Bricks and mortar made from fly ash and preparation method

A technology of fly ash bricks and production methods, applied in the field of building bricks and mortars, can solve the problems of raw material cost reduction, unfavorable production and popularization and application, and complex processes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

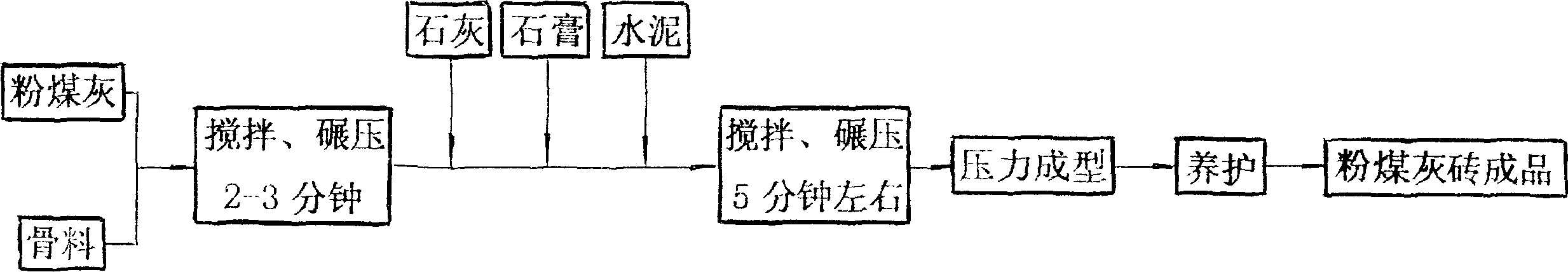

Method used

Image

Examples

Embodiment Construction

[0014] The implementation of the present invention is completed on the production line of Xiongying Building Material Factory in Laibin City, Guangxi. The factory's production site is less than 3,000 square meters, the investment is less than 2 million yuan, and the number of employees is less than 25. After the invention is adopted, it can produce more than 30 million fly ash standard bricks per year. The implemented products are mass-produced and sampled by the officials of Guangxi Wall Reform Office, and then sent to the Quality Supervision and Inspection Station of Building Materials Products of the Quality and Technical Supervision Bureau of the Autonomous Region for inspection and commissioned by the National Building Materials Industry Wall and Roofing Materials Quality Supervision, Inspection and Testing Center for inspection. The items all meet the requirements of JC239-2001 "fly ash brick" standard MU15 qualified products and first-class products: the average compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com