Nozzle structure for overfired air of boiler combustor

A technology of boiler combustion and burn-out air, which is applied in the direction of combustion equipment, lighting and heating equipment, etc. It can solve the problems of inability to swing up and down at the same time, large deviation of flue gas temperature at the furnace outlet, and large NOx emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

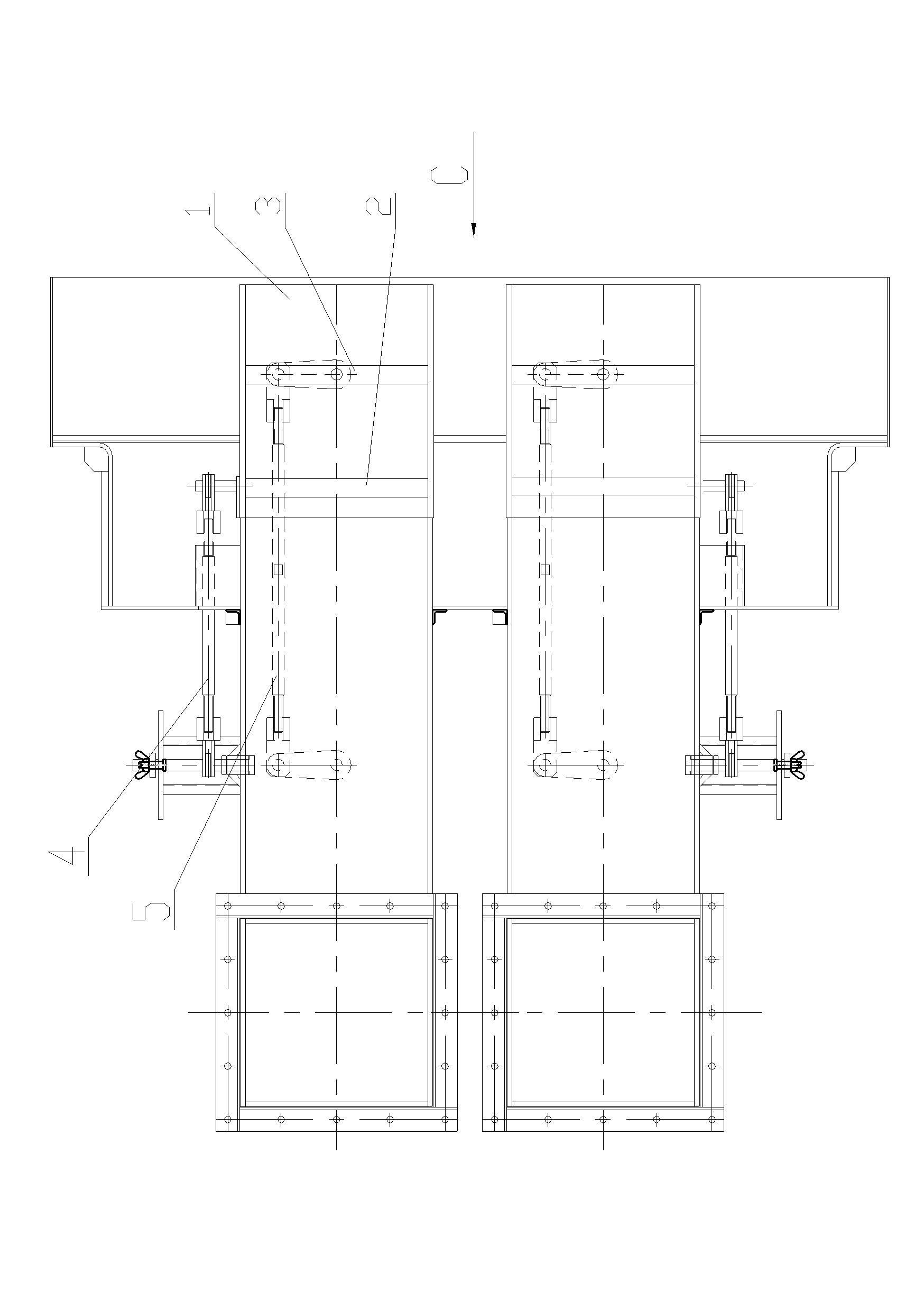

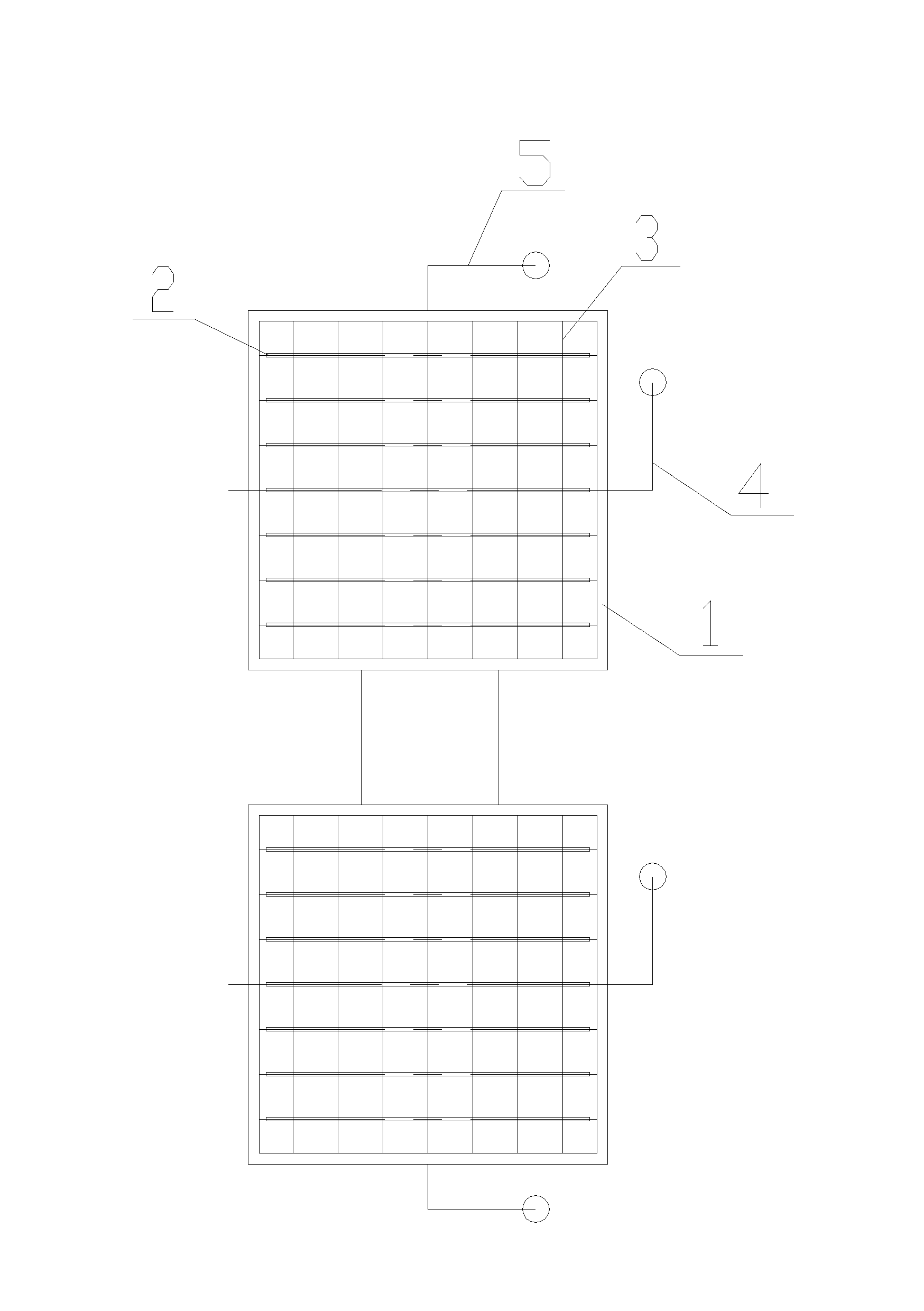

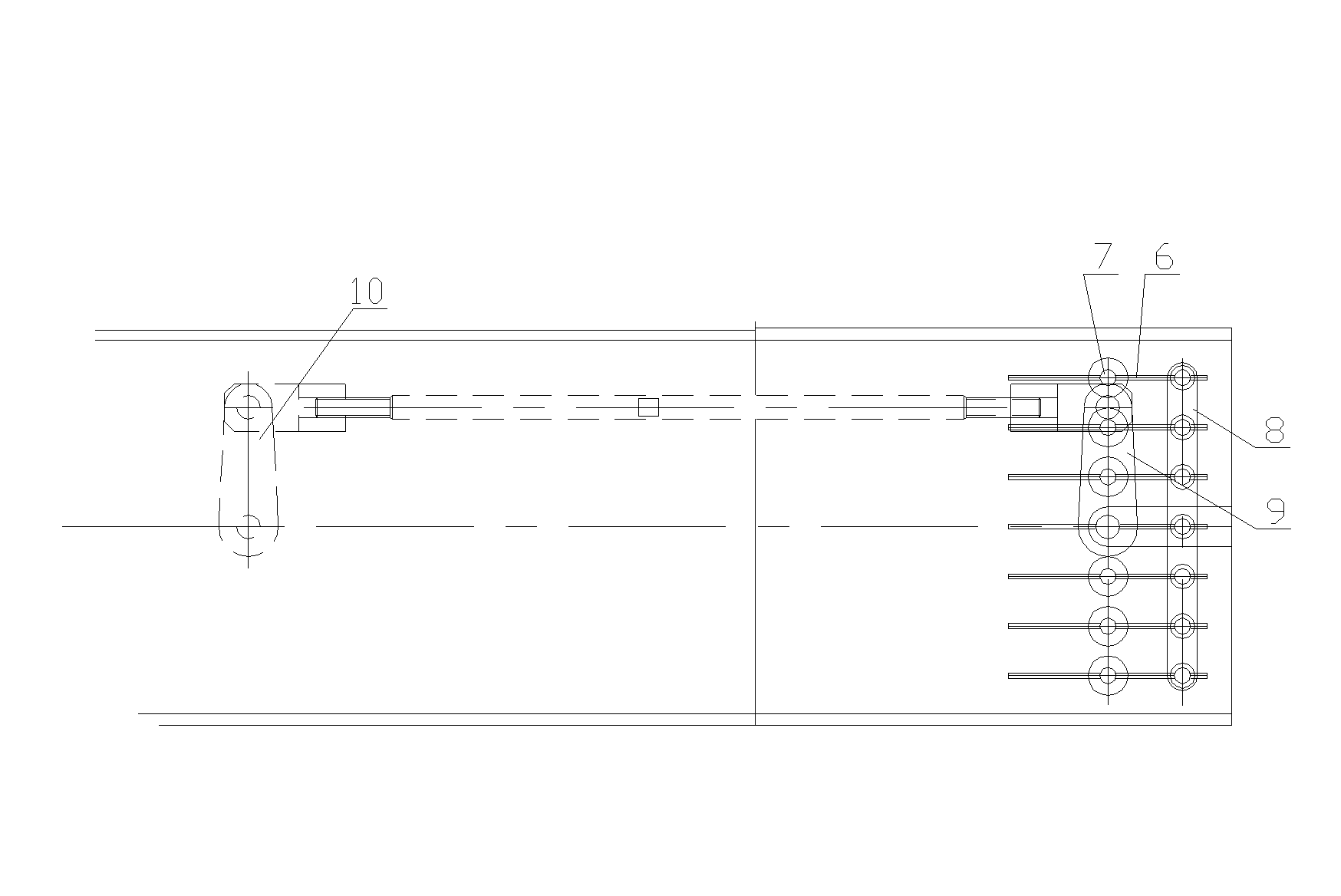

[0013] See figure 1 , figure 2 , image 3 , Figure 4 , which includes a pipeline 1, the outlet area of the pipeline 1 is provided with a swing blade, the swing blade is divided into an up and down swing blade assembly 2, a left and right swing blade assembly 3, the up and down swing blade assembly 2, and the left and right swing blade assembly 3 are not in the same plane area, up and down The swing blade assembly 2 is connected with a vertical swing pull rod 4 , and the left and right swing blade assembly 3 is connected with a left and right swing pull rod 5 .

[0014] The structure of the up and down swinging blade assembly 2 and the left and right swinging blade assembly 3 specifically includes a blade 6, a blade rotating shaft 7, and a fastening assembly 8 at the front end of the blade. The inner wall of the inner wall, the front end of the blade 6 is respectively supported on the blade front end fastening assembly 8, the blades 6 are all arranged in parallel, the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com