A multi-purpose fluidized bed fluidized bed furnace and system with fully reducing atmosphere

A technology of fluidized bed and fluidized bed furnace, which is applied in the field of fluidized bed type fluidized bed furnace device and system, which can solve problems such as anaerobic reduction and roasting of materials that cannot be used, and achieve the effect of wide application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

[0076] In the specific embodiment, the airtight feeding device 26 adopts "Application Number: 2019102236149 A Dual-purpose Positive or Negative Pressure Rotary Explosion-proof Feeding Device", which effectively prevents the leakage of furnace top flue gas at the feeding port;

[0077] In a specific embodiment, the drying and preheating device 23 adopts "Application Number: 202020163017X An Integrated Shaft Furnace for Drying, Preheating and Sintering of Metal Ore / Nonmetal Ore Pellets".

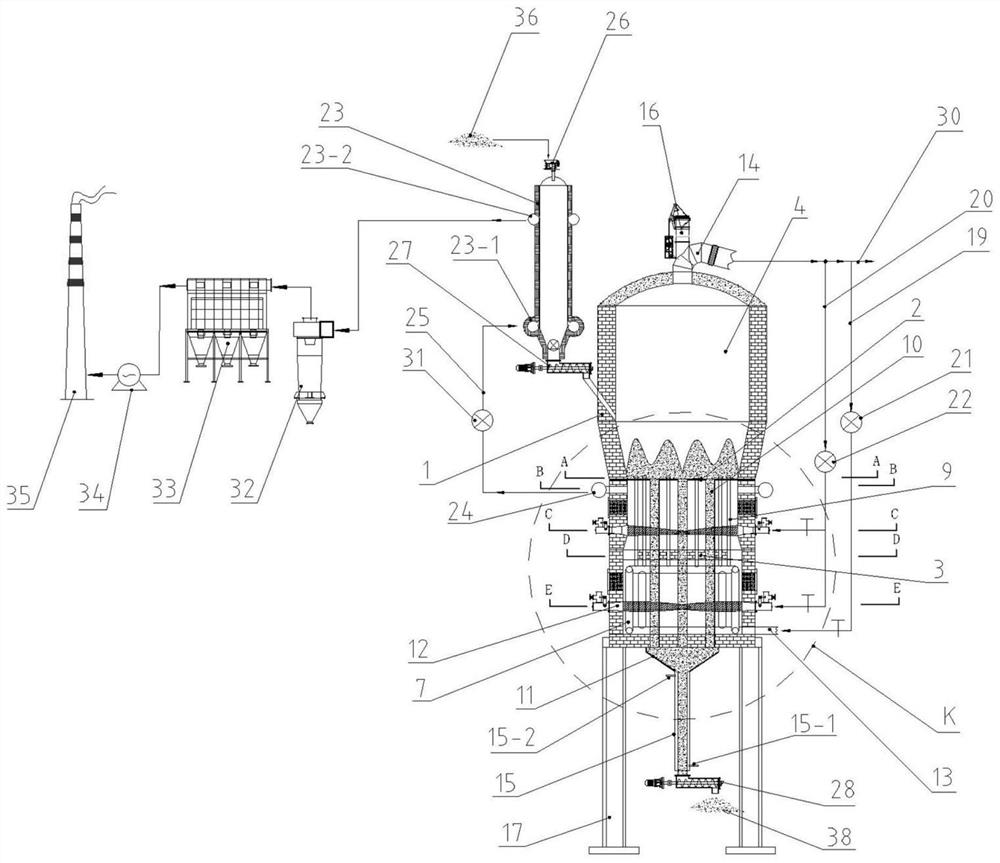

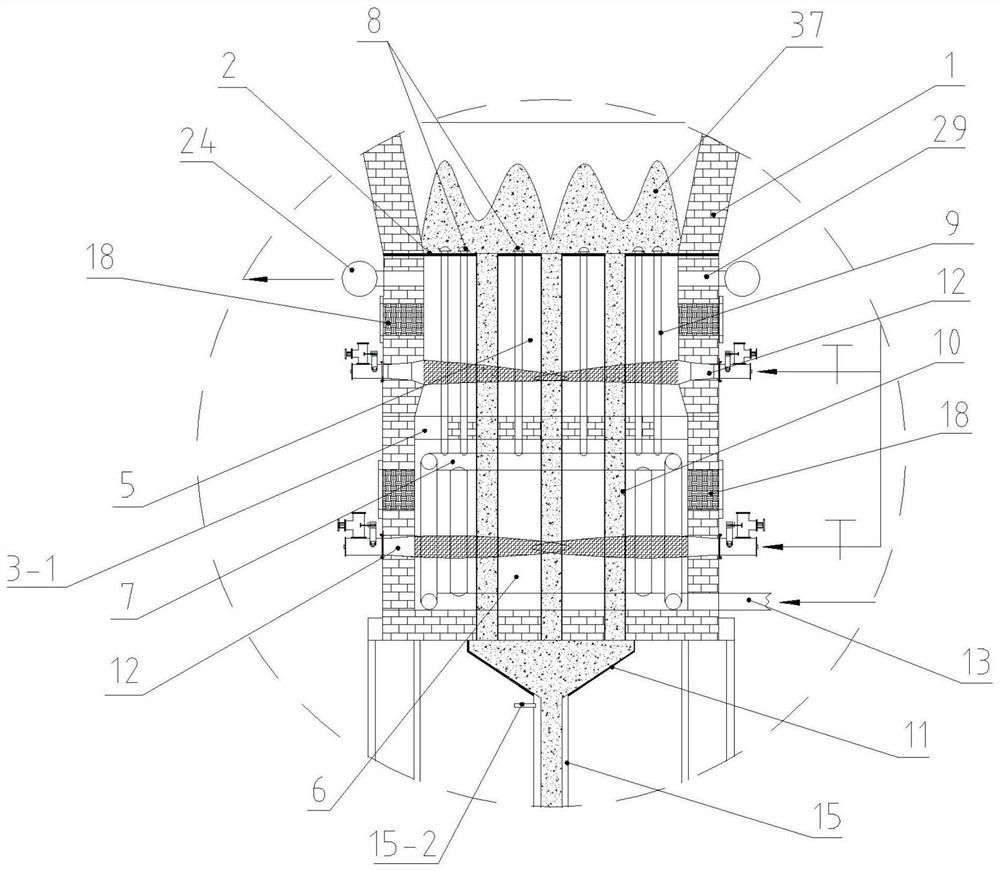

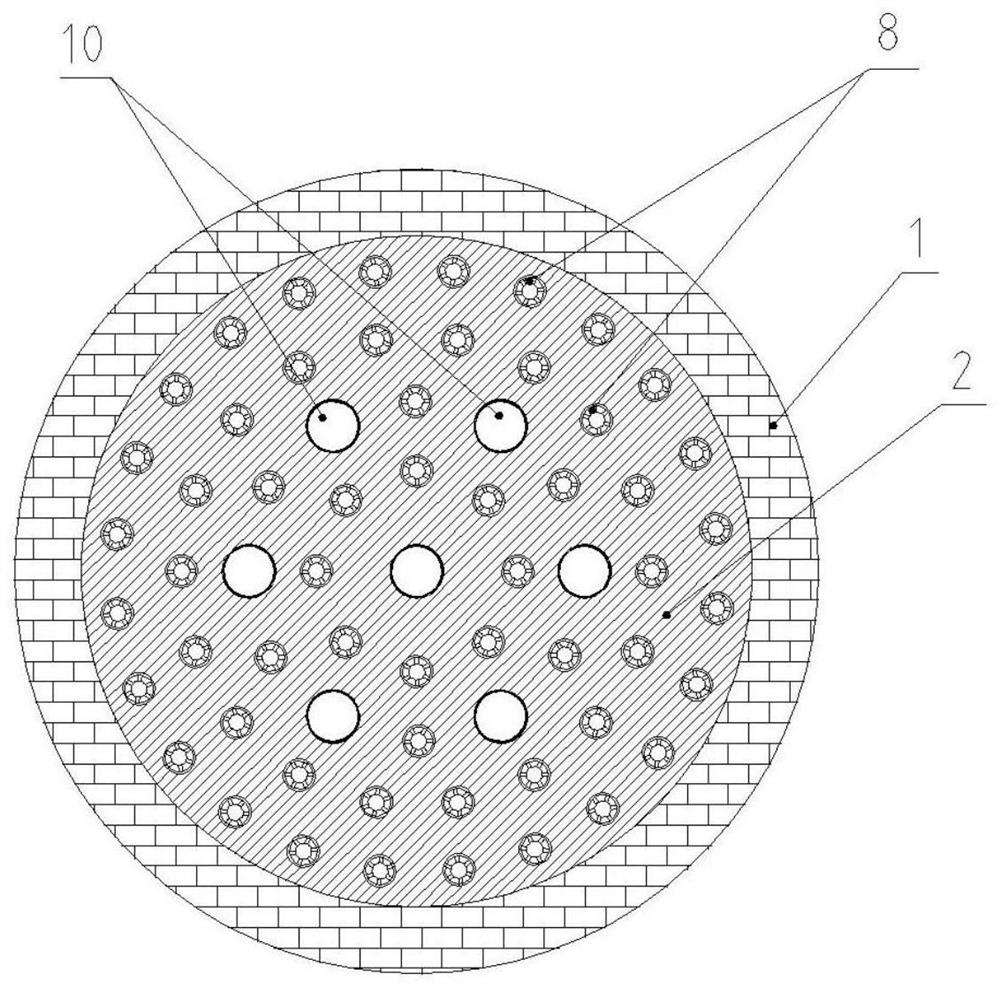

[0078] A multi-purpose fluidized bed fluidized bed furnace device with fully reducing atmosphere, such as Figure 1-9As shown, the furnace body is built by refractory brick furnace wall 1, and the whole fluidized fluidized furnace device is supported by fluidized flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com