Constant temperature valve with electronic control

An electronic control module, thermostatic valve technology, applied in non-electric variable control, flow control using electrical devices, temperature control without auxiliary power supply, etc., can solve the problems of output temperature swing, performance degradation, trouble, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

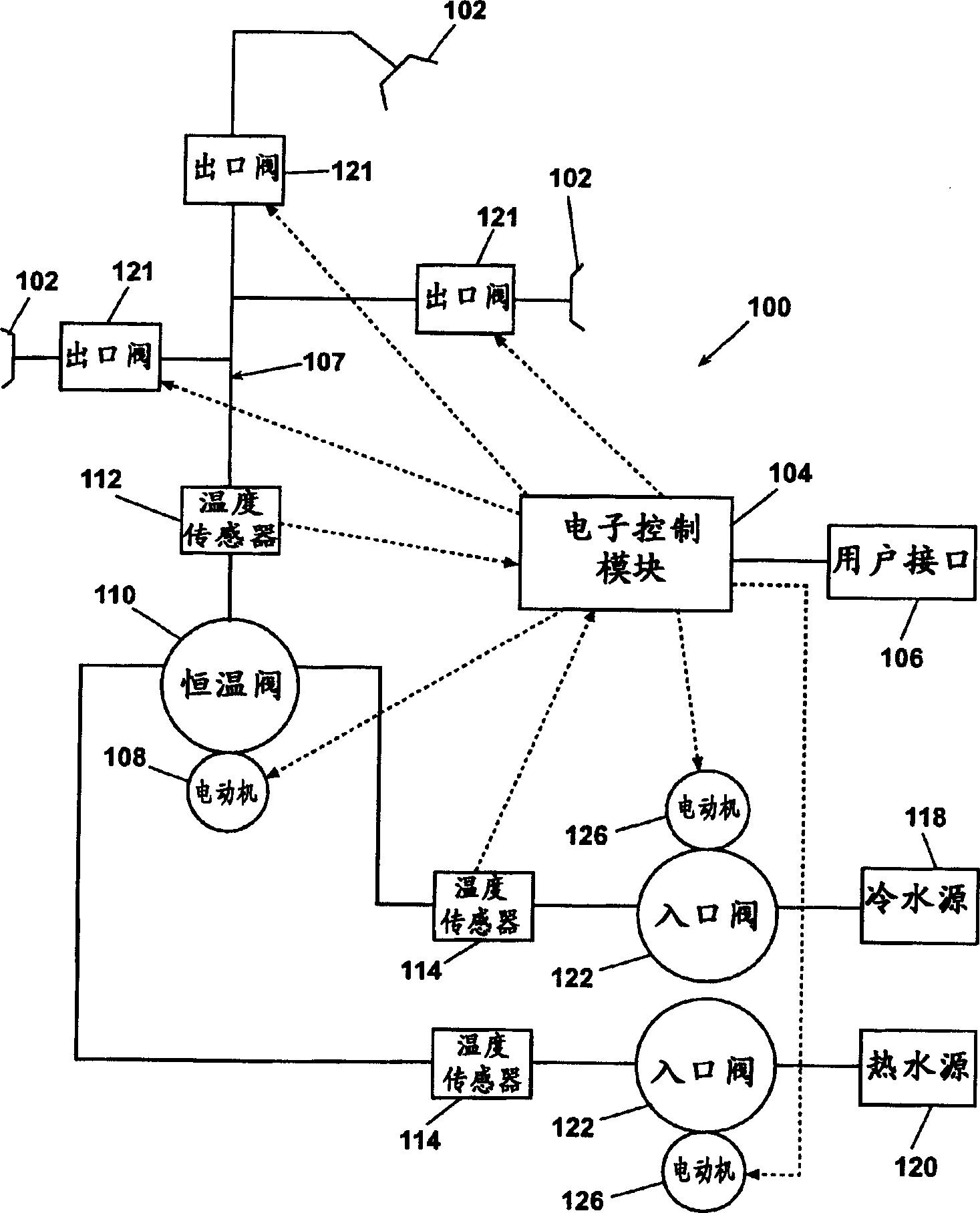

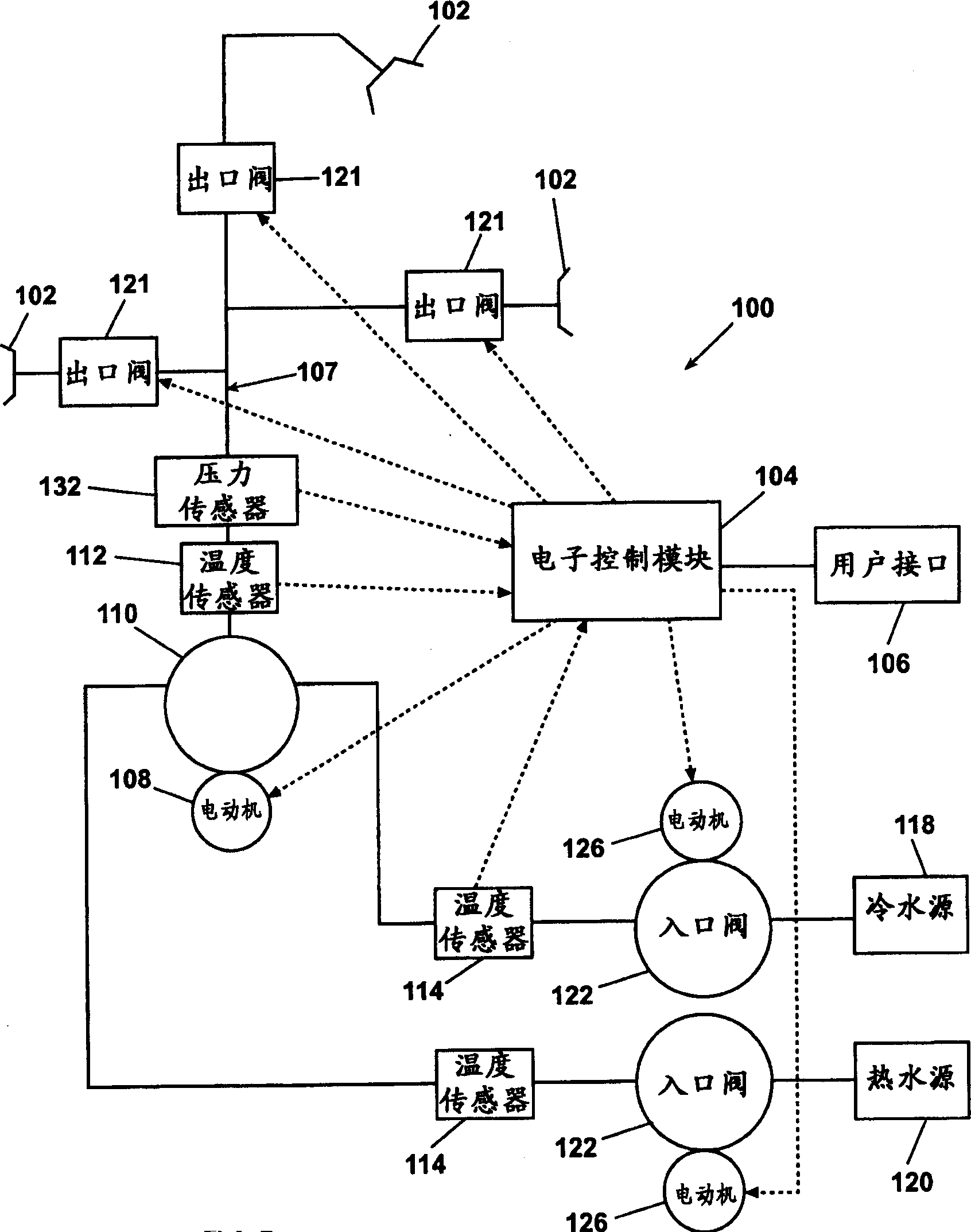

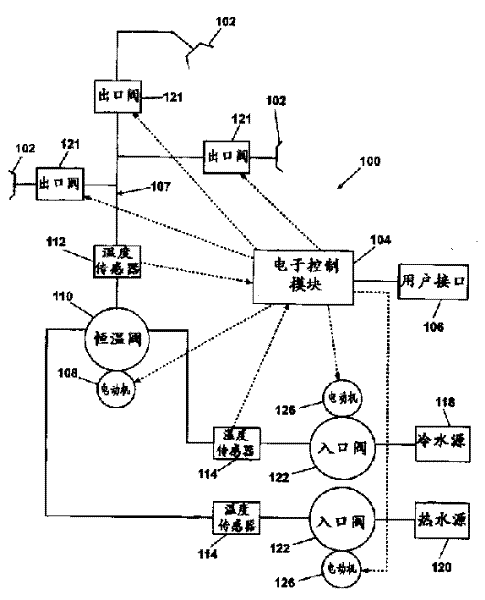

[0010] figure 1 is a schematic block diagram illustrating one embodiment of a thermostatic valve system 100 according to one embodiment of the present invention. The system 100 is designed to control the flow of liquid through one or more outlet devices 102, such as bodysprays, nozzles, and the like. System 100 includes an electronic control module (ECM) 104 serving as a control point for operation of the valve system. The incorporation of electronic controls into the manual valve system 100 allows for quick and accurate control of water temperature and flow, ensuring that the system 100 maintains balanced temperature and pressure even with sudden pressure changes.

[0011] The ECM 104 itself is any known preprogrammed circuit capable of being powered by a battery or a hardwired power connection. A user interface 106 may be coupled to the ECM 104 to allow a user to specify a temperature, select an outlet for use, open or close an outlet valve, or control the operation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com