Patents

Literature

31results about How to "Reduce smoke temperature deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

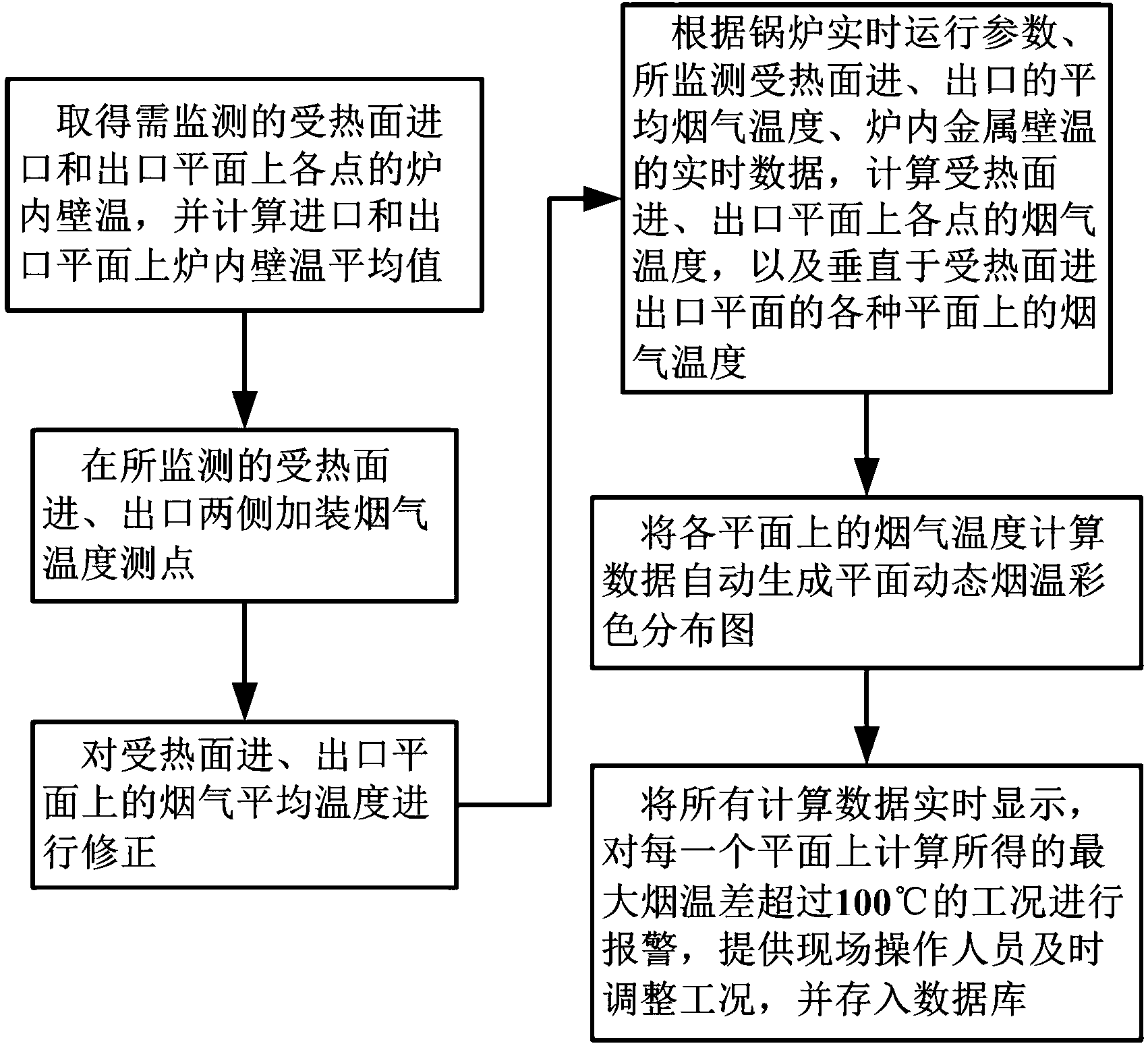

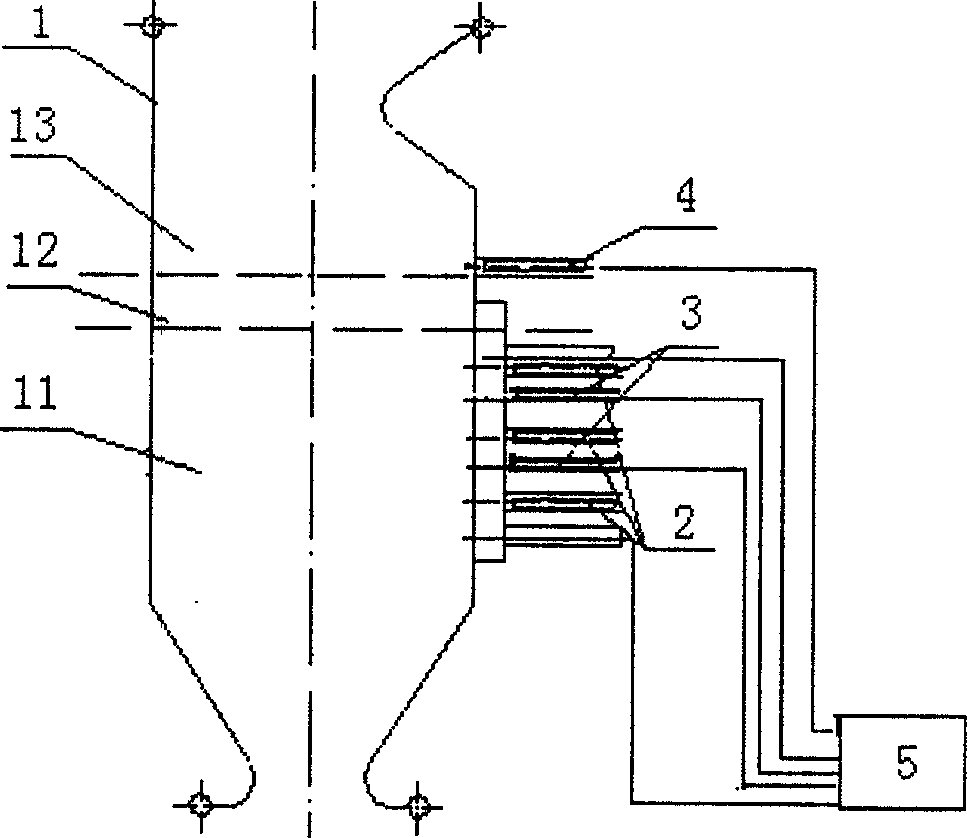

Method for on-line monitoring and alarming of convection heating face flue gas temperature field of power station boiler

ActiveCN103216812AEnsure safe and economical operationEliminate squibBoiler indication operationsBoiler controlSuperheaterProcess engineering

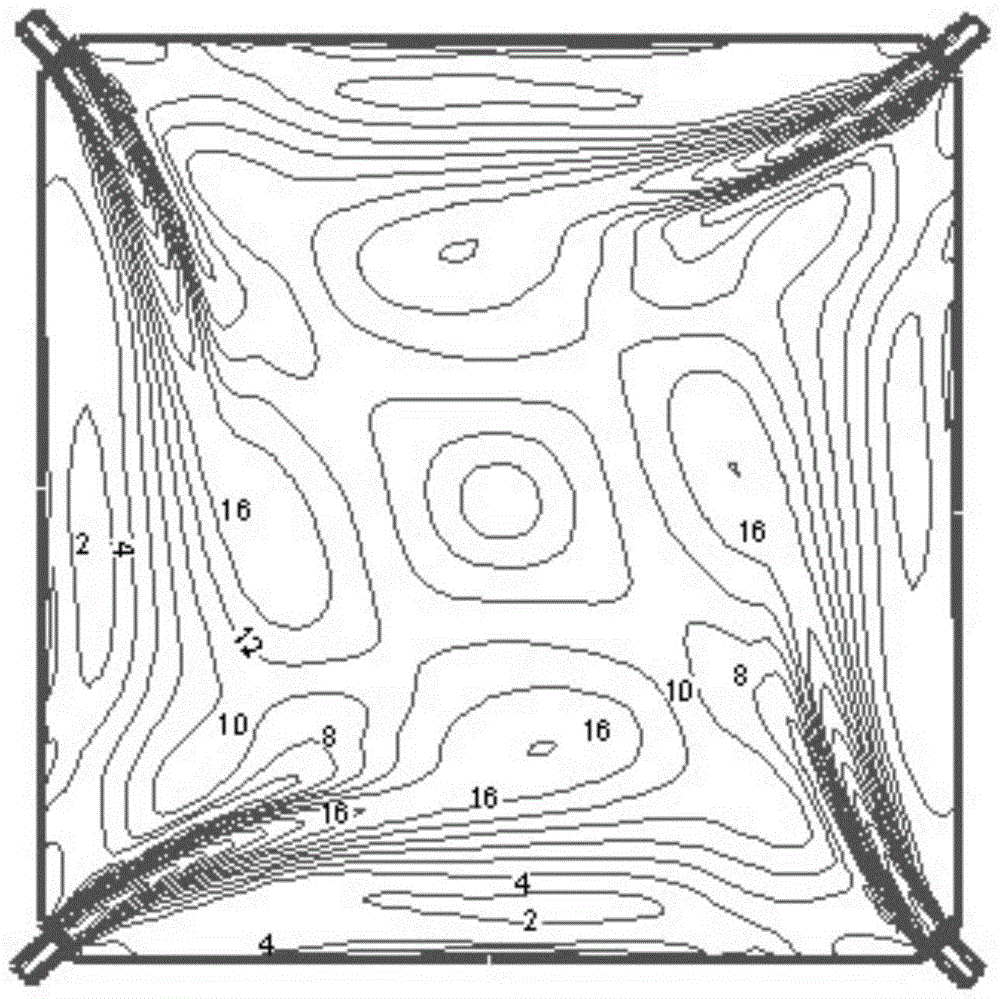

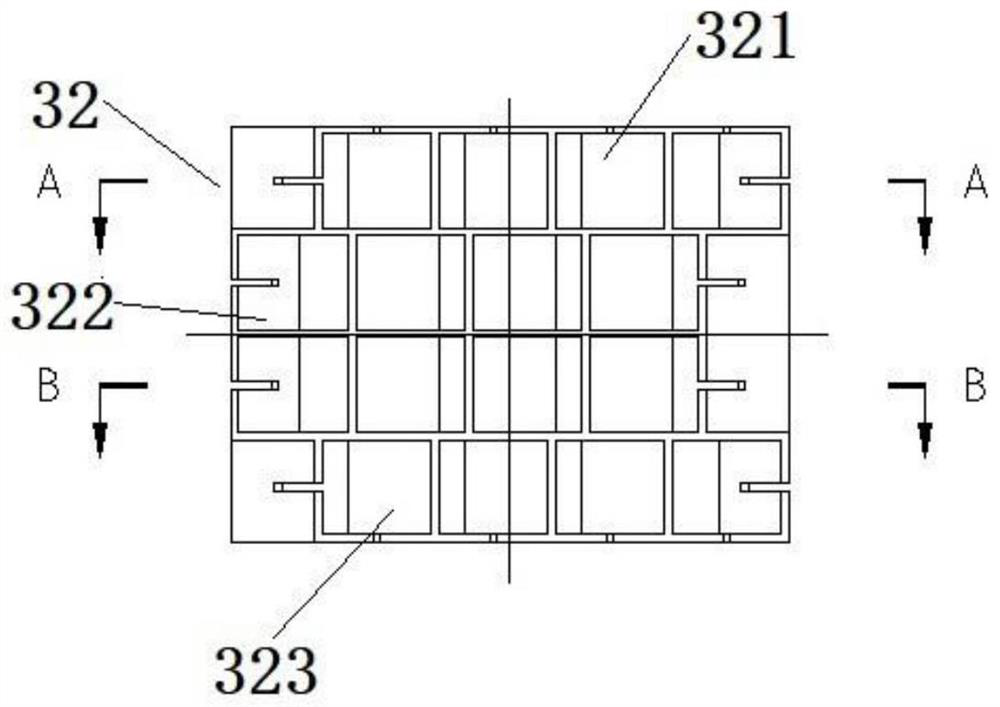

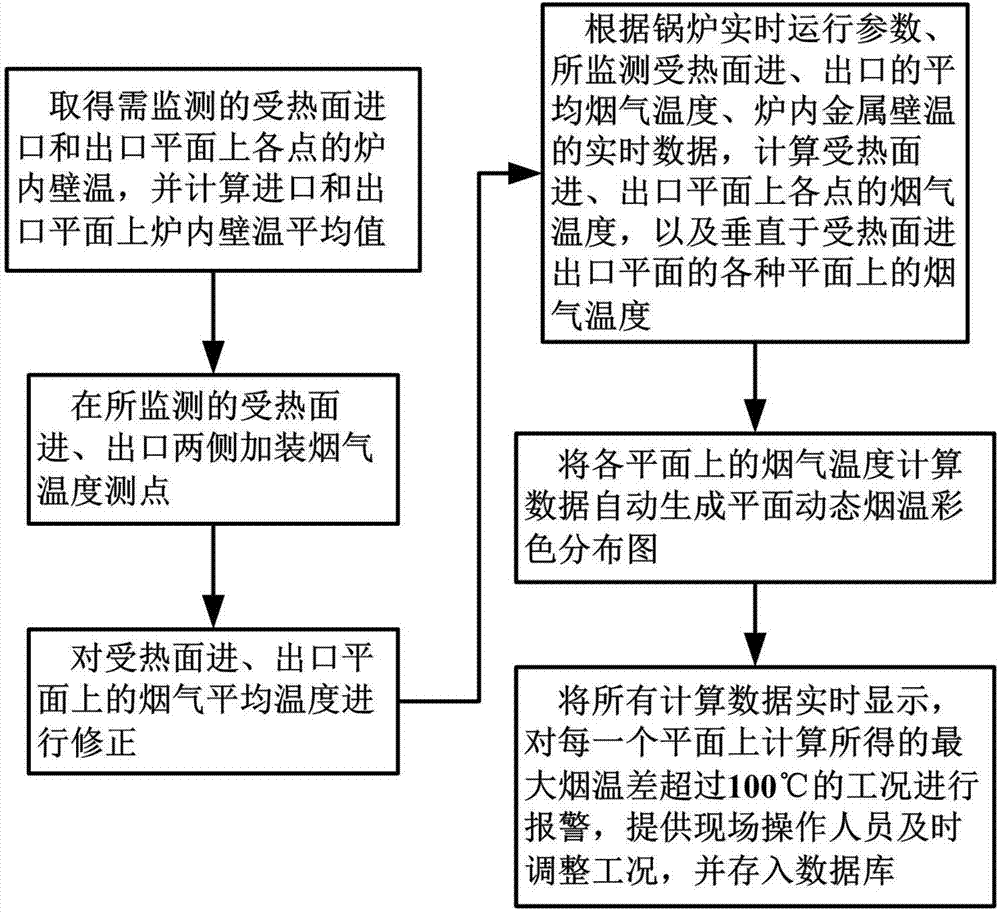

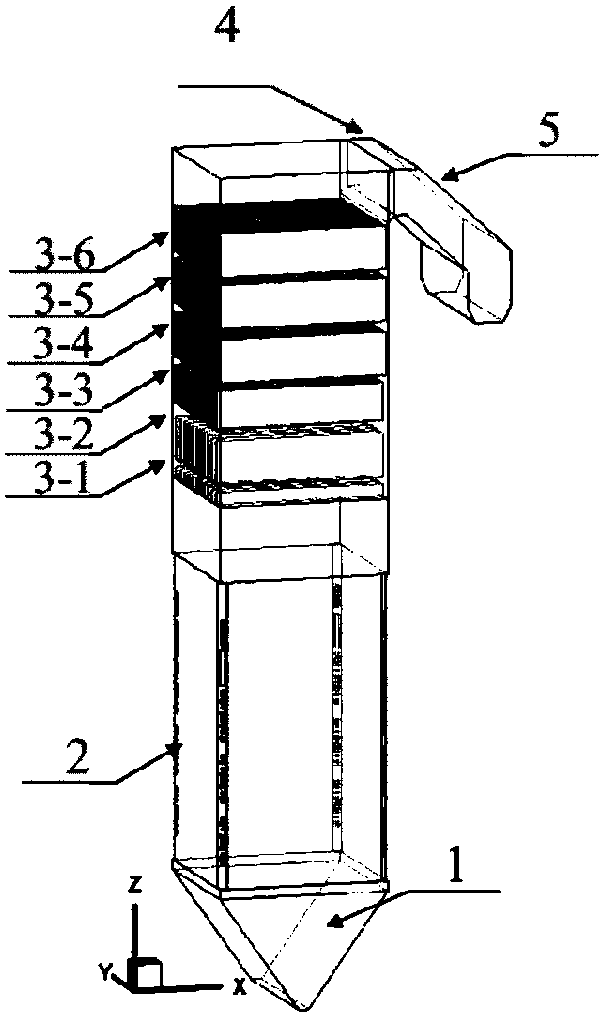

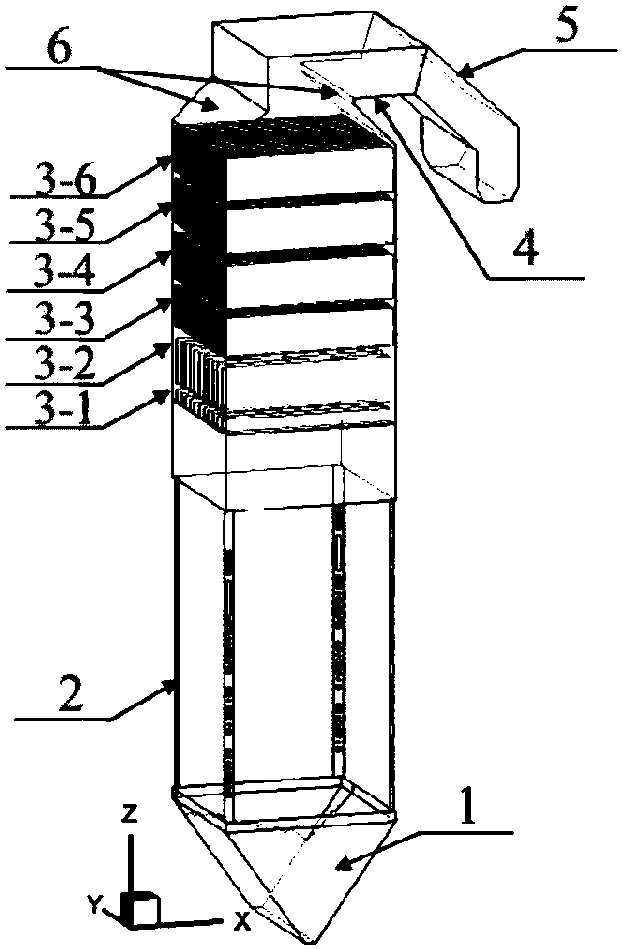

The invention belongs to a method for the on-line monitoring and alarming of a convection heating face flue gas temperature field of a power station boiler, which comprises the steps of calculating the average value of temperatures of furnace inner walls on inlet and outlet planes according to monitoring values of the temperatures of the furnace inner walls; additionally arranging flue gas temperature monitoring points at two sides; amending a flue gas average temperature; calculating the flue gas temperature of each point in the inlet and outlet planes of the heating faces, and the flue gas temperature of various planes vertical to the inlet and outlet planes of the heating faces; automatically generating a planar dynamic flue gas temperature colorful distribution diagram; and displaying in real time and providing site conditions and timely adjusting work conditions. The method disclosed by the invention realizes the accurate data monitoring and corresponding and visual diagram distribution display of flue gas temperature fields in the inlet and outlet planes and various longitudinal and horizontal planes vertical to the inlet and outlet planes of each convection heating face of superheater and reheater pipeline systems, provides direct data support for adjusting the burning work condition of the operation site of the power station boiler, and realizes the safe and economic operation of the convection heating faces of the superheater and reheater pipeline systems of the power station boiler.

Owner:王衡 +1

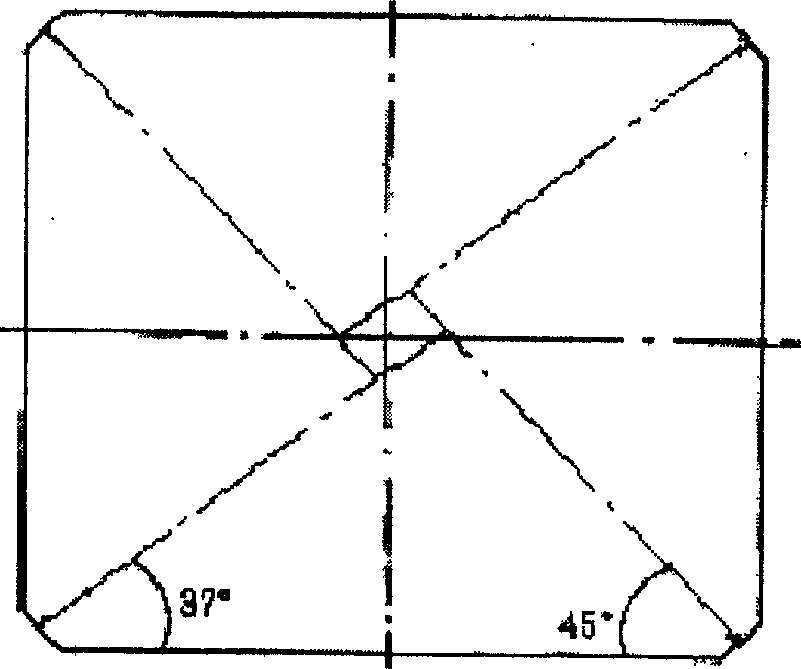

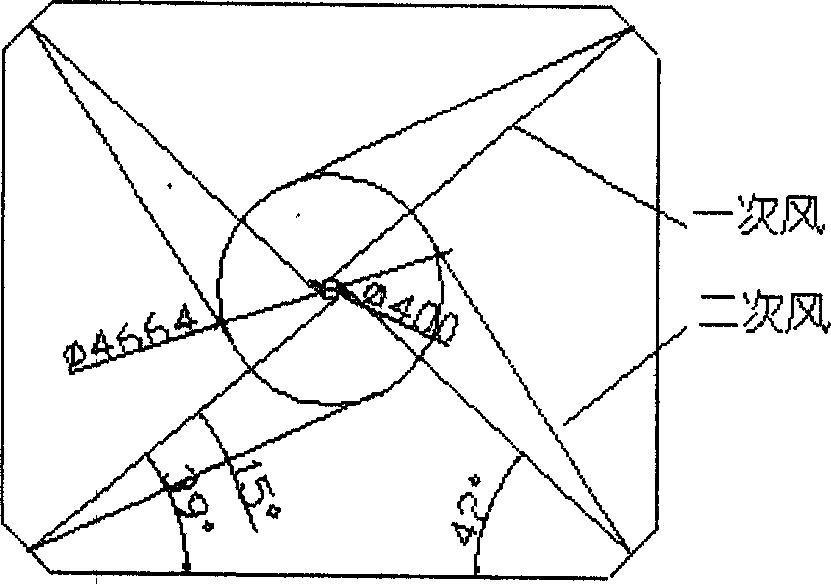

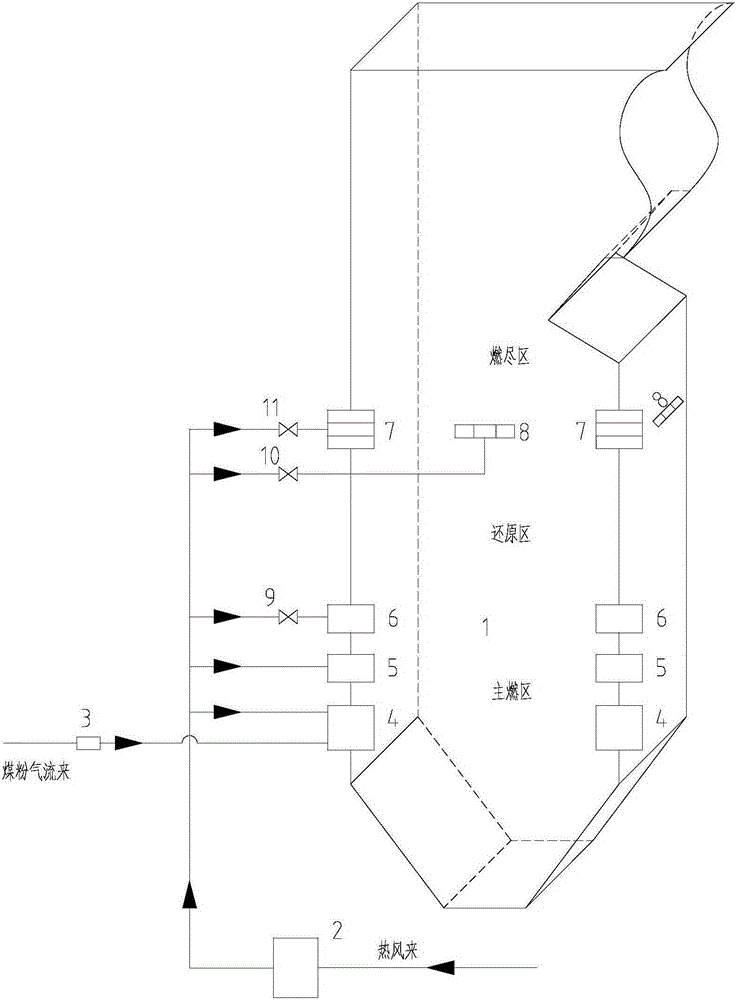

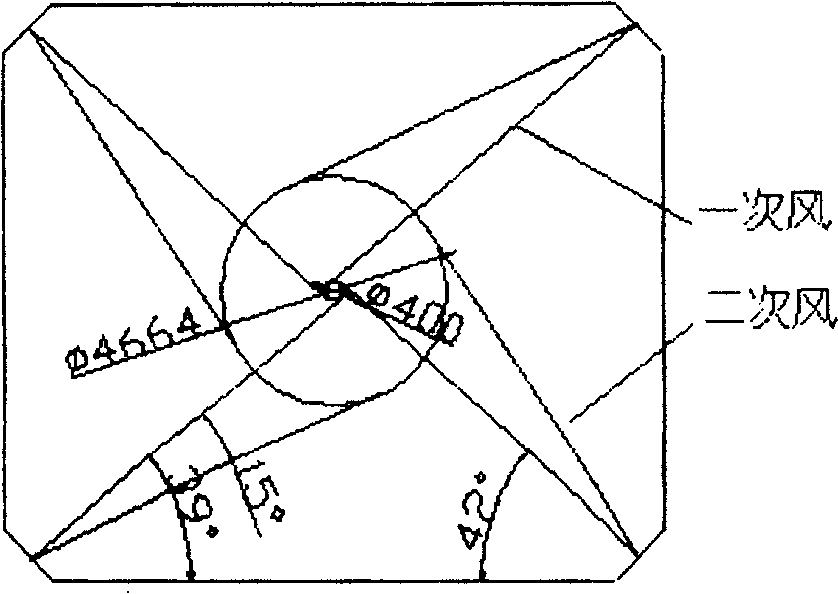

Combustion technology of low nitrogen oxide

InactiveCN1757966AReduce smoke temperature deviationAvoid slagging corrosion problemsCombustion using gaseous and pulverulent fuelCombustion chambersCombustorLow nitrogen

A low-Nox combustion technology features that the combustion box is divided into primary combustion region, reduction region and burning off region from bottom to top. In the primary combustion region, the multi-layer horizontal coal powder combustion technique is used. In the reduction region the under-oxygen reduction technique is used. The burn0off air is fed into the burning off region. The jet direction of the secondary wind among each two burner layers is deflected clockwise by 10-15 deg. relative to the jet direction of primary wind and coal powder stream. The excessive coefficient of air in reduction region is 1.0. The horizontal direction of burn-off windjet is deflected anticlockwise by 5-10 deg. relative to the jet direction of primary wind. Its advantages are stable and uniform combustion, and low release of Nox.

Owner:DONGDIAN BURNING APP LIAONING +1

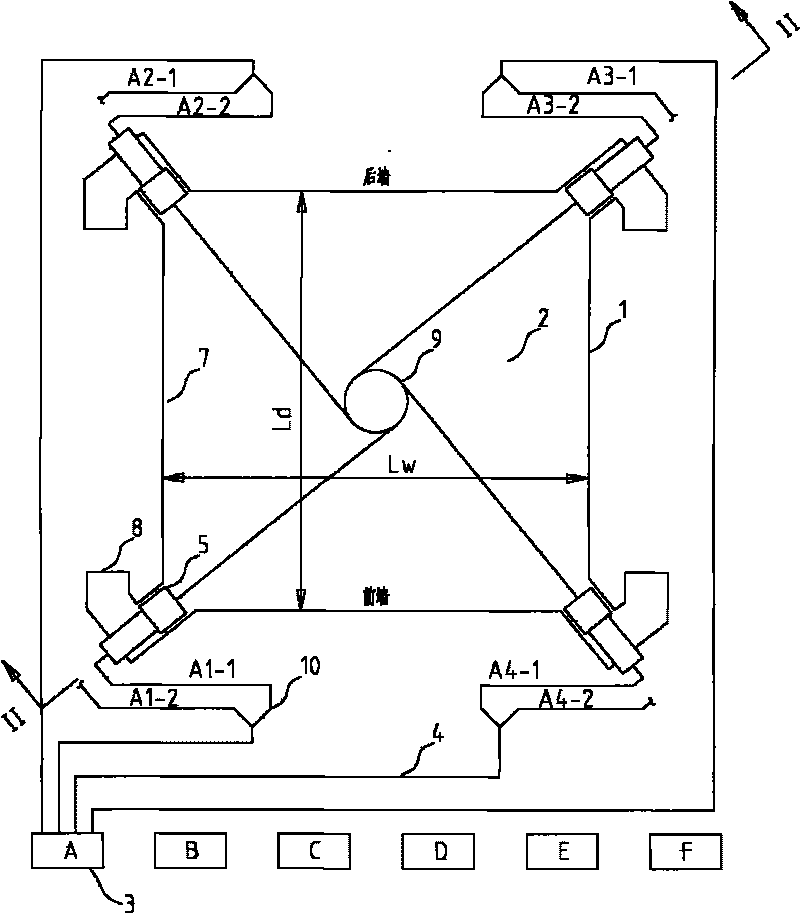

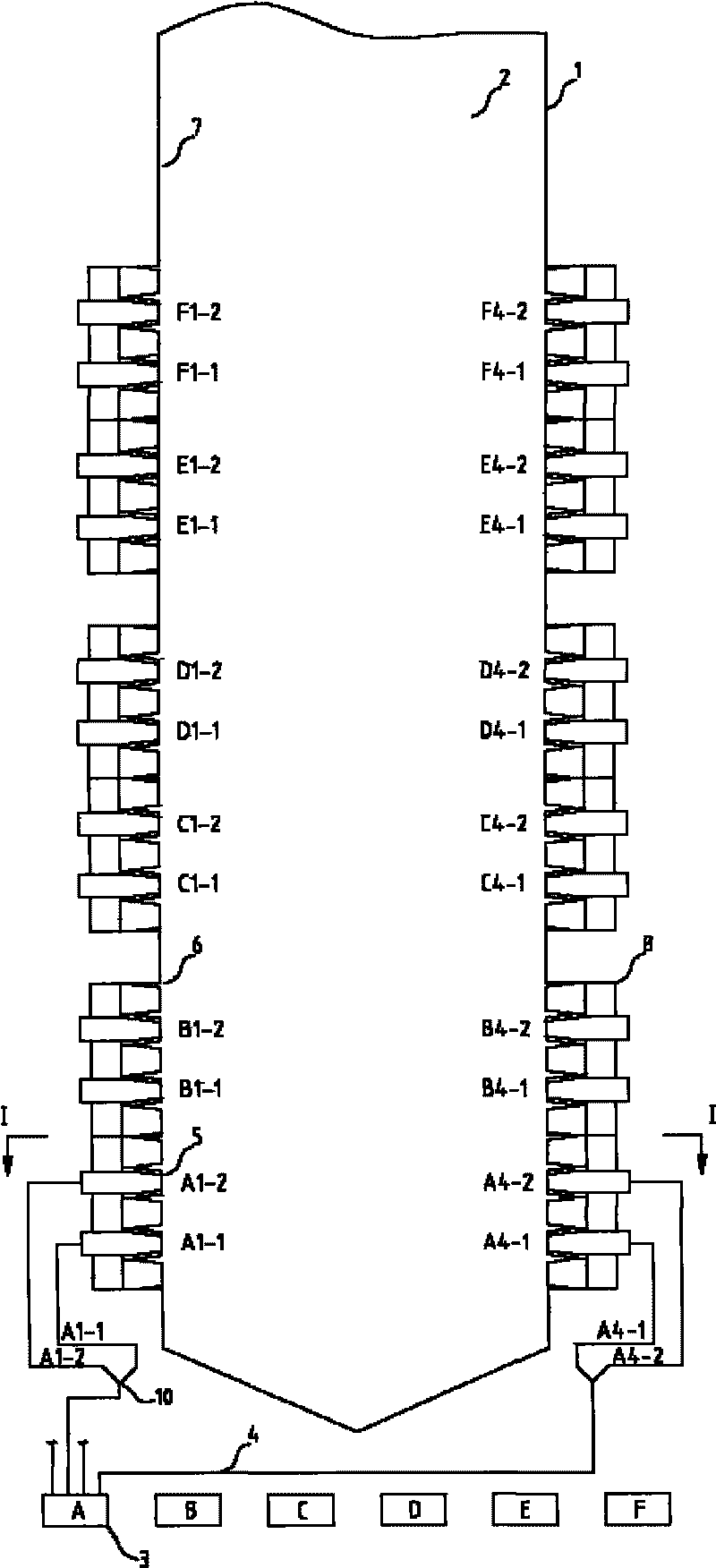

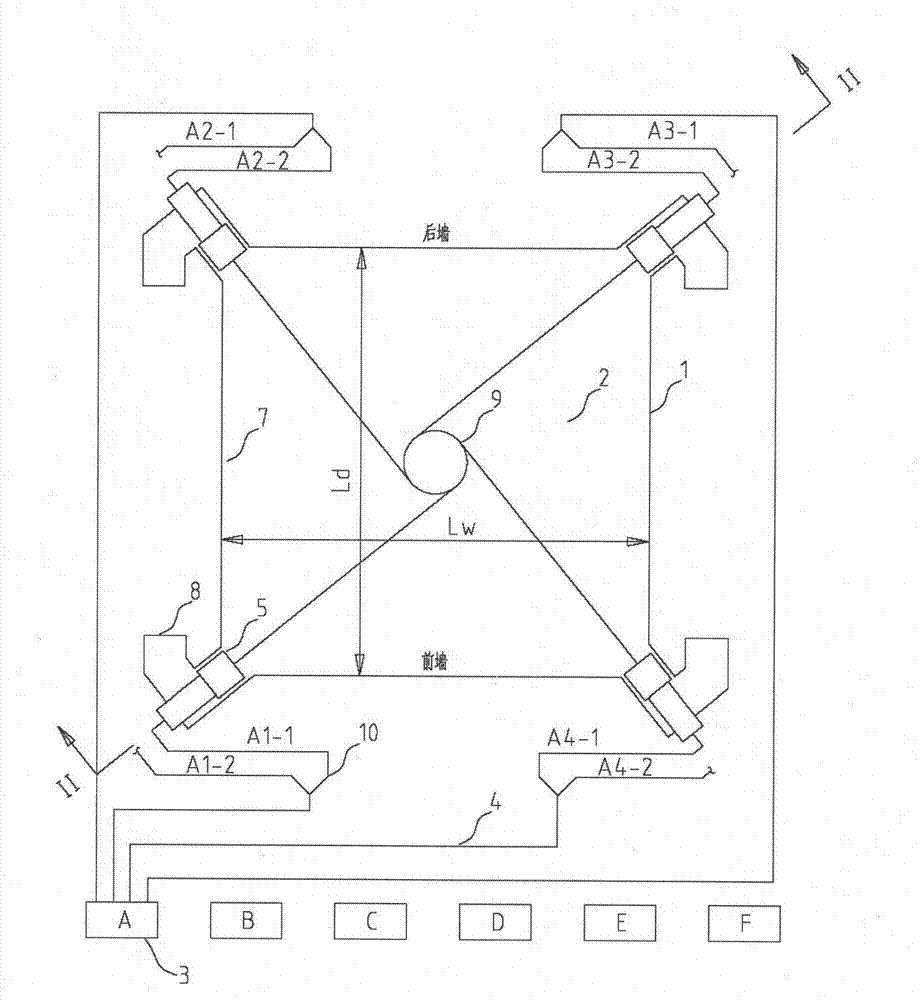

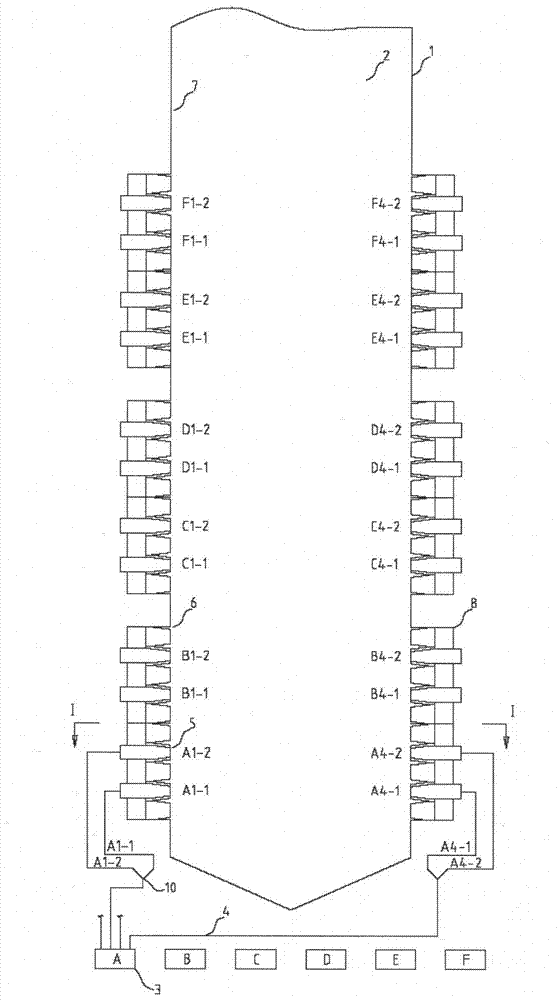

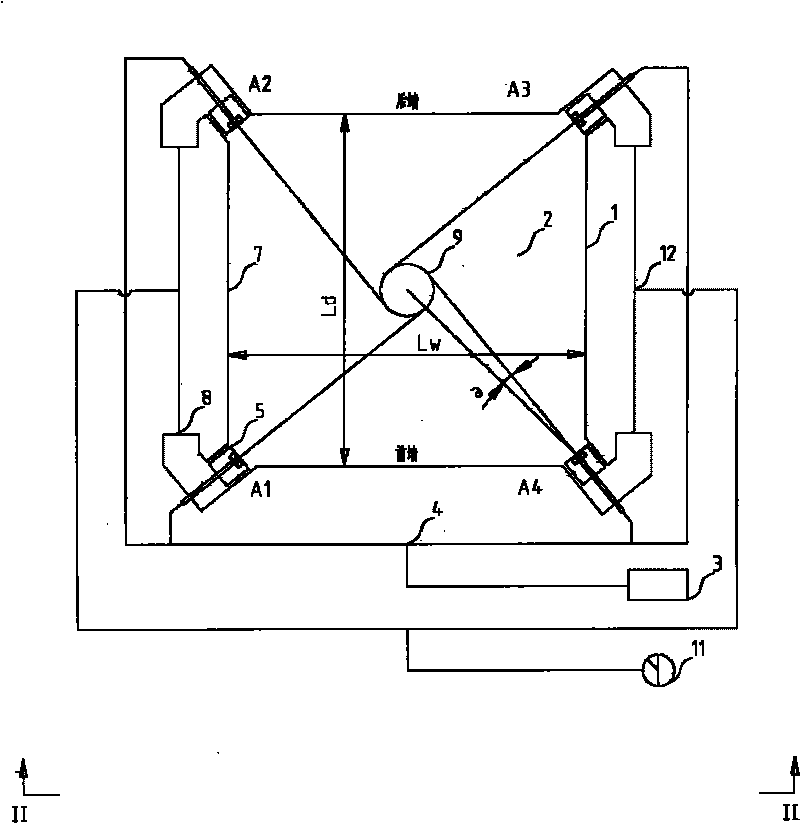

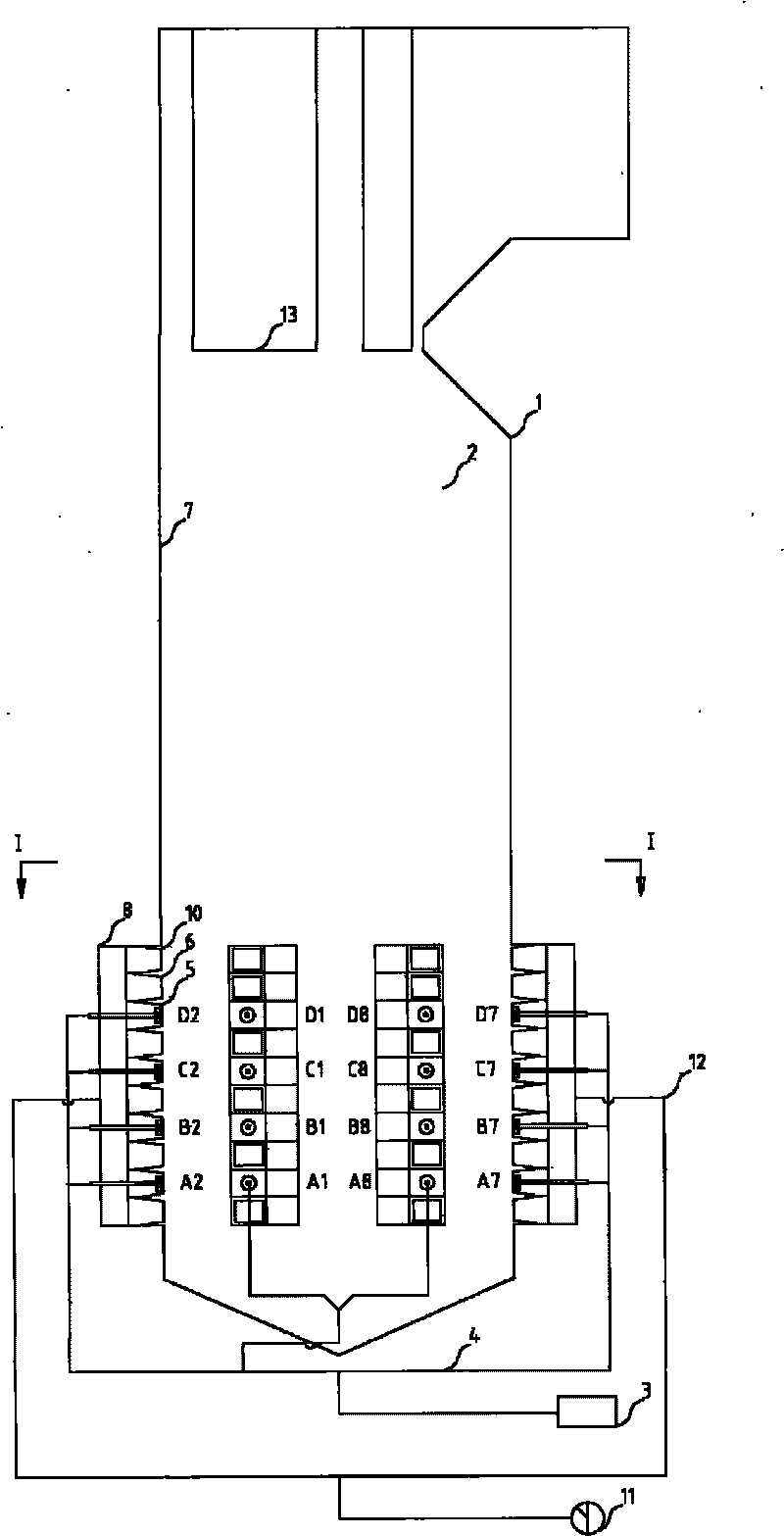

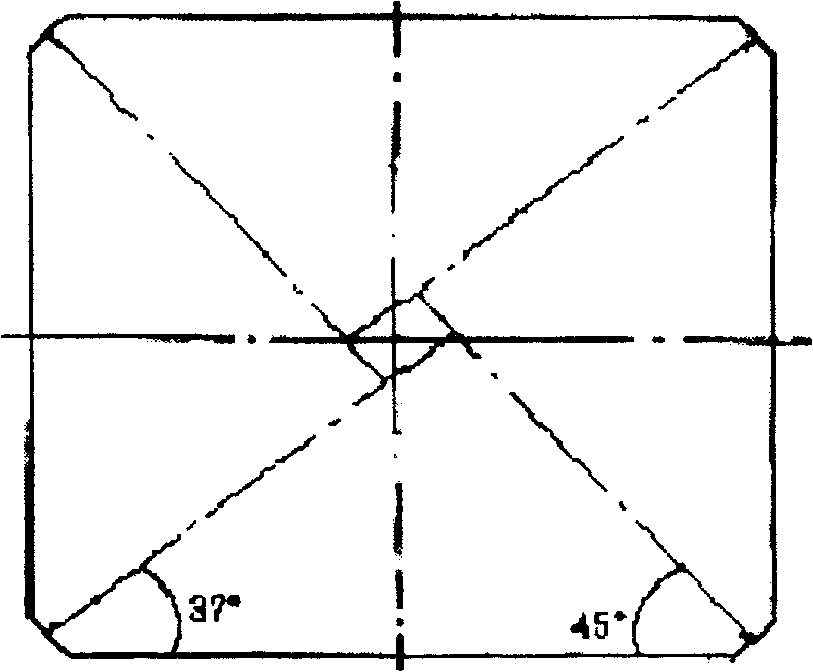

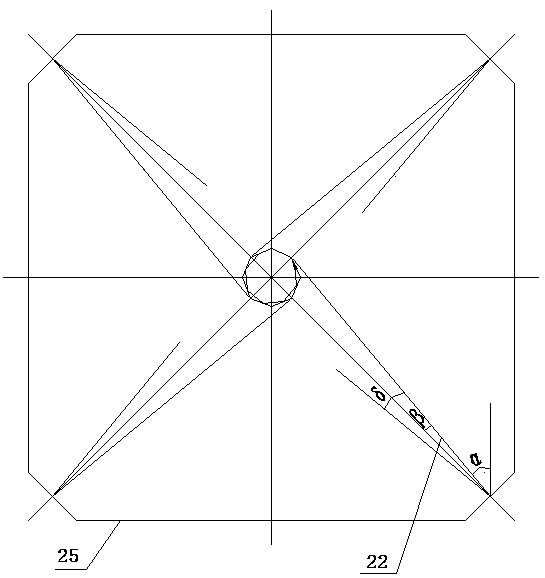

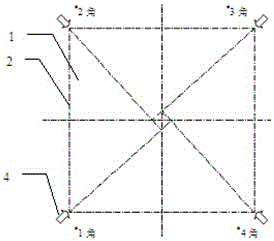

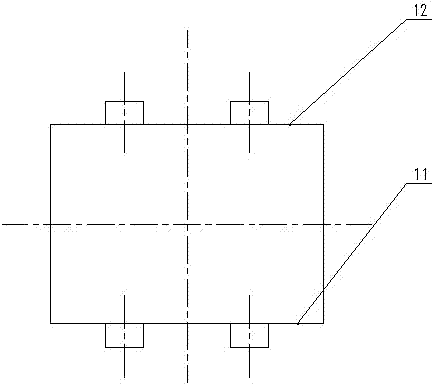

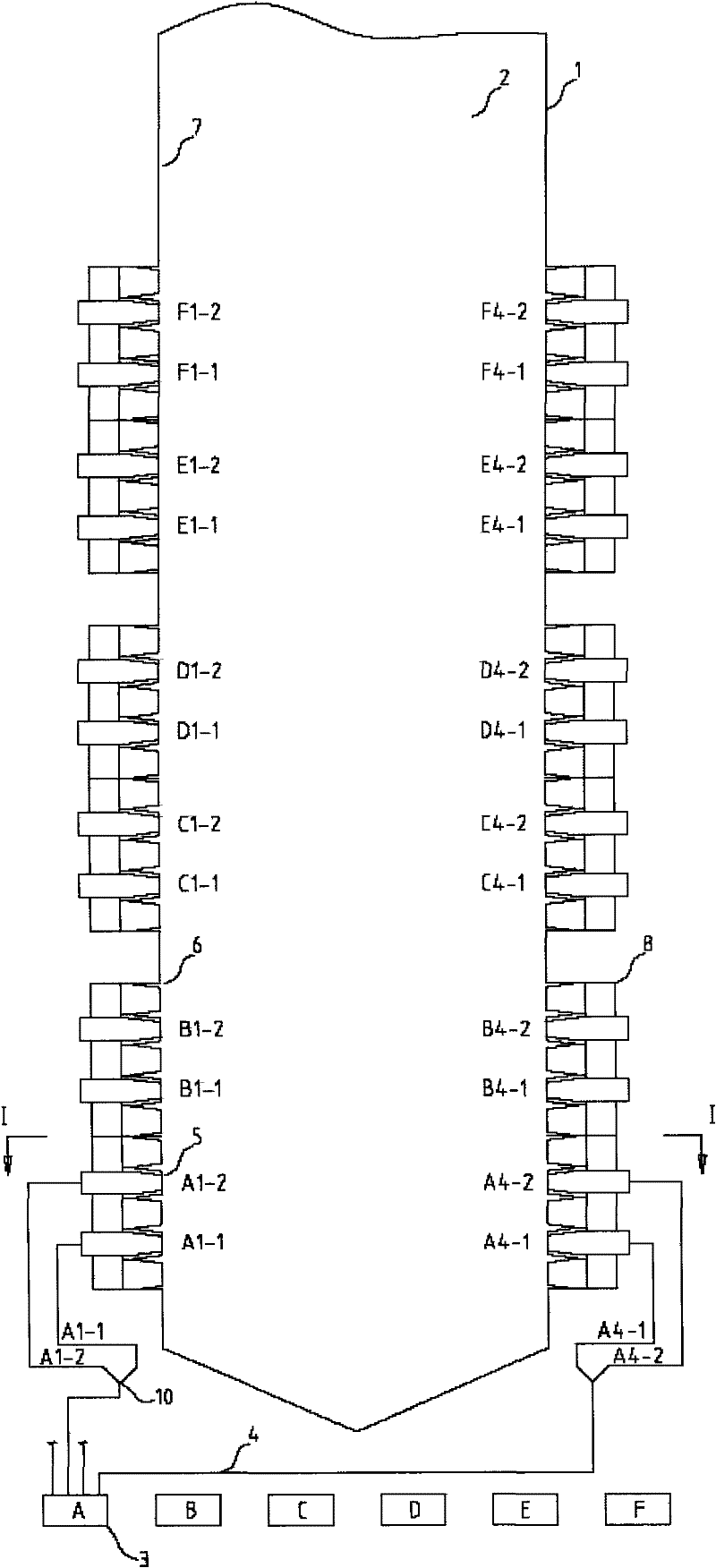

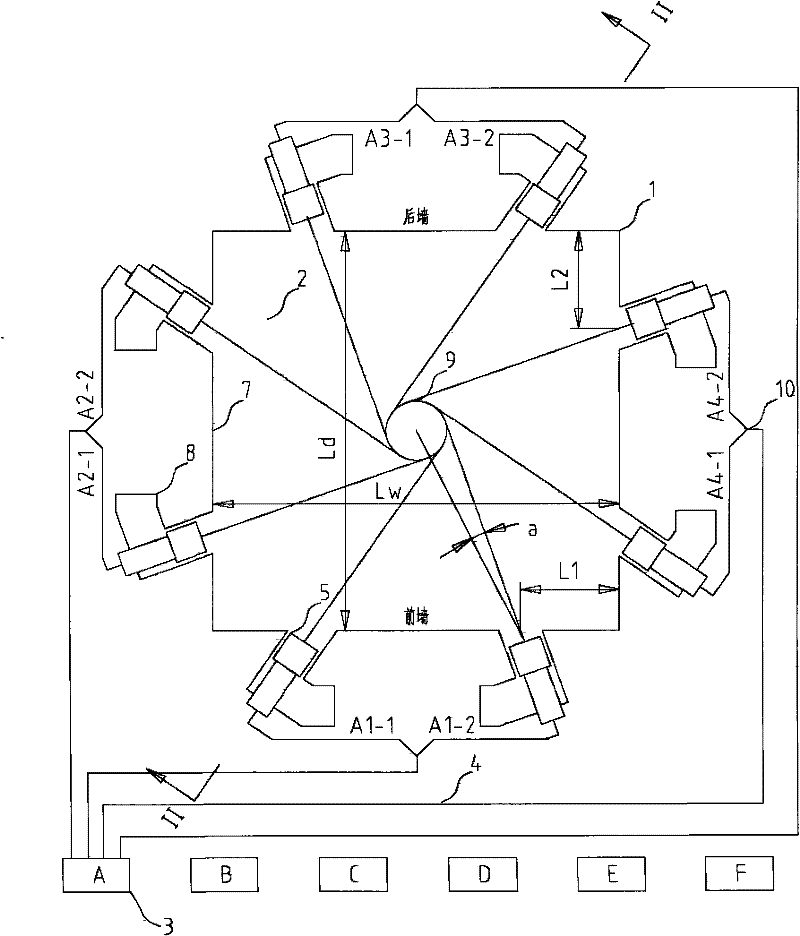

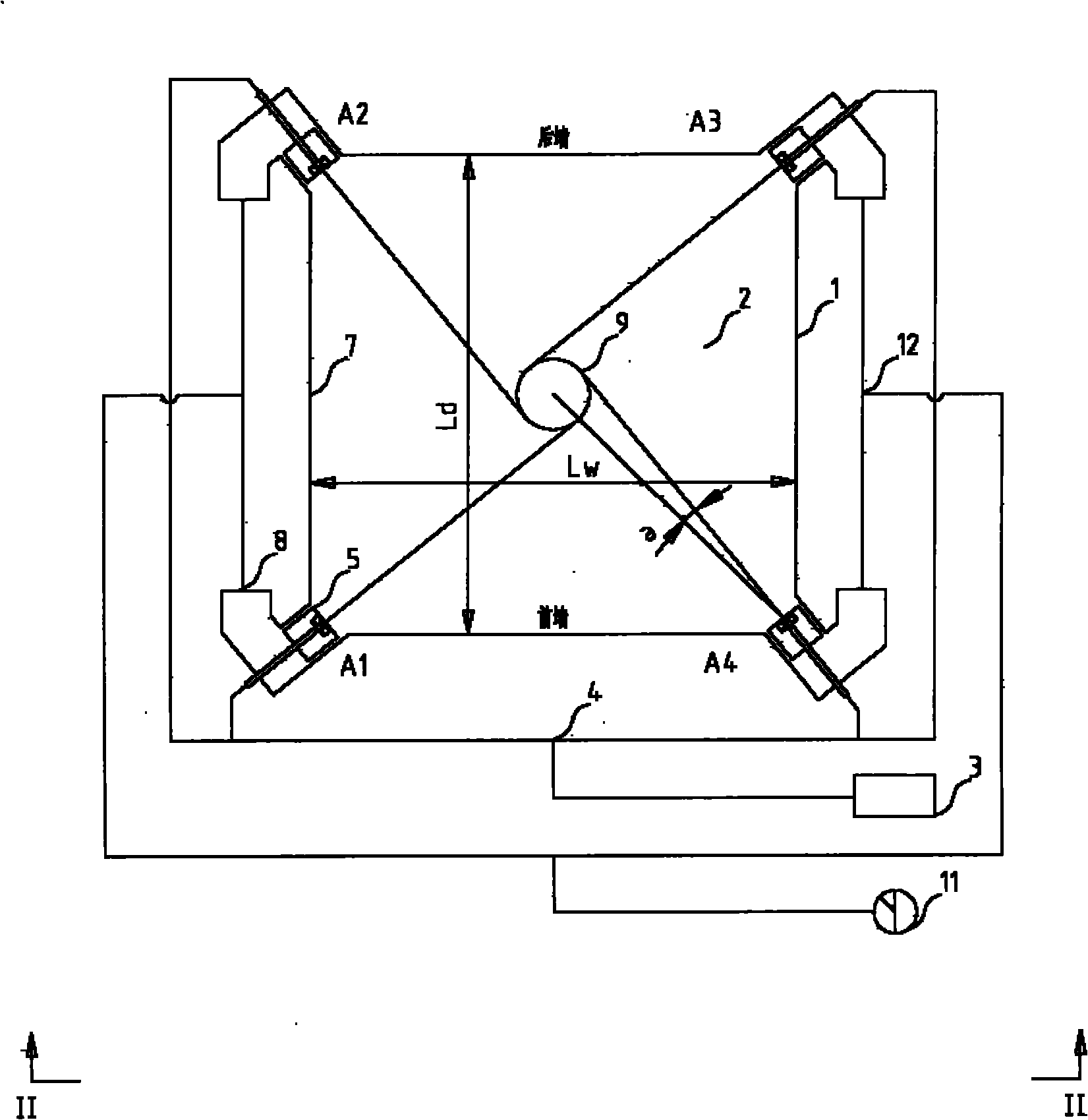

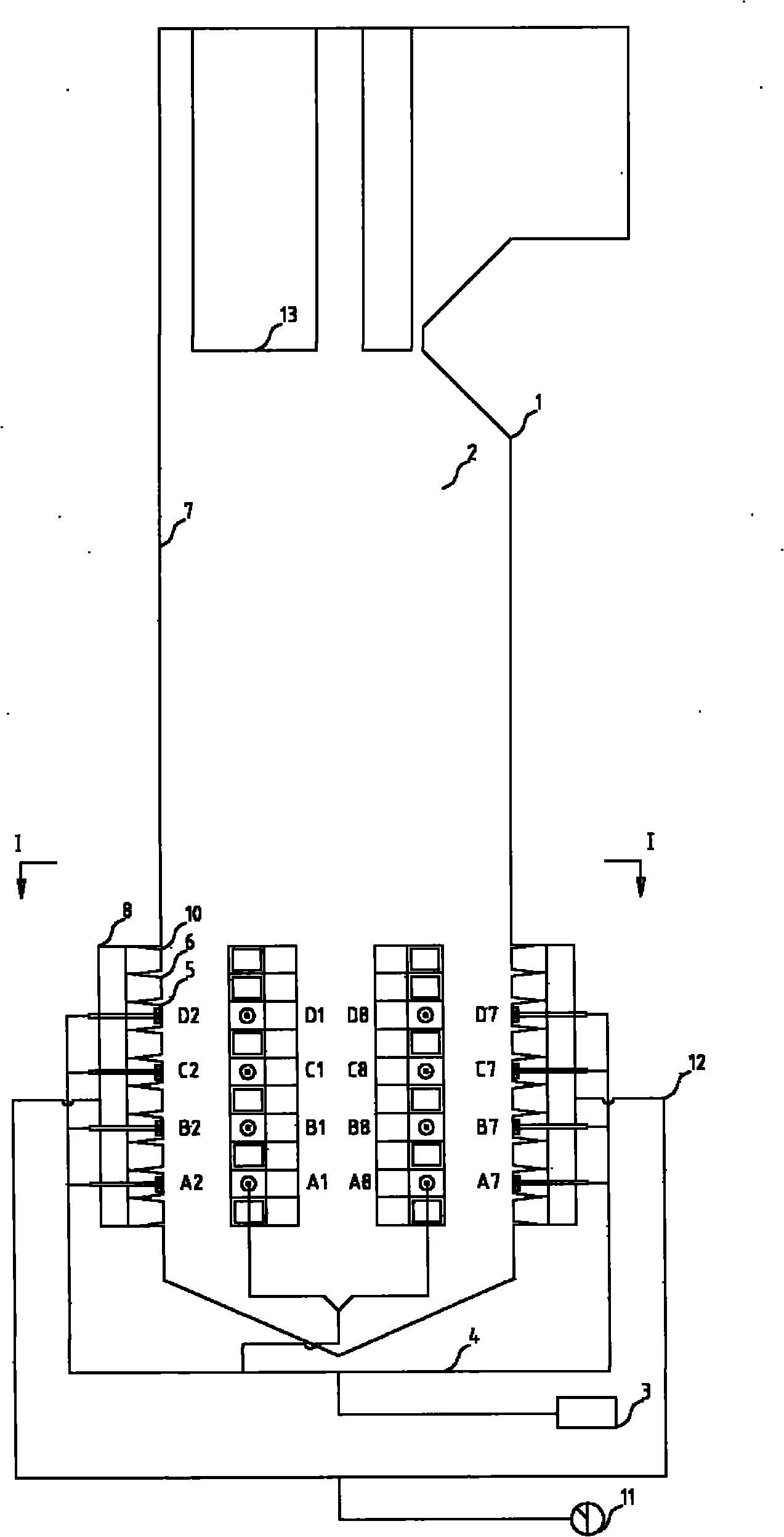

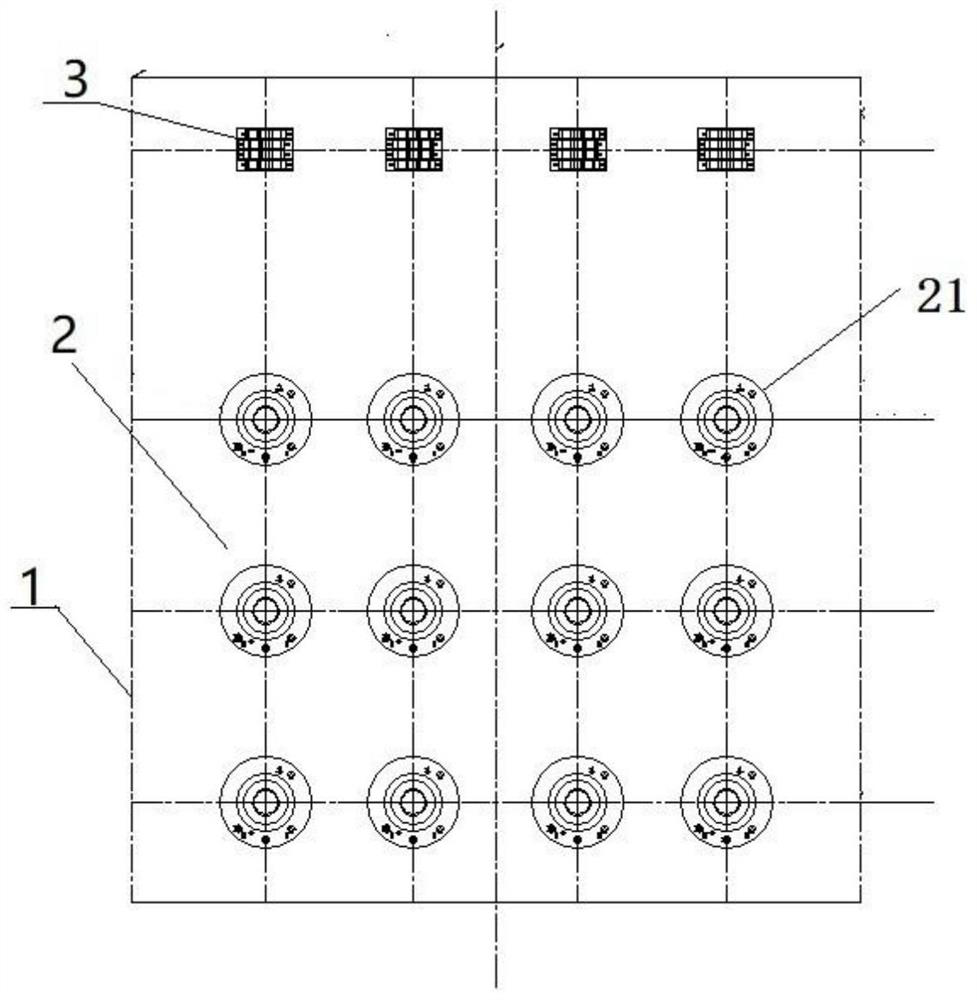

Hexagonal or octagonal tangential arrangement of anthracite burning single-fireball direct-flow combustors

ActiveCN101709871AGuaranteed to catch fire in timeReduce overall heightCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelLow loadAirflow

The invention provides hexagonal or octagonal tangential arrangement of anthracite burning single-fireball direct-flow combustors, which is characterized in that: two groups of combustors are arranged on each water-cooling wall or two groups of combustors are arranged on two opposite water-cooling walls of a hearth respectively and a group of combustors are arranged on the other two opposite water-cooling walls respectively, each group of combustors are at least divided into a small group; and each small group of combustors are vertically provided with at least two primary air pulverized nozzles and three secondary air pulverized nozzles at intervals. Each coal mill is connected with eight or six primary air pulverized nozzles which have the same level with that of the coal mill. The start and stop of each coal mill affect the running of the eight or six primary air pulverized nozzles which are on the same layer. The hexagonal or octagonal tangential arrangement of the anthracite burning single-fireball direct-flow combustors can decrease the number of the air pulverized nozzles in a single group of combustors on the premise of meeting the requirements of the thermal power of a single air pulverized nozzle and the number of the total air pulverized nozzles, allows the thermal load qHr of a wall in a combustor area to be relatively high, and guarantees the timely ignition of an pulverized anthracite flow and low-load combustion of a boiler without oil.

Owner:SHANGHAI BOILER WORKS

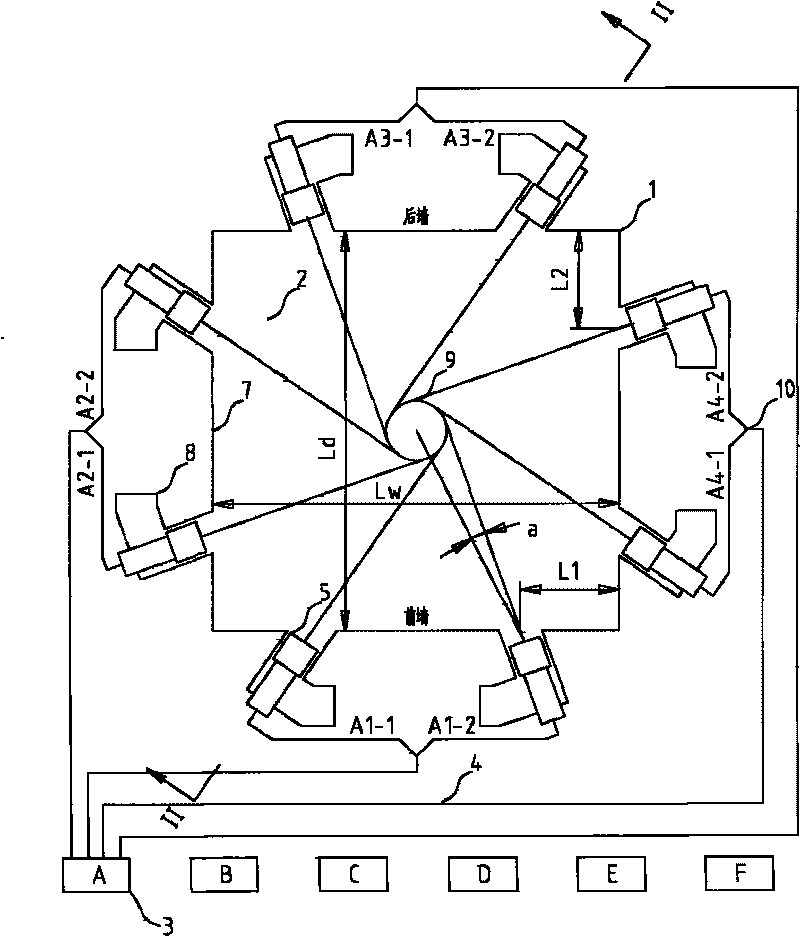

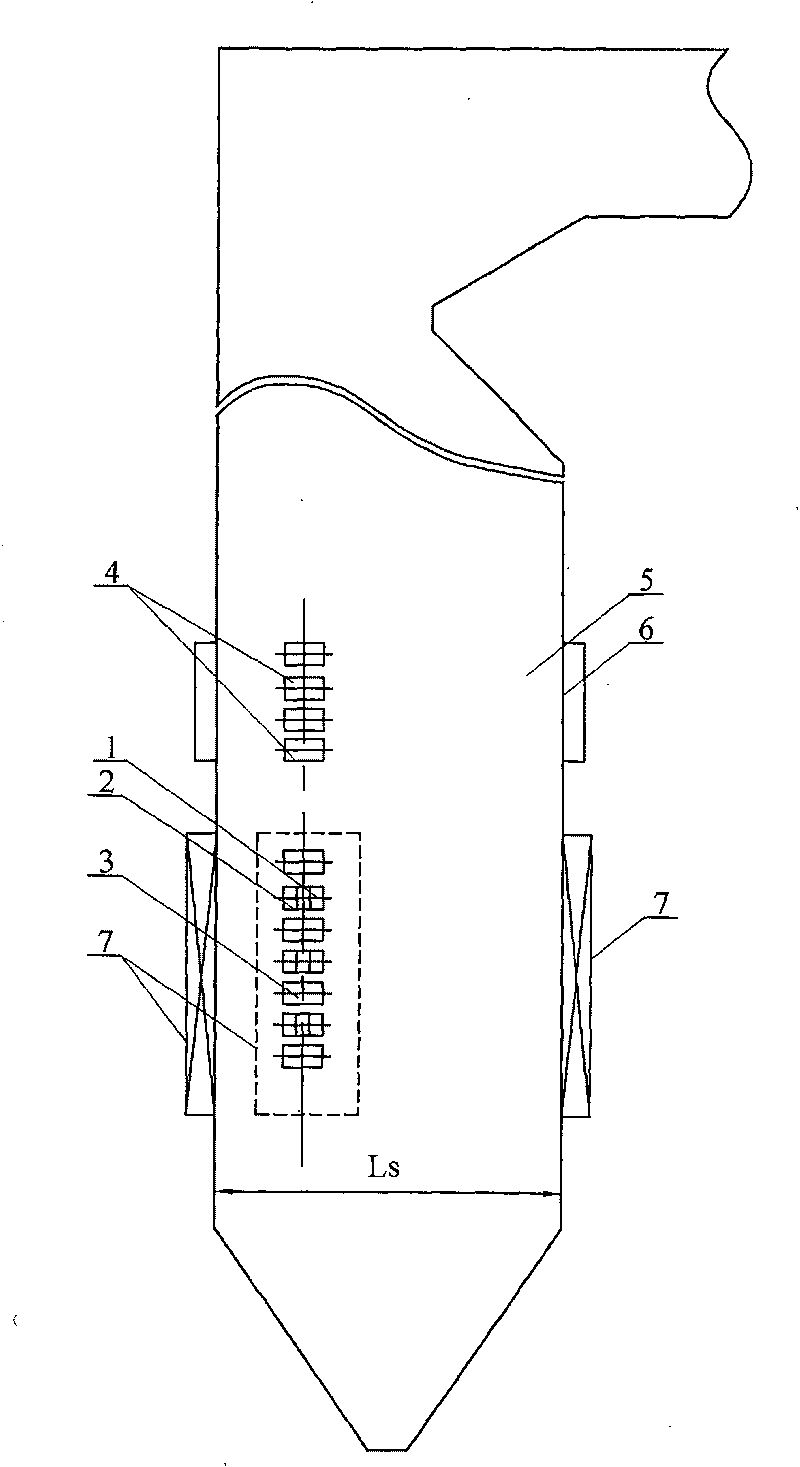

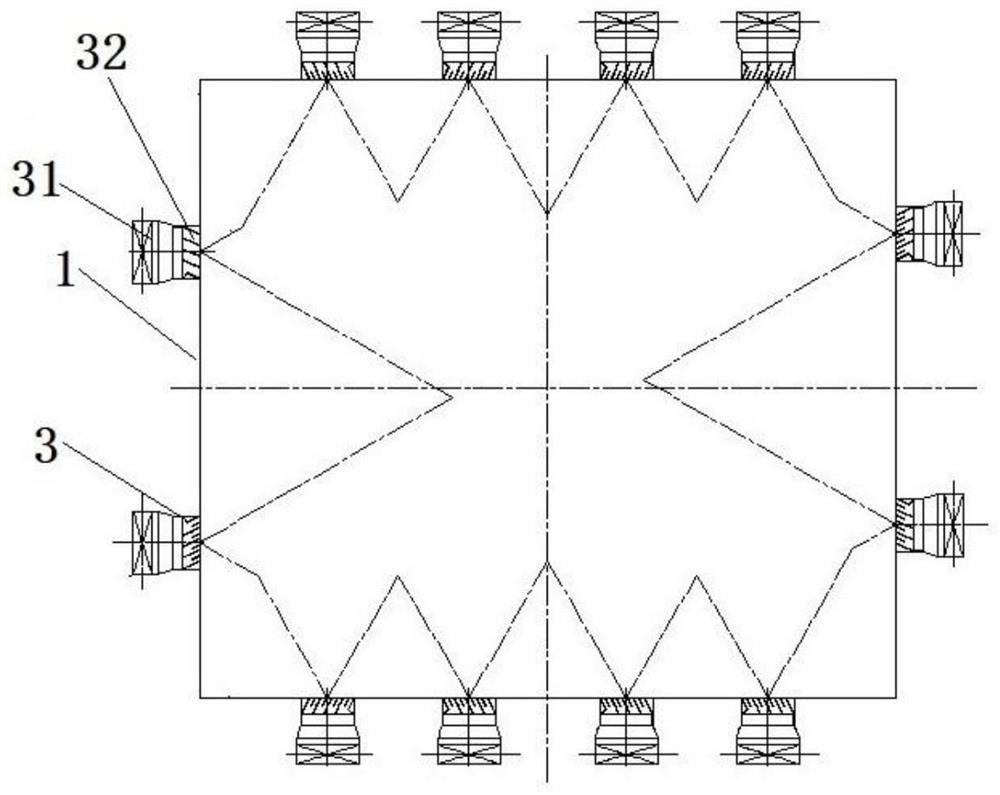

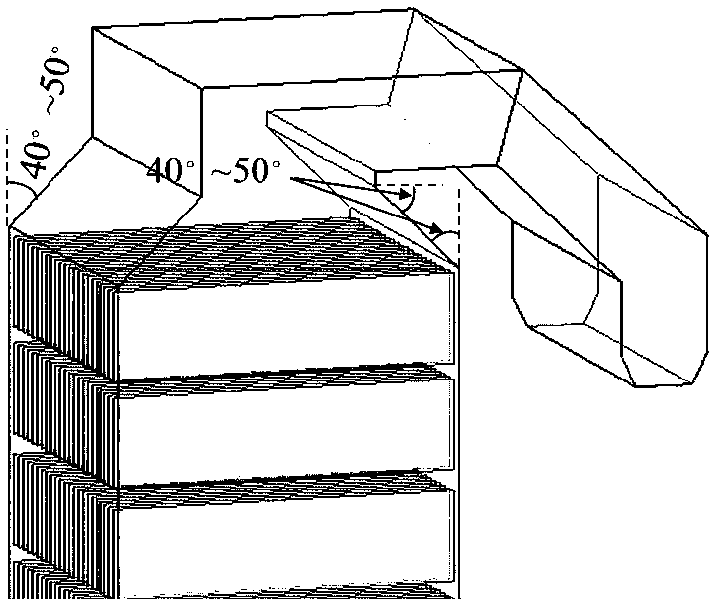

Air staged-combustion vertical and horizontal combined arrangement type over fire air system for tangential boiler

ActiveCN105114944AIncrease the lengthIncreased burnout timeCombustion apparatusCombustionCoal pipeline

The invention discloses an air staged-combustion vertical and horizontal combined arrangement type over fire air system for a tangential boiler. The air staged-combustion vertical and horizontal combined arrangement type over fire air system for the tangential boiler comprises a hearth, a hot air box, a pulverized coal pipeline, a primary air nozzle, a secondary air nozzle, a compact over fire air nozzle, a corner separation over fire air nozzle, a wall type separation over fire air nozzle and the like. According to the system, the tangential boiler is innovated in the conventional hearth height direction on the aspect of the way that over fire air is arranged at the corner, and the purposes of decreasing the excess air coefficient of a main combustion area and reducing NOx generation are realized by arranging corner separation over fire air nozzle and the wall type separation over fire air nozzle which are controlled independently on the upper portion of the main combustion area. By the adoption of the air staged-combustion vertical and horizontal combined arrangement type over fire air system, a sufficient over fire air rate, a reasonable reduction area length, good later-stage intra-boiler mixing and sufficient burn-out time can be guaranteed, smoke remaining rotation and temperature deviation can be effectively eliminated, the requirement for restraining NOx generation and the requirement for promoting pulverized coal to be burnt out are both considered, and the requirements for achieving safety operation of the boiler and being economical and environmentally friendly are met.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD

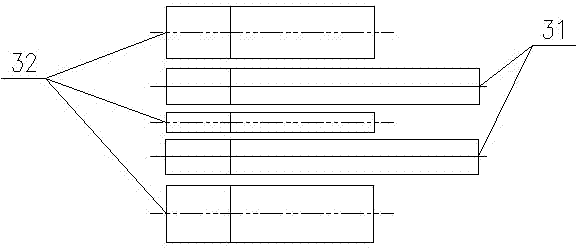

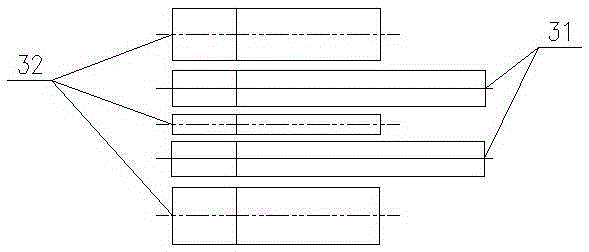

Pulverized coal shade separate arrangement mode of direct-current burner with double fireballs

ActiveCN103090368AIncrease concentrationGuaranteed not to oilCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorLow load

The invention provides a pulverized coal shade separate arrangement mode of a direct-current burner with double fireballs for burning anthracite coal. The pulverized coal shade separate arrangement mode is characterized in that each boiler is provided with eight groups of burners; the eight groups of burners are at the same level; four groups of burners form an imaginary circle inside a hearth; the other four groups of burners form another imaginary circle inside the hearth; each group of burners are divided into two small groups in the vertical direction; the first small group of burners are named as 'primary air / thick pulverized coal' burners; and the second small group of burners are named as 'primary air / thin pulverized coal' burners. The thermal load qHr of the wall surface of a burner zone is high under the premise of ensuring the power of the entire boiler; and timely inflaming of anthracite pulverized coal air flow and low-load stable combustion of the boiler without oil can be ensured.

Owner:SHANGHAI BOILER WORKS

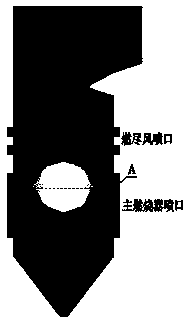

Efficient low-pollution W-shaped flame boiler OFA (over fire air) device and method

ActiveCN103672867ASimple structureReduce construction costsAir supply regulationNon-combustible gases/liquids supplyCycloneAir volume

The invention relates to an efficient low-pollution W-shaped flame boiler OFA (over fire air) device and method. Conventional large-capacity W-shaped flame boiler OFA equipment occupies large space and is complex in structure. The OFA device comprises main combustion zone OFA nozzles, wing wall OFA nozzles, an upper hearth, an annular air duct and an air box provided with OFA layers, and is characterized in that one end of each main combustion zone OFA nozzle is fixed on the water-cooled wall, close to the throat position, of the upper hearth, and the other end of each main combustion zone OFA nozzle is fixed on the air box; one end of each wing wall OFA nozzle is connected onto the annular air duct through a pipeline, and the other end of each wing wall OFA nozzle is connected onto the water-cooled wall, close to the side wall position, of the upper hearth; and each OFA nozzle comprises a center air duct, an outer annular air duct and a cyclone, and the center air ducts are located in the outer annular air ducts. The OFA method is characterized in that OFA is fed to the OFA nozzles, and the OFA volume accounts for 19%-25% of total volume of air entering the boiler. The efficient low-pollution W-shaped flame boiler OFA device is simple in structure and can guarantee full mixing of OFA and main stream smoke.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

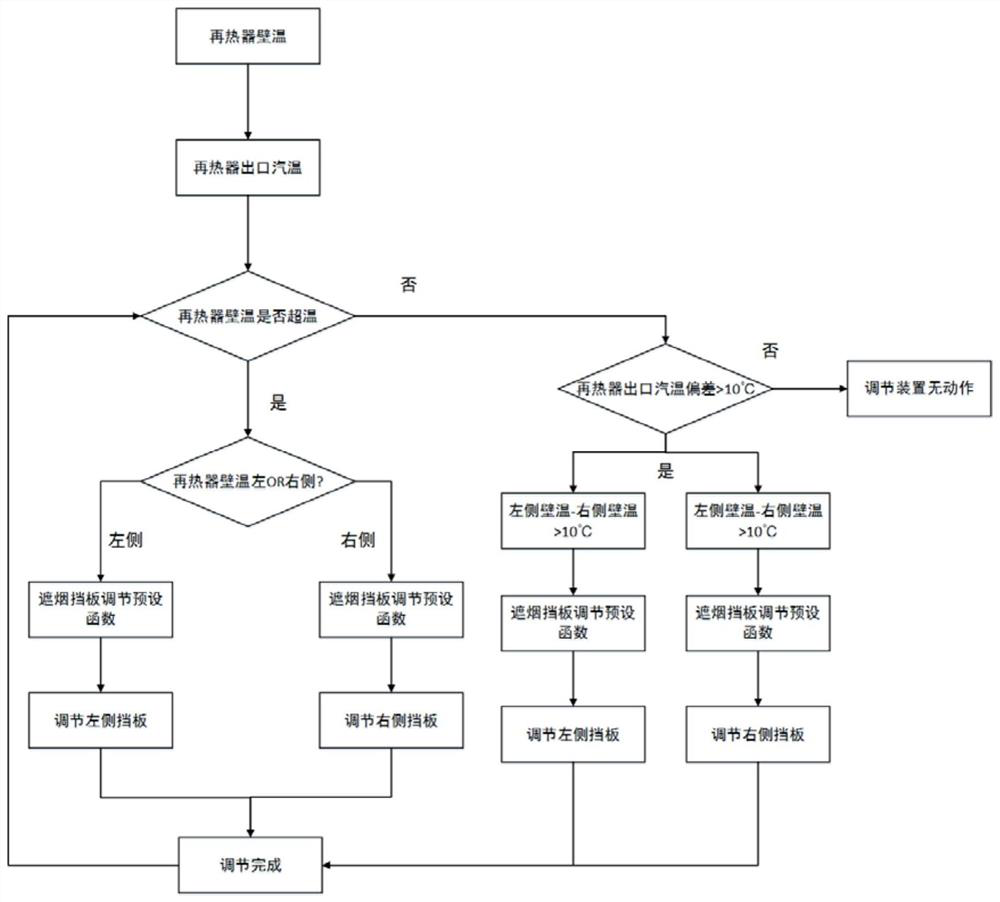

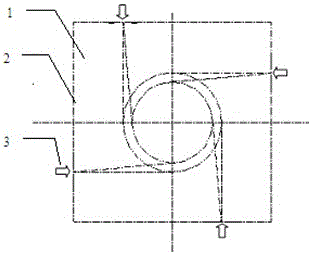

Method for adjusting deviation of two sides of reheating steam temperature of four-corner tangential firing boiler by SOFA air doors

ActiveCN109578992AReduce smoke temperature deviationReduce hot spotsCombustion apparatusWater flowEngineering

The invention relates to a method for adjusting deviation of two sides of the reheating steam temperature of a four-corner tangential firing boiler by SOFA air doors. The method for adjusting the deviation of the two sides of the reheating steam temperature of the four-corner tangential firing boiler by the SOFA air doors comprises the steps that horizontal pendulum angles of the SOFA air doors are adjusted; when the deviation of two sides of the reheating steam temperature is removed, vertical pendulum angles of the SOFA air doors are no longer adjusted; when the deviation of two sides of thereheating steam temperature is not removed, the vertical pendulum angles of the SOFA air doors are adjusted; and when the vertical pendulum angles of the SOFA air doors are adjusted, firstly, the vertical pendulum angles of a second SOFA air door and a third SOFA air door are adjusted obliquely upwards, and then, the vertical pendulum angles of a first SOFA air door and a fourth SOFA air door areadjusted to horizontal positions. The adjustment of the reheating steam temperature and temperature-decreased water flow is realized through the cooperative cooperation of the horizontal pendulum angles and the vertical pendulum angles of the SOFA air door, through the nonsynchronous adjustment of the horizontal pendulum angles and the vertical pendulum angles, the deviation of two sides of smoketemperature of the four-corner tangential firing boiler is rapidly reduced, the high-temperature point of the reheater pipe wall is reduced, the problems of large deviation of a reheater outlet stream temperature and the unbalanced temperature-decreased water flow on two sides are solved, finally, the average stream temperature of the reheater outlet is improved, and the temperature-decreased water flow of the reheater is reduced.

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Hexagonal or octagonal tangential arrangement of fuel-oil or fuel-gas single-fireball direct-flow combustors

ActiveCN101709870AReduce in quantityReduce overall heightCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorJet flow

The invention provides hexagonal or octagonal tangential arrangement of fuel-oil or fuel-gas single-fireball direct-flow combustors, which is characterized in that: six or eight groups of combustors are arranged in a hearth; each group of combustors are vertically provided with at least two oil guns or gas guns at intervals, two fuel blast nozzles and three secondary blast nozzles; the fuel oil or the fuel gas at a fuel oil or fuel gas operation station outlet in front of the furnace is connected with at least two layers of oil guns or gas guns arranged on four walls of a boiler through fuel oil or fuel gas pipelines; and each layer of oil guns or gas guns consist of six or eight oil guns or gas guns which are in the same level but not in the same group. The hexagonal or octagonal tangential arrangement of the fuel-oil or fuel-gas single-fireball direct-flow combustors can ensure that the distance between the uppermost and undermost two oil guns or gas guns and the thermal load of the walls of the combustor area are controlled in ideal ranges, the total height of the boiler is decreased and the manufacturing cost of the boiler is greatly reduced. Because air supplying conditions on two sides of a jet flow are good, flames of the oil guns or gas guns are not easy to attach to the walls and the safety of the work of a water-cooling wall is improved.

Owner:SHANGHAI BOILER WORKS

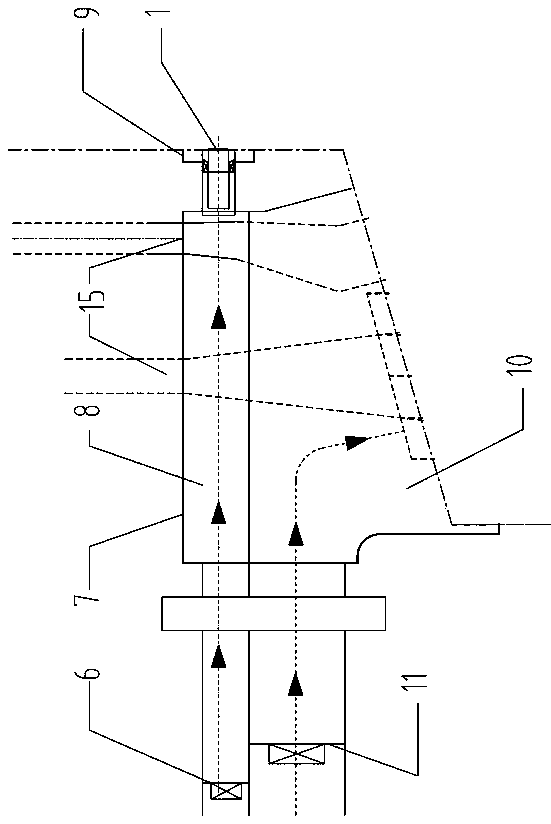

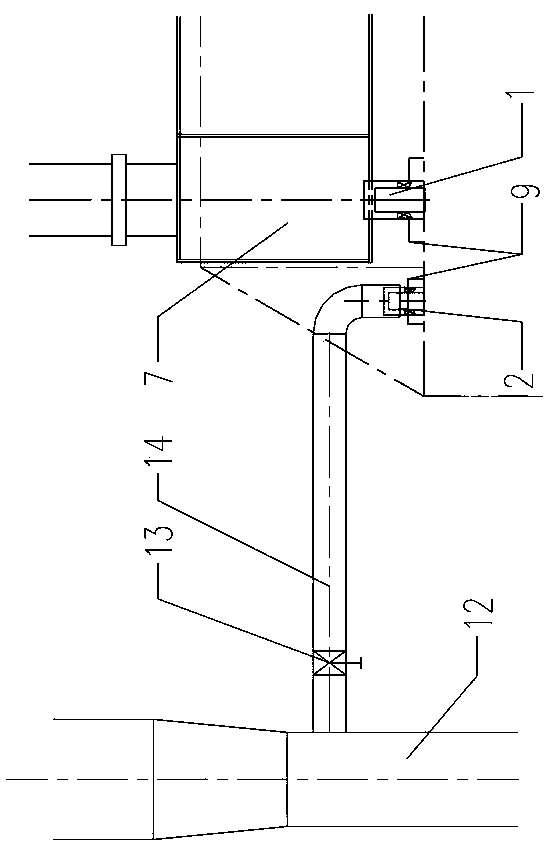

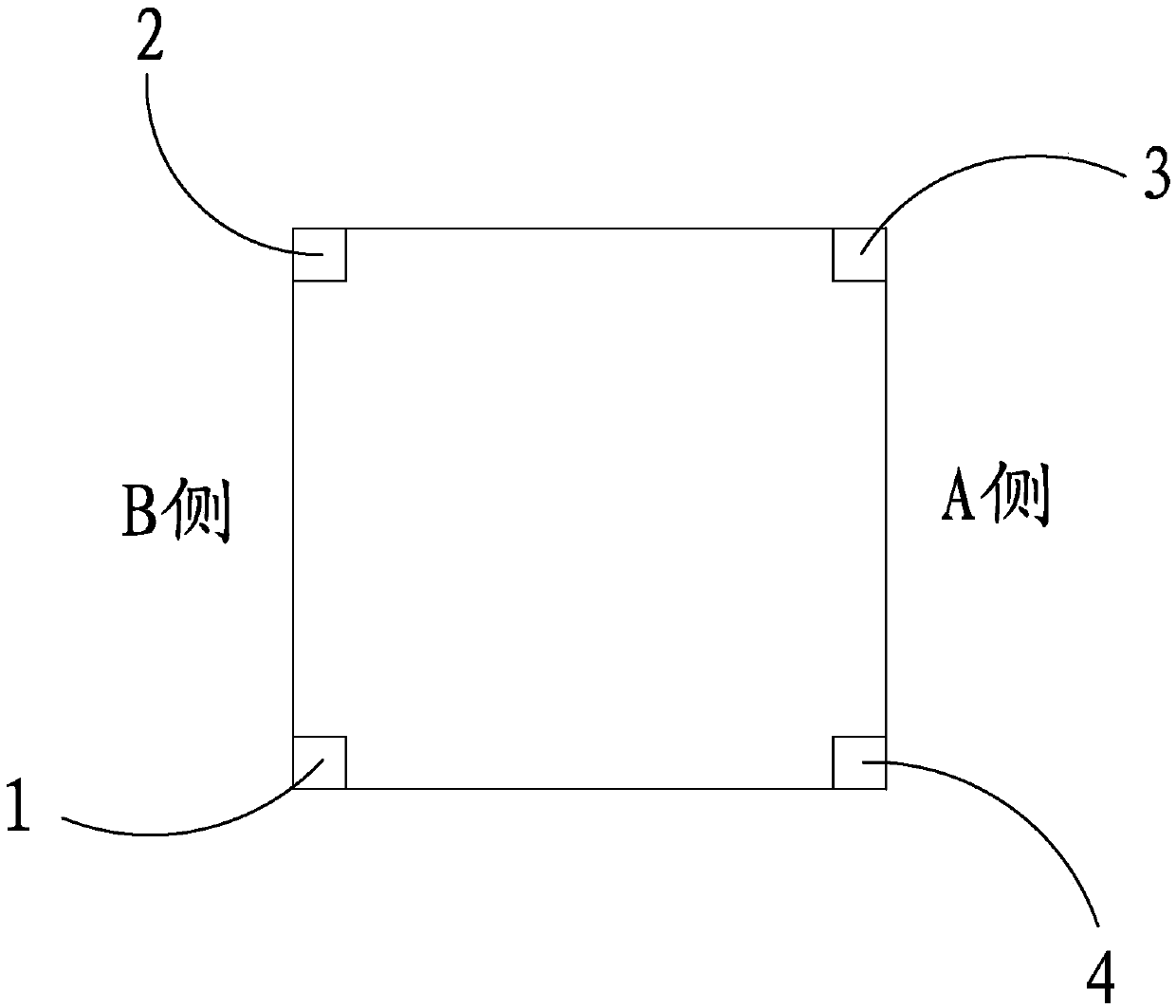

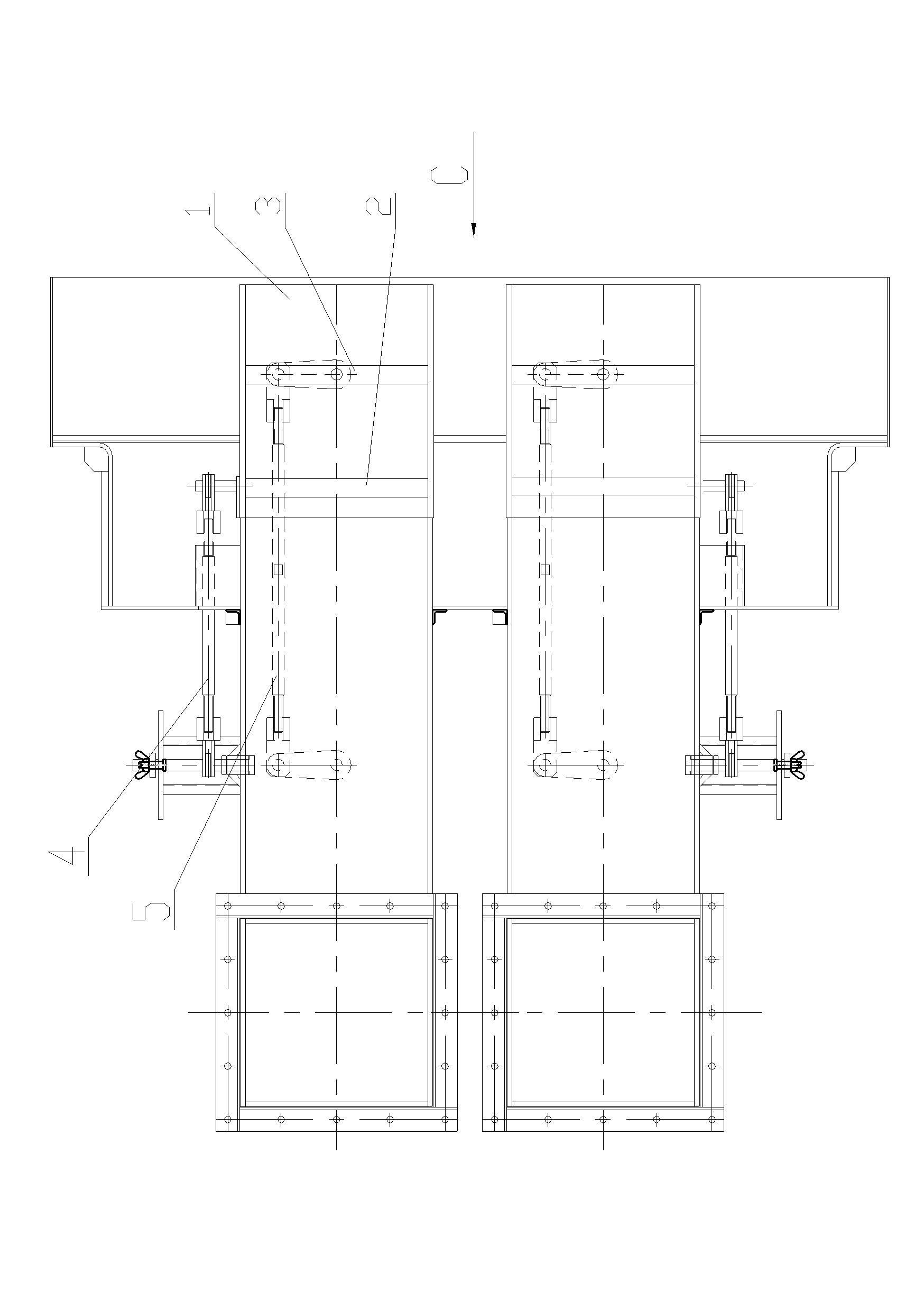

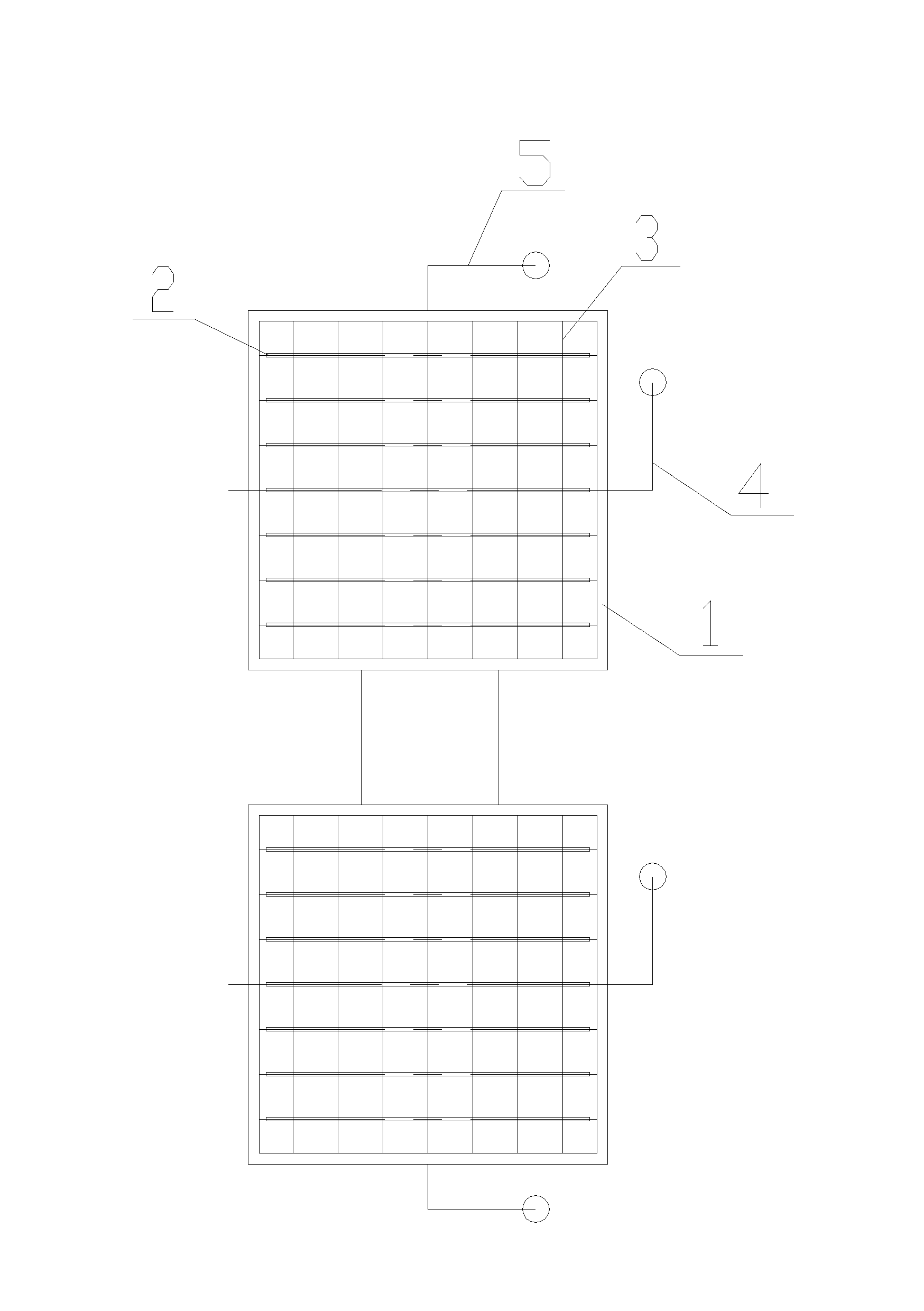

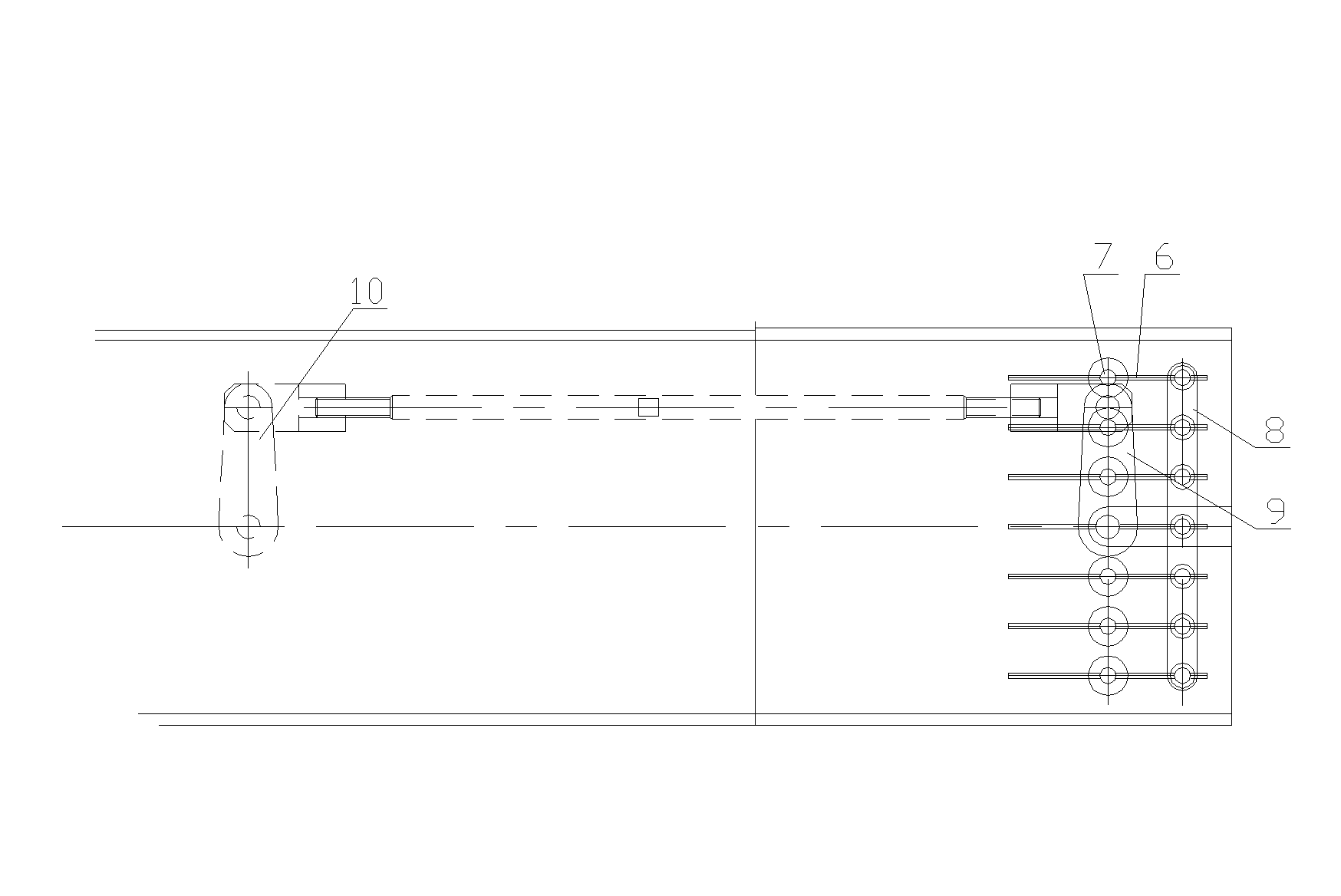

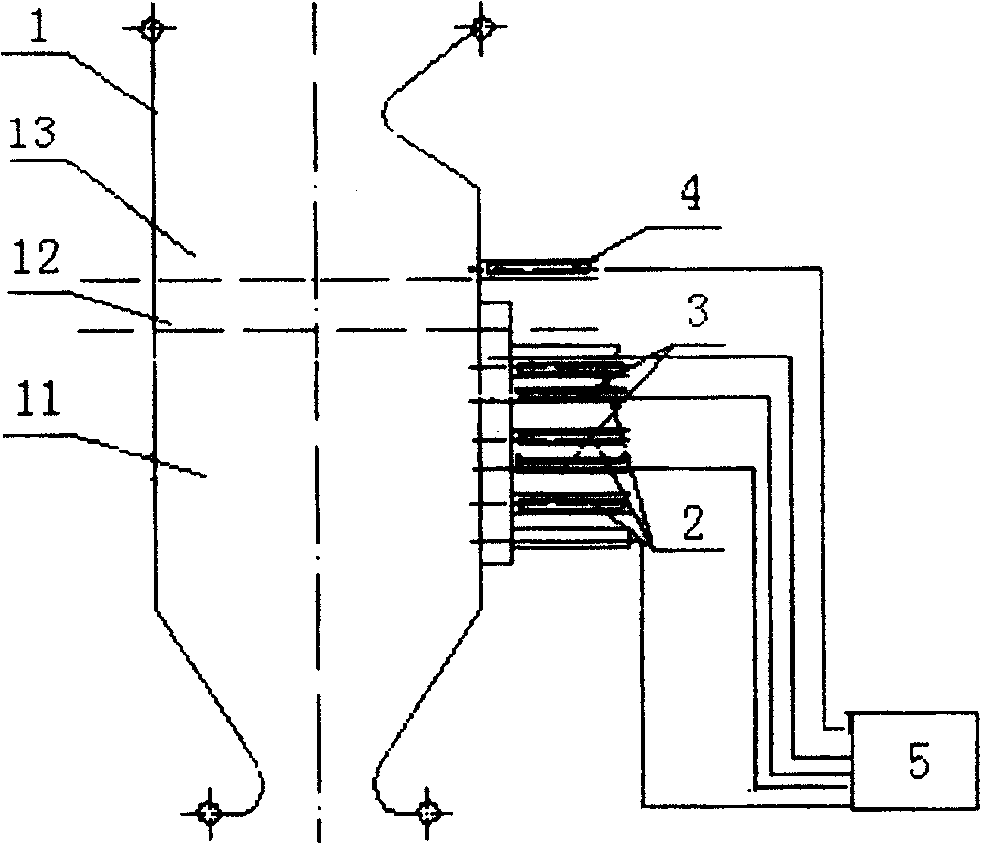

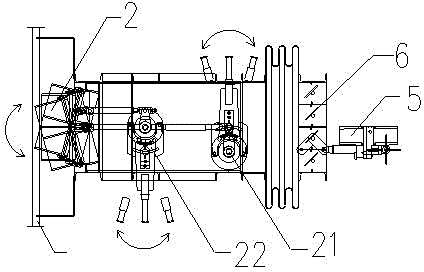

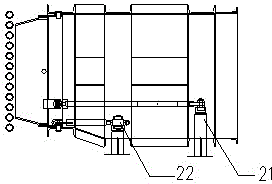

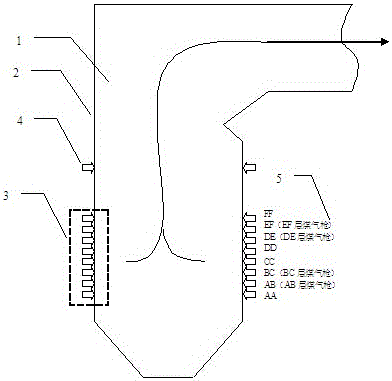

Final-stage reheater temperature adjusting device and operation method thereof

PendingCN111810926AReduce fouling and slaggingAlleviate the phenomenon of contamination and slagging on the heating surfaceSteam superheatersSteam generation using hot heat carriersHydraulic cylinderDrive wheel

The invention discloses a final-stage reheater temperature adjusting device and an operation method thereof. The final-stage reheater temperature adjusting device comprises a controller, a rotating motor, a driving wheel, a driven wheel, a hydraulic cylinder, a hydraulic cylinder piston rod, a smoke shielding baffle and a power box used for providing electric energy, wherein the smoke shielding baffle is located between a high-temperature superheater in a boiler horizontal flue and a final-stage reheater, an output shaft of the rotating motor is connected with the driving wheel, the driving wheel is matched with the driven wheel, the and driven wheel is connected with the upper end of the smoke shielding baffle; one end of the hydraulic cylinder piston rod is matched with the hydraulic cylinder, and the other end of the hydraulic cylinder piston rod is inserted into the boiler horizontal flue and then connected with the smoke shielding baffle; and the controller is connected with the control end of a piston cylinder and the control end of the rotating motor. According to the device and the operation method of the device, the phenomenon of contamination and slagging of the heating surface of the final-stage reheater in the long-term high-load operation state of the boiler can be effectively relieved, and the operation safety and reliability of a unit are improved.

Owner:HUANENG POWER INTERNATIONAL +1

Nozzle structure for overfired air of boiler combustor

The invention provides a nozzle structure for overfired air of a boiler combustor. Combustion of a boiler can be subjected to fine adjustment, so that coal powder in the boiler can be combusted fully, and simultaneously low NOx emission can be realized, so that smoke temperature deviation at the outlet of a hearth is reduced. The nozzle structure comprises a pipeline, wherein swing blades are arranged in the outlet region of the pipeline. The nozzle structure is characterized in that the swing blades are classified into a longitudinal swing blade component and a transverse swing blade component which are positioned in different planar regions; and the longitudinal swing blade component is connected with a longitudinal swing pull rod; and the transverse swing blade component is connected with a transverse swing pull rod.

Owner:WUXI HUAGUANG BOILER

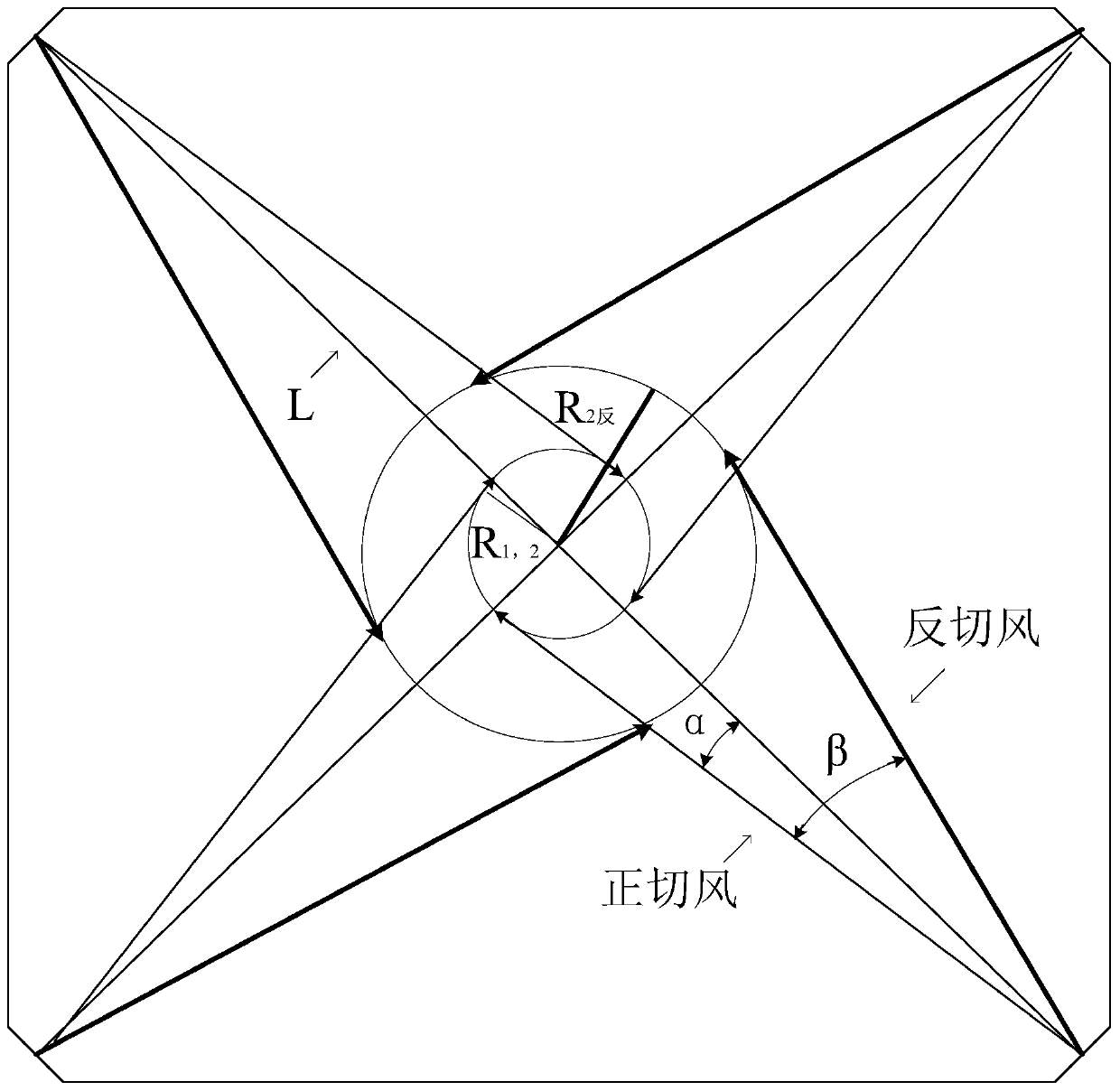

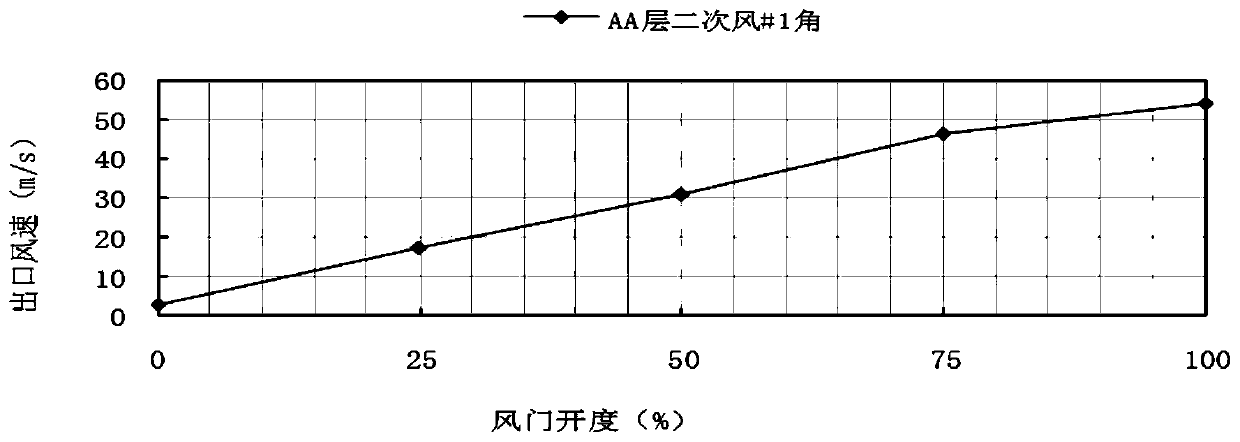

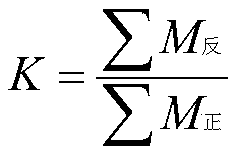

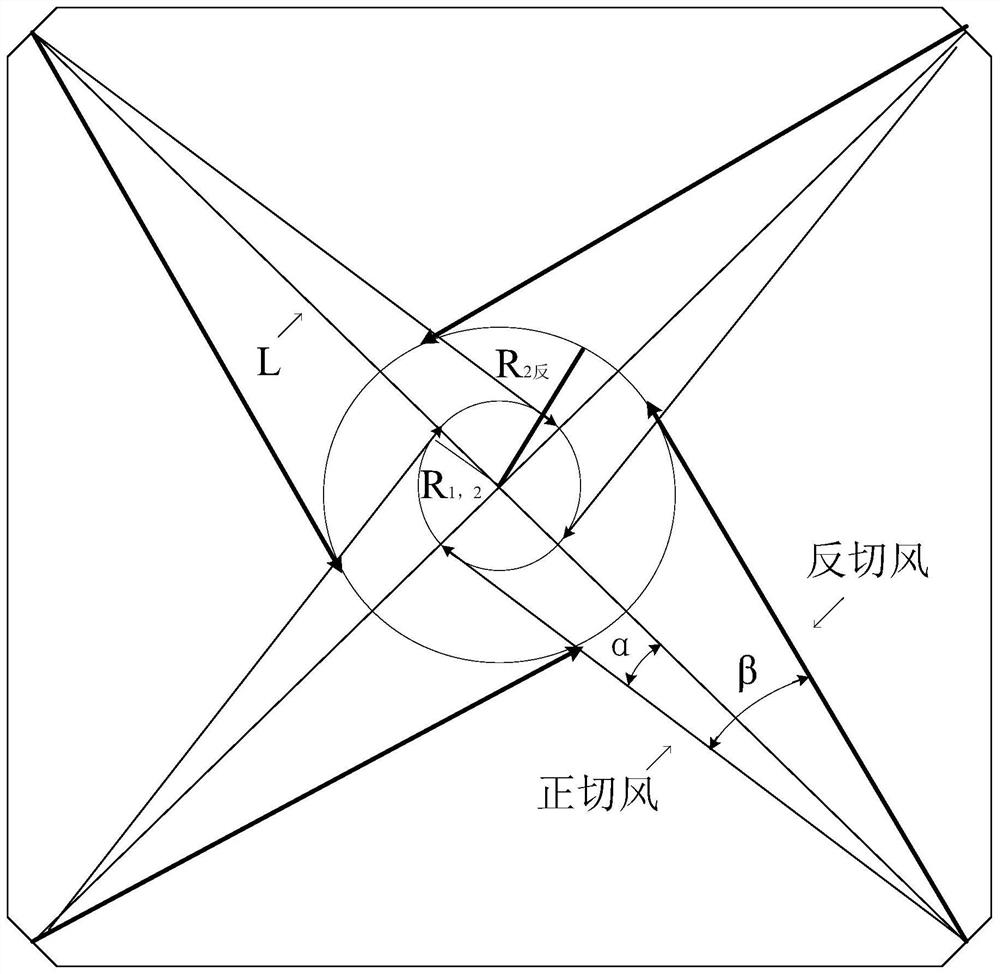

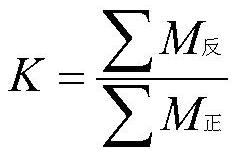

Boiler over-fire air adjusting method based on momentum moment

ActiveCN111550820ASimple methodSimplify workflow and workloadAir supply regulationAir/fuel supply for combustionFlueThermal state

The invention relates to a boiler over-fire air adjusting method based on momentum moment. According to the technical scheme, the method comprises steps as follows: burner momentum moment in oppositerotating directions in a main burning zone is summated to obtain reverse tangent wind momentum moment; burner momentum moment in the same rotating direction in the main burning zone is summated to obtain tangent wind momentum moment; a ratio of the sum of the reverse tangent wind momentum moment to the sum of the tangent wind momentum moment is obtained, and a reverse tangent angle of over-fire air is adjusted through an over-fire air adjusting mechanism until the ratio is in a range of 0.8-1.2. According to the method, a thermal state adjusting effect is realized by a cold state test, workingprocess and workload are simplified, and working efficiency is greatly increased; by adjustment for the boiler over-fire air, a rotary cutting effect of the over-fire air is improved, residual rotation of a boiler is eliminated, flue gas in a horizontal flue of the boiler is uniformly distributed, finally, dust is accumulated in the horizontal flue uniformly, besides, the falling dust has no influence on boiler disturbance, negative pressure avoids fluctuating sharply, flue gas temperature difference and steam temperature difference of the horizontal flue are reduced, and safe operation of the boiler is improved.

Owner:CENT CHINA BRANCH OF CHINA DATANG CORP SCI & TECH RES INST CO LTD

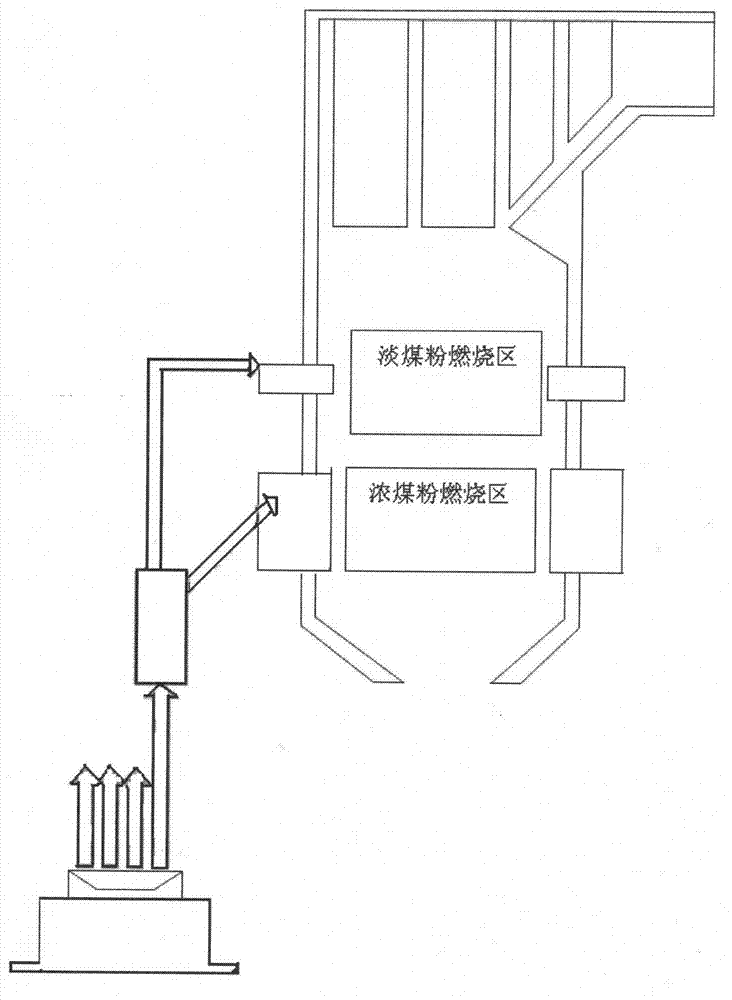

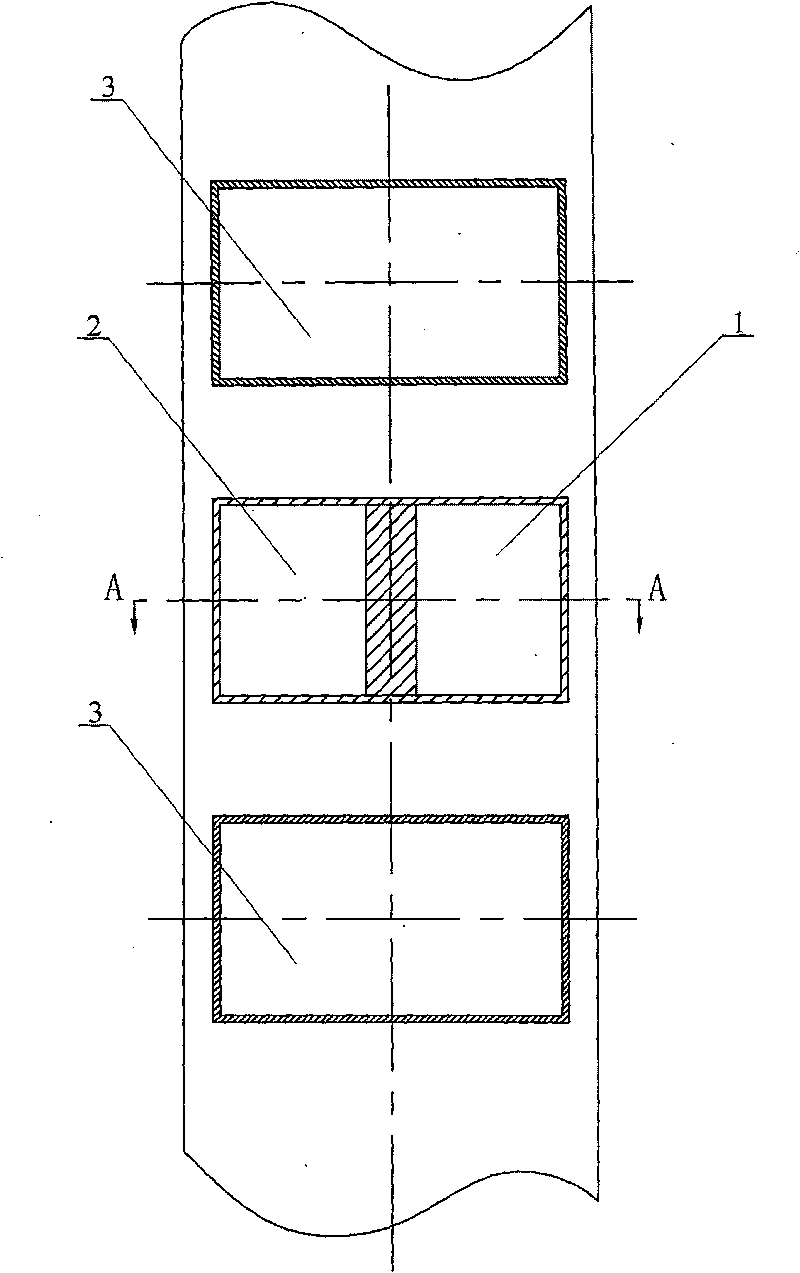

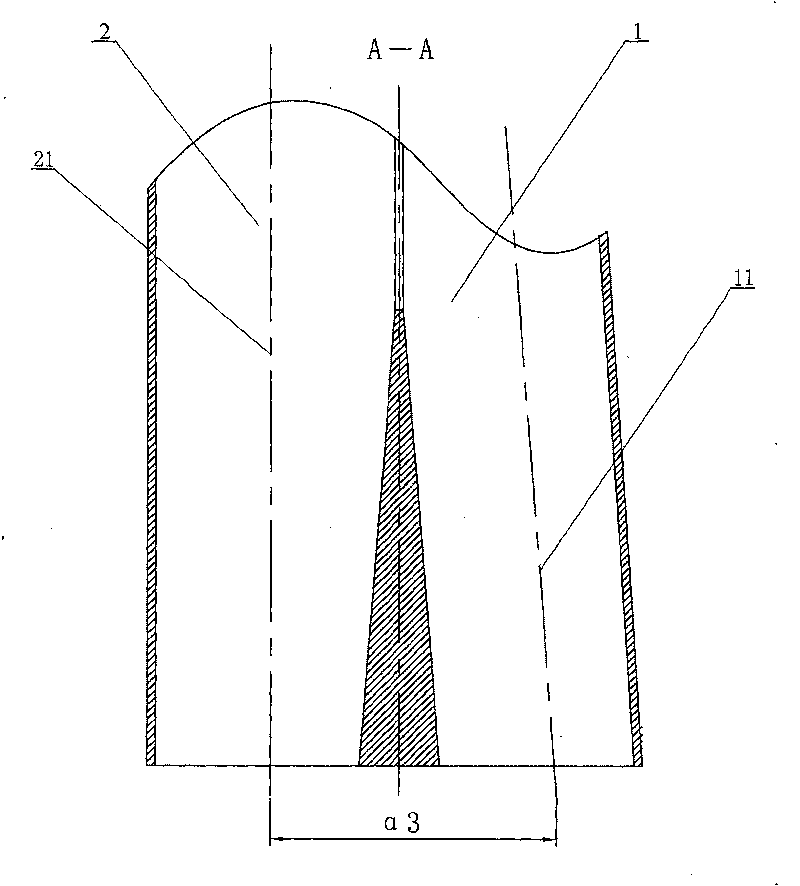

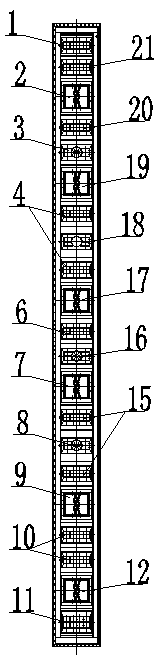

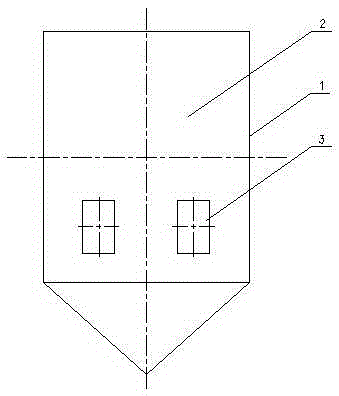

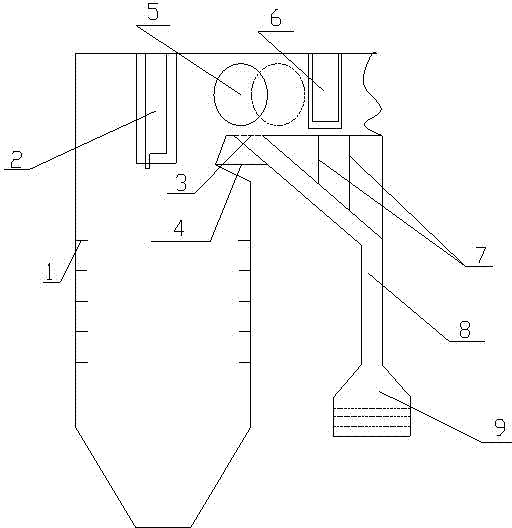

Wall type arranged horizontal rich-lean direct current combustion device

ActiveCN101315184BReduce skewReduce smoke temperature deviationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorLow load

A wall-mount horizontal bias direct-flow combustion device relates to a horizontal bias direct-flow combustion device. The invention solves the problems of the prior direct-flow combustor, such as four-corner tangential arrangement, different air supply conditions of coal flows on two sides, high risk of slag deposition due to declination and corrosion at high temperature. First dense / dilute air jet ports and a second air jet port (3) are formed on the water-cooled wall (6) of a furnace cavity (5) and combined to form a group of combustors (7). The central line (31) of the second air jet portand the central line (21) of the first dilute air jet port (2) are positioned in the fire-facing side direction, and have the included angles of alpha 1 and alpha 2 with relative to the water-cooled wall (6), on which the jet ports are positioned. The included angle between the central line (11) of the first dense air jet port and the central line (21) of the first dilute air jet port (2) is alpha3. After-burn air jet ports (4) are arranged on the water-cooled wall (6) or at each corner of the furnace cavity (5). The After-burn air jet ports (4) are positioned above the combustors (7). The wall-mount horizontal bias direct-flow combustion device realizes reasonable combination of coal particles and air, prevents the deflection of coal flow, and ensures stable combustion, low load and lowNOx discharge of boilers.

Owner:HARBIN INST OF TECH

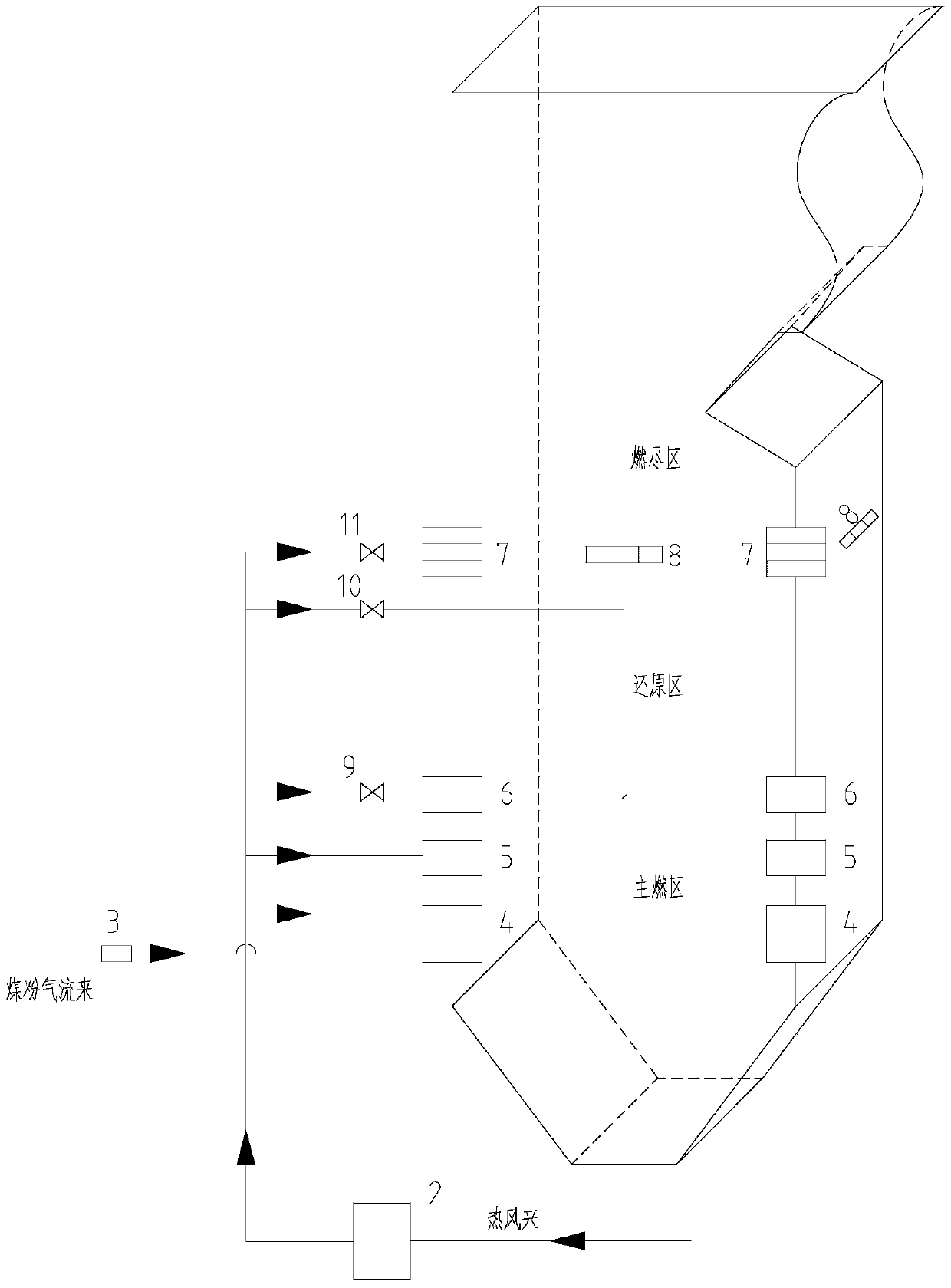

Combustion technology of low nitrogen oxide

InactiveCN100434797CReduce smoke temperature deviationAvoid slagging corrosion problemsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorLow nitrogen

A low-Nox combustion technology features that the combustion box is divided into primary combustion region, reduction region and burning off region from bottom to top. In the primary combustion region, the multi-layer horizontal coal powder combustion technique is used. In the reduction region the under-oxygen reduction technique is used. The burn0off air is fed into the burning off region. The jet direction of the secondary wind among each two burner layers is deflected clockwise by 10-15 deg. relative to the jet direction of primary wind and coal powder stream. The excessive coefficient of air in reduction region is 1.0. The horizontal direction of burn-off windjet is deflected anticlockwise by 5-10 deg. relative to the jet direction of primary wind. Its advantages are stable and uniform combustion, and low release of Nox.

Owner:DONGDIAN BURNING APP LIAONING +1

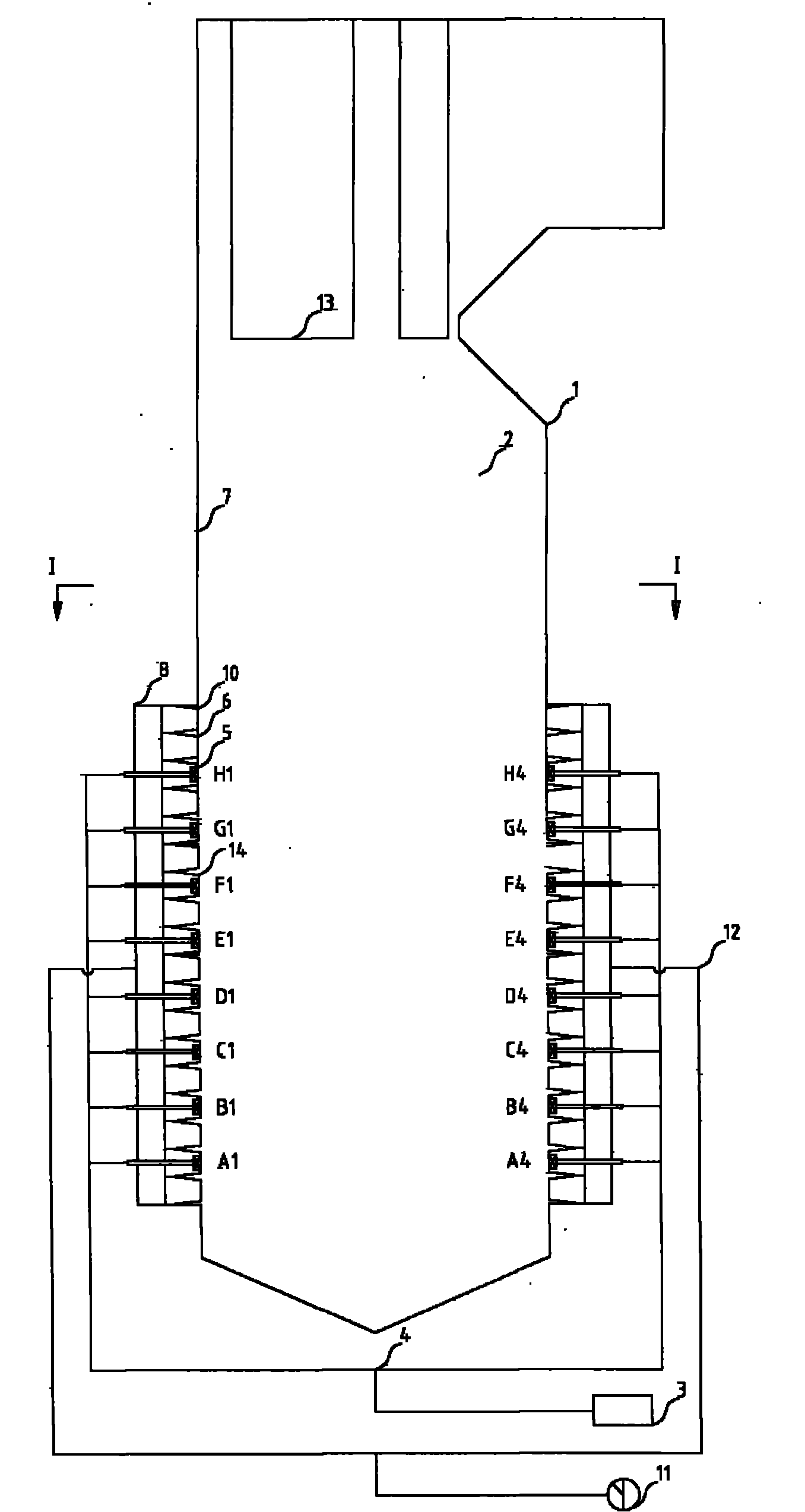

Multi-dimensional air staged low NOx combustion system and layout method

ActiveCN109028135BEmission reductionPrevent slaggingPulverulent fuel combustion burnersNon-combustible gases/liquids supplyLow loadSlag

Owner:HARBIN BOILER CO LTD

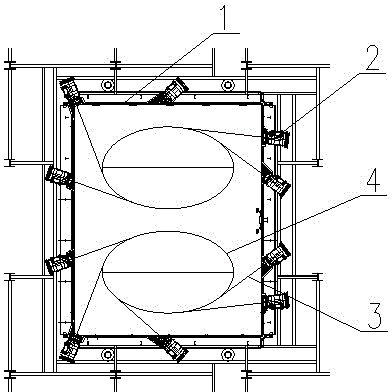

Over-fire air distribution manner in front and back wall opposed firing boiler

The invention discloses an over-fire air distribution manner in a front and back wall opposed firing boiler; a boiler firing method is in the form of front and back wall opposed firing, and over-fire air is fed by using a tangent circle method. The front and back wall opposed firing boiler comprises a front and back wall opposed firing boiler; with a symmetric central line of a long edge of the boiler as boundary, the over-fire air is divided into two groups; 4-5 over-fire air nozzles are arranged in each group; central lines of the over-fire air sprayed by the over-fire air nozzles in each group are tangential to the same imaginary ellipse; rotation directions of the ellipses in the two groups are reverse to each other; and one ellipse rotates in an anticlockwise direction and the other ellipse rotates in a clockwise direction. The over-fire air is high speed direct current over-fire air; and the over-fire air nozzles swing up and down and from left to right in a full-swinging form. The over-fire air distribution manner in the front and back wall opposed firing boiler, disclosed by the invention, is beneficial for enhancing the mixing of the over-fire air and rising flue gas and increasing the travel of the flue gas and prolonging the staying time of a fuel in the oven, and has the advantages that NOx emission of the boiler is obviously reduced and the increase of carbon content in boiler fly ash and the increase of the temperature-reduction water quantity are effectively suppressed.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

The method of adjusting the deviation of the reheat steam temperature on both sides of the four-corner tangentially fired boiler with the sofa damper

ActiveCN109578992BReduce smoke temperature deviationReduce hot spotsCombustion apparatusThermodynamicsWater flow

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Combustion adjustment method of a supercritical boiler mixed with coke oven gas

ActiveCN104713064BReduce air volumeReduce smoke temperature deviationAir supply regulationSteam generationSupercritical steam generatorCombustion

The invention discloses a combustion adjustment method for a supercritical boiler capable of performing blending combustion of coke oven gas. The device comprises a supercritical boiler capable of performing blending combustion of coke oven gas. The combustion adjustment method comprises the following steps: adopting nonlinear normal pagoda type air door air distribution openings by virtue of an eight-layer secondary air door, sequentially reducing the air door opening upwards, allowing the air door opening of a burnout air door at a diagonal part to be smaller than the air door opening at another diagonal part, and feeding two layers of secondary air at least by virtue of a gas gun by adopting a normal pagoda type air distribution mode. The normal pagoda type air door distribution opening of the secondary air door and different air door openings at two diagonal parts of the burnout air door are adopted, and multilayer air is fed by virtue of the gas gun, so that the fume temperature deviation at the hearth outlet can be effectively reduced, and the detonation accidents of the boiler are reduced. Moreover, according to stable combustion in a fuel enriched area on the middle lower part of the hearth and feeding of the gas gun, the NOx generation amount is greatly reduced, the boiler operates in a high-efficiency economic performance area, the comprehensive operating cost is reduced, and the adjustment method is simple.

Owner:ELECTRIC POWER SCI RES INST OF GUIZHOU POWER GRID CO LTD

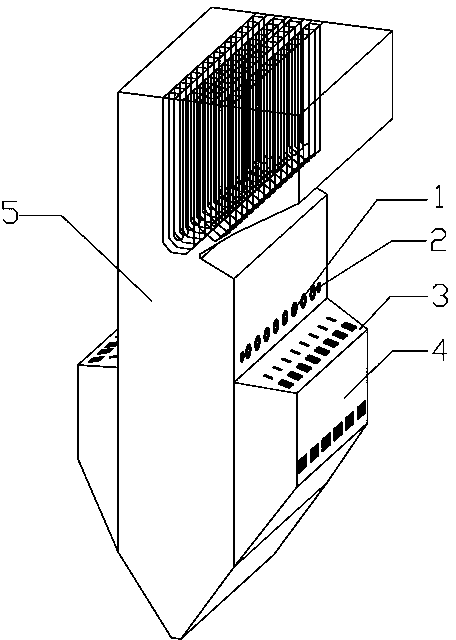

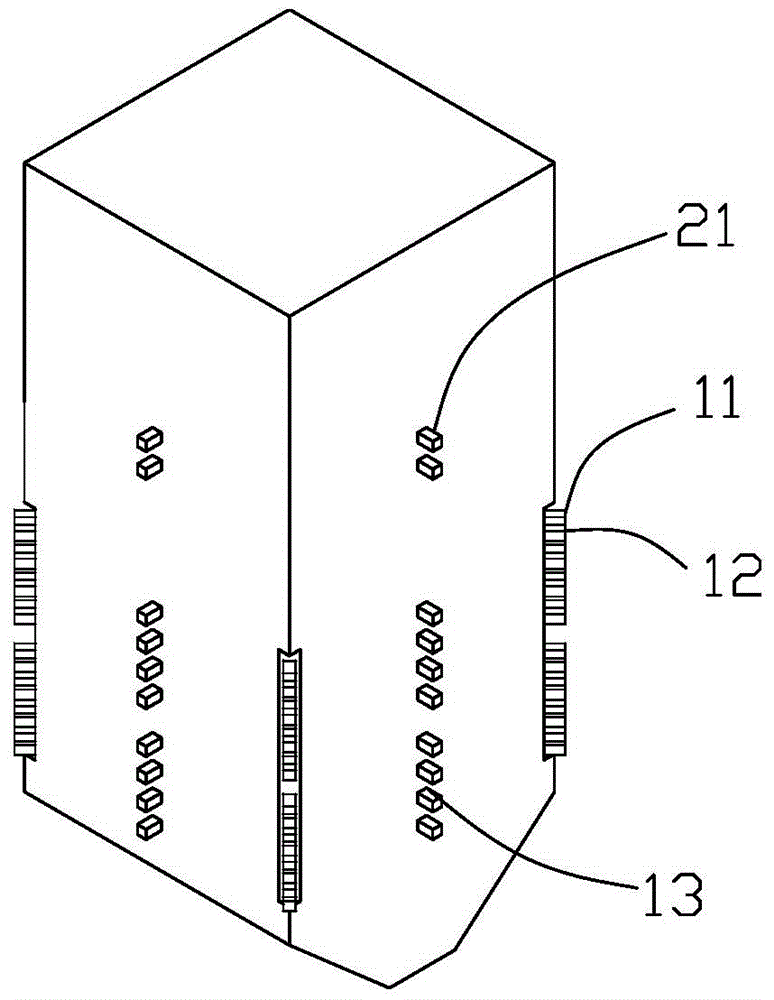

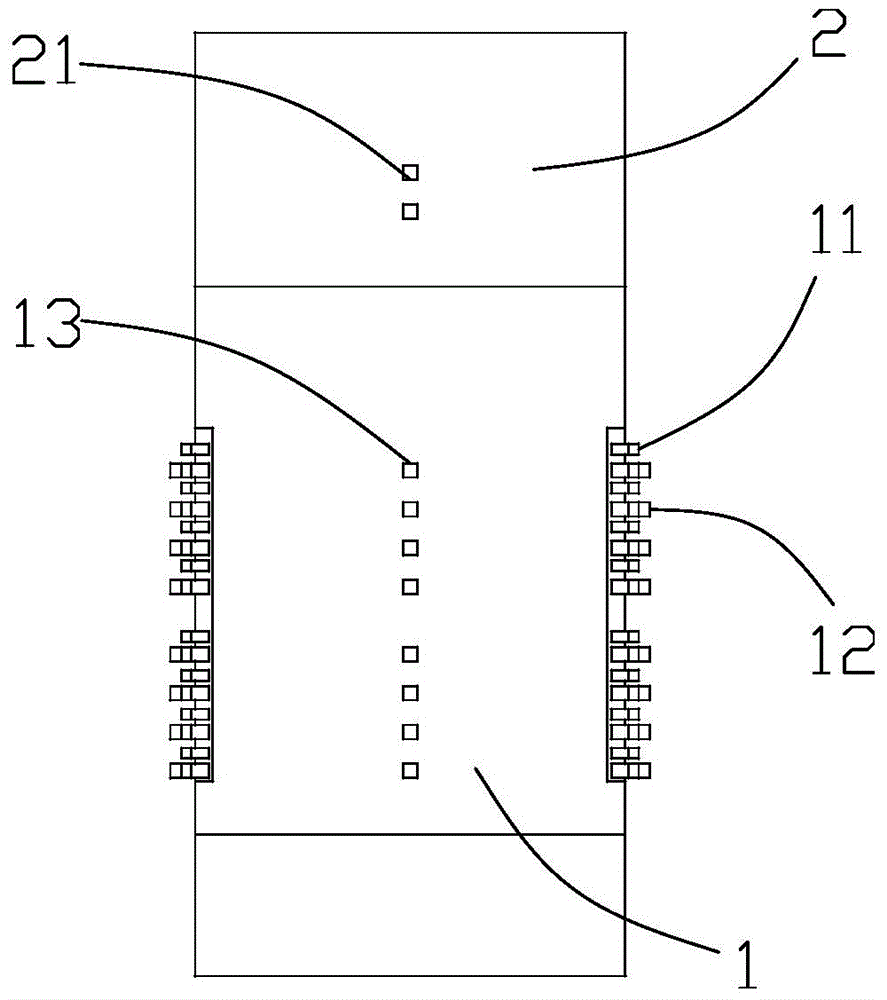

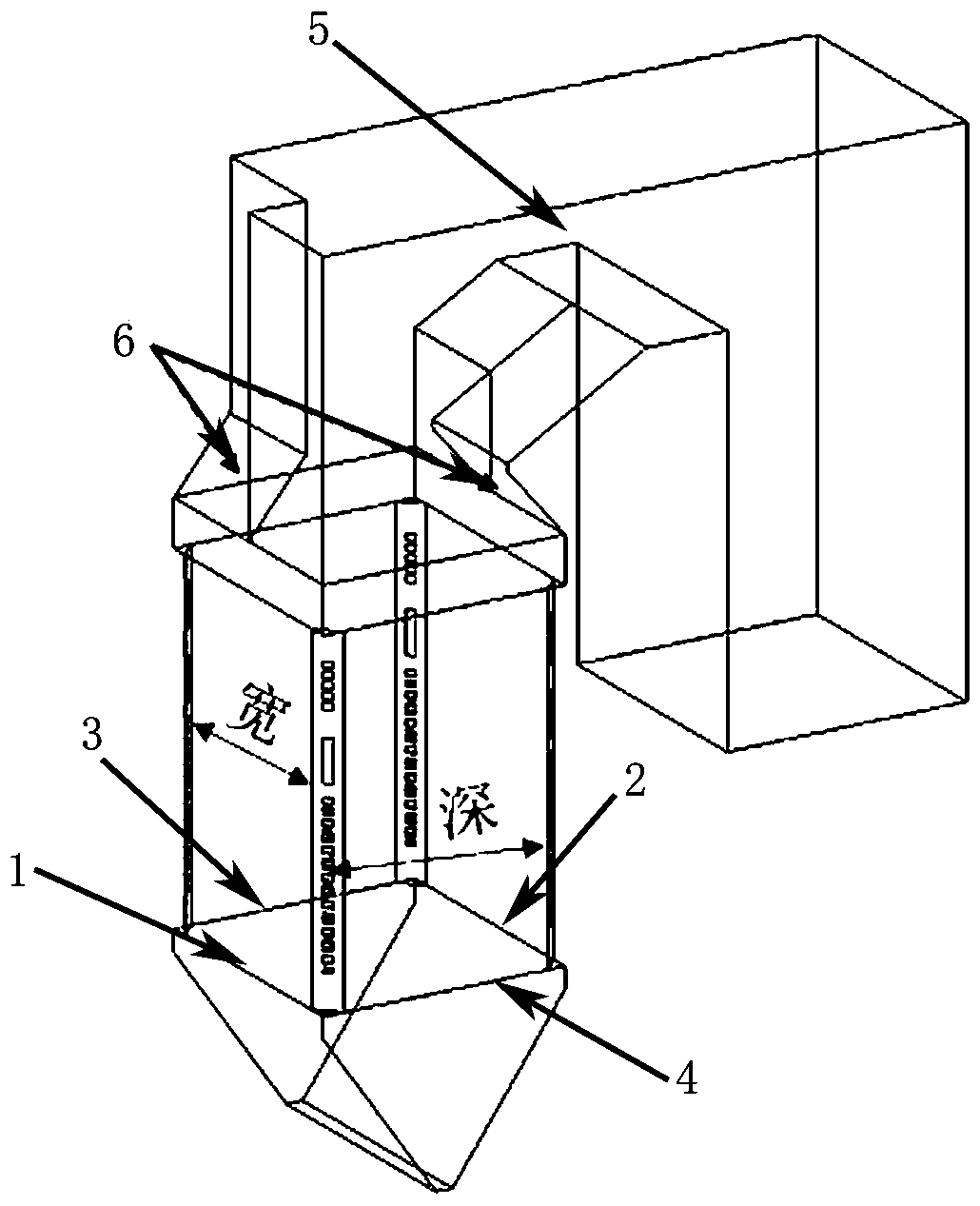

Wall type arrangement direct-current pulverized coal combustion technology used for industrial pulverized coal boiler

ActiveCN103712204APrevent slaggingLow shape requirementCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorSlag

The invention relates to a wall type arrangement direct-current pulverized coal combustion technology used for an industrial pulverized coal boiler, and belongs to the pulverized coal boiler filed. The problems of slag bonding and high temperature corrosion of present industrial pulverized coal boilers are solved in the invention. The boiler comprises a boiler body, the boiler body comprises a front wall, a rear wall and a hearth formed in the boiler body, each of the front wall and the rear wall is provided with at least one direct current combustor connected with the hearth, and the direct current combustor of the front wall is arranged facing to the direct current combustor of the rear wall. The wall type arrangement direct-current pulverized coal combustion technology can avoid the slag bonding caused by the phenomena comprising too large tangent circle and deflective wall attachment, and has low requirements on the shape of the cross section of the hearth because of the wall type arrangement combustion mode, so with the increase of capacity of a set, the width of the hearth needs to be increased, there is no need to increase the depth of the hearth, the capacity of the boiler is not restricted by the sectional area of the hearth, and it is convenient to carry out the arrangement of the heated surface of a tail portion.

Owner:芮城县丰蕴热力有限公司

A Boiler Overfire Air Adjustment Method Based on Momentum

ActiveCN111550820BImprove the whirling effectImprove safe operationAir supply regulationAir/fuel supply for combustionCombustorFlue gas

The invention relates to a method for adjusting boiler burn-out air based on dynamic moment. The technical solution is to sum the momentum moments of burners with opposite rotation directions in the main combustion zone to obtain the anti-tangential wind momentum moment; and rotate the main combustion zones to the same combustion The sum of the momentum moment of the burner is the tangential wind momentum moment; the sum of the antitangential wind momentum moment and the sum of the tangential wind momentum moment are compared, and the inverse tangential angle of the overburning air is adjusted through the overburning air adjustment mechanism until the ratio is between 0.8 and 1.2 During the period, the present invention realizes the hot state adjustment effect through the cold state test, simplifies the work flow and workload, and greatly improves the working efficiency. Make the flue gas in the horizontal flue of the boiler evenly distributed, finally the ash accumulation in the horizontal flue is uniform, and the ash fall has no effect on the boiler disturbance, the negative pressure no longer fluctuates greatly, and the deviation of the flue gas and steam temperature in the horizontal flue is reduced , Improve the safe operation of the boiler.

Owner:CENT CHINA BRANCH OF CHINA DATANG CORP SCI & TECH RES INST CO LTD +1

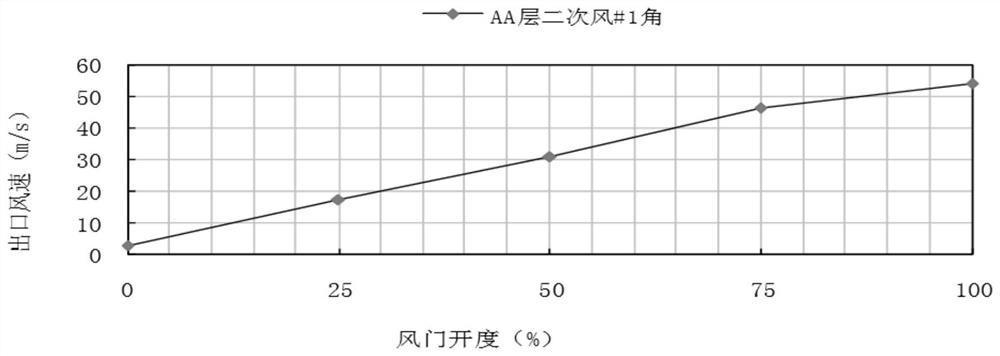

Coal-fired boiler secondary damper damper control method based on burner heat load

ActiveCN104728857BImprove combustion economyEmission reductionAir supply regulationCombustorEngineering

The invention relates to a coal-fired boiler secondary air valve baffle control method based on burner heat loads. The secondary air valve aperture is set according to different burning characteristics of burners on all layers, the secondary air interlayer distribution is controlled, and real-time matching control over secondary air distribution of burner areas and the heat loads of the burners on all layers is carried out. Compared with the prior art, the coal-fired boiler secondary air valve baffle control method has the advantages that burning conditions of the different heat loads of the burners can be met, the boiler burning economical efficiency is improved, the NOx emission is reduced, and the smoke temperature deviation is reduced.

Owner:SHANGHAI MINGHUA ELECTRIC POWER TECH & ENG +1

A Wall Type Arrangement Direct-flow Pulverized Coal Combustion Device Used in Pulverized Coal Industrial Boiler

ActiveCN103712204BPrevent slaggingLow shape requirementCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorSlag

The invention relates to a wall type arrangement direct-current pulverized coal combustion technology used for an industrial pulverized coal boiler, and belongs to the pulverized coal boiler filed. The problems of slag bonding and high temperature corrosion of present industrial pulverized coal boilers are solved in the invention. The boiler comprises a boiler body, the boiler body comprises a front wall, a rear wall and a hearth formed in the boiler body, each of the front wall and the rear wall is provided with at least one direct current combustor connected with the hearth, and the direct current combustor of the front wall is arranged facing to the direct current combustor of the rear wall. The wall type arrangement direct-current pulverized coal combustion technology can avoid the slag bonding caused by the phenomena comprising too large tangent circle and deflective wall attachment, and has low requirements on the shape of the cross section of the hearth because of the wall type arrangement combustion mode, so with the increase of capacity of a set, the width of the hearth needs to be increased, there is no need to increase the depth of the hearth, the capacity of the boiler is not restricted by the sectional area of the hearth, and it is convenient to carry out the arrangement of the heated surface of a tail portion.

Owner:芮城县丰蕴热力有限公司

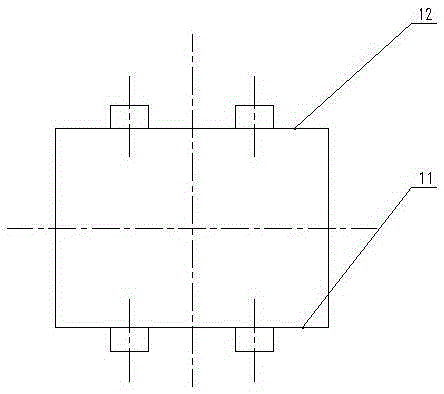

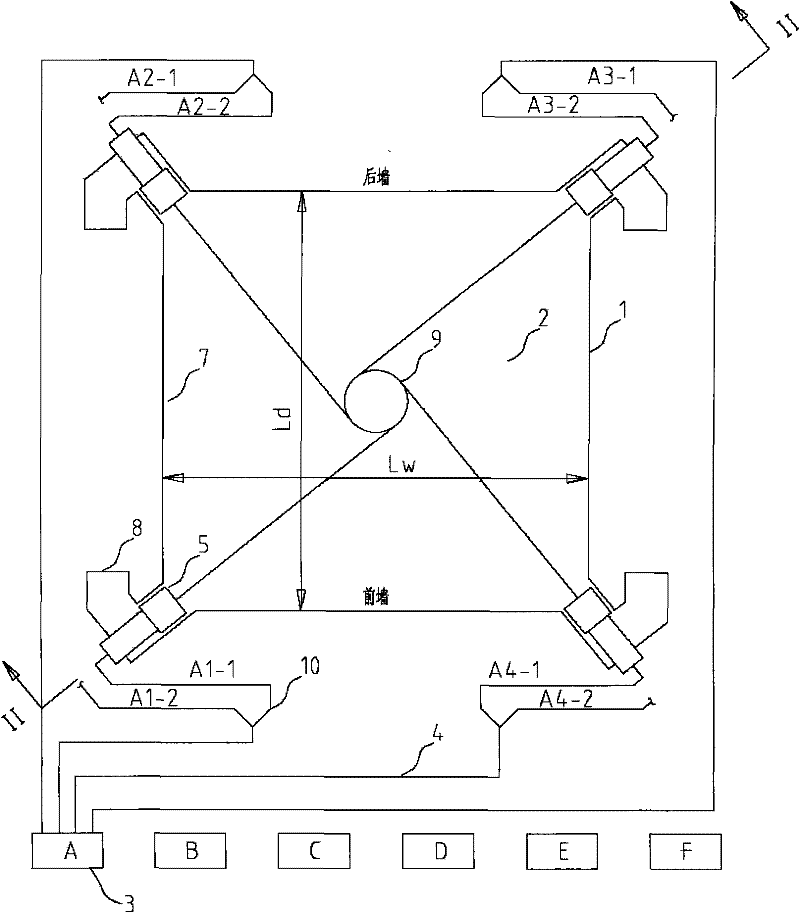

A boiler with controllable tangential combustion

ActiveCN103994423BAvoid coking tendencyIncrease turbulent mixing intensityCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorNitric oxide

The invention provides a boiler with a controllable combustion tangent circle. The boiler comprises a hearth which is encircled by a plurality of walls, wherein the hearth comprises a main combustion area and a burnout area; the main combustion area and the burnout area are respectively provided with combustors which are connected with nozzles through pipelines; a plurality of corner-type primary air nozzles and corner-type secondary air nozzles which are vertically arrayed are respectively arranged at the corners of the adjacent walls of the main combustion area; a plurality of wall-type secondary air nozzles which are vertically arrayed are respectively arranged at the secondary air equal-height positions of all the walls of the main combustion area; each nozzle faces the interior of the boiler, and the jet flow direction can be adjusted. When the boiler with the corner-type secondary air nozzles and the wall-type secondary air nozzles works, combustion can be controlled by regulating the flow and the jet flow direction of the corner-type secondary air nozzles and the wall-type secondary air nozzles according to actual requirements. Therefore, the size of the combustion tangent circle of the hearth can be quite effectively controlled, generation of nitric oxides is effectively reduced, and coking of the hearth caused by combustion operation of the combustors close to the walls is avoided.

Owner:SHANGHAI JIAO TONG UNIV

Hexagonal or octagonal tangential arrangement of anthracite burning single-fireball direct-flow combustors

ActiveCN101709871BReduce in quantityTimely airflowCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorLow load

Owner:SHANGHAI BOILER WORKS

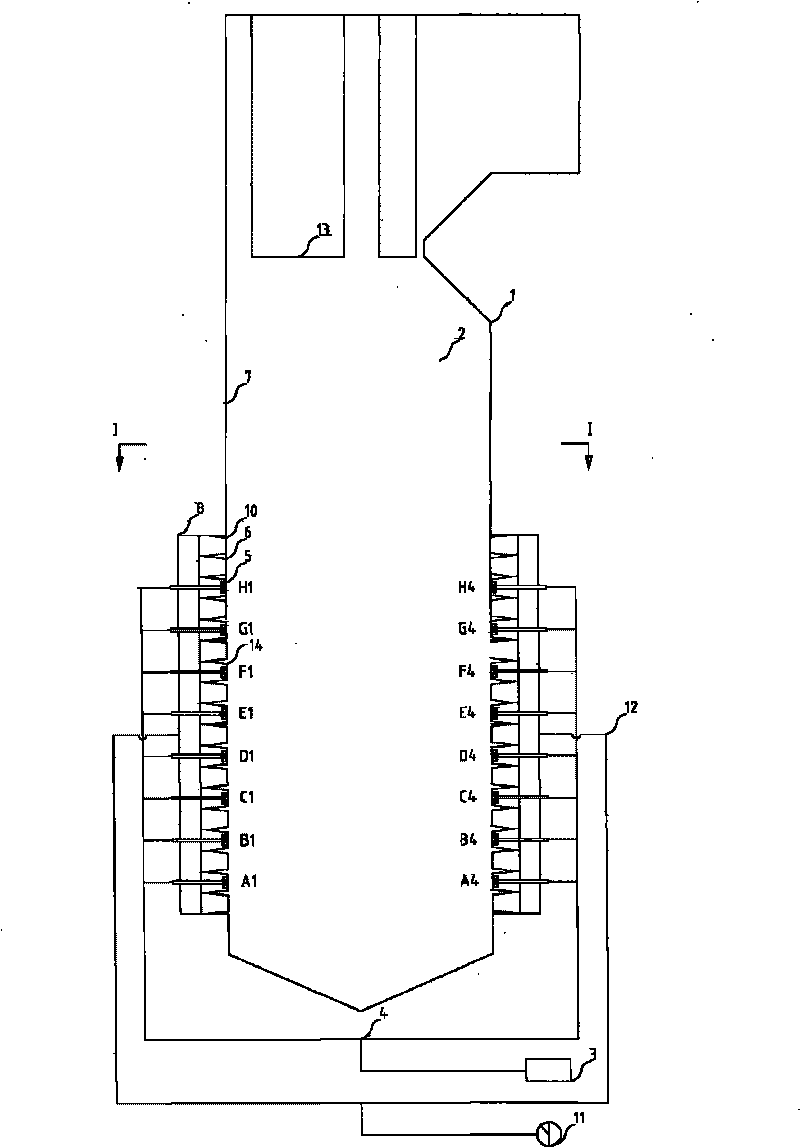

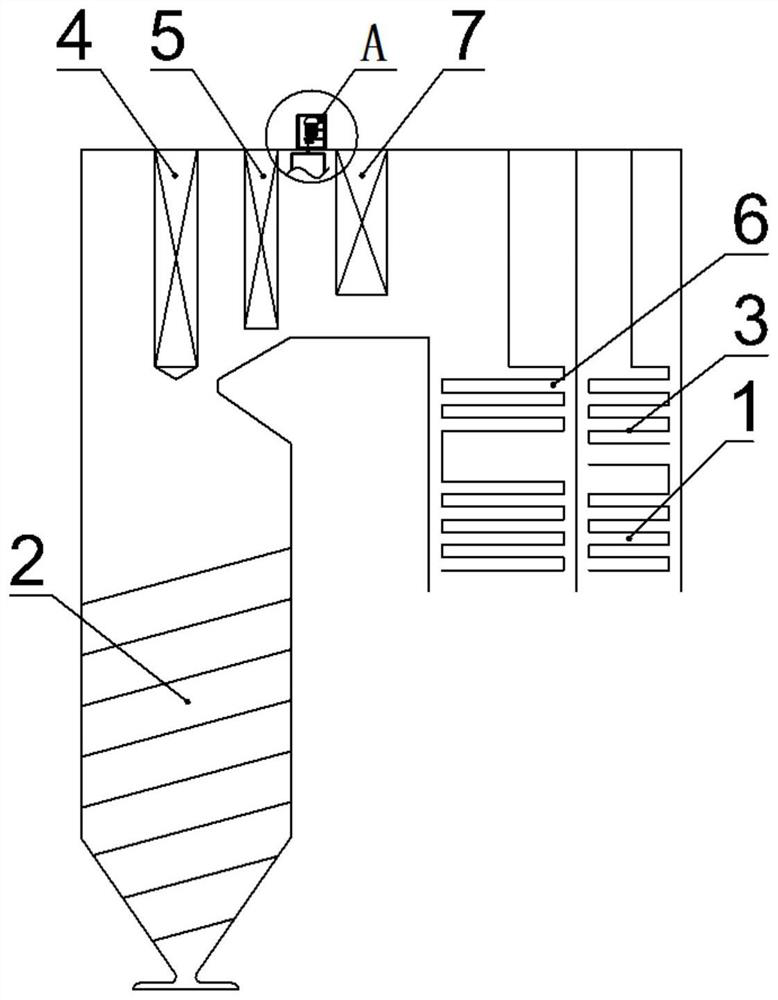

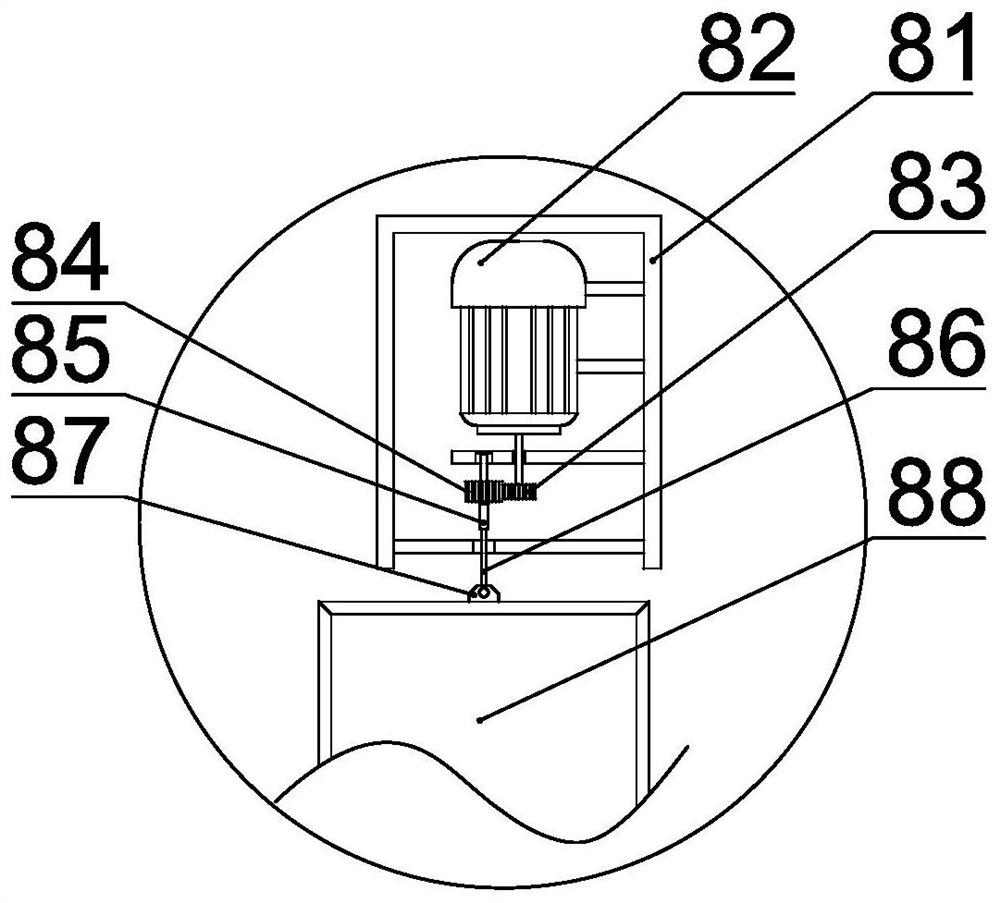

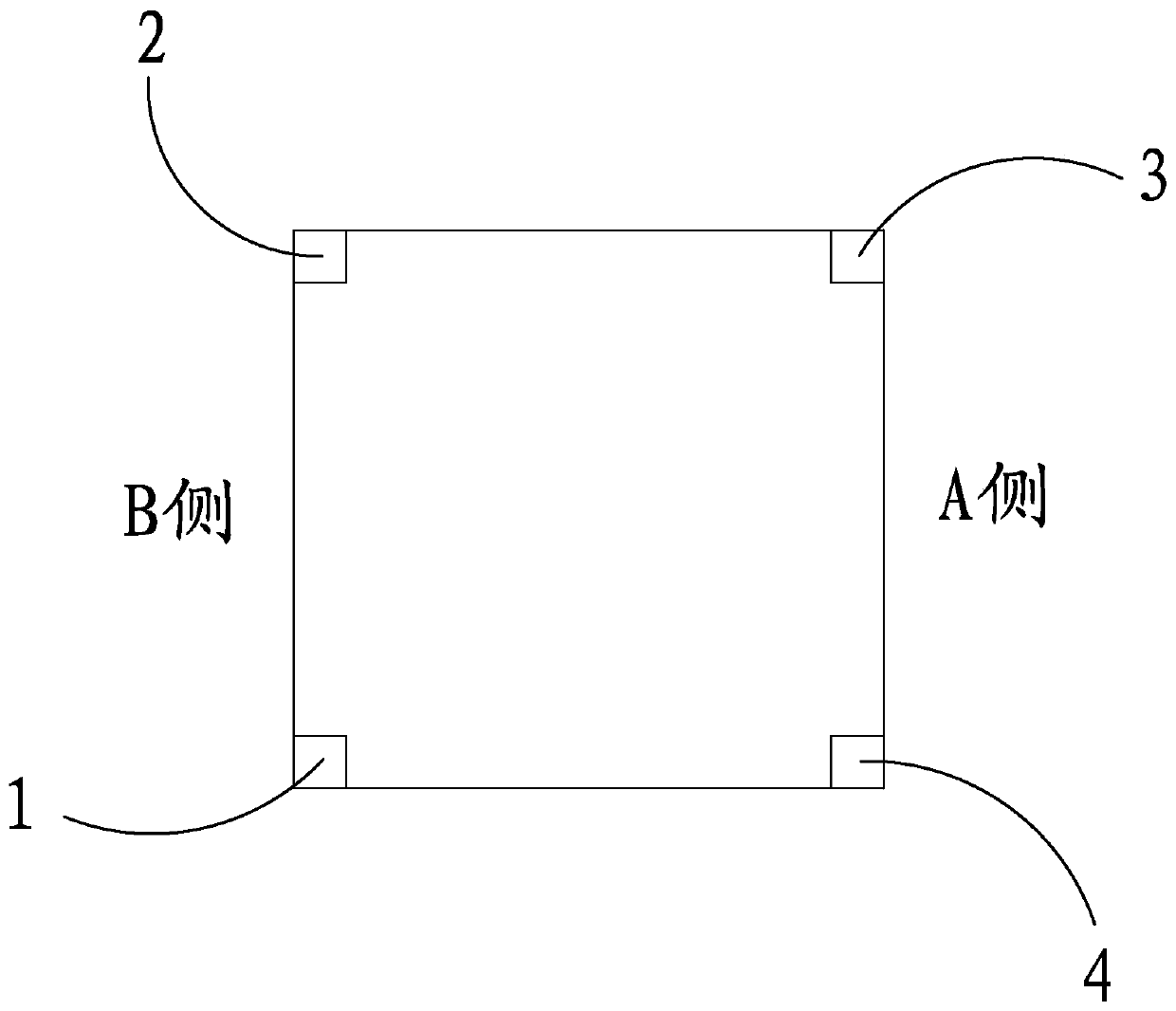

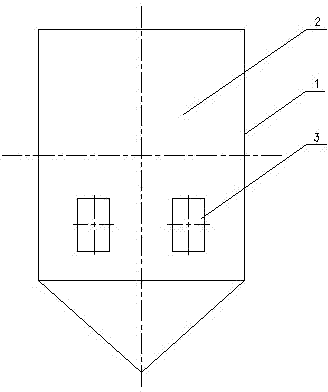

A system for alleviating slagging on convection heating surface of boiler

ActiveCN102798130BExtended run timeGuaranteed cleanlinessLighting and heating apparatusCombustionSlag

The invention relates to a technology for relieving scorification of a convection heated surface of a boiler, in particular to a system for relieving scorification of the convection heated surface of a boiler. The system comprises a crust block machine arranged in a flue of a boiler, wherein the crust block machine is positioned at the front end of the windward side of a convection superheater at the top of the flue; the crust block machine comprises two symmetrically arranged disks and a straight pipe fixedly arranged between the two disks; and the crust block machine can roll in the axial direction of the flue. The crust block machine is applicable to various boilers using high-alkali metal content coal; scorification can be made in advance; safe operation of the convection heated surface is ensured; the operation time of the boiler is increased; offset of smoke temperature at a hearth outlet and uneven flow field caused by combustion of a quadrangle tangent circle boiler are reduced by the arrangement of the crust block machine; frequent explosion of the convection superheater and the reheater is avoided; normal operation of the boiler is not affected in the process of slag removal and scorification cleaning; the operation time of the boiler is prolonged; and the economical efficiency of a power plant is improved.

Owner:DONGFANG ELECTRIC CORP LTD

Hexagonal or octagonal tangential arrangement of fuel-oil or fuel-gas single-fireball direct-flow combustors

ActiveCN101709870BReduce in quantityReduce overall heightCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorFuel oil

The invention provides hexagonal or octagonal tangential arrangement of fuel-oil or fuel-gas single-fireball direct-flow combustors, which is characterized in that: six or eight groups of combustors are arranged in a hearth; each group of combustors are vertically provided with at least two oil guns or gas guns at intervals, two fuel blast nozzles and three secondary blast nozzles; the fuel oil or the fuel gas at a fuel oil or fuel gas operation station outlet in front of the furnace is connected with at least two layers of oil guns or gas guns arranged on four walls of a boiler through fuel oil or fuel gas pipelines; and each layer of oil guns or gas guns consist of six or eight oil guns or gas guns which are in the same level but not in the same group. The hexagonal or octagonal tangential arrangement of the fuel-oil or fuel-gas single-fireball direct-flow combustors can ensure that the distance between the uppermost and undermost two oil guns or gas guns and the thermal load of thewalls of the combustor area are controlled in ideal ranges, the total height of the boiler is decreased and the manufacturing cost of the boiler is greatly reduced. Because air supplying conditions on two sides of a jet flow are good, flames of the oil guns or gas guns are not easy to attach to the walls and the safety of the work of a water-cooling wall is improved.

Owner:SHANGHAI BOILER WORKS

A tangential boiler air staging combustion vertical and horizontal combined layout overburning air system

The invention discloses a burn-off air system arranged vertically and horizontally in a tangential boiler air staged combustion, including a furnace, a hot air box, a pulverized coal pipeline, a primary air nozzle, a secondary air nozzle, a compact burn-off air nozzle, and a corner separated combustion chamber. Exhaust air nozzles, wall-type separated overfire air nozzles, etc., this system is innovative in the conventional way of arranging the overfire air at the corner of the boiler along the furnace height direction of the tangential boiler. The corner separated burn-off air nozzle and the wall-type separated burn-off air nozzle can achieve the purpose of reducing the air excess coefficient in the main combustion area and reducing the generation of NOx. The invention can ensure sufficient burn-off air rate, reasonable reduction zone length, good post-mixing in the furnace and sufficient burn-out time, effectively eliminate residual flue gas rotation and temperature deviation, and take into account the suppression of NOx generation and the promotion of pulverized coal burn-out meet the needs of boiler operation safety, economy and environmental protection.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD

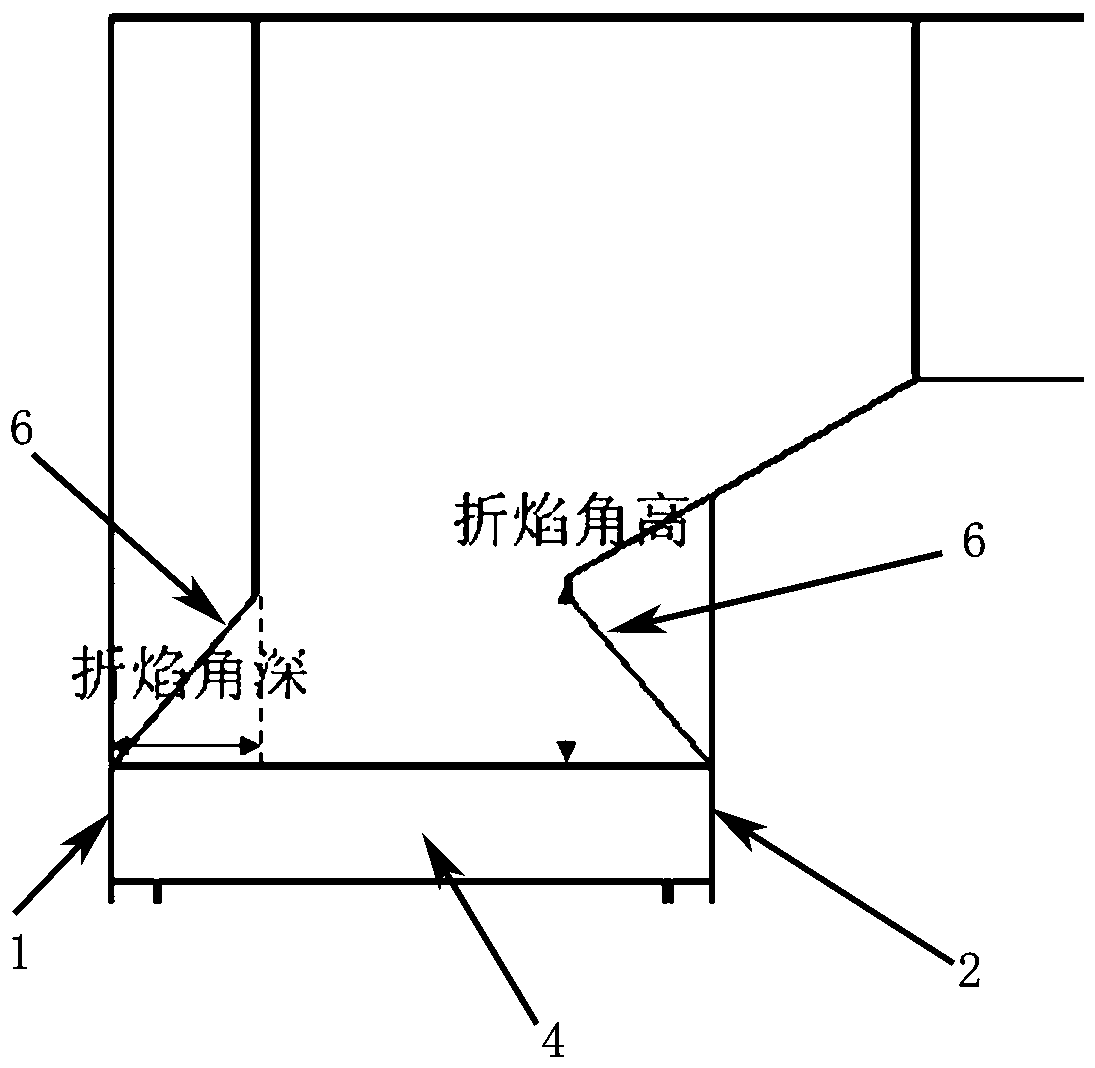

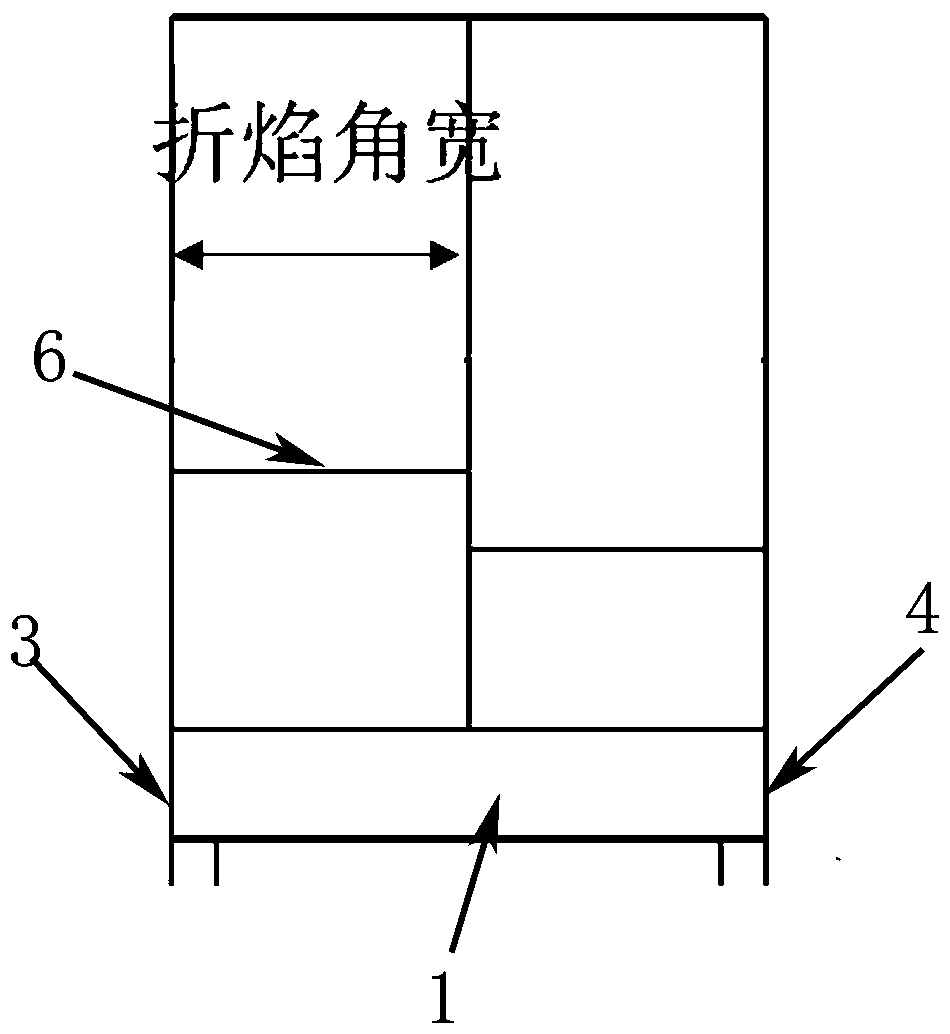

Asymmetric furnace arch structure capable of reducing boiler flue gas temperature difference

The invention discloses an asymmetric furnace arch structure capable of reducing boiler flue gas temperature difference, and relates to a structure of tangent arrangement of a combustor hearth, in particular to the asymmetric furnace arch structure capable of reducing the boiler flue gas temperature difference. The structure comprises two furnace arches which are arranged at the connecting position of a horizontal flue and a hearth main combustion area, and the two furnace arches are arranged on a hearth front wall and a hearth rear wall, and the two furnace arches are arranged on the hearth front wall and the hearth rear wall in an asymmetric manner. The structure is simple, when the main combustion area airflow rotates anticlockwises, the furnace arch, close to the left side, of the hearth front wall can guide the flow direction of the flue gas on the left side to the horizontal flue as far as possible, the deviation degree of the flue gas to the hearth front wall is greatly weakened, the guide effect on the flue gas on the right side is not changed, flue gas flow rates of the left side and the right side of a hearth outlet are finally consistent, and are consistent with the heatexchange amount of the heating face, and the flue gas temperature difference is greatly reduced.

Owner:NORTHWEST BRANCH OF CHINA DATANG CORP SCI & TECH RES INST

Over fire air nozzle structure

PendingCN114183746AHigh speedRigid footCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelThermodynamicsCombustor

The invention discloses an over fire air nozzle structure. According to the main technical scheme, the over fire air nozzle structure comprises a boiler body; the main combustion area combustor comprises a plurality of pulverized coal combustors, and the pulverized coal combustors are all installed on the front wall and the rear wall of the boiler body; the plurality of separated over-fire air nozzles are mounted above the main combustion area combustors and are arranged on four walls with the same elevation, the plurality of separated over-fire air nozzles on the front wall and the rear wall correspond to the plurality of pulverized coal combustors one by one up and down, and the plurality of separated over-fire air nozzles are of square structures; the airflow inlet direction of the multiple separated type over fire air nozzles is of a straight section structure, the airflow outlet direction of the multiple separated type over fire air nozzles is of an inclined section structure, and the inclined section structure is divided into an upper inclined section, a middle inclined section and a lower inclined section. The upper deflection section and the lower deflection section are offset by 20 degrees to 35 degrees in the clockwise direction, and the middle deflection section is offset by 20 degrees to 35 degrees in the anticlockwise direction.

Owner:THERMAL POWER TECH RES INST OF CHINA DATANG CORP SCI & TECH RES INST +1

Method for on-line monitoring and alarming of convection heating face flue gas temperature field of power station boiler

ActiveCN103216812BGrasp the temperature deviationShort reaction timeBoiler indication operationsBoiler controlPower stationFlue gas

Owner:王衡 +1

A tower boiler outlet diversion method, mechanism and boiler

ActiveCN106195993BExtended stayImprove smoke temperature deviationSteam boilersSteam boilers componentsFlue gasHearth

The invention discloses a tower-type boiler outlet guide method and mechanism and a boiler. The guide method specifically comprises the steps that the position, close to the top of a hearth, of the front wall of an existing tower-type boiler and the position, close to a horizontal flue, of the rear wall of the existing tower-type boiler are bent towards the inside of the boiler by a certain angle to be connected with the horizontal flue, and then the outlet guide mechanism is formed. The outlet guide mechanism enables flue gas in an upper hearth heat exchange area to enter the horizontal flue after the direction is changed; dwelling time of hearth left side flue gas inside the boiler is correspondingly lengthened, flue gas distribution is more even, and temperature differences of flue gas on the left side, the right side, the front side and the rear side of the hearth are effectively reduced; and at the same time, the outlet guide mechanism prevents the flue gas in the upper hearth heat exchange area from seriously deflecting towards the rear wall of the hearth, abrasion from dust particles in the flue gas to the tube walls of heat exchangers close to the rear wall is reduced, and safe operation of a unit is facilitated.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com