Polycomponent combined degradable foamed plastic and its preparation method

A foamed plastic and multi-component technology, applied in the field of foamed plastics and its preparation, can solve problems such as poor thermal stability, difficult molding, and high cost performance of foamed plastics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

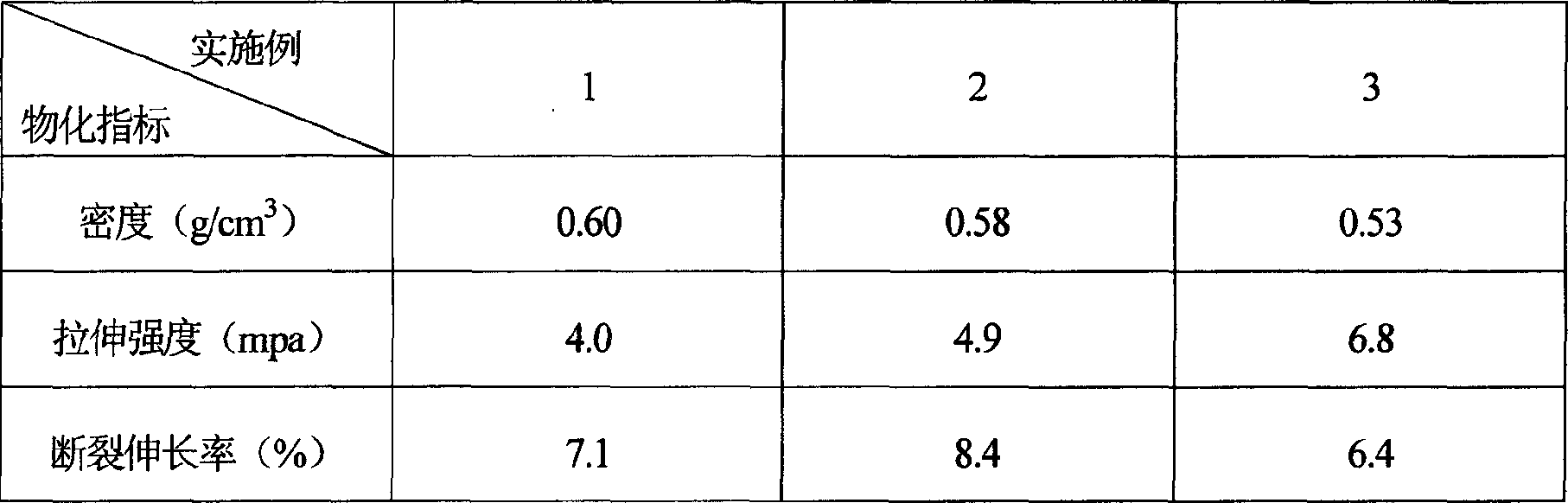

Examples

specific Embodiment approach 1

[0012] Specific embodiment 1: The multi-component degradable foamed plastic of this embodiment is composed of the following components according to the weight ratio: modified polylactic acid masterbatch 70~100, carbon dioxide resin and / or aliphatic polycaprolactone 1~ 20. Lubricating release agent 0.5-1.5, foaming agent and foaming aid 1-5, cross-linking agent 1-5.

[0013] The modified polylactic acid masterbatch in this embodiment is composed of the following components in parts by weight: polylactic acid 60-100, modified inorganic powder 5-40, modified starch 5-20, and flexibilizer 5-10 .

[0014] In this embodiment, the crosslinking agent is one or more mixtures of dicumyl peroxide, di-tert-butyl peroxide, borax, and formaldehyde; the flexibilizer is aliphatic aromatic copolyester or naphthenic oil The foaming agent is one or more mixtures of azodicarbonamide, azoaminobenzene, p-toluenesulfonyl hydrazide, p-toluenesulfonylsemicarbazide, and azobisisobutyronitrile; the foa...

specific Embodiment approach 2

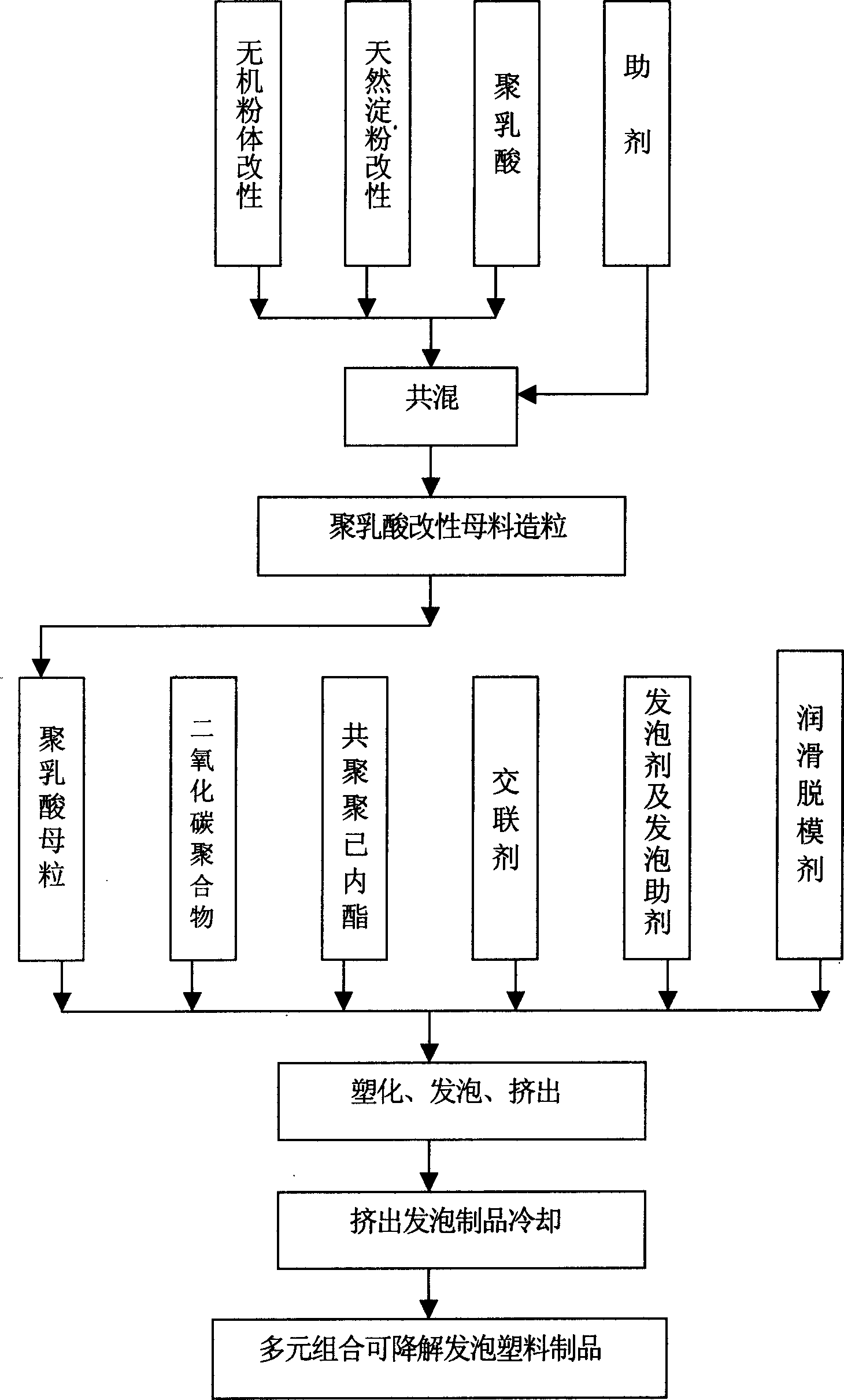

[0015] Specific implementation mode two: as figure 1 As shown, the steps of the preparation method of the multi-combination degradable foamed plastic in this embodiment are as follows:

[0016] 1. Inorganic powder modification:

[0017] Due to the poor compatibility between inorganic powder materials and plastics, they are easy to agglomerate and disperse unevenly in the product, which affects the quality of the product. Therefore, it is necessary to carry out surface modification treatment on the inorganic mineral powder in the multi-component combination. The purpose of modification is to solve the compatibility with other components, dispersibility and processability. Grind the inorganic powder to fineness ≥ 300 mesh, heat to 80-120°C, stir-fry for 10-20 minutes while heating, fully dehumidify, then add 0.1-2wt.% modifier, continue to heat and stir-fry for 10-20 minutes After 20 minutes, mix well, cool it out of the pot, pack it into a bag and keep it moisture-proof for l...

specific Embodiment approach 3

[0025] Specific embodiment three: The steps of the preparation method of the multi-component degradable foamed plastic in this embodiment are as follows:

[0026] 1. Inorganic powder modification:

[0027] CaCO 3 , Montmorillonite, TiO 2 Grind to fineness > 300 mesh, heat to 120°C, stir fry for 10-20 minutes while heating, fully dehumidify, then add 0.5wt.% GO-2, 0.2wt.% silane coupling agent, continue heating and stirring Stir-fry for 20 minutes, mix well, cool out of the pan, and store in bags to prevent moisture for later use.

[0028] 2. Starch modification:

[0029] Get starch by weight and number ratio: 93.6%, n-butyltin: 1%, lactic acid: 10%, potassium persulfate and sodium sulfite (molar ratio is 2: 1): 0.2%, dicumyl peroxide: 0.2%, Sorbitol: 1%, tri-n-butyl citrate: 1%, glycerin: 2%, after blending, place in a mixer with a heating device, control the temperature at 60-120°C and mix for 10-20 minutes to remove moisture , and then add 0.5 parts by weight of GO-2, h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com