Patents

Literature

497results about How to "Eject evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

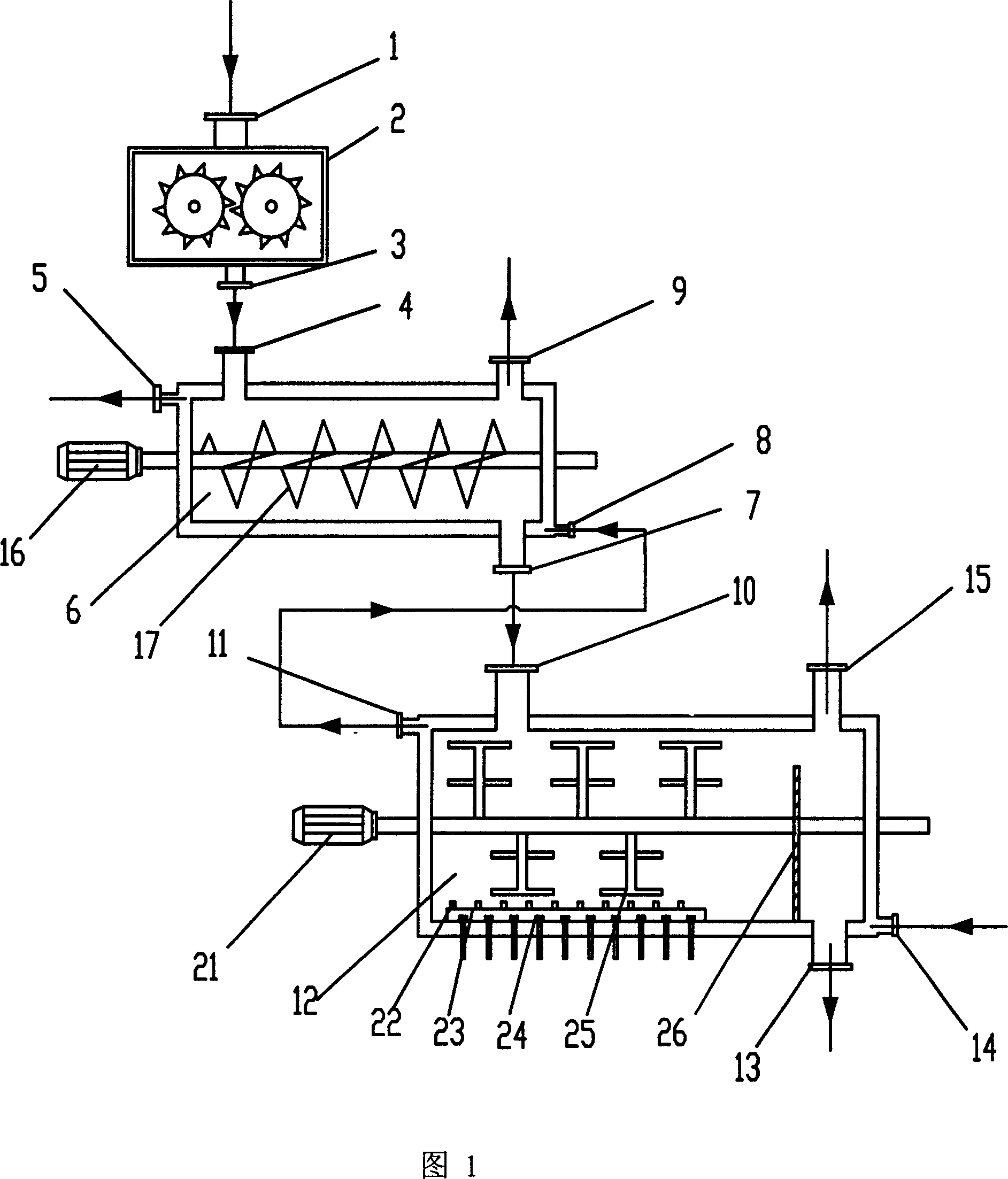

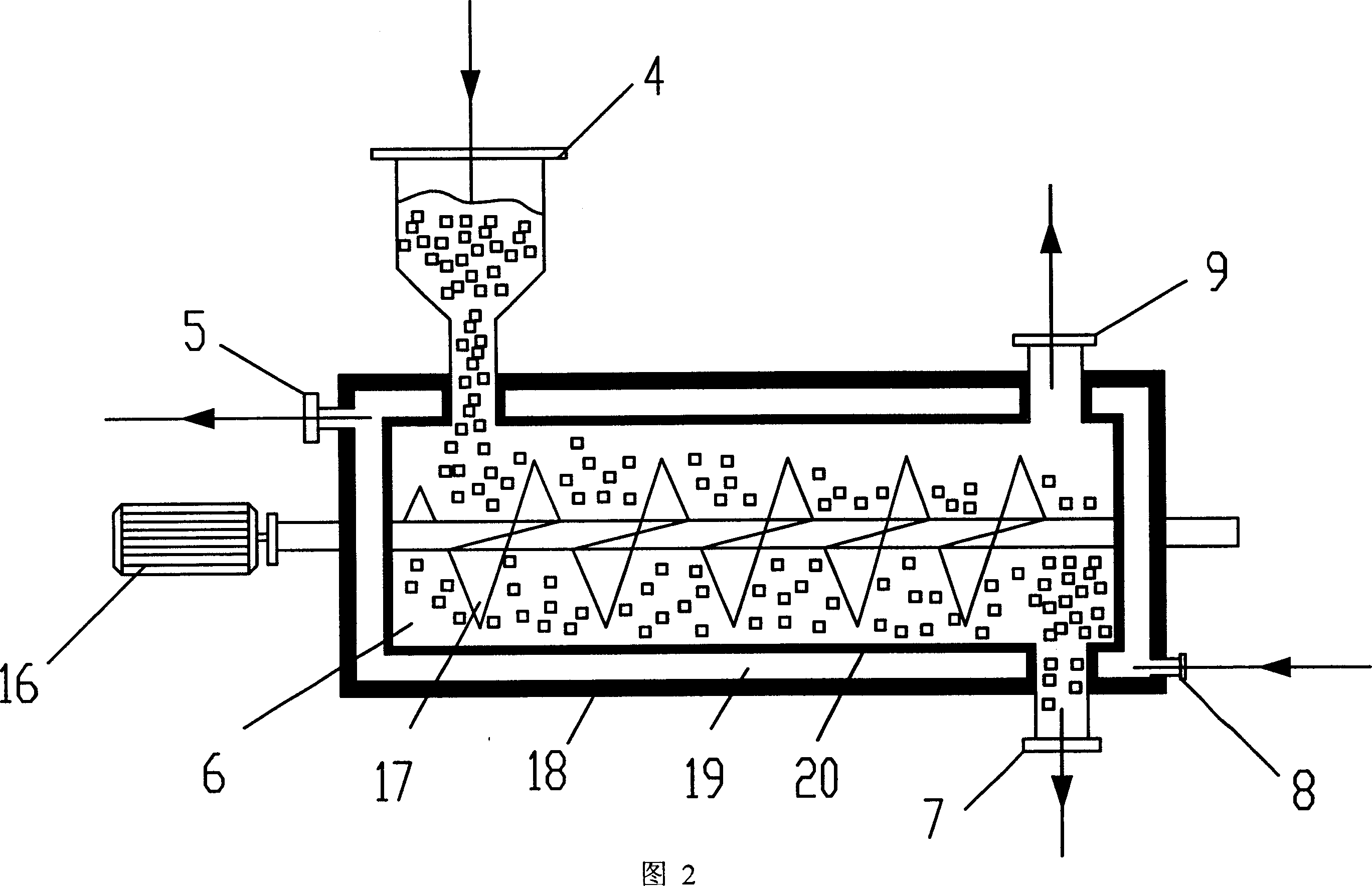

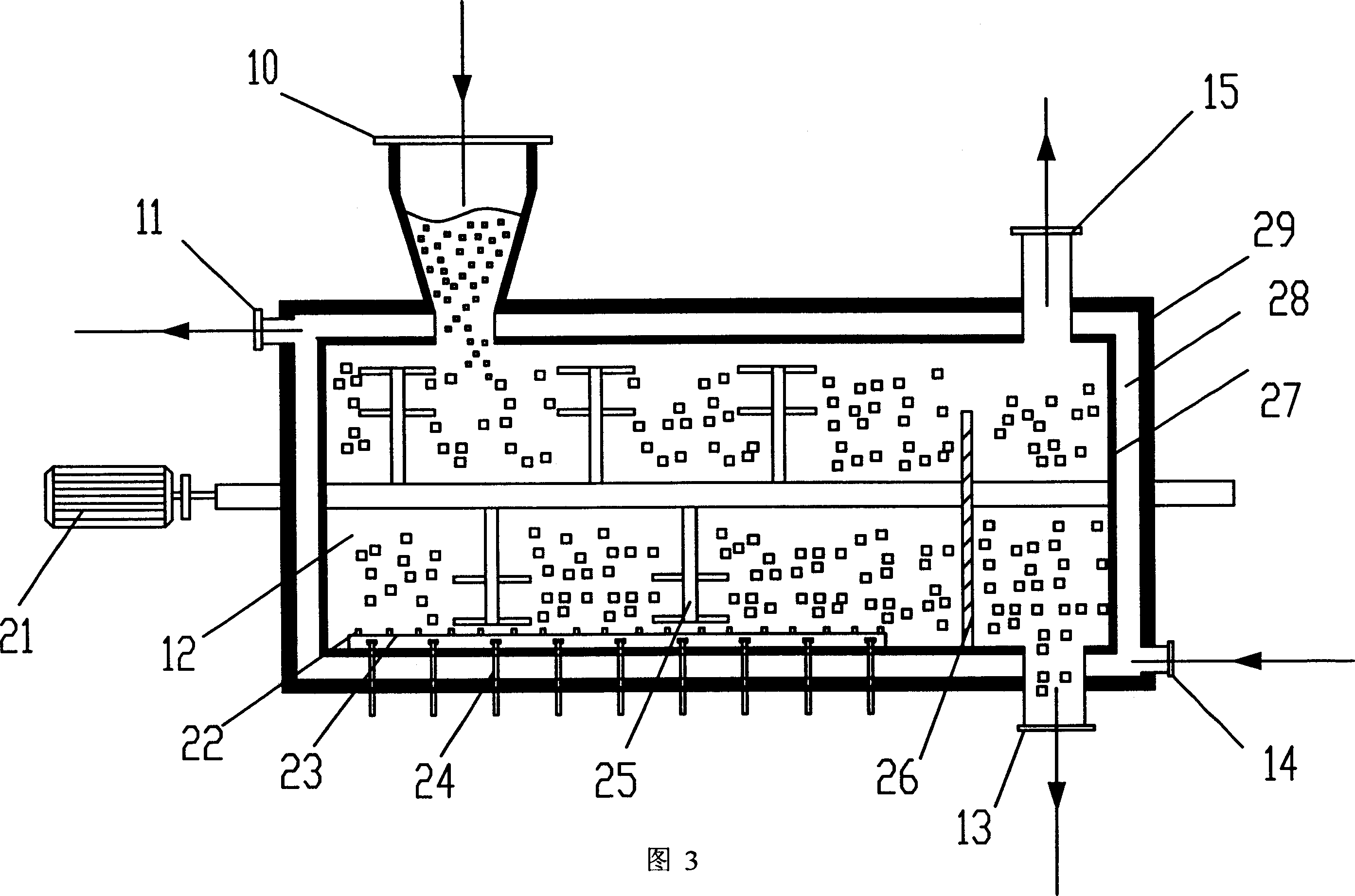

Biomass deep dehydration carbonization continuous processing technology and device thereof

ActiveCN1928013AHigh thermal efficiencyNo or less pyrolysis reactionBiofuelsSpecial form destructive distillationReaction temperatureProduct gas

Continuous biomass deeply dewatering and carbonizing process and apparatus are disclosed. The technological process includes the steps of deeply dewatering biomass to separate out water at 120-160 deg.c with external heat source, and carbonizing biomass at 300-500 deg.c to obtain biomass charcoal and pyrolytic fuel gas. The apparatus includes one drier and one carbonizing unit with material inlet connected to the outlet of the drier and sandwiched heat exchange cavity connected to that of the drier. Inside the carbonizing unit, there is also one gas assistant jetting device for controlling the reaction temperature in the carbonizing process. The present invention has high heat efficiency, high heat value of the pyrolytic gas and high biomass charcoal yield.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

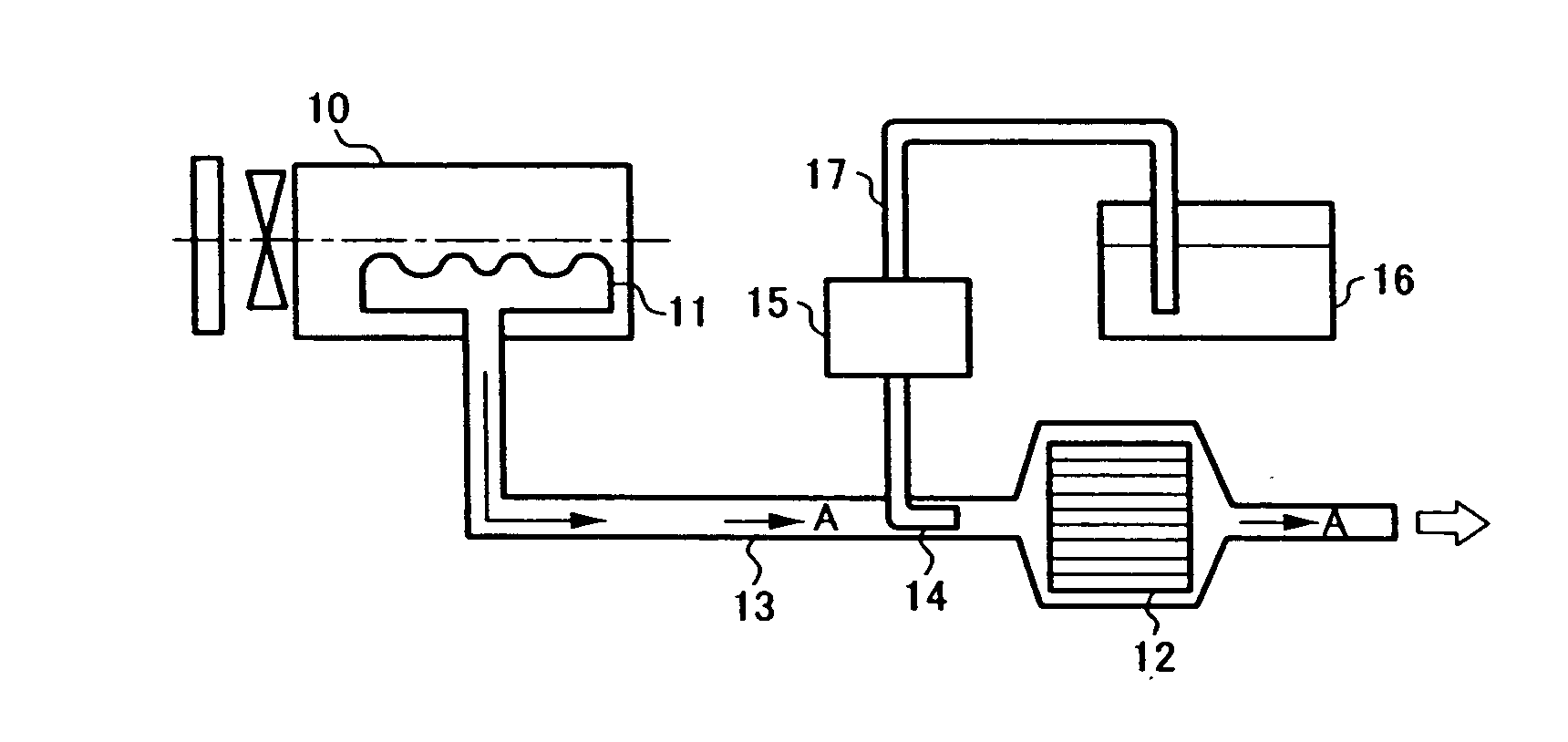

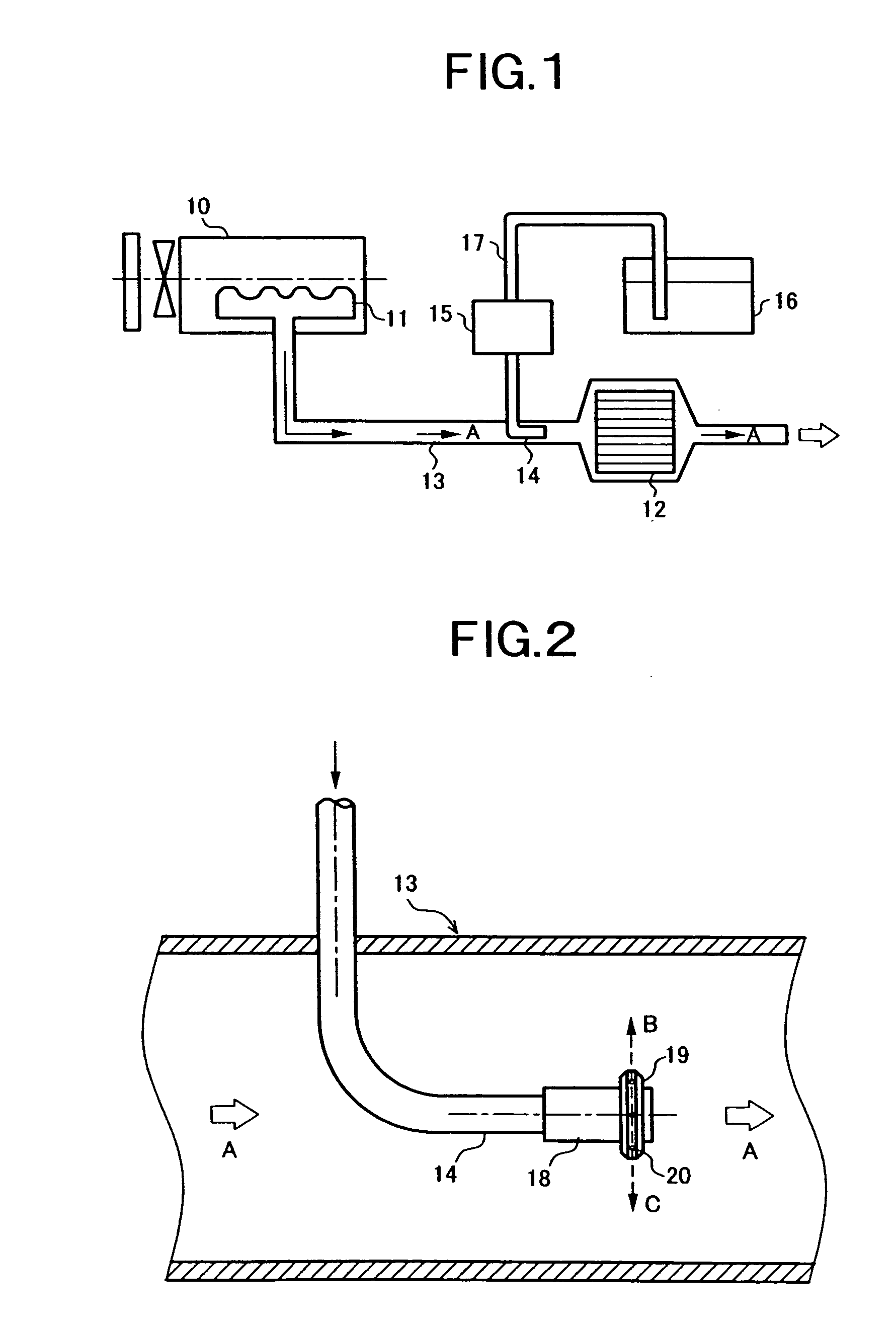

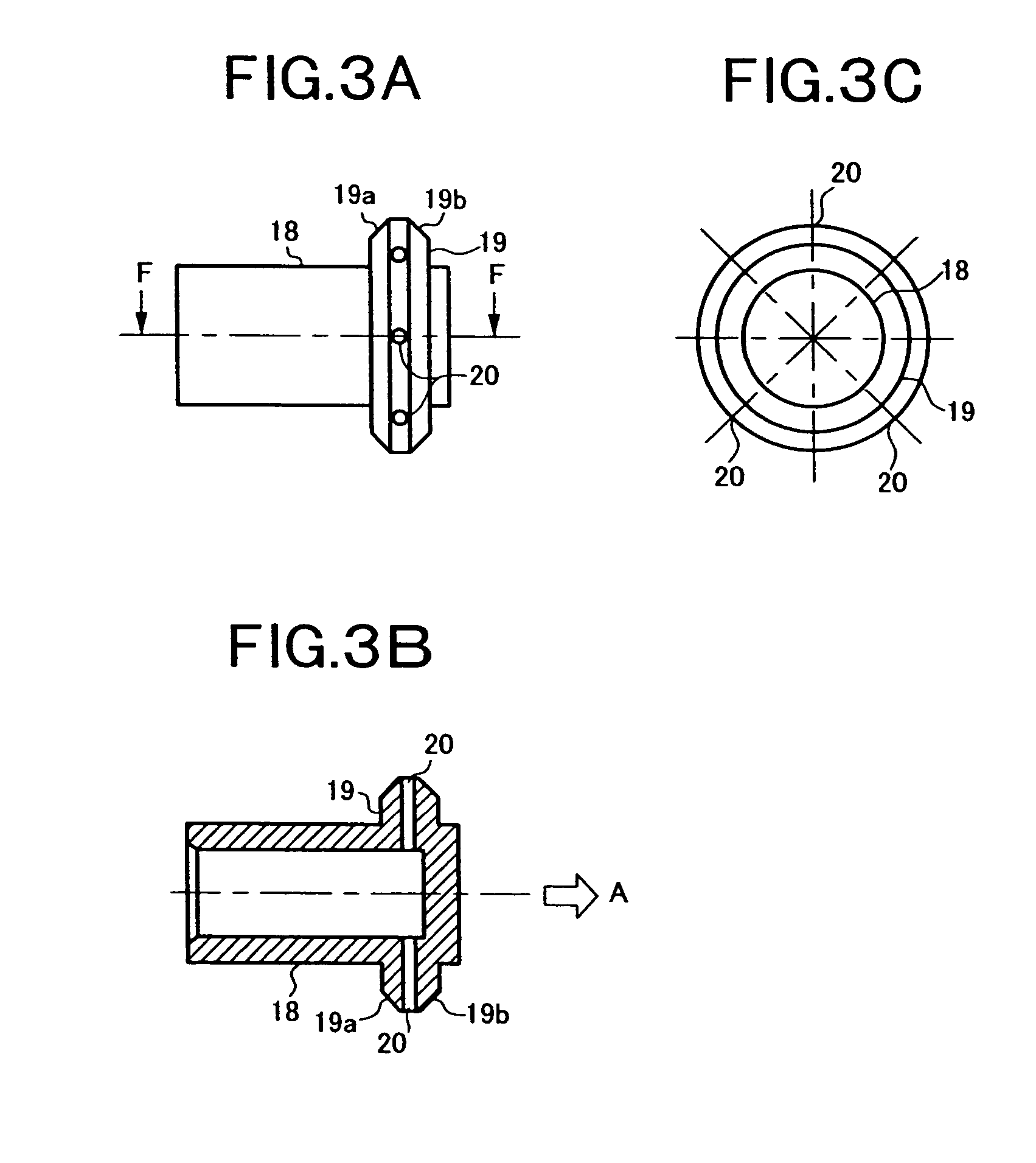

Exhaust gas purification apparatus of engine

ActiveUS20070101700A1Prevent cloggingMix proportion be improveInternal combustion piston enginesFlow mixersExhaust gasExhaust fumes

For preventing clogging in an injection nozzle for supplying a reducing agent to exhaust gas flow on an upstream side of a reducing catalyst and for improving the efficiency of NOx purification processing, the injection nozzle 14 has a tip end portion 18 provided with a ring shaped protruding ridge 19 disposed on an outer peripheral surface of an exhaust gas downstream side end portion of the tip end portion 18 that is arranged substantially in parallel with an exhaust gas flow direction A inside an exhaust pipe 13, the ring shaped protruding ridge 19 being provided with injection hole or holes 20 drilled outward from the central axis of the injection nozzle 14, so that the reducing agent is ejected on the exhaust gas upstream side of the reduction catalyst, from the injection holes 20. The injection holes 20 do not directly open on a wide outer peripheral surface of the injection nozzle 14, and then when injection stops, the reducing agent does not become attached to or does not remain around the injection holes 20, or the remaining amount thereof becomes small, so that clogging of the injection holes 20 of the injection nozzle 14 is prevented, and the efficiency of NOx purification processing is improved.

Owner:VOLVO LASTVAGNAR AB

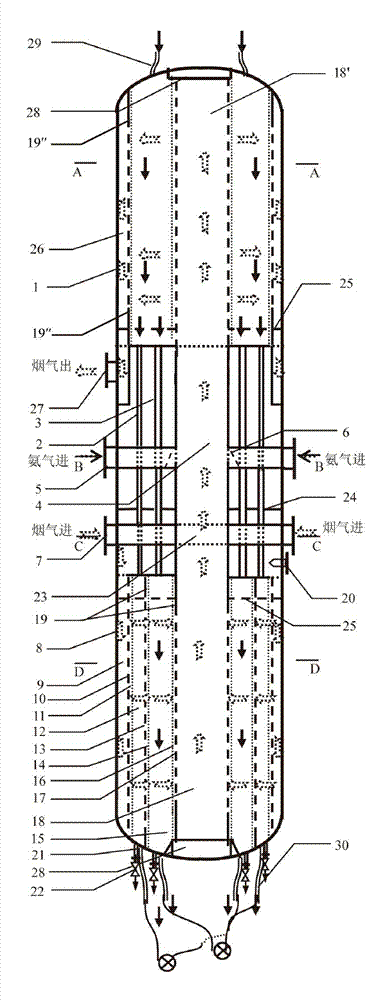

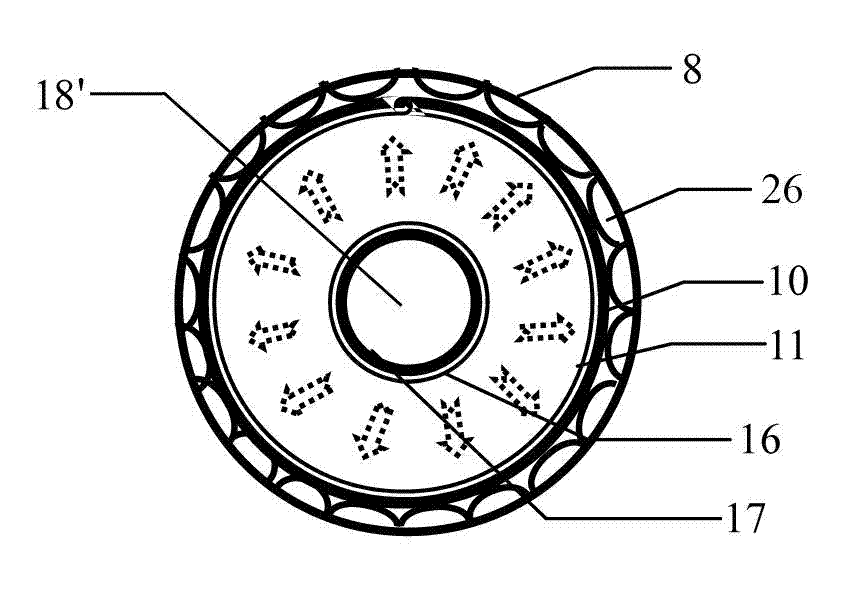

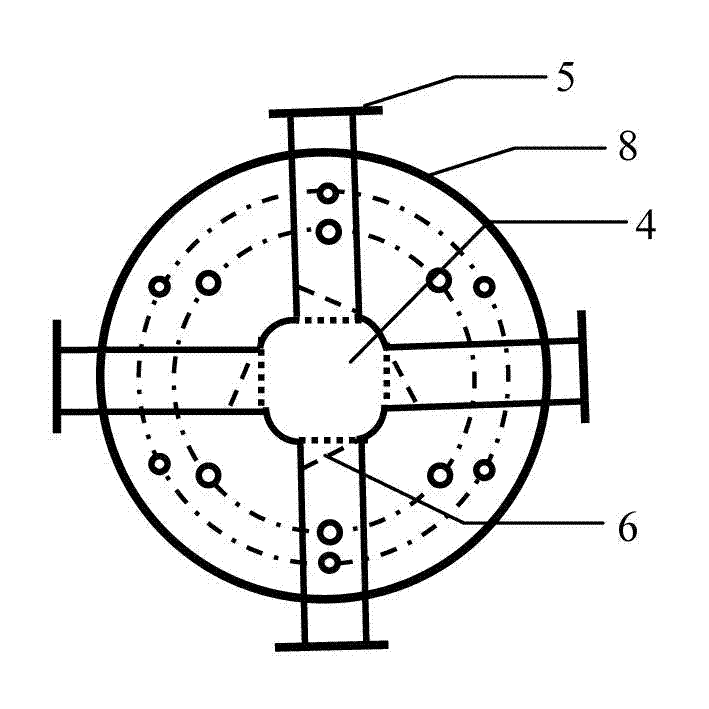

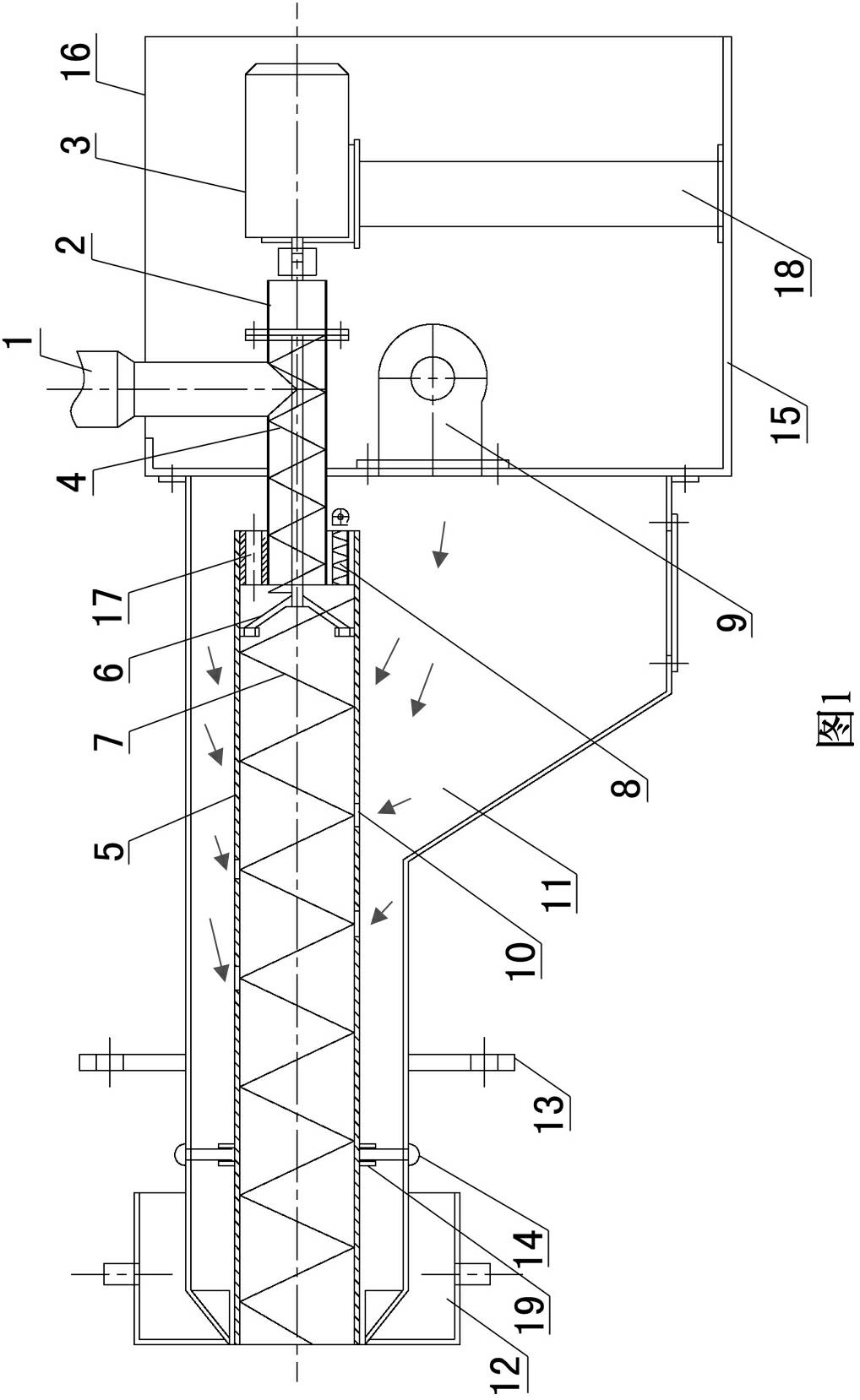

Axial and radial cross flow moving bed reactor and activated coke flue gas desulfurization and denitration technology thereof

ActiveCN102824846ACombined removalAchieve efficient utilizationDispersed particle separationAir quality improvementThermodynamicsFlue gas

An axial and radial cross flow moving bed adsorption reactor and an activated coke flue gas desulfurization and denitration technology thereof are used for realizing the purposes that SO2, NOx, mercury, dioxin and other pollutants in flue gas are unitedly removed and integrally purified in an adsorption reactor, and belong to the technical field of comprehensive waste flue gas treatment. The adsorption reactor is a combined type double-section double-inverse U-type axial and radial cross flow moving bed, awherein desulfurization area is arranged at a lower section of the axial and radial cross flow moving bed, an annular internal activated coke particle layer and an annular external activated coke particle layer are arranged, and the desulfurization area is divided into a coarse desulfurization area and a fine desulfurization area; a denitration area is arranged at an upper section of the axial and radial cross flow moving bed, and an activated coke particle layer is arranged; an ammonia spray pipe is arranged between the upper section and the lower section; and flue gas is filled along a double-port counter annular gas flow channel structure, the flue gas of the lower section centripetally flows to be desulfurized, and the flue gas of the upper section centrifugally flows to be denitrated. According to the reactor and the technology, desulfurization and denitration are realized in one adsorption reactor, so the adsorption reactor has the advantages of efficient utilization of activated coke, uniform flue gas mixing, sufficient gas-solid contact, stability and reliability in operation, operation cost saving and the like.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

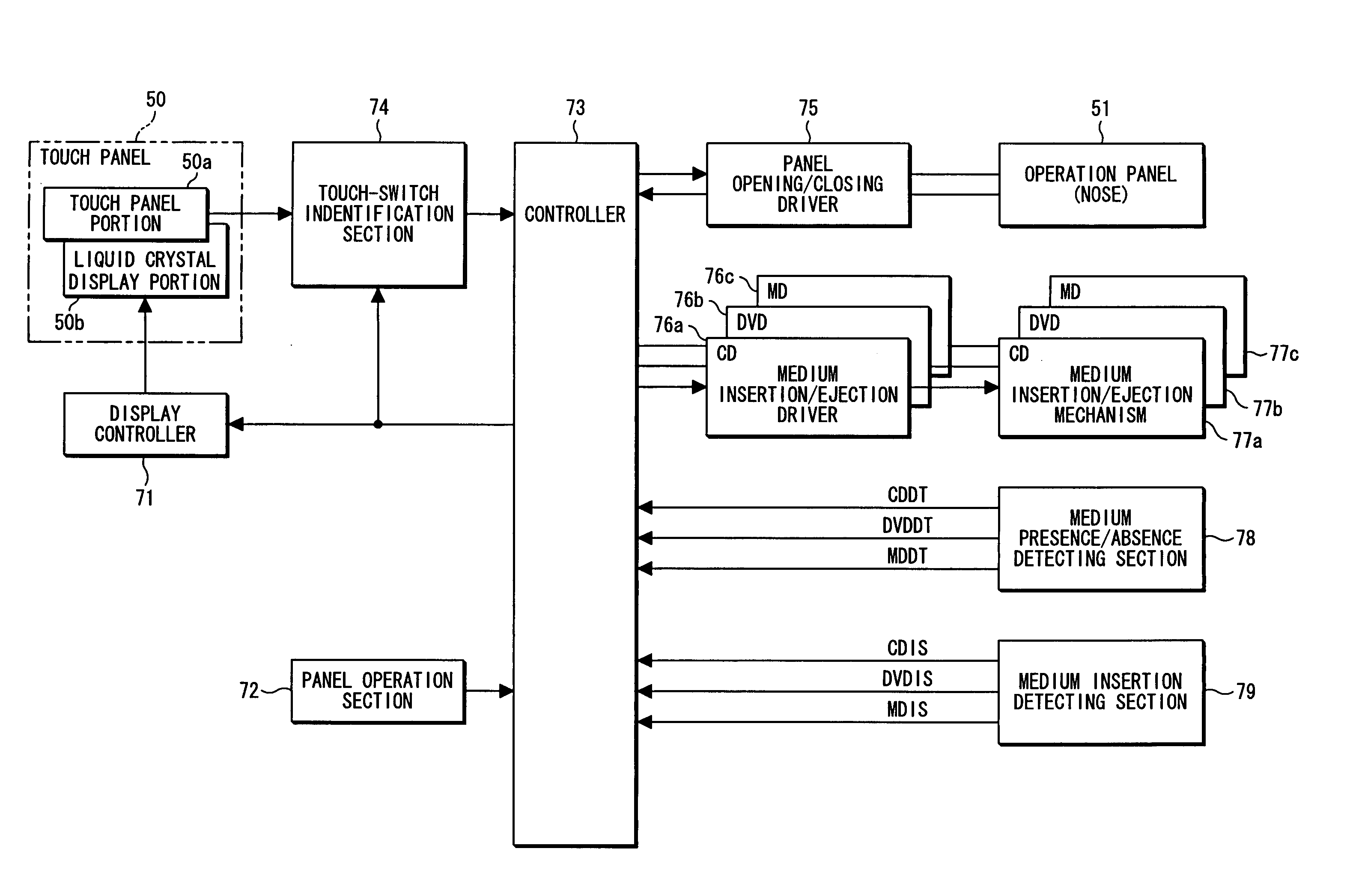

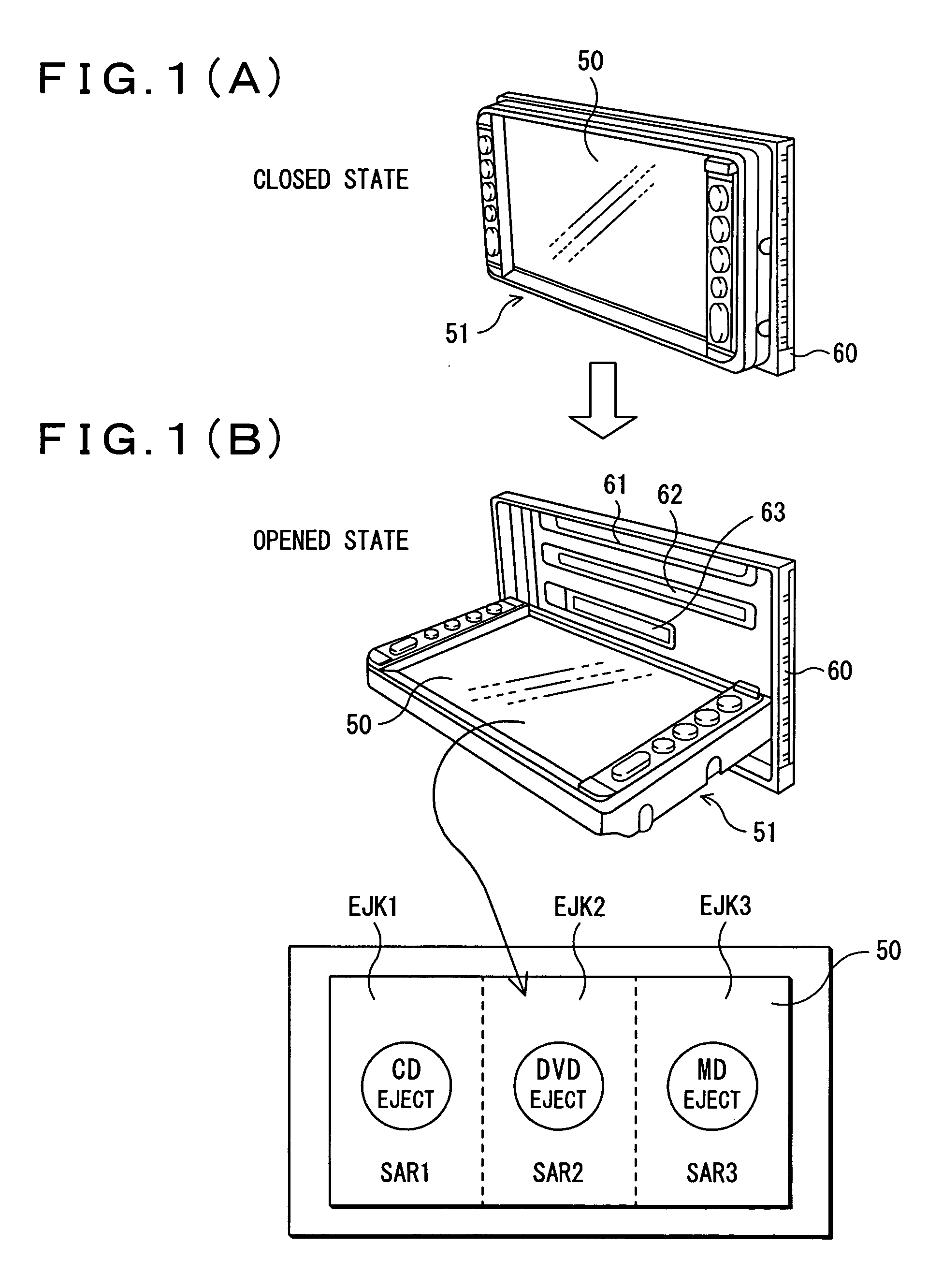

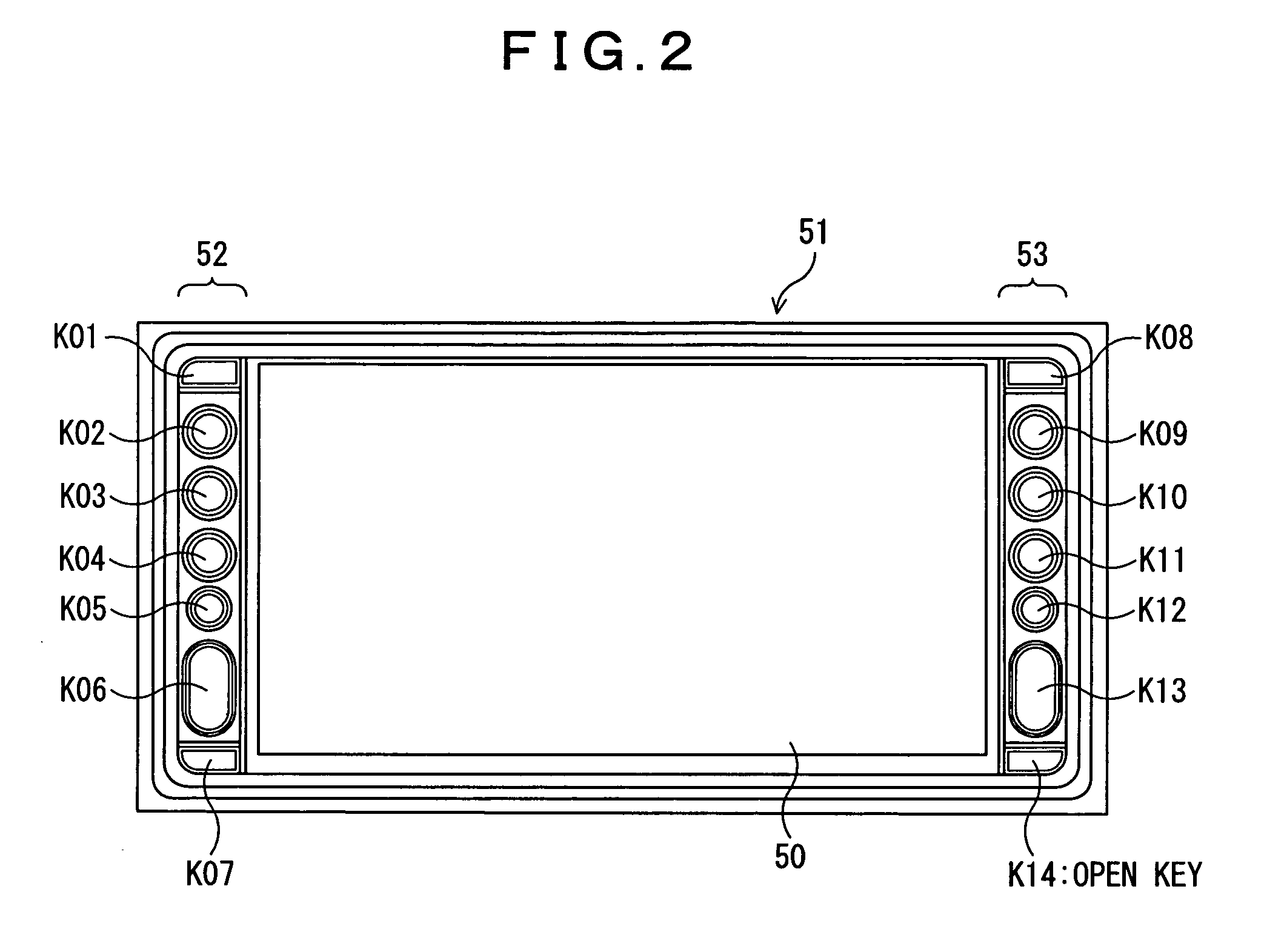

Method and apparatus for ejecting a medium

InactiveUS20060002258A1Smooth eject operationEject evenlyCarrier indicating/warning arrangementsFilamentary/web record carriersEngineeringTouch panel

An electronic apparatus and a method for ejecting a medium are provided that can ensure identification of eject keys for media even when the display of a touch panel surface is difficult to view. In the electronic apparatus, a touch panel 50 is slid to open a plurality of medium insertion / ejection ports 61 to 63, so that the predetermined medium (CD, DVD, MD) can be inserted therein and ejected therefrom. When the medium insertion / ejection port is opened, a touch panel surface is divided into areas, and the divisional areas SAR1 to SAR3 are allocated to touch switches EJK1 to EJK3 for ejection of the respective predetermined media. When the touch panel surface is touched, it is detected which touch switch is turned on, and then the medium corresponding to the touch switch turned on is ejected.

Owner:ALPINE ELECTRONICS INC

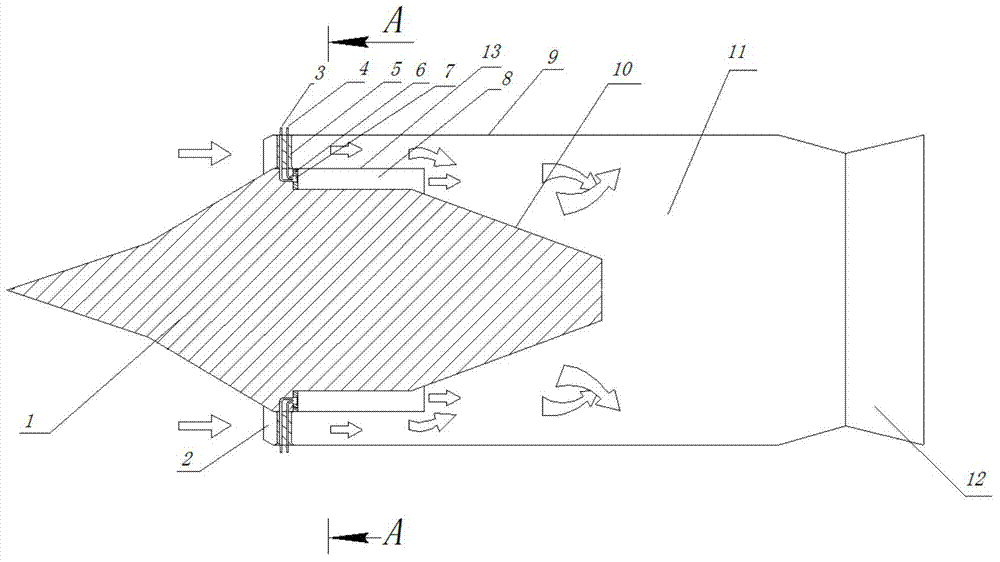

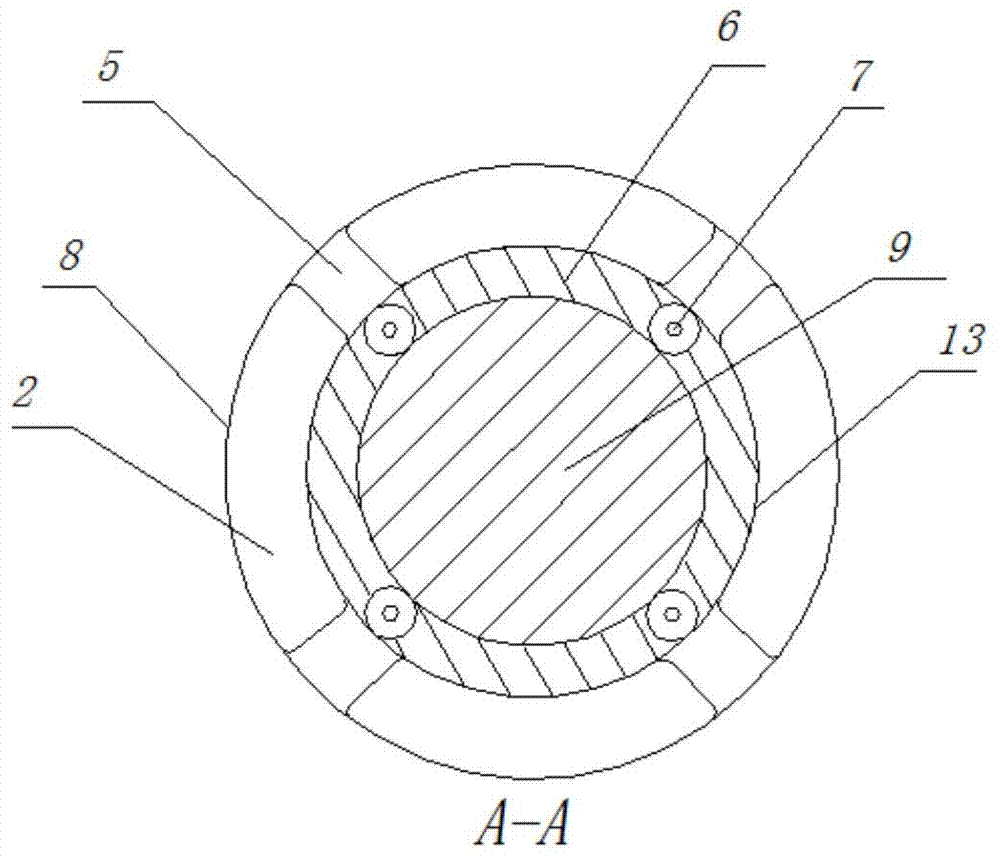

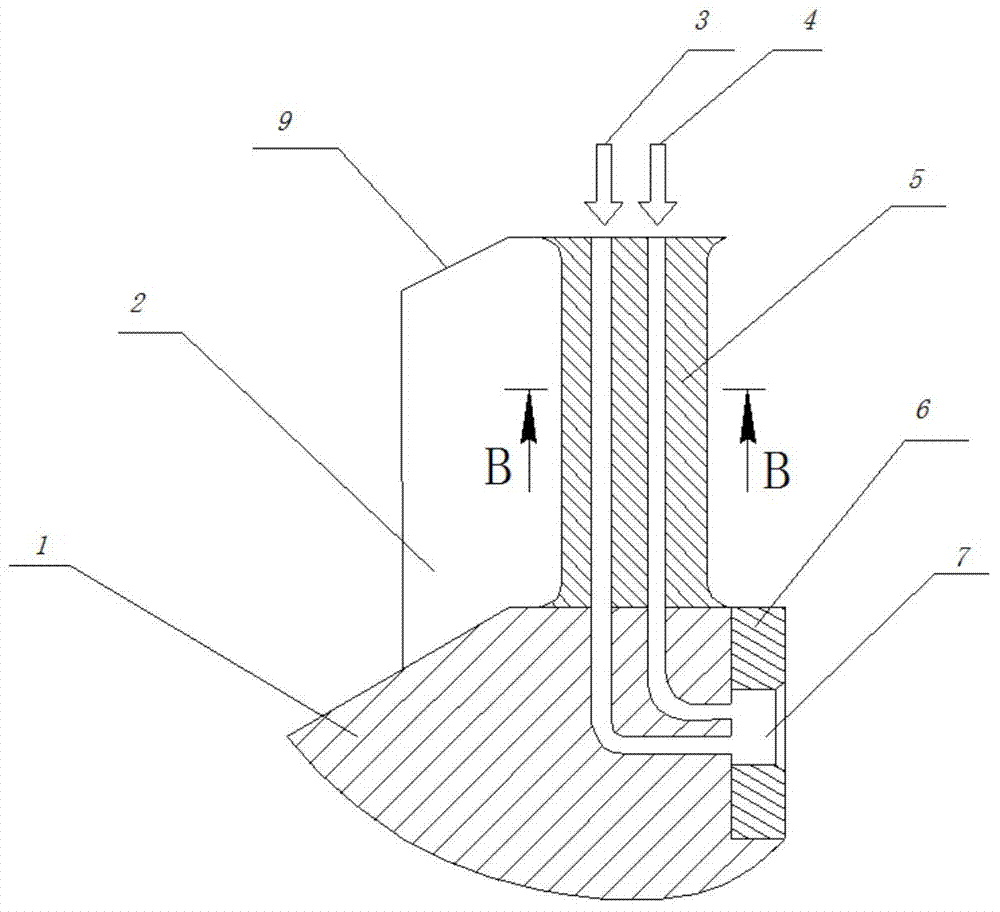

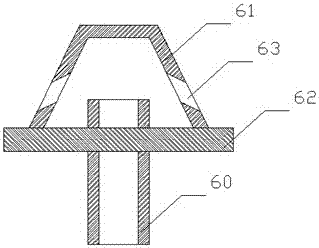

Rocket stamping combination engine with annular injection structure

ActiveCN104295406AImprove combustion efficiencyImprove space utilizationRam jet enginesComposite engine plantsCombustion chamberRocket

The invention relates to a rocket stamping combination engine with an annular injection structure, and belongs to the technical field of space equipment. An outer shell of the engine and a rectification head are oppositely fixed through a fixing guide column, an oxidizing agent inlet and a fuel inlet are formed in the fixing guide column, and an air inlet is formed in the front end of the outer shell. The front body of the rectification head stretches out of the front end of the outer shell of the engine, the rear body of the rectification head is in a step shape and is inserted into the outer shell, and a trumpet-shaped supersonic velocity nozzle is formed in the rear end of the outer shell. An inner shell is fixed in the middle of the rectification head through a fixing ring, a fuel and oxidizing agent mixing jet opening is formed in the inner shell, an annular combustion chamber is formed between the inner shell and the rectification head, and a mixed combustion chamber is formed between the outer shell and the rectification head. According to the rocket stamping combination engine, the size of the engine combustion chambers is reduced, the weight of the combination engine is reduced, and the economical performance of a power system is improved. Fuel gas is evenly sprayed out in the circumferential direction through the annular combustion chamber, the spayed fuel gas can be mixed with the air twice, and combustion efficiency is improved.

Owner:清航空天(浙江)科技有限公司

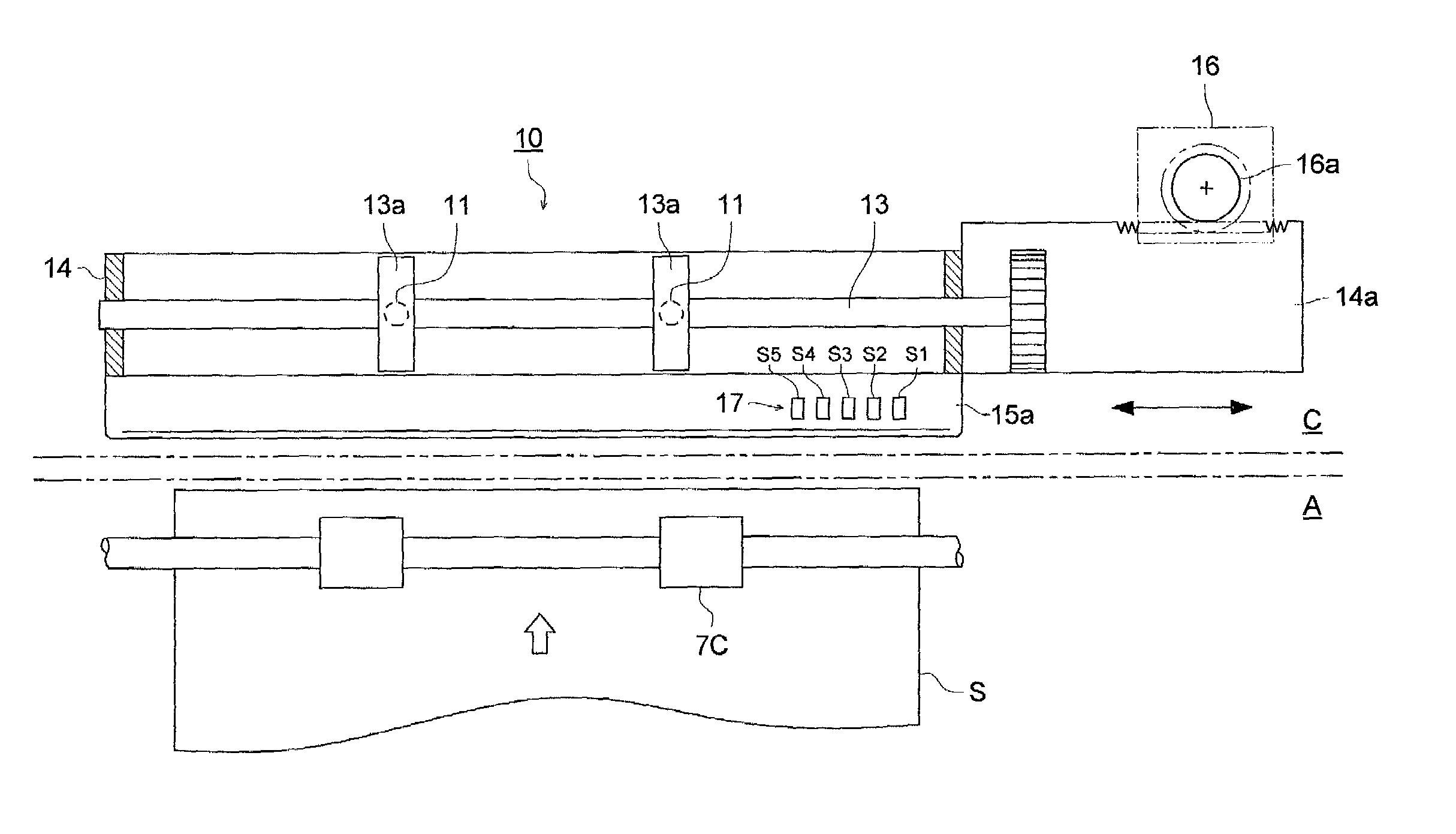

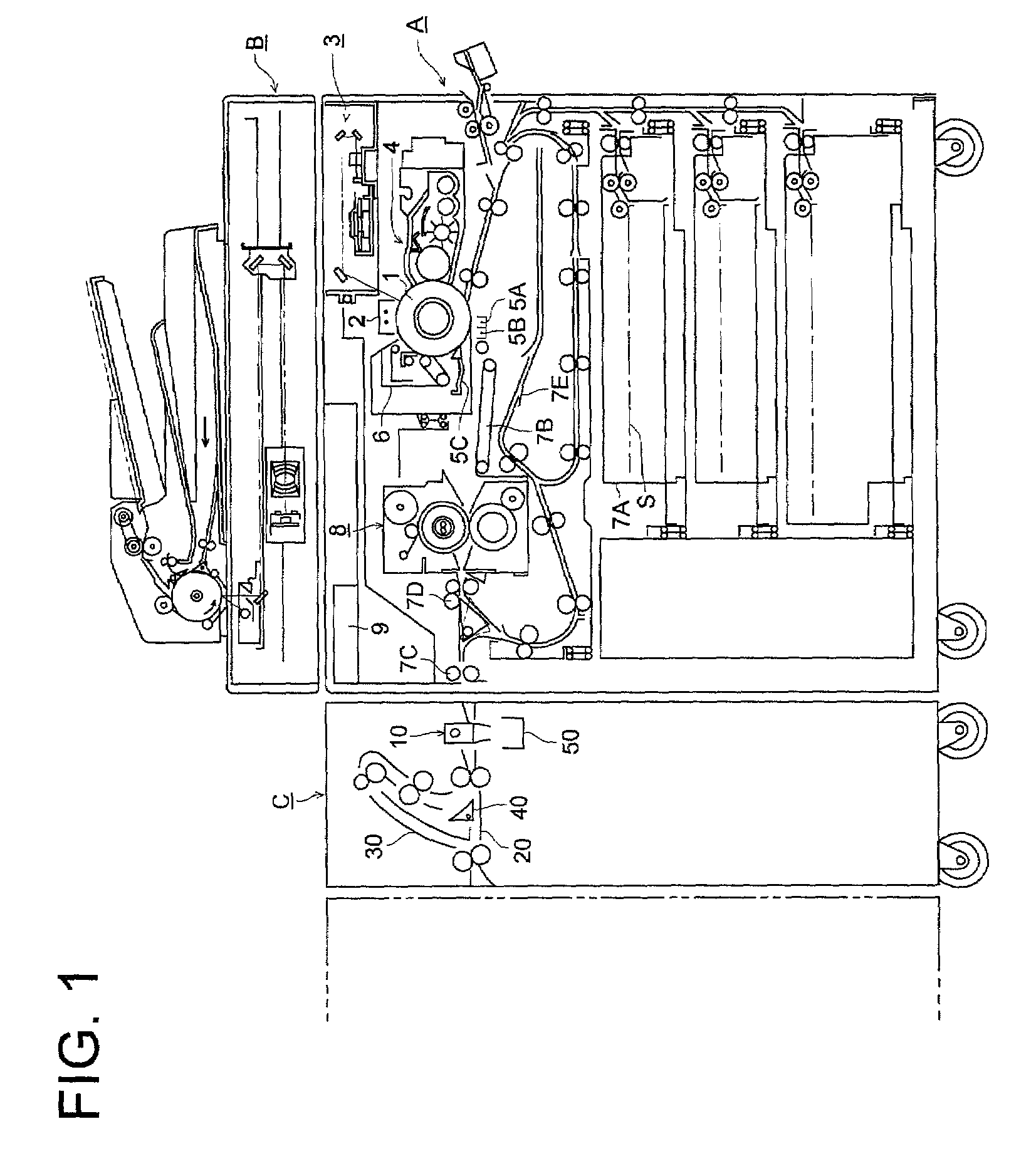

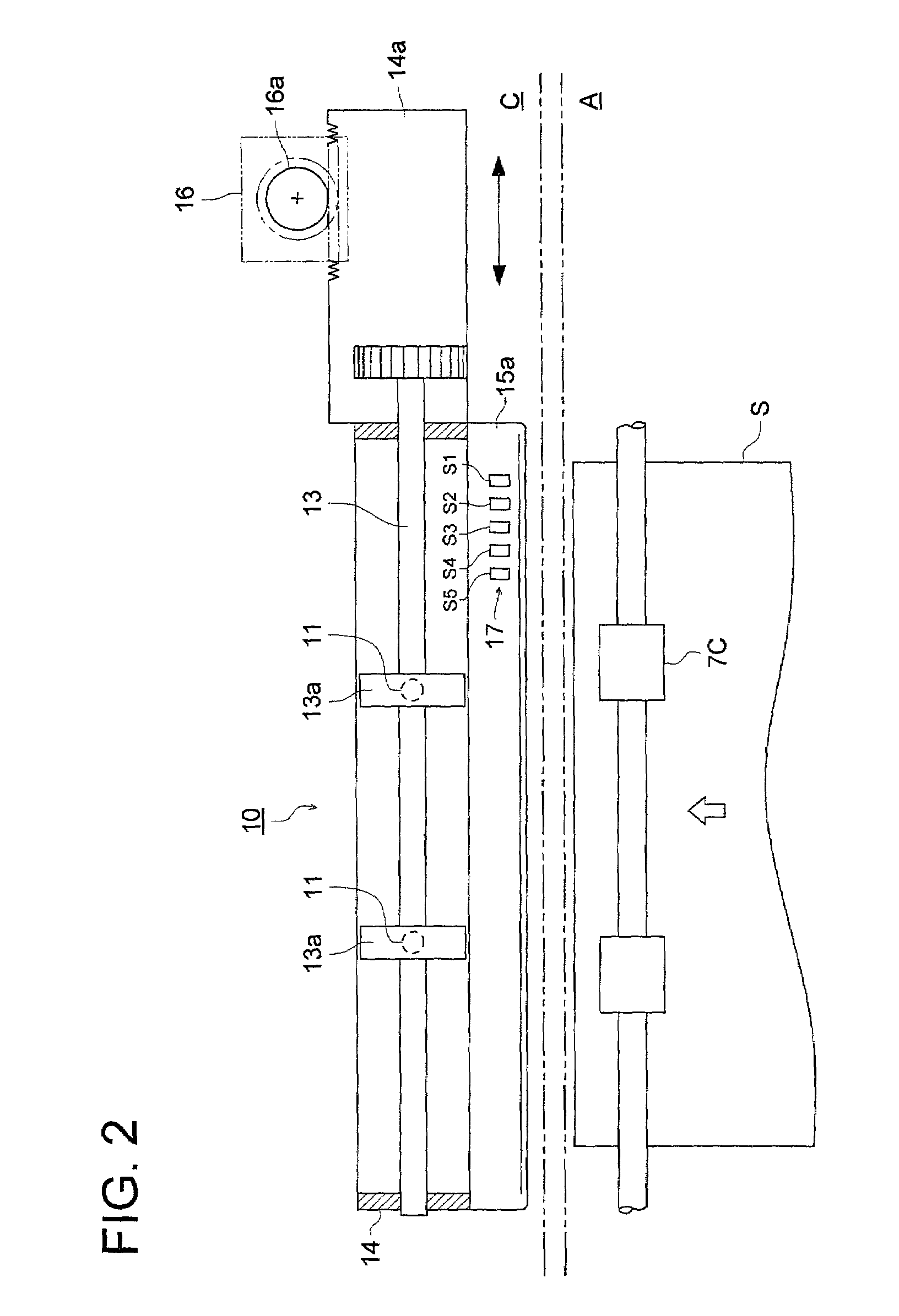

Hole-punching processor and image forming apparatus

InactiveUS7003257B2Simple structureSmall sizeElectrographic process apparatusMetal working apparatusImage formationEngineering

The invention concerns a hole-punching processor that forms punched-holes, for binding sheets into a file, on the sheets, which are ejected after images are formed on them from an image forming apparatus such as, for example, a copying machine, a printer, a facsimile machine or a compound machine thereof. The hole-punching processor forms a punched-hole on a sheet residing in a conveying path for conveying the sheet through the hole-punching processor. The hole-punching processor includes a hole-punching device being movable in a direction perpendicular to a conveyance direction of the sheet and a sheet-edge detector to detect a side-edge of the sheet in a direction parallel to the conveyance direction of the sheet. The hole-punching device moves with the sheet-edge detector to a center of the sheet, based on positional information of the side-edge detected by the sheet-edge detector, to punch a hole in the sheet.

Owner:KONICA CORP

Sewage treatment tank

InactiveCN107954545AReduce exposureReduce consumptionTreatment involving filtrationMultistage water/sewage treatmentSewageAir blower

The invention discloses a sewage treatment tank, comprising a tank body; a water pump and a water inlet pipe are installed on the top of the tank body; the water pump is connected with the water inletpipe; the tank body is internally provided with an inlet water spray assembly and a chemical feeding assembly; the inlet water spray assembly comprises a main water pipe and an auxiliary water pipe;the auxiliary water pipe is communicated with the main water pipe and is vertical to the main water pipe; a plurality of water outlet holes are formed in the auxiliary water pipe; a water spray pipe is installed at each water outlet hole; the chemical feeding assembly comprises a chemical feed pipe and an air blower; the air blower is fixed on the side face of the tank body; one end of the chemical feed pipe extends into the tank body, and the other end of the chemical feed pipe extends out of the tank body; the end, extending out of the tank body, of the chemical feed pipe is connected with the air blower; a plurality of chemical outlet holes are formed in the chemical feed pipe extending into the tank body; a chemical blowing pipe is installed at each chemical outlet hole. The sewage treatment tank can enable sewage to be fully contacted with chemical powder, thus improving the purification effect and enabling the quality of the purified water to be better.

Owner:湖州道场污水处理有限公司

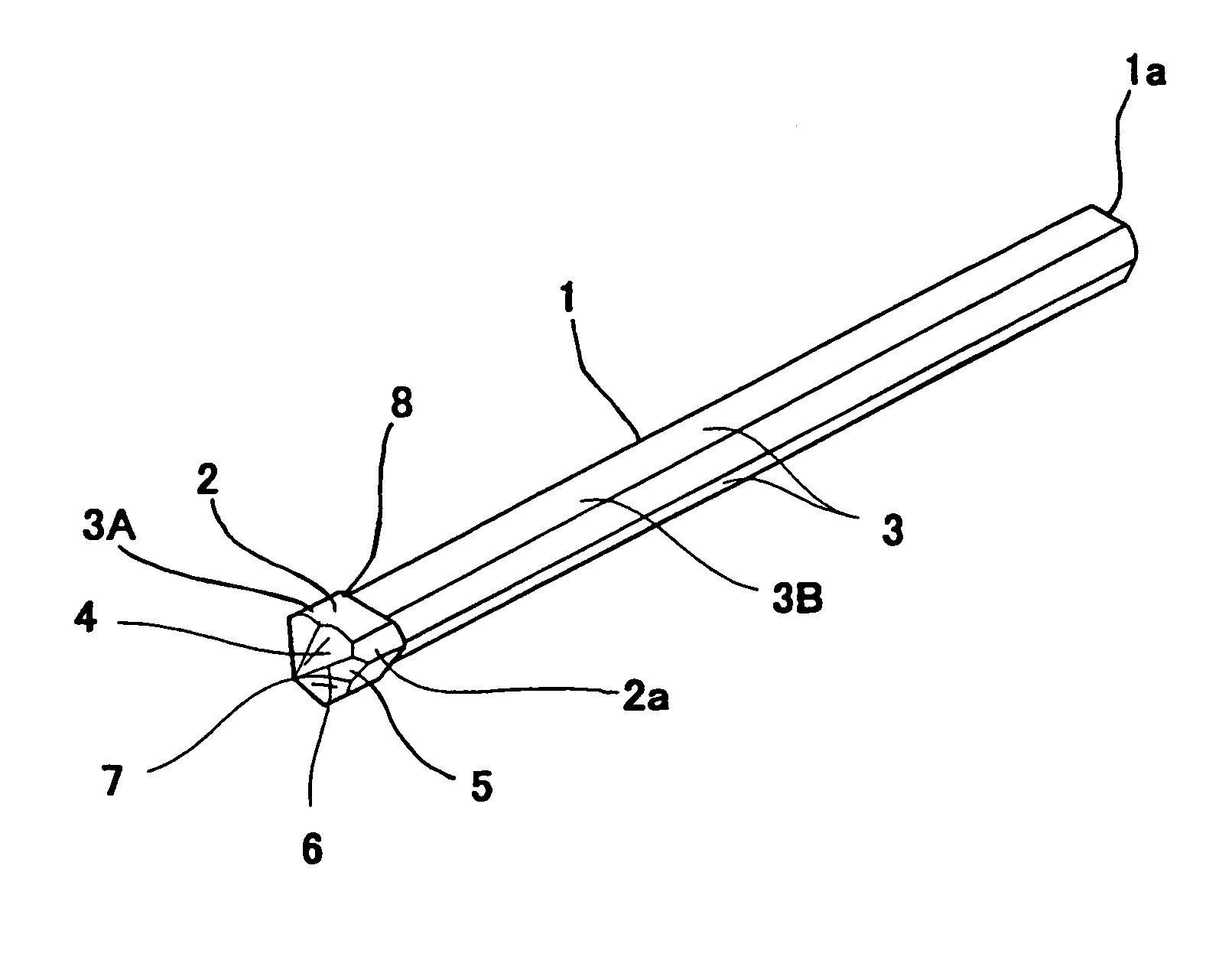

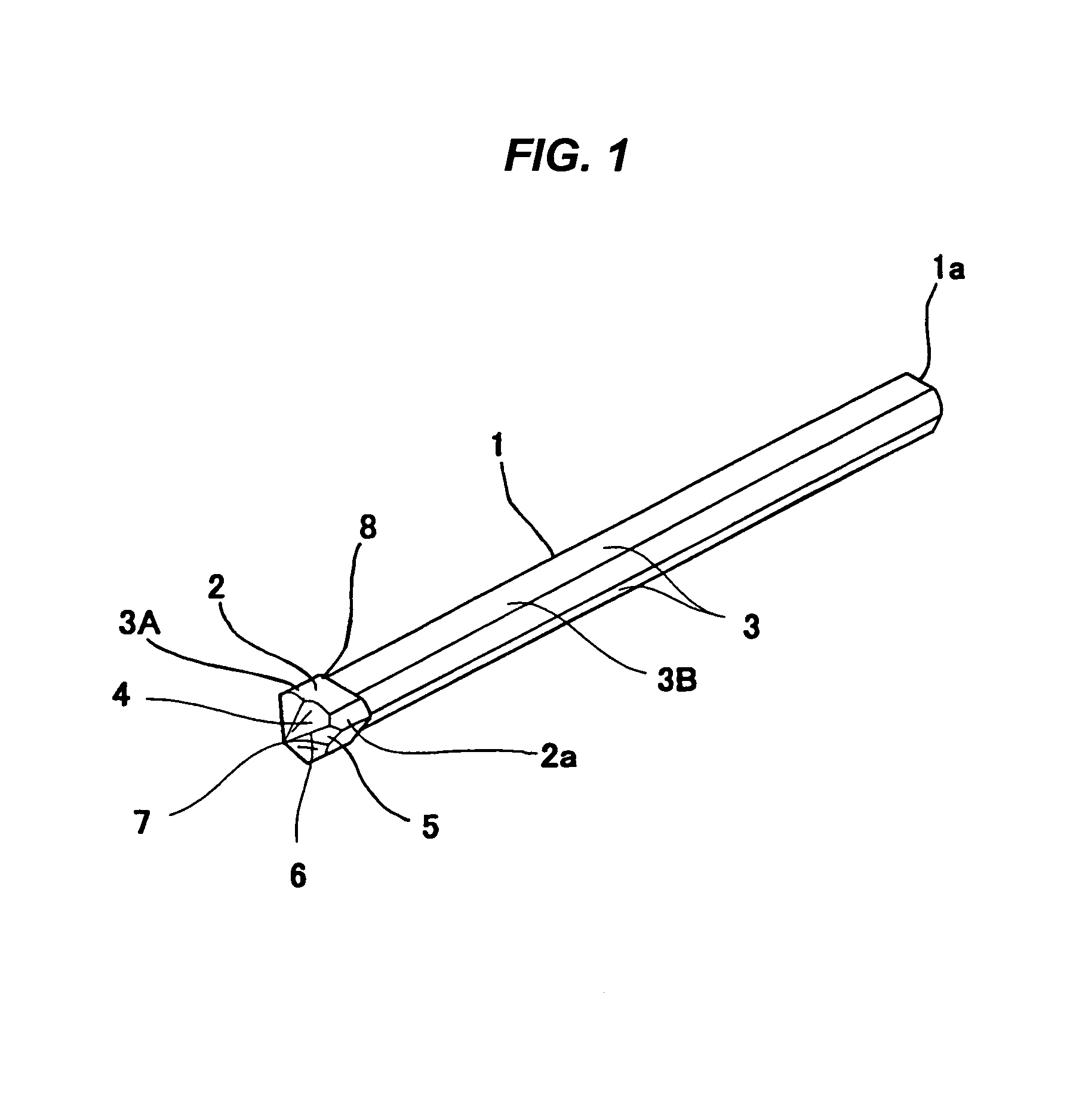

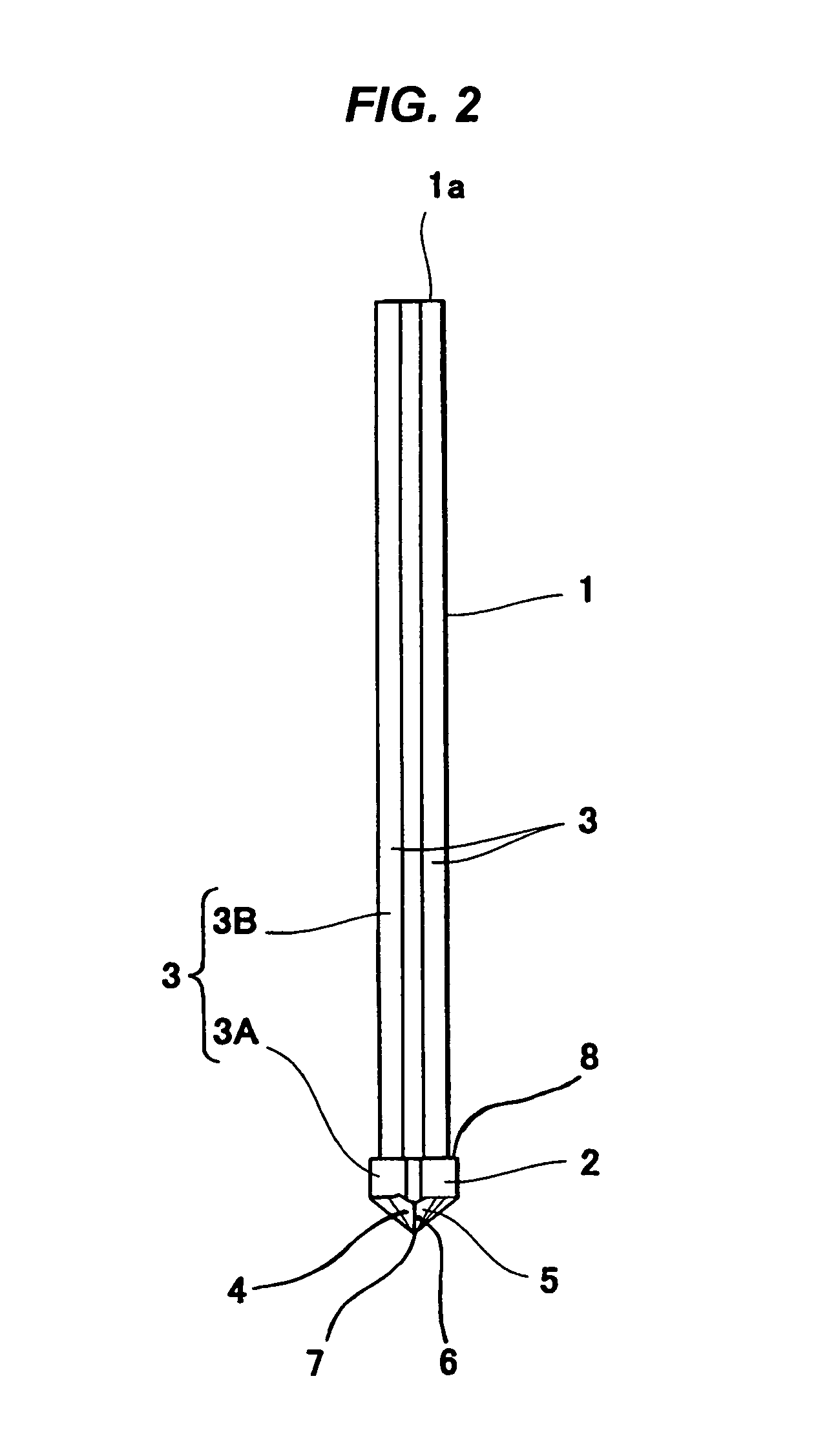

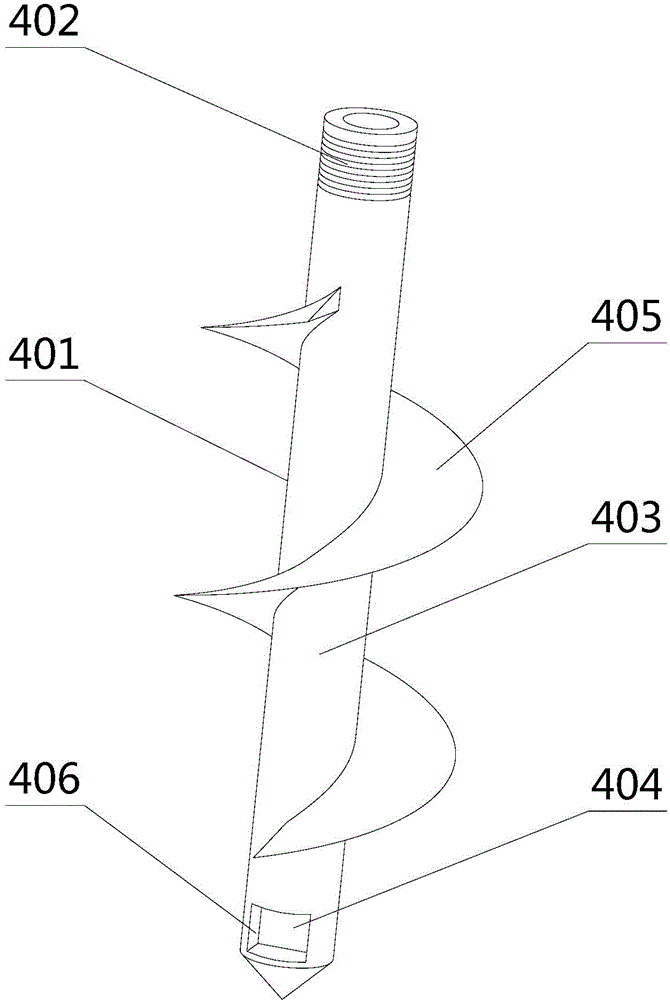

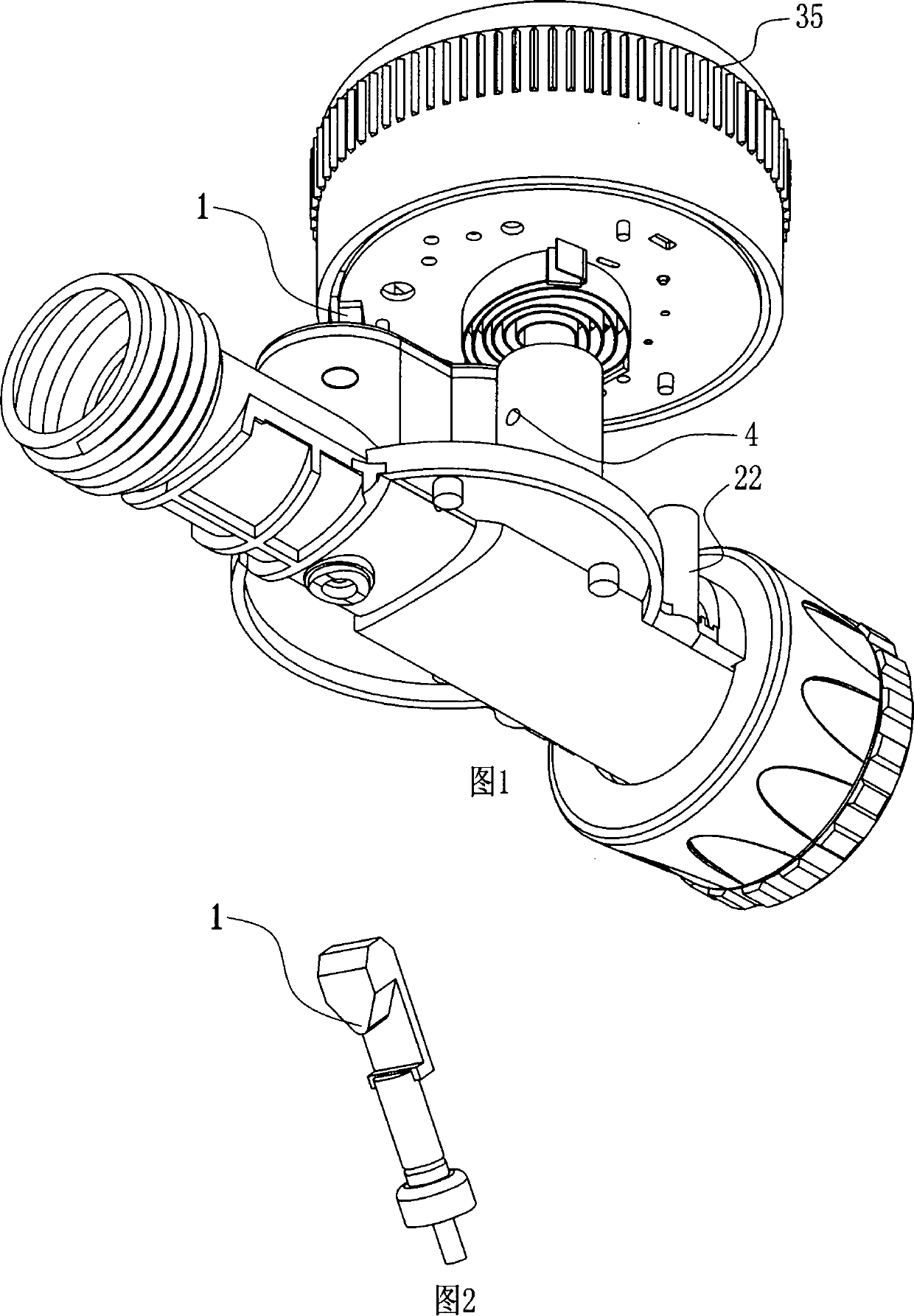

Drill bit

InactiveUS7097396B1Simple designImprove productivityDrill bitsTool workpiece connectionDrill holeEngineering

An object of the present invention is to provide a drill bit which is simple in design, high in rigidity, and superior in durability and whose drilling function is in no way inferior to that of conventional drilling bits. To this end, in a drill bit comprising a cutting blade tip 2 which is united tightly to a tip end of a bit body 1 and a plurality of cutting blade portions 2a, 2b and 2c which are formed around the cutting blade tip 2, a flat surface portion 3 is formed in a side surface of the drill bit from between adjacent cutting blade portions to a base portion of the bit body 1 so that the bit body 1 is formed into a straight configuration having an approximately polygonal cross section.

Owner:MIYANAGA KK

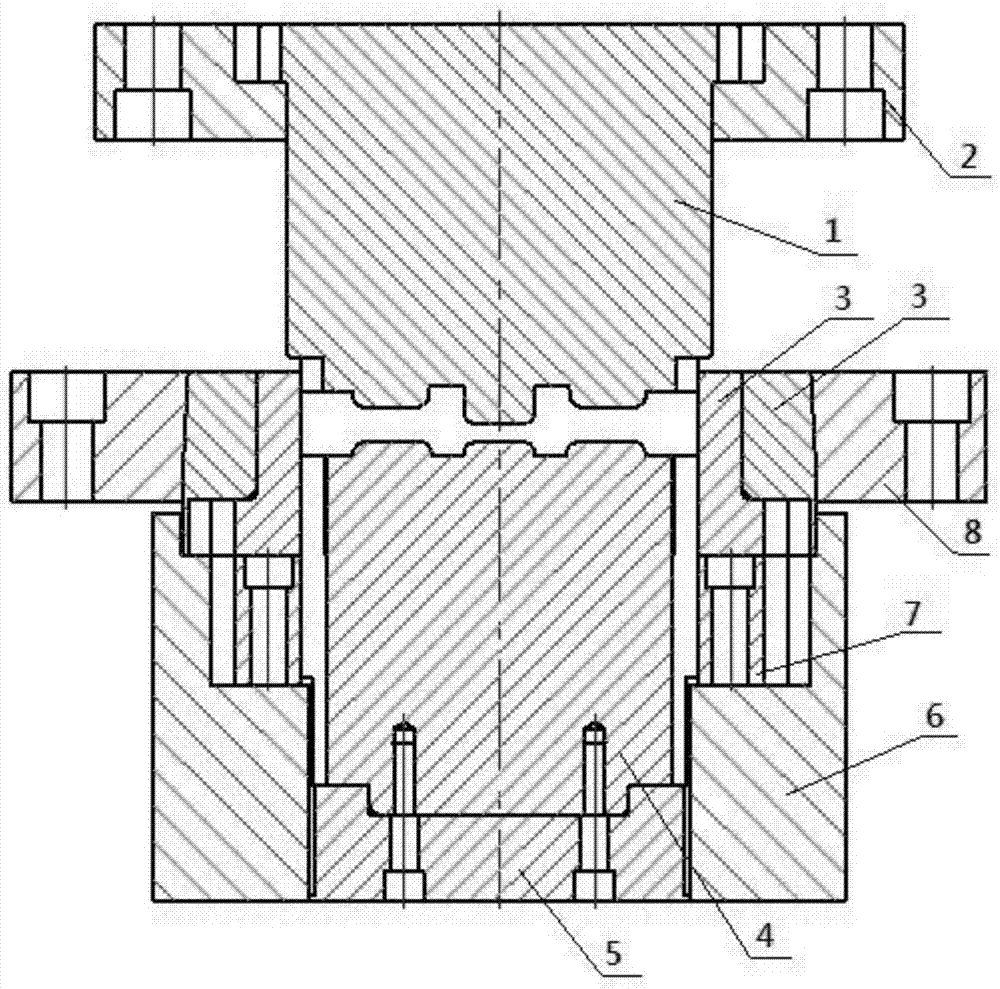

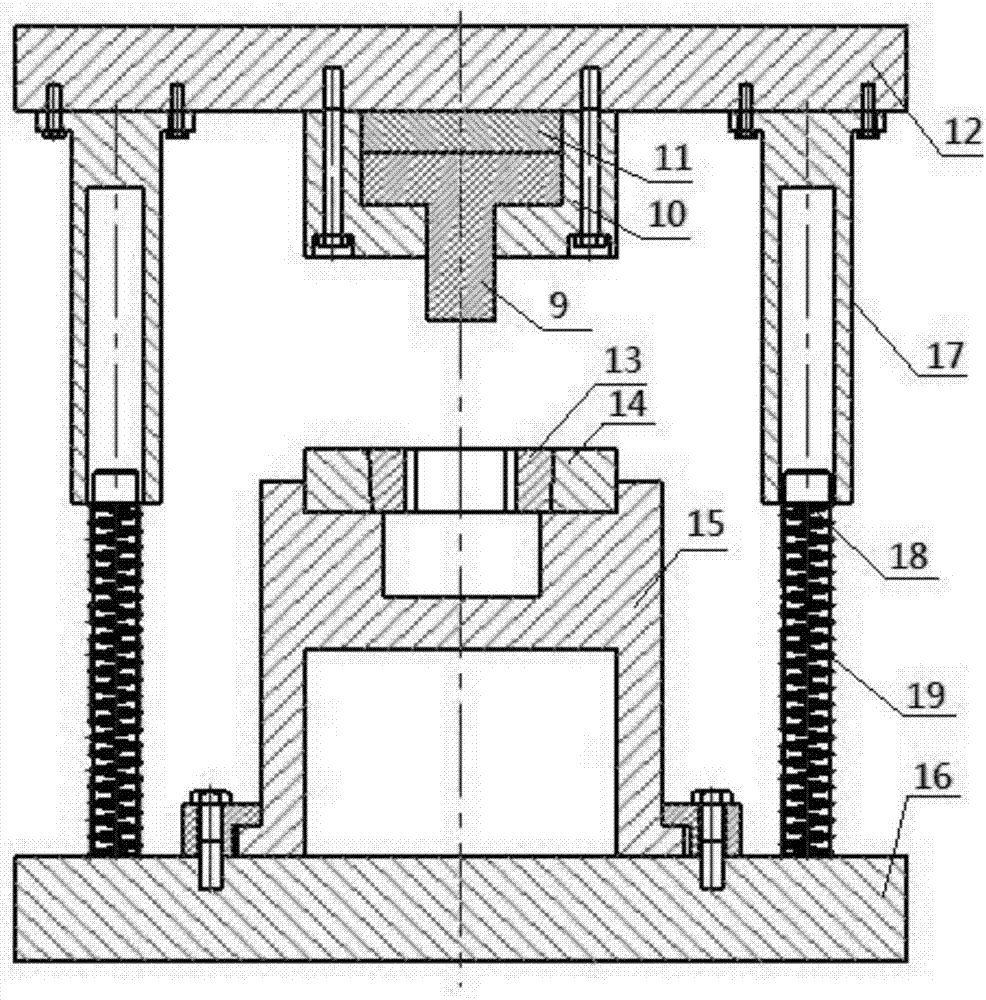

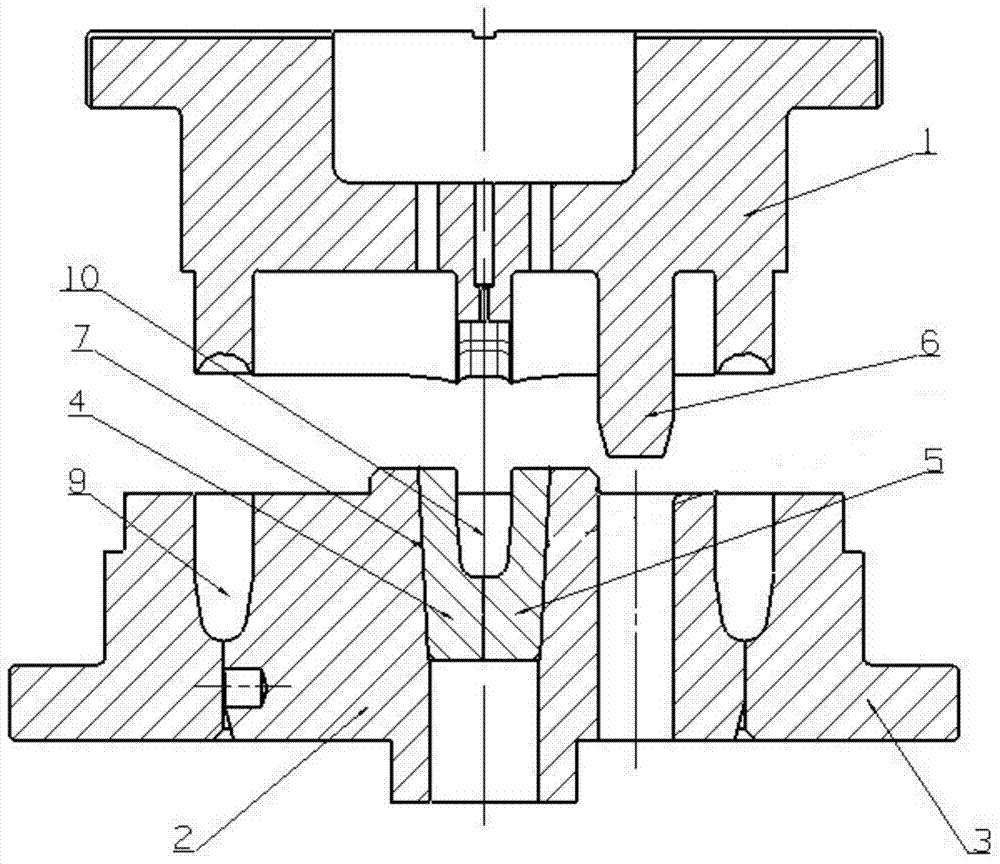

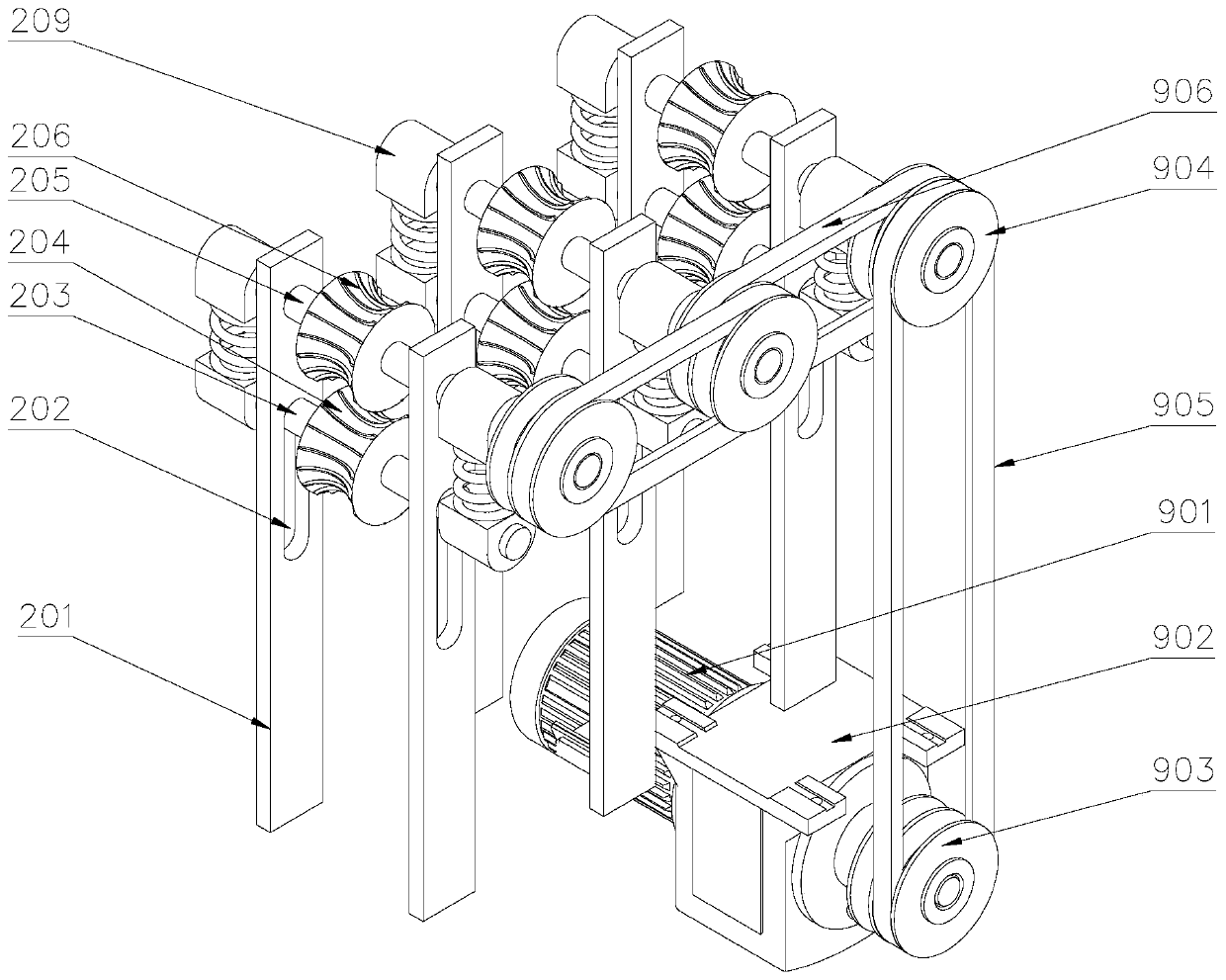

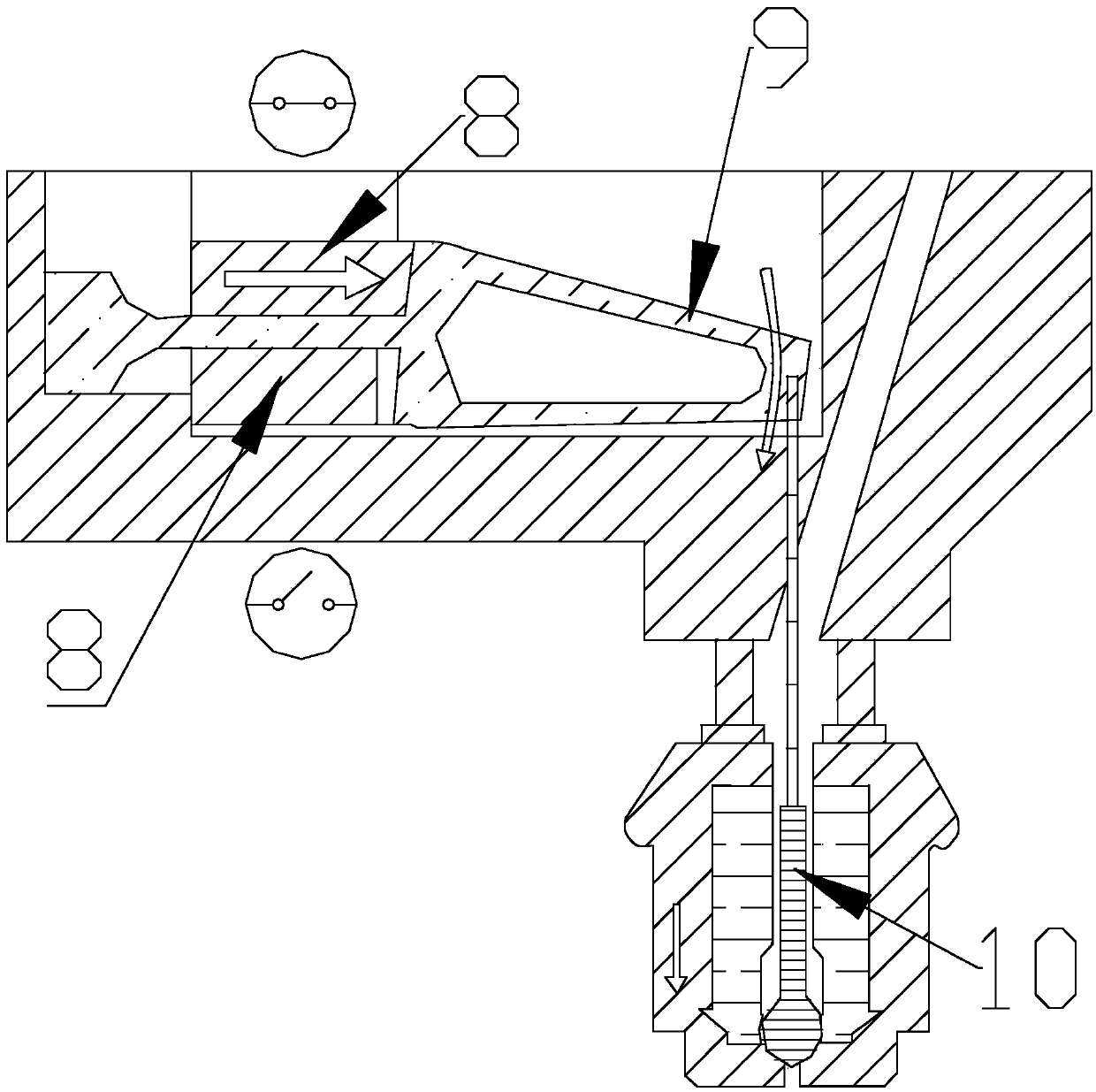

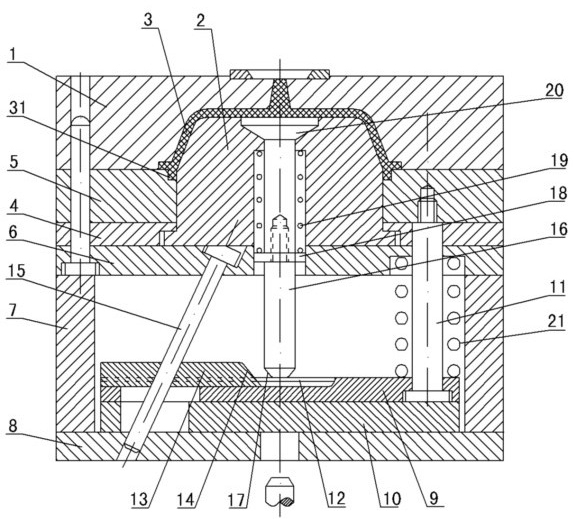

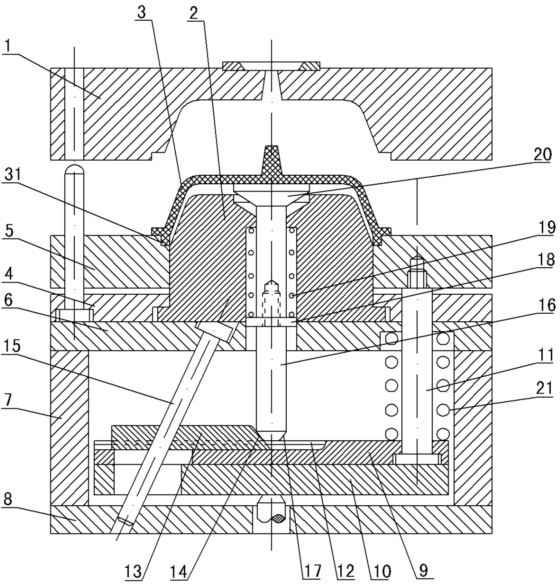

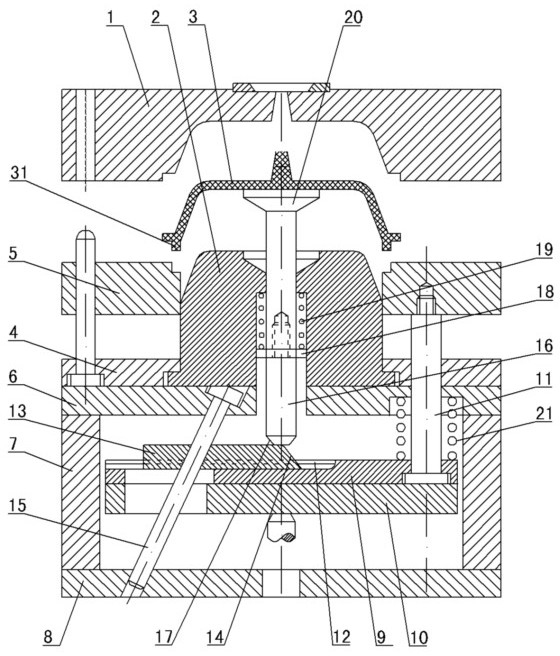

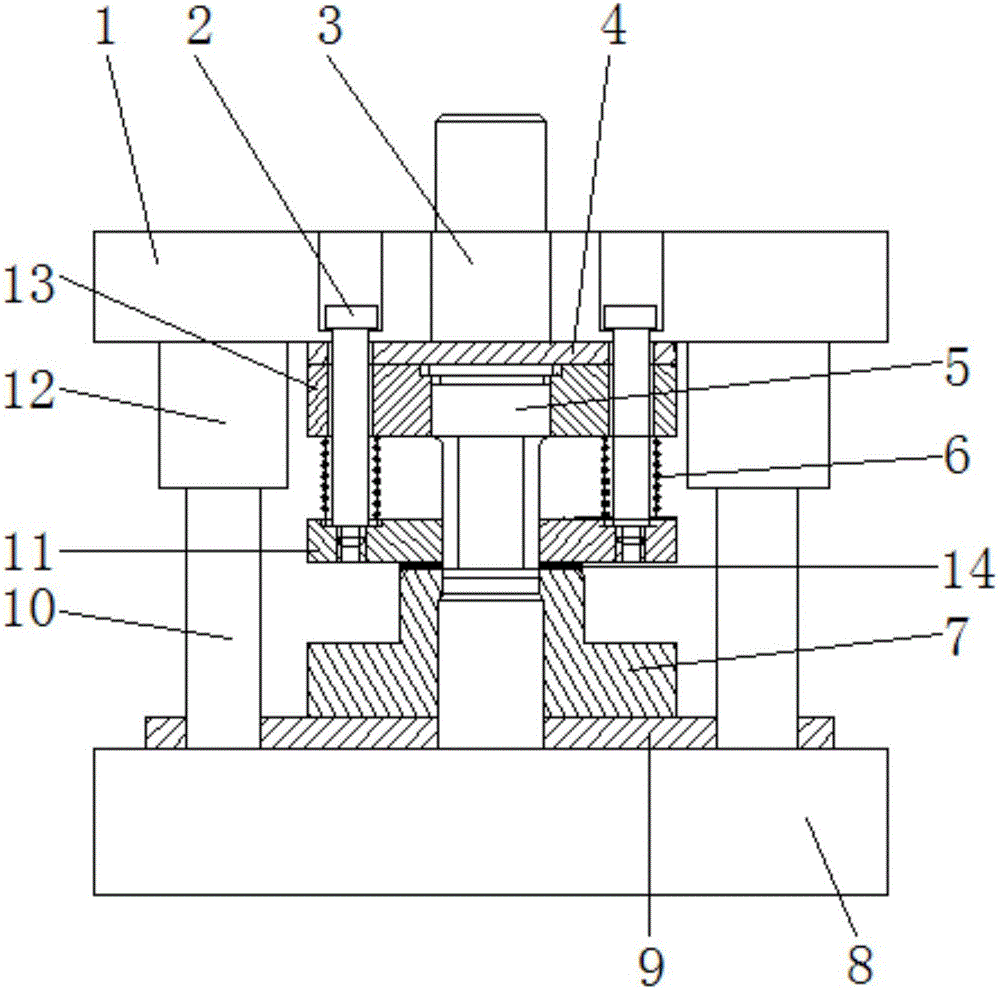

Idler machining method and combined mold for machining

PendingCN107470533AExtend your lifeAvoid chippingShaping toolsForging/hammering/pressing machinesPunchingCold sizing

The invention discloses an idler machining method and a combined mold for machining. The machining method includes accurate discharging, coating of an oxidizing preventing coating, non-oxidation induction heating, upsetting, forging forming, punching, spheroidizing annealing, shot blasting, cleaning, coating of a metal lubricant and cold sizing. The combined mold for machining comprises a hot fine forging forming mold; the hot fine forging forming mold comprises an upper mold part and a split type lower mold part; the upper mold part comprises a tooth-shaped upper mold and an upper pressing plate; the split type lower mold part comprises a lower mold body, a tooth-shaped lower mold and a lower ejecting rod; the lower ejecting rod is located below the tooth-shaped lower mold; a lower ejecting rod cushion plate is arranged below the lower ejecting rod; the lower mold body surrounds the lower ejecting rod and the lower ejecting rod cushion plate; a platform is arranged on the upper portion of the lower mold body along the periphery, and a lower cushion plate is arranged between the tooth-shaped lower mold and the platform; and an annular lower pressing plate is further included, and the tooth-shaped lower mold and the lower mold body are centered by the lower pressing plate. The near-net forming principle is adopted for the machining method, tooth profiles are forged at a time, and it is achieved that subsequent machining is little and even no subsequent machining exists.

Owner:山东大为齿轮传动有限公司

Drying device for wood boards for furniture

InactiveCN107401904AAchieve dryingImprove drying efficiencyDrying gas arrangementsDrying chambers/containersRotational axisDrive wheel

The invention discloses a drying device for wood boards for furniture. The drying device comprises a drying cylinder, a fixed plate, a blower, a motor, heating blocks, a heating wire, a rotary shaft and a bearing plate. The drying device is characterized in that the drying cylinder is arranged on brackets, the fixed plate is arranged between the brackets, the blower is arranged on the fixed plate, the motor is arranged on the fixed plate, a power line and a driving wheel are arranged on the motor, the heating blocks are arranged in the drying cylinder, power lines are arranged on the heating blocks, the heating wire is arranged between the heating blocks, one end of the rotary shaft is arranged in a bearing, the other end of the rotary shaft passes through the bearing, a driven wheel is arranged on the rotary shaft, and the bearing plate is arranged on the rotary shaft by virtue of an installation ring. According to the drying device, the heating wire is arranged between the heating blocks in the drying cylinder, and heat can be supplied to a drying chamber by virtue of the heating wire, so that the wood boards in the drying cylinder are dried.

Owner:李琪

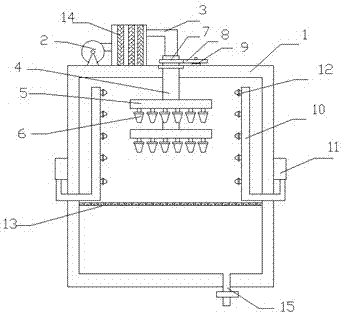

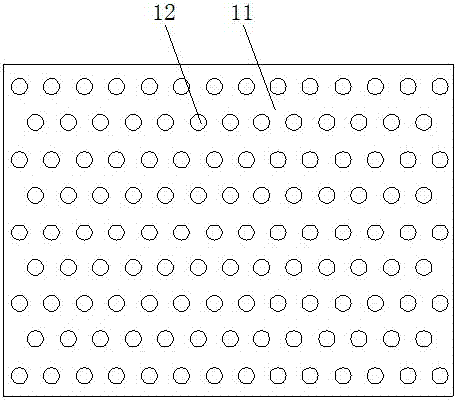

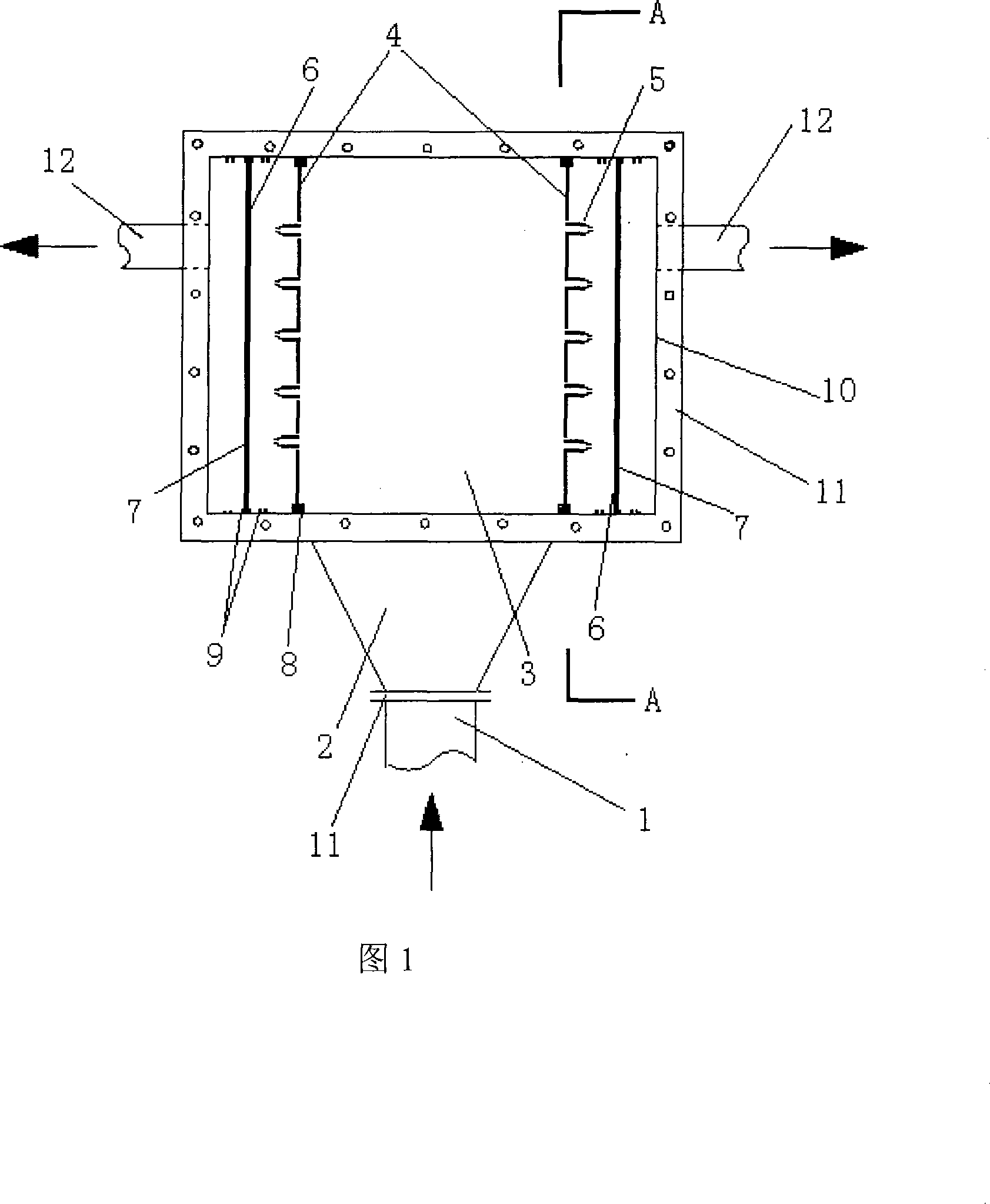

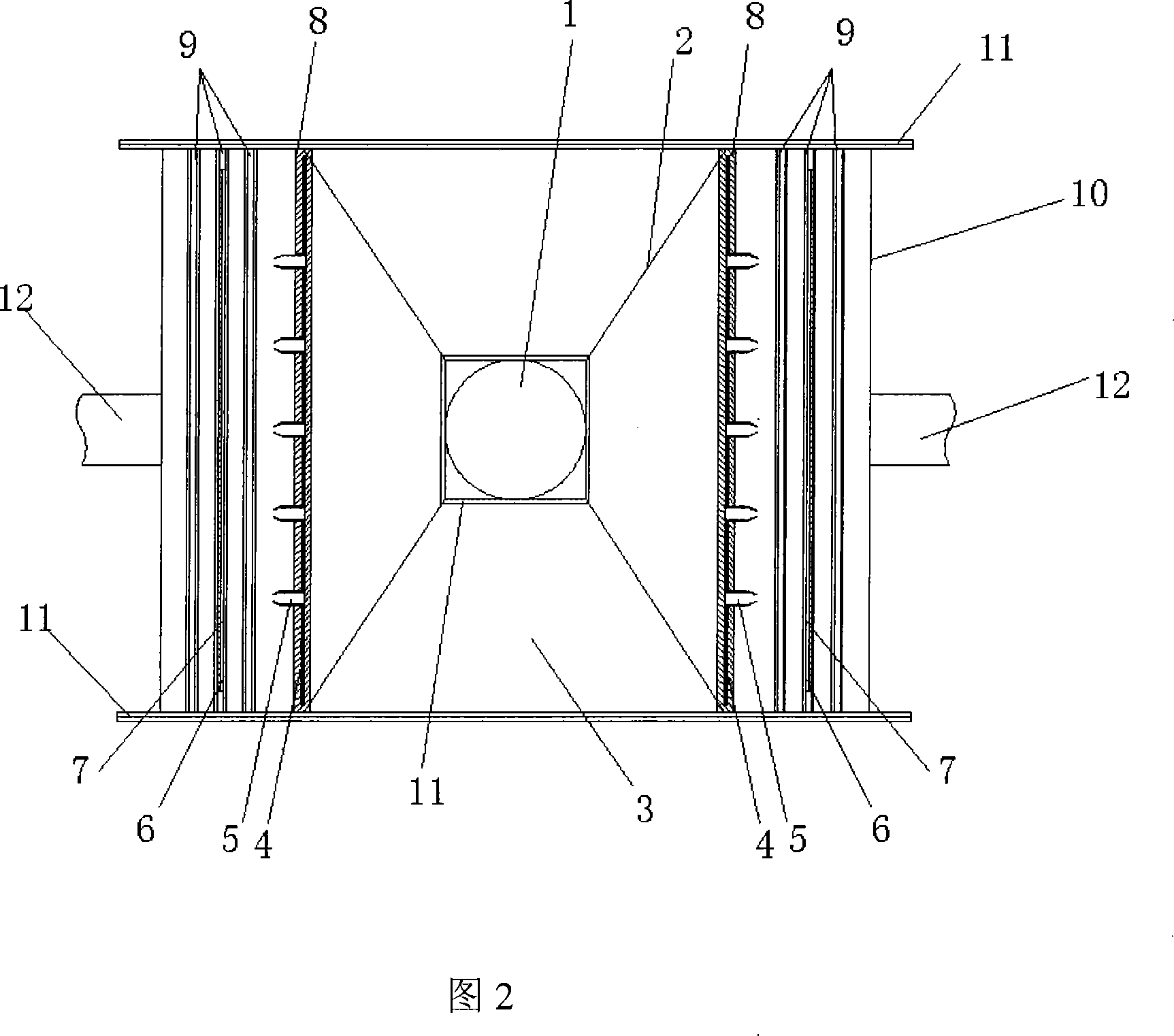

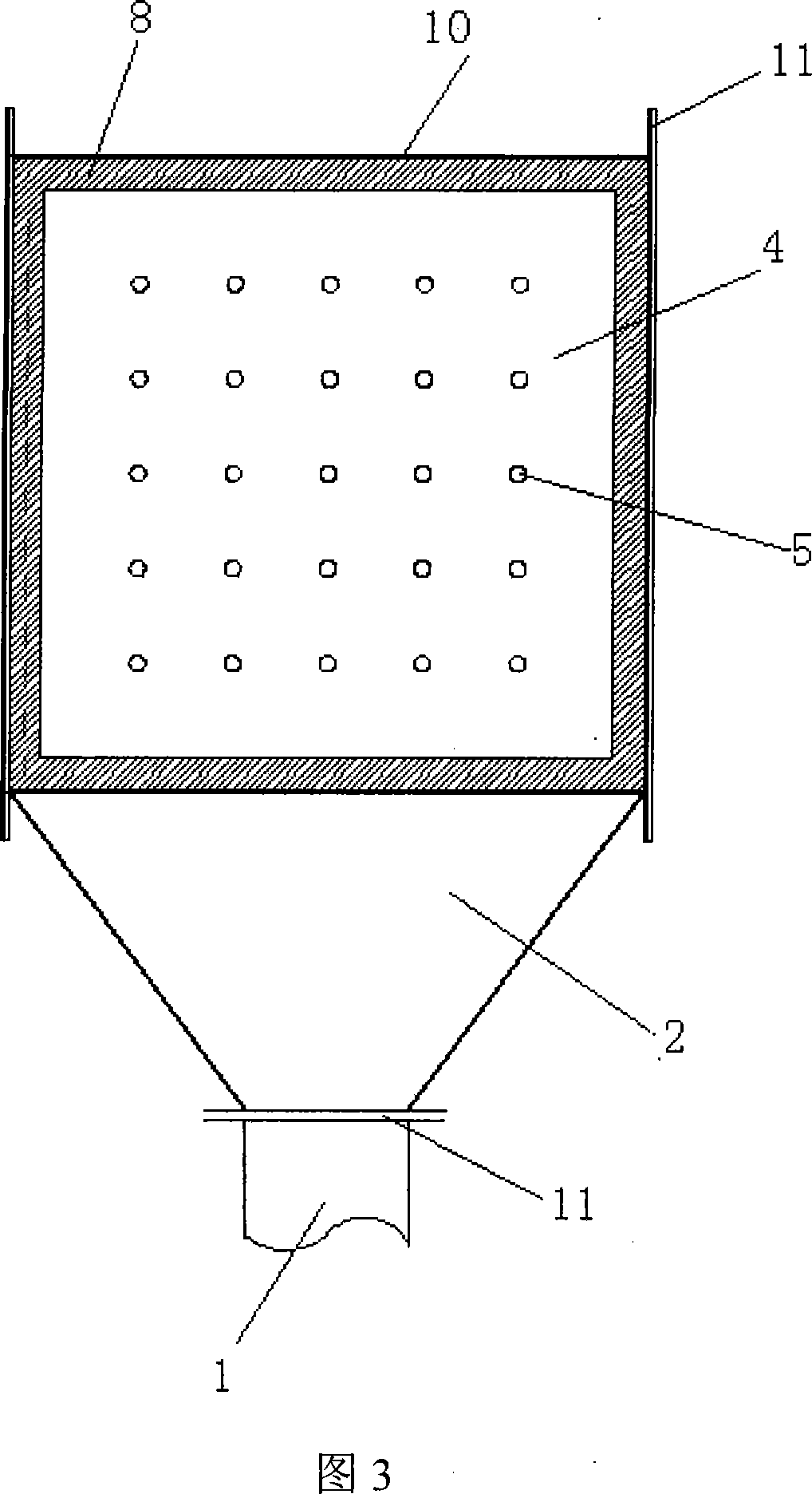

Low temperature plasma device for treating volatile organic

InactiveCN101121095AIncrease profitReduce energy consumptionDispersed particle separationEnergy based chemical/physical/physico-chemical processesExhaust gasVolatile organic compound

The present invention relates to a low temperature plasma device for disposing volatile organic matter and belongs to the volatile organic exhaust gas disposal field. An air inlet (1) of the device is connected with a reactor crust (10) by a gradually diffusing apparatus (2). A high pressure polar plate (4) is arranged inside the reactor crust (10), and the high pressure polar plate (4) is connected with the reactor crust (10). The high pressure pole nozzles (5) are uniformly distributed on the high pressure polar plate (4) and are used for producing the plasmas. A ground plate (7) is arranged between the high pressure polar plate (4) and the reactor crust (10). A gap is left between the ground plate (7) and the reactor crust (10) for air to pass. The air outlets (12) are arranged at two side faces of the reactor crust (10). The present invention improves the utilization rate of the plasma, and a medium baffle layer avoids occurrence of electric arc. The present invention also has the advantages of simple structure, strong applicability, high disposal efficiency and low operation charge.

Owner:BEIJING UNIV OF TECH

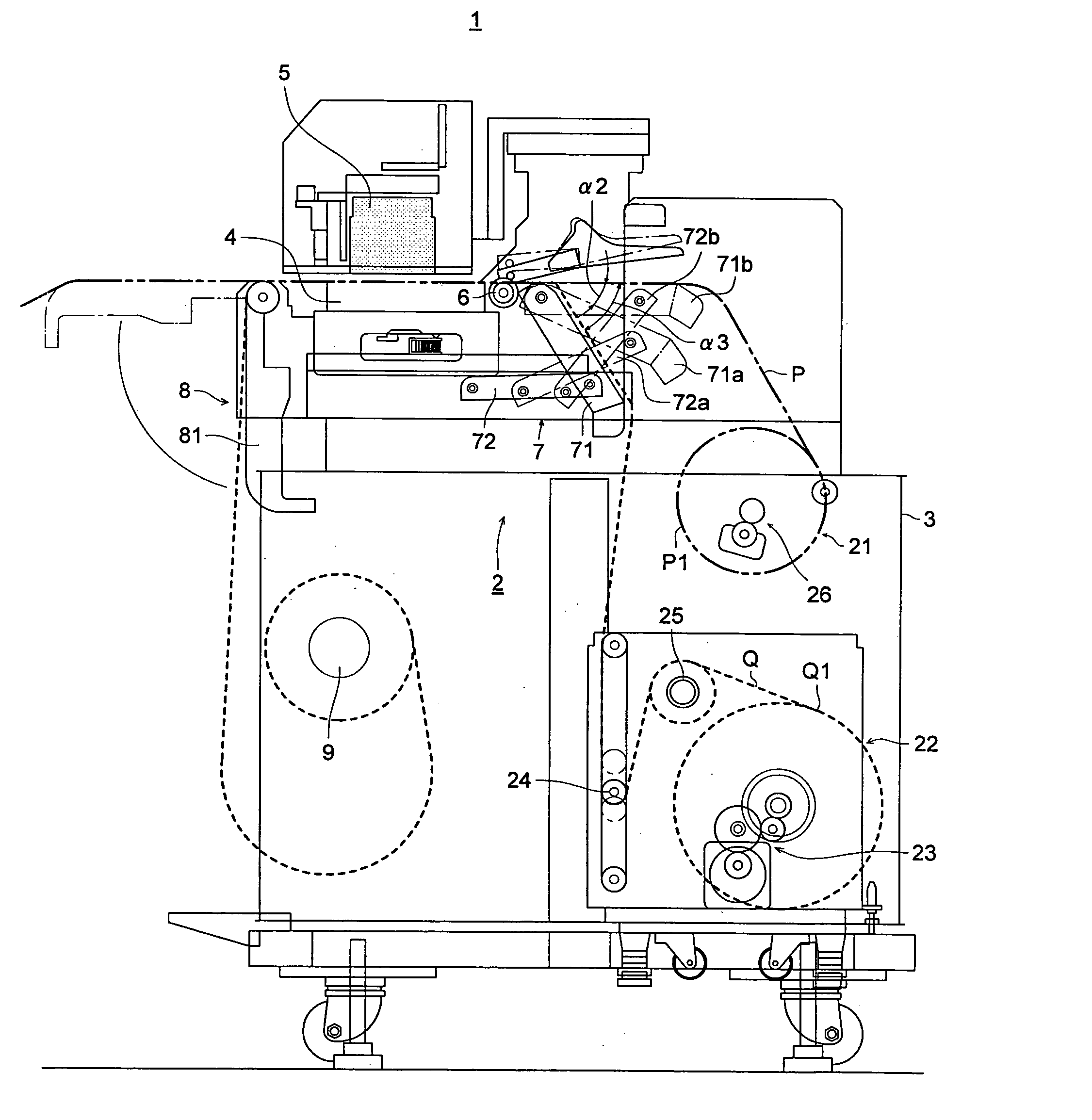

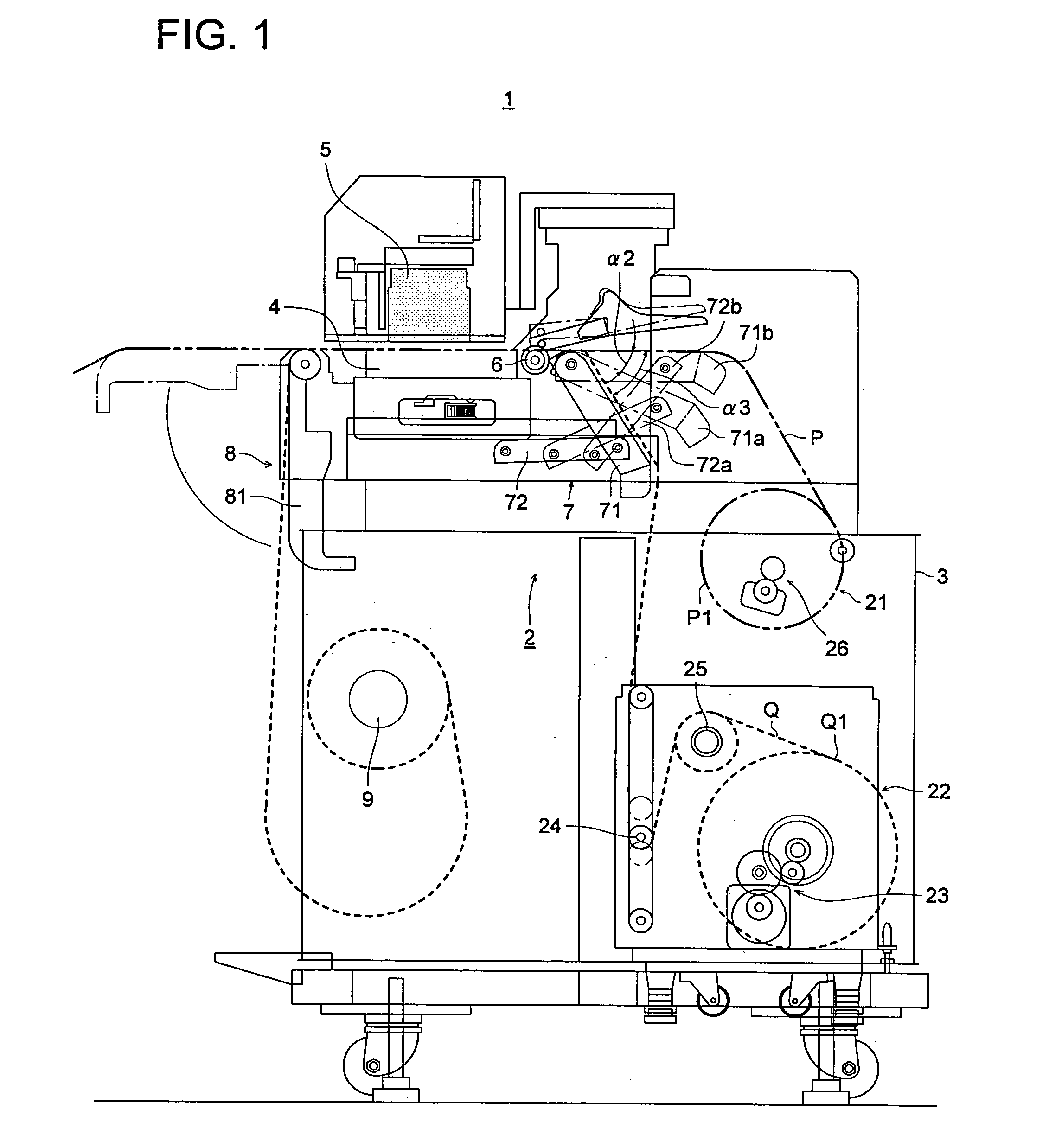

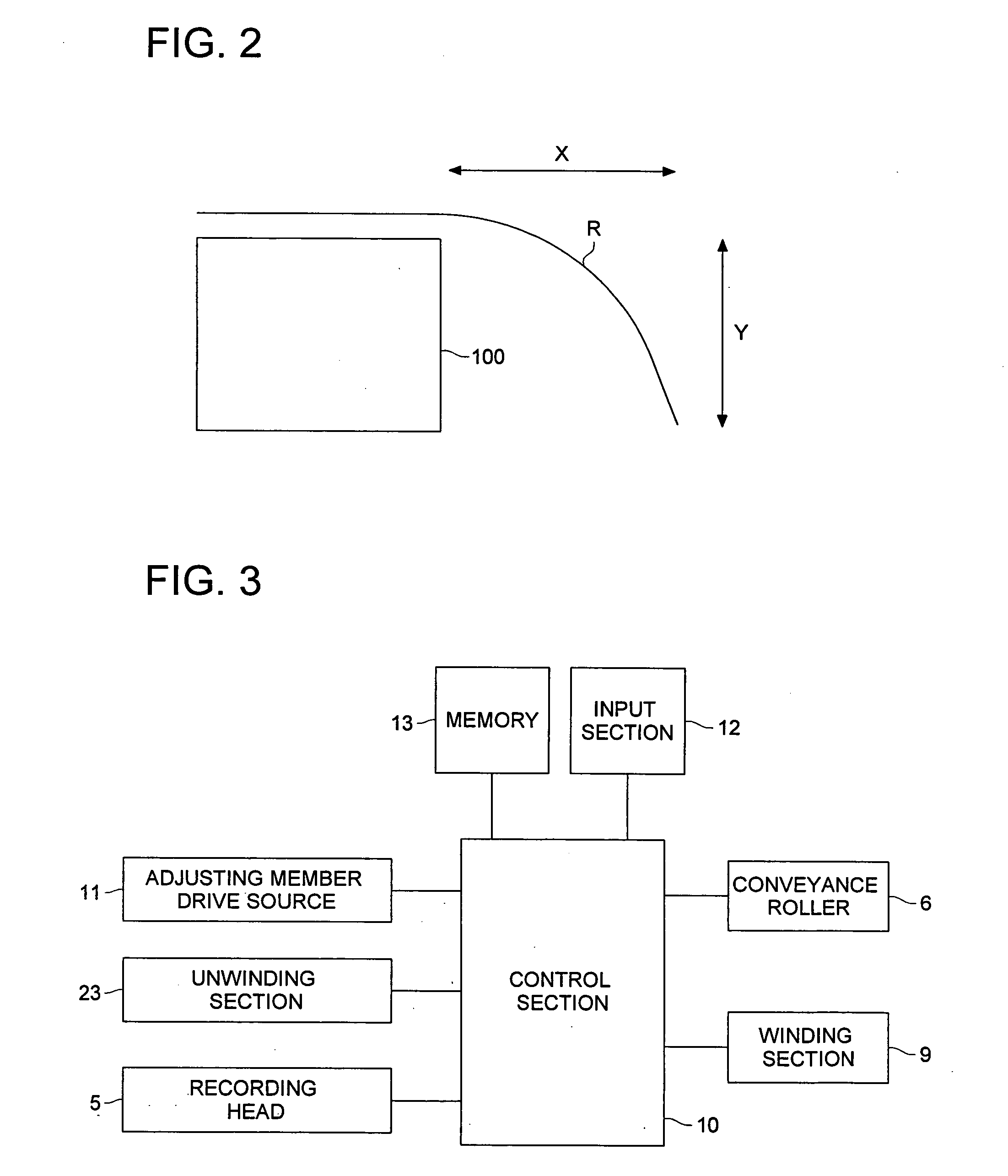

Recording medium conveying device

InactiveUS20060056899A1Improve flatnessEject evenlyOther printing apparatusImage recordingEngineering

A recording medium conveying device comprising: a master roll holder to hold a master roll of a recording medium; a platen to support the recording medium supplied from the master roll holder in an image recording section; a conveyance roller positioned upstream of the platen to convey the recording medium by adding driving force to the recording medium and a guide positioned near the platen to guide the recording medium, wherein the guide changes an angle of the recording medium against the platen according to a stiffness of the recording medium.

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

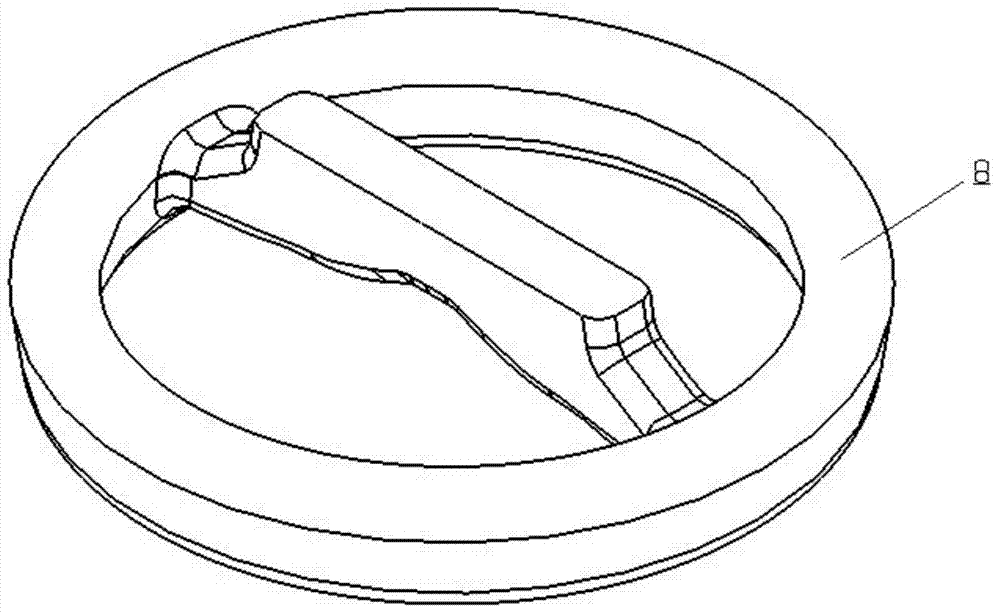

Cross beam type salt-core pressing die and salt core production method adopting pressing die

ActiveCN103658545AReduce the rejection rate of pressingHigh strengthFoundry mouldsFoundry coresButt jointEngineering

The invention discloses a cross beam type salt-core pressing die which comprises an upper pressing die, a lower pressing die outer ring, a lower pressing die inner ring and movable blocks, wherein a first groove is formed in the top end of the outer wall of the lower pressing die inner ring; a second groove matched with the first groove is formed in the top end of the inner wall of the lower pressing die outer ring; the first groove and the second groove form a first annular groove; a second annular groove, corresponding to the opening of the first annular groove, is formed in the bottom surface of the upper pressing die and communicated with the first annular groove; the second annular groove and the first annular groove are in butt joint to form a salt-core die cavity I; the cavity volume ratio of the salt-core die cavity I is 1: (1+0.7); a third groove is formed in the center of the lower pressing die inner ring; a pressing block corresponding to the third groove is arranged on the bottom surface of the upper pressing die; the third groove and the pressing block are in butt joint to form a salt-core die cavity II; the cavity volume ratio of the salt-core die cavity II is 1: (1+0.8); the movable blocks are embedded around the third groove and moves relatively to the lower pressing die inner ring. The invention further provides a method for manufacturing a salt core by utilizing the cross beam type salt-core pressing die.

Owner:BINZHOU BOHAI PISTON CO LTD

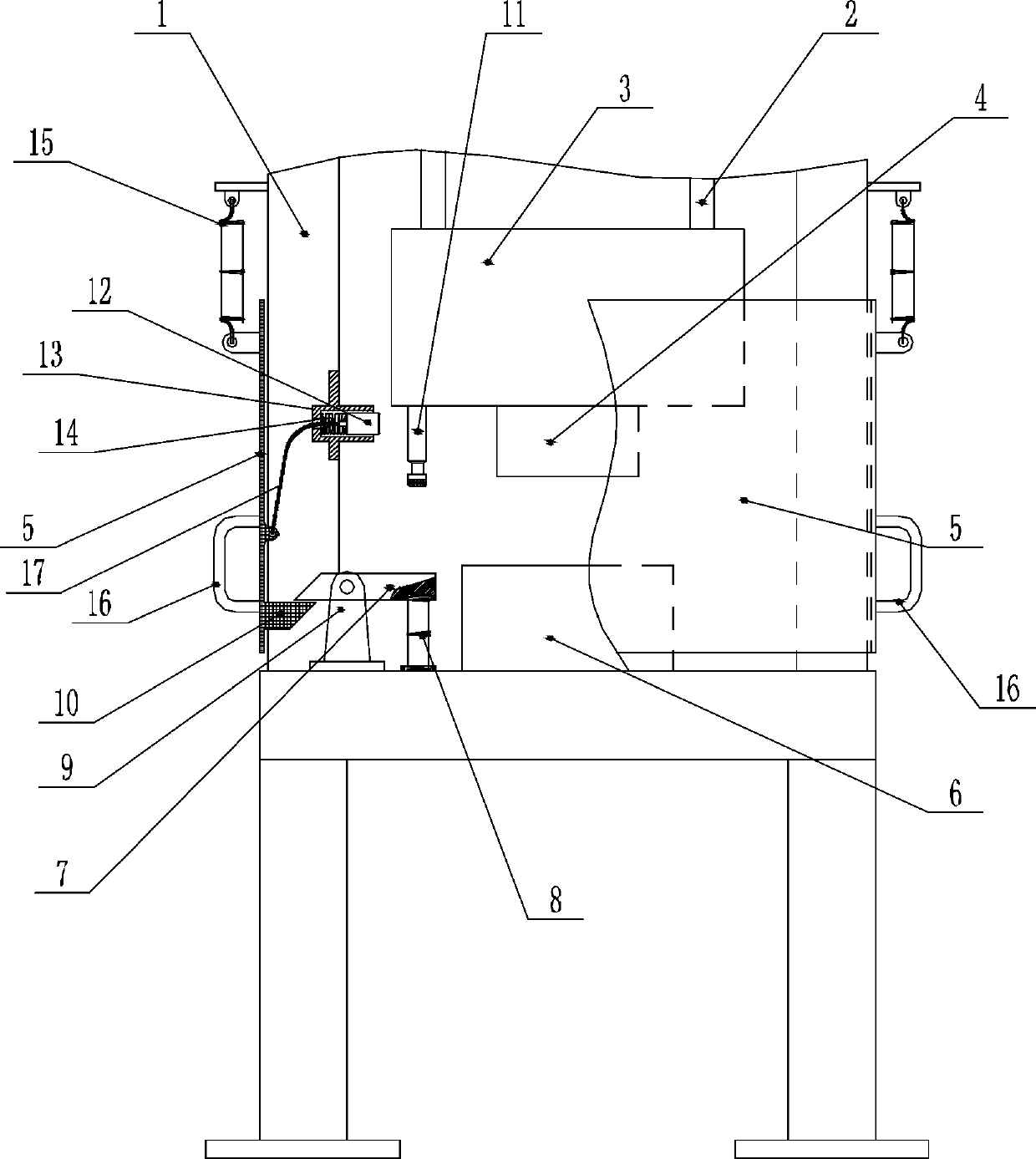

Safety protective cover on punch press and application method thereof

The invention discloses a safety protective cover on a punch press and an application method thereof. The safety protective cover comprises a machine frame, guide rods, a sliding block, an upper mold,a protective cover body, a lower mold and a limiting device; a buckling device is arranged on the left side of the lower mold and comprises a support, a first buckling plate and a first spring; and the limiting device comprises a top block, a limiting base and a third spring. According to the protective cover for preventing scraps and dust generated in the workpiece punching process from splashing in the working process of the punch press, the sliding block is automatically limited after punching is completed, so that safety accidents in the workpieces taking process caused due to misoperation can be avoided, and therefore the production safety is improved.

Owner:ZHEJIANG JINAOLAN MASCH TOOL CO LTD

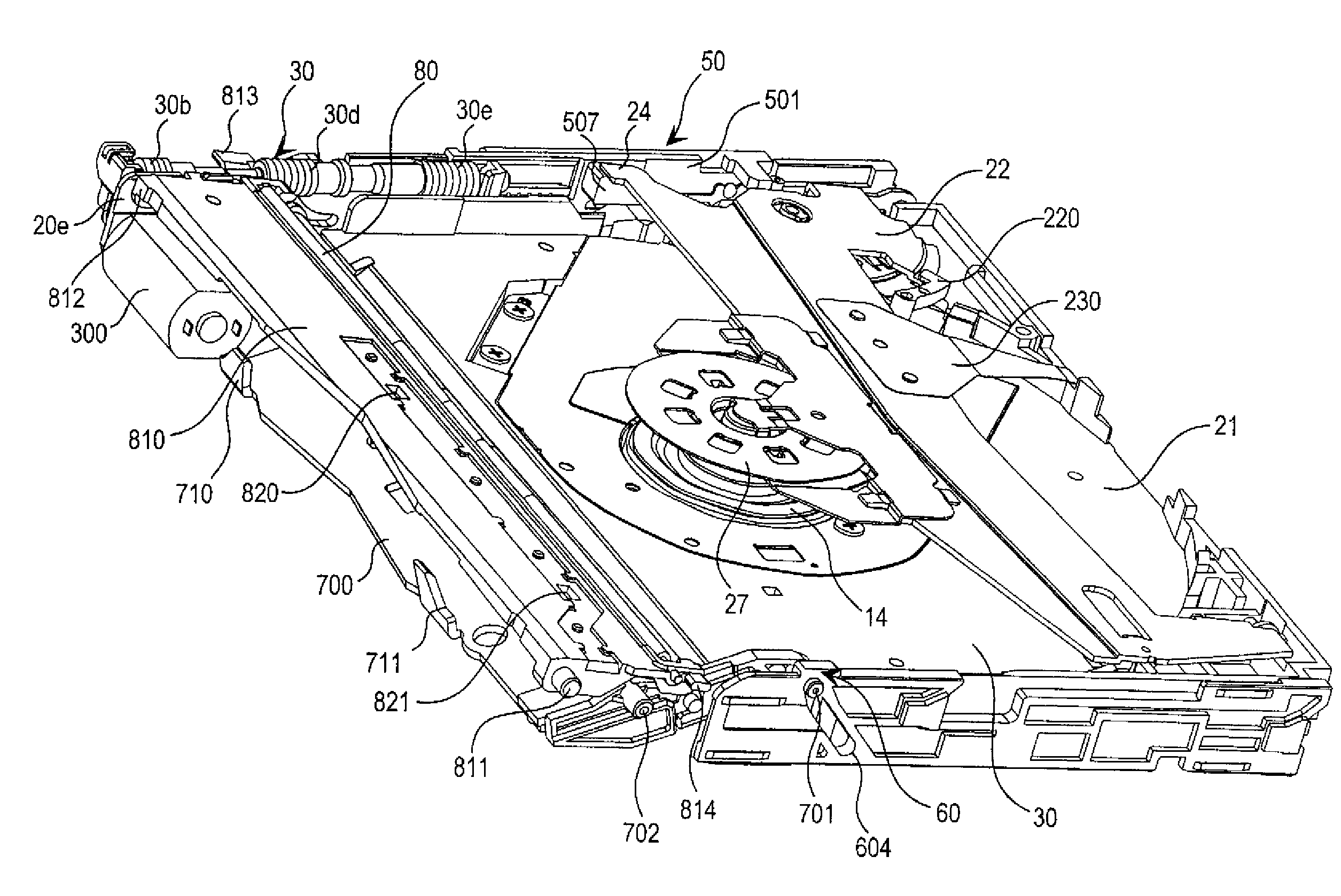

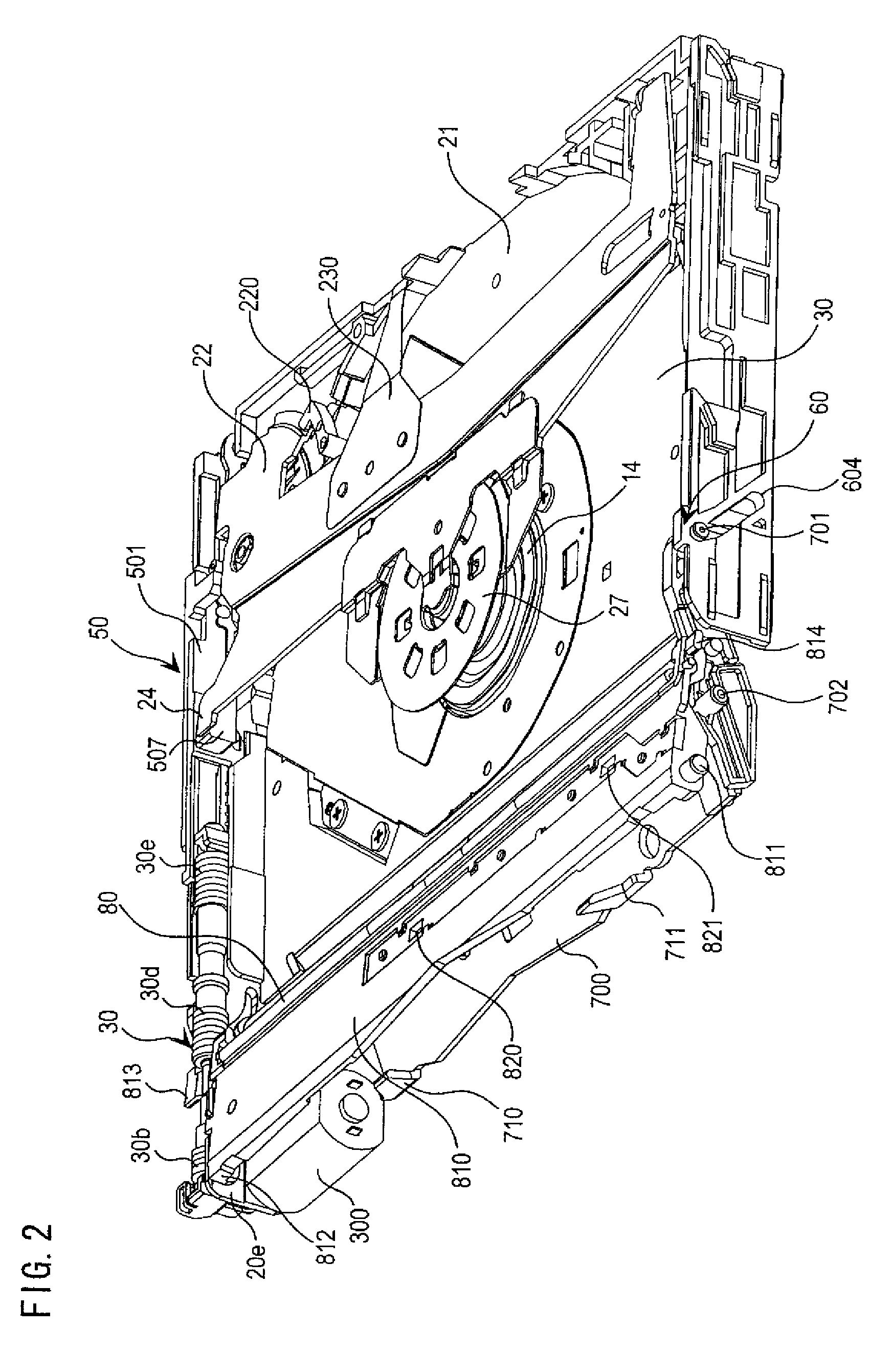

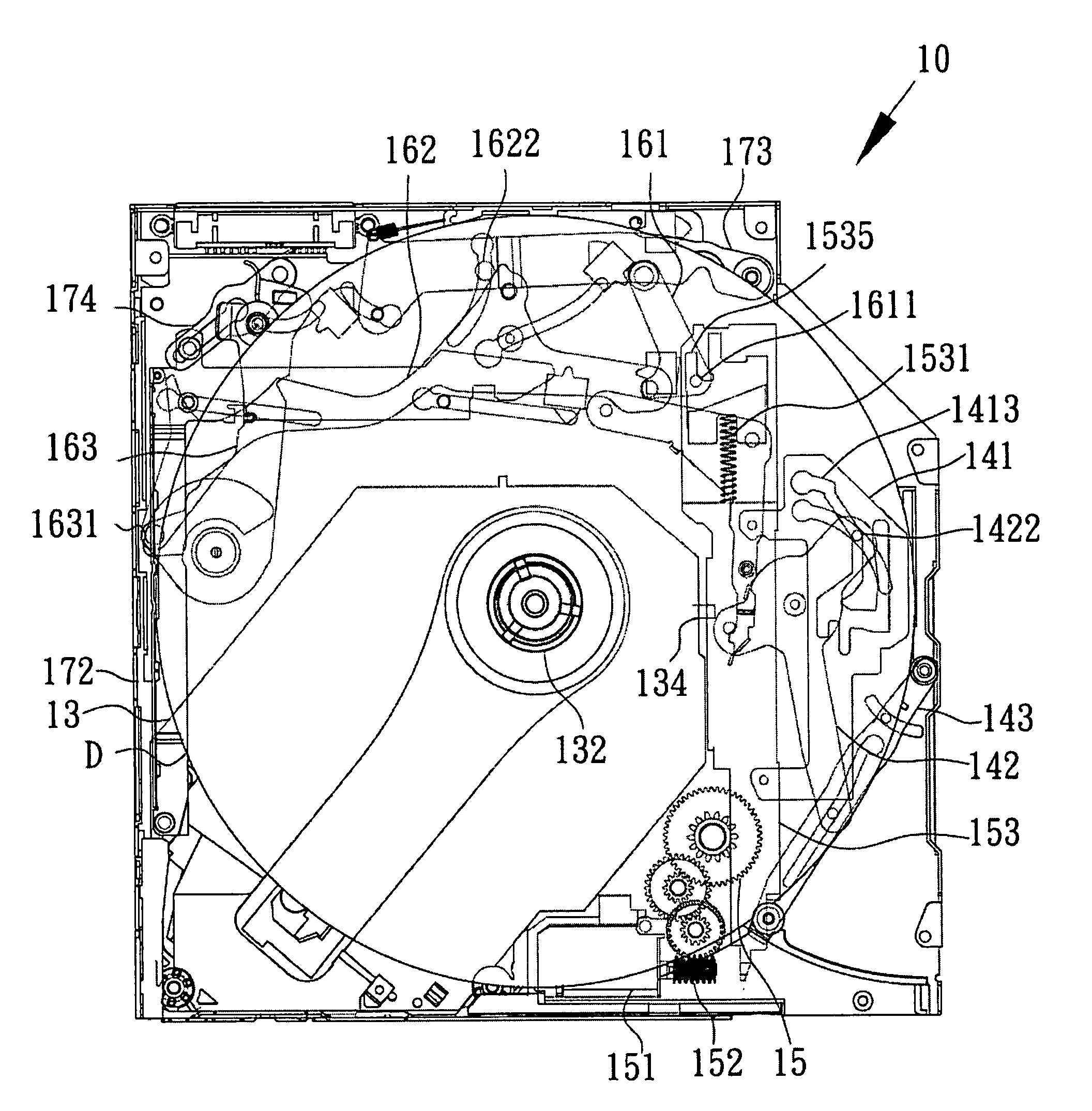

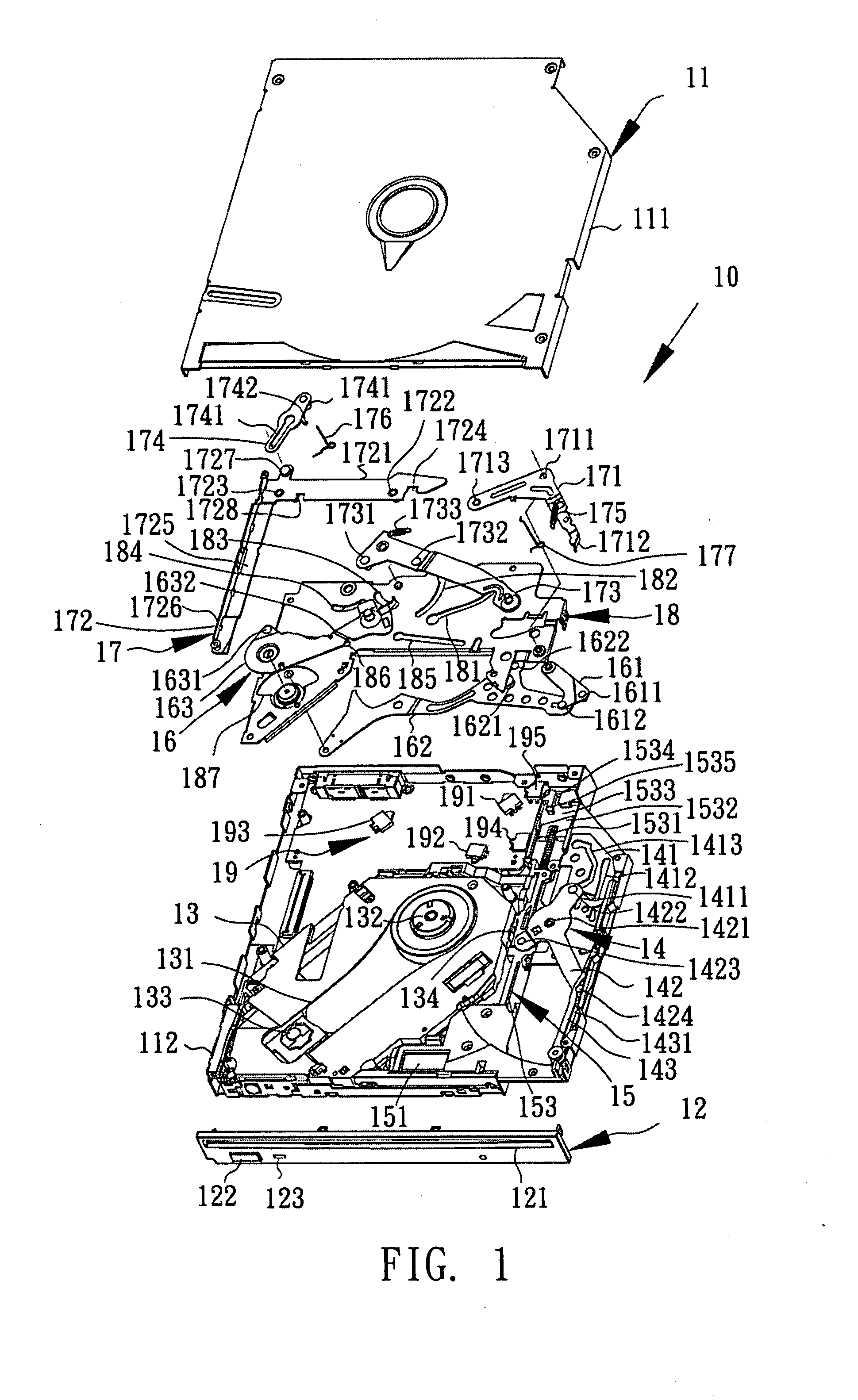

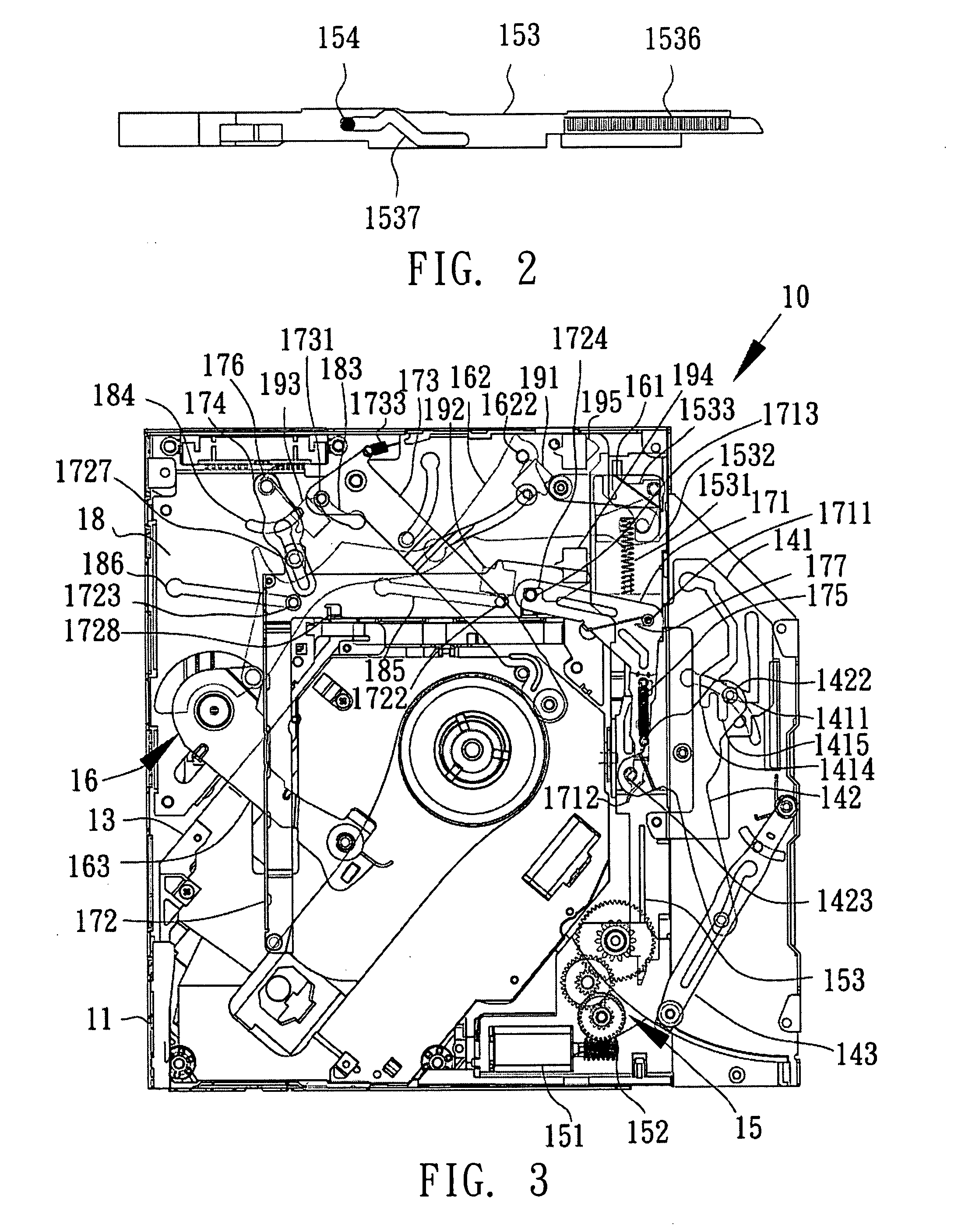

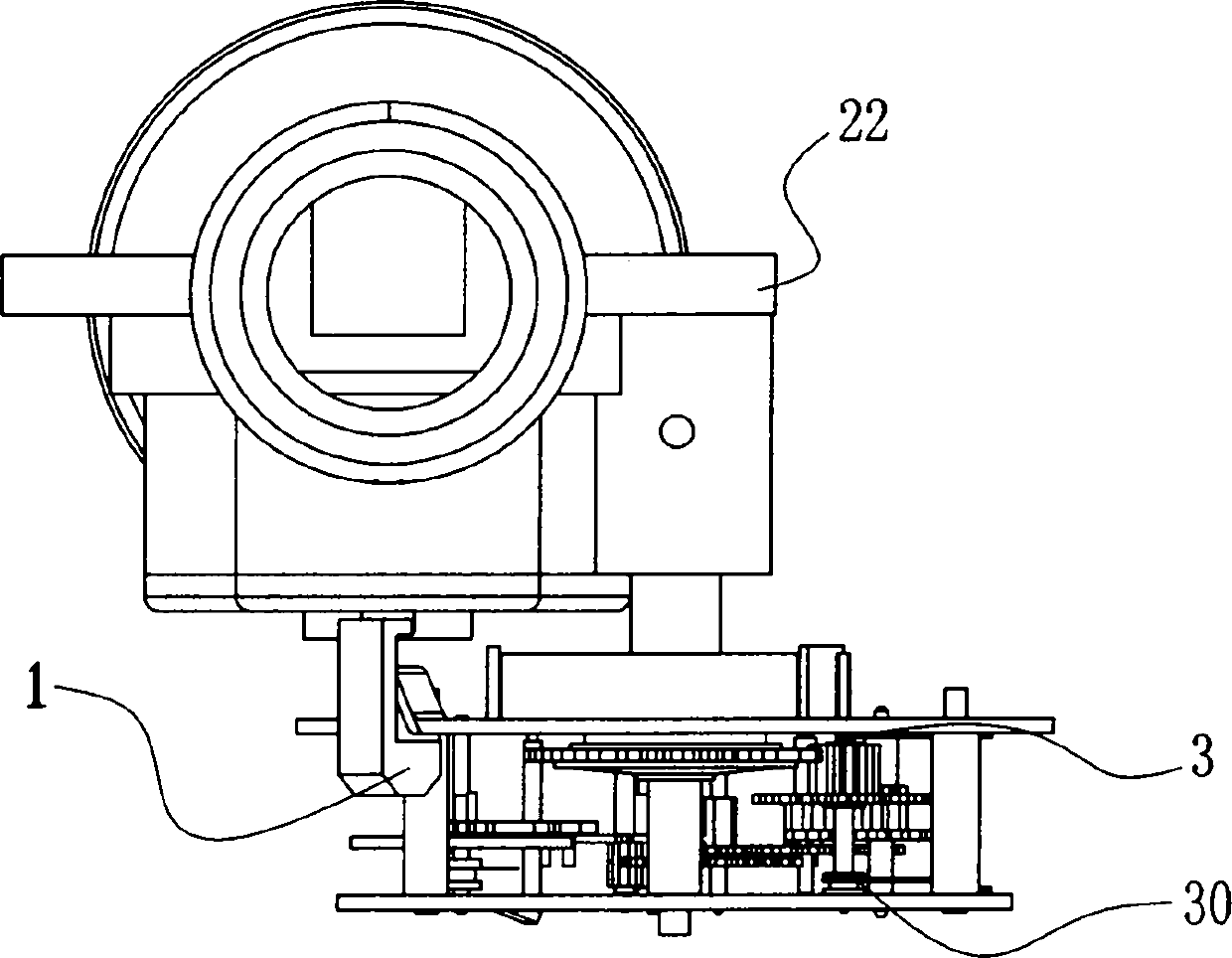

Disc player apparatus with upper and lower rollers for transporting and guiding a disc

InactiveUS7814504B2Easy to assembleEliminate impact noiseUndesired vibrations/sounds insulation/absorptionRecord information storageMechanical engineering

There is provided a disc player apparatus capable of transporting a disc (11) by holding the disc (11) between a lower roller (70) and an upper roller (80). The lower roller (70) and the upper roller (80) are rockably supported with respect to a main body (20a). A flat spring (210) which urges the upper roller (80) is attached to an upper case (200a) that is attached to the main body (20a). The urge of the flat spring (210) is applied via a roller support member (810) which supports the upper roller (80). The pressure is applied evenly to the upper roller (80), enabling to reduce diagonal travel of the disc for example, and to transport the disc smoothly.

Owner:SANYO ELECTRIC CO LTD +1

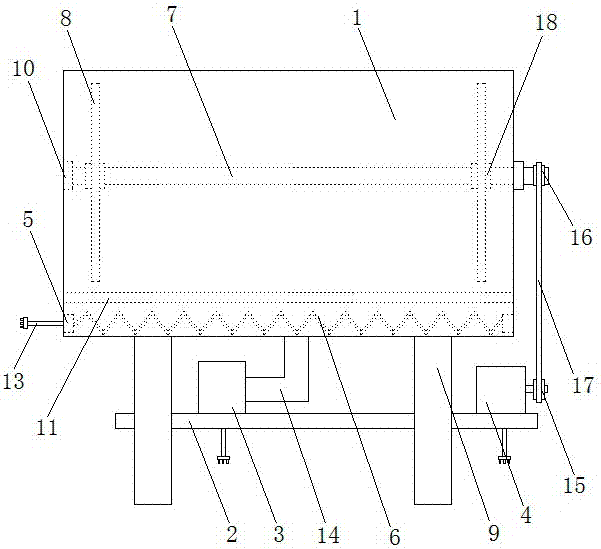

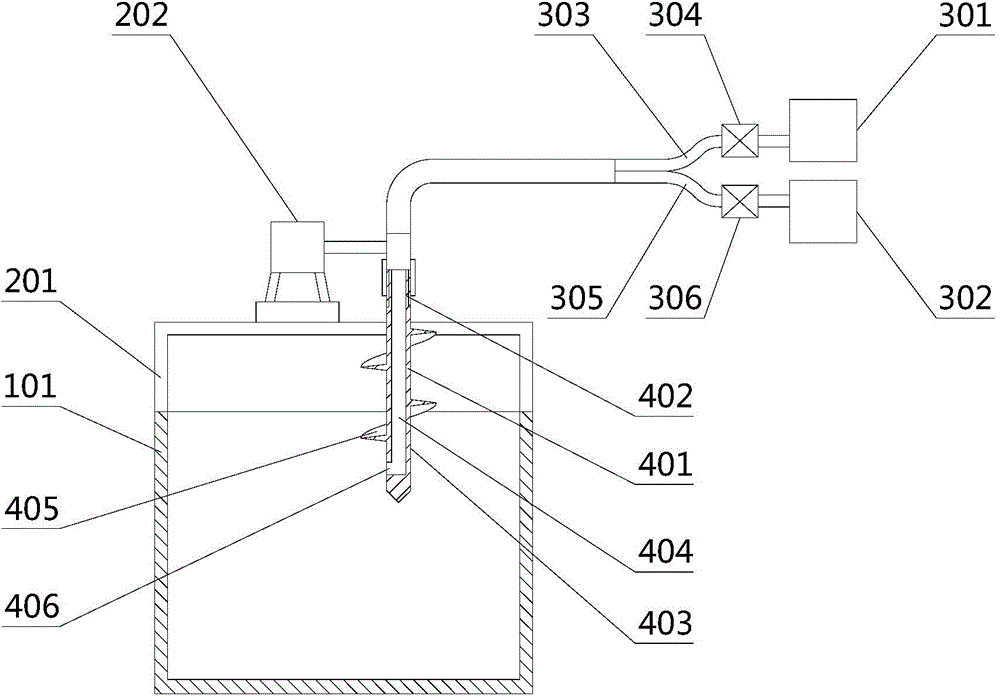

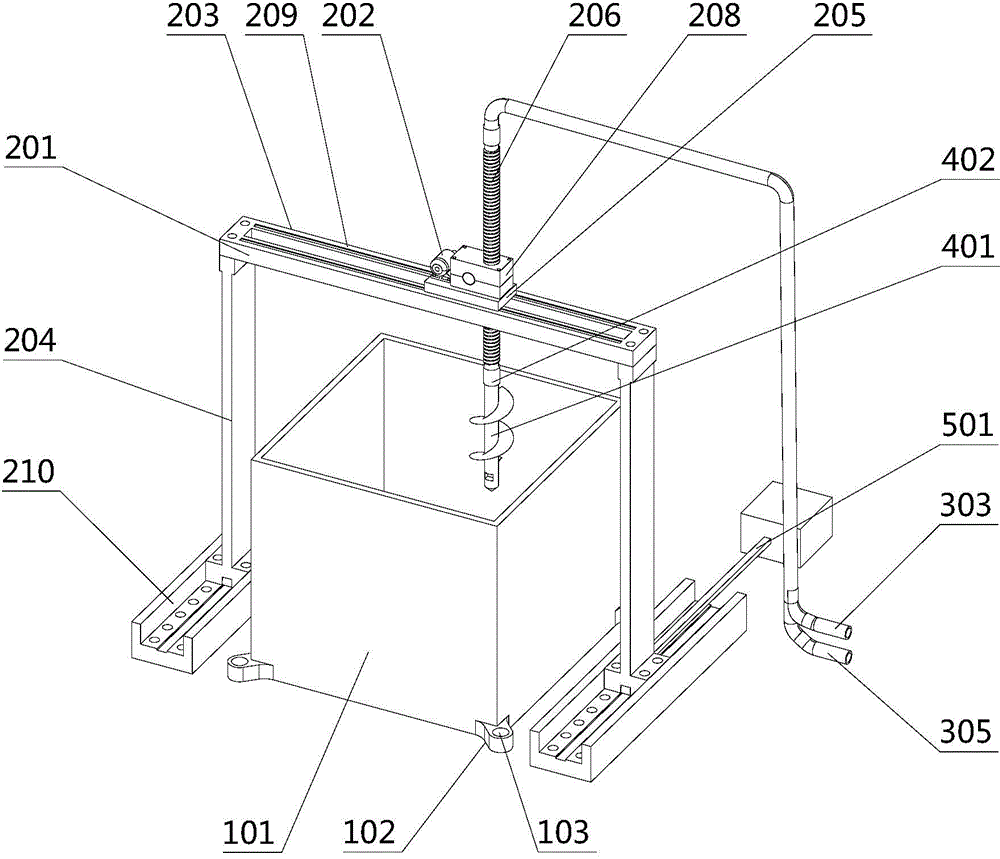

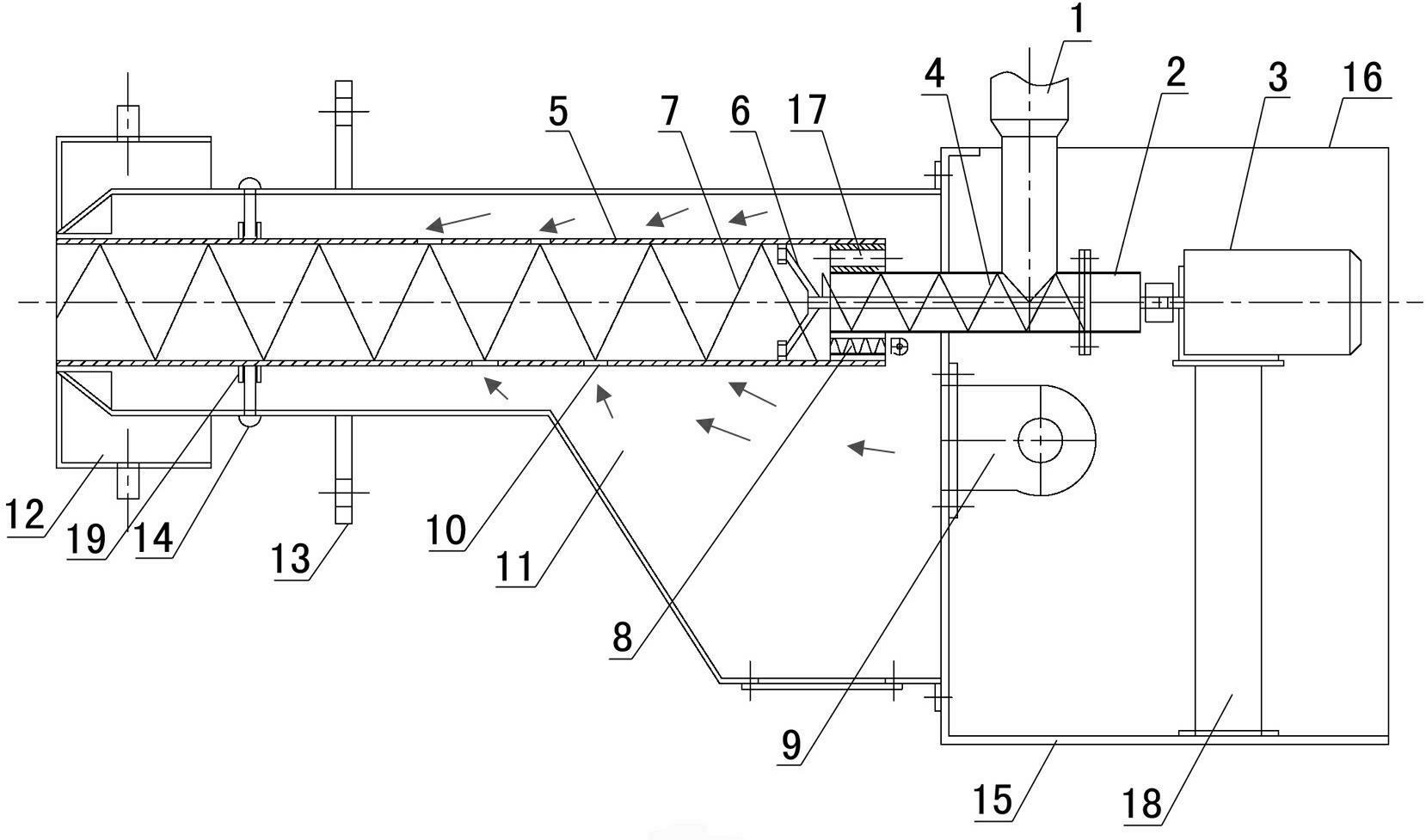

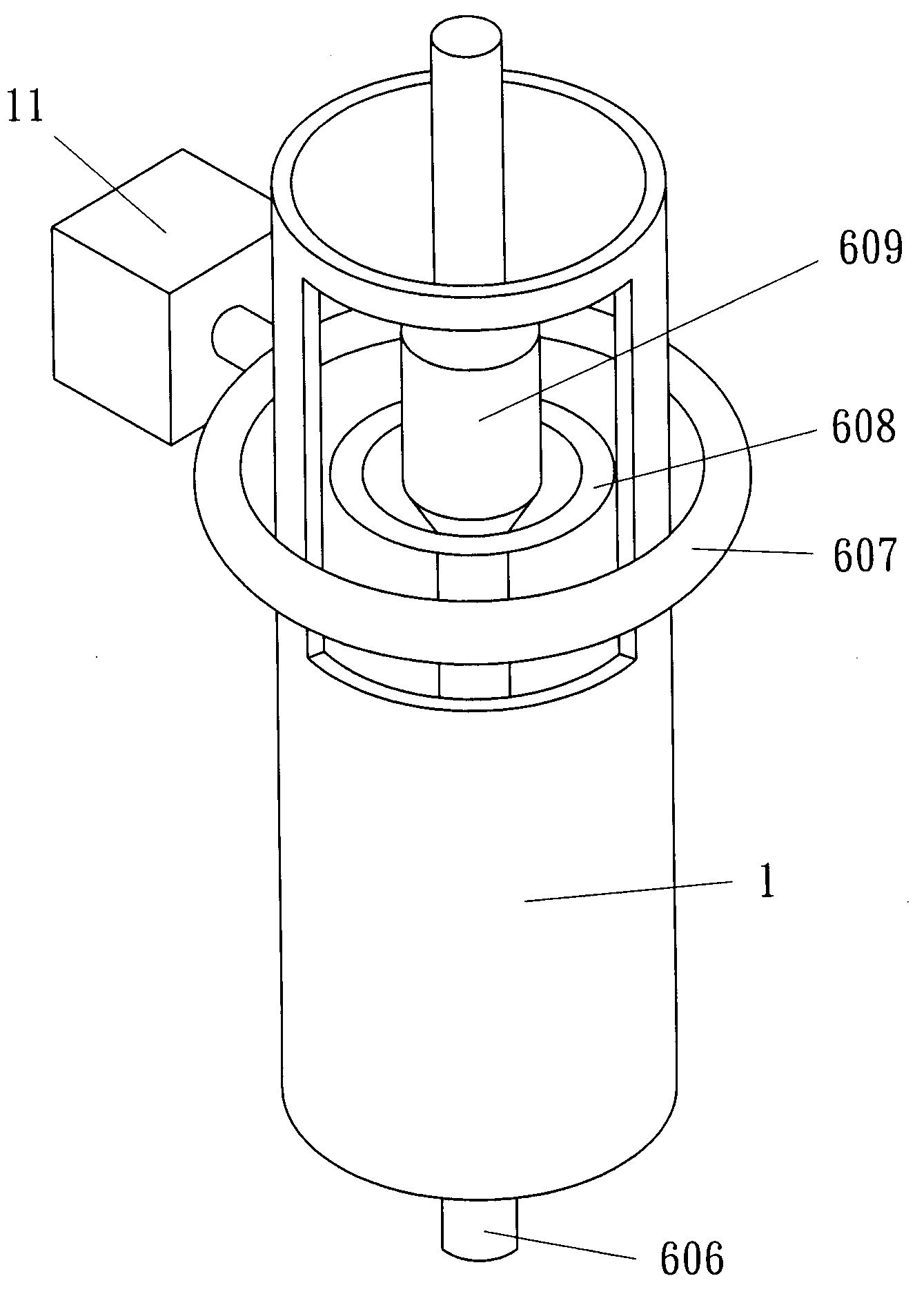

Indoor soft soil powder spraying solidifying device

InactiveCN104908162AEject evenlySquirt GuaranteeClay mixing apparatusSold ingredients supply apparatusPulp and paper industryHigh pressure

The invention discloses an indoor soft soil powder spraying solidifying device and belongs to the field of soft soil solidifying devices. The indoor soft soil powder spraying solidifying device comprises a test box and a bracket which is arranged above the test box, the bracket is provided with a stirring device, and the stirring device is connected with an input device. The input device comprises a feeding pump for spraying powder-shaped solidifying agent and an air compressor for filling high-pressure air, the feeding pump is connected with a feeding pipe, the feeding pipe is provided with a feeding valve, the air compressor is connected with an air supply pipe, and the air supply pipe is provided with an air supply valve. The stirring device comprises a stirring shaft and a motor, the stirring shaft comprises a rotating part and a stirring part, and the rotating part is connected with the motor. A solidifying agent flow passage is arranged in each of the rotating part and stirring part, the upper end of the rotating part is communicated with each of the feeding pipe and air supply pipe through a pipeline, and a stirring blade and an opening are arranged at the lower end of the stirring part. The indoor soft soil powder spraying solidifying device is simple in structure, easy to operate, more uniform in stirring and good in solidifying effect.

Owner:GUANGDONG UNIV OF TECH

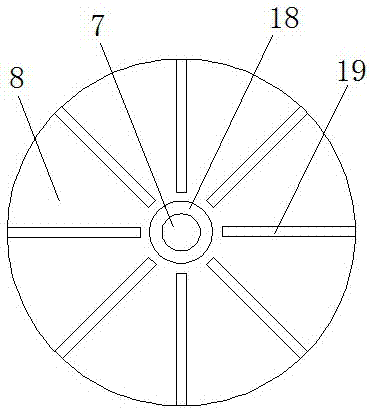

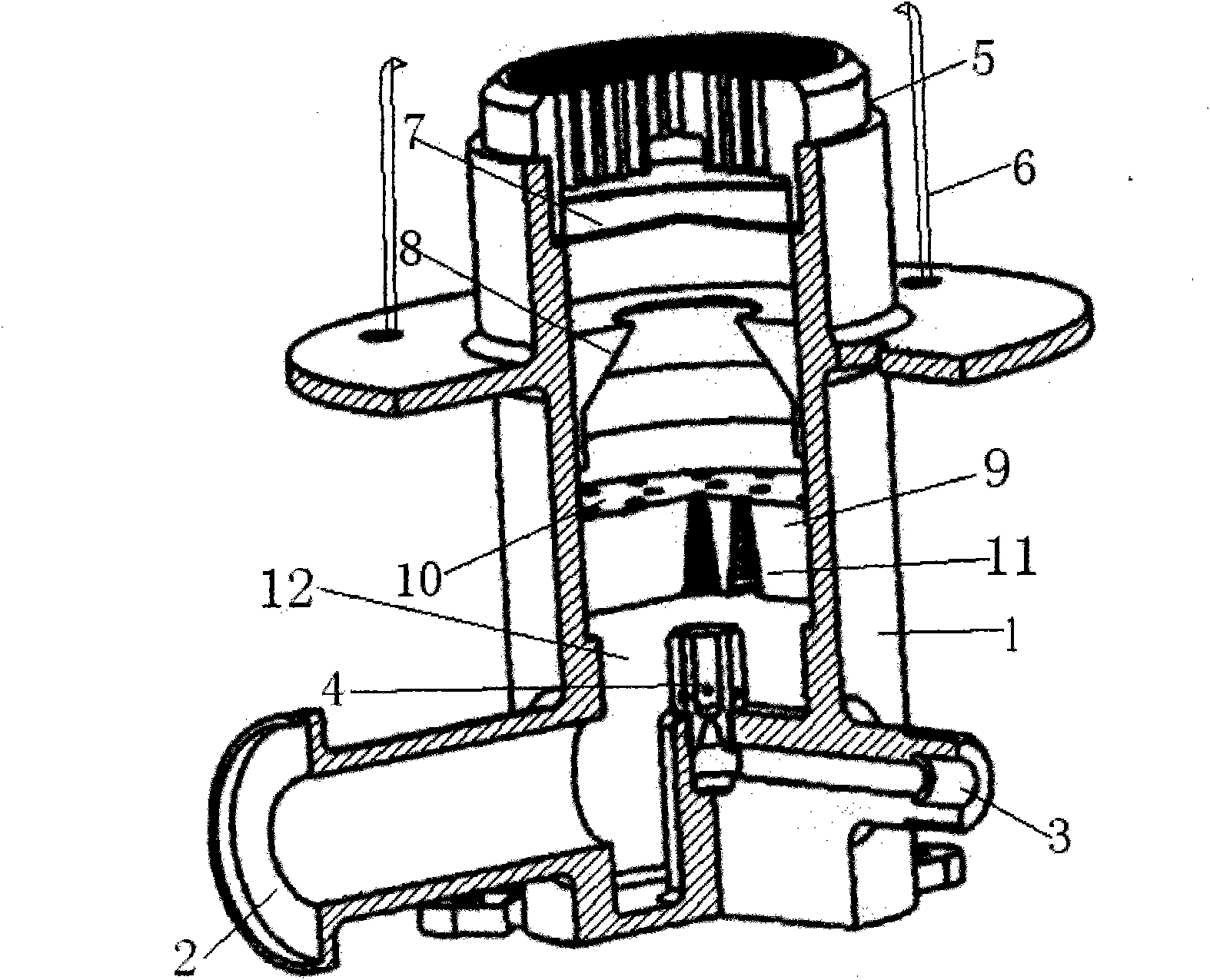

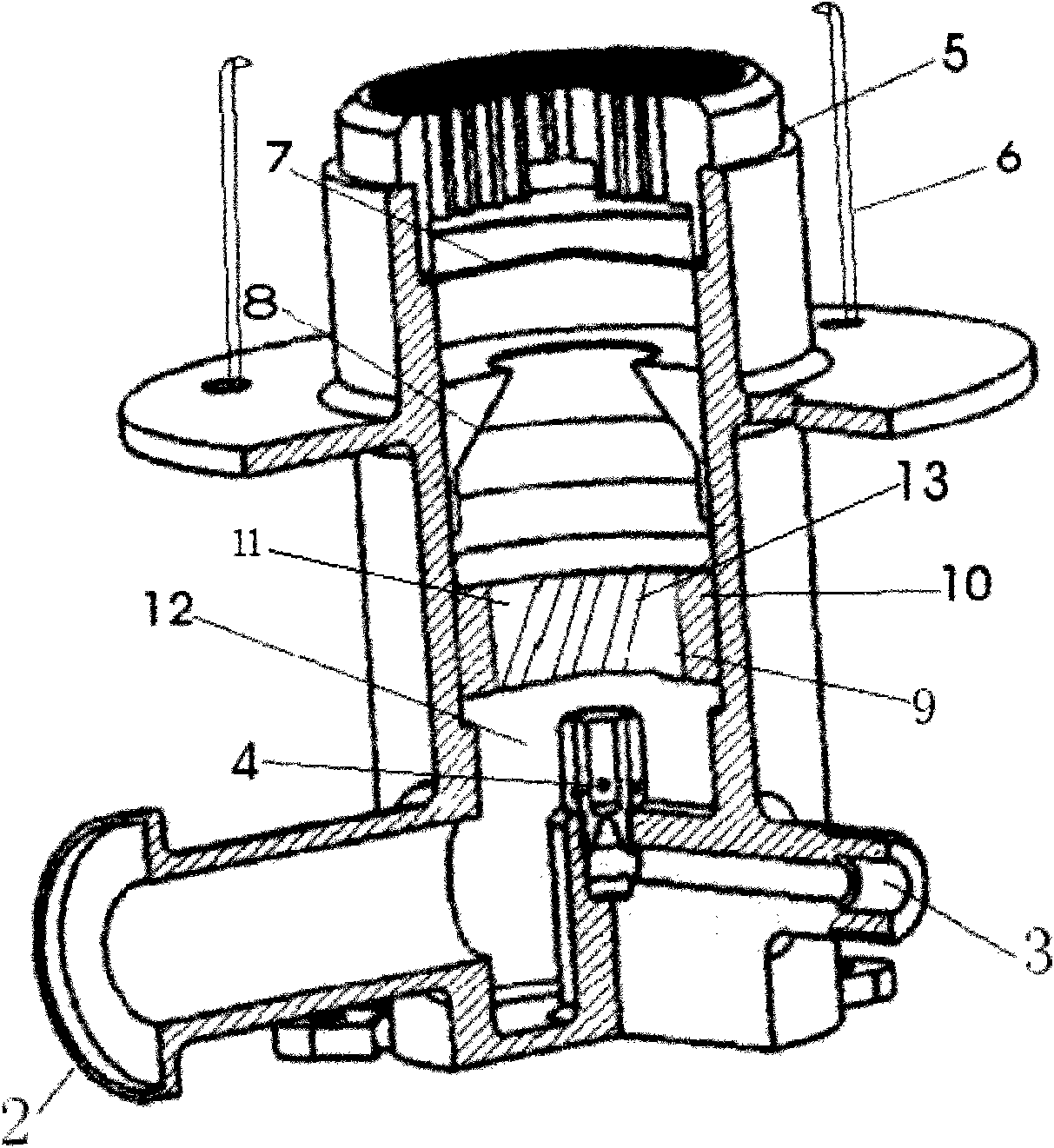

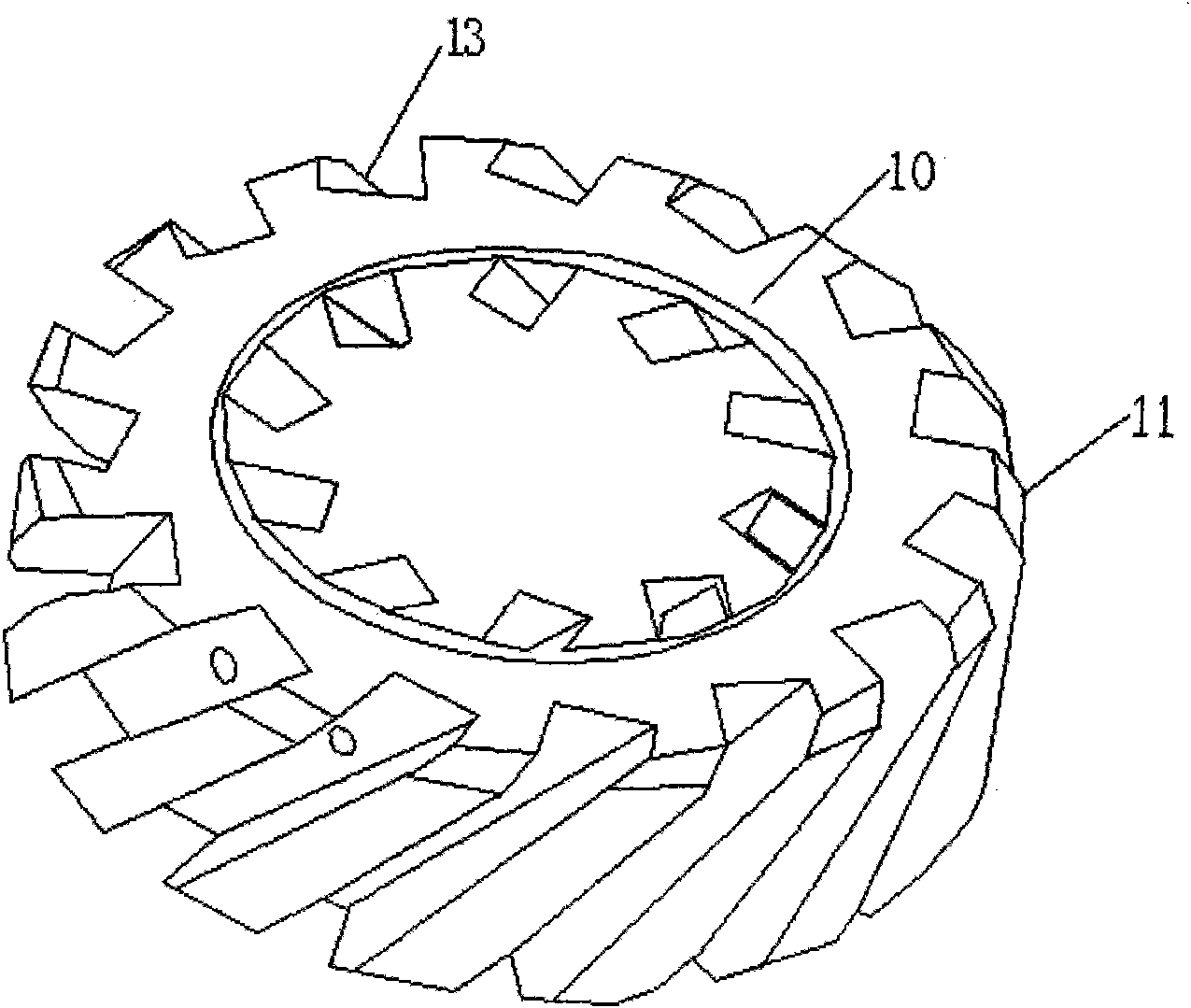

Rotary water-cooled spray-burning type biomass particle burner

ActiveCN102537939AEject evenlyPrevent backflowSolid fuel combustionBlast-producing apparatusThermal ignitionCombustor

The invention discloses a rotary water-cooled spray-burning type biomass particle burner, comprising a burning cylinder arranged horizontally and an air chamber which surrounds the periphery of the burning cylinder and is used for covering the air outlet of a blower; the external wall of the air chamber is provided with a flange for connecting a hearth; the internal side wall of the burning cylinder is fixedly provided with a spiral fin; the side wall of the burning cylinder is provided with an air hole for communicating the inside of the burning cylinder with the air chamber; the feeding inlet of the burning cylinder is provided with an electro-thermal ignition device and a axial directional air inlet for communicating the inside of the burning cylinder with the air chamber; one end of the feeding inlet of the burning cylinder is concentrically and fixedly sleeved with the discharging end of a material pipe; an auger in the material pipe is fixedly connected with the burning cylinder through a connecting piece; a concentric locating piece is connected between the air chamber and the burning cylinder; and a speed regulating motor is used for driving the auger and the burning cylinder to rotate. The burner is applicable to burning straw pellets; bonding slag obtained after burning can be automatically cleaned out of the burning cylinder; and the spray-burning port of the burning cylinder is provided with a water jacket, so that the slag-bonding can be prevented or lightened.

Owner:北京恩派苏阳清洁燃烧技术有限公司 +1

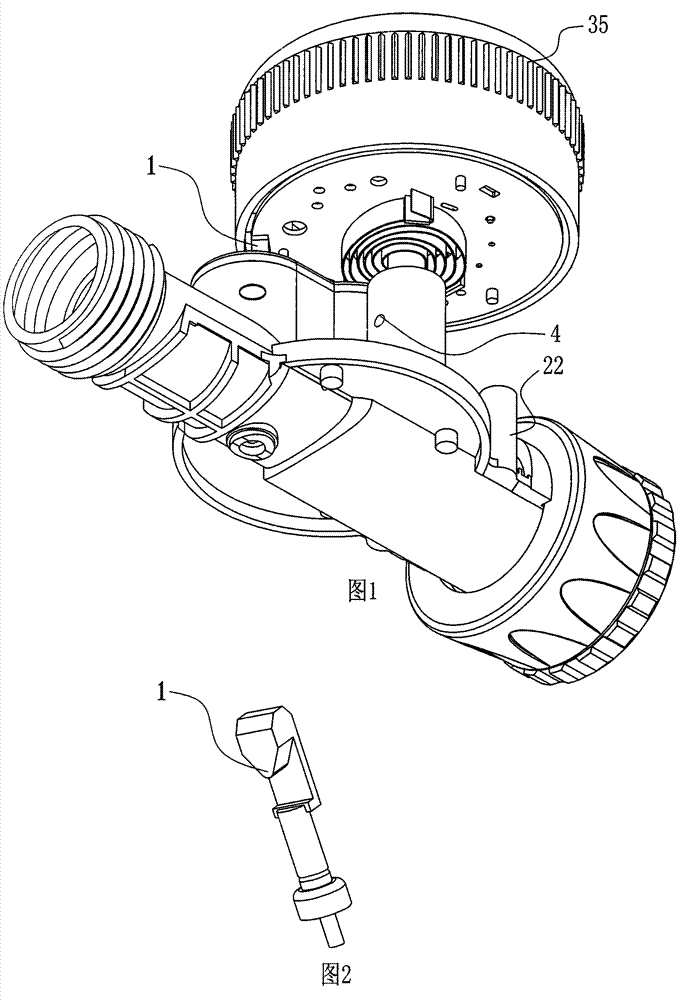

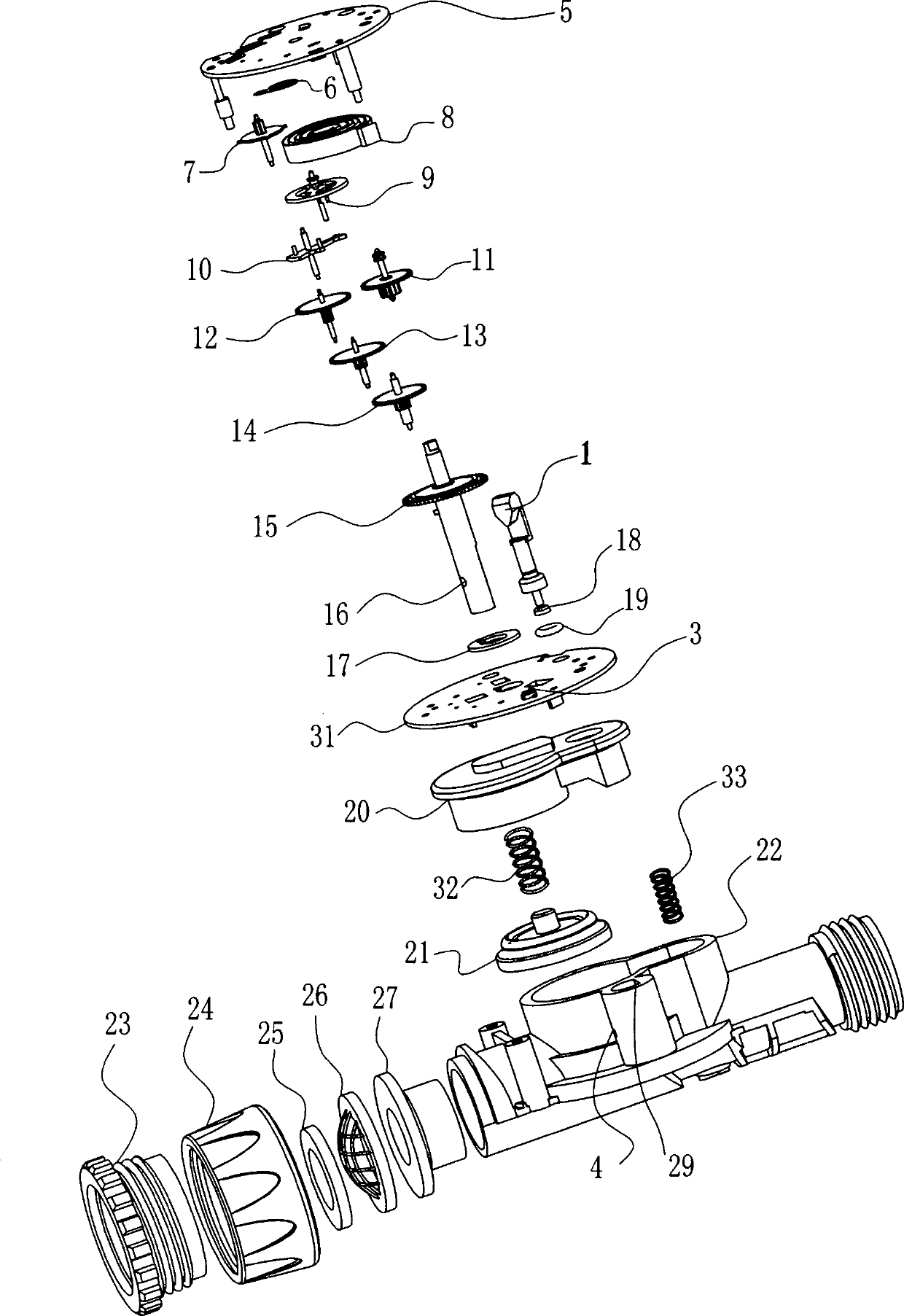

High-performance anti-dirt swing sprinkler and water saving method

ActiveCN104719096AEasy to irrigateWide applicabilityWatering devicesCultivating equipmentsIrrigationEngineering

The invention discloses a high-performance anti-dirt swing sprinkler and a water saving method. The high-performance anti-dirt swing sprinkler comprises a sprinkler body, an electromagnetic flow meter, a flow adjustable dripper, a 360-degree sprinkling head, an energy-saving type sprinkling irrigation timer and a water distribution device, wherein the energy-saving type sprinkling irrigation timer and the water distribution device are used in cooperation with each other to save water. Due to the facts that multiple swing sprinkling heads (59) are connected to a commutator of the high-performance anti-dirt swing sprinkler and each swing sprinkling head is provided with a swing sprinkling cap (591), an anti-dirt effect is achieved; the swing sprinkling caps (591) are arranged above horn-shaped outlets of the swing sprinkling heads (59), and the swing sprinkling caps are slightly of a flake shape; semicircular swing sprinkling cap balls (592) are arranged at the positions, corresponding to the portion above the horn-shaped outlets of the swing sprinkling heads (59), of the swing sprinkling caps; the swing sprinkling caps slightly of the flake shape are connected with swing sprinkling cap handles (593) fixed onto the swing sprinkling heads through flexible shakable filmy swing sprinkling cap grooves (594); the swing sprinkling cap grooves (594) play the role of movable hinges, when water is sprinkled, the water rushes through the swing sprinkling caps to open the swing sprinkling caps, and when no water exists, the swing sprinkling heads are covered with the swing sprinkling caps, so that the anti-dirt effect is facilitated.

Owner:NINGBO DAYE GARDEN IND

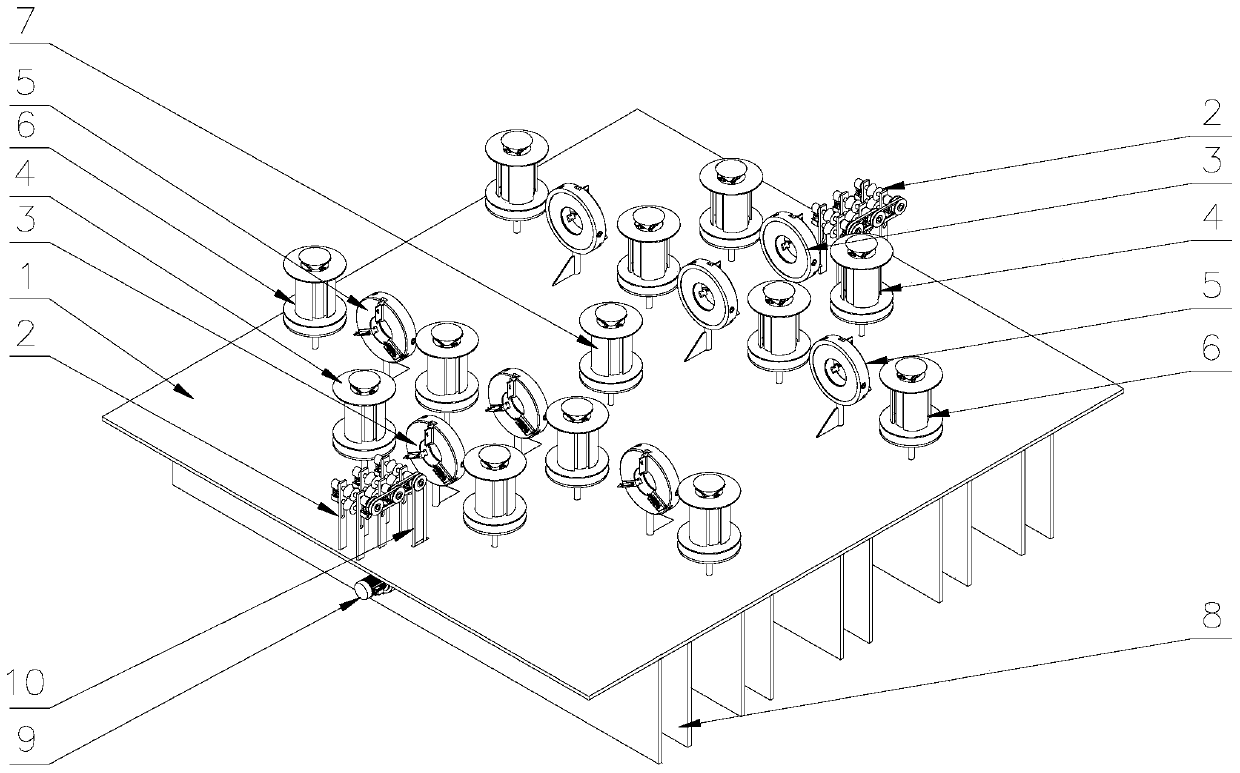

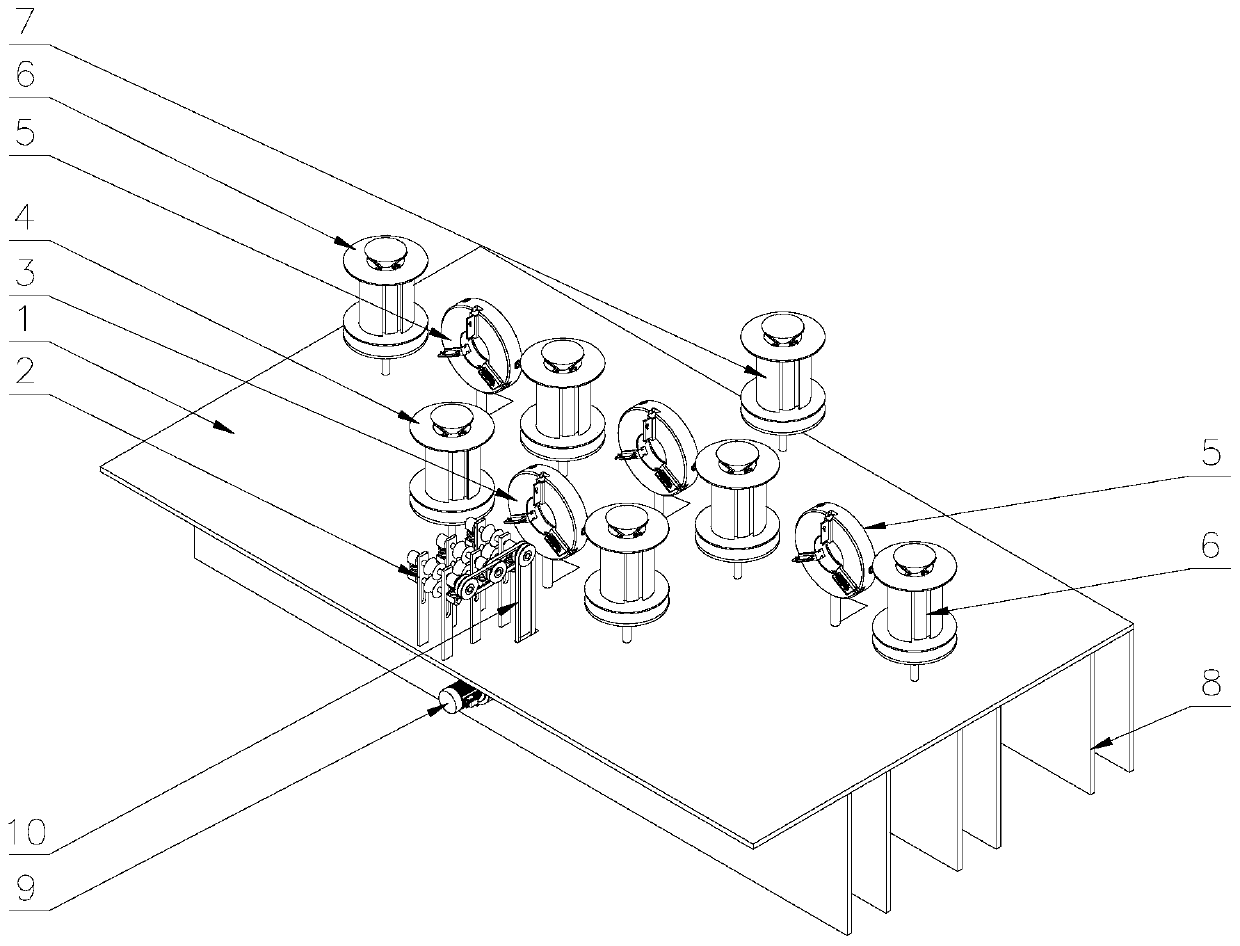

Power cable recycling device

ActiveCN110212462AImprove recycling efficiencyReduce labor intensityBasic electric elementsMechanical energy handlingPower cableElectric power

The invention discloses a power cable recycling device. A plurality of separator plates are arranged under a platform. A plurality of conveyer devices are arranged on the platform. A cable is installed between a first pulley and a second pulley. A first power device is arranged under each conveyer device. One side of each conveyer device is provided with a first cutter disc. The first cutter discis provided with a plurality of cutter bases. The two sides of the first cutter disc are respectively provided with a first reel. A third rotation shaft is arranged under a tray. A driving mechanism is arranged under the third rotation shaft. One side of the driving mechanism is provided with a second power device. One side of the first cutter disc is provided with a third reel. The third reel isarranged in the middle of the plurality of cable recycling devices. The driving mechanism is connected with the second power device. Multiple cable recycling devices are arranged on the platform, thereby avoiding manual cable recycling, reducing labor intensity of workers, and improving cable recycling efficiency; and each cable recycling device recycles one bundle of cables, thereby further improving cable recycling efficiency.

Owner:DONGMING POWER SUPPLY CO STATE GRID SHANDONG ELECTRIC POWER CO +1

Blast-injecting forced-advancing full pre-mixing energy-saving combustor

The invention provides a blast-injecting forced-advancing full pre-mixing energy-saving combustor which comprises a main cavity, a blast pipe, a fuel gas pipe, a nozzle, a fire distributor and a firing needle, wherein the blast pipe and the fuel gas pipe are connected with the main cavity; the nozzle is connected with the fuel gas pipe; and the fire distributor and the firing needle are arranged at the top of the main cavity. The blast-injecting forced-advancing full pre-mixing energy-saving combustor is characterized in that a screen, a flow fixer and a gas flow mixer are sequentially arranged between the fire distributor and the nozzle in the main cavity; the caliber of the gas outlet end of the flow fixer is smaller than the caliber of a gas inlet end of the flow fixer; the flow mixer is a cylinder of which the diameter corresponds to the internal diameter of the main cavity; and a plurality of gas mixing holes are arranged vertically along the cylinder and the calibers of all gas outlet ends of the gas mixing holes are smaller than the calibers of all gas inlet ends of the gas mixing holes. By adopting the structure, the effects of the high efficiency, the energy conservation and the environment protection are achieved.

Owner:何梅顺

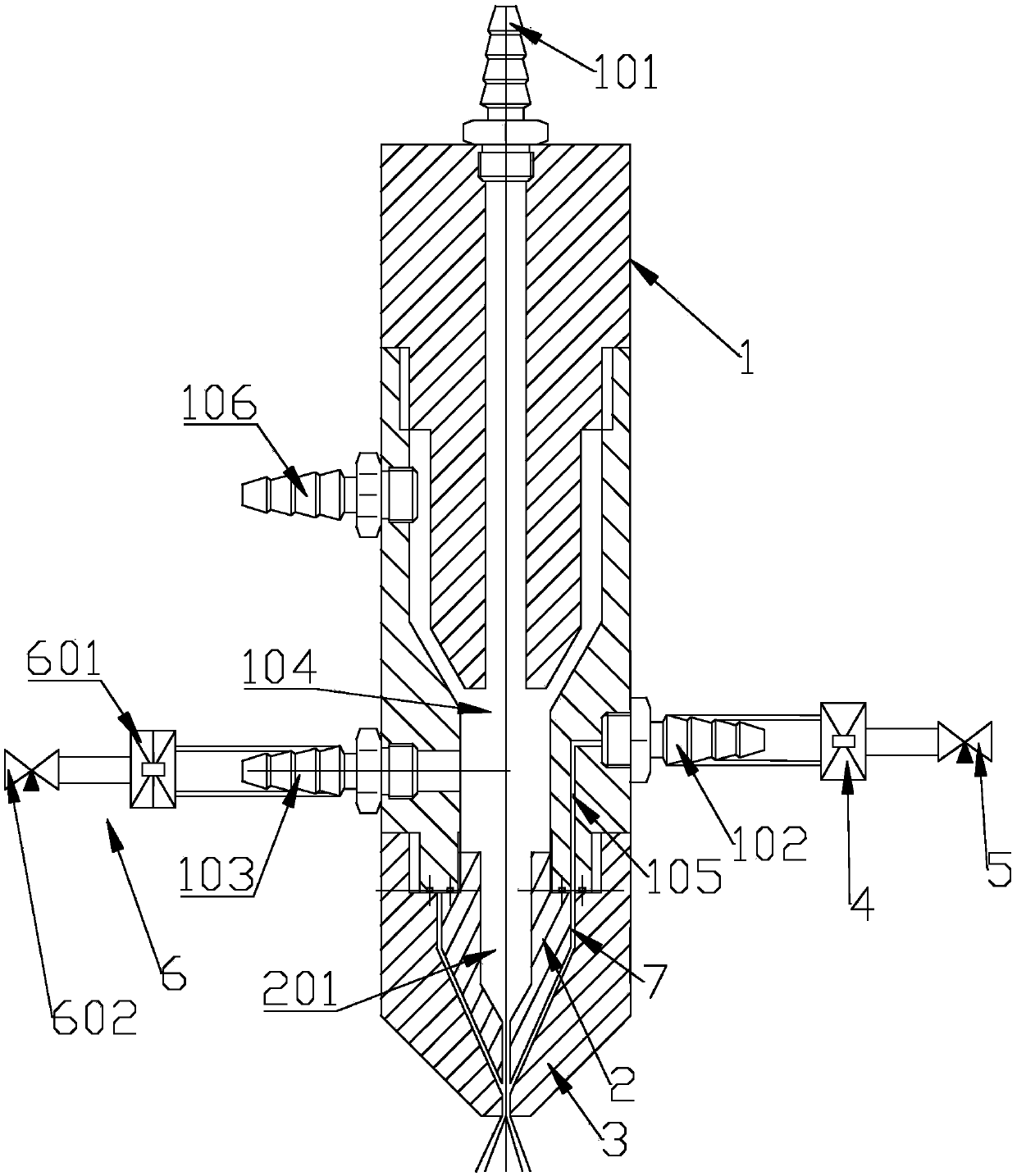

Novel liquid spot-spray torch and spot-spray method thereof

ActiveCN105499003AHigh control precisionFast dynamic responseLiquid spraying apparatusSpray nozzleEngineering

The invention discloses a novel liquid spot-spray torch and a spot-spray method thereof, comprising a torch body, an air guide cone and a nozzle. The torch body is provided with a liquid inlet, an air inlet and a negative pressure port, the torch body is internally provided with a first liquid storage cavity and a first air cavity, the liquid inlet is communicated with the first liquid storage cavity, one end of the air inlet is communicated with the first air cavity, the other end of the air inlet is connected with a piezoceramic direct-drive valve which is connected with a first pressure adjusting valve, the negative pressure port is close to a liquid incoming end of the torch body, one end of the negative pressure port is communicated with the first liquid storage cavity, the other end of the negative pressure port is connected with a negative pressure generator, the air guide cone is connected with a liquid outgoing end of the torch body, the air guide cone is internally provided with a second liquid storage cavity which is communicated with the first liquid storage cavity, the nozzle sleeves the liquid outgoing end of the torch body, and the inner wall of the nozzle and the outer wall of the air guide cone form a second air cavity which is communicated with the first air cavity. The novel liquid spot-spray torch and the spot-spray method thereof have the advantages that the spraying requirements for high frequency and high precision can be met, high-speed spot spraying can be implemented, and production efficiency can be improved.

Owner:广州高印力信息技术有限公司

Gun type continuous clip ejecting apparatus

Disclosed is a gun type continuous clip ejecting apparatus. The gun type continuous clip ejecting apparatus includes a body including bodies symmetrically combined by each other with a curved shape and a clip guide groove therein; a cover inserted into the upper front end of the body; a slider installed slidably along a guide groove formed within the body; a clip loading push rod in which protrusions are formed at an end thereof and hooked to the hook of the slider, a hook is protruded upwardly at the other end thereof and protrusions are protruded at sides thereof; a tension spring in which an end thereof is hooked to the hook of the clip loading push rod and the other end thereof is pulled upwardly and fixed to the upper inside surface of the slider; a discharge push rod; a tension spring; and a trigger rotatably fixed to a bottom side of the body by a hinge shaft and including upper hooking protrusions contacted with a bottom end between both sides of the discharge push rod.

Owner:LEE YONG WOO

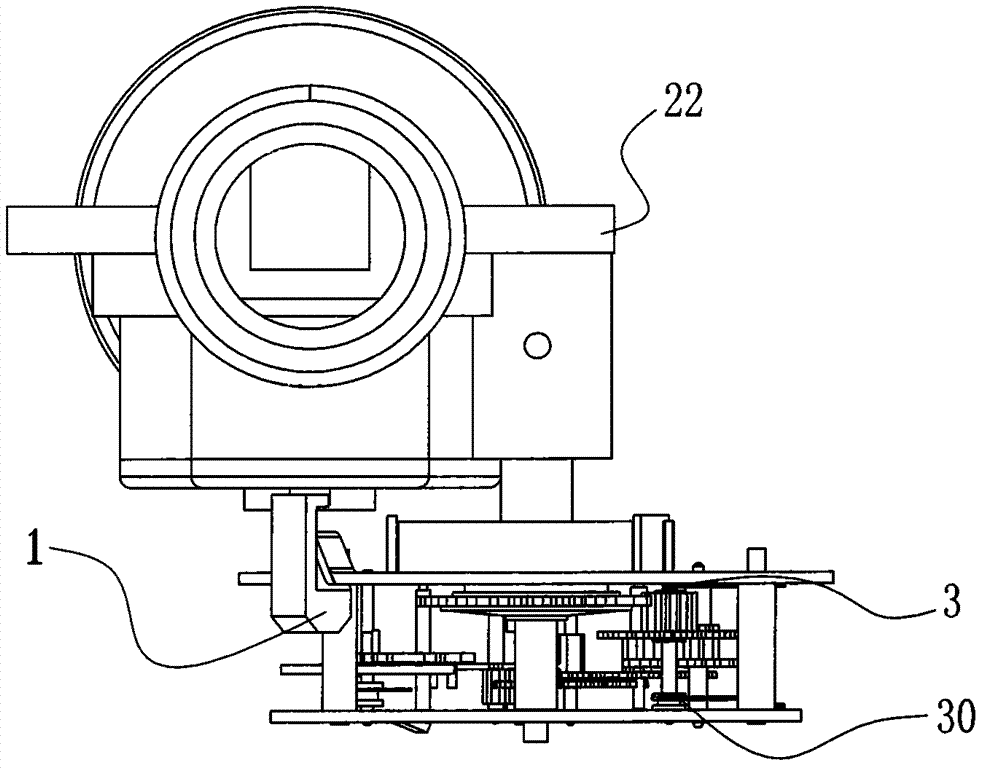

Inclined guide pillar slide block type secondary demolding mechanism of injection mold

The invention relates to an inclined guide pillar slide block type secondary demolding mechanism of an injection mold. The secondary demolding mechanism mainly comprises a mold cavity and a core insert, wherein a core plate is mounted outside the core insert; a stripper plate is arranged on the core plate; a molded product is formed among the mold cavity, the core insert and the stripper plate; convex ribs are arranged at the bottom surface of the product; the stripper plate matches the convex ribs of the product; the core insert and the core plate are mounted on a core fixing plate; a mold feet are mounted below the core fixing plate; lower templates are mounted below the mold foot; an upper ejector plate and a lower ejector plate are arranged between the mold feet; the upper ejector plate is connected with an ejecting pillar, which is connected with the stripper plate after penetrating through the core fixing plate and the core plate; the demolding mechanism is characterized in that an I-shaped groove is formed in the upper ejector plate, a slide block is arranged in the I-shaped groove, the head part of the slide block is made as an inclined surface, an inclined guide rod is connected below the core fixing plate and penetrates through the slide block, an ejector rod is mounted in the core insert, the head part of the ejector rod is in contact with the bottom surface of the product, and an arc surface is made at the bottom of the ejector rod, and the arc surface matches with the inclined surface of the slide block.

Owner:ZHEJIANG KAIHUA MOLDS

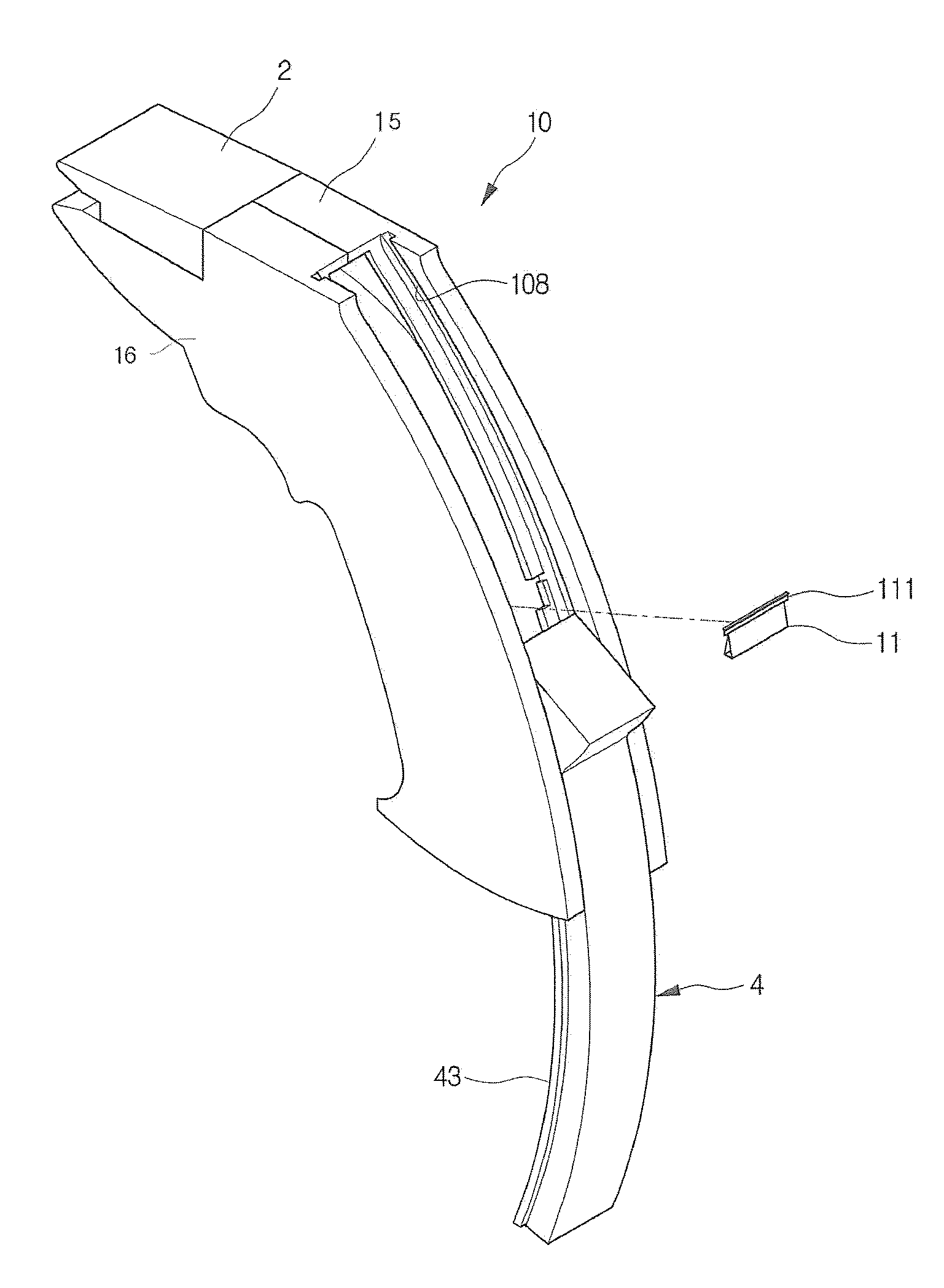

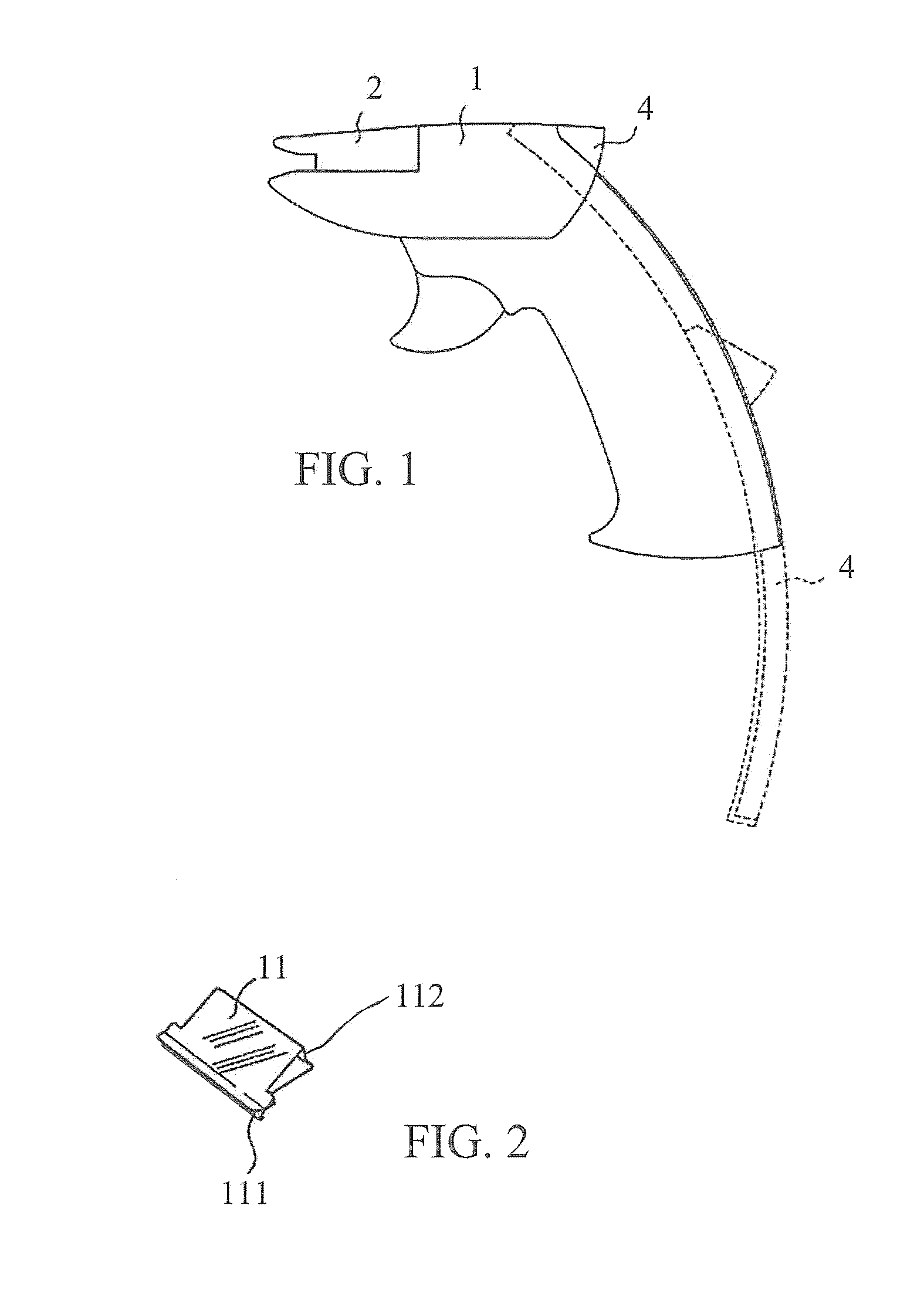

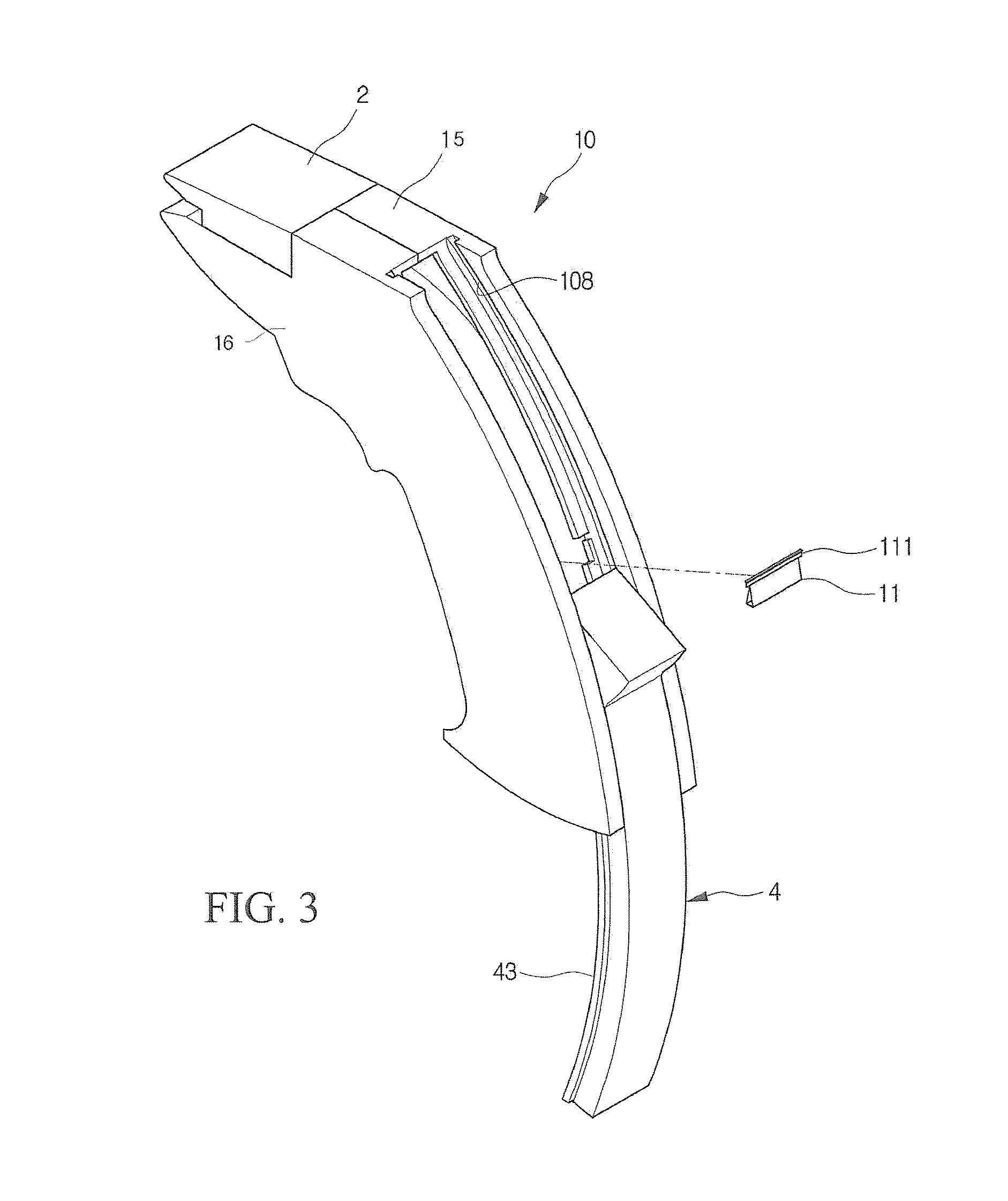

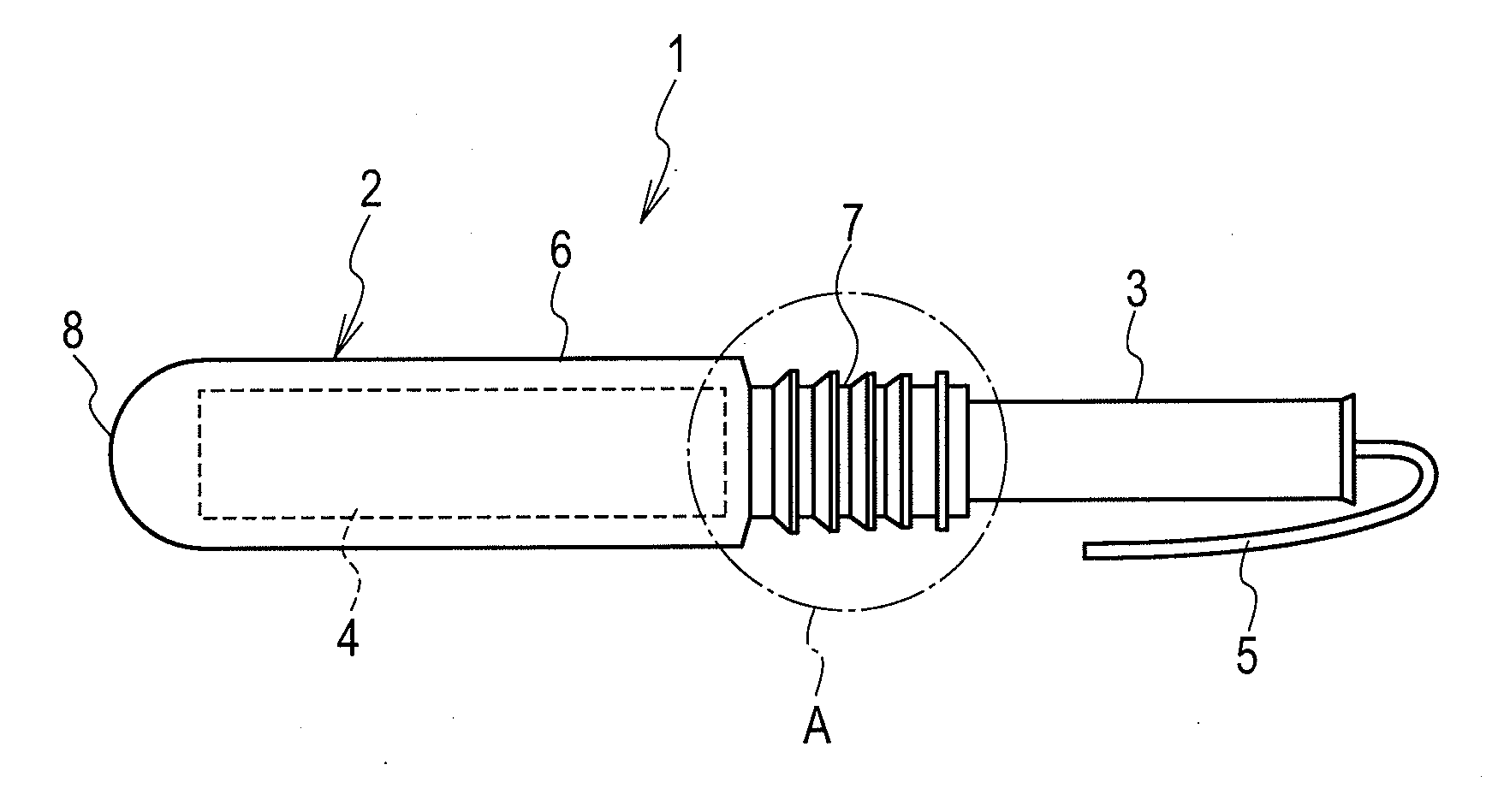

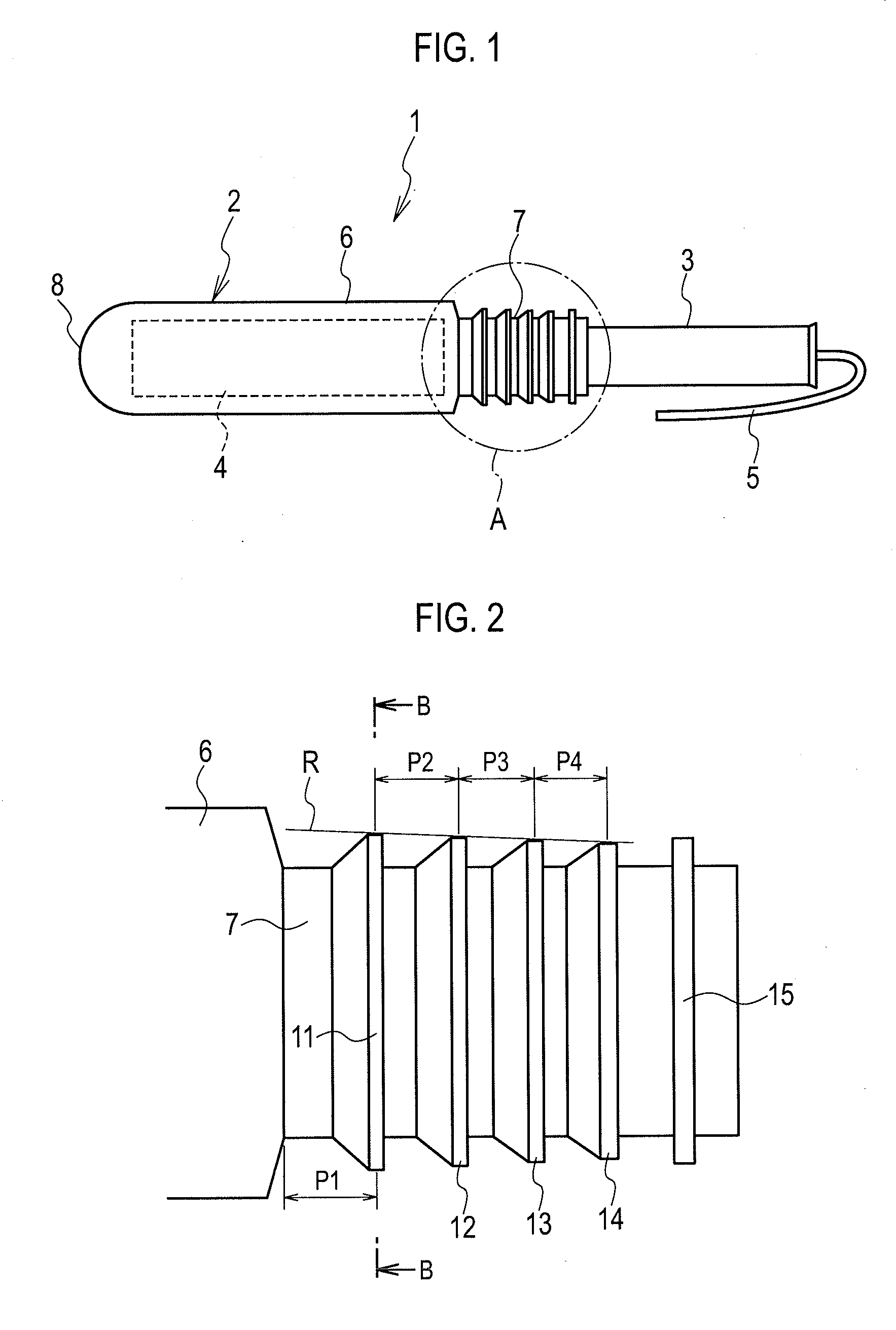

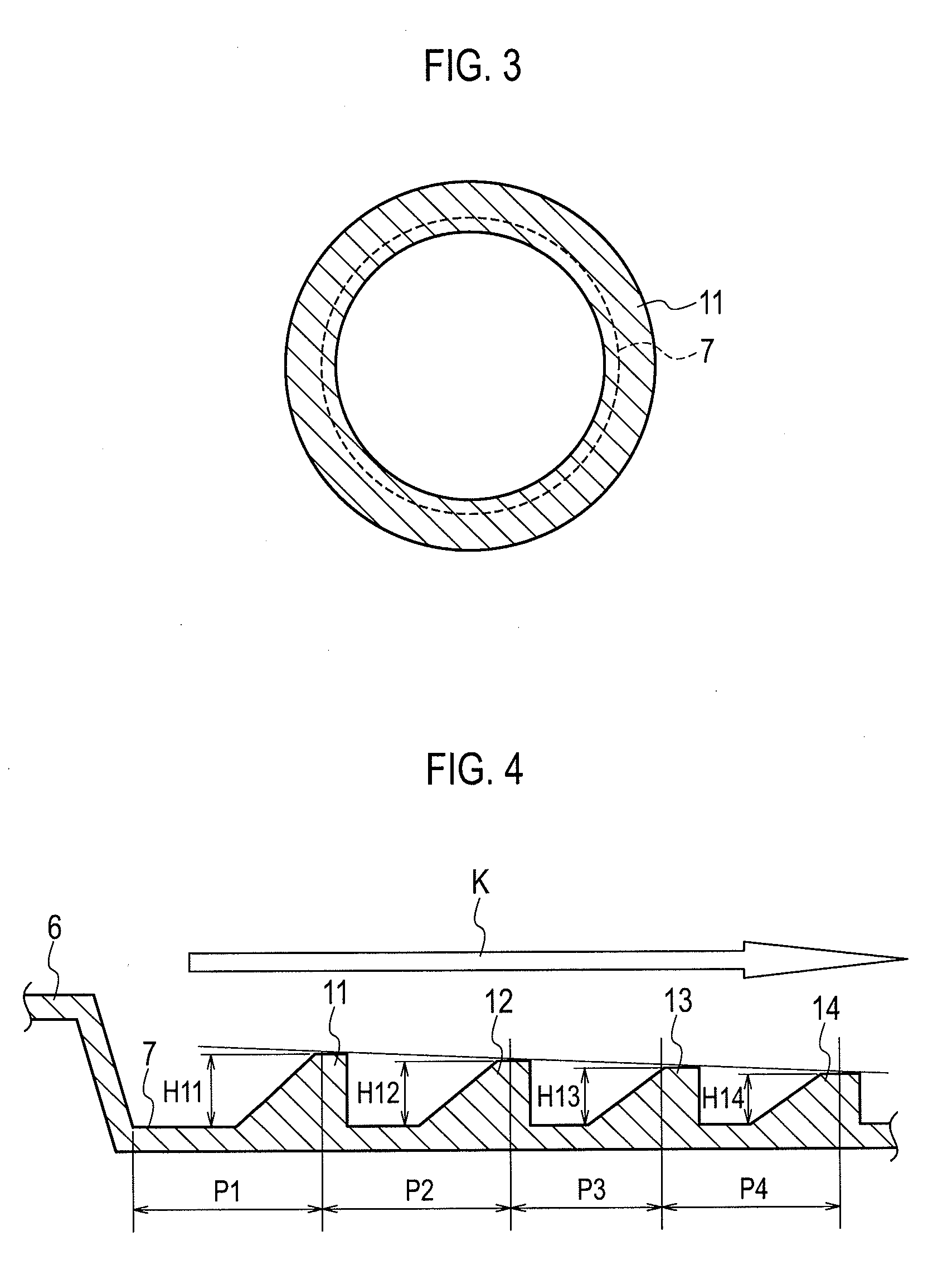

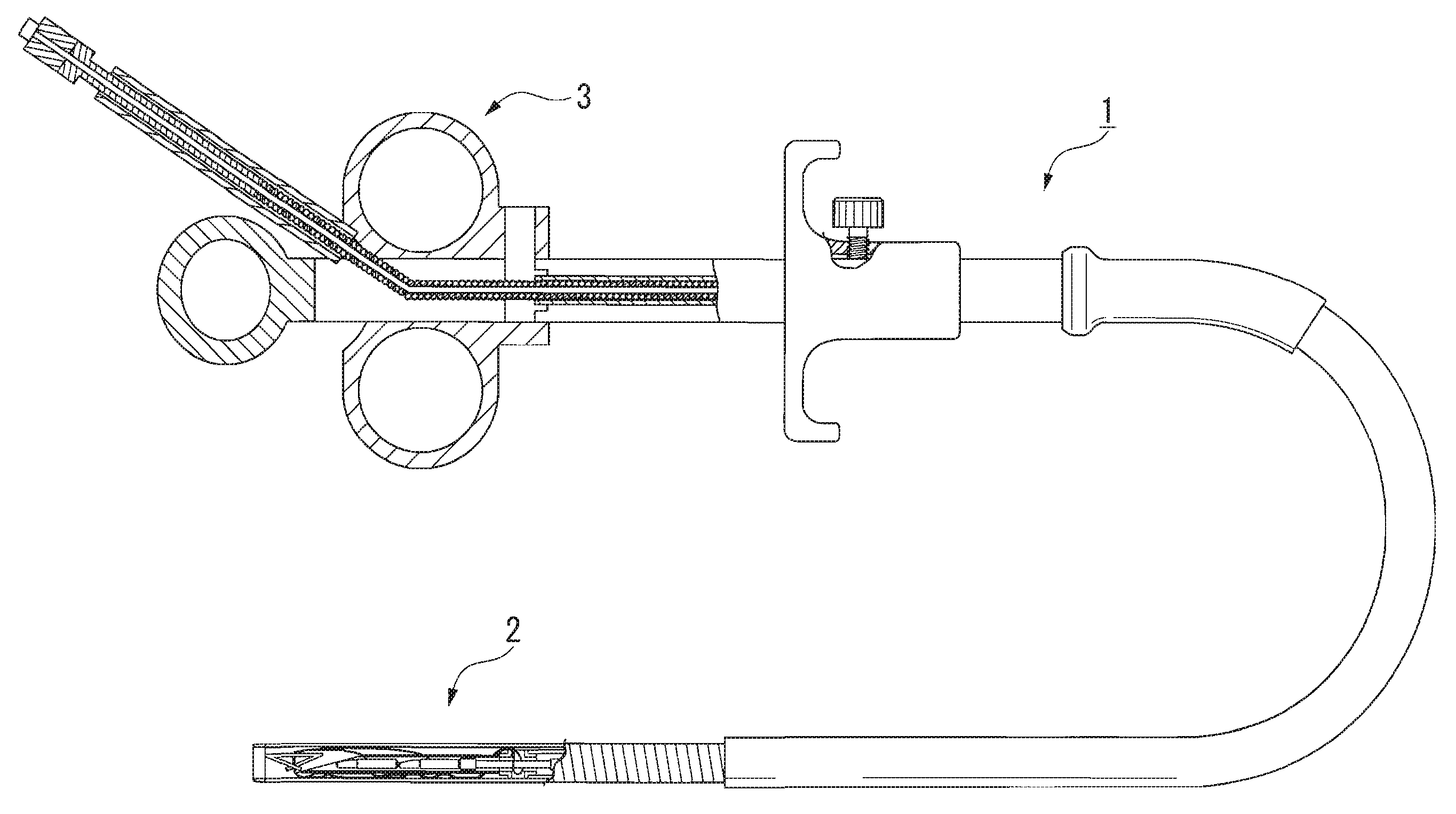

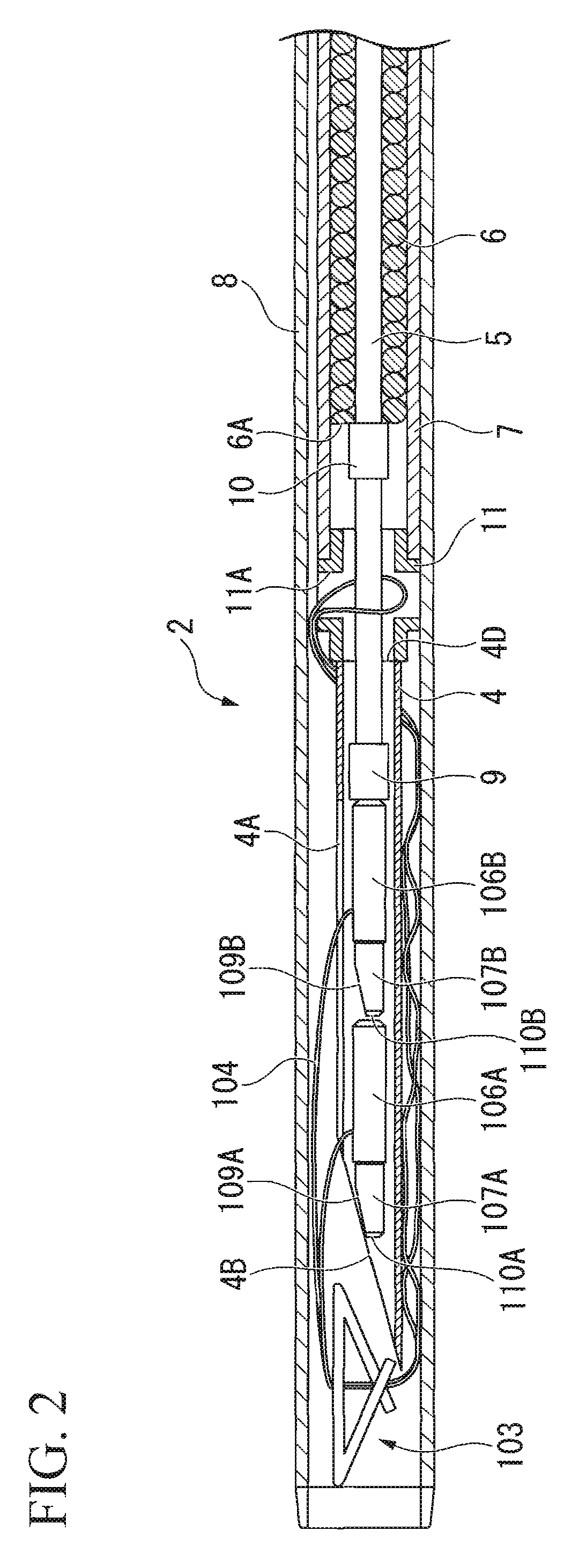

Applicator for tampon

InactiveUS20110144561A1Suppression problemNone has been successful as solutionTamponsBandagesEngineeringTampon

An applicator for a tampon comprises an outer cylinder (2) containing an absorber (4) therein and provided with a petal-like components (8) for pushing out the absorber (4) on one side thereof and with a grip cylinder (7) on the other side thereof, and an inner tube (3) which is inserted into the grip cylinder (7) and can push out the absorber (4) to the outside from the petal-like components (8) by moving into the outer cylinder (2). A plurality of rows of annular protrusions (11, 12, 13, 14) are formed in the whole area of the grip cylinder (7) in the circumferential direction, such that the height from the outer circumferential surface of the grip cylinder (7) decreases gradually toward the side of the inner tube (3) being inserted into the grip cylinder (7).

Owner:UNI CHARM CORP

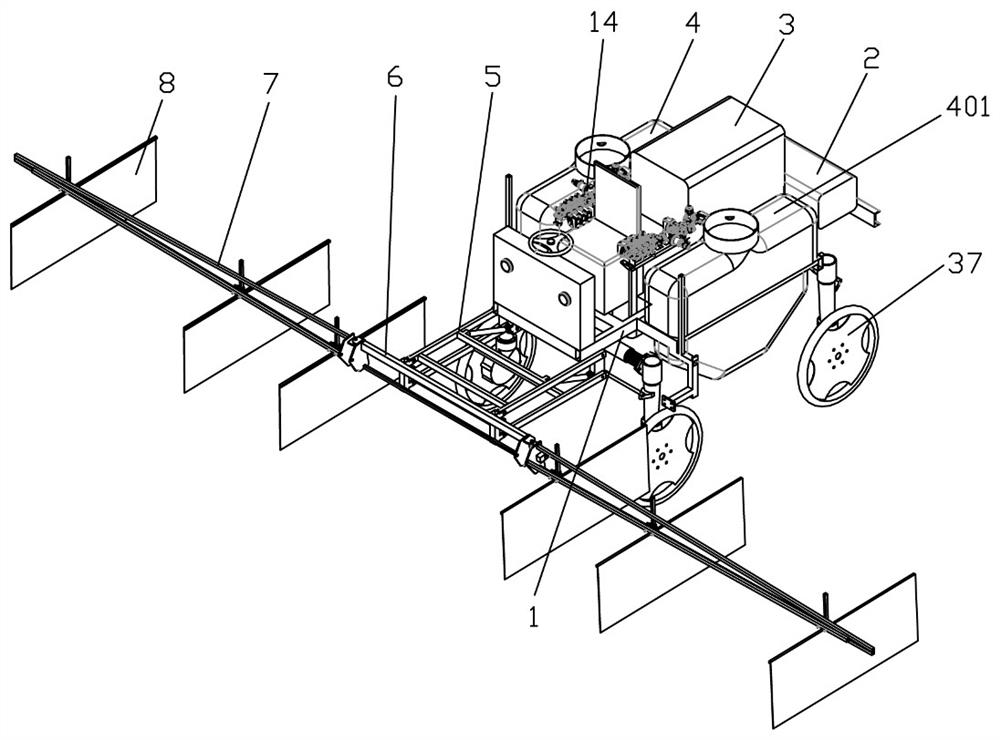

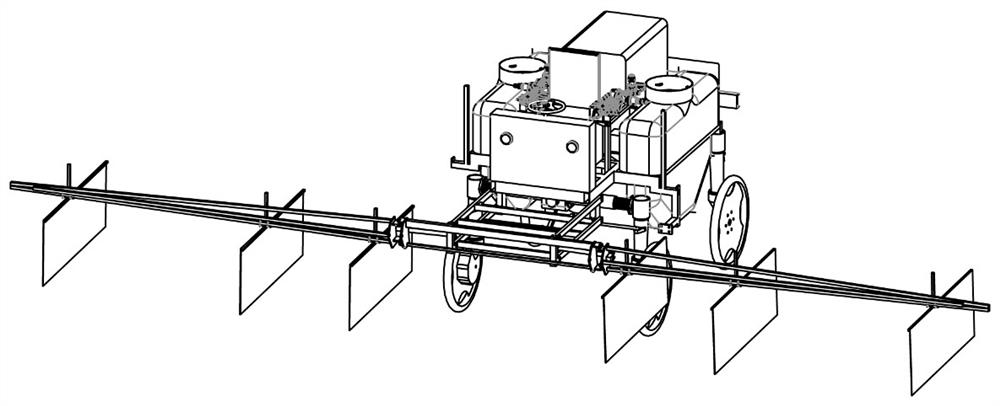

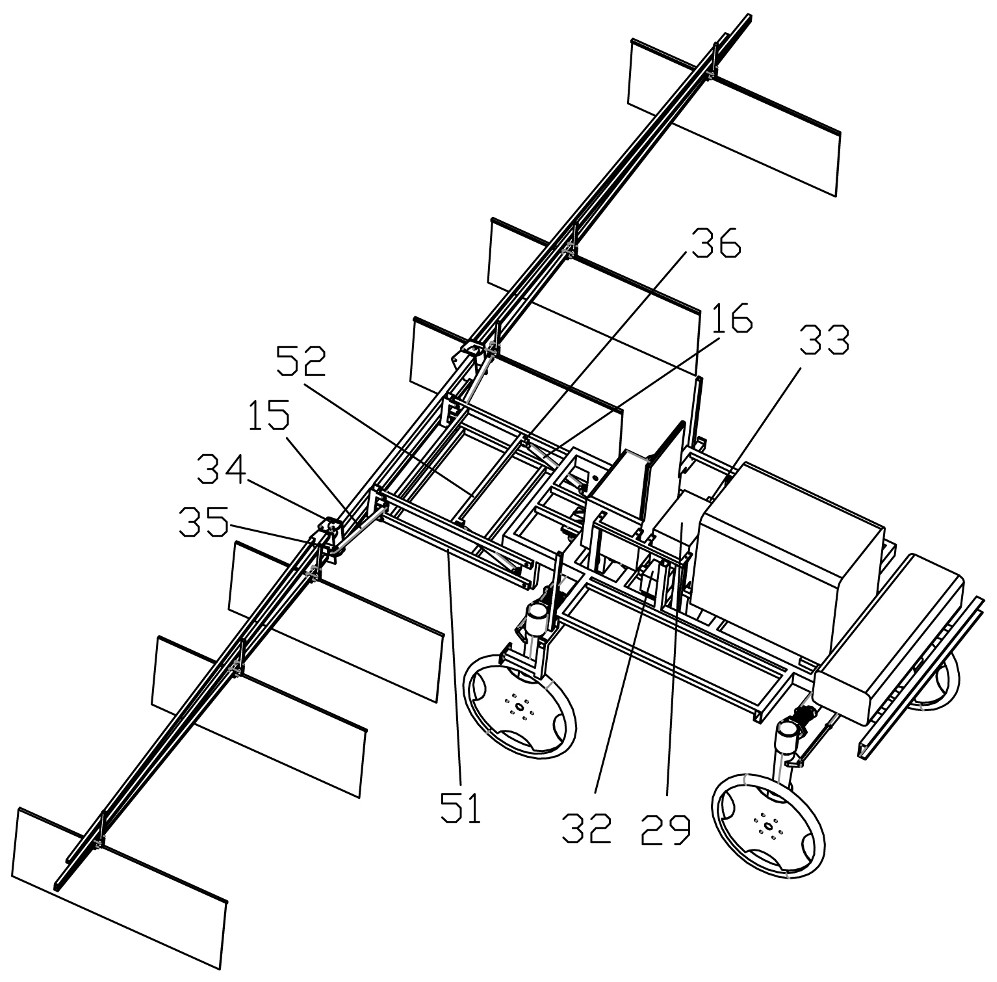

Strip-shaped composite planting high-ground-clearance zoning boom sprayer

PendingCN112753677AEasy to operateFlexible applicationInsect catchers and killersPesticideAgricultural engineering

The invention relates to the technical field of agricultural mechanical equipment, in particular to a strip-shaped composite planting high-ground-clearance zoning boom sprayer. The sprayer comprises a rack, a parallel four-bar mechanism, a hydraulic lifting steering mechanism, a boom mechanism and an anti-interference mechanism are arranged at the front end of the rack, and a wheel track adjusting mechanism and a hydraulic steering mechanism are arranged below the rack. A variable spraying mechanism is arranged on the rack, operation is convenient, under the action of the anti-interference mechanism, when sprayers spray pesticide, an anti-interference plate can partition the sprayers, sprayed pesticide is prevented from interfering with one another, pesticide damage caused by mutual interference of different kinds of pesticide is avoided, the variable spraying mechanism can adjust the spraying pressure and the spraying flow according to the vehicle speed under the action of a speed sensor, the spraying distribution uniformity is improved, and spraying is uniform.

Owner:HENAN AGRICULTURAL UNIVERSITY +1

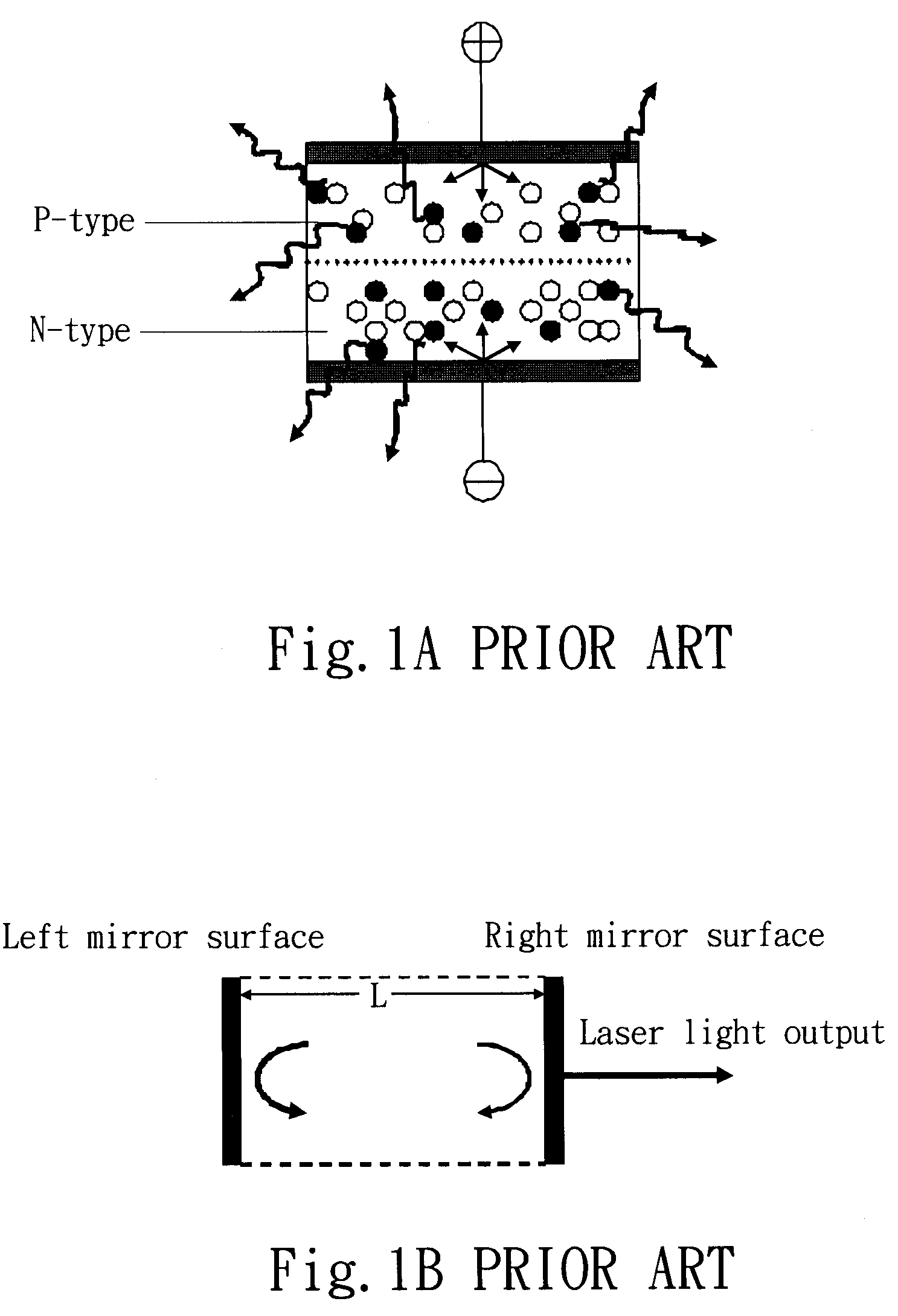

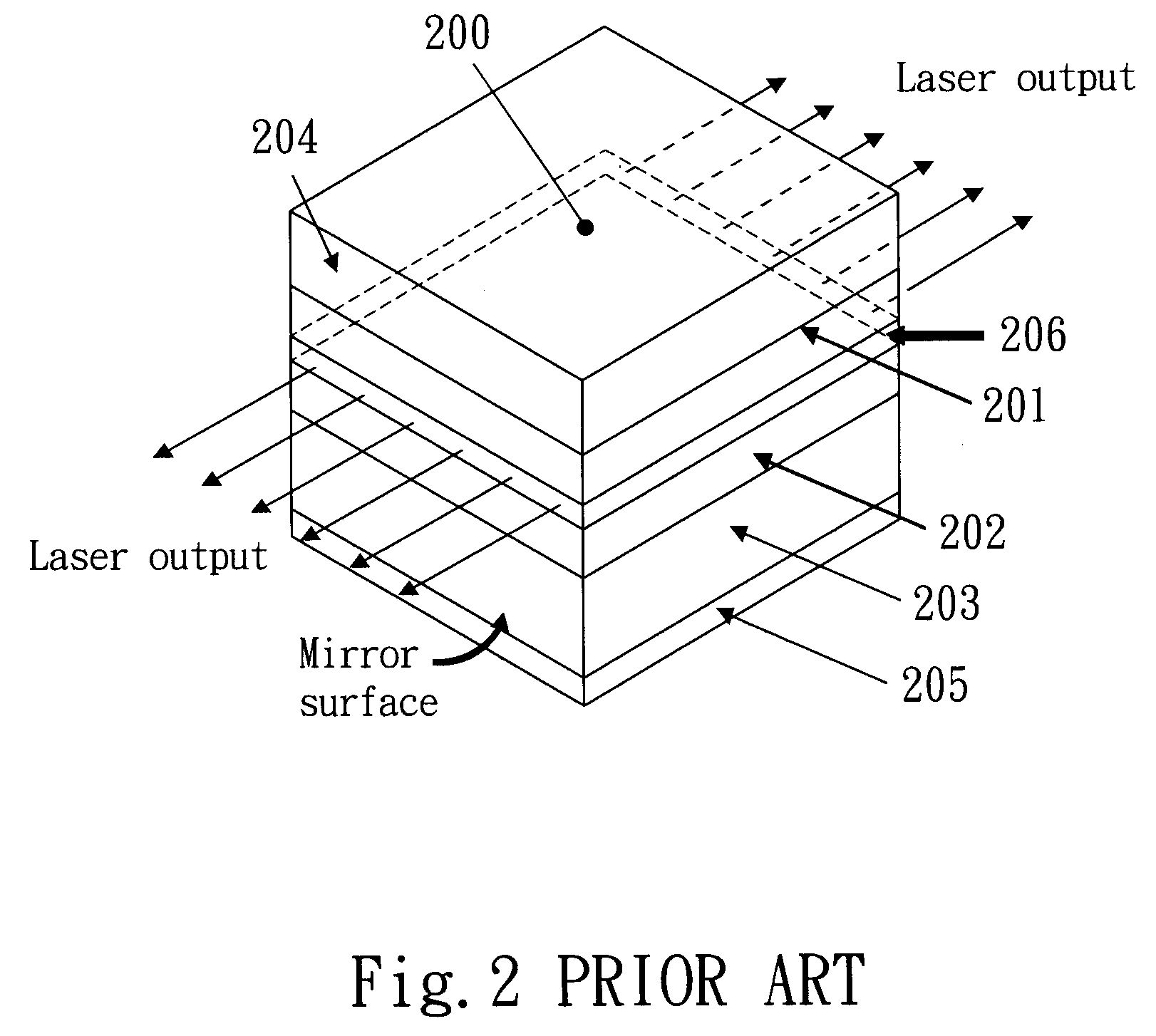

Lighting Device Equipped with Coaxial Line Laser Diodes and Fabrication Method Thereof

ActiveUS20090135877A1Low costImprove efficiencyLaser detailsLaser optical resonator constructionEffect lightCoaxial line

The present invention provides a fabrication method of coaxial line laser diodes and a coaxial lighting optical fiber which disperses and guides uniform emission of light from a coaxial line laser diode. The line coaxial laser diode can be extended at a greater length to generate more spontaneous emission photons which are emitted from an elongated tubular active layer. The active layer has a uniform built-in electric field to distribute uniform current therein to get higher quantum efficiency. The length of the coaxial laser diode can be increased through a VLSED method. A longer laser ingot can be produced and cut to a large number of coaxial laser diodes. This method can reduce the waste of cutting in the wafer process and get larger lighting areas. Both the coaxial line laser diode and the coaxial lighting optical fiber can be coupled to form a high efficiency white-emitting luminescence device.

Owner:YANG CHUN CHU

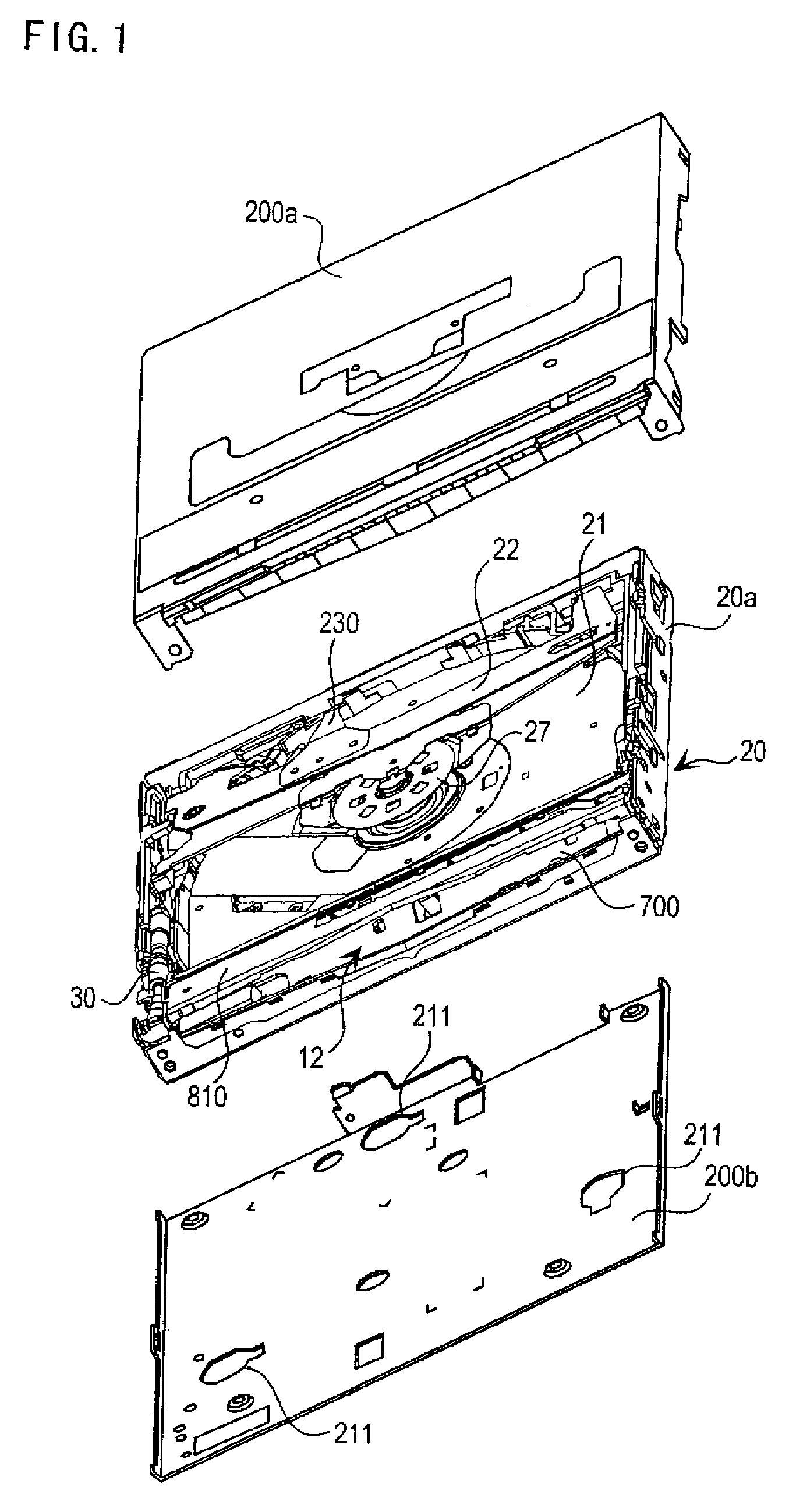

Slot-in disk drive device and method

InactiveUS20080052733A1Guaranteed uptimeImprove reliabilityRecord information storageDisposition/mounting of headsElectrical and Electronics engineeringLinkage concept

Owner:QUANTA STORAGE INC

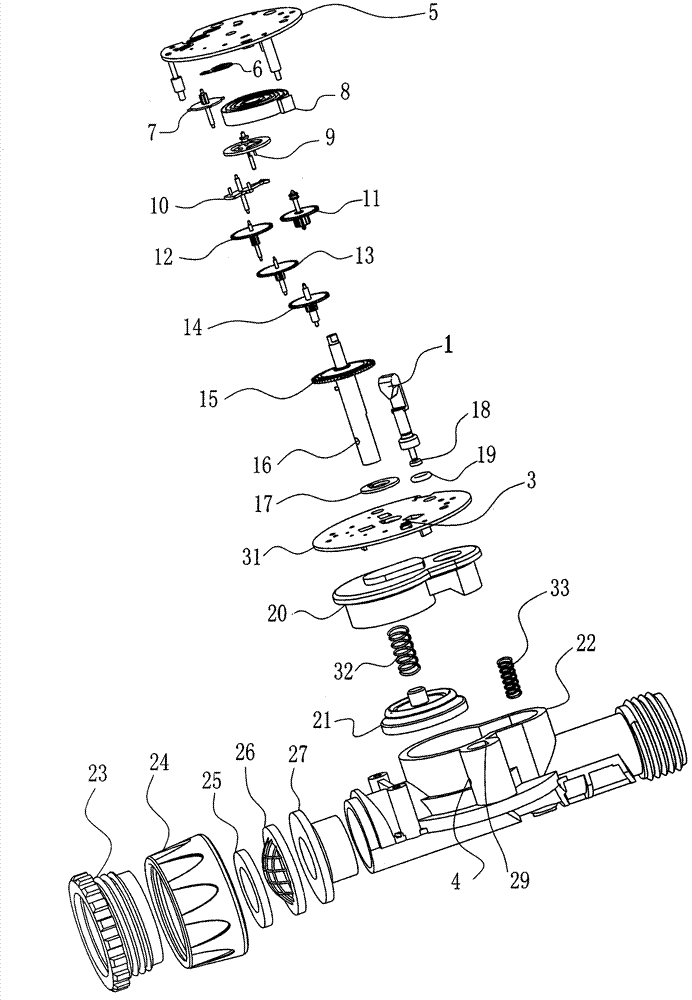

Water saving method adopting electronic control and novel 360-degree spraying head

ActiveCN104160921AEasy to irrigateWide applicabilityWatering devicesSpray nozzlesWater savingWater channel

The invention discloses a water saving method adopting electronic control and a novel 360-degree spraying head. According to the water saving method, through cooperation of the novel 360-degree spraying head, a soil moisture content measurement and control device, a connector with the size of a thread ring and the screw pitch capable of being finely adjusted, an energy-saving type spray irrigation timer with a multifunctional port and a water distributor, efficient irrigation energy conservation and water conversation of gardens are convenient. The novel 360-degree spraying head is characterized by comprising a spraying head ball preventing the tip portion of a cone body of the novel 360-degree spraying head from easily deflecting and moving, and a top concave bowl with the tip portion removed is arranged in the center of the inner top portion of the cone body of the novel 360-degree spraying head, so that sprayed water is adjusted automatically and does not deflect. The novel 360-degree spraying head is further characterized in that the product quality is improved by adopting the function curve. A cubic curve with the buffering curve effect between a straight channel and an arc water channel is adopted in the inner wall, with a plurality of through holes, of the side portion of a spraying head cap and buffers the impact phenomenon of water flow in the turning process. Protruding ribs are arranged between every two through holes and are shaped like equiangular spirals, namely, logarithmic spirals, and therefore the pressure angles are equal, and the water can be sprayed out uniformly.

Owner:NINGBO DAYE GARDEN IND

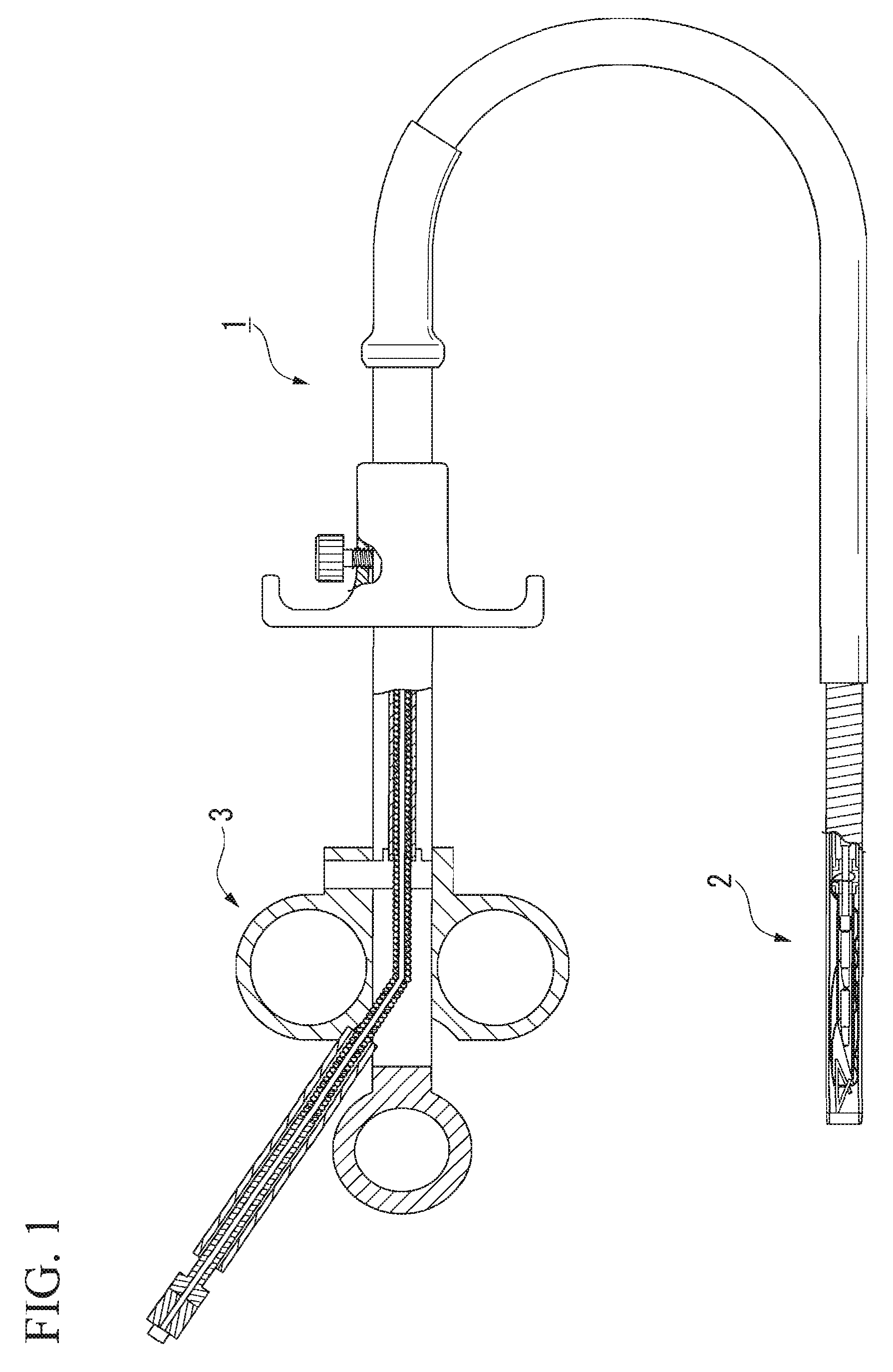

Suture device

A suture device which sutures tissue using a suture unit having a first anchor and a second anchor respectively attached to both ends of a suture thread, wherein a hollow distal member is provided which houses said first anchor and second anchor, the end face of the distal side of said distal member is formed so as to constitute a first sharp angle with the axis of said distal member, the distal side of said second anchor is provided with a sloped face so as to constitute a second sharp angle with the axis of said second anchor which is an angle at or below said first sharp angle, and said first anchor and said second anchor are axially aligned and housed inside said distal member so that said second anchor is positioned on the proximal side.

Owner:OLYMPUS MEDICAL SYST CORP

Stamping die for automobile metal part machining

InactiveCN106270210AEject evenlyAvoid stickingShaping toolsStripping-off devicesEngineeringMachining process

The invention discloses a stamping die for automobile metal part machining. The stamping die comprises stripper bolts, springs, a stripper plate and rubber pads, wherein an inner cavity of an upper die seat is connected with a grib head of a press; the bottom of the upper die seat is connected with an upper padding plate; the bottom of the upper padding plate is connected with a male die fixing plate; the stripper bolts are arranged in an inner cavity of the male die fixing plate, and the bottoms of the stripper bolts are connected with the stripper plate; guide sleeves are fixedly mounted at the bottom of the upper die seat, and the bottoms of the guide sleeves are connected with guide columns; the bottoms of the guide columns are fixedly connected with a lower die seat; a female die is arranged at the top of a lower padding plate; the lower padding plate is fixedly mounted at the top of a lower die seat. The stamping die for the automobile metal part machining can effectively relieve the generation of noise in production and machining processes, so that the noise pollution is reduced; by the arrangement of the automatic stripper plate, a workpiece is ejected under the elasticity of the springs, so that the workpiece is prevented from being connected to the die in a sticking manner; a material is steadily discharged, and the production efficiency is favorably improved.

Owner:十堰派生工贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com