Patents

Literature

62 results about "Blastpipe" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

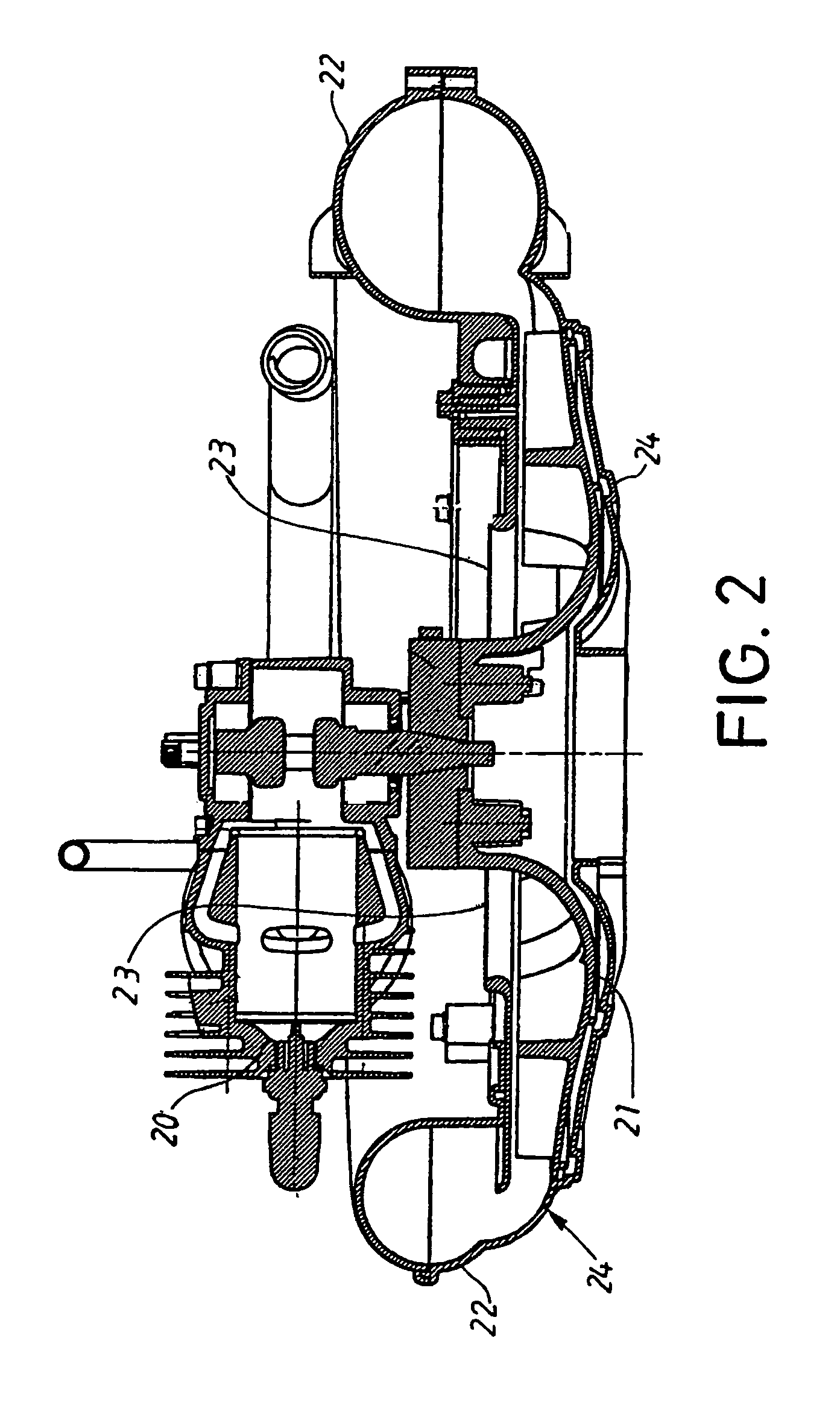

The blastpipe is part of the exhaust system of a steam locomotive that discharges exhaust steam from the cylinders into the smokebox beneath the chimney in order to increase the draught through the fire.

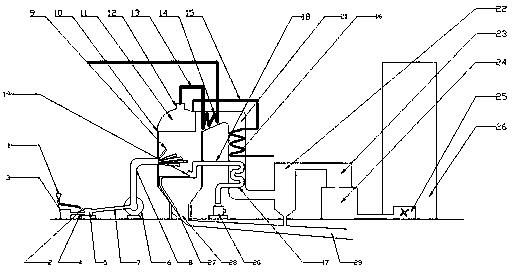

Pulverized coal burner

InactiveCN101576255AHas a burning effectUniform burning effectPulverulent fuel combustion burnersFuel tankEngineering

The invention relates to a pulverized coal burner which is characterized by comprising an air box, a powder feeding pipe, an ignition device and a blast pipe; a cylindrical fixed baffle plate with a conical cross section is axially arranged in the air box, an annular gap is left between one end of the fixed baffle plate and the air box, and a plurality of swirl vanes are circumferentially arranged in the annular gap; a precombustion chamber is arranged inside the fixed baffle plate; the outlet end of the powder feeding pipe penetrates the center of the air box to enter in the precombustion chamber, the inlet end of the powder feeding pipe is arranged outside the air box and connected with a feeder device, and the powder feeding pipe is fixedly connected with the air box; a return flow cap is arranged at the tail end of the outlet end of the powder feeding pipe and a special gap is left between the return flow cap and the outlet end of the powder feeding pipe; the ignition device comprises a fuel tank, a conduct pipe and an ignition electrode, wherein the fuel tank is arranged outside the air box; one end of the conduct pipe is connected with the fuel tank and the other end of the conduct pipe penetrates the air box to enter in the precombustion chamber to form a spouting vent; the ignition electrode is arranged at one side adjacent to the spouting vent; and one end of the blast pipe is connected with the air box and the other end of the blast pipe is connected with an air blower. The invention can be widely used in various small and medium-sized industrial coal powder boilers.

Owner:CHINA COAL RES INST

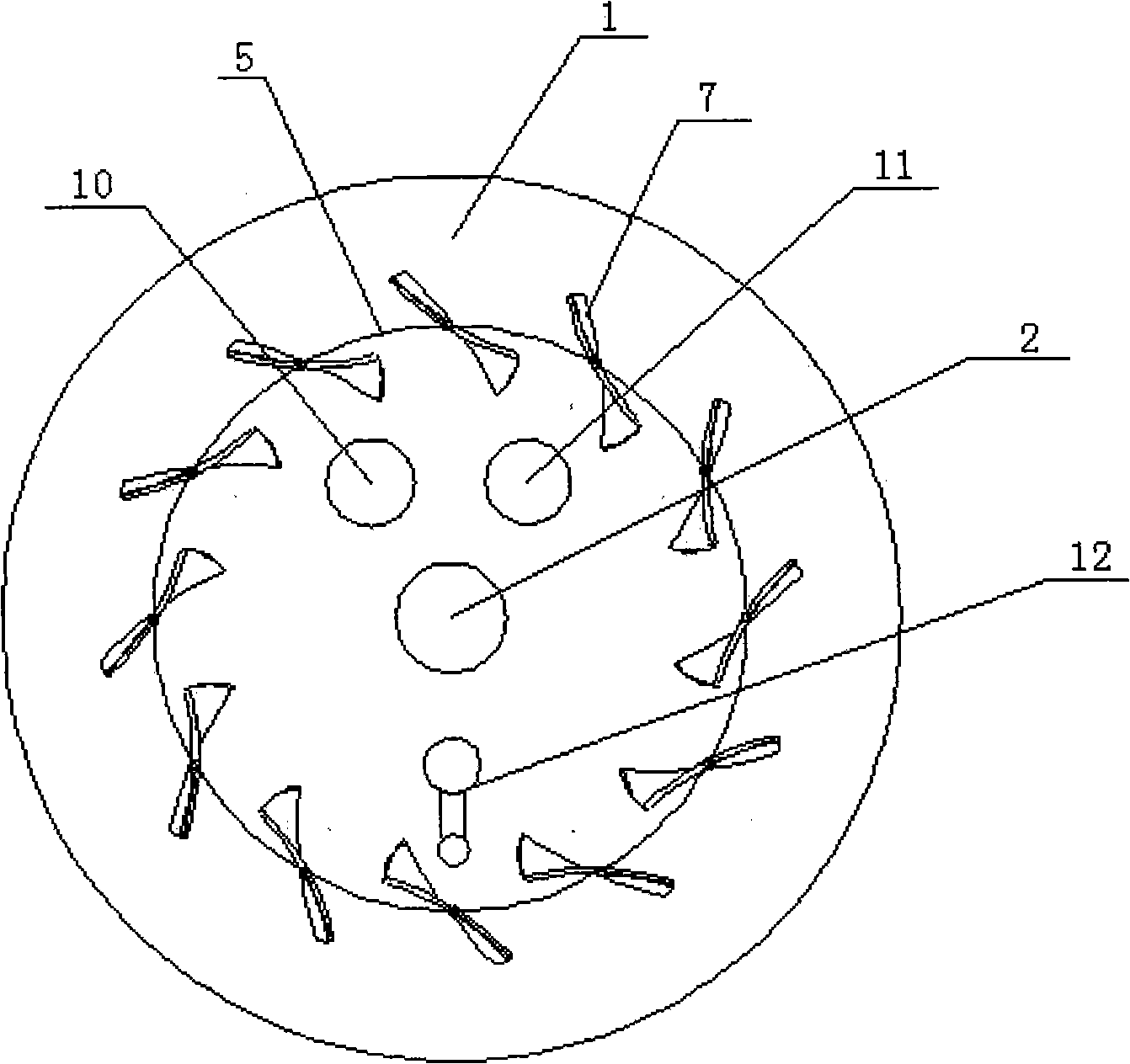

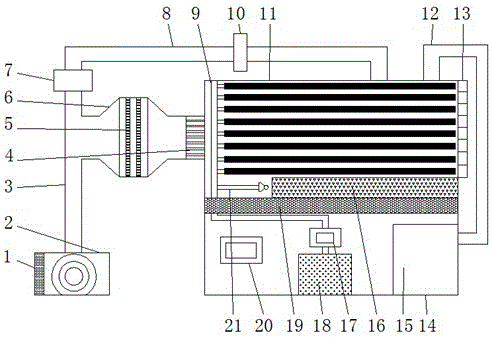

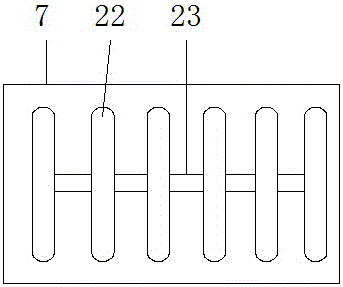

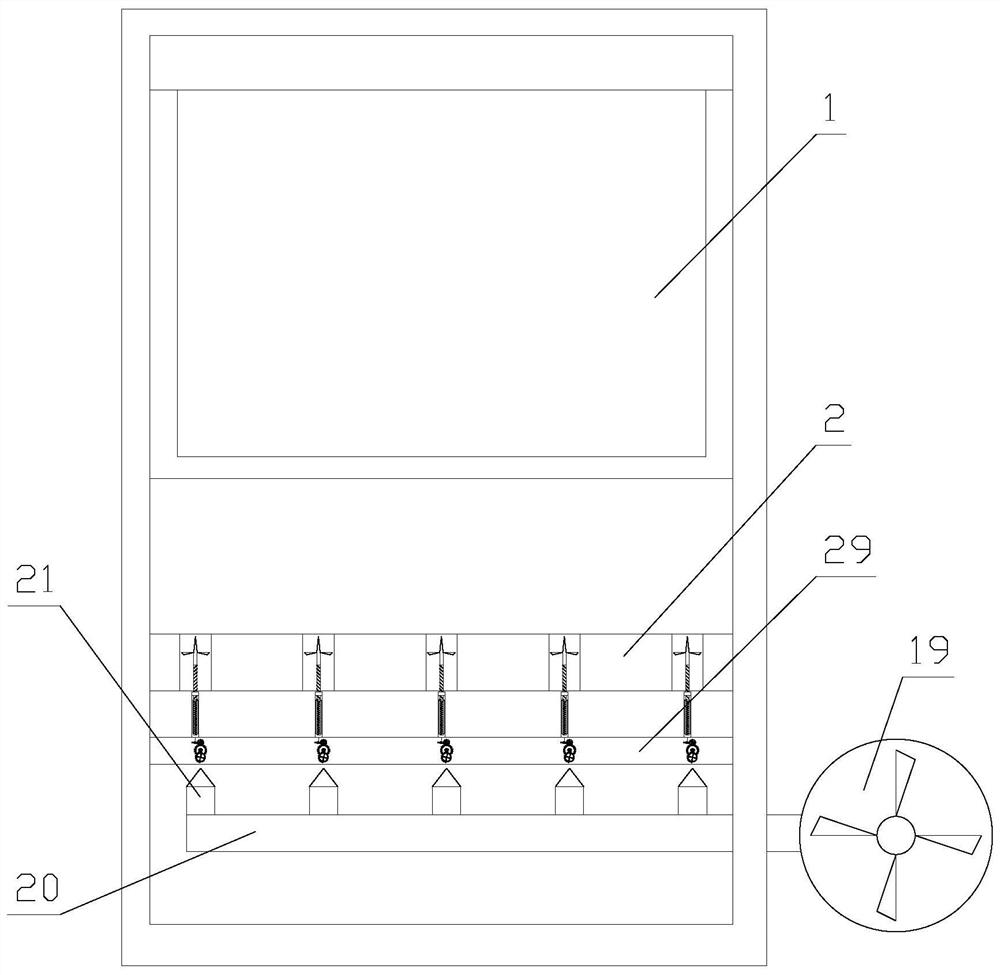

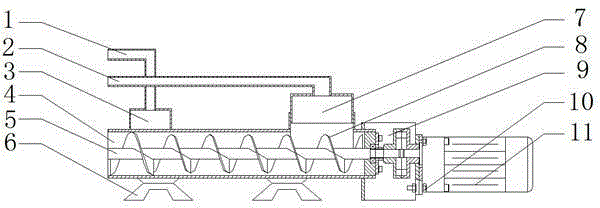

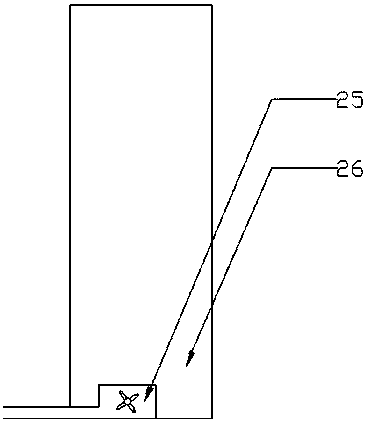

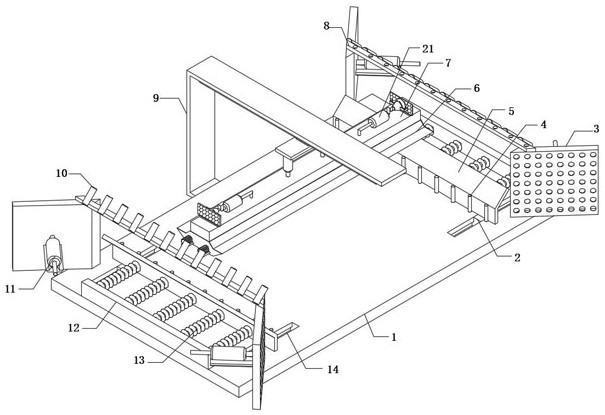

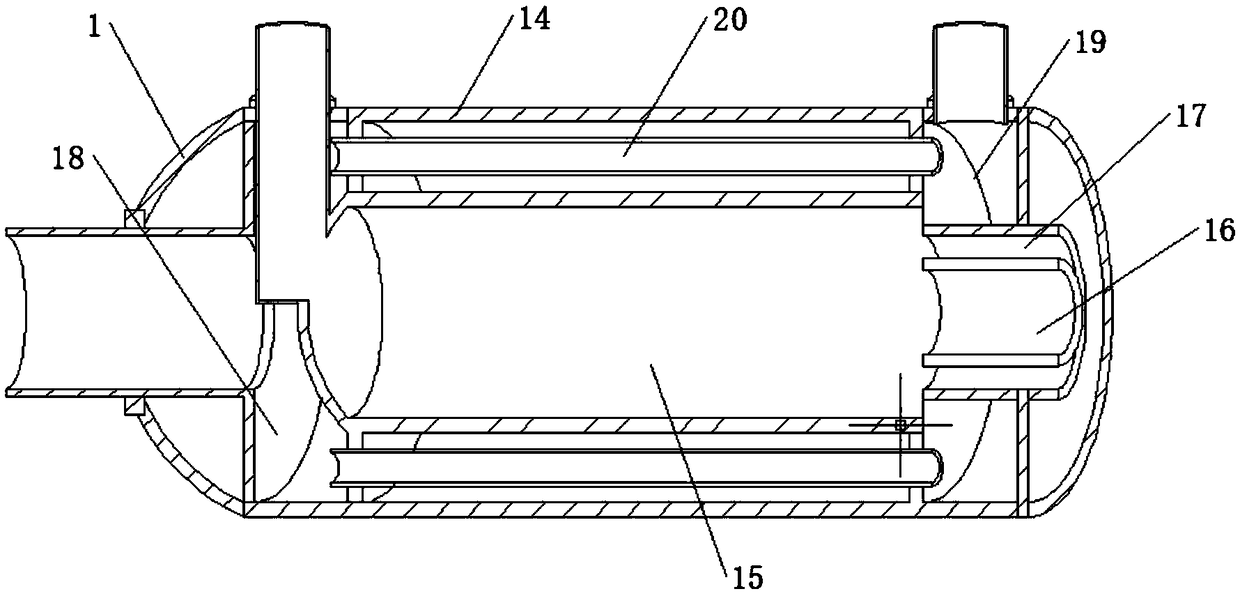

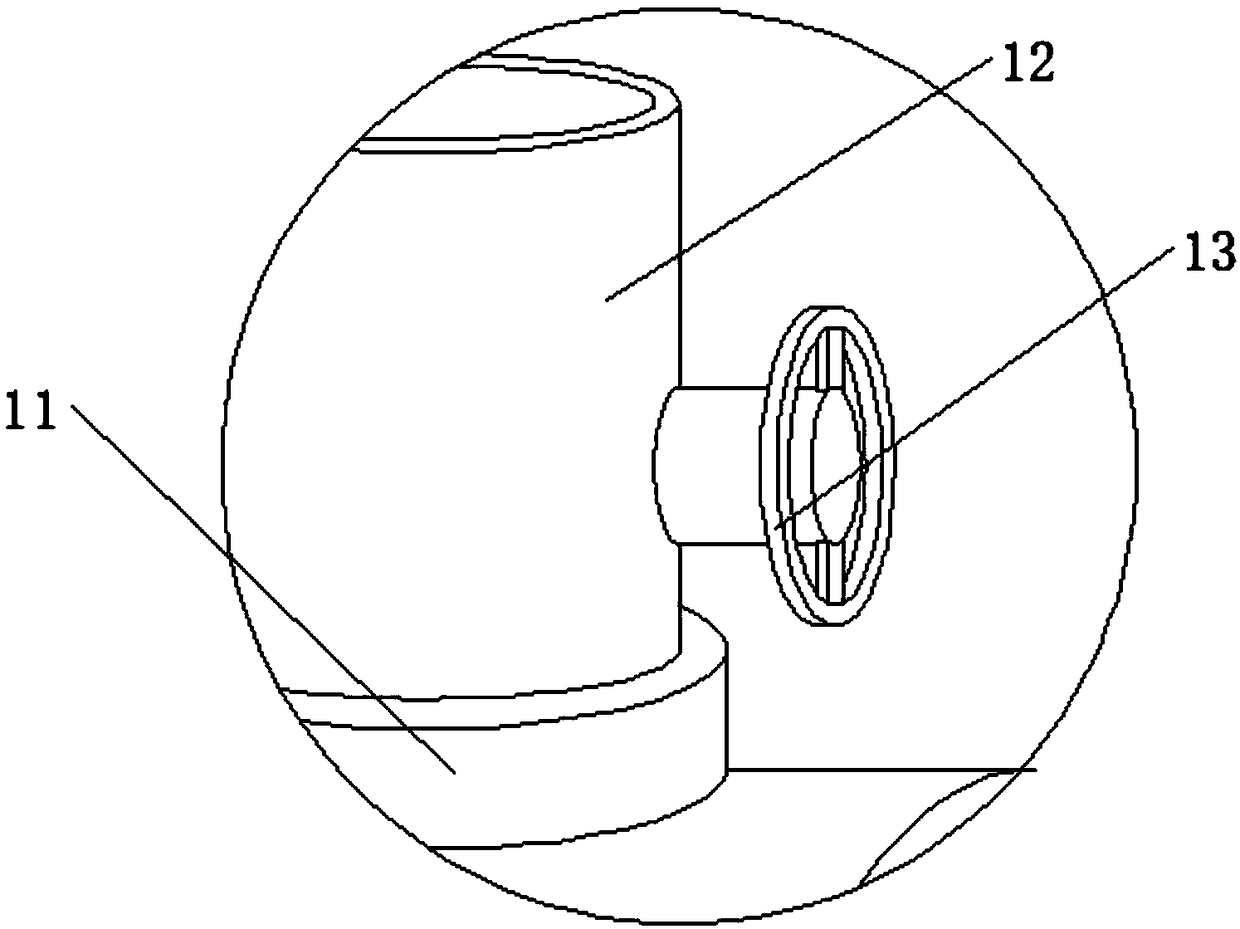

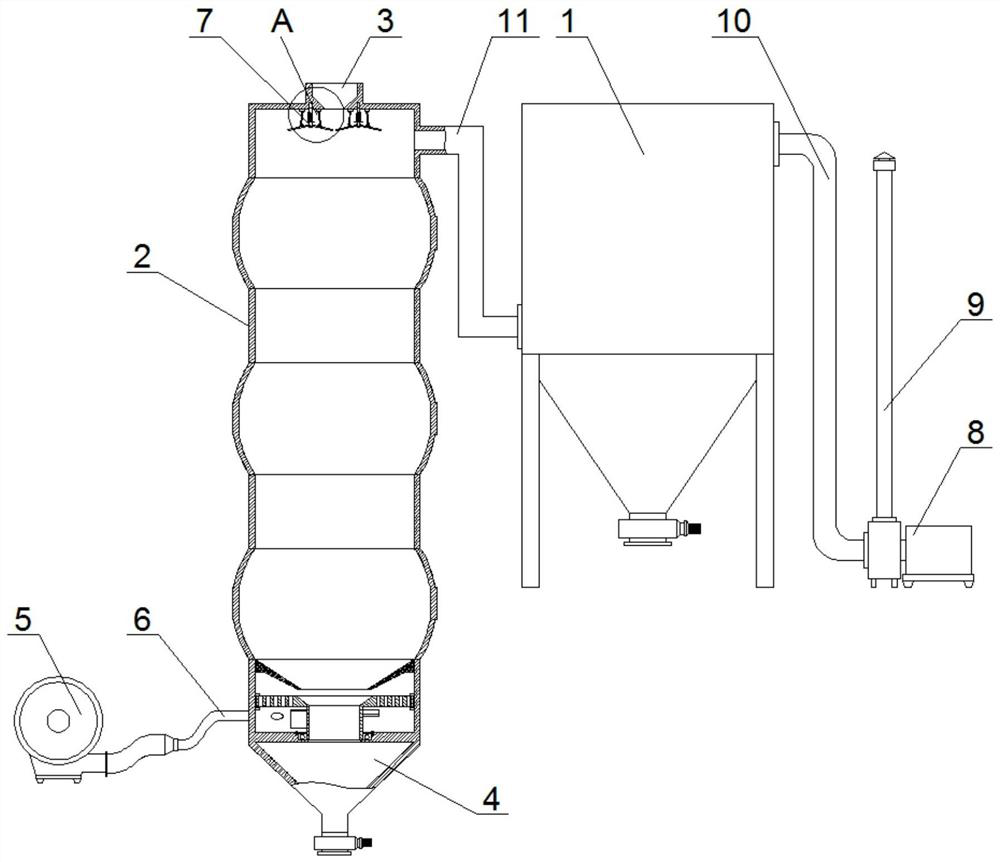

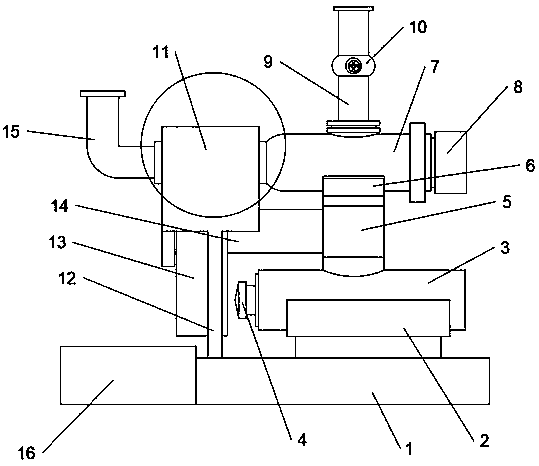

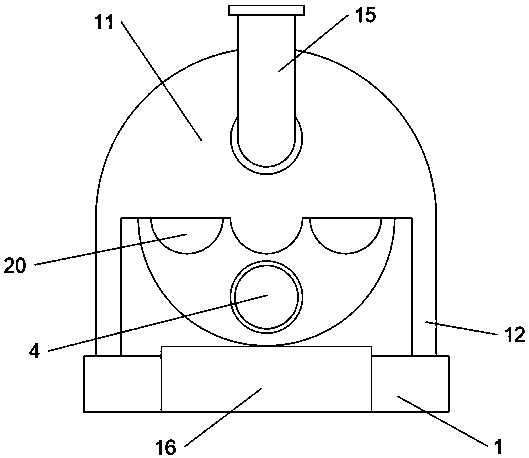

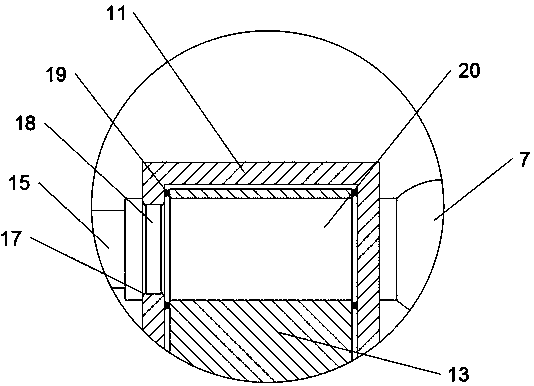

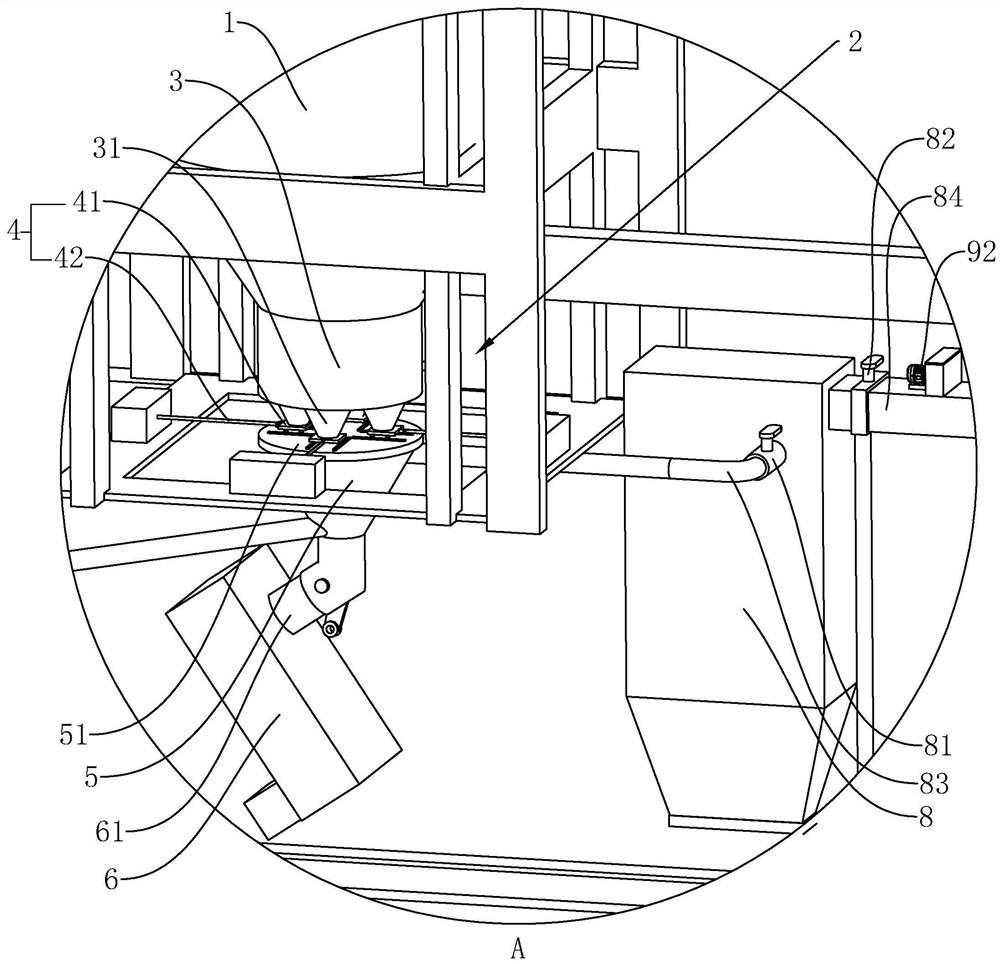

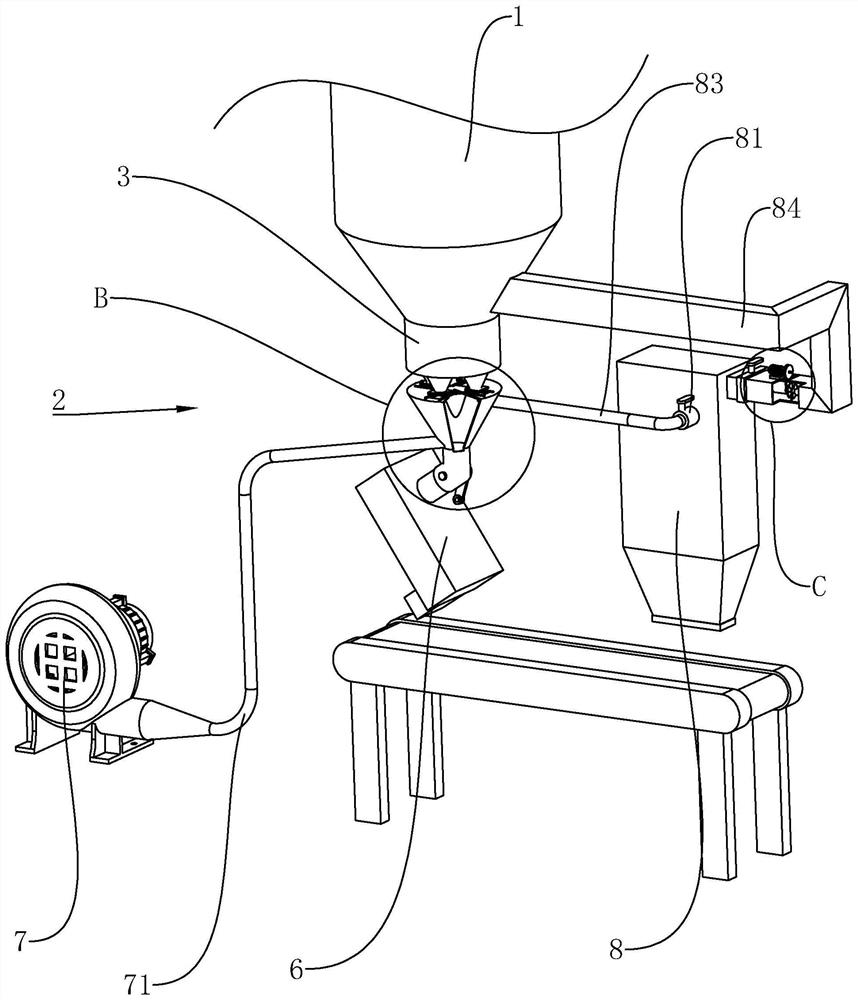

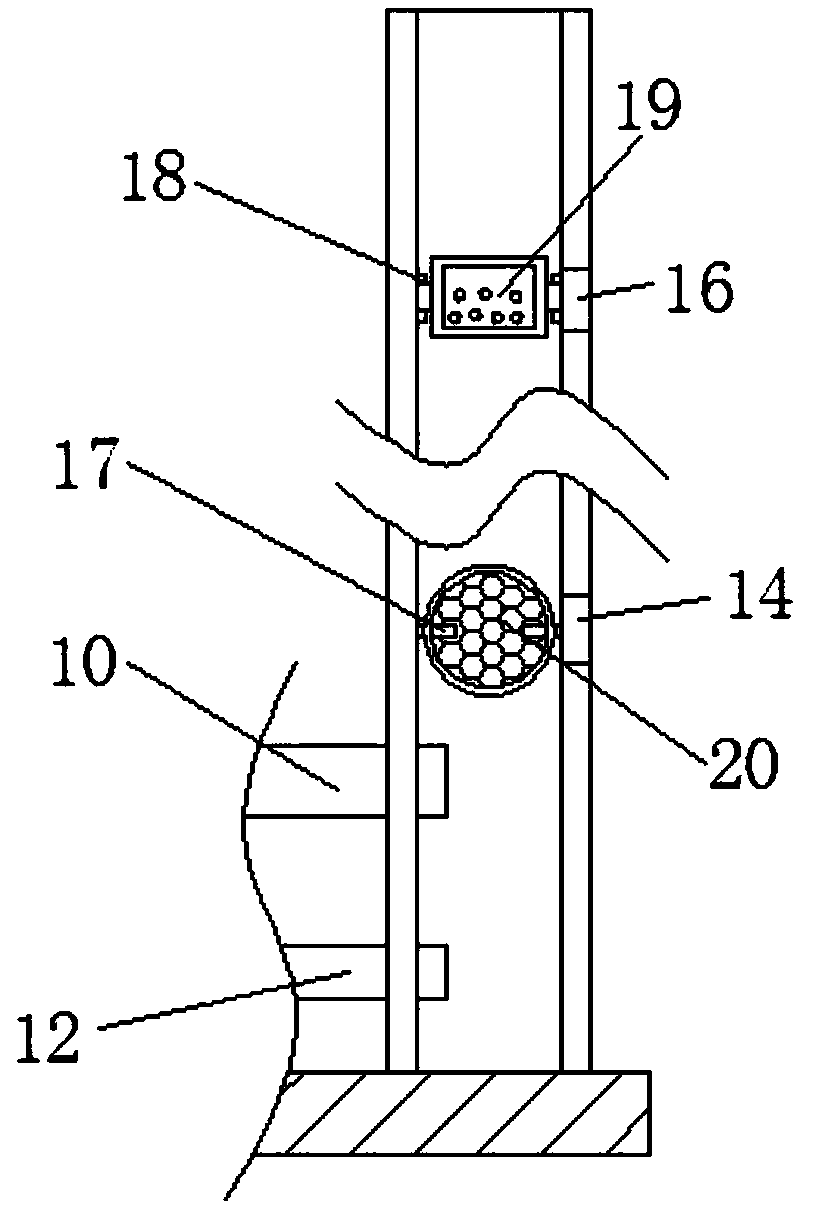

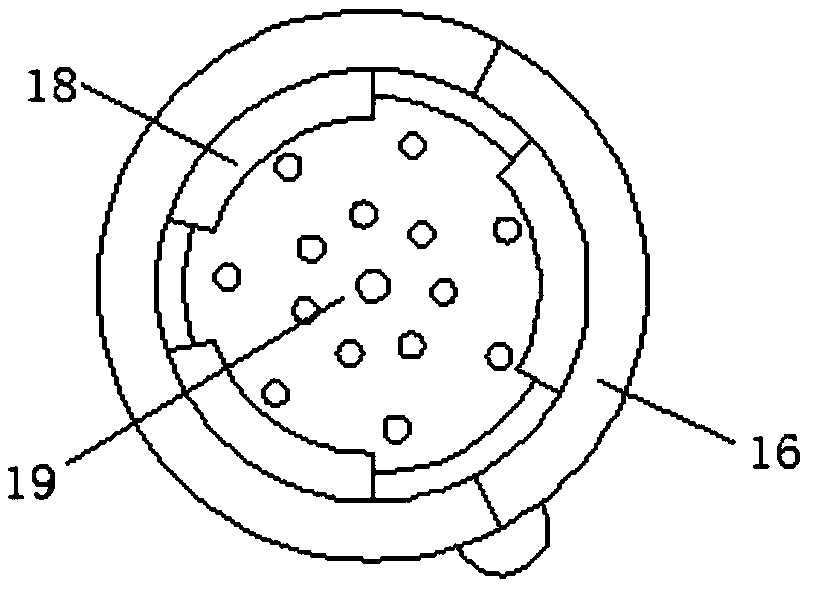

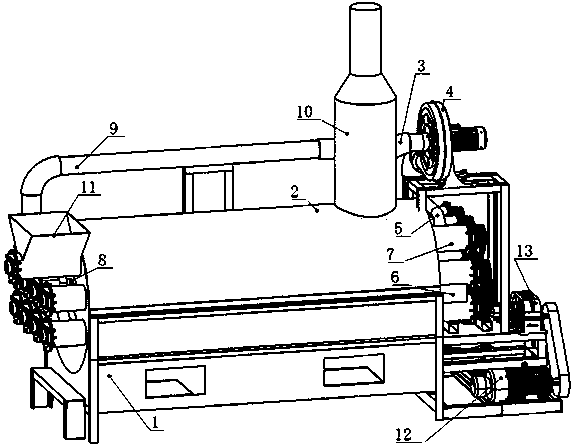

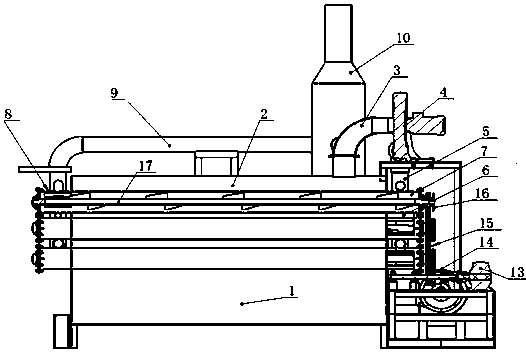

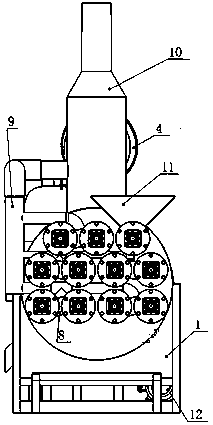

Screening machine for superfine powder

ActiveUS20130206650A1Improve screening efficiencyIncrease the effective areaSievingGas current separationAgricultural engineeringDrive motor

A screening machine for superfine powder. The screening machine includes a casing, a screen drum, a funnel, a negative pressure chamber, a rotary air spray pipe, a drive motor, a blast pipe, and a feed pipe. The screen drum is disposed in the middle part of the inner cavity of the casing. The funnel is disposed beneath the casing. The opening of the screen drum is arranged on the bottom of the screen drum and communicates with the upper opening of the funnel. The inner cavity of the casing communicates with the external induced draft fan via the negative pressure chamber disposed on the upper part of the casing. The rotary air spray pipe is arranged in the space between the screen drum and the casing. The middle part of the transverse pipe is connected via a transmission with the drive motor.

Owner:HENAN KANGXING PHARMA

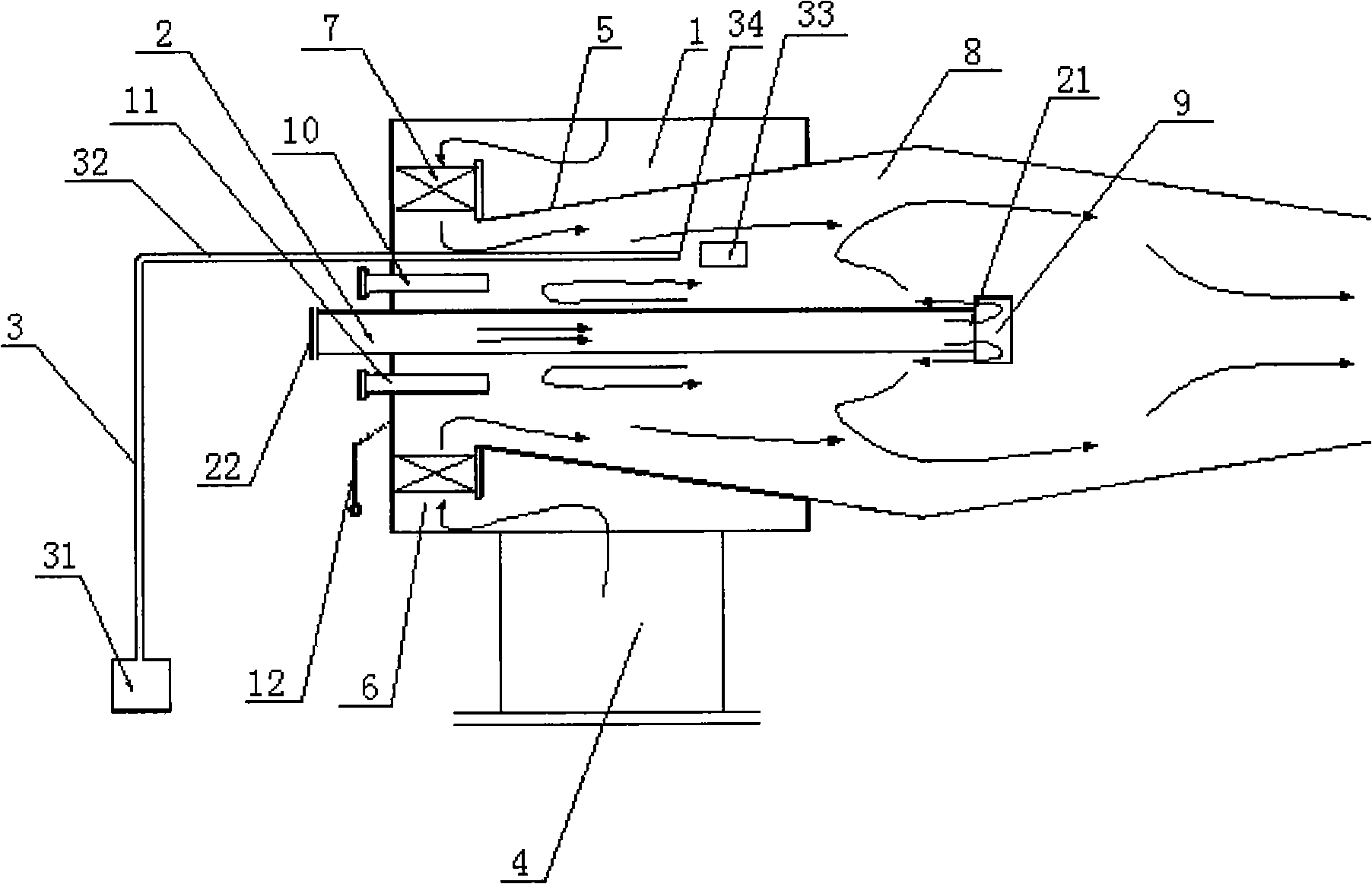

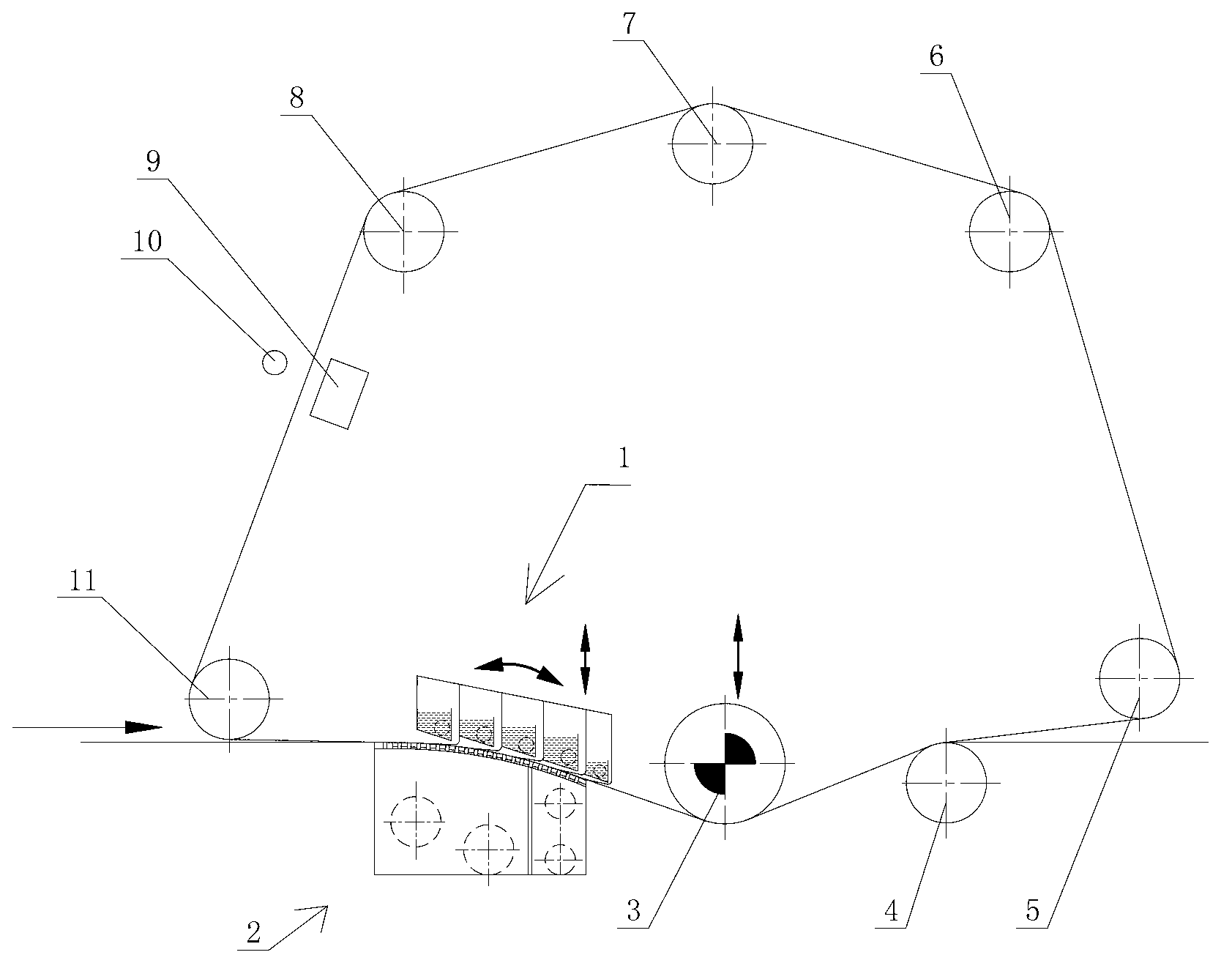

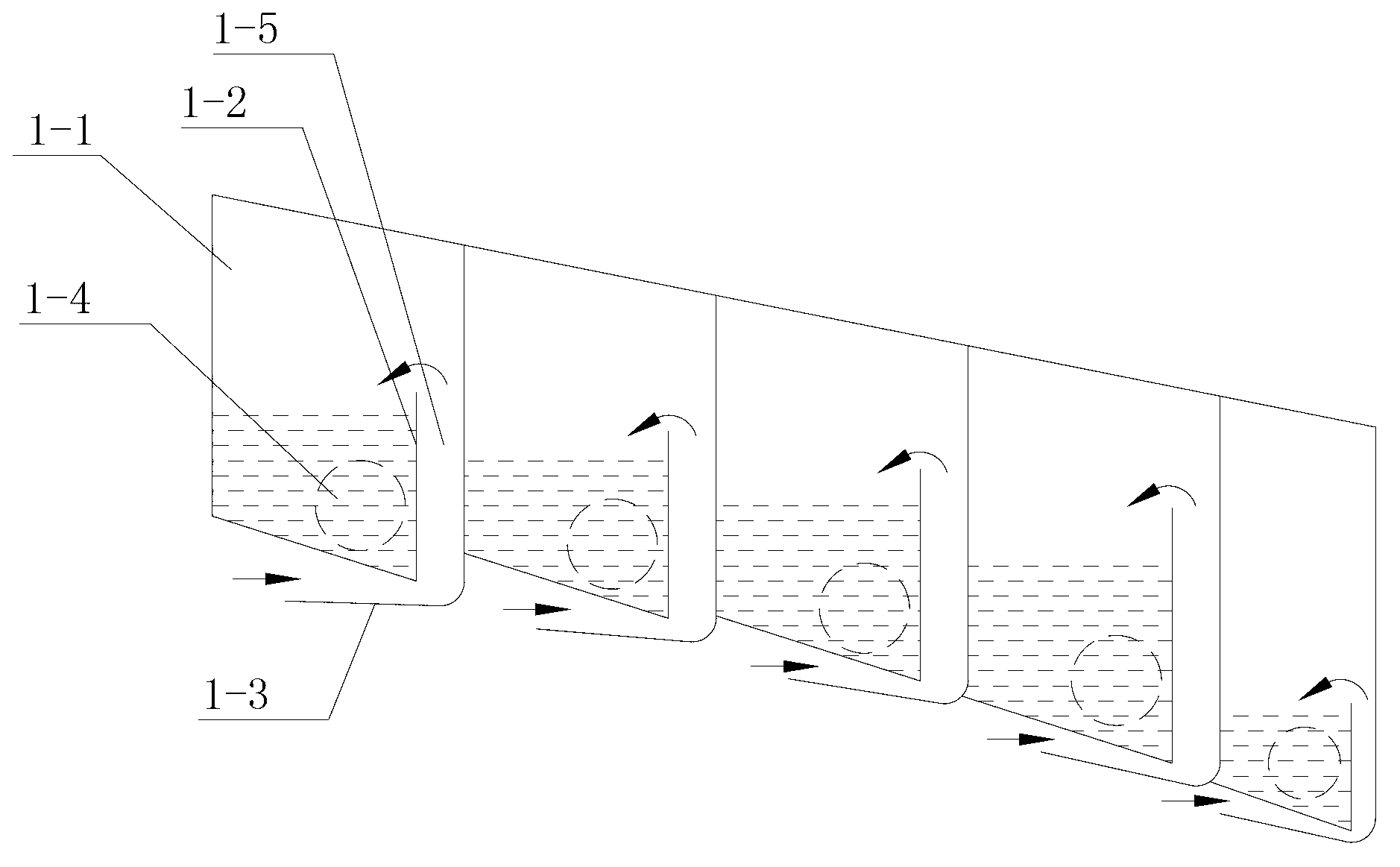

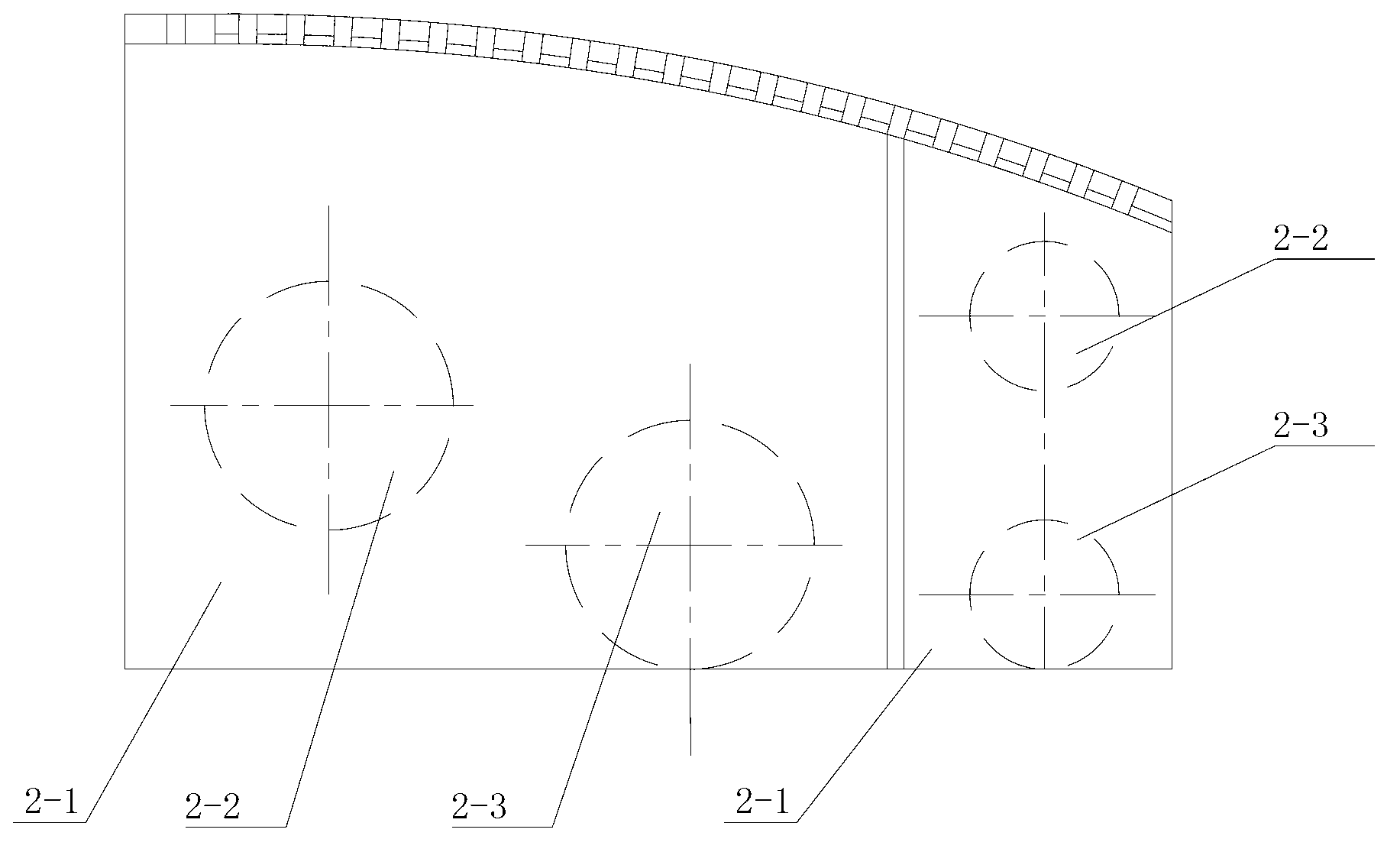

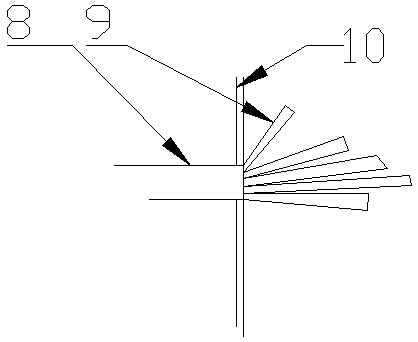

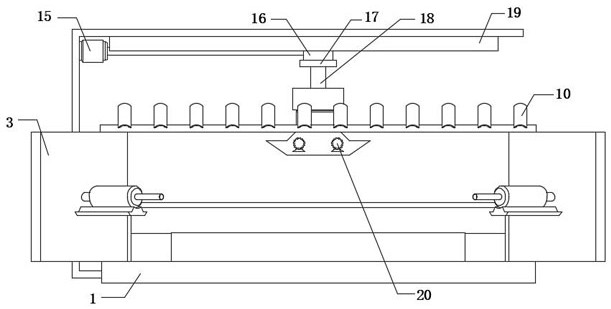

Top net forming machine capable of adjusting two-side difference of paper

The invention discloses a top net forming machine capable of adjusting a two-side difference of paper. The top net forming machine comprises a top net suction box and a bottom net suction box. The top net suction box is composed of a plurality of top net suction areas arranged in the heading direction of the paper in sequence, each top net suction area comprises a water scraping plate used for scraping moisture on the surface of the paper and arranged on the lower surface of the top net suction box, a water blocking plate preventing backflow of water in the top net suction areas and a top net drain pipe arranged on the bottom portion of the top net suction areas, and a water suction channel is formed between each water scraping plate and each water blocking plate. The bottom net suction box comprises a plurality of bottom net suction area arranged in the heading direction of the paper in sequence, a blastpipe arranged in the bottom net suction areas and a bottom net drain pipe. Through the mentioned structure, the top net forming machine has the advantages of independently adjusting the upward dehydration amount and the downward dehydration amount of wet paper and the two-side difference of the paper on the basis of not influencing the normal operating of a top net and paper evenness adjusting.

Owner:SOUTH CHINA UNIV OF TECH

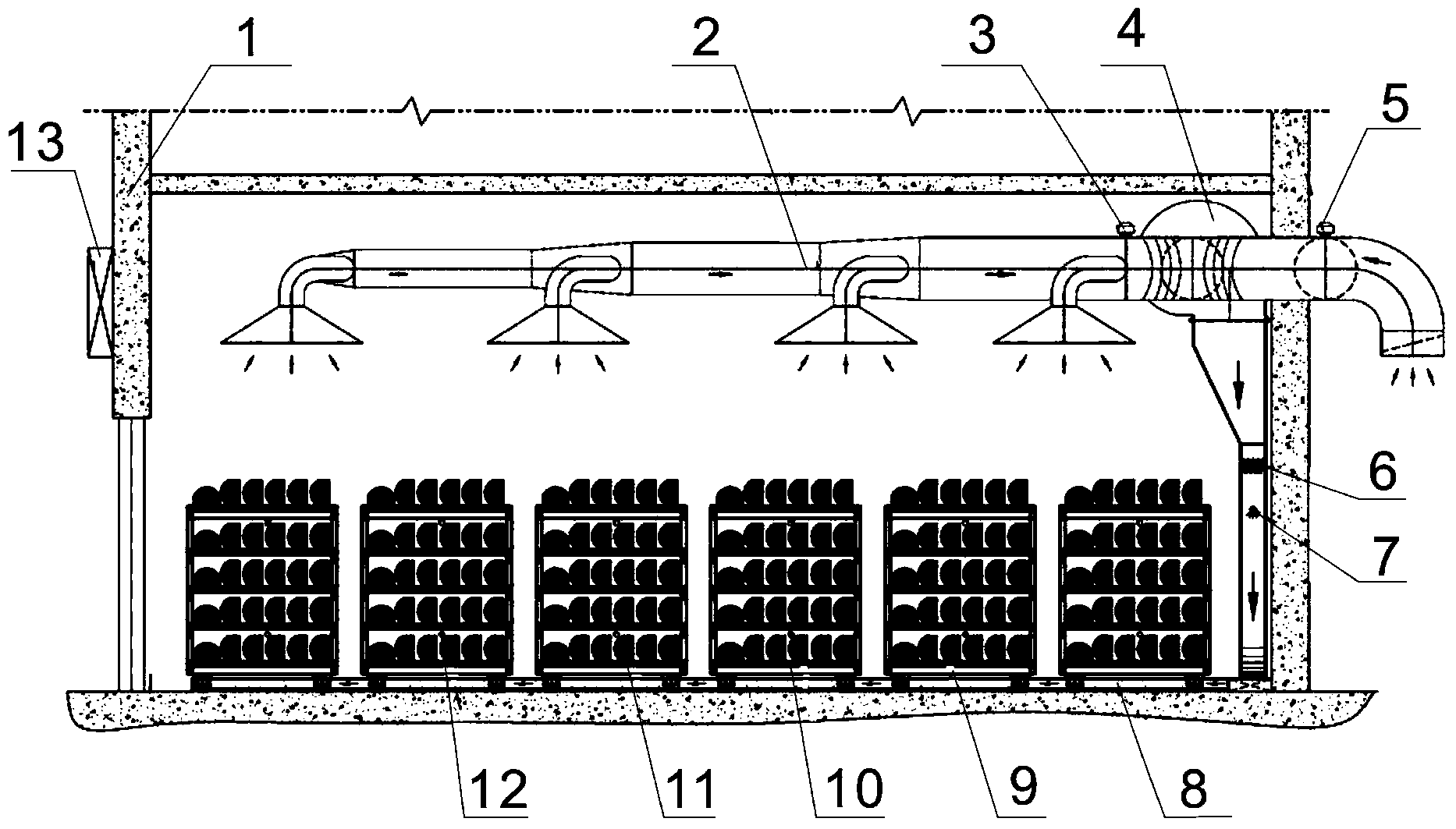

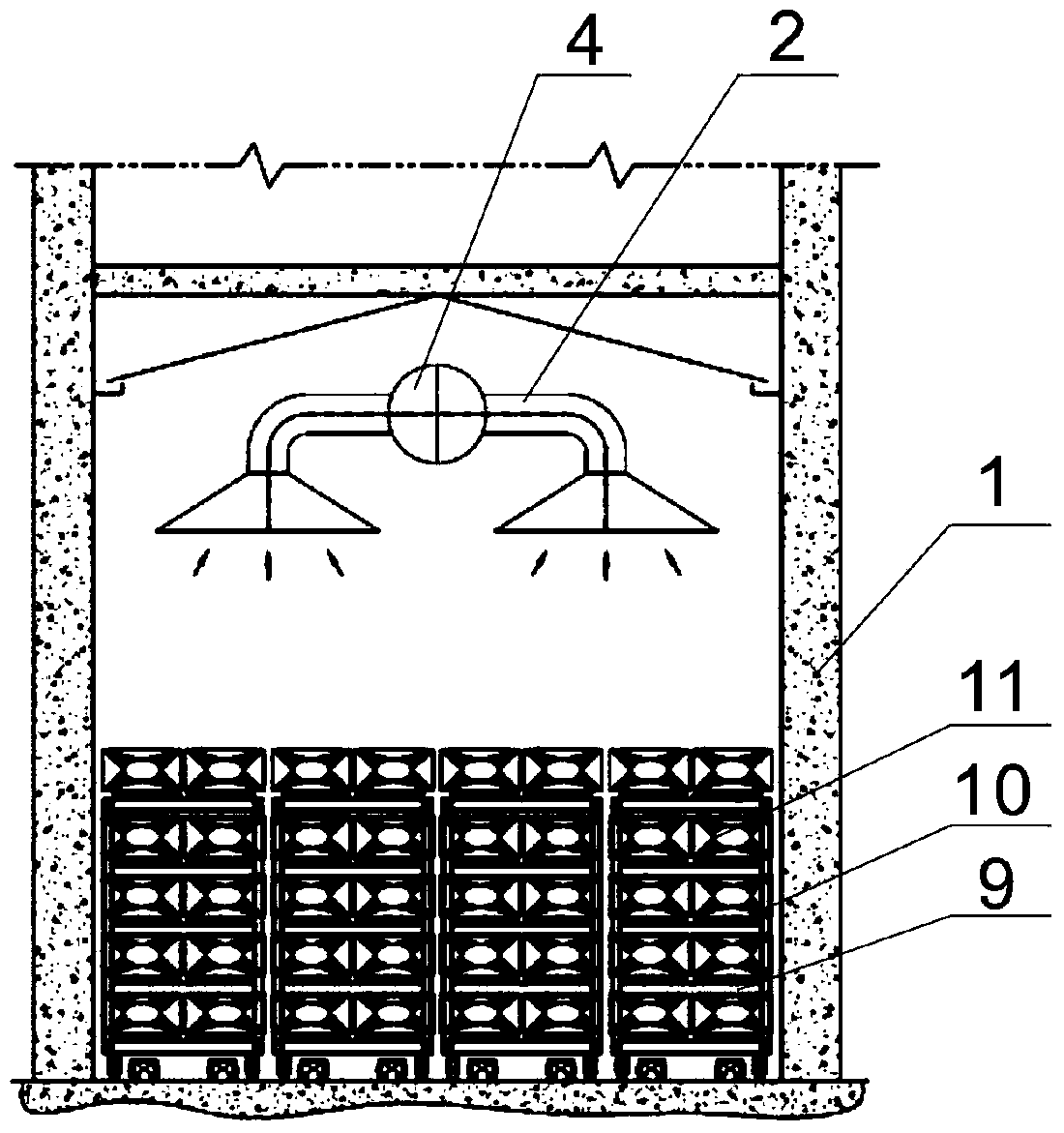

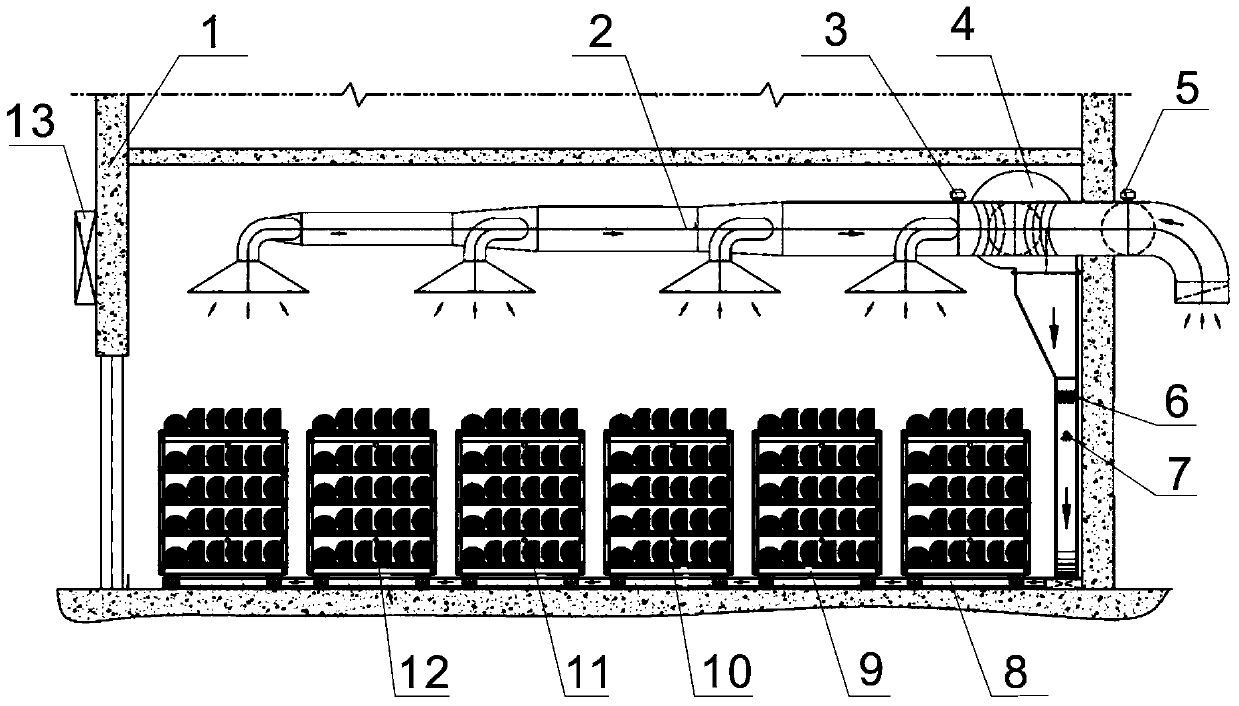

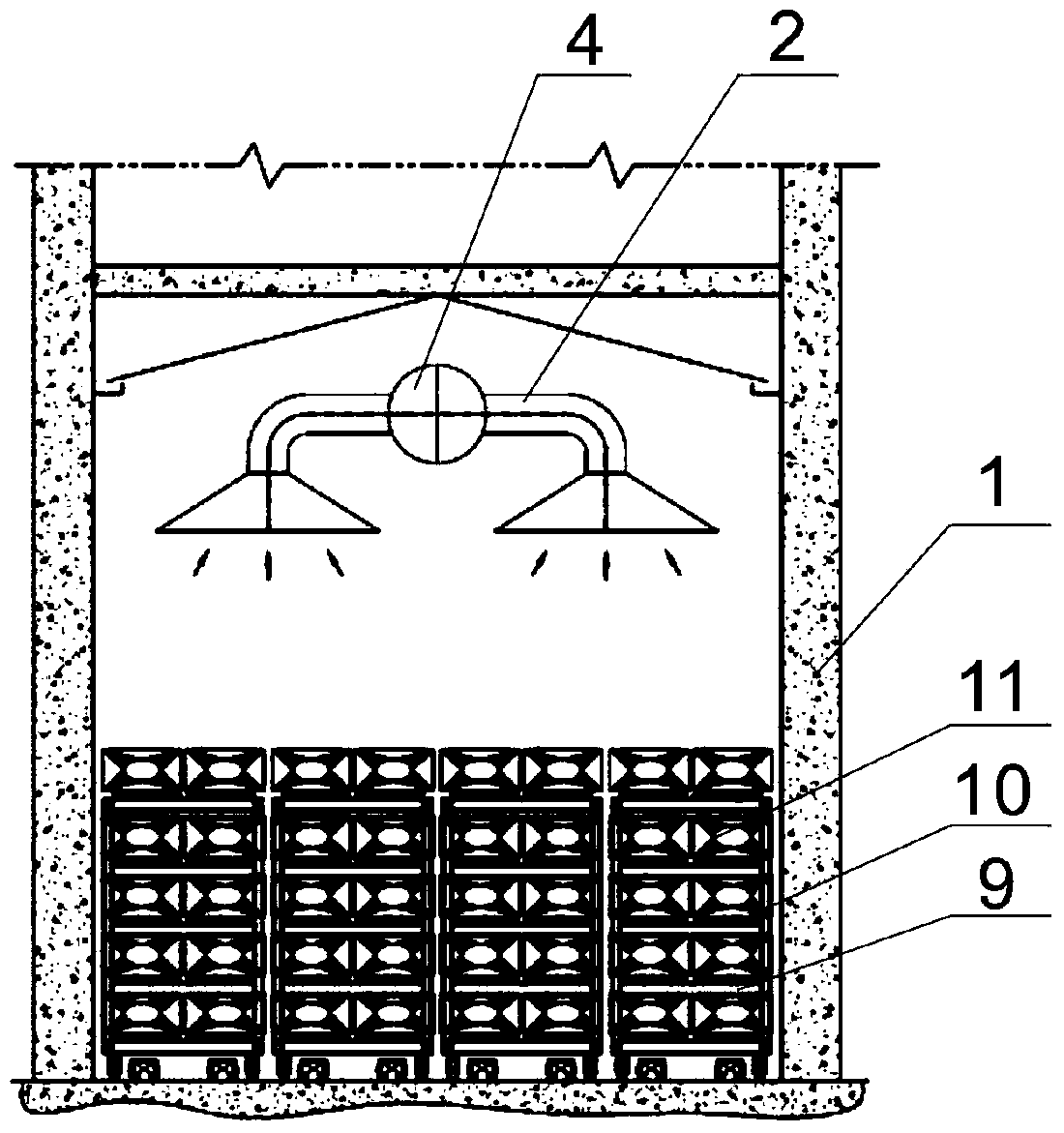

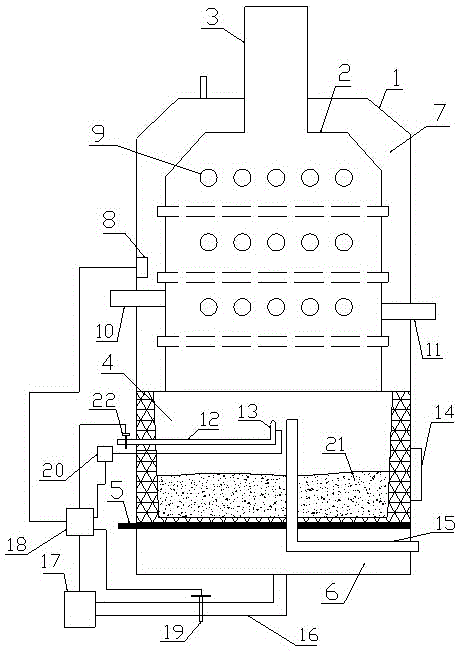

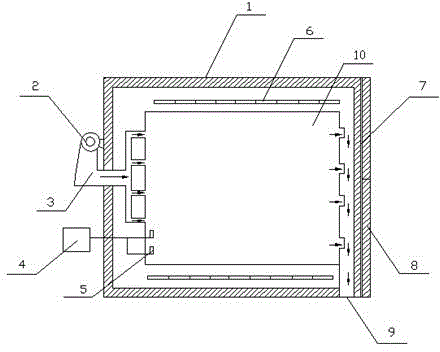

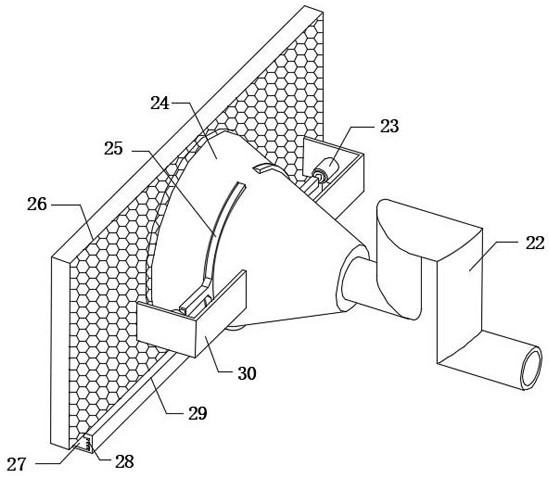

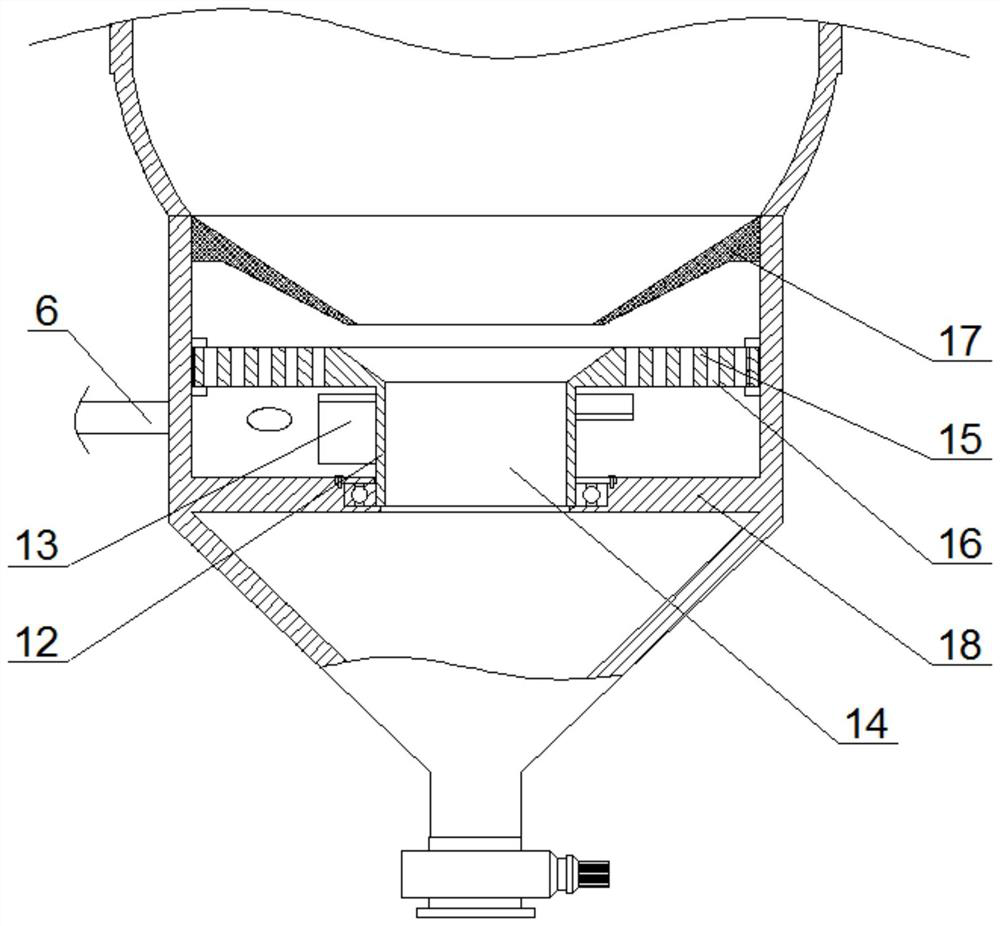

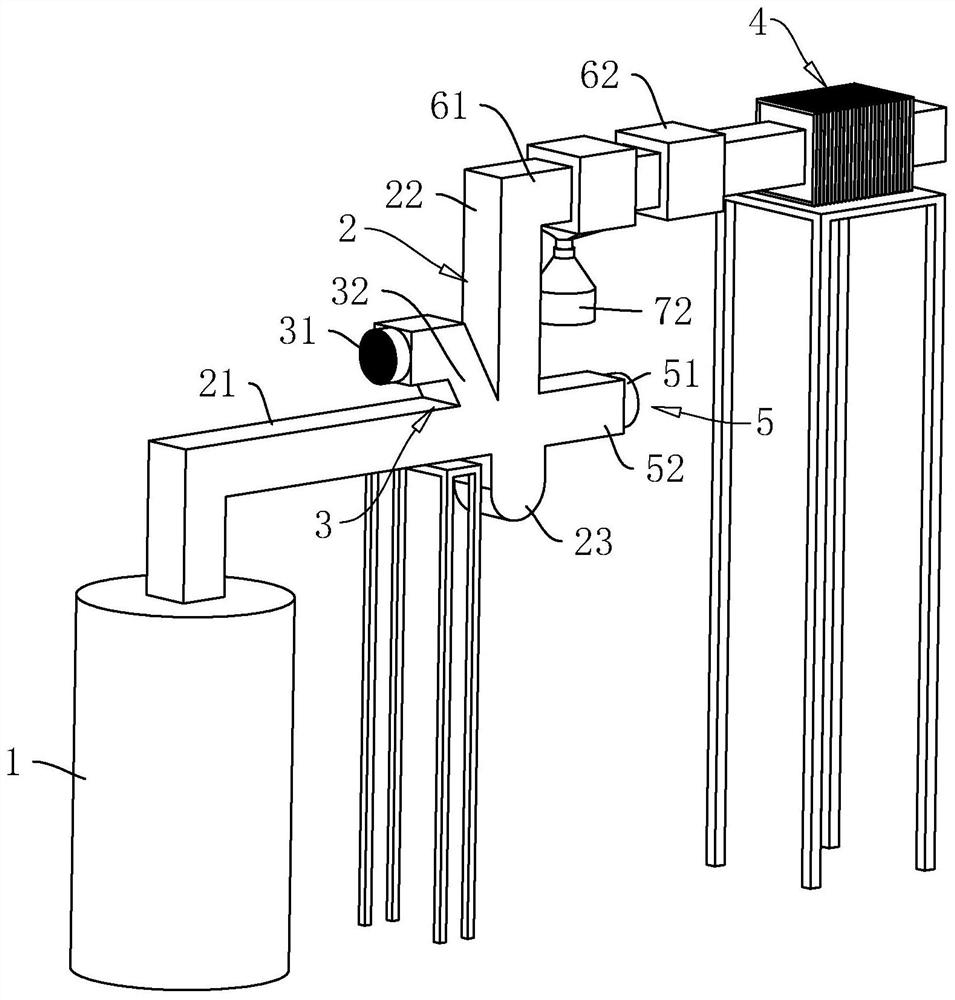

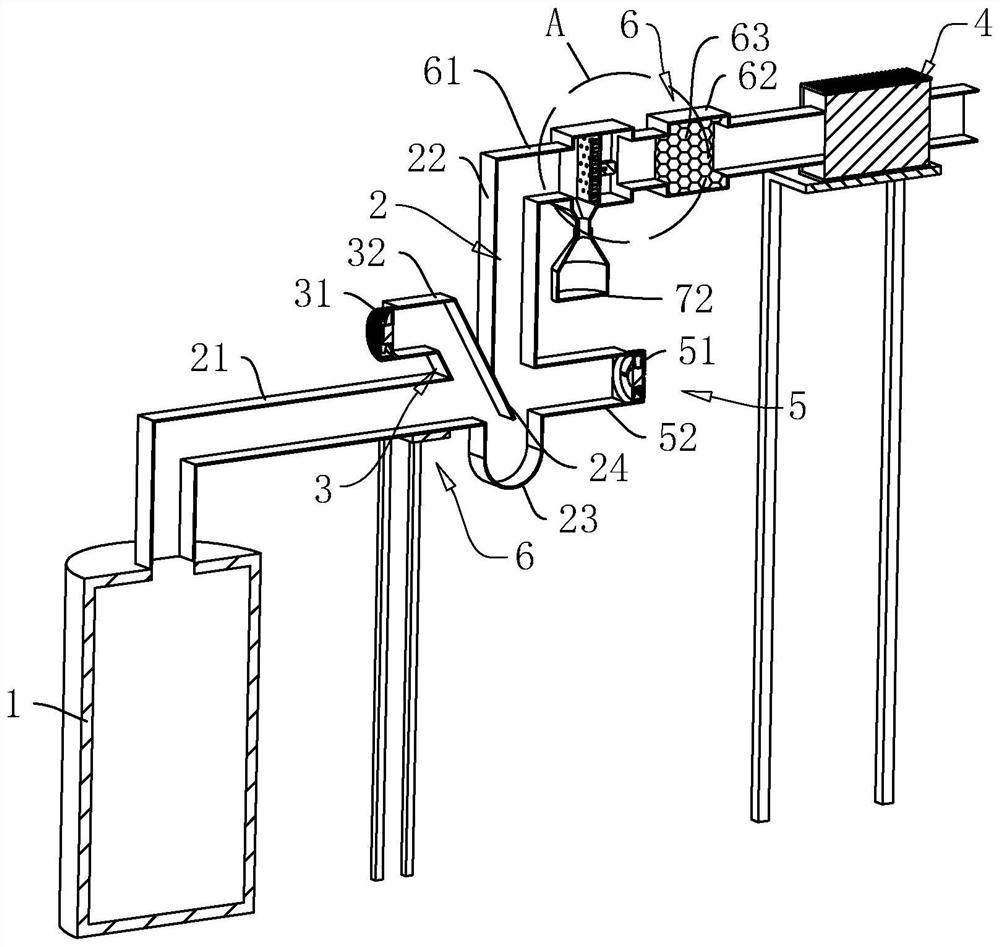

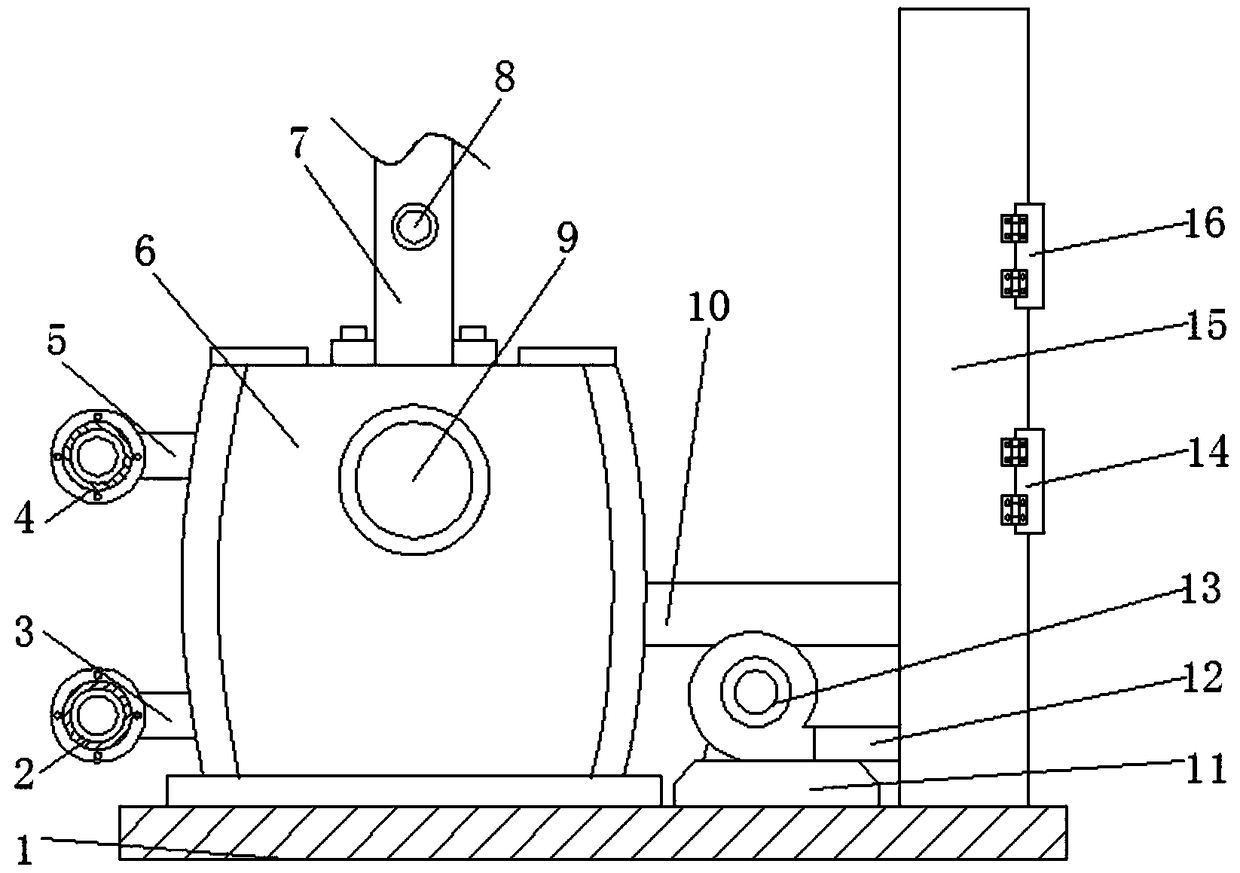

Intelligent fermentation leaven room

ActiveCN103397793AQuality improvementQuality assuranceAlcoholic beverage preparationIndustrial buildingsControl systemEngineering

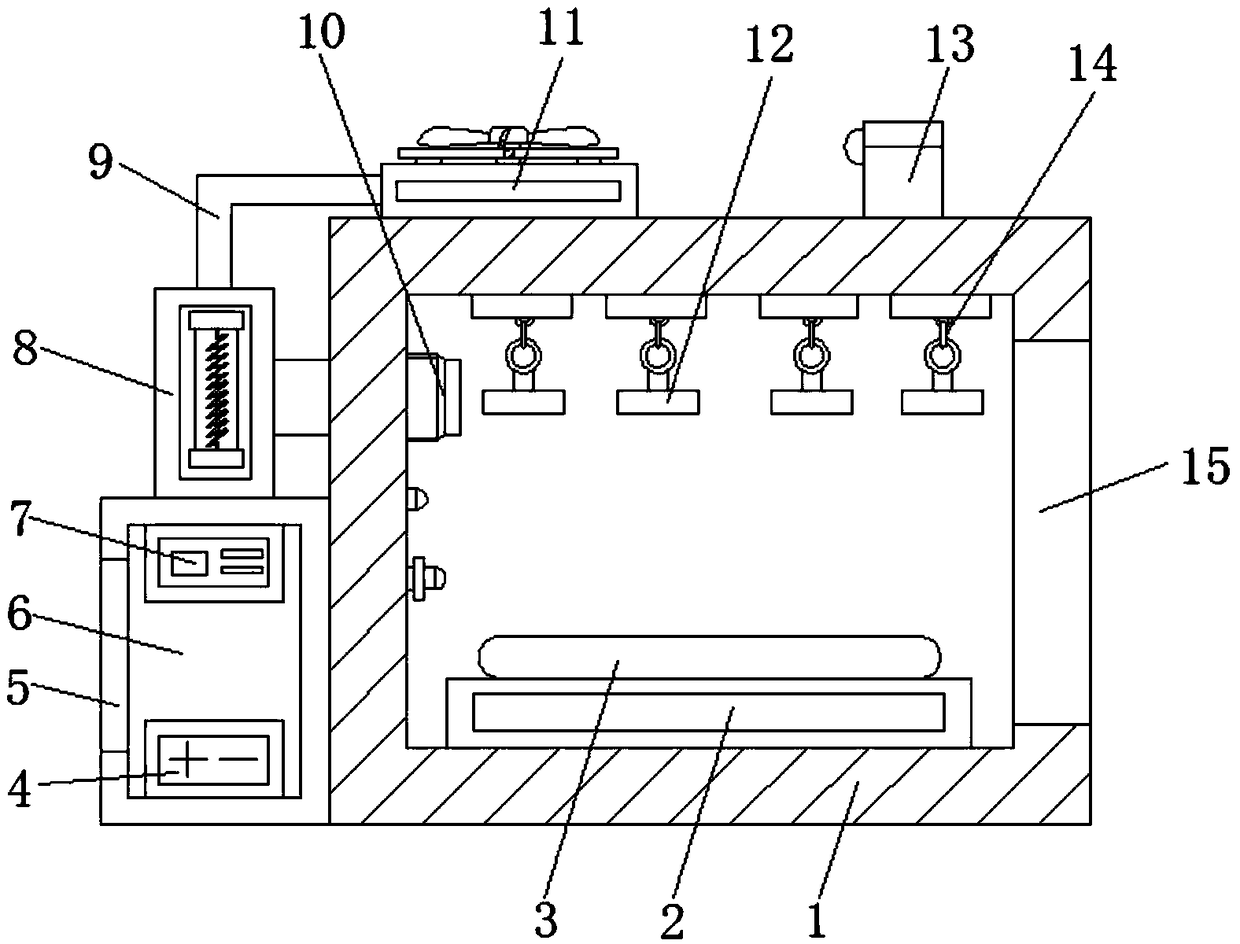

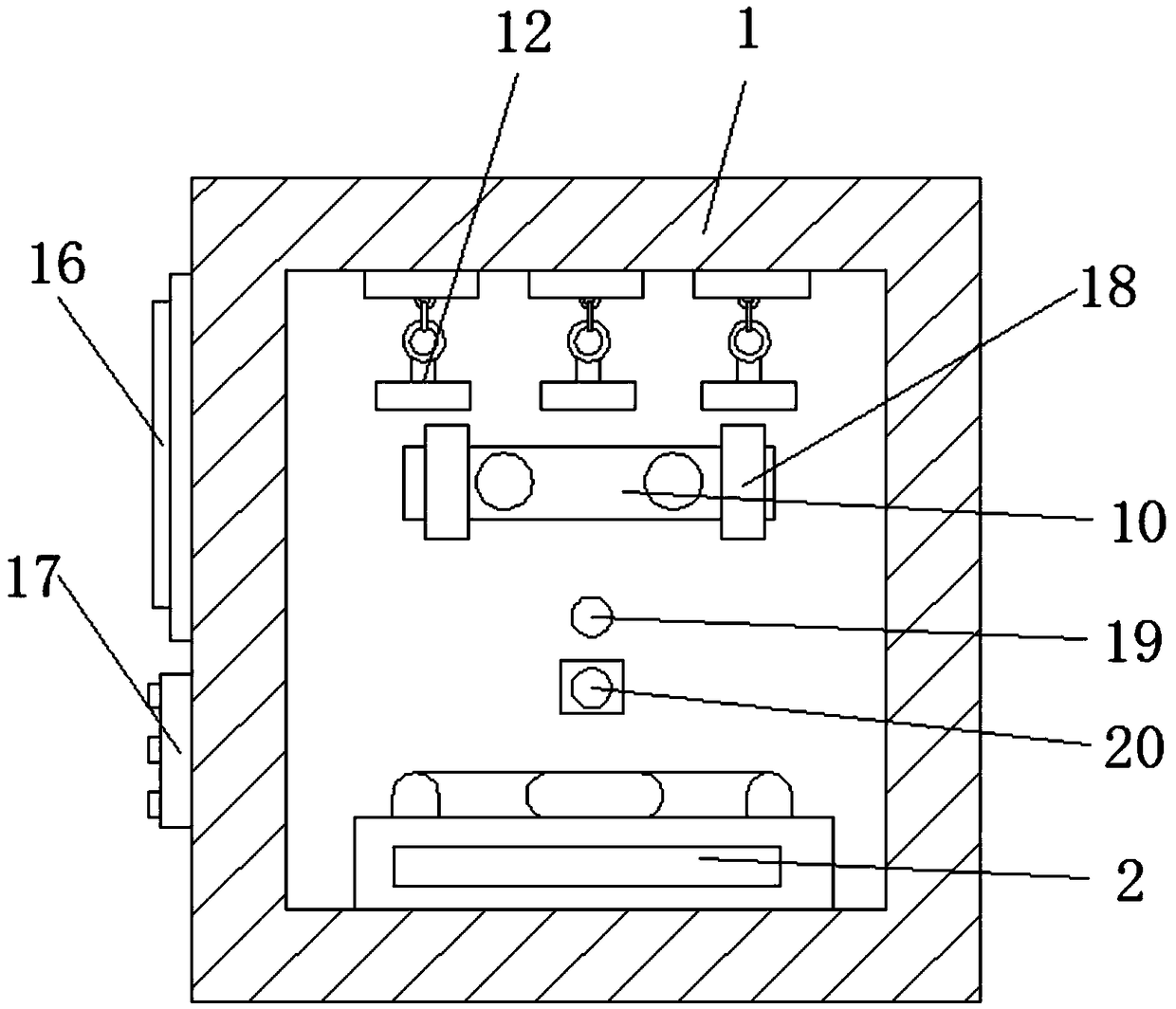

The invention discloses an intelligent fermentation leaven room. The intelligent fermentation leaven room comprises a leaven room body, an air regulating air blower, an air regulating blastpipe, an air regulating exhaust pipe, movable shelves and a control system arranged outside the leaven room body. The air regulating blastpipe, the air regulating air blower and the air regulating exhaust pipe are arranged inside the leaven room body in a series connection mode. A control valve A and a control valve B are arranged on the two sides of the air regulating air blower respectively. The movable shelves are arranged inside the leaven room body. A plurality of bamboo rafts are arranged on each movable shelf. A heating assembly and a humidification assembly are arranged in an air channel of the air regulating air blower. The heating assembly and the humidification assembly are communicated with the air regulating blastpipe respectively. A temperature and humidity measurement assembly is arranged on each movable shelf and connected with the control system through a cable. The control system is used for describing the temperature field and humidity field inside the intelligent fermentation leaven room according to data detected by the temperature and humidity measurement assemblies, the air regulating air blower, the heating assembly, the humidification assembly and the control valves are regulated according to set parameters, and therefore the temperature and humidity inside the intelligent fermentation leaven room are regulated and controlled.

Owner:KWEICHOW MOUTAI COMPANY

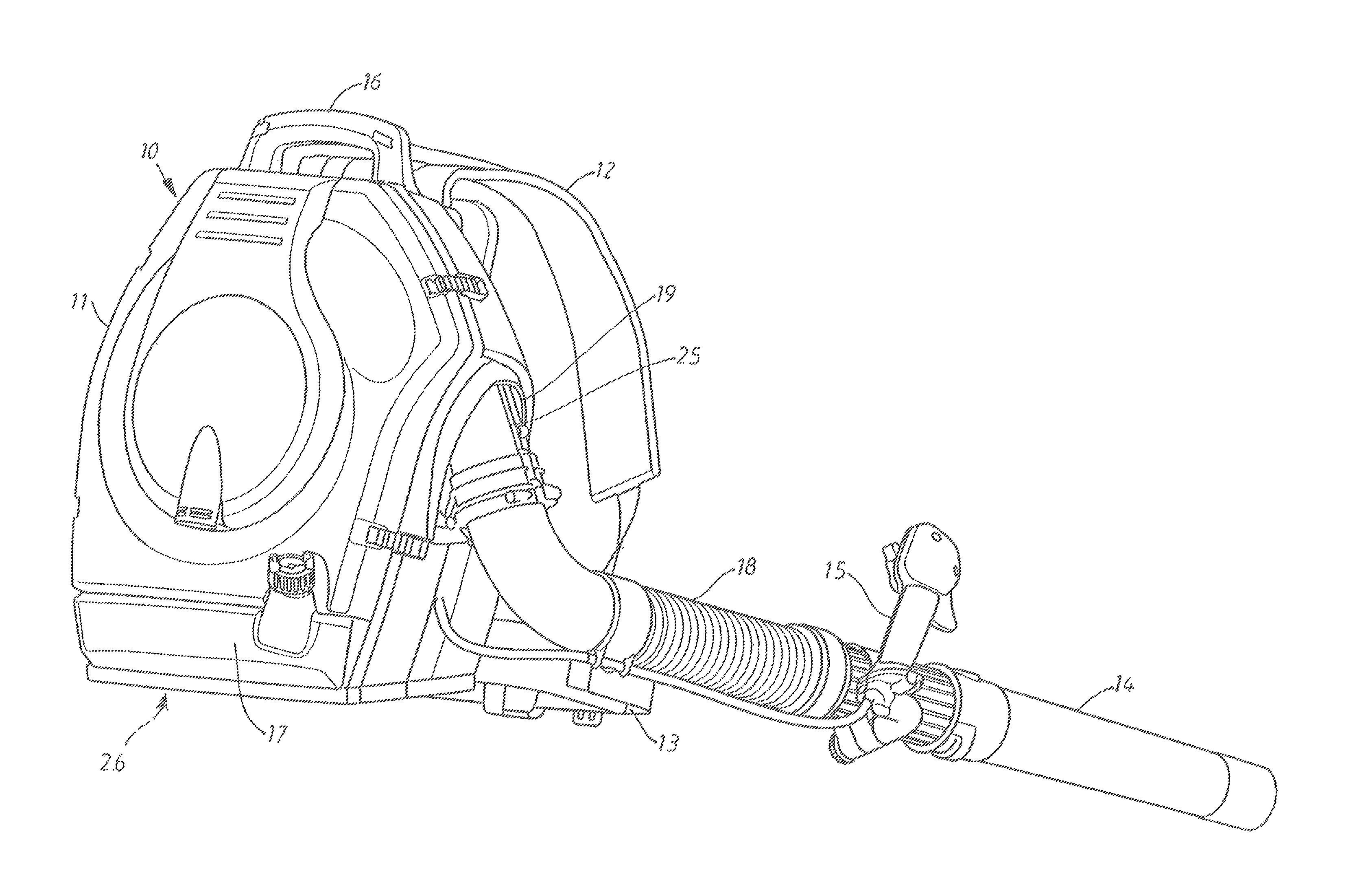

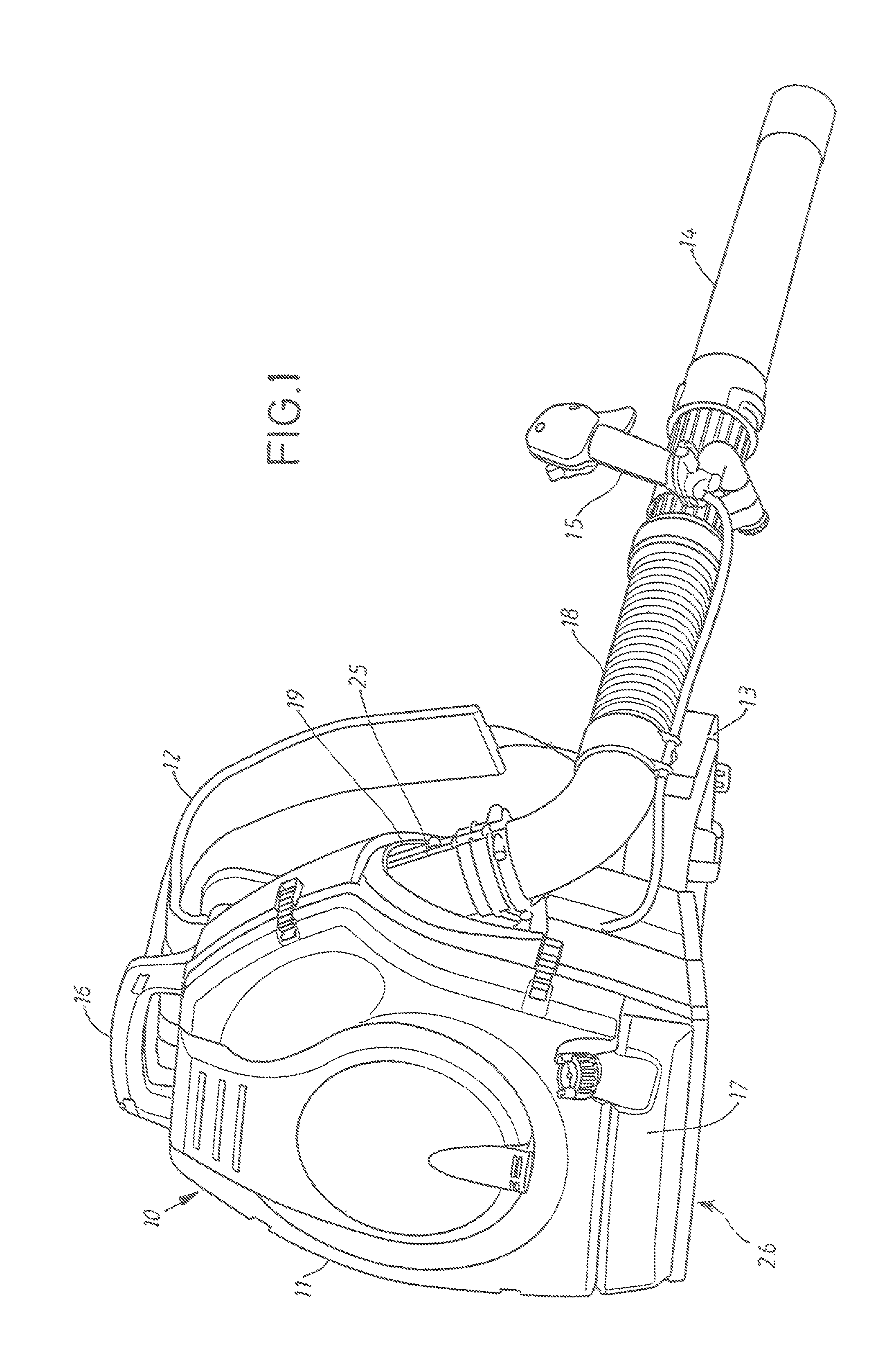

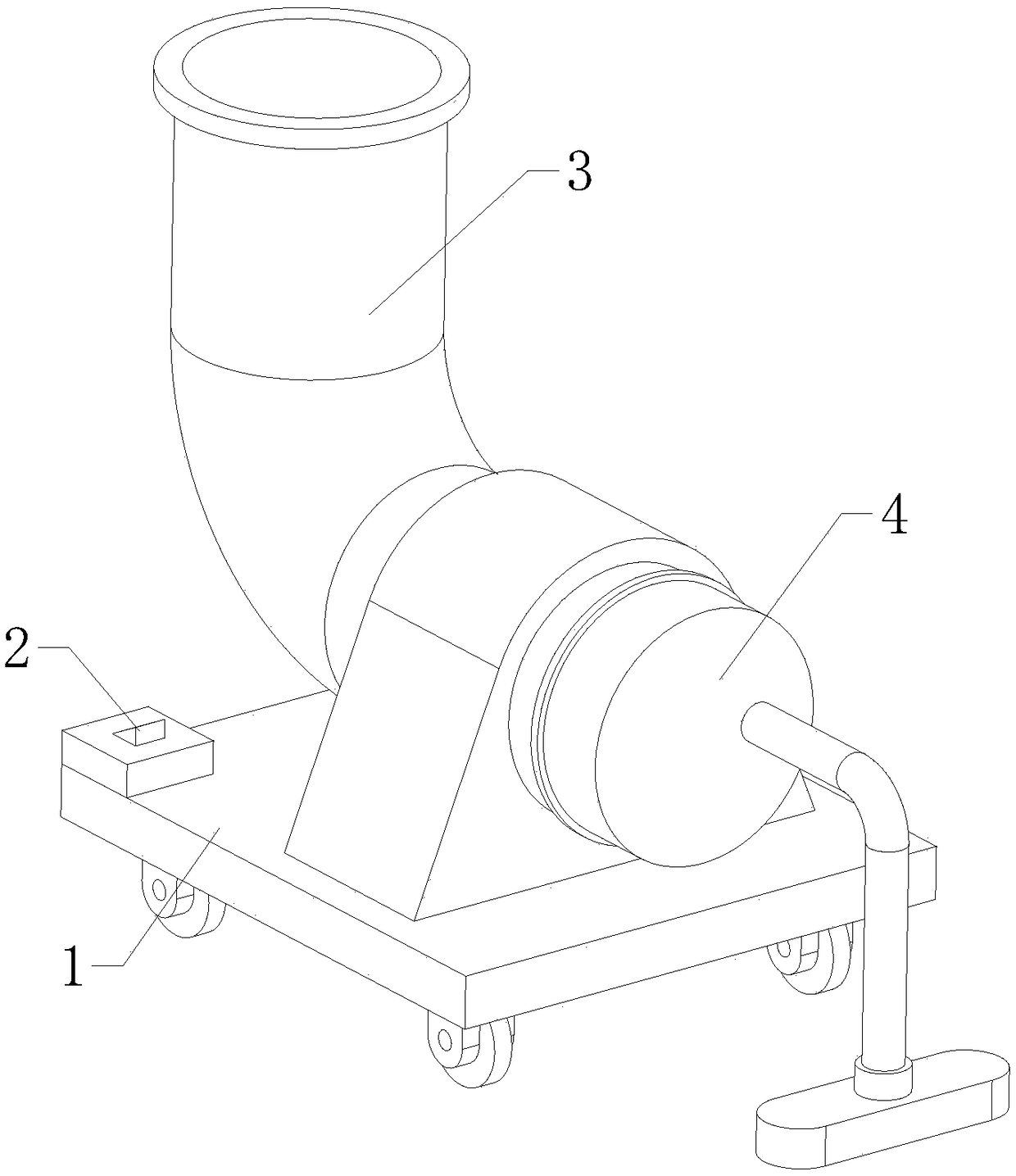

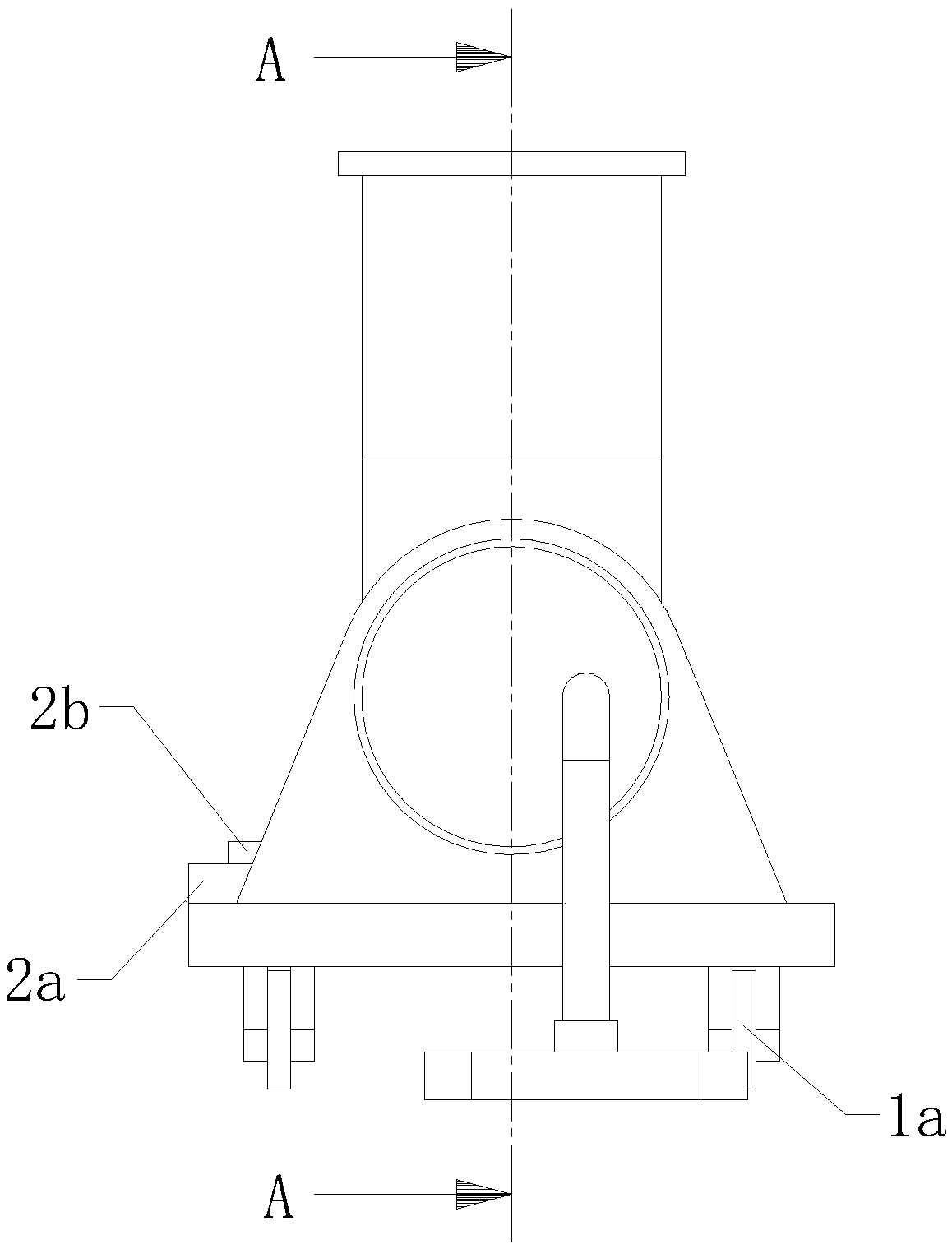

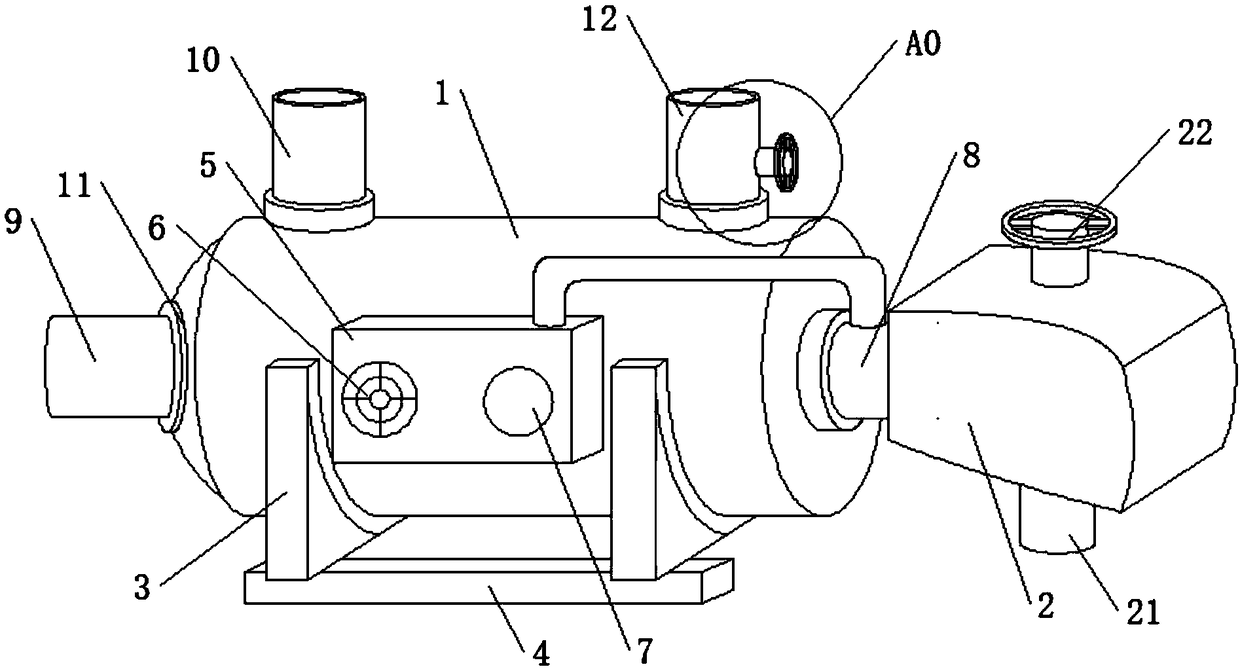

Cooling system for a blower

InactiveUS8262370B2Reduce pressureIncrease internal pressurePositive displacement pump componentsHops/wine cultivationImpellerComputer engineering

Arrangement in a blower including at least an engine and a fan, the fan includes a fan housing enclosing a fan wheel and a fan inlet. The engine and fan are surrounded by a casing provided with an air inlet to let air in to the fan inlet placed inside the casing. The air stream from the air inlet in the housing to the fan inlet cools the engine and components inside the casing before it enters the fan inlet and leaves the blower via a blower tube. The fan housing is provided with an opening (31) placed in the fan housing so that air is allowed to leave the fan in case of blocked air stream in the fan outlet or blower tube.

Owner:HUSQVARNA AB

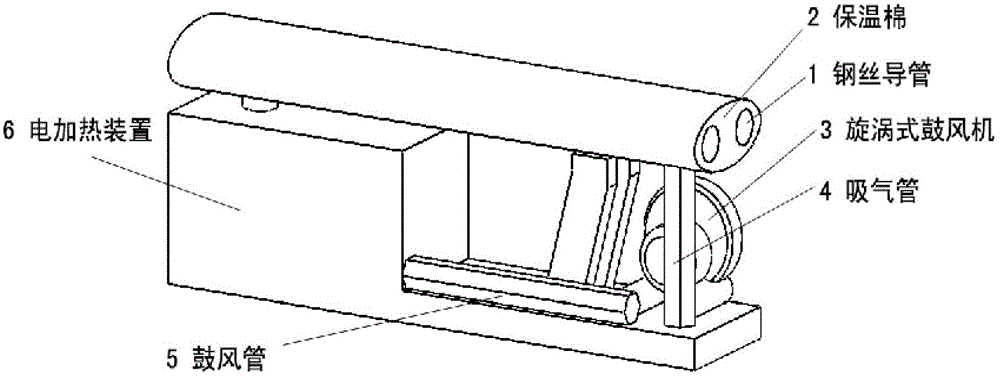

Online drying device and online drying method for bead wire

InactiveCN102944107AOvercoming Drying Processing ProblemsImprove the failure of drawing powder and affect the quality of productsDrying solid materials with heatDrying machines with progressive movementsEngineeringAir blower

The invention relates to an online drying device for a bead wire. The online drying device for the bead wire comprises a base. An electric heating device which is supported and connected to a steel wire conduit through a circular through tube is arranged on the base. An online drying method for the bead wire comprises the following steps of: A: feeding the steel wire into the steel wire conduit; B: sucking air into the steel wire conduit through an air suction pipe by virtue of a swirl type air blower; and C: feeding the swirl type air blower into the electric heating device through a blastpipe to blow so as to dry water on the surface of the steel wire. By utilizing the technical scheme provided by the invention, the problem that no devices are used for drying the steel wire coated with boron in the conventional production process is overcome, the problems that the drawing powder loses efficacy due to the water on the surface of the steel wire and the product quality is affected in the environment of high air humidity are solved, and normal subsequent drawing is ensured.

Owner:ZHANGJIAGANG SHENGDA STEEL ROPE

Fan having dust suction function

The invention relates to the field of fans, in particular to a fan having the dust suction function. The fan comprises a bottom disc, a control assembly, an air blowing assembly and a dust suction assembly, wherein the control assembly is arranged on the bottom disc, and the air blowing assembly is fixedly arranged on the bottom disc. The air blowing assembly comprises an air blowing pipe and an exhaust fan. The dust suction assembly comprises a storage component and a dust suction component. The storage component is detachably arranged inside the air blowing pipe. The dust suction component is detachably arranged on the air blowing pipe and communicates with the air blowing pipe. When the fan carries out the dust suction work, the control assembly controls the air blowing assembly to be opened; the exhaust fan exhausts air out of the air blowing pipe, and furthermore, reverse direction air suction can be conducted; the dust suction assembly is used for filtering out dust while conducting air suction; the dust suction component is used for sucking in air and the dust; and the storage component is used for incepting the dust in the air and stores the dust into the storage component,and furthermore, the dust removal effect is achieved.

Owner:安徽悦达环保科技有限公司

Biomass hot air stove system

InactiveCN106196592AImprove heat exchange efficiencyImprove thermal efficiencyFuel supply regulationAir heatersElectricityAir blower

The invention discloses a biomass hot air stove system. A hearth of a heat exchange stove body of the system is connected with an ash discharging device, the hearth is connected with a first stroke returning flue, the first stroke returning flue is connected with a second stroke returning flue which is connected with a smoke inducing pipe, the smoke inducing pipe is connected with a smoke induced draft fan, the first stroke returning flue and the second stroke returning flue are connected, the second stroke returning flue and a third stroke returning flue are connected, the third stroke returning flue is connected with the hot air induced draft fan which is connected with a hot air outlet, the hot air outlet is provided with a hot air temperature sensor, and the hot air temperature sensor is electrically connected with a hot air temperature control instrument. A hopper of a feeding system is connected with a spiral feeding auger, the spiral feeding auger and an air blower are connected with the hearth through a conveying pipe, and the air blower is connected with the bottom of a fire grate through an air blowing pipe. Biomass fuel particles are sufficiently combusted, hot air is output, heat exchange efficiency is high, use is convenient, production is stable, and maintaining is easy.

Owner:横县华能生物质燃料有限公司 +1

Efficient drying machine for bamboo floor

InactiveCN105841443AEnsure consistent drying resultsAvoid wastingDrying gas arrangementsDrying solid materialsAir filterHydraulic pump

The invention discloses a high-efficiency drying machine for bamboo and wood floors, which comprises an air blowing pipe, a drying box and a base; A heat exchanger is installed on the upper side of the air duct, a temperature generator is installed on the right side of the blast pipe, and a high temperature rod is installed in the temperature generator, and a heat insulation layer is installed on the lower side of the drying box, and the heat insulation layer A discharge port is installed on the right side, a return pipe is installed on the upper side of the drying box, a dust pipe is installed on the upper side of the drying box, a dust box is installed in the base, and the dust box is connected to the drying box through the dust pipe. A hydraulic pump is installed in the base, and a hydraulic controller is installed on the upper side of the hydraulic pump. A digital control panel is installed on the surface of the base. The invention can process hot gas through the flow stabilizer installed on the left side of the drying box. Evenly enter the drying box to ensure the consistency of the drying effect of the bamboo and wood floors in the drying box.

Owner:苏清安

Intelligent fermentation leaven room

ActiveCN103397793BQuality improvementQuality assuranceAlcoholic beverage preparationIndustrial buildingsControl systemEngineering

The invention discloses an intelligent fermentation leaven room. The intelligent fermentation leaven room comprises a leaven room body, an air regulating air blower, an air regulating blastpipe, an air regulating exhaust pipe, movable shelves and a control system arranged outside the leaven room body. The air regulating blastpipe, the air regulating air blower and the air regulating exhaust pipe are arranged inside the leaven room body in a series connection mode. A control valve A and a control valve B are arranged on the two sides of the air regulating air blower respectively. The movable shelves are arranged inside the leaven room body. A plurality of bamboo rafts are arranged on each movable shelf. A heating assembly and a humidification assembly are arranged in an air channel of the air regulating air blower. The heating assembly and the humidification assembly are communicated with the air regulating blastpipe respectively. A temperature and humidity measurement assembly is arranged on each movable shelf and connected with the control system through a cable. The control system is used for describing the temperature field and humidity field inside the intelligent fermentation leaven room according to data detected by the temperature and humidity measurement assemblies, the air regulating air blower, the heating assembly, the humidification assembly and the control valves are regulated according to set parameters, and therefore the temperature and humidity inside the intelligent fermentation leaven room are regulated and controlled.

Owner:KWEICHOW MOUTAI COMPANY

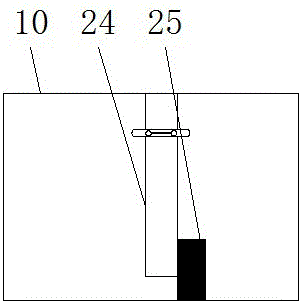

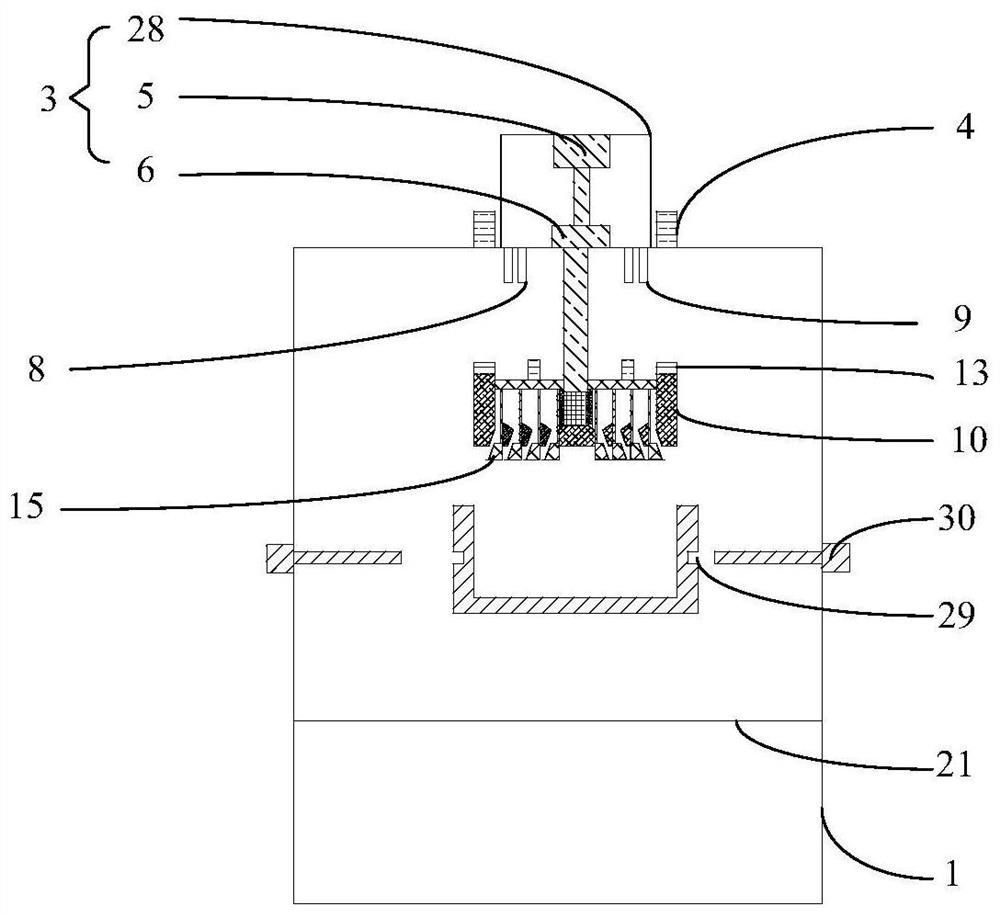

Boiler capable of preventing vent holes from being blocked

InactiveCN113028443ARealize online dredgingAvoid entanglementBlast-producing apparatusSolid removalMarine engineeringElectric machine

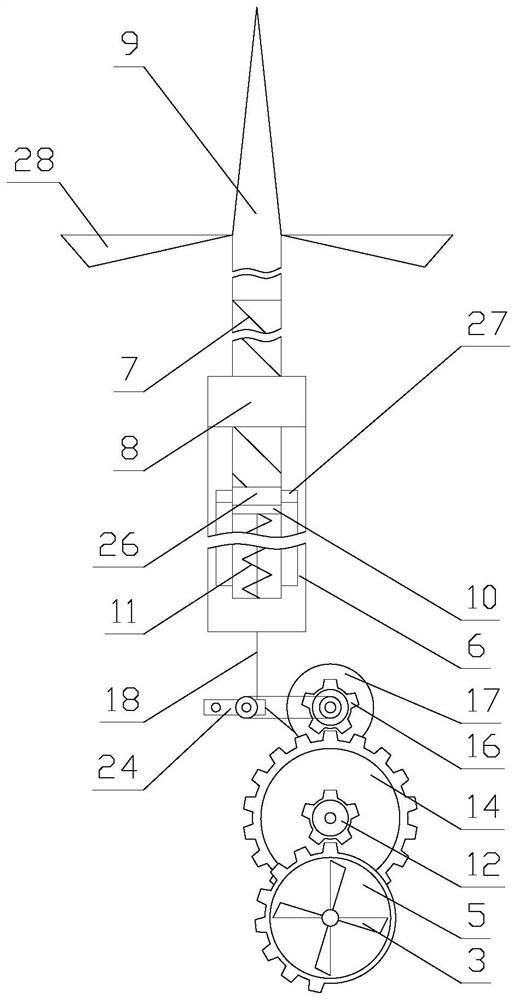

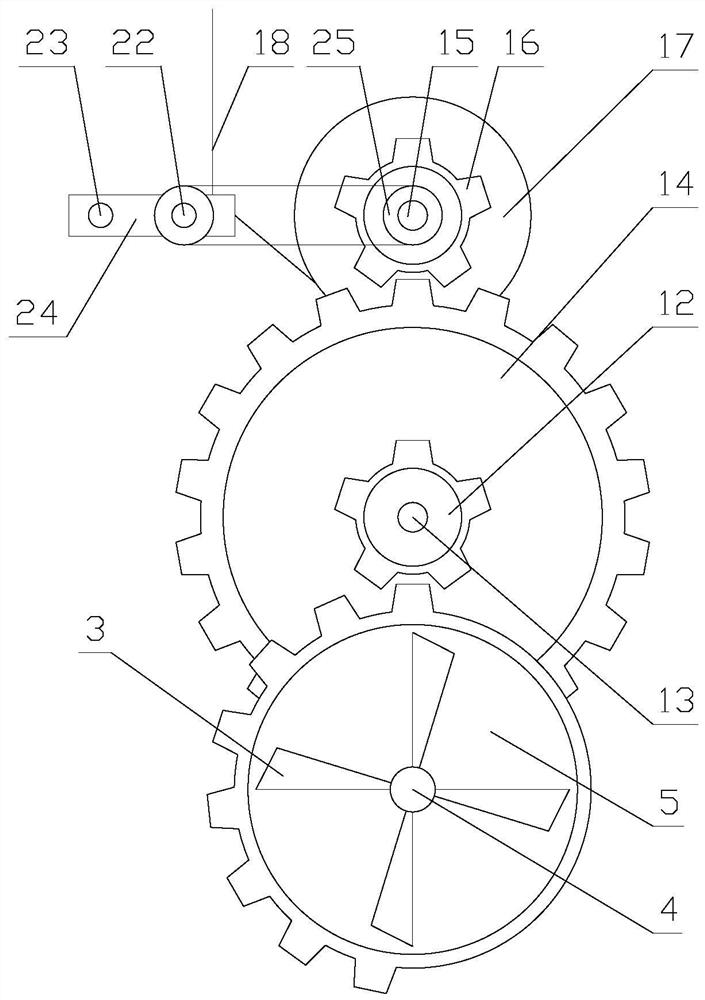

The invention relates to a boiler capable of preventing vent holes from being blocked. The boiler comprises a main body, a bottom plate, an air blowing mechanism and a dredging mechanism, the bottom plate is arranged in the main body, the air blowing mechanism is arranged below the bottom plate, the dredging mechanism is arranged in the main body, the dredging mechanism comprises a driving assembly, a pulling assembly and a dredging assembly, and the air blowing mechanism comprises a fan, an air blowing pipe and a nozzle. According to the boiler capable of preventing the vent holes from being blocked, air blowing is achieved through the air blowing mechanism, dredging of the vent holes is achieved through the dredging mechanism, online dredging of the vent holes is achieved through linkage of the dredging mechanism and the air blowing mechanism, a pure mechanical structure is adopted in linkage, the stability of the device is improved, the service life of the device is prolonged, meanwhile, air blown out by the fan serves as a driving source of the dredging mechanism, driving sources such as a motor are not needed for driving, energy is saved, a pull rope is evenly wound around a wire coil through a winding assembly, winding and knotting of the pull rope are avoided, the device runs more stably, and practicability is improved.

Owner:广州涛博石油有限公司

Cloth drying device with high safety and based on computer technology

InactiveCN108955111AWon't fallImprove securityDrying gas arrangementsDrying solid materialsEngineeringAir blower

The invention discloses a cloth drying device with high safety and based on computer technology. The cloth drying device comprises a drying oven, wherein a drying machine is fixed on the inner wall atthe bottom of the drying oven through a bolt; a drying heating tube is fixed on the outer wall of the top of the drying machine through the bolt and is distributed on the top outer wall of the dryingmachine in a disc shape; an air blower is fixed at one end of the top outer wall of the drying oven through the bolt; a blastpipe is connected with the blower nozzle of the air blower in an insertingmanner; a control cabinet is fixed on the outer wall of one side of the drying oven through the bolt; a heater is fixed on the top outer wall of the control cabinet through the bolt; and the air inlet of the heater is connected with the end, far away from the air blower, of the blastpipe in an inserting manner. The cloth drying device can be far away from the heating tube, enables cloth not to fall off, avoids the phenomena that the dried heating tube is damaged due to baking and burns, improves the safety, dries the cloth with hot-blast air to uniformly heat the cloth and improves the practicality.

Owner:ZHENGZHOU CHENGHE INFORMATION TECH CO LTD

Marsh gas-coal dual-purpose fuel boiler for poultry farming and using method

The invention discloses a marsh gas-coal dual-purpose fuel boiler for poultry farming and a using method. The marsh gas-coal dual-purpose fuel boiler comprises a boiler body. An inner cavity is formed in the boiler body and connected with a flue. A hearth is arranged below the inner cavity. A flame bridge is arranged below the hearth. An air chamber is arranged below the flame bridge. A water tank is arranged between the boiler body and the inner cavity. A temperature sensor is arranged in the water tank and connected with a controller. A convection bank is arranged in the inner cavity. One end of the convection bank is connected with a water inlet pipe. The other end of the convection bank is connected with a water outlet pipe. The side wall of the upper portion of the hearth is provided with a marsh gas inlet pipe connected with a nozzle. The other side wall of the hearth is provided with a boiler door. A vent pipe is arranged on the lower portion of the hearth, and penetrates through the side wall of the air chamber to be communicated with the outside world. The lower portion of the air chamber is connected with an air blower through a blower pipe. The marsh gas-coal dual-purpose fuel boiler has the advantages of saving the fuel cost, relieving environment pressure and reducing environment pollution.

Owner:嘉兴金旅燕科技有限公司

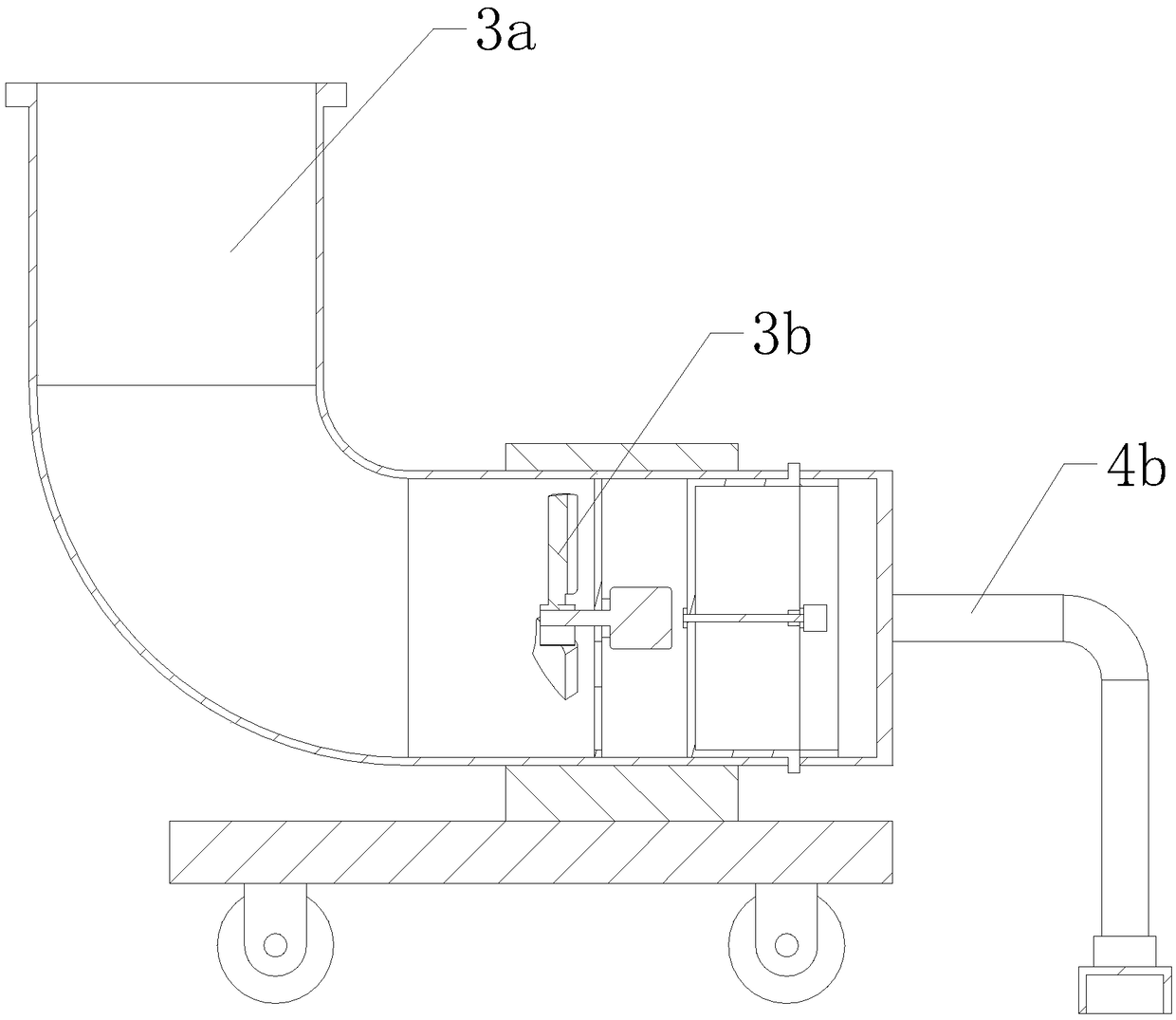

Blower device for air blowing coal stove

ActiveCN105258165AScientific and reasonable structureEasy to useDomestic stoves or rangesBlast-producing apparatusCombustionEngineering

The invention discloses a blower device for an air blowing coal stove. The blower device comprises a third-stage blowing hose, a second-stage blowing hose, a center supporting rod, a bottom supporting frame, a self-locking type first-stage ventilation cavity and a wind wing type strong air blower. The wind wing type strong air blower is mounted on the right side of the self-locking type first-stage ventilating cavity through hexagon bolts in an airtight manner, and a first-stage air blowing pipe is arranged on the right side of the self-locking type first-stage ventilating cavity. The center supporting rod is mounted in the middle inside the first-stage air blowing pipe. A spiral air blowing guide plate is arranged on the peripheral outer wall of the center supporting rod. A third-stage ventilating cavity and a second-stage ventilating cavity are formed in the top of the first-stage air blowing pipe. The bottom supporting frame is arranged at the bottom of the first-stage air blowing pipe. Through the cooperation of the self-locking type first-stage ventilating cavity, the second-stage ventilating cavity and the third-stage ventilating cavity, coal can obtain enough oxygen at all the combustion stages and different combustion positions, and combustion is more complete; and resources are saved, emissions of harmful gas are reduced, and environmental pollution is reduced.

Owner:LEIYANG XINGNONG ANIMAL HUSBANDRY CO LTD

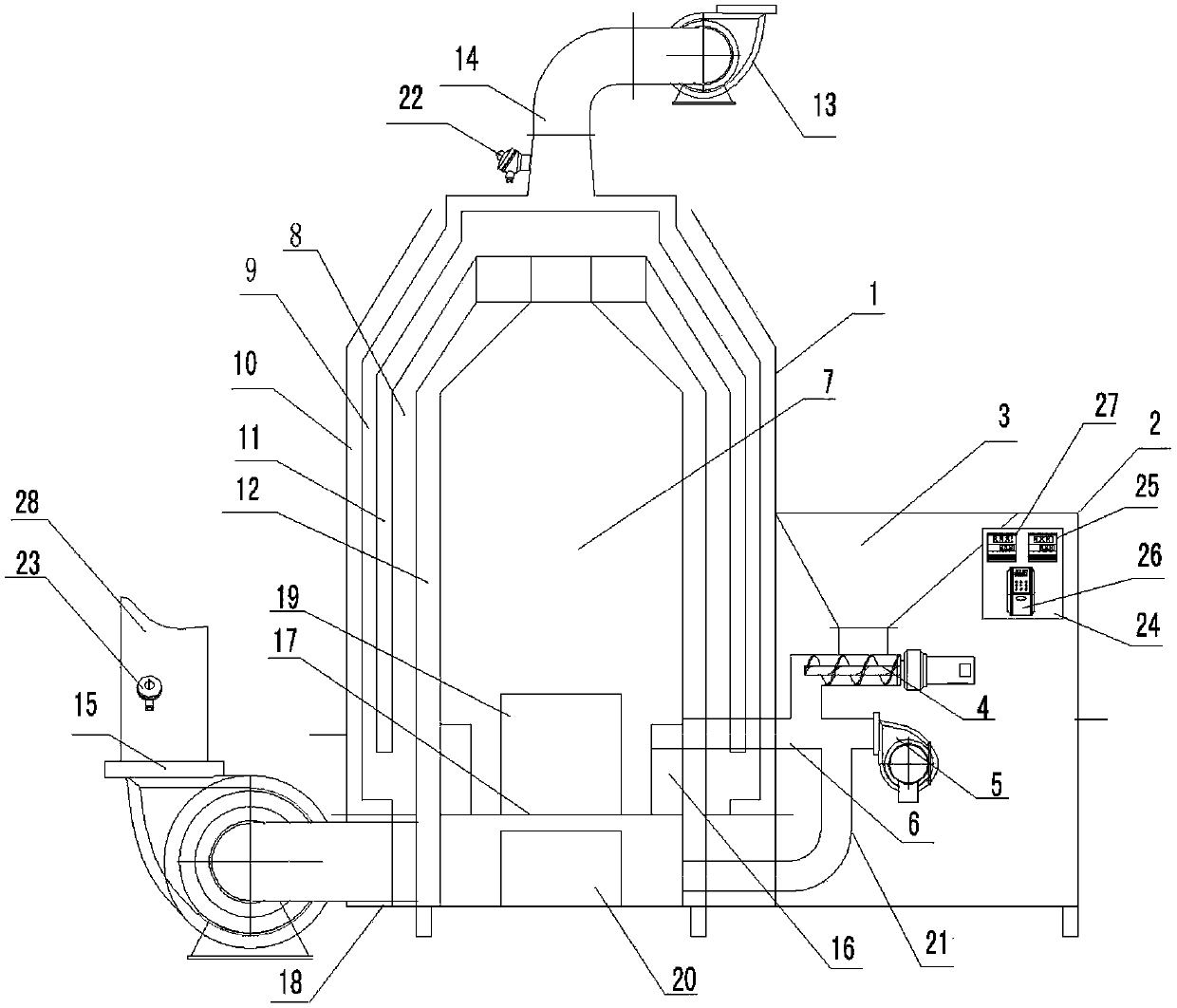

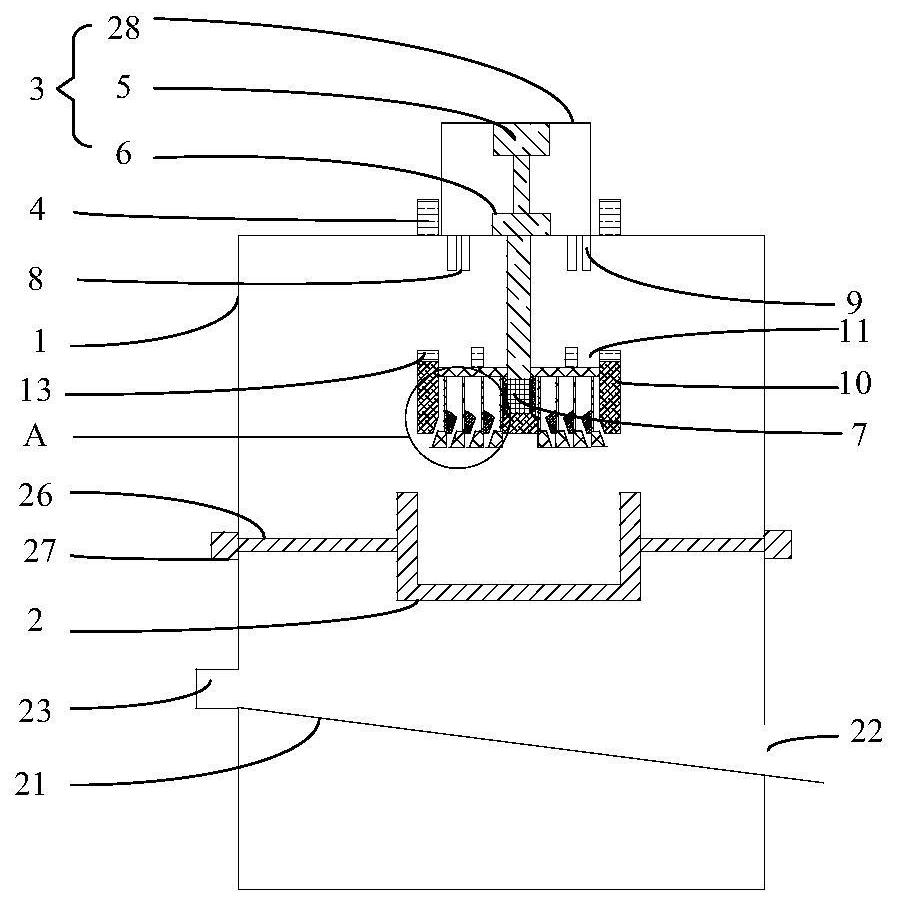

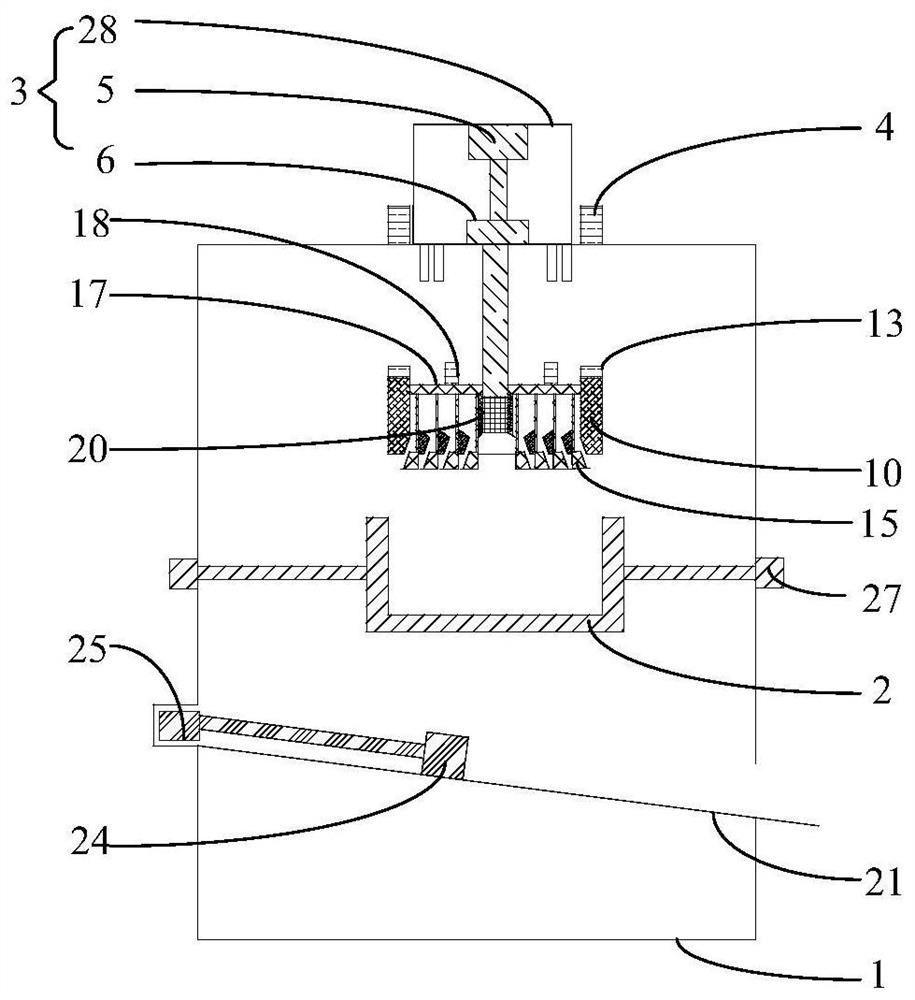

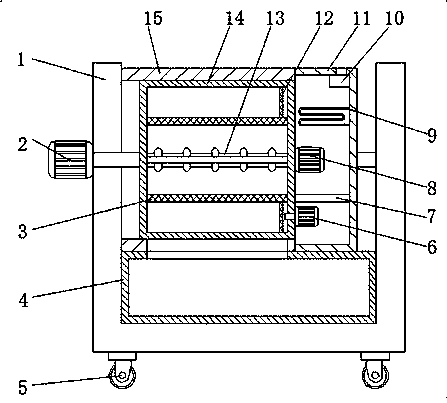

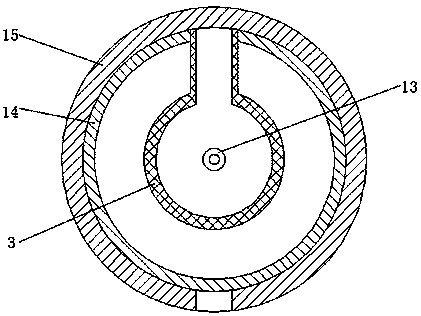

Tempered glass homogenizing furnace

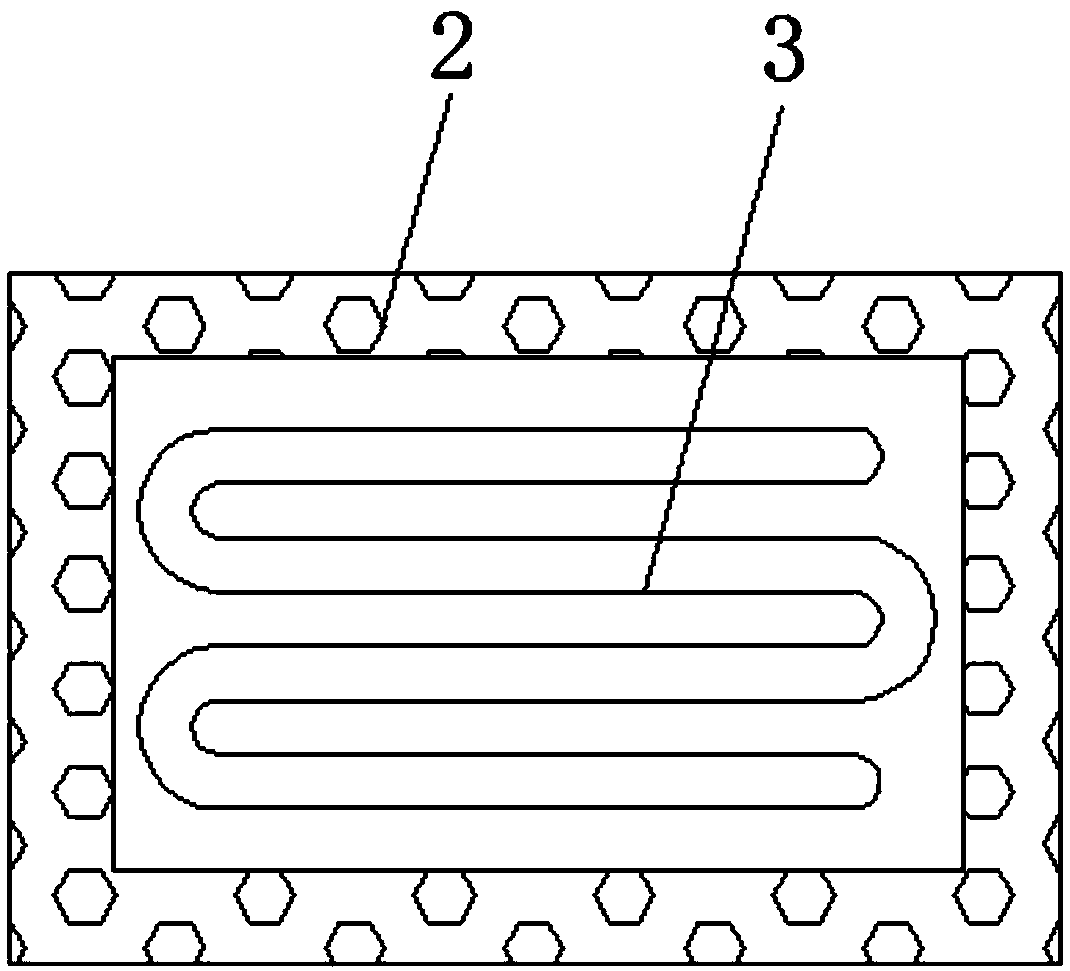

InactiveCN104891794AUniform temperatureQuality assuranceGlass tempering apparatusFurnace temperatureTemperature control

Relating to tempered glass processing equipment, the invention provides a tempered glass homogenizing furnace. The upper side and lower side of an inner cavity (10) are provided with a heating pipe (6), the left side wall of the homogenizing furnace body (1) is provided with a fan (2), the fan (2) is in connection with a blastpipe (3), and the blastpipe (3) is communicated with the inner cavity (10), the right side wall of the homogenizing furnace body (1) is provided with a slide rail (7), the slide rail (7) and a double acting door (8) are in sliding connection, and an air outlet (9) is disposed at the lower part of the homogenizing furnace body (1) on the right side. The tempered glass homogenizing furnace has the characteristics of simple structure, convenient installation and maintenance, and uniform in-furnace temperature, also is provided with a temperature control system, has no need of heating by means of worker experience, and ensures the quality of tempered glass. At the same time, the furnace door adopts sliding open-close, does not occupy space, and is suitable for furnace body butt joint.

Owner:肥西县三星玻璃有限公司

Energy-saving and environment-friendly boiler for thermal power plant

InactiveCN107726286ARealize multiple recyclingReduce the temperatureSteam boilersFeed-water heatersAir preheaterSlag

The invention discloses an energy-saving and environment-friendly boiler for a thermal power plant, which comprises a coal inlet, a coal inlet pipe, a blower, a blast pipe, a coal mill, a pulverizer, a pulverizer blowing pipe, a pulverized discharge pipe, a multi-head pulverized coal outlet, and a boiler. Wall, evaporation chamber, drum boiler, steam pipe, superheater, water inlet pipe, economizer, air preheater, air inlet pipe, air outlet, blower, exhaust gas pipe, dust collector, desulfurization chamber, nitrogen removal chamber, Exhaust gas turbine, chimney, slag blowing outlet, slag outlet and slag discharge ditch, the coal inlet is connected to the coal inlet pipe, the coal inlet pipe is connected to the coal mill, the bottom of the coal mill is connected to the blast pipe, and the drum The air duct is connected to the blower, the position of the pulverizer relative to the blast pipe is connected to the powder blowing pipe, the powder blowing pipe is connected to the powder discharger, and the powder discharger is connected to the powder discharge pipe. The temperature of the waste gas is lowered while the temperature of the inlet water and the intake air is increased, which saves energy, and the waste gas is treated with dust removal, desulfurization and nitrogen removal to reduce the degree of waste gas pollution.

Owner:东莞旺科知识产权运营有限公司

Paint surface drying device for aluminum alloy door and window production

ActiveCN113357881AReduce impactAvoid damageDrying gas arrangementsPretreated surfacesAir pumpEngineering

The invention belongs to the technical field of aluminum alloy door and window production, and especially relates to a paint surface drying device for aluminum alloy door and window production. The following scheme is disclosed: the paint surface drying device for aluminum alloy door and window production comprises a workbench and a heating cover, wherein connecting holes are formed in the outer wall of the bottom of the heating cover at equal intervals, and the inner wall of each connecting hole is fixedly connected with a blast cover; and the outer wall, located at the inner side, of each blast cover is fixedly connected with a sealing ring, the inner wall of each sealing ring is fixedly connected with a blast pipe, each blast cover communicates with the corresponding blast pipe, and adaptive holes are formed in the outer wall, located at the inner side, of each blast cover at equal intervals. According to the invention, by arranging a retention assembly, after gas is guided into a heating cover through a gas pump, the gas flows through an electric heating pipe, the electric heating pipe heats the gas, and most of the heated gas passes through an arc-shaped reciprocating plate and reaches the electric heating pipe again under the action of a retention plate and a baffle at the two sides of the electric heating pipe; and therefore, the gas is heated in a reciprocating mode through the electric heating pipe, the temperature of the blown gas is increased, and the hot gas drying effect is improved.

Owner:南通诚润包装制品有限公司

Lateral-blowing air-blowing gas burning boiler

The invention discloses a lateral-blowing air-blowing gas burning boiler which comprises a boiler shell and a burner. A coaxial pipe is arranged on one side of the boiler shell in an embedded manner and composed of a burning pipe and an air blowing pipe, the burner is mounted at one end of the coaxial pipe, a gas incoming pipe is arranged at the bottom of the burner, a gas incoming control valve is arranged at the top of the burner, an air blower is arranged on the side face of the boiler shell and fixedly connected with the boiler shell through bolts and communicated with the air blowing pipethrough a pipeline, an air blowing adjusting valve is arranged on the side face of the air blower, and a smoke discharging pipe and a water incoming pipe are arranged at two ends of the top of the boiler shell in an embedded manner respectively. The boiler is compact in shell structure, stable in structure, high in safety, convenient and flexible to use, safe and reliable in operation, high in stability and wear resistance, less prone to being damaged, convenient and quick for mounting and demounting, low in casting cost, wide in application prospect and practical.

Owner:浙江杭兴锅炉有限公司

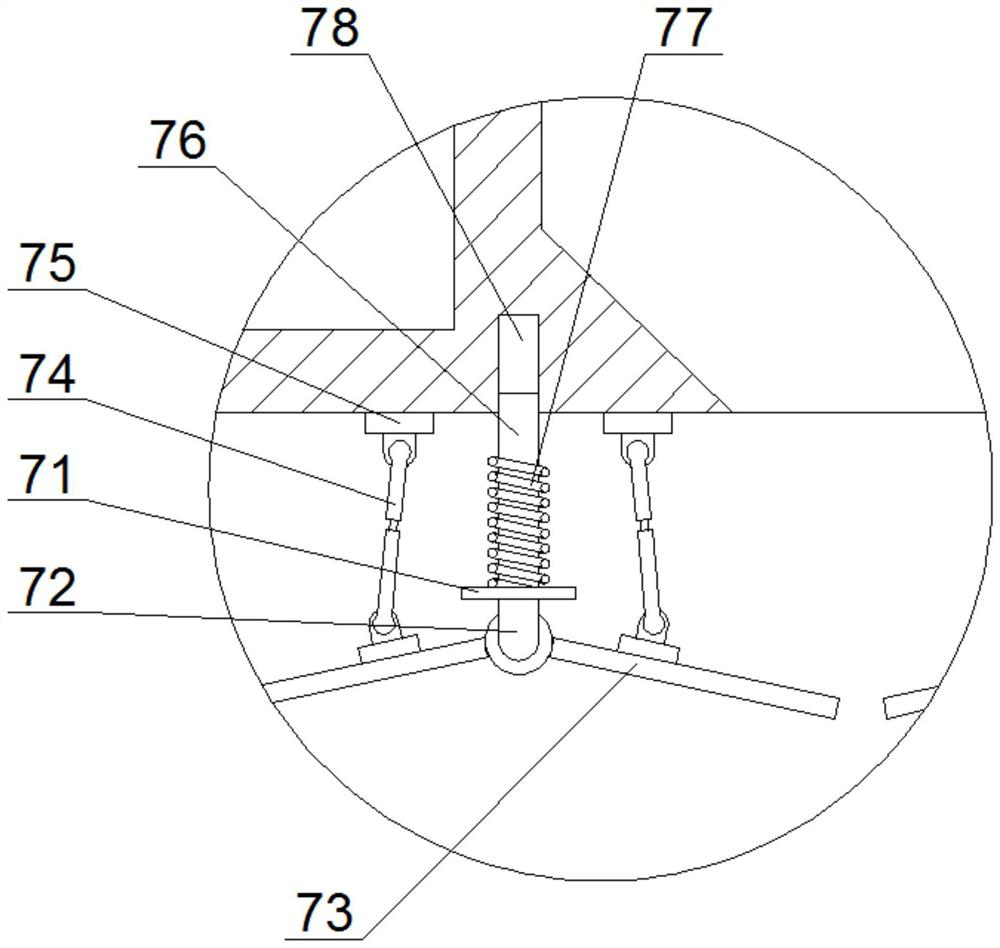

Coal mine quality detection device

ActiveCN112595568AAvoid affecting test resultsIncrease impactPreparing sample for investigationFuel testingMining engineeringMechanical engineering

The invention discloses a coal mine quality detection device, which comprises a pulverizer, and the pulverizer comprises: a shell, which is internally equipped with a grinding bowl, and is provided with a spray head and a blast pipe on the top surface; a grinding block, which is located above the grinding bowl, and has a top face sinking downwards to form a cavity, wherein the cavity is fixedly connected with an elastic rod and provided with at least one circle of spraying holes in a penetrating mode, and a first electromagnet is arranged at the top of the side wall of the cavity; a first driving mechanism, which is arranged on the outer side of the top of the shell, drives the grinding block to rotate along the horizontal plane and vertically move up and down, and is externally equipped with a second electromagnet; a blocking piece, which comprises a plurality of hole plugs, wherein any hole plug is fixedly provided with a connecting rod, the connecting rod is connected with a sieve tray, a third electromagnet is arranged on the top surface of the sieve tray, the bottom surface of the hole plug horizontally extends to form an abutting edge, and a spring is further arranged betweenthe sieve tray and the bottom surface of the cavity. A coal mine sample can be automatically cleaned after being ground, and the influence on the detection result of a next ground coal mine sample isavoided.

Owner:通标标准技术服务(天津)有限公司

Automatic gypsum powder dust treatment device

ActiveCN111672849AWide range of advocacyEasy to take awayHollow article cleaningDirt cleaningDust controlEngineering

The invention discloses an automatic gypsum powder dust treatment device which comprises an air blower, a dust collection barrel, a cloth bag type dust remover and an exhaust fan. A dust discharge pipe is connected between an air inlet of the cloth bag type dust remover and the upper portion of the dust collection barrel, the exhaust fan is connected with an air outlet of the cloth bag type dust remover through an exhaust pipe, a feeding hopper and a discharging hopper are arranged at the top and the bottom of the dust collection barrel correspondingly, a discharging valve is installed on thedischarging hopper, a flow dividing flange plate is arranged on the lower portion of an inner cavity of the dust collection barrel, an inner supporting flange is formed on the lower portion of the inner cavity of the dust collection barrel, the part, close to the end face, of the diameter reducing end of the flow dividing flange plate is rotationally connected with an inner hole of the inner supporting flange, a blast pipe is connected to the air blower, one end of the blast pipe tangentially penetrates into the dust collection barrel, and a pipe opening of the penetrating end of the blast pipe directly faces one blade. According to the automatic gypsum powder dust treatment device, a suction mechanism is arranged at one end of a container, a blowing mechanism is arranged at the other endof the container, and compared with an existing single-side suction mode, the suction device has the advantages of being wider in suction face and better in suction efficiency.

Owner:四川蓝鼎新材料有限公司

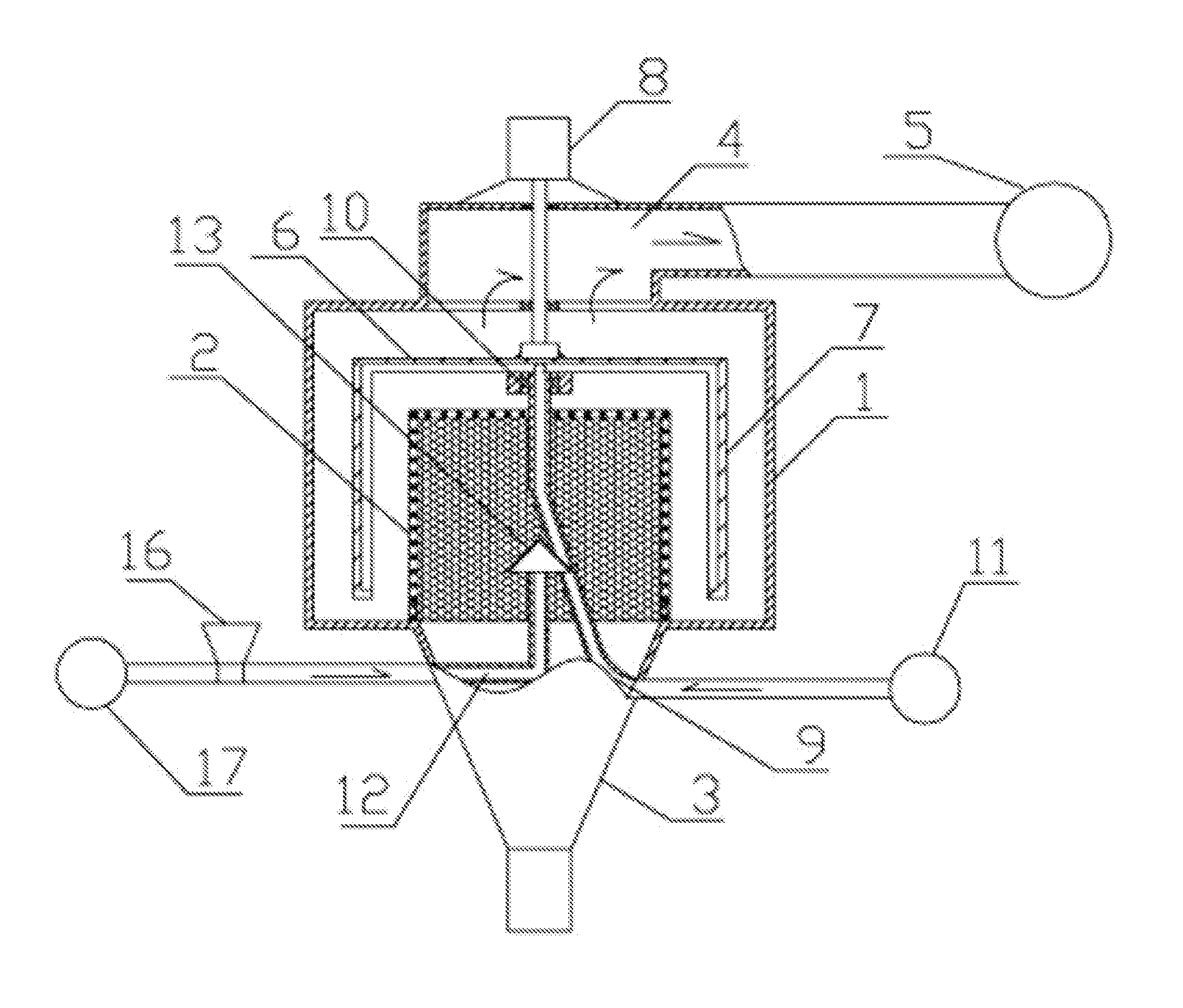

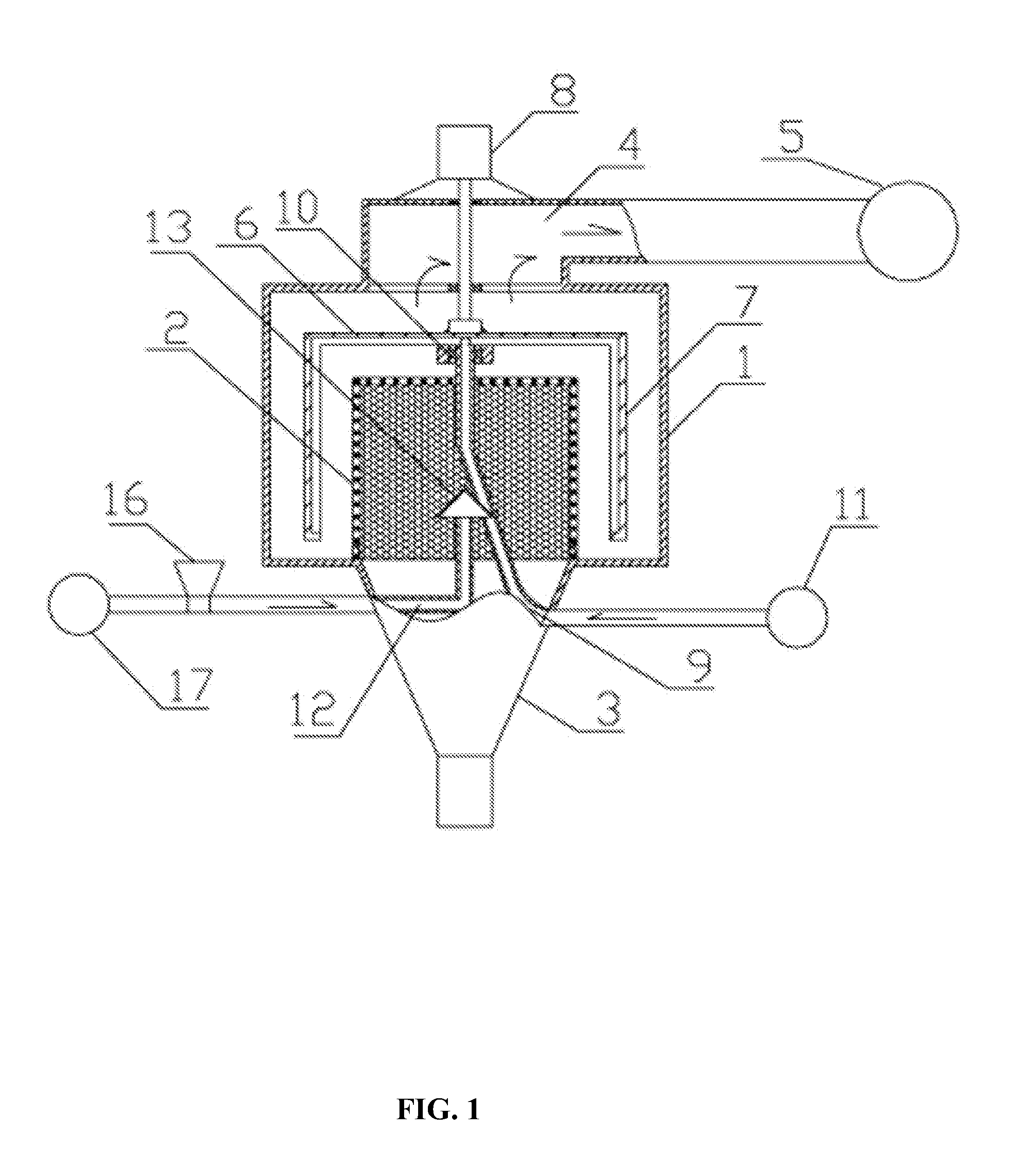

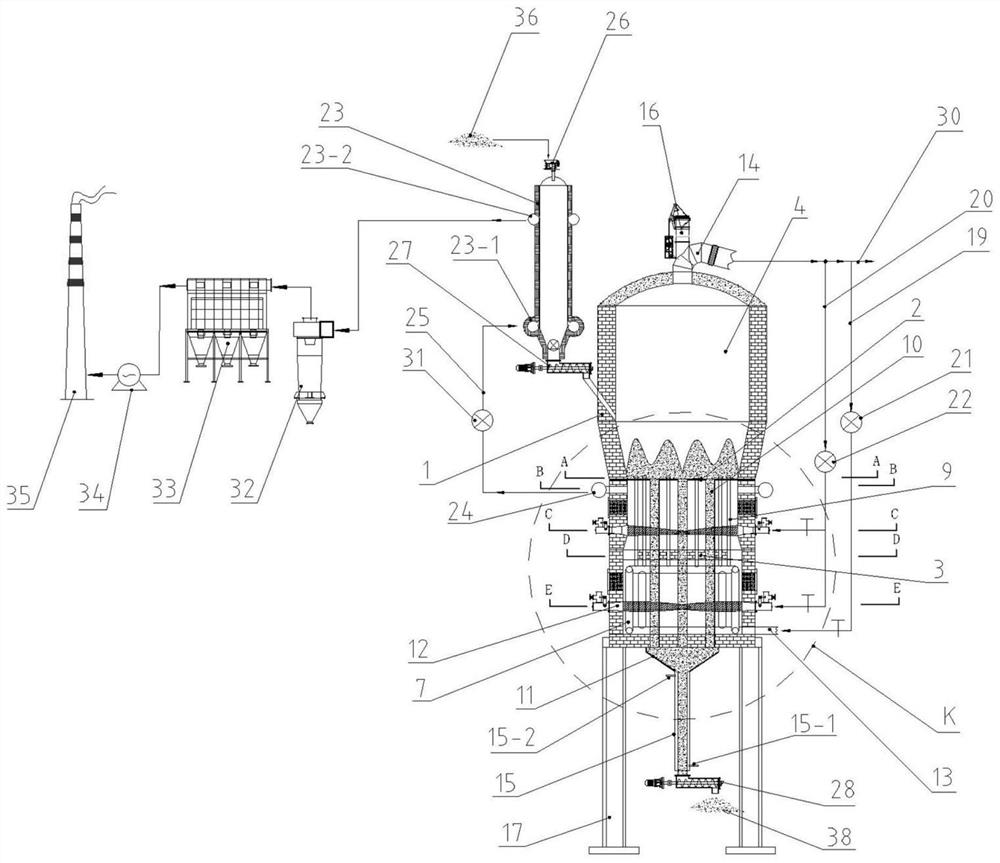

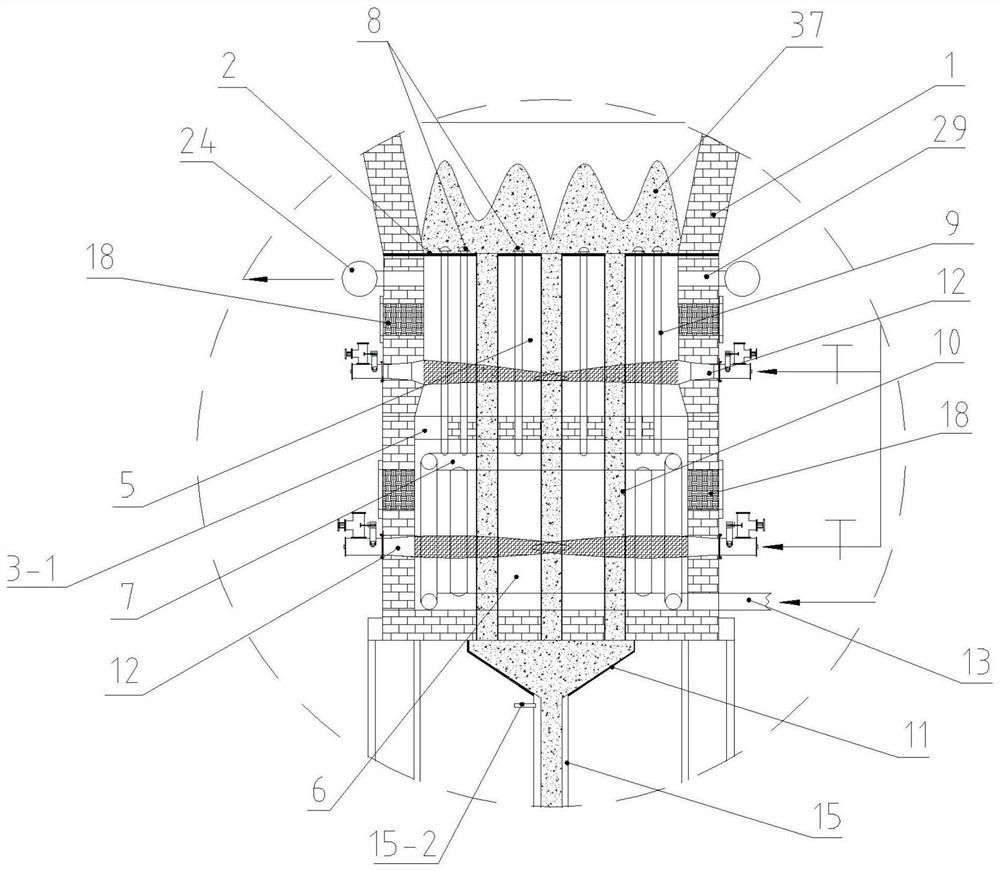

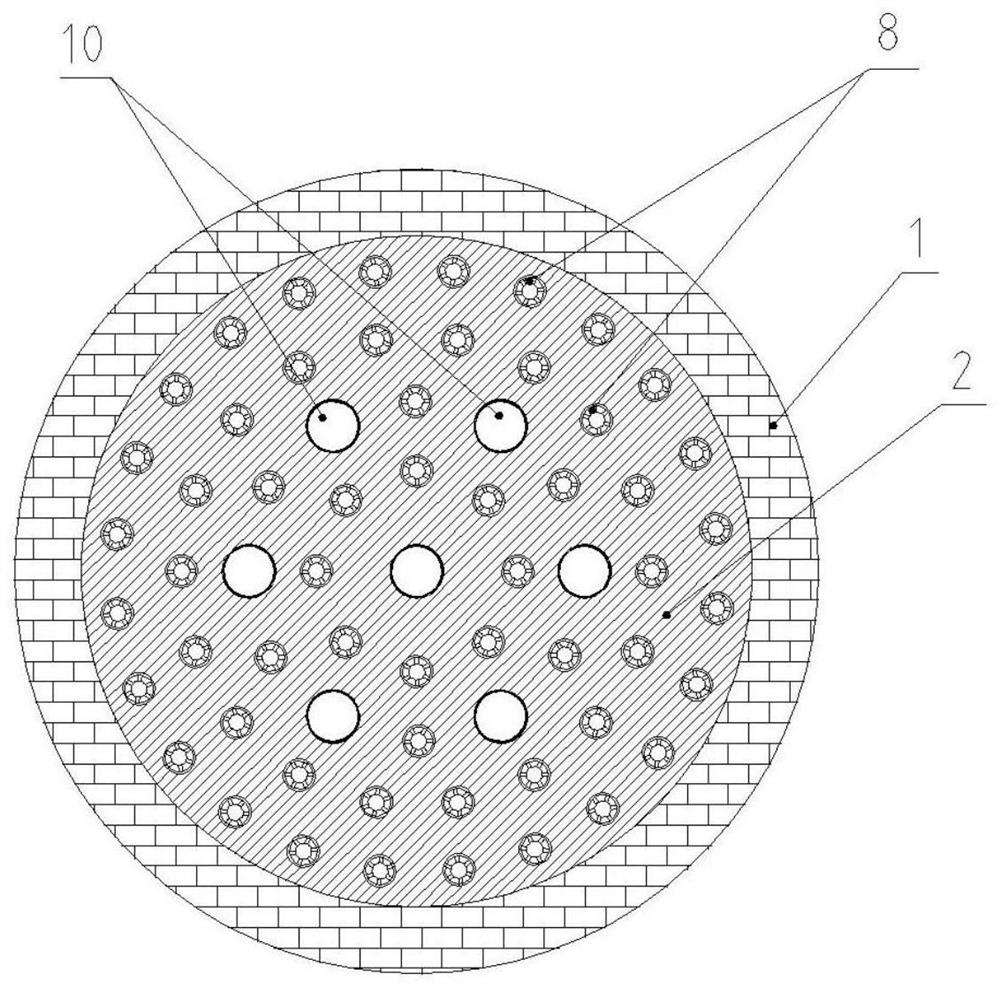

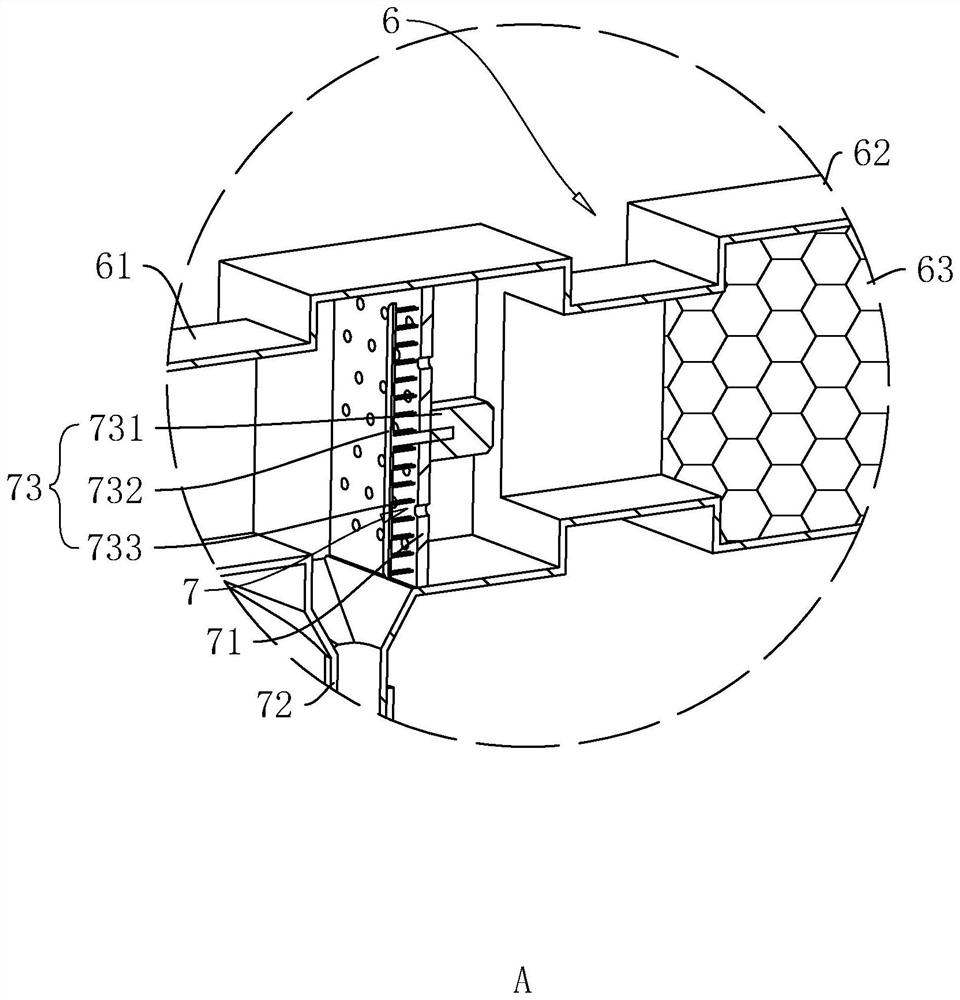

A multi-purpose fluidized bed fluidized bed furnace and system with fully reducing atmosphere

ActiveCN112610951BFast Roasting DehydrationIntense reduction reactionFluidized bed combustionProcess efficiency improvementFurnace temperatureEngineering

The present invention provides a multi-purpose fluidized bed fluidized bed furnace device and system with sufficient reducing atmosphere. The inner cavity of the fluidized bed furnace is divided into a furnace and an upper heating chamber from top to bottom by a blast heat-resistant steel bottom plate and a heating chamber partition. and the lower heating chamber; a heat exchange ring pipe is arranged in the lower heating chamber; a plurality of wind caps are arranged on the blast heat-resistant bottom plate, and the air inlet of the wind cap passes through the partition plate of the heating chamber to communicate with the heat exchanger through the blast pipe. Heat ring pipe: multiple blanking holes are provided on the blast heat-resistant bottom plate, and the blanking reaction tubes are connected to the corresponding blanking holes. The blanking reaction tubes pass through the heating chamber partition and lead to the The collecting hopper at the bottom of the body; multiple heating chamber burners are installed in the upper and lower heating chambers. The device and system of the present invention have the characteristics of continuous production, high thermal efficiency, stable furnace temperature, uniform roasting temperature, easy temperature control, and balanced quality, and it is also a fluidized bed fluidized bed furnace device system with a fully reducing atmosphere.

Owner:烟台市红森林节能环保科技有限公司

Hazardous waste stable solidification system

PendingCN108435758AExcellent adhesionEasy to stickSolid waste disposalTransportation and packagingExhaust fumesGuide tube

The invention discloses a hazardous waste stable solidification system. The hazardous waste stable solidification system comprises a base, a pneumatic dredging device, a dust solidification cabin, a solidified waste rotating disc, a blast pipe and an air humidifier; a pneumatic dredging device bracket is welded to the upper surface of the base, the left portion of the upper surface of the base iswelded with a dust solidification cabin support, the upper surface of the pneumatic dredging device bracket is welded with the pneumatic dredging device, a pneumatic rod is in sliding connection intothe pneumatic dredging device, an electric casing pipe is welded to the middle of the upper surface of the pneumatic dredging device, waste gas with hazardous waste particles is guided into the blastpipe from a waste guide pipe, the waste particles are accumulated in a waste solidification groove, the next empty waste solidification groove is switched for repeating the accumulation process, and when accumulated objects are rotated to the lowest end, the pneumatic rod of the pneumatic dredging device ejects the accumulated objects into a recycling groove, and the stable solidification processof the dust hazardous waste can be finished.

Owner:山东中再生环境科技有限公司

Anti-corrosion waste incineration boiler superheater system

PendingCN114484462AImprove work efficiencyReduce heat transferSteam superheatersIncinerator apparatusPipe fittingSuperheater

The invention relates to the technical field of waste incineration, in particular to an anti-corrosion waste incineration boiler superheater system which comprises a boiler body, a smoke outlet pipe fitting, a first blower device and superheater equipment, the first blower device and the superheater equipment are located on the smoke outlet pipe fitting, one end of the smoke outlet pipe fitting is communicated with a smoke outlet of the boiler body, and the other end of the smoke outlet pipe fitting is communicated with the superheater equipment. The first blowing device is arranged on the smoke outlet pipe fitting and comprises a first blower and a first blowing pipeline, the first blower is arranged on the smoke outlet pipe fitting, an air outlet of the first blower is communicated with the first blowing pipeline, and the first blowing pipeline is communicated with the smoke outlet pipe fitting. Low-temperature air is blown into the smoke outlet pipe fitting, so that the low-temperature air exchanges heat with high-temperature corrosive smoke generated by the boiler body to generate high-temperature air, direct heat exchange between the high-temperature corrosive smoke and superheater equipment is reduced, the problem of corrosion of the superheater equipment is fundamentally solved, and the working efficiency of the boiler body can be improved.

Owner:慈溪中科众茂环保热电有限公司

Thermodynamic cycle accumulation-free efficient incineration boiler

PendingCN112113227AAvoid concentrated accumulationSave drive energyRotary stirring mixersTransportation and packagingProcess engineeringIncineration

The invention discloses a thermodynamic cycle accumulation-free efficient incineration boiler. The efficient incineration boiler comprises an incineration cavity, an air blowing pipe, a fan and a stirring device, wherein an air outlet of the air blowing pipe is connected to the bottom of the incineration cavity, the fan is connected with the air blowing pipe and blows air into the air blowing pipe, and the stirring device is arranged at the lower end inside the incineration cavity and used for stirring garbage in the incineration cavity; and the incineration cavity comprises a double-layer wall, wherein the side face of the double-layer wall is connected with an air collecting pipe, and the air collecting pipe collects flowing gas between the double-layer wall of the incineration cavity todrive the stirring device to rotate. According to the thermodynamic cycle accumulation-free efficient incineration boiler, incinerated garbage in the incineration boiler can be fully dispersed, accumulation is avoided during incineration, combustion is sufficient, and meanwhile hot gas outside the incineration cavity can be collected and utilized, so that the incinerated garbage is further fullydispersed.

Owner:江阴市锦绣江南环境发展有限公司

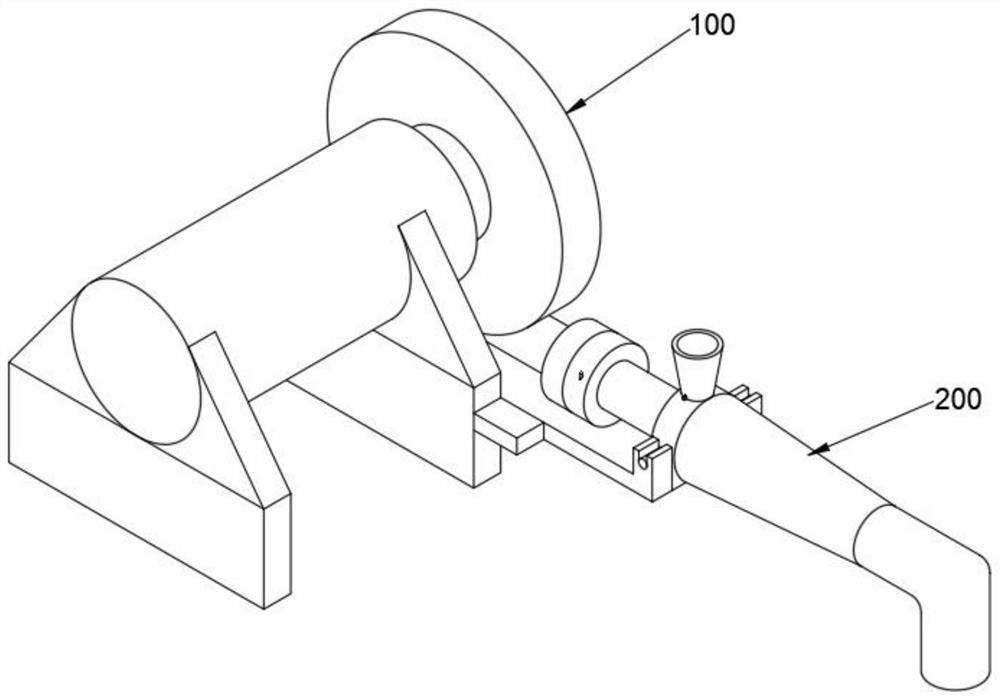

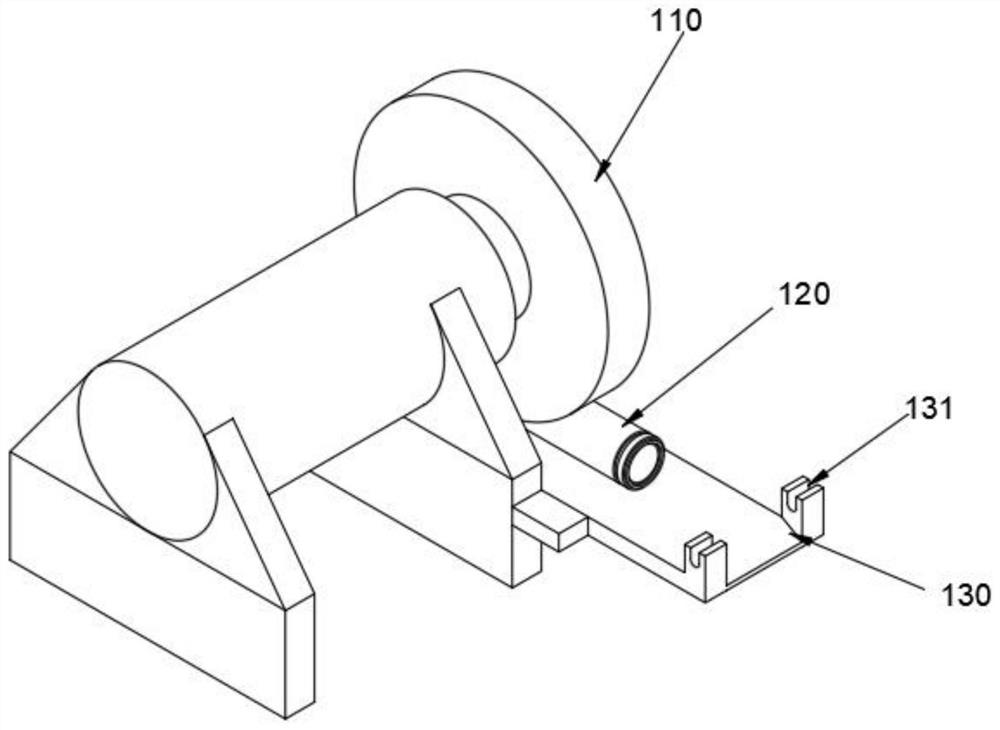

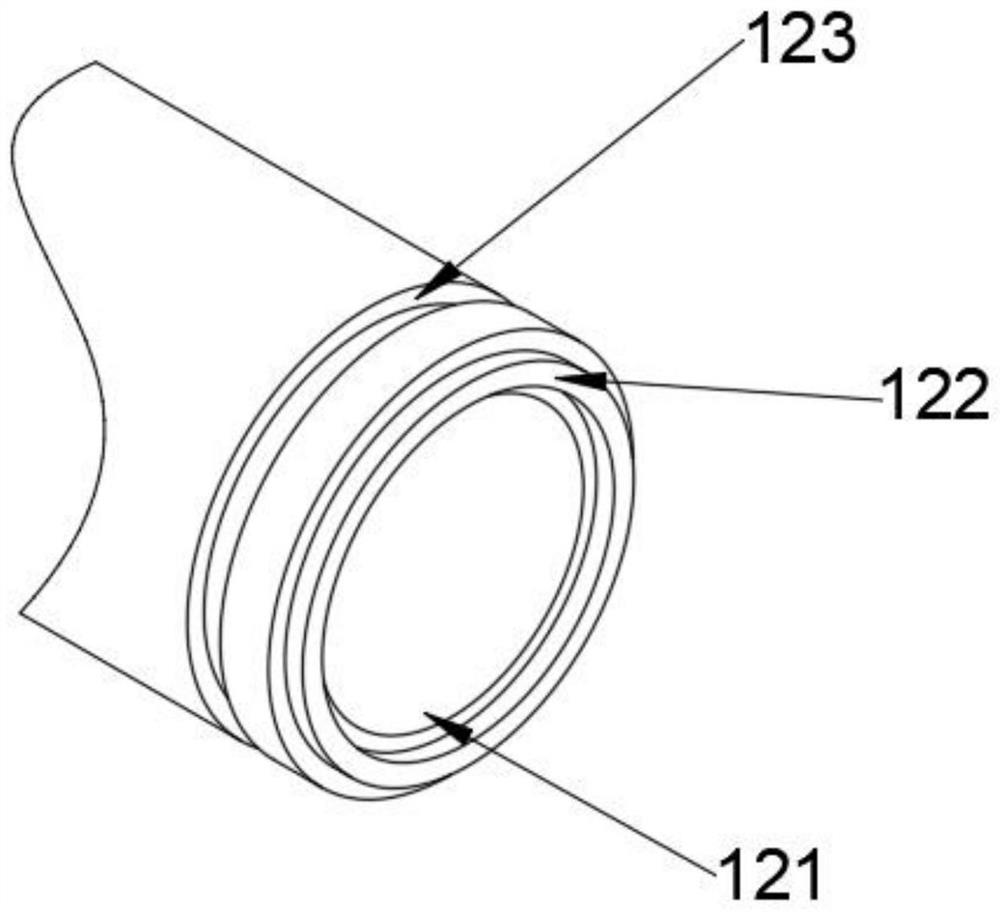

Feeding device for spray type refractory material spray coating machine

The invention relates to a feeding device, in particular to a feeding device for a spray type refractory material spray coating machine. The feeding device comprises an air supply mechanism used for providing high-pressure air, and the air supply mechanism is connected with a material supply mechanism used for supplying materials. The air supply mechanism comprises an air blower used for generating high-pressure air, and the air blower is connected with a blast pipe used for conveying out the high-pressure air. The material supply mechanism comprises a hopper used for containing materials, the bottom of the hopper is connected with a material supply shell used for providing a spraying environment, one end of the material supply shell is connected with an air inlet pipe used for introducing the high-pressure air, and the other end of the material supply shell is connected with a material supply connecting pipe used for outputting materials. The feeding device for the spray type refractory material spray coating machine mainly solves the problem that due to the fact that the size difference of refractory materials sprayed by an existing spray coating machine is too large, the spray coating speed and the spray coating effect of the spray coating machine are affected.

Owner:张建新

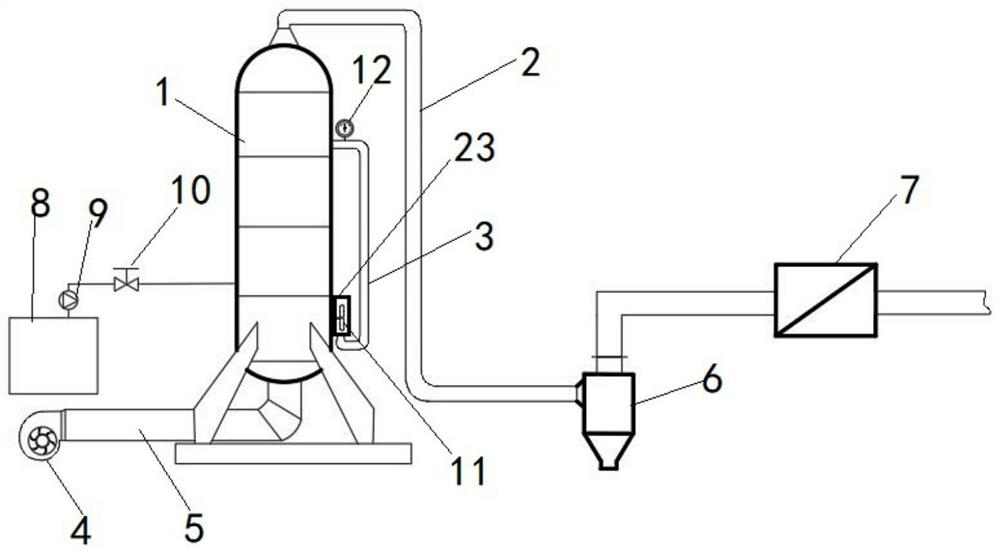

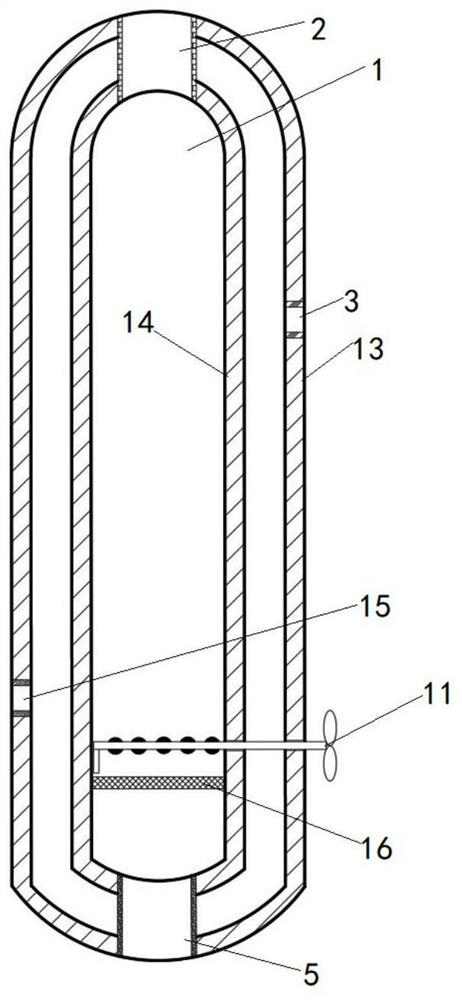

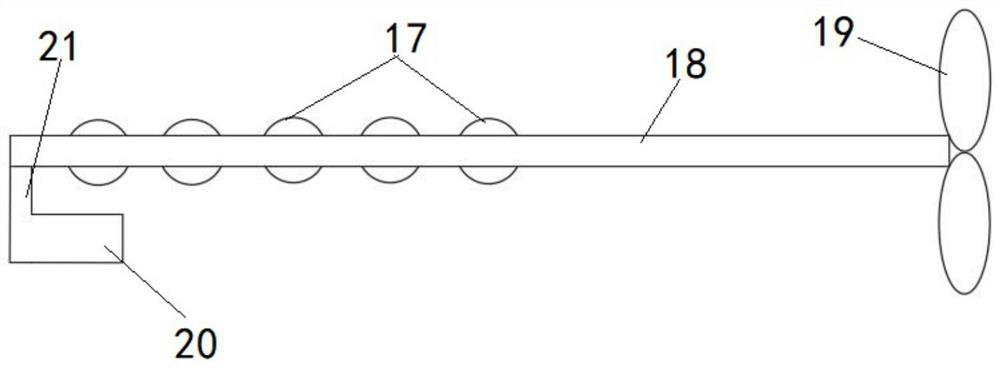

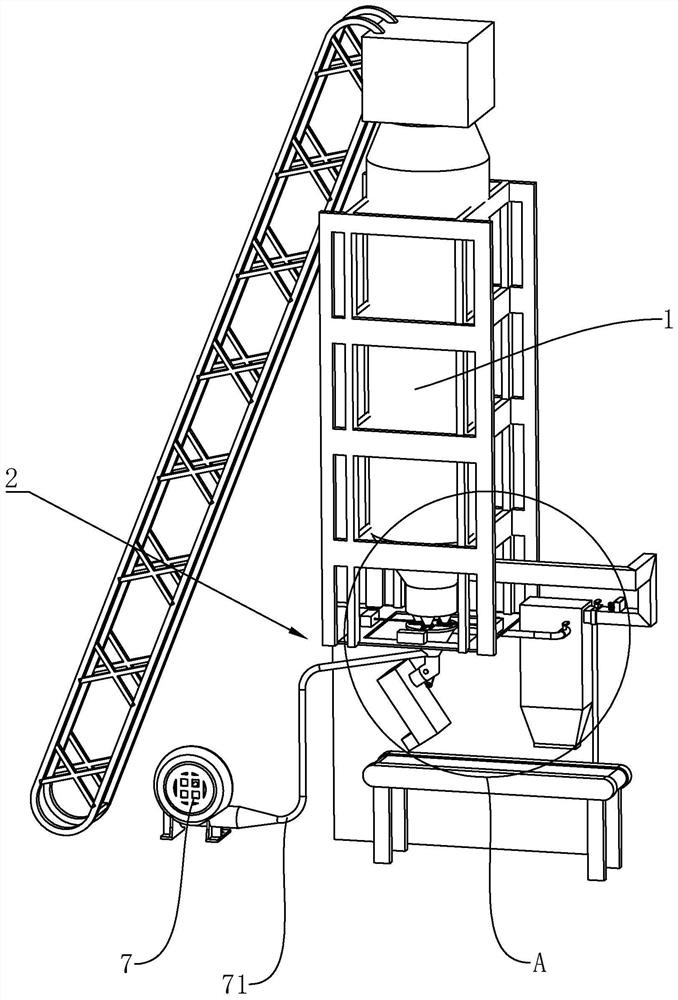

A lime production system

ActiveCN110590194BReduce the amount of pulverized coalQuality improvementProcess engineeringPulverized fuel ash

The invention relates to a lime production system, which includes a kiln body and an ash unloading device. The ash unloading device consists of a receiving bucket, an ash discharge machine, a first ash unloading hopper and a second ash unloading hopper connected sequentially from top to bottom. The ash unloading device A blower is connected to the blower, and a blast pipe is connected to the blower; the first ash discharge hopper is conical, and the axis of the cone is parallel to the horizontal plane, the lower end of the first ash discharge hopper is a conical sharp end, and the second ash discharge hopper The upper end is connected with a feed valve, the lower end of the first ash discharge hopper is connected with the feed valve on the second ash discharge hopper, the end of the blast pipe away from the blower is connected to the side of the first ash discharge hopper, and the end of the blast pipe is far away from the blower The axis of the shaft is tangent to the outer surface of the first ash discharge bucket, and a coal ash box is arranged on one side of the first ash discharge bucket, and the upper end of the coal ash box is connected with a first coal ash discharge pipe and a second coal ash discharge pipe. It can reduce the amount of pulverized coal in the produced lime and improve the quality of the lime.

Owner:江苏北山建材有限公司

Multifunctional separation device for pharmaceutical production

InactiveCN108188026AConducive to screeningEasy to control separation effectGas current separationDrying gas arrangementsDrive shaftEngineering

The invention discloses a multifunctional separation device for pharmaceutical production. The multifunctional separation device for pharmaceutical production comprises a machine frame. Universal wheels are fixed to four corners of the outer wall of the bottom of the machine frame through screws. A receiving box is fixed to the inner wall of the bottom of the machine frame through screws. Transmission shaft installing holes are formed in the outer walls of two sides of the machine frame. Transmission shafts are connected with the inner walls of the two transmission shaft installing holes through bearings. The outer walls of one sides of the two transmission shafts are connected with an installing box and a separating box separately through keys. The outer wall of one side of the separatingbox is fixed to the outer wall of one side of the installing box through a screw. A motor is fixed to the outer wall of one side of the machine frame through a screw. Powder in medicines can be removed in time, powder mingled inside can be screened out conveniently, the separating effect is convenient to control, the separating efficiency is improved, the drying effect is achieved, and the possibility that powder gets wet and adheres to the surfaces of medicines is reduced. A temperature and humidity sensor is used for detecting the temperature and humidity inside a blastpipe, and control over the quality of medicines is facilitated.

Owner:蚌埠市宏大制药机械有限公司

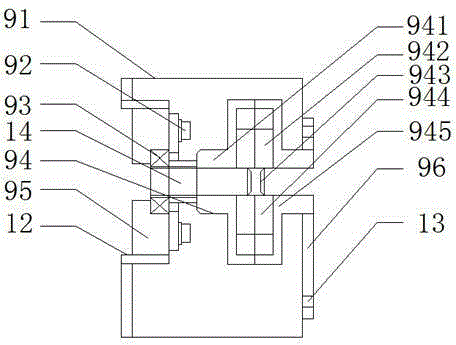

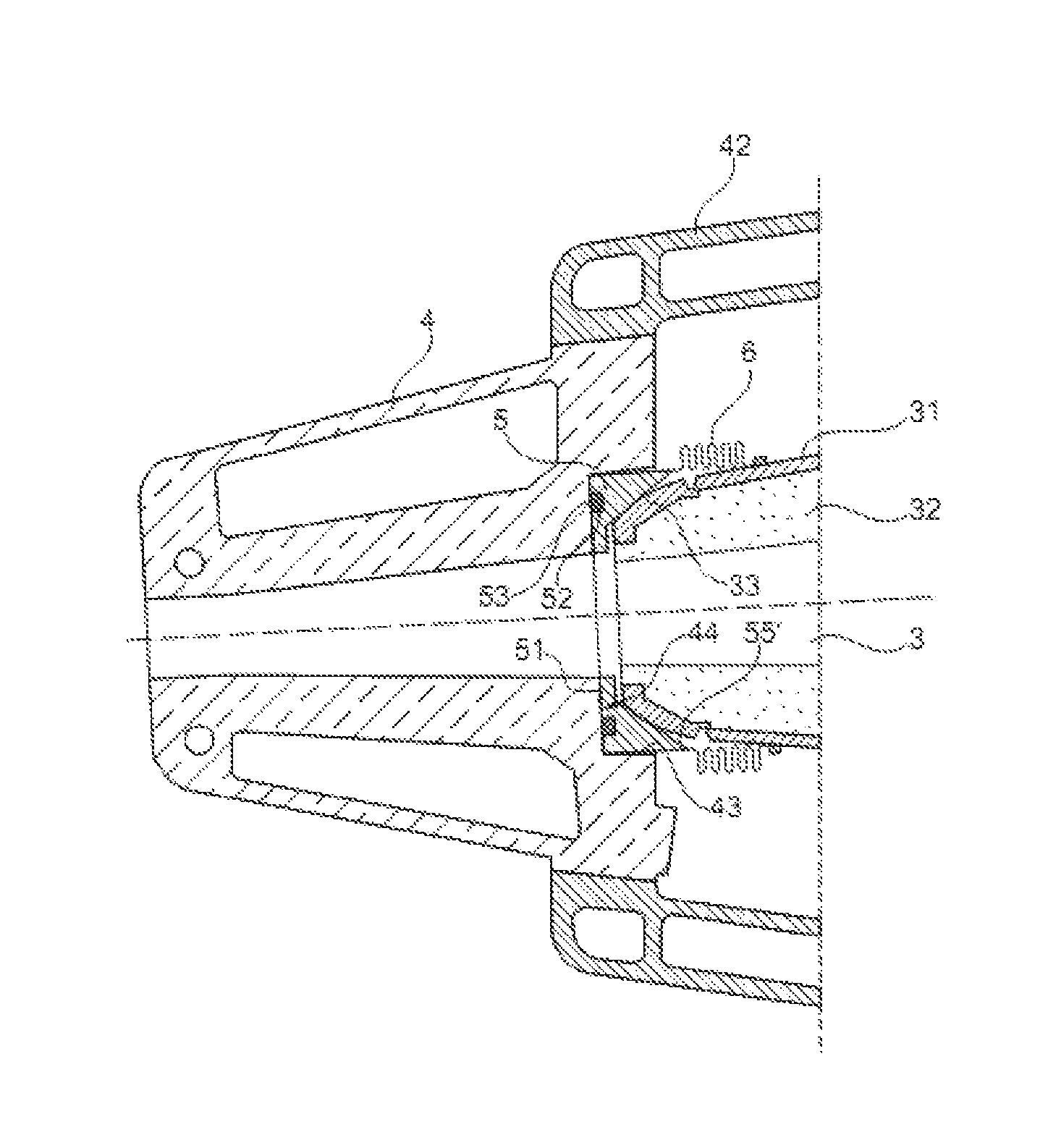

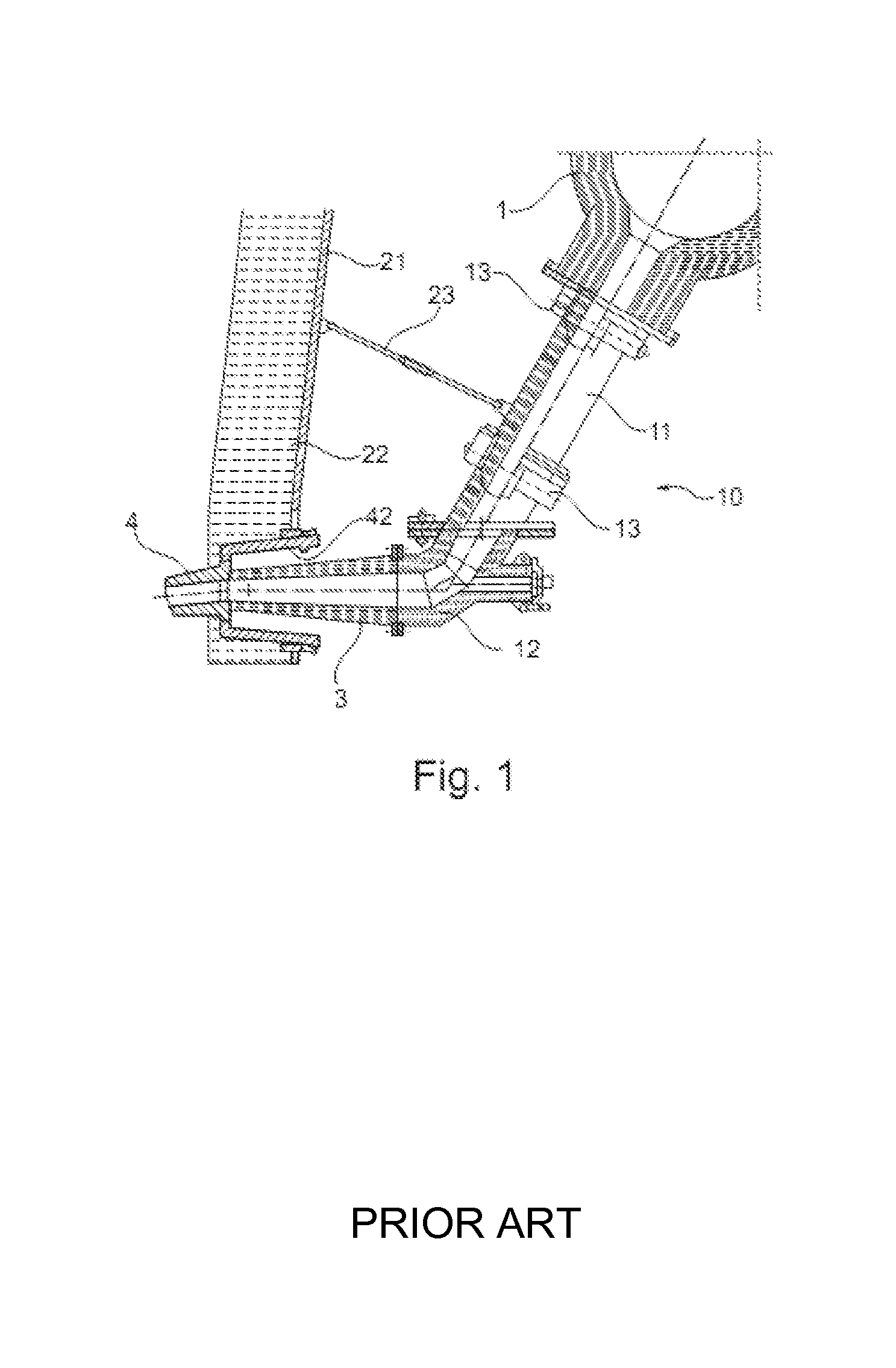

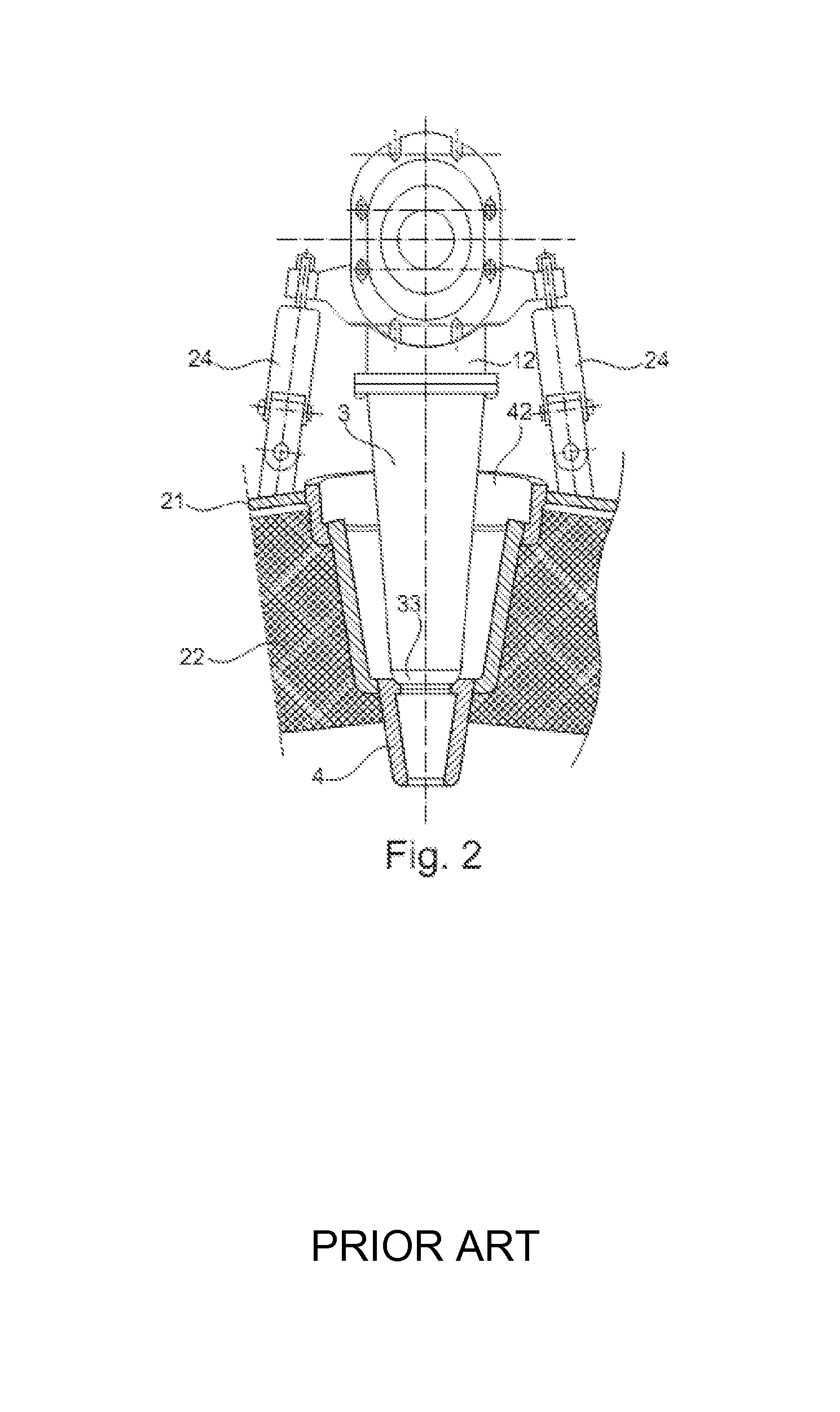

System of leaktight connection between a tuyere and a hot blast inlet nozzle for a shaft furnace, and steel-making blast furnace comprising such a system

The sealed connection system between a tuyere of a shaft furnace, such as a steelmaking blast furnace, and an air blast pipe, in which a tip of the blast pipe is pressed towards a rear end of the tuyere, being centered thereon while still retaining freedom of pivoting movement relative thereto, including an added annular blast pipe seat, placed between the tip of the blast pipe and tuyere and immobile relative to the tuyere, the blast pipe tip resting against a rear face of the seat and an immobile gasket being placed between the seat and the tuyere such that the seat rests in sealed manner against a rear face of the tuyere, and a sleeve arranged around the contact zone between the blast pipe tip and the seat, is connected in sealed manner to the seat and to the blast pipe.

Owner:PAUL WURTH SA

Combustion furnace with exhaust cylinder having airflow intensity balance function

The invention discloses a combustion furnace with an exhaust cylinder having an airflow intensity balance function. The combustion furnace comprises a bottom plate, wherein the outer wall of the top of the bottom plate is fixed with a boiler body through bolts, the outer wall of the top of the boiler body is fixed with an auxiliary air inlet pipe through bolts, a valve is arranged on the outer wall of one side of the auxiliary air inlet pipe, a frequency conversion draught fan mounting base is fixed on the outer wall of the top of the bottom plate through bolts, and a frequency conversion draught fan is fixed on the outer wall of the top of the frequency conversion draught fan mounting base through bolts; a blower nozzle of the frequency conversion draught fan is in inserted connection with an air blowing pipe; and the exhaust cylinder is fixed on the outer wall of the top of the bottom plate through bolts. The frequency conversion draught fan works and generates wind to blow exhaust gas into the exhaust cylinder, the flow speed of the exhaust gas is increased, the exhaust convenience of the exhaust gas is added, a wind balance net ball rotates to make the wind even, a light plastic ball moves up and down on a circular balance speed reduction net column to balance the wind again, and the balance capacity of the combustion furnace is increased.

Owner:HUBEI AIFUWEI ENVIRONMENTAL ENERGY TECH CO LTD

Production apparatus and process for fertilizer deodorized at high temperature

PendingCN108997031AImprove qualityReduce pollutionManure dryingClimate change adaptationAgricultural engineeringHearth

The invention discloses a production apparatus and process for a fertilizer deodorized at high temperature. The production apparatus is characterized in that heating pipes are arranged above a hearth;the pore of each heating pipe is internally provided with an auger; a furnace roof is located above the heating pipes; a steam pipe is located above the furnace roof and is connected with a chimney;the furnace roof is connected with a hot blast drawing pipe; the hot blast drawing pipe is connected with a heat-insulation blast blower; the heat-insulation blast blower is connected with a hot blastpipe; the hot blast pipe is connected with a behind-heating-pipe connector; the rear end of each heating pipe is provided with the behind-heating-pipe connector; the front end of each heating pipe isprovided with a before-heating-pipe connector; the lower end of each auger is provided with an auger chain wheel; the auger chain wheel is connected with a chain; the chain is connected with a chainwheel; the chain wheel is connected with a speed changer; the speed changer is connected with a motor; the bottom of the hearth is provided with a hearth blast blower; a dried material outlet is formed in bottom of the hearth; a feed hopper is connected with the heating pipes; the diameter-length of the heating pipes is increased through series connection of the heating pipes via the before-heating-pipe connector; the before-heating-pipe connector and the behind-heating-pipe connector are connected with the front and rear openings of the heating pipes; and the tail end of the series heating pipes is connected with the dried material outlet. The production apparatus has the advantages of simple structure, easy manufacturing, and convenient installation and usage.

Owner:GUANGXI SHENHUANG BREEDING GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com