Patents

Literature

31results about How to "Solve the problem of high temperature corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

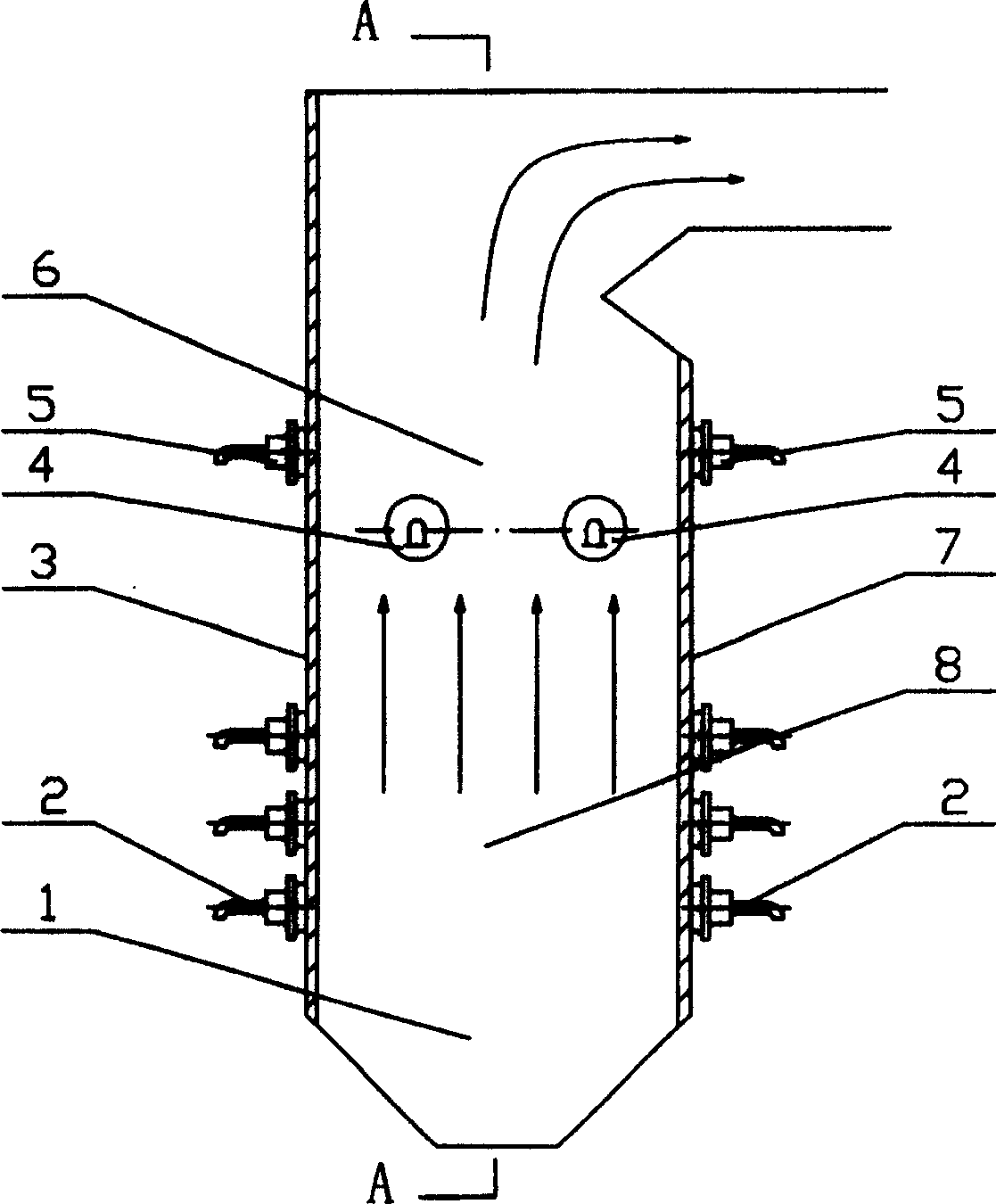

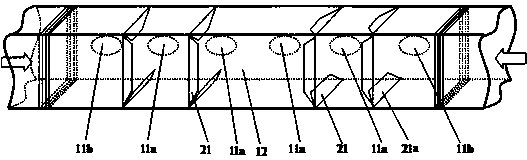

Boiler water wall air film protection device

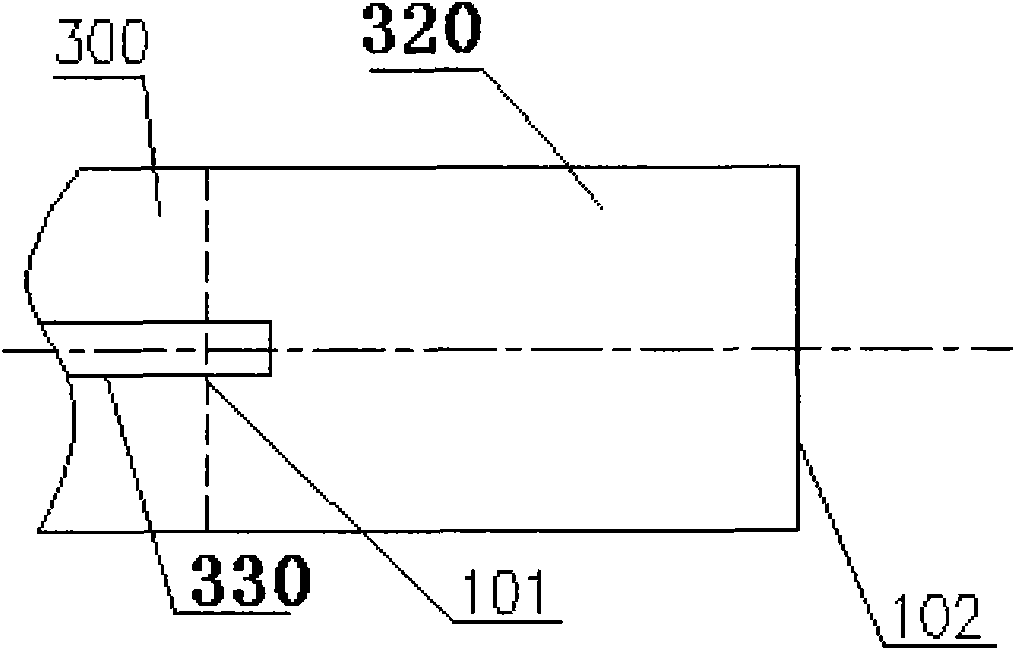

Provided is a boiler water wall air film protection device. A plurality of tuyeres are arranged obliquely in an upstream boiler wall of high-temperature flame and flue gas coal dust airflow in the boiler water wall area and each tuyere communicate with an air flue arranged on the outer side of a hearth. Air is jetted into the hearth through the tuyeres, airflow forms an air curtain between the downstream portion of the flame and high-temperature flue gas flow and a water wall along the flue gas and the air curtain is towards the water wall under pushing of the flame and the high-temperature flue gas to form an air isolation layer, on the one hand, the action of the air curtain can push the wall-eroding coal dust airflow or flame to the center of the cross section of the hearth, so that erosive wear and corrosion to the water wall from the wall-eroding coal dust airflow or flame are avoided, and on the other hand, the air curtain is turned to the downstream water wall area under the action of the upstream high-temperature flame and flue gas, a layer of oxidizing atmosphere protection film is formed on the downstream water wall area, and the problem of high-temperature corrosion of the water wall is solved fundamentally.

Owner:XIAN THERMAL POWER RES INST CO LTD

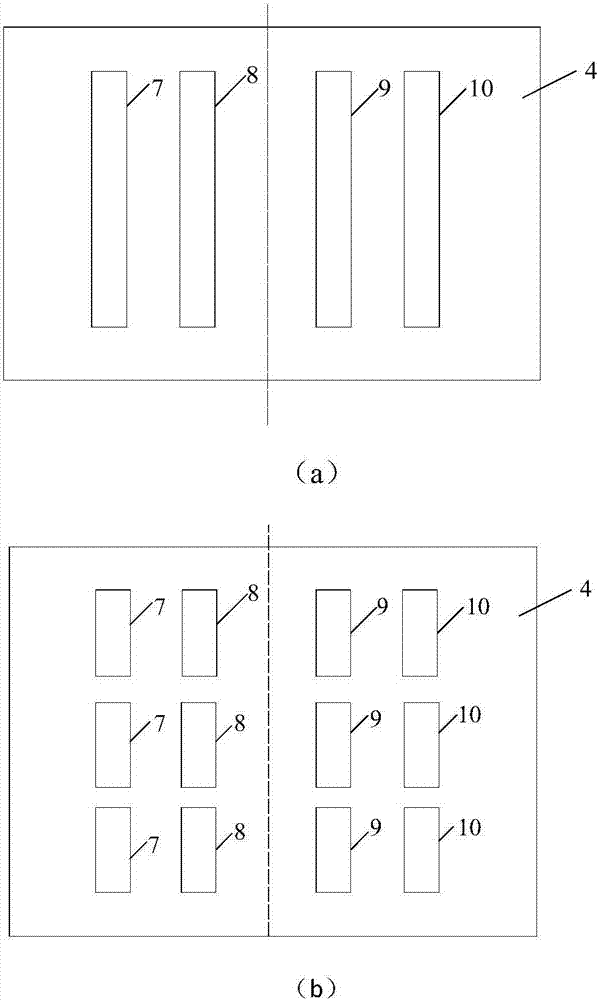

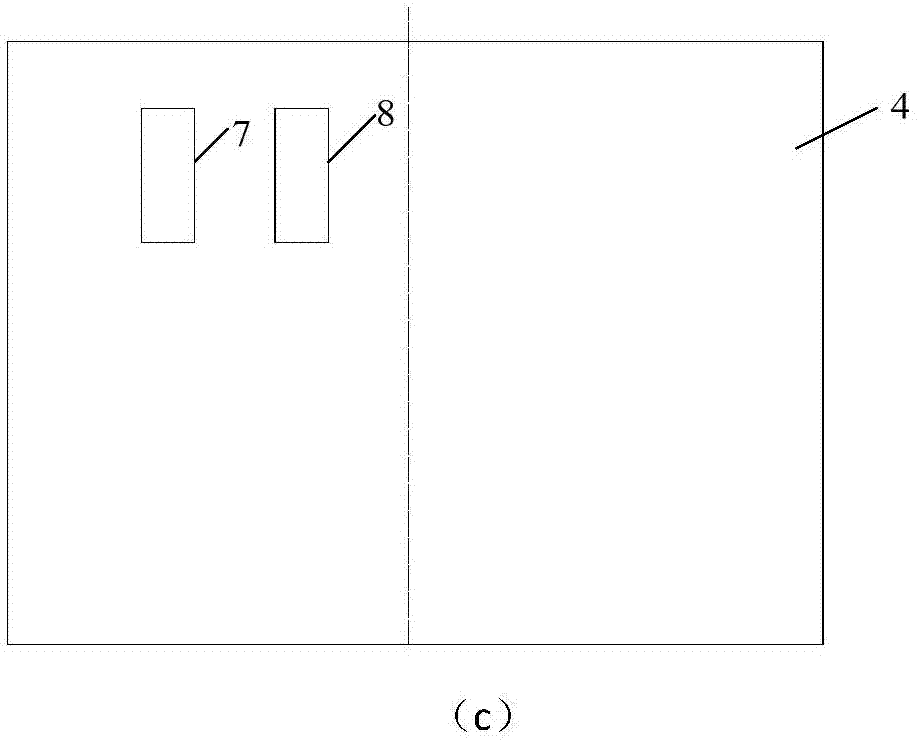

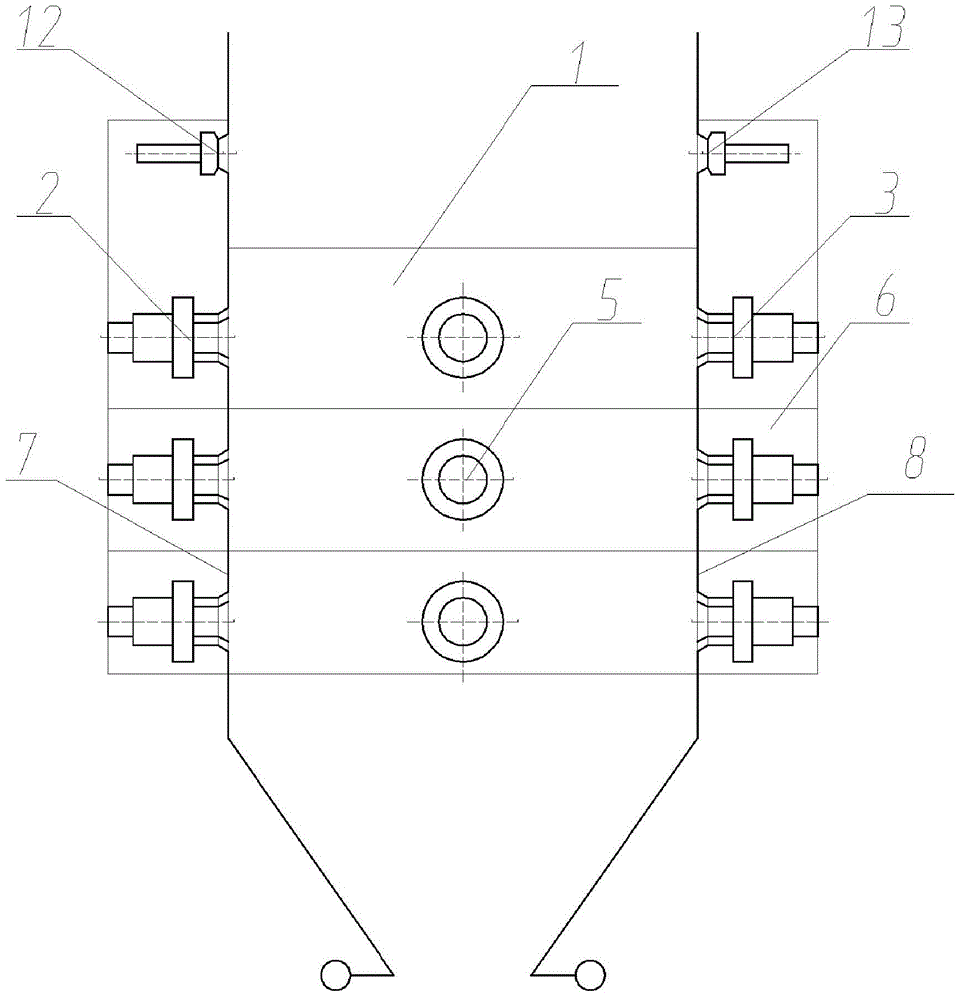

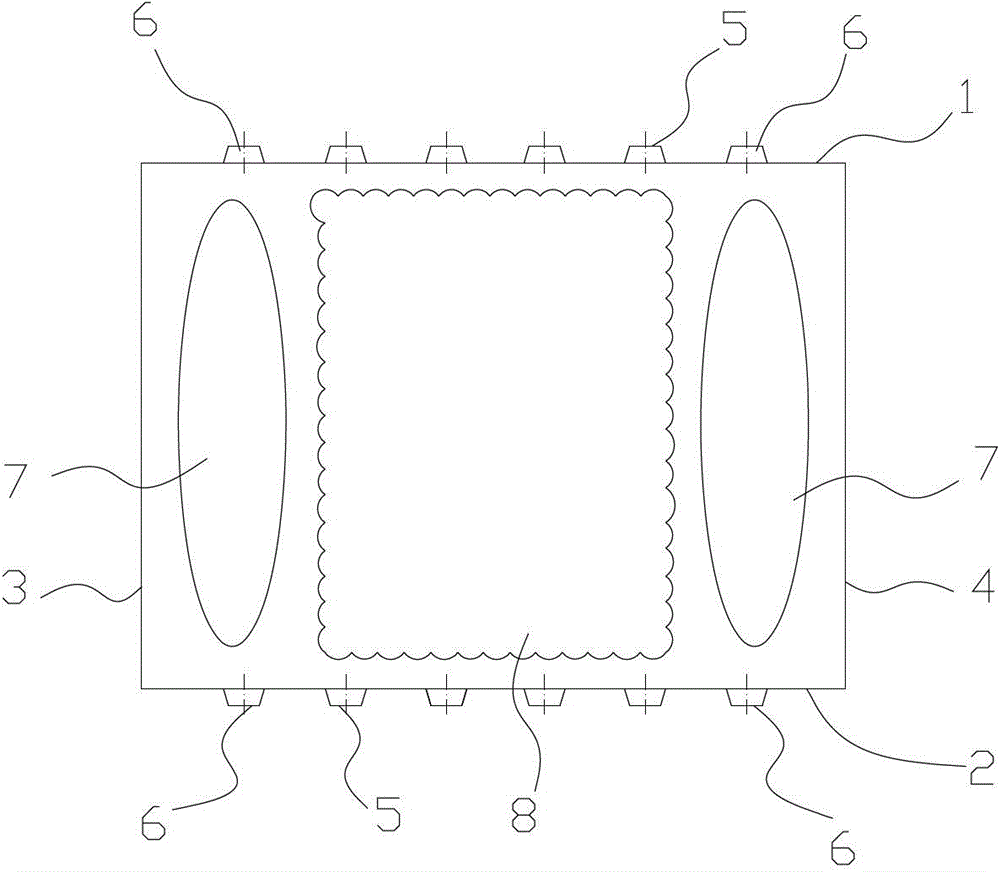

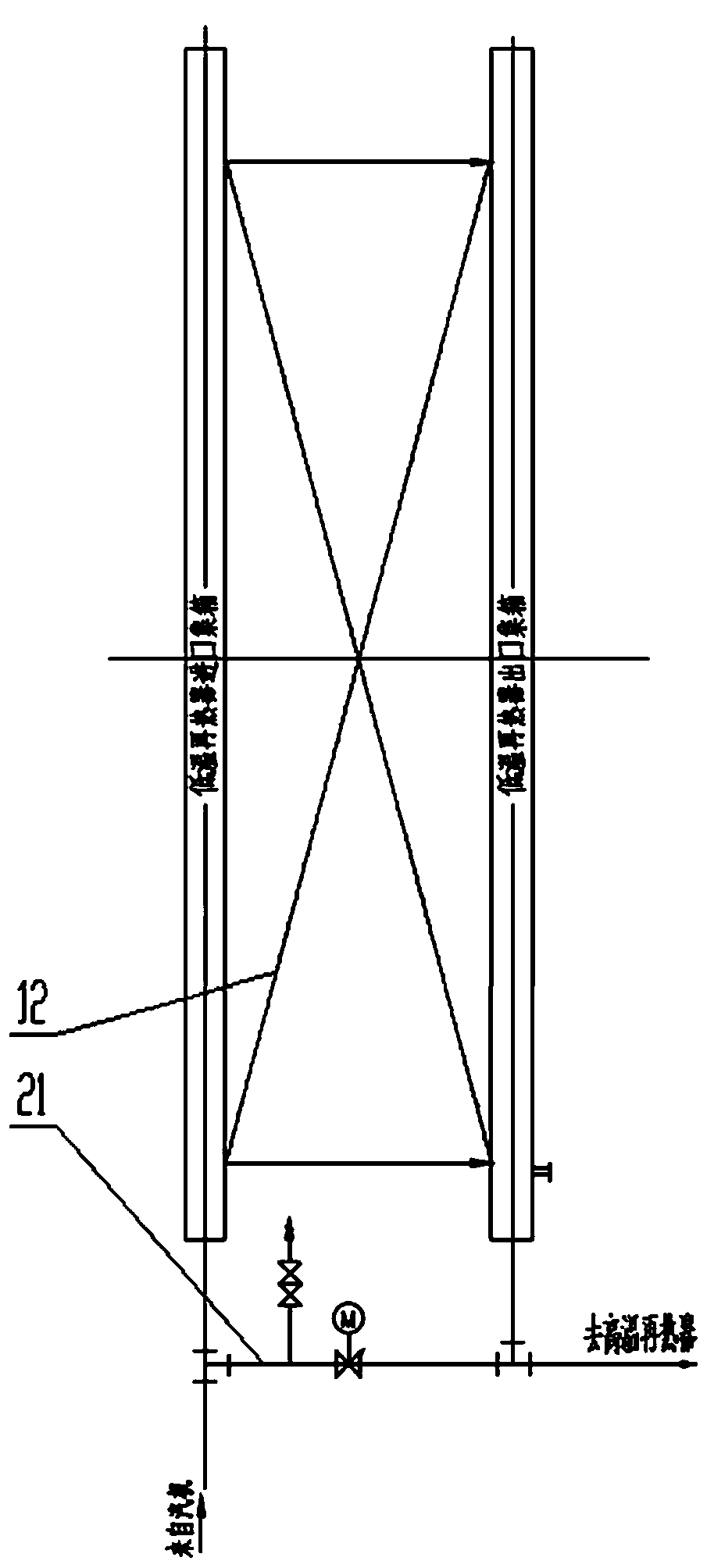

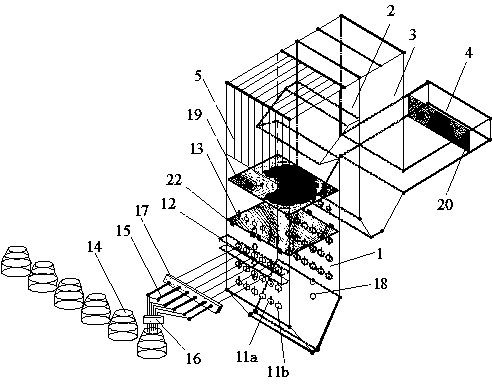

Side wall water-cooling wall adherence protecting device based on horizontal shade separation

PendingCN112709985AReduce heat loadReduce the impact of washoutPulverulent fuel combustion burnersCasings/liningsCombustorCoal pipeline

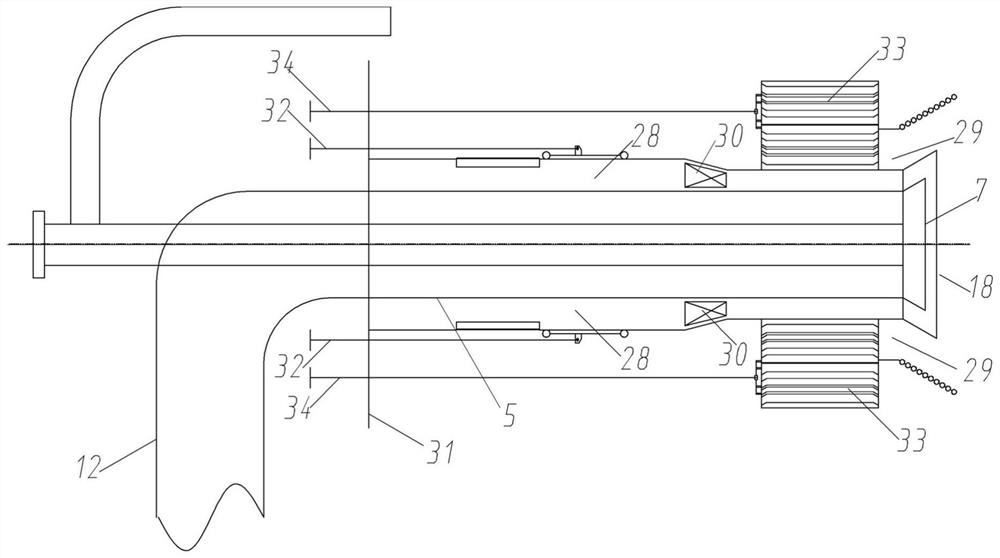

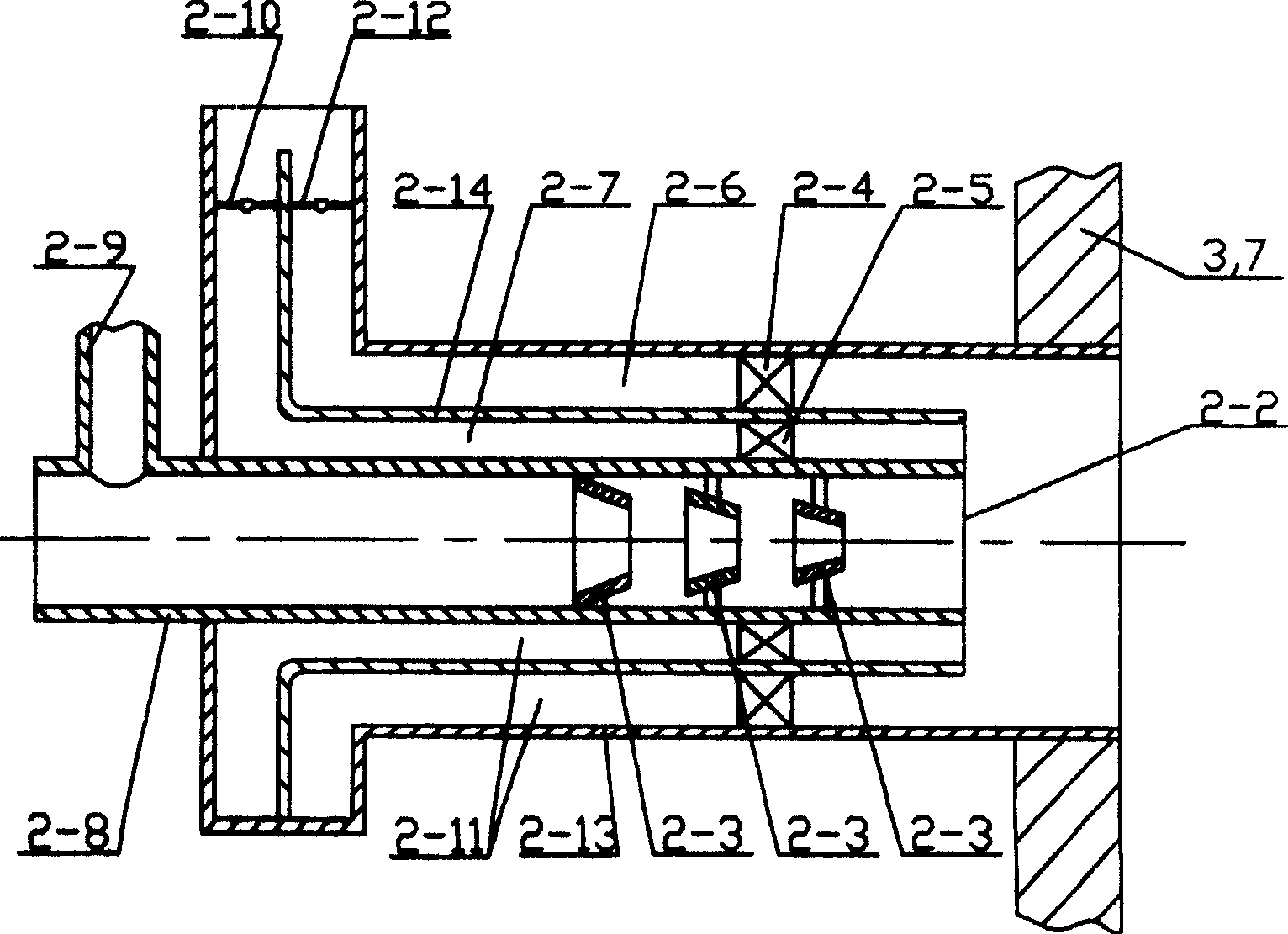

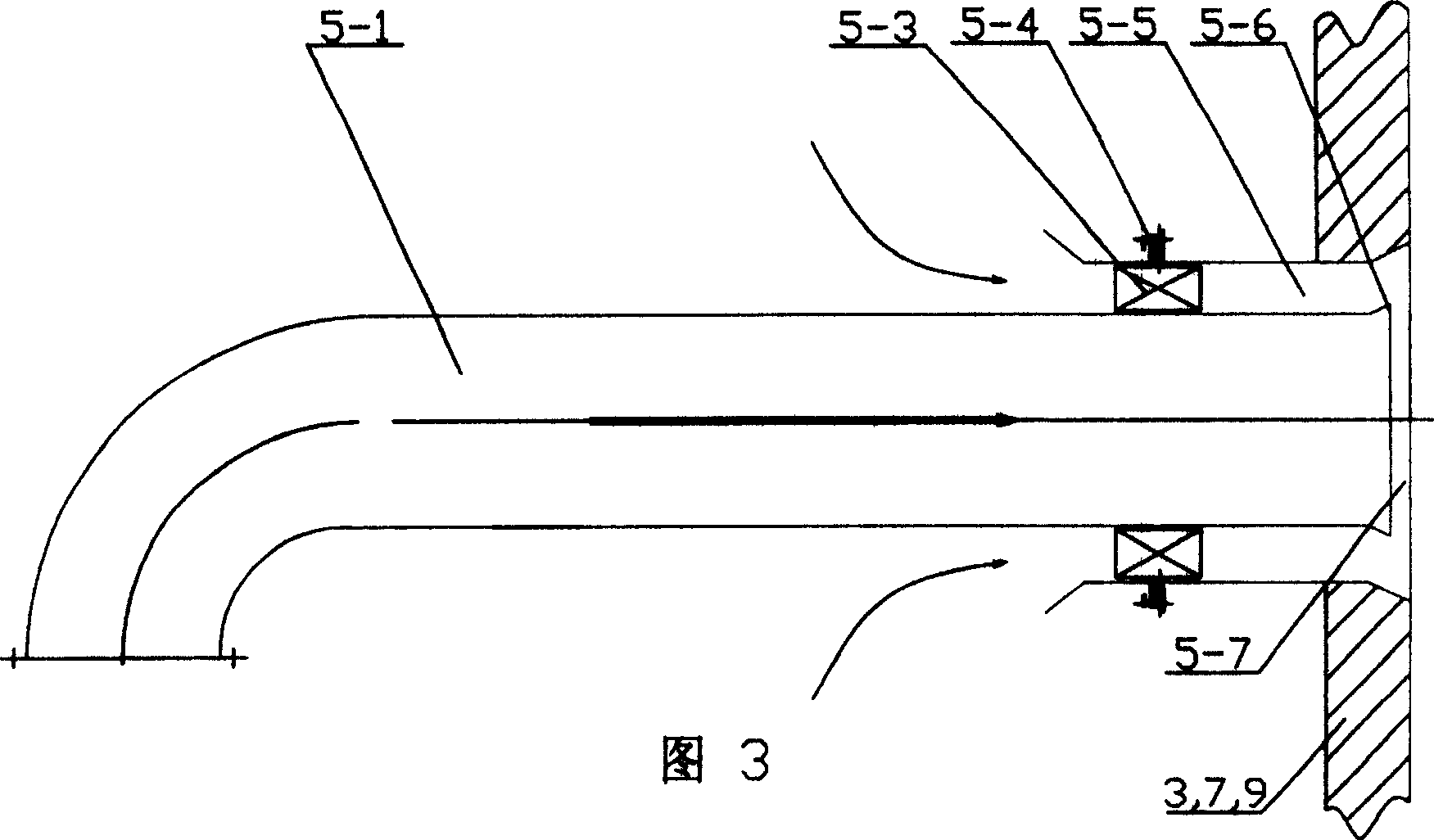

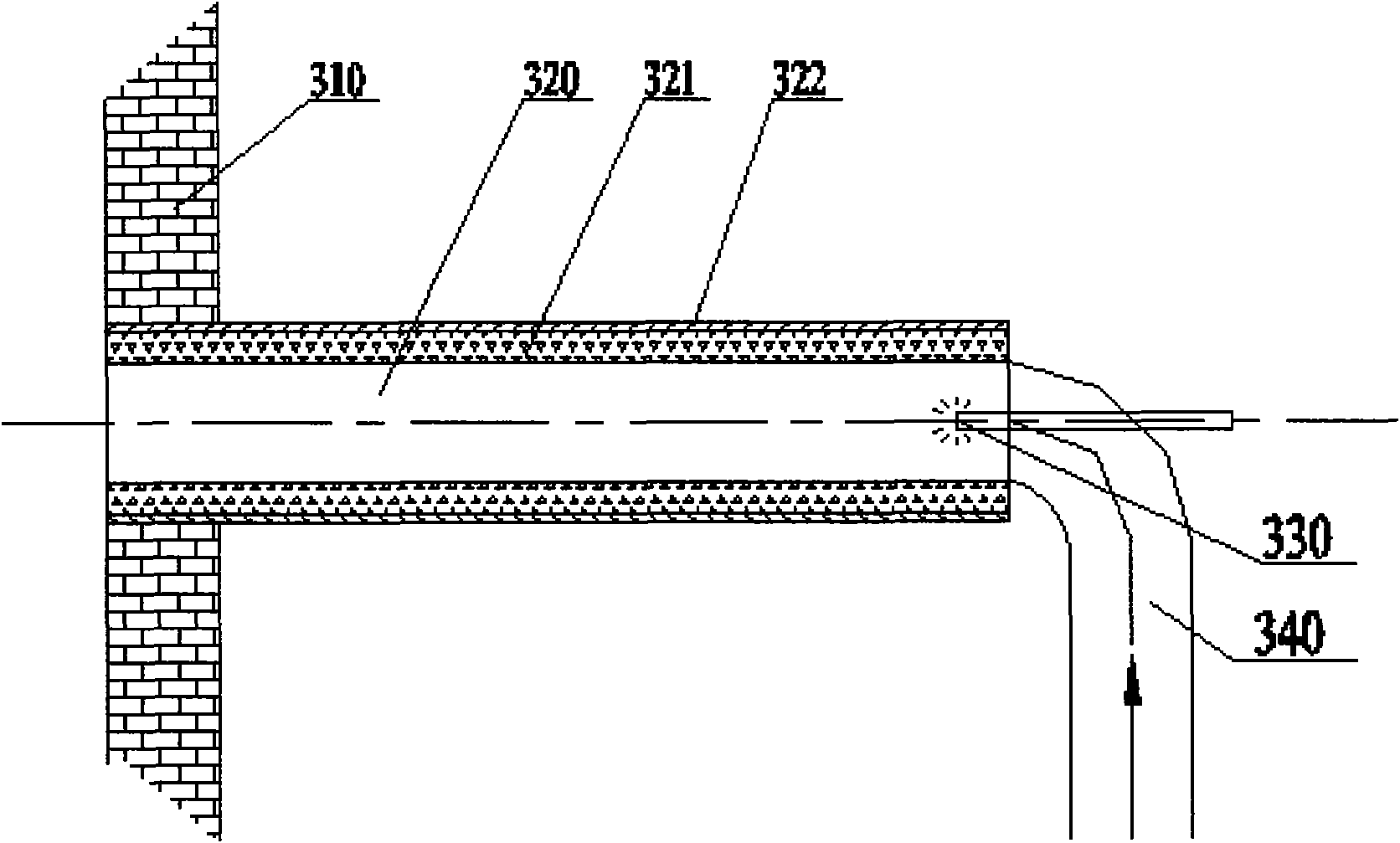

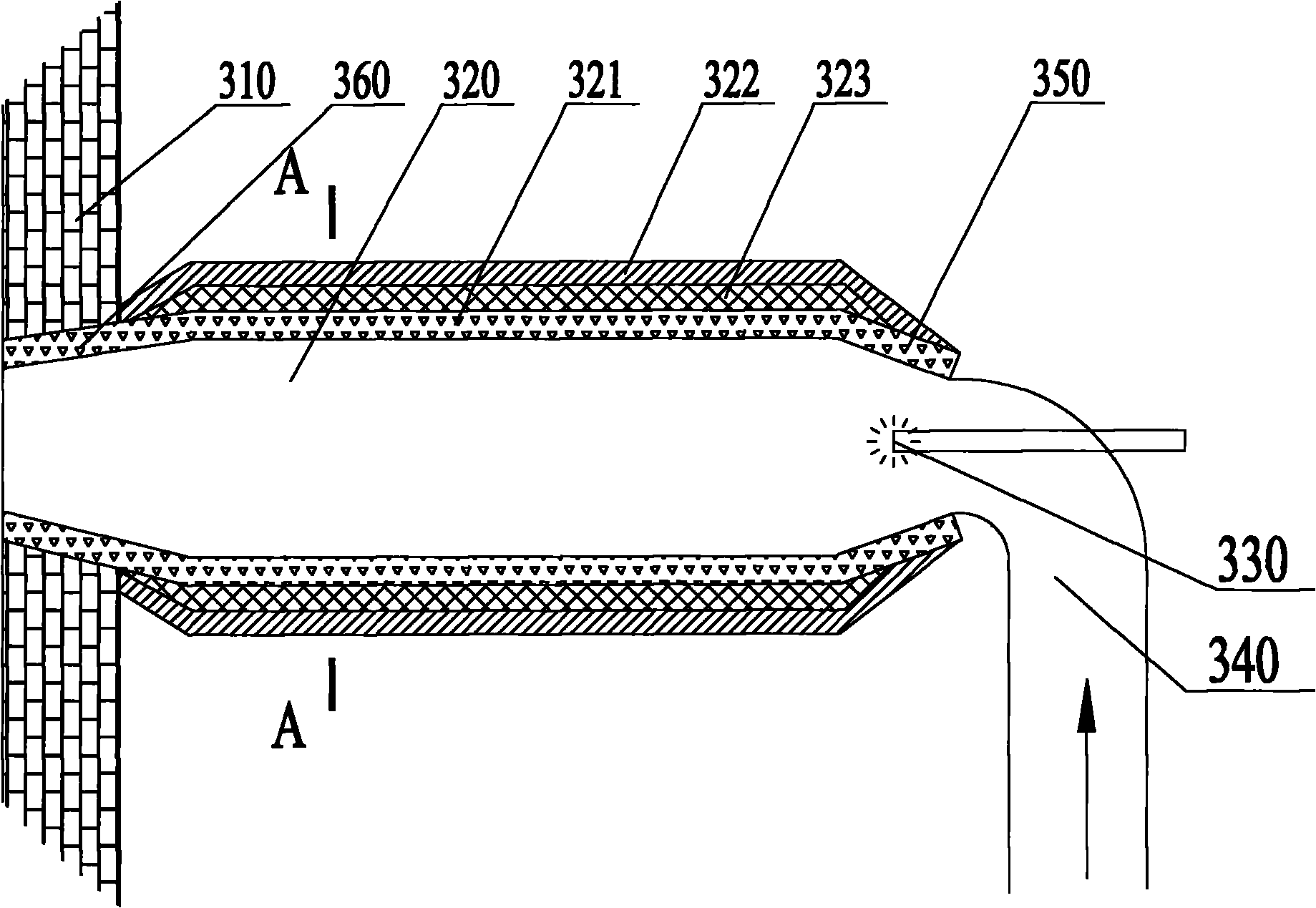

The invention relates to a side wall water-cooling wall adherence protecting device based on horizontal shade separation. The device comprises wall-adhering air nozzles arranged on two sides of a front wall and a back wall of a fired coal power station boiler respectively, wherein burners are arranged between the wall-adhering air nozzles on two sides of the front and back walls. Each burner comprises an outermost burner adjacent to the wall-adhering air nozzles and other several middle regional burners; a window-shades type pulverized coal concentrator is arranged in a primary air pipe of the outermost burner, the primary air pipe of the outermost burner is divided into a concentrated pulverized coal nozzle and a light pulverized coal nozzle, the concentrated pulverized coal nozzle is arranged on the side, close to the middle regional burner, along the width direction of the boiler, the light pulverized coal nozzle is arranged on the side, close to the left or right side wall of the boiler, a pulverized coal pipeline of the outermost burner is introduced from a horizontal height direction of the primary air pipe and is connected to the primary air pipe through a bend; and air distribution adjustment can be carried out on the concentrated pulverized coal nozzle and the light pulverized coal nozzle through air valve baffle plates arranged independently. The device can improve a wall adherence atmosphere of the side wall water-cooling wall obviously.

Owner:XIAN THERMAL POWER RES INST CO LTD

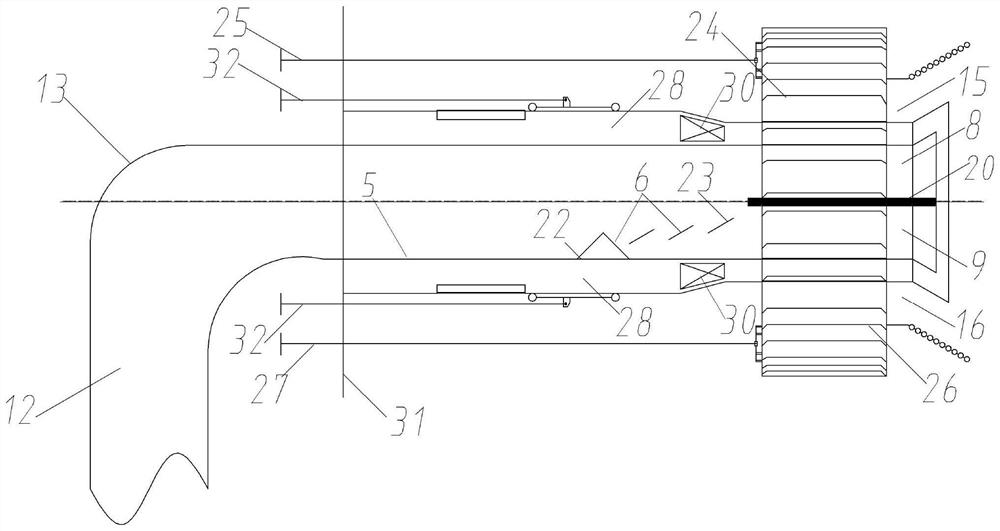

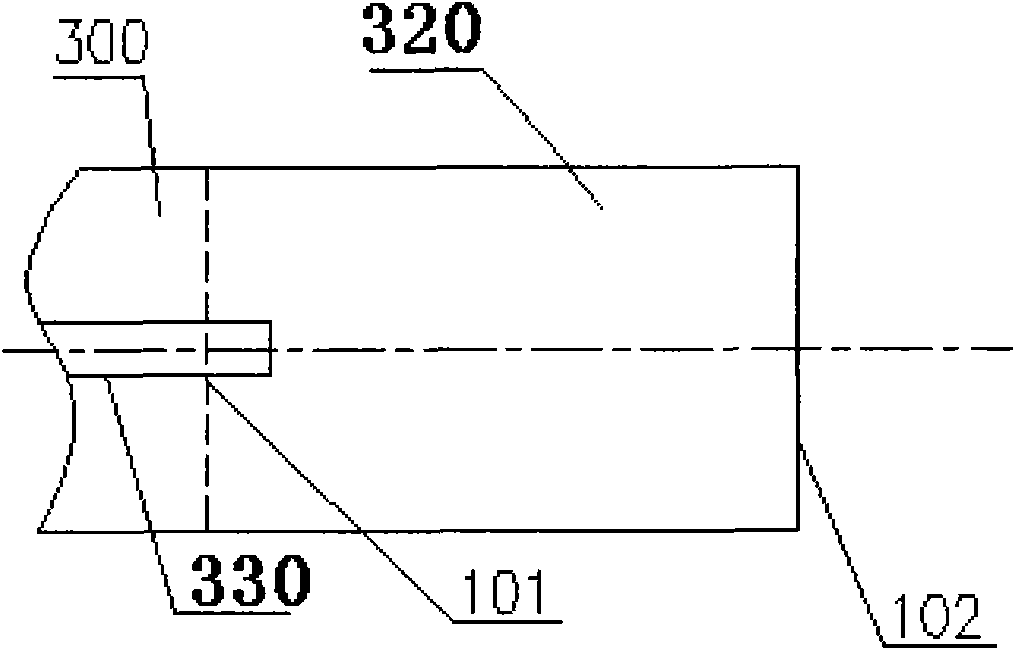

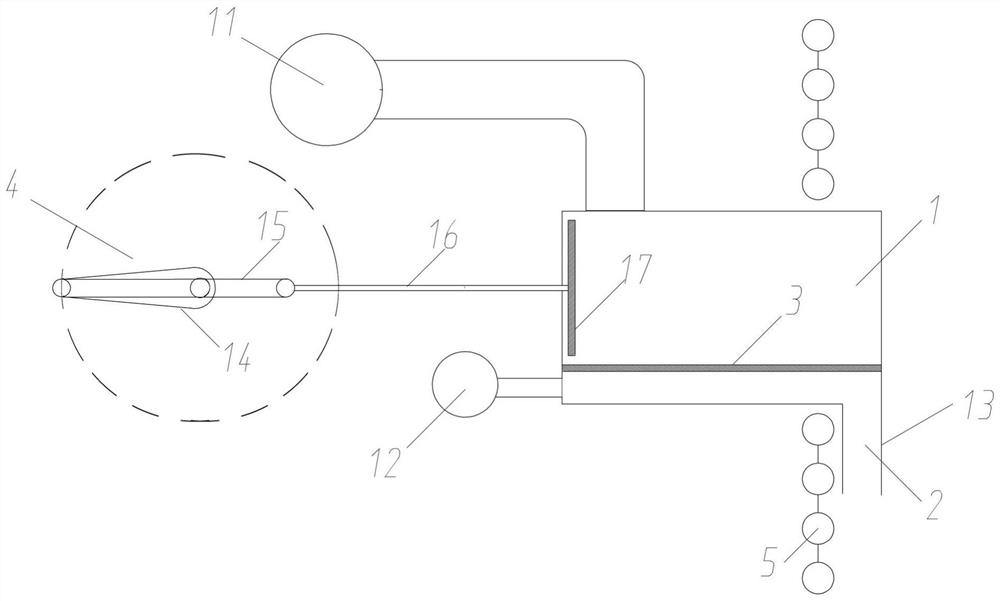

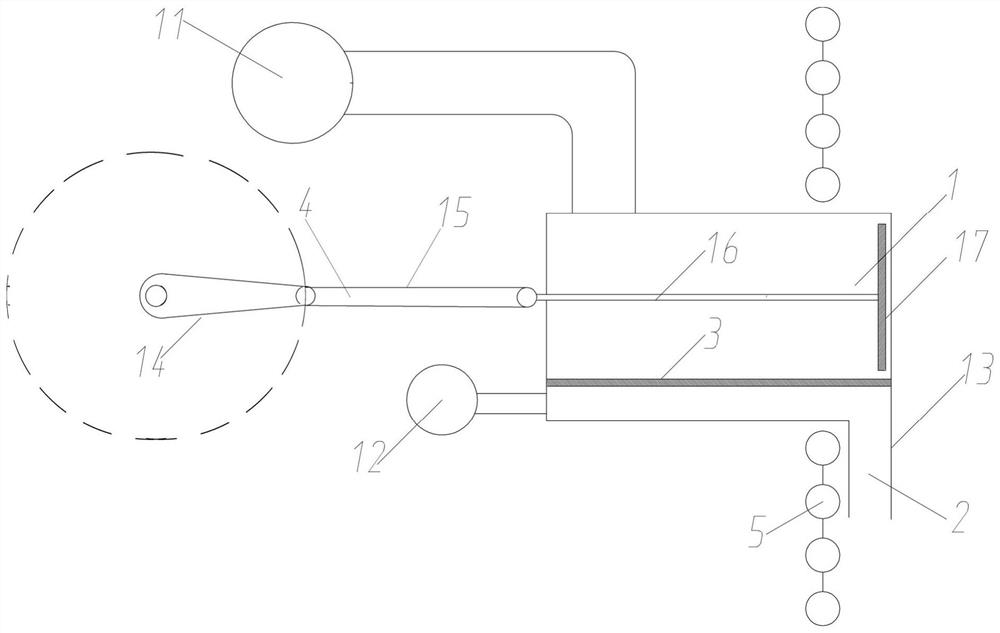

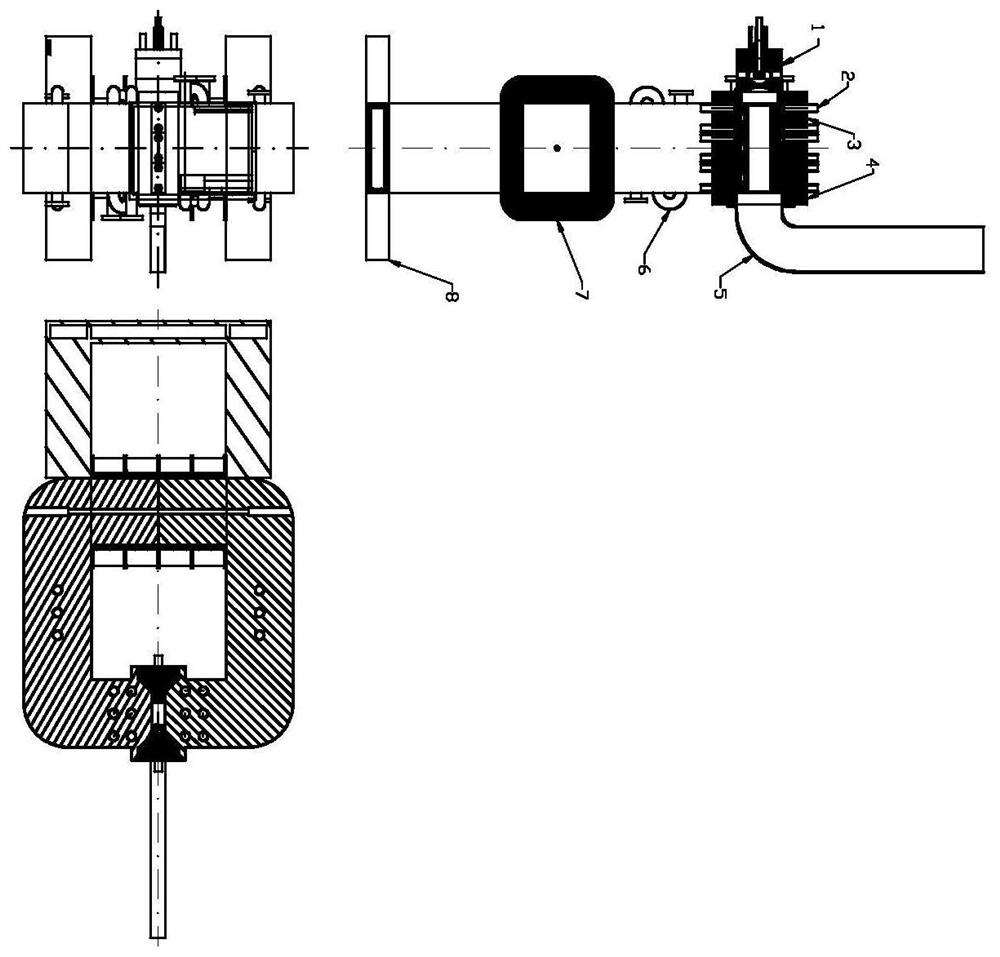

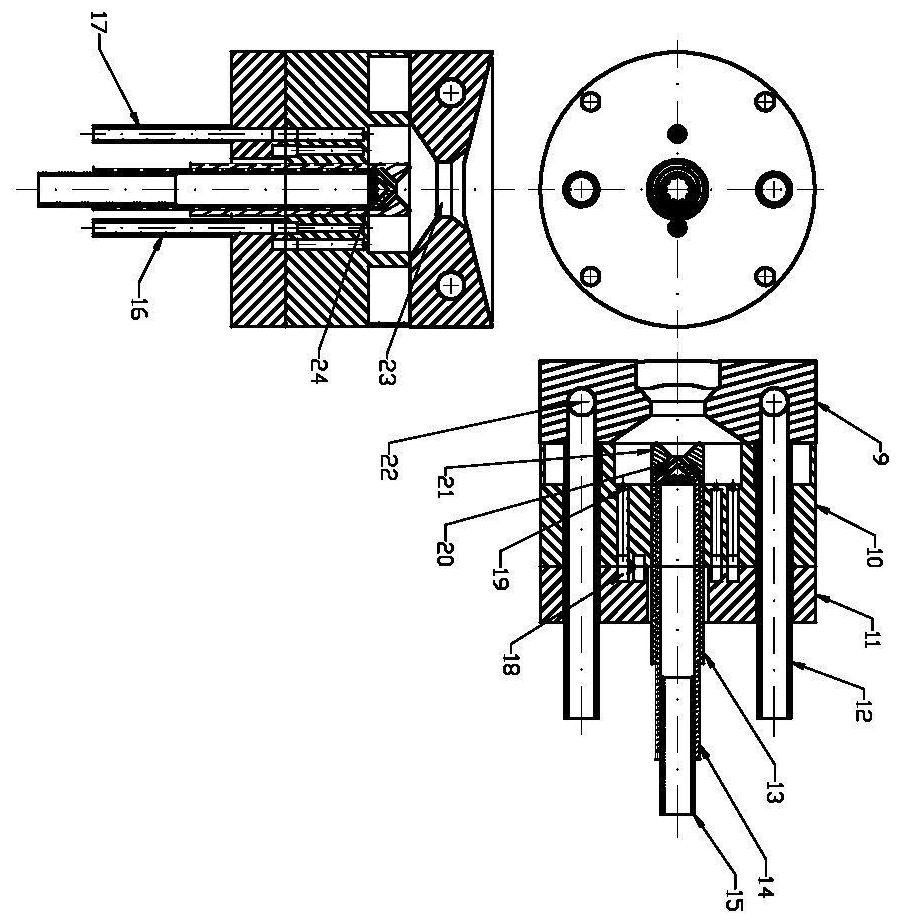

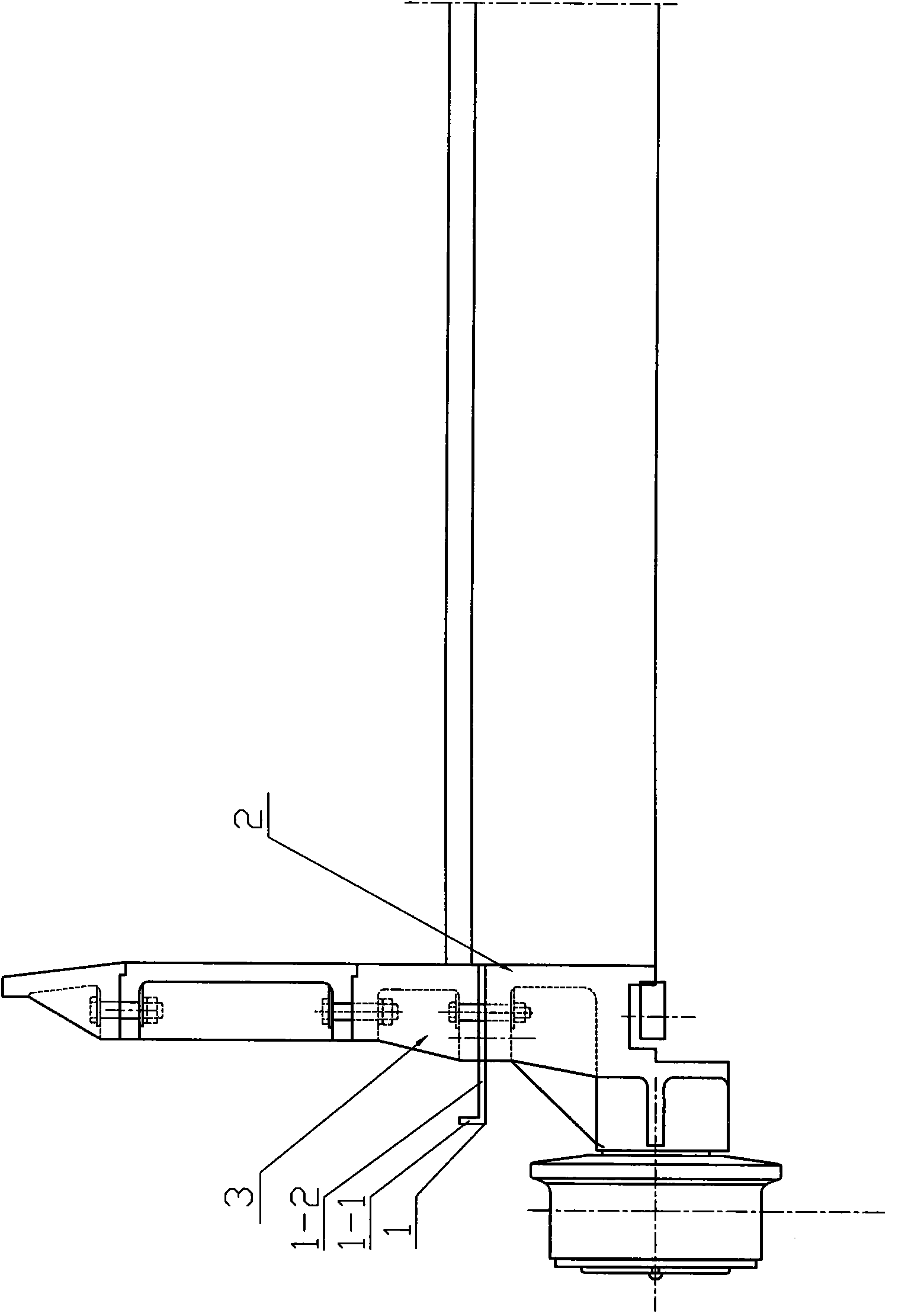

Pulverized coal burner and boiler having same

ActiveCN102032564AReduce the temperatureExtended service lifeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberThermal insulation

The invention discloses a pulverized coal burner and a boiler having the same. The pulverized coal burner comprises a heat source and an internal-combustion chamber for keeping the preset excess air coefficient of an internal pulverized coal air flow, wherein the heat source is positioned in the combustion chamber, and the internal-combustion chamber has an inlet and an outlet; and the heat source can light pulverized coal in the internal-combustion chamber and make the pulverized coal undergo reducing burning in the internal-combustion chamber; and the internal-combustion chamber comprises ametal outer cylinder and a ceramic liner. The ceramic material for making the liner of the pulverized coal burner has excellent high-temperature performance, and can retain corresponding mechanical performance under a continuous high-temperature condition; and the ceramic material has high thermal-insulation effect and can keep a higher temperature in the internal-combustion chamber of the pulverized coal burner.

Owner:YANTAI LONGYUAN POWER TECH

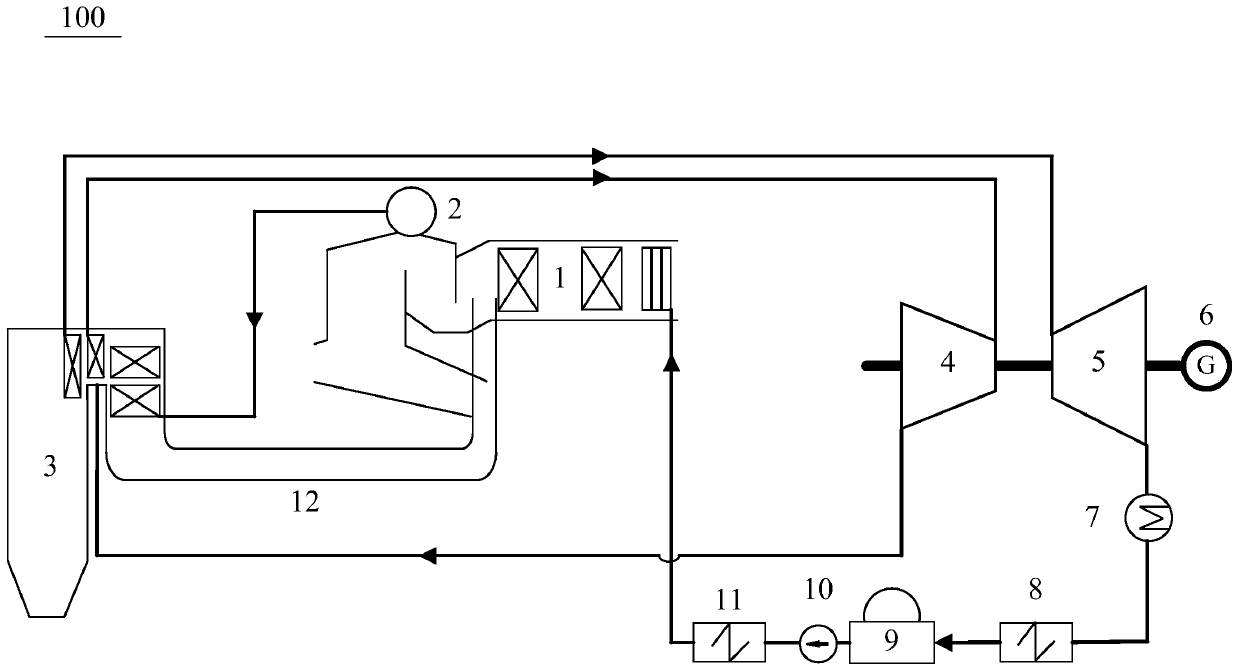

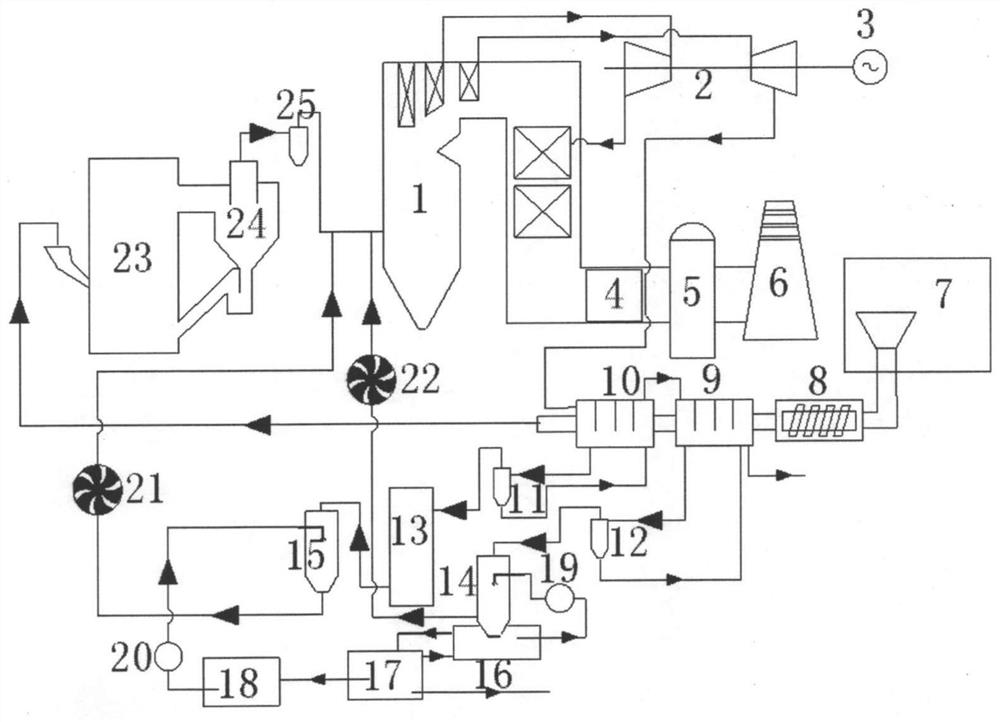

Waste incineration power generation device capable of improving main steam parameters

ActiveCN110397481AImprove parametersSolve the problem of high temperature corrosionSteam engine plantsSteam generation using hot heat carriersSaturated water vaporEngineering

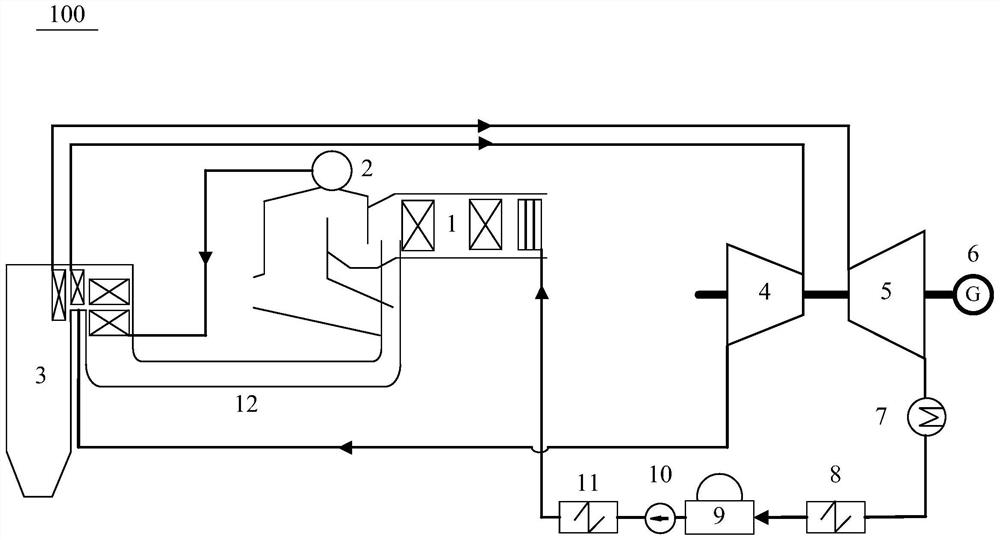

The invention provides a waste incineration power generation device capable of improving main steam parameters. The waste incineration power generation device comprises a waste heat boiler, a steam pocket, a coal-fired boiler and a steam turbine, wherein the waste heat boiler is provided with a low-temperature heating surface for heating feedwater; the feedwater is separated into saturated water and saturated water steam through the steam pocket, and the saturated water returns to the low-temperature heating surface of the waste heat boiler; the coal-fired boiler is provided with a high-temperature heating surface, and the saturated water vapor separated from the steam pocket is overheated at the high-temperature heating surface; and the overheated main steam enters a high-pressure cylinder to work and drives a generator to generate electricity, the waste steam discharged from the high-pressure cylinder returns to the high-temperature heating surface of the coal-fired boiler for reheating, the reheating steam enters a low-pressure cylinder to work and drives the generator to generate electricity, and the waste steam discharged from the low-pressure cylinder enters a water supply circulation unit to be converted into the feedwater again. According to the waste incineration power generation device capable of improving the main steam parameters, the main steam parameters of wasteincineration power generation can be improved, and the intermediate reheating technology is used, so that the generating capacity of the steam turbine and the economic benefits of a incineration powerplant are improved.

Owner:EVERBRIGHT ENVIRONMENTAL TECH RES INST NANJING CO LTD +1

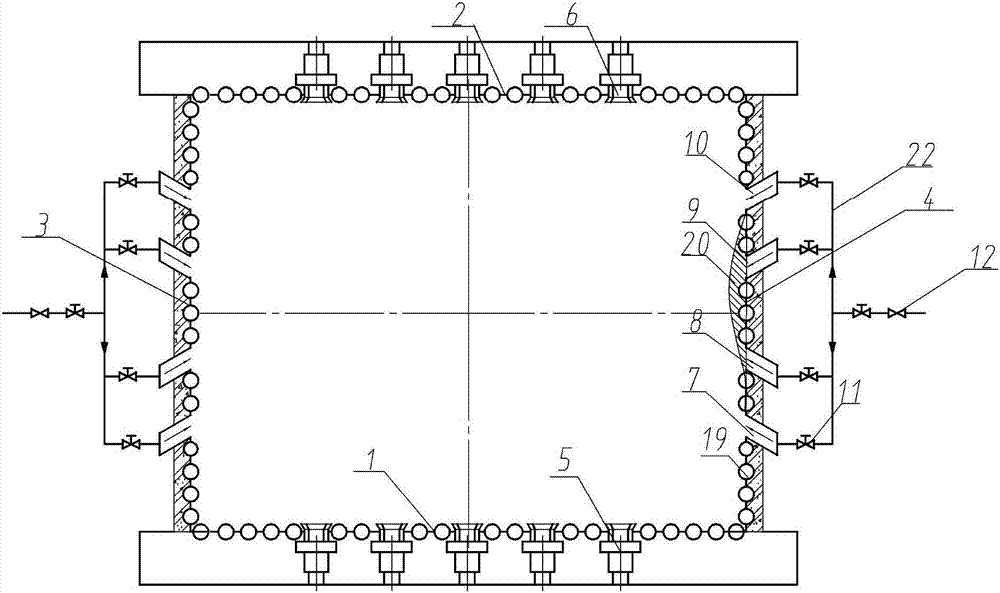

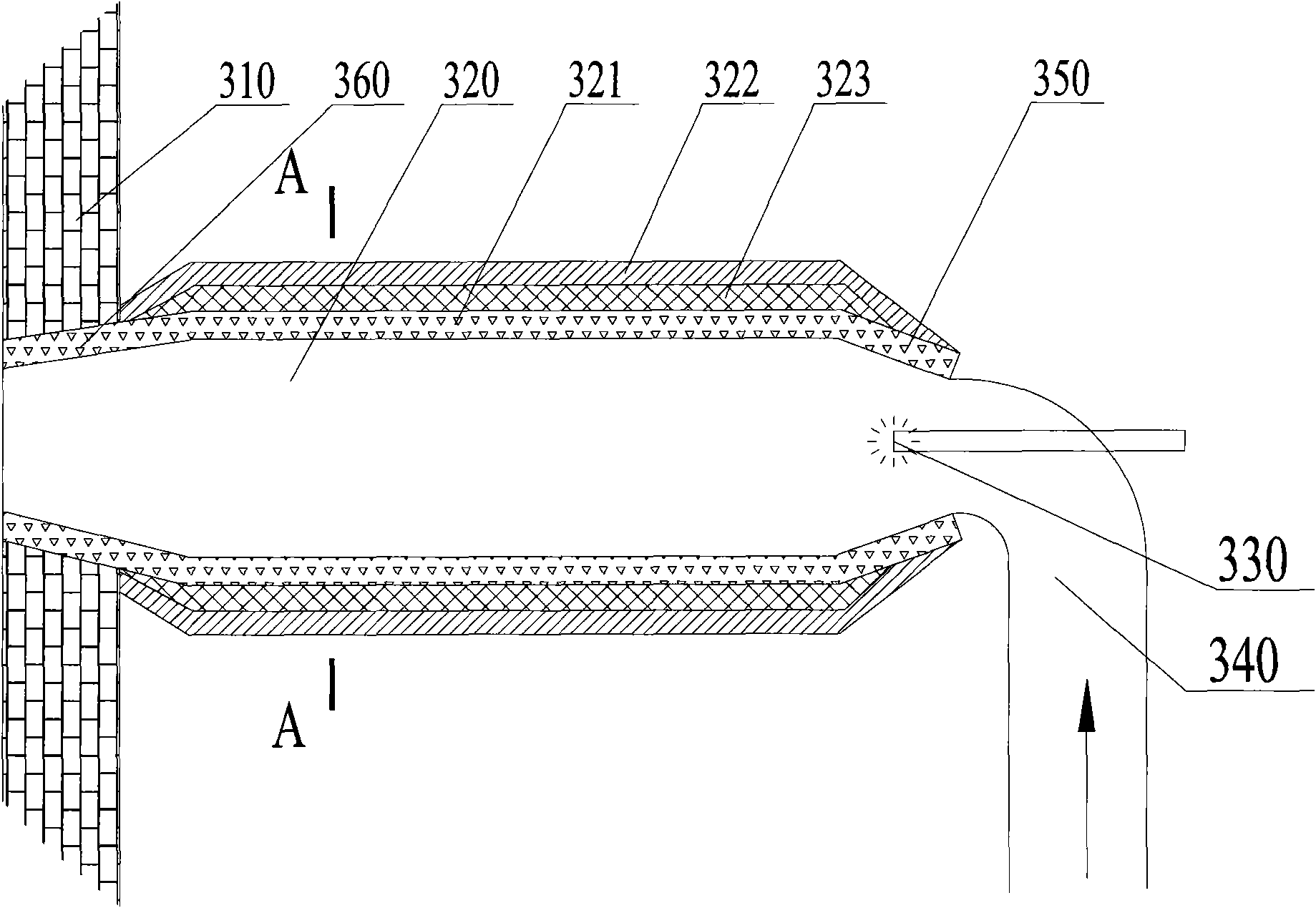

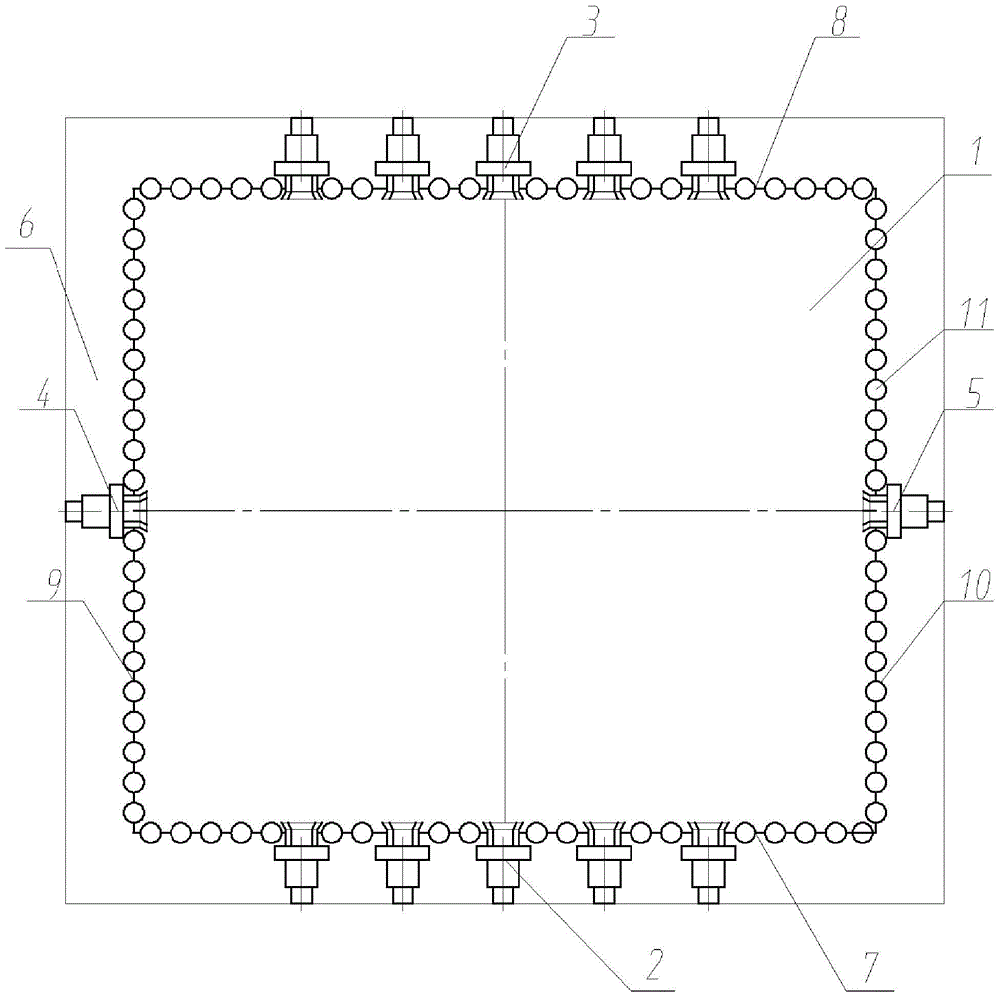

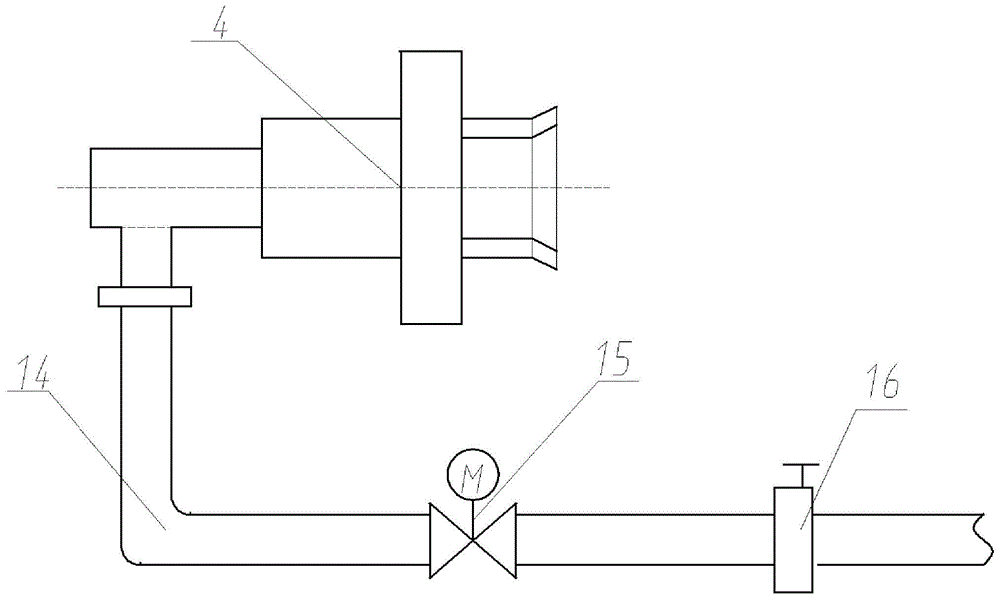

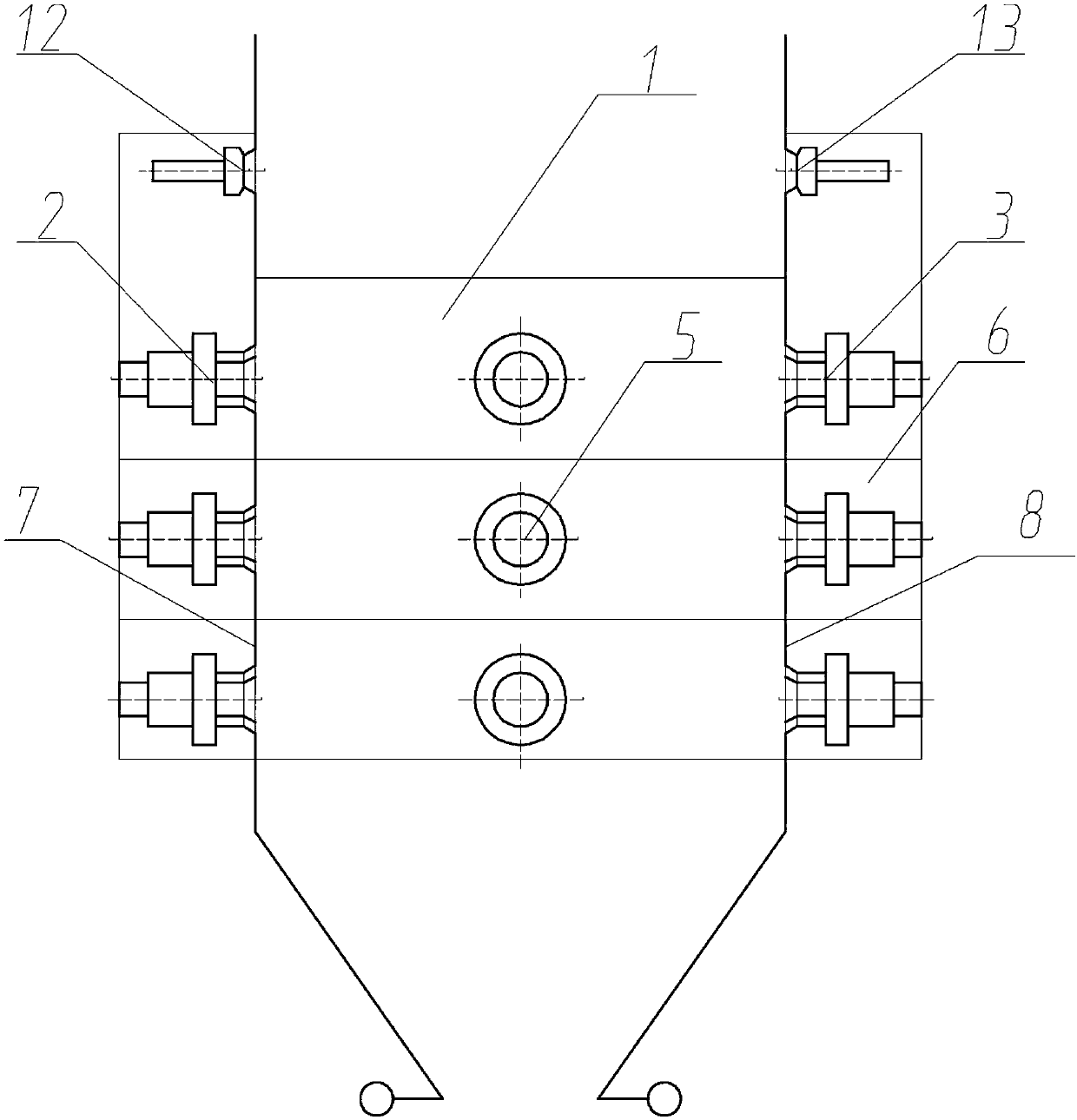

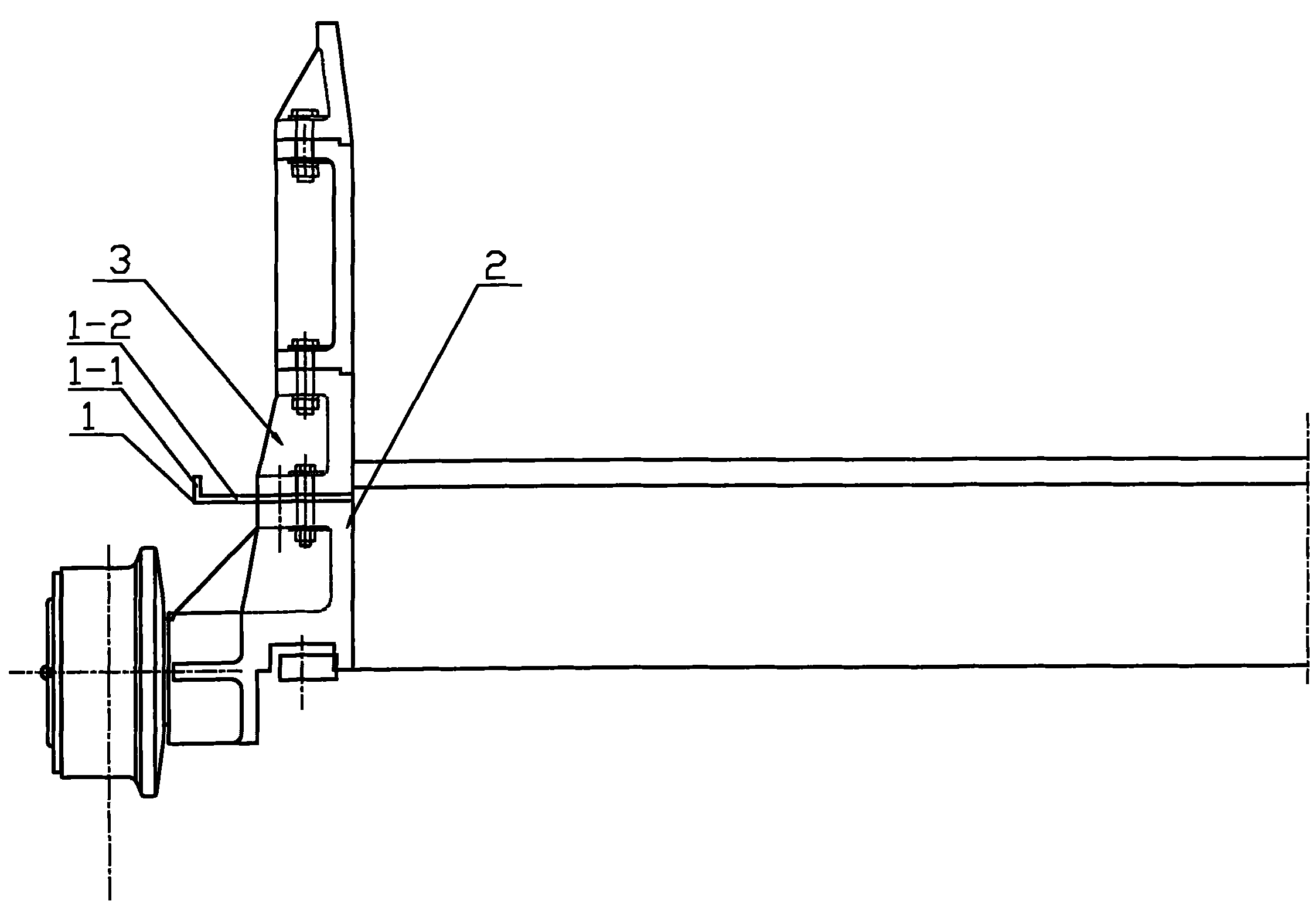

Slag blocking preventing type wall-attached air device based on air staged combustion

PendingCN112283736AAchieve staged combustionIncrease the atmosphereBlast-producing apparatusCasings/liningsSlagEngineering

The invention relates to a slag blocking preventing type wall-attached air device based on air staged combustion. The slag blocking preventing type wall-attached air device comprises a wall-attached air nozzle consisting of a jet flow air nozzle and a protective air nozzle; the jet flow air nozzle faces the air flow jet direction of a pulverized coal combustor, and the protective air nozzle is arranged back to the air flow jet direction of the pulverized coal combustor; the jet flow air nozzle and the protective air nozzle are separated by a partition plate; and a coke poking device is arranged in the jet flow air nozzle and can push coke slag adhered to the jet flow air nozzle into a hearth. According to the slag blocking preventing type wall-attached air device, air staged combustion isrealized, and NOx generated by combustion is reduced advantageously; protective air forms an air film at the wall-attached position of a water-cooled wall, and the atmosphere at the wall-attached position of the water-cooled wall is improved. Under the action of jet flow air and protective air, the problem of high-temperature corrosion of the boiler water-cooled wall can be solved. Meanwhile, slagbonding or burning loss of the nozzle due to the fact that coke slag particles adhere to the wall-attached air nozzle in the combustion process can be prevented.

Owner:XIAN THERMAL POWER RES INST CO LTD

High-temperature high-pressure waste incineration boiler

PendingCN110360569AAvoid cokingSolve concentrationSuperheating controlCoatingsCombustion chamberSteam pressure

The invention relates to the field of municipal solid waste incineration, in particular to a high-temperature high-pressure waste incineration boiler, a waste incineration boiler with the main steam temperature of 540 DEG C and the main steam pressure of 9.8 MPa. According to the high-temperature high-pressure waste incineration boiler, a water-cooled combustion chamber is adopted, and then a first channel, a first channel and second channel connecting channel, a second channel and a third channel are sequentially arranged according to the flowing direction of flue gas; and a platen superheater is arranged on the upper portion of the second channel. The high-temperature high-pressure waste incineration boiler has the advantages that by adopting the platen superheater, steam can be heated to 540 DEG C, so that the heat efficiency of a steam turbine generator unit system of a matched waste incineration power plant is improved to 34%.

Owner:SHANGHAI SUS ENVIRONMENT

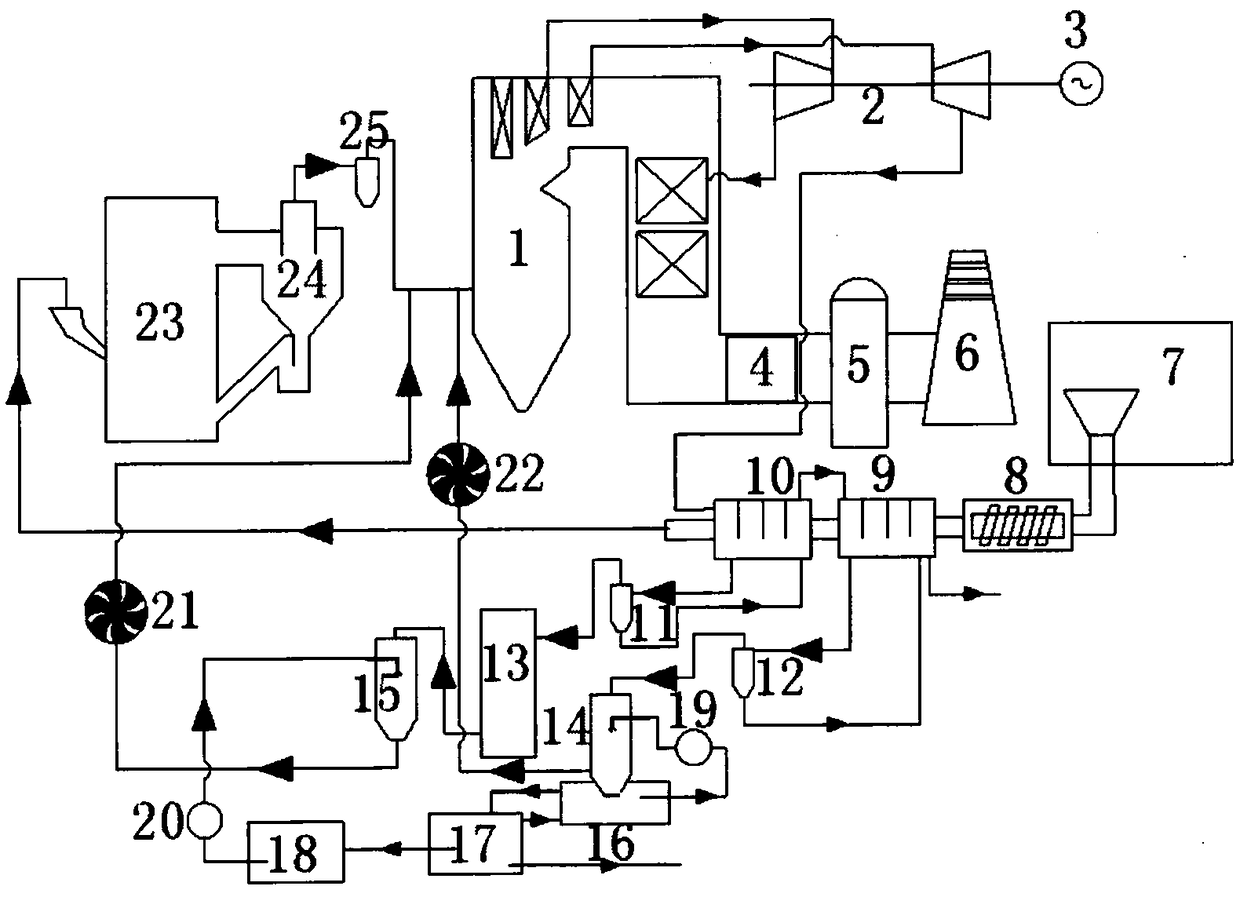

Power generation system of urban garbage pyrolysis and gasification coupled coal-fired power plant

ActiveCN109207178AReduce generationSolve the problem of high temperature corrosionMachines/enginesSpecial form destructive distillationEngineeringHigh-temperature corrosion

The invention discloses a power generation system of an urban garbage pyrolysis and gasification coupled coal-fired power plant, wherein the system comprises a boiler; the boiler drives an electric generator to generate electricity by a steam turbine; the system is characterized by also including a garbage low-temperature pyrolysis system and a garbage drying system. The invention provides the power generation system of the urban garbage pyrolysis and gasification coupled coal-fired power plant. The low-temperature pyrolysis system is used for pyrolysis of the urban living garbage at low temperature, HCl in the urban living garbage can be volatilized and removed, the generation amount of dioxin is reduced from the source, the high temperature corrosion problem of HCl generated in the process of urban living garbage incineration to a coal-fired boiler heated surface is solved, and the safety of heated surfaces of large coal-fired units is ensured.

Owner:SHANGHAI POWER EQUIP RES INST

High-temperature and high-pressure garbage incineration horizontal boiler

PendingCN110220198AAvoid cokingSolve the problem of high temperature corrosionSuperheating controlCoatingsSteam pressureCombustion chamber

The invention relates to the field of urban household waste incineration, in particular to a high-temperature and high-pressure garbage incineration horizontal boiler. The main steam pressure of the garbage incineration horizontal boiler is 9.8 MPa, and the main steam temperature of the garbage incineration boiler is 540 DEG C. The garbage incineration horizontal boiler is of a horizontal suspending structure, and a water cooling combustion chamber is adopted. A first channel, a first and second channel connecting channel, a second channel, a third channel and a horizontal channel are sequentially arranged in the flue gas flowing direction. A screen type overheater is arranged at the upper portion of the second channel, a special high-heat-conduction plastic material is laid at the outer portion of the screen type overheater. An evaporation protector I is arranged at the lower portion of the third channel. An evaporation protector II, a high-temperature overheater, an intermediate-temperature overheater, a low-temperature overheater and an economizer are sequentially arranged in the horizontal channel. The heat efficiency of a matched garbage incineration power plant steam turbinegenerator set system can be increased to 34%.

Owner:SHANGHAI SUS ENVIRONMENT

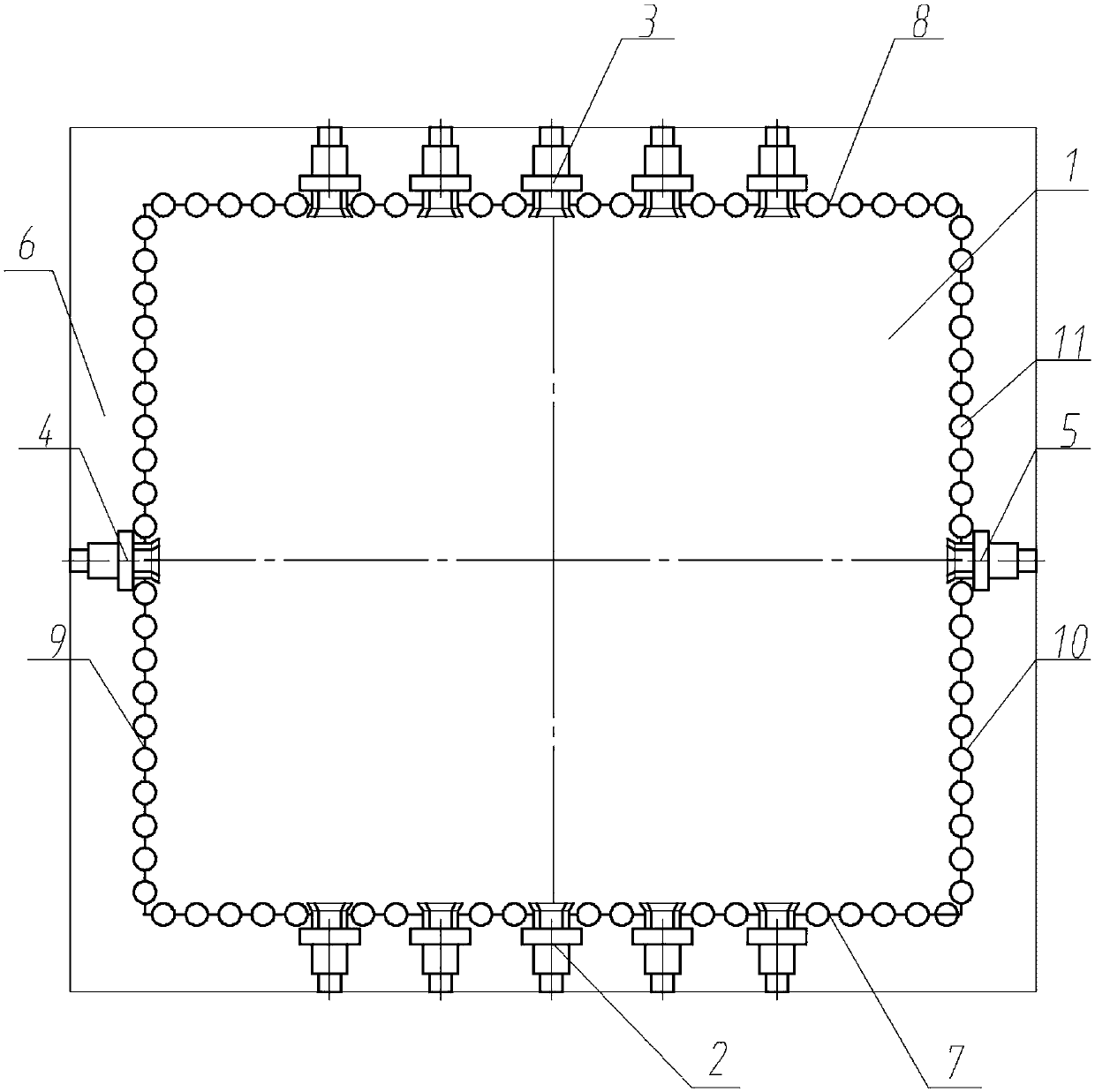

Opposed firing structure of boiler

ActiveCN104595891AIncrease oxygen contentReduce oxygen contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorStructural engineering

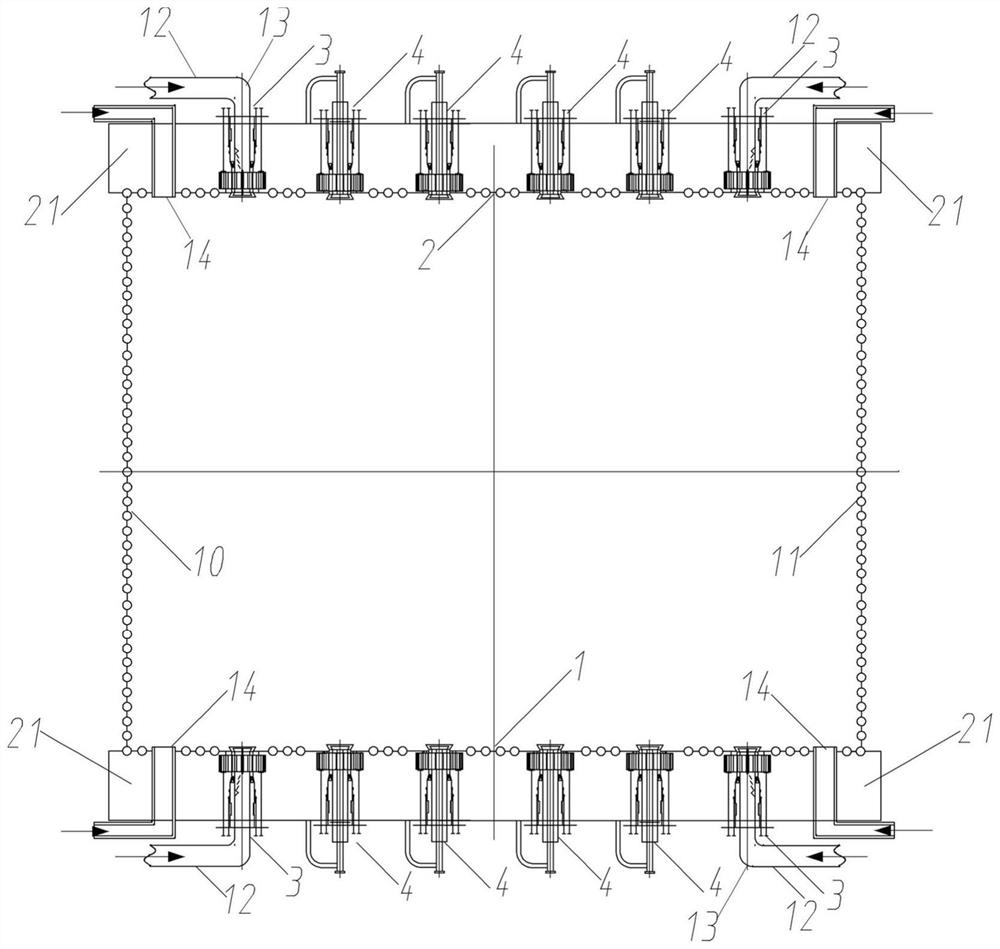

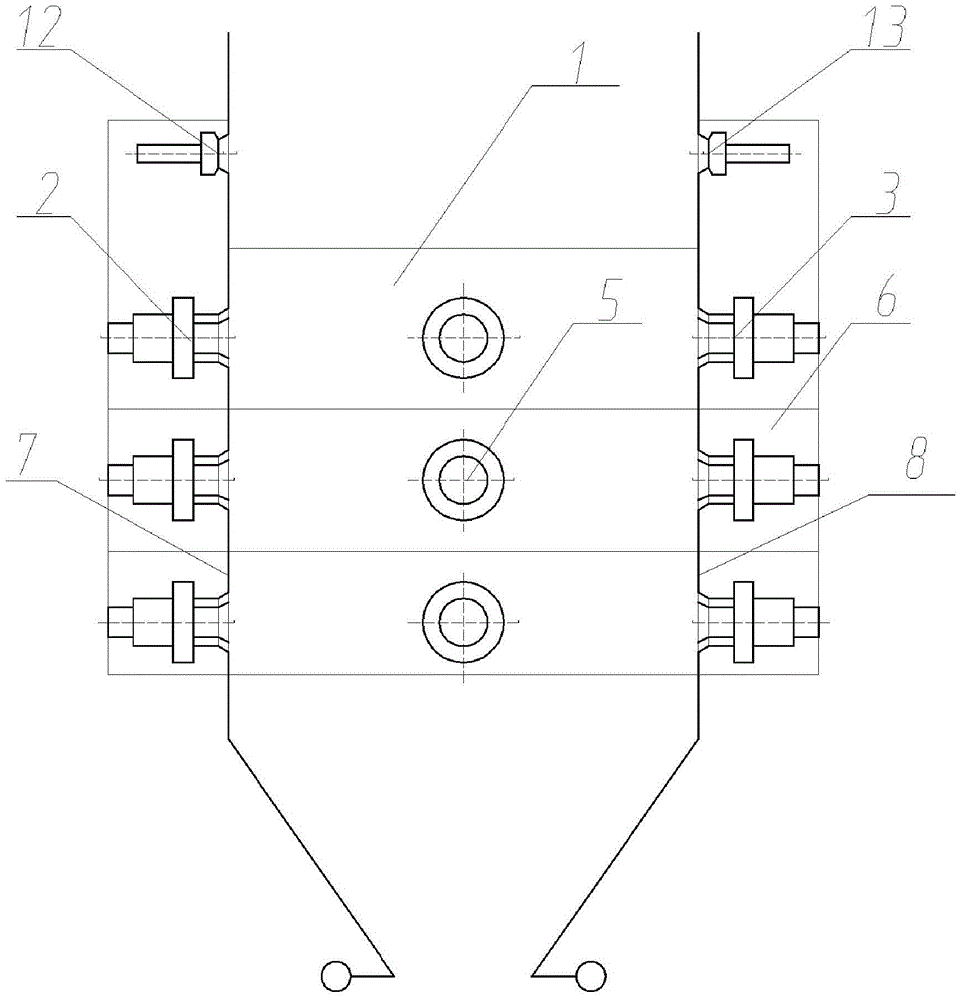

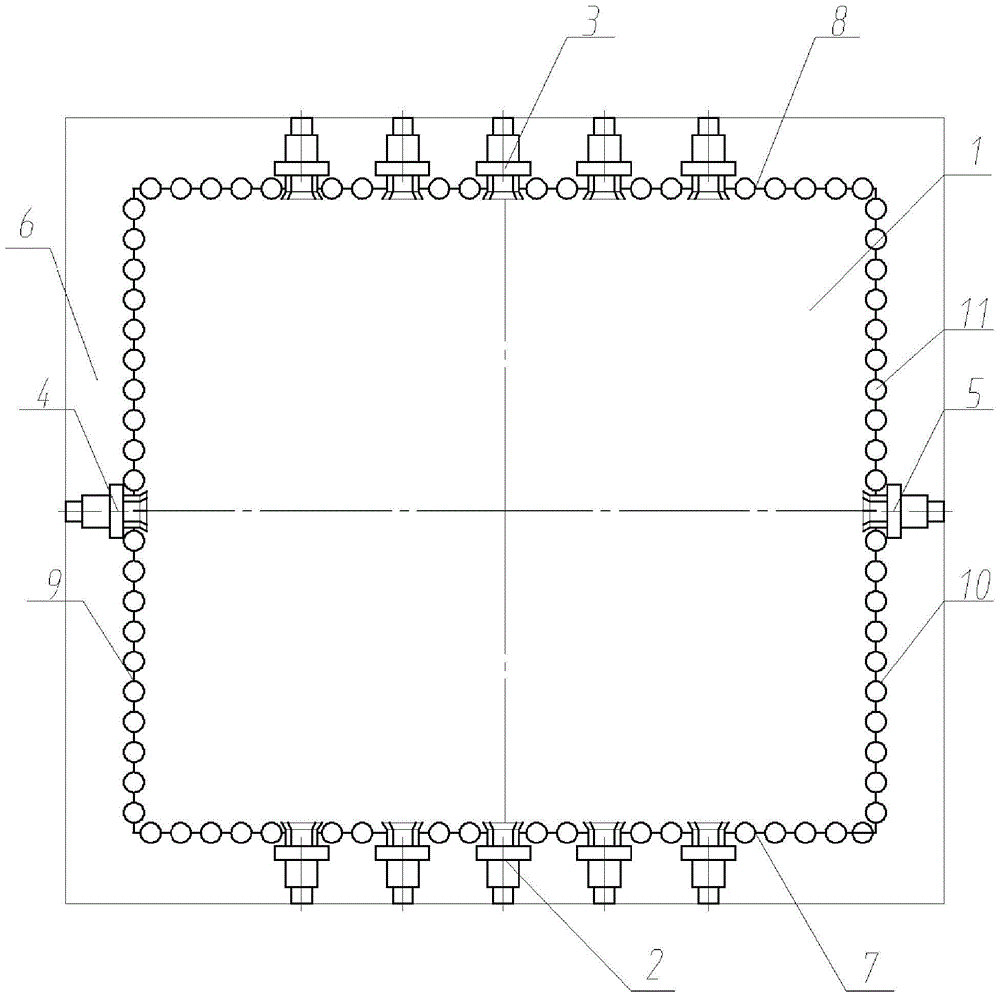

The invention discloses an opposed firing structure of a boiler. The opposed firing structure comprises a hearth, wherein the hearth is formed by enclosing of a boiler left-side wall, a boiler right-side wall, a boiler front wall and a boiler rear wall; left-side wall burners are distributed on the middle line of the boiler left-side wall along the height direction of the hearth; right-side wall burners are distributed on the middle line of the boiler right-side wall along the height direction of the hearth; a plurality of rows of front-wall burners are distributed on the boiler front wall; a plurality of rows of rear-wall burners are distributed on the boiler rear wall; and the peripheries of the boiler left-side wall, the boiler right-side wall, the boiler front wall and the boiler rear wall are provided with bellows for providing secondary air and over-fired air for the hearth. The opposed firing structure disclosed by the invention has the advantage that on the basis of not influencing the original coal-powder burning mode, the problem of corrosion caused by high temperature of water cooling walls of the side walls is thoroughly solved.

Owner:XIAN THERMAL POWER RES INST CO LTD

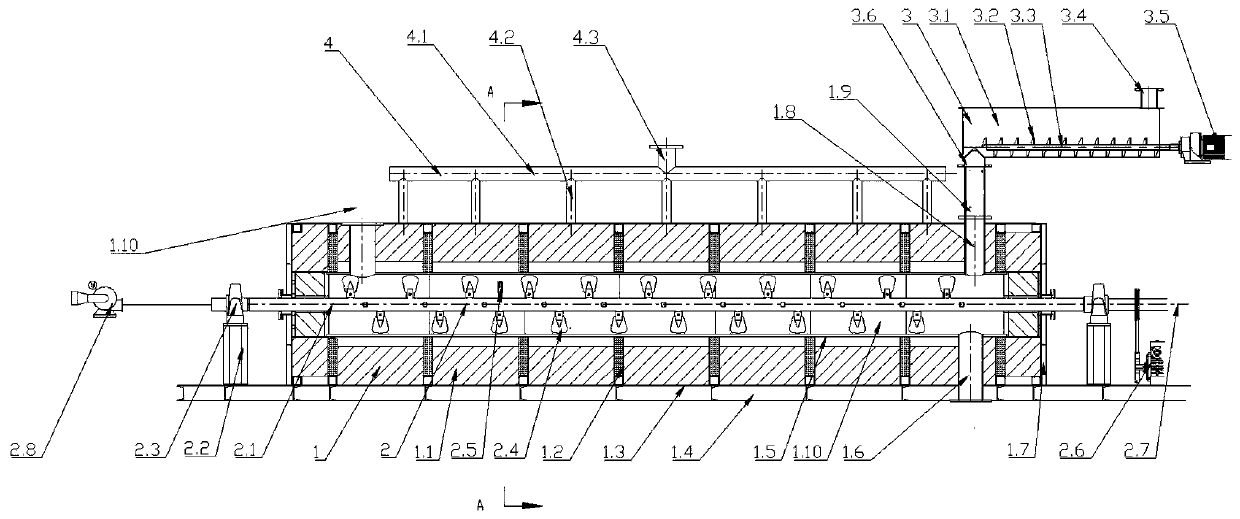

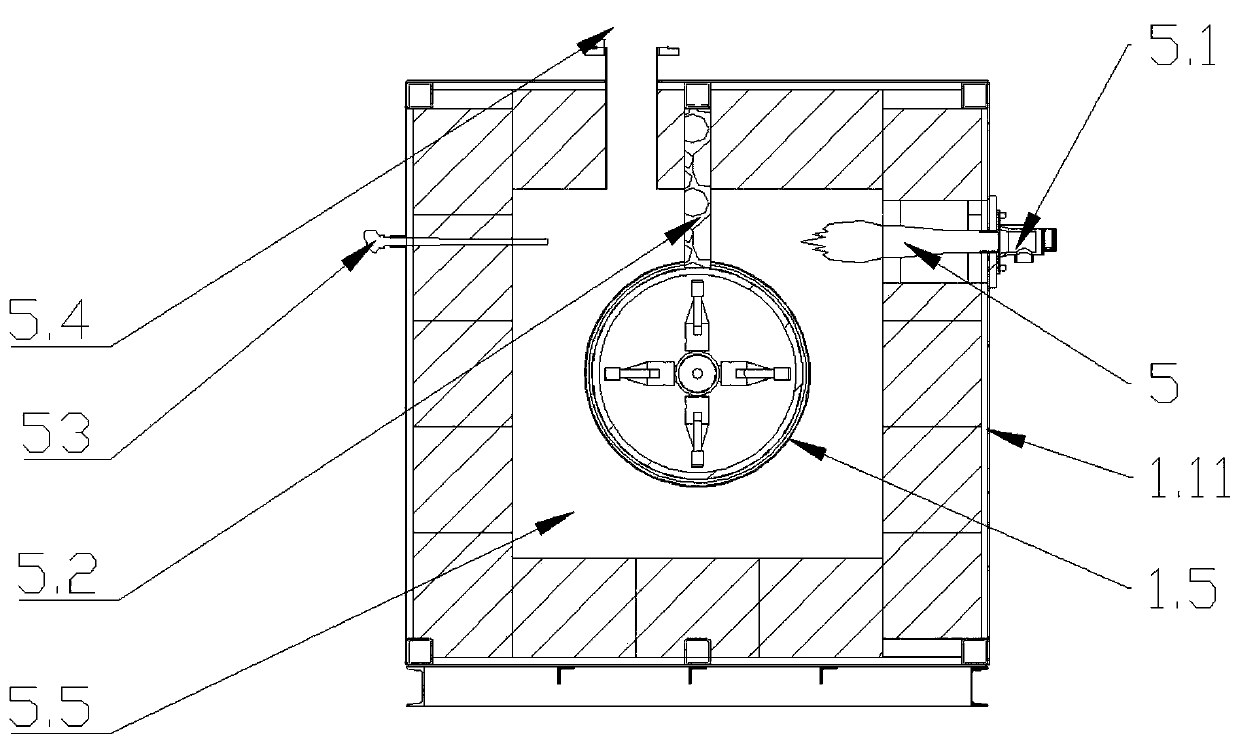

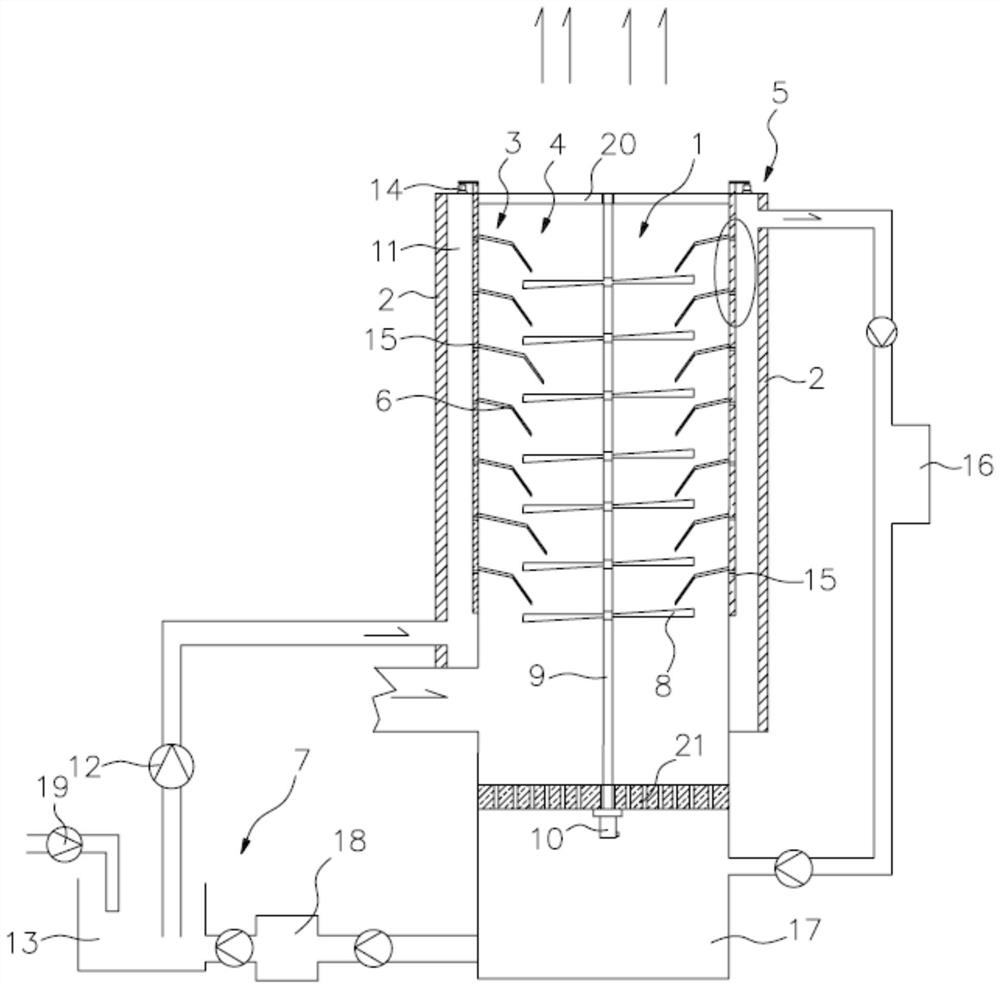

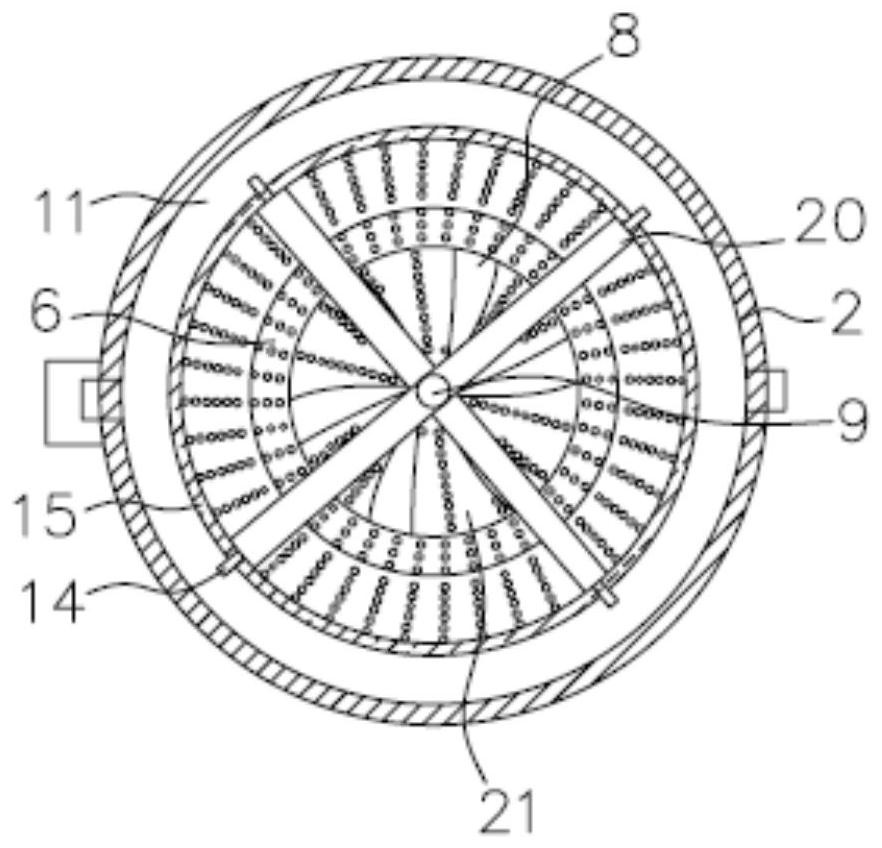

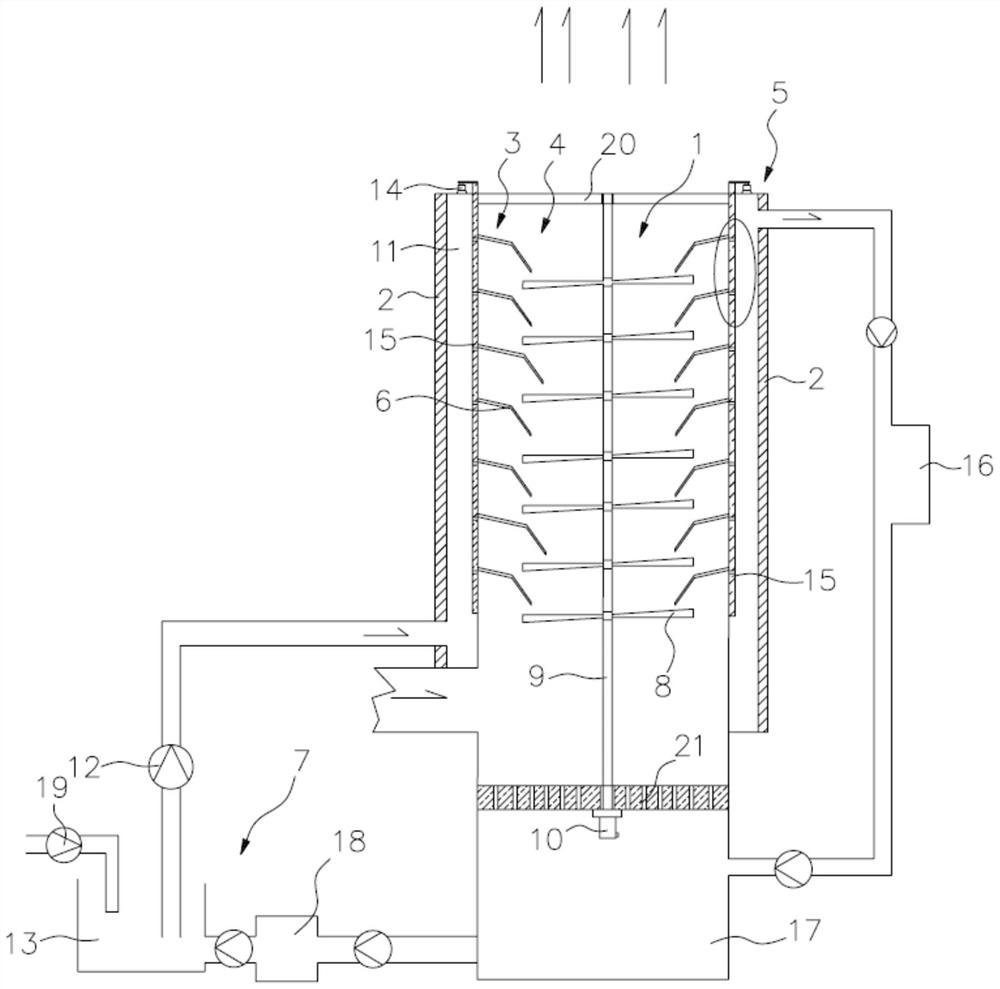

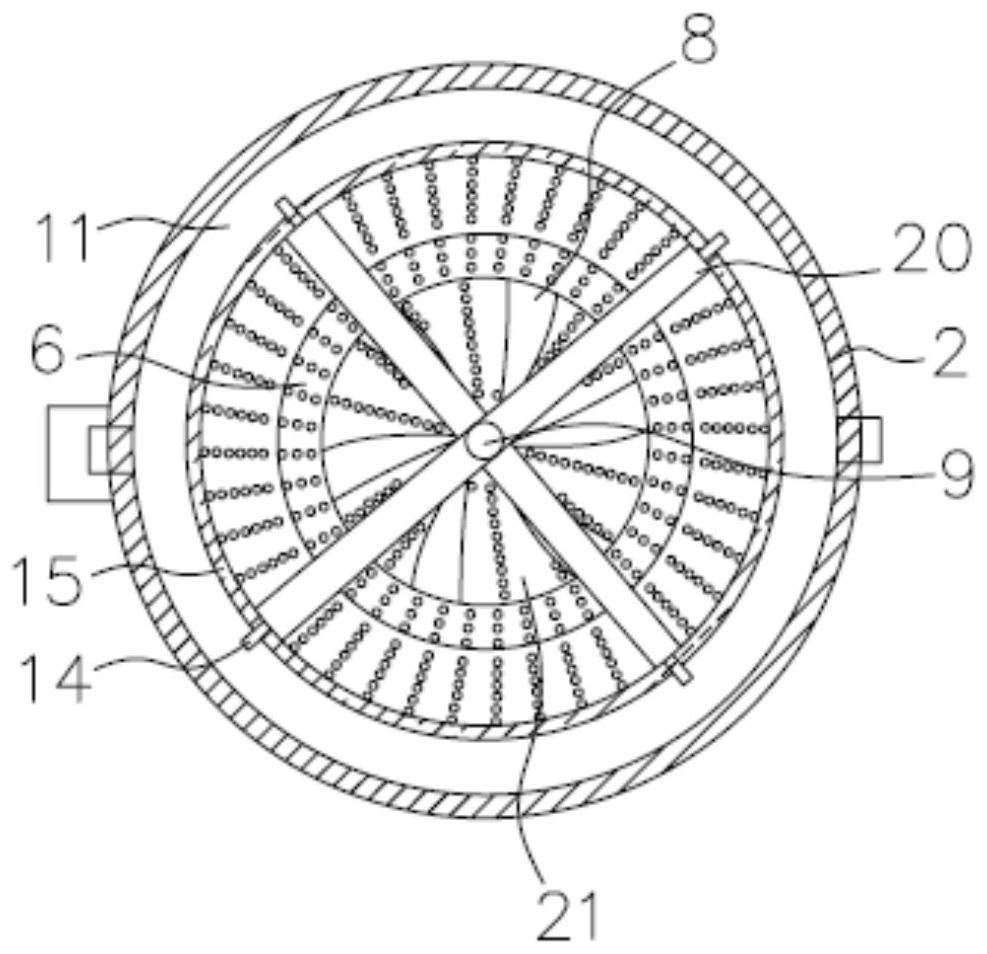

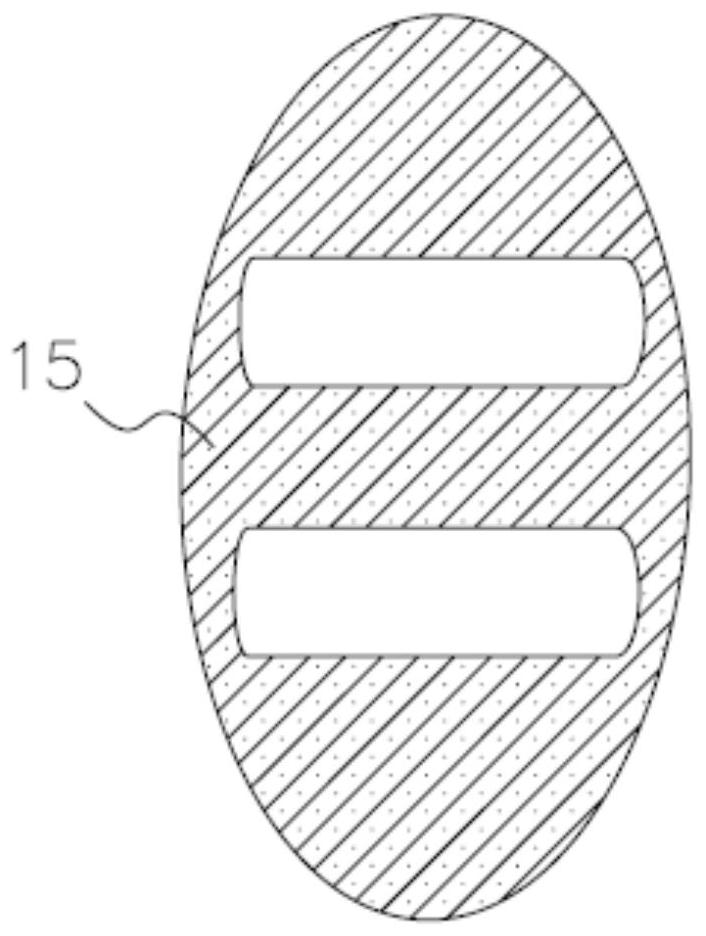

Furnace tube fixed type gas-heating regeneration furnace for powdered activated carbon

PendingCN110841615AIncrease in sizeLarge rotary transmission powerOther chemical processesCombustible gas purificationFlueActivated carbon

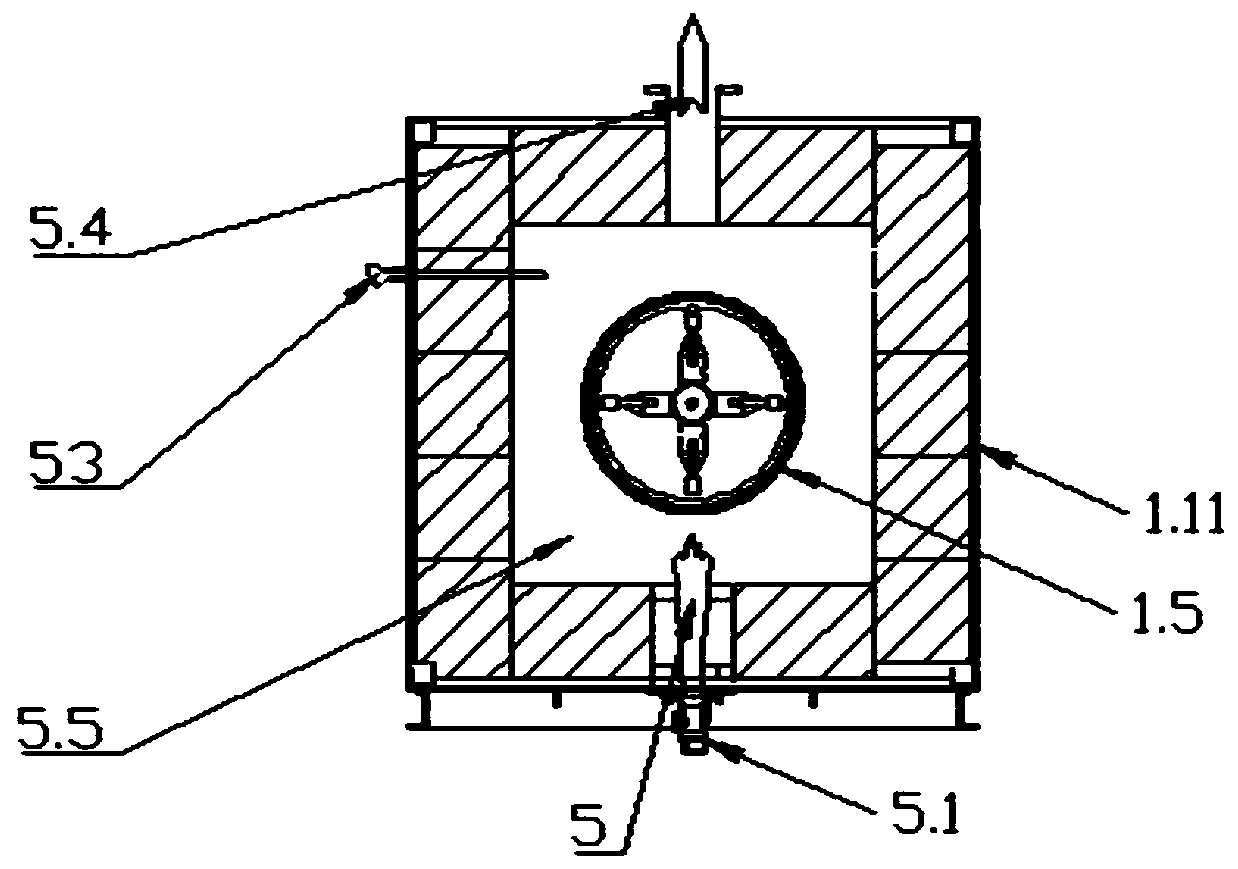

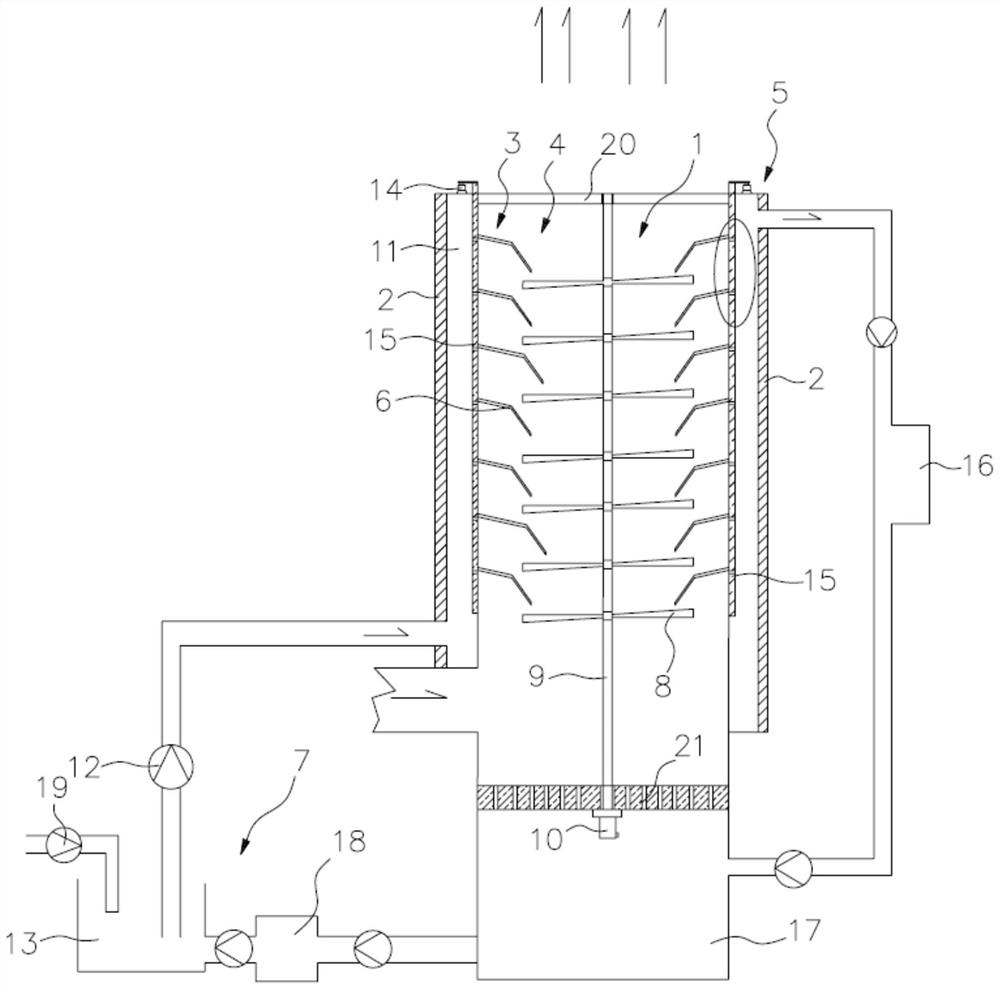

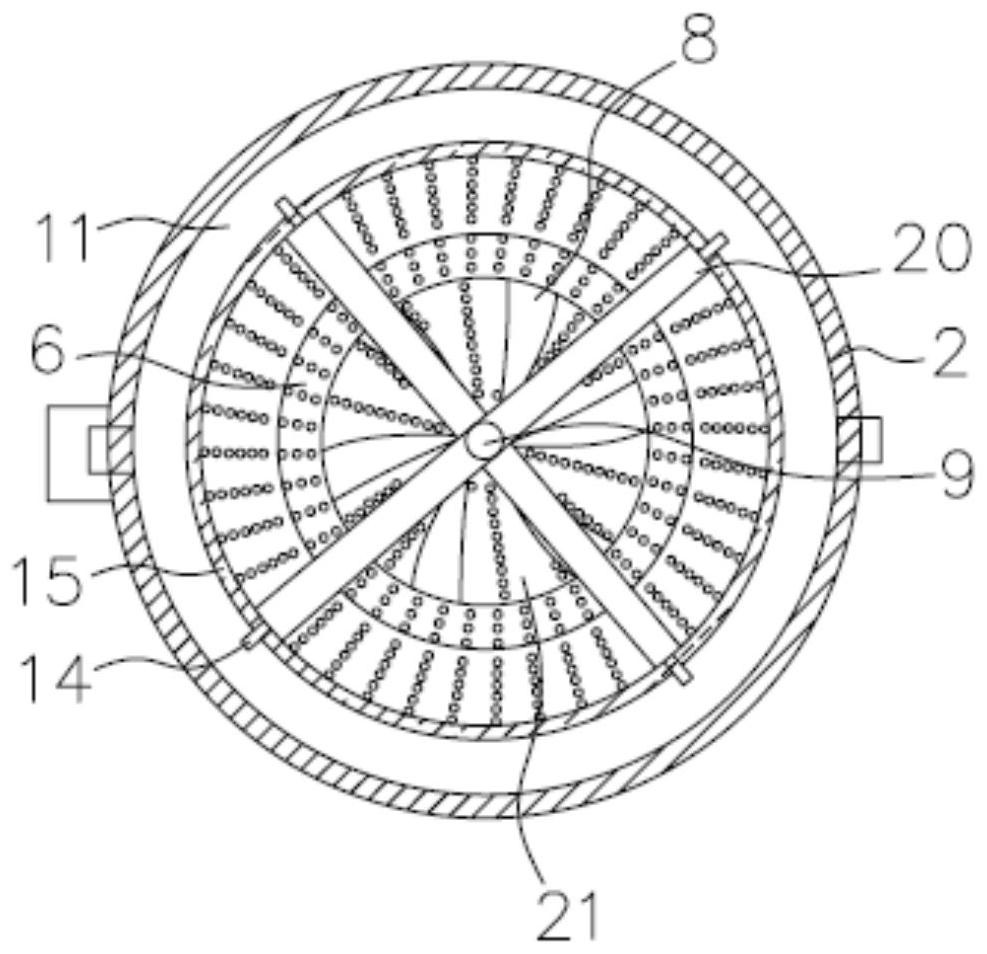

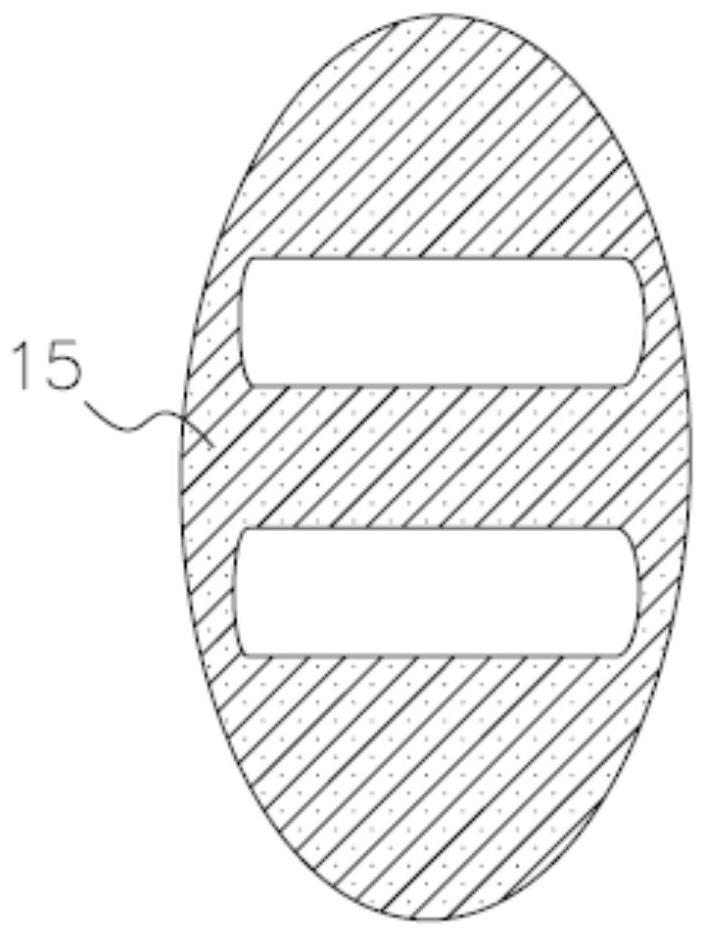

The invention provides a furnace tube fixed type gas-heating regeneration furnace for powdered activated carbon. The regeneration furnace comprises a regeneration furnace body, a regeneration furnacestirring device, a powdered activated carbon recovery device, an exhaust gas emission system and a gas heating system, wherein the regeneration furnace body stirring device is arranged in the regeneration furnace body; an outlet of the regeneration furnace body is connected to the powdered activated carbon recovery device through a regeneration waste gas flue and a powdered activated carbon material outlet of the recovery device; the regeneration furnace body is connected with the exhaust gas emission system through a flue branch pipe; the gas heating system 5 is arranged in the regeneration furnace body; and the upper side of the regeneration furnace body is connected with the powdered activated carbon recovery device through the regeneration waste gas flue. According to the invention, afurnace tube fixed type structure is adopted, only the stirring shaft is required to perform rotational motion, and required rotation power is low; fixing equipment for a furnace tube of the furnace body has characteristics of simple structure and reliable installation; and the furnace is long in service life and convenient in maintenance.

Owner:SHANGHAI HEYUAN ENVIRONMENTAL TECH CO LTD

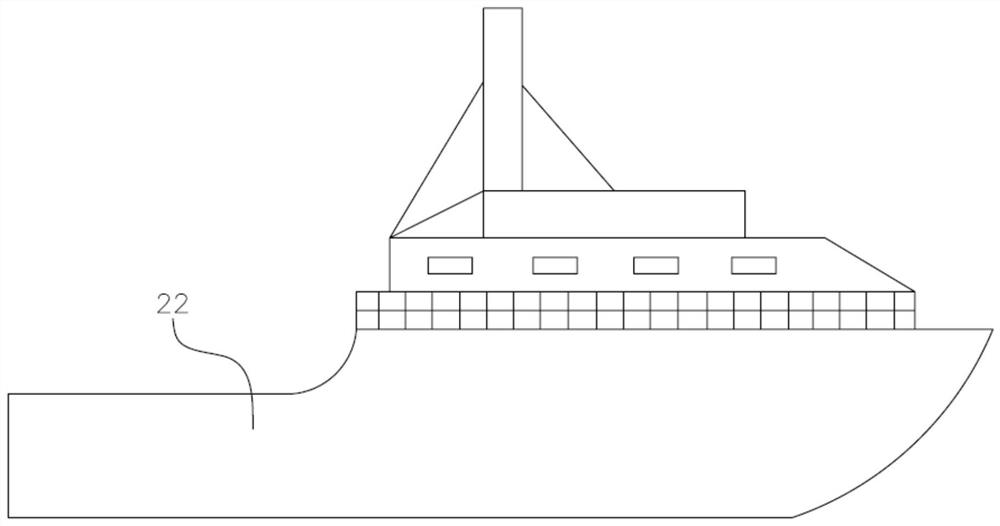

Novel anti-corrosion noise-reduction chimney for ship

ActiveCN112361366AReduce the temperatureSolve the problem of high temperature corrosionPropulsion power plantsPropulsive elementsInsulation layerLiquid medium

The invention discloses a novel anti-corrosion noise-reduction chimney for a ship. The novel anti-corrosion noise-reduction chimney comprises one chimney body used for exhausting waste gas, a conversion device arranged at the central axis position of the chimney body and used for converting kinetic energy of the waste gas into electric energy, an internal cooling device arranged on the inner wallof the chimney body and used for reducing internal temperature and smoke dust of the chimney body, a silencing device used for reducing noise of the chimney body, an external cooling device arranged on the outer wall of the chimney body, a heat insulation layer arranged on the surface of the external cooling device, a circulating and purifying device used for purifying and recycling cooling liquid, and a controller. According to the novel anti-corrosion noise-reduction chimney for the ship, the internal temperature and the external temperature of the chimney body are effectively reduced through multi-stage cooling, and the temperature of the chimney body is visually controlled and adjusted in real time through a detection control system, so that the problem of high-temperature corrosion iseffectively solved; and by arranging the silencing device, the exhaust noise of the chimney body is reduced, energy of the exhausted flue gas is fully recycled, and harmful substances and the smoke dust in waste gas can be effectively removed by changing a cooling liquid medium.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

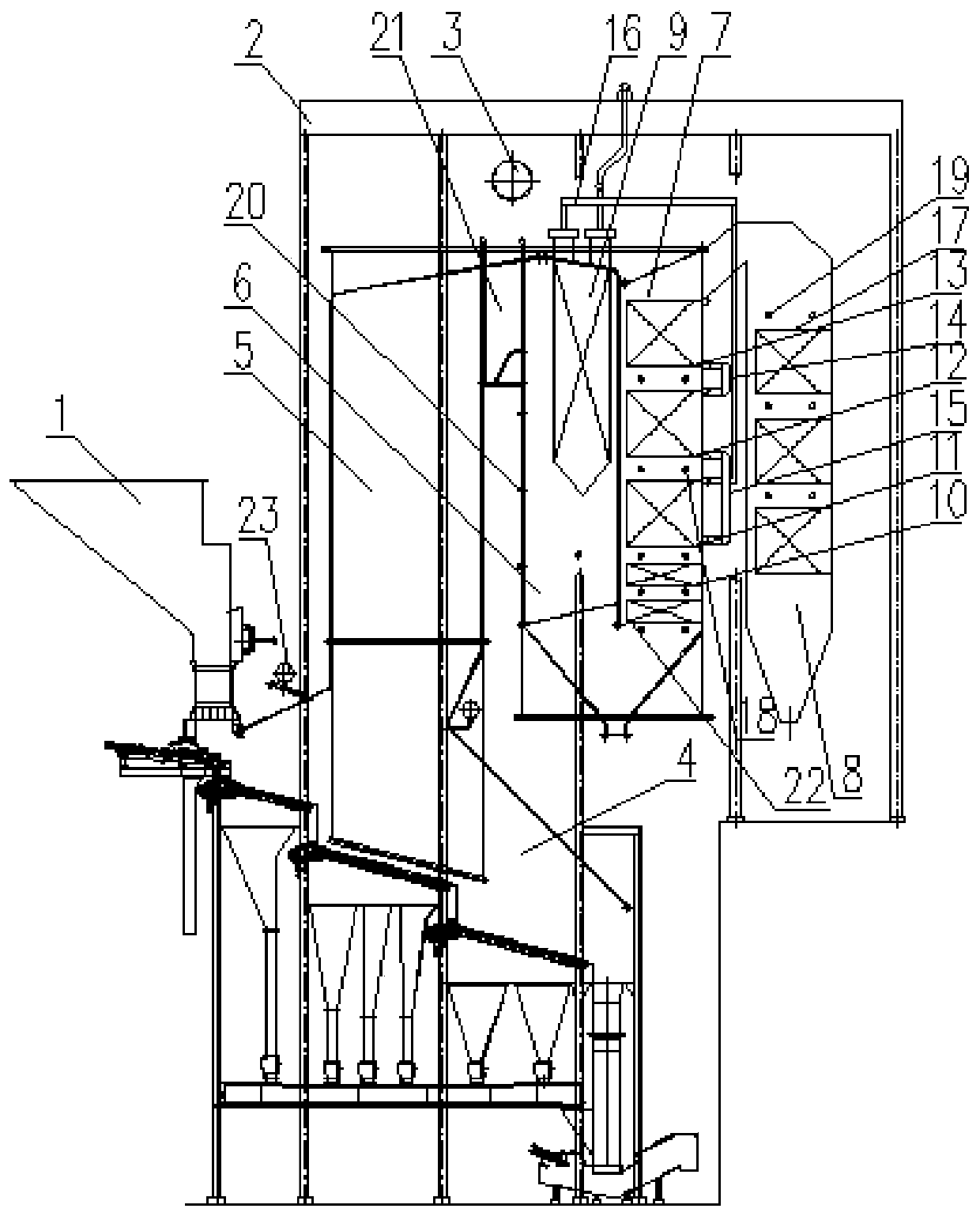

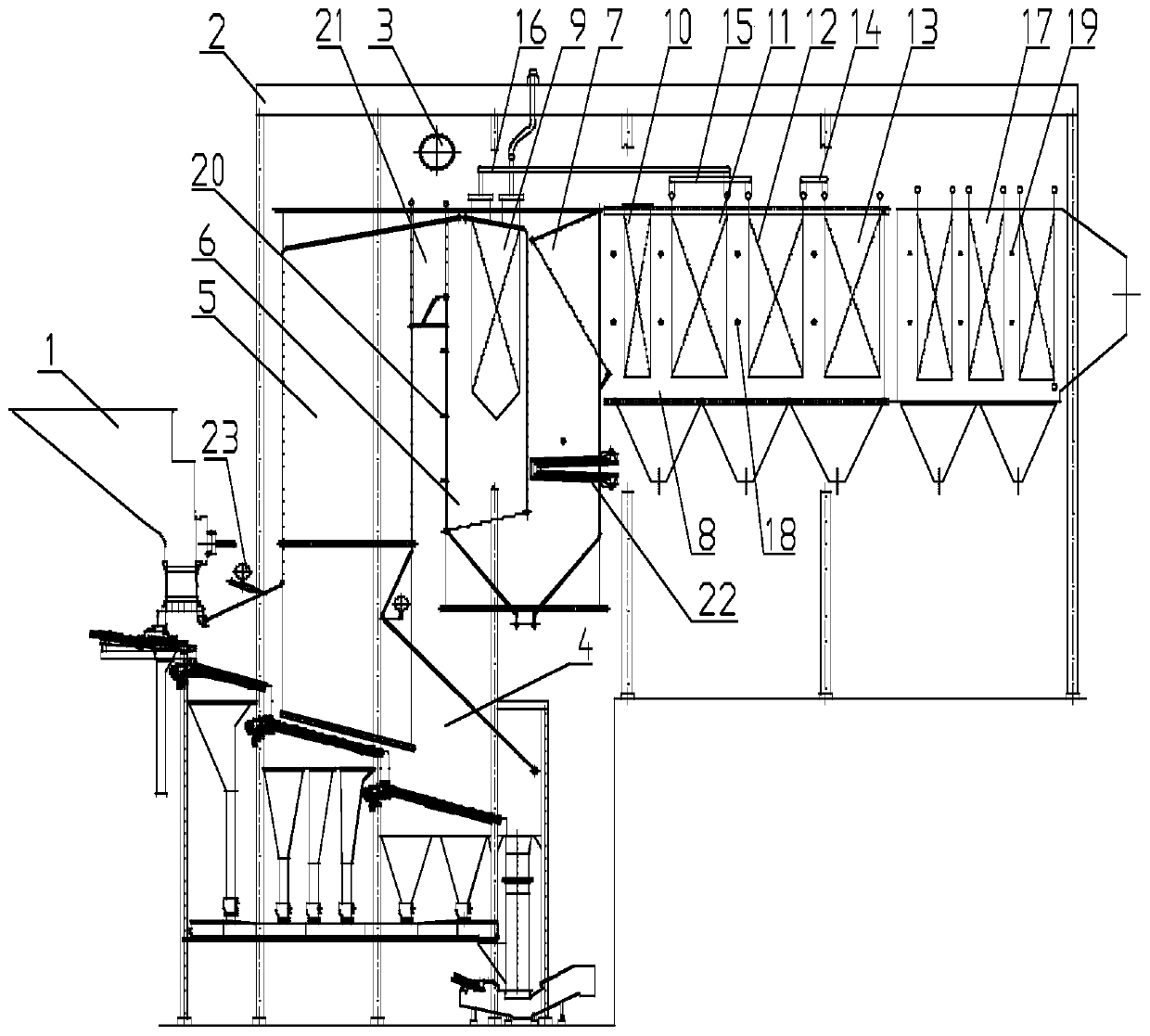

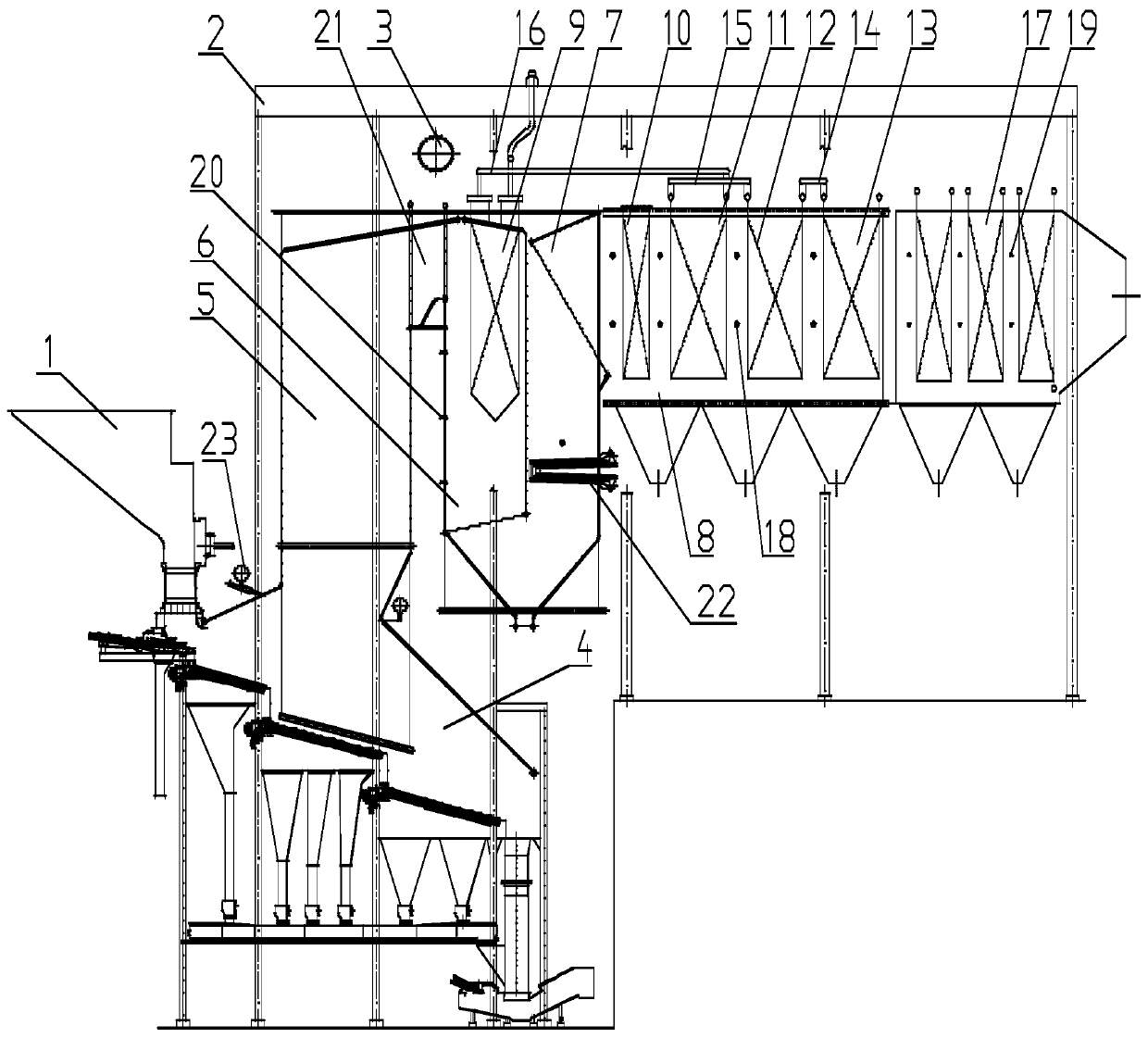

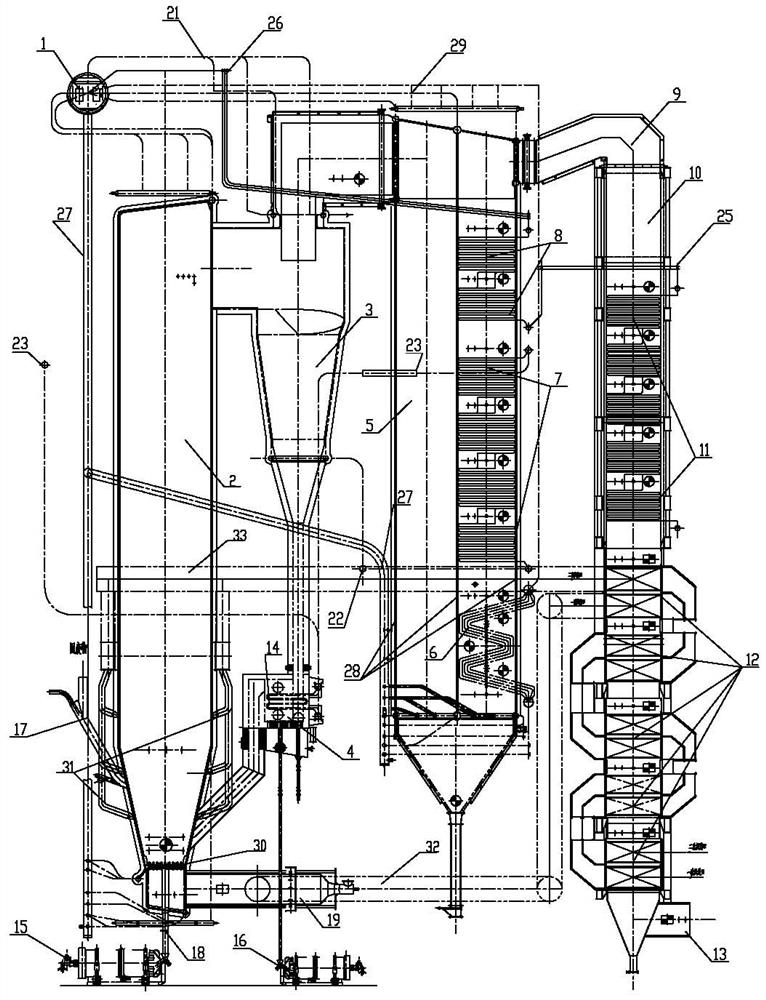

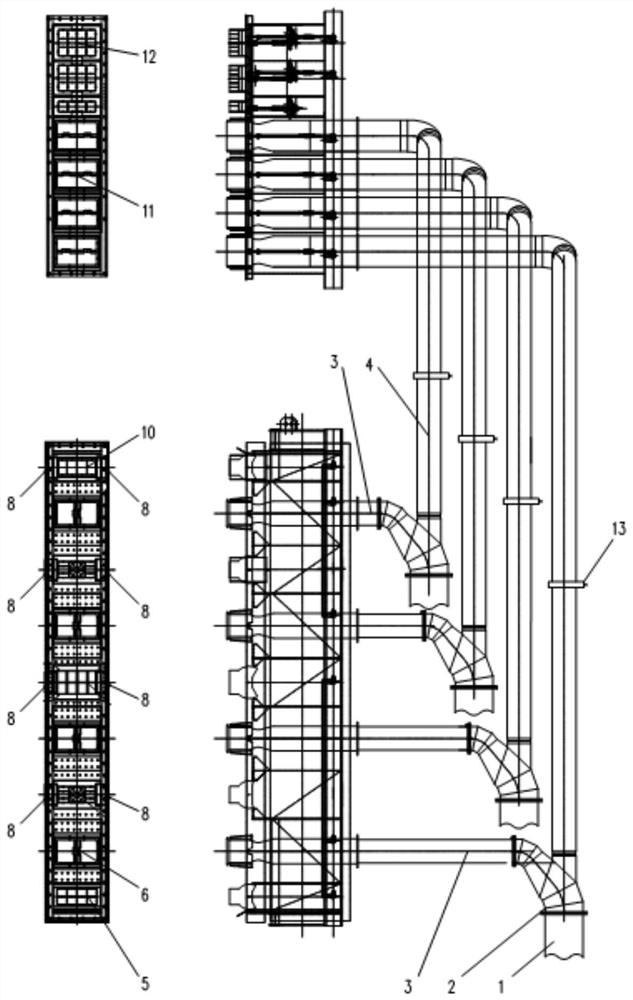

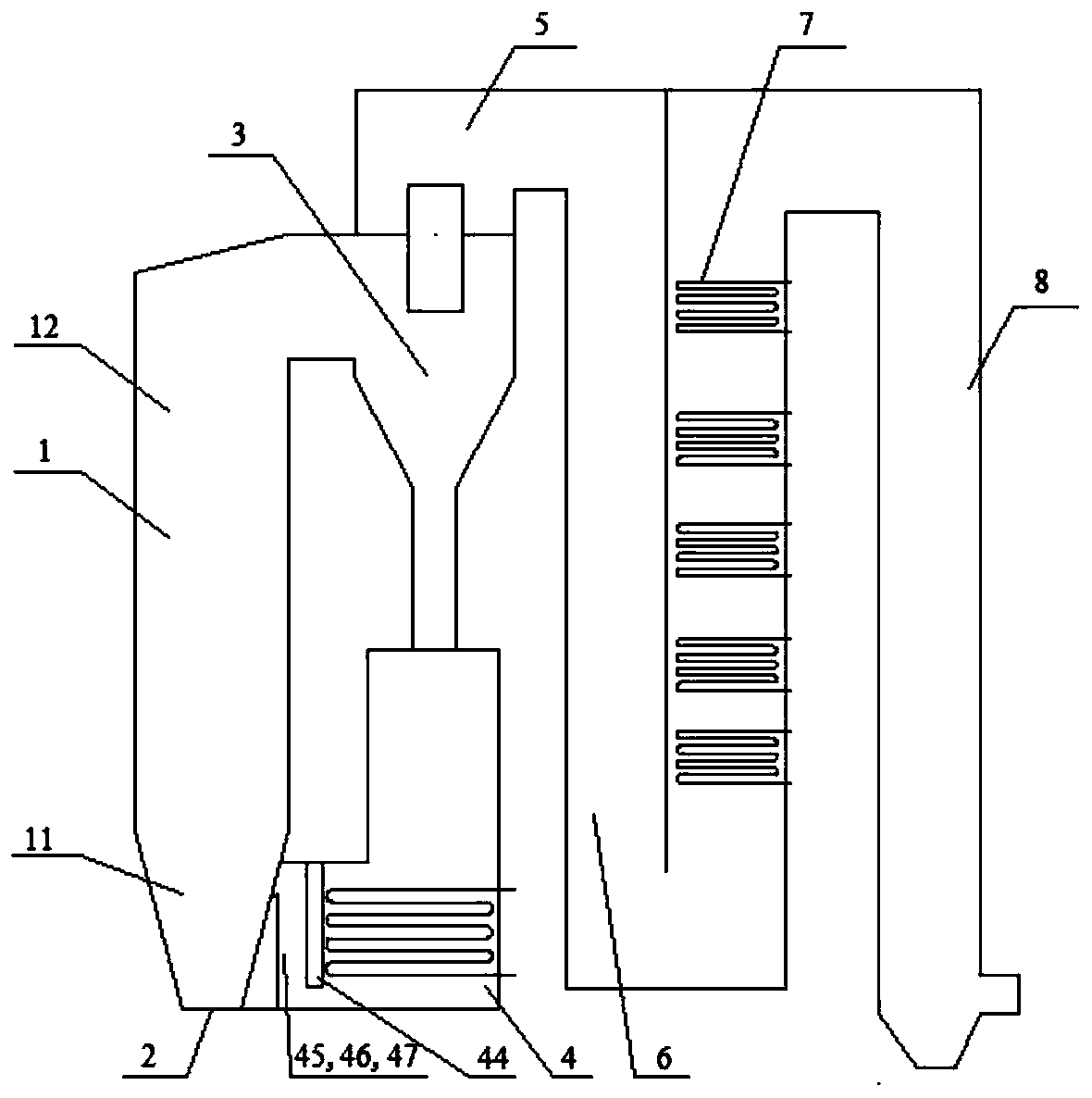

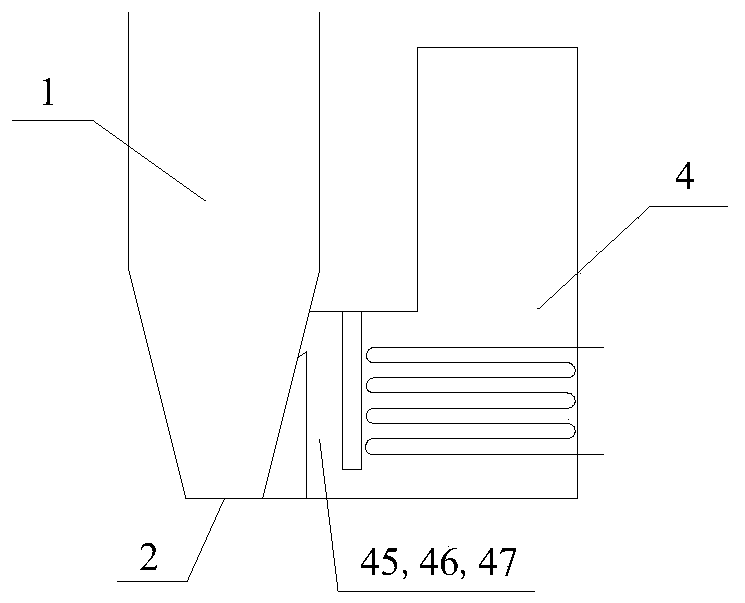

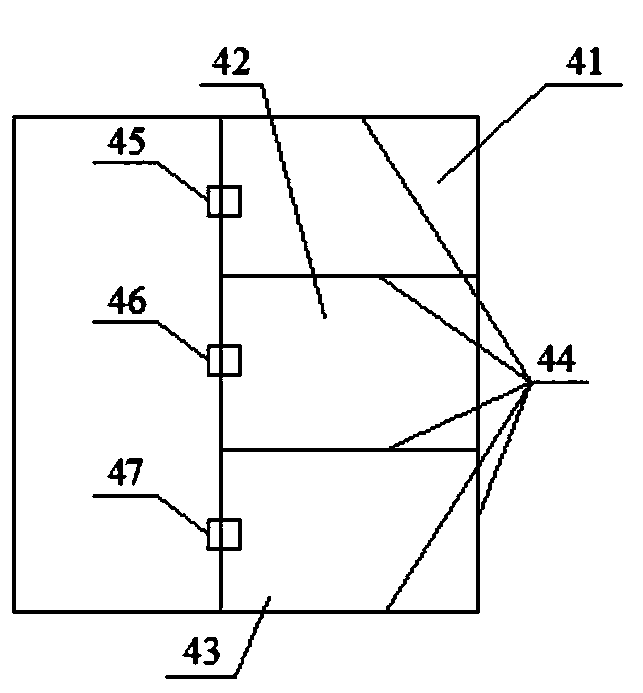

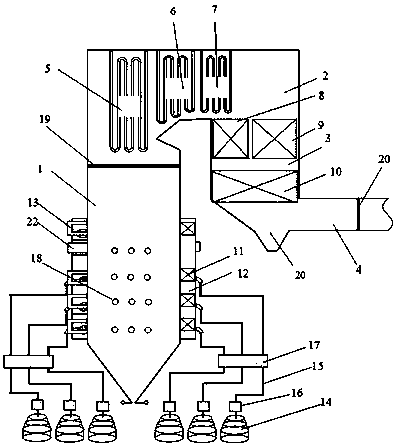

Circulating fluidized bed incineration boiler for combusting solid waste

PendingCN112664953AAdd air-cooled flueExtended burn timeFluidized bed combustionSteam superheatersFlueSlag

The invention relates to the technical field of boiler structures, in particular to a circulating fluidized bed incineration boiler for combusting solid waste. The circulating fluidized bed incineration boiler can effectively reduce the corrosion effect, does not have the phenomenon of material blockage, is continuous and stable in combustion and meets the flue gas emission standard. The circulating fluidized bed incineration boiler comprises a hearth, a separator device and a tail flue which are sequentially arranged; a material return device is arranged between the separator device and the hearth; a feeding pipe and a secondary air pipe are arranged on the side wall of the hearth; a fluidized bed is arranged at the bottom of the hearth; and an ignition device and primary air are arranged at the position of the fluidized bed. The circulating fluidized bed incineration boiler is characterized in that the hearth is composed of a water cooling wall; a refractory material layer is laid on the fire facing face of the hearth; the aperture ratio of an air distribution plate of the fluidized bed is 2%-4%; air caps are staggered on the air distribution plate; the air distribution plate is connected with a slag tube; an air cooling flue is arranged between the separator device and the tail flue; an ash discharging pipe is arranged at the bottom of the material return device; a high-temperature superheater is installed in the material return device; and the tail flue comprises a front ascending flue and a rear descending flue.

Owner:WUXI HUAGUANG BOILER

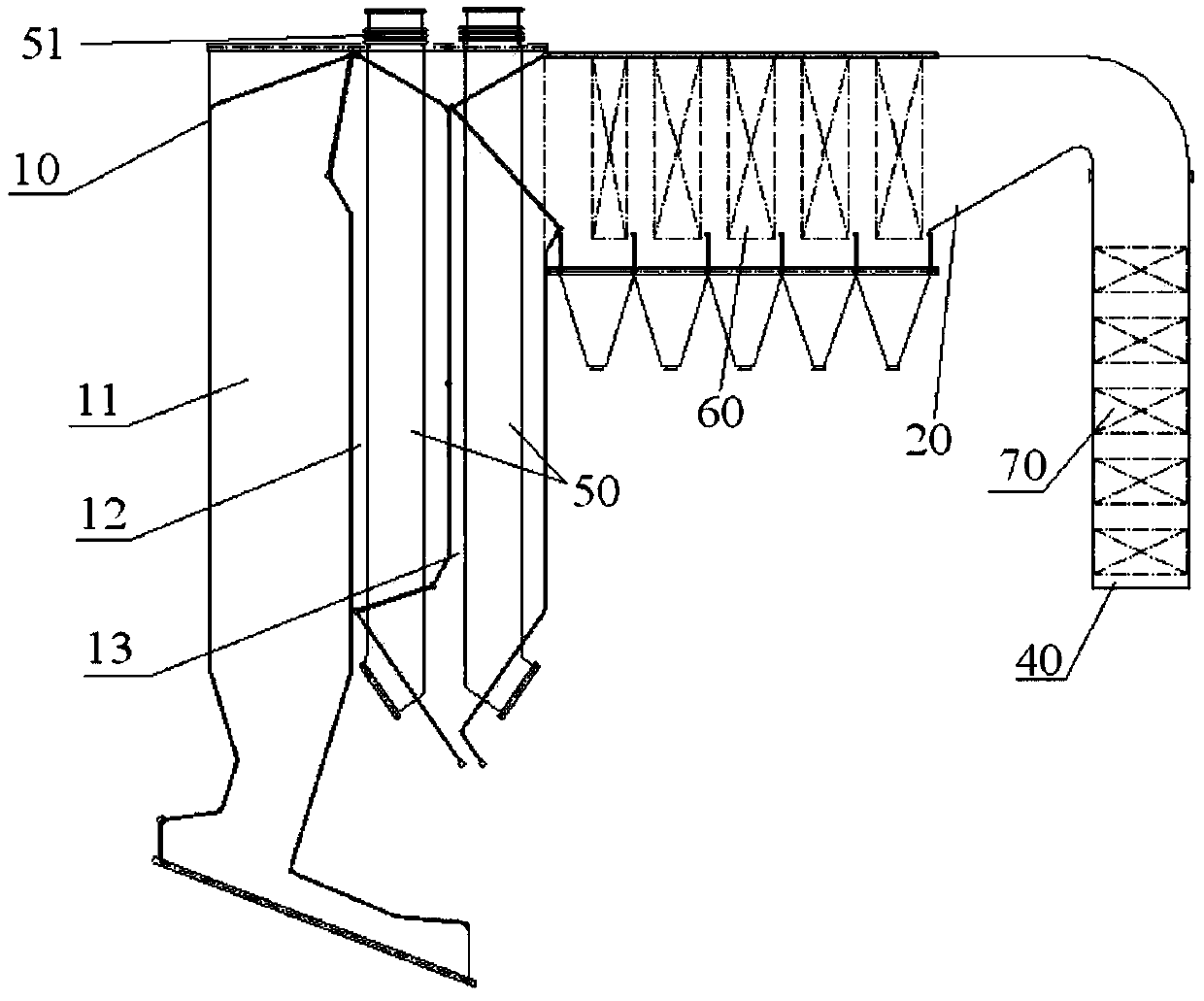

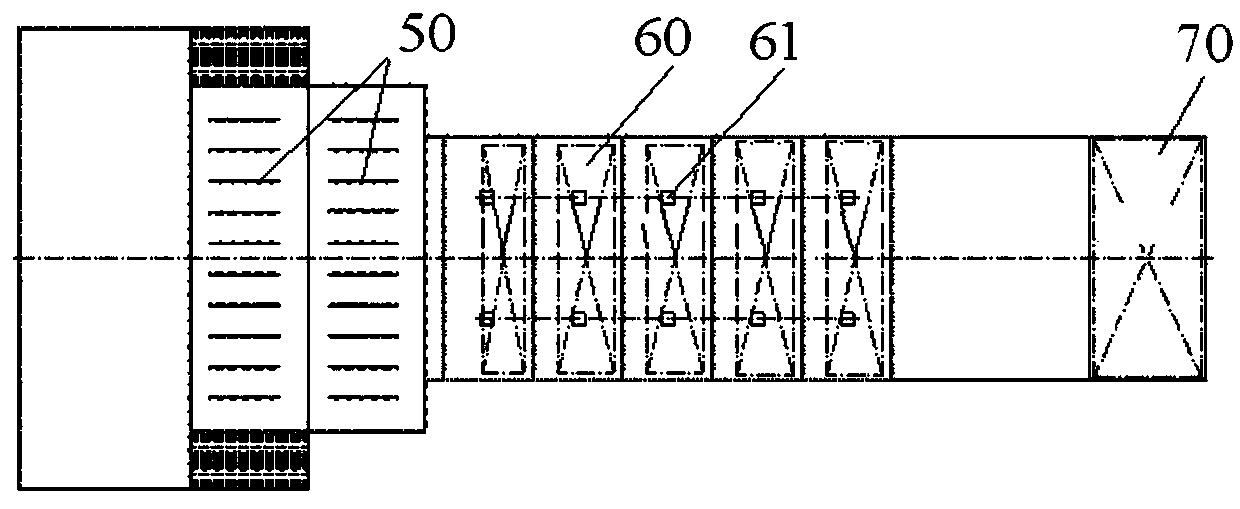

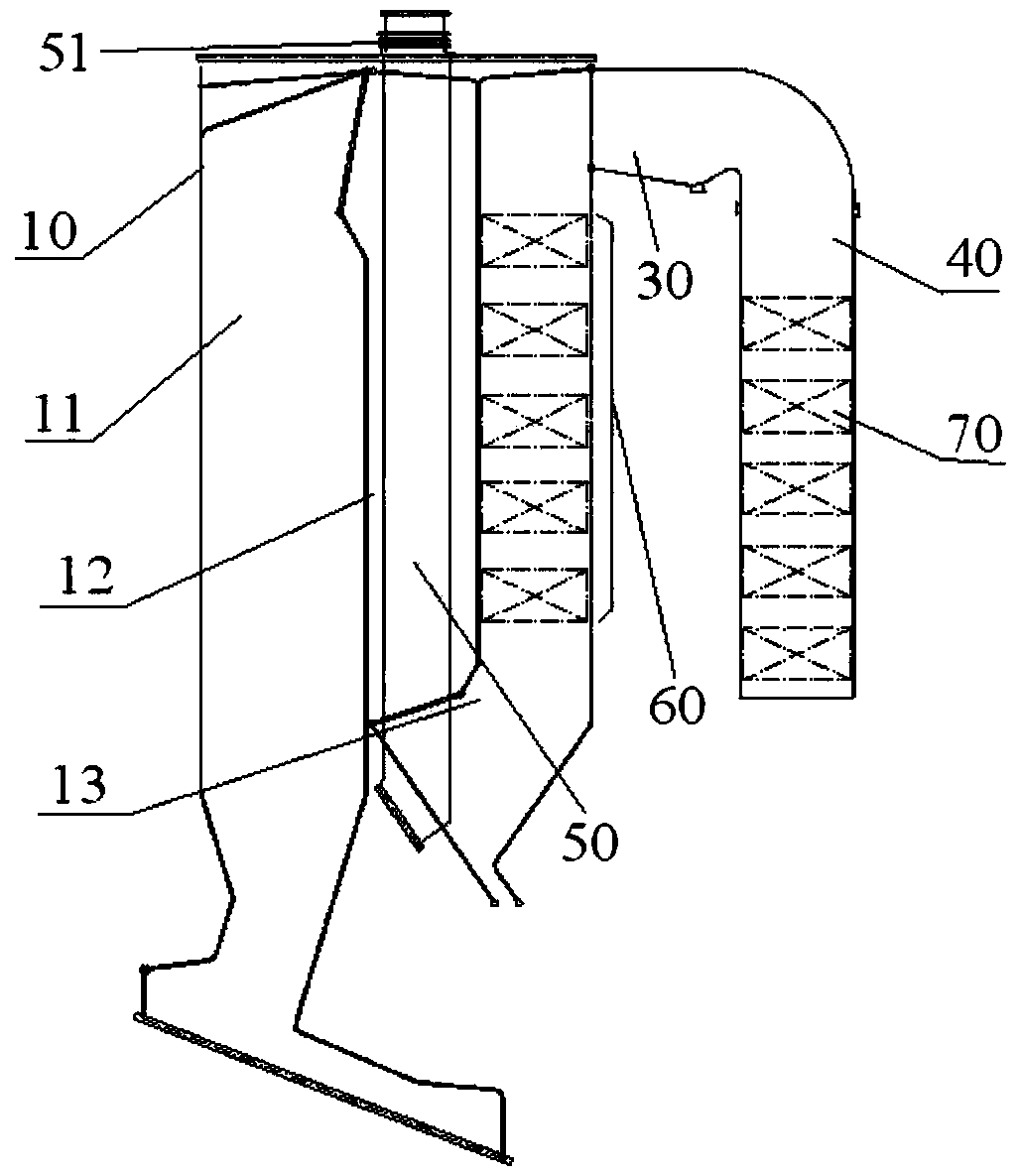

High-parameter waste heat boiler suitable for garbage incinerator grate

PendingCN109630998ASolve the problem of high temperature corrosionImprove power generation efficiencySteam superheatersIncinerator apparatusSuperheaterHigh-temperature corrosion

The invention discloses a high-parameter waste heat boiler suitable for a garbage incinerator grate. The high-parameter waste heat boiler suitable for the garbage incinerator grate comprises a water cooling flue, a tail flue and a horizontal flue or a connecting flue located between the water cooling flue and the tail flue, and a heating surface of a high-temperature superheater is arranged in thewater cooling flue, so that the temperature of a superheated steam outlet of the high-parameter waste heat boiler reaches 450-540 DEG C and the pressure reaches above 6.4MPa. According to the high-parameter waste heat boiler suitable for the garbage incinerator grate, by reasonably designing the arrangement positions of the heating surfaces of the boiler high-temperature stage superheater and reheater, effective anti-corrosion measurements are adopted in the surfaces of the heating surfaces, high-temperature corrosion of the heating surfaces is effectively prevented and the steam parameter ofthe boiler is improved, and the steam parameter of the waste heat boiler can be improved to high-temperature and high-pressure and ultrahigh pressure parameter is even further improved to efficient ultrahigh pressure. Further, a reheater system is arranged in the boiler to heat steam which is from a turbine high-pressure cylinder and has relatively low outlet temperature to 540 DEG C again, and higher power generation efficiency is obtained.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Opposed firing boiler

InactiveCN110617473AIncrease oxygen contentReduce oxygen contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorHearth

The invention discloses an opposed firing boiler. The opposed firing boiler comprises a hearth surrounded by a boiler left-side wall, a boiler right-side wall, a boiler front wall and a boiler rear wall. A left-side wall burner is arranged on the center line of the boiler left-side wall in the height direction of the hearth, a right-side burner is arranged on the center line of the boiler right-side wall in the height direction of the hearth, several front wall burners are arranged on the boiler front wall, and several rear wall burners are arranged on the boiler rear wall; and a bellow for providing secondary air and over-fire air for the hearth is arranged at the peripheries of the boiler left-side wall, the boiler right-side wall, the boiler front wall and the boiler rear wall. According to the structure of the opposed firing boiler, on the basis that an original pulverized coal firing mode is not influenced, the problem of high temperature corrosion to side wall water cooling wallsis thoroughly solved.

Owner:XIAN ANT PETROLEUM TECH

Boiler apparatus for preventing high temperature corrosion of water screen and method therefor

ActiveCN103225805BSolve the problem of high temperature corrosionNo increase in operation and maintenance costsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorLow nitrogen

The invention relates to a boiler apparatus for preventing high temperature corrosion of a water screen, which comprises a body of heater, a low nitrogen eddy flow combustor and a high nitrogen eddy flow combustor. And the body of heater comprises a front wall, a back wall, a left side wall and a right side wall; the high nitrogen eddy flow combustor is installed on the areas of the front wall and the back wall near the left side wall and the right side wall, and the low nitrogen eddy flow combustor is installed on the central section area of the front wall and the back wall far from the left side wall and the right side wall. The invention replaces the combustors close to the left side wall and the right side wall into a high nitrogen eddy flow combustor by reasonable arrangement of two kinds of eddy flow combustors, thereby solving the problem of high temperature corrosion of the side wall water screen with simple operation and convenient operation management and without negative influences to the stability of the combustion in furnace and increased boiler operation maintenance cost.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

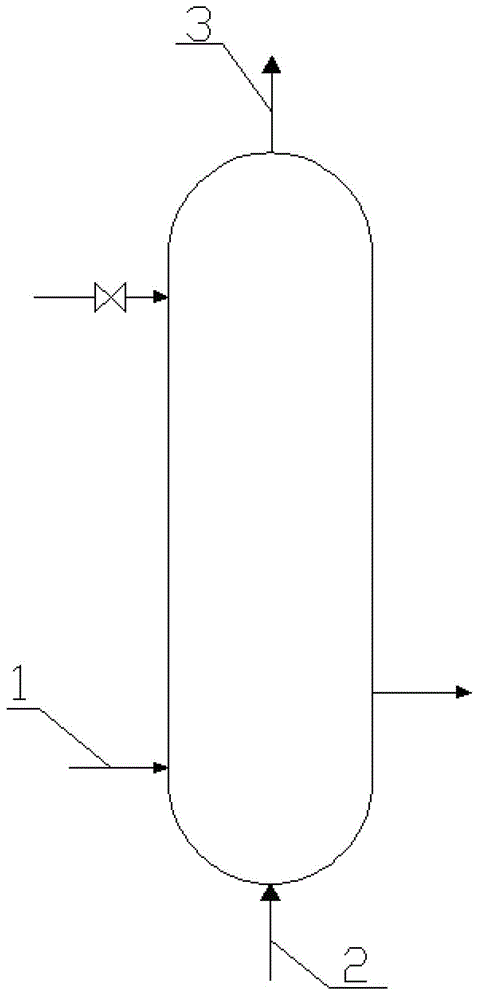

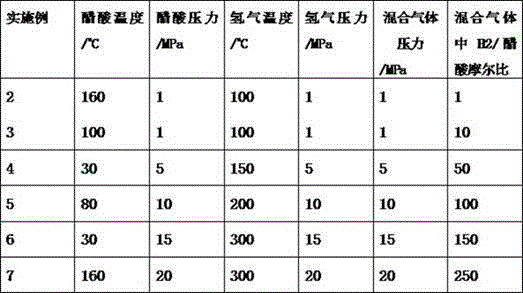

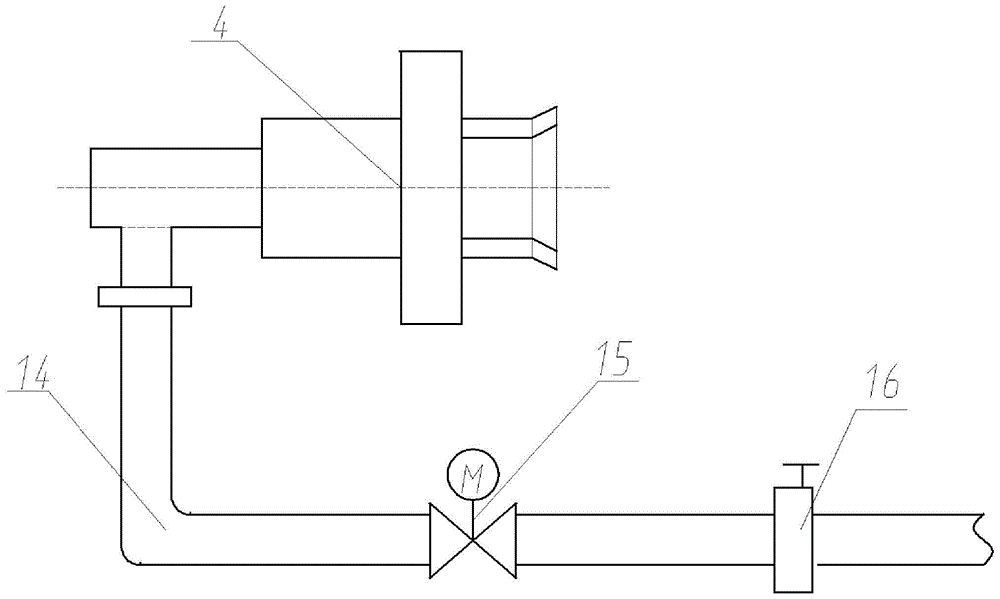

Method for mixing and gasifying liquid-phase acetic acid and hydrogen

ActiveCN102908958AGasification GuaranteeSolve the problem of high temperature corrosionOrganic compound preparationHydroxy compound preparationAcetic acidHydrogen pressure

The invention provides a method for mixing and gasifying liquid-phase acetic acid and hydrogen, comprising the steps of mixing and gasifying acetic acid and gas containing hydrogen in an evaporator, wherein the temperature of the hydrogen before mixing is 100-300 DEG C, the temperature of the acetic acid is 30-160 DEG C and the pressure of the acetic acid and the hydrogen is 1.0-20.0 MPa; and controlling the temperature of mixed gas of the top of the evaporator to obtain the mixed gas with an H2 / acetic acid mol ratio of 1-250 and the pressure of 1.0-20.0 MPa. According to the method disclosed by the invention, the acetic acid can be gasified at the temperature which is lower than an acetic acid boiling point under operation pressure and the problem of high-temperature corrosion of the liquid-phase acetic acid is solved; and the H2 / acetic acid mol ratio in the mixed gas can be well controlled. Furthermore, in a process of mixing and gasifying the liquid-phase acetic acid and the gas containing the hydrogen, the acetic acid is heated by an external heat source to provide gasification latent heat of the acetic aid, and the requirement on an external heat supply can be reduced.

Owner:JIANGSU SOPO CHEM +1

High-temperature and high-pressure waste incineration pi type boiler

PendingCN110186047ASolve furnace cokingSolve high temperature corrosionSuperheating controlCoatingsSuperheaterFlue gas

The invention relates to the field of urban household waste incineration, in particular to a high-temperature and high-pressure waste incineration pi type boiler. The boiler comprises a water-coolingcombustion chamber, a first channel, a first and second channel connecting channel, a second channel, a third channel, a horizontal channel and a fourth channel, wherein the first channel, the first and second channel connecting channel, the second channel, the third channel, the horizontal channel and the fourth channel are arranged in the flue gas flowing direction in sequence, wherein a platensuperheater is arranged on the upper portion of the second channel, and the outer portion of the platen superheater is coated with high-heat-conduction plastic refractory; an evaporation protector I is arranged on the lower portion of the third channel; the horizontal channel is internally provided with an evaporation protector II, a high-temperature superheater, an intermediate-temperature superheater and a low-temperature superheater in sequence; and an economizer is arranged in the fourth channel. According to the high-temperature and high-pressure waste incineration pi type boiler, the platen superheater is coated with the high-heat-conduction plastic refractory to isolate contact between a pipe and flue gas, and the problem of high-temperature corrosion is solved thoroughly. The platen superheater can heat steam to 540 DEG C. Accordingly, the thermal efficiency of a matched waste incineration power plant steam turbine generator unit system is improved to 34%.

Owner:SHANGHAI SUS ENVIRONMENT

Waste incineration power plant with improved main steam parameters

ActiveCN110397481BImprove parametersSolve the problem of high temperature corrosionSteam engine plantsSteam generation using hot heat carriersWater circulationProcess engineering

The invention provides a waste incineration power generation device for improving the main steam parameters, which includes: a waste heat boiler, which is provided with a low-temperature heating surface to heat feed water; a steam drum, through which the feed water is separated into saturated water and saturated steam, and the saturated water is returned to the waste heat boiler The low-temperature heating surface of the coal-fired boiler is equipped with a high-temperature heating surface, and the saturated water vapor separated from the steam drum is superheated on the high-temperature heating surface; for the steam turbine, the superheated main steam enters the high-pressure cylinder to do work and drives the generator to generate electricity, and the steam discharged from the high-pressure cylinder The exhaust steam returns to the high-temperature heating surface of the coal-fired boiler for reheating. The reheated steam enters the low-pressure cylinder to do work and drives the generator to generate electricity. The exhaust steam discharged from the low-pressure cylinder enters the feed water circulation unit to be converted into feed water again. According to the waste incineration power generation device for increasing the main steam parameters of the present invention, the main steam parameters of the waste incineration power generation can be improved, and the intermediate reheating technology is used, thereby increasing the power generation of the steam turbine and the economic benefits of the incineration power plant.

Owner:EVERBRIGHT ENVIRONMENTAL TECH RES INST NANJING CO LTD +1

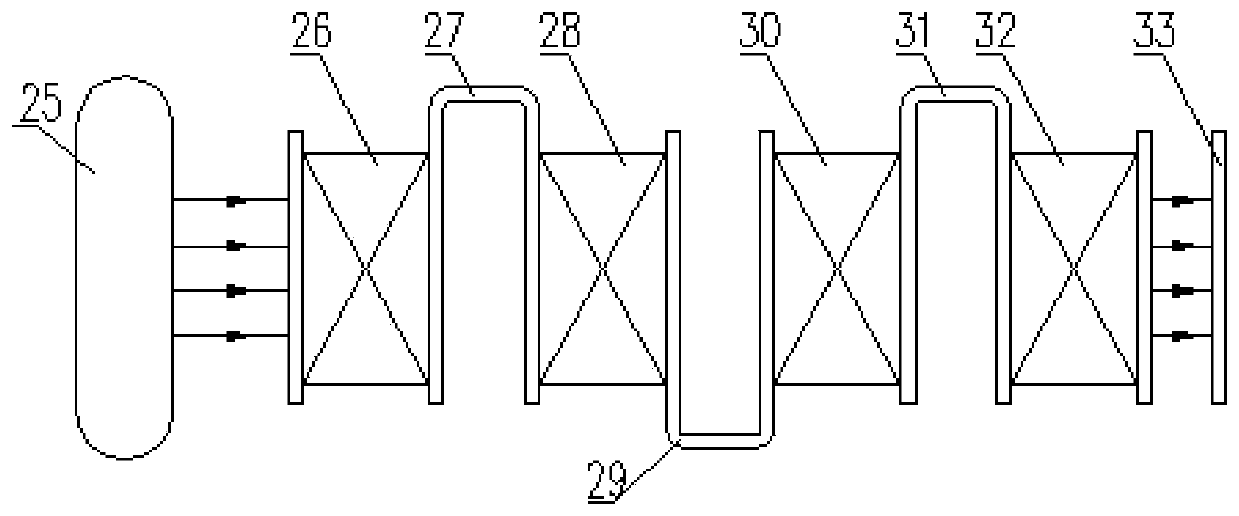

Medium-temperature sub-high pressure reheating waste incineration boiler provided with sound wave temperature measurement denitration system

PendingCN111043585AIncrease steam working capacityImprove thermal cycle efficiencySuperheating controlEmission preventionFlueSuperheater

The invention belongs to the technical field of combustion equipment and particularly relates to a medium-temperature sub-high-pressure reheating waste incineration boiler provided with a sound wave temperature measurement denitration system. The boiler comprises a fire grate, a furnace chamber, a horizontal flue and a tail flue. The furnace chamber comprises a hearth, a burnout chamber and threeflues which are connected in sequence; and the horizontal flue and the tail flue are sequentially arranged behind the furnace chamber. A plurality of water cooling screens are arranged at an upper part of the hearth; a plurality of partition wall water cooling walls are arranged in the burnout chamber; a high-temperature reheater, a high-temperature superheater, a low-temperature reheater and a medium-temperature superheater I are sequentially arranged in the three flues from bottom to top; a medium-temperature superheater II and a low-temperature superheater I are arranged in the horizontal flue; and the tail flue is sequentially provided with a low-temperature superheater II and an economizer from top to bottom. The waste incineration power generation heat efficiency can be effectively improved, the steam consumption rate is reduced, nitrogen oxide emission is efficiently controlled, and long-term safe and stable operation of the water cooling walls, the reheaters and the superheaters is guaranteed.

Owner:ZHEJIANG WEIMING ENVIRONMENT PROTECTION

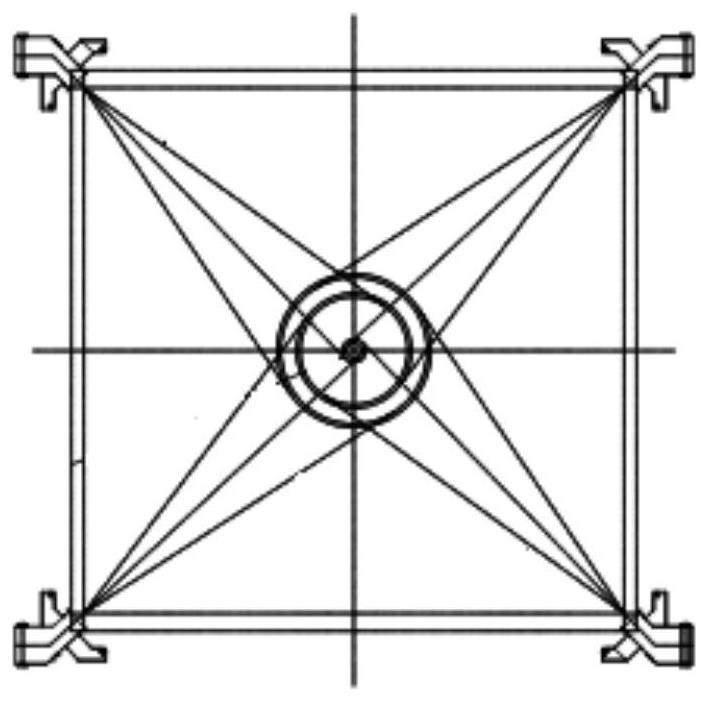

Ultra-low NOX combustion system and method of tangential combustion boiler

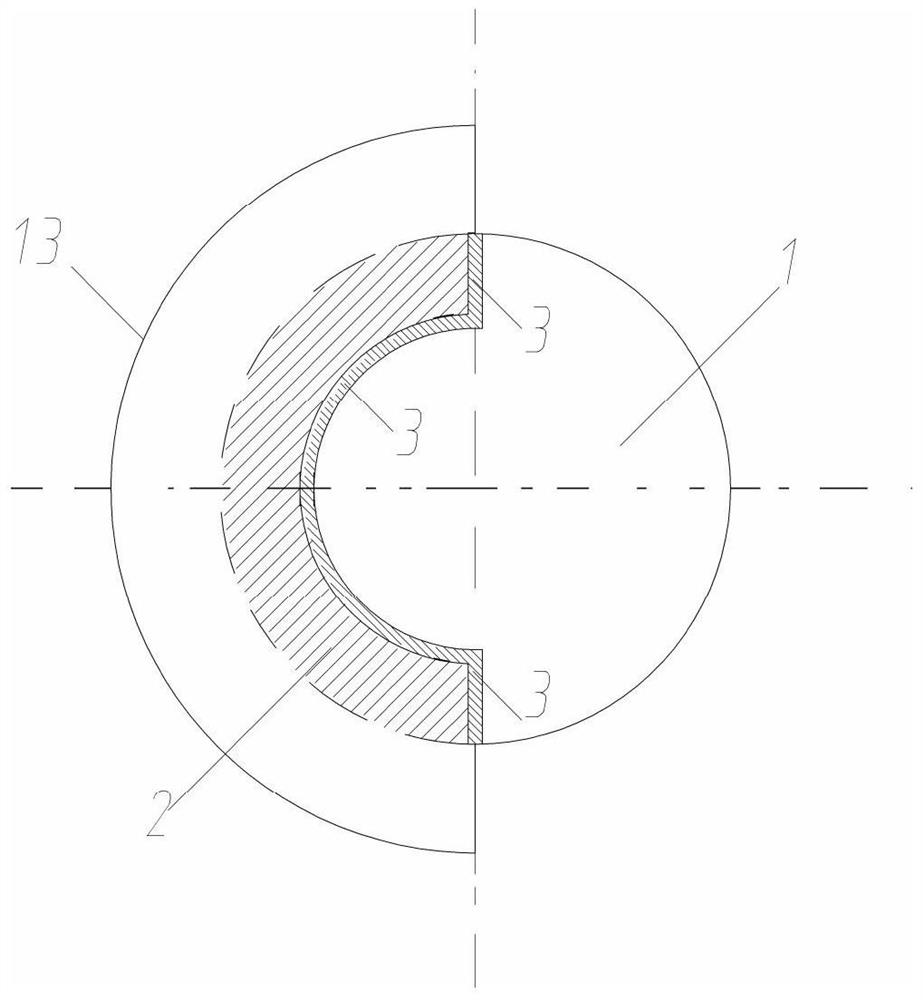

PendingCN113623643AReduce primary wind ratePrimary wind rate increasesCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion systemThermodynamics

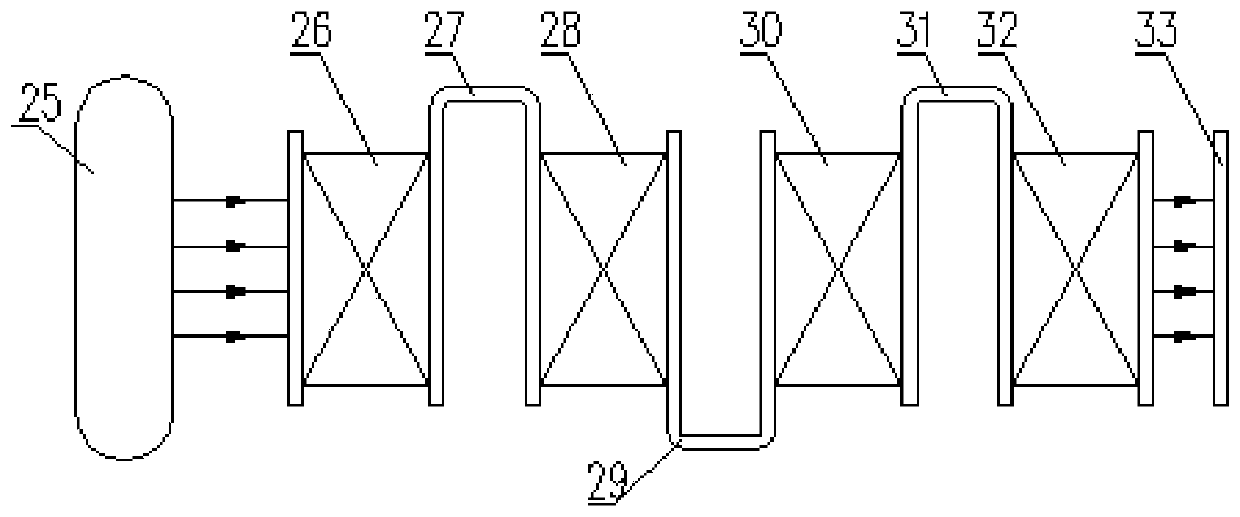

The invention relates to an ultra-low NOX combustion system and method of a tangential combustion boiler. The ultra-low NOX combustion system comprises a hearth, primary air combustors, over-fire air nozzles and secondary air nozzles. The primary air combustors are arranged at the four corners of the lower portion of the hearth in a four-corner tangential mode. Each primary air combustor comprises a plurality of layers of pulverized coal pipelines and a primary air nozzle, and the pulverized coal pipelines are each provided with a pulverized coal dense-thin separation device, a dense-phase pulverized coal pipeline and a thin-phase pulverized coal pipeline. The pulverized coal dense-thin separation devices are used for separating air pulverized coal in the pulverized coal pipelines into dense-phase airflow and thin-phase airflow. The over-fire air nozzles are arranged at the upper portion of the hearth, each over-fire air nozzle comprise an over-fire air exhaust nozzle and an over-fire air secondary air nozzle, and the over-fire air exhaust nozzles are connected with the thin-phase pulverized coal pipelines. The secondary air nozzles are arranged between the adjacent primary air nozzles, are arranged above the primary air nozzle at the top and are arranged below the primary air nozzle at the bottom. According to the ultra-low NOX combustion system and method of the tangential combustion boiler, the problem that the ratio of secondary air to primary air in a main combustion area is unbalanced is thoroughly solved.

Owner:TRANSTEK IND HK LTD KOWLOON

New energy generator

PendingCN112838788ASolve the problem of high temperature corrosionThermal cycle increaseKinetic-electric generatorElectro conductivityElectric energy

A new energy generator is composed of a plasma generator assembly, an electromagnetic system, water, electricity, gas and the like. A Faraday channel magnetic pole and an electrode are cooled by circulating water, so that the high temperature of about 3650 DEG C is reduced to the temperature of water vapor, about 200 DEG C, and the noise of the temperature on the magnetic performance is reduced to the minimum. The cooling problem of a Faraday channel magnetic pole is solved, and steam power is generated for a turbine to drive a generator to generate electricity. Electric energy is used as auxiliary fuel, water is used as main fuel, and the plasma conductivity in magnetohydrodynamic power generation is increased. Water is used as a new energy source. And water is decomposed into fuel for use, so that economic benefits and social benefits are incomparable.

Owner:熊英雕

A scientific research vessel with an anti-corrosion and noise-reducing chimney

ActiveCN112377939BReduce the temperatureSolve the problem of high temperature corrosionLighting and heating apparatusPropulsion power plantsThermal insulationEngineering

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

Anti-corrosion and noise reduction chimney for ships

ActiveCN112361366BReduce the temperatureSolve the problem of high temperature corrosionPropulsion power plantsPropulsive elementsHazardous substanceEngineering

The invention discloses a novel anti-corrosion and noise-reducing chimney for ships, which includes a chimney for discharging exhaust gas, a conversion device arranged at the central axis of the chimney for converting kinetic energy of exhaust gas into electric energy, and a conversion device arranged on the inner wall of the chimney for Internal cooling device for reducing the internal temperature and smoke of the chimney, noise reduction device for reducing the noise of the chimney, external cooling device installed on the outer wall of the chimney, heat insulation layer installed on the surface of the external cooling device, used for purifying and recycling the cooling liquid Circulation purification device and controller, the present invention effectively reduces the internal and external temperature of the chimney through multi-stage cooling, and conducts visual real-time control and adjustment of the chimney temperature through the detection and control system, effectively solving the problem of high temperature corrosion, and reducing the chimney exhaust by setting the muffler device noise, and fully recover and utilize the energy of the exhausted flue gas. By changing the coolant medium, the harmful substances and smoke in the exhaust gas can be effectively removed.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

High temperature corrosion resisting low NOx vortex burning device

InactiveCN100464118CInhibition formationReduce generationCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneCombustor

The present invention relates to a low NOx cyclone combustion equipment capable of preventing high-temperature corrosion. It is characterized by that the invented side wall OFA nozzles are respectively set on the upper portion of two side walls in the furnace cavity interior, the furnace cavity zone where the side wall OFA nozzle lower-side central powder-feeding cyclone coal powder combustor is placed is main combustion zone, the furnace cavity zone where the side wall OFA nozzle and cyclone OFA nozzle are placed is burning zone, several central powder-feeding cyclone coal powder combustors are respectively set on the front and rear walls of main combustion zone side, and the cyclone OFA nozzles are respectively set on the front and rear walls of burning zone side. When the coal powder is combusted, it can further inhibit the formation of NOx, can reduce discharge of NOx by above 80%.

Owner:HARBIN INST OF TECH

A boiler opposing combustion structure

ActiveCN104595891BIncrease oxygen contentReduce oxygen contentCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorHearth

A boiler hedging combustion structure, including a furnace surrounded by the left wall of the boiler, the right wall of the boiler, the front wall of the boiler and the rear wall of the boiler; the left wall burner is arranged along the height direction of the furnace on the center line of the left wall of the boiler, The center line of the right side wall of the boiler is arranged along the furnace height direction with right wall burners, several rows of front wall burners are arranged on the boiler front wall, and several rows of rear wall burners are arranged on the boiler rear wall; the left side wall of the boiler, The right side wall of the boiler, the front wall of the boiler and the rear wall of the boiler are equipped with air boxes that provide secondary air and overfired air for the furnace. This structure completely solves the problem of high-temperature corrosion of the side wall water wall without affecting the original pulverized coal combustion method.

Owner:XIAN THERMAL POWER RES INST CO LTD

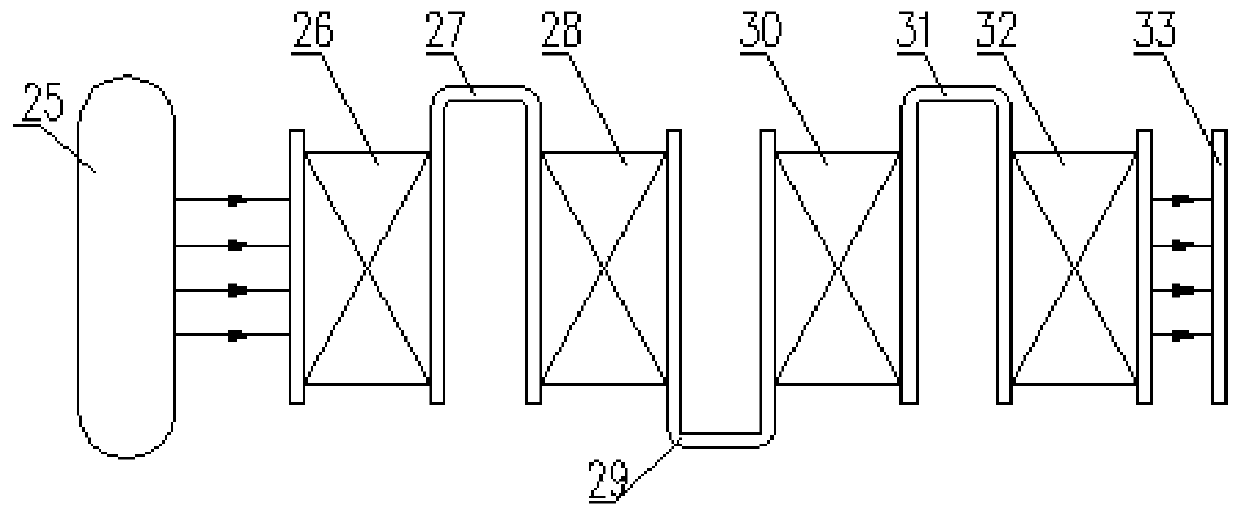

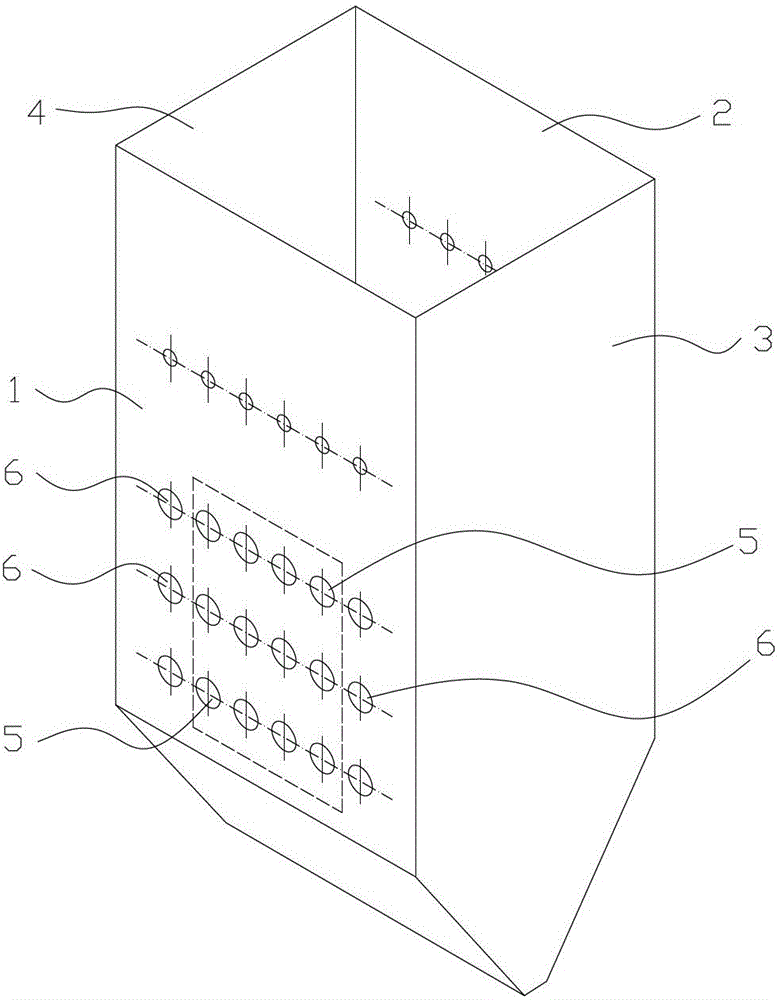

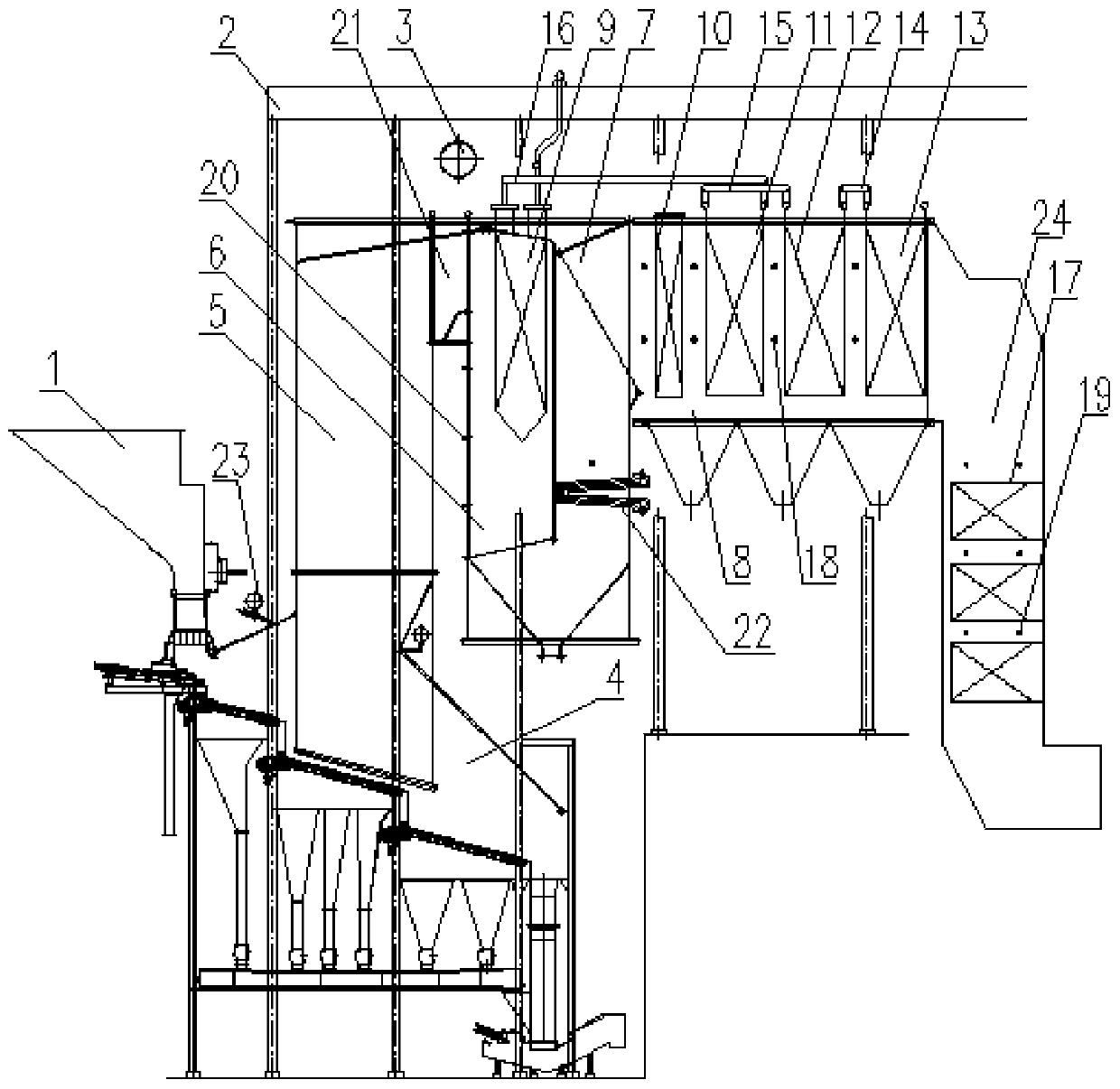

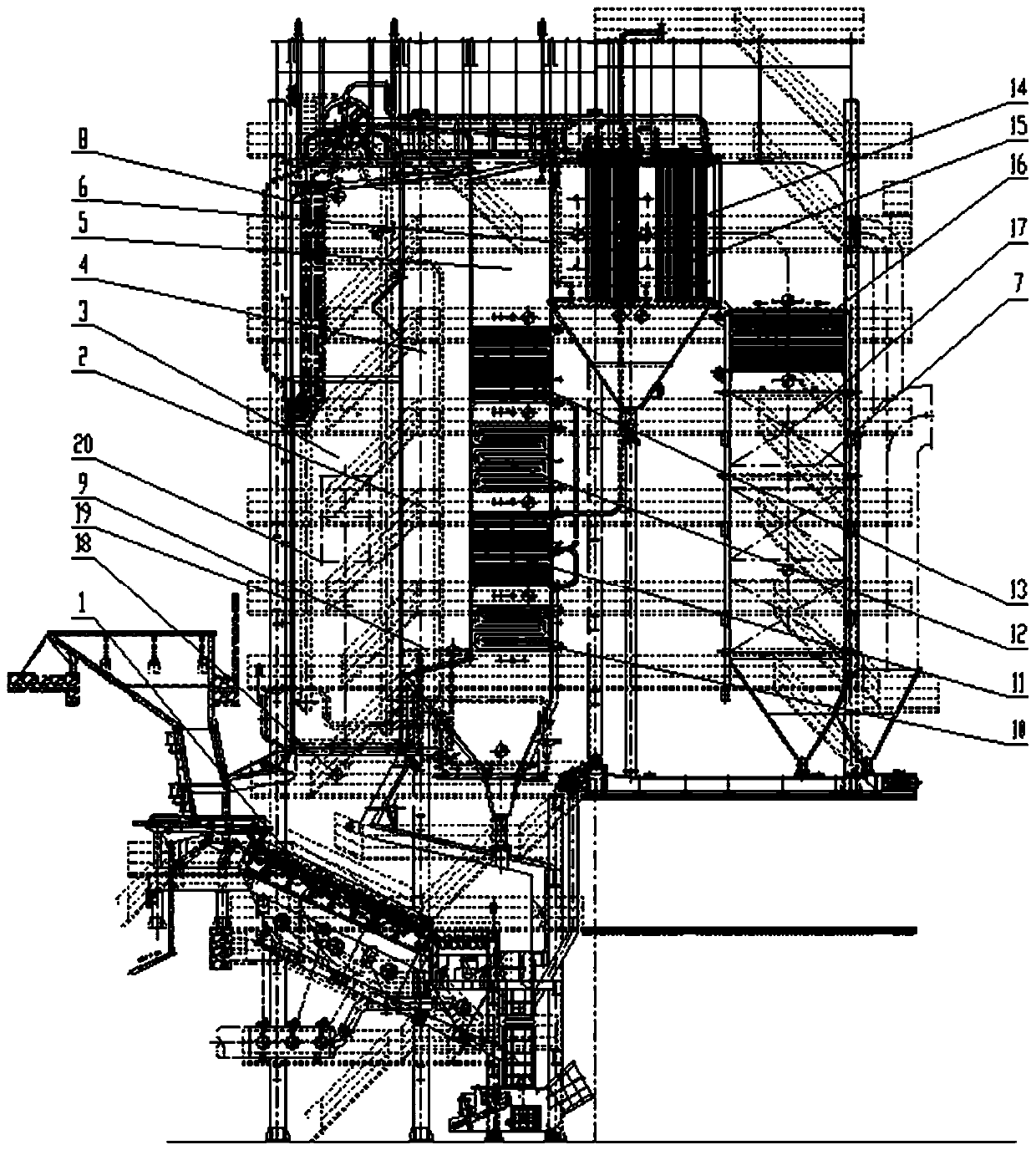

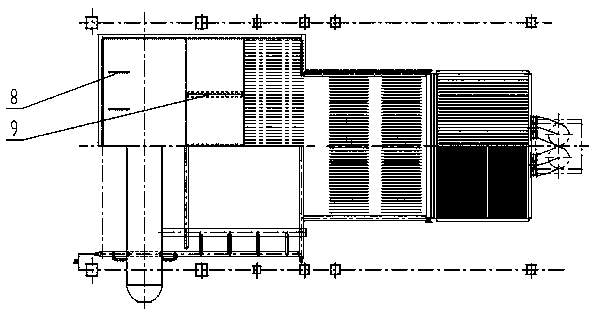

Biomass boiler equipped with external fluidized bed

PendingCN111140835ASolve the problem of high temperature corrosionEnsure normal dischargeFluidized bed combustionSteam superheatersFurnace temperatureFluidized bed

The invention provides a biomass boiler equipped with an external fluidized bed. The biomass boiler comprises a hearth, an air distribution plate, two separators, the external fluidized bed and a tailflue; the bottom of the hearth is provided with the air distribution plate; the two separators are arranged on the rear side of the top of the hearth; the tops of the separators are connected to thetail flue; blanking pipes at the lower ends of the separators are connected to the upper end of the external fluidized bed; an ash return port in the side wall at the lower part of the hearth is connected with the side wall at the lower end of the external fluidized bed; the external fluidized bed is provided with the hearth 1, the hearth 2 and the hearth 3 side by side along the width of the hearth; a first-level high-temperature superheater, a reheater and a second-level high-temperature superheater are separately arranged in the hearth 1, the hearth 2 and the hearth 3. The biomass boiler fundamentally avoids the problem of high temperature corrosion of the superheater and reheater of the existing biomass fluidized bed boiler. Because the external fluidized bed has the function of adjusting the furnace temperature, the biomass boiler can adapt to large changes in load and fuel, and meanwhile, ensures lower pollutant emissions.

Owner:杭州国祯伊泰克工程技术有限公司

Pulverized coal burner and boiler having same

ActiveCN102032564BReduce the temperatureExtended service lifeCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberThermal insulation

Owner:YANTAI LONGYUAN POWER TECH

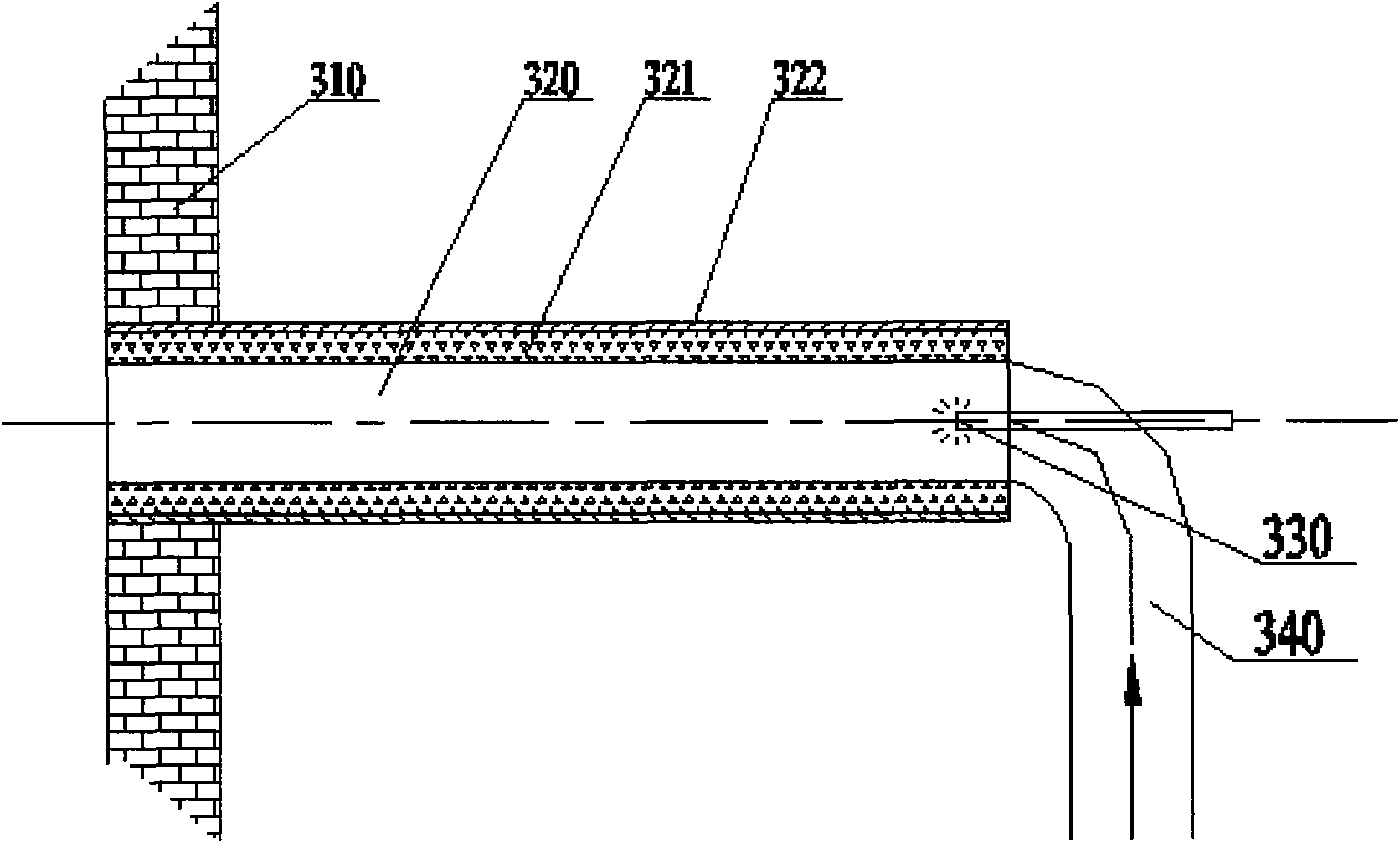

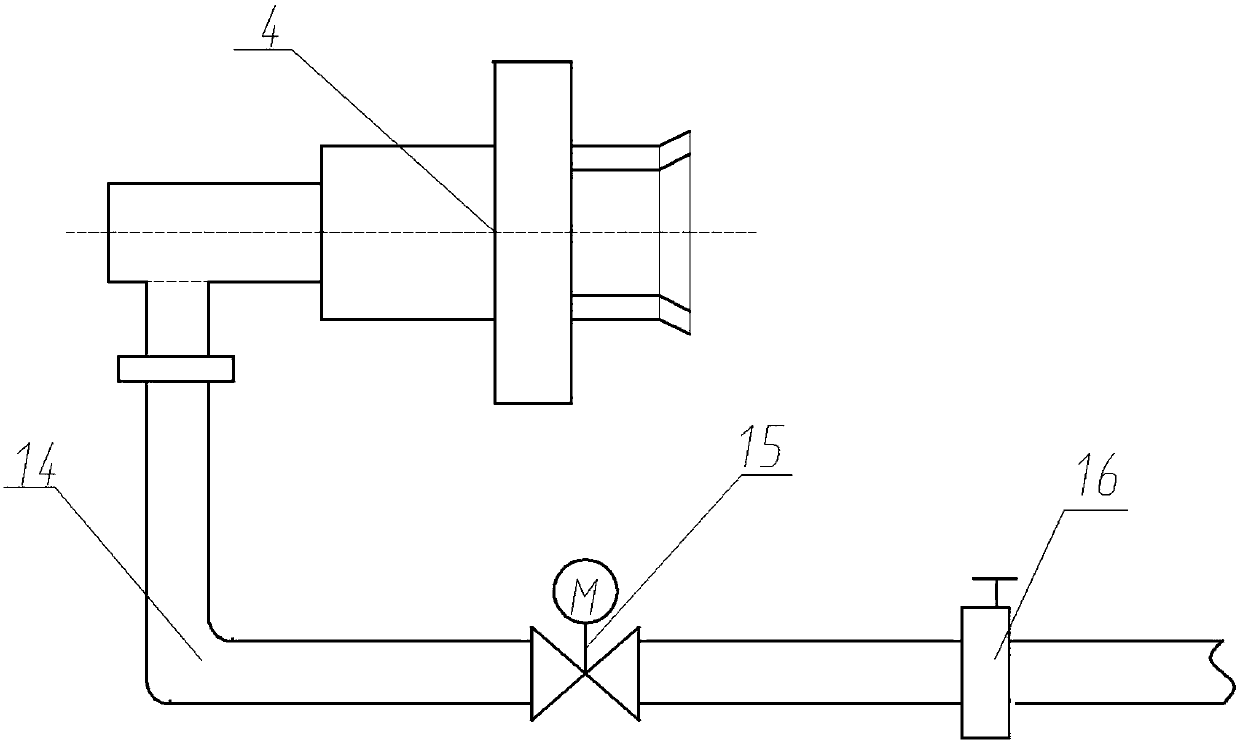

Combustion optimization system and adjustment method for preventing high temperature corrosion of water wall

ActiveCN106678783BIncrease oxygen contentAdjust the same openingBoiler controlCasings/liningsMeasurement deviceAir volume

The invention provides a combustion optimization system and adjustment method for preventing water wall high-temperature corrosion. The combustion optimization system comprises air and pulverized coal adjustment devices, secondary air distribution adjustment devices, two water wall near wall region smoke component measuring devices, a plurality of auxiliary over fire air nozzles, a temperature field measuring device and a coal economizer outlet smoke oxygen content field measuring device. A first air and pulverized coal pipeline corresponding to each combustor is provided with the corresponding air and pulverized coal adjustment device. Each secondary air box is internally provided with the corresponding secondary air distribution adjustment device. The two water wall near wall region smoke component measuring devices are separately mounted on the water wall on the two sides of a boiler. The multiple auxiliary over fire air nozzles are separately arranged below over fire air nozzles. The temperature field measuring device is arranged on the portion, below a platen overheater, in a hearth. The coal economizer outlet smoke oxygen content field measuring device is arranged at a coal economizer outlet flue. By adoption of the combustion optimization system, high-temperature corrosion to the water wall of the opposite cyclone combustion boiler can be effectively relieved.

Owner:GUODIAN SCI & TECH RES INST +1

A city waste pyrolysis and gasification coupled coal-fired power generation system

ActiveCN109207178BReduce generationSolve the problem of high temperature corrosionMachines/enginesSpecial form destructive distillationHigh-temperature corrosionElectric generator

Owner:SHANGHAI POWER EQUIP RES INST

Sintering trolley

InactiveCN101986087AEnhanced effect of blocking igniter flamesReduce high temperature erosionFurnace typesHigh-temperature corrosionFire damper

The invention discloses a sintering trolley, relating to the field of technical equipment of a metallurgical machinery sintering trolley. The sintering trolley comprises a trolley body, wherein two sides above the trolley body are respectively fixedly connected with a lower breast board; an L-shaped fire damper board made of a heat-resistant anticorrosion material is arranged between the trolley body and each lower breast board respectively; and each L-shaped fire damper board comprises a longitudinal section and a transverse section, the lower end of the longitudinal section is fixedly connected with the outer end of the transverse section, and the inner end of the transverse section is arranged between the trolley body and the lower breast boards. After the fire damper boards are installed, the overflow flame of an igniter can not be directly sprayed on the trolley body and wheels, and the flanges of the fire damper boards are upward to strengthen the effect of blocking flame of the igniter, thereby reducing the high temperature corrosion to which the trolley body and the wheels are subject when the sintering trolley is in use and prolonging the service life.

Owner:徐宏亮

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com