Side wall water-cooling wall adherence protecting device based on horizontal shade separation

A technology of concentration separation and protection device, which is applied in the direction of the burner burning powder fuel, the transportation of non-flammable liquid/gas, and the burner, etc. The problems such as the weakening of swirling flow intensity can solve the problem of high temperature corrosion, reduce the combustion heat load, and reduce the effect of coal dust erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

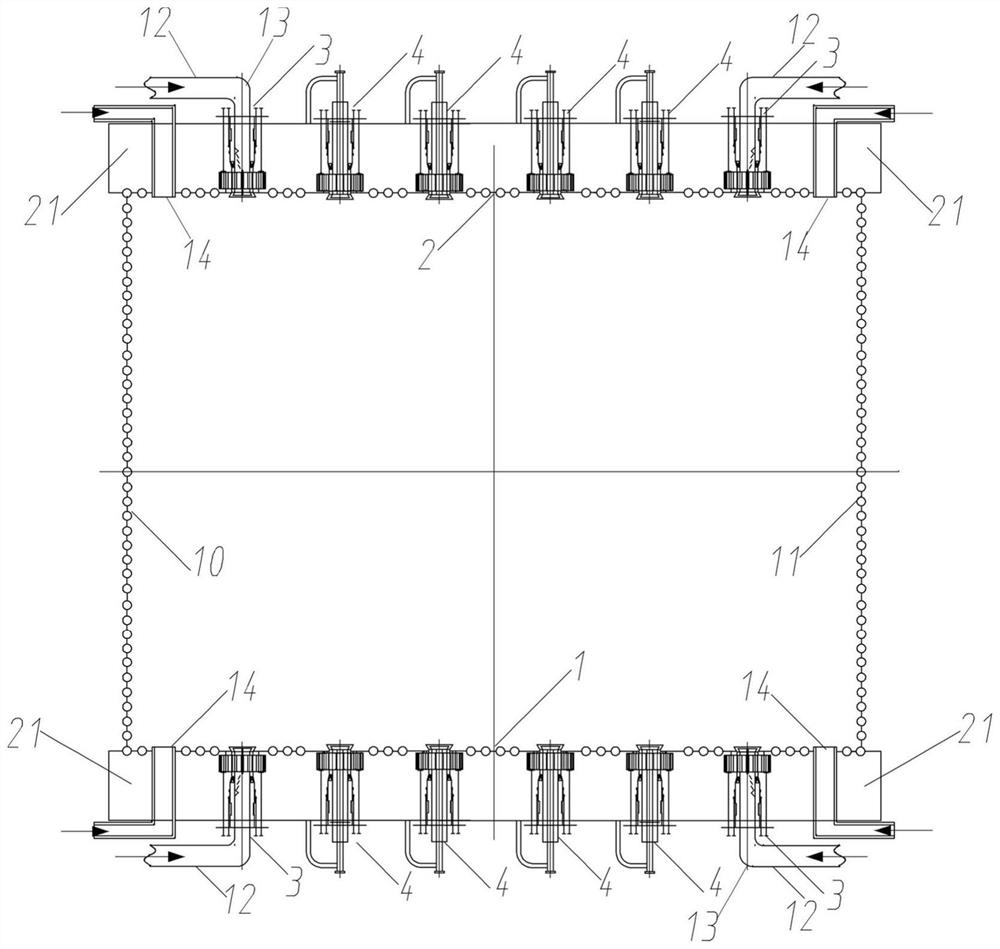

[0022] Aiming at the problem of high-temperature corrosion of the water-cooled wall of the front and rear walls of the opposing combustion boiler, the present invention proposes a side wall water-cooled wall attachment protection device based on horizontal concentration separation, including wall attachments arranged on both sides of the front wall 1 and the rear wall 2 of the coal-fired power plant boiler. Air nozzles 14, burners are arranged between the wall-attached air nozzles 14 on both sides of the front wall 1 and the rear wall 2, and the burners include the outermost burner 3 adjacent to the wall-attached air nozzle 14 and the outermost burner arranged on the outermost side. Several intermediate zone burners 4 between burners 3.

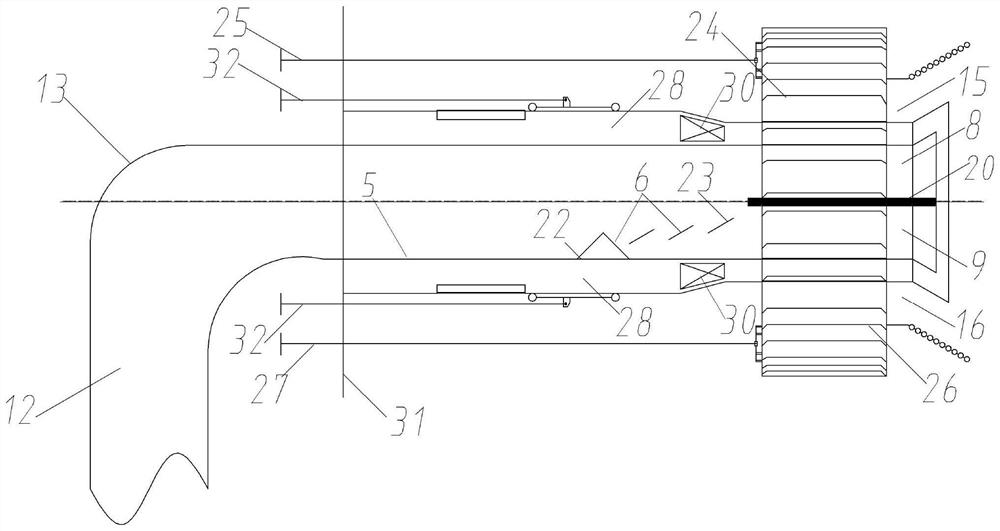

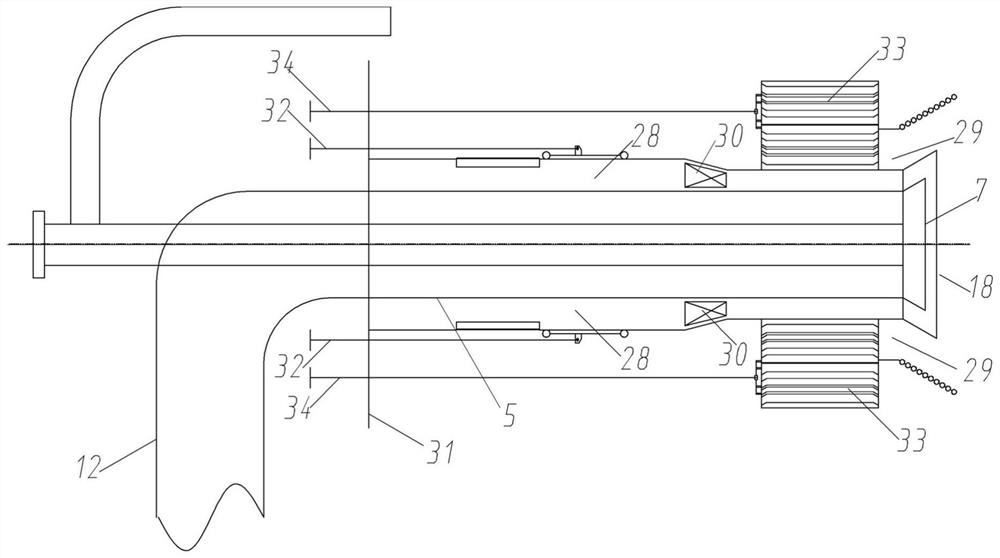

[0023] see figure 2 , The intermediate zone burner 4 of the present invention divides the combustion air into primary ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com