Fume treatment system and method

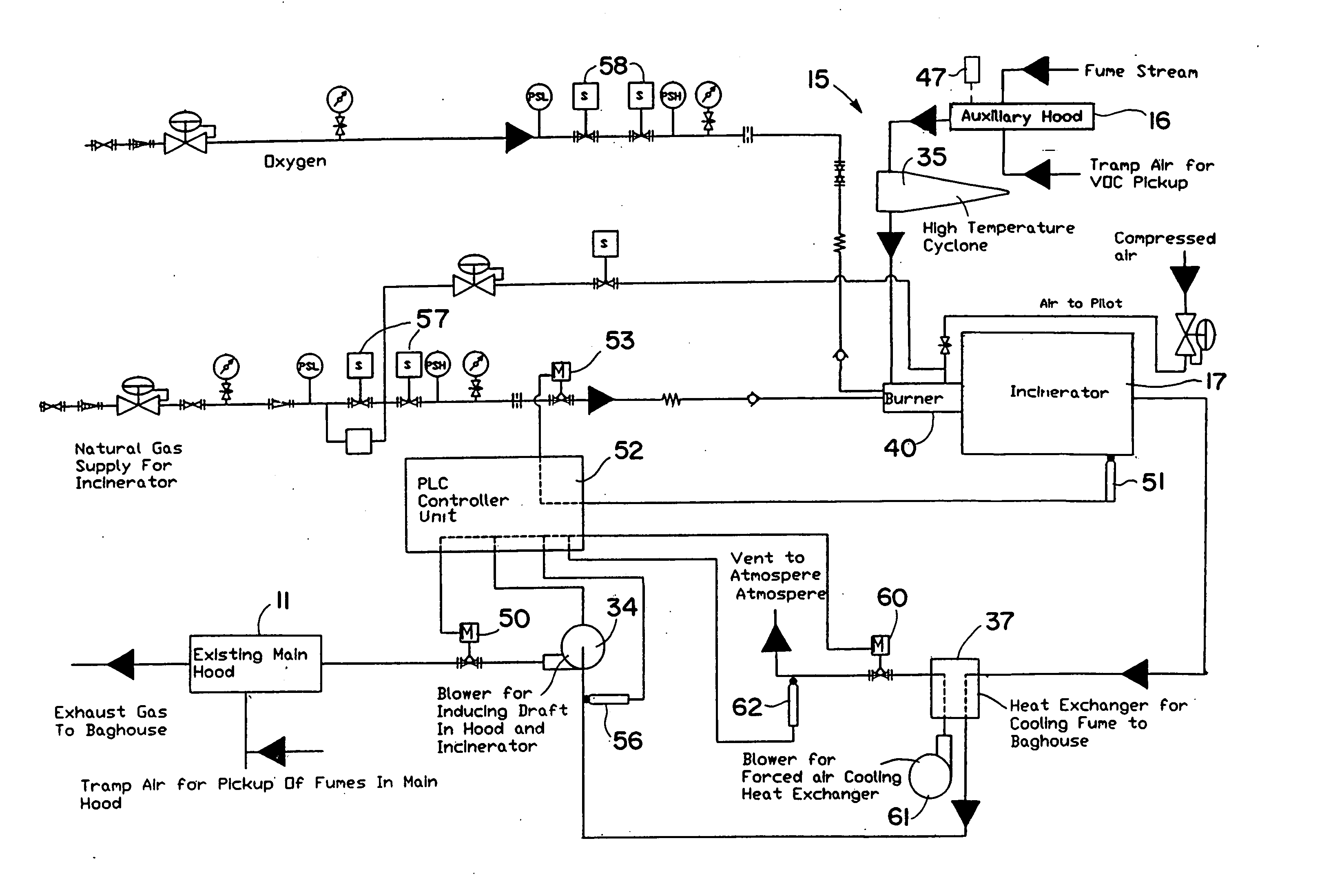

a fume treatment system and furnace technology, applied in heat treatment equipment, furnaces, manufacturing converters, etc., can solve the problems of high air flow, large capture velocity, and large cost of burners to control and operate afterburner incinerators to treat this magnitude of air flow, so as to reduce the volume of gases, reduce the size of the bag house, and reduce the effect of exothermic reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

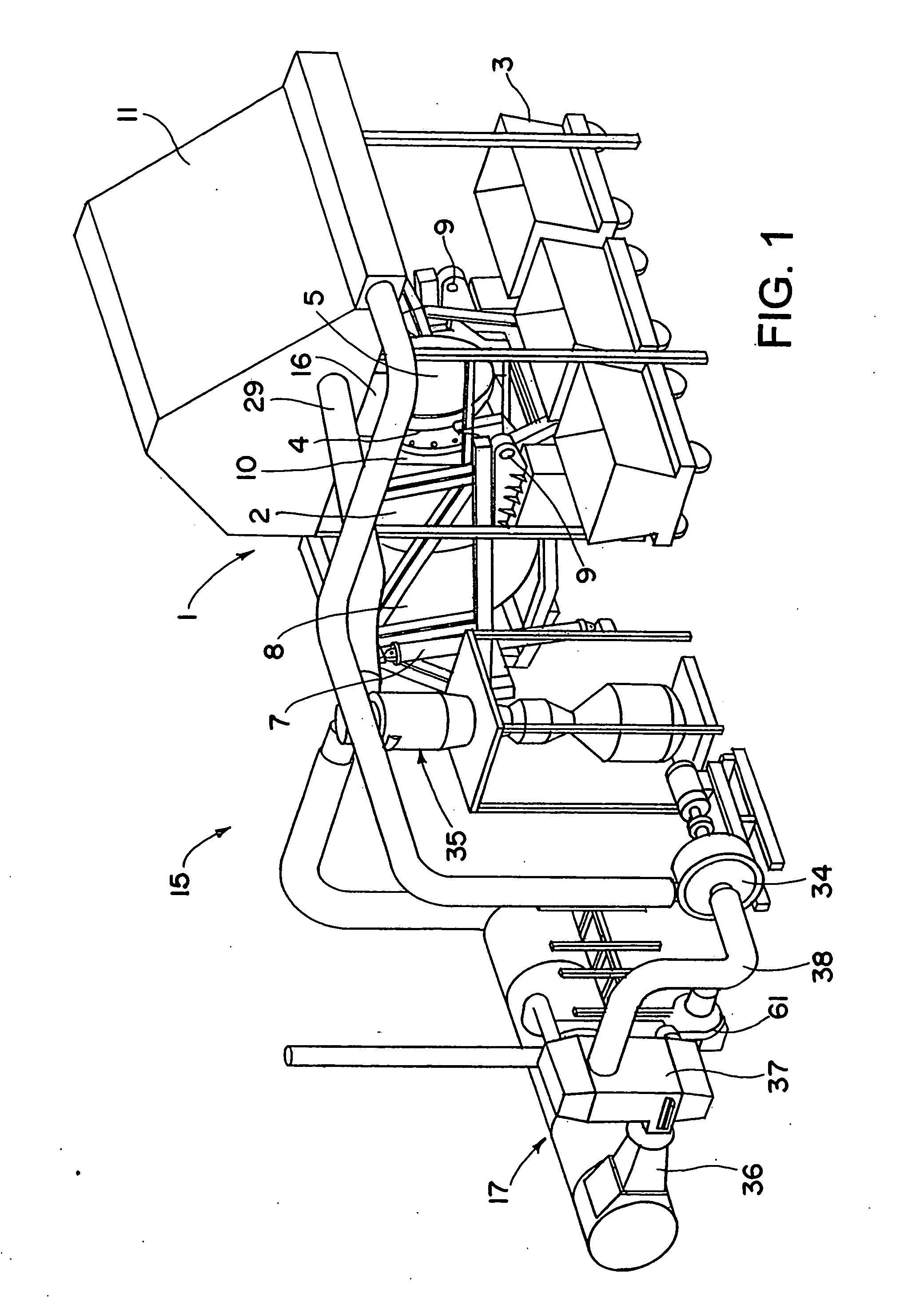

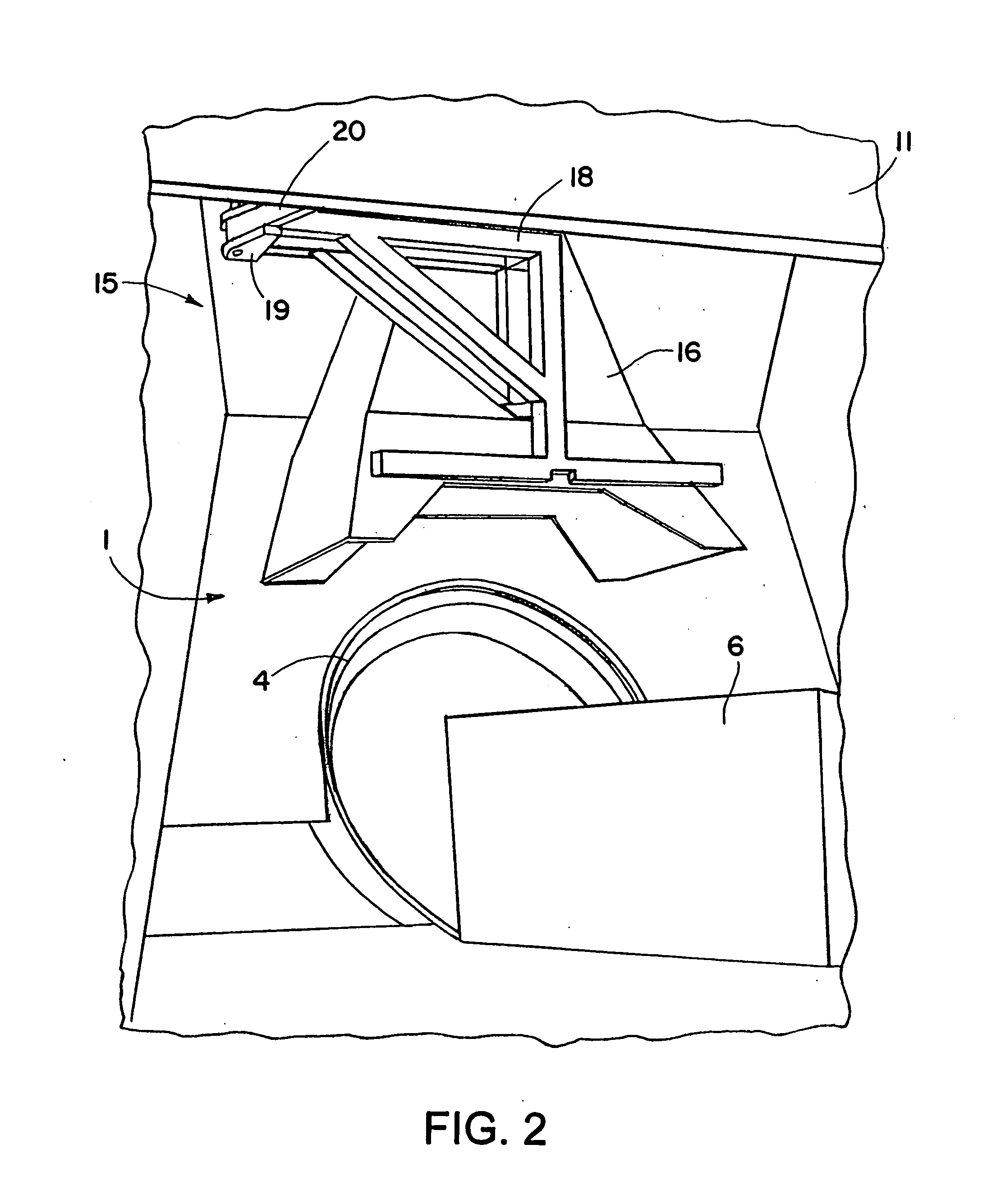

[0027] Referring now in detail to the drawings, and initially to FIG. 1, there is shown by way of example a tilting rotary furnace system 1 used to recover a metal from scrap material containing the metal or from dross material containing the metal obtained from some other industrial process. The scrap or dross material (collectively referred to herein as scrap material) containing the metal along with flux material is charged into the furnace chamber 2 and melted to separate and recover the desired metal. Dross, as used herein, may include the solid scum that forms on the surface of a metal when molten or during melting, and is largely the result of oxidation, but may also include other impurities that rise to the surface of the mixture. Dross may also include a mixture of salt, flux and waste or foreign matter mixed with a substance or what is left as a residue after the substance has been used or processed. A common non-ferrous metal that is recoverable using such a furnace syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com