High-plastic-forming fly ash steam curing brick

A technology of fly ash and steam-cured bricks, applied in the field of building materials, can solve the problems of difficult process control, difficult to guarantee brick quality, high power consumption of products, etc., and achieve good plasticizing effect, low energy consumption of products and low capital investment little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

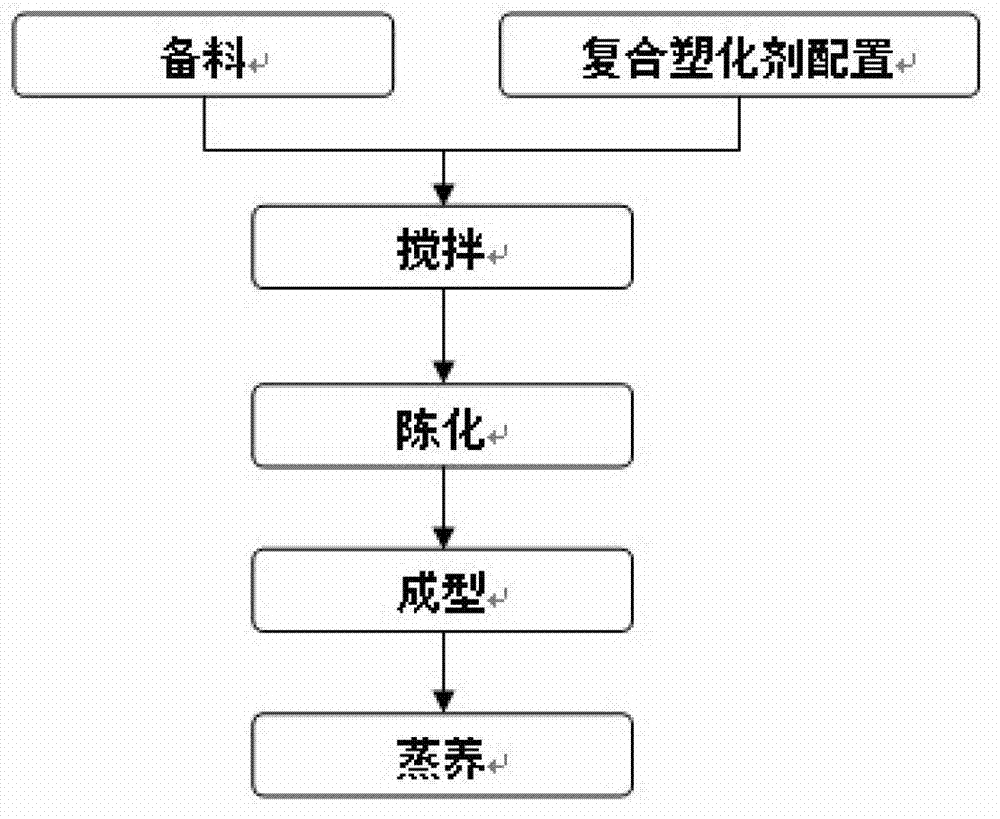

Method used

Image

Examples

Embodiment 1

[0034] 1) Material preparation: put 1000g of fly ash, slag, cement and other dry materials in the mixer, of which the content of fly ash is 800g, the amount of slag is 90g, the amount of cement is 30g, the amount of quicklime is 50g, and the amount of gypsum is 5g;

[0035] 2) Compound plasticizer preparation: take 10g of sodium naphthalenesulfonate, add 150g of water, control the solution temperature to 60°C, fully stir and hydrolyze, add 5g of wood calcium and 10g of water glass into the hydrolyzate and stir fully, that is Obtain high-volume fly ash brick blank composite plasticizer;

[0036] 3) Stirring: Mix dry materials such as fly ash with the high-volume fly ash brick blank composite plasticizer obtained in step 2 and stir vigorously to make them fully mixed to obtain fly ash brick blank;

[0037] 4) Aging: leave the fly ash brick blank obtained in step 3) to stand and age for 3-5 hours.

[0038] 5) Forming: Put the fly ash brick blank into the mold and extrude or pres...

Embodiment 2

[0045] 1) Material preparation: put 1000g of fly ash, slag, cement and other dry materials in the mixer, of which the content of fly ash is 770g, the amount of slag is 120g, the amount of cement is 30g, the amount of quicklime is 50g, and the amount of gypsum is 5g;

[0046] 2) Compound plasticizer preparation: take 10g of sodium naphthalenesulfonate, add 150g of water, control the solution temperature to 60°C, fully stir and hydrolyze, add 5g of wood calcium and 10g of water glass into the hydrolyzate and stir fully, that is Obtain high-volume fly ash brick blank composite plasticizer;

[0047]3) Stirring: Mix dry materials such as fly ash with the high-volume fly ash brick blank composite plasticizer obtained in step 2 and stir vigorously to make them fully mixed to obtain fly ash brick blank;

[0048] 4) Aging: leave the fly ash brick blank obtained in step 3) to stand and age for 3-5 hours.

[0049] 5) Molding: Put the fly ash brick blank into the mold and extrude or pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com