Battery exchange system for a battery-driven industrial truck

A switching system, battery-driven technology, applied in battery/battery traction, electric vehicle charging technology, electric vehicles, etc., can solve the problems of battery maintenance, battery removal and exchange, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

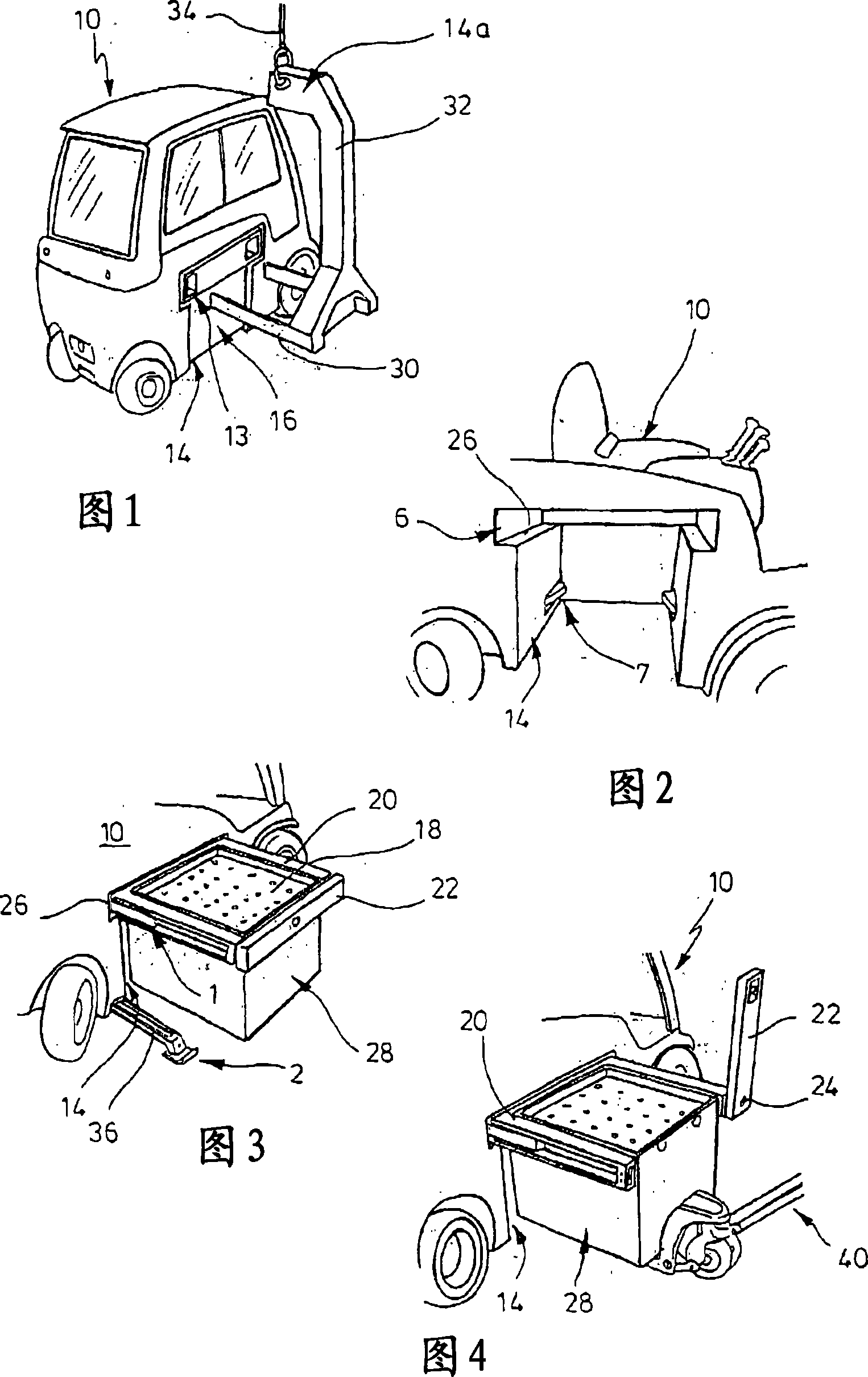

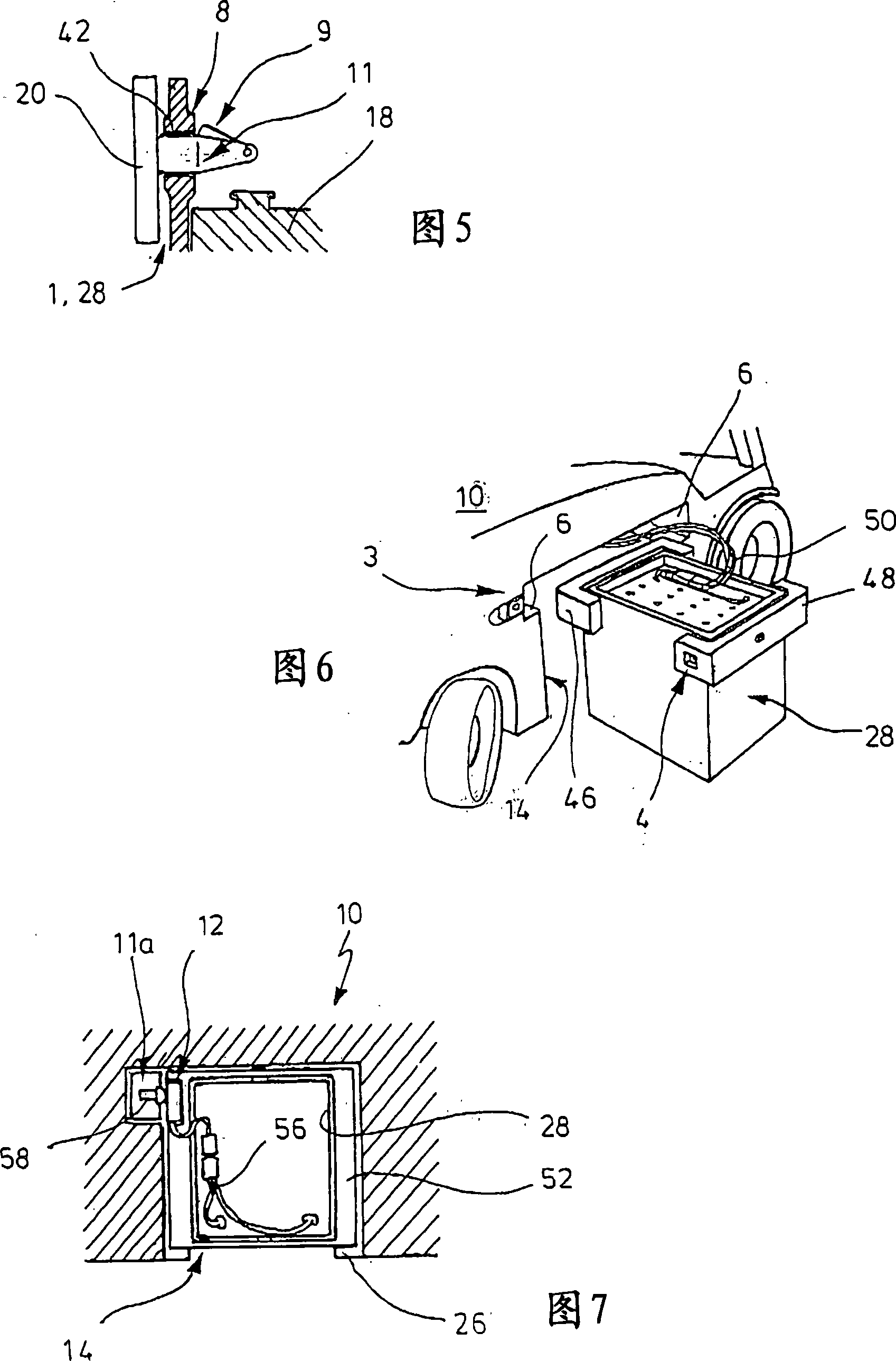

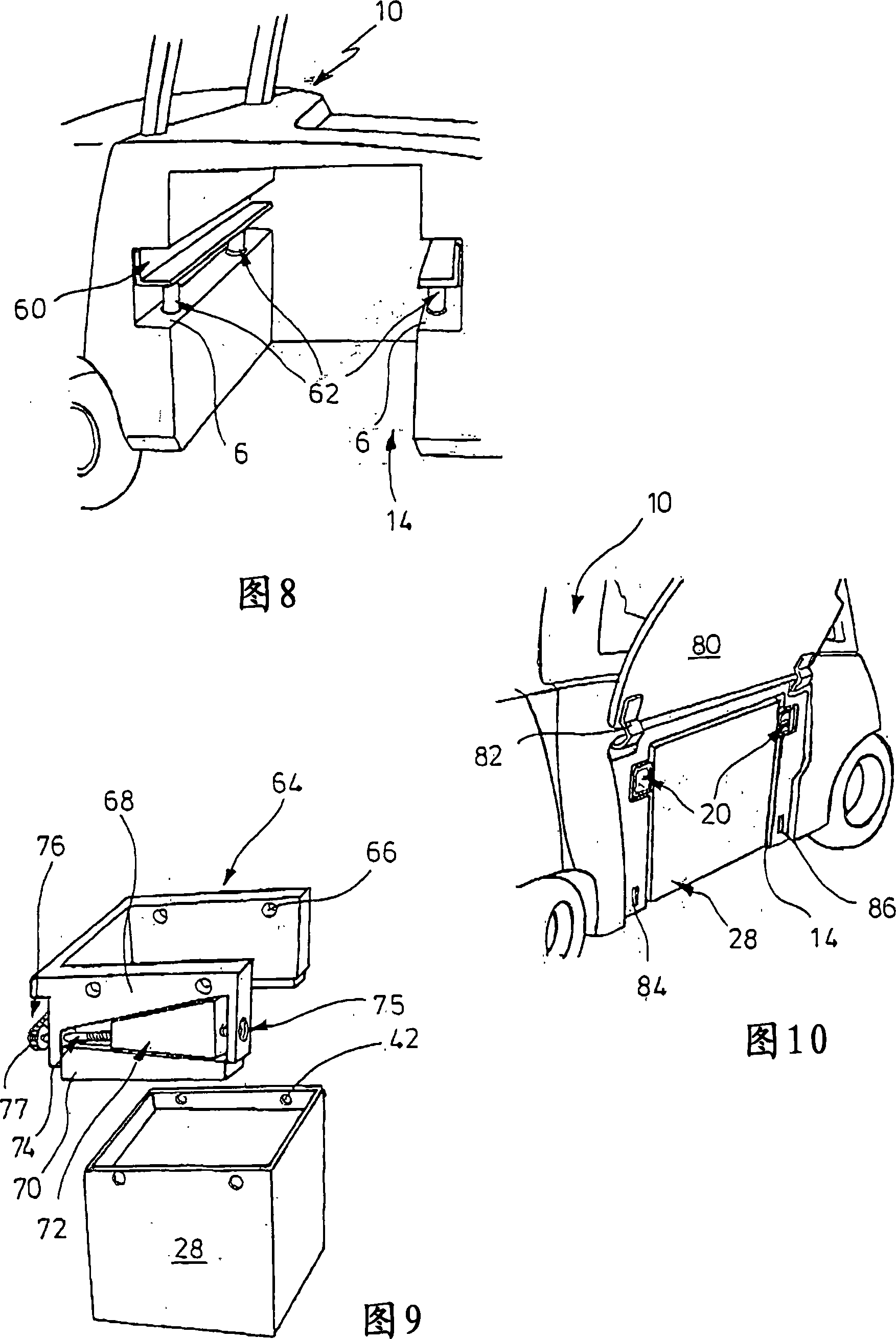

[0033] The industrial truck 10 shown in Figures 1-4 is of conventional construction. In the case shown, the industrial truck is a counterbalanced forklift. It is not explained in detail here.

[0034] As can be seen from FIGS. 1-4 , the industrial truck includes a battery compartment 14 that is open to one side for receiving a battery container 16 . As shown in Figures 3 and 4, the edge 8 of the battery container protrudes above the battery 18 (Figure 5), and the battery container is provided with frame-like support elements. In FIGS. 3 and 4 , a U-shaped frame portion 20 can be seen which surrounds the battery container from the rear to the sides. In terms of height, the frame part 20 does not extend higher than the edge 8 of the battery container. At the free end, the arms of the U-shaped frame portion 20 engage a strip-like support element 22, which can be seen at 24 in FIG. The horizontal axis on the right pivots upwards. Frame portion 20 and strip support member 22 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com