Patents

Literature

195 results about "Fly ash brick" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fly ash brick (FAB) is a building material, specifically masonry units, containing class C or class F fly ash and water. Compressed at 28 MPa (272 atm) and cured for 24 hours in a 66 °C steam bath, then toughened with an air entrainment agent, the bricks last for more than 100 freeze-thaw cycles. Owing to the high concentration of calcium oxide in class C fly ash, the brick is described as "self-cementing". The manufacturing method saves energy, reduces mercury pollution, and costs 20% less than traditional clay brick manufacturing.

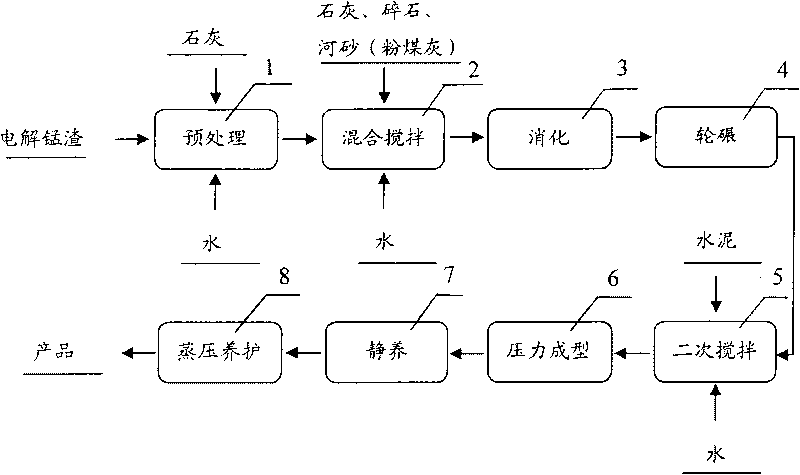

Preparation method of electrolytic manganese slag autoclaved brick

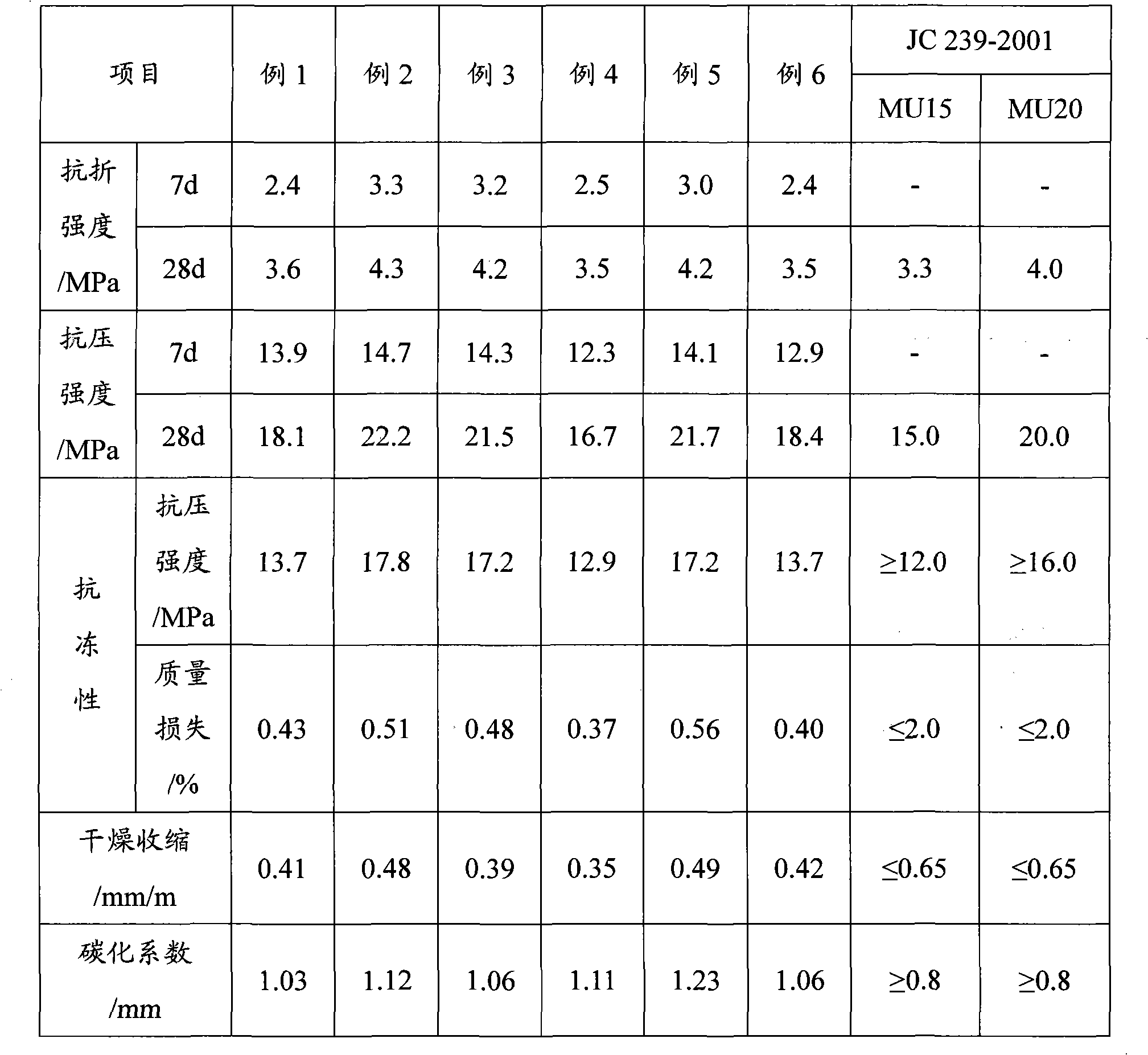

The invention provides a preparation method of an electrolytic manganese slag autoclaved brick. The method comprises the following steps: after preprocessing the electrolytic manganese slag, adding river sand (or fly ash), broken stone and lime in proportion; and stirring, assimilating, rolling, molding, standing, autoclaving and curing, and the like to obtain the electrolytic manganese slag autoclaved brick. The product meets the corresponding index requirements of Autoclaved Sand-lime Brick (GB11945-1999) or Fly Ash Brick (JC239-2001) for a first quality product with the strength level of more than 15MPa. The method has simple technology, high product quality, low production cost and good social, economic and environmental benefits.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

Bayer process red mud composite brick and producing method thereof

InactiveCN101215142AEliminate pollutionComprehensive Utilization of Effective ResourcesSolid waste managementRed mudSlag

The invention discloses bayer process red mud composite bricks and the production method thereof. The composite bricks are mixed and produced the following raw materials, bayer process red mud 20 -35 parts, fly ash 15-34 parts, carbide slag 5-15 parts, slag 30-40 parts, cement 5-12 parts and gypsum 0-5 parts. The preparation process of the composite bricks is that after the bayer process red mud is dewatered, mixing and stirring the bayer process red mud with other raw materials, controlling the moisture content of wet base in the range of 12%-20%, the mixture is shaped under the pressure of 15-40MPa, the shaped bricks are produced into products in steam with 0.1-1.3MPa keeping pressure for 5-8h. The product can reach the requirement of the strength grade of fly ash bricks reaching to 10 or more. The total amount of use of industrial waste residue of the technology nearly reaches 90%, the technology has the advantages of no sintering, low energy consumption, no emission of exhaust gas, meeting the country policy of energy saving and emission reduction, having distinctive effects on environmental benefit, social benefit and economic benefit.

Owner:HUAZHONG UNIV OF SCI & TECH

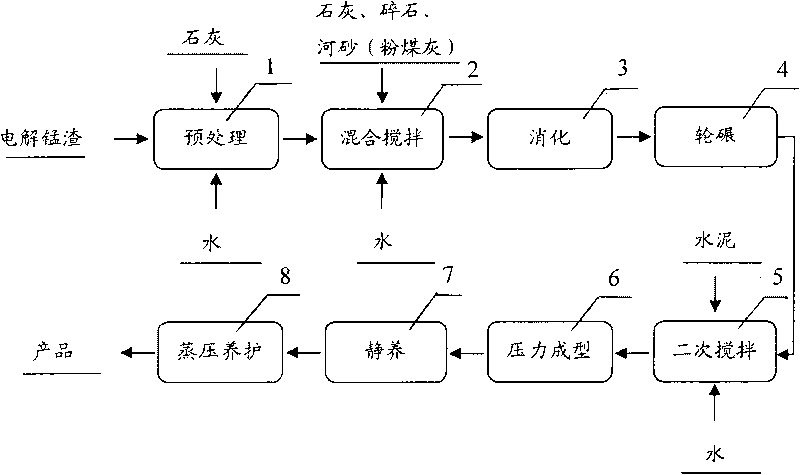

Bricks and mortar made from fly ash and preparation method

InactiveCN1686907AReduce manufacturing costReasonable proportionSolid waste managementFly ash brickBrick and mortar

The present invention belongs to a building brick made of fly ash, mortar and their production method. The raw material composition of brick includes (by wt%) fly ash 70-80, lime 7-13, gypsum 0-1.3, cement 0-5 and the rest is aggregate, and the raw material composition of mortar includes fly ash 70-80, lime 7-13, cement 0-5 and the rest is aggregate. Besides, said invention also provides the concrete steps of their production method.

Owner:韦柳青

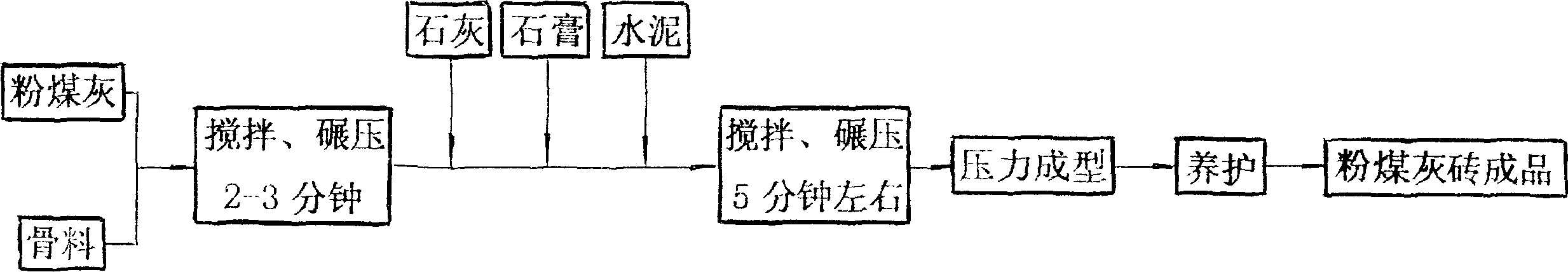

Plant fiber enhanced color clinker solid brick and preparation method thereof

The invention relates to a plant fiber reinforced color clinker solid brick and preparation method thereof. The invention has following steps: smashing plant fiber into short fiber of 5-15 mm, smashing pyrite cinder into 100-200 screen mesh fine powder, mixing 2-10% plant short fiber, 10-20% pyrite cinder fine powder, 20-30% fly ash, 10-30% granulating slag, 5-15% carbide ash, 0-15% caustic sludge, 5-10% cement, 20-30% inert aggregate, 2-3% additive (the quality sum of each solid raw material is 100%), as well as water 10-15% by weight of solid material overall quality, stirring, pressing and molding, demolding, resting, stooking, natural maintenance in normal pressure, product quality inspection, getting plant fiber reinforced color clinker solid bricks, the quality of color clinker solid brick accords with JC239-2001 flyash brick . The plant fiber reinforced color clinker solid brick of the invention has advantages of beautiful, cheap, light weight, high strength, baking-free, non-steaming, heat preservation, saving energy, environmental protection, high waste utilization.

Owner:HENAN POLYTECHNIC UNIV

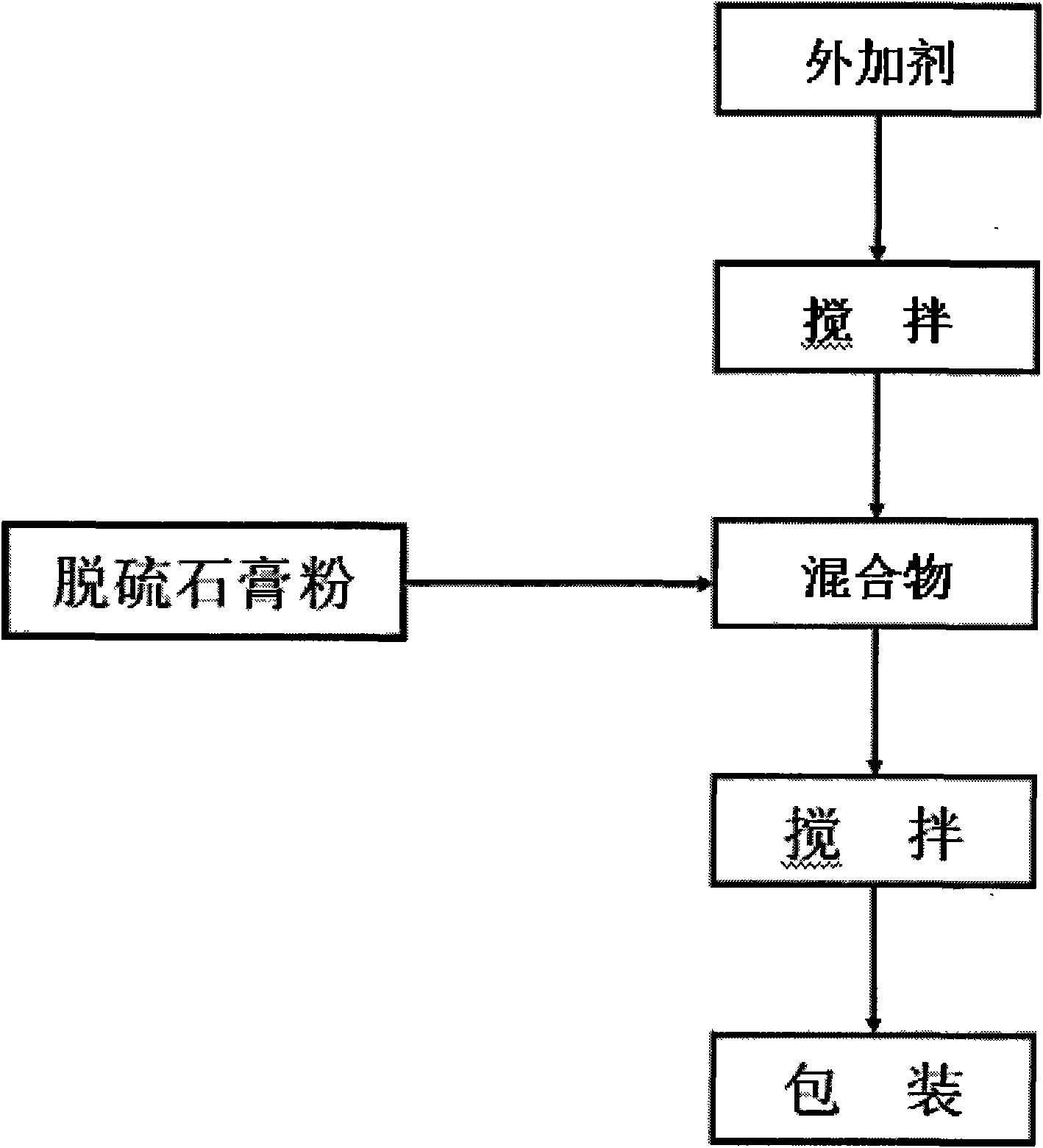

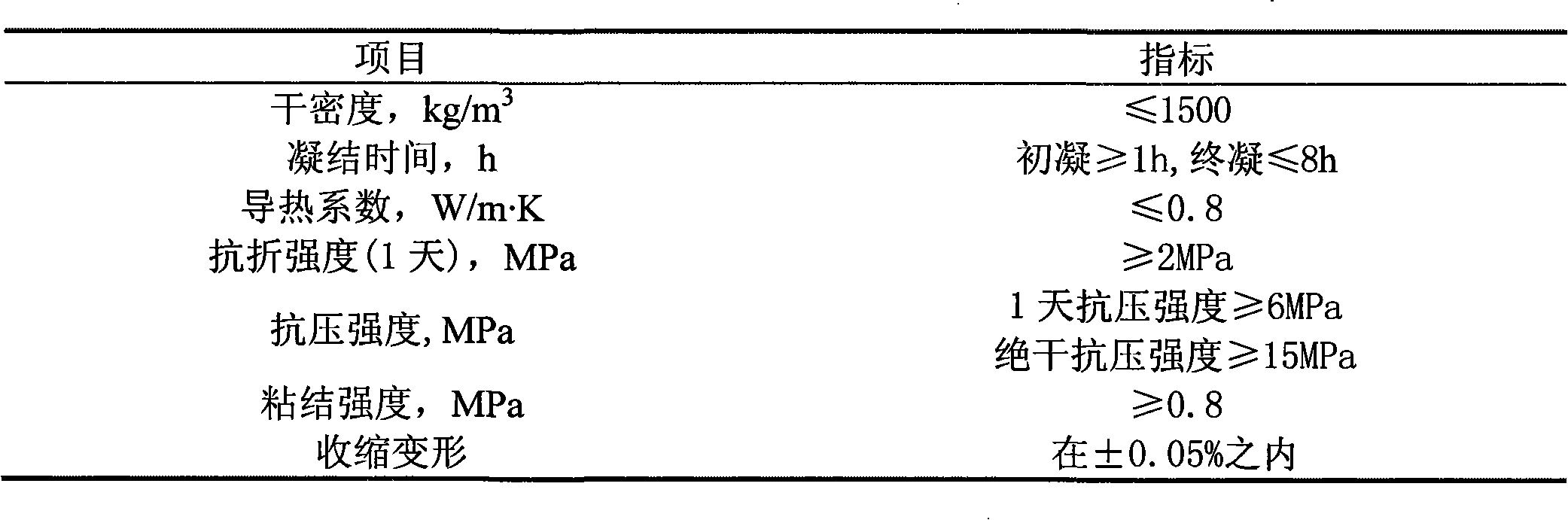

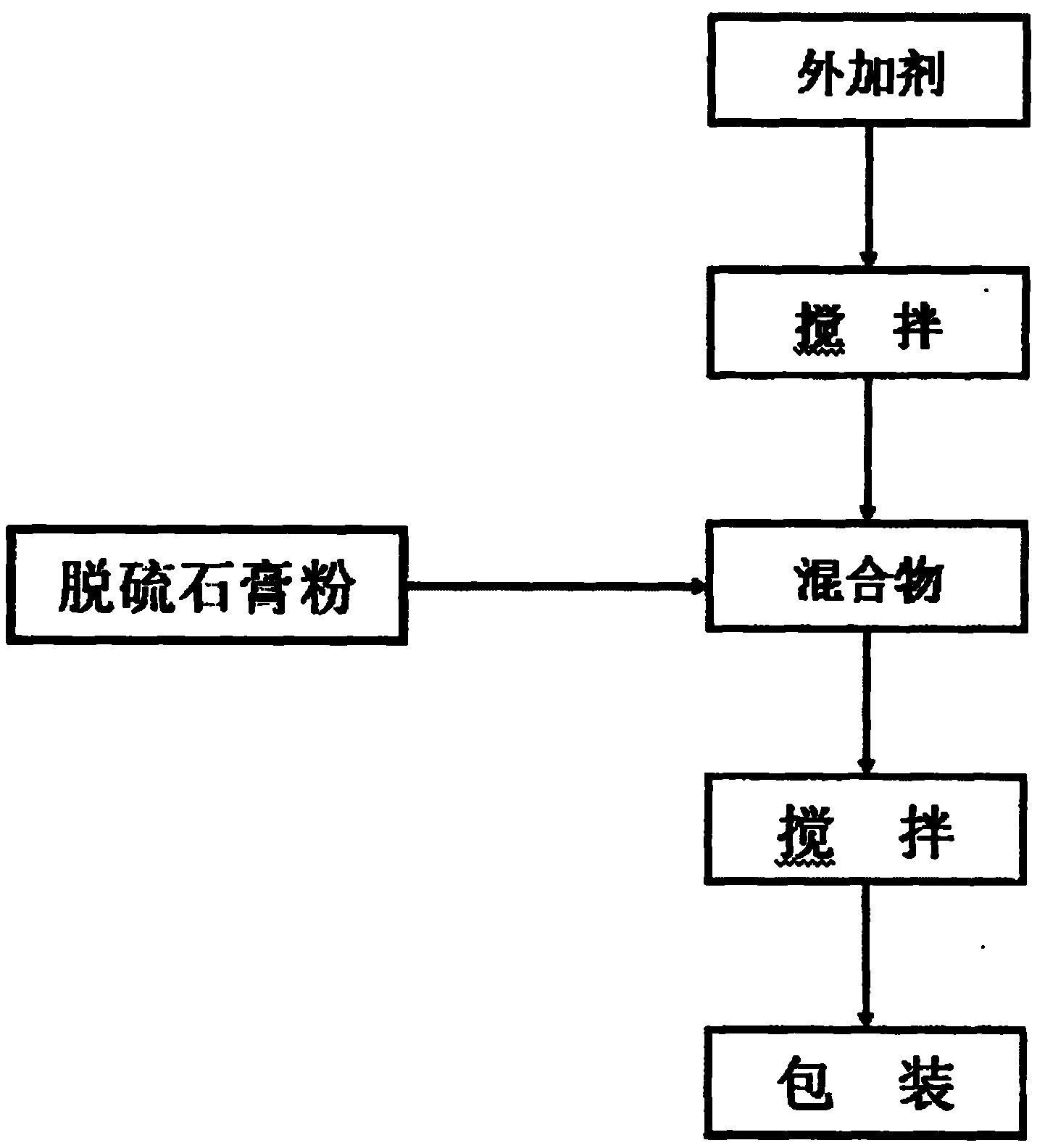

Crack-resisting masonry mortar for air-entrapping brick wall body, prepared from desulfurization gypsum powder

InactiveCN101993232APromote sustainable developmentRaw materials are cheap and easy to getSolid waste managementCrack resistanceCellulose fiber

The invention relates to a method for preparing a crack-resisting masonry mortar for an air-entrapping brick wall body from desulfurization gypsum powder in the construction industry. The cracking-resisting masonry mortar is prepared by mainly using a desulfuration product (desulfuration gypsum) of a power plant as a main raw material. The preparation method comprises the step of doping 1-5 thousandths of cellulose fiber, 0.1-3 thousandths of retarder, 0.2-50 thousandths of water retaining agent, 0.5-5 percent of reinforcing agent, 10-30 percent of mineral doping material and 10-40 percent of fine river sand to obtain the crack-resisting masonry mortar with excellent property. The invention develops a new method for producing the excellent gypsum based masonry mortar with high crack resistance, low contraction distortion, high binding power, high strength and low cost by using the desulfuration gypsum, develops a new method for the comprehensive utilization of the desulfuration gypsum as a sold waste, and solves the problem of cracking of wall bodies of an air-entrapping brick, a flyash brick and the like in China at present.

Owner:江苏仁和建材科技有限公司

Producing steam pressure brick by using construction garbage

The invention discloses an autoclave test powder coal ash garbage brick with building garbage, which comprises the following steps: choosing building garbage, powder coal ash, lime (or carbide slag) and additive as main raw material; bruising building garbage (waste concrete, sand pulp, brick, tile and stone) to continuous grading particle with particle size smaller than 10mm; using as skeletal material of autoclave fly ash bricks; using powder coal ash and lime material as cementing agent; adopting hydrothermal synthesis craft; making usage of building garbage at 15%-55% and optimum range at 20%-35%. The hydrothermal synthesis craft is placing the product in the saturated steam with temperature higher 100 deg.c.

Owner:李秋义 +2

Fly ash brick unbaking shaping method

InactiveCN1597596AReasonable process designStrong activation responseSolid waste managementPolymer scienceMolding machine

Owner:辽宁中田干燥设备制造有限公司

Method for preparing high-performance autoclaved flyash-lime brick by static molding

ActiveCN102775125AHigh strengthSmall shrinkageSolid waste managementSocial benefitsProgrammable logic controller

The invention discloses a method for preparing a high-performance autoclaved flyash-lime brick by static molding, belonging to the technical field of building materials. The flyash-lime brick is produced under an autoclaved condition by using coal ash, tails, slag, silt and limestone as main raw materials, cement and carbide slag as excitants, ardealite and titanium gypsum as retarders and other additives as auxiliary raw material. By the technology, silicate products such as flyash-lime brick is produced under the autoclaved condition by mixing, stirring, grinding and delivering coal ash, tails, slag, silt and limestone through a programmable logic controller (PLC) system, and carrying out static pressing through an autoclaved brick automatic hydraulic press. The autoclaved flyash-lime brick prepared by static molding has the superior characteristics of high strength, little shrinkage and small volume weight, the indexes conform to the national standard even the standard of high-class products, and the product meets the requirement of Autoclaved Flyash-lime Brick (GB11945-1999) and Flyash-lime Brick (JC239-2001). The method is simple in process, high in efficiency and low in cost, and thereby having remarkable economic benefit and social benefit.

Owner:安徽建鑫新型墙材科技有限公司

Non-fired and non-steamed fly ash brick produced by using CFBC desulphurization residues and preparation process thereof

InactiveCN101805162ASimple production processLow costSolid waste managementCeramic shaping apparatusEconomic benefitsProcess engineering

The invention discloses a non-fired and non-steamed fly ash brick produced by using CFBC desulphurization residues and a production process thereof. A production raw material of the brick comprises the following components in proportion by weight: 50 to 70 percent of the CFBC desulphurization residues, 10 to 25 percent of furnace bottom slag, 4 to 8 percent of cement, 10 to 14 percent of quicklime and 3 to 6 percent of gypsum. The production process comprises the following steps of: mixing the components together and then stirring the mixture uniformly; adding water which is 12 to 18 percent of the mass of the mixture into the mixture; and performing press forming on the mixture by adopting a pressure of 16 to 22 MPa, and then performing curing to obtain the fly ash brick. The non-fired and non-steamed fly ash brick has a high mixed content of the CFBC desulphurization residues, not only can solve the problems of low utilization ratio of the CFBC desulphurization residues and resource wastes, but also can provide a novel production process of the non-fired and non-steamed fly ash brick; besides, the non-fired and non-steamed fly ash brick has the advantages of simple production process, low cost, convenient popularization and application, and great economic benefits, social benefits and environmental benefits.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

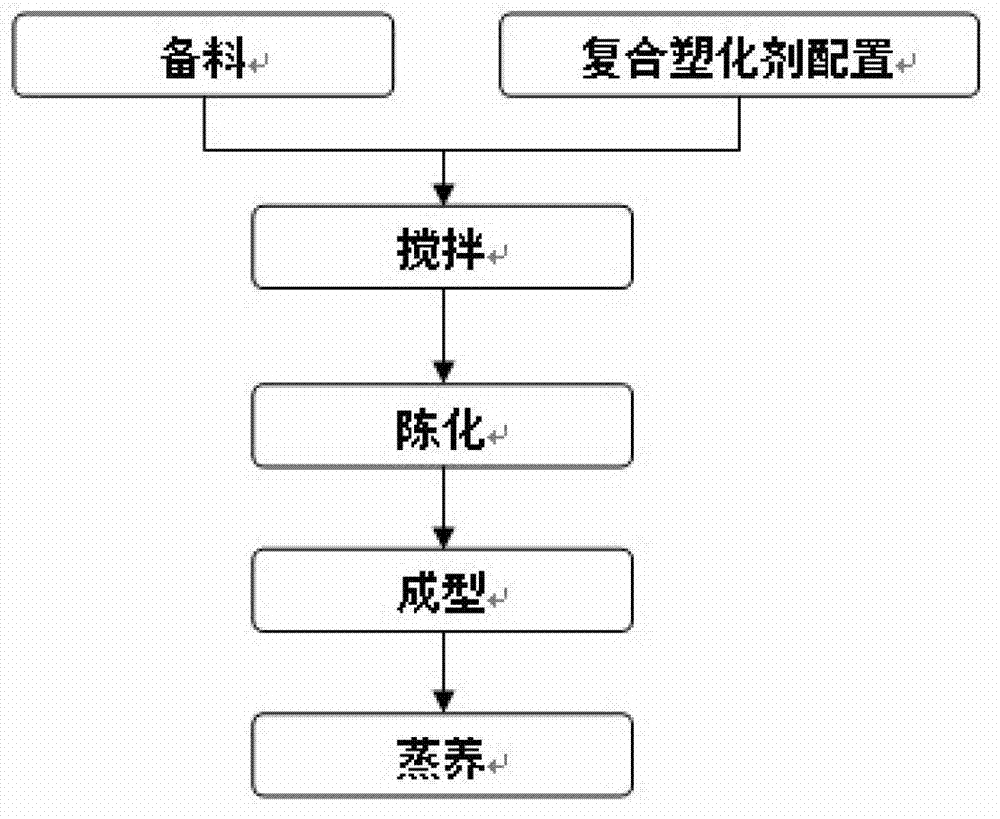

Production of blocks from flyash by steaming and pressing process

InactiveCN1644555AAchieve lightweightAchieve heat preservationSolid waste managementSlagPulverized fuel ash

Production of steam-pressing fly-ash brick with big blending account is carried out by batching dewatered fly-ash, slag or aggregate chips, lime crystal or plaster by proportioning, agitating, digesting, wheel milling, mechanical shaping, maintaining blanking brick, piling blank, and steam maintaining in steam-pressing kettle at high temperature and pressure. It achieves light weight, high strength, soil and energy saving, and no environmental pollution.

Owner:伍林元

No-baking and no-steaming environment protection solid fly ash-cinder brick

InactiveCN1931772AImprove early strengthGood compatibilitySolid waste managementCooking & bakingFly ash brick

The present invention relates to green building material, and features that the no-braking and no-steaming green brick is produced with cementing industrial waste, small amount of cement, aggregate and admixture. Cementing industrial waste, such as fly ash, calcium carbide slime, etc, cement, aggregate and admixture in certain weight proportion are produced into the no-braking and no-steaming green brick through mixing, forming, curing, stocking, naturally curing and inspection. The brick meets the requirement of fly ash brick, and has the features of saving clay resource, no need of steam curing, simple production and low cost.

Owner:HENAN POLYTECHNIC UNIV

Light fly-ash brick

The invention relates to a light fly-ash brick. The brick comprises components in parts by mass as follows: 10-15 parts of lime powder, 45-50 parts of fly ash, 10-12 parts of cement, 5-8 parts of aluminum oxide and 10-15 parts of river sand. The light fly-ash brick is low in price and high in quality.

Owner:无为县华标新型墙体材料有限公司

Autoclaved flyash-lime brick and preparation method thereof

The invention discloses an autoclaved flyash-lime brick and a preparation method thereof, and belongs to the technical field of metallurgical solid waste resource comprehensive utilization. The autoclaved flyash-lime brick is prepared from the following raw materials in percentage by weight: 40-50% of flyash, 0-30% of coarse slag, 0-30% of crushed stone, 0-15% of water granulated slag, 0-12% of calcined lime and 0-8% of fly ash. The preparation method of the autoclaved flyash-lime brick is high in production efficiency, good in formation quality, low in price and high in profit margin, and comprises the steps of ingredient stirring, digesting, forming and steam boiling so as to obtain the finished product. Related raw material replacements are sought and the optimal process control parameter is explored, so as to be applied to the production line after laboratory tests, the material quality is improved, the material ratio is effectively improved, the product cost is reduced, the phenomena of brick falling, brick collapse and the like in the formation process are greatly reduced, and the formation efficiency and the finished product appearance quality are greatly improved.

Owner:太原钢铁(集团)有限公司

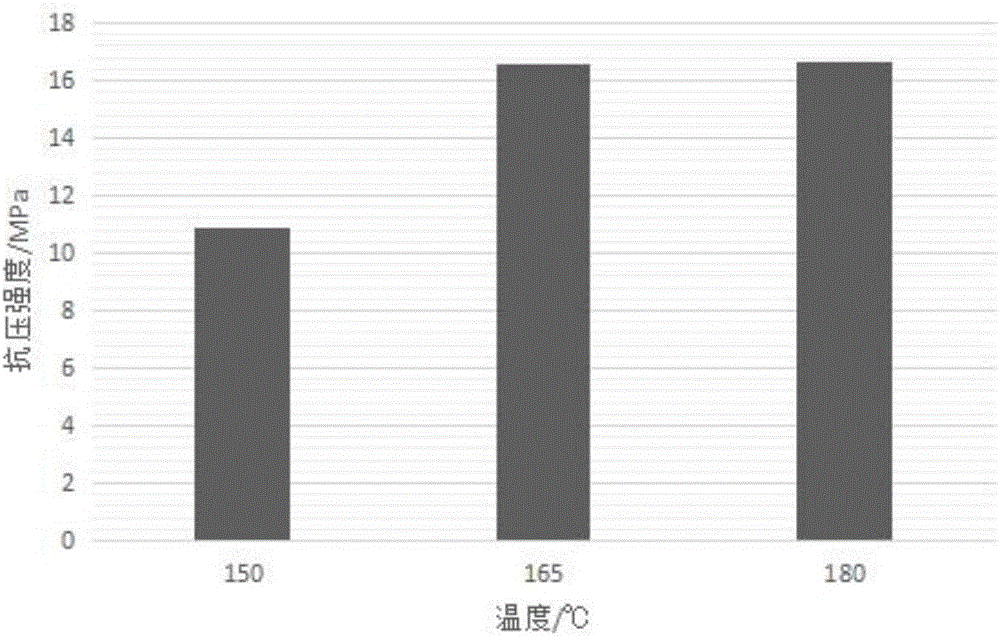

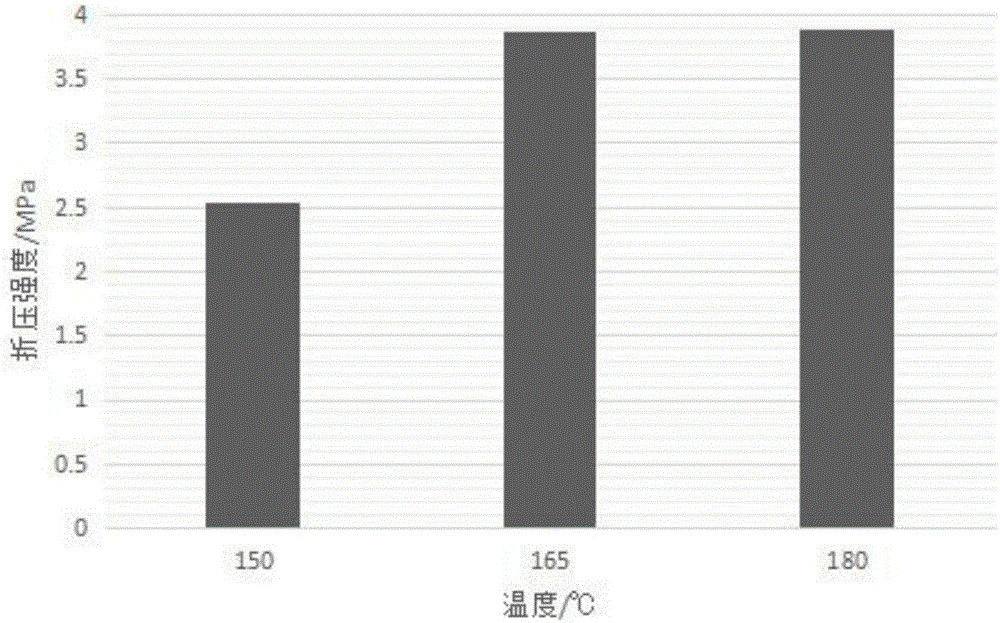

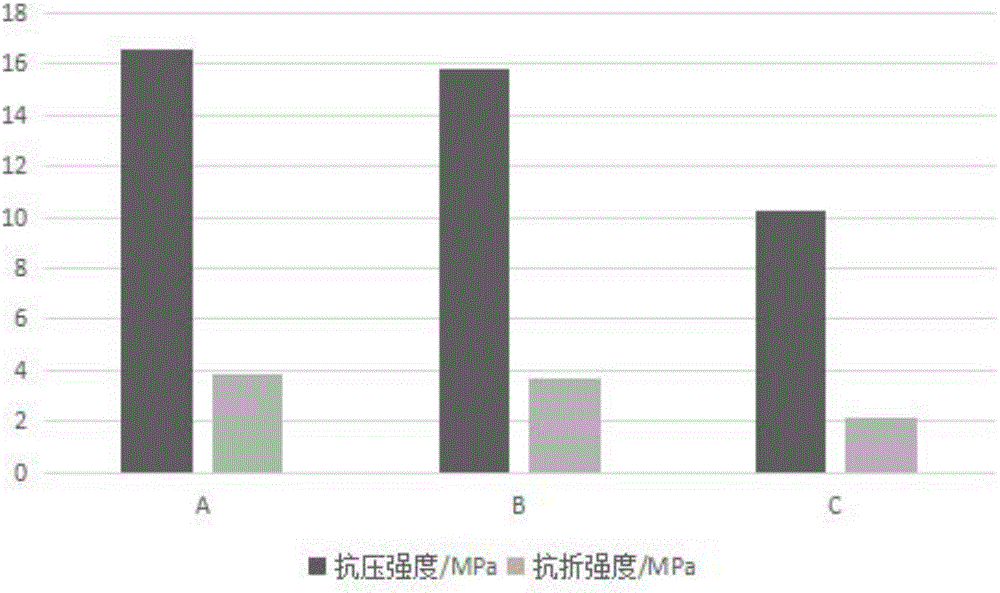

Coal ash sintered brick and sintering process

InactiveCN102718548ALow costHigh compressive strengthCement productionCeramicwareBreaking strengthProduct inspection

The invention relates to a coal ash sintered brick and a sintering process, which belong to the technical field of material engineering. The sintered brick is made in the following steps: sodium metasilicate and sodium carbonate which are used as exciting agents are added into coal ash to form a geopolymer, and Si-O-Al bond formed by the geopolymer is used as a net support frame to sinter ceramic at high temperature. The sintered brick consists of coal ash, sodium metasilicate with modulus of 1-3.5, and sodium carbonate. The sintering process comprises the following steps: (1) burdening; (2) molding; (3) sintering; and (4) product inspection: picking out rejected products and obtaining the qualified pure coal ash brick. The sintering process provided by the invention has the advantages that ingredients and blanks not containing clay protect cultivated land and clay resources, various sintered bricks sintered by the sintering process is low in cost, has high compressive strength and breaking strength, and low water absorption and even have high strength at 1000 DEG C, and the coal ash contains a large amount of unburned carbon, thereby saving part of fuel. An insulation board can be sintered with the sintering process by an insulation board mold according to the ingredient proportion.

Owner:张书源

Autoclaved fly ash brick

The invention discloses an autoclaved fly ash brick and relates to the technical field of building materials. The autoclaved fly ash hollow brick is characterized by consisting of the following components in percentage by weight: 35 to 45 percent of fly ash, 20 to 28 percent of carbide slag, 20 to 30 percent of yellow sand, 7 to 14 percent of stone chips and 1 to 2 percent of gypsum. The autoclaved fly ash brick manufactured by the scheme has the advantage that: according to detection, various technical indexes reach the national standard. A great amount of carbide slag is added into the raw materials, so the cost of the autoclaved fly ash brick is reduced.

Owner:SHANGHAI DATUN ENERGY

High-plastic-forming fly ash steam curing brick

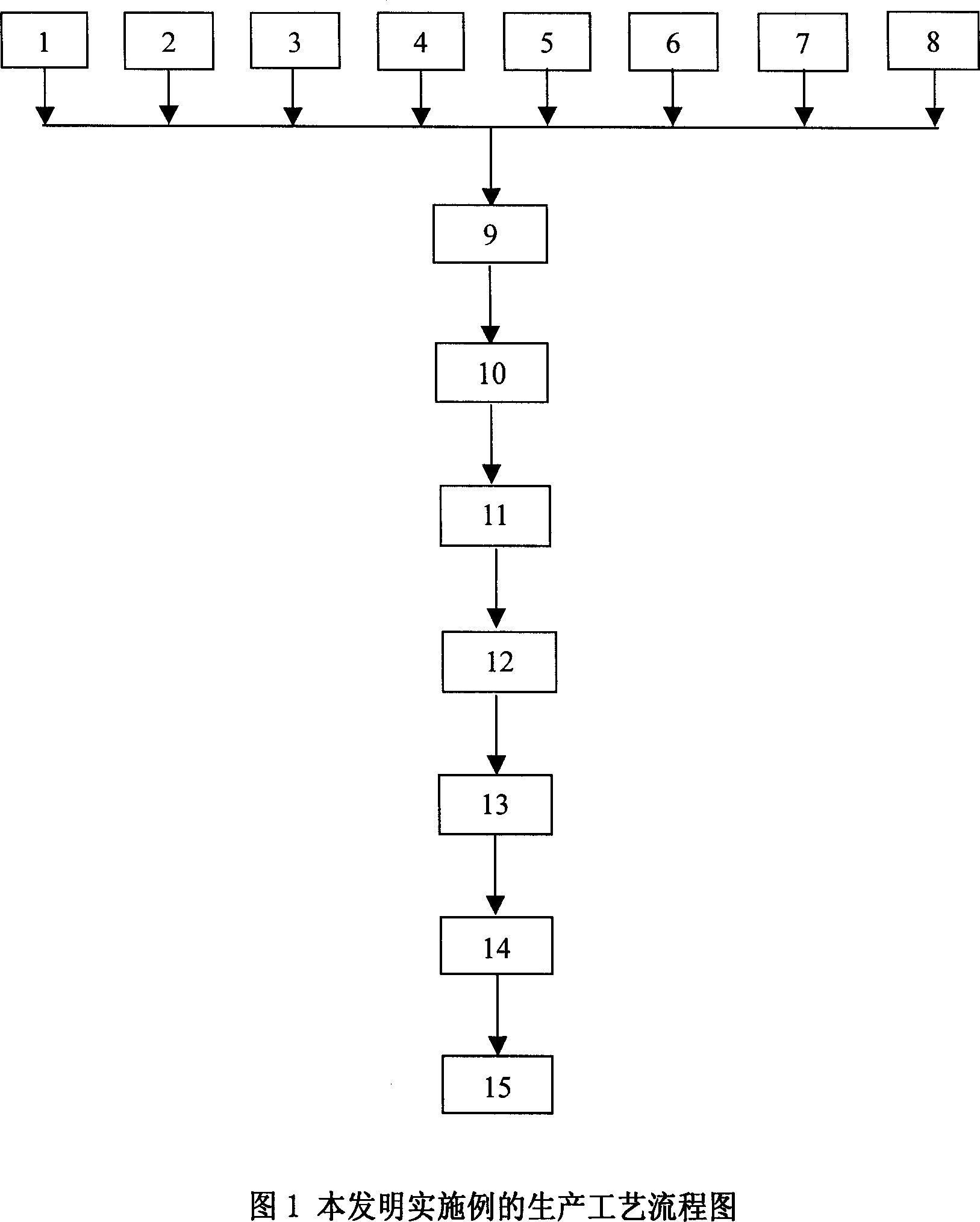

The invention discloses a high-plastic-forming fly ash steam curing brick. The brick comprises, by weight, 75-80% of fly ash, 10-15% of slag, 2.5-3.5% of cement, 4.5-5.5% of calcium oxide, 0.4-0.6% of gypsum and 2.3-2.7% of fly ash plasticizing agent. The use amount of the special fly ash brick plasticizing agent is small, the plasticizing effect of the special fly ash brick plasticizing agent is good, the proportion of the fly ash brick is improved greatly, the operation is simple in production, the production cost is reduced, the source of raw materials is wide, the cost is low, and the production cost is reduced greatly. The invention also provides a formula and a production process for producing the high-proportion fly ash brick. The process is combined with the fly ash brick plasticizing agent, the fly ash brick is produced through a steam curing method, the device investment is few, the product energy consumption is little, the total cost of products is reduced effectively and economic benefits and social benefits are high.

Owner:芜湖露盾新材料科技有限公司

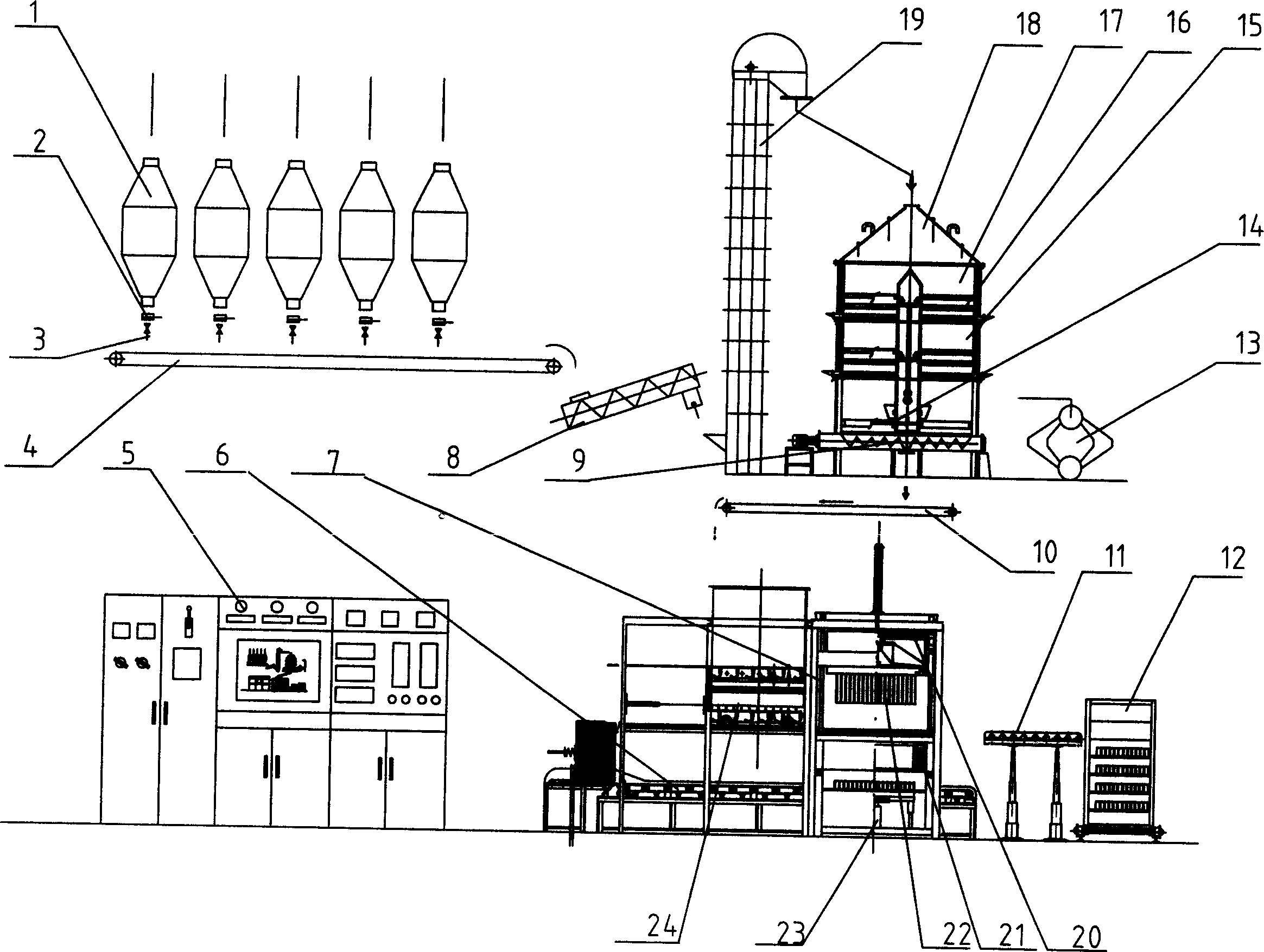

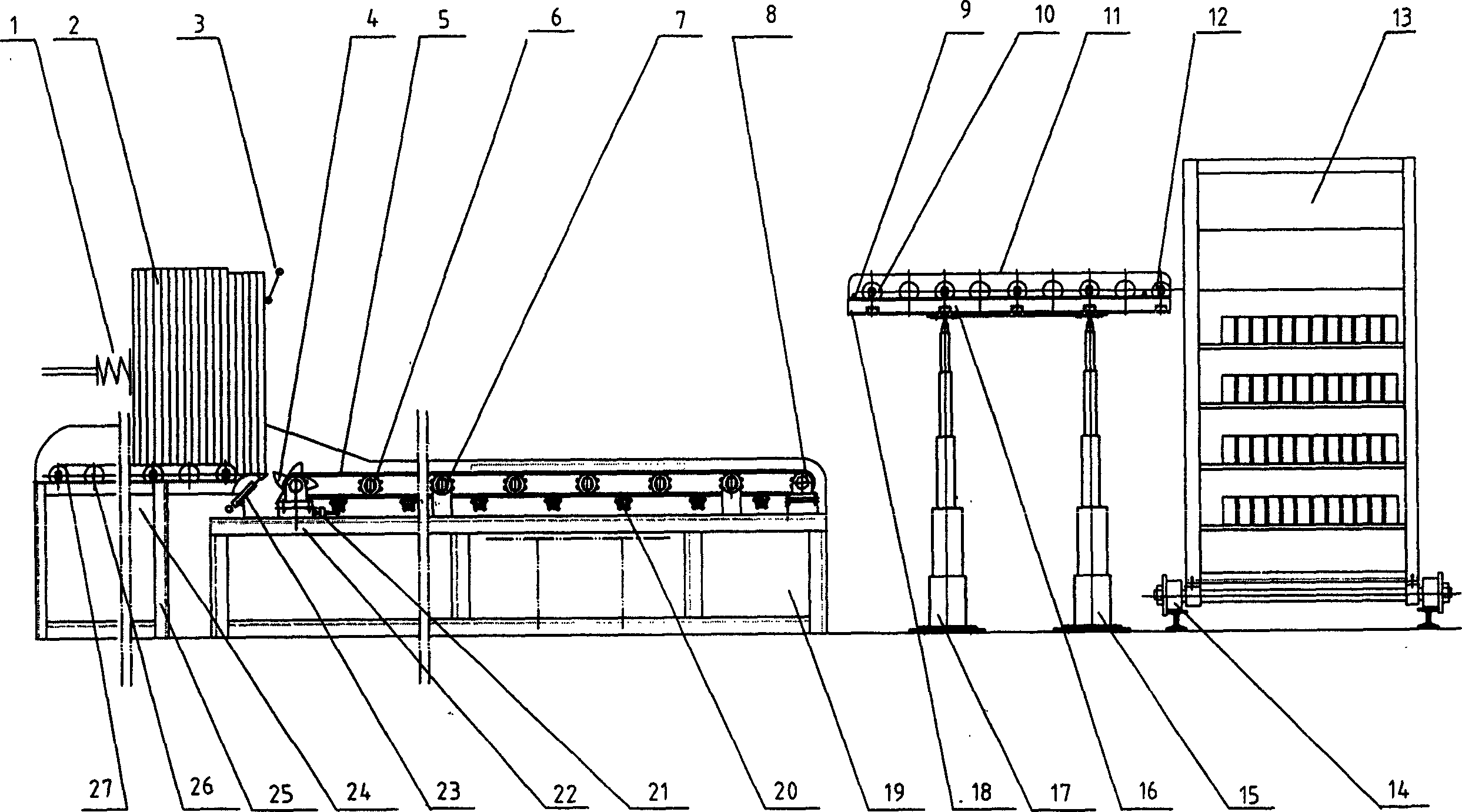

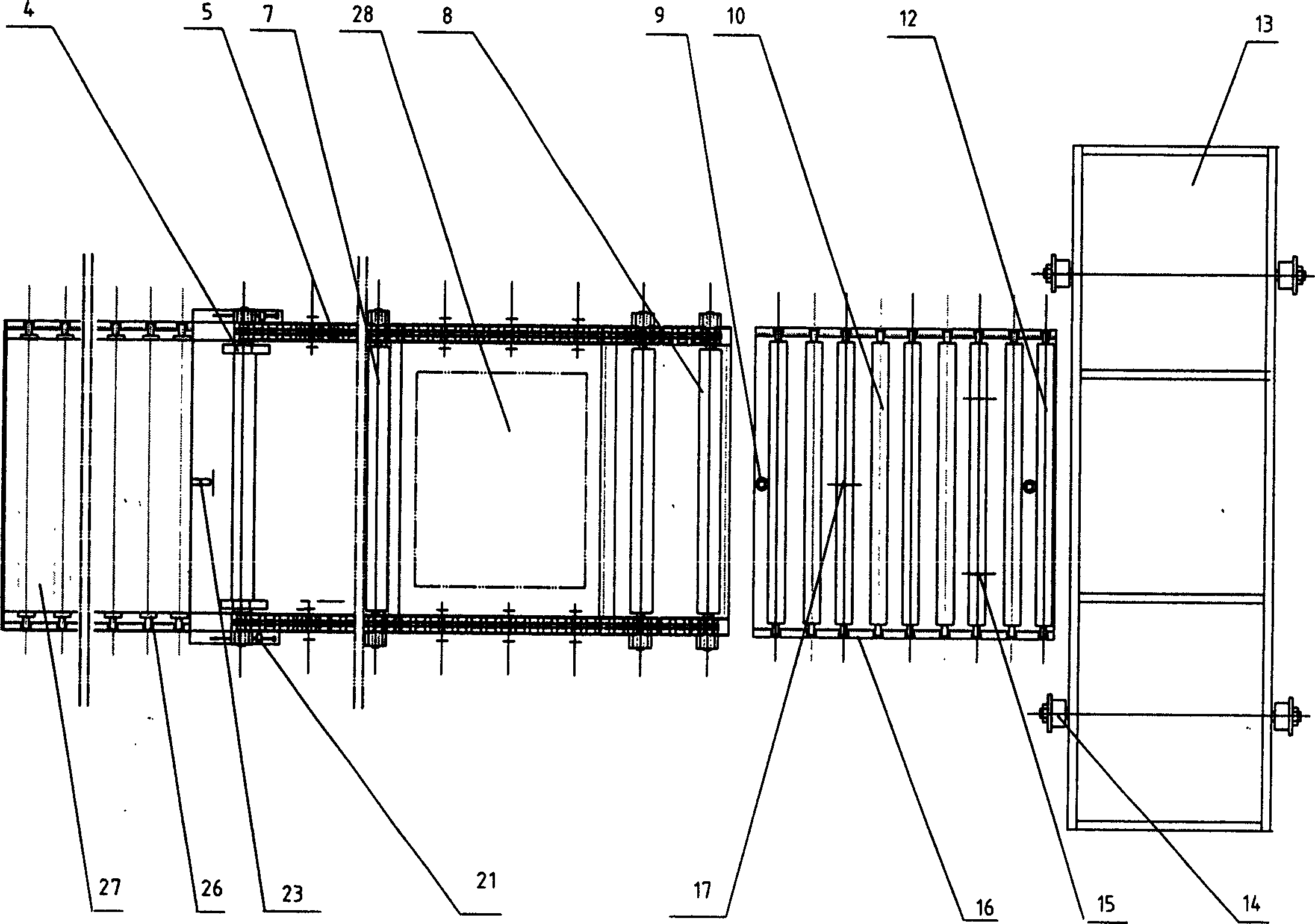

Flyash brick transfer device

InactiveCN1597468AOvercoming many, high energy consumptionOvercome the costConveyorsCeramic shaping apparatusHydraulic cylinderDrive wheel

A conveyer for flyash bricks consists of a conveying part and a piling up part. An automatic lifting device is installed between them. The conveying part is equipped with a primary electric cylinder, a sub-cylinder, a chain or band conveying belt supported by tensioning shafts, and limiting plates on its frame. The automatic lifting device consists of a servo cylinder, which is actuated by the primary cylinder, limiting plates fixed on a movable support, and primary hydraulic cylinder and secondary hydraulic cylinder to lift it, and photoelectric shifting sensor. It is compact it size and easy for maintenance, does not need covneying other trolleys, works automatically, loads / unloads stably, and costs low in a continuous production of quality products.

Owner:辽宁中田干燥设备制造有限公司

Garbage incineration fly ash brick/watt and its preparation method

InactiveCN109180150AImprove plasticityImprove completenessCeramic materials productionClaywaresDecompositionSlurry

The invention discloses a garbage incineration fly ash brick / watt and its preparation method and belongs to the technical field of environmental engineering. The brick / watt comprises, by weight, 18 to32 parts of clay, 24 to 55 parts of waste incineration fly ash or / and bottom ash after cement chelation treatment, 0 to 22 parts of tile edge grinding wastes and 0 to 16 parts of solid construction wastes. The preparation method comprises: putting raw materials into a ball mill according to a ratio, adding a ball milling aid into the raw materials, carrying out ball milling to obtain slurry, carrying out milling and drying, carrying out pressing under high pressure to obtain a blank and carrying out firing at 1020-1250 DEG C. The garbage incineration fly ash brick / watt has the advantages of low treatment cost, large doping amount, good decomposition of dioxins and good solidification effects of heavy metals.

Owner:张晓蓓

Method to produce durable non-vitrified fly ash bricks and blocks

A method of making durable, non-vitrified masonry units comprising fly ash, the method comprising mixing fly ash comprising a minimum of 15% CaO by weight and no more than about 10% loss on ignition, water, and an air entrainment agent to form a fly ash mixture; compacting the fly ash mixture in a shaping device by applying pressure of at least 1000 psi to the fly ash mixture; and curing the compacted fly ash mixture to cause the mixture to harden and gain strength.

Owner:ECOLOGIC TECH

Production method of steam-pressure saponification flyash bricks

ActiveCN102603244ASolve the bottleneck of sustainable developmentAdvanced production technologySolid waste managementSteam pressureEvaporation

The invention discloses a production method of steam-pressure saponification flyash bricks. The method is characterized by comprising the steps of: crushing and grinding waste generated by saponification of epoxypropane, mixing the crushed and ground waste with stone chippings / flayash and binder, adding water, stirring, digesting, rolling, compression moulding through building material machinery, heating with high-pressure steam, reacting the binder with effective components in waste generated by the saponification of epoxypropane under the temperature of about 200 DEG C and the pressure of 1.5-1.6 Mpa, and after reaction, naturally cooling to form the steam-pressure saponification flyash bricks. By adopting the technical scheme, the process is advanced, and has automatic operation and high requirement on equipment; the produced evaporation saponification flyash bricks accord with the requirements of national standard in the aspects of pressure-bearing, heat conduction, radiation and the like after being subjected to examination by the National Institute for Materials Science; the environment protecting problem caused by a situation that the waste generated by the saponification of epoxypropane is stacked in a rented land is solved, the bottleneck problem of sustainable development of an enterprise is solved, and considerable economic benefits can be created for the enterprise.

Owner:FUJIAN MEIZHOU BAY CHLOR ALKALI IND

Autoclaved fly ash brick for construction and manufacturing method thereof

The invention discloses an autoclaved fly ash brick for construction, which is prepared from the following raw materials by weight in mixture ratio: 13 to 17 of boiler slag, 13 to 17 of fly ash, 8 to 12 of granolithic, 18 to 22 of carbide slag and 38 to 42 of mountain flour. When the fly ash brick is prepared, the boiler slag, the fly ash, the granolithic, the carbide slag and the mountain flour which are ground into a powder shape are mixed evenly according to the mixture ratio by weight of 13 to 17:13 to 17:8 to 12:18 to 22:38 to 42, water is added, and a mixed material with the water content of 10 to 15wt% is prepared and is autoclaved and cured to prepare a finished product after the mixed material is pressed and molded. The invention has simple technological formula, easy control of the technological operation and stable product quality and is a novel energy-saving environment-friendly process.

Owner:GAOMI FURI BUILDING MATERIALS

Autoclaved fly ash brick

InactiveCN102452827AImprove frost resistanceImprove corrosion resistanceSolid waste managementSlagCarbide

The invention discloses an autoclaved fly ash brick, which relates to the technical field of construction materials. The autoclaved fly ash brick is characterized by being prepared from the following components in percentage by weight: 50-60 percent of fly ash, 10-15 percent of carbide slag, 20-25 percent of medium and fine sand, 7-14 percent of quicklime, 1-2 percent of gypsum and 5-8 percent of cement. The autoclaved fly ash brick has the beneficial effects that: the adding amount of the fly ash is high, and the cost of the autoclaved fly ash brick is lowered. As proved by detection, each technical index of the autoclaved fly ash brick manufactured by adopting the scheme reaches the national standard.

Owner:孙清海

Method to Produce Durable Non-Vitrified Fly Ash Bricks and Blocks

InactiveUS20070000412A1Other chemical processesWood working apparatusSmall Business Innovation ResearchMaterials science

This patent deals with a method to make durable (i.e., freeze / thaw resistant), non-vitrified (non-fired) fly ash masonry units (bricks, blocks, tiles and other construction products), that can pass contemporary standards for building bricks established by the American Society for Testing and Materials (ASTM). In contrast, existing processes for making non-vitrified fly ash masonry units cannot make products durable—passing the 50 freeze / thaw cycles required by ASTM. By using the process specified in this invention, fly ash can be made into durable bricks and other products without having to heat the green products in kilns at high temperature, thereby reducing energy consumption and costs associated with making ordinary clay bricks. The process resulted from a Small Business Innovation Research (SBIR) project sponsored by the National Science Foundation (NSF), which demonstrated that durable, non-vitrified, fly ash masonry units can be produced by using this process. Since fly ash is a material generated in large quantity at coal-fired power plants and since currently (in 2006) only about a third of the fly ash generated in the United States is used with the rest being disposed of as solid waste, use of fly ash to make bricks and other construction products not only has commercial value but also helps to reduce and to recycle wastes generated at coal-fired power plants. Furthermore, use of such non-vitrified (non-fired) fly ash products in the future reduces the use of fired clay products, which require using fossil fuel to heat the units in kilns, which in turn generates air pollution and carbon dioxide that causes greenhouse effect and global warming. Therefore, use of the fly ash brick invented here has the additional advantage of being environmentally friendly—reducing air pollution and global warming.

Owner:ECOLOGIC TECH

Autoclaved flyash-lime brick and manufacturing method thereof

ActiveCN106278105AImprove pollutionReduce pollutionSolid waste managementAuxillary shaping apparatusSlagSludge

The invention provides an autoclaved flyash-lime brick and a manufacturing method of the autoclaved flyash-lime brick, and refers to the technical field of building materials. The autoclaved flyash-lime brick comprises the following raw materials, coal gasification slag, fly ash, aggregate, acetylene sludge, and ardealite; according to a formula of the invention, content of fly ash is low; meanwhile, a certain amount of coal gasification slag is mixed, thus the production environment of big dust capacity caused by high content of fly ash is improved, utilization of coal gasification slag is increased, production cost is reduced, and performance index of the autoclaved flyash-lime brick product is improved; moreover, the product appearance and color are similar to antique black brick.

Owner:中盐安徽红四方新型建材科技有限公司

FCC (Fluid Catalytic Cracking) waste catalyst doped autoclaved flyash-lime brick and making method thereof

The invention discloses a method for manufacturing an autoclaved flyash-lime brick by using an FCC (Fluid Catalytic Cracking) waste catalyst. The method comprises the following step: by taking the FCC waste catalyst, coal ash, thiourea filter residues (Ca(OH)2) as main raw materials, doping a proper amount of aggregate, performing raw material pretreatment, pressing molding and high-temperature high-voltage steam curing, thereby obtaining the autoclaved flyash-lime brick. The autoclaved flyash-lime brick can replace conventional clay red bricks, and is a novel wall body material which is greatly developed and applied in China. The autoclaved flyash-lime brick is manufactured by using the FCC waste catalyst safely and efficiently. Not only are local solid-waste treatment problems solved, but also farmlands can be saved, pollution can be reduced, and the environment can be protected; as a great deal of industrial waste residues can be utilized, the autoclaved flyash-lime brick is good in durability and relatively high in wall body strength, and has great significances of environment protection and waste utilization.

Owner:山东京博环保材料有限公司

Steam-curing free coal ash brick and making method thereof

InactiveCN108059431AEfficient use ofRealize energy-saving productionSolid waste managementSocial benefitsPolymer science

The invention relates to a steam-curing free coal ash brick and a making method thereof. According to the steam-curing free coal ash brick and the making method thereof, coal ash, cement, gypsum, aggregate, an alkali mixing material, an excitant, a water retaining agent, a fiber and water are adopted as raw materials, and a coal ash brick which meets strength standard requirements is made throughpremixing, aging, cloth pressing and steam-curing free normal-temperature maintenance. By adopting the steam-curing free coal ash brick and the making method thereof, efficient utilization of coal ashis achieved, the mixing utilization rate is greater than 70%, reactions can be implemented at a normal temperature, steam-curing is avoided in a maintenance mode, energy-saving production is achieved, coal ash bricks which meet strength standard requirements can be made, and remarkable environment benefits, economic benefits and social benefits can be made.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

Method for producing wastewater treatment material with microporous flyash brick fragment

InactiveCN101428873AEasy to operateImprove mechanical propertiesOther chemical processesWater/sewage treatment by flocculation/precipitationWastewaterSewage treatment

The invention relates to the technical field of sewage treatment, in particular to a method for preparing sewage treatment materials through microporous fly ash brick chips. The method comprises the following steps: A. granulation; B. cleaning and draining; C. the preparation of active matters; D. soaking and stirring; E. air drying and polymerization; and F. packaging. The product has good mechanical performance and low manufacturing cost, and makes use of the microporous characteristic of the crude fly ash brick chips to polymerize and solidify a flocculant and an oxidizer into micropores, thereby obtaining the solid material with a microporous structure, endowing the material with the flocculating performance and oxidation performance while simultaneously further strengthening the absorbability of the material, and changing the material into the multifunctional sewage treatment material.

Owner:DONGGUAN UNIV OF TECH

Red fly ash sintered brick material

InactiveCN105254278AHigh strengthImprove compactnessCeramic materials productionClaywaresDiiron TrioxideFly ash brick

The invention relates to a red fly ash sintered brick material. The brick material comprises 30-35 parts by mass of fly ash, 12-15 parts by mass of lime, 15-16 parts by mass of coal cinder, 8-10 parts by mass of gypsum and 2-5 parts by mass of ferric oxide. The red fly ash sintered brick material is red, cheap and high in quality.

Owner:无为县华标新型墙体材料有限公司

Building method for controlling temperature cracks of masonry

InactiveCN102182316AEasy to useHigh recovery rateBuilding material handlingSocial benefitsTransformer

The invention relates to a building method for controlling temperature cracks of a masonry, which comprises the following steps of: A. pouring water over bricks and fully soaking the bricks before brick laying, ensuring that the water content ratio of fly ash bricks is 8 to 12% and the water absorbing depth around the cross section of each fly ash brick is 15 to 20mm; B. locating, paying-off and laying bricks; C. building a brick masonry, wherein a control joint and a concrete slab strip of a steel bar are arranged on the brick masonry so as to control masonry damage caused by temperature fluctuation and drying shrinkage and deformation of materials: and D. carrying out sedimentation and maintenance after the brick laying of a wall is completed. The invention has the advantages that: in the process of the brick masonry construction of a transformer substation building, the cracks caused by temperature and material shrinkage are greatly reduced; from the application condition of the transformer substation construction, the building method has obvious effects, and the temperature cracks of the masonry are better controlled; from the aspect of economic benefit, the recovery rate of guarantee deposit is increased; meanwhile, the improvement for construction quality ensures the safe operational performance of the building, and favorable social benefit is obtained.

Owner:SHANDONG ELECTRIC POWER TRANSMISSION & SUBSTATION ENG CO

Fly ash archaized black brick

InactiveCN106278078ADark colorFull of ancient charmSolid waste managementAuxillary shaping apparatusSlagCrushed stone

The invention relates to an autoclaved fly ash archaized black brick. The autoclaved fly ash archaized black brick comprises the raw material components in percentages by weight: 45-55% of fly ash, 10-15% of slag, 15-20% of yellow sand, 6-10% of crushed stone powder, 6-10% of quicklime, 4-6% of black iron oxide and 2-4% of iron oxide green. The sum of weight percentages of the various components is 100%. A method for producing the archaized black brick by using the components comprises the following specific steps: after batching and stirring the various raw materials in corresponding proportions according to the required use amounts to prepare a mixture, digesting the mixture in a digesting device; and then carrying out wheel rolling, green brick forming and autoclaved curing to obtain the finished black brick, transferring the finished black brick to a storage yard, and naturally stacking for 15-20 days to leave the factory. On the basis of the traditional autoclaved flyash-lime brick, the archaized black brick is researched by technical staffs through repeated tests. The fly ash archaized black brick is low in production cost. The effect of the fly ash archaized black brick can be compared favorably with a black brick fired by clay. The autoclaved fly ash archaized black brick is full in ancient charm, and quite meets requirements of development of markets.

Owner:袁正秋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com