A boiler opposing combustion structure

A technology for hedging combustion and boilers, which is applied in the direction of using a variety of fuel combustion, combustion types, combustion equipment, etc., can solve problems such as increasing boiler maintenance workload, increasing the risk of water wall operation by anti-corrosion coating, and preventing high-temperature corrosion. , The effect of increasing oxygen content and protecting operation safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

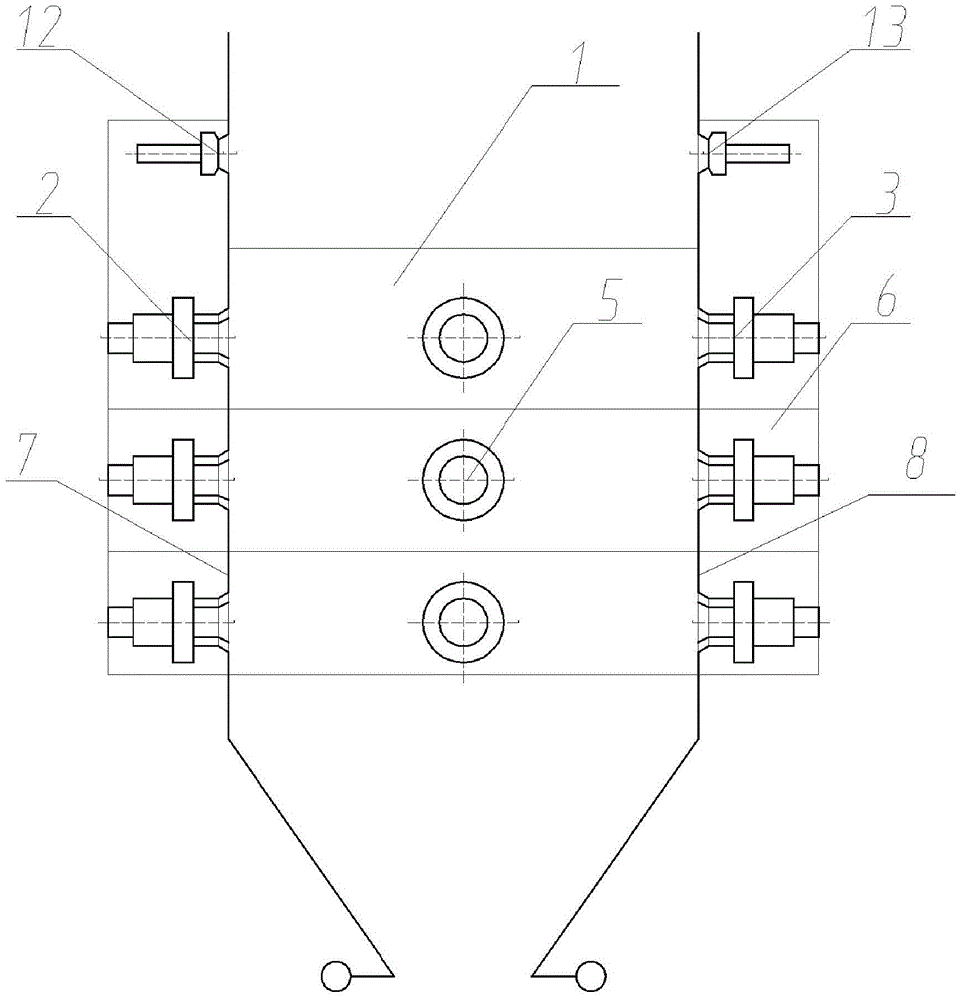

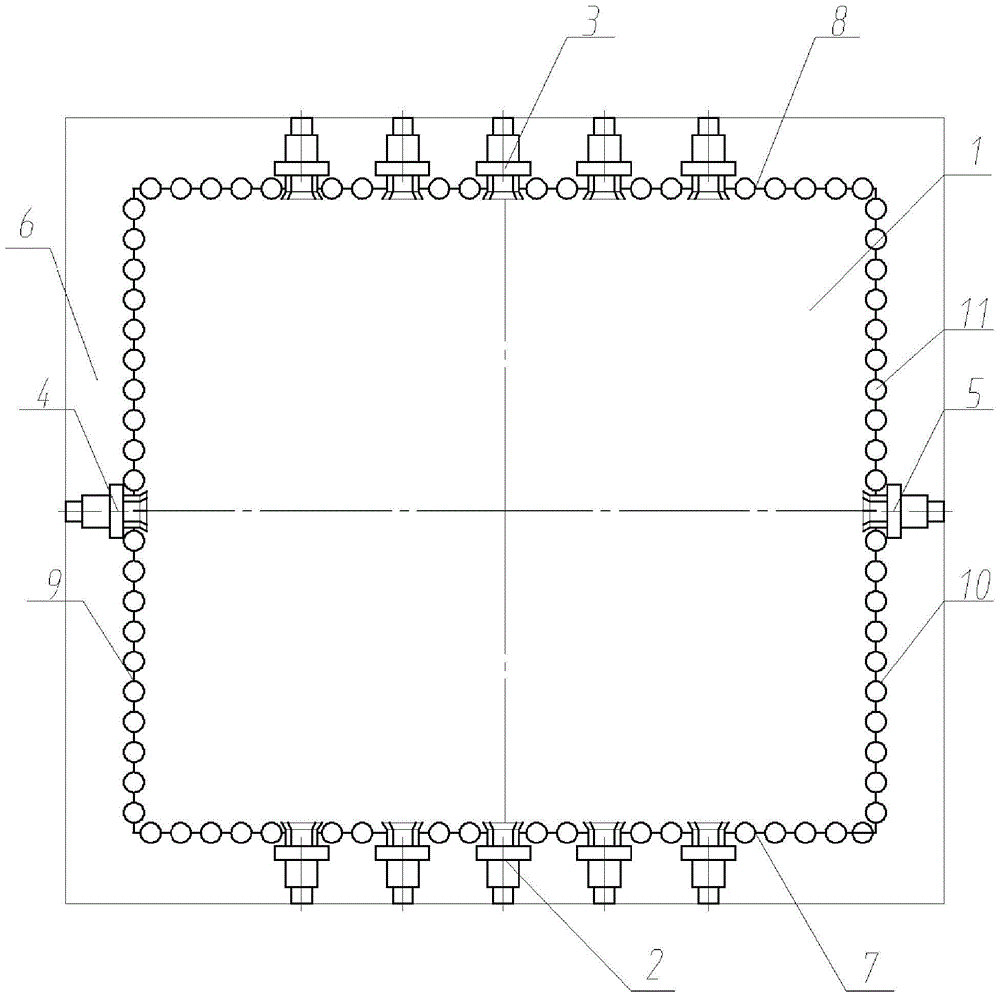

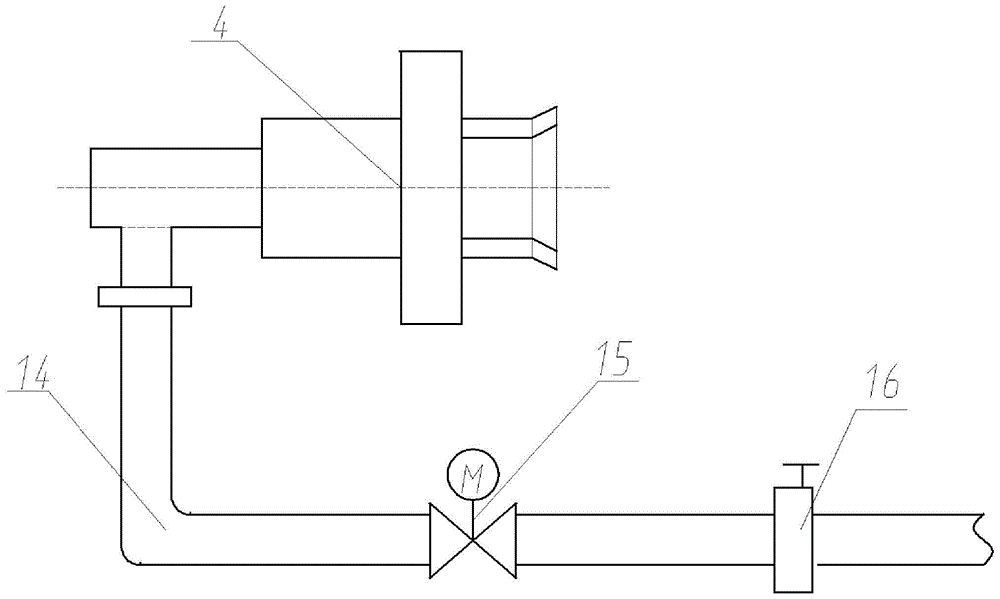

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0024] see Figure 1-2 , the present invention proposes a boiler hedging combustion structure based on the hedging combustion mode of the front and rear walls. The problem of high temperature corrosion of the water wall of the side wall. Including the furnace 1 surrounded by the boiler left wall 9 and the furnace right wall 10, the boiler front wall 7 and the boiler rear wall 8; because the boiler left wall 9 and the boiler right wall 10 are prone to high temperature corrosion, therefore, the boiler left The center line of the wall 9 is arranged along the height direction of the furnace 1 with single or double rows of burners 4 on the left side wall, and the center line of the right wall 10 of the boiler is arranged with single or double rows of burners 5 on the right side wall along the height direction of the furnace 1 In this way, it is possible to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com