Patents

Literature

1665 results about "Plasticulture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The term plasticulture refers to the practice of using plastic materials in agricultural applications. The plastic materials themselves are often and broadly referred to as "ag plastics." Plasticulture ag plastics include soil fumigation film, irrigation drip tape/tubing, nursery pots and silage bags, but the term is most often used to describe all kinds of plastic plant/soil coverings. Such coverings range from plastic mulch film, row coverings, high and low tunnels (polytunnels), to plastic greenhouses.

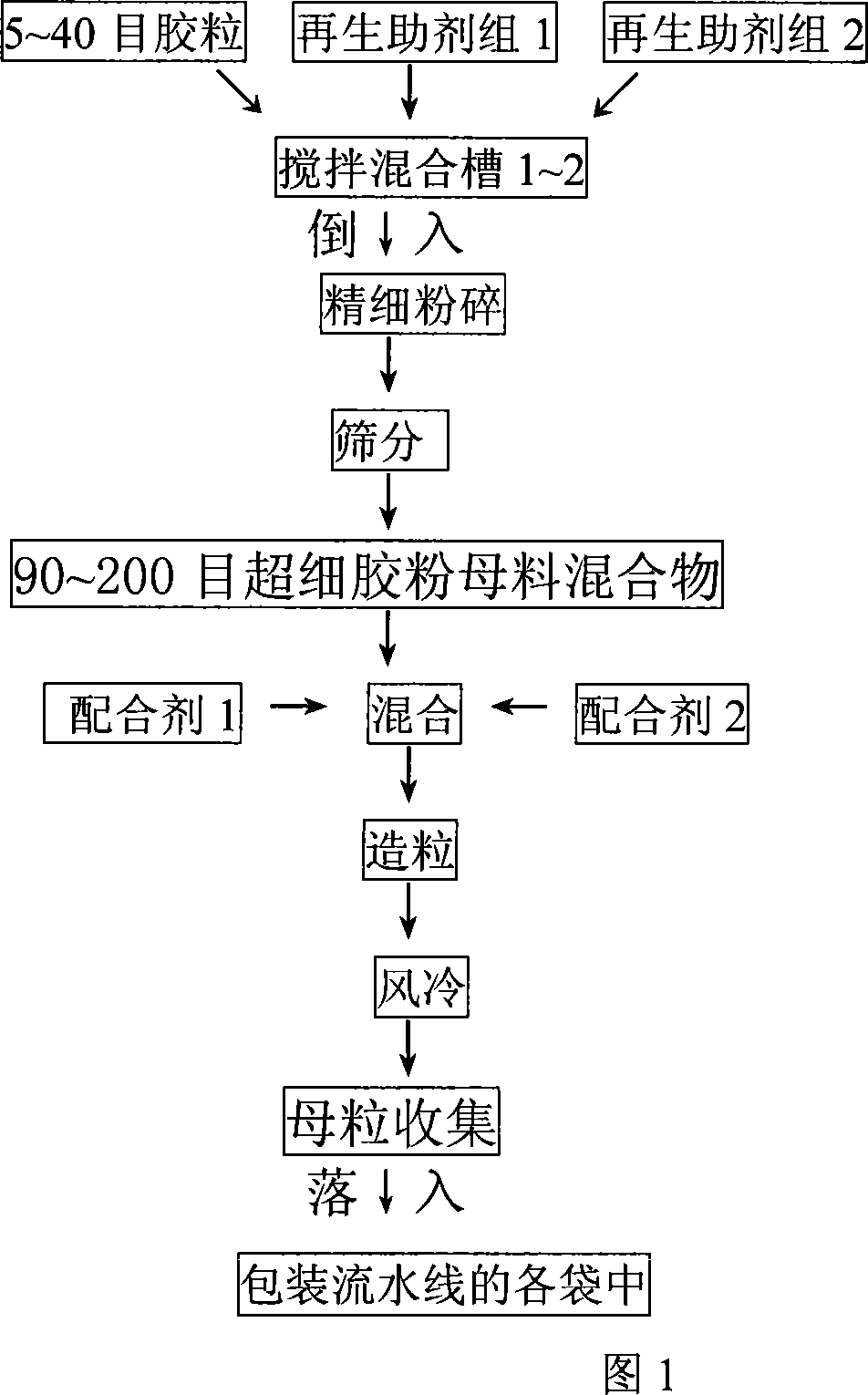

Reproduction new method for waste elastomer and plastic

InactiveCN101041725AThe ratio is roughly constantReduce or eliminate the impact of flow fluctuationsPlastic recyclingElastomerEngineering

The invention discloses a new regenerating method of waste elastics and plastic, which comprises the following steps: 1. blending waste elastics or / and plastic with grain size between 5 and 80 order and non-polluted regenerative adjuvant according to proportion; placing into the manufacturing machine; grinding; sieving; heating to desulfurize; bulking; soaping; emulsifying; kneading; pressing; graining; obtaining composite product 1 with mother material or mother particle or mother gel of plastic elastic powder; 2. weighing product 1 and non-polluted mating agent into mixing machine according to proportion; kneading; blending evenly; pressing; graining; obtaining the product 2 of mother material or mother particle or mother gel with 5-95% waste elastic or / and plastic.

Owner:陈书怡 +1

Method for using phosphogypsum as polyvinyl chloride resin filler

The invention discloses a method for using phosphogypsum as a polyvinyl chloride resin filler. The method is as follows: the phosphogypsum is subjected to modified treatment; a coupling agent is added in a milling process, so as to obtain the product which can be used as the polyvinyl chloride resin filler. The method comprises following concrete processes: (1) screening; (2) calcining; (3) grinding and adding the coupling agent; and (4) mixing, so as to obtain an aluminate ester modified phosphogypsum filler. The method has the advantages that (1) organic impurities and crystal water are removed by screening and calcining the phosphogypsum; the whiteness is improved; the grain sizes of the grains are controlled in a grinding manner; the method meets the requirements of the polyvinyl chloride (PVC) filler, and is low in cost; (2) the method is even to modify, and good in effect; no externally added water enters inside; the bubbling of the PVC in a machining process is avoided; (3) the method is simple in process, low in cost, good in processing rheological property and easy to mold, and the plasticization of the phosphogypsum in the PVC resin can be accelerated. The method is suitable for reinforcing and toughening of a polymer material, not only can be applied to the PVC resin, but also can be used as fillers of the materials such as polyethylene (PE), polypropylene (PP) and polystyrene (PS).

Owner:贵州开磷遵义碱厂

Paper-imitating biodegradable resin and preparation method

ActiveCN101914294AAvoid pollutionAvoid degradationInorganic fibres/flakesPaper/cardboardBiopolymerVegetable fibers

The invention discloses a paper-imitating biodegradable resin and a preparation method. For improving the degradability and natural recoverability of paper-imitating materials and making the paper-imitating materials have similar lightness, foldability and printing and writing performance as the conventional paper. The paper-imitating biodegradable resin uses mineral fibers, vegetable fibers and starch fibers as main components, and concretely comprises the following components in part by weight: 40 to 70 parts of mineral fibers, 10 to 30 parts of vegetable fibers, 5 to 20 parts of starch fibers, 5 to 15 parts of biopolymer, 3 to 5 parts of modifier, 3 to 5 parts of compatibilizer and 3 to 8 parts of processing assistant. The mineral fibers, vegetable fibers and starch fibers are interweaved through thermoplastic processing, and the preparation process is clear and pollution-free. The paper-imitating biodegradable resin can be processed into various paper-imitating products by hot plasticizing equipment, and the products, when discarded, can be swallowed and decomposed by microbes without polluting the environment.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

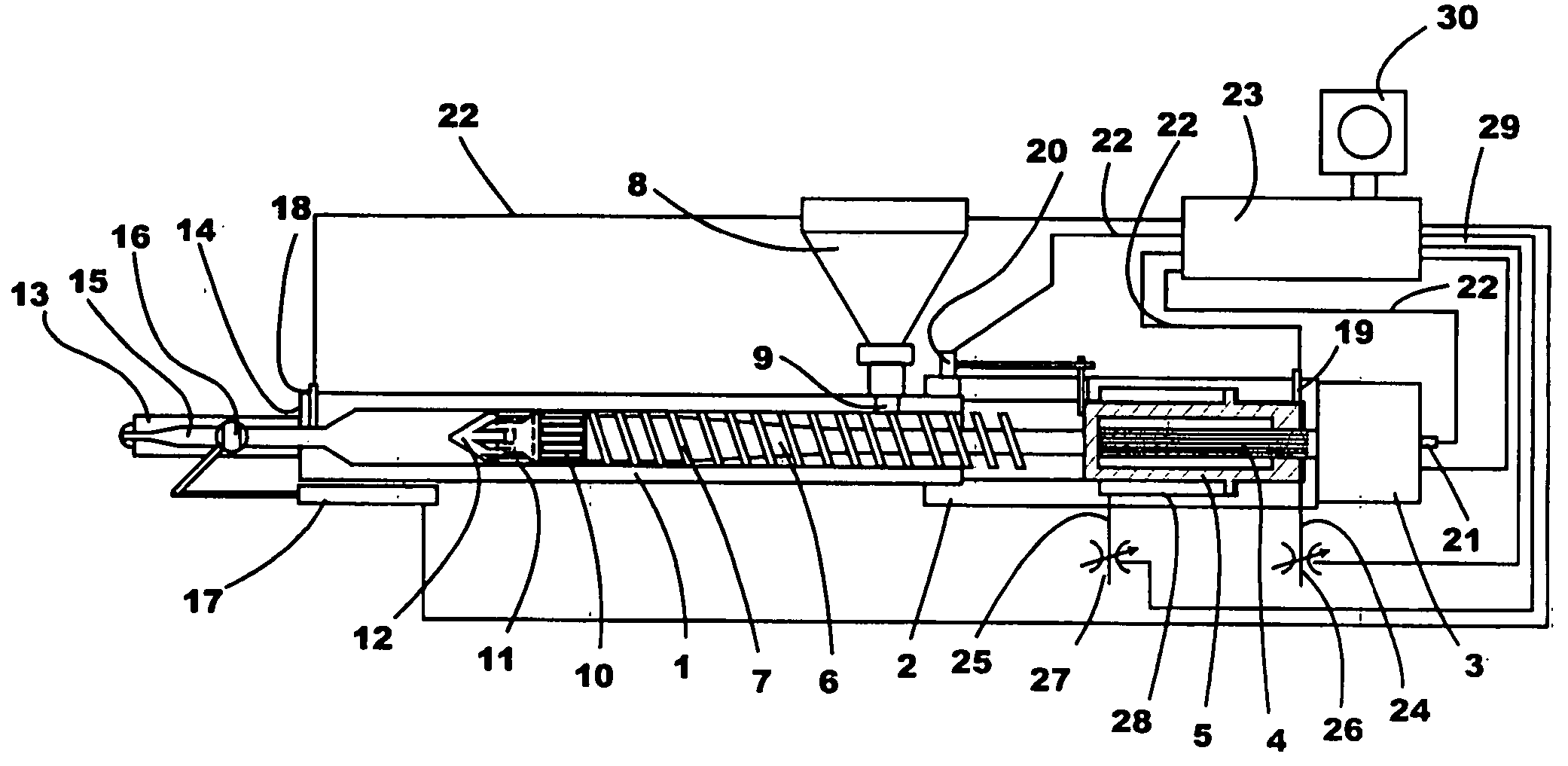

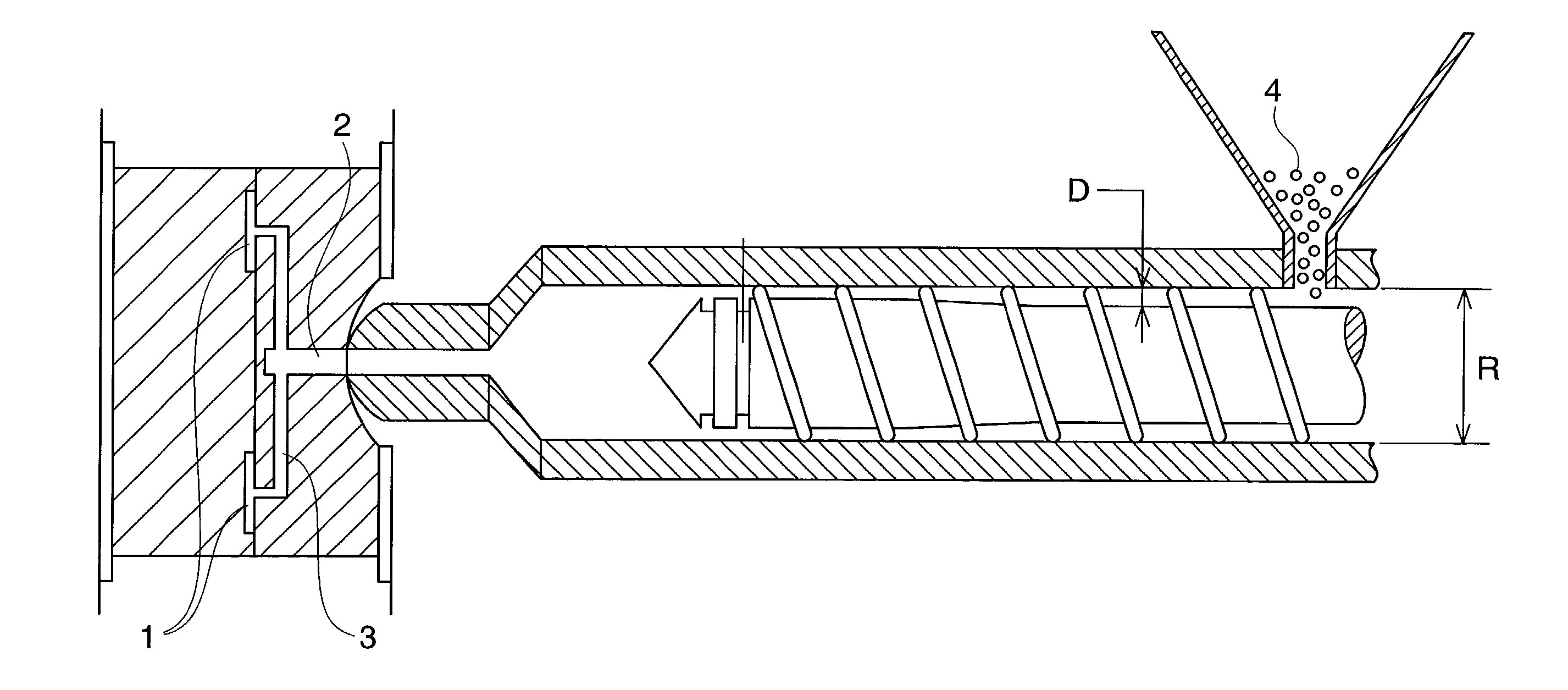

Injection molding method and apparatus for continuous plastication

InactiveUS20050161847A1Improve output efficiencyLower energy requirementsAuxillary shaping apparatusFood shapingEngineeringInjection moulding

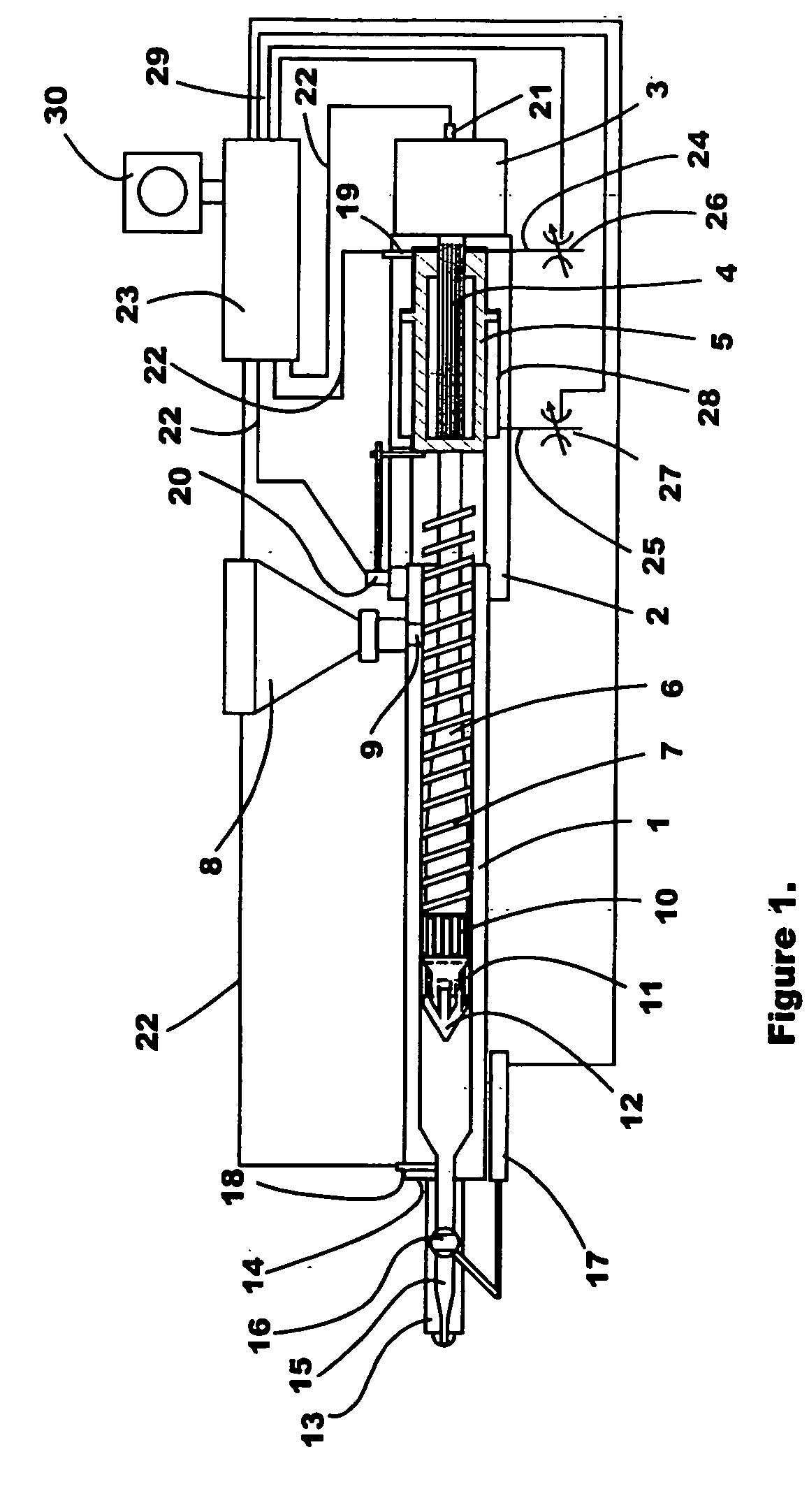

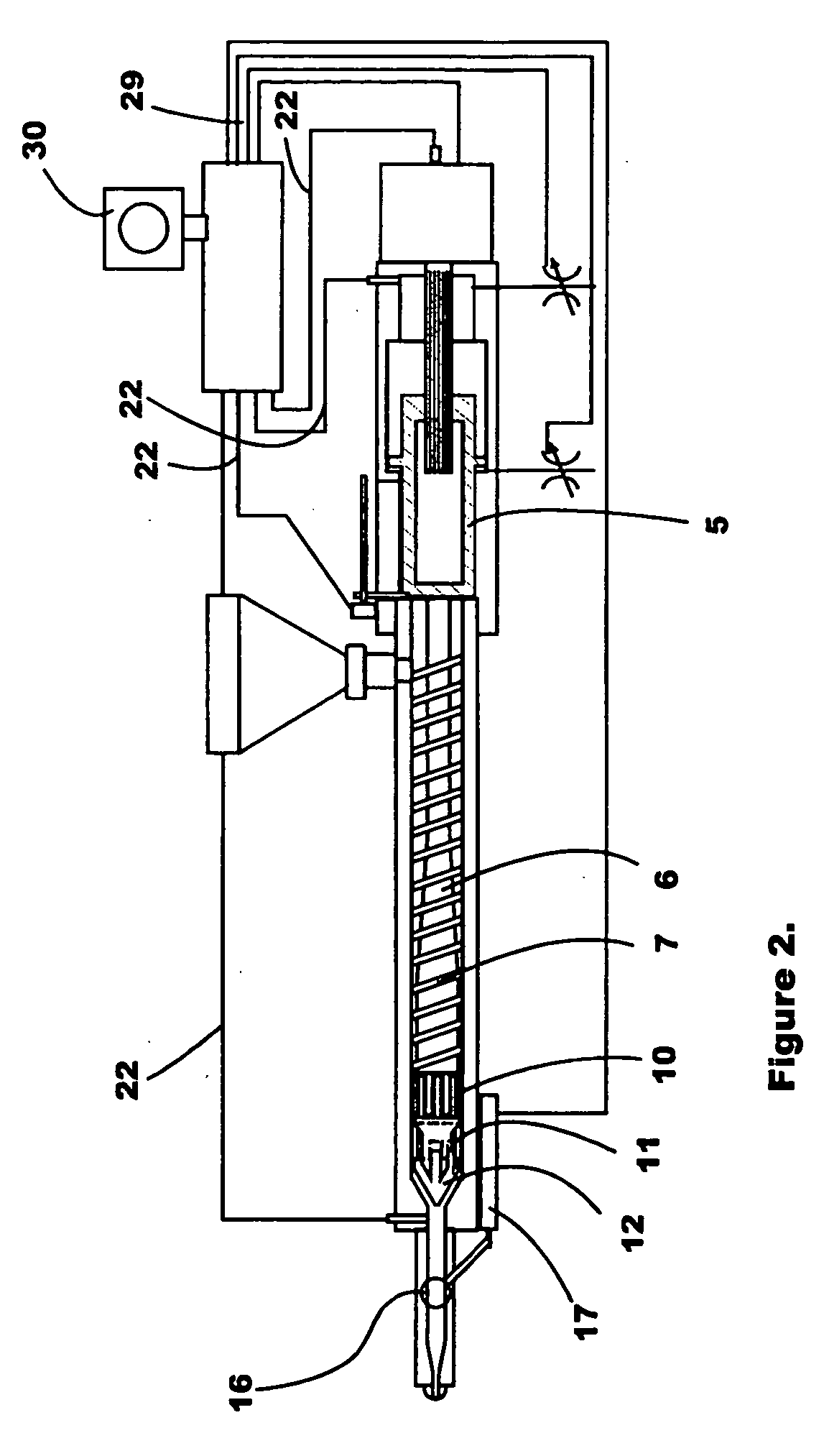

In a reciprocating (RS) injection unit environment, as shown in FIG. 1, a controller of the injection unit is arranged to continuously rotate the screw during both conventional plasticizing operation and shot injection. In this way the RS unit is more efficient, utilizing less energy and producing greater resin output. The injection unit includes a non-return valve adjacent a nozzle, which non-return valve is either configured to rotate with the screw to reduce wear or presented as a ball check style noon-return valve. In an injection molding environment, the rotating screw includes flights that allow granules of resin to melt and mix in spaces between adjacent flights, but the flights are arranged substantially to inhibit excessive displacement of resin around the flights.

Owner:HUSKY INJECTION MOLDING SYST LTD

Fully biodegradable material with polylactic acid/polyterephthalic dibutyl adipate used as base materials and preparation method thereof

The invention discloses a fully biodegradable material with polylactic acid / polyterephthalic dibutyl adipate used as base materials and a preparation method thereof. The material provided by the invention is composed of polylactic acid, polyterephthalic dibutyl adipate, a bio-based filler, an inorganic filler and a few amount of auxiliaries. The material has been certified by American ASTMD6400, European EN13432 and Australian AS4736 and is a fully biodegradable material. The fully biodegradable material contains the following ingredients, by weight, 5-60 parts of polylactic acid (PLA), 5-60 parts of polyterephthalic dibutyl adipate, 5-40 parts of the bio-based filler, 5-45 parts of the inorganic filler and 0.3-10 parts of the auxiliaries. The above ingredients are fully mixed, and the mixture undergoes melt plastification by a screw and then is directly extruded to obtain a board of 0.2-2mm thick. The board can undergo embossed work to obtain fruit trays, vegetable trays, disposable knives and forks and the like.

Owner:江苏天仁生物材料有限公司

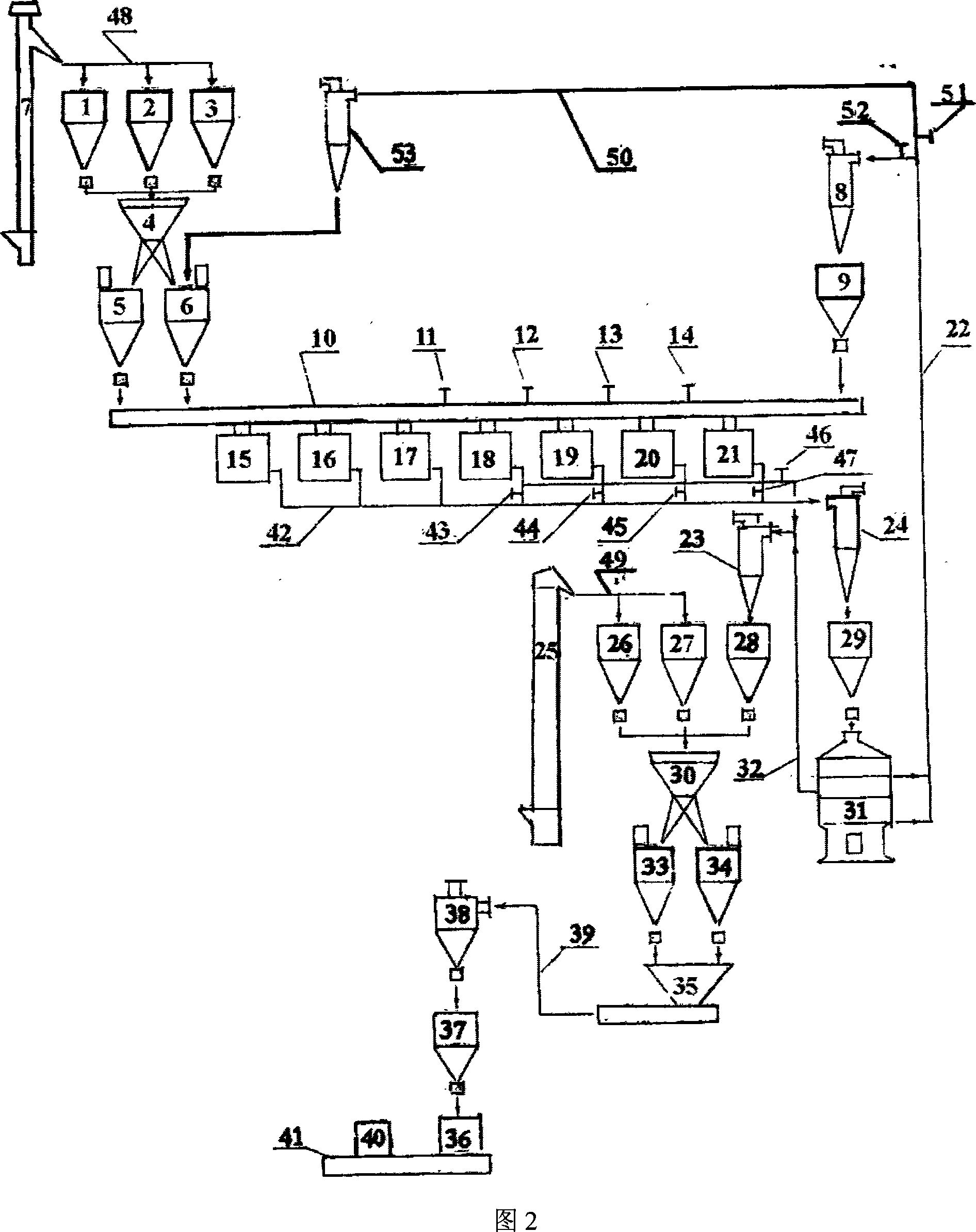

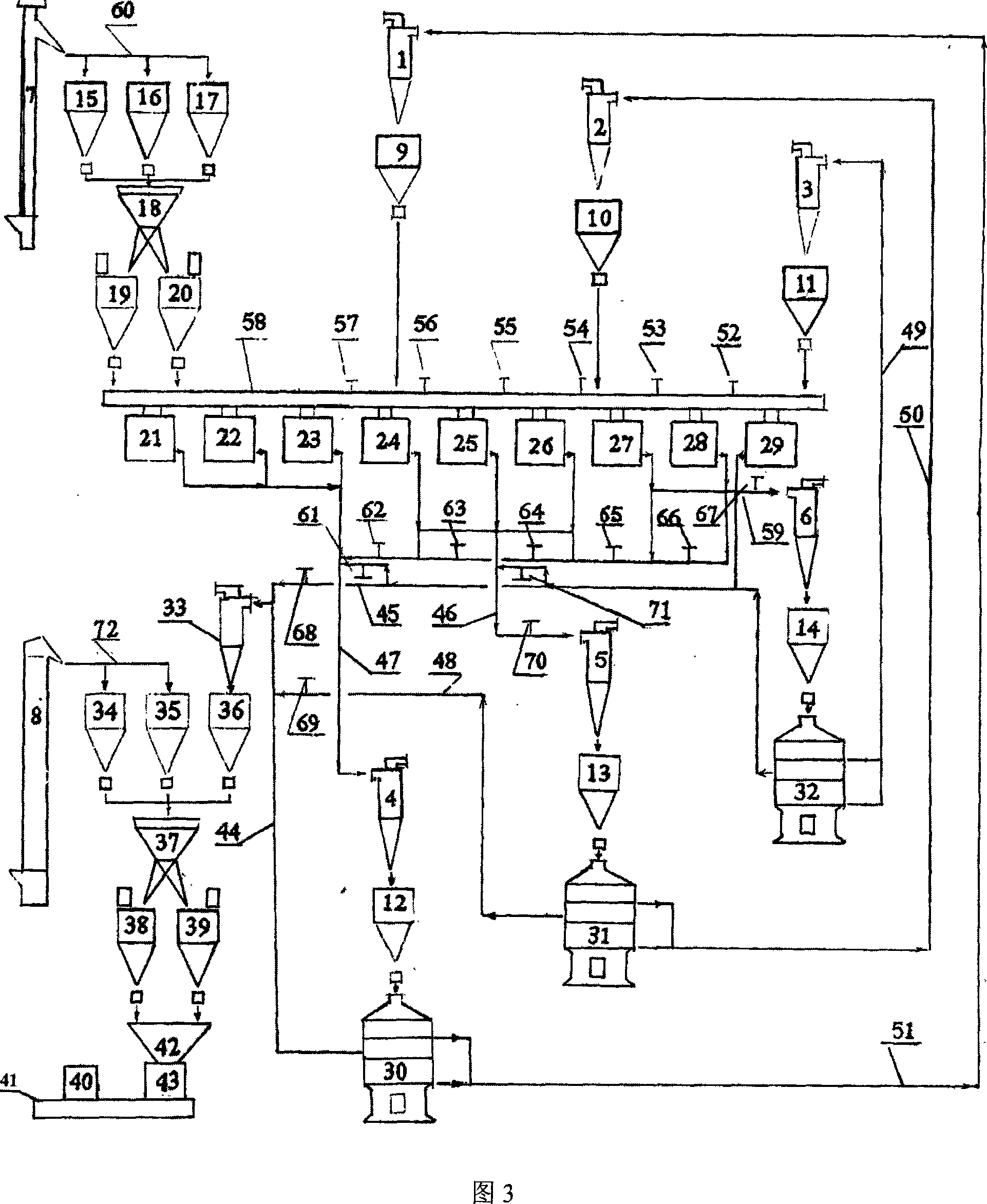

Method and apparatus for combination regeneration, or coproduction with hydrocarbon black of waste and old macromolecule material

ActiveCN101402745AReduce wasteExcellent energy qualityPlastic recyclingLiquid hydrocarbon mixture productionFiberRubber material

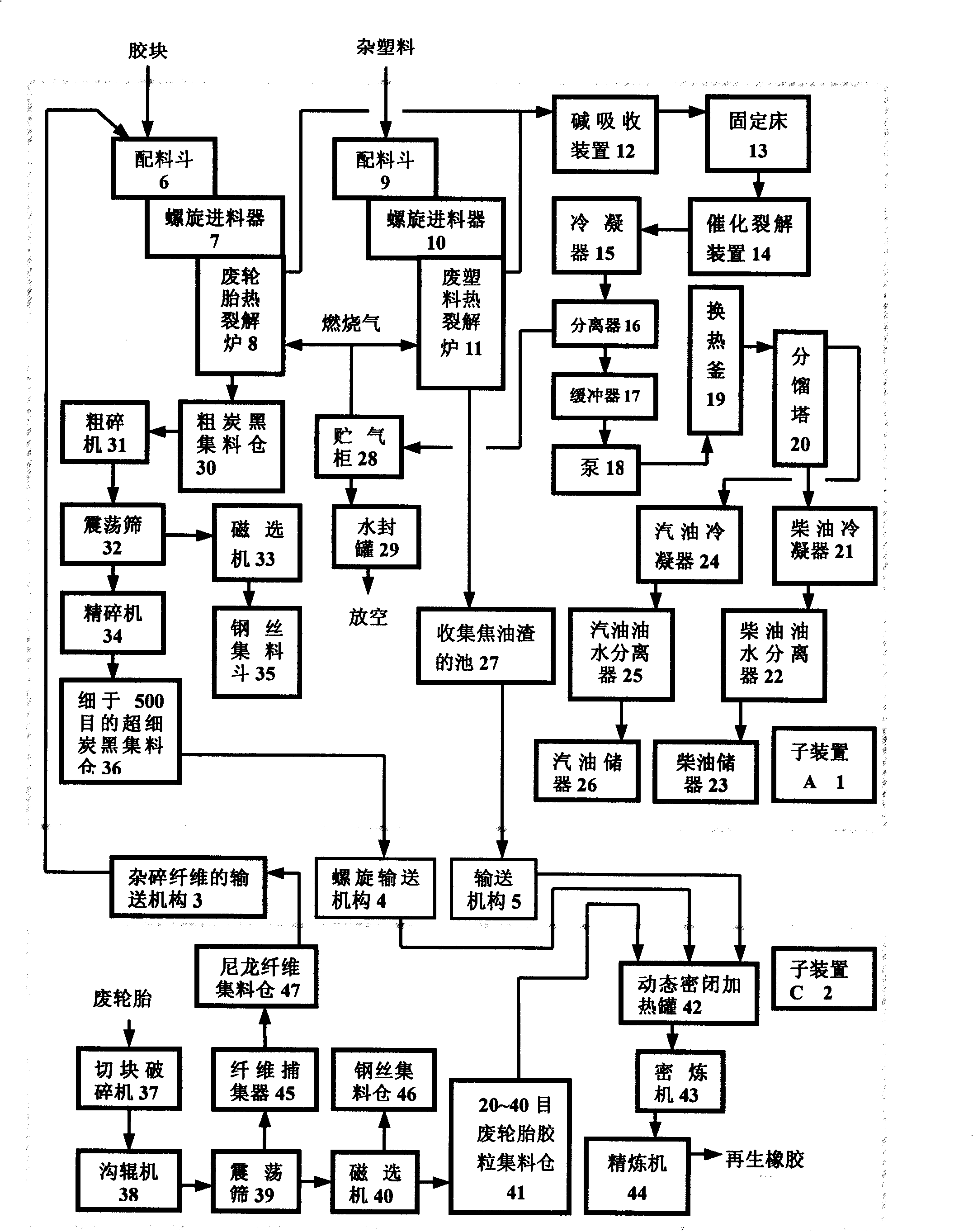

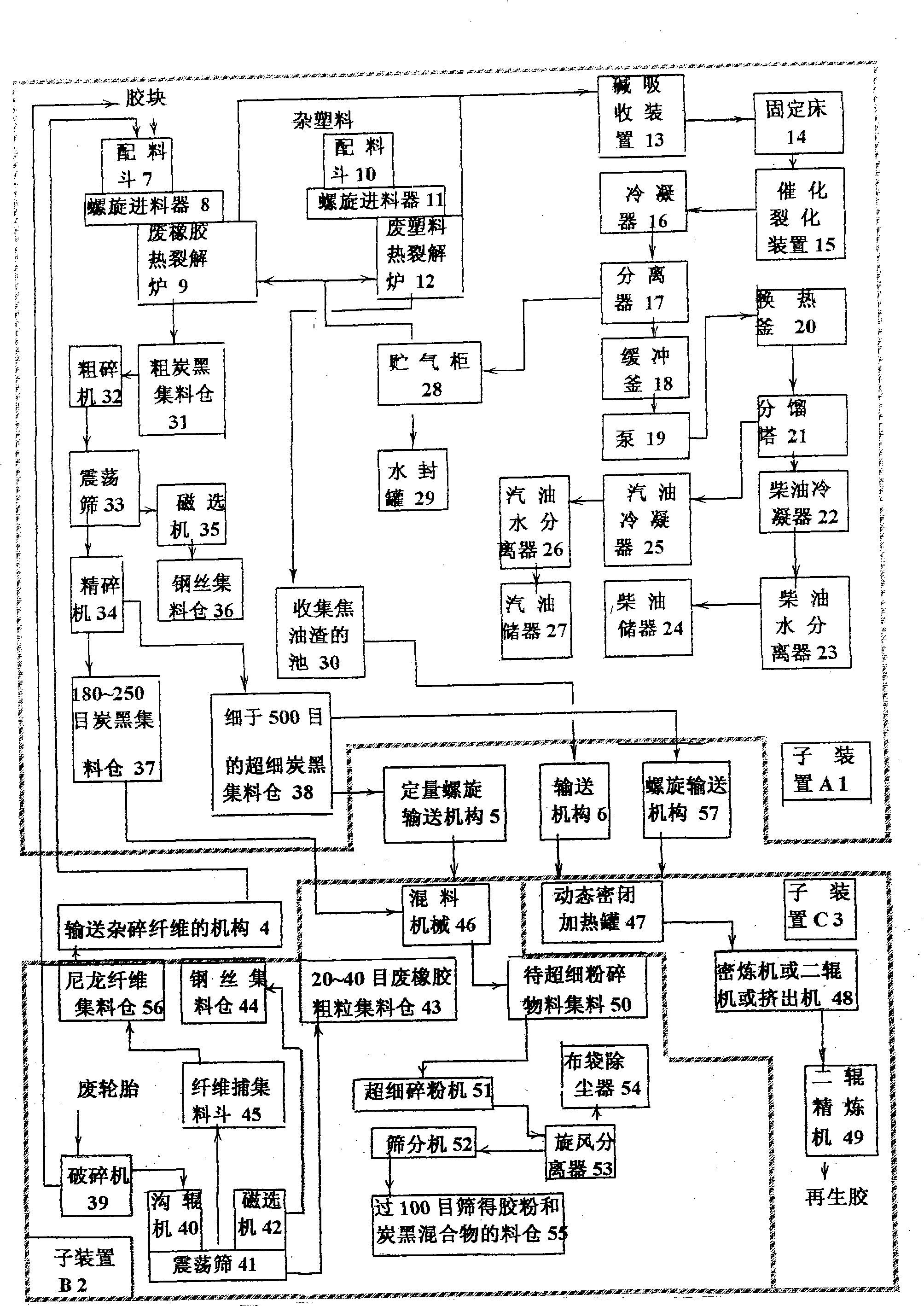

The invention discloses a method of combination and regeneration of waste high molecular materials or co-production of the waste high molecular materials and carbon black, and a device thereof, relating to two technologies of existing thermal cracking and non-thermal cracking of the waste high molecular materials and improvement and combination among various technological branches and also relating to the regeneration process of the waste high molecular materials and the combination of the regeneration process of the waste high molecular materials and the production process of general carbon black and an integration device used in the embodiment thereof; and comminution at normal temperature or the combination of the comminution at normal temperature and various branches of renovated rubber technology and an integration device adopted by the embodiment thereof are also included. The method also provides a treatment proposal for applying mixed fiber to recycling and products thereof, which are characterized in that the mixed fiber and plasticized rubber materials or / and oil materials are matched by the weight percentage of 100:5 to 100:100 to obtain a mixture taking the shape of a felt or a rubber felt or a treated felt. The proposal of the integration device also provides a combination device with fractional efficiency higher than that of the existing fractional process for the granularity of rubber powder only by means of a power screen.

Owner:上海橡源驰晨环保科技发展有限公司

A kind of production method of superfine high-strength high-modulus viscose fiber

InactiveCN102296373AIncrease contact areaIncreasing the thicknessSpinnerette packsArtificial filaments from viscoseCellulosePolymer science

The invention discloses a production method of ultra-fine, high-strength and high-modulus viscose fibers. The cellulose xanthate polymer spinning viscose which is still in a viscous flow state is provided with viscose ejection holes and coagulation baths respectively. The composite spinneret of the spray hole is sprayed out, and is solidified and formed by a low-acid, high-zinc, low-salt and low-temperature coagulation bath, and then combined with bath stretching and air stretching, and drawn by nozzles with different ratios , inter-disk drafting and plasticizing drafting, and then post-treatment to obtain a fineness of 0.44~0.78dtex, dry strength ≥ 3.1cN / dtex, wet strength ≥ 2.1cN / dtex, wet modulus ≥ 0.5cN / dtex, whiteness ≥82.0% ultra-fine high-strength high-modulus viscose fiber. The invention realizes the effective coordination of the ultrafine denier fiber spinning forming process and drafting, and the normal implementation of the spinning process, and the produced ultrafine high-strength high-modulus viscose fiber has a uniform structure, and the fiber strength and modulus are 50% higher than conventional varieties. %above.

Owner:CHTC HELON

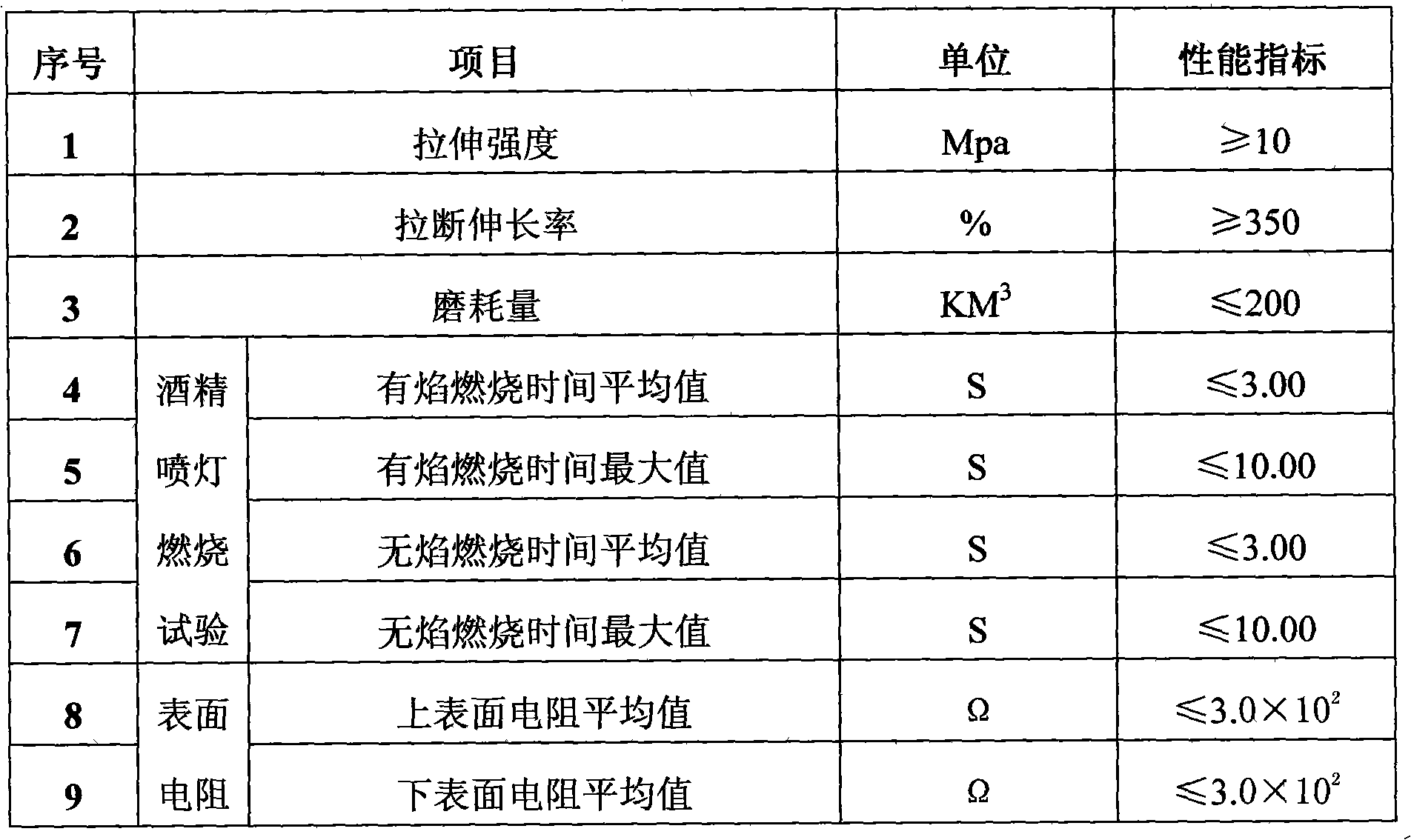

Thermoplastic elastomer surface unitary-core flame-resistant conveying belt and manufacturing method thereof

The invention discloses a thermal-plastic elastic-face whole core fire resistant conveyer belt and the preparing method. The conveyer belt comprises skeleton and covering glue out of the skeleton, which is characterized in that said covering glue adopts NBR powder and PVC; thermal-plastic flame retardant and antistatic elastic body is prepared by mixing, granulating and dynamically vulcanizing with extruder; the thermal-plastic flame retardant and antistatic elastic body is bonded with fabric integral belt core together in thermal status after dipping and plasticizing. The invention leaves out refining glue, calendaring and plate vulcanization so on. Producing efficiency and product quality can be improved greatly.

Owner:ANHUI ZHONGYI RUBBER BELTS

Preparation and application of open-cell foamed polyolefin

ActiveCN101531770AOther chemical processesWater/sewage treatment by sorptionPolymer sciencePolyolefin

The invention relates to a preparation method of open-cell foamed polyolefin. The preparation method comprises the following steps of: mixing the polyolefin with nucleating agent master batch prepared by same olefin type polyolefin granules, a nucleating agent, a foaming-assisting anti-shrinking agent and an antioxidant, putting the obtained mixture into a single-screw or double-screw extruder with the length-diameter ratio of 20-50 for heating, plasticizing and melting, injecting high-pressure gas, fully melting, mixing and extruding out the high-pressure gas and the polyolefin, releasing, expanding, foaming when extruding the obtained mixture out of a mold at an outlet mold of the extruder so as to prepare open-cell foaming products with various shapes. The open-cell foamed products are used as adsorption substrates and adsorption carriers, and can also be used as sound-insulating, sound-absorbing, and heat-insulating materials. According to the strength and visco-elasticity of the polyolefin melt, the invention selects an appropriate position to inject the high-pressure gas, and adjusts the structure of the screw, gas pressure and gas quantity, and the heating temperature so as to lead the polyolefin to be fully foamed and cells to be opened thereon when the materials are extruded out of the outlet mold of the extruder, therefore, the gas among the cells is mutually communicated, thus having relatively high adsorption capacity, overcoming the shortage of difficult cell-opening in the existing polyolefin foaming technology and causing the polyolefin application to be more diversified and practical.

Owner:上海高分子功能材料研究所 +1

Method for plasticizing biological specimen

ActiveCN102125025AShrinkage reductionEasy to observeDead plant preservationDead animal preservationCooking & bakingPlasticizer

The invention discloses a method for plasticizing a biological specimen. The method is characterized by comprising the following steps of: a, immobilizing the biological specimen, namely completely immobilizing the biological specimen by using formalin; b, dehydrating and degreasing, namely manufacturing the immobilized biological specimen, and then replacing by using acetone until the water content of the specimen is less than 1 percent; c, performing vacuum impregnation, namely impregnating the completely replaced biological specimen in a biological vacuum impregnation plasticizer to finishthe replacement in a vacuum negative-pressure freezer; d, baking by a baking oven, namely putting the completely replaced biological specimen into the baking oven for high-temperature baking, and completely removing the excessive biological vacuum impregnation plasticizer in the biological specimen; and e, hardening, namely putting the biological specimen baked by the baking oven into an airtightcontainer for hardening. The method effectively shortens the manufacturing time of the specimen, and is easy to operate; and the overall shape of the specimen is not changed, and the specimen has strong sense of reality and certain flexibility, so that the specimen observation at the later stage is facilitated.

Owner:山东聚众数字医学科技开发有限公司

High-efficiency heat-insulation environmentally-friendly flame-retardant modified polyolefin indoor heat-insulation foam and preparation method thereof

ActiveCN102329447AImprove flame retardant performanceEffective isolation of conductionChemical industryCoatingsLow-density polyethylenePolymer science

The invention relates to high-efficiency heat-insulation environmentally-friendly flame-retardant modified polyolefin indoor heat-insulation foam and a preparation method thereof. The preparation method comprises the following steps of: kneading low-density polyethylene resin, a composite flame retardant, an anti-smoke agent, an antioxidant and a lubricant at normal temperature, then discharging to an internal mixer for internal mixing, then discharging to a single-screw extrusion granulator, and carrying out melting, plastication and granulation to obtain a master batch A; adding low-density polyethylene resin to a high-speed mixer, then adding azobisformamide, talc powder, a lubricant and zinc stearate, kneading at normal temperature, and then discharging to a single-screw extruder for granulating to obtain a master batch D; adding low-density polyethylene resin, ethylene-vinyl acetate copolymer, ethylene propylene terpolymer, the master batch A, a master batch B, hollow ceramic microbeads, a rheologic agent and a lubricant to a high-speed mixer, kneading at normal temperature for 3 minutes, then discharging to a single-screw extruder, and extruding into sheets; carrying out radiation cross-linking on the extruded sheets through an electronic accelerator; placing the cross-linked sheets in a foaming furnace for foaming; and coating expansible fireproof paint on the surface of the foam.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

Formulation for super high molecular weight polythene article and preparation method thereof

The invention discloses a super high molecular weight polyethylene (UHMWPE) product-as the dispense and the method preparing for the pipe materials and the sheet materials, which comprises the following parts: 92%-97% super high molecular weight polyethylene resin, 2-7. 5% lubricant, 0. 05%-0. 7% nuclearyer, 0. 01%-0. 4% rheology processing adjuvant. The method comprises the following steps: adding the every composition meter mixture to a helical rotor force out machine designed according to the approaching fusible point concept; forcing out at 100-200DEG C; plasticizing the materials in the die and cooling, congealing in the shape procedure after preheating the materials; producing the continuously stabilizing UHMWPE pipe materials with 2. 5 million molecular weight and 50-200mm diameter or the sheet materials with (5-20)X500 dimension. The invention can be applied in a plurality of trades and fields.

Owner:江苏联冠科技发展有限公司 +1

High-definition transparent PVC (polyvinyl chloride) film and preparation method thereof

The invention relates to the technical field of preparation of furnace decoration PVC (polyvinyl chloride) films and particularly to a high-definition transparent PVC film and a preparation method of the high-definition transparent PVC film. The PVC film is prepared from the following raw materials in parts by weight: 100 parts of a PVC resin, 1-4 parts of a PVC stabilizer, 1-4 parts of a non-toxic plasticizer, 30-50 parts of a plasticizer, 0-6 parts of a liquid fire retardant, 0-10 parts of an anti-freezing agent, and 0.01-0.02 part of ultramarine toner, the materials are added into a high-speed mixer to be fully mixed, the well mixed materials are conveyed to a planet machine to be pre-plasticized, then the pre-plasticized materials are conveyed to a filter to be repeatedly plasticated, filtered and plasticized, and then conveyed to a calendar for calendaring, the calendared PVC film is cooled in a water tank and unoiled to obtain the PVC film having the advantages of high glossiness, high transparency, excellent thermal endurance and chemical stability and strong tensile strength.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

Special N-phthalate reinforced soft polyethylene plastics for circulation loop and preparation method thereof

The invention discloses special N-phthalate reinforced soft polyethylene plastics for a circulation loop, which comprises the following ingredients by weight parts: 100 weight parts of PVC resin powder, 20 to 50 weight parts of N-phthalate plasticizers, 5 to 35 weight parts of auxiliary stabilizing agents, 0.5 to 5.0 weight parts of stabilizing agents, 0.1 to 2.0 weight parts of lubricating agents and 0.1 to 1.0 weight part of antioxidants. The invention also discloses a preparation method of the special N-phthalate reinforced soft polyethylene plastics for the circulation loop. The method comprises the following steps: carrying out high-speed mixing on ingredients; using a double-screw extruding machine for plastification; and using a single screw for cooling and forming to obtain rubber grains. The recipe of the invention is suitable for the manufacture of the circulation loop, particularly the varieties with high processing precision and long operation time and the varieties needing ray sterilization.

Owner:YANGZHOU KAIER CHEM

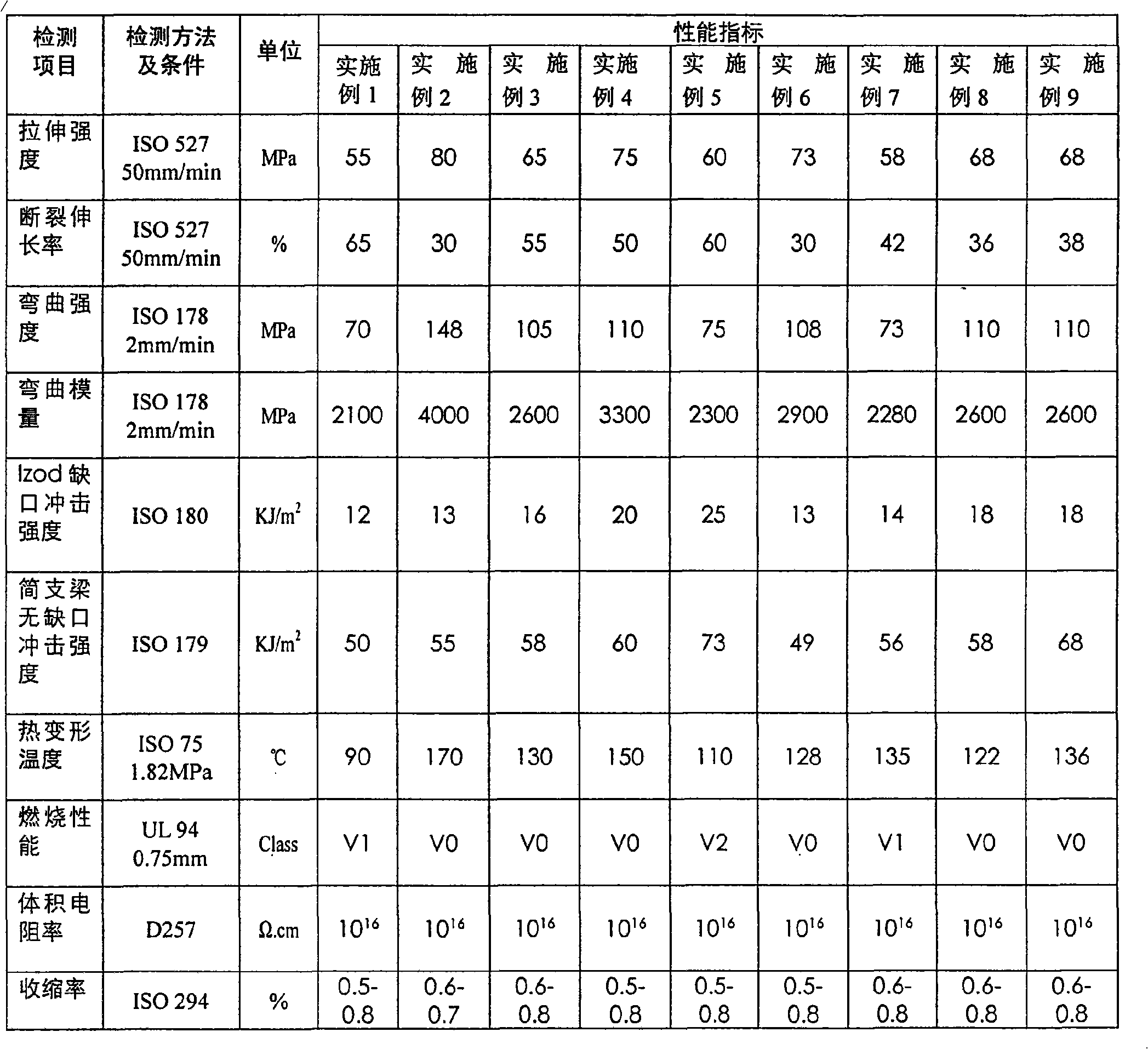

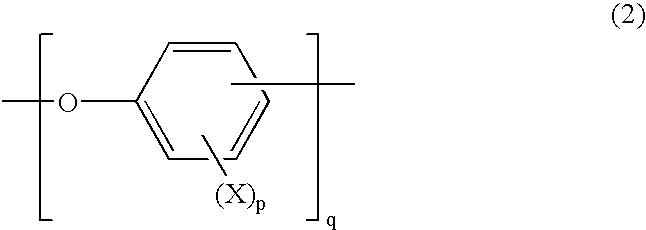

High-heat resistance halogen-free fire-retarding polyphenylether and polystyrene composite and preparation method thereof

The invention discloses a high-heat resistance halogen-free fire-retarding polyphenylether and polystyrene composite and a preparation method thereof. The composite comprises polyphenylene oxide resin, polystyreneresin, toughener, processing aid and a halogen-free fire retarding agent, wherein the halogen-free fire retarding agent is microencapsulated coated red phosphor and is used in combination with one or more of organic phosphates or phosphite esters in a separate charging mode. The components are subjected to melt blending as well as plasticization and blending in a double screw extruder to form the composite material of the invention. The method is continuous in processing process and high in production efficiency. The composite material of the invention can radically solve the problems of the prior fire retarding art such as halogen content of the fire retarding agent, easy precipitation, low fire retarding level and the like. Products made from the composite material are high in heat resistance, smooth in surface, environmentally-friendly, free from any halogen substance and applicable in the fields of electronic appliances, office equipment, fluid engineering and the like.

Owner:NANJING JULONG SCI&TECH CO LTD

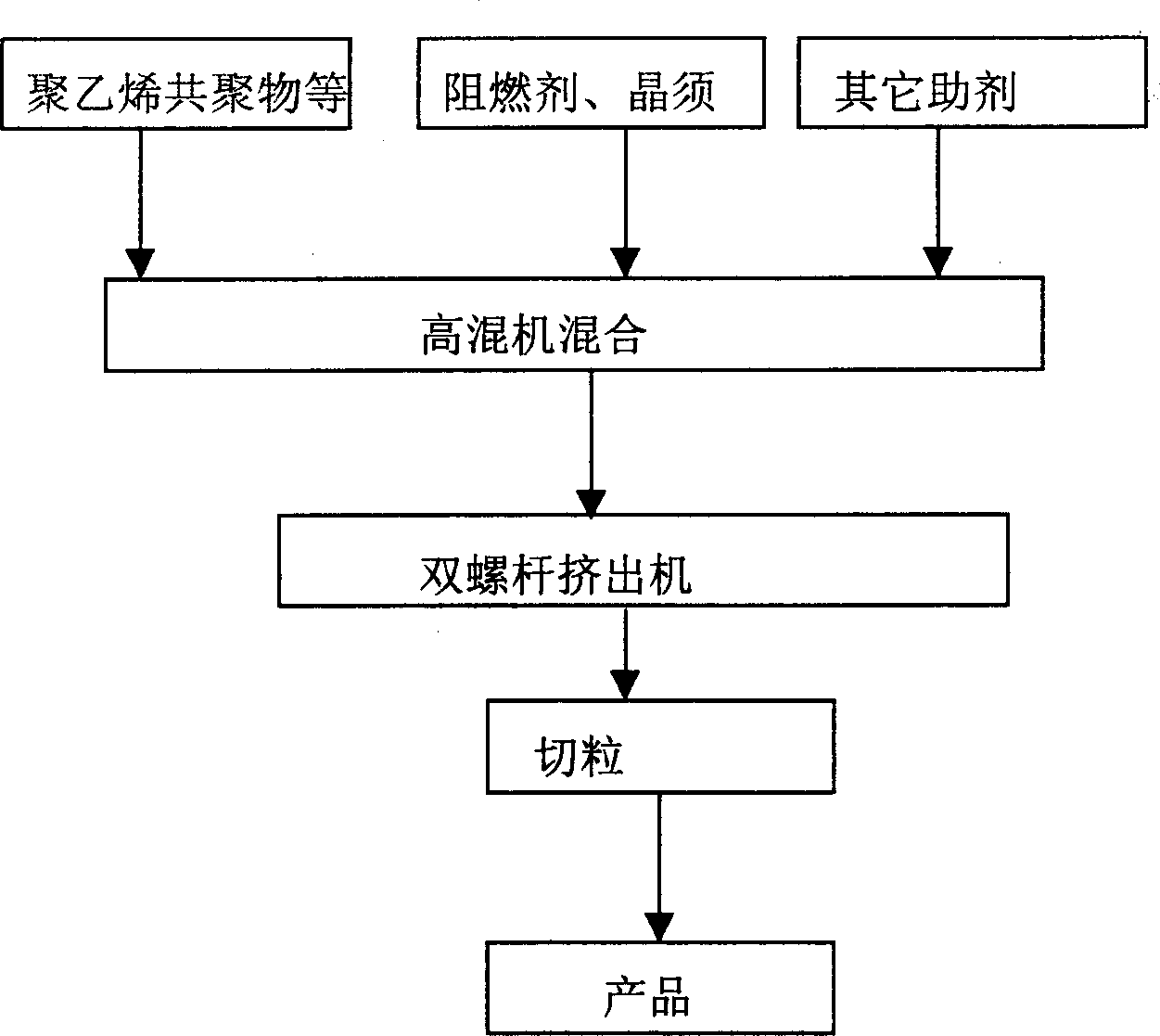

Thermoplastic non-halogen low fume fire resistant cable isolation material and processing tech. thereof

InactiveCN1787120AGood mechanical propertiesExcellent processing performanceRubber insulatorsPlastic/resin/waxes insulatorsInorganic crystalsMagnesium

The invention relates to a formula design for a thermoplastic halogen-free low-smoke flame-retardant cable insulating material and the manufacturing process thereof, concretely, using polyethene copolymer and / or modified ethylene-propylene rubber as a substrate, adding in halogen-free and nontoxic flame-retardant agent (nano magnesium hydroxide or aluminum hydroxide) and inorganic crystal whisker strengthening material as primary components, and adding in proper assistant, proportioning, mixing, plasticizing and making grains to make the insulating material. Its technical characters: not containing halogen, P, Al and other heavy metals; having god mechanical property, machining property and superior flame retardancy and having excellent thermal deforming, thermal ageing and thermal shock properties. The made cables have high safety and reliability. It is applied to the cables operating at 70 deg.C-105 deg.C long time, such as ship cables, cables for nuclear power plants, power and control cables for high-rise buildings, etc.

Owner:大连圣迈化学有限公司

Method for preparing wood-plastic composite material

The invention relates to a method for preparing a wood-plastic composite material, which is characterized by comprising the following steps of: (1) pretreatment: pretreating wood fibers by using a chemical graft modifier to remove the polarity of the wood fibers; (2) high speed blending: performing high speed stirring and blending on polyvinyl chloride (PVC) resin, the pretreated wood fibers and aids for preplastification; (3) extrusion molding: feeding the pre-plasticized materials into an extruder, fully plasticizing the materials at proper temperature, extruding the plasticized materials into a moulding mould, and performing extrusion molding on the materials under the action of extrusion force; and (4) cooling and shaping: cooling and shaping the extruded blanks. The content of the wood fibers in the wood-plastic composite materials can be greatly improved, the bonding tightness of the wood fibers and the plastic is enhanced, the wood texture of the wood-plastic composite materials is enhanced, the production cost is reduced, and the wood-plastic composite material has good physical and mechanical properties.

Owner:福建弘景木塑科技股份有限公司

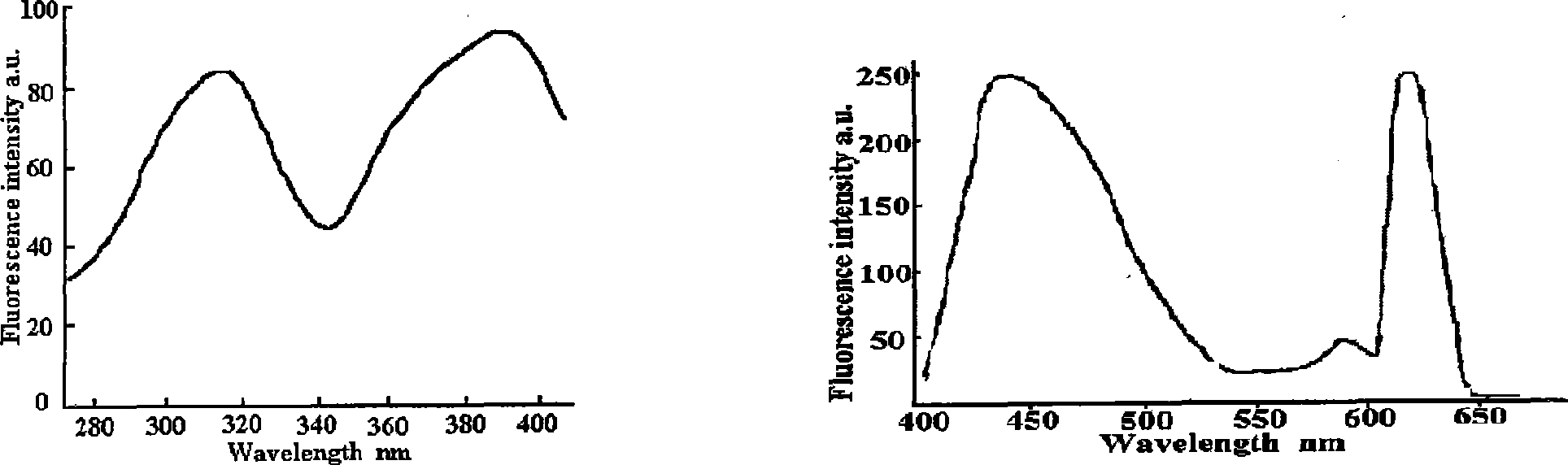

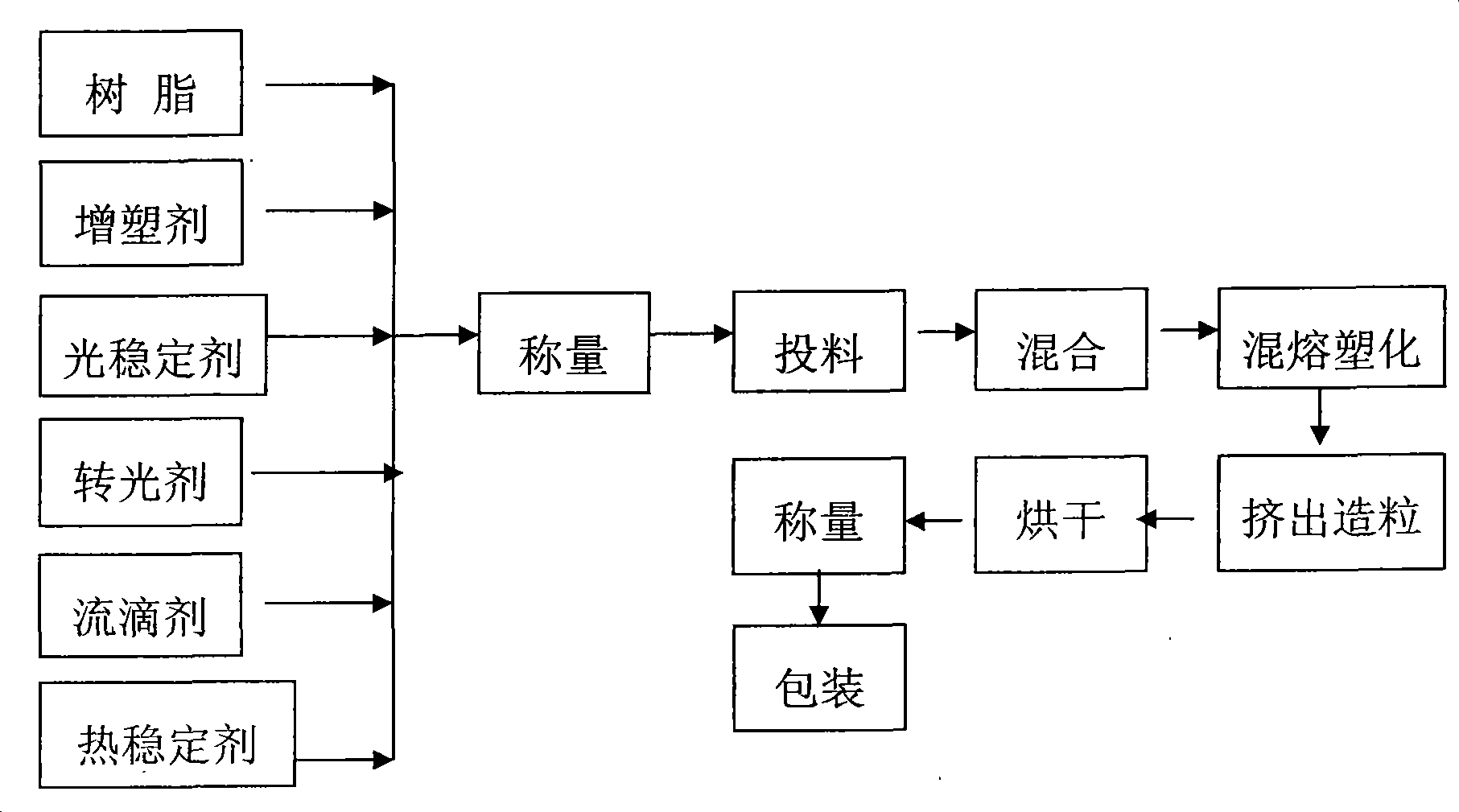

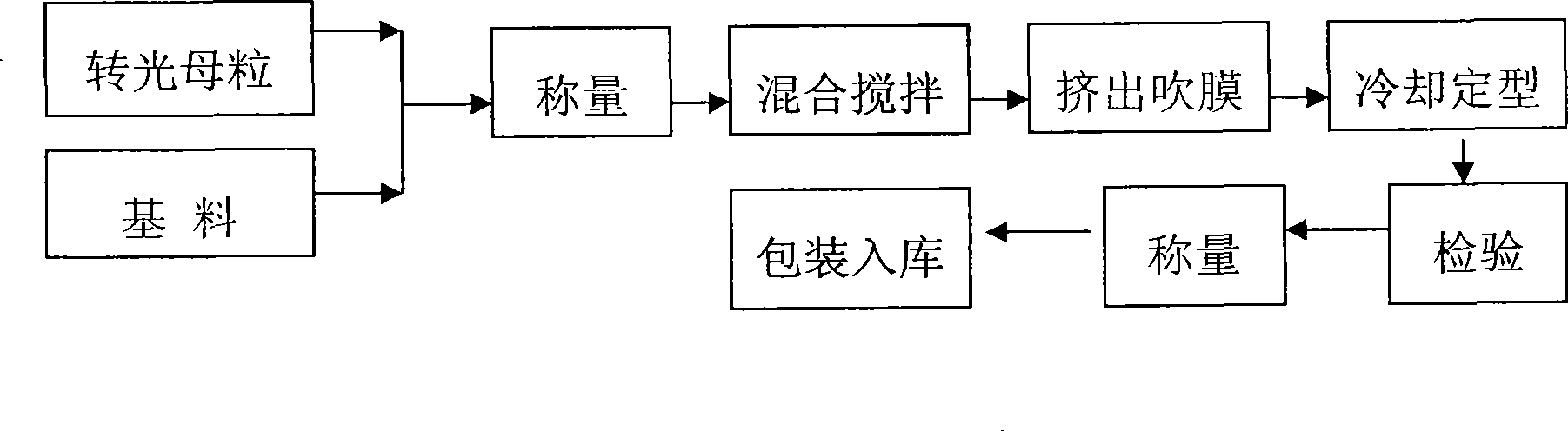

Novel ecology imitating two band optical energy conversion agricultural film and technique for producing the same

InactiveCN101434725ALong light lifeReduce manufacturing costClimate change adaptationGreenhouse cultivationEngineeringOptical energy

The invention discloses a novel imitative-ecological double-band light-energy conversion agricultural film and a production technology thereof. The light conversion film has long service life and good light conversation performance, a light conversion agent used has low production cost and amount and the mixing ratios of re-light conversion agent and the blue-light conversion agent can be regulated according to different types of plants so as to more effectively use the sun light. The production technology comprises the following steps: light stabilizer, thermal stabilizer, dripping agent, mixed light conversion agents and the like are weighed according to a respective ration against resin, are added into a plasticator, and stirred in a high speed with the stirring speed being controlled; the temperature is controlled till the resin taking the shape of plasticized state; the mixture is discharged and put into a granulation extruder for granulation; and then various types of resins and master batch are weighed accurately, according to the requirements of a technological formula, put into a stirrer for stirring and added into an extruder for extrusion, and coiling, coil stripping and packaging are carried out finally.

Owner:SHANDONG NORMAL UNIV

Special material for mining flame-retardant conveyer belt coating rubber and manufacturing method thereof

InactiveCN101348590AGood flame retardant and antistaticEnergy savingConveyorsEarth drilling and miningLubricationCarbon black

The invention discloses a special material for mine-used flame retardant conveyor belt covering glue and a making method thereof. The components in portion by content of the special material are: 30 to 50 portions of polyvinyl chloride resin, 10 to 30 portions of powdered butyronitrile rubber, 0.3 to 0.5 portions of carbon black, 10 to 30 portions of flame retardant system, 30 to 50 portions of plasticization system, 1 to 3 portions of lubrication system, 2 to 5 portions of stabilization system, 2 to 4 portions of antistatic system and 5 to 8 portions of crosslinking agents. The making process comprises the following steps that: (1) raw materials are weighed and then put into a high-speed mixing machine, the machine is turned on for high-speed mixing, the mixing temperature is controlled to be about 90 DEG C, the mixing time is not more than 15 minutes, and after uniform plasticization, a material discharge valve is opened to discharge material; (2) the raw materials well mixed are put into a material bucket of an extruder, then the preheated extruder is turned on, and the rotational speed is controlled to be between 60 and 80 rpm; and (3) after extrusion, the raw materials are air-cooled, granulated and air-conveyed, and then finished products are packaged. The special material for mine-used flame retardant conveyor belt covering glue is mainly applicable to adopt the extruder extrusion method to produce rubber-covering whole-core flame retardant conveyor belts, and is also applicable to a plate vulcanization method for producing the rubber-covering whole-core flame retardant conveyor belts. When the extrusion method is adopted to produce the rubber-covering whole-core flame retardant conveyor belts, the production process parameters are basically similar to that of whole-core flame retardant conveyor belts produced through an extrusion process (the temperature of the extruder and molds are slightly higher).

Owner:徐凤祥

Method for processing plastic floor material by utilizing PVC waste material

The invention relates to a method for processing plastic floor material by utilizing PVC waste material, including: (1) PVC waste material is cleaned, dried and smashed and is subject to extrusion filtering at 130-150 DEG C by virtue of an extrusion machine, so that impurities are removed, and plasticizer is added, so as to form membrane feed back; (2) PVC resin, plasticizer, stabilizer, foaming agent and filler are added into the membrane feed back, mixing is carried out to obtain mixture, the mixture is subject to banburying at 140-160 DEG C for 150-220s, then is subject to milling at 140-160 DEG C for 3min and then is subject to extrusion filtering at 140-160 DEG C by virtue of the extrusion machine, and the working speed of the extrusion machine is 300r / min, film is made by virtue of a calendaring machine, and film pressing temperature is 130-160 DEG C; (3) the film is compounded onto a surface course coated with wear layer at 170-190 DEG C, heating foaming plasticizing and drying are carried out at 200-220 DEG C by virtue of a baking oven, and then cooling, trimming and crimping are carried out, thus forming the product. The invention utilizes PVC waste material to produce film, the produced film substitutes the blade coating foaming layer in plastic floor production process, production cost is reduced, recycling of waste PVC material is realized, and plentiful natural resources are saved.

Owner:赵如勇

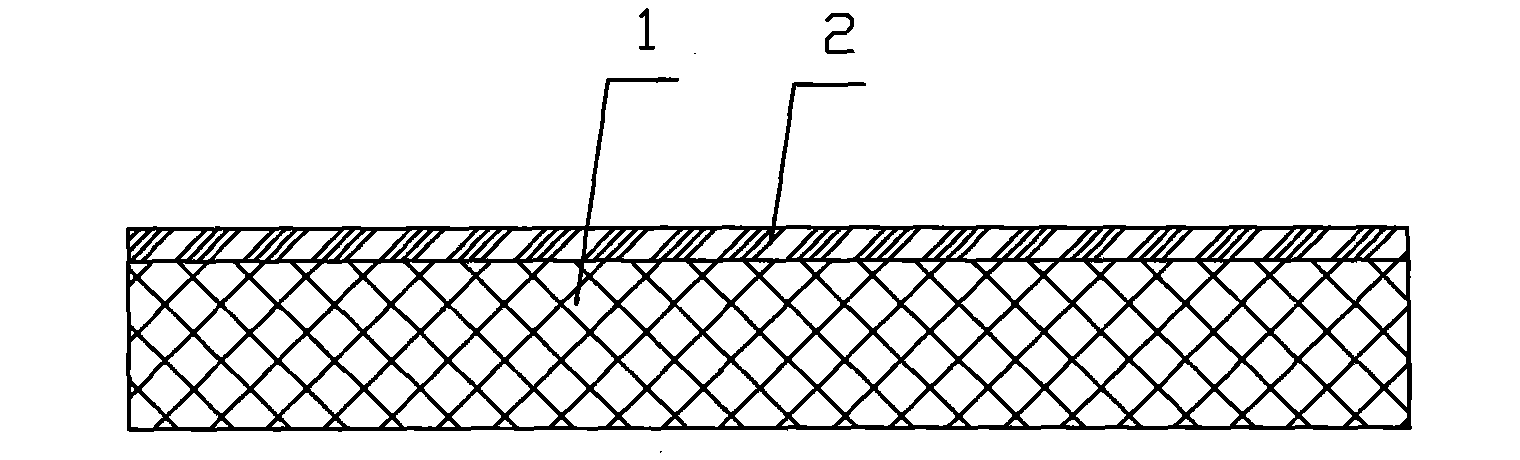

High-elasticity polyvinyl chloride synthetic leather and production method thereof

InactiveCN102002865AEasy to process in mass productionSynthetic resin layered productsLaminationFoaming agentPolyvinyl chloride

The invention relates to a high-elasticity polyvinyl chloride (PVC) synthetic leather and a production method thereof. The synthetic leather is combined by three layers, wherein the base material is cloth, the middle layer is made from foaming PVC, and the upper layer is made from non-foaming PVC. The middle layer comprises the following components in parts by weight: 60-80 parts of PVC1, 20-40 parts of PVC2, 65-90 parts of DOP, 80-120 parts of calcium carbonate, 2-3.5 parts of foaming stabilizer, 5-9 parts of AC foaming agent and 4-6 parts of pigment. The upper layer comprises the following components in parts by weight: 60-80 parts of PVC1, 20-40 parts of PVC2, 65-90 parts of DOP, 10-20 parts of calcium carbonate, 2-3.5 parts of stabilizer and 6-8 parts of pigment, wherein the PVC1 and PVC2 are PVCs with different polymerization degrees, the type of the PVC1 is S-70 and the type of the PVC2 is HS-200. The production method of the synthetic leather comprises the following steps: mixing the raw materials, plasticizing, performing open mixing, laminating, foaming, and treating to obtain the finished product. Each technical index of the finished product meets the requirement of the relevant regulation and is characterized by having the similar hand feeling of the real feather. The synthetic leather of the invention is beneficial for the product promotion and suitable for large scale production and processing.

Owner:JIEYANG CITY ZONCEN CHEM INDAL

Preparation method of high-content superfine inorganic powder master batch for filling plastic

The invention discloses a preparation method of high-content superfine inorganic powder master batch for filling plastic. The invention is characterized in that in the preparation method, metering feed is used, a twin-screw extruder with two side feeds is used for plasticizing extrusion, hot cutting wind cold is adopted for pelleting, and then superfine inorganic powder master batch is obtained; the master batch formula comprises the following components by weight percent: 75-90wt% of inorganic superfine powder, 2-12wt% of additive and 8-20wt% of carrier. By using the preparation method in the invention, the problems that in the process of preparing the high-content superfine inorganic powder filling master batch, the superfine powder is difficult to feed and uneven to disperse, pollutes environment and the like are solved. The master batch has the advantages of good dispersion effect and excellent product performance when being used in enhancing modification of plastic.

Owner:SHANGHAI UNIV

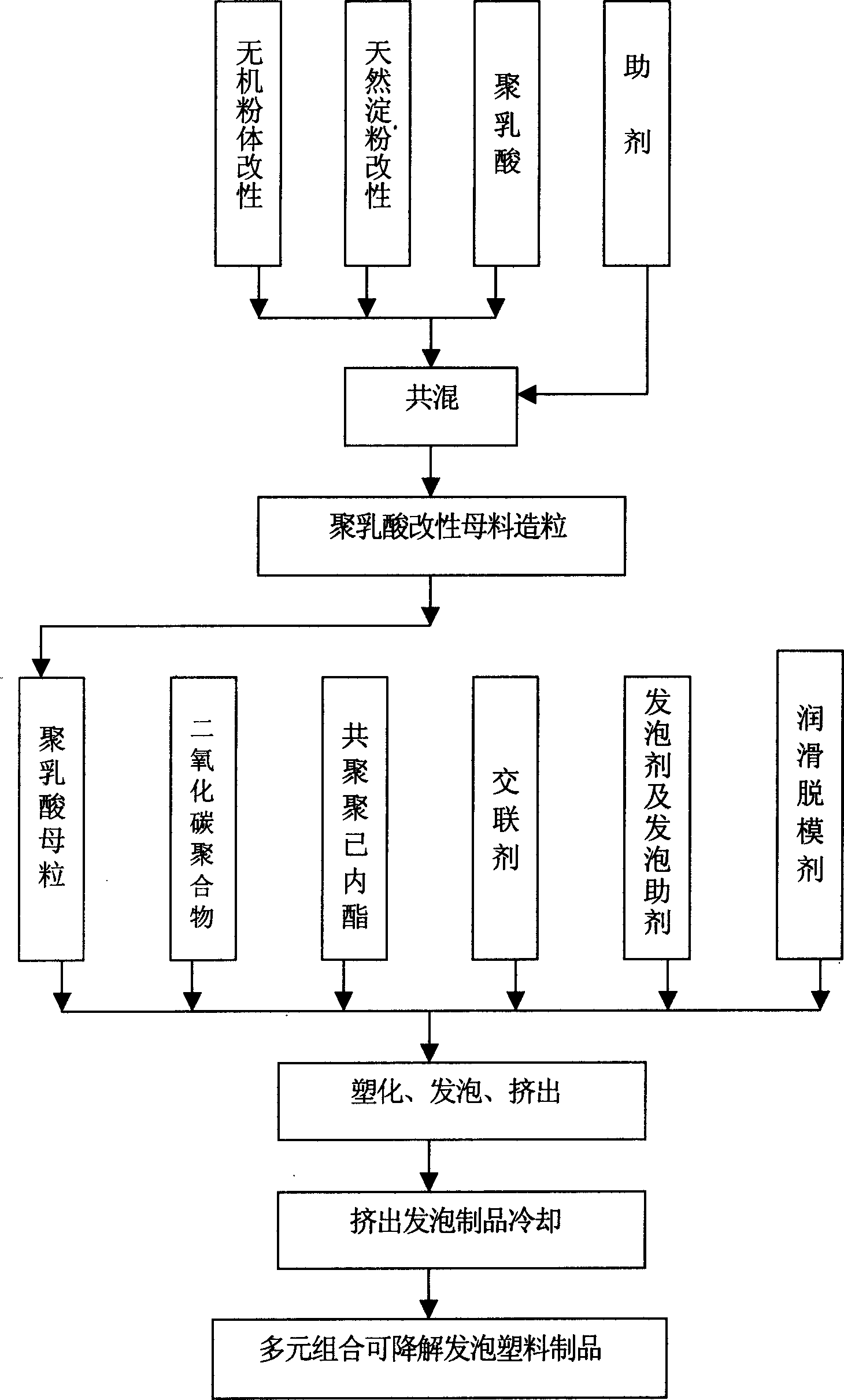

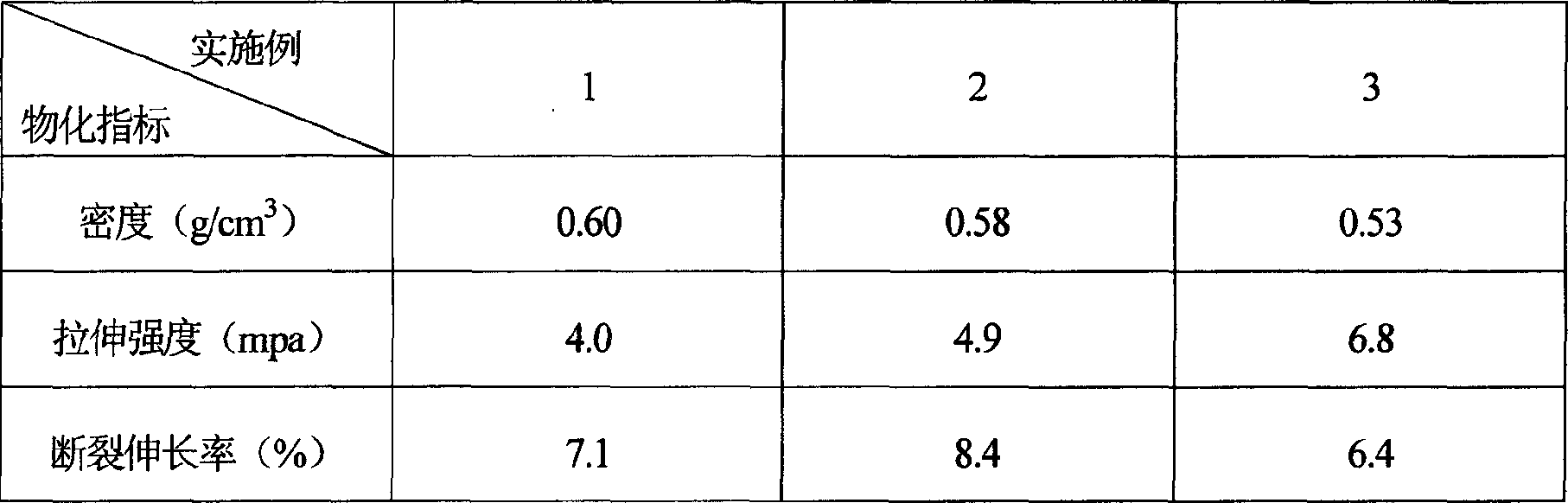

Polycomponent combined degradable foamed plastic and its preparation method

InactiveCN1786072AImprove the level of environmental protectionImprove the value-added ability of conversionPolymer scienceFoaming agent

The present invention relates to a multicomponent combined degradable foamed plastic material and its preparation method. Its composition includes (by weight portion) 70-100 portions of modified polylactic acid mother granules, 1-20 portions of carbon dioxide resin and / or fatty polycaprolactone, 0.5-1.5 portions of lubricant demoulding agent, 1-5 portions of foaming agent and foaming adjuvant and 1-5 portions of cross-linking agent. Its preparation method includes the following steps: (1). inorganic powder body modification; (2). starch modification; (3). polylactic acid modification; and (4). plasticization foaming so as to obtain the degradable foamed plastic sheet material.

Owner:朱家牧

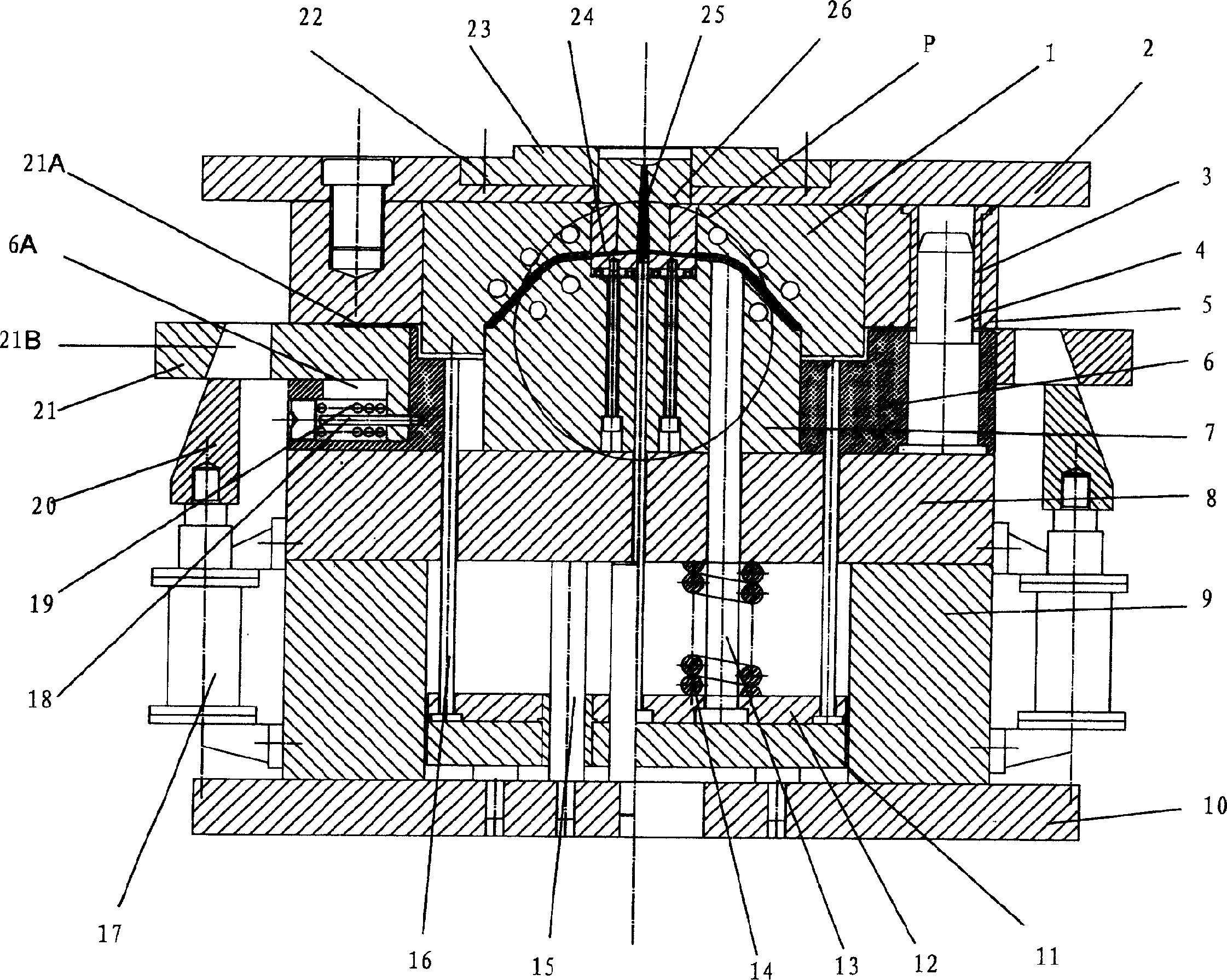

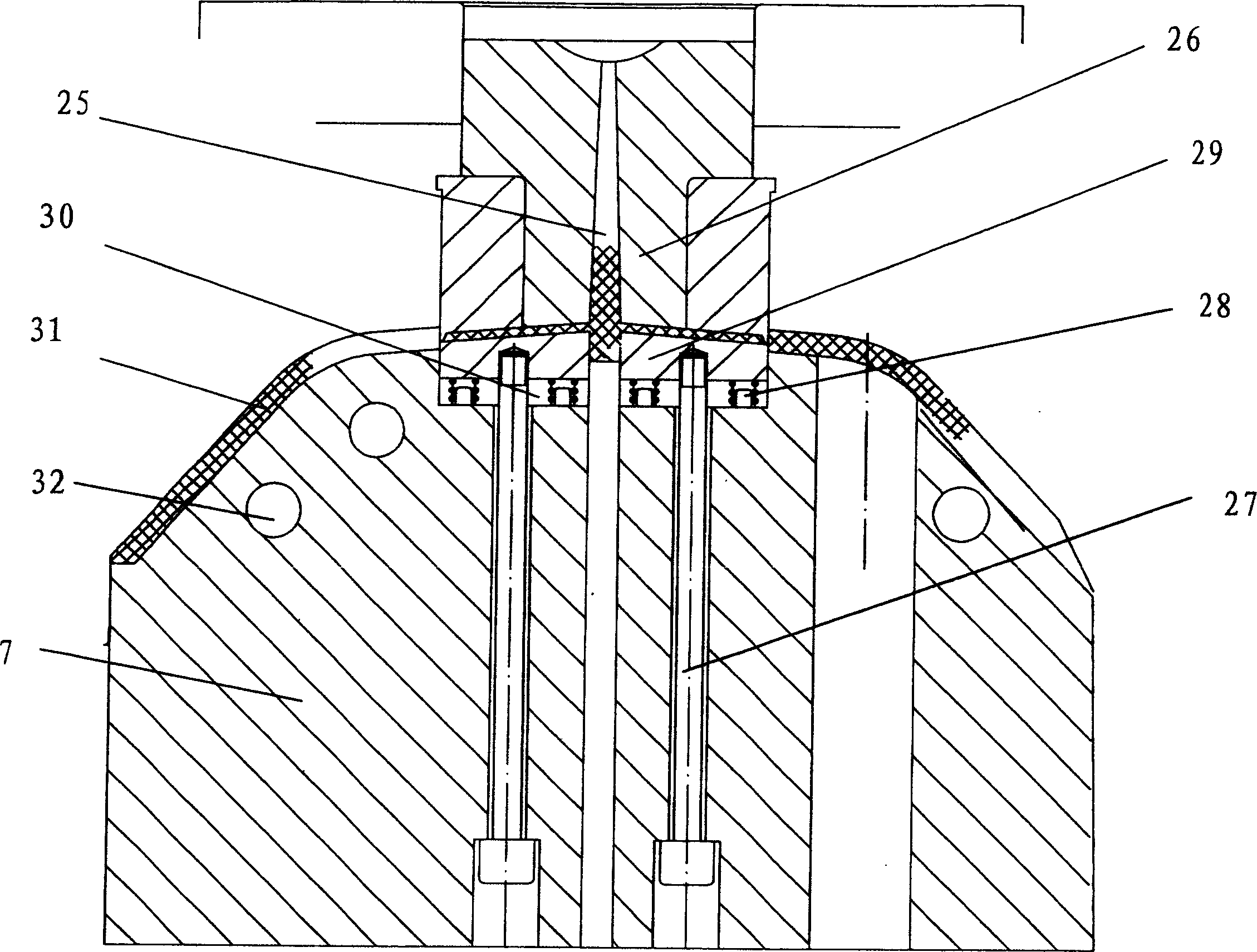

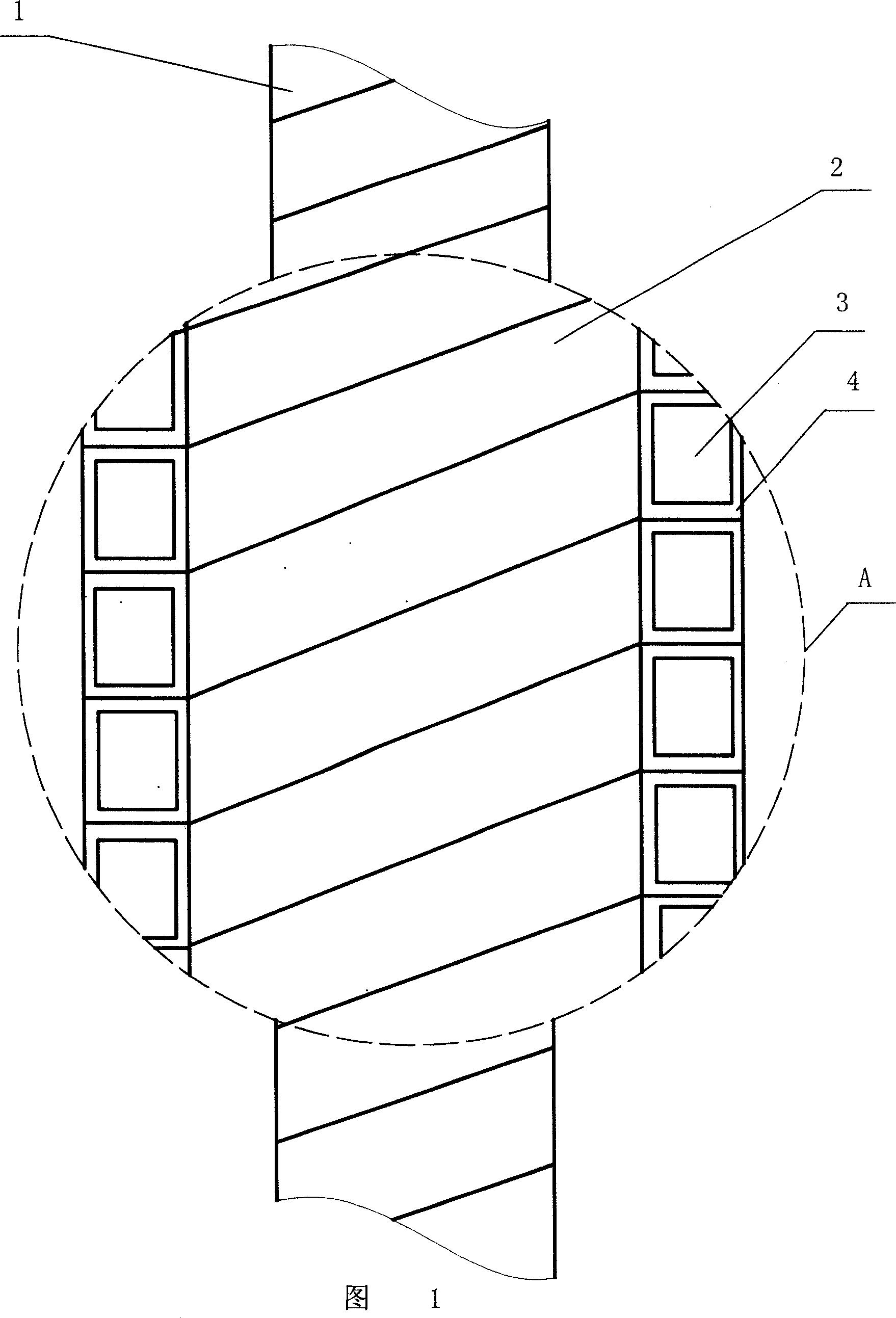

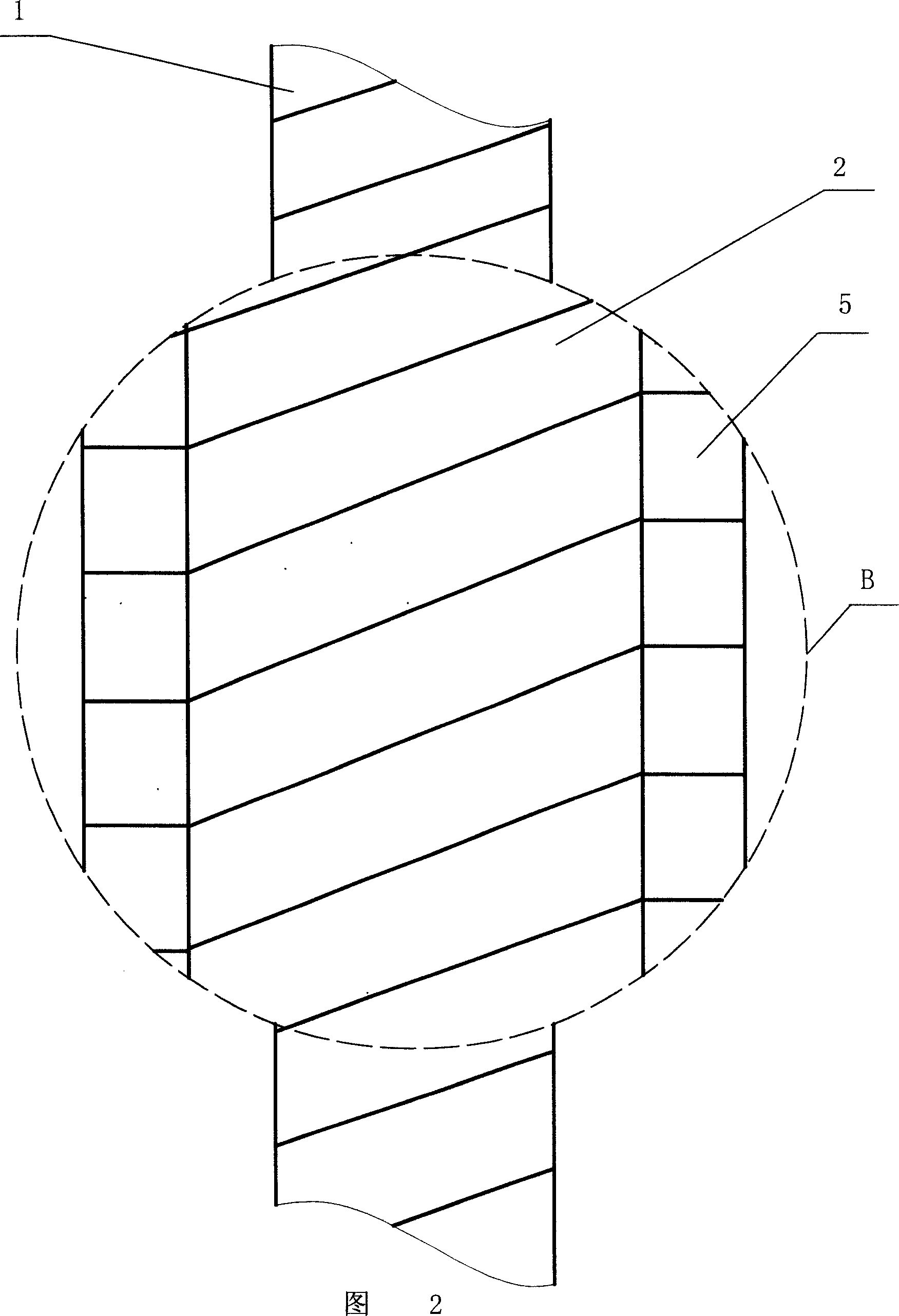

Plastic injection-pressing compound forming process and its mould

The compound plastic injection-pressing formation process includes heating to plasticize, the first mold clamping, injecting molten plastic into the closed mold cavity, heating and maintaining, the second mold clamping, cooling to set inside the mold cavity and demolding. The mold includes female mold, male mold, mold clamping guide mechanism and two stages of mold closing and opening mechanism. The present invention has improved production environment and high production efficiency, can produce precise large plastic part with complicated shape, is favorable to the production with plastic with poor flowability and great viscosity.

Owner:GUANGDONG UNIV OF TECH

Heavy caliber high-strength plastic wound pipe having pipe wall made of wrapping material and manufacture method therefor

The invention relates to a method for producing big high strength plastic coil tube which uses coil material to form tube wall, wherein the coil material is a composite plastic section bar formed by an inner core and an outer layer, which is alternatively or irregularly arranged, and nearby side walls are fused to connected or adhered by fused material, to be screwed to form tube wall. The coil material is drawn to direct the molecule longitudinally. The outer layer is thermal plastic, while the inner corn is strength material and / or flameproof material and / or static resistance composed in plastic base material. The fusing connecting material is plastic polymer or added with strength material and / or flameproof material and / or static resistance, to form plastic fused material. The strength material is distributed in the coil material and / or fusing connecting material, directionally distributed along the screw of high-strength coil tube. The invention has high strength, flameproof property and static resistance.

Owner:淄博寿山特种塑料有限公司

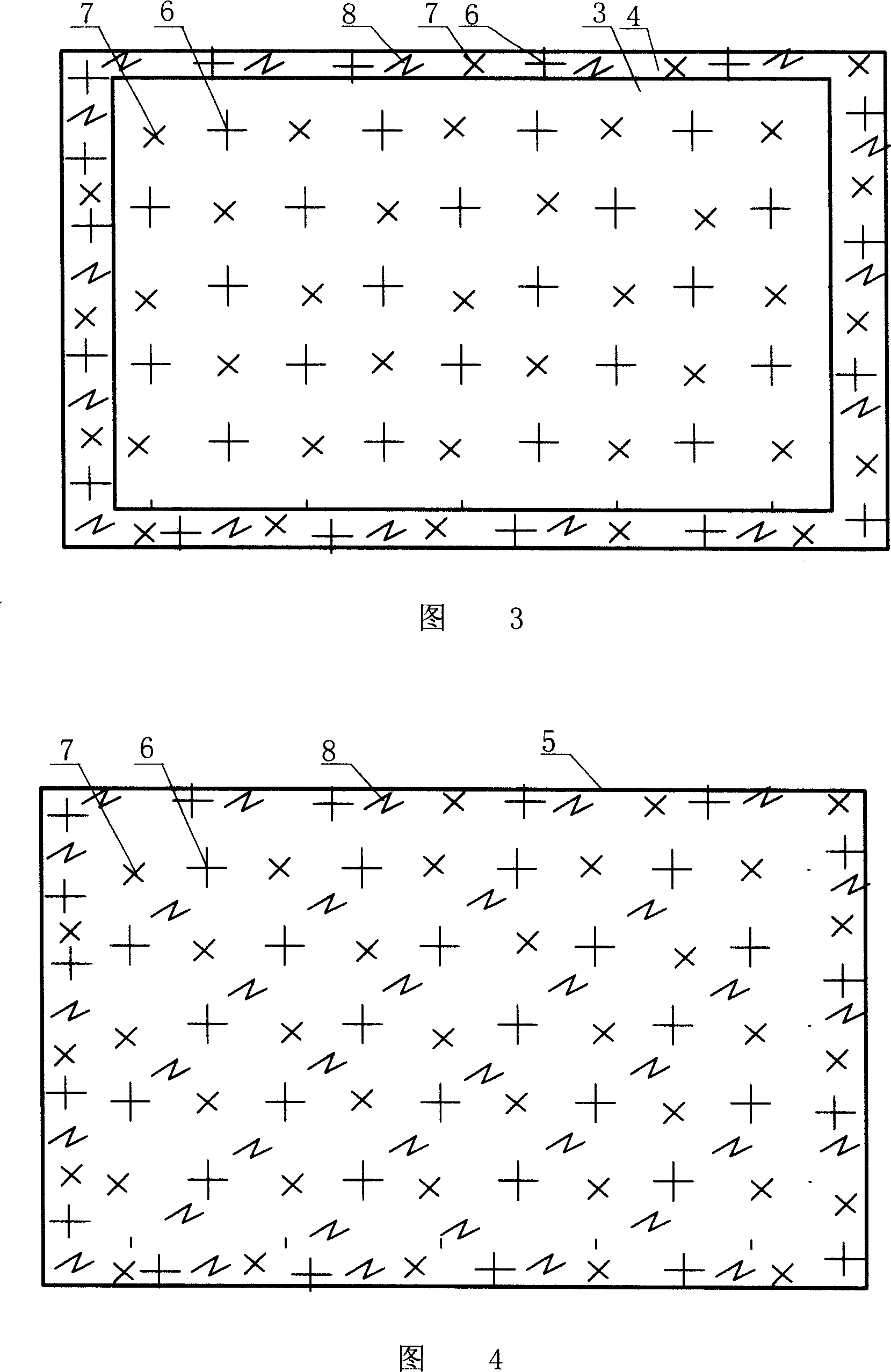

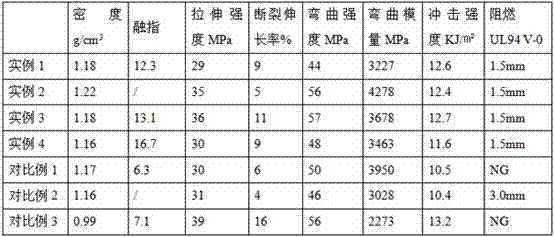

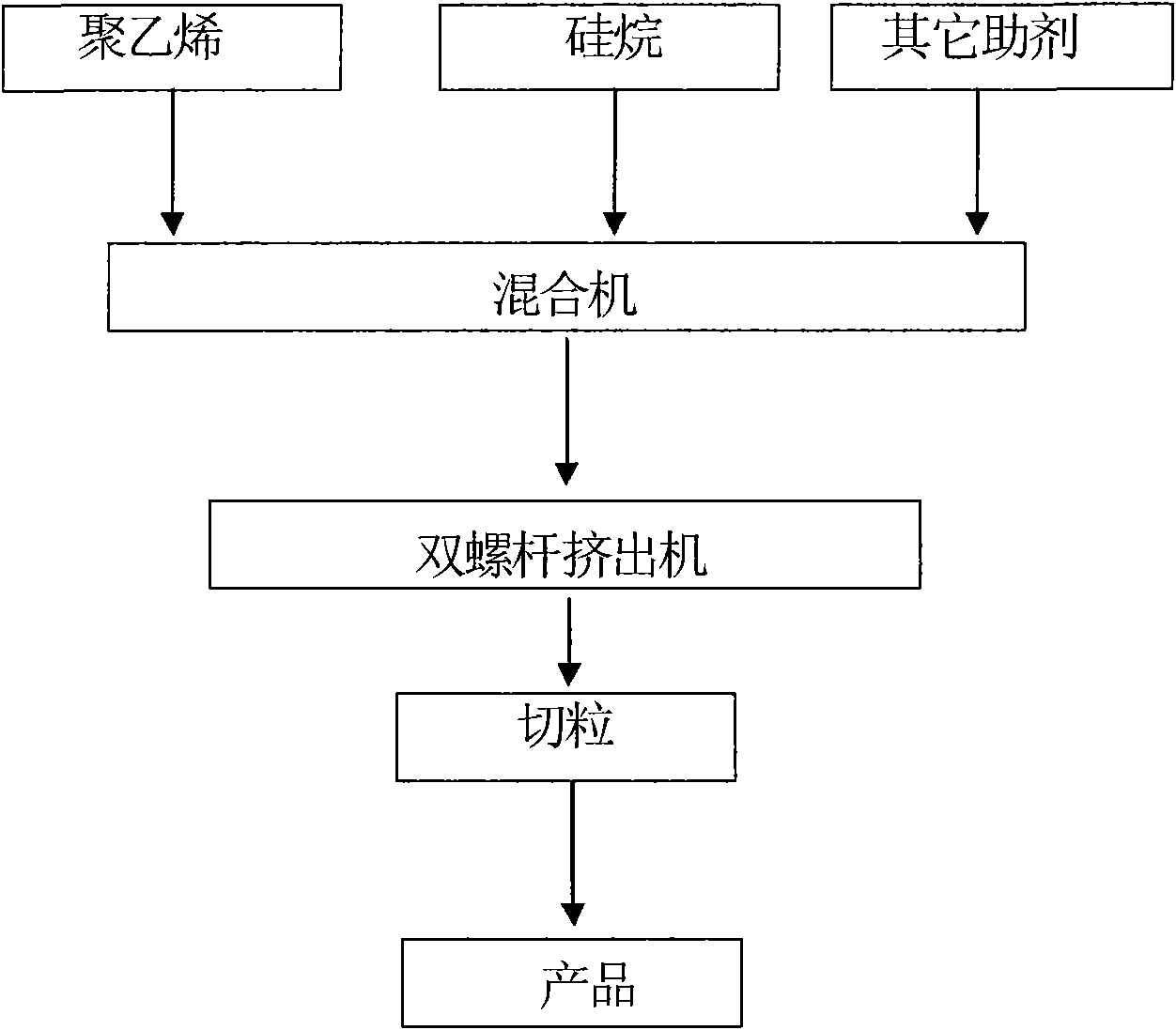

Halogen-free flame retardant wood-plastic composite material and preparation method thereof

ActiveCN104497607AImprove mechanical propertiesImprove flame retardant performancePlasticultureAntioxidant

The invention discloses a halogen-free flame retardant wood-plastic composite material which is prepared from the following raw materials: a natural fiber, plastic, a fire retardant, a compatilizer, an antioxidant, a lubricant and a coupling reagent. The preparation method comprises the following steps: drying the natural fiber in advance; mixing the dried natural fiber with the coupling agent evenly, and placing for 3-10 minutes; fully mixing the mixture with the fire retardant, the plastic, the compatilizer, the lubricant and the antioxidant; and extruding, plastifying, dicing, and carrying out injection molding. The wood-plastic composite material disclosed by the invention does not contain halogen; the composite fire retardant is introduced into a formula system, and works together with other components, so that high flame retardant property can be achieved; specifically, the 1.5mm UL94 V-0 flame retardant level can be achieved; LOI is over 30; and the formula system disclosed by the invention contains the composite fire retardant, but the mechanical property of the composite material is relatively good.

Owner:PRESAFER QINGYUAN PHOSPHOR CHEM

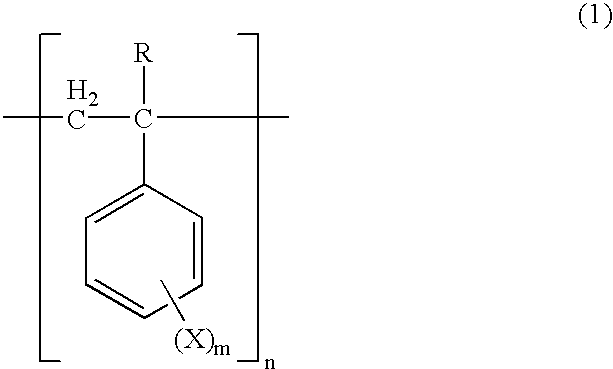

Composition of single-component silane natural cross-linking polyethylene materials and processing process thereof

ActiveCN101838410ANo pre-crosslinking phenomenonEasy to usePlastic/resin/waxes insulatorsCross-linkPolymer science

The invention relates to the field of application of silane natural cross-linking polyethylene materials, in particular to a composition of single-component silane natural cross-linking polyethylene materials and a processing process thereof. The composition comprises polyethylene resin, silane cross-linking agents, antioxidizers, initiators and catalyst mixtures. The processing process comprises the following steps: using the polyethylene resin as base materials; adding the silane cross-linking agents, and adding proper antioxidizers, initiators and catalyst mixtures to be mixed and stirred; and adopting a double-screw extruding machine for fused plasticized mixed filtering granulation for preparing the silane natural cross-linking polyethylene materials. The invention adopts a one-step method granulation process, the polyethylene rein is made into products through the fused plasticized mixed filtering granulation via the screw extruding machine under the effect of the silane cross-linking agents, antioxidizers, initiators and catalyst mixtures, the products are single-component materials, and materials A and materials B are not needed to be distinguished. The materials have good flowability, high extrusion speed and long storage time, no pre-cross-linking phenomenon occurs in the technical processing process, the technical temperature range is wide, the use is convenient, and the invention is applicable to industries such as electric wires and cables, plastic products and the like.

Owner:上海永进电缆(集团)有限公司

Polyamide resin pellet for a miniature part

InactiveUS20020115818A1Low water absorptionSmooth effectWorking-up pitch/asphalt/bitumen by chemical meansSynthetic resin layered productsShell moldingHeat resistance

A polyamide resin pellet for a miniature part, comprising a polyamide resin (A) whose melting point as measured by DSC is in the range of 280 to below 330° C., which has an average volume of 0.001 to 21 mm3, the average volume determined by randomly sampling 50 pellets, measuring the weight and specific gravity of each of the pellets and dividing the weight by the specific gravity. The polyamide resin pellet exhibits low water absorption and is excellent in moldability, mechanical strength characteristics and heat resistance. Further, it has specified average volume, configuration, average diameter and average length, so that, in an injection molding, plasticization is smoothly effected to thereby enable obtaining a molded item or article which exhibits low dispersion of weight and strength and has excellent hue. The polyamide resin pellet is especially suitable for use in a molding material for forming miniature parts for motor vehicles and electrical or electronic equipments.

Owner:MITSUI CHEM INC

Resource-conserving type gray plastic foaming polymer composite material and preparation method thereof

The invention belongs to the field of building materials, and particularly relates to a resource-conserving type gray plastic foaming polymer composite material. The invention also relates to a preparation method of the composite material. The invention has the technical scheme that the resource-conserving type gray plastic foaming polymer composite material comprises thermoplastic plastic polyvinyl chloride (PVC), filler coal ash, an auxiliary heat stabilizer, a coupling agent, a compound stabilizer, an inside and outside lubricating agent, a plasticizing accelerating agent, a general foaming agent and a foaming regulator. The resource-conserving type gray plastic foaming polymer composite material can be used for utilizing the coal ash with a high added-value in a reclamation way, thus not only saving a great deal of calcium carbonate and timber resources, but also reducing environmental pollution and protecting the human health.

Owner:赵芳

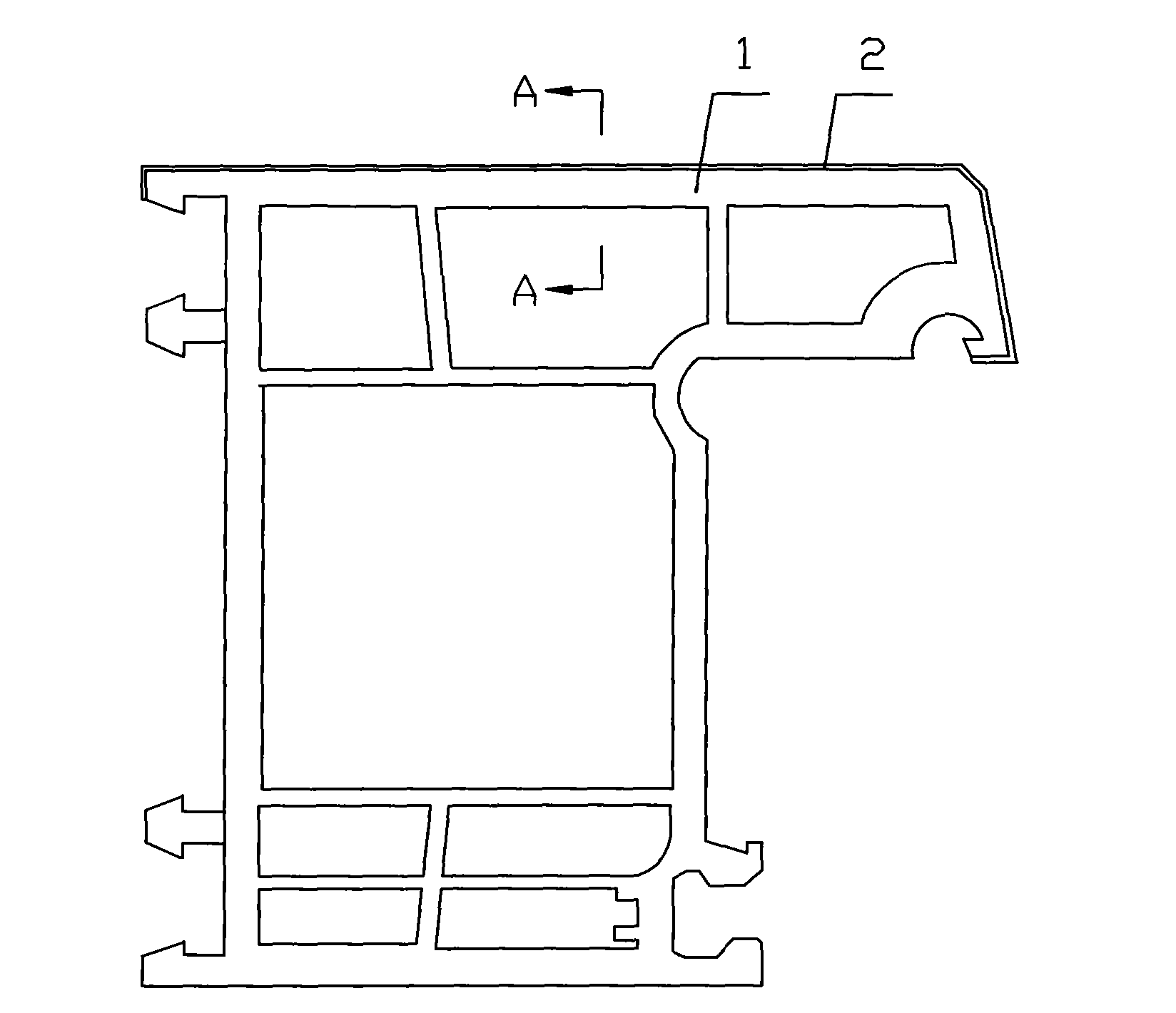

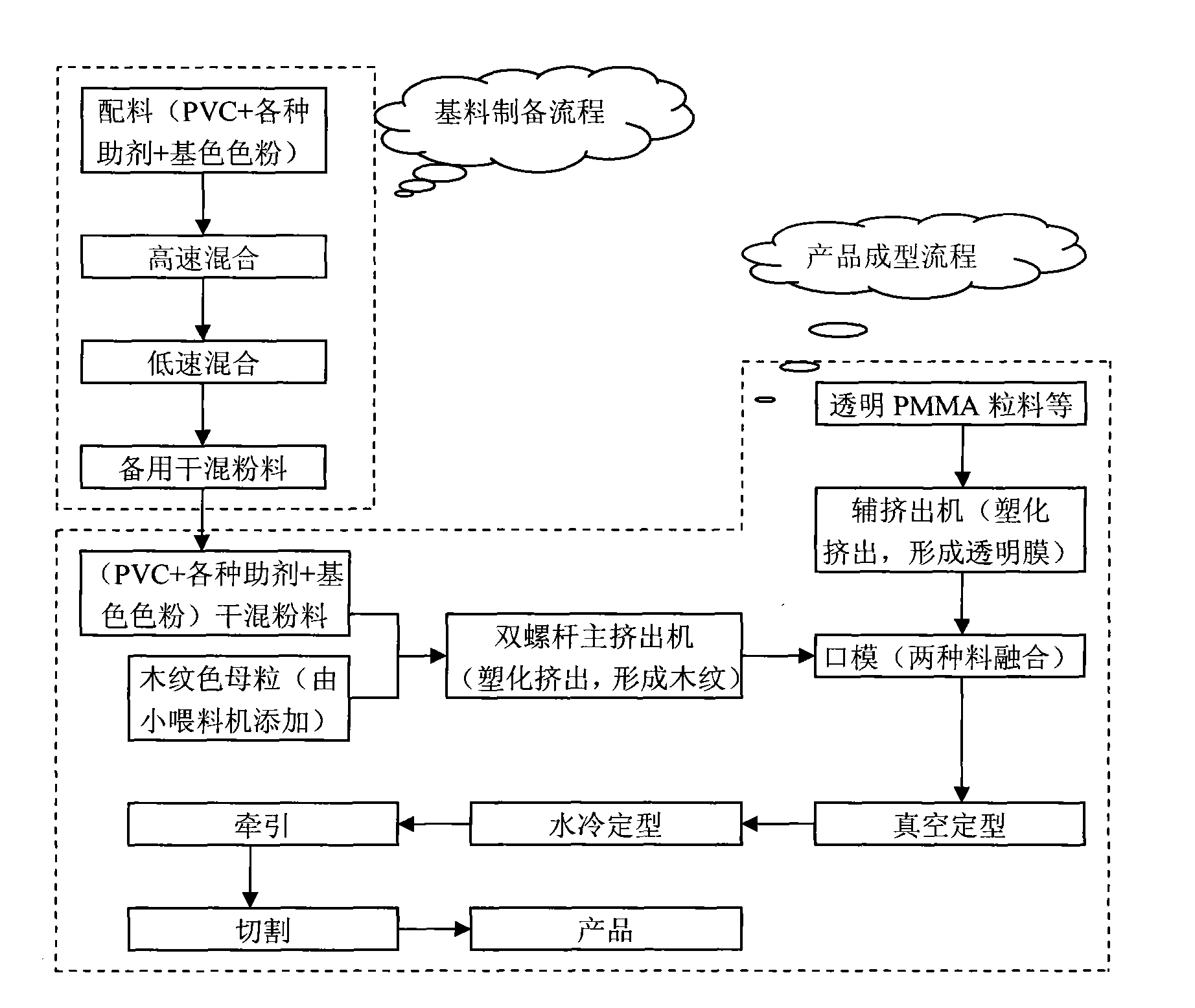

Weather resistant wood-grain imitating PVC plastic profiled bar and method for manufacturing same

InactiveCN101492987ASimple moldingNo separationSynthetic resin layered productsWing framesWeather resistanceEngineering

The invention relates to PVC plastic profiled material, in particular to a weather-resistant colored PVC plastic profiled material and a manufacturing method thereof. The weather-resistant wood-grain-like PVC plastic profiled material comprises PVC profiled material the entire body of which is colored by imitation wood grain. A transparent material layer with high weather resistance is compounded on the outer surface of the PVC profiled material by co-extrusion. The transparent material layer with high weather resistance has transparent optical effect and is suitable for plasticizing extrusion. The transparent material layer with high weather resistance is preferably PMMA or ASA. The invention also provides the manufacturing method for the PVC plastic profiled material. The PVC plastic profiled material in the invention is characterized by long-term preservation of color and pattern and mature manufacturing technique.

Owner:HUAZHIJIE PLASTIC BUILDING MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com