Friction-spring three-dimensional compounded shock isolating pedestal

A seismic isolation bearing and three-dimensional composite technology, which is applied in the direction of building types, buildings, protected buildings/shelters, etc., can solve the problems of poor vertical pull-out resistance, small self-damping, height increase, etc., to ensure work Safety, guaranteed return ability, effect of overall height reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

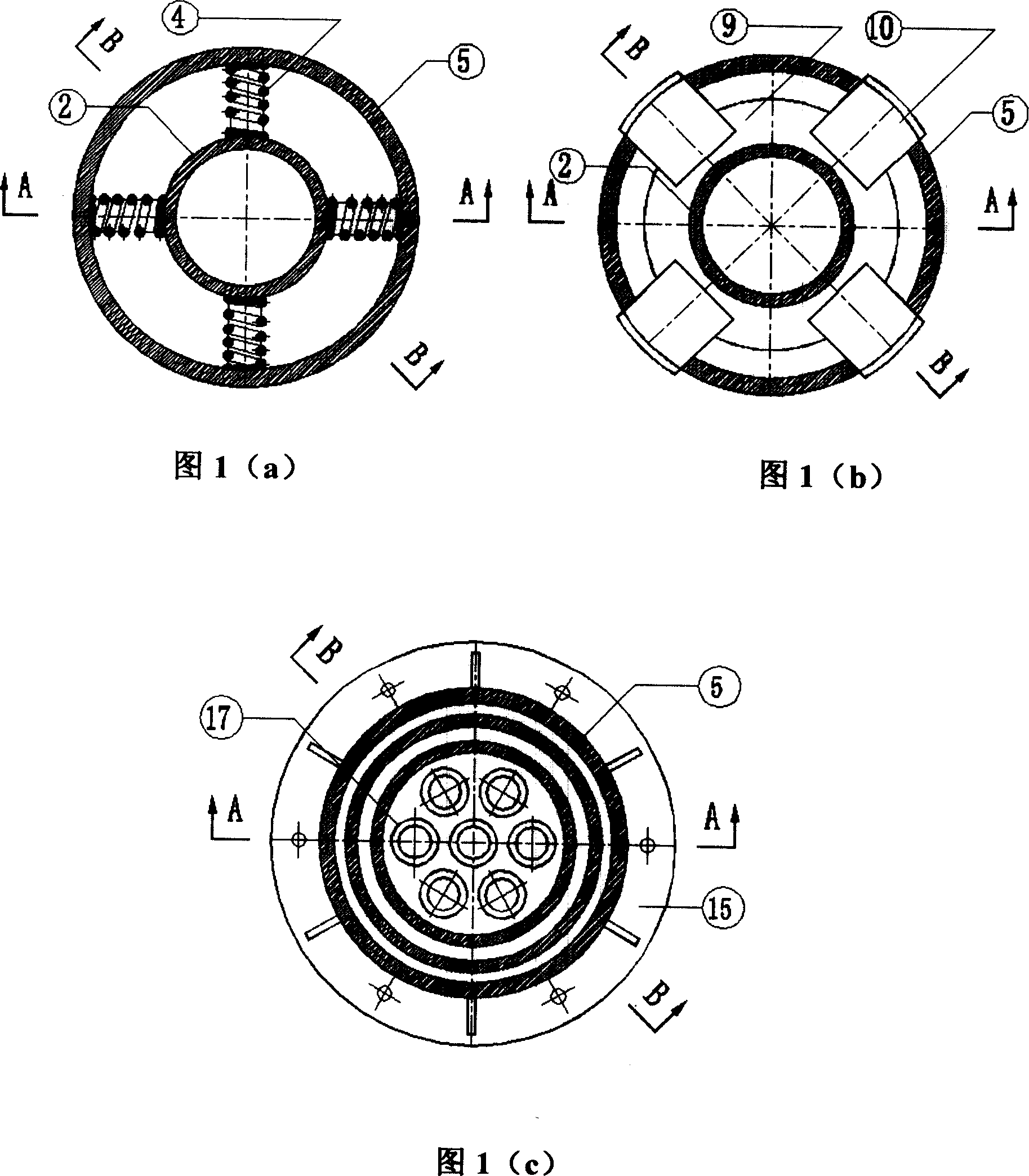

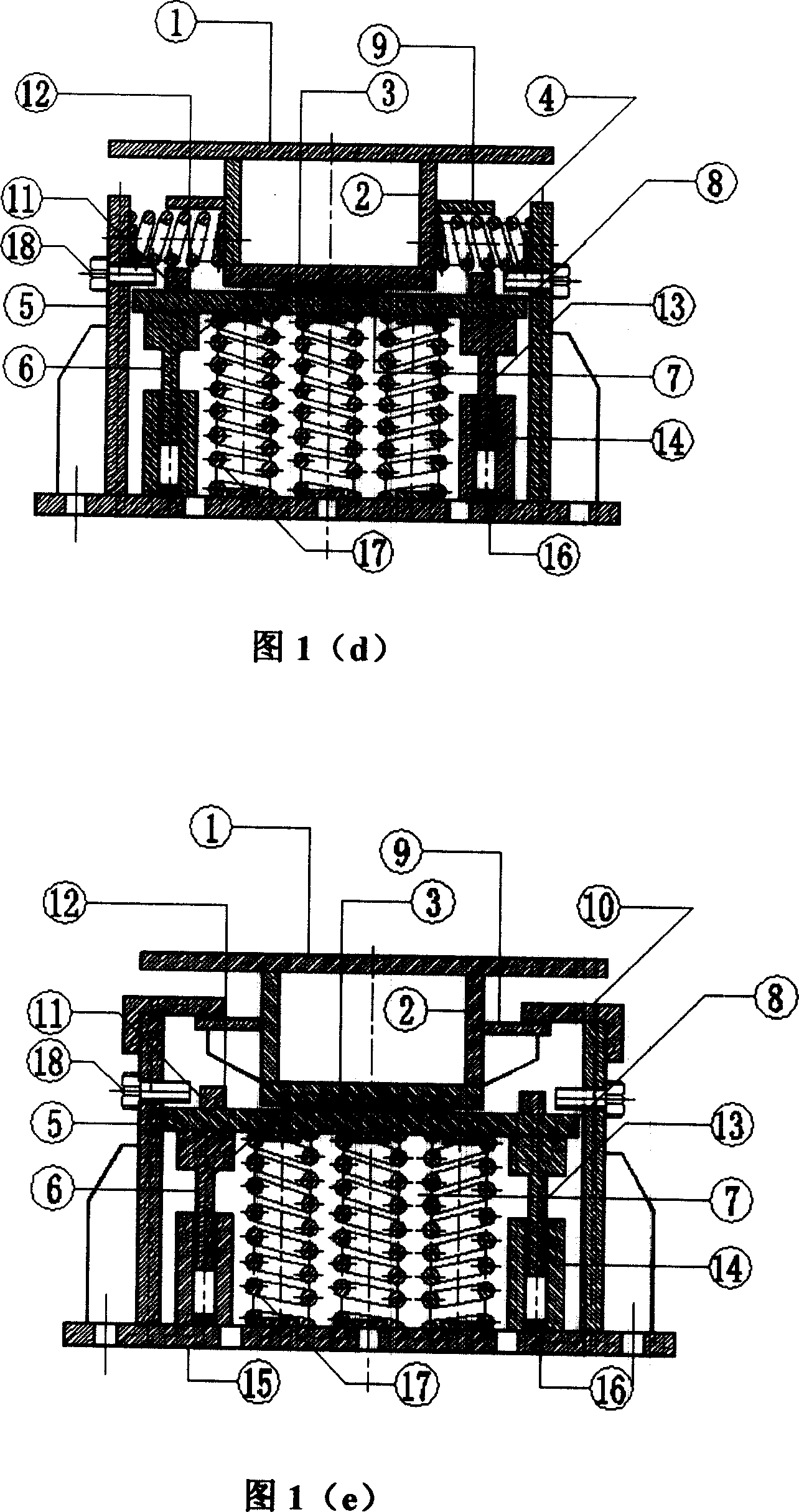

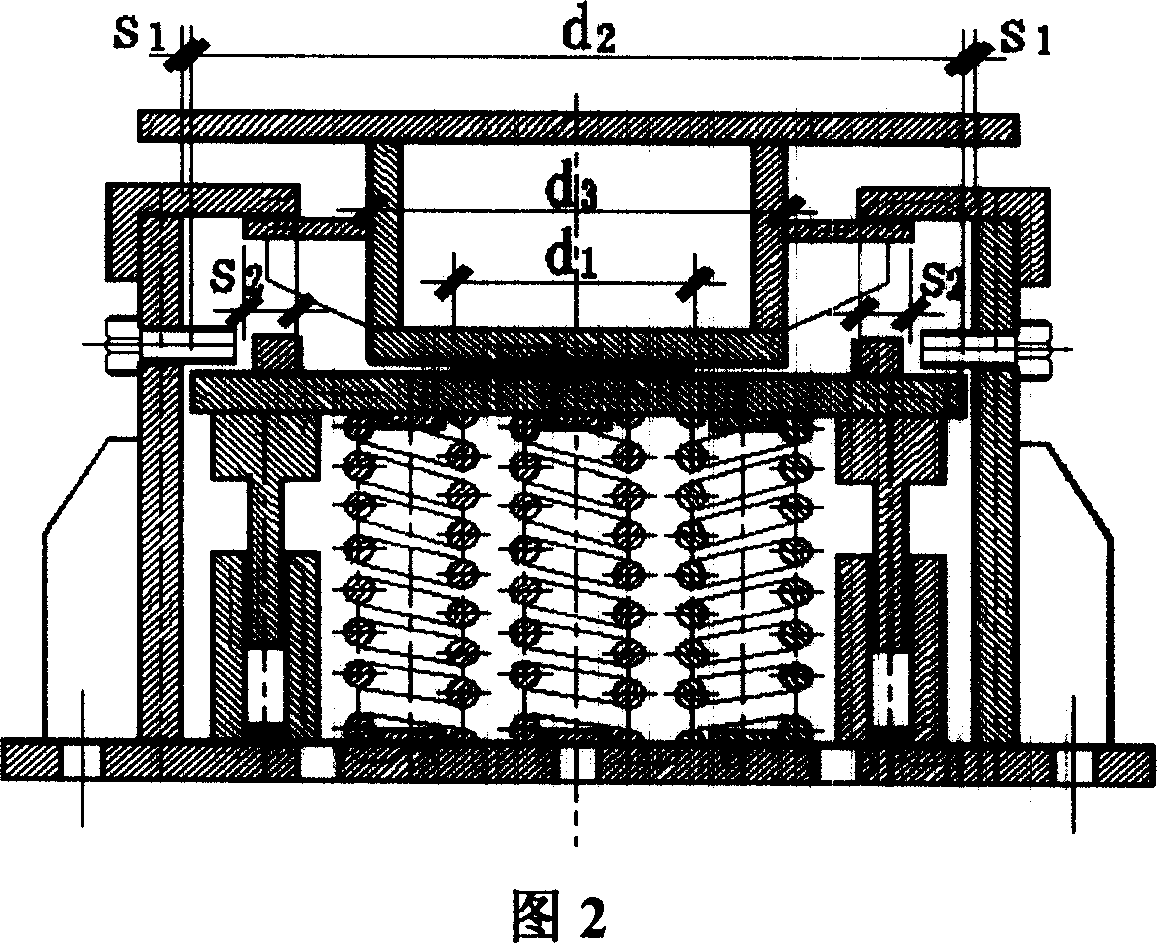

[0026] The implementation basis of the present invention is Fig. 1, can process according to six main components according to the support structure and assembly procedure. Part I is composed of the outer casing 5 fixed on the bottom connecting plate 15 and the guide tube 14. Part II is a vibration isolation spring 17. Part III includes a vertical spring pressure plate 8 and a sliding cylinder 13. The sliding cylinder 13 is fixed on On the lower surface of the vertical spring pressure plate 8, part IV is a vertical spring limiter, part V is a horizontal supporting member, a horizontal return spring 4 and a limit plate 9, and part VI is a limit baffle 10. First of all, the main components are processed, and then assembled. The assembly sequence is from bottom to top. The main steps can be summarized as follows:

[0027] (1) Install a vertical vibration isolation spring in part I;

[0028] (2) Installation part II;

[0029] (3) Installation part III;

[0030] (4) Apply vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com