Patents

Literature

53 results about "Stream temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Good temperatures are dependent on the type of stream you are monitoring. Lowland streams, known as "warm-water" streams, are different from mountain or spring fed streams that are normally cool. In a warm-water stream temperatures should not exceed 89° Fahrenheit (about 31.7° Celsius).

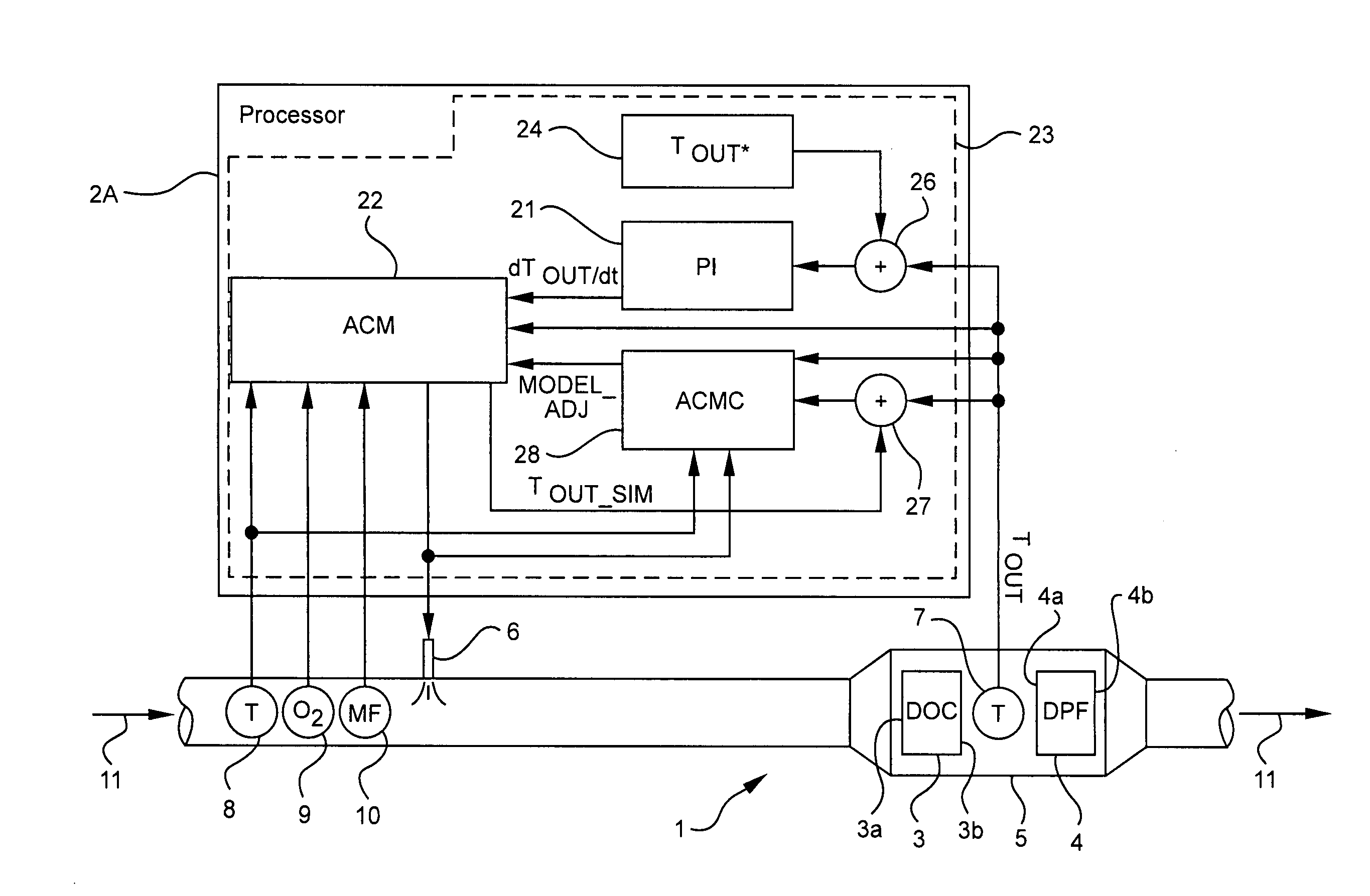

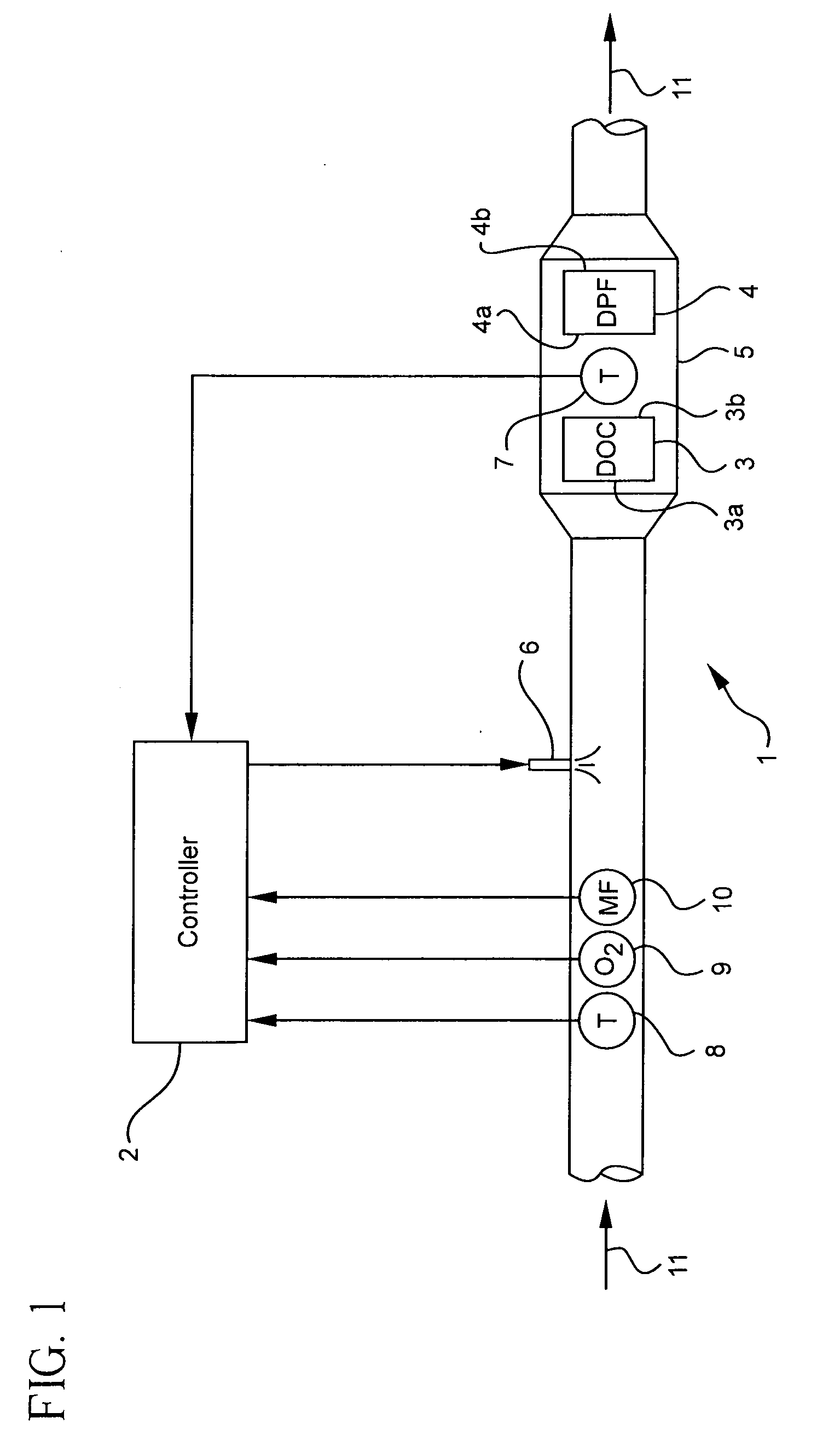

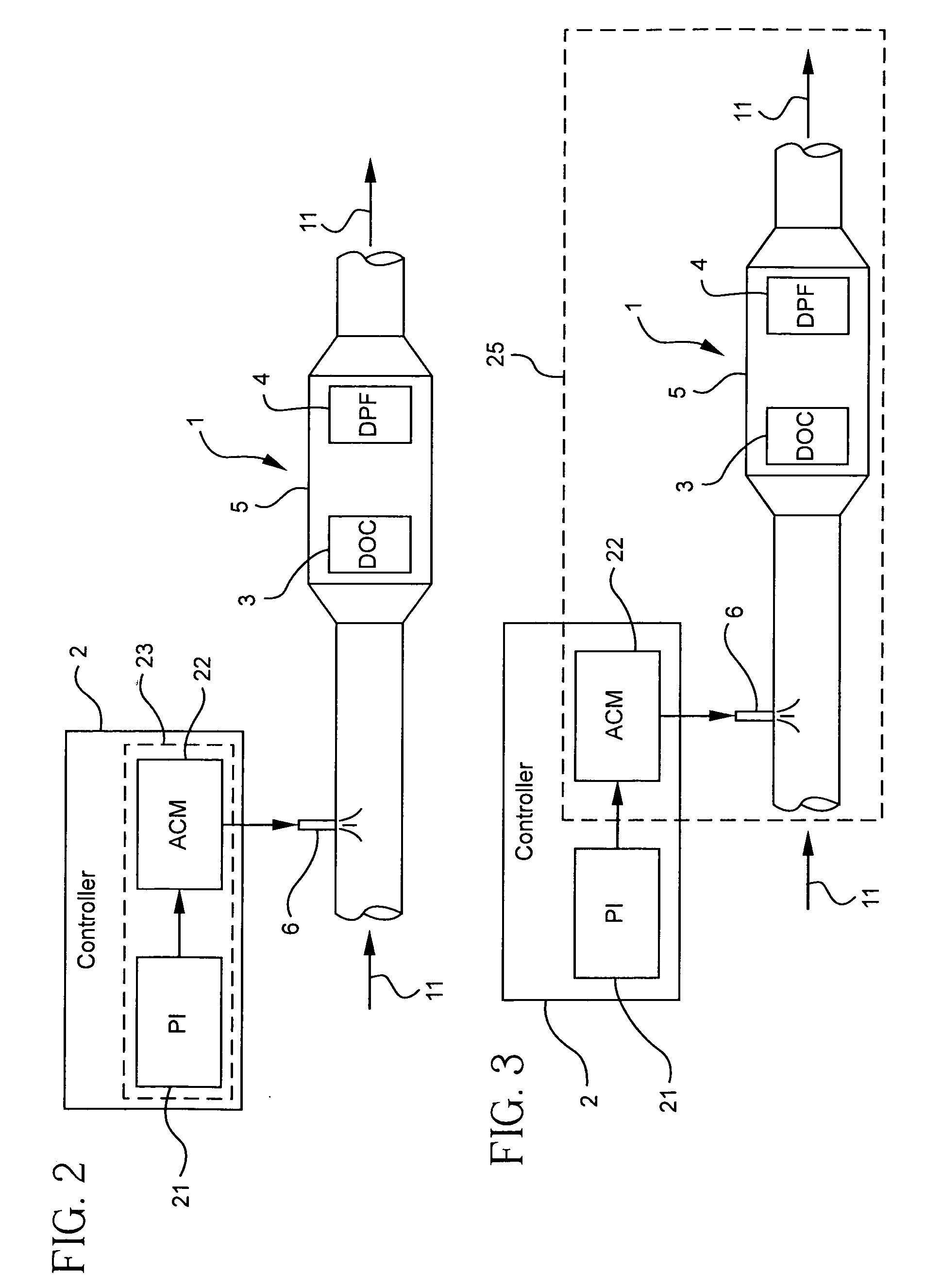

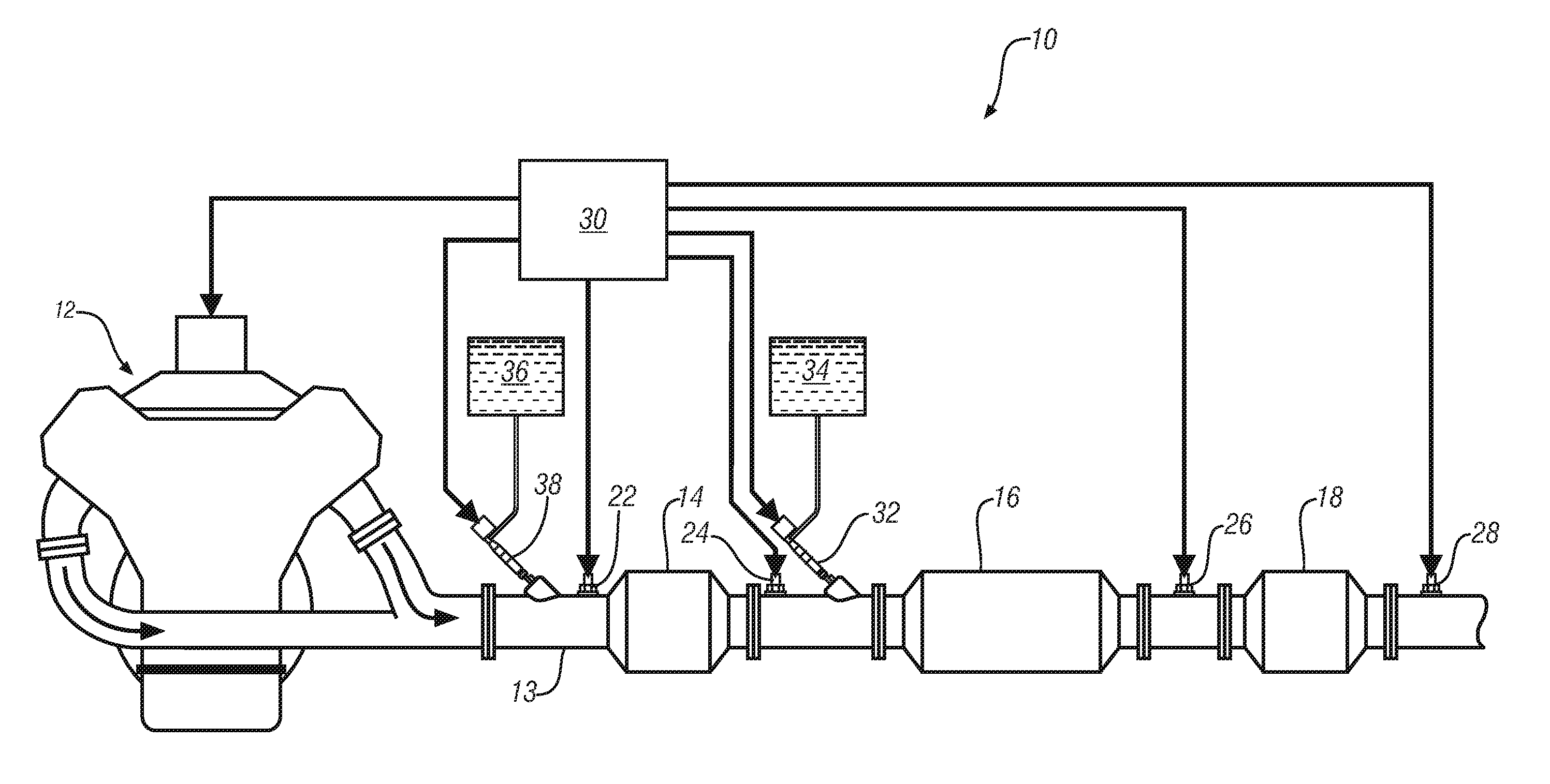

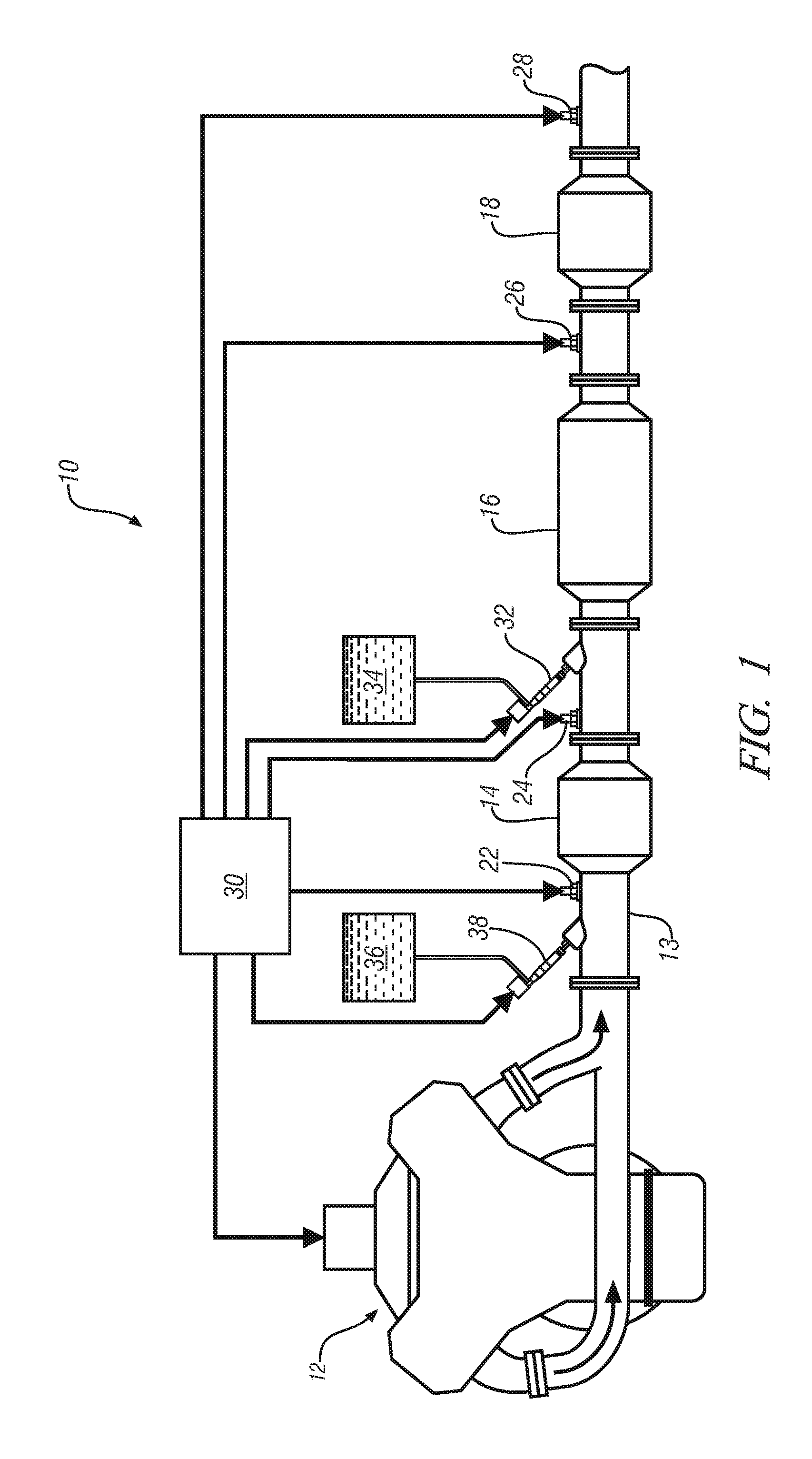

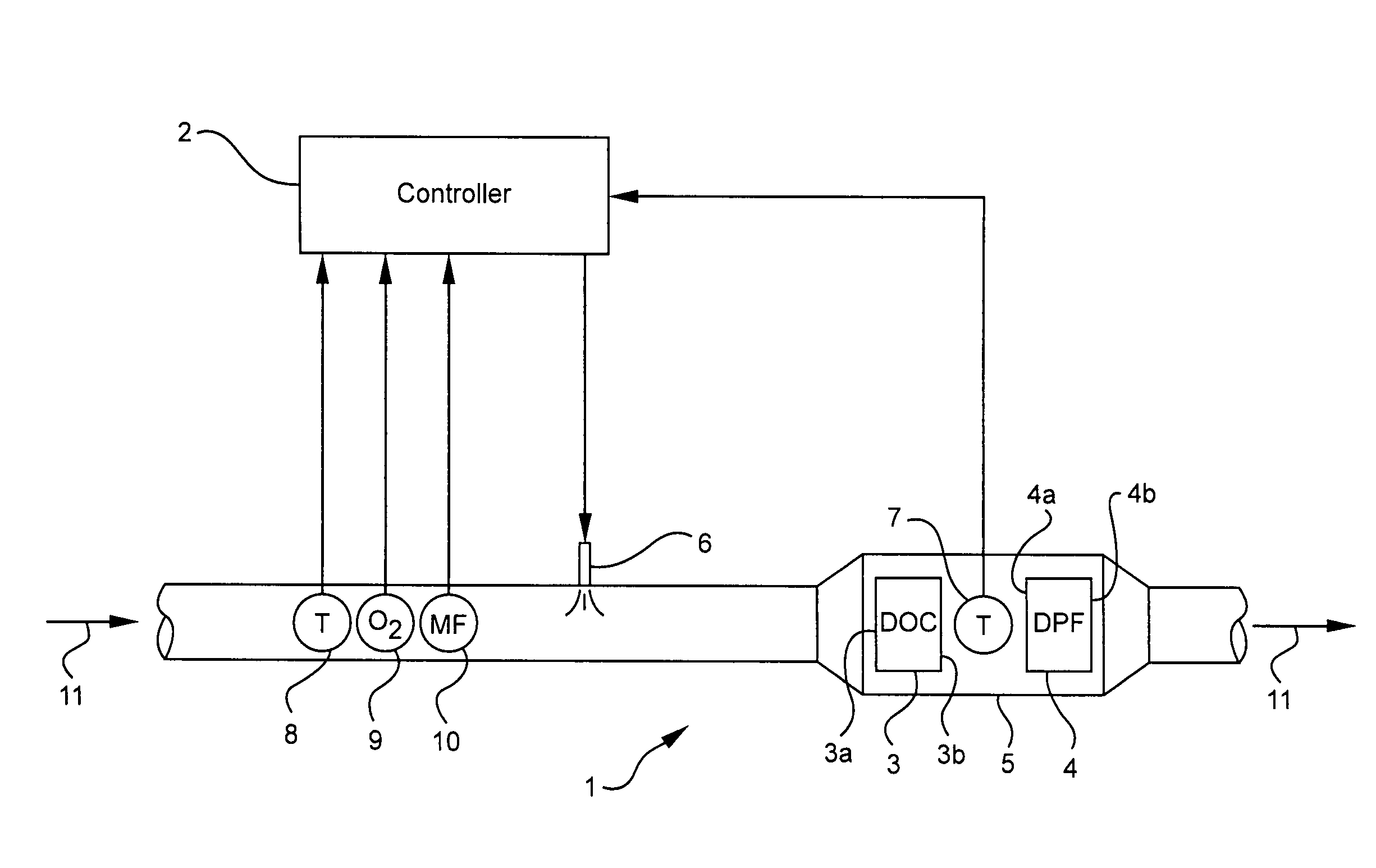

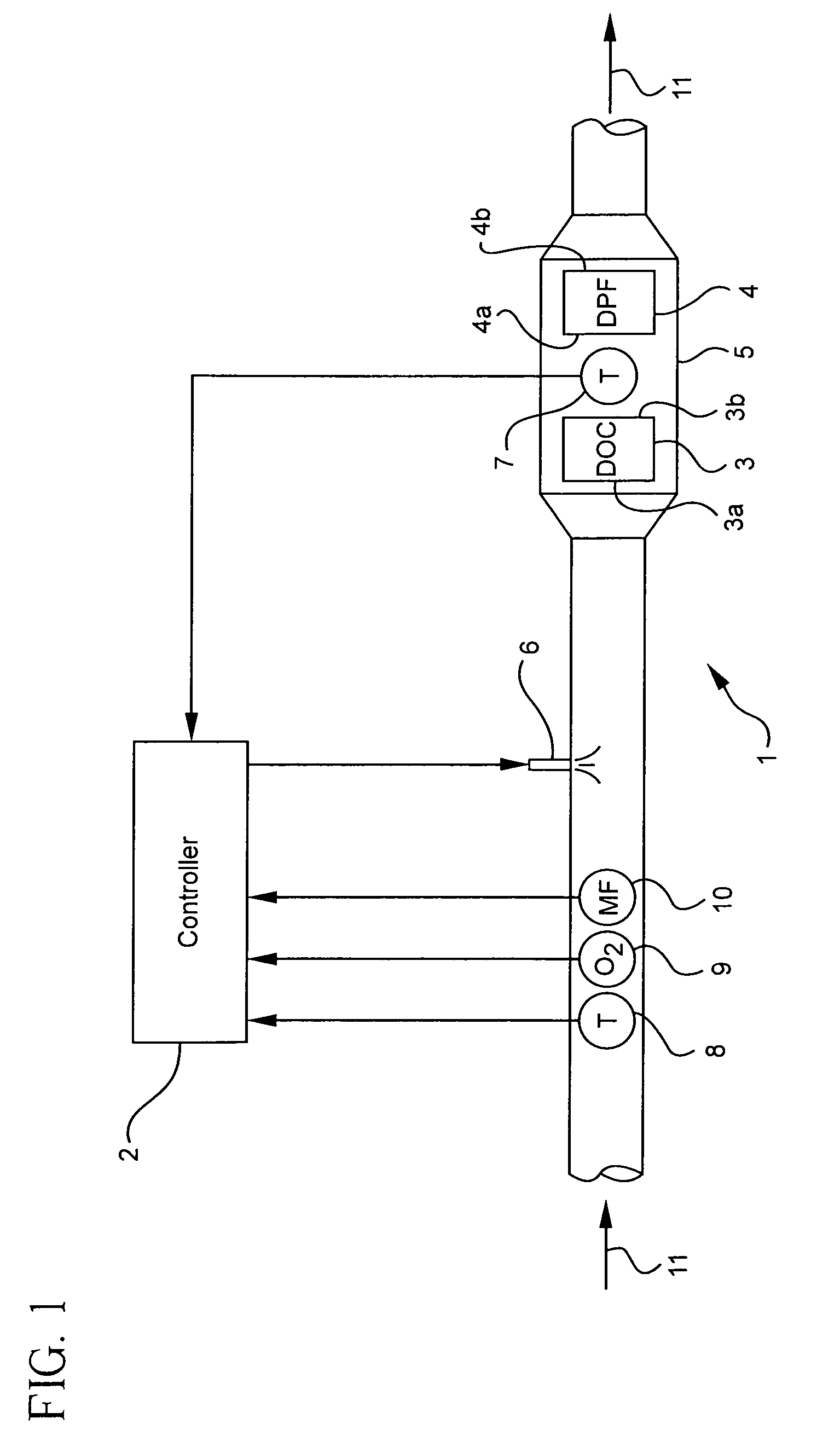

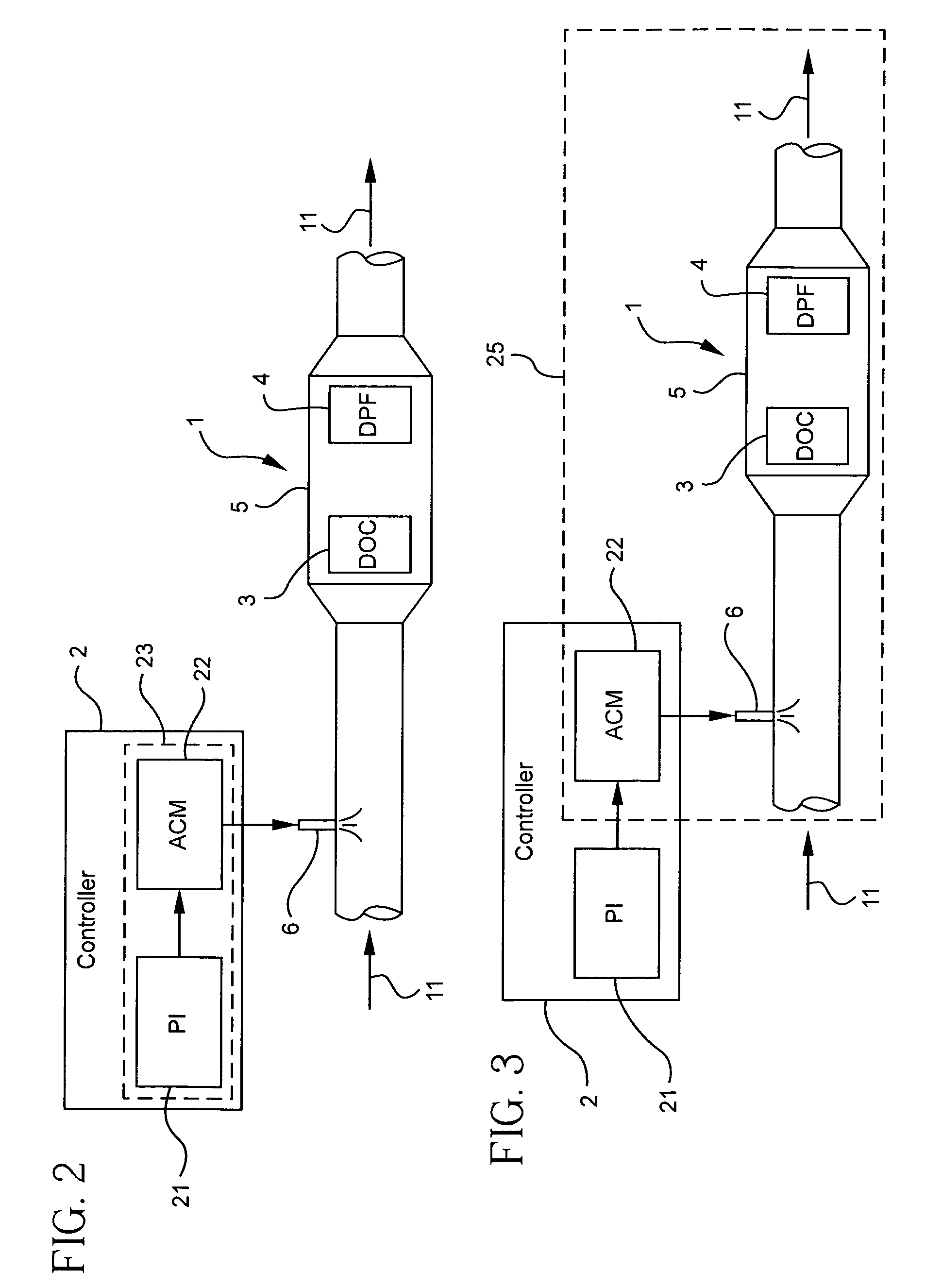

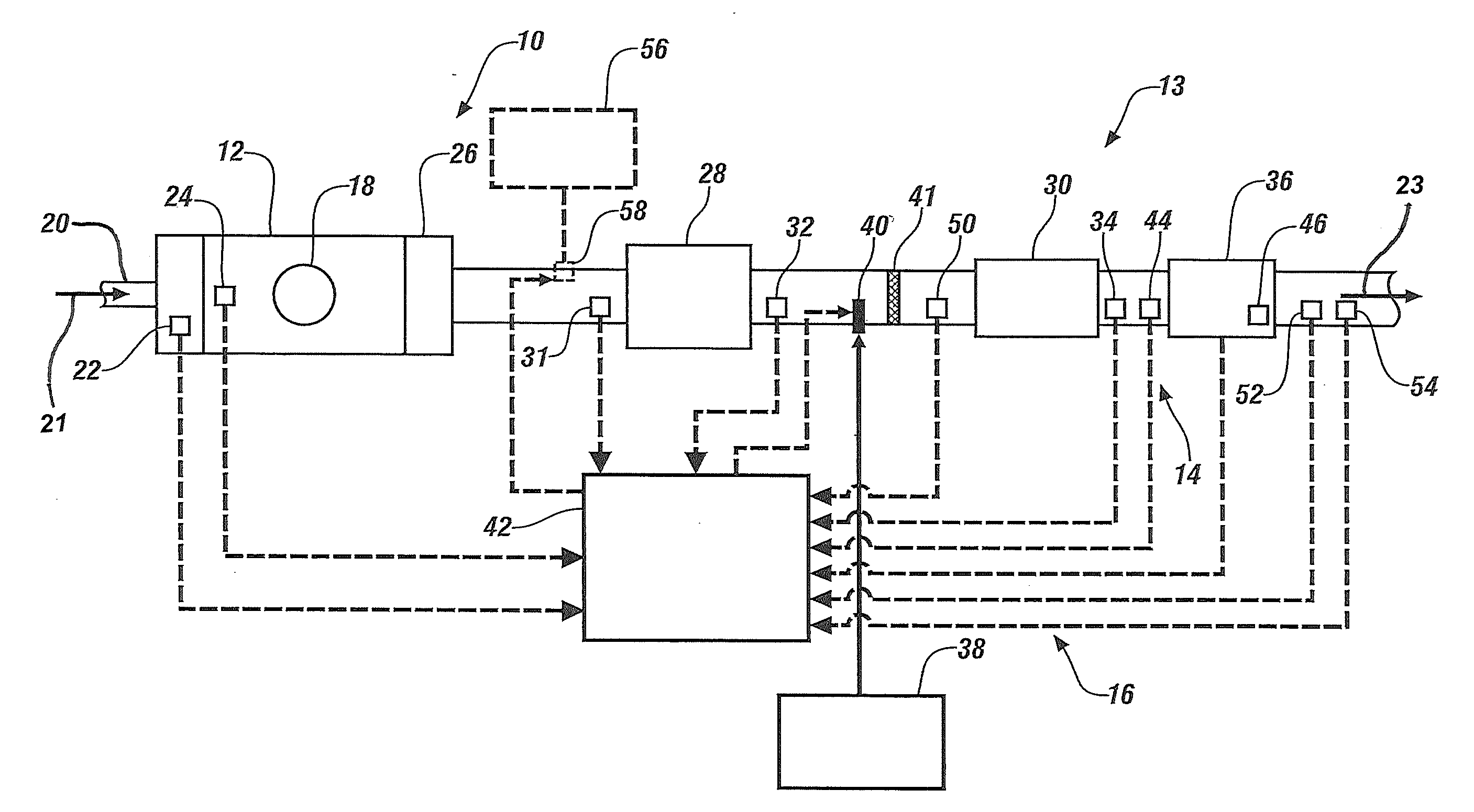

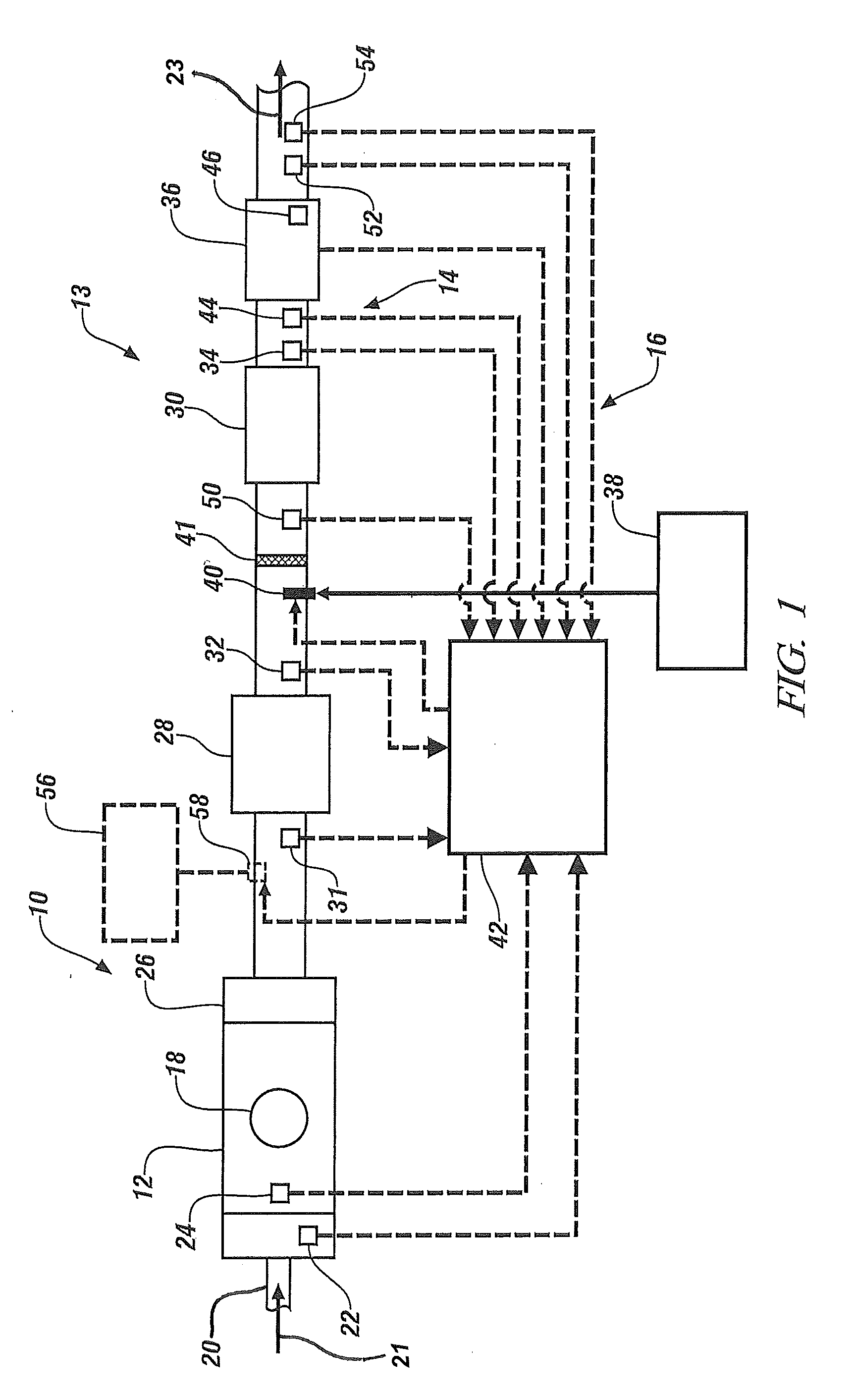

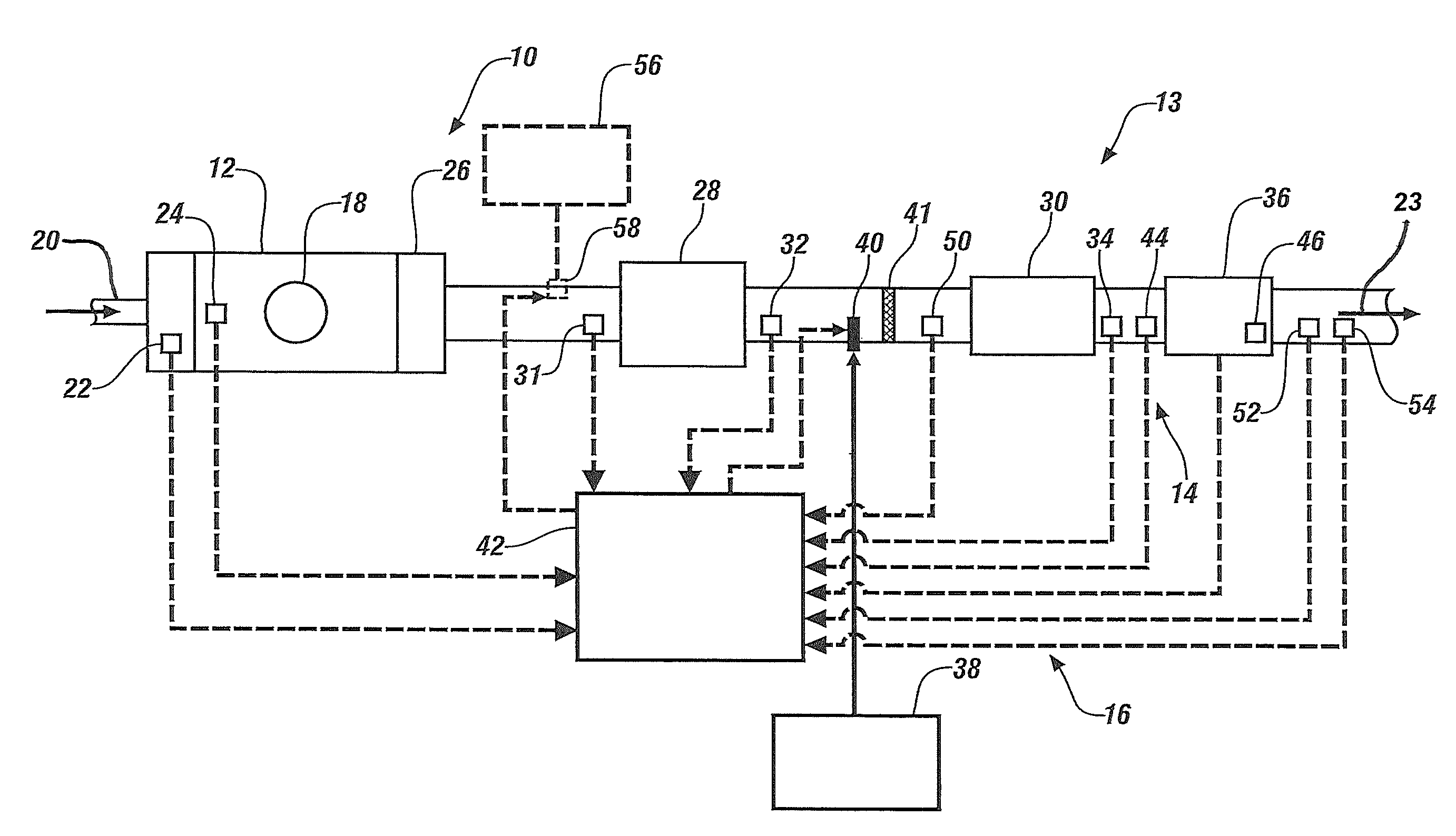

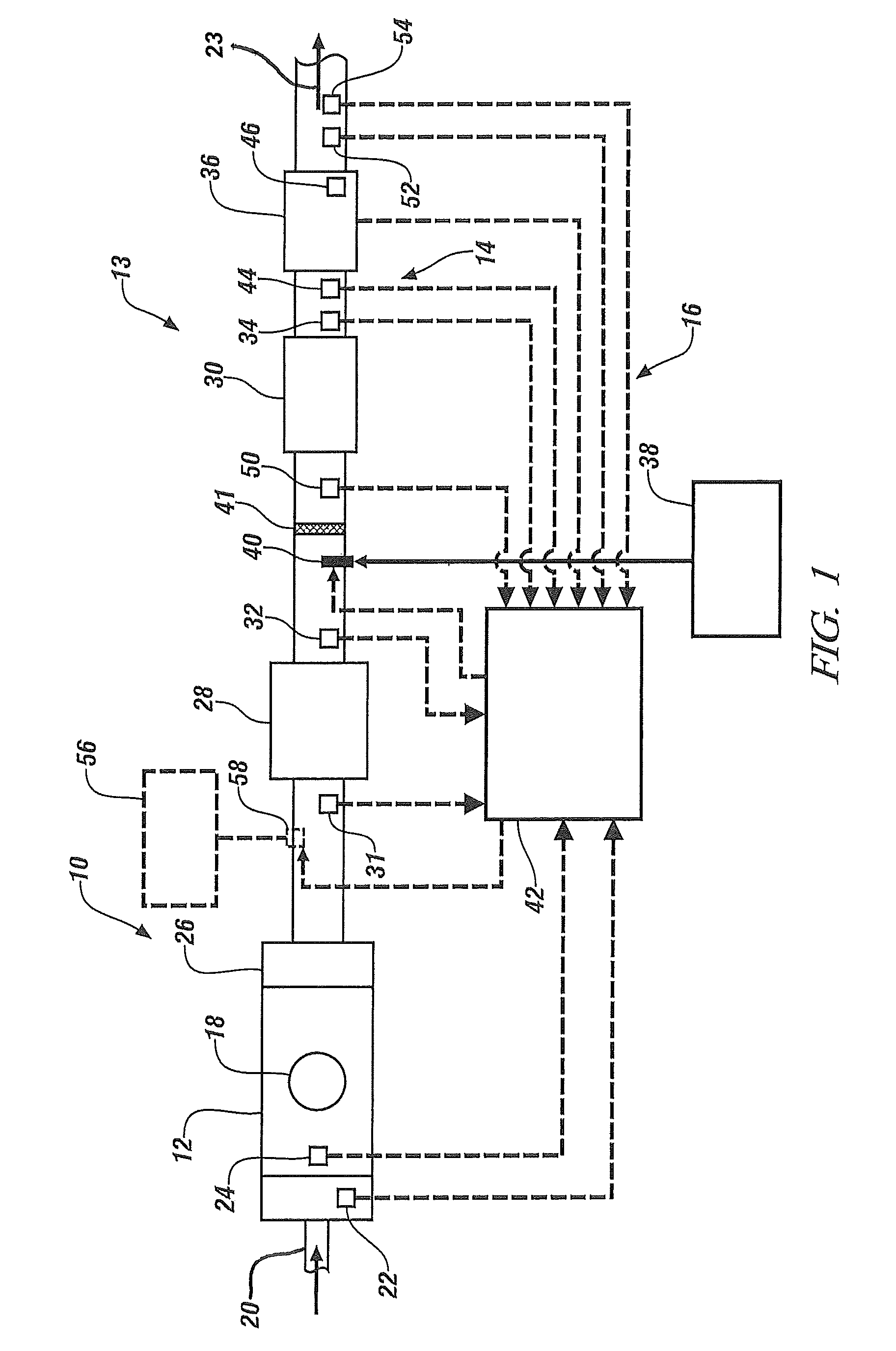

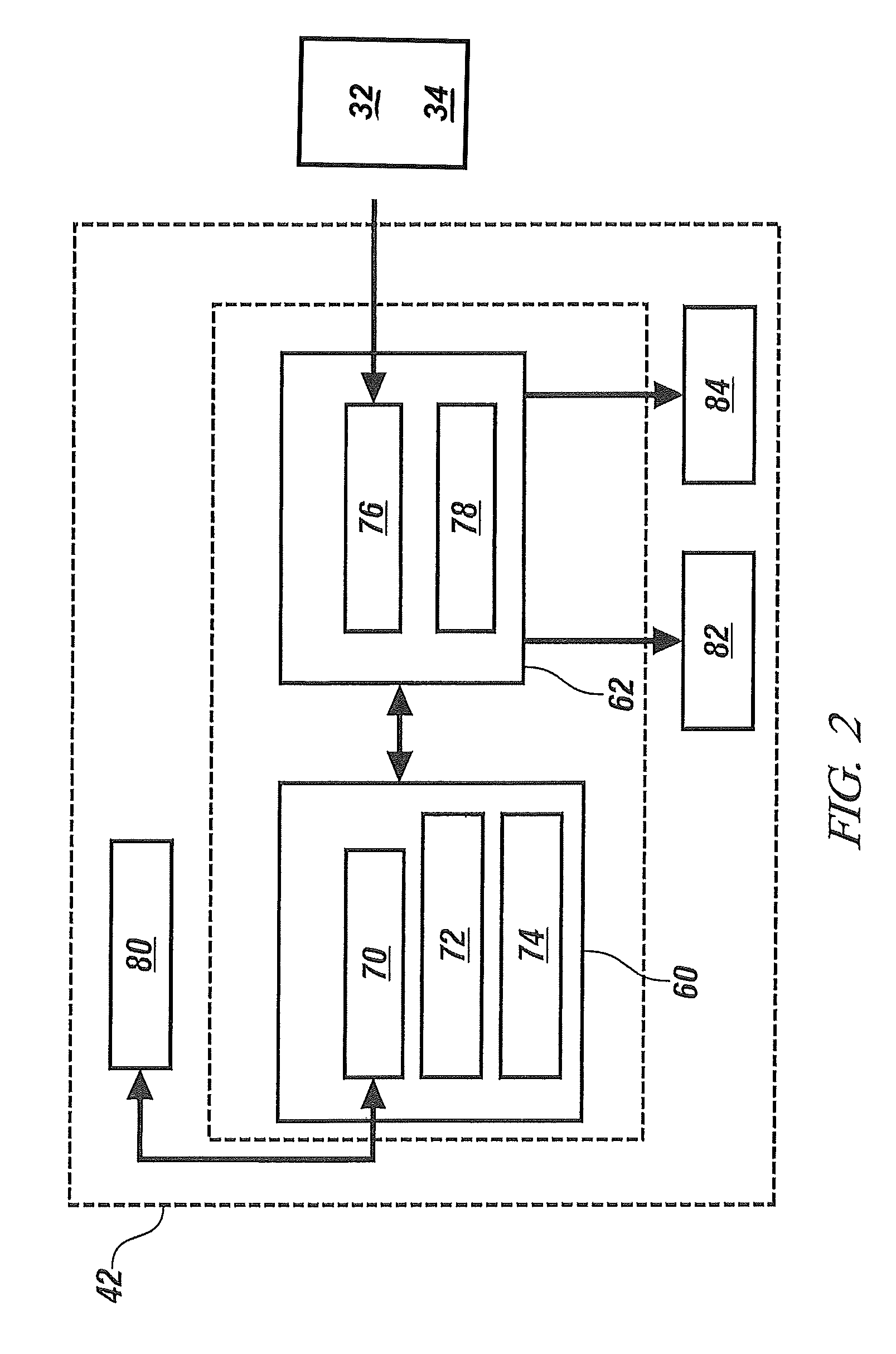

System and method for controlling exhaust stream temperature

ActiveUS20100050607A1Reduce errorsInternal combustion piston enginesExhaust apparatusParticulatesStream temperature

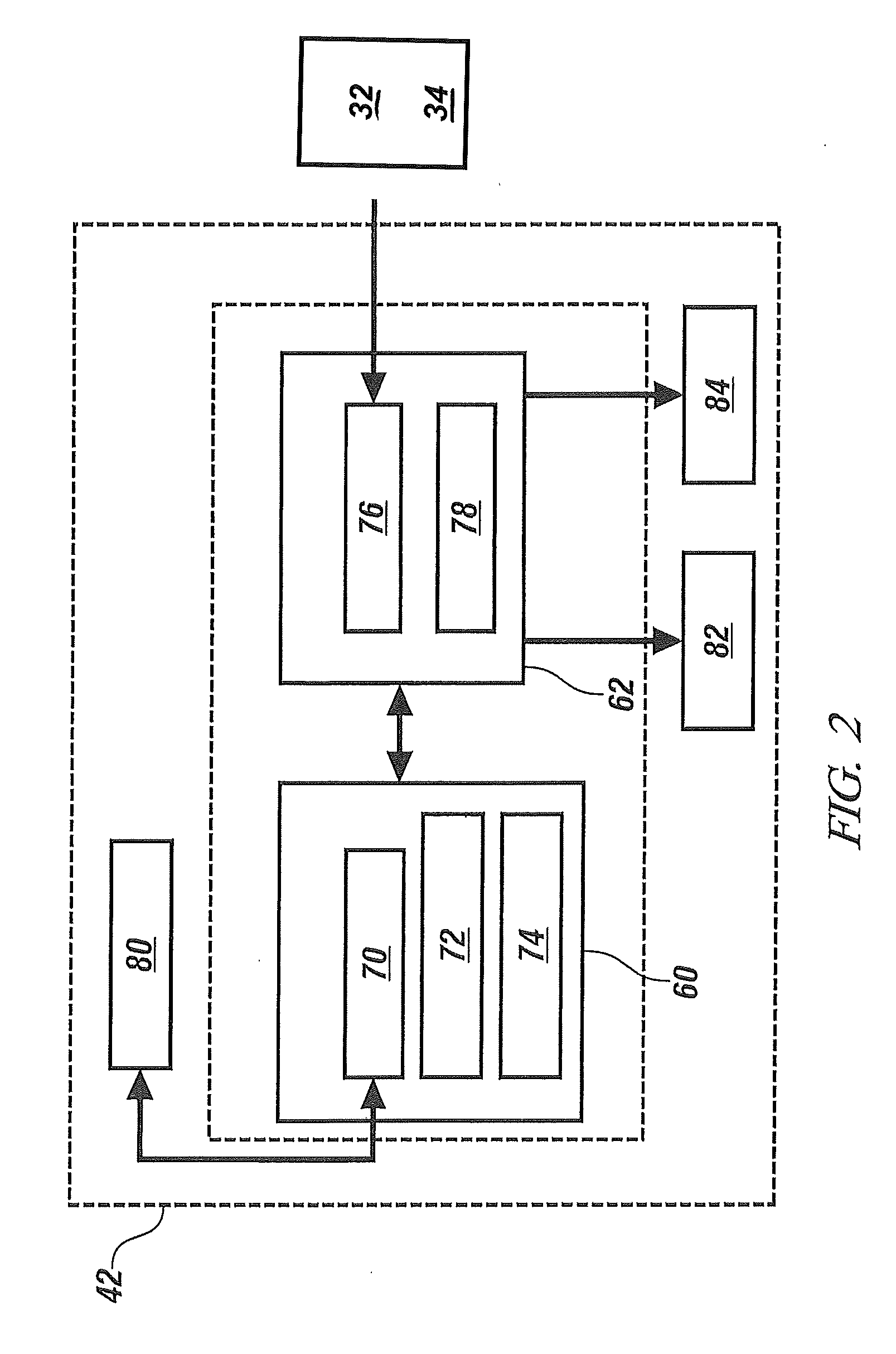

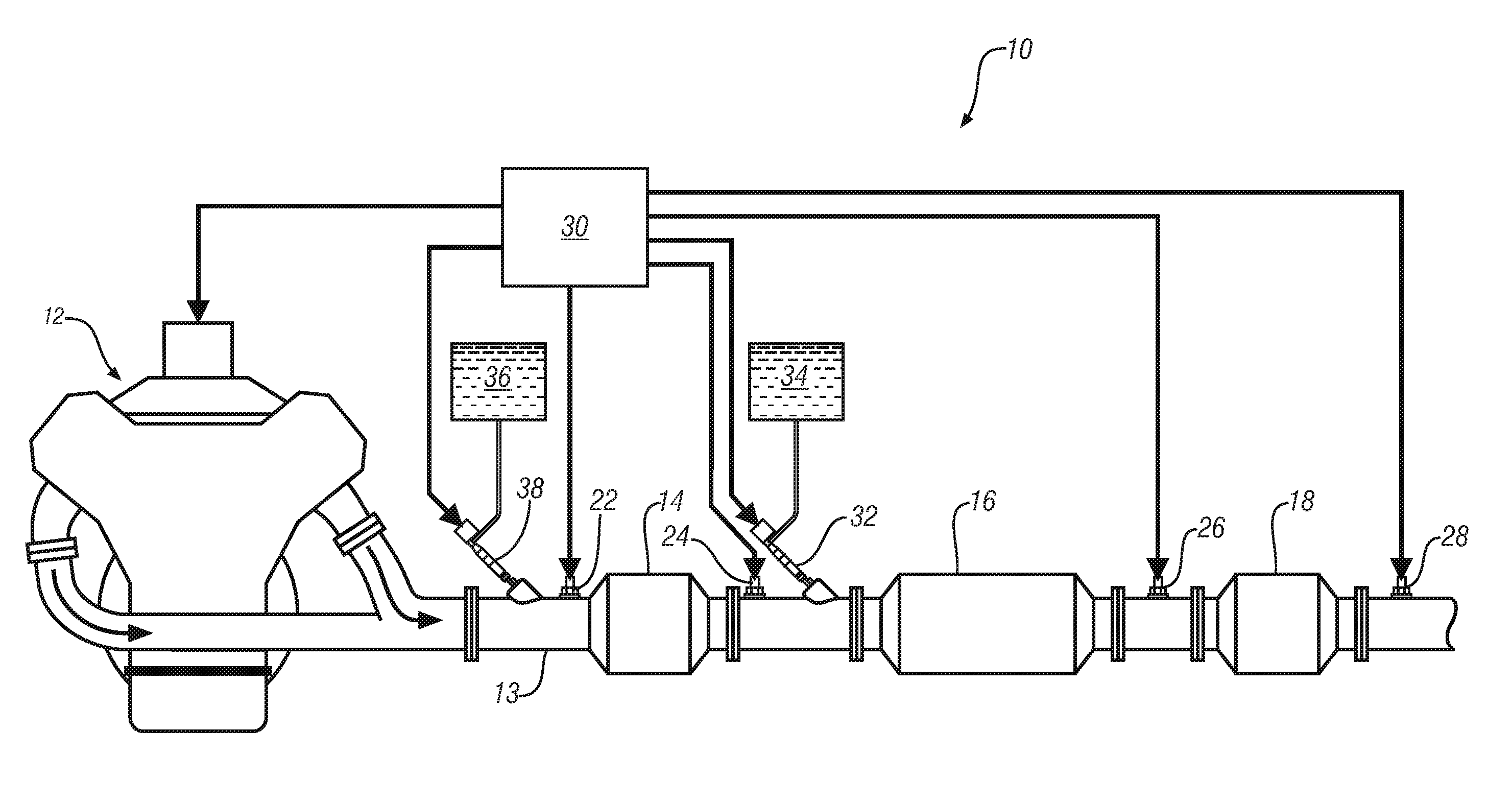

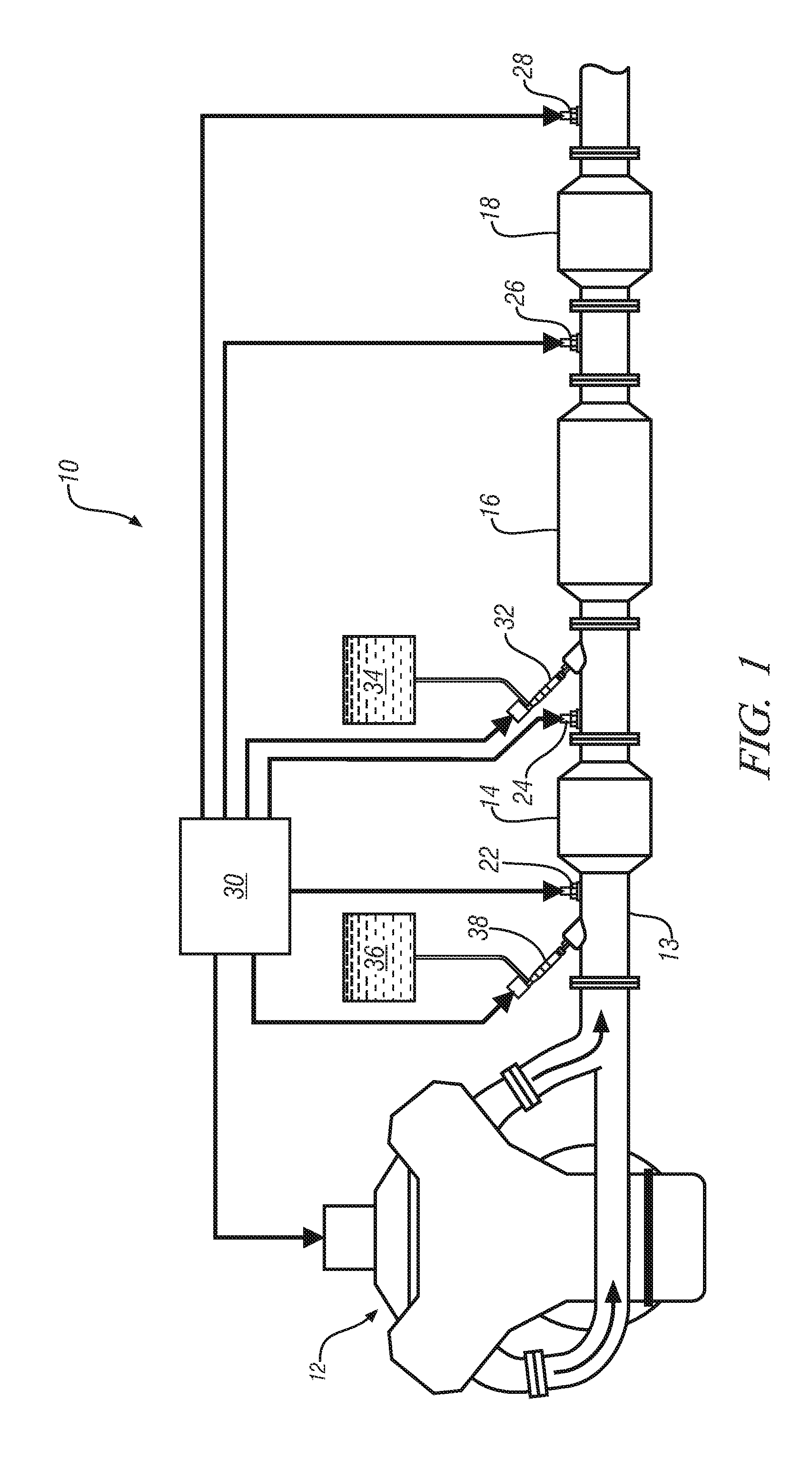

Systems and methods are provided for controlling an exhaust stream temperature at a point along an exhaust system. The exhaust system can include an oxidation catalyst, a particulate filter having an outlet, and a fuel injector for injecting fuel into an exhaust stream at a location upstream from the outlet. An adaptive control can be provided to model a portion of the exhaust system. A fuel injection flow rate at which fuel is injected into the exhaust stream by the fuel injector can be calculated based on the adaptive control model. An operation of the fuel injector can be controlled based on the calculated fuel injection flow rate, to control the exhaust stream temperature at point along the exhaust system. A condition of the exhaust stream can also monitored and an error in the adaptive control model can be determined based on the monitored condition. The adaptive control model can also be changed to reduce the error.

Owner:CORNING INC

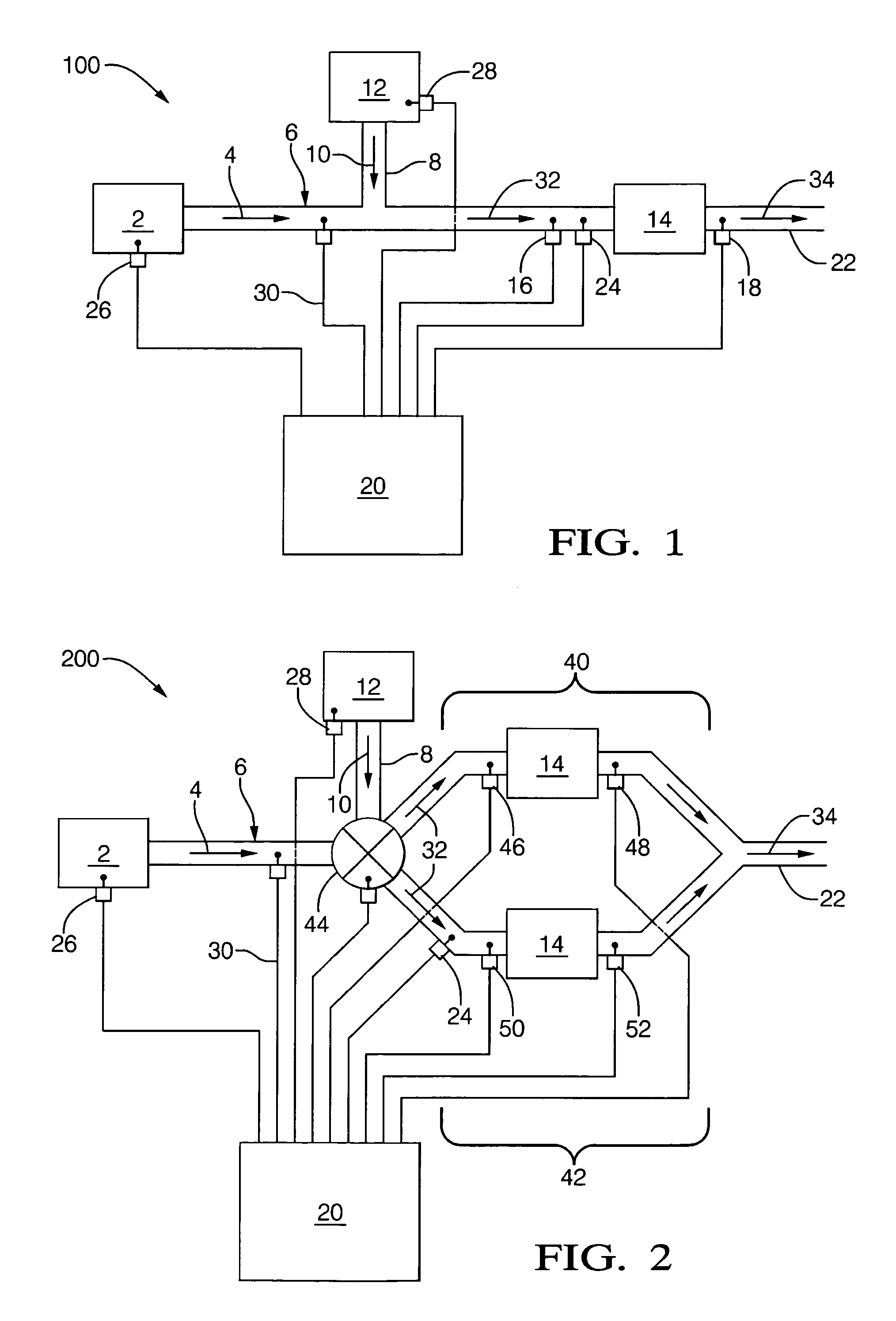

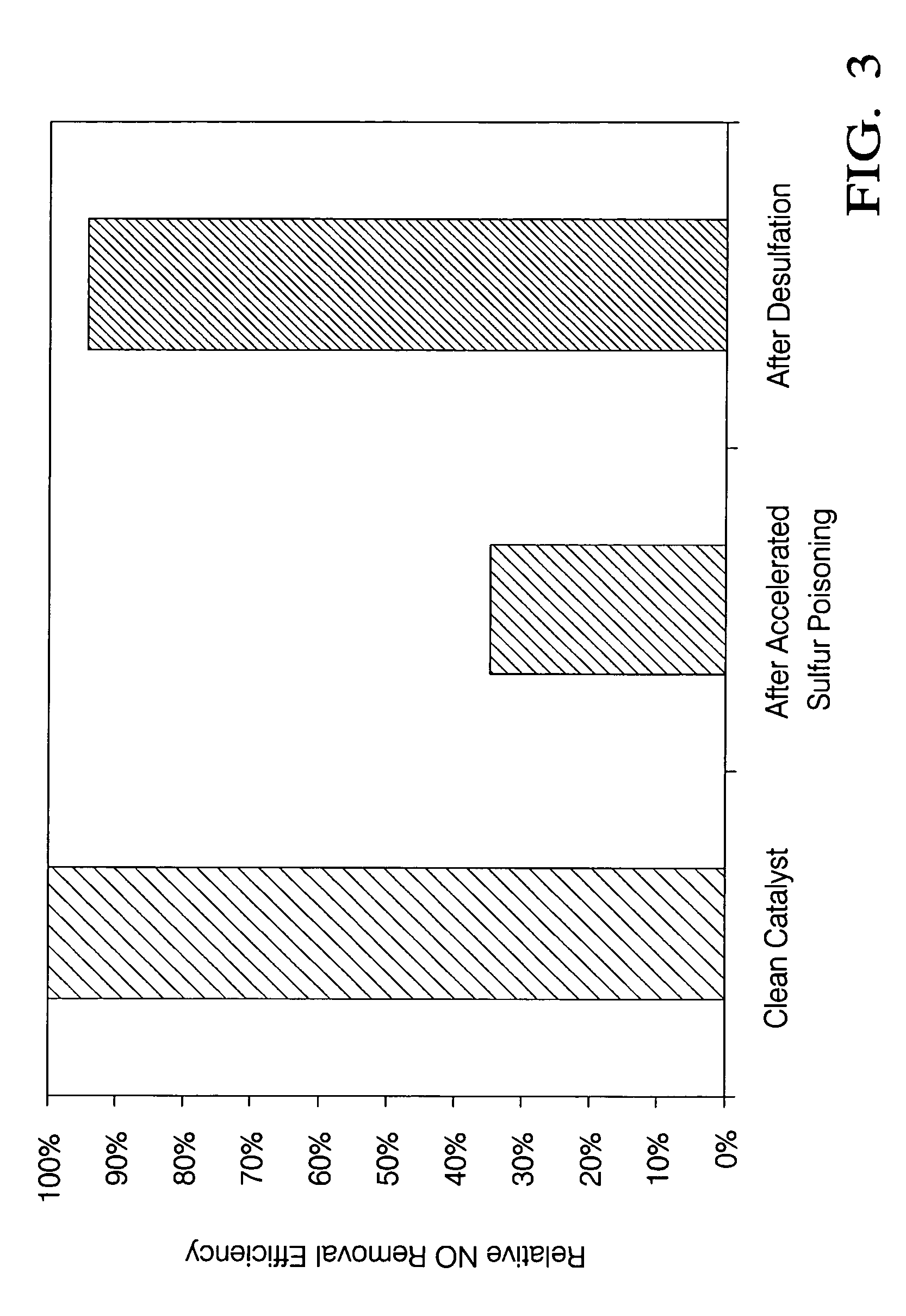

Exhaust system and methods of NOx adsorber desulfation

ActiveUS7036489B1Increase temperatureInternal combustion piston enginesExhaust apparatusCombustionHydrogen

Owner:DELPHI TECH IP LTD

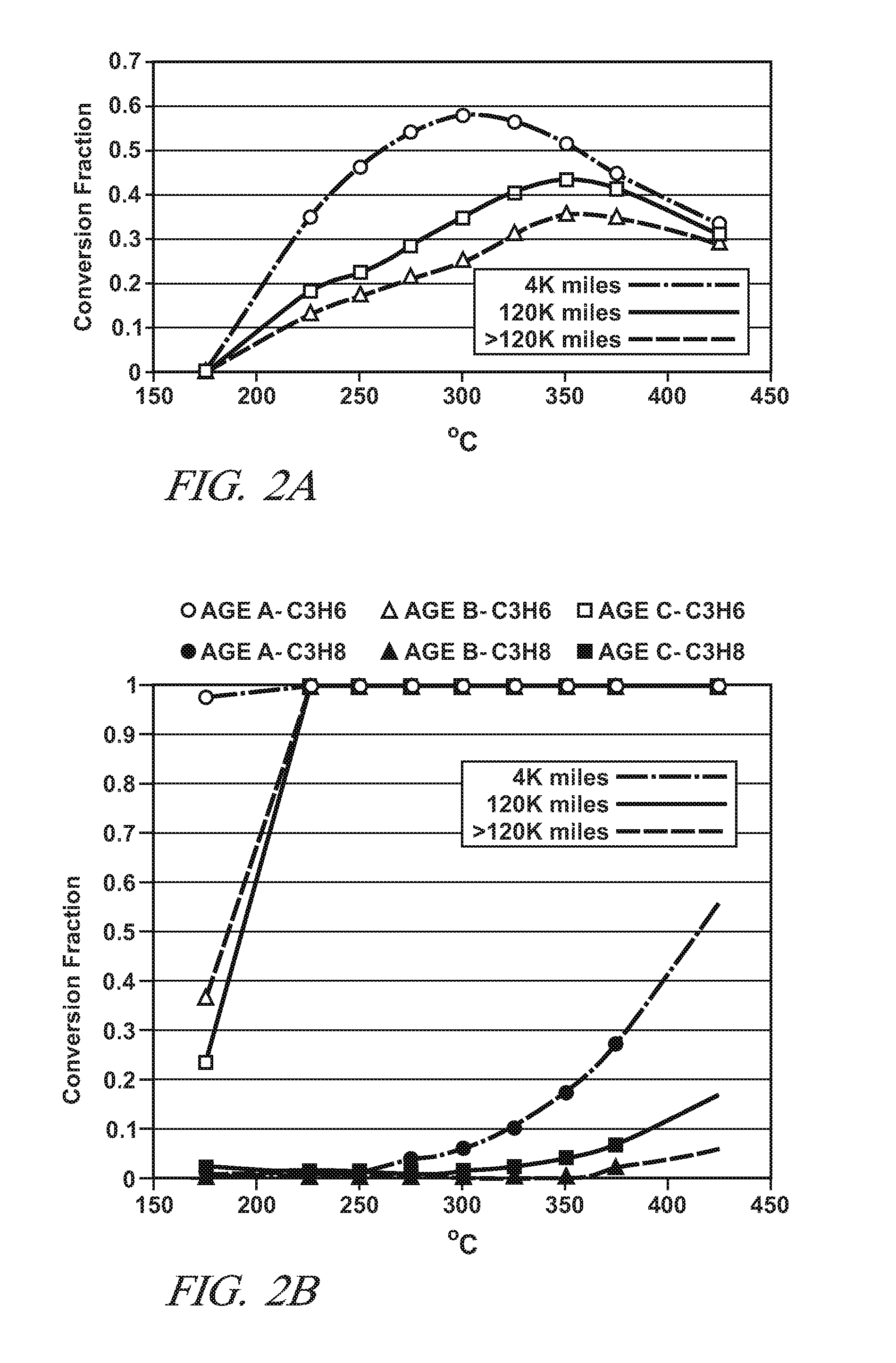

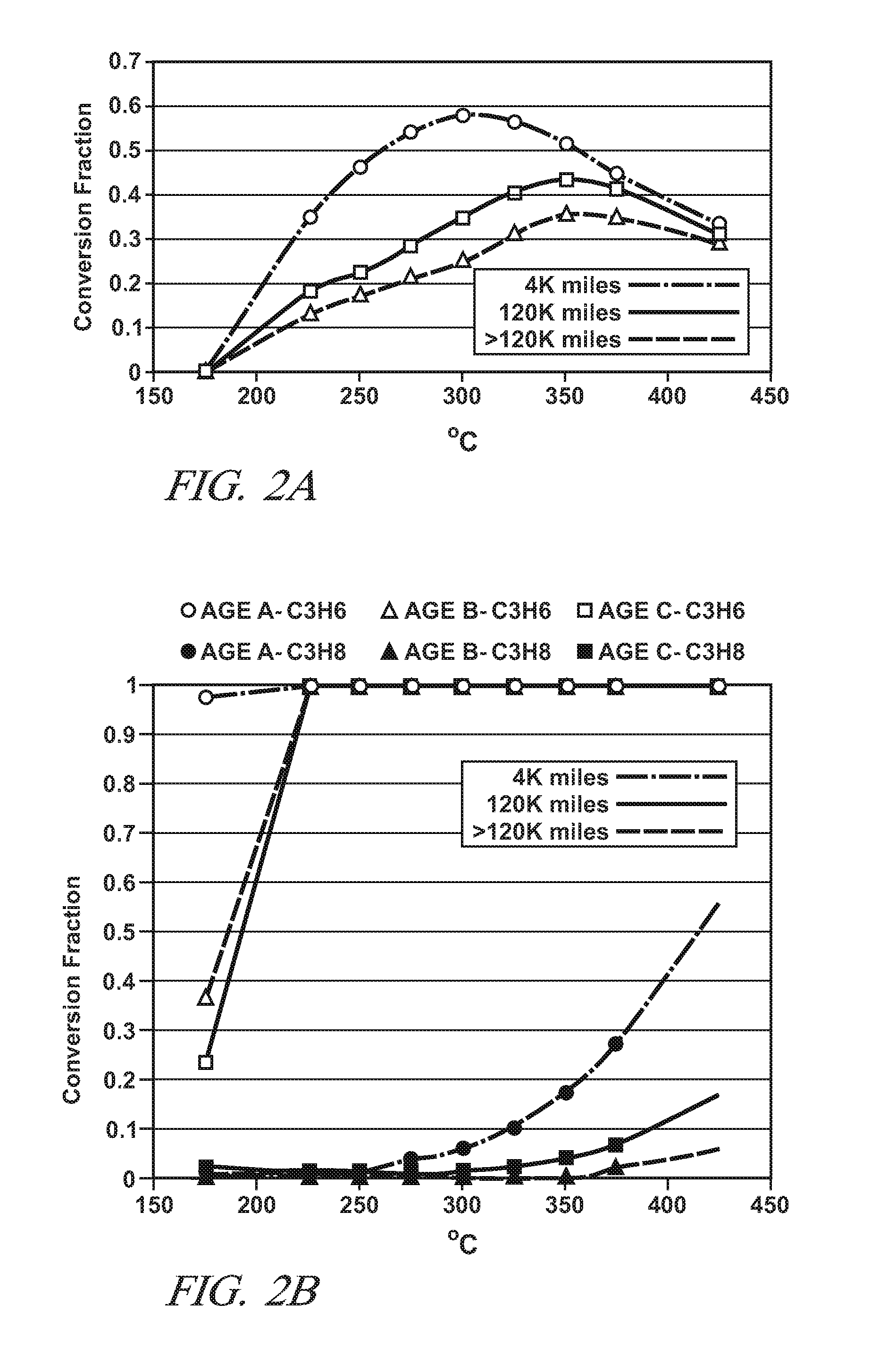

Apparatus and method for onboard performance monitoring of oxidation catalyst

InactiveUS20120186226A1Internal combustion piston enginesExhaust apparatusEngineeringStream temperature

A method and system for determining conversion of NO to NO2 in an engine exhaust stream by an oxidation catalyst during operation of the engine is disclosed based on injecting hydrocarbon fuel into the exhaust stream upstream of the oxidation catalyst, measuring a temperature of the exhaust stream on the upstream and downstream sides of the oxidation catalyst, calculating a difference in exhaust stream temperature between the upstream and downstream sides of the oxidation catalyst, and determining the conversion of NO to NO2 by the oxidation catalyst from the difference in exhaust stream temperature based on a predetermined correlation profile between the temperatures on the upstream and downstream sides of the oxidation catalyst and conversion of NO to NO2.

Owner:GM GLOBAL TECH OPERATIONS LLC

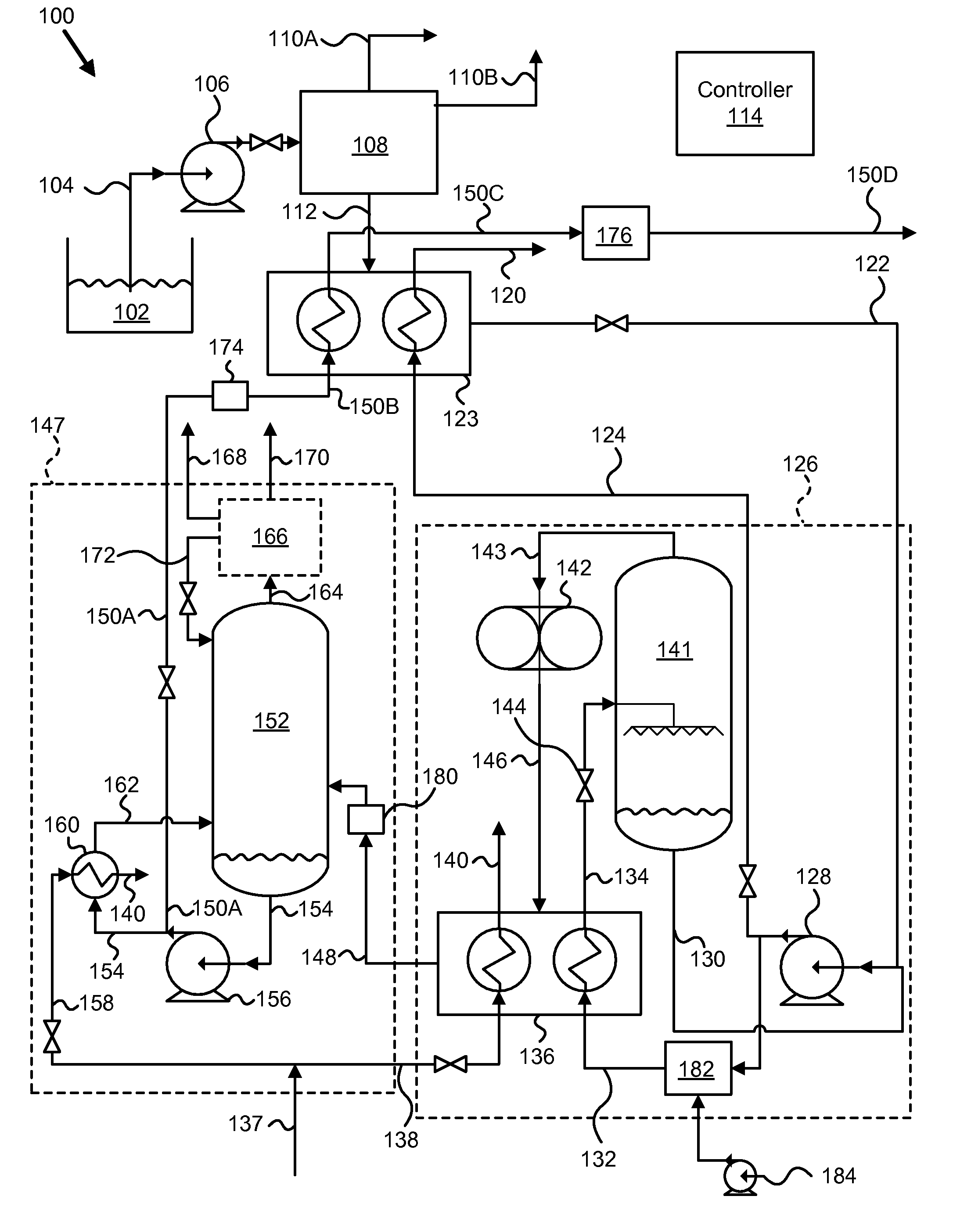

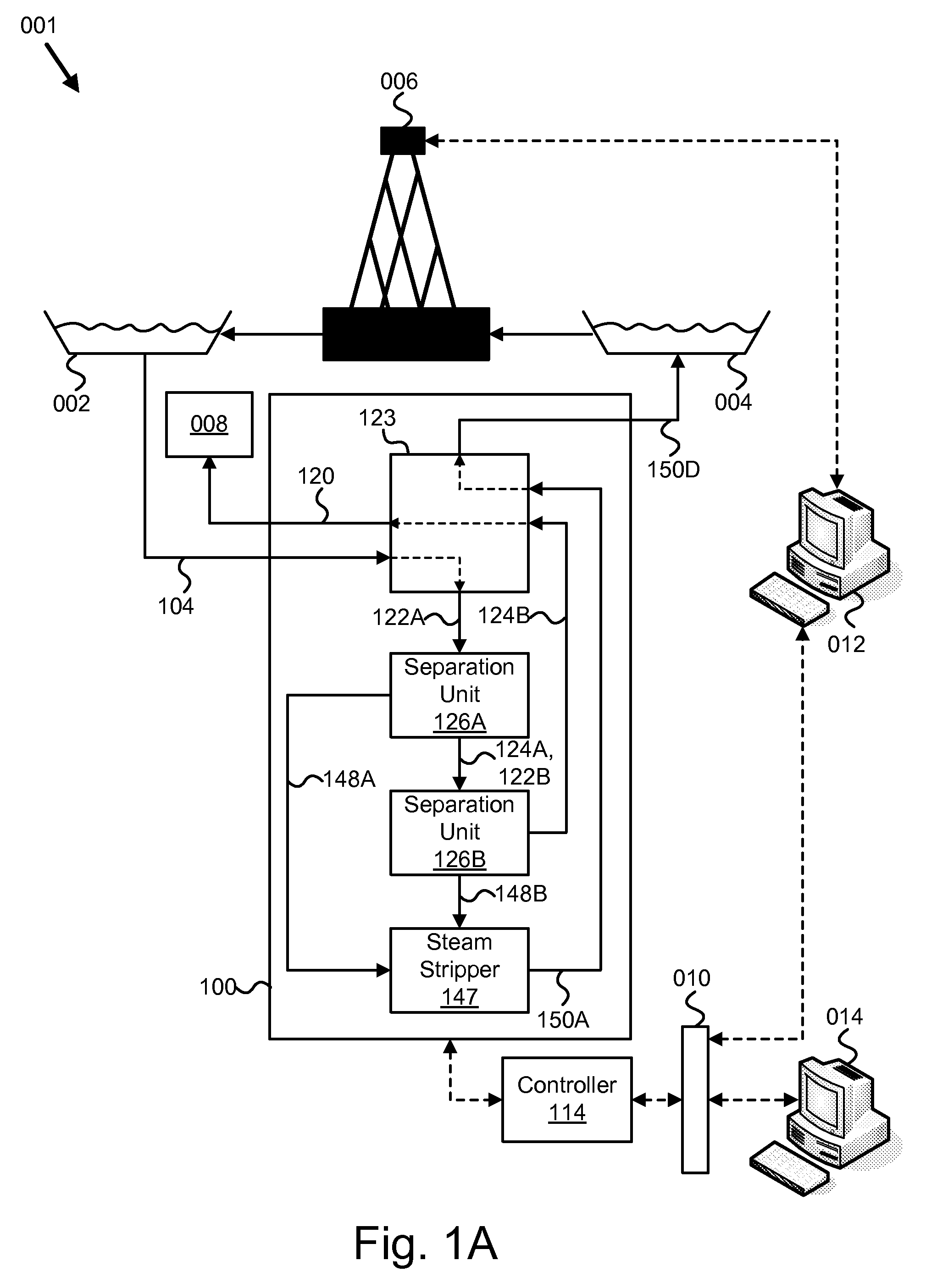

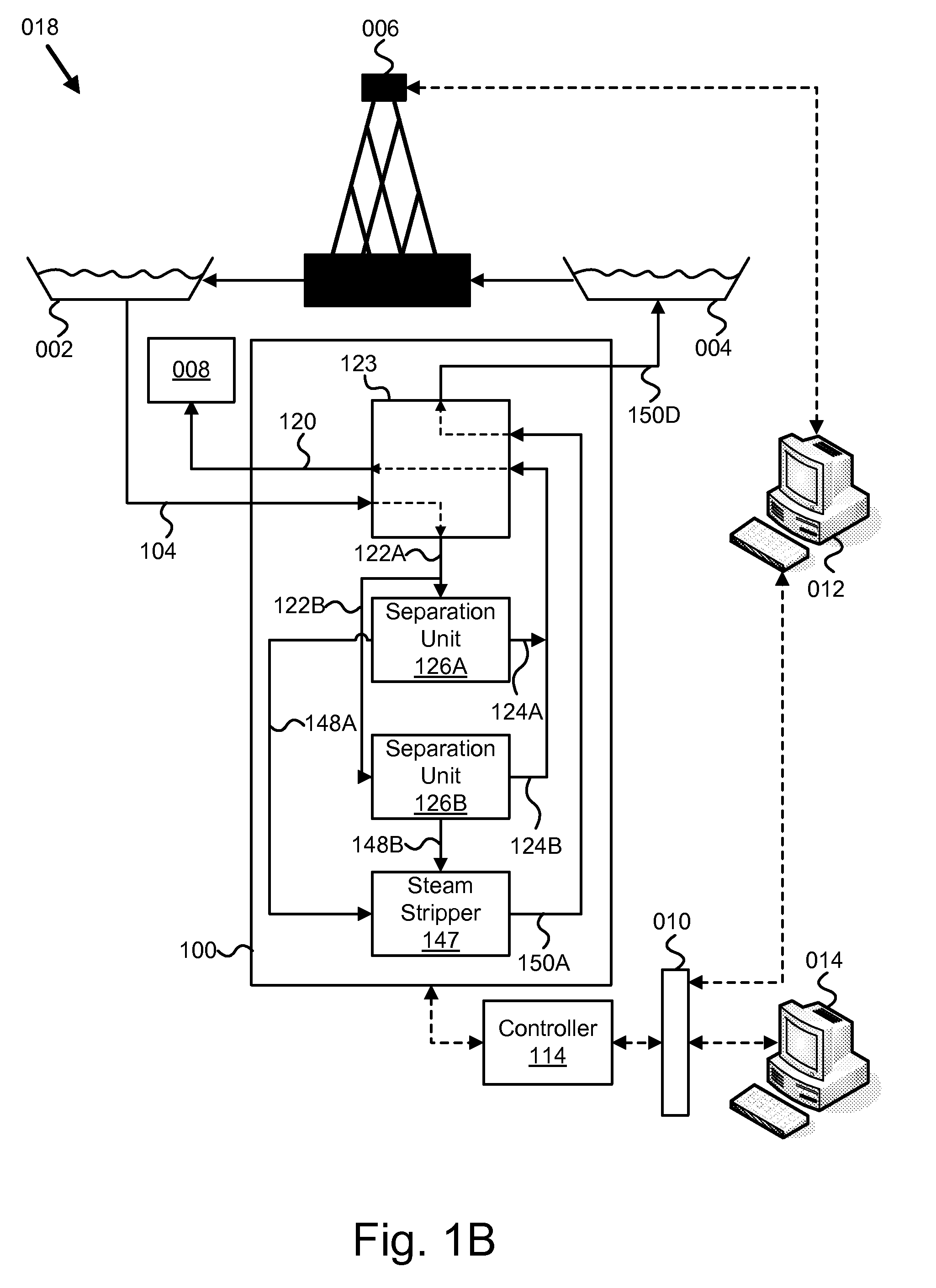

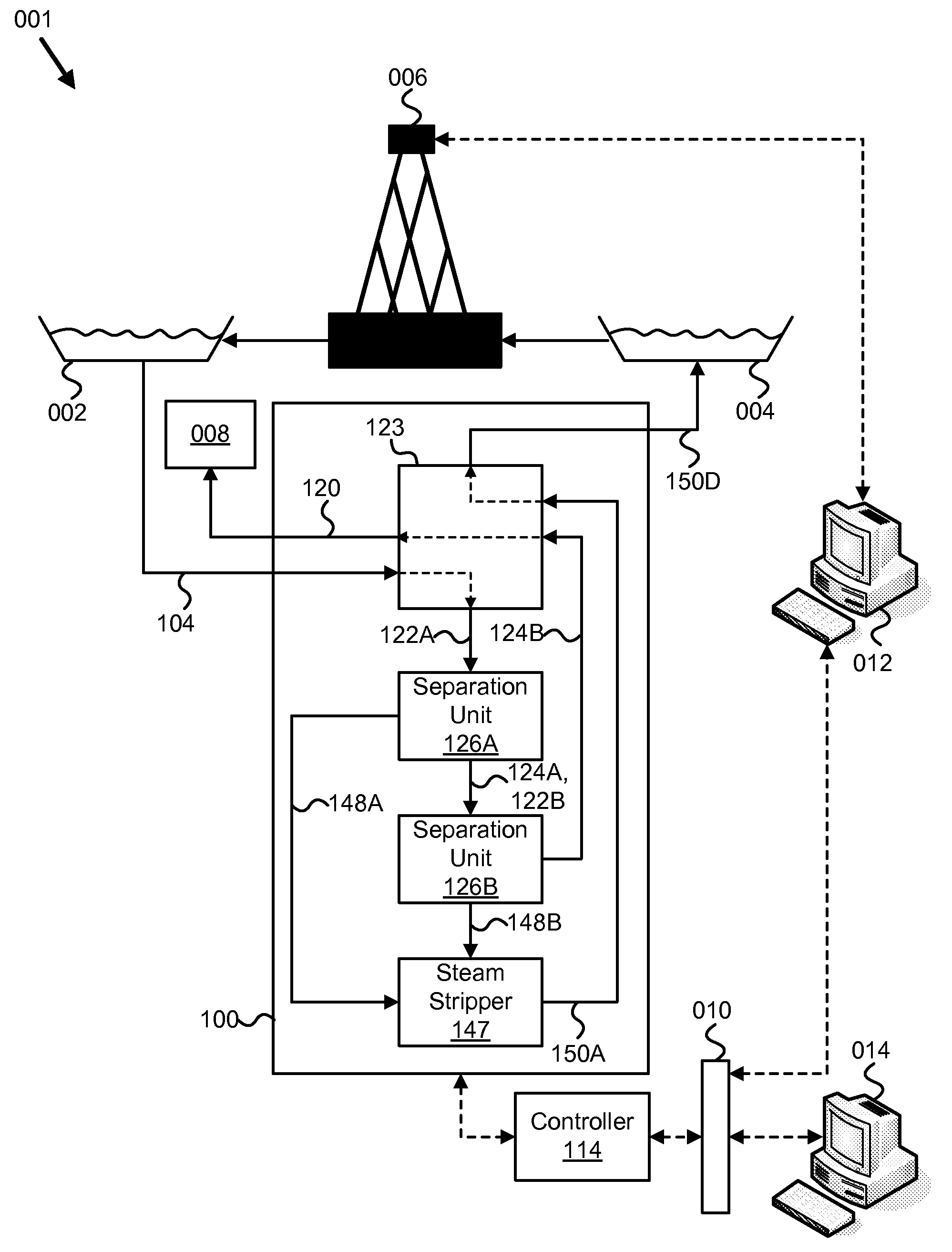

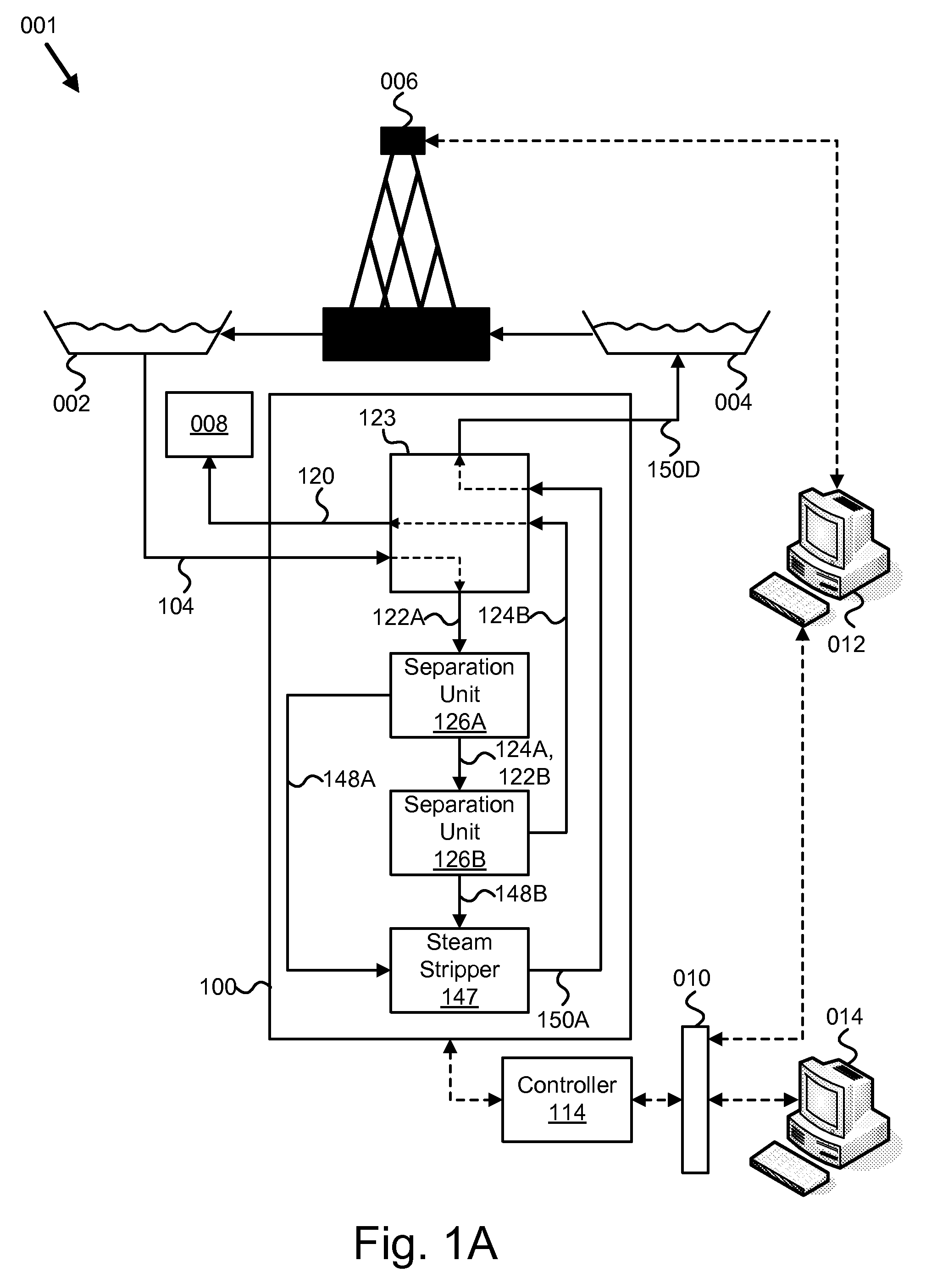

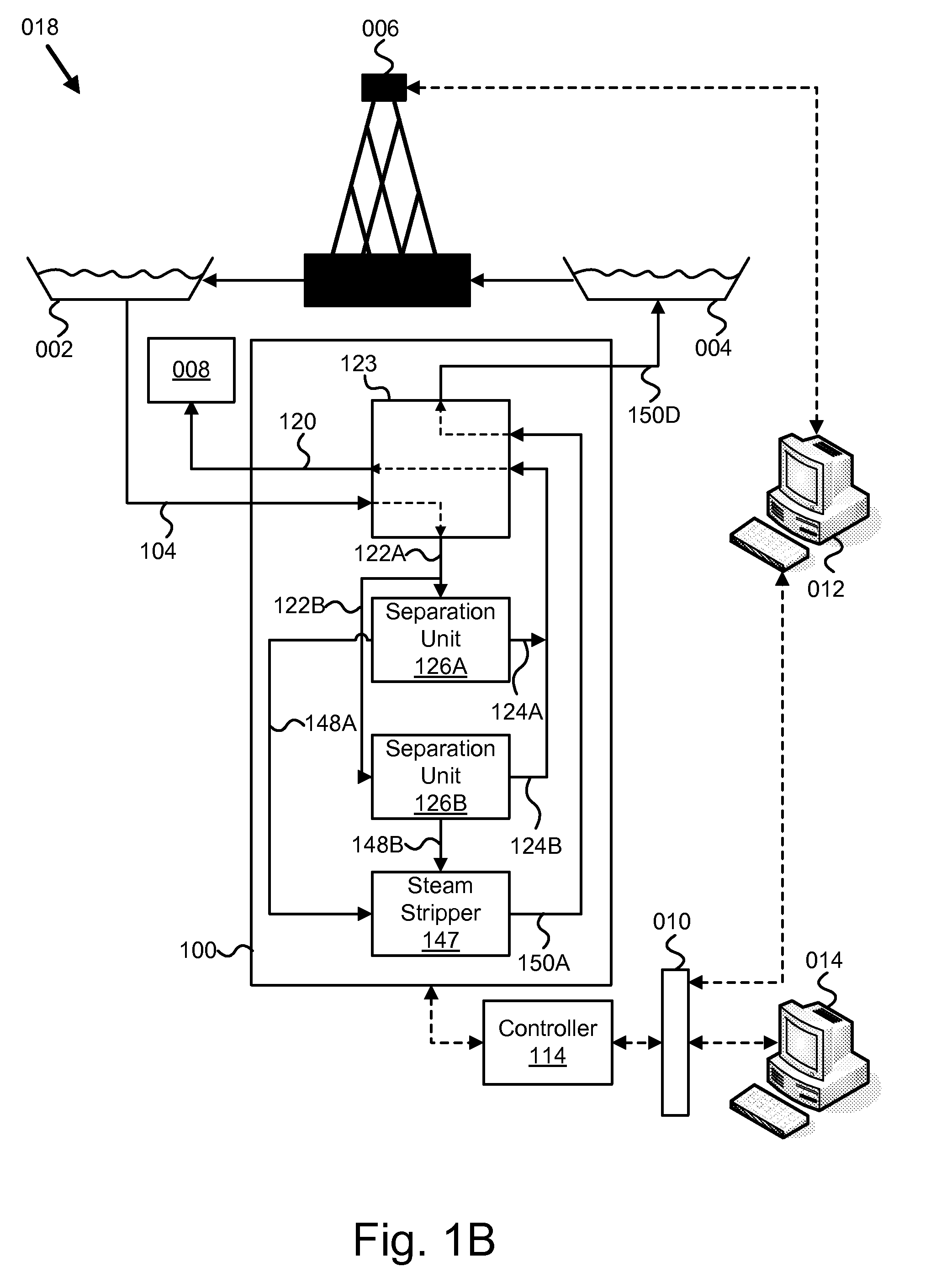

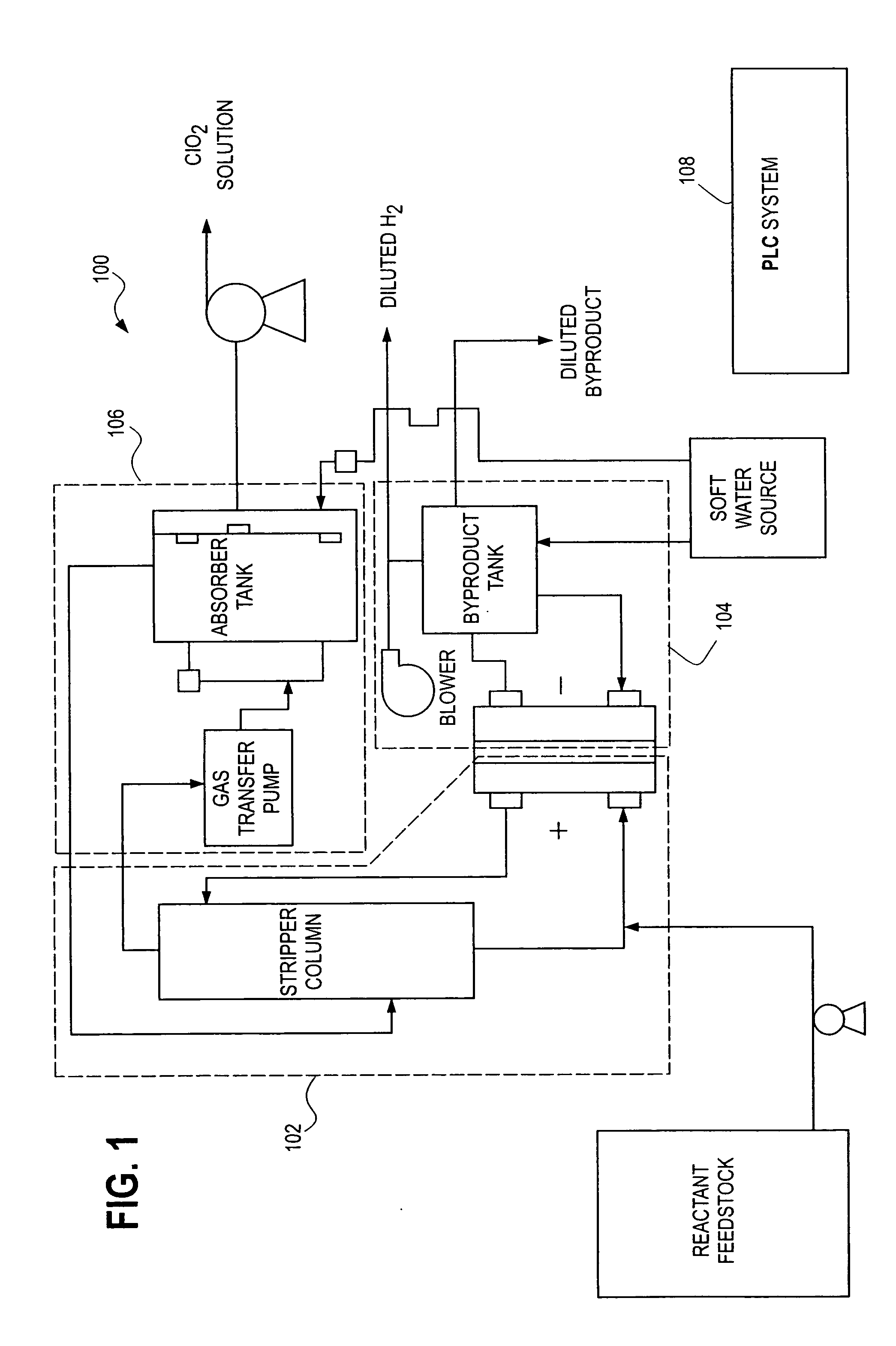

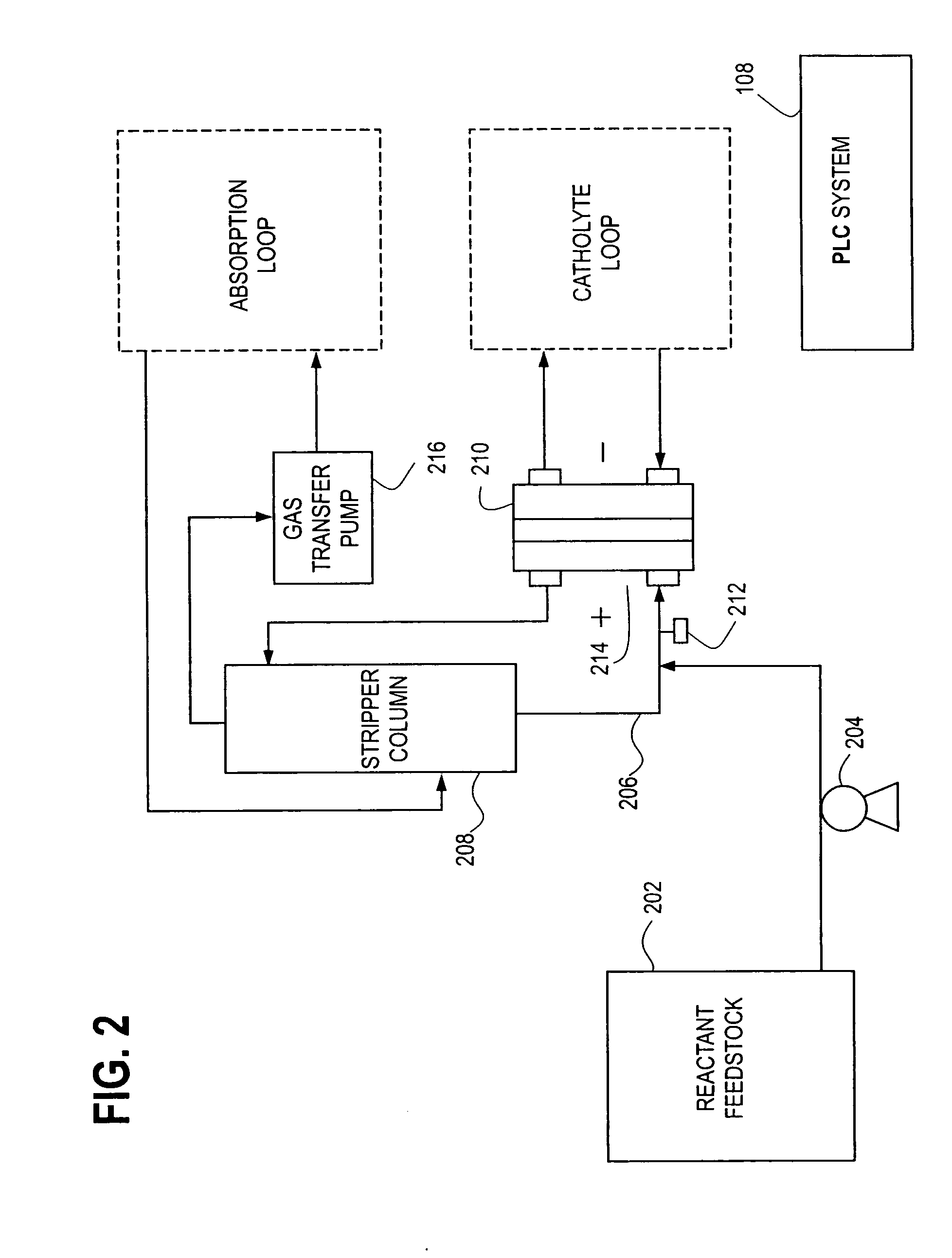

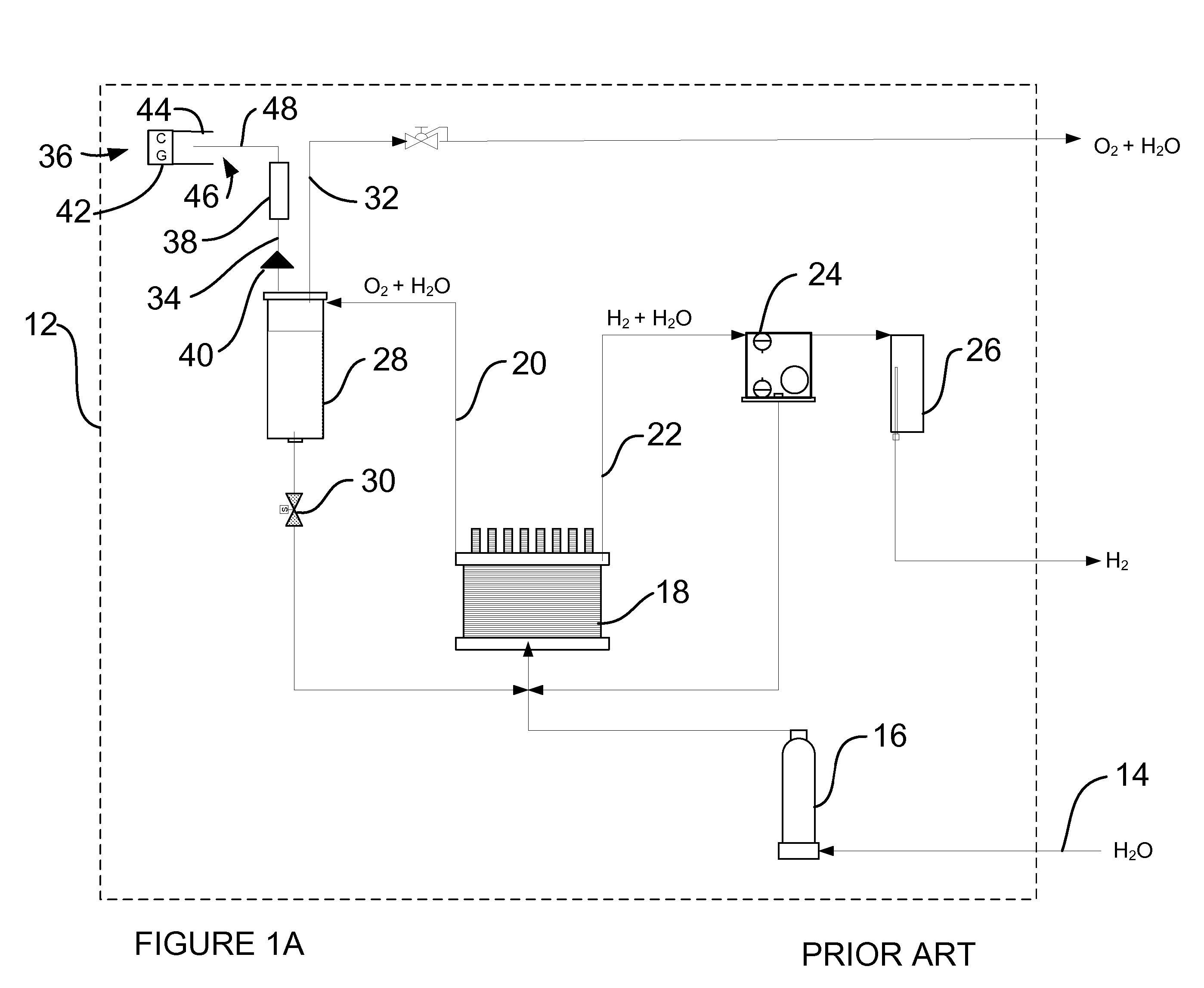

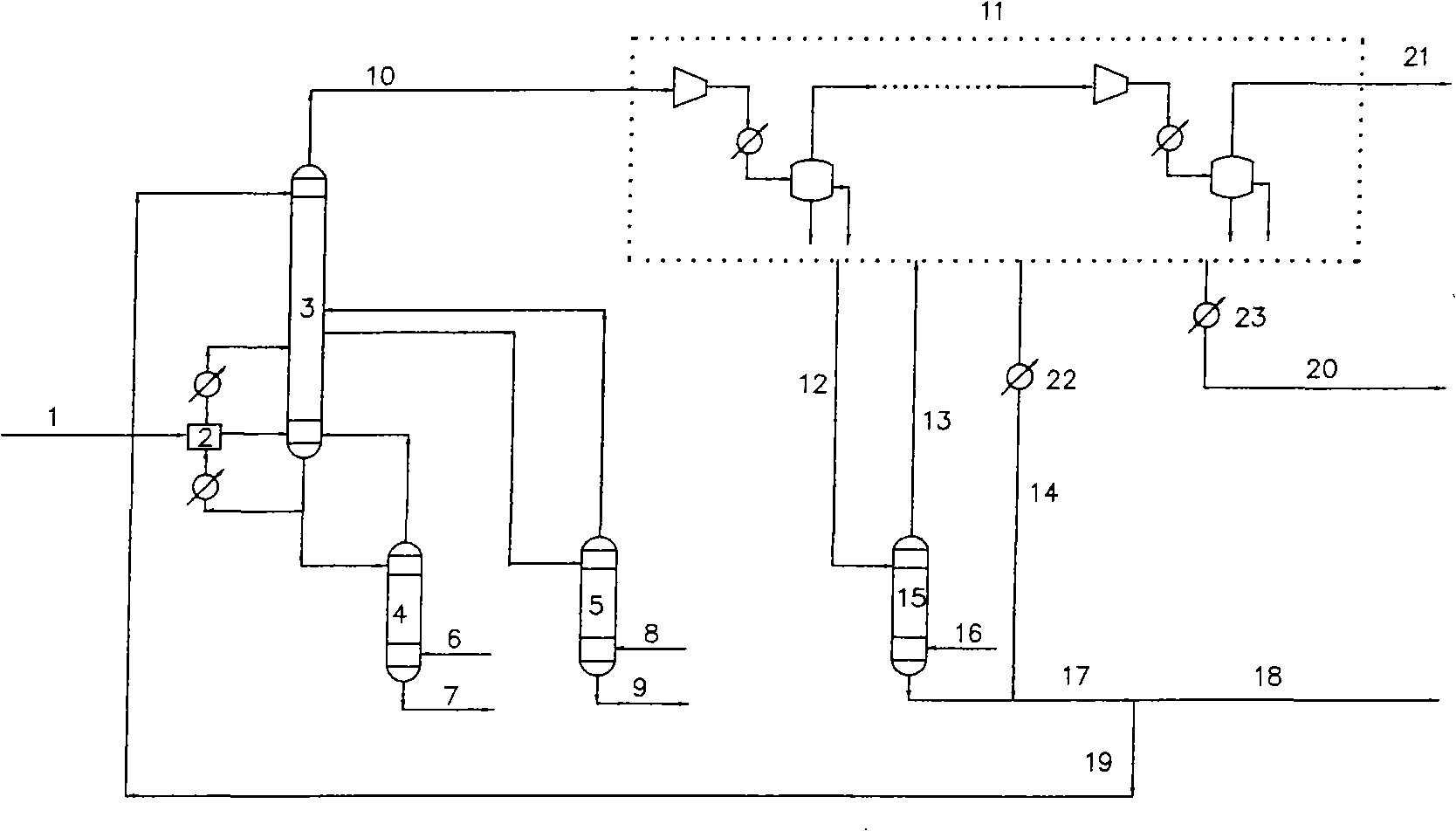

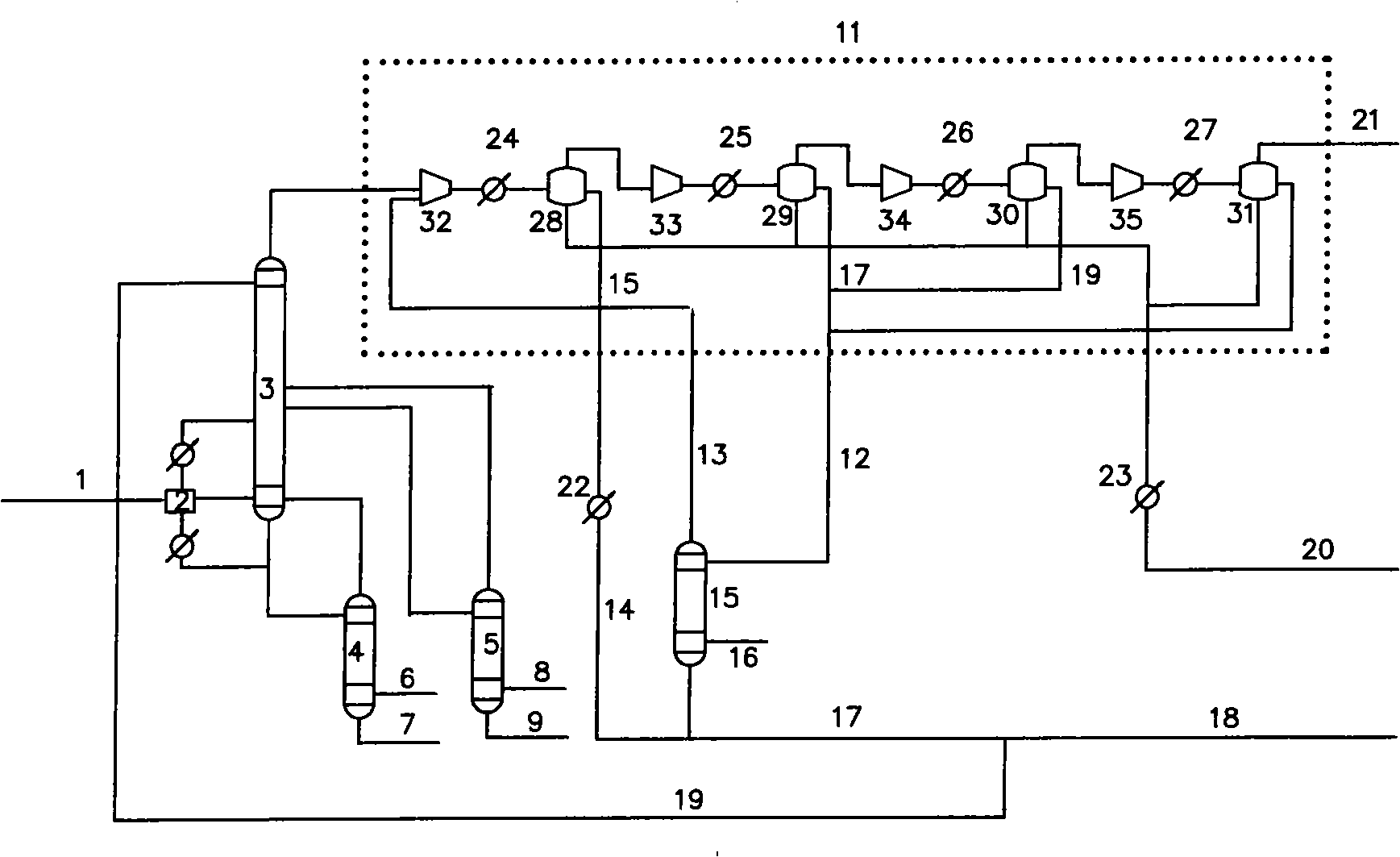

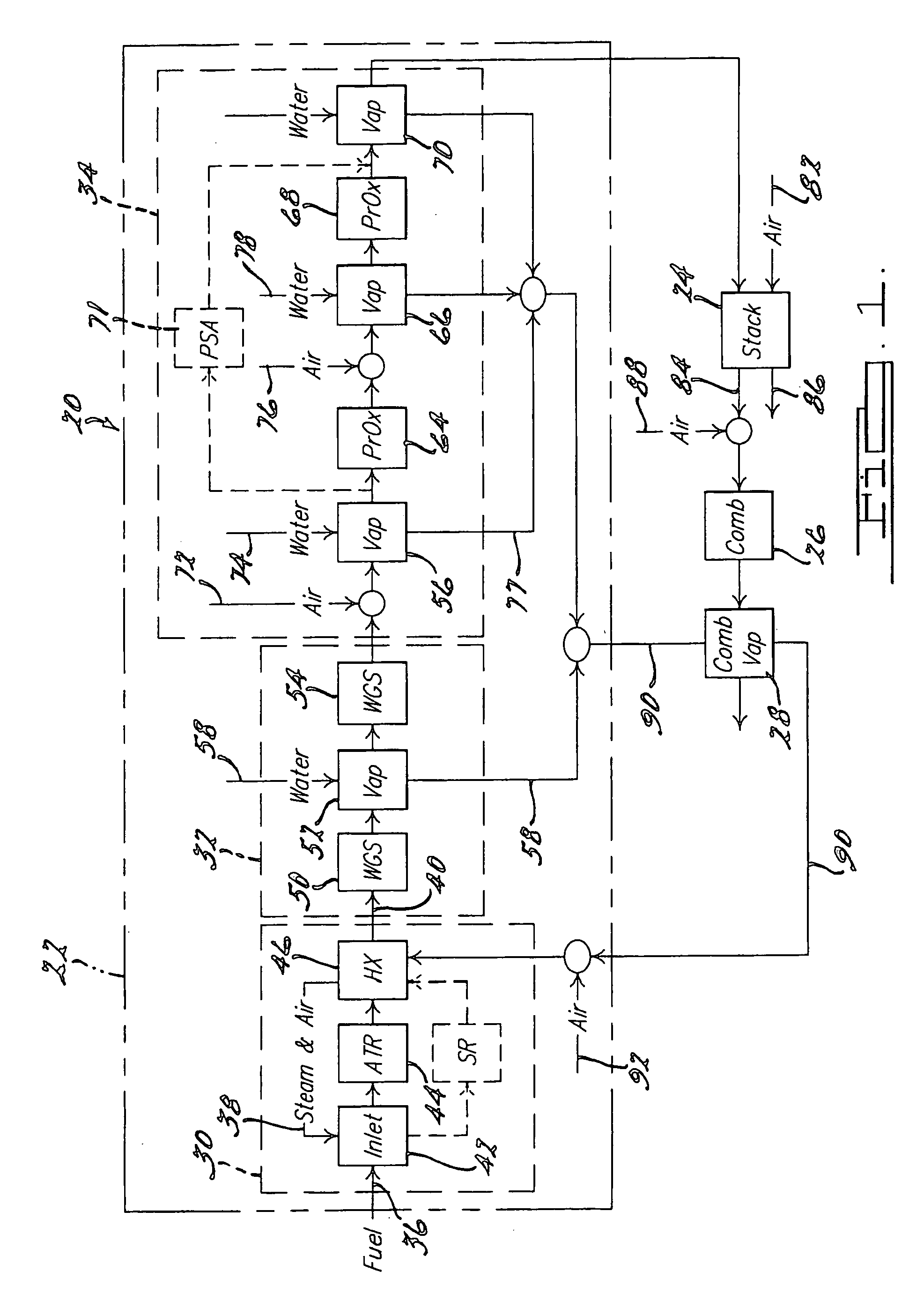

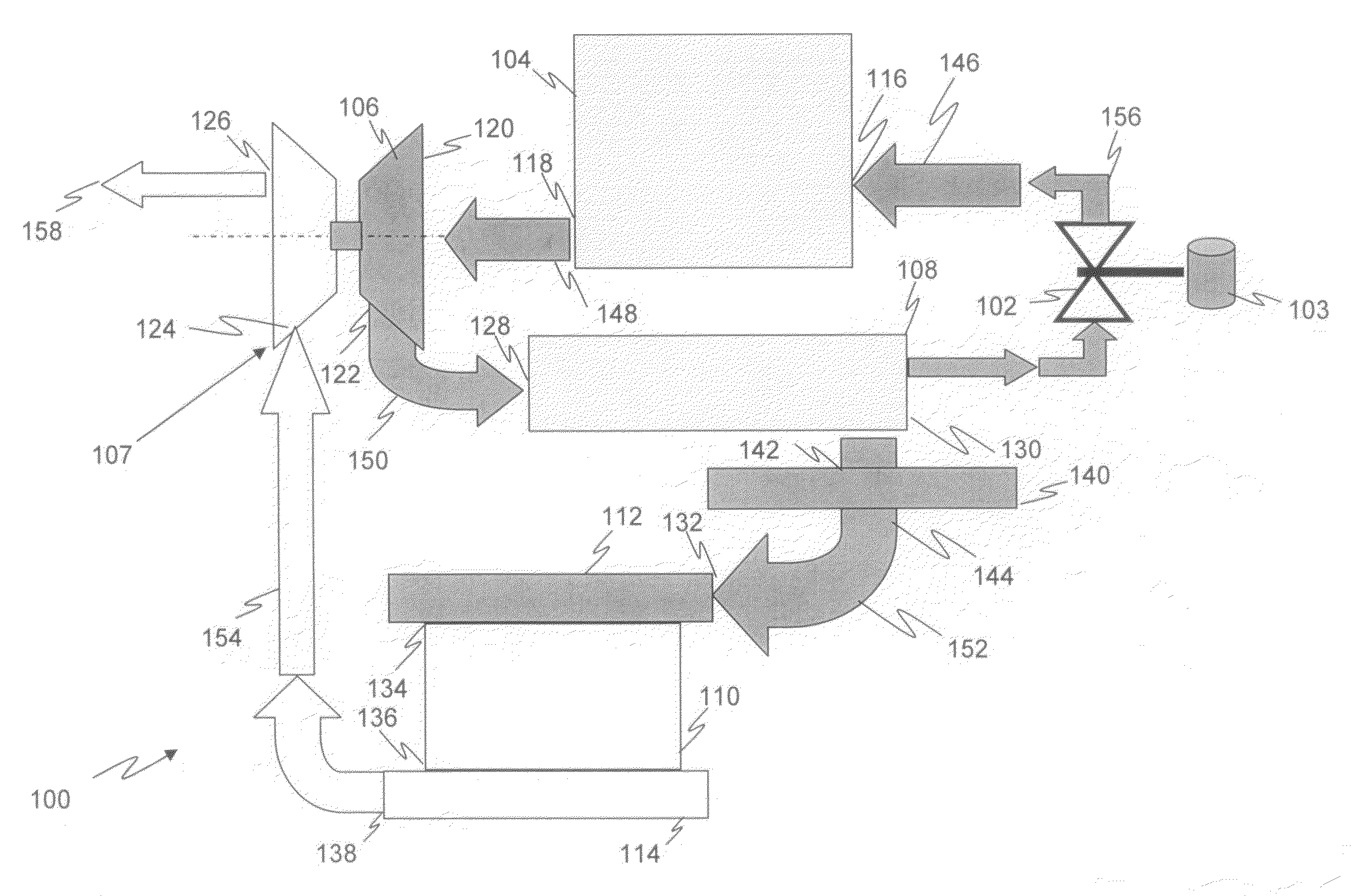

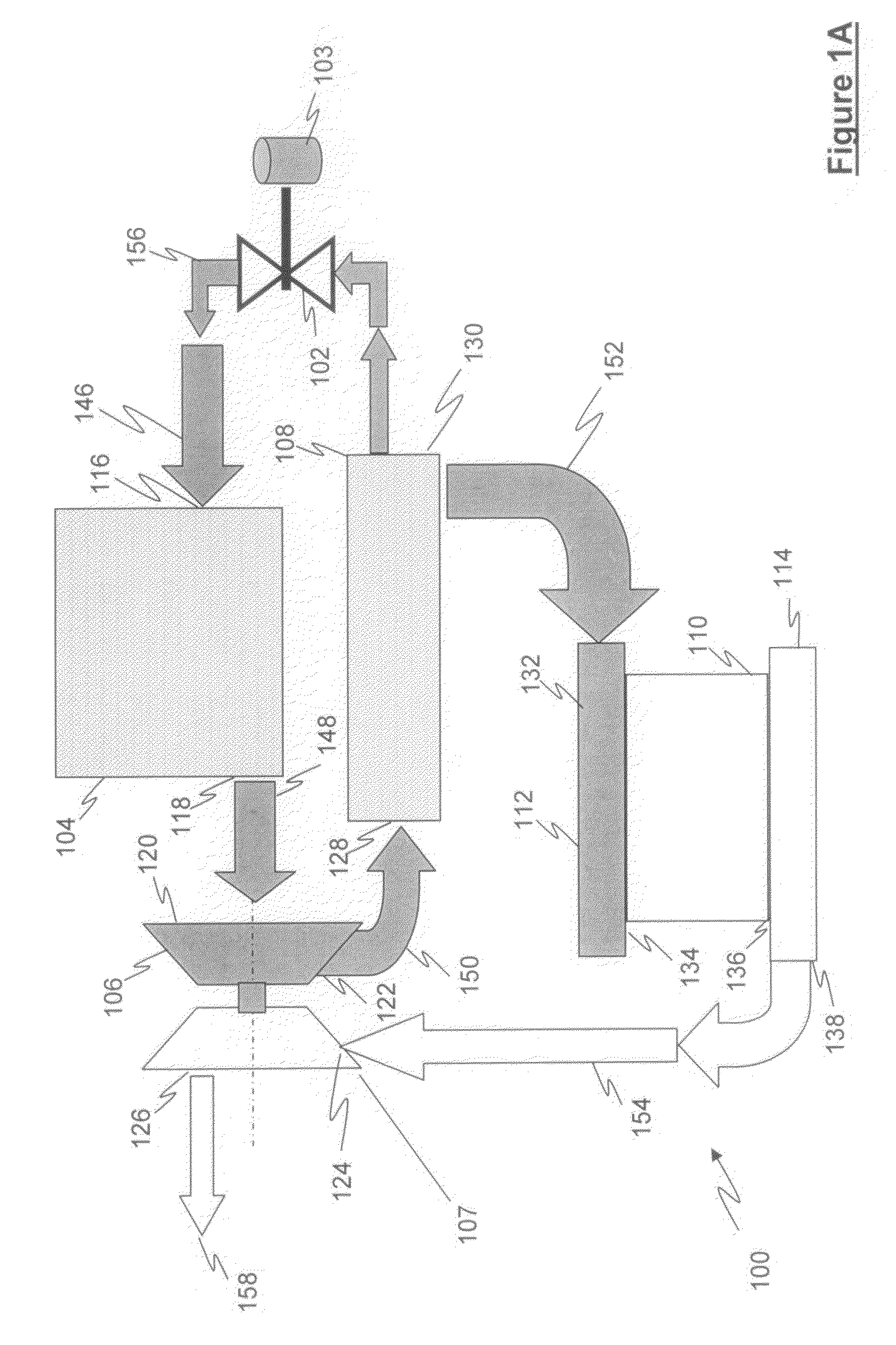

System and method for providing aqueous stream purification services

A system and method are disclosed for providing aqueous stream purification services. The system includes at least one separation unit. Each separation unit may include a mechanical vapor recompression separator, a steam stripper, and a secondary recovery heat exchanger. The system for wastewater purification may receive water from a waste water storage, purify the water, and return the purified water to a purified water storage. The system may include a controller. The controller may include an operating conditions module configured to interpret at least one operating condition. Operating conditions may be waste fluid stream impurity concentrations, waste fluid stream flow rates, steam inlet temperatures, recirculation stream flow rates corresponding to the at least one separation unit, recirculation stream temperatures corresponding to the at least one separation unit, purified product stream flow rates, purified product stream impurity concentrations, and / or purge stream concentrations corresponding to the at least one separation unit.

Owner:H2OIL

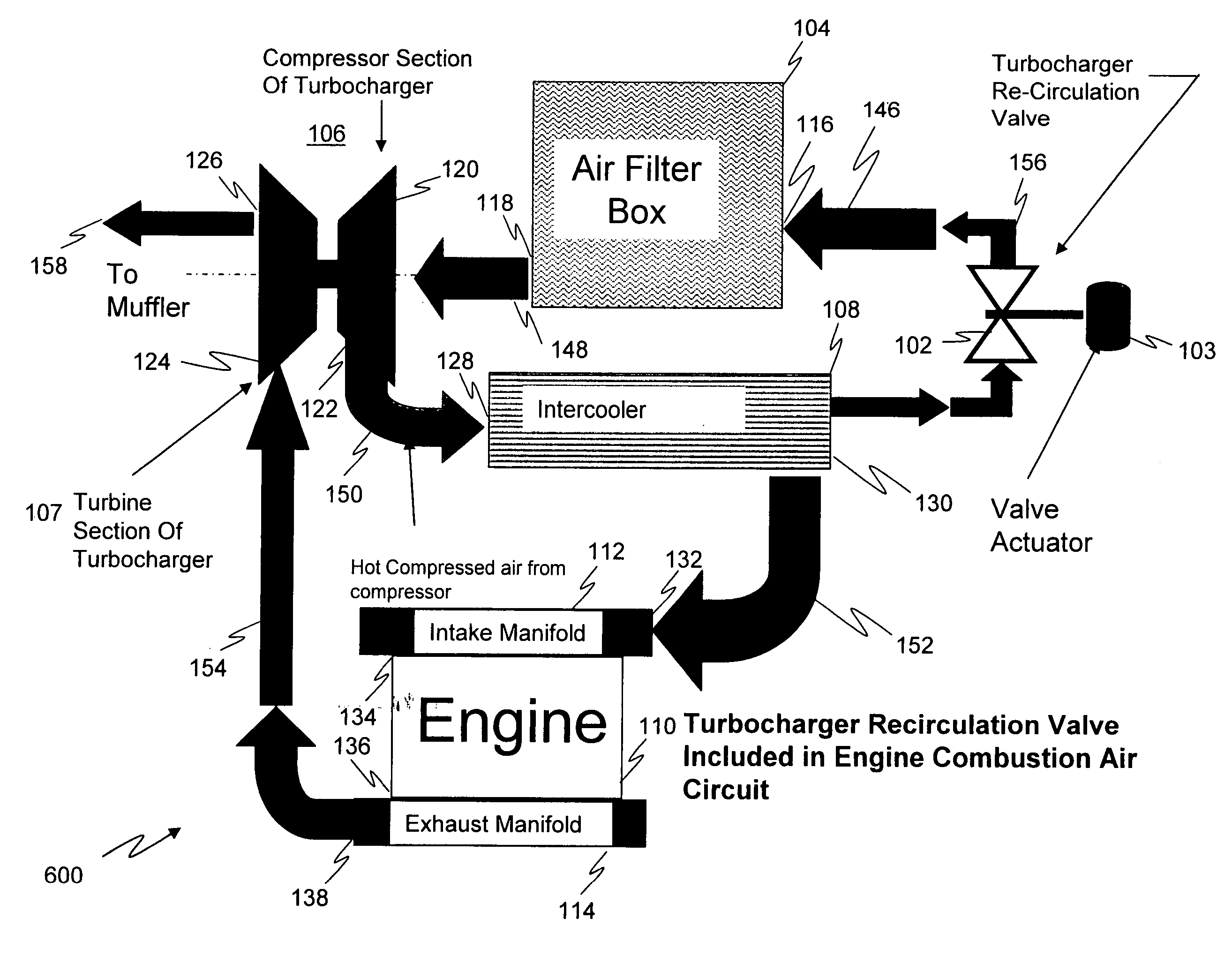

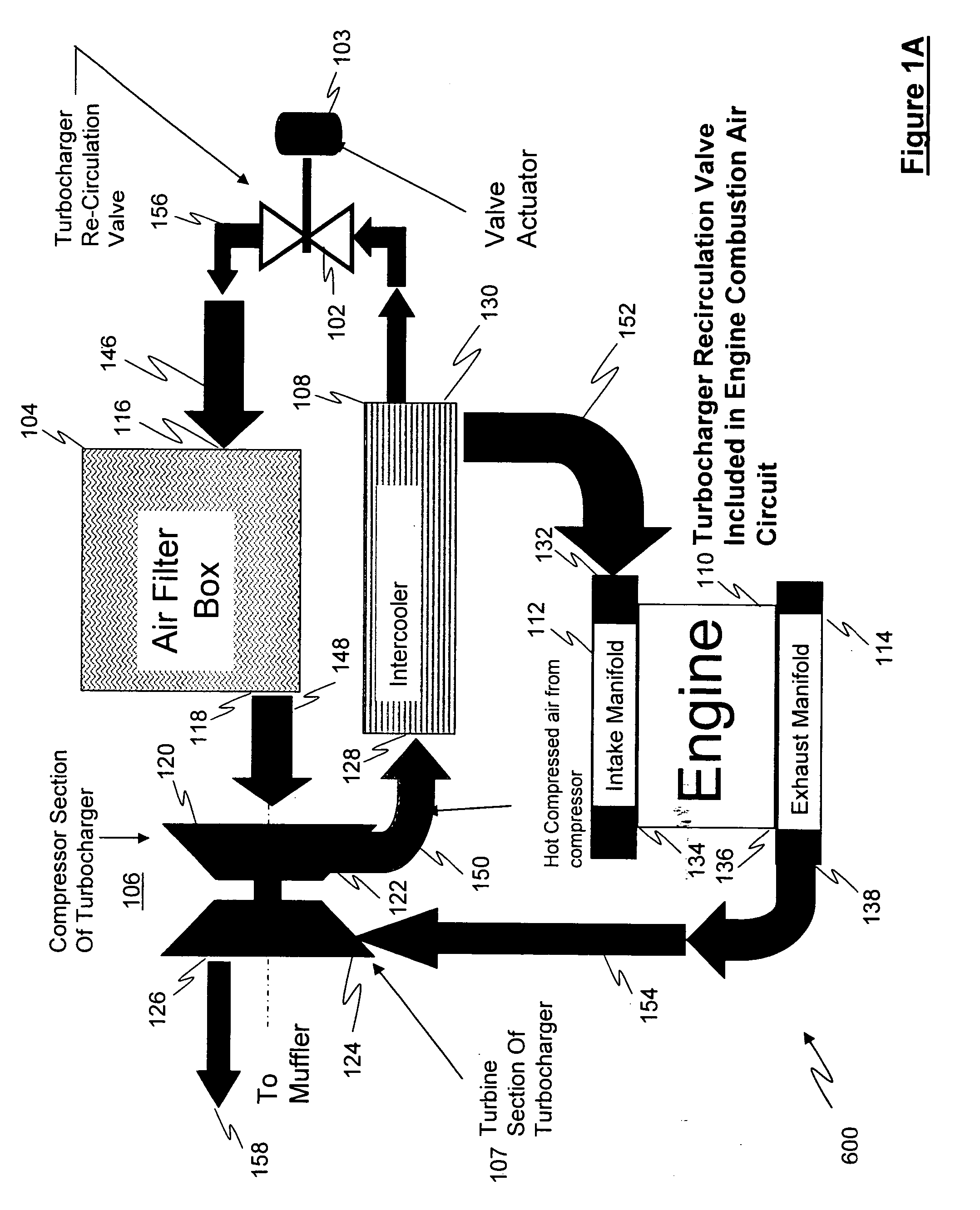

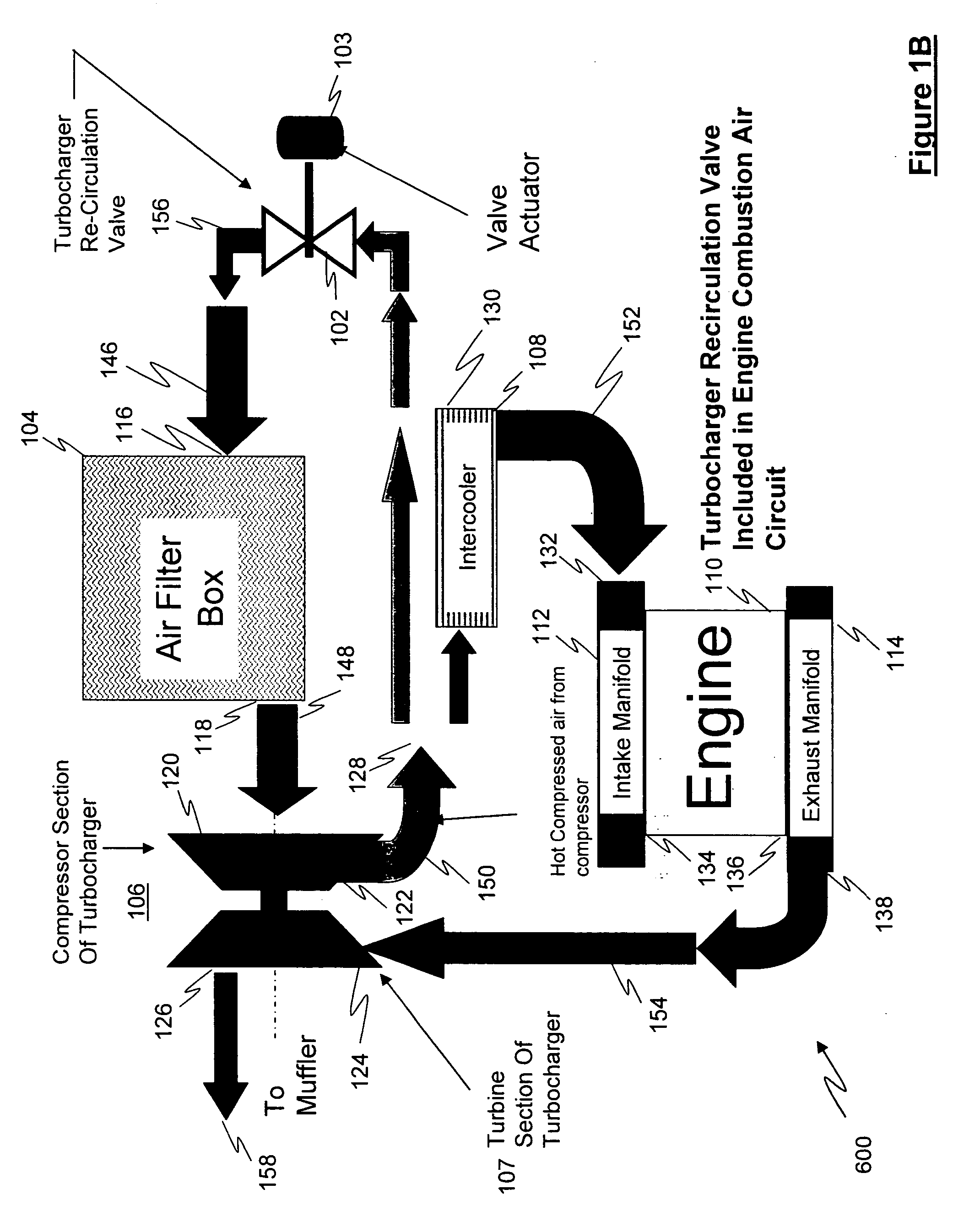

Turbocharger recirculation valve

InactiveUS20060016187A1Reduce exhaust pressureReduce stepsInternal combustion piston enginesAir cleaners for fuelStream flowTurbocharger

A system and method for maintaining an airflow path to a turbocharger system on a locomotive operating at high altitude and in a low ambient temperature environment, is provided and includes generating an ambient air stream flow into the turbocharger system to create a compressed air stream flow having a compressed air stream temperature, wherein the ambient air stream flow includes an ambient air stream flow temperature, processing the compressed air stream to create an intercooler air stream having an intercooler air stream temperature, wherein the compressed air stream temperature is greater than the intercooler air stream temperature, directing at least a portion of at least one of the compressed air stream and the intercooler air stream toward a controllable re-circulation device, wherein the controllable re-circulation device is communicated with at least one of the compressed air stream flow and the ambient air stream flow, operating the controllable re-circulation device to combine the at least a portion of at least one of the compressed air stream and the intercooler air stream with at least one of the compressed air stream flow and the ambient air stream flow to increase at least one of the compressed air stream temperature and the ambient air stream temperature to a predetermined level.

Owner:GENERAL ELECTRIC CO

System and method for providing aqueous stream purification services

ActiveUS20090082906A1Efficient processingSampled-variable control systemsWater treatment parameter controlWater storageWastewater

A system and method are disclosed for providing aqueous stream purification services. The system includes at least one separation unit. Each separation unit may include a mechanical vapor recompression separator, a steam stripper, and a secondary recovery heat exchanger. The system for wastewater purification may receive water from a waste water storage, purify the water, and return the purified water to a purified water storage. The system may include a controller. The controller may include an operating conditions module configured to interpret at least one operating condition. Operating conditions may be waste fluid stream impurity concentrations, waste fluid stream flow rates, steam inlet temperatures, recirculation stream flow rates corresponding to the at least one separation unit, recirculation stream temperatures corresponding to the at least one separation unit, purified product stream flow rates, purified product stream impurity concentrations, and / or purge stream concentrations corresponding to the at least one separation unit.

Owner:H2OIL

System and method for controlling exhaust stream temperature

ActiveUS8245501B2Reduce errorsInternal combustion piston enginesExhaust apparatusParticulatesStream temperature

Systems and methods are provided for controlling an exhaust stream temperature at a point along an exhaust system. The exhaust system can include an oxidation catalyst, a particulate filter having an outlet, and a fuel injector for injecting fuel into an exhaust stream at a location upstream from the outlet. An adaptive control can be provided to model a portion of the exhaust system. A fuel injection flow rate at which fuel is injected into the exhaust stream by the fuel injector can be calculated based on the adaptive control model. An operation of the fuel injector can be controlled based on the calculated fuel injection flow rate, to control the exhaust stream temperature at point along the exhaust system. A condition of the exhaust stream can also monitored and an error in the adaptive control model can be determined based on the monitored condition. The adaptive control model can also be changed to reduce the error.

Owner:CORNING INC

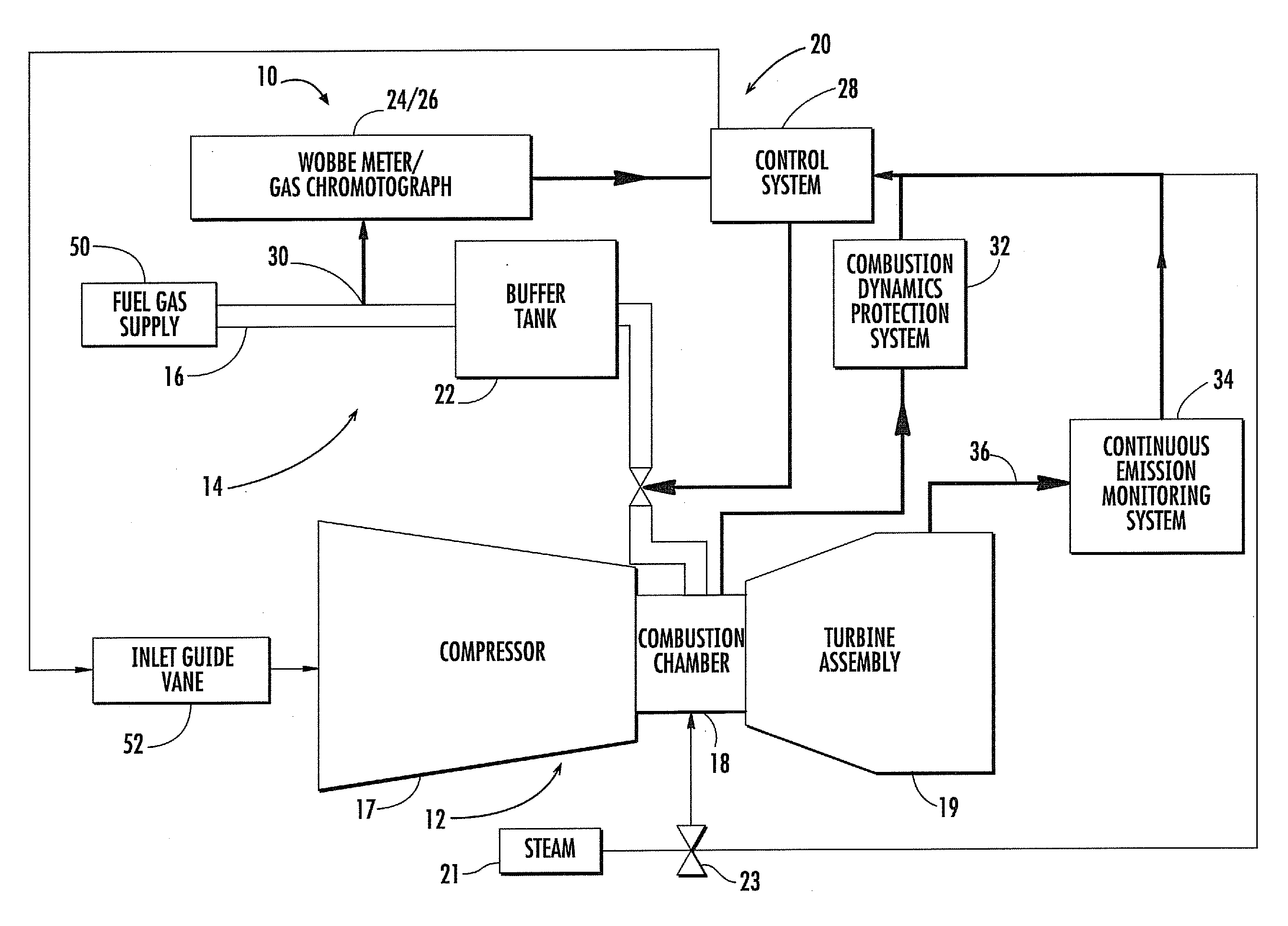

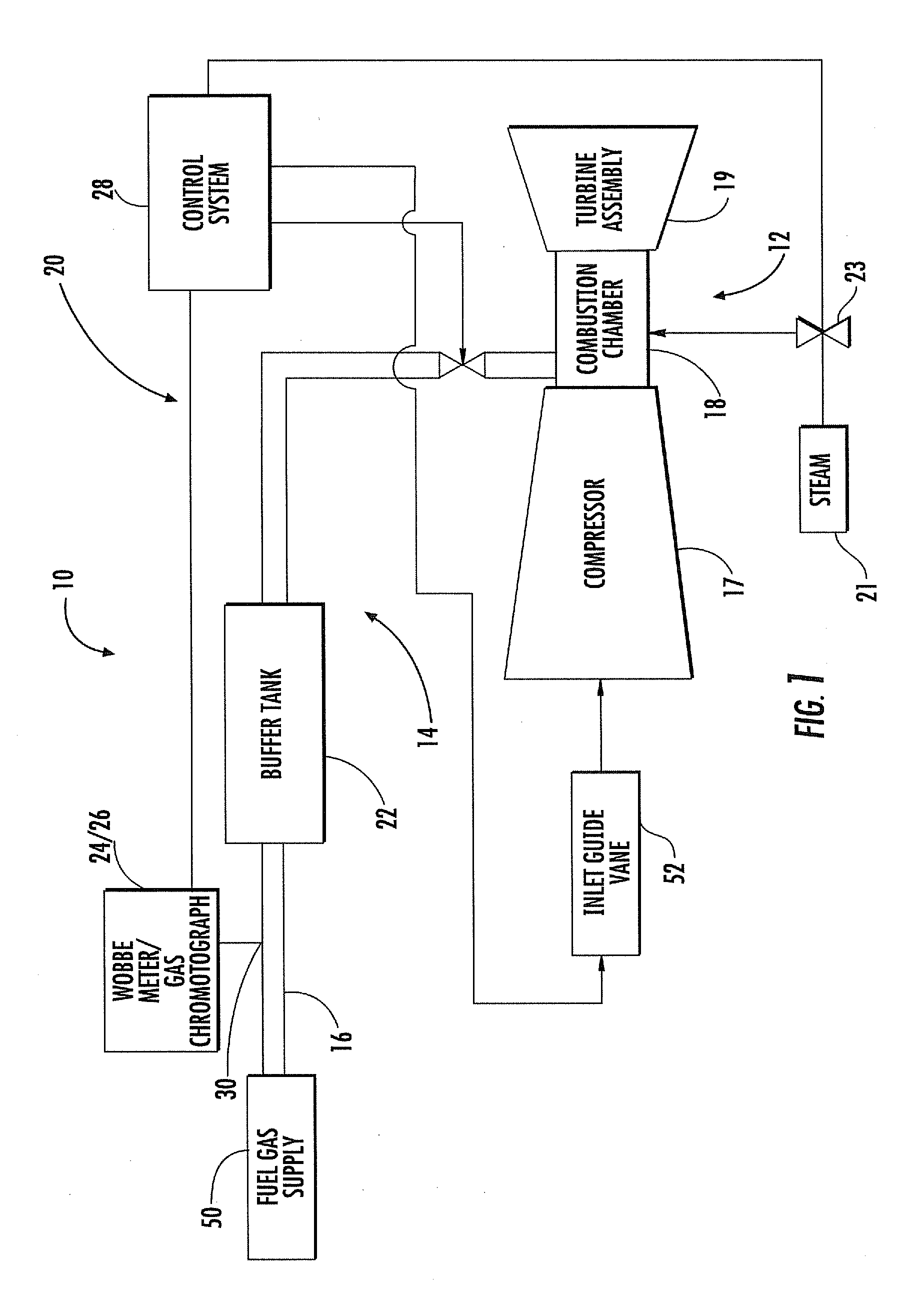

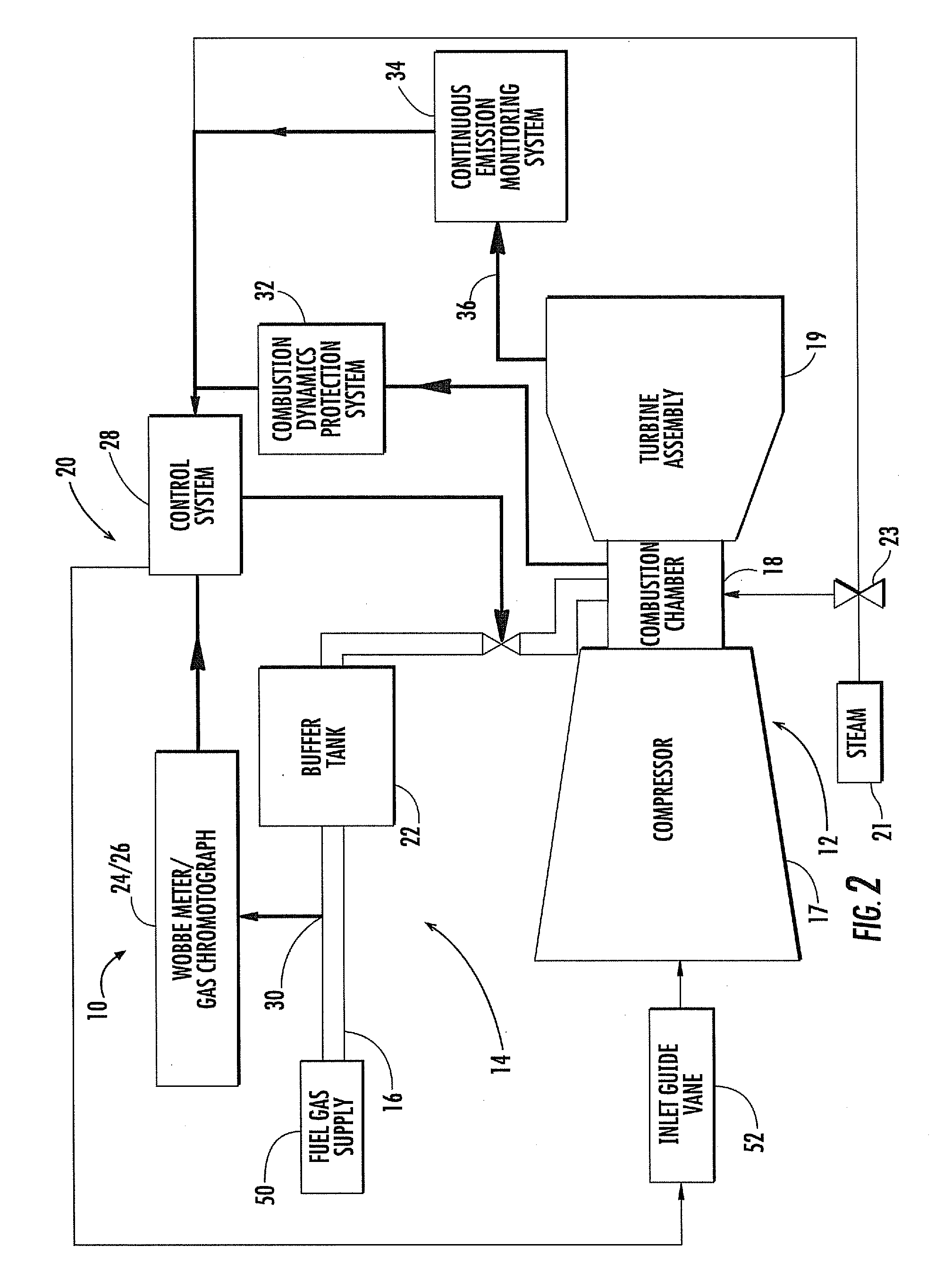

Integrated fuel gas characterization system

InactiveUS20100205976A1Improve startup reliabilityAvoid substantial load swingGas turbine plantsTurbine/propulsion fuel controlBuffer tankProduct gas

A gas turbine engine that includes a compressor, a combustion stage, a turbine assembly, a fuel gas feed system for supplying fuel gas to a combustion stage of the gas turbine, an integrated fuel gas characterization system, and a buffer tank is disclosed. The integrated fuel gas characterization system may determine the heating value of the fuel and adjust engine operating parameters such as fuel flow; or steam flow or water injection, or both, input to maintain a design fuel-to-air ratio. The integrated fuel gas characterization system can minimize or eliminate megawatt load swings experienced by the gas turbine engine, extending turbine component life and reducing other operational issues, such as the risk of flashback, engine overfiring, combustion dynamics, increased emissions, and exhaust stream temperature spikes.

Owner:SIEMENS ENERGY INC

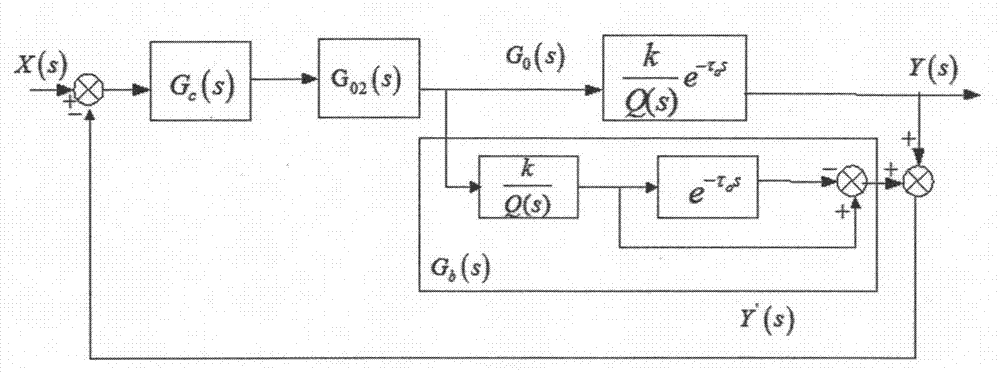

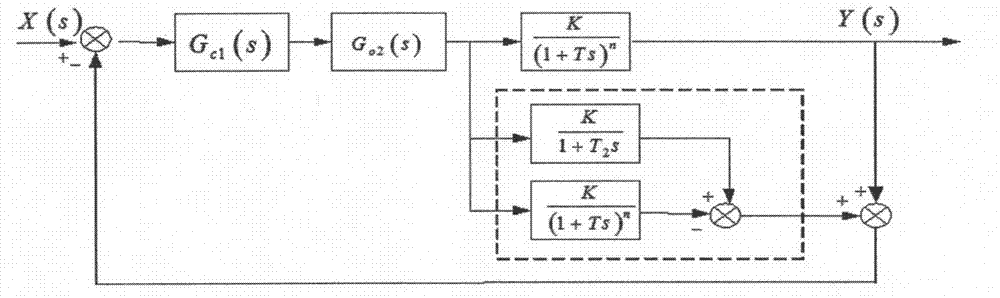

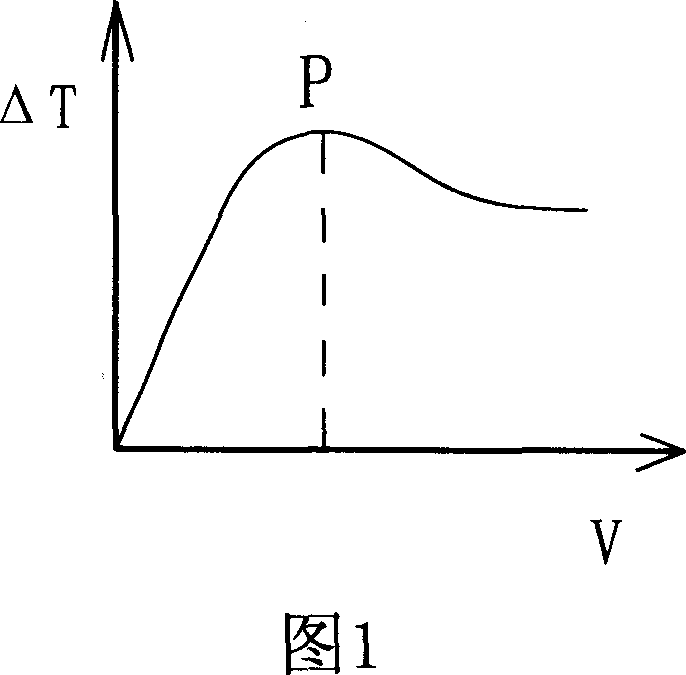

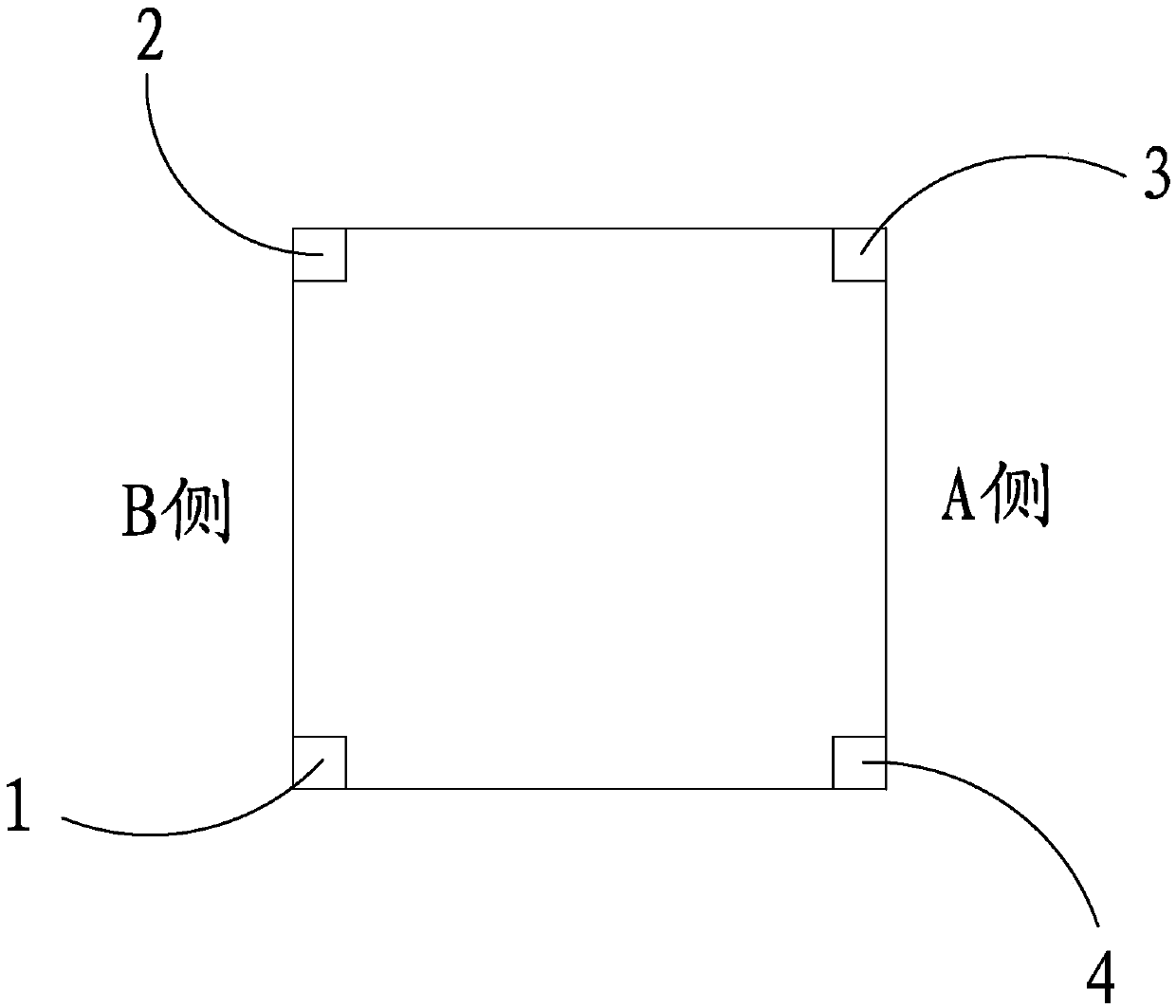

Modified Smith prediction main stream temperature control structure

ActiveCN104503502AReduce dynamic deviationChange propertiesTemperatue controlAdaptive controlSignal transfer functionEngineering

The invention provides a modified Smith prediction main stream temperature control structure. The modified Smith main stream temperature control prediction structure is characterized by a system transfer function. The another technical scheme includes that a novel Smith predictor is added, and a modified Smith main stream temperature prediction structure is provided and characterized by a system transfer function. The modified Smith prediction main stream temperature control structure has the advantages that the function transferring manner that the one-order inertia adds the delay link of the conventional Smith predictor is replaced by the high-order system, allowing the prediction system stable, thus dynamic deviation of the system is decreased and engineering application is convenient.

Owner:SHANGHAI POWER EQUIP RES INST

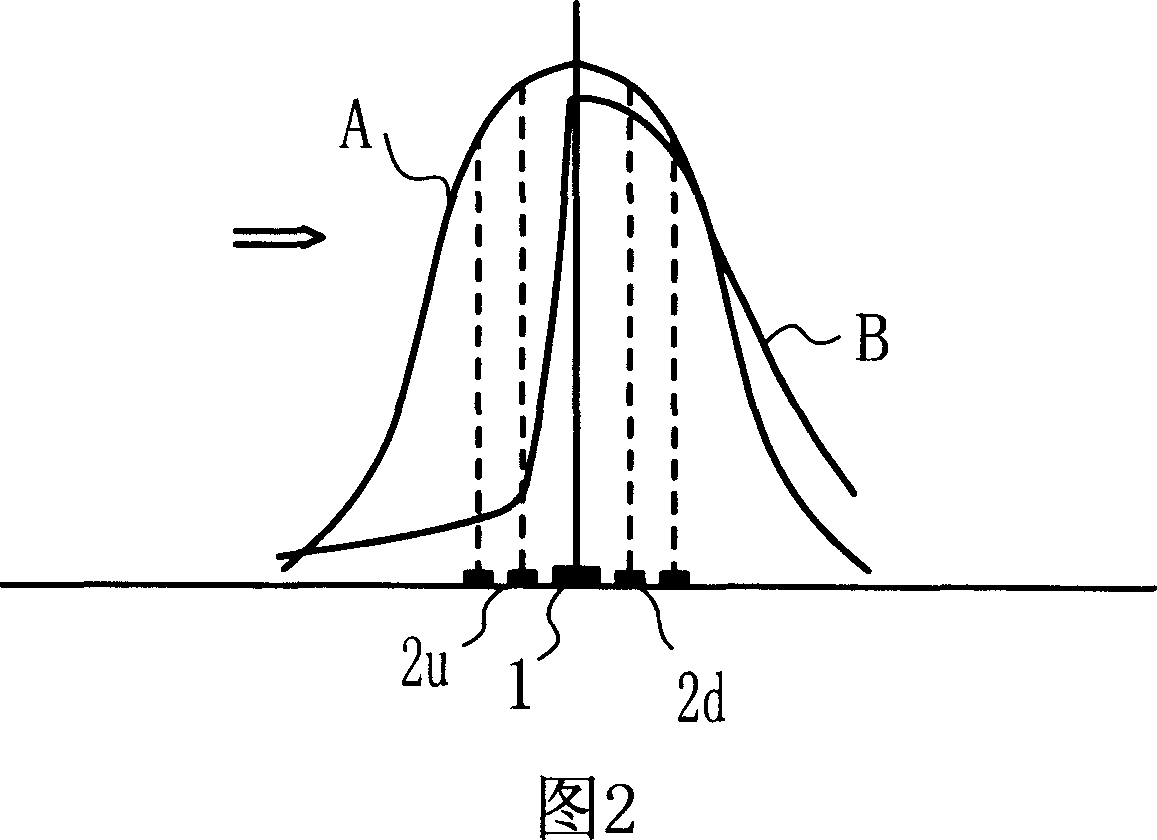

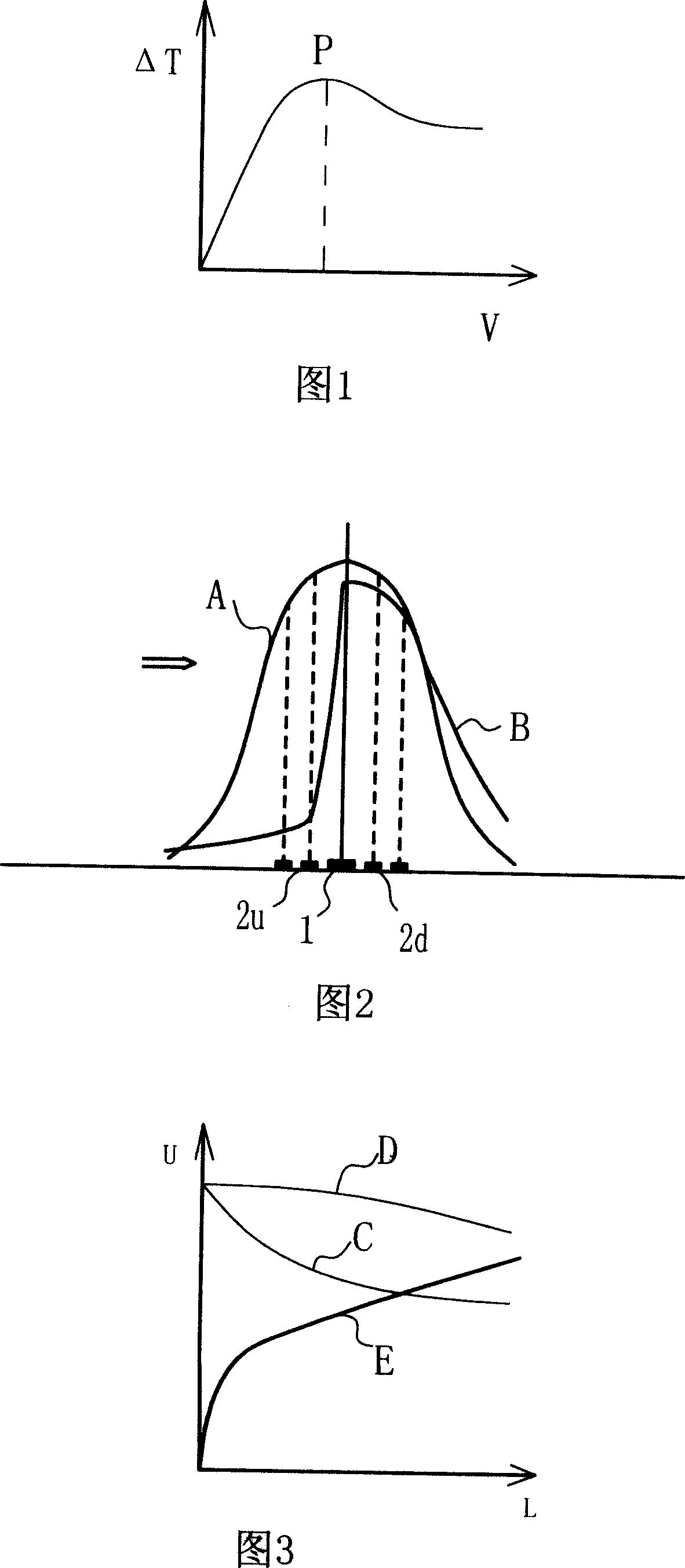

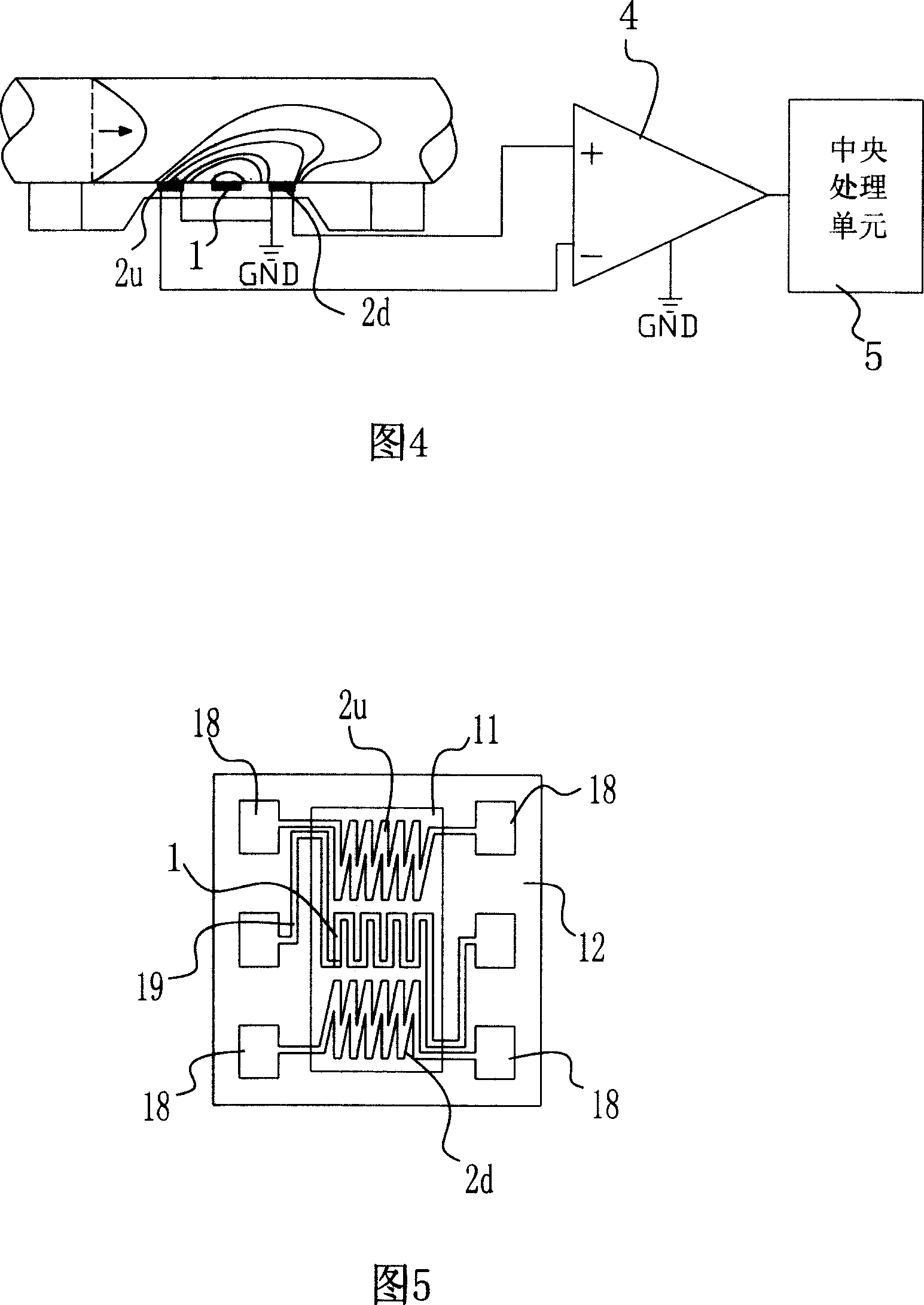

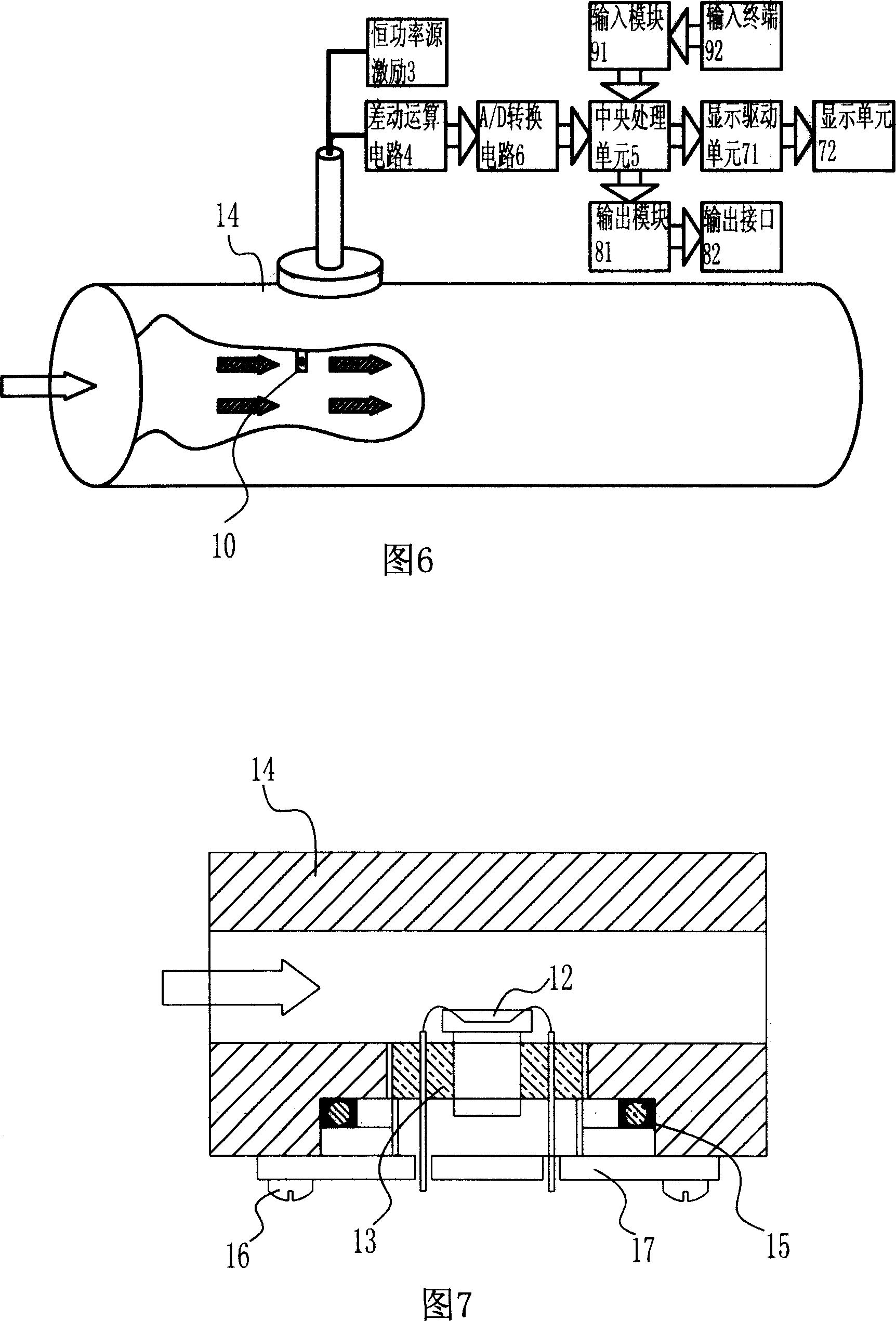

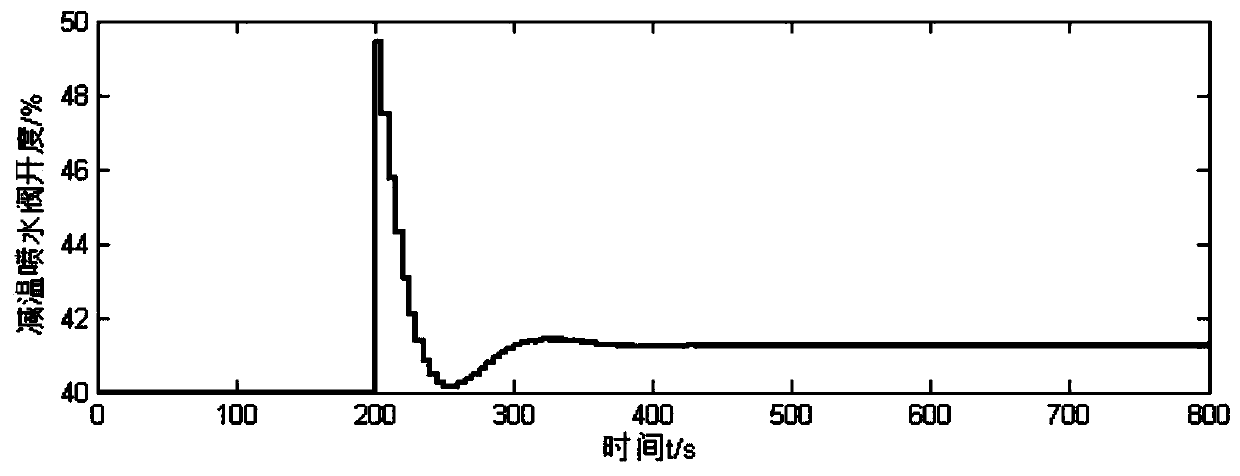

Measuring method and sensor for secondary differential flow of up-stream and down-stream temperature distribution and use

InactiveCN101050974AExpand the scope of testingSmall declineMass flow measurement devicesConstant powerTransducer

A measurement transducer of secondary differential flow rate based on up-down stream temperature distribution is prepared for connecting heating element to constant power source excitation, connecting up-stream temperature detection element and down-stream temperature detection element separately to two signal input ends of differential operation circuit and connecting output end of said differential operation circuit to central processing unit.

Owner:MEMSIC SEMICON WUXI

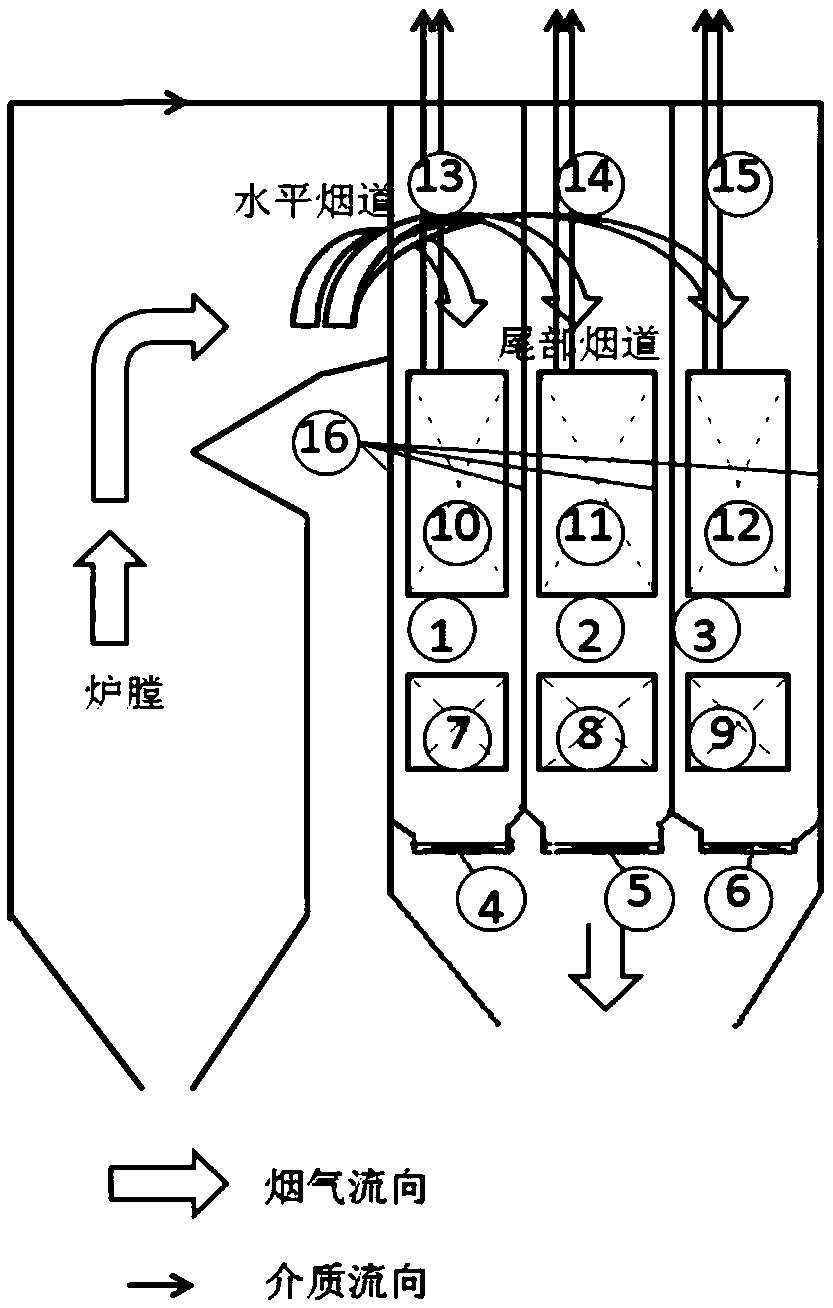

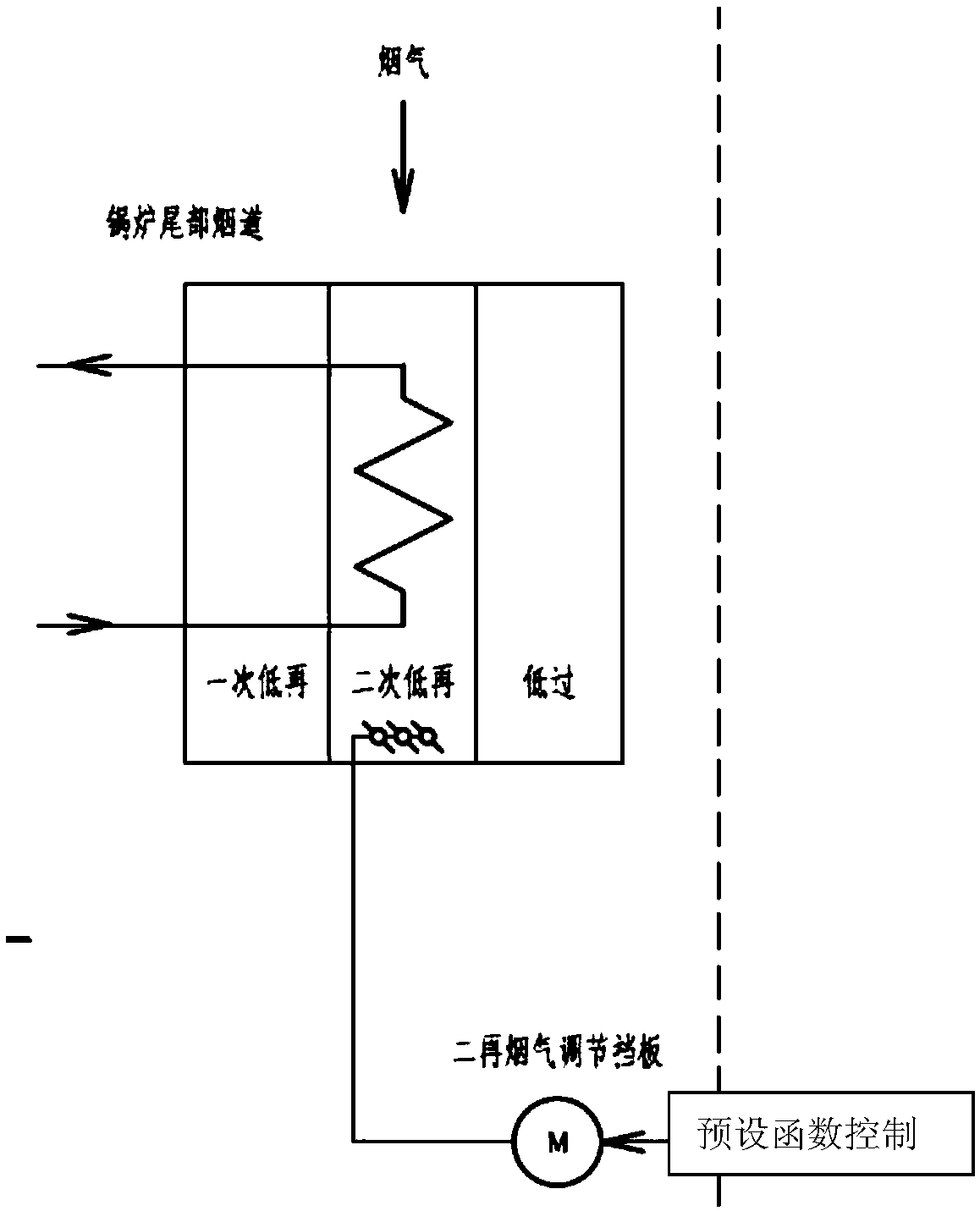

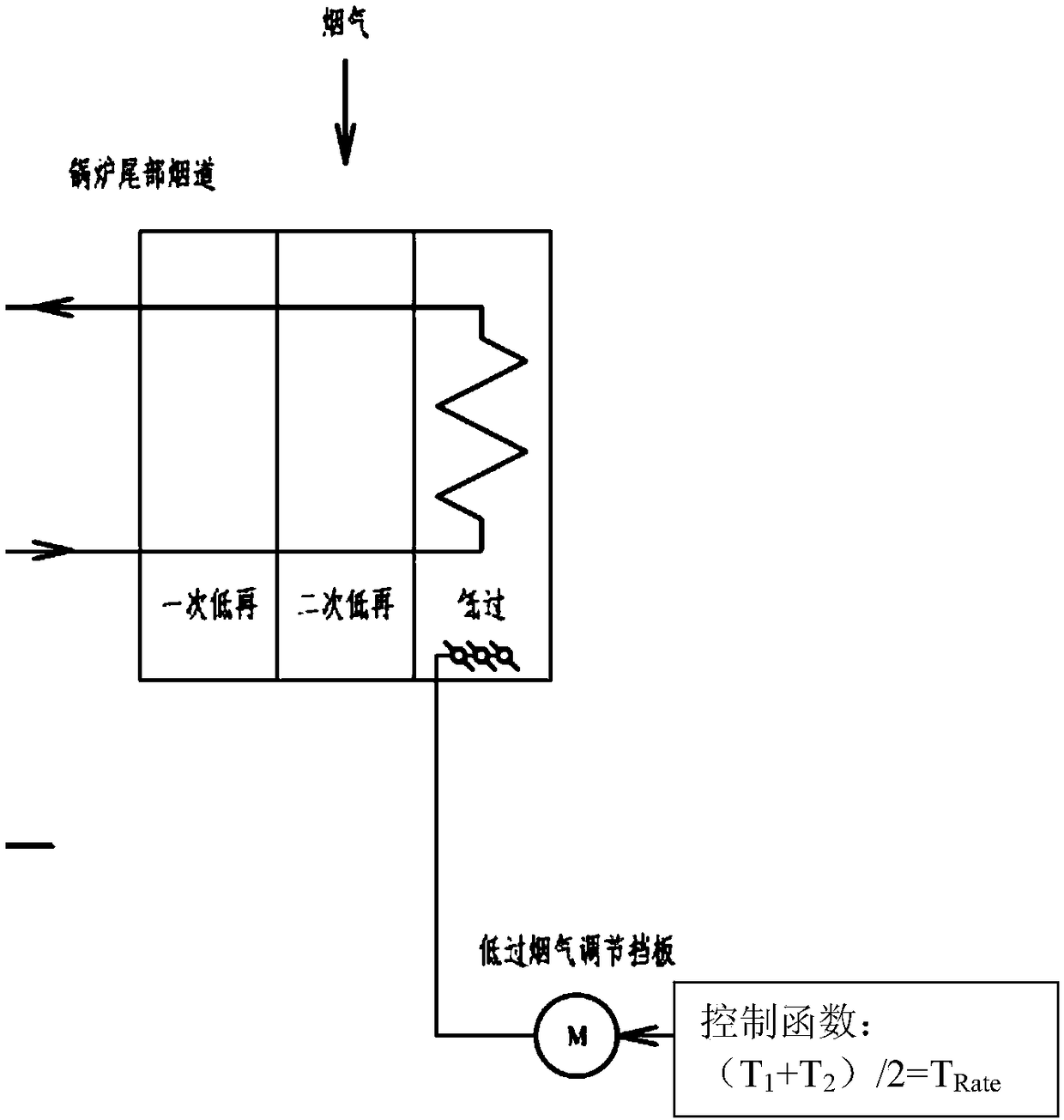

Three-baffle temperature adjusting control method of secondary reheating boiler

The invention discloses a three-baffle temperature adjusting control method of a secondary reheating boiler. Once reheating stream temperature T1 and twice reheating stream temperature T2 are adjustedby relatively fixing the opening of one flue gas adjusting baffle in a tail flue of the secondary reheating boiler and by adjusting the opening of the other two flue gas adjusting baffles. Accordingto the three-baffle temperature adjusting control method of the secondary reheating boiler, a set of temperature adjusting logic capable of meeting the rated value requirement of the pitch peak and stream temperature of the secondary reheating boiler under the wide load aiming at the secondary reheating boiler is put forward, so that the secondary reheating boiler with tail three-flue and even four-flue pure baffle temperature adjusting realizes the capacities of high efficiency, low coal consumption and flexible adjusting, can realize that To,T2 and T2 fluctuation in a set value interval in the lifting and loading process, so that a machine set reaches a rated parameter in the wide loading range, the machine set coal consumption loss caused by stream temperature difference in the dynamiclifting and loading process is reduced, and the economical efficiency is improved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

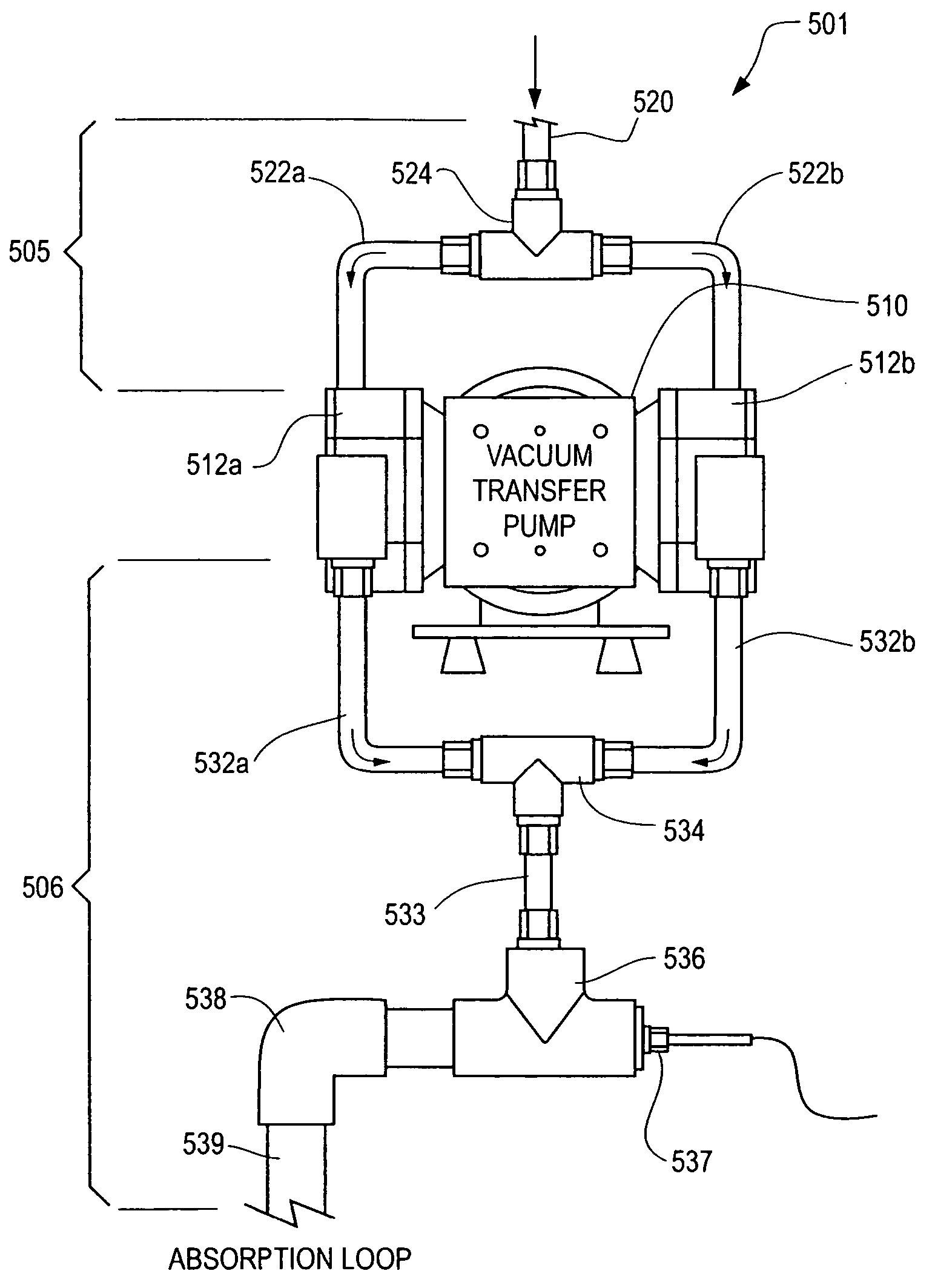

Chlorine dioxide solution generator with temperature control capability

InactiveUS20060022360A1Avoid decompositionWater treatment parameter controlElectrolysis componentsTemperature controlChlorine dioxide

A chlorine dioxide solution generator includes a chlorine dioxide gas source and an absorption loop for effecting the dissolution of chlorine dioxide into a liquid stream. A gas transfer assembly is interposed between the chlorine dioxide gas source and the absorption loop. The gas transfer assembly includes a gas transfer pump and an exhaust manifold assembly. The exhaust manifold assembly includes a manifold conduit defining an interior volume for directing the pressurized chlorine dioxide gas stream from the pump outlet to the absorption loop. The manifold conduit interior volume is sufficiently large to inhibit chlorine dioxide decomposition in the pressurized chlorine dioxide gas stream by induce a pressurized chlorine dioxide gas stream temperature within the manifold conduit of less than about 163° F. (73° C.).

Owner:PURELINE TREATMENT SYST

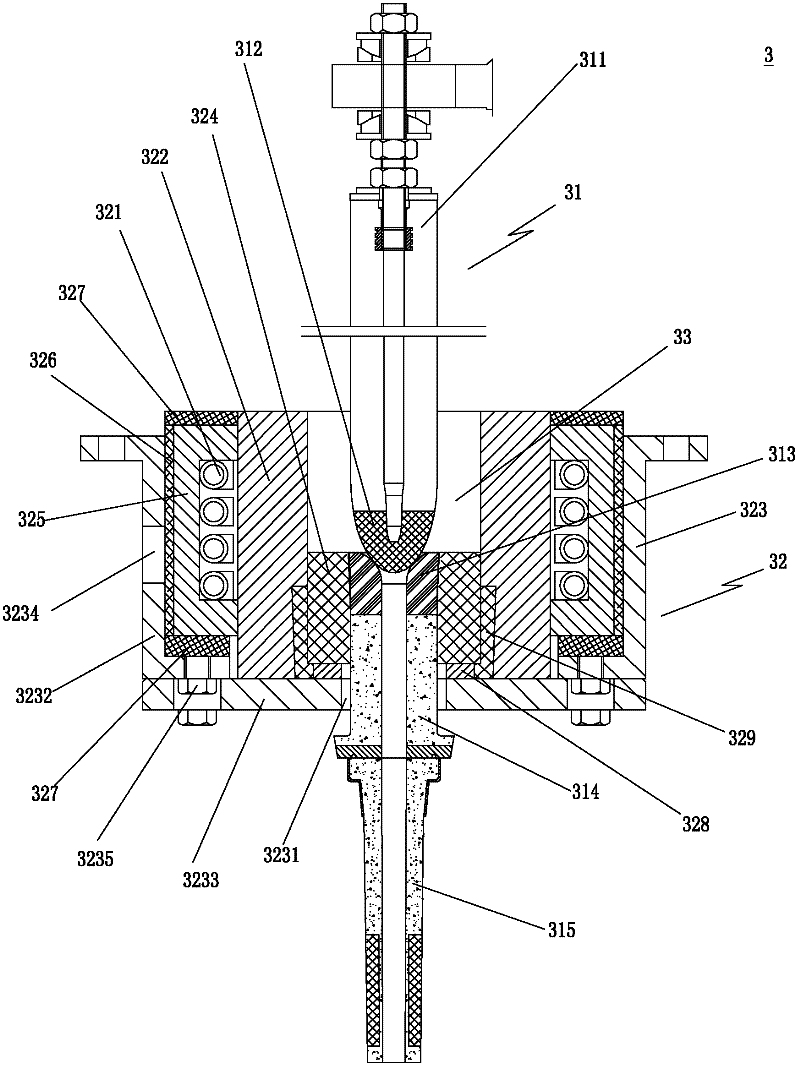

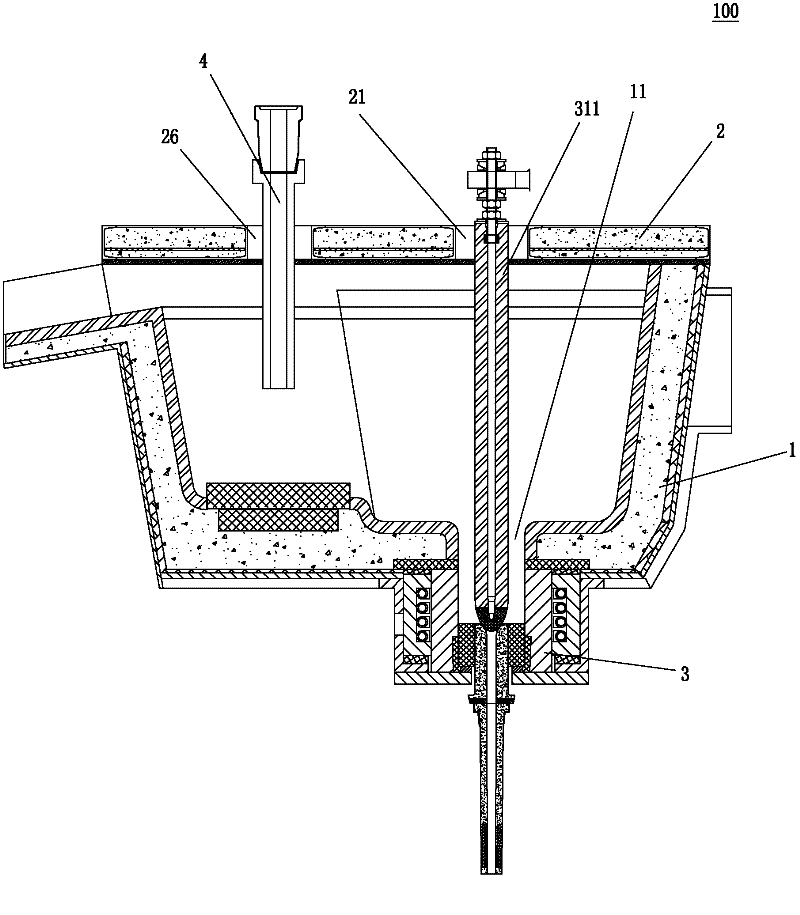

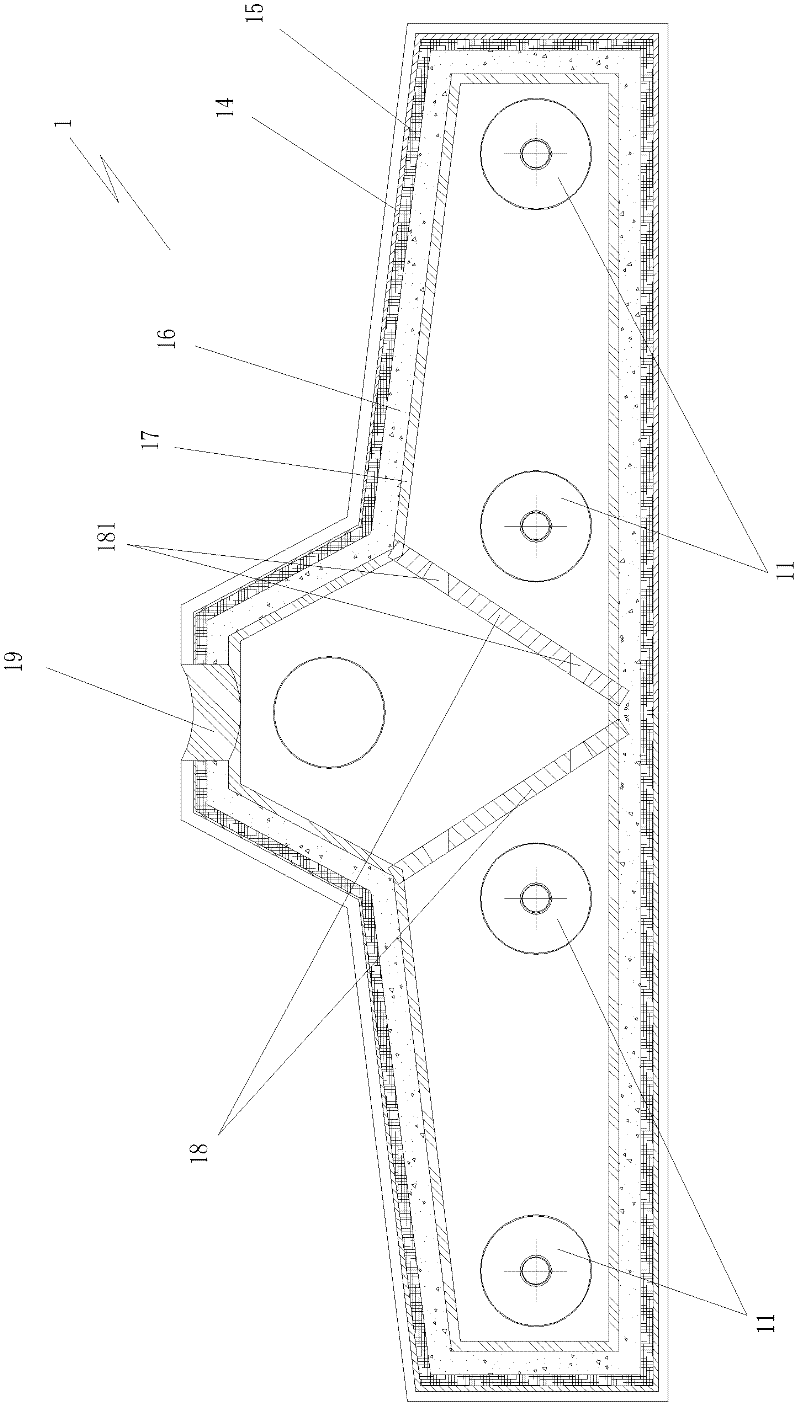

Tundish with electromagnetic heating water gaps

ActiveCN102228986AAvoid cloggingImprove heating efficiencyMelt-holding vesselsTemperature controlEngineering

The invention discloses a tundish with electromagnetic heating water gaps. Special electromagnetic heating water gaps are arranged on the bottom of the tundish body, so as to form the tundish capable of adjusting and controlling stream temperature of the water gap. One or more electromagnetic heating water gaps can be mounted on the bottom of the tundish according to the need, so as to form a tundish capable of controlling stream temperature of each water gap independently. The tundish is high in heating efficiency and capable of adjusting and controlling temperature of each pouring stream temperature independently, so that purposes of realizing optimum pouring temperature, avoiding block of water gaps, reaching low-superheat degree pouring and increasing quality of casting blanks are achieved; the tundish can be widely applied to metallurgy continuous casting production, particularly to production of multi-stream, multi-stream and large-section, and oversized-section continuously cast blooms; the tundish is accurate in temperature control, high in controllability, low in operation cost, and capable of increasing quality of products remarkably and reducing production cost.

Owner:北京京诚华宇建筑设计研究院有限公司

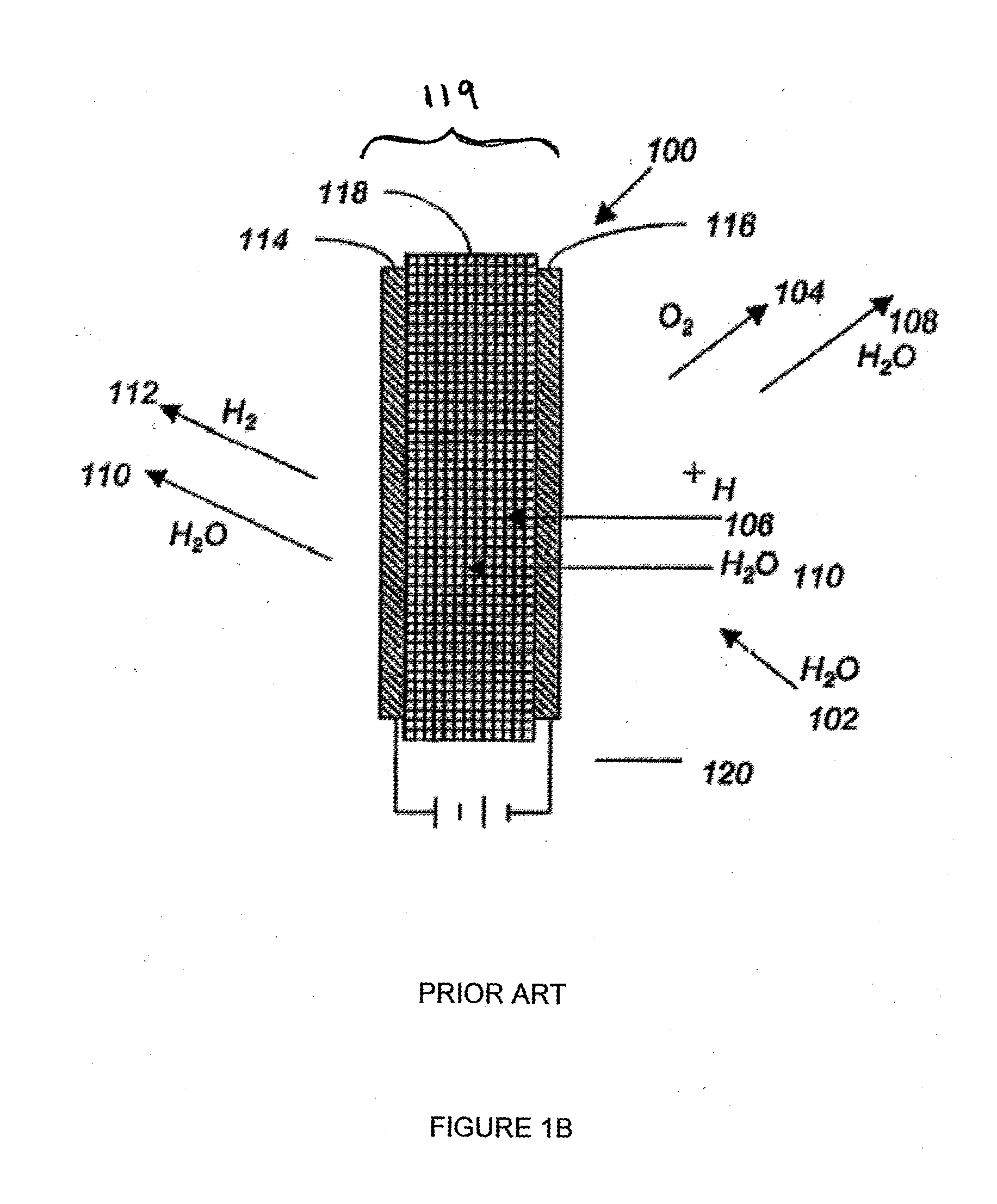

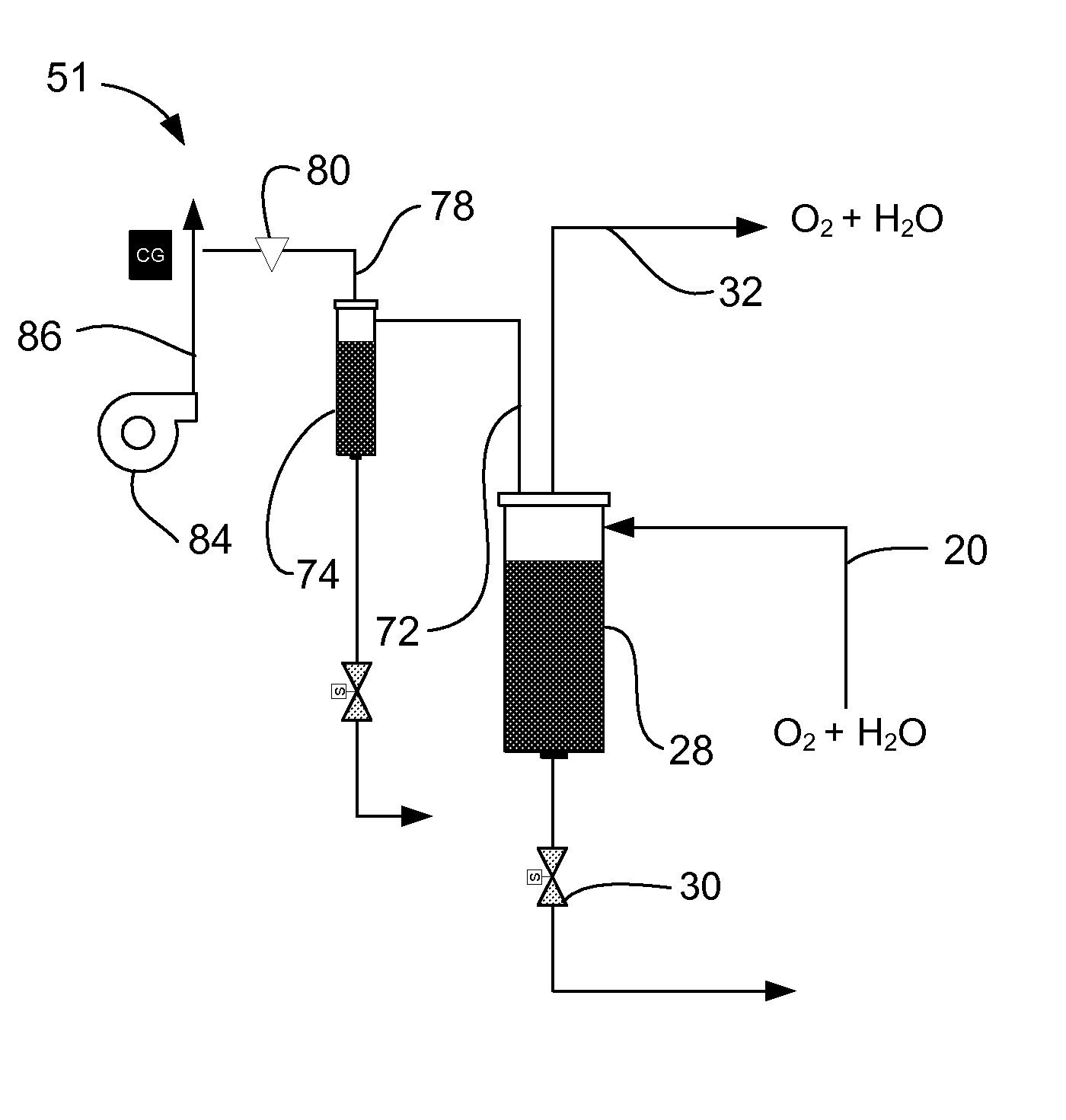

Combustible gas detection system

A system is provided for monitoring the levels of combustible gas in a gas stream. The system includes means for controlling the relative humidity of the gas stream and maintain a humidity level in the performance range of combustible gas sensors. A number of methods are illustrated for achieving the humidity control including secondary phase separations and the adjusting of the gas stream temperature.

Owner:PROTON ENERGY SYST

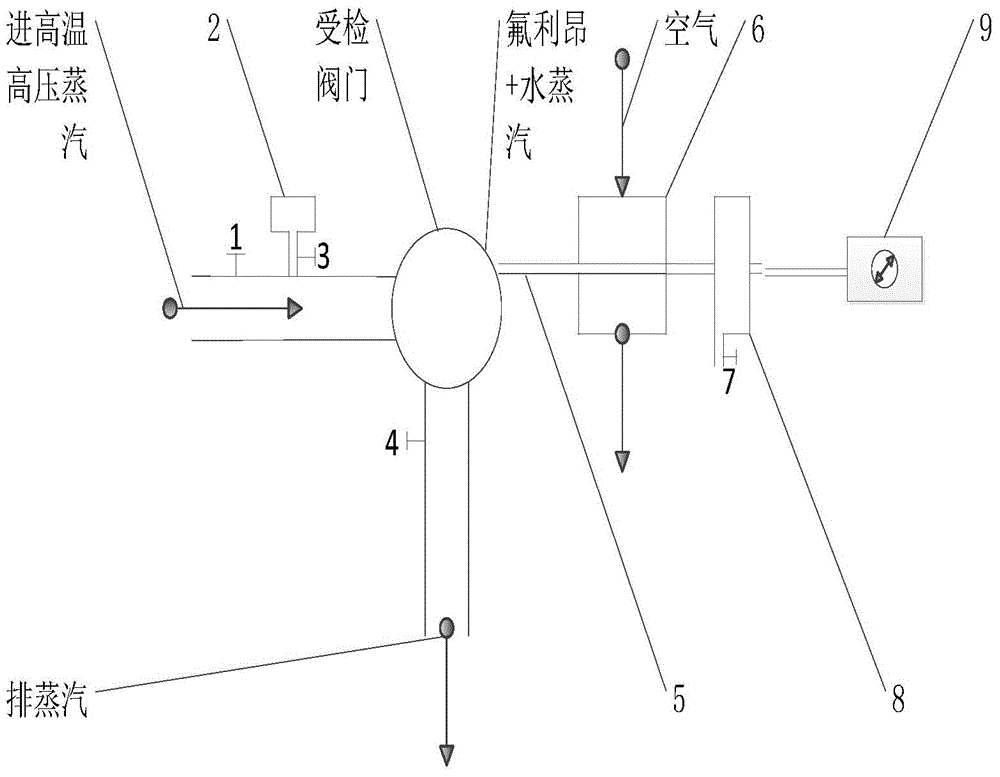

New method for leakage detection of Freon valve

ActiveCN104913886AReduce usageIncrease pressureDetection of fluid at leakage pointWater vaporHigh pressure

The invention provides a new method for leakage detection of a Freon valve, and belongs to the technical field of valve supervision and inspection. Freon is input via a Freon control vale firstly, high-temperature high-voltage water vapor is input via a high-temperature high-voltage stream control valve then, a mixed gas of the high-temperature high-voltage water vapor and the Freon enters a checked valve, multipoint step-by-step air extraction is performed on the checked valve by using an air extracting device, the extracted mixed gas is cooled in an air cooling device firstly, gas-liquid separation is performed in a gas-liquid separation device subsequently, and, finally, a halogen detector performs detection at air outlet of the gas-liquid separation device. The usage amount of the Freon is reduced, and serious pollution caused by that total fluoride as a working medium performs detection is reduced; a leakage point is accurately located through detection for the tracer gas Freon, and the leakage grade is determined through the number of lit alarm indicating lamps; and the cooling and gas-liquid separation devices are increased, an influence of too high stream temperature is prevented, and inspection precision is improved.

Owner:温州市特种设备检测研究院 +1

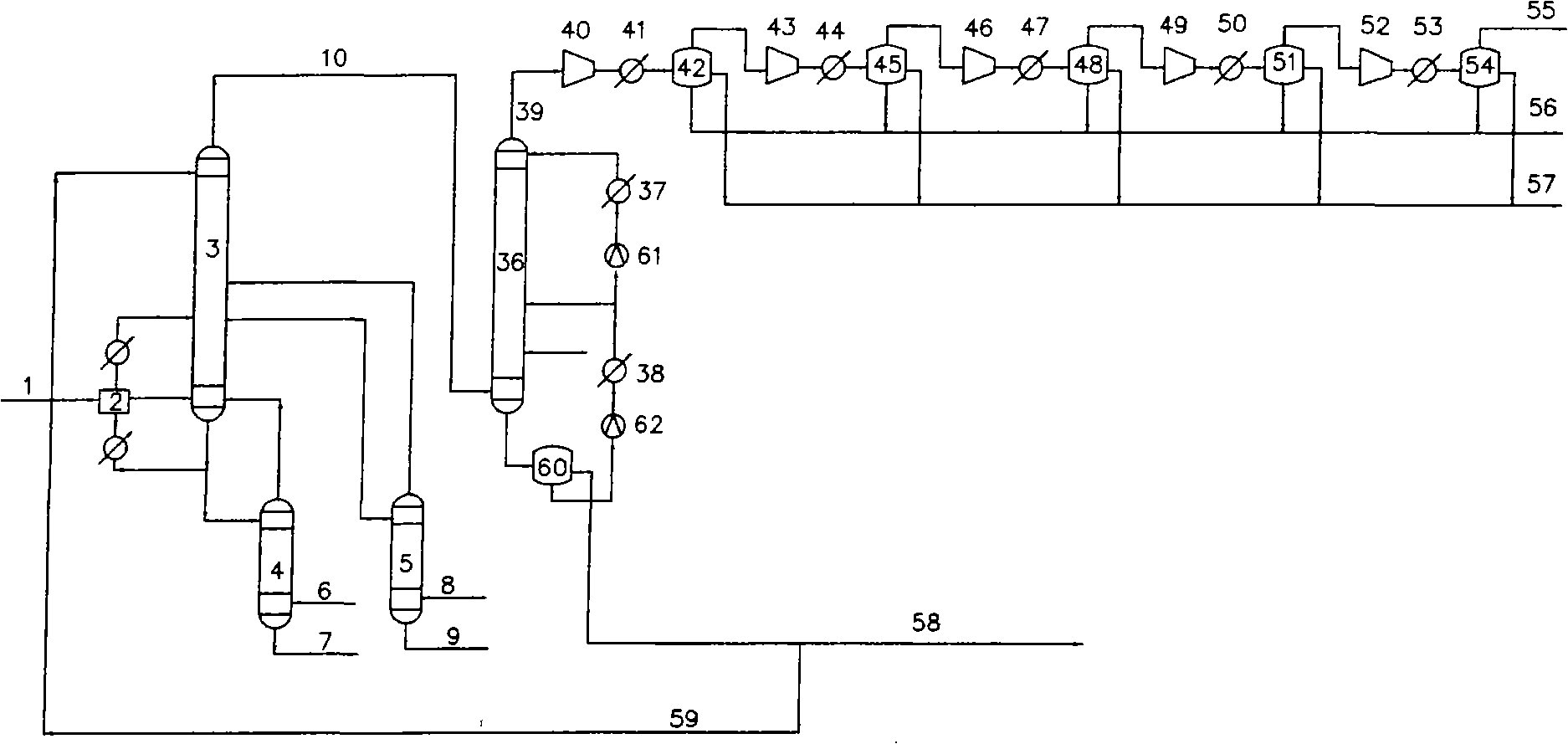

Ethylene quenching apparatus and compressing energy-saving technique

InactiveCN101358143AReduce energy consumptionLess investmentThermal non-catalytic crackingEthylene productionHigh energyEngineering

The present invention relates to an ethylene quenching device and a compressing and energy-saving technique; the ethylene quenching device comprises a quencher, a gas-oil fractionating tower, a diesel stripping tower, a fuel oil stripping tower and a compression and separation system; and after being fractionated and cooled by the quencher and the gas-oil fractionating tower, the pyrolysis gas coming from a waste heat boiler directly enters into the compression and separation system. The present invention has the following characteristics: the pyrolysis gas collected from the top of the gas-oil fractionating tower directly receives compression, separation and heat exchange; and a quenching water tower is not needed. The present invention has the following obvious advantages: a water scrubbing tower is not needed, equipment investment and energy used by a quenching water circulating pump are saved, the stream temperature of the outlet of the compressor of each section is high, and a great deal of high-energy-level latent heat can be recovered by heat exchange.

Owner:TIANJIN UNIV

Exhaust diagnostic system and method with scr nh3 depletion cleansing mode for initial step in the def quality service healing test

ActiveUS20130014575A1Internal-combustion engine testingElectrical controlEngineeringStream temperature

An exhaust diagnostic system comprises a selective catalyst reduction (SCR) component testing module, an exhaust stream temperature management module, and a test enabling module. The component testing module executes an SCR component efficiency test. The exhaust stream temperature management module adjusts a temperature of the SCR component to a predetermined temperature range. The test enabling module executes a process for depleting a reductant load and subsequently initiates an SCR component efficiency test while the temperature of the SCR catalyst is within the predetermined temperature range.A method for diagnosing an exhaust system comprises determining an efficiency of an SCR component and selectively adjusting a temperature of the SCR component to a predetermined temperature range. The method also includes executing a process for depleting a reductant load and initiating an SCR component efficiency test while the temperature of the SCR component is within the predetermined temperature range.

Owner:GM GLOBAL TECH OPERATIONS LLC

Apparatus and method for onboard performance monitoring of oxidation catalyst

A method and system for determining conversion of NO to NO2 in an engine exhaust stream by an oxidation catalyst during operation of the engine is disclosed based on injecting hydrocarbon fuel into the exhaust stream upstream of the oxidation catalyst, measuring a temperature of the exhaust stream on the upstream and downstream sides of the oxidation catalyst, calculating a difference in exhaust stream temperature between the upstream and downstream sides of the oxidation catalyst, and determining the conversion of NO to NO2 by the oxidation catalyst from the difference in exhaust stream temperature based on a predetermined correlation profile between the temperatures on the upstream and downstream sides of the oxidation catalyst and conversion of NO to NO2.

Owner:GM GLOBAL TECH OPERATIONS LLC

Method for growing rhenium disulfide nanometer sheets on silicon substrate of non-oxidation layer

The invention discloses a method for growing rhenium disulfide nanometer sheets on a silicon substrate of a non-oxidation layer. The method comprises the following steps that S1, the silicon substrateis cleaned and is subjected to pretreatment; S2, in a multi-temperature-zone tubular furnace, one aluminum oxide boat is arranged in each of two adjacent temperature regions, wherein the distance between the two aluminum oxide boats is 20 to 30cm; a sulfur source is arranged in the center position of the aluminum oxide boat in the upper stream temperature region; a rhenium source is arranged in the lower stream edge of the aluminum oxide boat of the lower stream temperature region; a growth surface of the silicon substrate faces the downward position; the distance from the silicon substrate to the lower stream edge of the aluminum oxide boat of the lower stream temperature region is 0 to 1cm; S3, then, inert gas is introduced into a dual-temperature-region tubular furnace, heating is performed for reaction; the rhenium disulfide nanometer sheets can grow on the silicon substrate of the non-oxidation layer. The sublimed sulfur is used as a sulfur source; rhenium trioxide is used as a rhenium source; a chemical gas phase precipitation method is used; by regulating the distance between the sulfur source and the rhenium source and the position of the rhenium source in the lower streamtemperature region and the position of the silicon substrate, the rhenium disulfide nanometer sheets on the silicon substrate can directly grow on the silicon substrate of the non-oxidation layer.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

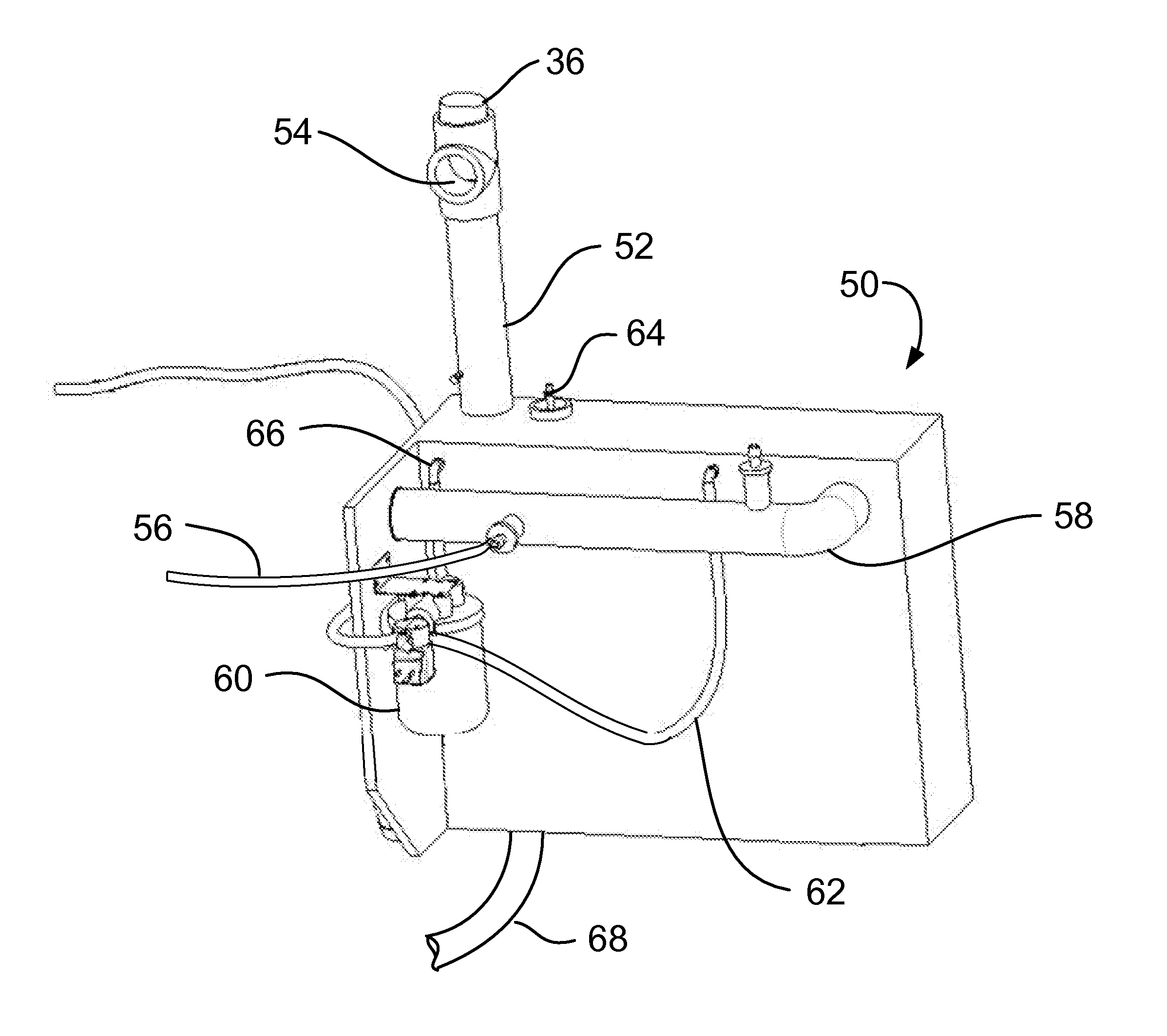

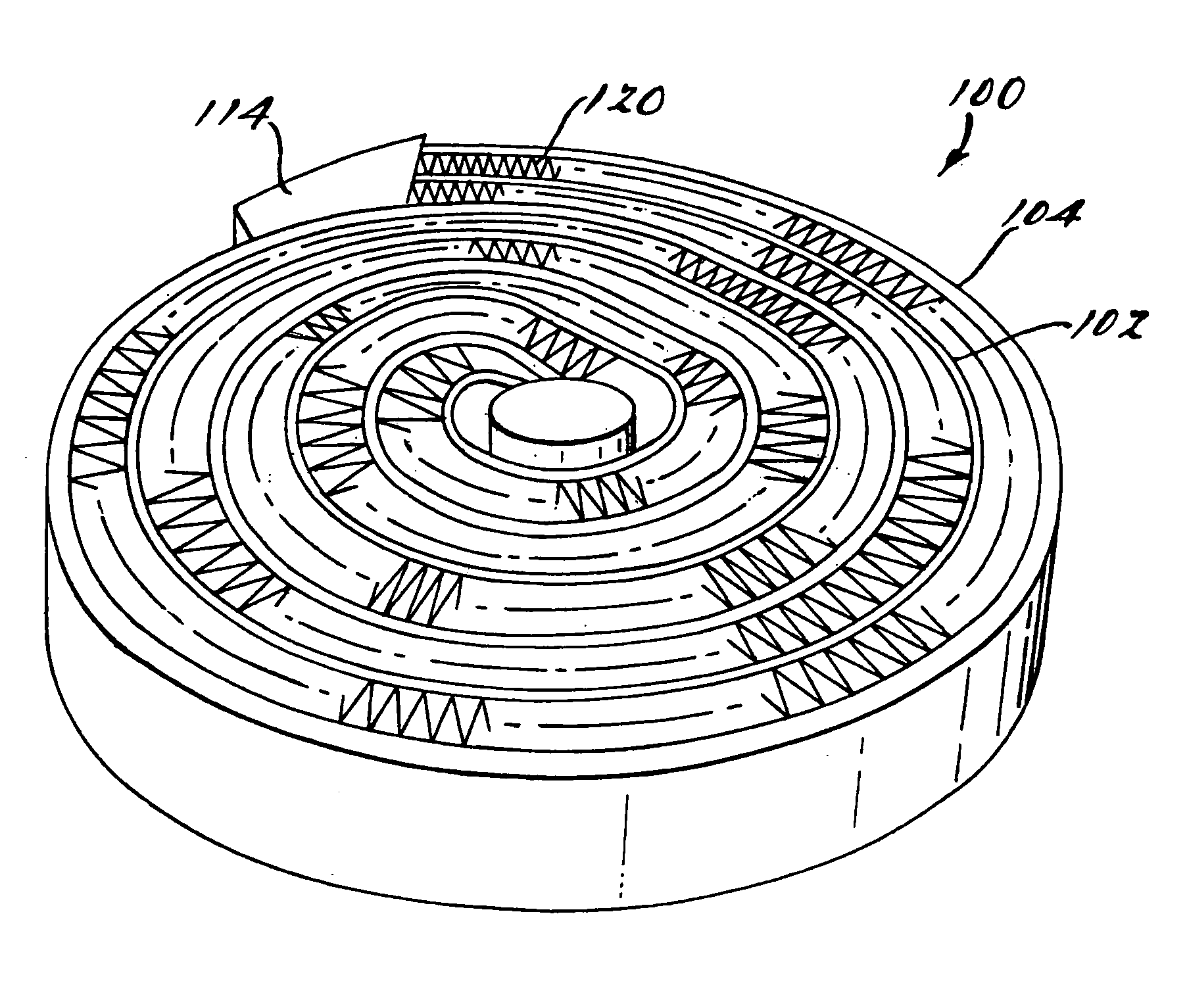

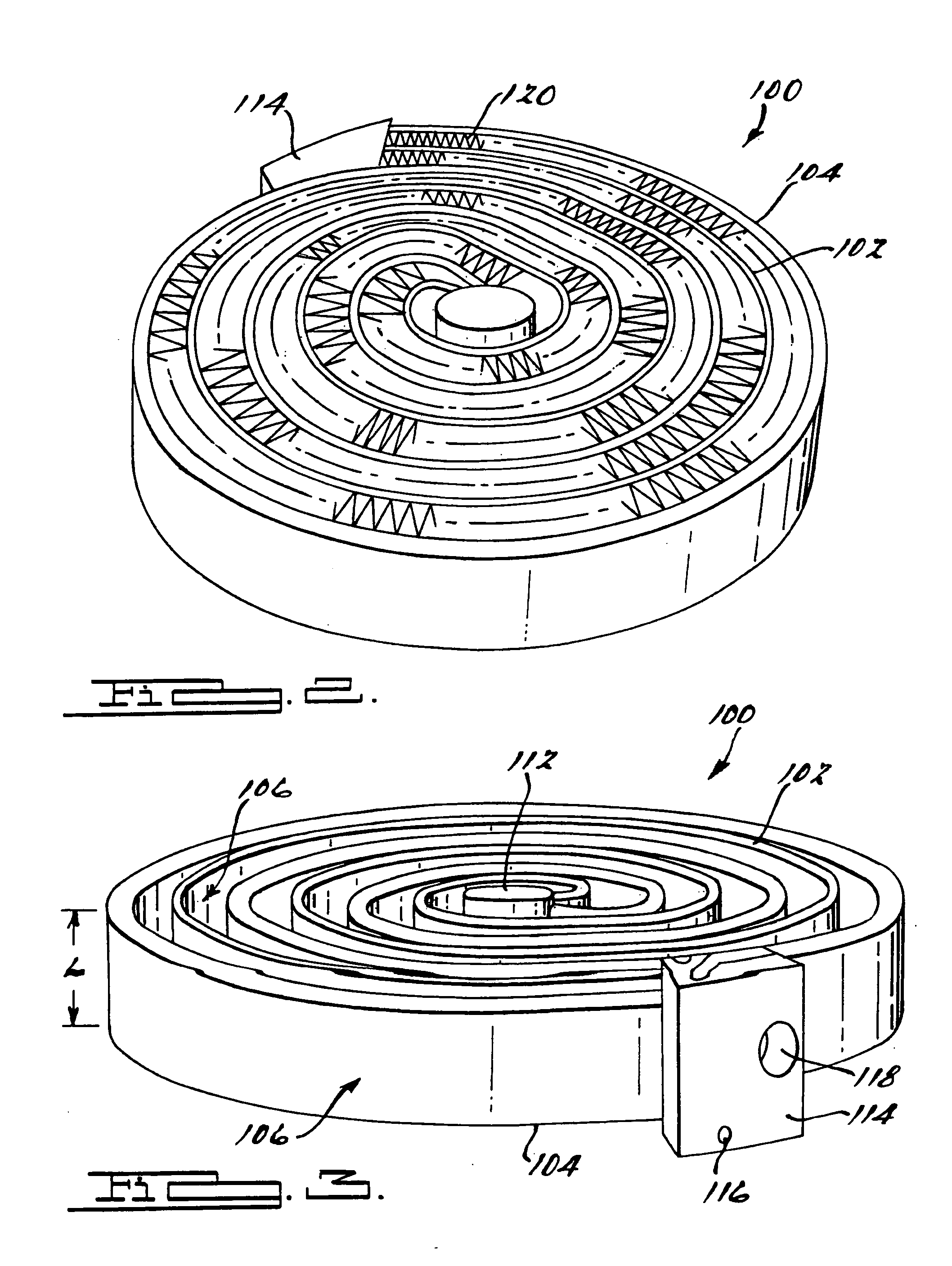

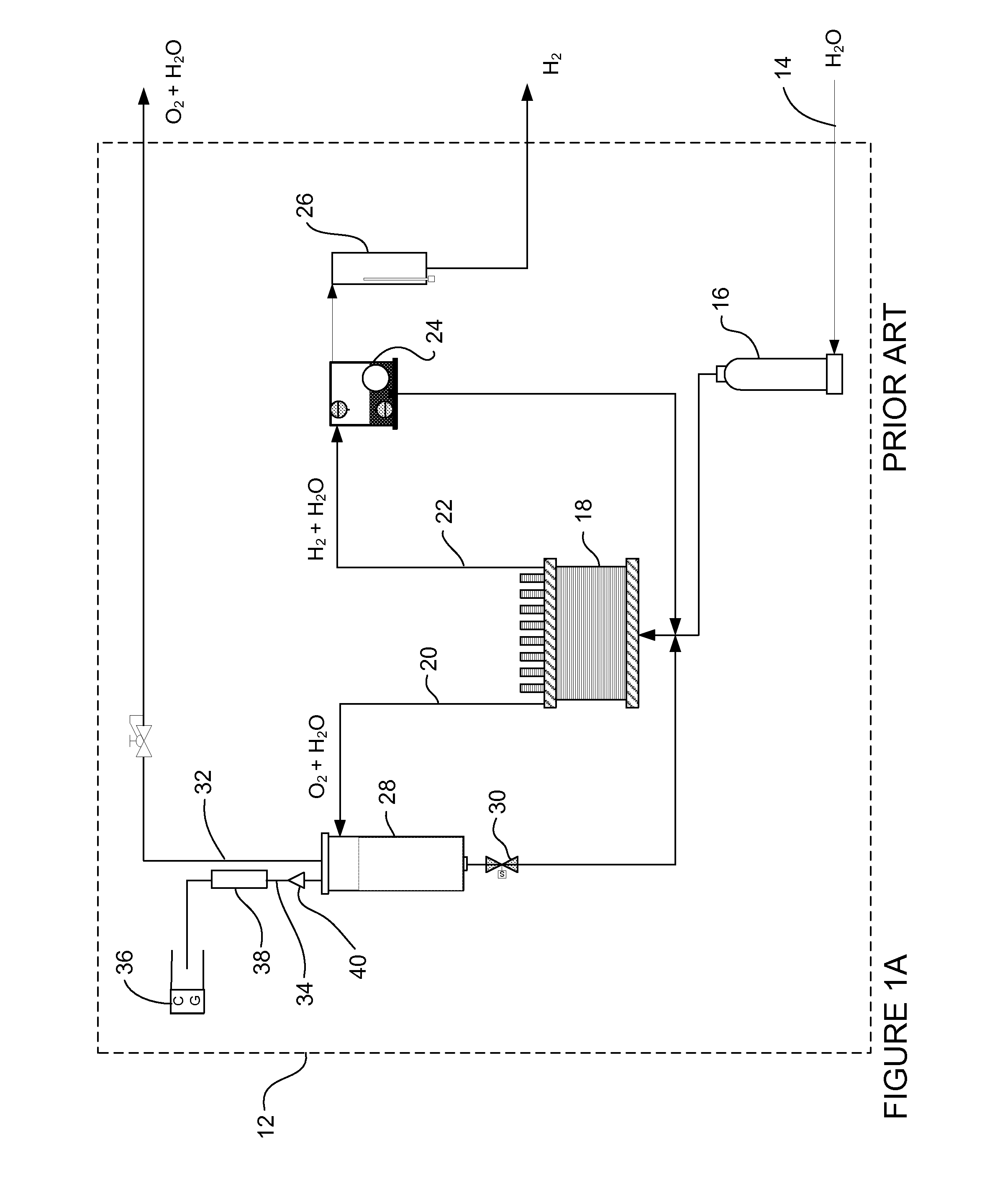

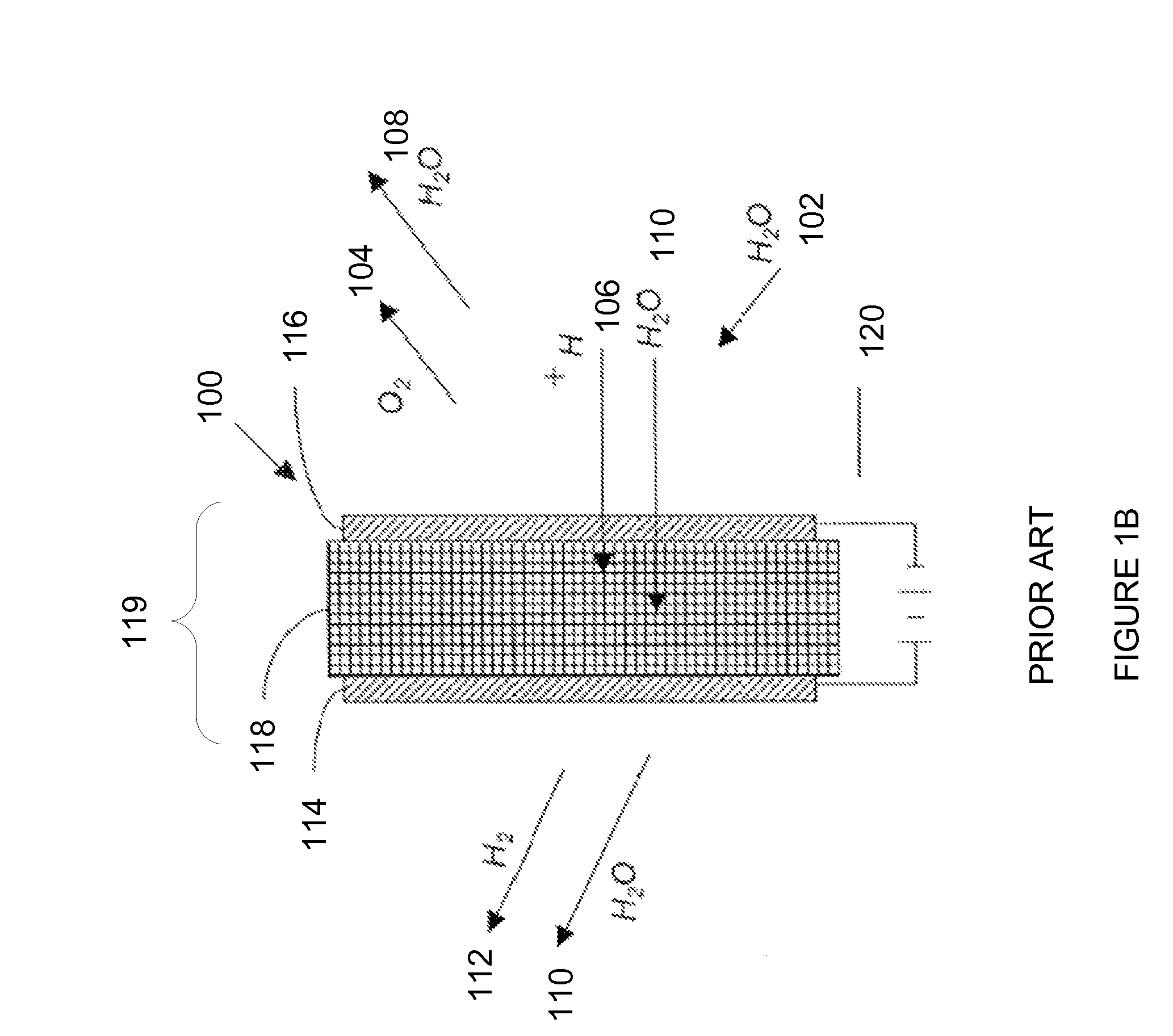

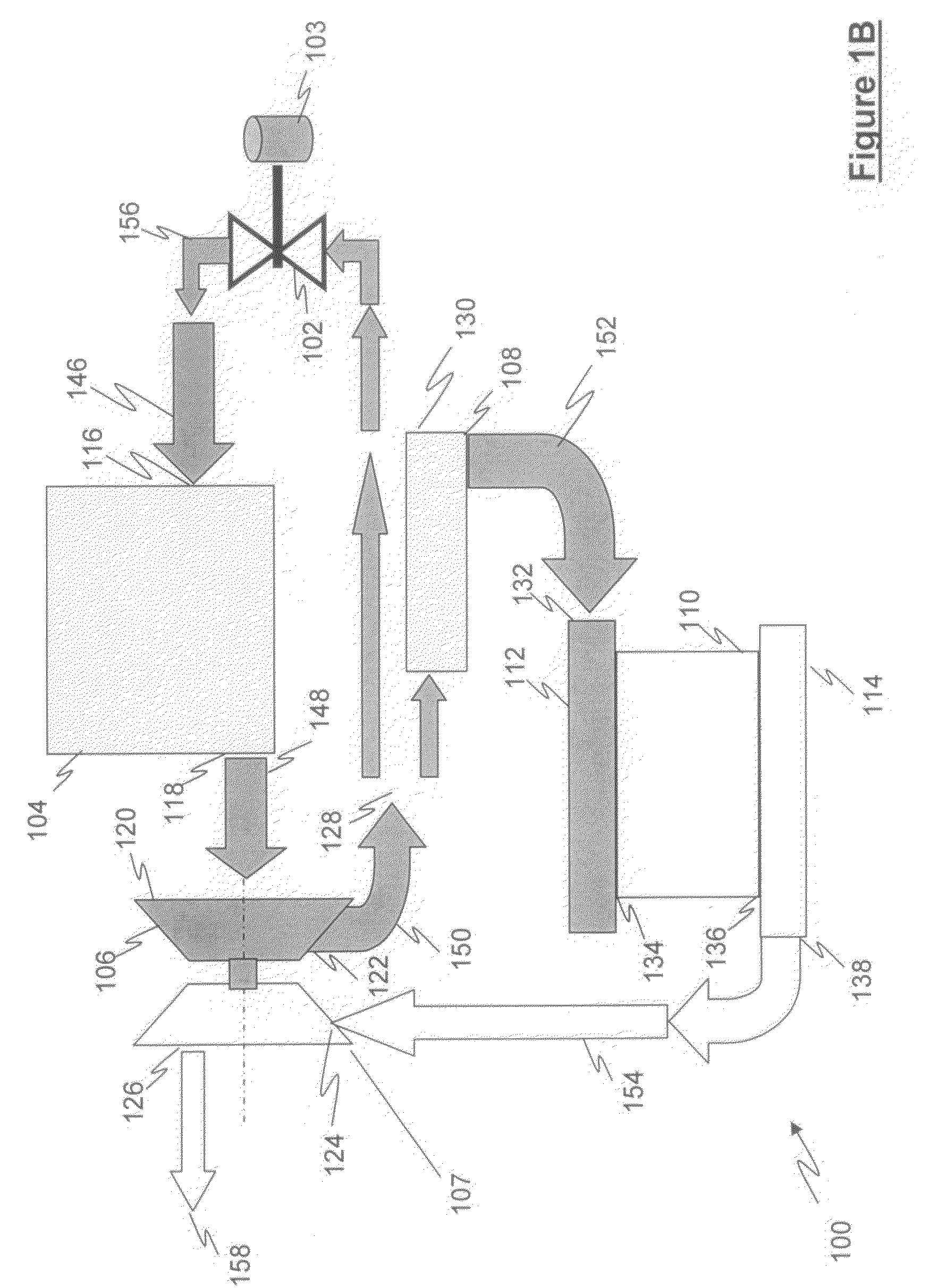

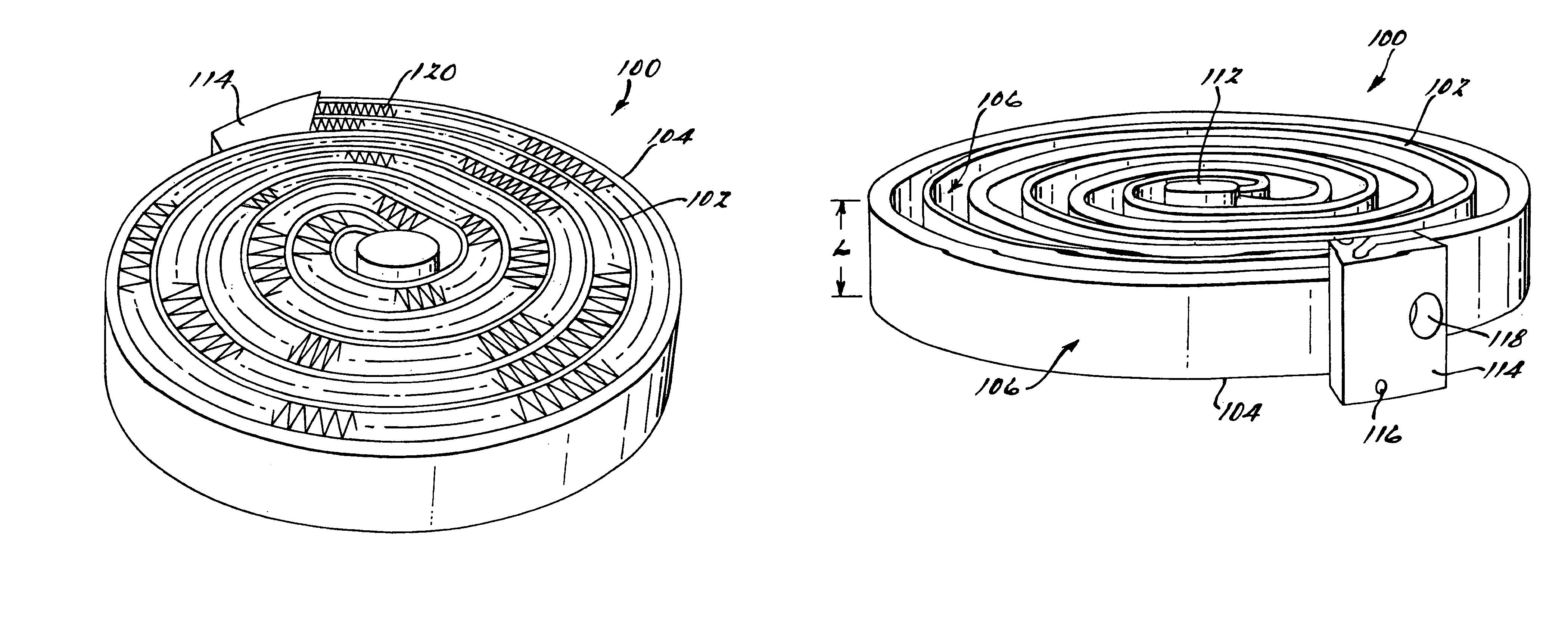

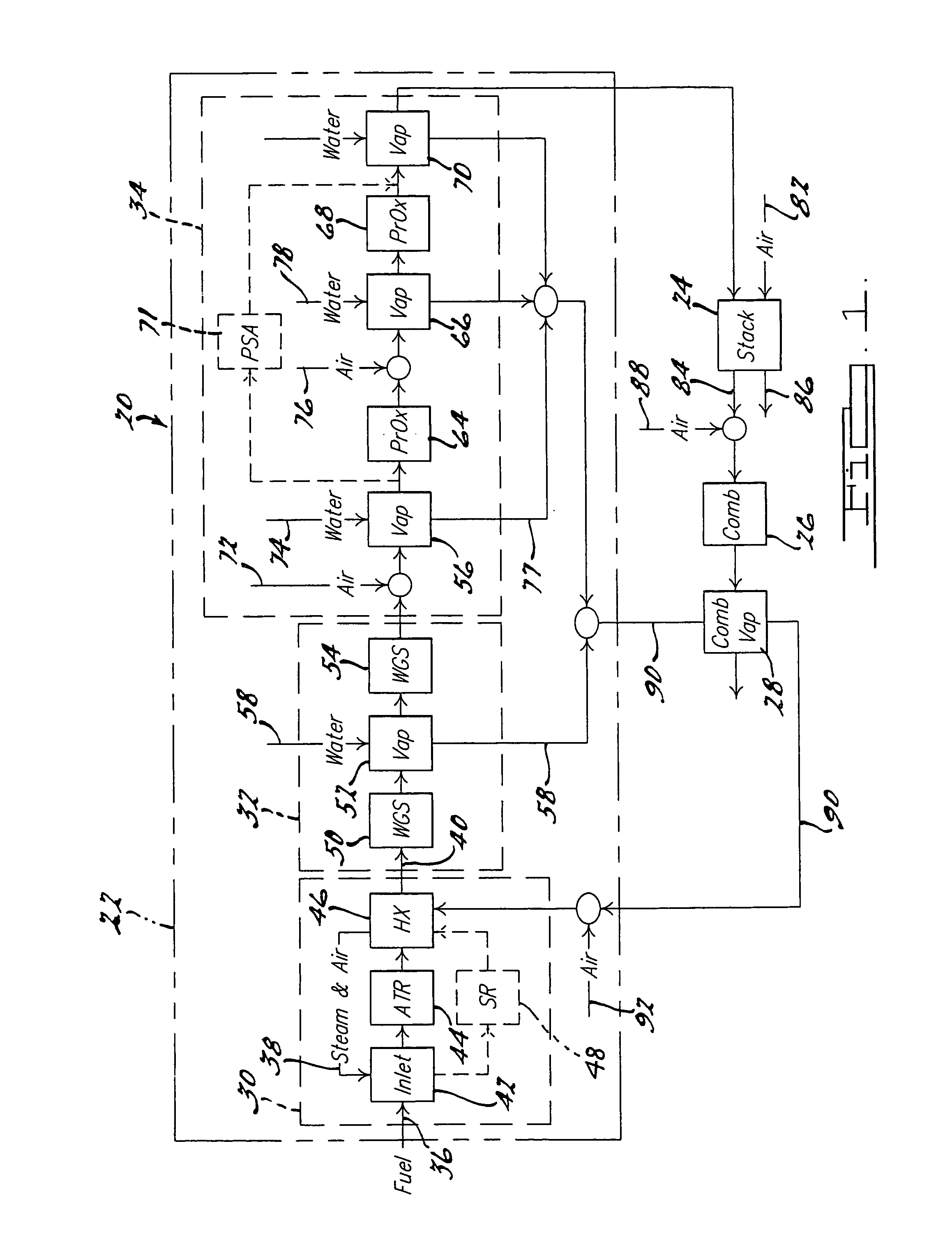

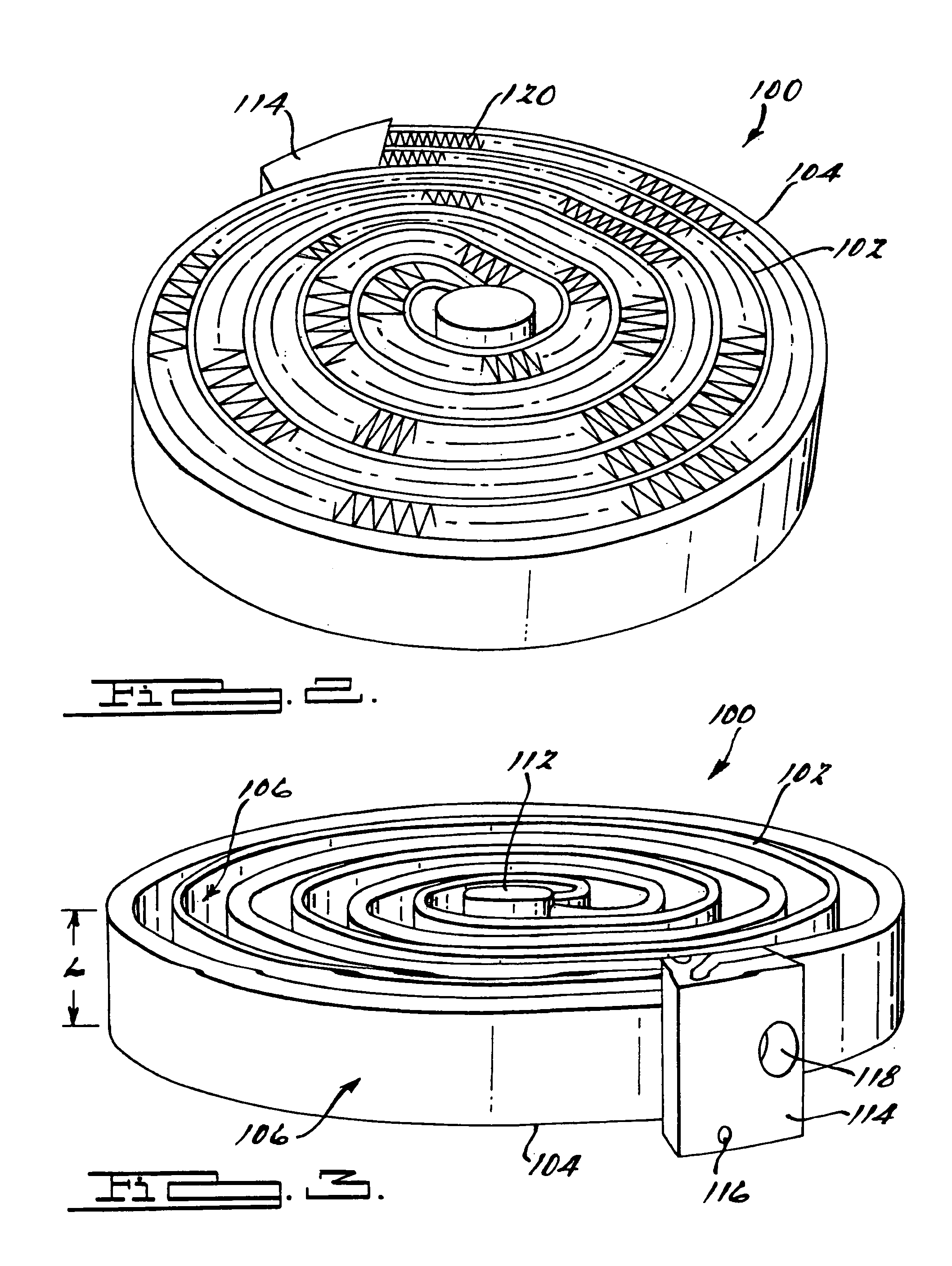

Compact water vaporizer for dynamic steam generation and uniform temperature control

ActiveUS20050100490A1Lower the volumeMinimal complexityBoiler water tubesSolid waste disposalTemperature controlCounter flow

A compact cylindrical vaporizer for simultaneous reduction of a reformate stream temperature and generation of a process stream is disclosed. The vaporizer utilizes counter flowing nested tubular portions that spiral between an outer section of the vaporizer and a central section of the vaporizer. The return spiral has a larger cross-sectional area than the inward spiral to accommodate a higher volumetric flow rate of the water flowing there through as it vaporizes while keeping the fluid velocity below erosion design constraints. The counter spiraling flow provides a substantially uniform spatial temperature profile of a reformate stream flowing on the exterior of the tubular portions. The vaporizer can be sized to be substantially the same as that of an upstream reactor to minimize velocity losses and pressure drops in the reformate stream flowing there through. A plurality of fins are positioned between the opposing tubular portion to enhance the heat transfer.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Exhaust diagnostic system and method with SCR NH3 depletion cleansing mode for initial step in the def quality service healing test

An exhaust diagnostic system comprises a selective catalyst reduction (SCR) component testing module, an exhaust stream temperature management module, and a test enabling module. The component testing module executes an SCR component efficiency test. The exhaust stream temperature management module adjusts a temperature of the SCR component to a predetermined temperature range. The test enabling module executes a process for depleting a reductant load and subsequently initiates an SCR component efficiency test while the temperature of the SCR catalyst is within the predetermined temperature range. A method for diagnosing an exhaust system comprises determining an efficiency of an SCR component and selectively adjusting a temperature of the SCR component to a predetermined temperature range. The method also includes executing a process for depleting a reductant load and initiating an SCR component efficiency test while the temperature of the SCR component is within the predetermined temperature range.

Owner:GM GLOBAL TECH OPERATIONS LLC

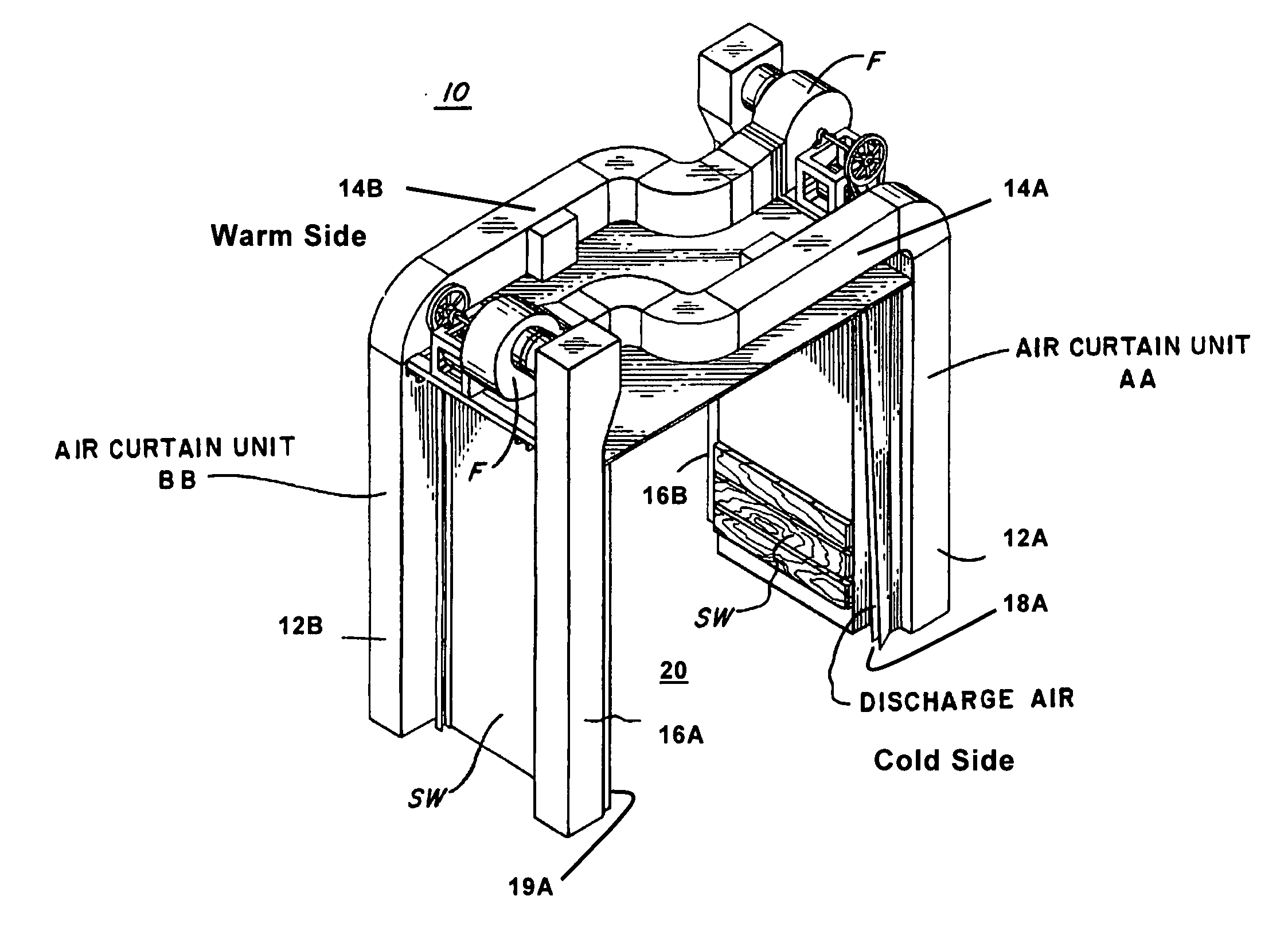

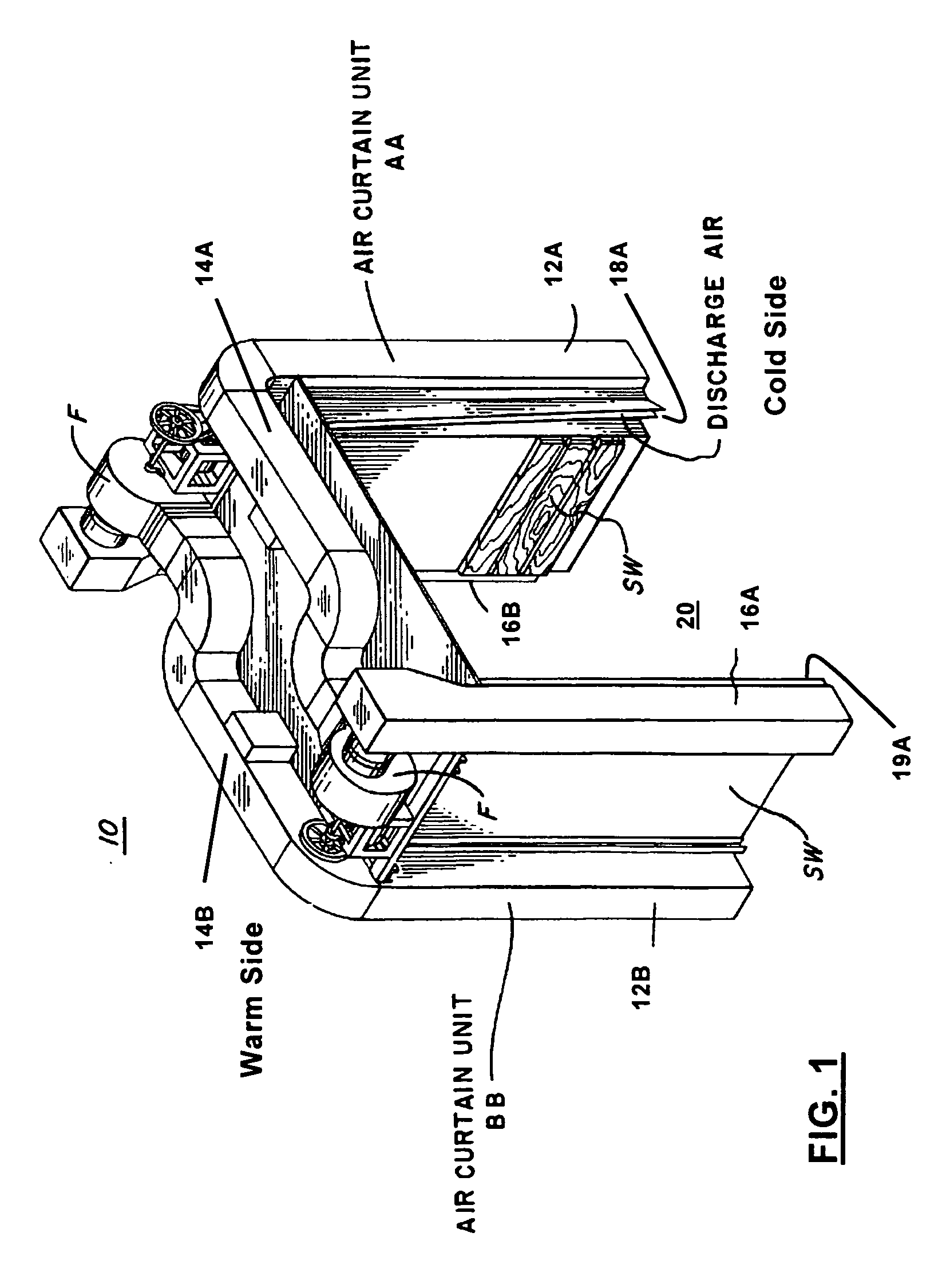

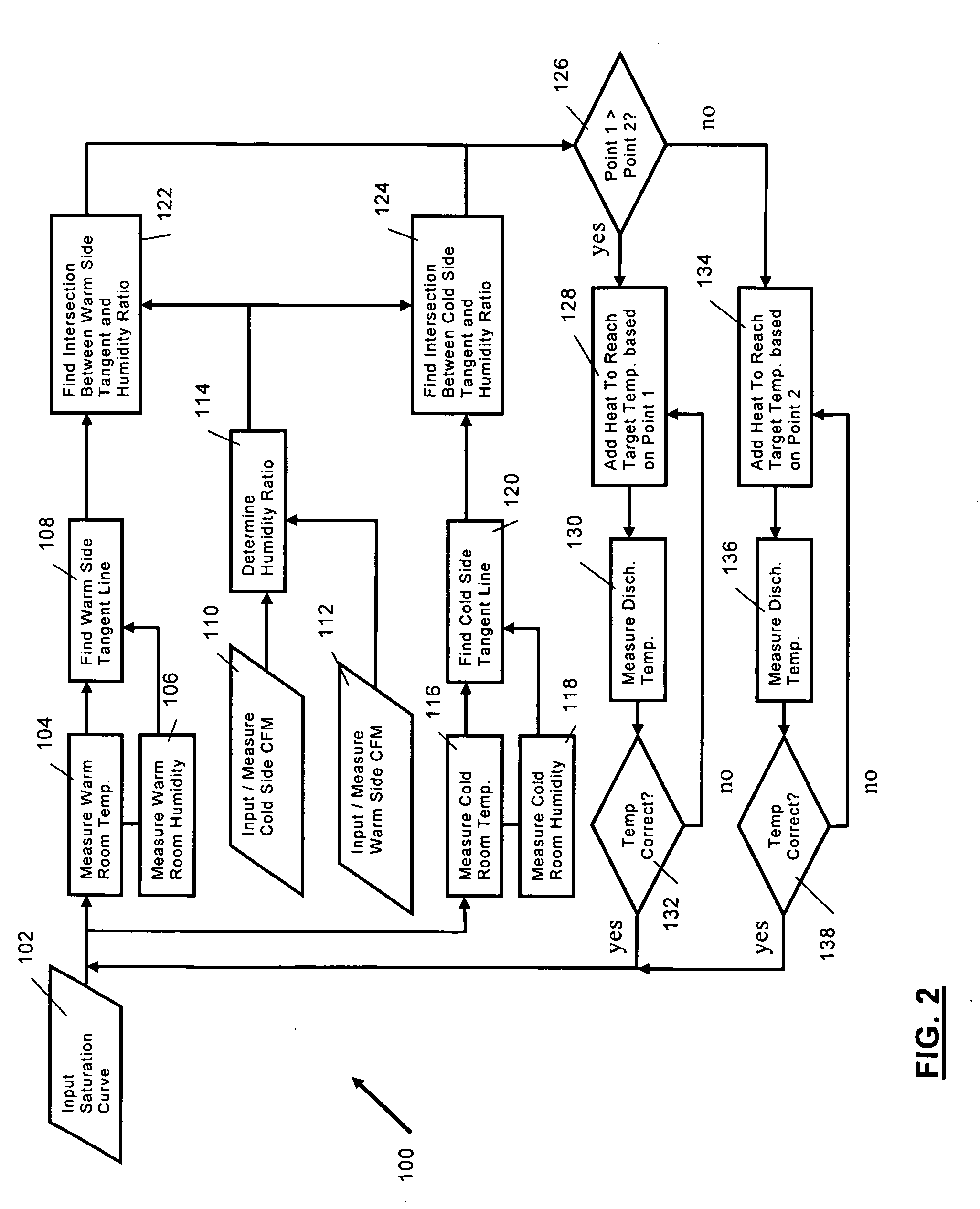

Cold storage doorway with airflow control system and method

ActiveUS20080233859A1Overcome deficienciesMaintain temperatureUltrasound therapyAir-treating devicesAntechamberControl cell

Owner:HCR

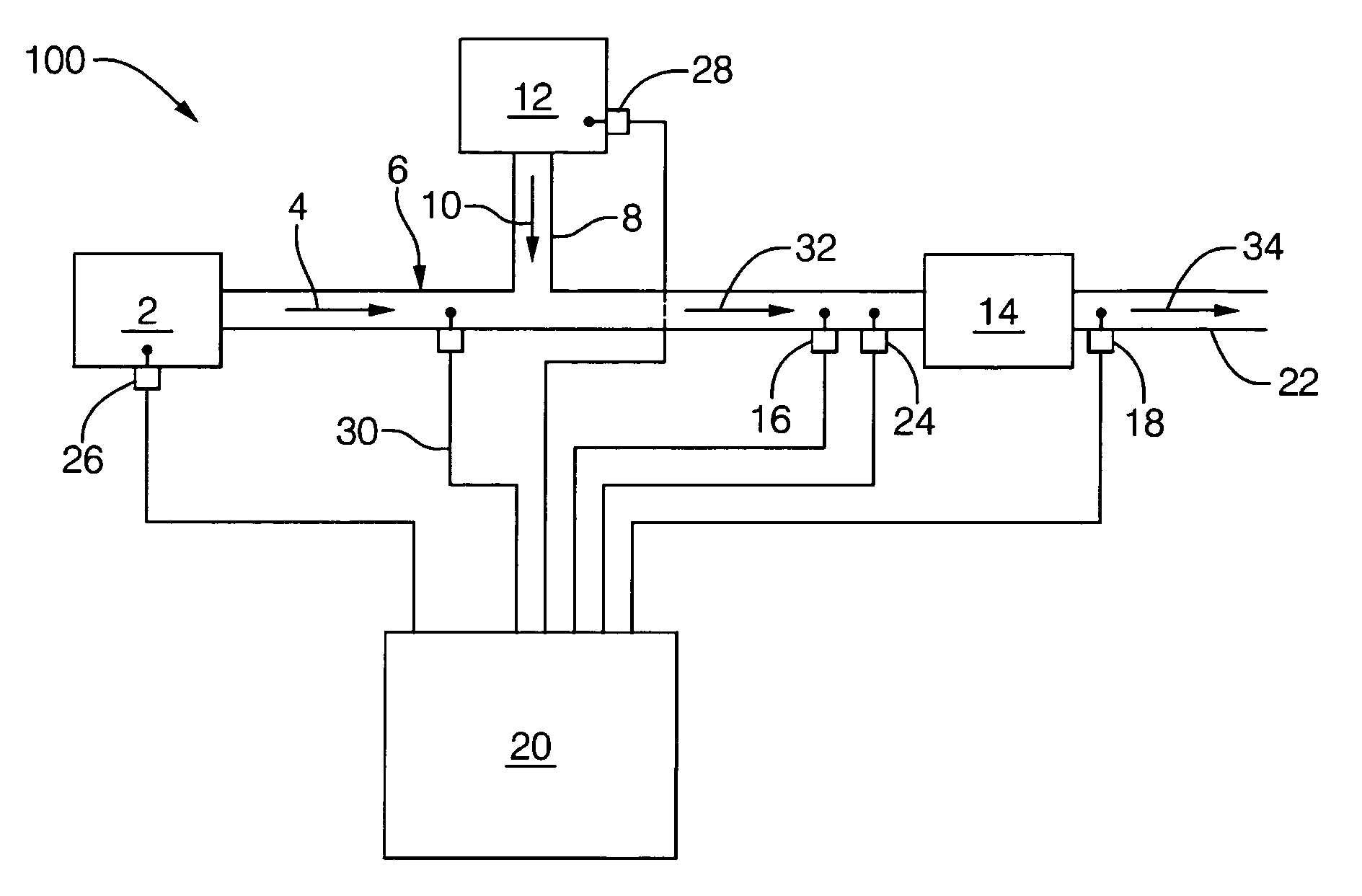

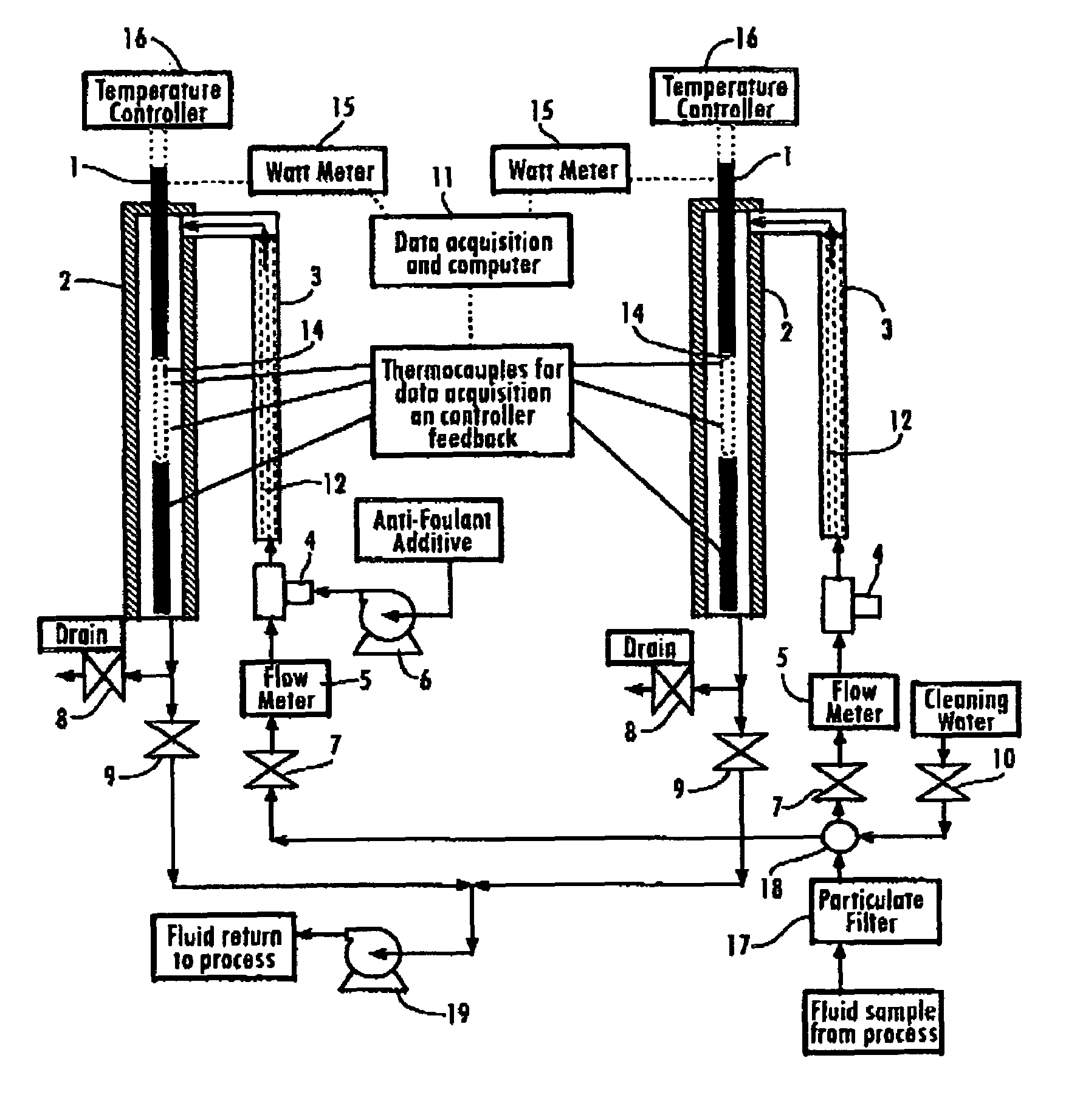

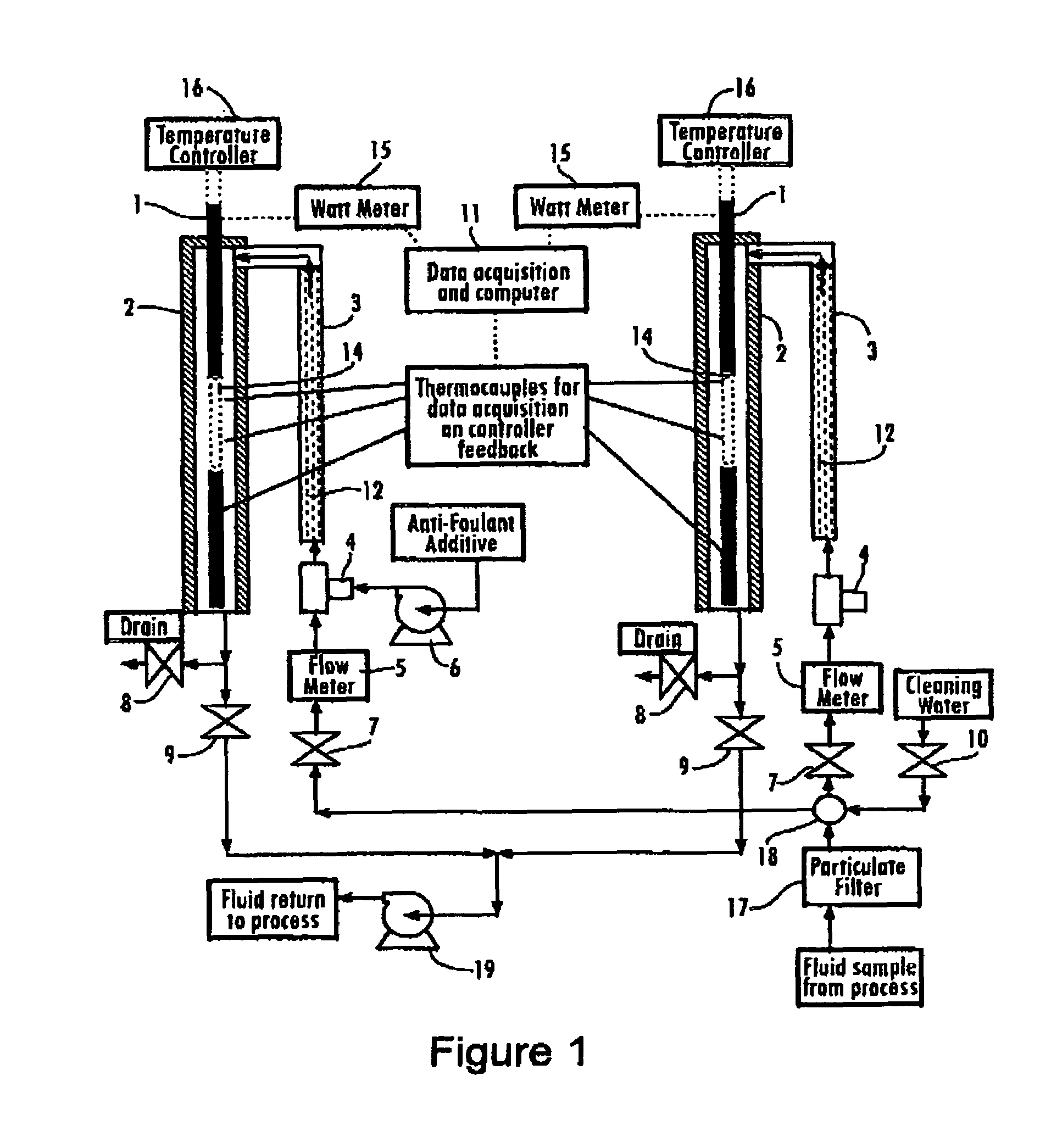

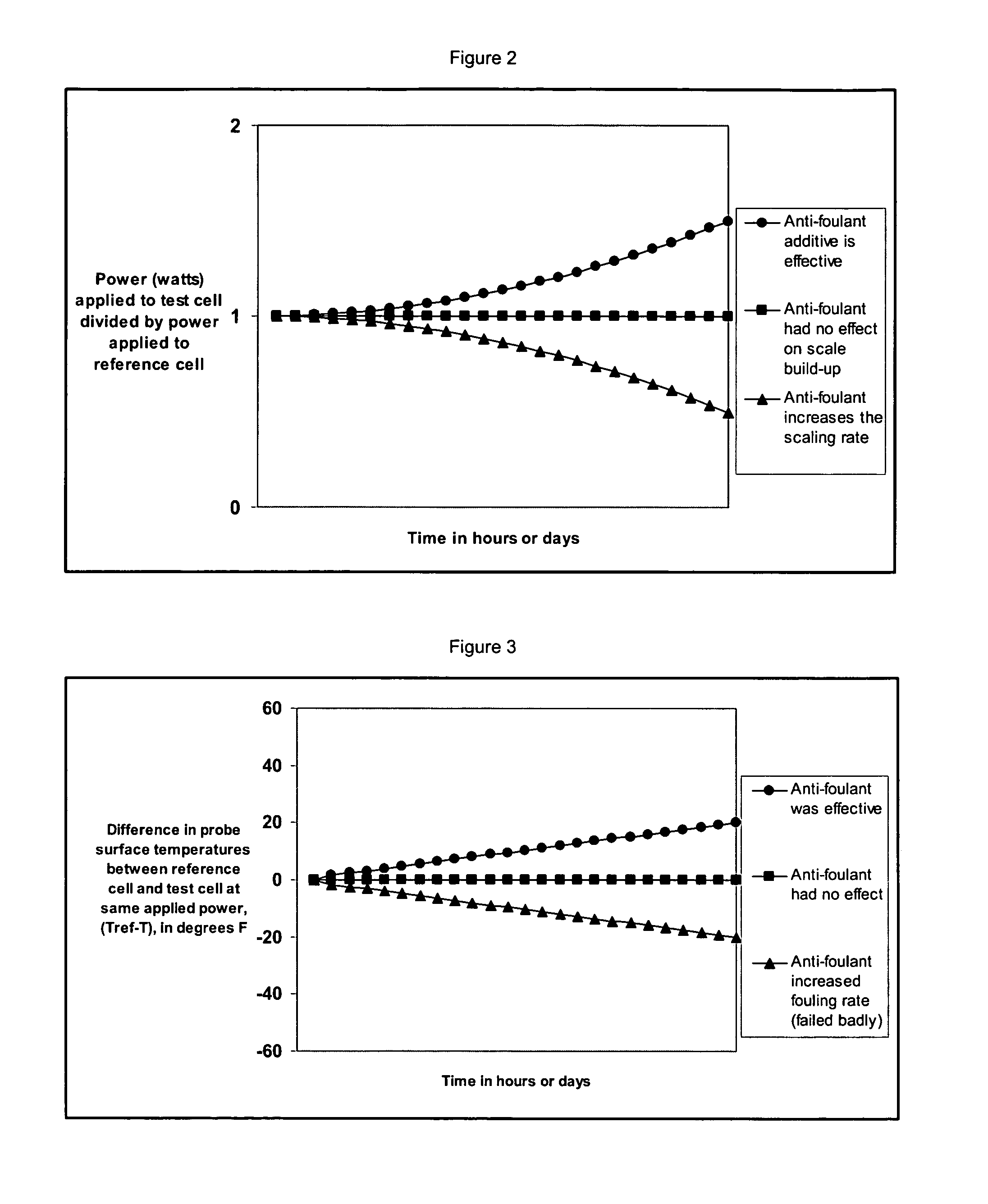

Fouling test apparatus and process for evaluation of anti-foulants

InactiveUS6978663B1Weather/light/corrosion resistanceMaterial heat developmentStream flowEngineering

An apparatus and process are described to test the effect of anti-foulant additives on scale information in industrial fluid streams. An apparatus of at least two cells plumbed in parallel is used in which at least one cell is a reference cell. The apparatus and process allow the simultaneous measurement of different conditions of anti-foulant additives, including anti-foulant concentration, fluid stream temperature, fluid stream flow rate, and heat transfer surface temperature.

Owner:GEORGIA TECH RES CORP

Gas-mass-flow up-down-stream temperature distribution secondary differential measuring method, sensor and flowmeter

InactiveCN1936513AExpand the scope of testingSmall thermal inertiaMass flow measurement devicesConstant powerLow speed

This invention relates to a secondary difference measurement method, sensors and flow meters for temperature distribution of the upper and lower reaches of a gas mass flow including a temperature-adding element and a temperature test element set symmetrically at either side of the temperature-adding element, namely an upper reaches test element and a lower reaches test element characterizing that said temperature adding element is connected with the constant power source, the two test elements are connected with the input ends of two signals of the difference operation circuit, the output of which is connected with a central process unit, which has small influence on the linearity of low speed segments by carrying secondary difference operation to the difference value of temperature variance of the upper and lower reaches, the saturated point of the relation curve of the flow rate of the gas mass flow and output voltage is push forward to enlarge the range sphere and linearity.

Owner:MEMSIC SEMICON WUXI

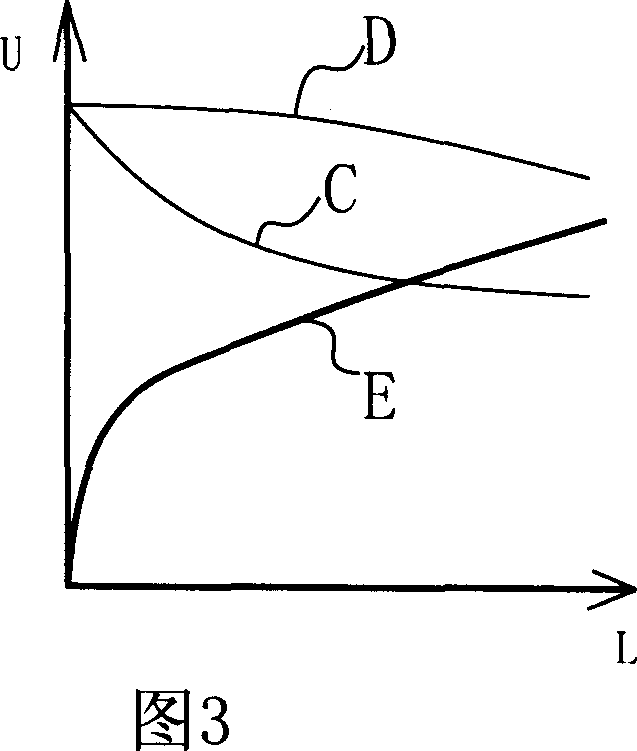

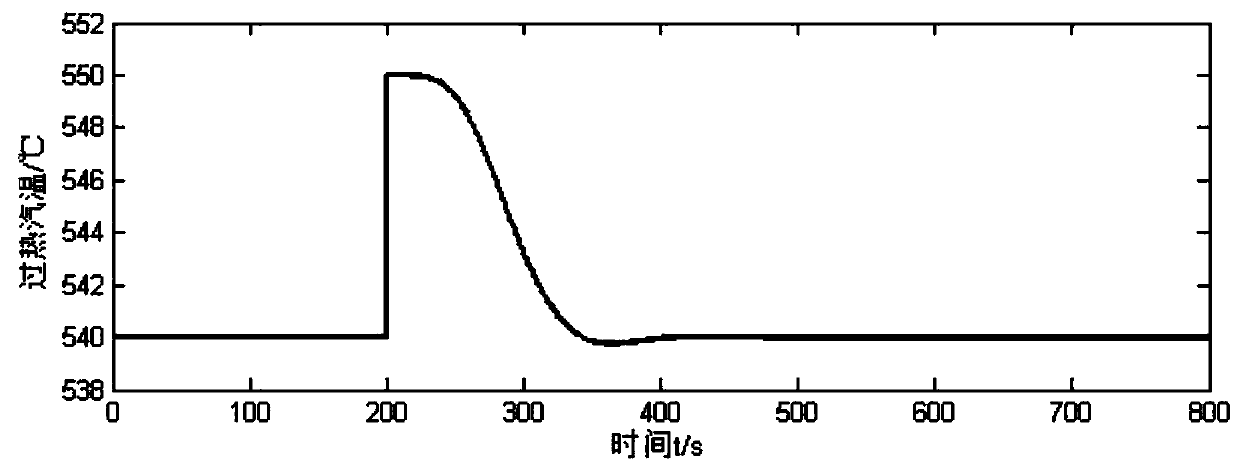

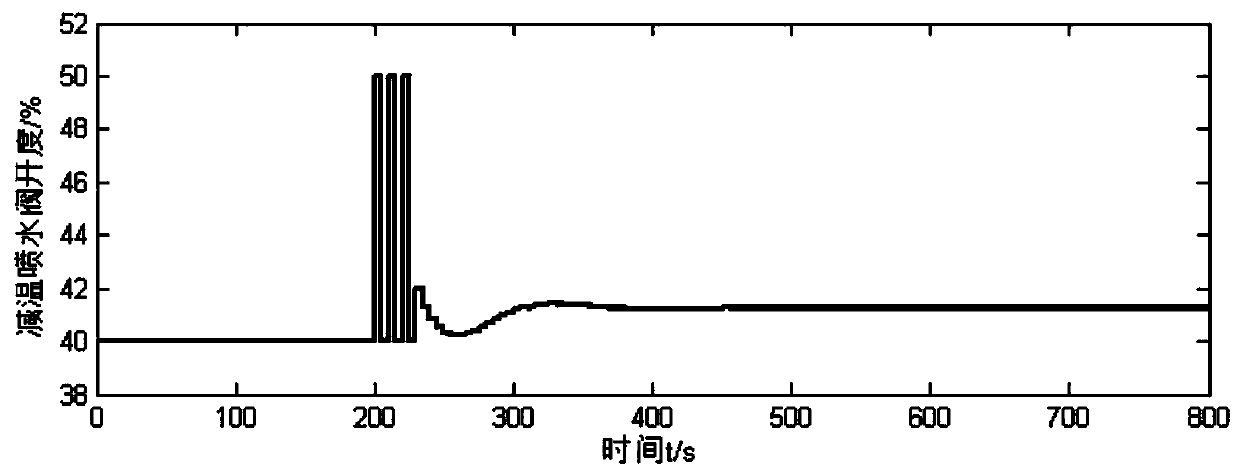

Rapid energy-saving prediction control method for overheat steam temperature

ActiveCN104181958AGuaranteed qualityStable controlAuxillary controllers with auxillary heating devicesAdaptive controlProcess dynamicsUnit operation

The invention discloses a rapid energy-saving prediction control method for an overheat steam temperature. The method obtains a prediction control model of a controlled object through step testing of an overheat steam temperature object. An overheat stream temperature control system records a temperature reduction water spraying valve opening degree control quantity sequence and an overheat steam temperature measurement value sequence in an online and real-time manner. According to novel performance indexes proposed in the method, the control system obtains the of a current temperature reduction water spraying valve opening degree through simple calculation. The control method solves problems, which exist in traditional limited prediction control, that optimization problems are complex, calculation quantity is large and effective control parameters for adjustment of the control performance of a system are lacked so that overheat steam temperature control is stable and rapid and a process dynamic deviation is small and no stable deviation exists. The method is capable of ensuring control quality and at the same time, also capable of reducing a temperature reduction water spraying quantity in a control process and thus economy of unit operation is improved.

Owner:NANJING GUITU TECH DEV

Method for adjusting deviation of two sides of reheating steam temperature of four-corner tangential firing boiler by SOFA air doors

ActiveCN109578992AReduce smoke temperature deviationReduce hot spotsCombustion apparatusWater flowEngineering

The invention relates to a method for adjusting deviation of two sides of the reheating steam temperature of a four-corner tangential firing boiler by SOFA air doors. The method for adjusting the deviation of the two sides of the reheating steam temperature of the four-corner tangential firing boiler by the SOFA air doors comprises the steps that horizontal pendulum angles of the SOFA air doors are adjusted; when the deviation of two sides of the reheating steam temperature is removed, vertical pendulum angles of the SOFA air doors are no longer adjusted; when the deviation of two sides of thereheating steam temperature is not removed, the vertical pendulum angles of the SOFA air doors are adjusted; and when the vertical pendulum angles of the SOFA air doors are adjusted, firstly, the vertical pendulum angles of a second SOFA air door and a third SOFA air door are adjusted obliquely upwards, and then, the vertical pendulum angles of a first SOFA air door and a fourth SOFA air door areadjusted to horizontal positions. The adjustment of the reheating steam temperature and temperature-decreased water flow is realized through the cooperative cooperation of the horizontal pendulum angles and the vertical pendulum angles of the SOFA air door, through the nonsynchronous adjustment of the horizontal pendulum angles and the vertical pendulum angles, the deviation of two sides of smoketemperature of the four-corner tangential firing boiler is rapidly reduced, the high-temperature point of the reheater pipe wall is reduced, the problems of large deviation of a reheater outlet stream temperature and the unbalanced temperature-decreased water flow on two sides are solved, finally, the average stream temperature of the reheater outlet is improved, and the temperature-decreased water flow of the reheater is reduced.

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Combustible gas detection systems and method thereof

InactiveUS7159444B2Reduce humidityCellsAnalysing fluids using sonic/ultrasonic/infrasonic wavesCombustible gasProcess engineering

A system and method are provided for monitoring the levels of combustible gas in a gas stream. The system includes means for controlling the relative humidity of the the gas stream to maintain a humidity level in the performance range of combustible gas sensors. A number techniques are illustrated for achieving the humidity control, including, secondary phase separations, mixing the gas with dry air and adjusting of the gas stream temperature.

Owner:PROTON ENERGY SYST

Turbocharger recirculation valve

InactiveUS7614232B2Reduce exhaust pressureReduce stepsInternal combustion piston enginesAir cleaners for fuelStream flowTurbocharger

A system and method for maintaining an airflow path to a turbocharger system on a locomotive operating at high altitude and in a low ambient temperature environment, is provided and includes generating an ambient air stream flow into the turbocharger system to create a compressed air stream flow having a compressed air stream temperature, processing the compressed air stream to create an intercooler air stream having an intercooler air stream temperature, directing at least a portion of at least one of the compressed air stream and the intercooler air stream toward a controllable re-circulation device, operating the controllable re-circulation device to combine the at least a portion of at least one of the compressed air stream and the intercooler air stream with at least one of the compressed air stream flow and the ambient air stream.

Owner:GENERAL ELECTRIC CO

Compact water vaporizer for dynamic steam generation and uniform temperature control

ActiveUS7258081B2Lower the volumeMinimal complexityBoiler water tubesFuel cell auxillariesTemperature controlCounter flow

A compact cylindrical vaporizer for simultaneous reduction of a reformate stream temperature and generation of a process stream is disclosed. The vaporizer utilizes counter flowing nested tubular portions that spiral between an outer section of the vaporizer and a central section of the vaporizer. The return spiral has a larger cross-sectional area than the inward spiral to accommodate a higher volumetric flow rate of the water flowing there through as it vaporizes while keeping the fluid velocity below erosion design constraints. The counter spiraling flow provides a substantially uniform spatial temperature profile of a reformate stream flowing on the exterior of the tubular portions. The vaporizer can be sized to be substantially the same as that of an upstream reactor to minimize velocity losses and pressure drops in the reformate stream flowing there through. A plurality of fins are positioned between the opposing tubular portion to enhance the heat transfer.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

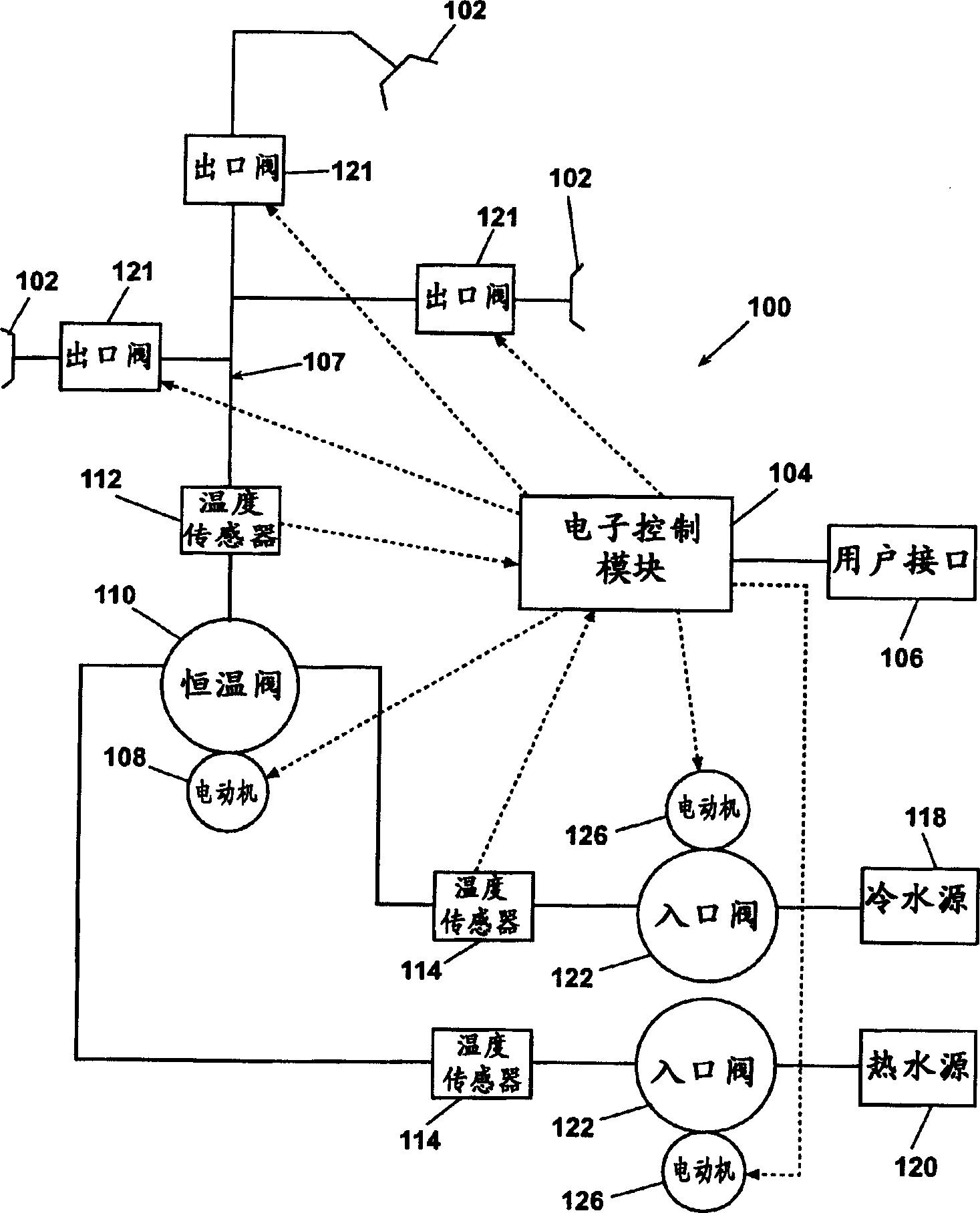

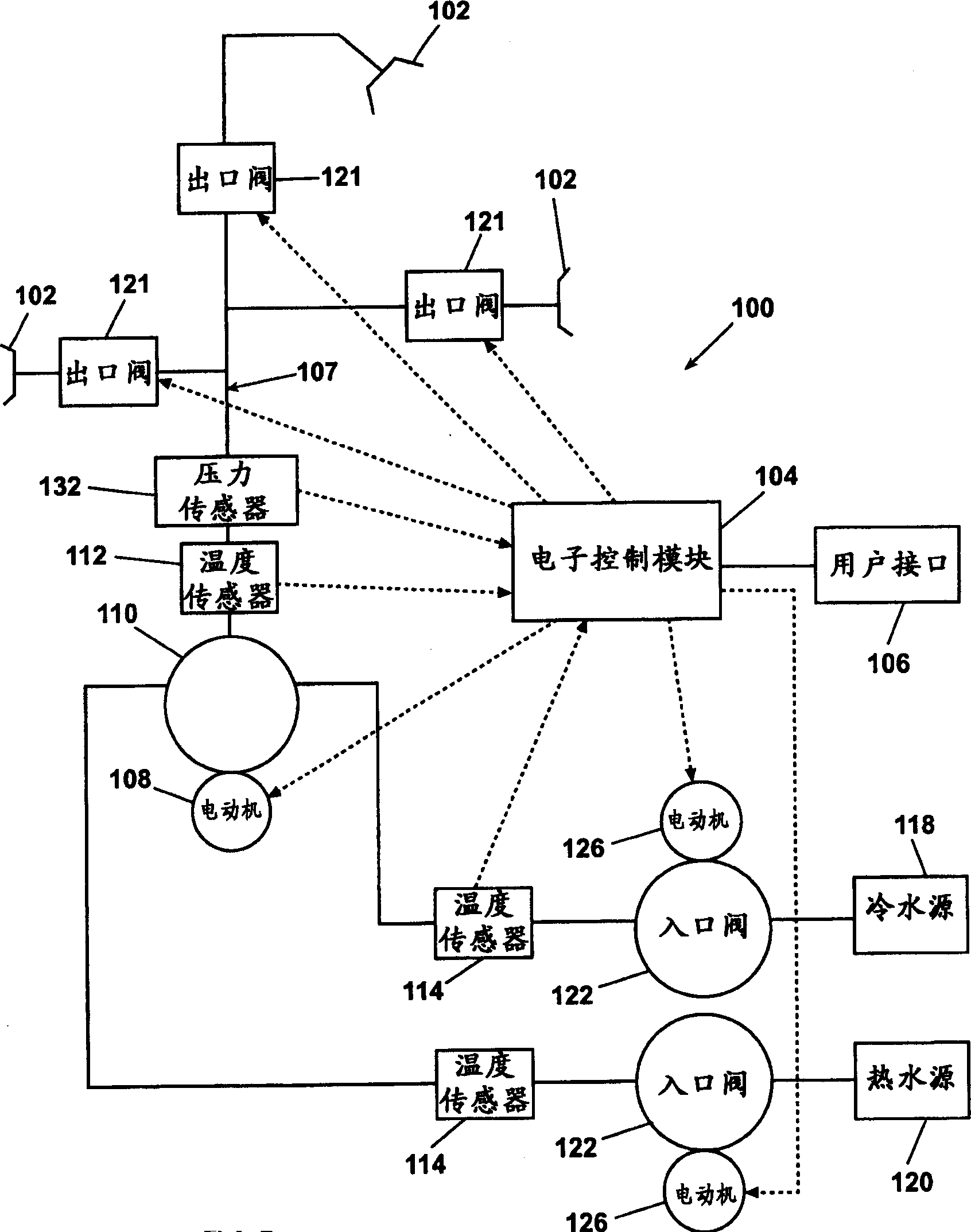

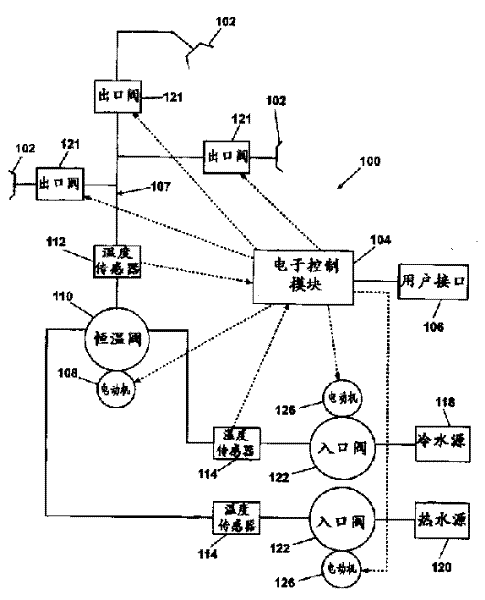

Constant temperature valve with electronic control

InactiveCN1487383ASimple designEasy maintenanceTemperature control without auxillary powerOperating means/releasing devices for valvesWater flowInlet valve

A thermostatic valve is controlled by a motor that receives signals from an electronic control module (ECM). The ECM sends an electric signal corresponding to a desired outlet stream temperature to the motor, which turns the thermostatic valve to a location corresponding to the desired temperature. The ECM also adapts the thermostatic valve capacity to outlet flow demands by restricting and opening inlet valves, ensuring that the thermostatic valve can maintain an equilibrium temperature for both high and low outlet flow applications.

Owner:MASCO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com