Self-lubricating manual pressure machine

A press and self-lubricating technology, which is applied in the field of presses, can solve problems such as reduced processing efficiency, increased invalid travel, and the impact of loading and unloading workpieces, and achieves the effects of smooth action relations, improved service life, and efficient lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

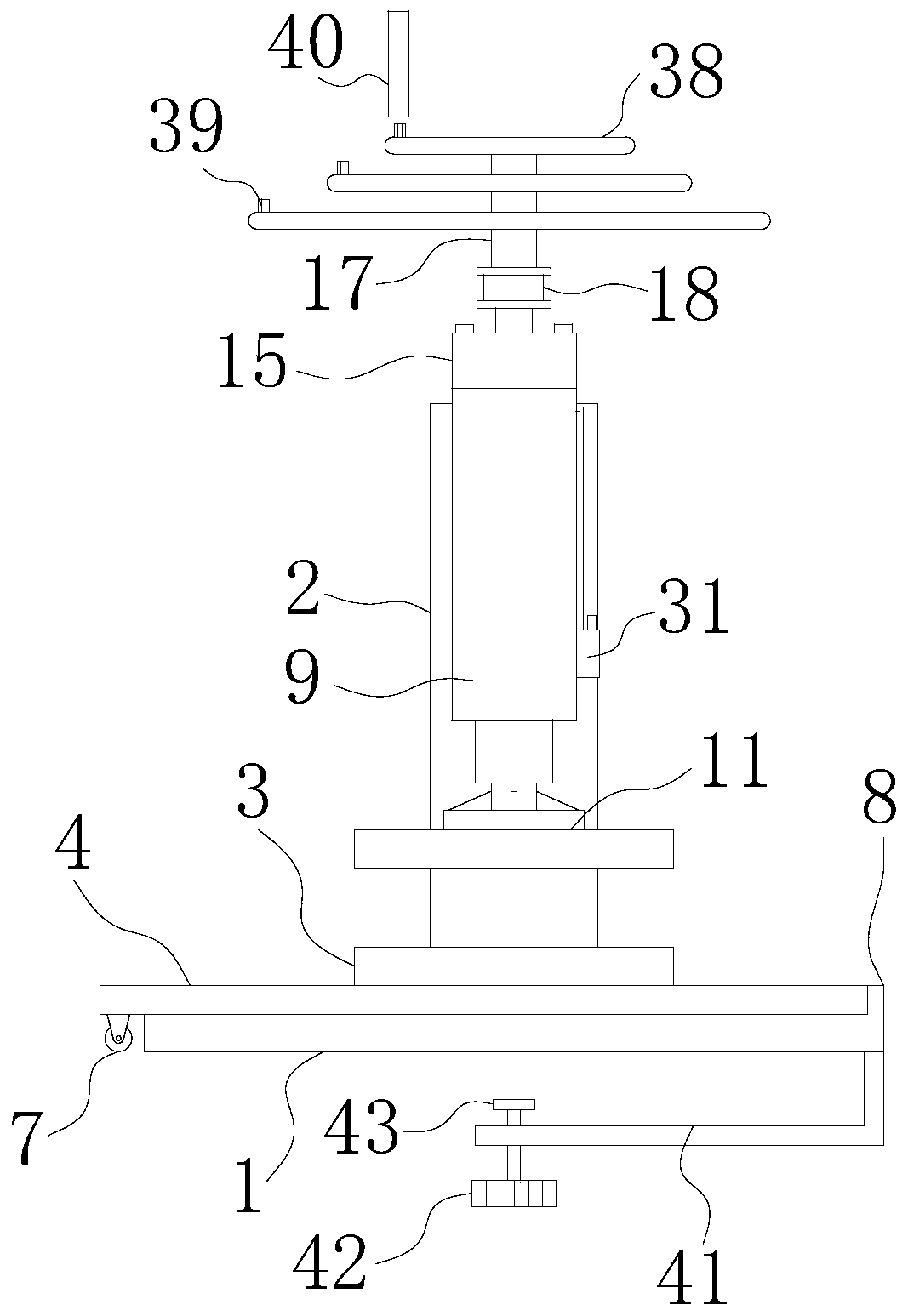

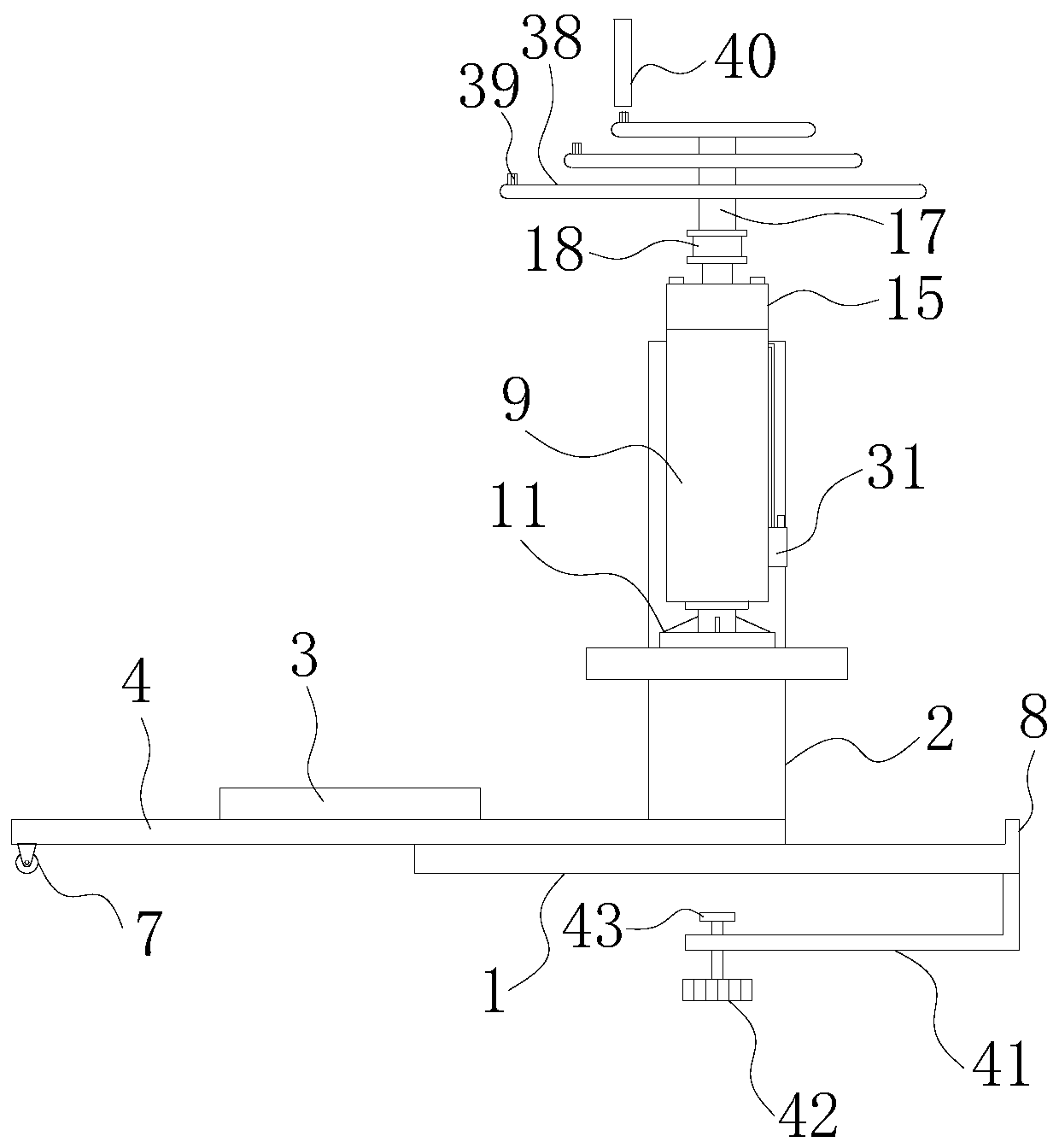

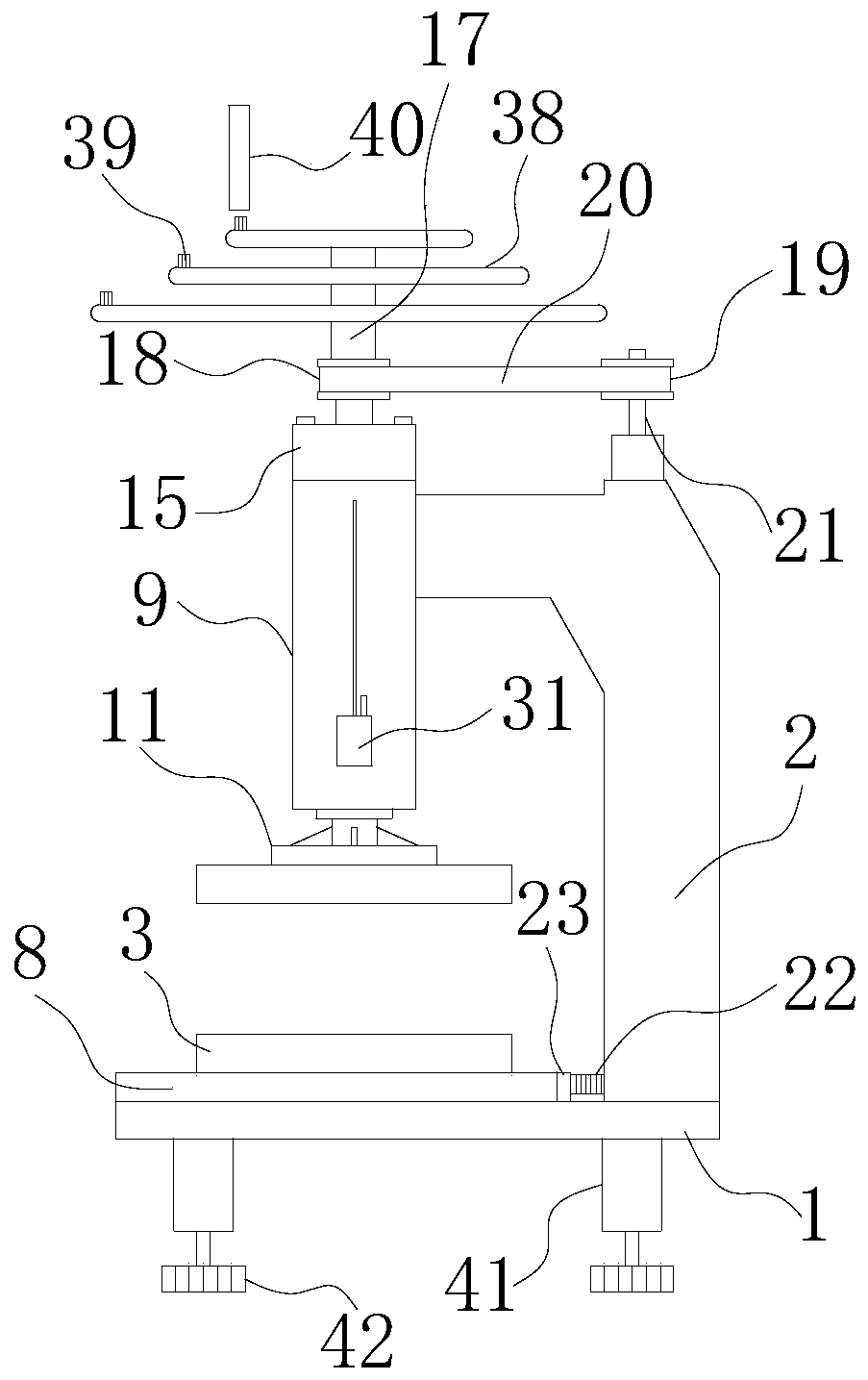

[0026] combine Figure 1-9 The manual press shown is improved from many aspects in order to improve the comprehensive performance of the manual press from various aspects in view of several main problems existing in the current manual press.

[0027] A self-lubricating manual press, like a traditional manual press, also includes a base 1 and a pressing device, and the pressing device is erected above the base 1 through a support arm 2 . The base 1 is provided with a workpiece fixing block 3, the role of the workpiece fixing block 3 is to fix the workpiece, which is usually a set of fixtures, in some cases, it can also be a set of molds, and the workpiece positioning is installed on the mold Inside.

[0028] Compared with the existing manual presses, the present invention differs in one aspect in that the base 1 is provided with a slide plate 4 capable of reciprocating movement toward the left or right side of the base 1, that is to say the slide plate 4 can move back and for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com