Patents

Literature

537results about "Dust arresters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

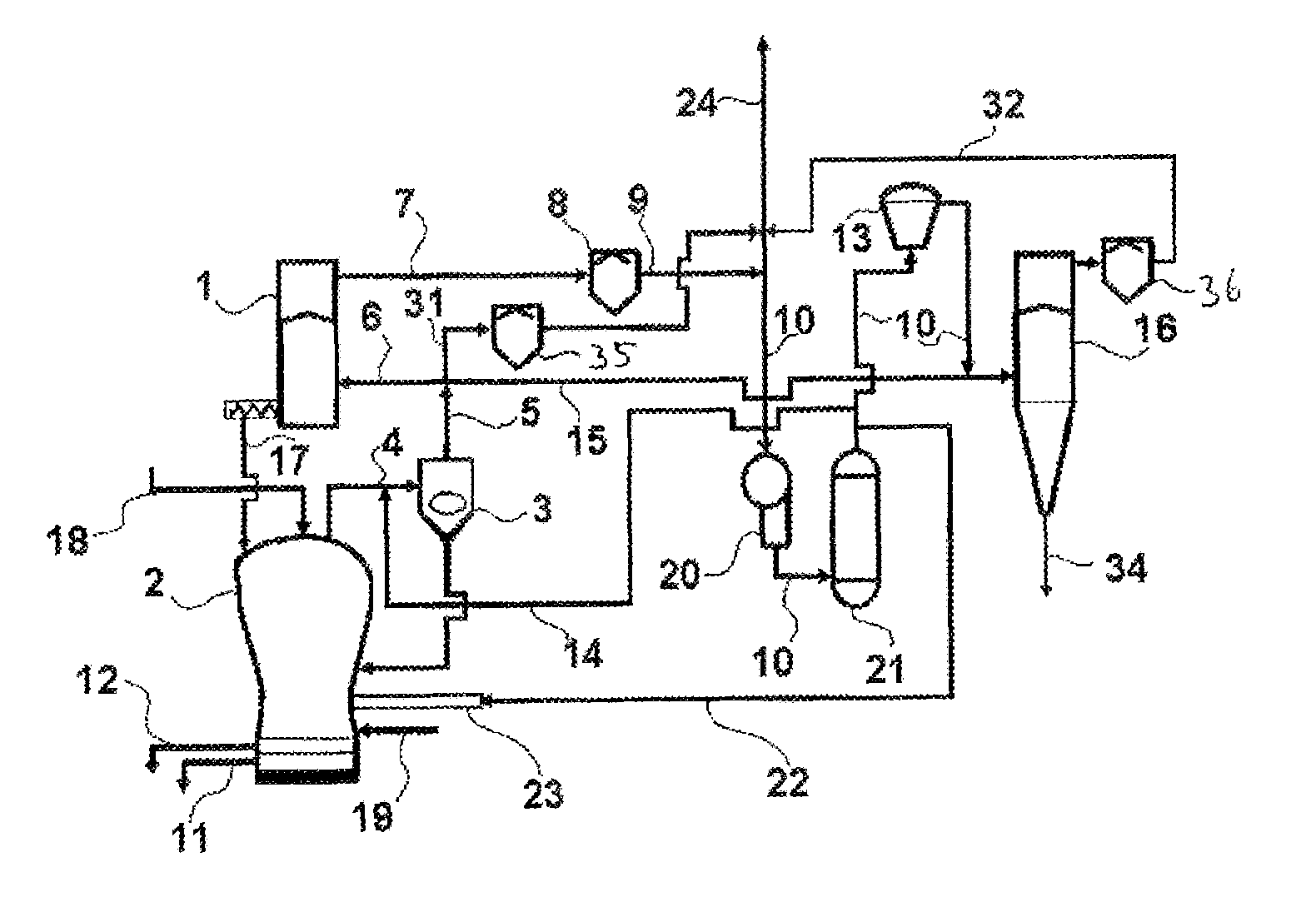

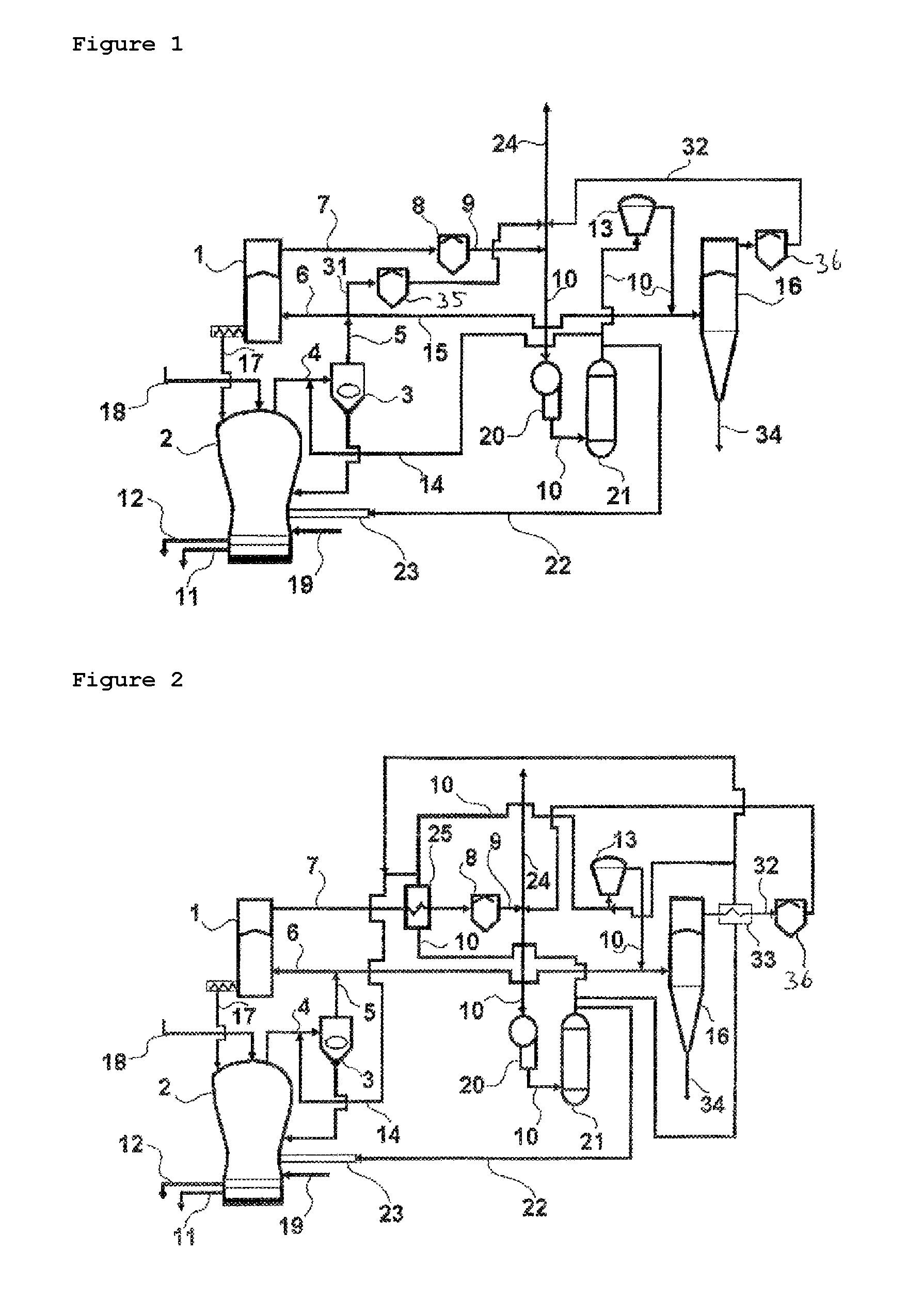

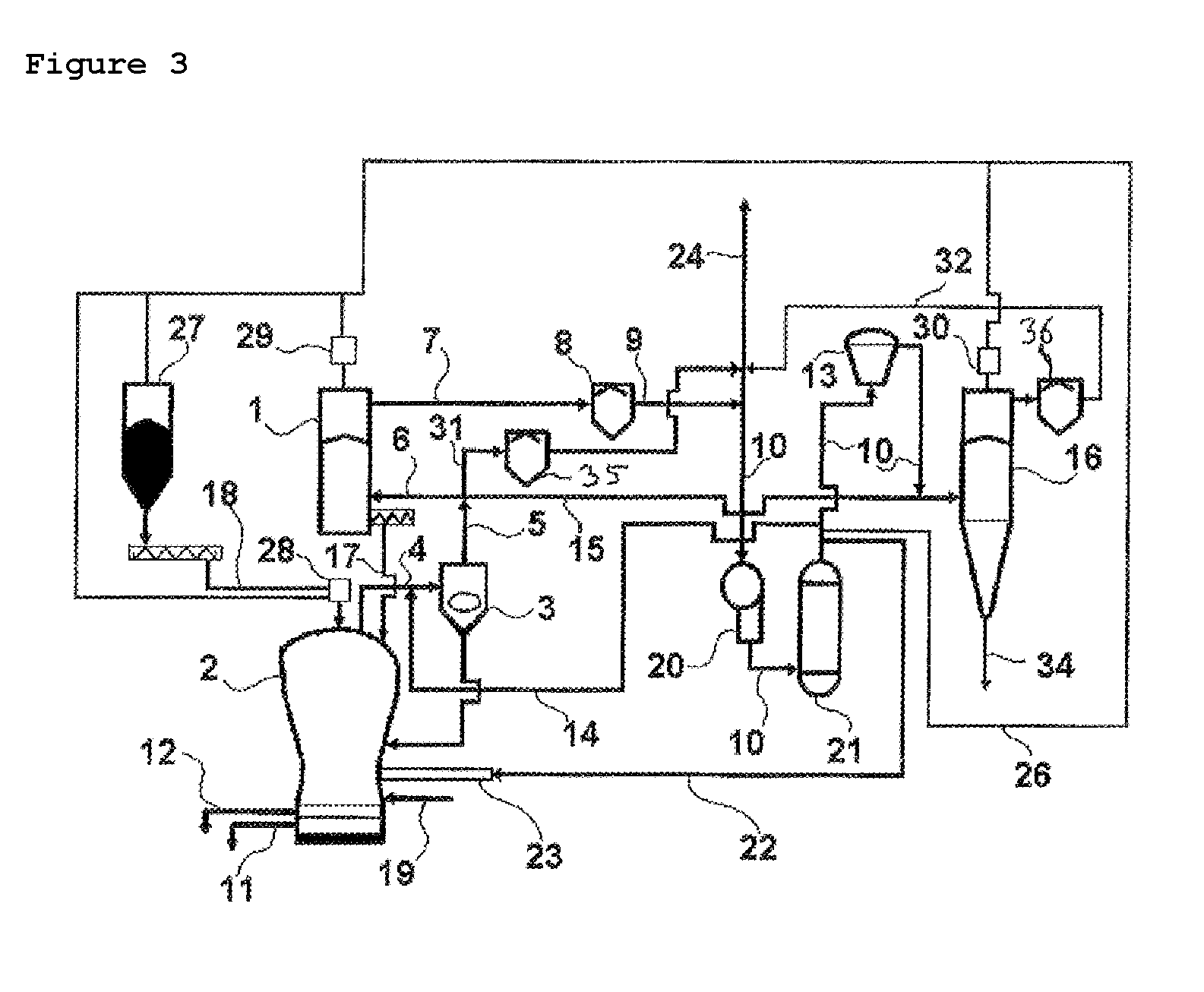

Method and system for energy-optimized and CO2 emission-optimized iron production

InactiveUS8419825B2Emission reductionIncrease profitBlast furnace detailsExhaust gas handlingProcess engineeringProduct gas

A process for energy- and emission-optimized iron production and an installation for carrying out the process. A first partial amount of a generator gas produced in a melter gasifier is used as a first reducing gas in a first reduction zone. A second partial amount is fed to at least one further reduction zone as a second reducing gas. In addition, after CO2 scrubbing, a partial amount of top gas removed from the first reduction zone is admixed with the generator gas after the latter leaves the melter gasifier, for cooling the generator gas.

Owner:PRIMETALS TECH AUSTRIA GMBH

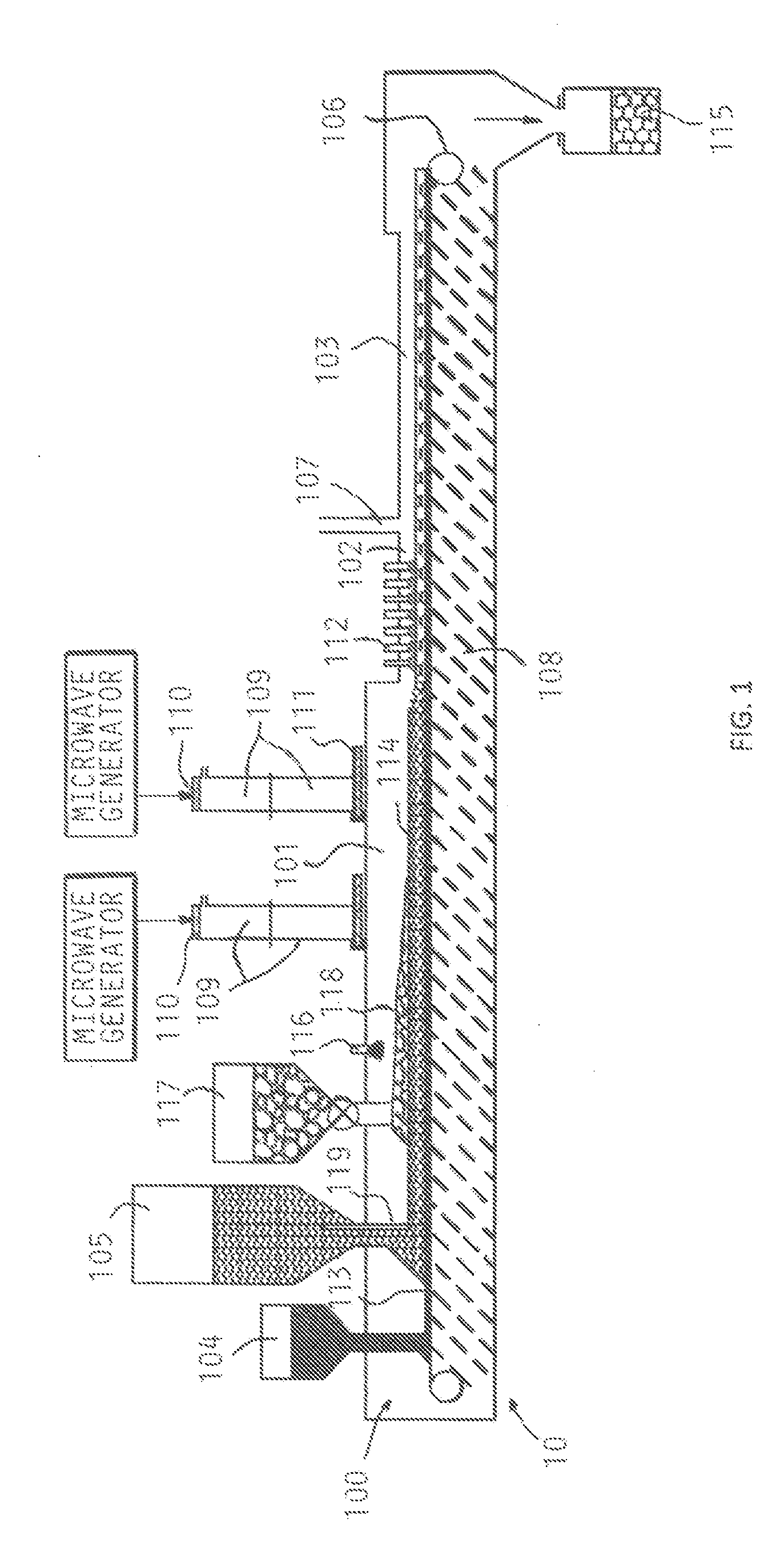

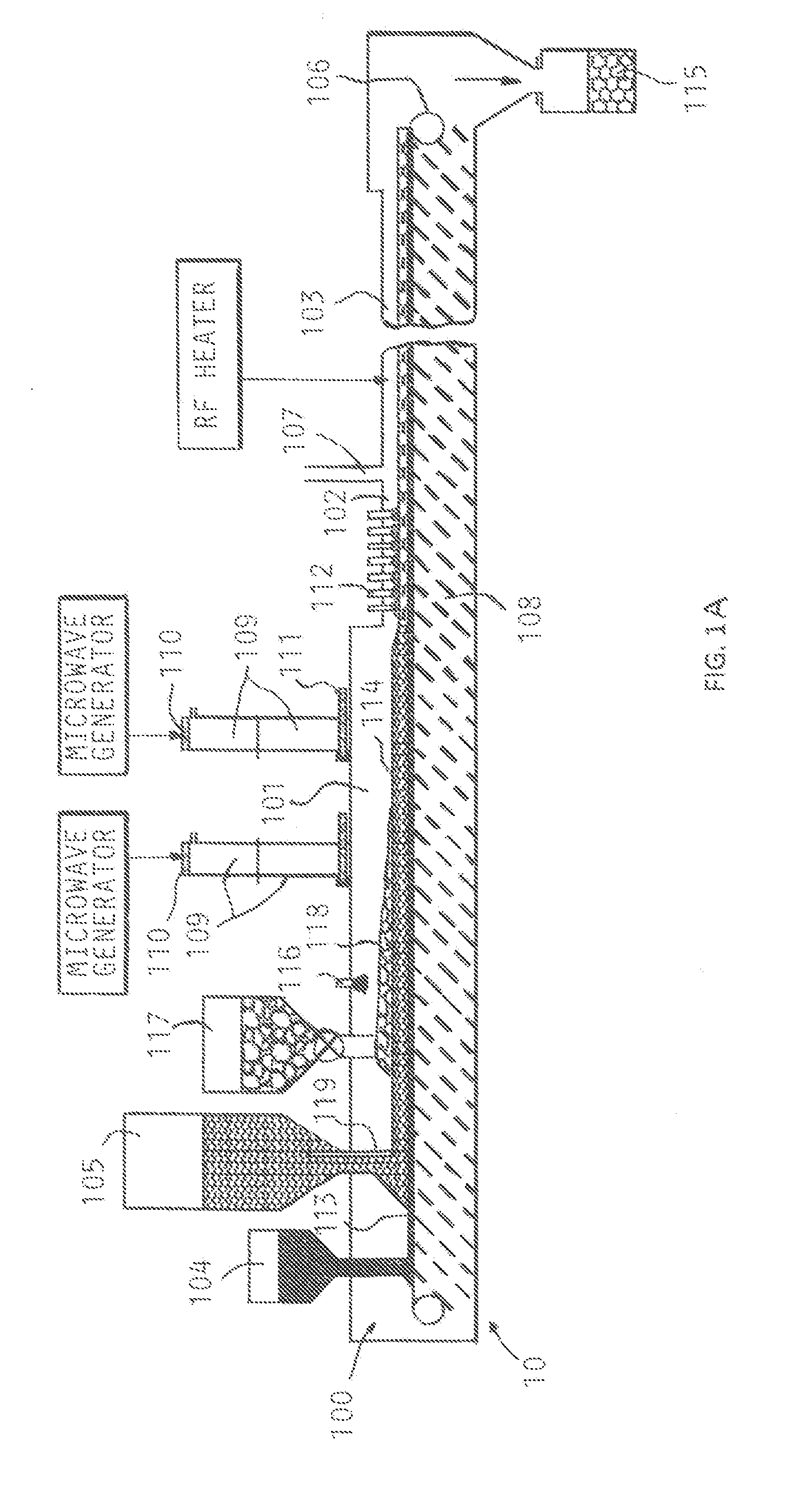

Method and Apparatus For Coproduction of Pig Iron and High Quality Syngas

ActiveUS20120031232A1Improve microwave absorption performanceHeating up fastBlast furnace detailsCharge manipulationSludgeLiquid fuel

Combined microwave heating and plasma / electric arc heating is utilized in several processes and apparatus which involve co-production of pig iron and high quality syngas, biomass to liquid fuel production, coal to liquid fuel production, co-gasification of biomass and coal, municipal solid waste treatment, waste-to-energy (agriculture waste, ASR and PEF), EAF dust and BOF sludge treatment to recover zinc and iron, hazardous bottom ash vitrification, and bromine, chlorine and sulfur removal / recycling.

Owner:HUANG XIAODI +1

Facility for producing reduced iron

In the method of producing reduced iron according to the invention, fine iron oxides and powdery solid reductants are mixed, compacted into sheet-like compacts, and charged onto the hearth of a reduction furnace for reduction while maintaining the temperature inside the furnace at not less than 1100 DEG C. As the sheet-like compacts can be obtained by compacting mixture of raw material by use of rollers or the like, processing time is much shorter than the case of pelletization or agglomeration. A drying step is unnecessary since feeds are placed no the hearth via a feeder chute or the like. The method is carried out with ease by use of the facility according to the invention. High quality hot metal can be produced by charging reduced iron in hot condition obtained by the method described as above into a shaft furnace or a in-bath smelting furnace for melting at high thermal efficiency.

Owner:SUMITOMO METAL IND LTD

Asymetric membrane FeAl intermetallic compound porosint filter element and application thereof

ActiveCN101524609AGood degree of pore structure controlWide range of regulationIncreasing energy efficiencyManufacturing convertersPorosityVulcanization

The invention belongs to the field of inorganic porosint and particularly relates to an asymetric membrane FeAl intermetallic compound porosint filter element and the application thereof. The filter element of the invention consists of a multiaperture support body and complex film; wherein, the multiaperture support body is in tubular shape or platy shape, the complex film is made in the following steps: a compound sizing agent is coated on outer surface of a single side of the multiaperture support body; and degreasing, bias diffusion, reaction synthesis and sintering are carried out to form thin-layer complex film with millipores. The millipores on the surface of the filter element is small and uniform, porosity is high, no dust is blocked inside filter material, filtering gas circuit is smooth, and resistance is small; in addition, the element has good resistance to high temperature oxidation / vulcanization and good normal temperature and high temperature mechanical properties. The element can directly carry out solid-gas separation on industrial gasses, bear top load and high-pressure and high-speed back washing, thus saving relative cooling devices, saving a large amount of water resources, avoiding cooling water treatment, lowering energy loss, shortening process flow and improving work efficiency.

Owner:CHENGDU INTERMENT TECH

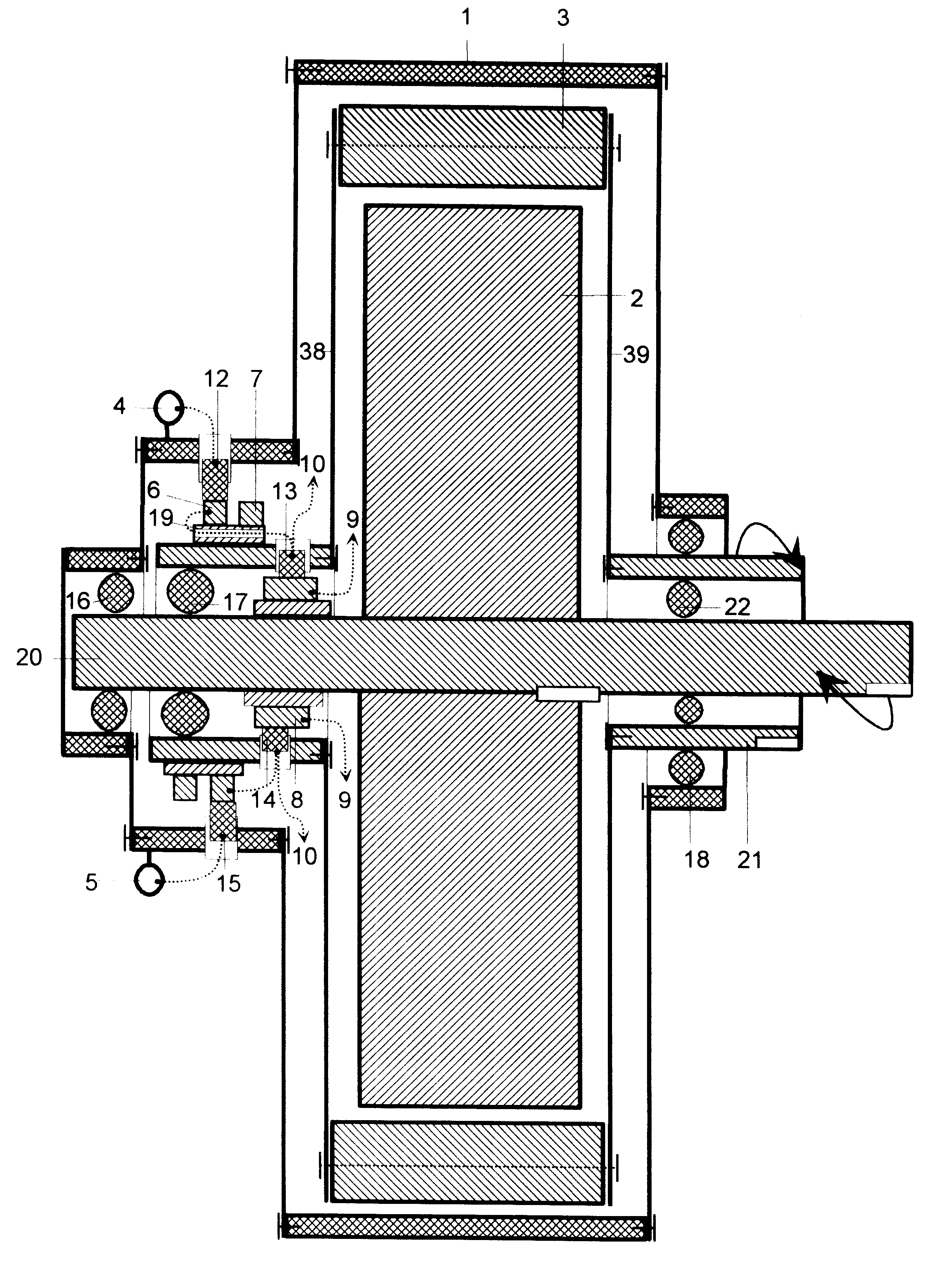

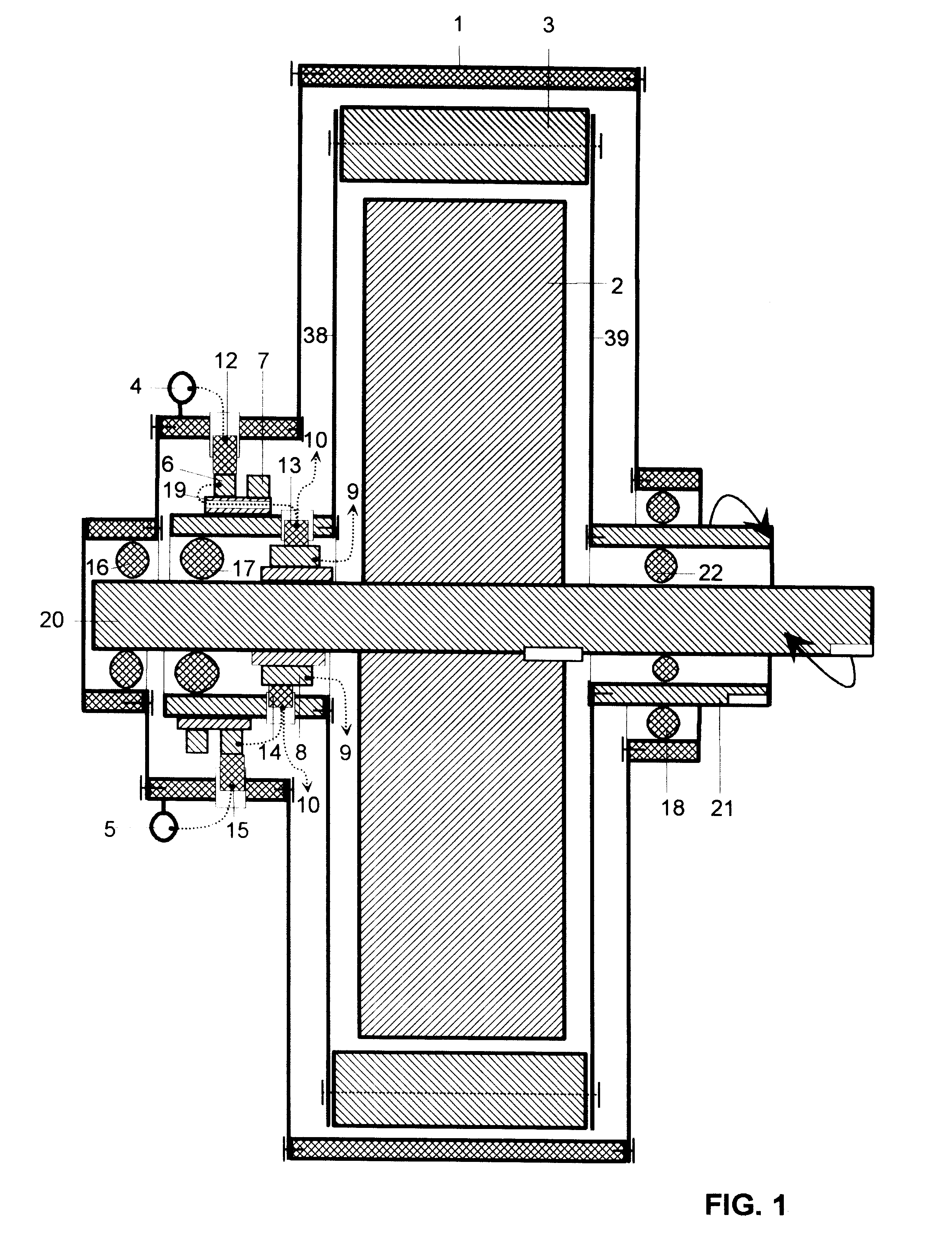

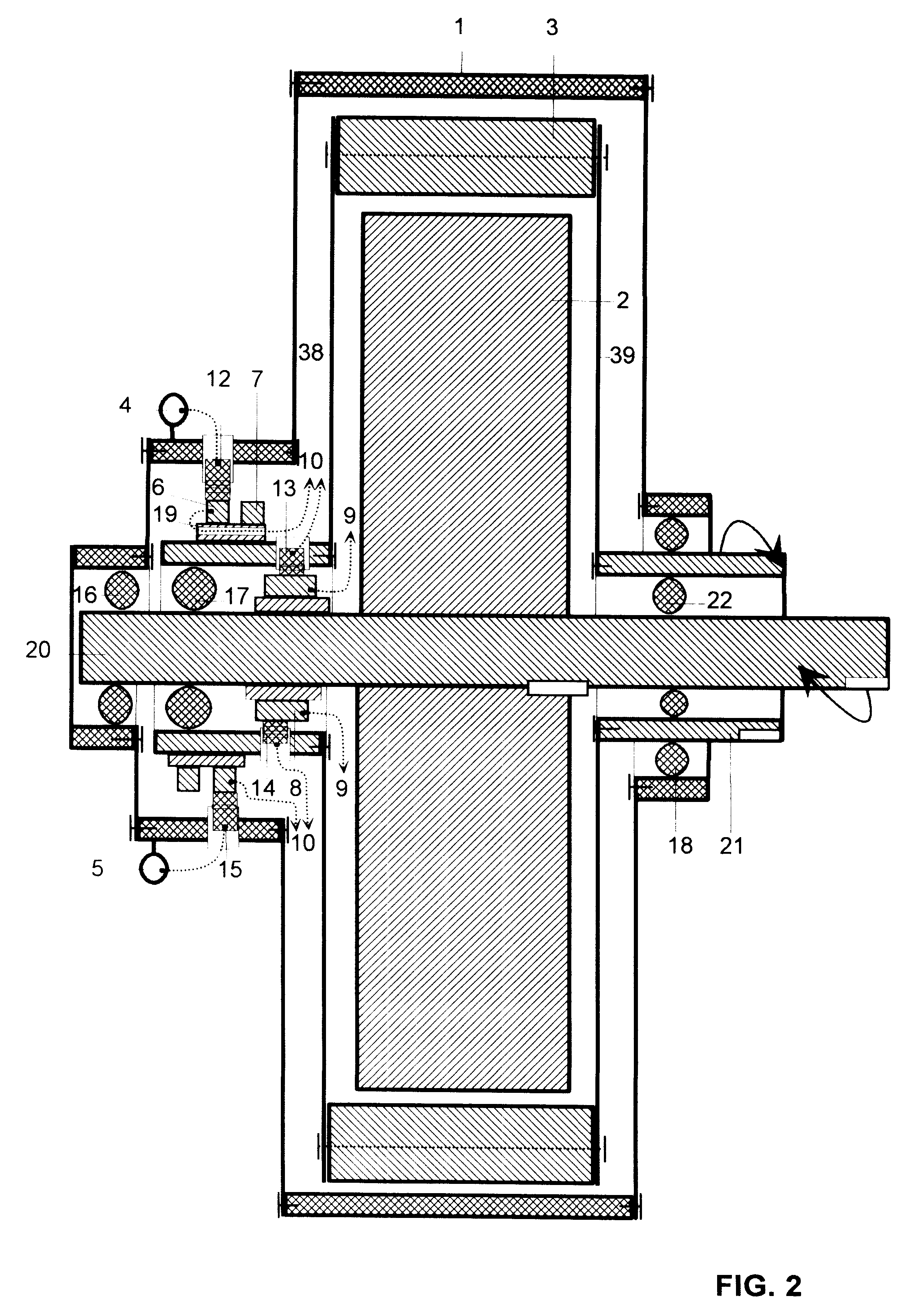

Method and electric motor with rotational stator

An electric composite rotating machine haveing two rotors, capable of developing mechanical power and of runing on two rotational direction at selfadjutable speeds, of differential type, with 40% increase of output, doubling the torque at 30% reduction of used electrical energy.

Owner:CHERCIU TRAIAN

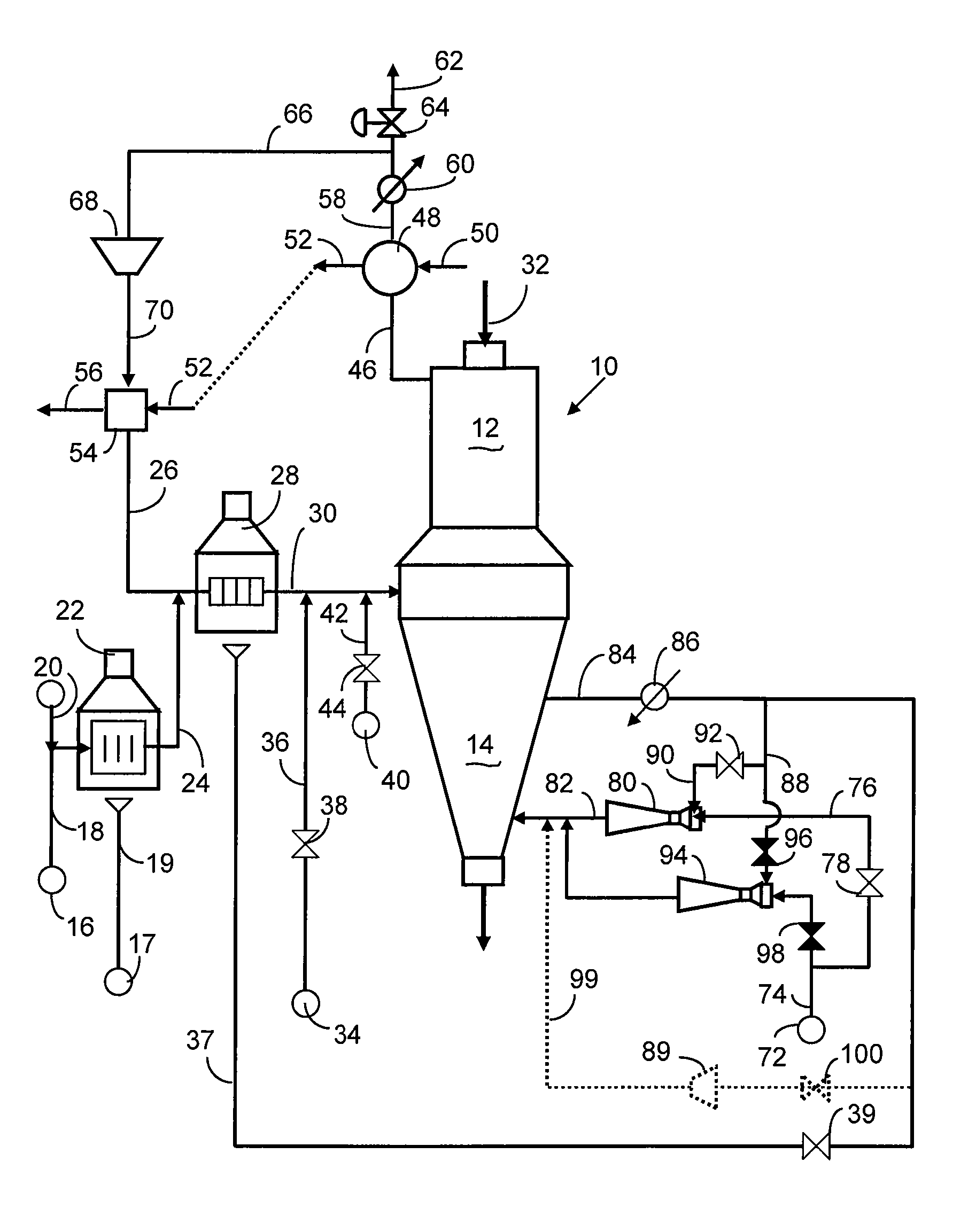

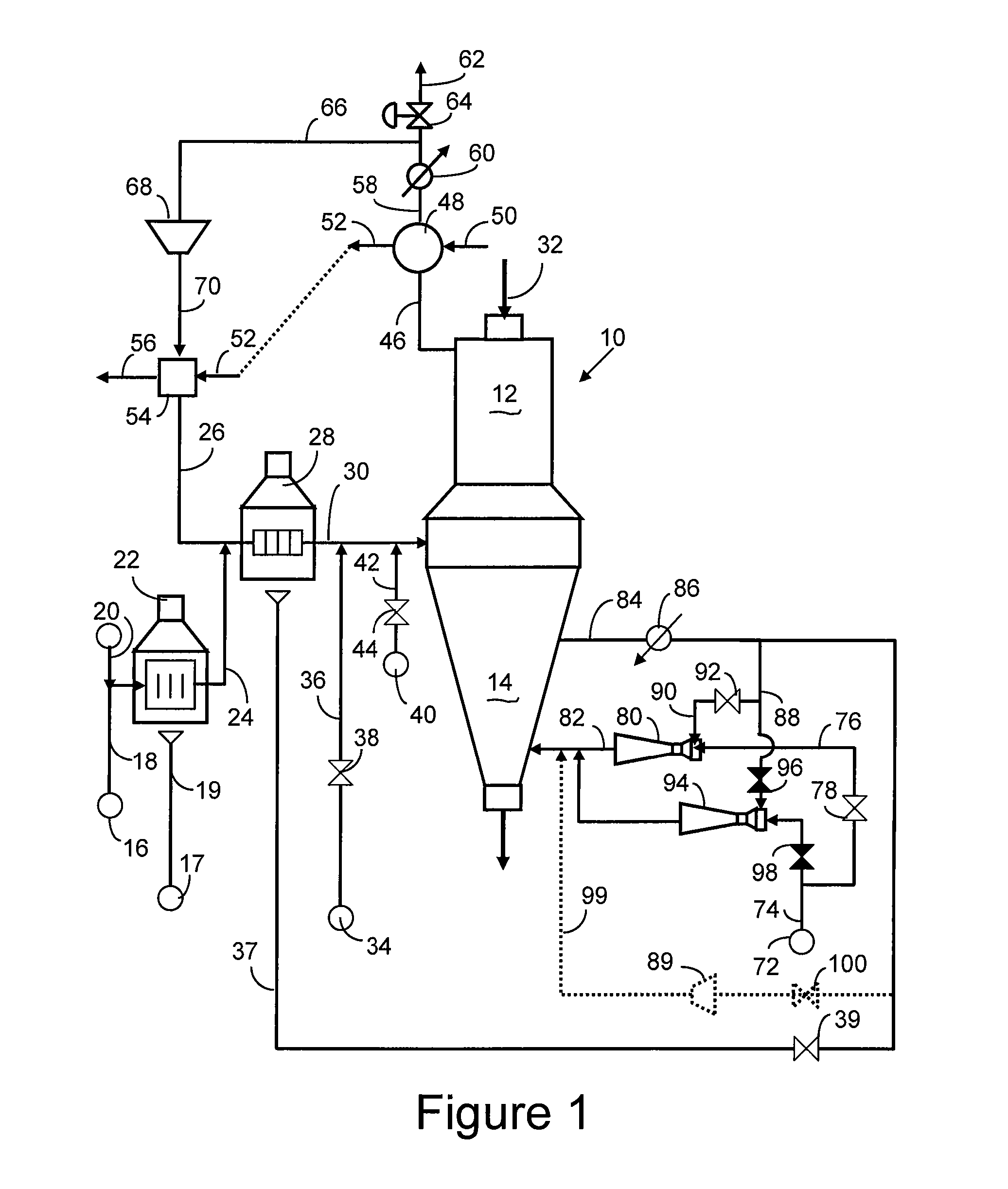

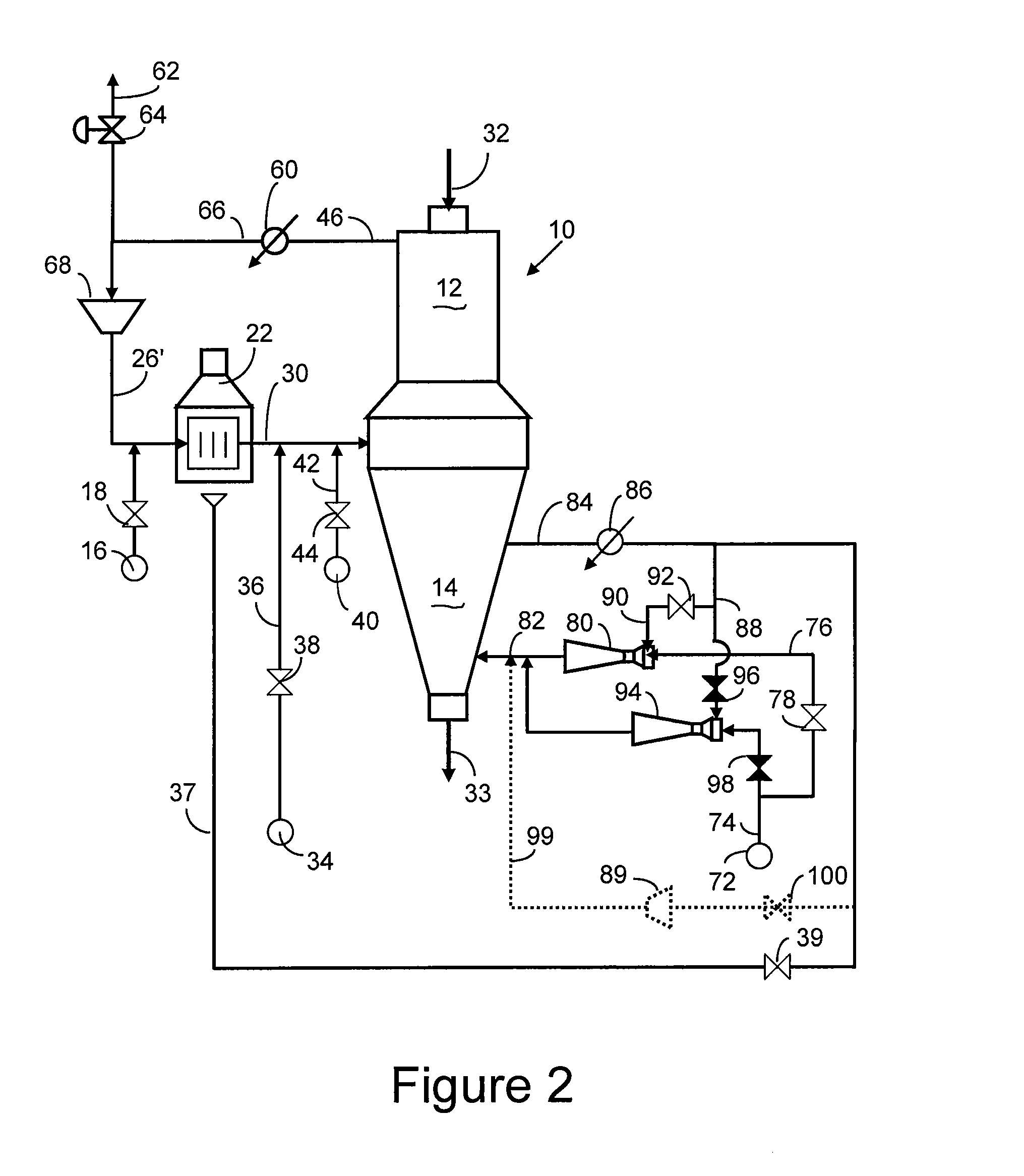

Method and Apparatus for Producing Direct Reduced Iron

ActiveUS20070245855A1Cutting costsLess-expensive equipmentBlast furnace detailsManufacturing convertersElectricityGas cooler

A direct reduction process for producing direct reduced iron (DRI) in a reduction reactor having a reduction zone for reducing iron-oxides-containing particles, such as iron ore pellets, to DRI by reaction of said iron oxides with a high temperature reducing gas, and a cooling zone for lowering the temperature of the DRI produced in said reduction zone, wherein a stream of cooling gas, usually natural gas, is circulated through said cooling zone, a portion of said cooling gas is withdrawn from the cooling zone, cooled and cleaned in a gas cooler and a portion of the cooled gas is recycled to said reduction zone by means of an ejector utilizing the high-pressure natural gas make-up feed as the ejector's motive fluid. Using an ejector for recycling the cooling gas instead of using a mechanical compressor provides significant savings in electricity and in capital, operational and maintenance costs. A direct reduction plant having a DRI cooling zone which uses at least one ejector in recycling at least a portion of cooling gas to the cooling zone.

Owner:HYL TECH SA DE CV

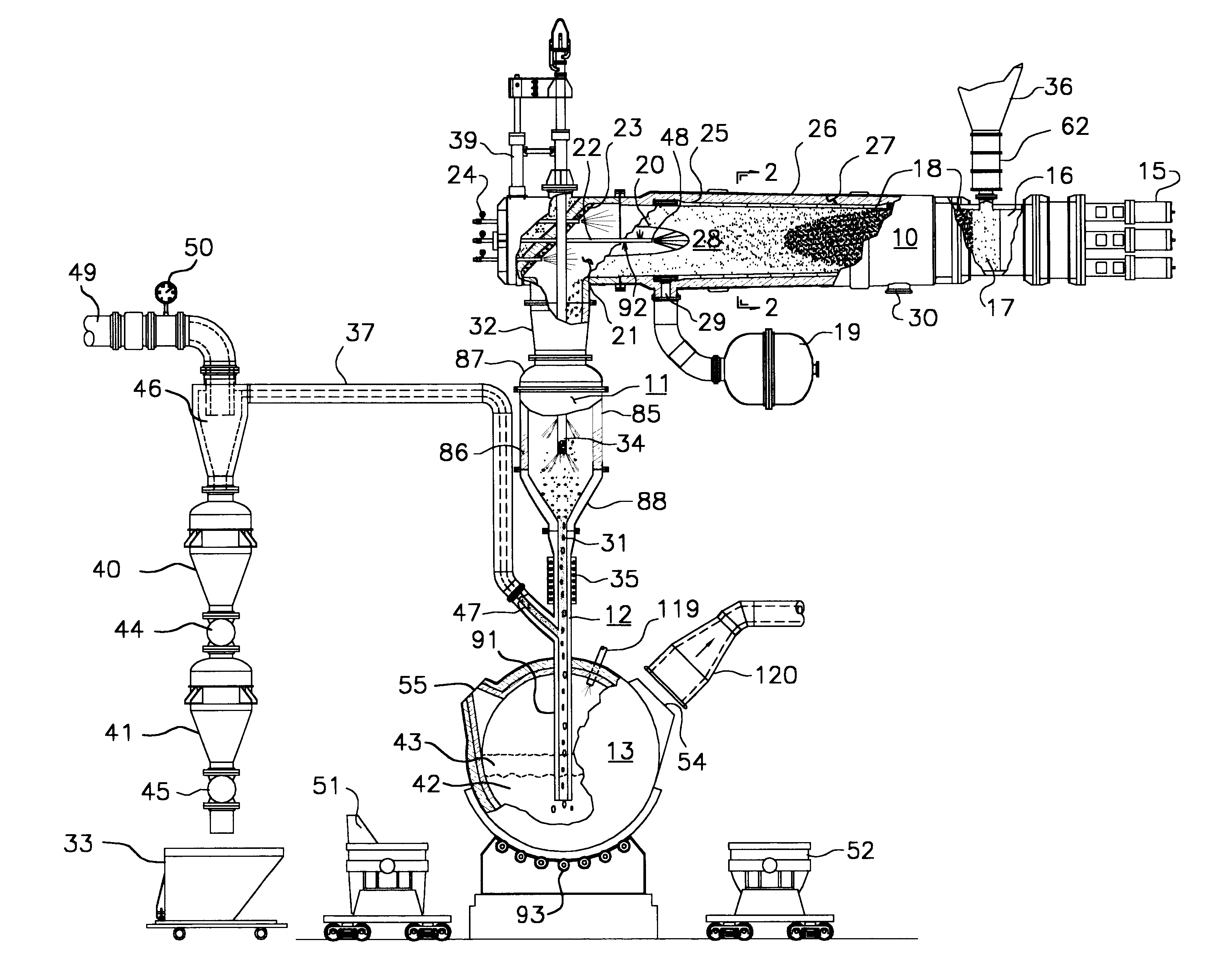

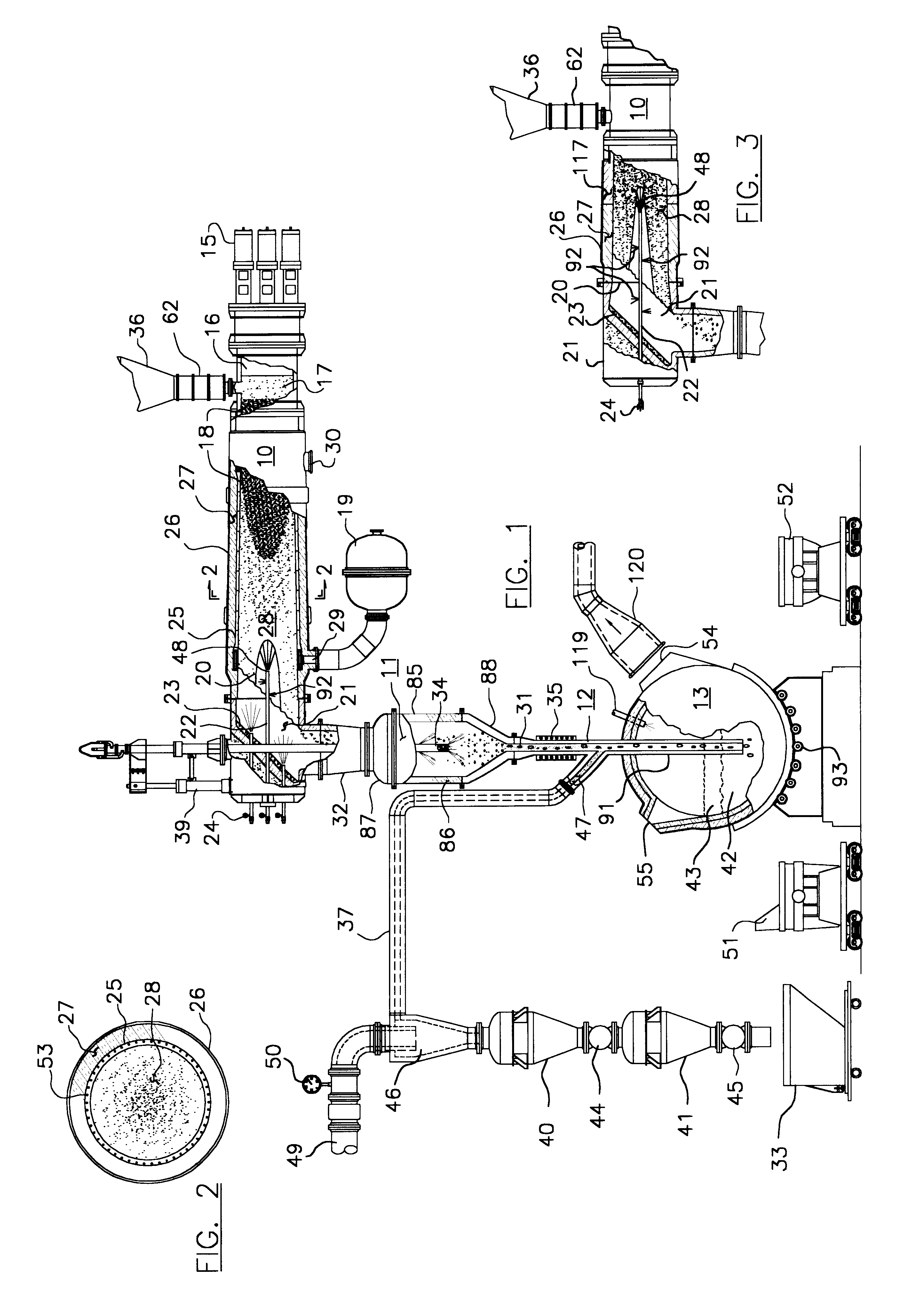

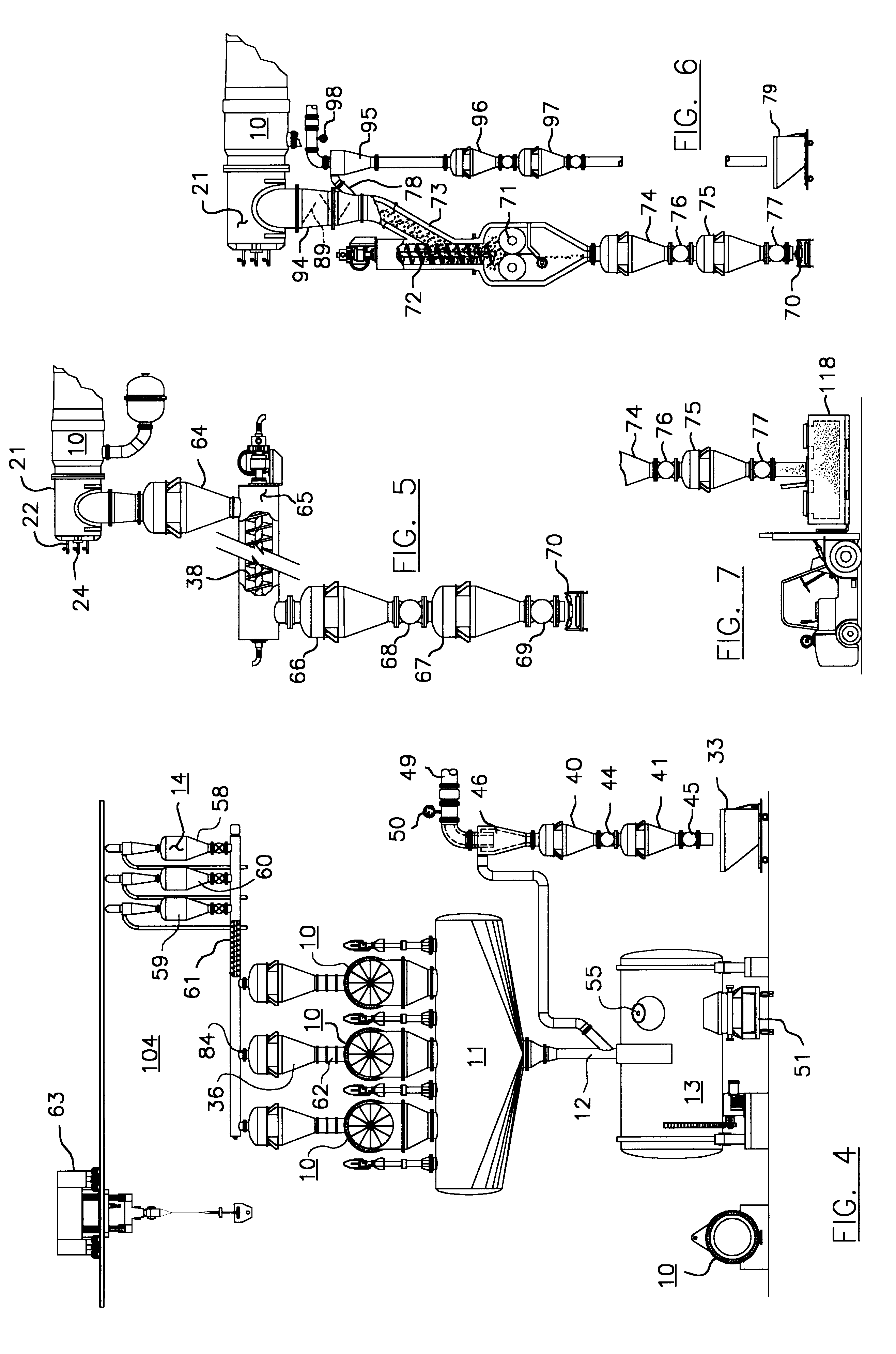

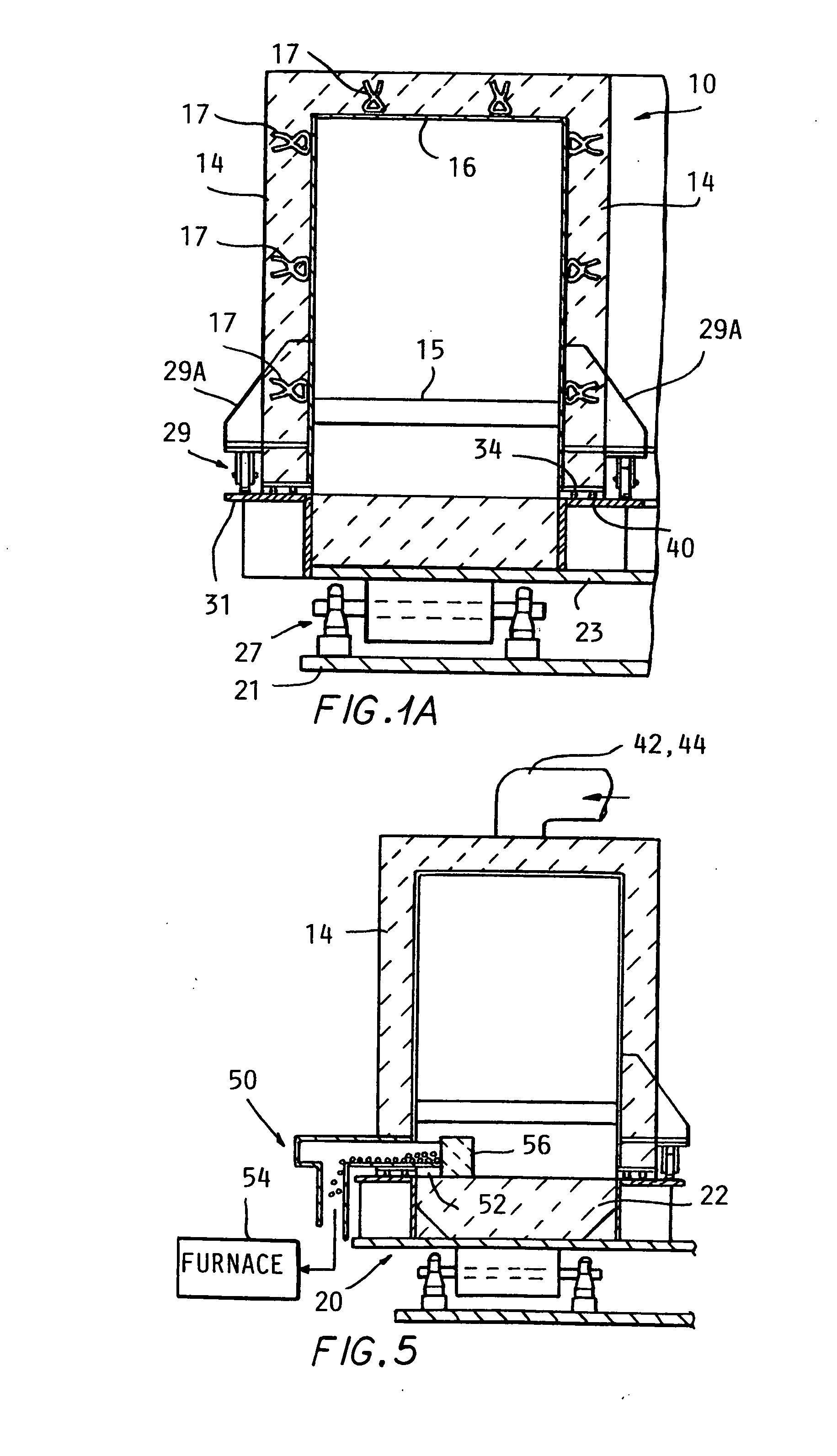

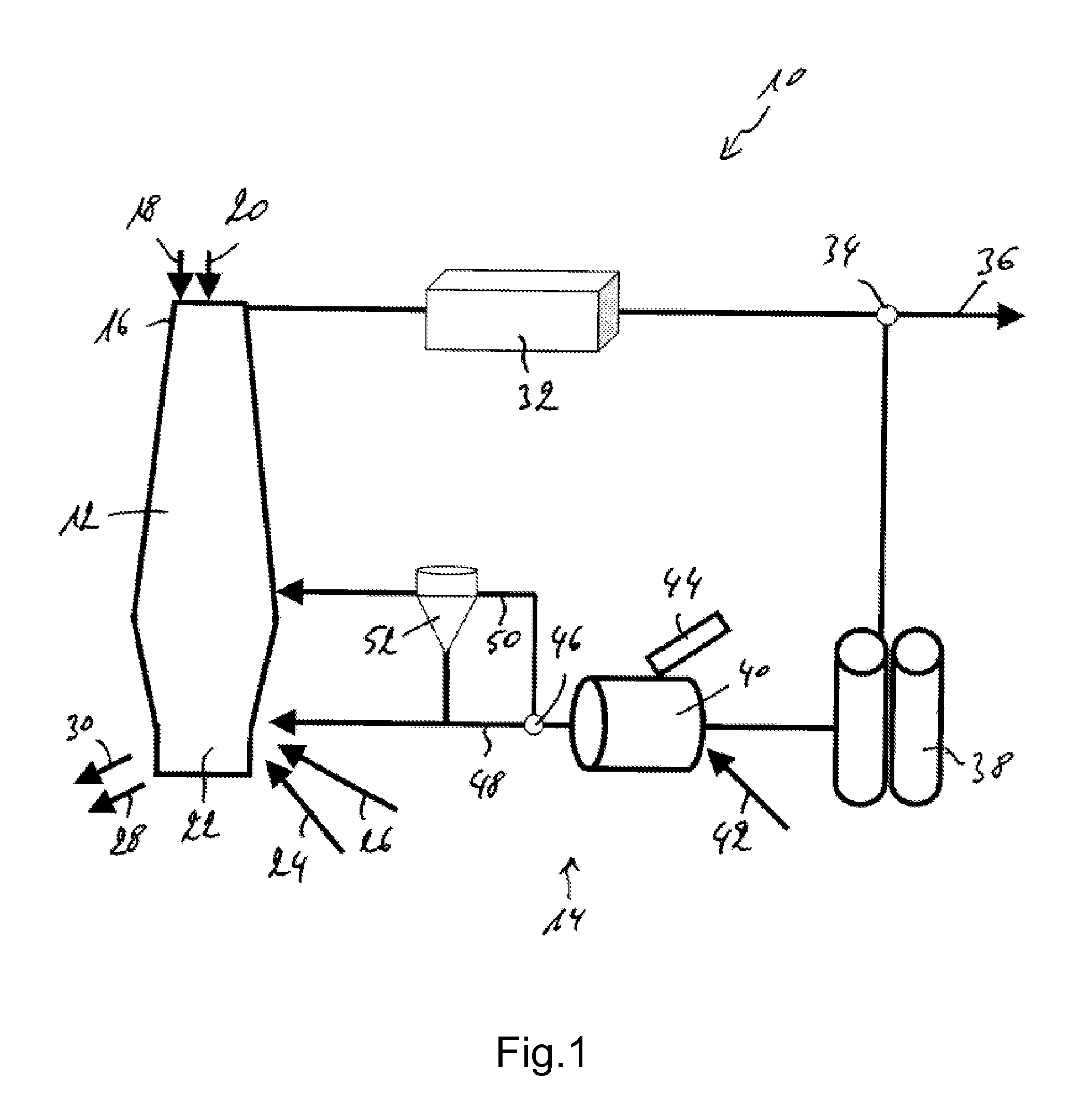

Method and apparatus for practicing carbonaceous-based metallurgy

InactiveUS6409790B1Low costReduce capital investmentMaintainance of heating chambersBlast furnace detailsThermal energyOperational costs

An energy efficient, coal-based method and apparatus that are environmentally friendly which produce under pressure metallized / carbon product and molten metal directly from abundant coal or other carbonaceous material, and low cost fines (or ore concentrate) wherein the metal is devoid of gangue material and possesses the inherent advantage of retaining the heat for subsequent processing. This method and apparatus which are modular and highly integrated significantly reduce capital and operating costs; they also provide the capability selective placement of the reductant for the delivery of high levels of thermal energy input which leads to ease of desulflurization and high productivity. The technology herein disclosed is entirely closed and is applicable to various ores including ferrous and non-ferrous.

Owner:CALDERON ENERGY OF BOWLING GREEN

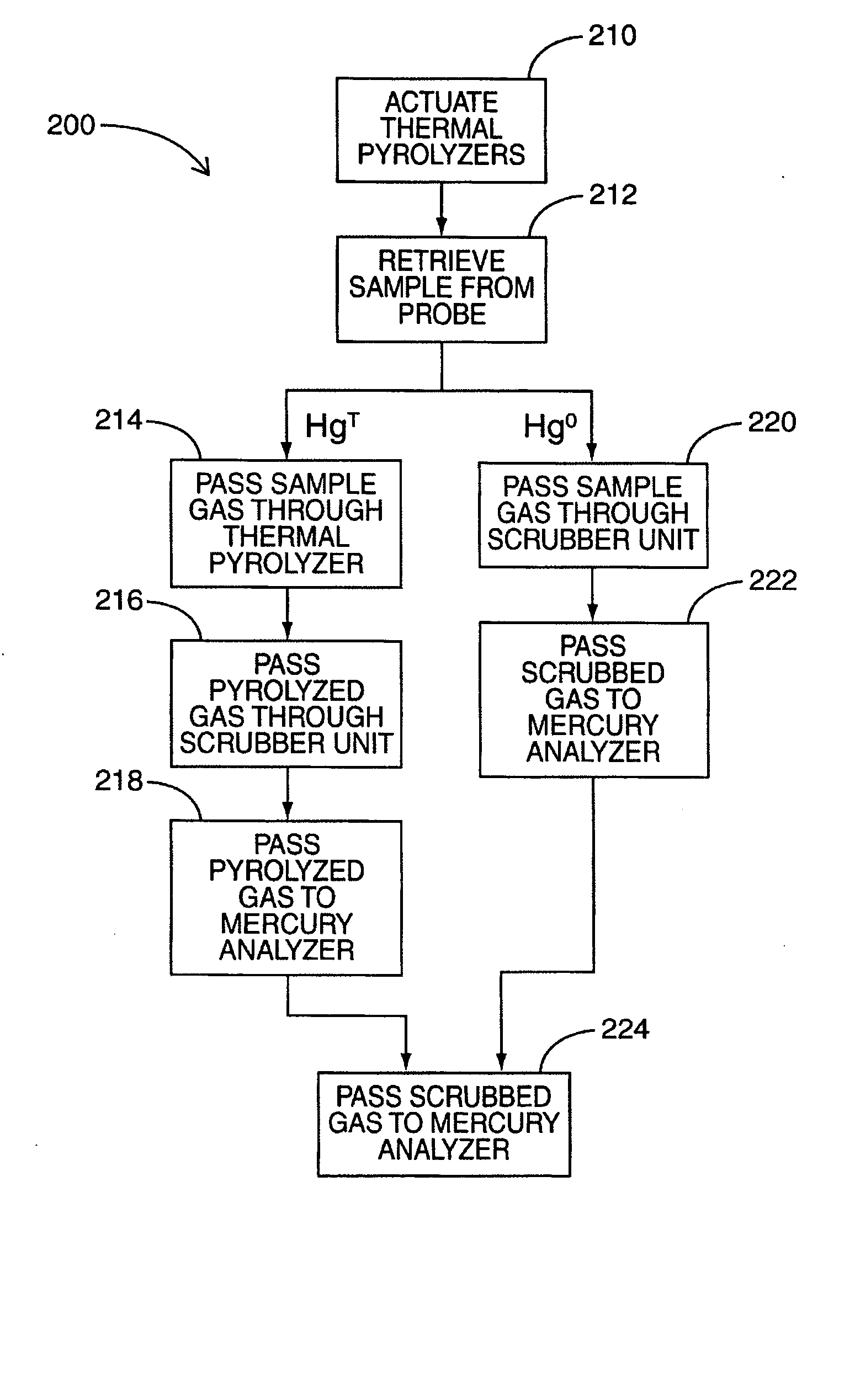

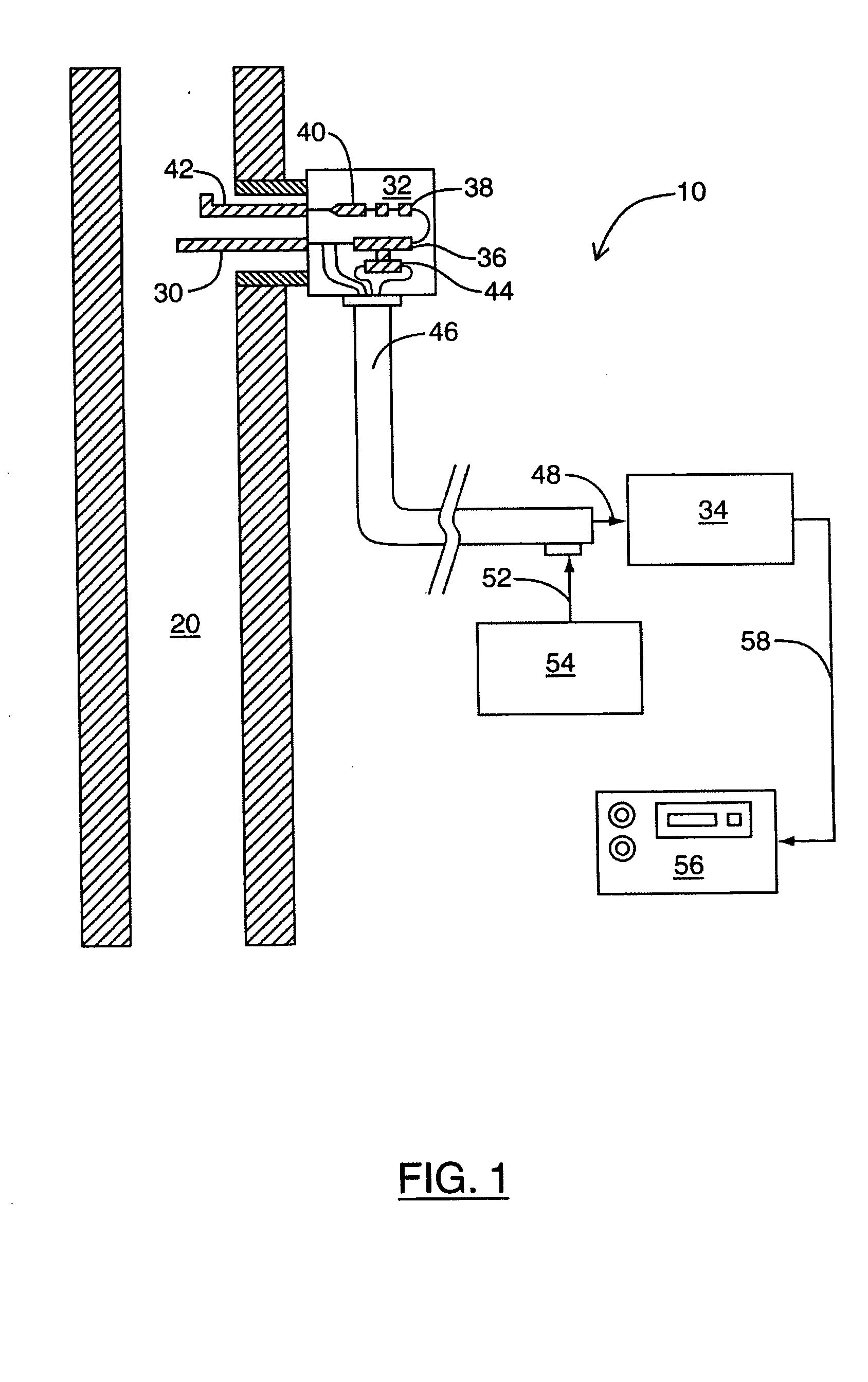

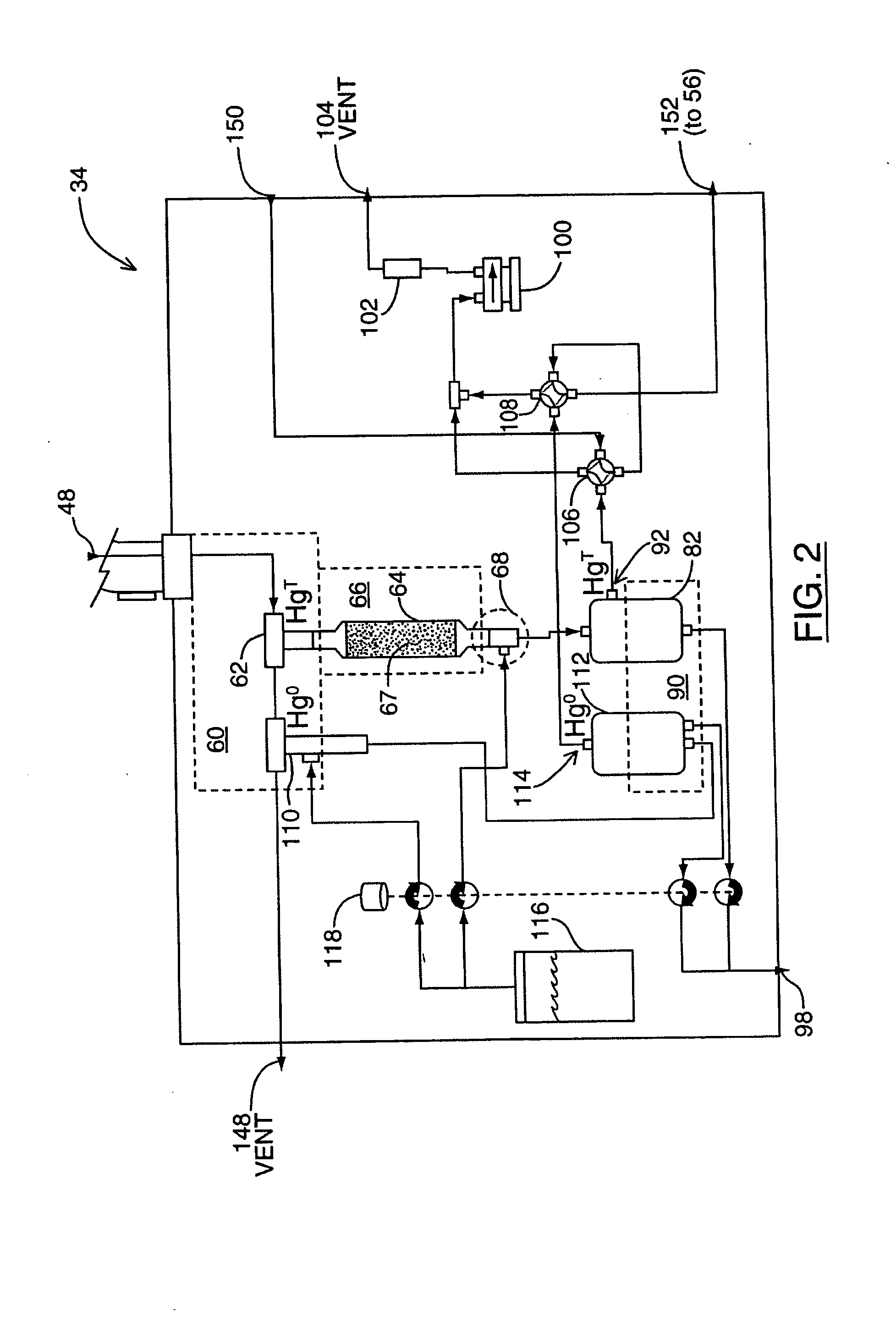

Conditioning system and method for use in the measurement of mercury in gaseous emissions

ActiveUS20050061110A1Avoid reorganizationReduced form requirementsGas treatmentSamplingBoron nitrideSilicon boride

Embodiments of the invention relate generally to systems used to measure mercury in gaseous emissions. In one aspect, the invention is directed to the use of silicon carbide as material for a thermal pyrolysis unit. In another aspect, at least one of silicon nitride, silicon boride, and / or boron nitride is used as material for a thermal pyrolysis unit. In another aspect, the invention is directed to an improved pyrolyzer design, in which a thermal pyrolysis unit comprises a tailpiece that allows water to be injected at the heated exit of the thermal pyrolysis unit. In another aspect, the invention is directed to the use of a coalescing filter in a scrubbing unit. In another aspect, the invention is directed to the use of a hydrophobic filter element in a scrubbing unit. One or more of these elements may be used in a conditioning module of a continuous emissions monitoring system, for example.

Owner:TEKRAN INSTR CORPORTION

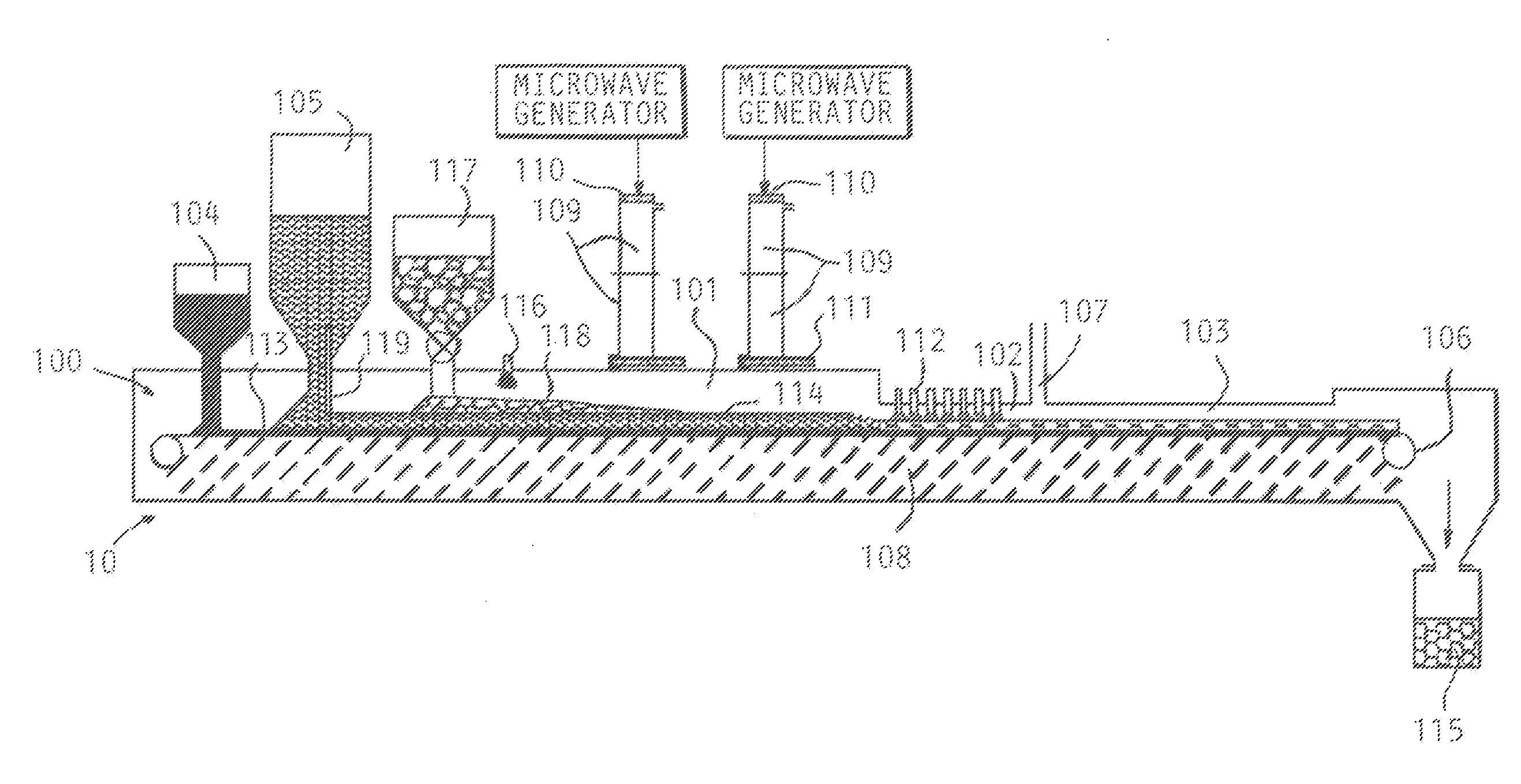

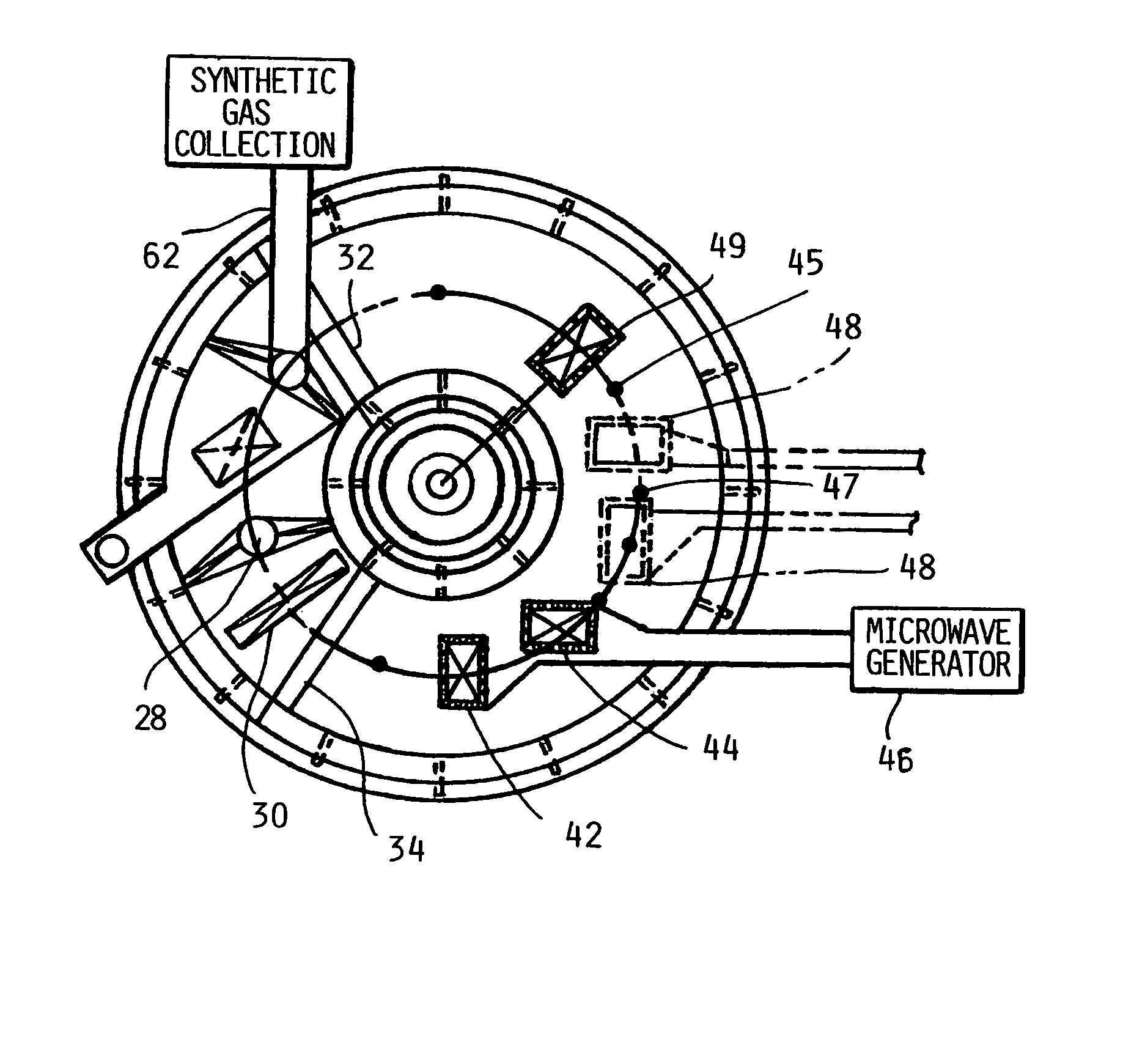

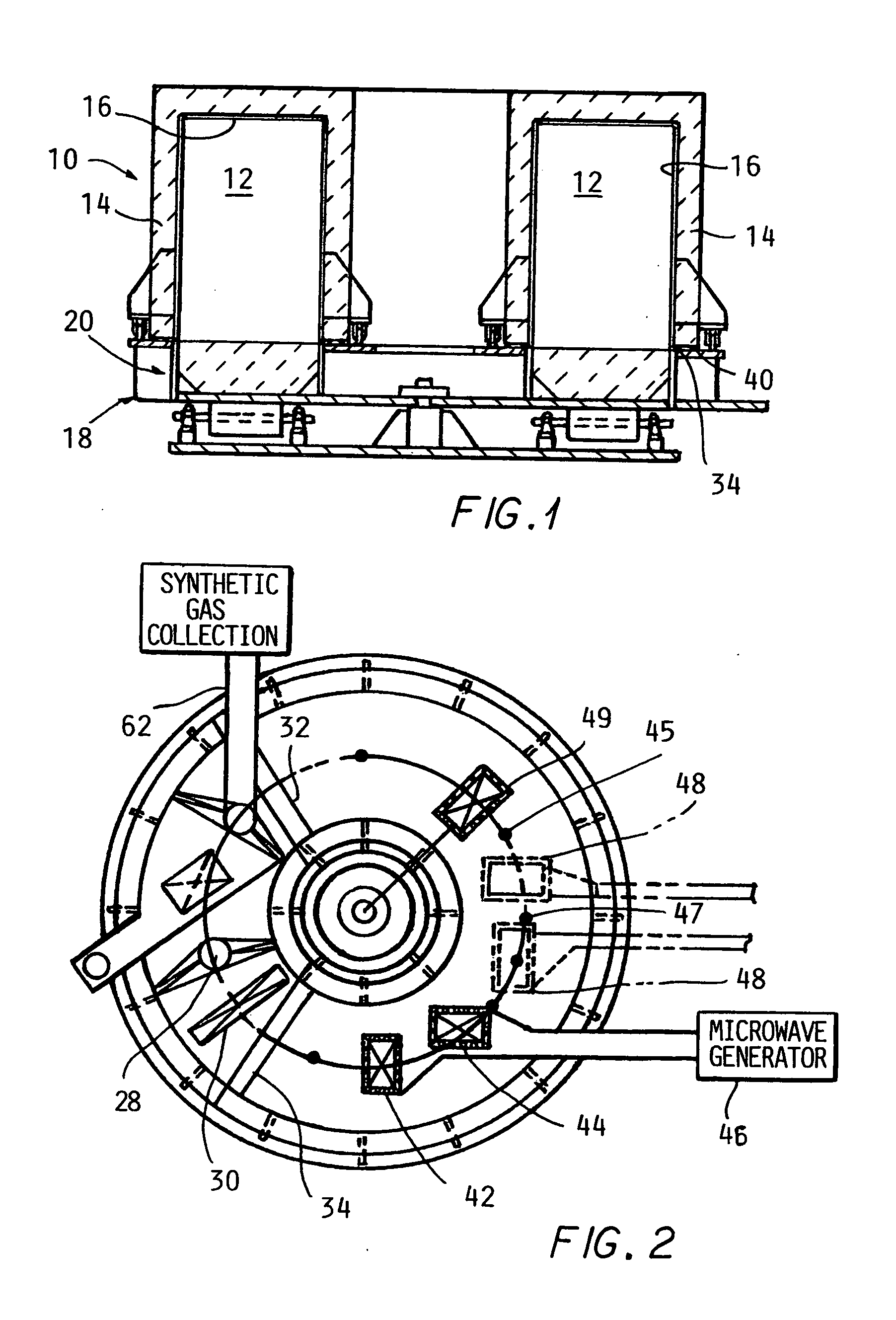

Microwave heating method and apparatus for iron oxide reduction

A method and apparatus for reducing iron oxides using microwave heating in a furnace chamber which is sealed against the entrance of air reduces the energy required and produces a low temperature reduction and allows the recovery of combustible synthetic gas as a byproduct of the process. Avoidance of the reduction of sulfur, phorphorus and silica is also insured, as is the need to reduce the silica content of the feed material prior to reducing the ore. A continuous rotary hearth furnace, a rotary kiln, a linear conveyor and vertical shaft furnace chamber configurations are described. A secondary heating zone can also be included to process the reduced iron into iron nuggets or liquid metallic iron.

Owner:HWANG JIANN YANG +1

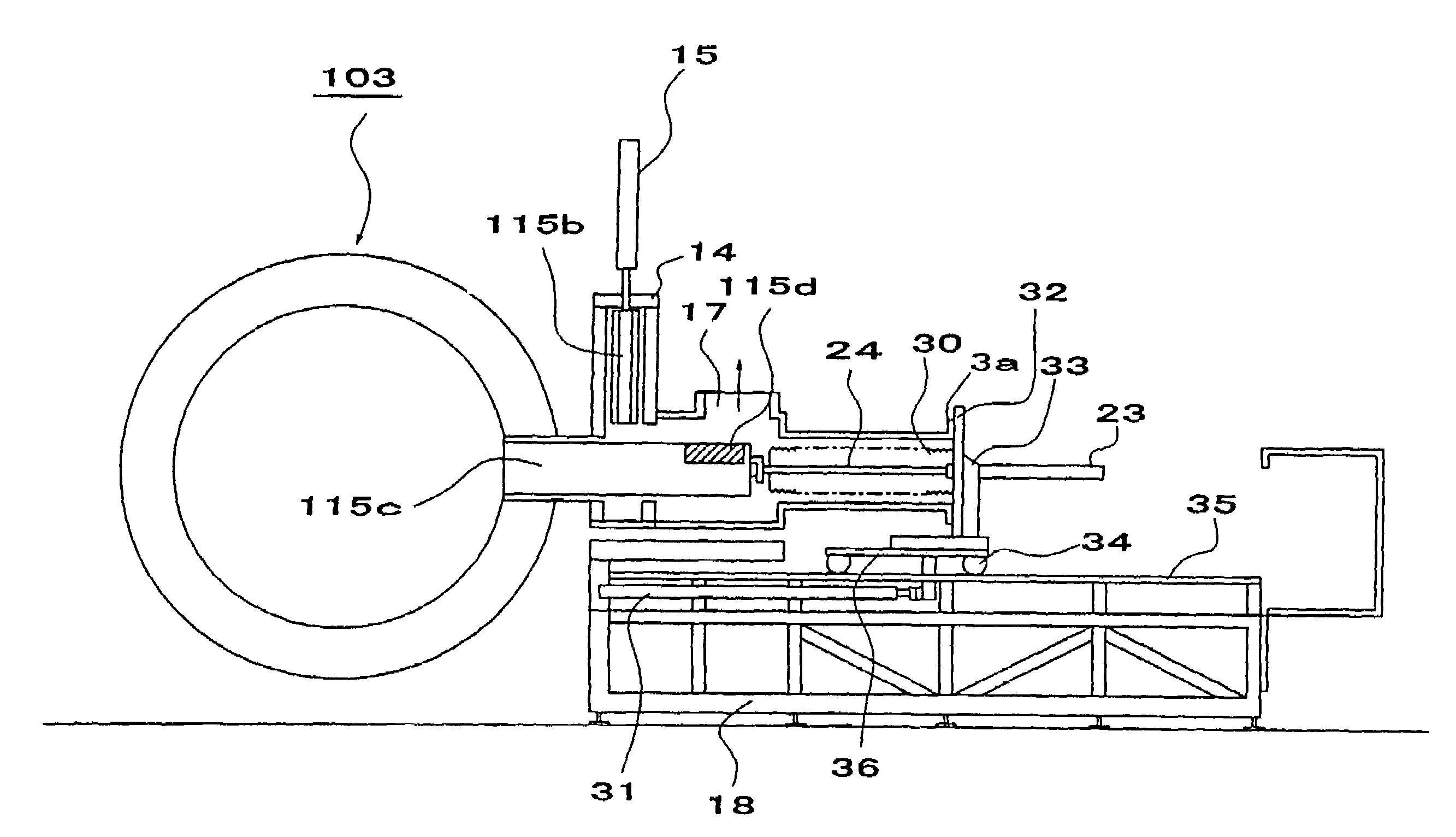

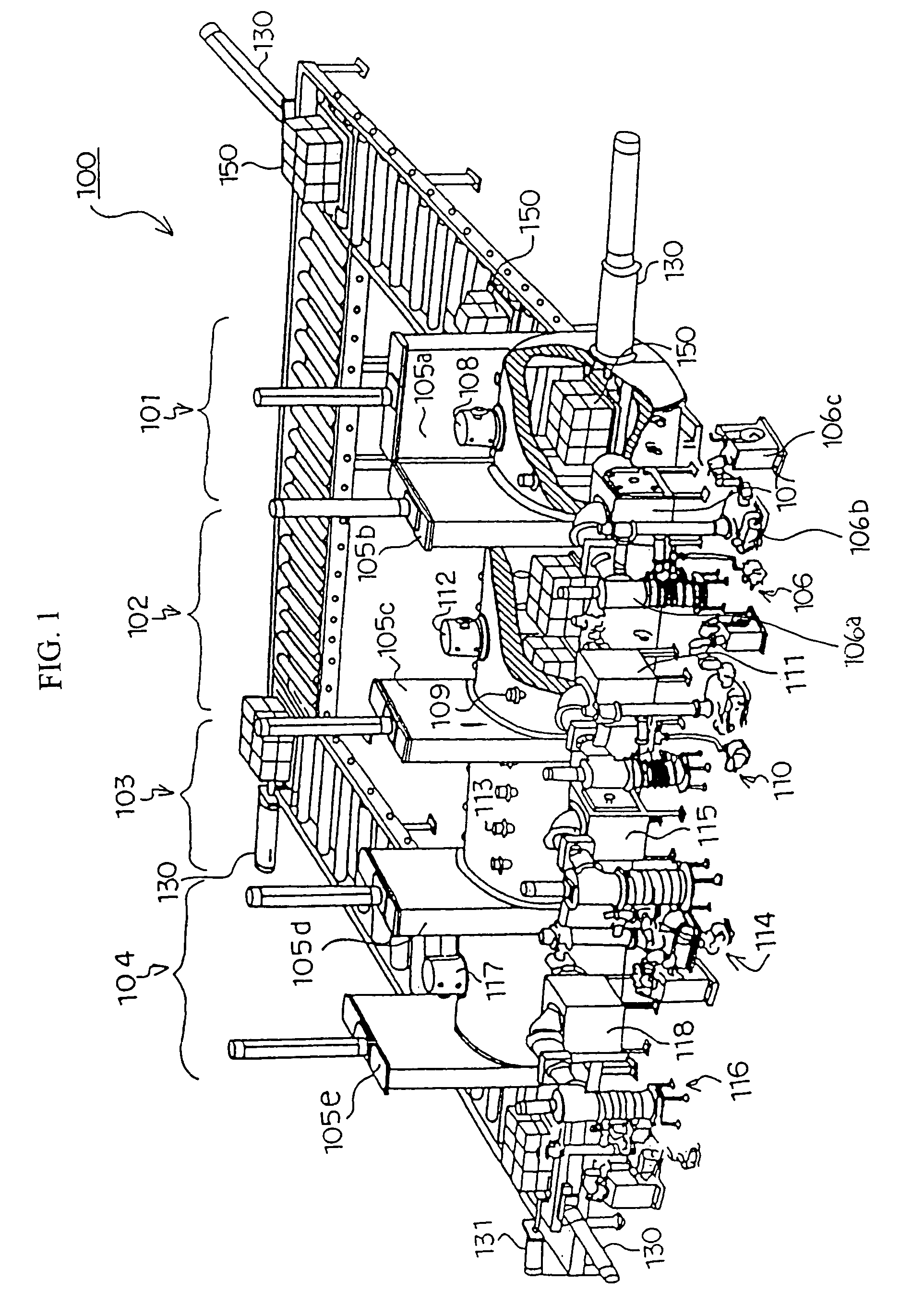

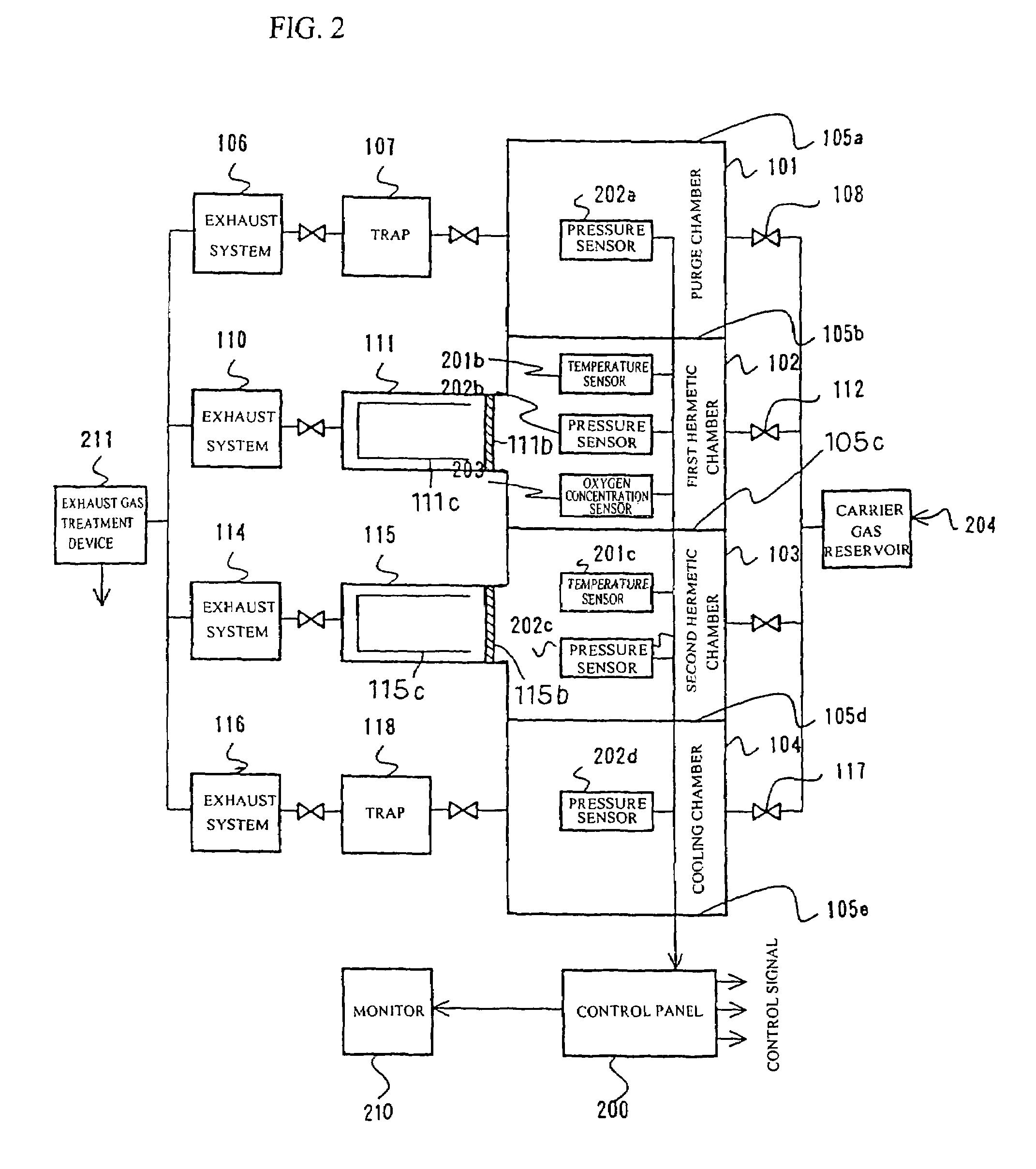

Treating apparatus, treating method and method of treating soil

InactiveUS7381383B1Good energyLow thermal conductivityPressurized chemical processMuffle furnacesProduction rateEngineering

A treatment apparatus of the present invention includes a hermetic door 115b and a retort 115c as an interface for taking out a gaseous emission containing vaporized substances from an object to be treated which is being heated in a reduced pressure state in a second hermetic chamber 103 while maintaining conditions in the second hermetic chamber. When the retort 115c is inserted into a first opening 103b of the second hermetic chamber, the hermetic door 115b in an open state is shielded from the second hermetic chamber 103, whereby condensation of the gaseous emission at the hermetic door is prevented. Accordingly, condensates can be taken out while conditions such as temperature and pressure in the hermetic chamber are maintained without the treatment apparatus being stopped. The productivity of treatment is greatly improved by continuous operation of such a treatment apparatus.

Owner:HOEI SHOKAI CO LTD

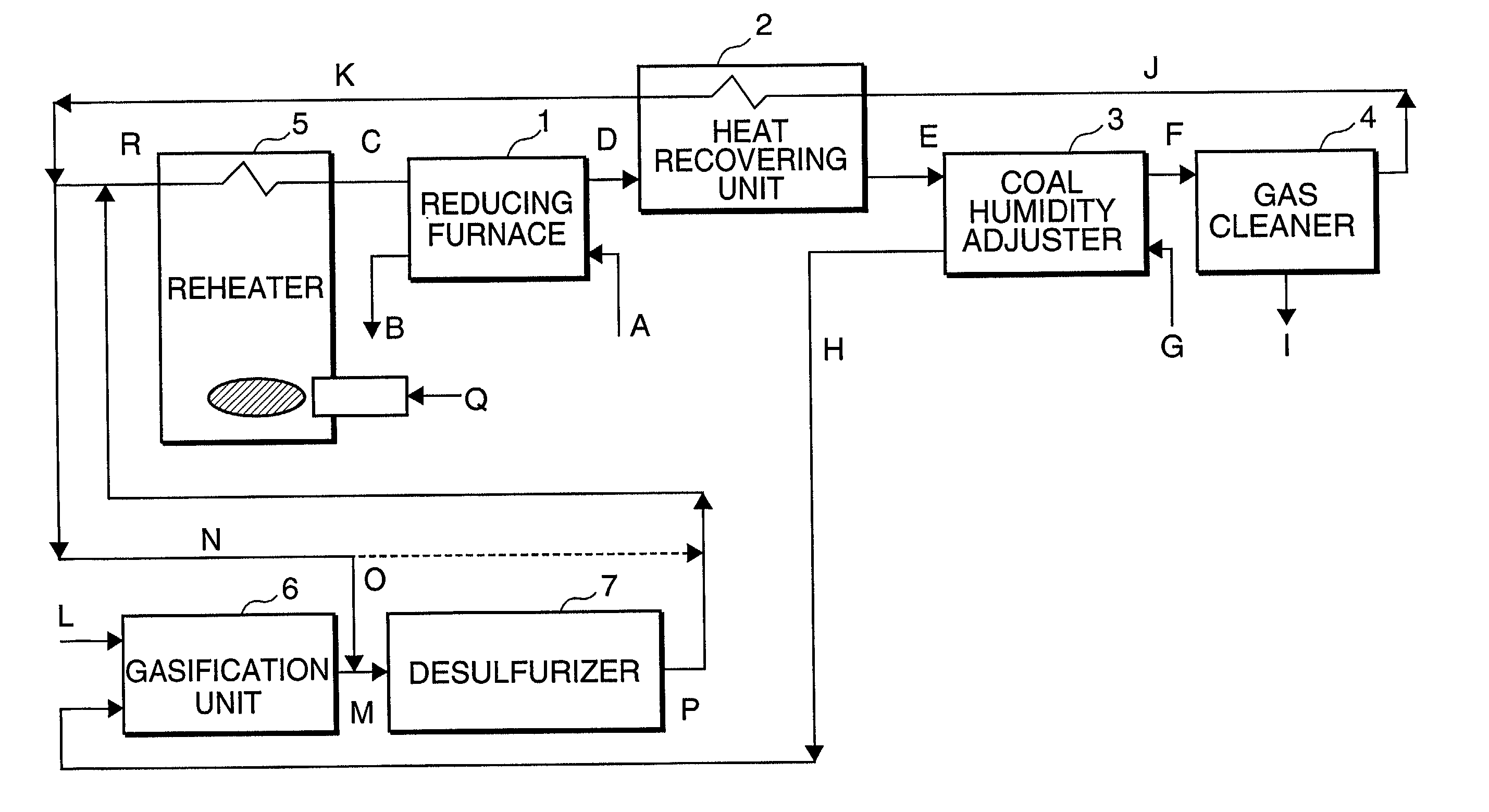

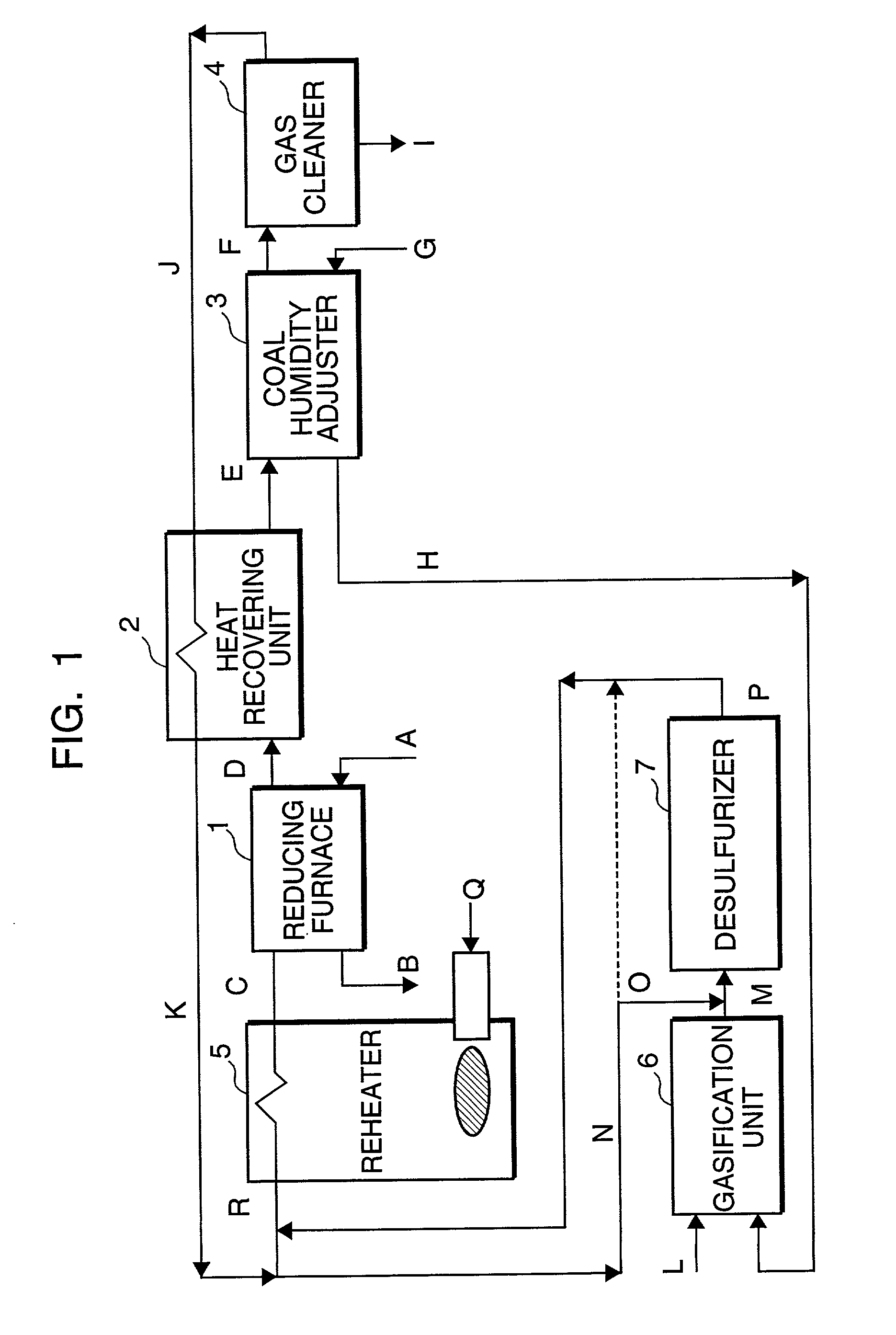

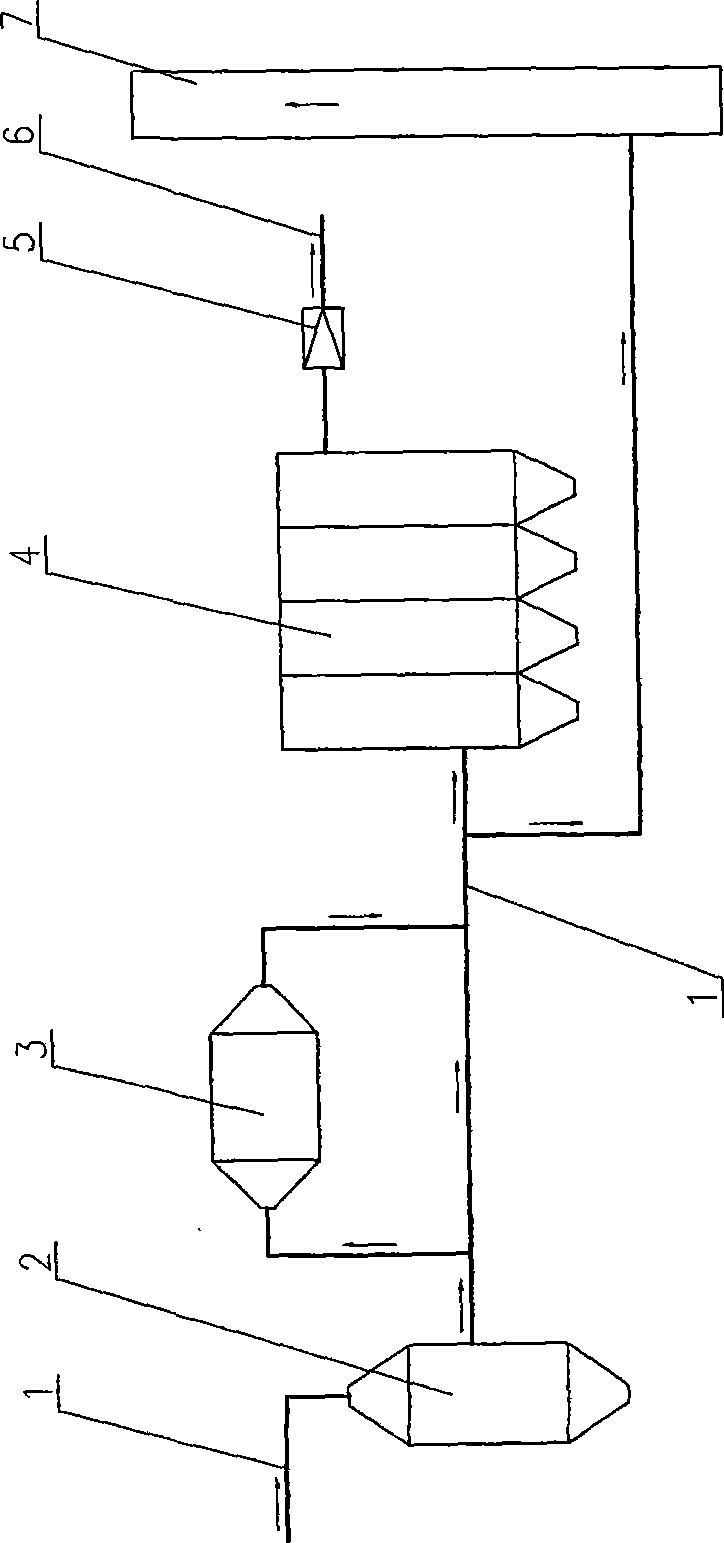

Method of producing direct reduced iron with use of coal-derived gas

InactiveUS20020078795A1Efficient use ofLow degreeTuyeresBell-and-hopper arrangementProduct gasCoal gasifier

In a method of producing direct reduced iron with use of a coal-derived gas, coal is heated to lower the moisture thereof, and the moisture-lowered coal is gasified in a coal gasification furnace to produce a coal-derived gas containing a reducing gas. The reducing gas is then utilized to reduce iron ore in an iron ore reducing furnace. With use of an exhaust gas from the iron ore reducing furnace, the coal is heated in the step of heating coal.

Owner:KOBE STEEL LTD +1

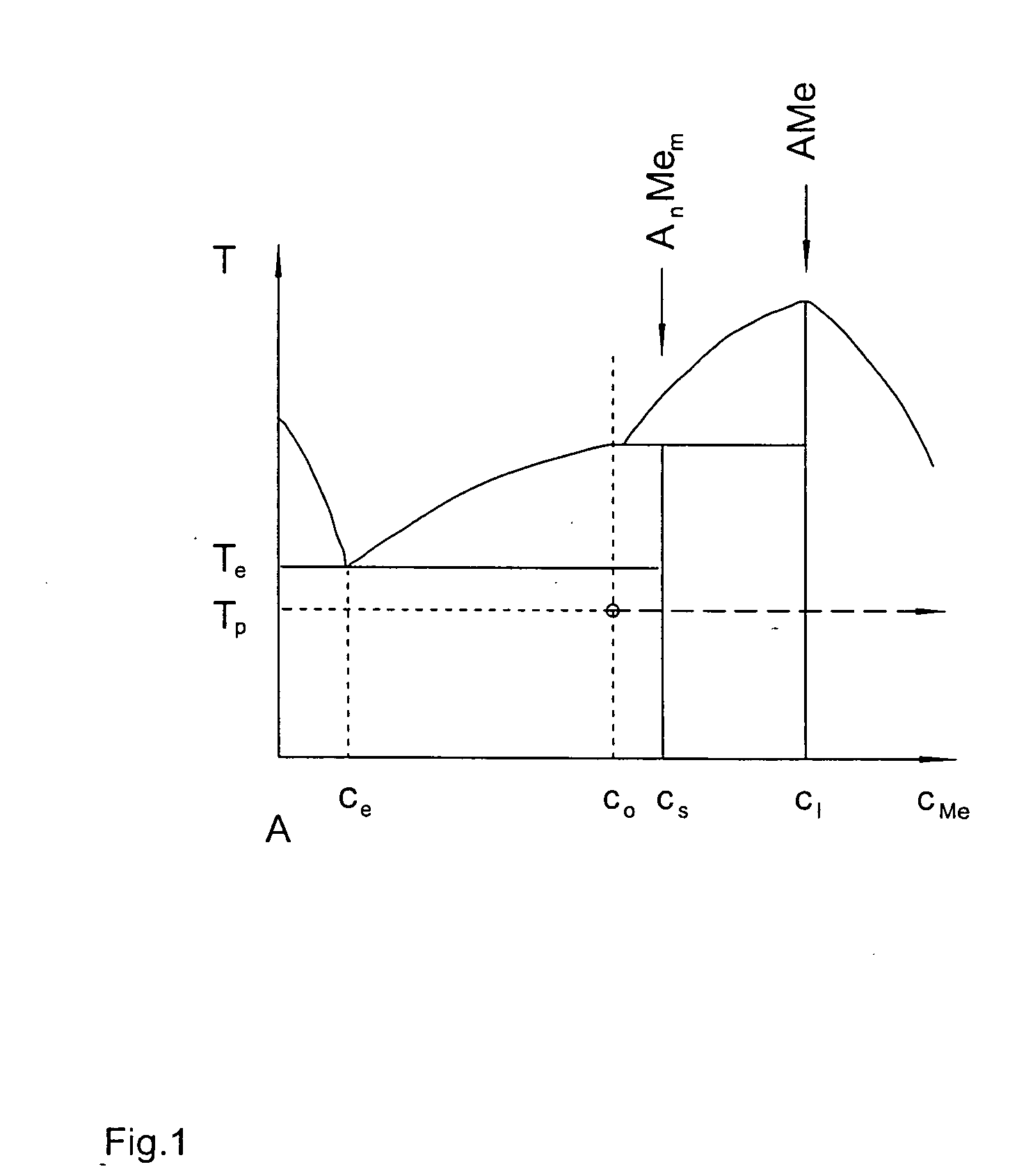

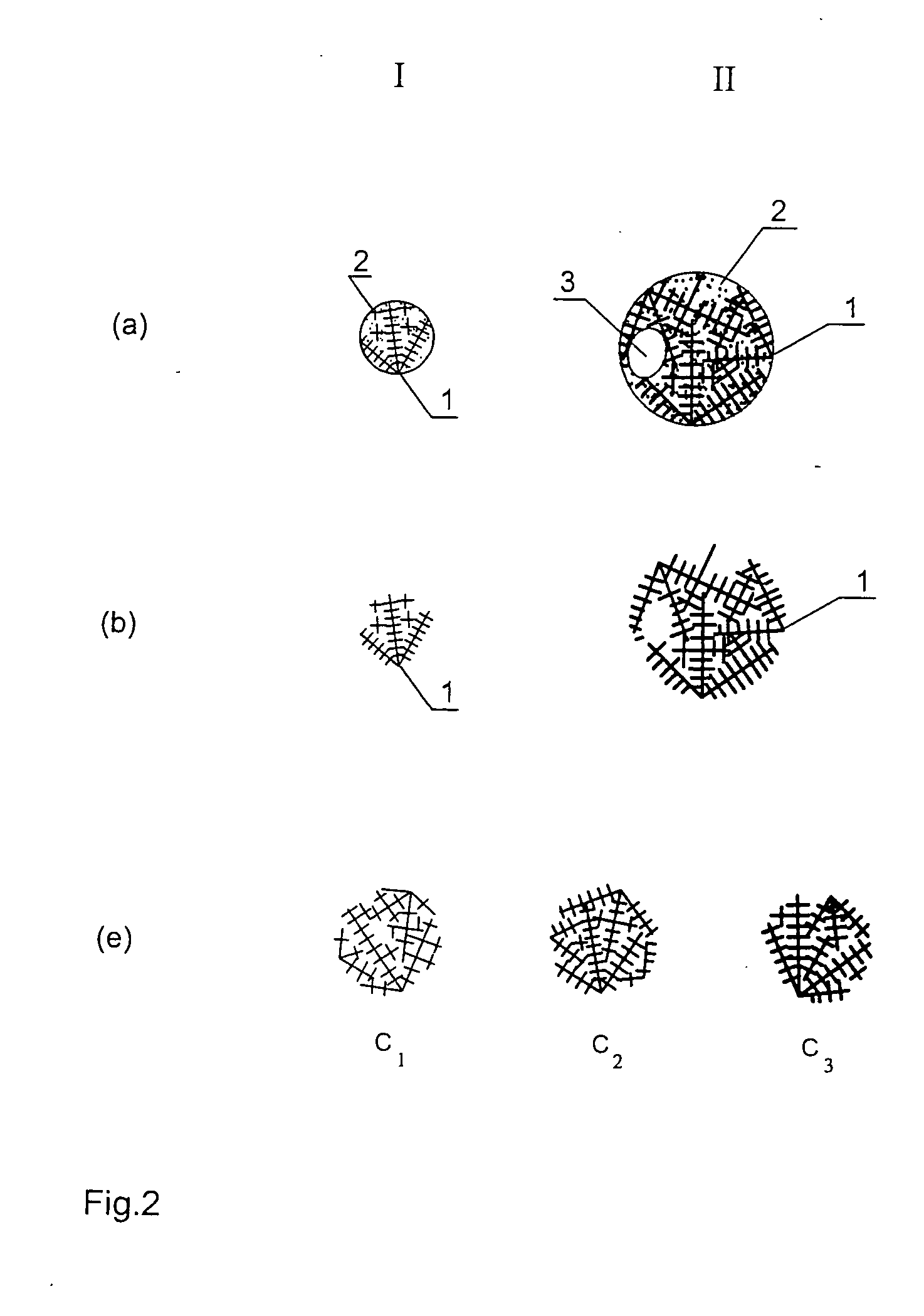

Gas sorbents on the basis of intermetallic compounds and a method for producing the same

InactiveUS20060225817A1Large specific surface areaDispersed particle separationBlast furnace detailsSorbentPositive pressure

The present invention relates to new gas sorbents on the basis of intermetallic compounds and a method for producing the same. The method comprises the following steps: mixing and melting of initial metals and homogenization of the melt under negative pressure of inert gas, manufacturing of cast shot by quenching of melted droplets under positive pressure, obtaining of skeleton-type granules by evaporation of the excess of the component A from cast shot under vacuum.

Owner:NANOSHELL MATERIALS RES & DEV

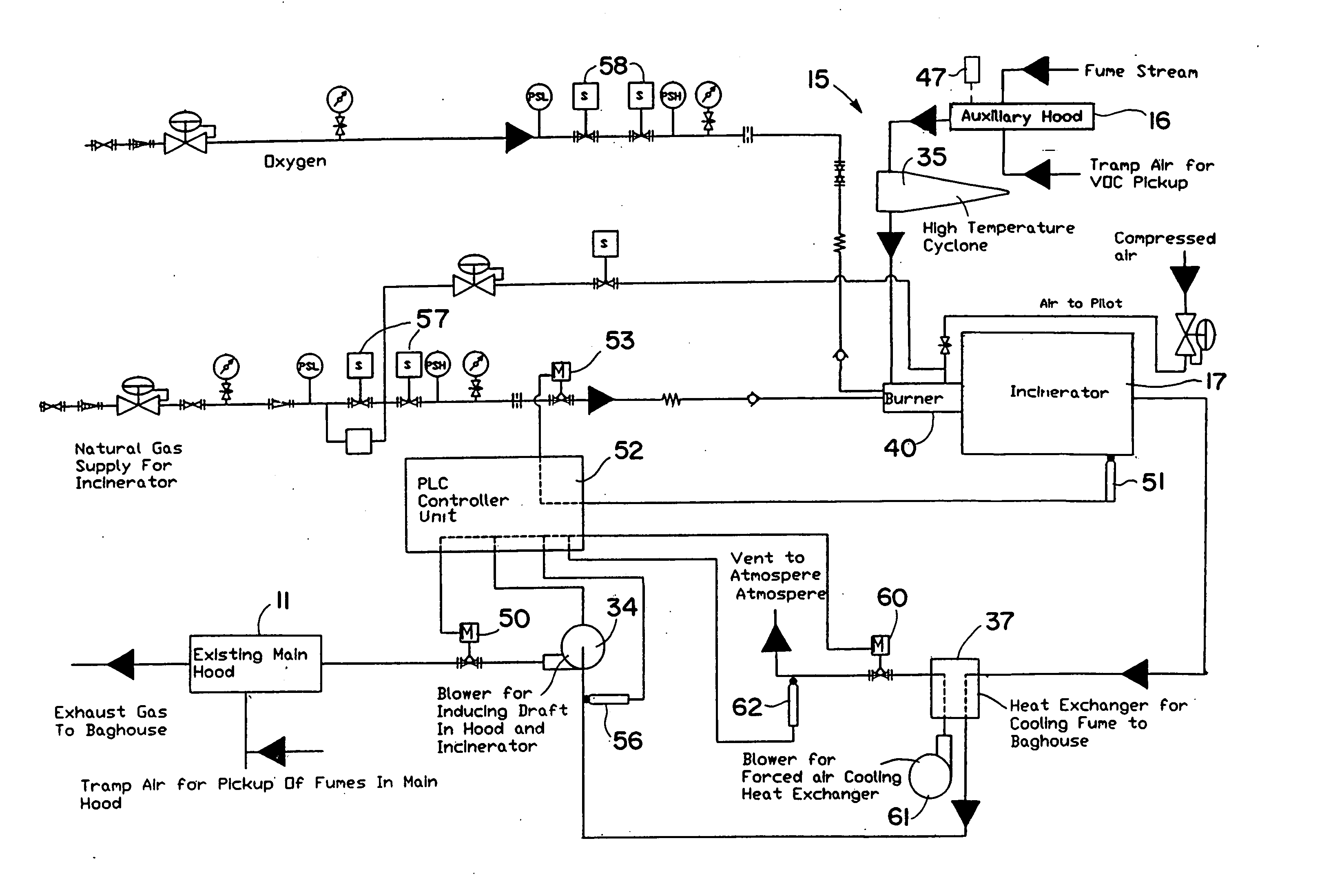

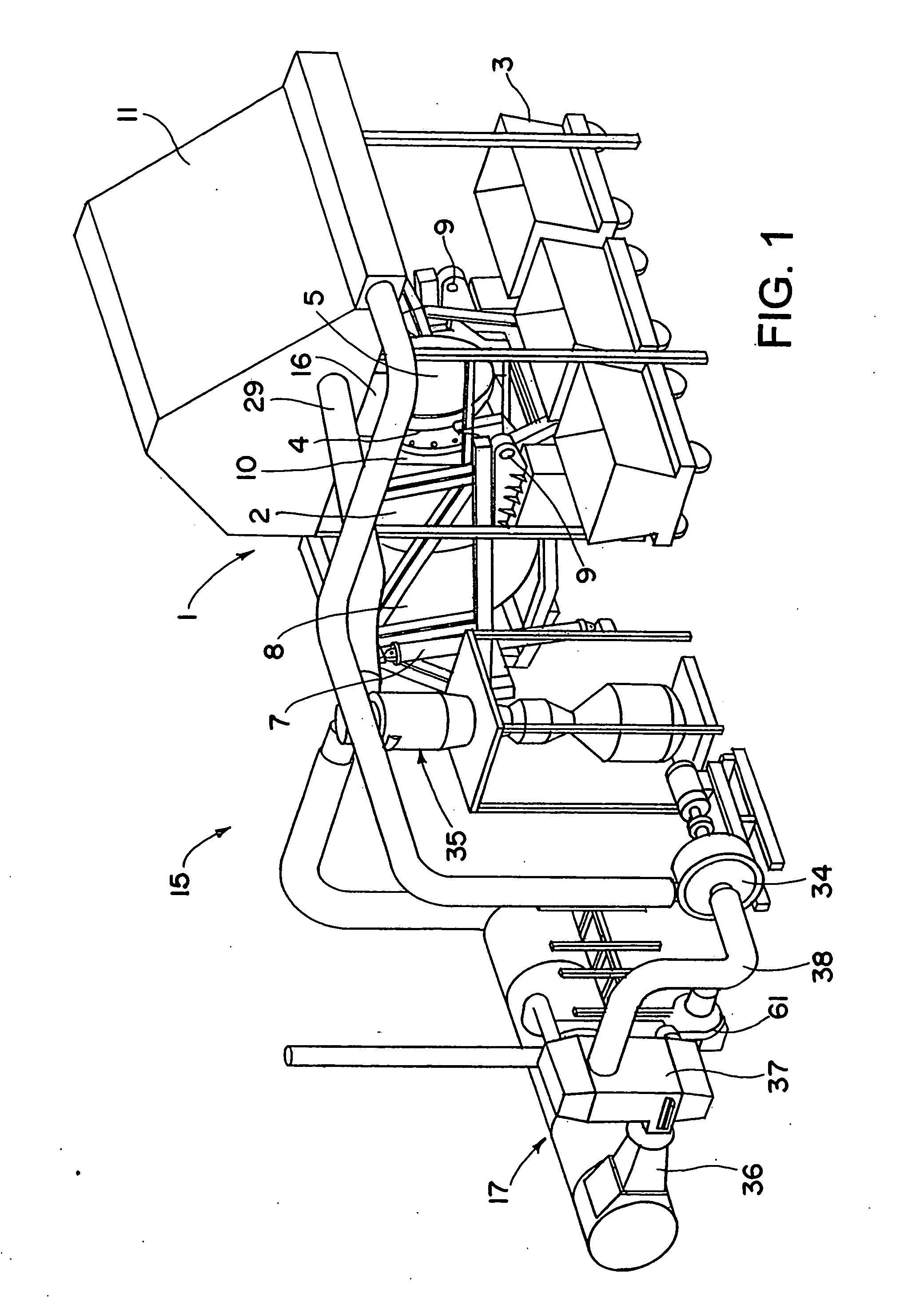

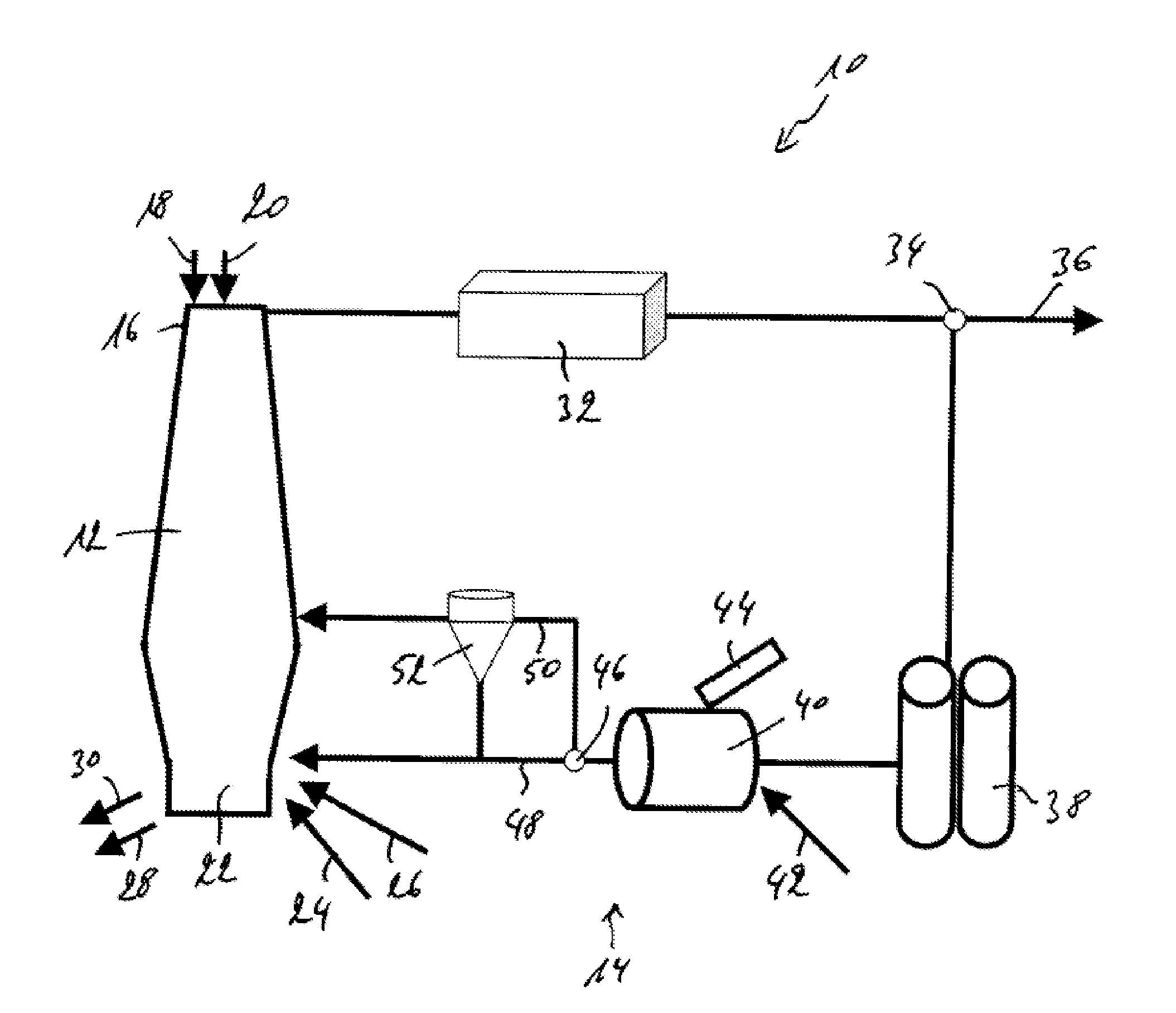

Fume treatment system and method

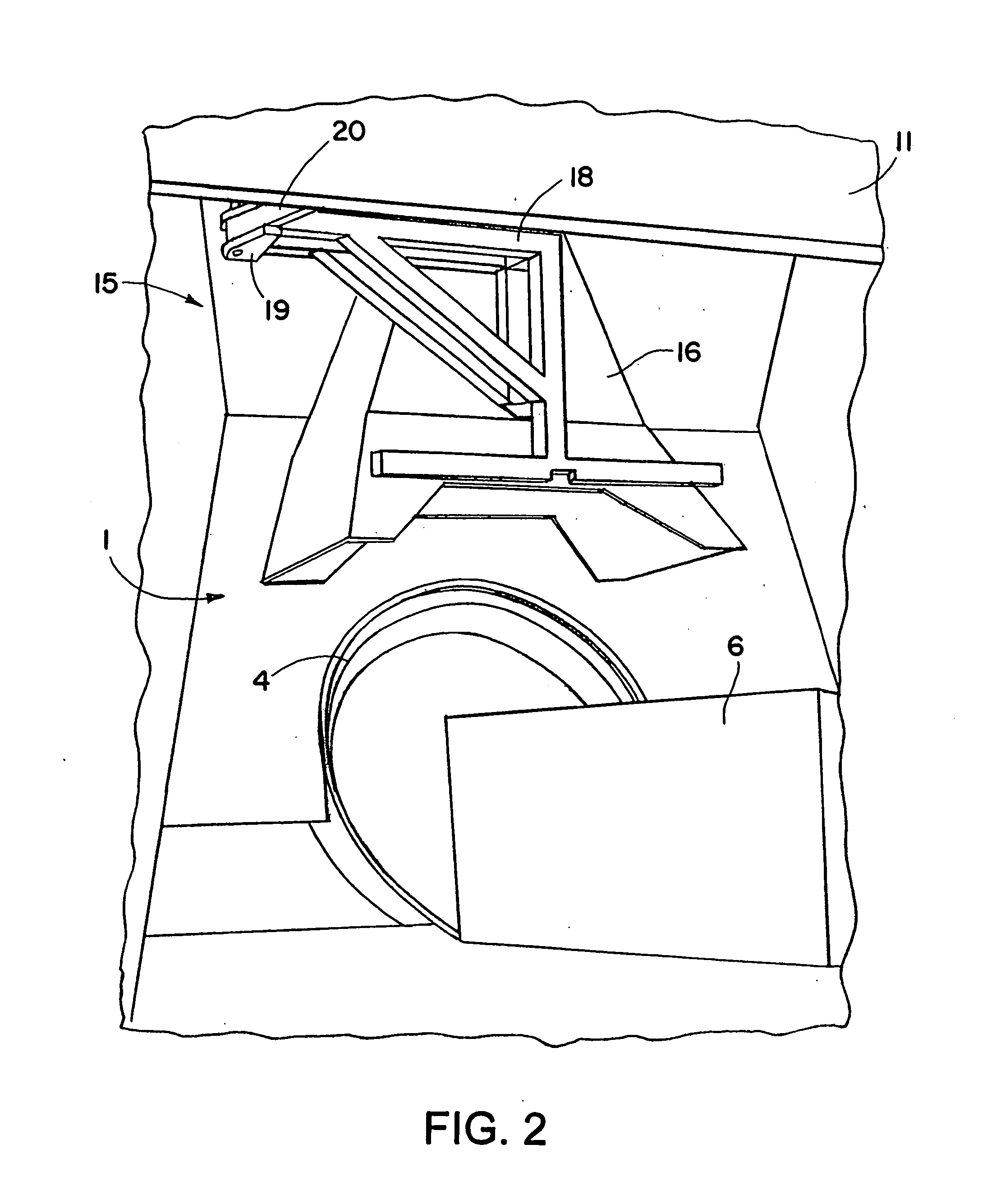

InactiveUS20050077658A1Minimized volumeSmall sizeBlast furnace detailsManufacturing convertersCycloneParticulates

A fume treatment system and method for treating a fume stream emitted from the mouth of a furnace chamber of a metal reclamation furnace system during a portion of the reclamation process includes an auxiliary hood that is smaller than the main overhead hood and is movable between an operative position over the furnace chamber mouth within the main overhead hood for collecting the fume stream emitted by the furnace chamber mouth and another position spaced from, the furnace chamber mouth. An incinerator is in fluid communication with the auxiliary hood when in the operative position. A fume stream blower causes the fume stream collected by the auxiliary hood when in the operative position to flow to the incinerator for incinerating hydrocarbons or other combustible compounds present in the fume stream during operation of the incinerator. A cyclone may be in the flow path between the auxiliary hood and the incinerator for removing particulates from the fume stream prior to entering the incinerator. Also a heat exchanger may be downstream of the incinerator for reducing the temperature of the fume stream exiting the incinerator prior to returning the fume stream to the main overhead hood for further processing.

Owner:ALTEK LLC

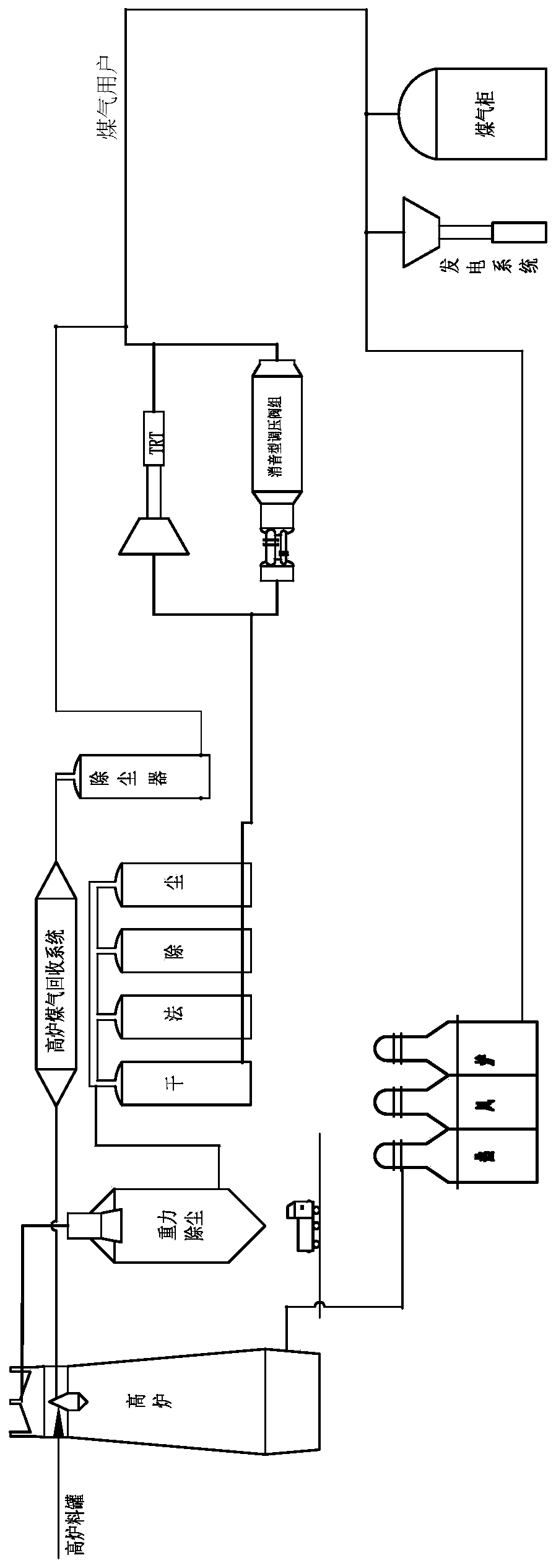

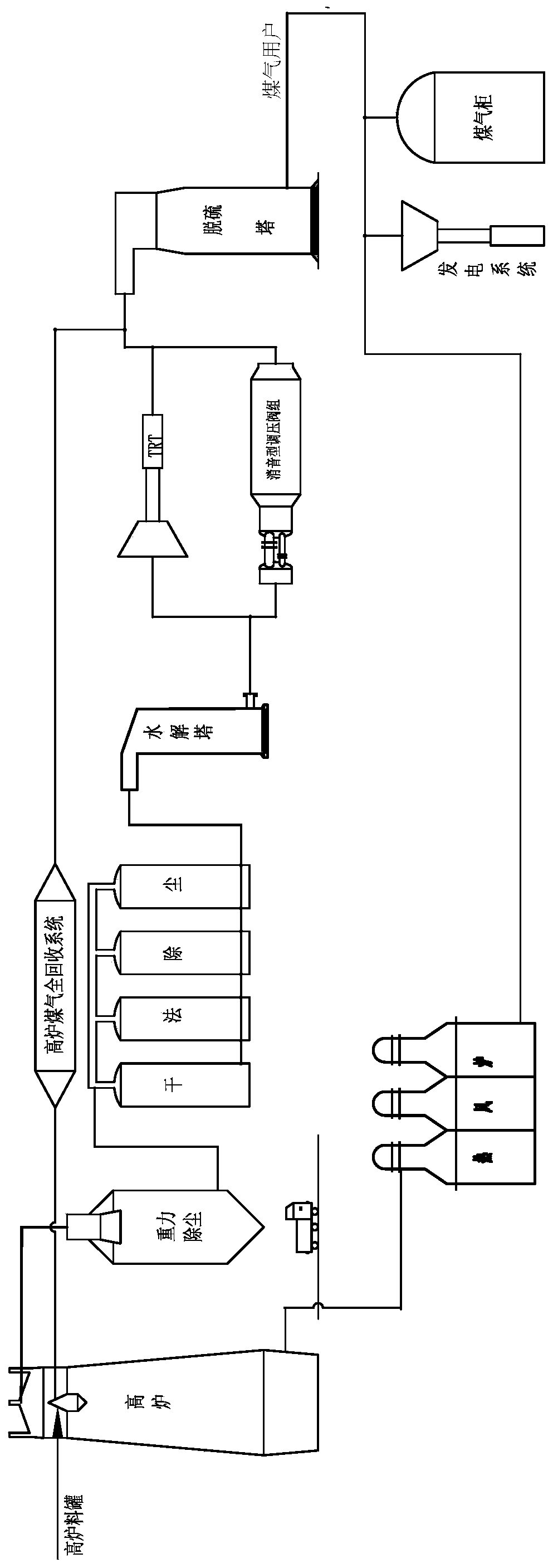

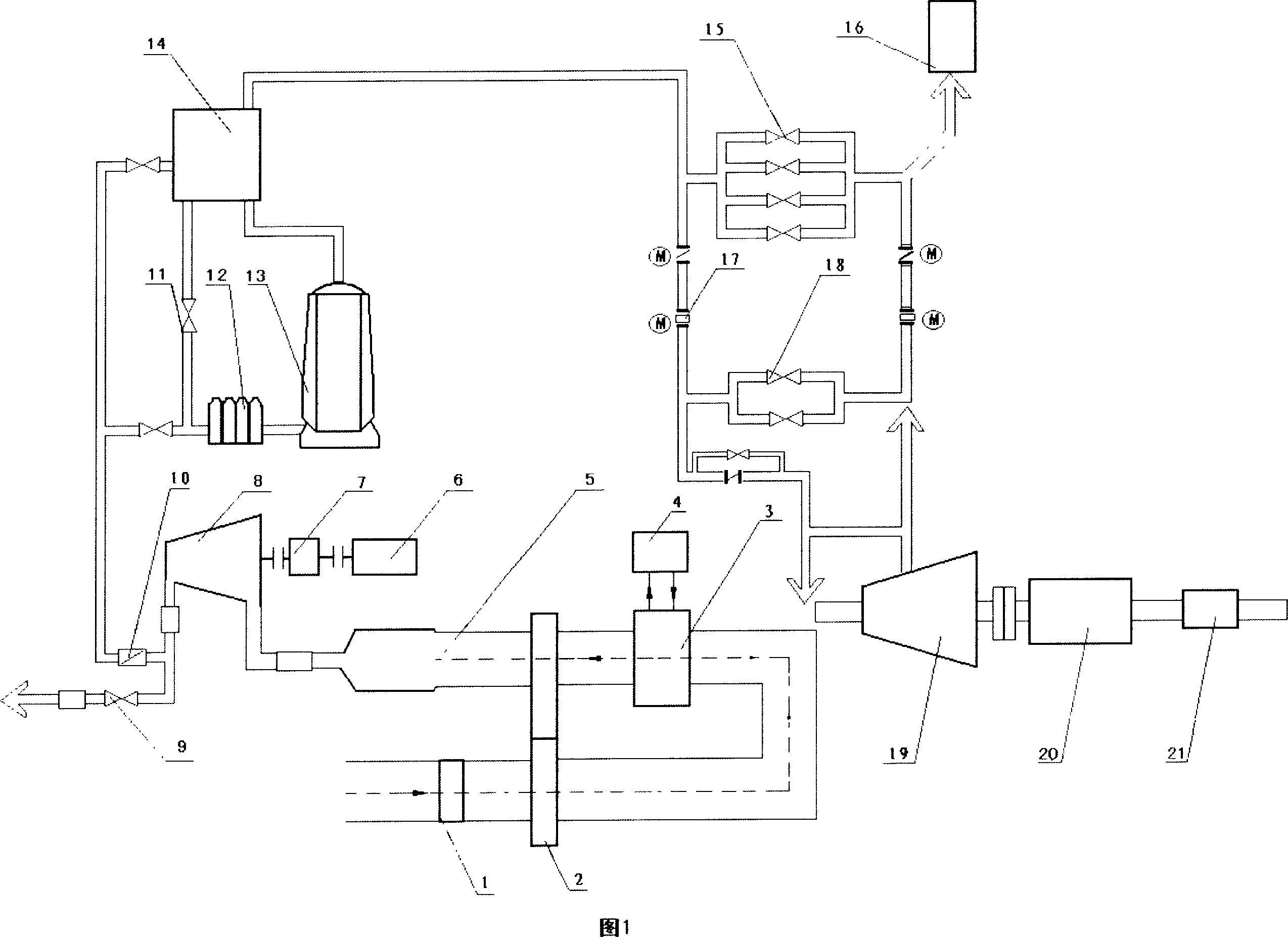

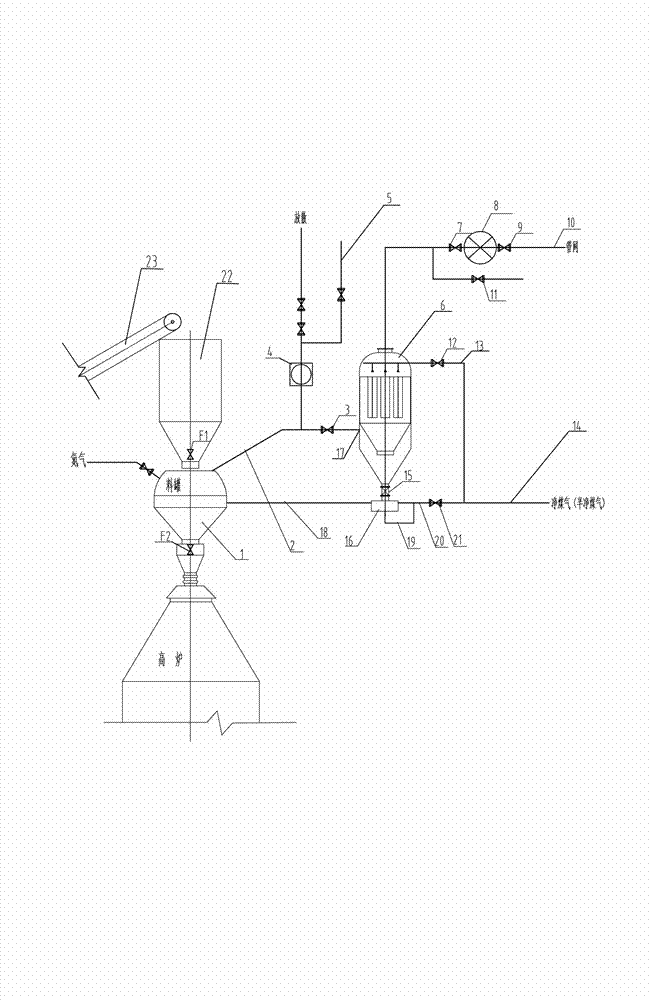

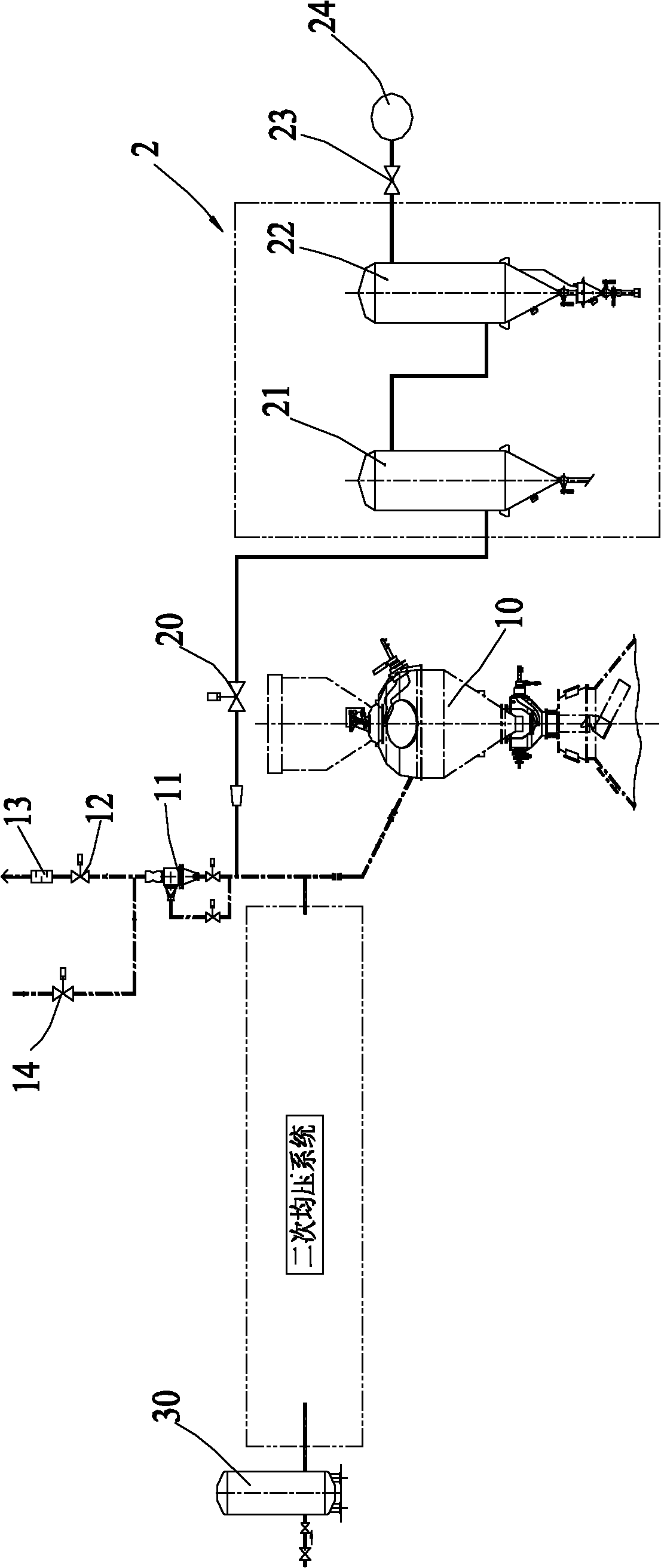

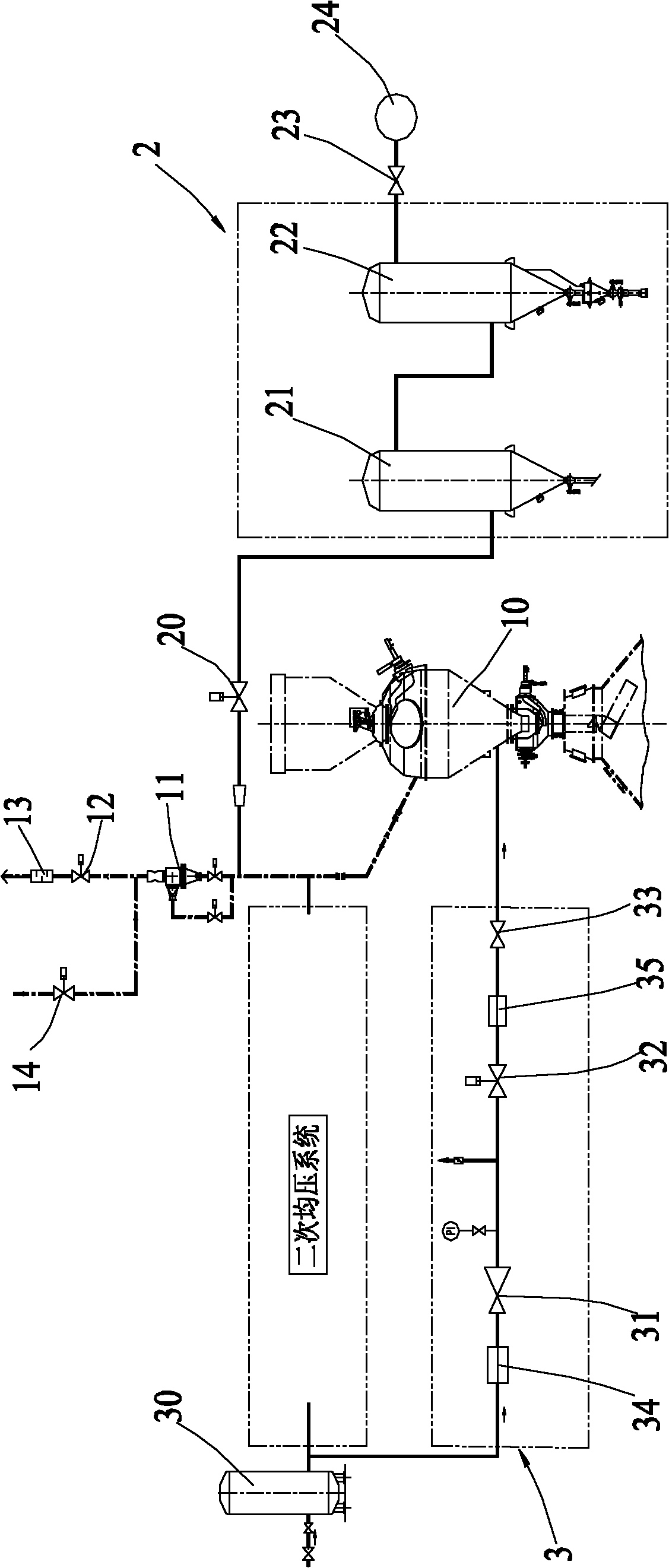

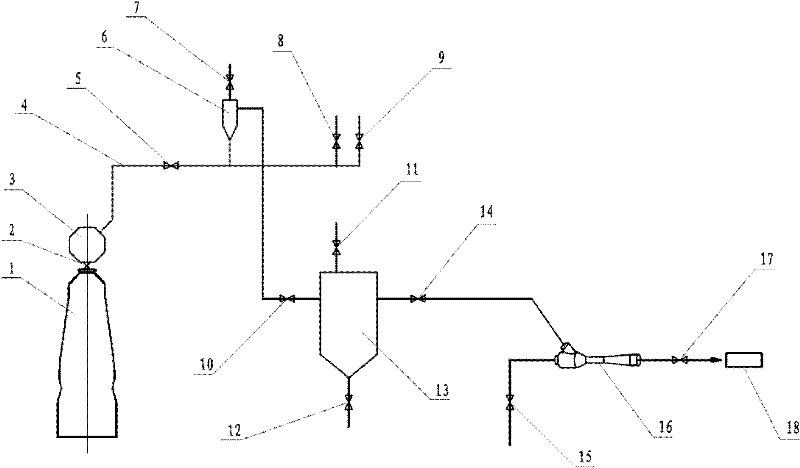

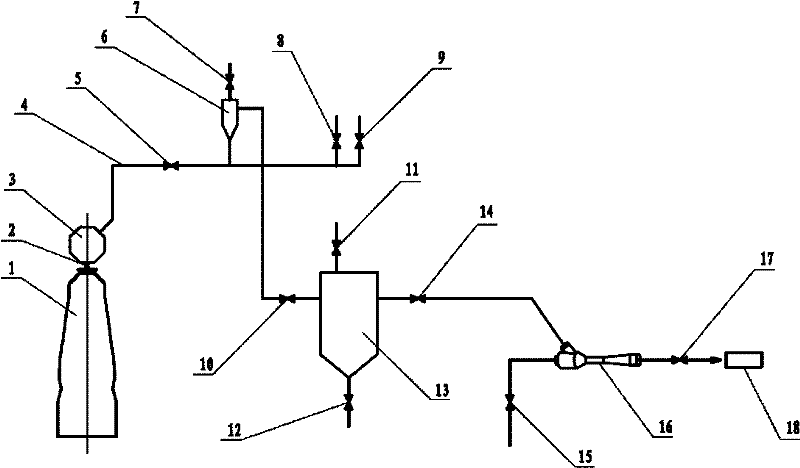

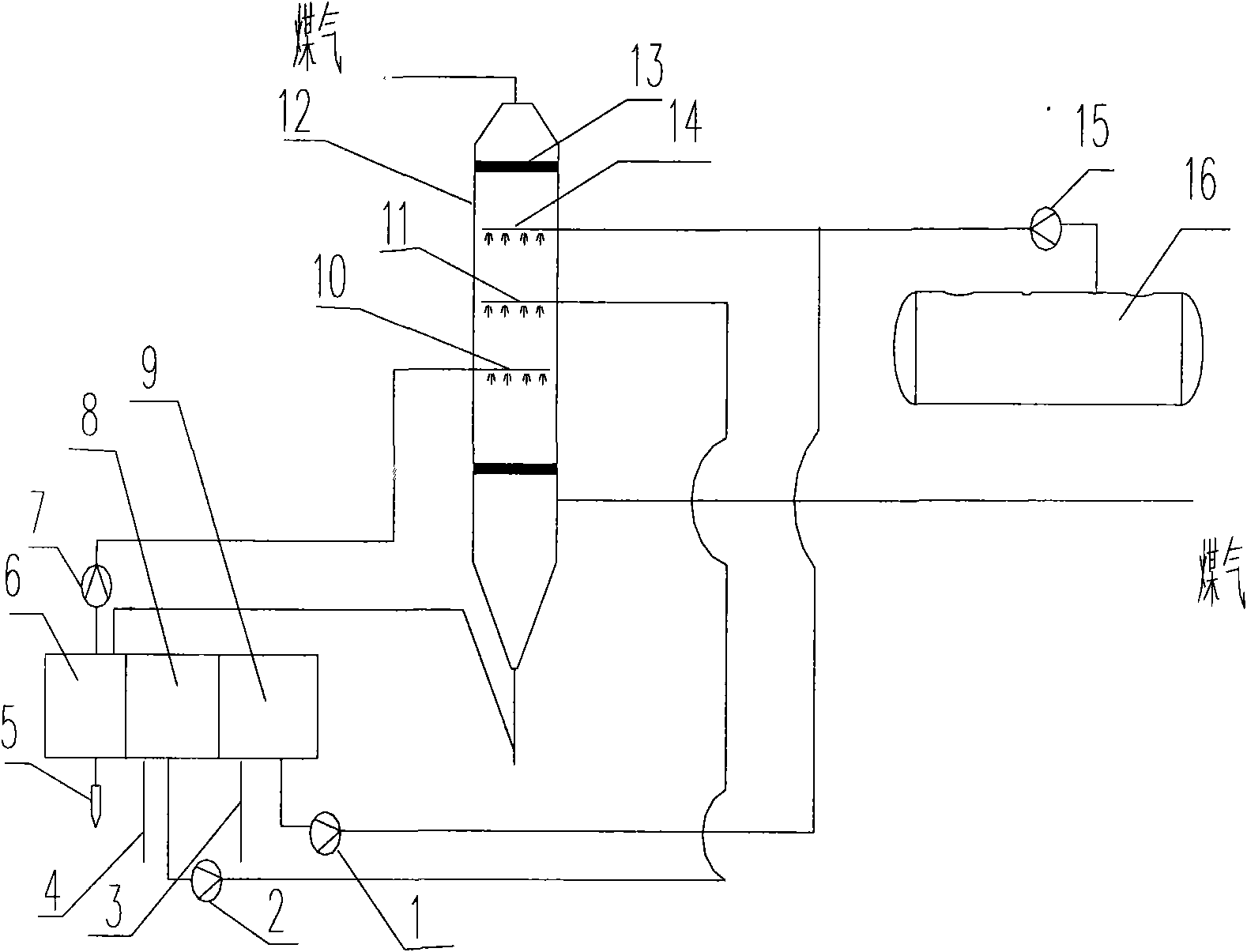

System and technology for environmentally-friendly comprehensive treatment of iron making blast furnace gas

PendingCN110452744AEfficient removalGroundbreakingBlast furnace detailsDust arrestersFull recoveryMetallurgy

The invention provides a system and a technology for environmentally-friendly comprehensive treatment of iron making blast furnace gas. The system comprises a blast furnace top uniform pressure gas full-recovery system, a gravity deduster and a dry bag filter, and further comprises a blast furnace gas hydrolysis tower and a blast furnace gas desulfurization tower. The blast furnace gas goes through the gravity deduster and the dry bag filter, and then is conveyed into the blast furnace gas hydrolysis tower, COS in the blast furnace gas is hydrolyzed by the blast furnace gas hydrolysis tower toform H2S; the treated blast furnace gas goes through a TRT / or pressure regulating valve group, and then is conveyed into the blast furnace gas desulfurization tower, and the blast furnace gas desulfurization tower desulfurizes and dechlorinates H2S and Cl<-> in the blast furnace gas; and the treated blast furnace gas is conveyed into a blast furnace gas user or is stored in a gas cabinet througha gas pipe network. The integral treatment technology which integrates blast furnace gas desulfurization, dechlorination and blast furnace top uniform pressure gas recovery has a high integration degree, and can run stably and reliably.

Owner:LOFON CONTROL EQUIP BEIJING

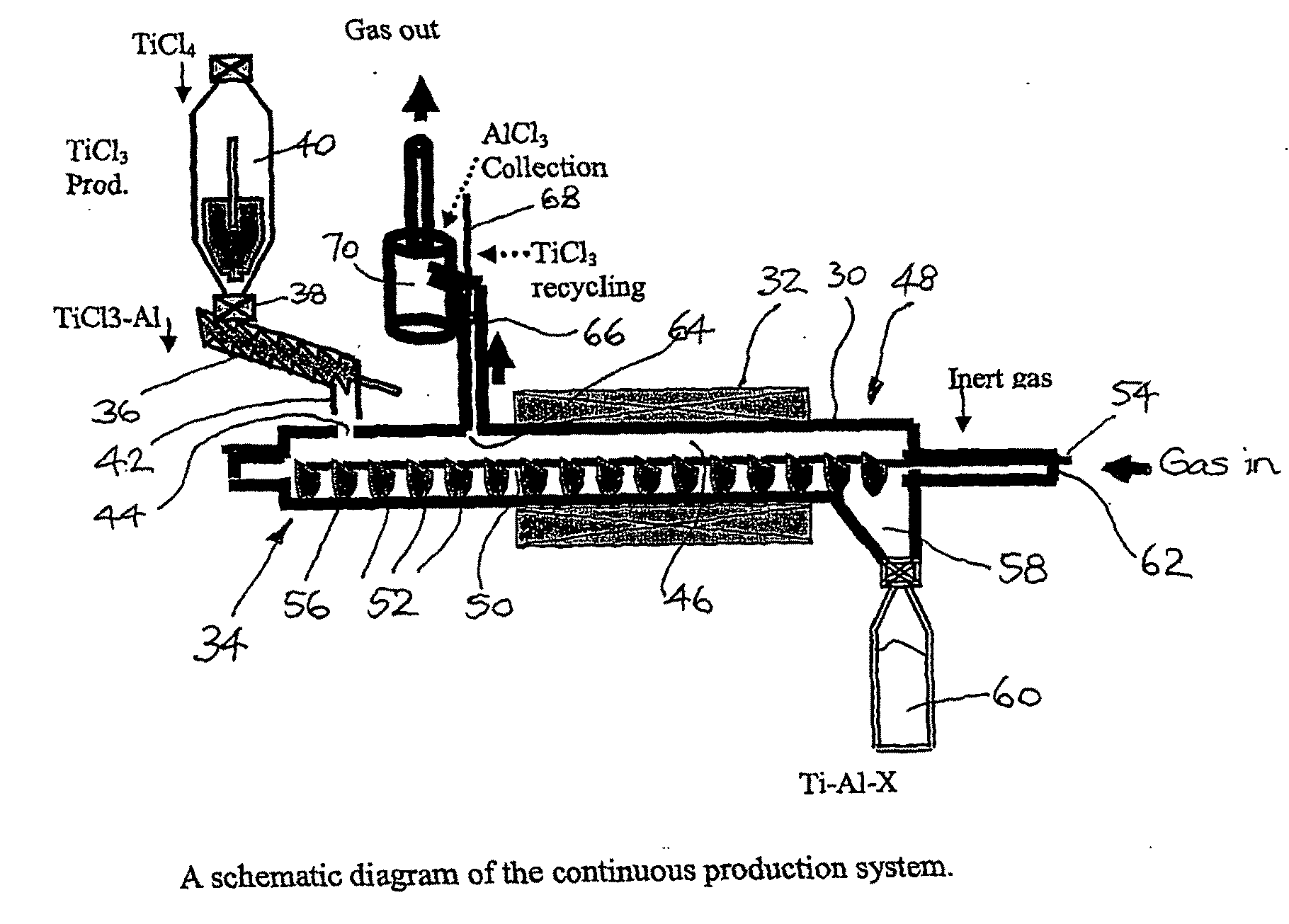

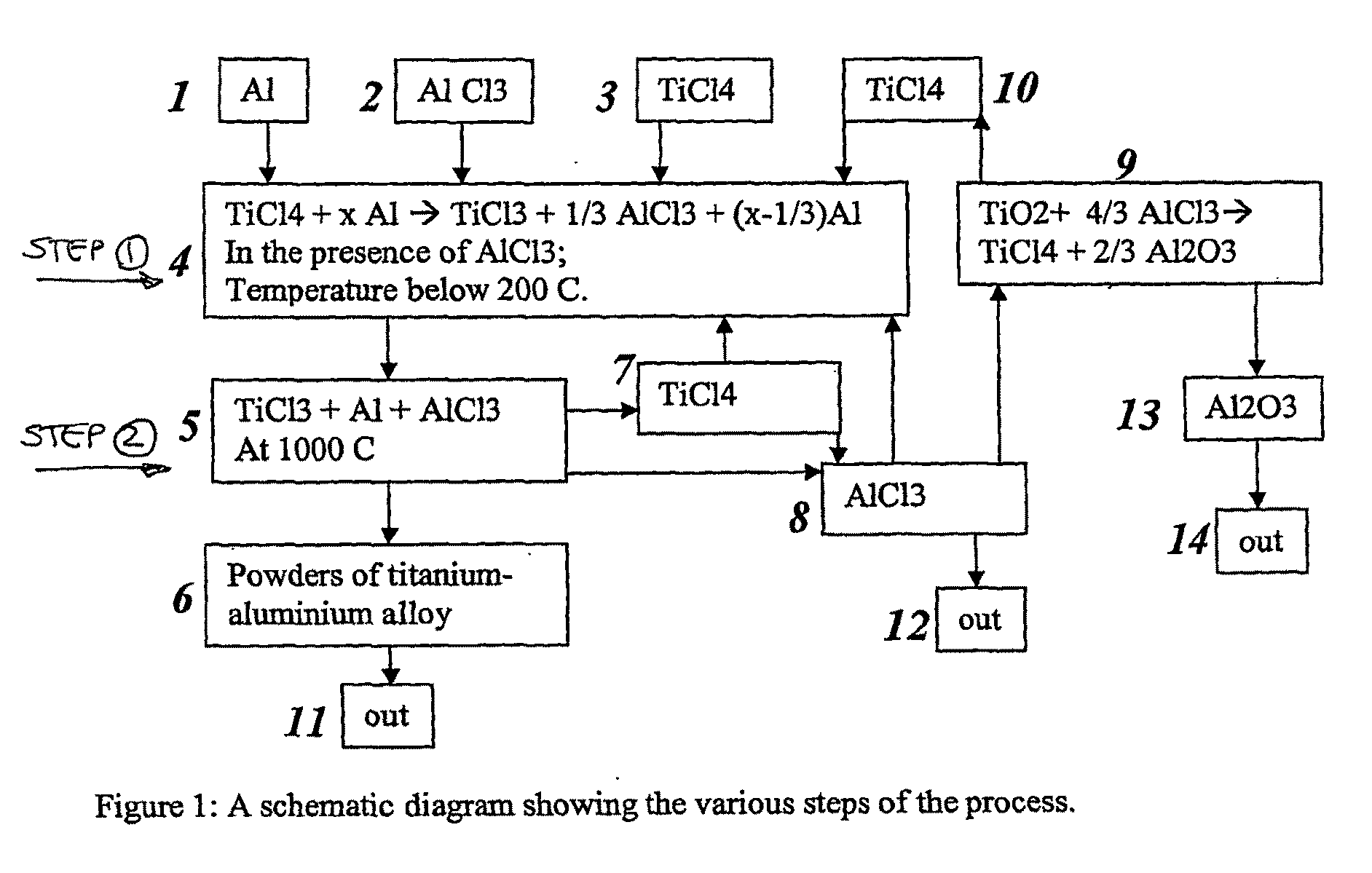

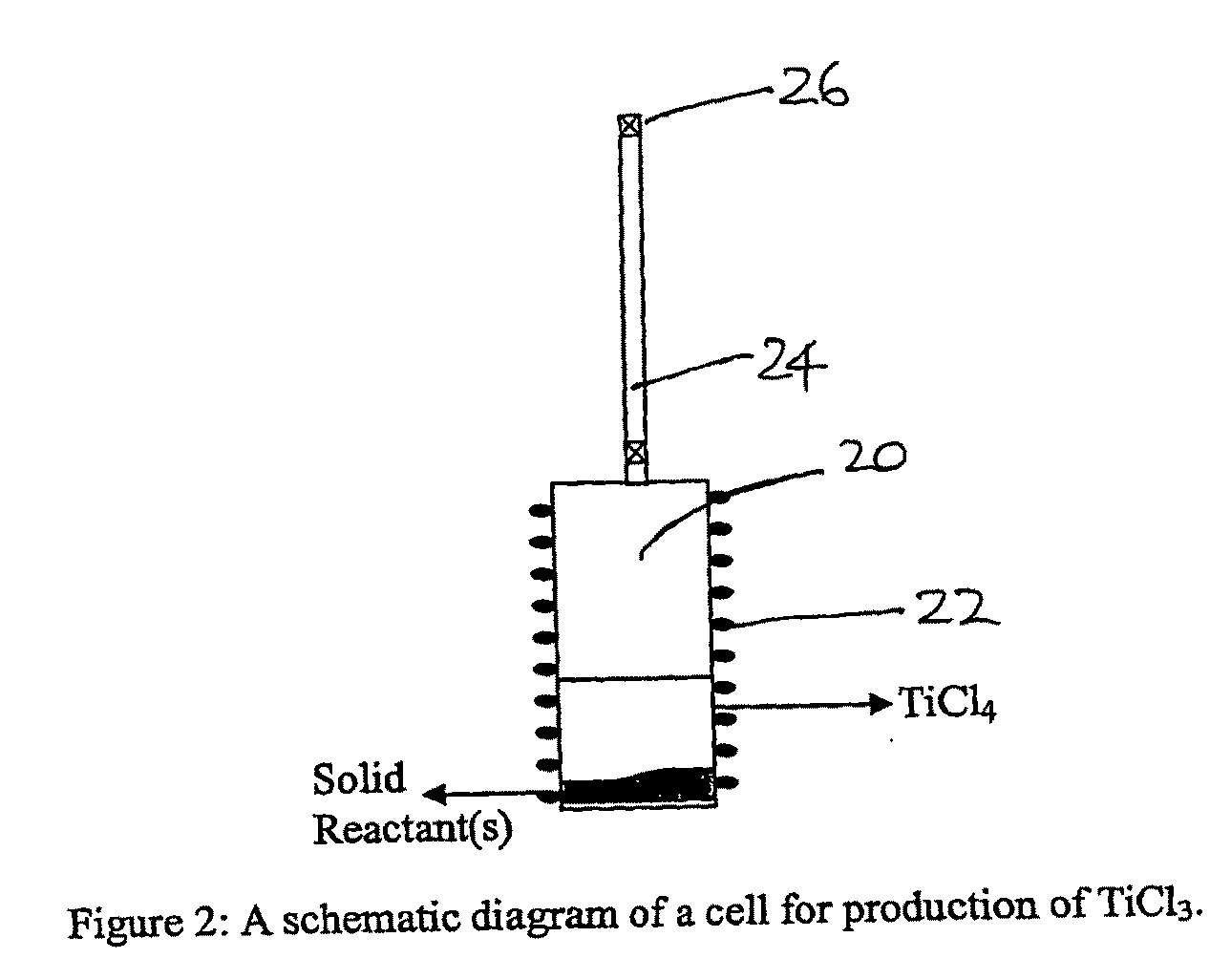

Apparatus and Methods for the Production of Metal Compounds

ActiveUS20090165597A1Improve thermal conductivityInexpensive materialsBlast furnace detailsManufacturing convertersAluminium chlorideTitanium chloride

The present invention relates to a stepwise method for the production of titanium-aluminium compounds and some titanium alloys and titanium-aluminium inter-metallic compounds and alloys. In a first step an amount of aluminium is mixed with an amount of aluminium chloride (AlCl3) and then an amount of titanium chloride (TiCl4) is added to the mixture. The mixture is heated to a temperature of less than 220° C. to form a product of TiCl3, aluminium and AlCl3. In a second step, more aluminium can be added if required, and the mixture heated again to a temperature above 900° C. to form titanium-aluminium compounds. This method results in the production of powdered forms of titanium-aluminium compounds with controllable composition. Suitable reactor apparatus is also described.

Owner:COMMONWEALTH SCI & IND RES ORG

Efficient economical dust collecting method and dust collector for iron-smelting blast furnace

InactiveCN101074453AImprove the efficiency of waste heat recovery and utilizationIncrease temperatureBlast furnace detailsCooling devicesCombustionHeat transfer efficiency

An efficient energy-saving dust-collecting method and its apparatus for iron-smelting blast furnace are disclosed. The procedure is carried out by pre-cooling wet air before entering them into air blower, re-cooling, lowering temperature below saturated temperature, coagulating while precipitating for water content in wet air, re-cooling, delivering into blast furnace by air blower, discharging smoke from blast furnace, heat-exchanging, recovering partial tailed heat, lowering temperature, bagged collecting dust, storing or generating. It's cheap and simple, has higher heat-transfer rate, long utilizing life, less apparatus, full combustion and recovery and better high-temperature resistance for bagged dust collector.

Owner:童裳慧

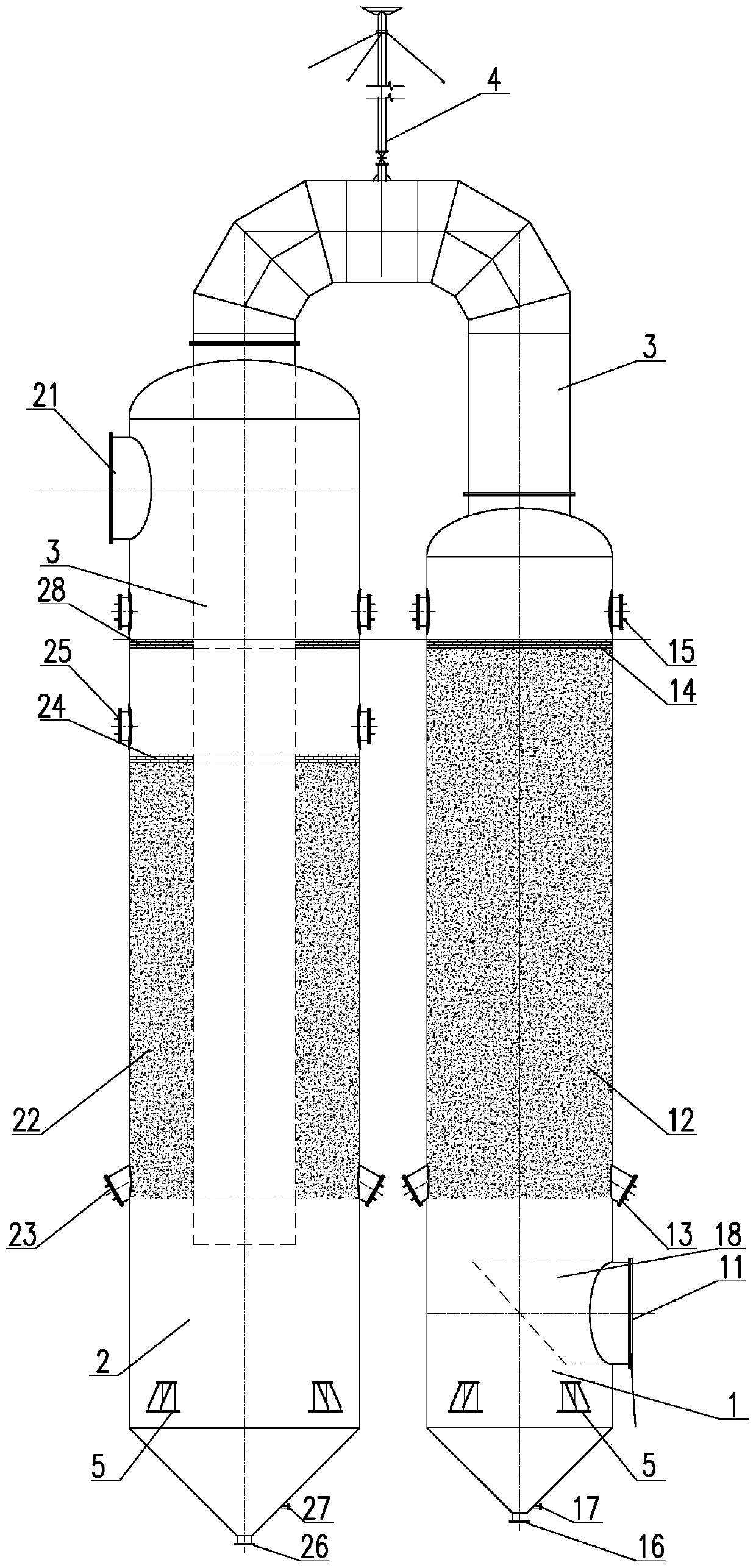

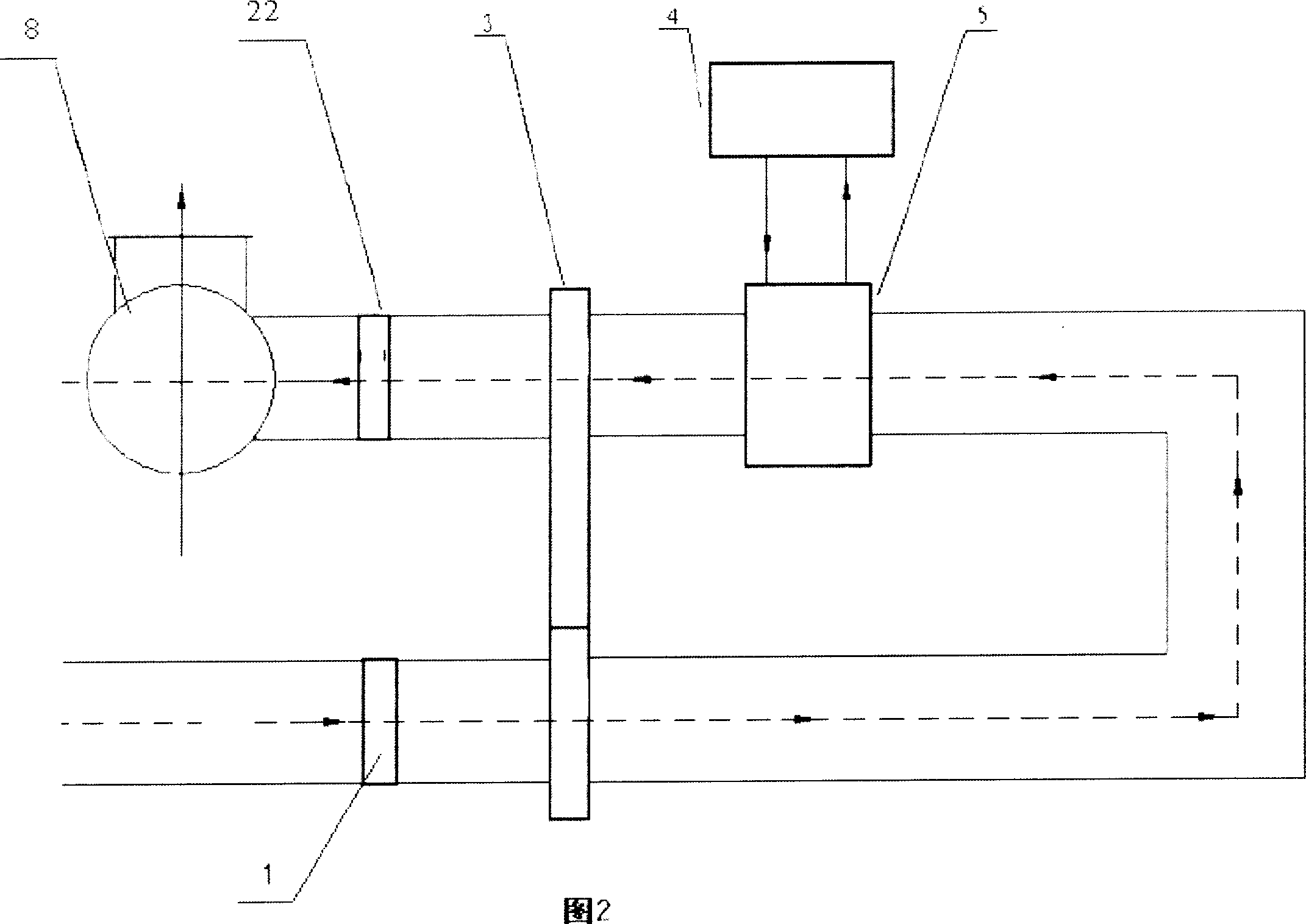

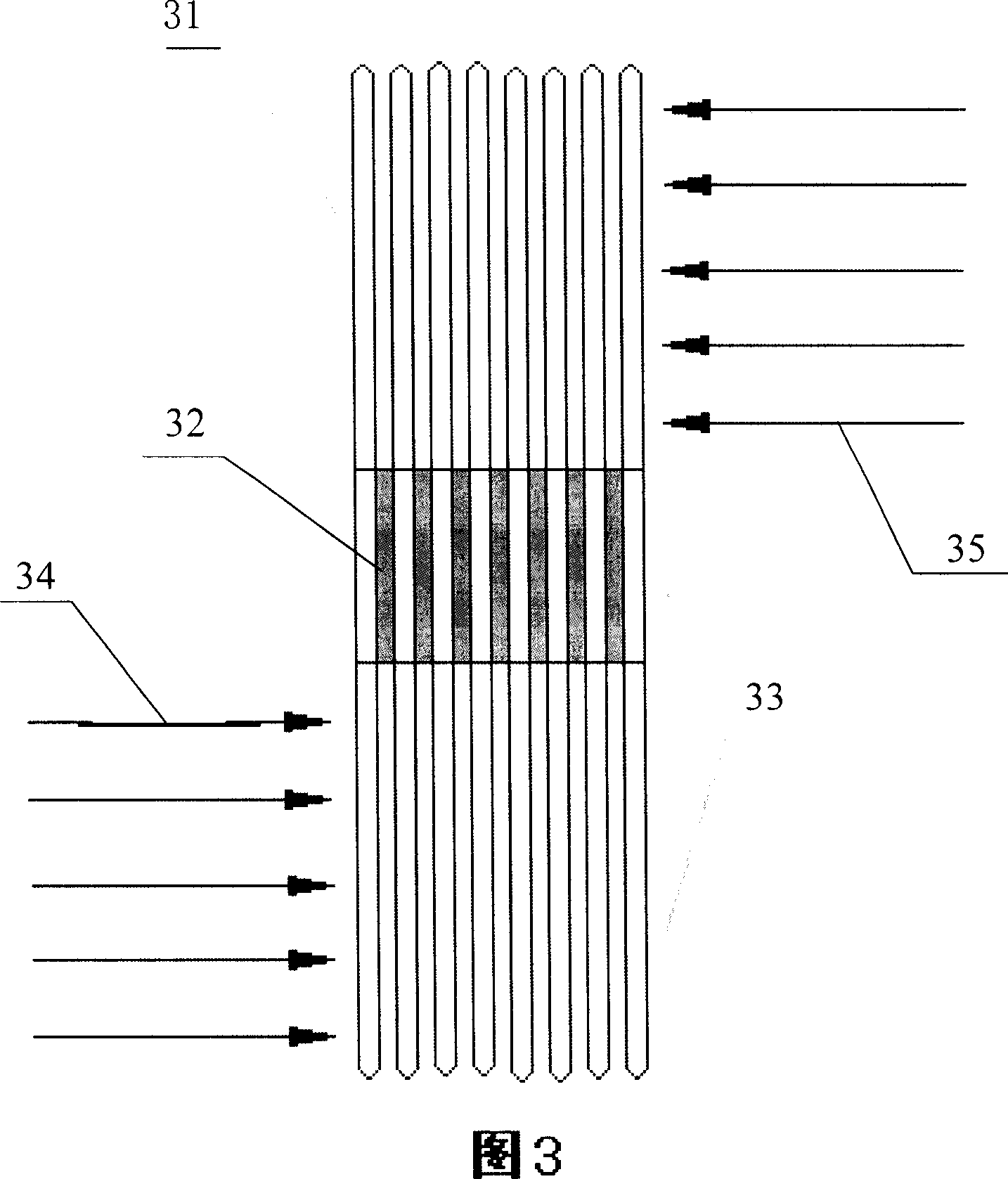

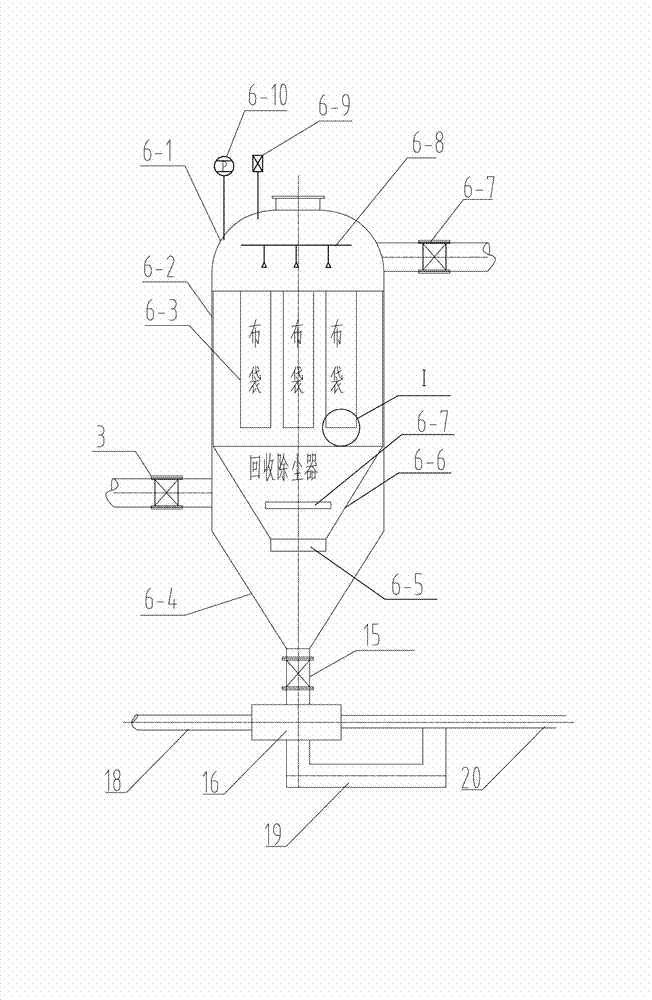

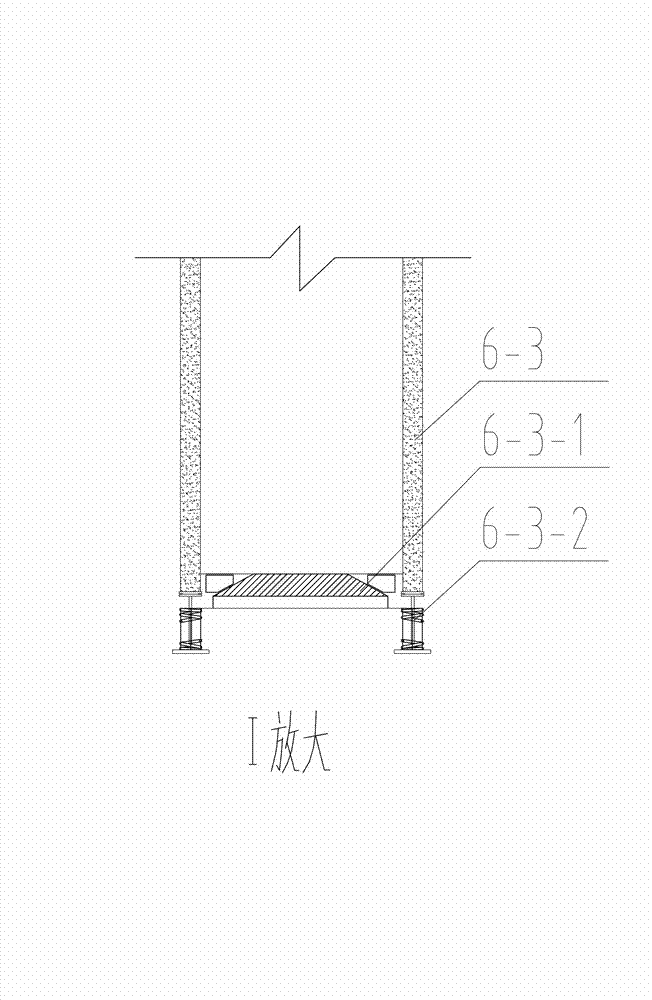

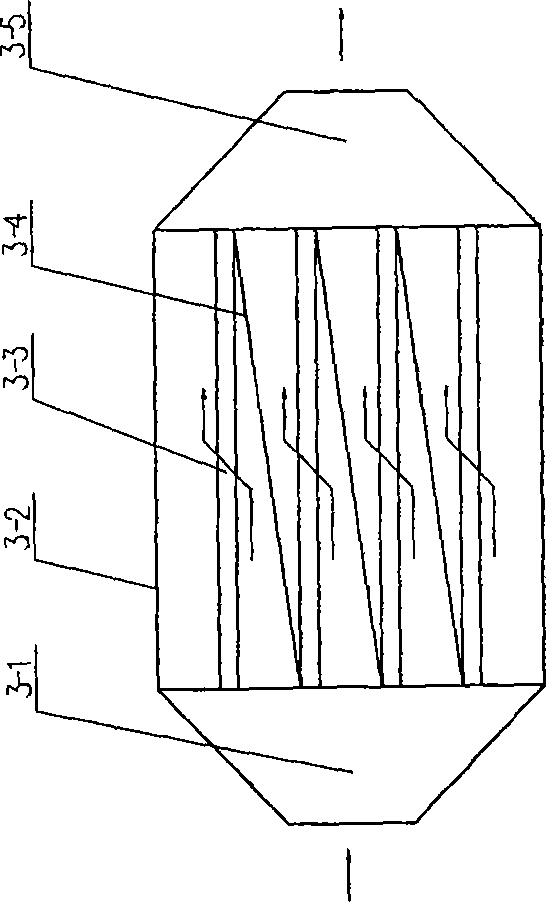

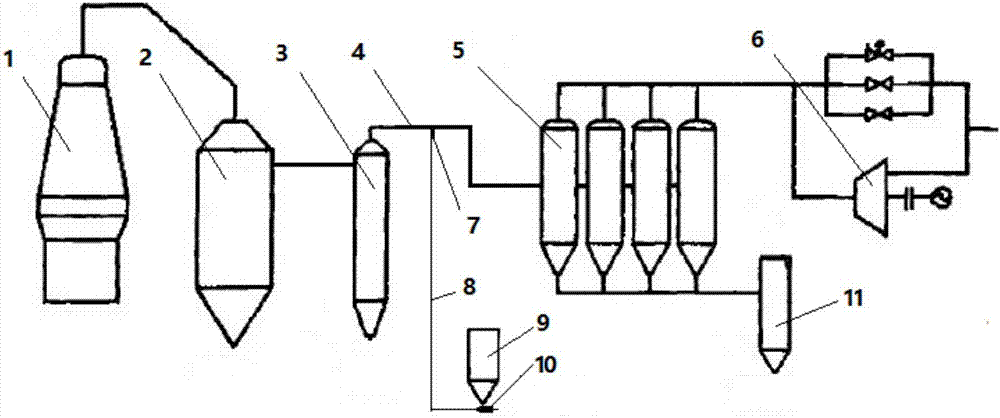

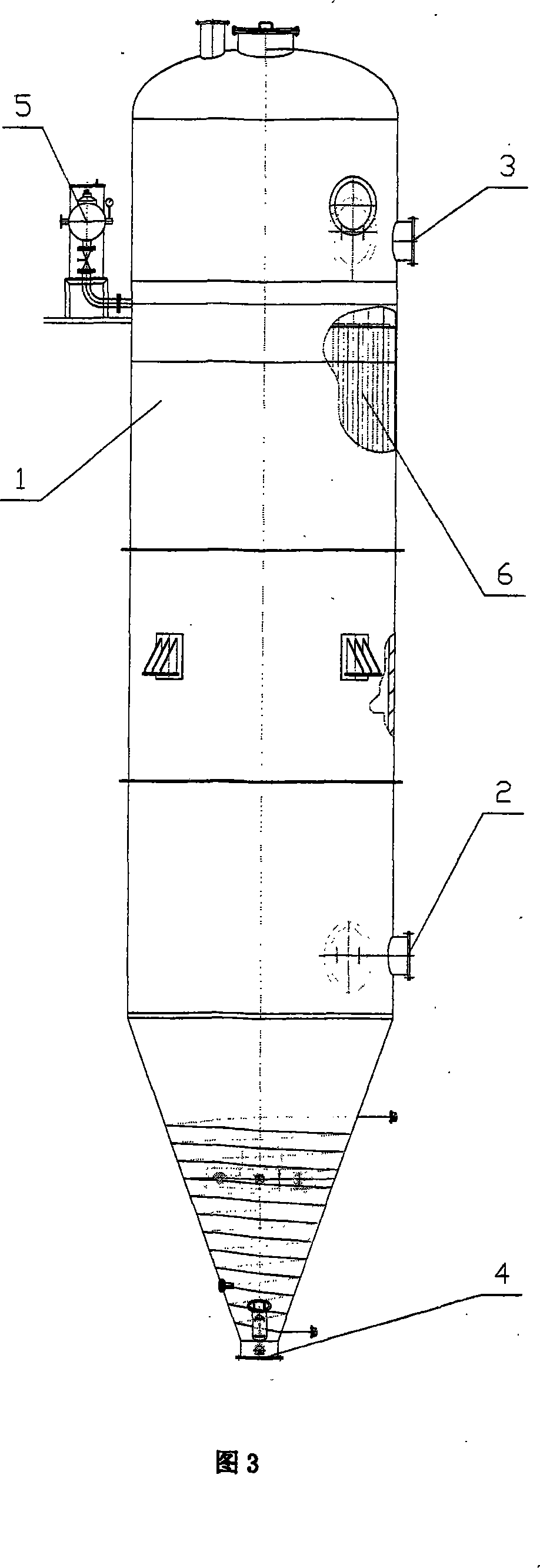

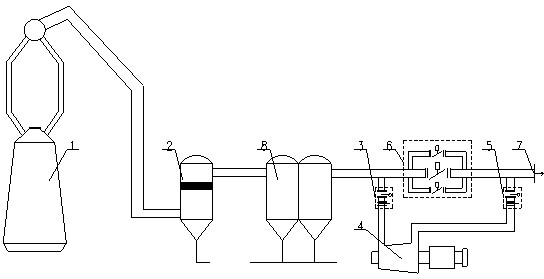

System for rotational flow dust removal and recovery of blast furnace roof raw gas and recovering method of blast furnace roof raw gas

The invention relates to a system for rotational flow dust removal and recovery of blast furnace roof raw gas and a recovering method of the blast furnace roof raw gas. According to the system and the method, the blast furnace roof raw gas which is diffused in a pressure equalizing mode from a blast furnace charging bucket is directly fed into a blast furnace gas bag-type dust remover for dust removal, a built-in type round platform-shaped cyclone is additionally arranged on the lower portion of a casing of the blast furnace gas bag-type dust remover, the raw gas which enters the blast furnace gas bag-type dust remover rotates in a tangential direction inside an annular cyclone chamber, then enters an upper portion gas purification chamber and uniformly passes through dust collecting bag groups which are arranged at intervals under the action of a guide plate for dust removal, the structure is good in dust removal effect, and the temperature of the raw gas which enters upper portion gas purification chamber is greatly reduced, so that the service life of bags is effectively prolonged.

Owner:唐忠库

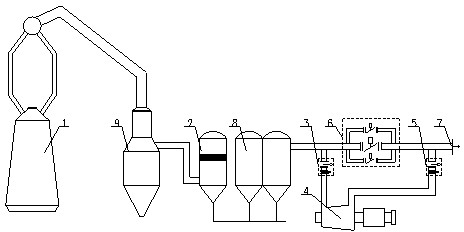

Method and device for recovering pressure-equalized coal gas at top of blast furnace

The invention provides a method and device for recovering pressure-equalized coal gas at the top of a blast furnace. The method comprises the steps of: naturally recovering and forcedly recovering. The device comprises a buffer tank and at least one bag-type dust collector, wherein the buffer tank is connected with a blast furnace tank through a coal gas recovering valve, the bag-type dust collector is connected with the buffer tank in series, the outlet end of the bag-type dust collector is connected with a pure coal gas pipe net, a coal gas check valve is arranged between the bag-type dust collector and the pure coal gas pipe net, the bottom of the blast furnace tank is further connected with a nitrogen supply device, and a control valve for controlling the nitrogen supply is arranged between the blast furnace tank and the nitrogen supply device. The invention effectively solves the problems of toxic gas emission and dust pollution, does not occupy the limited space of the top of the blast furnace and increase the load of a frame on the top of the blast furnace, has simple structure and high safety, and is easy to distribute. Meanwhile, the invention has the advantages of good dust collecting effect and thorough recovery of the coal gas, the recovered coal gas directly enters the pure coal gas pipe net nearly without being influenced by pressure fluctuation.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

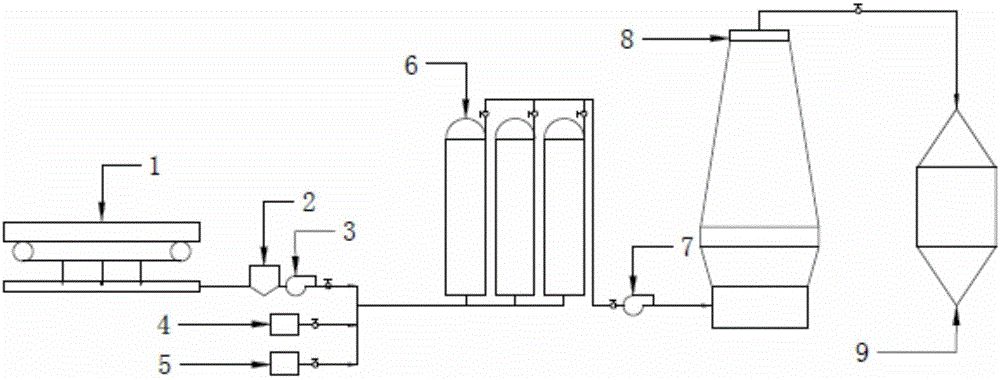

Dry dust collection method and apparatus for blast furnace gas

A blast furnace gas dry type dust collection method, a paralleled gas drying equipment is provided after the gravity dust collector and before the cloth bag dust remover in the blast furnace gas dry type dust collection system as a constituent part of the blast furnace gas dry type dust collection system, and a temperature sensor is provided on the export of the gravity dust collector; when the system export (the blast furnace) generates low-temperature raw coal gas, the humidity is usually relatively high, before the cloth bag dust remover performs dust exhaustion, the gas from the export of the gravity dust collector passes through the paralleled gas drying equipment, the gas drying equipment firstly performs dehumidification processing to the raw coal gas to remove the water in the raw coal gas, and then enters into the cloth bag dust remover for dust exhaustion; when the temperature of the blast furnace raw coal gas is in a normal range, the blast furnace raw coal gas enters the gravity dust collector through a raw gas pipeline to perform coarse dust exhaustion, and then directly enters the cloth bag dust remover for dust exhaustion, the clean gas after dust exhaustion enter in the pressure reducing valve through a clean gas pipeline for pressure reduction, and finally loads in a gas holder through the clean gas pipeline.

Owner:WUXI HONGQI DUST COLLECTOR EQUIP +1

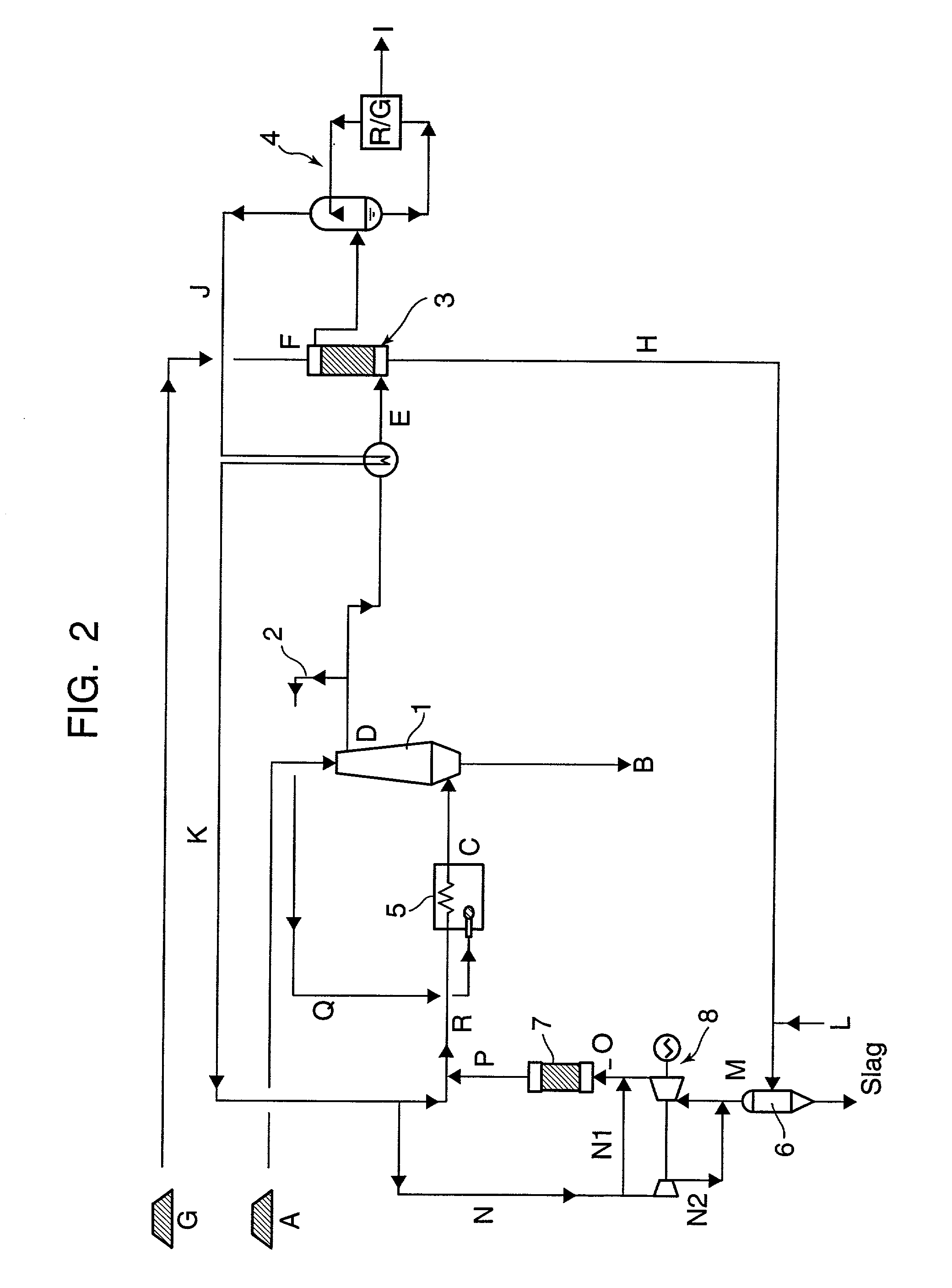

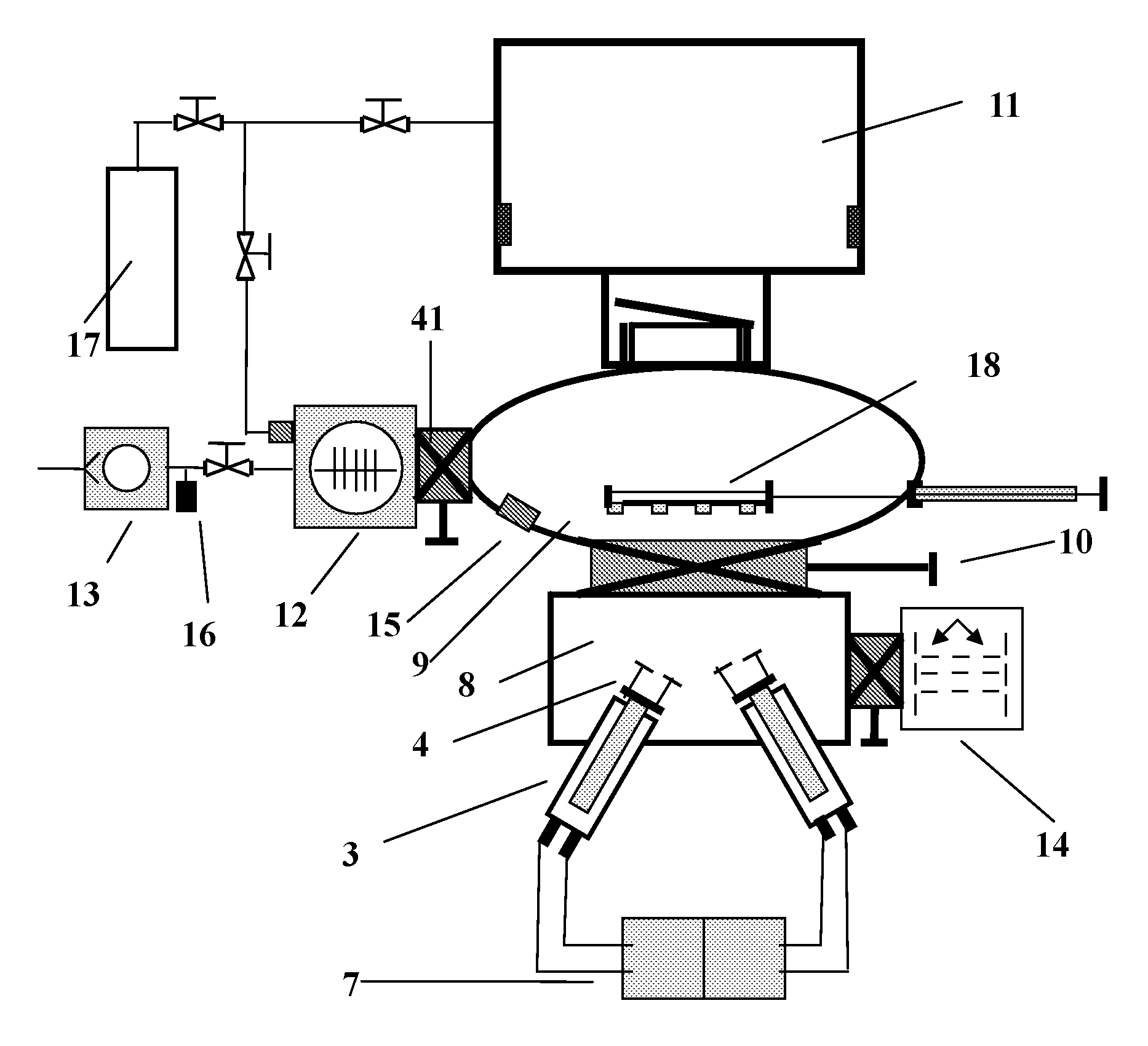

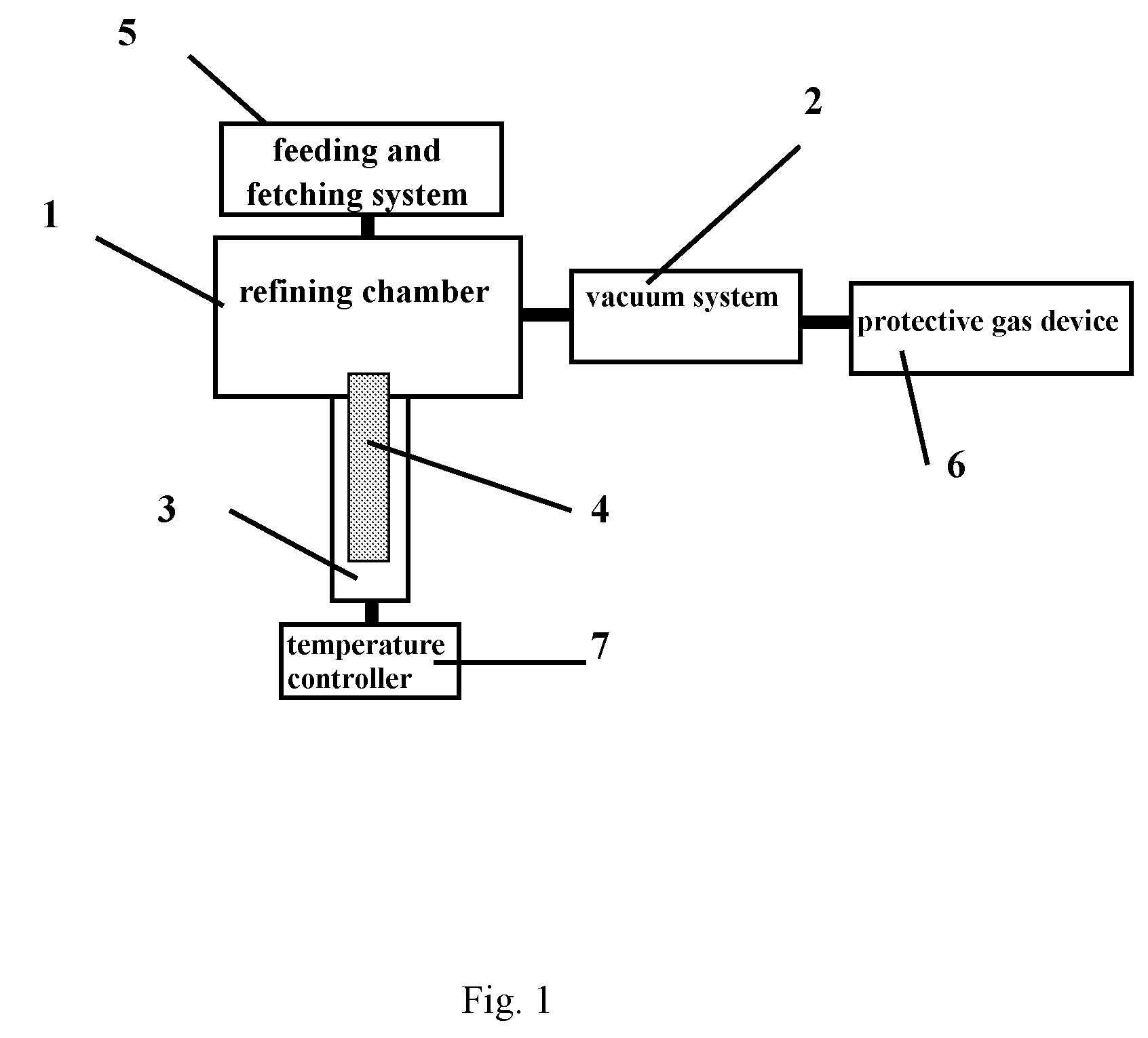

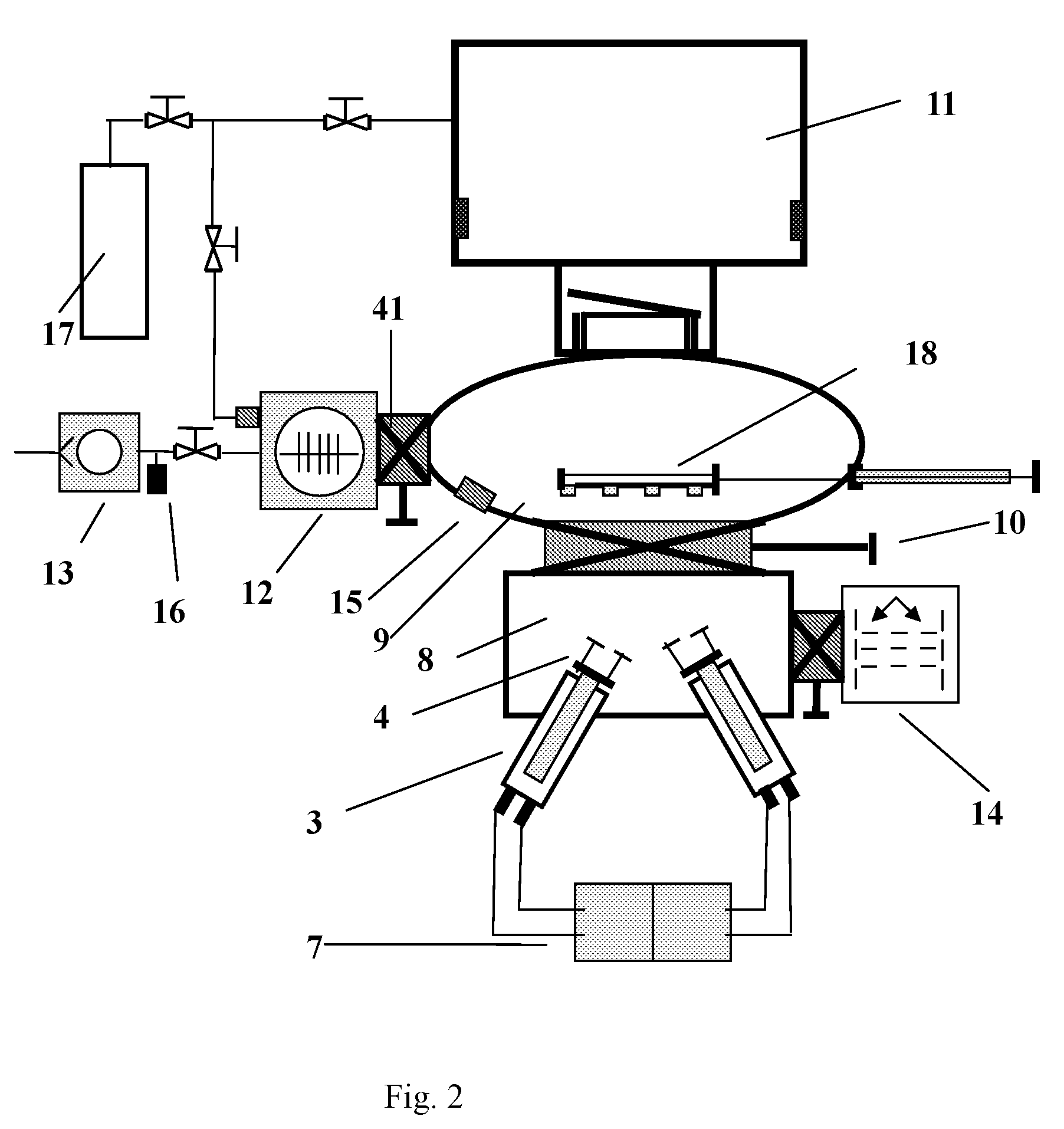

High Vacuum In-Situ Refining Method for High-Purity Materials and an Apparatus Thereof

InactiveUS20080257109A1Improve purification effectEnvironmentally friendlyBlast furnace detailsDust arrestersVapor pressureDiffusion

The present invention concerns a high vacuum in-situ refining method for high-purity and superhigh-purity materials and the apparatus thereof, characterized in heating the upper part and lower part of crucible separately using double-heating-wires diffusion furnace under vacuum, thereby forming the temperature profile which is high at upper part and low at lower part of crucible, or in reverse during different stages; then heating the crucible in two steps to remove impurities with high saturation vapor pressure and low saturation vapor pressure respectively in efficiency; and obtaining high-purity materials eventually. The whole procedure is isolated from atmosphere, reducing contamination upon stuff remarkably. The present invention could provide products with high-quality and high production capacity, which are stable in performance, therefore is reliable and free from contamination. The present invention is appropriate for manufacture of high-purity and superhigh-purity materials, particularly for manufacture of high-activity high-purity materials.

Owner:SHENGZHOU GUOSHENG NEW ENERGY TECH

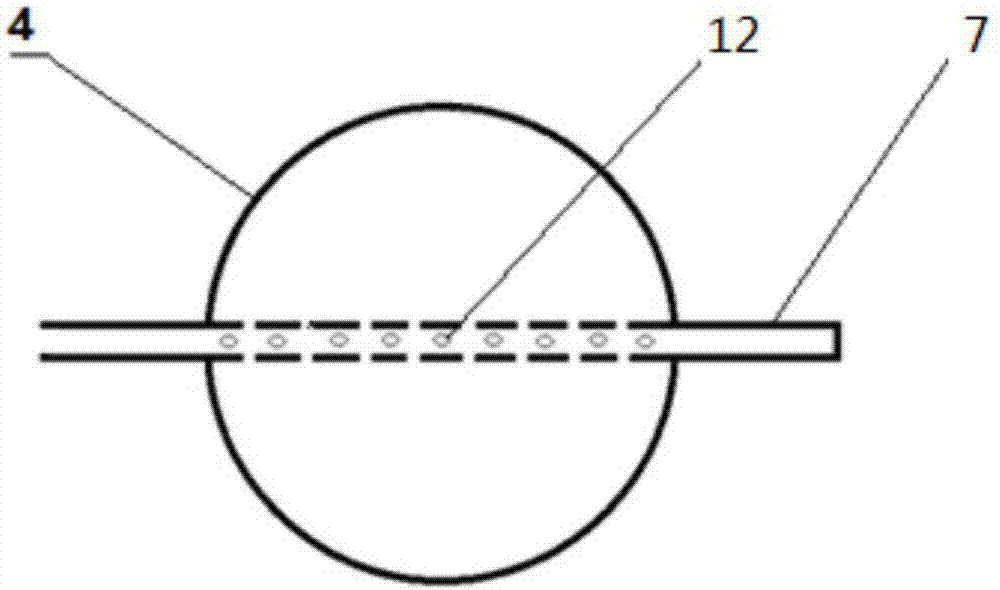

Blast furnace gas deacidification device

ActiveCN107034330AReduce generationHigh operating costsBlast furnace detailsIncreasing energy efficiencyEngineeringCorrosion

The invention relates to a blast furnace gas deacidification device which comprises a powder spray gun, an injection tank and a gas source, wherein the powder spray gun is connected with a gas pipeline and comprises a spray pipe penetrating the gas pipeline and spray nozzles arranged on the spray pipe; the spray nozzles are located in the gas pipeline; the injection tank is fixedly connected with the powder spray gun through a powder spray pipeline and is provided with a fluidization spray nozzle; and the gas source is connected with the fluidization spray nozzle through a gas pipe and used for conveying an injection carrier. The blast furnace gas deacidification device can absorb most acid gases such as chlorine and sulfur in blast furnace gas, save water and electricity, reduce the generation of high-salinity wastewater, alleviate the corrosion of the gas pipeline and downstream gas user facilities caused by blast furnace gas, and guarantee the calorific value of gas and the generating capacity of a blast furnace top gas recovery turbine unit.

Owner:SHOUGANG CORPORATION

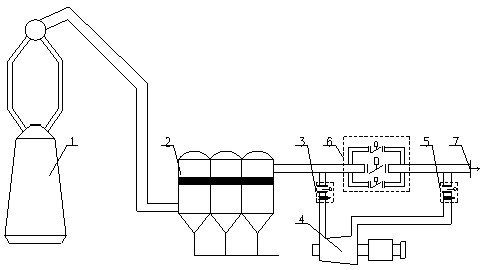

Device for recovering coal gas in equalizing and relieving process of furnace top of blast furnace

InactiveCN102337364ASolve the problem of air emissionsSolve pollutionBlast furnace detailsDust arrestersSocial benefitsBaghouse

The invention relates to a device for recovering coal gas in the equalizing and relieving process of a furnace top of a blast furnace and belongs to the technical field of the iron and steel industry. The device comprises a blast furnace weighing charging bucket, a equalizing and relieving pipeline connected with the charging bucket, a plurality of types of valves, a cyclone dust collector and a cloth bag dust collector connected in series behind the cyclone dust collector and is characterized in that an ejector is connected in series behind the cloth bag dust collector; crude gas which is equalized and relieved from the blast furnace weighing charging bucket enters the cyclone dust collector to carry out primary dust removal through the equalizing and relieving pipeline and then enters the cloth bag dust collector connected in series behind the cyclone dust collector to form clean gas; and under the action of the ejector, the clean gas is rapidly ejected and enters a clean gas pipe network, so that the rapid relief and recovery of the equalized and relieved coal gas in the weighing charging bucket are realized. The process is simple, is convenient to operate and has low operation and maintenance cost. Besides the economic benefits caused by the recovery of the coal gas, the coal gas and dust discharge can also be reduced so as to generate good social benefits; a conventional process is changed less; and the process is convenient to improve the existing conventional equalized and relieved coal gas system of the blast furnace.

Owner:WISDRI ENG & RES INC LTD

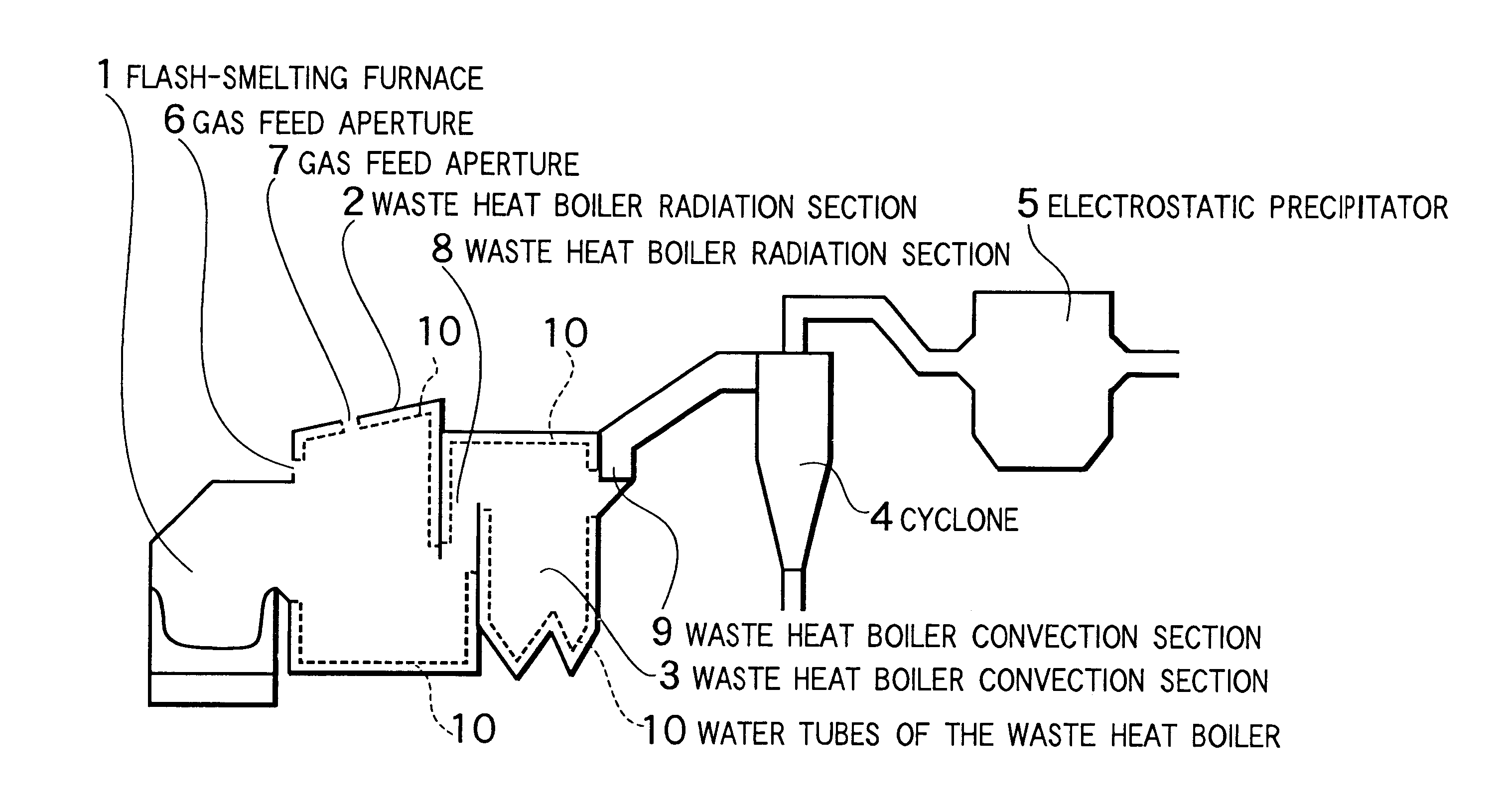

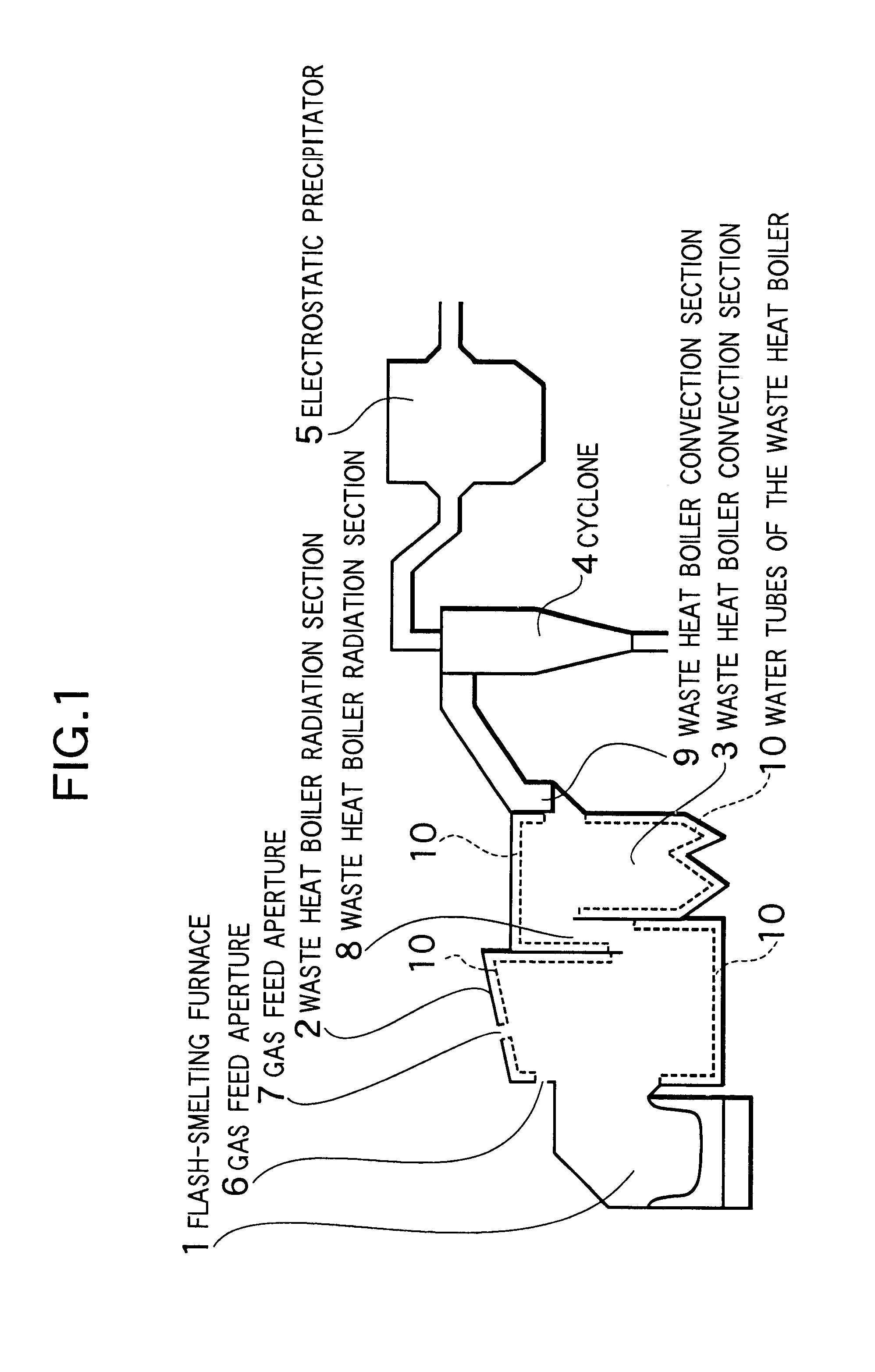

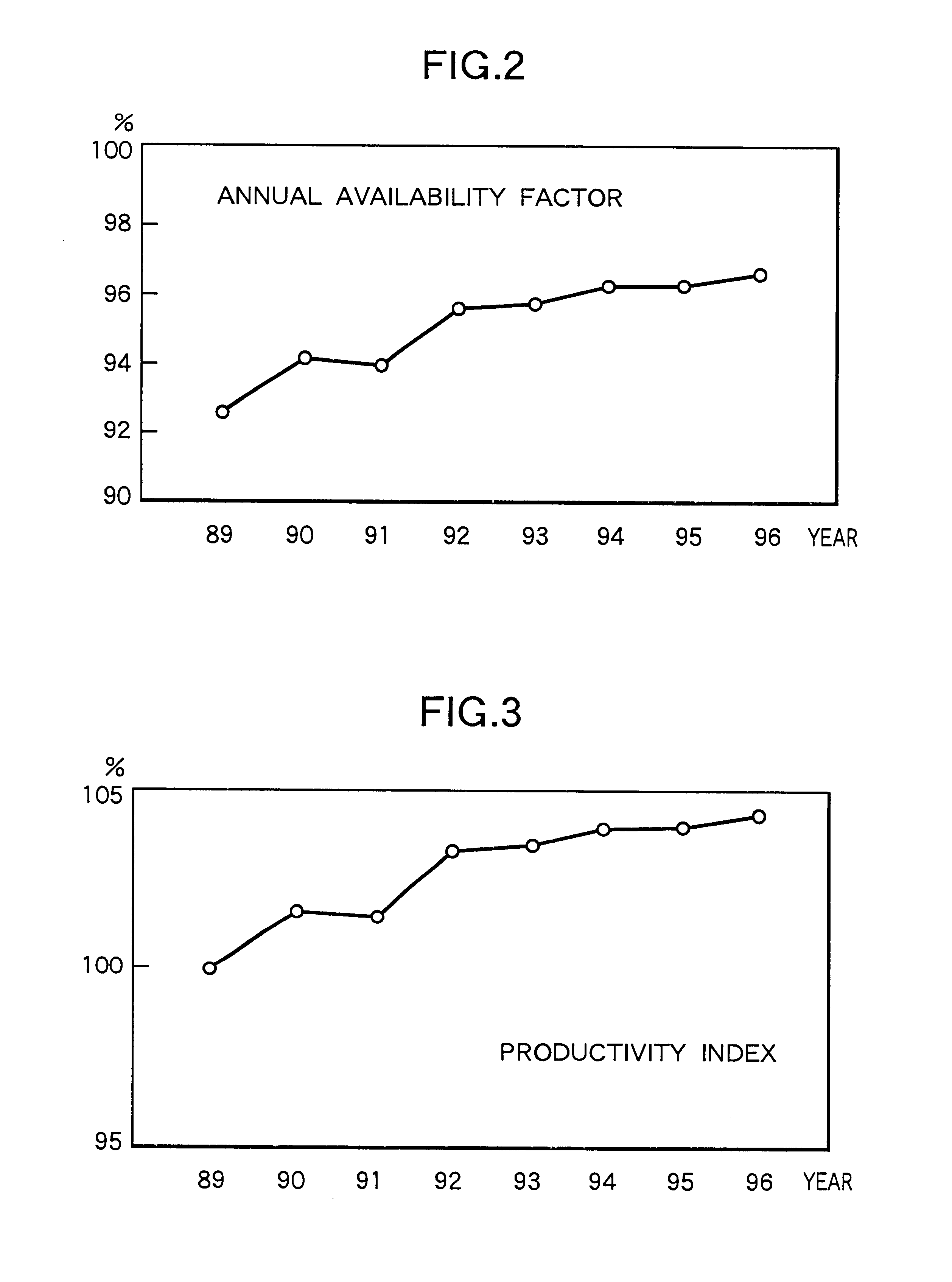

Method for operating waste heat boiler in flash-smelting furnace

In a copper flash-smelting works, forced oxidation of dust is prevented, adhesion of dust to a boiler water tube is reduced, and on-line ratio and productivity index is improved. The temperature at the WHB radiation section outlet is greatly reduced and the atmosphere within the WHB radiation section is controlled by blowing the mixed gas of nitrogen gas and air from the feed aperture established in the wall into the boiler radiation section of the waste heat boiler of the flash-smelting furnace in a copper flash-smelting works.

Owner:DOWA METALS & MINING CO LTD +1

Method for operating a blast furnace and blast furnace installation

InactiveUS20110209576A1Easy to installSimple methodDirect heating destructive distillationBiofuelsMaterials scienceBlast furnace

A method for operating a blast furnace and a corresponding blast furnace, the method including recovering top gas from the blast furnace, submitting at least a portion of the top gas to a recycling process, and feeding the recycled top gas back into the blast furnace, where the recycling process includes feeding the recovered top gas to a reformer unit, feeding volatile carbon containing material to the reformer unit, proceeding to flash gasification of the volatile carbon containing material in the reformer unit, at a temperature between 1100 and 1300° C., and thereby producing devolatised carbonaceous material and synthesis, and allowing the devolatised carbonaceous material and synthesis gas to react with the recovered top gas.

Owner:PAUL WURTH SA

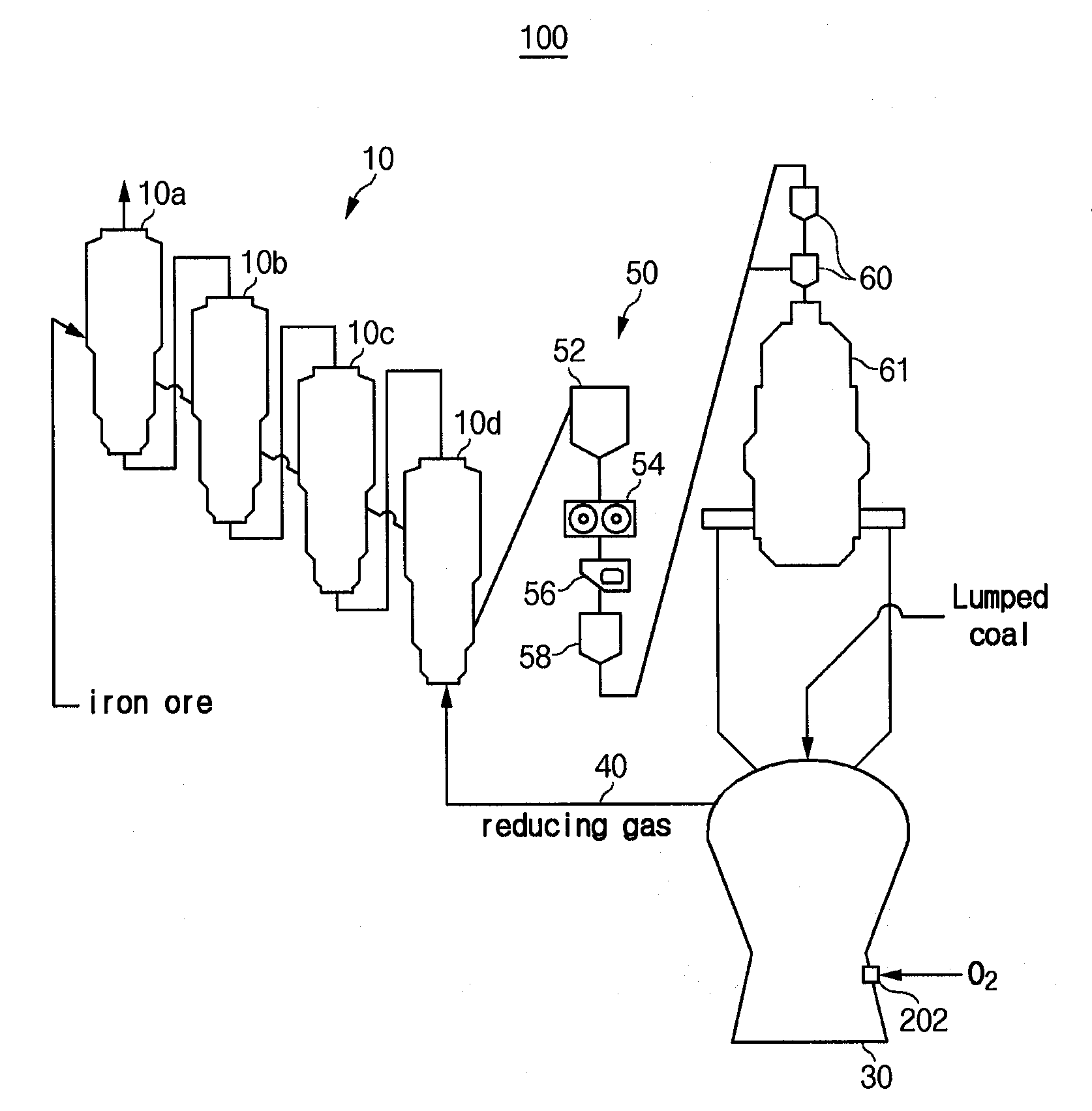

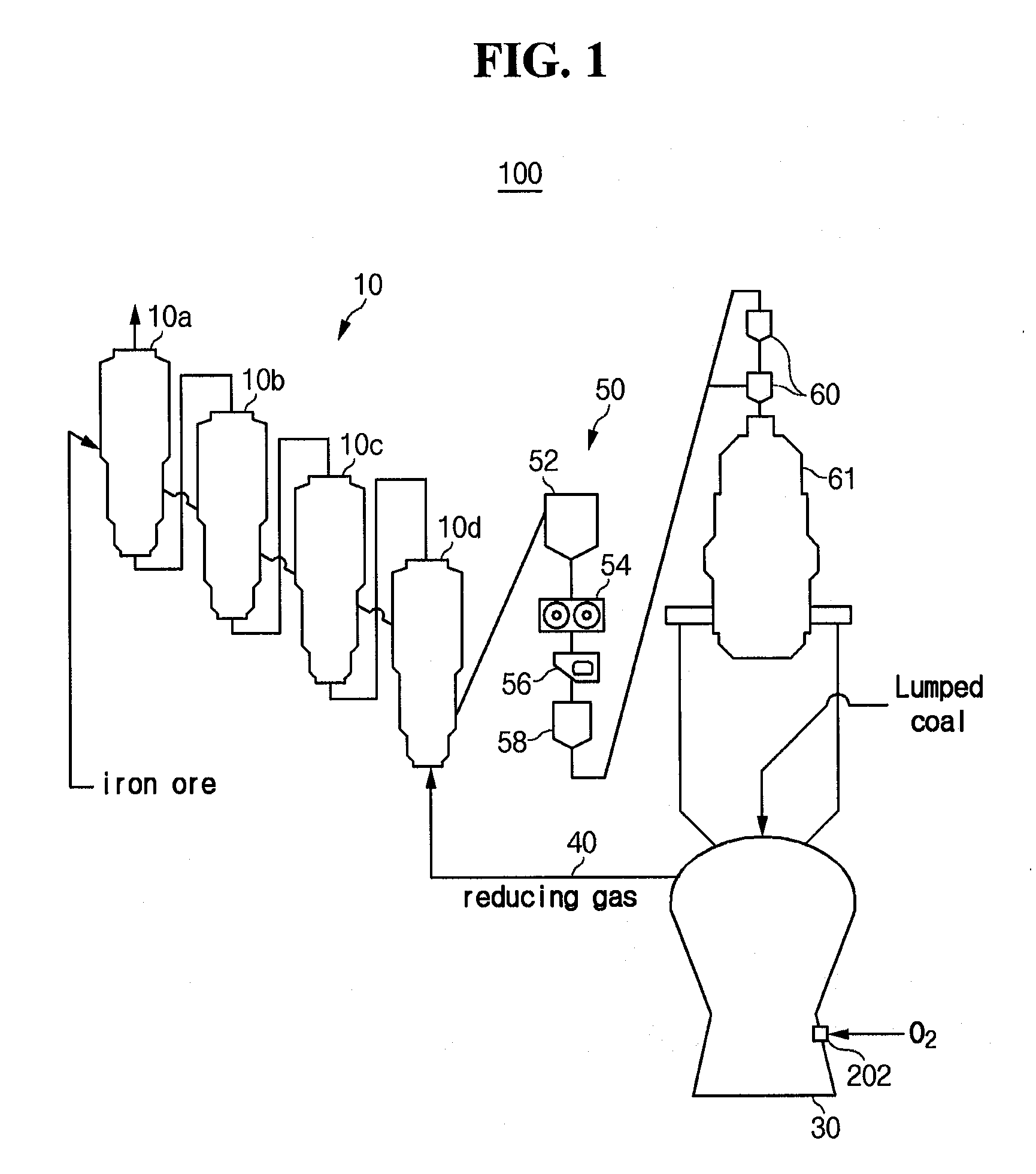

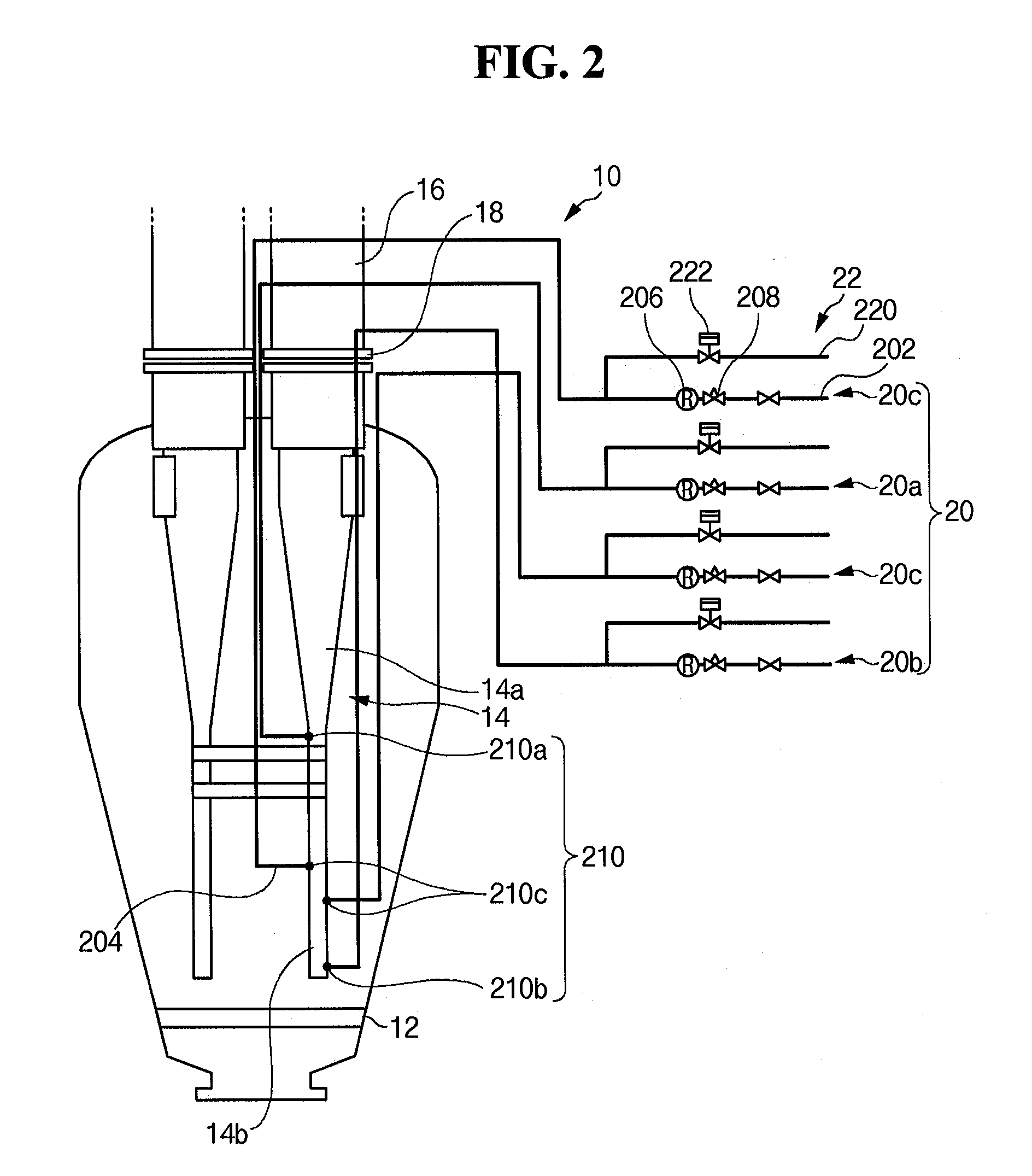

Apparatus for Manufacturing Molten Irons

ActiveUS20080277842A1Easy to operateTime is not consumedDispersed particle separationBlast furnace detailsCycloneFluidized bed

An apparatus for manufacturing molten iron includes i) at least one fluidized-bed reduction reactor that reduces and plasticizes iron ore and converts the iron ore into reduced materials, ii) a melter-gasifier into which the reduced ore is charged and oxygen is injected, the melter-gasifier manufacturing molten iron, and iii) a reducing gas supply line that supplies a reducing gas discharged from the melter-gasifier to the fluidized-bed reduction reactor. The fluidized-bed reduction reactor includes a cyclone that is installed in the fluidized-bed reduction reactor to collect fine iron ore. A gas injector, which prevents the fine ore from adhering by injecting gas containing carbon, is connected to the cyclone.

Owner:POSCO HLDG INC +1

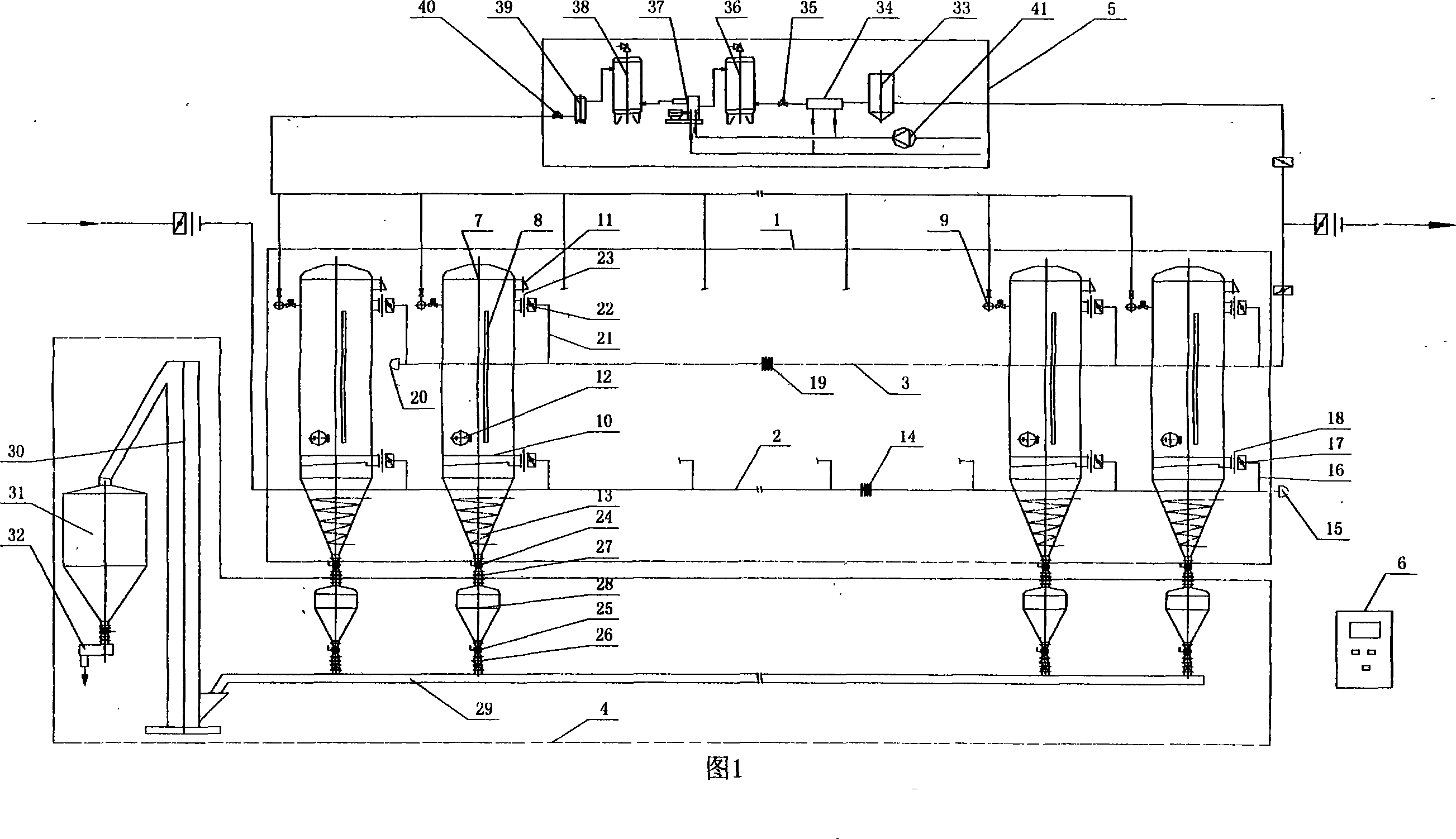

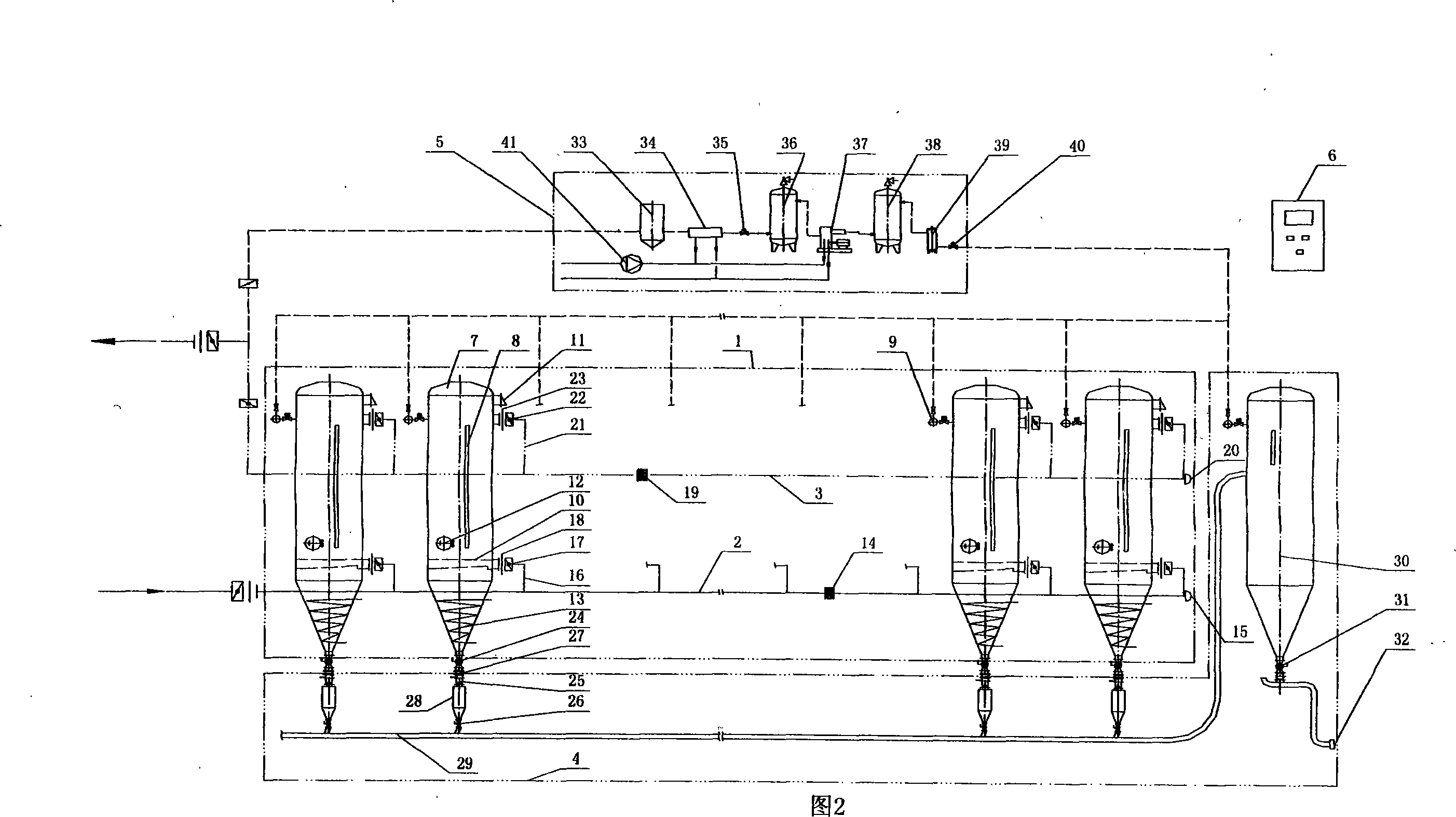

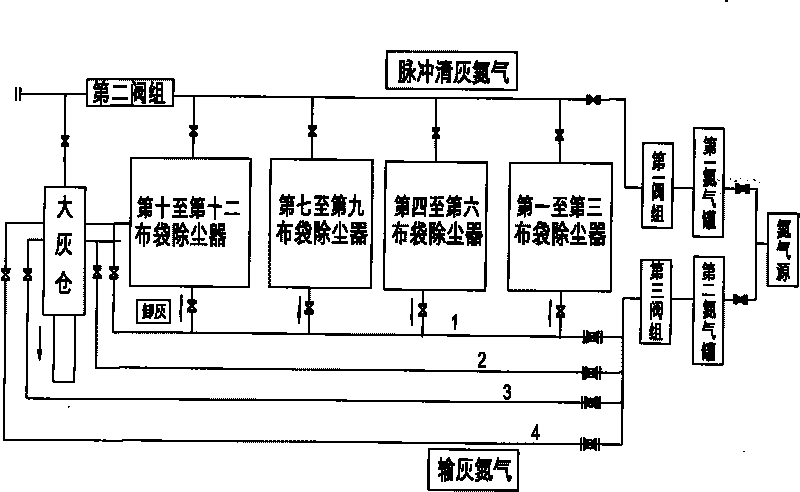

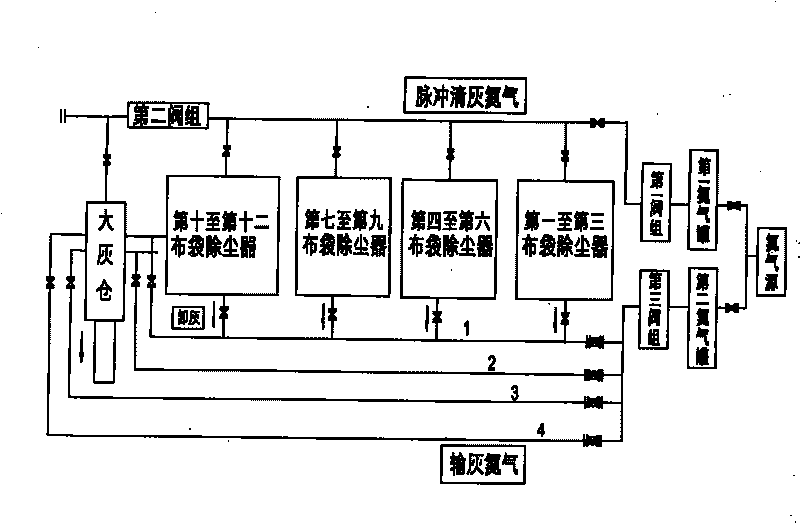

Blast furnace gas impulse blowing purification dust removal system adapted for multiple volumes

InactiveCN101230410AHigh calorific valueReduce dust contentDust arrestersThermal energyAutomatic control

The invention relates to a pulse bellowing, purifying and dedusting system which can be used in a blast furnace with a variety of capacities in the field of environmental-protection equipment. The invention comprises a pulse bellowing bag-type dust collector, a crude gas pipeline, a purified gas pipeline and a dust transmission pipeline. A purified gas-pressurized backblowing device and an automatic control system can be connected with the crude gas pipeline by pipelines. The crude gas pipeline is connected with the inlet of the pulse bellowing bag-type dust collector; and the purified gas pipeline is connected with the outlet of the pulse bellowing bag-type dust collector. The dust transmission pipeline is connected with the dust outlet of the pulse bellowing bag-type dust collector. The outlet of the purified gas-pressurized backblowing device can be connected with the pulse bellowing bag-type dust collector by pipelines; and the automatic control system can be connected with pulse bellowing bag-type dust collector by signal circuits. The invention can be used when the temperature is about 250 DEG C and can avoid heat waste and secondary pollution. And when factories have no nitrogen gas source, the invention can use the purified gas-pressurized backblowing device to dedust. In addition, the invention has two dust transmission manners which are machinery dust transmission and pneumatic dust transmission.

Owner:上海泰山除尘设备有限公司

Dry-process dust-removing and dechlorination combined device for blast furnace gas

InactiveCN102534082AImprove dust removalImprove desulfurization efficiencyDust arrestersAdditive ingredientChloride

The invention discloses a dry-process dust-removing and dechlorination combined device for blast furnace gas. The device comprises a power generation device and a reducing valve group which are connected to the back of a blast furnace through a pipeline and connected with each other in parallel, and is characterized in that a grain bed dust remover before the power generation device and the reducing valve group is connected in series with the power generation device and the reducing valve group; and dechlorination grains, desulfuration grains and deamination grains are filled in the grain bed dust remover. The device can be used for conducting dust removing, dechlorination, desulfuration, deamination, moisture absorption, and recycling of residual heat and excess pressure on blast furnace gas effectively, and has the advantages as follows: the suitability on ingredient variation of blast furnace gas is high; problems of corrosion on equipment and pipelines and salification caused by dry-process dust removing are solved; and no corrosion-resistant measure is required in pipelines and equipment to follow-up users. The dust content of purified gas at the outlet of the device is 0 to 5 mg / Nm<3>; the chloride ion content in gas condensed water is smaller than 300 mg / L; and the pH value is 6 to 8.

Owner:CISDI ENG CO LTD

Treatment and utilization method for sintering flue gas

ActiveCN104988264AHigh nitrogen contentIron production impactBlast furnace detailsDust arrestersFlue gasOxygen

The invention relates to a treatment and utilization method for sintering flue gas. The method comprises the steps that dedusted sintering flue gas is heated through a hot blast heater, and the flue gas is heated to the temperature of 1000 DEG-1400 DEG C; heated flue gas is blown into a blast furnace through a blast-furnace tuyere to replace air for ironmaking production; high-temperature and highly reduced conditions in the blast furnace are utilized for conducting desulfuration, denitration and dioxin and furan removal on the sintering flue gas; and sensible heat in the flue gas and oxygen, carbon dioxide and carbon monoxide in the flue gas are utilized in ironmaking production. Compared with other sintering flue gas treatment techniques, the treatment and utilization method utilizes existing ironmaking production equipment for treating the sintering flue gas, the running cost is low, no new secondary products are produced, the latent heat of the sintering flue gas can be utilized, and carbon dioxide and carbon monoxide in the flue gas are caught and utilized.

Owner:UNIV OF SCI & TECH BEIJING

System for removing corrosive substances in coal gas obtained by dry dedusting of blast furnace and process thereof

ActiveCN101603107AIncrease pHReduce salt contentCombustible gas purificationDust arrestersSoftened waterAcid substances

The invention discloses a system for removing corrosive substances in coal gas obtained by dry dedusting of a blast furnace and a process thereof, which belong to the technical field of blast-furnace dedusting. The system comprises a NaOH alkaline solution preparation and spraying system, a softened water assisted alkaline solution spraying system, a circulating water system, a reuse water supplementing and spraying system, a cleaning tower and a cleaning tower packing layer. An outlet pipe of an alkaline solution metering pump in the NaOH alkaline solution preparation and spraying system is connected with an outlet pipe of a softening water pump in the softened water assisted alkaline solution spraying system, pressurized alkaline solution is pumped into pressurized softened water, and the mixture is conveyed into the cleaning tower through a pipeline and is sprayed into the cleaning tower on a common nozzle of the alkaline solution and the softened water. The system and the process have the advantages that the system and the process can successfully remove an acid substance NH4CL with extremely strong corrosiveness in the coal gas, improve the PH value of condensed water of the coal gas, reduce the salt content and electrical conductivity of the condensed water of the coal gas, greatly delay the corrosion rate of coal gas transmission pipeline networks and coal gas user facilities, and guarantee the safe operation of steel production.

Owner:BEIJING SHOUGANG CO LTD

Group control method of blast furnace gas cloth bag dust catcher system for pipeline dust conveying

InactiveCN101708406ARealize multi-level grouping controlImprove work efficiencyDispersed particle filtrationDust arrestersBaghouseNitrogen gas

The invention relates to a group control method of blast furnace gas cloth bag dust catcher system for pipeline dust conveying, which adopts a group control device of the blast furnace gas cloth bag dust catcher system for pipeline dust conveying to realize the multi-stage group control of the blast furnace gas cloth bag dust catcher system. The device comprises a big dust cabin, a plurality of groups of cloth bag dust catchers and a valve bank. The method comprises the following steps of: controlling the sleeve bodies of the cloth bag dust catchers and the pulse blowing nitrogen pressure of the big dust cabin by grade, setting a dust conveying nitrogen pressure, and realizing group control management for the sleeve bodies of the cloth bag dust catchers by separately controlling each dust conveying pipeline. The group control method of the invention can improve the operation efficiency, prolong the service life of equipment, realize the multi-grade control of a dust clearing gas source pressure and safe production of a blast furnace, and is suitable for the improvement of newly-built or traditional de-dusting systems.

Owner:WISDRI ENG & RES INC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com