Patents

Literature

174 results about "Coal pipeline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal pipelines are pipelines used to transport coal from where it is mined to where it is consumed. For very short distances, large trucks are used to transport coal, but trains and barges are preferred for long distances. In some cases it is more economical to move the coal by pipeline than by train or barge. This can happen when there is no suitable railway or waterway to transport the coal, or when it must be moved very long distances.

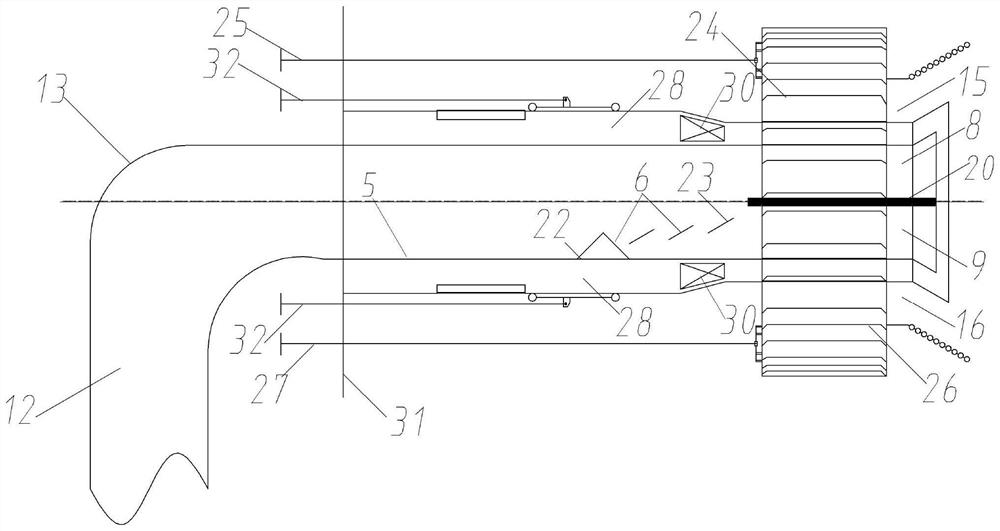

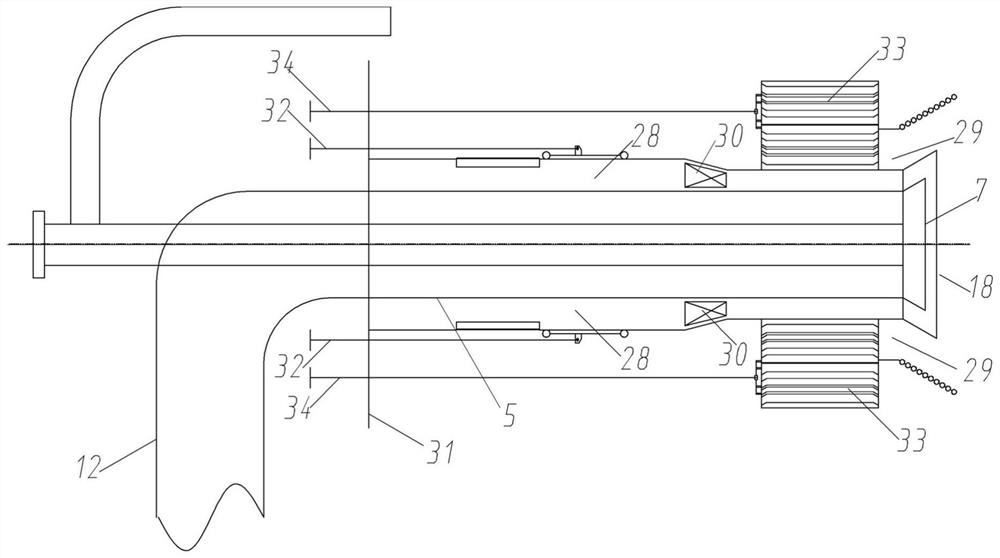

Combustion optimization system and adjustment method for preventing water wall high-temperature corrosion

ActiveCN106678783AIncrease oxygen contentAdjust the same openingBoiler controlCasings/liningsMeasurement deviceAir volume

The invention provides a combustion optimization system and adjustment method for preventing water wall high-temperature corrosion. The combustion optimization system comprises air and pulverized coal adjustment devices, secondary air distribution adjustment devices, two water wall near wall region smoke component measuring devices, a plurality of auxiliary over fire air nozzles, a temperature field measuring device and a coal economizer outlet smoke oxygen content field measuring device. A first air and pulverized coal pipeline corresponding to each combustor is provided with the corresponding air and pulverized coal adjustment device. Each secondary air box is internally provided with the corresponding secondary air distribution adjustment device. The two water wall near wall region smoke component measuring devices are separately mounted on the water wall on the two sides of a boiler. The multiple auxiliary over fire air nozzles are separately arranged below over fire air nozzles. The temperature field measuring device is arranged on the portion, below a platen overheater, in a hearth. The coal economizer outlet smoke oxygen content field measuring device is arranged at a coal economizer outlet flue. By adoption of the combustion optimization system, high-temperature corrosion to the water wall of the opposite cyclone combustion boiler can be effectively relieved.

Owner:GUODIAN SCI & TECH RES INST +1

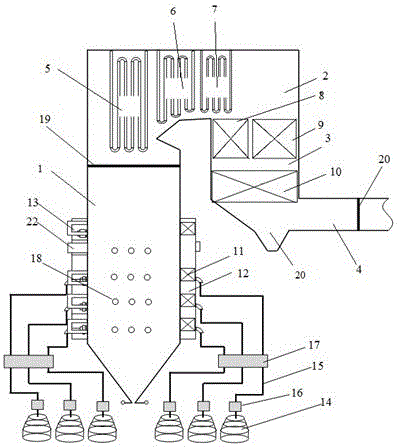

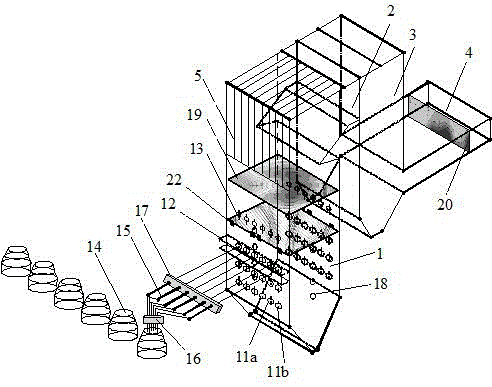

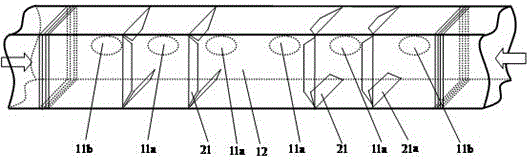

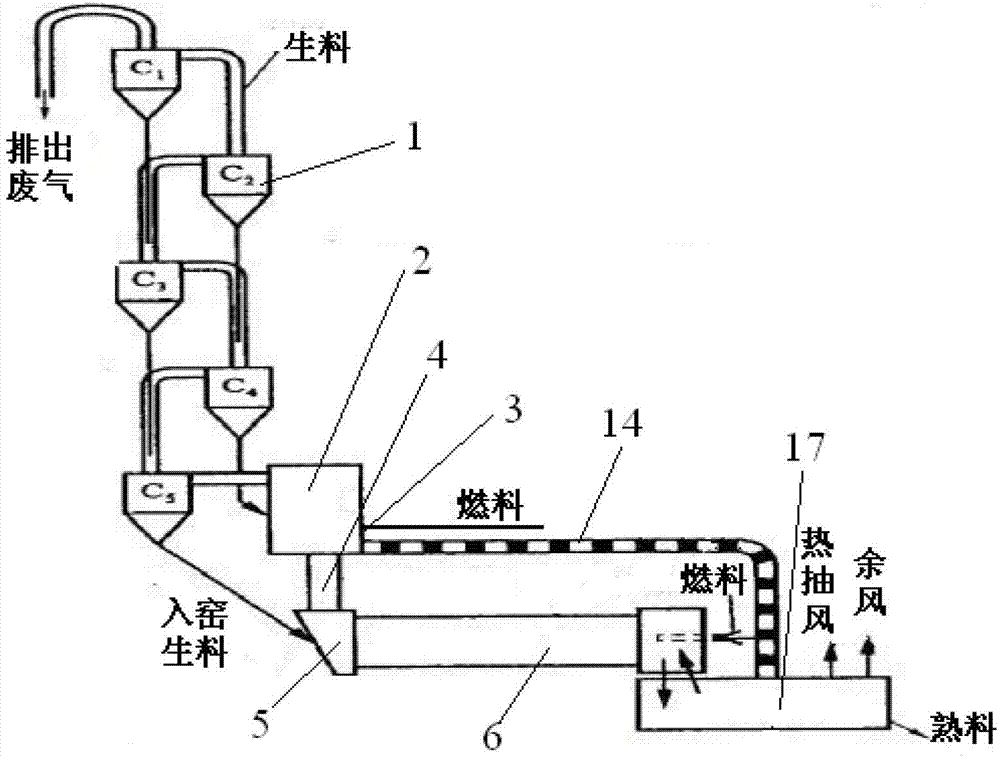

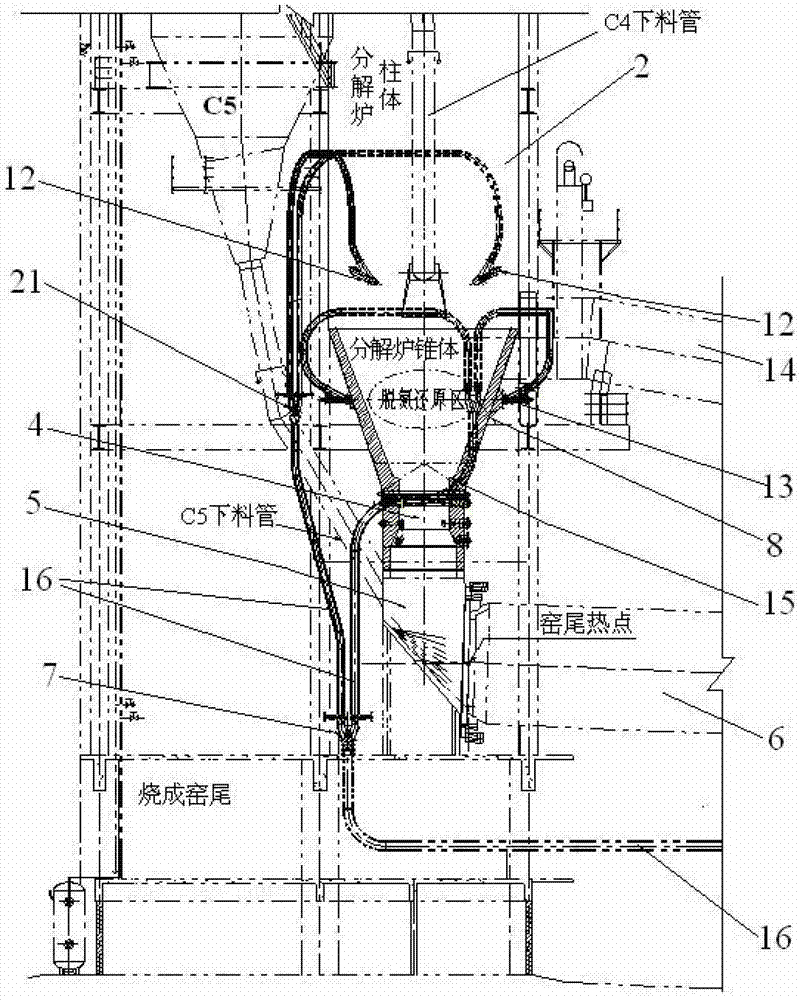

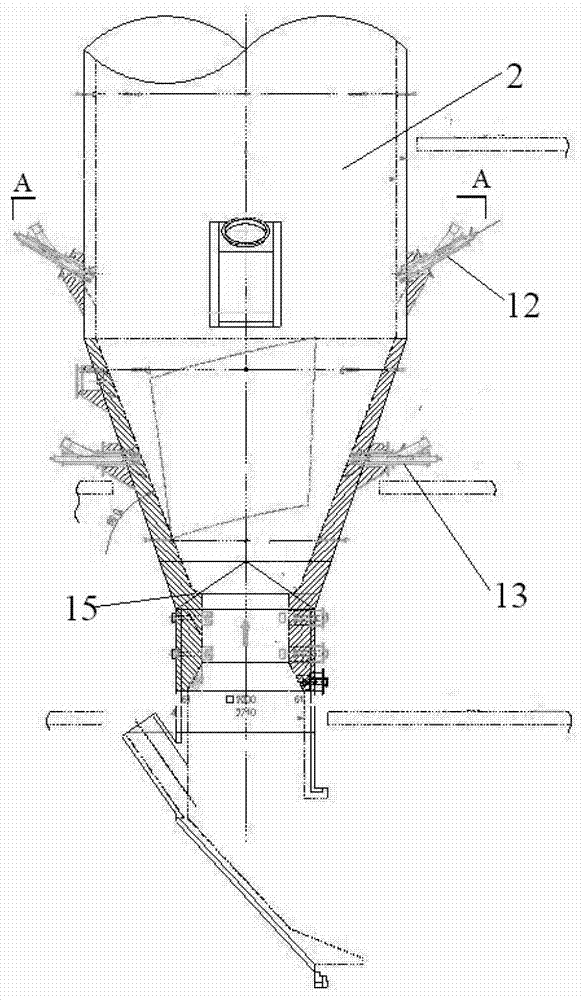

Clinker production line for novel dry process cement kiln and denitration process method for clinker production line

ActiveCN102923979AReduce generationSuppress generationClinker productionProduction lineCoal pipeline

The invention discloses a clinker production line for a novel dry process cement kiln. Pulverized coal in a pulverized coal pipeline which is communicated with the tail of the kiln is divided into two channels by a first pulverized coal distributor, wherein one channel is communicated with a column body on the upper part of a decomposition furnace, and the pulverized coal is divided into two channels again by a second pulverized coal distributor and symmetrically enters the column body on the upper part of the decomposition furnace; and the other channel is communicated with a cone on the lower part of the decomposition furnace, and the pulverized coal is divided into two channels again by the second pulverized coal distributor and symmetrically enters the cone on the lower part of the decomposition furnace. The invention also provides a denitration process method adopted by the production line. By the technical scheme, thermal NOx generated in the kiln is decreased and reduced, and the generation of fuel NOx is inhibited, so that NOx can be effectively reduced from the source; and after process improvement, operation parameters are optimized, the operation quality and stability of the system are promoted, and a certain energy-saving effect is achieved.

Owner:ANHUI CONCH GRP +2

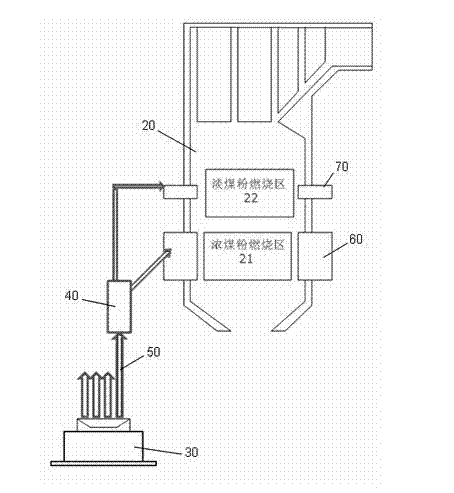

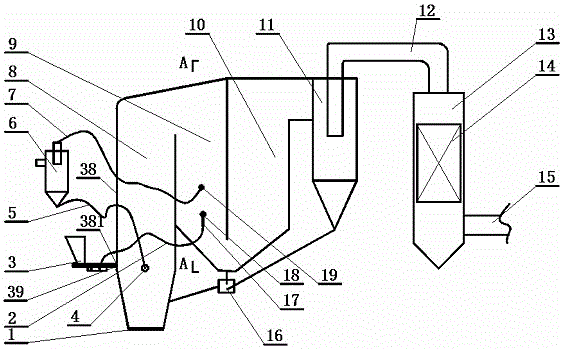

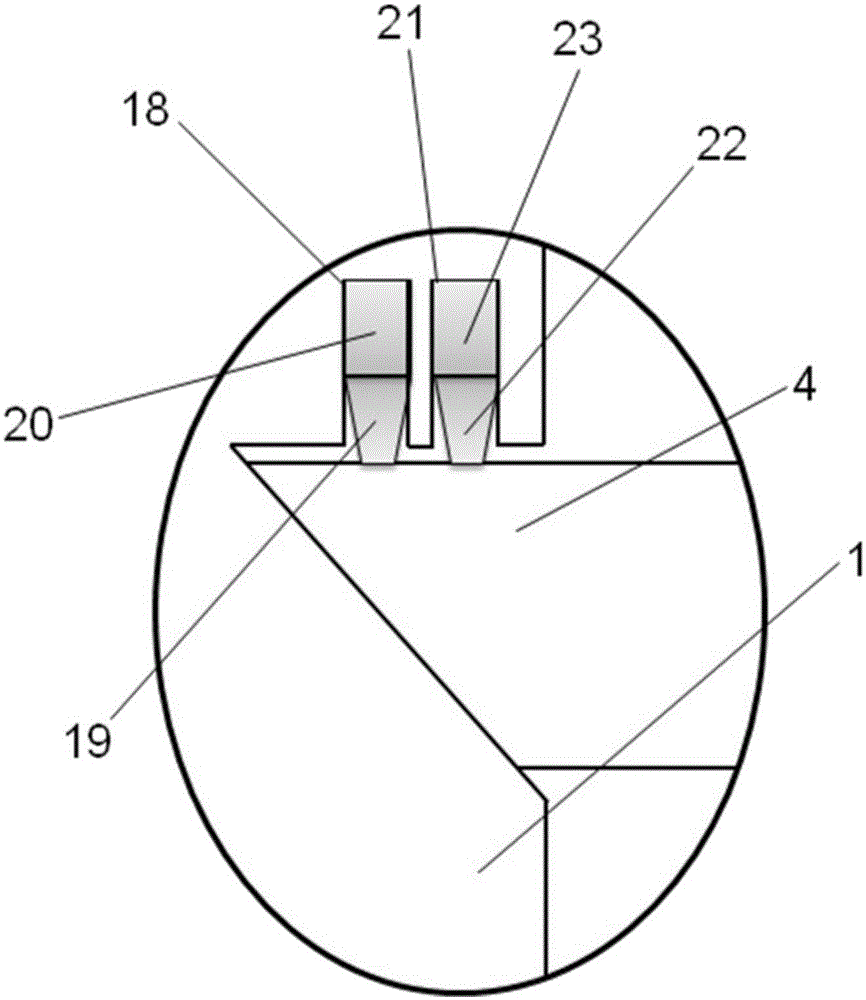

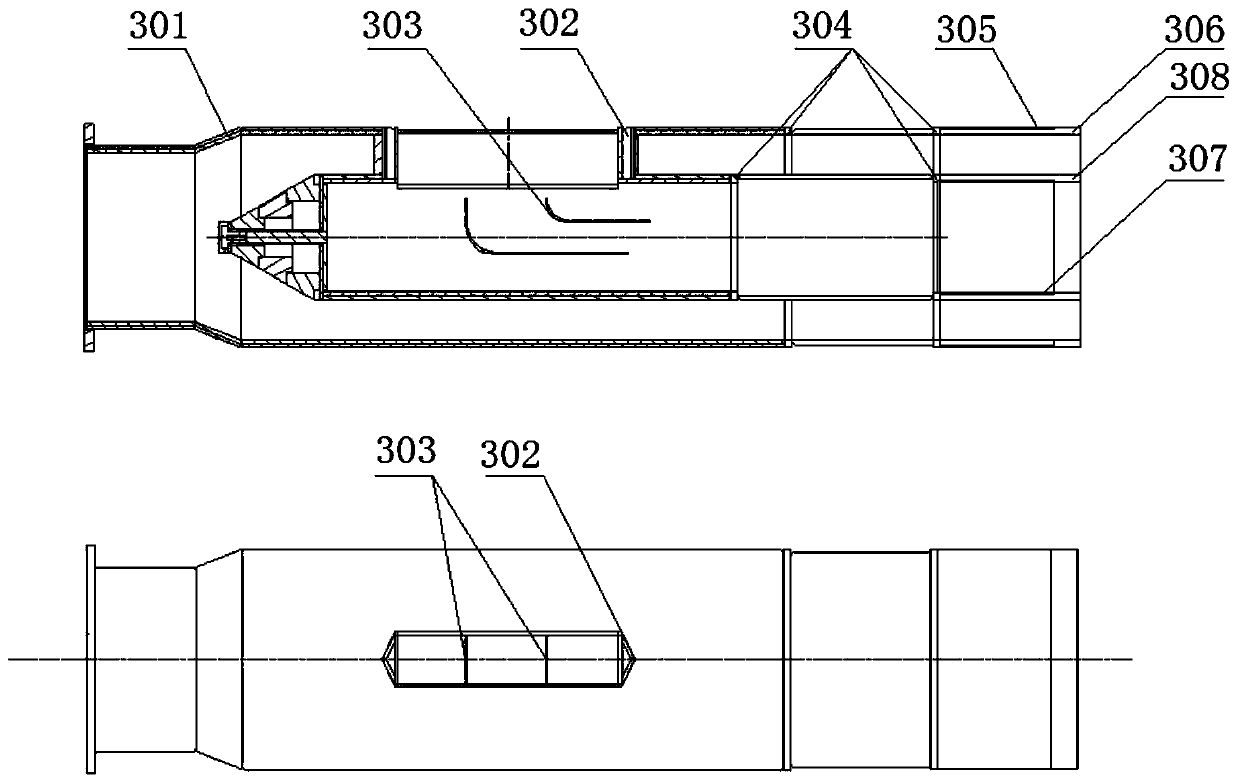

Central powder-feeding omega-shaped industrial pulverized coal boiler adopting flue gas recirculation

ActiveCN107606606AReduce generationExtended stayLump/pulverulent fuel feeder/distributionCombustion chambersCombustorCoal pipeline

The invention provides a central powder-feeding omega-shaped industrial pulverized coal boiler adopting flue gas recirculation and relates to the technical field of an industrial pulverized coal boiler. The problems that the existing industrial pulverized coal boiler is high in NOx discharge quantity, poor in burnout and high in structural complex maintenance difficulty are solved. The central powder-feeding omega-shaped industrial pulverized coal boiler adopting flue gas recirculation comprises a rotational flow pulverized coal combustor, a wind powder system and a boiler body; a primary airpipe, a direct-flow secondary air pipe, a rotational flow inner secondary air pipe and a rotational flow outer secondary air pipe are arranged sequentially from inside to outside; the inlet end of theprimary air pipe is connected with the outlet end of a pulverized coal pipeline; the outlet end of a recirculation flue gas pipeline is connected with the inlet ends of the direct-flow secondary airpipe, the rotational flow inner secondary air pipe and the rotational flow outer secondary air pipe separately; the outlet ends of the primary air pipe, the direct-flow secondary air pipe, the rotational flow inner secondary air pipe and the rotational flow outer secondary air pipe are connected with a nozzle of the rotational flow pulverized coal combustor respectively; and the boiler body is arranged in the form of a horizontal omega shape. The central powder-feeding omega-shaped industrial pulverized coal boiler adopting flue gas recirculation is applied to the industrial pulverized boiler.

Owner:HARBIN INST OF TECH

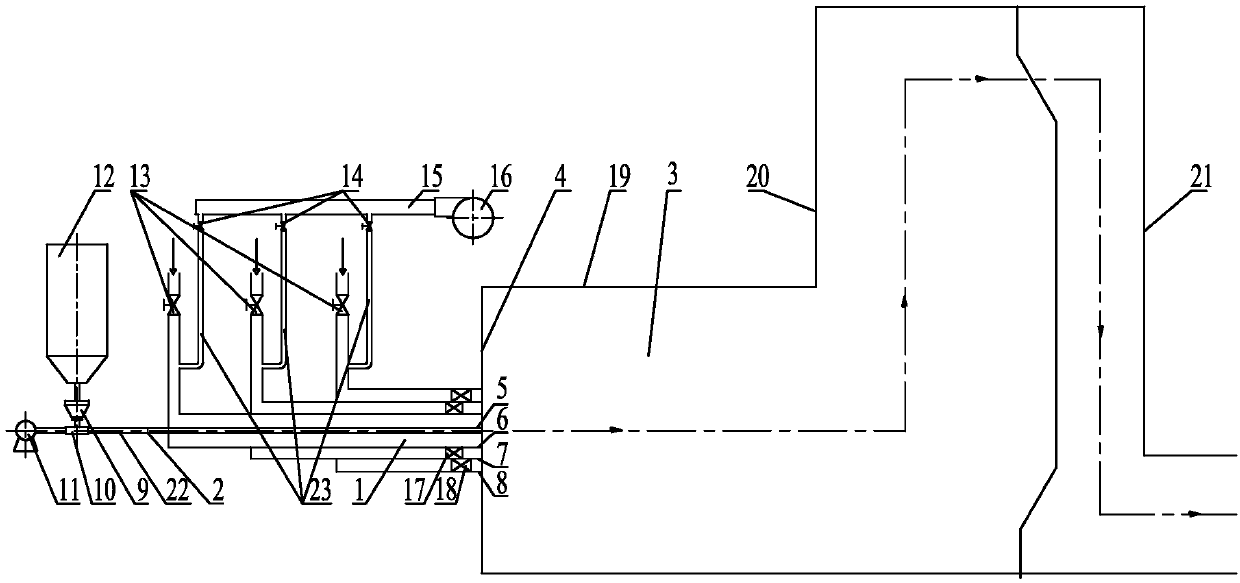

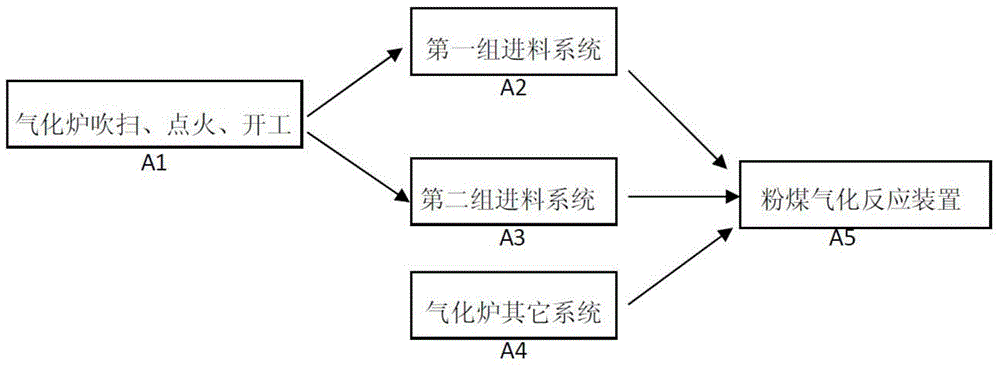

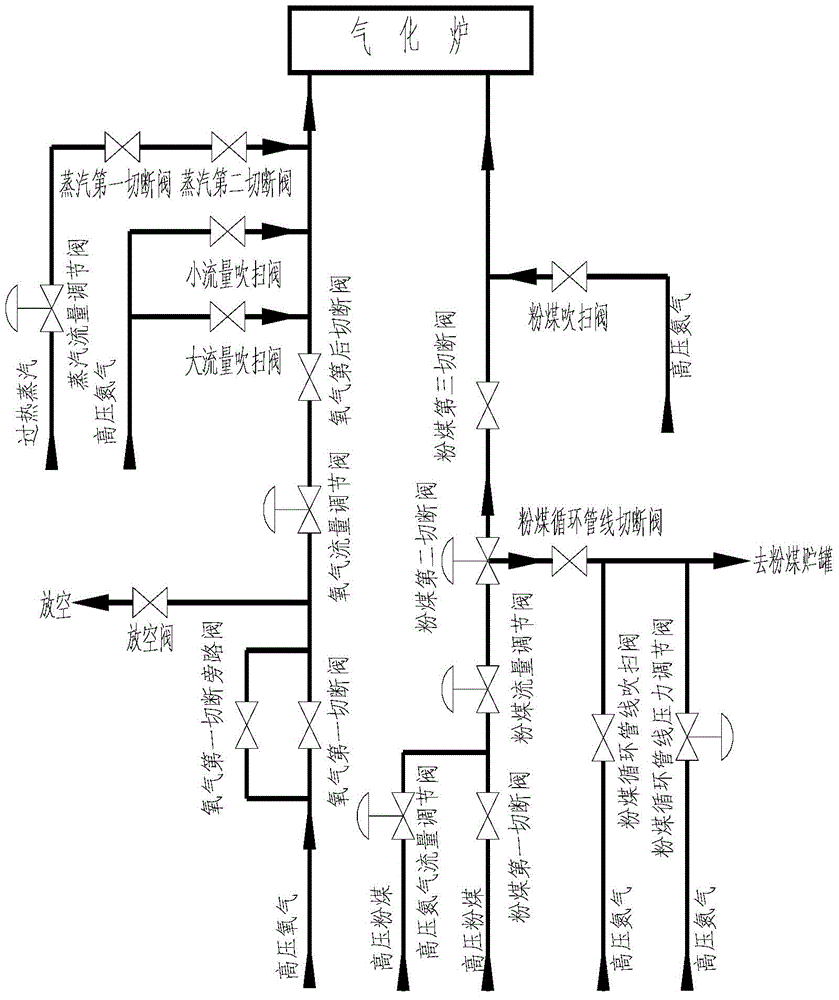

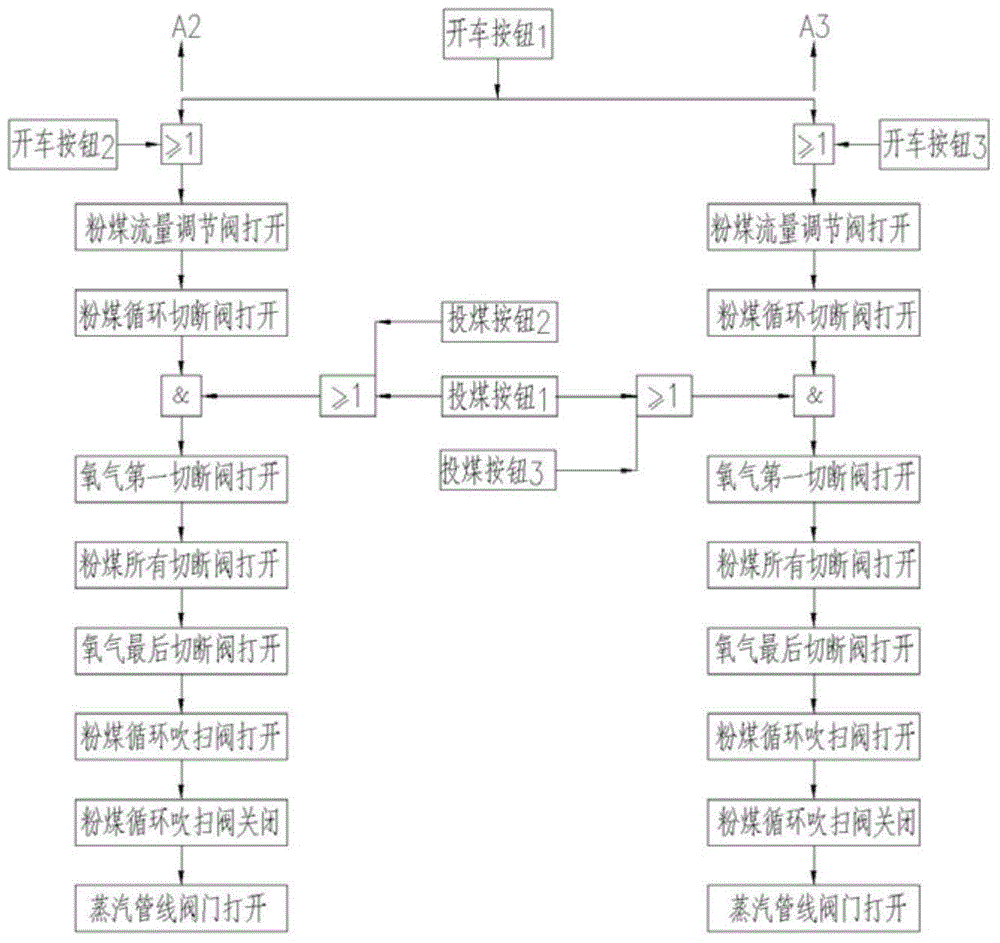

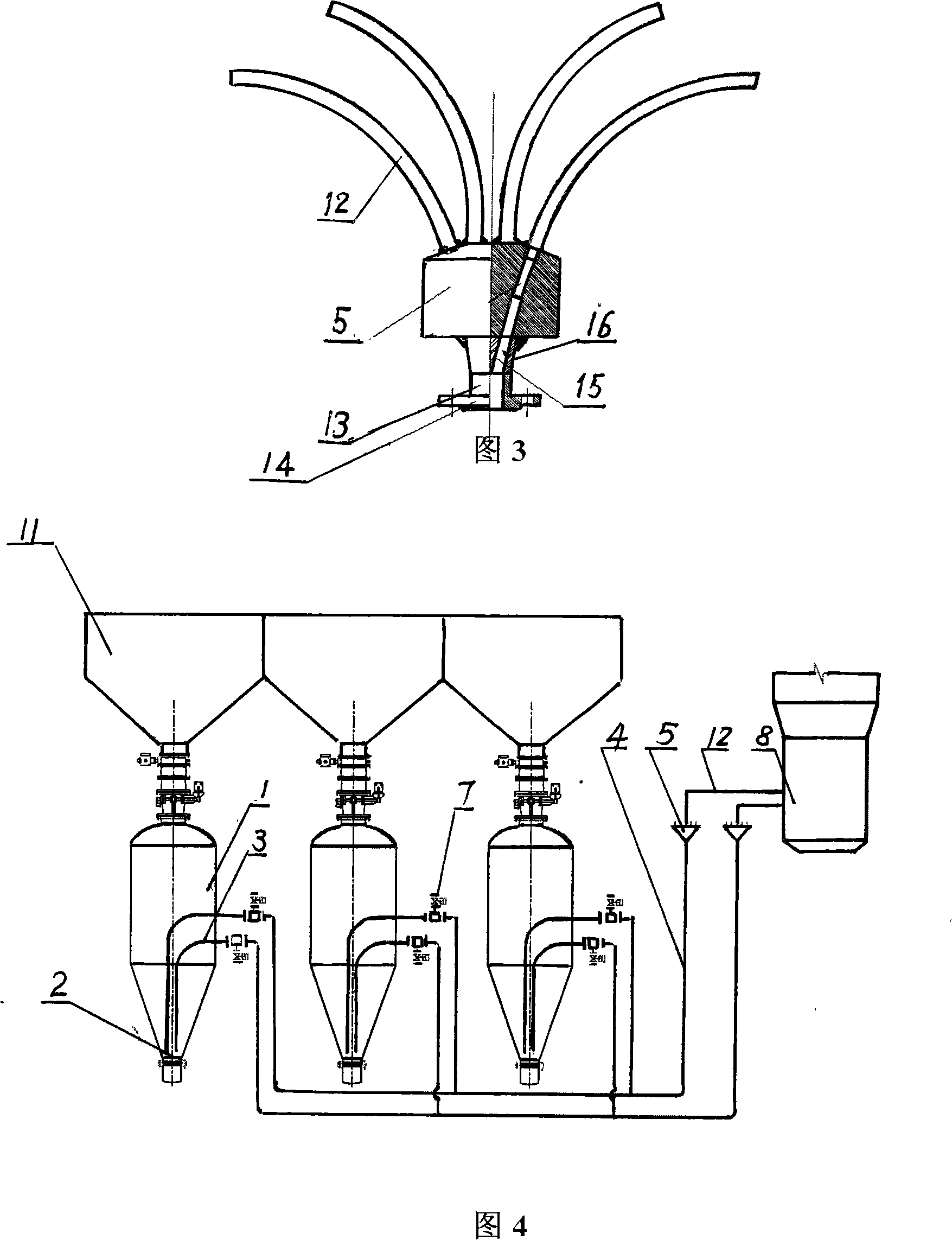

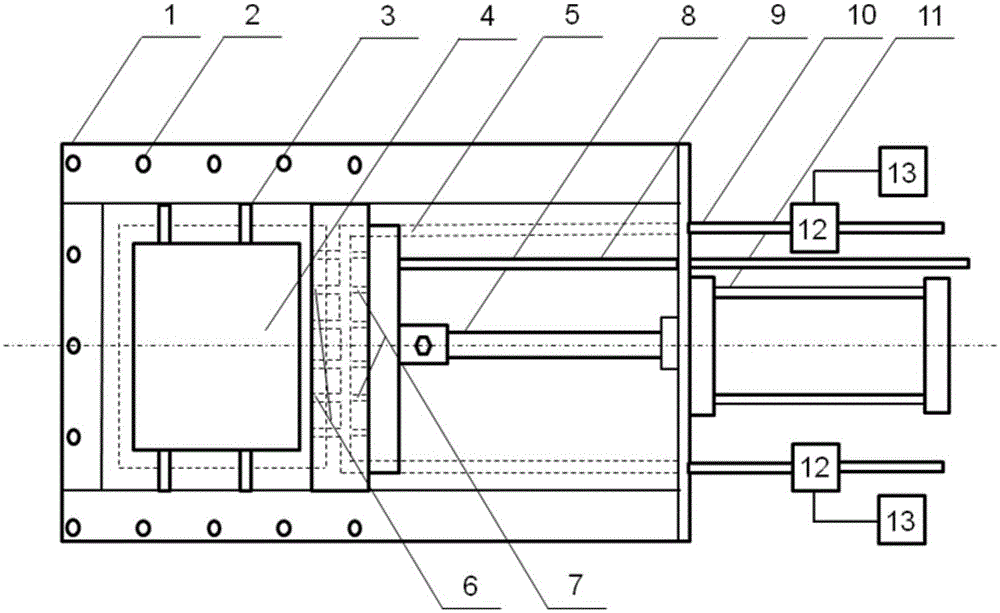

Control method of running of pulverized coal burner of pulverized coal pressurization gasification reaction device

ActiveCN104974798AHigh degree of automationRealize online maintenanceCombined combustion mitigationGranular/pulverulent flues gasificationCoal pipelineProcess engineering

The invention provides a control method of running of a pulverized coal burner of a pulverized coal pressurization gasification reaction device; the control method is used for feeding grouping control of a plurality of oxygen pipelines and a plurality of pulverized coal pipelines of the pulverized coal burner of the pulverized coal pressurization burner gasification reaction device, and comprises starting, running, stopping and purging of the pulverized coal burner. The control method can achieve simultaneous feeding or grouping feeding of the plurality of oxygen pipelines and the plurality of pulverized coal pipelines of the pulverized coal burner, can also achieve simultaneous stopping or grouping stopping of the plurality of oxygen pipelines and the plurality of pulverized coal pipelines of the pulverized coal burner, can achieve on-line maintenance of the oxygen pipelines and the pulverized coal pipelines, and ensures long-period, continuous and stable safe running production of the pulverized coal pressurization gasification device. A gasifier emergency safety system keeps the device running, and allows the device to be safe to start, stop and gasifier purging.

Owner:CHANGZHENG ENG

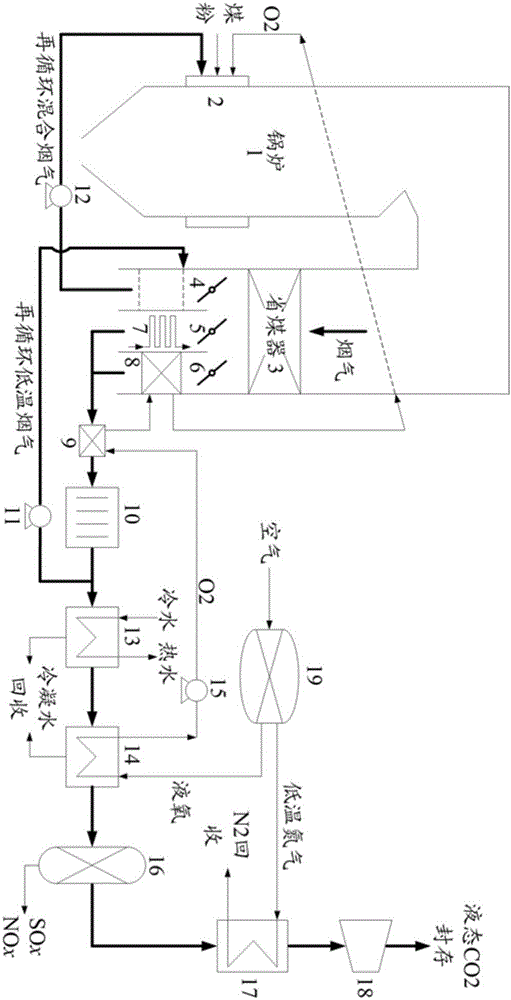

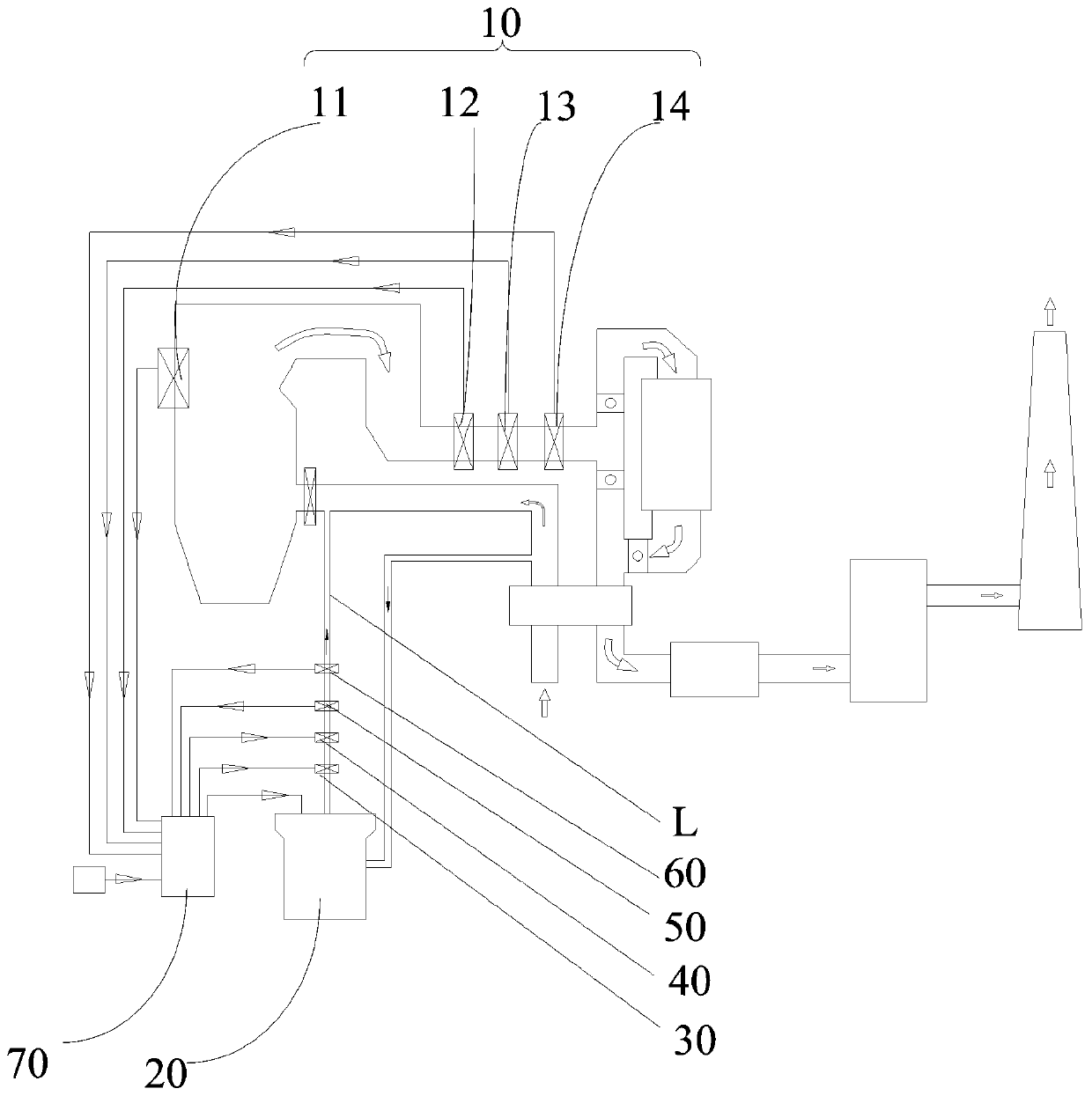

High-efficiency tail flue gas energy utilization and treatment system of oxygen-enriched combustion boiler

ActiveCN106369595AImprove adaptabilityAvoid the phenomenon of clogging the pulverized coal pipelineSolidificationLiquefactionAir preheaterWater vapor

The embodiment of the invention provides a high-efficiency tail flue gas energy utilization and treatment system of an oxygen-enriched combustion boiler. The system achieves coupling of an air separator system of the oxygen-enriched combustion boiler with a flue gas recirculation system and a tail flue gas energy recovery and treatment system; a tail flue of the boiler is divided into three parallel flues to adjust recirculating flue gas amount and temperature; the adaptability of the system to a coal type is improved; a low-pressure economizer recovers flue gas waste heat; the oxygen temperature at an outlet of an air preheater is adjusted; the three parallel flues are coupled to increase an adjustment margin of the flue gas temperature. Recirculating flue gas formed by mixing high-temperature flue gas and low temperature recirculating flue gas serves as primary air to avoid blocking of a pulverized coal pipeline due to liquefaction of accumulated steam during flue gas recirculation when the temperature of the primary air is lower; the size of the air preheater is reduced; the cost is saved; and the economy is improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

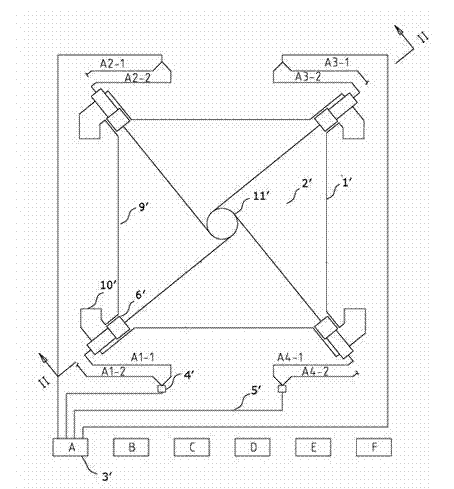

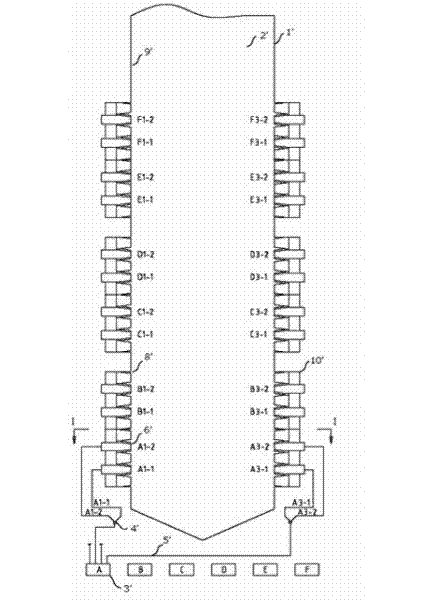

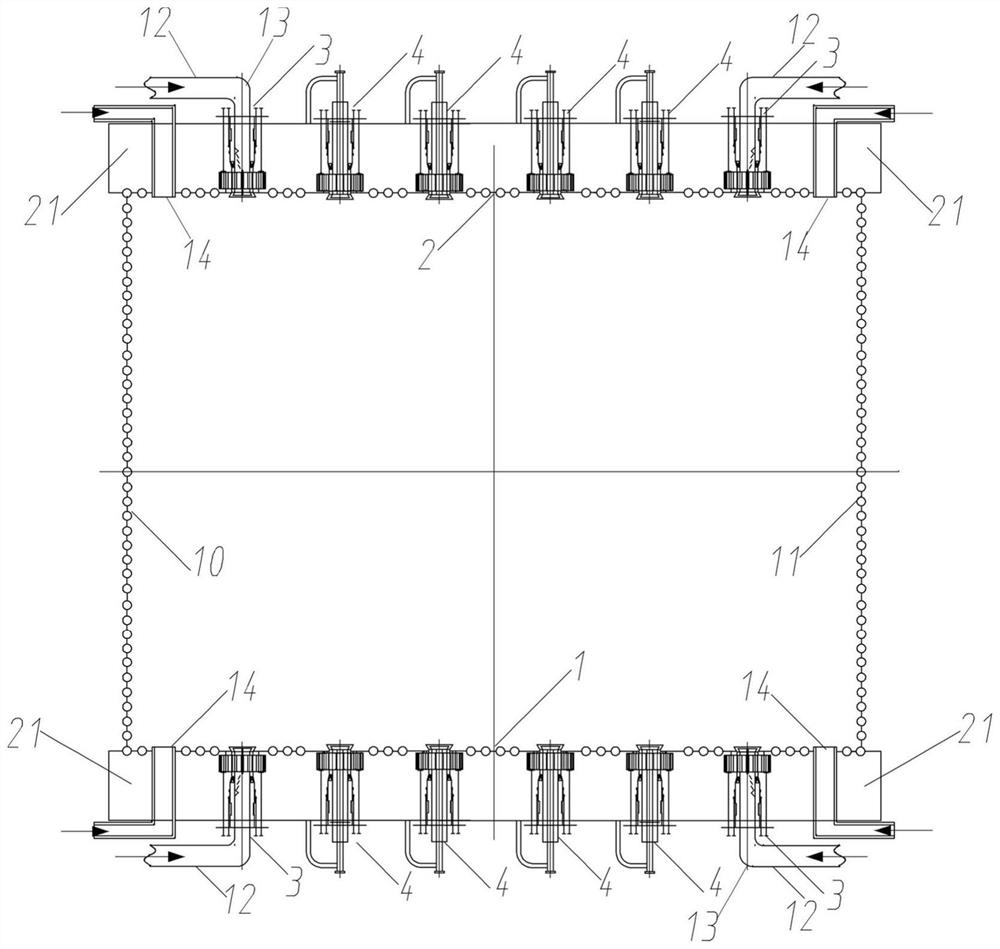

Anthracite-combusted single fire ball four-corner direct current burner

ActiveCN102494333AFire stableIncrease concentrationFuel feeding arrangementsSolid fuel pretreatmentLow loadHearth

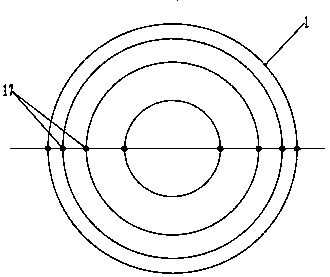

An anthracite-combusted single fire ball four-corner direct current burner includes four burner groups placed at the four corners at a hearth and at least one coal pulverizer, wherein the pulverized coal airflow sprayed by the burner groups forms an imaginary tangent circle at the center of the hearth; two groups of burners are vertically arranged at each burner group at intervals; four pulverized coal pipelines are arranged at the outlet of each coal pulverizer and are connected to four concentrated / thin pulverized coal separators correspondingly; the separated four ways of concentrated pulverized coal airflow is transferred to four primary air / concentrated pulverized coal nozzles on the same horizontal plane and at the lower parts of the four corners of the hearth; and the separated four ways of thin pulverized coal airflow is transferred to four primary air / thin pulverized coal nozzles on the same horizontal plane and at the upper parts of the four corners of the hearth. Under the premise of meeting the heat power of the entire boiler, the anthracite-combusted single fire ball four-corner direct current burner increases the pulverized coal concentration at the concentrated pulverized coal area, and enables the wall thermal load qHr at the lower part of the burner to be higher, thereby enabling the combustion temperature at the lower part of the burner to meet the requirement of inflammation and stable combustion for the anthracite, and guaranteeing the anthracite pulverized coal airflow to be combusted timely and the low-load stable combustion of the oilless boiler.

Owner:SHANGHAI BOILER WORKS

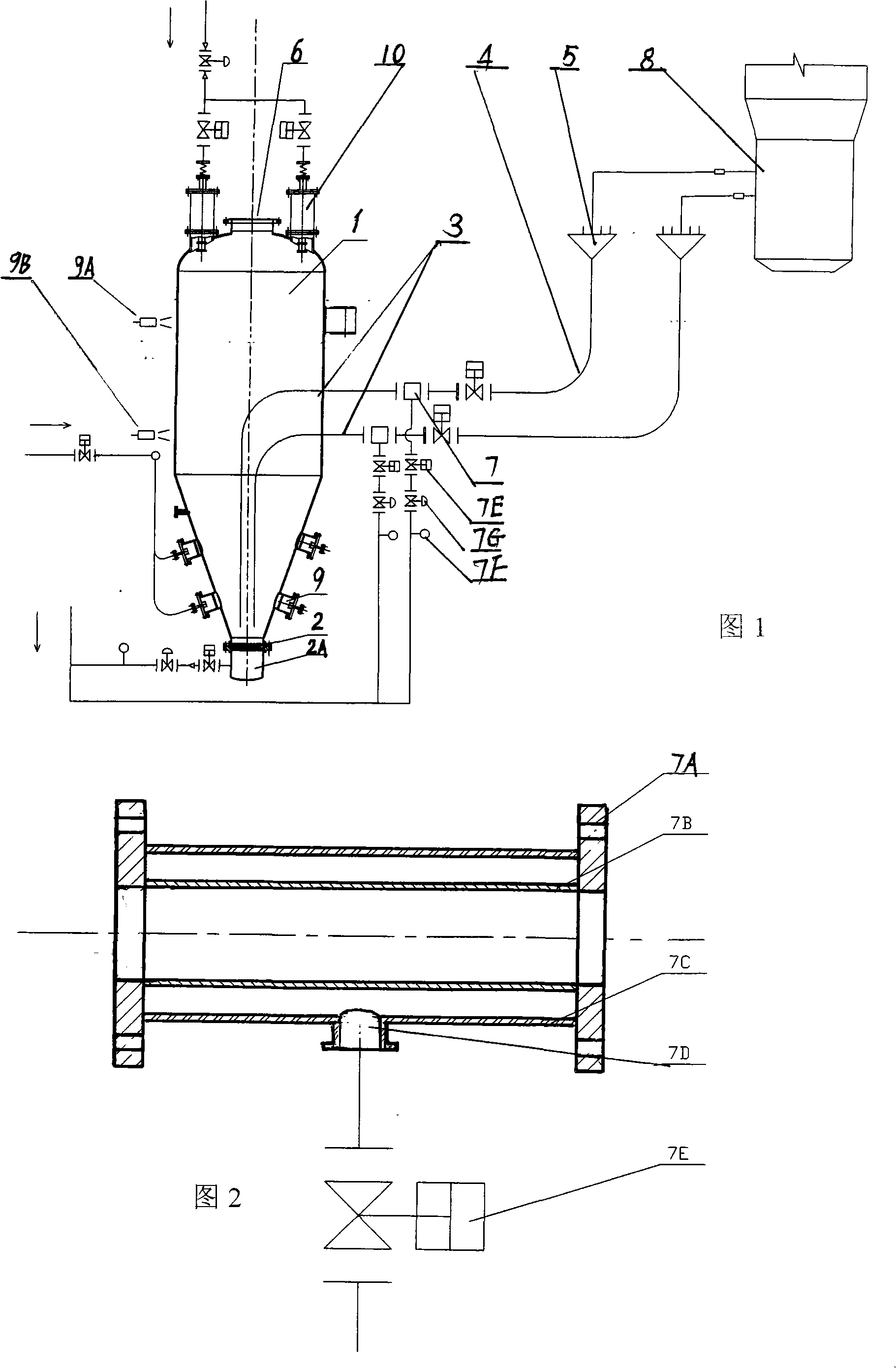

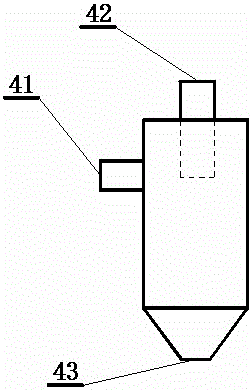

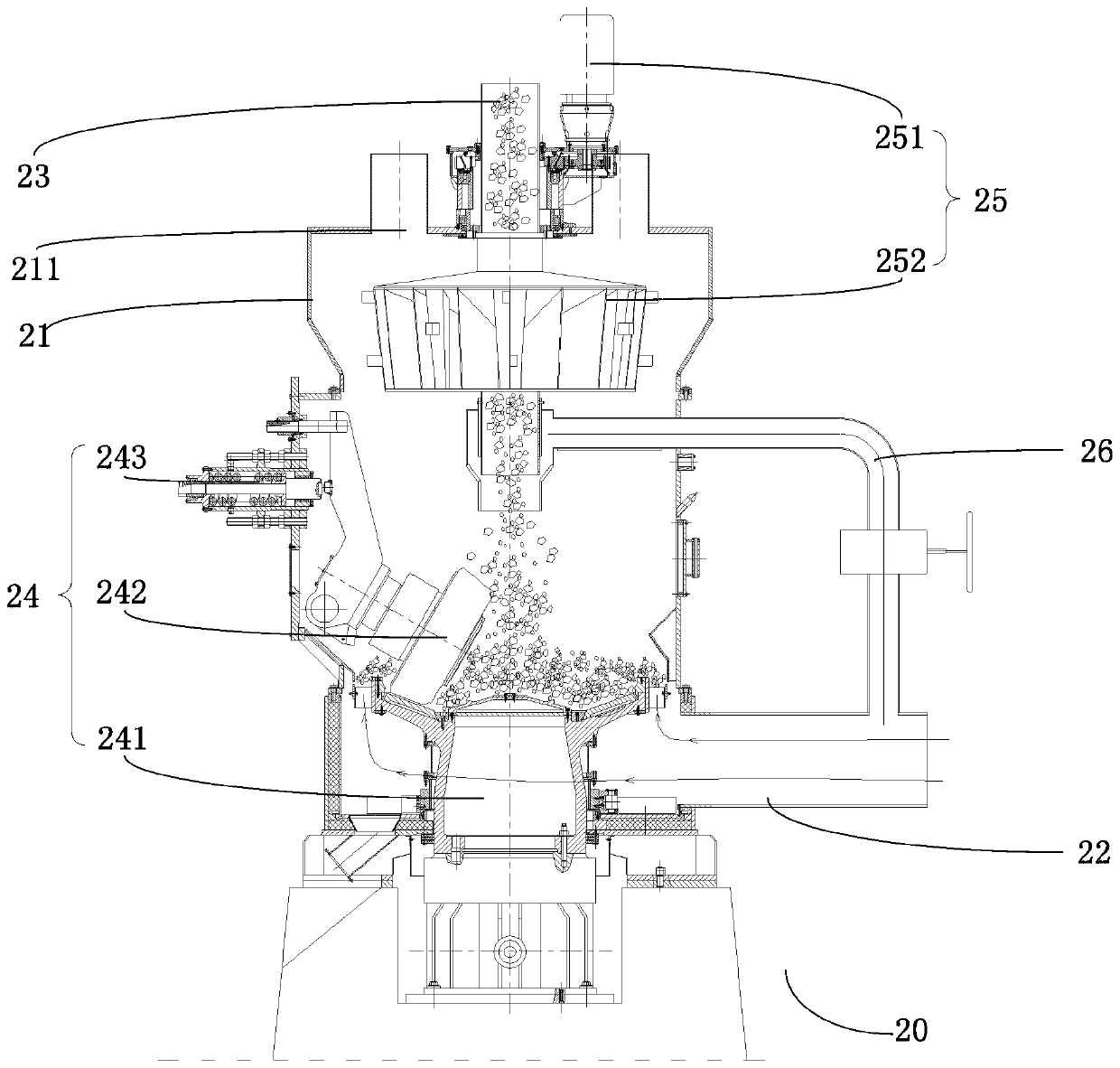

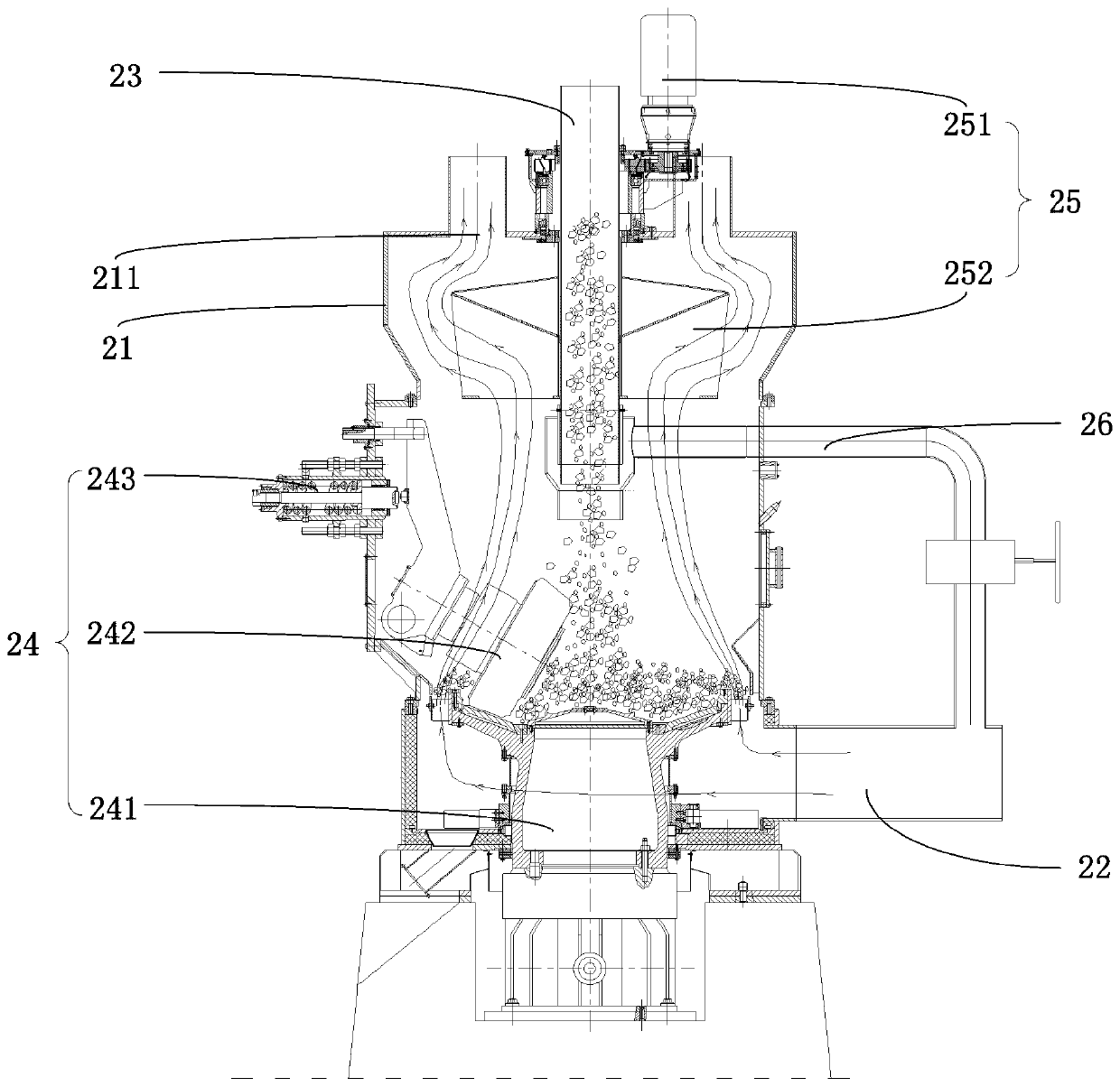

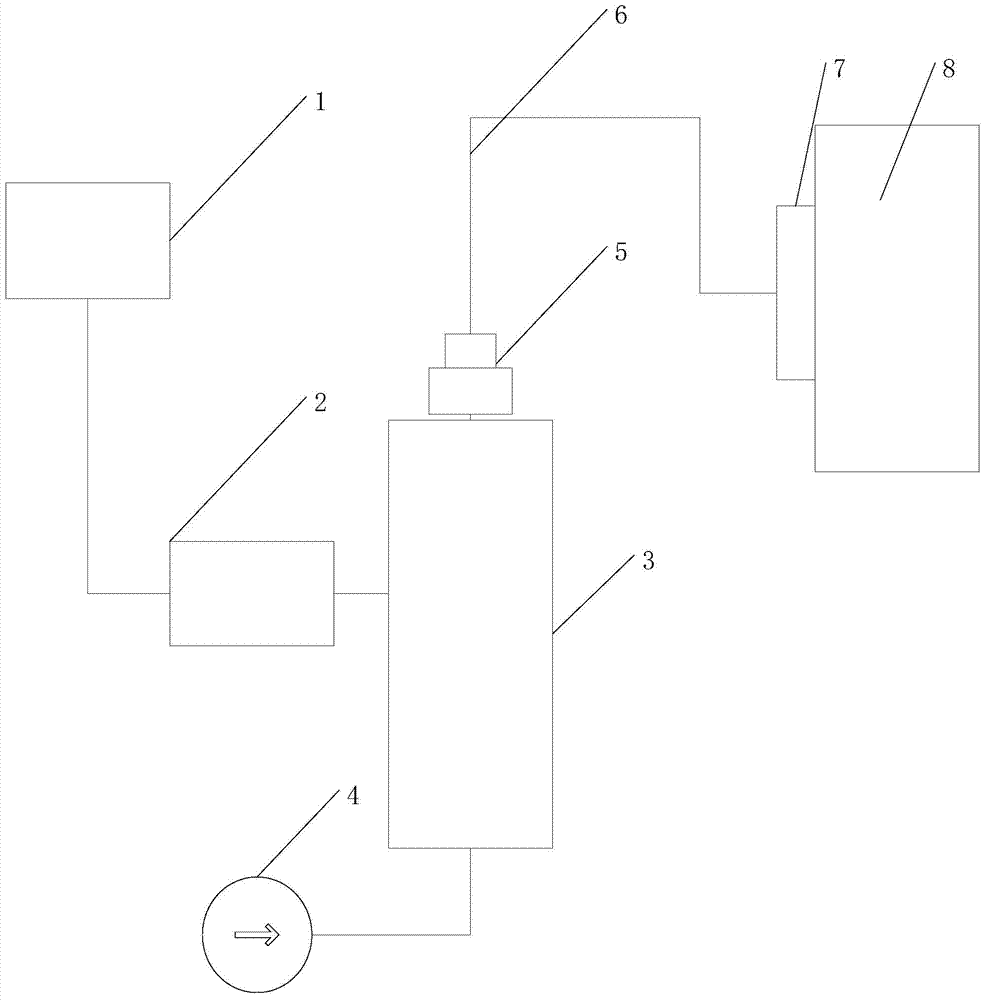

Fine coal dense phase conveying system of fusion reducing furnace

InactiveCN101254861AGuaranteed continuous supplyImprove reliabilityMechanical apparatusFurnace componentsCoal pipelineProcess engineering

The invention relates to a dense phase fine coal conveying system for smelting / reducing furnace, comprising a fine coal bunker; fluidized injection tanks arranged under the outlet of the fine coal bunker; and dense phase fine coal distributors arranged in front of the furnace. The devices are communicated through fine coal pipelines, and a fine coal flow monitor, a nitrogen pressure flow meter and a flow controller thereof are arranged on the pipelines. The key design includes that each independent system comprises at least two fluidized injection tanks that are parallelly arranged, at least one suction pipe is led out from each independent injection tank and connected with the matched main coal conveying pipes, and at least two independent main coal conveying pipes are respectively connected with the matched dense phase fine coal distributors for feeding fine coal from corresponding injection orifices on the smelting / reducing furnace with distributing branch pipes and the manager circuits of the distributors.

Owner:王向明 +1

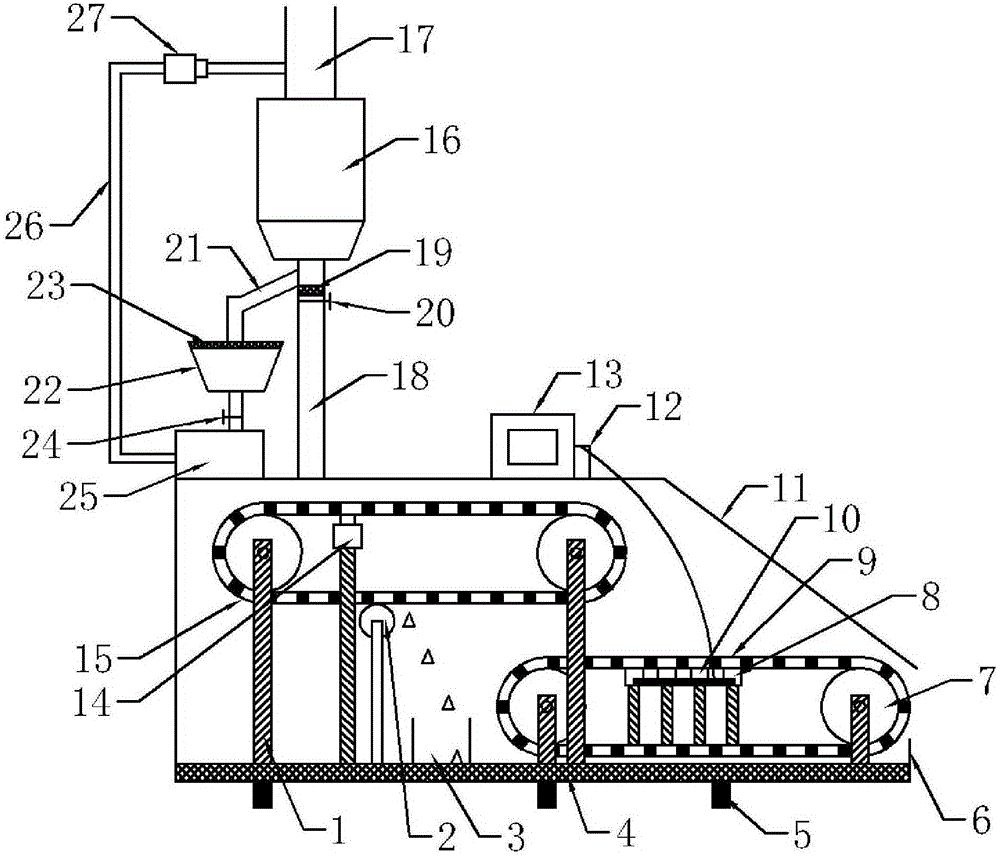

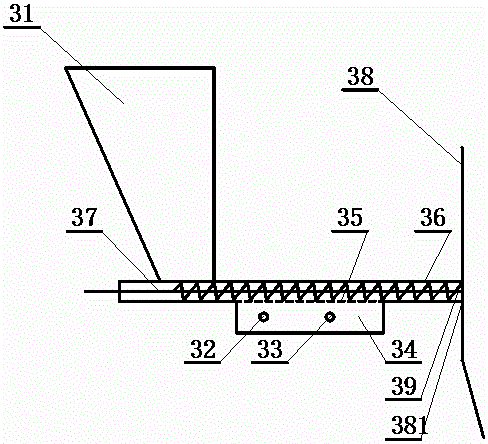

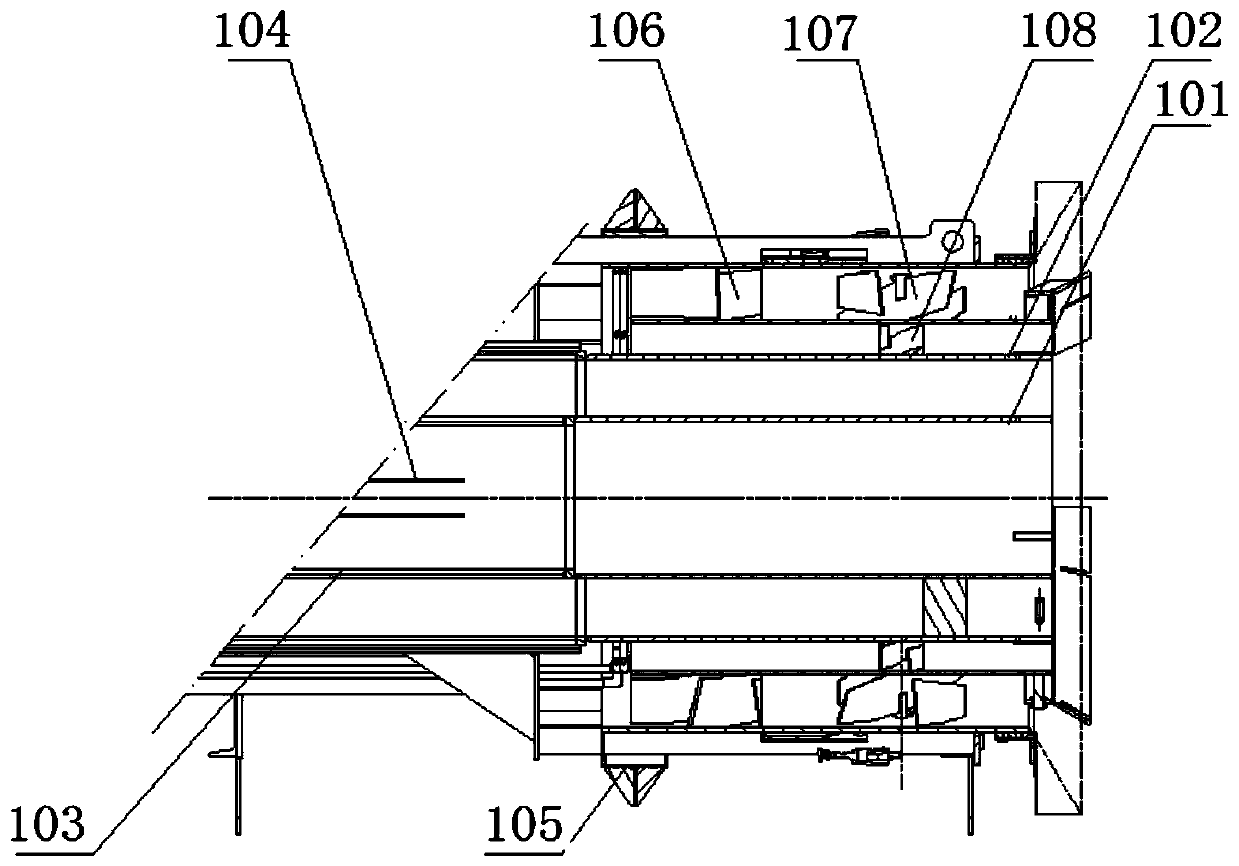

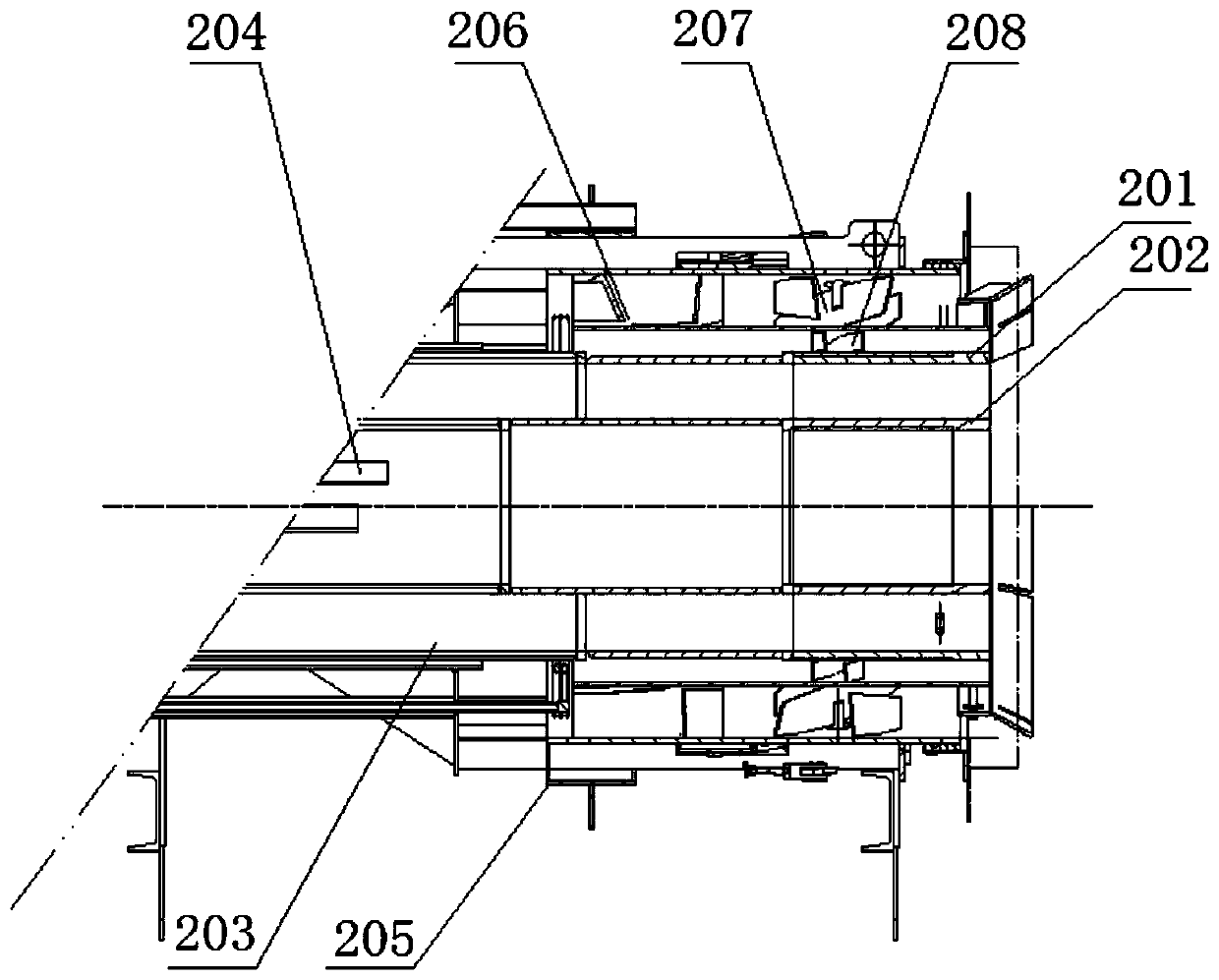

Coal grinding, impurity removing and coal feeding integrated device for power plant

InactiveCN105170281ABurn fullyQuality assuranceControl devices for conveyorsMagnetic separationCombustionCoal pipeline

The invention discloses a coal grinding, impurity removing and coal feeding integrated device for a power plant. The coal grinding, impurity removing and coal feeding integrated device for the power plant comprises a shell, a fire coal pipeline and a pulverizer. Base legs are arranged at the bottom of the shell. An iron removing conveying belt is arranged in the shell and located above the left side of a weighing conveying belt. The iron removing conveying belt and the weighing conveying belt are both closed loops. A plurality of magnets are embedded in the iron removing conveying belt. A coal inlet is formed in the top of the shell and located in the upper portion of the left side of the iron removing conveying belt. A coal mill is arranged above the coal inlet. A raw coal pipeline is arranged at the upper end of the coal mill. By filtering, breaking and grinding pebble coal in raw coal in a circulating mode, the pebble coal can meet the combustion requirement of a combustion boiler and enter a coal feeder to be supplied to the boiler to be combusted; the design of a connecting structure is reasonable, and full combustion of the raw coal is guaranteed; in addition, when coal powder is thrown onto the iron removing conveying belt through the fire coal pipeline, scrap iron and screws in the coal powder can be attracted by the magnets on the iron removing conveying belt, thereby being prevented from falling onto the weighing conveying belt, and the quality of the coal powder is guaranteed.

Owner:中国大唐集团科学技术研究总院有限公司

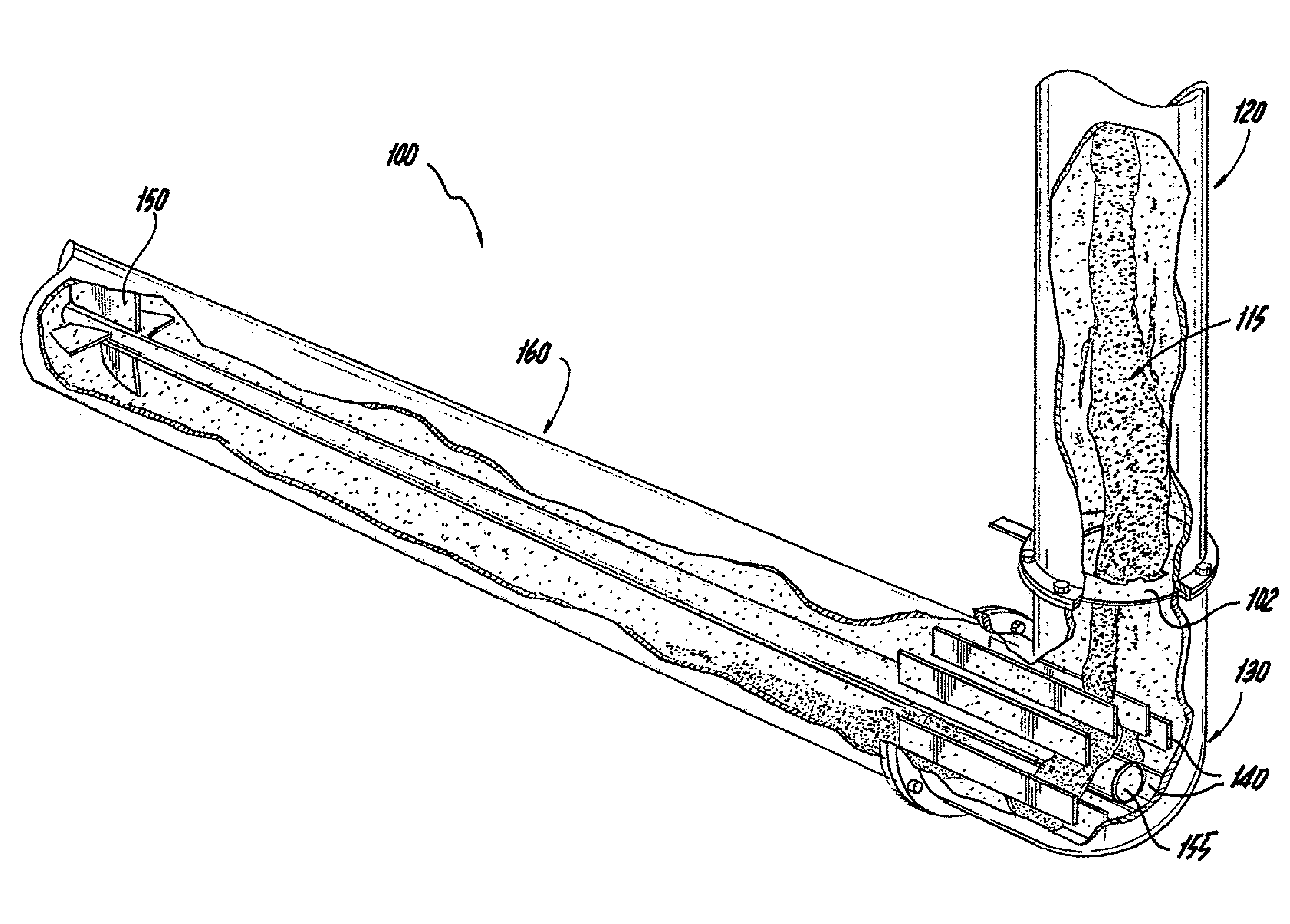

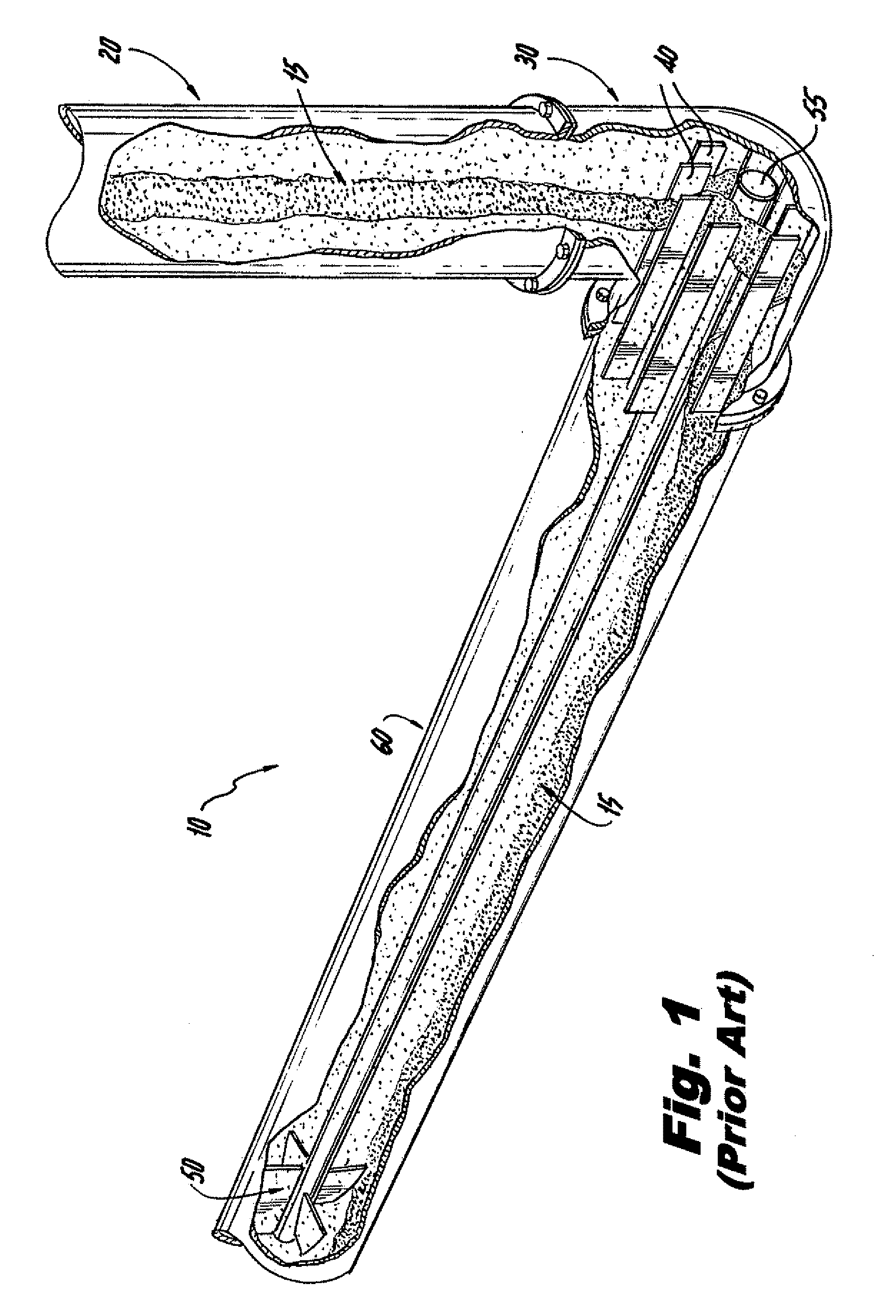

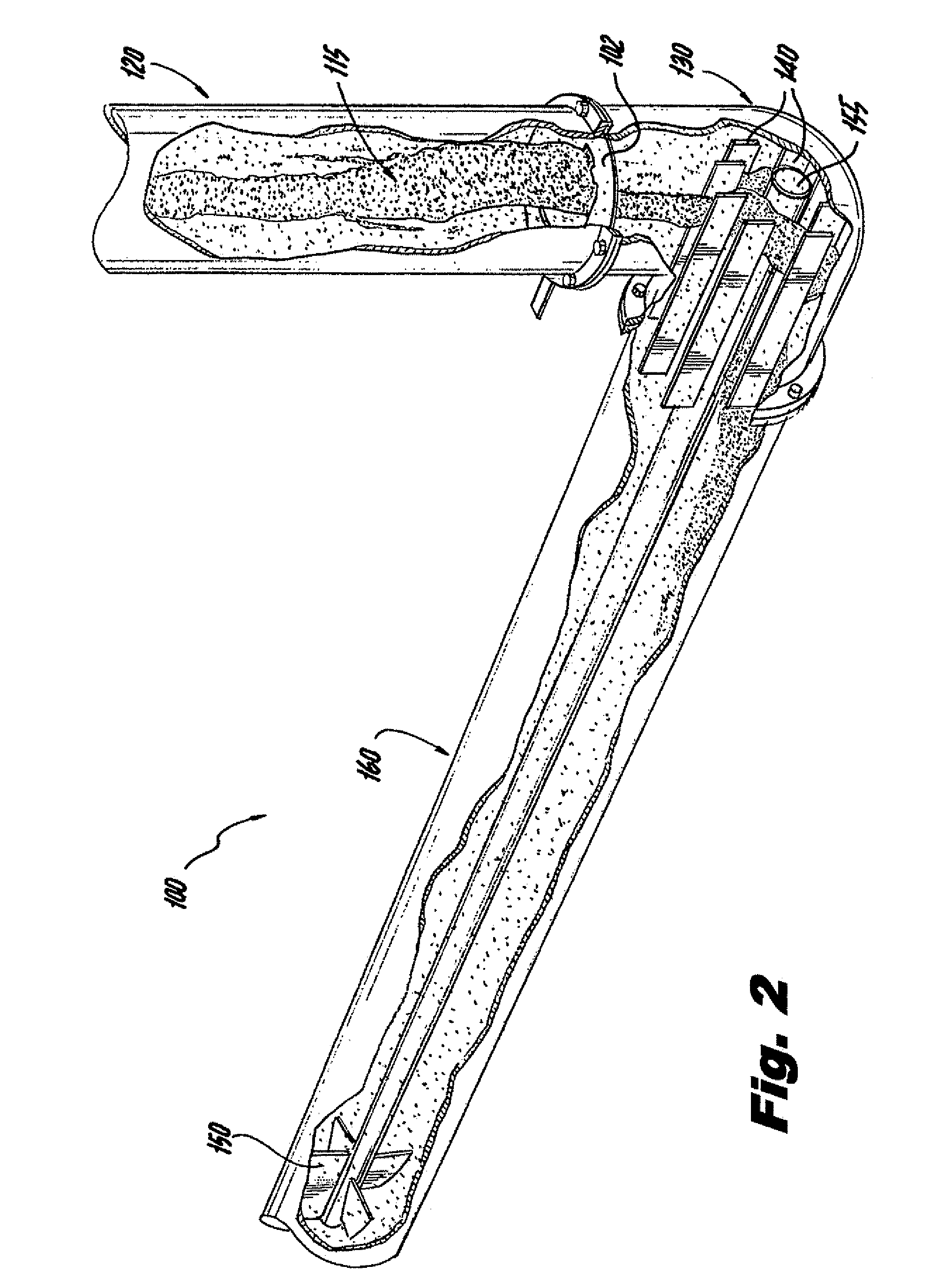

Anti-roping Device for Pulverized Coal Burners

ActiveUS20090272303A1Improve particle distributionCombustion using gaseous and pulverulent fuelFluidized bed combustionFlow disruptionParticle flow

An orifice plate for improving particle distribution within a coal piping system includes a plate body defining a central orifice therethrough bounded by an inner periphery of the plate body. The plate body is configured and adapted to be affixed between end flanges of adjacent pipes in a coal piping system so as to generally align the central orifice with an internal flow passage through the coal piping system. Flow disruption features are defined in the inner periphery of the plate body. The flow disruption features are configured and adapted to disrupt a flow of air and particles flowing through the central orifice to provide a more uniform distribution of particles downstream of the plate body than upstream.

Owner:BABCOCK POWER SERVICES

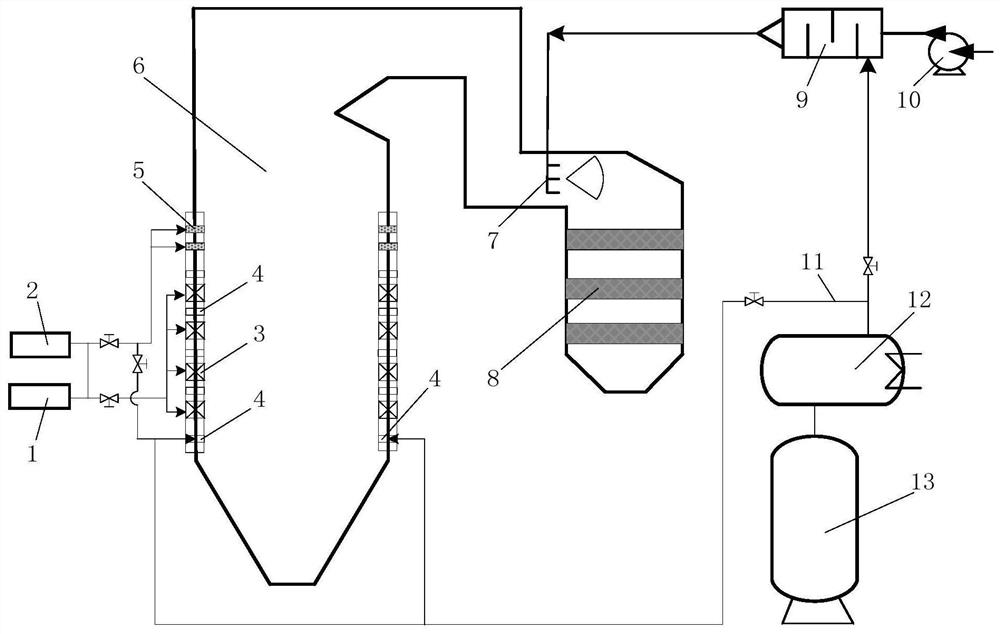

Low-emissioncirculating fluidized bedboiler with characteristic of fuel and desulfurizer graded supply

ActiveCN106838890ALower the altitudeLow costFluidized bed combustionApparatus for fluidised bed combustionCombustion chamberRetention time

The invention provides a low-emission circulating fluidized bed boiler with the characteristic of fuel and desulfurizer graded supply. The low-emission circulating fluidized bed boiler comprises a main combustion chamber, an auxiliary combustion chamber, a burning-out chamber, a fuel graded supply device, a desulfurizer graded supply device and the like, wherein the fuel graded supply device is arranged in front of the main combustion chamber, the desulfurizer graded supply device is arranged in front of the main combustion chamber and above the fuel graded supply device; two auxiliary combustion chamber pulverized coal inlets are formed in two side walls of the auxiliary combustion chamber in a bilaterally symmetric manner; fine pulverized coal spray pipes are arranged in the bilaterally symmetric manner; a mass ratio of desulfurizers sent out froma coarse desulfurizer outlet and a fine desulfurizer outlet is 3:1-10:1, and mass of fuel sent to the auxiliary combustion chamber through an undersizedfine pulverized coal pipeline is 2%-20% of total mass of fuel in a coal hopper. The low-emission circulating fluidized bed boiler has the advantages as follows: fuel / air dual-graded combustion and solid fuel re-burning are realized, circulating times and retention time of the fuel and the desulfurizers in the bed are increased, ultralow NOxemission and deep desulfurization are realized and the like.

Owner:TSINGHUA UNIV +1

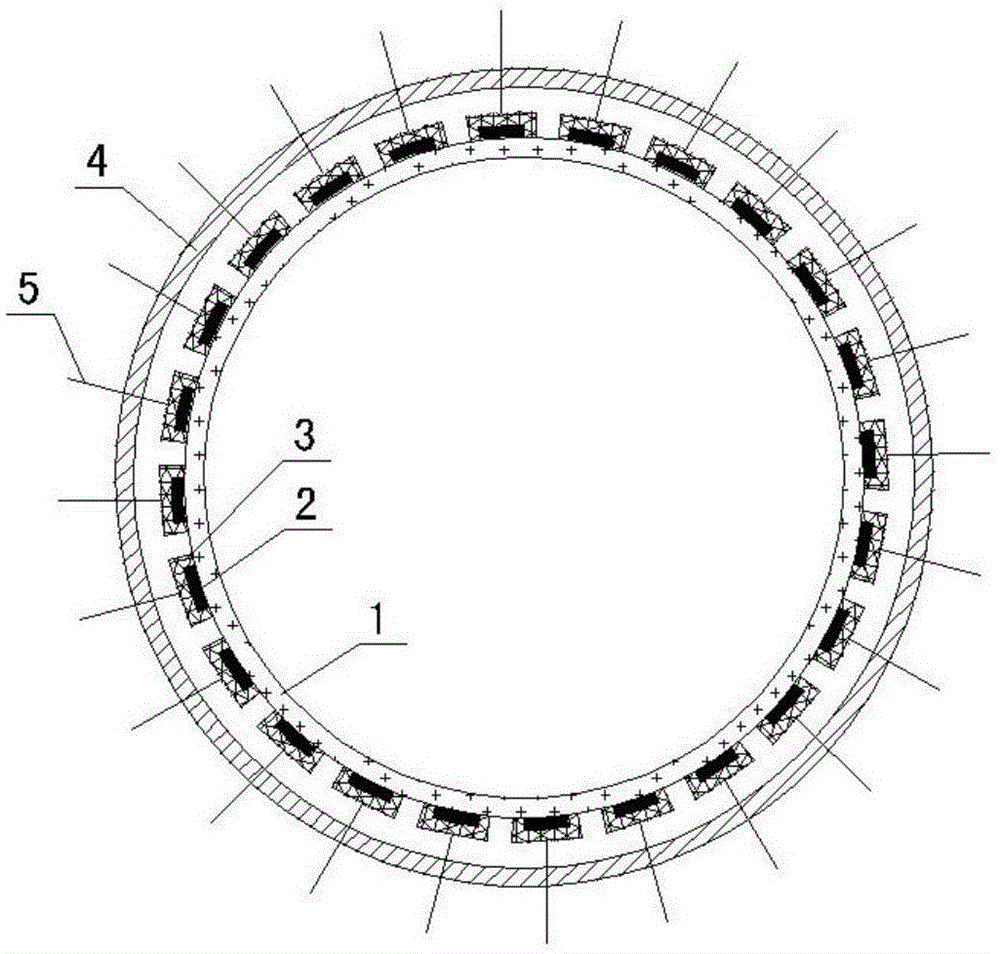

Pulverized coal flow online measuring device and measuring method

ActiveCN105157774AReduce measurement errorAvoid powder accumulationIndirect mass flowmetersElectricityCombustion

The invention discloses a pulverized coal flow online measuring device and measuring method. The device is characterized in that a measuring pipe is connected to a primary air pipeline in series and is made of a ceramic material; the two ends of the measuring pipe are each provided with two sets of capacitance sensors; the capacitance sensors are 2n electrode plates annularly and evenly distributed on the outer wall of the measuring pipe, and the 2n electrode plates are n plate capacitors oppositely arranged in pairs; capacitance of the plate capacitors serves as an output signal of the measuring device. Interval measurement of the plate capacitors is adopted, measurement errors caused due to uneven spatial distribution of pulverized coal concentration and speed are effectively reduced, and measuring precision is improved. By means of the measuring device, adjustment can be carried out in time according to data of pulverized coal flow online measuring, so that the problem that burning of the primary air pipeline, overheat of a heated face, slagging, thermal deviation and the like are caused due to pipeline pulverized coal accumulation, pulverized coal pipeline blocking and unbalance of pulverized coal distribution is avoided, and boiler combustion is optimized.

Owner:ANHUI XINLT POWER TECH CONSULTING +1

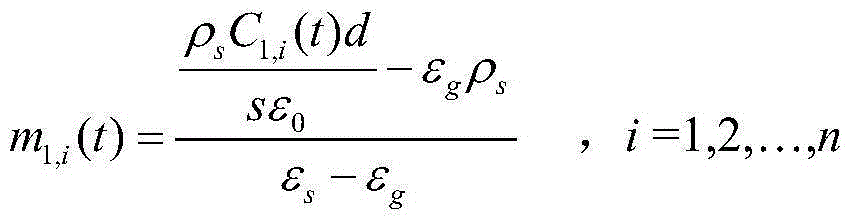

Air staged-combustion vertical and horizontal combined arrangement type over fire air system for tangential boiler

ActiveCN105114944AIncrease the lengthIncreased burnout timeCombustion apparatusCombustionCoal pipeline

The invention discloses an air staged-combustion vertical and horizontal combined arrangement type over fire air system for a tangential boiler. The air staged-combustion vertical and horizontal combined arrangement type over fire air system for the tangential boiler comprises a hearth, a hot air box, a pulverized coal pipeline, a primary air nozzle, a secondary air nozzle, a compact over fire air nozzle, a corner separation over fire air nozzle, a wall type separation over fire air nozzle and the like. According to the system, the tangential boiler is innovated in the conventional hearth height direction on the aspect of the way that over fire air is arranged at the corner, and the purposes of decreasing the excess air coefficient of a main combustion area and reducing NOx generation are realized by arranging corner separation over fire air nozzle and the wall type separation over fire air nozzle which are controlled independently on the upper portion of the main combustion area. By the adoption of the air staged-combustion vertical and horizontal combined arrangement type over fire air system, a sufficient over fire air rate, a reasonable reduction area length, good later-stage intra-boiler mixing and sufficient burn-out time can be guaranteed, smoke remaining rotation and temperature deviation can be effectively eliminated, the requirement for restraining NOx generation and the requirement for promoting pulverized coal to be burnt out are both considered, and the requirements for achieving safety operation of the boiler and being economical and environmentally friendly are met.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD

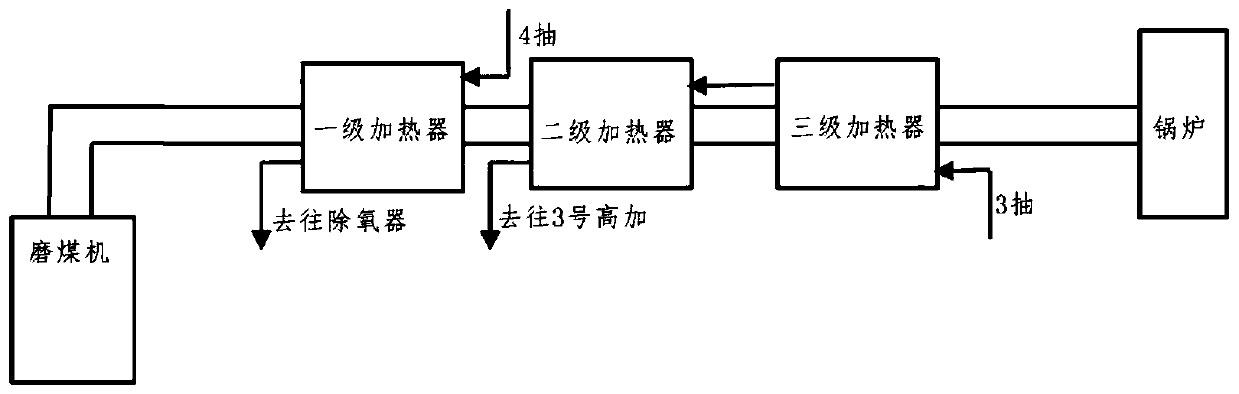

Energy-saving type boiler ultralow-load combustion stabilization system

PendingCN110388637APromote fireGood for burnoutLiquid degasificationBoiler controlCoal pipelineEngineering

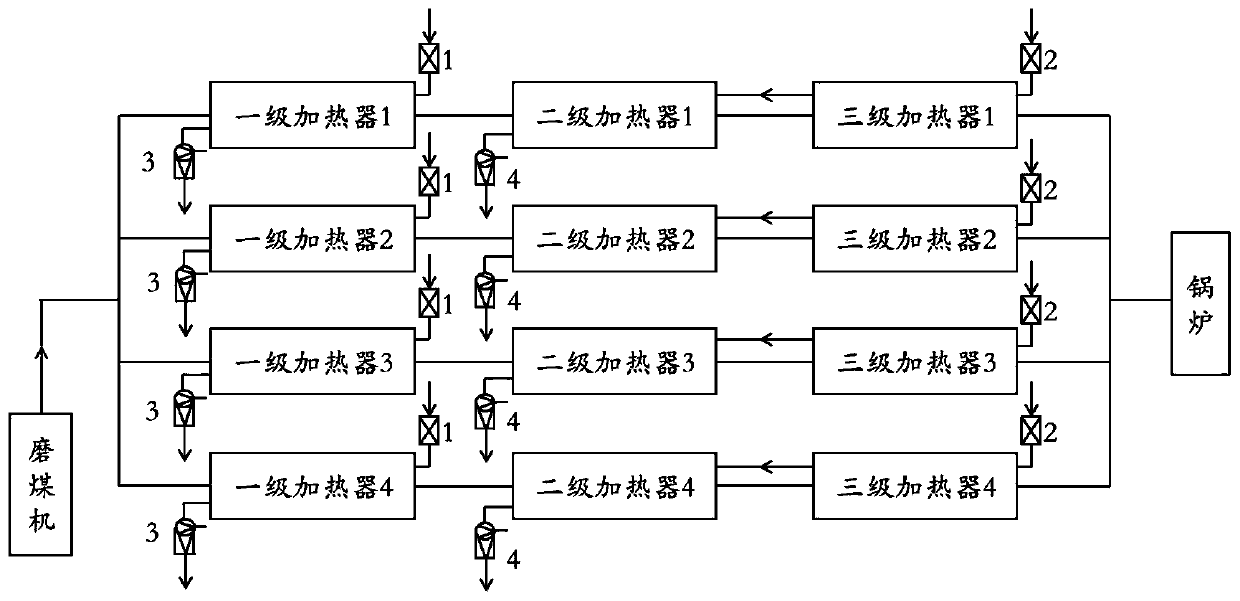

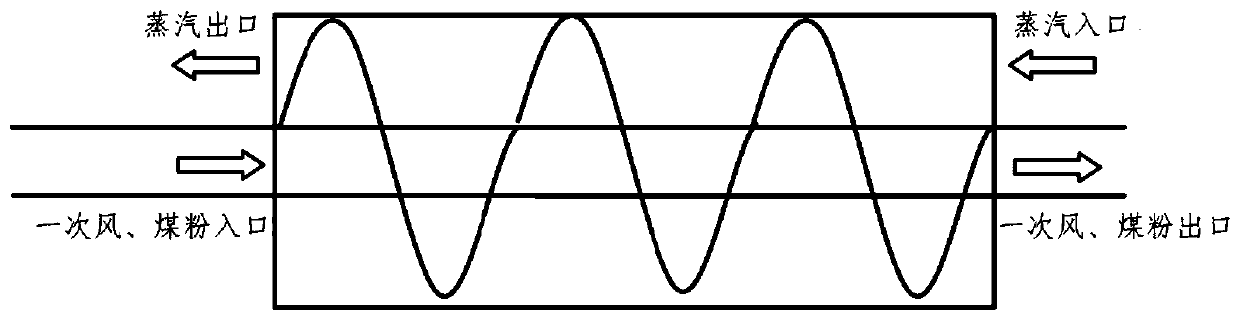

The invention provides an energy-saving type boiler ultralow-load combustion stabilization system. The energy-saving type boiler ultralow-load combustion stabilization system comprises a coal mill anda boiler which are connected through a pulverized coal pipeline, a steam heat exchanger is arranged on the pulverized coal pipeline between the coal mill and the boiler, the steam side of the steam heat exchanger is connected with the steam extraction end of a steam turbine through a steam extraction pipeline, the pulverized coal side of the steam heat exchanger penetrates through the pulverizedcoal pipeline between the coal mill and the boiler, and a steam flow regulating valve is arranged on the steam extraction pipeline. According to working condition change and requirements, the flow ofsteam entering the steam heat exchanger is adjusted so as to meet the requirements of combustion stabilization; according to the provided system, the extract steam of the steam turbine is utilized toenter high-efficiency spiral pulverized coal pipeline heaters to heat primary air and pulverized coal mixtures in the pulverized coal pipeline, pulverized coal firing and burnout can be flexibly promoted according to fuel combustion requirements, then pulverized coal adaptability of the boiler is improved, the boiler efficiency is greatly improved, moreover, pulverized coal firing and burnout under deep peak shaving working conditions are promoted, and stable combustion capability is high.

Owner:SHANGHAI POWER EQUIP RES INST

Chemical waste recycling system and method

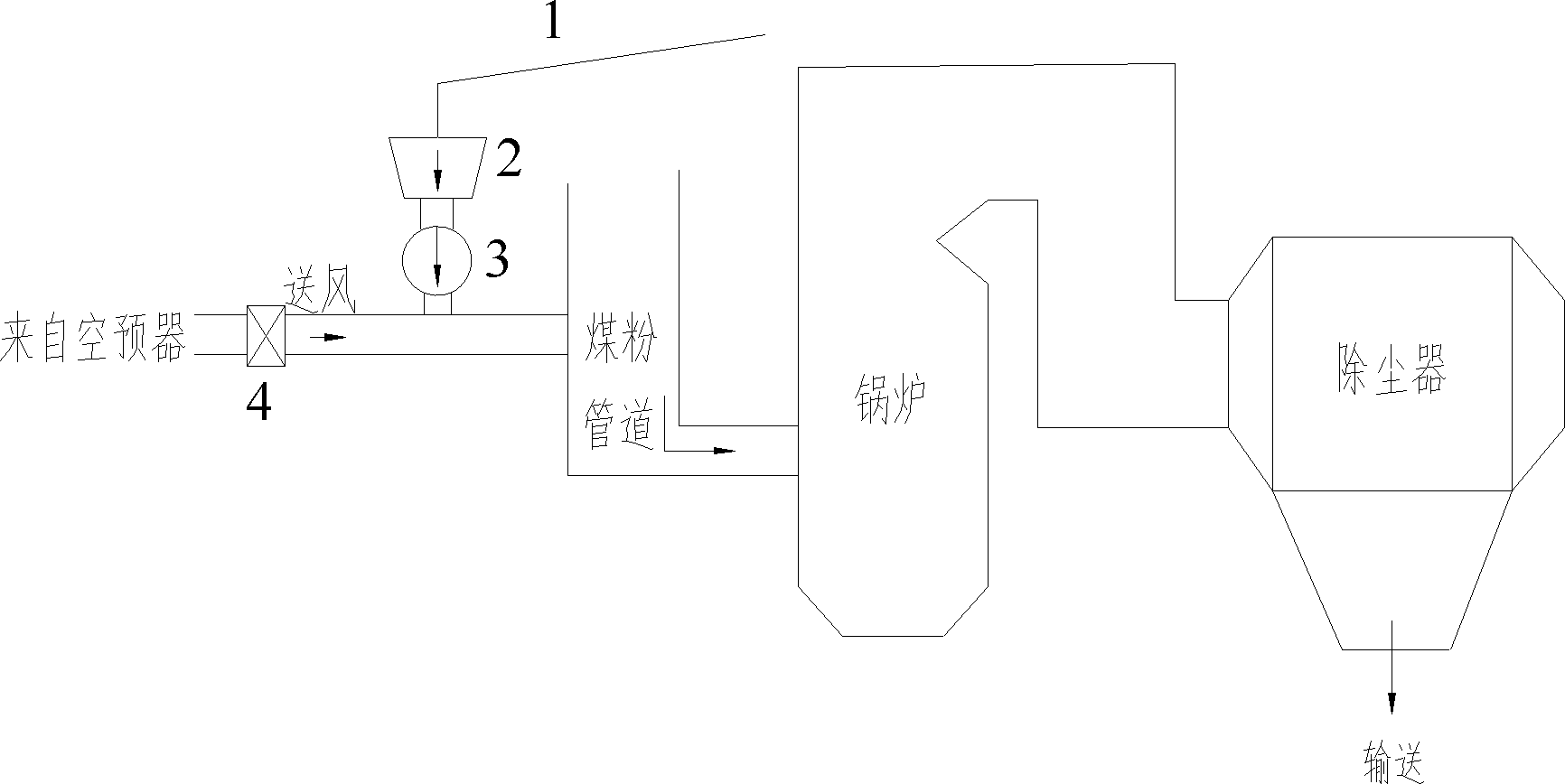

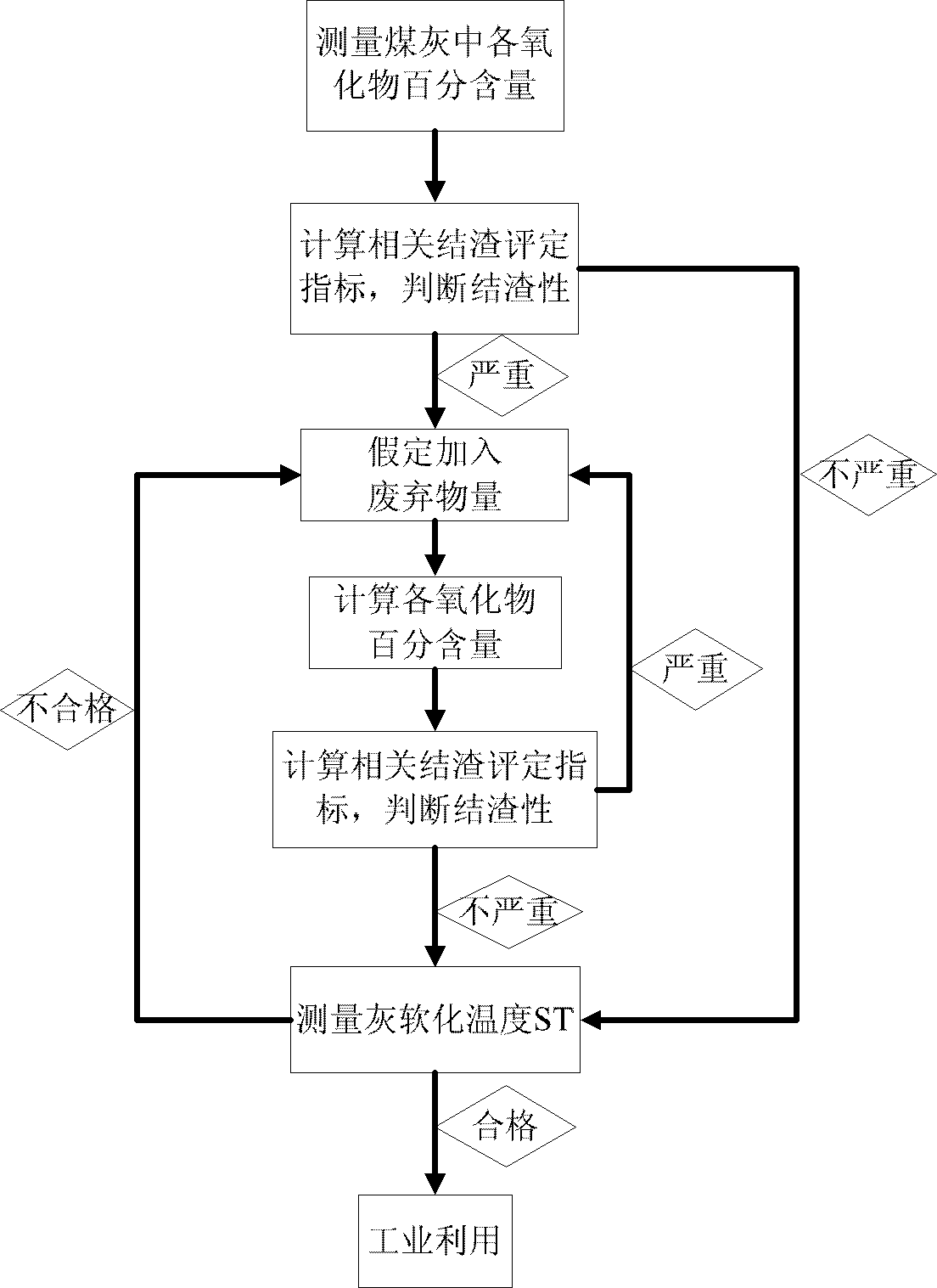

InactiveCN102519046AReduce or prevent slaggingReduce energy consumptionIncinerator apparatusLump/pulverulent fuel feeder/distributionAir preheaterCombustion

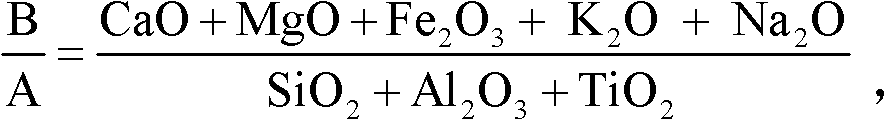

The invention discloses a chemical waste recycling system and a method therefor. Reasonable waste adding ratio is determined according to slagging evaluation indexes; waste is conveyed into a powder bin through a special conveying system, and enters an air supply pipeline through a powder feeder, air supplied by an air preheater is adjusted by a pressure regulating valve and brings the waste into a pulverized coal pipeline, and through the turbulence of high speed airflow, the powdery waste and pulverized coal are fully mixed to enter a hearth for combustion. The adding amount of the waste can be adjusted through a spiral powder feeder. Because the waste is rich in SiO2, and after the waste is mixed with the pulverized coal, an ash fusion point can be improved and slagging can be reduced or prevented; because the waste is added, the yield of flyash is improved, and the flyash is a common concrete ingredient in the construction industry, so the aim of recycling the waste is fulfilled finally.

Owner:XI AN JIAOTONG UNIV

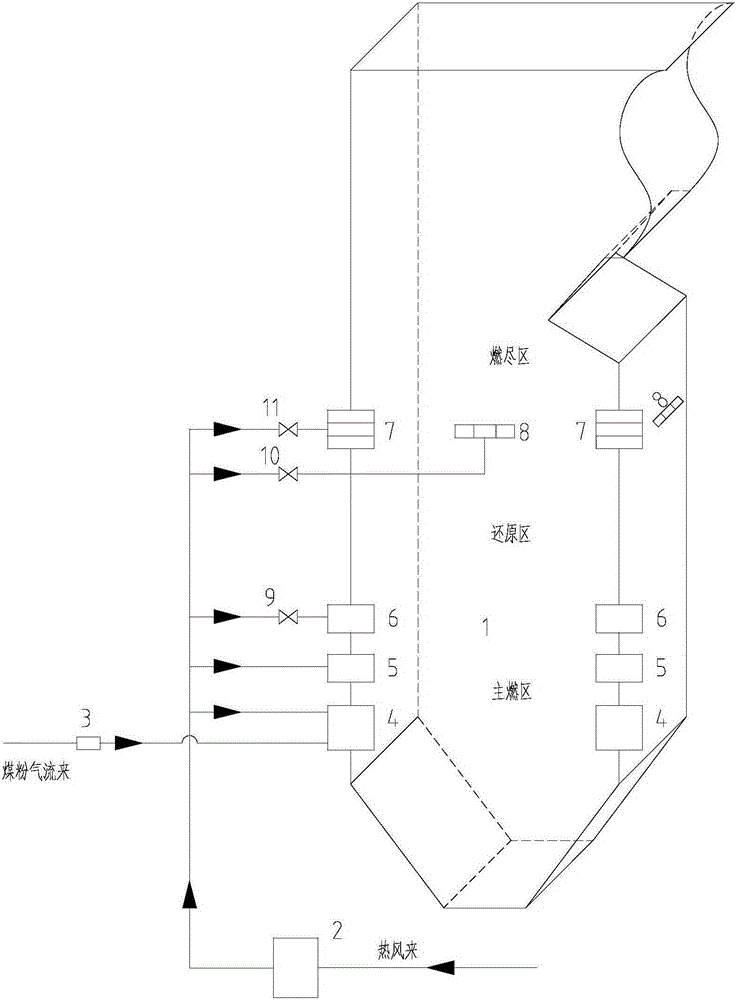

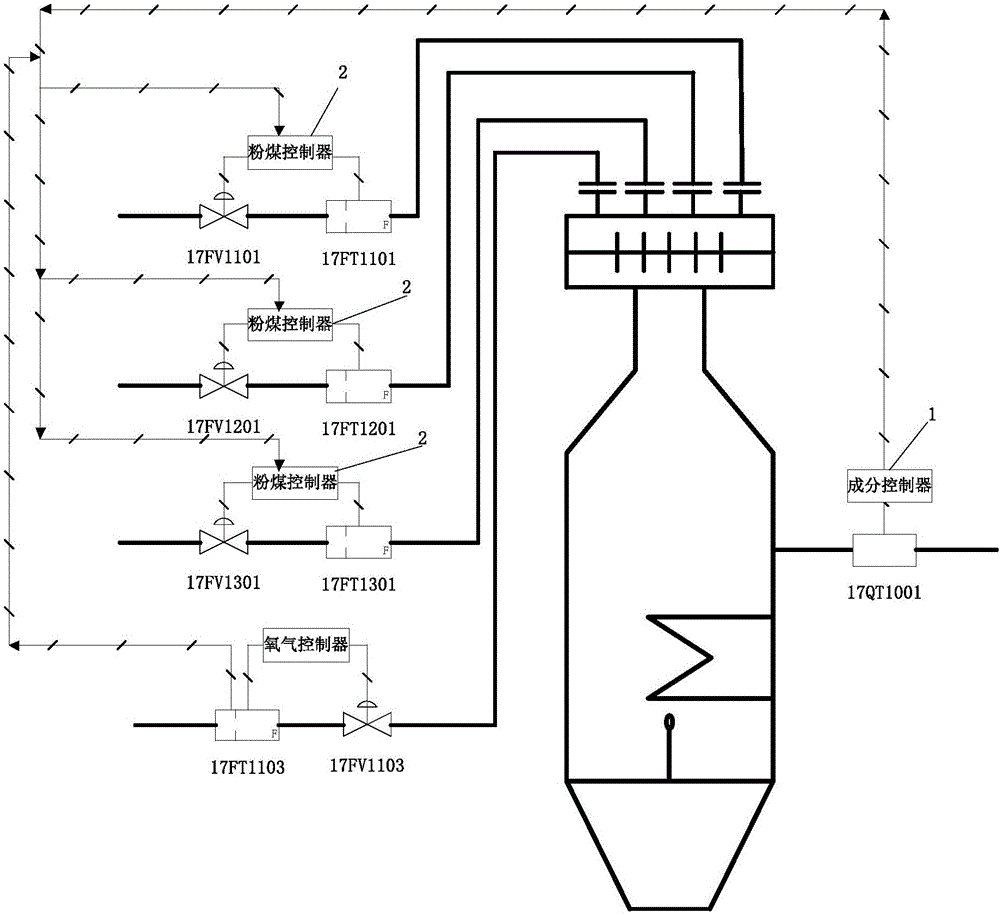

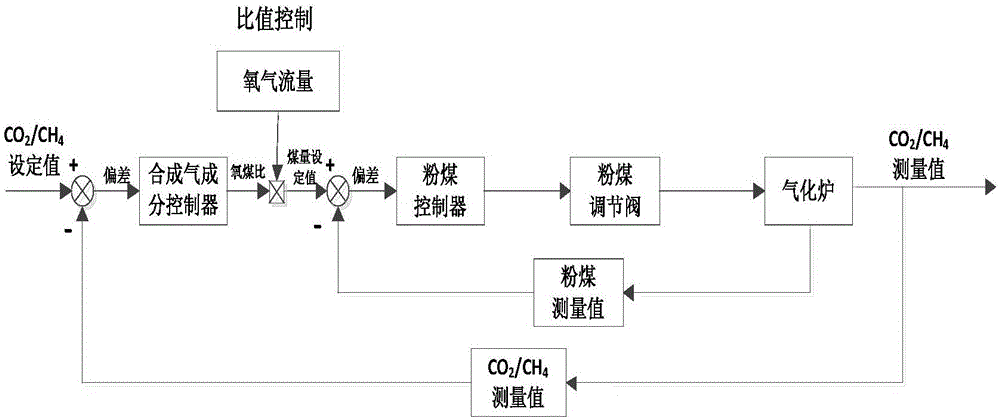

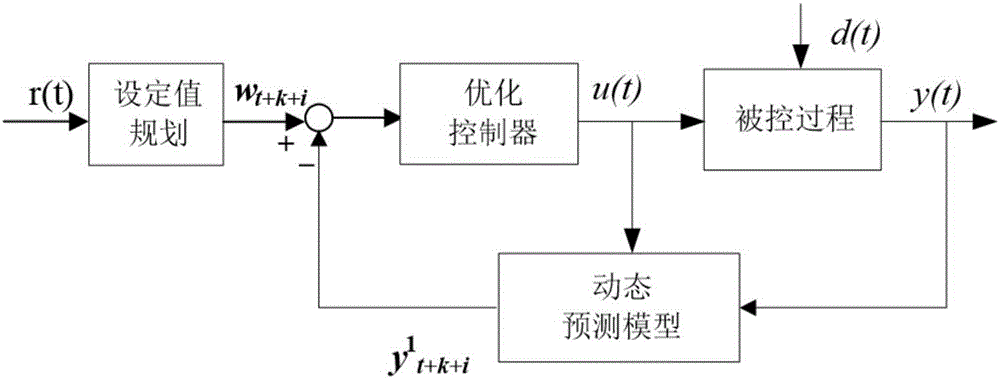

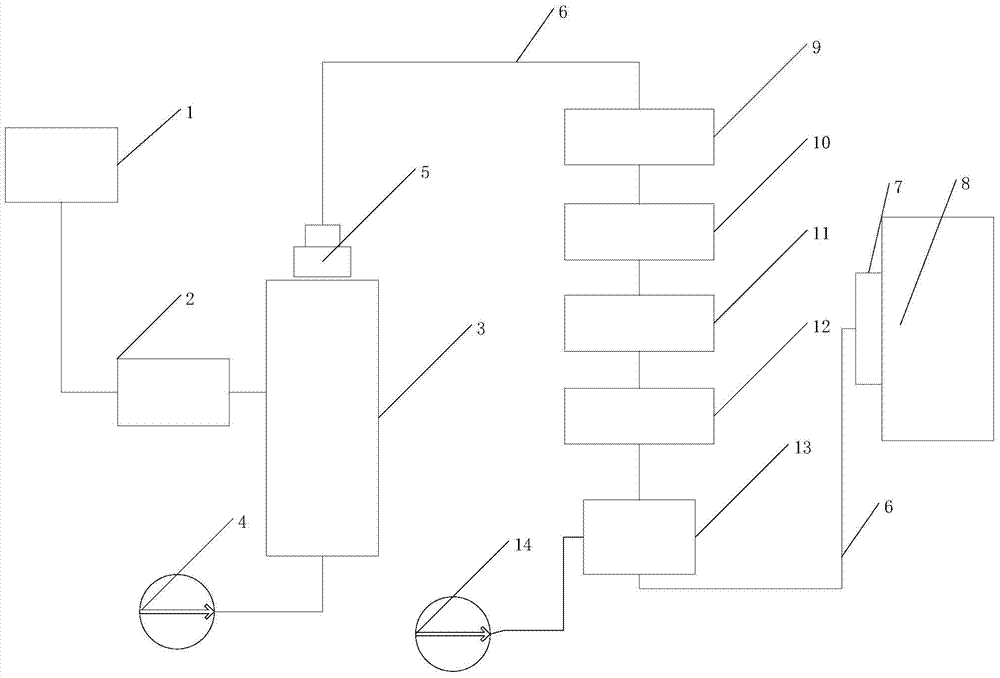

Oxygen-carbon ratio control system and gasifier oxygen-coal ratio control method thereof

PendingCN106773718AGuaranteed uptimeEasy to control automaticallyControlling ratio of multiple fluid flowsAdaptive controlLoop controlAutomatic control

The invention relates to a gasifier oxygen-coal ratio control method based on prediction control. An oxygen-carbon ratio control system comprises a cascade loop taking synthetic gas ingredient as a controlled variable, the cascade loop comprises a main loop and an auxiliary loop, the main loop comprises a main loop controller, the auxiliary loop is a powdered coal flow adjusting loop, the main loop controller comprises a synthetic gas ingredient controller, the auxiliary loop comprises a powdered coal controller, the synthetic gas ingredient controller is connected with the powdered coal controller which is sequentially connected with a powdered coal adjusting valve, a powdered coal pipeline and a gasifier, and the synthetic gas ingredient controller is controlled by a prediction controller. In the oxygen-carbon ratio control system, oxygen flow is determined by load of the gasifier, the synthetic gas ingredient controller determines oxygen-coal ratio according to the measured synthetic gas ingredient, and then the oxygen-coal ratio is multiplied with the oxygen flow to acquire a set value of powdered coal flow. By the gasifier oxygen-coal ratio control method, optimized automatic control of the oxygen-coal ratio is realized, safe and reliable running of the gasifier is guaranteed, and large-scale application and popularization of the gasifier are promoted.

Owner:CHANGZHENG ENG

Pulverizing system and method

PendingCN111594866AGuaranteed economyEnsure safetyFuel supply regulationLump/pulverulent fuel feeder/distributionThermodynamicsCoal pipeline

The invention relates to a pulverizing system and method, and the system is carried in a boiler system. The pulverizing system comprises an air and pulverized coal homogenizing coal mill which is connected to the boiler system through a plurality of pulverized coal pipelines; a pulverized coal concentration regulating valve, a pulverized coal flow regulating valve, a pulverized coal concentrationdetection sensor and a pulverized coal flow detection device are sequentially mounted on each pulverized coal pipeline from the end close to the air and pulverized coal homogenizing coal mill to the boiler system end; and a control system is carried on an industrial personal computer, and the control system is electrically connected with the air and pulverized coal homogenizing coal mill, the pulverized coal concentration regulating valves, the pulverized coal flow regulating valves, the pulverized coal concentration detection sensors, the pulverized coal flow detection devices, as well as anin-boiler flame detection sensor, a flue gas fly ash carbon content detection sensor, a flue gas NOX detection sensor and a flue gas CO detection sensor in the boiler system. By comparing target values of the industrial personal computer and combining with pulverized coal concentration, a flow detection signal and coal quality condition on each pulverized coal pipeline, an instruction is sent to each actuator, so that the deviation of air and pulverized coal in each pulverized coal pipeline is reduced, and fine control is achieved.

Owner:上海卡山科技股份有限公司

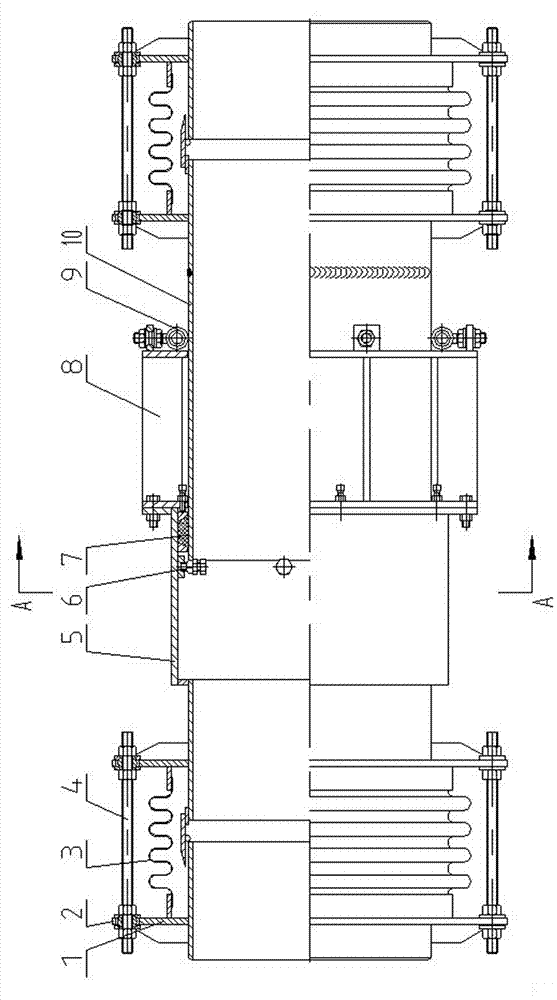

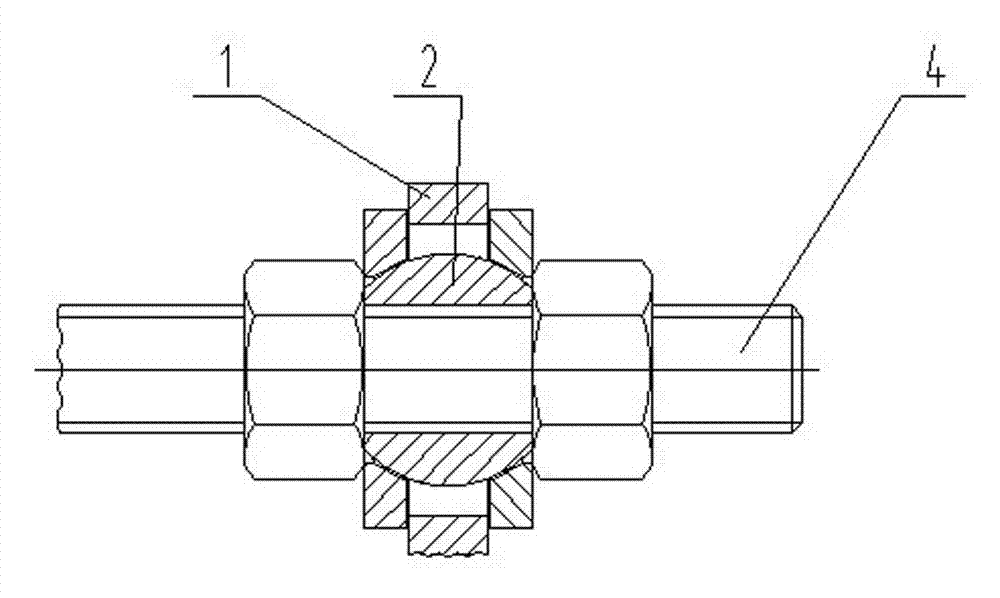

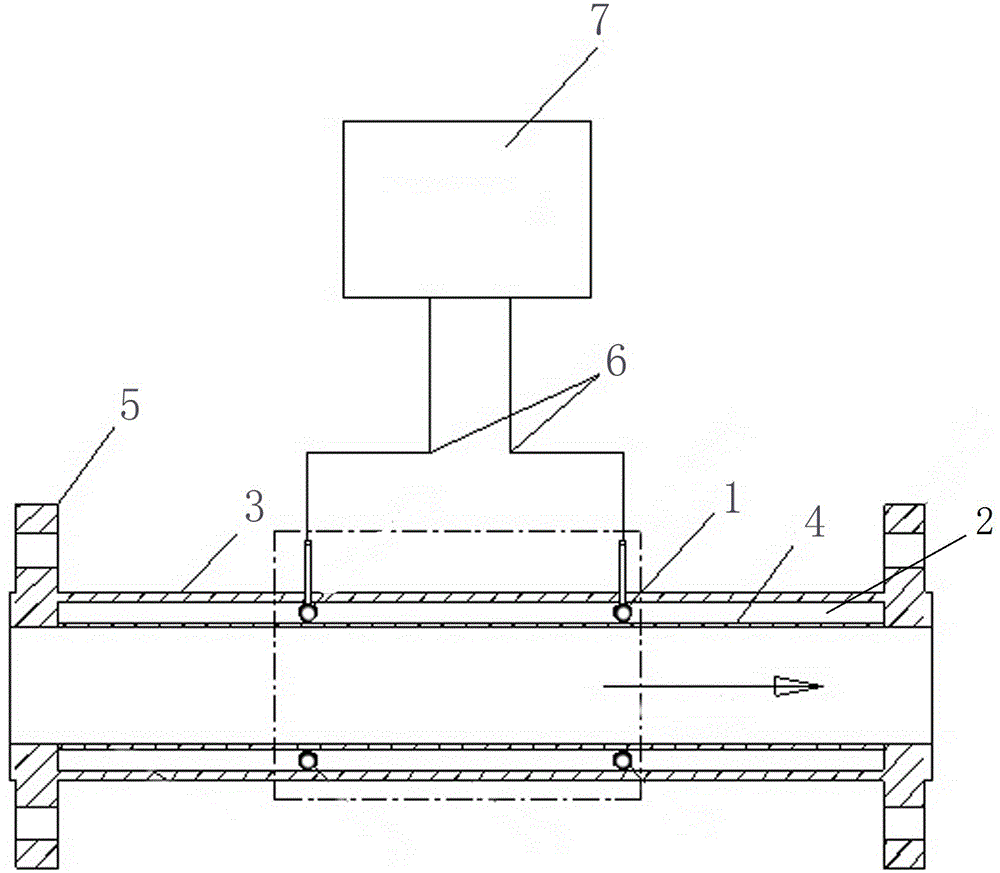

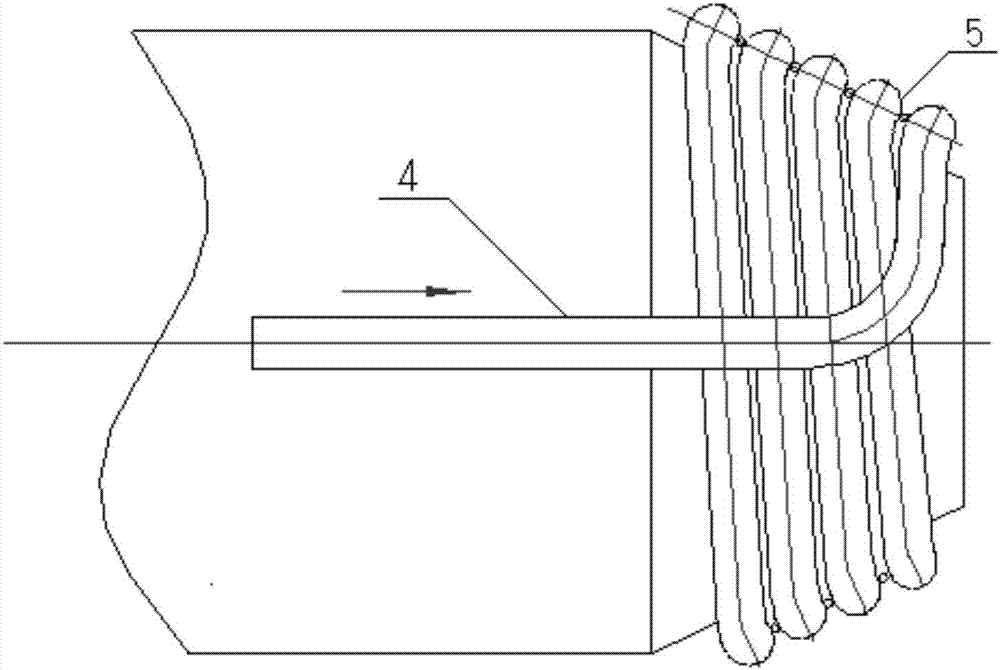

Combined-type powdered coal pipeline compensation device

InactiveCN103016891AHigh positioning accuracyAxial compensation motion balancePipeline expansion-compensationAxial displacementCoal pipeline

The invention discloses a combined-type powdered coal pipeline compensation device, which consists of a centered sleeve type expansion joint and two corrugated expansion joints, wherein the two corrugated expansion joints are respectively and coaxially connected at both ends and are equal in caliber. Axial through holes are respectively and evenly distributed in radial annular plates respectively at both ends of each corrugated pipe; a sphere seat is arranged in each axial through hole; one double-thread screw is connected in series and axially and tightly spliced with the two sphere seats respectively at both ends of each corresponding corrugated pipe to form a hinge joint structure; the axial movement of each corrugated pipe is limited by the corresponding hinge joint structure, and the lateral displacement of a powdered coal pipeline is only assorted with flexible absorption of the corrugated expansion joints. Right ends of outer pipes of the two corrugated expansion joints are coaxially connected with a ring stand; rollers which are adjustable in radial position are evenly distributed on the right end face of the ring stand; and the rollers axially roll along outer walls of inner pipes to form an external guide structure. In order to further improve the quality of the axial displacement of the inner pipes, screw bolt assemblies connected in the radial direction are evenly distributed on ring pipe walls of the left ends of the inner pipes to form an internal guide structure. The combined-type powdered coal pipeline compensation device disclosed by the invention is clear in division of axial compensation and lateral compensation, flexible in compensation, high in compensation dosage and good in sealing effect.

Owner:江苏亿丰机械制造有限公司

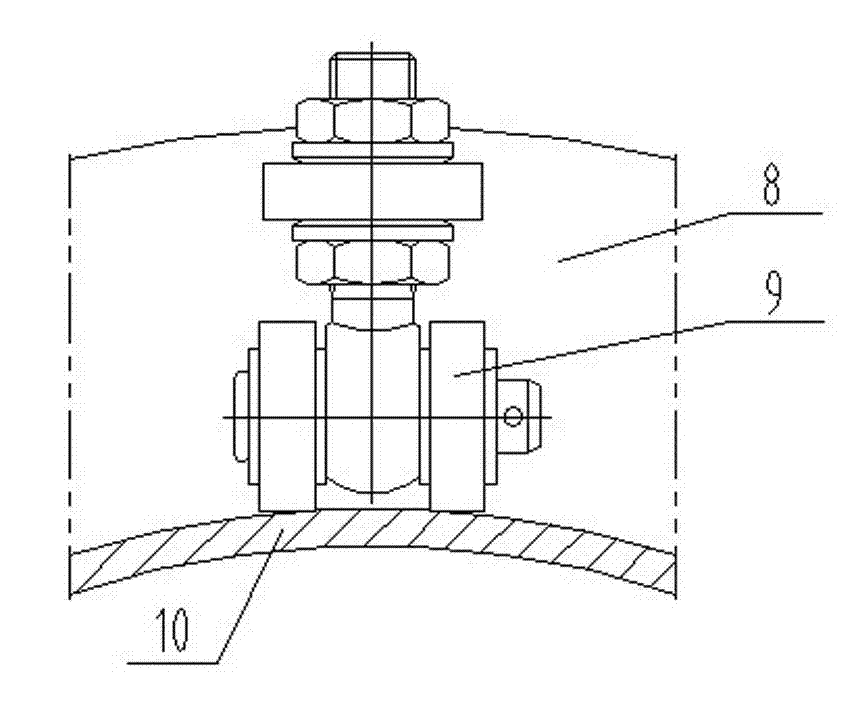

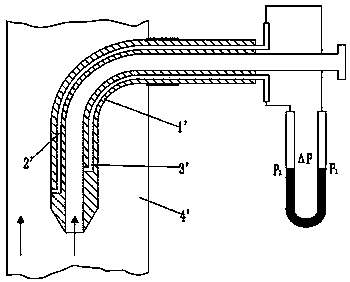

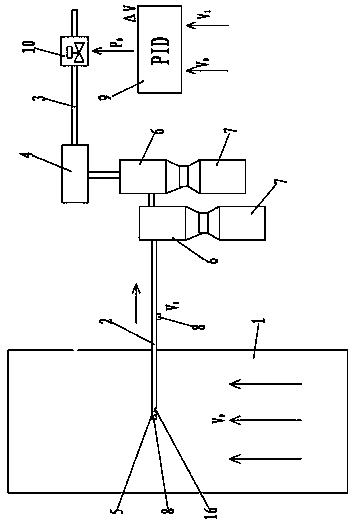

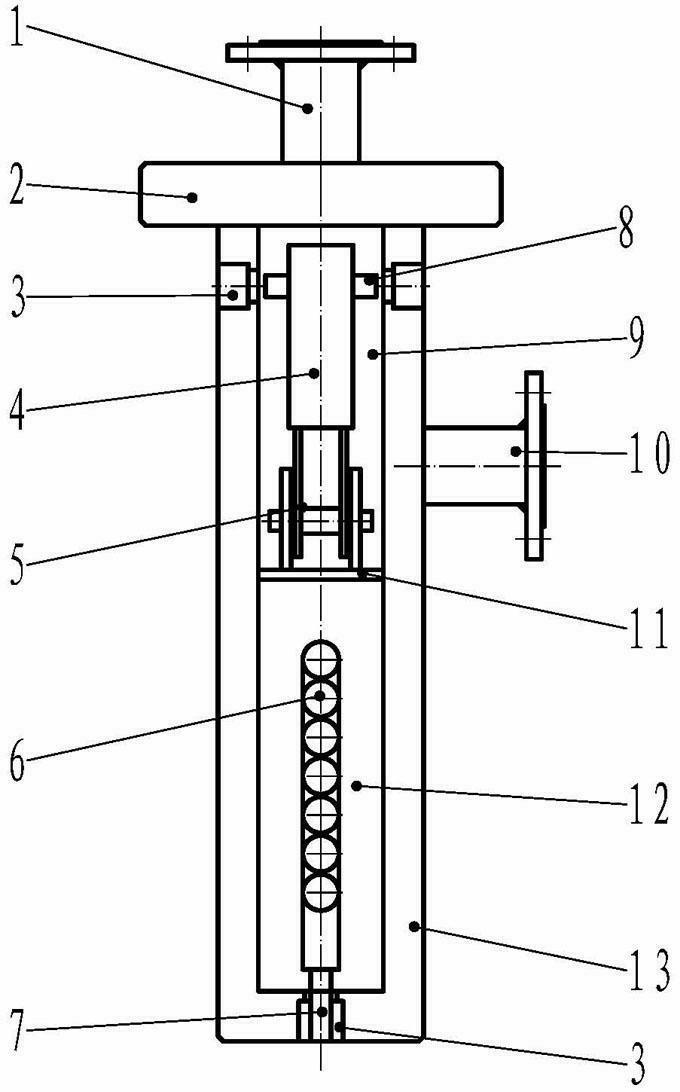

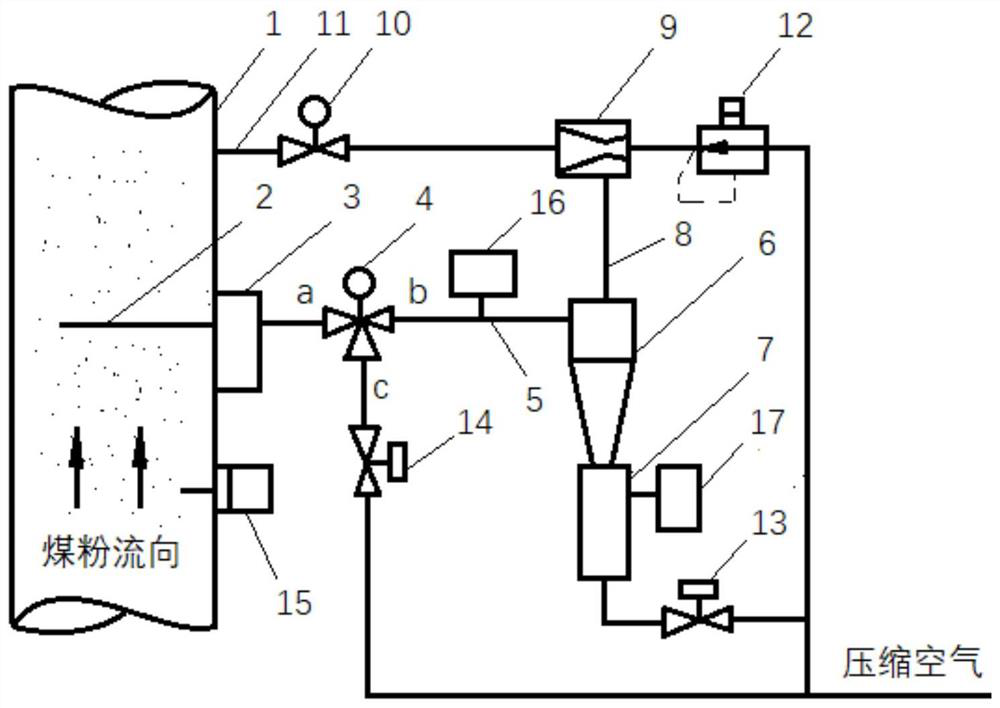

Constant speed sampling method and sampling device of pulverized coal

PendingCN107664588ATo overcome the disadvantage of sampling errorImprove accuracyWithdrawing sample devicesThermodynamicsCoal pipeline

The invention discloses a constant speed sampling method and sampling device of pulverized coal. The sampling method comprises the following steps: measuring flow velocity of the pulverized coal in apulverized coal pipeline and the pulverized coal pumped into a sampling pipe by adopting an electrostatic speed measurement way, and regulating gas extraction pressure in the sampling pipe to ensure that sampling is carried out when the flow velocity of the pulverized coal is equal to that of the other pulverized coal; the sampling device comprises a negative pressure gas extraction mechanism forpumping the pulverized coal in the pulverized coal pipeline into an inner cavity of the sampling pipe, a gas extraction pipe, a sampling collection mechanism, an electrostatic speed measurement mechanism, and a PID (Proportional-Integral-Differential) adjustment mechanism, wherein a gas extractor is mounted between the gas extraction pipe and the sampling pipe; the sampling collection mechanism isused for collecting the pulverized coal which enters into the sampling pipe; the electrostatic speed measurement mechanism is used for measuring the flow velocity of the pulverized coal in the pulverized coal pipeline and the pulverized coal pumped into the sampling pipe; the PID adjustment mechanism is used for adjusting gas extraction pressure in the sampling pipe so that the flow velocity of the pulverized coal in the pulverized coal pipeline is equal to the flow velocity of the pulverized coal in the sampling pipe. The constant speed sampling method disclosed by the invention is suitablefor sampling the pulverized coal in a primary air pipe, accurate constant speed sampling is realized, sampling errors can be reduced, and sampling of the pulverized coal has representativeness; the sampling device has a simple structure and is convenient to operate.

Owner:BEIJING ENLANDAR TECH

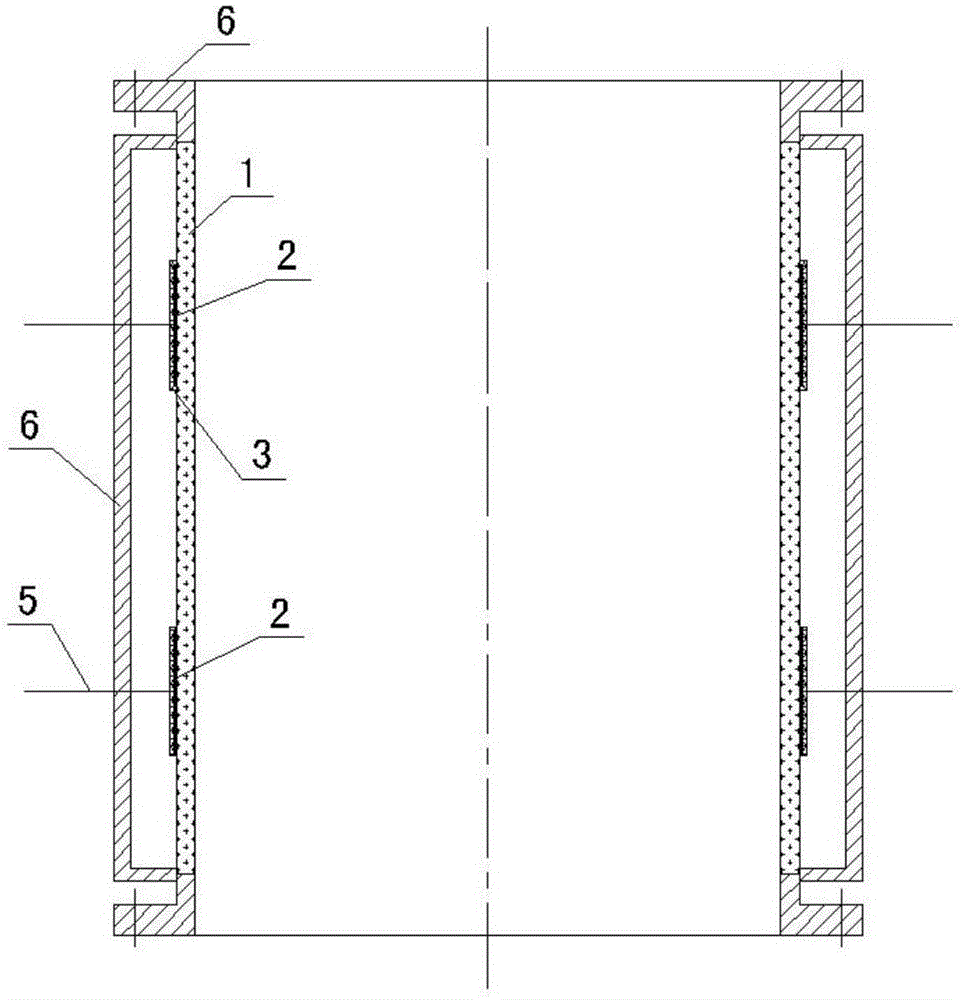

Anti-jamming pneumatic slide plate gate of pulverized coal pipeline and work method based on anti-jamming pneumatic slide plate gate

ActiveCN105135034ASolve the jamAvoid influenceOperating means/releasing devices for valvesSlide valveAnti jammingCoal pipeline

The invention discloses an anti-jamming pneumatic slide plate gate of a pulverized coal pipeline and a work method based on the anti-jamming pneumatic slide plate gate. The anti-jamming pneumatic slide plate gate comprises a rectangular frame which is connected with the pulverized coal pipeline through fixing bolts, wherein a slide plate which can block airstreams in the pulverized coal pipeline is arranged in the center of the rectangular frame; the rectangular frame comprises a front side frame, a rear side frame, a left side frame and a right side frame; the left and right side frames are separately provided with a sliding rail, so that the slide plate can slide along the sliding rails of the rectangular frame; the slide plate is connected with a slide plate draft device; asymmetrical chevron air passages are arranged above the rear side frame; symmetrical chevron air passages are arranged below the rear side frame; the air passages are all connected with compressed air pipelines; the compressed air pipelines are connected with a compressed air source; electromagnetic valves are arranged on the compressed air pipelines; the electromagnetic valves are connected with compressed air control systems; and in processes of inserting the slide plate into the rectangular frame and pulling the slide plate out of the rectangular frame, dust accumulated on the upper part, the lower part, the front part and the rear part of the slide plate is cleaned through airstreams in the compressed air pipelines, so that the problem of jamming of the slide plate caused by large friction force of the dust is solved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

Dense-phase pulverized coal mass flowmeter

InactiveCN104655214AHigh measurement accuracyNo clogging problemIndirect mass flowmetersGas solidShaped charge

The invention relates to a mass flowmeter, and particularly relates to a dense-phase pulverized coal mass flowmeter. The dense-phase pulverized coal mass flowmeter is characterized by comprising a conduit and two charge induction sensors, wherein the front part and the back part of the conduit are connected to a to-be-measured pulverized coal pipeline, the conduit wall of the conduit is divided into an inner conduit wall and an outer conduit wall, a gap is left between the inner conduit wall and the outer conduit wall, the charge induction sensors are in shapes of circular rings, and the two circular ring-shaped charge induction sensors are arranged in different front and back positions of the gap between the inner conduit wall and the outer conduit wall of the conduit. Gas-solid two-phase flows of pulverized coal flow through the charge induction sensors, the total amount of the pulverized coal, i.e. the mass flow of the pulverized coal, is measured through mediums and induction charges of the charge induction sensors, then the accurate medium velocity is measured through charge induction signals, and the stable pulverized coal concentration is obtained by calculating the instantaneous total amount of the pulverized coal and the instantaneous flow velocity of pulverized coal media, which are measured at the same time and in the same measuring point.

Owner:兖矿水煤浆气化及煤化工国家工程研究中心有限公司

Compound combustion beam for lime kiln

The invention relates to a compound combustion beam for a lime kiln. The compound combustion beam consists of a beam body, nozzles and a T-shaped cover, wherein the nozzles are positioned on two sides and the lower part of the beam body; the beam body is provided with a cavity for heat-transfer oil to circulate; the cavity for the heat-transfer oil to circulate is connected with a heat-transfer oil inlet and a heat-transfer oil outlet; the beam body is separated into an upper part and a lower part by a clapboard; the upper part of the beam body comprises a gas channel, an upper combustion air channel and gas nozzles; the gas channel is connected with the gas nozzles; the gas nozzles are opposite to the nozzles on the two sides of the beam body; the lower part of the beam body is provided with a pulverized coal pipeline, pulverized coal nozzles and a lower combustion air channel; the pulverized coal pipeline are connected with the pulverized coal nozzles; and the pulverized coal nozzles are opposite to the nozzles on the lower part of the beam body. According to the compound combustion beam for the lime kiln, the beam body of the compound combustion beam is separated into two parts through the clapboard, upper gas or lower pulverized coal can be selected to be independently or simultaneously used, the operation flexibility of the combustion beam is improved and the usability of the combustion beam is improved.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

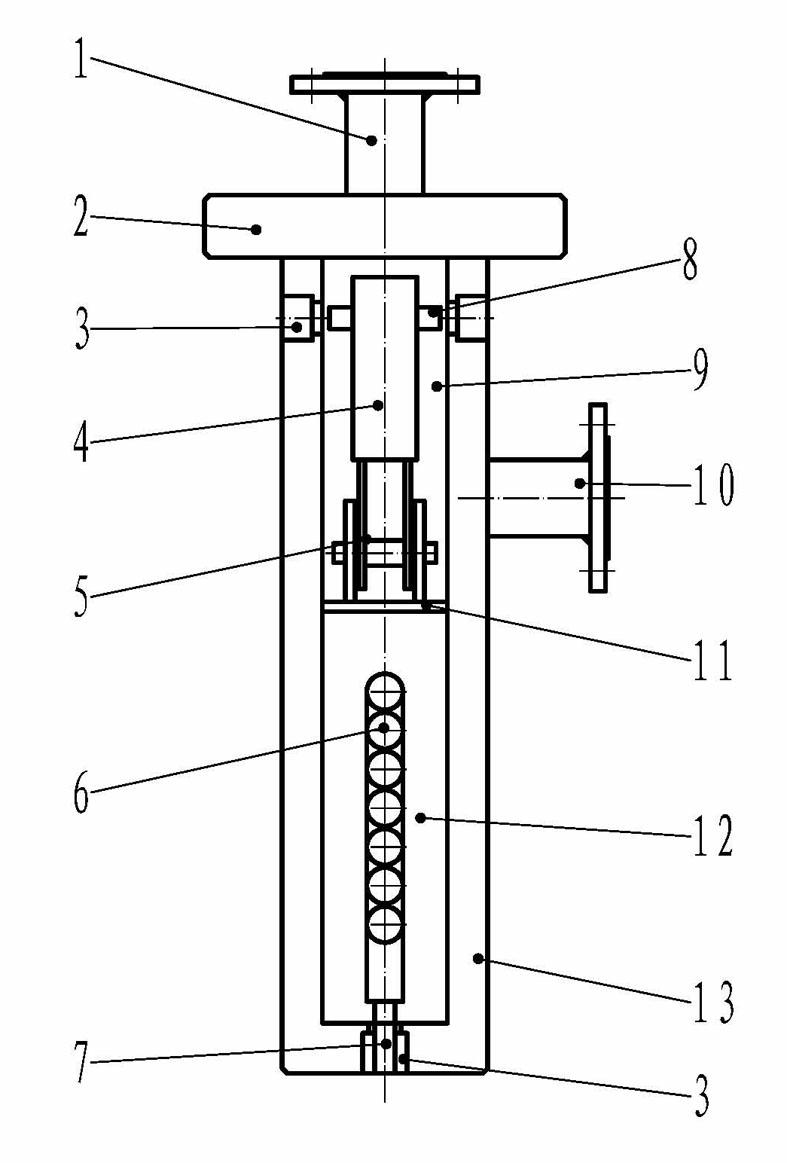

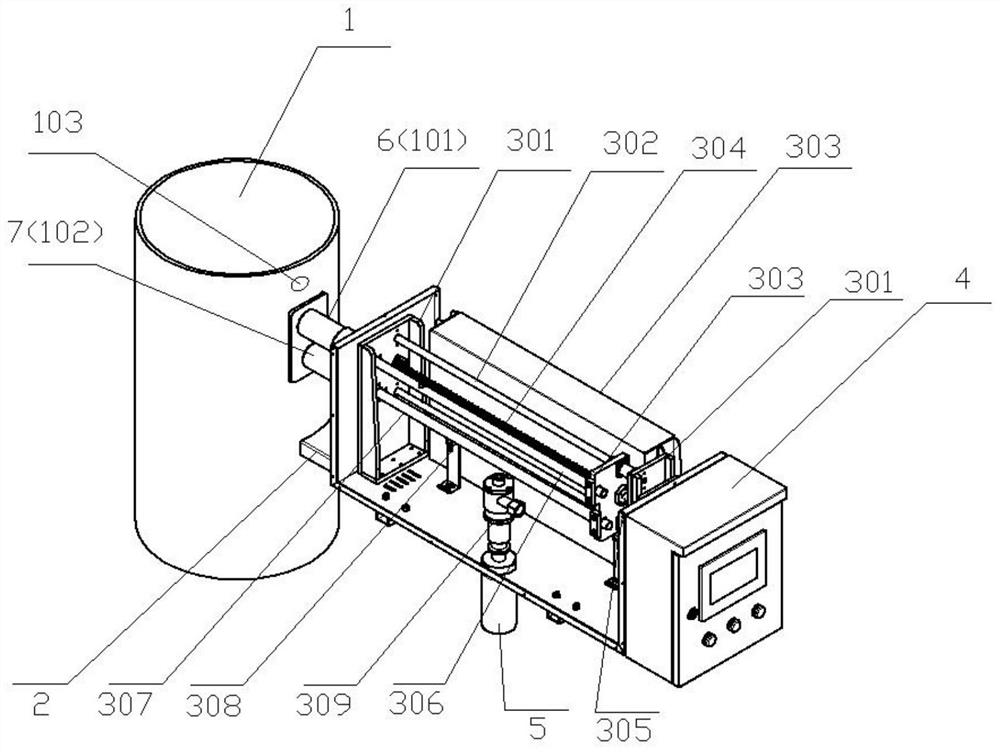

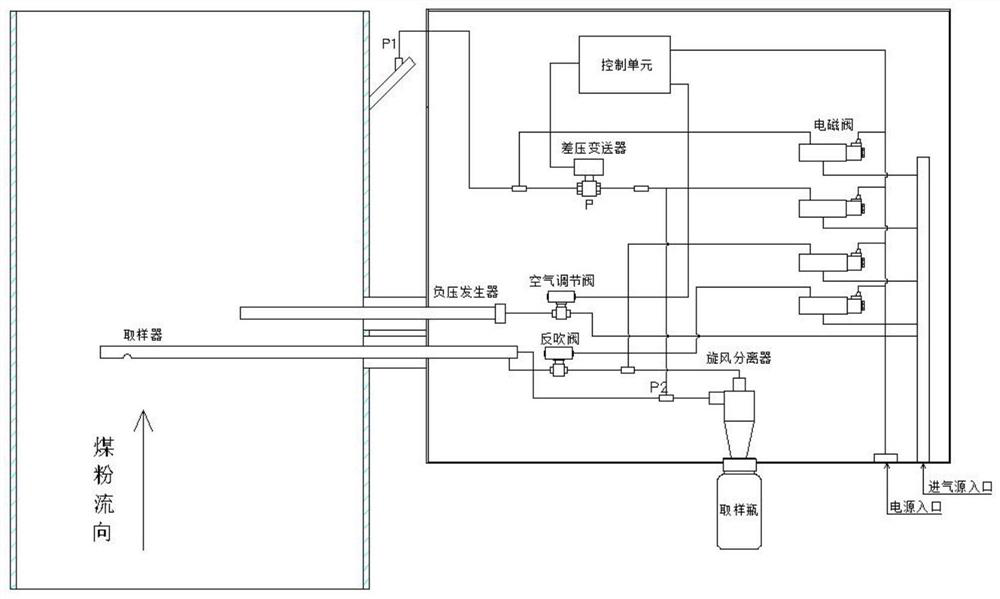

Full-automatic online pulverized coal sampling device and sampling method thereof

PendingCN111879568AImprove representationUndisturbedWithdrawing sample devicesCoal pipelineElectrical control

The invention discloses a full-automatic online pulverized coal sampling device and a sampling method thereof. The full-automatic online pulverized coal sampling device comprises a bracket mounted ona pulverized coal pipeline, a sampling box mounted on the bracket, an electrical control box connected to the sampling box, and a sampling bottle mounted below the sampling box, wherein fixed plates are respectively mounted at two ends of the sampling box, a guide pillar is fixedly connected between the two fixed plates, a movable plate is sleeved on the guide pillar, and the movable plate can slide along the guide pillar; a sampling gun, a negative pressure generator, a lead screw and a cyclone separator are further installed in the sampling box, one end of the lead screw penetrates through the movable plate and then is connected with a stepping motor, and a control unit, a differential pressure transmitter, a power source, an electromagnetic valve, a blowback valve and an air adjusting valve are installed in the control box. According to the full-automatic pulverized coal online sampling device and the sampling method thereof, large workload caused by manual sampling is avoided, constant-speed sampling is achieved through the differential pressure transmitter and the negative pressure generator, and representativeness of taken samples is improved.

Owner:柯宁能源科技(南京)有限公司

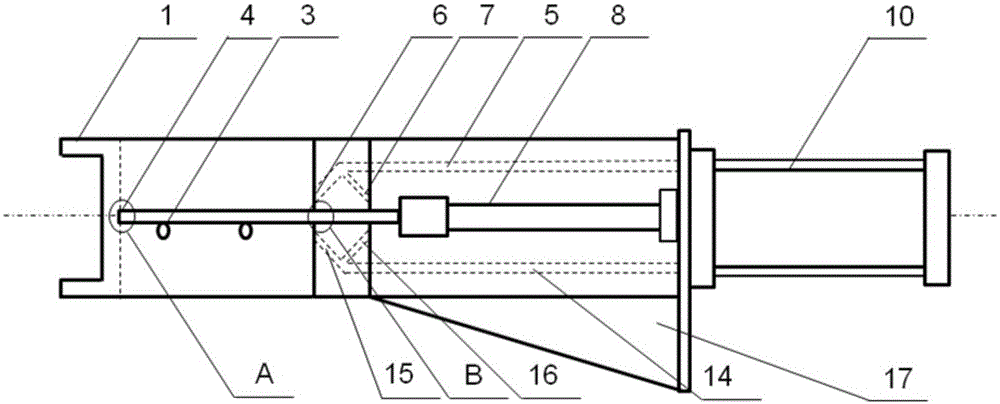

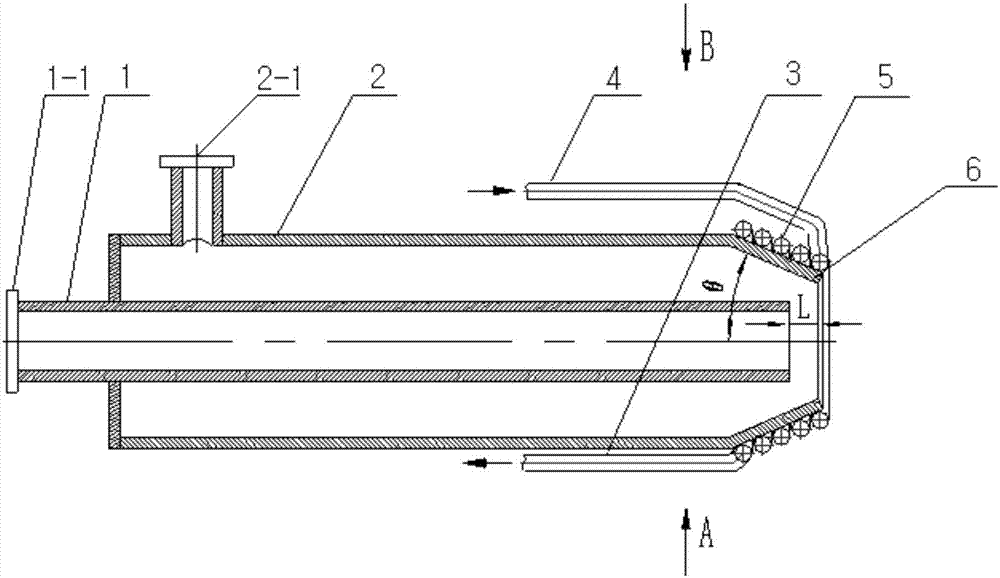

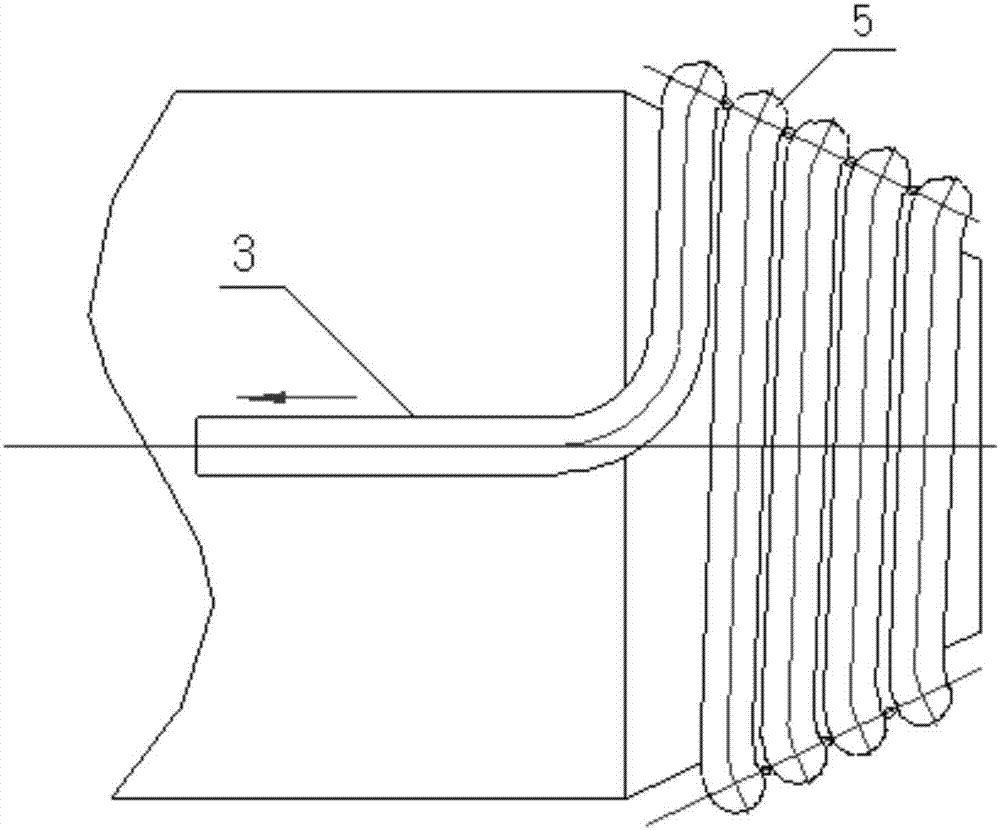

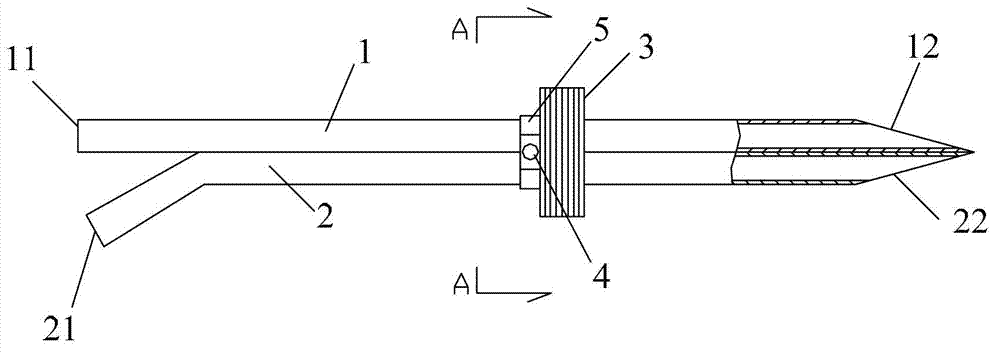

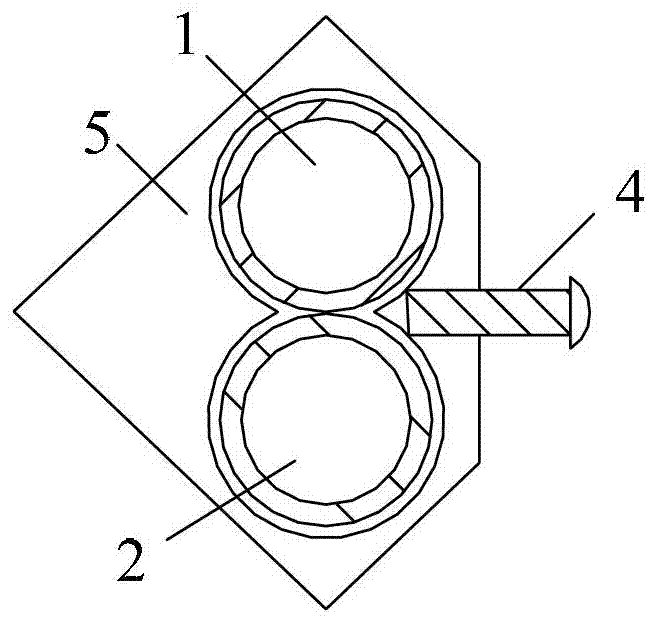

Gasifier burner with water-cooled coiled tube protection for dry feed entrained flow bed

InactiveCN107022379ASimple structureReduce manufacturing costGasifier feeding meansGranular/pulverulent flues gasificationCoal pipelineEngineering

The invention discloses a gasifier burner with water-cool that ed coiled tube protection for a dry feed entrained flow bed, and relates to the gasifier burner. The invention aims at solving the problems of an existing gasifier burner that manufacturing cost is high, burning loss is easy to cause in a gasifier under the high temperature condition, and the service life is short, so that shutdown of the gasifier often occurs. A pulverized coal pipeline and a gasifying agent pipeline are coaxially arranged from inside to outside; one end, away from the head of the burner, of the gasifying agent pipeline is connected with the outer side wall of the pulverized coal pipeline in a sealing manner; a pulverized coal air current inlet is formed in the top end of the pulverized coal pipeline; a gasifying agent inlet is formed close to the top end of the gasifying agent pipeline; a cooling water inlet pipe and a cooling water outlet pipe are respectively arranged at two ends of the water-cooled coiled tube; a contraction opening is formed in the outlet end of the gasifying agent pipeline. The cost of the burner disclosed by the invention is 0.5 to 1 million yuan and is about 30 to 50 percent of the manufacture cost of an existing burner; by trial firing, the burner disclosed by the invention has no ablation phenomenon; the temperature of a position 100mm away from an outlet of the burner is kept at about 1000DEG C; the service life of the burner can reach 2 to 3 years or longer, and is 4 to 6 times that of the existing burner.

Owner:HARBIN INST OF TECH

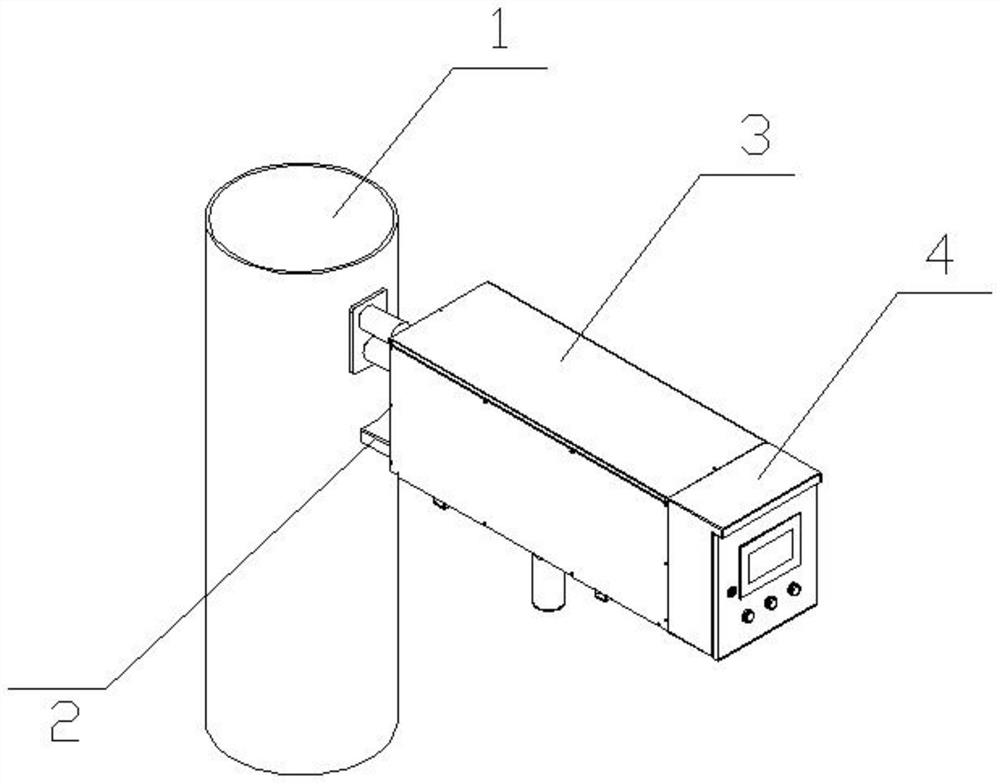

Measuring device for wind speed of pulverized coal pipeline

InactiveCN102809666ALow costMeasurement Requirements AdaptationFluid speed measurementCoal pipelineEngineering

The invention discloses a measuring device for wind speed of a pulverized coal pipeline. The measuring device comprises a first measuring pipe, a second measuring pipe and a seal head. The first measuring pipe and the second measuring pipe simultaneously extend into the pulverized coal pipeline and are arranged side by side to form a group of back-to-back pipes, the seal head is used for being fixedly connected with the pulverized coal pipeline, and the back-to-back pipes are simultaneously penetratingly arranged in the seal head and are slidably movably connected with the seal head. The effective measurement length of the measuring device can be changed, the measuring device can be reused, and coefficients only need to be calibrated at one step when the measuring device is delivered from a factory, so that the measuring device is high in utilization efficiency and low in manufacturing cost.

Owner:SHANGHAI ELECTRIC POWER CONSTR STARTING ANDADJUSTMENT TESTING LAB

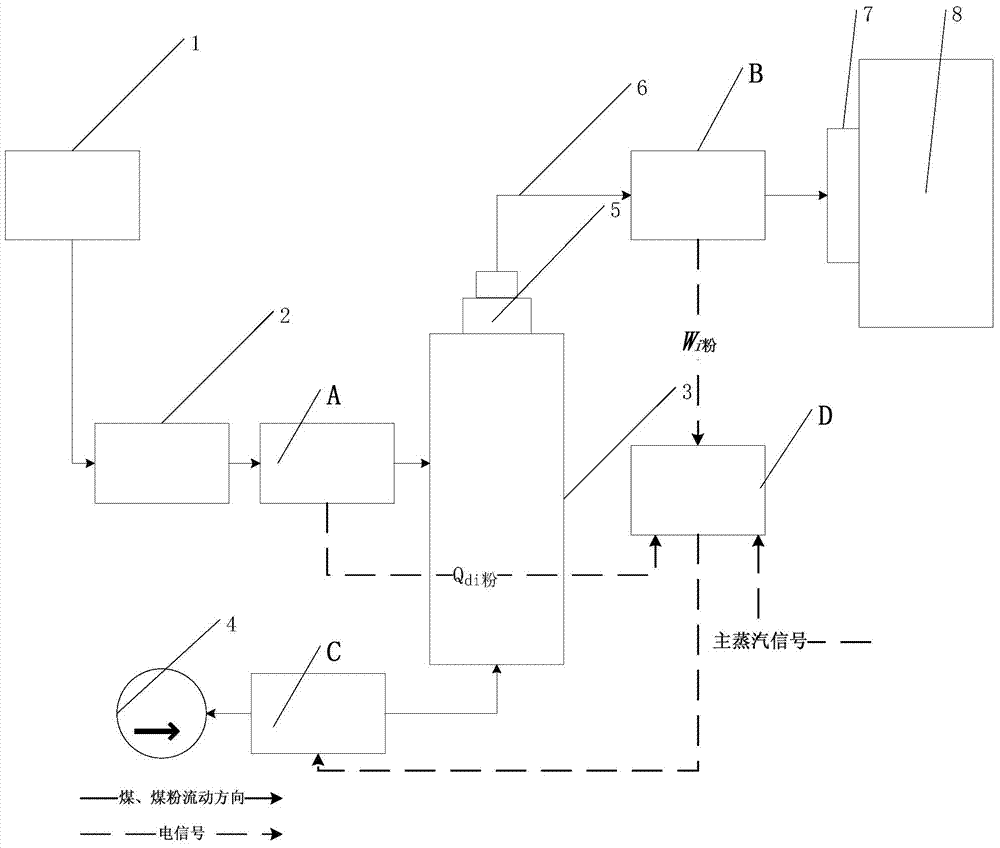

Pulverized coal preparation system and method with air-blew pulverized coal heat measurement and control functions

ActiveCN104728854AReduce heat fluctuationsLump/pulverulent fuel preparationControl signalCoal pipeline

The invention discloses a pulverized coal preparation system and method with air-blew pulverized coal heat measurement and control functions. The system comprises a heat coal supply system, an air-blew pulverized coal weighing meter, an air speed adjusting controller and a data processing controller; the heat coal supply system is used for supplying coal for a coal pulverizing machine and performing measurement and raw coal heat control on raw coal heat Qadi coal, moisture Madi coal and weight Wi coal; the air-blew pulverized coal weighing meter is used for weighing Wi pulverized coal of the air-blew pulverized coal; the air speed adjusting controller is installed on an air conveying pipeline of a fan and is used for adjusting the air speed to adjust the Wi pulverized coal of the air-blew pulverized coal fed into an air-blew pulverized coal pipeline; the data processing controller receives the Qadi coal, the Madi coal, the Wi coal and the Wi pulverized coal, calculating the heat Qdi pulverized coal and heat Ji pulverized coal conveyed by the coal pulverizing machine. The data processing controller sends control signals to the air speed adjusting controller according to a difference deta of the Ji pulverized coal to adjust the air speed, the Ji pulverized coal is closer to J control pulverized coal, and the air-blew pulverized coal heat enclosure control is implemented.

Owner:邸生才

Low air cooling volume burner adopting composite material nozzle

PendingCN110242952AIncrease stacking angleReduce oxygenPulverulent fuel combustion burnersLump/pulverulent fuel feeder/distributionAir volumeMetallic materials

The invention discloses a low air cooling volume burner adopting a composite material nozzle. The low air cooling volume burner comprises a central air channel and a pulverized coal pipeline, wherein a central air nozzle is arranged at the end part of the central air channel; a pulverized coal nozzle is arranged at the end part of the pulverized coal pipeline; the central air nozzle is provided with a central air nozzle metal section connected with the central air channel and a central air nozzle nonmetal material section sleeving the central air nozzle metal section; the pulverized coal nozzle is provided with a pulverized coal nozzle metal section connected with the pulverized coal pipeline and a pulverized coal nozzle nonmetal material section inserted into the pulverized coal nozzle metal section. A covering wall temperature attenuation region at the front end of the nozzle is made of a ceramic material resisting high temperature wear; a nozzle connecting section uses a conventional metal material; a high-order wall temperature fault is formed on the connected surface of two materials, so that burning loss of the metal nozzle is avoided, the operation of a shutdown burner at low cooling air volume is realized, oxygen consumption in the burner region is reduced and the control over nitric oxide is more favorable. The low air cooling volume burner is an efficient and environment-friendly reliable burner and is particularly suitable for high volatile bituminous coal.

Owner:国能浙江北仑第一发电有限公司 +1

Side wall water-cooling wall adherence protecting device based on horizontal shade separation

PendingCN112709985AReduce heat loadReduce the impact of washoutPulverulent fuel combustion burnersCasings/liningsCombustorCoal pipeline

The invention relates to a side wall water-cooling wall adherence protecting device based on horizontal shade separation. The device comprises wall-adhering air nozzles arranged on two sides of a front wall and a back wall of a fired coal power station boiler respectively, wherein burners are arranged between the wall-adhering air nozzles on two sides of the front and back walls. Each burner comprises an outermost burner adjacent to the wall-adhering air nozzles and other several middle regional burners; a window-shades type pulverized coal concentrator is arranged in a primary air pipe of the outermost burner, the primary air pipe of the outermost burner is divided into a concentrated pulverized coal nozzle and a light pulverized coal nozzle, the concentrated pulverized coal nozzle is arranged on the side, close to the middle regional burner, along the width direction of the boiler, the light pulverized coal nozzle is arranged on the side, close to the left or right side wall of the boiler, a pulverized coal pipeline of the outermost burner is introduced from a horizontal height direction of the primary air pipe and is connected to the primary air pipe through a bend; and air distribution adjustment can be carried out on the concentrated pulverized coal nozzle and the light pulverized coal nozzle through air valve baffle plates arranged independently. The device can improve a wall adherence atmosphere of the side wall water-cooling wall obviously.

Owner:XIAN THERMAL POWER RES INST CO LTD

Ammonia-mixed fuel thermal power generation system and method

PendingCN112879942AGuaranteed combustion efficiencyEmission reductionAir/fuel supply for combustionNon-combustible gases/liquids supplyBoiler furnaceNitrogen oxides

The invention relates to a thermal power plant carbon emission reduction technology, in particular to an ammonia-mixed fuel thermal power generation system and method. The system comprises an over fire air nozzle, secondary air nozzles and primary air nozzles which are sequentially formed in the side wall of a boiler hearth from top to bottom, an SCR reactor arranged at a tail flue of a boiler, and an ammonia supply system connected to the boiler. The ammonia supply system comprises an ammonia supply pipeline and an ammonia preparation device; the ammonia preparation device is respectively communicated with the boiler hearth and the boiler tail flue through the ammonia supply pipeline; the amount of ammonia gas introduced into the boiler hearth by the ammonia supply pipeline is 10%-30% of the thermal load of the hearth; the secondary air nozzles and the primary air nozzles are arranged at intervals along the side wall of the hearth; the bottommost secondary air nozzle is connected with the ammonia supply pipeline and an air pipeline, and the other secondary air nozzles are only connected with the air pipeline; the over fire air nozzle is connected with the air pipeline; and the primary air nozzles are arranged between the adjacent secondary air nozzles and are respectively connected with a pulverized coal pipeline and the air pipeline. According to the system, combustion is stable, the emission of nitrogen oxides and carbon is low, and the combustion efficiency of the boiler can be effectively guaranteed.

Owner:XIAN THERMAL POWER RES INST CO LTD

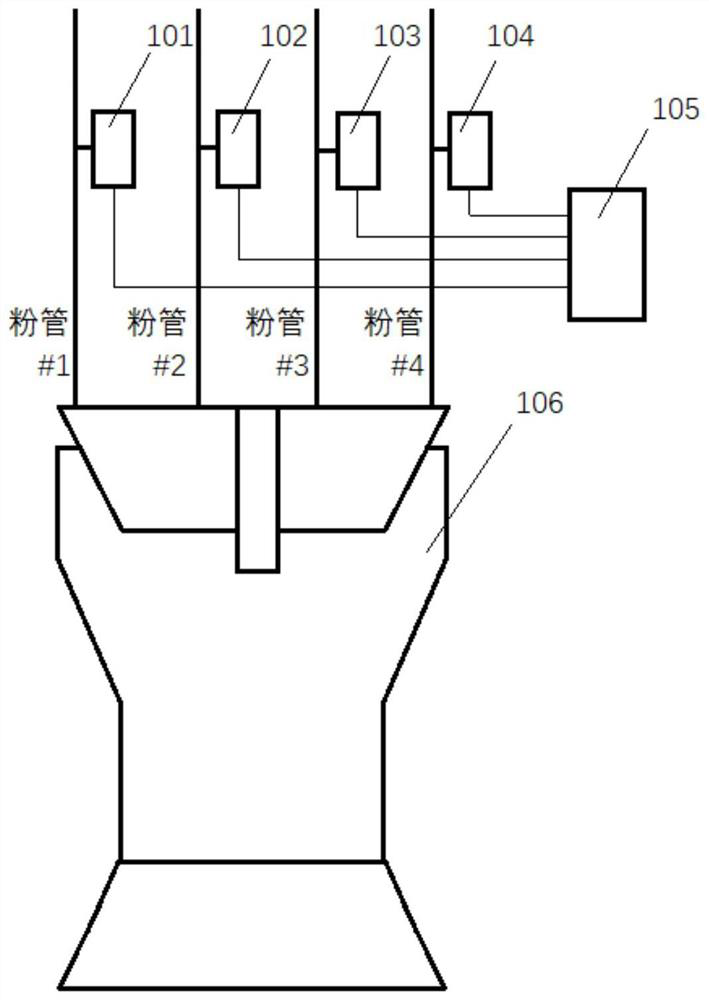

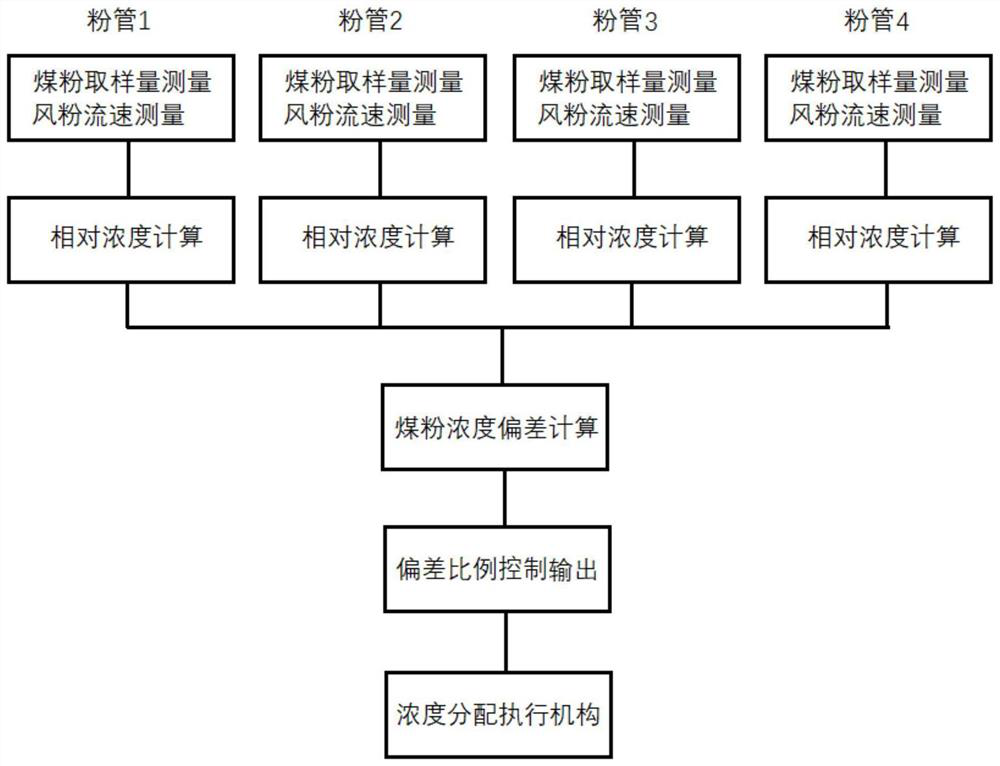

On-line monitoring system and method for concentration deviation between pulverized coal conveying pipelines of coal mill

PendingCN112763388AEquilibrium concentrationConcentration distribution balanceWithdrawing sample devicesParticle suspension analysisThermodynamicsCoal pipeline

The invention provides an on-line monitoring system for concentration deviation between pulverized coal conveying pipelines of a coal mill, which comprises a plurality of on-line constant-speed pulverized coal sampling and measuring devices and a system measurement control unit, and the on-line constant-speed pulverized coal sampling and measuring devices are respectively arranged on a plurality of pulverized coal pipelines at the outlet of the same coal mill; and the on-line constant-speed pulverized coal sampling and measuring devices are respectively connected with the system measurement control unit through control signal lines, and the system measurement control unit comprises an intelligent processor and a display unit and is used for performing logic sequential control on the online constant-speed pulverized coal sampling and measuring devices and processing and transmitting measurement signals. By measuring the relative concentration deviation between the pulverized coal pipelines of the same coal mill, pulverized coal concentration distribution balance between the pulverized coal pipelines is achieved, and pulverized coal concentration balance control between the different pipelines of the coal mill is simplified.

Owner:南京聚控智能科技有限公司

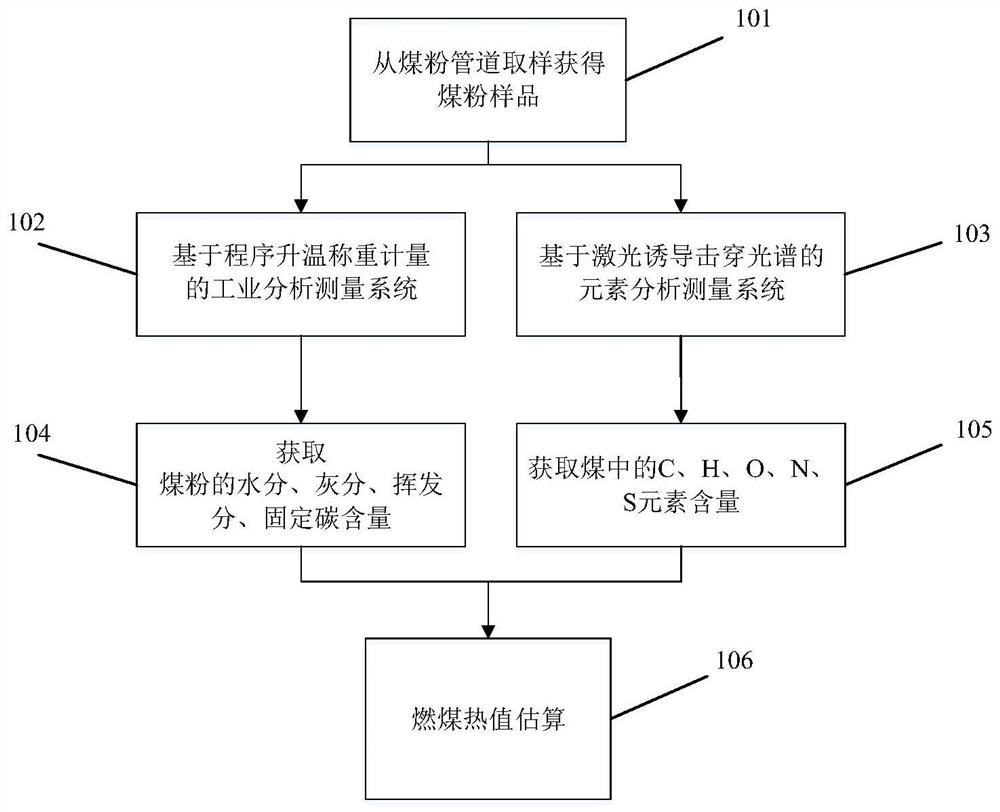

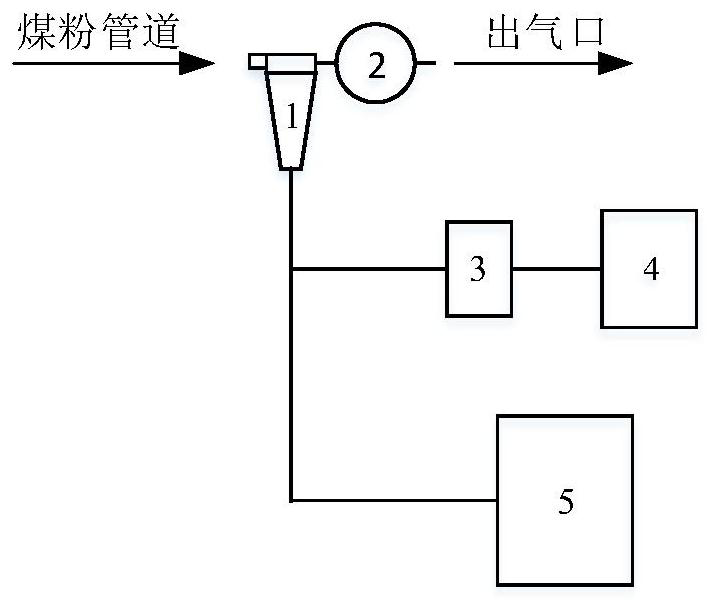

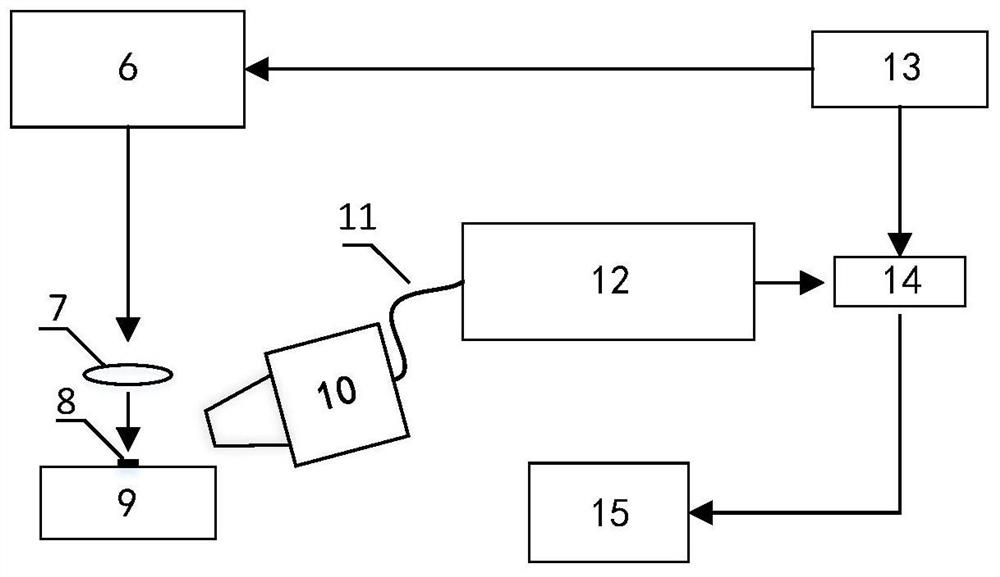

Method and device for rapidly testing coal quality components of coal-fired power plant on line

ActiveCN112834484ARealize measurementRealize regulationWeighing by removing componentAnalysis by thermal excitationThermodynamicsCoal pipeline

The invention relates to a fire coal quality measurement technology, and aims to provide a method and a device for rapidly testing coal quality components of a coal-fired power plant on line. The method comprises the steps of extracting pulverized coal from a pulverized coal pipeline of a coal-fired power plant, separating and capturing pulverized coal particles through a cyclone separator, and evenly mixing and then dividing the pulverized coal particles into two parts; measuring the moisture, ash content, volatile component and fixed carbon content of one part of the pulverized coal through industrial analysis based on temperature programming weighing metering; measuring the concentrations of C, H, O, N and S elements in the other part of pulverized coal through elemental analysis based on laser-induced breakdown spectroscopy; and calculating the calorific value of the fire coal by combining the two measurement results. According to the device and the method, the content of water, ash, volatile components and fixed carbon and the concentration of C, H, O, N and S elements of fire coal can be measured at the same time, and real-time monitoring and operation parameter adjustment of a coal-fired power plant are facilitated. A more accurate and reliable fire coal calorific value calculation result can be obtained, so that continuous online fire coal calorific value analysis of a coal-fired power plant is realized.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com