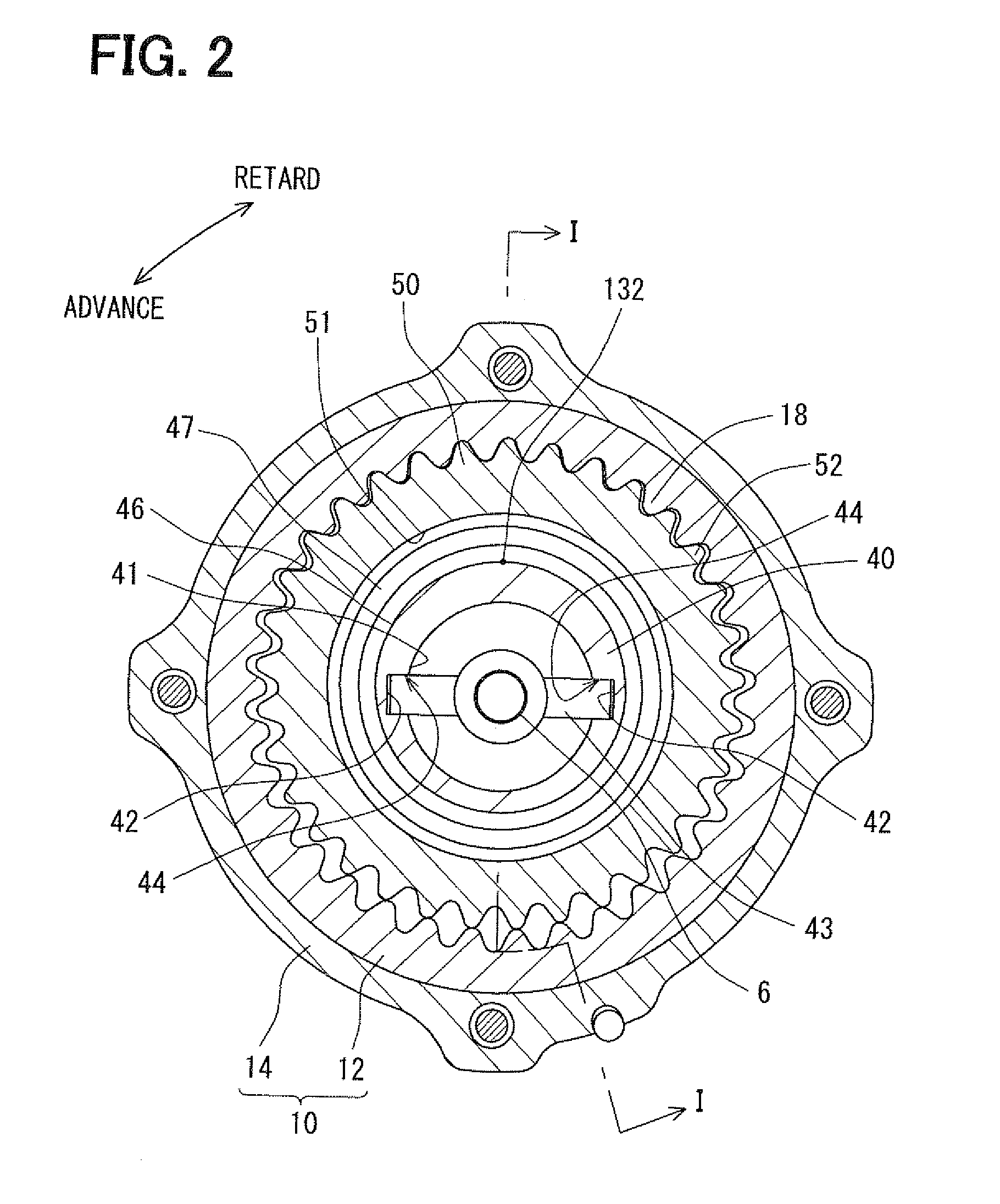

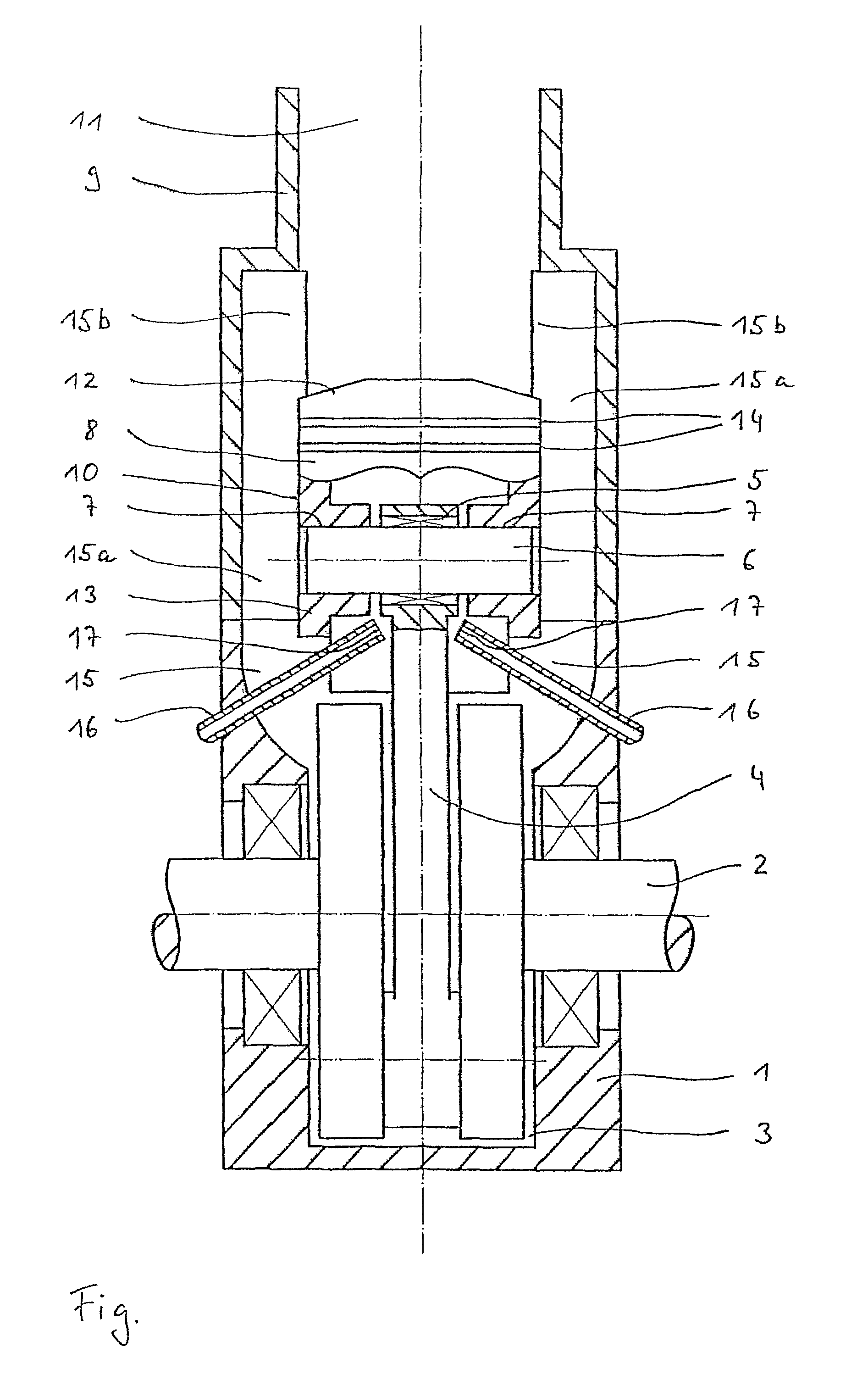

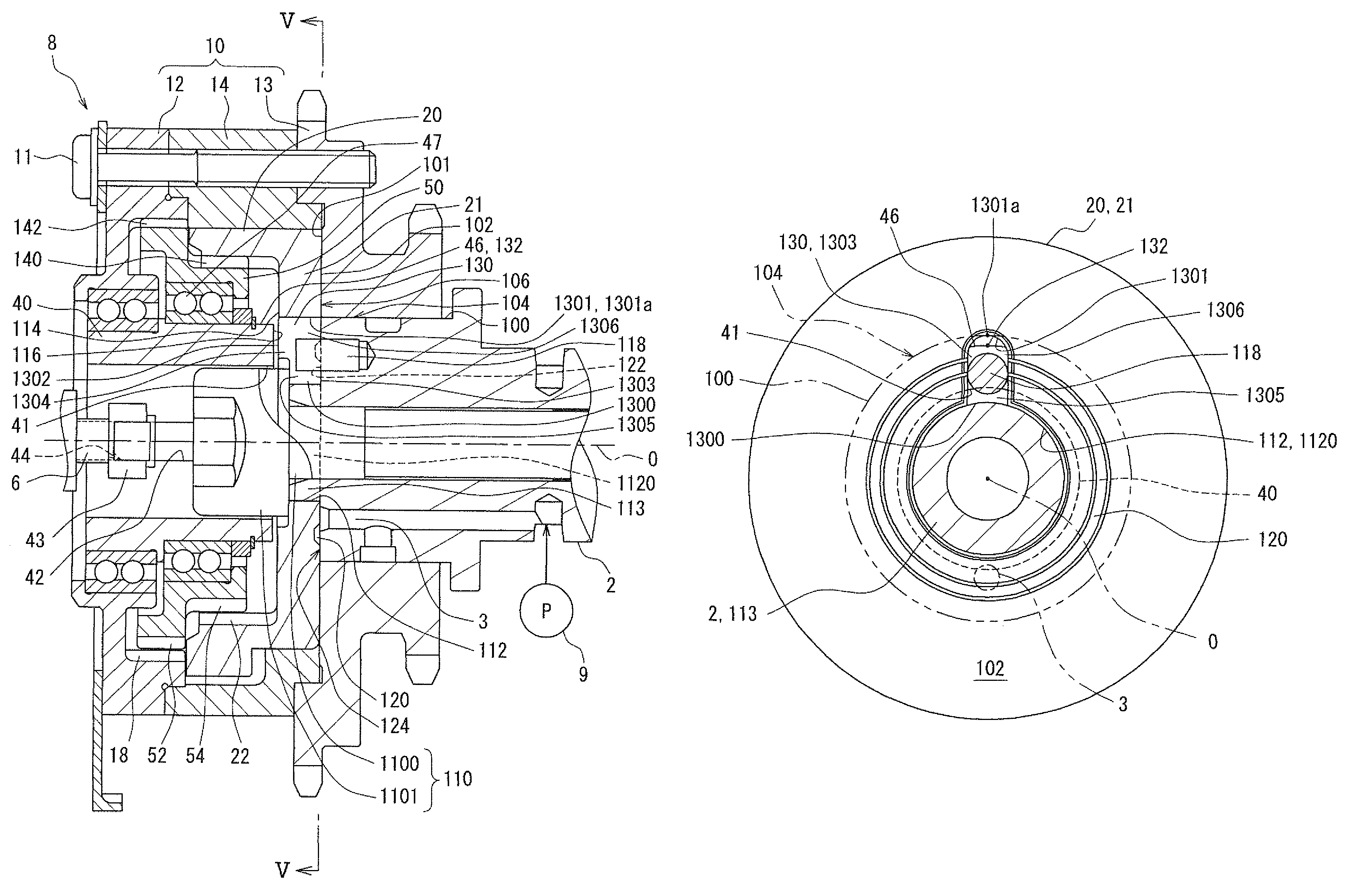

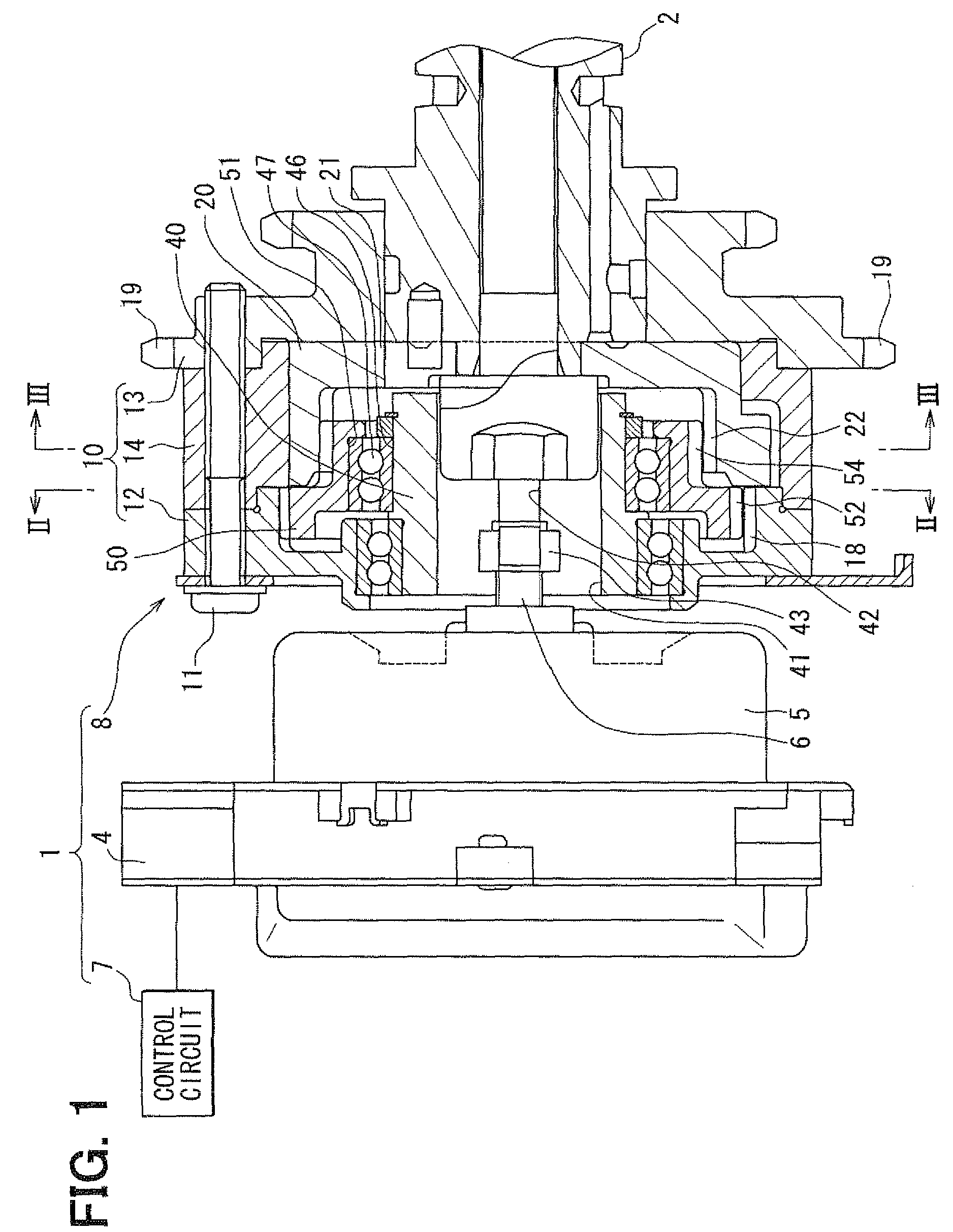

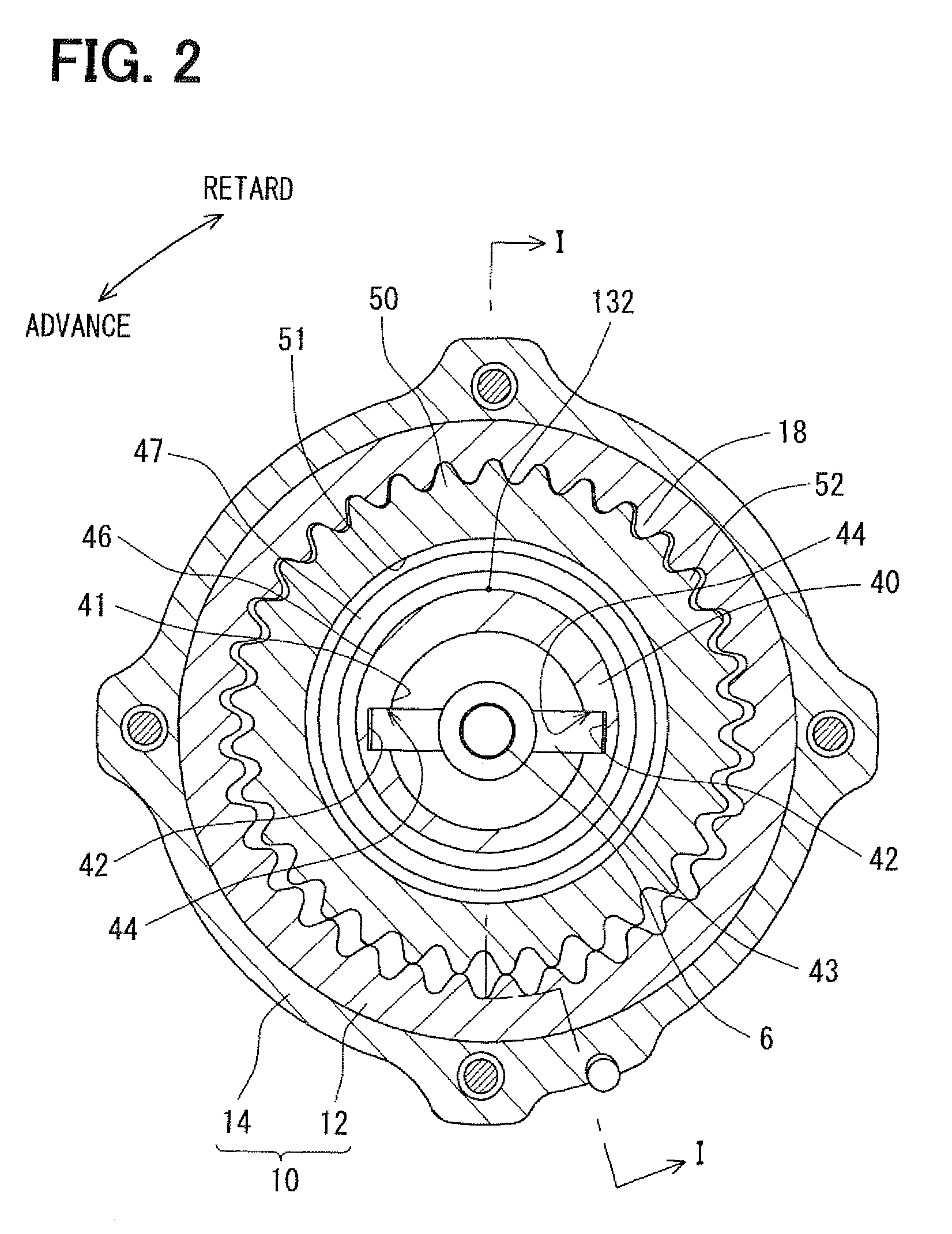

Valve timing controller

ActiveUS20100180845A1Improve the lubrication effectSimple lubrication structureDrip lubricationValve arrangementsGear wheelMotor shaft

A valve timing controller is provided with a driving rotor rotating along with a crankshaft, a driven rotor rotating along with a camshaft, a planetary gear performing a planetary motion to adjust a rotational phase between the camshaft and the crankshaft, a motor shaft rotating for controlling the planetary motion, a cylindrical planetary carrier supporting the planetary gear and being connected with the control shaft so that the planetary gear performs the planetary motion, and a lubricating mechanism. The lubricating mechanism includes an introducing port which opens on a side surface of the second rotor axially confronting the planetary carrier. The introducing port extends across a supporting outer surface and a connecting inner surface. The lubricant is introduced into an interior of the first rotor through the introducing port.

Owner:DENSO CORP

Engine water pump structure

A water pump includes a pump body and a pump cover. An impeller is housed in a pump chamber defined by the pump body and pump cover. The impeller is attached to one end of a hollow pump shaft. The pump shaft is engaged with a driving section at its other end. An intermediate part of the pump shaft is supported by a shaft support section, in the form of a cylindrical section, of the pump body. The shaft support section is longer than a diameter of the pump shaft. The shaft support section is lubricated via an oil groove. One end of the shaft support section is brought into contact with a flange of the pump shaft via a washer. The flange is integrally formed on the pump shaft by a beading process.

Owner:HONDA MOTOR CO LTD

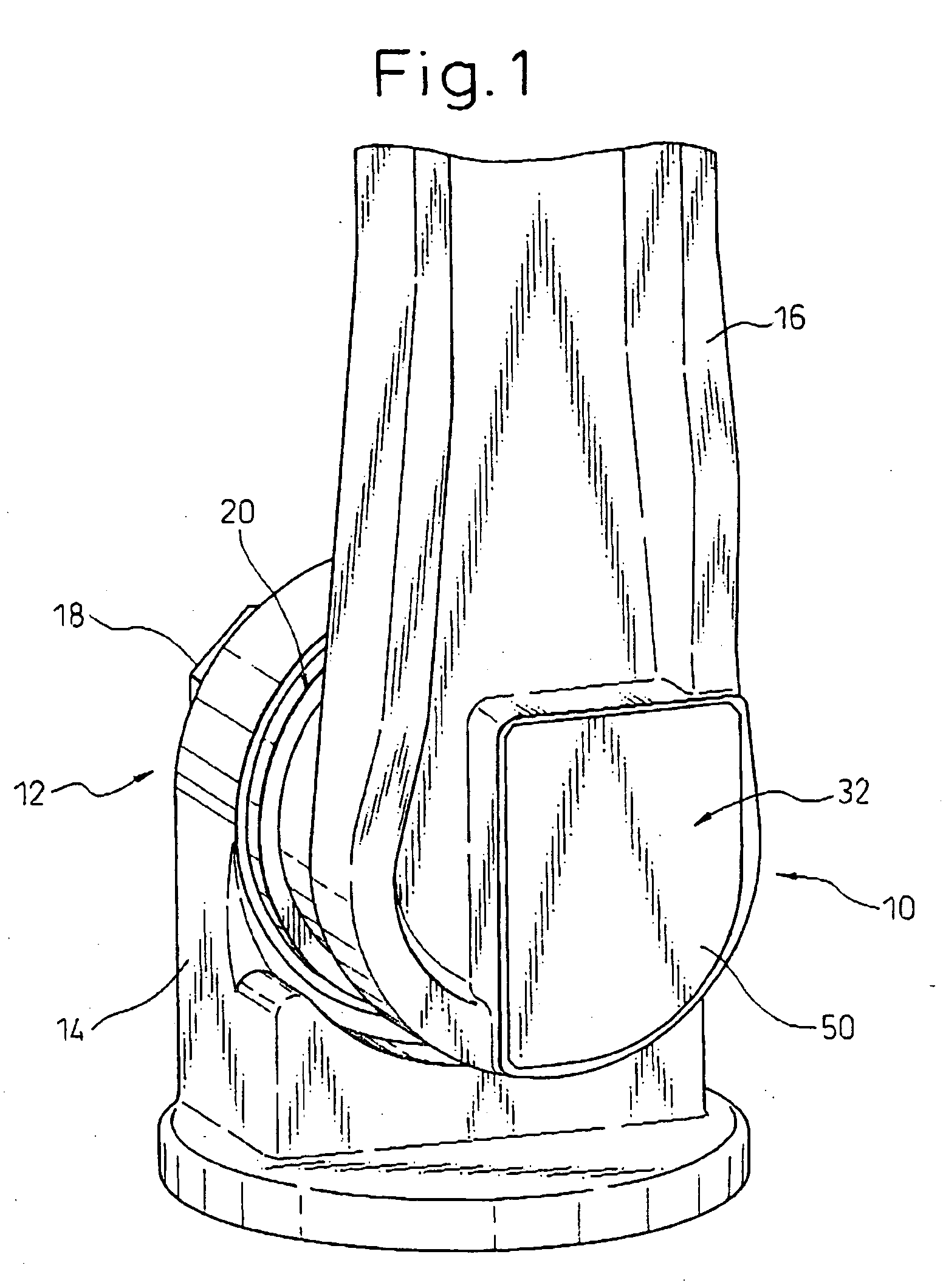

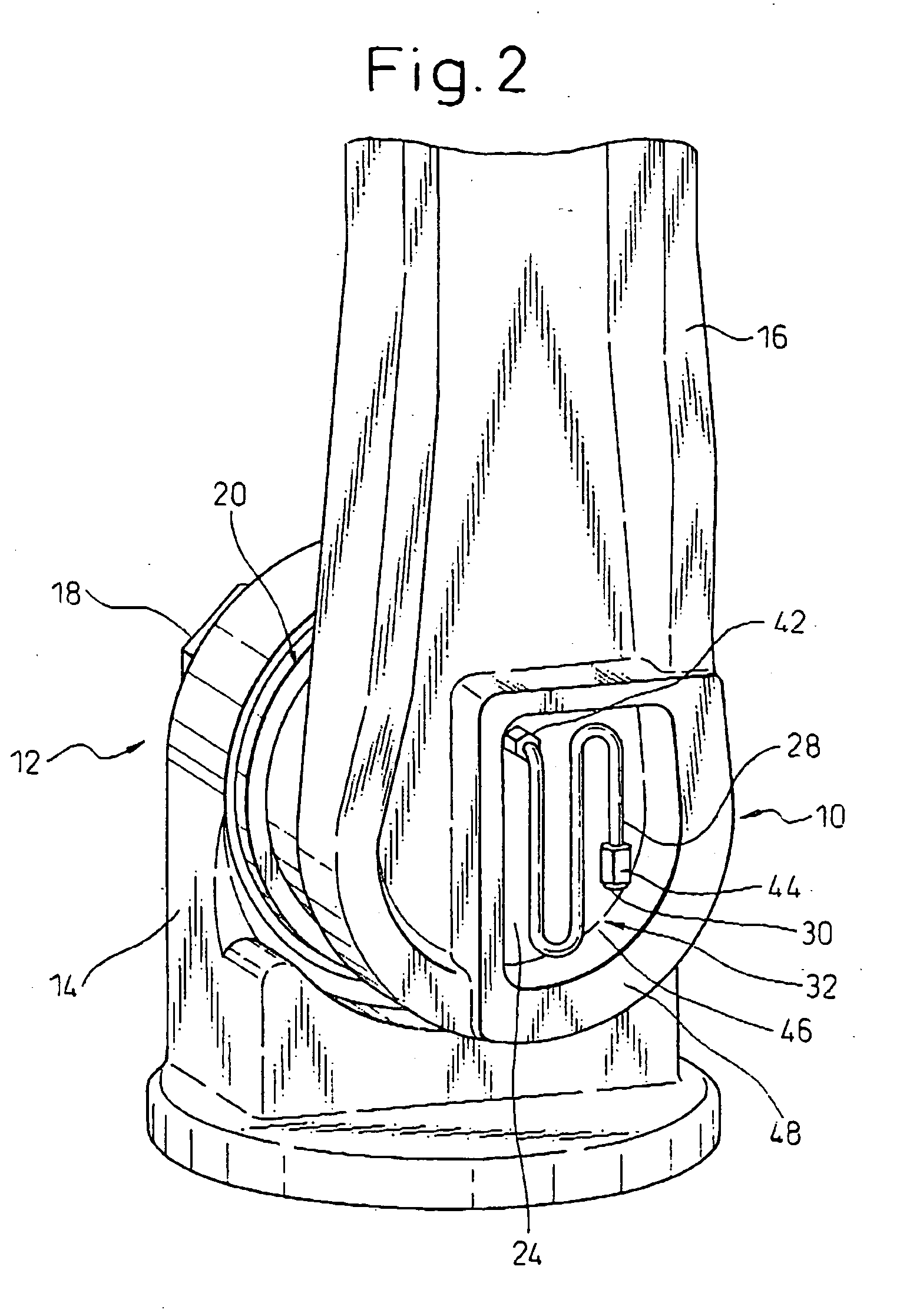

Lubricant draining device

InactiveUS20050133305A1Simplify and eliminate workDrip lubricationDrip or splash lubricationInterior spaceInjection molding machine

A lubricant draining device for draining a lubricant from a closed mechanical section provided in a machine structure such as a robot, a machine tool and an injection molding machine. The lubricant draining device includes a wall defining the mechanical section, the wall including a drain port communicated with an interior space of the mechanical section while permitting a lubricant to flow therethrough; a tube connected at a proximal end thereof to the drain port and permitting a lubricant to flow therethrough; a blocking member blocking a flow of a lubricant through the tube in a releasable manner; and a retaining section retaining the tube at a location adjacent to the wall with the tube being kept connecting with the drain port. The retaining section may include a chamber, provided on the wall, for accommodating the tube in its entirety with the tube being removable from the chamber. The chamber may be provided with a detachable cover.

Owner:FANUC LTD

Aircraft engine accessory drive air film riding bulkhead seal

The present invention provides a lubrication system for supplying lubricant between a first housing and a second housing, where the first and second housings each comprising air and lubricant. In one exemplary embodiment, the system includes a lubricant supply tube, an output shaft, and a seal assembly. The lubricant supply tube extends at least partially through the second housing and is configured to receive a supply of lubricant from the first housing. The output shaft is rotationally mounted within the second housing. The seal assembly is mounted on the output shaft and disposed within the second housing. The seal assembly is configured to pump at least a portion of the air out of the second housing.

Owner:HONEYWELL INT INC

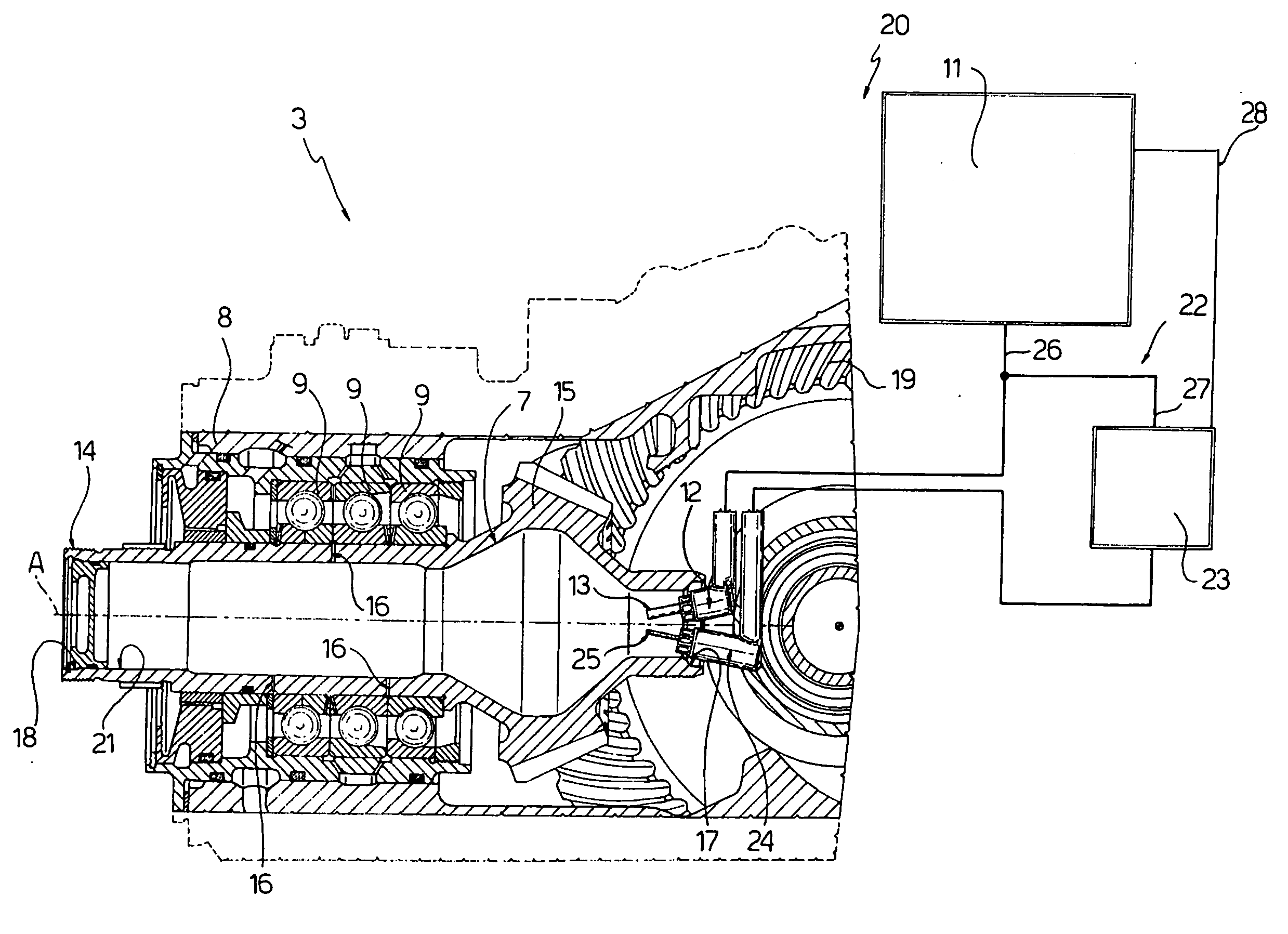

Helicopter with an auxiliary lubricating circuit

ActiveUS7651049B2Meet the requirementsDrip lubricationDrip or splash lubricationAuxiliary memoryMechanical engineering

Owner:LEONARDO FINMECCANICA SPA

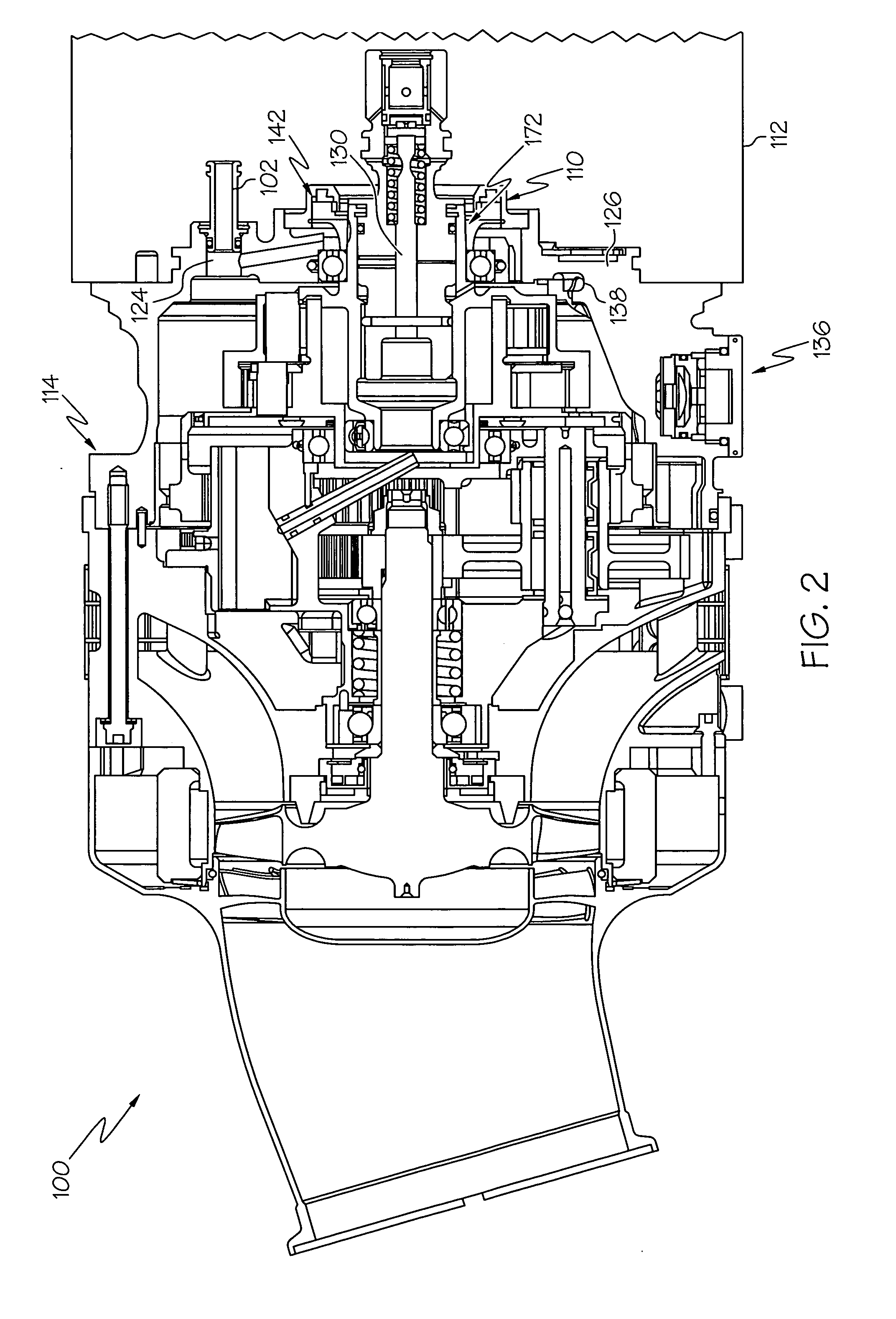

Secondary lubrication system with injectable additive

ActiveUS8602166B2Improve featuresEasy to operateDrip lubricationDrip or splash lubricationEngineeringLubrication

A lubrication system includes an additive and a delivery system. During normal operational conditions, the lubricating oil circulating in the transmission system is collected and contained in a secondary oil reservoir to retain a quantity of the lubricating oil for use in an oil-out condition. When an oil-out condition is detected, the additive is injected and mixed with the collected lubricating oil in the secondary oil reservoir or dispersed directly into a power transmission gearbox housing to enhance the characteristics of the lubricating oil and increases the operational time period of the power transmission gearbox during an oil-out condition.

Owner:SIKORSKY AIRCRAFT CORP

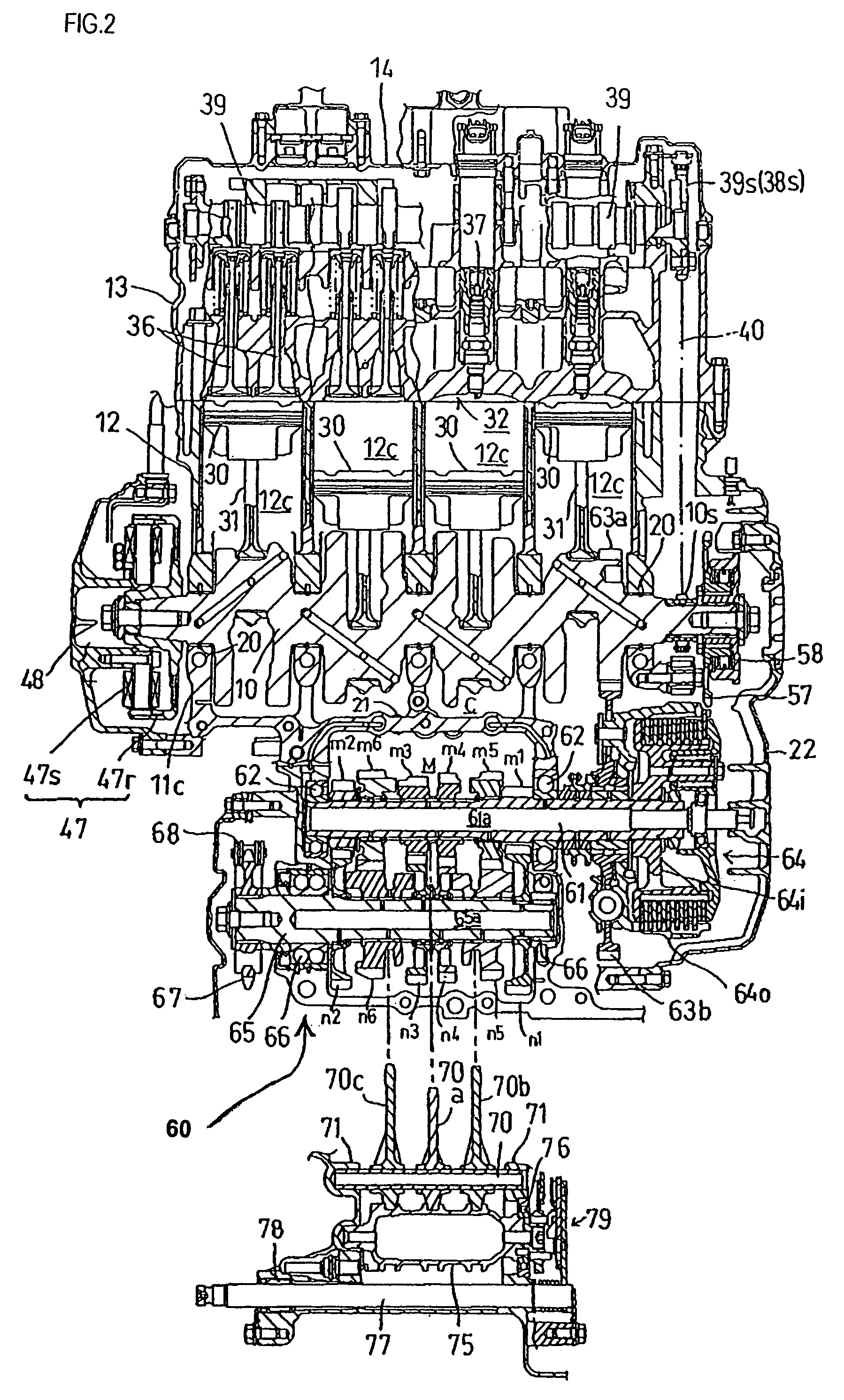

Oil supply for an internal combustion engine

InactiveUS7753024B2Increase supplyReliable functionDrip lubricationLiquid coolingReciprocating motionInternal combustion engine

The invention relates to an oil supply for an internal combustion engine, comprising an oil supply device for the supply of oil to a piston, reciprocating in a cylinder. The oil supply device is embodied such that at least at a point at which the piston is in the region of bottom dead centre, oil is introduced directly into a region below the piston, by means of the oil supply device, in particular, beneath the piston crown and within the piston skirt. The oil supply device thus comprises at least one tube element, extending into a region beneath the piston crown. The tube element terminates as close as possible to a gudgeon pin, when the piston is at bottom dead center. A targeted lubrication of the mechanically and thermally highly loaded gudgeon pin can thus be guaranteed. It is also possible by means of the oil supply to supply transfer ports of a two-stroke engine with oil, counteracting a tendency to coke up.

Owner:WACKER NEUSON SE

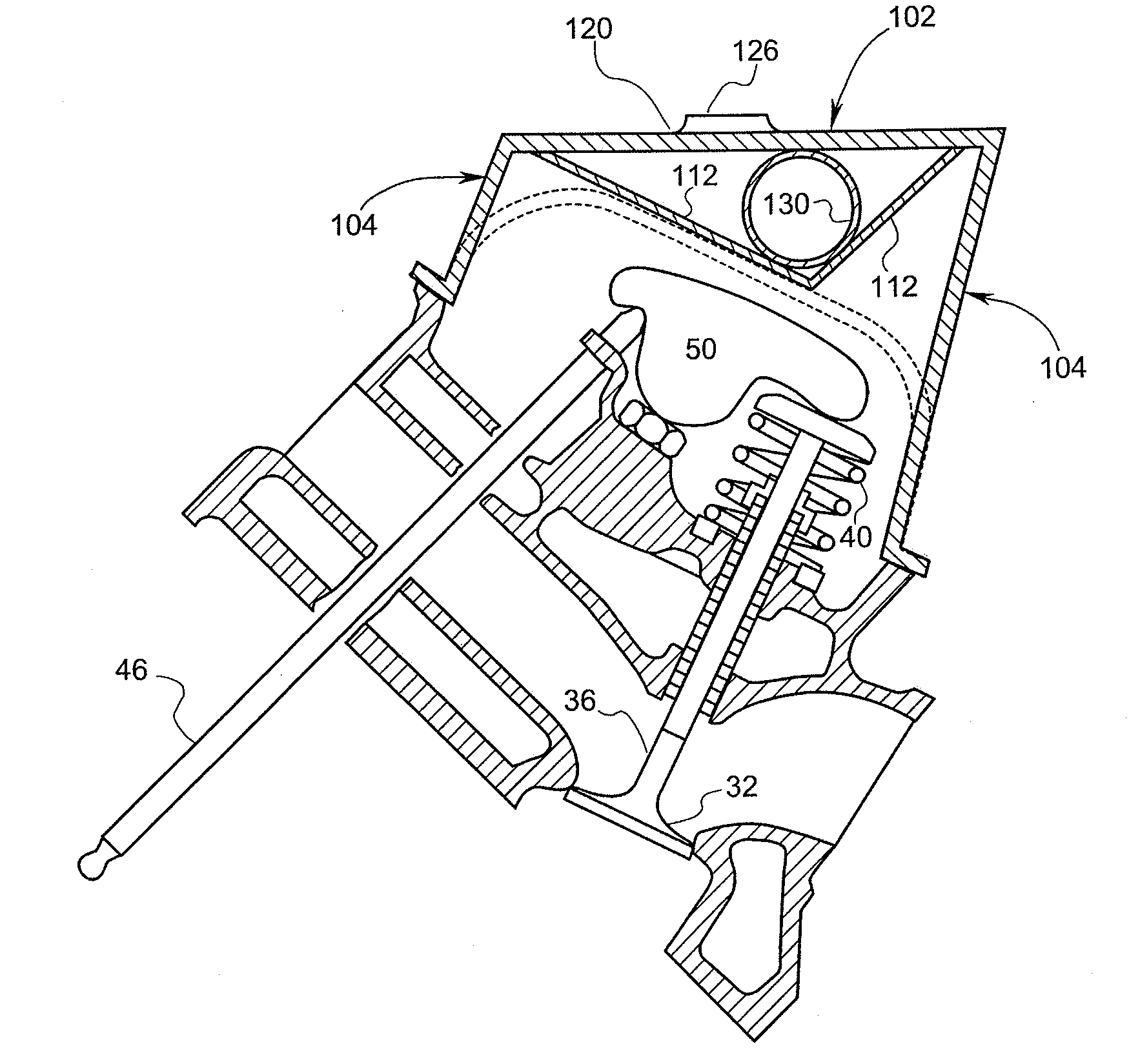

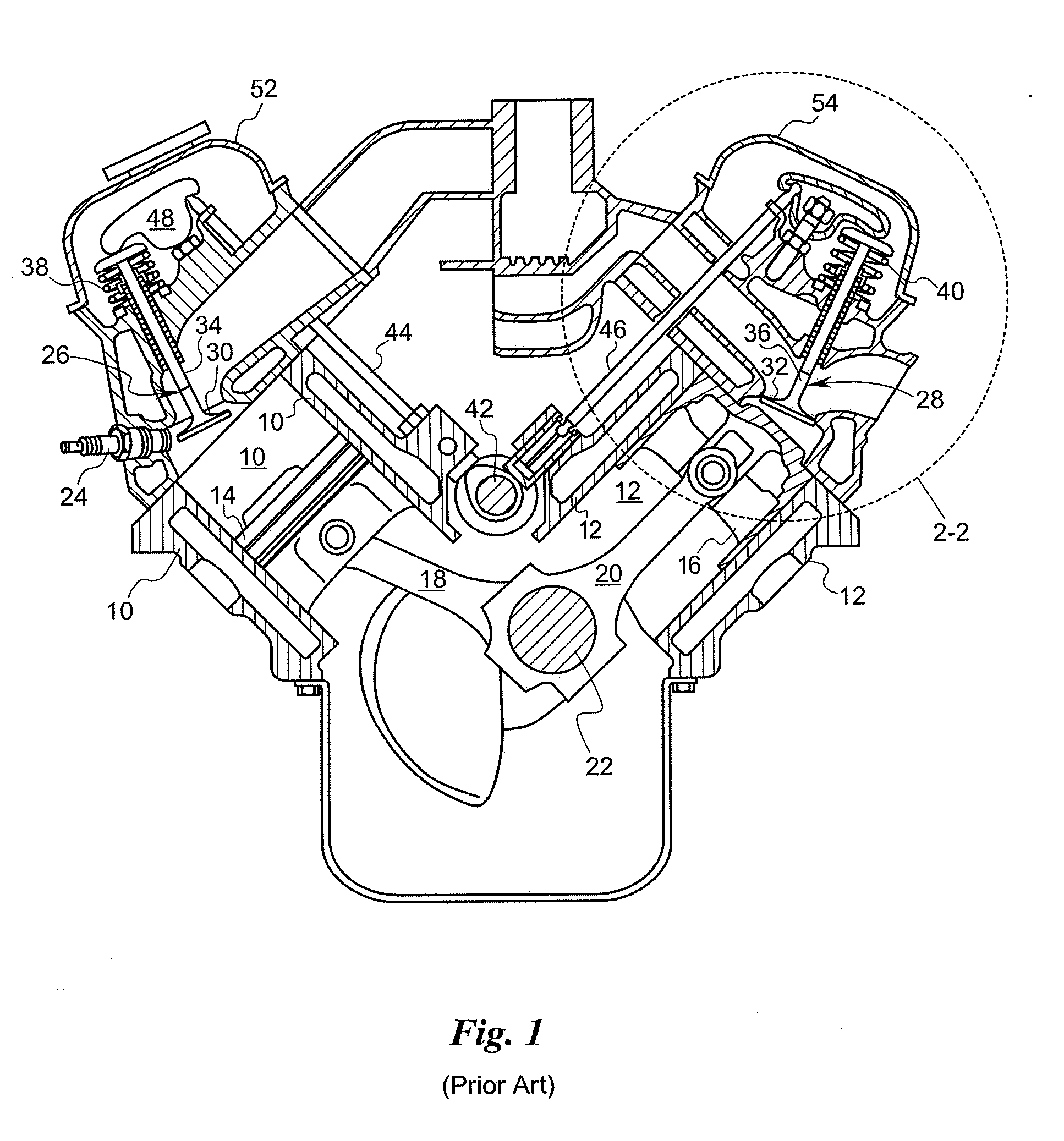

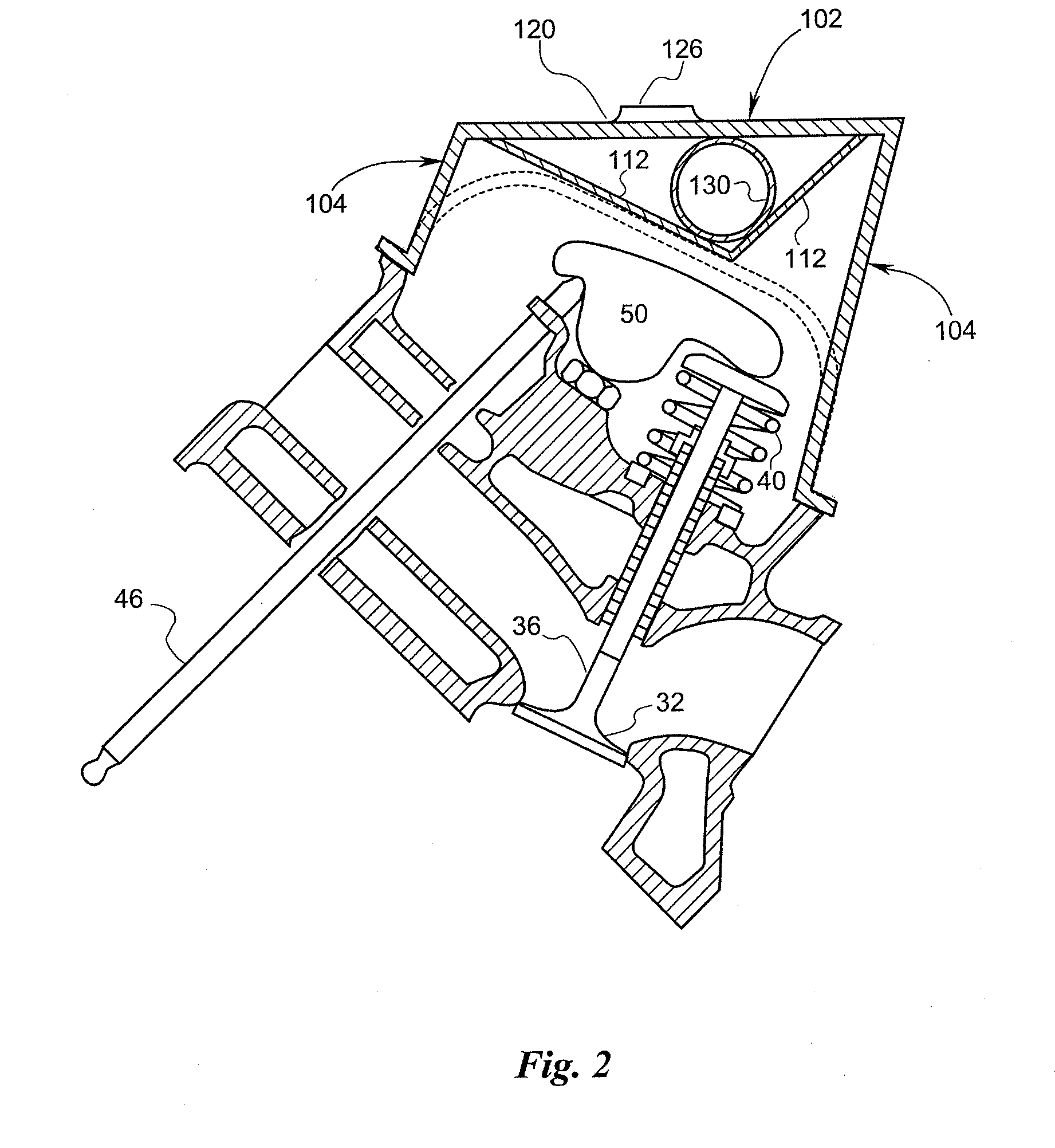

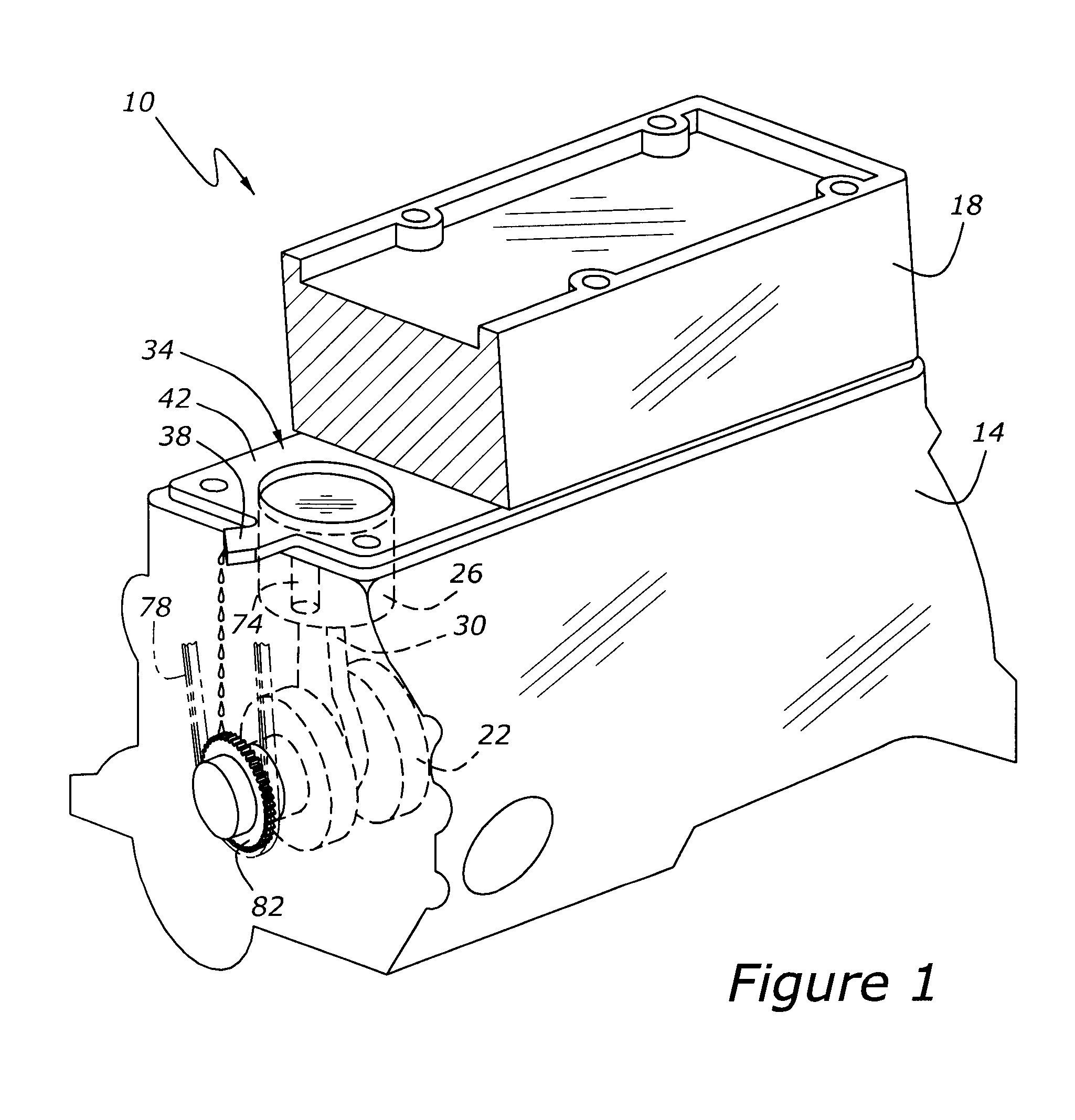

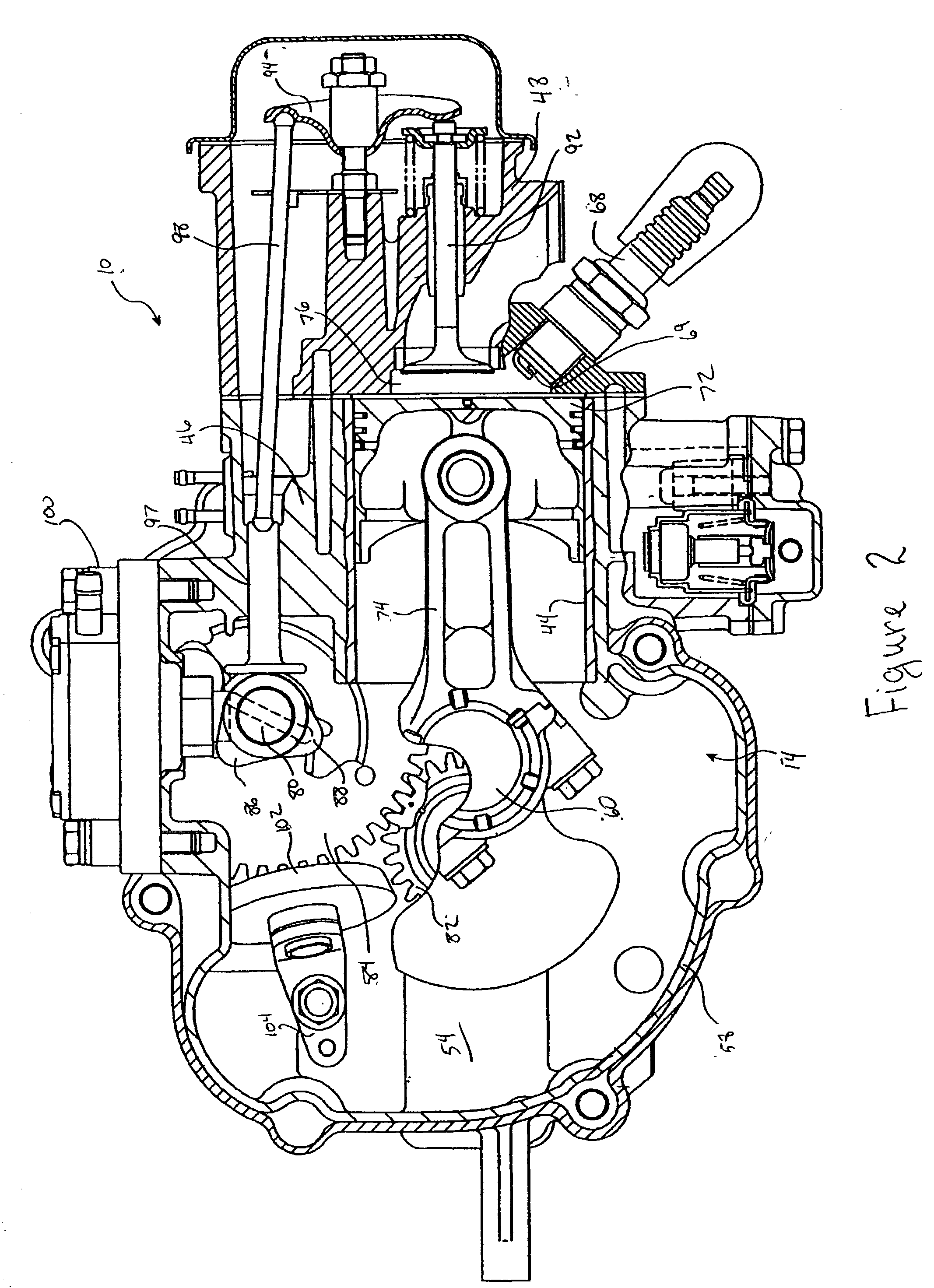

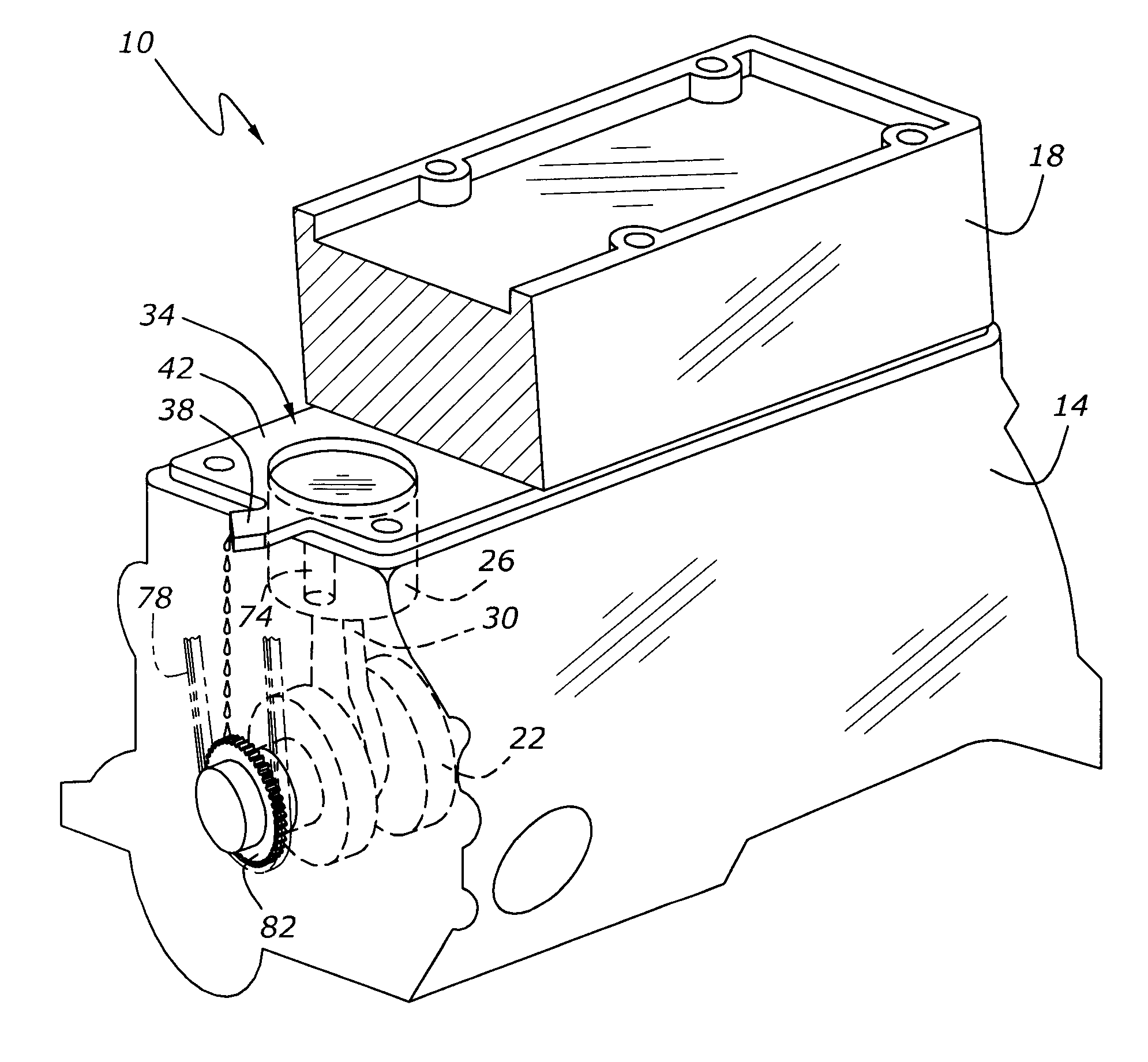

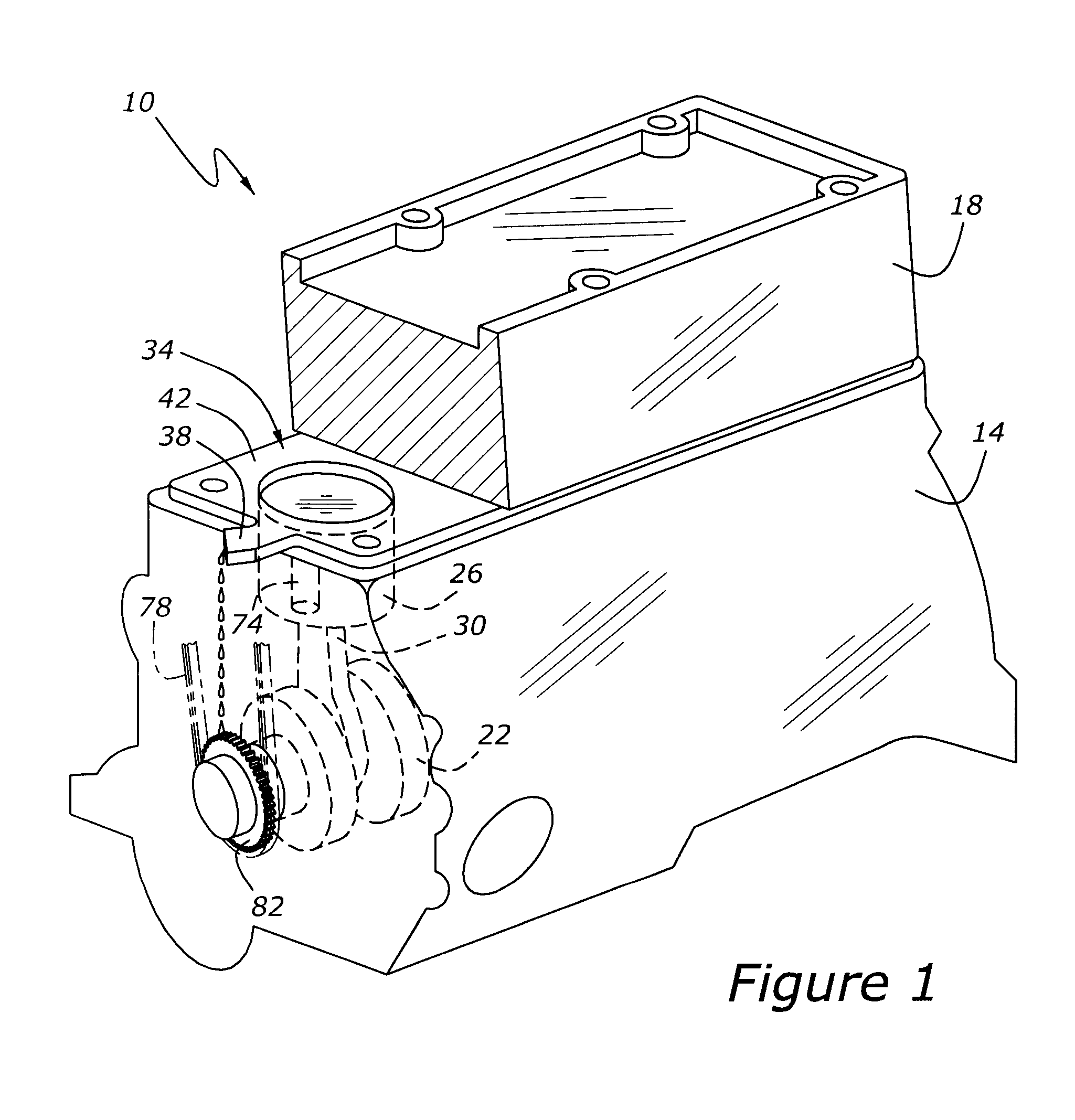

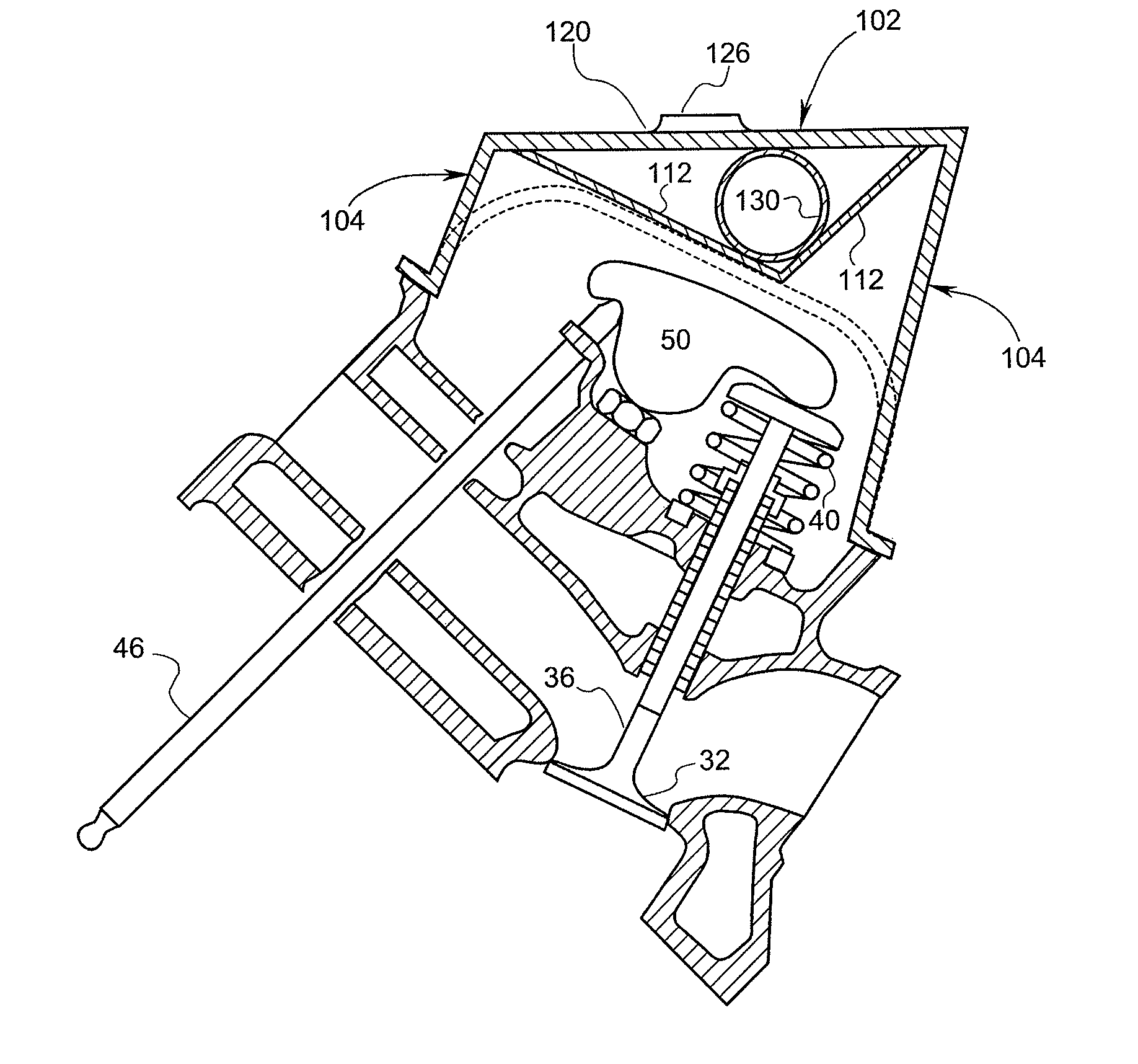

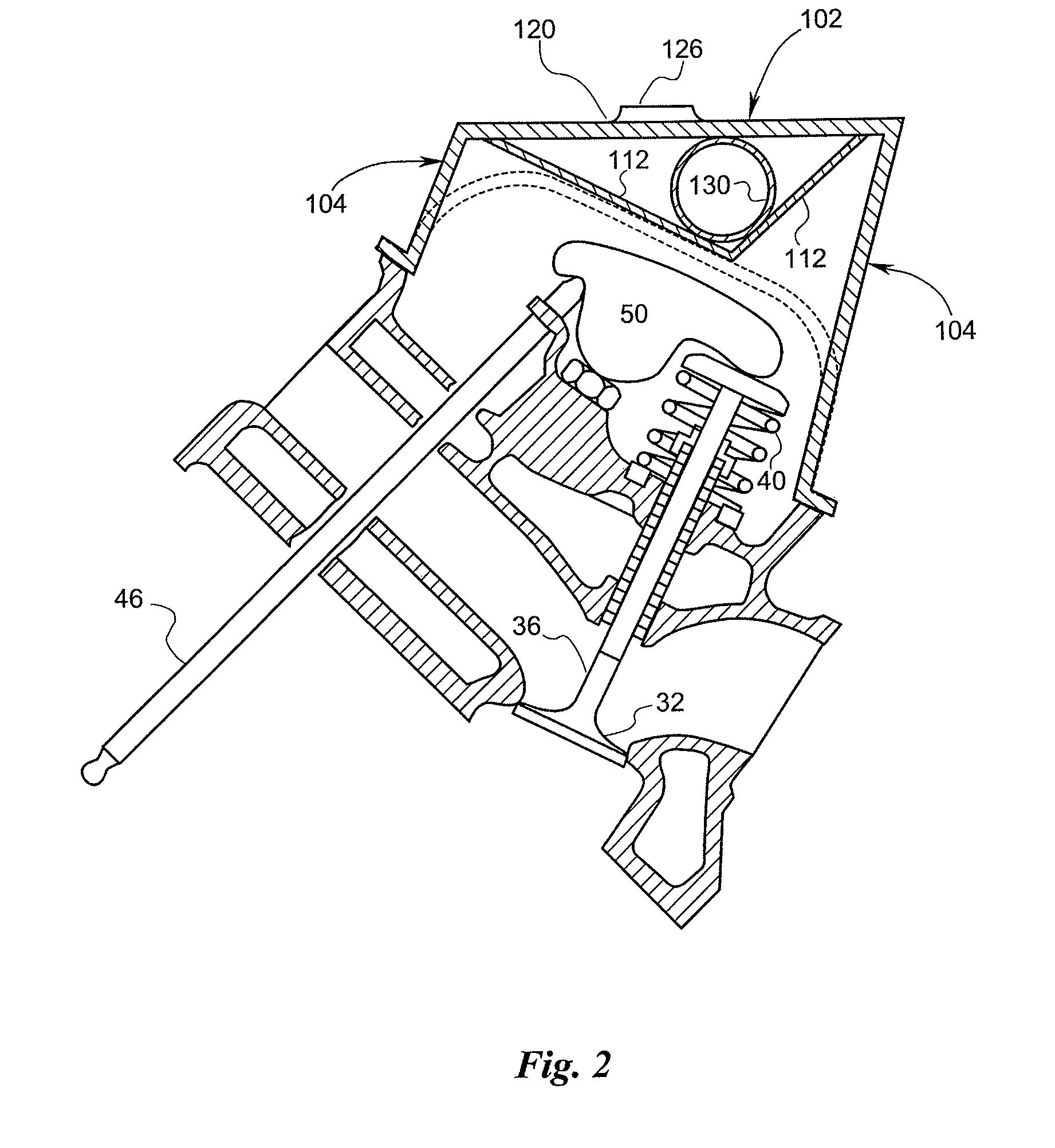

Valve cover housing for internal combustion engines

A valve cover housing for internal combustion engines. In one embodiment, the valve cover housing includes a conduit for passing a coolant fluid near the valvetrain, and in another embodiment, the housing includes an internal protuberance or other structure that promotes the dripping of oil or another lubricant onto a selected region or component of the valvetrain, such as the valve springs.

Owner:KOOL KOVER

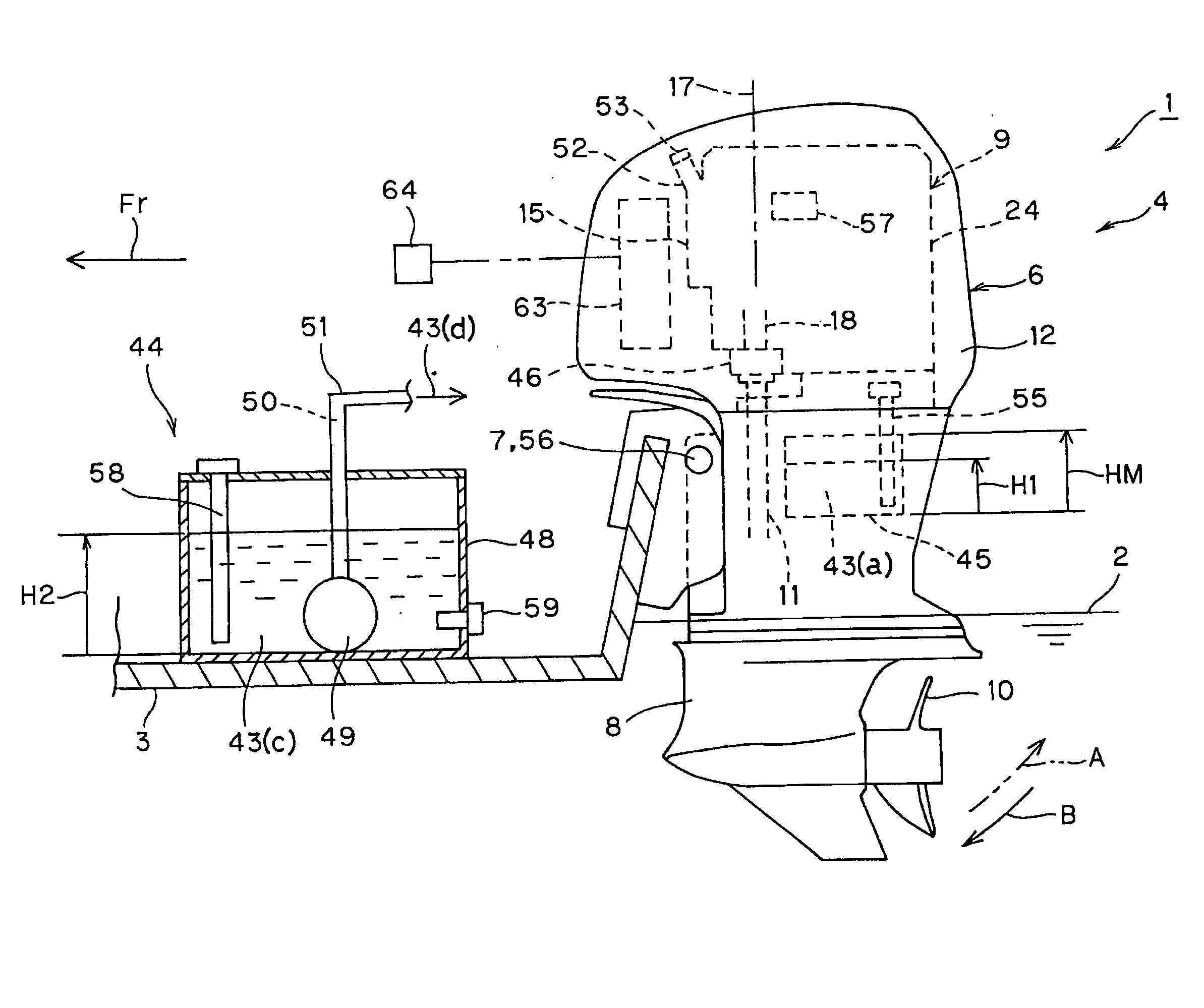

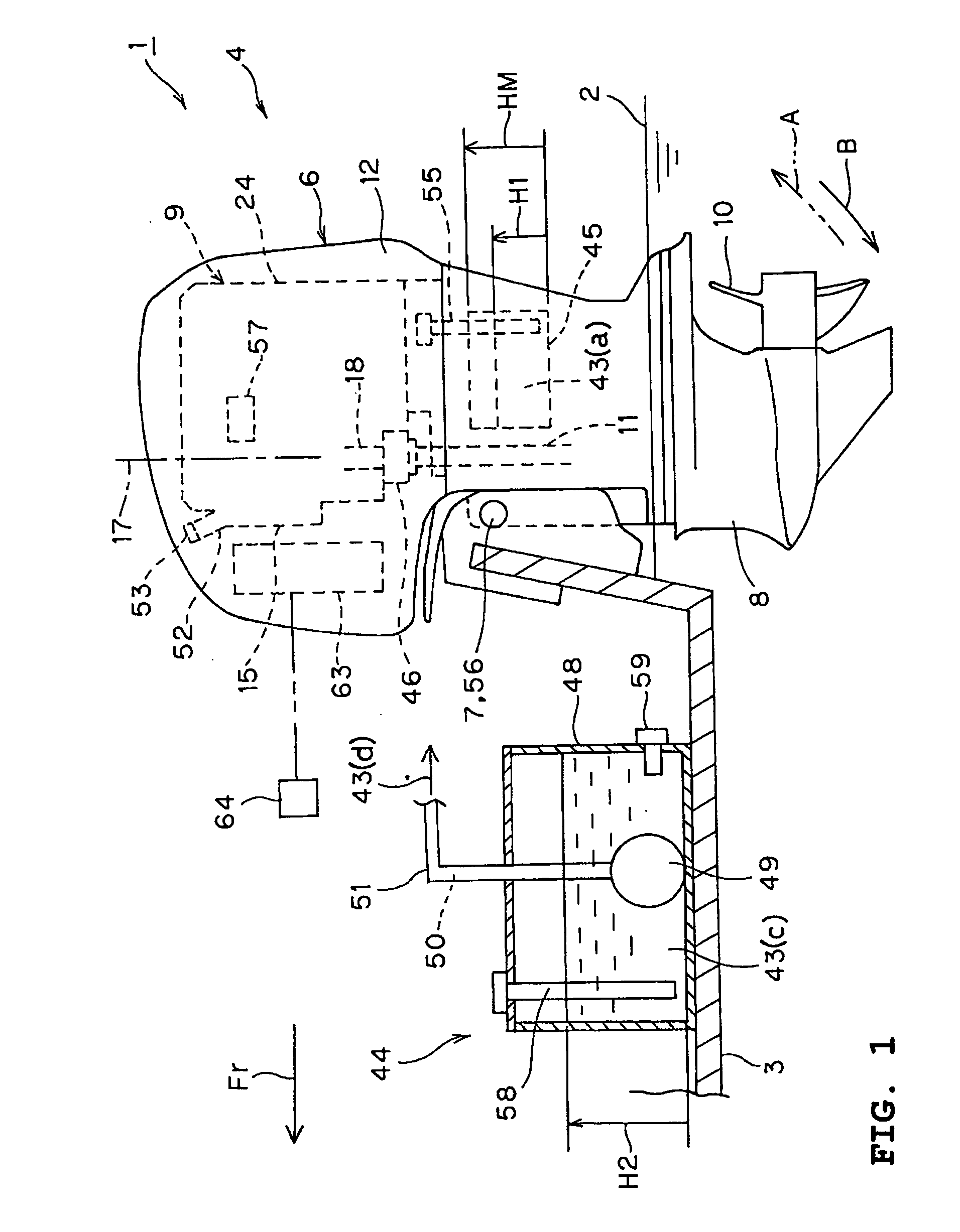

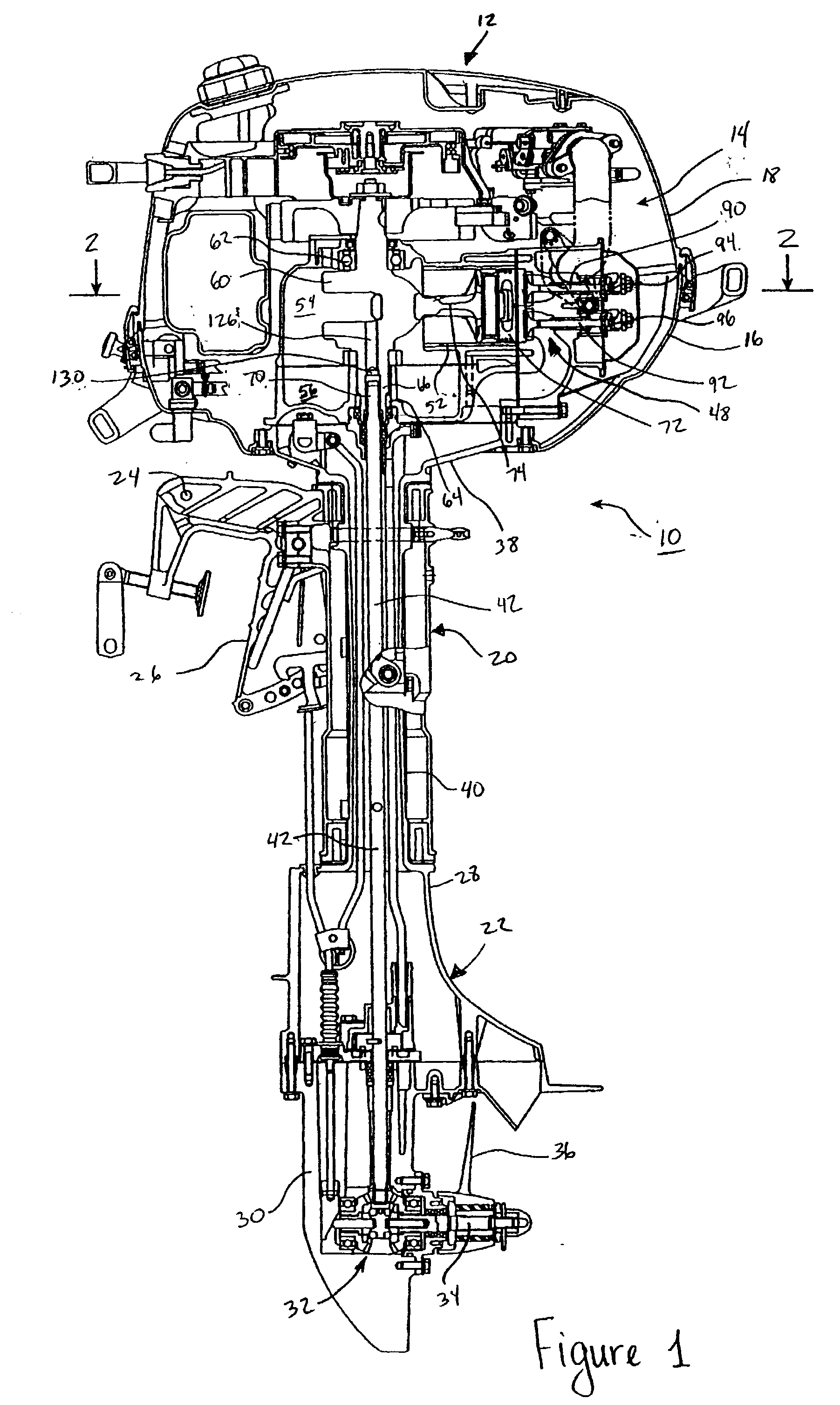

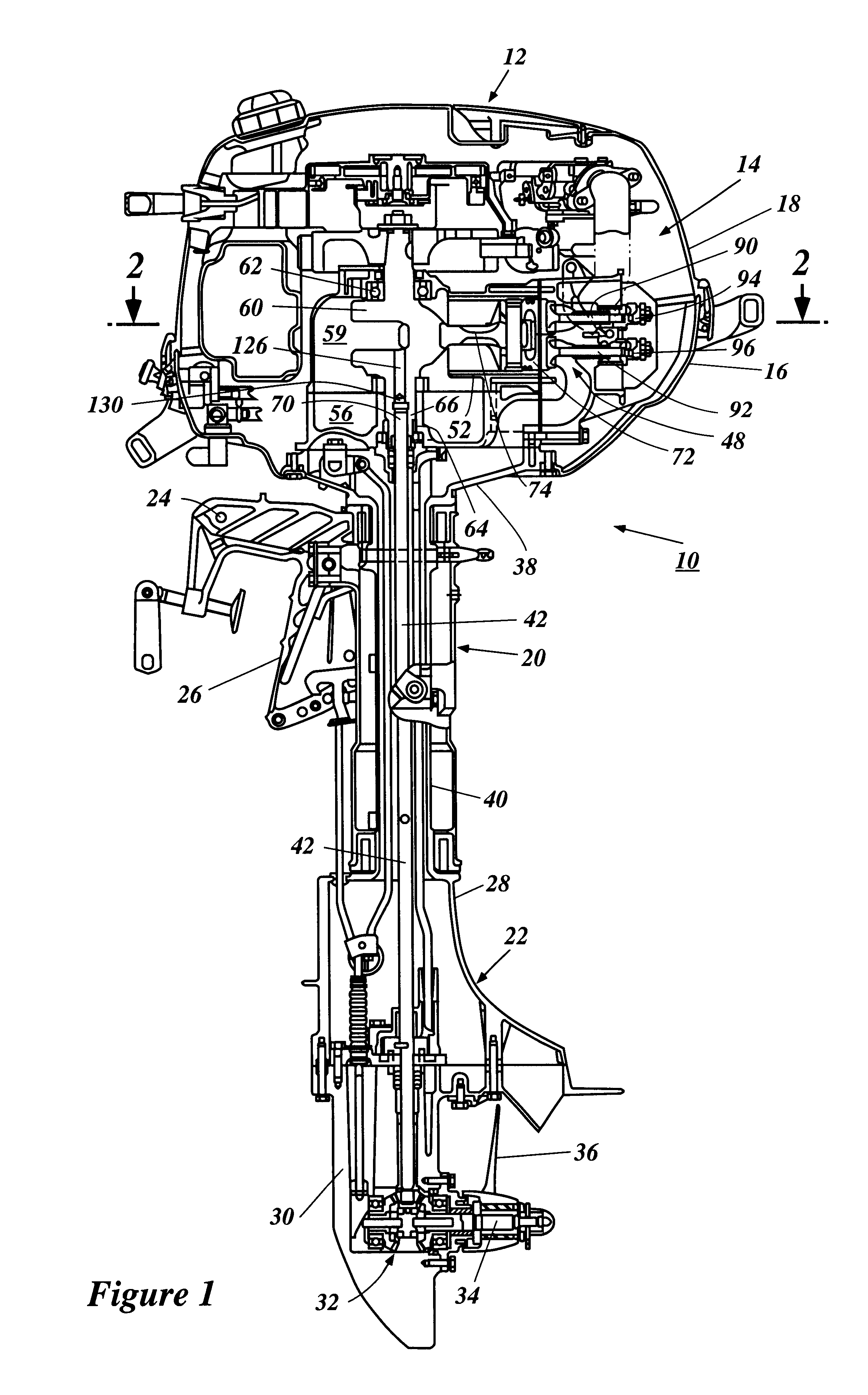

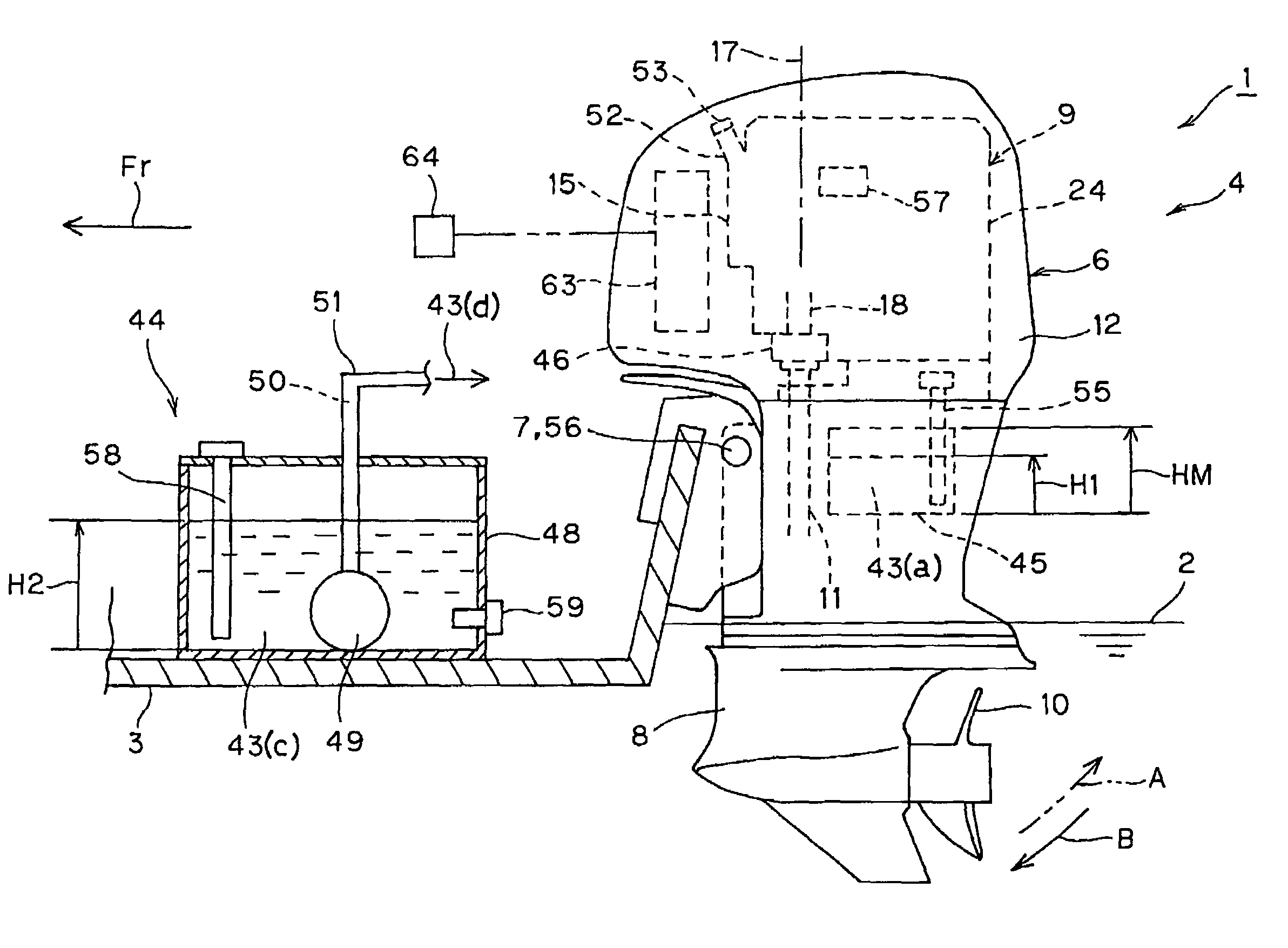

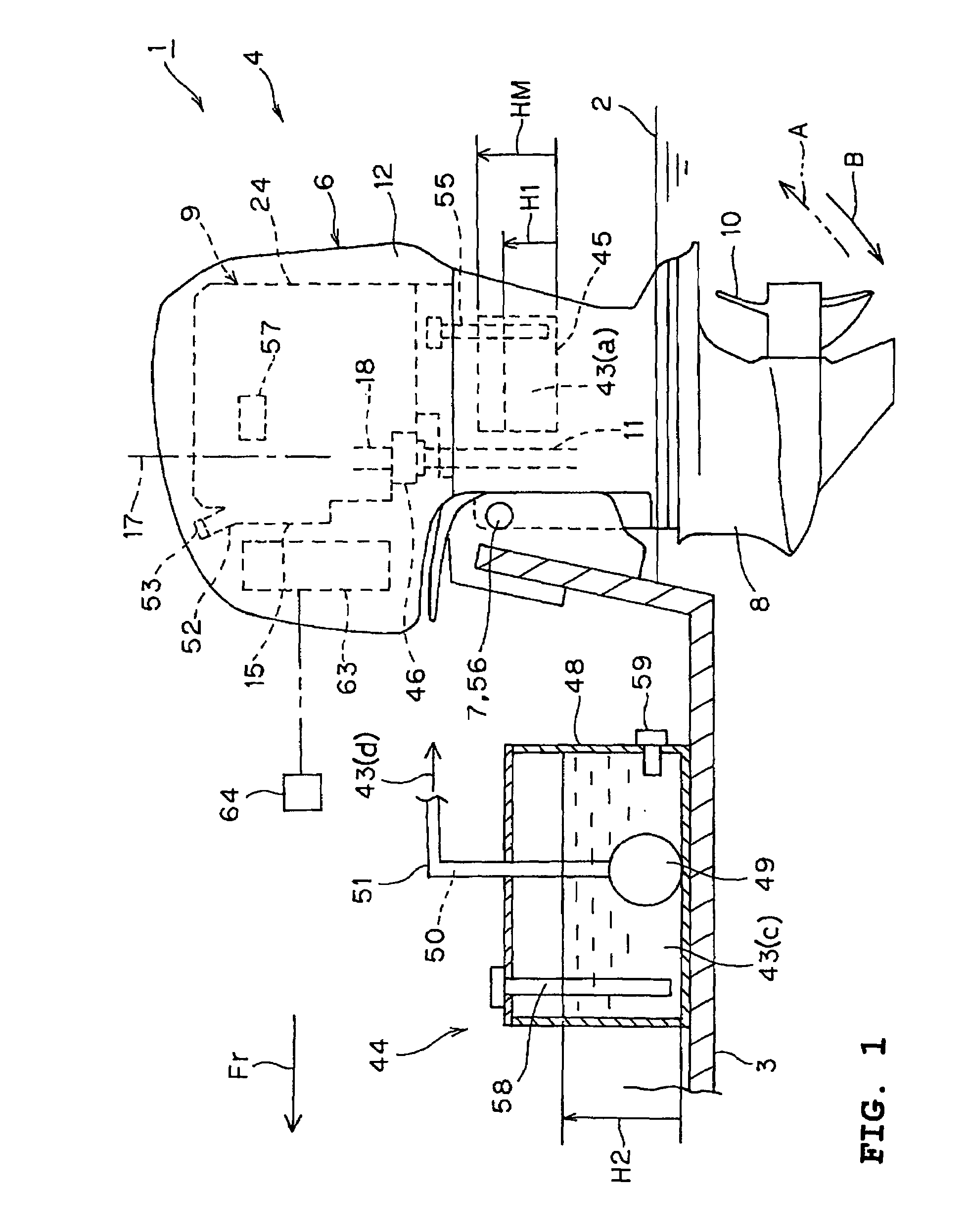

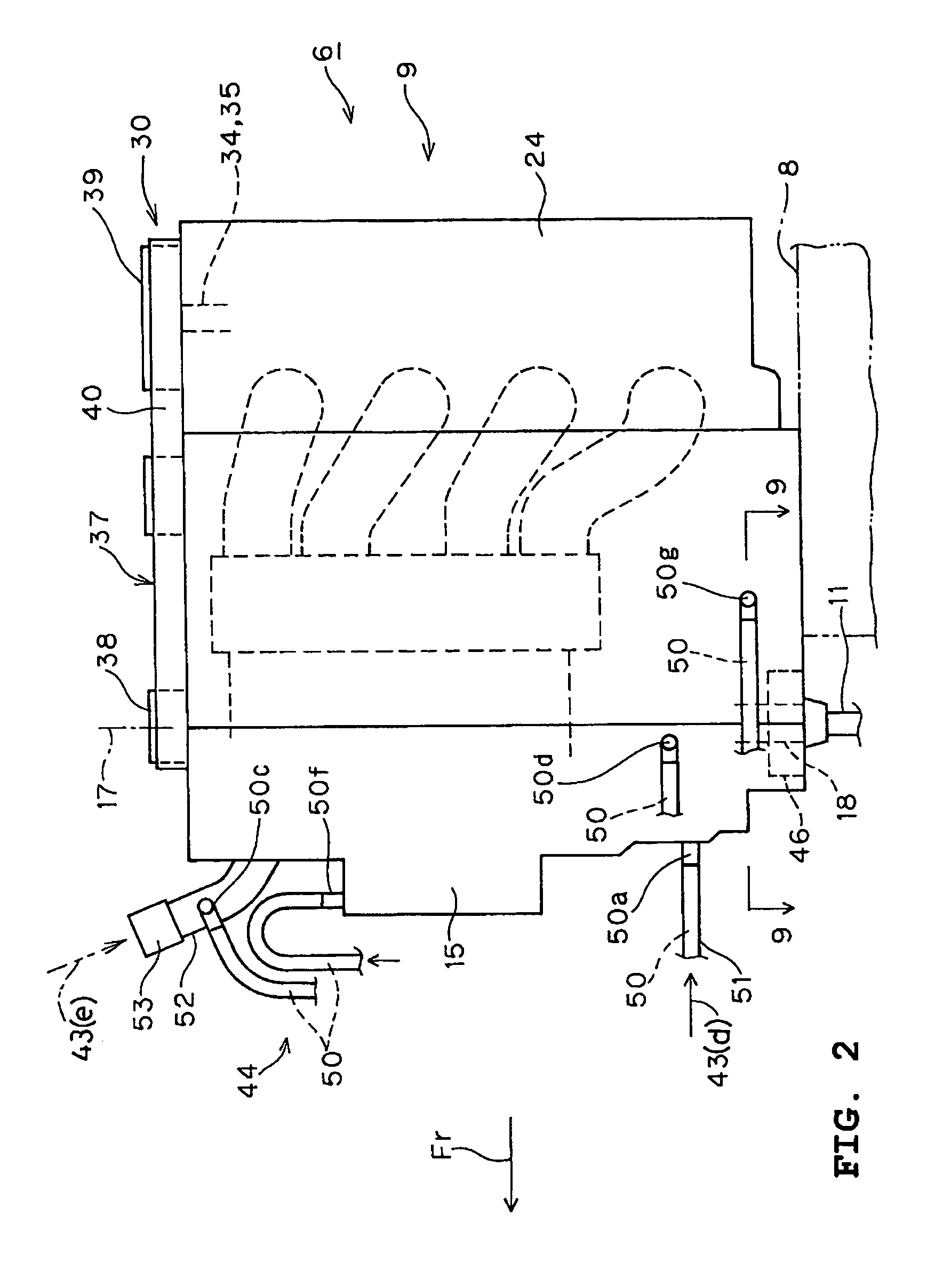

Outboard motor

A system for replenishing a lubricant pan with the lubricant comprises a lubricant tank provided separately from the lubricant pan. A lubricant replenishing pump is provided in the lubricant tank for replenishing the lubricant pan with the lubricant. A lubricant level sensor is adapted to detect the lubricant level in the lubricant tank upon a main switch of an engine being turned on. The lubricant replenishing pump is operated according to the detected lubricant level to replenish the lubricant pan with a specified replenishing amount of the lubricant from the lubricant tank.

Owner:YAMAHA MARINE KK

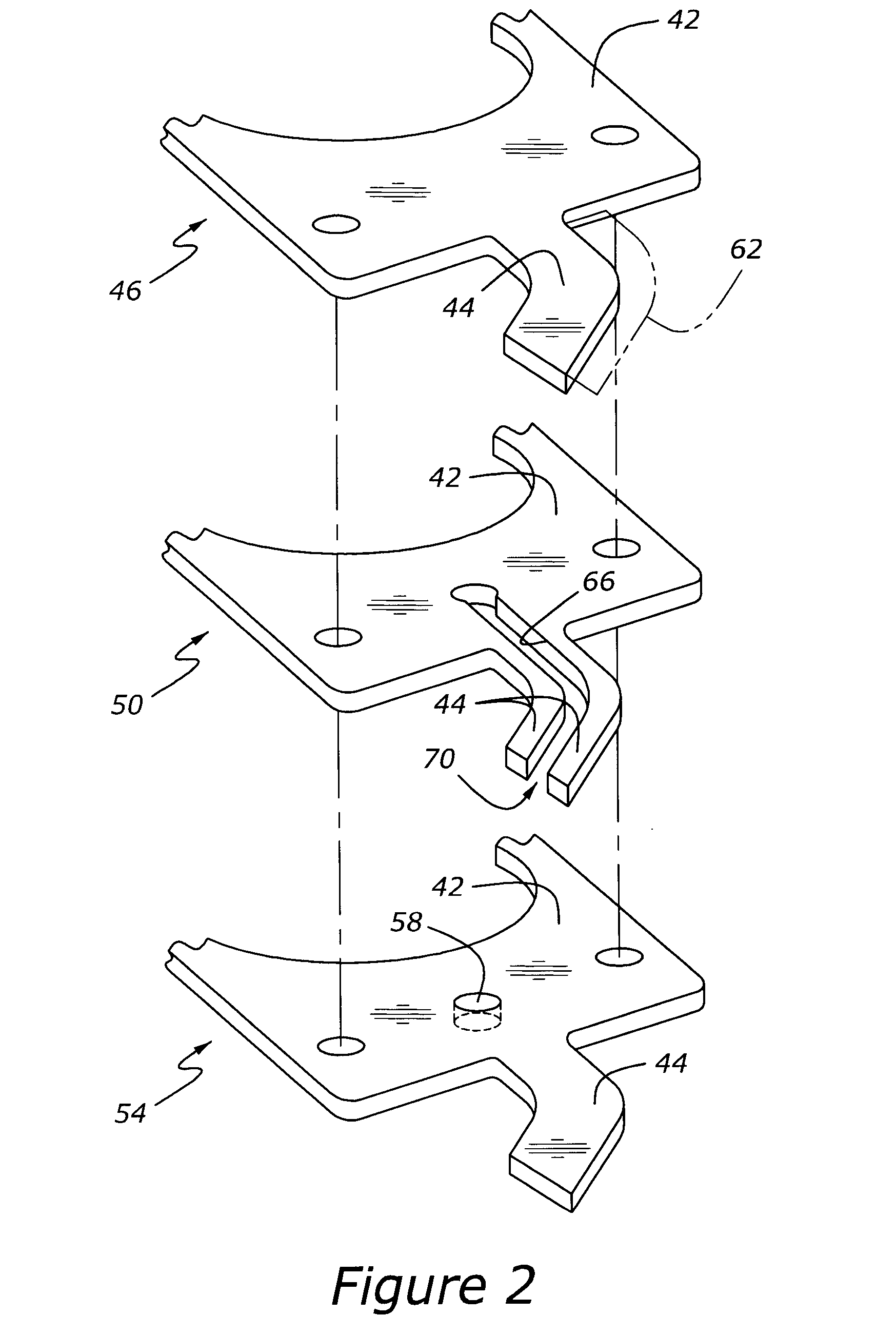

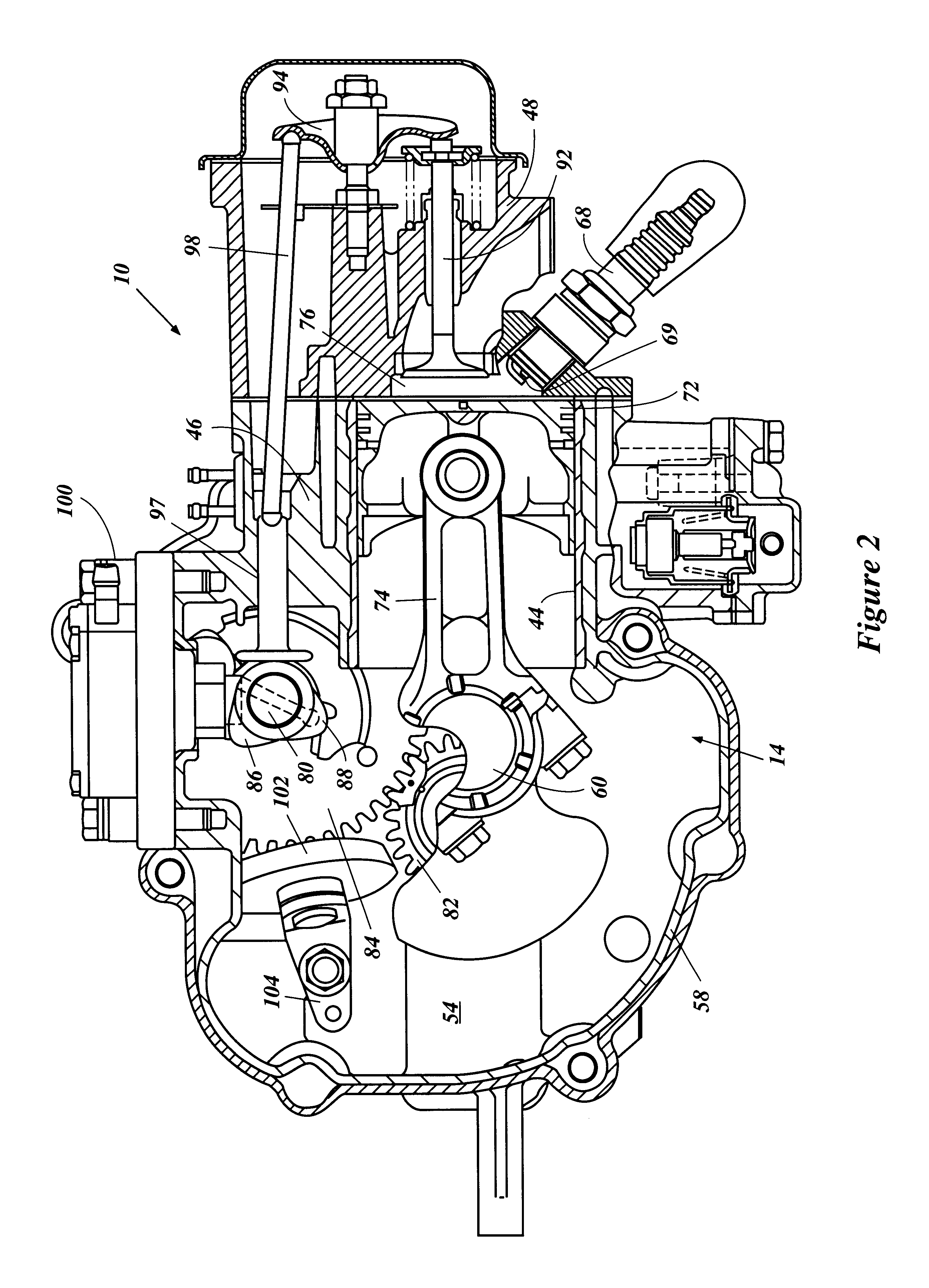

Lubrication and sealing system for internal combustion engine

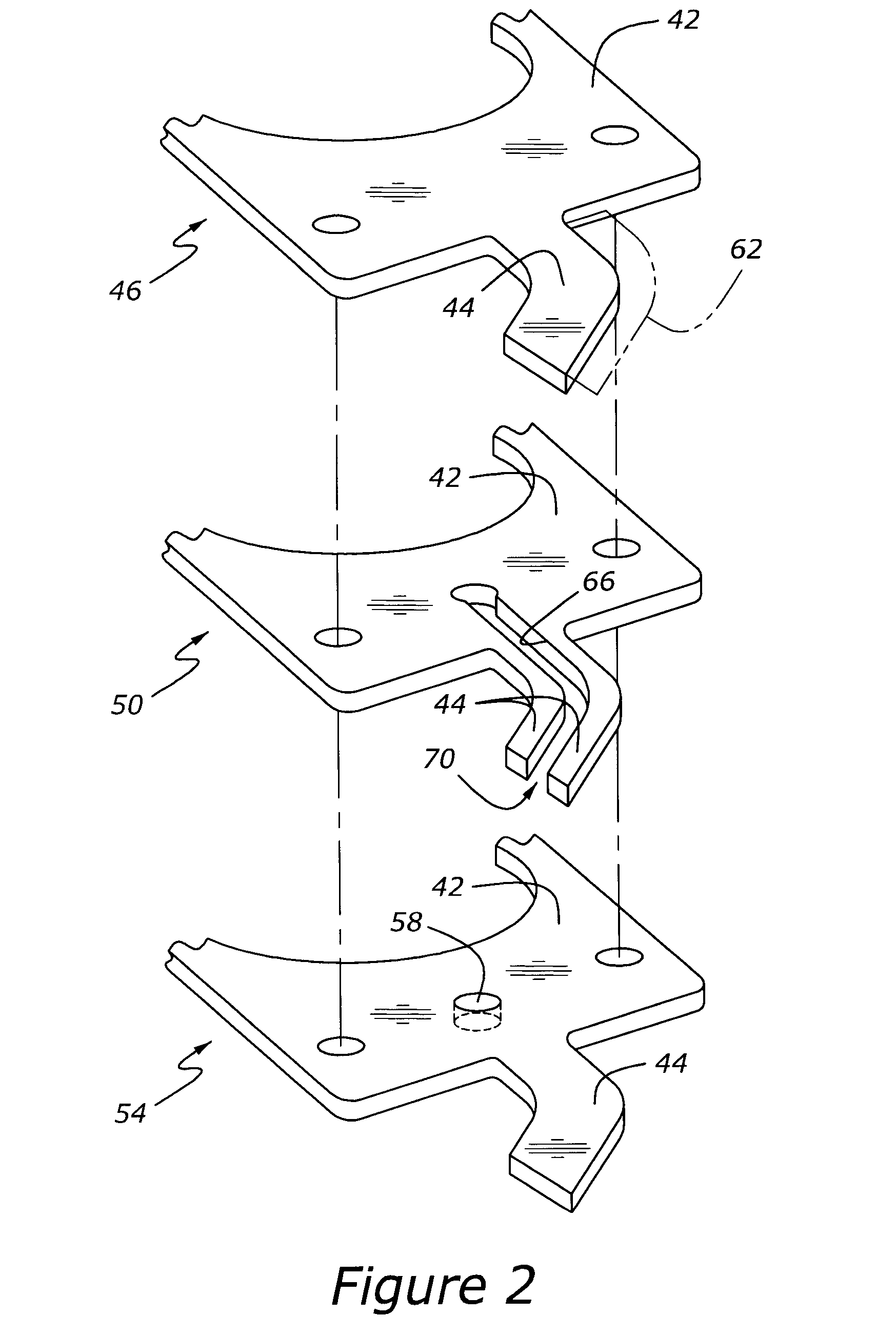

A sealing and lubrication system includes first and second machine components with a combination sealing and lubrication directing gasket mounted between the first and second machine components. The gasket includes a sealing portion extending between the components and a nozzle portion which is operatively connected with the sealing portion as well as with a lubrication supply passage. The nozzle portion extends from the sealing portion of the gasket to a region external to the first machine component and the second machine component. The nozzle provides lubricating oil to at least one moving part of a third machine component.

Owner:FORD GLOBAL TECH LLC

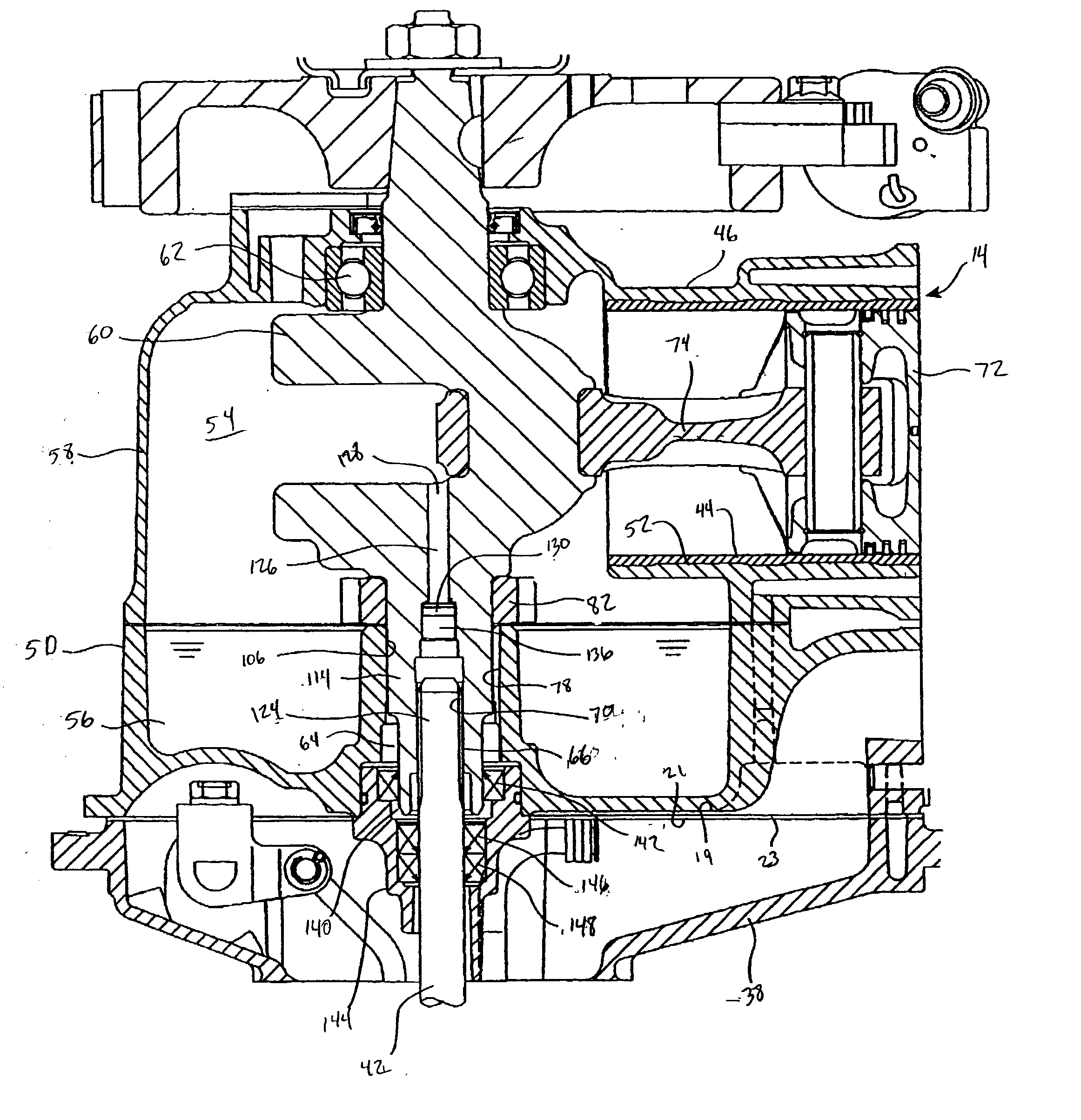

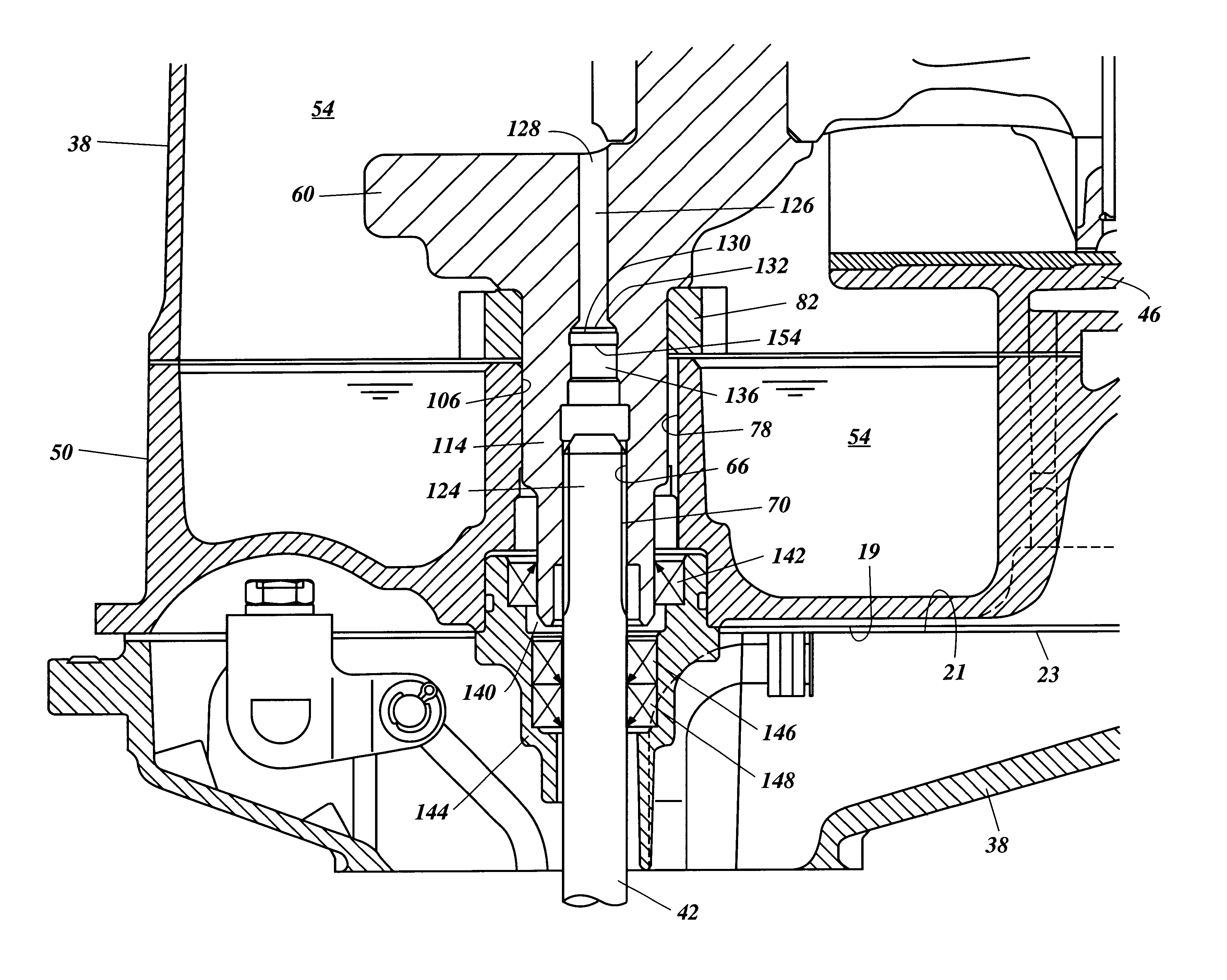

Lubrication system for outboard motor shaft coupling

A lubrication system is provided that allows delivery, and preferably regulated delivery, of lubricant to a coupling between a crankshaft and the driveshaft of, for example, an outboard motor. The lubrication system includes a passageway through which lubricant flows, and preferably a flow restrictor regulates the amount of lubricant delivered through the passageway. In one mode, the passageway is generally formed vertically through the central axis of a vertically oriented crankshaft and extends between the crankcase chamber and the coupling. Lubricant, such as crankcase oil, is able to flow through the passageway and onto the coupling. One or more seals preferably inhibit lubricant from flowing beyond the coupling.

Owner:YAMAHA MARINE KK

Lubrication system and method, and engine incorporating same

InactiveUS20050199213A1Improve oil recovery efficiencyImprove performanceDrip lubricationLubrication of auxillariesCrankcaseLubrication

An improved lubrication structure is provided in a engine by optimizing the structure for recovering scooped oil for enhanced oil recovery efficiency. The oil, which has been scooped up and scattered by the rotation of a clutch, is captured within a concave groove provided within a cylindrical inner surface of a case cover facing the clutch. The captured oil is smoothly guided from the concave groove to an oil receiver of a crankcase via a bent upper edge part of an oil guide plate. The recovered oil passes through dropping holes of a recovered oil path and is supplied to a gear engagement part of a transmission system located below the recovered oil path.

Owner:HONDA MOTOR CO LTD

Lubrication and sealing system for internal combustion engine

A sealing and lubrication system includes first and second machine components with a combination sealing and lubrication directing gasket mounted between the first and second machine components. The gasket includes a sealing portion extending between the components and a nozzle portion which is operatively connected with the sealing portion as well as with a lubrication supply passage. The nozzle portion extends from the sealing portion of the gasket to a region external to the first machine component and the second machine component. The nozzle provides lubricating oil to at least one moving part of a third machine component.

Owner:FORD GLOBAL TECH LLC

Lubrication system and method, and engine incorporating same

InactiveUS7121249B2Improve the lubrication effectEffectively guide oilDrip lubricationLubrication of auxillariesCrankcaseLubrication

Owner:HONDA MOTOR CO LTD

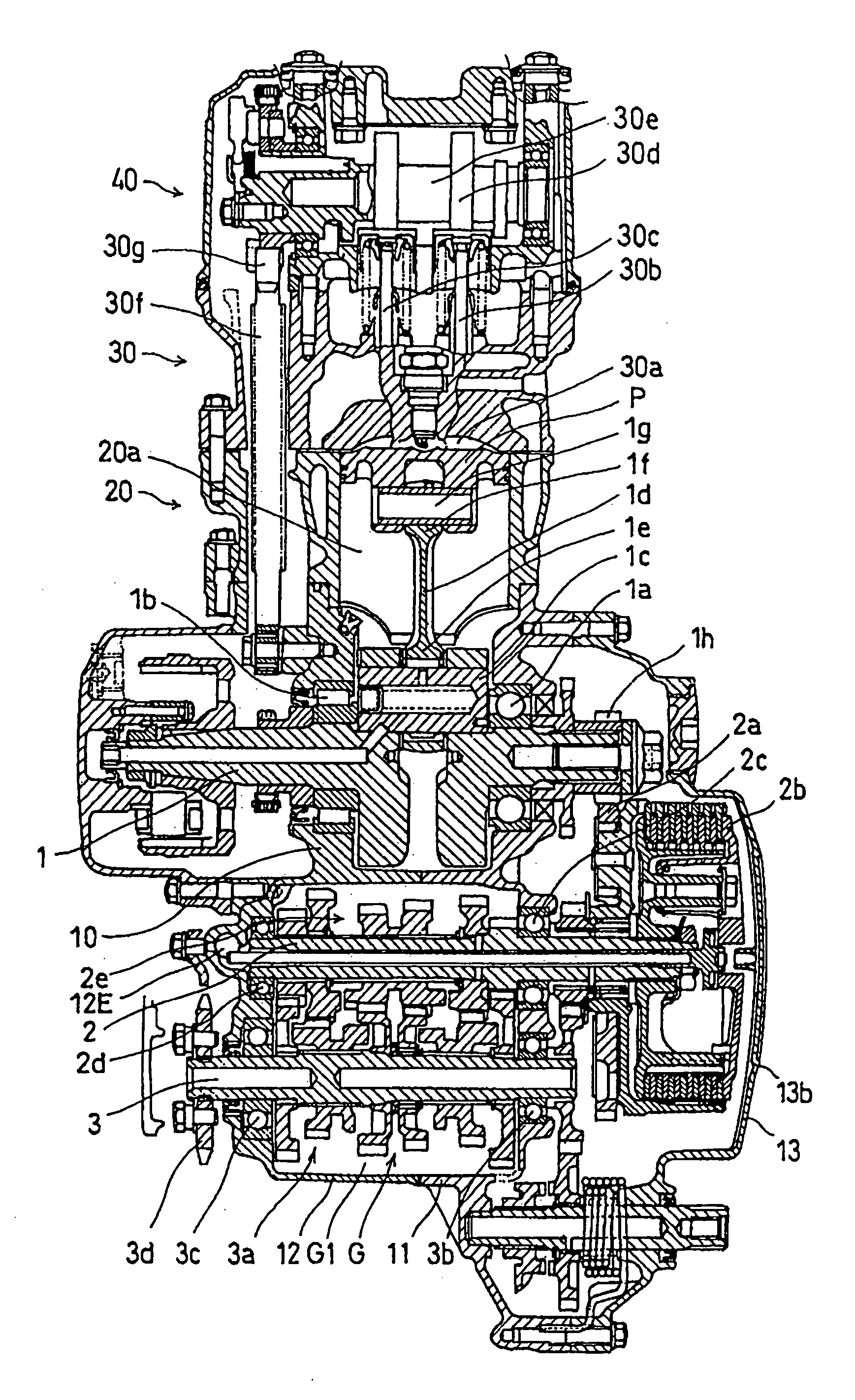

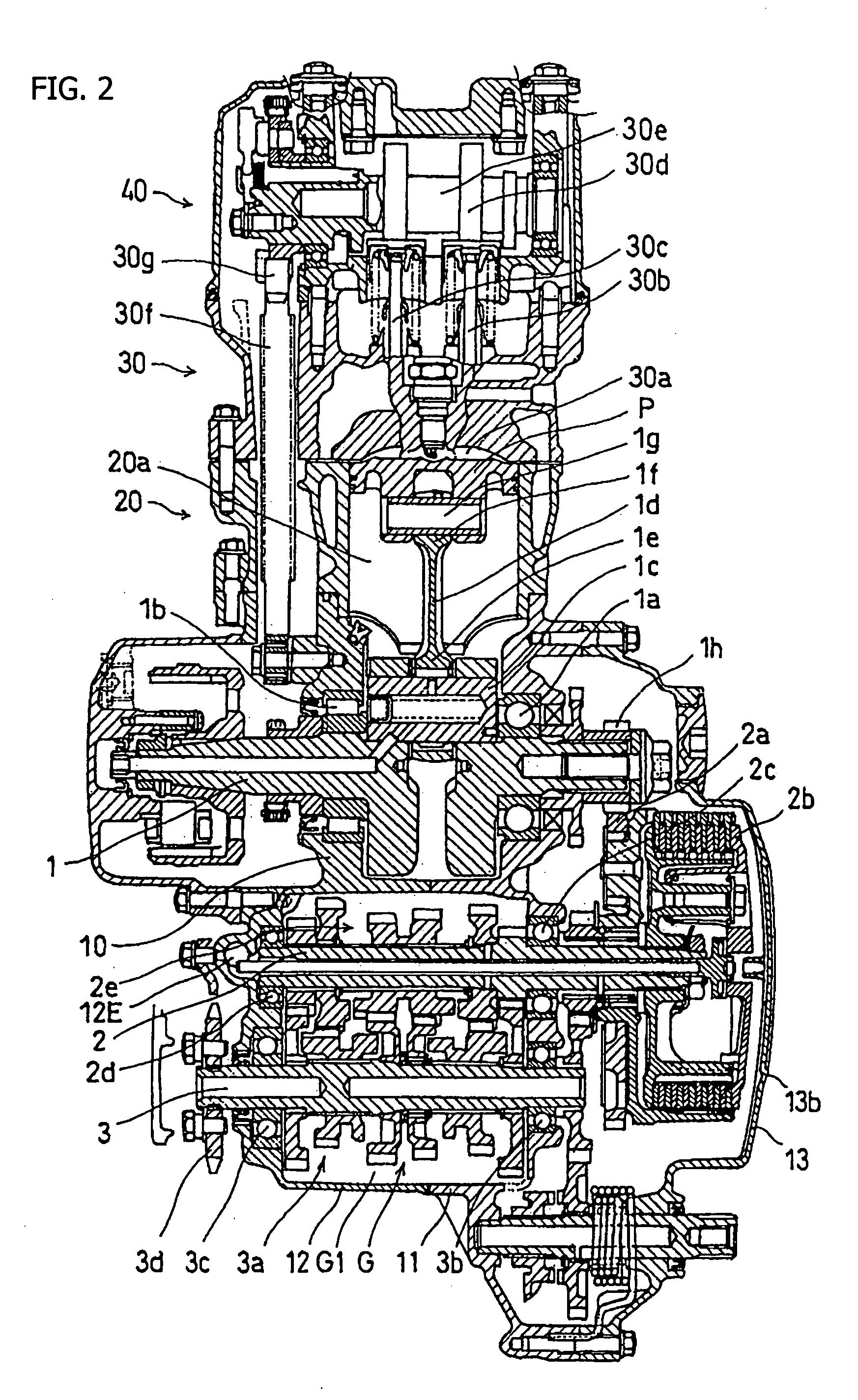

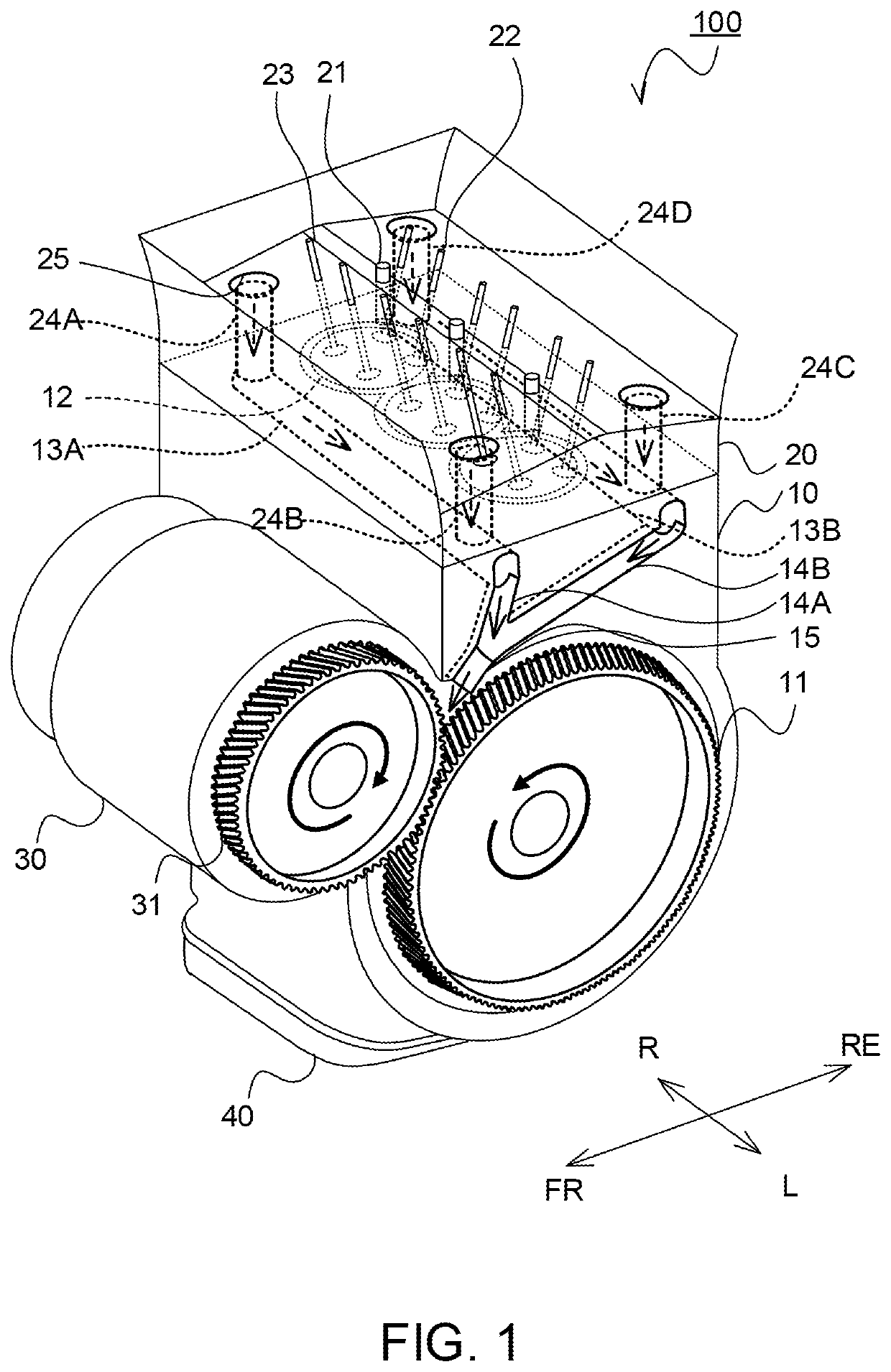

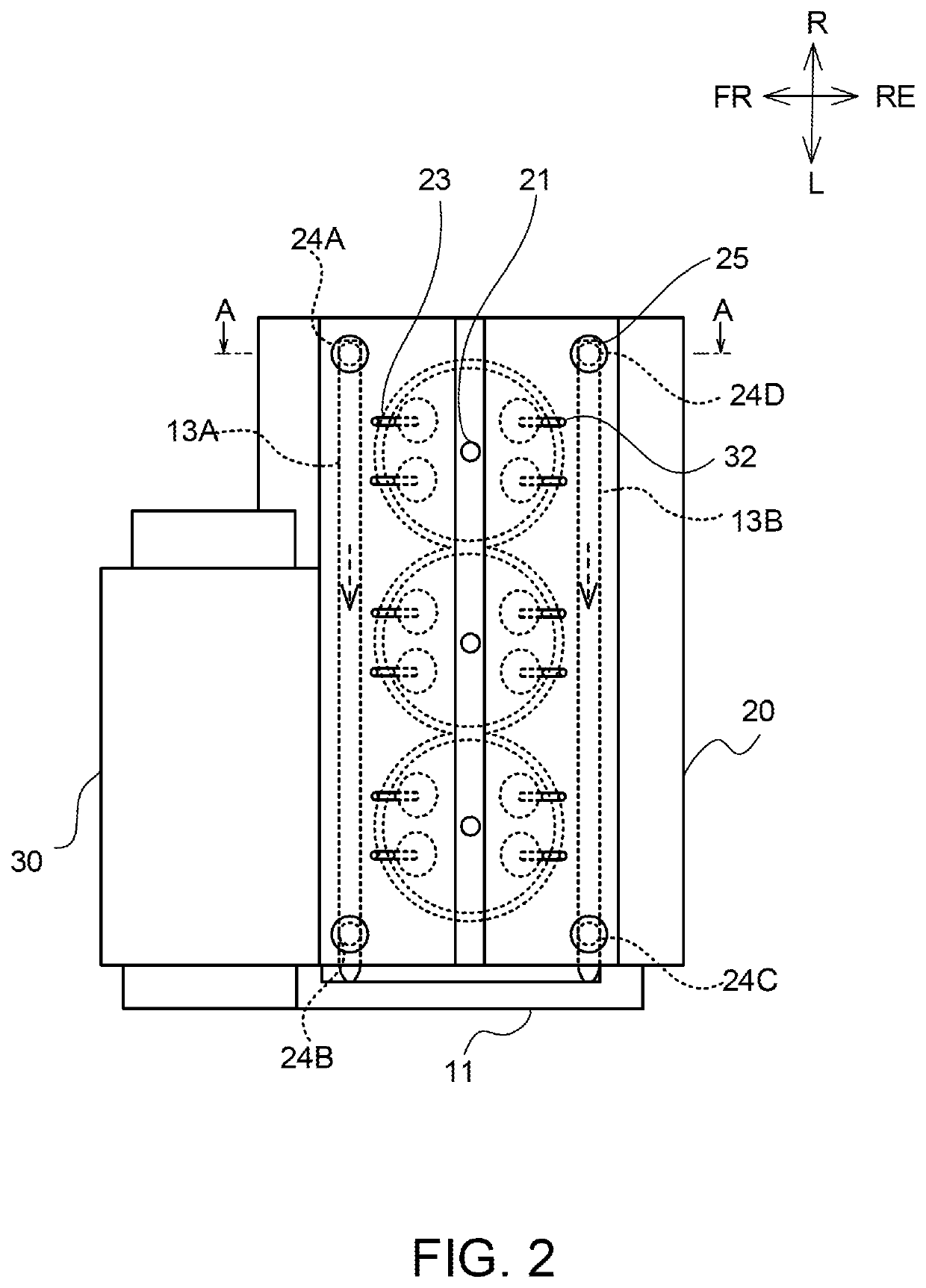

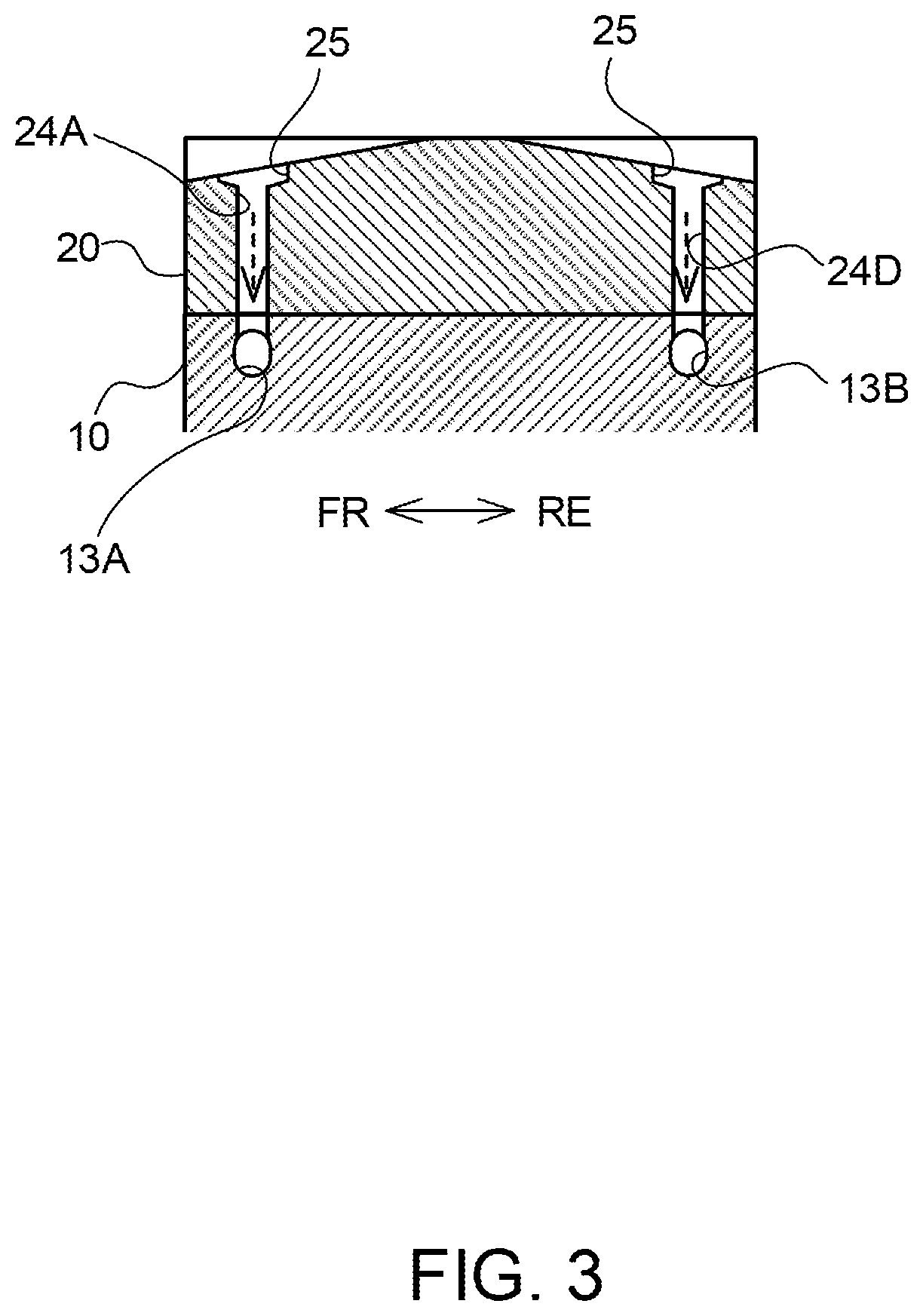

Power unit case configured to house both an engine and a transmission, and power unit including same

InactiveUS7779727B2Improve the lubrication effectSmall sizeDrip lubricationPower operated startersMedial axisInternal combustion engine

A power unit case for a power unit, including an internal combustion engine and a transmission, makes it possible to enhance the lubrication of a desired meshing portion of a group of transmission gears, while reducing the size of the engine. In the power unit case, a main shaft is arranged above a space between a crankshaft and a counter shaft arranged at a position substantially horizontally behind the crankshaft. A gear-ratio selecting member is arranged above a group of transmission gears on the counter shaft whose upper portion rotates toward a meshing portion between groups of transmission gears, and a lubricating projection that projects downwardly is formed in the transmission case above each of the transmission gears on the counter shaft and at a location on a ceiling surface of the transmission case where the gear-ratio selecting member is supported.

Owner:HONDA MOTOR CO LTD

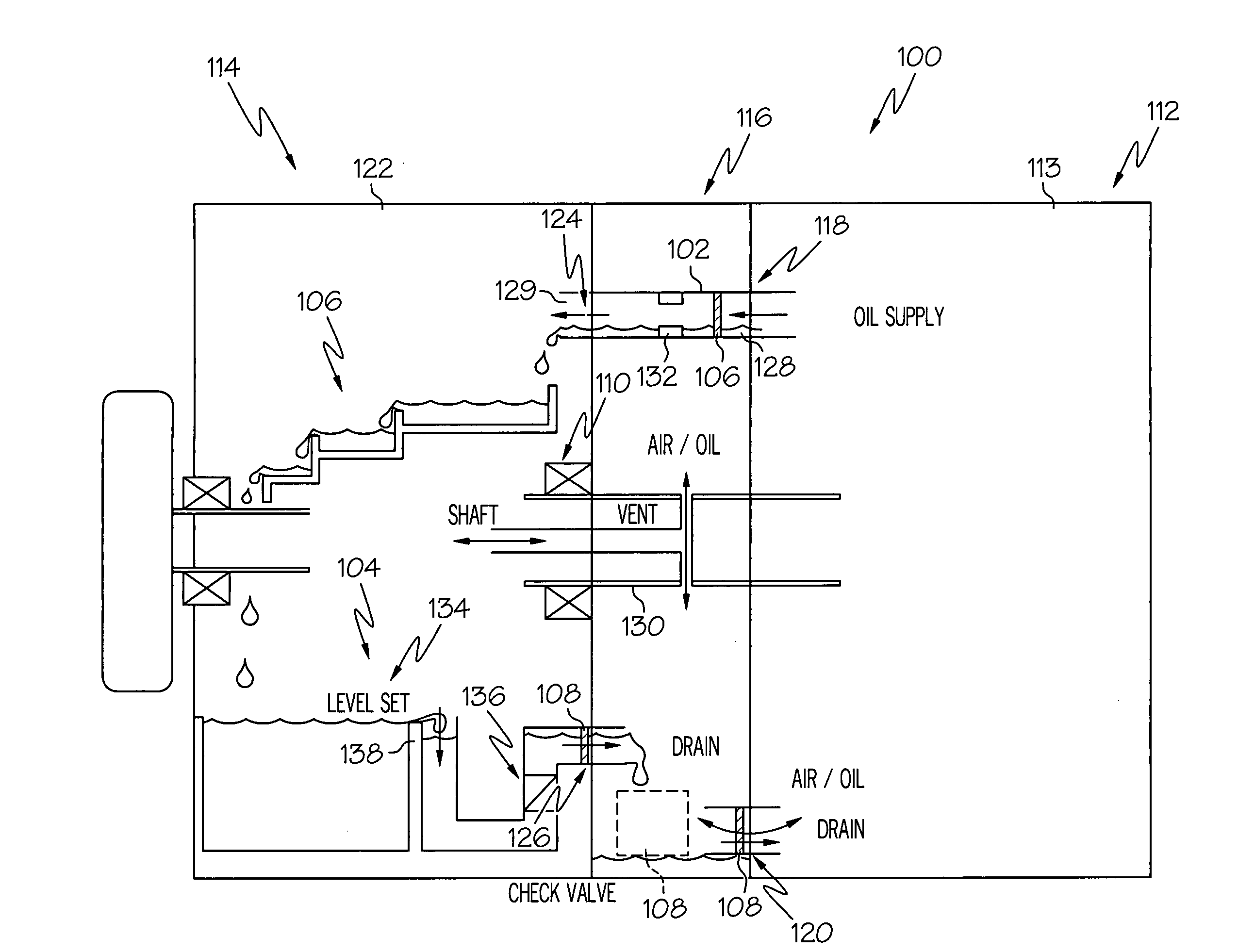

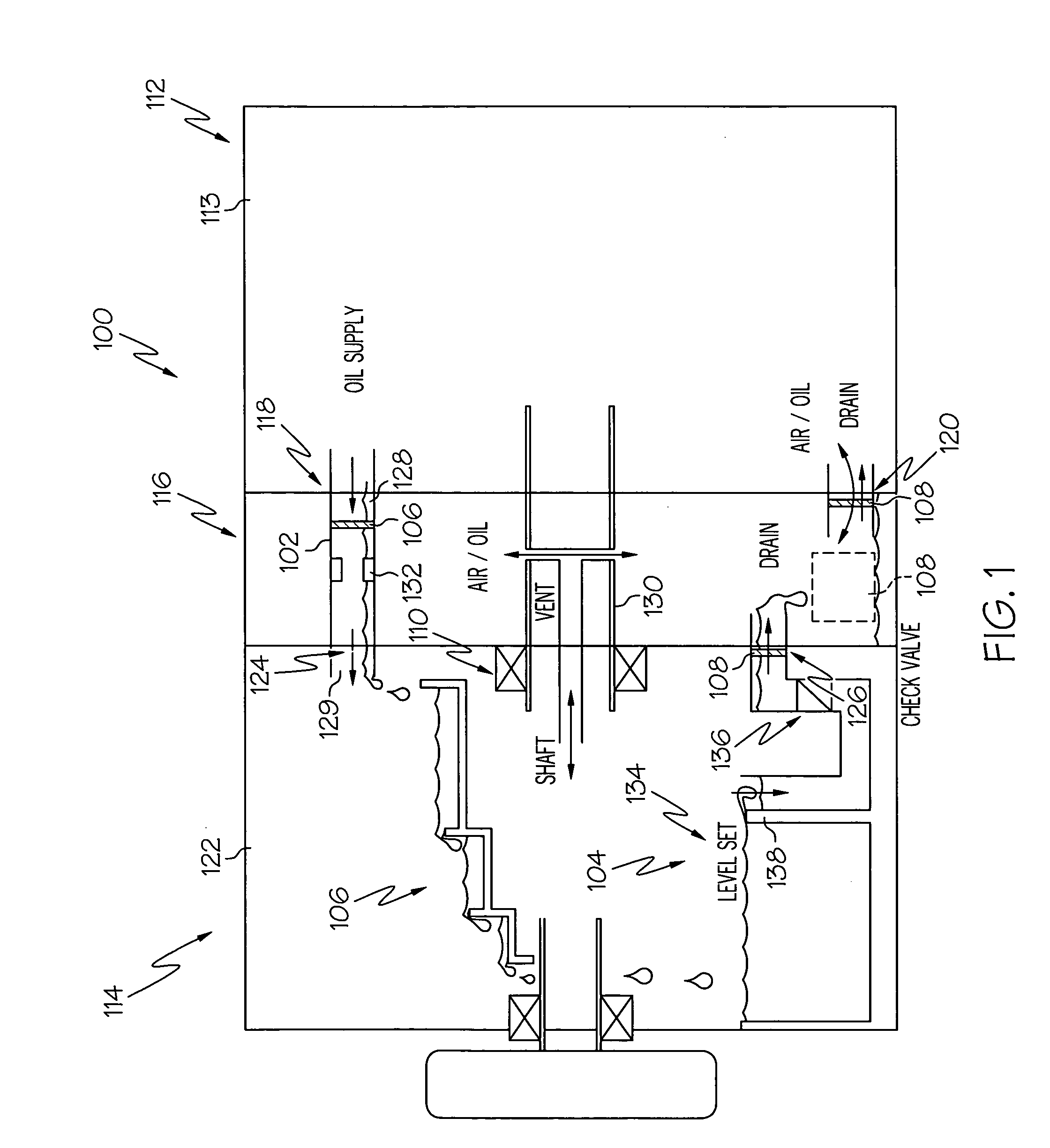

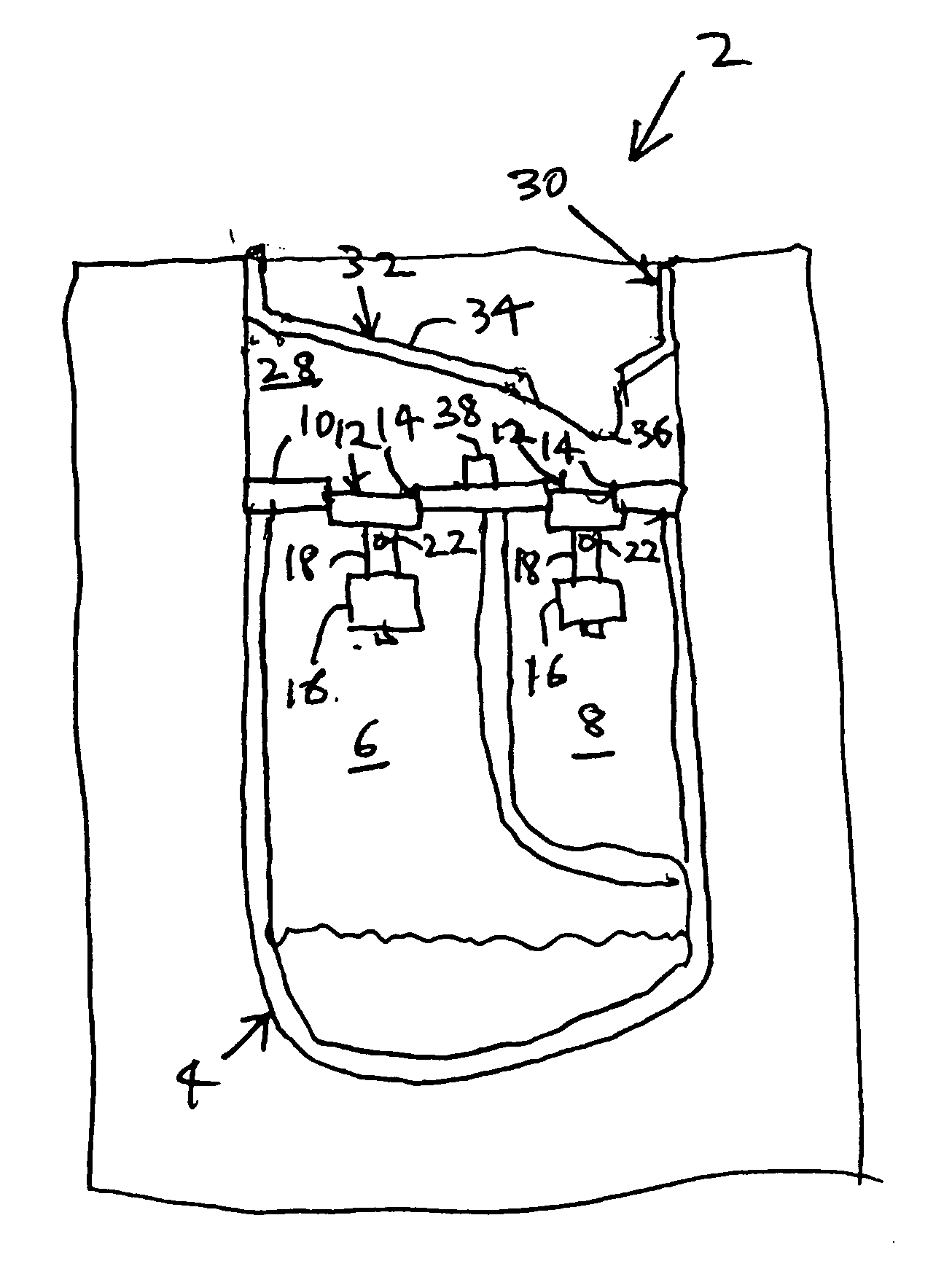

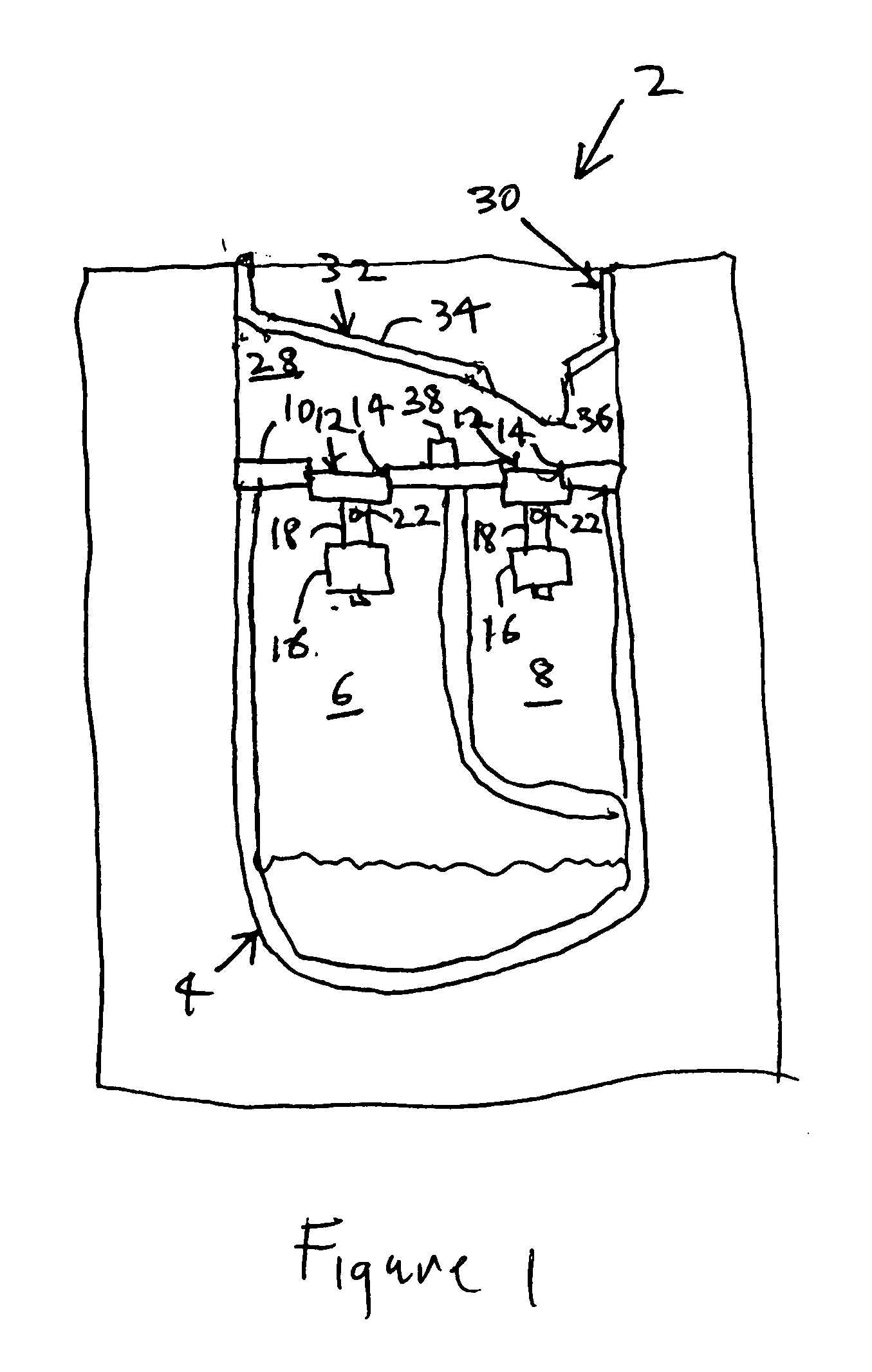

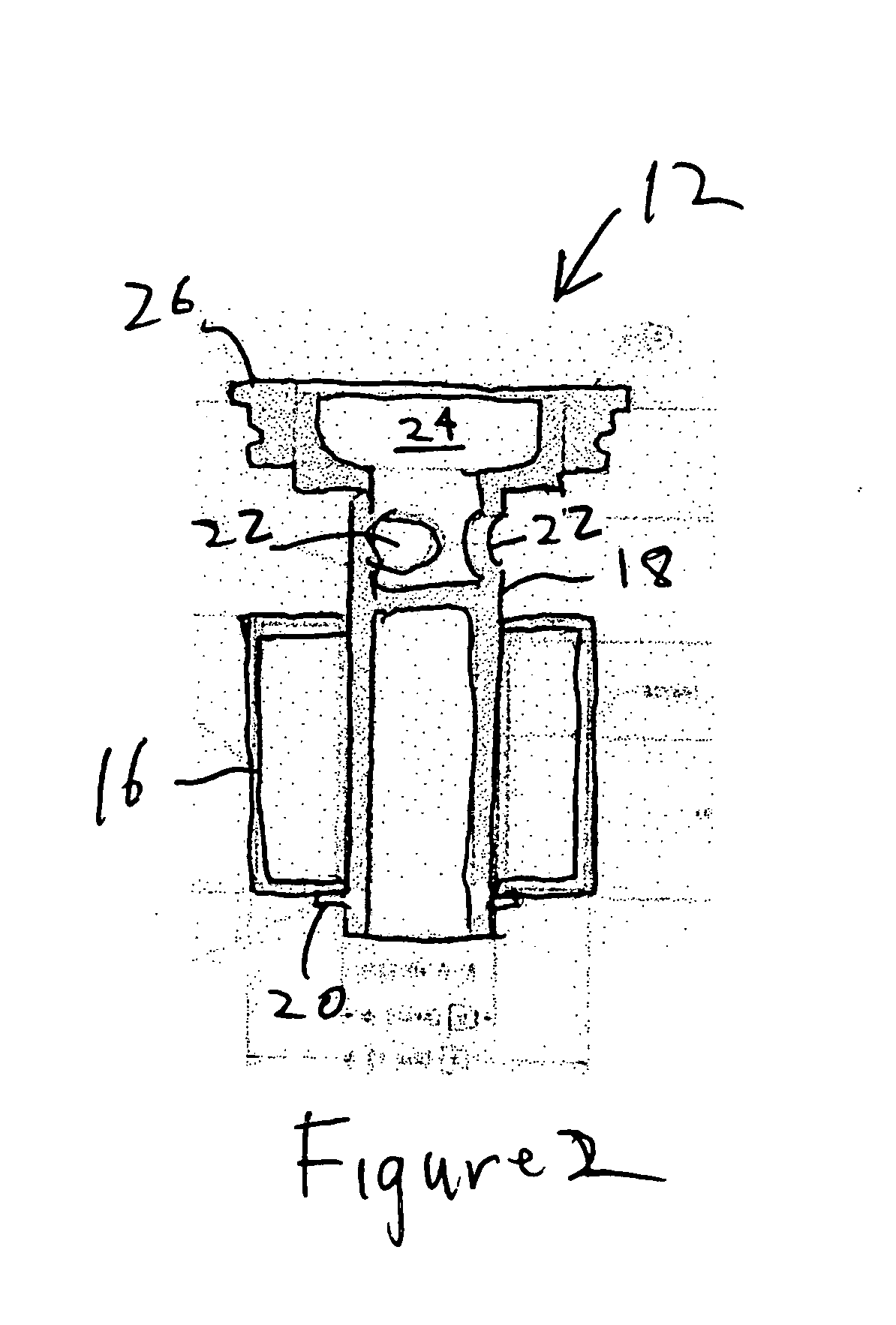

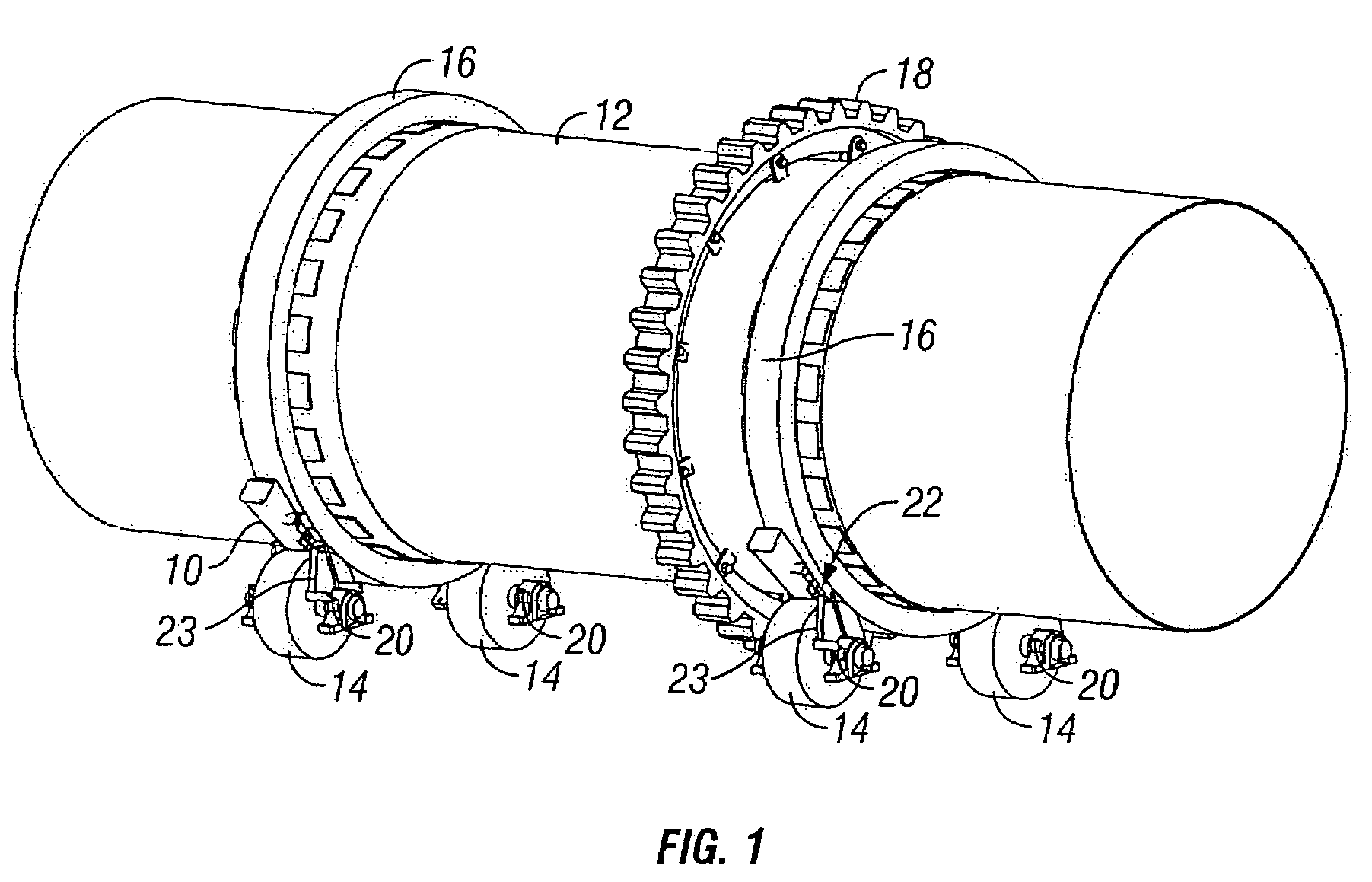

Twin lubrication tank filling system

A twin lubrication oil tank filling system with a single oil fill port that prevents overfilling of both a primary oil tank and a secondary oil with a gravity fill system by directing oil primarily into the secondary oil tank by means of a special oil diverter, a float valve for the secondary oil tank that closes when the oil level in the secondary tank reaches a full level to cause additional oil flow to pour into the primary oil tank and a float valve for the primary oil tank that closes when the oil level in the primary tank reaches a full level.

Owner:HAMILTON SUNDSTRAND CORP

Valve timing controller

ActiveUS8251029B2Improve the lubrication effectSimple structureDrip lubricationValve arrangementsGear wheelEngineering

A valve timing controller is provided with a driving rotor rotating along with a crankshaft, a driven rotor rotating along with a camshaft, a planetary gear performing a planetary motion to adjust a rotational phase between the camshaft and the crankshaft, a motor shaft rotating for controlling the planetary motion, a cylindrical planetary carrier supporting the planetary gear and being connected with the control shaft so that the planetary gear performs the planetary motion, and a lubricating mechanism. The lubricating mechanism includes an introducing port which opens on a side surface of the second rotor axially confronting the planetary carrier. The introducing port extends across a supporting outer surface and a connecting inner surface. The lubricant is introduced into an interior of the first rotor through the introducing port.

Owner:DENSO CORP

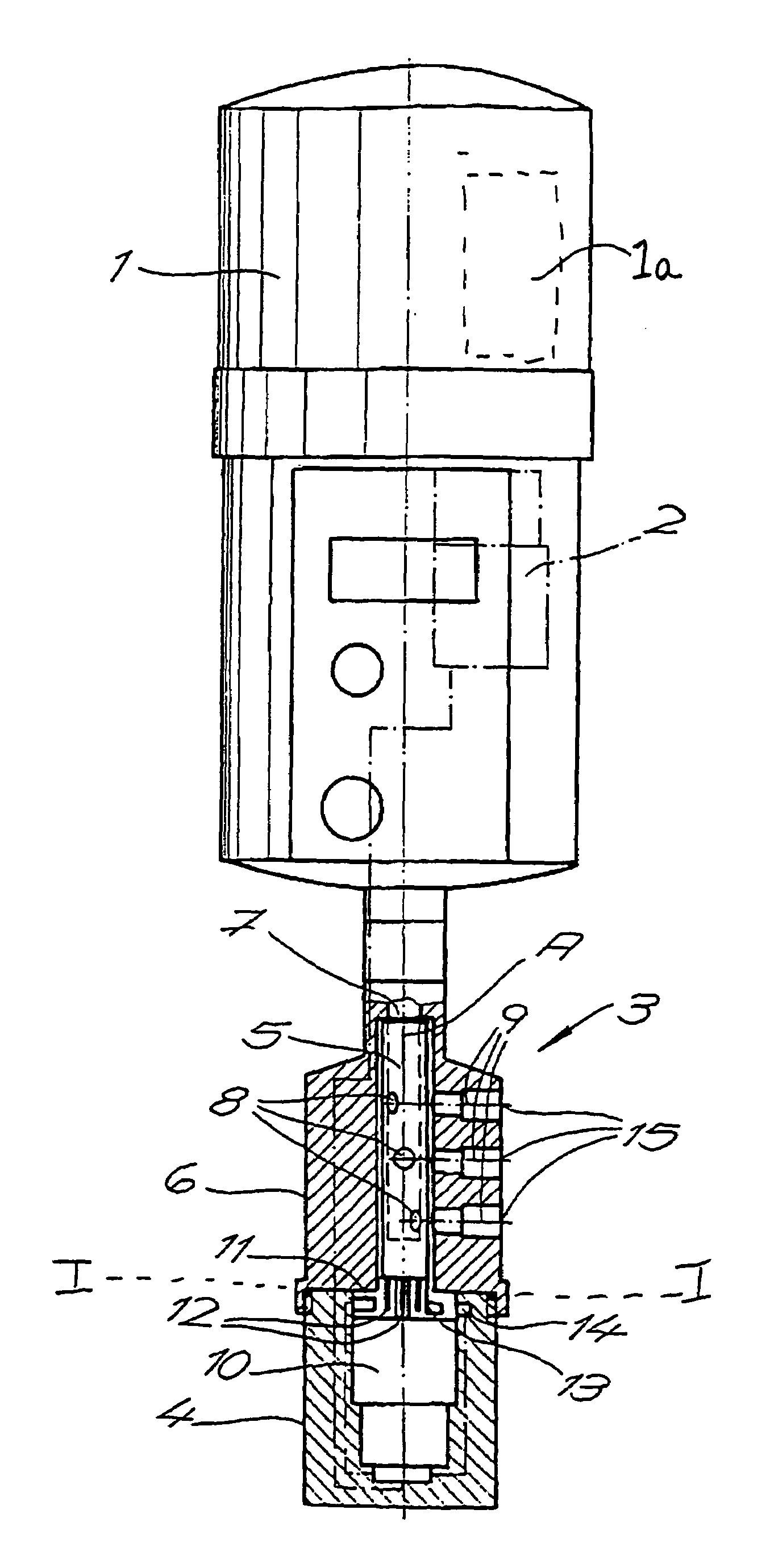

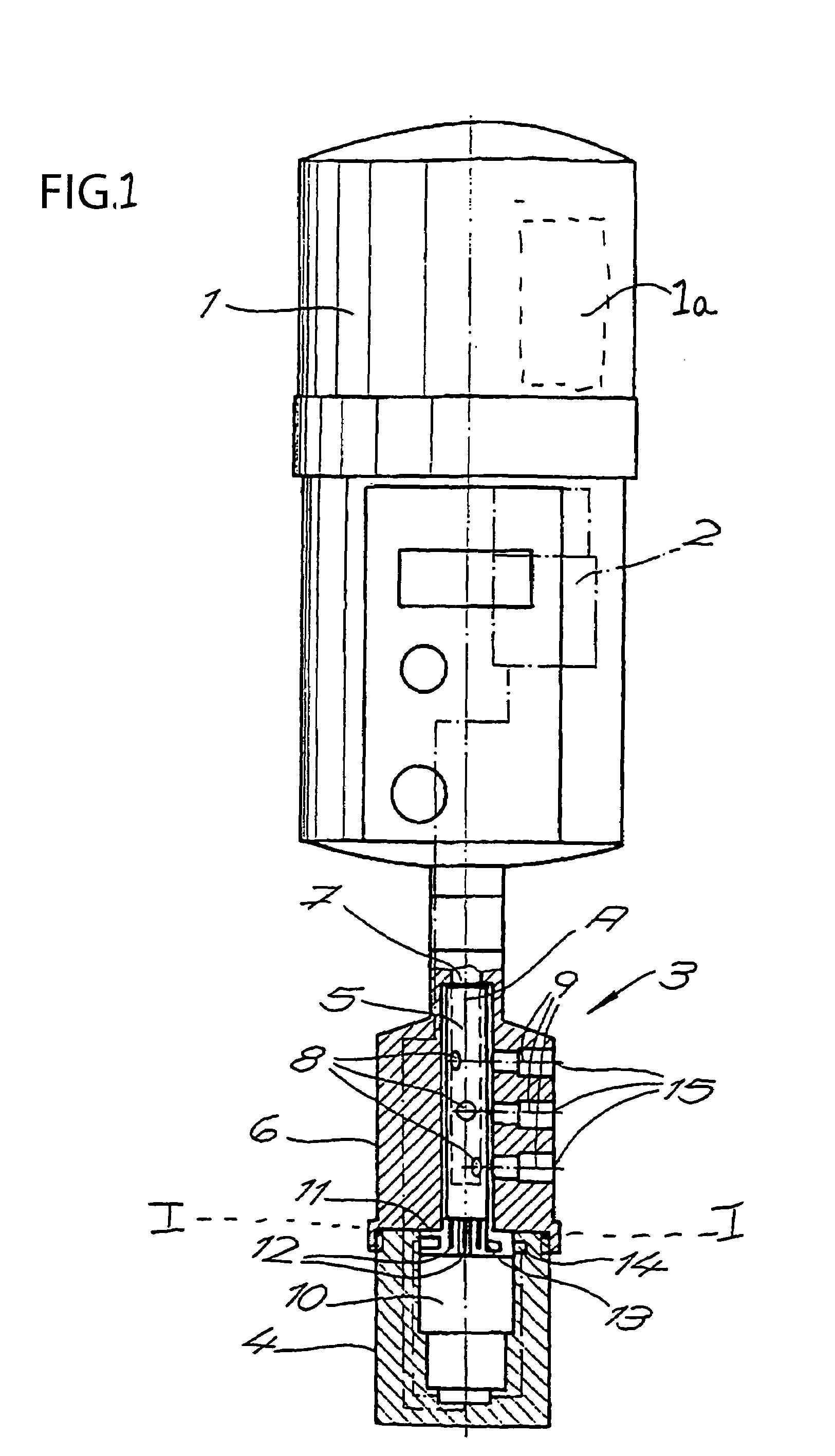

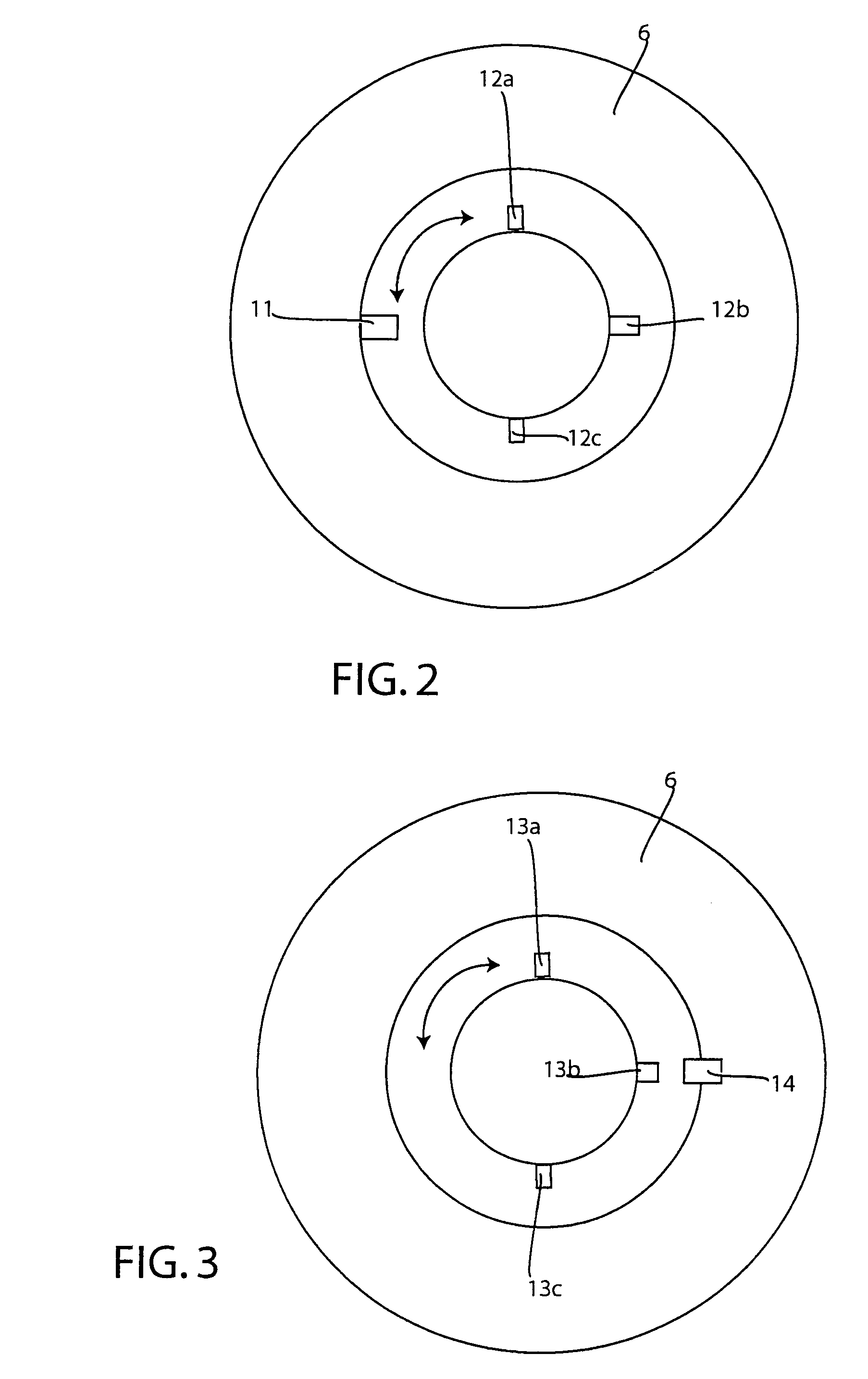

Device for supplying lubricant to several lubrication points on machine parts

InactiveUS7178634B2Accurate supplyIncreased pressure lossDrip lubricationDrip or splash lubricationContact freeMotor drive

A device for supplying several lubrication points on machine parts with a lubricant, comprising an electromechanical lubrication dispenser and a distribution device coupled to a lubricant outlet of the dispenser. The distribution device has a housing, a cylindrical hollow distributor body or tube which is mounted to rotate about a vertical axis. There is also a fixed cylindrical sleeve that surrounds the distributor body, forming a seal. The distributor body has an opening at the top for allowing the lubricant in, and has at least two distributor bores disposed on the circumference but offset axially from one another. Each of these distributor bores has a corresponding opening bore in the distributor sleeve that is assigned to it. This distribution device also has an electric motor drive that has a running path control that has a switch that functions electromechanically or in a contact free manner. This drive has a switch that stops the rotational movement in different release angle positions that can be variably established.

Owner:PERMA TEC

Lubrication system for outboard motor shaft coupling

A lubrication system is provided that allows delivery, and preferably regulated delivery, of lubricant to a coupling between a crankshaft and the driveshaft of, for example, an outboard motor. The lubrication system includes a passageway through which lubricant flows, and preferably a flow restrictor regulates the amount of lubricant delivered through the passageway. In one mode, the passageway is generally formed vertically through the central axis of a vertically oriented crankshaft and extends between the crankcase chamber and the coupling. Lubricant, such as crankcase oil, is able to flow through the passageway and onto the coupling. One or more seals preferably inhibit lubricant from flowing beyond the coupling.

Owner:YAMAHA MARINE KK

Outboard motor

A system for replenishing a lubricant pan with the lubricant comprises a lubricant tank provided separately from the lubricant pan. A lubricant replenishing pump is provided in the lubricant tank for replenishing the lubricant pan with the lubricant. A lubricant level sensor is adapted to detect the lubricant level in the lubricant tank upon a main switch of an engine being turned on. The lubricant replenishing pump is operated according to the detected lubricant level to replenish the lubricant pan with a specified replenishing amount of the lubricant from the lubricant tank.

Owner:YAMAHA MARINE KK

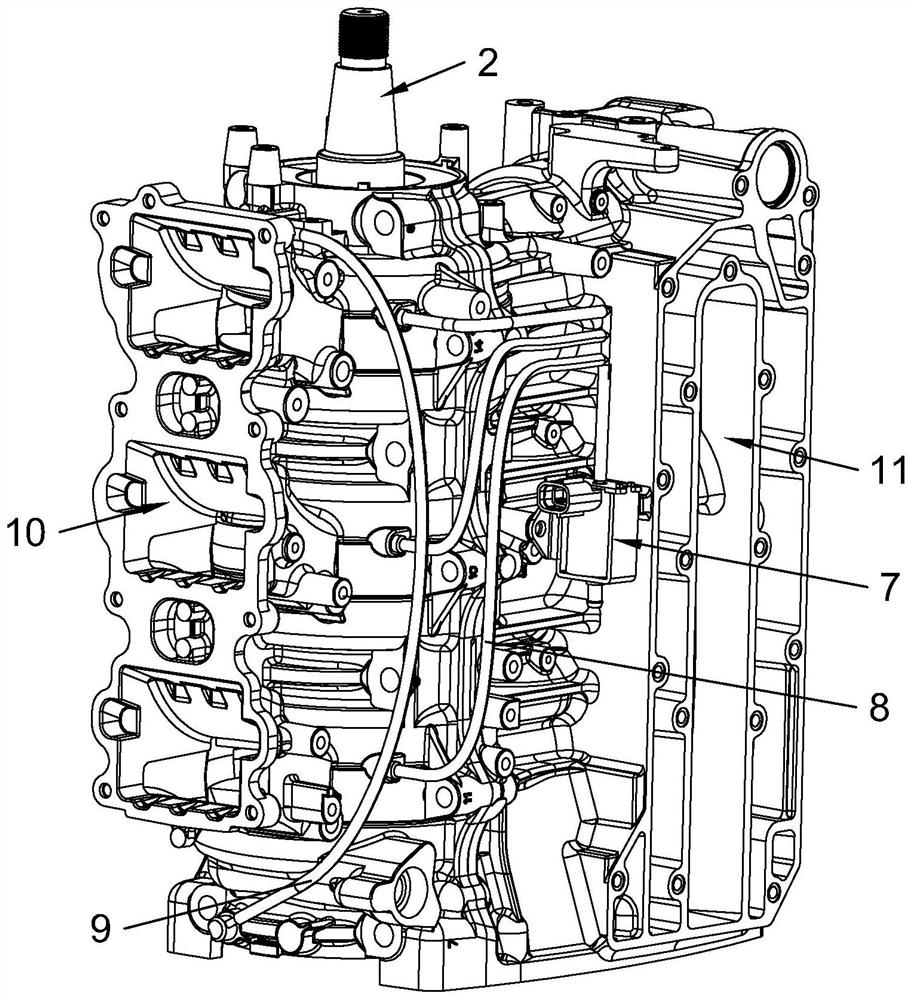

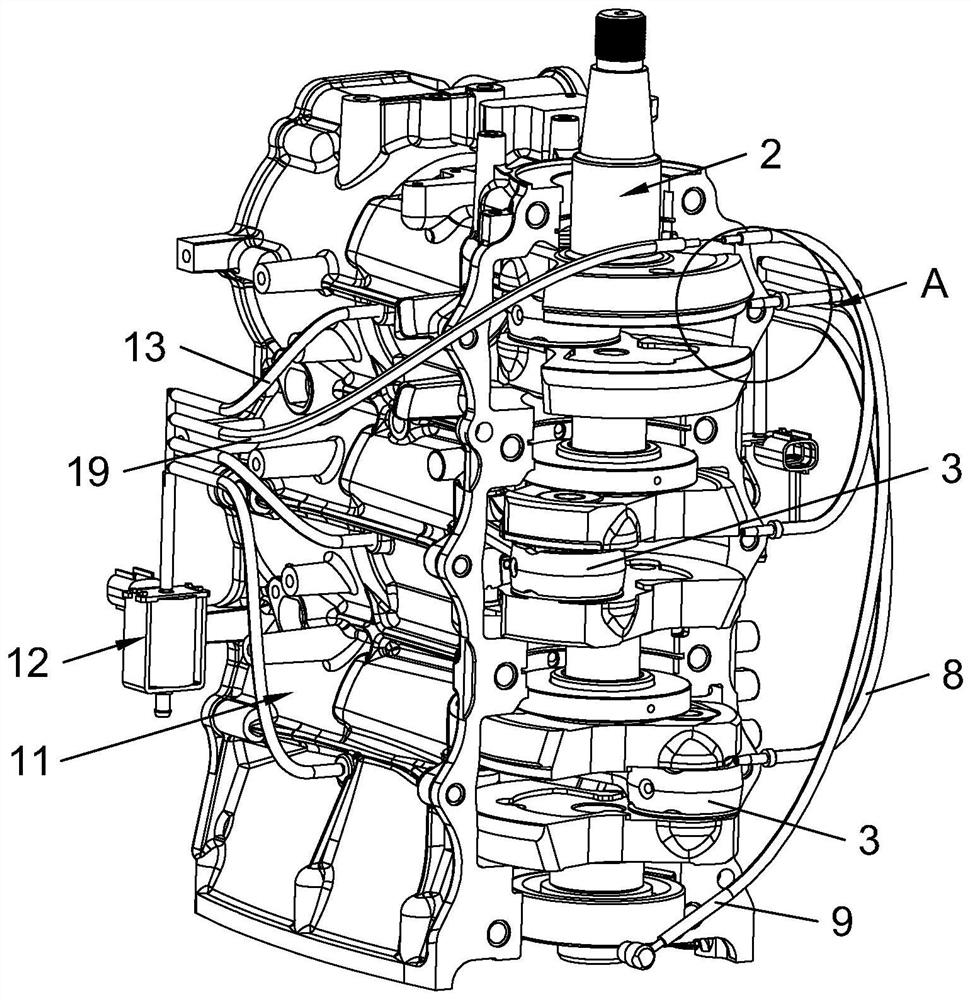

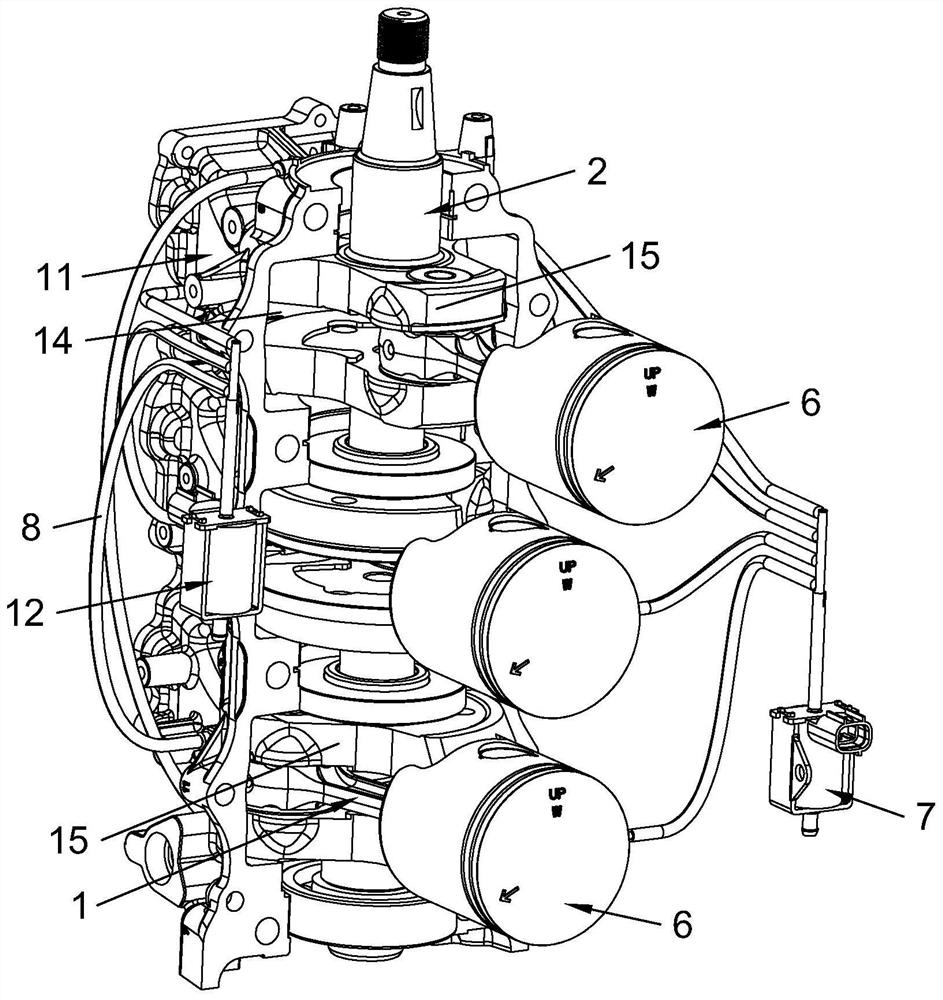

Outboard engine and separated lubricating system thereof

ActiveCN113047923AImprove cooling effectImprove the lubrication effectDrip lubricationMachines/enginesOil canExhaust fumes

The invention discloses a separated lubricating system of an outboard engine. The system comprises a crankcase and a power assembly arranged in a cavity of the crankcase, the system further comprises a lubricating oil tank, a first oil pump and a plurality of first oil pipes mounted on the first oil pump, the first oil pump communicates with the cavity of the crankcase through the multiple first oil pipes, and the first oil pump extracts lubricating oil from the lubricating oil tank and conveys the lubricating oil into the crankcase to lubricate the power assembly; the first oil pump is linked with the engine, so that the first oil pump conveys the lubricating oil with the oil quantity adaptive to the working condition of the engine into the crankcase; and meanwhile, the bottom of the cavity of the crankcase communicates with the upper portion of the cavity of the crankcase through a second oil pipe, so that the lubricating oil at the bottom of the cavity is conveyed to the upper portion of the cavity through the second oil pipe under the action of negative pressure. The separated lubricating system is adopted, so that the consumption of the lubricating oil can be reduced, and carbon deposition and exhaust emission can be improved; and the lubricating oil directly enters into the crankcase without being diluted by fuel oil, and the viscosity of the lubricating oil is large, so that cooling and lubrication of the power assembly are facilitated.

Owner:SUZHOU BAISHENG POWER MACHINE

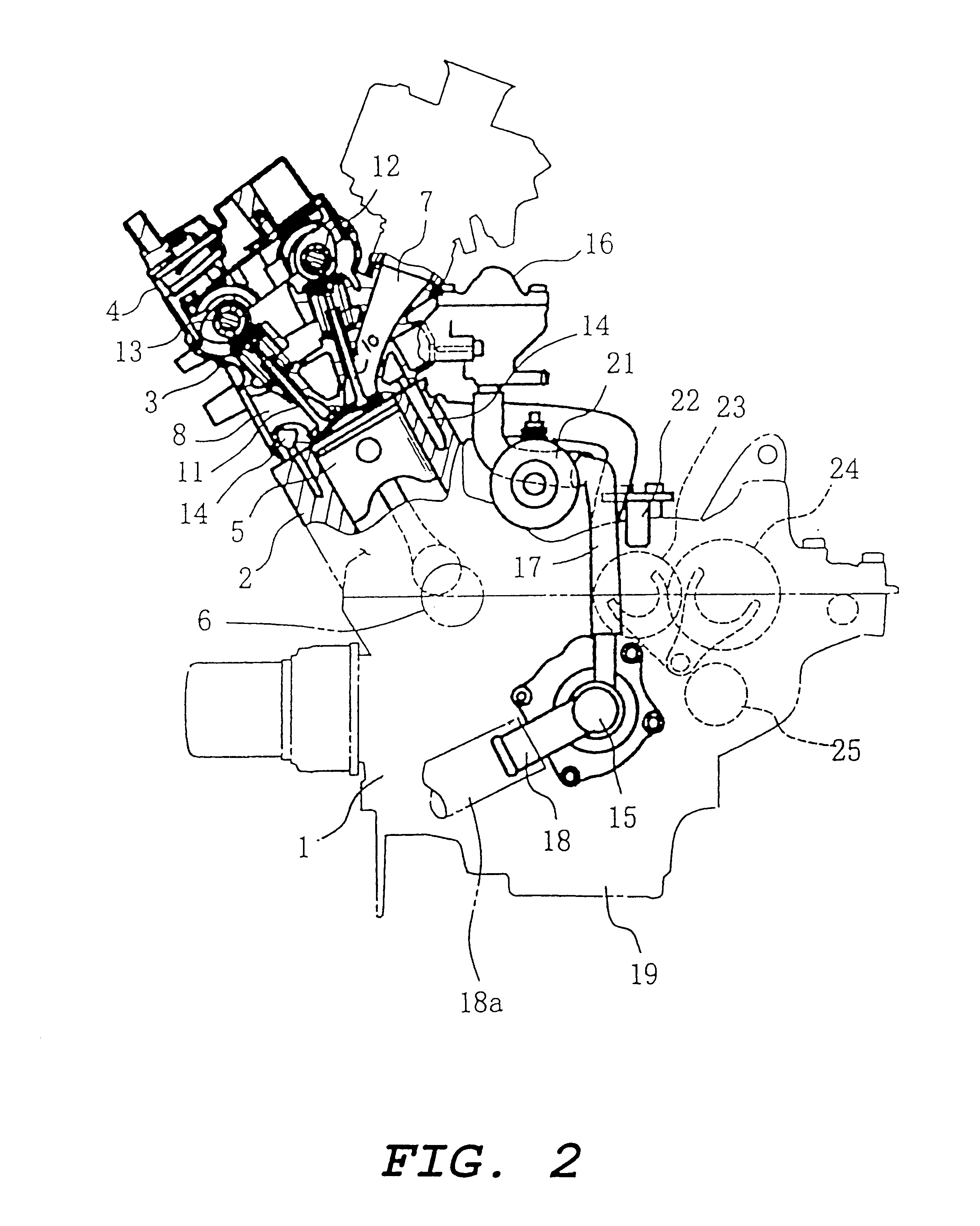

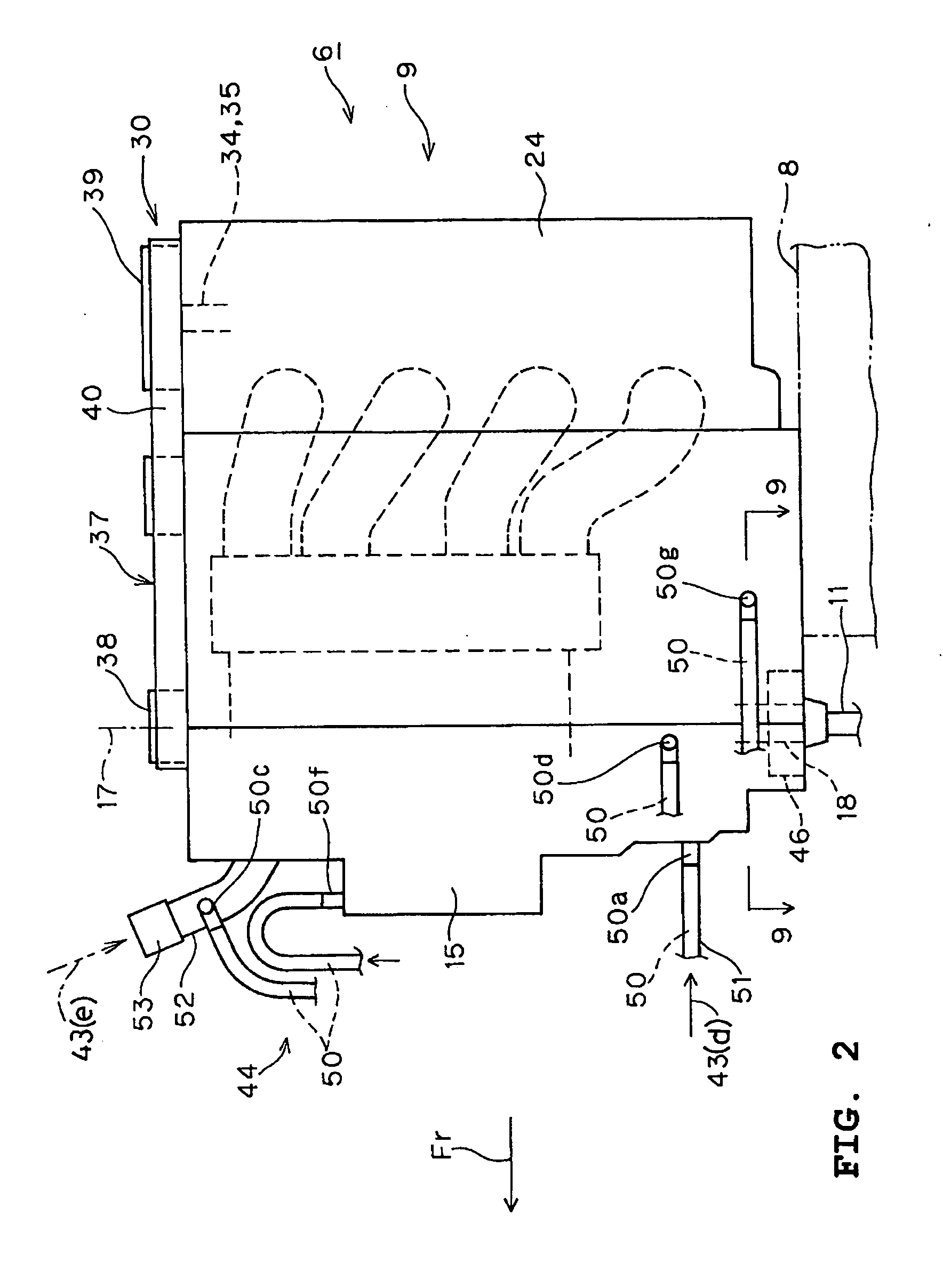

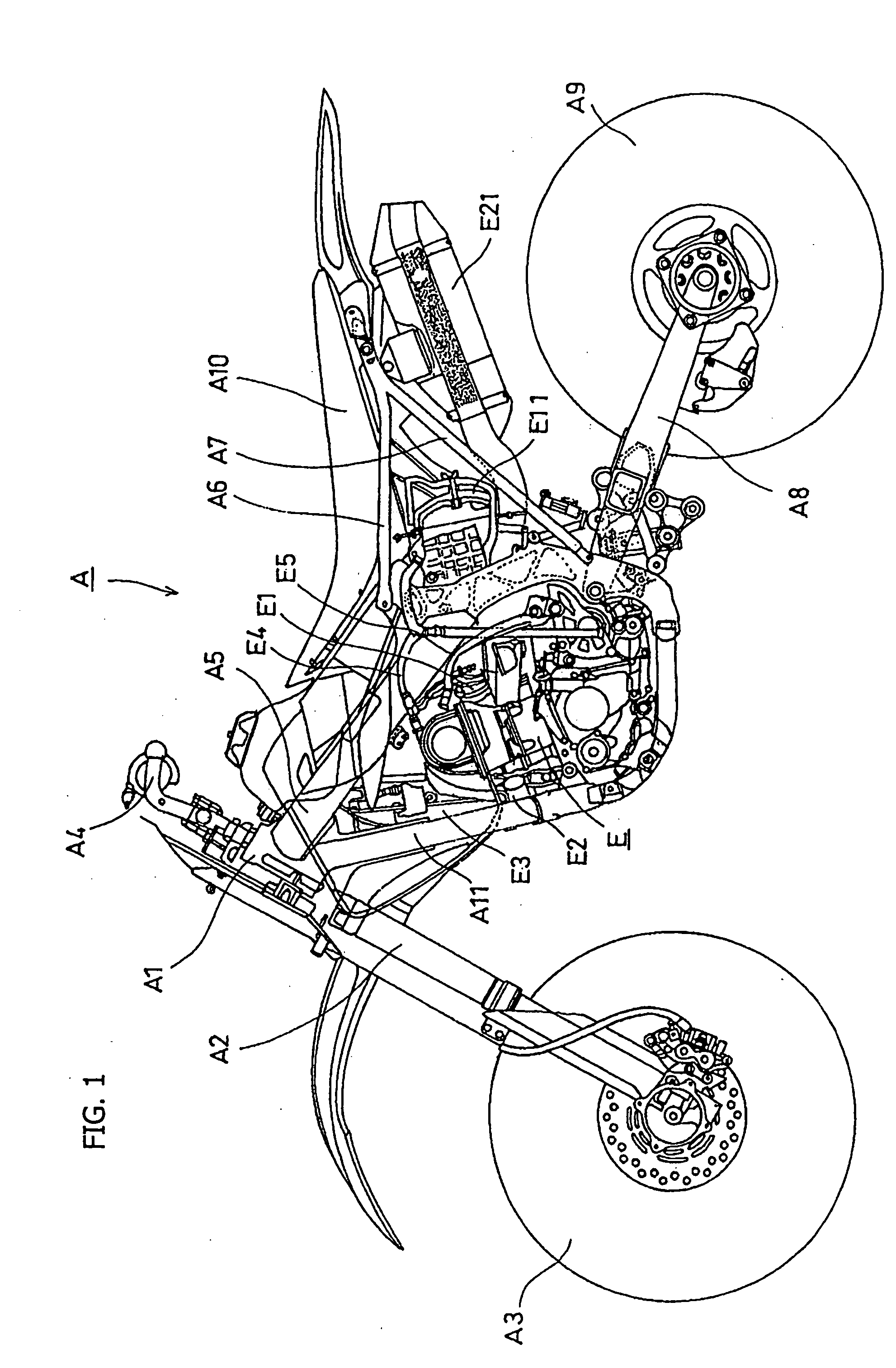

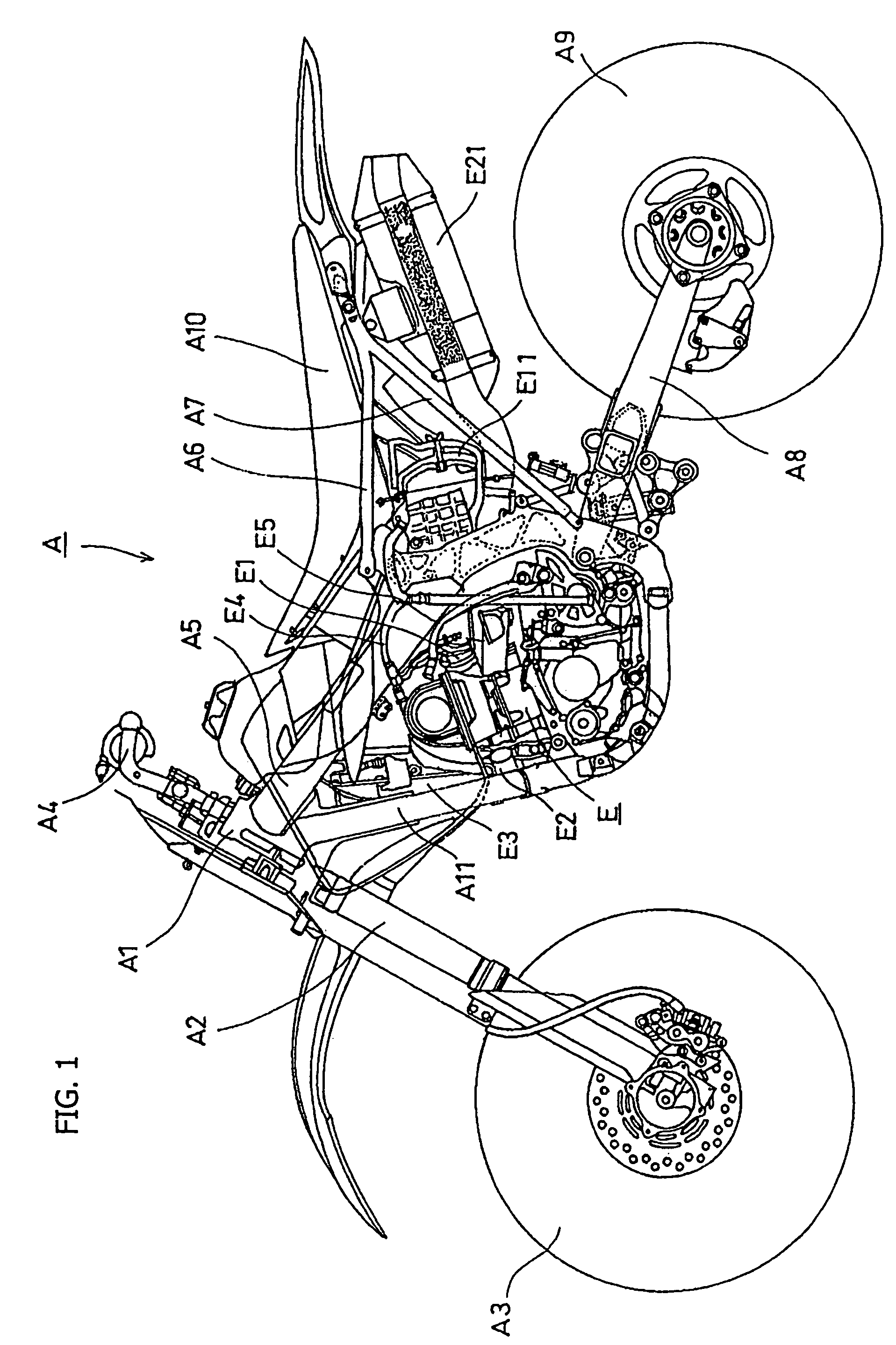

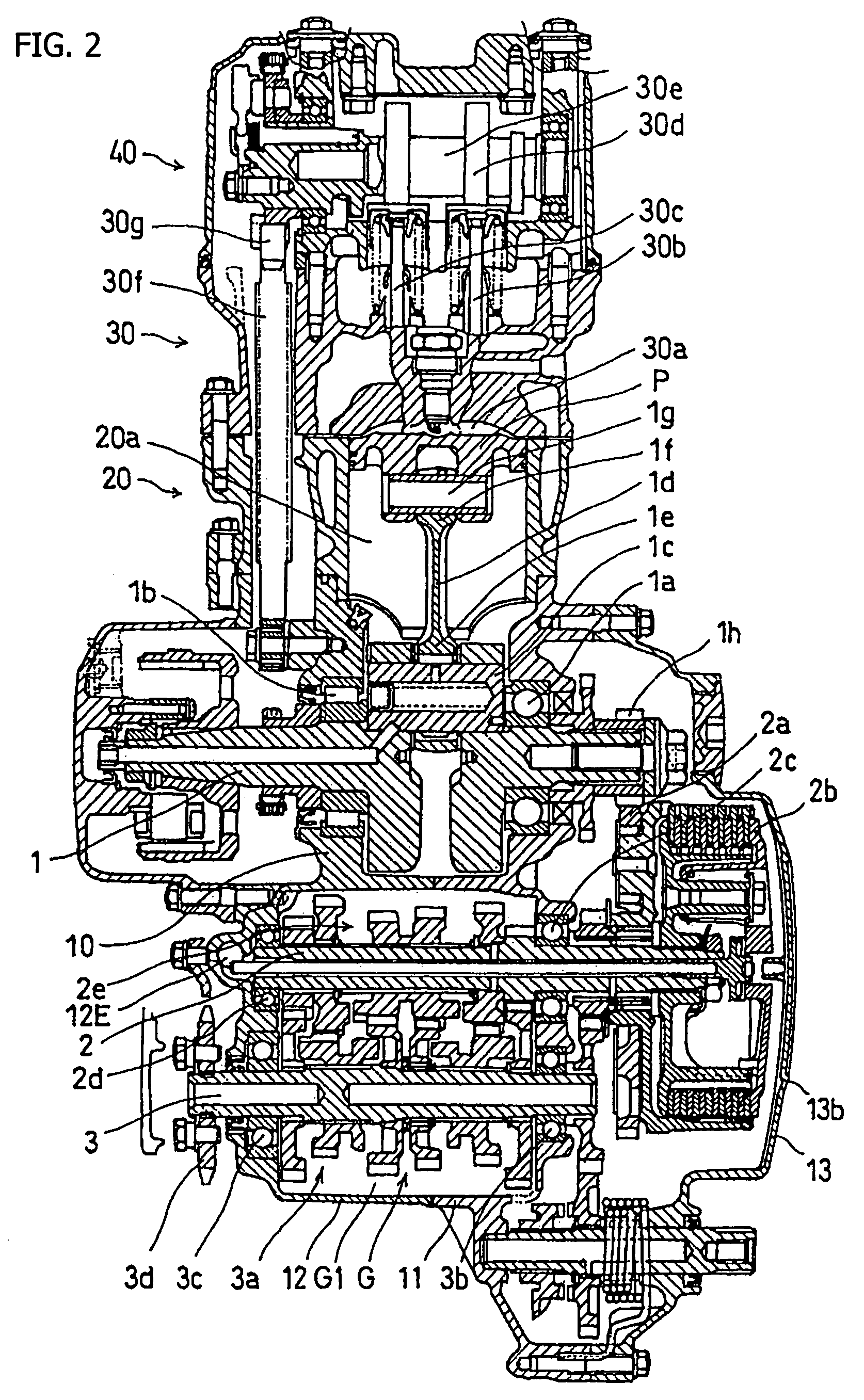

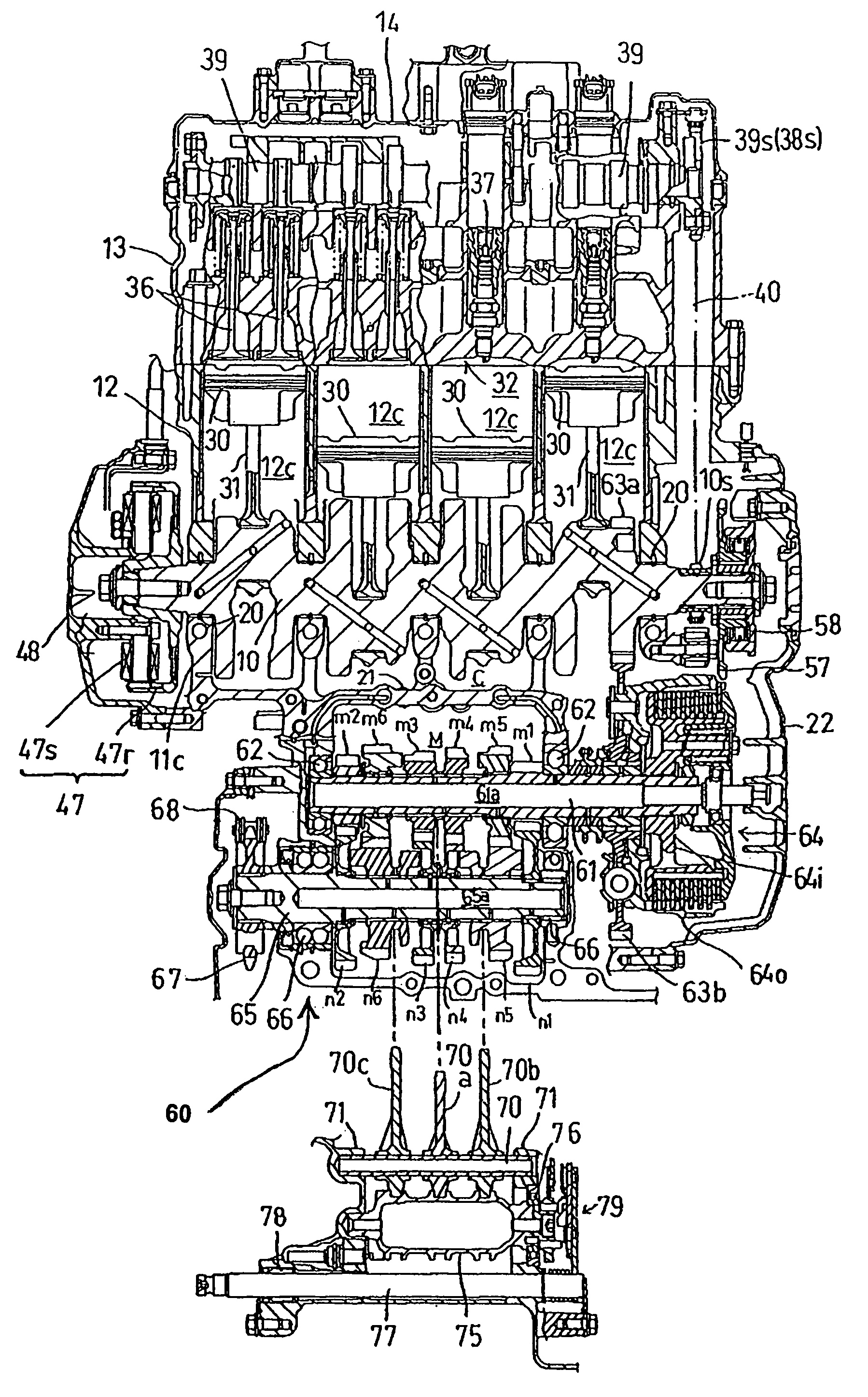

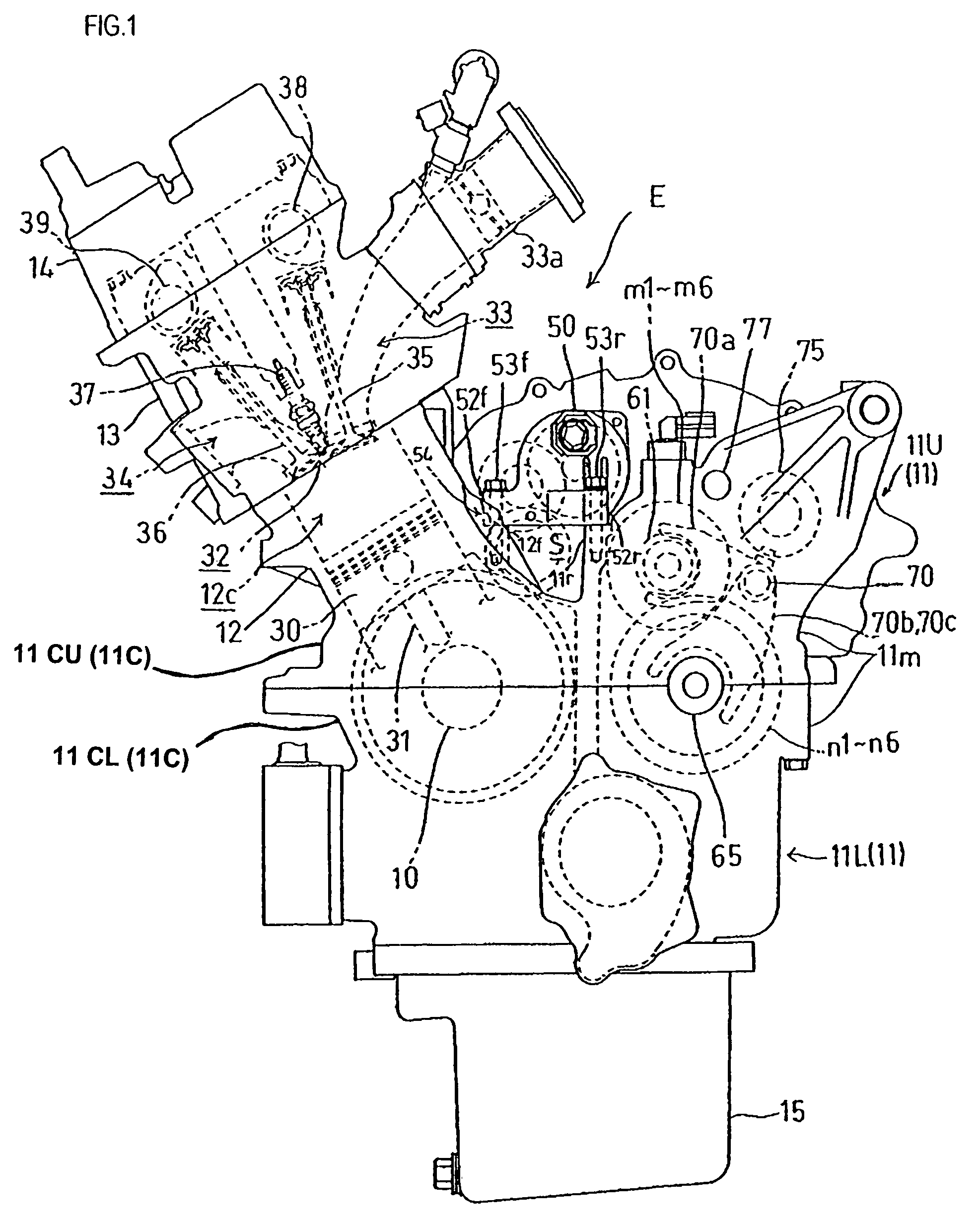

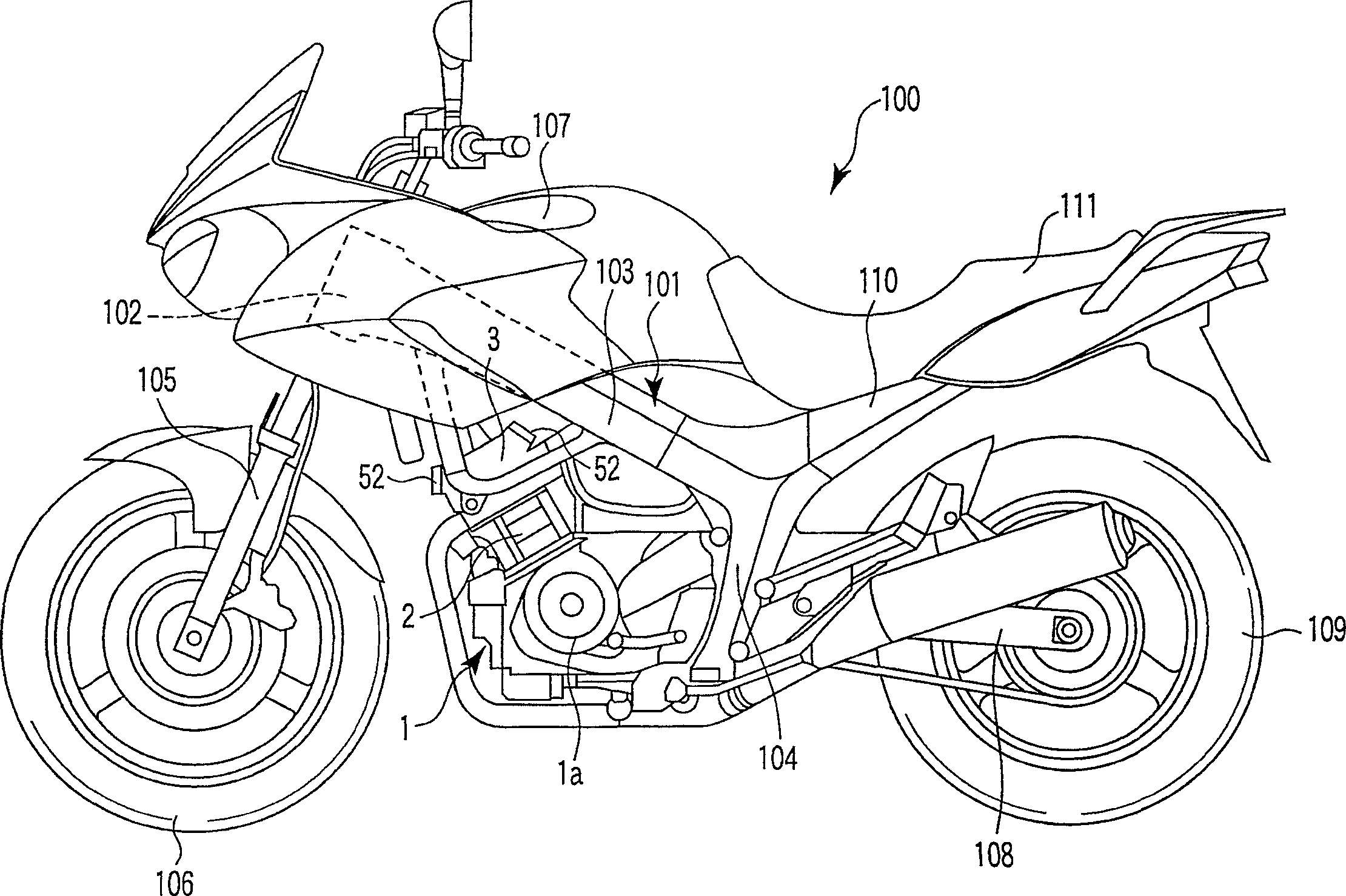

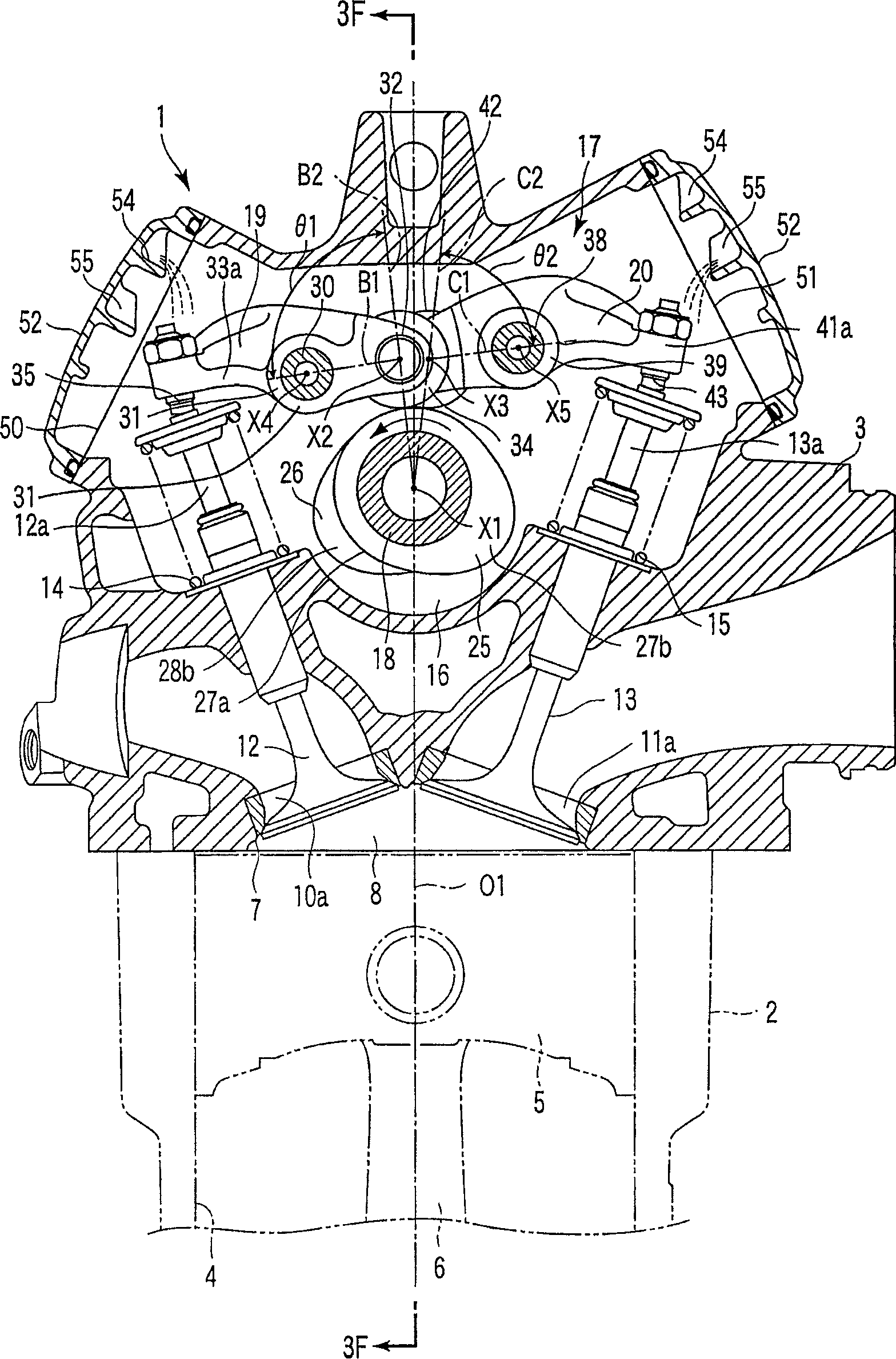

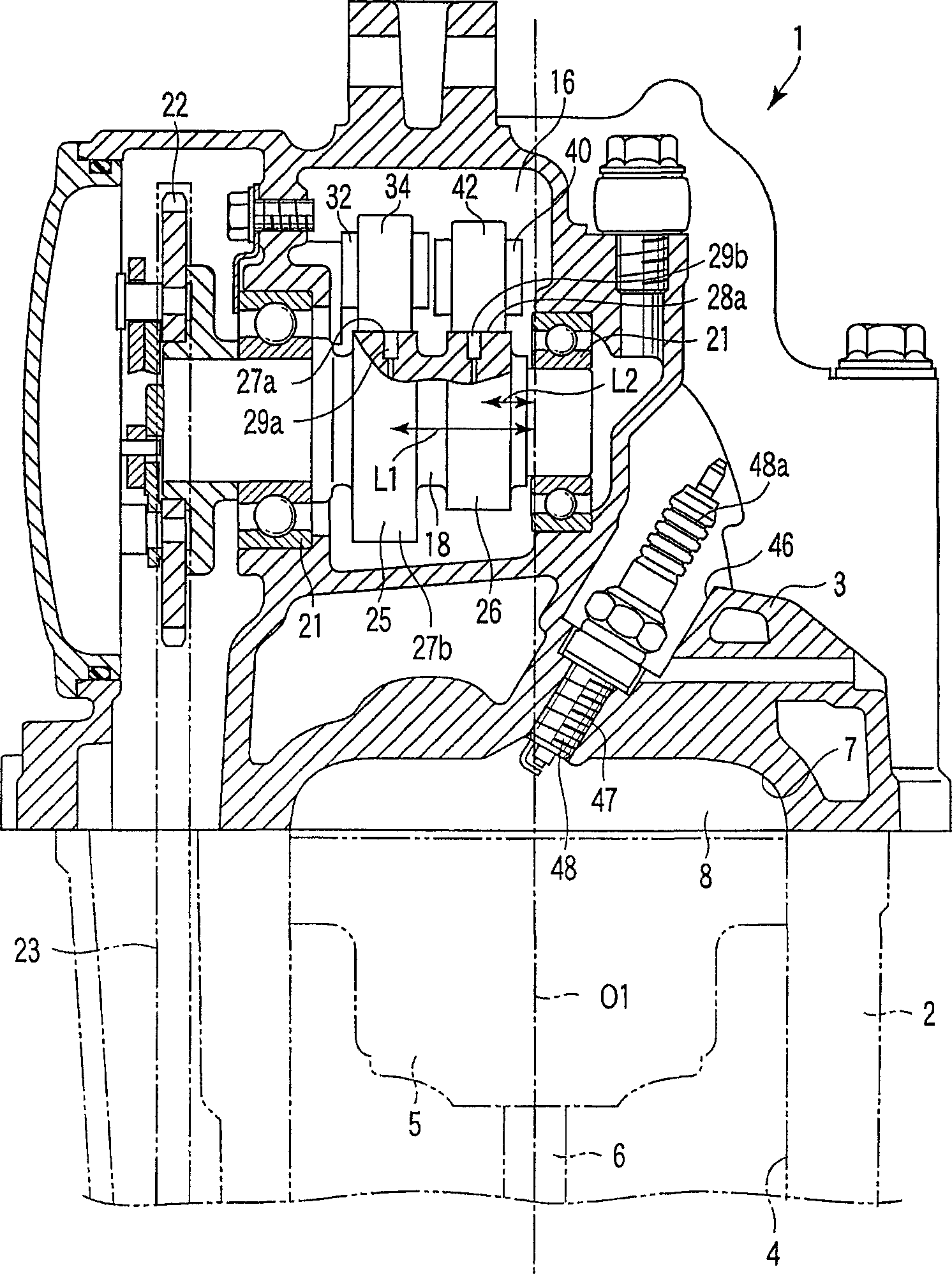

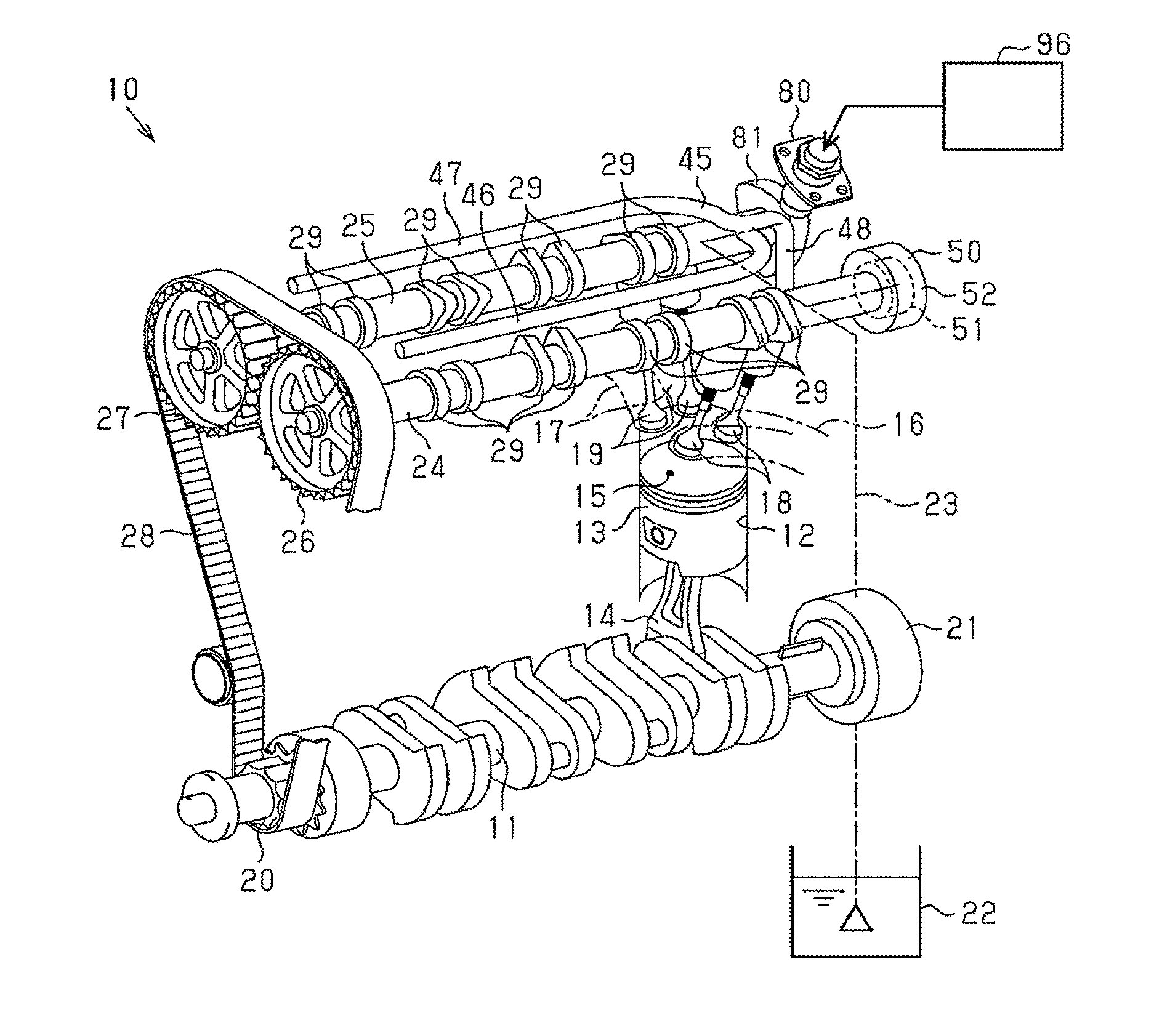

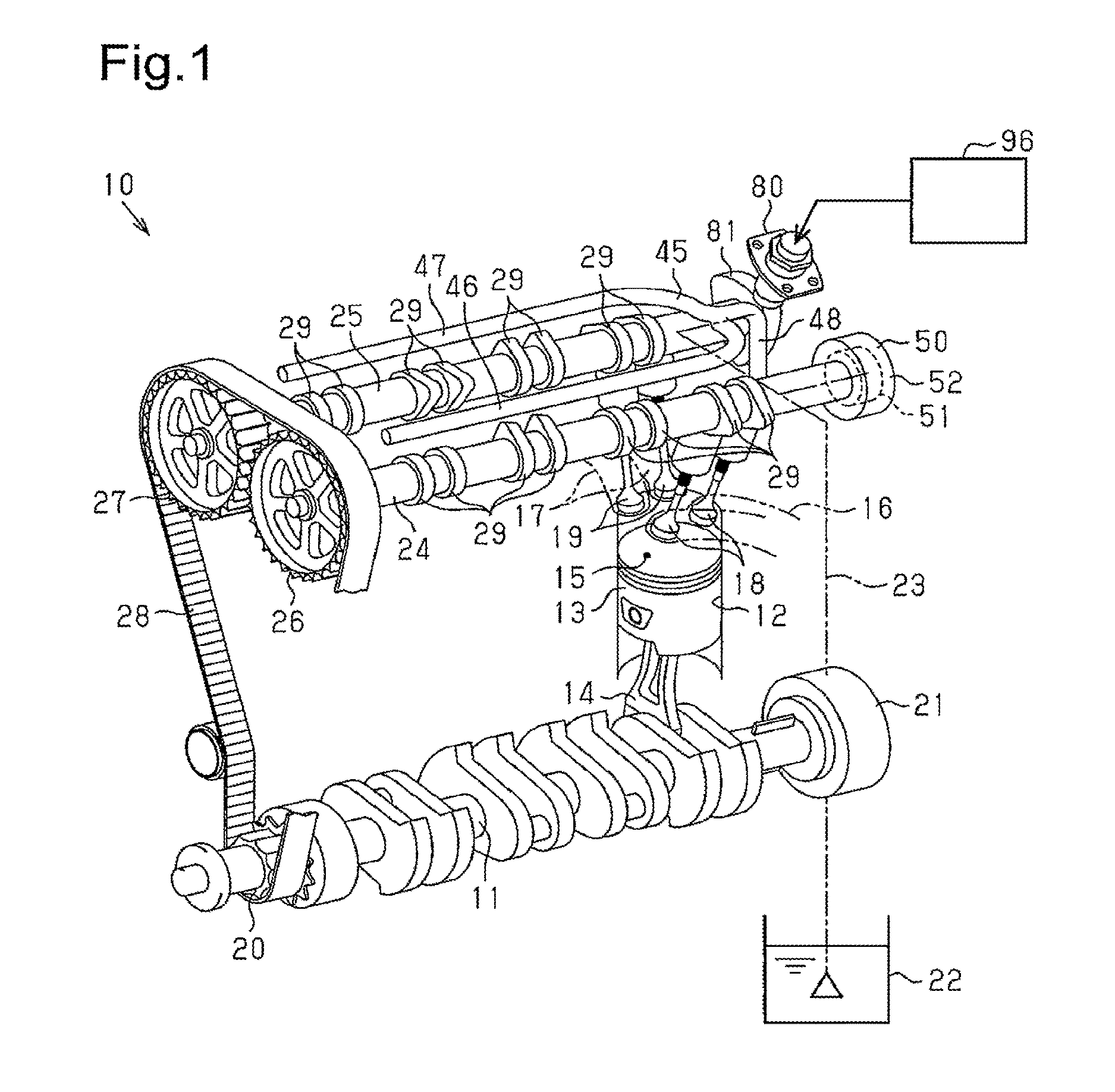

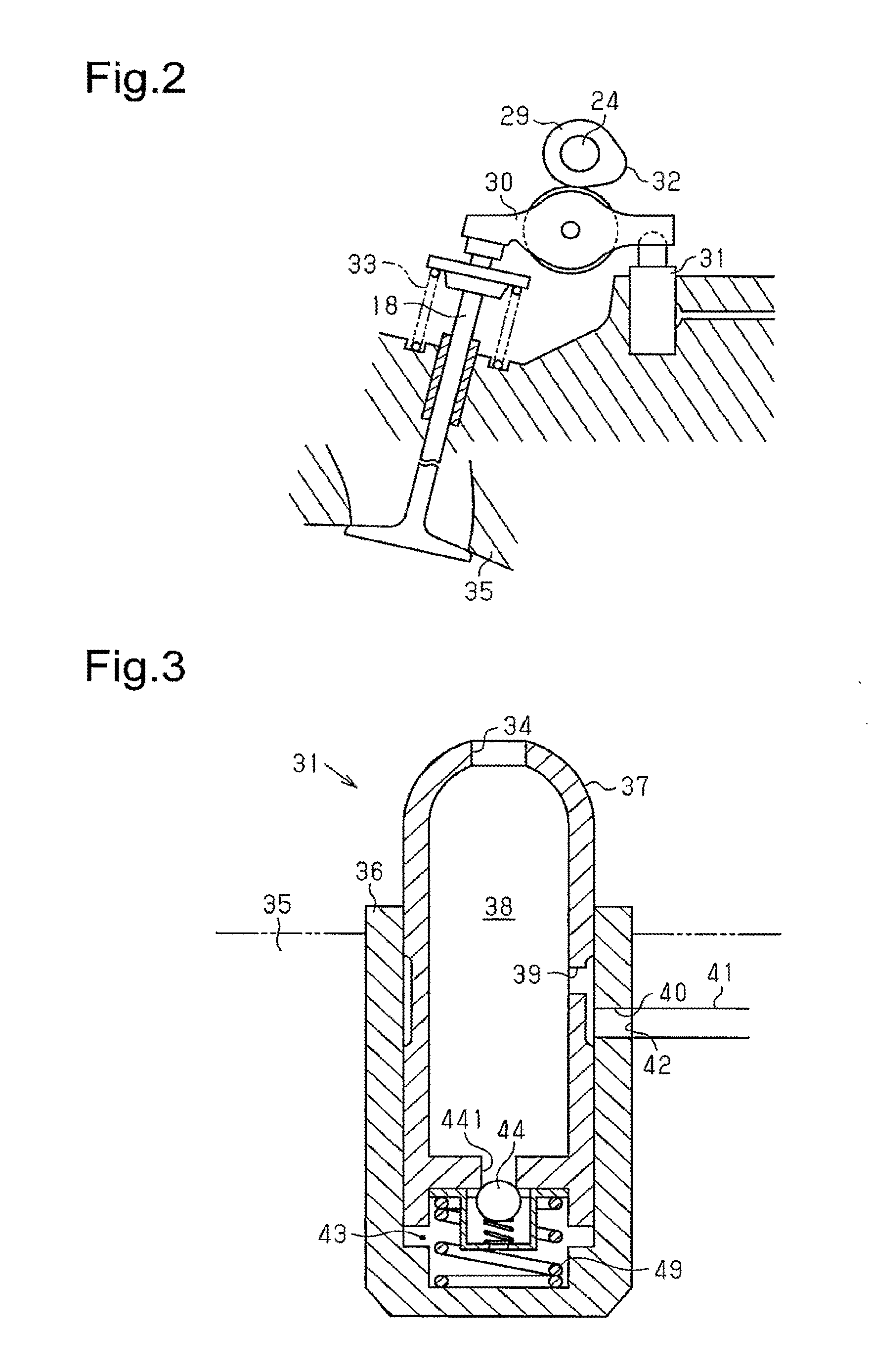

Valve operating mechanism with roller rocker arm, 4-cycle engine, and motorcycle having 4-cycle engine mounted thereon

The invention relates to a valve operating mechanism with roller rocker arm, a 4-cycle engine, and a motorcycle having 4-cycle engine mounted thereon. A valve operating mechanism (17) comprises a cam shaft (18) having valve operating cams (25, 26), first and second rocker shafts (30, 38), a first rocker arm (19) supported by the first rocker shaft (30), and a second rocker arm (20) supported by the second rocker shaft (38). The valve operating cams (25, 26) have cam noses (27b, 28b) projecting from base circles (27a, 28a), respectively, and the first rocker shaft (30) supporting the first rocker arm (19) is positioned more forwardly of the direction of rotation of the cam shaft (18) than a centerline (O1) extending axially of a cylinder (4) through the center of the cam shaft (18). When the roller bearing (34) of the first rocker arm (19) is in contact with the base circle (27a) of the valve operating cam (25), the first rocker shaft (30) is more offset than the center of rotation (X2) of a roller bearing (34) as seen in the direction in which the cam shaft (18) is approached.

Owner:YAMAHA MOTOR CO LTD

Valve cover housing for internal combustion engines

Owner:KOOL KOVER

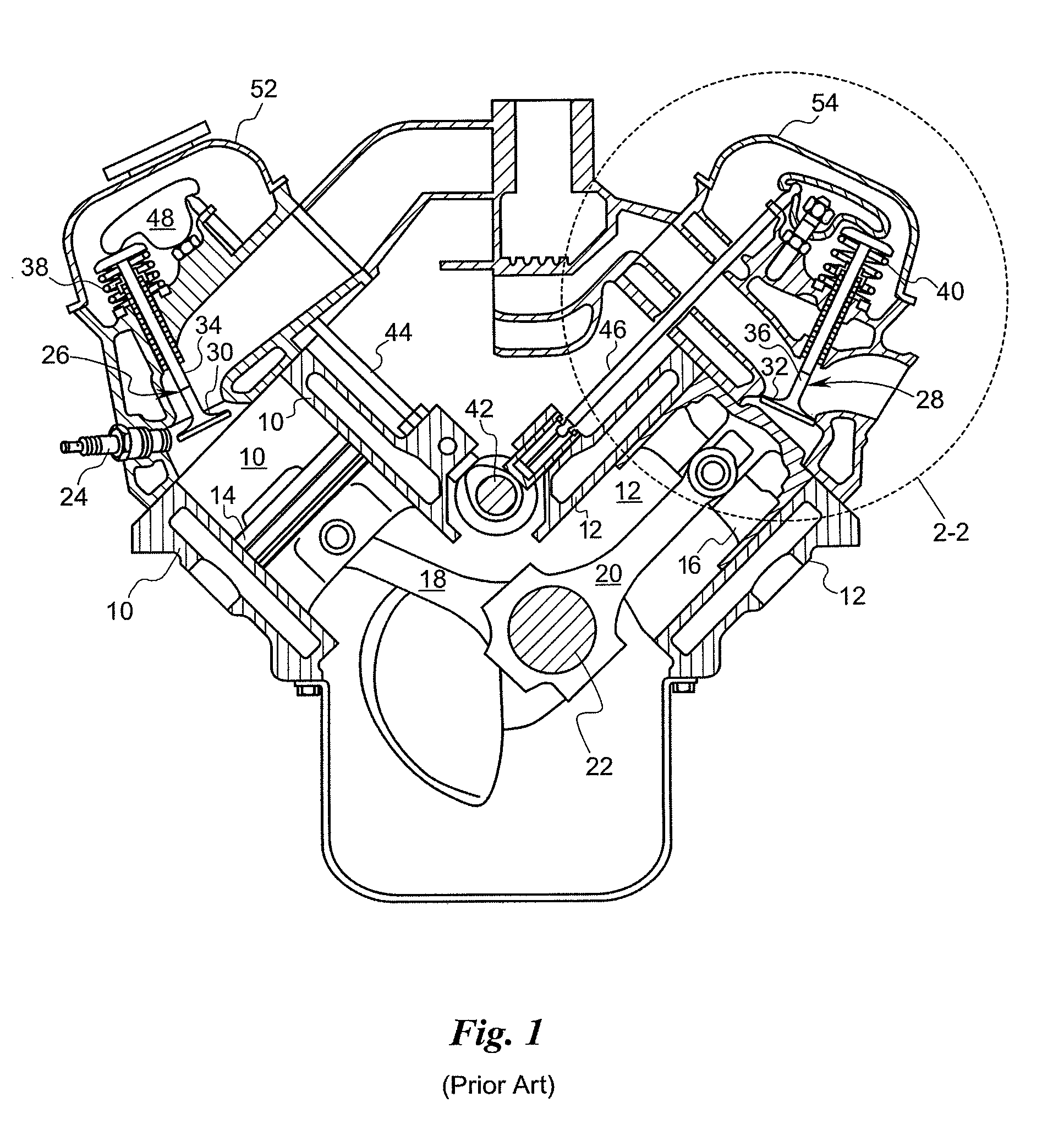

Internal combustion engine

ActiveUS20170022856A1Drip lubricationLubrication of auxillariesAtmospheric airPulp and paper industry

An internal combustion engine includes an intake camshaft, a vacuum pump, an oil pump, and an oil feeding passage serving as an oil supplying path. The vacuum pump includes a rotor and a housing. The vacuum pump is formed with a negative pressure chamber that generates a negative pressure, and an oil path connected to the negative pressure chamber. An atmosphere communication hole for supplying air to the negative pressure chamber through the oil feeding passage and the oil path when the vacuum pump is stopped is arranged in the oil feeding passage. The atmosphere communication hole communicates the negative pressure chamber and the atmosphere before an amount of oil in the housing exceeds an allowable oil amount when the vacuum pump is stopped.

Owner:TOYOTA JIDOSHA KK

Internal combustion engine

ActiveUS20220127981A1Easy to moveSuppress shortageDrip lubricationLubrication of auxillariesCylinder headGear wheel

Provided is an internal combustion engine having an oil circulating structure wherein oil used to lubricate valve operating members in the cylinder head drops onto an oil pan, and the oil accumulated therein is drawn up to the cylinder head again. Each on corners of the squire bottom face inside the cylinder head of the internal combustion engine, an oil dropping hole is provided to allow the oil used to lubricate valve operating members to flow thereinto. Also provided is an oil channel communicating with one or more of the oil dropping hole at the bottom thereof to guide the oil toward the driving gear transmitting the driving force of the engine.

Owner:NISSAN MOTOR CO LTD

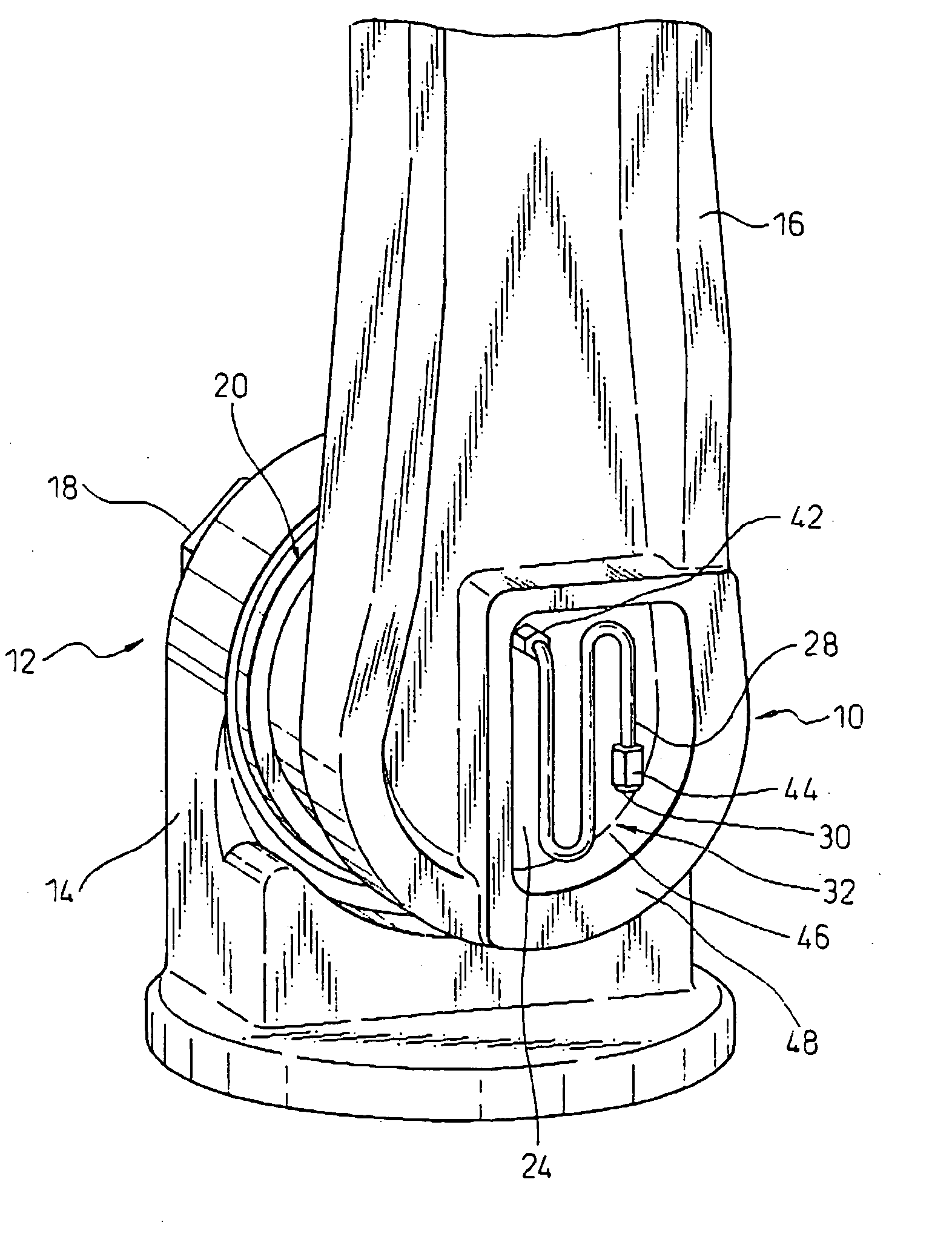

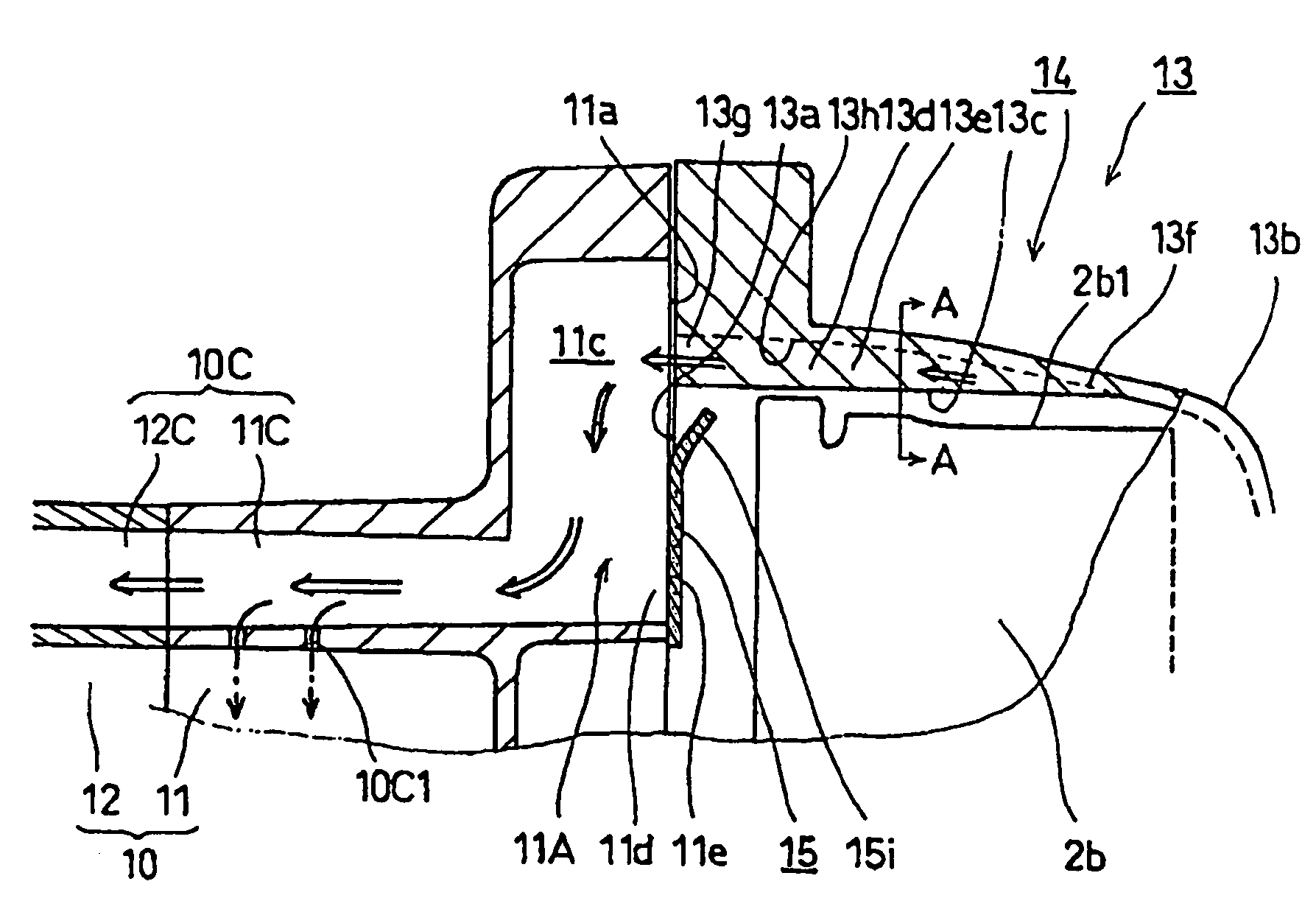

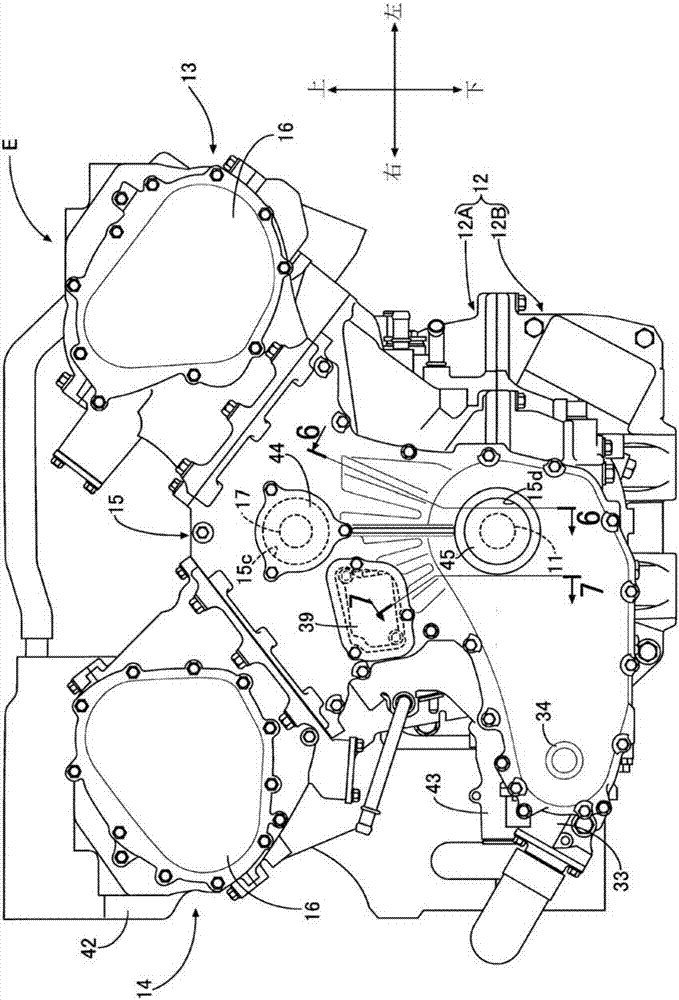

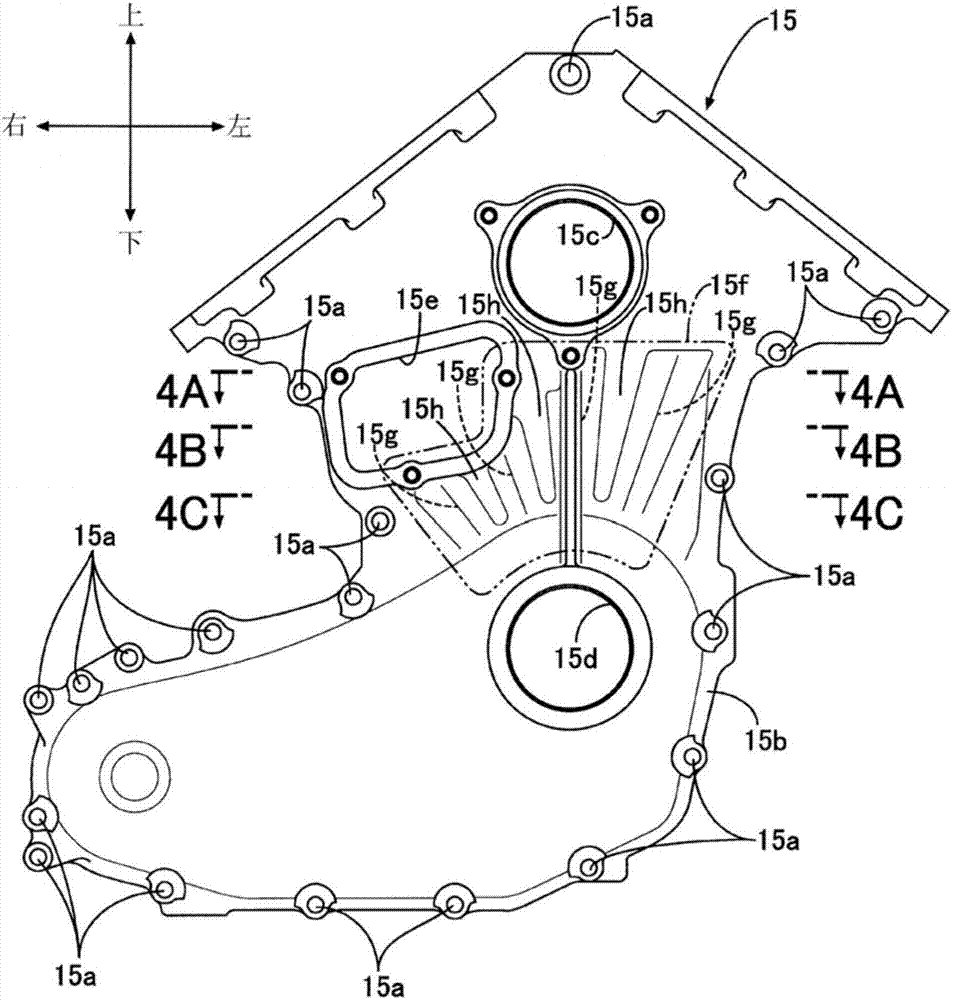

Cover member of internal combustion engine

The present invention provides a cover member for an internal combustion engine capable of improving the rigidity of a lid member of an internal combustion engine to suppress vibration and capable of smoothly guiding the oil flowing along the cover member to a through hole for supporting the shaft. A cover member (15) mounted on a crankcase (12) of an internal combustion engine (E) has a through hole (15d) rotatably supported by a shaft (11); a bulging portion (15f) which is located above the through hole and bulges toward the inside of the cover member; and a plurality of groove portions (15g) extending radially from the through hole so as to connect the upper portion and the lower portion on the inner surface side of the bulging portion. Therefore, it is possible to suppress the vibration by improving the rigidity of the cover member by the groove portion (15g) of the bulging portion (15f) without providing the ribs with weight, the oil inside the crankcase (12) can concentrated around the through hole (15d) along the groove portion (15g) of the bulging portion (15f) by means of the gravity, so that the rotating shaft can be efficiently lubricated.

Owner:HONDA MOTOR CO LTD

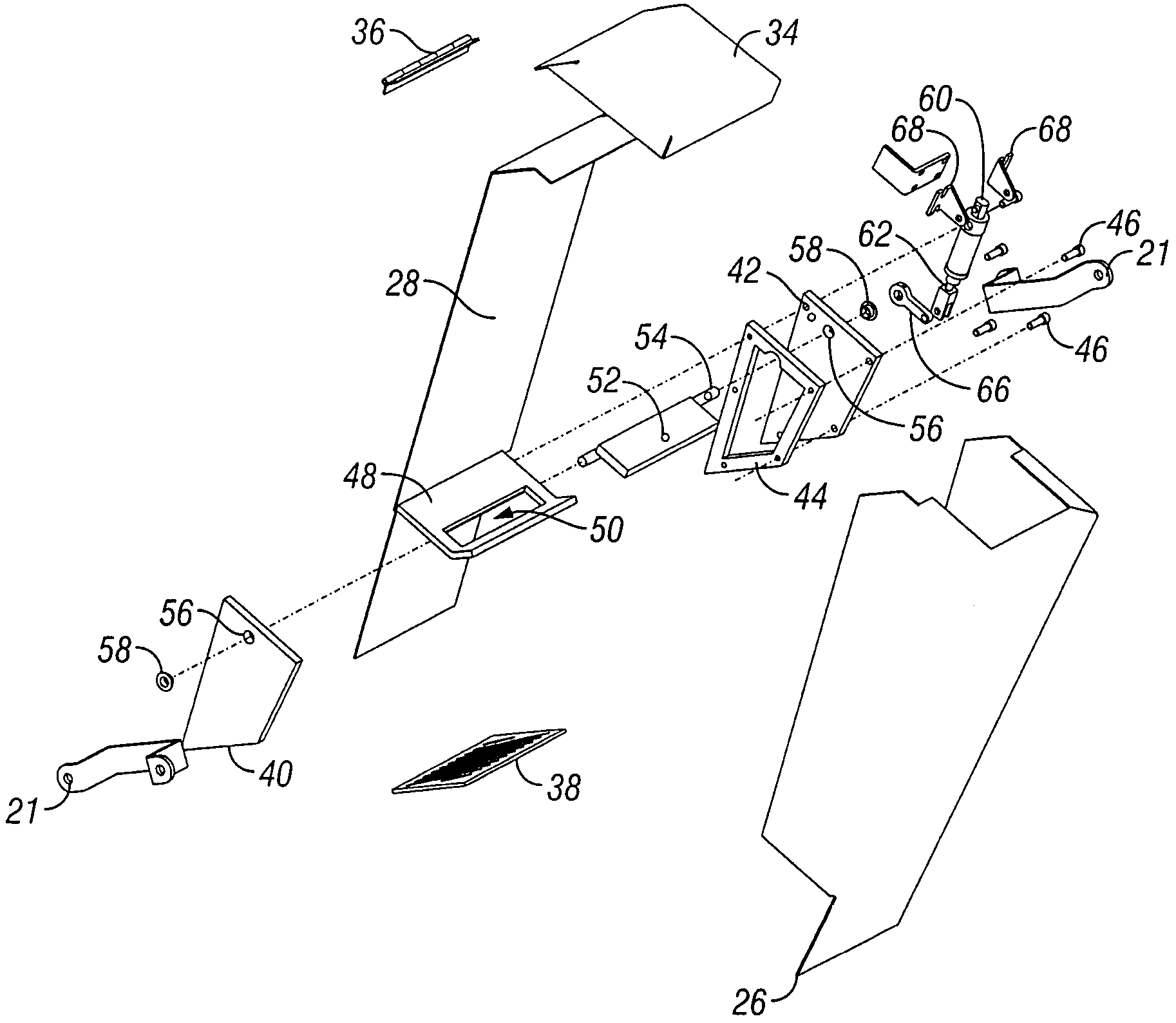

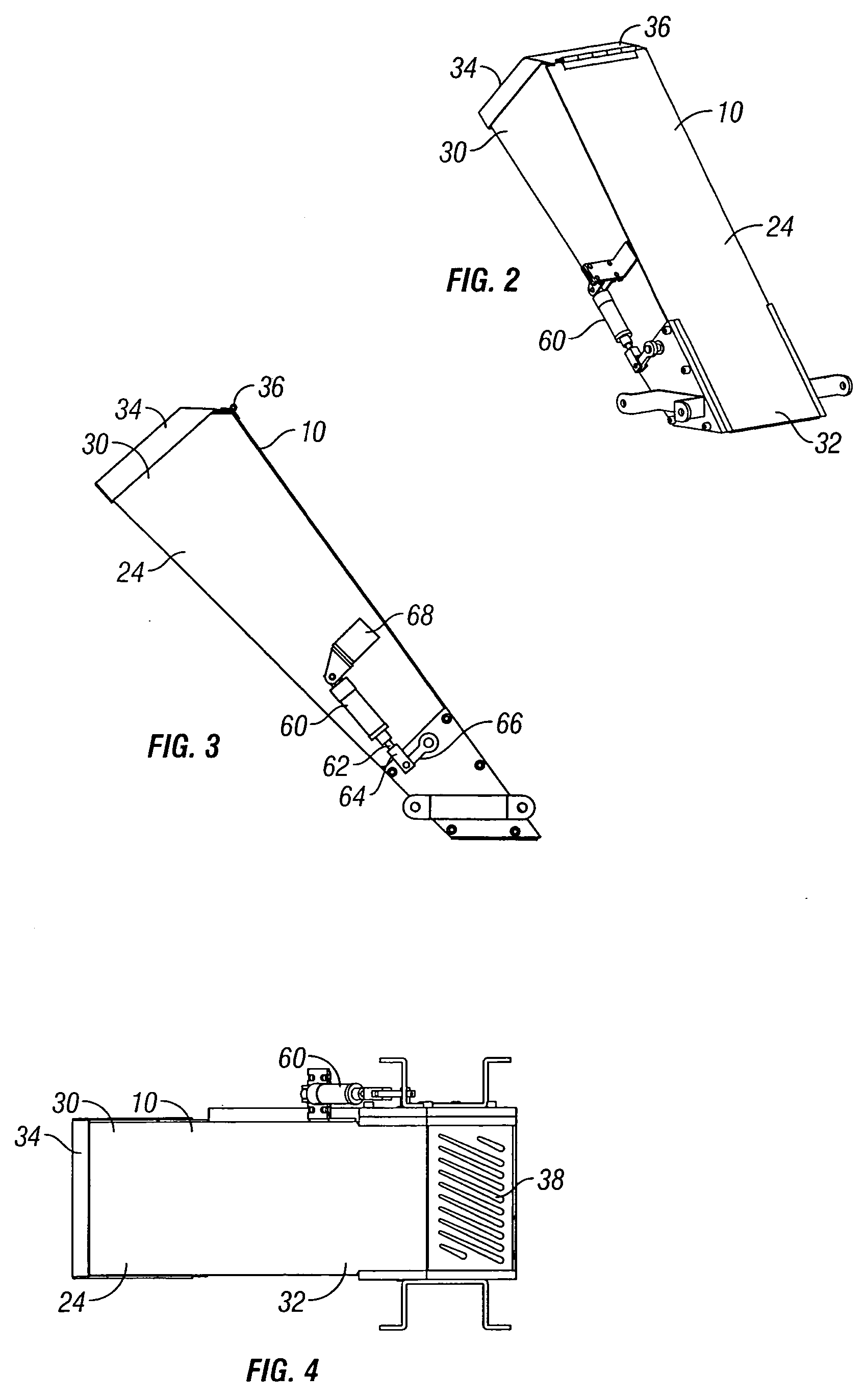

Powdered graphite applicator

The powdered graphite applicator includes a container with a lid at the upper end and a screen at the lower end. A plate is provided inside the container to define the bottom of the graphite chamber. The plate has an enlarged opening which is normally closed by a gate. The gate can be periodically opened to allow graphite to pass through the plate opening, and then to fall from the plate through the screen and onto the surface of an adjacent roller of a rotatable drum. Movement of the gate is controlled by a cylinder with an extensible arm. Extension and retraction of the cylinder arm is automatically controlled by a solenoid and a programmed controller.

Owner:PRECISION ROTARY EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com