Patents

Literature

621results about How to "Full response" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

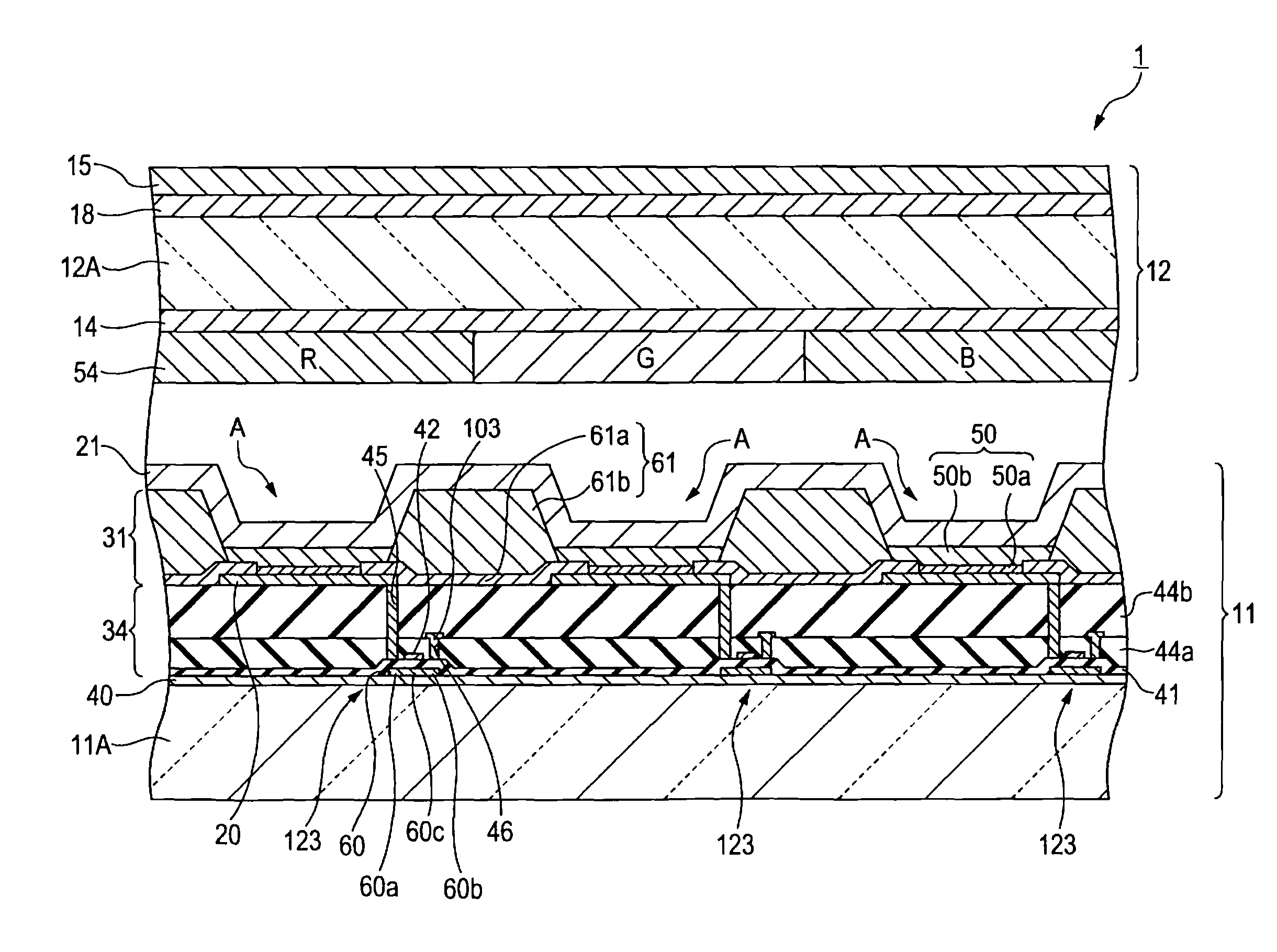

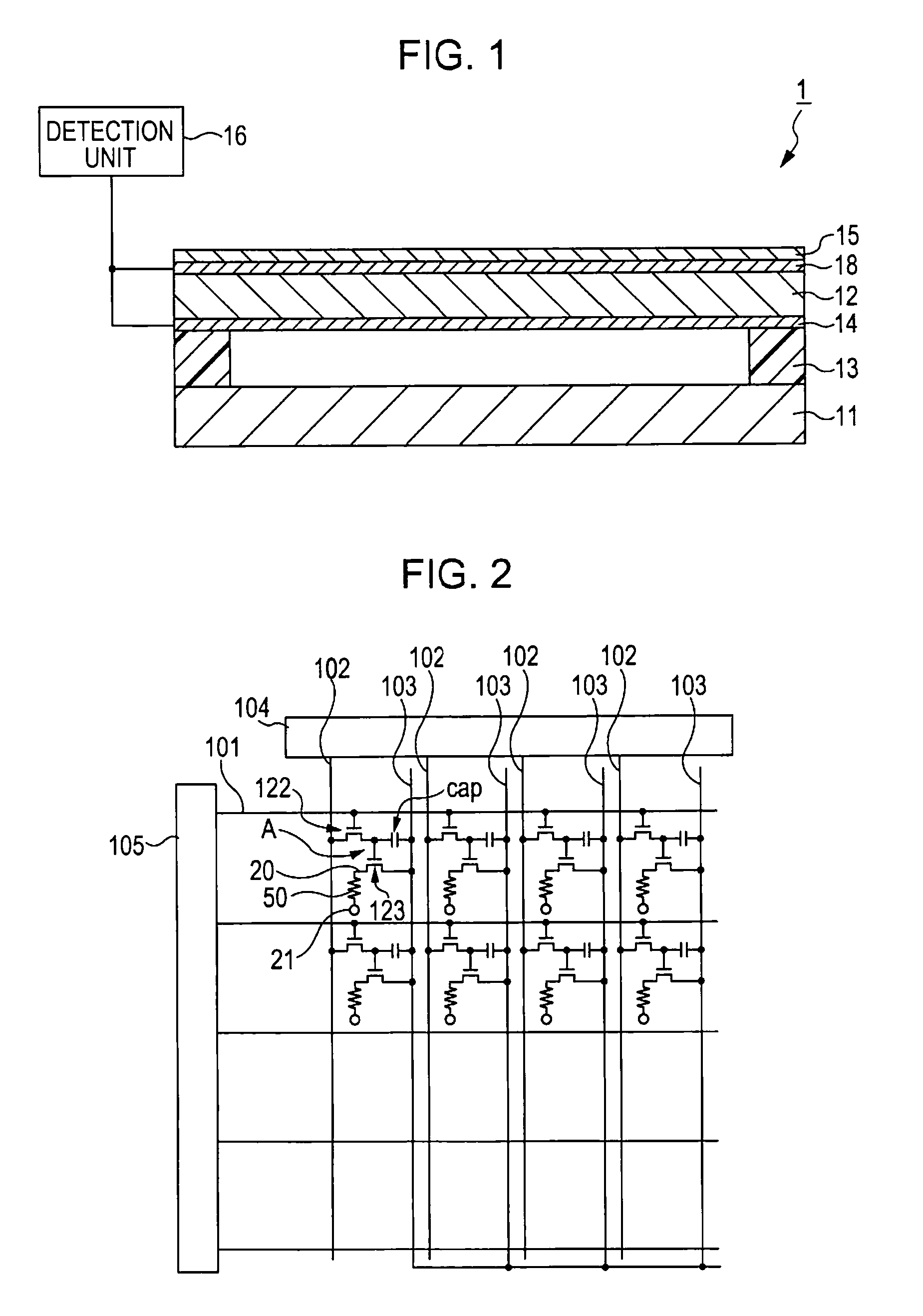

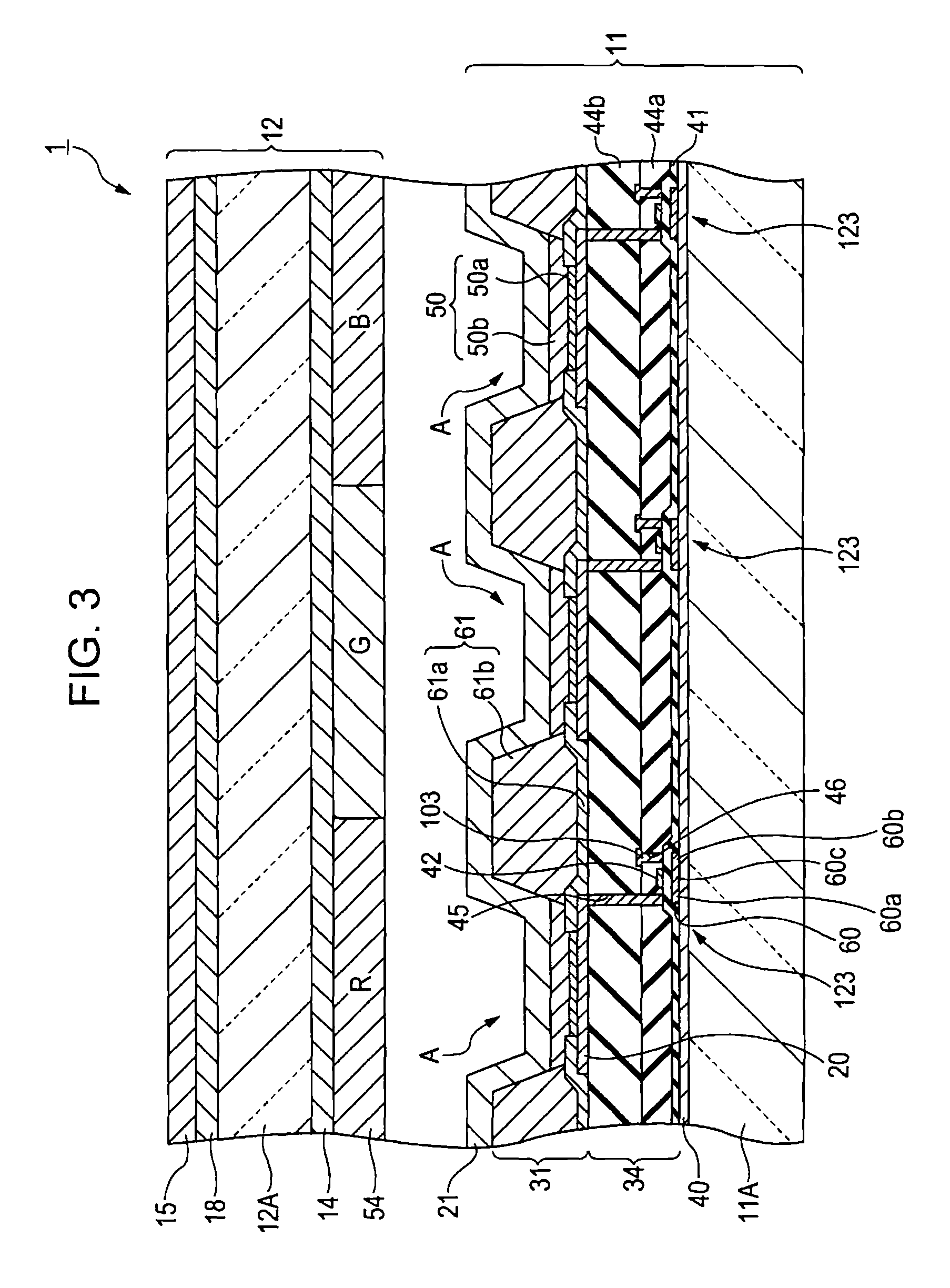

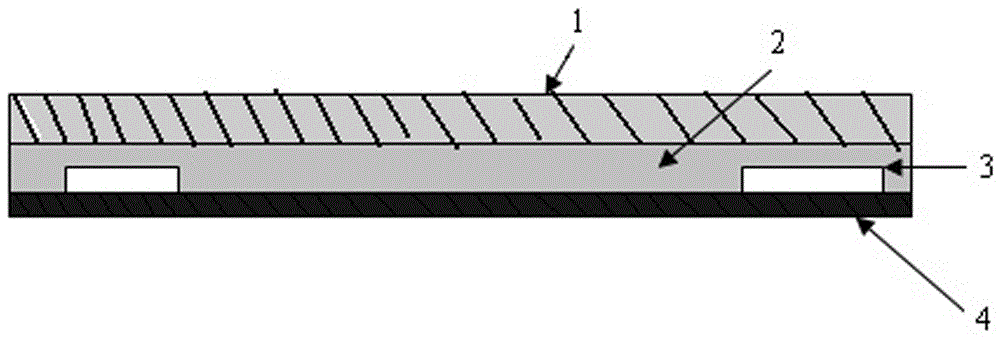

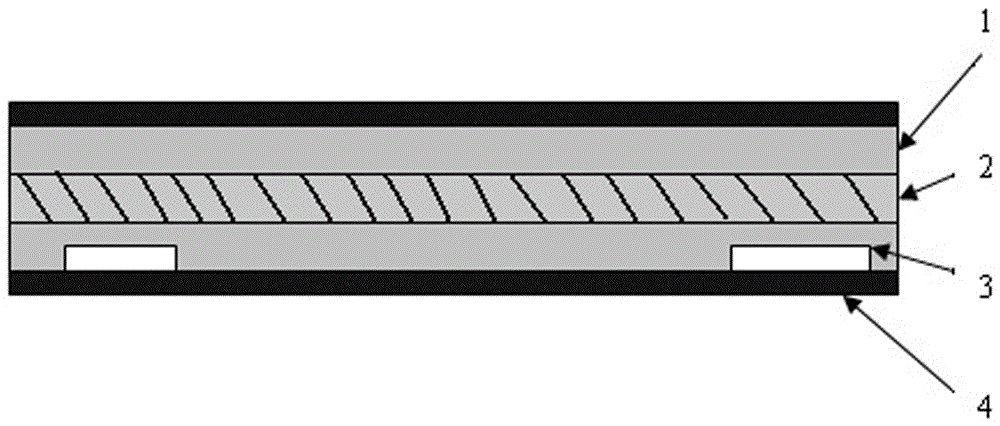

Organic electroluminescence device having input function and electronic apparatus

ActiveUS20080211395A1Improve detection accuracyImprove performanceInput/output for user-computer interactionDischarge tube luminescnet screensCapacitanceOrganic electroluminescence

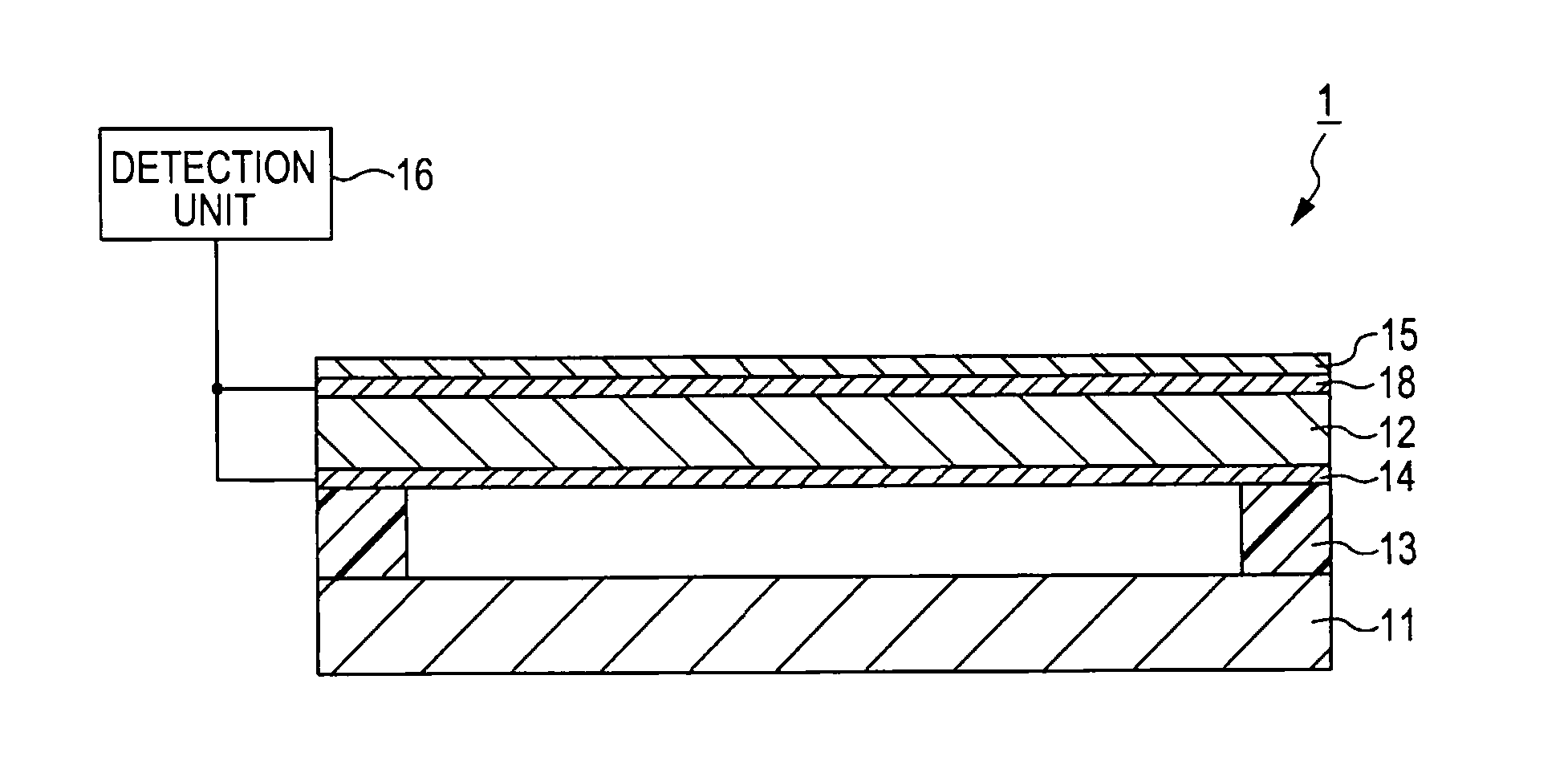

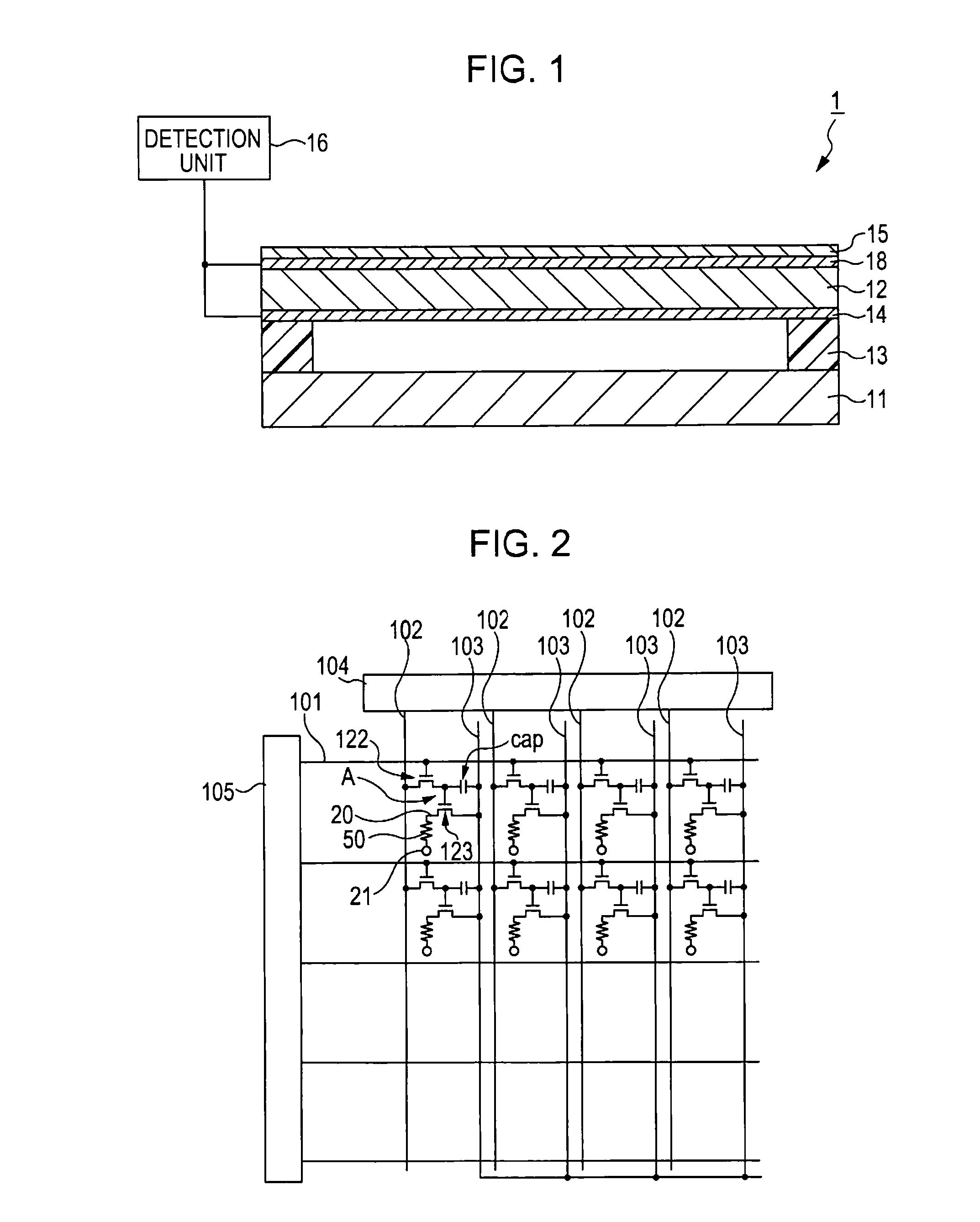

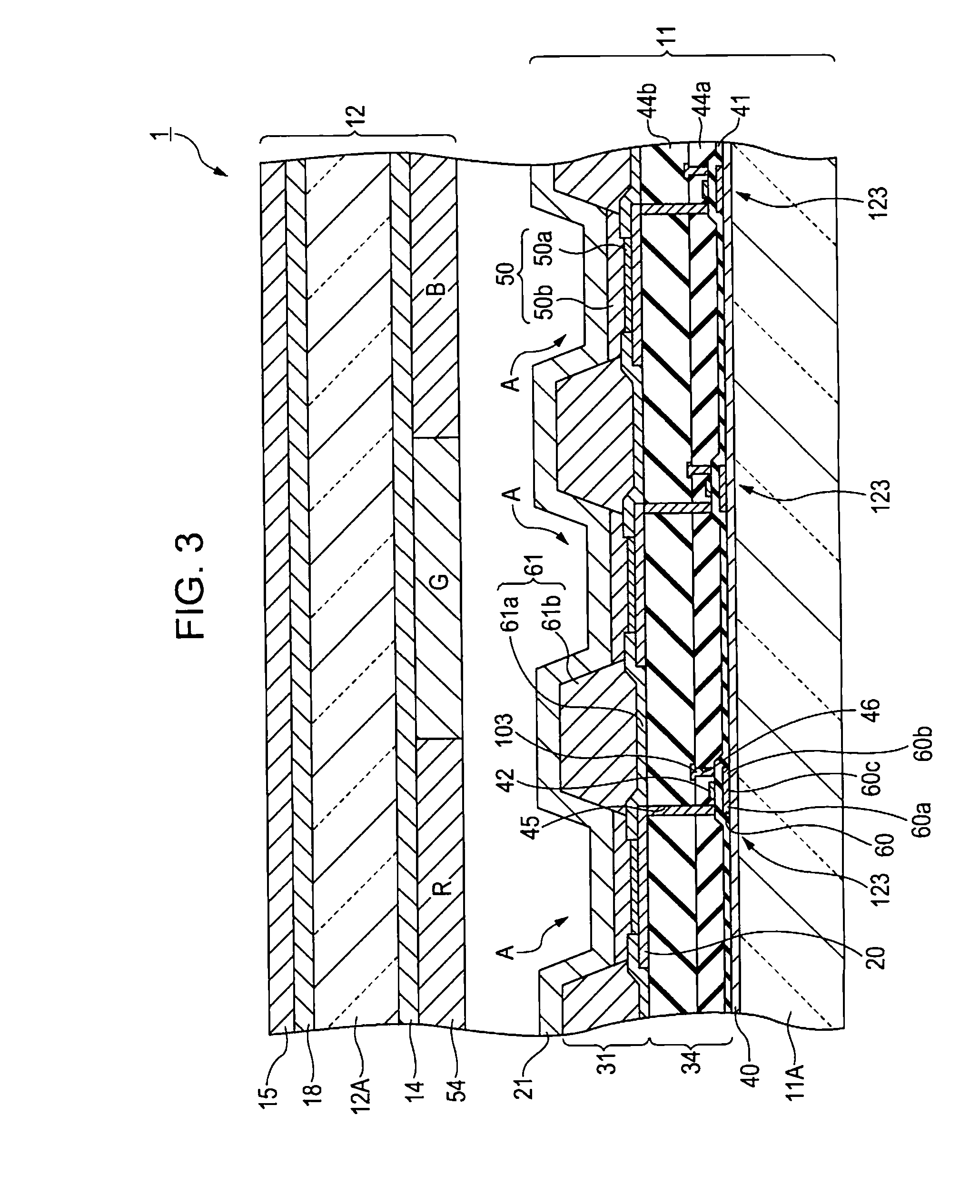

The invention provides an organic electroluminescence device having an input function, including: an element substrate that has a light-emitting layer sandwiched between a pair of electrodes; a sealing substrate that seals the element substrate; a first detection electrode that is provided at the inner-surface side of the sealing substrate; a second detection electrode that is provided at the outer-surface side of the sealing substrate; the second detection electrode having a detection axis that is not the same as that of the first detection electrode; a dielectric film that is formed on the second detection electrode; and a detection unit that detects a position at which electrostatic capacitance is generated via the dielectric film between the first detection electrode and the second detection electrode.

Owner:ELEMENT CAPITAL COMMERCIAL CO PTE LTD

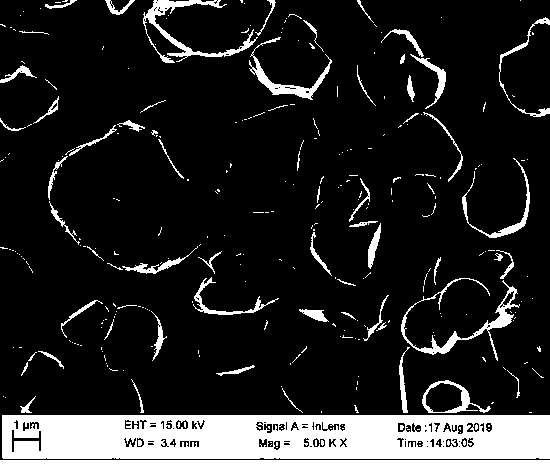

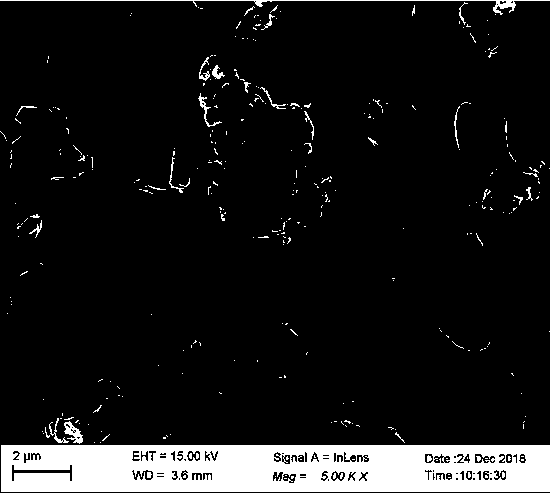

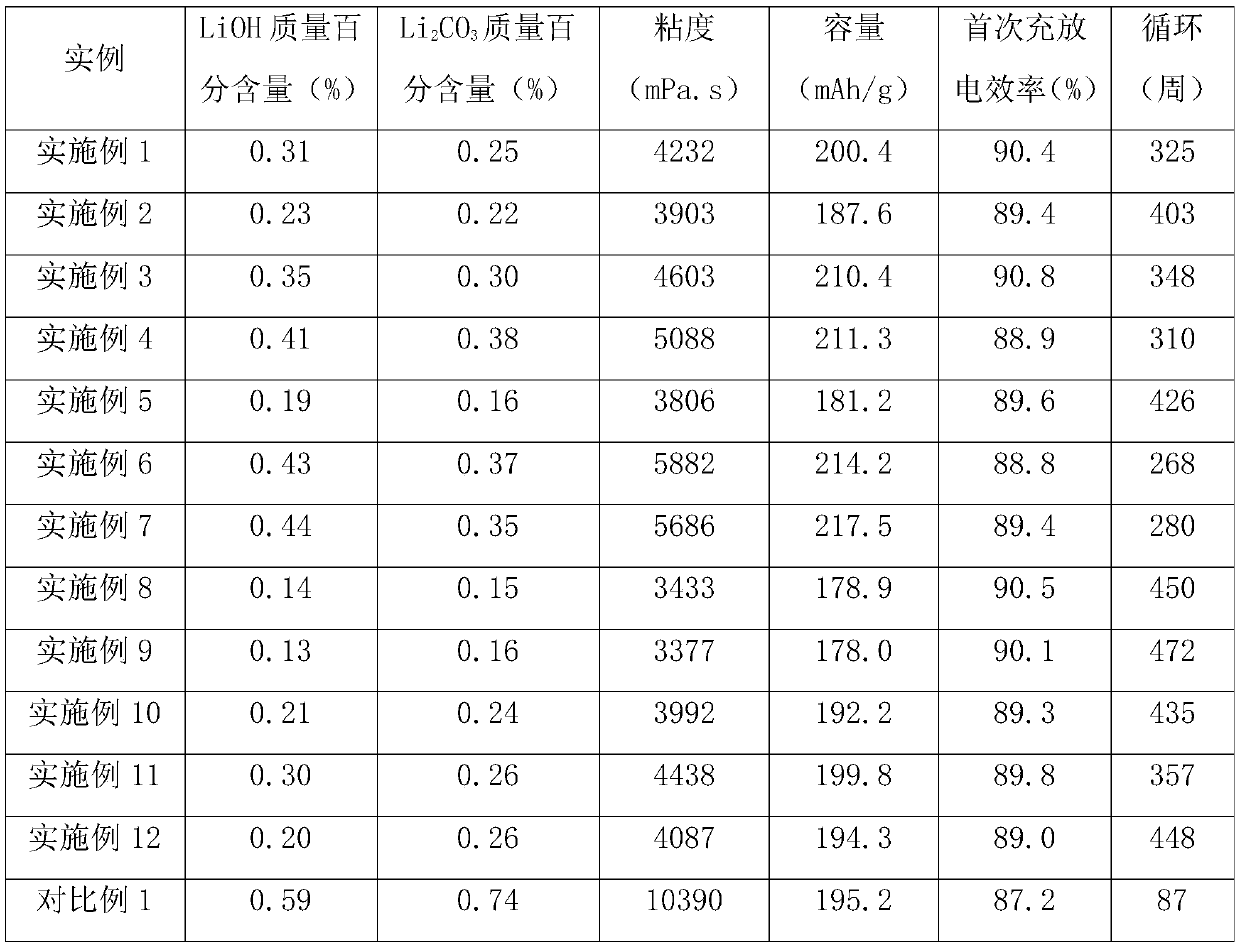

Preparation method of high-voltage lithium cobalt oxide cathode material

ActiveCN109326781AEvenly distributedWell mixedSecondary cellsPositive electrodesDual effectCobalt(II,III) oxide

The invention discloses a preparation method of a high-voltage lithium cobalt oxide cathode material which comprises the steps: (1) mixing cobaltosic oxide containing doped element M, a lithium source, oxide containing doped element M', a grain refiner and a fluxing agent to obtain a primary mixture; (2) sintering and smashing the primary mixture to obtain primary sintered powder; (3) mixing the primary sintered powder with a coating material to obtain a secondary mixture; (4) sintering and smashing the secondary mixture to obtain the lithium cobalt oxide cathode material. According to the preparation method disclosed by the invention, the problem of microscale segregation of distribution of doped elements in the product is solved by two modes of doped element premixing and dry-method mixing; a coulter type mixing technology is utilized to solve the problem of segregation of different matters in material mixing; the grain refiner and the fluxing agent are combined for use to synthesizea material in a mixed morphology; technologies such as dual effects of doped element surface crystallization catalysis and the coating material and the like are utilized; thus, performance of the high-voltage lithium cobalt oxide is obviously improved.

Owner:HUNAN CHANGYUAN LICO CO LTD

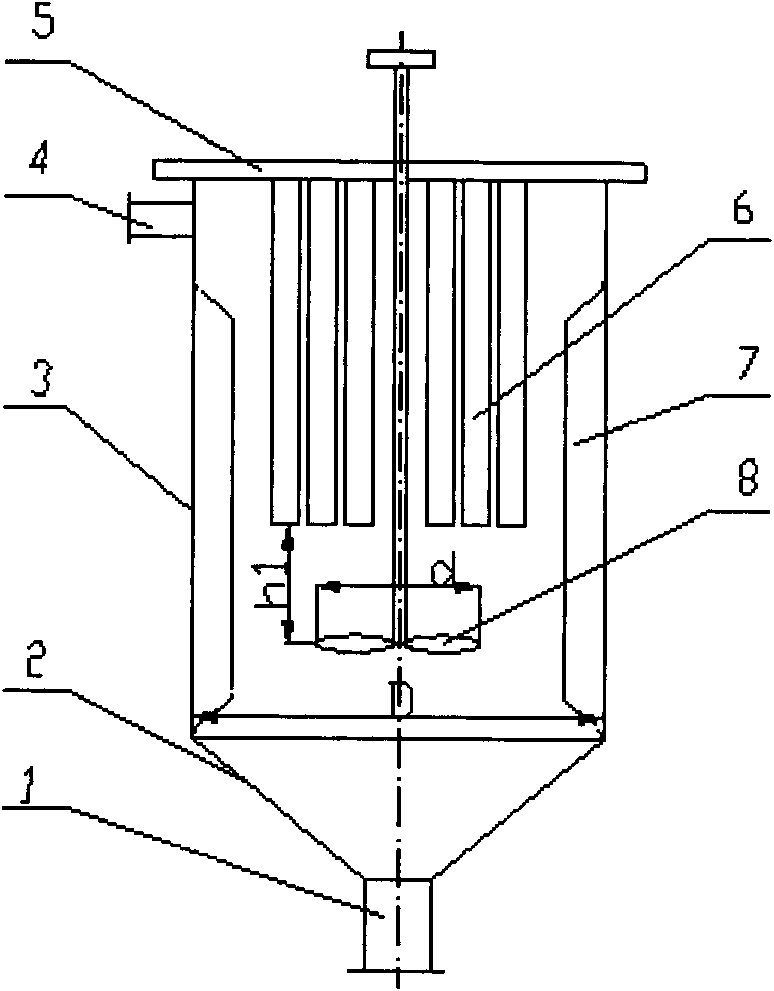

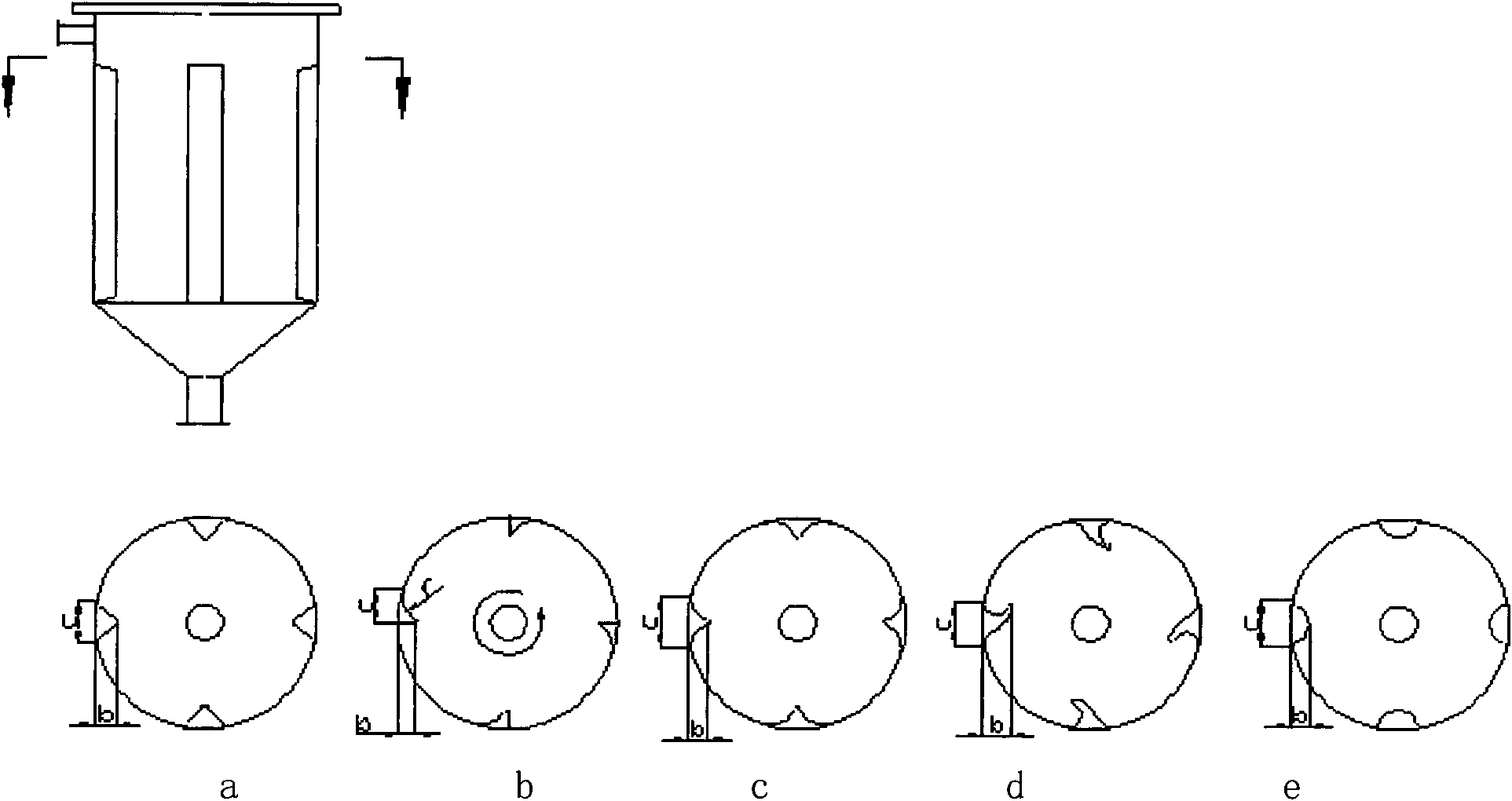

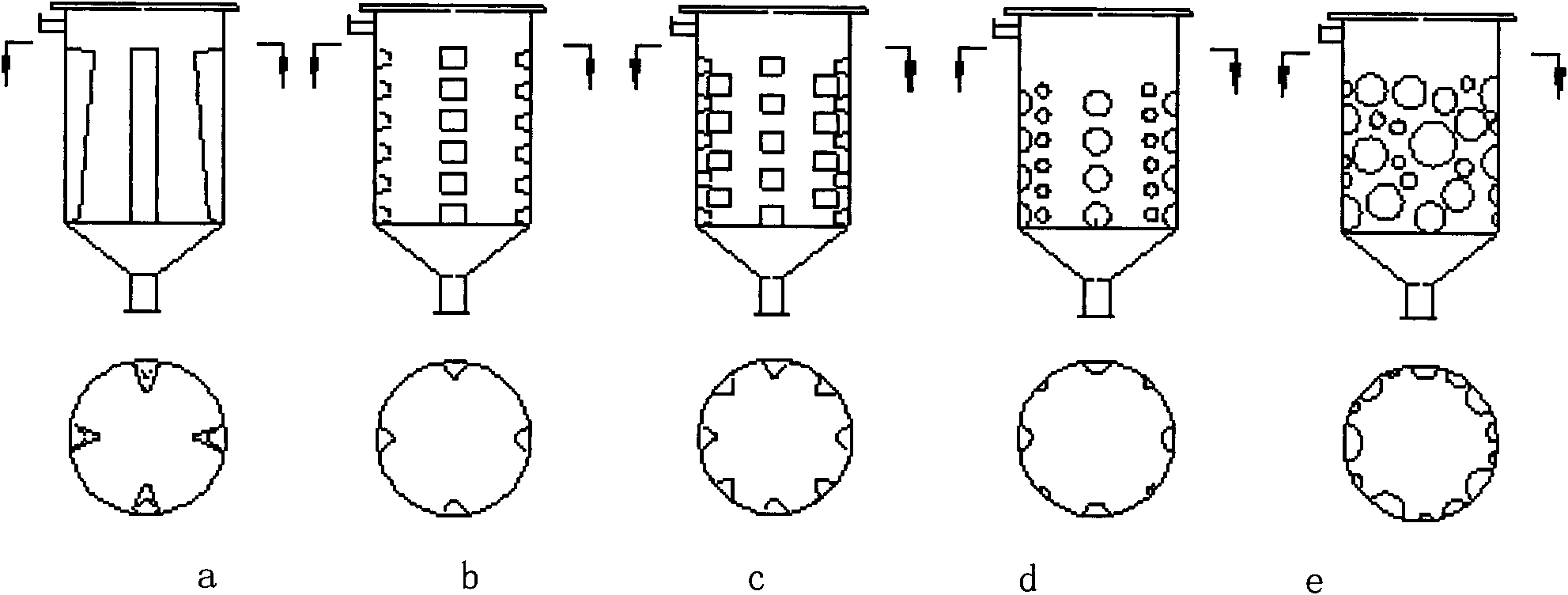

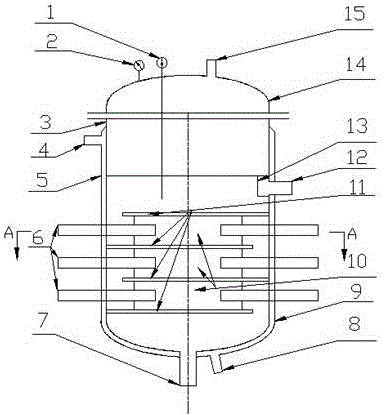

Flocculation reactor with special-shaped spoiler

InactiveCN102068955ASimple structureAvoid breakingChemical/physical/physico-chemical stationary reactorsFlocculationWave shape

The invention relates to a flocculation reactor with a special-shaped spoiler, and the flocculation reactor provided by the invention comprises a reactor shell, a stirrer arranged in the middle part of the reactor, special-shaped baffles arranged on the inner wall of the reactor and spoiler grids arranged on an upper head, wherein the upper part of the side wall of the shell is provided with a material charging port, and the bottom part of the side wall of the shell is provided with a material discharging port; the forms (the shapes of the axial cross sections) of the special-shaped baffles comprise bulges in a sine shape, a wave shape, a semicircular arc shape, a circle shape or an irregular shape; the baffles are arranged vertically, obliquely or horizontally; and multiple baffles are uniformly or irregularly scattered or continuously fixed on the inner wall of a flocculator. The height, width and thickness of the spoiler can be changed along the circumference direction or axial direction of the inner wall of the reactor. The spoiler and the stirrer are matched through different forms, thereby fully mixing a flocculating agent with liquid, improving the shearing rate of fluid, reducing dead zones of a flow field, enhancing a micro-vortex and achieving the purposes of strengthening a flocculation flow field and enhancing the flocculation effect. The flocculation reactor provided by the invention has the advantages of simple structure, high flocculation efficiency, low cost and good application prospect, and is convenient in installation and maintenance.

Owner:TIANJIN UNIV

Thermo-curable 3D printing photosensitive resin and preparation method thereof

ActiveCN106947034AIncrease activation energyHigh tensile strengthAdditive manufacturing apparatus3D object support structuresDecompositionHalf-life

The invention discloses a thermo-curable 3D printing photosensitive resin and a preparation method and an application thereof. The photosensitive resin includes, by weight, 50-70 parts of a prepolymer, 30-50 parts of a diluent, 1-5 parts of a photo-initiator and 0.5-5 parts of a thermal-initiator, wherein the decomposition temperature of the thermal-initiator is higher than or equal to 100 DEG C when the half-life period thereof is 1 h. After photo-curing 3D printing shaping, the 3D printing photosensitive resin can be subjected to curing by heating as a post-curing method with a stable constant temperature heating device, such as a drying box and the like, so that the 3D printing photosensitive resin develops application in a non-transparent sample, a sample having complex shape, an ultra-thick sample, a colored sample and the like, and enables the samples to have better mechanical performances.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

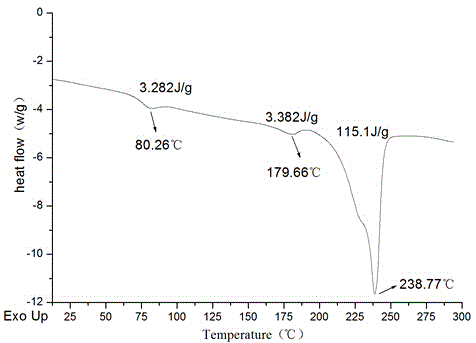

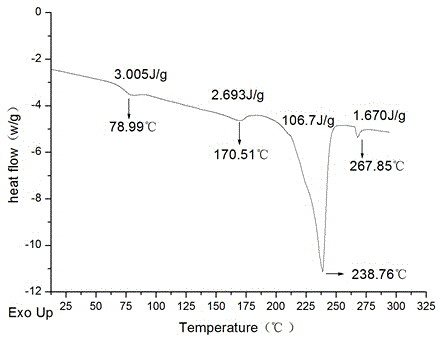

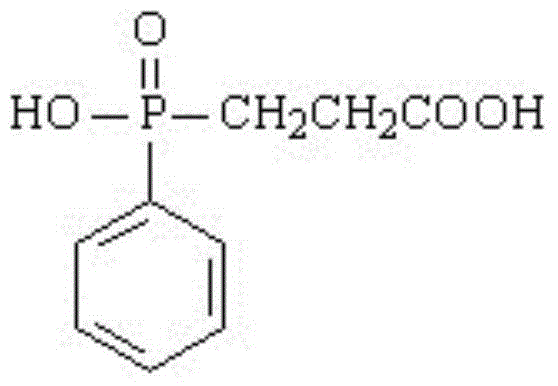

Phosphorous-nitrogen-containing polyethylene glycol terephthalate flame retardant copolyester and application of flame retardant copolyester

The invention discloses a phosphorous-nitrogen-containing polyethylene glycol terephthalate flame retardant copolyester and an application of the flame retardant copolyester. Through introducing phosphorous and nitrogen flame retardant monomers into a flame retardant polyester polymer, in situ synergistic interaction inflaming retarding of phosphorous and nitrogen flame retardant elements is achieved; phosphorus-containing polyester dihydric alcohol is introduced to adjust the phosphorous content of the flame retardant copolyester, and the flexibility, the spinnability and the dyeability of a chain segment; tri(2-ethoxy) isocyanurate is introduced, and has positive significance on extender chain crosslinking, tackifying and anti-dripping of the copolyester; the phosphorous-nitrogen-containing polyethylene glycol terephthalate flame retardant copolyester and the product of the flame retardant copolyester can be widely applied to the fields such as curtain fabrics, soft wall wrapping cloth, electric power industrial fabrics, energy industrial fabrics, water conservancy geotextile, carpets, hometextile and medical partition curtains; and the related flame retardant products pass through various flame retardant standards (for example, BS5852-2006 flame retardant standard, BS5867-2-2008 flame retardant standard, or B1 grade of GB8624-2012 flame retardant standard and the first grade of GB20286-2006 flame retardant standard).

Owner:HANGZHOU XIANGJUN TEXTILE FLAME RETARDANT TECH

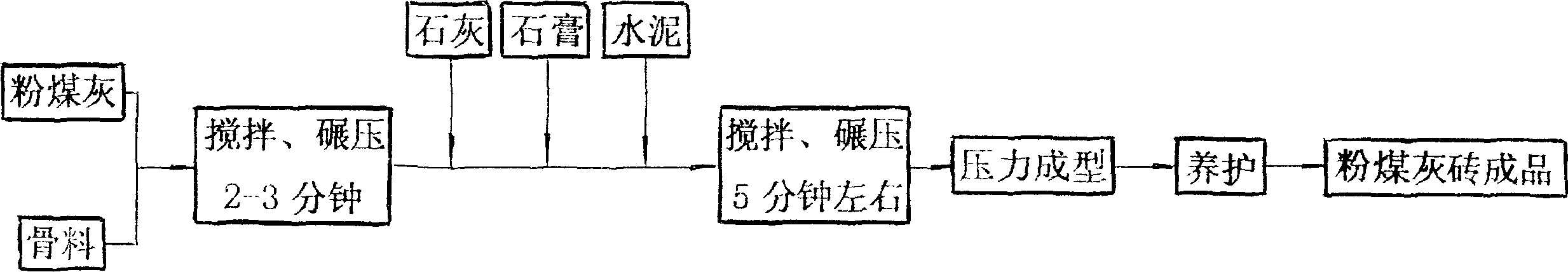

Bricks and mortar made from fly ash and preparation method

InactiveCN1686907AReduce manufacturing costReasonable proportionSolid waste managementFly ash brickBrick and mortar

The present invention belongs to a building brick made of fly ash, mortar and their production method. The raw material composition of brick includes (by wt%) fly ash 70-80, lime 7-13, gypsum 0-1.3, cement 0-5 and the rest is aggregate, and the raw material composition of mortar includes fly ash 70-80, lime 7-13, cement 0-5 and the rest is aggregate. Besides, said invention also provides the concrete steps of their production method.

Owner:韦柳青

Organic electroluminescence device having input function and electronic apparatus

ActiveUS7737637B2Improve accuracyImprove detection accuracyInput/output for user-computer interactionDischarge tube luminescnet screensCapacitanceOrganic electroluminescence

The invention provides an organic electroluminescence device having an input function, including: an element substrate that has a light-emitting layer sandwiched between a pair of electrodes; a sealing substrate that seals the element substrate; a first detection electrode that is provided at the inner-surface side of the sealing substrate; a second detection electrode that is provided at the outer-surface side of the sealing substrate; the second detection electrode having a detection axis that is not the same as that of the first detection electrode; a dielectric film that is formed on the second detection electrode; and a detection unit that detects a position at which electrostatic capacitance is generated via the dielectric film between the first detection electrode and the second detection electrode.

Owner:ELEMENT CAPITAL COMMERCIAL CO PTE LTD

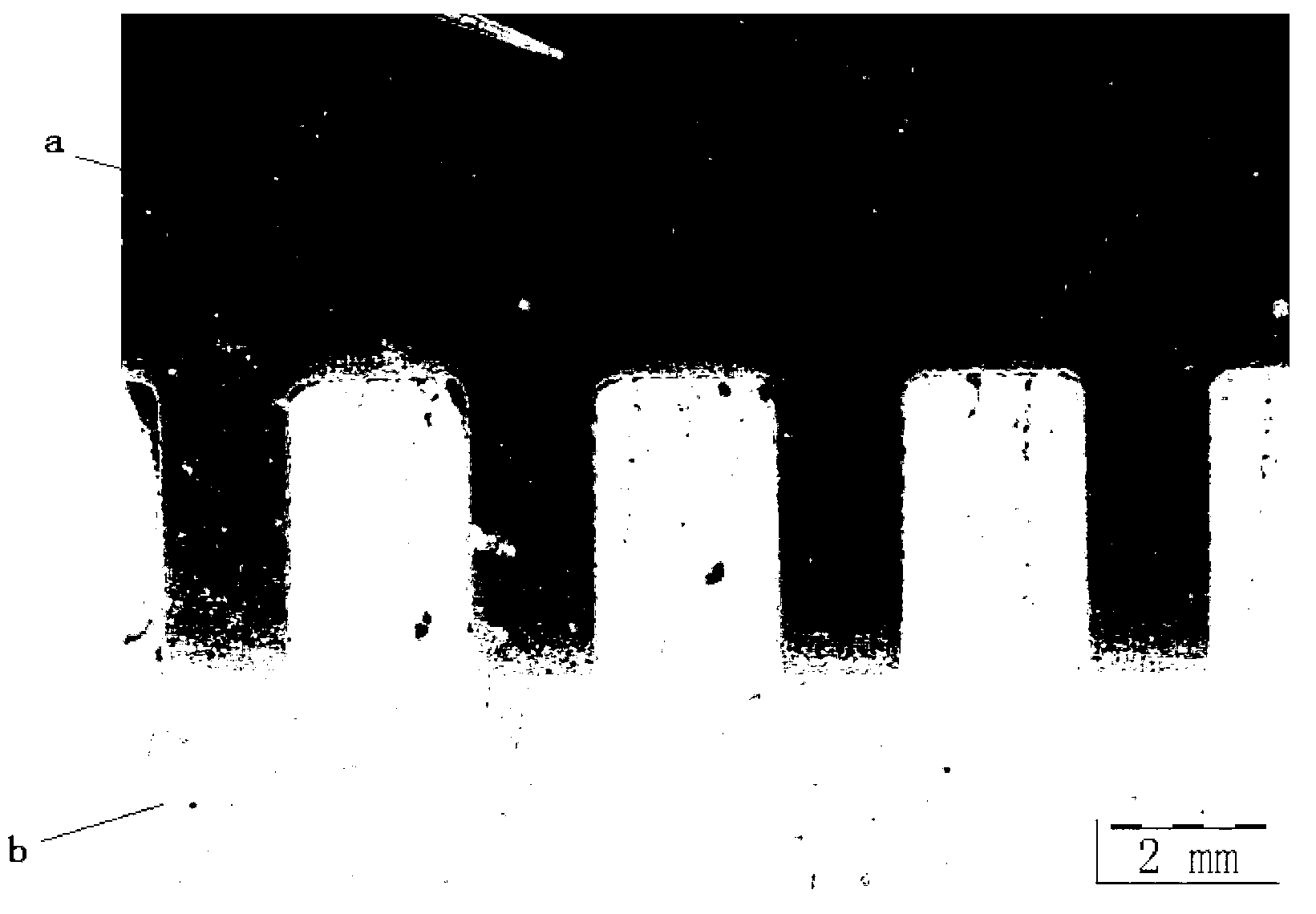

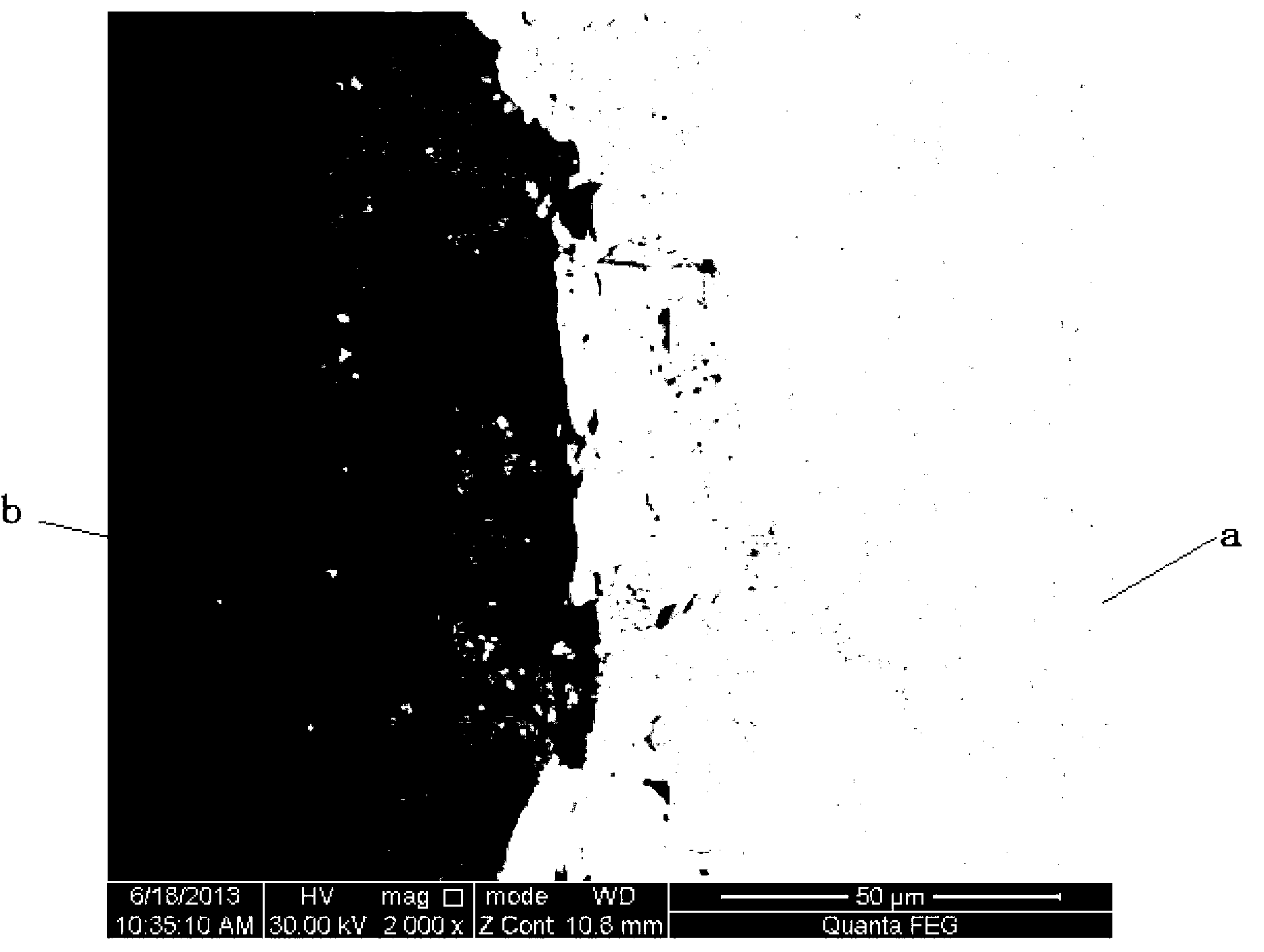

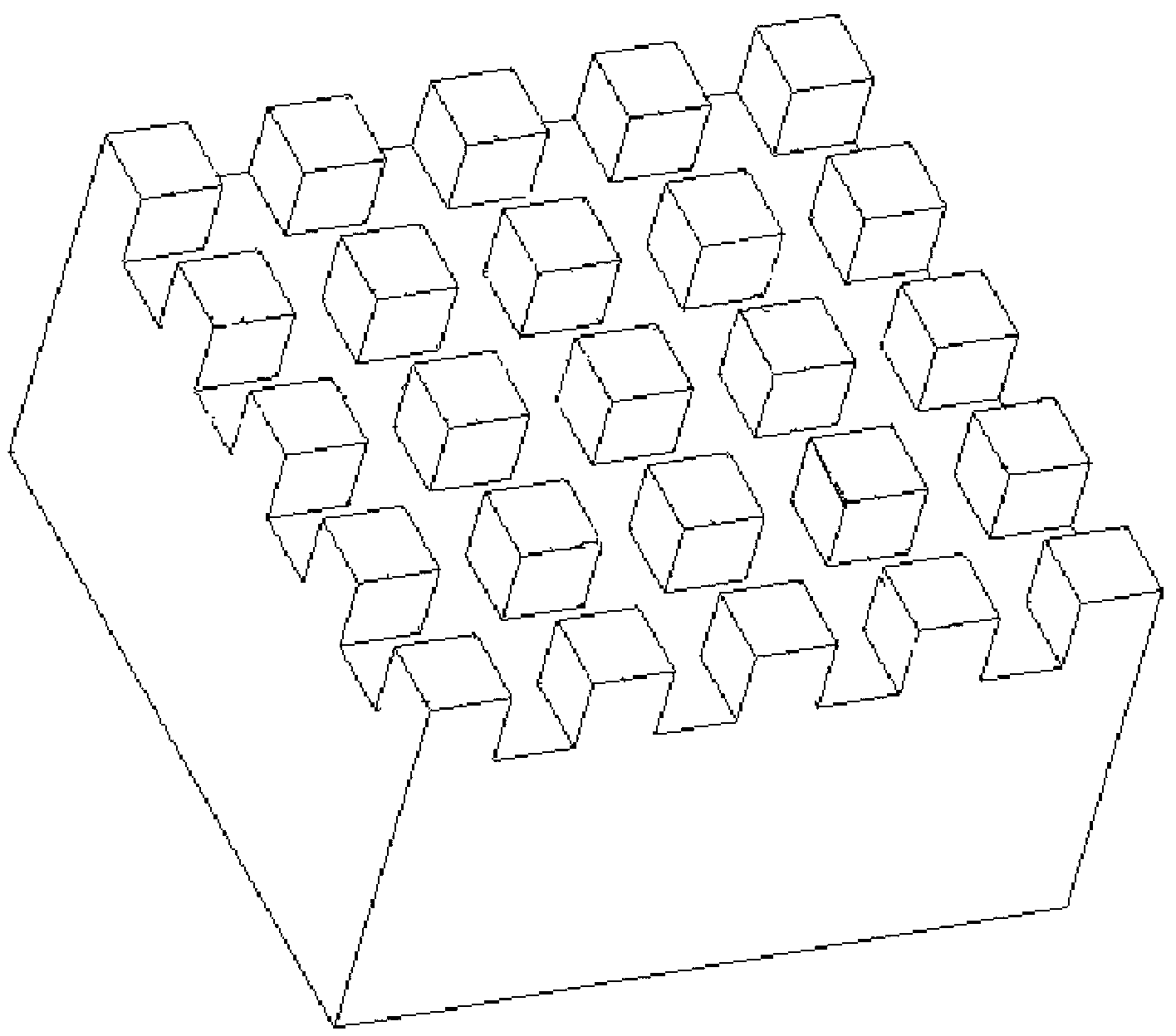

Diffusion bonding method of hard alloy and metal

ActiveCN103302371AIncrease connection areaFacilitates Diffusion and ReactionSoldering apparatusCemented carbideBonding strength

The invention relates to a diffusion bonding method of hard alloy and metal, and aims to solve the problems that the conventional bonding method is complicated in process and low in bonding strength. The diffusion bonding method comprises the following steps: 1, roughening a lug boss; 2, cleaning before welding; 3, performing diffusion bonding: putting the hard alloy and the metal which are cleaned into a diffusion bonding furnace, fixing the hard alloy and the metal with pressing heads, and performing diffusion bonding by the diffusion bonding process to achieve diffusion bonding of the hard alloy and the metal. The diffusion bonding method is simple in process and high in production efficiency; by the diffusion bonding method, metallurgical bonding of the hard alloy and the metal is effectively implemented, the bonding strength is improved, and using requirements of hard alloy / metal structural components can be met; the diffusion bonding method is applicable to the field of brazing.

Owner:哈尔滨瀚霖科技开发有限公司

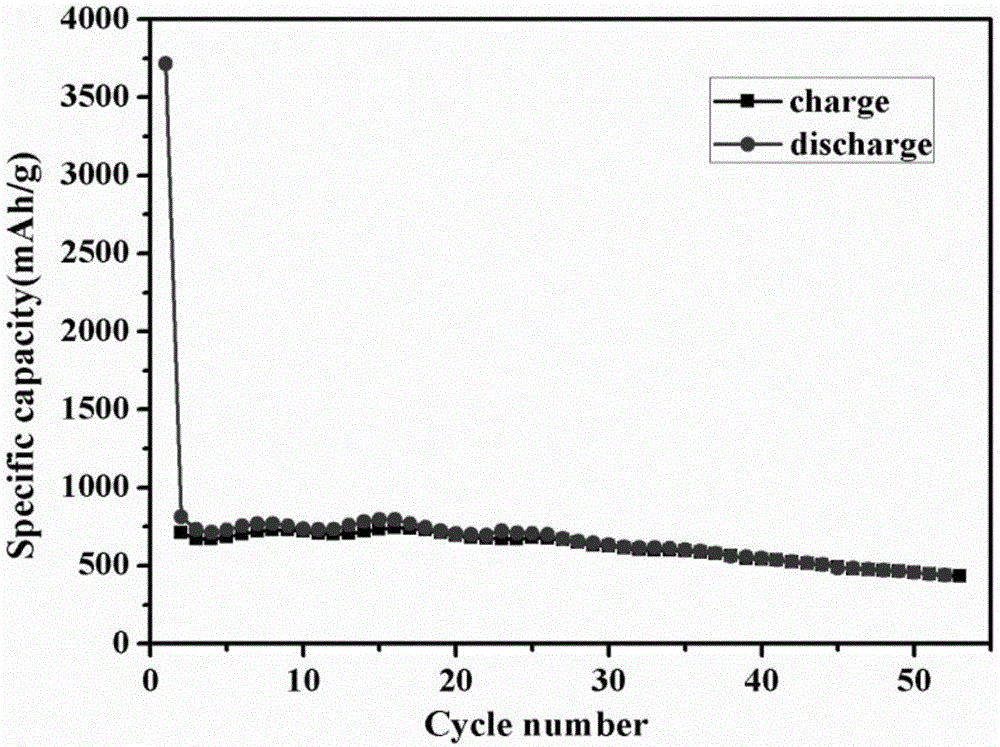

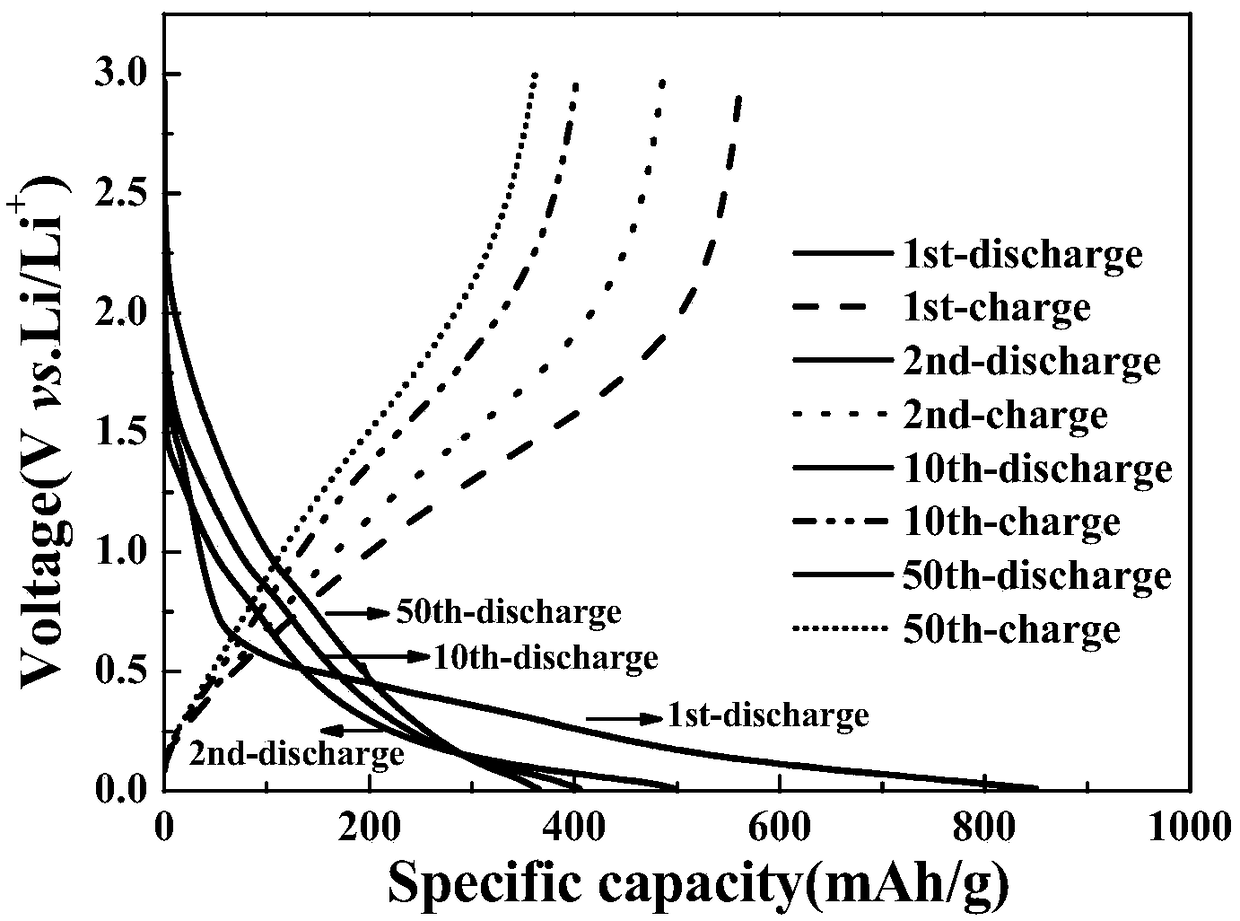

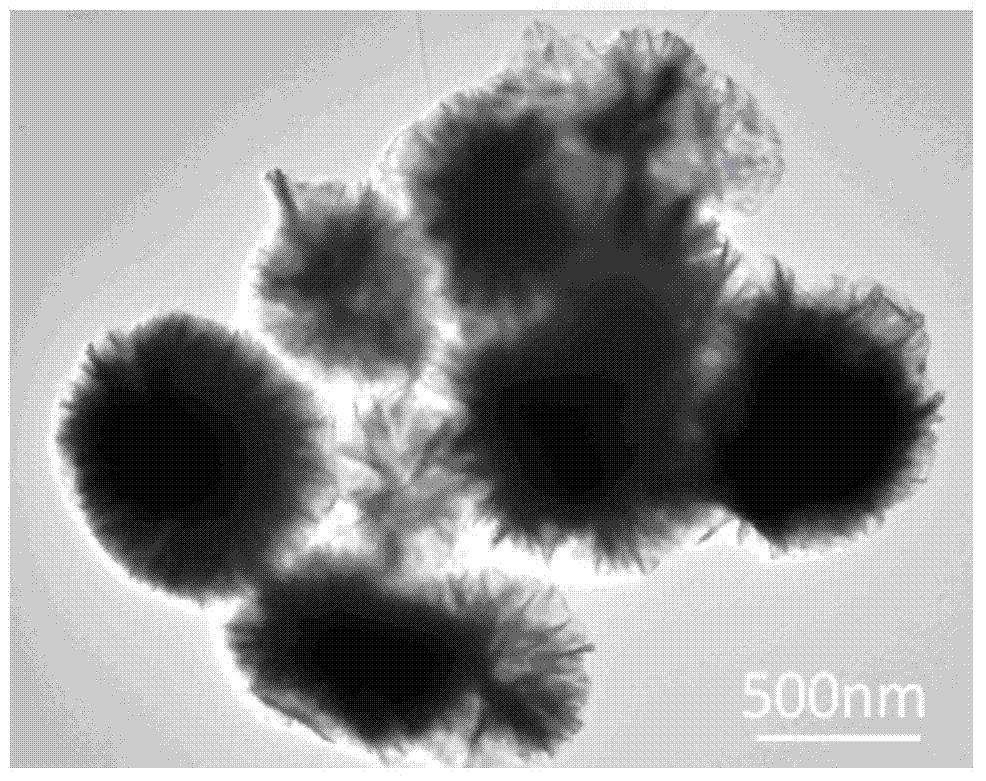

Preparation method for nano-flake SnS2 sodium-ion battery negative electrode material with good rate capability

InactiveCN105098181AReduce manufacturing costImprove charge and discharge performanceNegative electrodesSodium-ion batteryChemistry

The invention discloses a preparation method for a nano-flake SnS2 sodium-ion battery negative electrode material with good rate capability, comprises: 1) preparing an Sn source solution A with the concentration of 0.5-1.2 mol / L, regulating the pH of the solution A to be 1-9; and preparing an S source solution B with the concentration of 0.1-2.4 mol / L; 2) mixing the solution A and the solution B at an element molar ratio of nSn: nS being equal to (1.0-2.5): (2.0-4.3), and uniformly stirring to form a solution D; 3) putting the solution D into a homogenous phase hydrothermal reaction kettle for performing a homogenous phase hydrothermal reaction; and 4), cooling the reaction kettle, then centrifuging, washing, separating and drying to obtain the nano-flake SnS2 sodium-ion battery negative electrode material, wherein under 100 mA / g current density, the initial discharge capacity of the negative electrode material reaches 745 mAh / g; and after circulating for 100 times, the capacity is kept at 560 mAh / g.

Owner:SHAANXI UNIV OF SCI & TECH

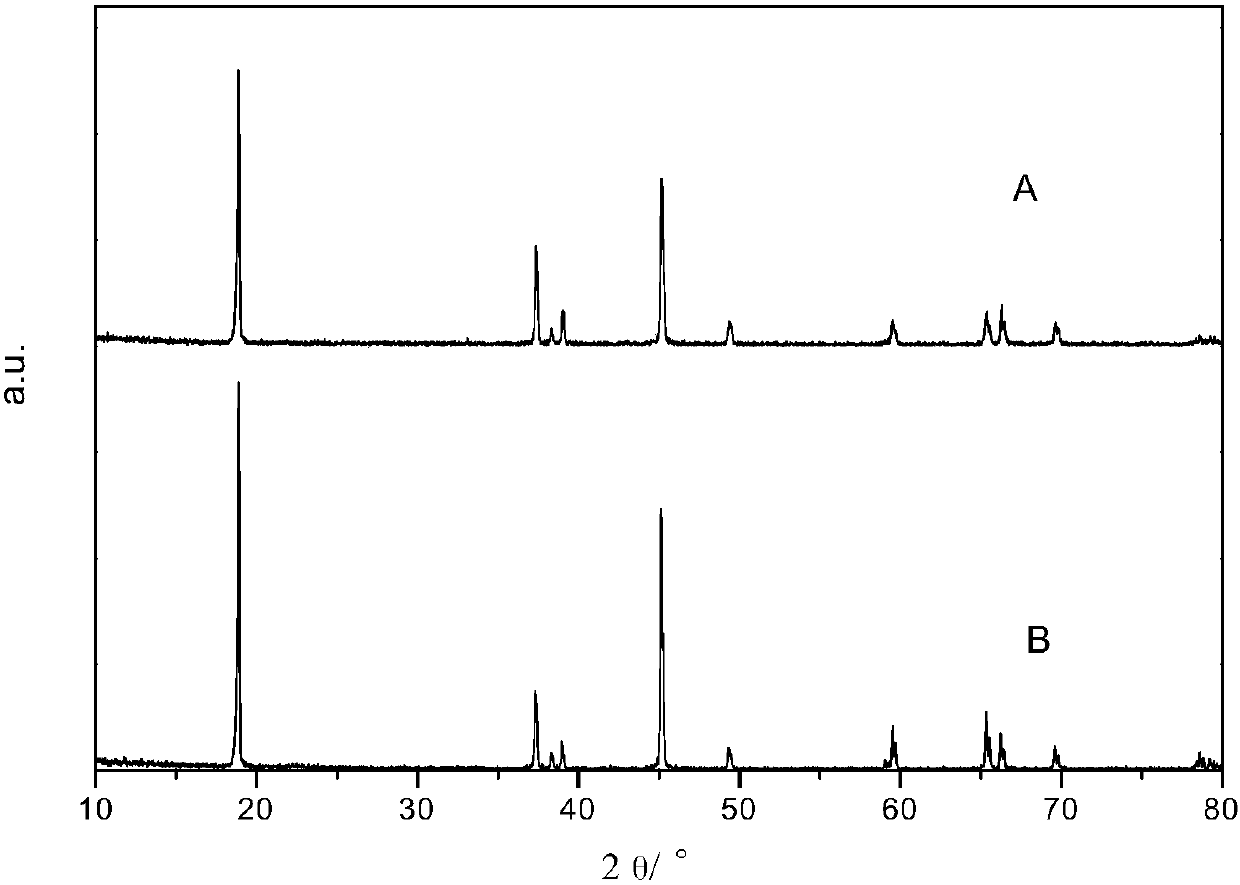

Quickly-rechargeable long-life high-voltage lithium cobaltate positive electrode material and preparation method

InactiveCN105958038AImprove structural stabilityImprove securityCell electrodesSecondary cellsLithiumHigh voltage

The invention relates to a preparation method of a quickly-rechargeable long-life high-voltage lithium cobaltate positive electrode material. The preparation method comprises the following steps: preparing Li<2>CO<3> and Co<3>O<4> as raw materials, adding a doping element M, adding a grain refiner and a cosolvent, and performing first sintering; and adding a grain refiner and a coating compound into a firstly-sintered material serving as a raw material, and performing surface coating and second sintering, wherein the doping element M is one or more of Ti<4+>, Zr<4+>, Mn<4+>, Sn<4+>, Ce<4+>, Ir<3+>, Mg<2+>, Al<3+>, V<5+>, Nb<3+> and Co<2+>, a molecular formula of doped lithium cobaltate is LiCo<1-x>M<y>O<2-y>; and the grain refiner is one or more of oxides of Ti, Nb, V, Al and Zr. The prepared lithium cobaltate positive electrode material has the characteristics of rapid charging, high capacity, high voltage, high cycle and low cost, can be applied under a rapid-charging high-voltage condition, and has superior electrochemical performance.

Owner:湖南美特新材料科技有限公司 +1

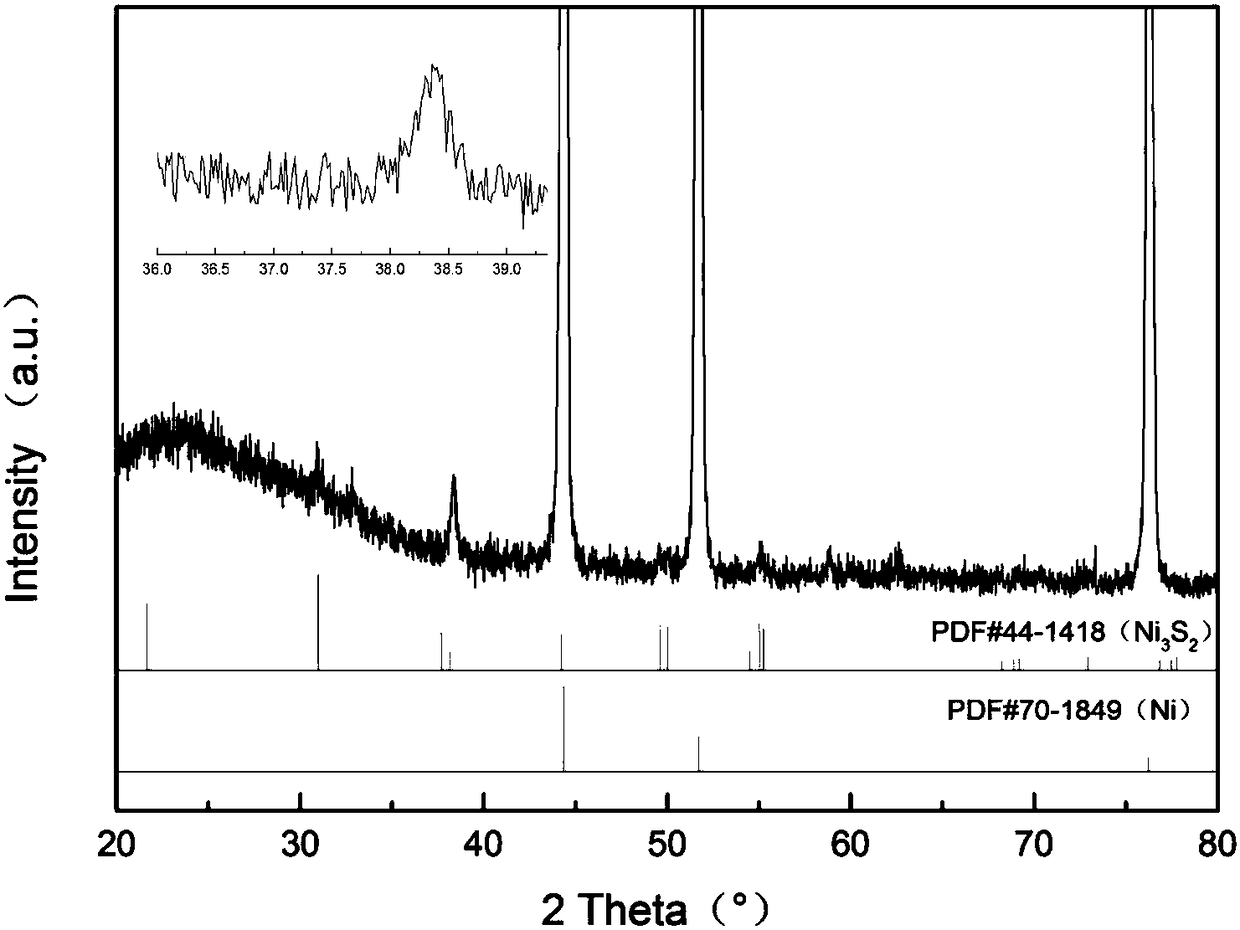

Synthesis method of self-assembled Ni3S2 nano-sheet

ActiveCN108423717ASimple processShort preparation cycleMaterial nanotechnologyPhysical/chemical process catalystsSynthesis methodsThiourea

The invention provides a synthesis method of a self-assembled Ni3S2 nano-sheet. The method comprises steps as follows: firstly, foamed nickel is ultrasonically cleaned in acetone and an HCl solution in sequence, then washed with deionized water and absolute ethyl alcohol respectively and air-dried at the room temperature; secondly, air-dried foamed nickel is put in a high-temperature and high-pressure reactor provided with a polytetrafluoroethylene lining, a thiourea solution and a polyvinylpyrrolidone morphological regulating agent are added to the reactor, the reactor is sealed and put in adrying oven, after the reaction is finished, a mixture is naturally cooled to the room temperature, and foamed nickel is taken out and repeatedly washed with water and absolute ethyl alcohol; finally,washed foamed nickel is put in a vacuum drying oven and dried at the room temperature, and a self-assembled Ni3S2 nano-sheet array self-supporting electrode is obtained. The solvothermal method has the characteristics of simple process, short preparation cycle and easily controllable reaction conditions, and reaction progress and morphology size can be controlled by adopting different temperatures, so that different special structural morphologies are obtained.

Owner:吉林省春泽露科技有限公司

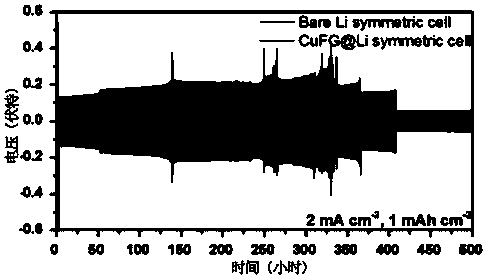

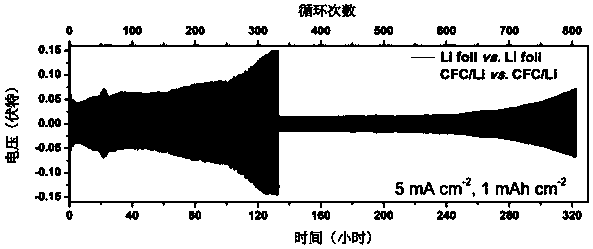

Metal lithium composite material and preparing method thereof, and multilayer metal lithium composite material and preparing method thereof

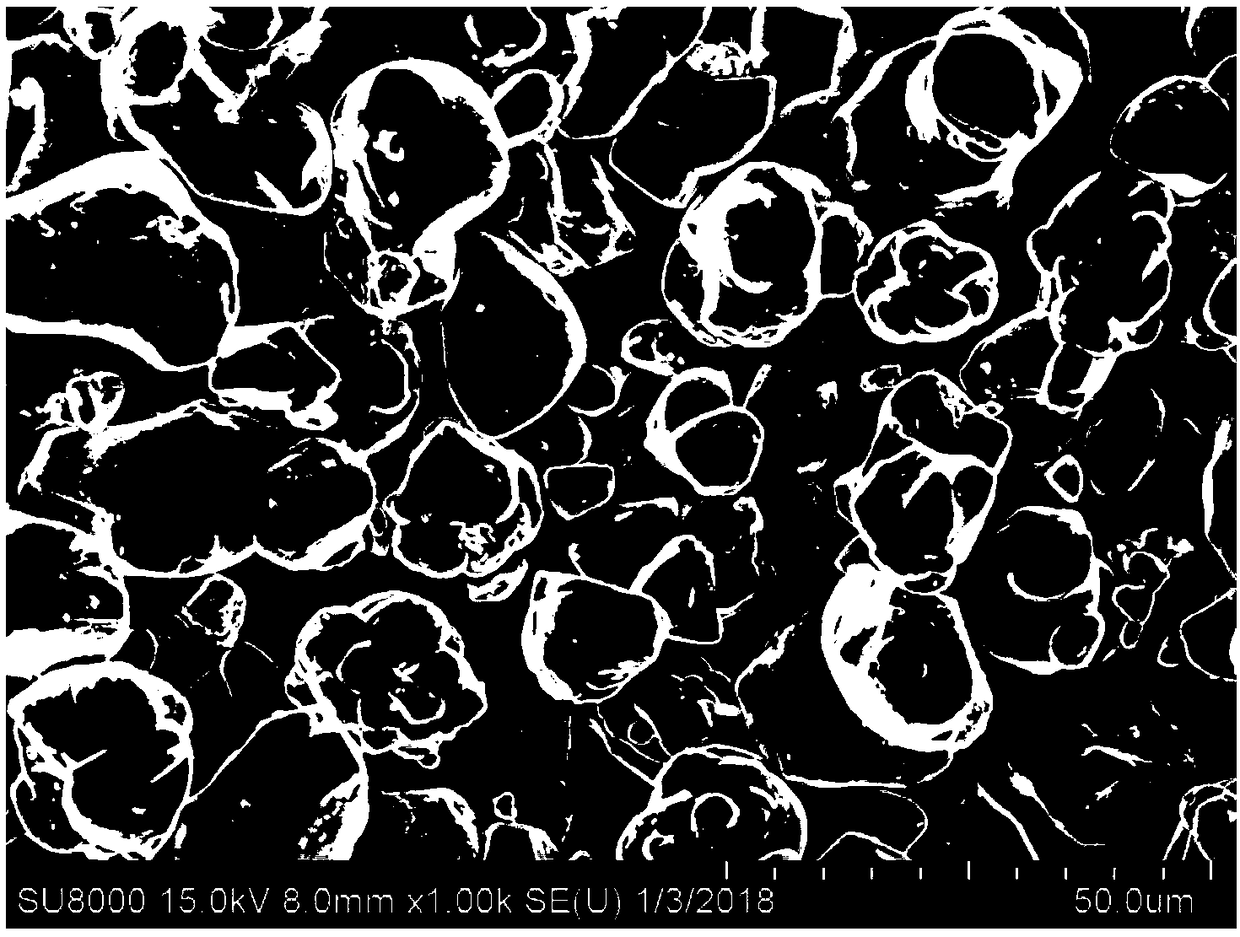

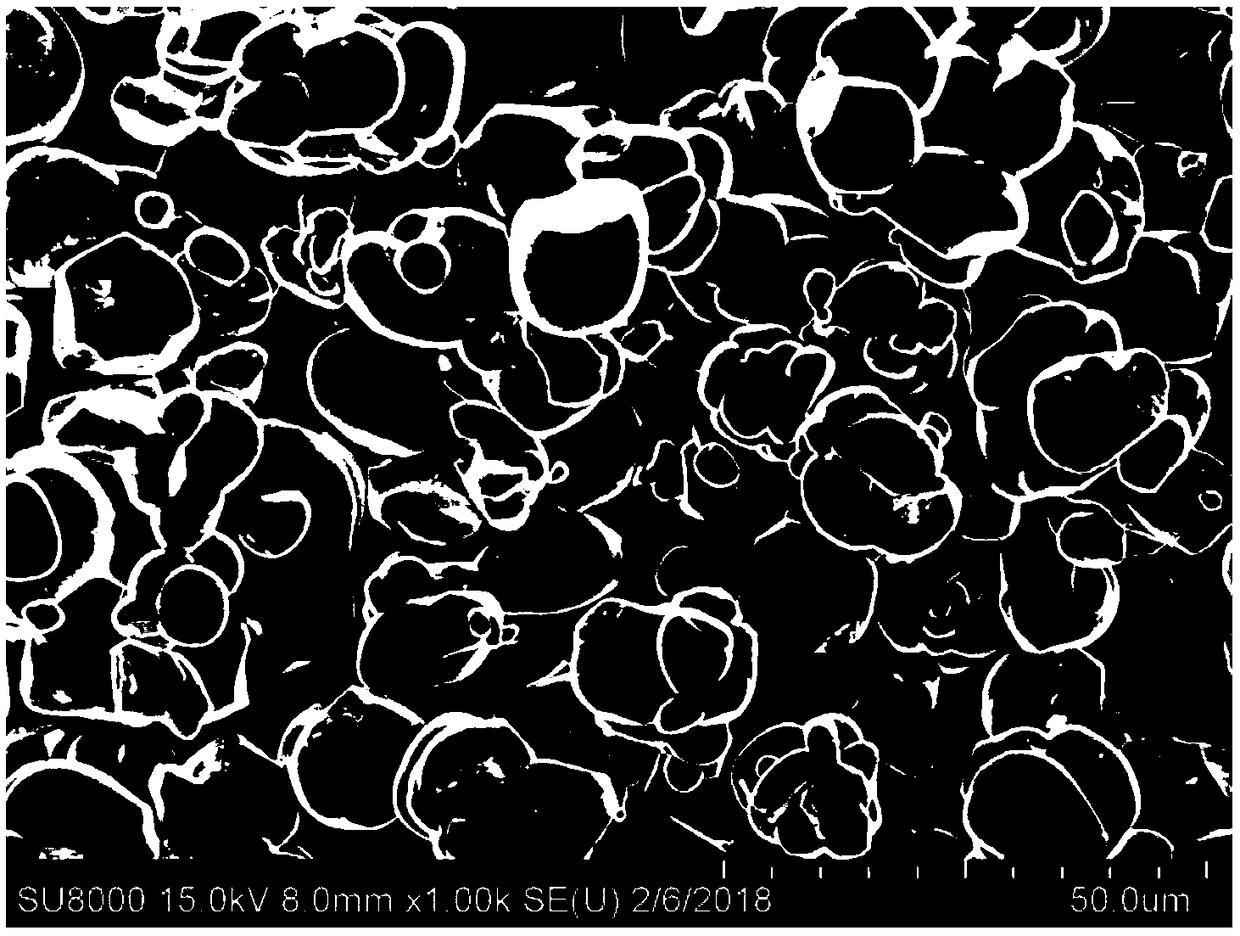

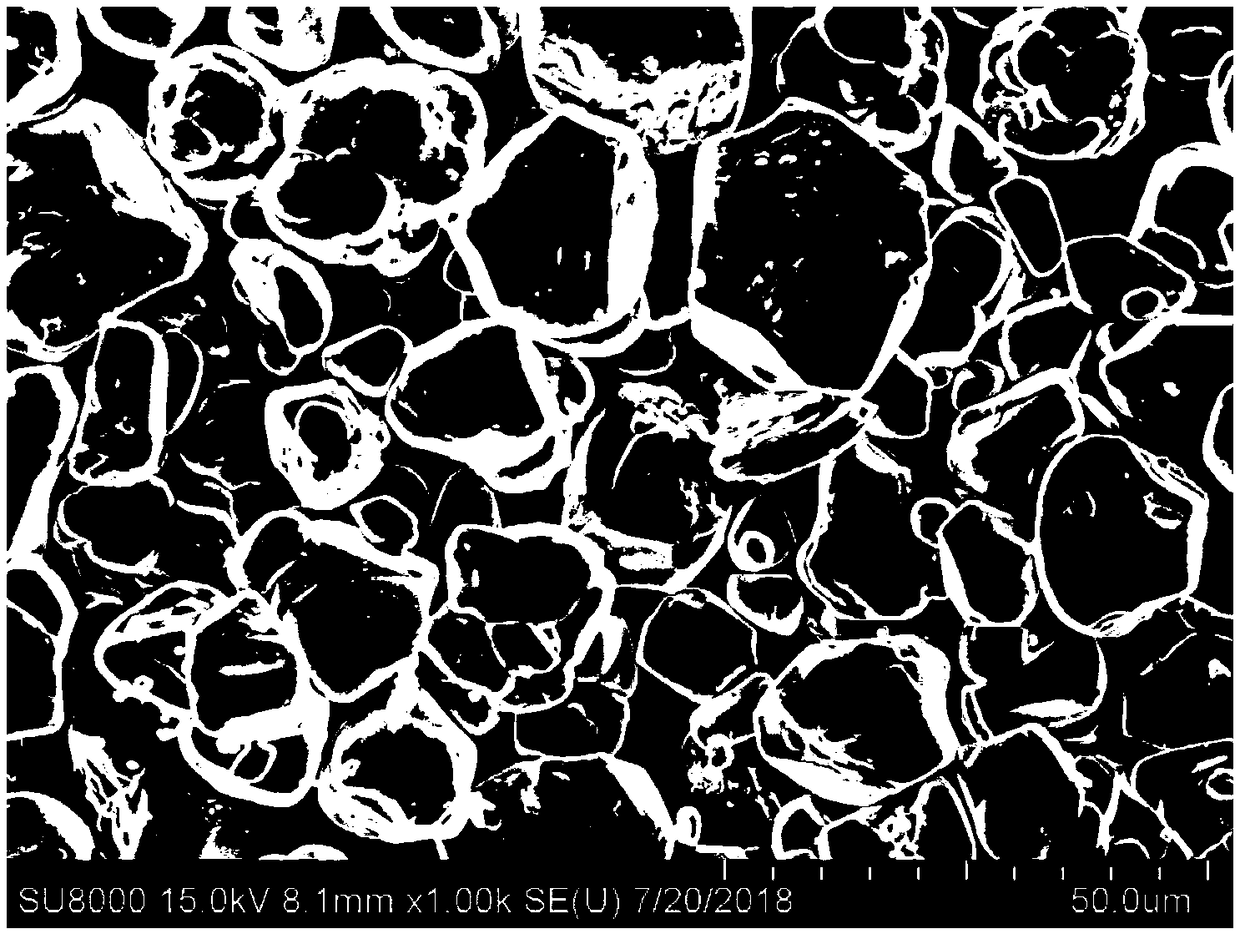

ActiveCN107732204AFull responseHigh specific capacityMaterial nanotechnologyCell electrodesHigh rateCyclic stability

The invention provides a preparing method of a metal lithium composite material. The preparing method comprises the steps of 1, soaking a first macroporous material into a solution to obtain the soaked macroporous material, wherein the solution contains a porous carbon material and / or a porous carbon material precursor; 2, annealing the soaked macroporous material after the macroporous material isdried to obtain a treated material; 3, loading metal lithium into the treated material and / or onto the surface of the treated material to obtain the metal lithium composite material. Compared with the prior art, the porous carbon material is utilized to construct a multistage pore passage structure in pores of the macroporous material, and thus a multistage contact interface of an electrolytic solution and metal lithium is constructed; meanwhile, metal lithium is divided and bounded within the space of a micrometer scale, and sufficient reaction and deposition of metal lithium are facilitated; the multistage structure provides a three-dimension channel for conduction of electrons, and the growth of metal lithium dendritic crystals is inhibited, so that the metal lithium composite materialhas high specific capacity, high-rate performance and high cycling stability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

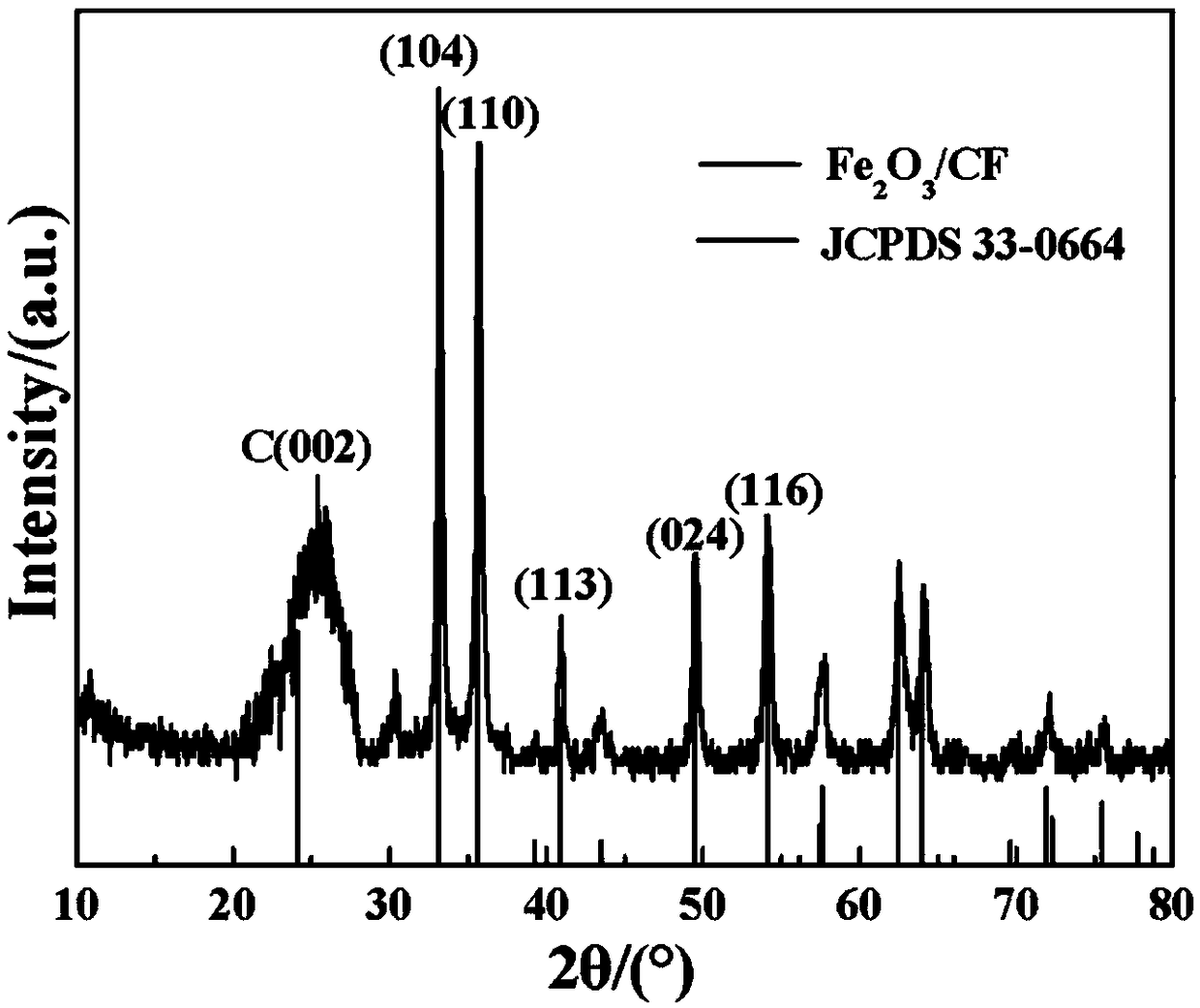

Preparation method of iron oxide/carbon fiber composite lithium ion battery negative electrode material

ActiveCN108630921ALarge specific surface areaWell-ordered pore structureCell electrodesSecondary cellsFiberHigh rate

The invention discloses a preparation method for an iron oxide / carbon fiber composite lithium ion battery negative electrode material. The preparation method comprises the following steps: taking an iron based metal organic framework as a precursor, mixing the precursor with a PAN solution, and performing electrostatic spinning to obtain a metal organic framework / PAN fiber; and thermally treatingthe metal organic framework / PAN fiber under inert atmosphere to prepare an iron oxide / carbon fiber composite material. The iron oxide / carbon fiber composite material prepared by the preparation methodhas good toughness, conductivity, an ordered pore channel structure and a great specific surface area, is taken as a lithium ion battery negative electrode material, and has relatively high first-time discharge specific capacity, relatively high charge specific capacity, highly high first-time coulomb efficiency, relatively high circulating stability and relatively high rate performance.

Owner:XIAN UNIV OF SCI & TECH

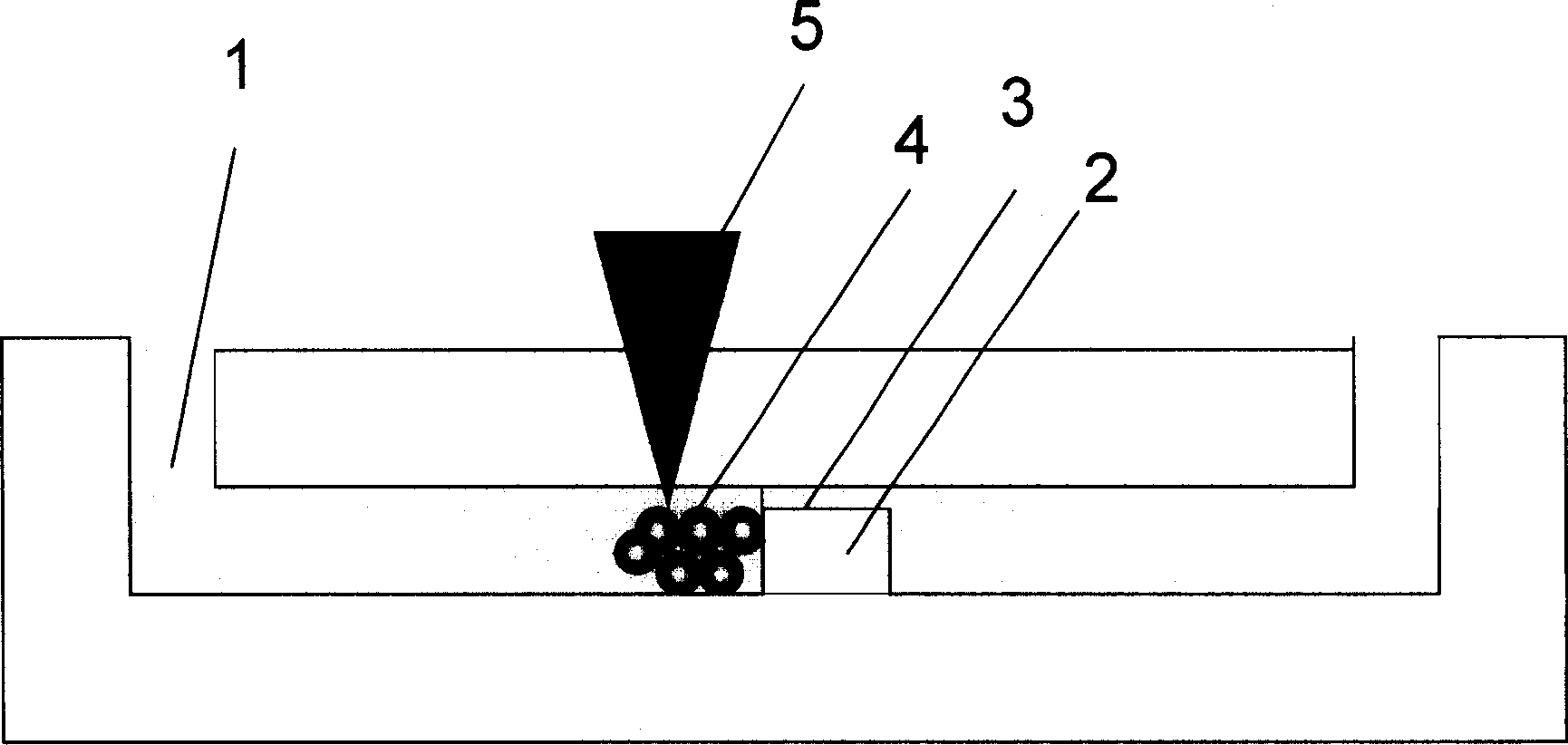

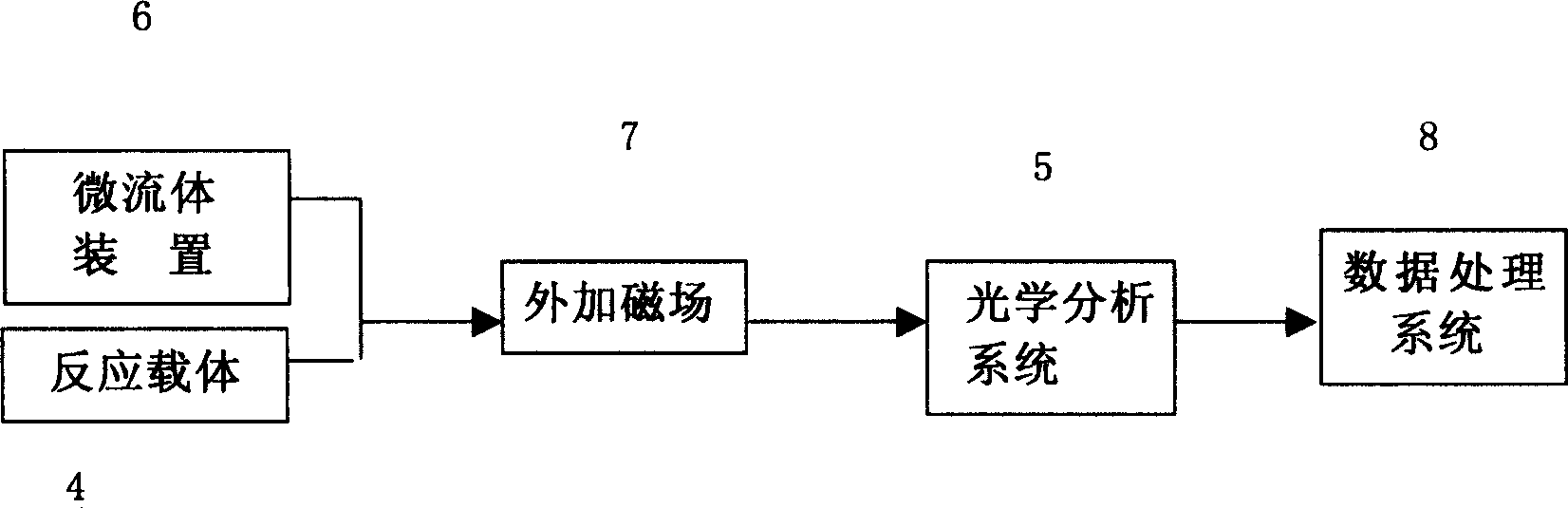

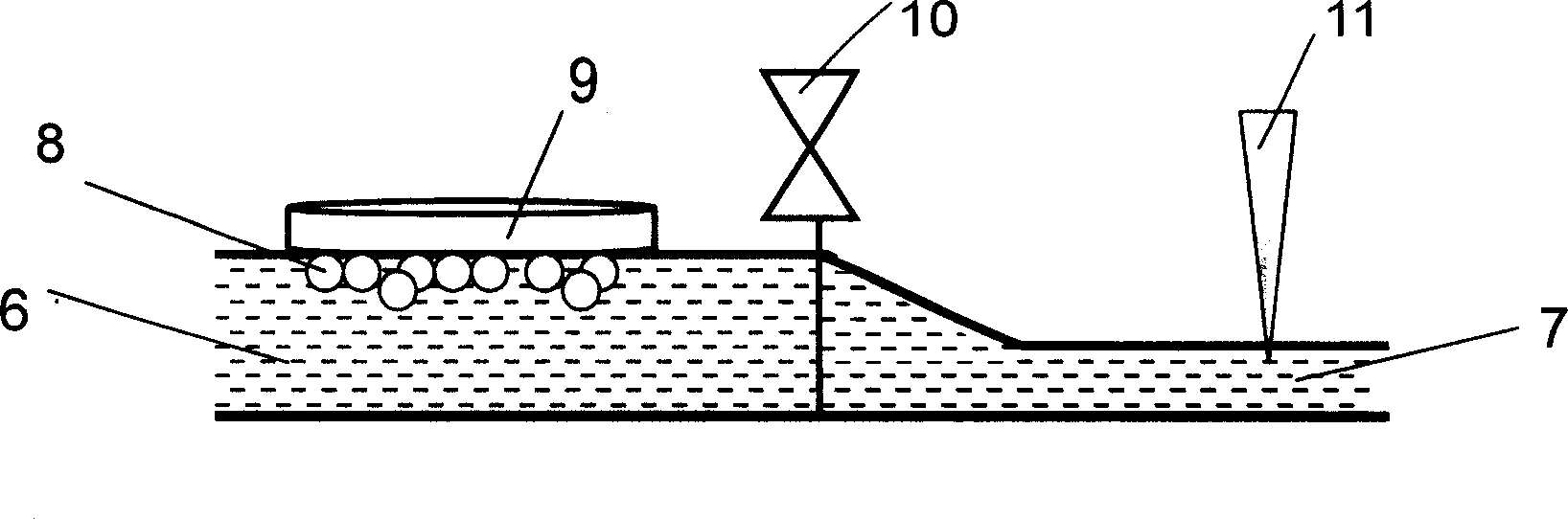

Microfluid analytical system using magnetic microsphere as medium and ivestigating method thereof

ActiveCN1598579AFull responseFully cleanedColor/spectral properties measurementsBiological testingEngineeringLight source

The invention discloses a micro fluid analysis system which is leaded by magnetic microsphere, the system includes micro fluid analysis system equipment, optic analysis system and data analysis system which is set in the output end of the optic analysis system, reaction carrier is in the micro fluid equipment, the optics analysis system includes detector, reaction aisle and detector aisle joint where has valve; the reaction carrier is magnetic microsphere or magnetic fluorescent microsphere. The invention can control the course to process truly, using the magnetism of magnetic microsphere during reaction and cleanout; because the process can be controlled, the reaction carrier can select different radius magnetic microsphere or magnetic fluorescent microsphere. The detector can be set at different position according to the demand, and it can analyze the result by CCD shooting method, color testing by spectroscope, the invention can also test the result of magnetic fluorescent microsphere and fluorescence signal of the tiny surface by laser lamp-house system.

Owner:XIAN GOLDMAG NANOBIOTECH

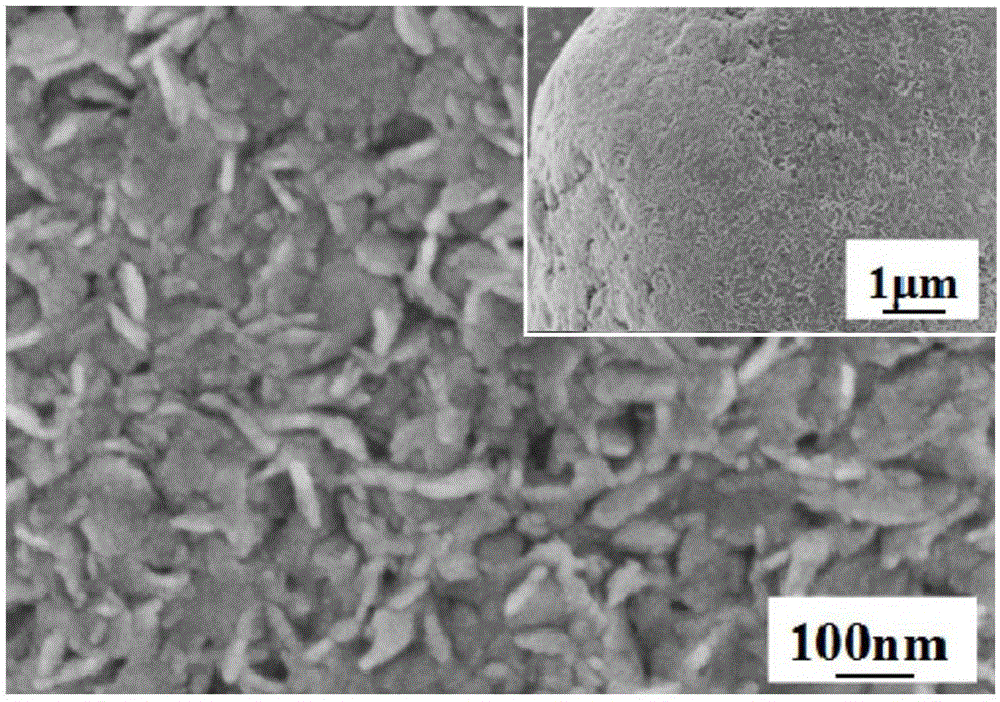

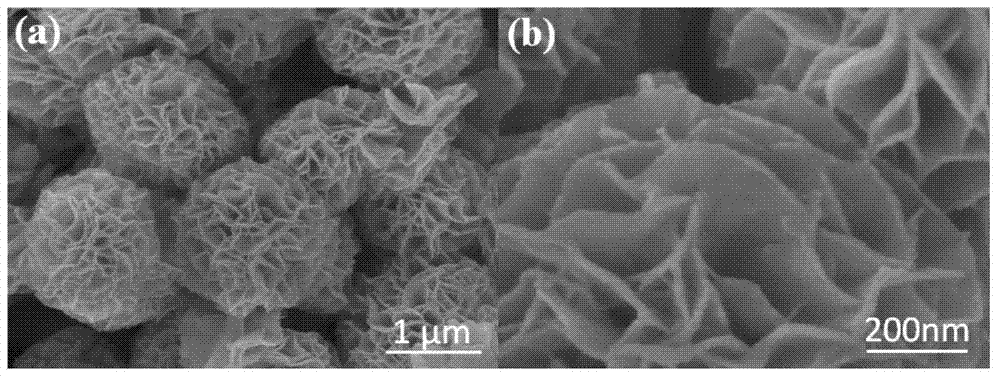

High-performance micro-nano multi-level structure BiOCl photocatalytic material and preparation method thereof

ActiveCN103537303AReduce energy consumptionLow costPhysical/chemical process catalystsChemistryFlower like

The invention relates to the field of nanomaterials and photocatalytic technologies and specifically relates to a high-performance micro-nano multi-level structure BiOCl photocatalytic material and a preparation method thereof. According to the preparation method provided by the invention, polyvinyl alcohol which is a non-toxic and biodegradable surfactant is introduced, so that BiOCl nano-sheets generated by reaction are self-assembled into micro-nano multi-level structure flower-like microspheres, wherein the diameter of the flower-like microspheres is 2-3 mu m, the length of the nano-sheets is 100-300nm, the width of the nano-sheets is 100-300nm, the thickness of the nano-sheets is 10-50nm, the nano-sheets are mutually overlapped to form a large number of pore structures with the aperture of 50-200nm, and the specific surface area is not less than 46.9m<2> / g. The BiOCl photocatalytic material not only can take the high catalytic activity and efficiency advantage of nano-units, but also can effectively overcome the defects that a nano-photocatalyst is difficult to recover and easily produces secondary pollution in use. The preparation method can be completed in one step at room temperature, has the advantages of simple process, low energy consumption, low cost, short preparation period and environmental friendliness, and is conductive to engineering large-scale preparation and application.

Owner:HEFEI UNIV OF TECH

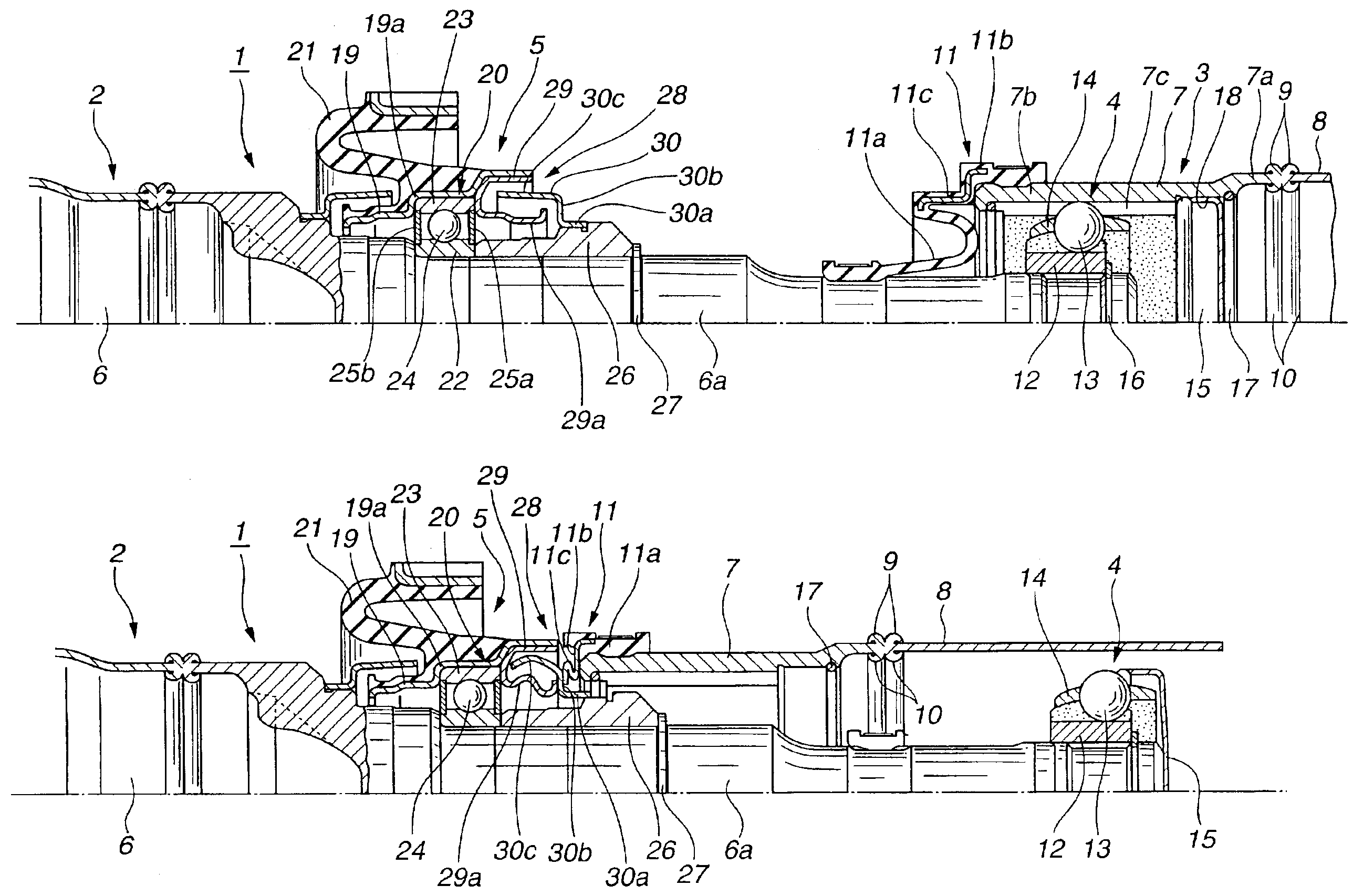

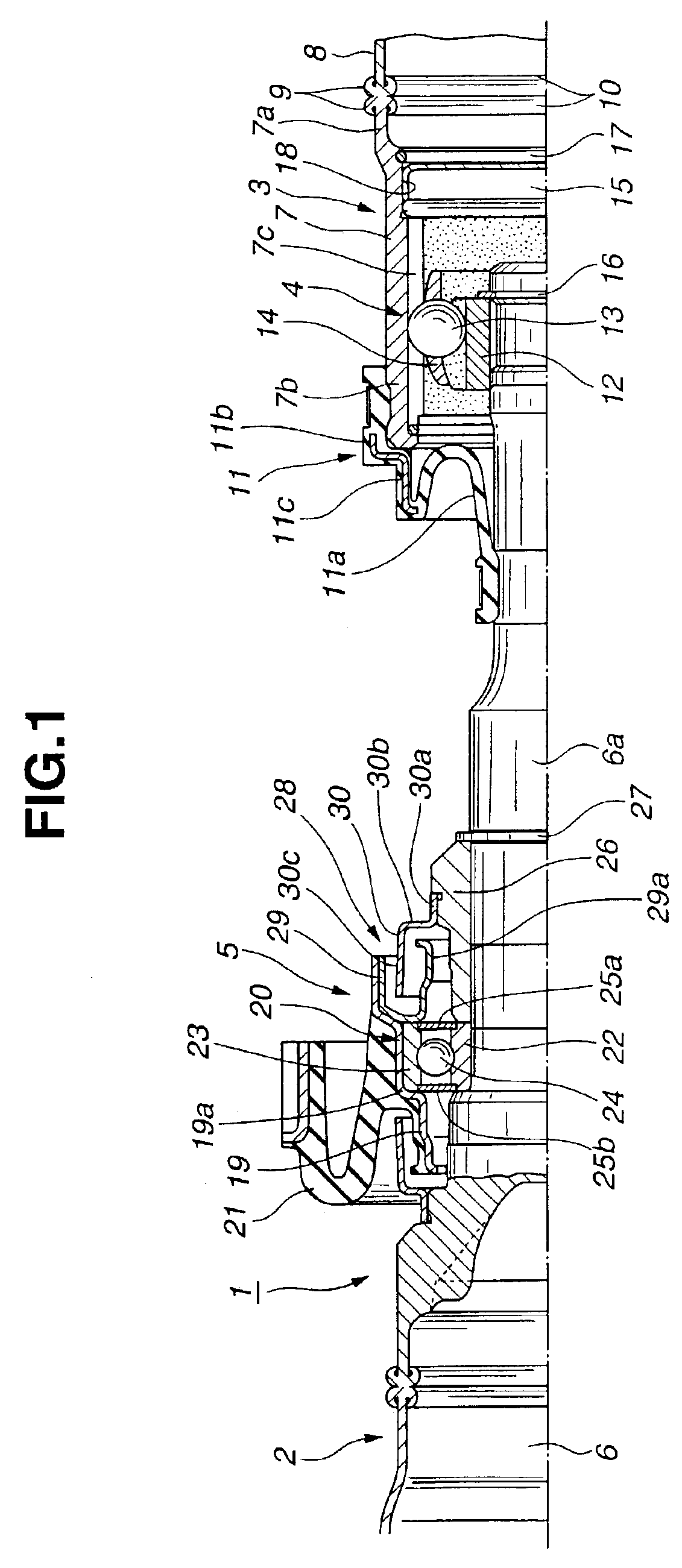

Shock-absorbing mechanism for power-transmission device

ActiveUS6913105B2Improve rigidityConsiderable strengthYielding couplingShaftsAxial loadPower transmission

A shock-absorbing mechanism for a power-transmission device includes a cylindrical driven-side shaft coupled to the driving-side shaft through a constant-velocity joint to be axially relatively slidable with respect to the driving-side shaft, a center bearing for rotatably supporting the driving-side shaft to the vehicle body, and a labyrinth mechanism for sealing the inside of the center bearing. An end of the driven-side shaft on the side of the driving-side shaft is disposed axially opposite to the labyrinth mechanism. When the two shafts are slid in the direction to approach each other by an axial load input thereto, the end of the driven-side shaft collides axially with the labyrinth mechanism.

Owner:HITACHI ASTEMO LTD

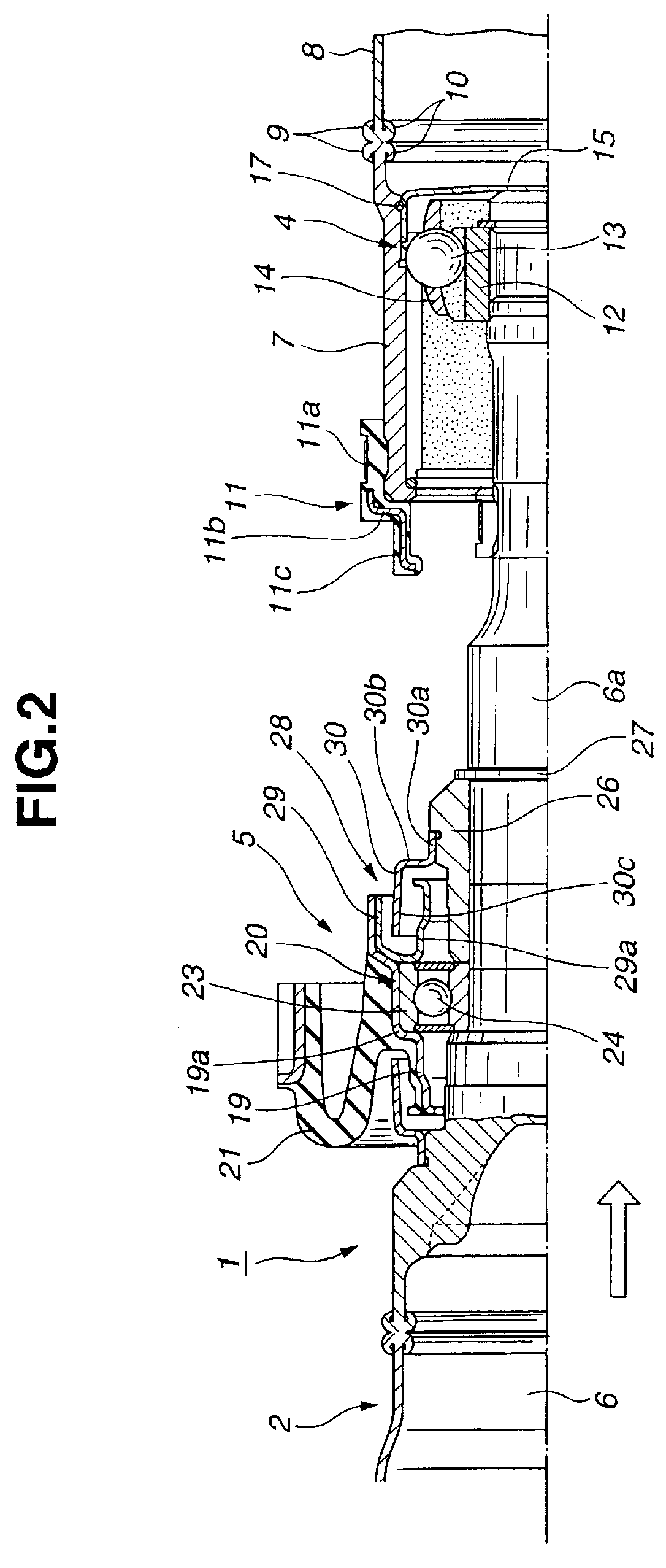

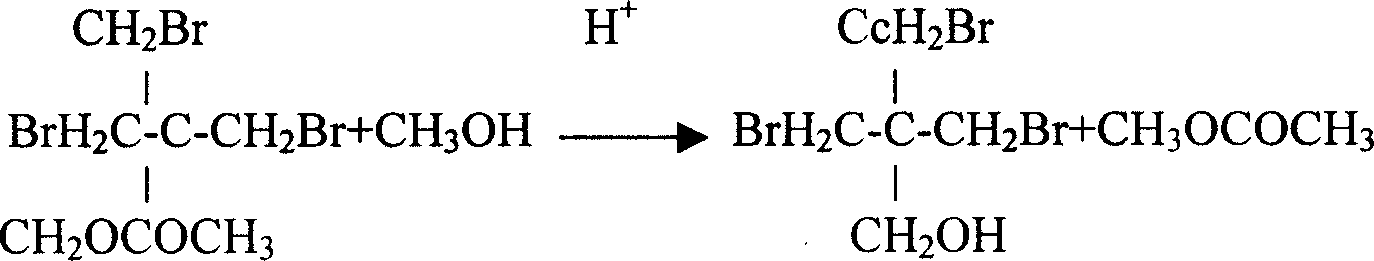

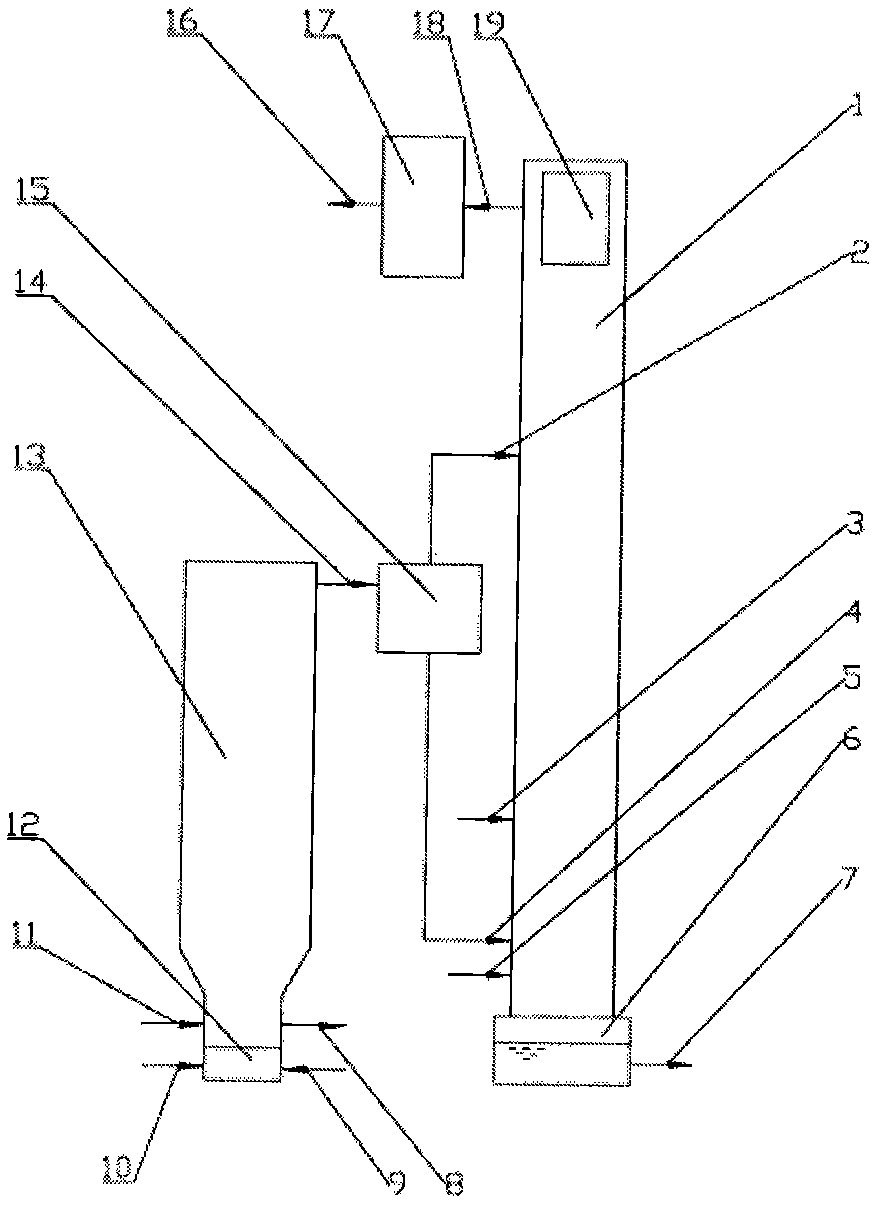

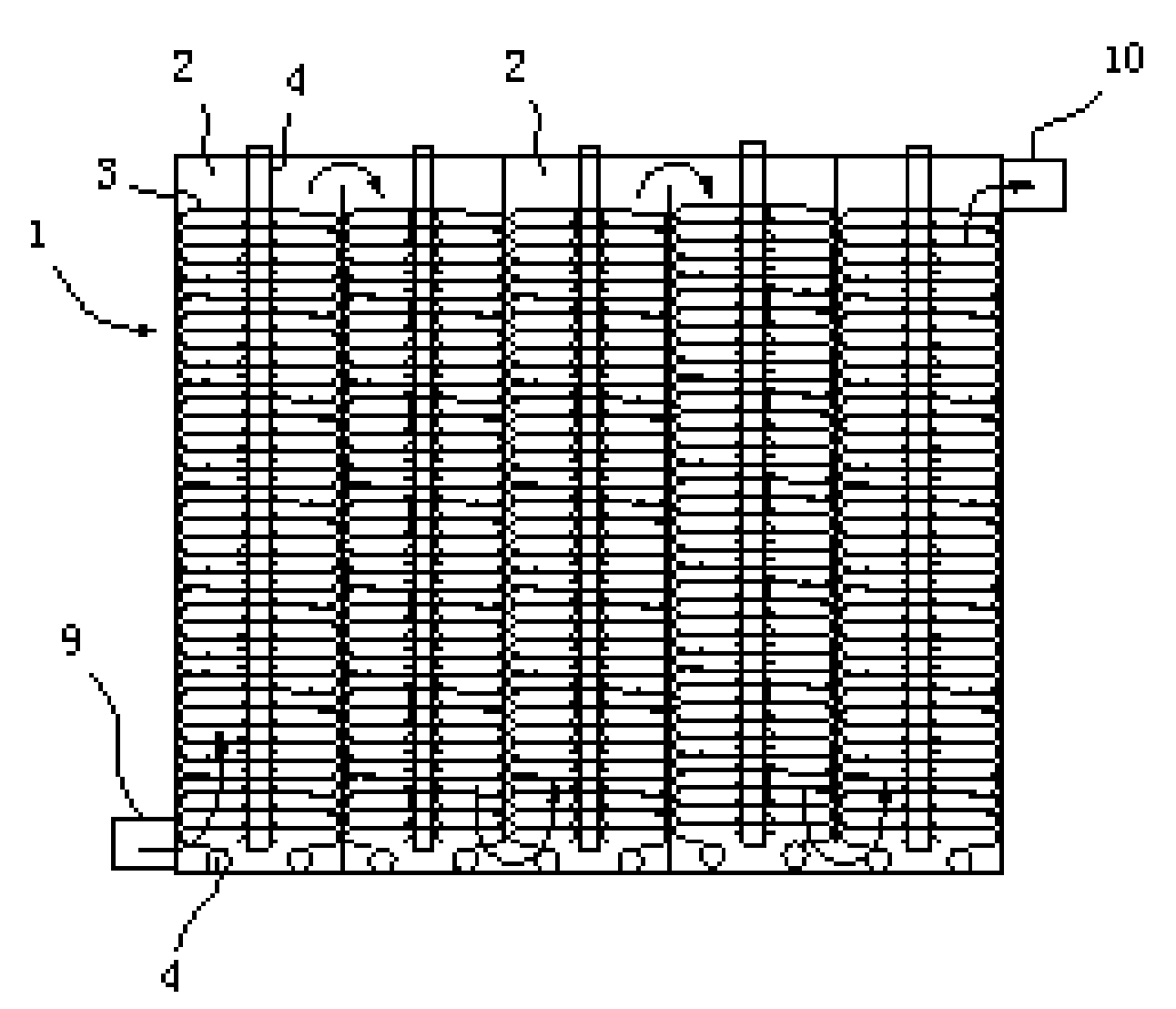

Improved A*N denitrifying dephosphatation and deep denitrification device and method

ActiveCN101538104ASolve the problem of excessive ammonia nitrogenFully release phosphorusTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentBiofilmAmmoniacal nitrogen

The invention relates to an improved A2N denitrifying dephosphatation and deep denitrification device and a method, belonging to the field of sewage treatment. The device is characterized in that a combined aeration tank is arranged between an anoxic tank and a final depositing tank; the combined aeration tank realizes synchronous aerobic phosphorus absorption and biofilm nitrification; a cube sponge filling is filled; the batching ratio of filling is 20 to 30 percent of effective volume of a reactor; and the combined aeration tank is provided with an air pump, an air flow meter and an aerator pipe. Under the condition of adding no reaction area in the original A2N technique, the invention replaces a post aeration reaction tank with the combined aeration tank adopting suspending sponge filling as carrier of nitrobacteria, and controls the parameters of aeration amount and temperature and the like to realize the nitrification and synchronous of nitrification-denitrification of ammonia nitrogen. The invention does not add the process flow and energy consumption of operation, solves the fatal problem of the traditional technique, and guarantees the stable and high-efficiency removal of nitrogen and phosphorus in effluent quality.

Owner:SDIC XINKAI WATER ENVIRONMENT INVESTMENT CO LTD

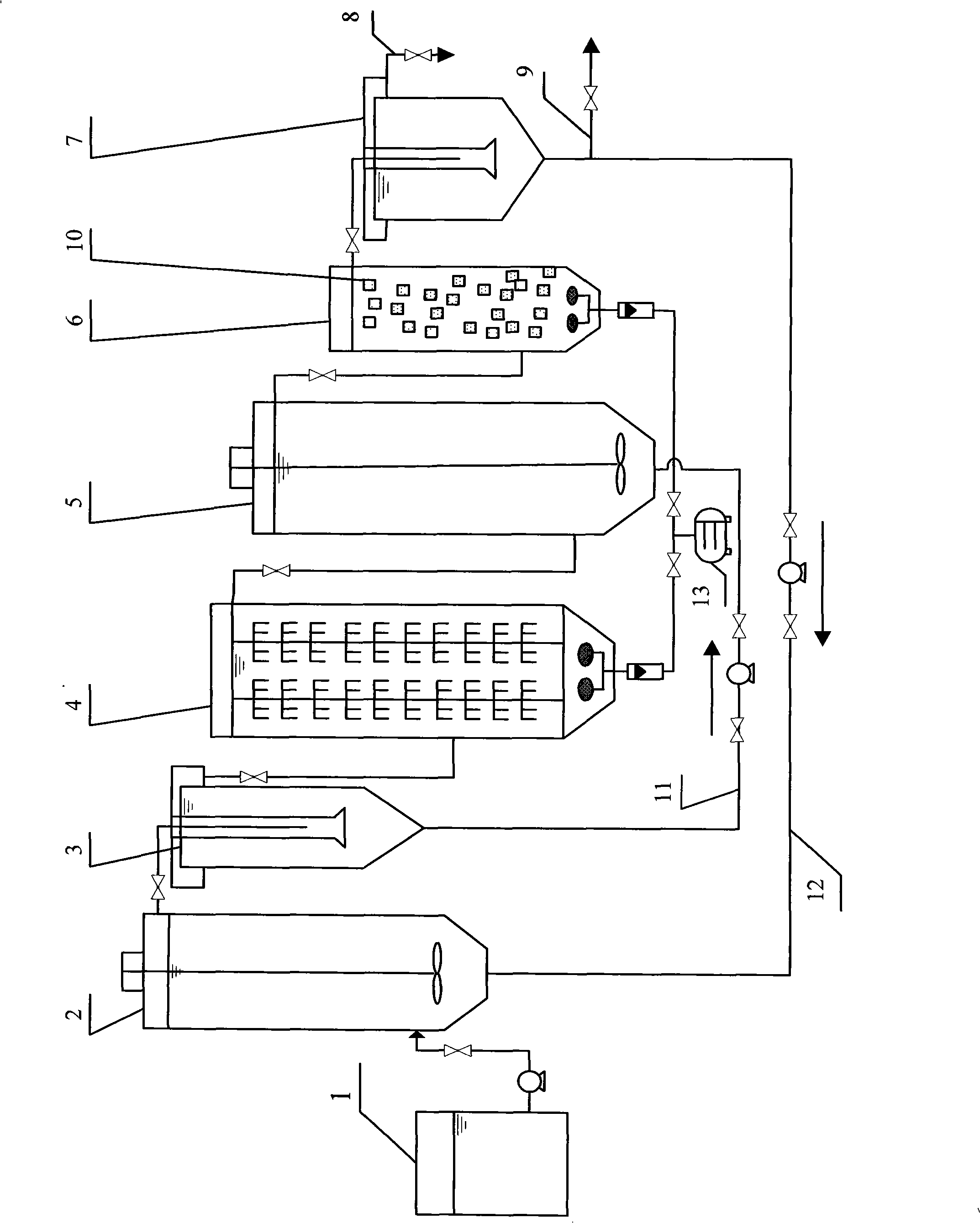

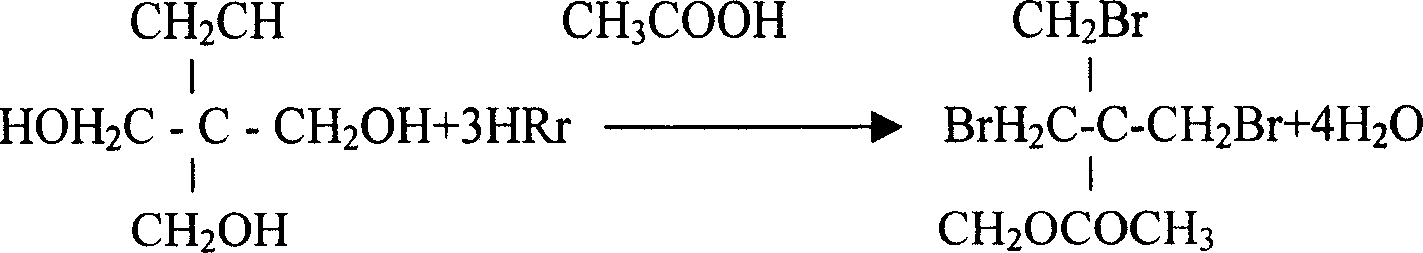

Synthetic method and refining for tribromoneoamyl alcohol

InactiveCN101016227AFull responseGood product qualityPreparation by halogen introductionDecompositionPentaerythritol

The invention discloses a synthesizing method of tribromo-neoamyl alcohol, which comprises the following steps: aerating hydrogen bromide into pentaerythrite to substitute; insulating; separating tribromo-neoamyl alcohol ester; adding carbinol and inorganic acid into tribromo-neoamyl alcohol to do ester decomposition under 0.4-0.6Mpa; insulating under 0.6-0.8Mpa after substituting; making the mass react completely; improving product property obviously.

Owner:宜兴市中正化工有限公司

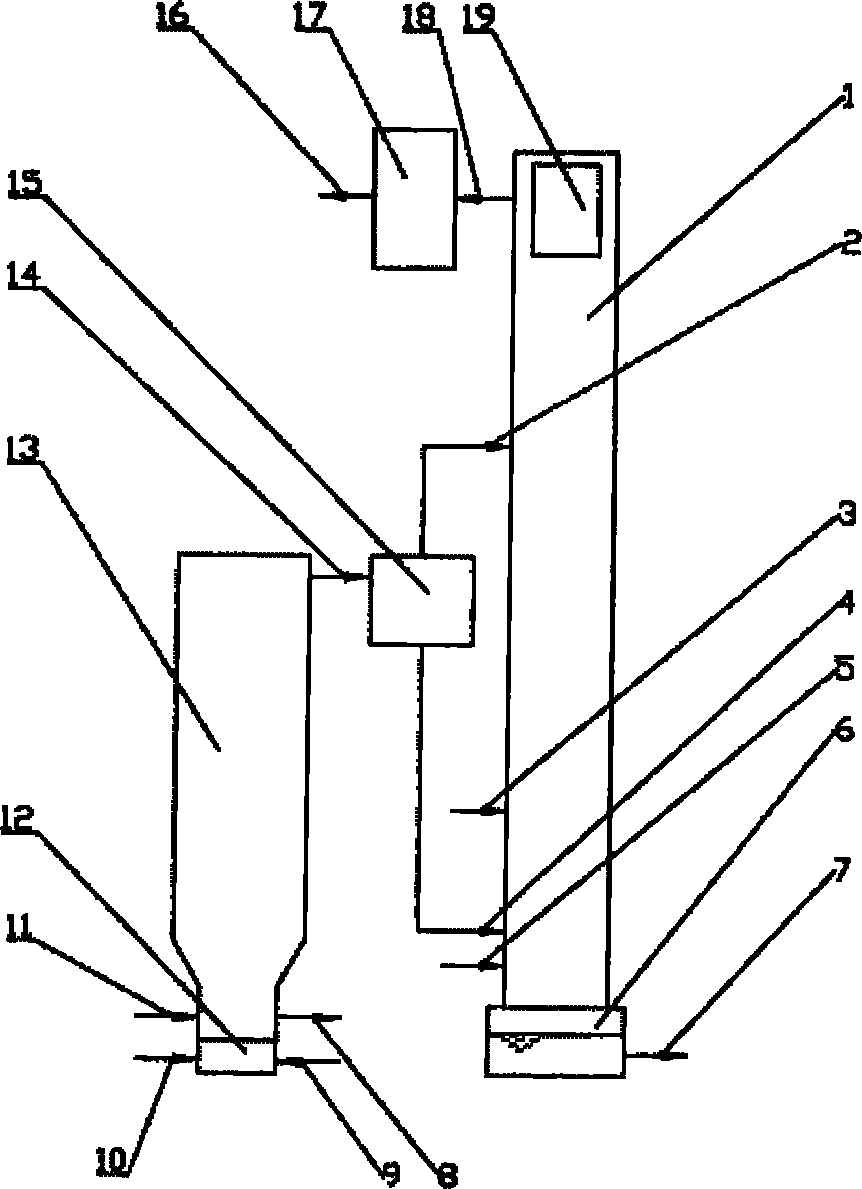

Coal gasification method

InactiveCN102373089ALow investment costLow running costGranular/pulverulent flues gasificationFluidized bedOxygen

The invention provides a fluidized bed-entrained flow bed gas gasification method. The method comprises the following steps: 1) carrying out reaction on raw material coal and a mixture of air and steam or a mixture of oxygen and steam to obtain gas containing incompletely reacted coal and ash; 2) separating the gas obtained from the step 1) to obtain condensed fine coal air-flow and light fine coal air-flow, and carrying out reaction on the condensed fine coal air-flow with air or oxygen to obtain gas containing coal and ash; 3) carrying out reaction on the gas obtained from the step 2) and steam to obtain gas containing coal and ash; 4) carrying out reaction on the gas obtained from the step 3), the light fine coal air-flow separated from the step 2) and a mixture of steam and carbon dioxide to obtain final gas containing coal and ash. The method lowers investment and operating cost of a traditional pulverizing system by an entrained flow bed gasification method and has a substantially increased gasification temperature than a traditional fluidized bed gasification method, so as to reduce equipment cost and increase gasification efficiency.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

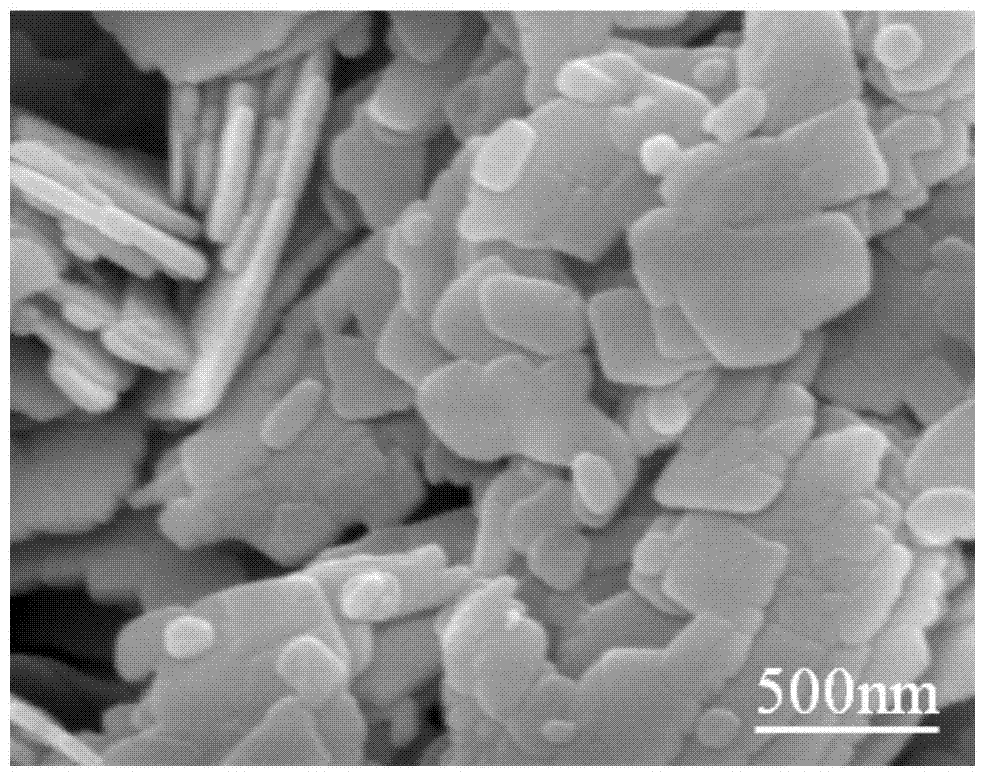

Ternary positive electrode material of high-nickel monocrystal-like lithium ion battery and preparation method thereof

ActiveCN110931768AEasy to processIncrease capacityCell electrodesSecondary cellsElectrical batteryPhysical chemistry

The invention discloses a preparation method of a ternary positive electrode material of a high-nickel monocrystal-like lithium ion battery and the prepared ternary positive electrode material. The preparation method comprises the following steps: sintering a precursor and a lithium source in air or oxygen; uniformly mixing the precursor metal oxide A and lithium oxide obtained by sintering according to a molar ratio of lithium to metal ions in A of 1.0-1.1, and carrying out primary sintering in oxygen to obtain B; adding 30-70% by mass of B into pure water, uniformly mixing, adding 0.5-3% bymass of an oxidizing agent without metal ions, and stirring at 10-50 DEG C for 10-30 minutes; filtering, drying, carrying out secondary sintering in oxygen, and sieving to obtain the ternary positiveelectrode material LiNi<x>Co<y>Mn<z>M<t>O<2> of the high-nickel single-crystal-like lithium ion battery, wherein x is more than or equal to 0.60 and less than or equal to 0.90, y is more than or equalto 0.05 and less than or equal to 0.20, z is more than or equal to 0 and less than or equal to 0.20, t is more than or equal to 0 and less than or equal to 0.005, x+y+z+t is equal to 1, and M is oneof Al, Ca, Mg, Zr, Ti, Sr, Mo, W and Ce. The ternary positive electrode material of the high-nickel single-crystal-like lithium ion battery contains divalent nickel, has few surface impurities lithiumand impurities, and is good in processability, high in capacity and good in cycle performance when being used for manufacturing the battery.

Owner:新乡天力锂能股份有限公司

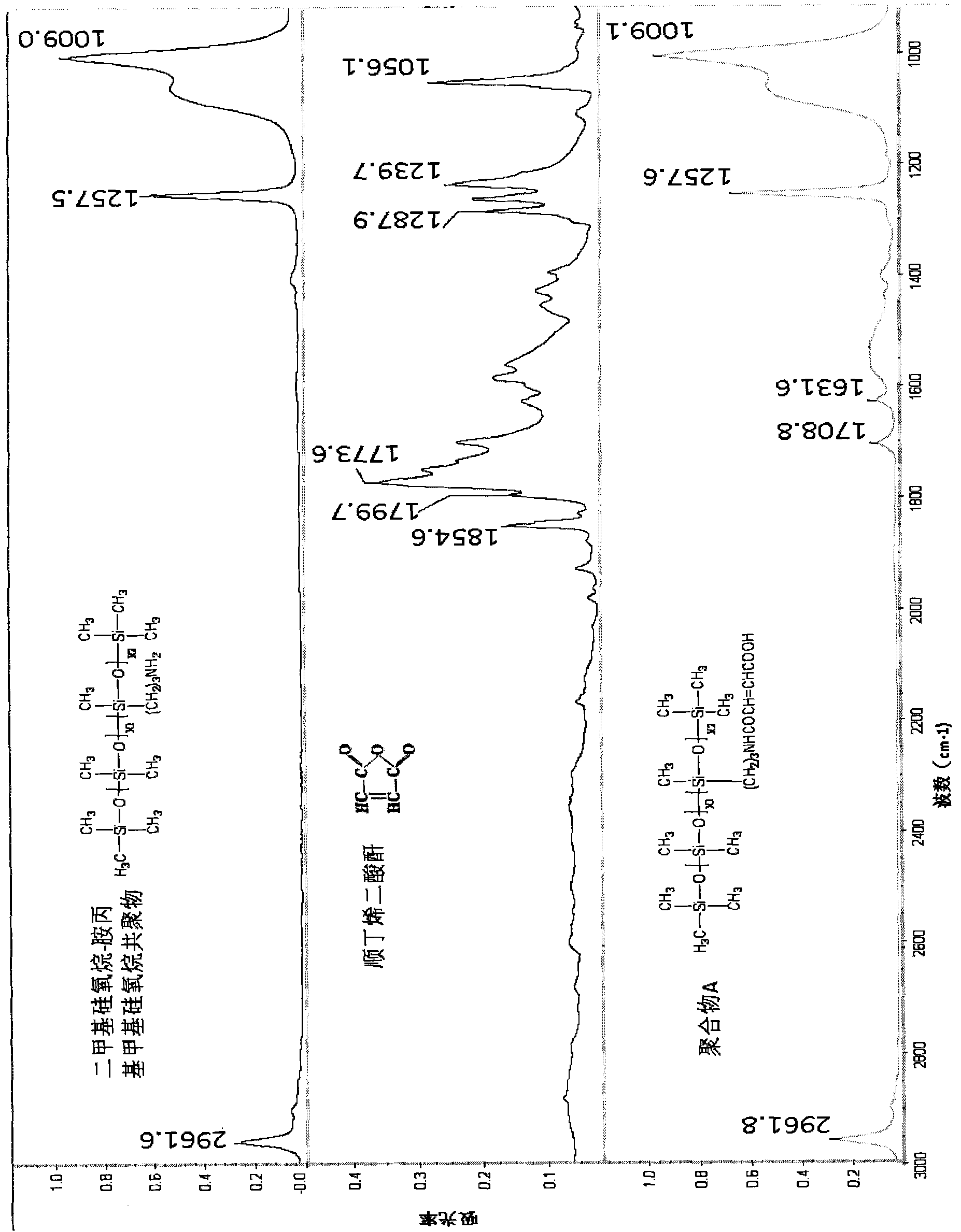

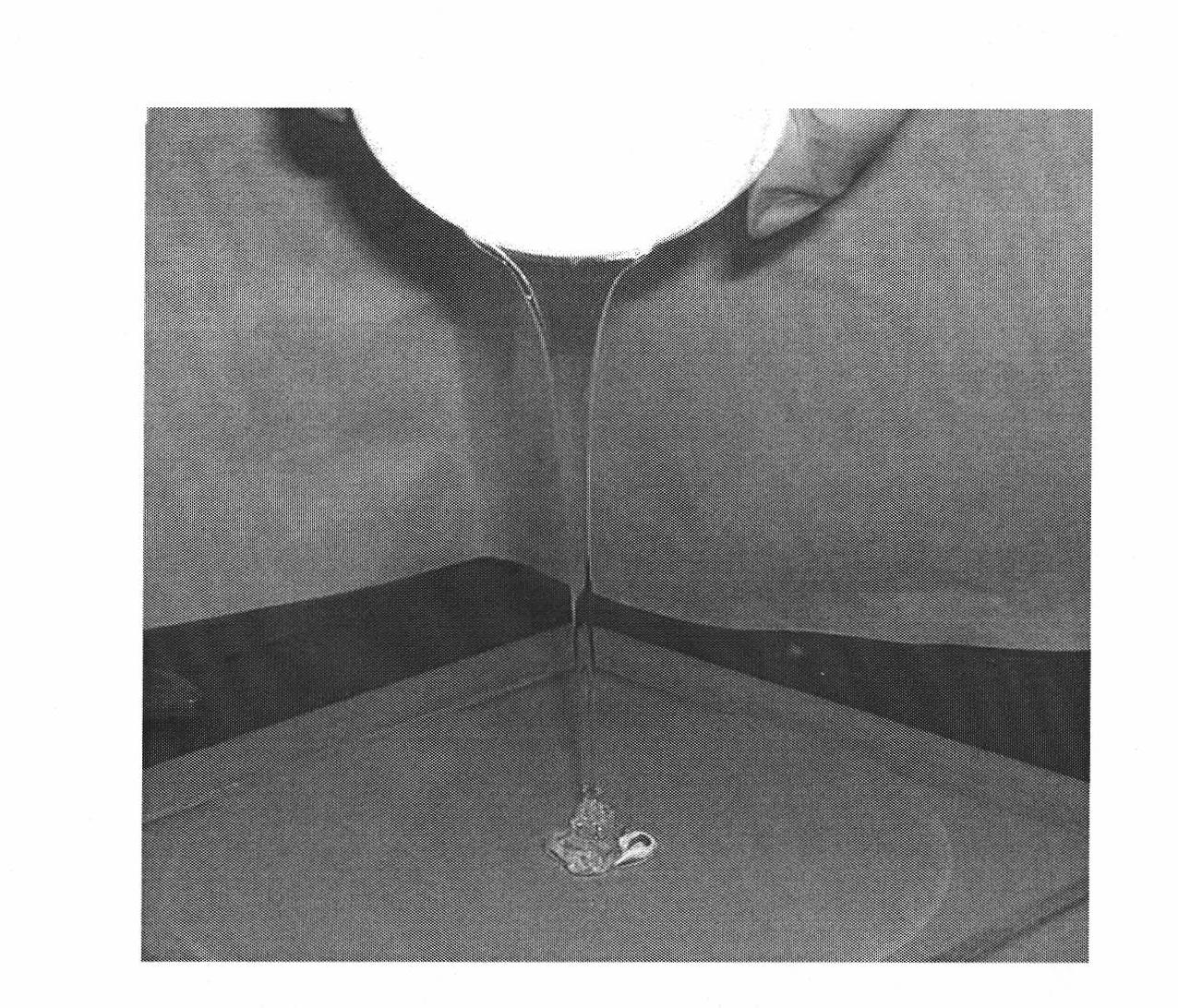

Composition for preparing organic silicon elastomer, organic silicon elastomer and preparation method and application thereof

InactiveCN101798464AMeet the needs of green environmental protectionQuick responseOther chemical processesCoatingsElastomerAziridine

The invention discloses a composition for preparing organic silicon elastomer, which contains polymer A and compound B, wherein the polymer A is silicones polymer containing at least two carboxyl groups, the compound B contains at least two aziridine rings, and the mol ratio of the carboxyl groups of the polymer A to the aziridine rings of the compound B is 1:0.2-10. The invention further discloses a method for preparing organic silicon elastomers by using the composition, and an organic silicon elastomer and application thereof.

Owner:HENKELCHINAINVESTMENT

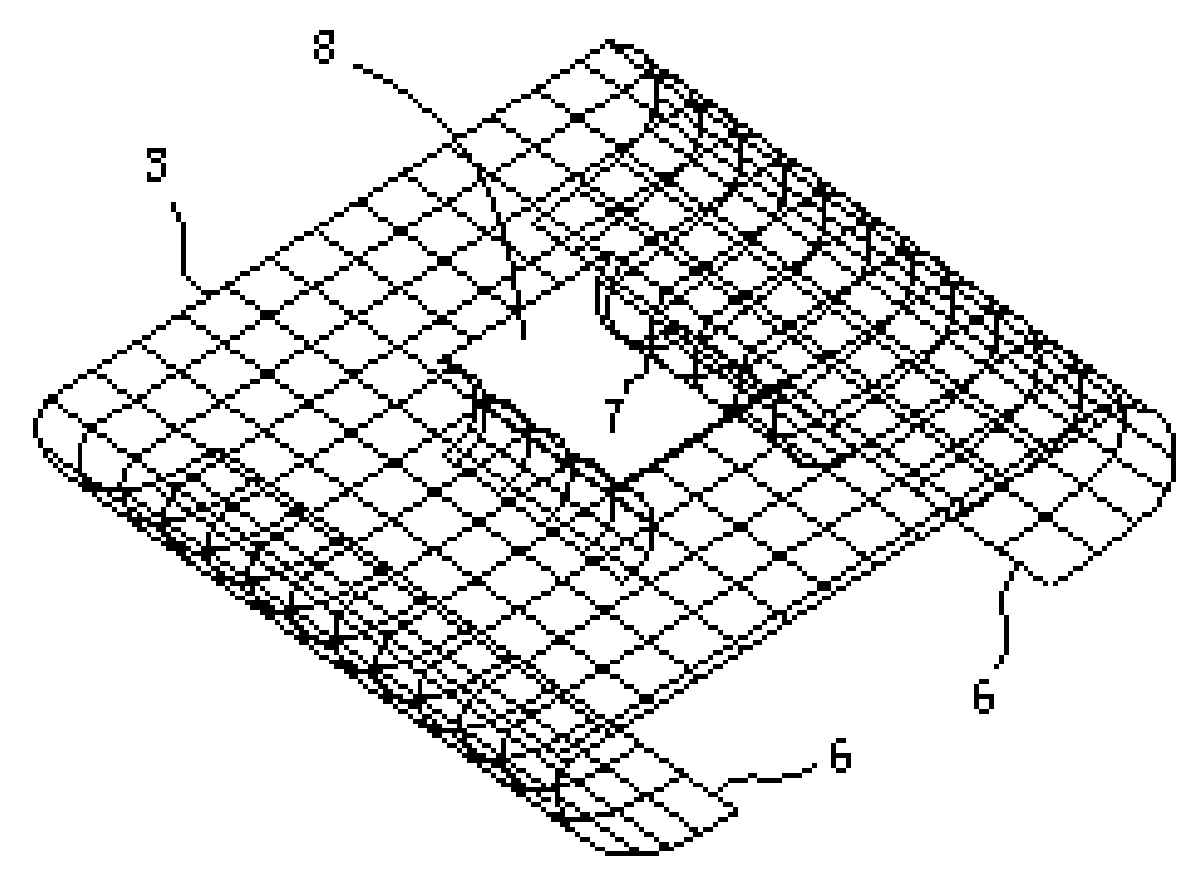

Manufacturing method of netted catalyst for degrading organic pollutant in wastewater by photocatalysis and organic pollutant wastewater treating device

ActiveCN101584996ATroubleshoot enhancementsExtend compound timeWater/sewage treatment by irradiationWater contaminantsEpoxyUltraviolet lights

The invention relates to a manufacturing method of a netted catalyst for degrading the organic pollutant in wastewater by photocatalysis and a wastewater treating device. The manufacturing method comprises: using the wire net plated with nickel as a carrier, coating a catalyst for solidification, wherein the catalyst mixed liquid includes nano TiO2, acetone, epoxy resin, solidifying agent and appropriate plasticizer, soaking in the acetone solution. A case of the treatment device is provided with a plurality of independent deflecting chambers connected end-to-end in turn, two ends of which are provided with a water inlet and a water outlet. A plurality of solid netted bodies solidified with the catalyst are overlapped at intervals in the deflecting chamber. A through hole is opened in the middle of the solid netted body. An ultraviolet light source is inserted in the through hole. An aeration pipe is arranged on the bottom of the deflecting chamber. The device can deeply degrade the organic matter in wastewater.

Owner:深圳市世纪清源环保技术有限公司

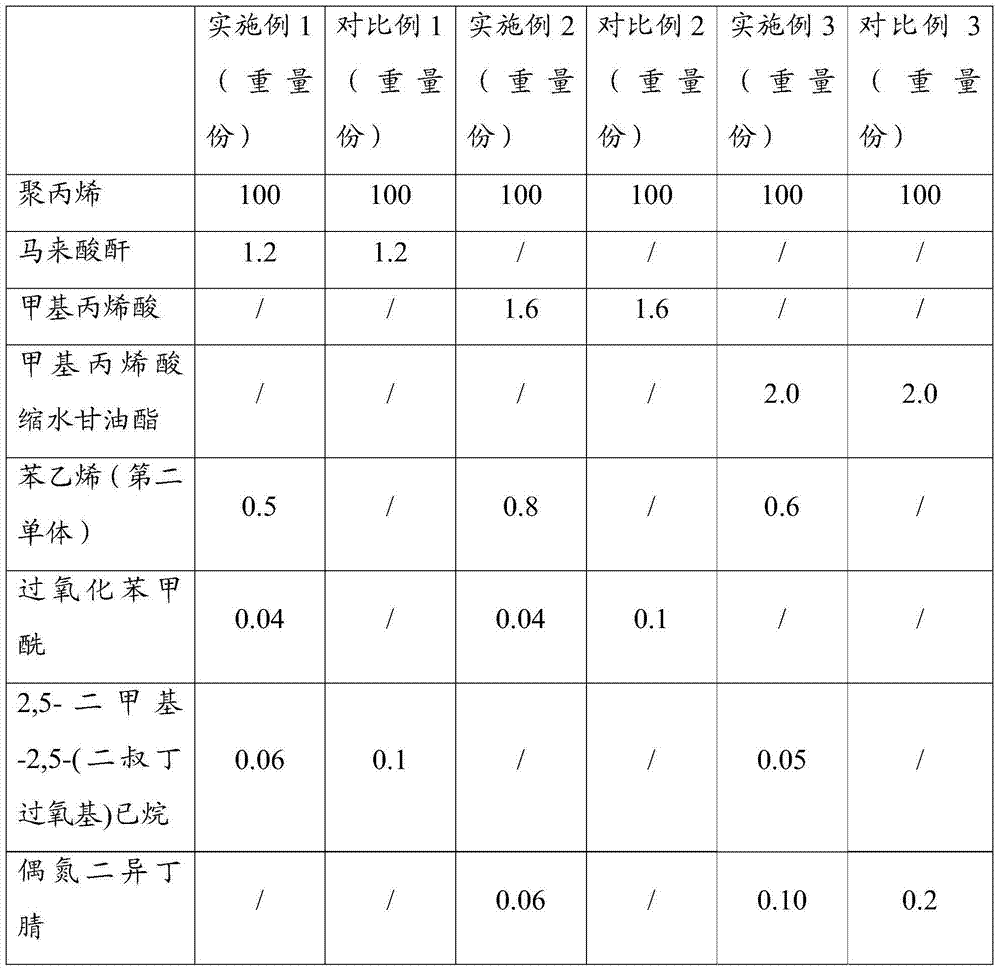

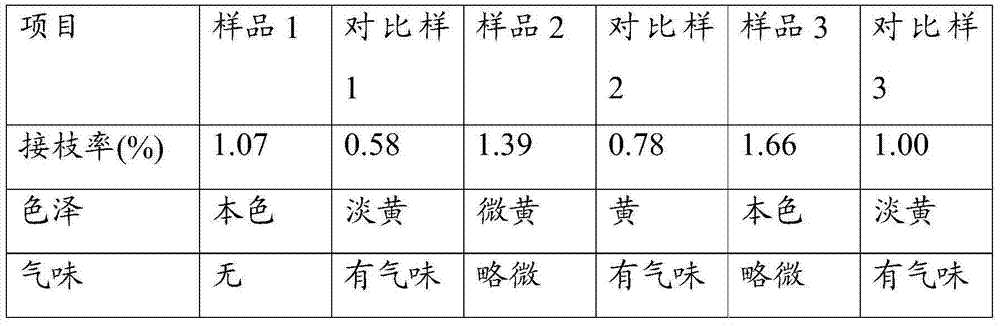

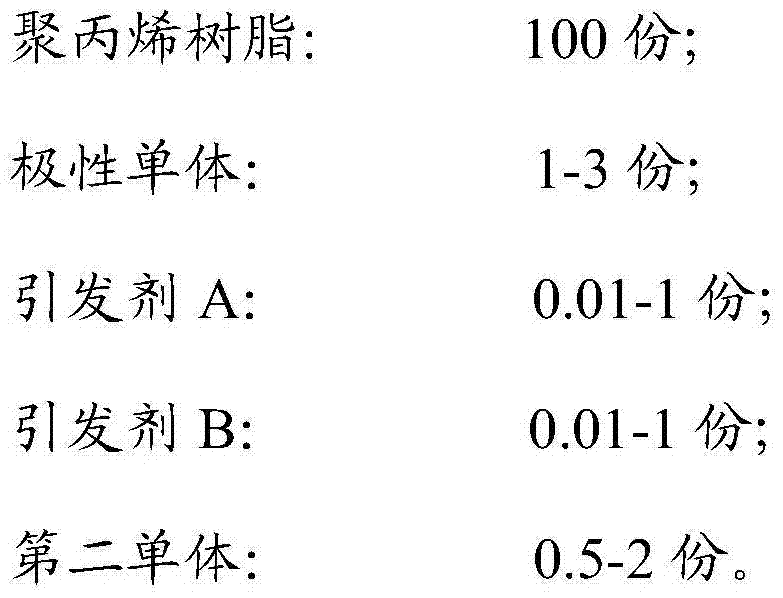

High-grating-rate and low-odor polypropylene resin composition and preparation method thereof

The invention provides a high-grating-rate and low-odor polypropylene resin composition and a preparation method thereof. The polypropylene resin composition consists of the following components in parts by weight: 100 parts of polypropylene resin, 1-3 parts of a polar monomer, 0.01-1 part of an initiator A, 0.01-1 part of an initiator B and 0.5-2 parts of a second monomer. The preparation method comprises the steps of weighing raw materials according to the weight part, mixing the raw materials in a high-speed mixer for 2-5min and discharging materials; and implementing reactive extrusion grafting on the mixed raw materials through a dual-screw extruder. The polypropylene resin composition disclosed by the invention, through selecting initiator and comonomer, reduces pungent odor of materials and improves grafting efficiency. The prepared polypropylene disclosed by the invention has the advantages of light product odor, high grating rate and low gel rate, and is applicable to a flexibilizer and a compatilizer of polar monomer and non-polar polymer alloy; the polypropylene resin composition is used for filling or strengthening polypropylene, and is capable of improving the mechanical performance and the heat resistance of the material.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

Preparation method of SiC/C-AlPO4-mullite antioxidation coating for C/C composite material

The invention relates to a preparation method of an SiC / C-AlPO4-mullite antioxidation coating for a C / C composite material, which comprises the following steps: mixing silicon powder and graphite powder to obtain powder A; mixing Al2O3 powder, WO3 powder and B2O3 powder to obtain powder B; mixing the powder A and the powder B to obtain embedded powder C; putting a sample in a graphite crucible, adding the embedded powder C, putting the graphite crucible in a vertical vacuum furnace, heating to react while introducing argon as a protective atmosphere, cooling to room temperature, and cleaning with anhydrous alcohol in ultrasonic waves to obtain a silicon carbide transition layer for the C / C composite material; adding the C-AlPO4 and the mullite powder into methanol, adding iodine to obtain a suspension, and putting the suspension in a hydrothermal kettle, wherein the cathode adopts the C / C composite material with the silicon carbide transition layer; and sealing the hydrothermal kettle, putting the hydrothermal kettle in an ultrasonic-microwave generator, depositing, taking out the sample, and drying to obtain the SiC / C-AlPO4-mullite antioxidation coating for the C / C composite material. The composite coating can protect the C / C composite material at 1500 DEG C in static air for 322 hours, and the oxidative weight loss is less than 2%.

Owner:深圳市贝尔新材料科技有限公司

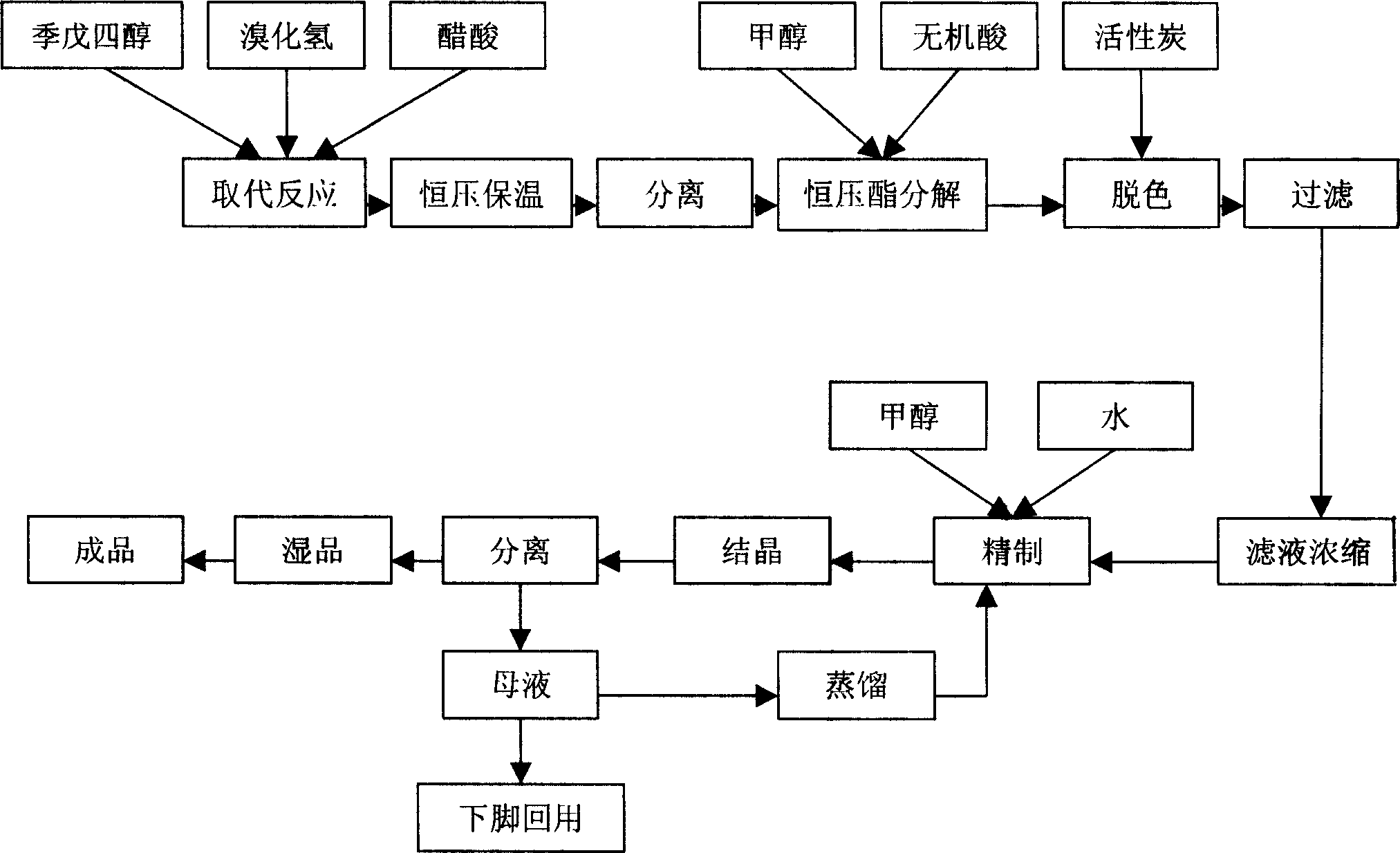

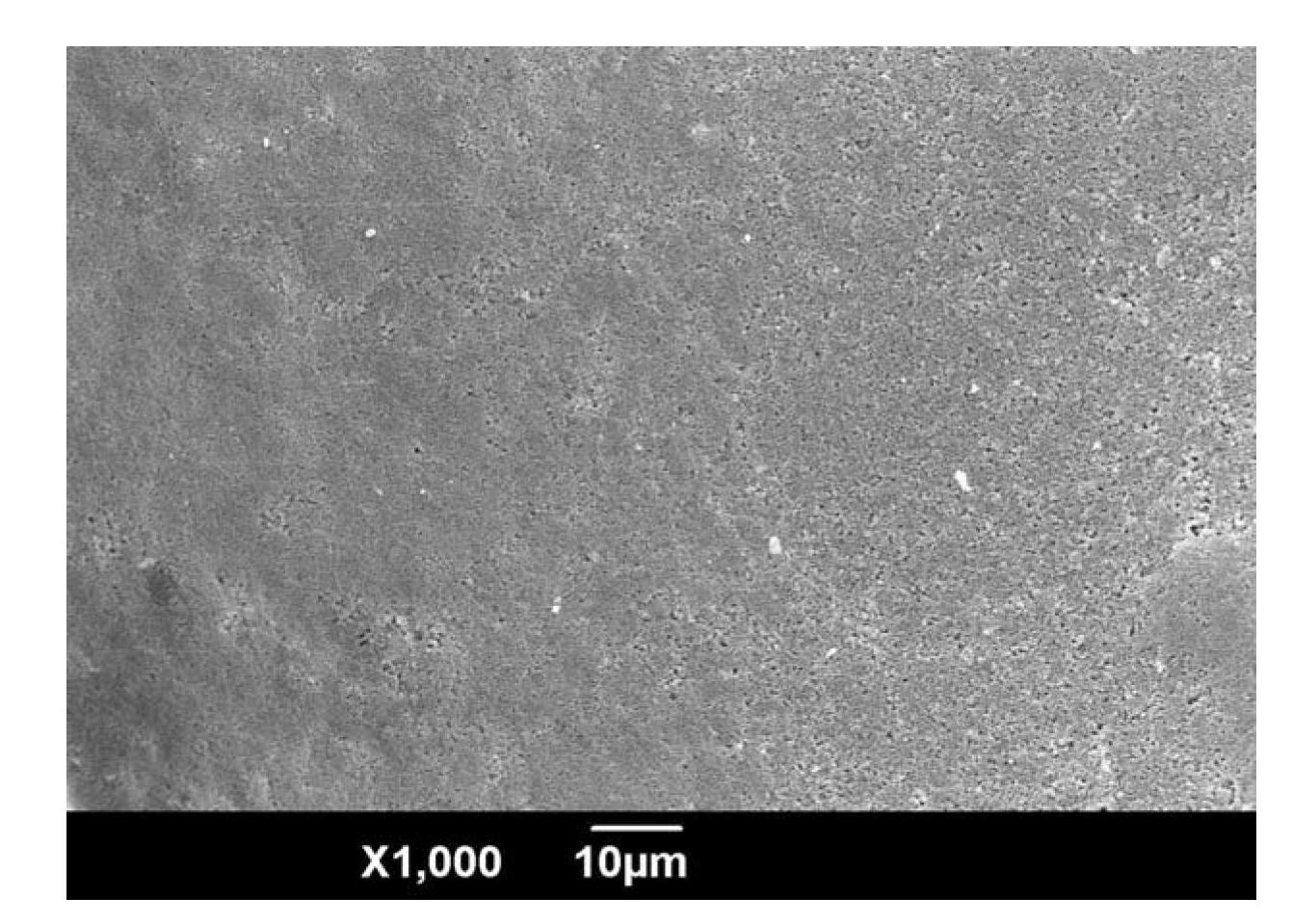

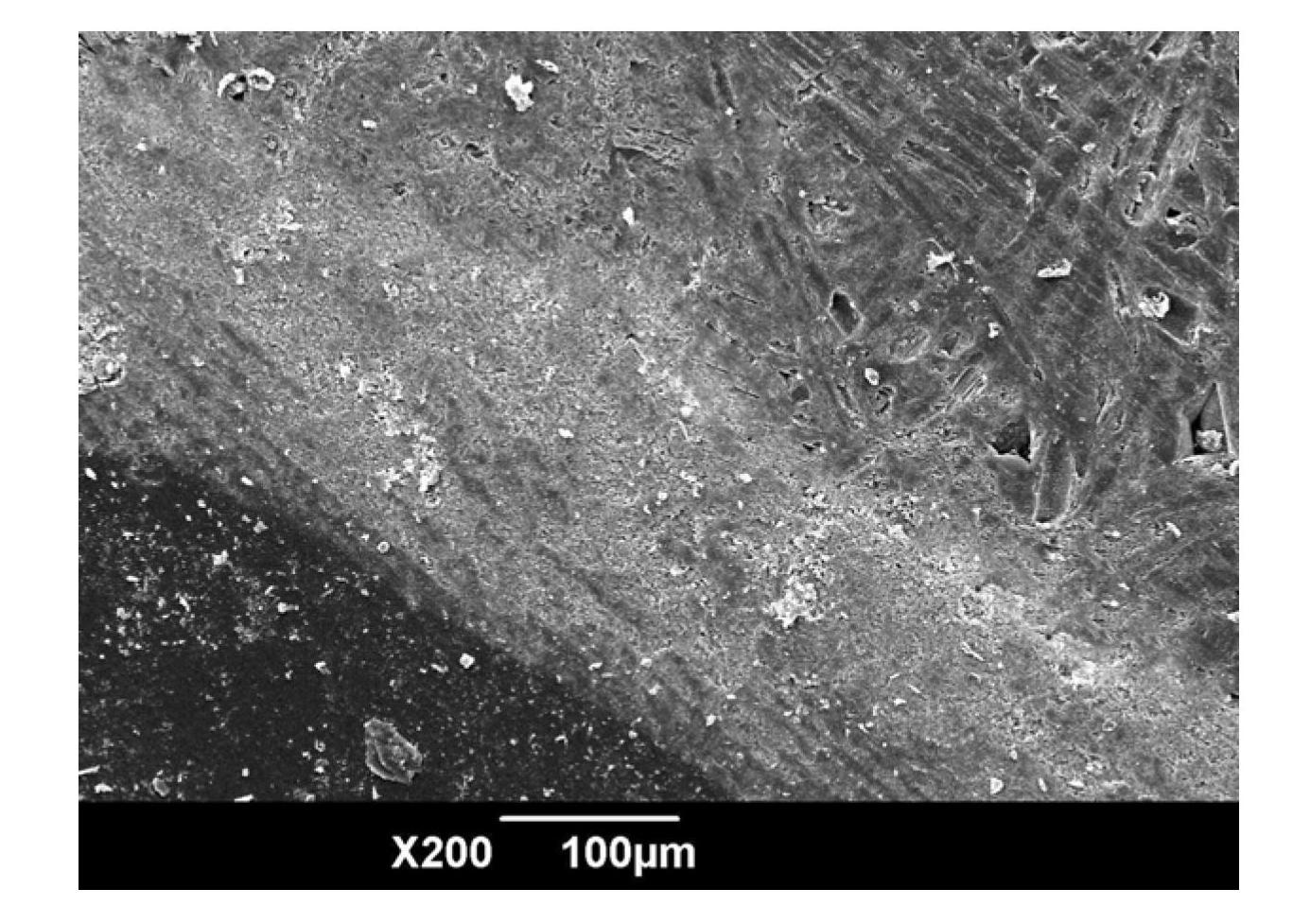

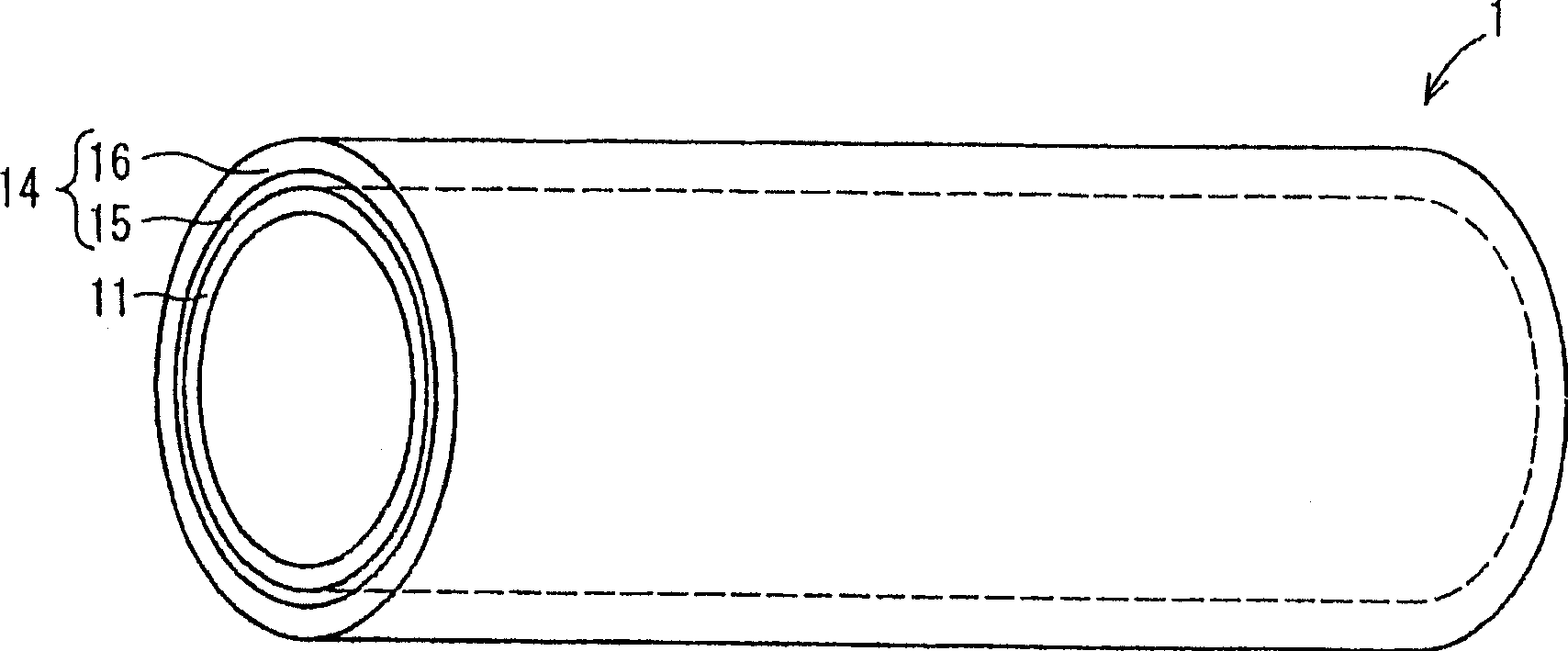

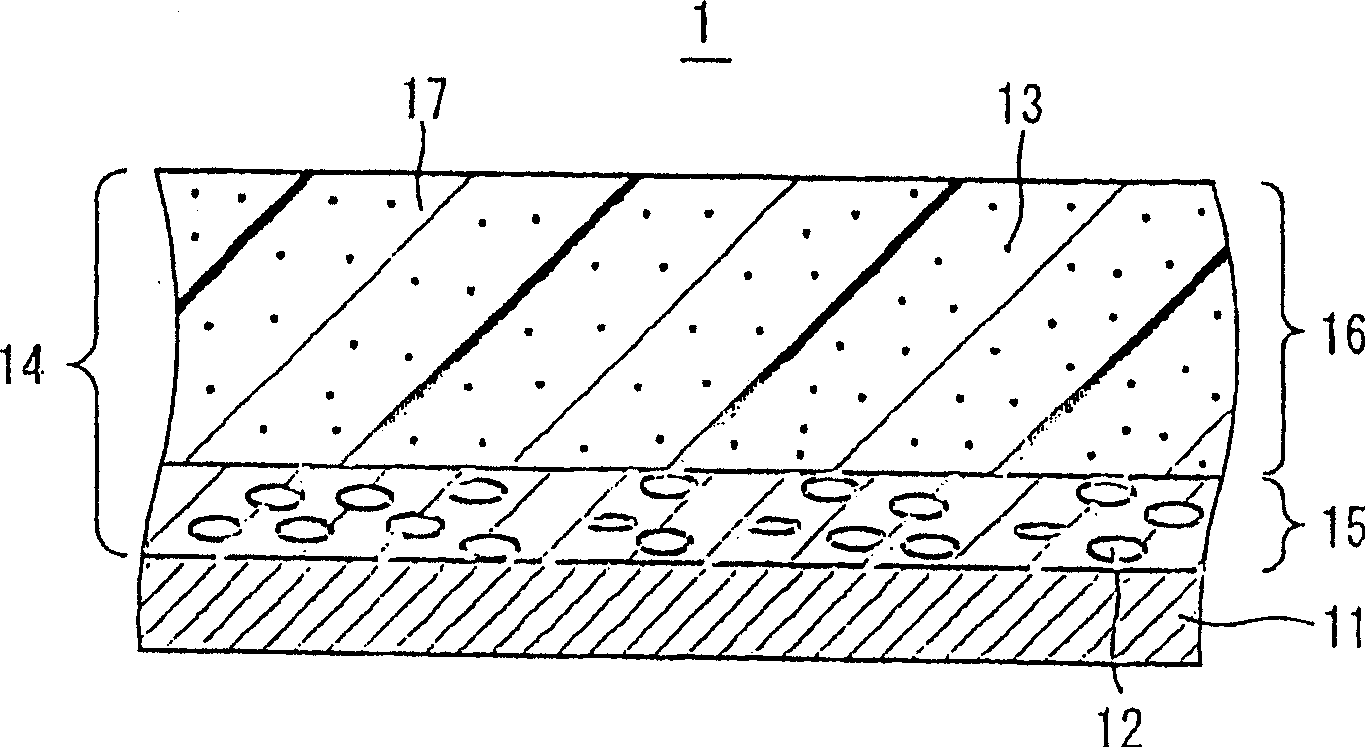

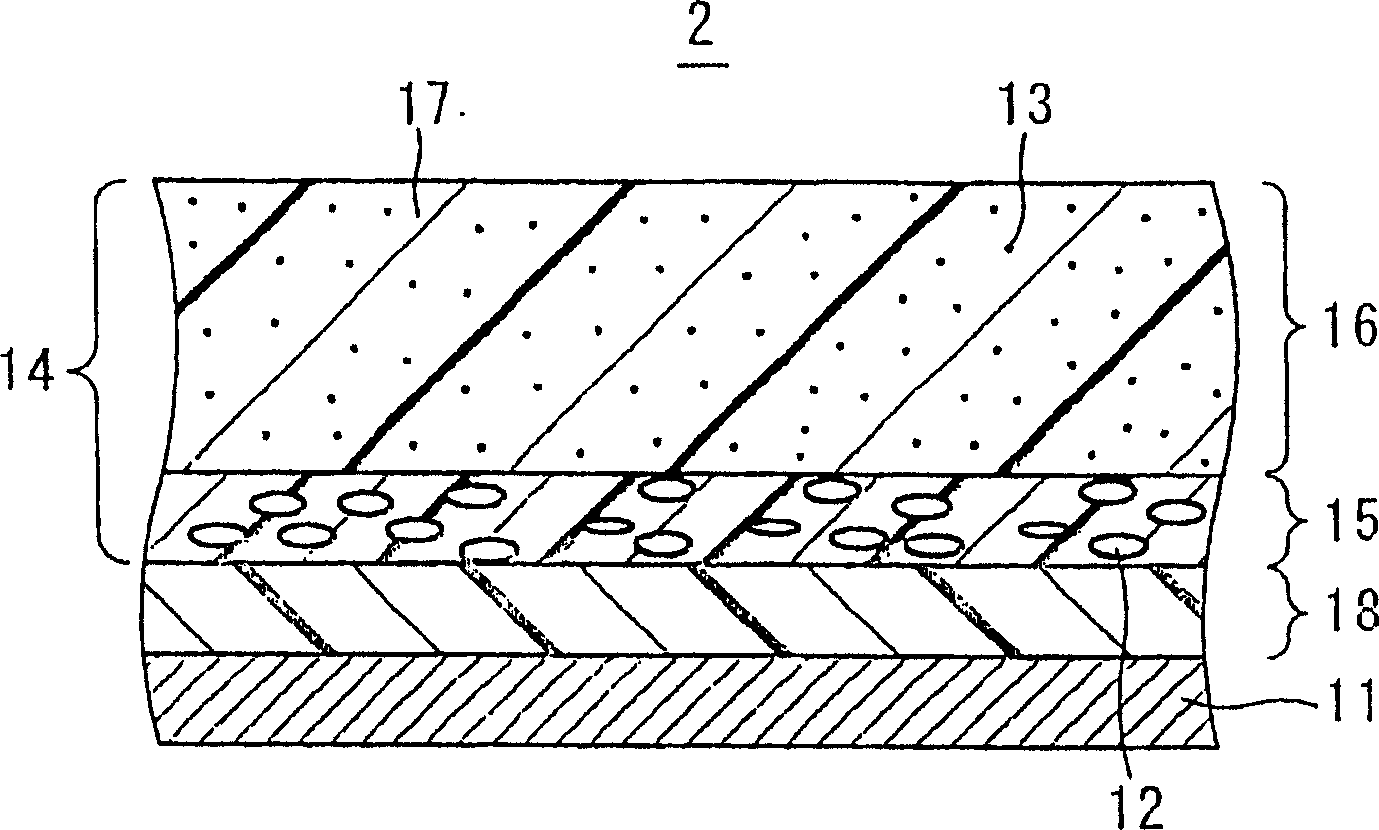

Electrophotographic photoreceptor and image forming apparatus including the same

ActiveCN1748184AReduce wearExcellent abrasion resistanceElectrography/magnetographyEnamineImage formation

An electrophotographic photoreceptor of high durability capable of providing stable excellent electrical characteristics over a prolonged period of time, which electrophotographic photoreceptor excels in mechanical strength. Photosensitive layer (14) of electrophotographic photoreceptor (1) comprises a polyarylate resin having structural units, for example, those of aforementioned formula (1-3) and an enamine compound represented by, for example, aforementioned formula (2-1). By virtue of these, electrophotographic photoreceptor (1) of excellent mechanical strength and favorable electrical characteristics can be realized.

Owner:SHARP KK

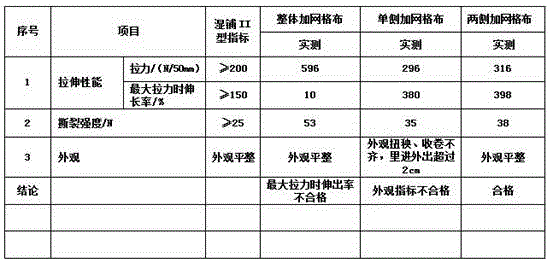

Modified asphalt waterproof coiled material with reinforced overlap edges and production method of modified asphalt waterproof coiled material

InactiveCN107175870AQuality improvementImprove mechanical propertiesRoof covering using flexible materialsSynthetic resin layered productsFiberBituminous waterproofing

The invention relates to a modified asphalt waterproof coiled material with reinforced overlap edges and a production method of the modified asphalt waterproof coiled material. The modified asphalt waterproof coiled material comprises a main body material layer, a modified asphalt layer and an isolating membrane, wherein two strips of fiber cloth are respectively embedded between the parts, which are respectively 0.1-1cm away from the edges of the two sides along the longitudinal direction of the modified asphalt layer, and the isolating membrane, so that the overlap edges are formed. After the method is adopted, the mechanical properties of the overlap edges are obviously improved after the modified asphalt waterproof coiled material is molded, so that the water resistance of the modified asphalt waterproof coiled material is more reliable; the production method provided by the invention solves the problems that in the traditional production process, due to mechanical mismatch of the left side and the right side of the coiled material, the coiled material is neat when being coiled and is twisted when being unfolded, and the like, and improves the quality of the waterproof coiled material.

Owner:XI NIU PI WATERPROOFING TECH CO LTD

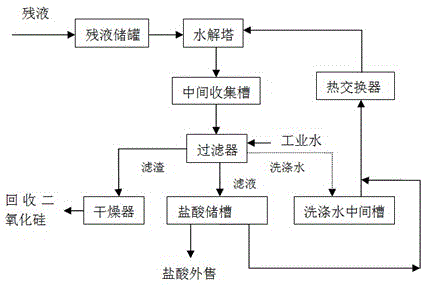

Impinging stream mixing reactor with multiple groups of layered symmetric baffles

ActiveCN106669582AImprove uniformityImprove mixing efficiencyFlow mixersTransportation and packagingRetention timeChemical reactor

The invention discloses an impinging stream mixing reactor with multiple groups of layered symmetric baffles, and relates to a chemical reactor. Multiple groups of material inlets of the reactor are coaxially and oppositely arranged, namely the reactor consists of multiple groups of coaxially and oppositely arranged material feeding pipes; mutually symmetric baffles perpendicular to each group of material inlets are arranged on the impinging surfaces of the material inlets; baffle plates are arranged between the material feeding pipes in each group. When the impinging stream mixing reactor works, two nozzles of each group of material feeding pipes jet materials to carry out impinging stream reaction; in the initial reaction stage, preliminary mixing is realized through axial high-turbulence dynamic impinging, and then a trend that the impinging stream outwards moves along two sides of the radial direction and leaves a central impinging stream field is generated; at the moment, by the arrangement of two symmetric baffles, the deviation trend is blocked, so that fluid flows back into a high-turbulence dynamic region to realize full reaction and mixing; furthermore, under the action of the baffle plates, the materials form cyclically reciprocating streaming, so that the retention time of the materials in an impinging region is greatly prolonged, and the working efficiency of the reactor is improved; meanwhile, the reactor is convenient to install, applicable to multiple working conditions and low in maintenance cost.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

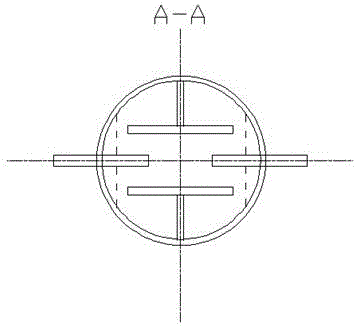

Method of preparing ultrafine silica from chlorosilane residual liquid

ActiveCN105129807AImprove qualityEfficient recyclingSilicaChemical industryLiquid storage tankNitrogen gas

The invention discloses a method of preparing ultrafine silica from chlorosilane residual liquid, and belongs to the technical field of treatment and recovery of chlorosilane residual liquid. The preparation method comprises the following steps: buffering chlorosilane residual liquid in a residual liquid storage tank, settling impurities in the tank, introducing the processed chlorosilane residual liquid to a hydrolysis tower, carrying out atomization by taking the nitrogen gas as the atomization gas source, contacting a prepared acidic absorber with the atomized chlorosilane residual liquid to carry out reactions, introducing the obtained mixed solution absorbed by hydrolysis reactions into a sealed intermediate collecting groove; subjecting the absorbed mixed solution to solid-liquid separation, delivering the separated hydrochloric acid, which can be used to prepare the absorber, to a hydrochloric acid storage tank; washing the separated silica to remove the hydrochloric acid and part of metal impurities, wherein the acid-containing water generated during the washing process can be used to prepare the absorber; and finally drying the washed silica so as to obtain the finished product of ultrafine silica. The nitrogen gas atomization is carried out under a sealed condition, and the provide method has the advantages of safety, reliability, low energy consumption, and no pollution, and converts the chlorosilane residual liquid into valuable resource.

Owner:云南冶金云芯硅材股份有限公司 +1

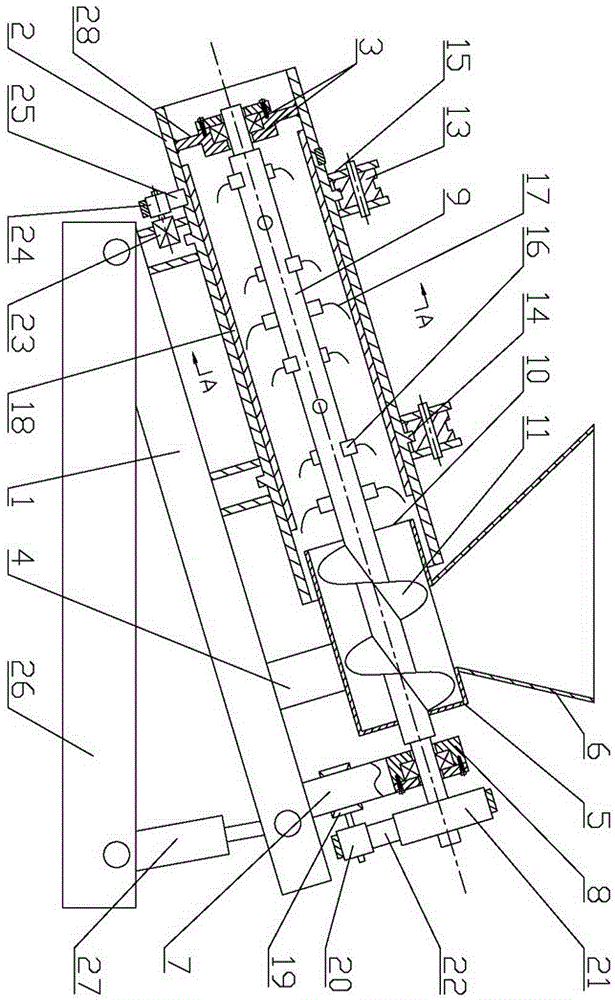

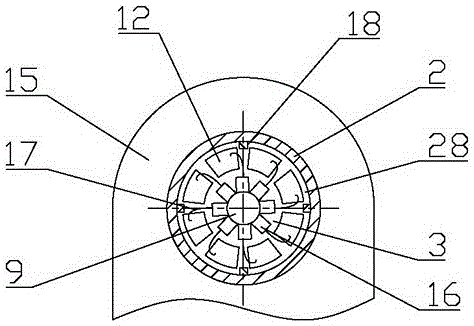

Contaminated soil repairing and crushing treatment device

PendingCN106734177AImprove crushing efficiencyImprove decomposition abilityContaminated soil reclamationGrain treatmentsSoil treatmentSludge

The invention relates to the technical field of soil treatment equipment, in particular to a contaminated soil repairing and crushing treatment device. The contaminated soil repairing and crushing treatment device comprises a base, a first support, a roller barrel, a stabilization assembly, a main shaft and a shaft body power driving assembly. The roller barrel capable of freely rotating is arranged on the base through the first support. The first support is provided with the stabilization assembly capable of limiting the roller barrel and making the roller barrel stably rotate. An inner hole of the roller barrel is in a left-right penetrating state. A left bearing block assembly is fixedly arranged on the inner side of the left end of the roller barrel through a hollow support. A fixing barrel is fixed to the part, on the right of the roller barrel, of the base through a second support. The contaminated soil repairing and crushing treatment device is reasonable in structure and capable of saving time and labor, through reverse rotation of the roller barrel and the main shaft and comprehensive actions on material crushing, stirring, aeration, material self-falling gravity and the like, the oily sludge crushing efficiency can be improved, the decomposing effect and the repairing effect of the oily sludge are improved, and the decomposing effect and the repairing effect of the oily sludge are further enhanced in cooperation with the magnetic interference function of a magnetic field generator.

Owner:张宝德

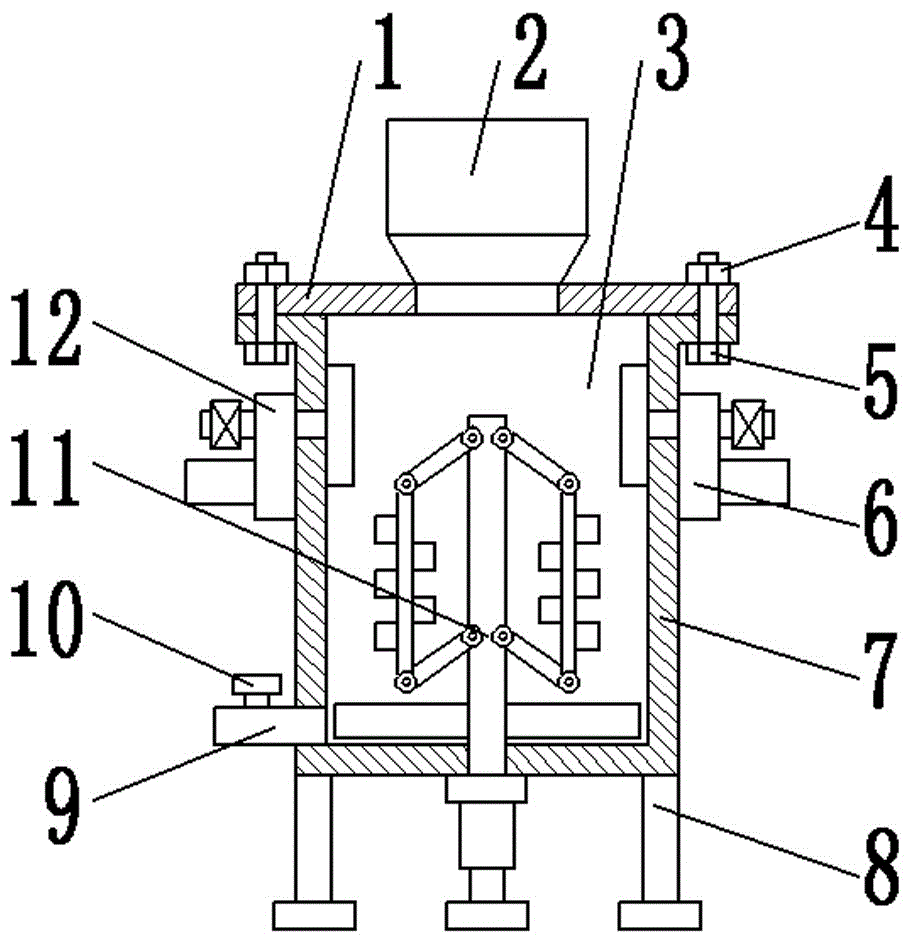

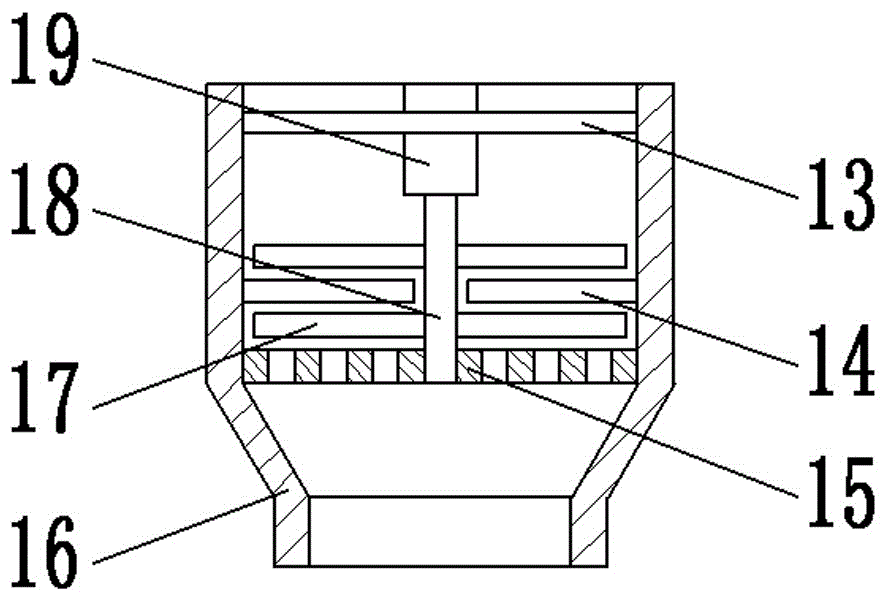

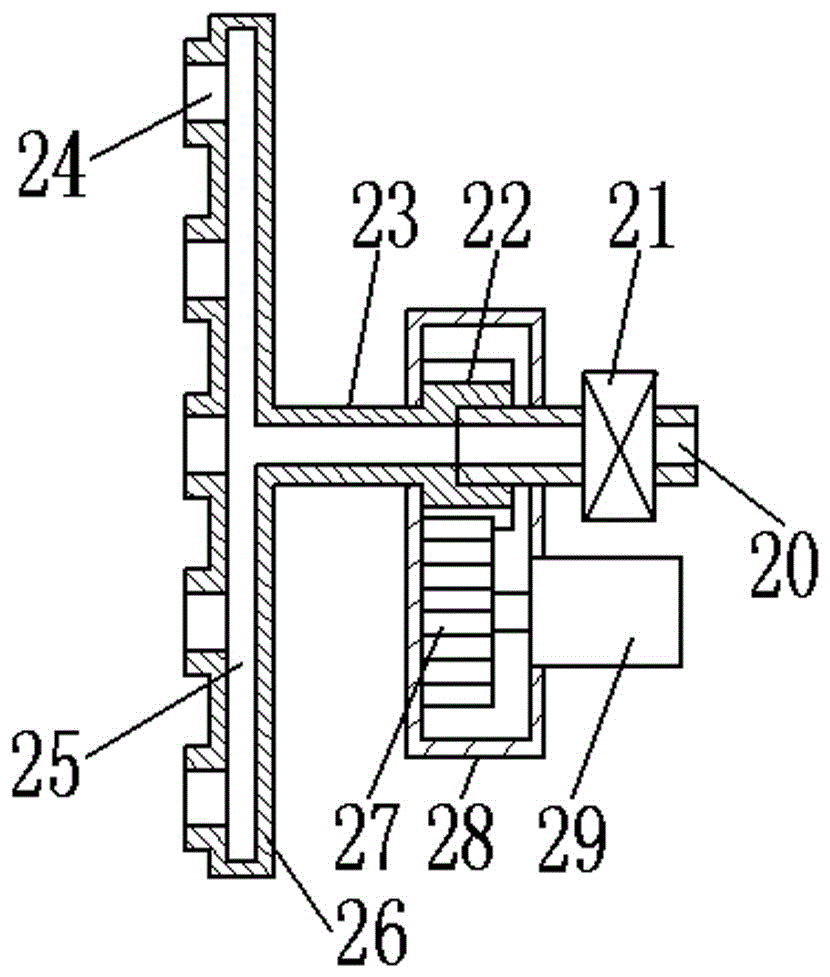

Solid and liquid mixing and reacting apparatus with solid material breaking device

InactiveCN106540645AAvoid uneven mixingStir wellRotary stirring mixersTransportation and packagingEngineeringKnife blades

The invention provides a solid and liquid mixing and reacting apparatus with a solid material breaking device. The apparatus comprises a tank body and an upper cover; a mixing chamber is arranged in the tank body; the upper cover is provided with the solid material breaking device; the solid material breaking device comprises a breaking tank, a breaking motor, a breaking rotation shaft, rotating cutter blades and a fixed cutter blade; a first liquid material feeding device and a second liquid material feeding device are arranged on the sidewall of the top of the tank body; each of the first liquid material feeding device and the second liquid material feeding device comprises a transmission box, a rotating motor, a liquid feeding tube and a rotating spray disc; a stirring device is arranged in the mixing chamber; the stirring device comprises a stirring motor, a stirring shaft, first rotating rods, fixed rods, second rotating rods and a scraper plate; a solid material is broken through the solid material breaking device; and the material is fully stirred through the stirring device to realize reaction acceleration.

Owner:梅新星

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com