Patents

Literature

66results about How to "Efficient lubrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nylon 66 composition for petroleum sucker rod centralizer material

InactiveCN101760022AHigh strengthGood wear resistanceDrilling rodsDrilling casingsPolyamideLubrication

The invention relates to the polyamide composition field, particularly to a nylon 66 composition for a petroleum sucker rod centralizer material, the material is mainly used for producing injection-molding petroleum sucker rod centralizers. The material is prepared by the following raw materials(by weight proportion): 30-60% of nylon 66 slices, 5-15% of nylon 6 slices, 5-15% of compatibilzer, 0.1-0.7% of anti-oxidant, 0.5-1.5% of lubricating agent, 20-35% of fiber glass,0.1-0.5% of color master batch, and 0.1-0.7% of inorganic mineral. The preparation method is as follows: 1. weighing the above raw materials; 2. besides the glass fiber, adding materials into a high-mix machine for mixing; 3. adding the mixed raw materials into the glass fiber, and put putting the mixture into a twin screw extruder for extruding granulation. The beneficial effects of the invention are that: the product of the invention can continuously maintain the characteristics of high efficient lubrication, wear resistance and high temperature oxidation resistance at high temperature of 184 DEG C, thereby greatly improving thermal stability.

Owner:PINGDINGSHAN HUABANG ENG PLASTIC

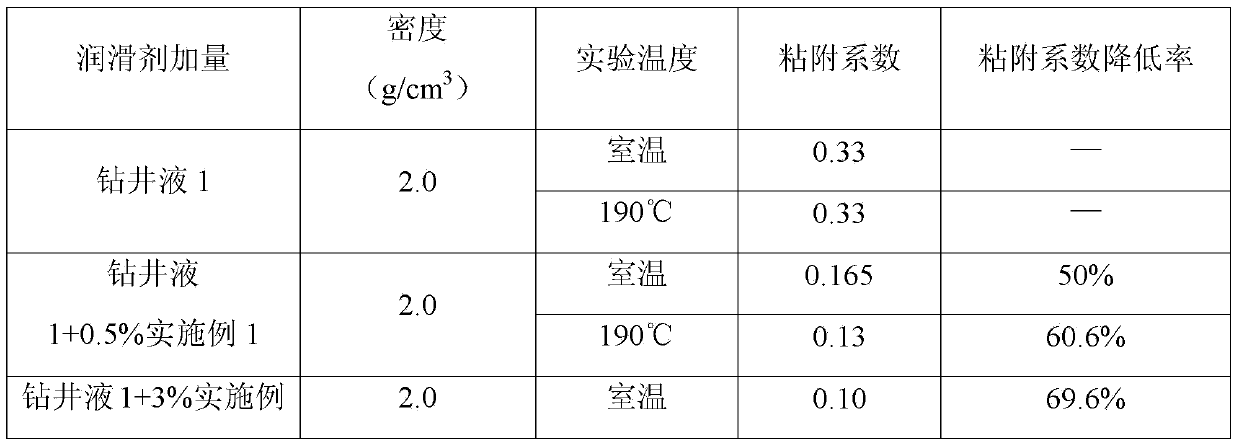

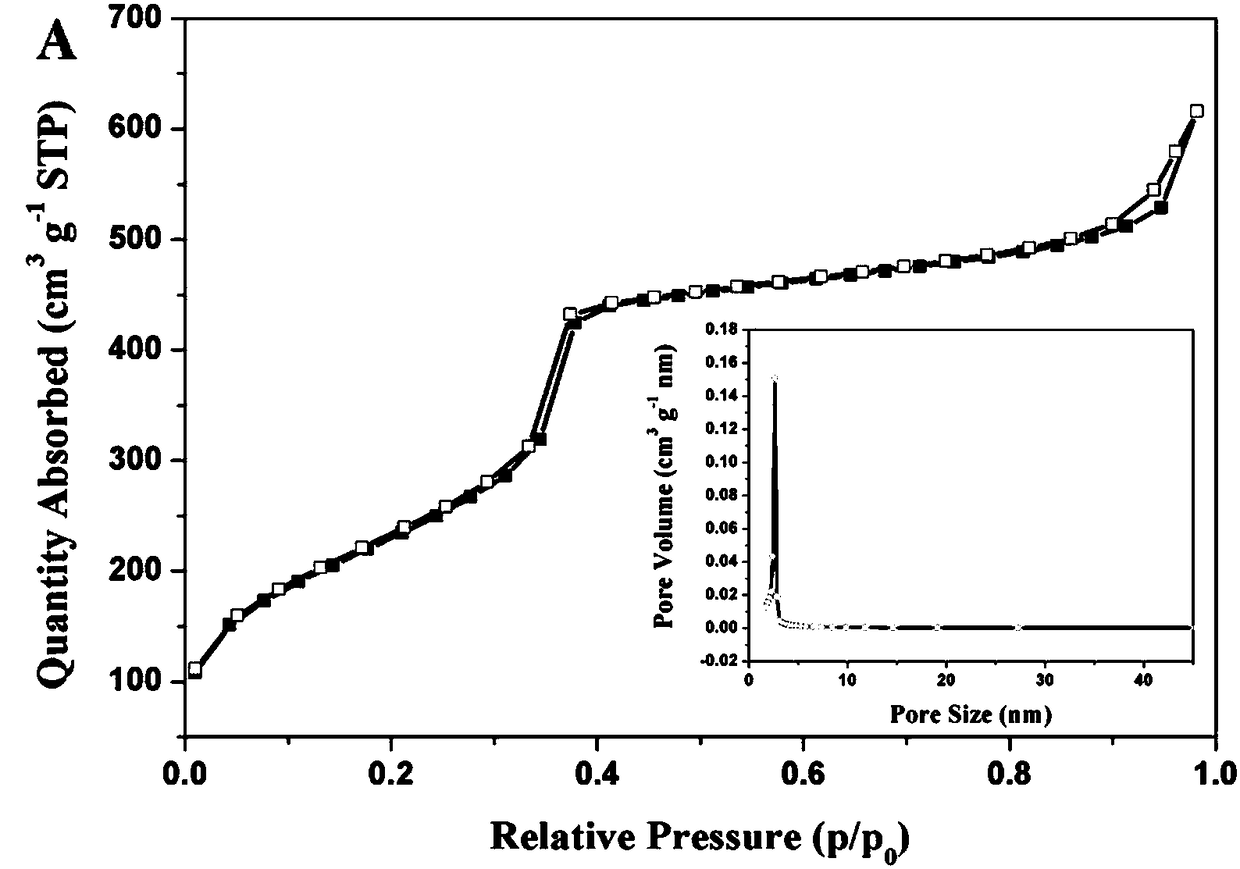

Preparation and application methods of high-temperature-resistant lubricant for drilling fluid

InactiveCN103725267AEfficient lubricationHigh temperature resistantDrilling compositionVegetable oilTemperature resistance

The invention discloses a preparation method of a high-temperature-resistant lubricant for a drilling fluid, which comprises the following steps: 1) while stirring, sequentially adding 100-120 parts by mass of waste animal and vegetable oil, 8-12 parts by mass of triethanolamine and 2-5 parts by mass of concentrated sulfuric acid into a reaction kettle, and reacting at 120-140 DEG C for 3-5 hours; 2) cooling the reaction product to 60-80 DEG C, adding 20-50 parts by mass of fatty acid methyl ester and 20-50 parts by mass of white oil into the reaction kettle in the stirring state, and stirring for 1-2 hours; 3) adding 3-10 parts by mass of molybdenum disulfide into the reaction kettle in the stirring state, and stirring for 1-3 hours; and 4) cooling to normal temperature to obtain the high-temperature-resistant lubricant for a drilling fluid. The lubricant has the characteristics of high lubricating efficiency and high temperature resistance; after rolling at 190 DEG C for 16 hours, the lubricating factor decreasing rate can still reach 50% above; and thus, the lubricant can satisfy the lubricating demands for deep wells and ultradeep wells.

Owner:CNPC BOHAI DRILLING ENG

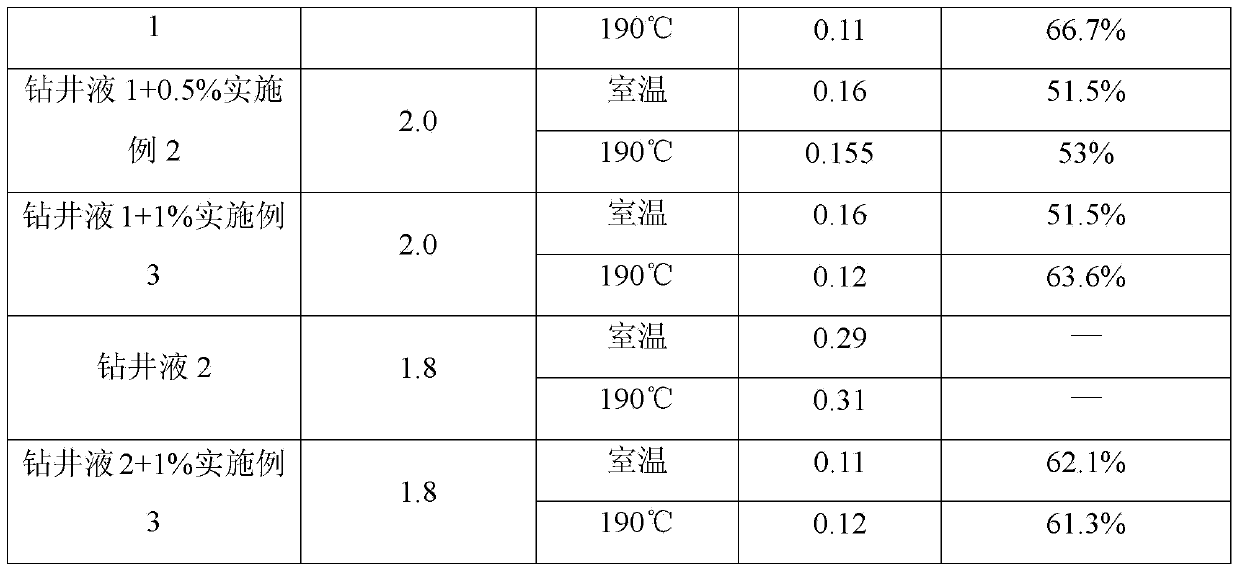

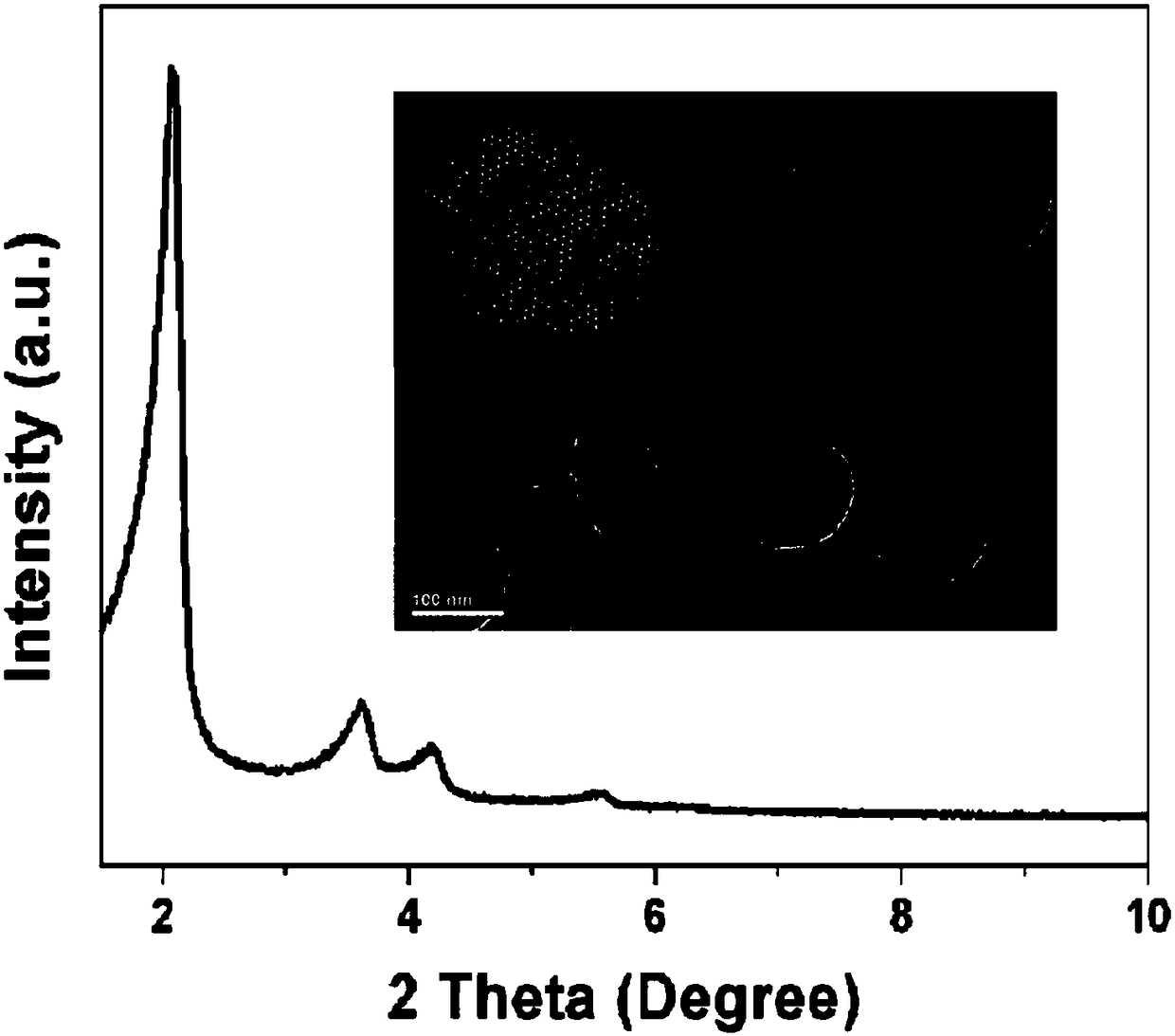

Application of aminated mesoporous silica nanomaterial as lubricating oil antiwear agent

InactiveCN108165341AImprove anti-wear and anti-friction performanceImprove carrying capacityAdditivesWear resistantMesoporous silica

The invention relates to an application of an aminated mesoporous silica nanomaterial as a lubricating oil antiwear agent. The aminated mesoporous silica nanomaterial with an ordered pore passage structure can be used as the lubricating oil antiwear agent, can significantly improve the wear resistant and friction reducing properties and the bearing capacity of the lubricating oil. The interior ofthe mesoporous silica nanomaterial has a highly ordered pore passage structure, and can provide good oil absorption and oil storage functions. In the process of friction, the lubricating oil stored inpores is released to form an oil film, cracks of the friction surface are filled, the wear can be further reduced and excellent lubrication effect is achieved. With application of the aminated mesoporous silica nanomaterial, the lubricating oil has the advantages of no corrosion of friction pair materials, environmental protection, no pollution, good chemical stability and the like. The preparation method of the aminated mesoporous silica nanomaterial has the advantages of high efficiency, rapidness, wide sources of raw materials and low cost. After the mesoporous silica nanomaterial is aminated, the mesoporous silica nanomaterial is dispersed evenly in the lubricating oil, and the antiwear property is more uniform.

Owner:北京天元陆兵汽车科技有限公司

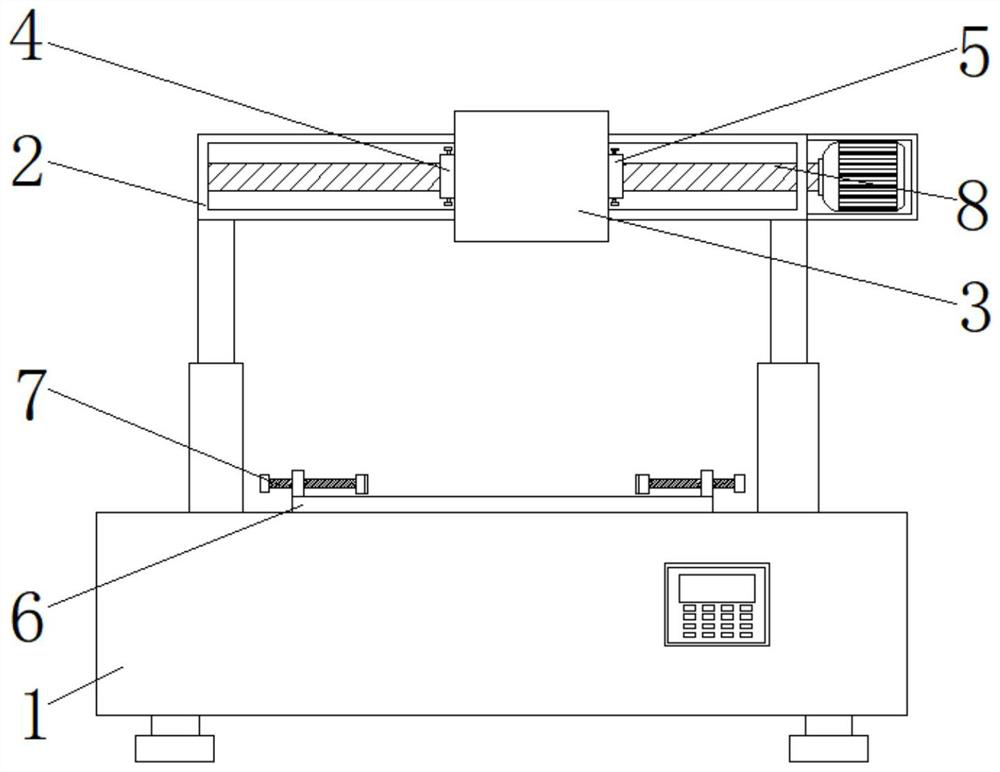

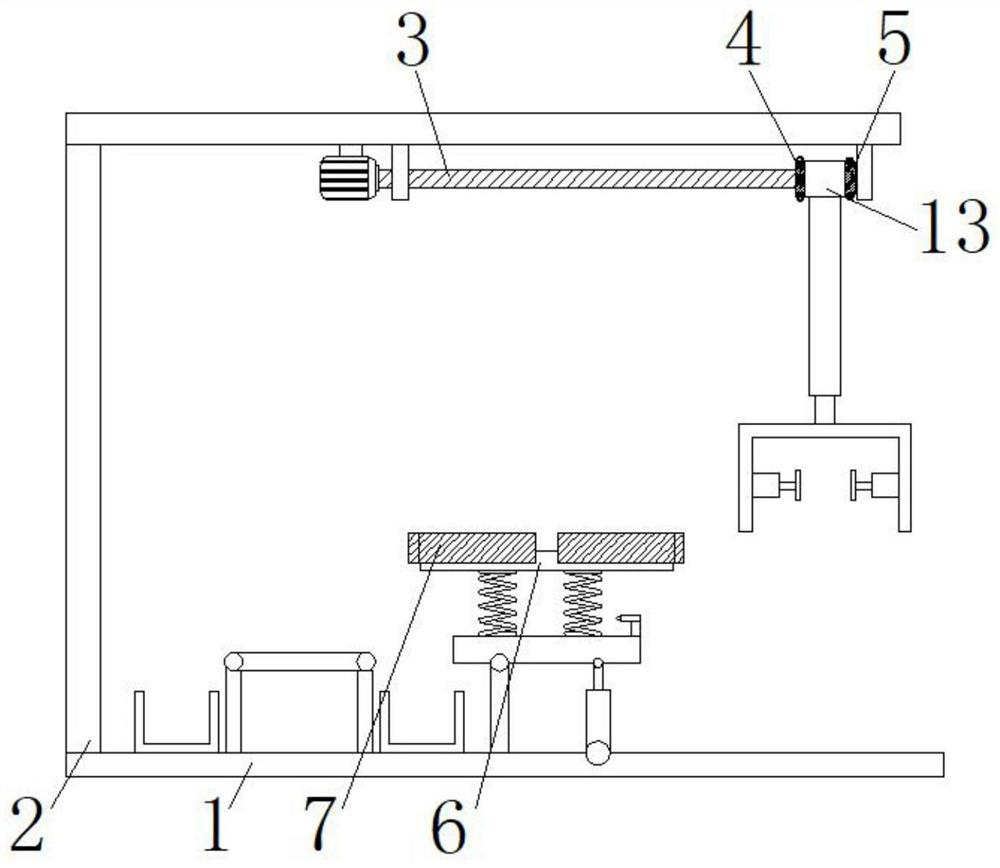

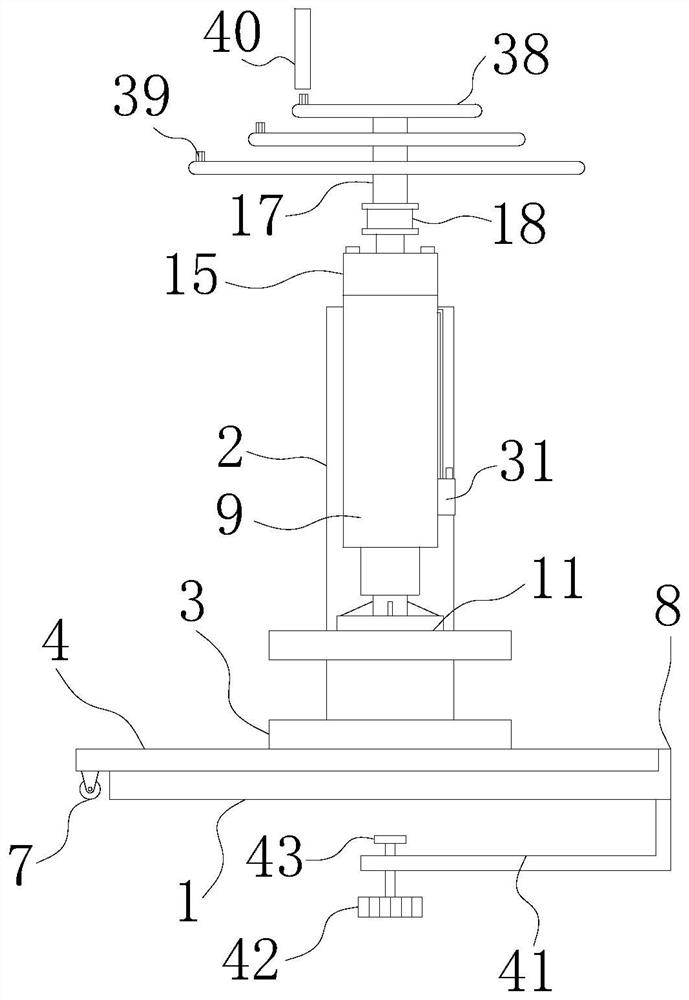

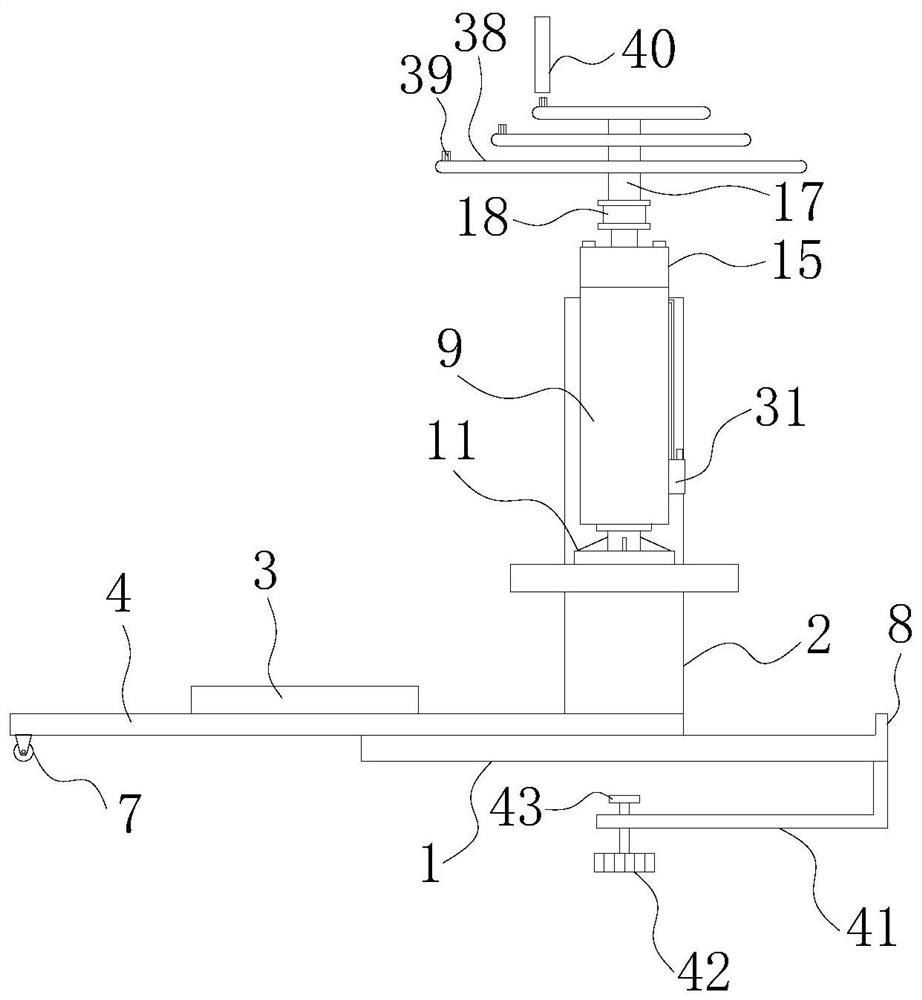

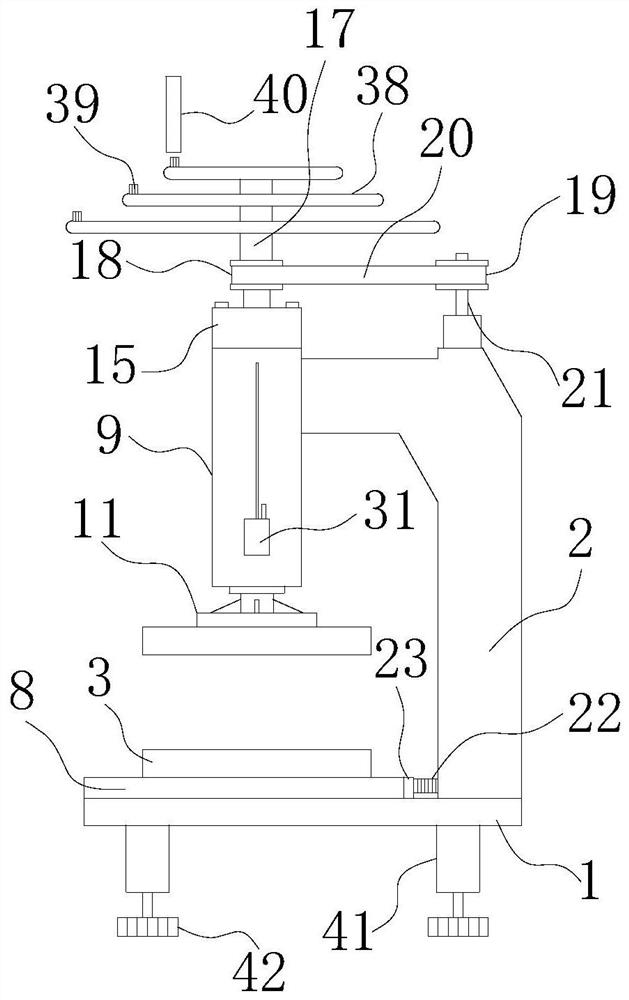

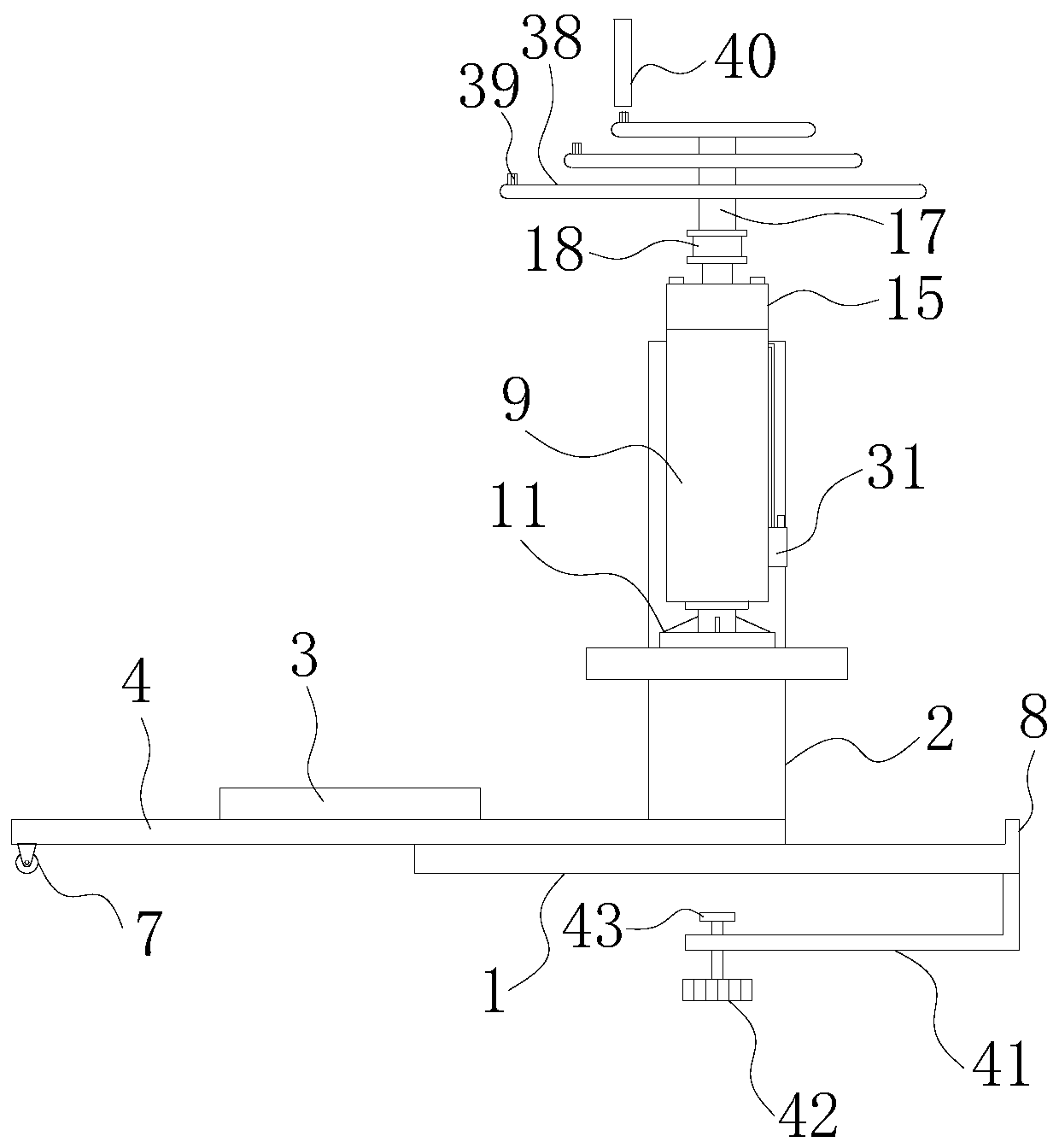

Repairing device applied to multi-main-grid photovoltaic module

ActiveCN111755573AAvoid problems that reduce the efficiency of screw driveAvoid transmission efficiency problemsFinal product manufacturePhotovoltaic energy generationElectric machineScrew thread

The invention discloses a repairing device applied to a multi-main-grid photovoltaic module, which comprises a base, wherein a cross beam is supported and fixed on the surface of the top end of the base, a motor is fixed to the surface of one side of the cross beam, an output shaft of the motor is rotationally connected with a lead screw, one end of the lead screw penetrates through the cross beamand extends into an inner cavity of the cross beam, a threaded moving block is connected to a bearing of the lead screw in a sleeving mode, and an infrared welding lamp box is fixed to the front surface of the threaded moving block; and a lubricating sleeve and a cleaning sleeve are sequentially fixed to the surfaces of the two sides of the threaded moving block from left to right and rotationally connected to the outer wall of the lead screw in a sleeving mode. By arranging the lubricating sleeve, the surface of the lead screw can be conveniently and efficiently lubricated, and the working efficiency of the device is improved; through the arrangement of the cleaning sleeve, the surface of the lead screw can be conveniently and rapidly cleaned; and through the arrangement of the screw, the multi-main-grid photovoltaic module can be conveniently and efficiently clamped and fixed.

Owner:江苏悦阳光伏科技有限公司

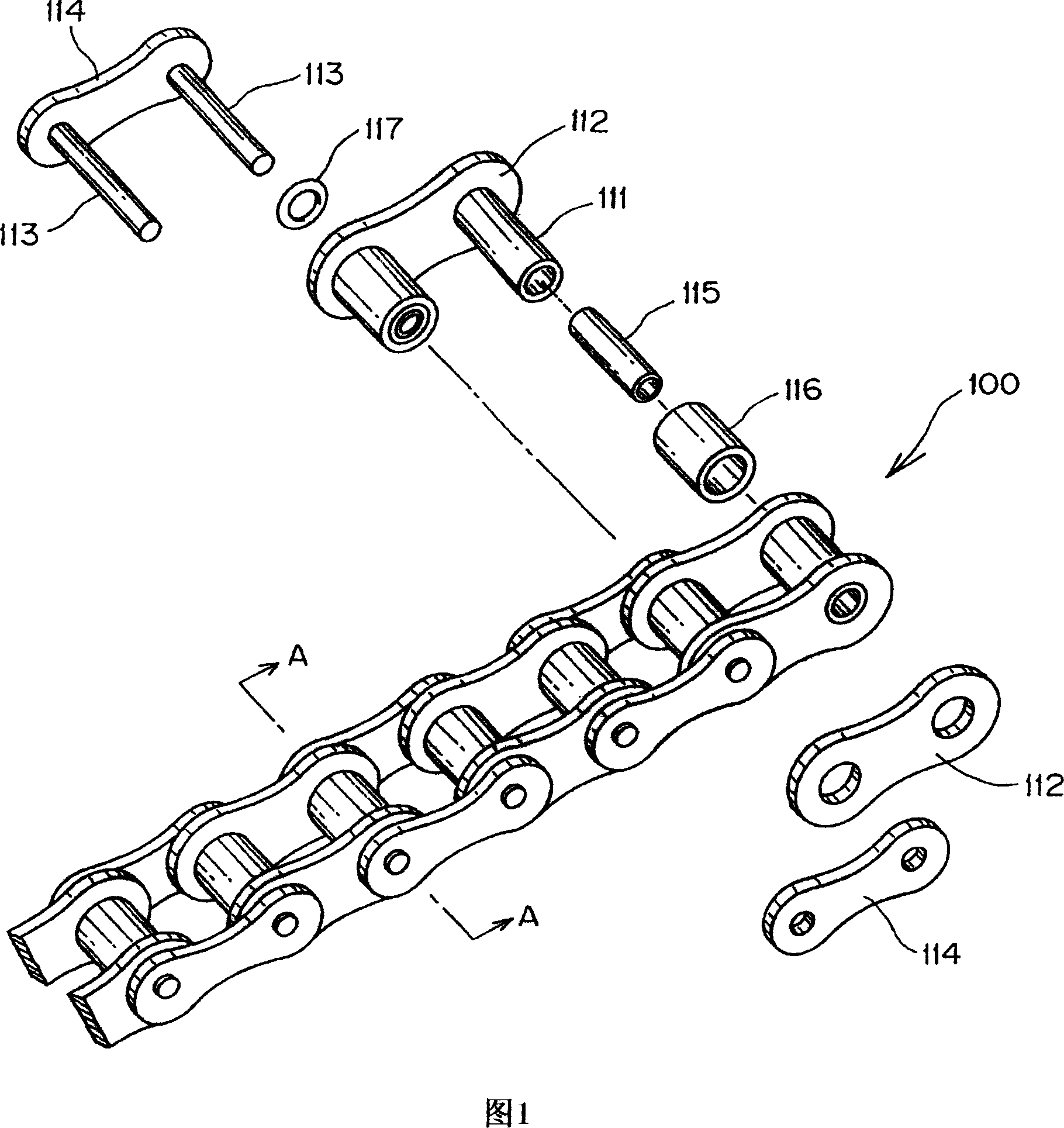

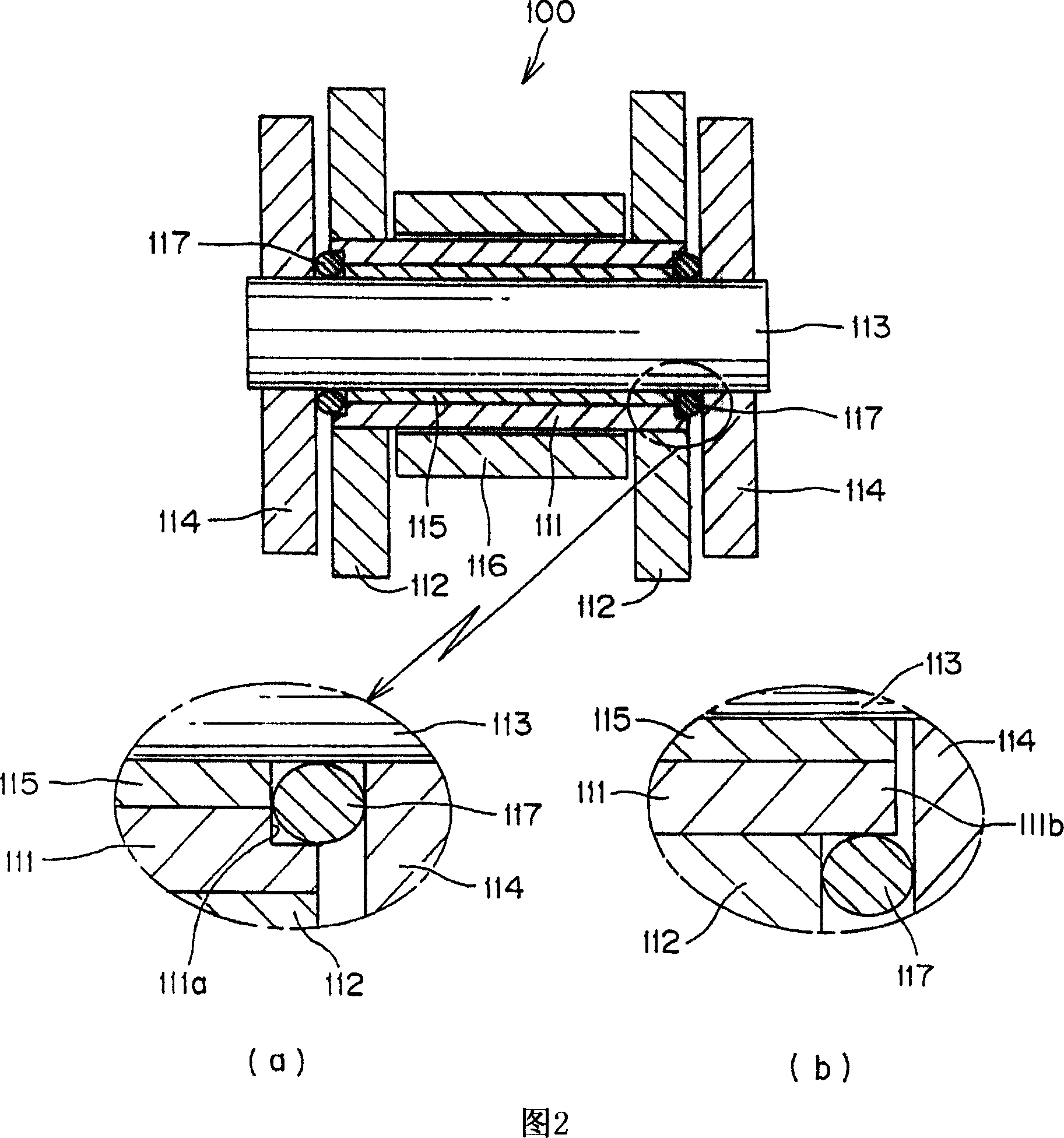

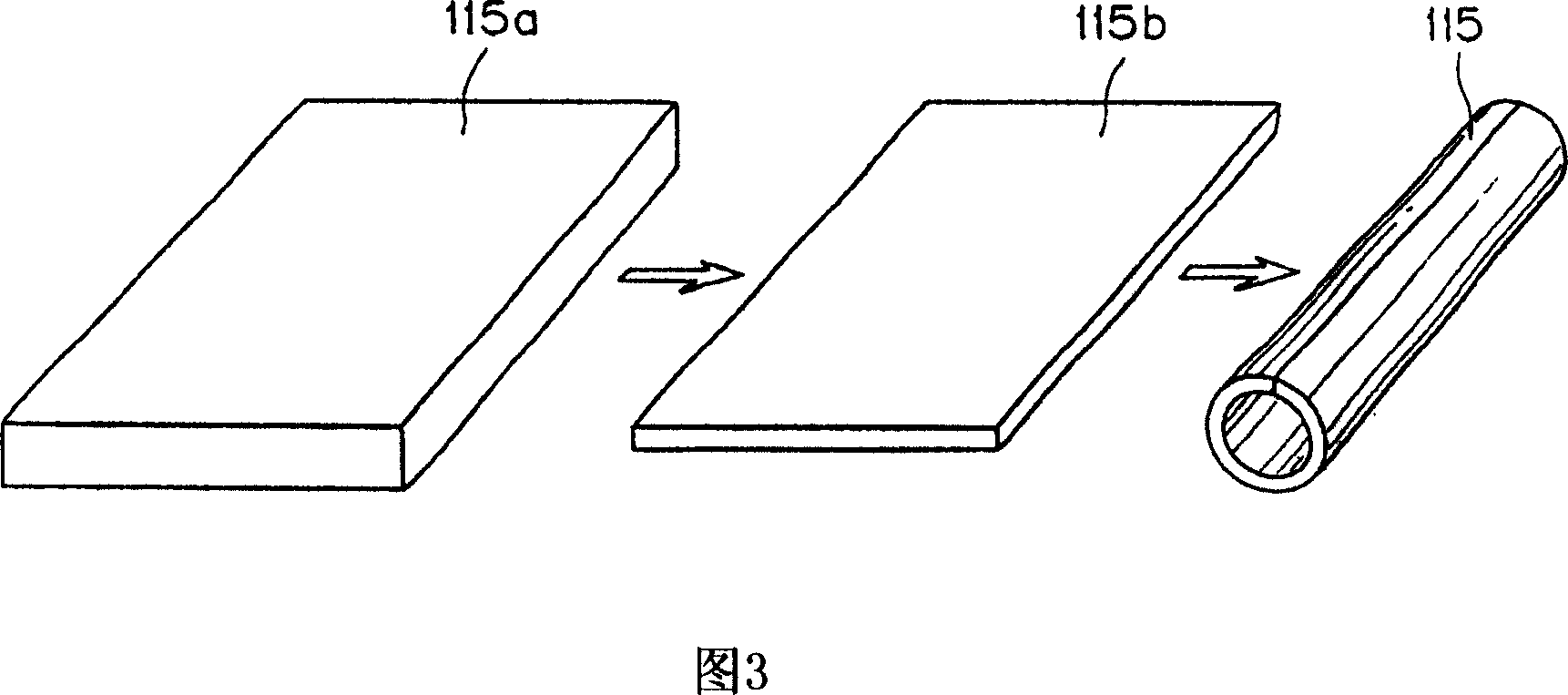

Solid lubrication oil-free chain

InactiveCN1987147AAvoid sliding frictionEfficient lubricating propertiesConveyorsDriving chainsFree rotationOil free

An oil-free chain that includes excellent lubricating properties, and satisfactorily maintains the lubricating properties even in high temperature atmosphere and dust particle atmosphere so that a stable lubrication effect can be maintained for a long period of time. The chain is a bush chain having a pair of inner plates into which the opposite ends of a bush are fitted, and a pair of outer plates which mount the opposite ends of a pair of pins. The pins are rotatably fit-inserted into the bushes of adjoining outer link plates. The inner and outer plates are connected in alternation to form the roller chain in which a roller is rotatably mounted on the outer surface of each bush. A sliding member formed of a 100% graphite sheet is provided between the bush and the pin and / or between the bush and the roller.

Owner:TSUBAKIMOTO CHAIN CO

Drilling fluid bionic lubricant, preparation method and applications thereof

ActiveCN110776881AImprove the lubrication effectImproves hydration and lubricationDrilling compositionOil fieldFatty alcohol

The invention relates to a drilling fluid bionic lubricant, a preparation method and applications thereof, and belongs to the technical field of oil field drilling fluids, wherein the drilling fluid bionic lubricant comprises, by weight, 100 parts of water, 2-15 parts of a bottle brush type polymer, 1-5 parts of sodium alginate and 1-10 parts of long-chain fatty alcohol. In the prior art, the drilling fluid liquid lubricant generally has problems of poor hydrophilicity and negative electricity, and can be affected by the competitive adsorption of other hydrophilic materials in the drilling fluid, so that the surface adsorption capacity on the drilling tool and the negatively-charged well wall mud cake is low so as to seriously affect the lubricating effect. According to the invention, thedrilling fluid bionic lubricant can be well adsorbed on the surfaces of the drilling tool and the well wall mud cake, enables a friction surface to be highly hydrated, has good and durable lubricatingeffect compared with the lubricant in the prior art, and has good application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

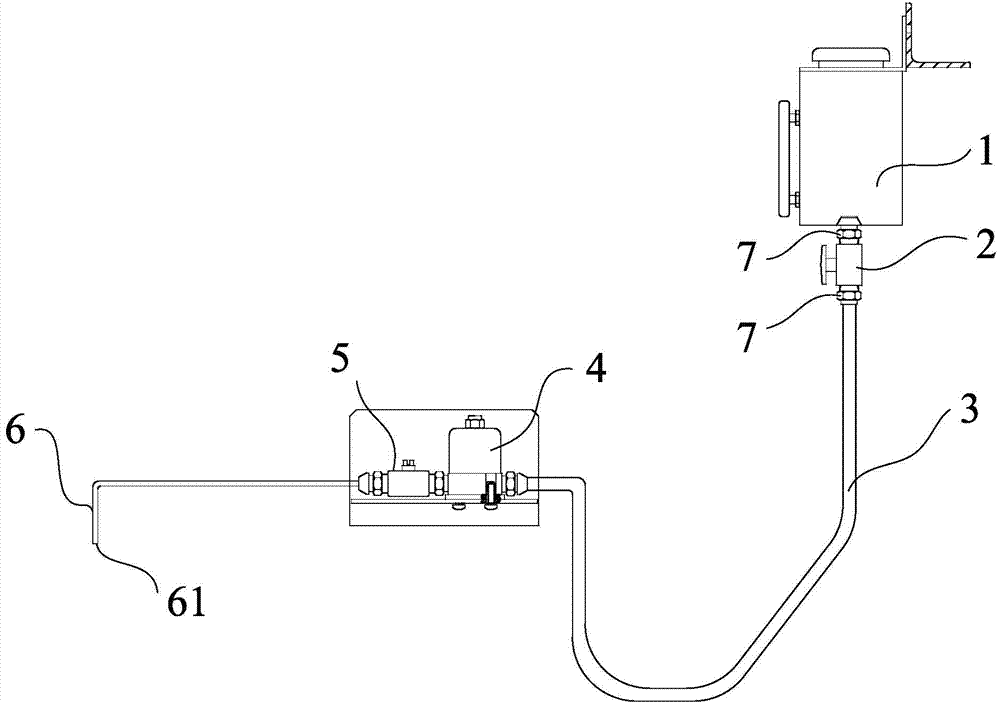

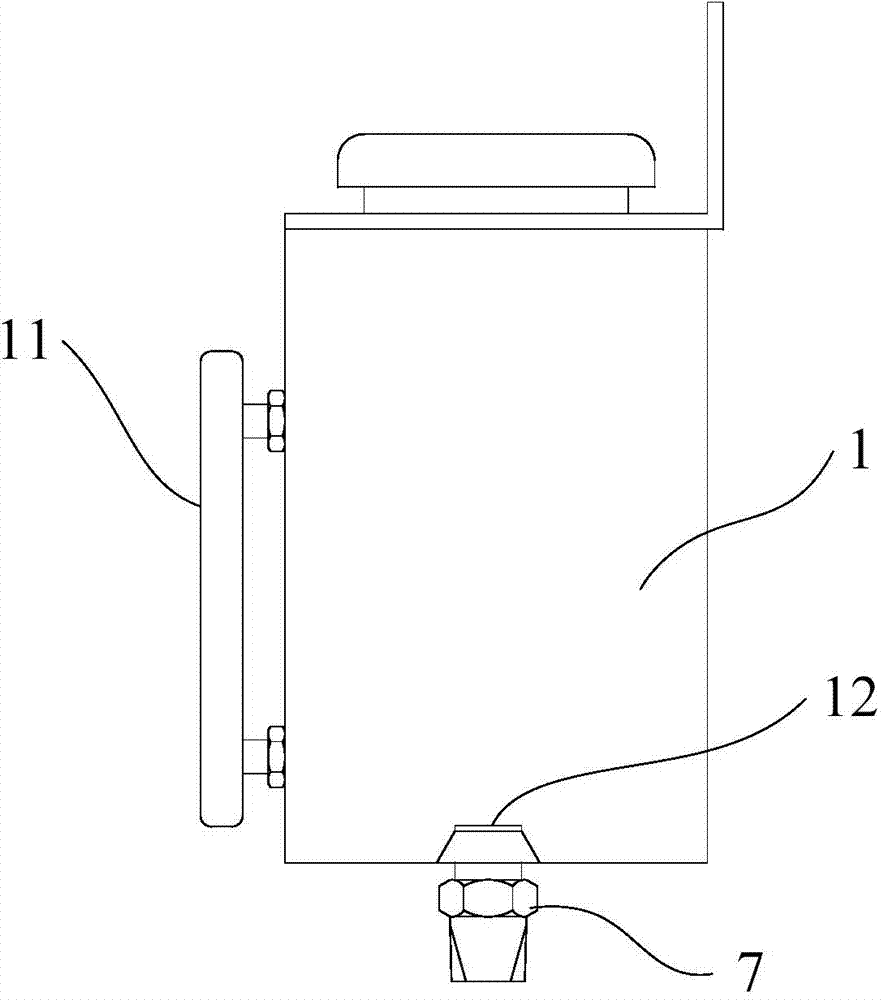

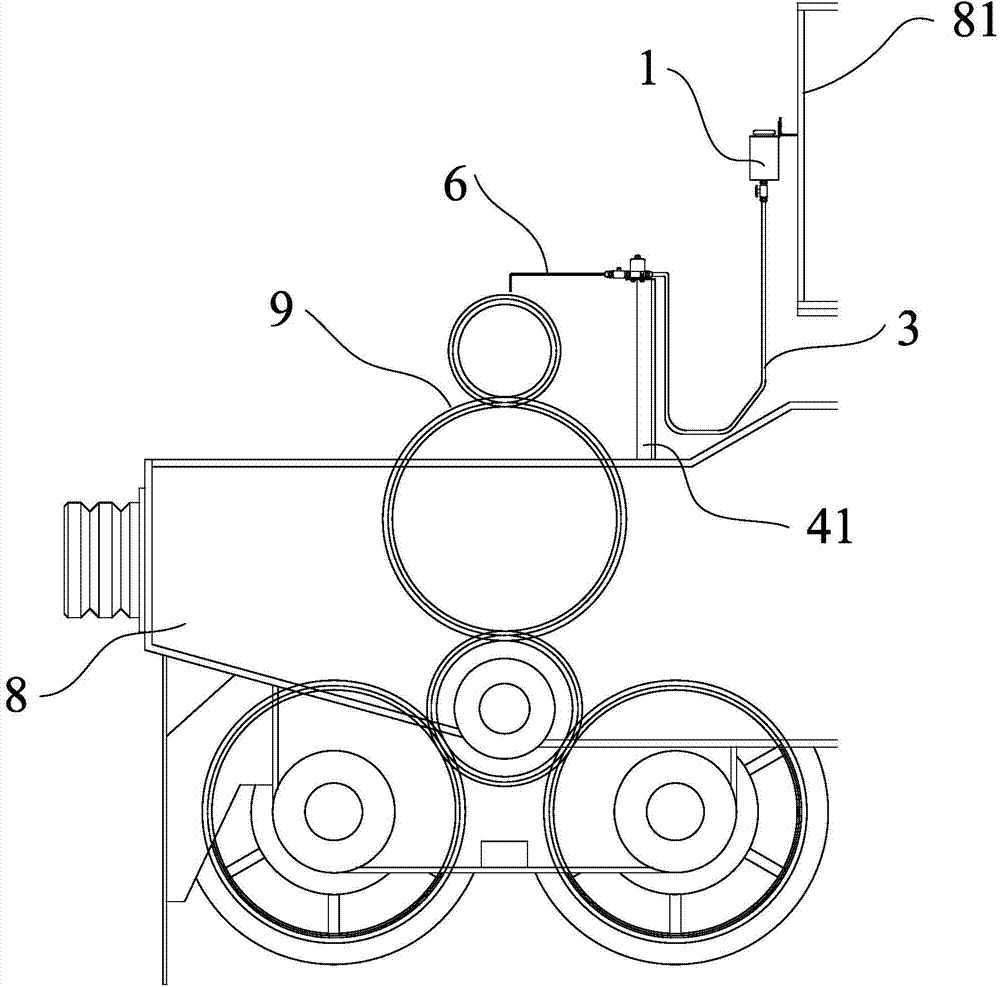

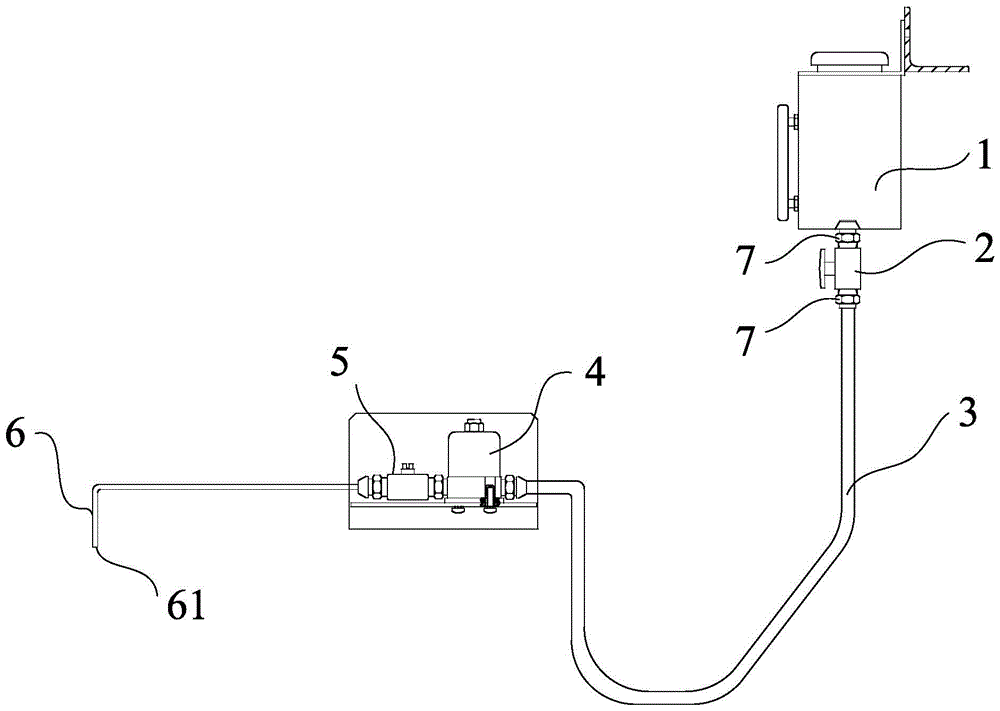

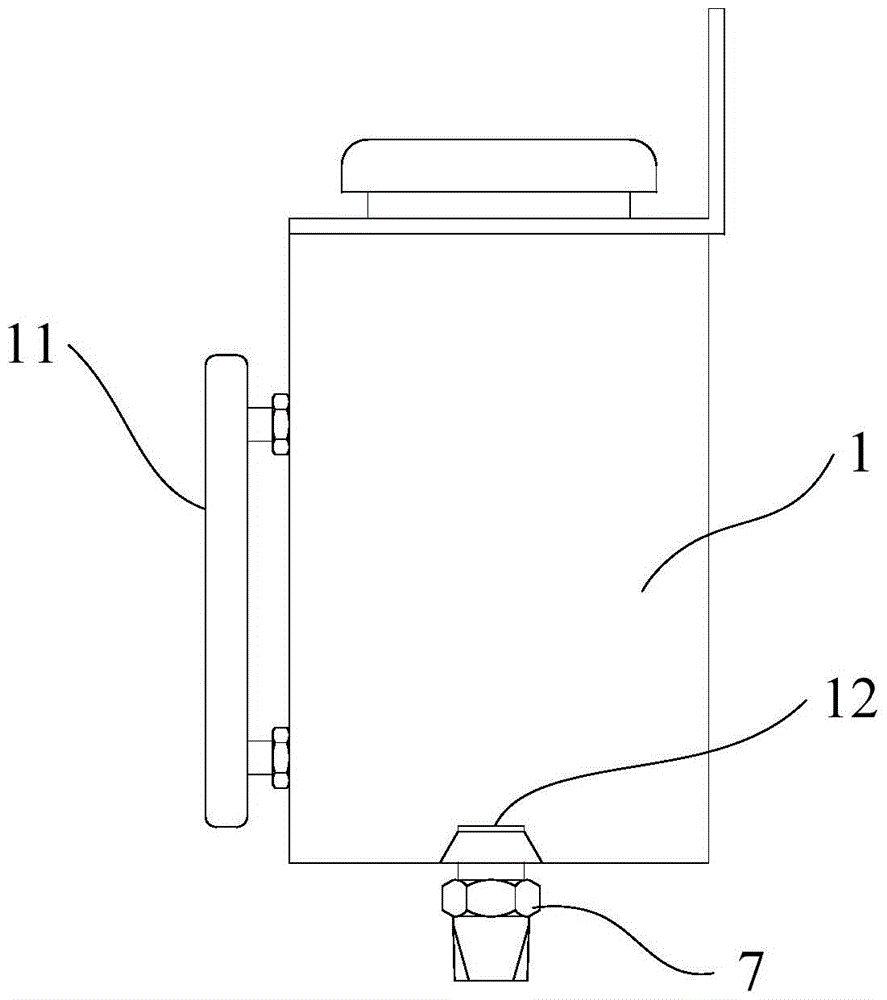

Lubricating systems for walking wheel opening gears of crane and crane comprising lubricating systems

InactiveCN103573999AEfficient lubricationEasy to installGear lubrication/coolingOil and greaseSolenoid valve

The invention provides lubricating systems for walking wheel opening gears of a crane and a crane comprising the lubricating systems. Each lubricating system comprises an oil tank, an oil pipe, a solenoid valve, a flow adjusting valve and an oil dripping pipe; one end of the oil pipe is connected with the oil tank; the other end of the oil pipe is connected with the solenoid valve; the solenoid valve is used for controlling the opening and closing of the lubrication system; a plurality of lubricating systems are arranged on a trolley balanced beam of the crane; each lubricating system corresponds to one group of walking wheel opening gears; a through hole is formed in the housing of the walking wheel opening gears and is aligned with the oil dripping pipe. Thicker gear oil is used for replacing grease, the oil dripping lubricating function is realized by using the solenoid valve to control the opening and closing of an oil path, automatic oiling and lubrication and precise oiling quantity are realized by using the controllability of the solenoid valve, time and labor are saved, the walking wheel opening gears are efficiently lubricated, and the whole system is simple, easy, light, convenient to disassemble and overhaul and low in cost.

Owner:SHANGHAI SHIPYARD

Efficient sorting device based on logistics information scanning recognition

InactiveCN112013092AGood lubricationImprove work efficiencyGearingGear lubrication/coolingStructural engineeringManufacturing engineering

The invention discloses an efficient sorting device based on logistics information scanning recognition. The device comprises a bottom plate. A support is fixed to the top end of the bottom plate, a lead screw is rotationally arranged at the top end of the support, and a ball nut rotationally sleeves the outer wall of the lead screw in a connection mode. A fixing block fixedly sleeves the outer surface of the ball nut in a connection mode, and a lubricating sleeve and a cleaning sleeve are fixed to the surfaces of the two sides of the fixing block respectively. Two push rods symmetrically andmovably penetrate through the outer wall of the lubricating sleeve, the push rods extend into a cavity of the lubricating sleeve, and an extrusion plate is fixed to the tail end of each push rod. Extrusion springs are fixed at the joint of the extrusion plates and the cavity of the lubricating sleeve and surround the outer surfaces of the push rods. Due to the arranged lubricating sleeve, the surface of the lead screw can be conveniently, rapidly and efficiently lubricated; due to the arranged cleaning sleeve, the surface of the lead screw can be conveniently and rapidly cleaned; and due to arranged protective baffles, the protective baffles can be conveniently and rapidly installed and disassembled, and objects can be conveniently protected.

Owner:上海贵蓉国际物流有限公司

Crane walking wheel open gear lubrication system and crane including the same

InactiveCN103573999BEfficient lubricationEasy to installGear lubrication/coolingSolenoid valveFuel tank

The invention provides lubricating systems for walking wheel opening gears of a crane and a crane comprising the lubricating systems. Each lubricating system comprises an oil tank, an oil pipe, a solenoid valve, a flow adjusting valve and an oil dripping pipe; one end of the oil pipe is connected with the oil tank; the other end of the oil pipe is connected with the solenoid valve; the solenoid valve is used for controlling the opening and closing of the lubrication system; a plurality of lubricating systems are arranged on a trolley balanced beam of the crane; each lubricating system corresponds to one group of walking wheel opening gears; a through hole is formed in the housing of the walking wheel opening gears and is aligned with the oil dripping pipe. Thicker gear oil is used for replacing grease, the oil dripping lubricating function is realized by using the solenoid valve to control the opening and closing of an oil path, automatic oiling and lubrication and precise oiling quantity are realized by using the controllability of the solenoid valve, time and labor are saved, the walking wheel opening gears are efficiently lubricated, and the whole system is simple, easy, light, convenient to disassemble and overhaul and low in cost.

Owner:SHANGHAI SHIPYARD

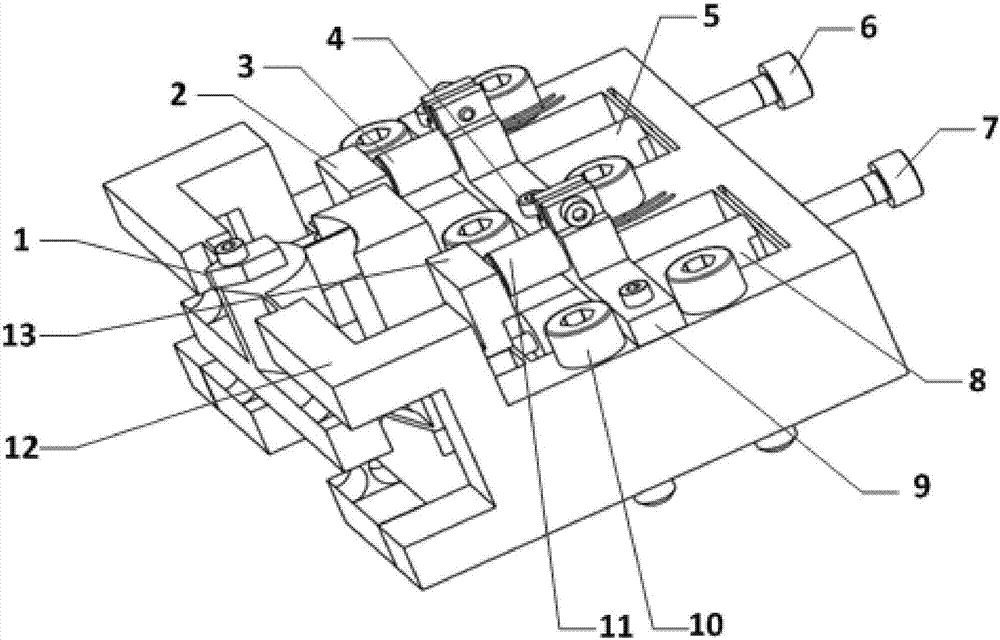

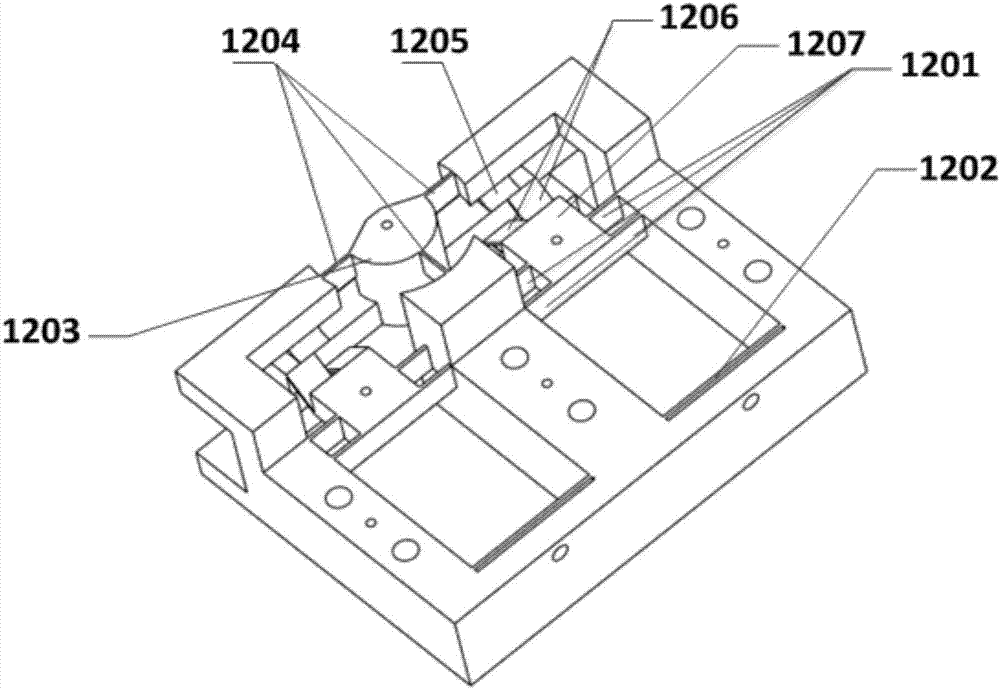

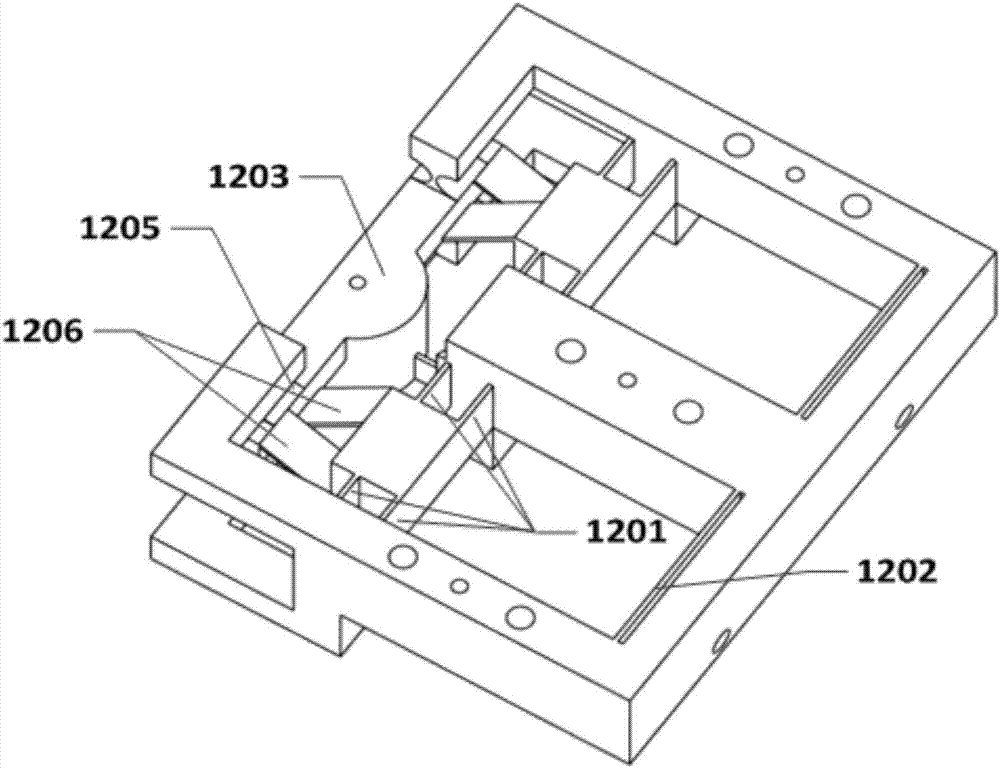

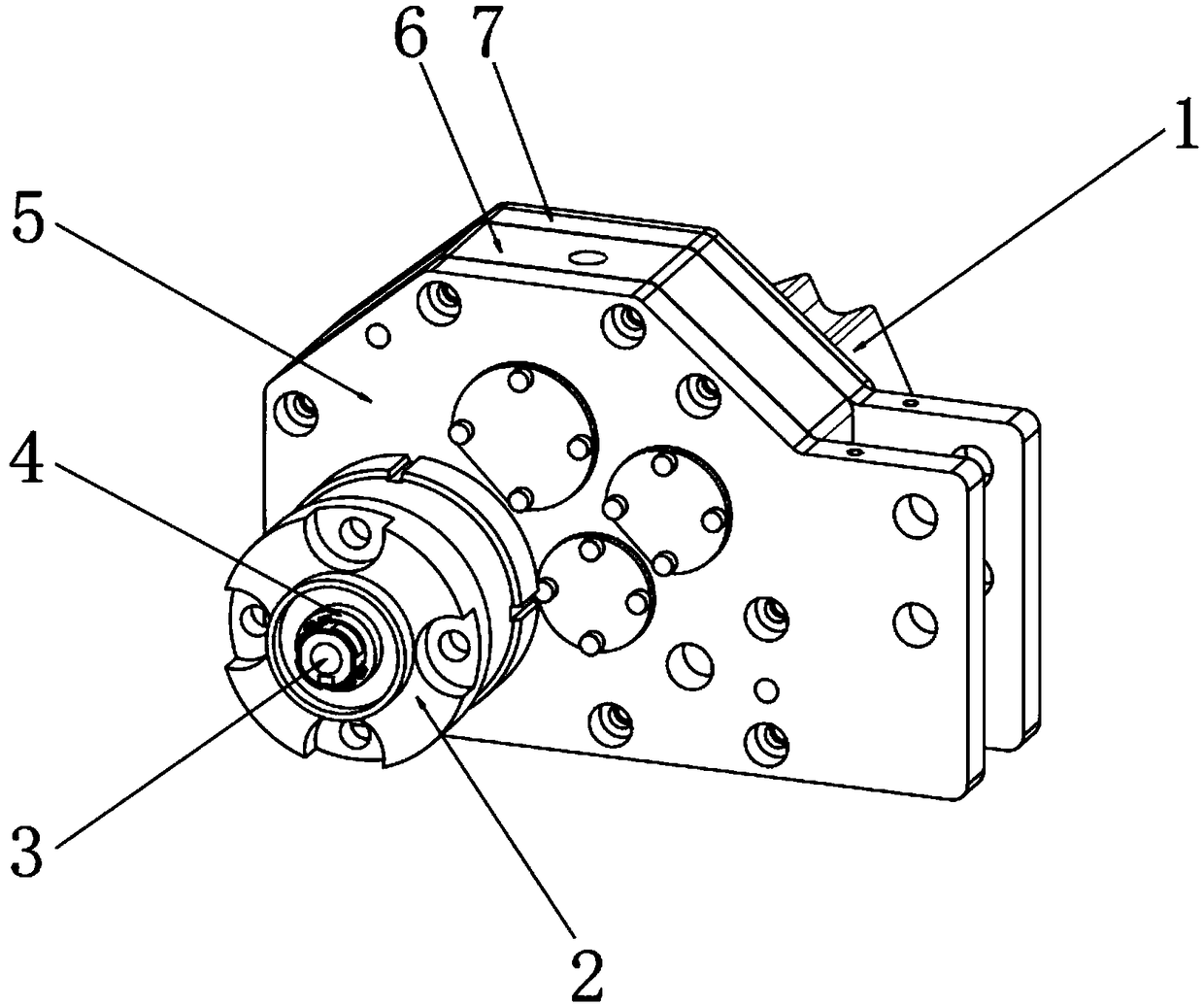

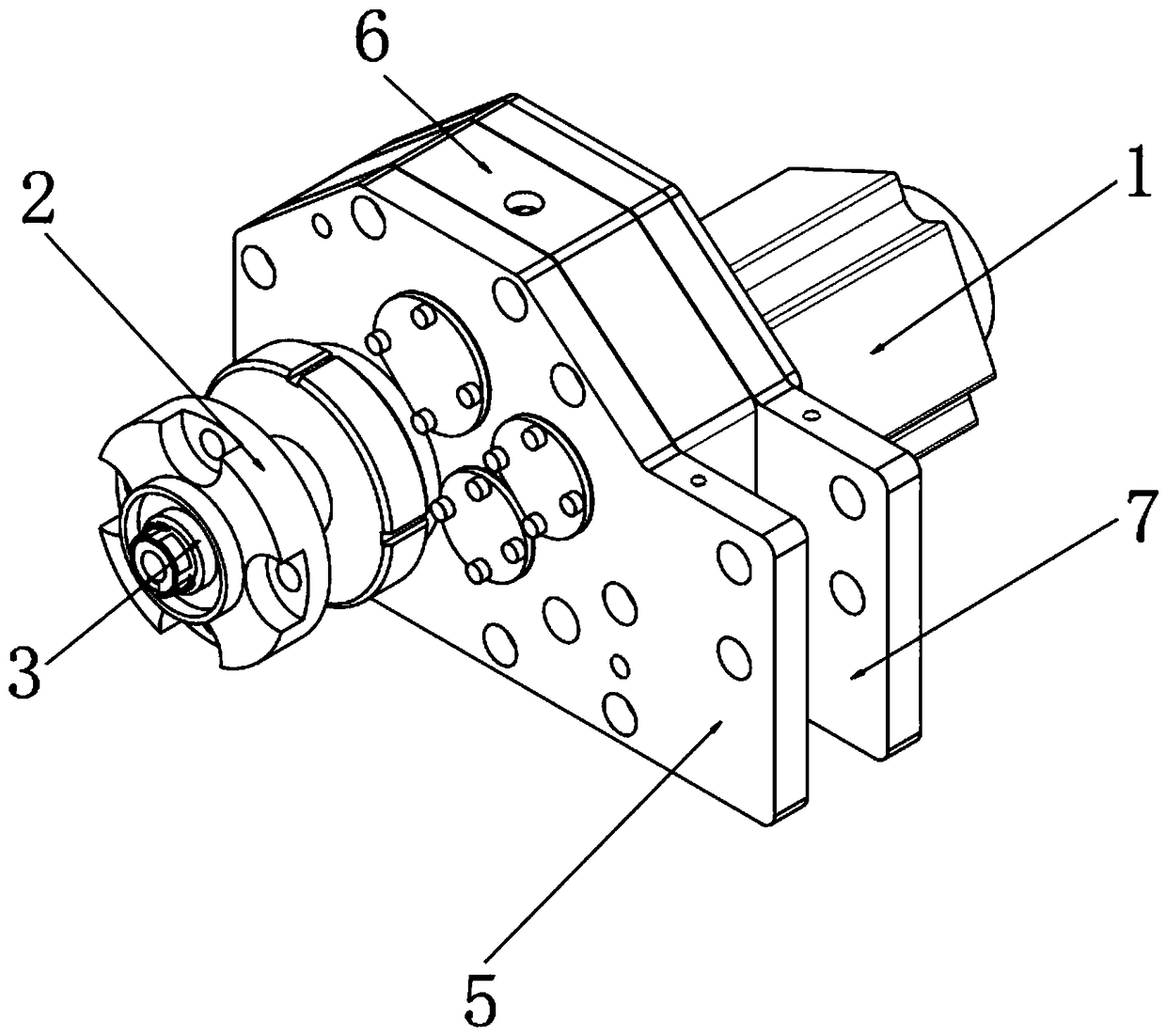

Vibration auxiliary rotation cutting device based on acute angle straight plate type flexible hinge

PendingCN106881619ALight in massEasy to realize high-frequency processingFeeding apparatusCapacitanceAcute angle

The invention relates to a vibration auxiliary rotation cutting device based on an acute angle straight plate type flexible hinge, and belongs to the technical field of superfine milling processing. A piezoelectric stack I and a piezoelectric stack II are respectively mounted on a flexible device platform by using a pretightening screw I and a pretightening screw II; a capacitance type displacement measurement baffle plate I and a capacitance type displacement measurement baffle plate II are respectively connected with the flexible device platform by using fastening screws; the capacitance type displacement measurement baffle plate I and the capacitance type displacement measurement baffle plate II are respectively mounted on capacitance type displacement sensor clamp bases by using fastening screws; the capacitance type displacement sensor clamp bases are mounted on the flexible device platform by using fastening screws; a diamond cutter is fixedly connected with the flexible hinge platform through fastening screws; the flexible hinge platform is connected with a mounting base through fixing screws. The vibration auxiliary rotation cutting device has the advantages of being novel in structure, periodic scallop height in the ellipse vibration cutting process can be eliminated, and relatively high control precision of the flexible device can be achieved.

Owner:CHANGCHUN UNIV OF TECH

Railway vehicle wheel flange lubrication dry-type continuous lubricating rod

InactiveCN106701275AExtended service lifeReduce maintenance frequencyLubricant compositionEnvironmental resistanceLubrication

The invention relates to a railway vehicle wheel flange lubrication dry-type continuous lubricating rod, and belongs to the field of lubricants. Efficient lubricity of scale graphite is utilized, molybdenum disulfide serves as a lubricating additive, polytetrafluoroethylene is low in high temperature friction coefficient, polyethylene wax has cold resistance, heat resistance and abrasion resistance, ethylene-vinyl acetate is a viscosity modifier, and the auxiliary material is tin powder with the repair function; the six materials can be prepared into the environmentally-friendly, abrasion-resistant, high-temperature-resistant, deformation-resistant, fluid-free and efficiently-lubricating railway vehicle wheel flange dry-type continuous lubricating rod through special processing, continuous efficient lubricating can be effectively conducted on a railway vehicle wheel flange and a railway, abrasion is reduced, and the maintenance frequency is decreased.

Owner:高天峰

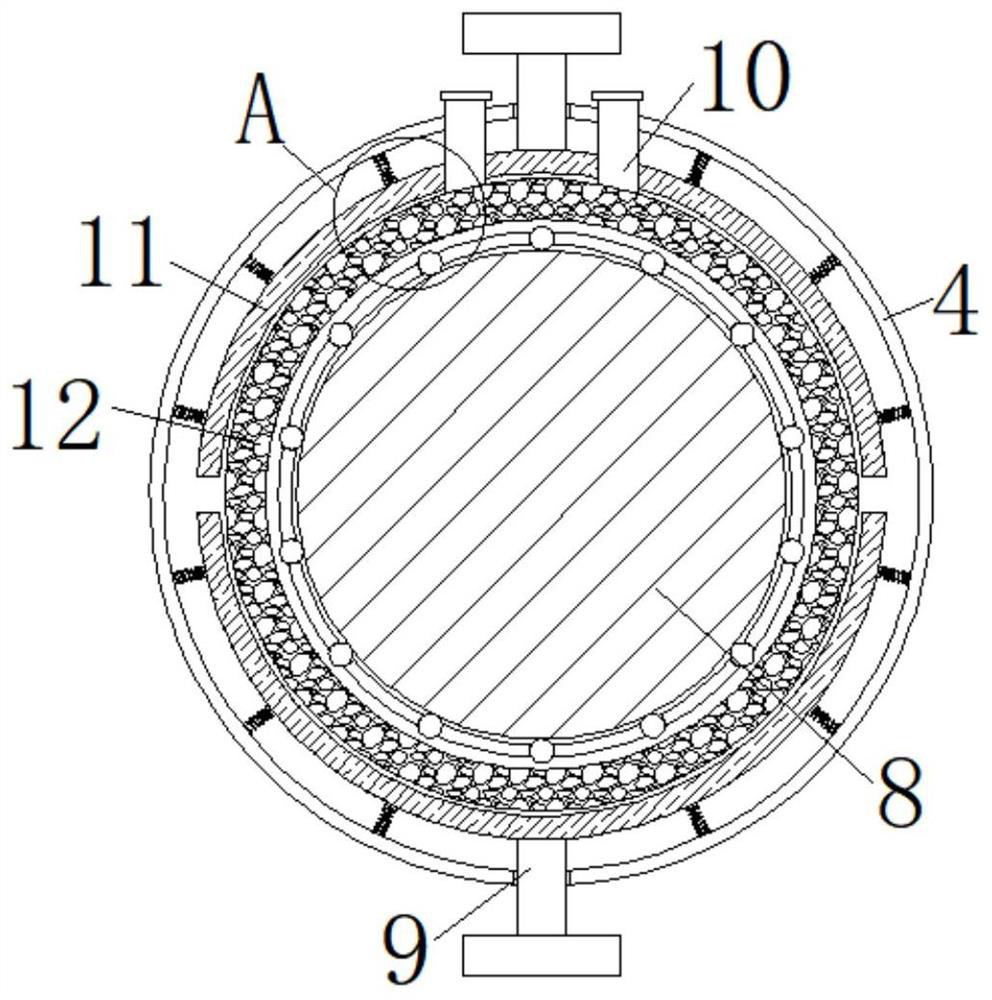

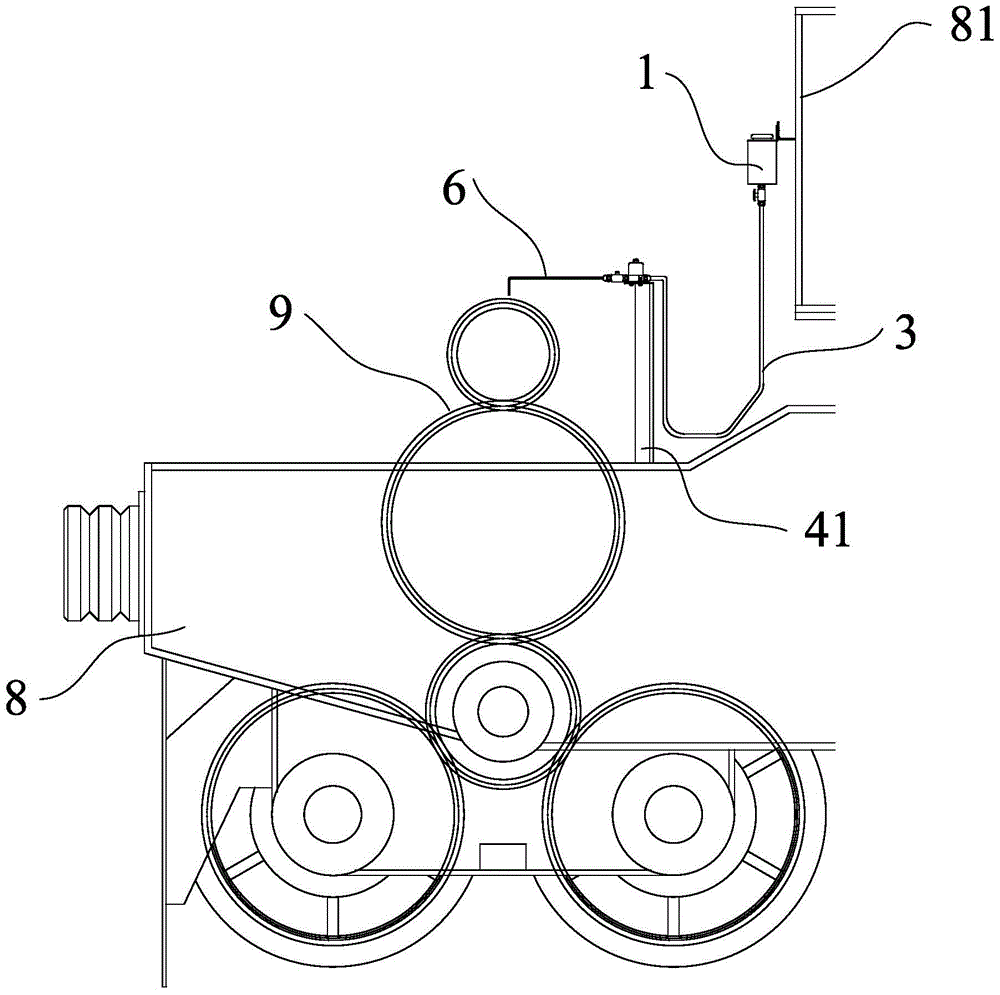

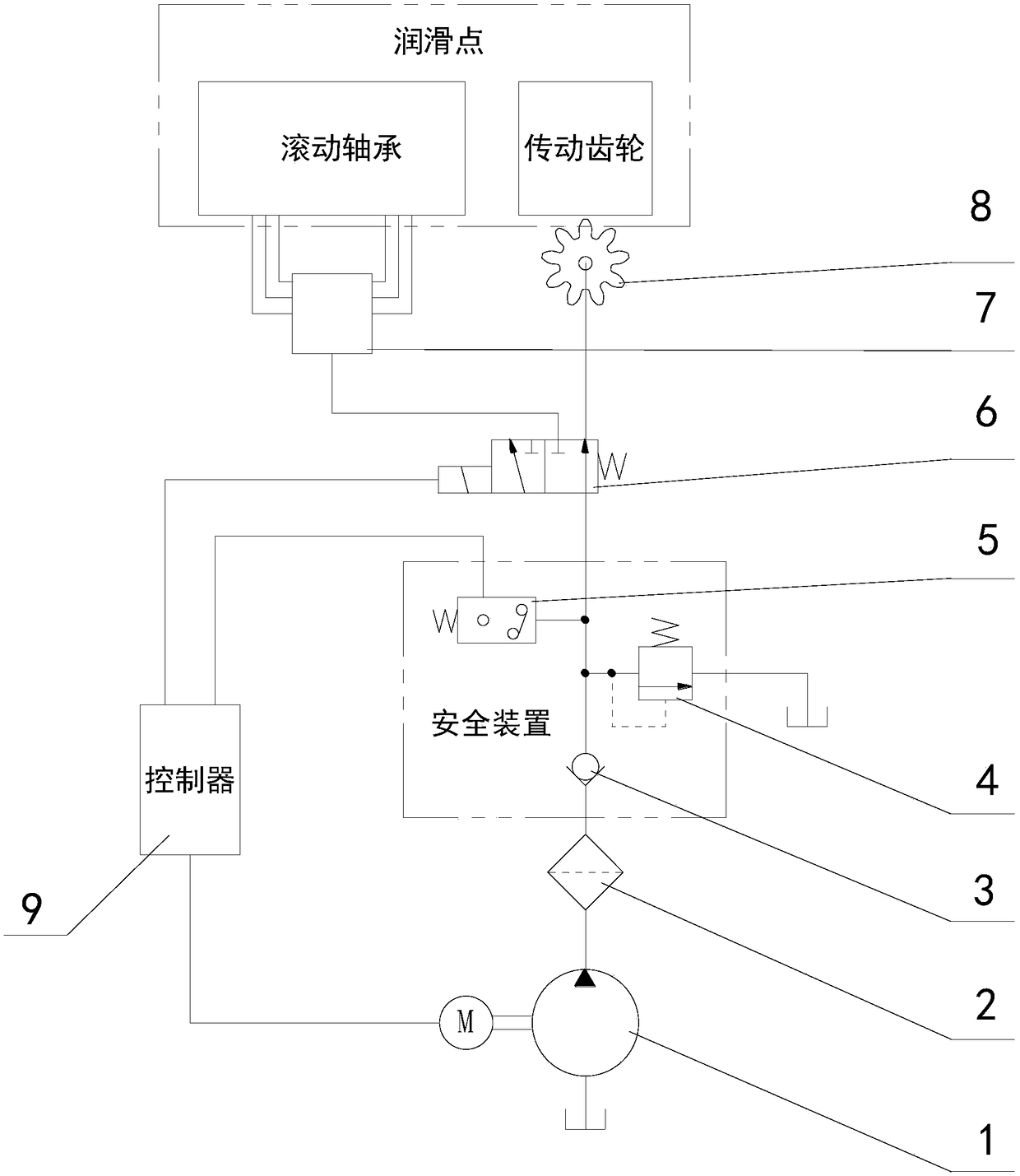

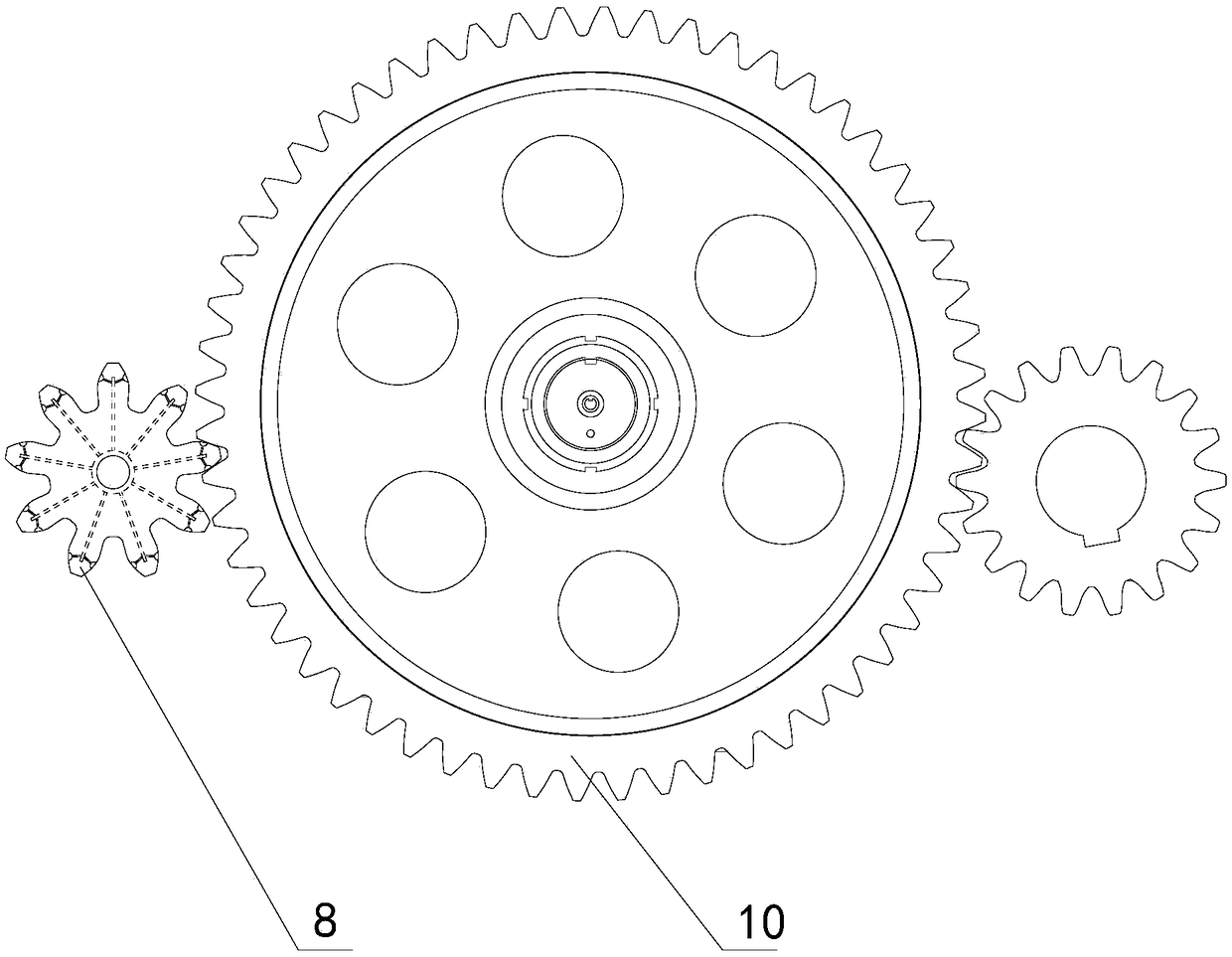

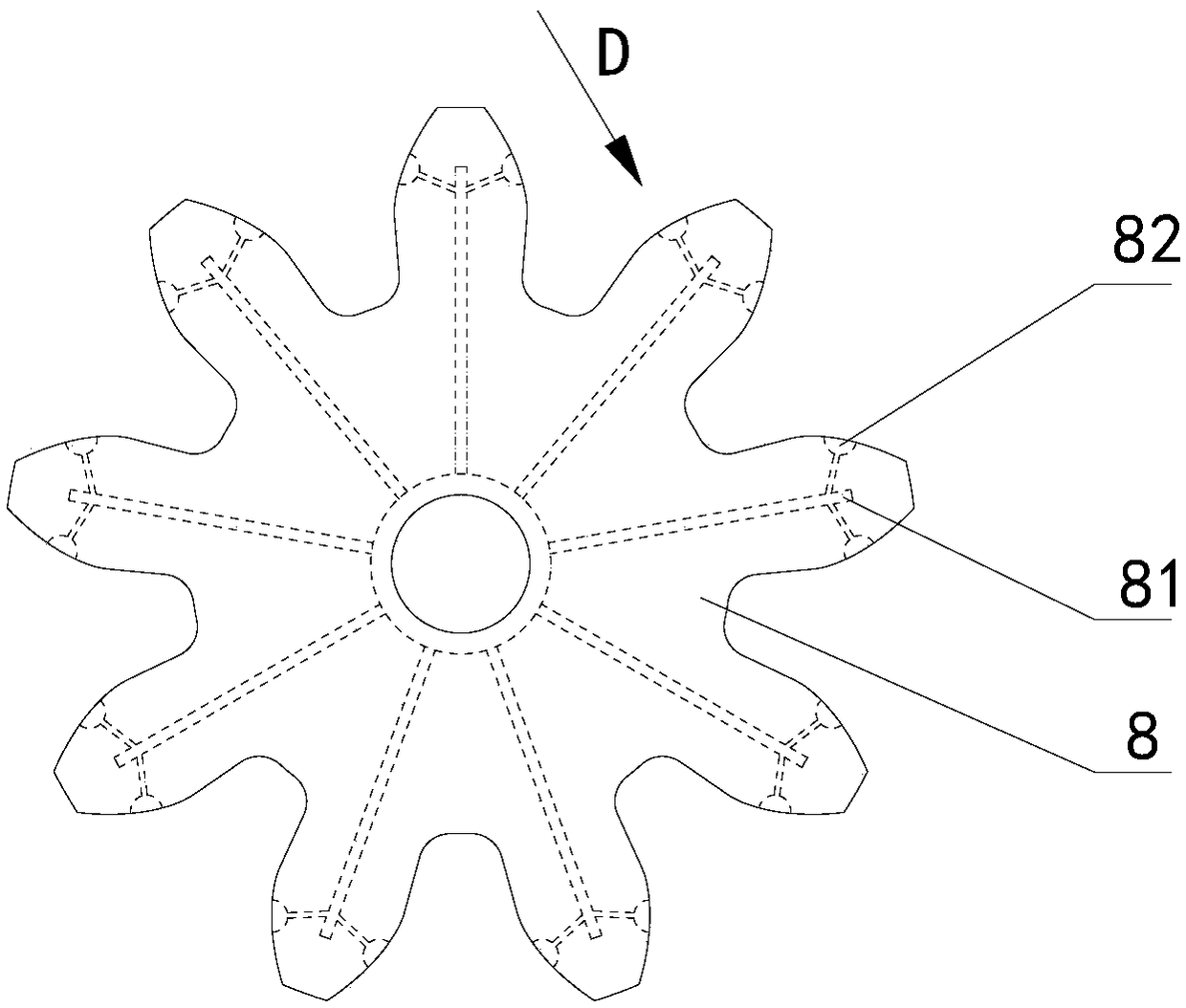

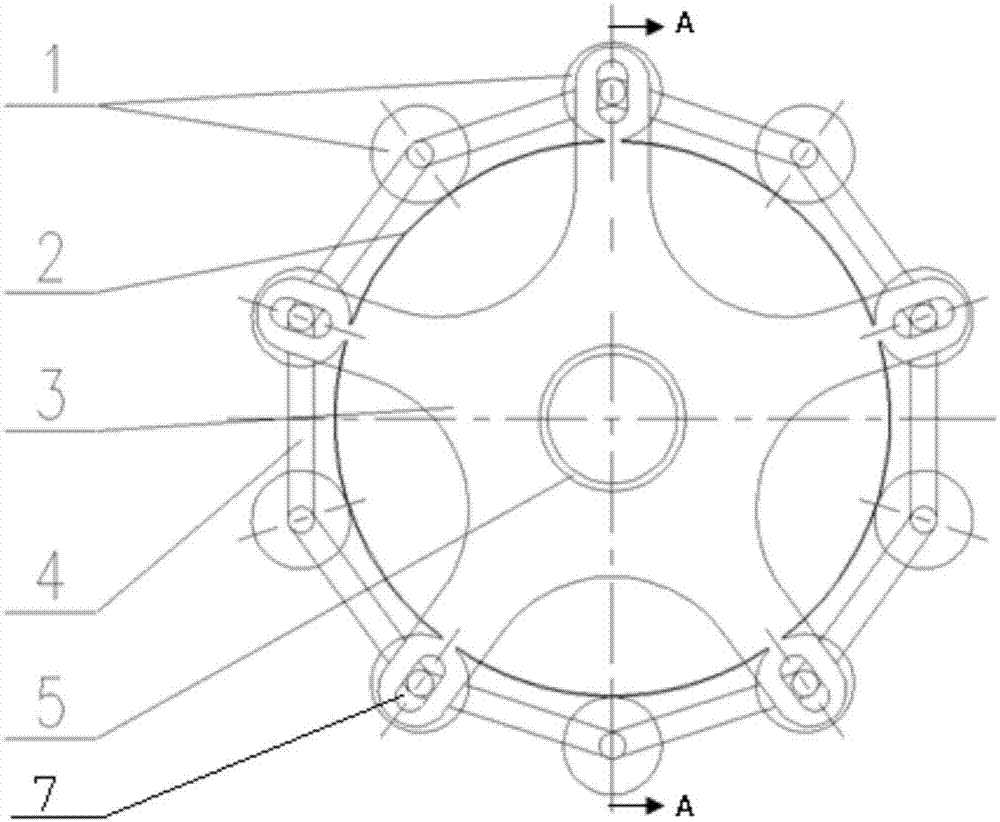

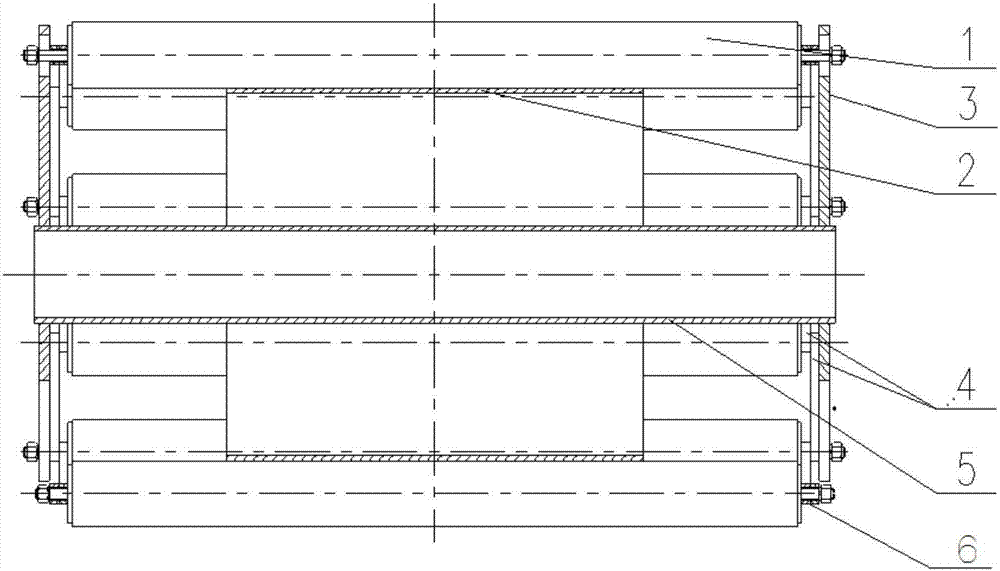

Dynamic compaction machine automatic lubricating system and control method thereof

PendingCN108825768AImprove the lubrication effectEfficient lubricationGear lubrication/coolingSoil preservationDynamic compactionEngineering

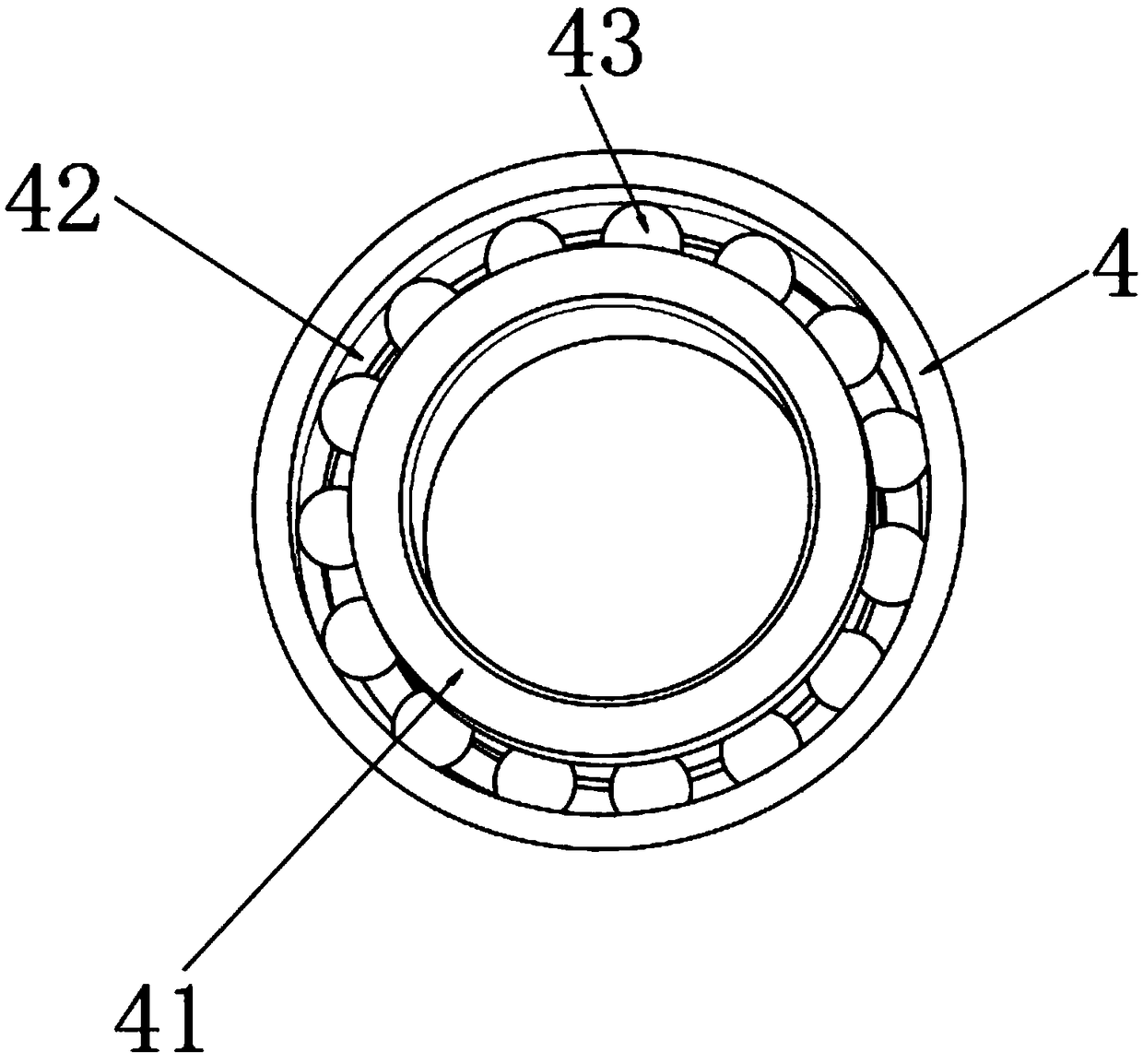

The invention provides an automatic lubricating system and a control method of a dynamic compaction machine. The dynamic compaction machine automatic lubricating system comprises an electric lubricating pump (1), an electromagnetic exchange valve (6), a distributor (7), a lubricating gear (8) and a controller (9), and an inlet of the electromagnetic exchange valve (6) is connected with an outlet of the electric lubricating pump (1) through a pipeline; the interior of the lubricating gear (8) is provided with first oil channels (81) which are radiated from the center to each gear tooth, outletsof the first oil channels (81) are located on the tooth surface of the gear teeth, and inlets of the first oil channels (81) are connected with a first outlet of the electromagnetic exchange valve through pipelines; the interior of the distributor (7) is provided with one-inlet and multiple-outlet second oil channels, the inlet of the second oil channels is connected with a second outlet of the electromagnetic exchange valve (6) through a pipeline. According to the dynamic compaction machine automatic lubricating system, the transmission gear and rolling bearings of the dynamic compaction machine can be conveniently and effectively lubricated, time and labor are saved, and labor cost is saved.

Owner:HANGCHA GRP

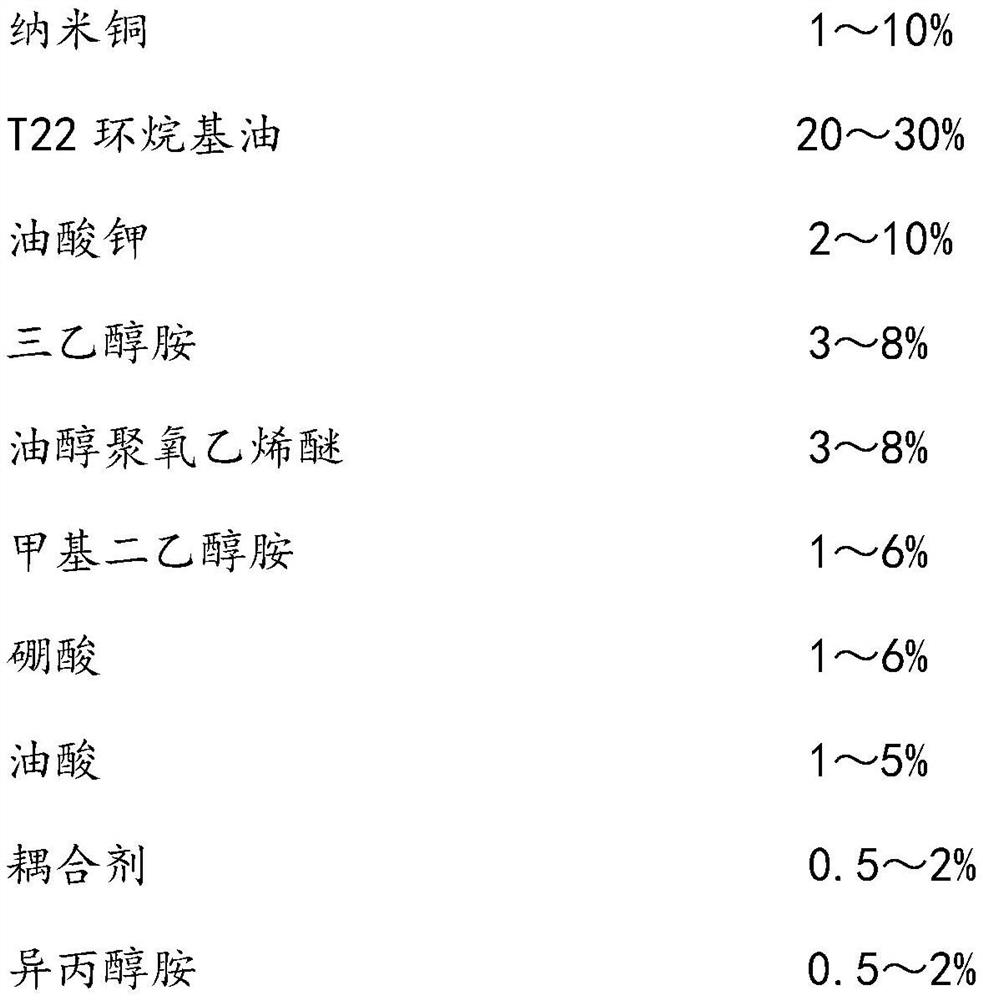

Application of nano-copper in cutting fluid

ActiveCN112280608AGood dispersionEvenly dispersedAdditivesBase-materialsCarbon chainMaterials science

Owner:SHENZHEN FRANCOOL TECH

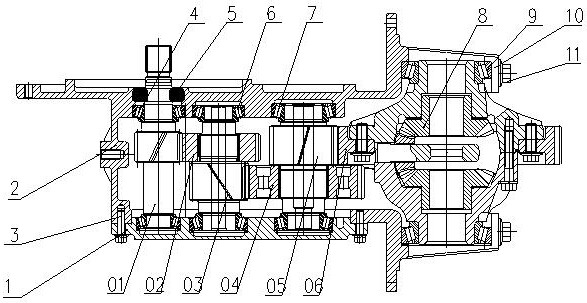

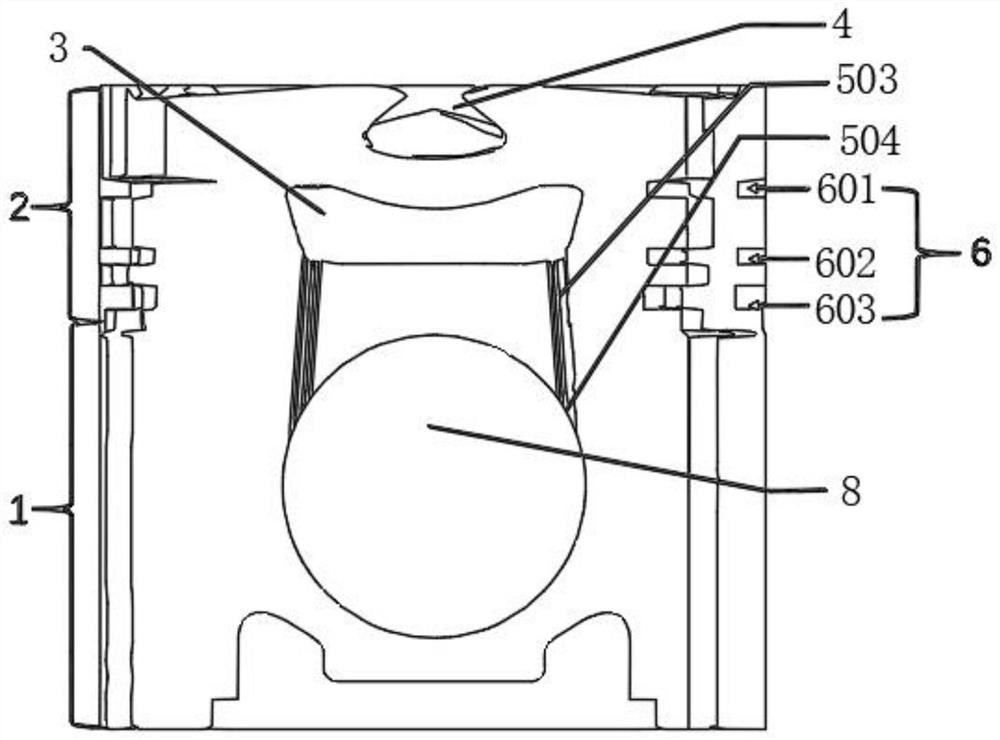

Crankshaft lubricating structure

PendingCN111946597AImprove oil storage capacity on slopesEfficient lubricationCrankshaftsPositive displacement pump componentsAutomotive engineeringEngineering

The invention provides a crankshaft lubricating structure, and belongs to the technical field of compressor equipment. When annular oil grooves are located in the outer side of a first through hole and located in the outer wall of a crankshaft long shaft, or the annular oil grooves are located in the outer side of a second through hole and located in the outer wall of the crankshaft long shaft, orthe annular oil grooves are located in the outer side of the first through hole and located in the outer wall of the crankshaft long shaft, as well as located in the outer side of the second throughhole and located in the outer wall of the crankshaft long shaft, the annular oil grooves play a role in improving the climbing oil storage capacity of a crankshaft, lubricating oil can efficiently lubricate a crankshaft body through a spiral groove, the lubricating performance between the crankshaft body and a machine frame is improved, and abrasion and locking between the crankshaft body and themachine frame are reduced.

Owner:ZHEJIANG MAIDI REFRIGERATION TECH CO LTD

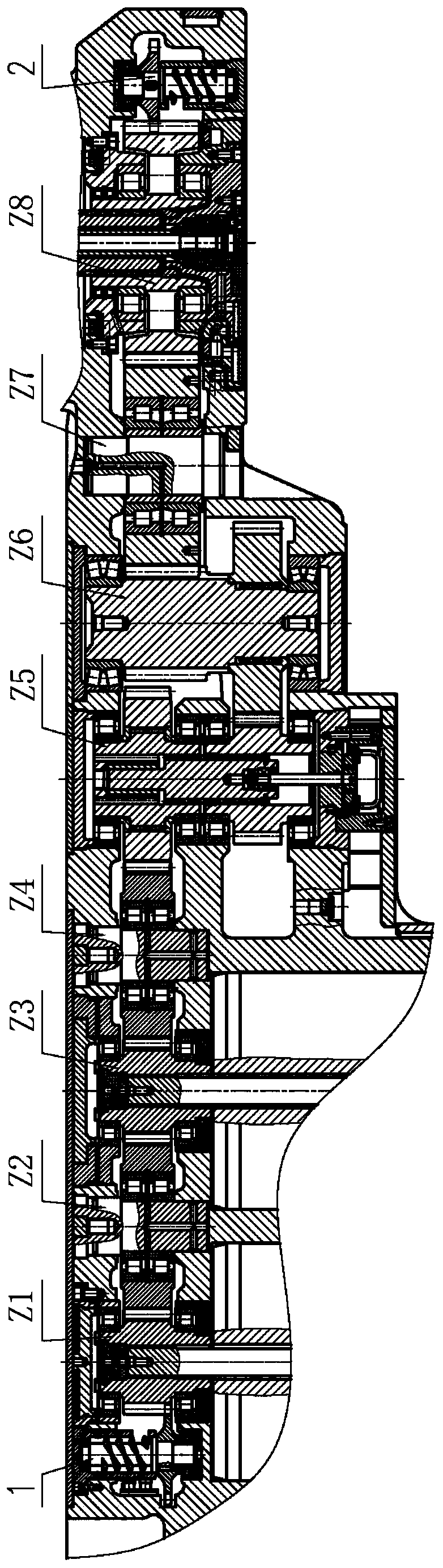

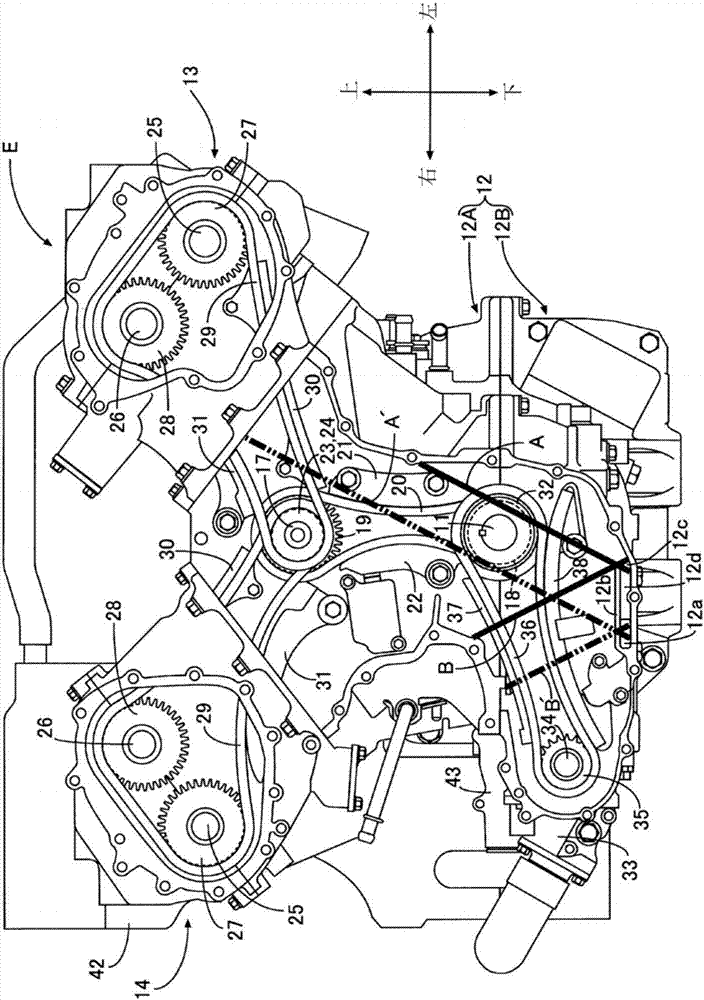

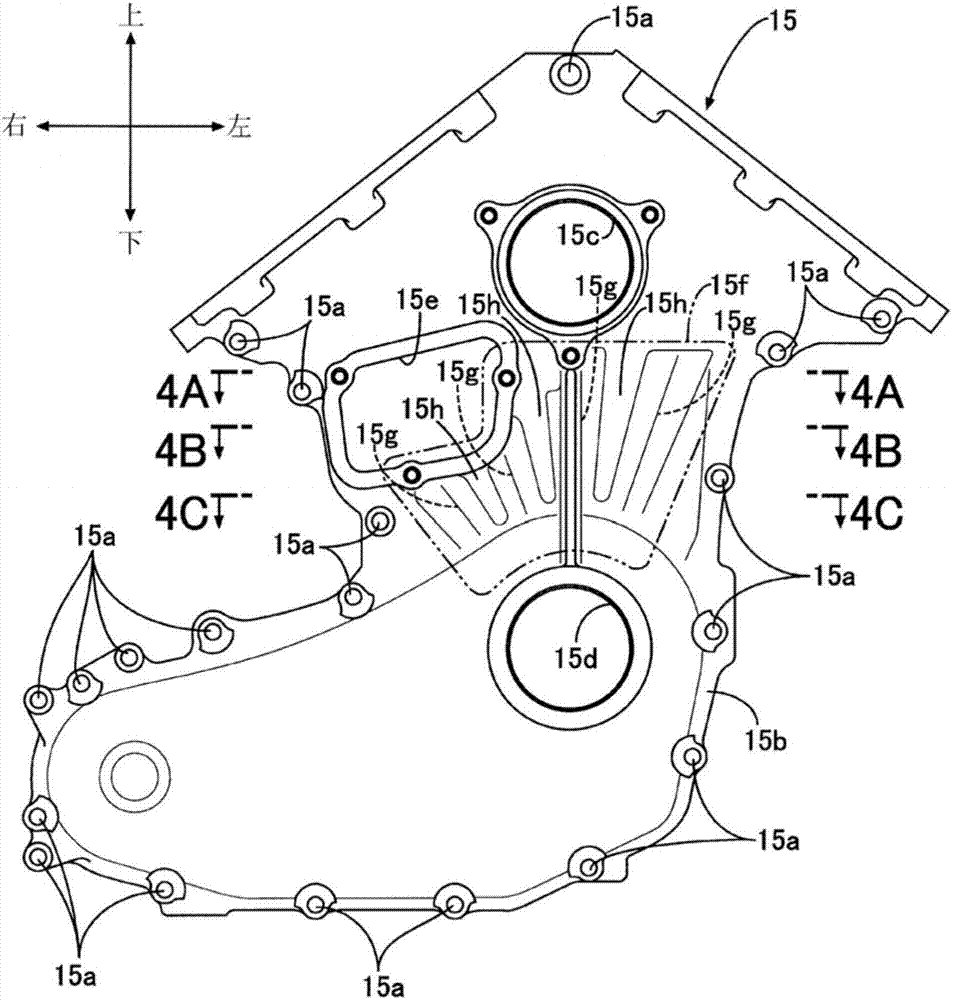

Speed Changer

ActiveCN104048027AEasy dischargeFully contactedGearboxesGear lubrication/coolingStructural engineeringEngineering

Owner:HONDA MOTOR CO LTD

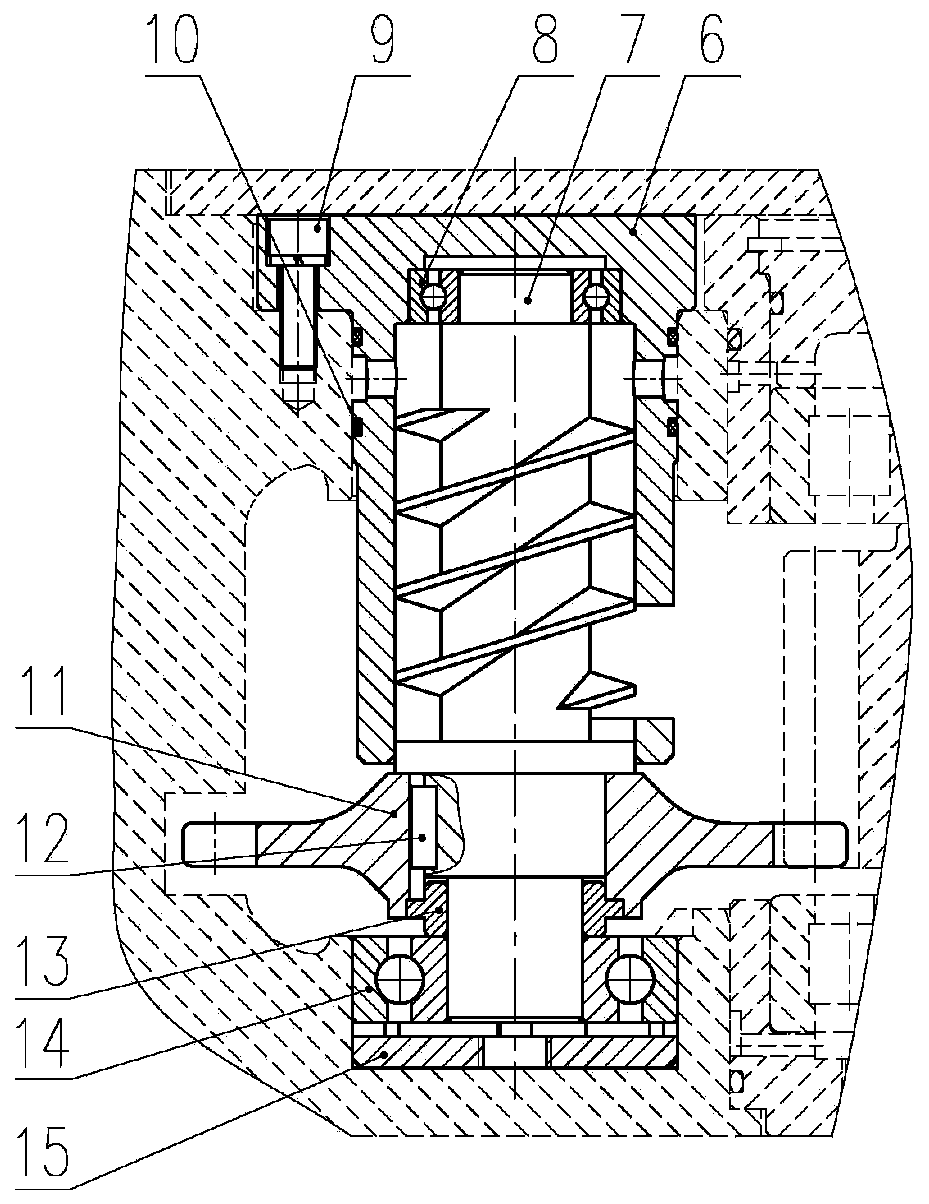

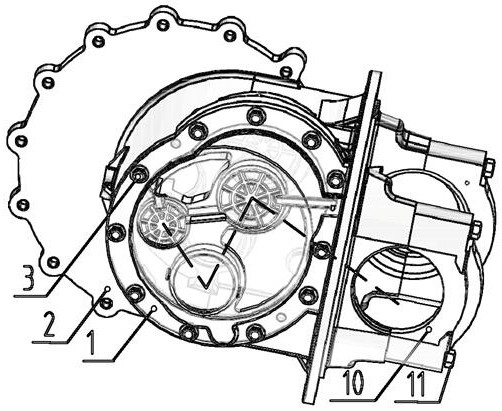

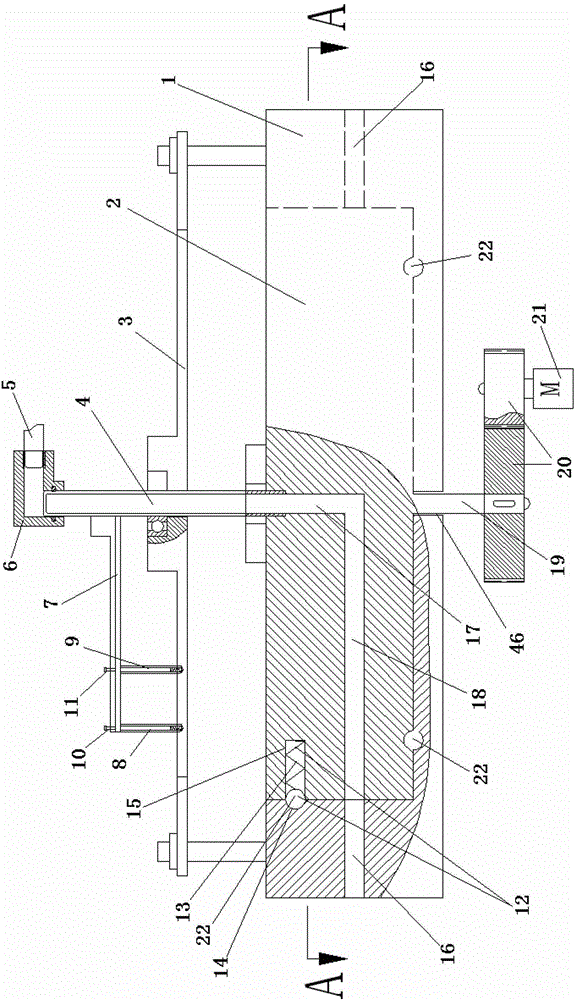

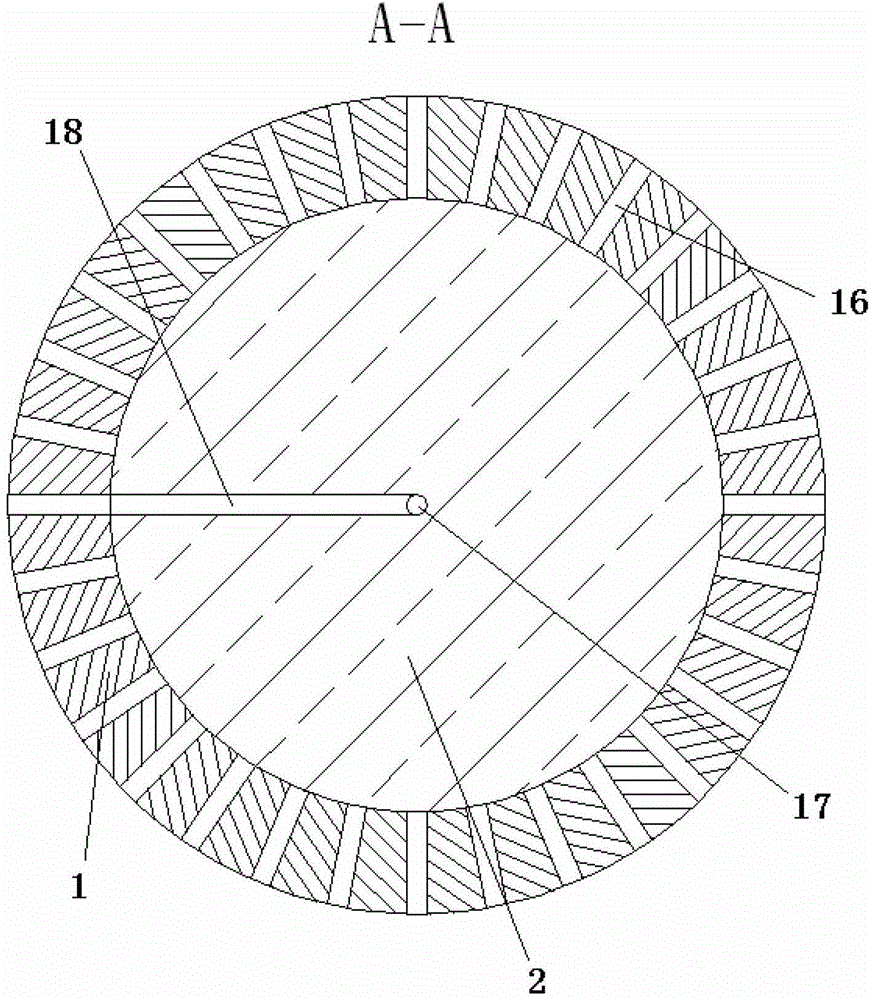

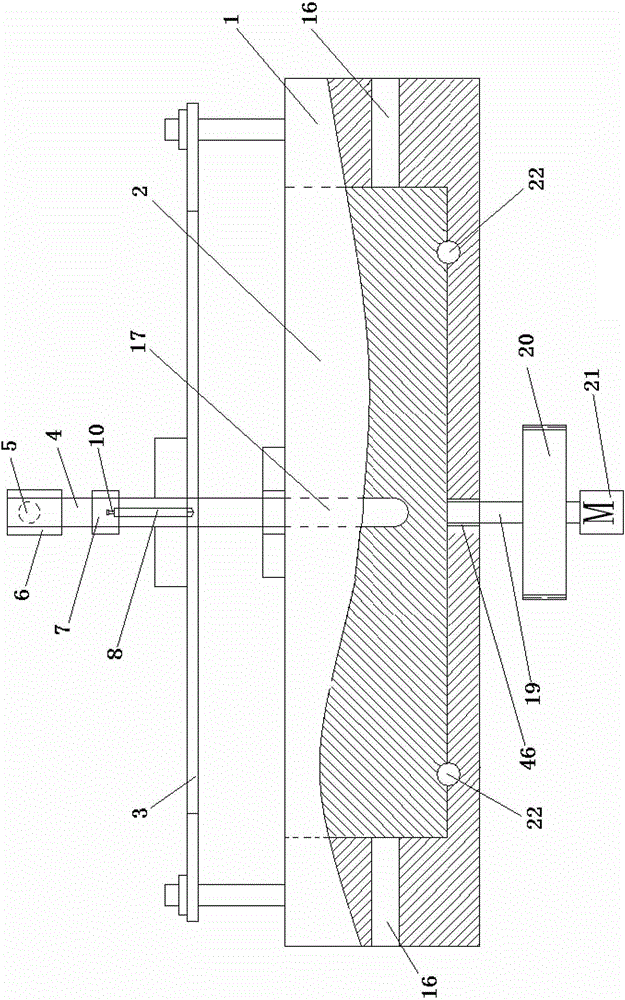

Efficient forced lubrication system with circulating lubrication function for coal mining machine

The invention relates to an efficient forced lubrication system with a circulating lubrication function for a coal mining machine. The efficient forced lubrication system comprises a high speed end lubrication pump, a low speed end lubrication pump and a lubrication oil passage, wherein the high speed end lubrication pump and the low speed end lubrication pump are arranged in a transmission case of a rocker arm; the lubrication oil passage is arranged in a transmission case housing of the rocker arm and comprises a main oil passage and multiple groups of branched oil passages; the main oil passage is communicated with the high speed end lubrication pump, the low speed end lubrication pump and lubricating points of all shaft assemblies of a diving system of the rocker arm, and is also communicated with oil discharge outlets of the high speed end lubrication pump and the low speed end lubrication pump. In the efficient forced lubrication system disclosed by the invention, one of the high speed end lubrication pump and the low speed end lubrication pump is always at low position at each time and can supply oil to the main oil channel, so that the main oil passage is always filled with oil; the oil is supplied to the high speed end lubrication pump, the low speed end lubrication pump and the lubricating points of all the shaft assemblies of the diving system of the rocker arm in real time through all the branched oil passages; even if the coal mining machine works on the work face with a large dip angle, all parts of the driving system of the rocker arm do not lack oil; the efficient forced lubrication system has high applicability.

Owner:SHANGHAI BRANCH TIANDI SCI&TECH CO LTD +1

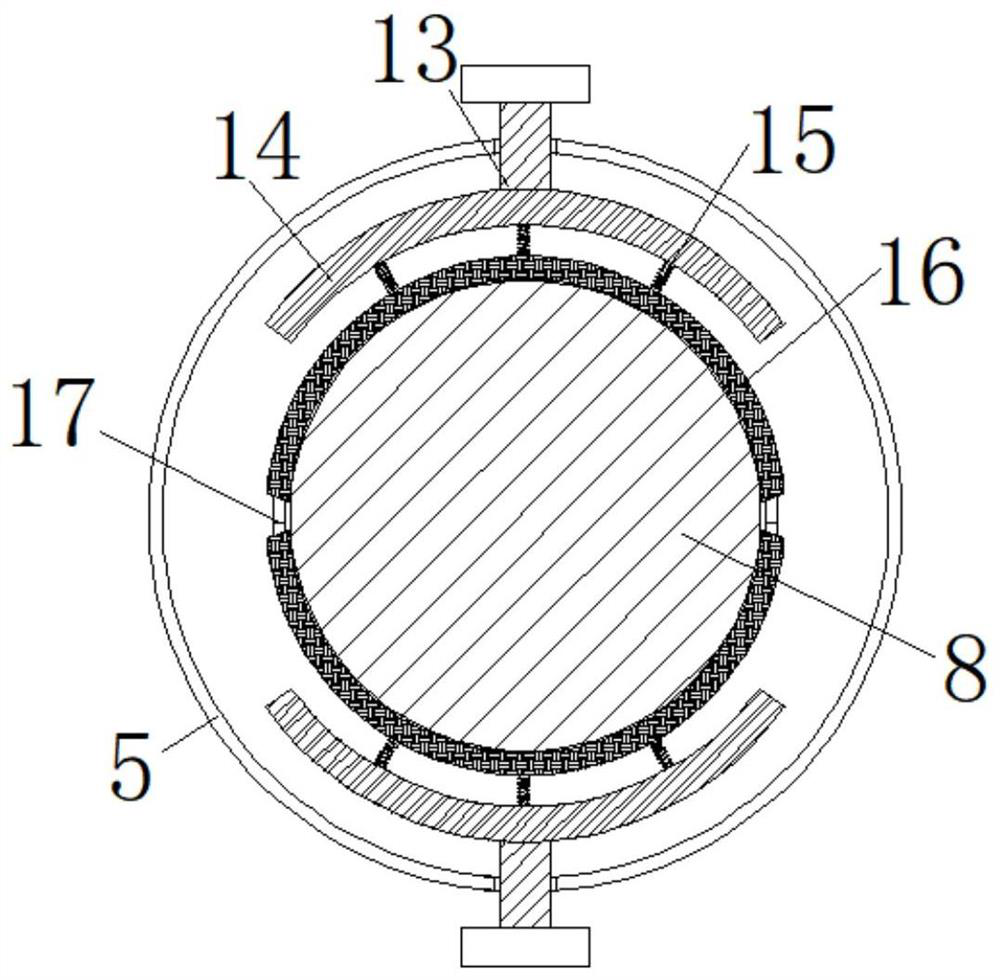

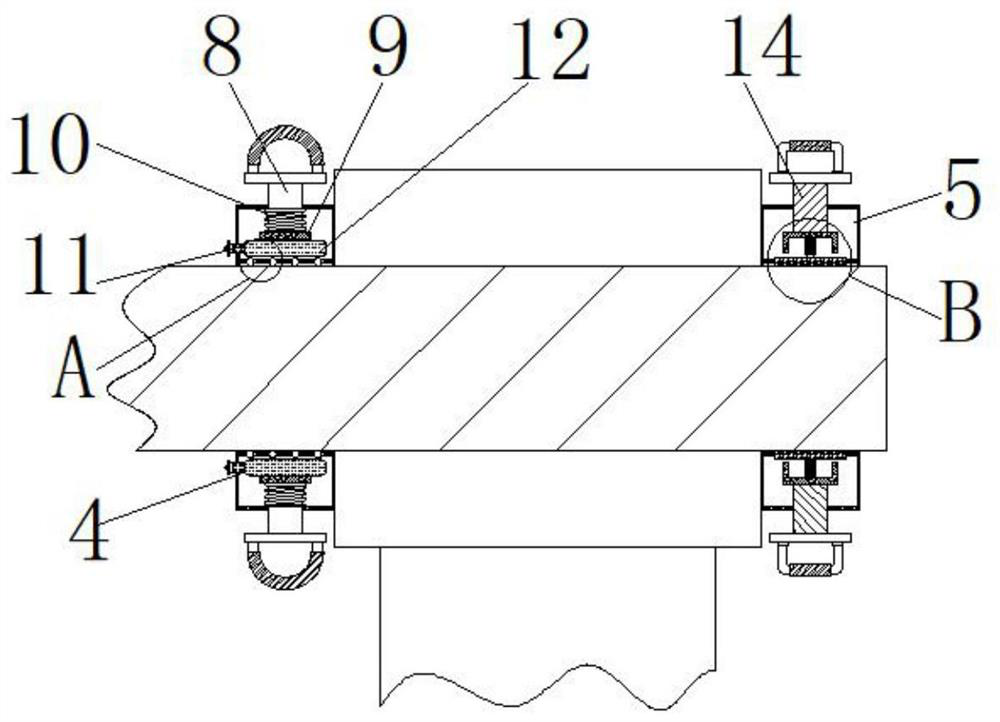

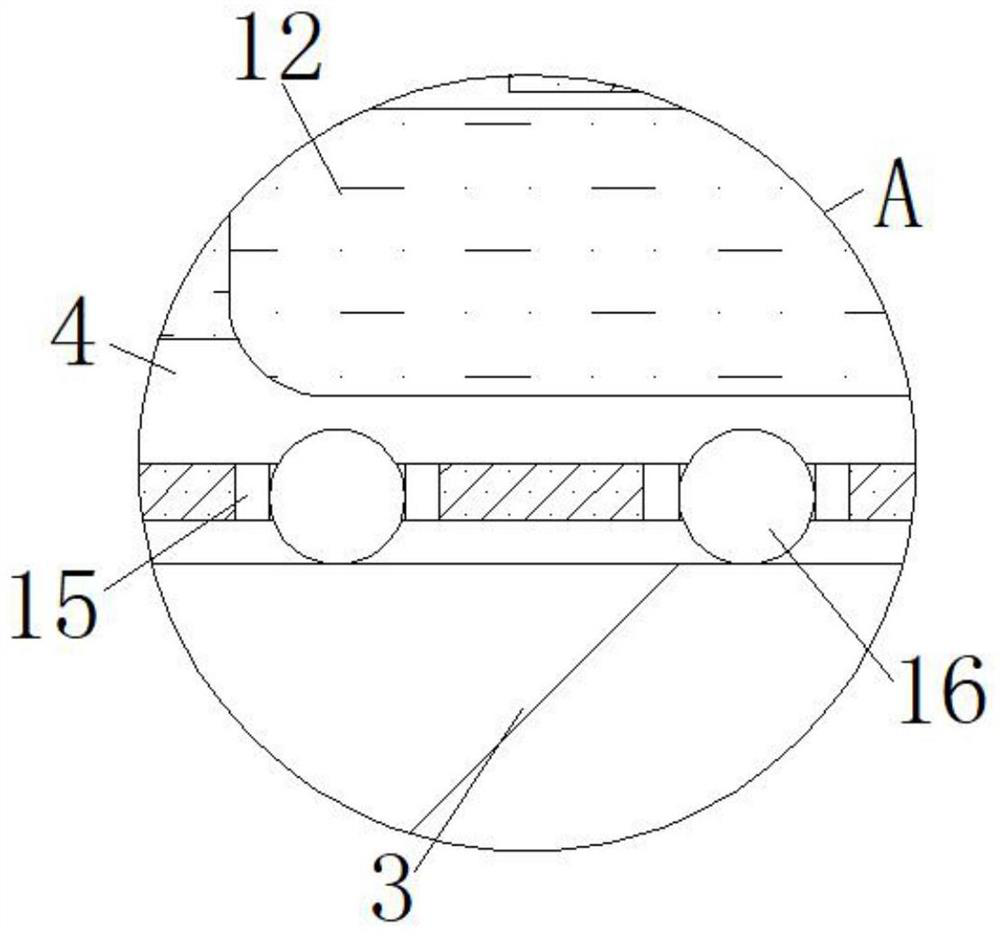

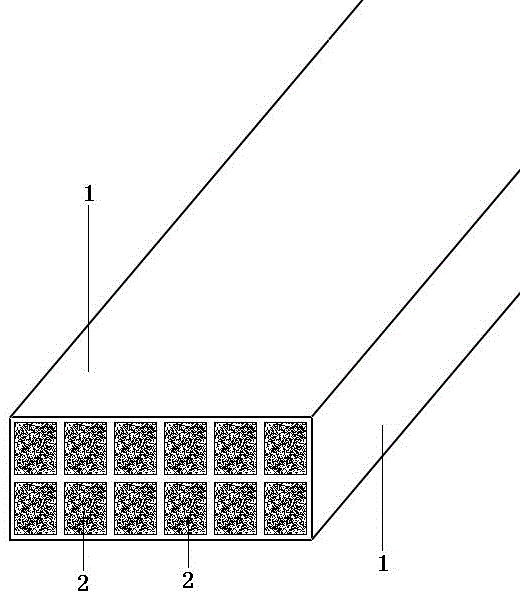

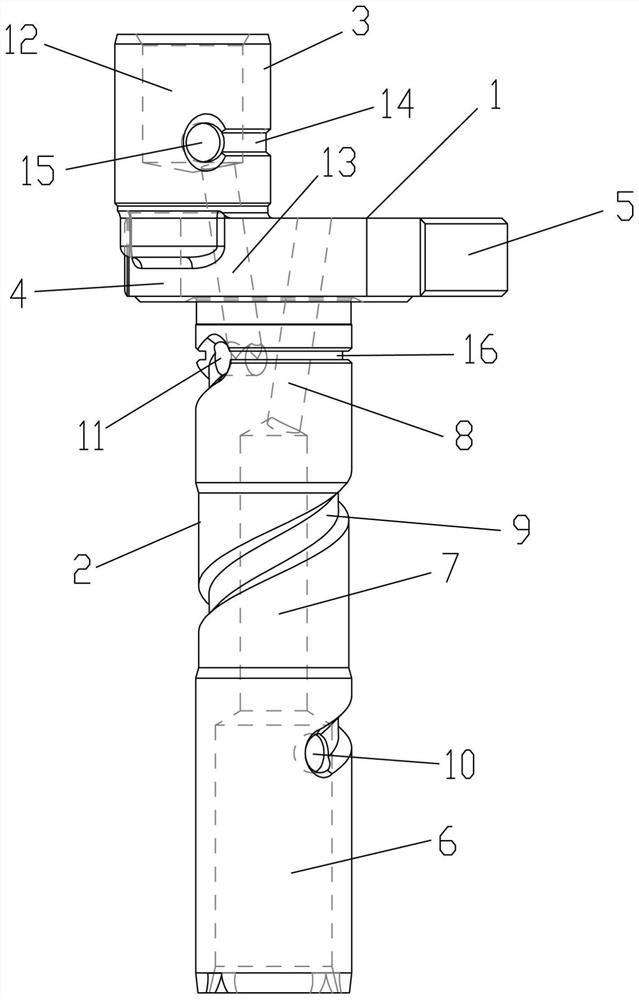

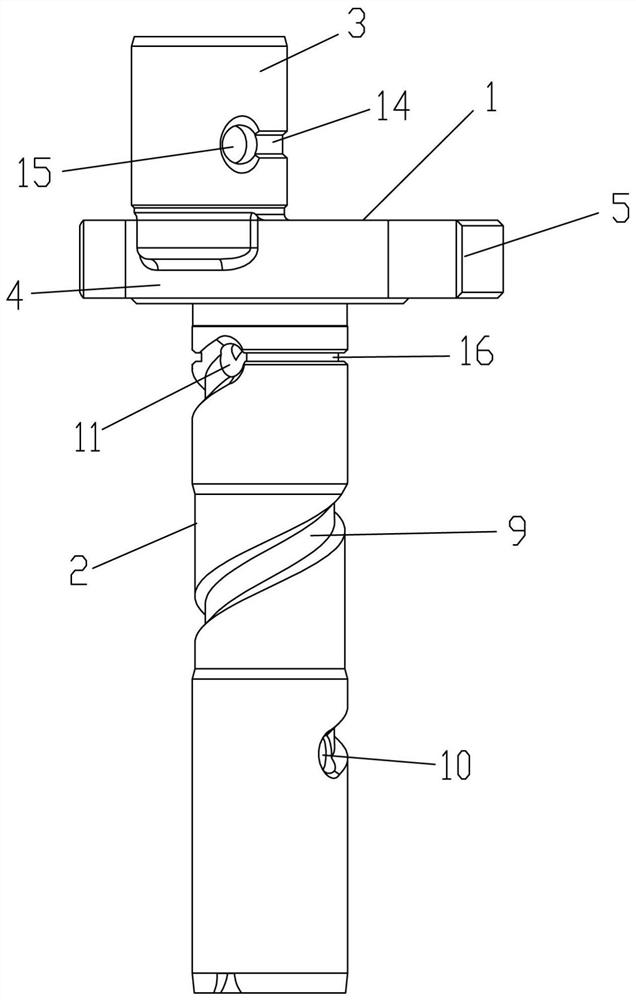

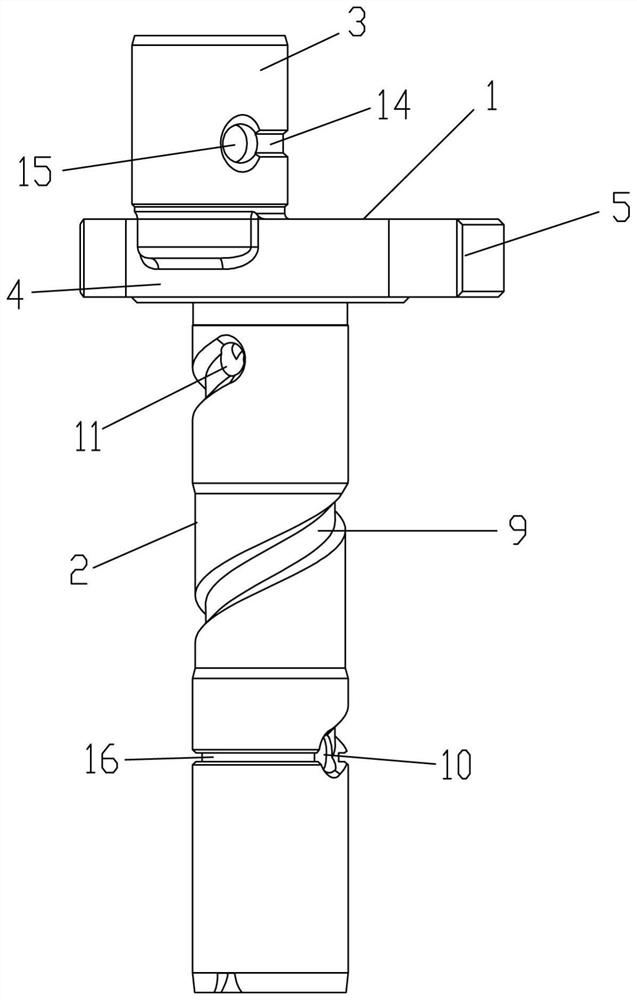

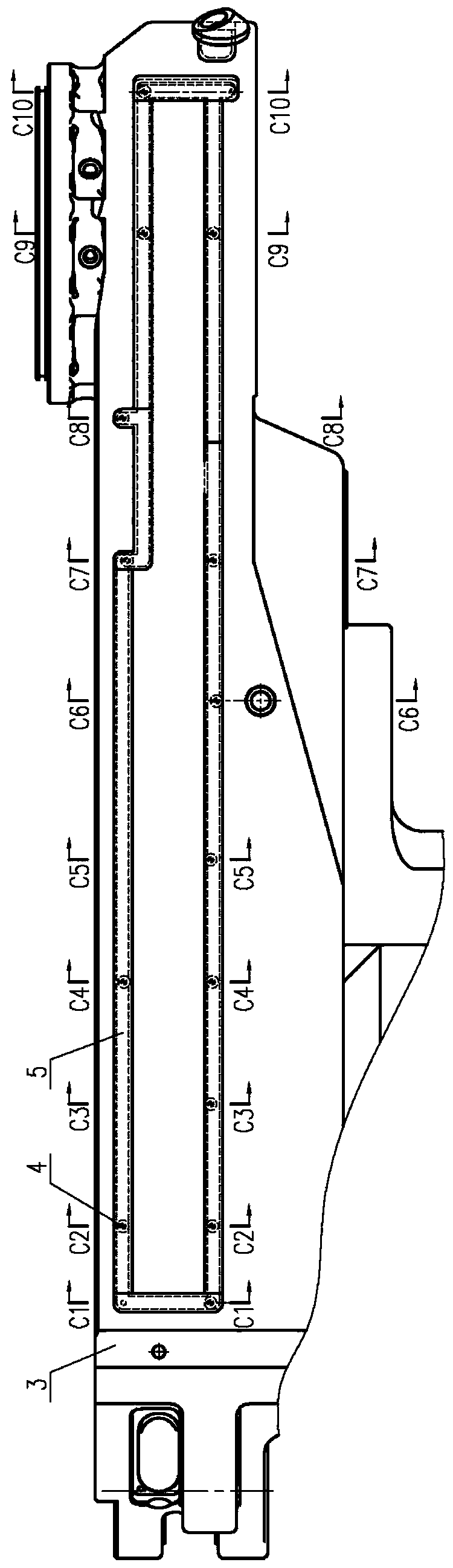

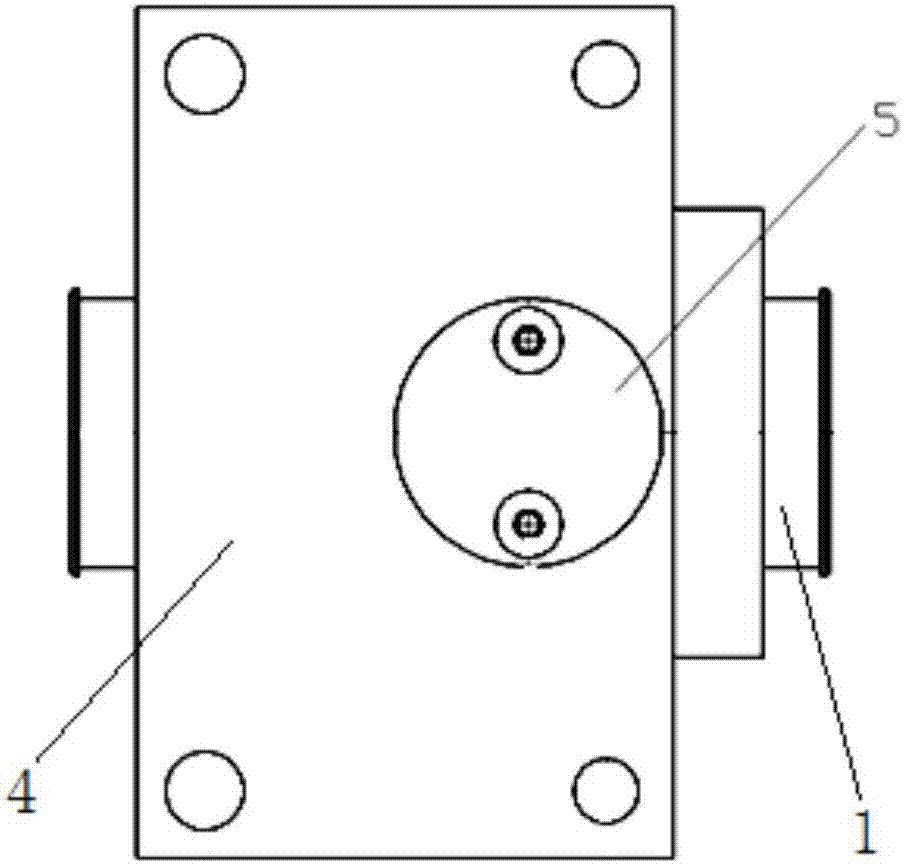

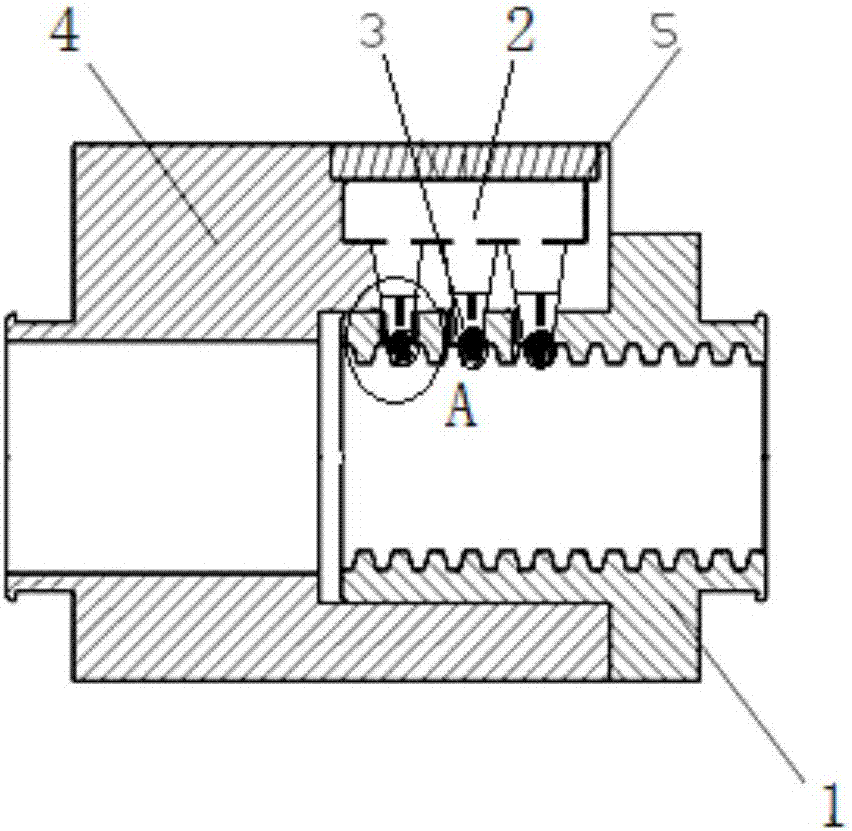

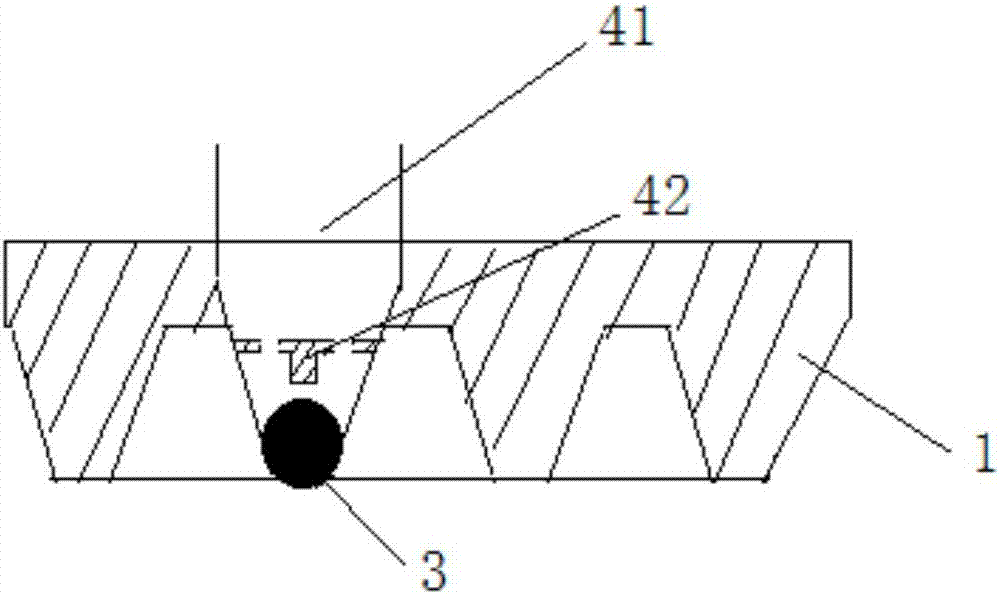

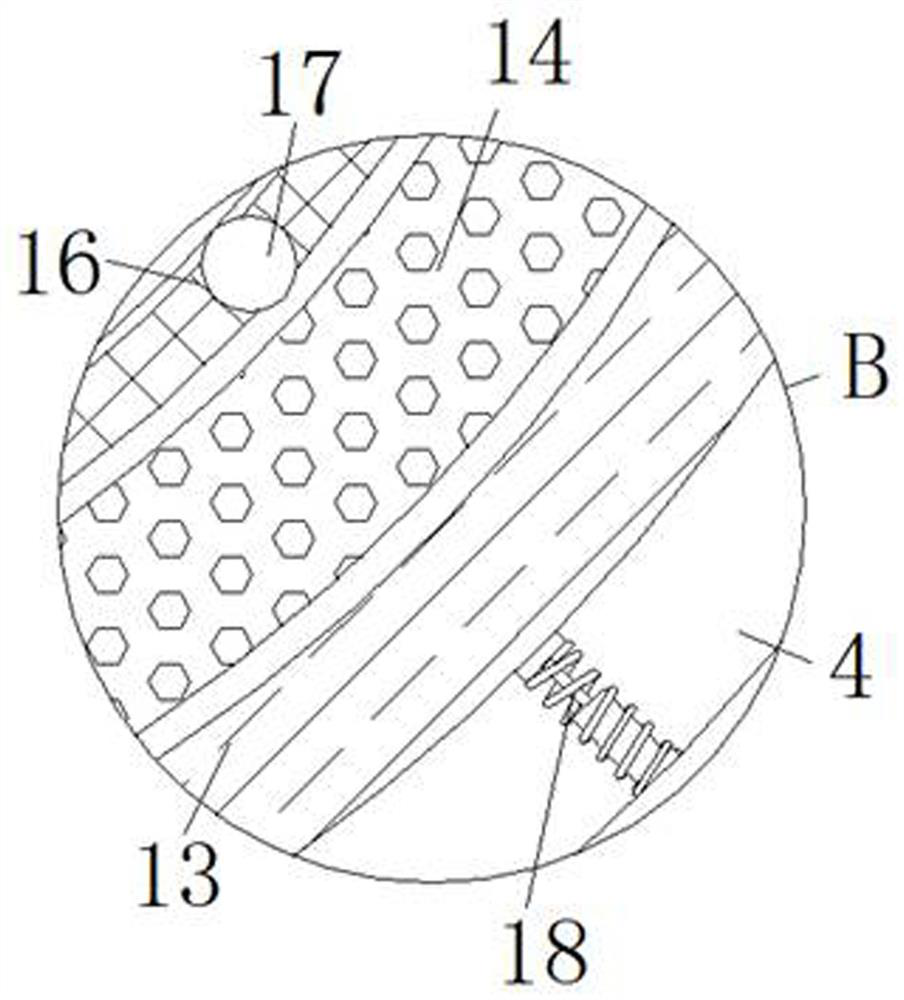

Solid lubricating device used for open-type lead screw nut transmission of numerical control machine tool

PendingCN107489755AEfficient lubricationReduce erosionGear lubrication/coolingMaintainance and safety accessoriesNumerical controlWorking environment

The invention relates to a solid lubricating device used for open-type lead screw nut transmission of a numerical control machine tool. The solid lubricating device is used for lubricating the surface of an open-type lead screw and comprises a nut and a nut seat. The nut is fixed to the nut seat, a hollow inner cavity used for storing solid lubricating agents is formed inside the nut seat and communicates with an inner cavity of the nut through a powder channel, and a circular ball is arranged in a connecting channel. Compared with the prior art, the solid lubricating agents are adopted as lubricating materials, so that friction and abrasion of the two surfaces making relative movement are reduced, and the surfaces are protected against being damaged, the situation that grease is used for lubricating is avoided, so that the overflowing grease is avoided, and not only is the steel grit erosion degree reduced, but also the working environment is improved.

Owner:上海瓦姆石油天然气管业有限公司

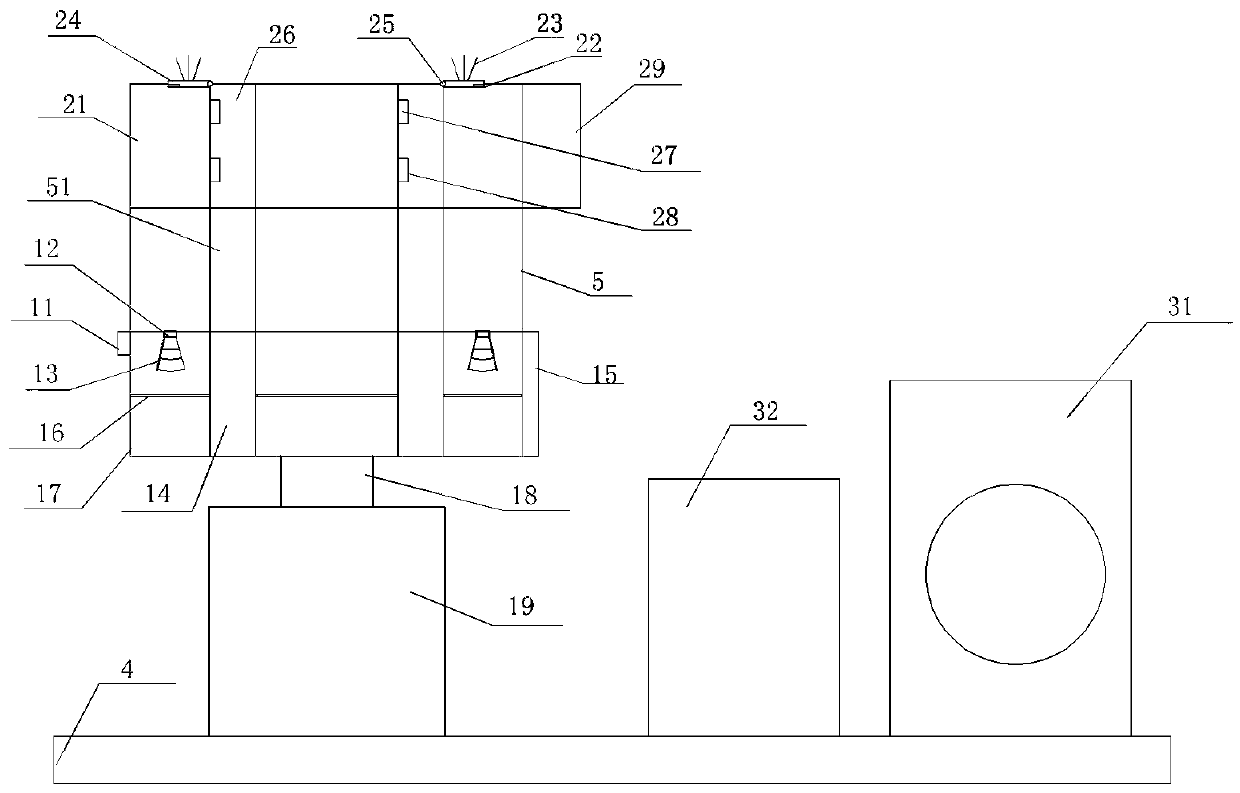

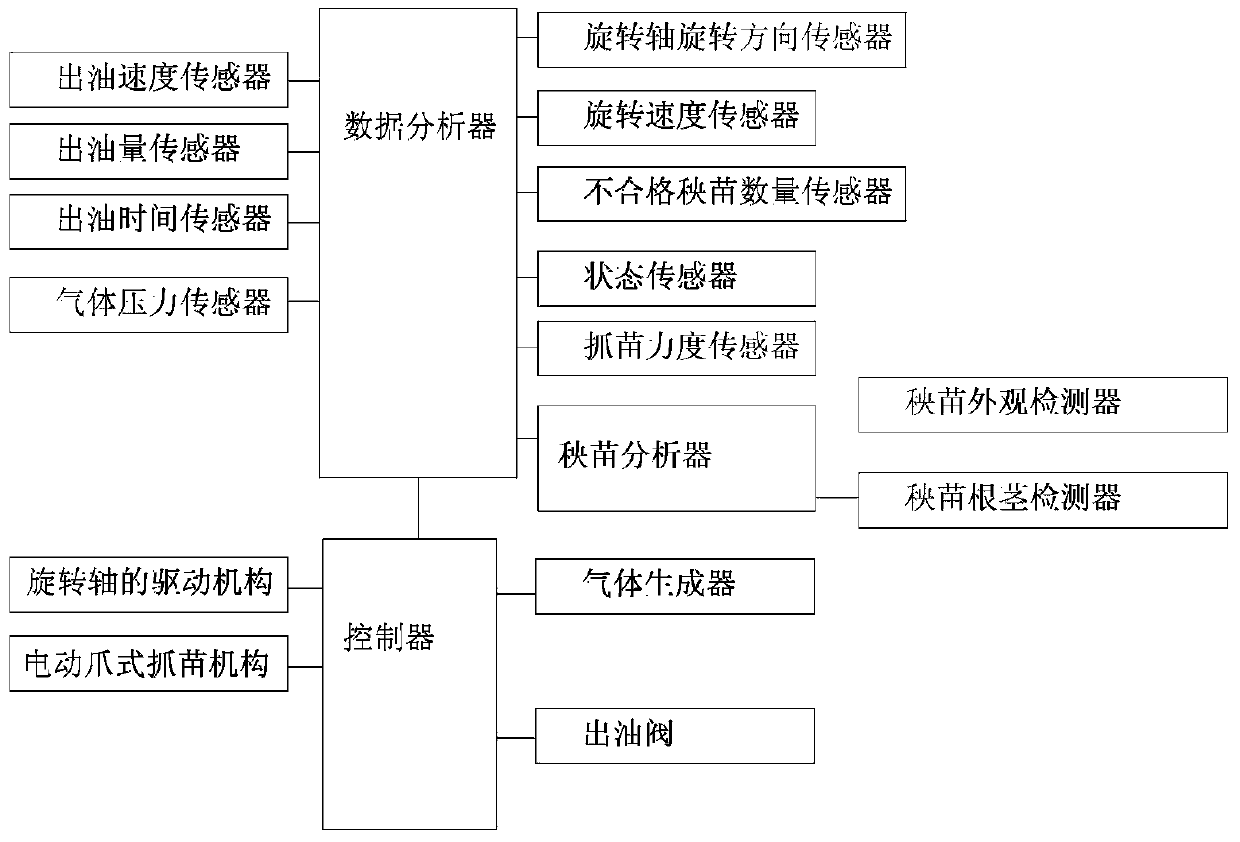

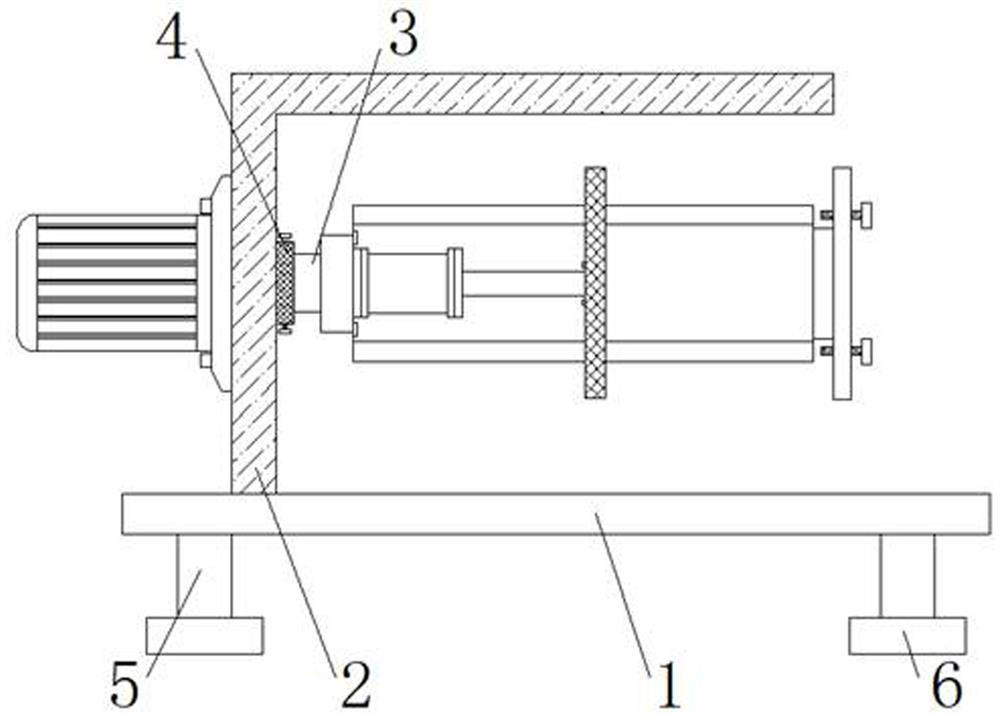

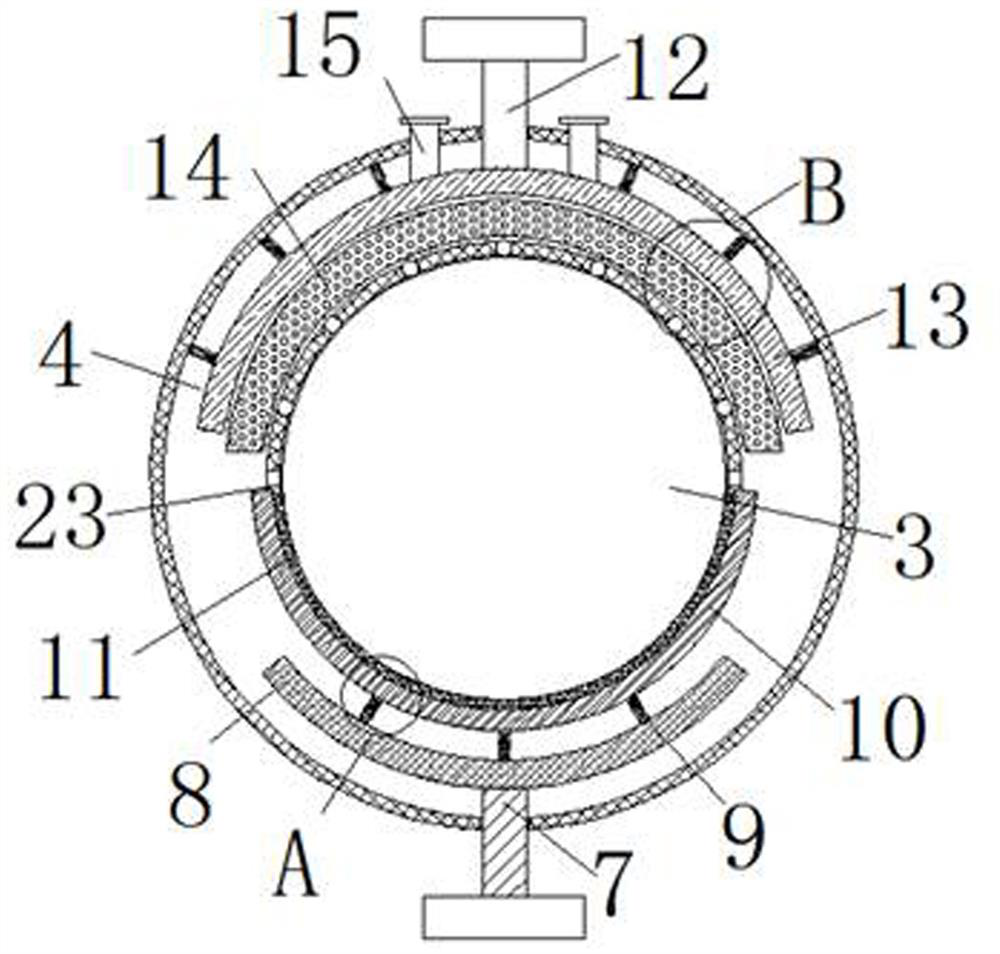

Lubricating and seedling selecting integrated device for seedling transplanter

The invention relates to a lubricating and seedling selecting integrated device for a seedling transplanter. The device comprises a seedling transplanting disc with a seedling channel, a lubricating disc is arranged below the seedling transplanting disc, and the lubricating disc is hollow and is vertically divided into an oil cavity and an air cavity by a horizontal oil film plate; the air cavityis communicated with an exhaust port of an air generator through an air circulating channel, the oil cavity is communicated with a plurality of oil outlet channels formed in the top surface of the lubricating disc and used for lubricating the seedling transplanting disc; a seedling selecting disc is arranged above the seedling transplanting disc, seedling inlet channels corresponding to the seedling channel are formed in the seedling selecting disc, and a seedling grabbing disc is arranged beside each seedling inlet channel in the seedling selecting disc; an electric claw type seedling grabbing mechanism is arranged on each seedling grabbing disc, the side of the bottom of each seedling grabbing disc is connected with the seedling selecting disc through a rotating shaft, and a speed reducing oil film layer is arranged on the inner wall of each seedling inlet channel. The integrated device is simple in structure, and can effectively achieve timely and efficient lubricating of the seedling transplanting disc. Meanwhile, unqualified seedlings can be removed, the overall service life of the seedling transplanter is prolonged, and the work efficiency of the seedling transplanter is improved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Household appliance stamping production process

ActiveCN108080498ADisperse in timePerformance impactShaping toolsLubricant compositionLubricantMaterials science

The invention discloses a household appliance stamping production process. The process comprises the following steps that S1, preparing work is carried out; S2, a heat conduction cover is arranged outside an upper mold and a lower mold of a forming mold, and a circulation condensation pipe is arranged outside the heat conduction cover; S3, a lubricant coats the inner surfaces of the upper mold andthe lower mold of the forming mold; S4, materials are injected, the upper mold and the lower mold are closed, pressure maintaining and blanking procedures are carried out, demolding is completed, thenumber of times of the blanking procedures is recorded, when the number of times reaches the limit, the forming and blanking procedures are stopped, a heat conduction cover switch is started, coolingis carried out, after cooling is completed, the forming and blanking procedures are started again, and the record of the number of times of the blanking procedures is reset to be 0; and S5, the subsequent stamping procedure is carried out until the material is conveyed to a discharging area, and the stamping production process is completed. According to the household appliance stamping productionprocess, the heat dissipation is fast in the production process, the abrasion of the mold is small, and the service life of instrument equipment is long; and the product production and instrument usecost is low, the product reproducibility is good, and the percent of pass and the production efficiency are high.

Owner:CHUZHOU XINKANGDA METAL PROD

Winding device for circuit laying

InactiveCN111891837AAvoid the problem of reducing the transmission efficiency of the rotating shaftImprove the lubrication effectFilament handlingElectric machineBrush

The invention discloses a winding device for circuit laying. The winding device for circuit laying comprises a bottom plate, wherein a support frame is fixed to the top end of the bottom plate; a motor is fixed to the surface of one side of the support frame; a rotary shaft is rotationally connected to the output shaft of the motor; the rotation of the rotary shaft is transmitted to the inner sideof the support frame and a winding reel is fixed to the tail end of the rotary shaft; a fixed sleeve is fixedly connected to the support frame and the rotary end of the rotary shaft in a sleeved manner; a push rod movably penetrates into the outer wall of the fixed sleeve; the push rod extends into an empty cavity of the fixed sleeve and a push plate is fixed to the tail end of the push rod; an extrusion spring is arranged at the junction of the push plate and the empty cavity of the fixed sleeve; and a sponge block is arranged on the surface of one side of the push plate. Through the arranged sponge block, convenient and efficient lubrication for the surface of the rotary shaft is benefited; through an arranged brush head, convenient and rapid cleaning for dust and other impurities on the surface of the rotary shaft is benefited; and through an arranged limit plate, a guarantee on the normal working of the device is benefited, buffering for vibration of the device during working is facilitated, and the stability of the device is improved.

Owner:国网内蒙古东部电力有限公司建设分公司 +1

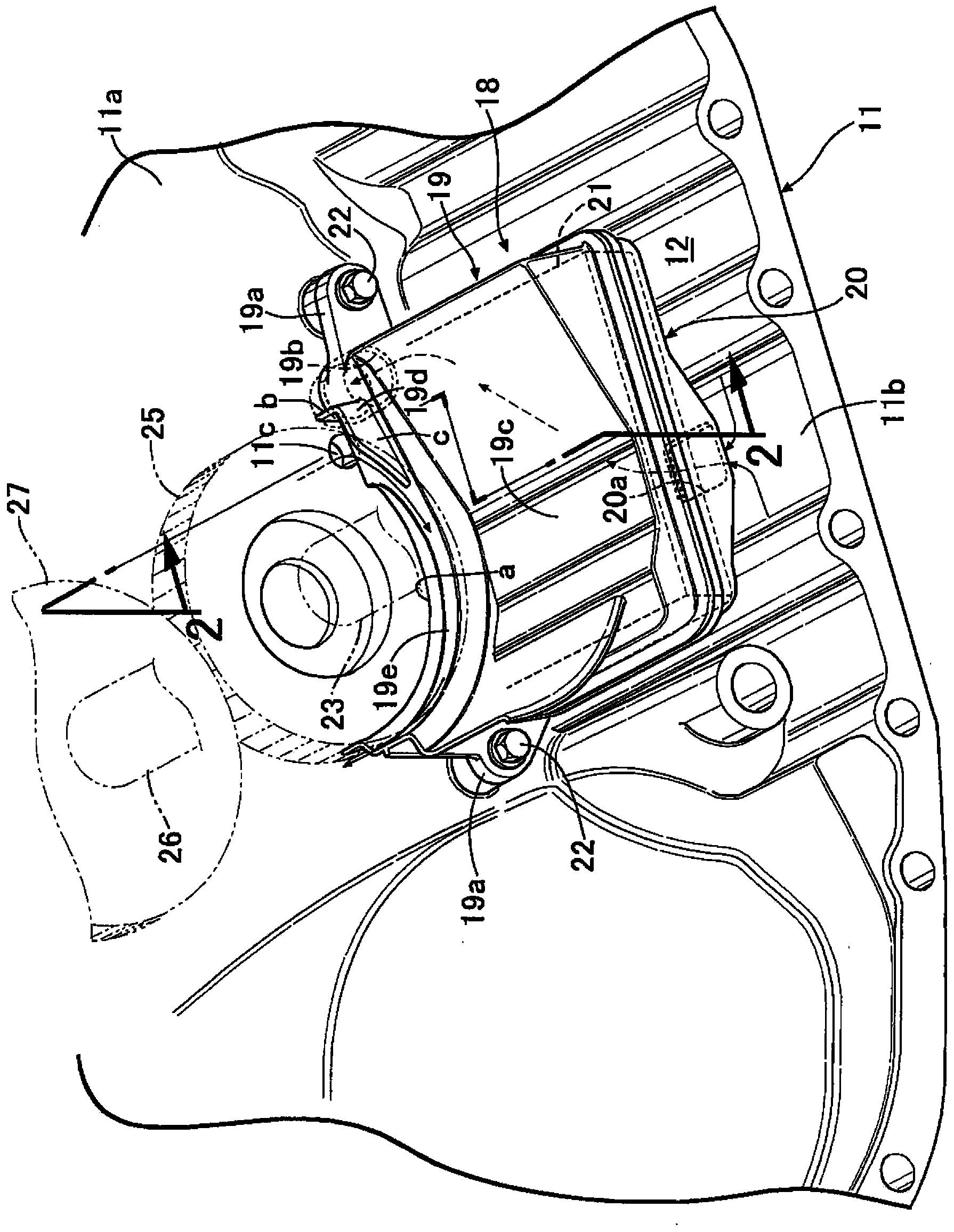

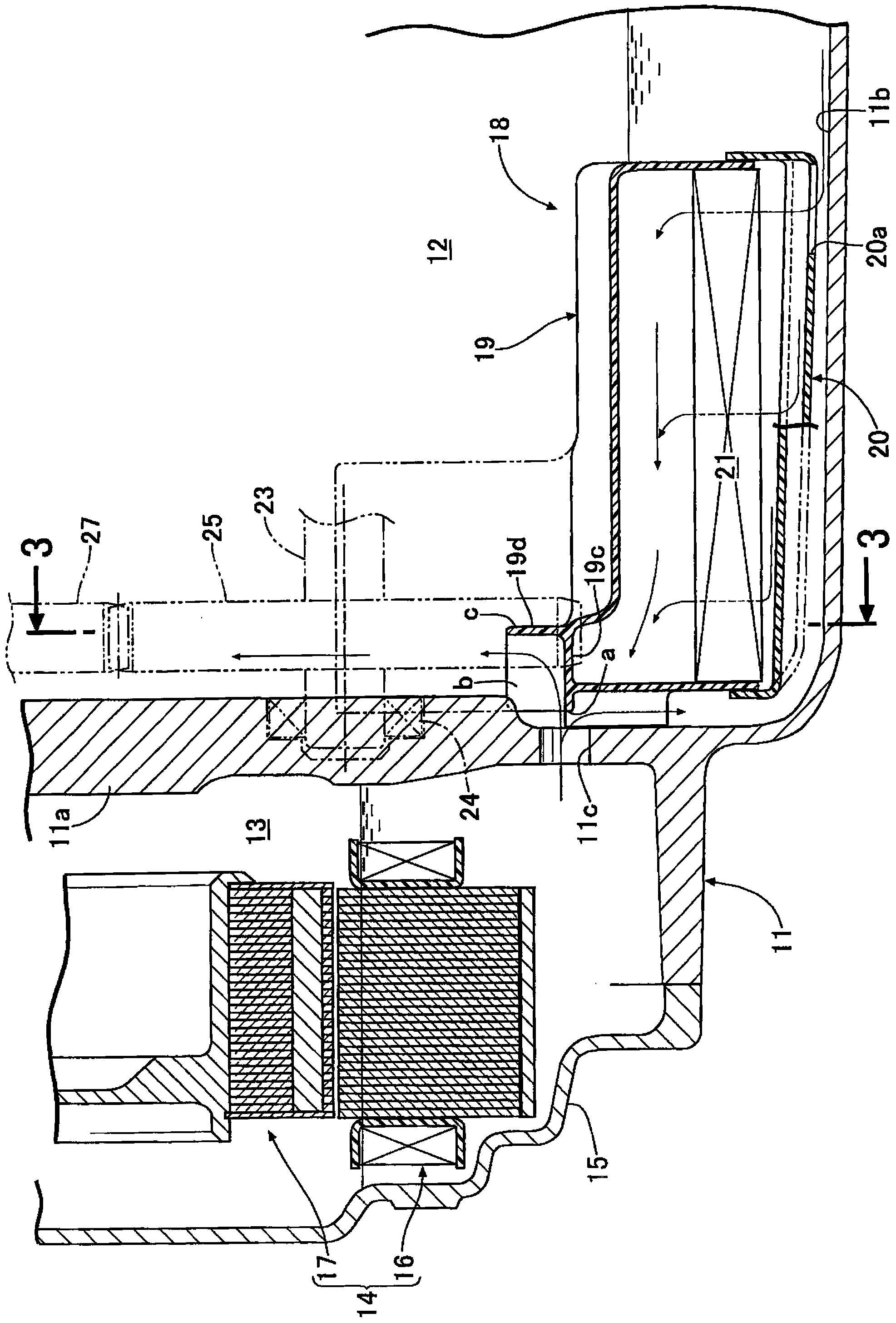

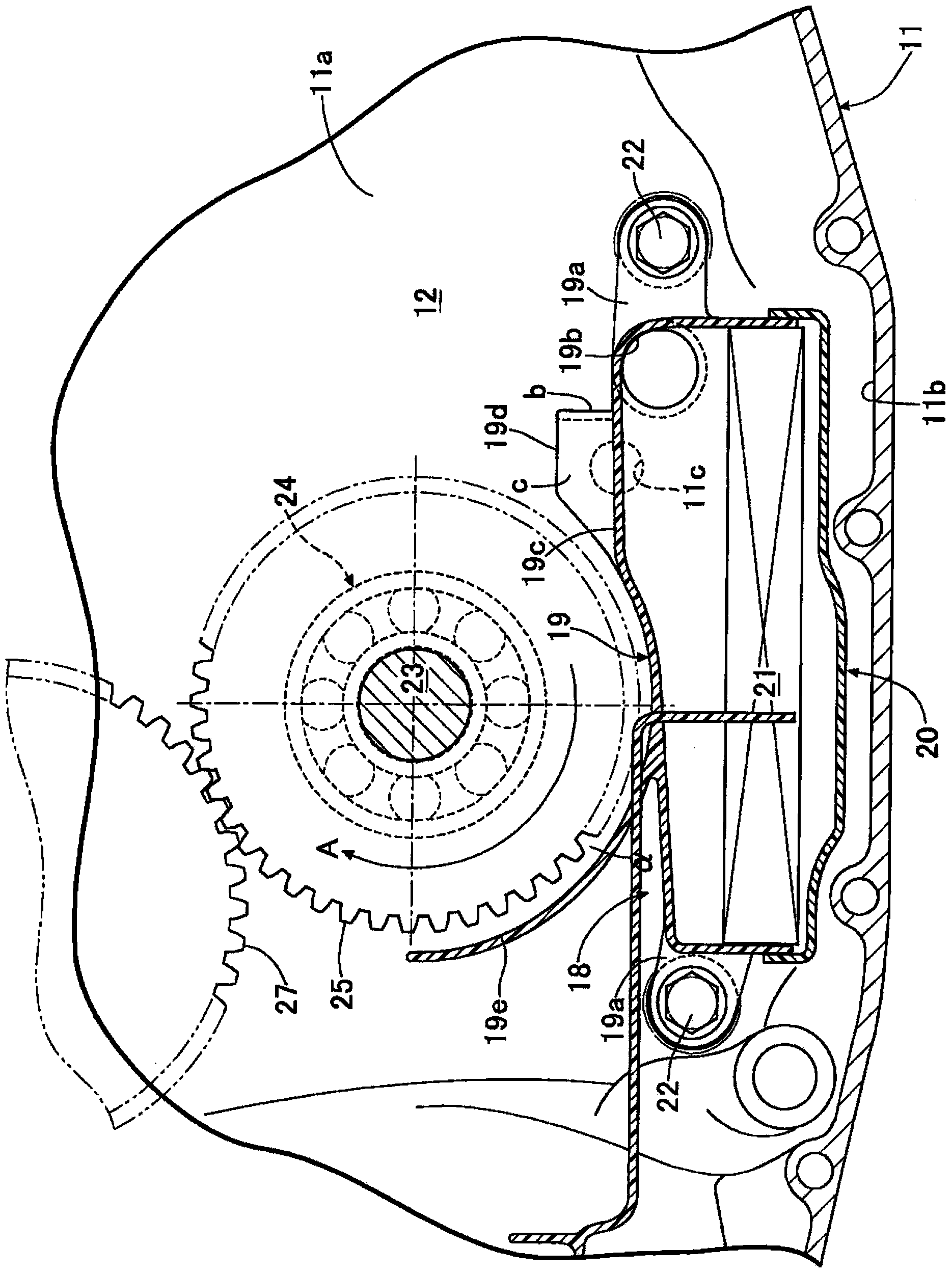

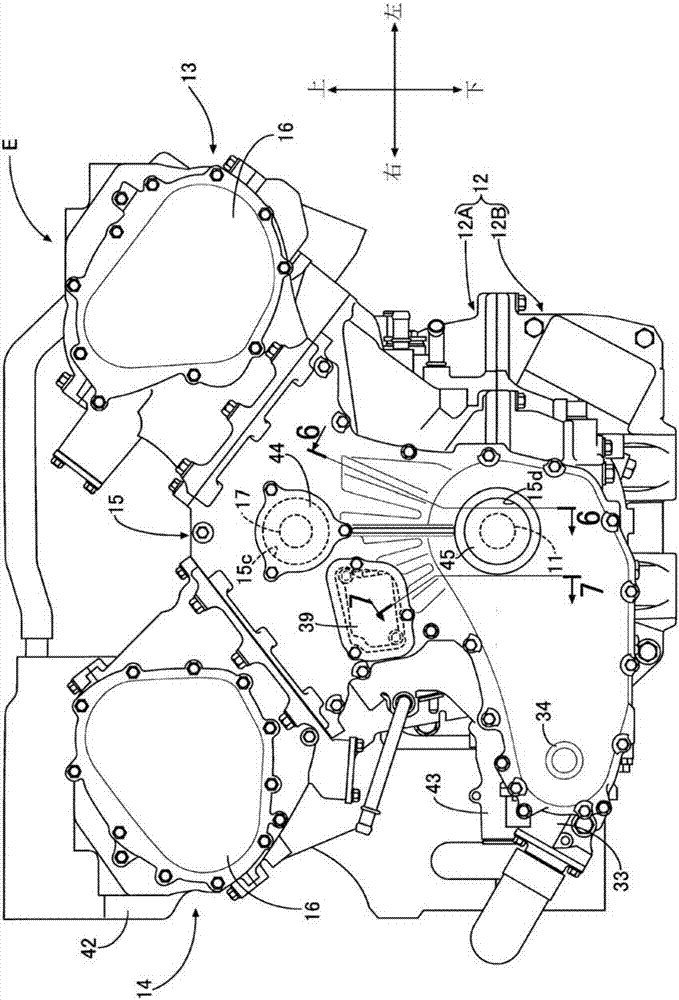

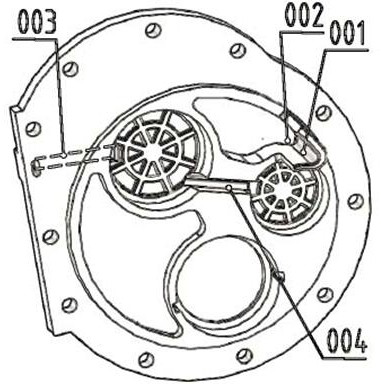

Cover member of internal combustion engine

The present invention provides a cover member for an internal combustion engine capable of improving the rigidity of a lid member of an internal combustion engine to suppress vibration and capable of smoothly guiding the oil flowing along the cover member to a through hole for supporting the shaft. A cover member (15) mounted on a crankcase (12) of an internal combustion engine (E) has a through hole (15d) rotatably supported by a shaft (11); a bulging portion (15f) which is located above the through hole and bulges toward the inside of the cover member; and a plurality of groove portions (15g) extending radially from the through hole so as to connect the upper portion and the lower portion on the inner surface side of the bulging portion. Therefore, it is possible to suppress the vibration by improving the rigidity of the cover member by the groove portion (15g) of the bulging portion (15f) without providing the ribs with weight, the oil inside the crankcase (12) can concentrated around the through hole (15d) along the groove portion (15g) of the bulging portion (15f) by means of the gravity, so that the rotating shaft can be efficiently lubricated.

Owner:HONDA MOTOR CO LTD

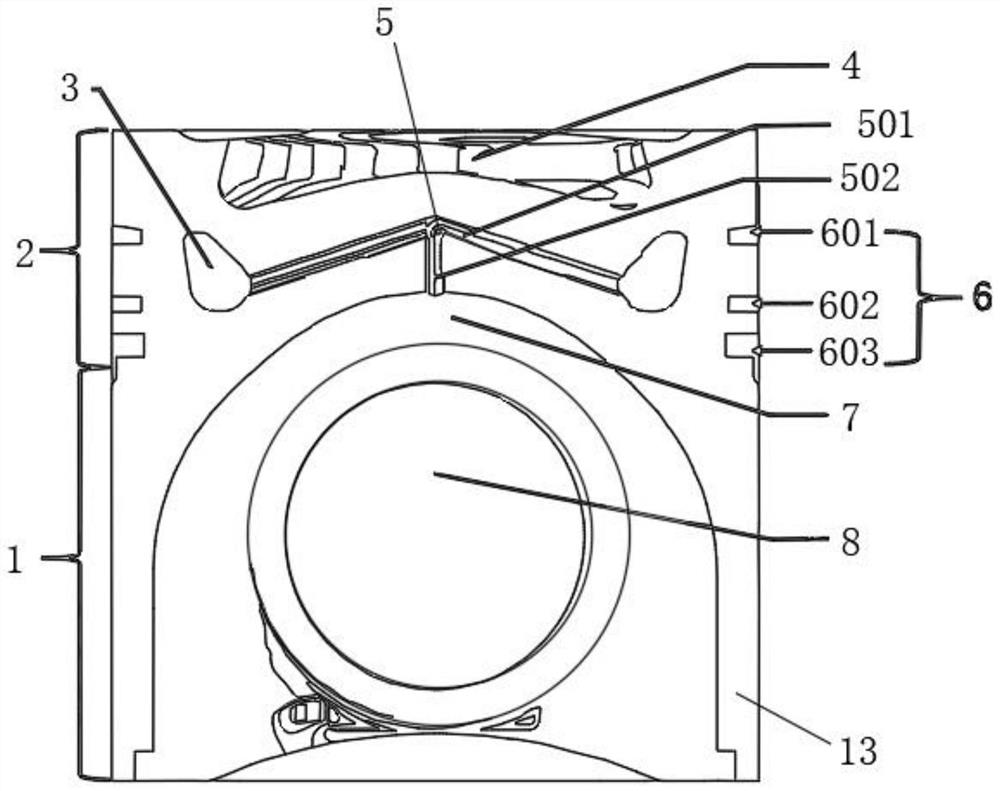

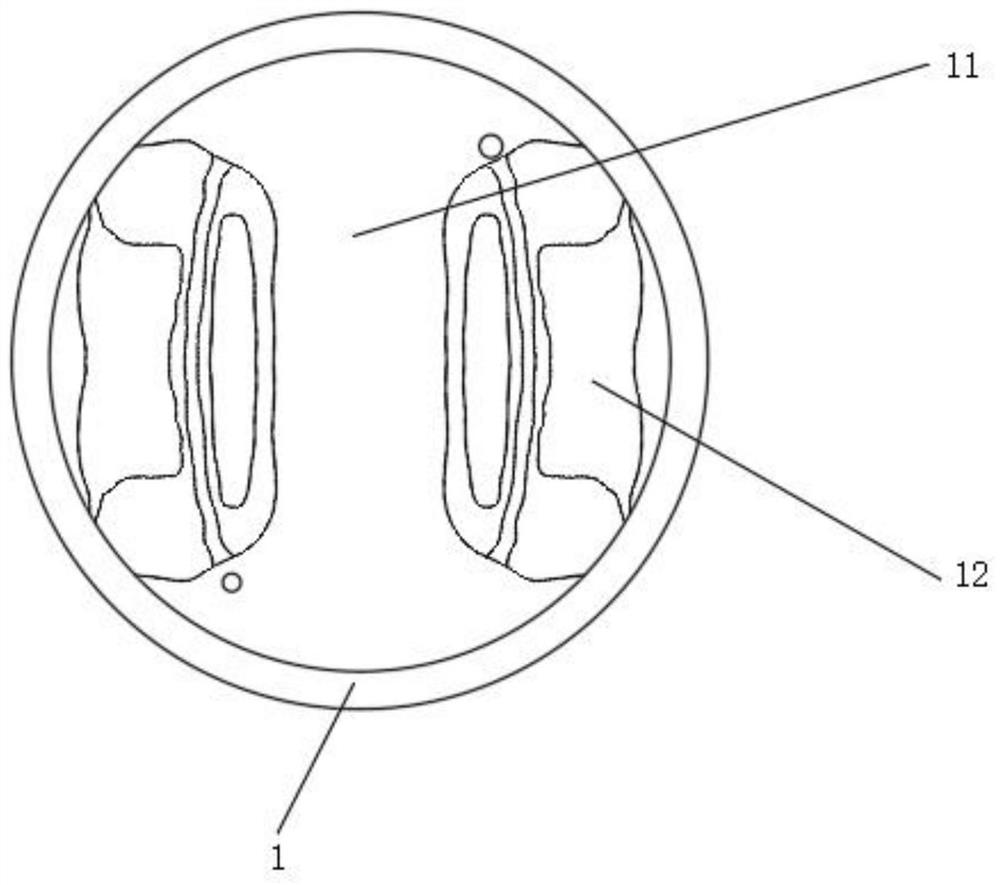

N-shaped arranged speed reducer shell for new energy vehicle

PendingCN111692321AEfficient lubricationEasy to castGearboxesGear lubrication/coolingNew energyReduction drive

The invention relates to a N-shaped arranged speed reducer shell for a new energy vehicle. The shell comprises a shell cover and a shell body which are connected with each other, three-axis bearing holes, two-axis bearing holes and one-axis bearing holes are formed in the shell cover and the shell body, a differential mechanism assembly is arranged on one side of the shell body, a differential mechanism bearing hole is formed in the differential mechanism assembly, and the circle center connecting line among the differential bearing hole, the three-axis bearing holes, the two-axis bearing holes and the one-axis bearing holes form an N-shaped structure from the side view angle. According to the the speed reducer shell, a split design is adopted, so that casting, production and processing ofthe shell body and the shell cover are facilitated, and the subsequent assembly of gears and a bearing pack is facilitated; and the efficient lubrication of a speed reducer during low-high-speed advancing or low-speed retreating of the whole vehicle is guaranteed through various oil baffles and oil grooves ingeniously designed on the shell body and the shell cover.

Owner:JIANGXI JIANGLING CHASSIS CO LTD

Oil supply structure based on precise lubrication of integral piston

InactiveCN112761806AReduce weightIncrease profitMachines/enginesPistonsCombustion chamberEngineering

The invention discloses an oil supply structure based on precise lubrication of an integral piston. The oil supply structure comprises a piston skirt part, a piston head part, a cooling oil cavity, an oil supply channel plane of a piston pin hole and a piston body, wherein the piston head part is arranged in the piston body, a combustion chamber is installed in the position, on one side of the piston head part, of the piston body, the outer wall of the combustion chamber is fixedly connected with the piston skirt part, the cooling oil cavity is formed in the position, below the combustion chamber, in the piston body, the outer wall of the cooling oil cavity is fixedly connected with the piston skirt part, a piston inner cavity is formed in the position, below the cooling oil cavity, in the piston body, the outer wall of the piston inner cavity is fixedly connected with the piston skirt part, and the piston skirt part is mounted in the piston body on one side of the piston inner cavity. According to the oil supply structure for precise lubrication of the integral piston, efficient oil supply is achieved, the utilization rate of lubricating oil is increased, the weight of the piston is reduced, and the bearing strength is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

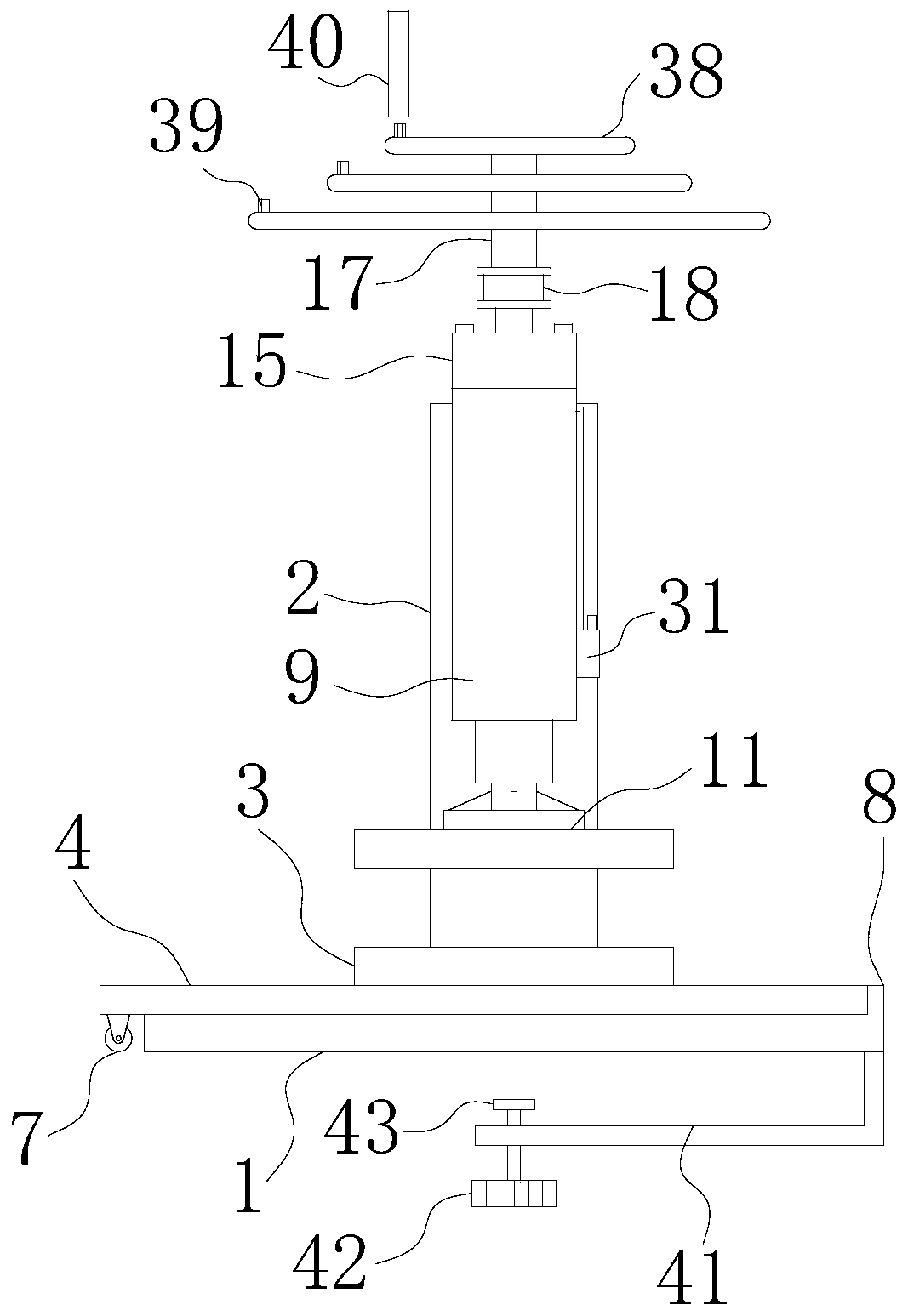

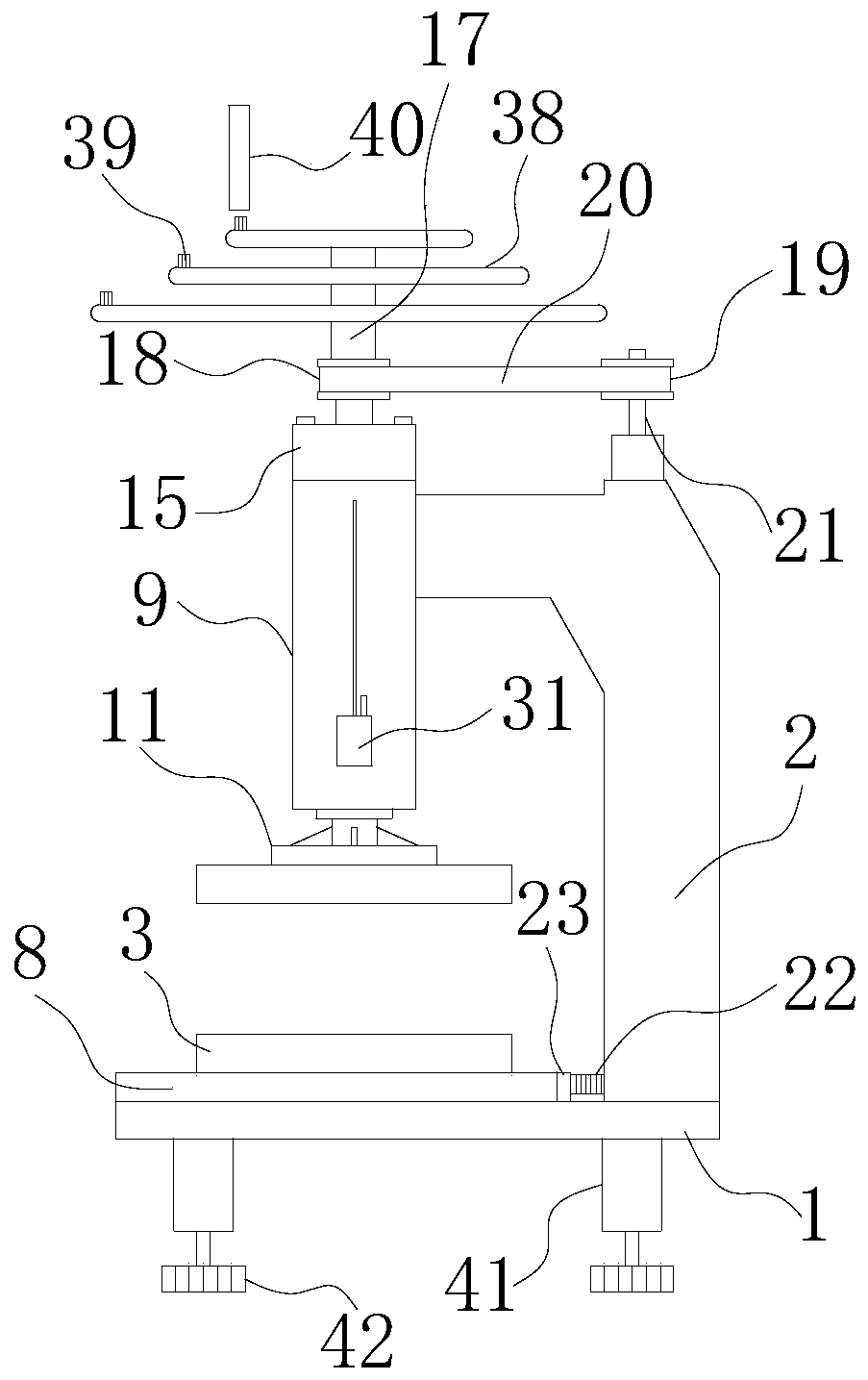

A self-lubricating manual press

Owner:嵊州市越通非开挖建设有限公司

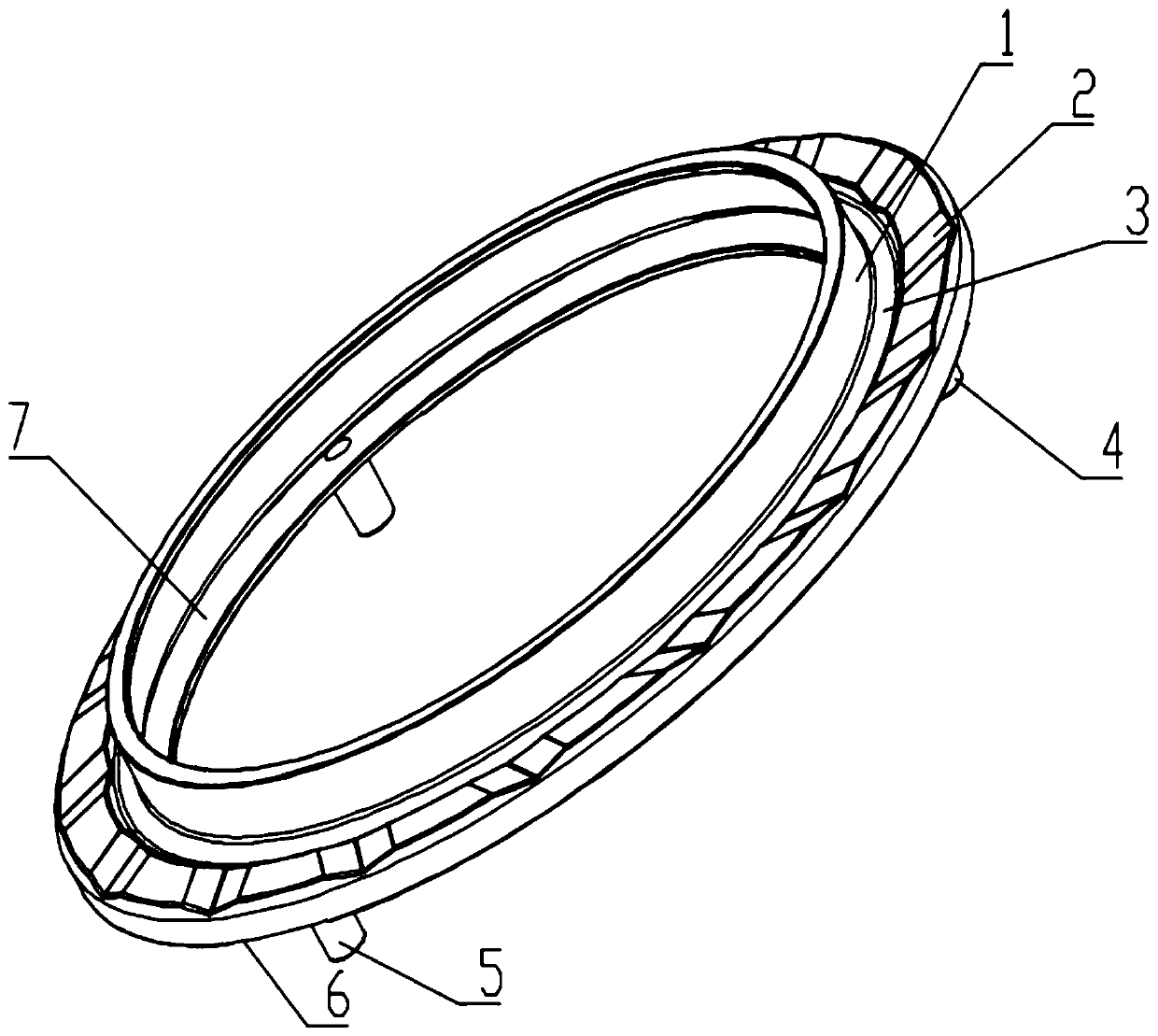

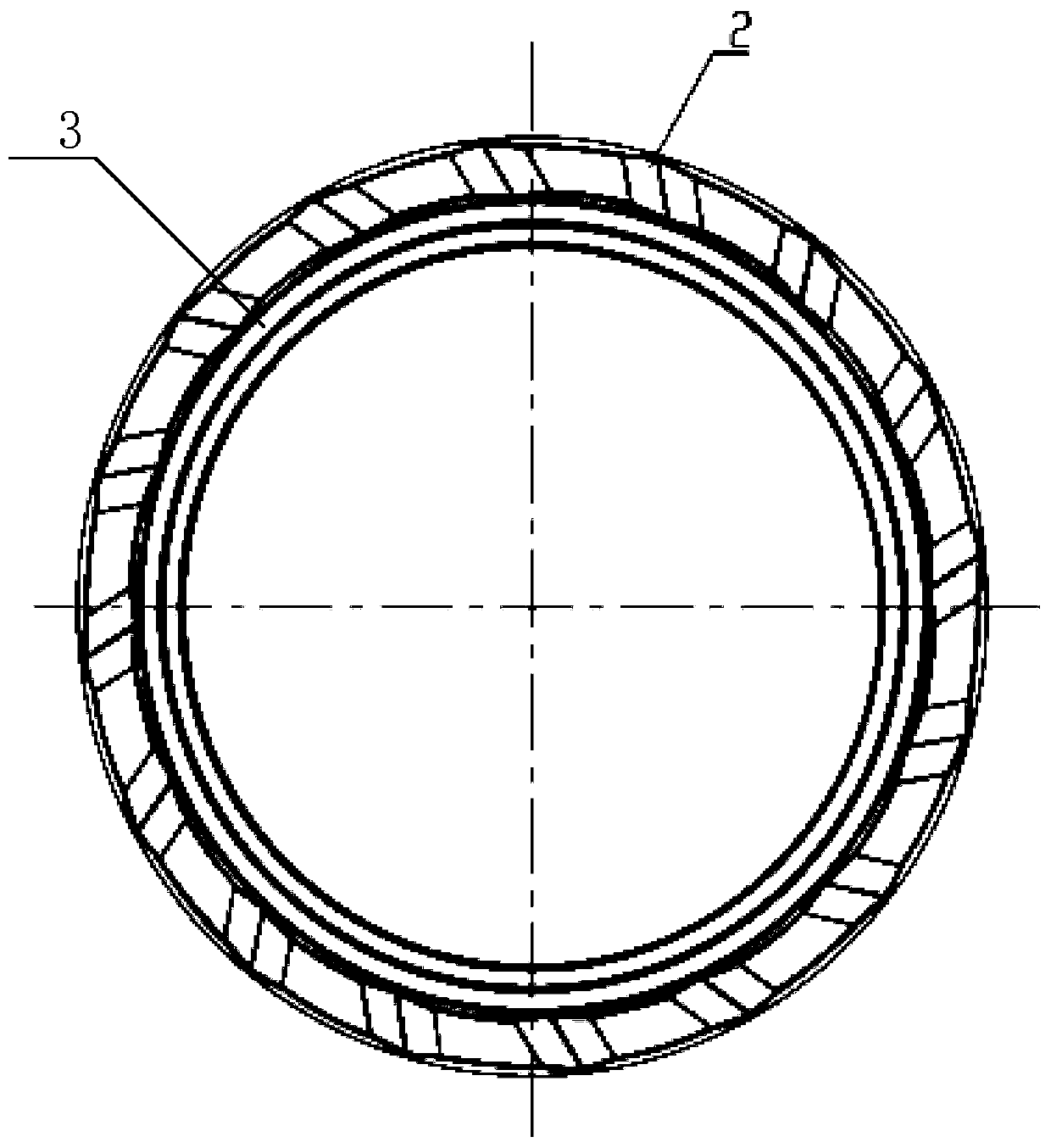

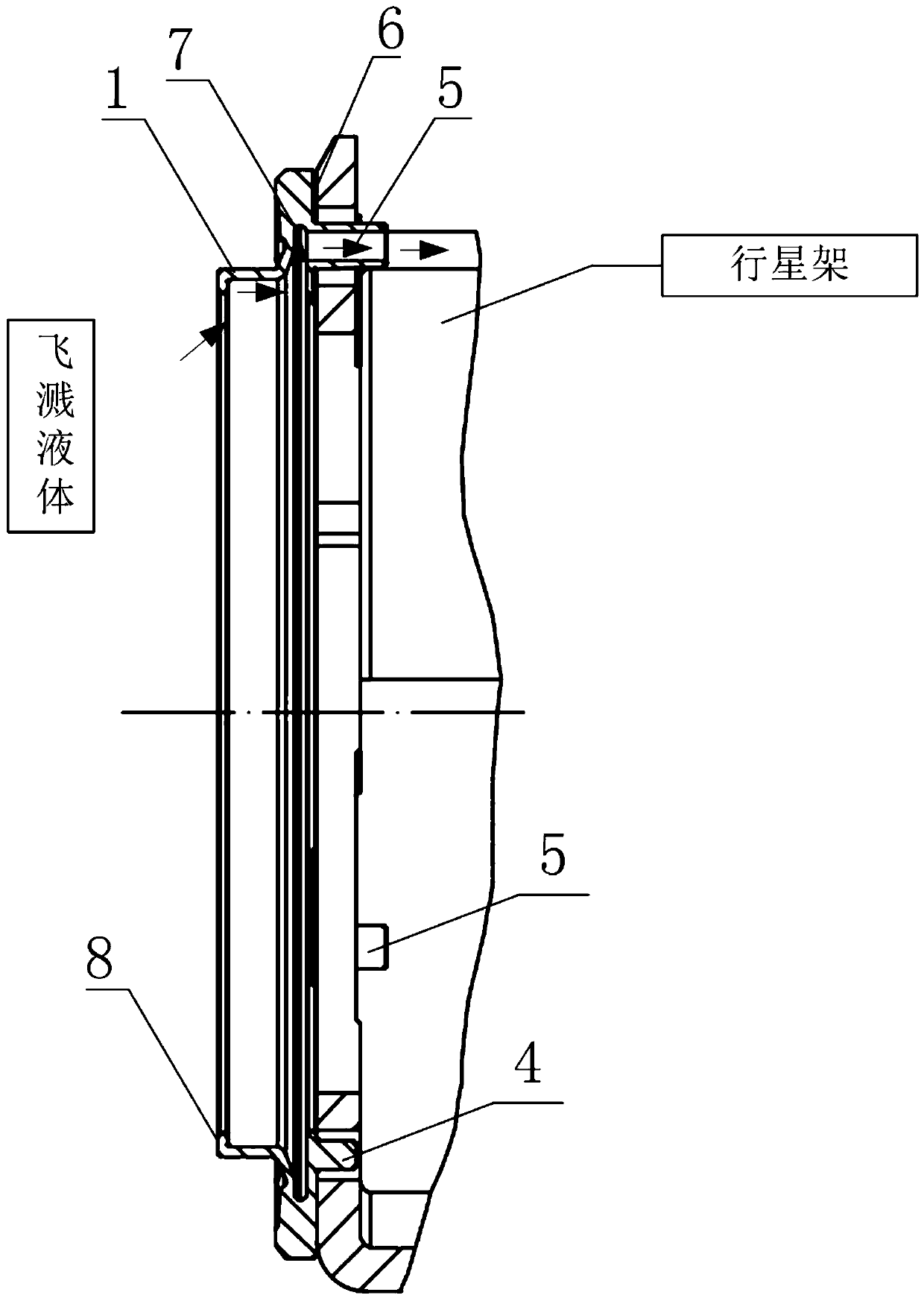

Liquid flow guide member

PendingCN110219972AEfficient lubricationLow costGear lubrication/coolingLiquid mediumAutomatic transmission

The invention discloses a liquid flow guide member. The liquid flow guide member is used for lubricating a planetary gear in an automatic transmission, and comprises an annular body, wherein a bulgedring is arranged at one side of the annular body, and the sidewall of the bulged ring has a reducing taper in the axial direction; a plurality of hollow guide columns are arranged at the other side ofthe annular body; and an annular groove is formed in the inner wall of the annular body in the radial direction, and the hollow guide columns communicate with the sidewall of the annular groove. In the liquid flow guide member, during the rotary working of the liquid flow guide member, a splashing liquid medium is subjected to flow guide by the bulged ring which has the reducing taper under a centrifugal effect and effectively collected through the annular groove to be pressurized, and then flows to the planetary gear via the hollow guide columns, efficient lubrication in a transmission partlimited by a space is realized, and an independent oil supply system is not needed, so that the purposes of low cost and good lubrication effect are achieved.

Owner:SHAANXI FAST GEAR CO

Belt oil wheel device capable of adjusting meshing automatically

InactiveCN107975590AControl precisionGood and stable lubricationGear lubrication/coolingLubricationPetroleum engineering

The invention provides a belt oil wheel device capable of adjusting meshing automatically. The belt oil wheel device comprises a wheel shaft, a plurality of belt oil wheel oil pipes and hub plates andfurther comprises an elastic pipe, wherein the belt oil pipes are connected through chain plates; the elastic pipe is arranged between the hub plates; the belt oil pipes fit the outer surface of theelastic pipe; the belt oil pipes are hinged to the chain plate; oblong holes are formed in the parts, connected with the end parts of the belt oil pipes, of the hub plates; and at least one belt oil pipe not connected with the hub plates, is arranged between every two adjacent belt oil pipes connected with the hub plates. The special structure of the belt oil wheel device enables any belt oil pipeto squeeze the elastic pipe while receiving meshing impact, and the belt oil pipe is enabled to have elastic deformation within certain range to reach the buffering effect, so that the destructiveness of the meshing impact is eliminated, the situation that the belt oil pipes always closely fit a tooth surface is ensured and an excellent and stable lubricating effect is realized. The novel belt oil device has the advantages of efficient lubrication, low manufacture cost, simple installation and steady and reliable operation.

Owner:NANJING KISEN INT ENG

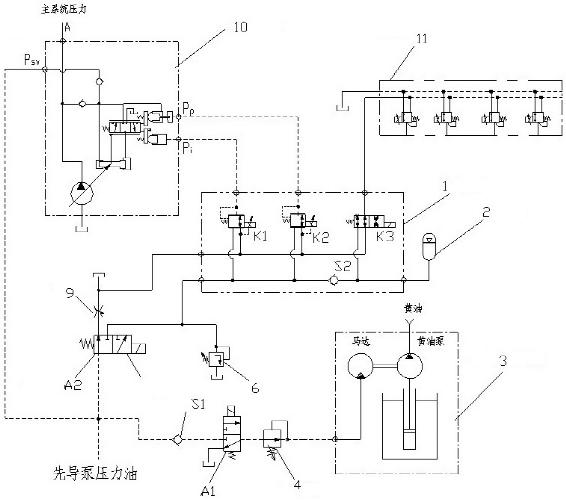

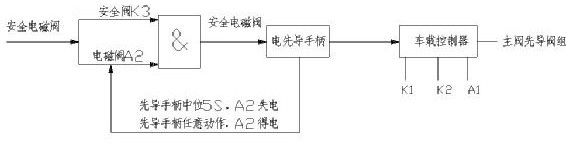

A super-large tonnage excavator pilot control oil circuit and control method

ActiveCN112012972BAvoid high pressure overflowReduce energy consumptionServomotor componentsAccumulator installationsSolenoid valveDrive motor

The invention discloses a super-large-tonnage excavator pilot control oil circuit and a control method, belonging to the field of engineering machinery. The pressure oil of the pilot pump is respectively connected to the Psv port of the variable pump, the solenoid valve A2, and the solenoid valve A1; The flow valve; the oil outlet of the solenoid valve A1 is connected to the motor in the butter filling system; the solenoid valve group is connected to the variable pump Pi port, Pp port and the main valve pilot valve group. In the present invention, after the excavator is started, the pilot oil circuit provides suitable pressure to different mechanisms according to the actual working conditions, avoiding the long-term high-pressure overflow of the pilot system and reducing energy consumption; The valve is periodically controlled to make the various mechanisms of the excavator lubricate efficiently, and the drive oil circuit of the butter filling system is provided with a pressure reducing valve, so that the pressure of the drive motor is not affected by pressure switching.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

A lubricating device with a turntable oil separator for large equipment

ActiveCN103388734BEfficient lubricationLubricating economyDistribution equipmentInlet channelProgrammable logic controller

The invention provides a lubricating device provided with a rotating disc type oil distributor and used for large-size equipment. An oil delivery pipe in a lubricating oil filling hydraulic unit is connected with an oil inlet pipe through a rotation connector; the oil inlet pipe penetrates through the center of an index plate to be communicated with a vertical oil inlet channel on a rotating oil distributing disc of the rotating disc type oil distributor; the oil inlet pipe is fixed on the rotating oil distributing disc; the rotating disc type oil distributor comprises an outer oil distributing disc and the rotating oil distributing disc mounted inside the outer oil distributing disc; the index plate is provided with position detection contacts and temperature detection contacts and is connected with a PLC (Programmable Logic Controller) through a position detection pointer and a temperature detection pointer; the PLC rotates a lubricating point through controlling a step motor to realize single-point lubrication and controls a hydraulic pump and a switch electromagnetic valve to realize timed and quantitative lubrication, so that the lubrication to the large-size equipment is more efficient and more economic.

Owner:宁波宏毅机械制造有限公司

Self-lubricating manual pressure machine

The invention particularly relates to a manual pressure machine, and provides a self-lubricating manual pressure machine capable of achieving automatic lubrication. The adopted technical scheme is that the self-lubricating manual pressure machine comprises a base and a pressing device, wherein the pressing device comprises a vertical mounting barrel; the mounting barrel is fixedly connected with asupporting arm; a central hole in the mounting barrel is square; a square ejector pillar matched with the central hole is arranged in the central hole; the peripheral surface of the ejector pillar sinks inwards to form an oil groove; a first rubber sealing ring is arranged between the lower parts of the mounting barrel and the ejector pillar; and a groove cavity, positioned above the first rubberseal ring, of the oil groove forms a pumping cavity. According to the self-lubricating manual pressure machine, a screw, an ejector rod, the mounting barrel and the ejector rod of the pressure machine can be efficiently lubricated, ejection is smooth, and utilization is relatively convenient.

Owner:嵊州市越通非开挖建设有限公司

Automobile speed reducer capable of achieving efficient lubrication and work method of automobile speed reducer

The invention belongs to the technical field of automobile speed reducers, and particularly relates to an automobile speed reducer capable of achieving efficient lubrication. The automobile speed reducer comprises a motor, a second installing plate arranged at the transmission end of the motor, and a gear case located on one side of the second installing plate and welded and fixed to the second installing plate. A first installing plate is welded and fixed to the face, away from the second installing plate, of the gear case. A transmission shaft of the gear case penetrates through the first installing plate. A transmission shaft is fixedly arranged on the transmission shaft of the gear case. A ball bearing is clamped to the transmission shaft, a power source is conducted for the motor, a transmission shaft of the motor drives the gear case to rotate, the transmission shaft of the gear case is used for driving the transmission shaft to rotate, and when the motor rotates, vibration is generated, lubricating oil in an oil guiding shaft drips onto balls, the balls rotate, lubricating oil on the surfaces of the balls drips onto a connecting shaft, the lubricating oil drips onto the transmission shaft through a through hole in the connecting shaft, and efficient lubrication is achieved.

Owner:南京南邦科技开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com