Hexagonal or octagonal tangential arrangement of anthracite burning single-fireball direct-flow combustors

An octagonal tangent and burner technology, which is applied in the direction of burning various fuels, burning block fuels and liquid fuels, burning block fuels and gaseous fuels, etc., can solve the problem of not being able to adapt to anthracite burning and heat load Low-level problems, to achieve the effect of timely ignition and stable combustion of the boiler without oil input and low load, the speed of secondary air is reduced, and timely ignition is ensured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

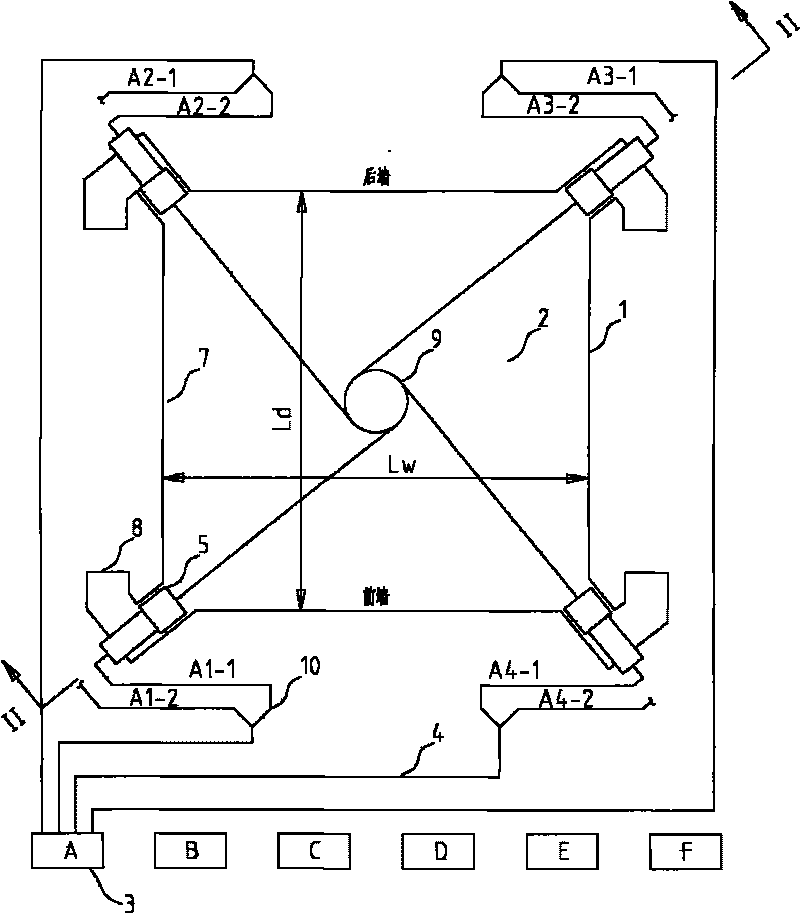

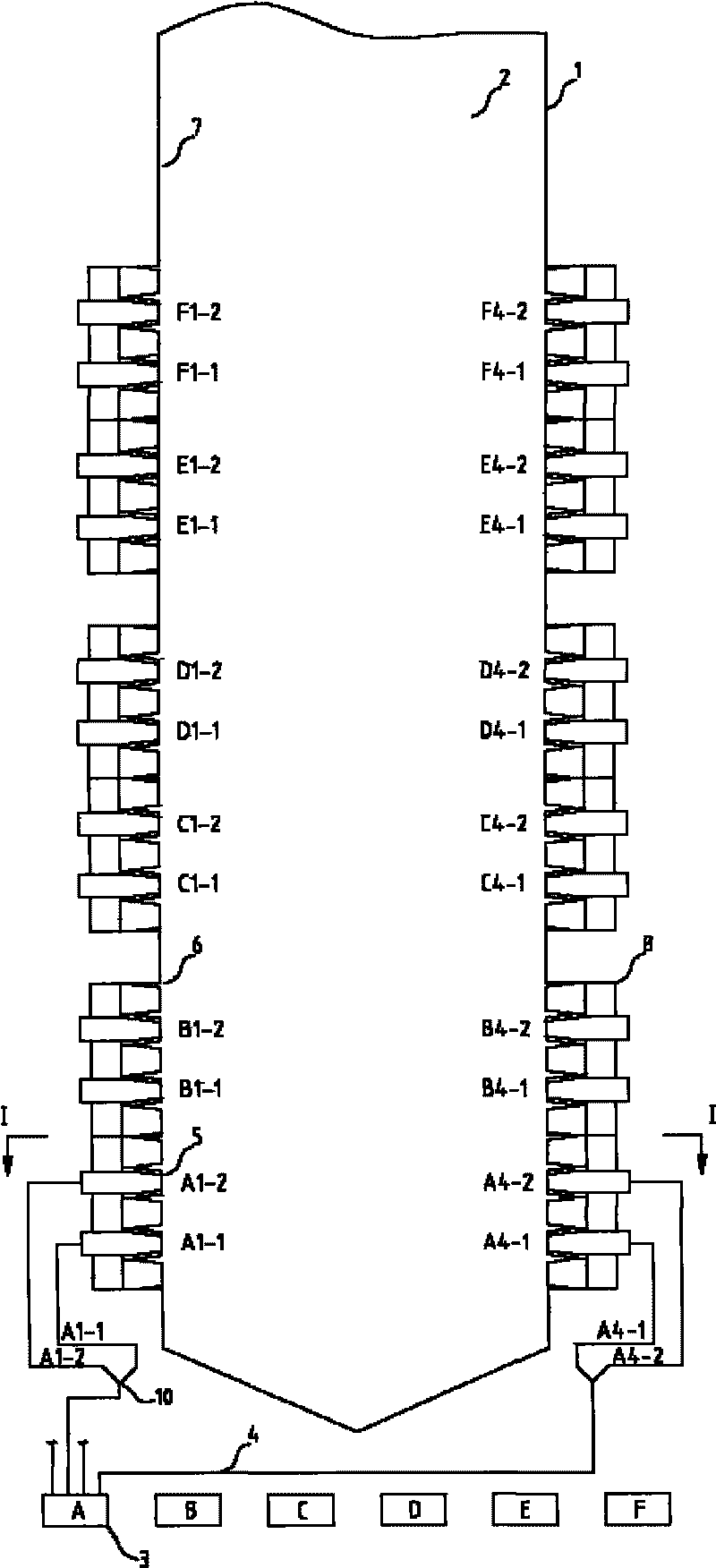

[0033] combine image 3 with Figure 5 To describe this embodiment, Figure 4 for image 3 I-I sectional view, image 3 for Figure 4 Section view of II-II.

[0034] The hexagonal or octagonal tangential arrangement of a single fireball DC burner for burning anthracite provided by the present invention includes a boiler body 1, a furnace 2, a coal mill 3, a pulverized coal pipeline 4, a primary air pulverized coal nozzle 5 and a secondary air nozzle 6. Each boiler body 1 is equipped with six coal mills 3, namely the first coal mill A, the second coal mill B, the third coal mill C, the fourth coal mill D, the fifth coal mill E and The sixth coal mill F. The furnace 2 is composed of four water-cooled walls 7, and two sets of burners 8 are arranged on each water-cooled wall 7 of the furnace 2. There are eight sets of burners 8 in total. The two sets of burners 8 on the front wall are 1-1 sets of burners respectively. 8, 1-2 groups of burners 8, the two groups of burners o...

Embodiment 2

[0038] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that each group of burners 8 is divided into two subgroups up and down, and each group of burners is arranged vertically with three primary air pulverized coal nozzles 5 and four secondary air nozzles 6 . In this way, it is possible to adjust the heat load q on the wall surface of the burner area Hr within a reasonable range to prevent the thermal load due to the wall q Hr Furnace slagging and high temperature corrosion caused by excessively high temperature.

Embodiment 3

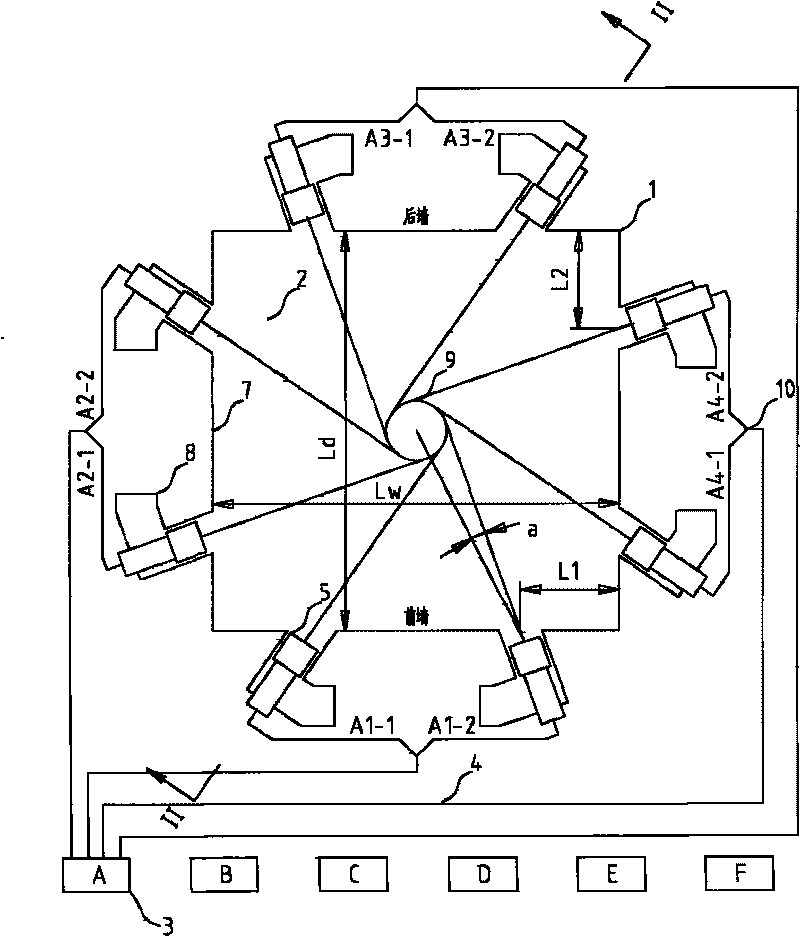

[0040] combine Image 6 with Figure 7 To describe this embodiment, Image 6 for Figure 7 I-I sectional view, Figure 7 for Image 6 Section view of II-II.

[0041] The difference between this embodiment and Embodiment 1 is that there are four pulverized coal pipelines 4 at the outlet of each pulverizer 3, and each pulverized coal pipeline 4 passes through a pulverized coal distributor 10 and the adjacent wall of the same elevation on the adjacent wall. Two primary air pulverized coal nozzles 5 are connected, for example, are connected with the primary air pulverized coal nozzles 5 of the 1-1 group of burners 8 arranged on the front wall and the 2-1 groups of burners 8 arranged on the left wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com