Patents

Literature

242results about How to "Reduce overall height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

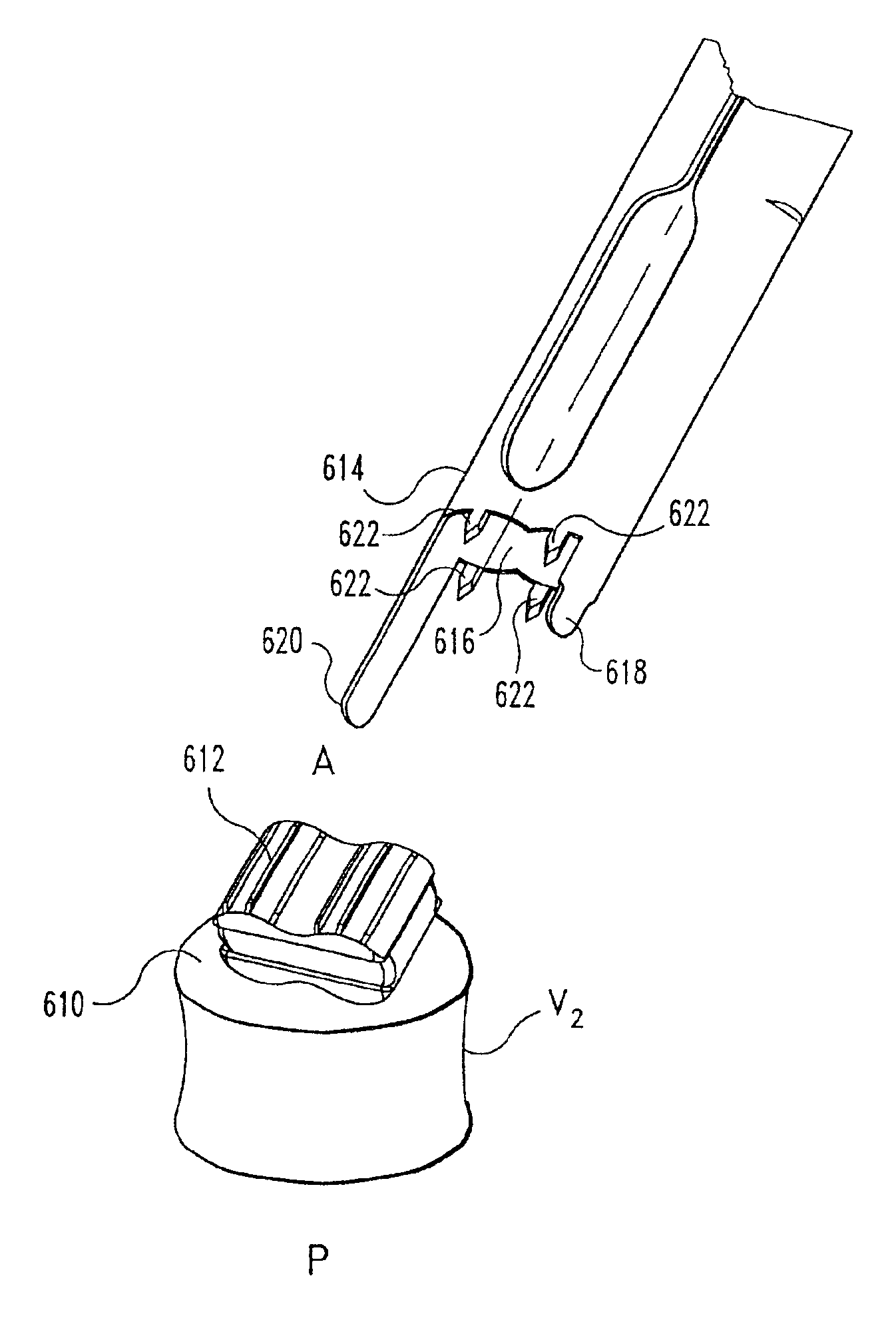

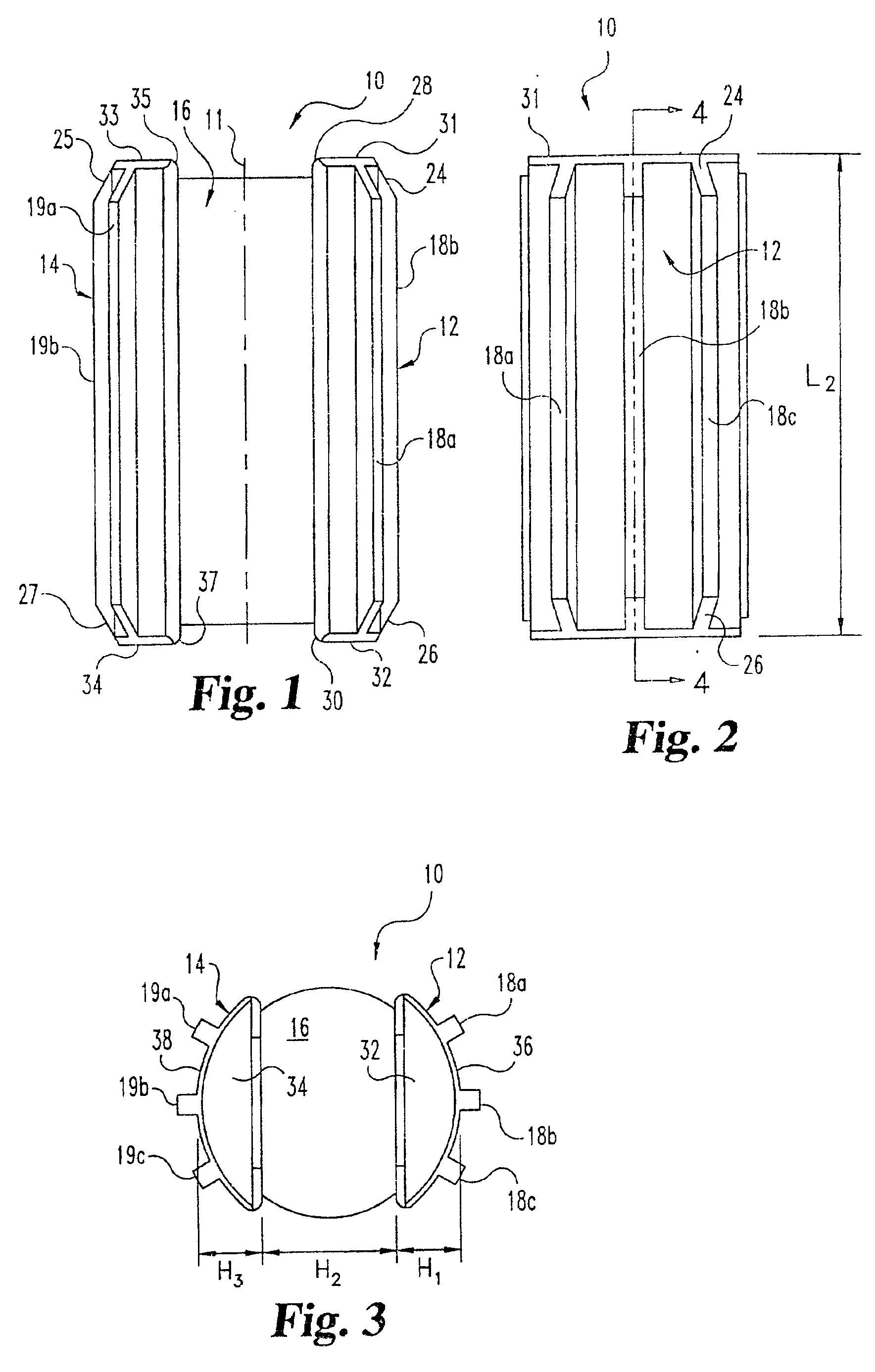

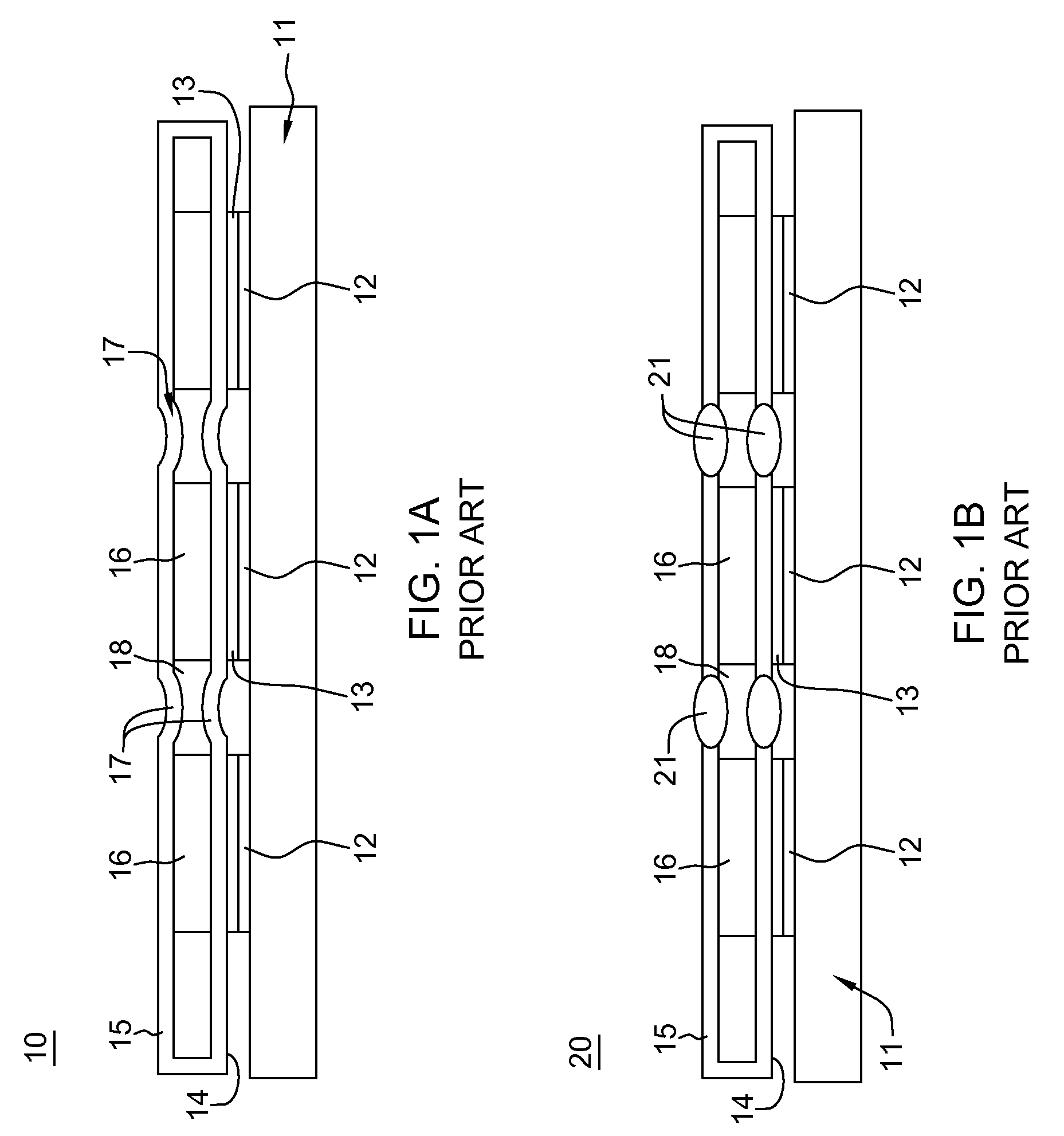

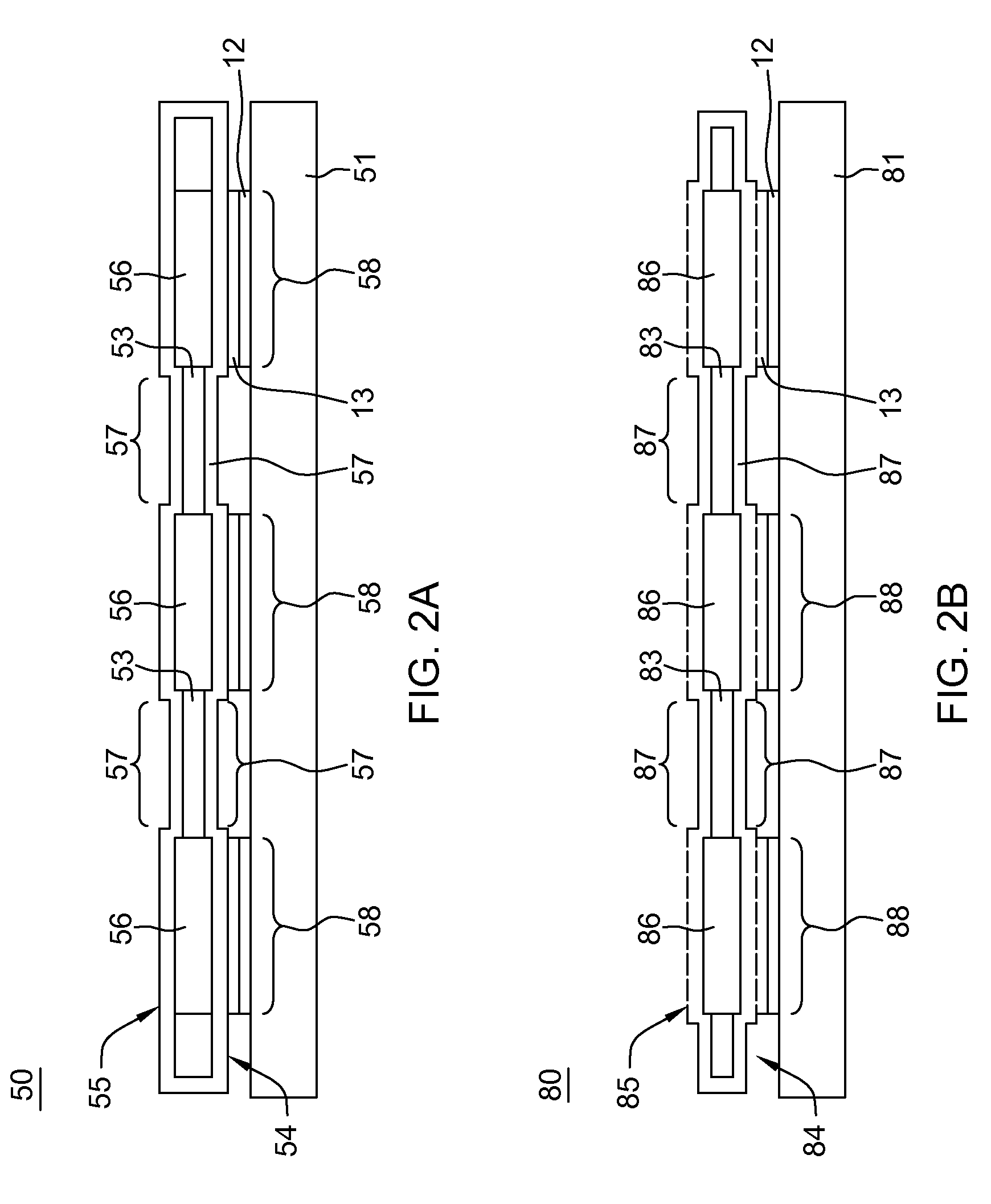

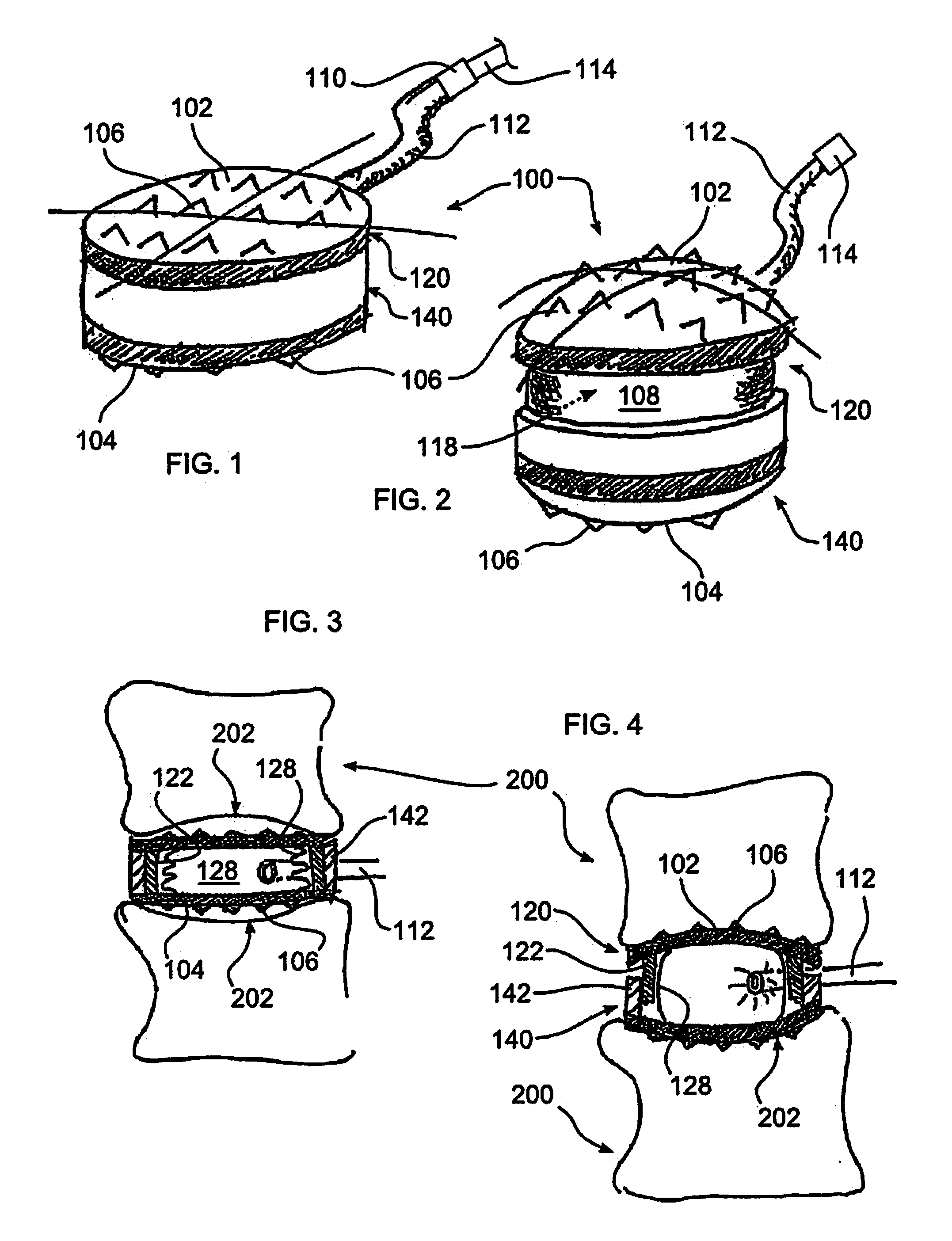

Artificial disc implant

InactiveUS6881228B2Reduce overall heightIncrease heightInternal osteosythesisJoint implantsBiomedical engineeringArtificial disc

An artificial disc implant includes an upper shell, a lower shell, and a spacer therebetween. The spacer preferably has properties similar to that of a natural spinal disc, while the upper and lower shells form a rigid interface between the implant and the adjacent vertebral bodies. The upper and lower shells can be configured to prevent expulsion of the spacer from the disc space. The implant upper and lower shells may further be configured into partially cylindrical shapes for ease of insertion through an insertion tube as presently known for interbody fusion devices. The devices may further be configured for insertion through a double-barreled insertion tube. Methods and instruments for inserting an artificial disc implant are also provided.

Owner:SDGI HLDG

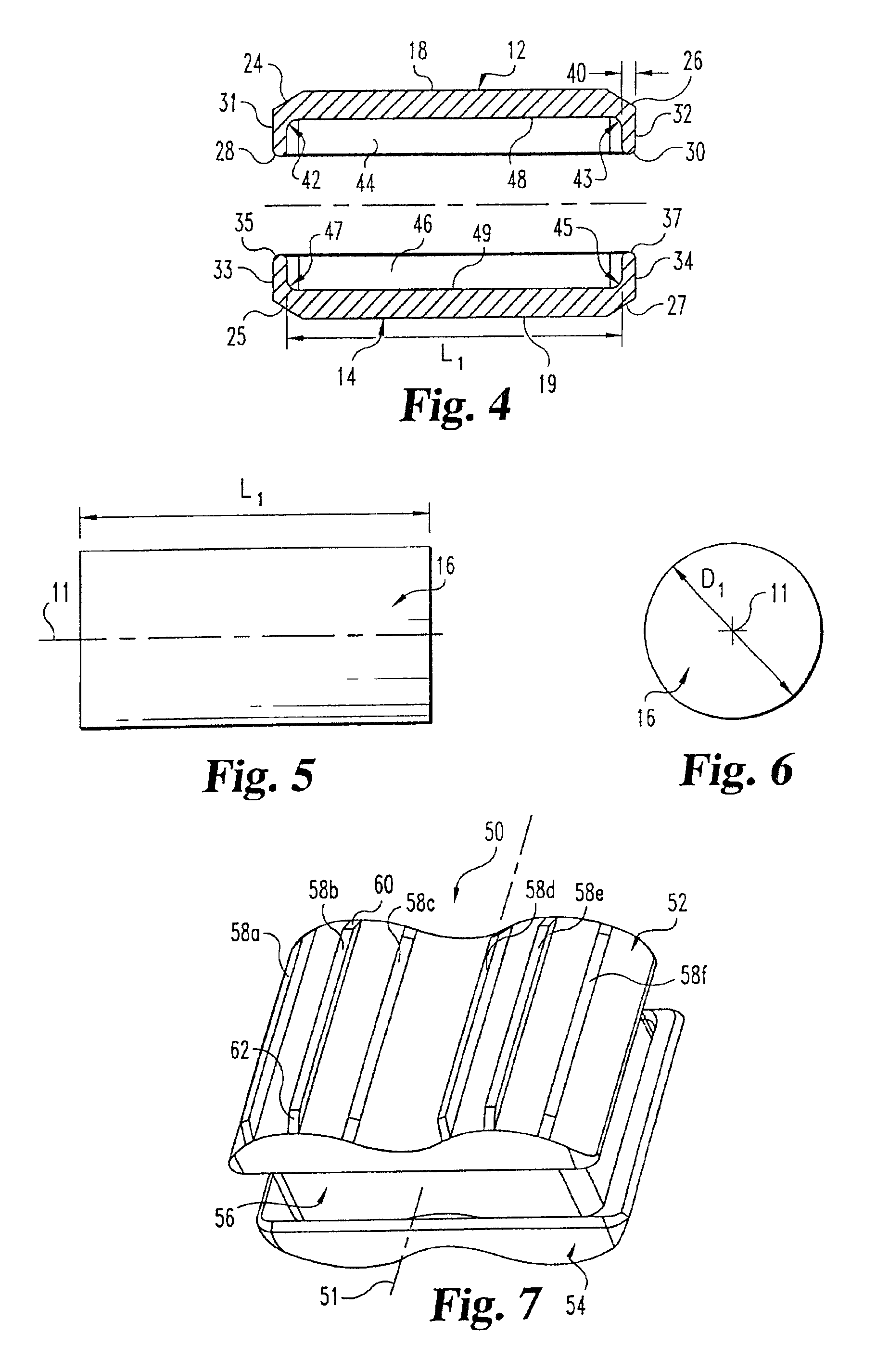

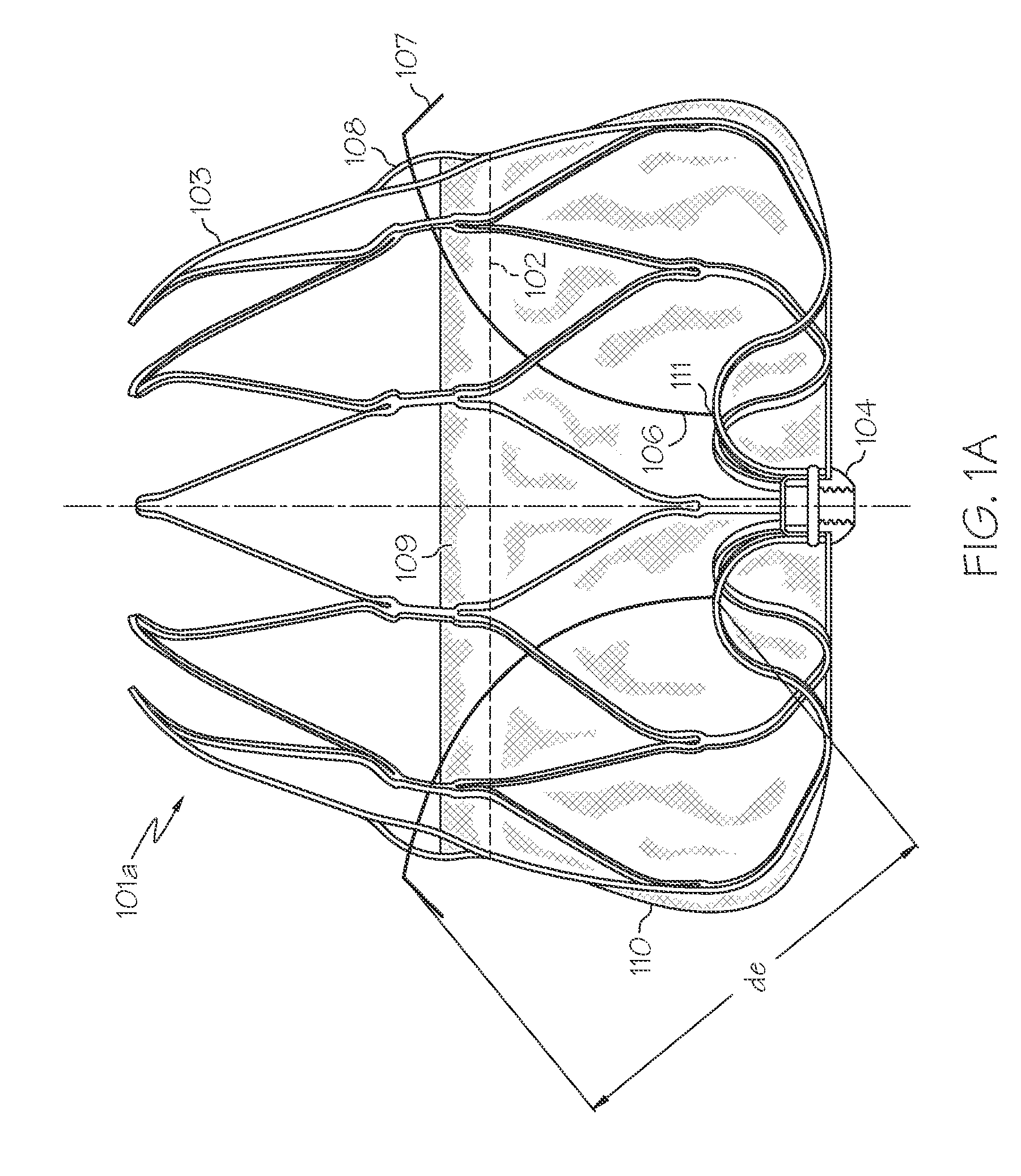

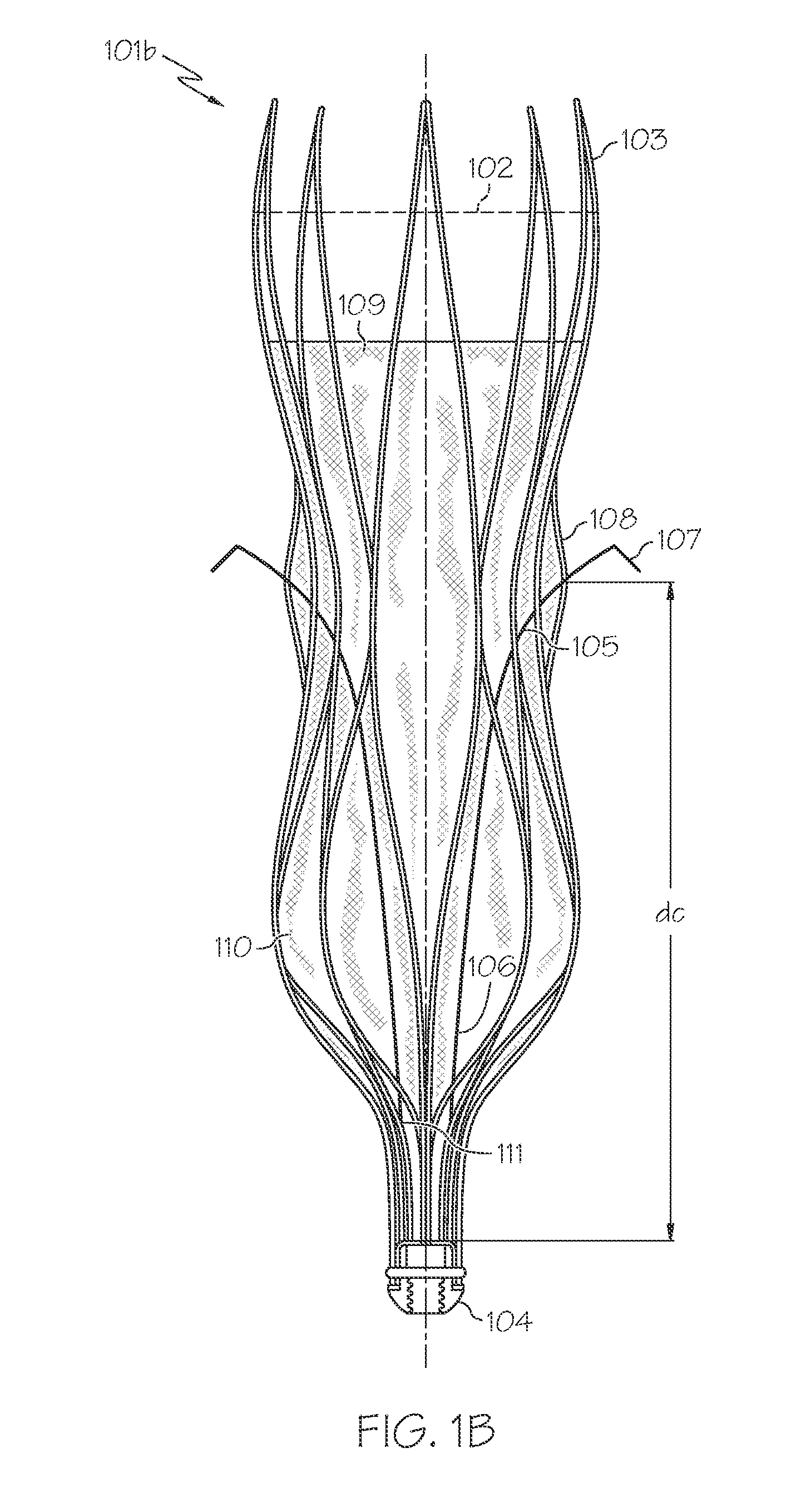

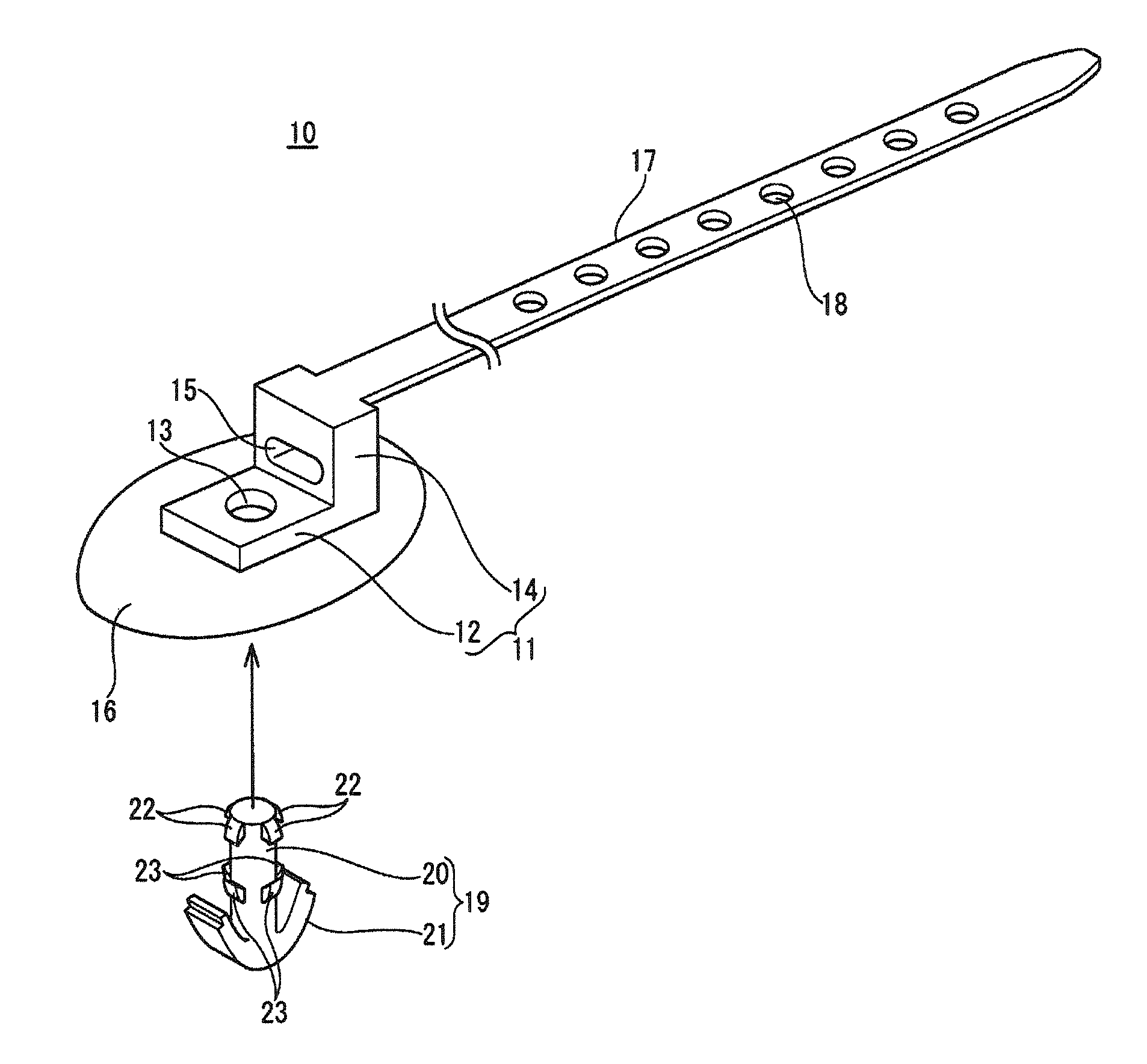

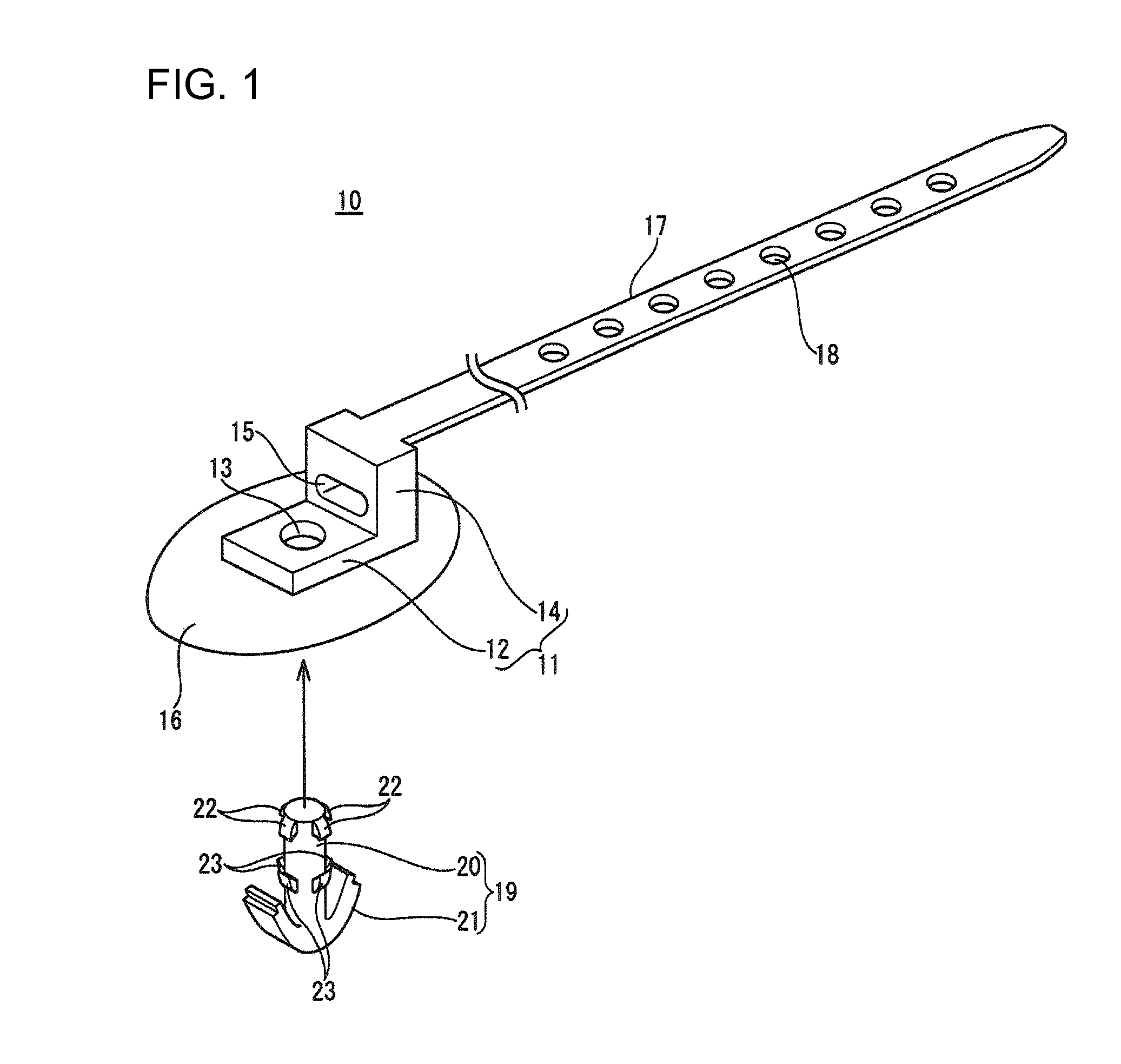

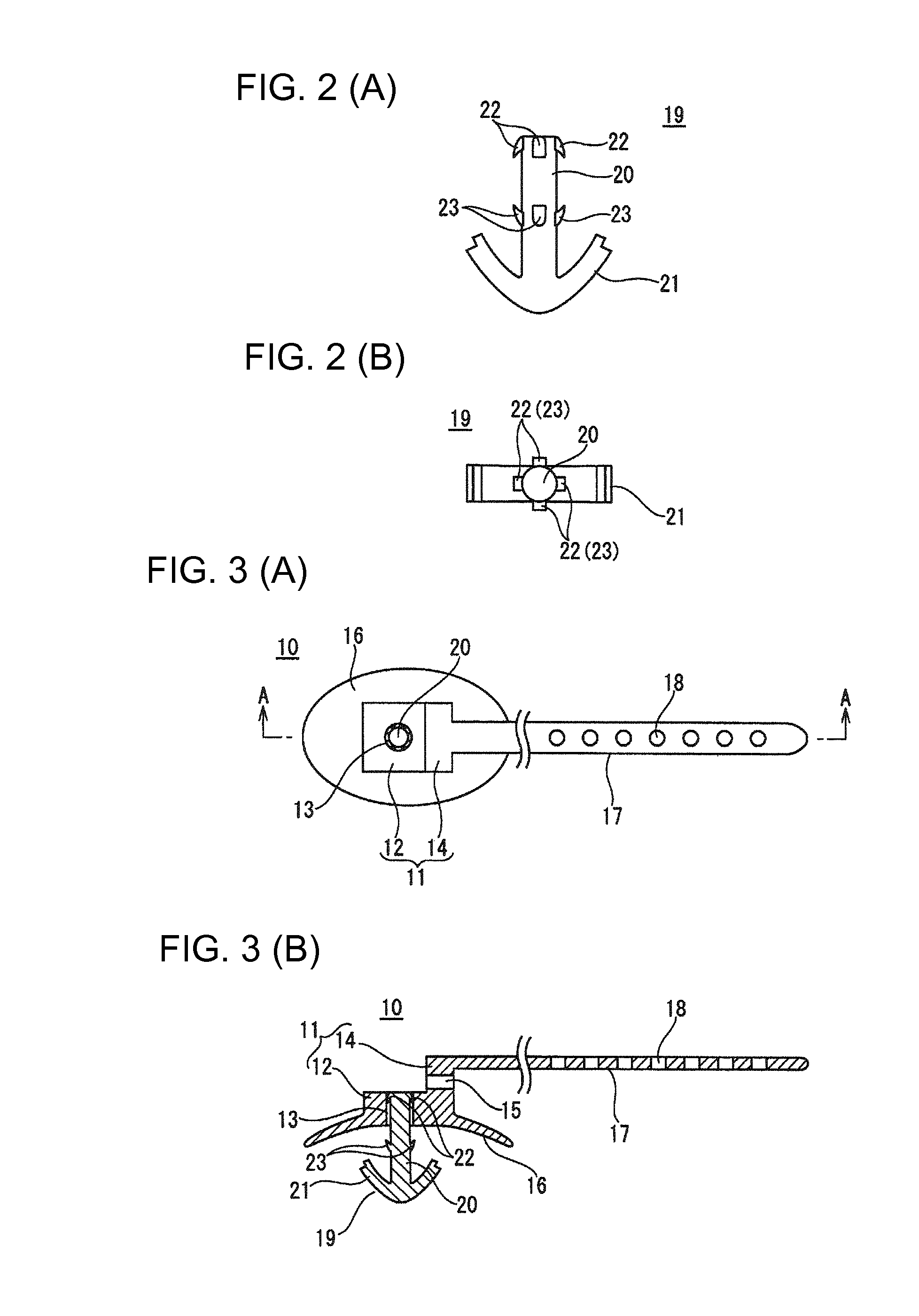

Fixation Anchor Design for an Occlusion Device

An implantable medical device having barbs reducing in height and / or changing angle as the implantable medical device transitions for an expanded state to a constrained state is disclosed which may lessen the risk of injury associated with the removal and / or repositioning of a deployed device. Within the main body of the device may be positioned a plurality of fixation struts having an end secured to the main body and a barb end exiting the main body at a point of egress and extending radially outwards from the main body. The fixation struts may be secured to the main body such that the distance between the point of attachment of the secured end of a fixation strut and the respective point of egress from the main body its free barb forming end is greater in the constrained than expanded state.

Owner:BOSTON SCI SCIMED INC

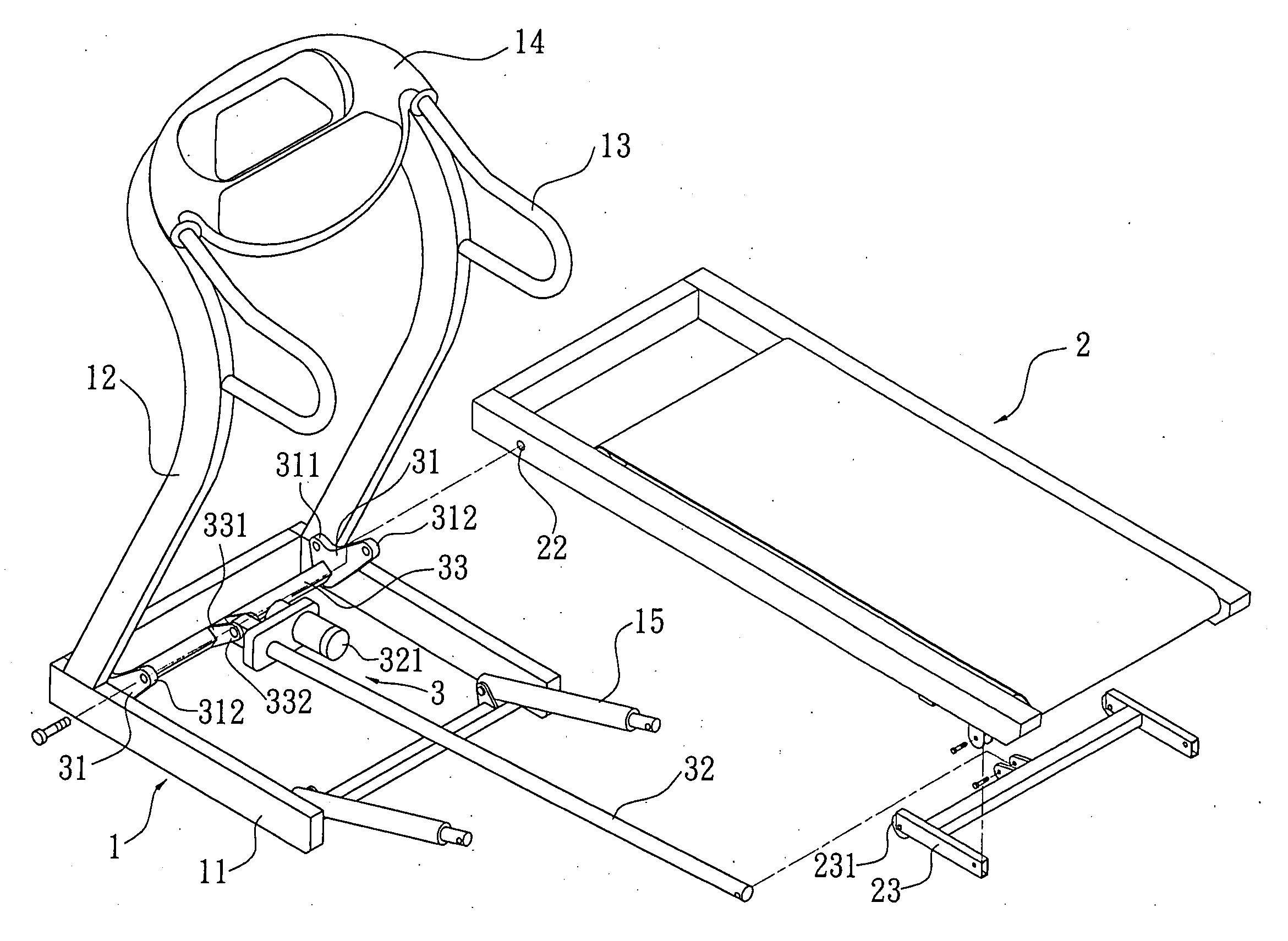

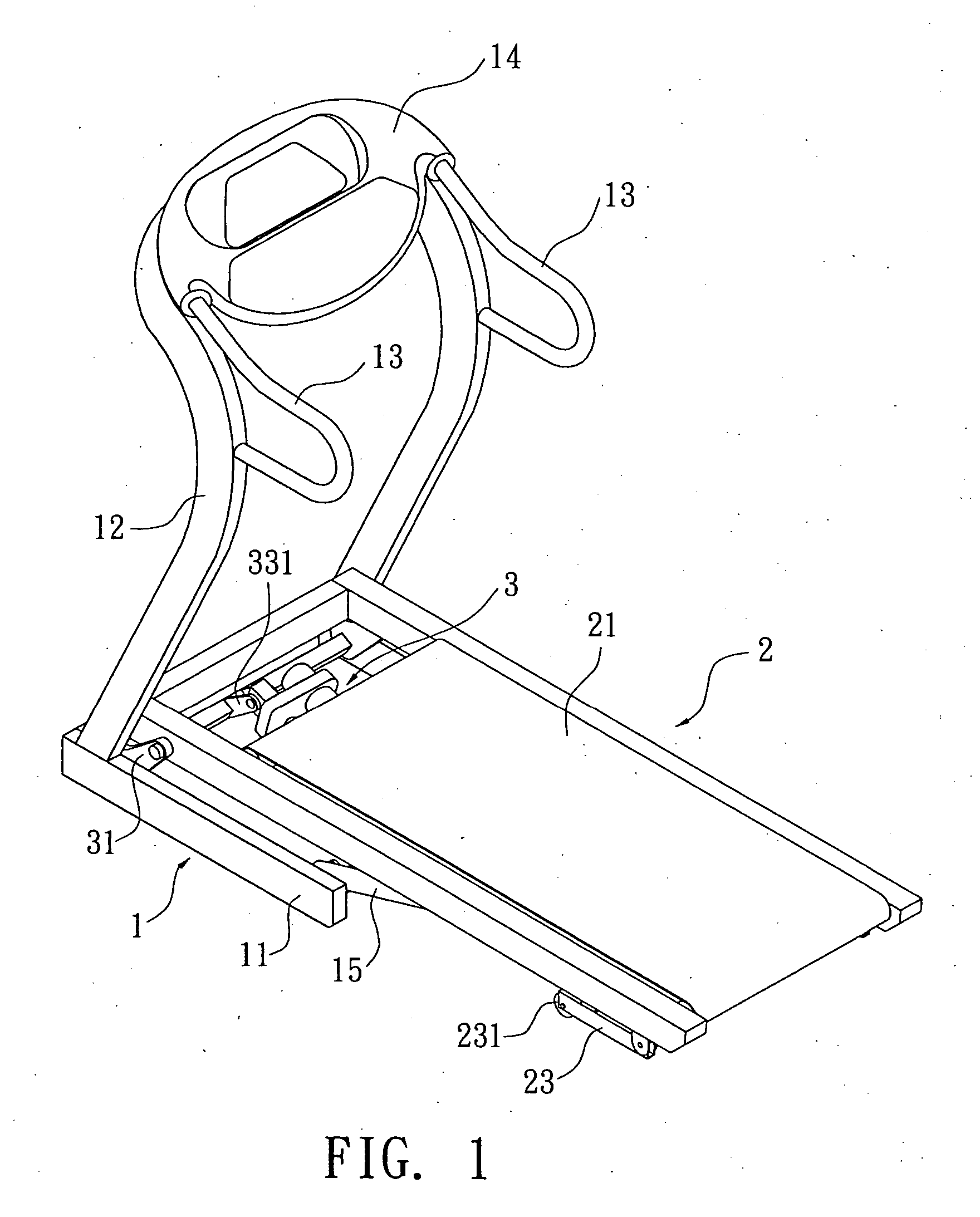

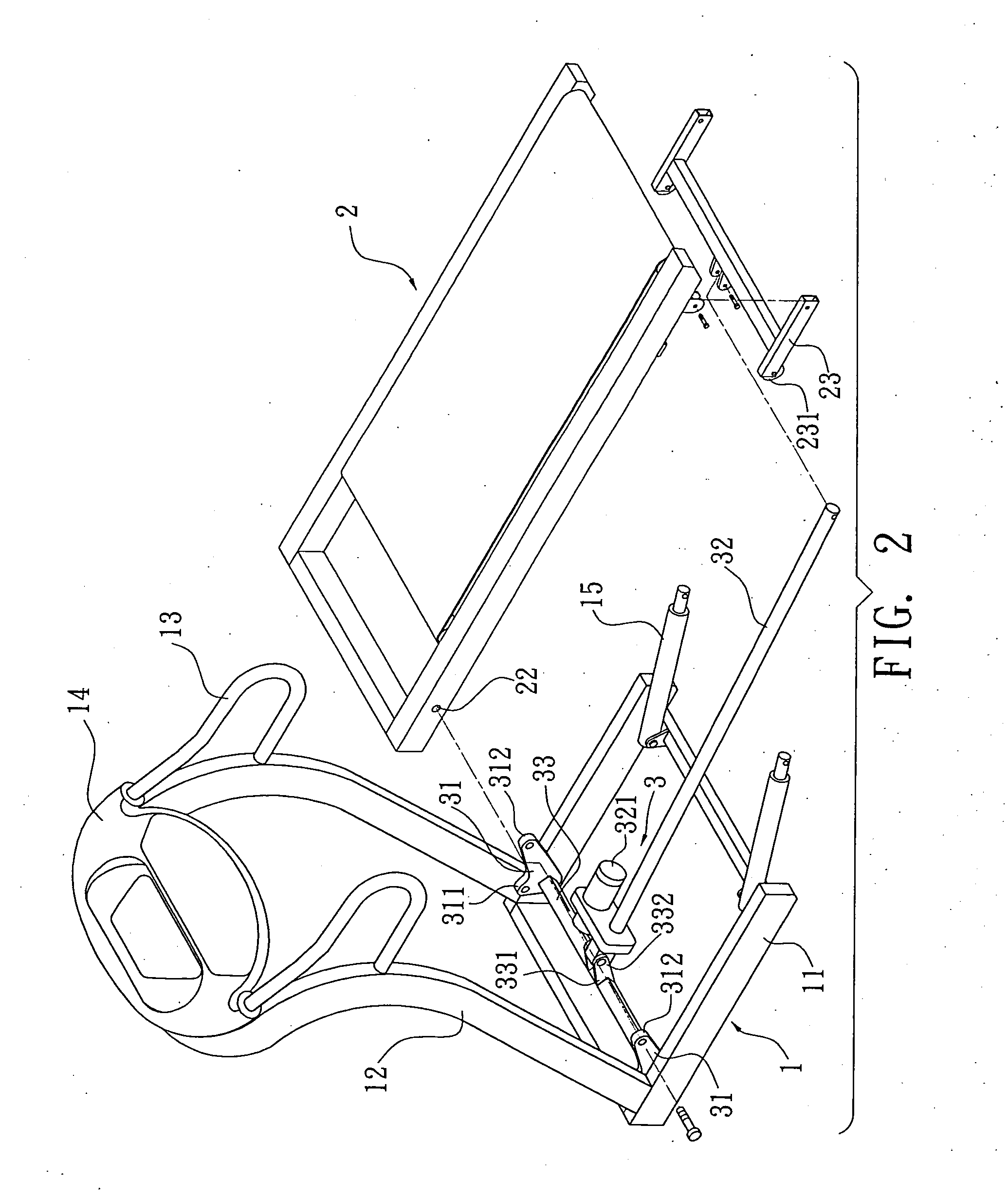

Treadmill with front and rear inclination adjustment unit

InactiveUS20050239607A1Improve securityReduce overall heightMovement coordination devicesCardiovascular exercising devicesEngineeringCaster

A treadmill with front and rear inclination adjustment unit, including a base seat having two support arms, a tread platform mounted between the support arms and an inclination adjustment unit disposed between the tread platform and the base seat. The inclination adjustment unit has two symmetrical ascending / descending members and a telescopic rod. First ends of the ascending / descending members are respectively pivotally connected with inner sides of bottom ends of the support arms. Second ends of the ascending / descending members are respectively pivotally connected with two sides of front end of the tread platform. A connecting seat is disposed at a middle section of the transverse beam. The connecting seat has a connecting end extending in the same direction as the second end of the ascending / descending member, whereby the connecting end and the second end are positioned on the same side. The connecting end of the connecting seat is pivotally connected with one end of the telescopic rod. The other end of the telescopic rod is pivotally connected with a caster rack under the bottom of the rear end of the tread platform.

Owner:ALILIFE INDAL

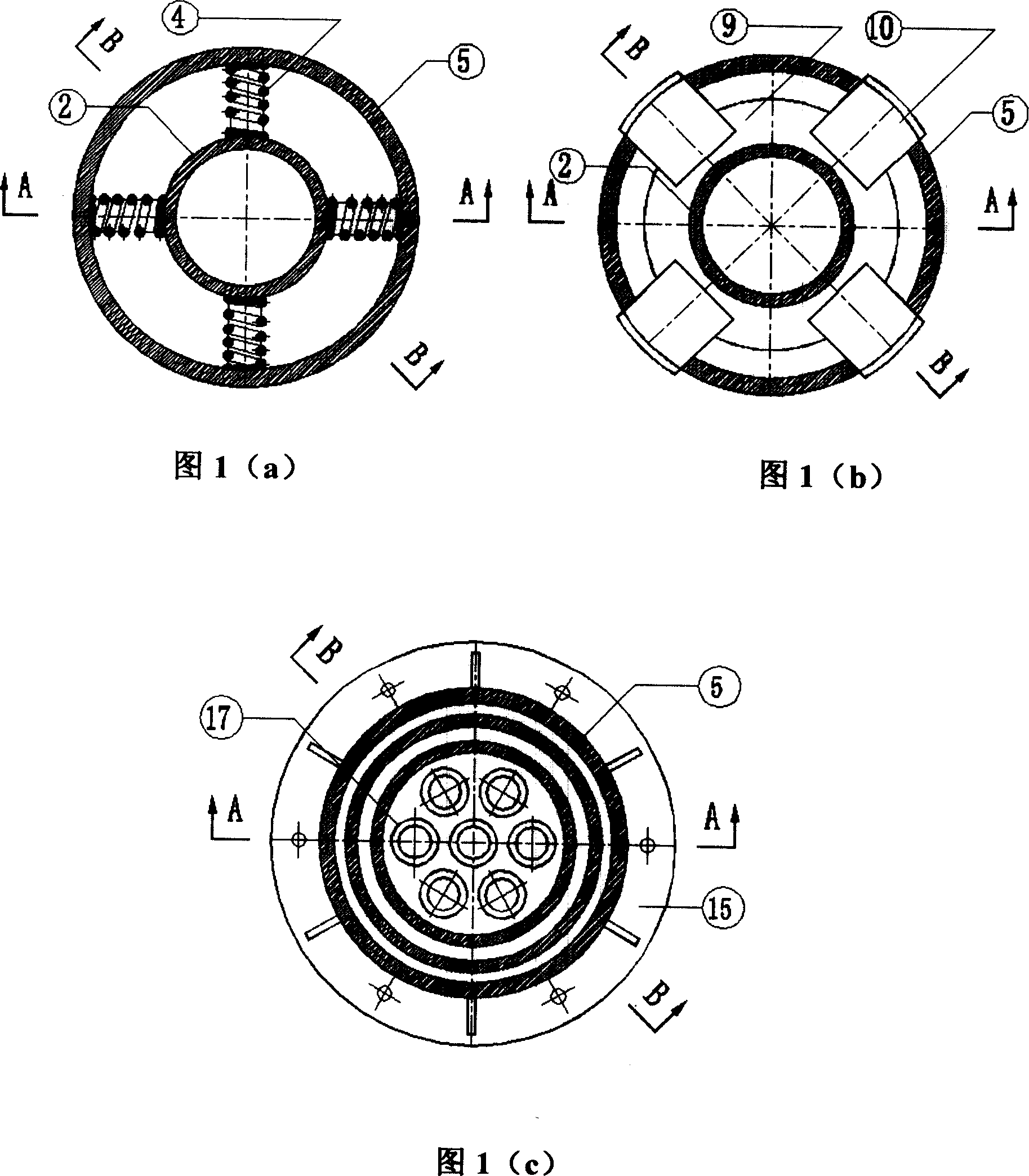

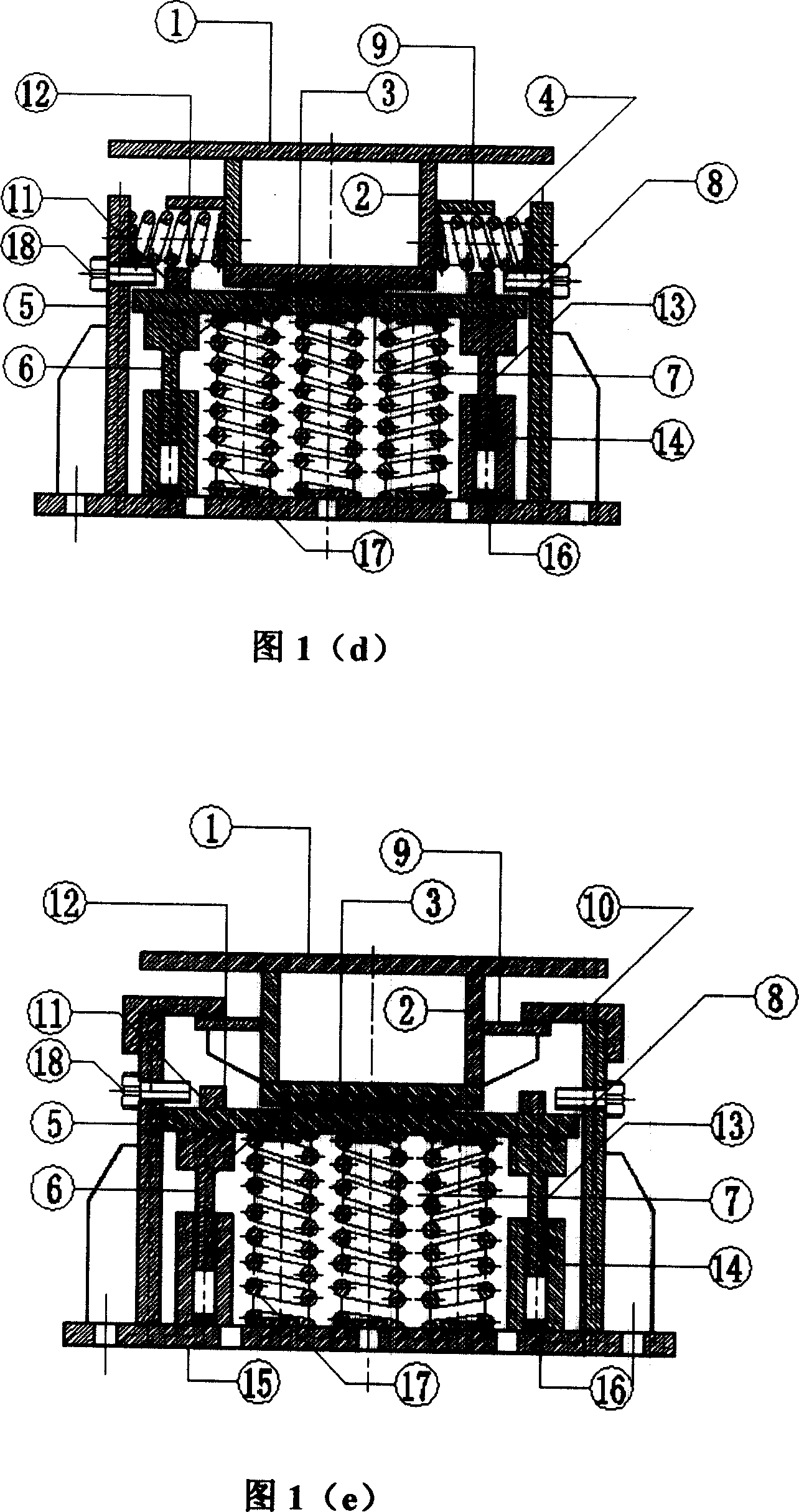

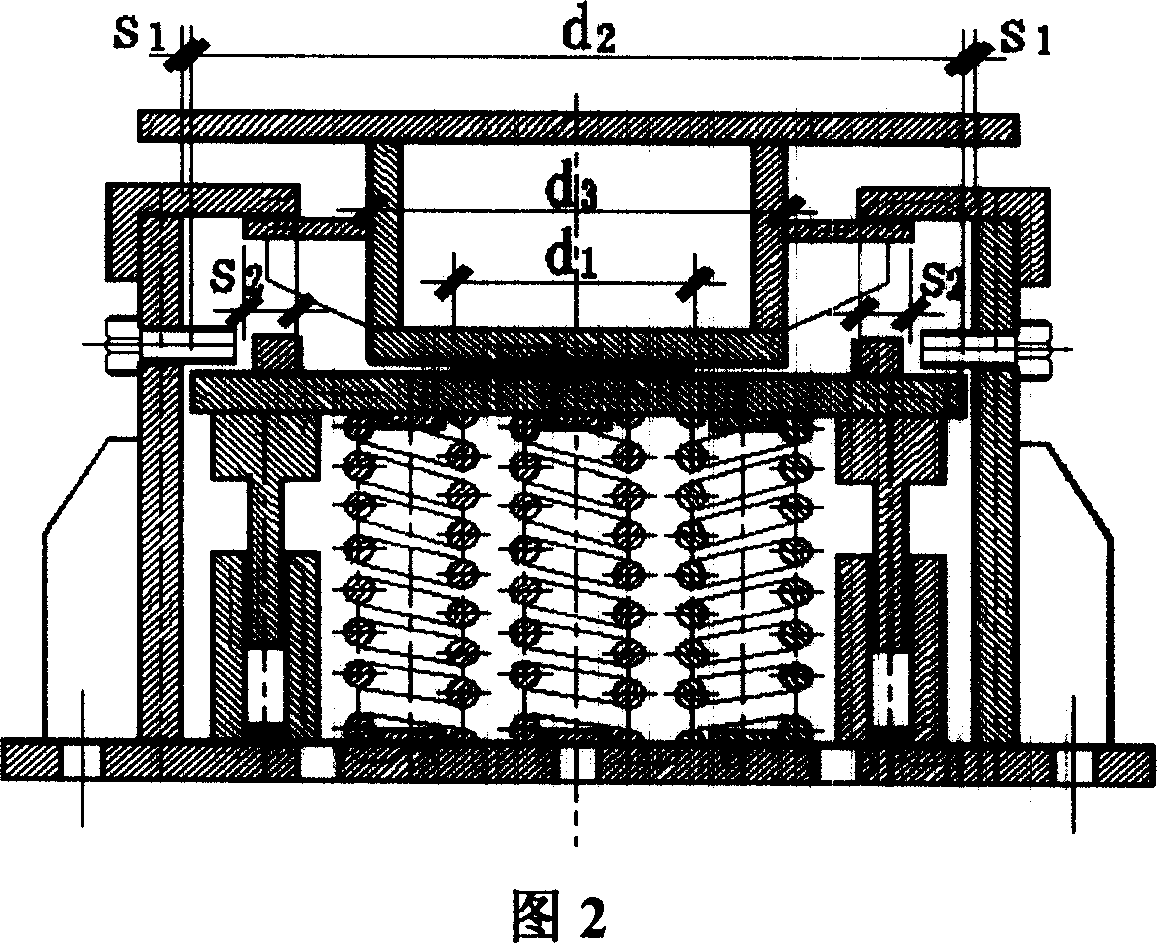

Friction-spring three-dimensional compounded shock isolating pedestal

InactiveCN101086189AReduce overall heightGuaranteed stabilityProtective buildings/sheltersMesh gridStructural engineering

The friction spring three-dimensional composite shock-proof bearing belongs to the shock insulation and damping control area. The application of the prior three-dimensional composite shock-proof bearing into the large span mesh roof structure has the following problems: (1) the level shock-proof bearing is series-connected with the vertical shock-proof device, the height of the bearing is large, so it is lack of stability ; (2) the horizontal displacement of the structure under earthquake is large, (3) it is lack of vertical pulling-proof ability, the bearing rotational capacity is insufficient. The composite shock-proof bearing in the invention mainly includes horizontal shock-proof device and vertical shock-proof device, the whole appearance of bearing is cylindrical. The horizontal direction of the bearing uses the plate slip shock-proof device to lower the height of bearing, and the stability is effectively guaranteed, at the same time the horizontal direction also is equipped with reset and spacing device to make the bearing has reset and spacing functions. The vertical direction uses spring shock-proof and has rational rotary capability through the structure design. In addition, the integral bearing in the invention has the anti-pulling performance.

Owner:BEIJING UNIV OF TECH

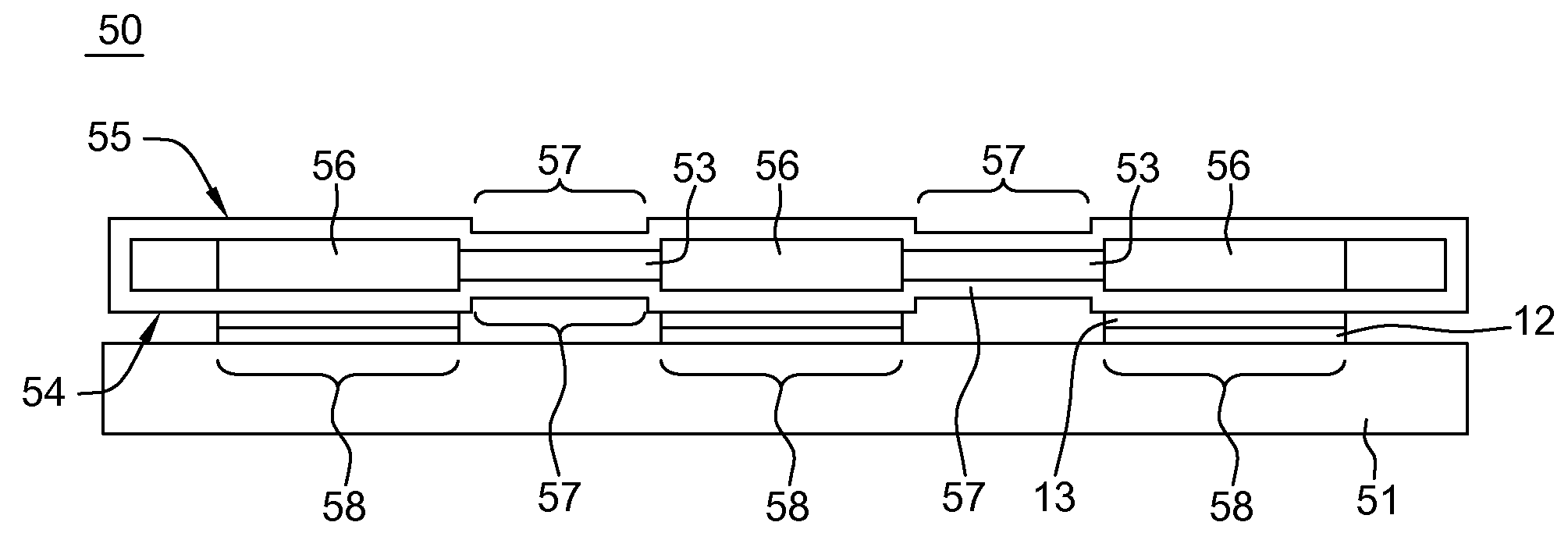

Flexible cold plate with enhanced flexibility

InactiveUS20160290728A1Reduce overall heightReduce stiffnessReinforcing meansSemiconductor/solid-state device detailsThermal energyEngineering

An apparatus for cooling an electronic component has a planar top member of a thermal energy conductive material and a parallel planar bottom member of the material, the planar bottom member including a surface having regions configured for heat exchange contact with the electronic component. The joined planar top and bottom members have a sidewall structure of reduced height (and generally the height of the cold plate) between active areas in order to improve flexibility. The stiffness of the sidewalls is reduced by very advantageously reduce the height of the sidewalls. In one embodiment, the sidewalls are shorter in height corresponding to regions only between active areas. Alternatively, the sidewalls are of reduced height everywhere by insetting the active areas within the top and / or bottom sheets.

Owner:IBM CORP

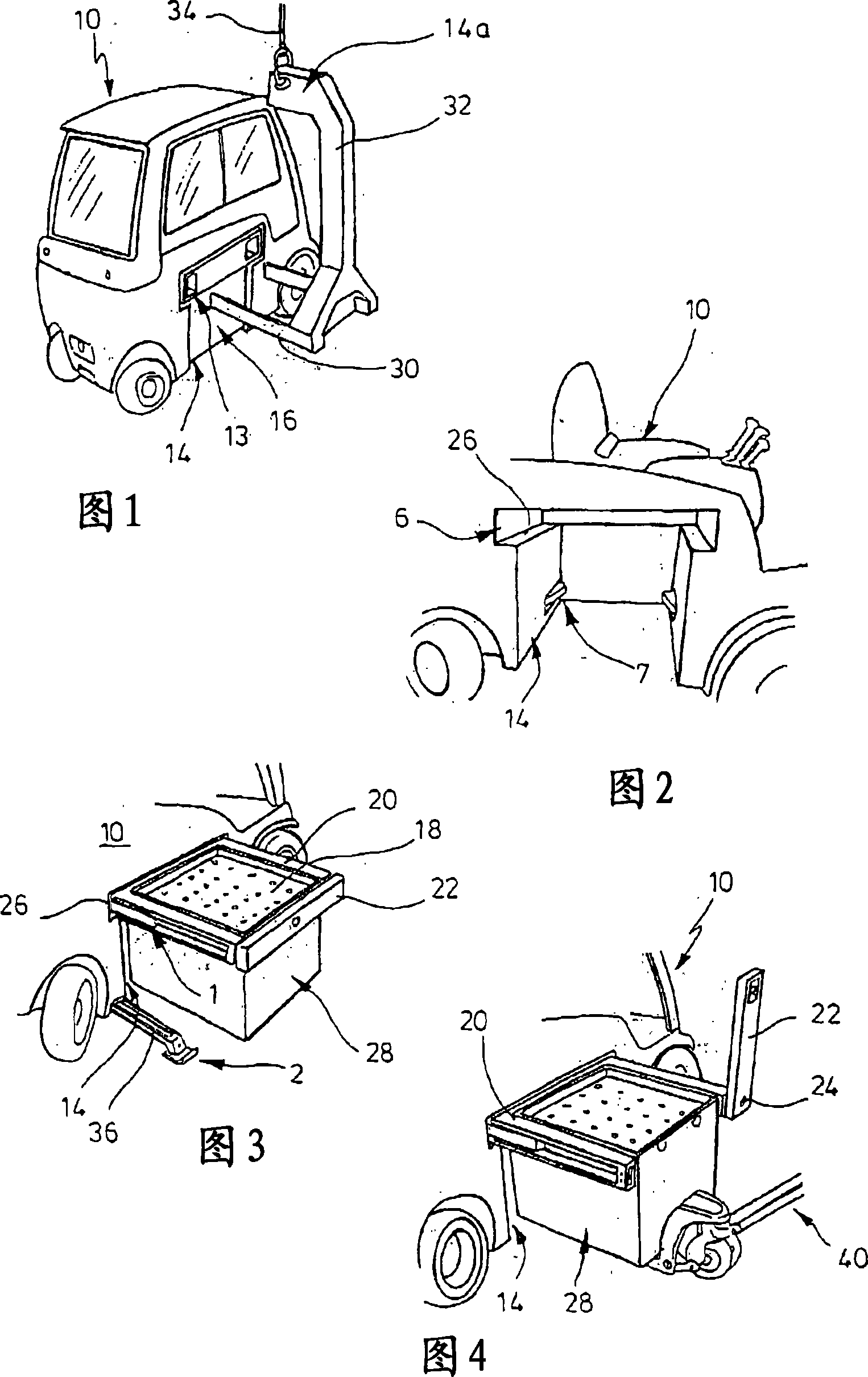

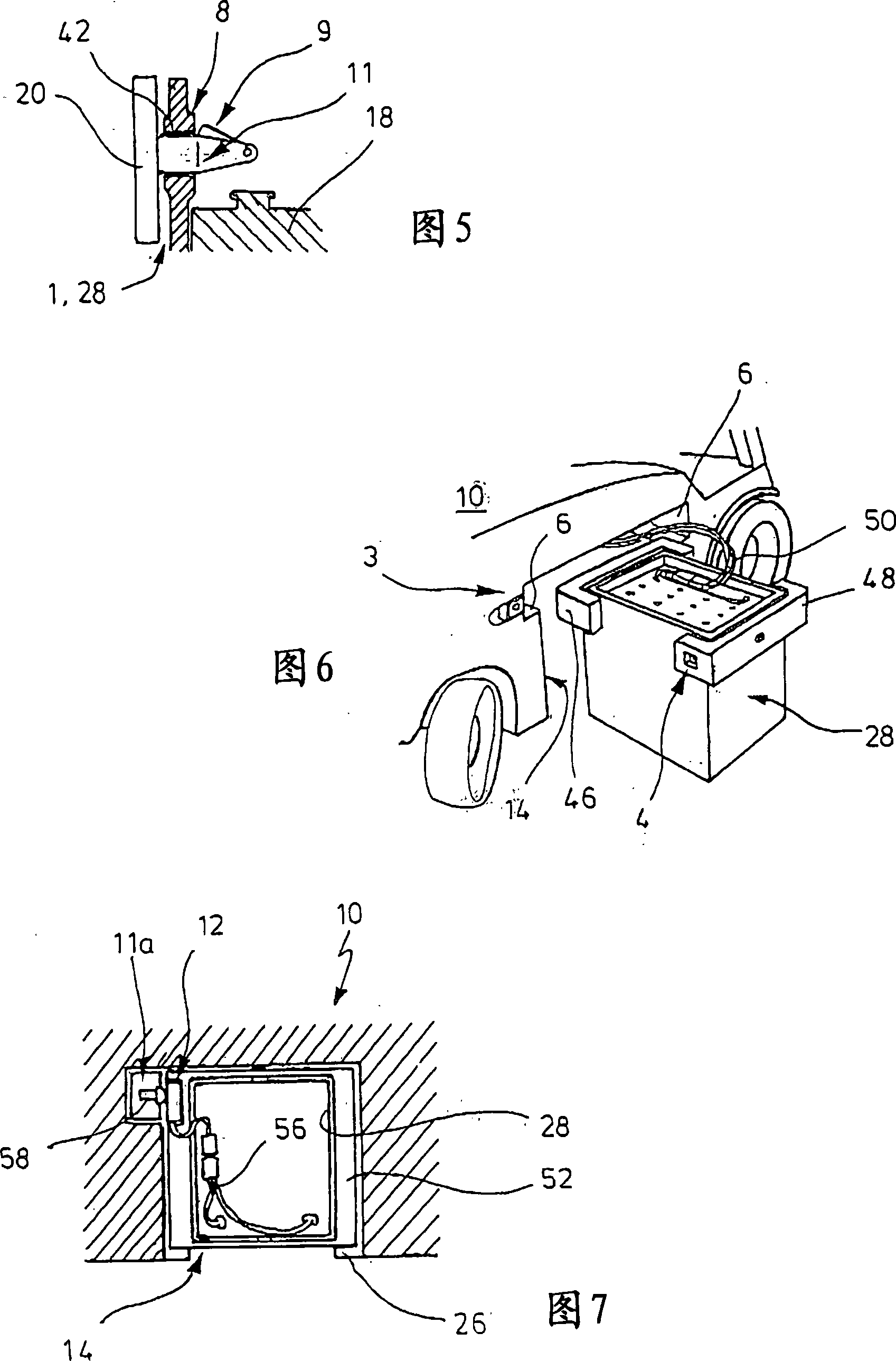

Battery exchange system for a battery-driven industrial truck

InactiveCN101100184AReduce overall heightCharging stationsElectric propulsion mountingTruckBearing surface

Battery exchange system for a battery-driven industrial truck, in which the chassis of the industrial truck comprises a battery compartment open to the side of the industrial truck for side installation and removal of a battery container, on the battery container on at least two opposing sides at least one respective laterally projecting support element being attached with a downwardly facing bearing surface and the battery compartment on opposing sides comprising horizontal support surfaces spaced apart from one another in parallel on which the support elements are supported with their bearing surfaces, when the battery container is inserted into the battery compartment.

Owner:JUNGHEINRICH AG

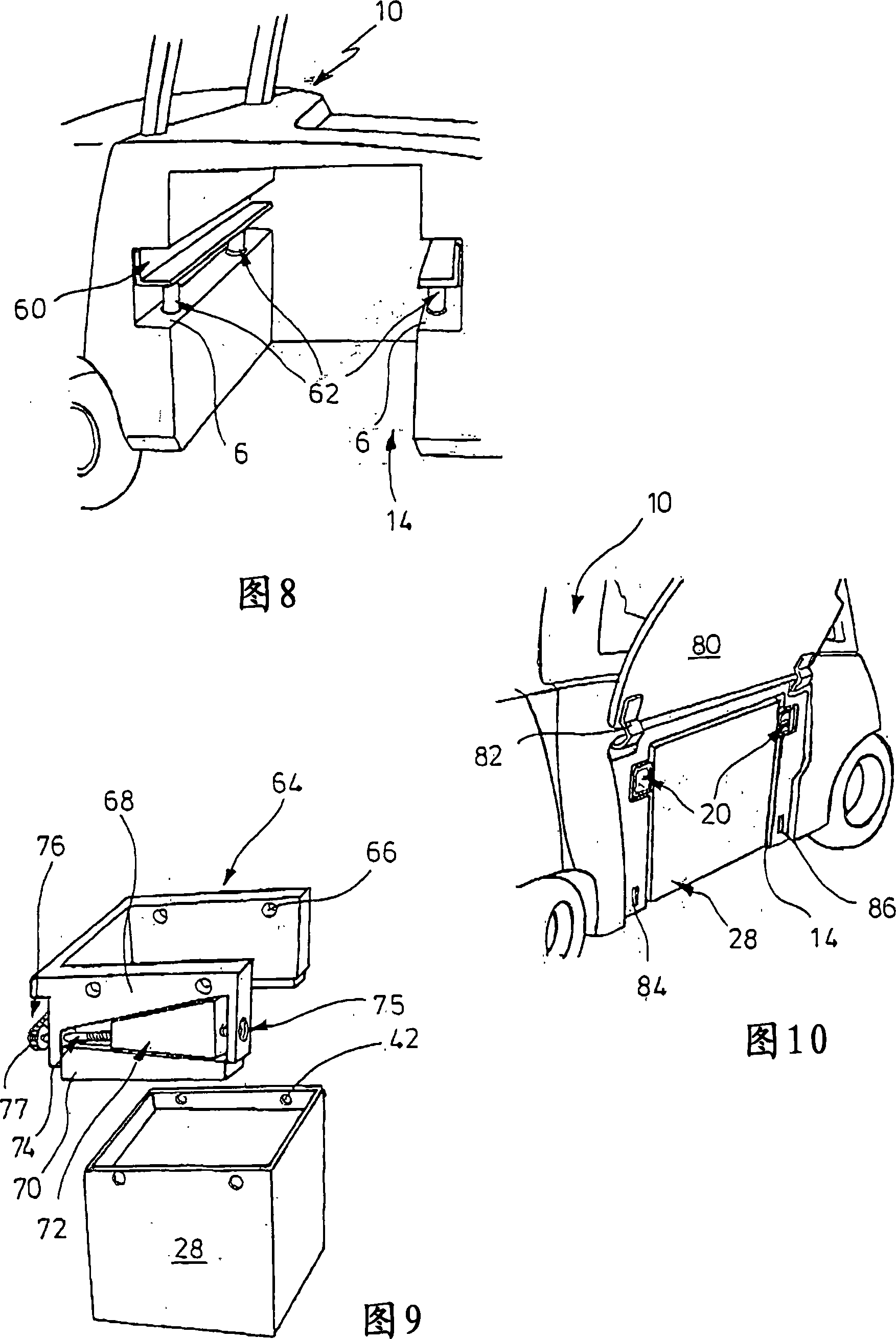

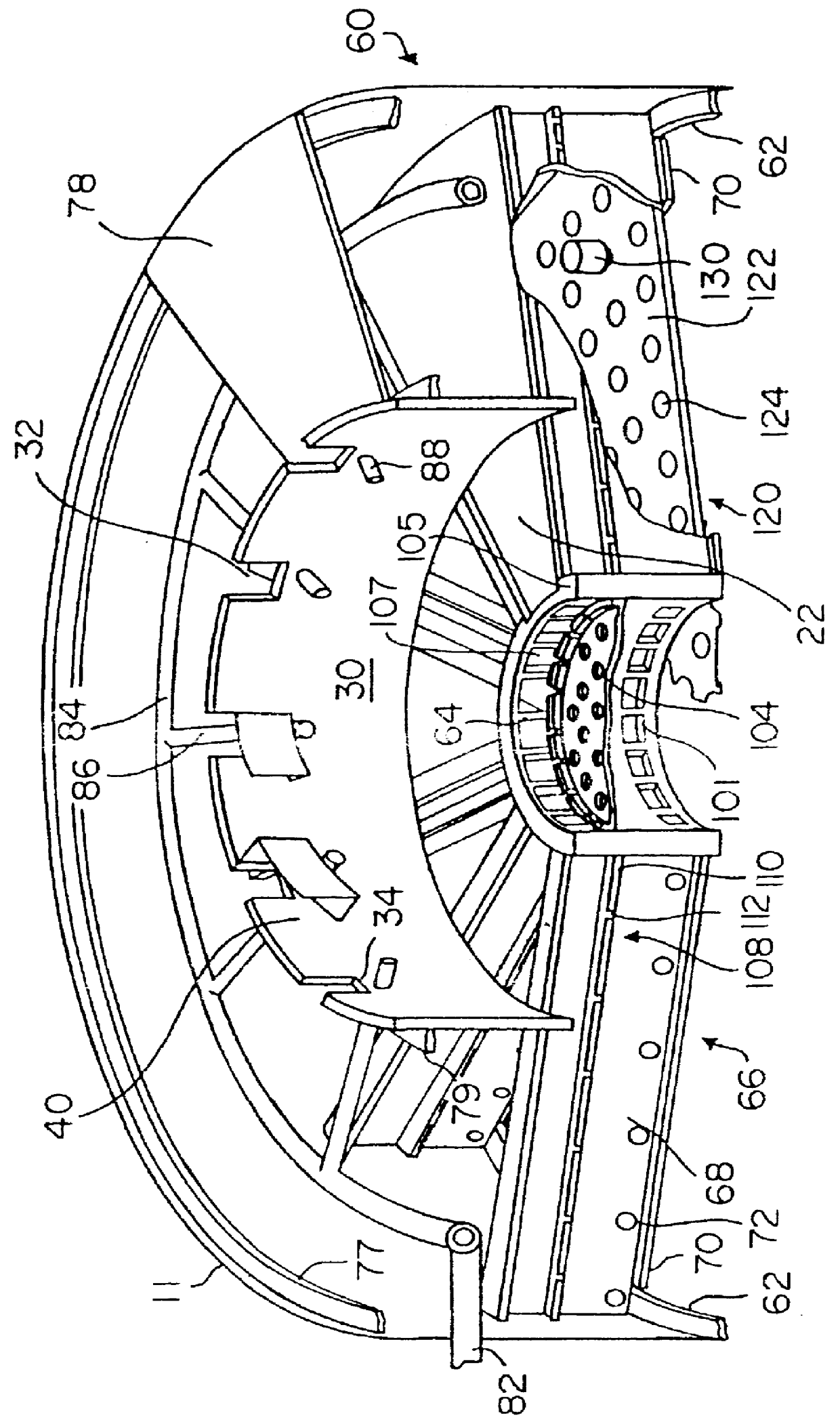

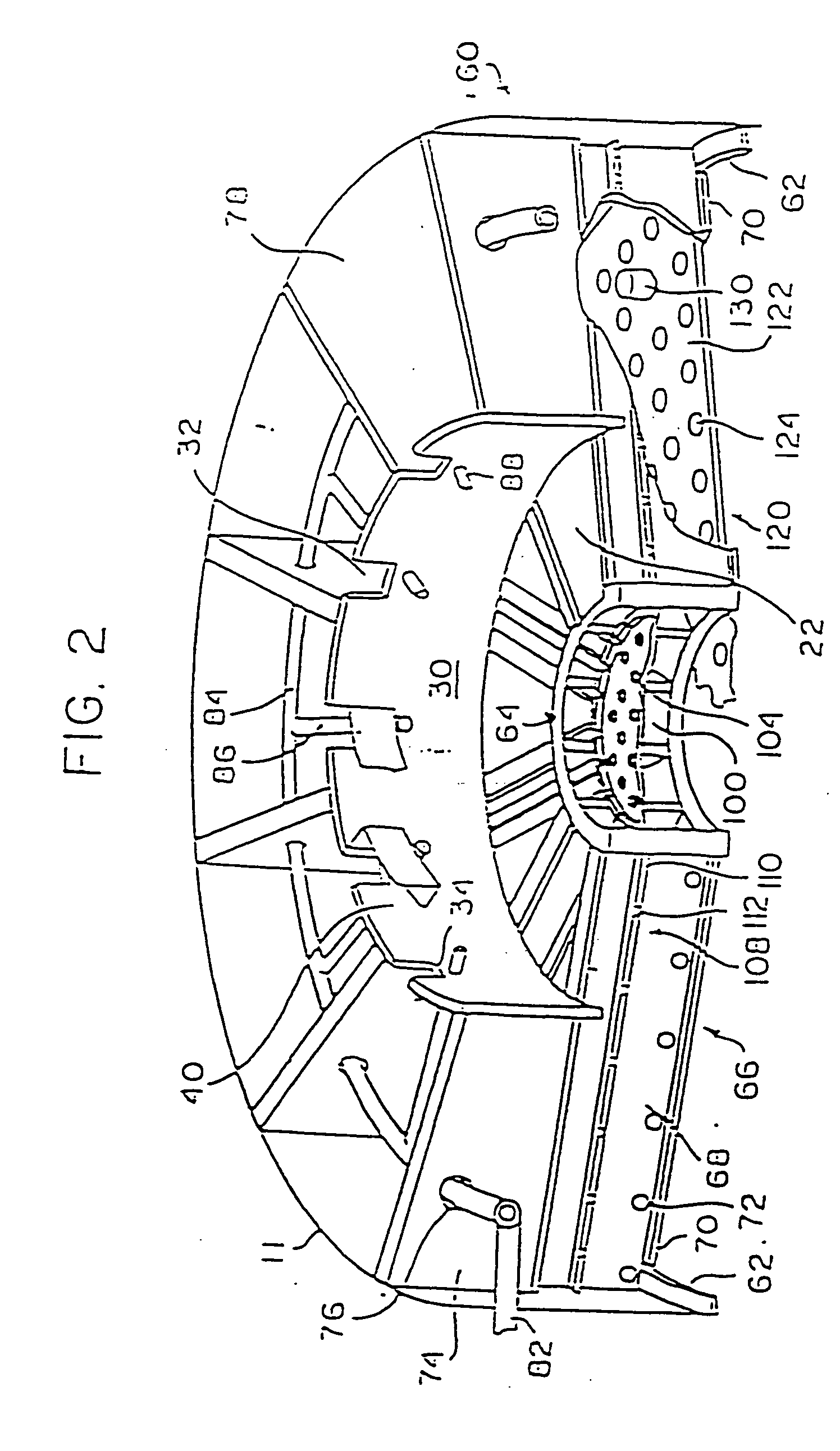

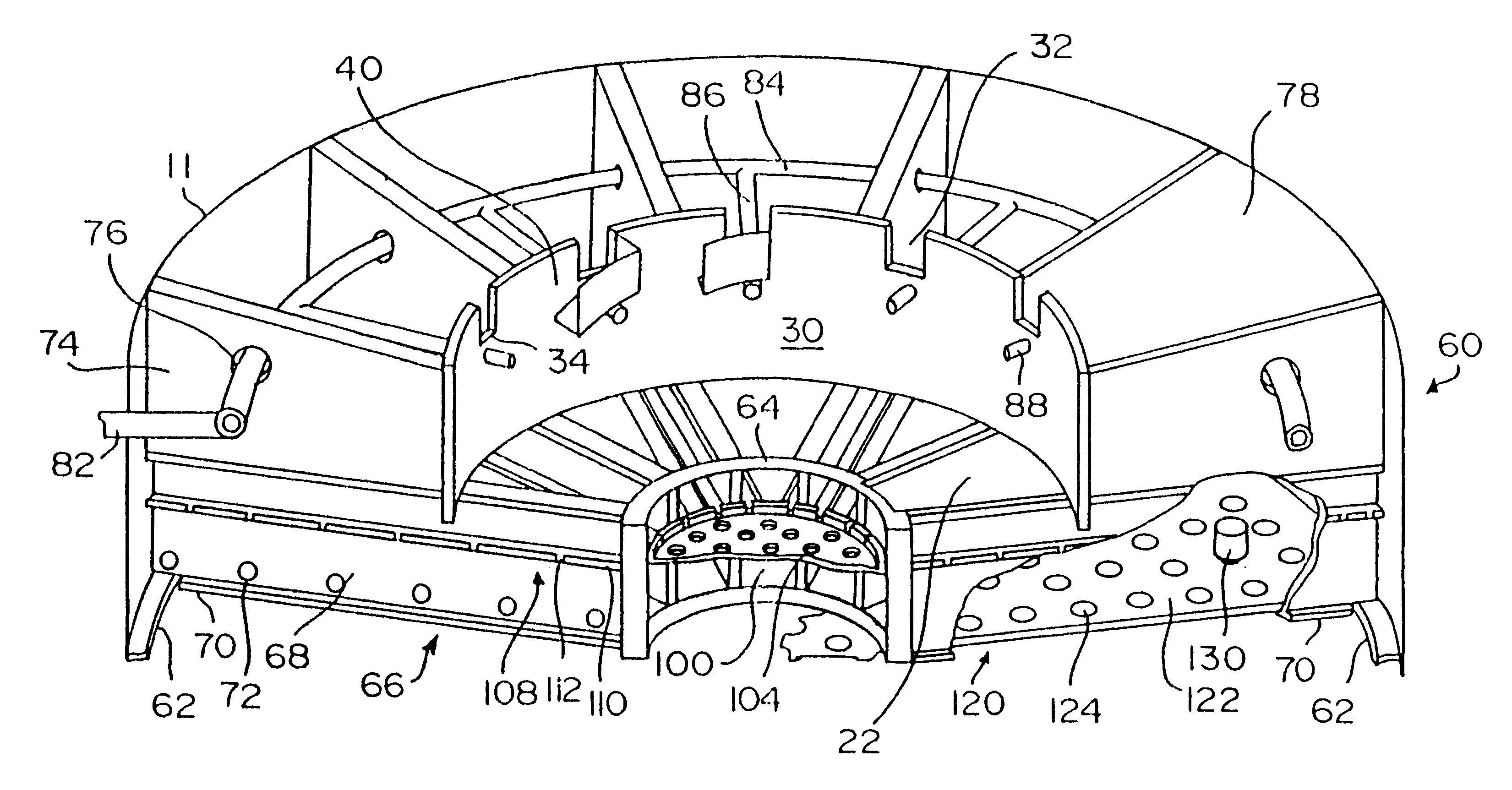

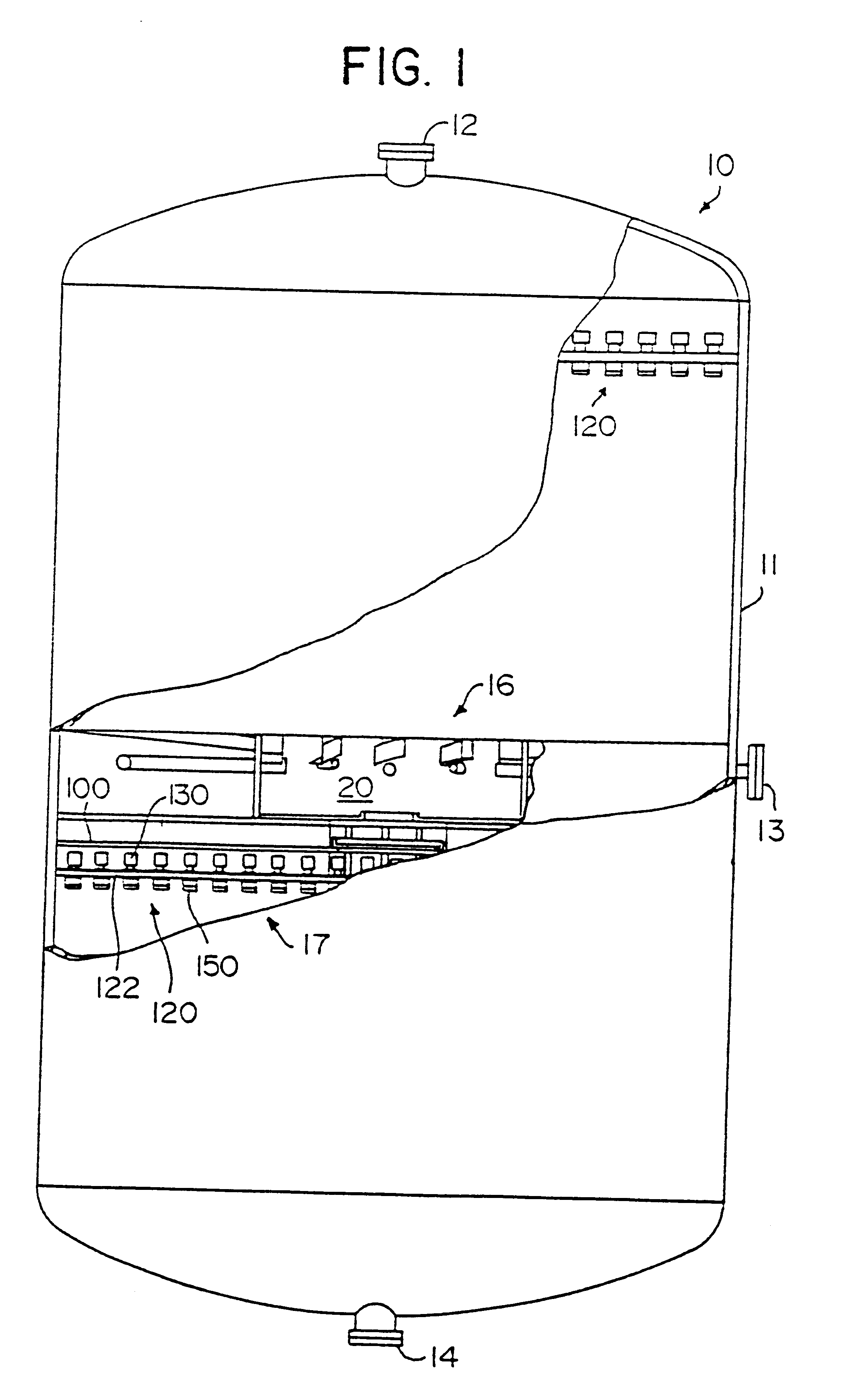

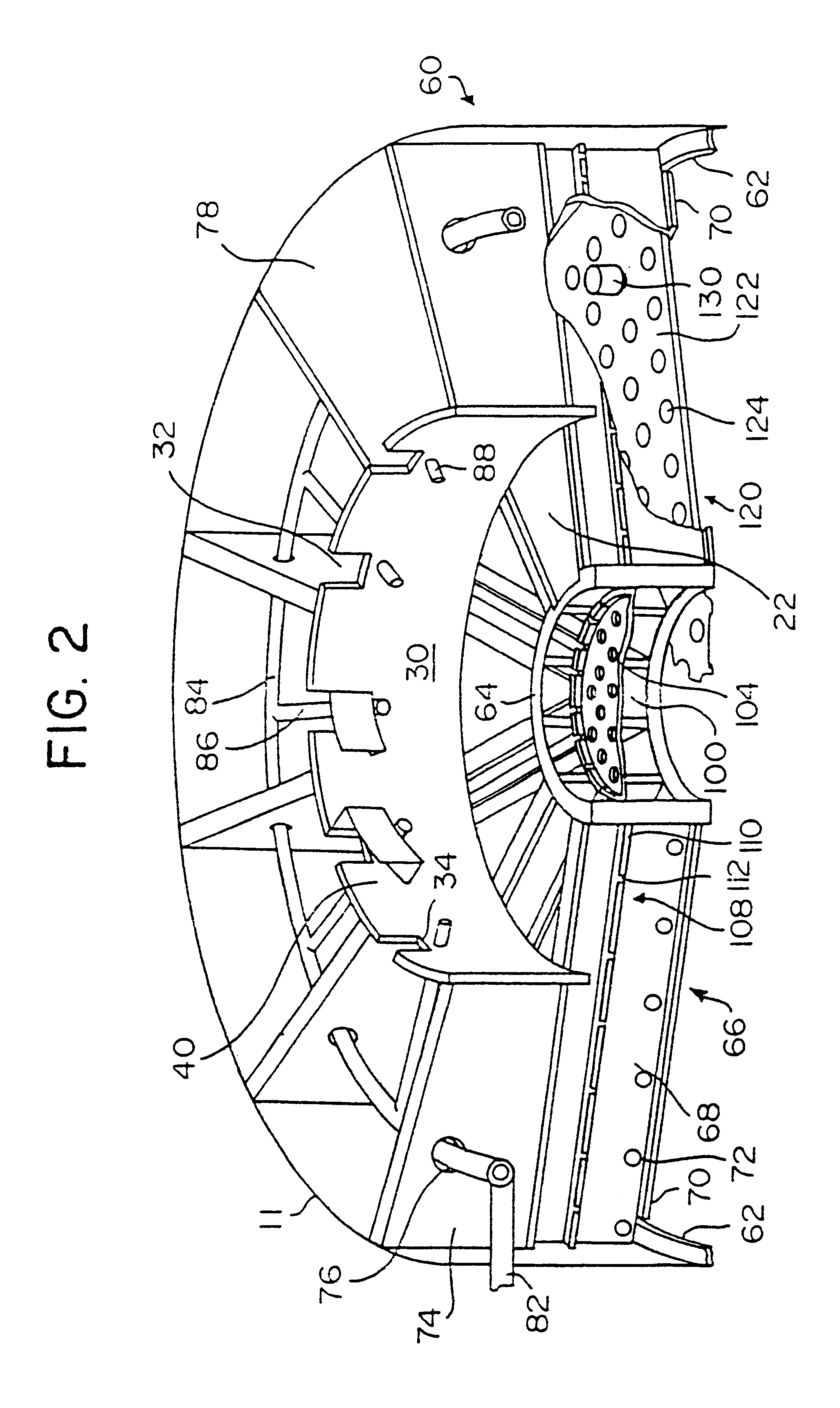

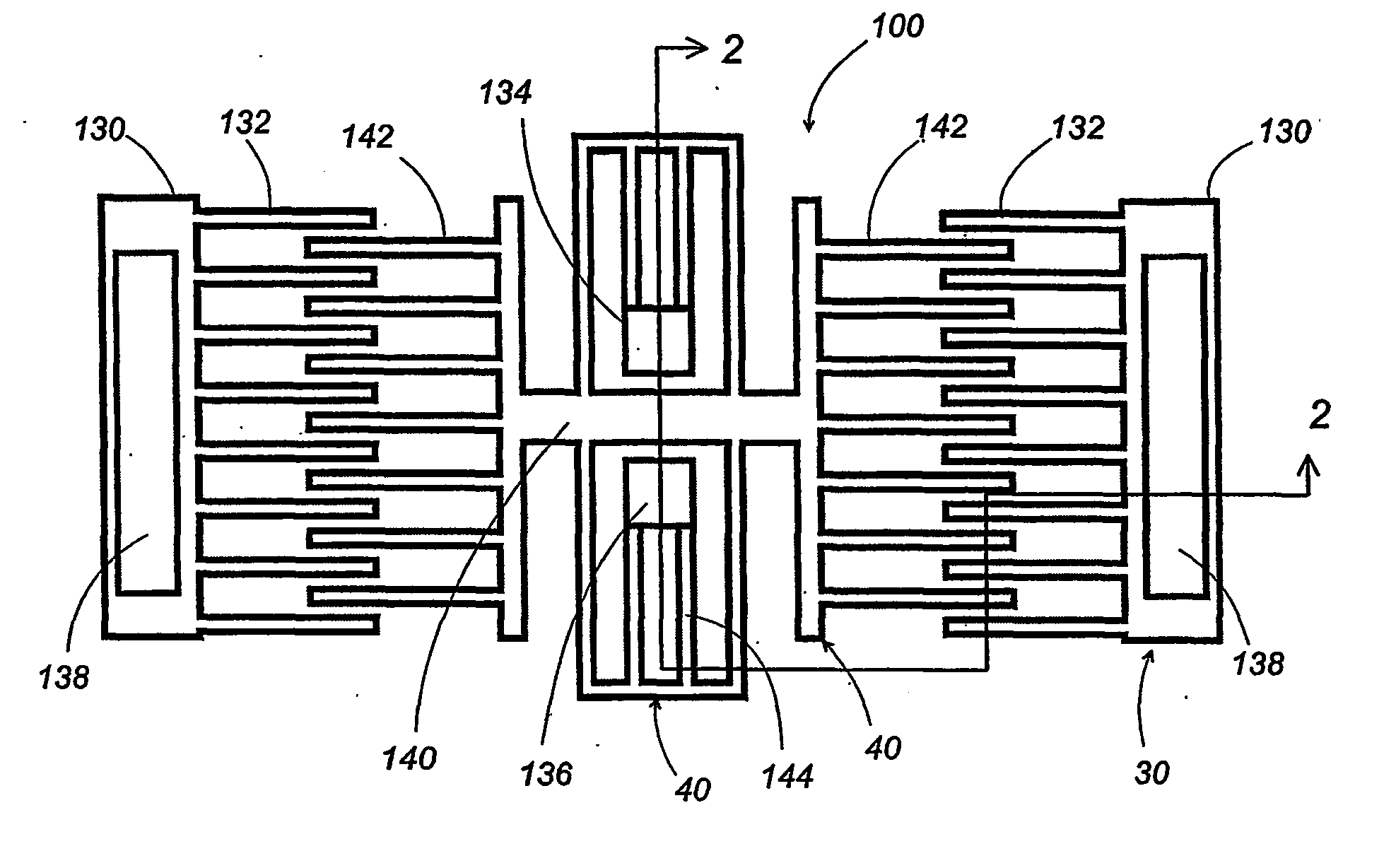

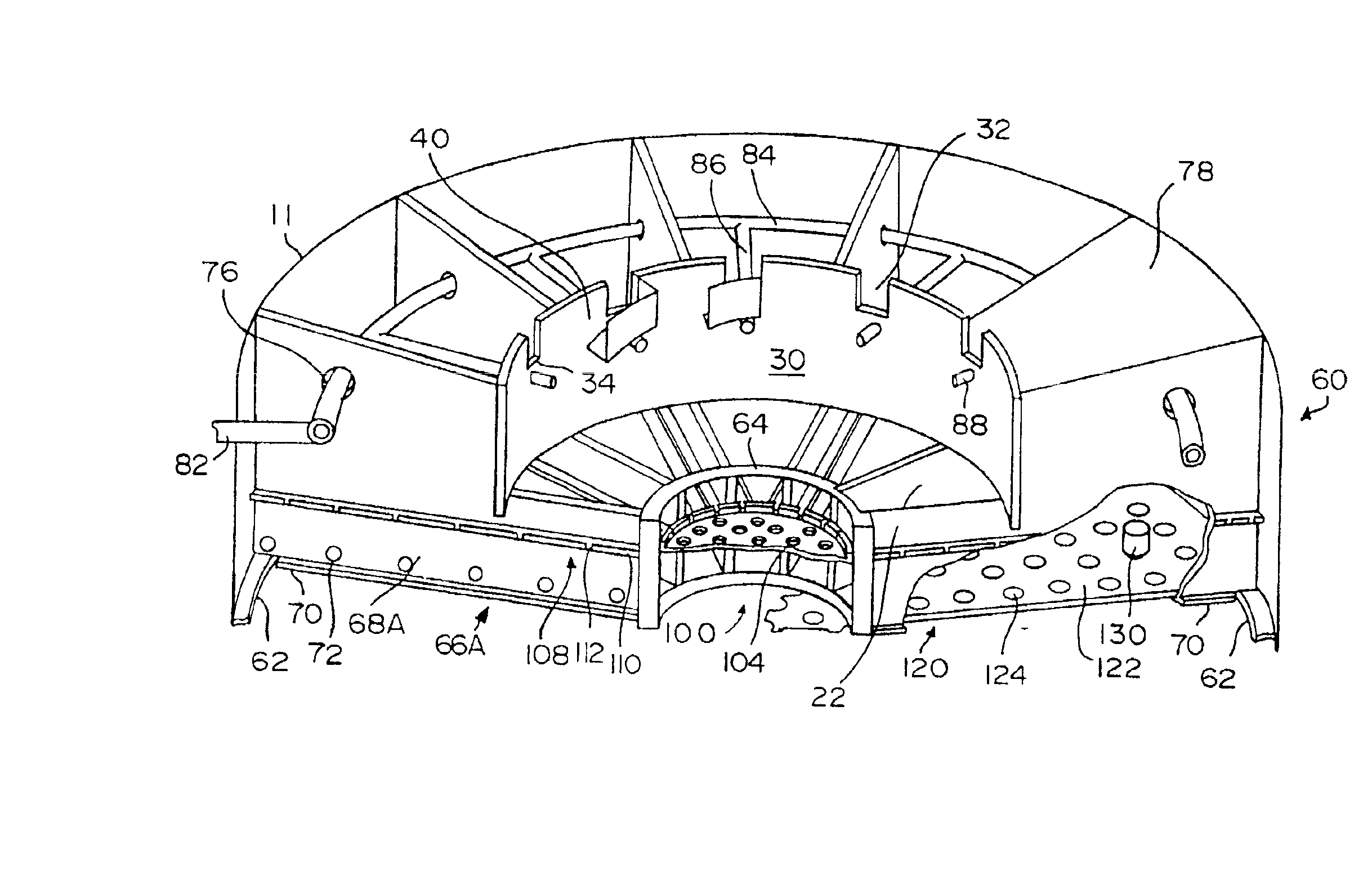

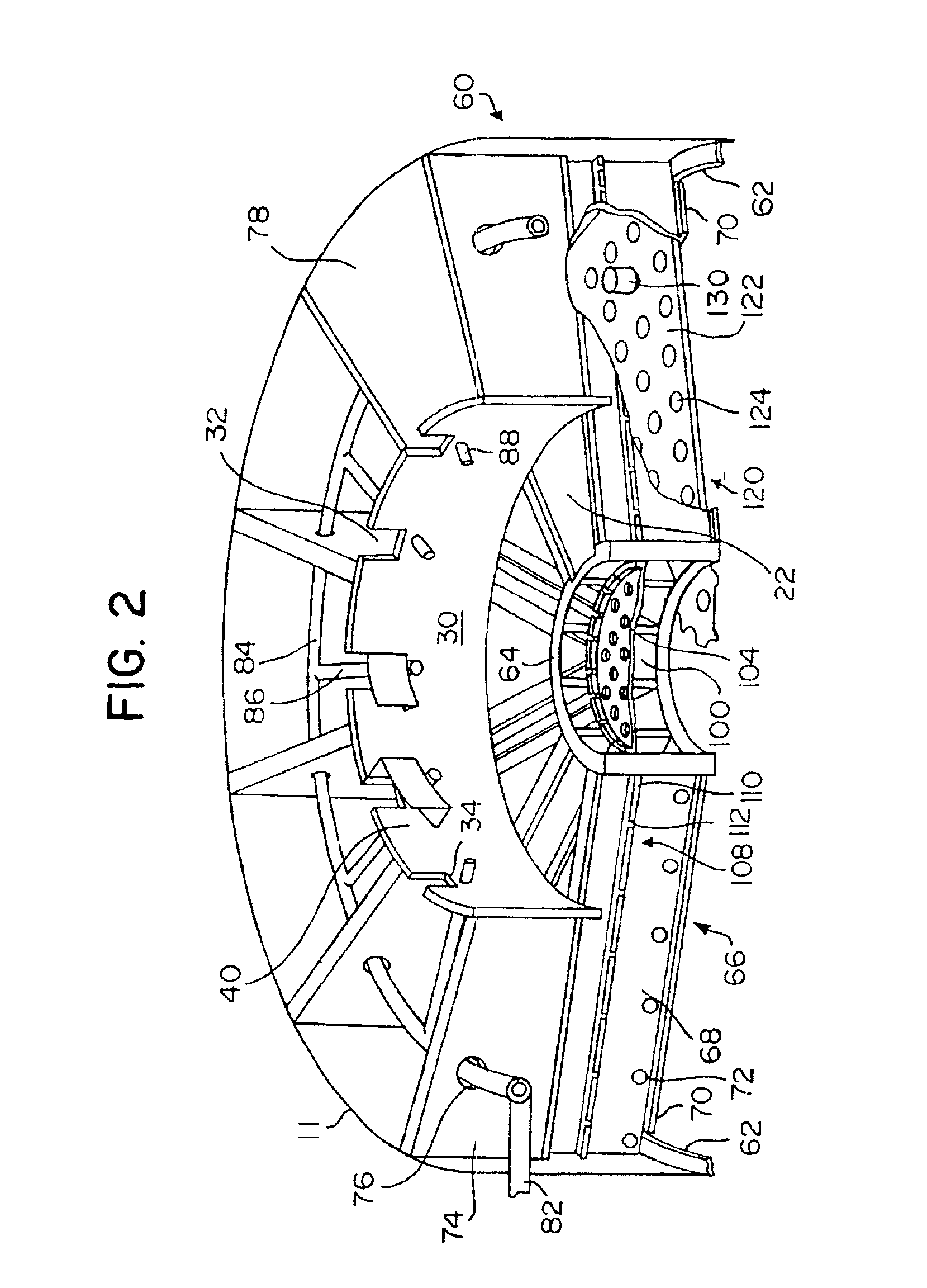

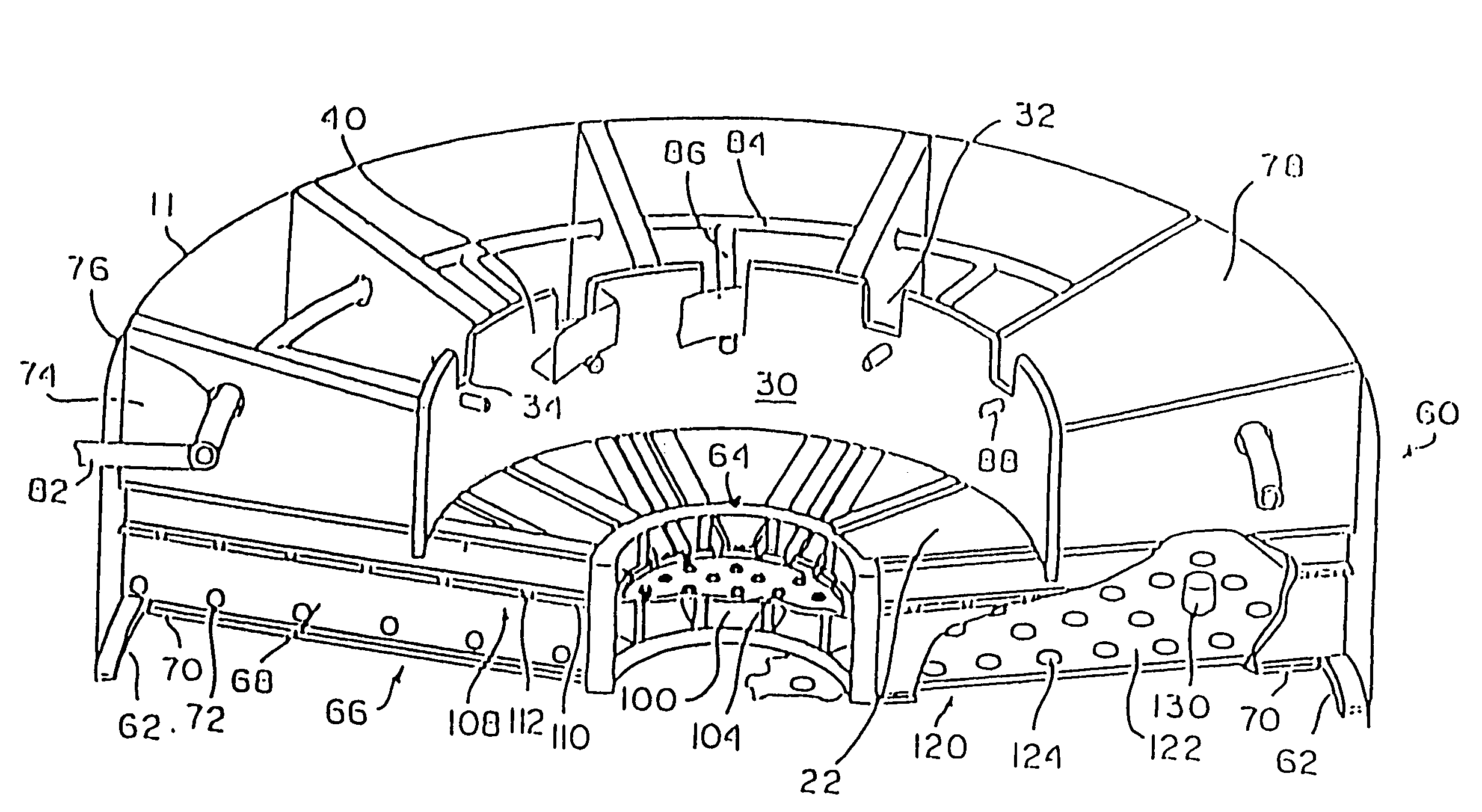

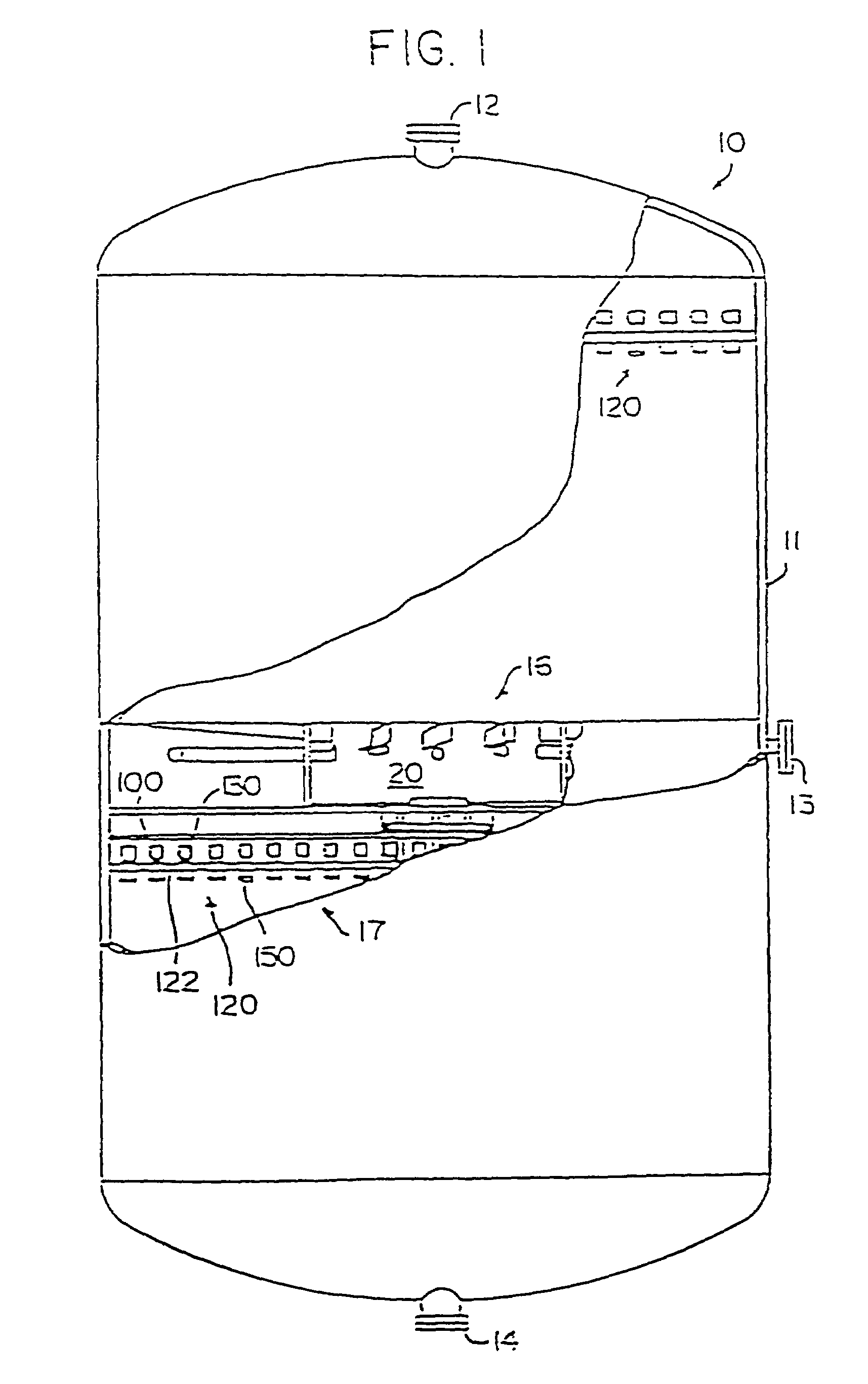

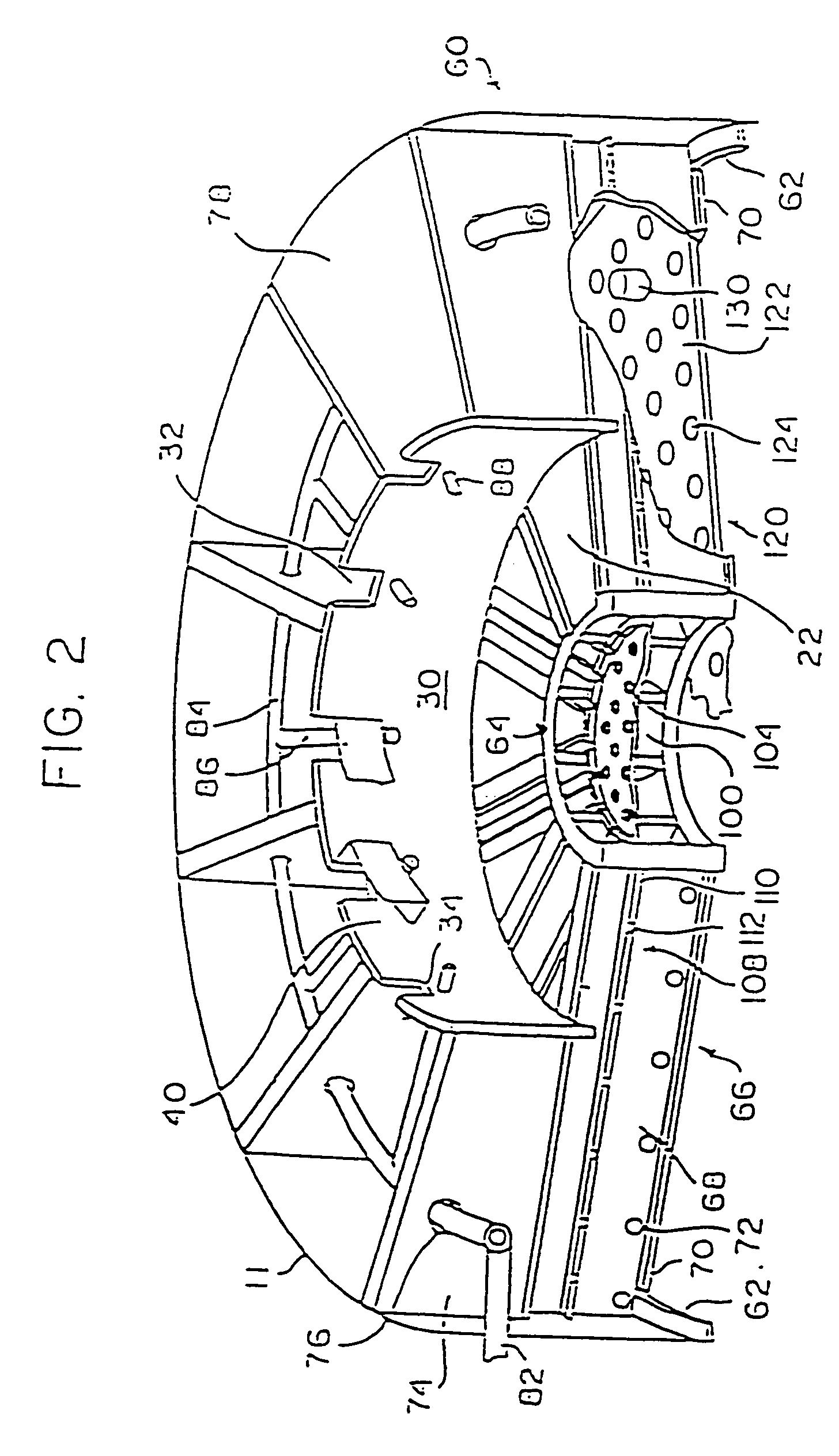

Reactor distribution apparatus and quench zone mixing apparatus

InactiveUS6098965AMinimizing vertical heightLower cost of capitalFlow mixersUsing liquid separation agentDistribution systemEngineering

A quench zone mixing apparatus that occupies a low vertical height and has an improved mixing efficiency and fluid distribution across the catalyst surface includes a swirl chamber, a rough distribution network, and a distribution apparatus. In the swirl chamber, reactant fluid from a catalyst bed above is thoroughly mixed with a quench fluid by a swirling action. The mixed fluids exit the swirl chamber through an aperture to the rough distribution system where the fluids are radially distributed outward across the vessel to the distribution apparatus. The distribution apparatus includes a plate with a number of bubble caps and associated drip trays that multiply the liquid drip stream from the bubble caps to further symmetrically distribute the fluids across the catalyst surface. Alternatively, deflector baffles may be associated with the bubble caps to provide a wider and more uniform liquid distribution below the plate. The distribution apparatus can be used in the reaction vessel without the swirl chamber and rough distribution system, e.g., at the top of a vessel.

Owner:FLUOR TECH CORP

Reactordistribution apparatus and quench zone mixing apparatus

InactiveUS20050163682A1Reduce overall heightWide range of operationsFlow mixersUsing liquid separation agentDistribution systemEngineering

A quench zone mixing apparatus that occupies a low vertical height and has an improved mixing efficiency and fluid distribution across the catalyst surface includes a swirl chamber, a rough distribution network, and a distribution apparatus. In the swirl chamber, reactant fluid from a catalyst bed above is thoroughly mixed with a quench fluid by a swirling action. The mixed fluids exit the swirl chamber through an aperture to the rough distribution system where the fluids are radially distributed outward across the vessel to the distribution apparatus. The distribution apparatus includes a plate with a number of bubble caps and associated drip trays that multiply the liquid drip stream from the bubble caps to further symmetrically distribute the fluids across the catalyst surface. Alternatively, deflector baffles may be associated with the bubble caps to provide a wider and more uniform liquid distribution below the plate. The distribution apparatus can be used in the reaction vessel without the swirl chamber and rough distribution system, e.g., at the top of a vessel.

Owner:FLUOR TECH CORP

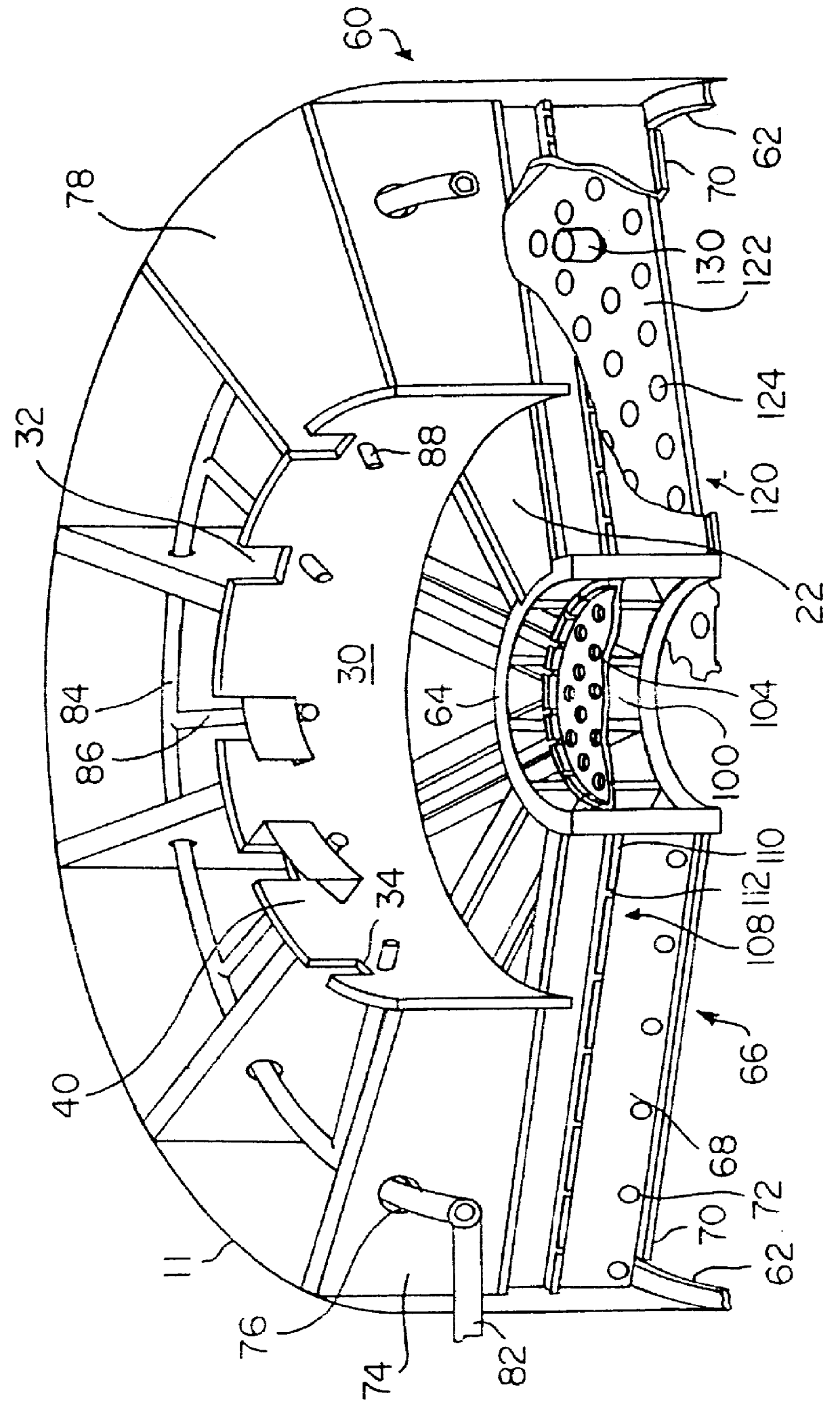

Reactor distribution apparatus and quench zone mixing apparatus

InactiveUS6338828B1Reduce overall heightWide range of operationsFlow mixersTransportation and packagingEngineeringFlange

A quench zone mixing apparatus is supported within a vessel of a reactor by a support structure that includes a concentric hub, which may be formed to act as a torsion tube, and at least a first set of radial beams extending radially outward from the hub and terminating at a support ring that is attached to the reactor vessel wall. In particular, the radial beams comprise a flange that supports the redistribution tray and a web of the beams preferably includes a plurality of openings to allow the passage of fluids across the vessel. In addition, the webs also carry the channels. The radial beams also support the mixing chamber and, in the area between the wall of the mixing chamber and the vessel wall, the radial beams may have a vertical height that slopes downward from the vessel wall to the mixing chamber wall.

Owner:FLUOR TECH CORP

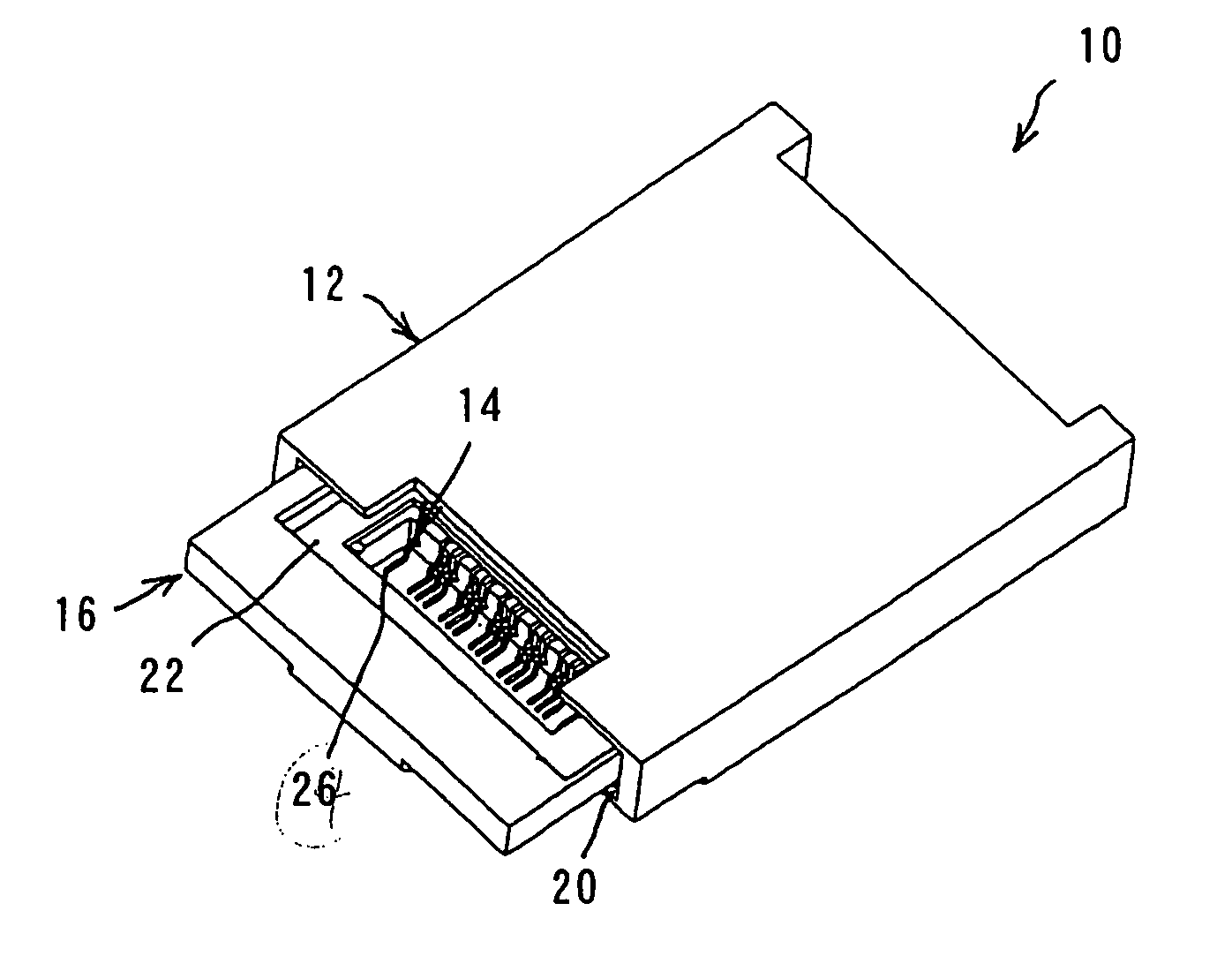

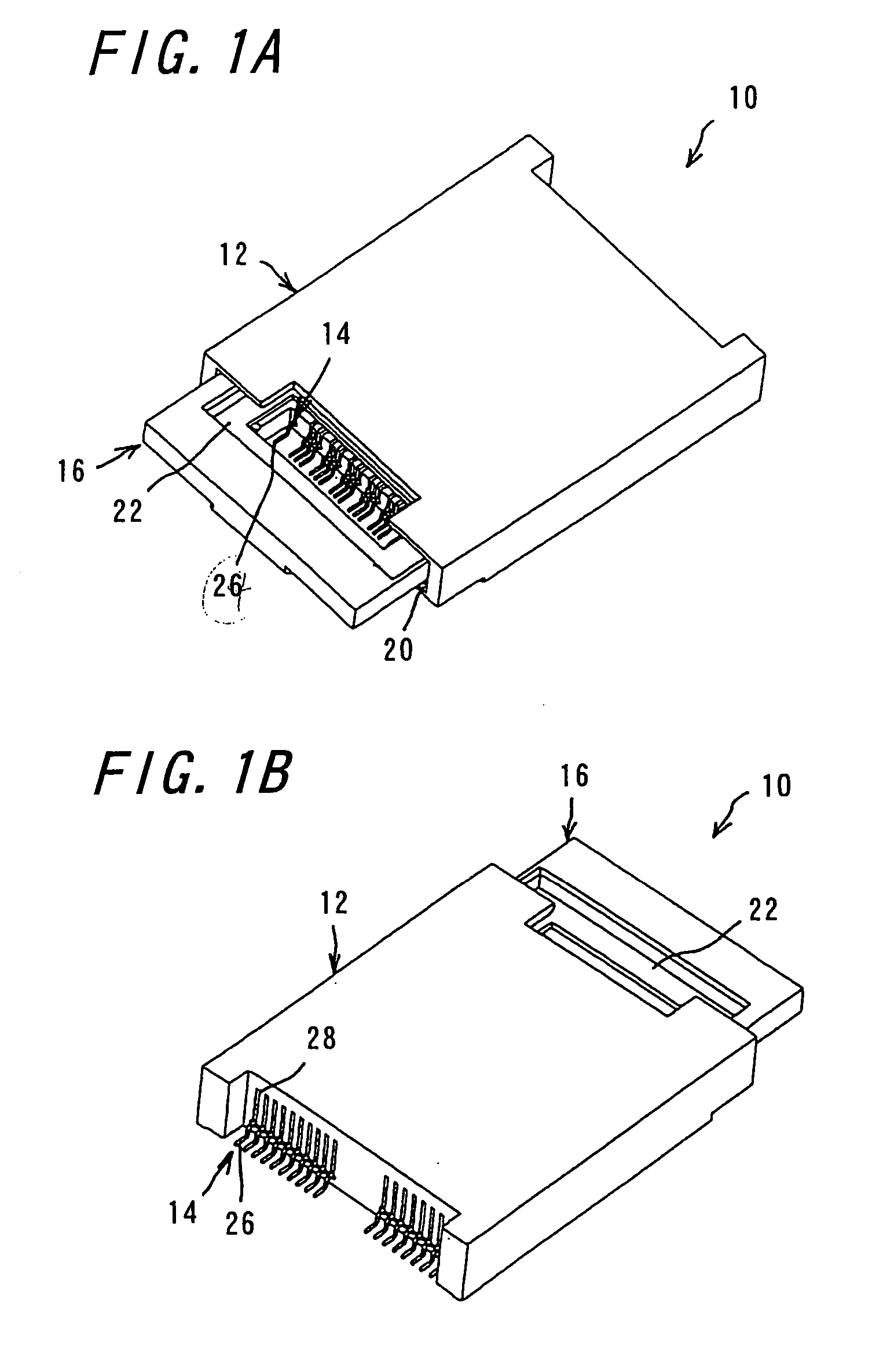

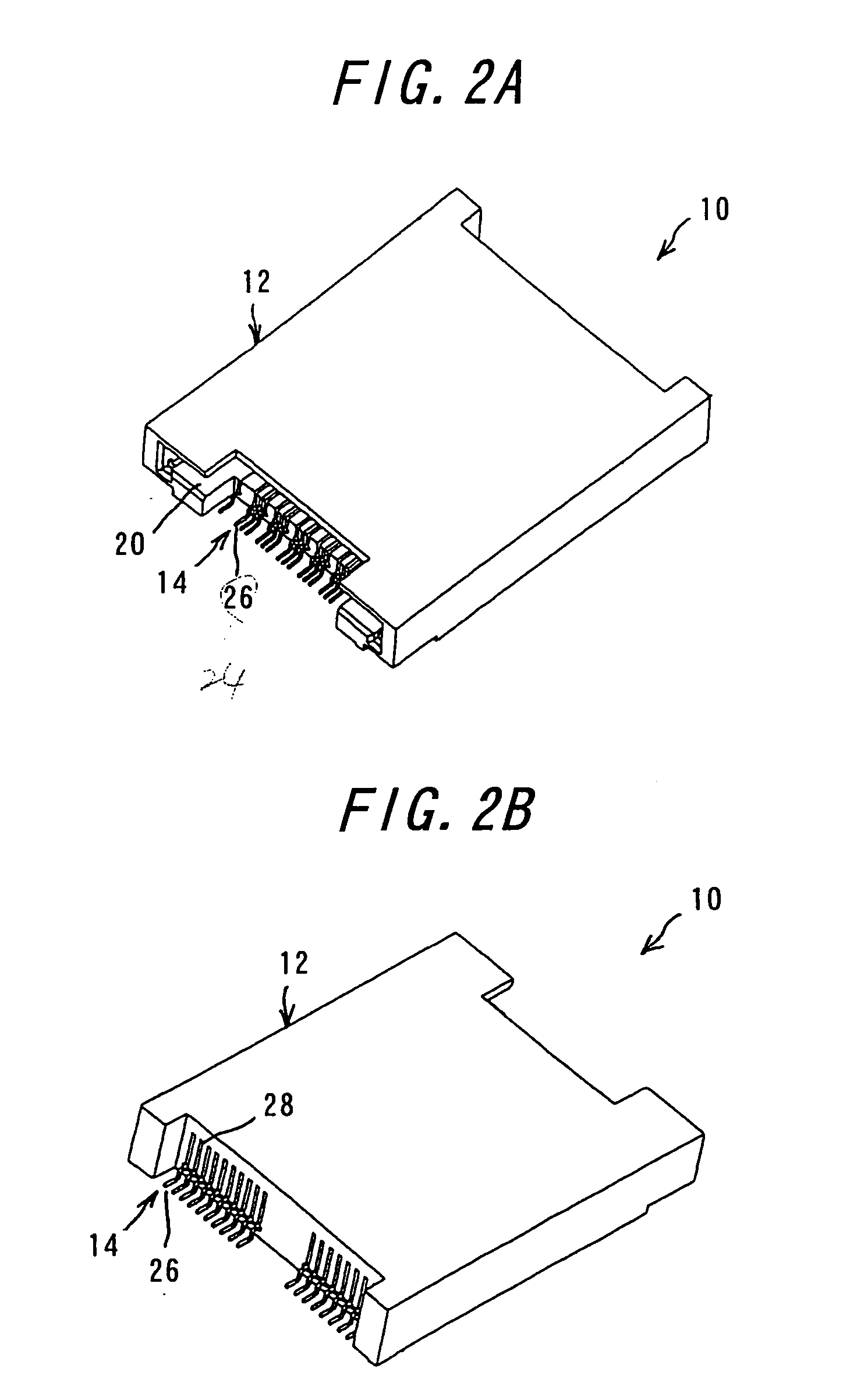

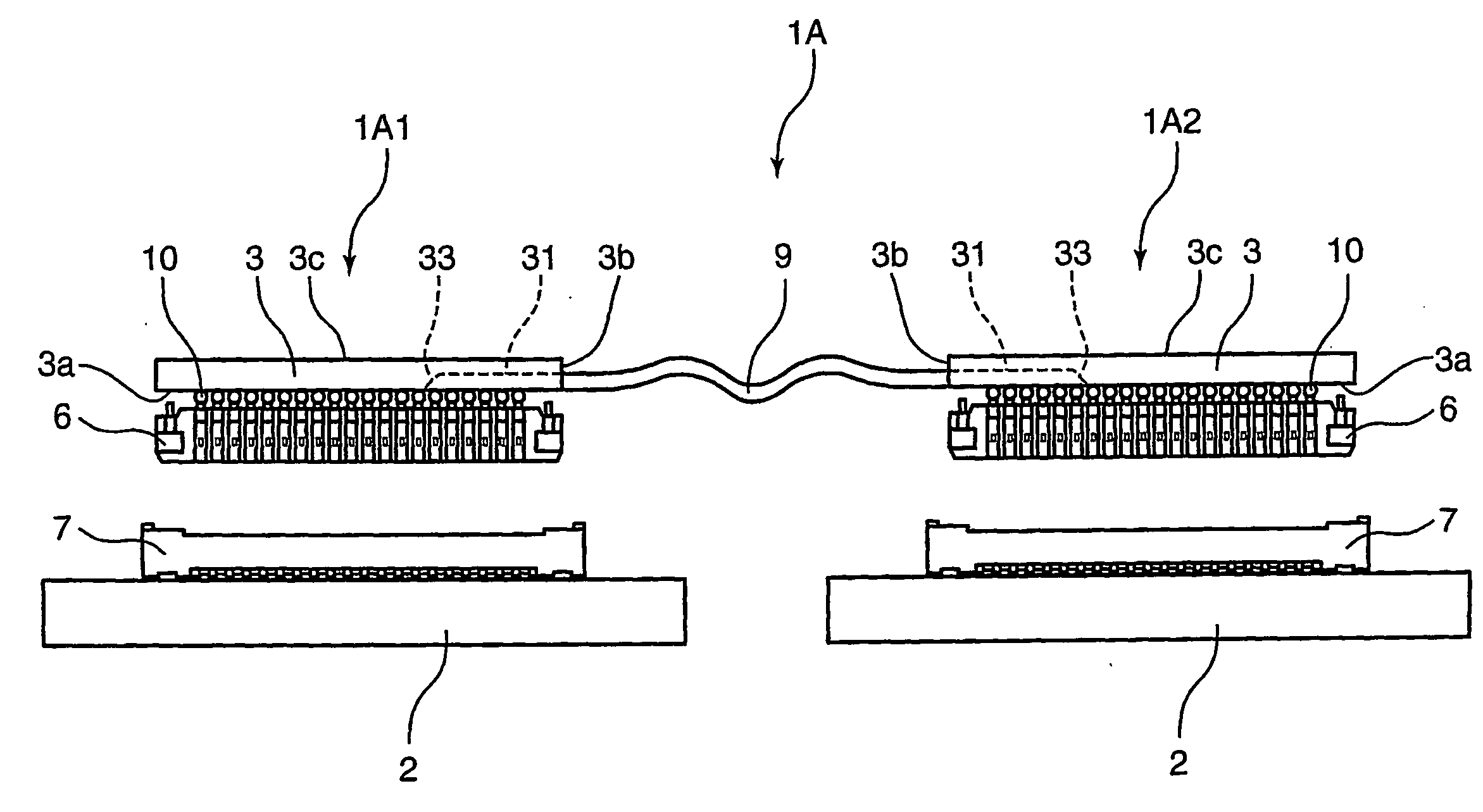

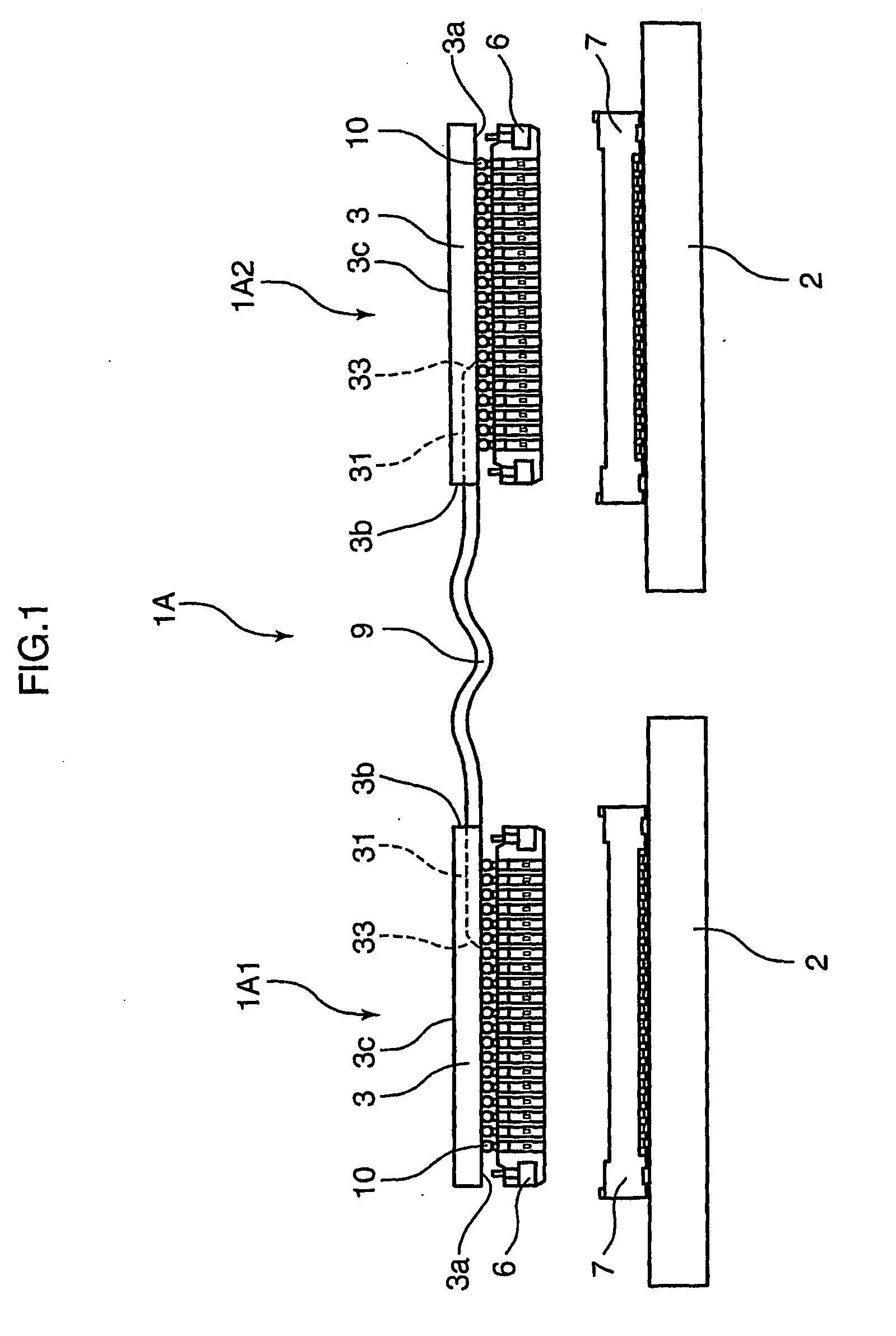

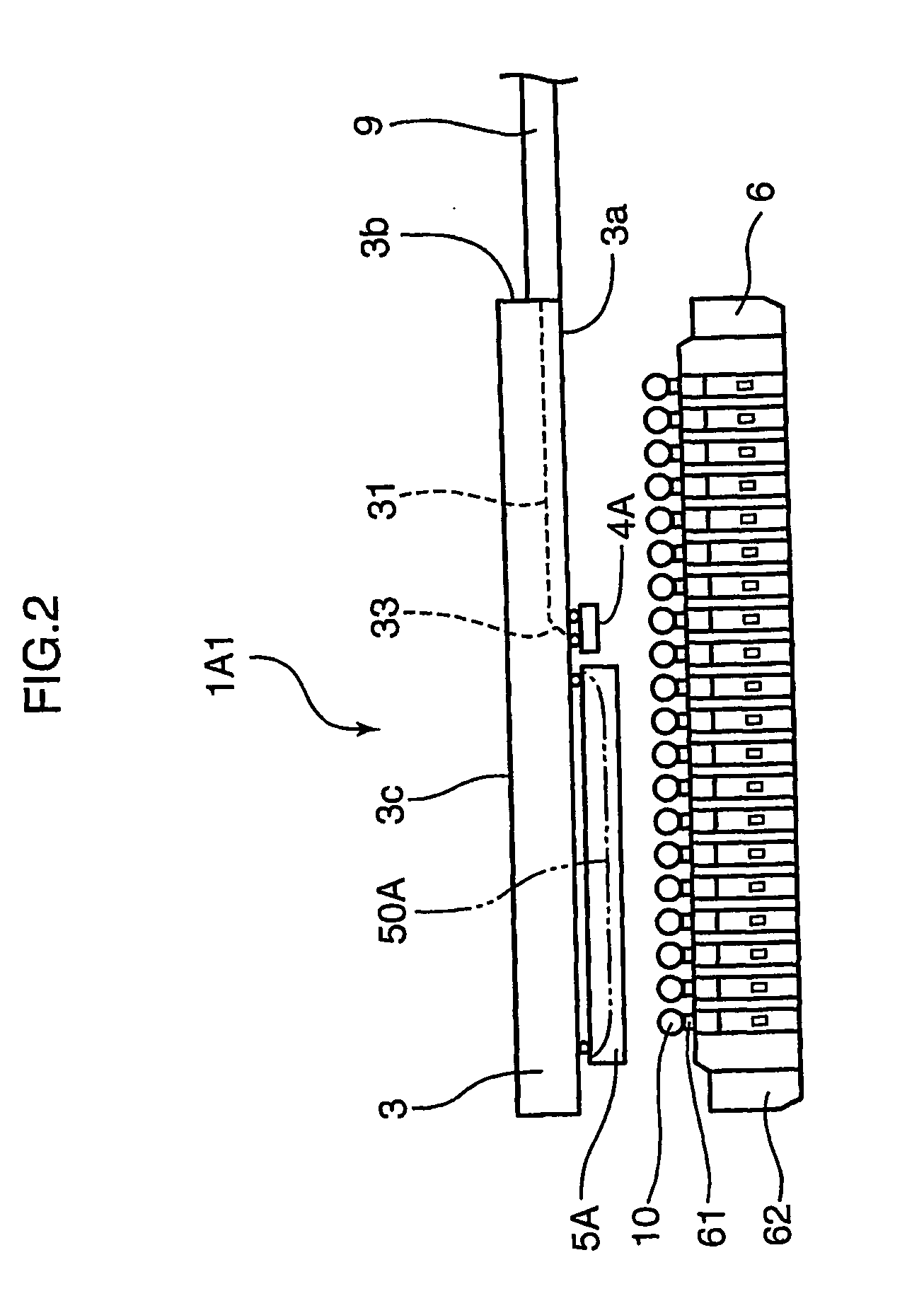

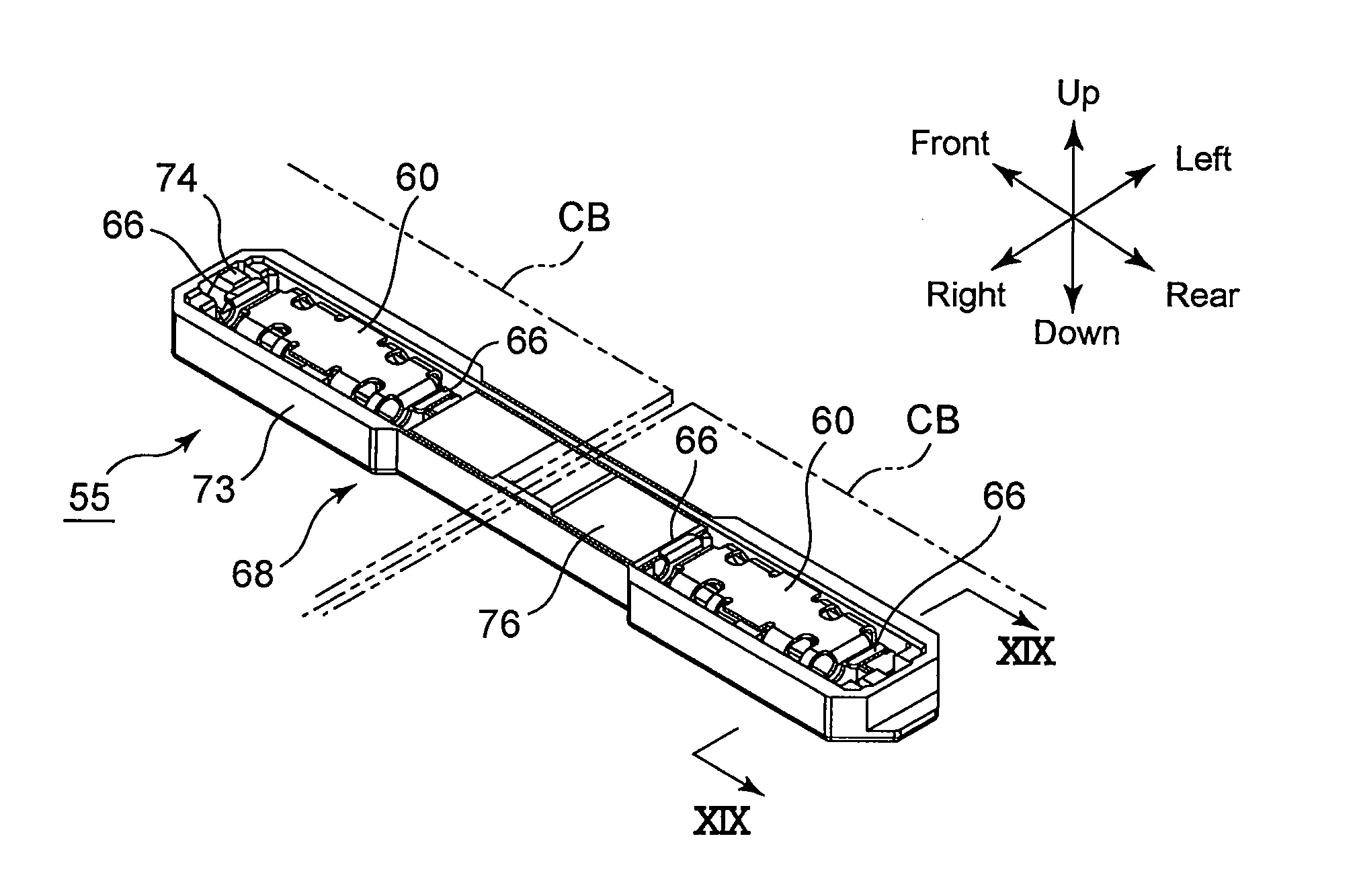

Card connector

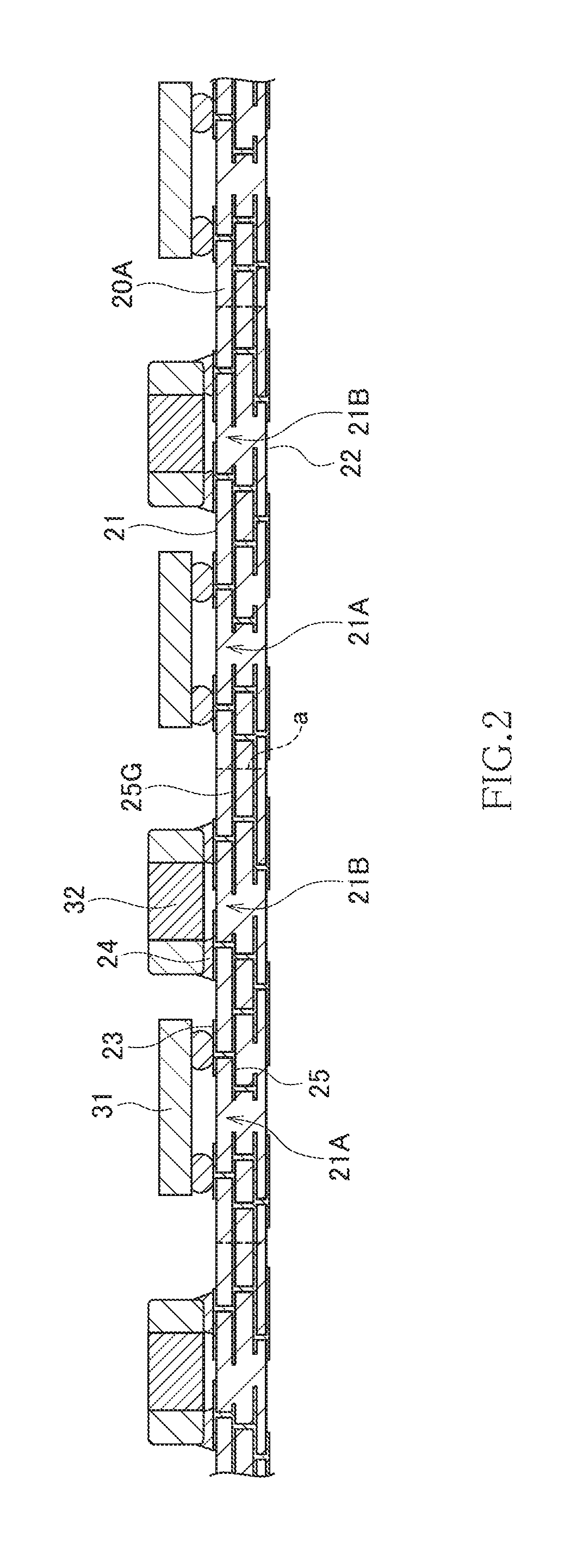

InactiveUS20060240713A1Simple constructionReduce overall heightTwo-part coupling devicesSensing record carriersEngineeringMiniaturization

A card connector which is able to be connected to at least two cards, includes contacts corresponding to the number of the cards, a tray in which at least two cards can be mounted, and a housing having a fitting opening for receiving the tray therein and for arranging and holding the contacts. Also, a card connector which is able to be connected to four cards, includes four kinds of contacts, a tray having card mounting sections in which four cards can be mounted, and a housing having a fitting opening for receiving the tray therein and for arranging and holding the four kinds of contacts. With these constructions, miniaturization in height or reduced overall height of connector is possible with a simple construction.

Owner:DDK LTD

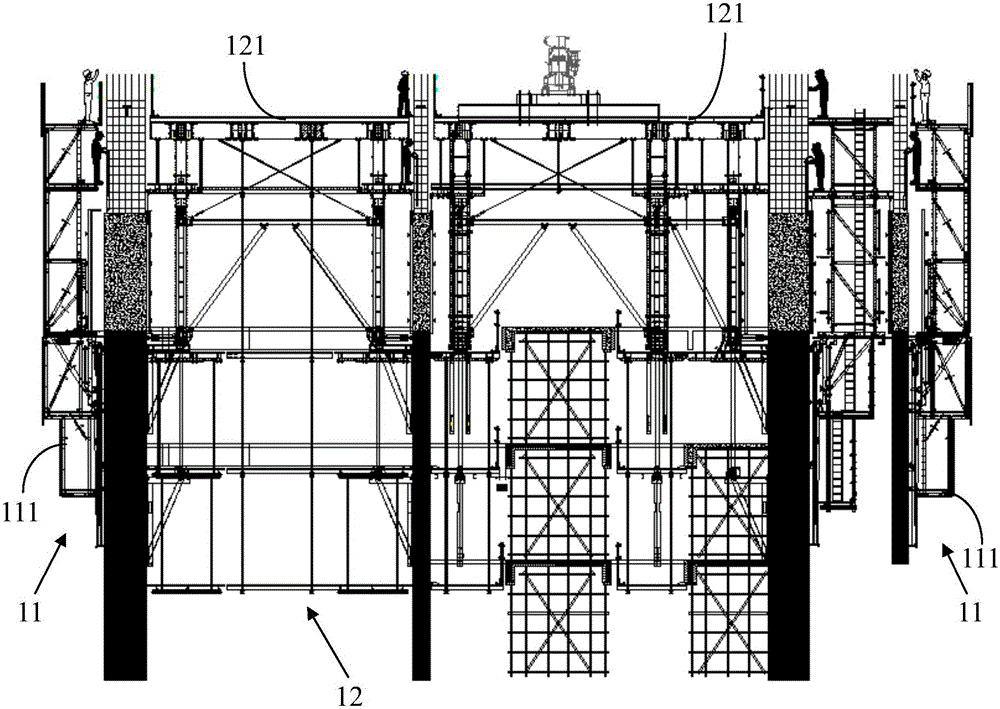

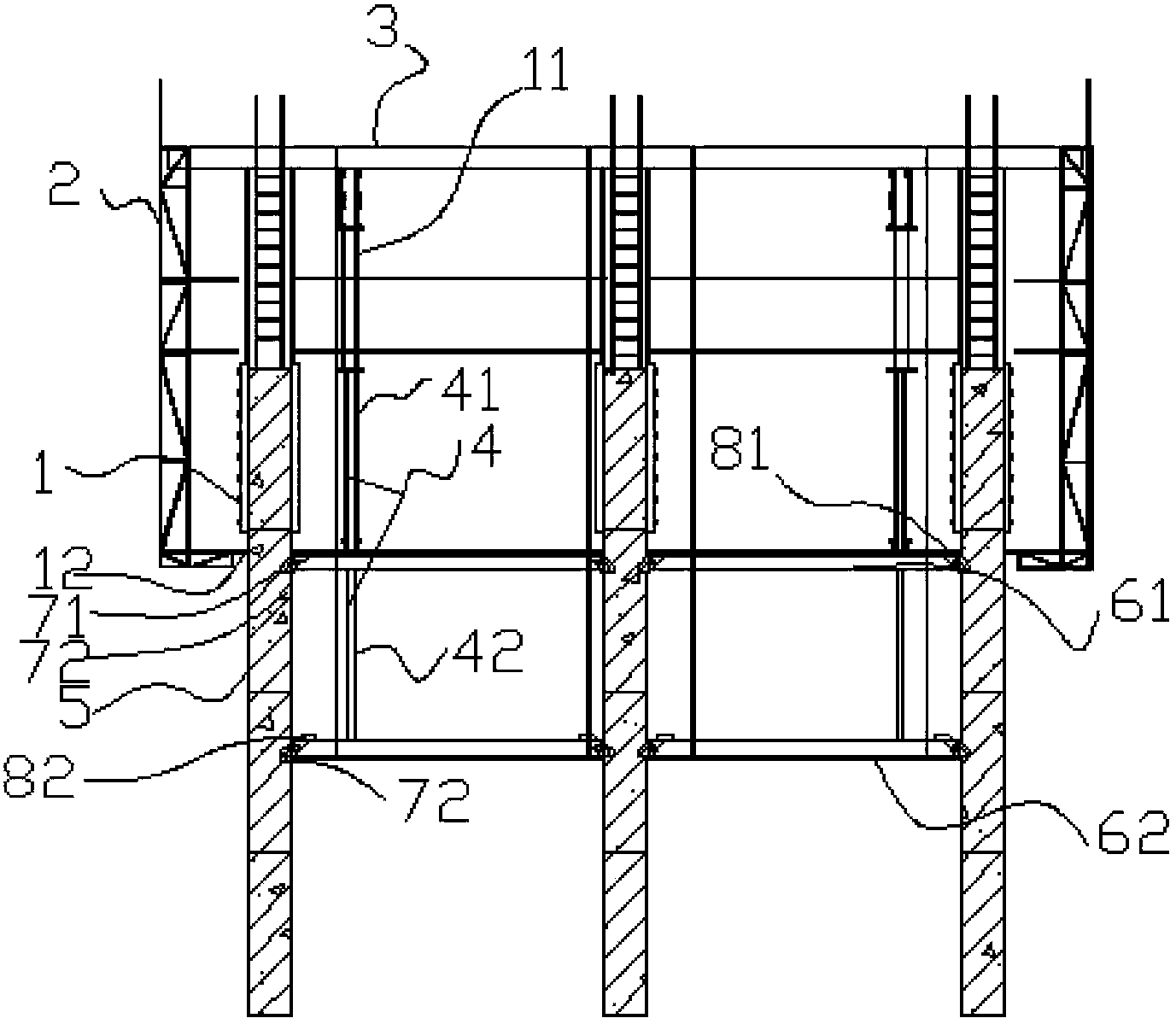

Inner roof external climbing type formwork construction platform for super high-rise building construction

InactiveCN106437130AReduce weightReduce the burden onBuilding support scaffoldsArchitectural engineeringEngineering

The invention discloses an inner roof external climbing type formwork construction platform for super high-rise building construction. The inner roof external climbing type formwork construction platform comprises a hydraulic creeping formwork system arranged on the outer side of a building and located on building walls and a jacking platform system arranged on the inner side of the building and located between adjacent building walls. The jacking platform system comprises a climbing device, an operating platform arranged on the climbing device and wall-attached embedder parts installed on the building walls and used for the climbing device to climb and attach. The hydraulic creeping formwork system adopted on a building external wall and the jacking platform system adopted on the inner side of the building and located between the building walls simultaneously operate to replace a traditional integral jacking type construction platform, horizontal supporting steel beams are not needed, oil cylinder climbing can be achieved only by installing the wall-attached embedder parts on the building walls, the total height of the construction platform and a supporting frame body of the platform is decreased, and a construction difference between a vertical structure and a horizontal structure is decreased, so that the hydraulic climbing system does not influence horizontal structure construction.

Owner:中国华西企业股份有限公司 +2

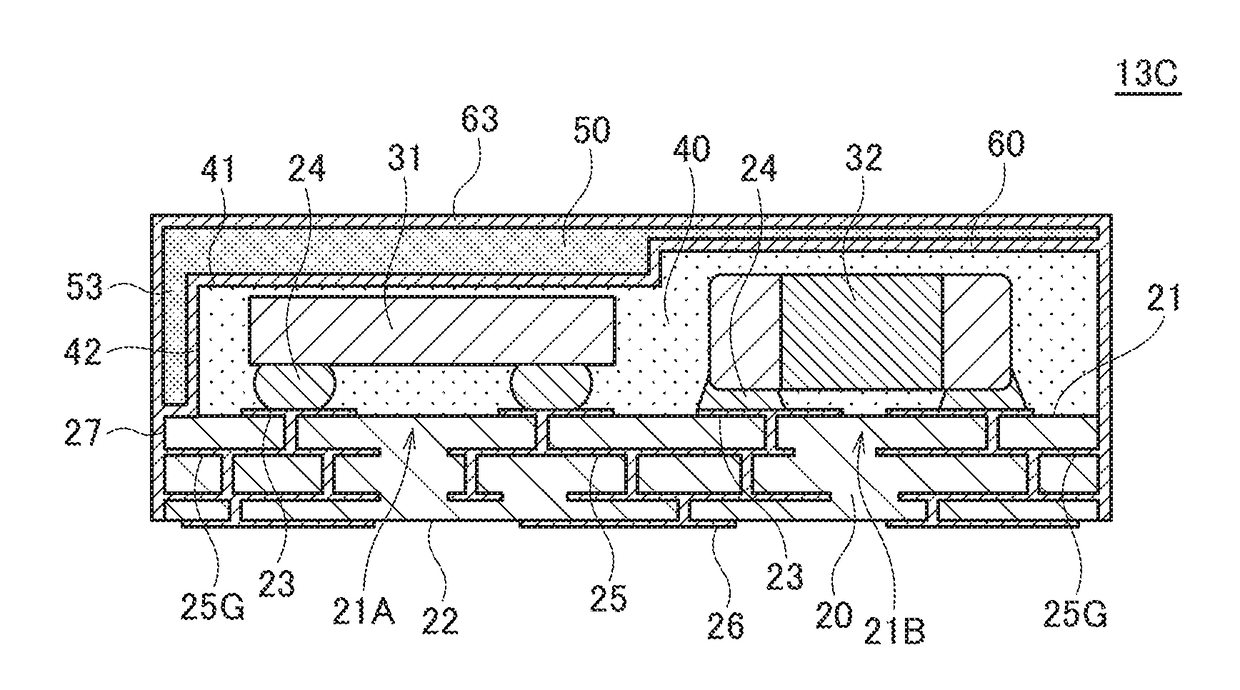

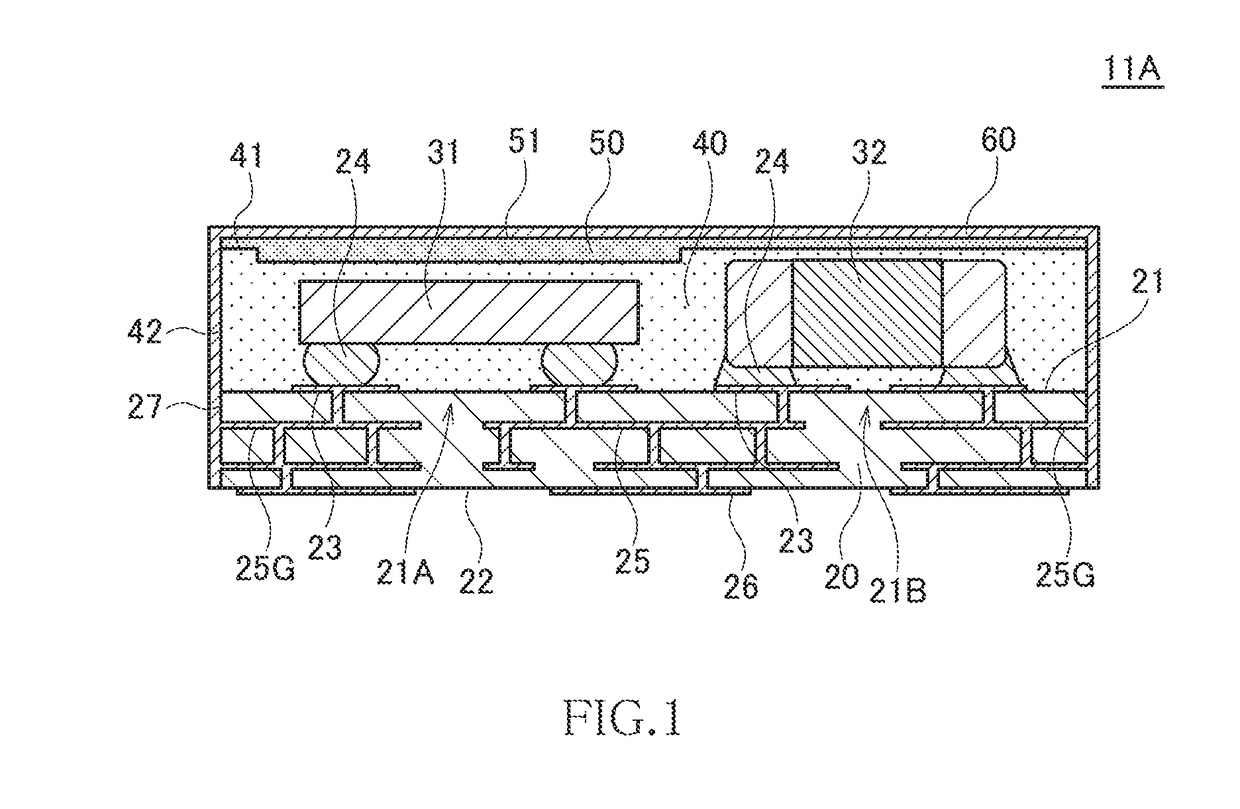

Photoelectric converter

ActiveUS20100171023A1Reduce overall heightCoupling effectPhotometry using reference valueRadiation pyrometryElectricityEngineering

To provide a photoelectric converter capable of reducing the height of the device. The photoelectric converter includes: a light emitting element or a light receiving element; an IC circuit for transmitting / receiving an electric signal to / from the light emitting element or the light receiving element; a mount substrate adapted to be mounted on one surface from the side on which the light emitting element emits light, or the side on which the light receiving element receives light; an electric connector adapted to be provided on the one surface or the other surface of the mount substrate, and to be attached and detached to and from an external connector; and a waveguide adapted to be provided on the mount substrate along the one surface or the other surface of the mount substrate, and to be optically coupled to the light emitting element or the light receiving element.

Owner:PANASONIC CORP

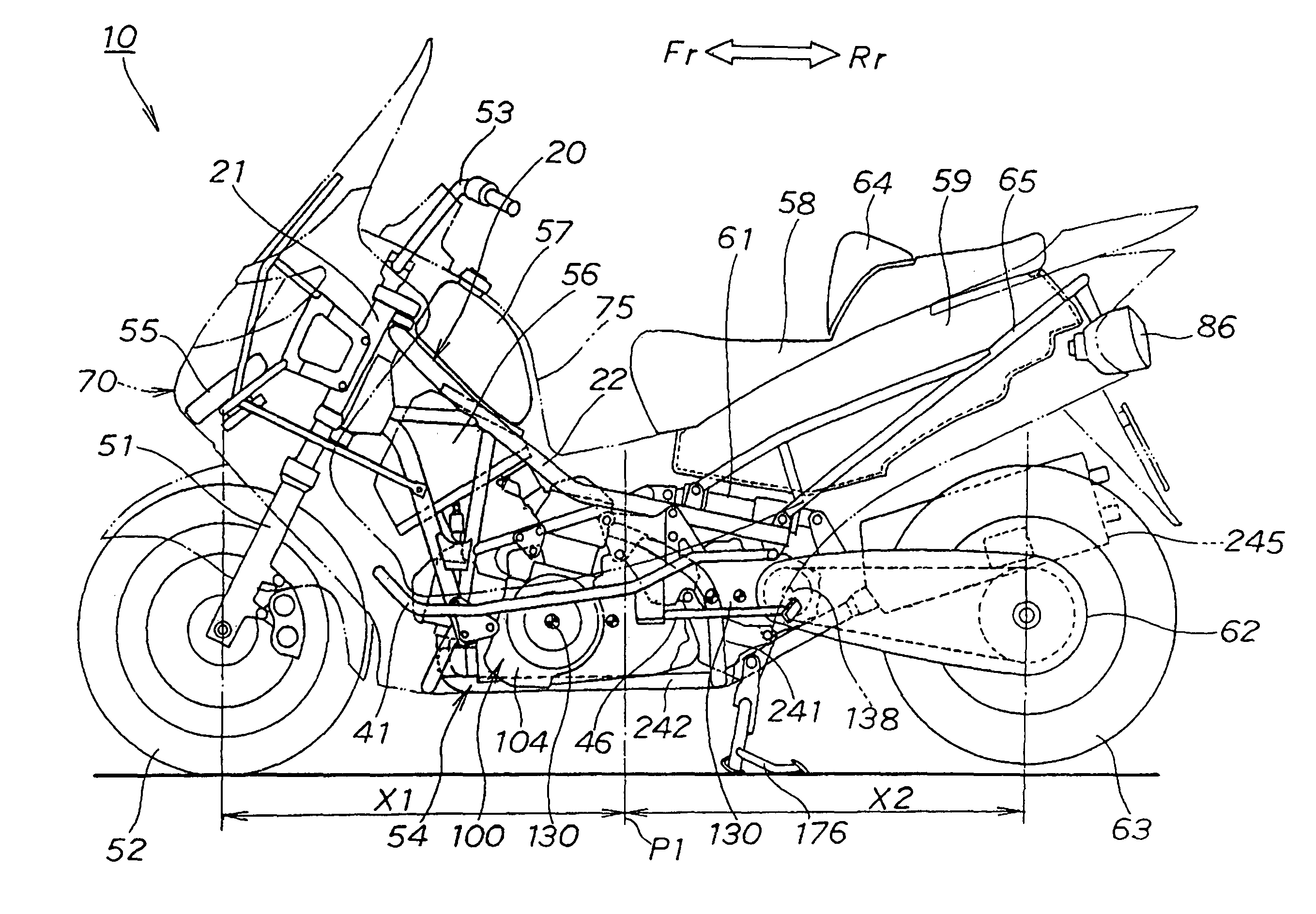

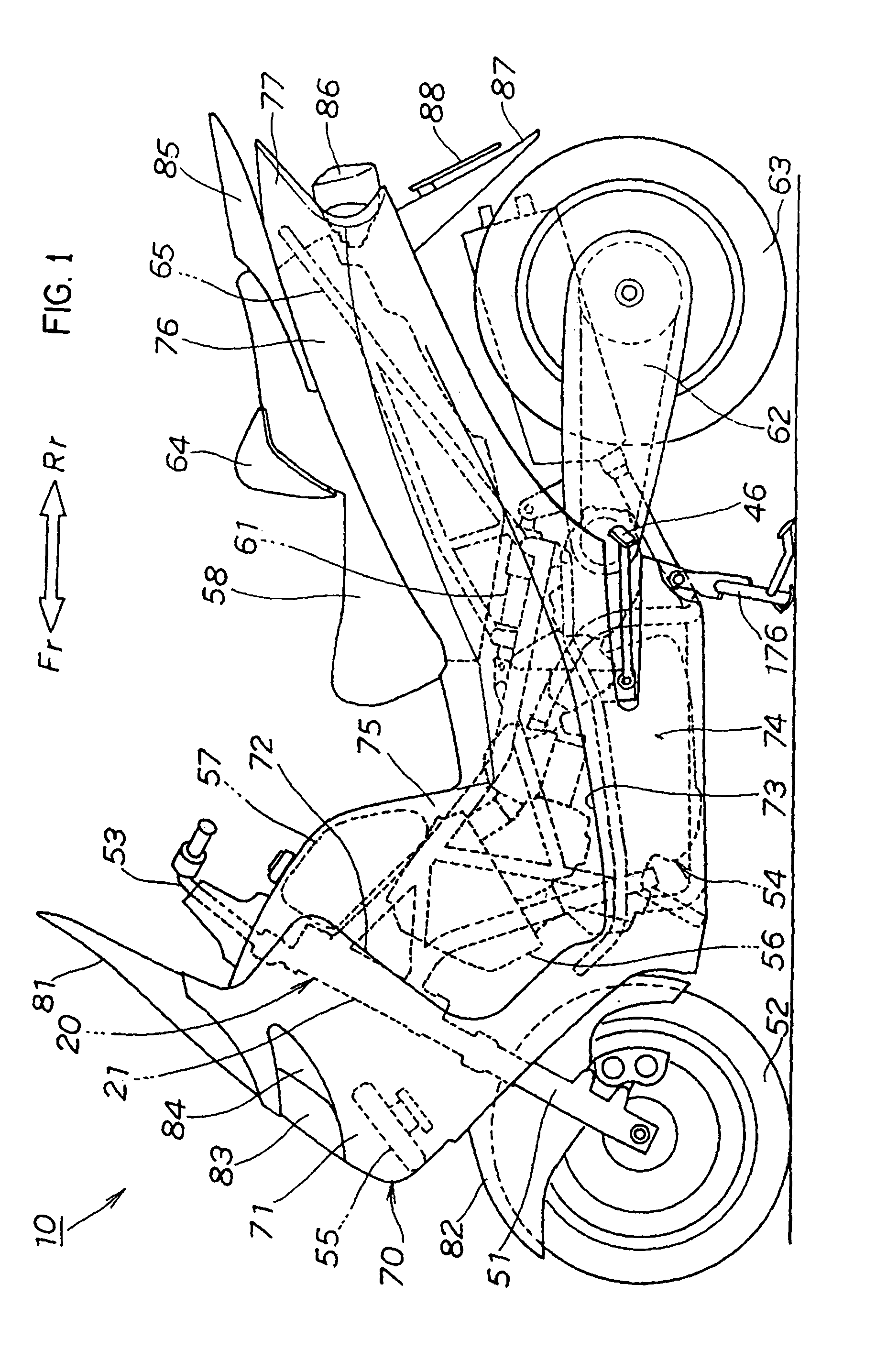

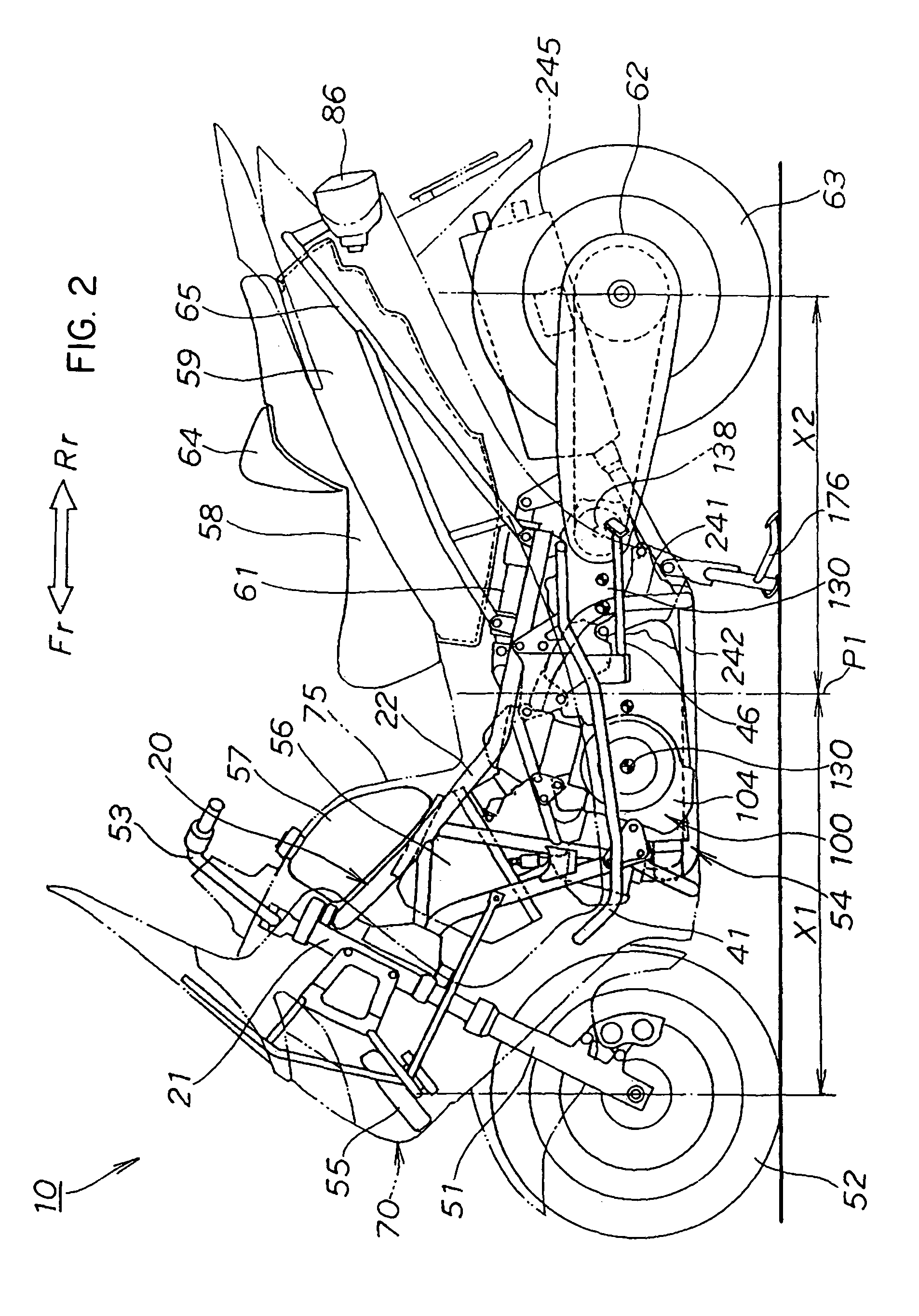

Engine mounting structure of low floor type vehicle

InactiveUS7360620B2Reduce overall heightIncrease degree of freedomMotorised scootersCombustion-air/fuel-air treatmentAutomotive engineeringEngine mount

In a low floor type vehicle 10, a banking angle θ1 of a longitudinal V-type engine 100 mounted below a low floor is set to an angle equal to or exceeding approximately 90°. The V-type engine is arranged with a bisector L1 of the banking angle directed toward a head pipe 21 of a body frame 20. The body frame is composed of a pair of right and left upper frames 22 extended backward and downward from the head pipe and a pair of right and left down frames 23 extended downward from the head pipe and coupled to the front of a crankcase 104 of the V-type engine and is a diamond type frame from which the V-type engine can be suspended.

Owner:HONDA MOTOR CO LTD

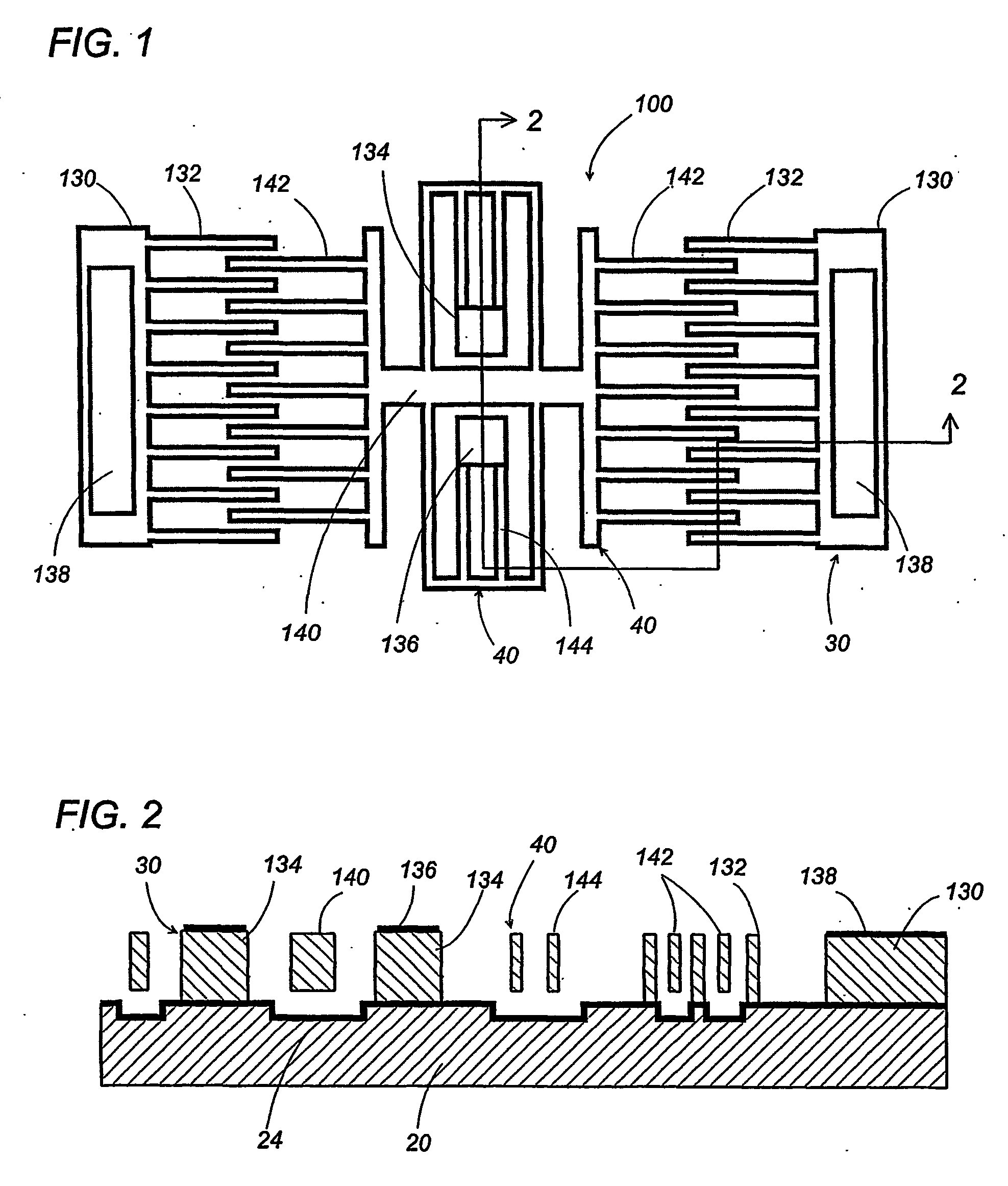

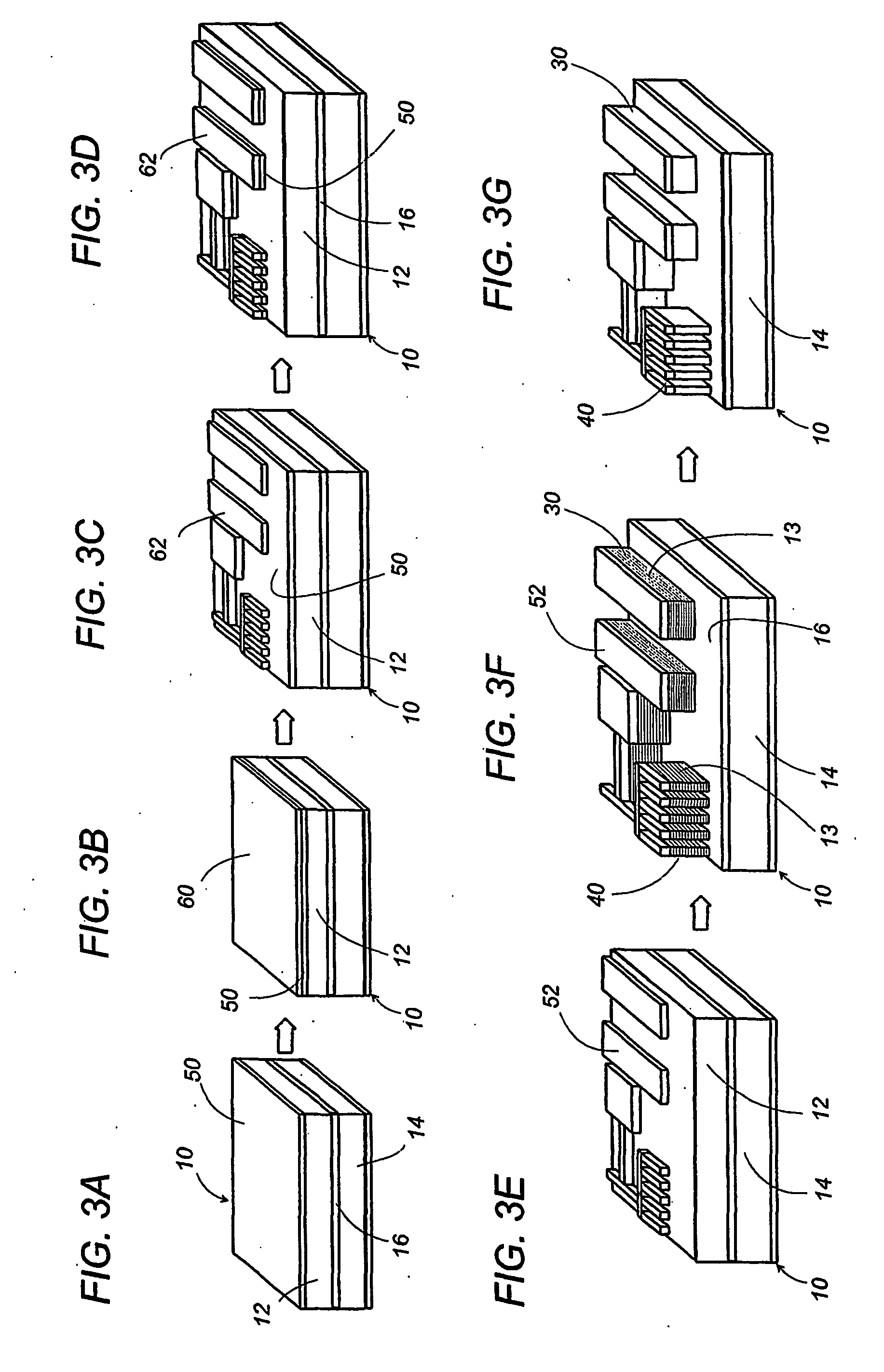

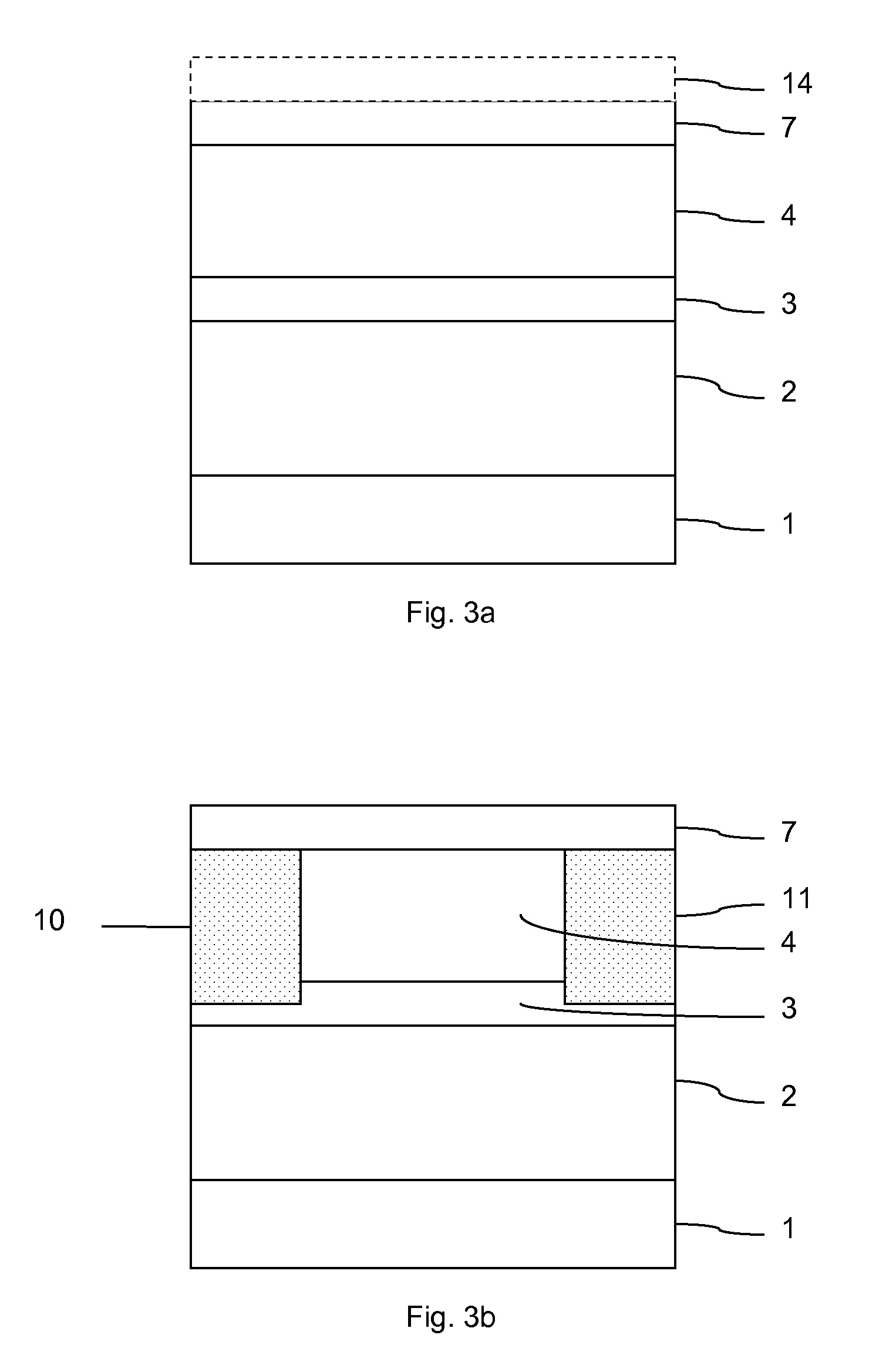

Process for fabricating a micro-electro-mechanical system with movable components

InactiveUS20070128831A1Reduce overall heightLow-profile microstructureDecorative surface effectsSoldering apparatusEngineeringMechanical system

A process for fabricating a micro-electro-mechanical system (MEMS) composed of fixed components fixedly supported on a lower substrate and movable components movably supported on the lower substrate. The process utilizes an upper substrate separate from the lower substrate. The upper substrate is selectively etched in its top layer to form therein a plurality of posts which project commonly from a bottom layer of the upper substrate. The posts include the fixed components to be fixed to the lower substrate and the movable components which are resiliently supported only to one or more of the fixed components to be movable relative to the fixed components. The lower substrate is formed in its top surface with at least one recess. The upper substrate is then bonded to the top of the lower substrate upside down in such a manner as to place the fixed components directly on the lower substrate and to place the movable components upwardly of the recess. Finally, the bottom layer of the upper substrate is removed to release the movable components from the bottom layer for floating the movable components above the recess and allowing them to move relative to the lower substrate, while keeping the fixed components fixed to the top of the lower substrate.

Owner:MATSUSHITA ELECTRIC WORKS LTD

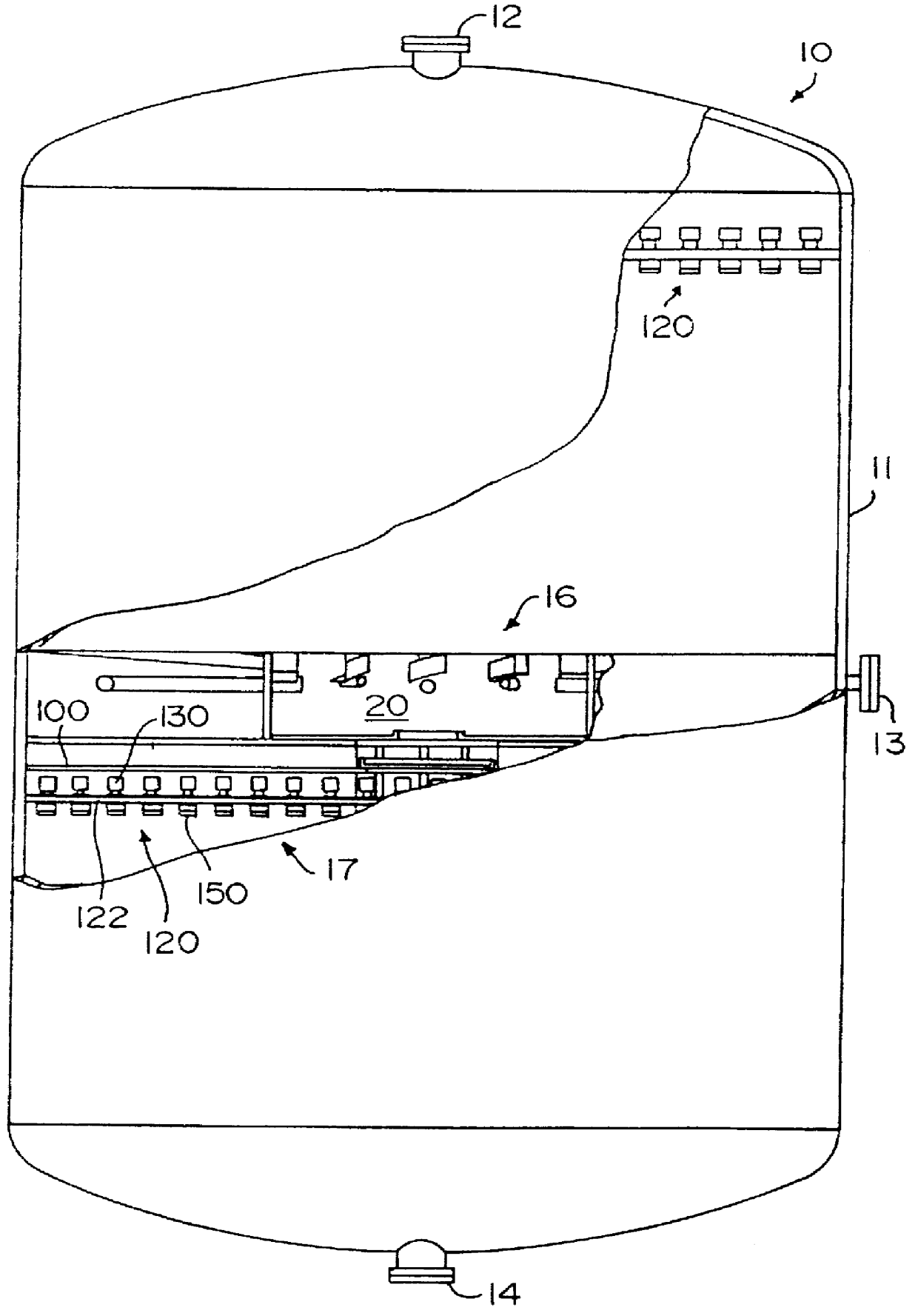

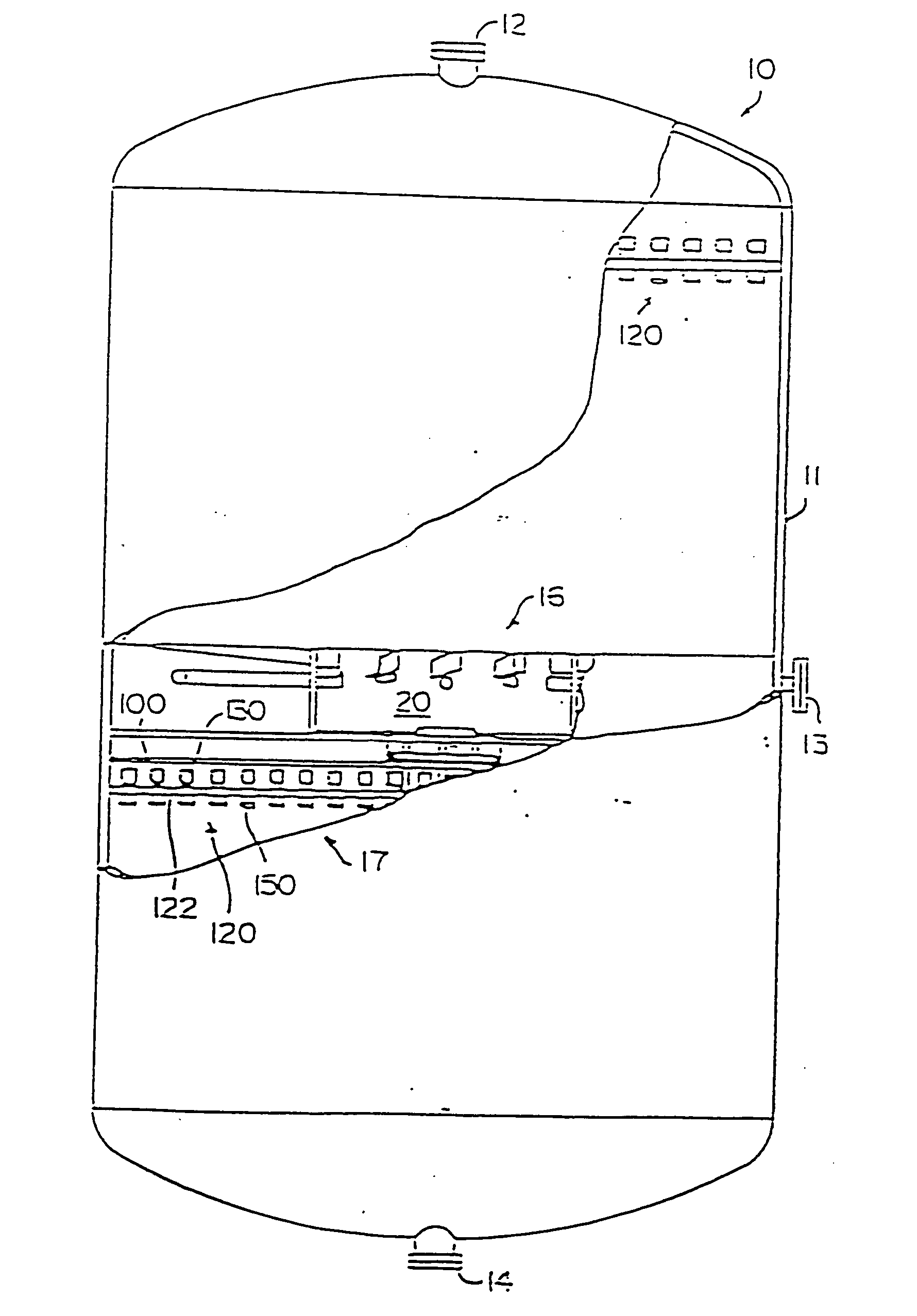

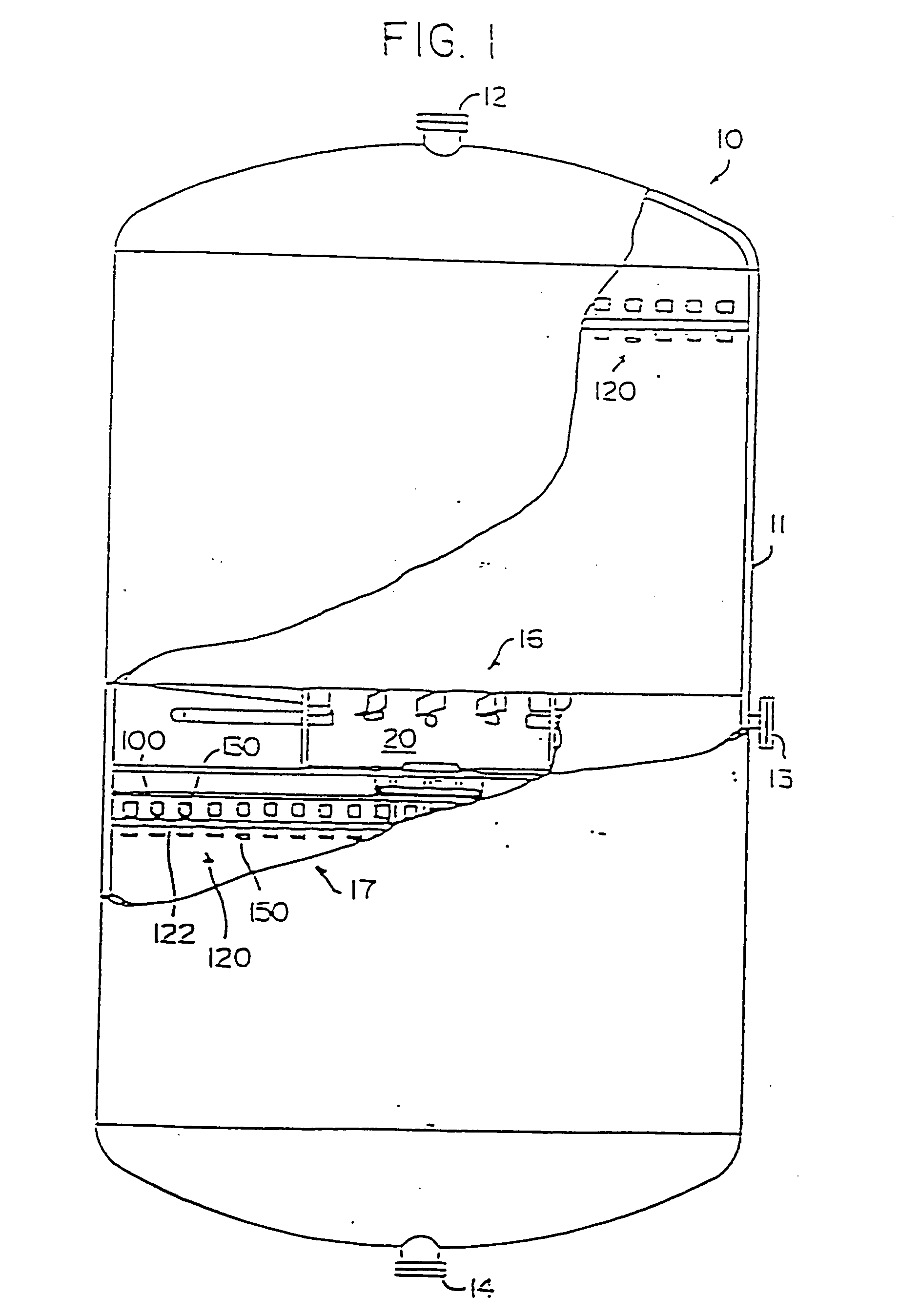

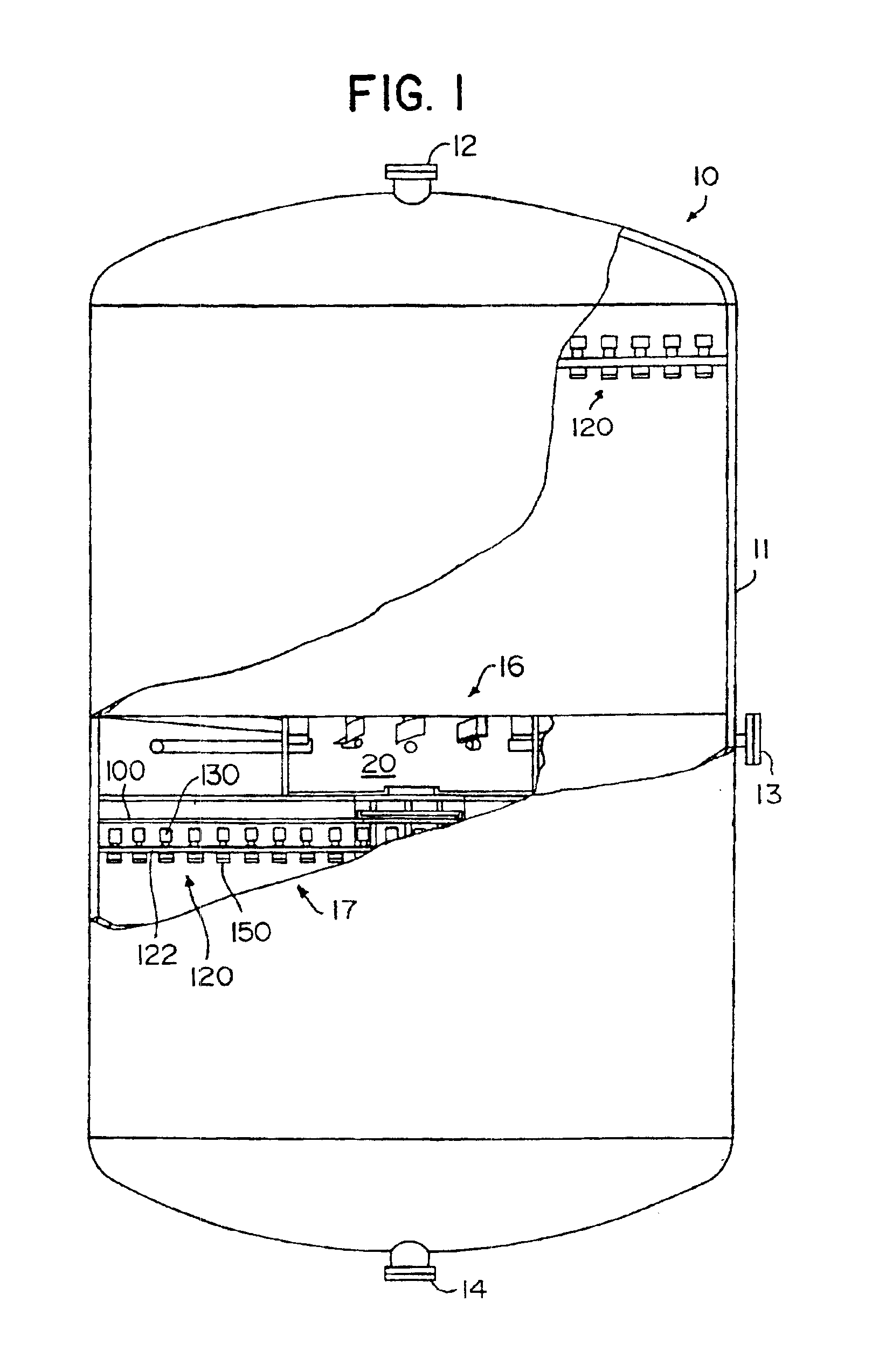

Reactor distribution apparatus and quench zone mixing apparatus

InactiveUS6881387B1Minimizing vertical heightLower cost of capitalFlow mixersLighting and heating apparatusDistribution systemEngineering

A quench zone mixing apparatus (16) that occupies a low vertical height and has an improved mixing efficiency and fluid distribution across the catalyst surface includes a swirl chamber (20), a rough distribution network (100), and a distribution apparatus (120). In the swirl chamber (20), reactant fluid from a catalyst bed above is thoroughly mixed with a quench fluid by a swirling action. The mixed fluids exit the swirl chamber (20) through an aperture to the rough distribution system (100) where the fluids are radially distributed outward across the vessel to the distribution apparatus (120). The distribution apparatus (120) includes a plate (122) with a number of bubble caps (130) and associated a drip trace (150) that multiply the liquid drip stream from the bubble caps (130) to further symmetrically distribute the fluids across the catalyst surface. Alternatively, deflector baffles may be associated with the bubble caps (130) to provide a wider and more uniform liquid distribution below the plate (122). The distribution apparatus (120) can be used in the reaction vessel (10) without the swirl chamber (20) and rough distribution system (100), e.g., at the top of a vessel.

Owner:FLUOR TECH CORP

Reactor distribution apparatus and quench zone mixing apparatus

InactiveUS7674439B2Reduce overall heightWide range of operationsFlow mixersUsing liquid separation agentDistribution systemEngineering

A quench zone mixing apparatus that occupies a low vertical height and has an improved mixing efficiency and fluid distribution across the catalyst surface includes a swirl chamber, a rough distribution network, and a distribution apparatus. In the swirl chamber, reactant fluid from a catalyst bed above is thoroughly mixed with a quench fluid by a swirling action. The mixed fluids exit the swirl chamber through an aperture to the rough distribution system where the fluids are radially distributed outward across the vessel to the distribution apparatus. The distribution apparatus includes a plate with a number of bubble caps and associated drip trays that multiply the liquid drip stream from the bubble caps to further symmetrically distribute the fluids across the catalyst surface. Alternatively, deflector baffles may be associated with the bubble caps to provide a wider and more uniform liquid distribution below the plate. The distribution apparatus can be used in the reaction vessel without the swirl chamber and rough distribution system, e.g., at the top of a vessel.

Owner:FLUOR TECH CORP

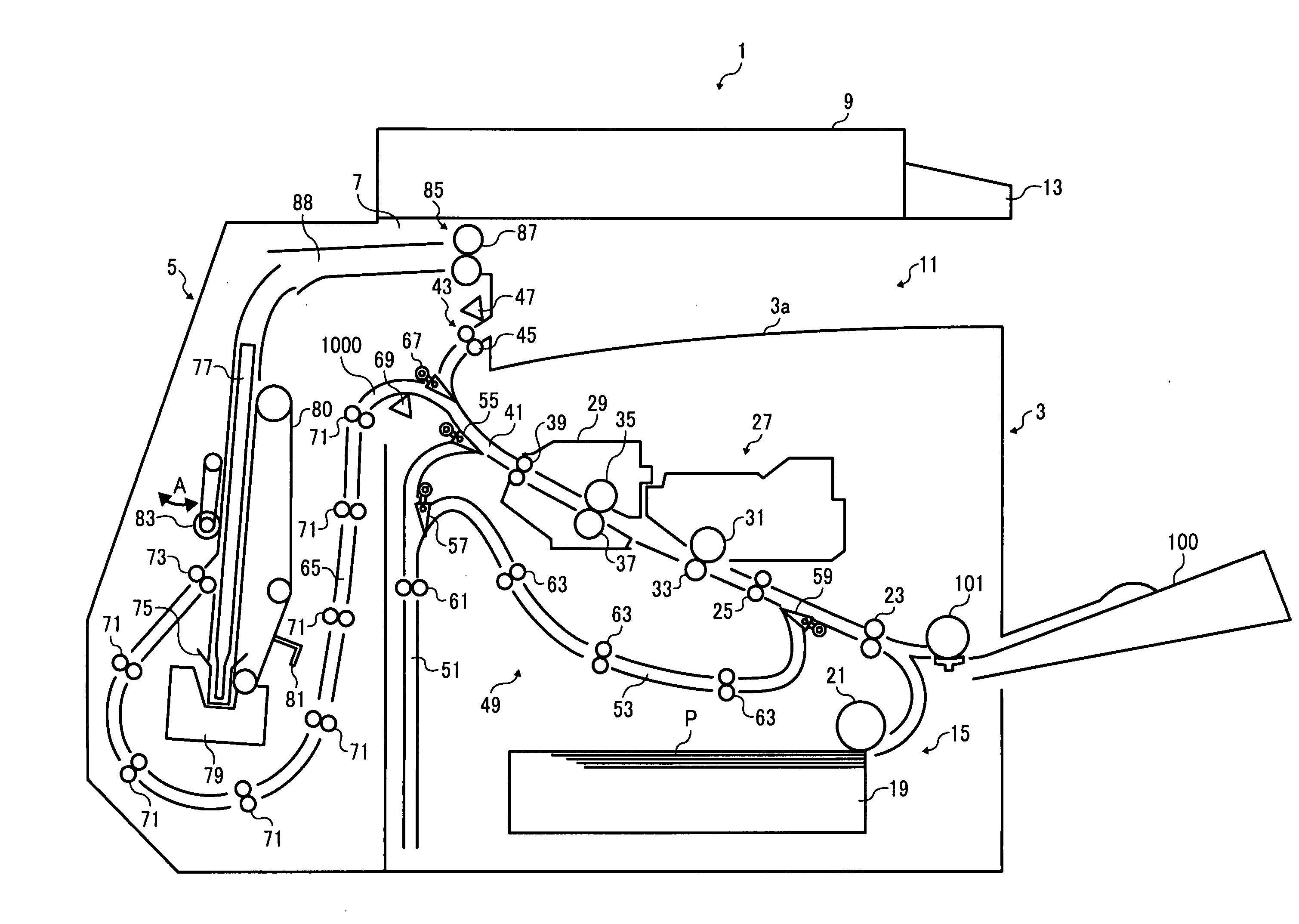

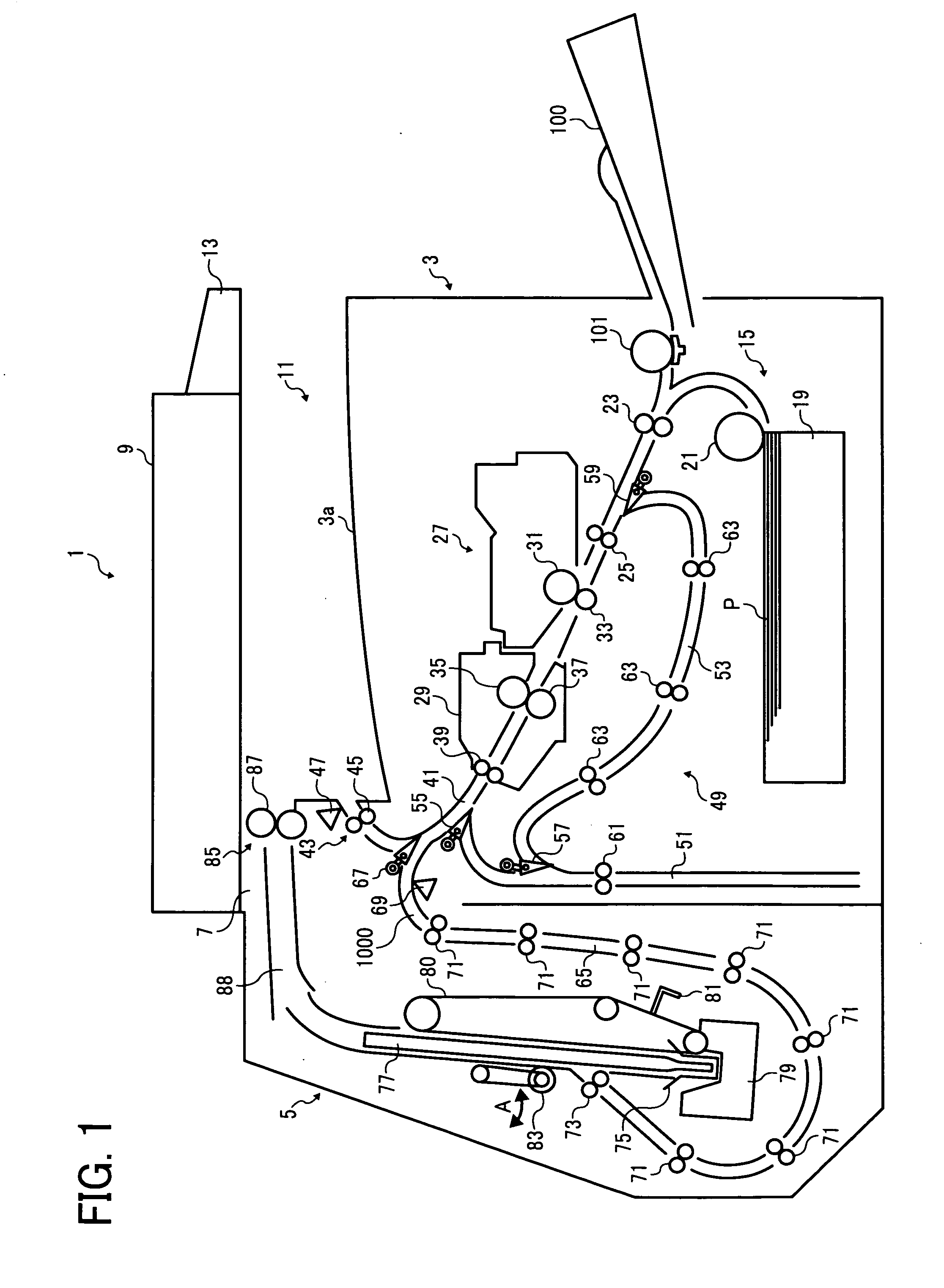

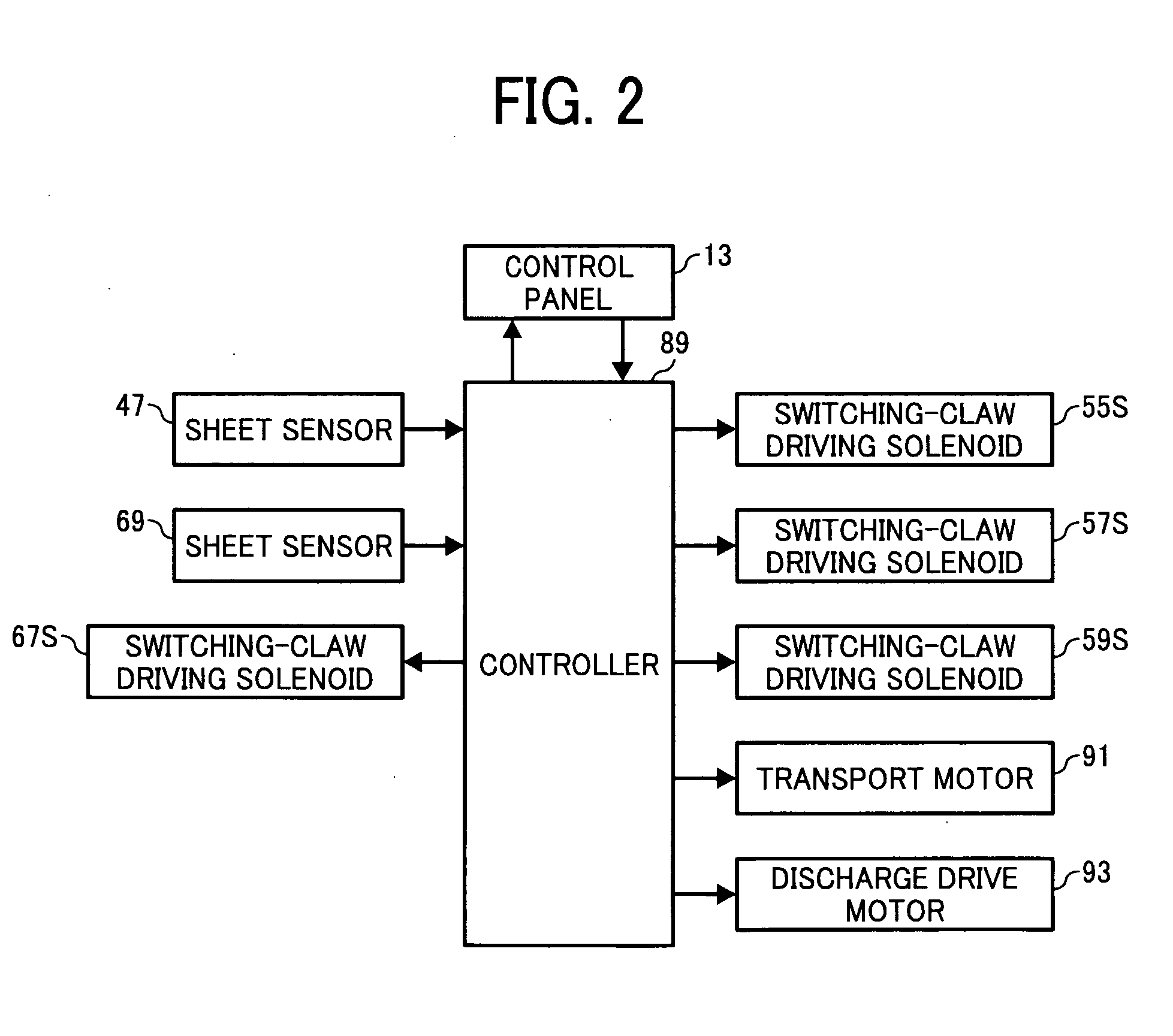

Image forming apparatus

InactiveUS20090162082A1Effectively using housing-internal spaceReduce overall heightElectrographic process apparatusEngineeringMechanical engineering

An image forming apparatus includes an image forming unit, a first sheet stack portion, a sheet output section, and a post processing unit. The image forming unit forms an image on a sheet. The first sheet stack portion is provided at an upper face of the image forming unit. The sheet output section outputs the sheet on which the image is formed by the image forming unit from one side of the image forming apparatus to the first sheet stack portion. The post processing unit is provided adjacent to a lateral side of the image forming unit at an upstream side of the sheet output section to execute post processing on the sheet. A sheet subjected to post-processing by the post-processing unit is output to the first sheet stack portion from the same direction as a sheet not subjected to post-processing by the post-processing unit.

Owner:RICOH KK

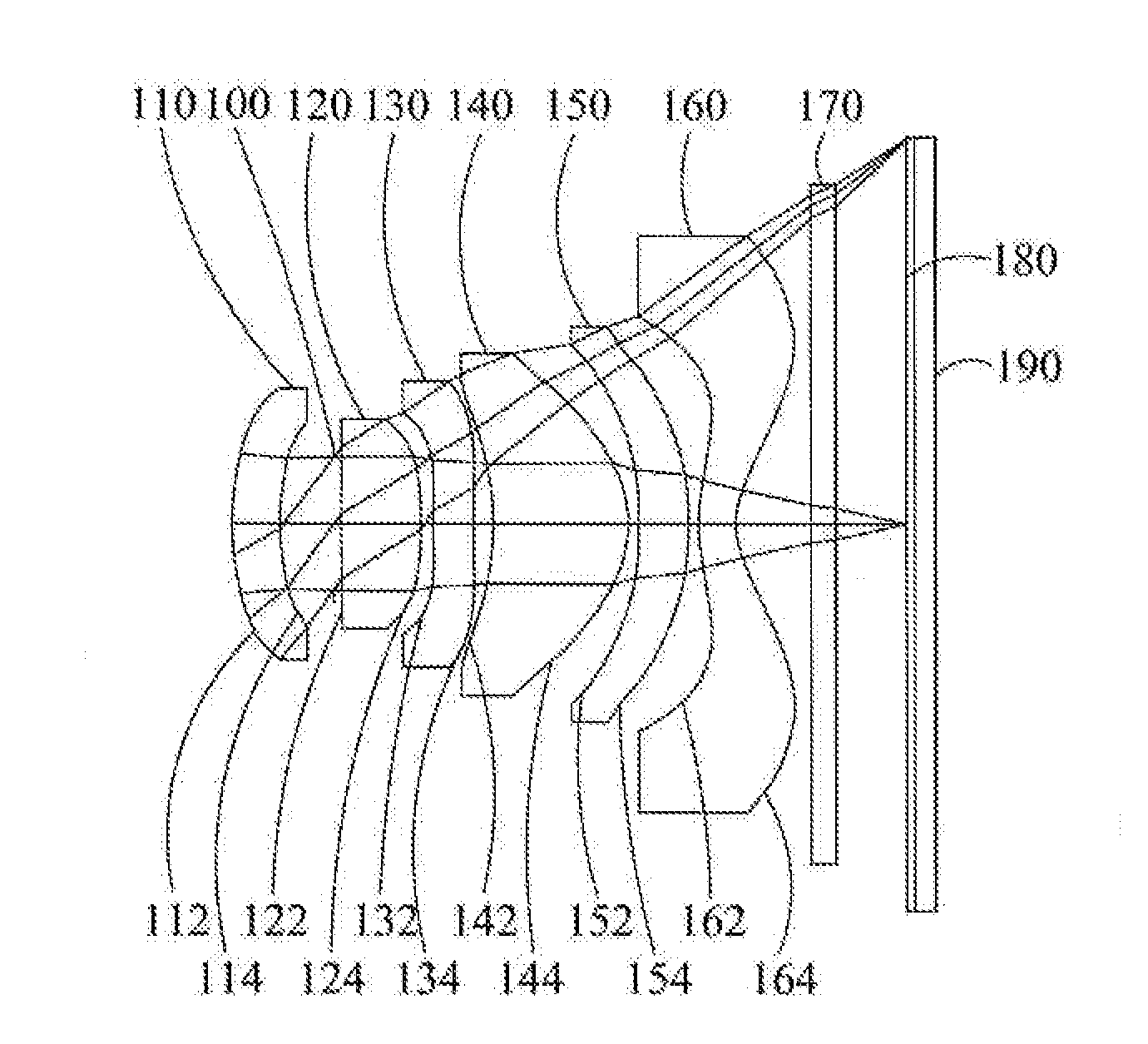

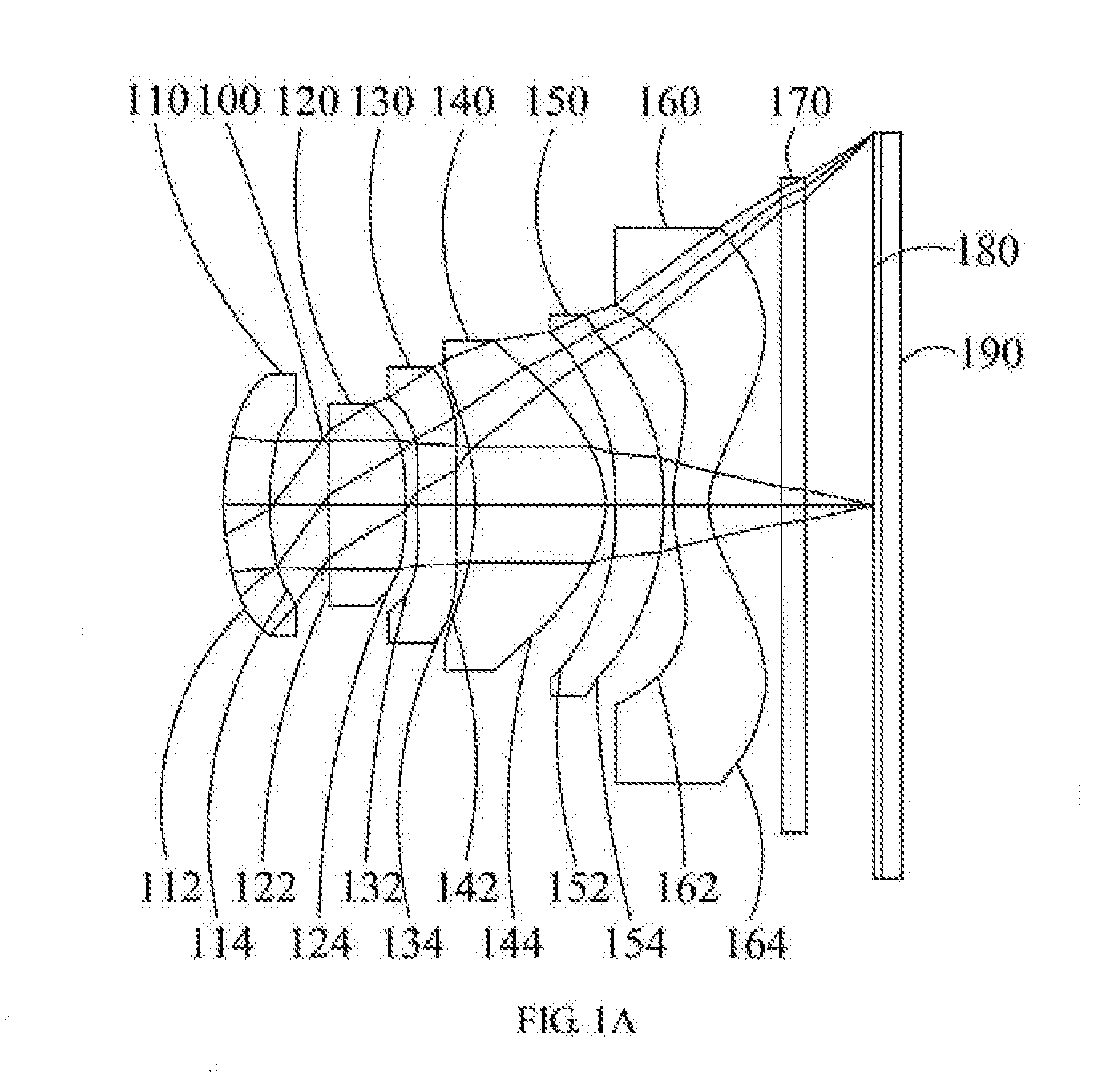

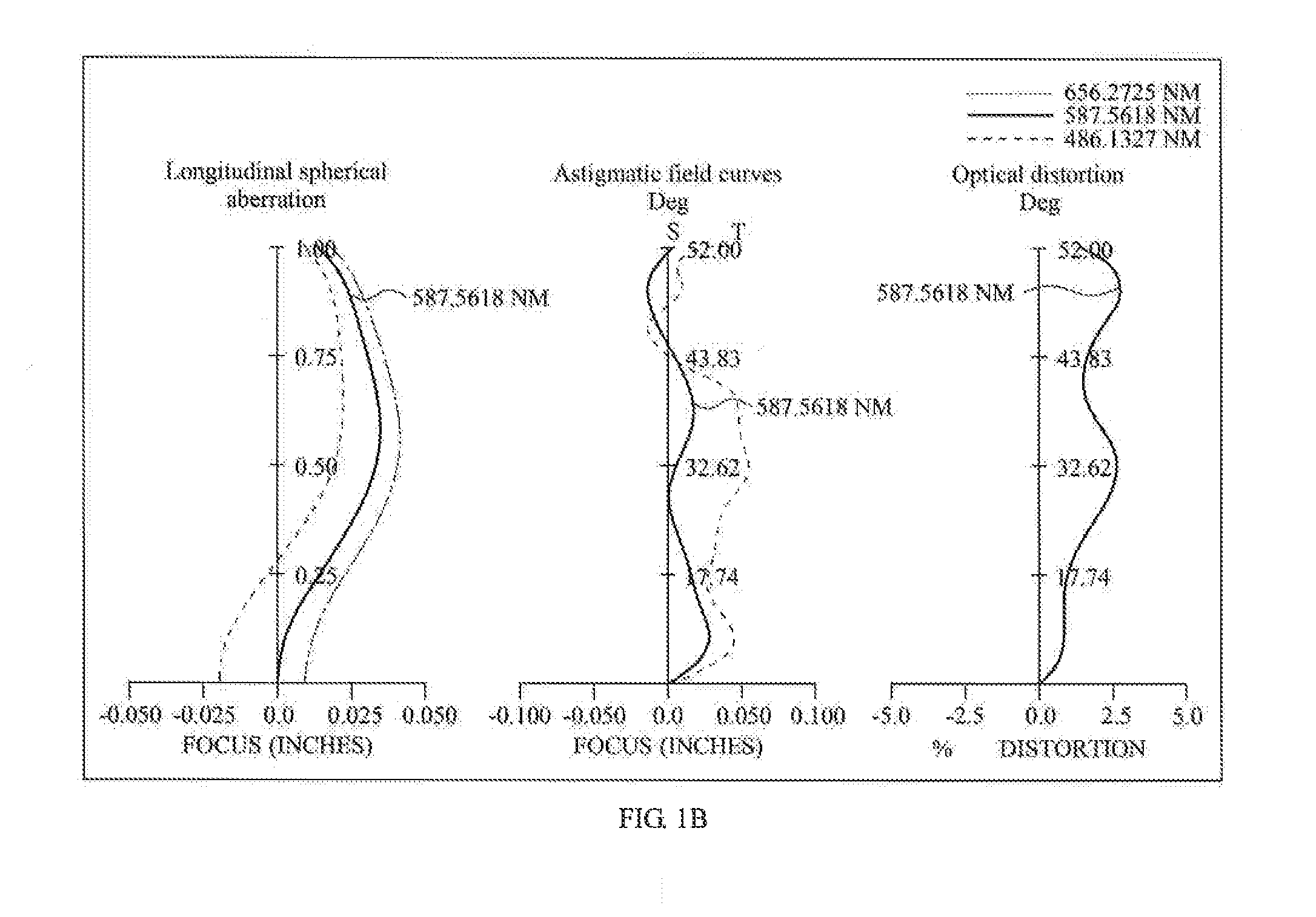

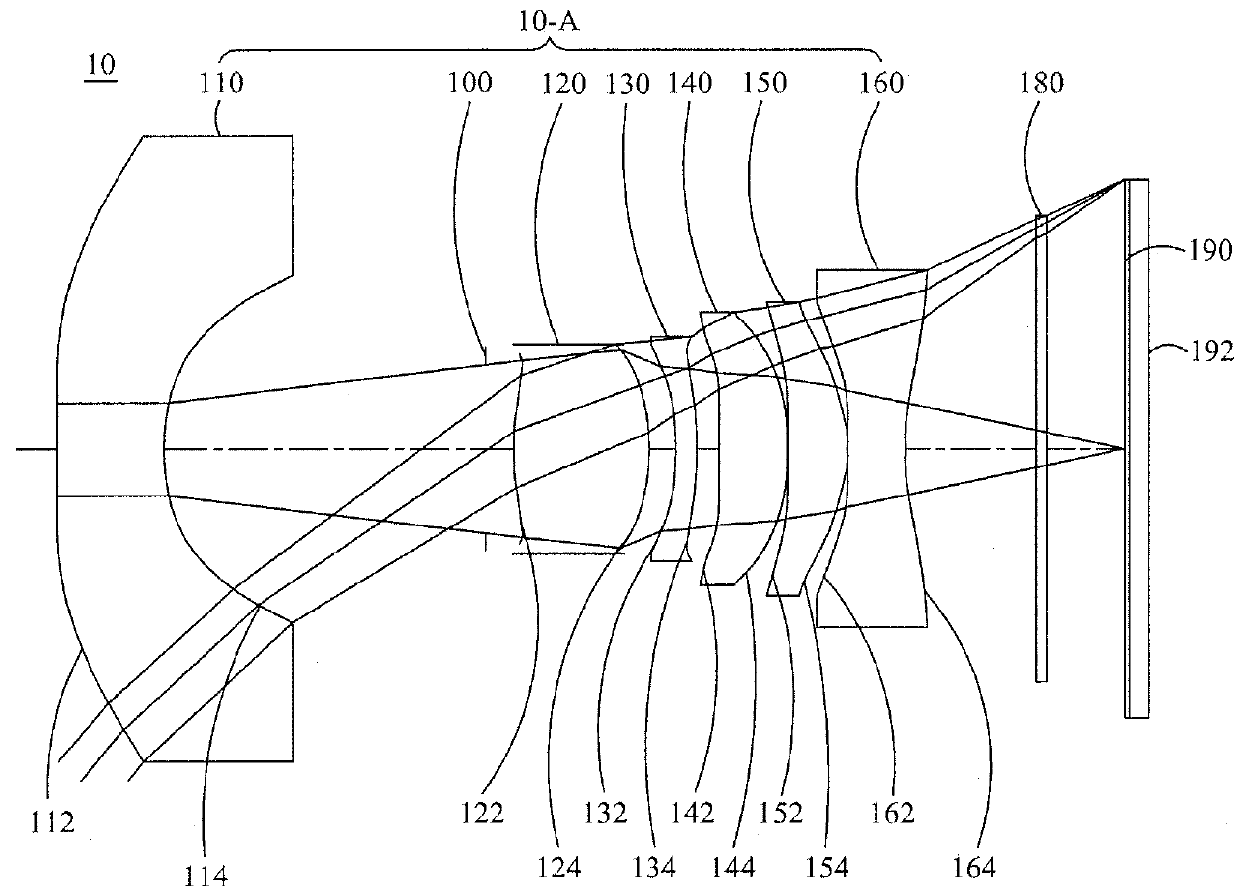

Optical image capturing system

An optical image capturing system, from an object side to an image side, comprises a first, second, third, fourth, fifth, and sixth lens elements. The first lens element with refractive power has a convex object-side surface. The second through fifth lens elements have refractive power and both of an object-side surface and an image-side surface of the four lens elements are aspheric. The sixth lens with negative refractive power has a concave object-side surface. Both of the image-side and object-side surfaces of the six lens elements are aspheric and at least one of the two surfaces has inflection points. Each of the six lens elements may have refractive power. When specific conditions are satisfied, the optical image capturing system can have a better optical path adjusting ability to acquire better imaging quality.

Owner:ABILITY OPTO ELECTRONICS TECH

Electronic circuit package

ActiveUS20180033738A1High composite shielding effectReduce overall heightSemiconductor/solid-state device detailsSolid-state devicesElectronic circuitMagnetic films

Disclosed herein is an electronic circuit package includes a substrate having a power supply pattern, a first electronic component mounted on a first region of a front surface of the substrate, a mold resin that covers the front surface of the substrate so as to embed the first electronic component therein, and a laminated film covering an upper surface of the mold resin, the laminated film including a magnetic film and a first metal film. The first metal film is connected to the power supply pattern. The magnetic film is selectively thick on the first region.

Owner:TDK CORPARATION

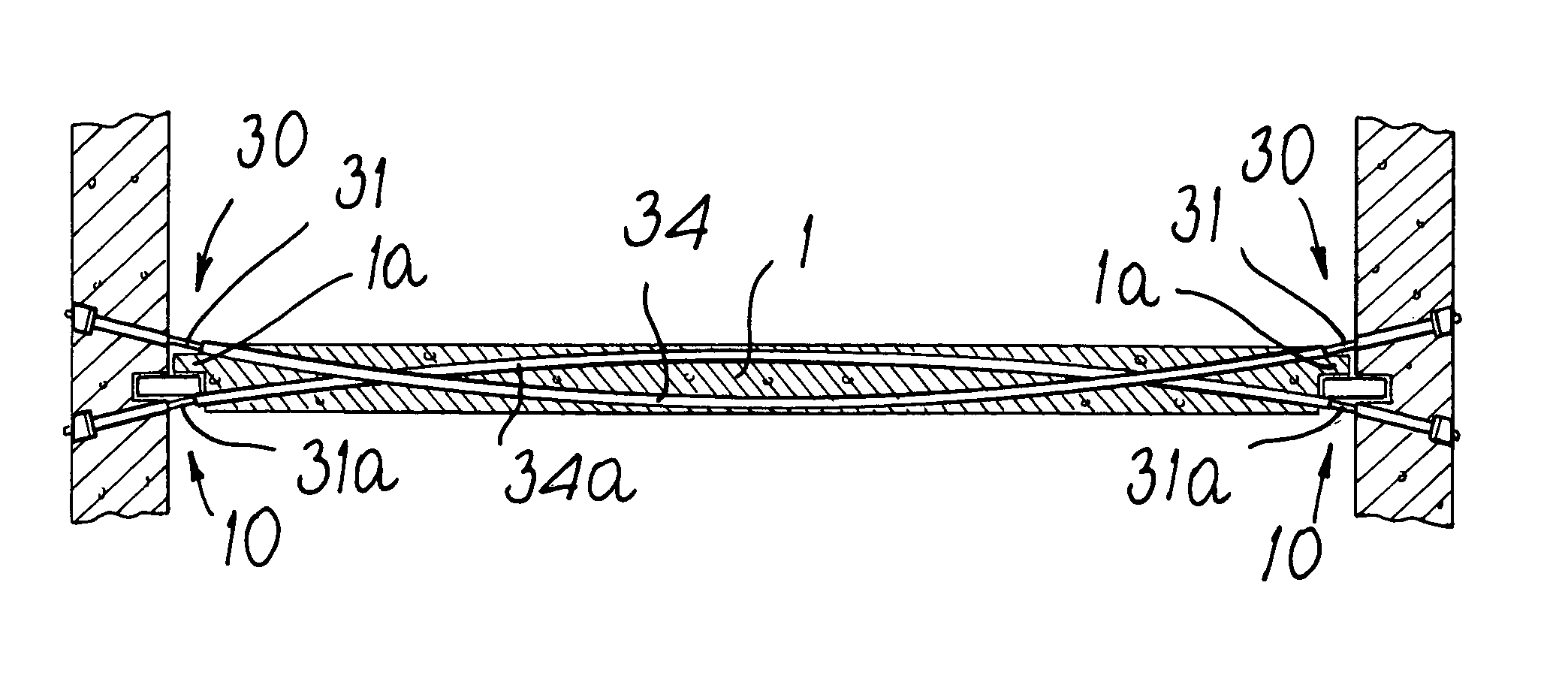

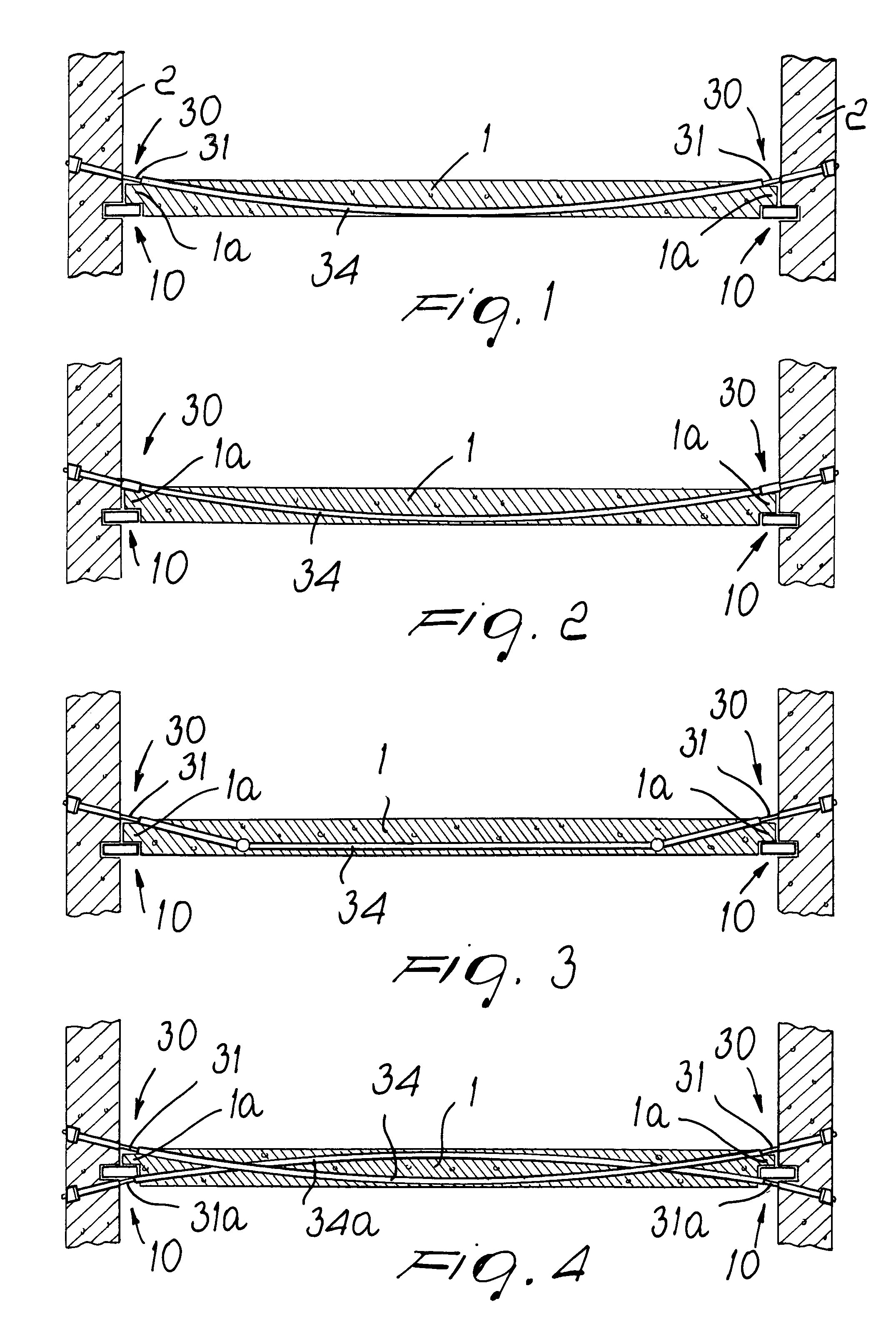

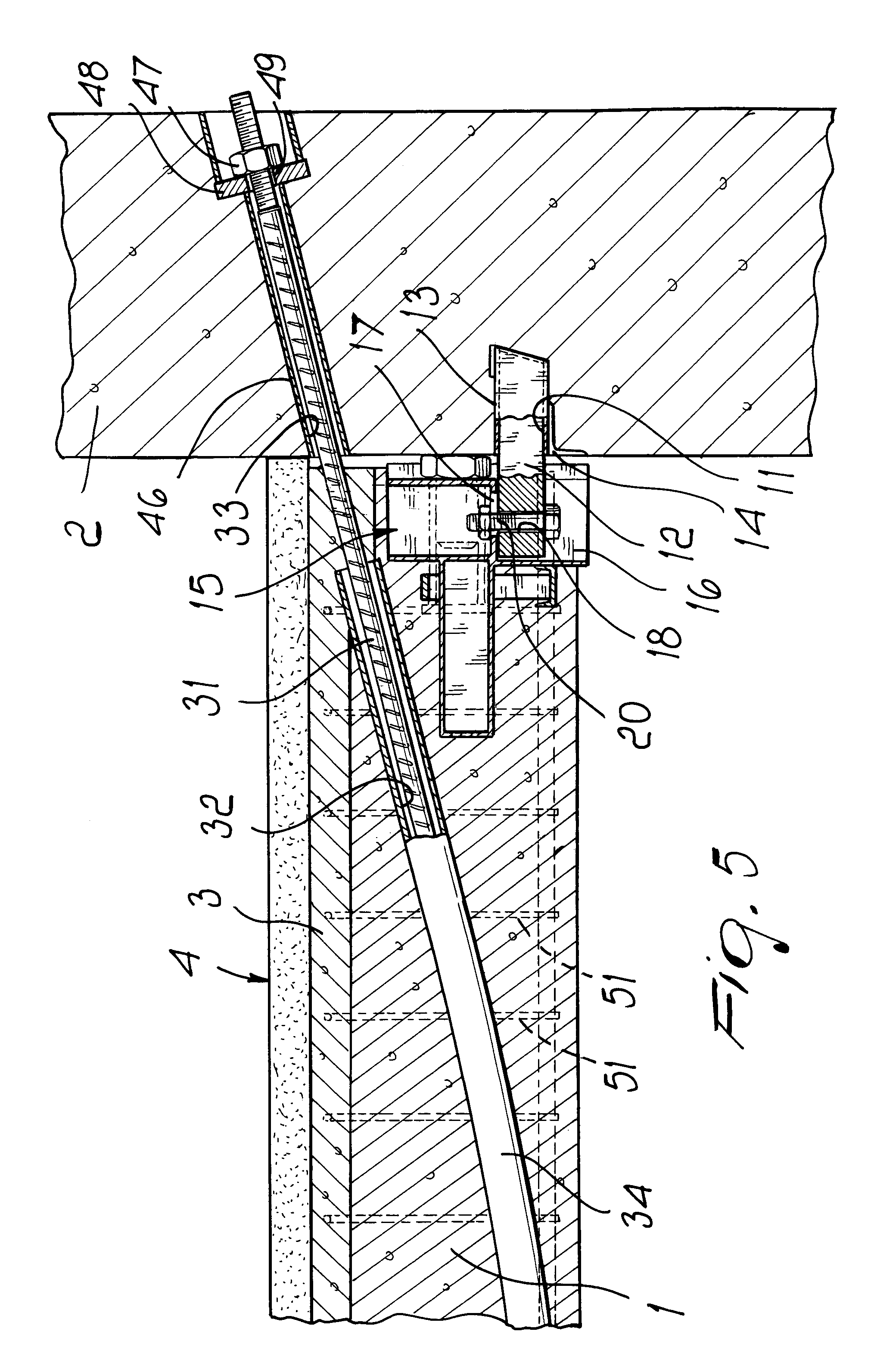

Device for connecting a beam to pillars or similar supporting structural elements for erecting buildings

InactiveUS7287358B2Reduce overall heightUniform stress distributionBuilding roofsFloorsStructural elementEngineering

A device for connecting a beam to pillars or similar supporting structural elements in order to erect buildings, particularly multistory buildings, by means of prefabricated concrete components, the device comprising first means for connecting two end regions of the beam to the pillars and second means for connecting the beam to the pillars, the first connection means provide a coupling at least of the hinge type between each one of the two end regions of the beam and the corresponding pillar; the second connection means comprise at least one tension element that passes through the beam and is connected to the pillars by means of the ends thereof that protrude from the beam.

Owner:ZAMBELLI SERGIO +1

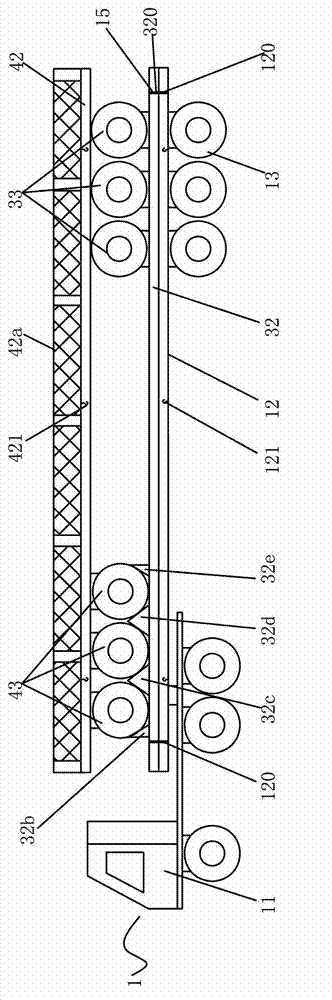

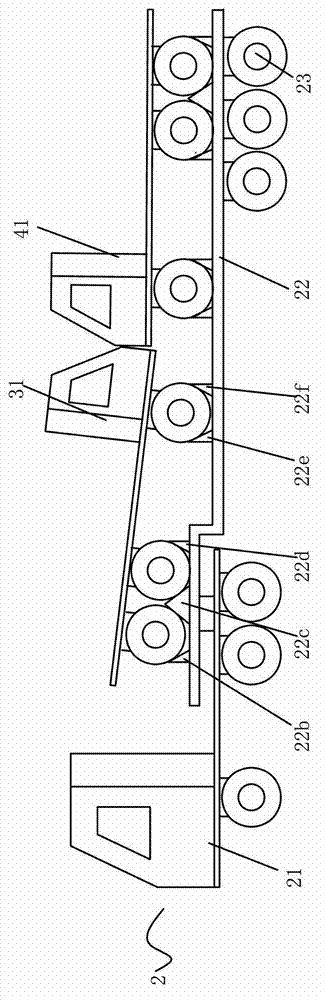

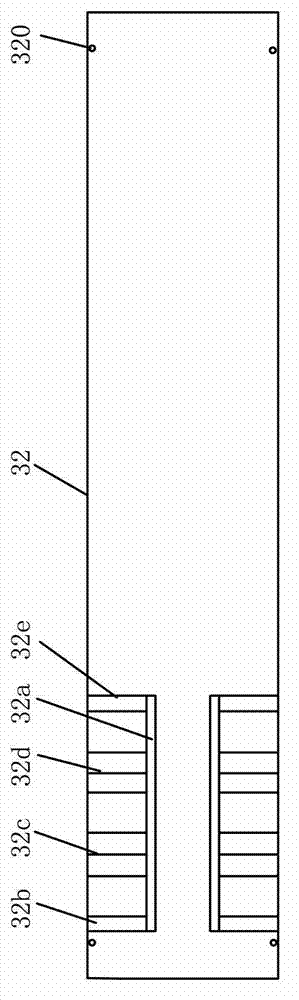

Large-scale transport vehicle parallel operation transporting system and method

ActiveCN102756763AReduce overall heightMeet shipping requirementsTractor-trailer combinationsVehicle carriersRolloverMode of transport

The invention discloses a large-scale transport vehicle parallel operation transporting system and a method. The parallel operation method includes that four large-scale semi-trailers are combined to form a transporting unit; when the transporting unit performs cargo-loading transportation, the four large-scale semi-trailers of the transporting unit perform cargo-loading transportation respectively; and when the transporting unit performs empty load transportation, by means of a rollover system, two large-scale semi-trailers of the transporting unit are loaded on the rest two large-scale semi-trailers so that a parallel operation transporting method that the two large-scale semi-trailers transport the rest two large-scale semi-trailers is formed. Under the condition that the transporting unit integrated by the four semi-trailers is not ultra-high, ultra-long and ultra-wide, the transporting unit is capable of performing reliable transportation according to requirements of road transportations and substantially reducing transportation costs.

Owner:河北省冀交物流有限公司

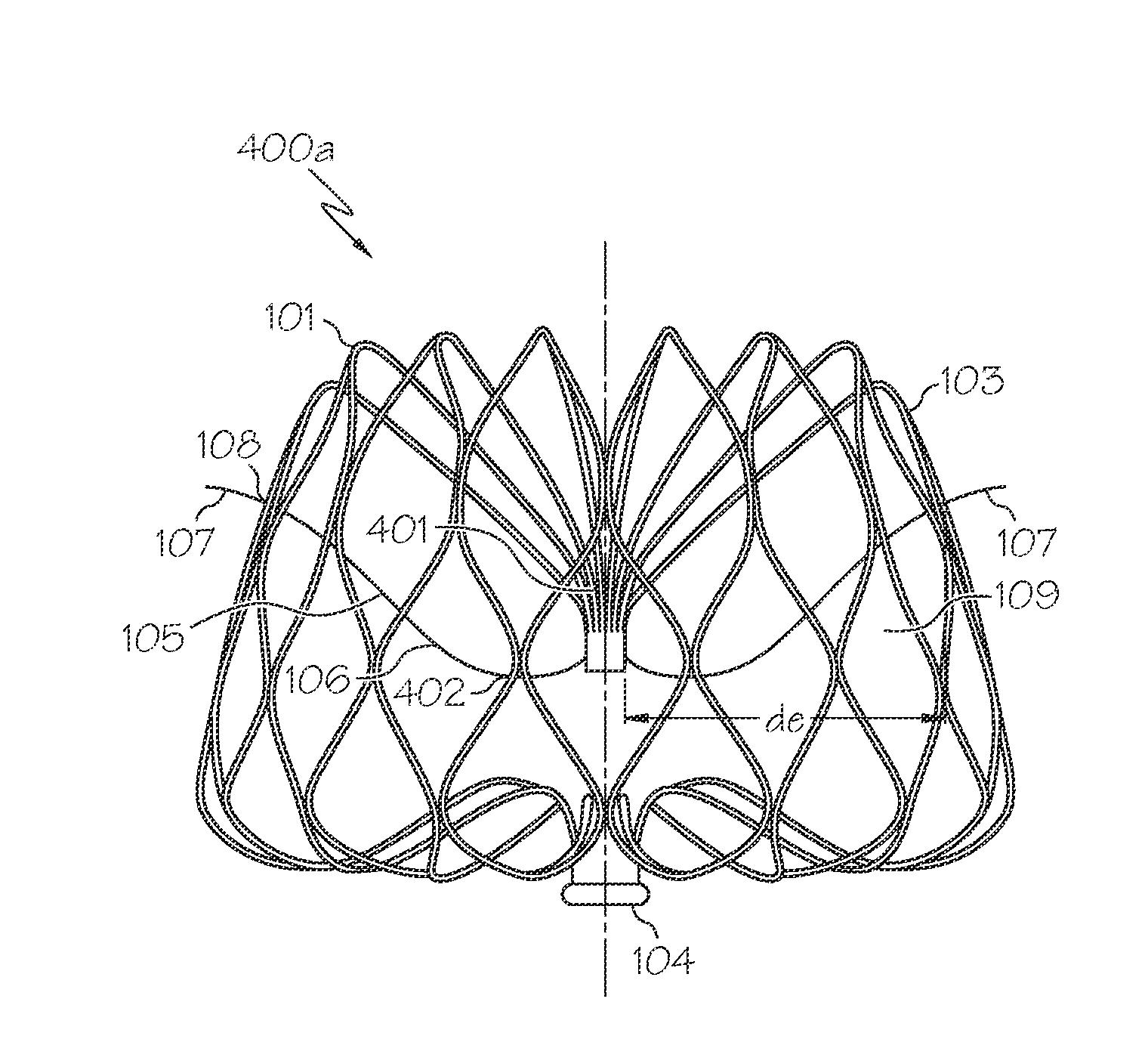

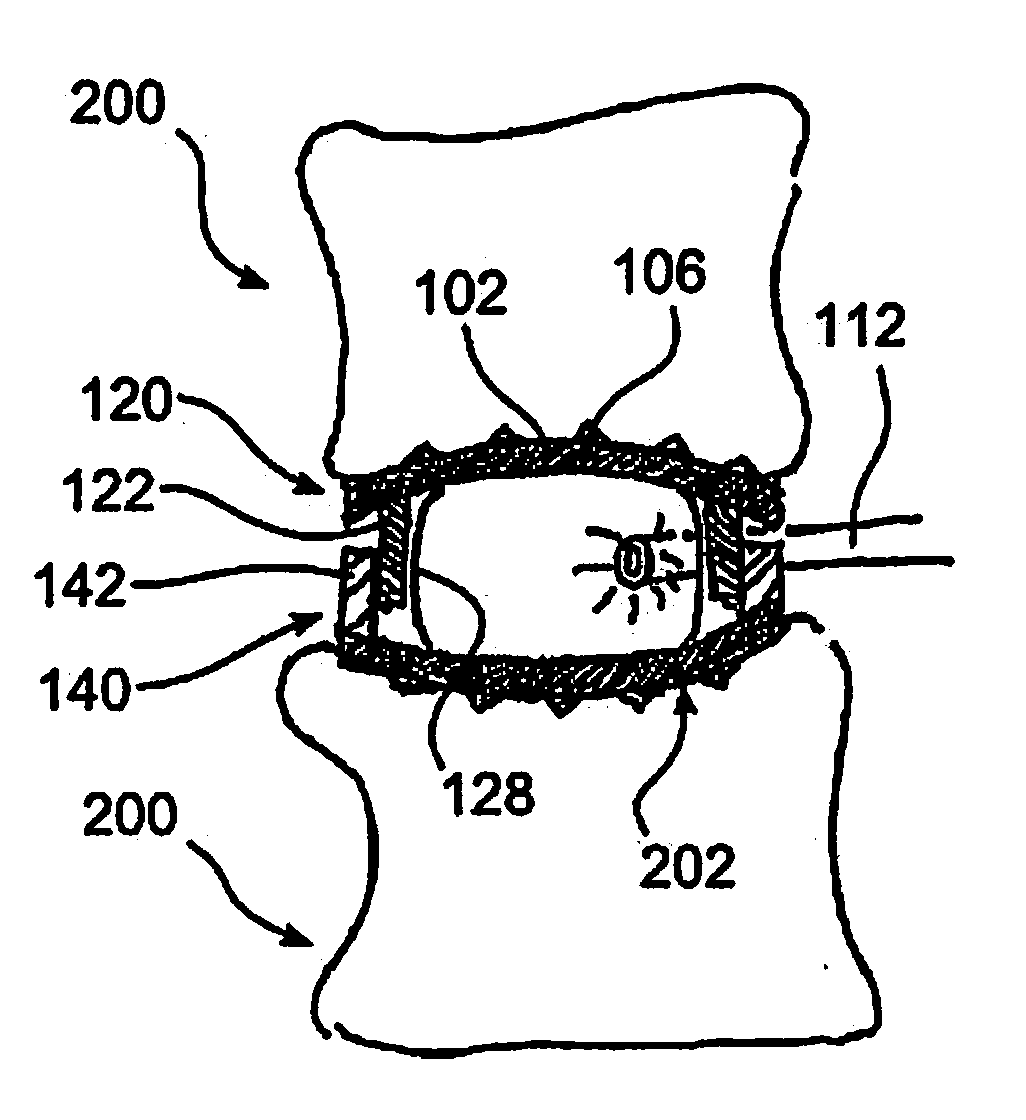

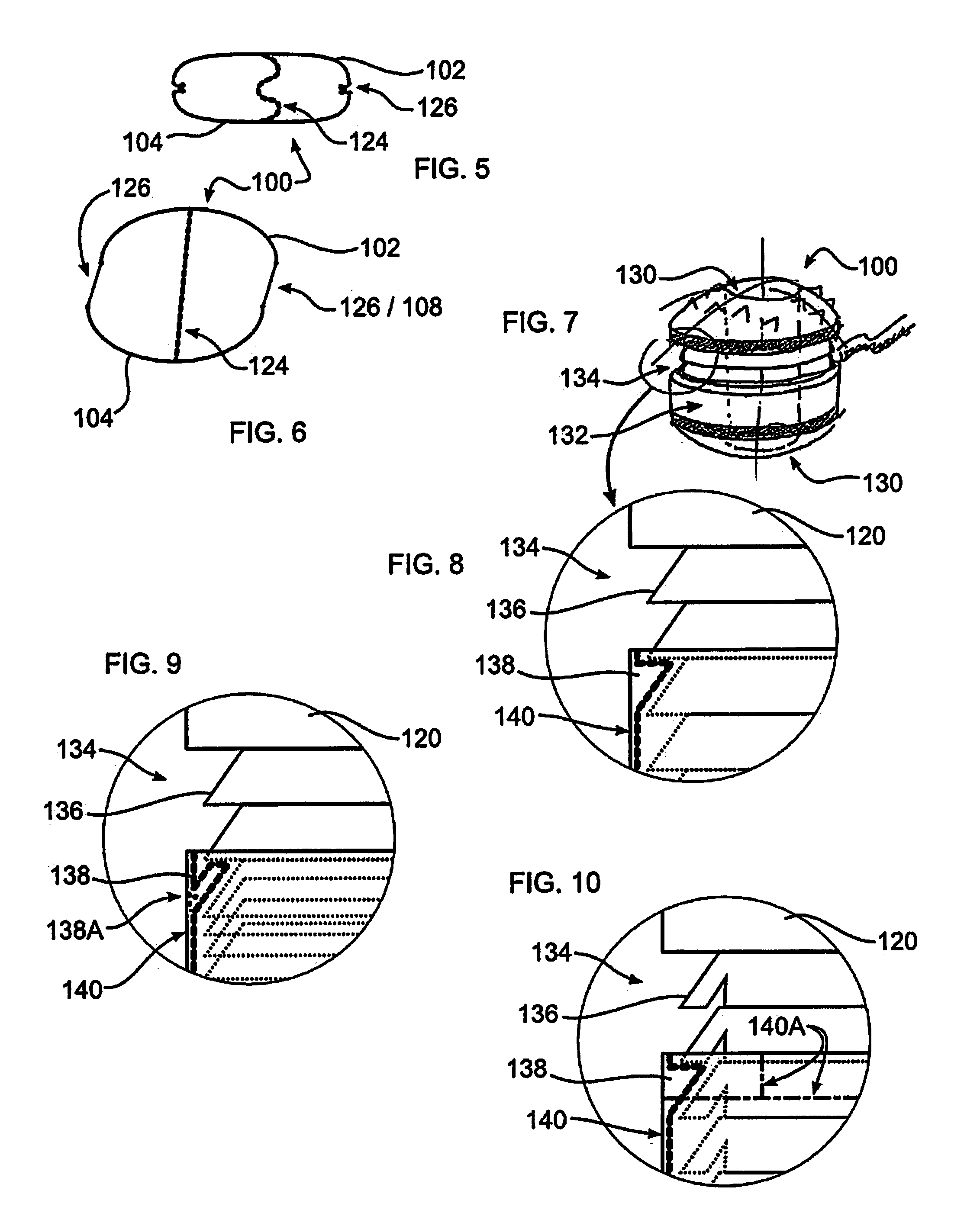

Stabilizing Vertebrae with Expandable Spacers

ActiveUS20130131808A1Reduce overall heightMaintain its heightInternal osteosythesisBone implantVertebraDistraction

A spinal distractor and stabilizer has resilient, conformable bone contacting sections which are separated by an expandable chamber that extends from one of the sections, and which forms a ratchet with the section, ensuring that once expanded by being filled with a substance, cannot contract absent intervention by a medical practitioner. The stabilizer may be filled with a material which solidifies, after which some or all of the device may biodegrade. The device may also be provided in separable portions to facilitate implantation. The conformable sections distribute the distraction and stabilizing force evenly over the bone surface, reducing the incidence of disruption to the integrity of the bone.

Owner:GLOBUS MEDICAL INC

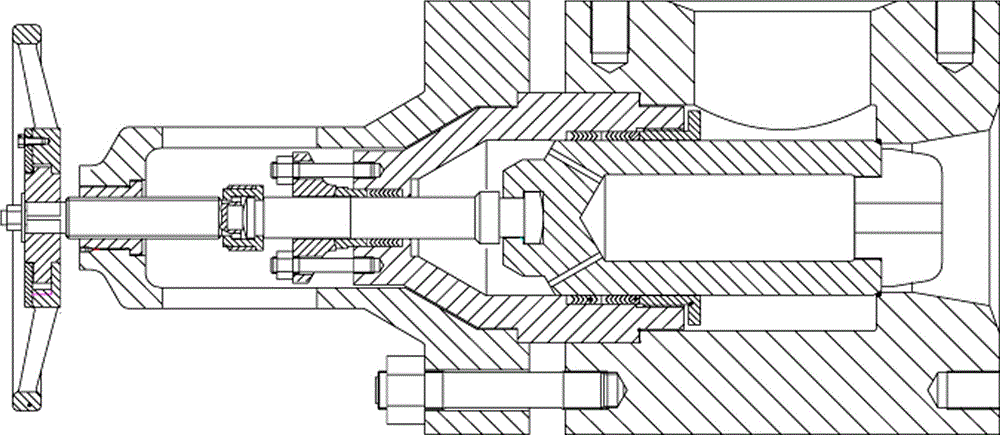

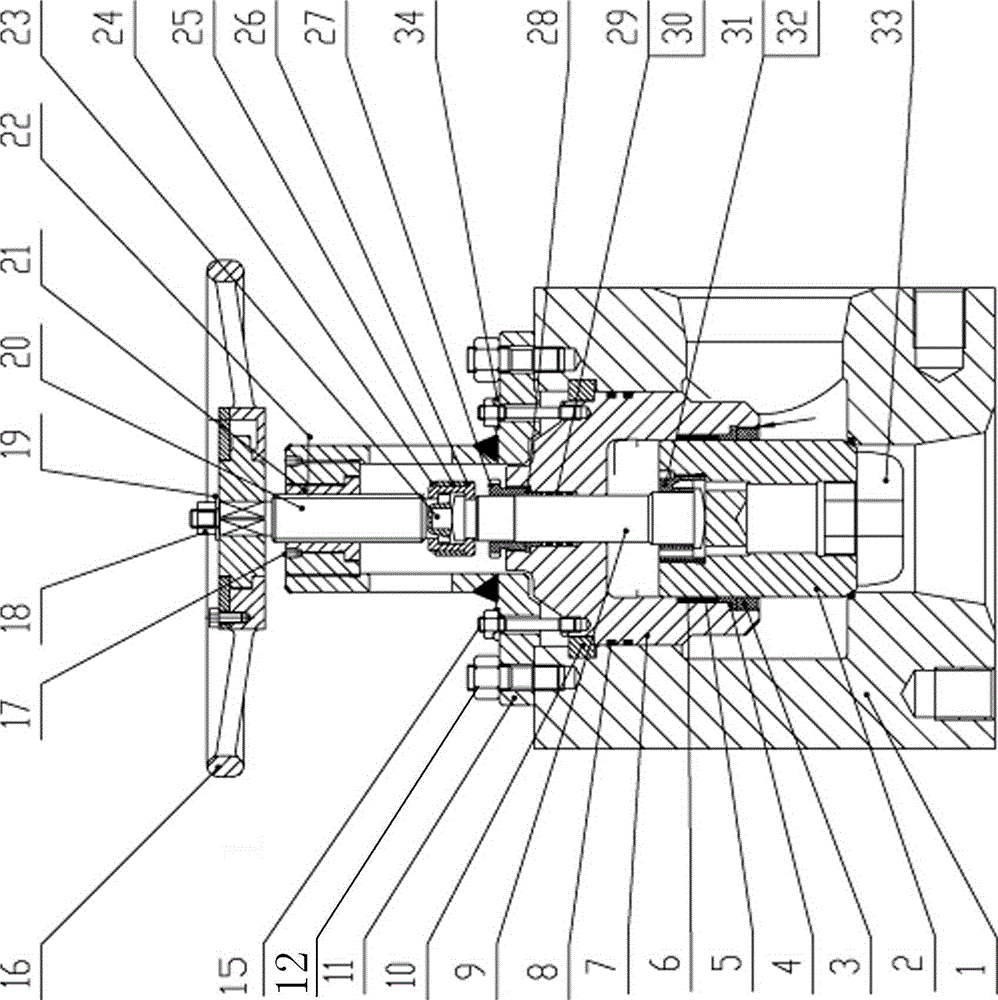

Novel structural high-pressure balance valve

ActiveCN102748483ALow costEasy to assembleSpindle sealingsOperating means/releasing devices for valvesFluid balanceEngineering

The invention relates to a novel structural high-pressure balance valve, which comprises a valve body (1), a stuffing box assembly, a valve rod assembly, a support assembly, a hand wheel assembly, a four-element ring (10) and a split jacket (26), wherein a concave groove is arranged on the inner wall of a top hole of the valve body, the four-element ring (10) is arranged on the concave groove, aninner ring of the four-element ring (10) protrudes out of the concave groove, and the bottom of a projection part is in contact with the top surface of the stuffing box assembly; the valve rod assembly comprises a valve rod (9) inserted into the stuffing box assembly and a valve clack (2), the top of the valve rod (9) is connected with the support assembly through the split jacket (26), the valveclack (2) is a cylindrical cavity, a pressing plate is arranged in the valve clack (2), an inner wall of the valve clack (2) at the upper part of the pressing plate is a screw thread, the screw thread is connected with a thread spacer sleeve (31), the bottom of the valve rod (9) is inserted into the thread spacer sleeve (31), the bottom of the valve rod (9) protrudes, the bottom of the thread spacer sleeve (31) is concave, the valve rod (9) and the thread spacer sleeve (31) are matched, so that the valve rod (9) and the thread spacer sleeve (31) are in lapped joint; the stuffing box assembly comprises a stuffing box (7), a first O-shaped sealing part, a second O-shaped sealing part and a third O-shaped sealing part; an O-shaped ring is an F4 type all-coated fluororubber O-shaped sealing ring, and is an axially assembled structure; and fluid balance holes are arranged on the pressing plate in the valve clack (2) and the thread spacer sleeve (31). The novel structural high-pressure balance valve, provided by the invention, has the advantages of simple structure, convenience for use and small volume.

Owner:YUEYANG ZHUSHENG VALVE PIPELINE

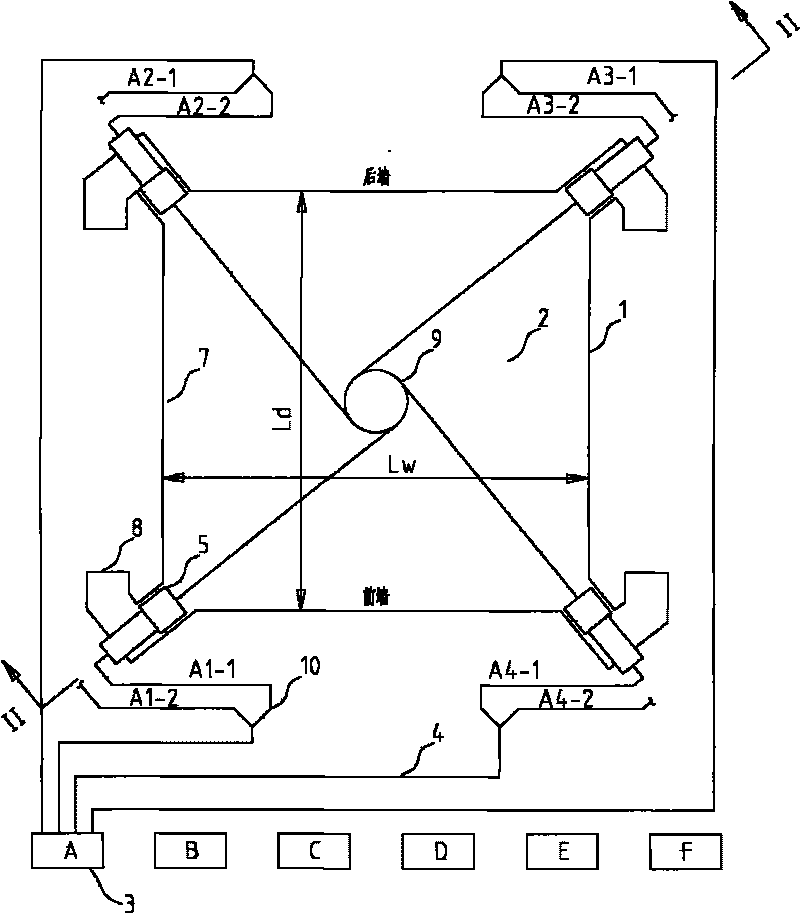

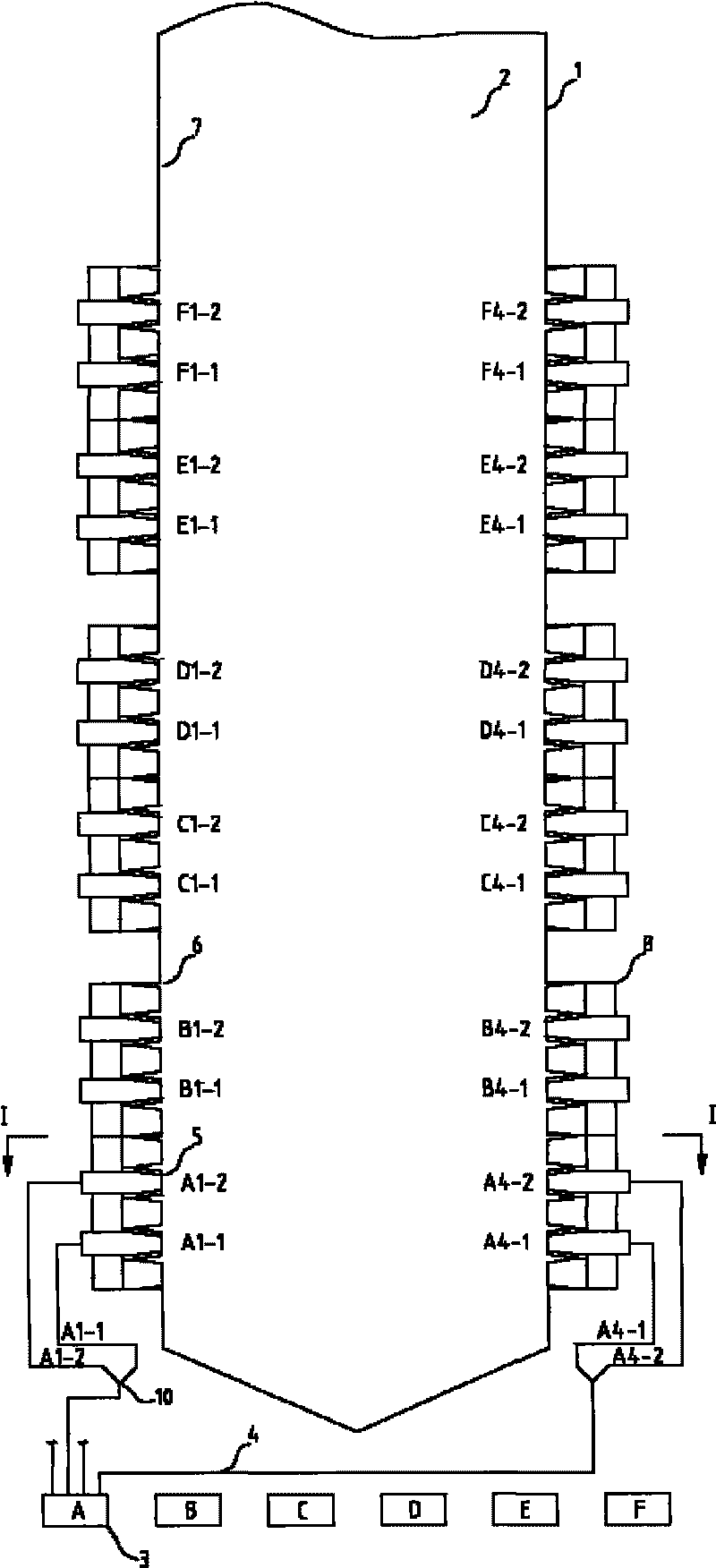

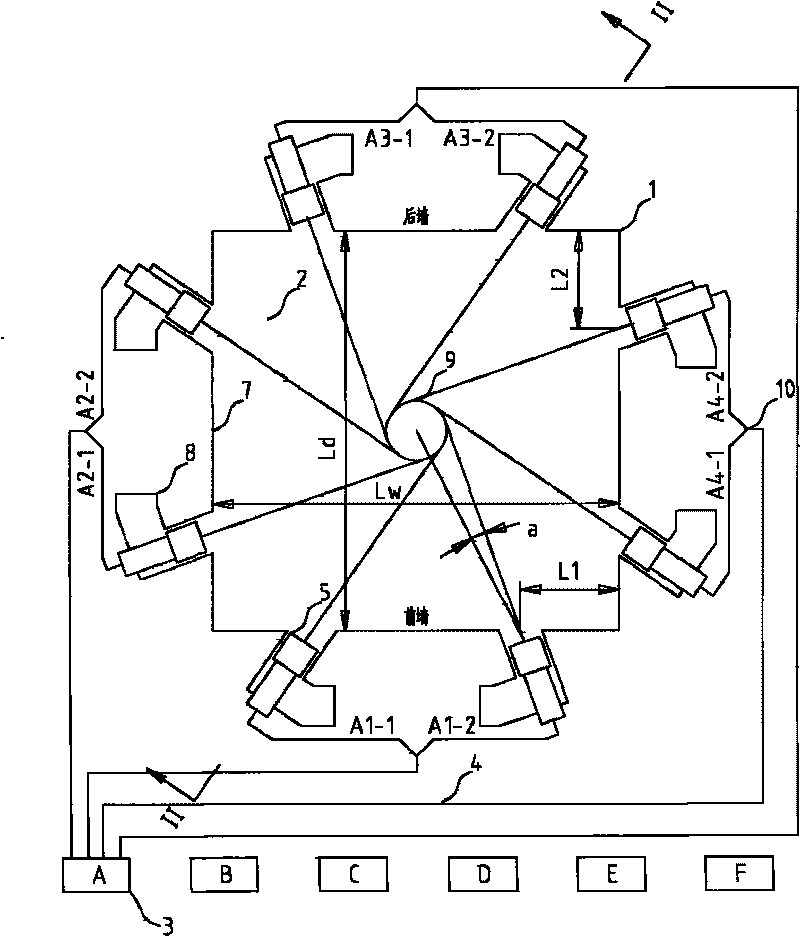

Hexagonal or octagonal tangential arrangement of anthracite burning single-fireball direct-flow combustors

ActiveCN101709871AGuaranteed to catch fire in timeReduce overall heightCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelLow loadAirflow

The invention provides hexagonal or octagonal tangential arrangement of anthracite burning single-fireball direct-flow combustors, which is characterized in that: two groups of combustors are arranged on each water-cooling wall or two groups of combustors are arranged on two opposite water-cooling walls of a hearth respectively and a group of combustors are arranged on the other two opposite water-cooling walls respectively, each group of combustors are at least divided into a small group; and each small group of combustors are vertically provided with at least two primary air pulverized nozzles and three secondary air pulverized nozzles at intervals. Each coal mill is connected with eight or six primary air pulverized nozzles which have the same level with that of the coal mill. The start and stop of each coal mill affect the running of the eight or six primary air pulverized nozzles which are on the same layer. The hexagonal or octagonal tangential arrangement of the anthracite burning single-fireball direct-flow combustors can decrease the number of the air pulverized nozzles in a single group of combustors on the premise of meeting the requirements of the thermal power of a single air pulverized nozzle and the number of the total air pulverized nozzles, allows the thermal load qHr of a wall in a combustor area to be relatively high, and guarantees the timely ignition of an pulverized anthracite flow and low-load combustion of a boiler without oil.

Owner:SHANGHAI BOILER WORKS

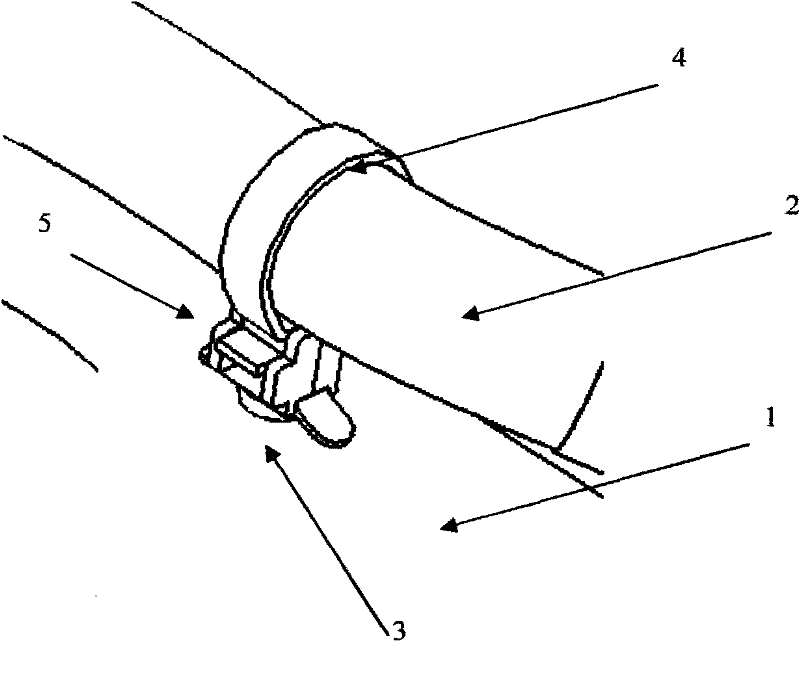

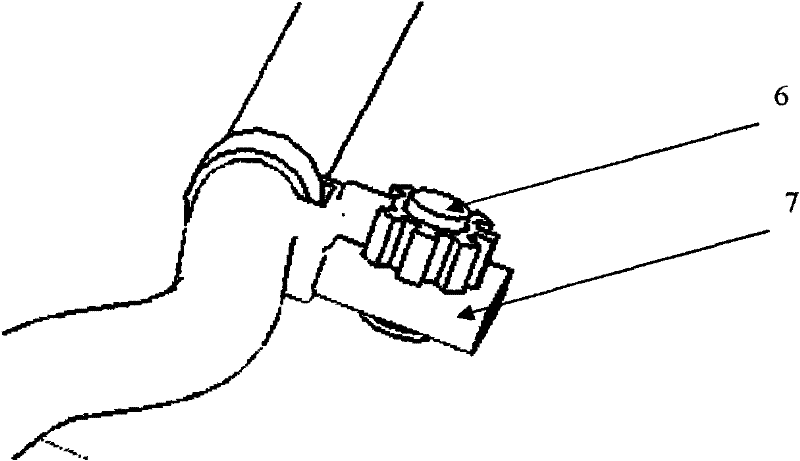

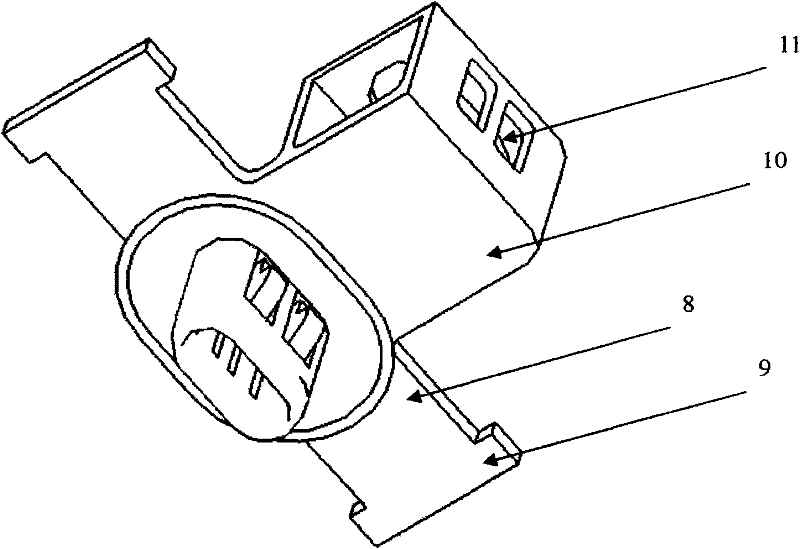

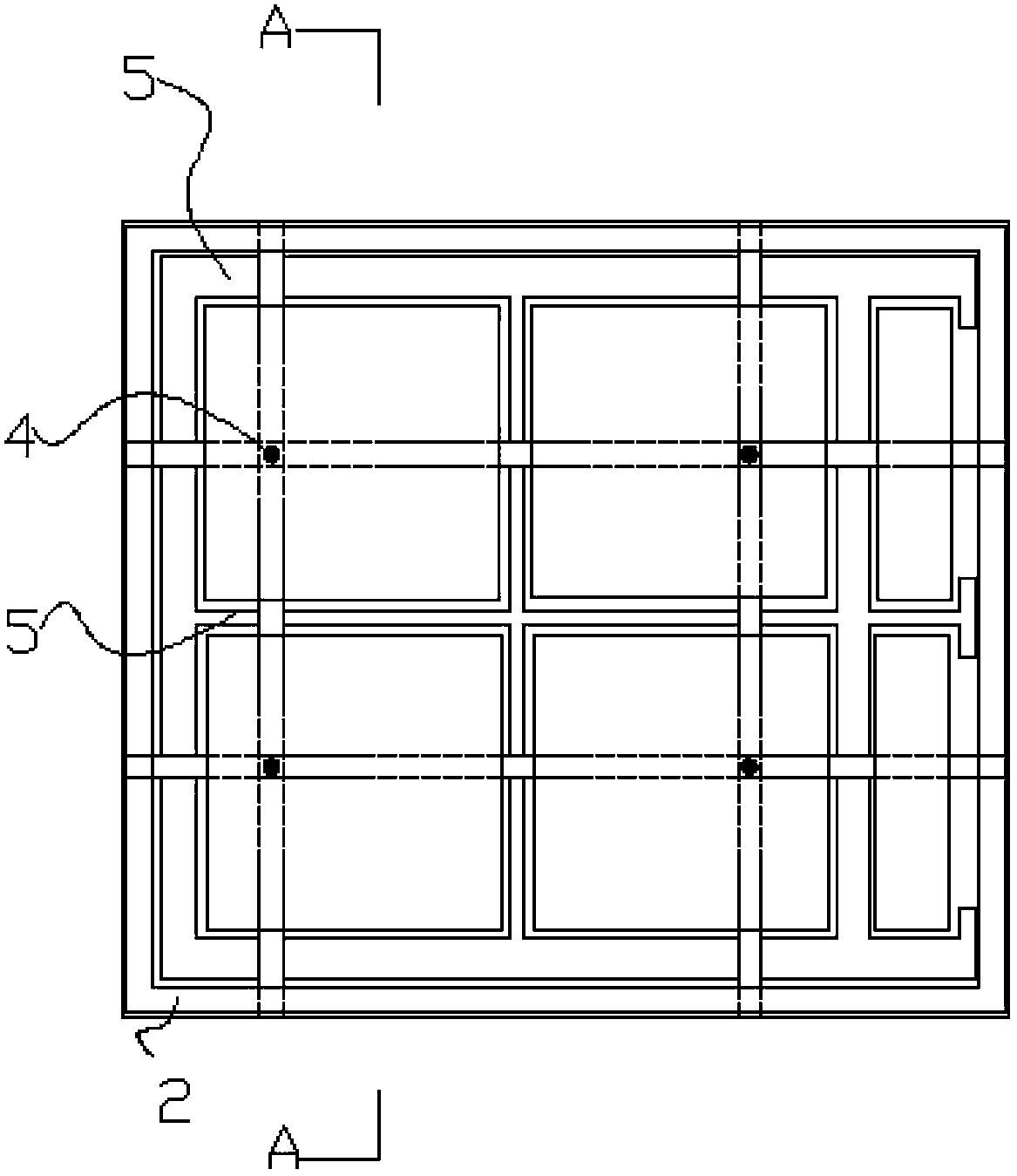

Wire bundle fixing bracket

ActiveCN101752812AAvoid taking up spaceReduce overall heightPipe supportsElectrical apparatusFastenerEngineering

The invention discloses a wire bundle fixing bracket which comprises a wire bundle fixing device, a clamp connecting structure and a protruding structure, wherein the protruding structure protrudes at the side of the wire bundle fixing device to provide a fixing point for a staple bolt or a binding tape which needs to be fastened; the clamp connecting structure comprises a stamping clamp connecting part, a crimping stamping skirt part and a snap fastener, wherein the cross section of the stamping clamp connecting part is in an oblong shape; the snap fastener is positioned at the side face of the clamp connecting part; and the crimping stamping skirt part is connected with the lower surface of the wire bundle fixing device to envelop the clamp connecting part. The flat wire bundle fixing bracket with the protruding structure of the invention prevents a binding tape locking mechanism of a common wire bundle binding tape from occupying space and reduces the overall height of the space that the wire bundle occupies. The protruding structure at the side of the fixing bracket avoids the conflict of requirements for stamping holes.

Owner:CHERY AUTOMOBILE CO LTD

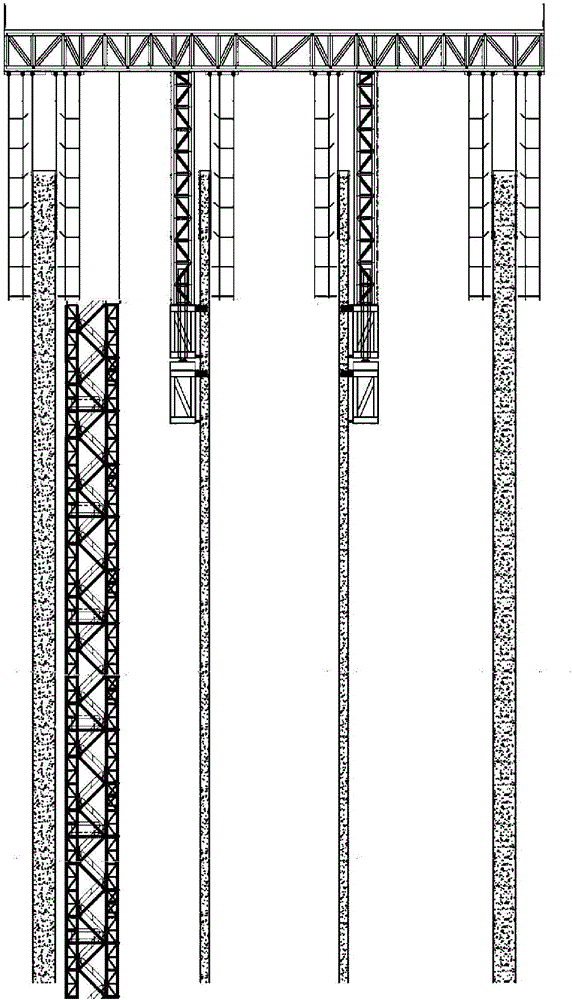

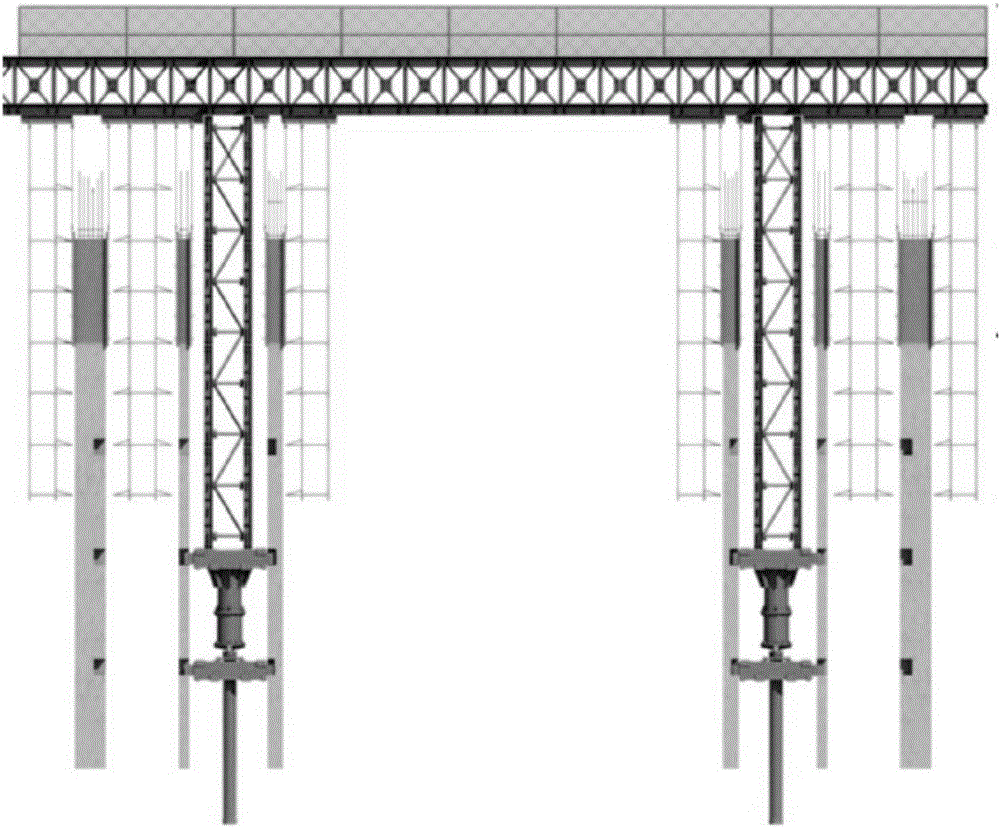

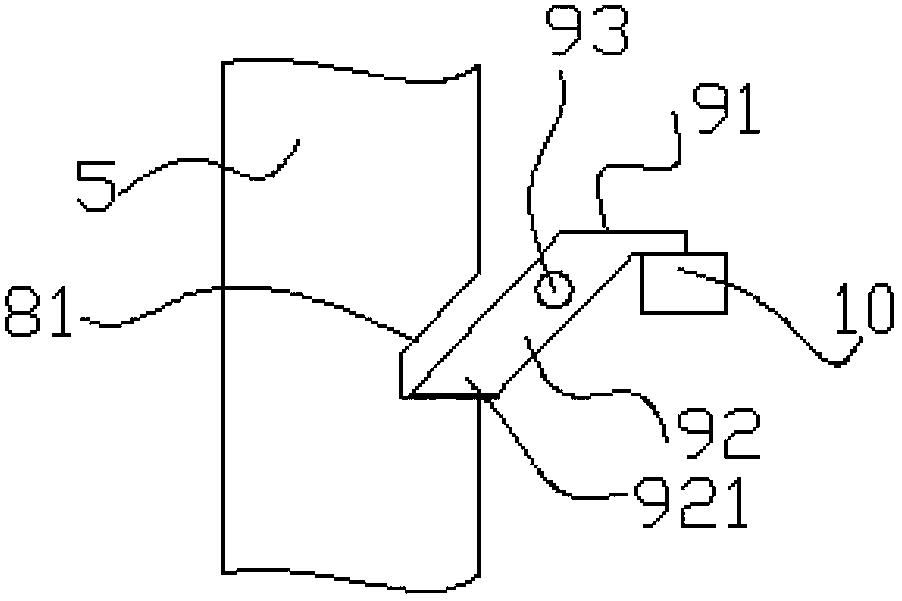

Hydraulic formwork creeping system and formwork creeping method

InactiveCN104120877AOvercome the defect that the formwork cannot be climbed from the bottomReduce overall heightForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksHydraulic ramHydraulic pressure

The invention discloses a hydraulic formwork creeping system and a formwork creeping method. The hydraulic formwork creeping system comprises a formwork for casting concrete to form a wall, an outer wall rail and a supporting platform. The supporting platform is arranged on the top of the wall. The formwork is arranged below the supporting platform and connected with the supporting platform. The hydraulic formwork creeping system further comprises a formwork creeping device for driving the formwork to creep, and the formwork creeping device is provided with an inverted hydraulic oil cylinder. The hydraulic formwork creeping system further comprises a first beam and a second beam respectively connected with the hydraulic oil cylinder. The supporting platform, the outer wall rail and the first beam are fixed to form a whole in space. The two ends of the first beam and the two ends of the second beam are respectively fixed to the cast wall, the hydraulic oil cylinder stretches out and draws back to drive the first beam and the second beam to ascend alternately so that the whole formed by the supporting platform, the outer wall rail and the first beam can drive the formwork to ascend along with the ascending of the hydraulic oil cylinder, and formwork creeping can be achieved. According to the hydraulic formwork creeping system and the formwork creeping method, the height of the overall formwork creeping is reduced, the hydraulic formwork creeping system is simple in structure and convenient to implement, and safety construction is facilitated through reduced dead weight.

Owner:SHENZHEN TECHEN SCI & TECH CO LTD

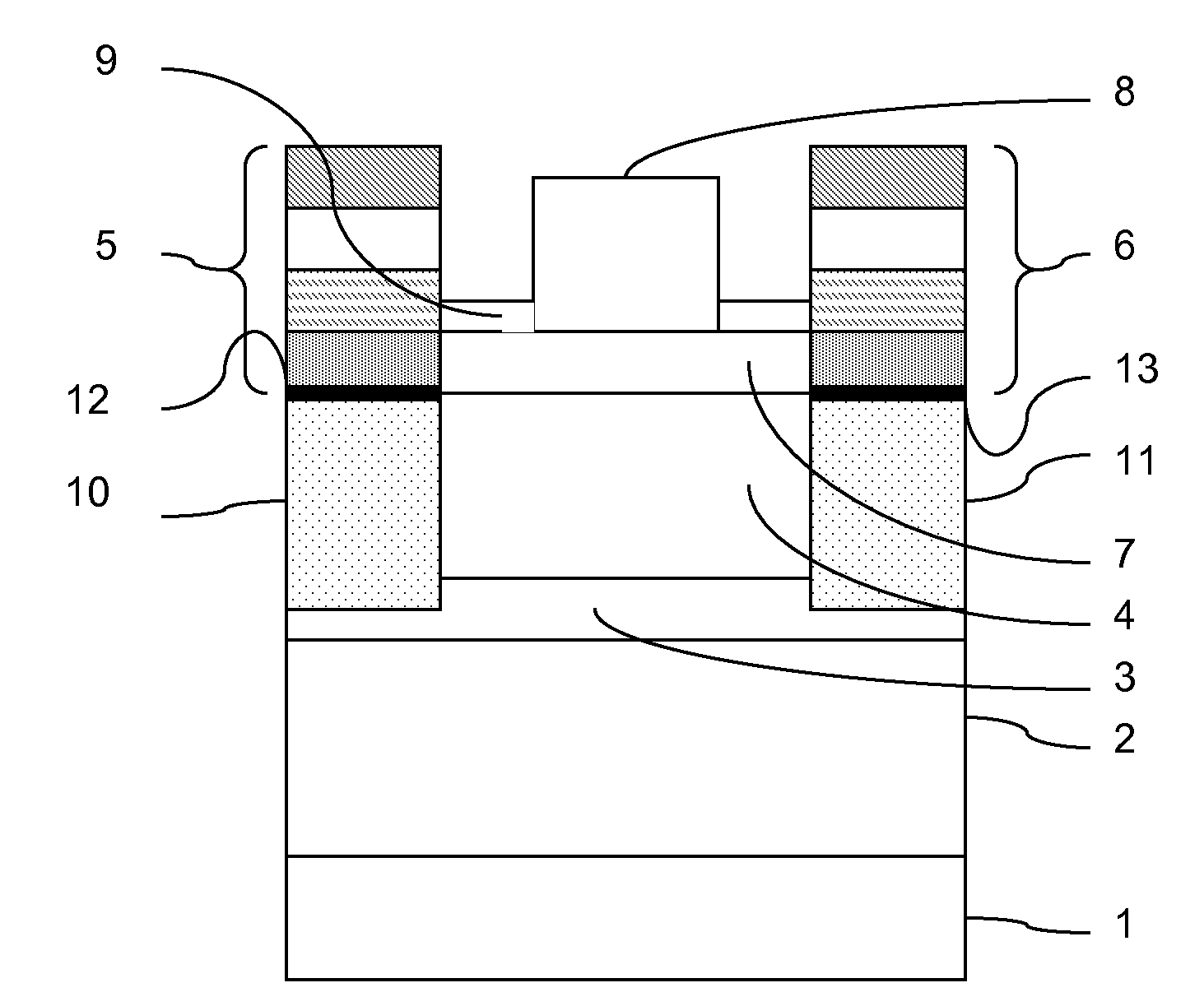

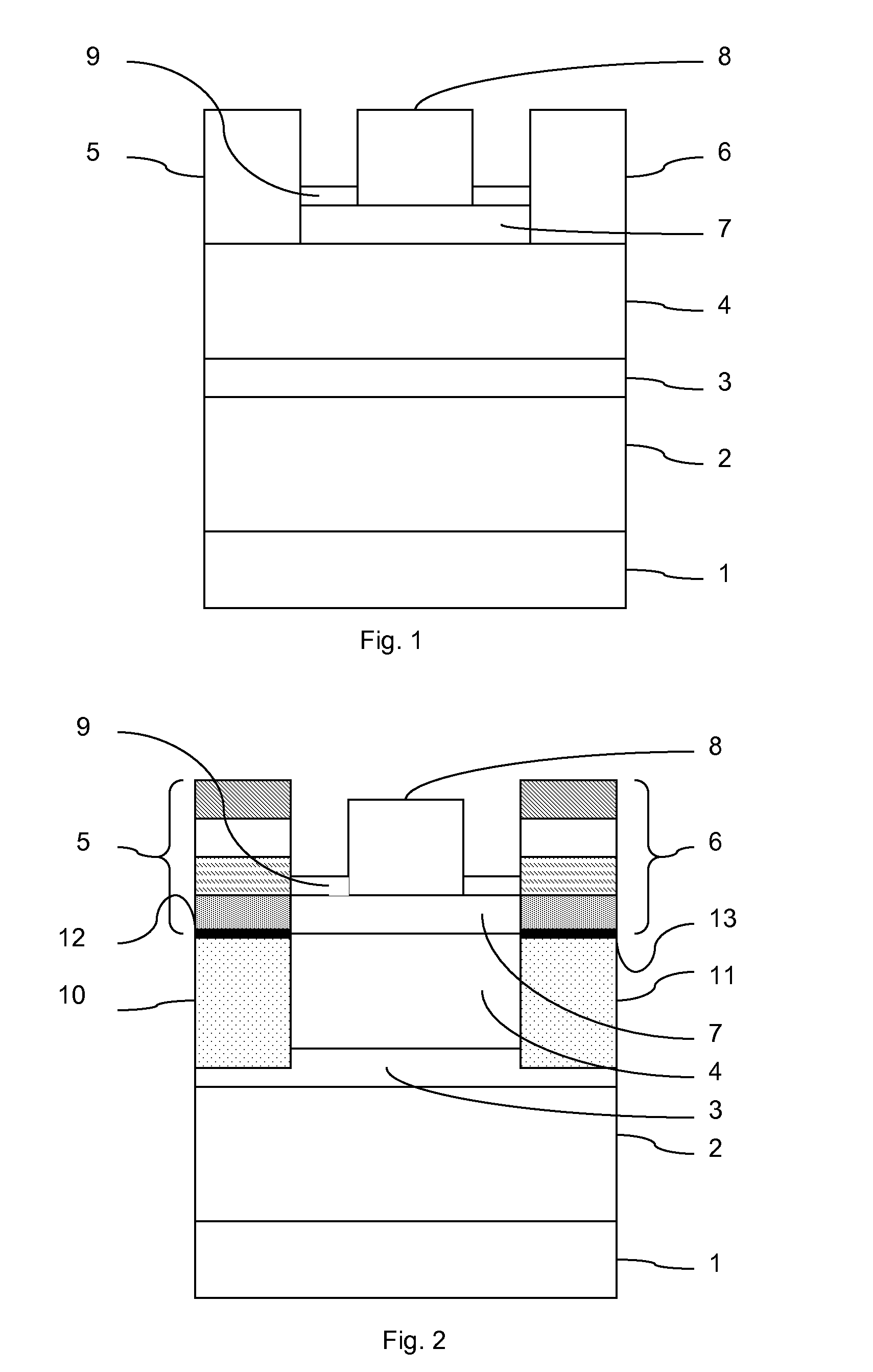

Electronic devices with improved ohmic contact

ActiveUS20100038682A1Lower barrier heightReduce overall heightSemiconductor/solid-state device detailsSolid-state devicesPhysicsOhm

In one embodiment, the disclosure relates to an electronic device successively comprising from its base to its surface: (a) a support layer, (b) a channel layer adapted to contain an electron gas, (c) a barrier layer and (d) at least one ohmic contact electrode formed by a superposition of metallic layers, a first layer of which is in contact with the barrier layer. The device is remarkable in that the barrier layer includes a contact region under the ohmic contact electrode(s). The contact region includes at least one metal selected from the metals forming the superposition of metallic layers. Furthermore, a local alloying binds the contact region and the first layer of the electrode(s).

Owner:S O I TEC SILICON ON INSULATOR THECHNOLOGIES

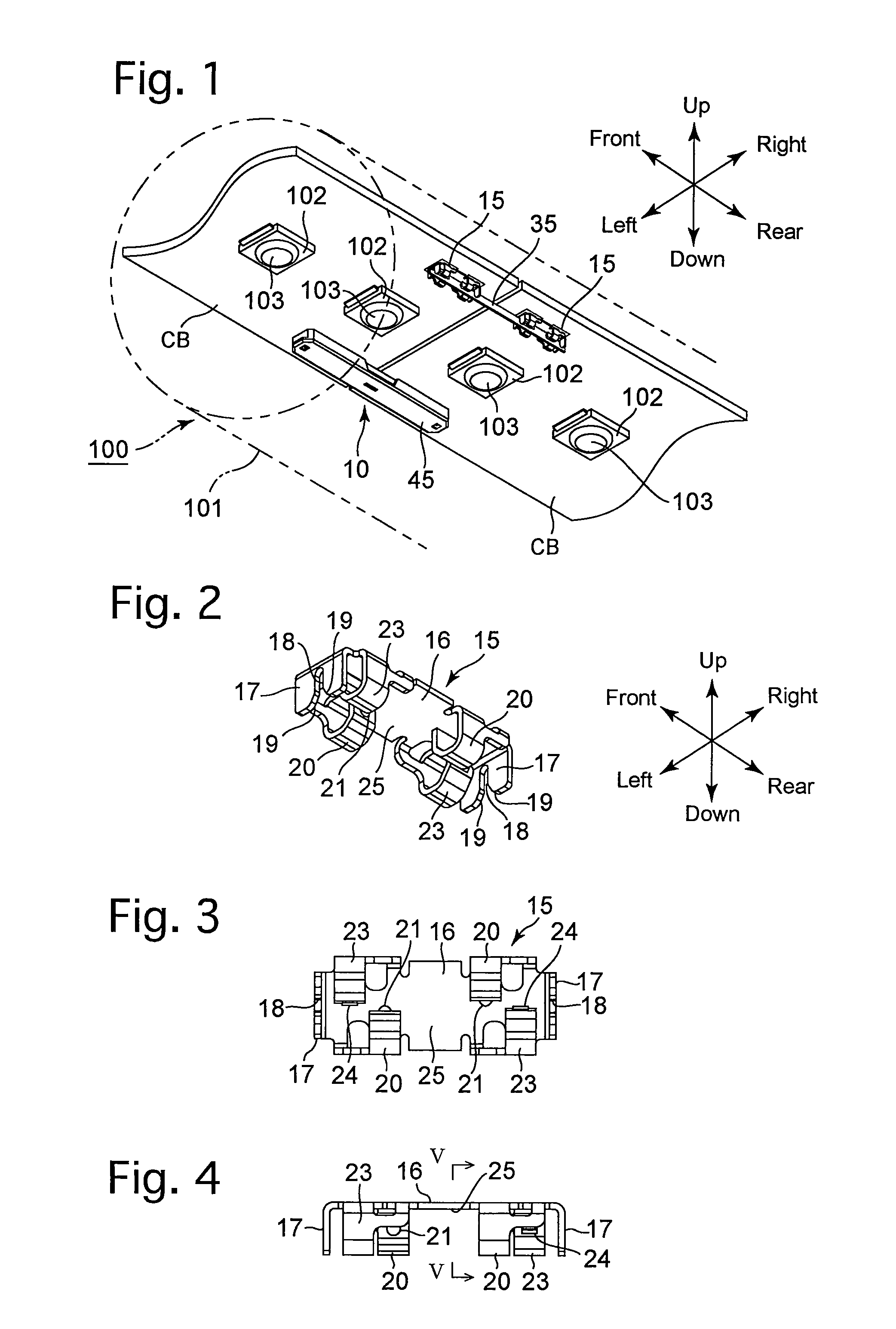

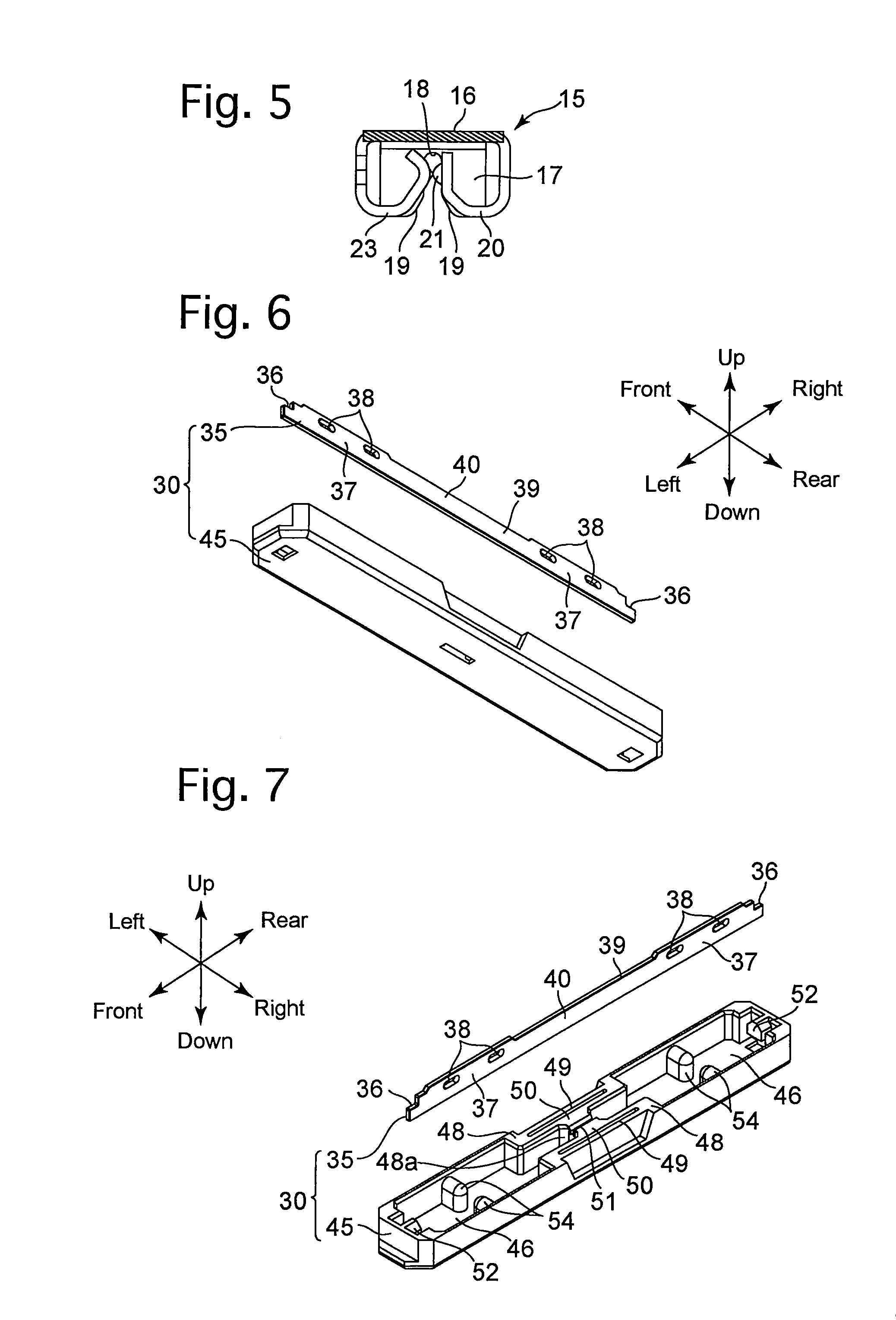

Connector, and LED lighting apparatus using the connector

InactiveUS20120020088A1Low-profile structureReduce overall heightCoupling device connectionsPoint-like light sourceEngineeringMechanical engineering

A connector includes a plug connector and a receptacle connector which connect a circuit board to a connecting object and allow relative movement therebetween in a common plane or in mutually parallel planes. The receptacle connector includes a receptacle contact including a pair of holding portions and a pair of guide portions which are spaced from each other with the pair of holding portions positioned therebewteen, wherein each guide portion includes a support groove. The plug connector includes a plug contact and a plug insulator which holds the plug contact. The plug contact is linearly elongated and resiliently deformable in a direction of thickness thereof and includes a contact portion that is engaged in the support grooves of the pair of guide portions. The plug insulator includes an opening facing the circuit board, and an accommodation space for accommodating the receptacle contact and the plug contact.

Owner:KYOCERA CONNECTOR PRODS CORP

Band clip

A band clip includes a body, a band integral with the body, and a clip that is attached to the body. The body has a vertical plate with a band insertion hole and a horizontal plate with a clip attachment hole. The band extends from the vertical plate. Locking holes penetrate the band at intervals. The clip includes a shaft that is fit into the clip attachment hole of the body, a wing on one end of the shaft, a band locking claw at another end of the shaft, and a body locking claw on an intermediate portion of the shaft. The band is wrapped around a group of wires and inserted into the band insertion hole. The band locking claw of the clip is inserted into and locked to a band locking hole, and the body locking claw contacts the surface of the body.

Owner:SUMITOMO WIRING SYST LTD

Optical image capturing system

InactiveUS20180106985A1Reduce overall heightAvoid undesired generationOptical elementsInfraredOptical axis

An optical image capturing system including an imaging lens assembly having at least three lens elements for capturing image is provided. The optical image capturing system includes at least three pieces of lens elements; a first image plane for visible ray; a second image plane for infrared ray; and an image sensing device located between the first image plane the second image plane. The distance on the optical axis can be minimized by the design of said optical lens elements to improve the imaging quality of both visible ray and infrared ray in compact cameras.

Owner:ABILITY OPTO ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com